Page 1

Programmes After Market Services

NHE–8/9 Series Transceivers

Disassembly &

Troubleshooting

issue 3 12/98

Page 2

NHE–8/9

PAMS

Disassembly & Troubleshooting

Technical Documentation

CONTENTS

Disassembly 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Module Troubleshooting 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone is totally dead 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash programming doesn‘t work 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power doesn‘t stay on or the phone is jammed 9. . . . . . . . . . . . . . . . . . . .

Display information: Contact service 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone doesn‘t register (no serv) or doesn‘t make a call 12. . . . . . . . . . . .

SIM Card is out of order (insert SIM card or card rejected) 14. . . . . . . . . .

Audio fault 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging fault 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UIF Module troubleshooting 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UIF– connector 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microphone 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earpiece 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buzzer 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard and display LEDs 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

issue 3 12/98

Page 3

PAMS

NHE–8/9

Technical Documentation

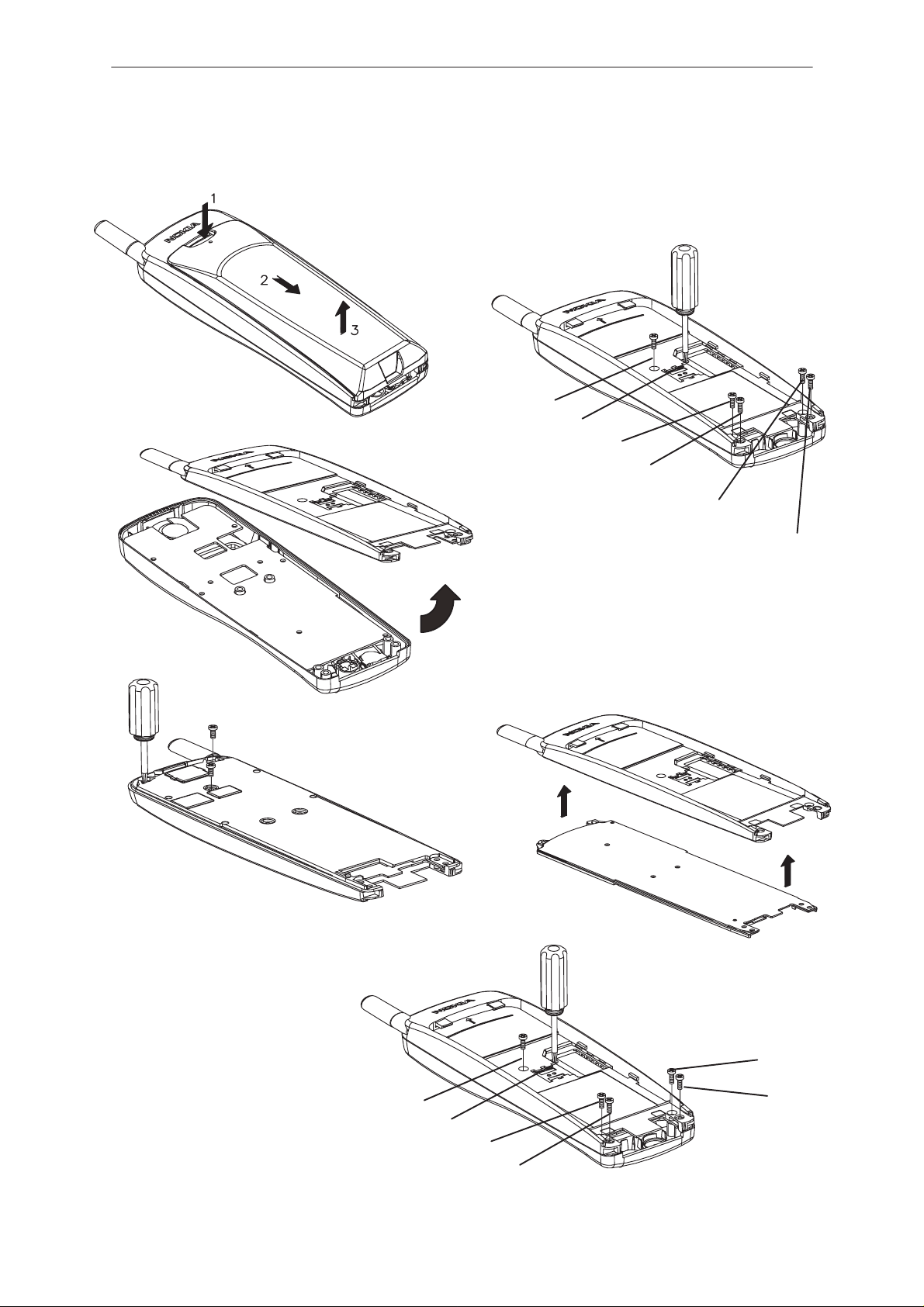

Disassembly

Remove battery

1

Disassembly & Troubleshooting

Remove 6 screws from the

2

chassis. Use the numbered

order.

