Page 1

►

OOISensors

Fiber Optic Sensors System

Installation and Operation Manual

Document Number FOXY-AL300-000-02-0207

Offices: Ocean Optics, Inc. World Headquarters

830 Douglas Ave., Dunedin, FL, USA 34698

Phone 727.733.2447

Fax 727.733.3962

8 a.m.– 8 p.m. (Mon-Thu), 8 a.m.– 6 p.m. (Fri) EST

E-mail: Info@OceanOptics.com (General sales inquiries)

Orders@OceanOptics.com (Questions about orders)

TechSupport@OceanOptics.com (Technical support)

Page 2

Additional

Offices:

Ocean Optics Asia

137 Xianxia Road, Suite 1802, Changning District, Shanghai, PRC. 200051

Phone 86.21.5206.8686

Fax 86.21.5206.8686

E-Mail Sun.Ling@OceanOptics.com

Ocean Optics B.V. (Europe)

Geograaf 24, 6921 EW DUIVEN, The Netherlands

Phone 31-(0)26-3190500

Fax 31-(0)26-3190505

E -Mail Info@OceanOpticsBV.com

Copyright © 2001-2007 Ocean Optics, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, by any means, electronic,

mechanical, photocopying, recording, or otherwise, without written permission from Ocean Optics, Inc.

This manual is sold as part of an order and subject to the condition that it shall not, by way of trade or otherwise, be lent, re-sold, hired out or

otherwise circulated without the prior consent of Ocean Optics, Inc. in any form of binding or cover other than that in which it is published.

Trademarks

All products and services herein are the trademarks, service marks, registered trademarks or registered service marks of their respective owners.

Limit of Liability

Ocean Optics has made every effort to make this manual as complete and as accurate as possible, but no warranty or fitness is implied. The

information provided is on an “as is” basis. Ocean Optics, Inc. shall have neither liability nor responsibility to any person or entity with respect to

any loss or damages arising from the information contained in this manual.

Page 3

Table of Contents

About This Manual .......................................................................................................... 7

Document Purpose and Intended Audience.............................................................................. 7

What’s New in this Document ................................................................................................... 7

Document Summary.................................................................................................................. 7

Product-Related Documentation ............................................................................................... 8

Upgrades......................................................................................................................... 8

Chapter 1: Sensors System Overview ..............................................1

Overview ......................................................................................................................... 1

Oxygen Sensors System Overview ................................................................................. 1

pH Sensors System Overview......................................................................................... 1

FOXY Probes ............................................................................................................................ 2

FOSPOR Probes ....................................................................................................................... 2

HIOXY Probes ........................................................................................................................... 2

MultiFrequency Phase Fluorometer (MFPF) ................................................................... 2

Hardware......................................................................................................................... 3

Included Hardware (Oxygen Sensor System)........................................................................... 3

Included Hardware (pH Sensor System)................................................................................... 3

Software .......................................................................................................................... 3

Documentation ................................................................................................................ 4

Packing List ............................................................................................................................... 4

Wavelength Calibration Data.....................................................................................................4

Software and Technical Resources CD .................................................................................... 4

Temperature Calibration Diskette (if requested) .......................................................................4

Chapter 2: OOISensors Software.......................................................5

OOISensors Overview..................................................................................................... 5

Installing OOISensors ..................................................................................................... 6

Configuring OOISensors Software .................................................................................. 8

Configure Menu Functions .............................................................................................. 8

Configure Hardware ..................................................................................................................9

Software..................................................................................................................................... 10

FOXY-AL300-000-02-0207 i

Page 4

Table of Contents

Sensors Tab for Spectrometer Systems ................................................................................... 11

pH .............................................................................................................................................. 16

Timing Tab................................................................................................................................. 18

Display Tab................................................................................................................................ 20

Log Tab...................................................................................................................................... 21

Display Functions ............................................................................................................ 22

Scan Control.............................................................................................................................. 22

Store Dark ................................................................................................................................. 23

Subtract Dark............................................................................................................................. 23

Data Acquisition Parameters.....................................................................................................24

Cursor Functions ....................................................................................................................... 25

Cursor Bar ................................................................................................................................. 26

Data Values ...............................................................................................................................27

Spectral Graph .......................................................................................................................... 27

Temperature Chart .................................................................................................................... 28

Log On/Off Switch .....................................................................................................................30

File Menu Functions ........................................................................................................ 30

Save Spectrum .......................................................................................................................... 30

Save Time Chart........................................................................................................................ 31

Open Spectrum ......................................................................................................................... 31

Open Time Chart ....................................................................................................................... 31

Page Setup................................................................................................................................ 31

Print Spectrum and Time Chart................................................................................................. 31

Exit............................................................................................................................................. 31

Graph&Chart Menu Functions......................................................................................... 31

Clear Spectrum Graph............................................................................................................... 32

Clear Time Chart ....................................................................................................................... 32

Enable Grid................................................................................................................................ 32

Autoscale Horizontal (Spectral Graph)...................................................................................... 32

Autoscale Vertical (Spectral Graph) .......................................................................................... 32

Autoscale Vertical (Time Chart) ................................................................................................ 32

View Temperature Chart ...........................................................................................................32

Spectrometer Menu Functions ........................................................................................ 32

Scan........................................................................................................................................... 33

Insert Event in Log File.............................................................................................................. 33

Calculate Sensor Values with Scan .......................................................................................... 33

Pulse LED.................................................................................................................................. 33

Calibrate Menu Functions ............................................................................................... 34

Configuring a Spectrometer in OOISensors.................................................................... 34

ii FOXY-AL300-000-02-0207

Page 5

Table of Contents

Chapter 3: Oxygen Sensors ...............................................................37

How the Oxygen Sensors Work ...................................................................................... 37

Fluorescence Quenching ................................................................................................ 38

Connecting the Fiber Optic Sensors System................................................................... 38

Calibration Requirements for Oxygen Sensors ............................................................... 39

Linear (Stern-Volmer) Algorithm................................................................................................ 39

Second Order Polynomial Algorithm ......................................................................................... 40

Theory - Henry’s Law ................................................................................................................41

Temperature.................................................................................................................... 42

Scattering Media ............................................................................................................. 43

Samples to Use ............................................................................................................... 43

Calibrating Oxygen Sensors............................................................................................ 44

Calibrating Oxygen Sensors without Temperature Compensation ...........................................44

Calibrating Oxygen Sensors with Temperature Compensation ................................................ 47

About Factory Calibration.......................................................................................................... 47

Calibrating With Factory Calibration.......................................................................................... 47

Calibrating Without Factory Calibration..................................................................................... 50

Calibration Data............................................................................................................... 55

Recalibration ...................................................................................................................56

Chapter 4: pH Sensors........................................................................57

Overview ......................................................................................................................... 57

pH Films .......................................................................................................................... 57

Probe Options............................................................................................................................ 57

More Information ............................................................................................................. 58

Start Up ........................................................................................................................... 58

pH Sensor Set Up...................................................................................................................... 58

Calibration ....................................................................................................................... 61

pH Sensor Calibration ............................................................................................................... 61

Chapter 5: Compatible Products and Accessories ..........................65

Overview ......................................................................................................................... 65

Probes ............................................................................................................................. 65

Factory Calibration Service ............................................................................................. 67

Overcoats ........................................................................................................................ 67

Temperature Compensating Components ...................................................................... 68

FOXY-AL300-000-02-0207 iii

Page 6

Table of Contents

Sol-Gel Coated Membranes, Microscope Coverslips, and Slides ................................... 68

Spectrometers ................................................................................................................. 69

Light Sources .................................................................................................................. 69

Bifurcated Optical Fiber Assemblies and Splice Bushing................................................ 70

Chapter 6: Hardware Datasheets and Instructions..........................71

Overview ......................................................................................................................... 71

Oxygen Sensing Probes – General Information.............................................................. 71

Probe Construction.................................................................................................................... 72

Accuracy.................................................................................................................................... 72

Measurement Range................................................................................................................. 72

Sampling Chambers.................................................................................................................. 73

Response Time ......................................................................................................................... 73

Environmental Conditions.......................................................................................................... 73

Chemical Compatibility.............................................................................................................. 73

Temperature and the Oxygen Probe......................................................................................... 74

Photodegradation ...................................................................................................................... 74

Ambient Light............................................................................................................................. 74

Lifetime ......................................................................................................................................74

Cleaning Oxygen Probes........................................................................................................... 74

Use Warnings ............................................................................................................................75

Oxygen Probe Specifications ....................................................................................................75

Sterilization Methods Tested on Oxygen Probes ......................................................................75

FOXY-R Stainless-steel 1/16" OD Fiber Optic Probe...................................................... 76

FOXY-R Specifications.................................................................................................... 77

FOXY-AL300 Aluminum-jacketed Fiber Optic Probe ...................................................... 78

FOXY-AL300 Specifications............................................................................................ 78

FOXY-PI600 Polyimide coated Fiber Optic Probe........................................................... 79

FOXY-PI600 Specifications............................................................................................. 80

FOXY-18G/21G Needle-tipped 18/21-gauge Fiber Optic Probes ................................... 80

FOXY-18G/21G Specifications........................................................................................ 81

FOXY-OR125 and FOXY-OR125G O-ring Fiber Optic Probes ....................................... 82

FOXY-OR125 and FOXY-OR125G Specifications.......................................................... 82

FOXY-T1000 Stainless-steel Fiber Optic Probe with Light Shield................................... 83

FOXY-T1000 Specifications ............................................................................................ 84

FOXY-T1000-RTD Stainless-steel Fiber Optic Probe with Light Shield.......................... 84

FOXY-T1000-RTD Specifications.................................................................................... 85

FOXY-RESP Respiration Probe...................................................................................... 86

iv FOXY-AL300-000-02-0207

Page 7

Table of Contents

FOXY-RESP Specifications ............................................................................................ 86

Factory Calibration Services............................................................................................ 87

FOXY-RECOV Probe Reconditioning ............................................................................. 87

FOXY-AF and FOXY-AF-MG Silicone Overcoats ........................................................... 88

Cleaning..................................................................................................................................... 88

Sterilizing ...................................................................................................................................89

Overcoat Specifications............................................................................................................. 89

Oxygen Probe Temperature Control Accessories........................................................... 90

FOXY-TS1 Omega Thermistor.................................................................................................. 90

FOXY-TK1 K-type Omega Thermocouple................................................................................. 91

FOXY-TK1-W K-type Omega Thermocouple............................................................................ 93

USB-LS-450-TP Temperature Probe ........................................................................................ 93

Light Sources .................................................................................................................. 94

LS-450 Blue LED Pulsed Light Source ..................................................................................... 94

R-LS-450 Rack-mount Blue LED Pulsed Light Source ............................................................. 96

OOISensors Flash Delay........................................................................................................... 100

Setting the Integration Time ...................................................................................................... 100

USB-LS-450 .............................................................................................................................. 101

Bifurcated Optical Fiber Assemblies................................................................................ 102

Use Notes.................................................................................................................................. 103

Bifurcated Fiber Assembly Specifications ................................................................................. 103

FOXY/HOXY/FOSPOR General Specifications .............................................................. 104

FOSPOR Specifications .................................................................................................. 105

FOXY/MFPF Specifications............................................................................................. 106

HIOXY/MFPF Specifications ........................................................................................... 107

Chapter 7: Troubleshooting ...............................................................109

Overview ......................................................................................................................... 109

General Troubleshooting Procedures ............................................................................. 109

Troubleshooting Device Installation ................................................................................ 111

Remove the Unknown Device from Windows Device Manager................................................ 112

Remove Improperly Installed Files ............................................................................................ 112

Appendix A: External Triggering .......................................................115

FOXY-AL300-000-02-0207 v

Page 8

Table of Contents

Appendix B: Chemical Effects on Oxygen Probes ..........................117

Summary of Chemical Effects on Oxygen Probes .......................................................... 117

Appendix C: pH Sensor Theory of Operation and Calculations.....119

Overview ......................................................................................................................... 119

Theory of Operation and Calculations............................................................................. 119

Model # 1................................................................................................................................... 120

Model # 2................................................................................................................................... 120

Model # 3................................................................................................................................... 120

Model # 4................................................................................................................................... 122

Revised Model #4...................................................................................................................... 123

Index.....................................................................................................125

vi FOXY-AL300-000-02-0207

Page 9

About This Manual

Document Purpose and Intended Audience

This document provides you with an installation and configuration instructions to get your system up and

running. In addition, user interface for SpectraSuite is provided.

