Page 1

PAMS Technical Documentation

RAE-3 Series PDA

8. Troubleshooting

Issue 1 06/01

Copyright 2001. Nokia Mobile Phones. All Rights Reserved.

Page 2

RAE-3

PAMS

8. Troubleshooting

Amendment

Number

Date Inserted By Comments

06/01 OJuntunen

Technical Documentation

AMENDMENT RECORD SHEET

Page 8 – 2

Issue 1 06/01

Page 3

PAMS

RAE-3

Technical Documentation

CONTENTS –Troubleshooting

Introduction 8 – 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAE–3 System HW / UI Troubleshooting 8 – 6. . . . . . . . . . . . . . . .

Tools needed for troubleshooting: 8 – 6. . . . . . . . . . . . . . . . . . . .

General guidelines 8 – 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System HW / UI Troubleshooting Cases 8 – 8. . . . . . . . . . . . . . . . . . .

Nominal Current Consumption 8 – 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 System HW / UI Troubleshooting Cases 8 – 10. . . . . . . . . . . . . . . . . .

1.1 Dead Device 8 – 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Keypad problems 8 – 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 BL8 System HW related 8 – 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Flash programming troubleshooting 8 – 13. . . . . . . . . . . . . . . . .

2.1.1 Flashing does not start 8 – 13. . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Flash memory fault indicated 8 – 14. . . . . . . . . . . . . . . . . . .

2.1.3 Flash VPP Error 8 – 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Flash Erasing /Programming Error 8 – 16. . . . . . . . . . . . . . .

2.2 General Power Checking 8 – 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Device does not stay ON 8 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Charging checking 8 – 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Backup Battery 8 – 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Backup battery troubleshooting 8 – 22. . . . . . . . . . . . . . . . .

2.6 Accessory Power Output Troubleshooting 8 – 24. . . . . . . . . . . .

2.6.1 No Accessory Voltage when needed 8 – 25. . . . . . . . . . . . .

2.6.2 Accessory Voltage ON all the time 8 – 26. . . . . . . . . . . . . . .

2.7 Clocks 8 – 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Clocks Troubleshooting 8 – 27. . . . . . . . . . . . . . . . . . . . . . . .

2.8 Memory Tests 8 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Test in boot up 8 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Test in PTS/WinTesla flashing 8 – 30. . . . . . . . . . . . . . . . . . .

2.9 Memory Troubleshooting 8 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.1 Memory fails In Boot Up tests 8 – 31. . . . . . . . . . . . . . . . . . .

2.9.2 CMT display backlight blinking 2 times in a loop 8 – 32. . .

2.9.3 CMT display backlight blinking 3 times in a loop 8 – 33. . .

2.9.4 CMT display backlight blinking 4 times in a loop 8 – 36. . .

2.9.5 Memory fails in PTS/WinTesla flashing 8 – 38. . . . . . . . . . .

2.9.6 Serial Flash id read test fails 8 – 40. . . . . . . . . . . . . . . . . . . .

2.10 Serial Interface Troubleshooting 8 – 41. . . . . . . . . . . . . . . . . . . .

2.11 CONTACT SERVICE in CMT display 8 – 44. . . . . . . . . . . . . . .

2.12 CCONT Serial interface Troubleshooting 8 – 46. . . . . . . . . . . .

2.13 SIM Card 8 – 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.1 SIM Card Error Troubleshooting 8 – 48. . . . . . . . . . . . . . .

2.13.2 SIM Card Rejected 8 – 49. . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Troubleshooting

Page No

Issue 1 06/01

Page 8 – 3

Page 4

RAE-3

PAMS

8. Troubleshooting

2.13.3 Insert SIM card 8 – 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 Memory Card 8 – 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14.1 Memory Card Interface Troubleshooting 8 – 53. . . . . . . .

2.14.2 Memory card switch troubleshooting: 8 – 55. . . . . . . . . . .

2.15 Lid Switch 8 – 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.1 Lid Switch Troubleshooting 8 – 56. . . . . . . . . . . . . . . . . . . .

2.16 Battery Removal Switch troubleshooting 8 – 58. . . . . . . . . . . .

2.17 COBBA Control Interface troubleshooting 8 – 60. . . . . . . . . . .

2.18 COBBA PCM Interface Troubleshooting 8 – 62. . . . . . . . . . . . .

2.19 Audio troubleshooting 8 – 65. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.1 Both Mic and Earpiece/PHF faulty 8 – 65. . . . . . . . . . . . . .

2.19.2 Mic faulty 8 – 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.3 Earpiece faulty 8 – 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.4 PHF Speaker faulty 8 – 69. . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.5 Headset out of order 8 – 71. . . . . . . . . . . . . . . . . . . . . . . . . .

2.20 RF Interface 8 – 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.1 Phone doesn’t register to the network l 8 – 73. . . . . . . . . .

2.21 IR Interface Troubleshooting diagram 8 – 74. . . . . . . . . . . . . . .

2.22 BL8 related Keyboard problems 8 – 75. . . . . . . . . . . . . . . . . . . .

2.23 BL8 related PDA UI problems 8 – 79. . . . . . . . . . . . . . . . . . . . . .

2.24 BL8 related CMT UI problems 8 – 84. . . . . . . . . . . . . . . . . . . . .

Technical Documentation

3 DL2 UI Troubleshooting 8 – 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 CMT and keypad illumination problems 8 – 86. . . . . . . . . . . . . .

3.2 CMT LCD Troubleshooting 8 – 86. . . . . . . . . . . . . . . . . . . . . . . . .

3.3 No picture on PDA LCD or picture is faulty 8 – 87. . . . . . . . . . . .

3.4 Backlight troubleshooting 8 – 100. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 DL2 related keyboard problems 8 – 105. . . . . . . . . . . . . . . . . . . . .

4 UL 8 FLEX related 8 – 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Audio troubleshooting 8 – 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Display problem 8 – 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Battery Removal Switch problem 8 – 108. . . . . . . . . . . . . . . . . . . .

4.4 UL8 related keyboard problems 8 – 108. . . . . . . . . . . . . . . . . . . . .

5 RF related 8 – 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to troubleshooting 8 – 109. . . . . . . . . . . . . . . . . . . . . . .

RF Key Component Placement 8 – 110. . . . . . . . . . . . . . . . . . . . . .

5.1 EGSM Receiver 8 – 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Instructions for troubleshooting 8 – 111. . . . . . . . . . . . . . .

5.1.1 Troubleshooting diagram for EGSM Receiver 8 – 112. . . . .

5.1.2 EGSM Signal Path 8 – 113. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 RX/TX Switch 8 – 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Front end 8 – 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Hagar 8 – 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 PCN Receiver 8 – 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Instructions for troubleshooting 8 – 115. . . . . . . . . . . . . . .

5.2.1 PCN Signal Path 8 – 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8 – 4

Issue 1 06/01

Page 5

PAMS

RAE-3

Technical Documentation

5.2.2 RX/TX Switch 8 – 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Front end 8 – 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Hagar 8 – 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 EGSM Transmitter 8 – 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General troubleshooting instructions 8 – 119. . . . . . . . . . . . . . . . . .

5.3.1 Path of transmitted EGSM signal 8 – 119. . . . . . . . . . . . . . . .

5.3.2 Troubleshooting diagram for EGSM Transmitter 8 – 120. . .

5.4 PCN Transmitter 8 – 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General troubleshooting instructions 8 – 122. . . . . . . . . . . . . . . . . .

5.4.1 Path of the transmitted PCN signal 8 – 122. . . . . . . . . . . . . .

5.4.2 Troubleshooting diagram for PCN Transmitter 8 – 123. . . . .

5.5 Synthesizer 8 – 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General troubleshooting instructions 8 – 125. . . . . . . . . . . . . . . . . .

5.5.1 26 MHz reference oscillator ( VCTCXO ) 8 – 125. . . . . . . . .

5.5.2 VCO 8 – 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Troubleshooting diagram for PLL Synthesizer 8 – 126. . . . .

5.5.4 PLL Block Diagram 8 – 128. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Frequency lists 8 – 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Troubleshooting

6 Diagrams of Test Points 8 – 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 06/01

Page 8 – 5

Page 6

RAE-3

PAMS

8. Troubleshooting

Introduction

This document is intend to be a guide for localizing and repairing electrical

faults in the RAE–3 device. First there is a brief guide for fault localizing. Then

fault repairing is divided into troubleshooting paths.

Before any service operation you must be familiar with the RAE-3 product and

module level architecture. You must also be familiar with the RAE-3 specified

service tools such as the WinTesla service software, Flashing tools and software. Basic skills of using RF measurement devices are required when starting

to follow the RF troubleshooting paths.

RAE–3 System HW / UI Troubleshooting

Tools needed for troubleshooting:

S Service tools defined in RAE–3 manual “Service Tools” section

S Laboratory power supply with current indicator

S Oscilloscope

Technical Documentation

S Digital multimeter . .

General guidelines

General notes about the RAE–3 product:

S RAE–3 has only one common engine – BL8 system HW, . . . .

comprising CMT (phone) and PDA (computer). . . . .

S There are separate CMT and PDA displays and keyboards

S CMT display/keyboard and PDA display are on the UI module

DL2. . . . .

S PDA QWERTY–keyboard UI is on UL8 flex module

S Audio connections for the handsfree speaker and earpiece are

on the UL8 flex module. . . . .

When you have a faulty RAE-3 device and you start to troubleshoot it, check

first the following items:

S If the RAE-3 cannot be turned on by any means, see ”dead . .

device” troubleshooting. . . . .

S Blinking CMT display means that a memory fault is preventing

normal boot up (–> Memory tests). . . . .

Page 8 – 6

S Current consumption (missing consumption) gives an idea . . .

whether the device able to start up. . . . .

S Dropping supply voltage indicates a short circuit

S Check whether the connection with Wintesla works and what can

be discovered with Wintesla. . . . .

S Check self tests with Wintesla if ”CONT ACT SERVICE” is shown

on the CMT display. . . . .

Issue 1 06/01

Page 7

PAMS

RAE-3

Technical Documentation

S Check visual display faults

S Check that all connectors make good contacts

– this might be the problem if the displays are dark or partially dark or if there

are keyboard problems.

Locate failed module (BL8, UL8, DL2) with the MJS–14 test jig.

This is the basis of further troubleshooting.

S Check the failed module(s) visually:

– mechanical damages?

– solder joints OK?

Continue with the specific troubleshooting procedure for the module:

S If there is an obvious fault, repair it before reflashing the device

S Flash first if a fault is not obvious

– Flashing troubleshooting leads to power checking and serial interface

checking if flashing does not start.

– At the beginning of flash programming, all memory interfaces are first

tested

– If flashing is aborted and error(s) return, refer to Memory testing section.

8. Troubleshooting

Due to CSP packages short–circuits or broken solder joints are not easily seen.

If the examined signal seems to be continuously in low or high level, then measure for possible short–circuit to ground (signal low) or to supply voltage (signal

high). Note that if a problem is not found from any visible contact/component it

can be under the CSPs where the signal is connected.

If there is no short circuit and the signal level is continuously at a low level, then

the following faults are possible:

– contact problem in output soldering (output active)

– contact problem in soldering of pin having internal pull–up (tri–stated signals)

Care must be taken when assembling and disassembling the transceiver. Refer to the instructions in this manual. Failure to do this may result in unnecessary damage to the device.

The PDA display must be calibrated after the following actions have been taken:

– RAE–3 has been flashed

– PDA display or DL2 module has been replaced

Note:

set the RTC running time to 10 hours.

– Service battery BBL-3B does that automatically.

– Always use only the BBL-3B service battery with Wintesla.

The last step in service before returning the RAE-3 to the customer is to

Issue 1 06/01

Page 8 – 7

Page 8

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

System HW / UI Troubleshooting Cases

1. Troubleshooting of System HW/UI is divided to following cases:

1.1 Dead Device. . . . . . . .

1.2 Keypad problem. . . . . . . .

2. BL8 System HW related:

2.1 Flash programming troubleshooting. . . . . . . .

2.2 General Power Checking. . . . . . . .

2.3 Device does not stay ON. . . . . . . .

2.4 Charging checking. . . . . . . .

2.5 Backup Battery. . . . . . . .

2.6 Accessory Power Output Troubleshooting. . . . . . . .

2.7 Clocks. . . . . . . .

2.8 Memory Tests. . . . . . . .

2.9 Memory Troubleshooting. . . . . . . .

2.10 Serial Interface Troubleshooting. . . . . . . .

2.11 CONTACT SERVICE in CMT display. . . . . . . .

2.12 CCONT Serial interface Troubleshooting. . . . . . . .

2.13 SIM Card. . . . . . . .

2.14 Memory Card. . . . . . . .

2.15 Lid Switch. . . . . . . .

2.16 Battery Removal Switch troubleshooting. . . . . . . .

2.17 COBBA Control Interface troubleshooting. . . . . . . .

2.18 COBBA PCM Interface Troubleshooting. . . . . . . .

2.19 Audio troubleshooting. . . . . . . .

2.20 RF Interface. . . . . . . .

2.21 IR Interface Troubleshooting diagram. . . . . . . .

2.22 BL8 related Keyboard problems. . . . . . . .

2.23 BL8 related PDA UI problems. . . . . . . .

Page 8 – 8

2.24 BL8 related CMT UI problems. . . . . . . .

3. DL2 UI Related:

3.1 CMT and keypad illumination problems. . . . . . . .

3.2 CMT LCD Troubleshooting. . . . . . . .

3.3 No picture on PDA LCD or picture is faulty. . . . . . . .

3.4 Backlight troubleshooting. . . . . . . .

3.5 DL2 related keyboard problems. . . . . . . .

Issue 1 06/01

Page 9

PAMS

RAE-3

Technical Documentation

4. UL8 Flex Related:

4.1 Audio troubleshooting. . . . . . . .

4.2 Display problem. . . . . . . .

4.3 Battery Removal Switch problem. . . . . . . .

4.4 UL8 related keyboard problems. . . . . . . .

Nominal Current Consumption

The following power consumption values (ref.Table 1 ) are measured from a

complete RAE-3.

Vbattery = 3.7 V.

Measured nominal currents are drawn from the main battery.

Measurements have been made with a current proble connected to an oscillo-

scope.

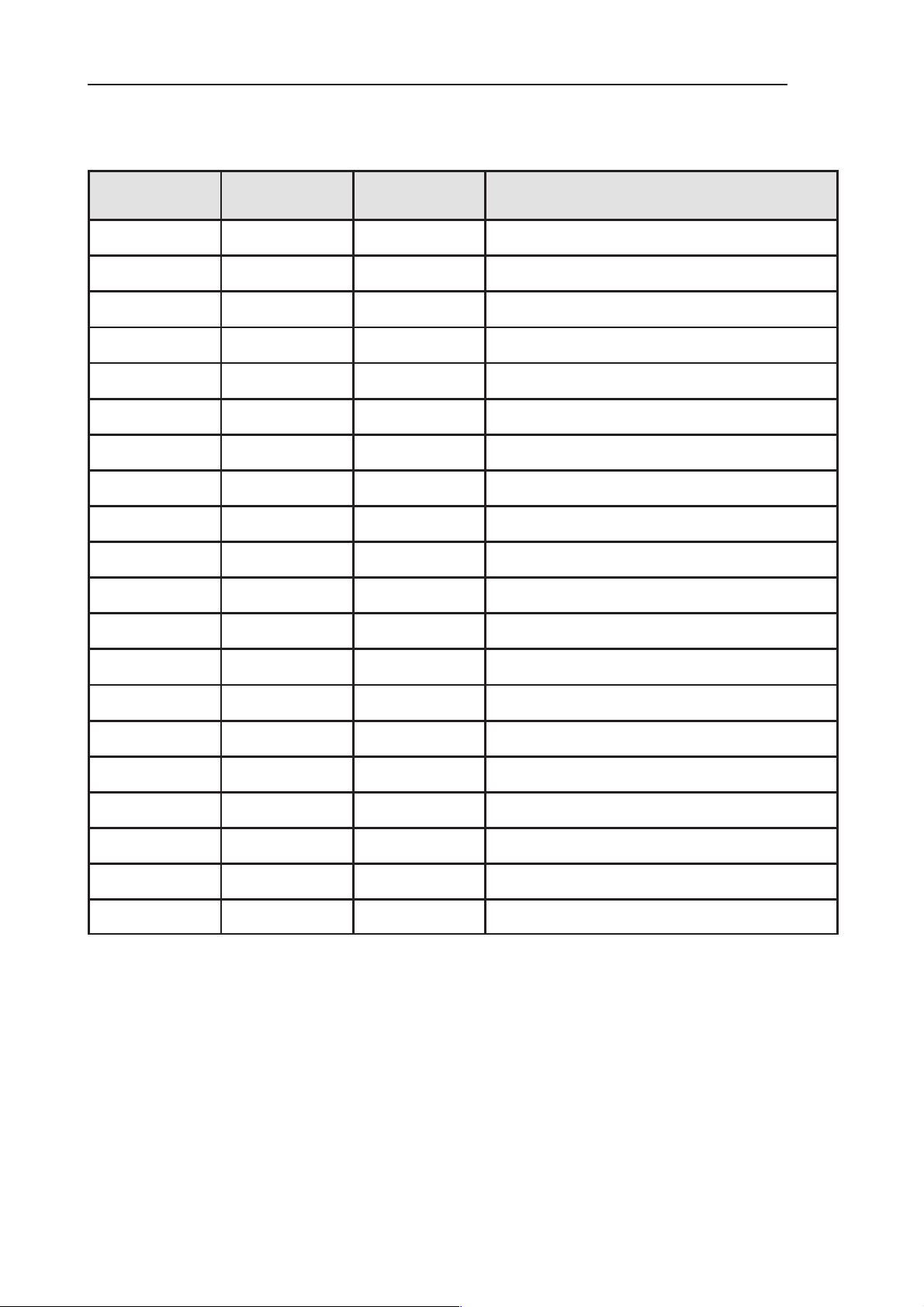

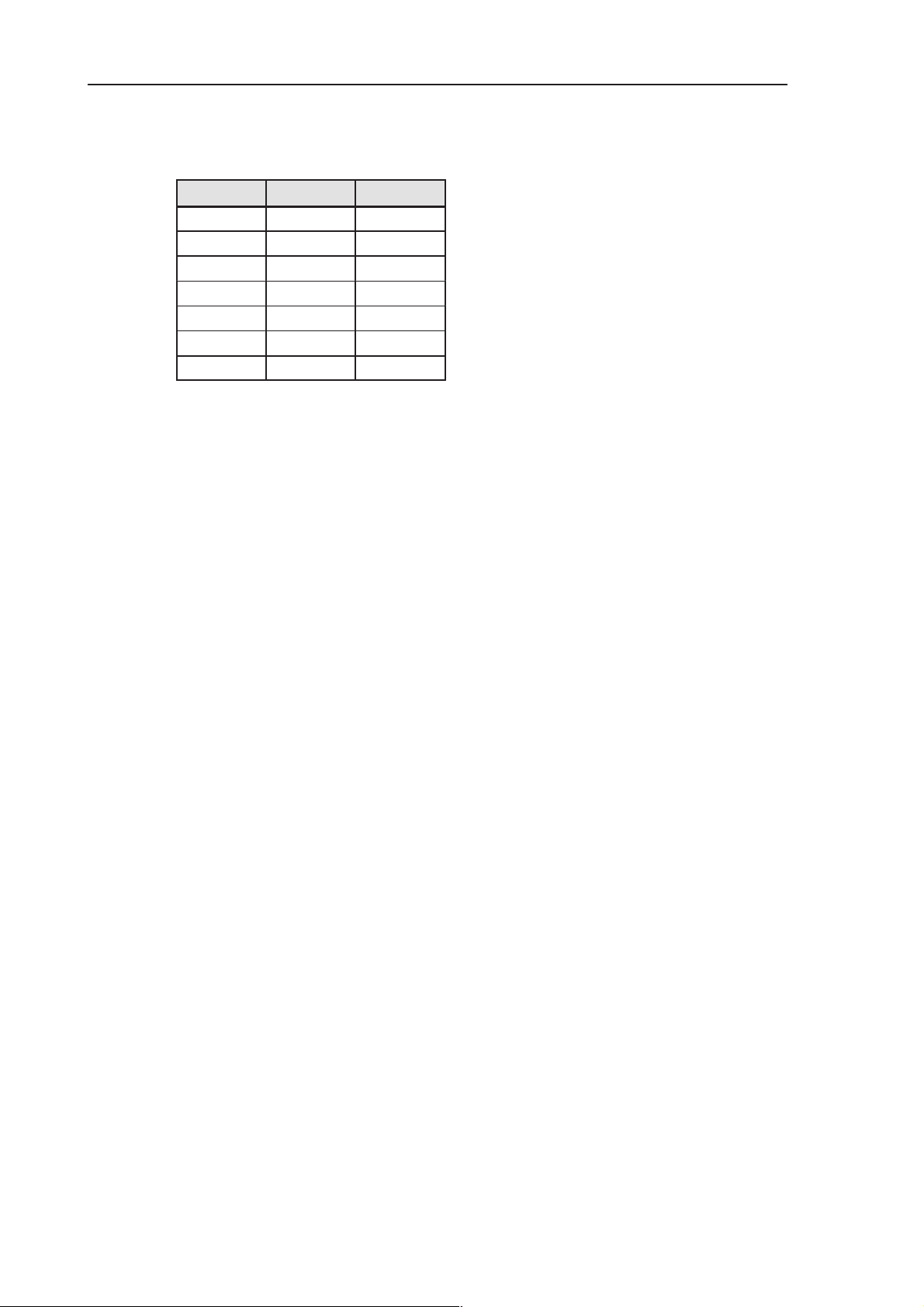

Table 1. Nominal current consumption in different operating modes

8. Troubleshooting

State CMT OFF CMT ON 2W Call (TX5) 0.2W Call (TX19)

Lid closed 2.4 mA 5.6 mA 310 mA

(Voice call)

Lid Open

(min. brightness

on PDA display)

Lid Open

(max. brightness

on PDA display)

60 mA (running) 65 mA (running) 365 mA

(HF call)

140 mA (running) 145 mA (running) 445 mA

(HF call)

120 mA

(Voice call)

170 mA

(HF call)

255 mA

(HF call)

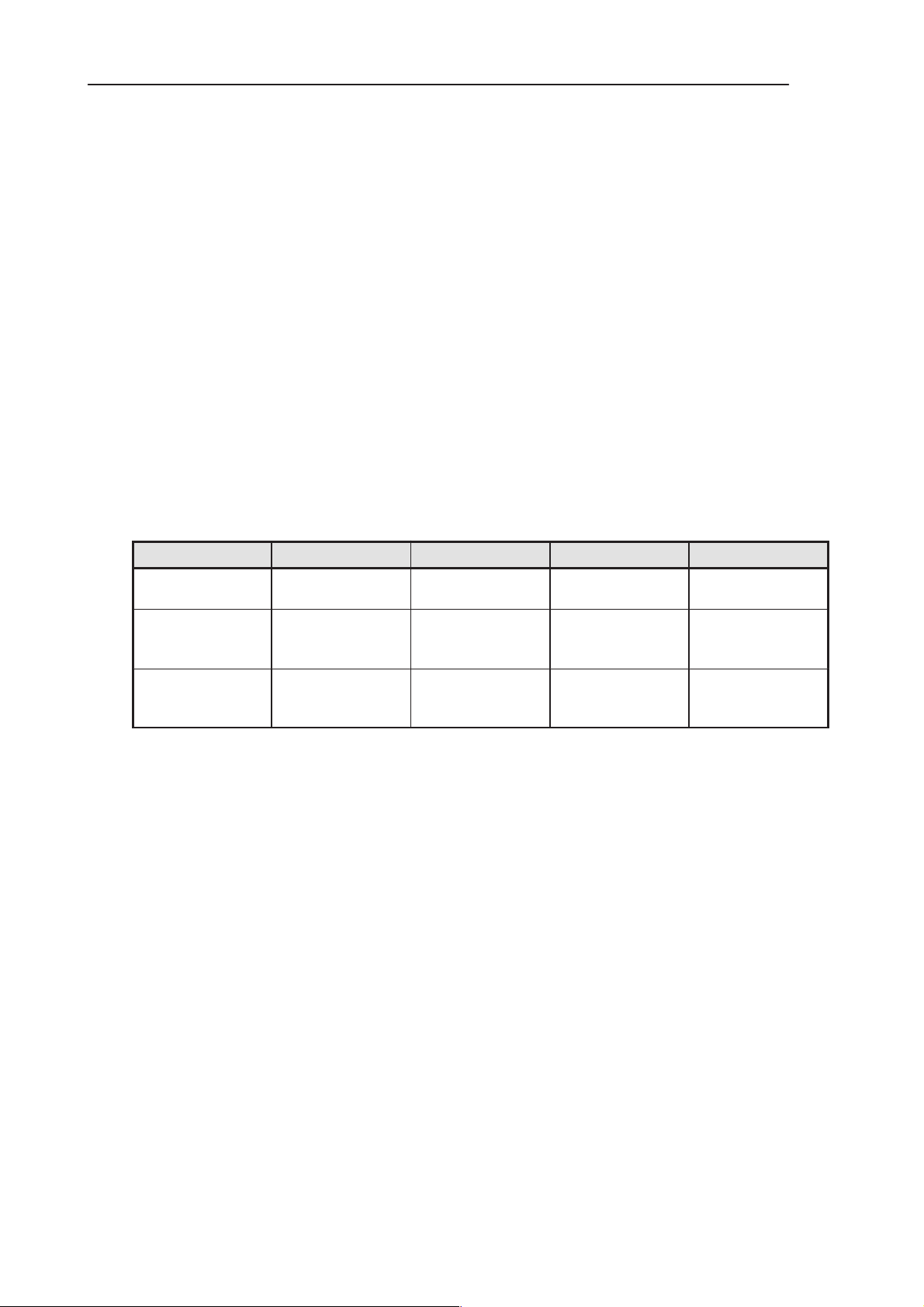

Identify the failed module (UL8, DL2, BL8) using the MJS–19 jig.