2

1

3

4

5

4

Remove 3 screws from the shield

3

Remove the B cover beginning

from the bottom of the phone. Be

careful not to damage the board

to board connector!

5

Remove the shield

6

6

Re–assemble the phone in

reverse order. Note! Use the

numbered order when assembling the 6 screws and

tighten them to a torque of

0.15 Nm.

issue 3 12/98

1

5

3

6

2

4

Page 3

Page 4

NHE–8/9

PAMS

Disassembly & Troubleshooting

Troubleshooting

General

The purpose is to define the faulty module block, and then to locate the

faulty component. The trouble shooting diagram has been planned so that

the fault, whatever it is, can be found by as simple measurements as

possible.

The flow charts give you the overview of the blocks. The purpose is that

you proceed through the flow diagram so that, if your answer is YES for

the asked question, go straight to the next level, but if your answer is NO,

you have to go the sub–branch.

Required servicing equipment:

– PC for Service Software

– Power supply (2.0 A)

– Digital multimeter

Technical Documentation

– Oscilloscope

– Spectrum analyzer

– Signal generator

– RF cables

– Modular cable

– RS232/MBUS adapter

– HP8922H or equivalent

– RF measuring chassis

System Module Troubleshooting

The following hints should facilitate finding the cause of the problem when

the circuitry seems to be faulty. This trouble shooting guide is divided into

the following sections.

1. Phone is totally dead

2. Flash programming doesn‘t work

3. Power doesn‘t stay on or the phone is jammed

4. Display information: Contact Service

5. Phone doesn‘t register to the network or phone doesn‘t make a call.

6. Plug in SIM card is out of order (insert SIM card or card rejected).

7. Audio fault.

Page 4

The first thing to do is carry out a thorough visual check of the module.

Ensure in particular that:

a) there is not any mechanical damage

b) soldered joints are OK

issue 3 12/98

Page 5

PAMS

NHE–8/9

Technical Documentation

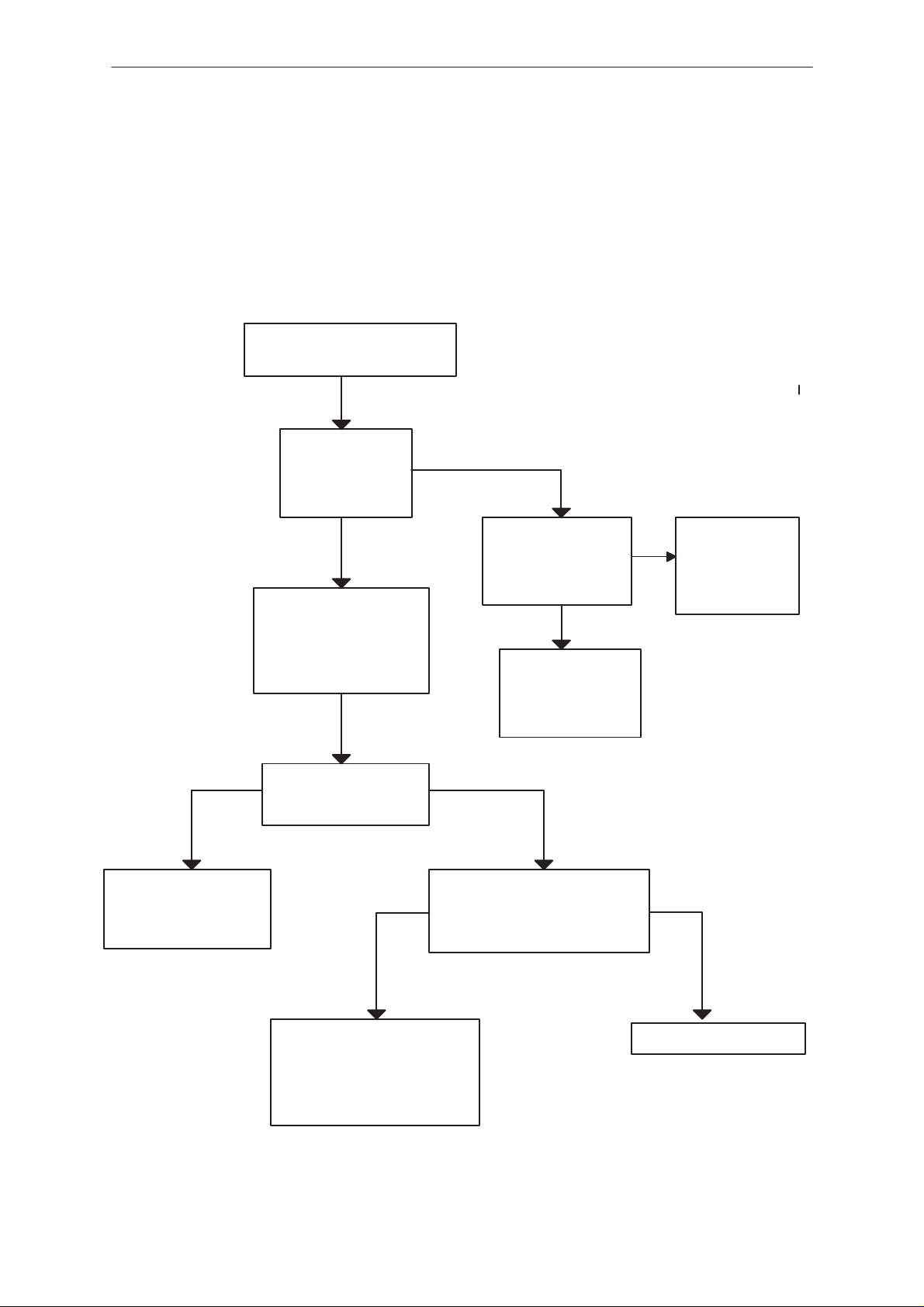

Phone is totally dead

Trouble shooting diagram for this fault is represented in figure below

Check at first that the battery back is OK and it is not empty.

This kind of fault has been limited around the system connector (X100)

and the PSCLD (N300).

If the phone is totally dead,

check that

Voltage level at

PSCLD (N300)

pin 25 is same

as VBA T

Connect pins 18, 22

and 31 together (X101)

and measure that voltage level at pin 25

(N300)drop to zero.

YES

NO

Disassembly & Troubleshooting

PSCLD N300

pins 5,21,37 voltage level is

same as VBAT

NO

Check coils L311 +

L301 and the sol–

dered joints of the

connector X100

Rise up PSCLD

pin 25.

YES

If the DC voltage

is still missing

change N300

NO

Check soldered joints

of X100 and PCB

wires between X100

and N300

The voltage level at

pin 25 (N300) is zero

PSCLD (N300) switches

power on so the regulated

voltages VL, VA and VSL are

3.16V

Check that capacitors C329,

C330, C310 and C311 are

soldered. Check also soldered joints of N300. If these

things are correct, change

N300

YES

YESNO

Check the UI board and

the PWR button.

issue 3 12/98

Page 5

Page 6

NHE–8/9

PAMS

Disassembly & Troubleshooting

Flash programming doesn‘t work

In error cases, the flash prommer can give some information about a

fault.

The fault information messages could be:

– MCU doesn‘t boot

– MCU flash Vpp error

– Serial data line failure

– Serial clock line failure

– External RAM fault

– Algorithm file or alias ID don‘t find

In cases that the the flash programming doesn‘t succeed, there is a

possibility to test the interface between the ASIC and the MCU.

This test is useful to do, when the fault information is: MCU doesn‘t boot

or Serial clock line failure.

Technical Documentation

The test procedure is following:

1. Connect a short circuit wire between Asic pins 137 and gnd.

2. Switch power on.

3. If the reset line of the MCU rises up, the interface is OK. Otherwise the

reset line stays low.

Note: this test can only find short circuits, not open pins.

Page 6

issue 3 12/98

Page 7

PAMS

NHE–8/9

Technical Documentation

Output voltages of PSCLD (N300)

are 3.16 V ( VL, VA, VSL )

Master Reset (Purx), PSCLD pin 26

is ”1” ( 3.16 V )

Clock signal at the input of MCU (D150),

pin 51 is 6.5 MHz square wave.

Flash programming doesn‘t work

YES

YES

Master clock input, ASIC (D151)

pin 22 is 13 MHz, 1 Vpp, sine

wave with 1 V DC level

YES

Disassembly & Troubleshooting

NO

NO

NO

NO

Check the soldered joints of

N300. If OK, change N300

Rise up pin 26. If the logic

evel is still ”0”, check soldered joints of N300. If OK,

change N300.

Check components R150 and C153.

If they are OK, check the VCXO

block. One must remember that the

control signal for the VCXO is taken

from the baseband (see figure 6 )

Check resistor R152. Check the

soldered joints of ASIC. If OK,

change ASIC

YES

NO

MCU Reset input, pin 48 is ”1”

YES

Check that the following lines are correct.

1. Vpp line from J310 to FLASH (D400) pin 11

Normal fault information: MCU FLASH Vpp error

2. RXD line from J311 to MCU (D150) pin 2

Normal fault information: Serial data line failure

3. TXD line from J312 to MCU (D150) pin 1

Normal fault information: MCU doesn‘t boot

4. SCK line from J313 to MCU (D150) pin 3.

Check R315 also.