What’s New in this Document

This version updates the installation information.

Document Summary

Chapter Description

Chapter 1: Sensors System Overview Contains descriptions of what is included in a sensor

system.

Chapter 2: OOISensors Software Contains instructions for installing and configuring the

OOISensors software when used with a spectrometer.

Chapter 3: Oxygen Sensors Provides information on how the sensors work, as well as

instructions for installing and calibrating the sensors.

Chapter 4: pH Sensors Provides a description of the pH sensors and a procedure

for calibration.

Chapter 5: Compatible Products and

Accessories

Chapter 6: Hardware Datasheets and

Instructions

Chapter 7: Troubleshooting Contains a table of troubleshooting suggestions and

Appendix A: External Triggering Provides information on external triggering as it relates to

Contains descriptions of compatible accessories and their

specifications.

Contains descriptions of the functions on the

Spectrometer Menu.

sensors.

Appendix B: Chemical Effects on Oxygen

Probes

Appendix C: pH Sensor Theory of Operation

and Calculations

FOXY-AL300-000-02-0207 7

Lists chemicals known to be harmful and chemicals that

have no effect on oxygen probes.

Contains equations that express the theory of pH sensor

operation and calculations.

Page 10

Table of Contents

Product-Related Documentation

• MultiFrequency Phase Fluorometer Installation and Operation Manuall

• Various USB spectrometer documents such as the

Operation Manual.

• SpectraSuite Spectrometer Operating Software Installation and Operation Manual

OOIBase32 Spectrometer Operating Software Installation and Operation Manual

•

You can access documentation for Ocean Optics products by visiting our website at

http://www.oceanoptics.com. Select Technical → Operating Instructions, then choose the appropriate

document from the available drop-down lists. Or, use the Search by Model Number field at the bottom

of the web page.

You can also access operating instructions for Ocean Optics products on the Software and Technical

Resources CD included with the system.

Engineering-level documentation is located on our website at Technical → Engineering Docs.

USB4000 Spectrometer Installation and

Upgrades

Occasionally, you may find that you need Ocean Optics to make a change or an upgrade to your system.

To facilitate these changes, you must first contact Customer Support and obtain a Return Merchandise

Authorization (RMA) number. Please contact Ocean Optics for specific instructions when returning a

product.

8 FOXY-AL300-000-02-0207

Page 11

Chapter 1

Sensors System Overview

Overview

The following sections provide a general overview of the Oxygen Sensors System and the pH Sensors

System.

Oxygen Sensors System Overview

Fiber Optic Oxygen Sensors are spectrometer and/or phase fluorometer-coupled chemical sensors for

monitoring oxygen partial pressure in gases and liquids. A fluorescence method measures the partial

pressure of dissolved or gaseous oxygen. Optical fiber carries excitation light produced by the blue LED

to the thin-film coating at the probe tip. The probe collects fluorescence generated at the tip and carries it

via the optical fiber to the high-sensitivity spectrometer. When oxygen in the gas or liquid sample diffuses

into the thin film coating, it quenches the fluorescence. The degree of quenching correlates to the level of

oxygen pressure.

Fiber Optic Oxygen Sensors are low-power, portable devices that offer high sensitivity, reversibility, and

stability. Their small size is useful for remote monitoring. What's more, the thin film used in the probe

tips consumes no oxygen, allowing for continuous contact with the sample. FOXY Sensors offer other

key advantages: They're ideal for viscous samples and are immune to interference caused by pH change

or from changes in ionic strength, salinity, and biofouling.

pH Sensors System Overview

Fiber optic probes for pH monitoring couple to Ocean Optics spectrometers to measure pH by monitoring

color changes in indicator dyes. These dyes are immobilized in polymer films. You then place the films in

the optical path of a transflection dip probe and exposed to the sample solution. These pH probe sensors

are especially useful for monitoring low conductivity samples such as boiler water, where potentiometric

devices fail; or for turbid, fouling environments, where particulate matter, slurries, and other media can

coat or destroy electrodes.

Ocean Optics' fully integrated pH systems provide full spectral analysis to help eliminate errors from dye

leaching or from changes in turbidity, temperature, and ionic strength. Inherent calibration based on the

physical properties of the immobilized indicator dye eliminates the need for frequent calibration.

FOXY-AL300-000-02-0207 1

Page 12

1: Sensors System Overview

FOXY Probes

FOXY oxygen sensors are designed for monitoring oxygen partial pressure in gas and aqueous solutions.

Standard FOXY comes with different probe sizes and configurations depending on the application.

FOSPOR Probes

FOSPOR is a new generation of highly sensitive probes for monitoring traces if oxygen in gas and

liquids. This sensor is capable of monitoring low ppm levels of oxygen in gas and ppb levels of dissolved

oxygen in liquids. This sensor can be used in environments where oxygen traces need to be monitored.

Some applications include vacuum systems, and food and pharmaceutical packaging. The sensor material

consists of a sol gel thin film immobilized with Pt-porphyrin.

HIOXY Probes

HIOXY (FOXY-hydrocarbon) is designed for monitoring oxygen partial pressure in nonaqueous vapors

and solutions. The sensor coating chemistry is designed for compatibility with oils, alcohols and

hydrocarbon-based vapors and liquids. HIOXY has been tested successfully in commercial and military

aviation fuels, gasoline, diesel, some alcohols, glycol, military hydraulic fluids, and wine.

MultiFrequency Phase Fluorometer (MFPF)

The MultiFrequency Phase Fluorometer (MFPF) is a flexible platform for measuring luminescence

lifetime, phase and intensity. The MFPF is a compact, self-contained, frequency-domain luminescence

monitor that is invariant to fiber bending and stray light, and has a wide dynamic range of optical

intensity as well as low optical and electronic crosstalk, and low drift and phase noise. Therefore, the

MFPF is especially useful for oxygen sensing applications where sensitivity to drift is important and

where sample set-ups must be left undisturbed for long periods of time. There are two MFPF models:

• MFPF100-1 – 1-channel unit includes one thermistor

• MFPF100-2 -- 2-channel unit includes two thermistors

The MFPF is available for use with FOXY, HIOXY, and FOSPOR custom probes. See the

MultiFrequency Phase Fluorometer Installation and Operation Manual for more information on the

MFPF.

The MFPF software works in conjunction with OOISensors software to manage the MFPF unit. If your

system uses a spectrometer instead, you will not install or use the MFPF software. See

OOISensors

The application for measuring oxygen concentrations is essentially the same for spectrometers and MFPF.

The main difference is that the spectrometers’ application is with raw data of spectrum intensity of

fluorescence at a particular wavelength, while the MFPF’s application raw data is Tau, which is an

indication of the decay of fluorescence over time as the result of a light pulse on sensor material.

for more information on installing software.

Installing

2 FOXY-AL300-000-02-0207

Page 13

1: Sensors System Overview

Hardware

The following hardware is included with the Fiber Optic Sensors System or is compatible with the Fiber

Optic Sensors System.

Included Hardware (Oxygen Sensor System)

Fiber optic fluorescence probe with proprietary oxygen-sensing thin-film coating on the tip

Miniature fiber optic spectrometer

LS-450 Blue LED Light Source

Bifurcated optical fiber assembly with splice bushing that connects the fluorescence probe to the

spectrometer and the LED

A/D Converter (if needed)

Included Hardware (pH Sensor System)

pH probe & film

Light Source (such as LS-1 or Mini-D2T)

Miniature fiber optic spectrometer (see Spectrometers for options)

A/D Converter (if needed)

Compatible Products and Accessories for information on these and other Ocean Optics products

See

designed for use with the Fiber Optic Sensor System.

Caution

Do not connect the spectrometer included with the Fiber Optics Sensors System to the PC

prior to installing the OOISensors software. Connecting this equipment prior to software

installation will result in incorrect driver configuration and may require Technical Support

to correct. See

Troubleshooting for more information.

Software

OOISensors software is Ocean Optics’ next generation of software for use with the Fiber Optics Sensor

System. OOISensors is an advanced data acquisition and display program that provides a real-time

interface to a variety of signal processing functions for users of Windows 95/98/ME/NT/2000/XP.

MFPF software is used with OOISensors when you have an MFPF unit. See

Fluorometer (MFPF)

for more information on the MFPF.

MultiFrequency Phase

FOXY-AL300-000-02-0207 3

Page 14

1: Sensors System Overview

Documentation

The Fiber Optic Sensors System contains various documentation components on paper, floppy diskette

and CD. These components include the following:

Packing List

Wavelength Calibration Data

Software and Technical Resources CD

Temperature Calibration Diskette (if requested)

Packing List

The packing list is located inside a plastic bag attached to the outside of the shipment box (the invoice is

mailed separately). The items listed on the packing slip include all of the components in the order,

including customized items installed in the spectrometer, such as the grating, detector collection lens, and

slit. The packing list also includes important information, such as the shipping and billing addresses, as

well as components on back order.

Wavelength Calibration Data

The spectrometer included with the Fiber Optic Sensors System is shipped in a silver-gray anti-static bag.

This bag also contains wavelength calibration information that is unique to your individual spectrometer.

Our spectrometer operating software simply reads these values from the spectrometer; however, this

information is provided in case, for some reason, you need to manually enter these values into the

software.

Software and Technical Resources CD

Each spectrometer order comes with Ocean Optics’ Software and Technical Resources CD. This disc

contains all Ocean Optics software and manuals for software operation, spectrometers, and spectroscopic

accessories. Documentation is provided in Portable Document Format (PDF). You need Adobe Acrobat

Reader version 6.0 or higher to view these files. Adobe Acrobat Reader is included on the CD.

With the exception of OOIBase32 Spectrometer Operating Software, all Ocean Optics software is

password protected. OOISensors Software must be purchased with your Fiber Optic Sensors System, and

the installation program is password protected. The password for the software can be found on the back of

the Software and Technical Resources CD package.

Temperature Calibration Diskette (if requested)

The Temperature Calibration Diskette can be used during temperature calibration setup. Insert the diskette

in the disk drive, and then load the data via the Multiple Temperature Calibration Screen.

4 FOXY-AL300-000-02-0207

Page 15

Chapter 2

OOISensors Software

OOISensors Overview

OOISensors Software is Ocean Optics’ next generation of operating software for the Fiber Optic Sensors

System. OOISensors is an advanced acquisition and display program that provides a real-time interface to

a variety of signal-processing functions for all Windows platforms. With OOISensors, you have the

ability to obtain oxygen partial pressure and concentration values, control all system parameters, collect

data from up to 8 spectrometer channels simultaneously and display the results in a single spectral

window, perform time acquisition experiments, and display and correct for temperature and/or ambient

pressure fluctuations in the sample.

OOISensors allows you to use the Second Order Polynomial algorithm in the calibration procedure. This

algorithm often provides more accurate data than the linear Stern-Volmer algorithm. Furthermore, you

can now monitor temperature with the OOISensors application. OOISensors corrects the data for any

fluctuations in temperature.

OOISensors can also display up to eight spectrometer channels in one spectral window, while providing

unique data acquisition parameters to each spectrometer channel.