Issue 1 06/01

Page 8 – 9

Page 10

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

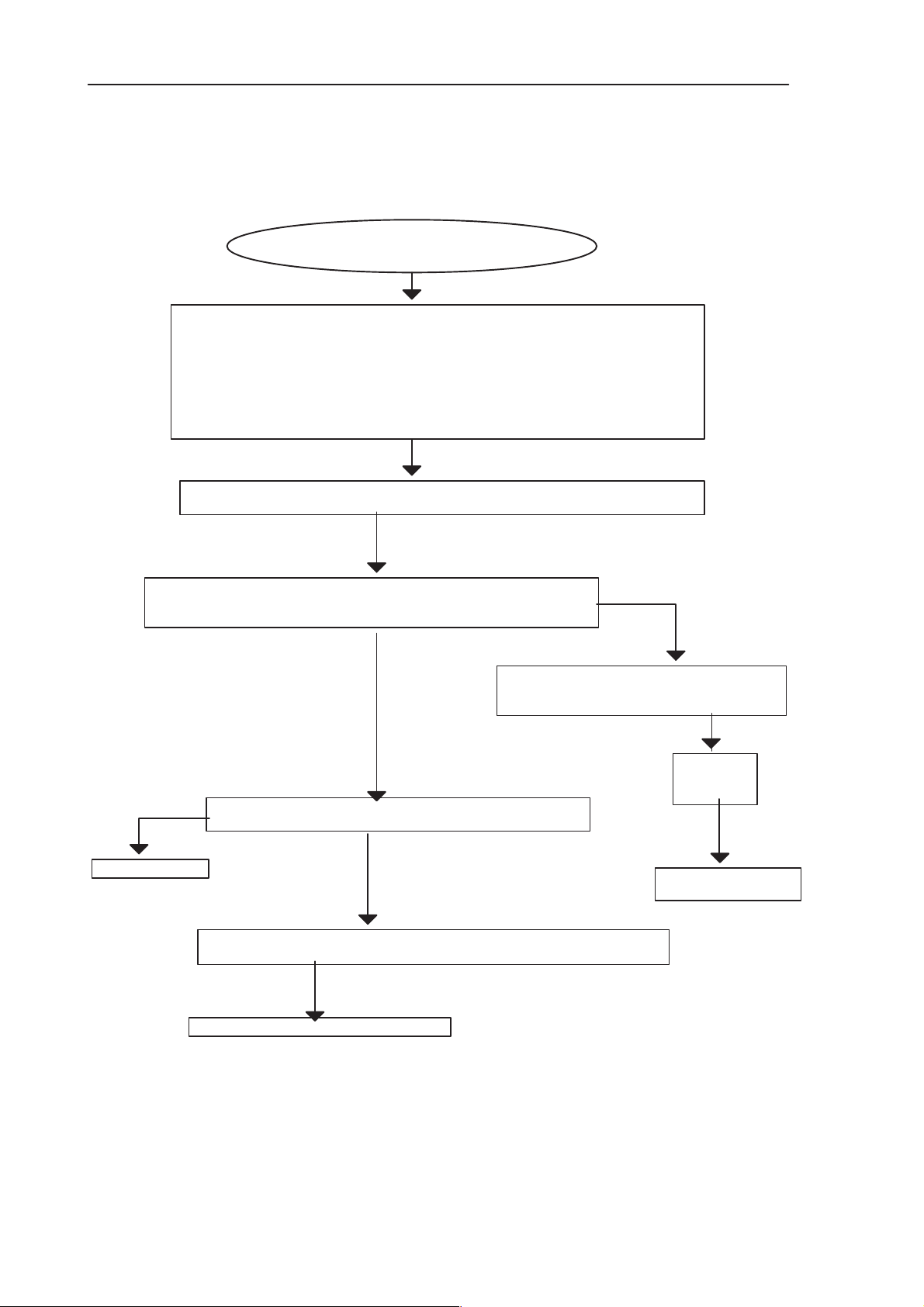

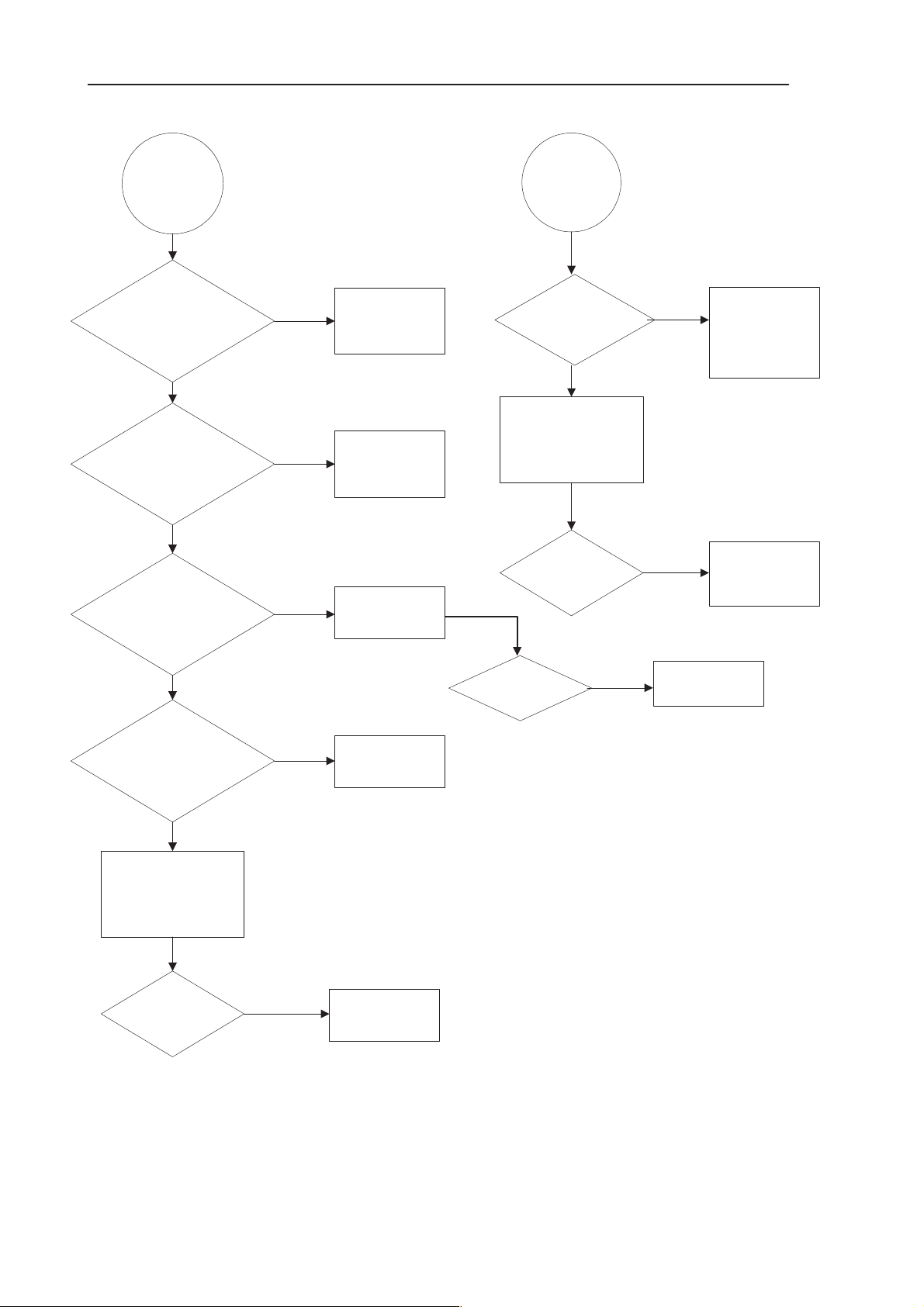

1 System HW / UI Troubleshooting Cases

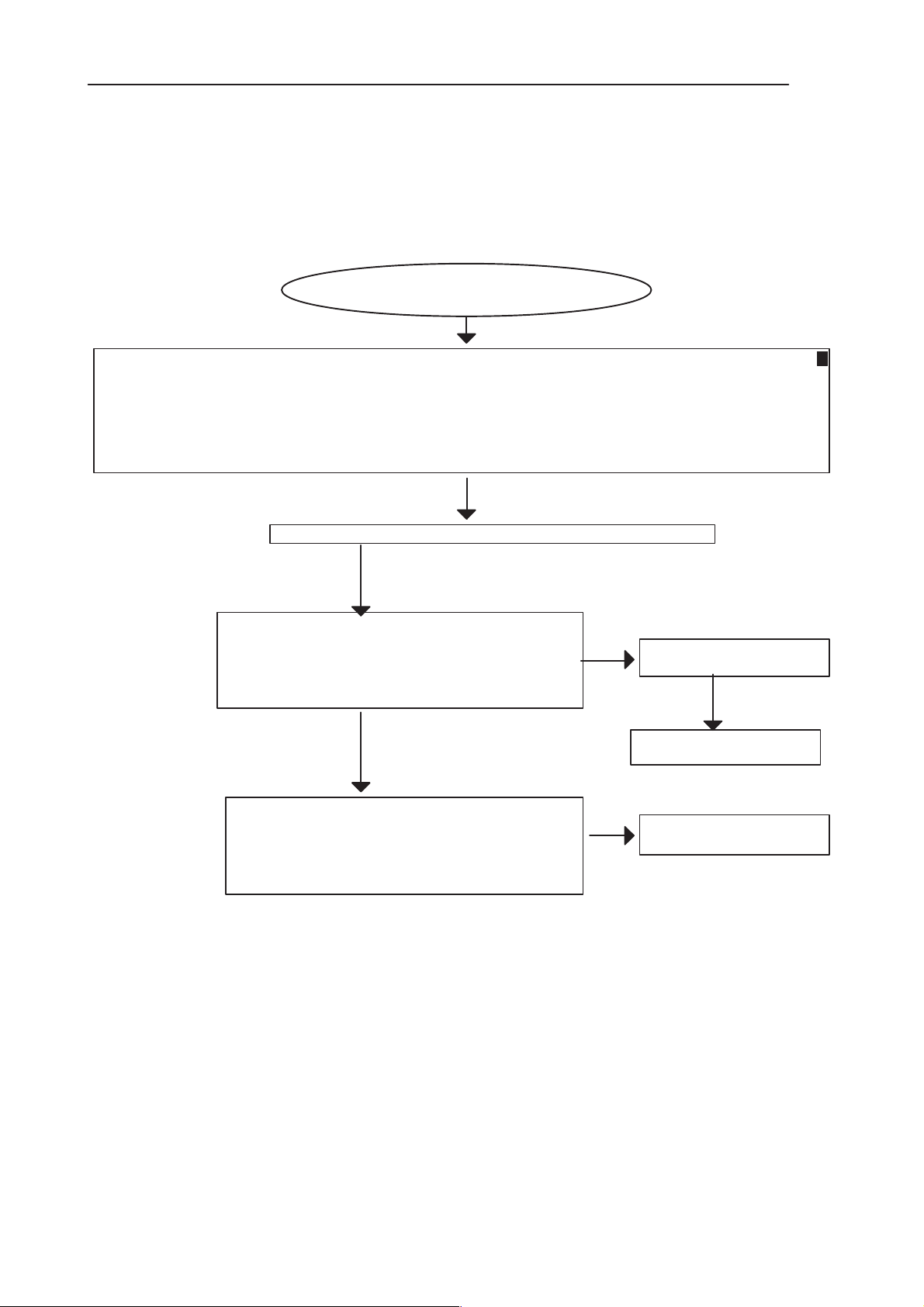

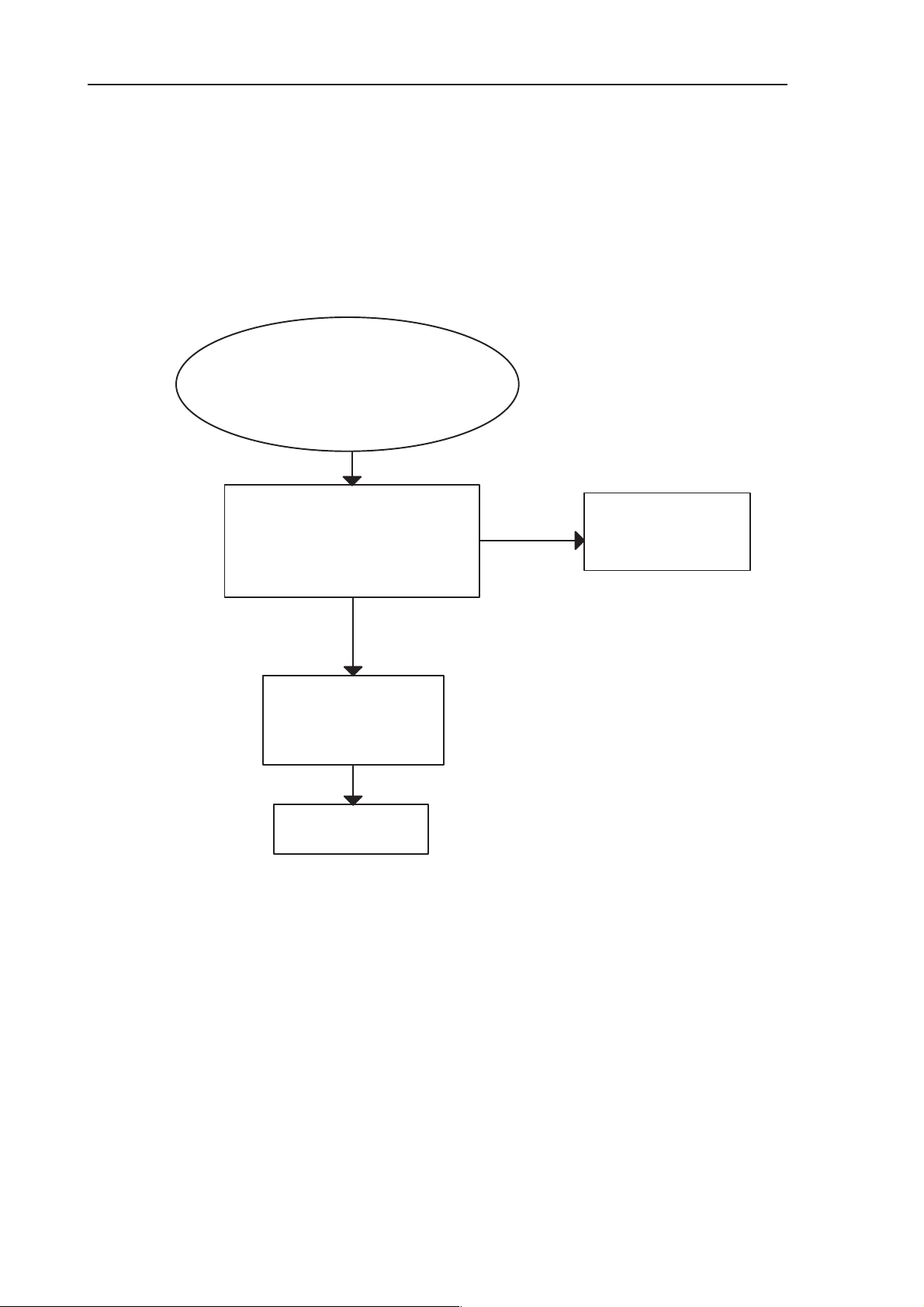

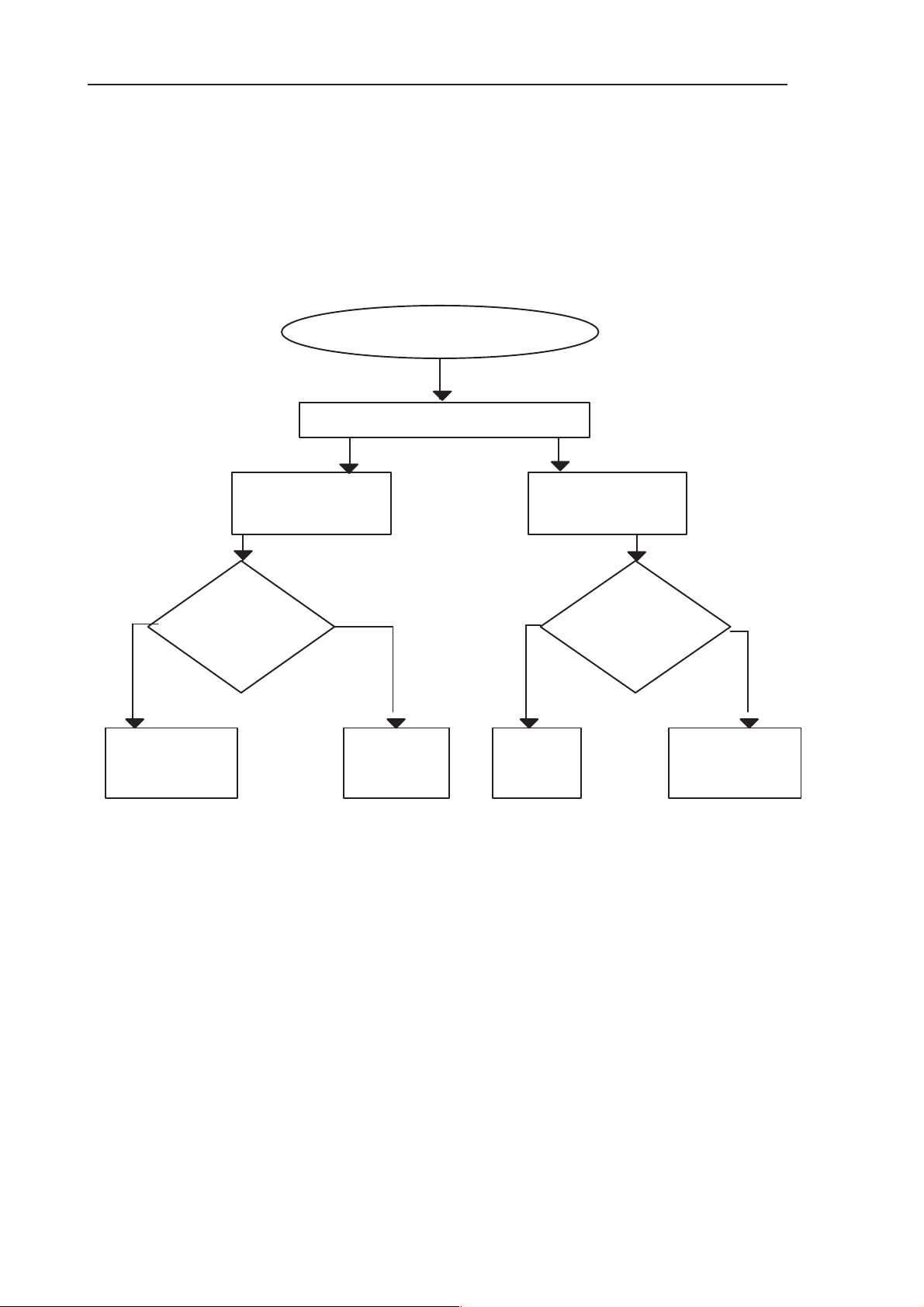

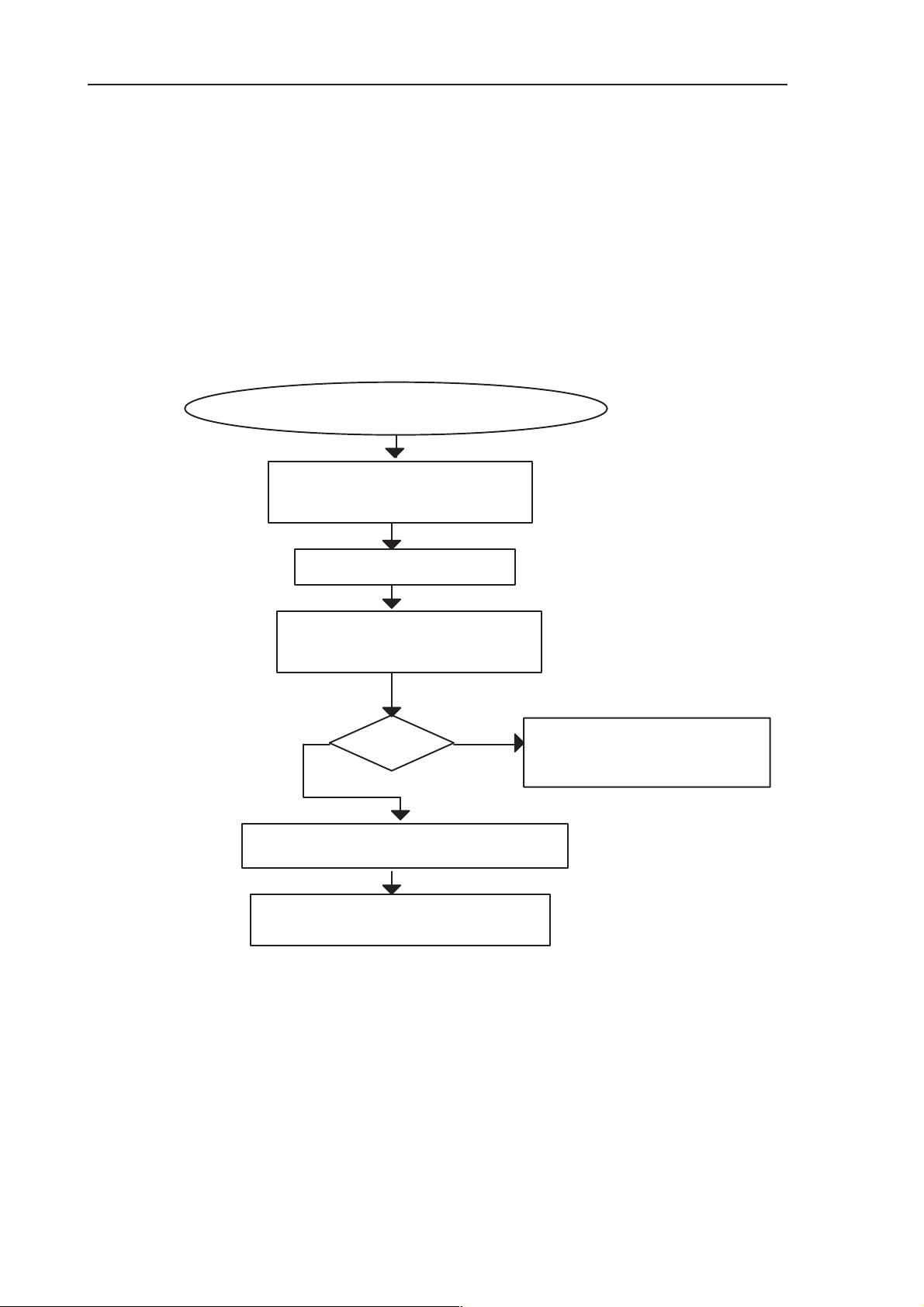

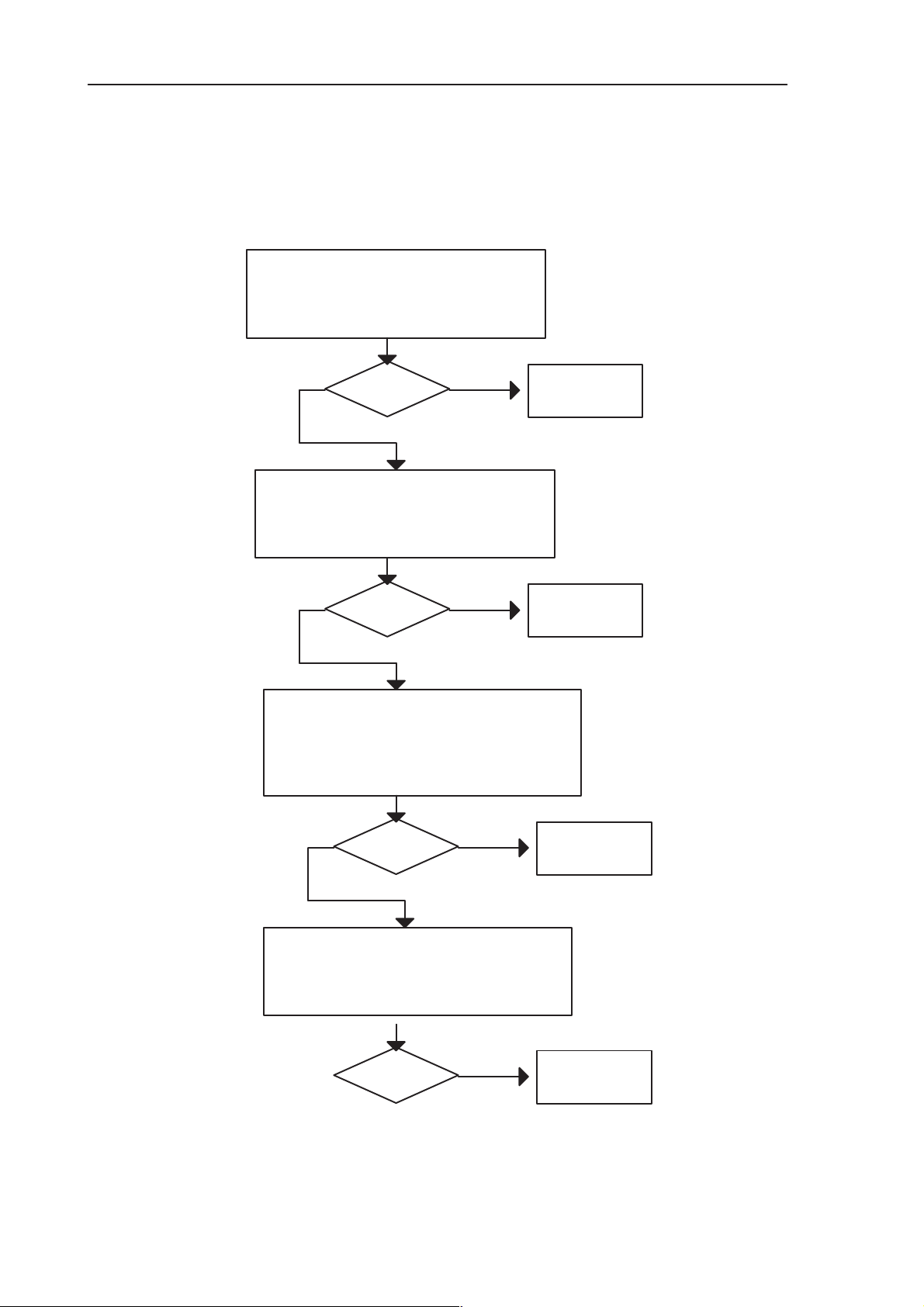

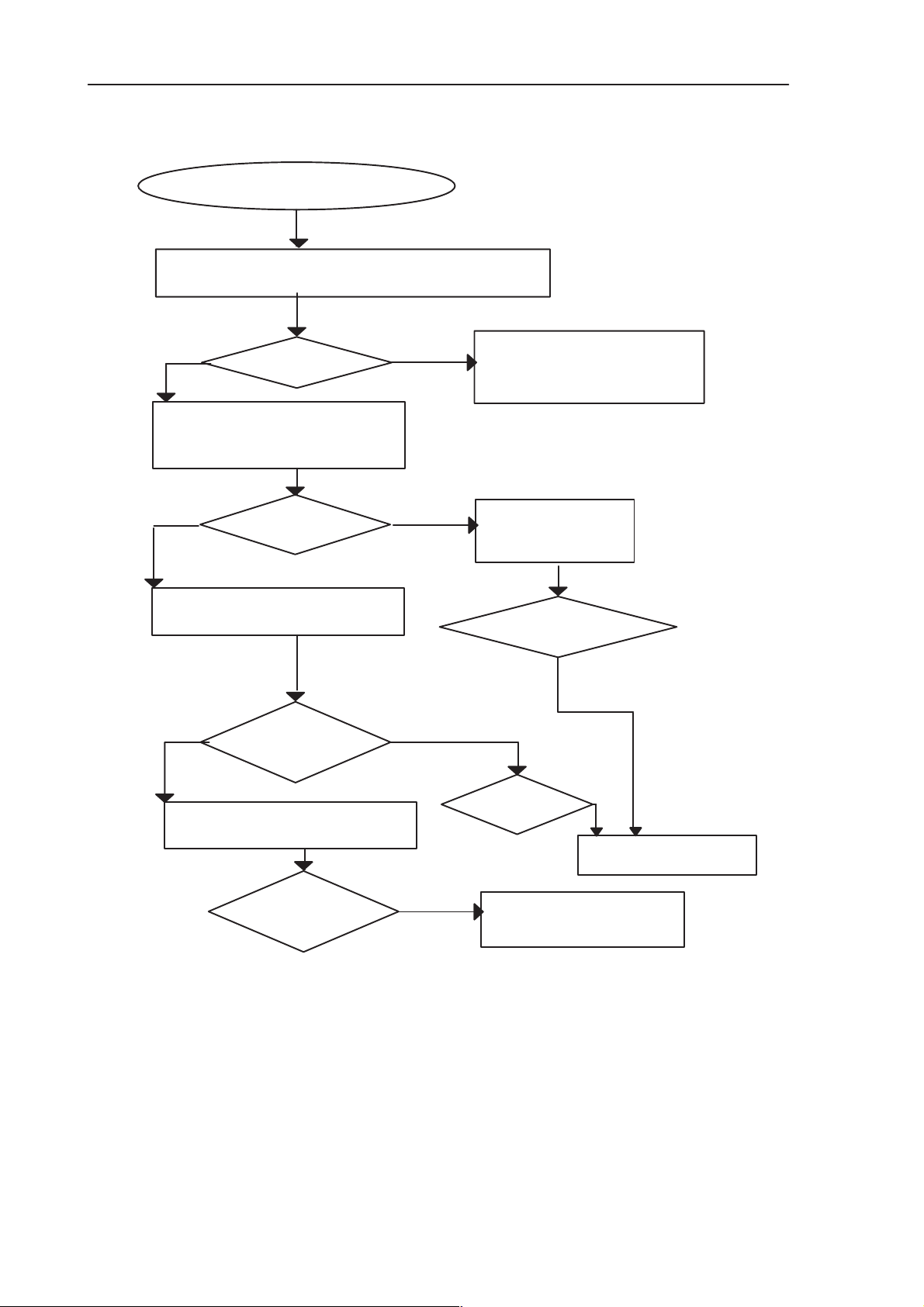

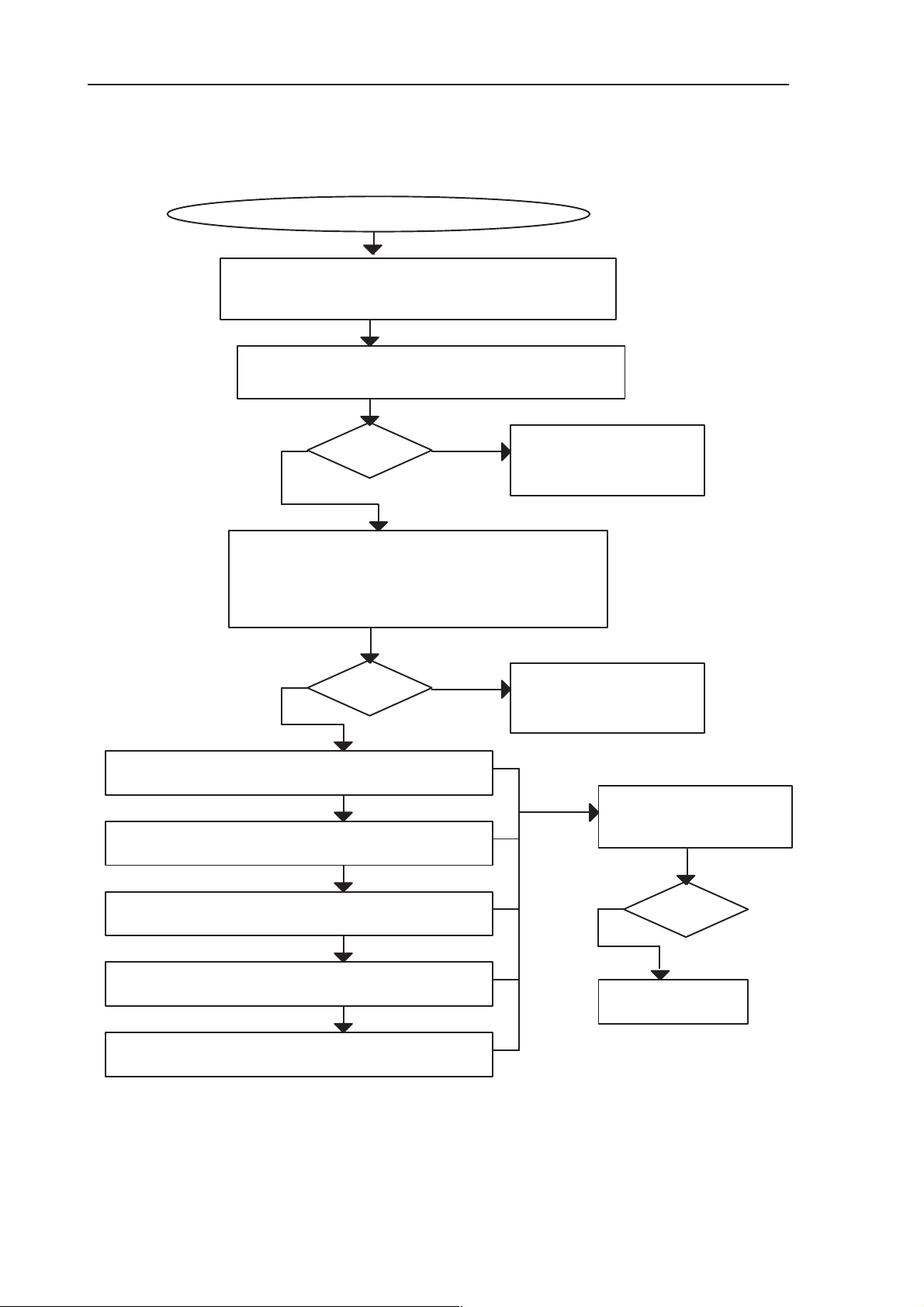

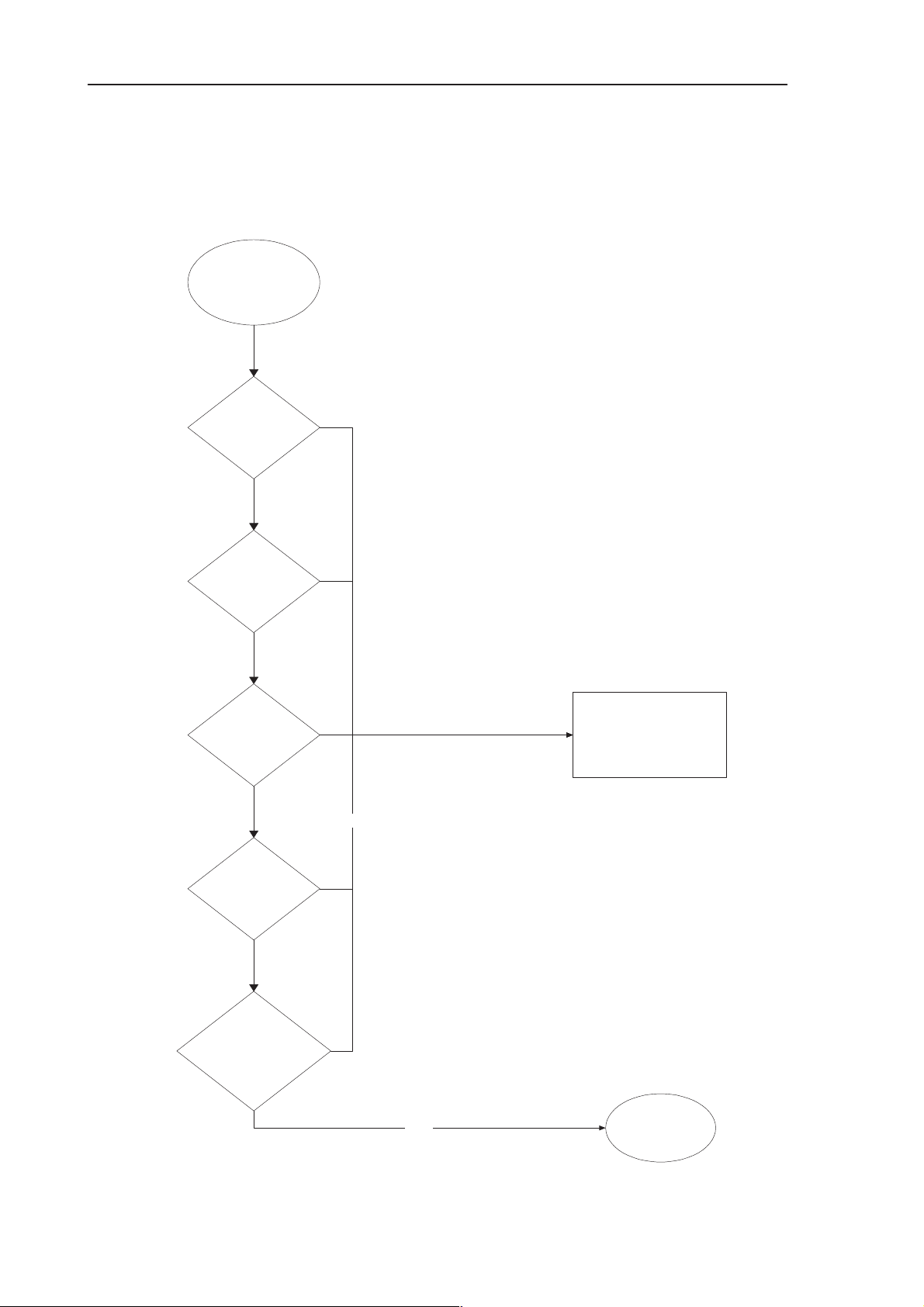

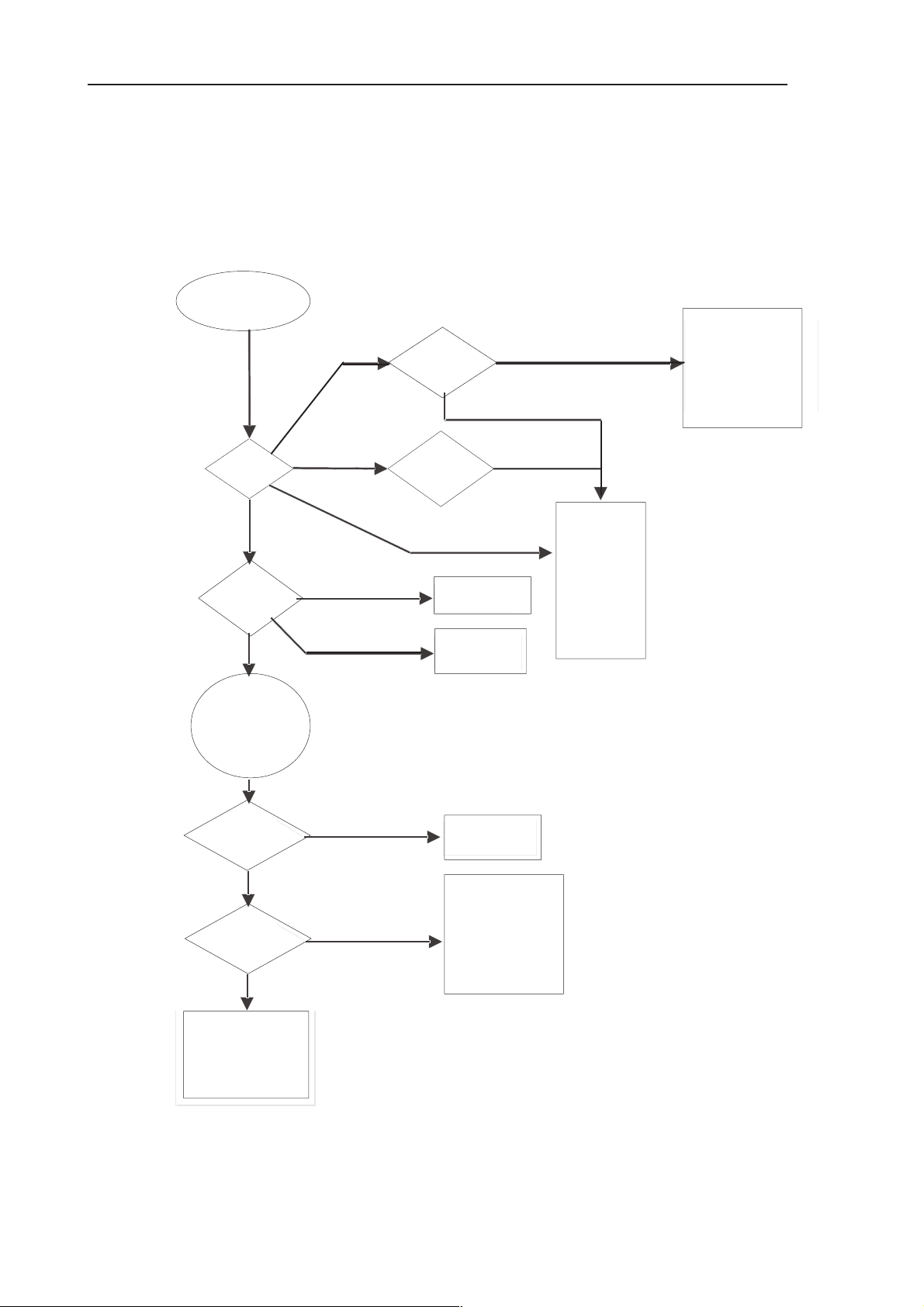

1.1 Dead Device

Dark display

Check

supply voltage

NO

Supply

voltage

drops ?

Check

YES

Go to General

Power Checking

(short circuit

possible)

Go to Flashing

troubleshooting/

general power check

NO

Replace

defective

connector

serial connection with WinTesla

OK?

Check connectors

BL8/UL8, UL8/DL2, DL2/displays

NO

UI related troubleshooting of failed module:

– BL8 related CMT UI troubleshooting (BL8 failed)

– BL8 related PDA UI troubleshooting (BL8 failed)

– CMT LCD troubleshooting (DL2 failed)

– No picture/faultly picture on PDA LCD (DL2 failed)

– PDA backlight troubleshooting (DL2 failed)

– UL8 keyboard module troubleshooting (UL8 failed)

Connectors

Identify failed module

(BL8, UL8, DL2)

with MJS-14 jig

YES

YES

OK ?

Go to

Page 8 – 10

Figure 1.

Issue 1 06/01

Page 11

PAMS

RAE-3

Technical Documentation

1.2 Keypad problems

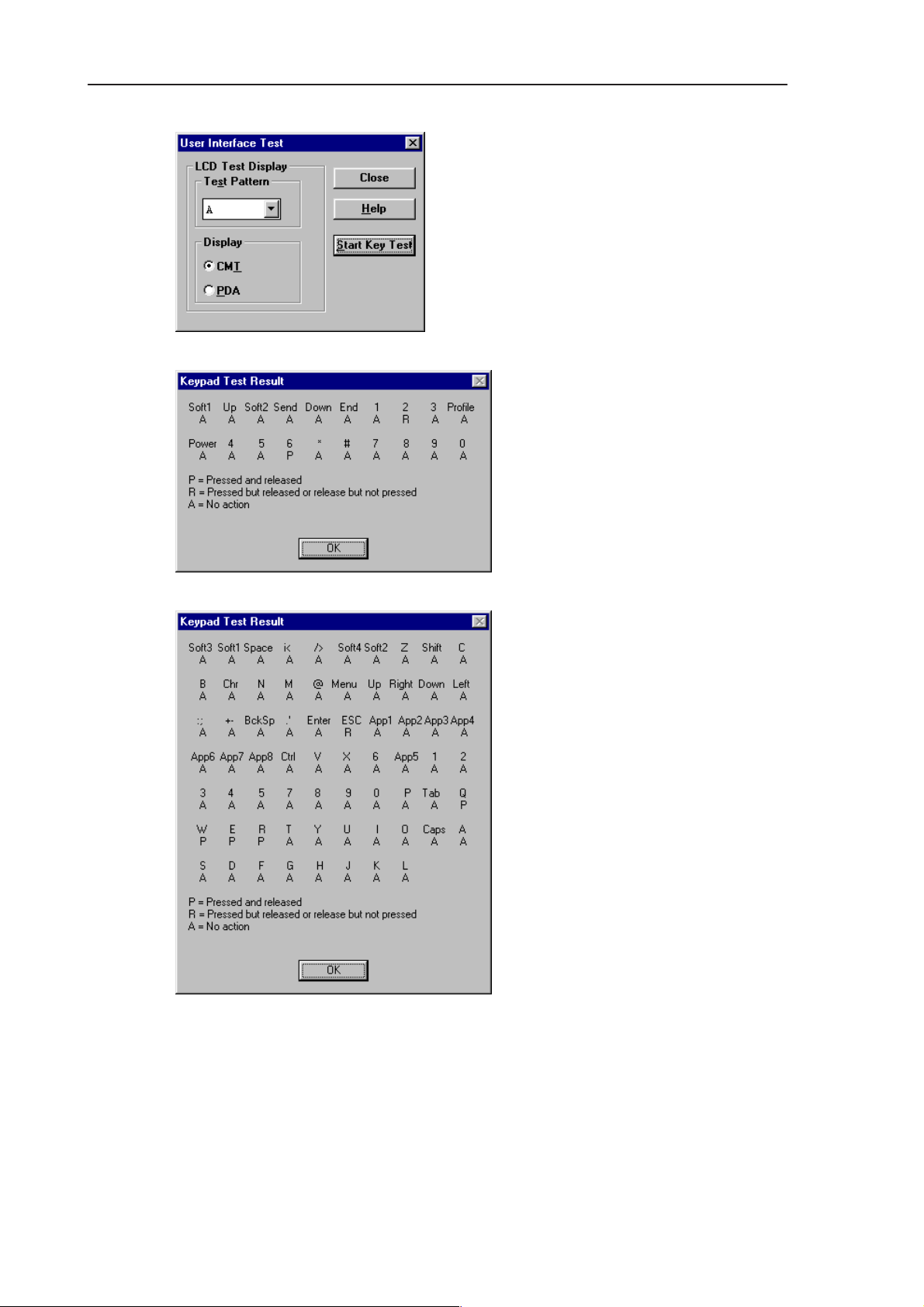

1. Connect the phone under test to Wintesla.

2. Select Testing –> User interface testing

