Page 1

Nokia Customer Care

RH-53/54

8-System Module

ISSUE 1 09/2004 Copyright © 2004 Nokia Corporation. All Rights Reserved.

Page 2

RH-53/54

Nokia Customer Care 8-System Module

[This page left intentionally blank]

2 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 3

RH-53/54

8-System Module Nokia Customer Care

Table of Contents

Page No

Abbreviations ......................................................................................................6

Introduction ......................................................................................................... 9

Technical Summary........................................................................................... 9

List of Features................................................................................................ 10

Technical Specifications ..................................................................................12

Modes of Operation ......................................................................................... 12

No supply .......................................................................................................12

Power off ........................................................................................................12

Acting dead ....................................................................................................13

Active .............................................................................................................13

Sleep mode ....................................................................................................13

Charging ........................................................................................................13

Regulators........................................................................................................ 14

DC Characteristics........................................................................................... 15

Supply Voltage Ranges .................................................................................15

Regulators Voltage Ranges ...........................................................................16

Interconnection Diagram.................................................................................. 17

External Signals and Connections................................................................... 17

Battery connector ...........................................................................................17

Baseband - RF interface ................................................................................18

Internal Signals and Connections.................................................................... 18

Audio ..............................................................................................................18

Speaker (Ringer & Earpiece) ......................................................................... 19

Hinge flex connection .....................................................................................19

Baseband board clocks.................................................................................... 21

Functional Description .....................................................................................22

Audio External ................................................................................................22

Headset Detection .........................................................................................22

PnPHF Detection ...........................................................................................23

Audio Internal................................................................................................... 23

Earpiece/Ringer .............................................................................................23

Microphone ....................................................................................................24

Vibra................................................................................................................. 25

Introduction ....................................................................................................25

Acoustic design ..............................................................................................25

Batteries........................................................................................................... 25

Keyboard.......................................................................................................... 26

Display & Keyboard Backlight.......................................................................... 27

LCD Backlight ................................................................................................27

Keyboard light effects ....................................................................................27

LCD.................................................................................................................. 28

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 3

Copyright © 2004 Nokia. All Rights Reserved.

Page 4

RH-53/54

Nokia Customer Care 8-System Module

Memory Module............................................................................................... 28

Fold detection-switch....................................................................................... 28

SIM Interface.................................................................................................... 28

SIM -reader ....................................................................................................29

SIM switch and card detection ....................................................................... 29

Assembly ...........................................................................................................31

Flex.................................................................................................................. 31

Security.............................................................................................................. 32

Test Interfaces................................................................................................... 33

Connections to Baseband................................................................................ 33

FBUS Interface ................................................................................................ 34

Test points ....................................................................................................... 34

RF Functional Descriptions ............................................................................. 36

RF block diagram............................................................................................. 36

Frequency synthesizers................................................................................... 36

VCXO .............................................................................................................36

VCO ...............................................................................................................36

PLL Synthesizer, Functional Description .......................................................37

Receiver........................................................................................................... 37

AGC ...............................................................................................................38

Transmitter....................................................................................................... 38

Dual band FEM ..............................................................................................38

Power control scheme ................................................................................... 38

List of Figures

Page No

Fig 1 RH-53/54 bb block diagram ......................................................................... 9

Fig 2 IPower distribution diagram.......................................................................... 17

Fig 3 Flex con. pin out........................................................................................... 20

Fig 4 External audio interface ............................................................................... 22

Fig 5 Earpiece/ringer interface..............................................................................24

Fig 6 Microphone interface.................................................................................... 25

Fig 7 BL-4C battery............................................................................................... 26

Fig 8 Keyboard PWB layout.................................................................................. 26

Fig 9 UEM, UPP and SIM interface....................................................................... 28

Fig 10 Upper block B-cover SIM-slide slot............................................................ 29

Fig 11 SIM draw and switch.................................................................................. 30

Fig 12 Test pattern............................................................................................... 33

Fig 13 RF block diagram....................................................................................... 36

Fig 14 Simplified BB, either I or Q channel ...........................................................37

Fig 15 Power loop.................................................................................................38

4 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

RH-53/54

8-System Module Nokia Customer Care

[This page left intentionally blank]

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 5

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

RH-53/54

Nokia Customer Care 8-System Module

Abbreviations

Abbr. Description

ADC Analog Digital Connector

ASIC Application Specific Integrated Circuit

ATR Answer To Reset

BB Baseband

BL-4C Battery type.

BSI Battery Size Indicator

Cbus Control bus (internal phone interface between UPP-UEM)

CTSI Clock Timing Sleep and Interrupt

Dbus DSP controlled bus (Internal phone interface between UPP-UEM)

DC Direct Current

DCT4.0 Digital Core Technology, generation 4.0

DSP Digital Signal Processor

EMC Electro Magnetic Compatibility

ESD Electro Static Discharge

Fbus Fast Bus, asynchronous message bus connected to DSP (communications

bus)

FPC Flexible printed circuit

GENIO General Purpose Input/Output

GPRS General Packed Radio Services

HW Hardware

IF Interface

IMEI International Mobile Equipment Identity

LCD Liquid Crystal Display

LDO Low Drop Out

LED Light Emitting Diode

Li-Ion Lithium Ion battery

Lion Battery program, Salo - Finland

LN Lotus Notes

6 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

RH-53/54

8-System Module Nokia Customer Care

MALT Medium And Loud Transducer

Mbus Asynchronous message bus connected to MCU (phone control interface).

Slow message bus for control data.

MCU Micro Controller Unit

NO_SUPPLY UEM state where UEM has no supply what so ever

NTC Negative temperature Coefficient, temperature sensitive resistor used as a

temperature sensor.

PA Power Amplifier (RF)

PDM Pulse Density Modulation

Penny HDA11, Phone program (1100)m Copenhagen-Denmark

Phoenix SW tool of DCT4.x

Pippi Hdb12, Phone program (3510), Copenhagen-Denmark

PLL Phase locked loop

PnPHF Plug and Play Handsfree

PUP General Purpose IO (PIO), USARTS and Pulse Width Modulators

PWB Printed Wired Board

PWR_OFF UEM state where phone is off

PWRONX Signal from power on key.

R&D Research and development

RESET UEM state where regulators are enabled

RTC UEM internal Real Time Clock

SIM Subscriber Identification Module

SLEEP UEM power saving state controlled by UPP

SPR Standard Product Requirements

SRAM Static RAM

SW Software

TB To Be Defined

TI Texas Instruments, American company

UEM Universal Energy Management

UI User Interface

UPP Universal Phone Processor

VBAT Main battery voltage

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 7

Copyright © 2004 Nokia. All Rights Reserved.

