Page 1

Operating Manual

and

User’s Guide

S1024DW Miniature Fiber Optic

Spectrometers and Accessories

Ocean Optics, Inc.

380 Main Street

Dunedin, FL 34698

(727) 733-2447

(727) 733-3962 fax

For the latest information, consult our web site:

www.OceanOptics.com

Or, e-mail our Technical Service Department:

TechSupport@OceanOptics.com

070699

Page 2

Copyright © 1999 Ocean Optics, Inc.

All rights re served. No part of this p ublication may be reproduced, stored in a retrieval

system, or transmitted, by any means, electronic, mechanical, photocopying, recording, or

other w ise, without wr it t en permission from Ocean Optic s , I n c.

This manual is sold as part of a spectrometer order and subject to the condition that it shall

not, by way of trade or otherwis e, be lent, re-sold, hired out or otherwise circulated without

the prior consent of Ocean Optics, Inc. in any form of bi nding or cover othe r than that in

which it is pu blished.

Every effort has been made to make this man ual as complete and as accurate as possible, but

no warranty or fitness is implied. The information p rovided is on an “a s is” basis. Ocean

Optics, Inc. shall ha v e neit her lia b ilit y n or res pon si bil it y to any per son or entit y with re spe ct

to any loss or damages arising from the information c o ntained in this manual.

Page 3

Table of Contents

Introduction

Software and Serial Port Interface Installation

Light Sources

D-1000 Deuterium Light Source............................................................................................ 8

DT-1000 Deuterium Tungsten Halogen Light Source ...........................................................10

LS-1 Tungsten Halogen Light Source ..................................................................................13

PX-2 Pulsed Xenon Lamp...................................................................................................15

HG-1 Mercury Argon Calibration Source..............................................................................17

LS-1-CAL Calibrated Light Source.......................................................................................20

Sampling Chambers

CUV-VIS, CUV-UV Cuvette Holders....................................................................................23

CUV-VIS-10, CUV-UV-10 Cuvette Holders..........................................................................25

CUV-ALL 4-way Cuvette Holder ..........................................................................................26

CUV-FL-DA Direct Attach Cuvette Holder ............................................................................28

ISS Integrated Sampling System.........................................................................................30

FHS In-lin e Fi l te r Ho lde r s....................................................................................................32

LPC Long Pass Flow Cells ..................................................................................................34

Sampling Optics

74-UV and 74-VIS Collimating Lenses.................................................................................36

74-UV-90 Right Angle Reflector...........................................................................................37

74-OPM Optical P ost M ount ................................................................................................38

74-ACH Adjustabl e Collimating Lens Holder........................................................................39

FVA-UV Fiber Optic Variable Attenuator..............................................................................40

WS-1 Diffuse Refl ec tance Standard.....................................................................................41

ISP-REF Integrating Sphere ................................................................................................42

....................................................................................................................... 1

...................................................... 3

.................................................................................................................... 7

......................................................................................................22

..............................................................................................................36

Fiber Optic Probes and Accessories

R200 Reflection P robes.......................................................................................................44

RPH-1 Reflection Probe Holder...........................................................................................46

T200 Transmission Pr obes..................................................................................................47

CC-3 Cosine-Correct ed Irradiance Probes...........................................................................48

Optical Fiber Assemblies

Experiment Tutorial

Absorbance Experiments.....................................................................................................52

Transmission Experiments...................................................................................................53

Reflection Experiments........................................................................................................54

Relative Irradiance Experiments..........................................................................................55

Time Acquisition Experiments..............................................................................................56

.............................................................................................49

.......................................................................................................51

Appendix A: Adjusting the Focus of a Collimating Lens

Appendix B: S1024DW Pin-outs and Jumpers

Appendix C: External Triggering

.......................................................................44

..................................58

.....................................................59

...............................................................................61

Page 4

Introduction

Ocean Optics miniature fiber op tic spectrometer s and accessori es h ave revolut ionized the analytical

instrumentation market by dramatically reducing the size and cost of optical sensing systems. More than

10,0 0 0 Ocean Optics spectromet ers have been sold worl d wide -- stri king evidence of t he far-reaching

impact of low-cost, minia ture componen ts for fiber op tic spectroscopy. Di verse field s s u ch as research and

development, industrial process contr ol, medical diagnostics and environmental monitoring have benefited

from access to Ocean Optics technology.

The Modular Approach

A typical Ocean Op tics small- fo ot p rint system compr ises of five basi c elements: a Miniat ure Fiber Op tic

Spectrometer , an A/D converter , our operatin g software, a light or ex citation source, and sa mp ling optics .

The light or excitation source supplies light through the illumination or excitation fiber to the sample and

then li ght interacts with the sample. The light is then collected and transmitted through the r ead fiber to th e

spectrometer . Th e s p ectromet er measures the amount of li gh t and the A/D converter transform s the analog

data collected by the spectrometer into digital information that is passed to the software, providing the user

with application-specific information.

This modular approach -- components are easily mixed and matched -- offers remarkable applications

flexibility. Users pick and choose from hundreds of products to create distinctive systems for an almost

endless variety of optical-sensing applications.

S1024DW Miniature Fiber Optic Spectrometer

The S1024DW Deep Well Detector Spectrometer is a 1024-element photodiode array detector for those

applications requiring extremely high signal-to-noise (2000:1) measurements. With the S1024DW, the user

can ach ieve micro-absorbance unit r esol ution. In fa ct, the user can relia bl y see an absorbance change of less

than 0.00001 absorbance units. Furthermore, the S1024DW can be multiplexed with up to 8 spectrometer

channels and is ideal for high light level applications such as dissolution testing.

The S1024DW accepts light energy tran sm itted thr ough singl e- s tr and optical fiber and disper ses it via a

fixed grating across the photodiode array, which is responsive from 200-1100 nm. An SMA 905 connector

allows for easy coupling to an extensive line of fiber optic light sources, probes, chemical sensors, and

other spectrophotometric accessor ies.

SAD500 Serial Port Interface

The S1024DW interfaces to our SAD500 Serial Port Interface, a 12-bit, 8-channel, microprocessor-controlled

A/D con verter with a 500 kHz sampl ing frequency. The SA D5 00 can be used to interface to desktop or

portable PCs, as well as to PLCs and other devices that support the RS-232 communication protocol. The

SAD500 A/D converter allows the S1024DW spectrometer to acquire spectra using integration times as rapid

as 31 millisecond s . For incr ea s ed s p eed , the SAD500 can be software configured to transmit only a por tion of

the spectra or the averages of multiple spectral acquisitions, or a combination of both.

OOIBase32 Spectrometer Operating Software

OOIBase3 2 Spectrom eter Opera ting Software is our n ext g en eration of oper ating softwa re for all Ocean

Optics spectrometers. OOIBase32 is a 32-bit, user-customizable, advanced acquisition and display program

that provides a r eal-time interface t o a variety of signal-processin g functions for Windows 95/98 and

Windows NT users. With OOIBase32, you have the ability to perform spectroscopic measurements such as

absorba nce, refl ectance an d emission ; control all system parameters; collect data from up t o 8 spectrometer

channels simultaneously and display the results in a single spectral window; and perform reference

monito r ing and time acq uisition experiments .

1

Page 5

OOIBase3 2 is the lates t edition of operating software for all Ocean Optics sp ectrometers. This change from

16-bit to 32-bit operating software reflects Ocean Optics’ decision to upgrade its software to accommodate

the increase of 32-bit oper at ing systems. OOIBase32 still includ es th e function s of the original OOIBase,

but numerous editing, viewing, and spectral process ing functions ha ve been added.

For detailed instructions on all of the features, menu items, and options in OOIBase32, please refer to

OOIBase32 Spectrometer Operating Software Manual

the

the OOIBase32 online help files.

included with y our spectrometer ord er or

In This Manual

This manual provides u sers with direct ions on configuring your SAD500 wit h your c omputer and operating

the S1024DW Miniature Fiber Optic Spectrometer. In addition, this manual covers instructions for using

some of our most popular spectroscopic components including light sources, sampling chambers, sampling

optics, fiber optic probes, and optical fiber ass embli e s . The

directions on taking absorbance, transmission, relative irradiance, and reflection measurements. Additional

information i s included in A p pendices, s u ch as the pin- outs and jump er s of the spectrometer, instruct ions

on adjusting the focus of a collimating lens, and directions on external triggering.

Experiment Tutorial

section provides specific

Packing List

A packing list comes with your order. It is located inside a plastic bag attached to the outside of the shipment

box. The invoice is mailed separately. The items listed on your packing slip include all of the components in

your order. However, some items on your packing list are actually items you have specified to be installed

into your spectrom eter, such as th e gr ating, d et ector coll ection lens , an d s lit. The pack ing list also includes

information s uch as the shippin g addre s s , bil l i ng address, and c ompon ents on back order. What you won’t

find on the packing list is OOIBa s e3 2 , the free operating softwa re that com es with ever y spect rometer order.

Wavelength Calibration Data Sheet

In your shipment box you will find your spectrometer in a silver-gray anti-static bag. Also inside this bag is

a cali br ation sheet wrapped around the oper ating soft ware diskettes. A calibrati on sheet comes wit h every

spectrometer channel, contains im p or tant infor mation sp ecific to your spectrom eter, and sh ou ld be retained.

Return Merchandise Authorization

Custom ers somet im es fi n d that they need Ocean Optics to make a change or an upgra de to their s ystem. In

order for Ocean Op tics to make th ese changes, the custom er must first contact u s and obtain a Return

Merchandise Authorization (RMA) number. Please contact an Applications Scientist for specific

instruc tions when re turning a pro d uct.

2

Page 6

Software and Serial Port Interface Installation

Step 1: Interface the SAD500 to your PC

The SAD5 00 Serial Por t Interface is a microprocessor-controlled A/D converter for s er ial port connection

or stand-alone operation. The SAD500 can be used to interface to desktop or portable PCs, PLCs, and other

devices that support the RS-232 communication protocol. Interfacing the SAD500 to a desktop or portable

PC is simple.

1. If you ordered your SAD500 mounted onto your S1024DW spectrometer, simply connect the 6-pin

DIN end of the ser i al cable to the SAD 500 and the DB9 end to your PC. S ome PCs ma y require a 9 -pin

to 25-pin c onver ter (not in cluded ). If you ordered your SAD 500 in its own housing, attach the 25- pin

conductor ribbon cable from the S1024DW-series spectrometer to the SAD500. Then connect the 6-pin

DIN end of the ser i al cable to the SAD 500 and the DB9 end to your PC.

2. For either configuration, note the serial port number (also called COM Port) on the PC to which you

are interfacing. (Older PCs may not have numbered ports.)

3. Plug th e +12VDC wall tr ansformer into an outl et and connect it to the SAD50 0.

Step 2: I ns ta ll OOIBase3 2

1. Before installing OOIBase32, make sure that no other applications are running.

2. In s ert “Di sk 1” into your floppy dri ve . (Whe n prompted, inst a l l Disks 2, 3, and 4.) Execute Set up.exe .

3. At th e “Welcome” dia log box, click Next>.

4. At th e “Dest ination Loca tion” dialog box, choose Browse, pick a destination directory and cli ck Nex t>.

5. At the “Backup Replaced Files” dialog box, select either Yes or No. We recommend choosing Yes. If

you select Y es , choose Browse to pick a d es tination directory and cli ck Next>.

6. At the “Installation Complete” dialog box, choose Finish>.

7. When the installation is complete, you will be prompted to restart your computer.

necessary for you to restart your computer before you run OOIBase32 for the first time.

