Oasis BU1PVECKY, BU1PVECHSY, BU1PVECK, BU1PVECHS Owner’s Manual

INSTALLATION &

SERVICE INSTRUCTIONS

BU1PVECHS(Y)

BU1PVECK(Y)

Series Coolers

BU1PVECHS(Y) / BU1PVECK(Y)

Installation & Service Instructions

030099-535 RevOrig pg 2 of 10 © Copyright 2016 OASIS Europe

BEFORE YOU START USING THIS WATER COOLER PLEASE READ THE FOLLOWING

INSTRUCTION VERY CAREFULLY.

WARNINGS:

• THIS APPLIANCE IS NOT INTENDED FOR USE BY PERSONS (INCLUDING

CHILDREN) WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES, OR

LACK OF EXPERIENCE AND KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE BY THE

PERSON RESPONSIBLE FOR THEIR SAFETY

• CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT THEY DO NOT PLAY WITH

THE APPLIANCE

• IF THE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY A SPECIAL CORD

OR ASSEMBLY AVAILABLE FROM THE MANUFACTURER OR ITS SERVICE AGE

• FAILURE TO FILL HOT TANK WITH WATER BEFORE TURNING ON THE HOT TANK

CAN DAMAGE THE UNIT

• THIS APPLIANCE MUST BE EARTHED

Contents:

• Technical Specification

• Pre-Delivery Inspection

• Installing the OASIS green filter system

• Cooler Installation

• General Troubleshooting Guidelines

• Accessing the Internal Chassis

• Cleaning and Sanitizing Instructions

Technical Specification:

• Product Dimensions

o Height: 1125mm

o Width: 318mm

o Depth: 405mm

o Net Weight:

§ 32.5 kg BU1PVECHS(Y)

§ 31.5kg BU1PVECK(Y)

• Electrical Specification

Model

BU1PVECKY

BU1PVECHSY

BU1PVECK

BU1PVECHS

Voltage

220 - 240V

50/60Hz

220 - 240V

50/60Hz

115V

60Hz

115V

60Hz

Current

(Total)

0.8 A

3.0 A

1.8 A

5.8 A

Power

(Cooling)

100 Watts

100 Watts

100 Watts

100 Watts

Power

(Heating)

-

520 Watts

-

450 Watts

BU1PVECHS(Y) / BU1PVECK(Y)