Page 8

RH-53/54

Nokia Customer Care 8-System Module

VCHAR Charger input voltage

VCHARDET Charger detection threshold level

VMSTR+,

VMSTR

Master Reset threshold level

8 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 9

RH-53/54

8-System Module Nokia Customer Care

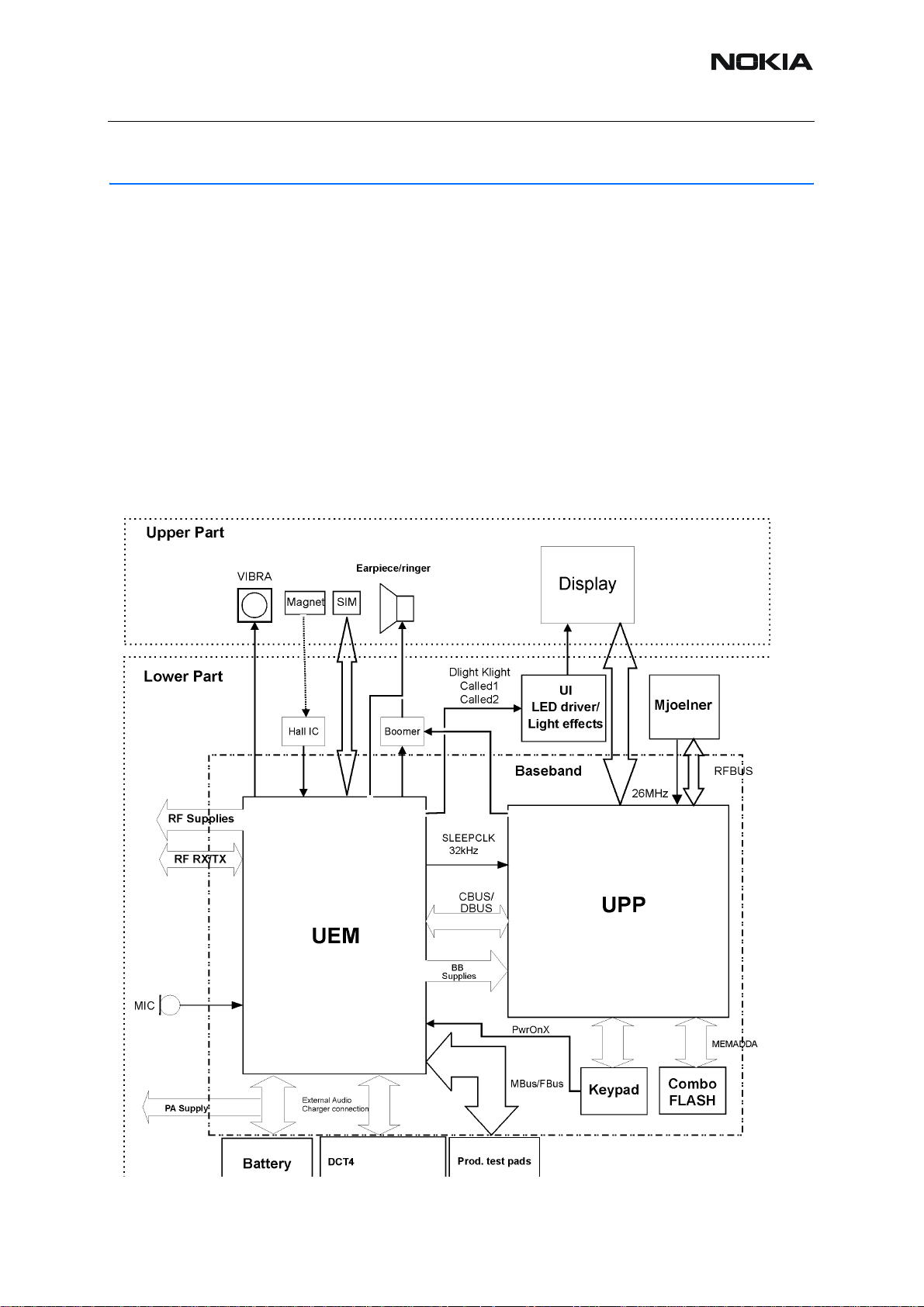

Introduction

This document specifies the baseband module for the RH-53/54 platform program. The baseband module includes the baseband engine chipset, the UI components and the acoustical

parts for the transceiver.

RH-53/54 is a hand-portable dualband GSM/GPRS 900/1800MHz fold-phone, having the

DCT4 generation baseband (UEM/UPP) and RF (MJOELNER) circuitry. The RH-53 platform

also supports a GSM 850/1900 US variant called RH-54. RH-53 platform is based on common

baseband engine 4.0.

■ Technical Summary

The baseband module contains 2 main ASICs named the UEM and UPP. The module furthermore contains a Combo Flash IC of 64Mbit flash and 16Mbit RAM.

Figure 1:RH-53/54 bb block diagram

Interface

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 9

Copyright © 2004 Nokia. All Rights Reserved.

Page 10

RH-53/54

Nokia Customer Care 8-System Module

The UEM supplies both the baseband module as well as the RF module with a series of voltage

regulators. Both the RF and baseband modules are supplied with regula ted voltages of 2.78 V

and 1.8V. UEM includes 6 linear LDO (low drop-out) regulators for baseband and 7 regulators

for RF. The UEM is furthermore supplying the baseband SIM interface with a programmable

voltage of either 1.8 V or 3.0 V. The core of the UPP is supplied with a programmable voltage

of 1.0 V, 1.3 V, 1.5 V or 1.8 V.

UPP operates from a 26MHz clock, coming from the RF ASIC MJOELNER, the 26 MHz clock

is internally divided by two, to the nominal system clock of 13MHz. DSP and MCU contain

phase locked loop (PLL) clock multipliers, which can multiply the system fr equency by factors

from 0.25 to 31.

The UEM contains a real-time clock, sliced from the 32768 Hz crystal oscillators. The 32768

Hz clock is fed to the UPP as a sleep clock.

The communication between the UEM and the UPP is done via the bi-directional serial busses

CBUS and DBUS. The CBUS is controlled by the MCU and operates at a speed of 1 MHz set

by SW. The DBUS is controlled by the DSP and operates at a speed of 13 MHz. Both processors are located in the UPP.

The UEM ASIC handles the interface between the baseband and the RF section. UEM provides A/D and D/A conversion of the in-phase, quadrature receive/transmit signal paths and

also A/D and D/A conversions of received and transmitted audio signals to and from the user

interface. The UEM supplies the analog signals to RF section according to the UPP DSP digital

control. RF ASIC MJOELNER is controlled through UPP RFBUS serial interface. There are

also separate signals for PDM coded audio. Digital speech processing is handled by the DSP

inside UPP ASIC.

UEM is a dual voltage circuit, the digital p art s ar e running from the baseband supply 1 .8V and

the analog parts are running from the analog supply 2.78V also VBAT is directly used by some

blocks.