It is absolutely

Step 3: Run OOIBase32

After you restart your computer, navigate to the OOIBase32 icon and select it. The first time you run

OOIBase32 after installation, you mu s t foll ow several prompts before you can beg i n taki ng mea s ureme nts.

Operator and Serial Number Dialog Box

Fir st, a prompt to enter a user name and serial n um ber appear s. Certain data files will in clude this

info rma tion in the head er. (If, at a later date, you wish to ch ang e the opera tor name and serial number,

Edit | Settings

select

of your OOIBase32 software on the Disk 1 label. Click

from the menu and then choose the

Default Spectrometer Configuration File

Next, the following message appea rs:

This appears to be the first time OOIBase32 has been executed. Please select a

spectrometer configur ation file from t he following screen. This s pectrom et er conf igur ation

file will be us ed each time OOIBase32 is started.

A file open dialog box then appears. You must choose the default spectrometer configuration file. Navigate

to the OO I Ba s e3 2 direct ory, and choose the file with

preced ed b y the serial nu mber of your spectromet er. (A default spectrom eter config uration fi le will be

named something similar to

I2J613.spec

.)

Registration

OK

.

.spec

as the extension. The

tab.) You can find the serial number

.spec

extension is

3

Page 7

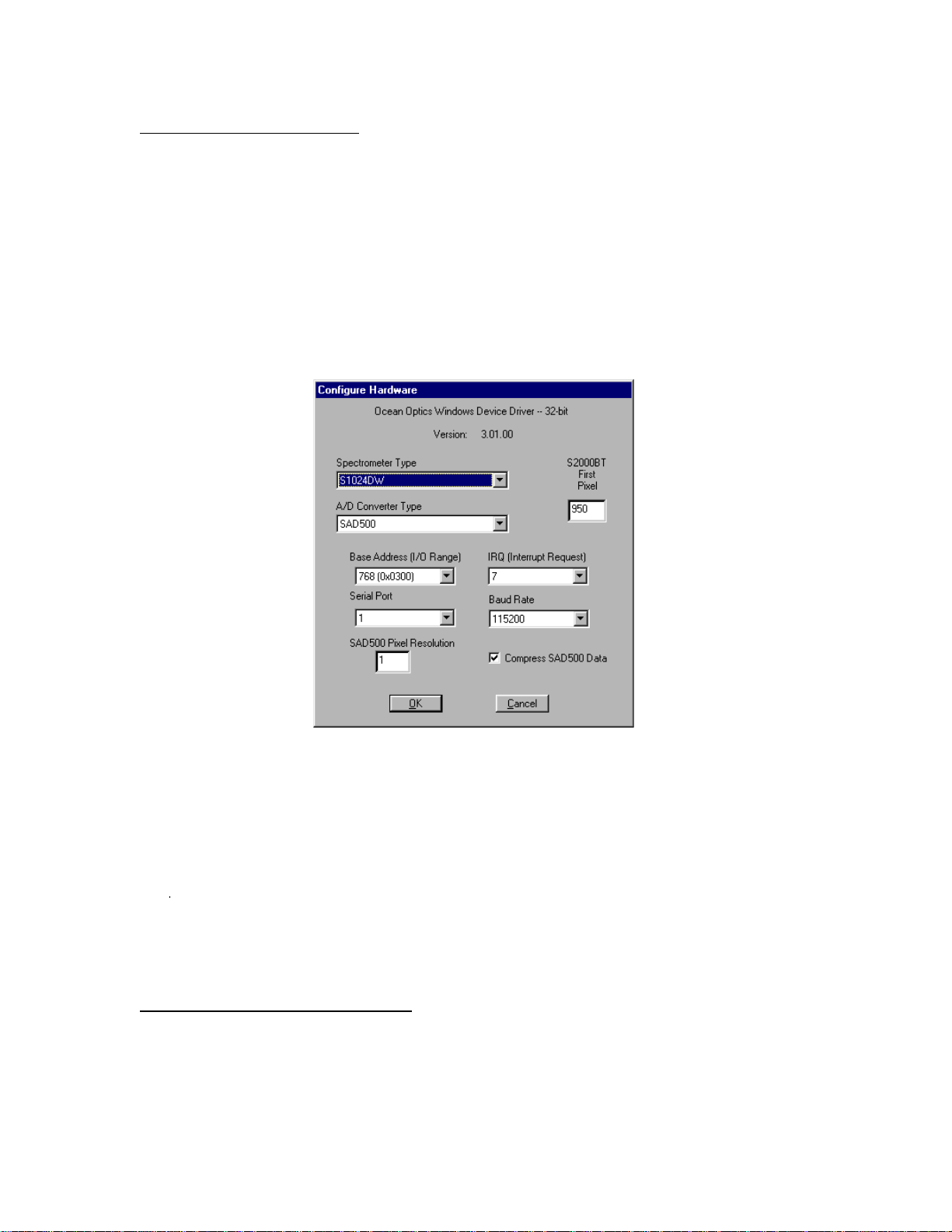

Configure Hardware Dialog Box

Next, the

once -- when OOIBase32 is first installed and the software first runs. You must specify your hardware

conf ig u ration in this di alog box.

1. Under

2. Under

3. Under

4. Under

5. Under

Conf ig ure Hardwa re

Spectrometer T y p e

A/D Converter Type

Serial P o rt

, choose the COM port number your computer is using to interface to your SAD500.

dialog box opens . The parameters i n this d i alog box are usually set only

, choose S1024DW.

, choose SAD500.

See the Tr oubleshooti ng se c tion on page 6 for help in determ i ning the COM P ort number.

Baud Rate

SAD Pixel Resolut ion

th

n

pixel of the spectrometer is transmitted from the SAD500 to the PC. Your resolution value

, select the speed at which the SAD500 will operate.

, en t er resolut ion values from 1 to 500. This va lue specifi es that ever y

depends on your experiment. By sacrificing pixel resolution, you gain speed. The transfer of one

complete spectra requires ~0.3 seconds when communicating at 115,200 baud rate. If you need your

information in <0.6 seconds, increase the resolution or enable data compression (see below).

6. Enable the

Compress SAD500 Data

functi on to minimize the amount of data transferred over the RS232 connection. Transmission of spectral data over the serial port is a relatively slow process. Enabling

this function insures that every scan transmitted by the SAD500 will be compressed, greatly increasing

the data transfer speed of the SAD500.

7. For your setup, only these parameters apply to your system. (Ignore the other settings; the driver will

only read settings that per tain to the spectrometer and A/D converter you have chosen .) Click OK. You

can always chang e these settings once OOIBase32 is fu lly operat ional by select ing

Configure | A/D Interface

.

Spectr ome t er |

If you do n ot see the “Configure Hardware” s cr een when you start OOIBas e3 2 , exit OOI Base32 by

selecting

File | Exit

. Then select

Start

|

Run

, and type

C:\windows\ooidrv.ini

. Notepad will

open. Edit the initialization file for our device driver by finding the “Initialized” entry and making

sure this line reads

Initialized=0

. Save the OOIDRV.INI file and exit Notepa d. Restar t

OOIBase32. You should now see the “Configure Hardware” dialog box.

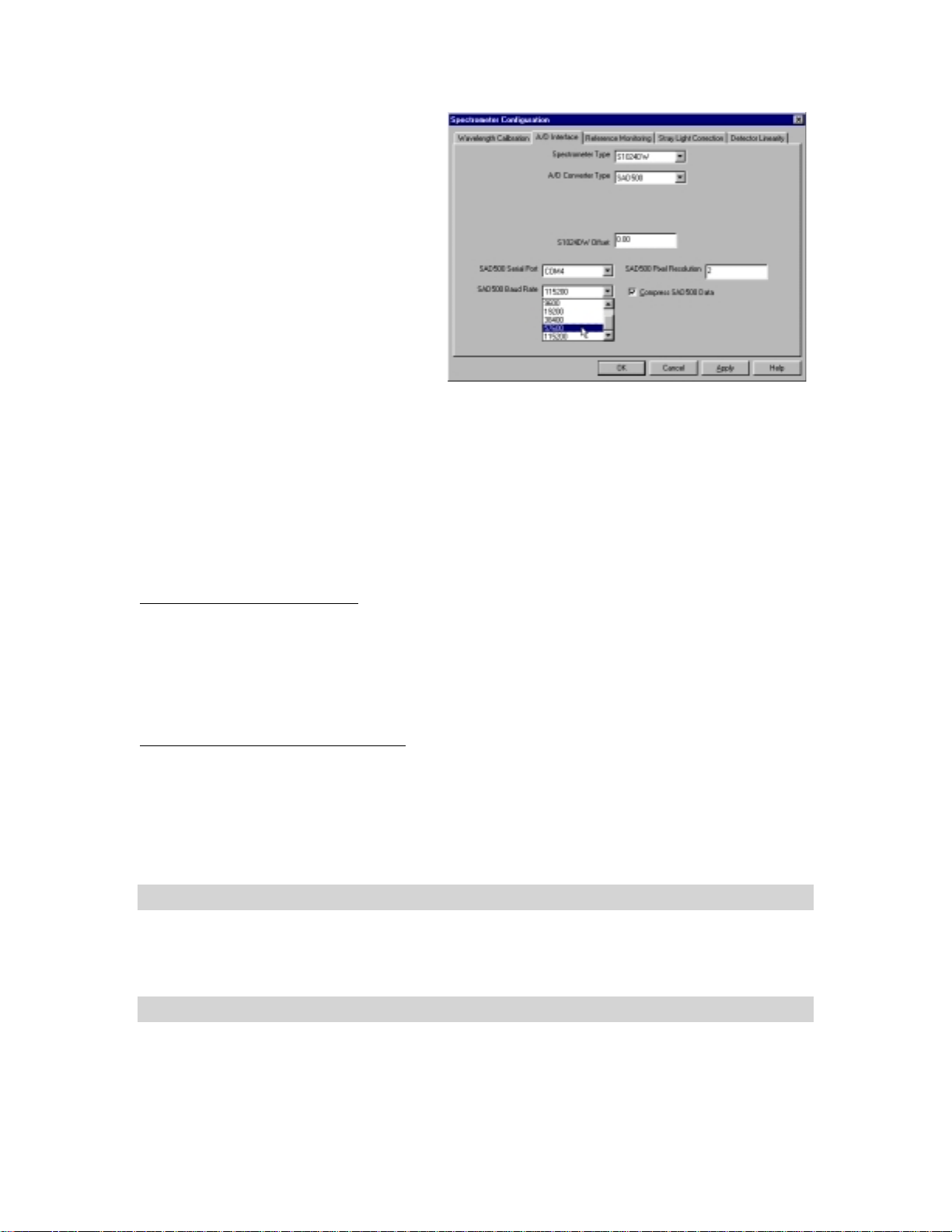

Spectrometer Configuration Dialog Box

Now tha t OO I Ba s e3 2 is running , you need to configure your s ystem. Select

from the menu. Go through each page in the

Spectrometer Configuration

paramet e rs. (For det ailed i nform a tion on each page of this dialog box, see the

Operating Software Manual

or the software’s help files.)

4

Spectrometer | Configure

dialog box to set system

OOIBase32 Spectrometer

Page 8

• In the

• In the

• The

At this point, OOIBase32 should be acquiring data from your spectrometer. There should be a dynamic trace

responding to light near the bottom of the displayed graph.

When you exit OOIBase32, all of this configuration information will be stored in the spectrometer

configuration file. The next time you run OOIBase32, the software will use the

file as the standard for your spectrometer configuration. If you wish, save the spectrometer configuration

file with a different name by choosing

Wavelength Calibration

coeffi cients for each spectrometer ch an nel

in your system have already been loaded

as part of the spectrometer configuration

file. Check the

spectrometer chan nel in your system.