Installation & Service Instructions

030099-535 RevOrig pg 3 of 10 © Copyright 2016 OASIS Europe

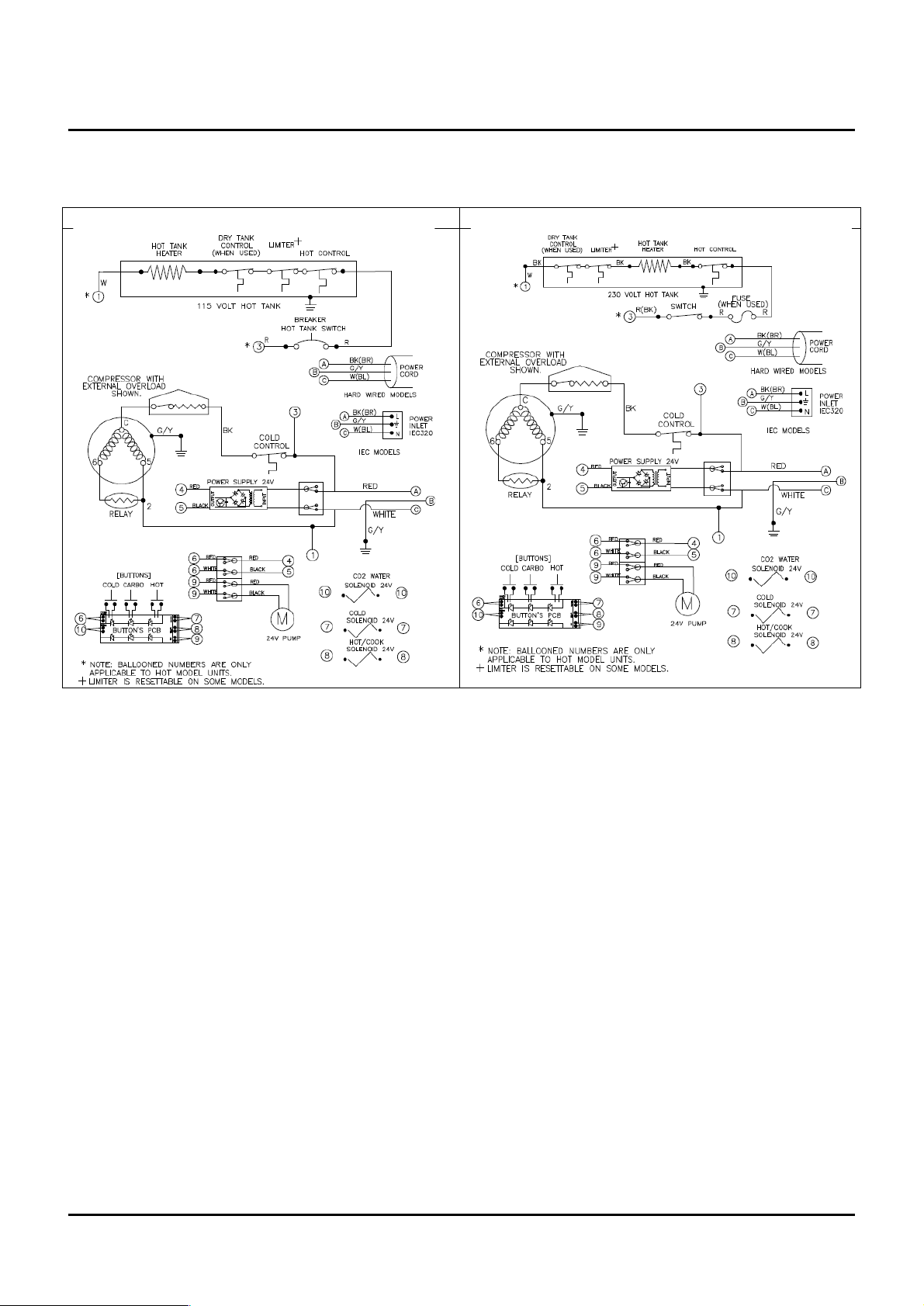

Wiring Diagram

115V

230V

General Information

• The BU1PVECHS Series coolers are designed for use with a supply of bottled water. The cooler

should not be used with water supplies of unknown bacterial quality or those that are not already

fit for human consumption.

• This unit is suitable for indoor use in domestic, commercial & industrial locations. They should

not be sited in locations where they may be subjected to rain or snow.

Cooling System

• The BU1PVECHS Series coolers use the OASIS Pressure Vessel Direct Chill (PVDC) cooling

tank system. The cooling tank is manufactured from 304 Stainless Steel which is non-corrosive

and inert.

• The cold water temperature is preset at the factory at approximately 7°C (45°F) – the water

temperature is controlled by a thermostat that is located on the back of the unit. Cold water

temperatures may be adjusted via a slotted screw on the body of the control (can be accessed

through wires on the condenser). Turning this screw in the clockwise direction will make the

water colder (and vice versa).

Hot Water System

• The hot water temperature is preset at the factory at approximately 86°C (187°F) – the water

temperature is controlled by a thermostat that is located on the hot tank. Hot water temperatures

may be adjusted depending on the hot tank model.

BU1PVECHS(Y) / BU1PVECK(Y)

Installation & Service Instructions

030099-535 RevOrig pg 4 of 10 © Copyright 2016 OASIS Europe

Carbonated Water Circuit

• The carbonation level of the water is based on coldness of the water and pressure of the CO2

bottle. The carbonation level in the water can be increased by either raising the CO2 pressure

(max 60psi/15 l per min) or reducing the temperature of the cold water used for carbonation.

• The pre carbonated cooled water is taken from the cold tank, pressurised through a pump and

mixed with CO2 gas within a carbonator tank inside the OASIS Pressure Vessel Direct Chill

(PVDC) cooling tank system. The tank is made from food grade plastics and 304 Stainless Steel

• Carbonated water temperatures are controlled by the temperature of the cold water inside the

OASIS Pressure Vessel Direct Chill (PVDC) cooling tank system. Adjusting the cold water

temperature also adjusts the carbonated water temperatures.

• The carbonator tank is a pressurised system and protected with expansion tank.

• Purging of the CO2 circuit is necessary at initial start up, after sanitization and after the water is

completely drained in the reservoir.

Compressor

• The compressor uses the hydrofluorocarbon refrigerant R134a which is a non-Ozone depleting

substance with a Global Warming Potential of 1,300. The compressor is controlled by an

electromechanical thermostat that controls the temperature of the water in the cold tank

• The compressor is equipped with an automatic reset protector that disconnects the motor from

the line in case of an overload.

• This unit is equipped with a sealed compressor that requires no additional lubrication.

Water Pipe and Fittings

• The entire internal water circuit and all the components which come in contact with water are

made from food grade approved material

Mounting Feet

• The unit is supplied with 4 mounting feet which can be used to level the cooler on uneven

surfaces.

Maintenance

• Periodically remove dirt and lint from the condenser. Inspection should be done every three

months. If cleaning is required, disconnect the power supply cord, and then clean the condenser

with a small stiff non-wire brush. Following this procedure will ensure adequate air circulation

through the condenser for efficient and economical operation.

NOTE: Under no circumstances should the cabinetry be cleaned using a water jet

• WaterGuard helps prevent foreign matter from entering the cooling tank. Its parts should be

inspected, cleaned and replaced (if necessary) at regular intervals. Operation of the cooler

without WaterGuard components in place may allow airborne dust particles to enter the cooling

tank.

• Cleaning of water contact components

o The European Bottled Water Association recommends that water contact parts should be

cleaned and sanitised every 3 months. It is recommended that this process is carried out

by trained personnel

Water Valves:

• Control of water dispensing is achieved by means of electrical solenoid valves (3x 24V).

Loading...

Loading...