The baseband supports both internal and external microphone inputs and speaker outputs.

RH-53/54 has two external serial control interfaces: FBUS and MBUS. These busses can be

accessed through production test pattern as described in section 8.

RH-53/54 transceiver modules are implemented on 8 layers and the surface are with selective

Ni/Au OSP.

■ List of Features

RH-53 platform common features:

• Jack UI style 20 keys (with 4 ways scroll) ESD-proof layout, multiple keypress.

• Battery BL-4C

•UEMK

• UPP8Mv2.6/2.10 Lead Free

• Combo Flash 8MByte flash memory and 2MByte PSRAM (64Mbit+16Mbit)

• Power key integrated in keypad (common with End key)

• Internal vibra

• Colour display (colures 4096, resolution: 130 columns x 130 rows, technology:

CSTN)

10 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 11

RH-53/54

8-System Module Nokia Customer Care

• Polyphonic ringing tones

• 2 white LED’s for LCD Backlight.

• 2 white LEDs for key mat & 3 blue LED’s for Light-effect in key mat.

•JAVA

•MMS

•GPRS

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 11

Copyright © 2004 Nokia. All Rights Reserved.

Page 12

RH-53/54

Nokia Customer Care 8-System Module

Technical Specifications

■ Modes of Operation

RH-53/54 baseband engine has six different ‘normal’ operating modes:

• Νo supply

• Power off

• Αcting dead

•Active

•Sleep

• Charging

No supply

In this mode the phone has no supply voltage.

The phone enters this mode if the battery is disconnected, or the battery voltage drops below

V

MSTR-

(1.8V~2.0V)

The phone exits ‘No supply’ mode, into hardware ‘Reset’ mode (not described here), after a

20ms delay, if the battery voltage rises above V

placing the battery with a new battery (V

the battery above V

MSTR+

.

BAT>VMSTR+

(2.0~2.2V). This will occur either by re-

MSTR+

), or by connecting a charger and charging

The phone exits ‘Reset’ mode into ‘Active’/Acting dead’ mode when the battery voltage rises

above V

V

COFF-

V

COFF+

COFF+

(2.7~2.9V) for a minimum of 240.5ms. If the battery voltage has not risen beyond

before the internal watchdog elapses the phone is forced into ‘Power of f’ mode instead.

(3.0~3.2V) within the watchdog time period, and subsequently stays above

Power off

In this mode the phone is powered off, but has a supply voltage.

The phone enters ‘Power off’ mode from all other modes, except ‘No su pply’, if internal watch-

dog elapses. VRTC regulator is active (enabled), and supplied from the main batte ry (the RTC

status depends on whether RTC was enabled or not when entering ‘Power off’ mode).

The phone exits ‘Power off’ mode, into hardware ‘Reset’ mode (not described here), after a

20ms delay, if either of the following conditions are met:

• Power on button detected (PwrOffX).

• Charger connection detected (VCharDet)(VCharIn>VCH

(1.9~2.1V)).

DET+

• RTC alarm detected (RTC_ALARM).

The phone exits ‘Reset’ mode into ‘Active’/Acting dead’ mode when the battery voltage rises

above V

12 COMPANY CONFIDENTIAL ISSUE 1 09/2004

, and stays above V

COFF+

for a minimum of 240.5ms.

COFF-

Copyright © 2004 Nokia. All Rights Reserved.

Page 13

RH-53/54

8-System Module Nokia Customer Care

Acting dead

This mode is just a sub mode of normal ‘Active’ mode, where everything, except for VSIM and

the RF parts, is powered up. This mode is only used for when t he phone is in ‘Power off’ or ‘No

supply’ mode and a charger is connected. To the user , the phone act s as if it was switched off.

A battery-charging alert is given and/or a battery charging indication on the display is shown,

to acknowledge the user that the battery is being charged. The software differentiation betwe en

‘Acting dead’ and ‘Active’ is based on whether or not a power on button was initially detected

(PwrOffX).

The phone exits from ‘Power off’ or ‘No supply’ mode, into hardware ‘Reset’ mode (not described here), after a 20ms delay, if a charger connection is detected (VCharDet)(VCharIn>VCH

The phone then enters ‘Acting dead’ mode, after a 100ms delay, if the battery voltage rises

above V

COFF+

(sub mode of normal ‘Active’).

The phone exits ‘Acting dead’, into ‘Active’ mode, if the power on button is detecte d (PwrOffX).

DET+

).

Active

In the active mode the phone is in normal operation, scanning for channels, listening to a base

station, transmitting and processing information. There are several sub-states in the active

mode depending on if the phone is in burst reception, burst transmission, if DSP is working, if

the phone is folded or unfolded etc.

In active mode the RF regulators are controlled by SW writing into UEMK’s registers wanted

settings: VR1B must be kept disabled. VR2 can be enabled or forced into low quiescent current

mode. VR3 is always enabled in active mode. VR4 -VR7 can be enabled, disabled or forced

into low quiescent current mode.

Sleep mode

The phone enters ‘Sleep’ mode when the UPP goes into standby mode and forces the UEM

into sleep mode by pulling SleepX low.

The UEM puts VCORE, VIO and VFLASH1 into sleep mode an d disables VANA and all of the

RF regulators except VR2, VSIM is also put into sleep mode if supported by the SIM card. The

main oscillator (26MHz) is also shut down and the 32 kHz sleep clock oscillator is used as reference clock for the baseband.

The phone exits sleep mode when SleepX is set high by the UPP, or by expiration of a sleep

clock counter in the UEM or by some external interrupt, generated by a charger connection,

key press, headset connection etc.

Charging

Charging can be performed in parallel with any other operating mo de. The charging will be controlled by hardware until the phone enters either ‘Sleep’, ‘Acting dead’ or ‘Active’ mode. Hereafter it will be controlled by software.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 13

Copyright © 2004 Nokia. All Rights Reserved.

Page 14

RH-53/54

Nokia Customer Care 8-System Module

A BSI resistor inside the battery pack indicates the battery type/size. The resistor value corresponds to a specific battery capacity and technology.

The battery voltage, temperature, size and current are measured by the UEM, and controlled

by the charging software running in the UPP.

The charging control circuitry (CHACON) inside the UEM controls the charging current delivered from the charger to the battery. The battery voltage rise is limited by turning the UEM

switch off when the battery voltage has rea ched VBATLim (programmable charging cut-off limits 3.6V / 5.0V / 5.25V). Charge current is monitored by measuring the voltage drop across a

0.22 ohm resistor.

■ Regulators

Overview of the regulator state in ‘Active’, ‘Acting dead’ and ‘Sleep’ mode is shown in table 1.