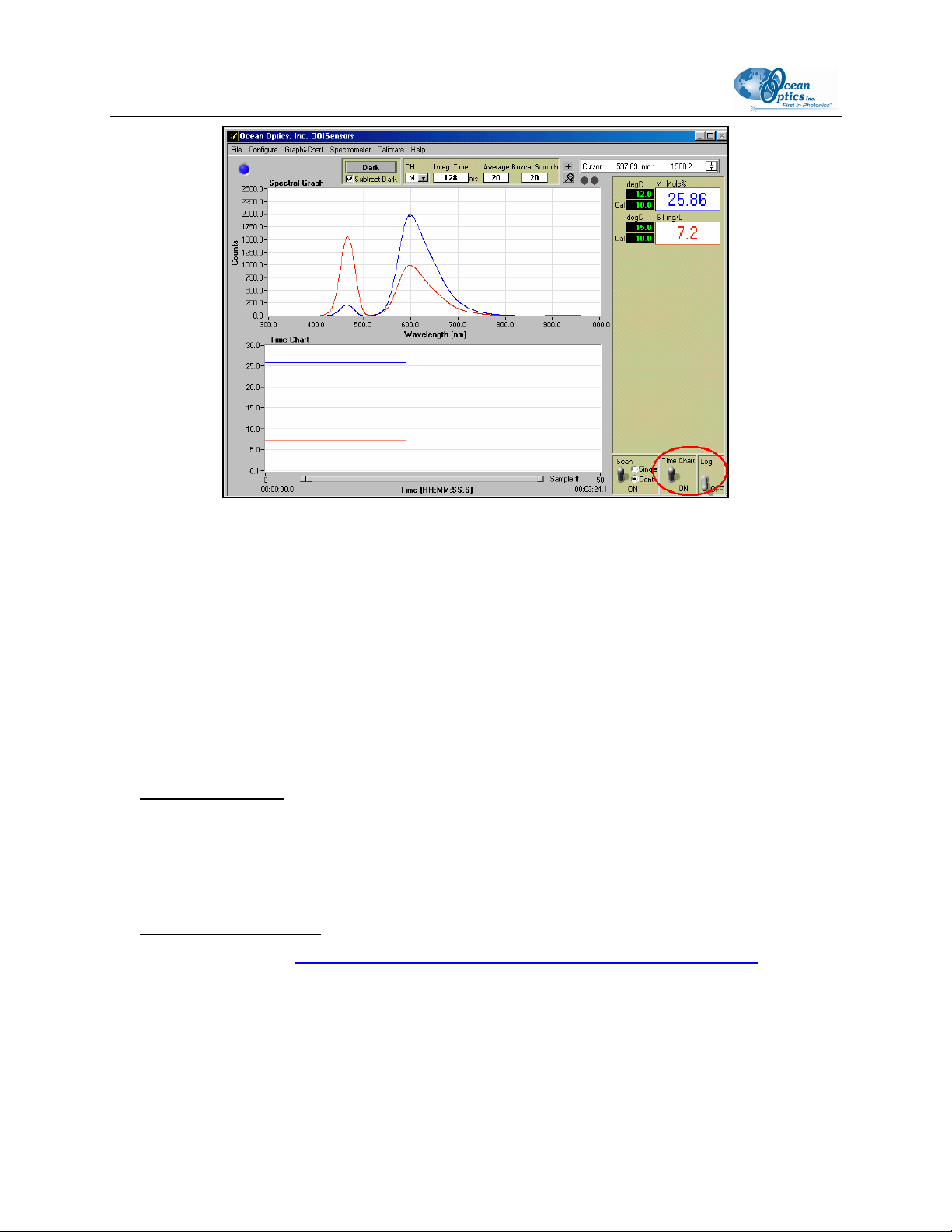

Additionally, the Time Chart feature in OOISensors can display O

all active channels at a specific wavelength over a period. During a timed data acquisition procedure, you

can enter text for an event into the log file. Both the Time Chart and Data Logging features are enabled by

a simple switch next to the graph.

OOISensors can support up to four MFPF units; up to eight channels can be supported when OOISensors

is used with MFPF100-2 (two-channel) units.

values, pH values, and the data from

2

FOXY-AL300-000-02-0207 5

Page 16

2: OOISensors Software

Installing OOISensors

Before installing OOISensors Software, make sure that no other applications are running.

► Procedure

Perform the steps below to install the OOISensors software on your PC:

1. Close all other applications running on the PC.

2. Start the software installation process.

Installing from CD:

a. Insert the CD containing the OOISensors and software.

b. Select the drive on your computer with the software CD.

c. Double-click on the Setup.exe. The installation wizard appears.

Installing from the Web:

a. Go to

b. Right-click on OOISensors Oxygen Measurement Software and select Save

http://www.oceanoptics.com/technical/softwaredownloads.asp.

Target As… to download the executable to your machine.

c. Click Save. The installation begins.

d. Click Run. The Installation Wizard appears.

6 FOXY-AL300-000-02-0207

Page 17

2: OOISensors Software

3. Click Next at the Welcome screen. The Choose Destination Location screen appears.

4. Accept the default or select another location for your software files. Click Next. The Backup

Replaced Files screen appears.

5. Select Yes or No, depending on whether you want to create backup replacement files. If you

select Yes, choose a location for these files. Then click Next. The Select Program Manager

Group screen appears.

6. Select the name of the Program Manager group to which you want to add the OOISensor icons.

Then click Next. The Start Installation dialog box appears.

7. Click Next. The Password dialog box appears. Type the password for your OOISensors software

and click OK. Passwords are located on the back of the software CD jacket. The software begins

installing.

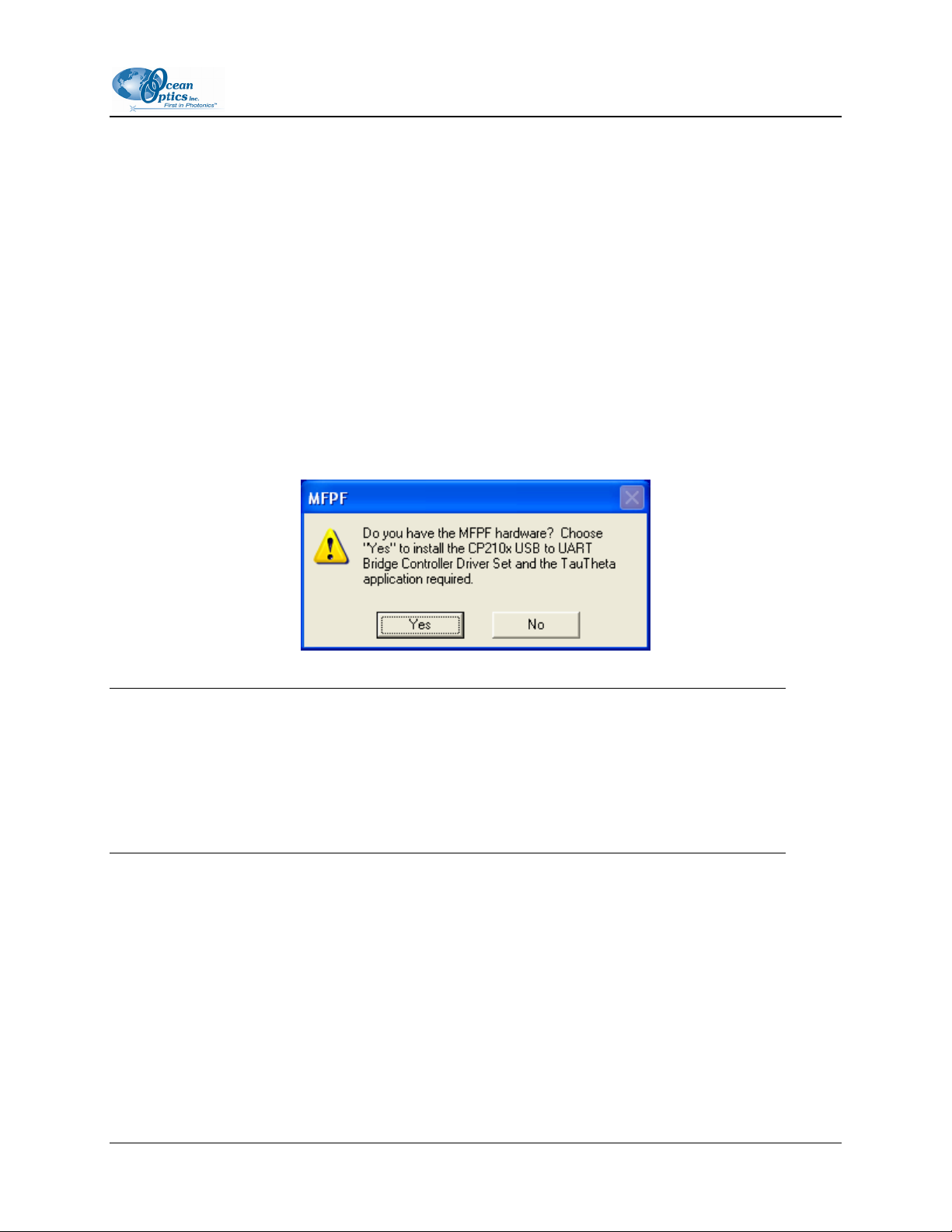

• The MFPF dialog box appears asking you if you have MFPF hardware.

Notes

If you have an MFPF unit, refer to the MultiFrequency Phase Fluorometer Installation and

Operation Manual for more information. These instructions assume that you are installing

OOISensors to use with a spectrometer.

You can reinstall the application again later to add support for the MFPF.

9. Click No. The installation begins. A message then appears informing you that your installation is

complete.

10. Click OK, then click Finish. You have now installed OOISensors software. You must restart

your computer to use the software.

FOXY-AL300-000-02-0207 7

Page 18

2: OOISensors Software

Configuring OOISensors Software

Once OOISensors is installed and the system has been rebooted, connect the spectrometer to the PC and

start the OOISensors program. Run OOISensors. If this is the first time you have opened the software, or

if the software is not configured yet, the Configure Hardware screen appears. You can also access this

screen manually by selecting Configure | Hardware from the OOISensors menu bar. See

Hardware

The first time that you run OOISensors, you will be prompted to configure the software for use with your

hardware.

The main OOISensors screen is shown below (the following example is for the spectrometer

configuration).

for more information.

Configure

Configure Menu Functions

Select Configure from the menu bar to configure the hardware and software parameters for your system.

