Page 1

Nokia Customer Care

RH-53/54

7-T roubleshooting

Instructions

ISSUE 1 09/2004 Copyright © 2004 Nokia Corporation. All Rights Reserved.

Page 2

RH-53/54

Nokia Customer Care 7-Troubleshooting Instructions

[This page left intentionally blank]

2 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 3

RH-53/54

Nokia Customer Care

Table Of Contents

Page No

Baseband Troubleshooting................................................................................ 7

Baseband test points ......................................................................................... 7

Troubleshooting diagrams ................................................................................. 8

Phone is dead.................................................................................................... 9

Flash programming does not work................................................................... 10

Power does not stay on or phone is jammed................................................... 11

Display information : "Contact Service"............................................................ 12

The phone does not register to the network, or the phone cannot make a call 13

Charging troubleshooting................................................................................. 14

Audio troubleshooting 1, 2............................................................................... 16

Audio troubleshooting 3: Headset does not work ............................................ 17

Upper block failures.......................................................................................... 18

Introduction to RH-53/54 RF Troubleshooting ...............................................23

General description of the RF circuits............................................................ 24

Receiver signal path ........................................................................................ 24

Transmitter signal path .................................................................................... 24

PLL................................................................................................................... 25

RF Key component placement......................................................................... 28

Troubleshooting................................................................................................ 29

Common circuit................................................................................................ 29

Power Supply Configuration ..........................................................................29

General instructions for Synthesizer troubleshooting ...................................... 31

26 MHz Reference Oscillator ( VCXO ) ........................................................... 31

Example Signal Measured at VCXO output (R420) ....................................... 32

VCO ...............................................................................................................32

Troubleshooting chart for the Synthesizer ....................................................... 33

Measurement points for the Synthesizer ......................................................... 34

Receiver Troubleshooting............................................................................... 37

Front End Module (FEM) control signals ......................................................... 37

Renesa FEM logic ..........................................................................................37

RFMD FEM logic ............................................................................................37

Measurements points....................................................................................... 38

Measurement points for the receiver .............................................................38

RH-54 Receiver ............................................................................................... 40

General Instructions for GSM850 RX Troubleshooting .................................. 40

General Instructions for GSM1900 RX Troubleshooting.................................. 43

RH-53 Receiver ............................................................................................... 46

General Instructions for GSM900 RX Troubleshooting .................................. 46

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 3

Copyright © 2004 Nokia. All Rights Reserved.

Page 4

RH-53/54

Nokia Customer Care

General Instructions for GSM1800 RX Troubleshooting ................................ 48

RH-53/54 Transmitter Troubleshooting........................................................... 53

Measurement points for the transmitter ........................................................53

General instructions for TX troubleshooting ...................................................54

Troubleshooting chart for GSM900 transmitter .............................................. 56

Logic signals for the Front End Module ......................................................... 57

Renesa FEM logic ..........................................................................................57

RFMD FEM logic ............................................................................................58

Analog Power control signals (TXC, VPC, VDET) .........................................58

I/Q signals ...................................................................................................... 60

Alignment........................................................................................................... 61

Manual alignment with Phoenix ....................................................................... 61

RX calibration................................................................................................... 61

RX Band Filter Response ................................................................................ 64

Tx Power tuning............................................................................................... 64

I/Q tuning ......................................................................................................... 66

RF control ........................................................................................................ 69

Autotune (RH-53 with CMU200) .......................................................................70

File adjustments............................................................................................... 70

Phoenix setup.................................................................................................. 70

List of Figures

Page No

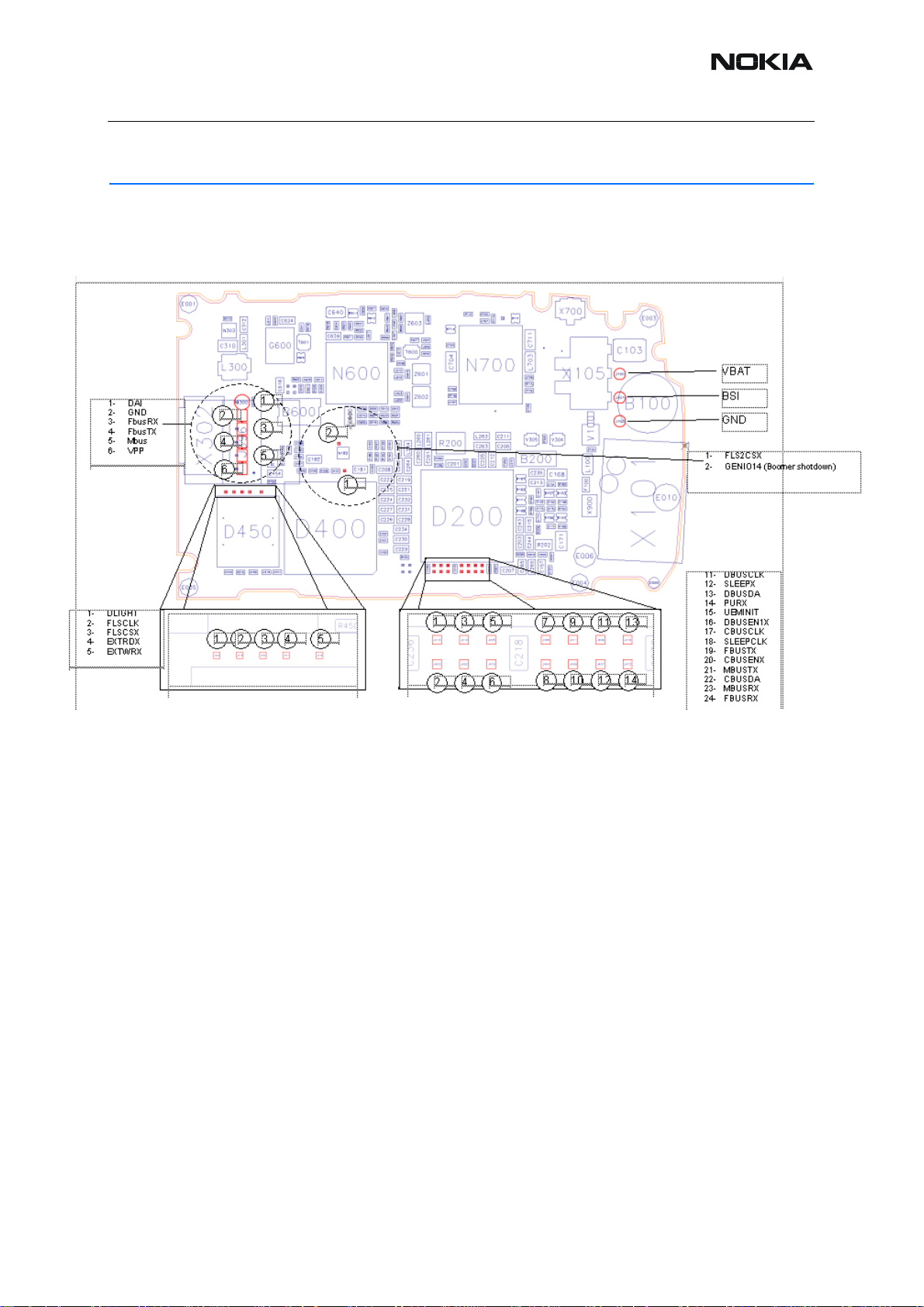

Fig 1 BB test points...............................................................................................7