3. Select the CMT to be tested from the ”Display” panel and click ”Start

key test” (figure 1). The test starts and the button text changes to ”Stop key

test”.

4. Click the ”Stop key test”. Result window (Figure 2) appears.

All letters under the key names should show ”A”. . . . . . . . .

If there is ”R”, the key is stuck. . . . . . . . .

Repeat the test. If the result is the same, use table 1 to find out the signals connected to the particular key(s).

5. Click ”Start key test” again.

This time, press and release all keys through, then stop the test. . . . . . . . .

There should be ”P” for every key. . . . . . . . .

If ”A” results are seen, repeat and press these keys again. If key. . . . . . . .

presses are not registered, find out the signals connected to the key.

6. Change the keypad to be tested to PDA. Repeat test steps 4 and 5

for the PDA keyboard. The result window is shown in Figure 3.

8. Troubleshooting

7. Open the CMT side cover. Check the 50–way connector on UL2.

Is it properly inserted, both parts of the connector properly soldered?. . . . . . . .

Repair, retest

8. Check CMT key mat alignment and membrane switches on the mat.

Replace key mat if broken.

9. Check 70–way connector on BL8.

Is it properly inserted, both parts of the connector properly soldered?. . . . . . . .

Repair, retest

10. Locate the faulty part by placing the parts into service jig and chang-

ing the parts one by one. Follow instructions in the proper section (2.23 for BL8

fault, 4.4 for UL8 flex fault, 3.5 for UL2 display module fault).