8 FOXY-AL300-000-02-0207

Page 19

2: OOISensors Software

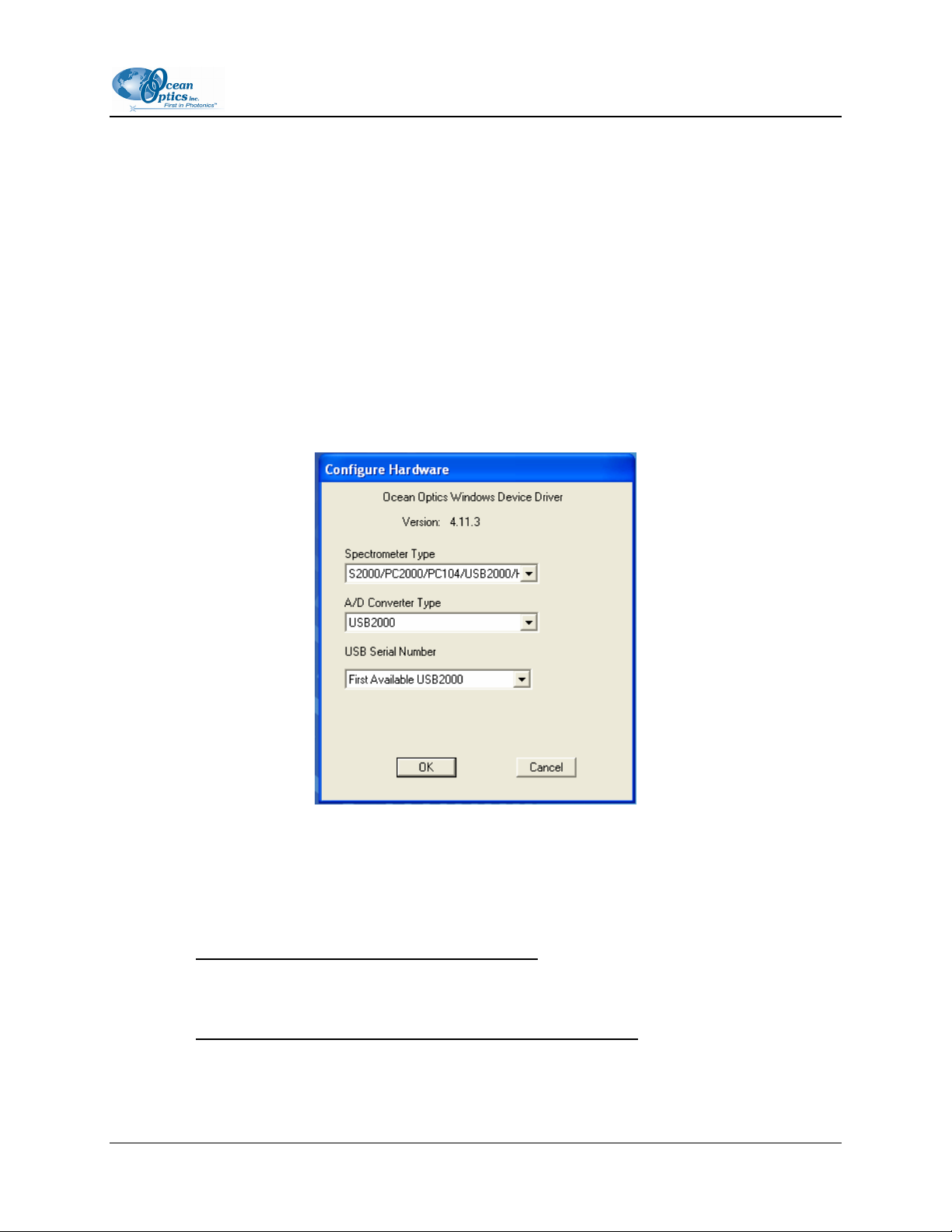

Configure Hardware

The Configure | Hardware dialog box allows you to specify the hardware parameters for the

spectrometer. Typically, you set these parameters only once, when you first install OOISensors. Upon

running OOISensors for the first time after installation, you will need to specify hardware settings in the

Configure Hardware dialog box. However, you can reconfigure these settings at any time by selecting

Configure | Hardware from the menu bar.

► Procedure

Follow the steps below to reconfigure hardware parameters:

1. Select Configure | Hardware from the OOISensors menu bar. The Configure Hardware screen

appears.

2. Specify a spectrometer type in the Spectrometer Type drop-down menu (the S2000-FL, SF2000

and USB series are S2000-series spectrometers).

3. Specify the A/D converter you are using to interface your spectrometer to your computer in the

A/D Converter Type drop-down menu.

If you choose the USB2000 A/D Converter:

Select the USB2000 A/D Converter from the drop-down menu. Then, specify the serial

number of the USB2000 in the Serial Number drop-down menu. Consult the USB2000

Operating Instructions for more information.

If you choose the ADC1000 or DAQ700 A/D Converter:

Select an available Base Address (or I/O Range) and IRQ (Interrupt Request) from the drop

down menus. Consult the operating instructions for the specific A/D converter more

information.

FOXY-AL300-000-02-0207 9

Page 20

2: OOISensors Software

If you choose the ADC1000-USB A/D Converter:

Specify the serial number of the ADC1000-USB, or select the First Available ADC1000-USB

option. Consult your A/D Converter documentation for more information.

If you choose the SAD500 or Serial USB2000 Spectrometer:

4. Specify the PC Serial Port (or COM Port) number to which the device is connected.

5. Select the Baud Rate at which the device will operate.

6. Enter a SAD500 Pixel Resolution, which specifies that the spectrometer transmit every nth pixel

from the SAD500 to the PC. Valid pixel resolutions are 1-500, and resolution requirements vary

by experiment.

Note

Lower pixel resolutions result in increased speed. The transfer of one complete spectra requires

~0.4 seconds when communicating at 115,200 baud rate. If you need your information in <0.4

seconds, increase the resolution or enable data compression. (This option does not appear for

Serial USB2000 users.)

7. Enable the Compress Data function to minimize the amount of data transferred over the RS-232

connection. Transmission of spectral data over the serial port is a relatively slow process.

Enabling this function insures that every scan transmitted will be compressed, which greatly

increases the data transfer speed.

8. Select the USB2000 Serial Number for the USB2000 you wish to use (Serial USB2000 users

only).

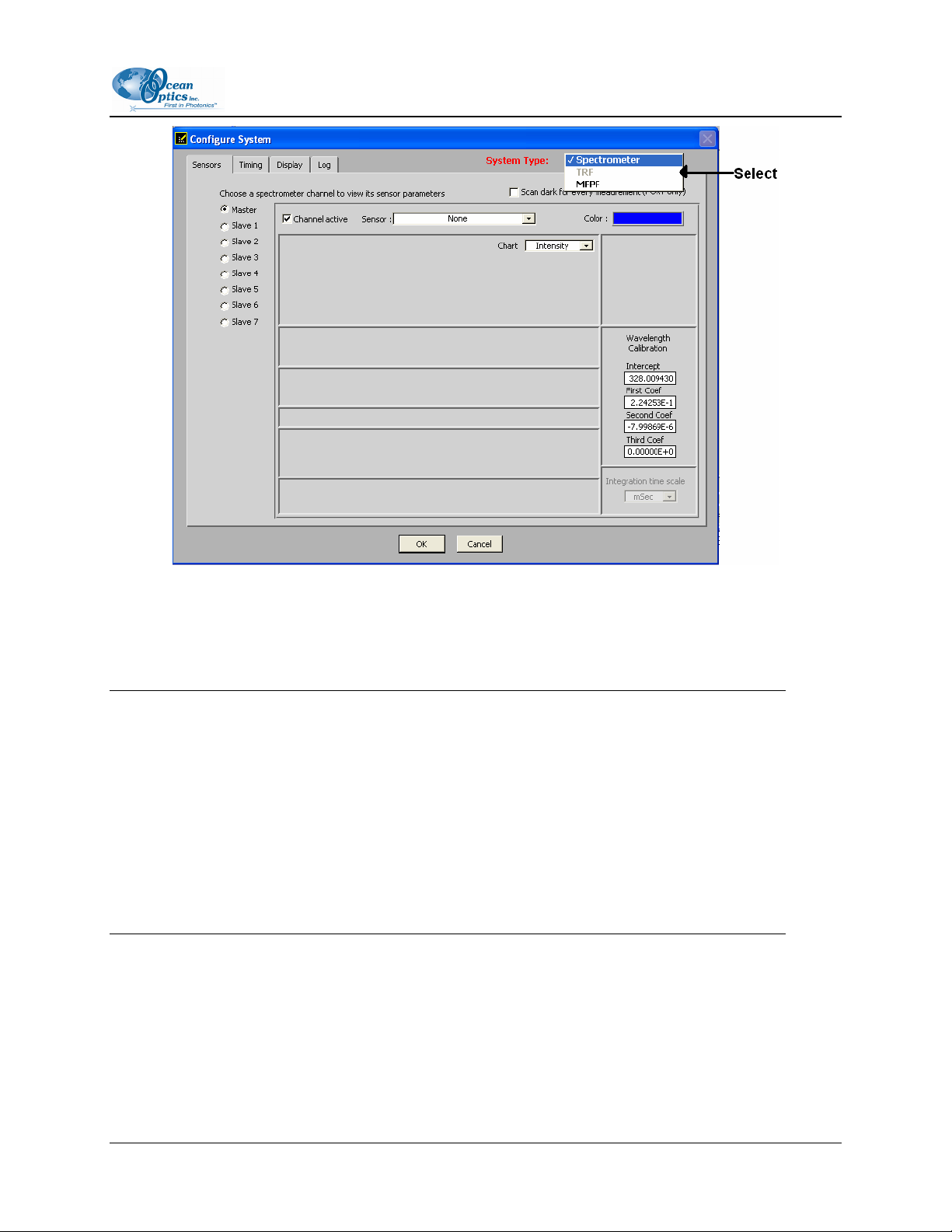

Software

Select Configure | Software to specify the spectrometer parameters in the OOISensors software.

To access the Configure System screen, choose Configure | Software from the OOISensors menu bar.

The Configure System screen contains tabs for specifying Sensor, Timing, Display, and Log options.

10 FOXY-AL300-000-02-0207

Page 21

2: OOISensors Software

The System Type field in the upper, right corner allows you to select either Spectrometer or MFPF for

the attached hardware. The differences between the two system types when using OOISensors are noted

where applicable throughout this manual. Depending on this selection, some tabs and other user interface

objects will be visible (or not) in main application window and in this configuration window.

Notes

If you have an MFPF unit, refer to the MultiFrequency Phase Fluorometer Installation and

Operation Manual for more information. These instructions assume that you are installing

OOISensors to use with a spectrometer. If you switch between Spectrometer and MFPF System

Type, most parameter settings will be retained as they are hardware-specific, but some parameters

are common to all hardware types.

If you switch from MFPF to Spectrometer System Type, the spectral graph will not be visible.

You must select the Display tab on the Configure System screen, and then change the Graph

and Chart Display Mode to display the spectral graph.