Fig 2 BB test points 2............................................................................................8

Fig 3 Phone is dead troubleshooting..................................................................... 9

Fig 4 Flash programming troubleshooting............................................................. 10

Fig 5 Phone jammed troubleshooting ................................................................... 11

Fig 6 Troubleshooting when Contact Service message seen............................... 12

Fig 7 No call troubleshooting................................................................................. 13

Fig 8 Phone is OFF:no current from charger ........................................................ 14

Fig 9 Display info:charger connected, not charging.............................................. 15

Fig 10 Microphone does not work.........................................................................16

Fig 11 Top: Earpiece does not work ..................................................................... 16

Fig 12 Headset does not work .............................................................................. 17

Fig 13 Vibra troubleshooting ................................................................................. 20

Fig 14 Receiver signal path................................................................................... 24

Fig 15 Transmitter signal path............................................................................... 25

Fig 16 Frequency plan .......................................................................................... 27

Fig 17 RF key component placement ................................................................... 28

Fig 18 Power supply configuration........................................................................29

Fig 19 UEM measuring points.............................................................................. 30

Fig 20 Measured signal at VCXO output............................................................... 32

Fig 21 Troubleshooting chart for synthesizer........................................................ 33

4 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

RH-53/54

Nokia Customer Care

Fig 22 Measurement points for Synthesizer.......................................................... 34

Fig 23 Measurement points for the VCO............................................................... 35

Fig 24 Measurement points for the FEM............................................................... 38

Fig 25 RX interface points between N600/SAW filters.......................................... 38

Fig 26 Serial Bus interface measurement points .................................................. 39

Fig 27 I/Q measurement points............................................................................. 39

Fig 28 RF controls................................................................................................. 40

Fig 29 Troubleshooting chart for GSM850 receiver ..............................................41

Fig 30 Measuring with oscilloscope ...................................................................... 42

Fig 31 Control values............................................................................................ 43

Fig 32 Troubleshooting chart for GSM1900 receiver ............................................44

Fig 33 Measuring with the oscilloscope ................................................................ 45

Fig 34 Control values............................................................................................ 46

Fig 35 Troubleshooting chart for GSM900 receiver ..............................................47

Fig 36 Measuring with oscilloscope ...................................................................... 48

Fig 37 Rf controls..................................................................................................49

Fig 38 Troubleshooting chart for GSM1800 receiver ............................................50

Fig 39 Measuring with oscilloscope ...................................................................... 51

Fig 40 Front End Module FEM..............................................................................53

Fig 41 MjoelnerN600 test points .......................................................................... 53

Fig 42 TXP and TXC test points............................................................................ 54

Fig 43 Control values............................................................................................ 55

Fig 44 Troubleshooting chart for GSM900 transmitter.......................................... 56

Fig 45 Signals .......................................................................................................57

Fig 46 Power control signals.................................................................................59

Fig 47 RX calibration............................................................................................. 61

Fig 48 Calibration tuning ....................................................................................... 62

Fig 49 Calibration tuning ....................................................................................... 62

Fig 50 Calibration tuning ....................................................................................... 63

Fig 51 Calibration tuning ....................................................................................... 63

Fig 52 TX tuning....................................................................................................64

Fig 53 TX tuning....................................................................................................64

Fig 54 TX tuning....................................................................................................65

Fig 55 TX tuning....................................................................................................65

Fig 56 TX tuning....................................................................................................66

Fig 57 i/Q tuning....................................................................................................67

Fig 58 I/Q tuning.................................................................................................... 67

Fig 59 I/Q tuning.................................................................................................... 68

Fig 60 I/Q tuning.................................................................................................... 68

Fig 61 I/Q tuning.................................................................................................... 69

Fig 62 RF controls................................................................................................. 69

Fig 63 Phoenix-GPIB card .................................................................................... 70

Fig 64 Set loss ......................................................................................................71

Fig 65 Set loss 2 ................................................................................................... 71

Fig 66 Set loss 3 ................................................................................................... 72

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 5

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

Nokia Customer Care

RH-53/54

[This page left intentionally blank]

6 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

RH-53/54

Baseband Troubleshooting

■ Baseband test points

Figure 1:BB test points

Nokia Customer Care

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 7

Copyright © 2004 Nokia. All Rights Reserved.