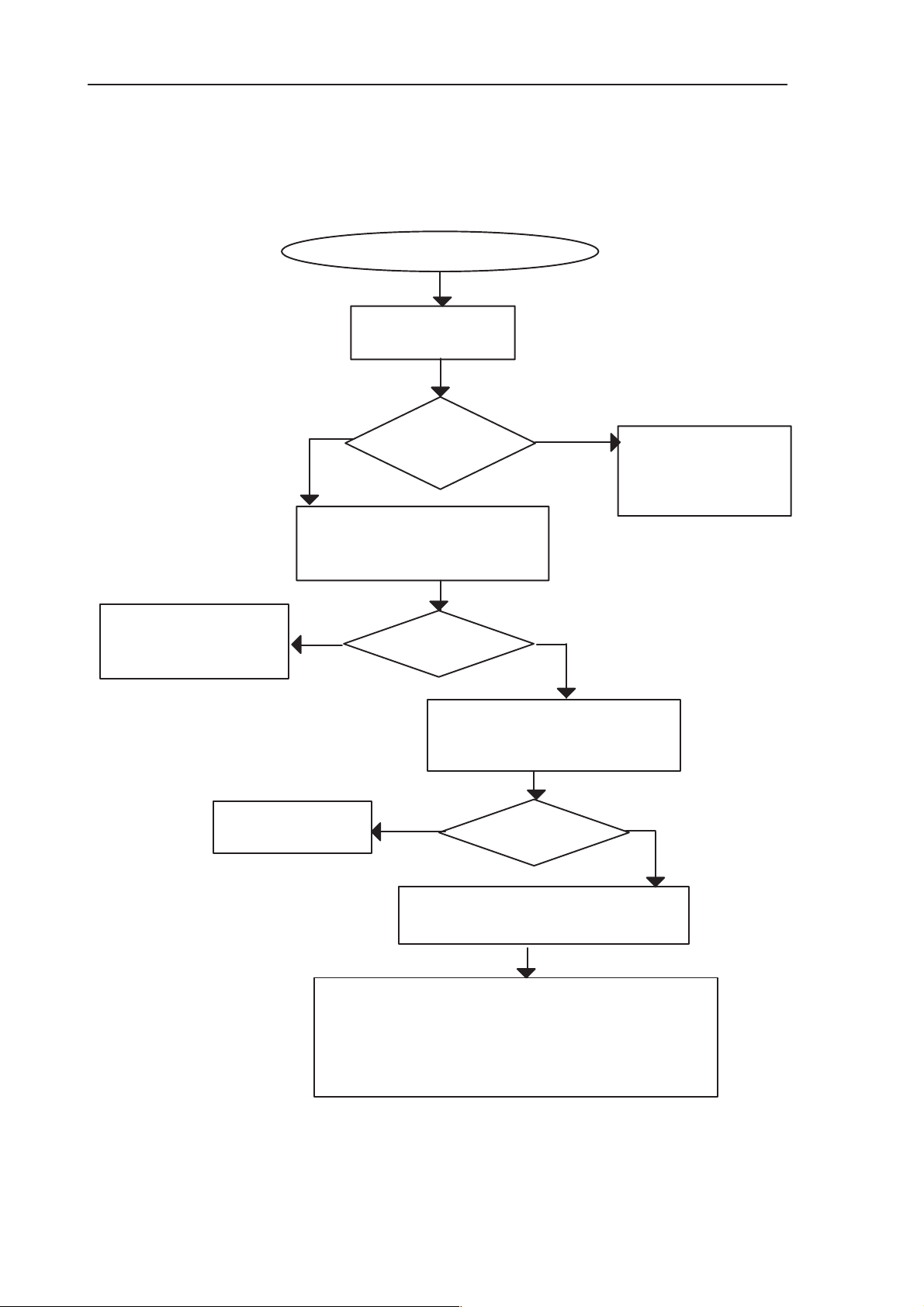

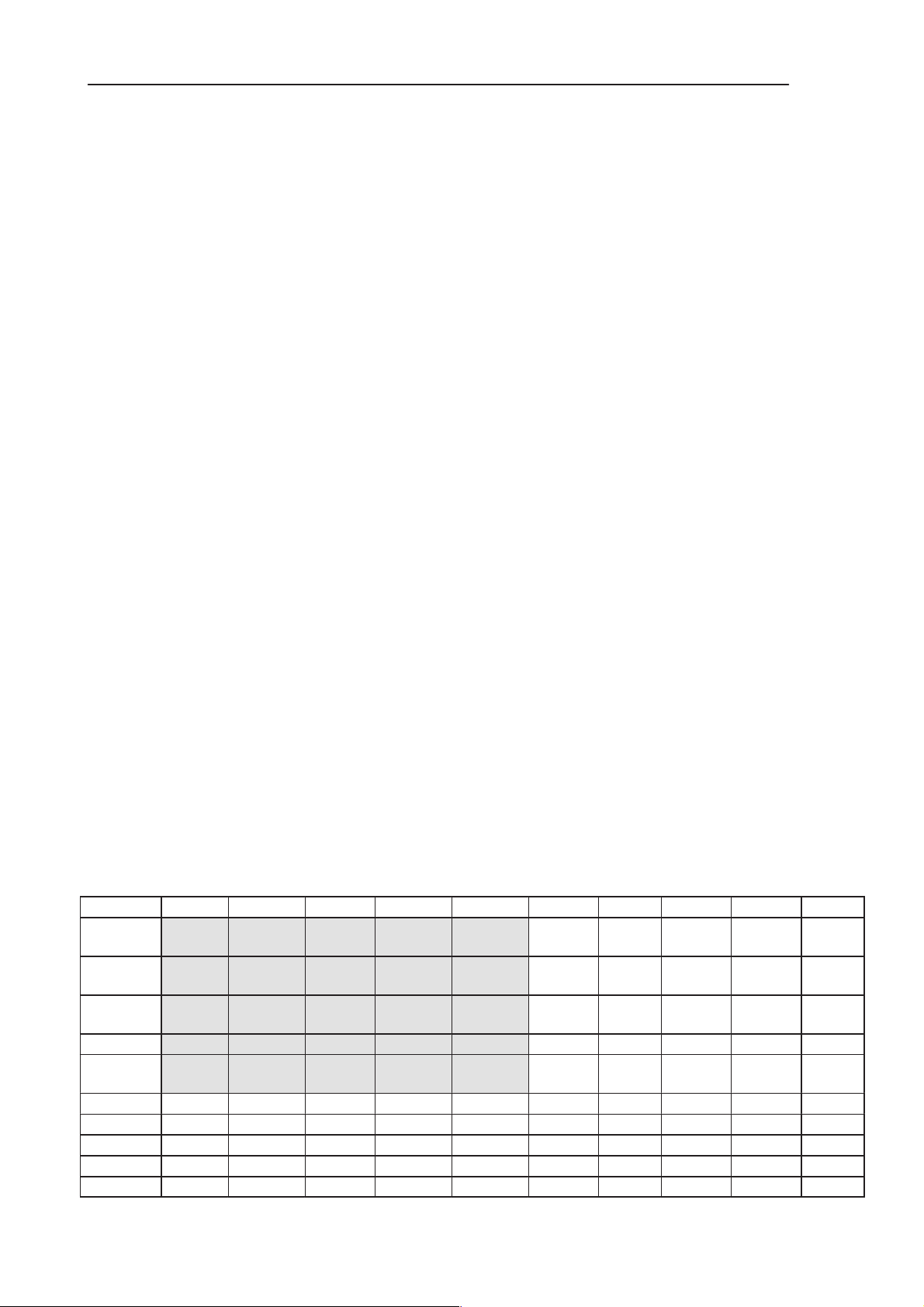

Table 1. Keyboard matrix (keys on UL2 module highlighted) – English keymat

Col0 Col1 Col2 Col3 Col4 Col5 Col6 Col7 Col8 Col9

Row0 cmt

Soft1

Row1 cmt

Send

Row2 cmt 1 cmt 2 cmt 3 cmt

Row3 cmt 4 cmt 5 cmt 6 cmt * cmt # Menu Up Right Down Left

Row4 cmt 7 cmt 8 cmt 9 cmt 0 :; +– Back-

Row5 ESC App1 App2 App3 app4 App6 App7 App8

Row6 Ctrl V X 6 App5

Row7 1 2 3 4 5 7 8 9 0 P

Row8 Tab Q W E R T Y U I O

Row9 Caps A S D F G H J K L

cmt

Up

cmt

Down

cmt

Soft2

cmt

End

pda

Soft 3

pda

Soft 4

Profile

pda

Soft 1

pda

Soft 2

cmt

Power

Space Info < / >

Z Shift C B

Chr N M , @

Enter

space

Issue 1 06/01

Page 8 – 11

Page 12

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

Figure 2. User interface test dialog

Figure 3. CMT keypad test results

Figure 4. PDA keypad test results

Page 8 – 12

Issue 1 06/01

Page 13

PAMS

RAE-3

Technical Documentation

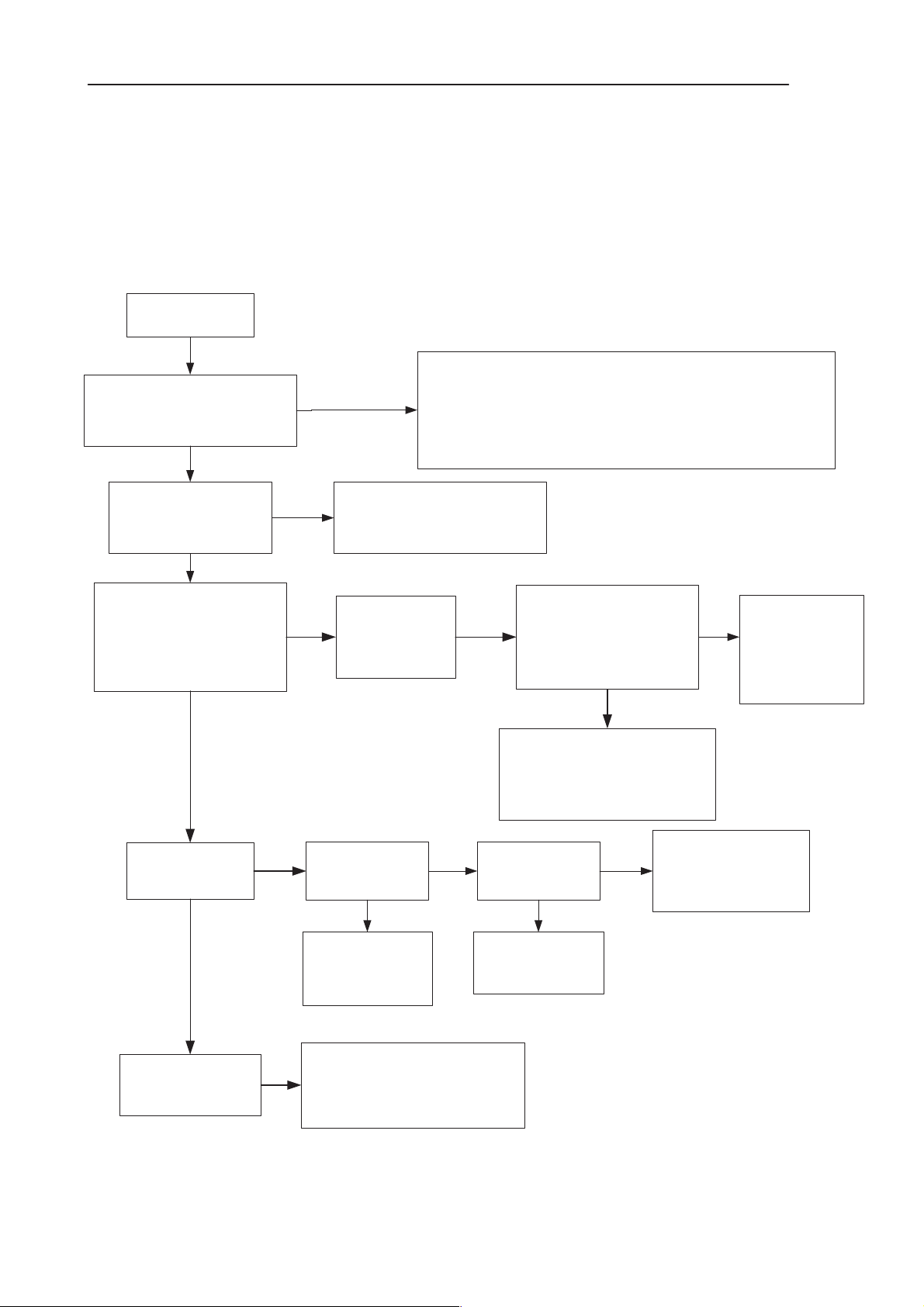

2 BL8 System HW related

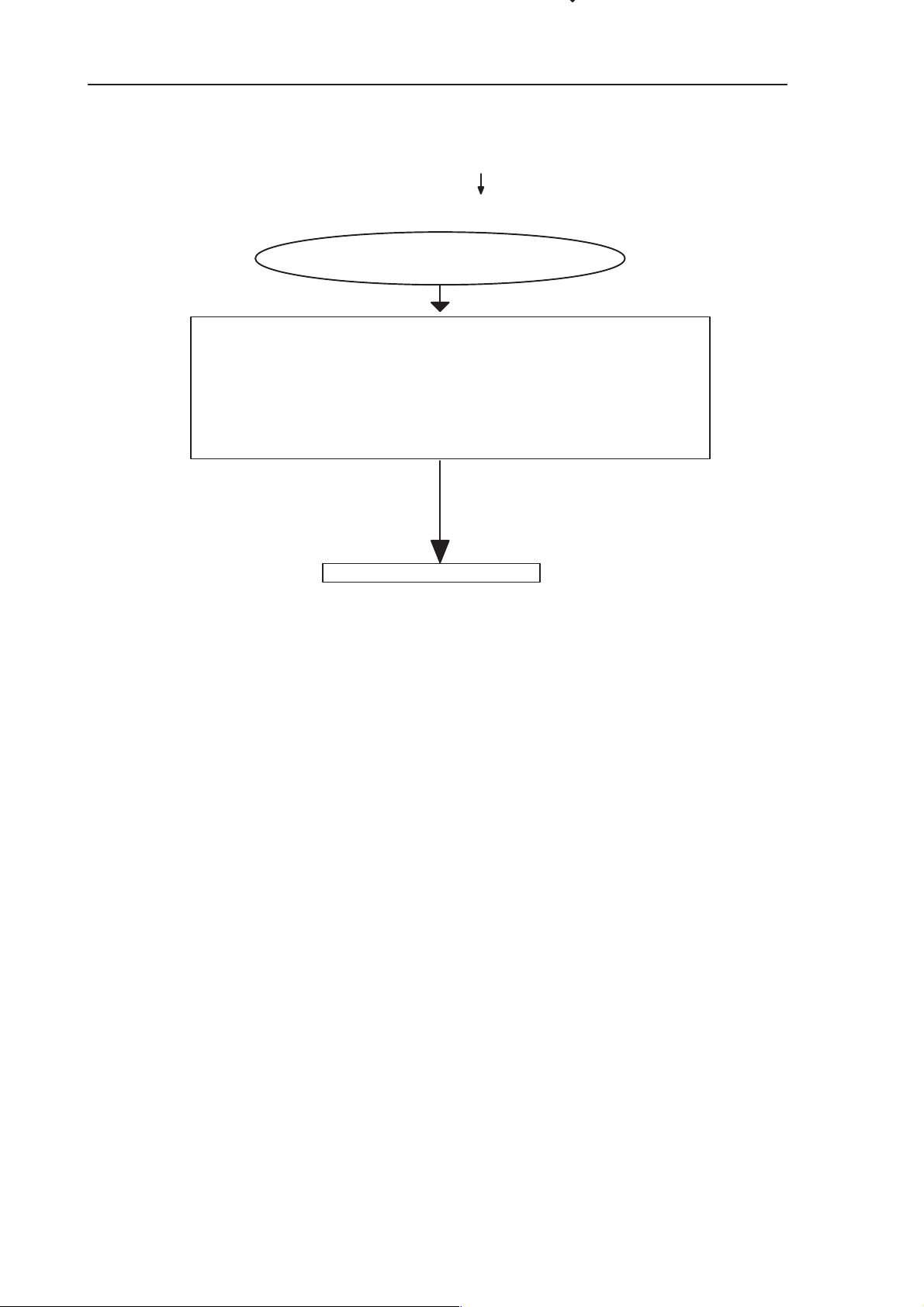

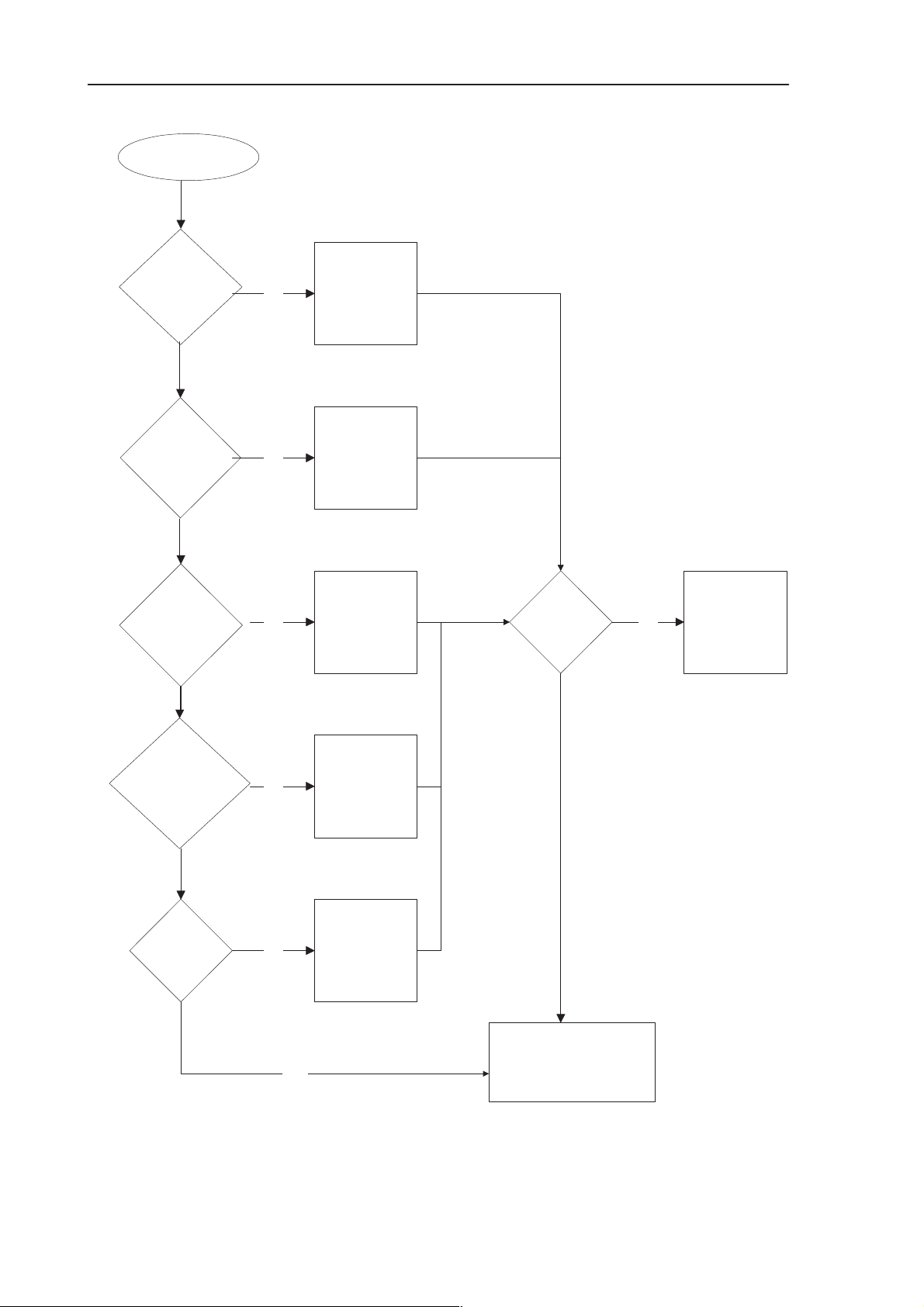

2.1 Flash programming troubleshooting

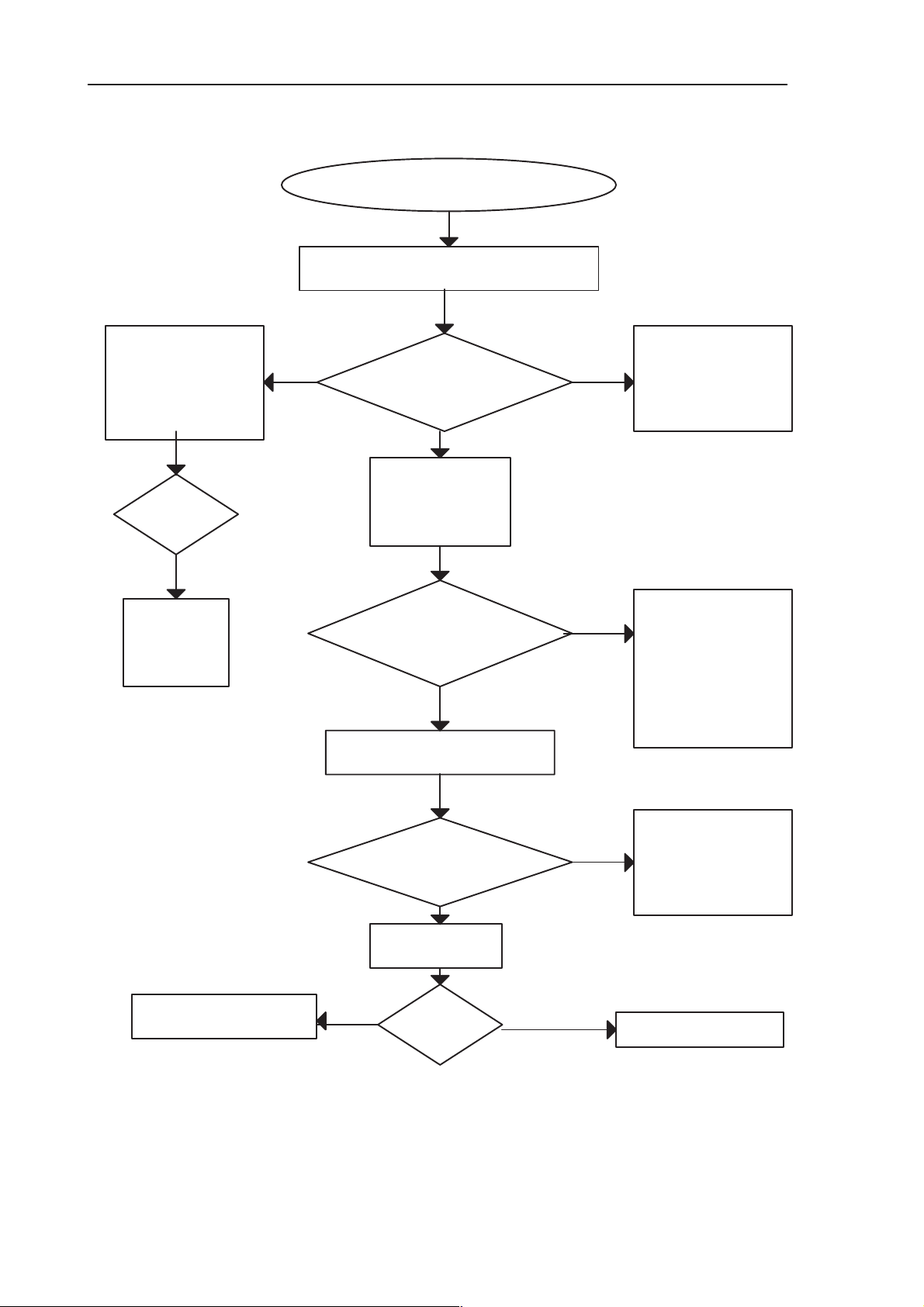

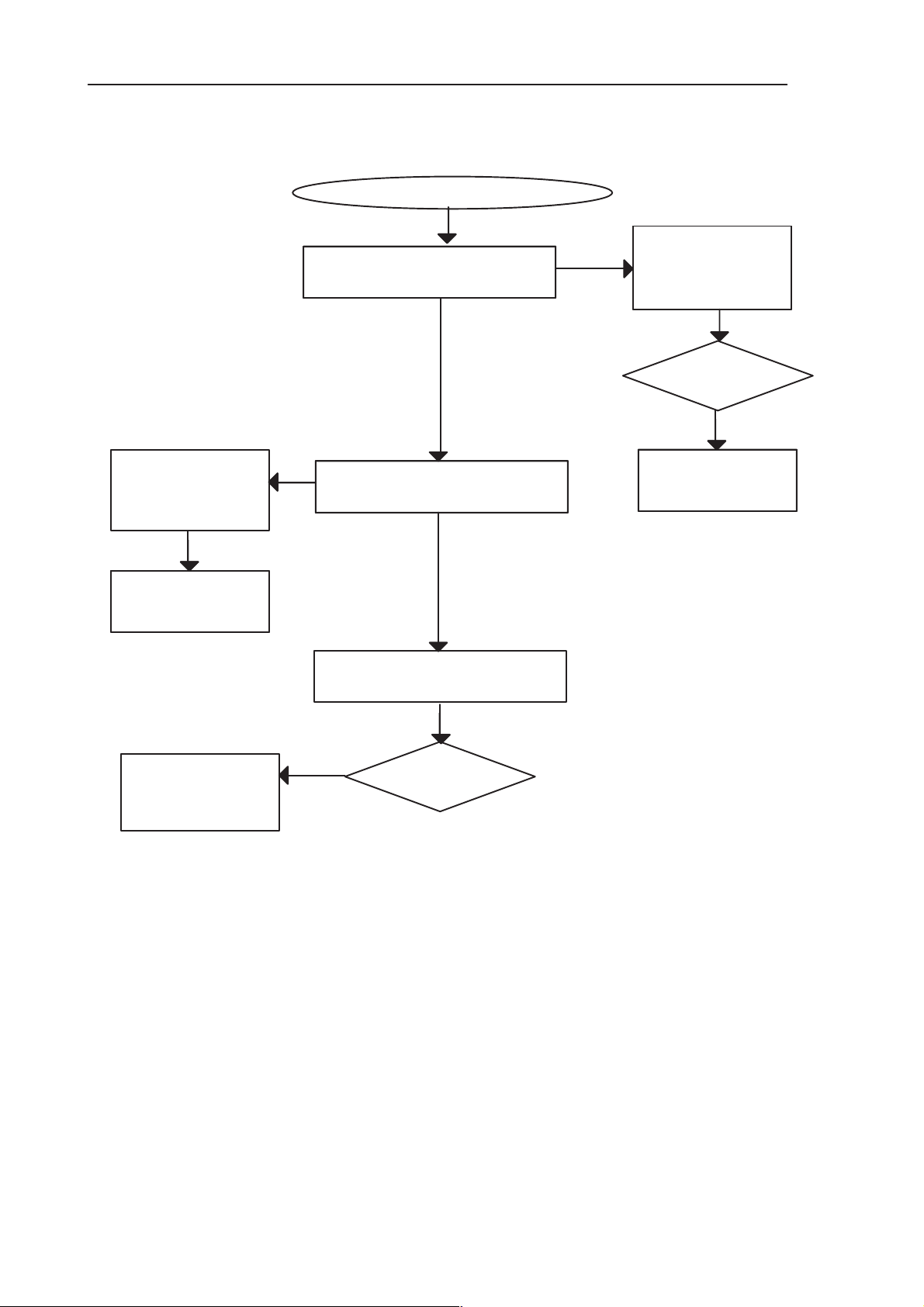

2.1.1 Flashing does not start

FLASH programming does not work

YES

If the fault information from the prommer is:

a) The Phone does not set Flashbus TXD line high after the startup

b) The Phone does not set Flashbus TXD line low after the line has been high. The Prommer generates this error also when the Phone is not connected to the Prommer.

c) The Phone MCU has not received the first dummy word correctly from the Prommer after the startup

d) The Phone has not received Secondary code bytes correctly

e) The Phone MCU can not start Secondary code correctly

OK

Check that Flashing equipment are functional and properly connected

8. Troubleshooting

YES

a) C138 VBB 2.8 V,

b) J304 (PURX) = ’1’ (= 2.8V)

c) J303 (SLEEPCLK) 32 kHz square wave

d) C303 13 MHz sine wave

Note: testpoints are explained more detailed in General Power

Checking – section

YES

Check that following lines are correct:

a) AccTxData line

b) AccRxData line

c) MBUS

Note: testpoints are explained more detailed in Serial

Interface troubleshooting – section

Figure 5.

NO

Jump to General Power

Checking

Powers OK

Jump to Clocks

Troubleshooting

NO

Jump to Serial Interface

troubleshooting

Issue 1 06/01

Page 8 – 13

Page 14

RAE-3

PAMS

8. Troubleshooting

2.1.2 Flash memory fault indicated

FLASH programming does not work

If the fault information from the prommer is:

a) The flash manufacturer and the device IDs in the existing Algorithm files do

not match with the IDs received from the phone.

b) The External RAM test failed in the Phone.

c) The Phone does not send acknowledge signal (ie. drop the Flashbus TXD

line to low state) after the Prommer has sent the Algorithm code.

d) The Prommer has detected a wrong ID byte in the MCU_ID_RESPONSE

message, which it has received from the Phone. See Note.

Technical Documentation

YES

YES

YES

YES

Jump to Memory Tests

Figure 6.

Note: Wintesla shows the following Flash ID’s for every flash device when

programming is going on.

If Flash ID bytes are correct the following bytes are shown:

Flash ID 0089–8896, 0089–8896, 0089–8896, 0000–0030

=Flash 0 =Flash 1 =Flash 2 = SF

But if one or more of Flash ID bytes is/are wrong the Flash is faulty or there is

short circuit in the flash interface.

Page 8 – 14

Issue 1 06/01

Page 15

PAMS

RAE-3

Technical Documentation

2.1.3 Flash VPP Error

FLASH programming does not work

If the fault information from the prommer is:

a) The erasing status response from the Phone informs about fail. The Prommer copies the

Phone response contents to the preceeding FIASCO_GENERAL_INFO_IND message.

b) The Prommer measures the PPD voltage level at flashing start. If the level is below the limit

the Prommer returns the corresponding error code.*

c) The programming status response from the Phone informs about fail.

The Prommer copies the phone response contents to the preceding FIASCO_GENERAL_

INFO_IND message

Note: A new error message will be shown with next coming Wintesla RAE–3 dll release

Check that UL8 flex connector is properly connected to Board to board connector on BL8

(=X400) ; (pins 15 (FLVPP) and 16 (PROG_EN) are connected in UL8 flex)

OK

YES

YES

8. Troubleshooting

* The VPP voltage level limit is 3 to 5 per cent below

the set VPP voltage level.

Check FLVPP voltage level

(= 2.8 V) during programming. (See Memory tests measurement points C368)

Note: By default tested with known good UL8 flex

NOT OK

Faulty UL8 Flex

Check voltage from Board to board adapter JC4

OK

connector pin 16 (= 2.8 V)

Note: By default tested with known good UL8 flex.

NOT OK

Check that UL8 Flex connector (=X12) is not broken and flex is OK.

Note: By default tested with known BL8 module.

OK

Wintesla informs which memory address the erasing fails. See note which

address corresponds which Flash components.

Erasing/programming fails

Faulty components D351, D352 or D353

NO

Check BL8’s

connector

X400

OK

Faulty MADLinda D300

(DSPGenOut2)

Note:

Flash 0 (=D351) erasing area starts 0x00000000

Flash 0 (=D351) erasing area stops 0x003FFFFF

Flash 1 (=D352) erasing area starts 0x01000000

Flash 1 (=D352) erasing area stops 0x013FFFFF

Issue 1 06/01

Note:

Flash 2 (=D353) erasing area starts 0x02000000

Flash 2 (=D353) erasing area stops 0x023FFFFF

Serial Flash (=D354) erasing area starts 0x8000000

Serial Flash (=D354) erasing area stops 0x841FFFF

Figure 7.

Page 8 – 15

Page 16

RAE-3

PAMS

8. Troubleshooting

2.1.4 Flash Erasing /Programming Error

FLASH programming does not work

If the fault information from the prommer is:

a) The erasing status response from the Phone informs about failure.

The Prommer copeies the contents of the response of the Phone into the

preceeding FIASCO_GENERAL_INFO_IND message.

b) The Phone has generated a NAK signal during data block transfer.

c) The programming status response from the Phone informs about failure.

The Prommer copies the contents of the response of the Phone into the

preceeding FIASCO_GENERAL_INFO_IND message.

Technical Documentation

YES

YES

Wintesla informs which memory address the erasing fails. See note which address

corresponds which Flash components.

Erasing/Programming fails

Change faulty flash D351, D352, D353 or D354

Note:

Flash 0 (=D351) erasing area starts 0x00000000

Flash 0 (=D351) erasing area stops 0x003FFFFF

Flash 1 (=D352) erasing area starts 0x01000000

Flash 1 (=D352) erasing area stops 0x013FFFFF

Flash 2 (=D353) erasing area starts 0x02000000

Flash 2 (=D353) erasing area stops 0x023FFFFF

Serial Flash (=D3534 erasing area starts 0x8000000

Serial Flash (=D3534 erasing area stops 0x841FFFF

Page 8 – 16

Figure 8.

Issue 1 06/01

Page 17

PAMS

RAE-3

Technical Documentation

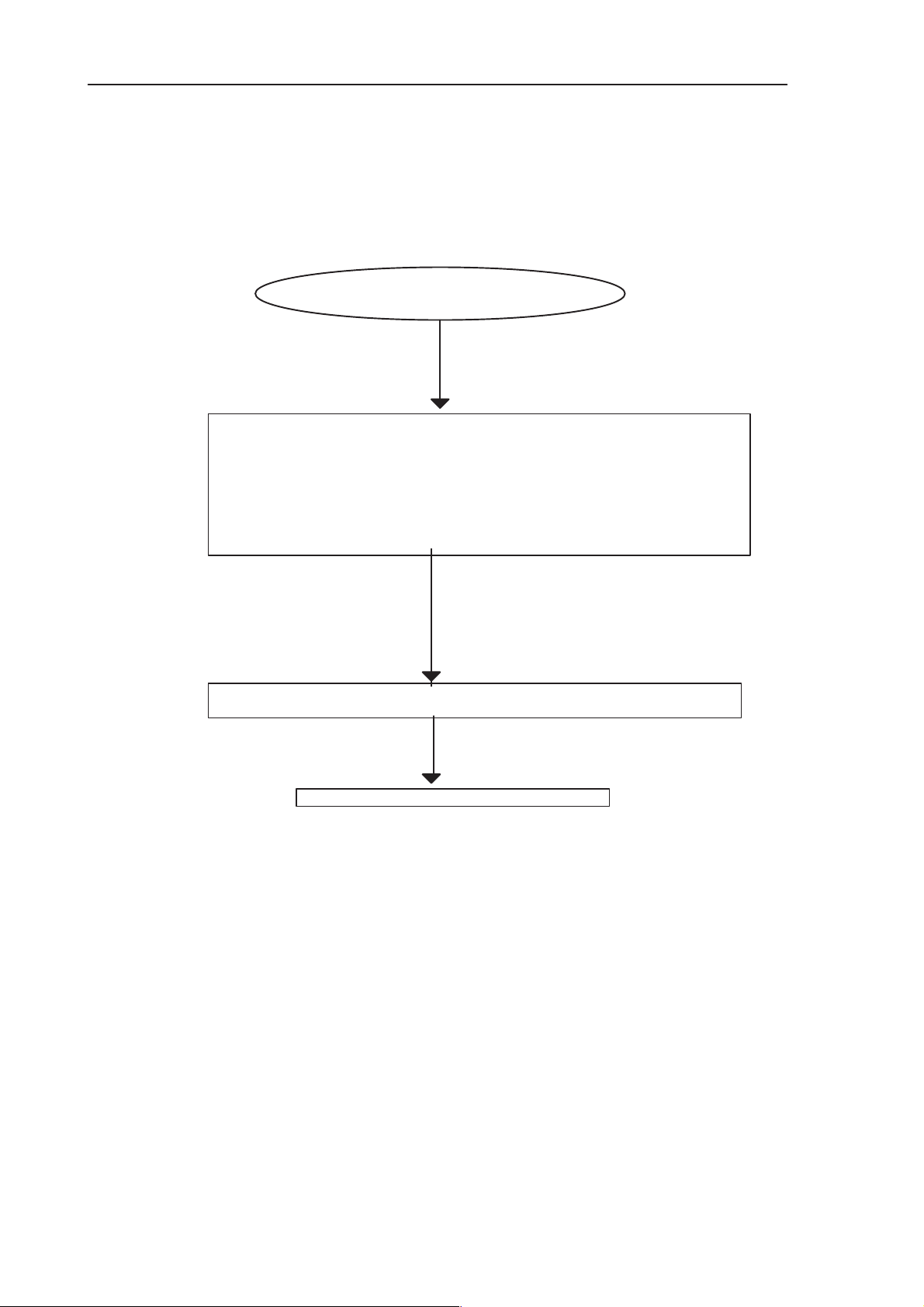

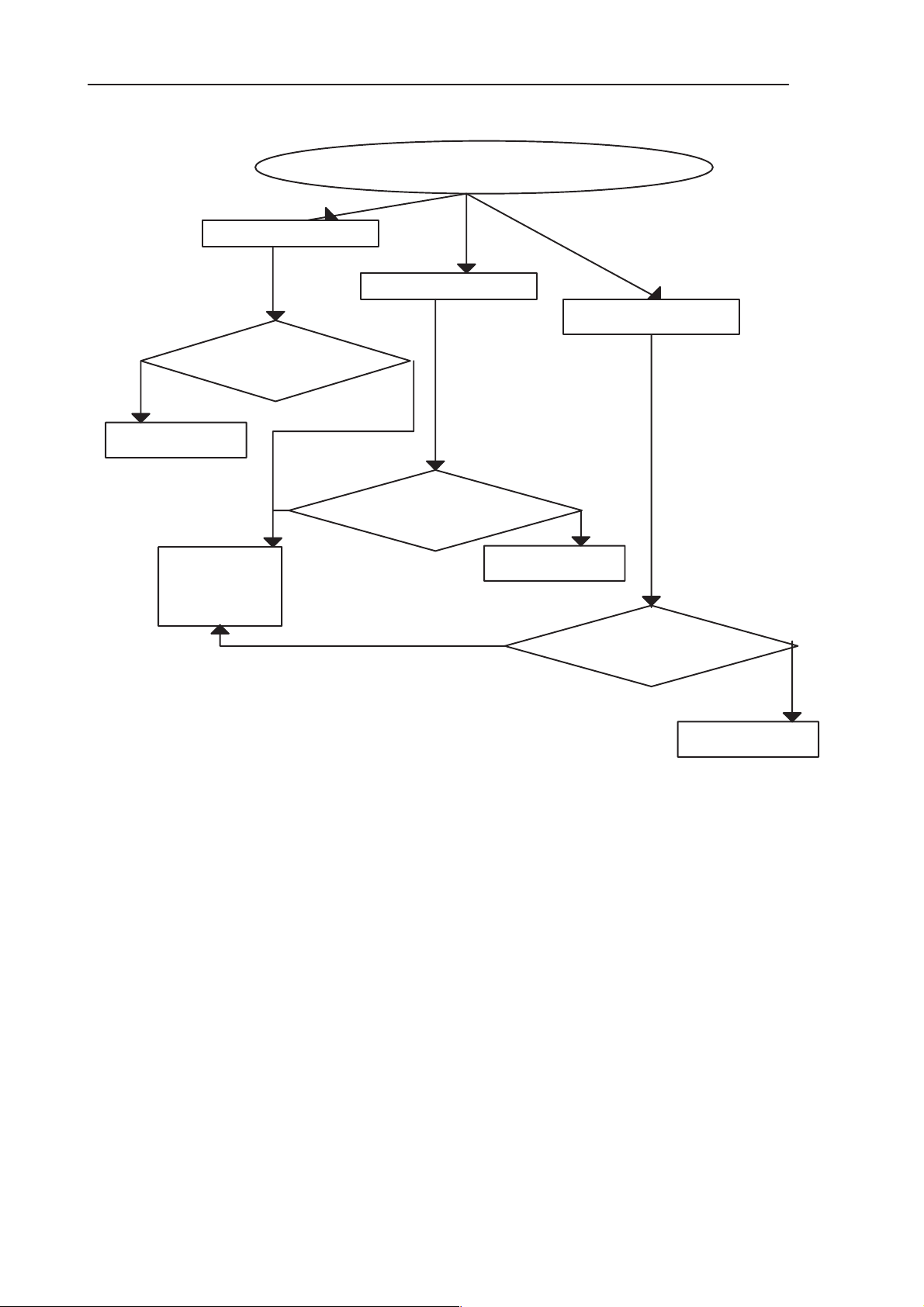

2.2 General Power Checking

Use BBL-3B service battery. Battery voltage must be 3.7 V.

Switch power

on

Supply voltage drops

when the power is

switched on

NO

VB (C124) and

VB_CCONT

(C115) 3.7V?

NO

YES

Failure in battery line

Check L100, L101 and

8. Troubleshooting

Short circuit in VBAT, VBB or VCORE line.

Switch power off and measure with multimeter which

of these voltages have a short circuit. Check visually

components which are connected to short circuited

voltage line.

X100

YES

PURX (J304) 2.8V

&

SLEEPCLK (J303)

32kHz

(typ. 32.768kHz)?

YES

VBB (C138)

2.8V?

YES

NO

NO

Remove

&

Insert service

battery

V2V (C140)

2.65V?