A/D Interface

settings and va lues as you di d in the

Conf igure Hardware

S1024DW Offset function allows you to

adjust th e signal baseline. Some

S1024DW units have a negative baseline,

which d oes not affect any data since all

data is referenced f ro m the same bas eline.

If your unit has a negative baseline and

you want to insure the baseline (and

therefore your data) is positive, you can enter an offset value to raise the baseline.

Detector Linearity

Enabled

box for each

page, enter the same

dialog box. The

page is for spectrom eters other than the S1024DW.

page, the

Spectrometer | Save Configurati on As

[your serial number].spec

from the OOIBase32 menu.

OOIBase32 Settings Dialog Box

At this point, it is a good idea, though not necessary, to configure several OOIBase32 operation parameters.

Choose

of this di a log box to selec t options for sa ving, opening, an d printing data; to choose waveform sound files

for various program events; to configure default setting files; and to select other important options such as

storing and copying data and choosing warning messages. (For detailed information on each page of this

dialog box, see the

Edit | Settings

OOIBase32 Spectrometer Operating Software Manual

from the menu to open the

OOIBase32 Settings

dialog box. Go through each page

or the software’s help files.)

Configure Data Acquisition Dialog Box

Fina lly, select

parameters in the

time and choose averaging and boxcar smoothing values. The

the ext ernal tri g ger mode and automatically save dat a for each ext ernal trigger. The

to control external str obe events with the spectrometer. (For detail ed information on each pa g e of t h is

dialog box, see the

Spectrum | Configure Data Acquisition

Configure Data Acquisition

OOIBase32 Spectrometer Operating Software Manual

dialog box. The

from the menu to set your data acquisition

Basic

External Trigger

page allows you to set the integration

page allows you to specify

Strobe

page a llows you

or the software’s help files.)

Step 4: Connect sampling optics

Check the

optics suc h as light s ources, sampling cham be rs, fibers, and other accessories .

Table of Contents

to find st ep - b y-step direction s for s etting up an d operatin g sp ecific sam p ling

Step 5: Start the software and receive data

Run OOI Base32 in Scope M ode and tak e a dark spectrum and a refer ence spectrum (see the

Tutorial

sample measurements.

section for details). Choose the absorbance, transmission, or relative irradiance mode to take your

5

Experiment

Page 9

Troubleshooting

Occasionall y, there will be problems associat ed wi th your PC configuration and the software. Here are a

few tips to assist you.

• To ensure that the software and h ar d wa re are in-syn ch, exit OOI Ba s e3 2 , cycle power on the SAD50 0

and restart OOIBase32.

• In Windows 95/9 8, you ca n find out your Serial Port number by selecting

Panel.

Then double-click on the

Ports (COM & LPT)

and this will display the COM port numbers. Ensure that there is no yellow or

System

icon and s elect the

Device Manager

Start | Settings | Control

tab. Double-click on

red warning sign next to the COM Port you are attempting to use.

• If the ports on your PC are not labeled and you don’t know which COM port you are using for your

SAD500, you may have to resort to trial and error. If you choose the wrong serial port number, you

will not see a dynamic trace responding to light near the bottom of the displayed graph. Instead, you

will see a straight line.

• The default baud rate is 57,600. If your computer is not capable of communicating at this speed, select

Spectrometer | Configure

SAD500 Baud Rate

, select a s lower baud ra t e.

from the O OIBase32 m en u an d choose the

A/D Interface

page. Under

• On some computers, users may have to disable any virus protection software to ensure timely and

complete transfer of the data.

Getting Help

Comprehensive online assistance is available from OOIBase32’s Help menu. The Help files provide

instructions on all buttons, options, items, and dialog boxes in OOIBase32. However, if the online Help

does not answer your question, please con tact Ocean O pt ics.

Ocean Optic s, Inc.

380 Main Street

Dunedin, FL 34698

(727) 733-2447

(727) 733-3962 f ax

TechSupport@OceanOptics.com

SAD500 Specifications

A/D resolution: 12-bit

A/D sampling frequency: 500 kHz (maximum)

Communication port: RS-232

Baud rate: 2400-115,200

Input voltage: 10 – 24V

Input current: 130 mA without spectrometer

Interface cable: 9-pin connector to PC, 25-pin connector to spectrometer

Multiple-channel capability: supports up to 8 spectrometer channels

Spectrometer compatibility: supports all S1024DW spectrometers

Software compatibility: supports all 32-bit Ocean Optics software products

Spec trometer integ ration time:

31 milliseconds to 60 seconds (S1024DW spectrometers)

5 milliseconds to 60 seconds (S2000 spectro mete rs)

6

Page 10

Light Sources

Ocean Optics light sources provide illumination and excitation sources in the UV, VIS or Shortwave

NIR ran g e for absorban ce or reflection measurement s, d iscrete line spectra for waveleng th calibrations,

and cal ibrated a bsol u te inten s ity standards for irra diance measurement s. Wall transformers are

supplied for laboratory use. Except for the deuterium lamps, all sources are powered by +12 VDC to

facilitate their use in the field. The S1024DW accepts light energy and disp erses it via a fi xed grating

across the array, which is responsive from 200-1100 nm. Though some light sources emit energy

<200 nm, or emit energy to 2

detector’s responsivity (200-1100 nm).

The D-1000 Deuterium Light Source is a high-output, fiber optic

light source optimized for the UV. It produces intense, continuous

spectral output from ~200-400 nm.

The DT-1000 Deuterium Tungsten Halogen Light Source combines

the con tinuous spectrum of a UV and VIS/NI R li gh t s ource in a

single optical path. Its output range is ~200-1100 nm.

µ

m, their u s e with Ocean O pt ics spectrom eters is limited by our

The LS-1 Tungsten Hal og en Light S ource is a versatile sour ce for the

VIS-Shortwave NIR (360 nm-2 µm). It offers high color temperature, a

long life and a built-in filter slot for color-correcting and other uses.

The LS-1 -CAL Calibrated Ligh t Source is a NIST-traceable

calibrated light source for the VIS-Shortwave NIR (300-1050 nm).

It has a highly Lambertian internal diffuser, and is specifically

calibrated for optical fibers. The calibration data includes absolute

inten s ities at th e fi ber entran ce port for wavel engths bet we en

300-1050 nm.

The PX-2 Pulsed Xenon Lamp (~225-700 nm) is a 220 Hz short-arc

flashlamp. It produces high-energy pulses of brief duration and has two

trigger modes for the hardware or software controlled flash rate.

The HG-1 Mercury Argon Calibration Source produces Mercury and

Argon emission lines from 253-922 nm for use in performing fast, reliable

spectrometer wavelength calibrations.

7

Page 11

Light Sources: D-1000 Deuterium Light Source

D-1000 D

The

for the UV. The D-1000 produces intense, continuous spectral output from ~200-400 nm, making it especially

useful for UV spectroscopy. The D-1000 has a highly stabilized microprocessor-based power supply designed

for optimum stability, with a maximum fluctuation of just 0.05% peak-to-peak and drift of +/- 0.5%/hr. The

lamp can be controlled from th e s witches on th e front pan el or through dig ital lin es.

• D-1000 Deuterium Light Source

• Safety eyewear for protection against dangerous ultraviolet radiation

• Power cord for connecting D-1000 to outlet

• Allen wrench for adjusting the focus of the collimating lens

The beam emerging from the D-1000 produces visible light and invisible ultraviolet radiation. Direct

!

contact with the beam could cause serious eye injury. Safety eyewear must be worn at all times while

operating the D-1000. Do not remove any safety device installed.

Dan gerous volt ages presen t.

Only qualified service personnel should service the D-1000.

""""

This instrument should not be used for any clinical or diagnostic purposes.

""""

Handle with care. Dropping the D-1000 ma y caus e p erman ent damag e.

""""

For optimum performance below 230 nm, use a solarization-resistant fiber with this lamp.

""""

EUTERIUM LIGHT SOURCE

is a high-output, high stability fiber optic light source optimized

Parts I nc luded

Caution!

Operation

1. Put on safety eyewear.

2. Lift t he black protective shutt er cover ing the fiber opt ic port . Remov e t he red pla s t ic cap that cov ers

the SMA connect or and insta l l a n optical fiber. (For be s t results, use our sola rizat ion-resi s t a nt fibe rs. )

3. Plug the power cord into the rear of the D-1000. Plug the other end into a 110 VAC outlet.

4. Locate the black p ower s wi tch at the rear of the D-10 0 0, just above where the p ower cord conn ects to

the D-1000. Turn on the power. When the power is on, the green

right of the front pan e l will l ight.

5. Push in the

Pushing in the

deuterium lam p i on izes the available deu t erium. At this point , th e yell o w

panel will light. Next, after ~30 seconds, the red

light. (The

deuterium lamp is ready for your application. Best results are obtained after the lamp has warmed up

for 30 minutes.

6. Without a solarization-resistant fiber, the spectral output will decrease significantly as a function of

time at wavelengths lower than 230 nm.

7. To turn off the deuterium lamp, first press the white

flip the power switch at the rear of the D-1000, just above where the power cord connects to the

D-1000. The green

8. Lift up th e black protec tive shutter and disconnect your op tical fiber from the SM A c onnector.

9. Replace t he red plas tic cap over the SMA connector.

UV Start

UV Start

Heater On

Pow er On

button located on the front panel. This white button turns on the deuterium lamp.

button in itiates the start up sequence for th e lamp. Firs t, the heater in the

UV On

light located at the top of the front panel will

light will turn off at the same time.) Once the red

UV Off

light on the front panel will go out.

Pow er On

button located on the front panel. Then,

light located at the bottom

Heater On

UV On

light on the front

light is lit, the

8

Page 12

Bulb Replacement

1. Order a replacement bulb, item D-1000-B, from Ocean Optics.

2. Make sure the D-1000 is turned off, the power cord is disconnected and the lamp has cooled.

3. Use a Phillips-head sc rewdriver to rem ove all 12 screws from t he si de pane ls of th e D -1000 c asing .

not

remove any screws fr om the front, back, or bottom panels. Re move the cover.

4. Locate the deuterium bulb. It is located at the front of the housing, mounted on a black platform. Three

wires lead from the bottom of the bulb to the bright green electronic board: one red wire (with a time

indicator on it) and two black wires.

5. Use a Phillips-h ead screwdriver to loosen the scr ews securing these three wires t o the green elect ronic

boar d. Once the screws are loose, gently rem ove the red wir e and the two black wi res. You d o n ot n eed

to compl etely rem ove the screws to detach th e wi res. (Note that on the gr een electr on ic board, ju s t

right of ea ch wir e , is a letter. To th e right of t he red wire i s t he let ter “A” . To the r ight of one bla c k

wire i s the letter “H” and to the right of the second black wire is the letter “C”.)

6. In order to remove the bulb, you will need to unscrew the nut holding the collimating lens and SMA

connector in place. It is positioned in such a way that if the nut remains in place, you will not be able to

take out the deuterium bulb. Use a 3/8” wrench to rem ove the nut.

7. Use a Phillips-head sc rewdriver to rem ove the two s c rews s e cur i ng th e bu lb to the black pla tform.

8. Remove the old bu lb unit.

9. Insp ect the new bulb unit, but

avoid touching the glass casing

(or envelope) around the bulb as the

oils from your skin will deteriorate the bulb. Inside the envelope is a triangle-shaped filament. The

filament has a

square

opening. The light passes through the square opening to the collimating lens.