Page 8

Nokia Customer Care

RH-53/54

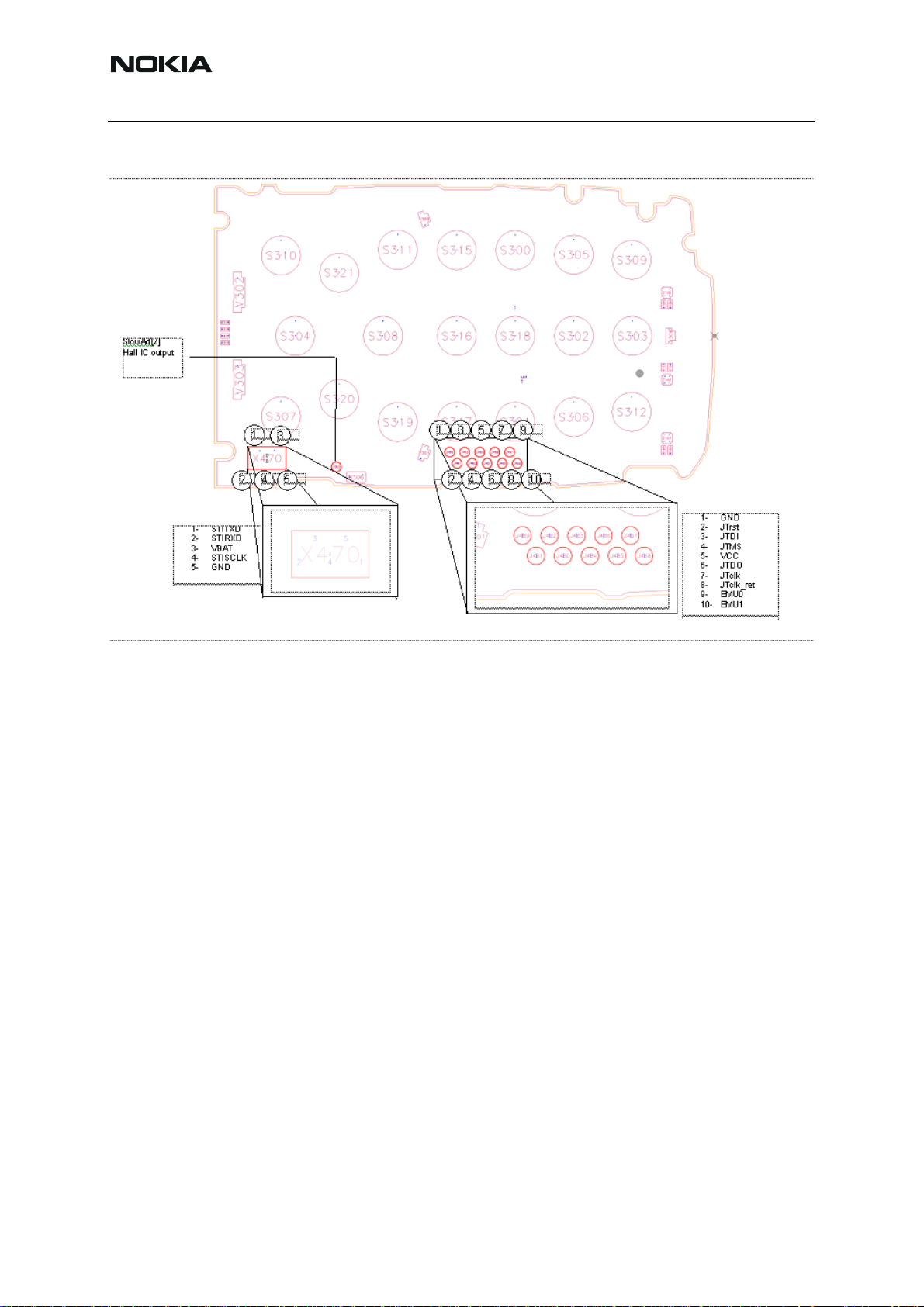

Figure 2:BB test points 2

■ Tr oubleshooting diagrams

INOTE : Since both D200 (UEM) and D400(UPP) are underfilled, they can not be replaced. If

either D200 or D400 is defective, the whole PWB has to be discarded.