NO

Faulty circuit

N100, C140 or

R104

YES

Pin 5 of N102

V108 or R105

Drain of V106 low

around 60–100ms

when battery inserted

(FIg. 10)

YES

Faulty circuit N100 or

faulty 32kHz clock circuit

(B100, C120, C121, C122,

R113, R114 or R115)

YES

0V?

NO

Faulty circuit

NO

D101, D102,

V106, R102,

R108 or V102

N100

Faulty circuit

N102, C138 or

C111

Faulty circuit

VCORE (C119)

1.8V?

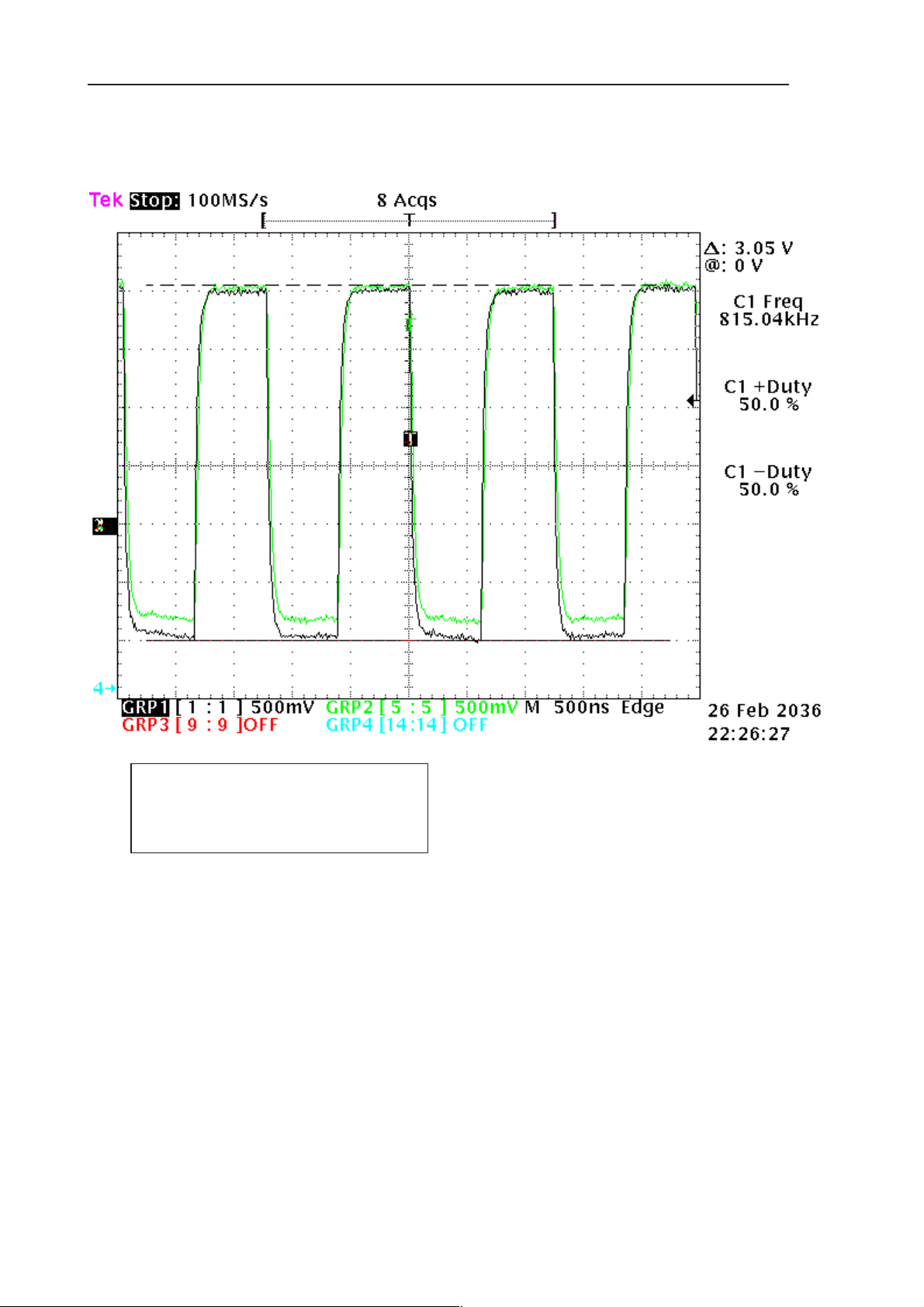

Oscilloscope screen shot (Figure 10) .

Issue 1 06/01

Faulty circuit L102, C131,

NO

V105, R118, L103, V104,

R116, R119, C118, C119

Figure 9.

Page 8 – 17

Page 18

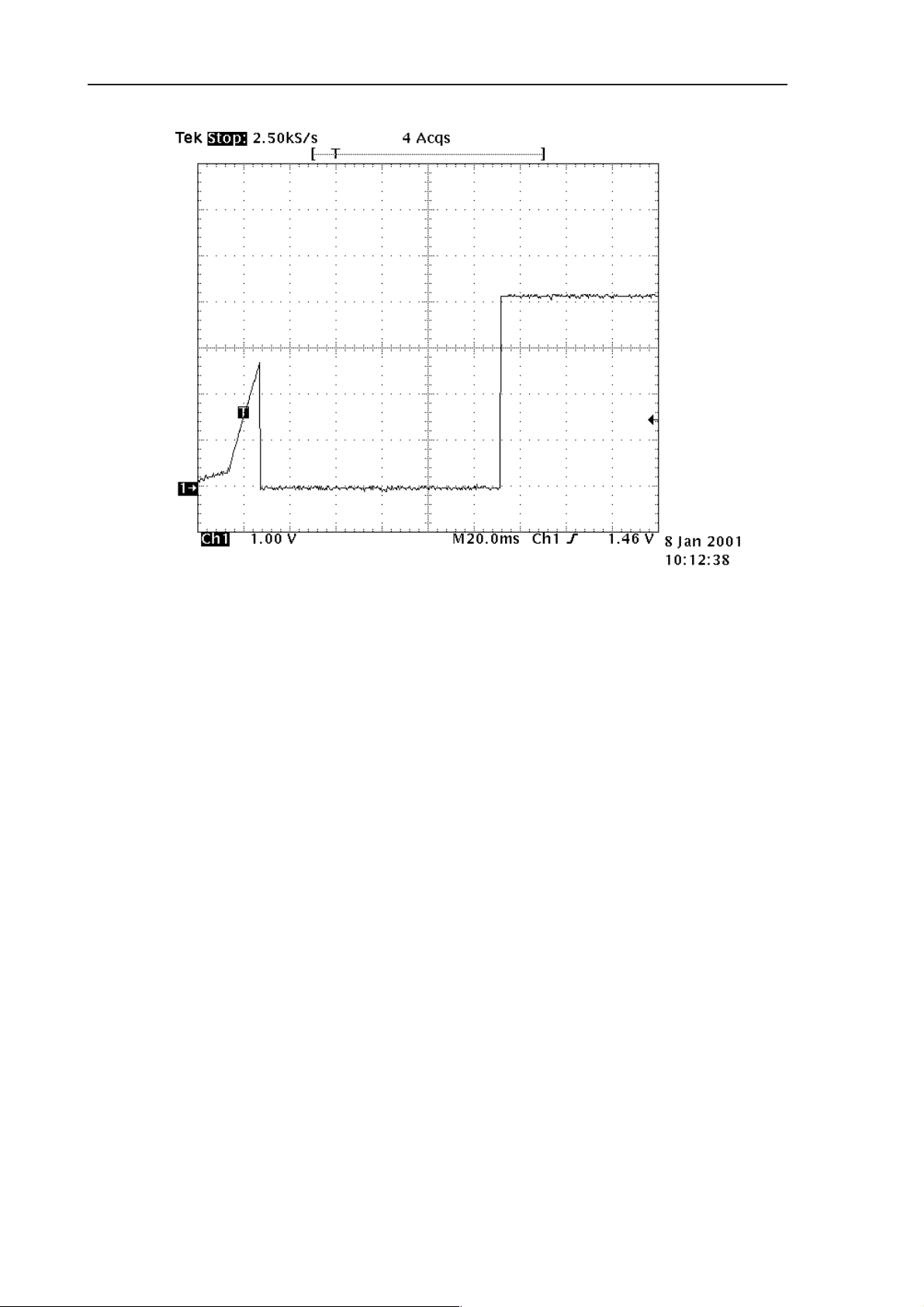

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

Figure 10. Drain of V106 when battery is inserted

Page 8 – 18

Issue 1 06/01

Page 19

PAMS

RAE-3

Technical Documentation

2.3 Device does not stay ON

If the device is switched off without any visible reason, there may be problems

in the following areas:

S CCONT watch dog problem

S BSI or BTEMP line problem

S Battery line problem

S Soldering problem

The most likely reason is CCONT WD (watchdog) problem, which turns the device off after about 32 s.

This may be caused by SW problem, MadLinda problem, CCONT problem or

memory problems.

The following tests are recommended:

S General Power Checking

8. Troubleshooting

S Clocks

S Memory testing

S CCONT serial interface

If there is something wrong in BSI and BTEMP lines, the device seems to be

dead after battery insertion. However, the regulators in the device are on 10s

before the powerdown.

This mode can easily be detected from the current consumption of the device.

After 10s the current consumption drops almost to 0mA.

In this case check components

C126, C127

R121, R122, R123,

C103, C104,

battery connector X100.

Issue 1 06/01

Page 8 – 19

Page 20

RAE-3

PAMS

8. Troubleshooting

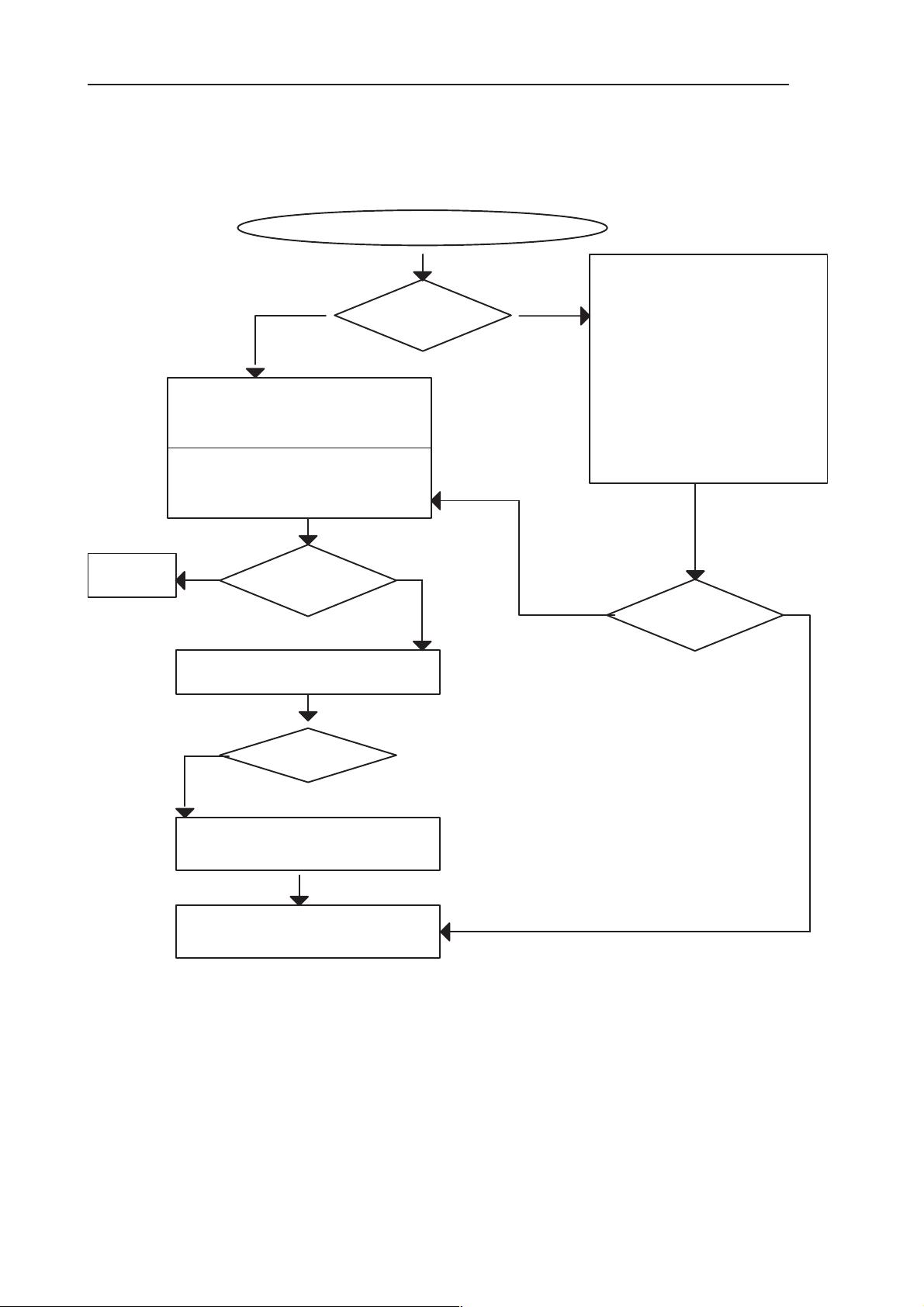

2.4 Charging checking

Use the BLL–3 battery and the JBE-2 calibration unit to test charging.

When you are charging totally empty battery, remember that start–up charging

might take 2 minutes with ACP–9 charger and several minutes with ACP–7

charger.

During this time display is blank. If charger is not NMP approved type and supported by phone then the software doesn’t start charging and display ’NOT

CHARGING’.

Remove and reconnect battery and charger few times before you start to measure module. This check ensures if module fault really exists.

See the diagram Figure 11 next page.

Technical Documentation

Page 8 – 20

Issue 1 06/01

Page 21

PAMS

RAE-3

Technical Documentation

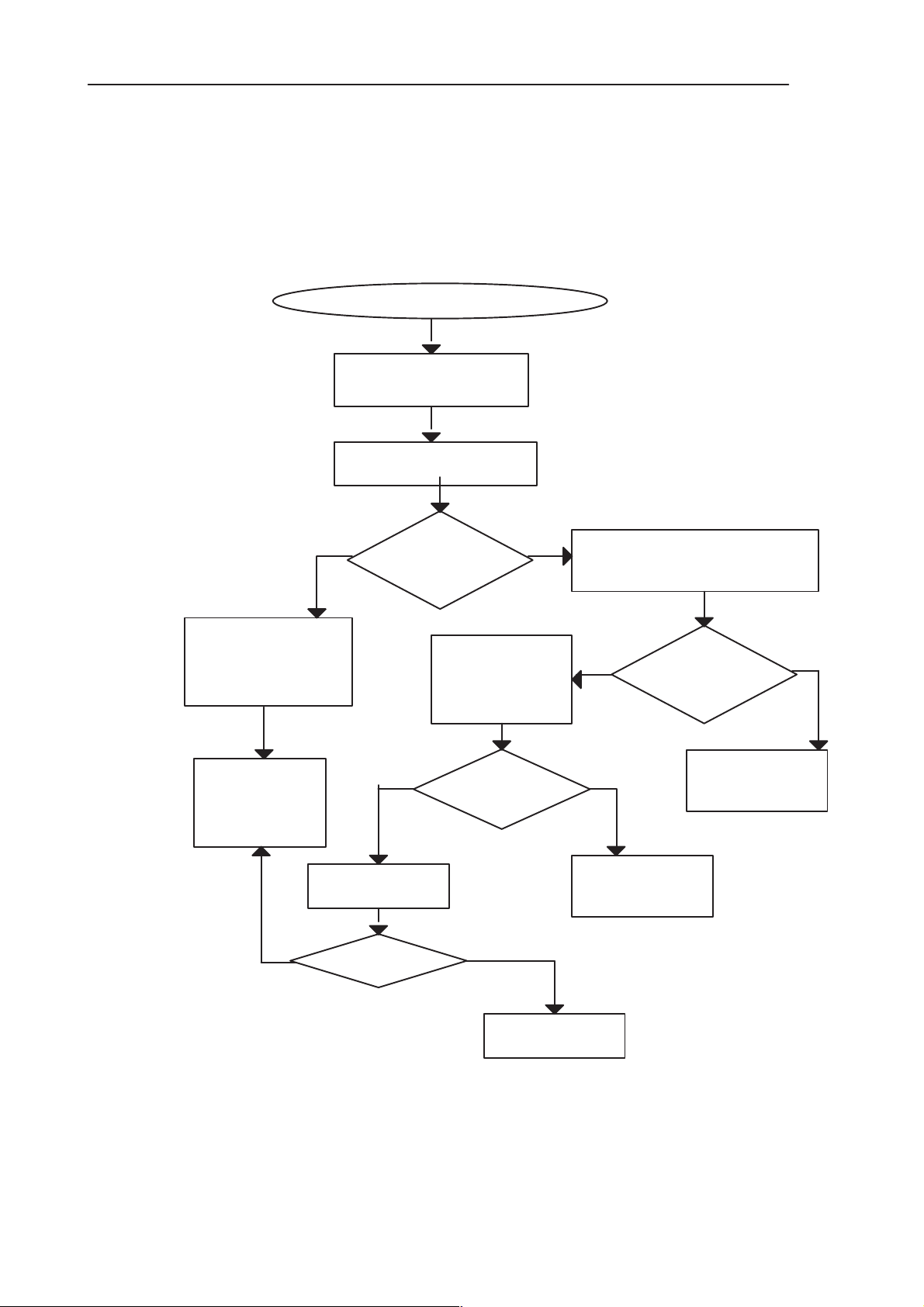

Display

information:

NOT

CHARGING

R121 voltage

is ~1.1V when charger is

connected

YES

R123 voltage

is ~0.5V when charger is

connected

YES

1Hz or 32Hz

square wave

(CHRG_CTRL) when charger

is connected *

NO

NO

NO

Check

BLL–3, BSI

resistor, X100,

R121, R122

Check

BLL–3, BTEMP

NTC, X100, R122,

R123

Check R451,

R461, C456

8. Troubleshooting

Nothing

happens when

charger is

connected

NO

V_in voltage at R111

>0.4 V ?

YES

Perform Energy

Management Calibration

with WinTesla software

and JBE–2 set

NO

Calibration OK ? Fault in N100 or

Check

BLL–3, X100,

X450, F450, V450,

L453. L454

R107, R111

C454, C455

N101

YES

Voltage over R101

> 0.1 V when

charger is connected

YES

Perform Energy

Management Calibration

with WinTesla software

and JBE–2 set

Charging OK? Fault in N101

NO

NO

Fault in N101

Figure 11.

NO

Charging OK?

Fault in N100

* Note:No square wave if phone displays

”NOT CHARGING”

Issue 1 06/01

Page 8 – 21

Page 22

RAE-3

PAMS

8. Troubleshooting

2.5 Backup Battery

CAUTION

Danger of explosion if the battery is incorrectly

replaced. Replace only with the same or

equivalent type recommended by the

equipment manufacturer.

Discard used batteries according to

Technical Documentation

the manufacturer’s instructions.

2.5.1 Backup battery troubleshooting

Main power supply to the device must be 3.7 V when used.

Symptom of Backup battery fault is:

Real Time Clock loses the correct time when the main battery is not connected.

The same symptom can also be seen when the backup battery is empty. About

one week is needed to fully charge the backup battery in the device.

Always check the backup battery visually for any leakage or any other visual

defect.

Check that the backup battery is correctly mounted in the device before closing

the cover.

KEEP IN MIND THAT THE BACKUP BATTERY DOES NOT TOLERATE EX-

CESS HEAT. WHENEVER HEAT BLOWER IS USED, FOR EXAMPLE TO REMOVE COMPONENTS, FIRST REMOVE THE BACKUP BATTERY AND

PLACE IT TO ADEQUATE DISTANCE FROM THE WORKING LOCATION.

Figure 12.

1. Remove the backup battery.

2. Measure the voltage of the backup battery:

S Normal operation when the voltage is >1.8V.

S Fully charged when voltage is about 3.1V.

3. Connect 3.7V power supply to the device.

Page 8 – 22

Issue 1 06/01

Page 23

PAMS

RAE-3

Technical Documentation

4. Check the backup battery connector X102 visually.

5. Measure voltage at terminal 1 of X102.

It must be 2.82 V to 3.3V.

–> if NOT OK, then N101 is faulty.

6. Insert the backup battery in the connector, make sure that the contact is

good.

7. Measure voltage at terminal 2 of X102.

It must be 1.8 V to 3.3V. This voltage increases because of charging if the

battery is not fully charged.

8. Read the backup battery with WinTesla.

–> if not OK then N100 is faulty.

9. Ensure that the RTC running time is set to 10 hours setting.

When the service battery BBL-3B is used, this is set automatically. (See General Guidelines)

8. Troubleshooting

Issue 1 06/01

Page 8 – 23

Page 24

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

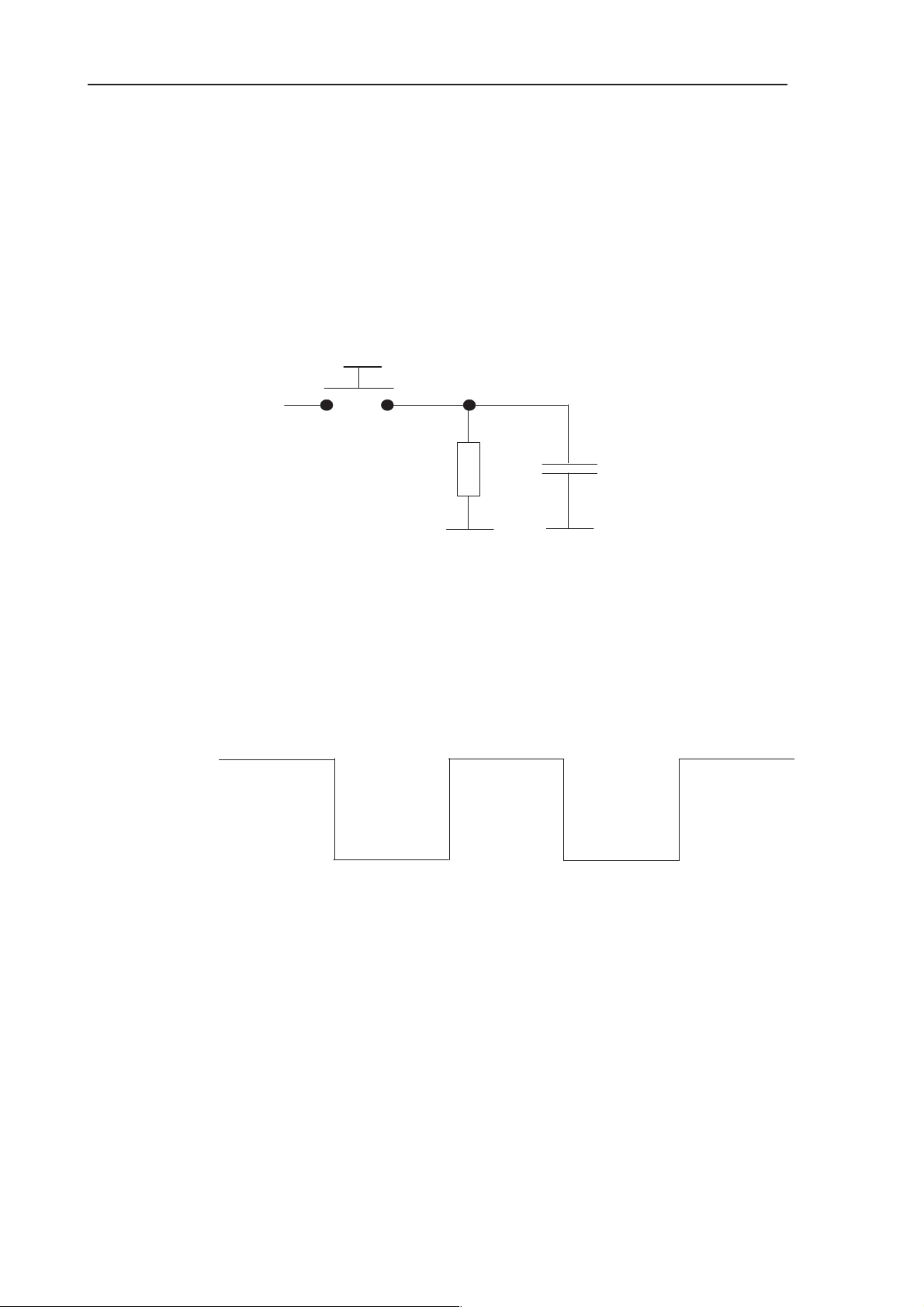

2.6 Accessory Power Output Troubleshooting

Accessory power output is connected to the system connector’s DCE_DTR pin

inside the device.Accessory power output can be tested with MJS–14 test jig

and Wintesla SW. There is a pushbutton called ACC VOLTAGE in MJS–14 test

jig which is used to connecting load to DCE_DTR pin of the system connector.

Following Figure 13 shows the connection in MJS–14 test jig (load side).

Pushbutton: ACC VOLTAGE

DCE_DTR

(pin 10)

In system

connector

47R

4.7µF

6.3V

DTR signal

Figure 13. ACC VOLTAGE test configuration in MJS–14 test jig

Figure 13 describes the ACC VOLTAGE test configuration in the MJS–14 test

jig. Status of the DTR signal in MADLinda is read by Wintesla SW. Test sequence in use is roughly shown in the following Figure 14:

.

VACC_CTRL

control goes ON

Press

ACC VOLTAGE button

Figure 14. Test sequence

VACC_CTRL control goes OFF

Release

ACC VOLTAGE button

Figure 14 describes the test sequence and status of DTR line during Accessory

Power Output Testing . Accessory output voltage test in Wintesla asks the test

person to press ACC VOLTAGE button and keep it pressed. After that SW automatically turns ON and OFF the accessory output voltage and gives the

passed/fail information. Wintesla SW gives guidance during this test.

Page 8 – 24

Issue 1 06/01

Page 25

PAMS

RAE-3

Technical Documentation

2.6.1 No Accessory Voltage when needed

– Power supply must be 3.7V.

– MJS–14 Test Jig must be used.

– Signals must be measured during Wintesla Accessory Power Output Test .

Fail in WinTesla

accessory power

out test

Check

V ACC = 3.3V

( Pin 5 of N104)

Yes

8. Troubleshooting

Check

X450, V451, R454,

R310, V489 and C459

No

Check

VB=3.7V (pin 1 of N104),

When

V ACC_CTRL=HIGH

(pin 3 of N104)

Yes

Check

N104, C129, C139, C1 16,

R310, V489

Test again with Win-

tesla

Figure 15.

No

Fault in D300

or N104

Issue 1 06/01

Page 8 – 25

Page 26

RAE-3

PAMS

8. Troubleshooting

2.6.2

Accessory Voltage ON all the time

– Power supply must be 3.7V.

– MJS–14 Test Jig must be used.

– This fault can be seen also as serial interface problem.

– Signals must be measured during Wintesla Accessory Power Output Test.

Fail in Wintesla accessory power out

test

Or

Jump from Serial Interface Troubles-

hooting

Check

VACC = 0V

(pin 5 of N104)

When V ACC_CTRL=LOW

(pin 3 of N104)

While ACC VOLTAGE button pressed

Yes

Technical Documentation

Check

X450, V451, R454,

R310, V489 and C459

No

Check

N104, C129, C139, C1 16,

R310, V489,

D300

Test again with Win-

tesla

Figure 16.

Page 8 – 26

Issue 1 06/01

Page 27

PAMS

RAE-3

Technical Documentation

2.7 Clocks

2.7.1 Clocks Troubleshooting

When the flashing of the device does not succeed, but the powering is OK, follow these instructions.

Note: The absence of clocks may indicate that the device is in sleep mode.

Move the magnet away from the sensor to simulate cover open situation.

IMPORTANT: Clock signals must be measured with 1MΩ (or greater) probe!

New Tektronix P6249 probes (20kΩ impedance) and similar cannot be used!