FOXY-AL300-000-02-0207 11

Page 22

2: OOISensors Software

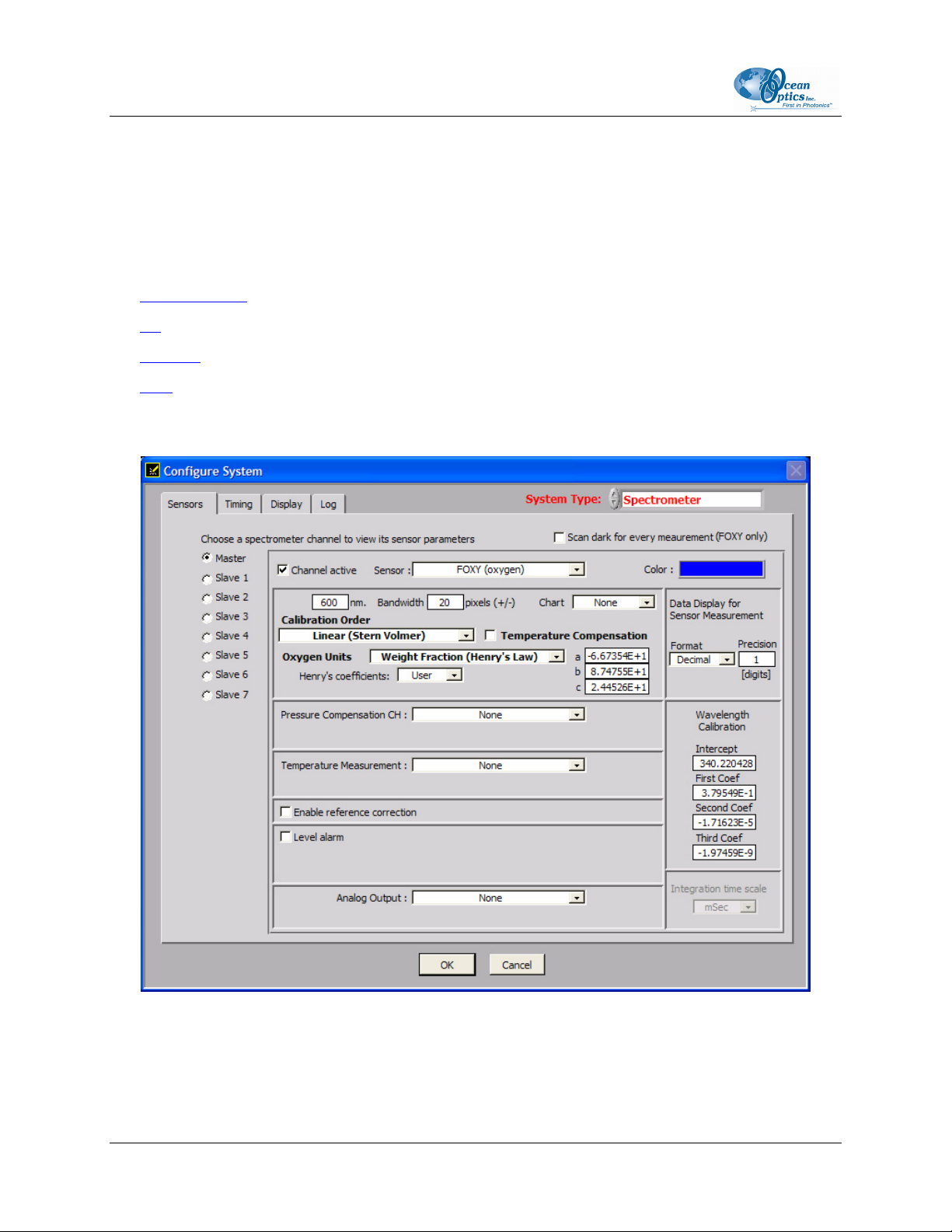

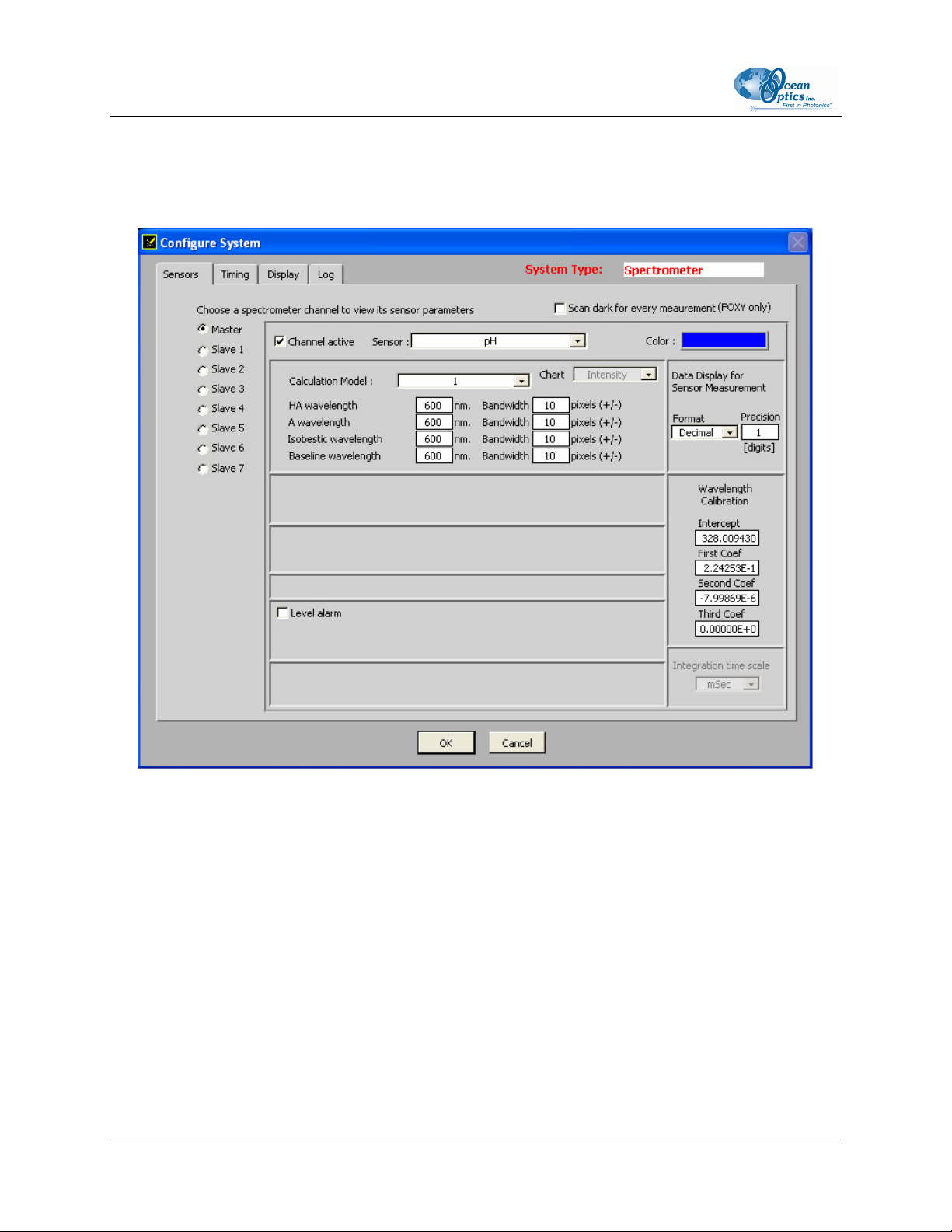

Sensors Tab for Spectrometer Systems

Click on the Sensors tab in the Configure System screen to access Sensor controls. The Sensors tab

contains the following options:

• None

• FOXY (oxygen)

• pH

• Pressure

• CO2

•

FOXY (oxygen)

12 FOXY-AL300-000-02-0207

Page 23

2: OOISensors Software

Option Name Description

Choose a spectrometer

channel to view its sensor

parameters

Scan dark for every

measurement (oxygen

sensor only)

Selects the spectrometer channel for which all sensor options will be

applied. Each spectrometer channel has its own parameters.

Automatically stores a dark spectrum each time a simple scan is taken.

Only for use with the SF2000 in pulsed mode, and the USB-LS-450 light

source.

Activates the currently selected spectrometer channel (see above). For

Channel active

some multichannel systems such as the ADC1000-USB, the software

sets the active channels according to what is stored in hardware and will

not allow you to activate or deactivate channels.

Sensor Selects the type of sensor used for each spectrometer channel.

Color

Changes the color of the spectral trace in the display graph. Click directly

on the color box to customize the color.

Enter the analysis wavelength. This number should be close to 600 nm,

Analysis Wavelength

since the ruthenium complex at the tip of the oxygen probe emits energy

at ~600 nm when it fluoresces.

Enter the number of pixels to average on either side of the analysis

Bandwidth Pixels

wavelength, typically 25. This value is in addition to the boxcar smoothing

on the main window. For best results, keep the boxcar value low.

Chart Specifies the type of information charted in the spectral graph.

Specify the data display format and precision of the data. Select Decimal

Data Display for Sensor

Measurement

or Scientific from the Format drop-down menu, and select a value (max.

5) to specify the precision of the oxygen data displayed on the screen and

saved in log files.

Calibration Order Select Linear (Stern Volmer) or Second Order Polynomial.

Temperature Compensation Select this checkbox to enable temperature compensation.

Oxygen Units

Henry’s coefficients

Select to use % oxygen (based on factory calibration for oxygen in air), or

Weight Fraction (Henry’s Law) for water

Enter Henry’s coefficients if you are using a liquid other than water (water

is the default).

Compare these values with the Wavelength Calibration Data Sheet that

Wavelength Calibration

Coefficients

accompanied your system to ensure that the values are identical. If

necessary, enter the correct values for each channel. Software retrieves

coefficients from hardware when possible.

FOXY-AL300-000-02-0207 13

Page 24

2: OOISensors Software

Option Name Description

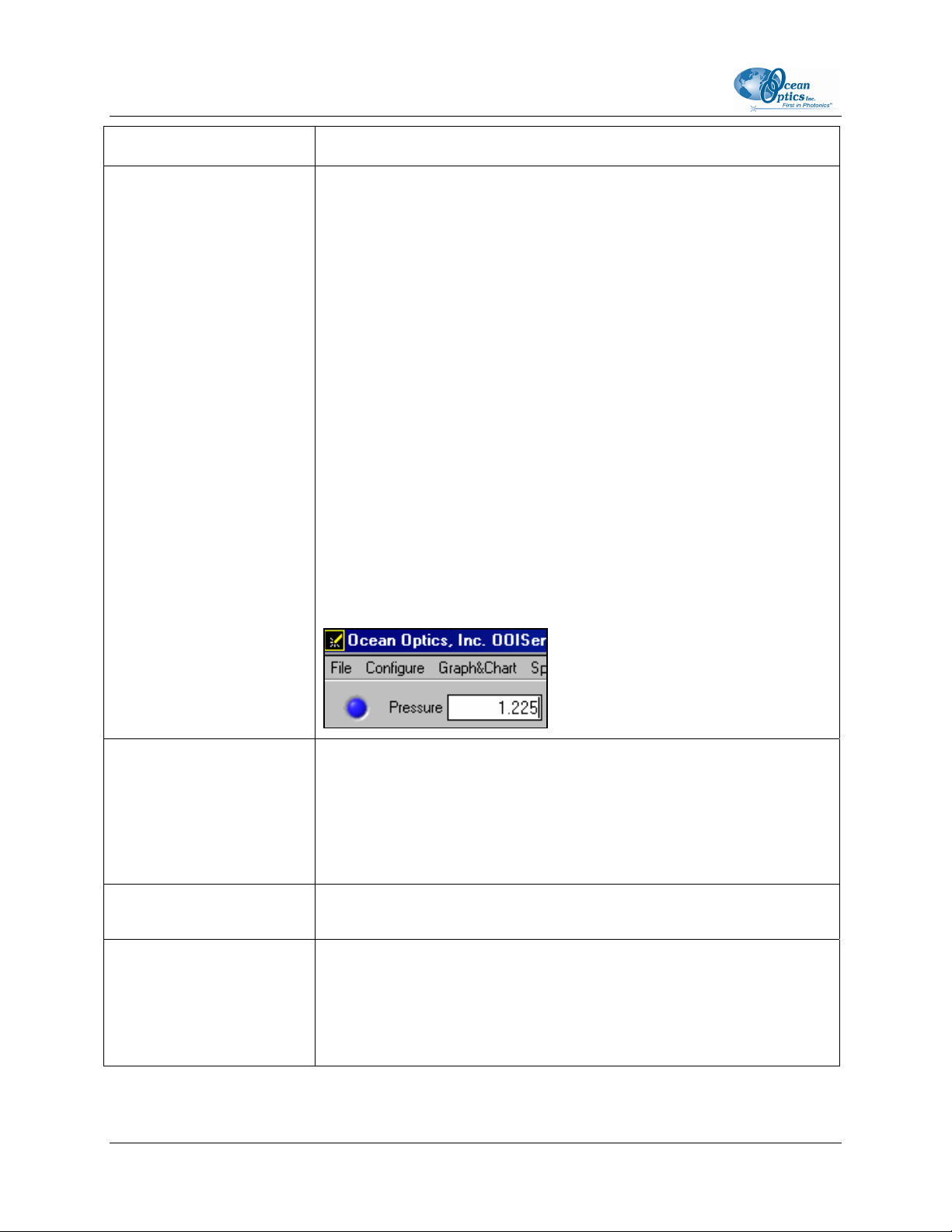

Monitors and corrects for pressure fluctuations in the sample (if you have

your own pressure transducer). You can use the pressure transducer

separately, or interface it with the sensor system.