Table 1: Overview

Regulator Active Acting dead Sleep

VFLASH1 Enabled Enabled Sleep mode

VFLASH2 Disabled (Not used) Disabled (Not used) Disabled (Not used)

VANA Enabled Enabled Disabled

VIO Enabled Enabled Sleep mode

VCORE Enabled Enabled Sleep mode

VSIM Enabled (voltage control-

led by software)

VR1A Enabled Enabled Disabled

VR1B Disabled (Not used) Disabled (Not used) Disabled (Not used)

VR2 Enabled (voltage control-

led by software)

VR3 Enabled Disabled Disabled

VR4 Disabled Disabled Disabled

Disabled Enabled/Sleep mode

(depending on SIM

card)

Enabled (voltage controlled by software)

Enabled (voltage controlled by software)

VR5 Enabled Disabled Disabled

VR6 Enabled Disabled Disabled

VR7 Enabled Disabled Disabled

Regulator Active Acting dead Sleep

IPA1-2 Disabled (not used) Disabled (not used) Disabled (not used)

14 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 15

RH-53/54

8-System Module Nokia Customer Care

■ DC Characteristics

Supply Voltage Ranges

Table 2: Supply voltage ranges

Signal Rating

Battery Voltage 0 ... 4.39V (VBAT)

Flashing Voltage 0 … 5.15V

Charger Input Voltage -0.3 ... 9.2VRMS (16,9 Vpeak)

Following voltages are assumed as normal and extreme voltages for used battery:

Table 3: Battery voltages

Source Min Nom Max Note

VBAT 3.21V 3.80V 4.39V 1

Vcoff+ 3.0V 3.1 3.2 HW off to on

Vcoff- 2.7V 2.8V 2.9V HW on to off

Vmstr+ 2.0V 2.1V 2.2V HW off to on

Vmstr- 1.8V 1.9V 2.0V HW on to off

Sw shutdown - 3.1V - In Call

1 TA will test with the nominal voltage at an 85% range (0.85 x 3.7V = 3.145V); therefore the

nominal voltage has been set to 3.8V. ADC settings in the SW might shutdown the phone

above the min value. During fast charging of an empty battery, the max voltage might exceed

this value. Voltages between 4.20 and 4.60 might appear for a short while.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 15

Copyright © 2004 Nokia. All Rights Reserved.

Page 16

RH-53/54

Nokia Customer Care 8-System Module

Regulators Voltage Ranges

Table 4: Regulators voltage ranges

Source Min Nom Max Note

VANA 2.70V 2.78V 2.86V I

VFLASH1 2.70V 2.78V 2.86V I

max

max

I

sleep

= 80mA

= 70mA

= 4mA

VFLASH2 2.70V 2.78V 2.86V Not used

VSIM 1.745V 2.91V 1.8V 3.0V 1.855V 3.09V I

max

I

sleep

= 25mA

=

0.5mA

VIO 1.72V 1.8V 1.88V I

max

I

sleep

= 150mA

=

0.5mA

VCORE Higher

range

1.000V 1.140V

1.235V 1.425V

1.710V

1.053V 1.2V 1.3V

1.5V 1.8V

1.106V 1.260V

1.365V 1.575V

1.890V

= 200mA

I

max

I

=

Sleep

0.2mA Used

voltages:

(c035) = 1.5V

(c027) = 1.3V

Table 5: RF regulators

Source Min Nom Max Note

VR1A 4.6V 4.75V 4.9V Imax = 10mA

VR1B 4.6V 4.75V 4.9V Not used

VR2 2.70V 2.78V 2.86V I

VR3 2.70V 2.78V 2.86V I

= 100mA

max

= 20mA

max

VR4 2.70V 2.78V 2.86V Not used

VR5 2.70V 2.78V 2.86V I

VR6 2.70V 2.78V 2.86V I

VR7 2.70V 2.78V 2.86V I

= 50mA

max

= 50mA

max

= 45mA

max

16 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 17

RH-53/54

r

8-System Module Nokia Customer Care

■ Interconnection Diagram

Figure 2:IPower distribution diagram

Battery

Baseband

LED+

LED

Driver

VBAT

UEM

RF Regulators

Baseband

Regulators

RTC

CHACON

VR1A

VR2-7

VSIM

VCORE

VANA

VIO

VFLASH1

6

SIM

UPP

FLASH

LCD

Boomer

PA Supply

System Connecto

■ External Signals and Connections

Battery connector

As a difference to previous NMP Battery Interfaces, BTEMP has been removed and battery

temperature is estimated by measurement in Transceiver PWB with a separate NTC resistor.

Thus the Battery Interface has only 3 contact s. BSI ranges has been a ltered and Battery Int erface will not support NiMh batteries.

Table 6: Battey connetor

Name Description Test usage

VBAT Battery voltage terminal. Battery calibration.

GND Battery ground terminal.

BSI Battery size identification. Flash and local mode forcing.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 17

Copyright © 2004 Nokia. All Rights Reserved.

Page 18

RH-53/54

Nokia Customer Care 8-System Module

Baseband - RF interface

The interface between the baseband and the RF can be divided into three categories:

- The digital interface from the UPP to the RF ASIC (Mjoelner). The serial digital interface is

used to control the operation of the different blocks in the RF ASICs.

- The analogue interface between UEM and the RF. The analogue interface consists of RX and

TX converter signals. The power amplifier control signal TXC and the AFC signal comes as well

from the UEM.

- Reference clock interface between Mjoelner and UPP, which supplies the 26Mhz system

clock for the UPP.

■ Internal Signals and Connections

The tables below describe internal signals. The signal names can be found on the schematic

for the PWB.

Audio

Table 7: Internal microphone

Signal Min

MIC1P (Differential input P) - 5mV - TBD

MIC1N (Differential input N) - 5mV - TBD

MICB1 (Microphone Bias) 2.0 V2.1 V2.25 V DC

External loading of MICB1 - - 600uA DC

Table 8: Internal speaker (Differential output EARP & EARN)

Signal Min

Output voltage swing 4.0 - - Vpp Differential output

Load Resistance (EARP to

EARN)

Load Capacitance (EARP to

EARN)

25,5 27,228,9 W 2*10Ù 5% +

- - 50 nF

No

m

No

m

Max

Max Units Note

Conditi

on

Note

7,2Ù±10%

18 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 19

RH-53/54

8-System Module Nokia Customer Care

Speaker (Ringer & Earpiece)

Table 9: Connections between UPP and Boomer

Signal From To Parameter Min. Max. Unit Notes

Shutdown

(Only

Ringer)

UPP

GENIO[14

]

Boomer

Shutdown (pin

5)

Table 10: Connections between UEM/Battery and Boomer

Signal

name

XAUDIO[1] Filtered

signal

Differential

between HF and

HFCM. No direct

connection

From To

BoomerOutput

between UEM

and Boomer

VBAT Battery Boome

r (pin 6)

Hinge flex connection

Vih Vil 1.2 - - 0.4 V V Boomer

Shutdown

treshold

levels

Paramete

r

Min. Max. Unit Notes

- 80mV Vpp Long-term

Swing

consumption

Supply 3.2 4.39 V Lower limit

is SW cutoff

Connection between main engine (lower block) and upper is done by hinge flex via 30 pins

board to board connector . Hinge flex includes Earpiece/Ringer, Display , SIM, LCD led and Vibra signals.