Normal fault information: Serial clock line failure

5. WDDIS line from J314 to PSCLD (N300) pin 22

6. GND , J315 is connected to ground

Rise up MCU pin 48. If the logic

level is still ”0”, check the soldered joints of the ASIC. If OK,

change ASIC.

issue 3 12/98

Page 7

Page 8

NHE–8/9

PAMS

Disassembly & Troubleshooting

In cases that fault information is

a) MCU doesn‘t boot

b) Clock line serial failure

the ASIC self test function can be used

1. Connect a short circuit wire between Asic pin 137

and GND

2. Switch power on and measure the state of the

MCU Reset line (pin 48)

If the Reset line rises up to ”1” state there are not short circuits

Check that there are not open pins

in components: D150, D151, D400,

D402

Reset is ”1”

Technical Documentation

Reset is ”0”

There is a short circuit between

the pins.

Check circuits: D150, D151

D400, D403, D402.

In case that fault information is:

External RAM fault

Check the pins of SRAM (D403)

Check also the control lines of SRAM:

WrX, RdX from MCU;

RAMCS from ASIC

In case that fault information is:

Algorithm file or alias ID don‘t

find, ID is unkwon etc.

Check pins of the FLASH (D400)

Check also the control lines of FLASH:

WrX, RdX from MCU

CSelX, PwrDown from ASIC

Page 8

issue 3 12/98

Page 9

PAMS

NHE–8/9

Technical Documentation

Disassembly & Troubleshooting

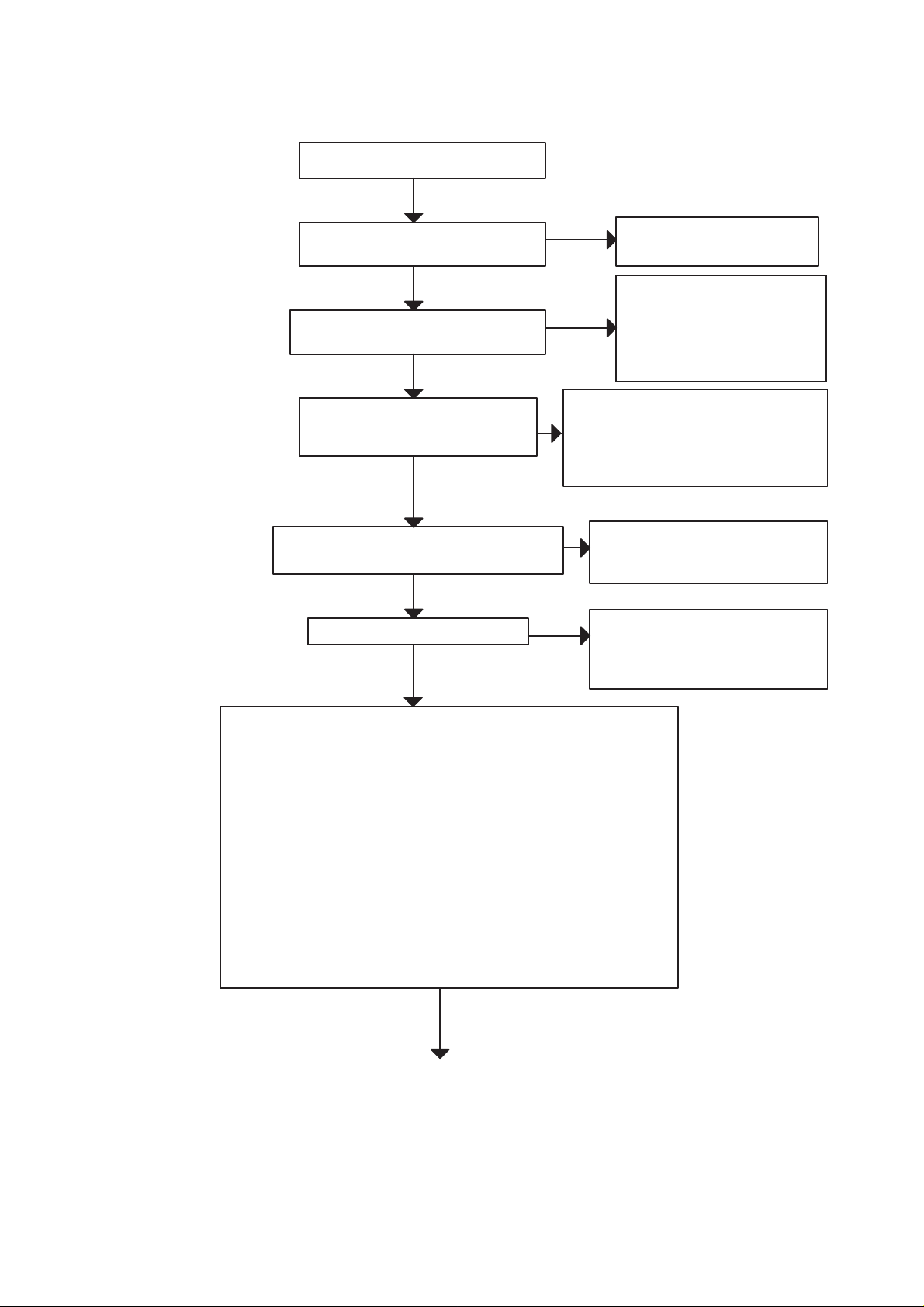

Power doesn‘t stay on or the phone is jammed

If a fault has come after the flash programming, there are most probably

open pins in IC‘s.