Take the new bulb, ca refully feeding th e three wires th rough th e hole in the bla ck p latform, an d

position it so that the square opening in the filament faces the collimating lens.

10. Screw in the two screws that secure the bulb to the black platform.

11. Screw on the nut that holds the collimating lens in place.

12. Secure the three wires to the gr een electron ic board. At tach the red wire to the top screw, labeled “A”.

Attach the bla c k wires to the sc rews on the boa rd labeled “ H” and “C”.

black wire is attached to screw “H” or “C”

.

It does not matter which

13. Put the D-1000 cover back on and secure it with the 12 screws.

Do

For directions on adjusting the focus of the collimating lens on the D-1000, turn to

Appendix A

Specifications

Spectral range: ~200-400 nm

Time to stabilized output: ~30 minutes

Power consumption: 25-30 Watts

Bulb lifetime: 1,000 hours (replacement bulbs available)

Stability: peak-to-peak = 0.05% (maximum); drift of +/-0.5%/hour

Ape rtu re: 0.5 mm (at lamp )

Connector: SMA 905

Window material: 0.4 mm thickness UV-transmissive glass

Lamp voltage: 85 volts DC (nominal)

Operating lamp current: 300 mA DC (+/- 1mA)

Timing: microprocessor-based

Inputs: trigger inputs for lamp (on/off)

Outputs: levels for lamp (on/off), filament (on/off)

120 volts AC @ 0.50 A, 50-60 Hz

Power requirements:

220 volts AC @ 0.25 A, 50-60 Hz

100 volts AC @ 0.60 A, 50-60 Hz

240 volts AC @ 0.20 A, 50-60 Hz

.

9

Page 13

Light Sources: DT-1000 Deuterium Tungsten-Halogen

!

Light Sou rce

DT-1000 D

The

deuterium UV light source and a tungsten-halogen VIS/Shortwave NIR light source in a single optical path.

The combined light source produces a powerful, stable output from ~200-1100 nm. It also has a highly

stabilized microprocessor-based power supply designed for optimum stability.

EUTERIUM TUNGSTEN-HALOGEN LIGHT SOURCE

Parts I nc luded

• DT-1000 Deuterium Light Source

• Safety eyewear for protection against dangerous ultraviolet radiation

• Power cord for connecting DT-1000 to outl et

• Allen wrench for adjusting the focus of the collimating lens

Caution!

The beam emerging from the DT-1000 produces visible light and/or invisible ultraviolet radiation.

!

.

Dir ect contact with the beam cou ld cause serious eye injury. Saf ety eyewear must be worn at all times

while operating the DT-1000. Do not remove any safety device installed.

Dan gerous volt ages presen t.

Only qualified service personnel should service the DT-1000.

""""

This instrument should not be used for any clinical or diagnostic purposes.

""""

Handle with care. Dropping the instr um en t may cause per manen t dam age.

""""

For optimum performance below 230 nm, use a solarization-resistant fiber with this lamp.

""""

combines the continuous spectrum of a

Operation

Allow several minutes for the lamp to warm up and for the power to stabilize, regardless of the bulb being

used. Best results are obtained after 30 min u tes. The sp ectral output as delivered by an optical fiber will

decrease significantly at wavelengths lower than 230 nm due to attenuation in the lamp envelope, the

decrease in detect or efficiency in the spectrom eter, and att enuation b y the fiber.

1. Put on safety eyewear.

2. Lift t he black protect ive shutter cover ing the fiber optic por t. Install an opti ca l fiber. (For best results,

use our solarizat i on-r esi st ant fibers.)

3. Plug the power cord into the rear of the DT-1000. Plug the other end into a 110 VAC outlet.

4. To turn on the power for the DT-1000, flip the power switch at the rear of the unit, just above where the

power cord connects to the DT-1000. When the power is on, the green

bottom r ight of the front panel will light. At this time the user can now po wer up the deuterium or

tung sten-hal og en sou rce or both . ( S ee

source

.) To turn off the DT-1000, both deuterium and tungsten-halogen sources must be off first. Only

then can the user flip the power switch at the rear of the unit to the off position. The green

light will turn off.

5. Lift up th e black protec tive shutter and disconnect your op tical fiber from the SM A c onnector.

Operating the D euterium source

Operating the Deuterium source

6. To power the deuterium lamp, push in the

button turns on th e d eu terium lamp. Pushin g in the

UV Start

button located on the front panel. This white

UV Start

button ini tiates th e start-up s eq u ence for

Power On

Operating the Tungsten - Halogen

and

light located at the

Power On

10

Page 14

the lamp. First, th e heater in the deuteri um lamp ionizes th e available d eu terium. At this poin t, the

Heater On

yellow

the top of the front panel will light. (The

7. To turn off the deuterium lamp, press the white

On

light shou ld go out.

light on th e front pan el will light. Aft er ~30 second s, the red

Heater On

light will turn off at the same time.)

UV Off

button located on the front panel. The red

UV On

light located at

UV

Operating the Tungsten-Halogen source

8. To power the tungsten-halogen lamp, push in the white button labeled

light will come on.

9. To turn off the tung st en-halogen lamp, pres s the white

The red

Vis. On

light will go out.

Visible On

button loca ted on t he front panel.

Visible On

. The red

Vis. On

Bulb Replacement

Replacing the Deuterium bulb

1. Order a deuterium replacement bulb, item DT-1000-BD, from Ocean Opt ics.

2. Make sure the DT-1000 is turned off, the power cord is disconnected, and the source has cooled.

3. Use a Phillips-head screwdriver to remove all 12 screws from the side panels of the DT-1000 casing.

Do not

remove any screws from the front, back, or bottom panels. Remove the cover.

4. Locate the deuterium bulb. It is located at the front of the housing, mounted on a black platform. Three

wir e s lead from th e bottom of the bulb to the gre en el ec t roni c board : one red wire and two black wires.

5. Use a Phillips-h ead screwdriver to loosen the scr ews securing these three wires t o the green elect ronic

boar d. Once the screws are loose, gently rem ove the red wir e and the two black wi res. You d o n ot n eed

to compl etely rem ove the screws to detach th e wi res. (Note that on the gr een electr on ic board, ju s t to

the ri gh t of ea ch wire, is a letter. To the right of th e red wire is the letter “A”. To the right of one black

wire i s the letter “H” and to the right of the second black wire is the letter “C”.)

6. Use a Phillips-head sc rewdriver to rem ove the two s c rews s e cur i ng th e bu lb to the black pla tform.

7. Remove the old bu lb unit.

8. Insp ect the new bulb unit, but

oils from your skin will deteriorate the bulb. Inside the envelope is a triangle-shaped filament. The

filament has a

Take the new bulb, ca refully feeding th e three wires th rough th e hole in the bla ck p latform, an d

position it so that the square opening in the filament faces the collimating lens.

9. Screw in the two screws that secure the bulb to the black platform.

10. Secure the three wires to the gr een electron ic board. At tach the red wire to the top screw, labeled “A”.

Attach the bla c k wires to the sc rews on the boa rd labeled “ H” and “C”.

black wire is attached to screw “H” or “C”

11. Put the DT-1000 casing back on an d secure it with the 12 screws.

square

opening. The light passes through the square opening to the collimating lens.

avoid touching the glass casing

.

(or envelope) around the bulb, as the

It does not matter which

Replacing the Tungsten-Halogen bulb

1. Order a tungsten-halogen replacement bulb, item DT-1000-BT, from Ocean Optics.

2. Remove all 12 screws from the side panels of the DT-1000 casing using a Phillips- head screwdriver.

Do not

remove any screws from the front, back, or bottom panels. Remove the cover.

3. Locate the tungsten-halogen bulb. It is inserted on the top of a cylindrical unit held by a set screw in a

hole in the black platform. The cylindrical unit is positioned behind the deuterium bulb. Two thin wires

lead from the bott om of the unit to a socket on the electroni c board.

4. Gently grip the top of the bulb and pull it away from the cylindrical unit. Discard the bulb.

5. Insert the new bulb into the top of the cylinder, being careful to position the bulb’s pins over the holes

in the t op of the cylinder.

""""

The c ylindric al unit is held in place with a small set screw. By loos ening i t, th e user can sli de the

bulb unit up and down, positioning it in front of the attenuator, a metal disc that attenuates the light

before going through the collimating lens. Another set screw holds the attenuator in place.

6. Put the DT-1000 casing back on and secure it with the 12 scr ews.

For directions on adjusting the focus of the collimating lens on the DT-1000, turn to

11

Appendix A

.

Page 15

Specifications

Spectral range: ~200-11 00 nm

Time to stabilized output: ~30 minutes

Deuterium bulb lifetime: 1,000 hours

Tungsten-halogen bulb lifetime: 900 hours

Power consumption: 25-30 Watts

Stability:

Ape rtu re: 0.5 mm (at lamp )

Connector: SMA 905

Lamp voltage: 85 volts DC (nominal)

Operating lamp current: 300 mA DC (+/- 1mA)

Inputs: trigger inputs for lamp (on/off)

Outputs: levels for lamp (on/off), filament (on/off)

Power requirements:

peak-to-peak = 0.05% (maximum)

drift of +/-0.5%/hour

120 volts AC @ 0.50 A, 50-60 Hz

220 volts AC @ 0.25 A, 50-60 Hz

100 volts AC @ 0.60 A, 50-60 Hz

240 volts AC @ 0.20 A, 50-60 Hz

12

Page 16

Light Sources: LS-1 Tungsten Halogen Light Source

!

LS-1 T

The

Shortwave NIR (360 nm-2

temper ature and extremely efficient output.

• LS-1 Tungsten Halogen Light Source

• 12 VAC power supply

• Allen wrench for adjusting the collimating lens

UNGSTEN HALOGEN LIGHT SOURCE

µ

m). The lamp, with either a 900-hour or 10,000-hour bulb, offers high color

is a versatile, white-light lamp utilized for the VIS-

Parts I nc luded

Caution!

The LS-1 becomes

DO NOT in sert plastic or flamma bl e materials in the filt er s lot. The material s could melt or ignite.

The unit could ignite flammable materials that come in contact with the metal housing.

HOT

during operation. No cooling fan is installed in the LS-1. Handle with care.

Operation

Turning On the Lamp

1. Plug the wall transformer end into a standard 110 V outlet. Plug the 12 V output end into the back of

your L S -1.

2. Scr e w a fiber into t he SMA c onnector on you r LS- 1.

3. Find the on/off switch on the back of the lamp and turn the lamp on. Allow the lamp to warm up for

approxi m atel y 30 minutes.

Using the Filter Slot

The slot between the lamp and the fiber coupler can be used to hold filters or light blocks. You can place a

filter into the filter slot; however, be aware of the following:

• The filter slot accepts filters up to 3 mm thick.

• Because the lamp can become hot, avoid plastic filters as they may melt.

• The uni t could igni te flammabl e materials that come in contact with the meta l h ou s ing.

• There is no filter clamping screw for holding filters in place.

The most useful filters include the following:

• an FG-3 blue filter for increasing the relative energy near 400 nm and 800 nm compared to 600 nm

• an IR cutoff filter to reduce stray light below 750 nm

• a 550 nm long pass filter to eliminate second-order effects on Shortwave NIR measurements

Replacing the Bulb

1. Order a rep lacement bu lb (LS- 1-B for a 90 0-hour bulb or LS-1 -LL-B for a 10,000- hour bu lb).

2. Turn off the LS-1 and allow the lamp to cool.

3. Use an Allen wrench to loosen the set screw on the bottom of the lamp. You do not need to remove the

set screw. This screw holds the bulb in place.