Table 11: Hinge flex signals

Pin Signal Comments

1,2,3,4 GND

5 LCD_CSL Display Serial Clock

6 LCD_CSX Display Chip Select

7,8,9 GND

10 Vibra PWM signal

11 Vbat For Vibra

12,13,14,15 GND

16 SIMCAR D_Det Detection of SIM Card

17 VSIM 3.0V/1.8V for SIM

18 SIM_RST SIM Reset

19 SIM_IO SIM Data

20 SIM_CLK SIM Clock

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 19

Copyright © 2004 Nokia. All Rights Reserved.

Page 20

RH-53/54

Nokia Customer Care 8-System Module

Pin Signal Comments

21 GND

22 EARP For MALT

23 EARN For MALT

24 GND

25 VDD "Vflash1" 2. 78 V for Display

26 LED- Return from LEDs

27 LED+ Pos supply for LEDs

28 VDDI "Vio" 1.80 V for Display

29 LCD_RESETX Display Reset

30 LCD_SI Display Serial Data

Figure 3:Flex con. pin out

Pin 30 Pin 1

20 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 21

RH-53/54

8-System Module Nokia Customer Care

■ Baseband board clocks

Table 12: Board Clocks

Signal name From To Min. Typ. Max. Unit Notes

RFCLK MJOEL-

NER

SLEEPCLK UEM UPP - 32.768 - KHz Active when

RFCONVCLK

RFBUSCLK UPP MJOEL-

DBUSCLK UPP (DSP) UEM - 13 13 MHz Only active

CBUSCLK UPP (MCU) UEM - 1 1.2 MHz Only active

LCDCAMCLK

UPP UEM 13 - MHz Active when RF

UPP LCD 0.3 6.25 8.4 MHz Only active

UPP - 26 - MHz Active when

SLEEPX is high

VBAT is supplied

converters are

active

- 13 13 MHz Only active

NER

when bus-enable is active

when bus-enable is active

when bus-enable is active

when bus-enable is active

MemClk/

Flash

UPP Flash 40 MHz

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 21

Copyright © 2004 Nokia. All Rights Reserved.

Page 22

RH-53/54

Nokia Customer Care 8-System Module

Functional Description

Audio External

RH-53/54 is designed to support fully differentia l external audio accessory connection. A headset and PnPHF can be directly connected to system connector. Detection of the different accessories is made in analog way by reading the DC voltage value of EAD converter.

Figure 4:External audio interface

2.7V

Hookint

/MBUS

Headint Headint

HFCM

EAD

Mic_bias

HF

UEM

MICB2

MIC2P

MIC2N

3...25k

Headset Detection

Not all components are shown

Bottom

Connector

33N

1k0

1k0

0.3V

1.8V

2.1V

33N

0.8V

0.8V

MicGnd

Supported headsets are 4-wire fully differential accessories. The hardware used to detect accessories is contained in the UEM and BB area. For interrupt purposes the UEM inputs

HOOKINT and HEADINT are used. The bottom connector contains a switch, which opens

when an accessory is connected. The switch is routed to the UEM HEADINT input.

The current generators on the HOOKINT and HEADINT pins acts as internally pull-up resistors

with values equivalent to 675 k - 2.86 M, tolerances of the current source and VFLASH1 considered. The HOOKINT input comparator threshold level can be set to two different values.

Levels can be found in the table.

Table 13: Comparator threshold levels and pull-up current source strength (hysteresis included)

Parameter Variable Min Typ Max

HOOKINT comparator thresh-

Vhook1 1.21 V 1.35 V 1.49 V

old

22 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 23

RH-53/54

8-System Module Nokia Customer Care

HOOKINT comparator threshold

HEADINT comparator threshold

VFLASH1 voltage regulator VFLASH1 2.70 V 2.78 V 2.86 V

Current source strength Ipullup 1 µA2 µA4 µA

Note that hysteresis of the comparators has been taken into account in the HOOKINT

and HEADINT Min and Max values.

Vhook2 0.50 V 0.60 V 0.70 V

Vhead 1.71 V 1.90 V 2.09 V

PnPHF Detection

PnPHF accessory uses 4-wire fully differential audio connection. The a ccessory is detected by

the Headint signal when the plug is inserted.

■ Audio Internal

Earpiece/Ringer

The choosen transducer that shall be used both as earpiece and ringer is the 16 mm loudspeaker called MALT.

The Earpiece/ringer solution will be build up around the 16 mm MALT speaker that shall be

used both as earpiece and ringer. This solution will implement polyphonic ringing tones.

The earpiece circuit includes only a few components:

-Two 10 ohm in order to have a stable output

The ringer circuit includes several components

-Four resistors for setting the boomer gain

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 23

Copyright © 2004 Nokia. All Rights Reserved.

Page 24

RH-53/54

Nokia Customer Care 8-System Module

Figure 5:Earpiece/ringer interface

UEM

EARP

EARN

10

10

HF

HFCM

UPP

GENIO14

Interface to

external audio

100n

100n

XEARP

XEARN

Vbat

Vdd

GND

33k

330p

Vo1

Vo2

Placed near

UEM

Placed outside

BB-can, near the

connections to

MALT

MALT

Interface to

DC-out

Not used / NA

1u

4k7

4k7

330p

33k

470 n

IN-

IN+

BYPASS

SHUTDOWN

Microphone

The acoustical design is copied from Nokia 7210 with some modifications. In comparison to

N7210, the microphone boot is a separate component placed next to the bottom connector.

The electrical Microphone design is a differential bias circuit, driven directly from the MICB1

bias output with external RC-filters. This is one solution that has previously been used with success in other projects.

The RC filter (220 Ω, 4.7µF) is scaled to provide damping at 217 Hz. TDMA noise (217 Hz au-

dible noise) will occur if the bias output MICB1 demodulates in-coming radio frequencies.

Common DCT4 BB specifies filtering of the reference voltage for the microphone bias gene rators. In next figure this filtering is included on the MICBCAP pin. This capacitor will not be

mounted when the UEMc will be used.

The microphone bias is controlled in the 8 bit AudioBiasR register . The figure below shows the

electrical interface.