The soldered joints of IC‘s : D150 (MCU), D151 (ASIC), N300(PSCLD),

D400 (FLASH), D403 (SRAM) is useful to check at first.

Normally, the power switch off after 30 seconds, if the watchdog of the

PSCLD can not be served by software. The power off function can be

prevented by connecting a short circuit wire from the PSCLD pin 22

(WDDIS) to the ground.

If the power switches off after 1..2 seconds, the pins of PSCLD and the

PSCLD‘s auxiliary components must be checked.

If the phone is jammed, and no other reason has been found, the function

of 32 kHz clock oscillator must be checked. This can be done by setting

the phone to the ASIC self test mode.

1. Connect a short circuit wire between Asic pin 137 and GND.

2. Make a short circuit between the ASIC pins 78 and 79.

3. Switch power on.

4. Measure the signal by oscilloscope at pins 78, 79 (ASIC).

PSCLD pin 26, PurX

(Master Reset)

ASIC pin 78 (MCUIRQ1X) and

ASIC pin 79 (MCUIRQ0X)

30.5 us

1 V

issue 3 12/98

Page 9

Page 10

NHE–8/9

PAMS

Disassembly & Troubleshooting

Power doesn‘t stay on or

the phone is jammed

(In case that fault has come after the flash programming).

Connect a short circuit wire from PSCLDs

pin 22 to the ground. This make sure that

power stays on during the measurements

Output voltages of PSCLD (N300)

are 3.16 V (VL, VA, VSL).

Master Reset, PSCLD pin 26 is

”1” (3.16 V)

YES

YES

Technical Documentation

ATTENTION !

Do not forget to check needed PCB wires between the

circuits.

NO

NO

Check the soldered joints

of N300. If OK, change

N300.

Rise up pin 26. If the log-

ic level is still ”0”,

check soldered

joints of N300. If OK,

change N300.

NO

Check resistor

R152.

Check that Master

Reset input pin,

ASIC pin 120 is ”1”.

If it is ”1” check

soldered joints of

ASIC. If OK,

change ASIC.

Master clock input, ASIC (D151) pin 22,

13 MHz about 1 Vpp sine wave signal

with 1 V DC level.

YES

MCU (D150) clock signal input, pin 51,

6.5 MHz square wave signal.

YES

MCU reset input, pin 48 is ”1”

YES

Check that there are not open pins

in components D150 (MCU), D151

(ASIC), D400 (FLASH), D403

(SRAM)

OK

Check the function of the 32 kHz oscillator

NO

NO

Check components R150

and C153. If they are OK,

check the VCXO block.

One must remember, that

the control signal for the

VCXO power supply is taken from baseband.

Rise up pin 48. If the logic

level is still ”0”, check the

soldered joints of the ASIC.

If OK, change ASIC.

Page 10

issue 3 12/98

Page 11

PAMS

NHE–8/9

Technical Documentation

Display information: Contact service

This fault means that MCU is able to run and the watchdog of the PSCLD

(N300) can be served.

Thus PCLOCAL functions can be used and some information about the

fault is possible to get.

In principle, the fault for contact service information can be found around

ASIC (D151), DSP (D152), RFI (N450), EEPROM (D402) or AUDIO

CODEC (N200).

DSP (D152) pin 66

or testpoint J152)

39 MHz square wave

YES

NO

DSP pin 69 (XRES)

is ”1”.

Disassembly & Troubleshooting

NO

DSP pin 68: 13 MHz

square wave

YES

Check the soldered joints

of DSP (D152). If OK,

change D152

NO

Check the soldered joints

of ASIC (D151). If OK,

change D151

YES

DSP pin 20 (XF) or testpoint J153

250 ms

Power On

Software download to

external RAMs

YES

XF stays ”1” after

download

Check soldered joints of DSP (D151) and

external RAMs D405, D415

RFI (N450) pin 51 (SYSRESX)

is ”1”.

YES

RFI (N450) pin 45: 13 MHz

square wave

YES

Check soldered joints of

RFI (N450), DSP (D152),

ASIC (D151)

Check R151 and soldered

joints of ASIC (D151). If OK

Change D151

NO

Download is failed. Check

soldered joints of ASIC

(D151 and DSP (D152)

Check the soldered joints

NO

of ASIC (D151). If OK,

change D151

Check the soldered joints

NO

of ASIC (D151). If OK,

change D151

issue 3 12/98

Check soldered joints of EEPROM (D405) and

connections to the MCU (D150).