8 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 9

RH-53/54

Nokia Customer Care

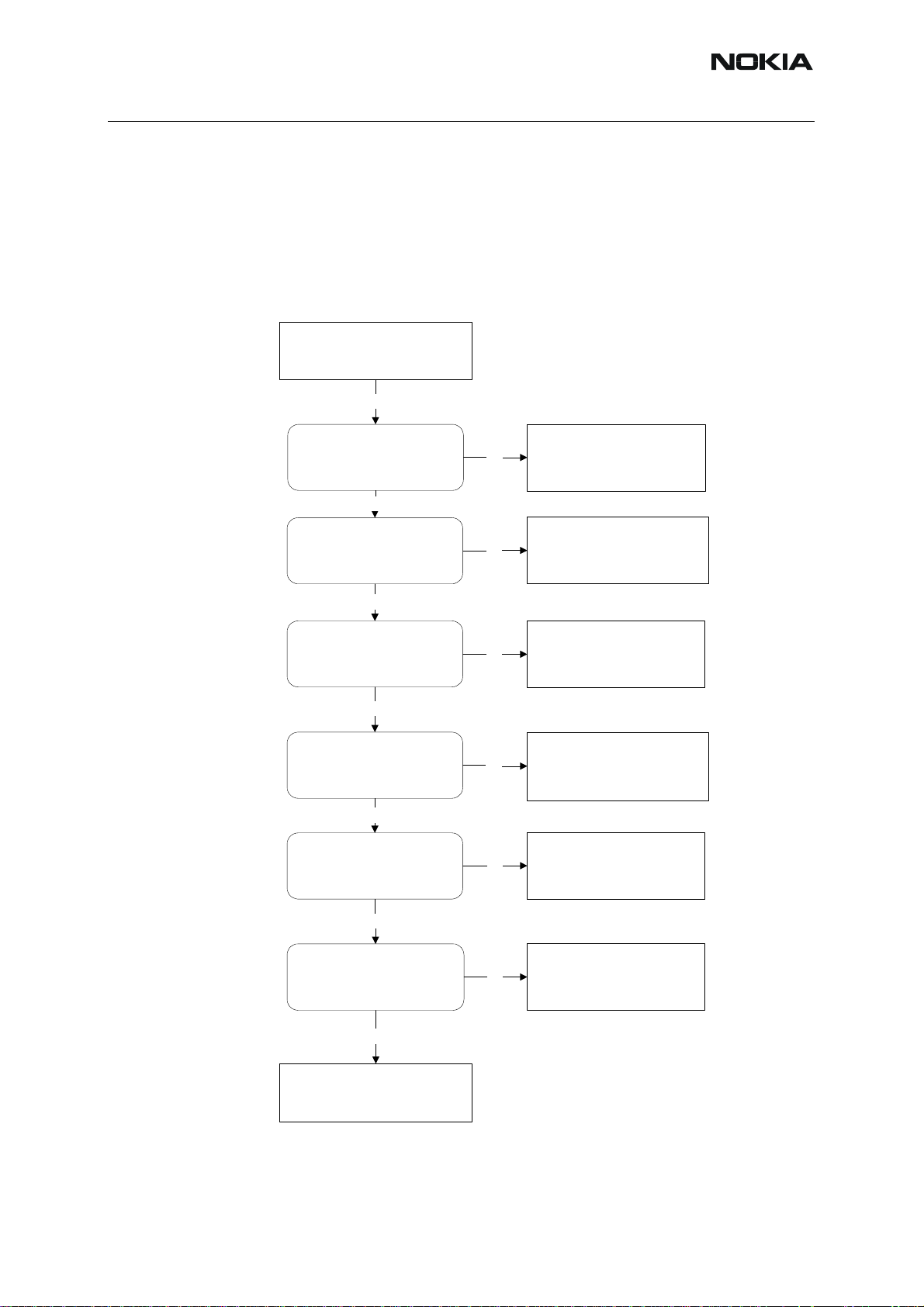

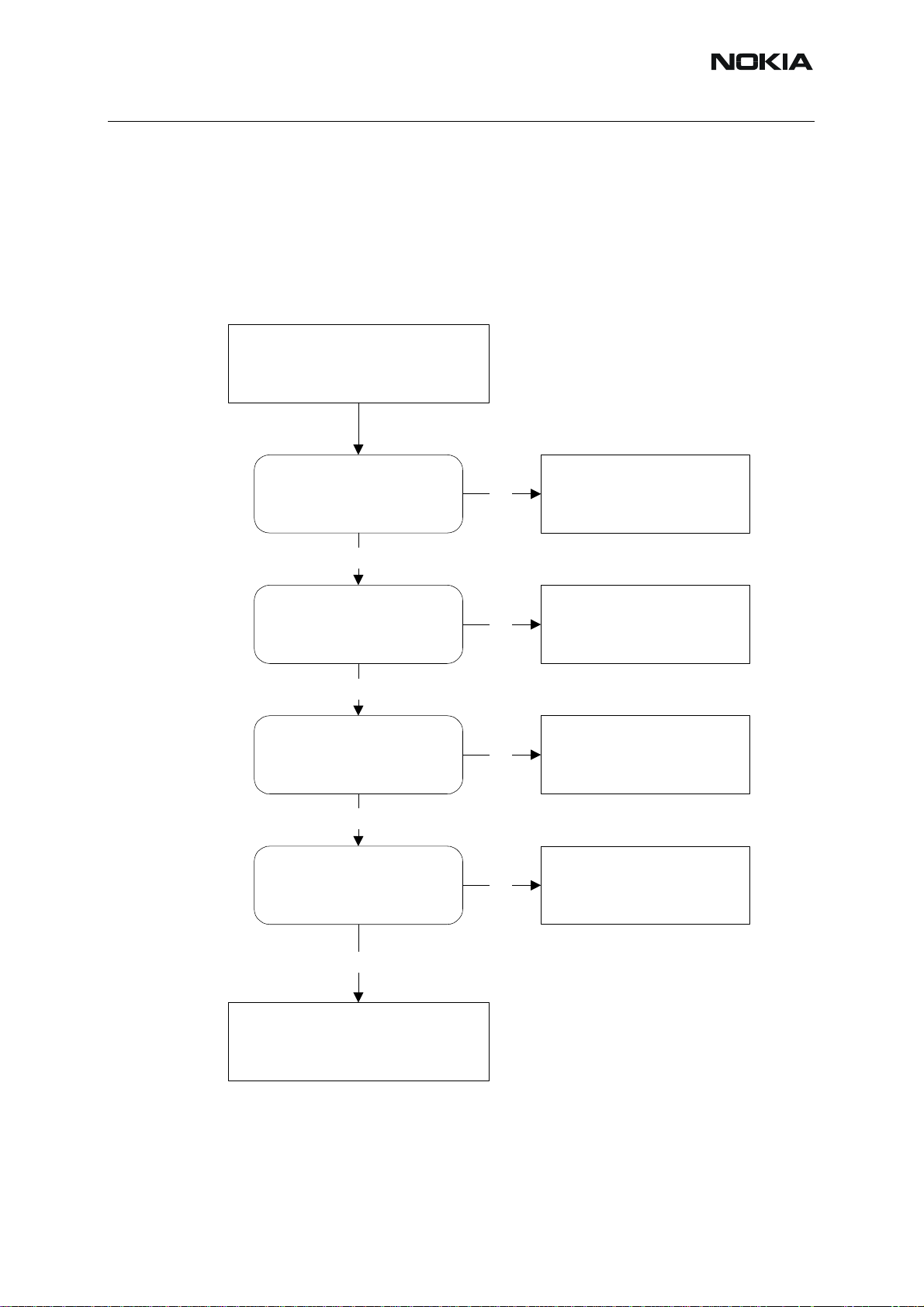

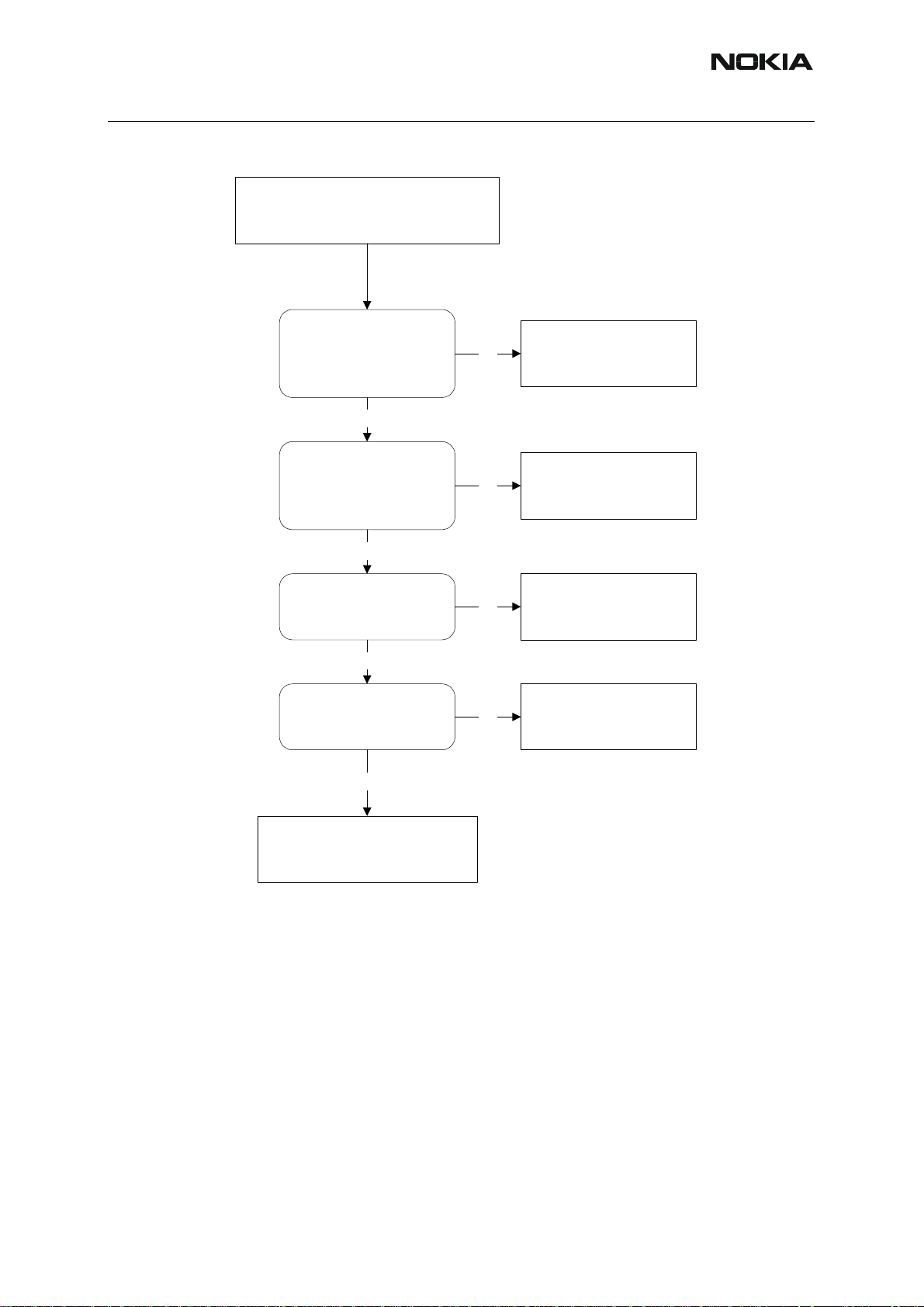

■ Phone is dead

This means that the phone do not draw any current at all when supply is connected and/or

powerkey is pressed.