13

Page 17

4. Locate the two set screws at the ba ck of t he lamp, one above each ba ck leg. These two screws keep t he

two halves of the lamp together. Remove the two screws.

5. Gently separate the two halves of the lamp.

6. Carefully pull the bulb out of its housing. Detach the wire and lamp leads from the socket. Remove the

old bulb un it an d discard.

7. Plug th e new bulb into the socket.

8. Slide the new bulb forward into the front of the lamp as far as it will go.

9. Gently tighten the set screw on the bottom of the lamp.

10. Close together the two halves of the lamp, being careful not to pinch the wires.

11. Replace the two screws at the back of the lamp.

For directions on adjusting the focus of the collimating lens on the LS-1, turn to

Appendix A

.

Specifications

Spectral range:

Dimensions:

Power input: 12 VDC/800 mA, 7-20 VDC/0.5-2 amps

Power output: 6.5 watts

Bulb life: 900 hours (standard), 10,000 hours (long-life)

Bulb color temperature: 900-hour bulb = 3100K, 10,000-hour bulb = 2800K

Out put to bulb: 5 volts/1.3 am ps

Output regulation: 0.2% voltage

Time to stabilized output: ~30 minutes

Bulb output: 7400 foot-candles (7.4MSCP)

Connector: SMA 905

*

The LS-1 has a spectral range of 360 nm-2 µm, however the range is limited to the spectral response

of the detector. For the S1024DW, the detector’s response goes to 1100 nm.

360 nm - 2 µm*

9.0 cm x 5.0 cm x 3.2 cm (LWH), 3 . 5

”

x 2.0” x 1.25” (LWH)

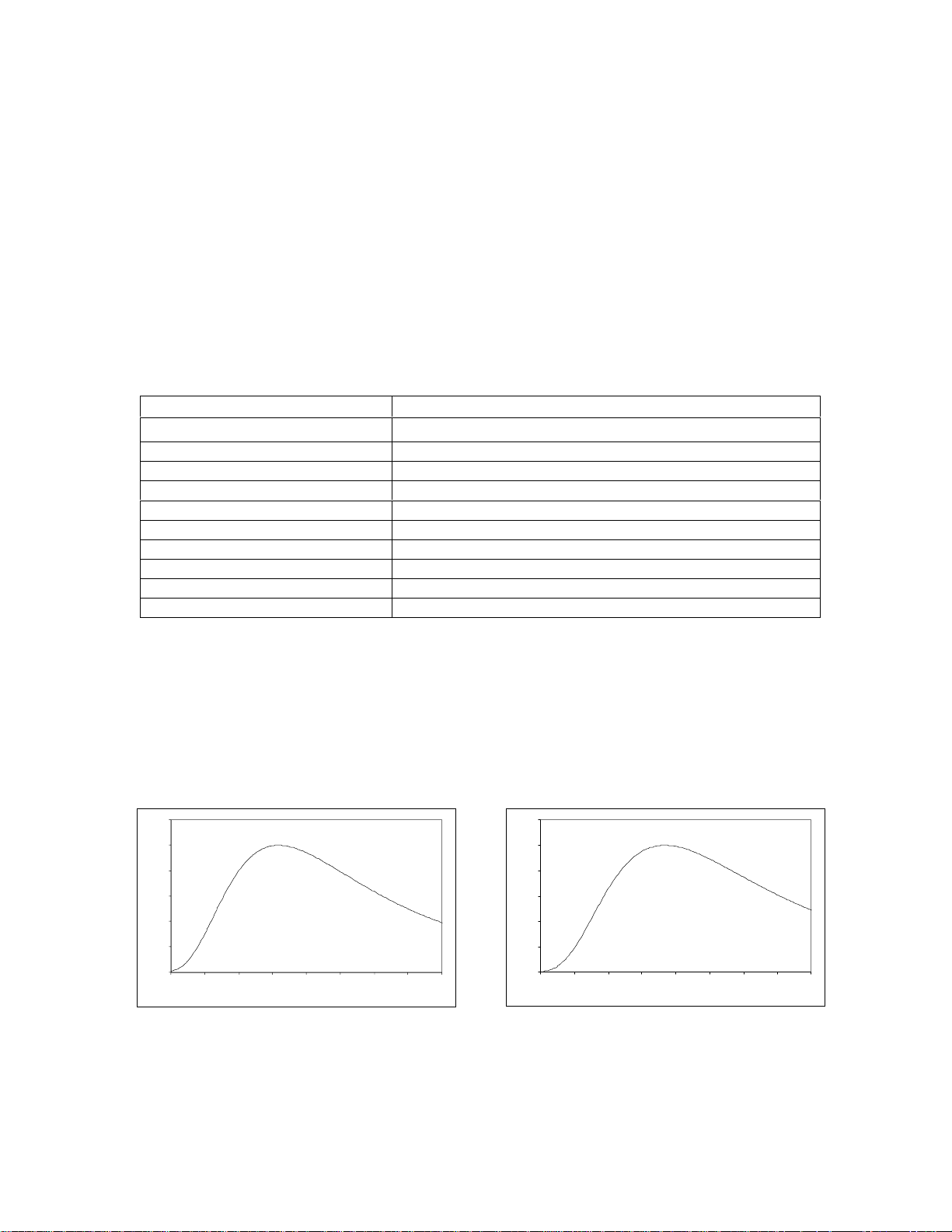

Spectral Output

These gr aphs repres ent normalized bla ck body curves for tung sten halogen li ght sources with 2800K an d

3100K color temperatures. The observed spectral output of the LS-1 will vary due to bulb type, the

spectrometer configuration, the sampling optics used, and inherent fluctuations in LS-1 output.

1.2

1

0.8

0.6

0.4

Normalized Intensity

0.2

0

300 500 700 900 1100 1300 1500 1700 1900

Wavelength (nm)

900-hour bulb / 3100K 10,000-hour bulb / 2800K

14

1.2

1

0.8

0.6

0.4

Normalized Intensity

0.2

0

300 500 700 900 1100 1300 1500 1700 1900

Wa ve l e n gth (nm )

Page 18

Light Sources: PX-2 Pulsed Xenon Lamp

PX-2 P

The

absorba nce, reflection, fluorescence and ph osphorescence measurements. The PX-2 opera tes at speeds u p

to 220 Hz and offers critical pulse-to-pulse stability.

• PX-2 Pulsed Xenon Lamp

• 15-pin cable for connecting the PX-2 to the spectrometer

• 12V DC wall transformer for supplying power to the PX-2

The beam emerging fr om the PX-2 produ ces u ltraviolet radiation . Direct cont act with the bea m could

!

cause serious eye injury. Never look directly into the light source.

Dan gerous volt ages presen t. Never operat e the PX-2 with out its hou s i ng intact.

The SMA con nector may get

This instrument should not be used for any clinical or diagnostic purposes.

""""

Handle with care. Dropping the instr um en t may cause per manent dam age.

""""

ULSED XENON LAMP

is a high flash rate, short-arc xenon lamp for applications involving

Parts I nc luded

Caution!

HOT

during operation.

Operation

The lamp is triggered with TTL pulses delivered through the 15-pin connector located at the rear of the

unit. Our S1024DW- s eries spectrometers and software, or any sour ce o f TTL signa ls, supplies these pul s es.

The lamp is powered by a 12V DC transformer, or from a 12V battery if field use is desired.

1. Plug the wall transformer into a 110V outlet. Plug the other end of the cord into the jack at the rear of

the PX- 2 .

2. Install the 15-p in cable int o the rear of the PX-2. Conn ect the other end to the 15-pin connect or on an

S1024DW.

3. Connect an optical fiber to t he SMA -term i nate d fiber optic port on the front panel.

4. Turn the power switch located at the rear of the source to the “ON” position.

5. Select ei ther “MULT I P LE ” or “SINGLE ” fl ash mode by moving the toggle on the rear of t he source.

You will need to match this mode in the operating software.

6. Config ure OOIBase3 2 operating software to operate the PX-2. In the

bar, ch eck the

Data Acquisition

7. The fla sh should fir e wi th a clearl y au d ible “pin g. ”

Strobe Enable

from the men u and then choosin g t he

box. You can also enable this function by selecting

Strobe

Acquisition Parameters

Spectrum | Configure

page of the dialog box.

dial og

Applic at ion Tips

Single Flash Mode

Using the Single flash mode results in one flash per integration cycle. Since the PX-2 has a maximum

repetition rate of 220 Hz, the minimum integration allowed in this mode is 31 milliseconds.