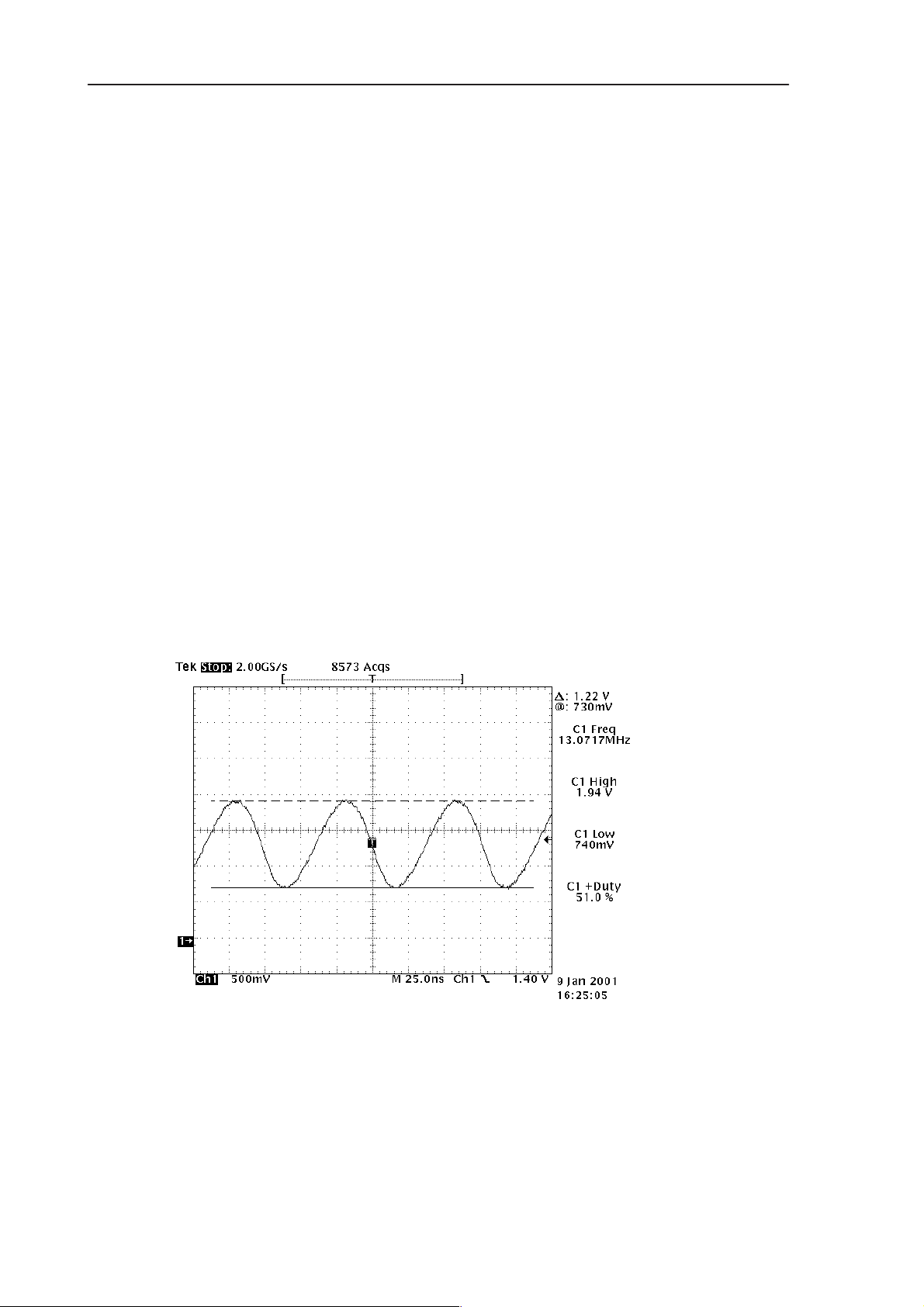

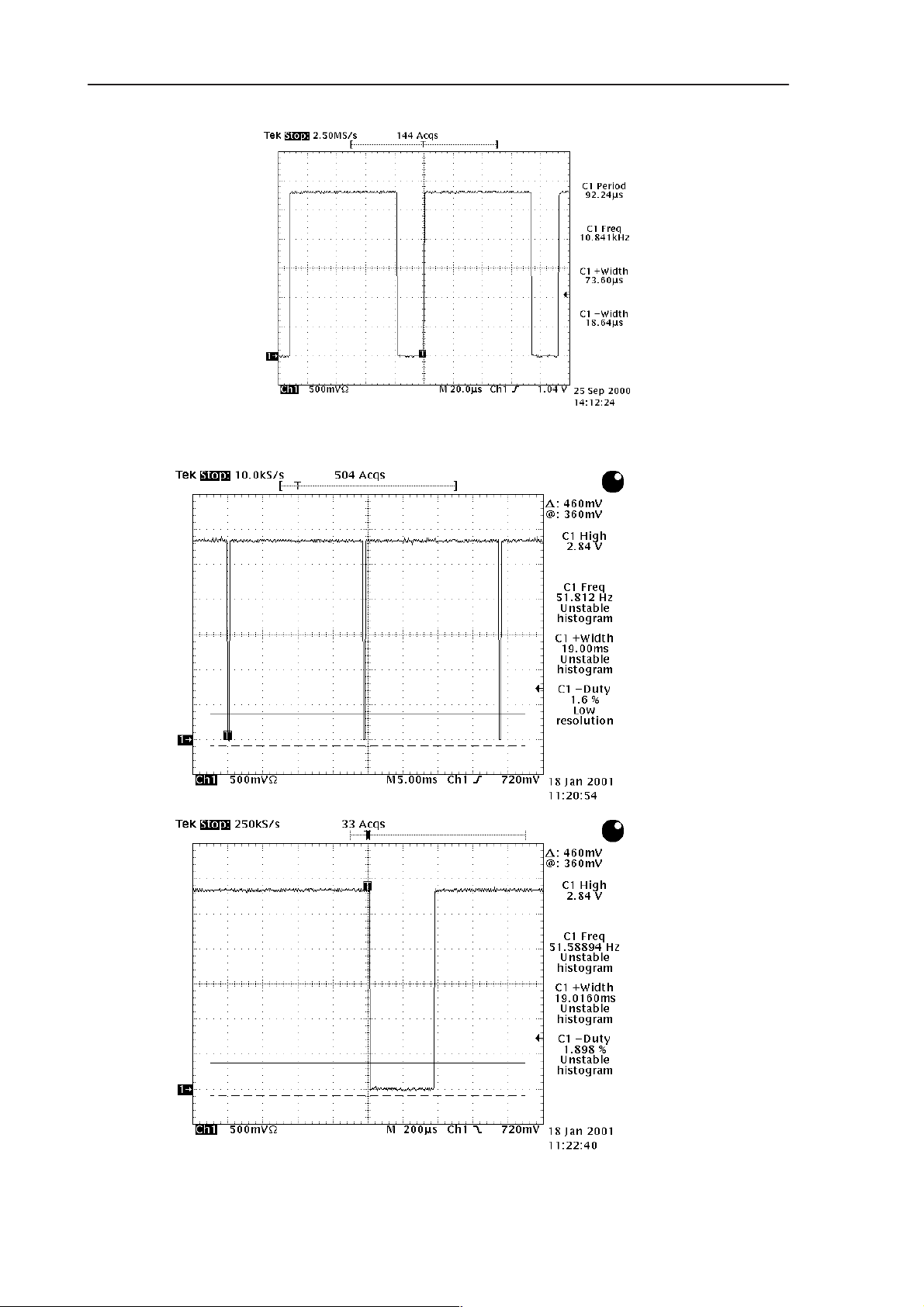

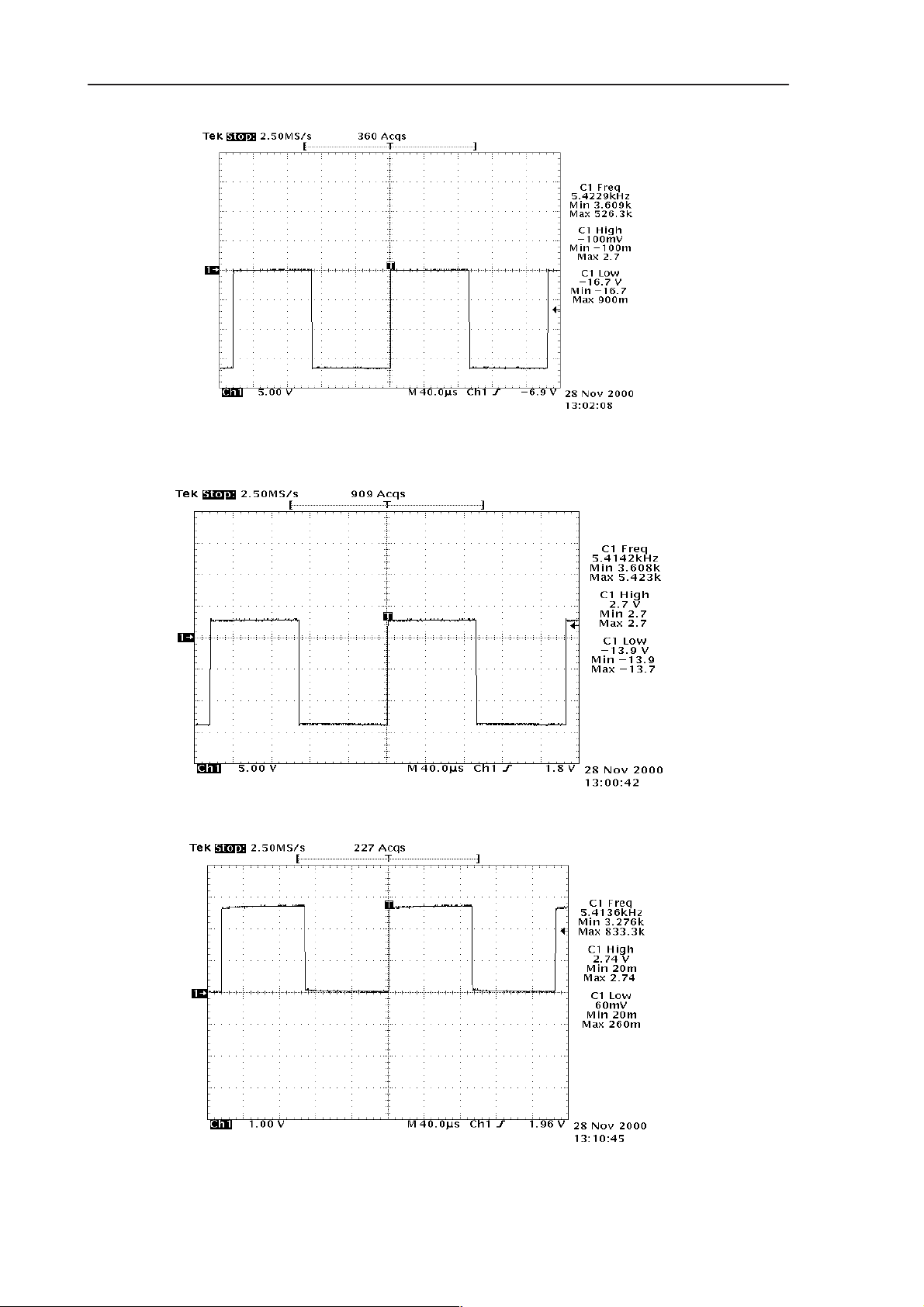

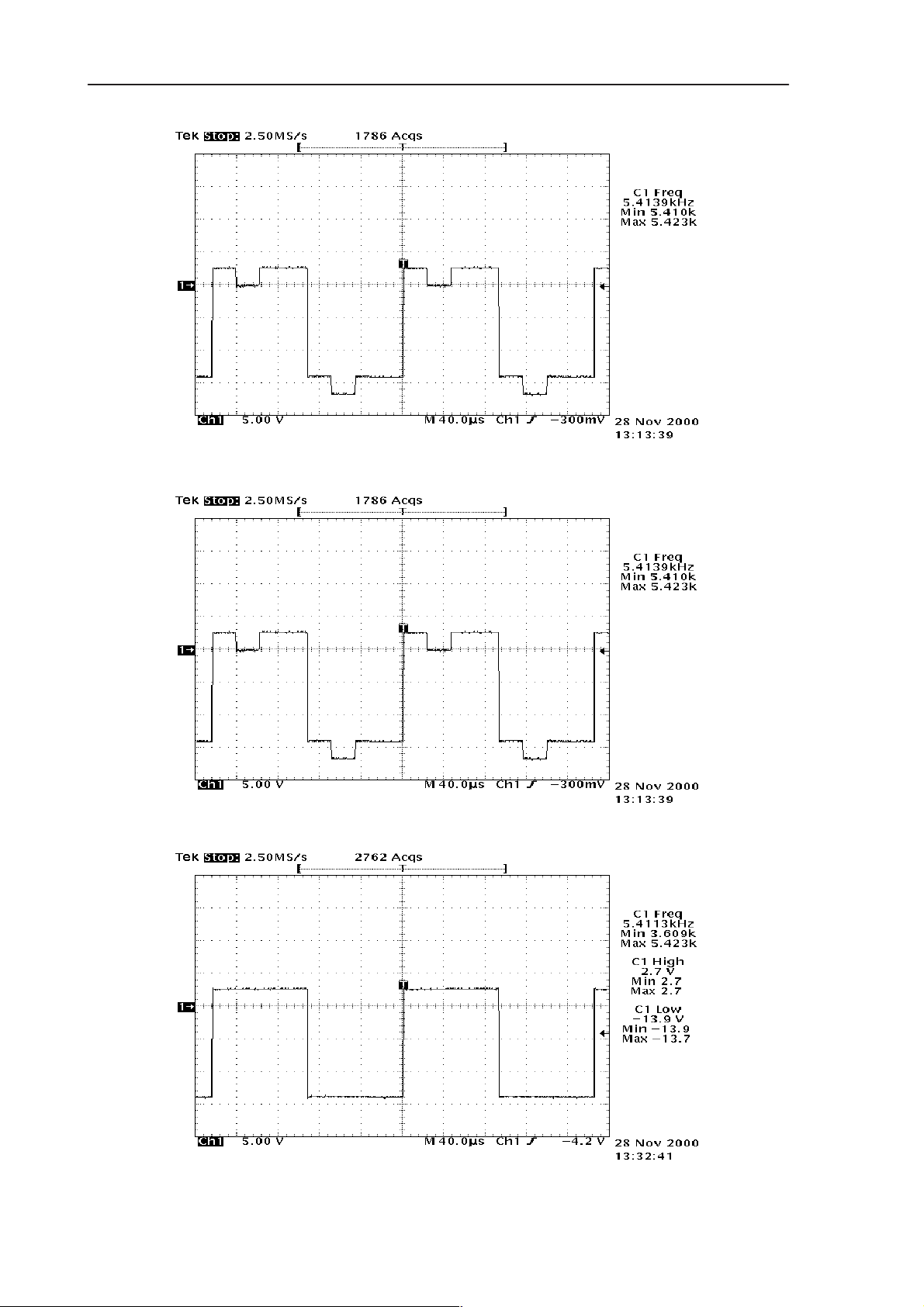

1 Measure RFC signal at C303. It should show 13.000 MHz sine wave,

approximately 1.2Vp–p with about 950mV DC–offset (see Figure 17). Check

the C303 capacitor.

• If this is OK, the processor gets the clock signal. The processor may

be faulty, or the fault is in the memories. Continue to ”Memories” section.

• If there is the clock signal, but there is no DC–offset (signal low level

around 0V), check the probe used so that it is not loading the signal. If the

probe is not responsible for missing DC–offset, try cycling the power a couple

of times. If this does not help, the clock slicer circuitry in the MADLinda (D300)

is faulty.

8. Troubleshooting

• If there is no clock signal at all, continue at 2.

Figure 17. Clock signal

2. Check VXO power line at C553. It should be around 2.8V. If it is,

move to 4.

3. Check VCXOPwr (J302). It should be around 2.8V.

• If it is 2.8V, CCONT (N100) is faulty.

• If VCXOPwr is 0V, MADLinda (D300) has shut down the regulators

(sleep) or it is faulty. Cycle the power and re–check.

Issue 1 06/01

Page 8 – 27

Page 28

RAE-3

PAMS

8. Troubleshooting

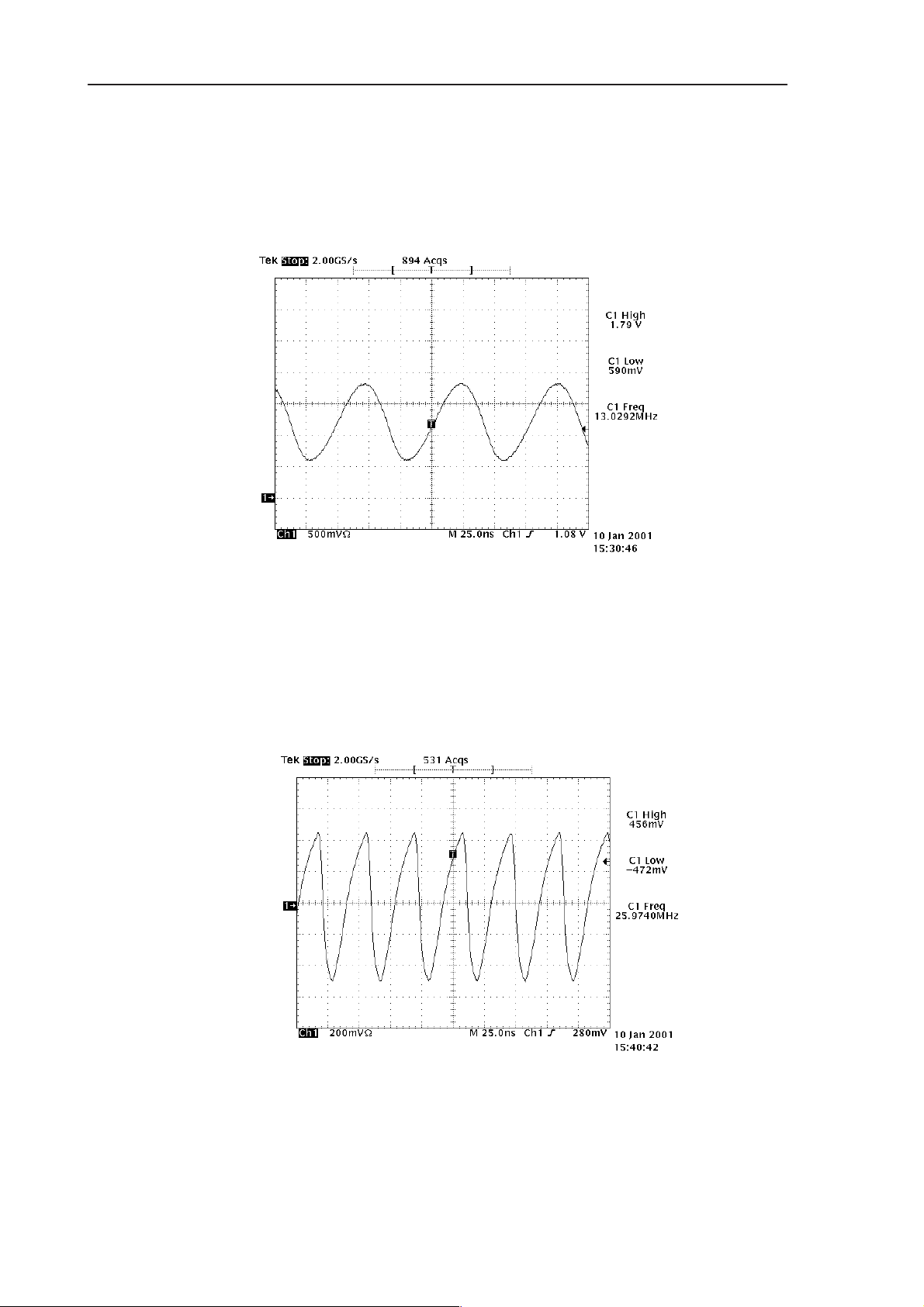

1. Open the smaller RF shield metal can. Check Hagar RFC–out signal

at V800. It should show sine wave of 1.2V amplitude, 13MHz frequency (see

Figure 18 ).

• If this is OK, the problem is in V800 transistor or in R834, R830,

C834, L800.

Technical Documentation

Figure 18. 13 MHz sine wave

2. Check VTCXO output at R833. This should be 26MHz sine wave

(see Figure 19 ).

• If this is OK, Check R835, C830 for shorts and bad connections. If

they are OK, Hagar (N505) or C800 or R829 is faulty.

• If this is not OK,

check

VTCXO (G830).

R835, C830, R833 may be faulty. If they are OK,

Page 8 – 28

Figure 19. 26 MHz sine wave

Issue 1 06/01

Page 29

PAMS

RAE-3

Technical Documentation

2.8 Memory Tests

2.8.1 Test in boot up

FLASHes 0 (D351), 1 (D352) and 2 D(353):

– manufacturer and device id are read from each of the flashes then compared

to value stored in FLASH 0.

– id read program code is executed from API RAM

– If FLASH 0 is broken the phone will not boot up properly (user test code re-

sides in FLASH 0) i.e. probably not even blink CMT backlights.

– If one or more flash manufacturer and device id read fail CMT display back-

lights will blink 2 times in a loop.

SDRAM (D350):

– Data bus test:

• Test will detect if lines are stuck at high or low state

8. Troubleshooting

• Test will detect any bridging faults

– Address bus test:

• data is written to certain addresses and read back and verified

– tested lines: address bus, data bus, SDRRASX, SDRCASX, SDRWEX and

SDRCLK

– SDRDQMU, SDRDQML and SDRCKE functionality is tested only partly

– If either of these tests fail CMT display backlights will blink 3 times in a loop

Serial FLASH (D354):

– Id is read and id bits (3–5) are compared to value 0x30

– If the test fails CMT display backlights will blink 4 times in a loop

– tested lines: SEPI, SEPO and SEPClk

SEPCSX (low) and EXT_SYS_RESETX (high) tested partly

– problems found with test SW:

• id read fails and CMT backlights blink but serial flash is ok ⇒ problem is in MADLinda

Issue 1 06/01

Page 8 – 29

Page 30

RAE-3

PAMS

8. Troubleshooting

2.8.2 Test in PTS/WinTesla flashing

These tests are in the beginning of device flashing. If any of these tests fail the

flashing will be stopped and a notification will be shown on the monitor screen.

SDRAM (D350):

– data is written to certain addresses, read back and compared

FLASHes 0 (D351), 1 (D352) and 2 D(353):

– device and manufacturer ids are read from each of the flashes and then the

values are compared (same test as in boot up)

Serial FLASH (D354):

– device id is read and the value is compared (same test as in boot up)

Technical Documentation

Page 8 – 30

Issue 1 06/01

Page 31

PAMS

RAE-3

Technical Documentation

8. Troubleshooting

2.9 Memory Troubleshooting

2.9.1 Memory fails In Boot Up tests, CMT Backlight is blinking

If the device won’t boot up and CMT display backlight is blinking

⇒ FLASH 0 (D351) probably ok !

To measure signals from D352, D353, D350 and D354 the device needs to re-

booted up constantly since the lines are active only a short time in the beginning of the boot.

Also CCONT WATCHDOG will shut the device off after 32 seconds !

Time between each memory device blinks is 1 second and time between differ-

ent memory device blinks is 2 seconds.

For example if FLASH1 and Serial Flash are broken the blinking sequence

goes:

2 blinks with 1 sec interval (FLASH fault)

2 sec without blinks

4 blinks with 1 sec intervals (Serial Flash fault)

2 sec without blinks

then to the beginning again

Issue 1 06/01

Page 8 – 31

Page 32

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

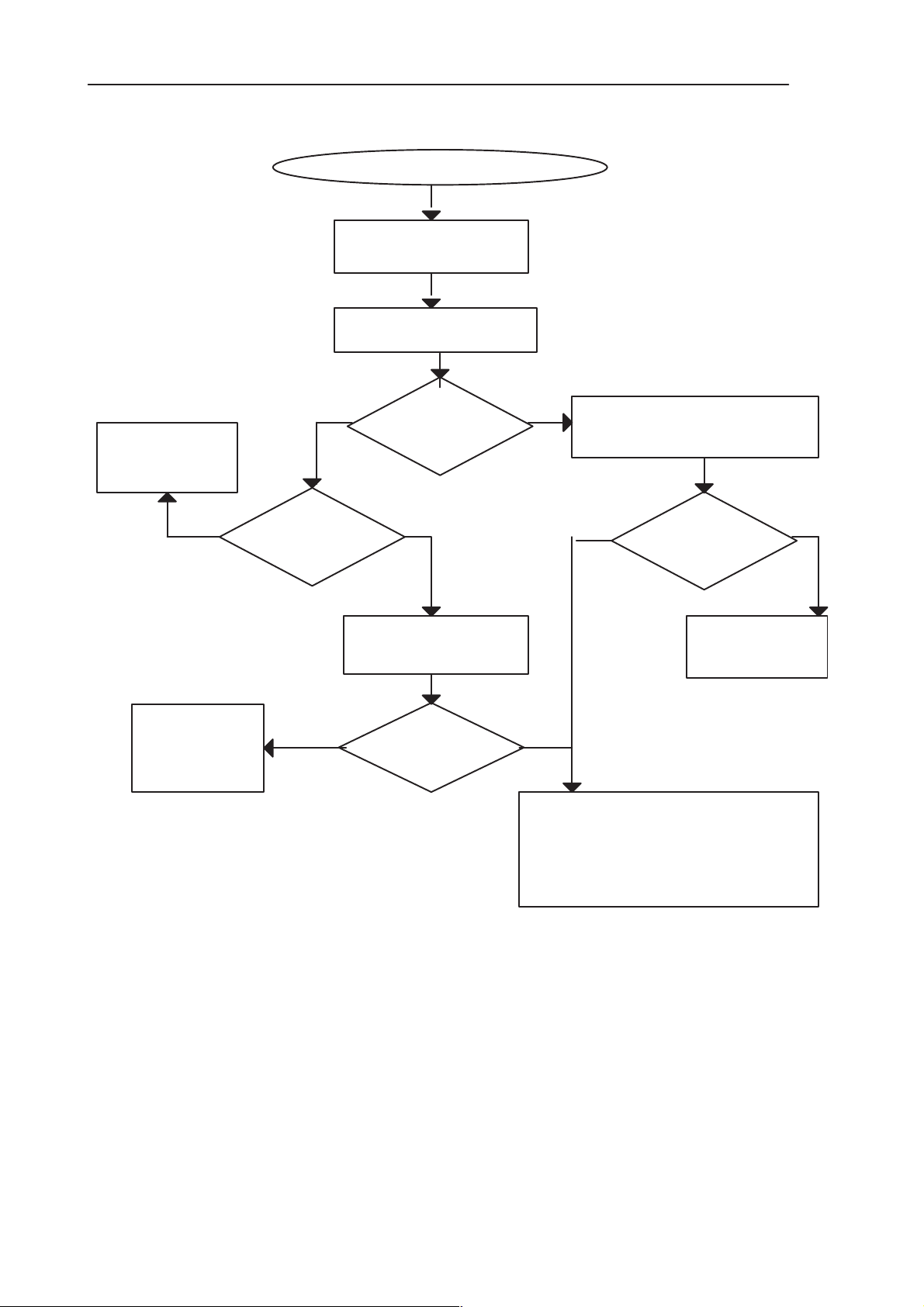

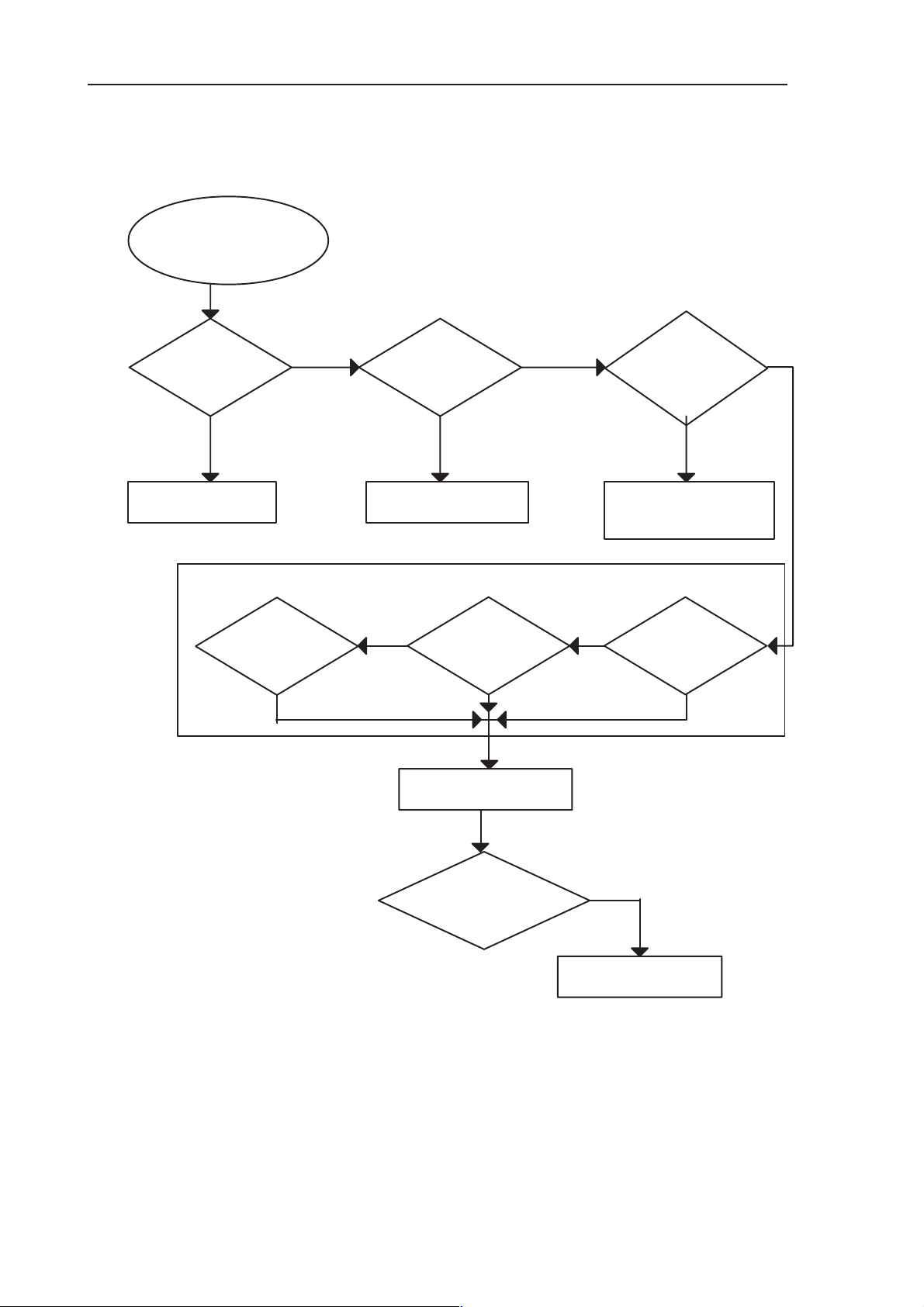

2.9.2 CMT display backlight blinking 2 times in a loop

CMT display backlight blinking 2 times in a loop (”Flash fault”):

Manufacturer and device id read from FLASH 1 (D352) or FLASH 2 (D353) or

from both fails.