24 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 25

RH-53/54

8-System Module Nokia Customer Care

Figure 6:Microphone interface

Placed near

bottom

connector

UEM

Placed near

UEM

1n 1n

1k

10n

2k2

2k2

1k

10n

MIC+

1n

MIC-

MICB1

MIC1P

MIC1N

MICBCAP

220

4.7uF

2k2

2k2

1u

22k

2*33n

■ Vibra

Introduction

Vibra is a small cylindrical DC motor with a ∅4.0-mm in diameter that generating vibration by

rotating an un-balanced mass (counter weight) with radius of R=2.5-mm when the applied voltage is on.

The vibration signal will be used as a silent alert call and also as a noticeable shock in gaming.

Acoustic design

The vibra is placed in the top of the phone when it is fold/closed but it placed under the display

when it is unfold. The counter weight is placed in the top middle (unfold) that may results to

shorter distance to the mass center of the phone. This mechanical solution will result to lower

vibration/velocity amplitude, as the axel of torque is shorter.

The vibra is electrically connected to the flexfilm by spring contacts.

The vibra is controlled from the UEMK by a PWM (Pulse Wide Modulated) square wave signal.

The nominal rated voltage for the vibra is approximately about 1.3 volts and the nominal battery

voltage is about 3.6 volts. To achieve an optimal voltage over the vibra, the following table

should be used.

■ Batteries

Type:BL-4C battery

Technology:Li-Ion. 4.2V charging. 3.1V cut-off

Capacity:760 mA/h

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 25

Copyright © 2004 Nokia. All Rights Reserved.

Page 26

RH-53/54

Nokia Customer Care 8-System Module

Figure 7:BL-4C battery

The BSI values for the batteries:

Inside the battery, an over-voltage protection circuit are present.

The battery does not contain a temperature sensor. Since the battery is using the Li-Ion tech-

nology , care should be t aken while charging. The material might be overheated when charged

above 60 degrees Celsius. Charging should be termina ted when this temperature is reached.

An external temperature sensor (NTC resistor) is placed on the PWB close to the end of the

battery. Real measurements should be performed to check if the location is sufficient.

■ Keyboard

The keyboard PWB layout consists of a grounded outer ring and an inner pad see Figure 8.

Figure 8:Keyboard PWB layout

The keyboard is not a matrix keyboard, but is connected direct to UPP. The following table

shows the keyboard connection.

Table 14:

UPP Pin RH-53 Key

GenIO1 0 In Up GenIOInt5 Falling edge interrupt

GenIO2/

P05

GenIO20 Soft Right In Up GenIOInt2 Falling edge interrupt

7 In Up P0 int Falling edge interrupt

Overview of keyboard configuration

In/

Out

Internal Pull

Up/down

Interrupt

GenIO21 * In Up GenIOInt3 Falling edge interrupt

GenIO25 Up In Up GenIOInt4 Falling edge interrupt

GenIO27 1 In Up GenIOInt6 Falling edge interrupt

26 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 27

RH-53/54

8-System Module Nokia Customer Care

GenIO28 Left In Up GenIOInt7 Falling edge interrupt

GenIO13 # In Up GenIOInt1 Falling edge interrupt

P00 Send In Up P0 int Falling edge interrupt

P01 3 In Up P0 int Falling edge interrupt

P02 9 In Up P0 int Falling edge interrupt

P03 8 In Up P0 int Falling edge interrupt

P04 Down In Up P0 int Falling edge interrupt

P10 6 In Up P1 int Falling edge interrupt

P11 4 In Up P1 int Falling edge interrupt

P12 Righ t In Up P1 int Falling edge interrupt

P13 5 In Up P1 int Falling edge interrupt

P14 Soft Left In Up P1 int Falling edge interrupt

P15 2 In Up P1 int Falling edge interrupt

UEM Pin

PwrOnX End / power

on/off

NOTES:

• Key number “#” is located on GenIO13 with interrupt on GenIOInt1. RH-53 Marketing accept the reduction in performance when there is no wake up from deep

sleep.

• Power on/off and End Call are combined. For ending call: “short” keypress. For

power off: “Long” keypress

All lines are configured as input, when there is no key pressed; the inputs are high due to that

the UPP has internally pull-up resistors on those lines. When a key is pressed, the specific line

where the key is placed is pulled low . This generates an interrupt to the MCU and the MCU now

starts its scanning procedure.

In Current source

Pull up

INT on UPP Falling edge interrupt

■ Display & Keyboard Backlight

LCD Backlight

LCD Backlight consists of 2 side firing white LED's, which are placed on the display FPC below

the LCD area.

Keyboard light effects

Keyboard is lighting up by 2 white side firing LED’s for keyboard. 3 blue LED’s are used for Light

effects in the keyboard.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 27

Copyright © 2004 Nokia. All Rights Reserved.

Page 28

RH-53/54

Nokia Customer Care 8-System Module

■ LCD

The LCD display module is a 130 x 3RGB x 130, 4096-color/ 256-color /8-color transflective

passive matrix (CSTN) LCD display.

The LCD module interface follows 130x130 X4_CSTN Display module interface specification

(Nokia doc. Code: DHS02040-EN 0.2). Nile display family is using serial interface only

■ Memory Module

The RH-53/54 baseband memory module consists of external burst NOR flash memory 8Mbyte

(64Mbit) and CMOS 2Mbyte (16Mbit) PSRAM

The flash interface follows the common baseband interface.

The operations voltage is Vcc=1.8 V (Voltage range 1.7-1.9 V).

■ Fold detection-switch

Detection for fold position has been done with HALL- switch SH248CSP which is located in lower block part and the magnet is located on upper block.

The output is high level for B=0mT (flip open).

■ SIM Interface

The SIM interface can be described as electrical interface between the SIM card and the phone

via UEM. The SIM interface in the UEM contains power up/down, port gating, card detect, data

receiving, ATR-counter, registers and level shifting buffers logic.

Figure 9:UEM, UPP and SIM interface

C4 C3 C2 C1

C5 C6 C7 C8

SIM Card

Passive

filter

SIMIO

SIMclk

SIMRST

VSIM

SimCardDet

UEM

SIMIO

SIMclk

SIMRST

SIM IF

Register

UEM

Digital

Logic

UPP

SIMIO

SIMclk

SIMR

UIF block

UEM int

Cbus Da

Cbus enX

Cbus clk

The data communication between the card and the phone is asynchronous half duplex. The

clock supplied to the card in GSM system is either 1.083 MHz or 3.25 MHz. The dat a baud rate

is SIM card clock frequency divided by 372 (by default), 64, 32 or 16.

28 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 29

RH-53/54

8-System Module Nokia Customer Care

SIM -reader

The SIM card reader is located on upper block p art of the phone and is connected to UEM via

the flex. For RH-53 a slide-in draw is used as SIM slot. Picture below depicts the SIM slot on

the side of the upper block.