15

Page 19

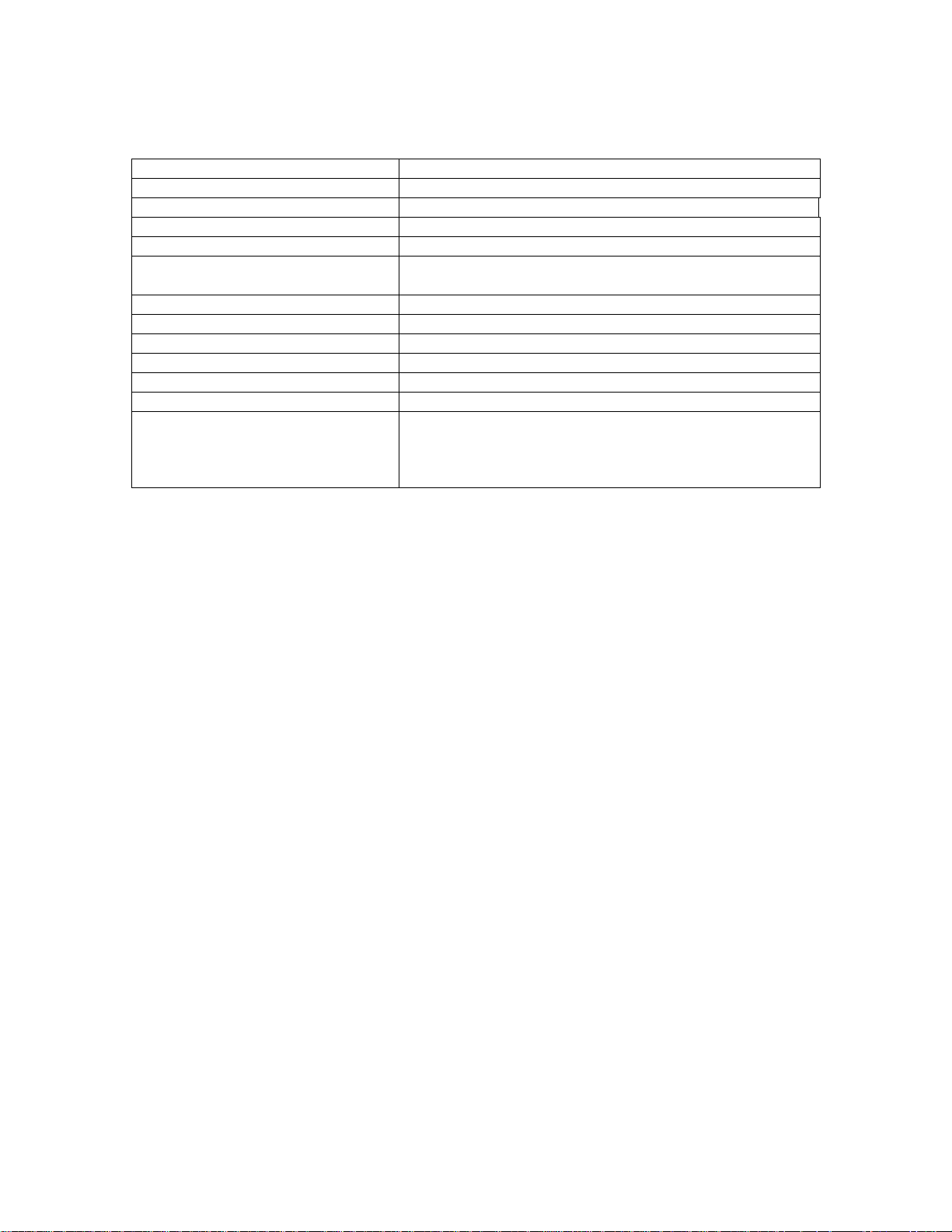

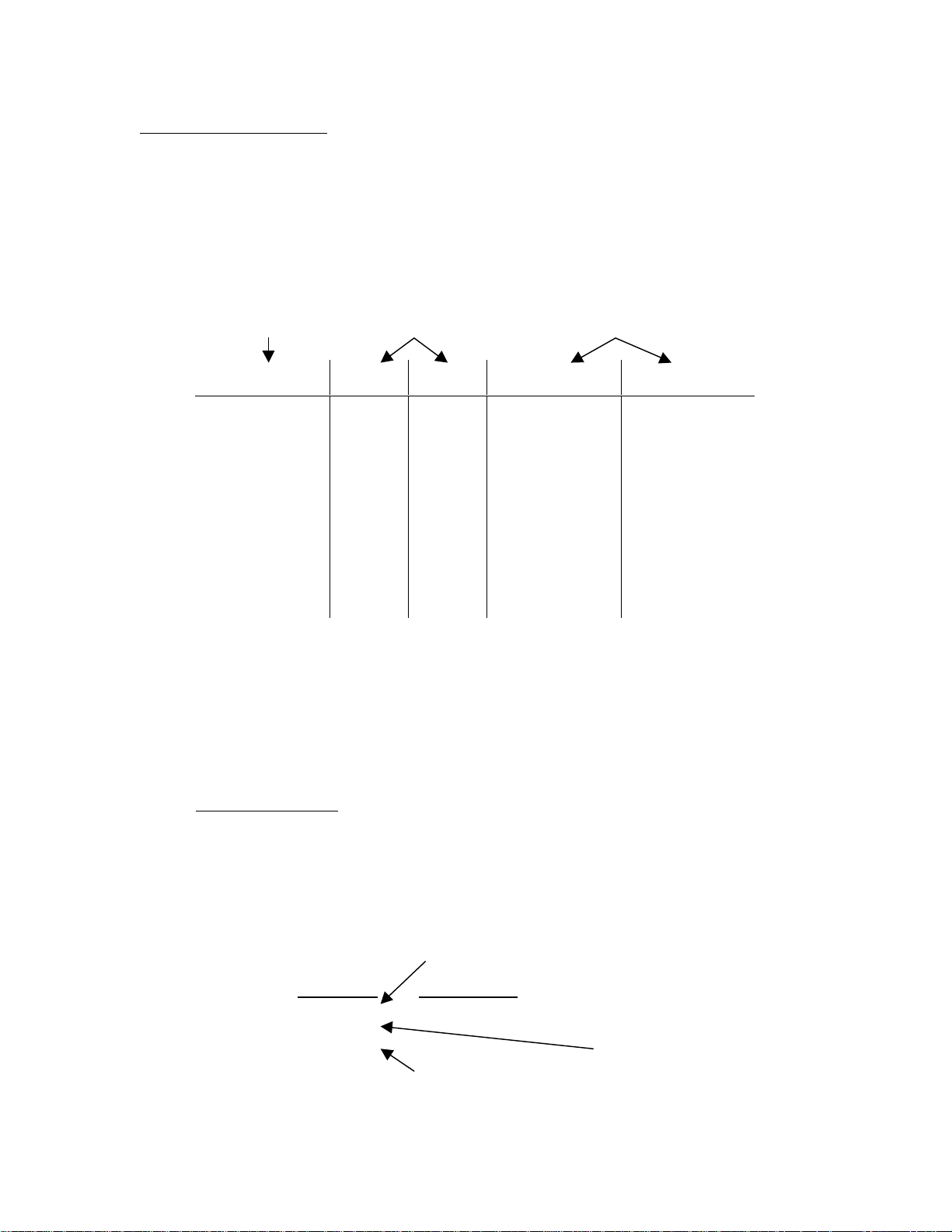

Multiple Flash Mode

When u sing the Multi p le flash mode the user needs to ensur e tha t a constant nu m ber of flashes occurs for

every integration cycle by setting the pulse rate and integration time. This achieves a continuous and stable

signal. The pulse rate is determined by a jumper setting inside the S1024DW (JP3). The integration time is

controlled via the operating softwar e. To achieve a constant n um ber of flash es p er integration cycle, the

integration time must be a multiple of those shown in the following table:

S1024DW JP3 setting

(factory default)

216

14

2

12

2

10

2

Integr atio n t ime must be a

multiple of

128

32

8

N/A

The PX-2 repetition rate is controlled via the S1024DW (JP3), but is also dependent upon the frequency of

your A/D card. With the S1024DW, the SAD500 operates at 200 kHz, the fastest rate the S1024DW allows

the SAD500 to operate. The table below shows the rep rate for the various combinations of hardware and

jumper settings. (Note that the default setting fr om the factory is 2

JP3 Post # Function Frequency (Hz)

1 Not enabled - for future software control

2 Divide by 2

3 Divide by 2

4 Divide by 2

5 Divide by 2

10

12

14

16

16

.)

195

48.8

12.2

3.1

Specifications

Spectral range: 220-750 nm

•

Approximate dimensions:

Power input:

Trigger input: external TTL positive pulse via 15-pin connector

Output:

Pulse duration: 5 microseconds (at 1/3 height of pulse)

Lifetime:

Apertu re: 3 mm

Connector: SMA 905

Timing signals available from

S1024DW spectrometers:

14 cm x 10.5 cm x 4 cm (LWH)

•

”

x 4.1” x 1.5” (LWH)

5.5

•

1.3 A @ 11V @ 220 Hz

•

100 mA @ 12V @ 10Hz

•

45 millijoules per pulse maximum

•

9.9 watts average power

•

220 Hz pulse rate maximum

9

pulses (estimated 230 days continuous operation at 50 Hz

10

pulse rate)

•

Multiple mode = up to 220 Hz (varies with A/D sampling

frequency)

•

Single mode = varies with scan rate

16

Page 20

Light Sources: HG- 1 Mercury Argon Calibration Source

!

!

HG-1 M

The

Shortwave NIR spectrophotometric systems. The HG-1 produces Mercury and Argon lines from 253-922 nm,

for us e in p erforming fa s t, accurat e s p ectrometer wa vel ength calibrati ons. The HG-1 h as an SMA 905

termination for connecting to optical fibers.

The beam emerging fr om the HG-1 produ ces ultraviolet radiation . Direct contact with the beam could

!

cause serious eye injury. Never look directly into the light source.

The SMA con nector may get

Dangerous voltages presen t. No user-serviceabl e p arts inside.

Never take apart th e HG- 1 . The HG-1 con tains mercury.

ERCURY ARGON CALIBRATION SOURCE

HOT

during operation.

Operation

1. Plug the wall transformer end into a standard 110 V outlet. Plug the 12 V output end into the back of

your HG-1. Or, insert a 9V battery (not included).

2. Screw a fi ber into th e S MA con nector on your HG-1. If your spectr om eter does n ot have an entrance

slit, use a 50 µm diameter (or smaller) optical fiber. Larger fibers and slits will have lesser optical

resolution. Also, keep in mind that if the spectrometer has no slit and your experimentation involves

using optical fibers of different diameters, wavelength calibration will be necessary. Calibration is also

recommended each time you un screw the fiber from the s p ectrometer .

3. Find the on/off switch next to the SMA connector and turn the lamp on. The red indicator will light

when the lamp is on.

is a wavelength calibration source for UV-VIS-

Caution!

Calibration

Users can perform wa vel ength calibrati on wi th a spreadsheet progr am such as Microsoft Excel , or a

calculator that performs polynomial regressions. The following describes how to calibrate the wavelength

of your spectrometer using the HG-1. Though each spectrometer is calibrated before it leaves Ocean

Optics, the wavelength for all spectrometers will drift slightly as a function of time and environmental

conditions. To recalibrate the wavelength of your spectrometer, just follow these simple steps.

What You Are Doing:

The rela tionship b etween pixel number a nd wavelength is a second-order polynomial . . .

= I +

λ

p

. . . where λ is the wavelength of pixel p, I is the wavelength of pixel 0, C1 is the first coe fficien t (nm/pixel)

and C

is the second coefficient (n m/pixel2). You will be calculating the valu e for I and th e two Cs.

2

C

+

p

1

What You Will Need:

• Your HG-1 Mercury-Argon lamp.

• Your spectrometer.

• An optical fiber. For spectrometers without a built in slit, a 50-

• Either a spread sheet progr am ( Excel or Qua ttro Pro, for example) or a calculator that per forms second -

order linear r egression s. ( I f you are using Mi crosoft Excel , select

Analysis ToolPak

that

has been chosen.)

C2p

2

µ

m fiber works best.

Tools | Add-Ins

and mak e sure that

17

Page 21

What You Will Need To Do:

1. After placing OOIBase32 into Scope Mode, take a spectrum of the HG-1. Adjust the integration time

until there are several peaks on the screen that are n ot off-scale.

2. Move the cursor to one of the peaks and carefully position it so that it is at the point of maximum

inten s ity. Record the pixel number that is di s p layed in the status bar. Repeat this s tep for all of th e

peaks in your spectrum.