ID read from FLASH1 or

FLASH2 fails

Flash the device

D352 ID read

fails during flashing

D353 ID read

fails during flashing

negative pulses

NO

Problem in

D300 (MCU)

See FLASH signal pictures later.

Check:

on J339

(1.8V)

OK?

YES

Change

D352

Figure 20.

YES

Change

D353

Check:

negative pulses

on J340

(1.8v)

OK?

NO

Problem in

D300 (MCU)

Page 8 – 32

Issue 1 06/01

Page 33

PAMS

RAE-3

Technical Documentation

8. Troubleshooting

2.9.3 CMT display backlight blinking 3 times in a loop

CMT display backlight blinking 3 times in a loop (”SDRAM fault”):

D350 SDRAM test fails

Check activity from SDRAM lilnes

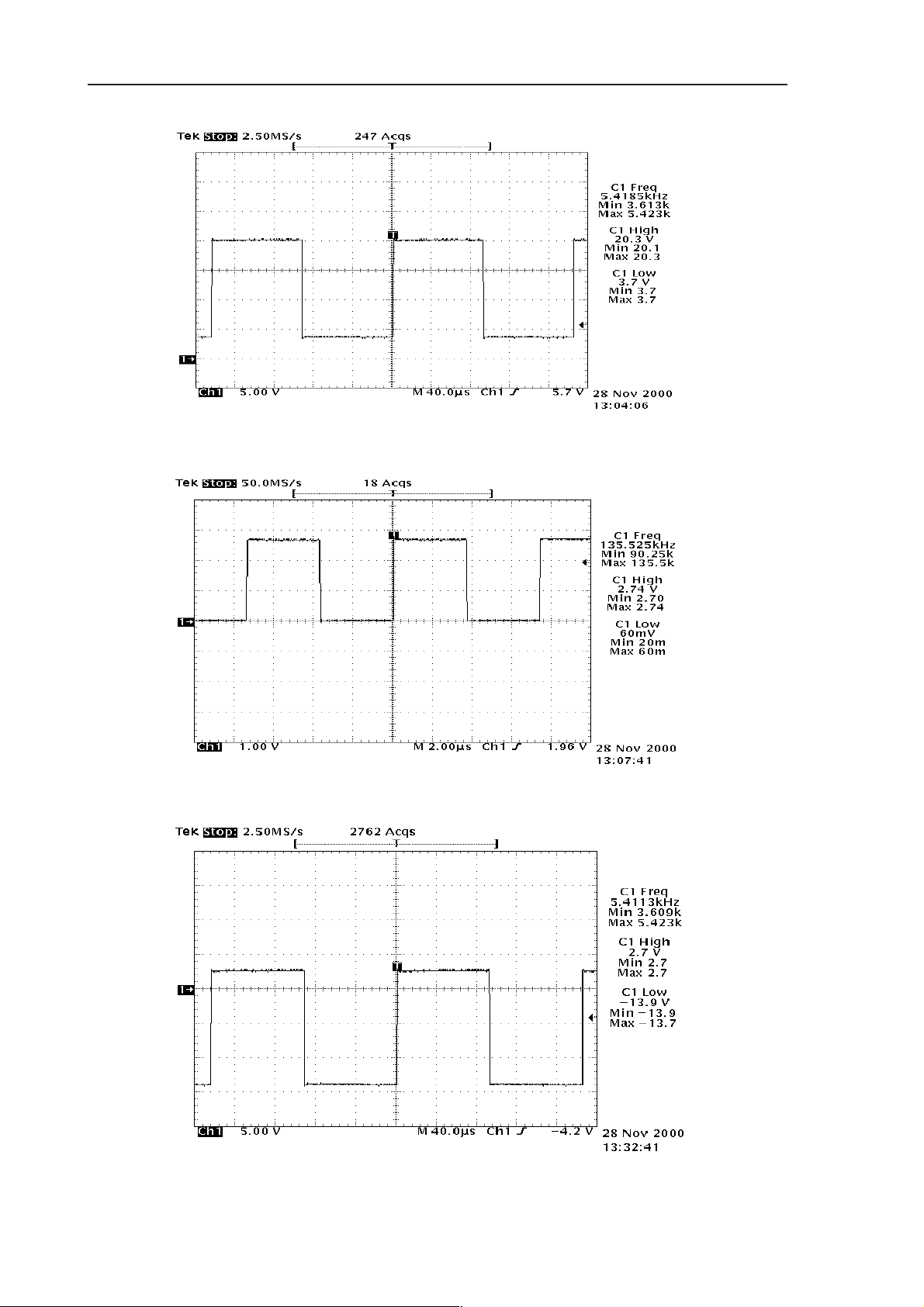

SDRRASX (J312): negative pulses (2.8V) SDRCASX (J313): negative pulses (2.8V)

SDRWEX (J314): negative pulses(2.8V) SDRCLK (J310): 13MHz clock (2.8V)

SDRAd6 (J348): postive pulses (2.8V) SDRDQML (J315): negative pulses (2.8V)

SDRDQMU (J316): negative pulses (2.8V) SDRCKE (J311): high (2.8V)

SDRDa8 (J349): positive pulses (data pulses driven by SDRAM have bigger

over shoot spikes than data driven by MADLinda MCU, see figure 23) (2.8V)

Pulses on MADLinda control lines J312, J313, J314,

J310, J348, J315, J316 or J349

NO

Replace D350 if J349

D300 faulty

Figure 21.

data pulses with big

overshoot spikes are

missing

OK

Issue 1 06/01

Page 8 – 33

Page 34

RAE-3

PAMS

8. Troubleshooting

SDRDa8

J349

Technical Documentation

Figure 22. SDRAM (D350) driven data line SDRDa8 (J349)

SDRCLK

J310

SDRRASX

J312

SDRCASX

J313

SDRWEX

J314

Figure 23. SDRAM signals and levels 1

Page 8 – 34

Issue 1 06/01

Page 35

PAMS

RAE-3

Technical Documentation

SDRCLK

J310

SDRAd6

J348

SDRDQML

J315

SDRCKE

J311

8. Troubleshooting

Figure 24. SDRAM signals and levels 2

Issue 1 06/01

Page 8 – 35

Page 36

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

2.9.4 CMT display backlight blinking 4 times in a loop

CMT display backlight blinking 4 times in a loop (”Serial Flash fault”):

D354 Serial Flash ID read

Check activity in serial FLASH lines

SEPClk (J327):6.5MHz clock (2.8V)

SEPO (J329): positive pulses (2.8V)

SEPCSX (J337): long negative pulse (2.8V)

EXT_SYS_RESETX (J301): high (2.8V)

SER_FL_RBY(J346): high (D300 internal pull–up, use passive

probe!) (2.8V)

SEPI (J328): Positive pulses

(D300 internal pull–up) (2.8V)

test fails

If no pulses found from J327, J328, J329 or from J337

problem is in D300

If J301 or J346 are low problem is D300

Figure 25.

If J328 stays always high change D354

Page 8 – 36

Issue 1 06/01

Page 37

PAMS

RAE-3

Technical Documentation

SEPCLK

J327

SEPO

J329

SEPI

J328

SEPCSX

J337

Figure 26. Serial Flash (D354) id read sequence.

8. Troubleshooting

Issue 1 06/01

Page 8 – 37

Page 38

RAE-3

PAMS

8. Troubleshooting

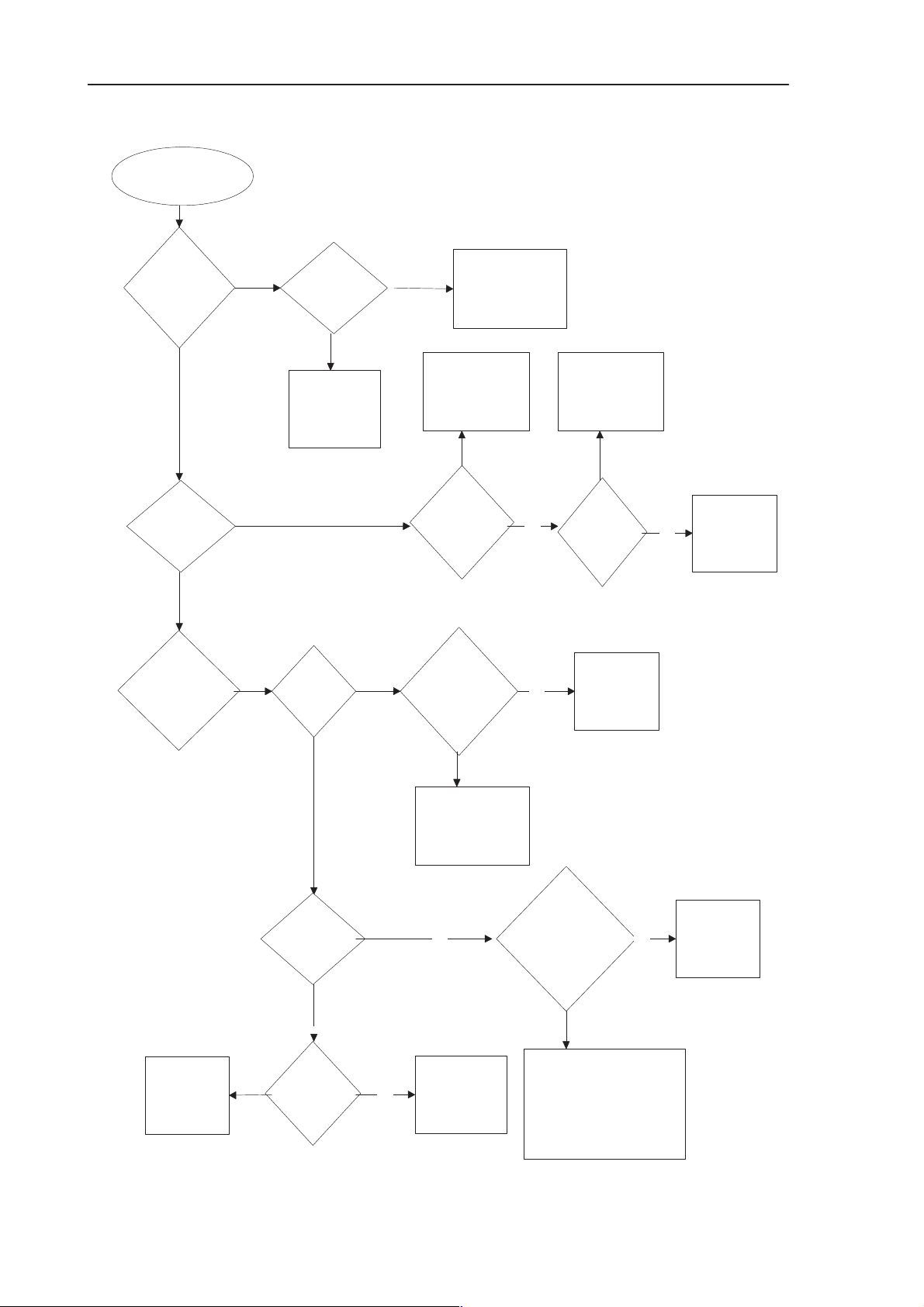

2.9.5 Memory fails in PTS/WinTesla flashing

1. SDRAM id read test fails

Refer to the previous ”SDRAM fault” chapter.

2. Flash manufacturer and device id read fails

a) If id read from all of the three flashes (D351, D352 and D353) fails

ly the problem is in D300.

Check D300 and control lines:

S FLDa7 (J351): positive pulses (1.8V)

S FLCS0X (J338): negative pulses (1.8V)

S FLOEX (J341): negative pulses (1.8V)

S FLCS1X (J339): negative pulses (1.8V)

S FLWEX (J342): negative pulses (1.8V)

S FLCS2X (J340): negative pulses (1.8V)

Technical Documentation

most like-

S FLAd5 (J350): positive pulses (1.8V)

S FLRPX (J343): high (1.8V)

S FLWPX (J347): low (1.8V)

If any of the signals is missing the problem is in D300.

b) If id read from one or two flashes fails

Page 8 – 38

Issue 1 06/01

Page 39

PAMS

RAE-3

Technical Documentation

D351 id read fails

D352 id read fails

Check if FLCS0X OK, J338

YES NO

NO

Check if FLCS1X OK, J339

8. Troubleshooting

ID read from FLASH fails

D353 id read fails

YES

Problem with

Change D352

D300

Check if FLCS2X OK, J340

NO

Change D353

Figure 27.

Refer to the oscilloscope screen shots next page for what the signals should

look like.

YES

Issue 1 06/01

Page 8 – 39

Page 40

RAE-3

PAMS

8. Troubleshooting

FLCS0X

J338

FLOEX

J341

FLWEX

J342

Figure 28. Flash 0 (D351) manufacturer and device id read

Technical Documentation

FLAd5

J350

FLDa7

J351

Figure 29. the Flash address and databus signals

2.9.6 Serial Flash id read test fails

Refer to previous chapter ”Serial Flash fault” 2.1.2

Page 8 – 40

Issue 1 06/01

Page 41

PAMS

RAE-3

Technical Documentation

2.10 Serial Interface Troubleshooting

Serial Interface problem

YES NO

Activate WinTesla,

observe

ADC–readings

Check that ”DTR Detection”

state changes by pressing

ACC_VOLT AGE switch

in the service jig

Flashing

successful?

8. Troubleshooting

1. Check Serial connector

X450 spring contacts

2. Check and replace

ESD protection device V451

3. Check DCE_Tx (AccRxData)

comp. R452, C458, R300

4. Check DCE_Rx (AccTxData)

comp. R453, C457, R307

5. Check DCE_DCD (MBus)

comp. R450, C453, R309

NO

Serial I/O

OK

NO

YES NO

OK?

Check DCE_DTR line

comp. R454, C459,V489, R310

OK?

Refer to Accessory power

output troubleshooting

OK

Faulty MAD (N300)

or PWB fault

Figure 30.

NOTE1: Ensure that the customer’s DLR–2L is OK.

Flashing

successful?

YES

NOTE2: Wintesla ADC–readings for ’DTR Detection’: state ”0” = DCE_DTR

– line at 2.8 – 3.0V

– line at 0 – 0.3V

NOTE3: Signal levels in practice: High 2.7V, Low 0.3V

Exception: Diode in DTR line causes voltage drop, see Figure 31 below:

Issue 1 06/01

Wintesla ADC–readings for ’DTR Detection’: state ”1” = DCE_DTR

Page 8 – 41

Page 42

RAE-3

PAMS

8. Troubleshooting

0.3V

Technical Documentation

2.95V

2.8V

With DLR–2L

C1, black: MAD end

C5, green: syscon end

Using DLR–2:

GRP1, black: MAD end

GRP2: System connector end

0 V

Figure 31. DTH line voltage

Page 8 – 42

Issue 1 06/01

Page 43

PAMS

RAE-3

Technical Documentation

MBUS (clock) Signal during flashing (Figure 32):

8. Troubleshooting

GRP1, black: MAD–end

GRP2: system connector end

Approx. 0.2V difference results from MBUS

pull–up resistor (R309, 4k7) & serial resistor

(R450, 270R) voltage slicing.

Figure 32. MBUS (clock) Signal during flashing

Issue 1 06/01

Page 8 – 43

Page 44

RAE-3

PAMS

8. Troubleshooting

2.11 CONTACT SERVICE in CMT display

CONTACT SERVICE in CMT display (Self-tests with WinTesla)

Display Information: ”Contact Service”

This fault means that software is able to run and thus the watchdog of CCONT

(N100) can be served. Self–test functions are executed when power is switched

on and software is started to execute from flash.

If any one of the self–tests fails (except no. 3, 7, 8, and F), the text ”Contact

Service” is shown in the phone display.

MCU Self–tests are divided into those executed while power up (tests: 1–5 and

9–I ) and the ones can be executed with the connected PC. The tests and included items are as follows (Figure 33, screendump from the WinTesla)

Technical Documentation

The information can be used for diagnosis.

Memory tests differ from normal DCT3 self–tests. They can not be executed in

the ENOS because memory protection.

There is no EEPROM. The EEPROM is emulated in the FLASH (part of CS2).

All contents where EEPROM is mentioned refer to emulated EEPROM.

Item no. 1; MCU ROM Checksum:

Page 8 – 44

Figure 33.

Issue 1 06/01

Page 45

PAMS

RAE-3

Technical Documentation

Calculates 16 bit checksum out of Flash code and compares it to the one found

in Flash. Items being checked are MADLinda <–> Flash data– and address

lines FLDa0–15 and FLAd1–21, FLCS0X (CE0), FLCS1X (CE1), FLCS2X

(CE2), FLWEX (WE), Vbb (Vcc), VCORE (Vccq), GND, and Flash internal functionality.

Item no. 2 MCU EEPROM Interface:

Checks current PMM error status. If this test FAILs, the PMM data is not valid

anymore and should be formatted.

Item no. D COBBA Serial

This test tests Audio interface (PCM) of the COBBA_GJP.

Item no. E COBBA Parallel

This test tests the serial control/RF interface of the COBBA_GJP.

8. Troubleshooting

Issue 1 06/01

Page 8 – 45

Page 46

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

2.12 CCONT Serial interface Troubleshooting

If there are problems in CCONT’s serial control interface, self tests fail and

there is ”Contact service” shown on the display. Wintesla shows this fail as

”CCONT Interface”.

NOTE: Low level means 0V, high level means approximately 2.8V.

Check GENSCLK line at J318

Square wave, Freq. 2.17 MHz ?

(see note below?)

Check CCONTCSX line at J317

Activity?

Signal active low

Check GENSDIO line at R308

Activity?

Signal active high

Check all three lines simultaneously , see fig. below

OK?

YES

NO

D300 or PWB

faulty

Figure 34.

(Note: Measurement should show 2.17MHz square wave. This interface is connected to CMT display also, so there is other activity too. The 3.1MHz clock is

targeted for CMT display, do not worry about that. The clock signal is low when

inactive.)

1. Measure all the three lines simultaneously (Figure 35).

Set the trigger to CCONTCSX line falling edge.

You should see the two cases, Figure 35 and Figure 36 .

(Channel 1–GENSClk,

Channel 2–CCONTCSX,

Channel 3–GENSDIO). High level is about 2.8V

Page 8 – 46

Figure 35.

Issue 1 06/01

Page 47

PAMS

RAE-3

Technical Documentation

MADLinda writes to CCONT. The data at sixth bit is ’0’ as marked with the cursors. The data after the read/write bit varies, just like the address before the bit.

If you can see this kind of traffic, MADLinda side of the interface is functioning

correctly.

8. Troubleshooting

Figure 36.

MADLinda reads from CCONT. The data at sixth bit is ’1’, marked with the cursors. There should be data seen after the ’read’ bit. All zero values may be

read, but there should be other data seen, too. CCONT read cycles are fairly

rare compared to write cycles. If there is not any non–zero reads from CCONT,

the CCONT (N100) may be faulty.

Issue 1 06/01

Page 8 – 47

Page 48

RAE-3

PAMS

8. Troubleshooting

2.13 SIM Card

2.13.1 SIM Card Error Troubleshooting

The fault information ”SIM Card error” means most likely that the SIM locked

phone has been inserted with a SIM which does not correspond to the lock

code.

Check the SIM lock status of the phone with WinTesla:

”SIM Card Error”

message in display ?

Set the phone in NORMAL mode

Technical Documentation

View–> Quick/RF Info

See ”SIM Lock Settings” field:

Blank

NO

SIM lock activated: inform customer

Customer contacts network operator

to ask for lock reset

field?

YES

Figure 37.

No SIM lock.

Refer to ”SIM Card Rejected”

troubleshooting

Page 8 – 48

Issue 1 06/01

Page 49

PAMS

RAE-3

Technical Documentation

2.13.2 SIM Card Rejected

The fault information ”SIM Card rejected” means that the ATR message (Answer To Reset; the first message from SIM card to phone after SIM card power

up) is sent, but it is corrupted somehow, eg. the dataline signal levels are wrong

or factory set values (stored in the EEPROM) are not correct.

NOTE1: CHECK THE MEASUREMENT POINT PICTURE BEFORE SERVICE

ACTIONS

SIM_xxx_Cardside – refers to signal which exists in SIM card contacts

SIM_xxx_o – refers to signal which exists in CCONT(N100) side

NOTE2: SIM Signals between CCONT (N100) and LindaMAD (D300) are not

possible to measure in bl8–module because traces are running in inner layers

of PWB.

8. Troubleshooting

Issue 1 06/01

Page 8 – 49

Page 50

RAE-3

PAMS

8. Troubleshooting

5V card:Check

5V charge pump

components

C107

V101

C110

Still

problem?

SIM CARD FAULT

Check VSIM at SIM card pin

NO

VSIM=

2,8V min. with 3V

4.5V min. with 5V

Check V103 pins

card

Pin_1: CLK

Pin_6: DA TA

Pin_4: Reset

YES

YES

card

Technical Documentation

NO

3V card: Check

N100 (CCONT)

C112, C113

Replace

if necessary

YES

Replace

N100

(CCONT)

D300 (MAD) faulty

Lines

rising

0V –>3V/5V

after power on

Check ATR data at

N100

R112

at N100 (CCCONT)

side /SIM_DA TA_0

Check

N100 (CCONT)

YES

problem?

?

OK?

Still

YES

YES

NO

NO

NO

Check

SIM card reader

mechanical

connections

and eventual

short circuits from

CLK, DA TA and

RESET lines

against GND

Check

X101, V103,

R109, R112

R125

N100 faulty

Page 8 – 50

Figure 38.

Issue 1 06/01

Page 51

PAMS

RAE-3

Technical Documentation

2.13.3 Insert SIM card

The hardware of the SIM interface from the MADLinda (D300) to the SIM connector (X101) can be tested without SIM card. This leaves SIM connector

(X101) contacts to be used as an measurement points.

When the power is switched on and if the BSI line (X100:2) is grounded by resistor (which happens automatically in service jig), all the used lines (VSIM,

RST, CLK & DATA) rise up to 3V and/or 5V four times (SW tries to ask SIM card

four times).

NOTE1: CHECK THE MEASUREMENT POINT PICTURE BEFORE SERVICE

ACTIONS

SIM_xxx_Cardside – refers to signal which exists in SIM card contacts

SIM_xxx_o – refers to signal which exists in CCONT(N100) side

NOTE2: SIM Signals between CCONT (N100) and LindaMAD (D300) are not

possible to measure in BL8–module because traces are running in inner layers

of PWB.

8. Troubleshooting

Issue 1 06/01

Page 8 – 51

Page 52

RAE-3

PAMS

8. Troubleshooting

5V card:Check

5V charge pump

components

C107

V101

C110

Still

problem?

Insert SIM card fault

YES

Check Voltage level between R121 and C126

When BSI resistor connected (included in

service jig

YES

NO

Volt.level

<1.5V ?

YES

NO–5V

Check VSIM, DA TA, RESET, CLOCK lines

at the pins of ASIM connector (X100)

VSIM at SIM card pin

2.8V min. with 3V card

4.5V with 5V card

YES

or SIM_xxx cardside signals at

measurement points

Technical Documentation

Check

R121, R122,

X100, C126

3V card: Check

NO– 3V

N100 (CCONT)

C112, C113

Replace

if necessary

YES

Faulty

N100

(CCONT)

Faulty PWB

Faulty D300

Still

problem?

Replace D300 (MAD)

YES

Lines

rising 0V–>3V/5V

after power on ?

NO

Check VSIM (V103 pin 3)

DATA_0 (R109)

SIMRST_0 (R125) at

(ref. Measurement point diagram)

N100/CCONT side

NO

rising 0V–>3V/5V

after power on ?

N100 (CCONT)

NO

Lines

Replace

Still

problem?

NO

YES

YES

YES

Check SIM card,

SIM card reader

mechanical

connections

Check

X100, V103

R109, R112

R125

SIM I/O OK,

N100 (CCONT)

faulty

Page 8 – 52

Figure 39.