Check soldered joints of AUDIO CODEC

(N200) and connections to the ASIC (D151).

Page 11

Page 12

NHE–8/9

PAMS

Disassembly & Troubleshooting

Technical Documentation

The phone doesn‘t register to the network (no serv) or phone

doesn‘t make a call

If the phone doesn‘t register to the network or the phone doesn‘t make a

call, the reason for this could be either the baseband or the RF part.

The phone can be set to wanted mode by PCLocals software and try to

find reason for fault.

The control lines for RF are supplied both the ASIC (D151) and the RFI

(N450).

The ASIC handles digital control lines (between ”0” = 0 V and ”1” = 3.16

V) and the RFI handles analog control lines and proper input and output

signals.

The DSP uses its external flag outpin (XF pin 20) as an indicator of its

operation state. During power up, DSP signals all completed functions by

changing the state of the XF pin.

DSP pin 20 (XF)

2 3 4 5

XF (pin 20) is ”1” after power on

1

2

DSP code download starts

DSP code download starts

DSP has performed self tests and

3

1

6 7

initalization succesfully

DSP has received SEARCH_LIST

4

command from MCU

( DSP starts channel search)

DSP starts PSW search

5

( Channel has been found)

( Rx and AGC are OK )

PSW has been found

6

( the synthesizer works OK)

DSP has received synchroniza–

7

tion.

( AFC works OK)

Page 12

issue 3 12/98

Page 13

PAMS

NHE–8/9

Technical Documentation

NO

Check components C452.

If OK, Change RFI (N450)

ASIC pin 33 (RxPwr) is ”1” during the receive slot

ASIC pin 34 (SynthPwr) is ”1” during the receive slot

ASIC pin 35 (SEna1X) is ”0” during the receive slot

ASIC pin 39 (SCLK) is ”1” during the receive slot

ASIC pin 38 (SDATA) is ”1” during the receive slot

Phone doesn‘t register

to the network or phone

doesn‘t make a call

RFI (N450) pins 9,10,11

DC level 4.5 V

YES

RFI (N450) pin 3 (REFOUT)

DC level 2.5 V

YES

Disassembly & Troubleshooting

Check regulator N451. One must re-

NO

member, that control signal for RFI regulator N451 pin 1 is taken from ASIC

(D151) pin 130 and routed to the RFI regulator via PSCLD (N300) pins 24, 20

( pins 17,13 ).

Check the soldered joints

of ASIC (D151) and the

connections to the RF part

YES

RFI pin 16 (TXCOUT) is ”1” during the receive slot

RFI pin 24 (PDATA0) is ”1” during the receive slot

RFI pin 24 (PDATA0) is ”1” during the receive slot

RFI pin 54 (RXINN): DC level 1.6 V during the receive slot

RFI pin 55 (RXINP): DC level 1.6 V during the receive slot

RFI pin 64 (AFC) : 1 V < DC level < 3 V

YES

Use PCLocals functions to turn transmitter on

ASIC pin 31 (TXP) is ”1” during the transmit slot

ASIC pin 32 (TXPWR) is ”1” during the transmit slot

YES

4.6 ms

YES

RFI pin 1 (TXQN)

RFI pin 2 (TXQP)

RFI pin 12 (TXIN)

2.6 V

1.1 V

RFI pin 13 (TXIP)

NO

Check the soldered joints

of RFI (N450) and the connections to the RF part

Check the soldered joints

NO

of ASIC(D151) and the

connections to the RF part

Check the soldered joints

NO

of RFI (N450) and the connections to the RF part

CHECK RF P ART

issue 3 12/98

0.6 ms

Page 13

Page 14

NHE–8/9

PAMS

Disassembly & Troubleshooting

Technical Documentation

SIM Card is out of order (insert SIM card or card rejected)

The hardware of the SIM interface from the ASIC (D151) to the SIM

connector (X102) can be tested without SIM card. When the power is

switched on and if the BSI line is grounded by resistor, all the used lines

(VSIM, RST, CLK, DATA) rises up to ”1” (5 V) four times. Thus the fault

can be found without SIM card most of the cases.

Page 14

issue 3 12/98

Page 15

PAMS

NHE–8/9

Technical Documentation

Display information:

Insert SIM card or

card rejected

ASIC (D151) pin 25 (CARDDETX):

DC level < 2 V, when 68k

resistor is connected from

BSI line (X100 pin 14) to the

ground

PSCLD (N300) pin 15 (SIMENA):pulses up to ”1” (3 V), when

the power is switched on

PSCLD (N300) pin 10 (SIM_I/O_CTRL):

pulses up to ”1” (3 V), when the power is

switched on

YES

YES

YES

Disassembly & Troubleshooting

NO

NO

Check resistors R311 and R312

Check system connector

X100 pin 14 (BSI)

Check connection to the ASIC; pin 30

Check also soldered joints of

ASIC (D151) and PSCLD (N300)

Check connection to the ASIC;

NO

pin 26.