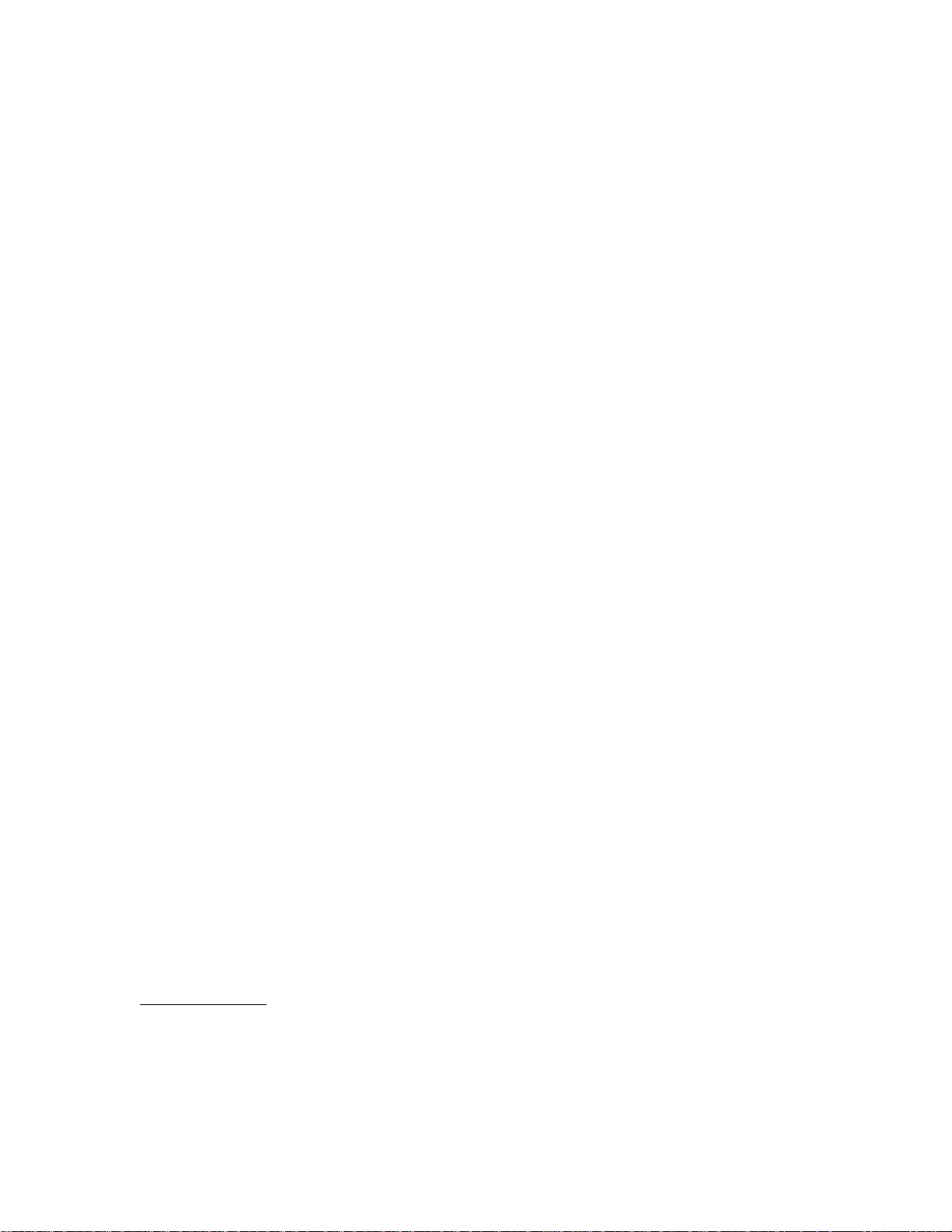

3. Using your spreadsheet, create a table like the one sh own bel ow. In the first column , p lace the exa ct

wavelength of the spectral lines that you used. In the second colu mn of this wor ksheet, pla ce the

observed pixel number. In the third column, place the pixel number squared.

Independent Dependent Values computed from

Variable Variables the regression output

TRUE

Wavelength (nm)

253.65

296.73

302.15

313.16

334.15

365.01

404.66

435.84

546.08

696.54

706.72

727.29

738.40

750.39

Pixel # Pixel #

105

179

188

206

243

298

368

423

626

921

942

984

1007

1033

11025

32041

35344

42436

59049

88804

135424

178929

391876

848241

887364

968256

1014049

1067089

2

Predicted

Wavelength

253.516577

296.979662

302.220703

312.6735

334.037188

365.489132

404.991651

435.615094

545.48766

696.302678

706.638812

727.151647

738.294786

750.814613

Difference

0.133422619

-0.249662049

-0.070702657

0.486499891

0.112812248

-0.479132164

-0.331651335

0.224905808

0.592339659

0.237321917

0.081187518

0.138352544

0.105214107

-0.424612735

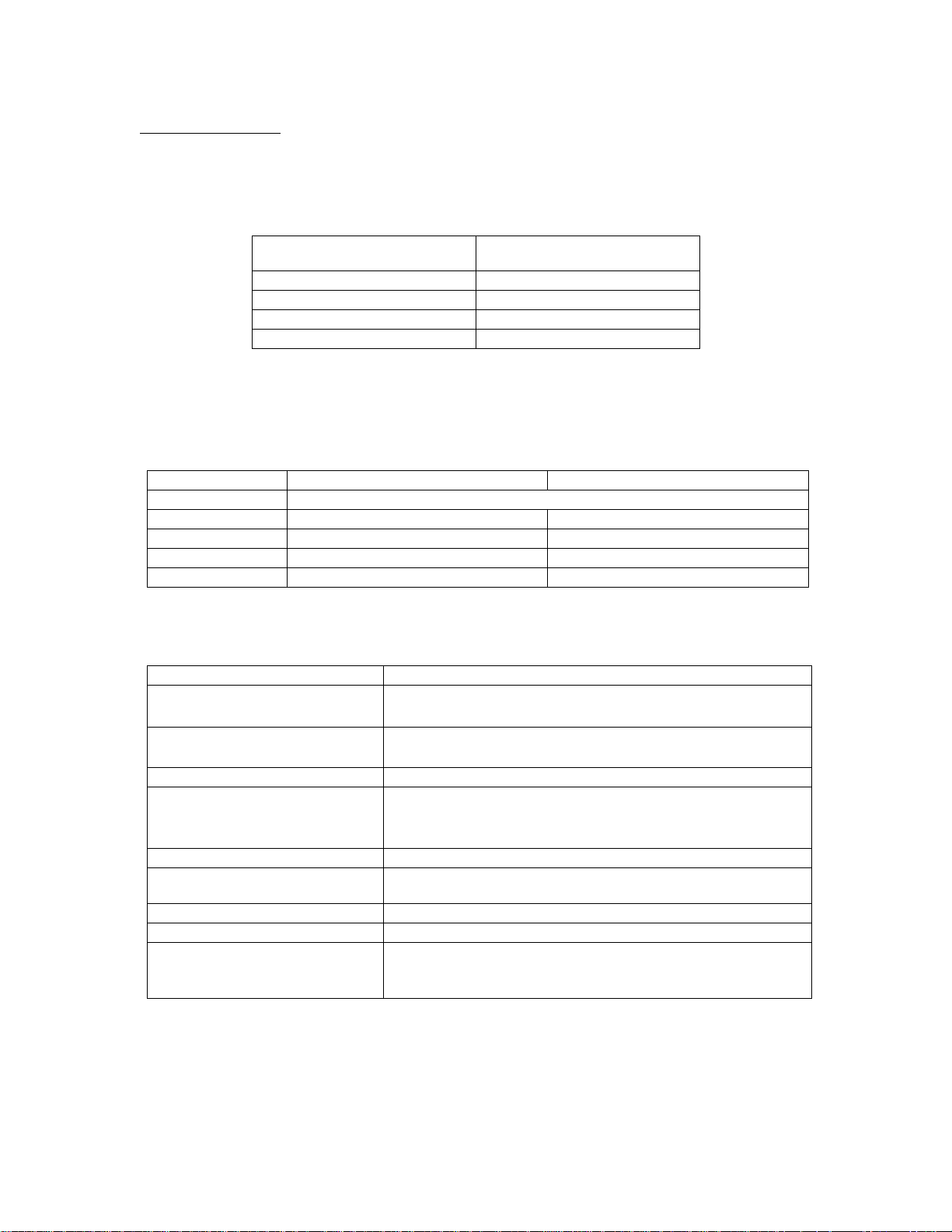

4. Now you are ready to calcu late the wa vel ength calibrati on coefficients. In your s preadsheet program,

find the functions to perform linear regressions:

• in Q uattr o P ro, l ook unde r

• in Excel, look under

Tools | Advanced Ma th

Tools | Data A n alysis

5. Select t he true wavel ength a s the dependen t variable (Y ) . S elect BOTH the pixel nu mber and pixel

number squared as the independent variables (X). After you execute the regression , an output similar

to the one shown be low is obtained.

Regression Statistics

Multiple R 0.999998327

R Square 0.999996654

Adjusted R Square 0.999996096

Standard Error 0.371756477

Observations 15

intercept

Coefficients Standard Error

Intercept 190.713498 0.369047536

X Variable 1 0.604451305 0.001684745

X Variable 2 -6.02547E-05 1.41503E-06

second coefficient

18

first coefficient

Page 22

6. You will need to record the Intercept as well as the First and Second Coefficients. Also, look at the

value for R s quared. It shoul d be very close t o 1. If it is not, you have probably assi gned one or more

spectral lines incorrectly.

7. Select the menu option

Spectrometer | Configure | Wavelength Calibration

to update the

wavelength coefficients within O O I Ba s e3 2.

8. Repeat this pr ocess for each channel in your spectrometer.

Spectral Output

Mercury emission lines are <600 nm.

Argon emissi on lines are >600 nm,

and are shown here on the right on an

exaggerated amplitude scale. Below is

a list of th e most p rominent mercur y

and argon peaks.

Mercury Lines

253.65

296.73

302.15

313.16

334.15

365.01

404.66

435.84

546.08

576.96

579.07

Argon Lines

696.54

738.40

750.39

763.51

772.40

794.82

800.62

811.53

826.45

842.46

912.30

4500

4000

3500

3000

2500

2000

1500

Ar bi t rary I nt e ns i t y

1000

500

0

200 400 600 800 1000

Wavelength (nm)

Specifications

Output:

Spectral range: 253-922 nm

Dimensions:

Power requirements: 12 VDC wall transformer (comes with unit) or 9 VDC battery

Internal voltage: 600 volts at 30 kHz

Bulb life: ~3,500 hours

Amplitude stabilization: ~1 minute

Apertu re: 3 mm

Connector: SMA 905

low-pressure gas discharge lines of Mercury and Argon

11.4 cm x 6.98 cm x 2.54 cm (LW H), 4.5

”

x 6.98” x 1.0” (LWH)

19

Page 23

Light Sources: LS-1-CAL Calibrated Light Source

!

LS-1-CAL C

The

with known absolute intensity values at several wavelengths, expressed in

intensity of the LS-1-CAL can be traced to an intensity standard provided by National Institute of Standards

and Technology (NIST), it can be used in measuring absolute spectral intensities. This lamp has a highly

Lambertian internal diffuser, and its 900-hour bulb has a 3100K color temperature.

• LS-1 -CAL T ungs ten Halogen L ight S ource

• Switching AC adapter for stabilizing power

• Power cord for supplying power to the power supply

• Two Lamp Ca libration repor ts; one for usi ng a bare fiber and one for u sing a CC-3 cos ine-corr e c ted

irradia nce probe

• A disk that holds files for both calibration reports

• Allen wrench for adjusting the collimating lens

ALIBRATED LIGHT SOURCE

for the VIS-Shortwave NIR (300-1050 nm) provides the user

µ

W/cm

2

. Since the spectral

/nm

Parts I nc luded

Caution!

The LS-1 -CAL becomes

DO NOT insert flammable materials in the filter slot. The materials could melt or ignite.

The LS-1 -CAL is not des igned as an illuminati on sou rce for abs orbance, transmission or r efl ection

""""

measurements. The LS-1 Tungsten Halogen Light Source should be used for those applications.

HOT

during operation. Handle with care.

Setting Up

Before beginning, make sure you have your LS-1-CAL, your spectrometer, an SMA-terminated optical

fiber or CC-3 cosine corrected irradiance probe, and Ocean Op tics OOIIrrad softwar e. (If you have an

IRRAD2000 spectroradiometric system, use a 200

setup -- one that is highly sensitive, for example -- you may not be able to use the LS-1-CAL as a

cal ibrat ion s ource. )

µ

m or s maller fiber. If you have a nother spe c t rometer

Calibration

1. Plug th e s witching AC ad ap ter (the black rectan g le-shap ed box) into the ba ck of the LS-1- C A L. The

adapt er stabilizes the power coming into the lamp to in s ure constant spectral intensity.

2. Plug the other end into the back of the switching AC adapter. Plug the wall transformer end of the

power cord into a standard 110V outlet.

3. Take off the fiber cover and screw a fiber all the way into the SMA connector.

Whatever optical setup you wish to use for your application, you must also use for your calibration.

For examp le, if you use a 200 µm fiber with a CC -3 cosine c orrec ted irradi ance probe for your

application, you must use the same 200 µm fiber and CC-3 for your calibration.