It is assumed that the voltage supplied is 3.6 VDC. The UEM will pre vent any functionality what

so ever at battery/supply levels below 2.9 VDC.

Figure 3:Phone is dead troubleshooting

Phone is dead

Yes

X105

VBAT = 3,6VDC

Yes

C103

L260,L261,L262,L263,L264,L265

C260,C261,C262,C263,C264,C265

Voltage = 3,6VDC

Yes

J404

Sleep-clock is

32.768 kHz, 1,8Vpp

Yes

J402

PURX = 1,8VDC,

1 sec. after power-key

is pressed

Yes

C227

VR3 = 2,78VDC

No

No

No

No

No

Check :

X105

Check :

C103

L260,L261,L262,L263,L264,L265

C260,C261,C262,C263,C264,C265

Check :

B200, C209, C210, PW B. Else

defective D200*

Check :

PWB.

Else defective D200*

Check :

C227, PWB.

Else defective D200*

Yes

26 MHz clock min. 300mVACpp,

R426

probe Cin=10-13 pF/10M

Yes

No

Check :

C227, C420, R420, PWB.

Else defective D200*

Check :

D450 (Flash).

Else defective D200*

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 9

Copyright © 2004 Nokia. All Rights Reserved.

Page 10

RH-53/54

Nokia Customer Care

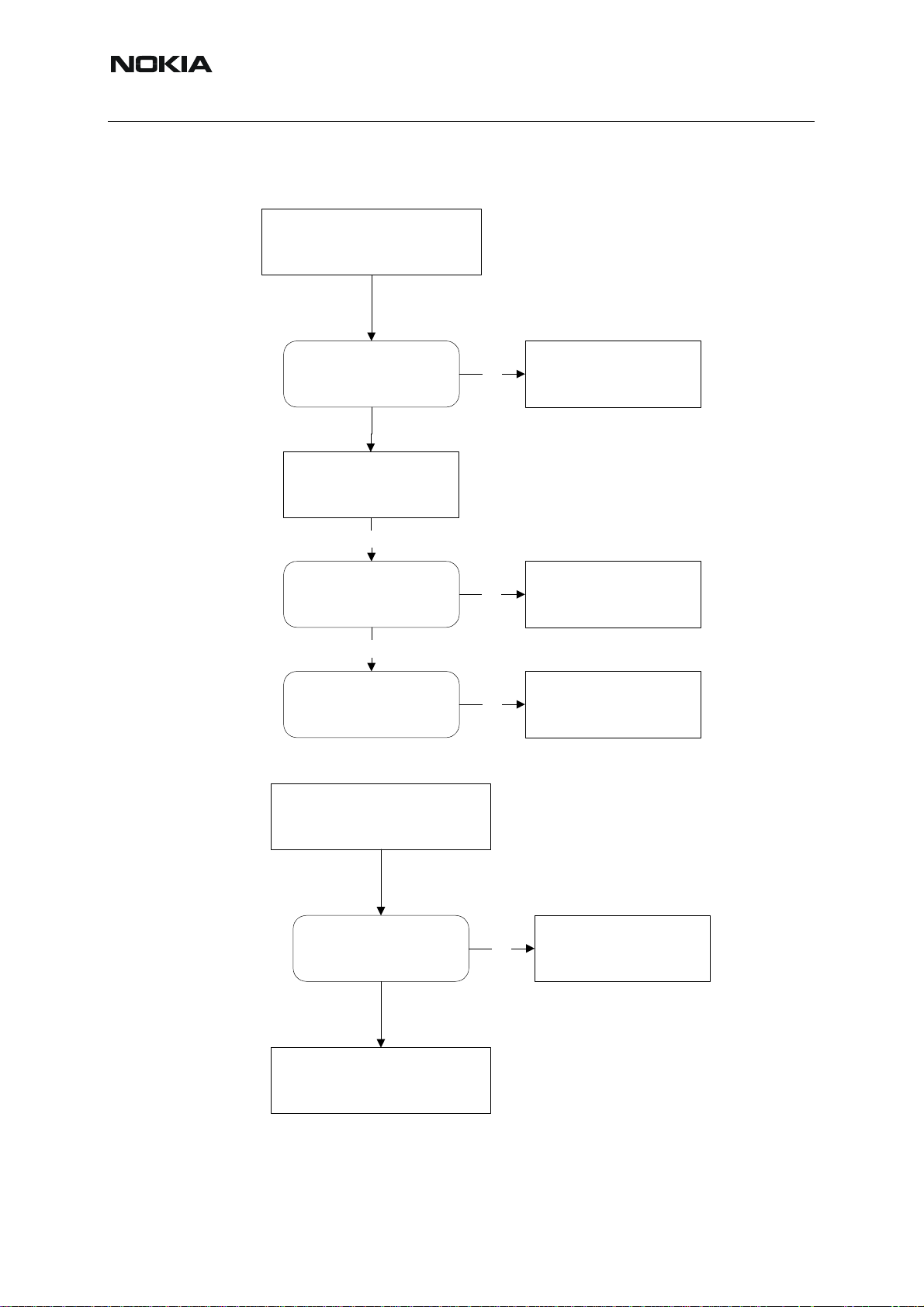

■ Flash programming does not work

The flash programming can only be done via the pads on the PWB (J396).

In case of Flash failure in FLALI station, problem is most likely related to SMD problems. Pos-

sible failures could be short-circuit of balls under µBGAs (UEM, UPP, FLASH). Missing or misaligned components.

In flash programming error cases the flash prommer can give some information about a fault.

The fault information messages could be:

- Phone doesn't set FBUS_TX line low

Because of the use of uBGA components it is not possible to verify if there is a short circu it in

control- and address lines of MCU (UPP) and memory (flash).