Check also soldered joints of

ASIC(D151) and PSCLD (N300)

YES

SIM CONNECTOR (X102) pin C1 (VSIM)

pulses up to ”1” (5 V), when the power is

switched on

YES

SIM CONNECTOR (X102) pin C2

(SIMRST) pulses up to ”1” (5 V), when

the power is switched on

YES

PSCLD (N300) pin 9 (SIMRST_A)

pulses up to ”1” (3V), when the

power is switched on

Check connection to the ASIC;

pin 28 (SIMRESETX).Check

also soldered joints of ASIC

(D151) and PSCLD (N300)

Check connection to the PSCLD

NO

(N300) pin 41 and the soldered

joints of PSCLD (N300)

PSCLD (N300) pin 2 (SIMRST_S):

NO

pulses up to ”1” (5 V), when the power

is switched on

NO

Check R322

NO

YES

Change N300

YES

SIM CONNECTOR (X102) pin C3 (CLK):

pulses up to ”1” (5 V), when the power is

switched on

issue 3 12/98

Page 15

Page 16

NHE–8/9

PAMS

Disassembly & Troubleshooting

SIM CONNECTOR (X102) pin C3 (CLK):

pulses up to ”1” (5 V), when the power is

switched on.

YES

Technical Documentation

NO

PSCLD (N300) pin 1 (SIMCLK_S):

pulses up to ”1” (5 V), when the

power is switched on.

PSCLD (N300) pin 8

(SIMCLK_A):pulses up to ”1” (3 V),

when the power is switched on.

YESNO

Change N300

Check connection to the ASIC (D151), pin 29 (SIMCLK)

Check also soldered joints of the ASIC (D151) and the

PSCLD (N300)

Check R324

YESNO

SIM CONNECTOR (X102) pin C7 (DATA):

pulses up to ”1” (5 V), when the power is

switched on.

PSCLD (N300) pin 7 (SIMDATA_A): pulses up to ”1” (3 V), when

the power is switched on.

NO

Check connection to the ASIC (D151), pin 27 (SIMDATA)

Check also soldered joints of the ASIC (D151) and the

PSCLD (N300)

PSCLD (N300) pin 3 (SIMDA TA_S):

pulses up to ”1” (5 V), when the

power is switched on.

YESNO

Check R323

YES

Change N300

Page 16

issue 3 12/98

Page 17

PAMS

NHE–8/9

Technical Documentation

Audio fault

In cases that audio routings are totally muted, a fault could be in serial

bus.

This serial bus is used for PSCLD (N300) and for Display driver also, so if

the PSCLD and the display are OK, there are open pins in the AUDIO

CODEC (N200) or the AUDIO CODEC is faulty.

Serial bus faults can be found with PCLocals software (self test).

Other possibilities are that PCM clock and sync lines are open. CODEC

(N200), ASIC (D151) and DSP (D152) must be checked.

Keytones are missing and

the earphone and the microphone are muted during a

call.

CODEC (N200) pins 18,41,42

(VA): 3.16 V

YES

YES

Disassembly & Troubleshooting

NO

Check the soldered joints of

PSCLD (N300). If OK,

change N300

Check Audio interface with the

PClocals software.

NO

Check the soldered joints of

ASIC (D151). If OK, change

D151.

ASIC (D151) pin 40 (PCMDCLK):

clock starts, when the power is

switched on.

Check UI board and connector X101

Keytones are OK. The earphone and

the microphone are muted during a

call.

ASIC (D151) pin 41 (PCMSCLK):

clock starts, when the power is

switched on.

DSP (D152) pin 29 (FSR0):

clock starts, when the power is

switched on.

Result: OK

YES

YES

YES

Result: Fault

NO

NO

CODEC (N200) pin 14 (CCLK):

pulses up to ”1”, when the power is

switched on.

CODEC (N200) pin 15 (CSX):

pulses down to ”0”, when the power is switched on.

CODEC (N200) pin 16 (CDI):

pulses up to ”1”, when the power is

switched on.

YES

Check the serial bus lines

to the ASIC (D151)

Change CODEC (N200)

Check the soldered joints of

ASIC (D151). If OK, change

D151.

Check the soldered joints of

ASIC (D151) and DSP

(D152).

NO

issue 3 12/98

YES

DSP (D152) pin 27 (CLKR0):

clock starts, when the power is

switched on.

NO

Check the soldered joints of

ASIC (D151) and DSP

(D152).

Page 17

Page 18

NHE–8/9

PAMS

Disassembly & Troubleshooting

Keytones are OK. Microphone (uplink) is OK.