Figure 10:Upper block B-cover SIM-slide slot

The entire SIM interface is located in the two ASICs, UPP and UEM. The UEM contains the

SIM interface logic level shifting. The SIM interface can be programmed to support 3 V and 1.8V

SIMs. A register in the UEM controlled by SW is used to select s SIM supply voltage for different

SIMs. However, it is only allowed to change the SIM supply voltage when the SIM IF is initialised i.e. SIM IF id powered down.

Of the eight card contacts only 5 will be connected: C1 (Vcc), C2 (Card Reset), C3 (Card

Clock), C5 (Ground) and C7 (Data I/O).

SIM switch and card detection

The SIM power up/down sequence is generated in the UEM. This means that the UEM gen erates the RST signal to the SIM. A mechanical switch is connect ed to UEM SimCardDet pin to

monitor the presence of the SIM card, i.e. card detection. When the SIM card is inserted, the

switch connects the SimCardDet to GND.

To avoid probable SIM card corruption caused by “hot-swapping”, the UEM will automatically

power down the SIM card interface within 2ms if the switch is opened.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 29

Copyright © 2004 Nokia. All Rights Reserved.

Page 30

RH-53/54

Nokia Customer Care 8-System Module

Figure 11:SIM draw and switch

30 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 31

RH-53/54

8-System Module Nokia Customer Care

Assembly

■ Flex

RH-53/54 uses a single layer flex with ground tracks distributed between signal groups, and

wide ground tracks running in both sides of the flex to serve as main ground.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 31

Copyright © 2004 Nokia. All Rights Reserved.

Page 32

RH-53/54

Nokia Customer Care 8-System Module

Security

The phone flash program and IMEI code are software protected, using an external security device that is connected between the phone and a PC. The security device uses IMEI number

(IMEI is stored in UEM non-volatile memory cells), the software version number and a 24bit

hardware random serial number that is read from the UPP, and calculates a flash authority

identification number, that is stored into the phone (emulated) EEPROM.

32 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 33

RH-53/54

8-System Module Nokia Customer Care

Test Interfaces

Test pattern is placed on engine PWB, for service and production purposes, same test pattern

is used for after sales purposes as well.

Through MBUS or FBUS connections, the phone HW can be tested by PC software (Phoenix)

and equipment (FLALI/FINUI/LABEL).

Figure 12: Test pattern

Figure 1 Production test pattern J396 (DAI is J300)

DAI

GND

FBUS RX

FBUS TX

MBUS

Vpp

■ Connections to Baseband

The flash programming box, FPS8, is connected to the baseband using a galvanic connector

or test pads for galvanic connection. The UEM watchdog is disabled during flash programming

to prevent a hardware reset of the timer. The flash programming interface connects the flash

prommer to the UPP via the UEM and the connections correspond to a logic level of 2.7 V . The

flash prommer is connected to the UEM via the MBUS (bi-directional line), FBUS_TX, and

FBUS_RX. The programming interface connections between the UEM and the UPP constitute

the MBUS_TX, MBUS_RX, FBUS_TX, and FBUS_RX lines. The interface also uses the BSI

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 33

Copyright © 2004 Nokia. All Rights Reserved.

Page 34

RH-53/54

Nokia Customer Care 8-System Module

(Battery Size Indicator) and the PURX signal connections for the connections between the

UEM and the UPP.

■ FBUS Interface

FBUS is an asynchronous data bus having separate TX and RX signals. Default bit rate of the

bus is 115.2 kbit/s. FBUS is mainly used for controlling phone in the production. Typical

VFLASH1 is 2.78V

Table 15: FBUS interface signals

Signal Min Nom Max

FBUS_TX Voh 0.7*VFLASH1 VFLASH1

Vol 0 0.3*VFLASH1

FBUS_RX Vih 0.7*VFLASH1 VFLASH1

Vil 0 0.3*VFLASH1

TX and RX

Tr 12.5 ns

Rise time

GND 0

■ Test points

The following table show the test points on the main board.

Table 16: Test points

Test point: Description:

J100 Vbatt on battery connector

J101 BSI on battery connector

J102 GND on battery connector

J300 DAI_CLK on production test pattern

J150 GENIO 14 (Boomer)

J002 DLight

J303 Keyb1 (output from Hall IC)

J396 Production test pattern (see

14

)

Figure

J402 PURX (UPP)

J403 SLEEPX (UPP)

34 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 35

RH-53/54

8-System Module Nokia Customer Care

J404 SLEEPCLK (UPP)

J405 UEMINT (UPP)

J406 CBUSCLK (UPP)

J407 CBUSDA (UPP)

J408 CBUSENX (UPP)

J409 MBUSTX (UPP)

J410 MBUSRX (UPP)

J411 FBUSTX (UPP)

J412 FBUSRX (UPP)

J413 DBUSCLK (UPP)

J414 DBUSDA (UPP)

J415 DBUSEN1X (UPP)

J416 EXTWRX (UPP)

J417 EXTRDX (UPP)

J418 FLS2CSX (UPP)

J419 FLSCLK (UPP)

J420 FLSCSX (UPP)

J421 RFBUSCLK

J422 RFBUSDA

J423 RFBUSEN1

J424 GENIO 7 (BB-RF Interface)

J600 RXIP (Mjoelner)

J601 RXIM (Mjoelner)

J602 RXQP (Mjoelner)

J603 RXQM (Mjoelner)

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 35

Copyright © 2004 Nokia. All Rights Reserved.

Page 36

RH-53/54

Nokia Customer Care 8-System Module

RF Functional Descriptions

■ RF block diagram

Block diagrams of direct conversion receiver and transmitter RF section has described in the

following figure.

The architecture is based on Mjoelner , the RF ASIC, which contains most of the functionality of

the RF Engine. The ASIC contains RX and TX functions, VCXO (crystal is placed external to

the ASIC), se the block diagram.

Figure 13:RF block diagram

Pinocchio RF block diagram

RX/TX switch

PA and detector

Vapc

VBATTRF

Diplexer

Vsense

Version : 0.1

Ant

SAW

INPL

RX900

INML

GSM RX

PCS RX

TX/RX GSM

TX/RX DCS

VTX

Band sel

PCN/PCS

GSM

SAW

PCN/PCS

Balun

VTX

SAW

PWloop

filter

RX1800/

1900

VPCTRL_G

INPM

INPH

INMH

VANTL

VANTM

VANTH

VB_DET

VTXLOL

VTXLOH

VTXBH

VTXBL

OUTHP

OUTHM

OUTLP

OUTLM

DET

PLFB1

PLFB2

INMM

LNA

Bias

ASIC

LNA

LNA

LNA

RF

Controls

RF

Controls

Open collector

Open collector

PWC

TXP

TXP

F

X

R

D

D

V

VDDDIG

VDDRXBB

TXC

TXC

Pre-gain

Pre-gain

Supply

filter

VR2

VDDTX

VTX

Rx

supply

filter

222

2

1/2

1/2

2

2

2

TXQP/TXQM

VRX

RXIP

RXIM

RXQP

RXQM

VPLL

VCXO

supply

filter

REFOUT

VCO

supply

filter

REF CLK SET

RESET_X_M

RFBUSX

RFBUSDA

RFBUSCLK

VBB (1.8V)

VR6

VR5

VXO

VR3

VR7

VIO

GENIO6

VIO

VR2

B

B

X

R

D

RBEXT

VBEXT

2,7k

LPF1

LPF1

D

V

NDIV

ADIV

RDIV

VCXO Bias

R2H/R2

VDDRXBB

Sensor

BIST / Temp.