If interfacing to the sensor system, you must have an available

spectrometer channel that is NOT connected to an oxygen sensor or

have the OMEGA D5251 4-20mA general purpose module. Specify the

pressure-monitoring method with the drop-down menu.

If an unused spectrometer channel is used as an analog-to-digital

converter (A/D) for your pressure transducer, typically Slave1 to Slave7,

activate it and assign that spectrometer channel as a pressure channel

and enter its calibration coefficients there. If a D5251 module is used,

select the serial COM port used and enter its calibration coefficients.

Pressure Compensation CH

Enable reference correction

CAUTION: This option is

not recommended. Speak

to an Ocean Optics

Application Scientist

before setting.

Bandwidth Pixels

Additionally, you can enter the pressure manually.

The Pressure applies to all channels which activated manual pressure

compensation and is displayed in the upper left corner of the OOISensors

screen as follows:

Monitors and corrects for any drift or change in the LS-450 Blue LED light

source. Click to enable this function, and then enter the reference

wavelength in the nm box.

To use this option correctly, be sure the peak at 470 nm is not saturated.

Only available if “Enable reference correction” is enabled. Specifies the

number of pixels around the reference wavelength to average.

Configures alarm properties. Click this box to enable the alarm feature,

and then enter alarm-monitoring parameters. When the value is within the

Level alarm

specified value range, the alarm indicator is green. If the value falls below

the specified alarm parameters, the on-screen indicator will turn red. If the

value rises above the specified alarm parameters, the indicator turns

yellow.

14 FOXY-AL300-000-02-0207

Page 25

2: OOISensors Software

Option Name Description

Specifies the method used to monitor and correct for temperature

fluctuations, if desired:

None: No monitoring

Manual: Temperature is monitored, but OOISensors will not read and

display temperature values. You must manually enter temperature values

in the display window.

Select Omega D5xx1 RS232 monitor temperature and have OOISensors

automatically read and display temperature values from thermistor or

thermocouple.

Ocean Optics offers the Omega Thermistor and the Omega

Thermocouple for monitoring temperature. The thermistor and

thermocouple should already be connected to your PC via an RS-232

module. Select the COM Port number (next to Serial Port) on your PC to

Temperature Measurement

which the thermistor or thermocouple is connected. Because the RS-232

module can support up to four thermistors or thermocouples, there are

four labeled ports. Next to D5xx1 CH, select the port to which the

thermistor or thermocouple connects to the RS-232 module. (If you only

have one thermistor or thermocouple, select 0.)

Select USB2000 LS-450 to instruct the USB-LS-450 to monitor and

correct for temperature fluctuations. The A/D converter in the USB-LS-

450 front end is configured for a 100 ohm platinum RTD (resistance

temperature device).

A similar method is used with the OMEGA D5251 general purpose 4-

20mA module, which requires your own temperature sensor with current

output. You must calibrate the input and create its calibration coefficients.

Enable the Compensate function if you want the software to correct for

temperature fluctuations. Enabling the Chart function allows you to view

a chart of the temperature values.

FOXY-AL300-000-02-0207 15

Page 26

2: OOISensors Software

pH

Use this screen to set parameters for a pH sensor.

16 FOXY-AL300-000-02-0207

Page 27

2: OOISensors Software

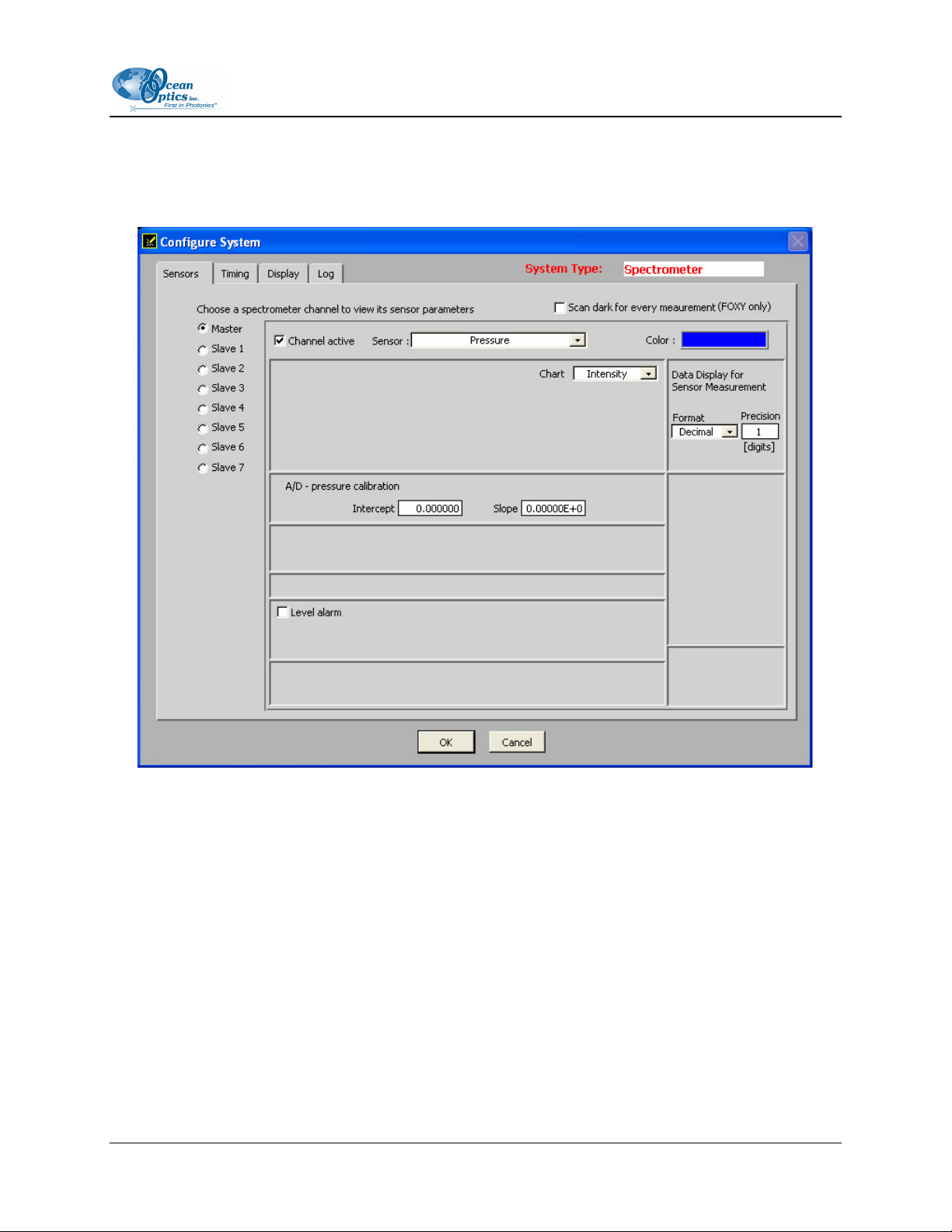

Pressure

Use this screen to set parameters for a pressure sensor.

FOXY-AL300-000-02-0207 17

Page 28

2: OOISensors Software

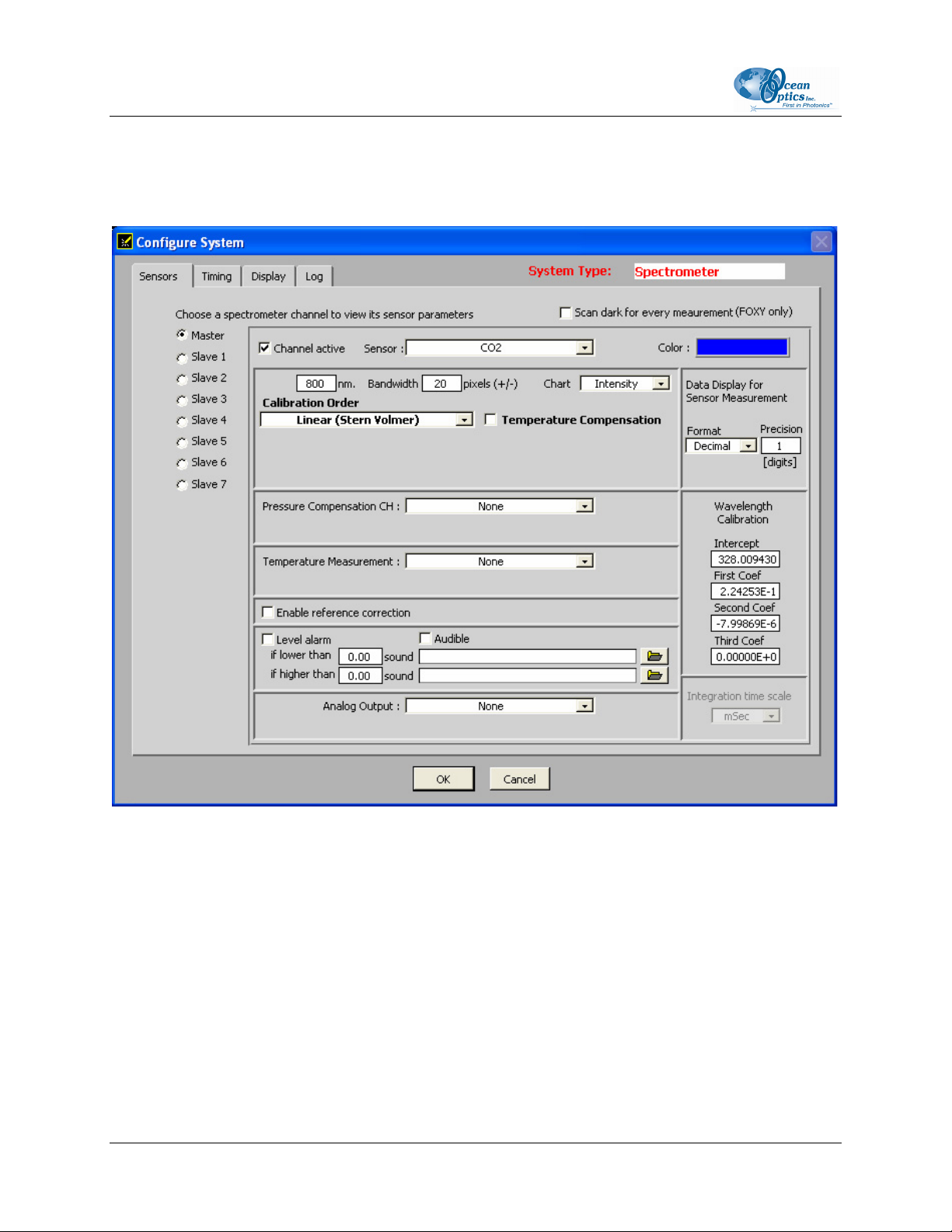

CO2

Use this screen to enter parameters for a CO2 sensor.