Earphone (downlink) is muted during a call.

DSP (D152) pin 33 (CLKX0):

clock starts, when the power

is switched on.

DSP (D152) pin 37 (FSX0):

clock starts, when the power

is switched on.

CODEC (N200) pin 10 (DR):

PCM signal during a call

YES

YES

YES

NO

NO

Technical Documentation

Check the soldered joints of ASIC (D151)

and DSP (152)

Check the soldered joints of ASIC (D151)

and DSP (152)

NO

Check the soldered joints of CODEC

(N200) and DSP (152)

Keytones are OK. Earphone (downlink) is OK.

Microphone (uplink) is muted during a call.

YES

NO

DSP (D152) pin 31 (DR0):

PCM signal during a call

YES

DC bias voltage (2.2 V) at

NO

MICP pin during a call

Check the soldered joints of CODEC

(N200) and DSP (152)

Check the soldered joints of CODEC

(N200) and bias voltage transistor

V200, R201, R202, R210, R221.

Page 18

issue 3 12/98

Page 19

PAMS

NHE–8/9

Technical Documentation

Charging fault

Two different kind of faults can be separated each other:

1. No information at all on the display, when a charger is connected.

2. Display information: Not charging.

1. In case that information on the display is not given, when a charger is

connected, means that PSCLD (N300) , pin 14, can not change the level

of the CHRG_IND line ( 0 –> 1) or the input pin of the ASIC (D151) pin

126 is unconnected.

2. If the display information is: Not charging, the charger indication has

been done, but the hardware control unit can not control the charging

switch transistor V304.

Charger voltage (10 V)

at emitter of V304

NO

Disassembly & Troubleshooting

Check L107 and L108

and connector X100

YES

Reference voltage 5.1 V

at base of V302

YES

Charger indication voltage R302/R303

(1.8 V) at PSCLD (N300) pin 28.

YES

Charger indication voltage R302/R303

(1.8 V) at PSCLD pin 27.

YES

PSCLD pin 14 (CHRG_IND) is ”1”,

when a charger is connected.

YES

PSCLD pin 23 (CHRGSW) is ”0”,

when a charger is connected.

NO

Check resistors R301,R326 and

zener V301

NO

Check resistors R302,R303

NO

Check soldered joints of PSCLD.

If OK. change PSCLD (N300).

NO

Check soldered joints of PSCLD.

If OK. change PSCLD (N300).

Check also connection to the

ASIC (D151) pin 129

NO

Check soldered joints of PSCLD.

If OK. change PSCLD (N300).

issue 3 12/98

YES

Check hardware control components V311,V302,V303,R305...

Page 19

Page 20

NHE–8/9

PAMS

Disassembly & Troubleshooting

Technical Documentation

Troubleshooting and Module Repairing at Service

The tests listed,can be executed on a complete phone either at module

level or by way of PC–locals on a complete handset.

UIF– connector

– if module seems not to work, first check the condition of B–B–

connector

LCD

1. LCD does not work

– check the voltages VL and V5, voltage difference (VL–V5) should be 7

to 9 volts

– check the solderings of the TAB on to the PCB, i.e. H400

– check that correct values of resistors R416 and R419 are mounted

– check the solderings of the periferal components arround the display

2. Missing rows in LCD

– check if there are broken connections in the TAB. If yes, change the

– check if there are breaks on LCD glass. If yes, change the module.

Microphone

1. Mic does not work

– check board–to–board connectors

– check microphone spring connection (eg. spring contact, dirt on

– change microphone if needed

Earpiece

1. Earpiece does not work

– Send tone to earpiece

– if no tone appears, check the spring contacts of earpiece (eg. spring

– change Earpiece if needed

module.

springs).

contact to pads, dirt on springs)

Buzzer

Page 20

1. Buzzer does not work

– check the voltage VBatt

– send tone to buzzer, connect PWM signal to BUZZER line

– if no sound appears, check the spring connection to the buzzer

– measure, that transistor V403 operates

– change buzzer or transistors if needed

issue 3 12/98

Page 21

PAMS

NHE–8/9

Technical Documentation

Keyboard and display LEDs

1. Keyboard LEDs do not work

– check the voltage VBatt

– connect ’KEYLIGHT’ line to logical HIGH and measure, that control

transistors V404 and V405 operate

– check the solder pads of LEDs

– change LED or transistor if needed

2. Display LEDs do not work

– check the voltage VBatt

– connect ’LCDLIGHT’ line to logical HIGH and measure, that control

transistor V402 operate

– check the solder pads of LEDs

– change LED or transistor if needed

Disassembly & Troubleshooting

issue 3 12/98

Page 21

Page 22

NHE–8/9

PAMS

Disassembly & Troubleshooting

[This page intentionally left blank]

Technical Documentation

Page 22

issue 3 12/98

Loading...

Loading...