Figure 4:Flash programming troubleshooting

Flash prgramming

do not work

Error fro m p ro mmer:

"Phone doesn't set

FBUS_T X line low"

Yes

J396, R108

Check connection between

pad 1,2 & 3 on J396

and R108

Yes

J409, J410, J411, J412

Voltage level at 1,8VDC

Yes

Try re a d in g MCU ID

with Phoenix.

Reading OK?

Yes

Try reading Flash ID

with Phoenix.

Reading OK?

No

No

No

No

Check :

R108, PW B

Check :

PWB.

Else defective D200*

Check :

PWB.

Else defictive D400*

Check :

Replace D450

Yes

Reflash phone

10 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 11

RH-53/54

Nokia Customer Care

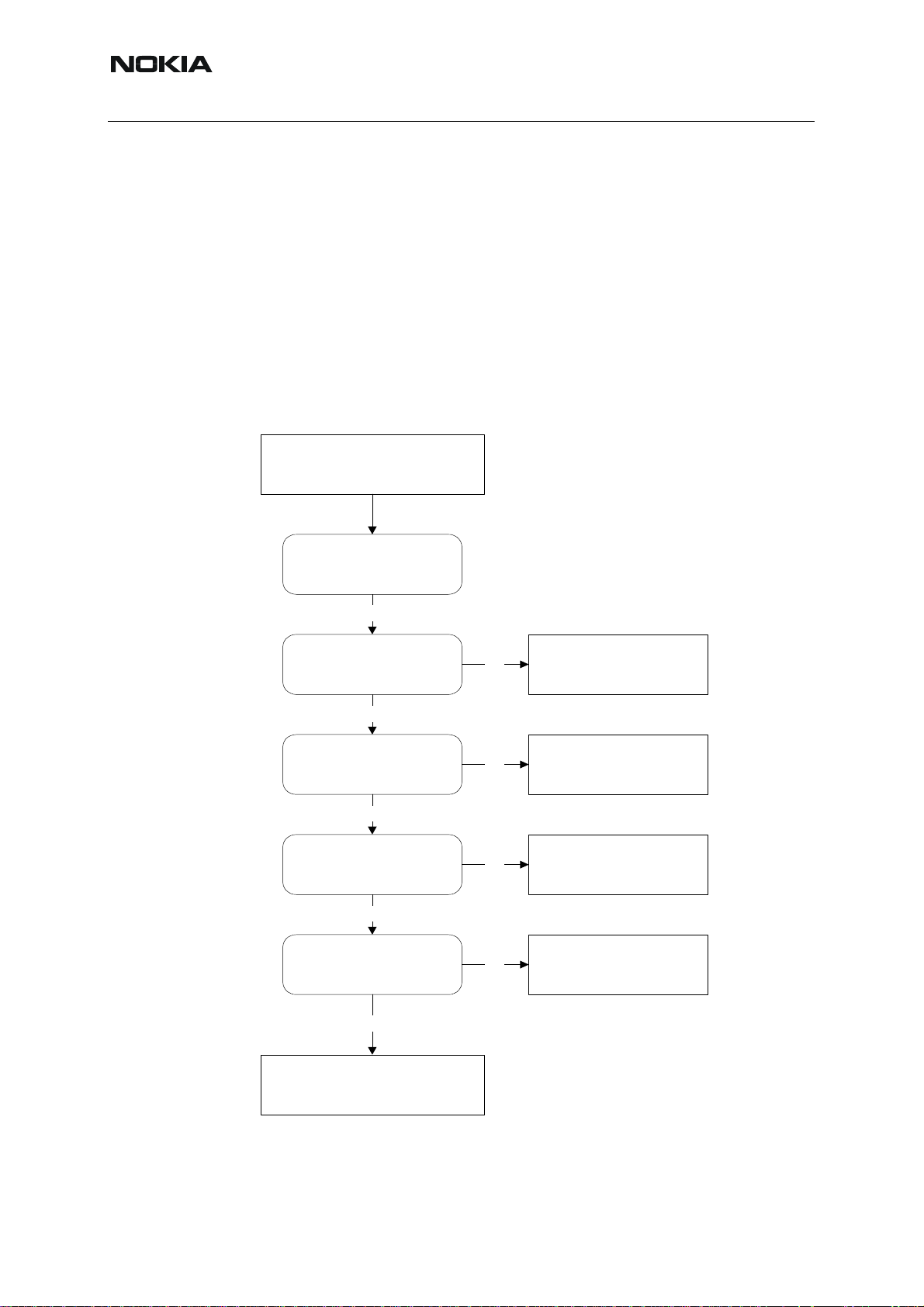

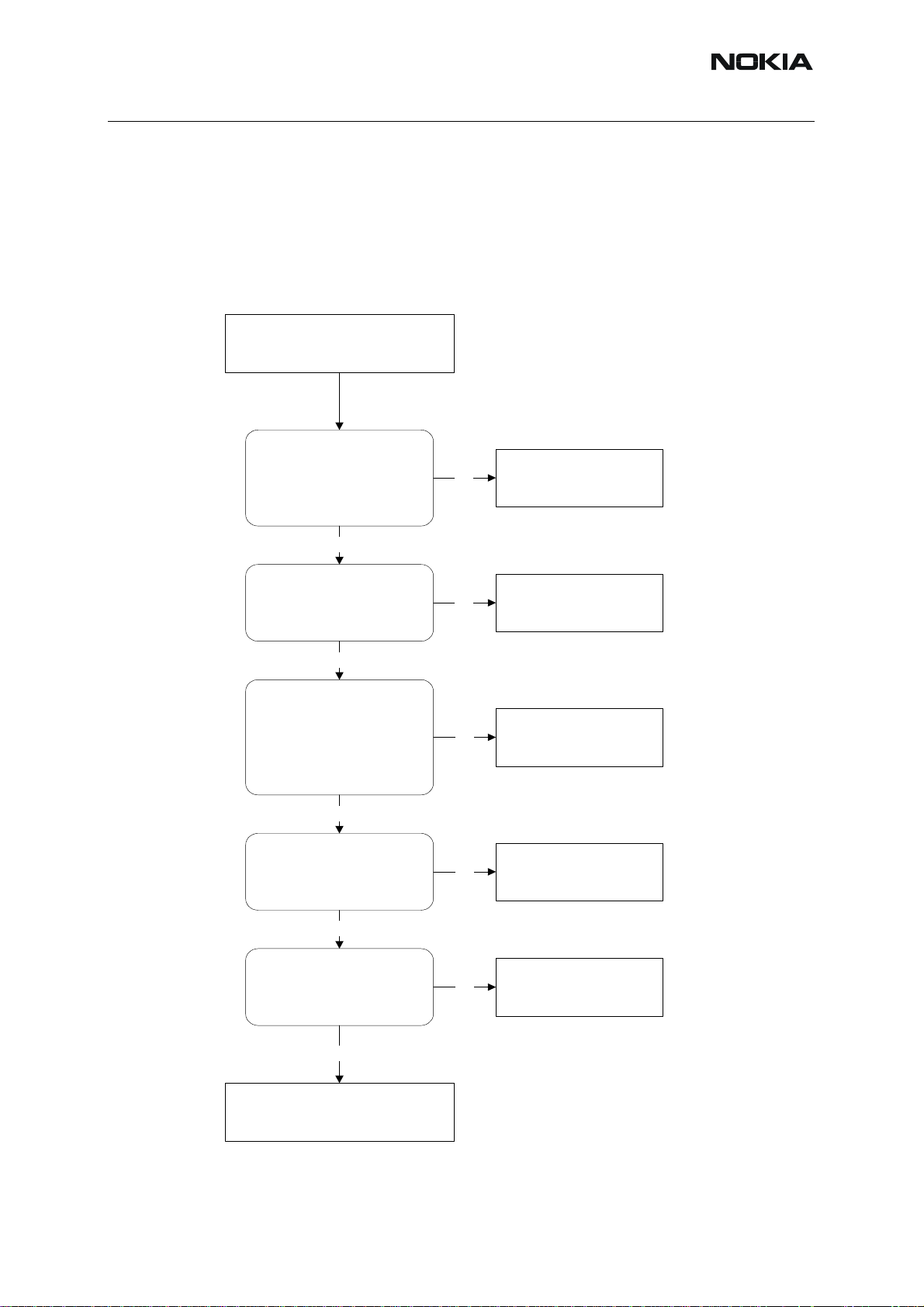

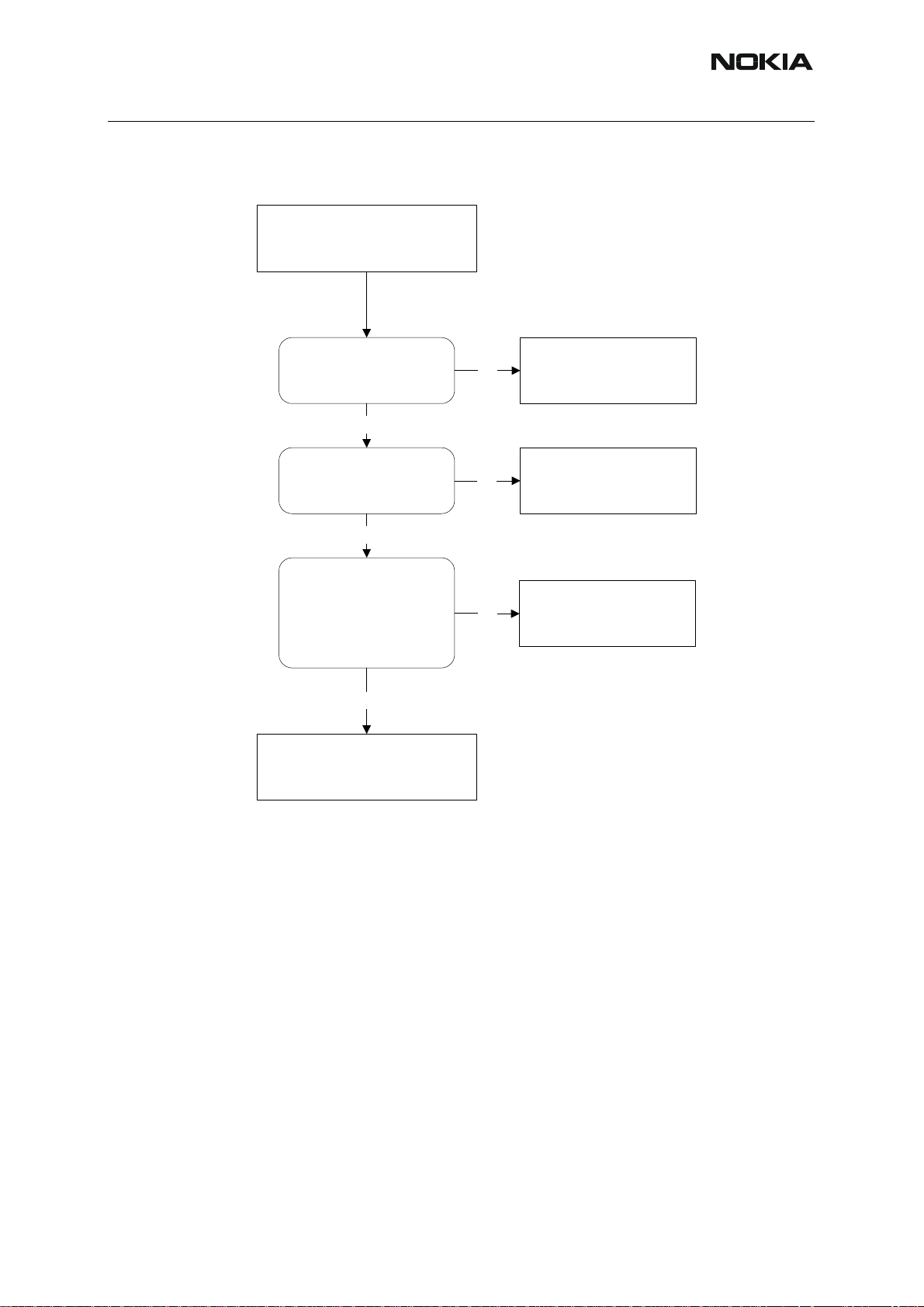

■ Power does not stay on or phone is jammed

If this kind of failure is presenting itself immediately after FLALI, it is most likely caused by

ASICs missing contact with PWB.

If for some reason the MCU does not service the watchdog register within the UEM, the operations watchdog will run out after approximately 32 seconds. Unfortunately , the service routine

can not be measured.

Figure 5:Phone jammed troubleshooting

Power doesn't stay on,

or phone is jammed

J404

Sleep clock = 32.768 kHz,

1.8Vpp

Yes

J402

PURX = 1,8VDC,

1 sec. after power-key i s

pressed

Yes

UI functionality,

and keys react

to pressure?

Yes

R426

26 MHz clock min.

300mVACpp,

probe Cin=10-13 pF/10M

No

No

No

No

Check :

B200, C209, C210, PW B.

Else defective D200*

Check :

PWB.

Else defictive D200*

Check :

D450, Keymat,

Lightguide, PWB .

Else defective D400*

Check :

C420, C426, R420,

R426, N600(Mjoelner)

Yes

Reflash phone

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 11

Copyright © 2004 Nokia. All Rights Reserved.