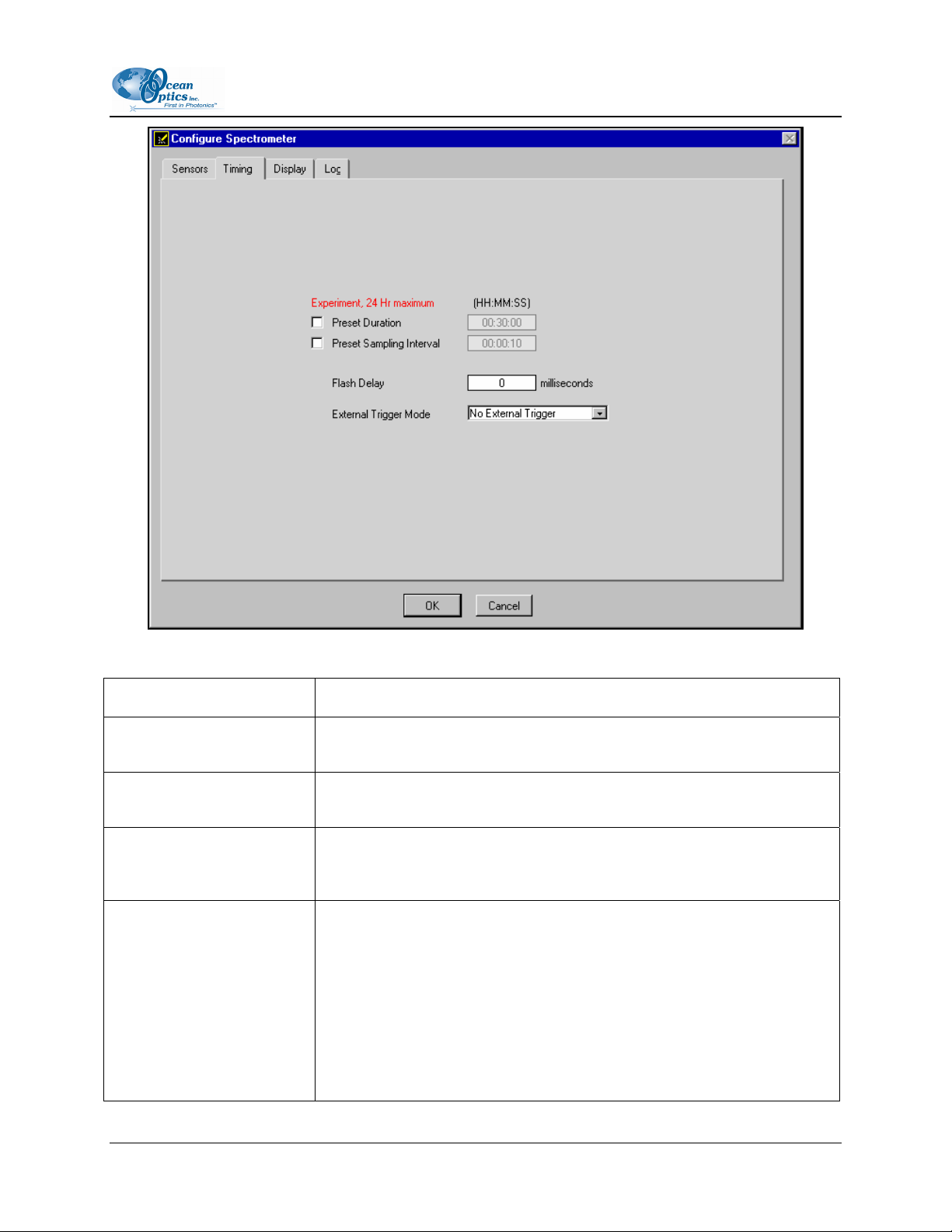

Timing Tab

Click on the Timing tab in the Configure System screen to access Timing controls. This screen allows

you to configure timed data acquisition parameters.

18 FOXY-AL300-000-02-0207

Page 29

2: OOISensors Software

The Timing tab contains the following options:

Option Name Description

Preset Duration

Preset Sampling Interval

Flash Delay

(For spectrometer systems

only)

External Trigger Mode

(For spectrometer systems

only)

Specifies the length of the entire timed data acquisition process. Enter the

duration in HH:MM:SS format.

Specifies the frequency of the data collected in the timed acquisition.

Enter the frequency interval in HH:MM:SS format.

Controls the flash delay time of the lamp, in milliseconds. This feature is

only applicable when using an ADC1000-PCI or ADC2000-PCI A/D

Converter and the LS-450 or R-LS-450 light sources.

Specifies the external trigger mode used when acquiring data:

No External Trigger: The spectrometer continuously scans, acquires,

and transmits data to the PC according to previously configured

acquisition parameters. This mode offers no way to synchronize data

acquisition with an external event.

FOXY-AL300-000-02-0207 19

Page 30

2: OOISensors Software

Option Name Description

External Software Trigger: This mode allows data acquisition to be

synchronized with external events. In this level-triggered mode, the

spectrometer is free running, only while level is high, just as in normal

mode. However, upon each trigger, the data collected up to the trigger

event is transferred to the software. For more information, consult the

External Triggering document on the Ocean Optics web site at:

http://www.oceanoptics.com/technical/externaltriggering.pdf

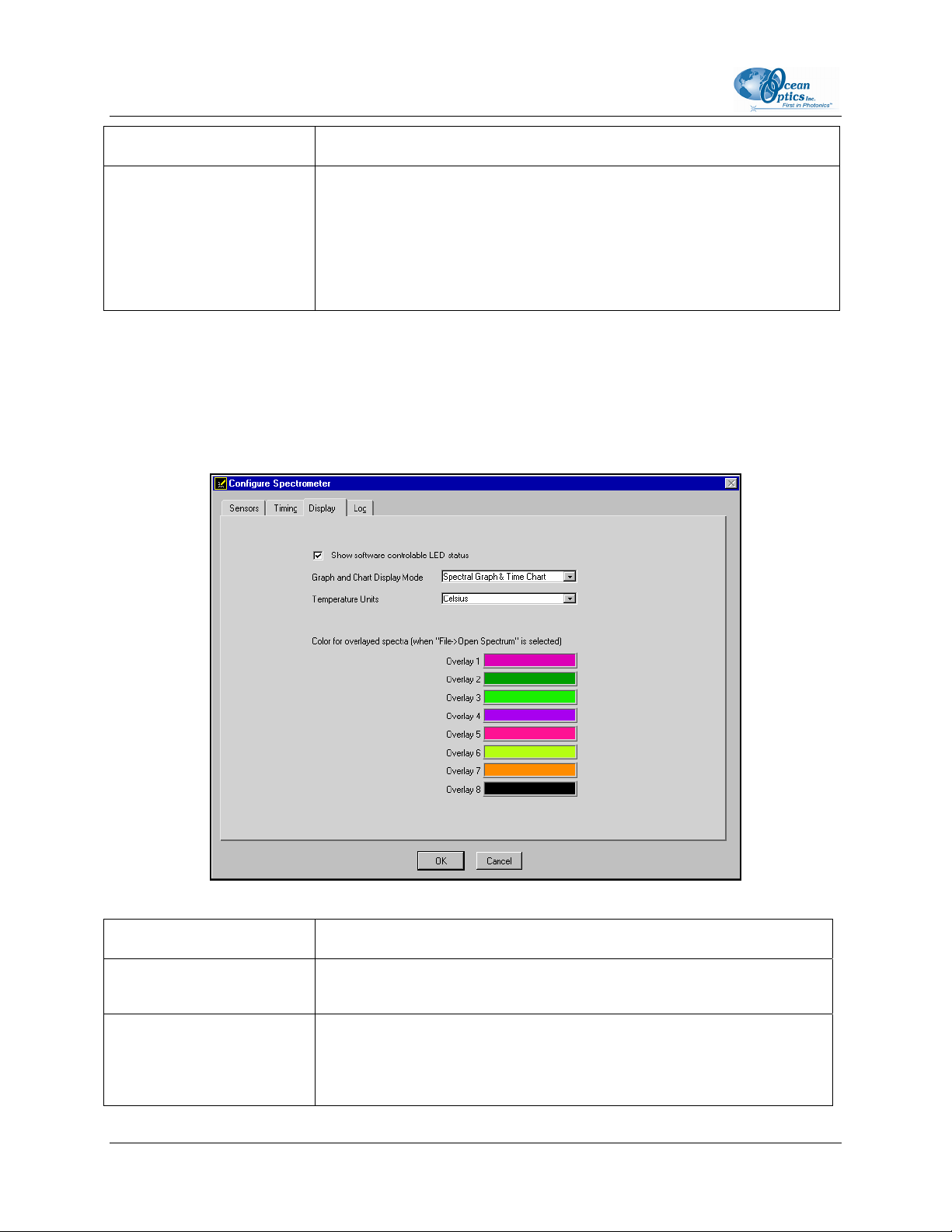

Display Tab

Click on the Display Tab in the Configure Spectrometer screen to access Display controls. This screen

allows you to configure display parameters for spectrometers in OOISensors. This tab does not exist for

systems with MFPF units.

The Display Tab contains the following options:

Option Name Description

Show software controllable

LED status

Graph and Chart Display

Mode

20 FOXY-AL300-000-02-0207

Displays the status of the LS-450’s blue LED.

Specifies the information that appears in the display window.

Spectral Graph Only: The Spectral Graph appears in the display

window.

Page 31

2: OOISensors Software

Option Name Description

Spectral Graph & Time Chart: The Spectral Graph appears in the top

of the display window and the Time Chart appears in the bottom of the

display window.

To view a Temperature Chart, select Graph&Chart | View Temperature

Chart from the menu bar. The Temperature Chart will replace the

Spectral Graph until View Temperature Chart is unchecked.

Specifies the format for temperature display. Select Celsius or

Fahrenheit from the drop-down menu.

Temperature Units

Note: OOISensors measures all temperatures in Kelvin and converts to

Celsius or Fahrenheit.

Specifies colors for static spectra opened with the File | Open

Color for overlaid spectra

Spectrum command from the menu bar. Stored static spectra are

displayed as overlays, and you should distinguish overlays from real-

time spectra by modifying the color of the traces.

Log Tab

Click on the Log Tab in the Configure Spectrometer screen to access data logging controls. These

controls allow you to configure the data logging parameters available in OOISensors.

FOXY-AL300-000-02-0207 21

Page 32

2: OOISensors Software

The Log tab contains the following options:

Option Name Description

Specifies the number of scans stored in RAM before the data is

Store to disk every X

acquisitions

saved to a log file. Smaller numbers cause saves that are more

frequent. Larger numbers cause saves that are less frequent, but

increase application performance by reducing save time.

Specifies the log file name for the timed data acquisition. Click on

the folder icon to browse to a specific folder.

Filename and Path

Insert Event in Log File

MS time stamp Stamps the data in the log file with the system time.

Note: The Insert Event in Log File option enables you to enter text

in the log file. Select Spectrometer | Insert Event in Log File

from the menu bar. A dialog box will prompt you to enter text,

which will be displayed in the log file next to the data that was

acquired at the time of text entry.

Enables you to enter text in the log file. Select Spectrometer |

Insert Event in Log File from the menu bar. A dialog box will

prompt you to enter text, which will be displayed in the log file next

to the data that was acquired at the time of text entry.

Display Functions

The following sections provide information on controls that are available directly from the OOISensors

main display panel. From the display window, you can choose a mode to acquire data, take scans of your

sample, store a dark spectrum, configure the cursor, configure the graph, enter data acquisition parameters

and analyze data.

Scan Control

This switch controls the mode of the OOISensors scan function. The Single mode option instructs the

Scan function to take one scan. The Cont. (continuous) mode option instructs the Scan function to take

continuous scans until scans are manually stopped.

22 FOXY-AL300-000-02-0207

Page 33

2: OOISensors Software

► Procedure

1. Select the Single or Cont. button from the Scan section of the OOISensors screen in the lower

right hand corner.

2. Click on the switch graphic to turn the Scan function on and acquire data. In Single mode, the

switch will automatically revert to the off position after one scan is completed. In the Cont.

mode, the switch will remain on and OOISensors will perform multiple scans.

3. Click on the switch graphic to turn the Scan function off and cease data acquisition (if in Cont.

mode).

Store Dark

This function stores the current spectrum as the dark spectrum for all active channels. You should store

the dark after you set the data acquisition parameters in OOISensors.

The dark spectrum is a sample spectrum taken with the light path to the sample blocked. Storing a dark

spectrum is required before the computer can make accurate measurements. This button stores the dark

values at the fluorescence and reference wavelengths.

If you are using an O

before storing a dark spectrum. Ambient light can interfere with dark spectrum measurements on probes

with no overcoat.