Issue 1 06/01

Page 53

PAMS

RAE-3

Technical Documentation

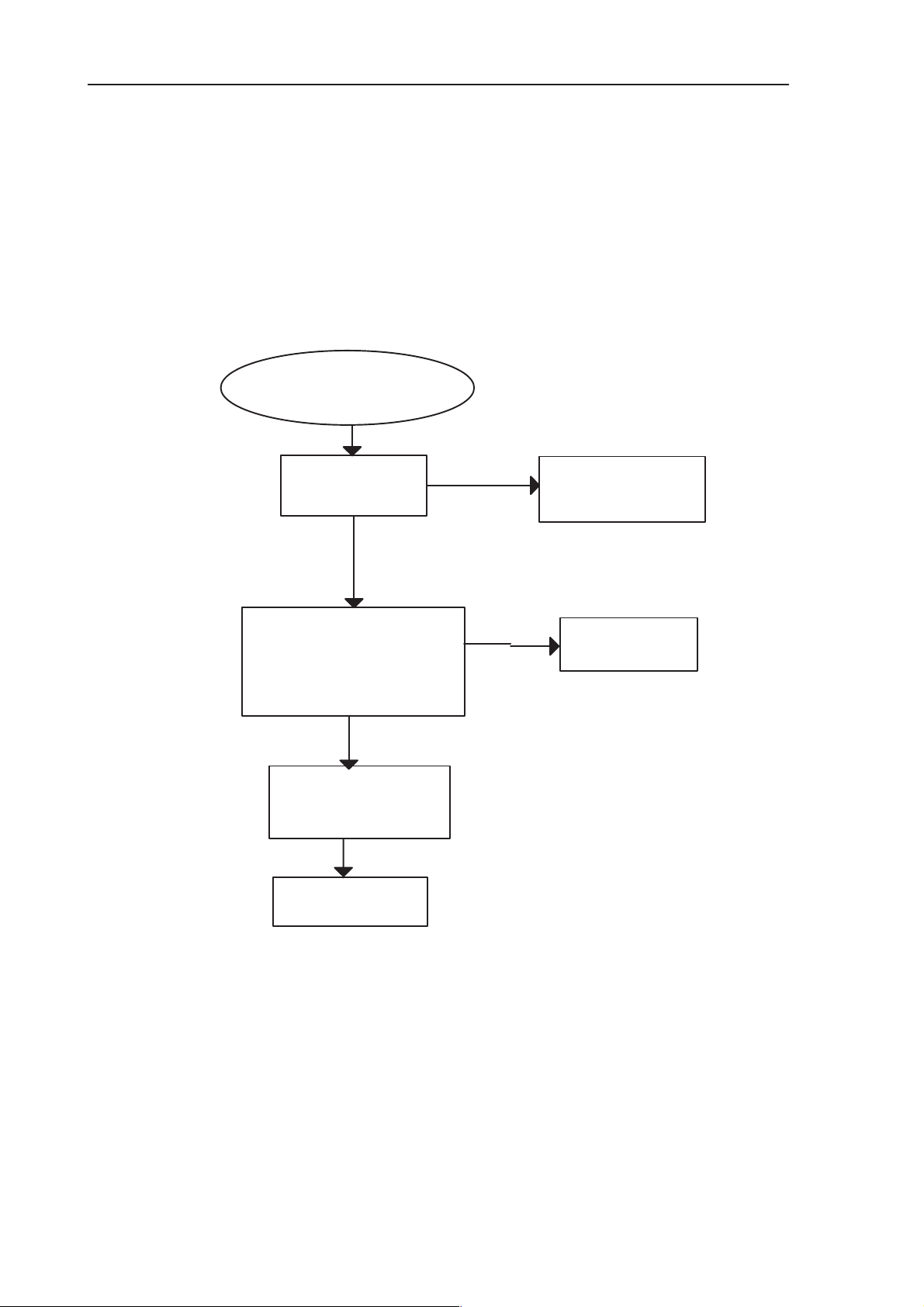

2.14 Memory Card

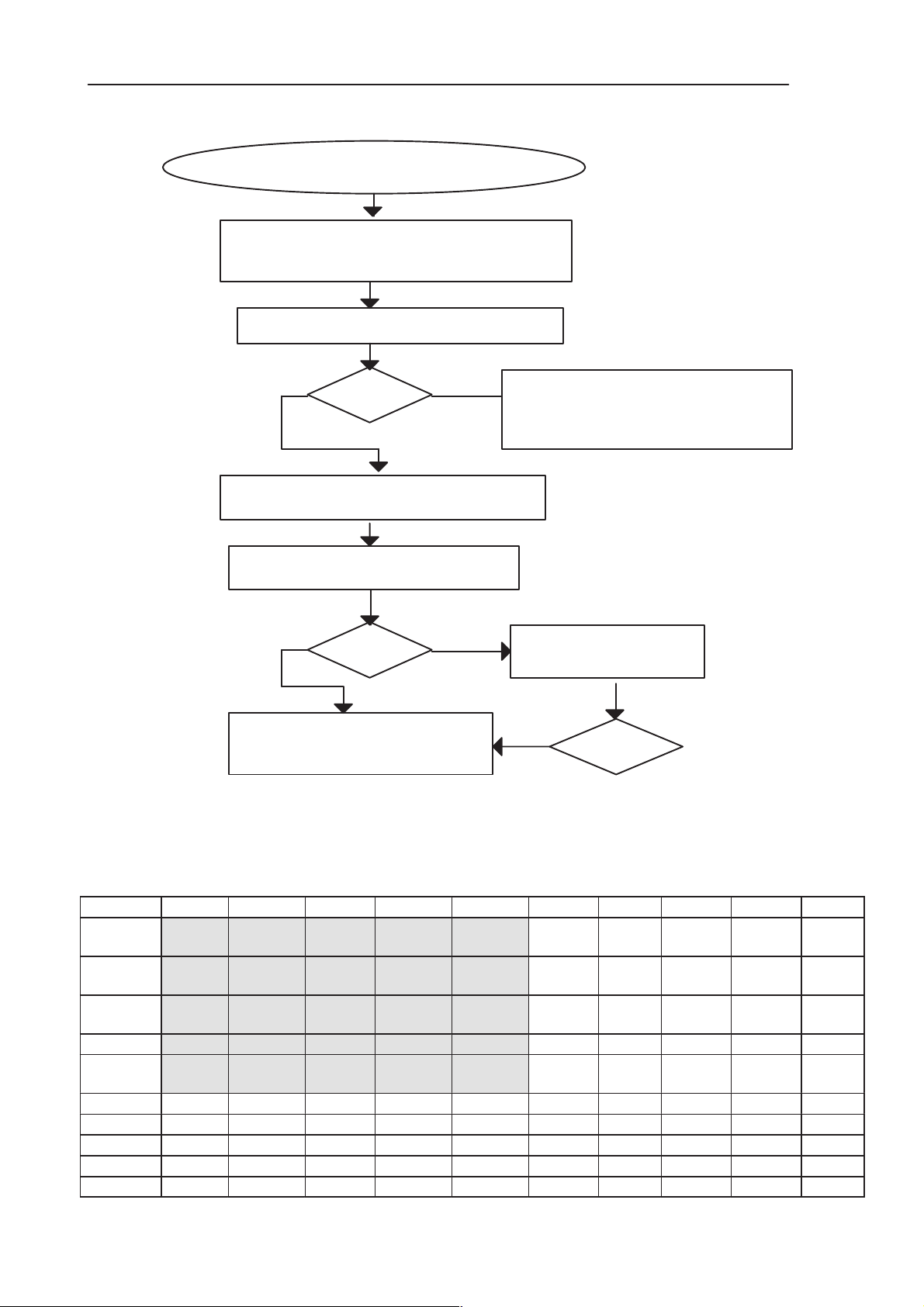

2.14.1 Memory Card Interface Troubleshooting

Start with assembled device with a faultless memory card inserted.

If necessary, proceed with tests in the jig with the faultless memory card in-

serted.

Clk, Cmd and Data OK means that frequency, rise and fall timing are OK during

various operating modes.

Note:

During initialization phase (MMCClk = lower frequency) the response via

MMCCmd line from card to MAD is sent in open drain mode i.e. rise time is

about 1us.

Voltage of MMCCmd and MMCDa signals depends on direction of transfer

(MAD I/O voltage is 2.8V and Card I/O is 3.0V).

Test pads J10x are located on the JL4 board of the Module Jig.

8. Troubleshooting

Troubleshooting diagram next page, Figure 40.

Issue 1 06/01

Page 8 – 53

Page 54

RAE-3

PAMS

8. Troubleshooting

Memory card

interface check

Run WinTesla

Memory card

test

Test

OK?

NO

Run Memory Card

cover Switch

fault test

Switch

OK ?

NO

Ref

Memory card

cover switch

fault tree

YES

YES

Technical Documentation

A faulty Memory Card used before ?

SW corruption ?

Assembled device

Disassembled device in jig

Measure VMMC

J104 while re–running

the MemCard test

NO

2.9 – 3.1V ?

YES

Measure MMCClk

J105 while re–running

the test

NO

Clk OK ?

YES

Measure MMCCmd

J102 while

re–running the test

Check X001/4

Measure N103/1

(control from

MAD while

re–running the

test

Check X001/5

R004 and

V001/4

Parts OK?

MAD I/O

fault

NO

Ctrl

OK?

YES

Check

N103

C114

C123

C124

R007

C001

YES

Page 8 – 54

CMD OK ?

YES

Measure MMCDa J107

Data OK?

YES

Figure 40.

NO

NO

Check X001/2

R005, R002

V001/3

OK?

Check X001/7

R001, R003

and V001/6

Parts OK ?

Issue 1 06/01

YES

YES

MAD I/OUndefined CPU error

fault

Page 55

PAMS

RAE-3

Technical Documentation

2.14.2 Memory card switch troubleshooting:

NOTE1: Memory card switch pressed (lid closed) => ADC reading ’Memory

Card Cover Detection’ is in state ”0” => MMC_Switch – line = 0V

Memory card switch released (lid opened) => ADC reading ’Memory Card Cover Detection’ is in state ”1” => MMC_Switch – line = 2.8V

MMC Card cover switch

Open RAE3 lid after boot

problem

YES

Open WinTesla

Testing–>

ADC Readings

OK

MMC

lid open

according to

WinTesla ?

*

8. Troubleshooting

YESNO

Close MMC card cover and

wait updated values

from WinTesla

Check J001

(MMC switch)

OK

Check C002 and V001

OK?

Faulty

circuit

D300 (MAD)

or PWB

Check

R006

OK?

* note:

Cover opened MMC cover detection =”1”

Cover closed MMC cover detection = ”0”

Check mech.

functionality

of J001

check contact

surfaces

OK?

R006

faulty

NO

NO

MMC cover

switch J001

broken

Lid

closed

according to

WinTesla ?

MMC cover

switch J001

Figure 41.

*

YES

OK

Issue 1 06/01

Page 8 – 55

Page 56

RAE-3

PAMS

8. Troubleshooting

2.15 Lid Switch

2.15.1 Lid Switch Troubleshooting

NOTE1:

Lid signal (MAD pin P2 gendet) :

Lid closed = ’Cover Detection’ from Wintesla ADC readings is state ”0”

=> V301 (HALL) output = 2.8V

Lid opened = ’Cover Detection’ from Wintesla ADC readings is state ”1”

=> V301 (HALL) output = 0V

Troubleshooting diagram Figure 42 next page.

Technical Documentation

Page 8 – 56

Issue 1 06/01

Page 57

PAMS

RAE-3

Technical Documentation

Lid

switch

trouble–

shooting

ASSEMBLED DEVICE

DEVICE IN JIG

Check

V301, C322

NO

YES

Open Wintesla

Select Testing –>ADC Readings

Turn the phone power on

Open the lid

Wintesla:

Lid Open OK

(cover

detection

state

1) ?

NO

N301

pin 1

(Hall supply volt)

2.8V ?

8. Troubleshooting

Place magnet above the TAB key,

note: pole toward the key !

then

wait Refresh from Wintesla

Wintesla:

Lid Closed OK

(ADC reading

Cover

switch=

”0”

NO

YES

Lid switch

OK?

Check/replace

magnet

in the lid

Check

V301,

(solders) R302

If OK,

replace V301

Faulty PWB

Faulty

circuit

D300

(MAD)

or

NO

YES

Use serv.jig

magnet

Out–

put toggle

of V301 pin 3

low state

(<0.3V)

?

level at V301 pin 1

Out–

put toggle

of V301 pin 3

high

?

YES

Check

Hall supply volt.

(VBB) 2.8V

OK?

YES

Use serv.jig

magnet

NOYES

high voltage level

NO

Check

V301 solders

Short

circuit inC323 ?

R302:

(2.8V) at both

ends?

Check

V301, C322

Issue 1 06/01

Replace V301

Figure 42.

OK

NO

Check trace between

V301 pin3 and R302

Page 8 – 57

Page 58

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

2.16 Battery Removal Switch troubleshooting

NOTE1: Switch itself is not possible to test in service jig.

NOTE2: Switch FREE position = Wintesla ADC–readings ’Battery Removal

Switch’ is in state ”0” =>BATT_REM – line = 2.8V

Switch CONNECTED position = Wintesla ADC–readings ’Battery Removal

Switch’ is in state ”1” => BATT_REM – line = 0V

NOTE3: Battery removal switch (latch spring) gets connected when battery

latch is pressed during battery release.

Refer to the diagram Figure 43 next page.

Page 8 – 58

Issue 1 06/01

Page 59

PAMS

RAE-3

Technical Documentation

Short circuit in

switch lines

(BATT_REM)

Check Z401

Reading

”1” though

YES NO

latch position

”FREE” ?

Battery removal switch

problem

YES

Open WinTesla

Testing–>

PDC readings

OK

Latch ”FREE” position

Battery

removal switch

state =”0”

?

8. Troubleshooting

YESNO

Keep latch in opposite position

wait updated values

from WinTesla

NO

State

changes to

”1” ?

YES

Faulty

circuit

D300

(MAD)

YES

Check B–to–B adapter

JC4 pin 42: BATT_REM

line:

Voltage

high (=2.8V)

?

Figure 43.

Battery removal

switch

OK

NO

1. Check latch spring and AF8 pads

2. Check B–to–B connector X400 of

UL8 and flex FL1

3. Check filter Z401 BATT_REM line

Issue 1 06/01

Page 8 – 59

Page 60

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

2.17 COBBA Control Interface troubleshooting

NOTE: If there are problems in COBBA serial interface, self tests fail and there

is ”Contact service” shown on the display. Wintesla shows fails at ”Cobba parallel”.

Check COBBACLK line at J322

Square wave, Freq. 13MHz ?

Signal rising/falling edge 3 to 5 ns?

Signal duty cycle about 50per cent?

Low when inactive?

Check COBBASDA line at J324

Activity?

Signal rising/falling edge 3 to 5 ns?

High when inactive ?

OK?

YES

NO

D300 or PWB

faulty

Check COBBACSX line at J323

Activity?

Signal rising/falling edge 3 to 5 ns?

High when inactive ?

Check COBBARSTX a J321

High (about 2.8V) ?

Check all lines simultaneously , see fig. below

Figure 44.

Figure 45 is a write sequence to COBBA. There should be non–all–zero writes

to COBBA.

Page 8 – 60

Figure 45. Write sequence to COBBA.

Issue 1 06/01

Page 61

PAMS

RAE-3

Technical Documentation

Figure 46 is a COBBA read.

8. Troubleshooting

Figure 46. COBBA read

The MADLinda writes first the address to be read, deactivates the COBBACSX

line and then activates the COBBACSX line again. Then the COBBA_GJP

sends the requested data. There should be non–zero reads.

If no non–zero reads from COBBA can be seen, COBBA (N200) may be faulty.

If both reads and writes of non–zero values can be seen and the signal charac-

teristics were good, the COBBA serial control interface is working correctly.

Issue 1 06/01

Page 8 – 61

Page 62

RAE-3

PAMS

8. Troubleshooting

2.18 COBBA PCM Interface Troubleshooting

PCM interface transfers digital audio data. Problems in this interface result in

missing or flawed audio in either or both in uplink and downlink directions. If

Wintesla shows errors in ”COBBA serial interface”, PCM interface is faulty.

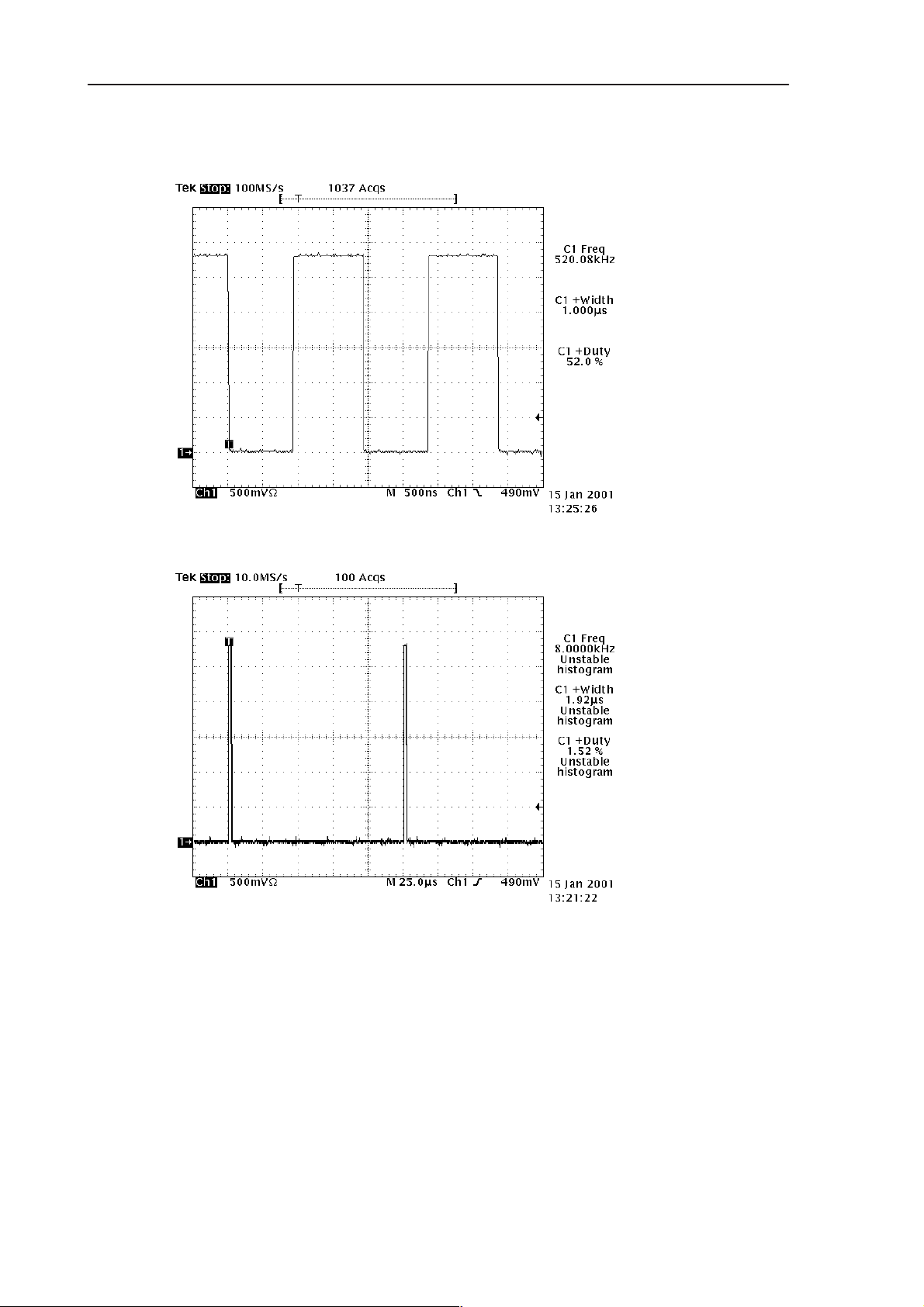

Check PCMDClk signal at J309:

520 kHz square wave

50 per cent duty cycle

Rising and falling edges about 3 to 5 ns

Inactive state low?

OK?

Check PCMSClk at J306

short pulse, rate 8.000kHz

1.52 per cent duty cycle

Rise and fall times about 3 to 5 ns

Inactive state low?

Ref. fig. 48

NOYES

N200 faulty

Ref. fig. 49

Technical Documentation

NOYES

OK?

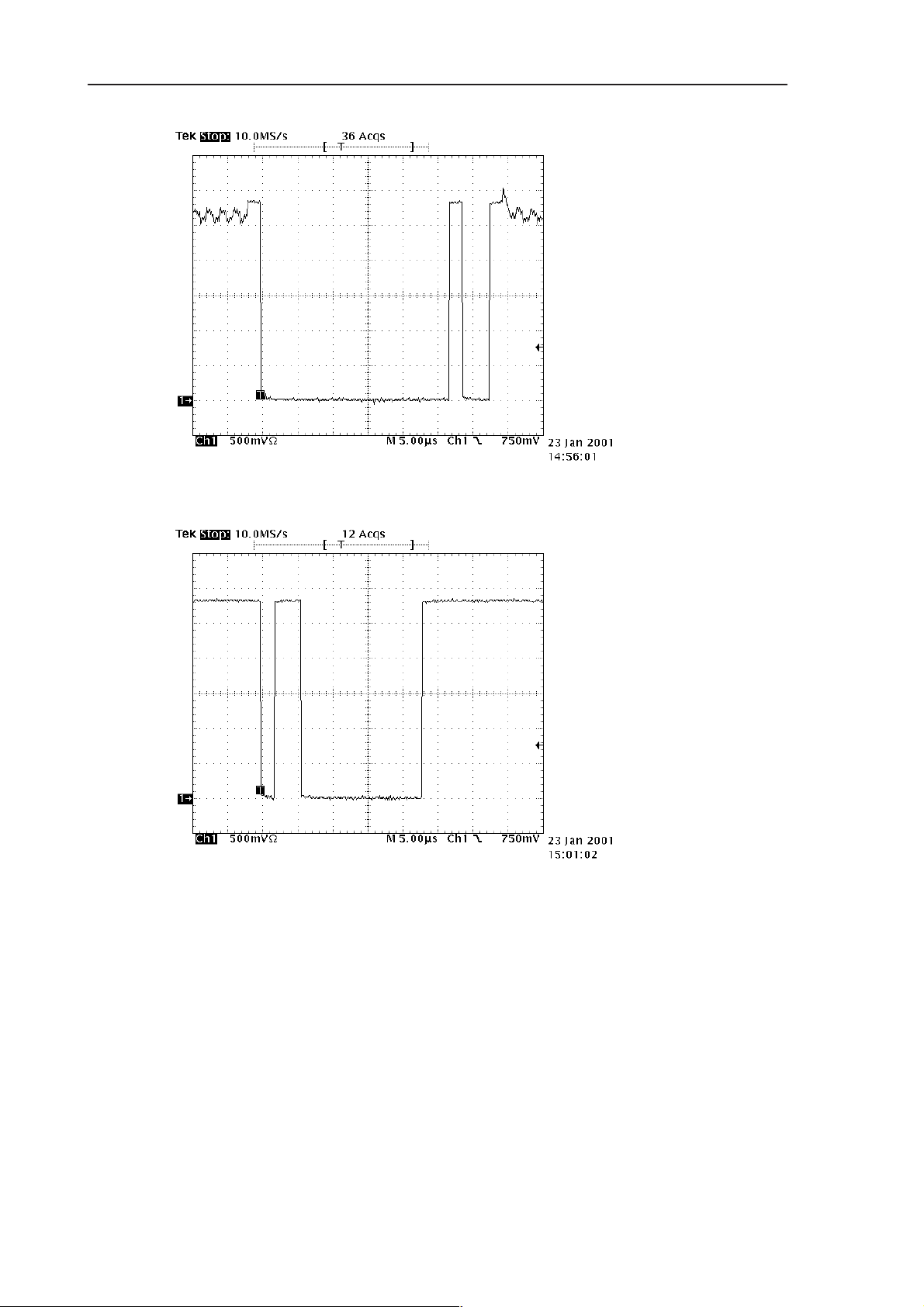

Check PCMRx Data signal at J308

Activity during call and voice recording

If mic picks up sound, higher states at the cycle start

Rise and fall times about 3 to 5 ns

Signal idle state High with some 13MHz noise?

N200 faulty

Ref. fig. 50

NOYES

OK?

Check PCMTx data signal at J307

Activity during call

Rise and fall times about 4 to 7 ns

Idle statle low?

Ref. fig. 51

N200 faulty

There is no traffic in PCM interface without a call or audio play (voice recorder,

video player, etc). These signals can be measured with a call, which generates

Page 8 – 62

OK?

NO

N200 faulty

Figure 47.

Issue 1 06/01

Page 63

PAMS

RAE-3

Technical Documentation

traffic in both directions. Audio play generates traffic in one direction only. Recording audio (voice recorder) generates traffic in the other direction.

8. Troubleshooting

Figure 48. PCMDClk signal at J309

Figure 49. PCMSClk signal at J306.

Issue 1 06/01

Page 8 – 63

Page 64

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

Figure 50. PCMRxData signal at J308.

PCMTxData signal at J307 (Figure 51). This signal comes from the other end’s

microphone or audio playing software (voice recorder, video player etc) and is

targeted for the earpiece or hands free speaker. There should be activity during

a call. Signal rise and fall times are around 4–7ns. Idle state is low.

Page 8 – 64

Figure 51. PCMTxData signal at J307

Issue 1 06/01

Page 65

PAMS

RAE-3

Technical Documentation

2.19 Audio troubleshooting

2.19.1 Both Mic and Earpiece/PHF faulty

MIC and Earpiece /PHF

faulty

Check voltage at cap C208

HOOKDET

without external audio devices

OK

HOOKDET

2,8V?

Check voltage at cap C202

HEADDET

without external audio devices

8. Troubleshooting

NO

Check

R206 and R207,

C208

* refer to section 2.17

in this document

OK

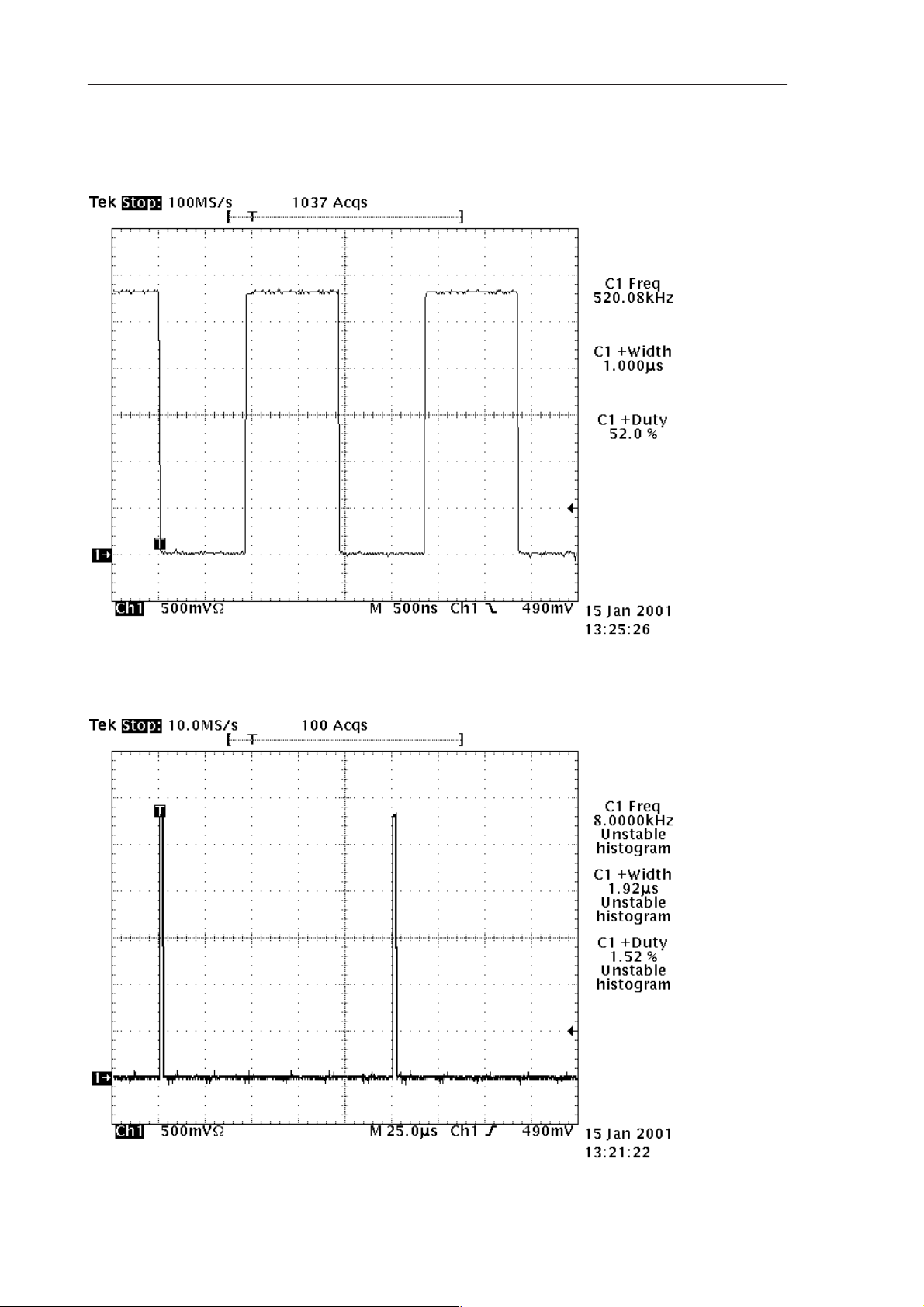

Check frequency at J309

PCMDClk during a call

OK

Check frequency at J306

PCMSClk during a call

HEADDET

2,8V?

520kHz

square wave 2.8Vpp

(ref.fig.53)

8 kHz

square wave 2.8Vpp

(ref.fig.54)

NO

Check

R203, R202, R200

C201,

C202

NO

Faulty

N200 (COBBA) *

NO

Faulty

N200 (COBBA) *

Issue 1 06/01

Figure 52. PCMDClk

Page 8 – 65

Page 66

RAE-3

PAMS

8. Troubleshooting

Technical Documentation

Figure 53. PCDClk

Page 8 – 66

Figure 54. PCMSClk

Issue 1 06/01

Page 67

PAMS

RAE-3

Technical Documentation

2.19.2 Mic faulty

MIC

faulty

Check microphone and mic connections to PWB

Check digital PCM data atJ308 (PCMRxData)

during a call

OK

Check voltages :

V202 pin 1 : 1.8V

V202 pin 3: 0.17V

OK

Data

OK?

during a call

Voltages

OK?

NO

NO

8. Troubleshooting

Faulty N200 (COBBA)

Refer to

COBBA control

interface troubleshooting

Check R222, R218

C231, C224,

C230

OK

DC voltage at C234 and C235

1.4V during call ?

OK

Check analog audio signal at

Voltages OK?

C232 during a call

Signal a few mV ?

*

NO

*

NO

Figure 55.

Mbias at R222

2.1V during call?

NO

Check

Check

C234, C235

C234, C235

C225, C240, R219,

R220 and PWB traces

OK

Check

*

Fault in

N200 (COBBA)

Note:* can not be measured in the service jig, because components are under

the SIM connector.

Use wire to measure them. After removing measurement wire, check that components are not defected. It is recommended to replace the components.

Issue 1 06/01

Page 8 – 67

Page 68

RAE-3

PAMS

8. Troubleshooting

2.19.3 Earpiece faulty

Earpiece

faulty

Check assembly of

earpiece and gasket

Check connections from

audio PWB to C229 and C228

OK

Check digital PCM data

at J307 (PCMTxData)

OK

Connection

during a call

OK?

Technical Documentation

1)

NO

Check Flex UL8 and

B–to–B conn X400

pins 47, 48

NO

Data

OK?

DC voltage at C228, C229

1.4V during call ?

OK

Check analog audio signal at

C228, C229 during a call

Voltages OK?

Signal a few mV ?

NO

NO

Faulty

D300 (MAD) 2)

Check R215, R216 and

connections.

Check

C228, C229

OK?

Faulty

N200 (COBBA)

Note:

1) If sound is distorted or too quiet fault is most probably in the gasket or in the

earpiece diaphragm.

2) Refer to section 2.16 in this document.

Page 8 – 68

Figure 56.

Issue 1 06/01

Page 69

PAMS

RAE-3