SENSE

Rpa

18 K : Vendor 1

47 K : Vendor 2

82 K : Vendor 3

BIQUAD

DCN1

DCN1

AGC

AGC

ϕ

Buf/

AGC

AFC/CAL

Control

VDDTX

VDDXO

Digital Control

VCOSENSE

BIQUAD

RESETX

VDDDIG

DCN2

LPF2

DCN2

LPF2

VDDLO

Synth

VDDPLL

supply

VDDPRE

VDDCP

Charge

Pump

CPOUT

Lock

Detect

3

1/2

I/O level

VDDXO

VDDBBB

REFOUT

Buffer

XTALM

XTALP

INPLO

INMLO

SELADDR

SELADDR

shift

RESETX

RF_EN

RF_CLK

RF_DATA

VDDDL

filter

Vcp

supply

filter

PLL

loop

filter

26MHz

3

Vio: VDDDL, SELADDR

Vr2: VTX, VDDTX, VDDDIG

Vr3: VDDXO, VDDBBB

Vr4: Not used

Vr5: VDDLO, VDDPLL, VDDPRE

Vr6: VDDRXBB, VDDRXF

Vr7: VVCO

VR1A: VDDCP

Mjølner

BBAMP

BBAMP

1/4

64/65

1/4

2

2

Main Bias Circuit

VDDRXBB

Resistor Ext/R2H/R2

2

TXIP/TXIM

Ref.

filter

RFCONV_0(9)

VBEXT

VREF1

■ Frequency synthesizers

VCXO

The VCXO is an on-chip oscillator with off-chip crystal with a frequency of 26 MHz.

VCO

The VCO used is a quad band which covers the neaded frequency range for both 900/1800

and 850/1900.

36 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 37

RH-53/54

8-System Module Nokia Customer Care

The VCO for the 900/1800 (RH-53) bands covers the range of 3420 to 3840 MHz, while the

VCO for 850/1900 (RH-54) (and thereby the quad band) covers 3296 to 3980 MHz.

PLL Synthesizer, Functional Description

The frequency synthesis PLL in conjunction with the VCO and 2/4 dividers generates the LO

signal for both RX and TX paths, locked to the VCXO which ag ain is locked to the base st ation

through the AFC.

■ Receiver

The Receiver, figure 14, is a dual band direct conversion linear receiver. The received RF signal

is routed from the antenna to the FEM, where the RX/TX switch is located. The RX/TX switch

performs both the switching between receive – transmit routing of the antenna signals as well

as the selection of the band to be used.

The RX signal is routed from the RX/TX switch, in the FEM, to the RX bandpass filter . The filter

input is single ended and the output is balanced in order to exploit the balanced nature of the

RF-ASIC. The bandlimited signal is amplified in the internal LNA and the Pre-gain amplifie r before being converted to a BB signal in the passive mixer.

Figure 14:Simplified BB, either I or Q channel

BBAMP

1

4 MHz

pole at

input

Gain ~24 dB Gain ~14 dB

AGC ~ 0 dB AGC ~ 0 dB AGC ~ 24 dB AGC ~ 48 dB AGC ~ 0 dB AGC ~ 0 dB

250

kHz

pole at

output

LPF 1 DCN 1 AGC LPF 2 DCN 2

86 kHz

pole

Gain ~ 0 to

24 dB

Gain ~ -48

to 0 dB

Step ~ 6 dBStep ~ 6 dB

114 kHz

pole pair

Gain ~20 dB Gain ~0 dB

The BB signal from the passive mixer is amplified by 24 dB in BBAMP1. In order to provide the

first band limitation a 4 MHz pole is added at the input and a 250 kHz pole at the output of

BBAMP1. No AGC is provided in this amplifier. BBAMP1 is followed by LPF1 with a gain of 14

dB and with a pole at 86 kHz. LPF1 is followed by DCN1 (DC compensation amplifier 1) with a

minimum gain of 0 dB and a maximum gain of 24 dB. The DCN1 output is followed by a controlled attenuator , which has a control range of 48 dB. The attenuator output is filtered in LPF2,

a biquad filter, before passing DNC2, (DC compensation amplifier 1). The total filter combination gives a flat transfer function from DC to 90 kHz. All capacitors for both filters are located in

the RF-ASIC.

The gain characteristic of the BB amplifier is an amplifier with a maximum gain of 80 dB with

an AGC range of 72 dB.

The receiver selectivity for out-of-band signals is defined by the RF front-end SAW filter.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 37

Copyright © 2004 Nokia. All Rights Reserved.

Page 38

RH-53/54

Nokia Customer Care 8-System Module

AGC

The AGC keeps the BB level form the receiver within a certain range in order to st ay within the

dynamic range for the BB, even during fading.

■ Transmitter

The transmitter chain consists of two direct frequency I/Q-modulators, one for the GSM850/EGSM900 and one for GSM1800/1900, and a dual-band power amplifier.

The I/Q-signals, generated in BB, are fed to the individual I/Q-modulators in the RF-ASIC. The

frequency and phasing parameters for the individual modulators/ban ds is generated by the LO

dividers, division is by 2 in GSM1800/1900 and by four in GSM900/E-GSM900. Each modulator

has a separate output.

In GSM850/E-GSM900 the modulator is terminated in a balanced input SAW filter.

The GSM1800/1900 modulator is using a balun instead of a SAW filter.

Dual band FEM

The dual-band FEM contains two separate gain chains, with separate inputs and outputs,

where the GSM850/E-GSM900 part is able to produce over 33 dBm and the GSM1800/

PCS1900 part over 30 dBm, both in 50 Ω. The two gain chains shares a common control line

to set the gain of amplifiers.

The output from the individual gain chains is feed to the internal RX/TX switch in the FEM.

Power control scheme

The detected voltage is compared in the error-amplifier in Mjoelner to TXC- voltage, which is

generated by a DA-converter in BB.

Figure 15:Power loop

Detect

Highband

Lowband

C644

100pF

R655

330R

Vpc

High band

input

Low band

input

Front End Module

R623

6K8

Rfb

Ffbl

Cfbl

TXC

R620

12K

C642

100pF

38 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Loading...

Loading...