You should see a flat line in the display screen prior to storing a dark spectrum.

sensor without an overcoat, you must physically place the sensor in a dark location

2

Note

This selection is not recommended for the USB-LS-450 light source.

If you have configured the spectrometer to control the LS-450, the software can take automatic

dark scans if you select

Scan Dark for every measurement. When this function is enabled, the LS-450 automatically turns

off, and a dark scan is stored, each time you take a sample scan.

Configure | Software from the menu, click on the Sensors tab, and select

Subtract Dark

This feature affects only the display of data on the screen.

Selecting this box under the Store Dark button subtracts the current dark spectrum from the spectra

displayed in OOISensors. This command is useful if you are trying to eliminate fixed pattern noise

(caused by a very long integration time) from the spectra.

FOXY-AL300-000-02-0207 23

Page 34

2: OOISensors Software

OOISensors always subtracts the dark measurement from the sample measurement in the OOISensors

algorithm.

Data Acquisition Parameters

This control, located at the top of the OOISensors screen, allows you to specify the integration time,

averaging and boxcar smoothing values. This control provides you with immediate access to the data

acquisition settings.

Channel [CH]

To set the data acquisition parameters (such as integration time, averaging and boxcar smoothing) for a

specific spectrometer channel, first select the spectrometer channel from the CH pull down menu.

Note

This pull down menu is not for selecting the spectrometer channels that are active in the display

graph. It is only used to specify the data acquisition parameter for a specific channel.

To activate and display specific spectrometer channels, select Configure | Spectrometer from

the menu bar and click on the Sensors tab. Then, enable each spectrometer in the system.

Integration Time

This parameter specifies the length of the spectral acquisition in milliseconds for the specified

spectrometer channel (in the CH pull down menu). The integration time of the spectrometer is analogous

to the shutter speed of a camera. The higher the value specified for the integration time, the longer the

detector "looks" at the incoming photons.

For Oxygen Sensors:

If your signal intensity is too low, increase this value. If the signal intensity is too high, decrease the

value. Adjust the integration time until the fluorescence peak (~600 nm) is about 2000 counts in air or

saturated water. The fluorescence peak should not exceed 3500 counts. The intensity of the LED peak

(~475 nm) does not affect your measurements. You only need to adjust the integration time if the

fluorescence peak is saturating the detector.

Note

If you are using any light source and the SF2000 with the switch on Pulse, only set the

integration time to powers of two (2, 4, 8, 16, 32, 64… etc.). This ensures a constant number of

LED pulses during each spectral acquisition.

24 FOXY-AL300-000-02-0207

Page 35

2: OOISensors Software

Average

This parameter specifies the number of spectra to average for the specified spectrometer channel. A

higher value for this parameter provides a better signal-to-noise (S:N) ratio.

Note

The S:N improves by the square root of the number of scans averaged.

Boxcar Smooth

This parameter specifies the number of pixels on either side of a particular pixel to average across an

entire spectral acquisition. This method averages a group of adjacent detector elements. A value of five,

for example, averages each data point with 5 points (or bins) to its left and 5 points to its right.

The greater this value, the smoother the data and the higher the signal-to-noise ratio. However, if the

value entered is too high, a loss in spectral resolution results.

Note

The S:N improves by the square root of the number of pixels averaged.

For best performance when using oxygen sensors, set the boxcar smoothing value to no more than

25 pixels.

Cursor Functions

The cursor functions section of the OOISensors screen allows you to configure specific cursor

parameters. You can label the cursor, monitor cursor X and Y values, magnify the cursor, and move the

cursor in small increments. Additionally, there is a cursor selection button (located to the right of the XY

values) used for choosing cursor and pointer style.

+ Button

When the + button is depressed, the pointer becomes a crosshair symbol, enabling you to drag the cursor

around the graph.

FOXY-AL300-000-02-0207 25

Page 36

2: OOISensors Software

Magnification Options

There are several magnification options from which to choose. The function chosen remains in use until

another magnification icon or the crosshair symbol is selected. Clockwise, beginning with the top left

symbol, the magnify icons perform the following functions:

1. Magnifies a specific area by clicking and dragging a box around the area

2. Zooms in on the horizontal scale, but the vertical scale remains the same

3. Zooms in on the vertical scale, but the horizontal scale remains the same

4. Reverts to the last zoom function

5. Zooms out approximately one point vertical and horizontal, click once or press continuously

6. Zooms in approximately one point vertical and horizontal, click once or press continuously

Cursor Diamonds

To move the cursor left or right in small increments in the graph area, click on the left and right cursor

diamonds.

Cursor Bar

The functions listed in the following sections are located in the Cursor Taskbar, inside the Cursor

Function section of OOISensors.

To move the cursor with the mouse, click directly on the cursor in the display panel and drag.

Cursor Label

The first box in the configure cursor taskbar allows you to label the cursor.

26 FOXY-AL300-000-02-0207

Page 37

2: OOISensors Software

X and Y Values

The cursor taskbar displays the X value and Y value of the cursor point.

Cursor Properties

To the right of the X and Y values of the cursor is a cursor properties button that allows you to utilize

many cursor features such as choosing a cursor style, selecting a point style and finding a color for the

cursor trace.

Data Values

The data displayed to the right of the graphs and chart areas provides you with the oxygen or pH values

for each spectrometer channel and probe combination. If you are monitoring and correcting for

temperature, these values appear in this area as well.

The upper temperature represents the current temperature reading. Additionally, this is where you would

manually enter the temperature, depending on your configuration.

The lower temperature represents the single point calibration temperature.

Spectral Graph

The Spectral Graph section is located in the upper half of the OOISensors main screen.

The Spectral Graph area of the display window provides you with real-time spectral scans of your sample.

You can change the vertical and/or horizontal scales of the graph by clicking on an X and Y endpoint and

manually typing in a value. The graph will then resize itself.

FOXY-AL300-000-02-0207 27

Page 38

2: OOISensors Software

Temperature Chart

The Temperature Chart, when enabled, displays in the upper half of the OOISensors main screen. When

this option is enabled, the Spectral Graph screen is replaced by the Temperature Chart.

Display the Temperature Chart

► Procedure

Perform the steps below to display the Temperature Chart:

1. Select Graph & Chart from the OOISensors menu bar.

2. Select the View Temperature Chart option from the pop up menu.

The Temperature Chart then takes the place of the Spectral Graph.

Save and Display the Temperature Chart

► Procedure

Perform the steps below to save the Temperature Chart and display it on the screen:

1. Select File from the OOISensors menu bar.

2. Select Save Time Chart from the pop up menu.

3. Specify the save information in the Save prompt that appears.

Note

The saved file is in ASCII format. The first column is the Time column, the second column is the

sensor time chart values, and the third column is the temperature readings.

4. Select Graph & Chart | View Temperature Chart again to de-select the View Temperature

Chart option. Once this option is disabled, the Spectral Graph reappears.

Save the Temperarure Without Displaying It

You can also save Temperature Chart data without displaying the chart.

28 FOXY-AL300-000-02-0207

Page 39

2: OOISensors Software

► Procedure

To save the Temperature Chart without displaying the chart:

1. Select Configure from the OOISensors menu bar.

2. Select Spectrometer from the pop-up menu.

3. Click on the Sensors tab and enable the Chart function, located under the Temperature

Measurement option. Temperature data will be collected, whether or not the Temperature Chart is

displayed.

4. Save the chart using the Save function.

Time Chart

The time chart displays the data from all active channels at a specific wavelength over time.

► Procedure

Perform the following steps to view the Time Chart:

1. Select Configure | Spectrometer from the menu bar.

2. Click on the Display tab.

3. Ensure that Spectral Graph & Time is selected next to Graph and Chart Display mode.

To configure a timed data acquisition procedure, select Configure | Spectrometer from the menu bar and

click on the Timing tab.

Time Chart Switch

The Time Chart switch allows you to start and stop data acquisition. Click on the switch to enable or

disable data acquisition.

► Procedure

To set timed data acquisition parameters:

1. Select Configure | Spectrometer from the menu bar.

2. Click on the Timing tab.

3. Enter the data acquisition parameters.

FOXY-AL300-000-02-0207 29

Page 40

2: OOISensors Software

Log On/Off Switch

You can enable or disable the saving of data to a log file with the Log switch. Click on the switch to

enable or disable data logging. Only the last 10,000 scans of a timed data acquisition can be saved in the

log file.

► Procedure

To set data logging parameters for timed data acquisition:

1. Select Configure | Spectrometer from the menu bar.

2. Click on the Log tab.

3. Specify the frequency in between data saves.

4. Specify a file name for the saved log.

File Menu Functions

The following sections detail commands available from the OOISensors File menu.

Save Spectrum

This menu option saves the current spectrum as a tab-delimited ASCII file. You can then open these files

as overlays in the spectral graph or import them into other software programs, such as Microsoft Excel.

30 FOXY-AL300-000-02-0207

Page 41

2: OOISensors Software

Save Time Chart

This menu option saves the current time chart as a tab-delimited ASCII file. You can then open these files

as a static chart or import them into other software programs, such as Microsoft Excel.

Open Spectrum

This menu option opens a dialog box that allows you to open a previously saved spectrum and to open it

as an overlay (a static spectrum) while still acquiring live data.

Open Time Chart

This menu option opens a dialog box that allows you to choose a previously saved time chart and open it

as a static chart.

Page Setup

This menu option allows you to select printing parameters.

Print Spectrum and Time Chart

This menu option allows you to print the current display in the Spectral Graph, or select File | Print Time

Chart from the menu to print the time chart.

Exit

This menu option closes the OOISensors software. You will be prompted to confirm before OOISensors

closes.

Graph&Chart Menu Functions

The following section provides information on options available from the Graph&Chart menu.

FOXY-AL300-000-02-0207 31

Page 42

2: OOISensors Software

Clear Spectrum Graph

This option removes static spectra overlays from the graph.

Clear Time Chart

This option clears the time chart traces. A message box confirms this action.

Enable Grid

This option generates a grid in the spectral graph. If you also have the time chart displayed, this function

generates a grid in the time chart as well. De-select Enable Grid from the menu to turn this option off.

Autoscale Horizontal (Spectral Graph)

This option automatically adjusts the horizontal scale of a current graph so the entire horizontal spectrum

fills the display area.

Autoscale Vertical (Spectral Graph)

This option automatically adjusts the vertical scale of a current graph so the entire vertical spectrum fills

the display area.

Autoscale Vertical (Time Chart)

This option automatically adjusts the vertical scale of a current time chart so the entire vertical chart fills

the display area. You can also adjust the vertical scale of a temperature time chart (if you first select the

View Temperature Chart option).

View Temperature Chart

This option displays temperature data. The temperature chart replaces the spectral chart. To view the

spectral graph again, select Graph&Chart | View Temperature Chart from the menu.

Spectrometer Menu Functions

The following section provides information on options available from the Spectrometer menu.

32 FOXY-AL300-000-02-0207

Page 43

2: OOISensors Software

Scan

This option takes a scan of your sample.

When in Single mode, this function acts as a snapshot. When the button is depressed, the Stop function

replaces the Scan function. The Scan switch enables and the scan begins. The switch remains on until the

scan completes (according to configured integration time).

When in Continuous mode, this function continuously takes multiple scans of the sample. After each

integration cycle, another scan begins immediately. The Scan switch enables and the system begins data

acquisition. Select Spectrometer | Scan from the menu bar or click on the Scan switch again to halt the

scanning process and discontinue acquiring data.

Insert Event in Log File

This option allows you to enter text into the log file during a logged, timed data acquisition.

When this option is selected, a dialog box appears prompting you to enter text. In the log file, this text

appears next to the data that was acquired at the time of text entry.

To use this feature, both the Time Chart and Log switches in the display window should be in the On

position.