4. Find the on/off switch on the back of the lamp and turn the lamp on.

5. Let the lamp warm up for 1 5 minutes.

6. Insert the disk that came with your lamp. The disk contains two ASCII files. These files have the same

information as the Lamp Calibration reports that came with your LS-1-CAL. One file has the

cali bration numbers for calibrating the lamp with a bare fiber; its name con tains the lamp’s serial

20

Page 24

number, followed by

CC-3 cosine-corrector an d fiber; its nam e contains th e lamp’s seria l n umber, follow ed b y

FIB.LMP

. The second file has the calibration numbers when calibrating with a

CC3.LMP

.

7. Copy these two files into your OOIIrrad directory.

8. Start OOIIrrad by selecting

9. Under the

Lamp

menu options, choose

Start | Programs | OOIIrrad | OOIIrrad

Select Lamp

. A window opens in which you must ch oose the

.

Lamp Calibration report file that reflects your optical setup.

10. Under the Spectrometer menu function, choose

Configure Fibers

. Enter th e fi ber diameter values for

each channel in your setup. If using a bare fiber, enter

the fiber’s diamet er here . If using a fiber with a CC-3

cosine corrector, enter 3, 900. Whatever optical set u p

you wish to use for your application, you must also use

for your calibra tion. For example, if you are going to

use a 200

your application, you must use the same 200

µ

m fiber with a CC-3 cosine corrector for

µ

m fiber

and th e same cosine cor rector for your calibration.

11. To the right of the di splayed spect rum, enter the

parameters for your setup next to

Smoothing Size

Integration Period (ms)

, and

Scans to Avg

,

.

• Scans to Avg: Enter a value to implement a

sample averaging function that averages x number

of spectra. The higher the val ue, the bett er the

Signal-to-Noise.

• Smooth ing Size: Enter a value to implemen t a smoothing technique that averages across s p ectral

data. A value of 5, for example, averages each data point with 5 points to its left and 5 points to its

righ t. The great er th is value, the smoother the data and th e higher the S:N. However , if the value is

too high, a loss in spectral resolution will result.

• Integration Period (ms): Enter a time in milliseconds to regulate the amount of time the detector

“looks” at the incoming photons. If your Scope Mode intensity is too low, increase this value. If

the int ensity is t oo hi gh, decrease the valu e. While watching the gra ph tr ace, adjust the integration

time until the signal intensity level is approximately 3500 counts.

12. Under

Spectrometer

menu options, choose

Calibrate

and then the channel you are calibratin g.

13. A dialog box opens with the message “Verify lamp was ON for at least 15 minutes for a REFERENCE

scan.” Click OK. You have just taken your reference measurement.

14. Anoth er di alog box open s with the messag e “Bl ock light pat h to spectr om eter for a DARK scan.”

Before clicking OK, be sure to block the light path by inserting an opaque object into the lamp’s filter

slot. Do not turn the lamp off. Click OK.

15. The spectromete r is no w calibrated .

Specifications

Spectral range (calibrated): 360-1050 nm

Dimensions:

Power input: 12 VDC/800 mA (regulated)

Power output: 6.5 watts

Bulb life: 900 hours (recalibrate after ~50 hours of use)

Bulb color temperature: 3100K

Out put to bulb: 5 volts/1.3 amps

Output regulation: 0.2% voltage

Time to stabilized output: ~30 minutes

Connector: SMA 905

9.0 cm x 5.0 cm x 3.2 cm (LWH); 3 . 5

21

”

x 2.0” x 1.25” (LWH)

Page 25

Sampling Chambers

Ocean Optics offers a comprehensive line of compact, low-cost sampling chambers for a variety of UVVIS-Shortwave NIR applications. All sampling chambers have SMA terminations for easy coupling to

optica l fibers. Op tions incl u d e a variety of cuvet te holders for 1-cm an d 10 -cm cuvettes, in-lin e fi lter

holders, flow cel ls, a nd oth e r samp l i ng devices.

Stan dard cuvett e h ol d ers are avail able for 1- cm an d 10-cm cuvett es ,

and coup le via SMA-terminat ed op tical fibers to our sp ectrometers

and li gh t s ources to cr eate small- fo ot p rint systems for a bsorbance

experiments. Each cuvette holder comes with a pair of 5-mm diameter

f/2 collimating lenses optimized for UV-VIS-NIR or VIS-NIR

applications, and has a slot for optical filters. Also available is the

CUV-FL-DA, a 1-cm cuvette holder that attaches directly to

light sources.

The CUV-ALL

couplings at four collimators -- a pair of 5-mm diameter f/2 collimating

lenses optimized for the UV-VIS and a pair optimized for the VIS-NIR.

Opti cal fibers can be attach ed a t these collimators to read or illuminate

the sample. When combined with our spectrometers and light sources,

the CUV-A LL can measure absorbance, flu orescence, s catterin g , or any

combin ation of th ese op tical ph enomena.

ISS Integrated Sampling System consists of a compact tungsten-halogen light

source with integrated cuvette holder for 1-cm cuvettes. This versatile sampling

device coup les to our miniature spectrom eters via op tical fibers to create fully

integrated, small-footprint sampling systems for VIS-NIR absorbance and

tran sm ission meas urements . The ISS is designed speci ally for use with

S1024DW Spectrometers.

FHS In-Line Filter Holders for the UV-VIS-NIR or VIS-NIR

provid e a convenien t platform for rapid absorbance or transmission

measurements of optical and other filters. Filter holders come with a

pair of 5-mm diameter collimating lenses, and accept 1” round or

any size square optical filters, up to 6 mm in thickness. FHS

assemblies are typically used either to measure filters or to put

filters into optical setups.

is a cuvette holder for 1-cm cuvettes that has fiber optic

LPC Long Pass Flow Cells couple to our fiber optic spectrometers and

compact light sources to measure low-concentration (ppb-ppt) aqueous

samples. LPC Flow Cells are available in 1-meter, 5-meter and 10-meter

path lengths for absorbance measurements, and in a 1-meter path length

with built-in 365-nm excitation source for fluorescence measurements.

Each assembly has 560 µm inner-diameter Teflo n tubing with an internal

volume of 250 µl/meter, and will function with most liquids having a

refractive index >1.30.

22

Page 26

Sampling Chambers: CUV-VIS, CUV-UV Cuvette Holders

CUV-VIS

The

optical fibers to our s pectr ometers an d light sourc e s to create small- footpr i nt spe c trophotom e tric s ystems for

absorbance and transmission experiments. These holders can be optimized for VIS-NIR (~360-1100 nm) or

UV-VIS-NIR (~200-1100 nm) applications.

CUV-UV C

and

UVETTE HOLDERS

for 1 -cm path length cuvettes couple via SM A - terminat ed

Parts I nc luded

• Cuvette holder assembly for holding 1-cm cuvettes

• Black co ver for eli minating ambient light

• Two barbed fittings for connecting a temperature stabilizing water source

• Screwdriver for adjusting the fit of the cuvette

• Allen wrench for adjusting the collimating lenses

Operation

Attaching the Fibers

1. Attach one end of a SMA-terminated optical fiber to one of the collimating lenses. Attach the other end

of this fiber – the illumination fiber – to a light source.

2. Attach another SMA-terminated optical fiber to the other collimating lens. Attach the other end of this

fiber – the read fiber – to the spectrometer.

Using the Fiber Supports

1. Snap th e clamps around the fiber s after the fibers are scr ewed into th e li ght source and spectr om eter.

2. Lift the clamps until they support the fibers.

3. Unsna p th e clamps to rem ove the fibers.

Installing Filters

1. Loosen the filter clamping screw with the provided screwdriver.

2. Insert the filter into the filter slot. The filter slot can accommodate filters up to 6 mm thick.

3. Clamp the filter in pl ace by gently tightening the cla mp ing screw finger-ti gh t.

Adjusting the Fit of the Cuvette

The Cuvette Holder is designed to hold 1-cm square cuvettes. When properly adjusted, the cuvette should

fit snugly into the holder.

1. Loca te th e two ball plunger s crews.

2. Remove t he fiber cla mps for easi er access to the screws.

3. Use t he provided s c rewdriver to loosen the two ba ll plunger screws until the ball end of th e s crews is

just visible in the cell holder and insert your cuvette into the holder.

4. Tighten the ball plunger screws until the ball contacts the cuvette and starts to compress. Do not

over-tighten.

Using the Temperature Stabilization Feature

This feature is used to heat or cool the cuvette holder base and cuvette.

1. Remove the plugs from the top side of the base. (The plug on the right side of the base should stay in

place but may require thread tape.)

2. Replace the plugs with the two barbed fittings (or any 1/8” NPT pipe thread fittings). Thread tape may

be required on the fittings to prevent leakage.

3. Connect the fittings to a water source. Water will circulate through the base.

23

Page 27

Specifications

Path length: 1 cm

Collimating lenses (VIS-NIR): BK 7 glass, 5 mm diameter, f/2

Collimating lenses (UV-VIS-NIR): Dynasil quartz, 5 mm diameter, f/2

Collimating lens termination: SMA 905

Collimating lenses assembl y (sam ple

compartment) dimensi ons:

Filter slot:

Base ma terial: aluminum

Base length:

Connections in base:

Water input fittings:

Typical optical fibers specified for optimum

performance (light throughput and optical

resolution)**:

* Though the VIS-NIR lens is optimized for use to 2 µm, it can b e confi gured to “see” only to 1100 nm

with our S1024DW spectrometer.

** For all intents, there is no single combination of optical fibers that will satisfy the requirements of

every application. As a rule, however, it is best to use a large-diameter (>50 µm) illumination fiber to

get the maximum light throughput, and a small-diameter (<50 µm) read fiber to achieve the best

optic al reso lution.

”

x 1.5” (LW)

2.0

accepts filters up to ¼

”

5.5

•

water inlet

•

water outlet

•

extra connection

”

NPT pipe thread

1/8

•

200 µm illumination fiber

•

50 µm read fiber

”

(6 mm) in th i c kn ess

24

Page 28

Sampling Chambers: CUV-VIS-10, CUV-UV-10 Cuvette Holders

CUV-VIS-10

The

and li gh t s ources to cr eate spectrophotomet ric system s for absorba nce and transmission measurements of

aqueous solutions and gases for VIS-NIR (~360-1100 nm) or UV-VIS-NIR (~200-1100 nm) applications.

CUV-UV-10 C

and

UVETTE HOLDERS

for 10-cm cuvettes couple to our spectrometers

Parts I nc luded

• Cuvette Holder assembly for holding 10-cm cuvettes

• Black C over for eli minatin g am bient light

• Two Bar bed F itting s for connecting a temperature stabilizing wa t er source

• Screwdriver for adjusting the fit of the cuvette

• Allen wrench for adjusting collimating lenses

Operation

Attaching the Fibers

1. Attach one end of a SMA-terminated optical fiber to one of the collimating lenses. Attach the other end

of this fiber -- the illumination fiber -- to a light source.

2. Attach another SMA-terminated optical fiber to the second collimating lens. Attach the other end of

this fiber -- the read fiber -- to the spectrometer.

Using the Fiber Supports

1. Snap th e clamps around the fiber s after the fibers are scr ewed into th e li ght source and spectr om eter.

2. Lift the clamps until they support the fibers. To remove the fibers, simply unsnap the clamps.

Installing Filters

1. Tighten the thumb wheel completely when not using a filter.

2. Loosen the thumb wheel on the left side of the cuvette holder, creating enough space for the filter.

3. Insert the filter into the filter slot, which can hold filters up to 6 mm thick, and tighten the thumb wheel.

Using the Temperature Stabilization Feature

This feature is used to heat or cool the cuvette holder base and cuvette.

1. Remove the two pl ugs from the top sid e of the ba s e . (The plug on the r ight side of the base s hould sta y