Page 12

RH-53/54

Nokia Customer Care

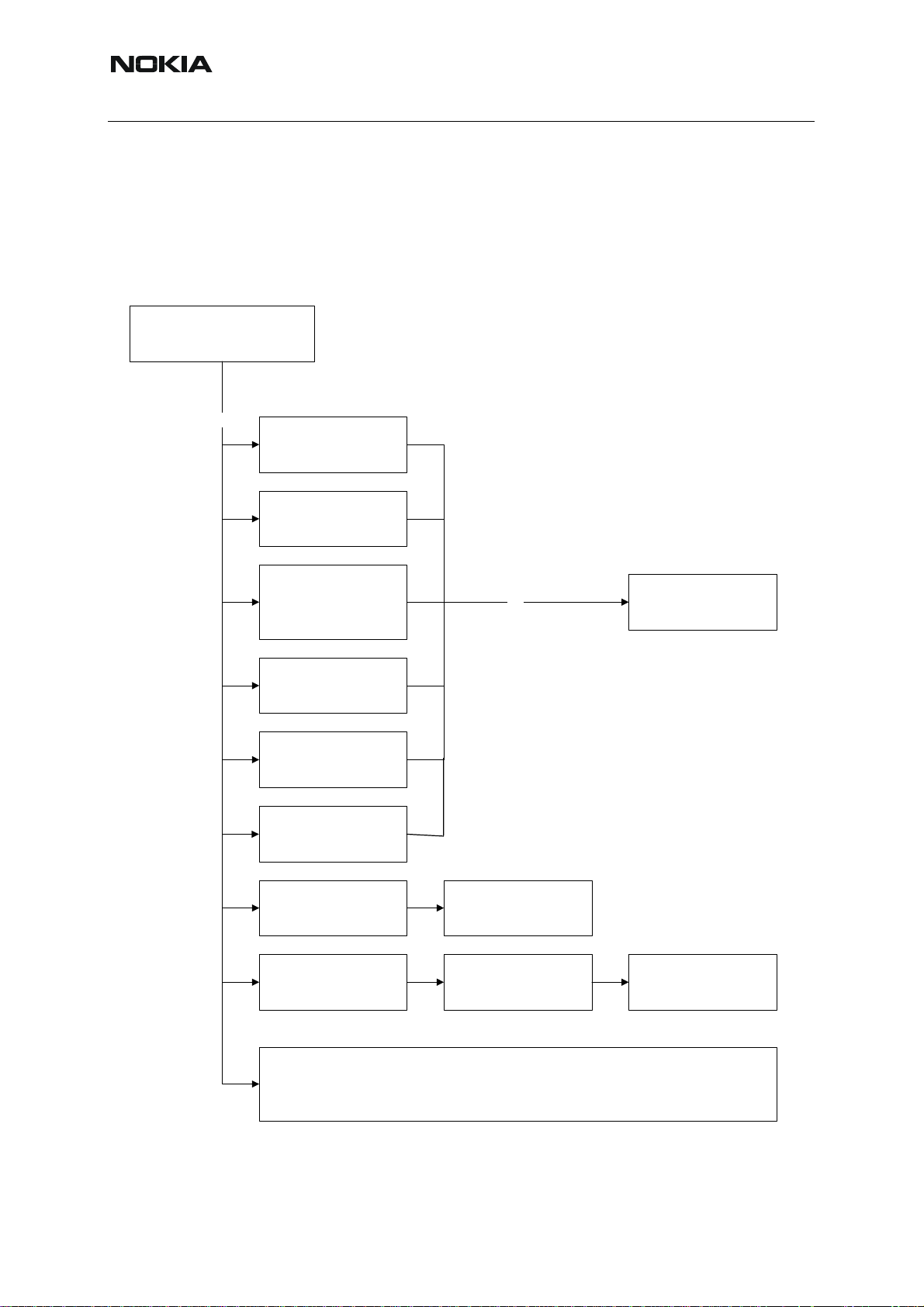

■ Display information : "Contact Service"

This error can only happen at power up where several self-tests is run. If any of these test cases

fails the display will show the message: "Contact Service".

It's individual test cases so the below lineup of error hunting's has no chronological order . Use

common sense and experience to decide which test case to start error hunting at.

Figure 6:Troubleshooting when Contact Service message seen

Display shows

"Contact Service"

Yes

EarDa & MicDa

between

UPP and UEM?

MBUS interface

between

UPP and UEM?

AuxDa & UEMInt

between

UPP and UEM?

SleepX & SleepClk

between UPP & UEM?

TXI/QD & RXI/QD?

SIM interface between

UPP & UEM

No

Check :

PWB.

Else defective D200*

or D400*

Key is stucked

Flash checksum

y ASIC version vs. compilation flag, PMM checksum

y PMM validity

y Warrenty Information State

y SIM-Lock

Check :

A-face, domesheet, PWB.

Reflash phone

Check :

PWB.

Else defective D450 (FLASH)

12 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 13

RH-53/54

Nokia Customer Care

■ The phone does not register to the network, or the phone cannot make a call

If the phone doesn't register to the network, the fault can be in either BB or RF . Only few signals

can be tested since several signals is 'burried' in one or more of the inner layers of the PWB.

First of all check that SIM LOCK is not causing the error by using a Test-SIM card and connect

the phone to a tester.

Figure 7:No call troubleshooting

Phone do not register to

network

or phone cannot make a call

C222, C223, C224, C225,

C226, C227

Voltage = ~2,78VDC

All during GSM frame-

call mode.

Use TXP on C646 as trigger

Yes

C230, C231

Voltage = ~1,35VDC

All during GSM frame (call mode)

Use TXP on C646 as trigger

Yes

J421, J422, J423

Check RF serial bus during

GSM-frame :

Logic HIGH = 1,8VDC

Logic LOW = 0V DC

RFBUSC LK (J421),

RFBUSD A (J422),

RFBUSEN1X (J423)

Yes

R601, R603

Check analog signals during

GSM-frame (RX slot):

RXIP/N (R601) = 0-1,45VDC

RXQP/N (R603) = 0-1,45VDC

Check :

No

C222,C223, C224, C225,

C226, C 227 , P WB .

Else defective D200 or D400*

Check :

No

C230, C 231 , P WB .

Else defective

D200* or D400*

Check :

No

Else defective D200*

Check :

No

Else defective D200*

PWB.

or D400*

PWB.

or D400*

Yes

R610, R611

Check analog signals during

GSM-frame (TX slot):

TXIP/N (R610) = 1-1,75VDC

TXQP/N (R611) = 1-1,75VDC

Yes

No

Check :

R610, R 611 ,P WB .

Else defective D200*

or D400*

Check RF

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 13

Copyright © 2004 Nokia. All Rights Reserved.

Page 14

Nokia Customer Care

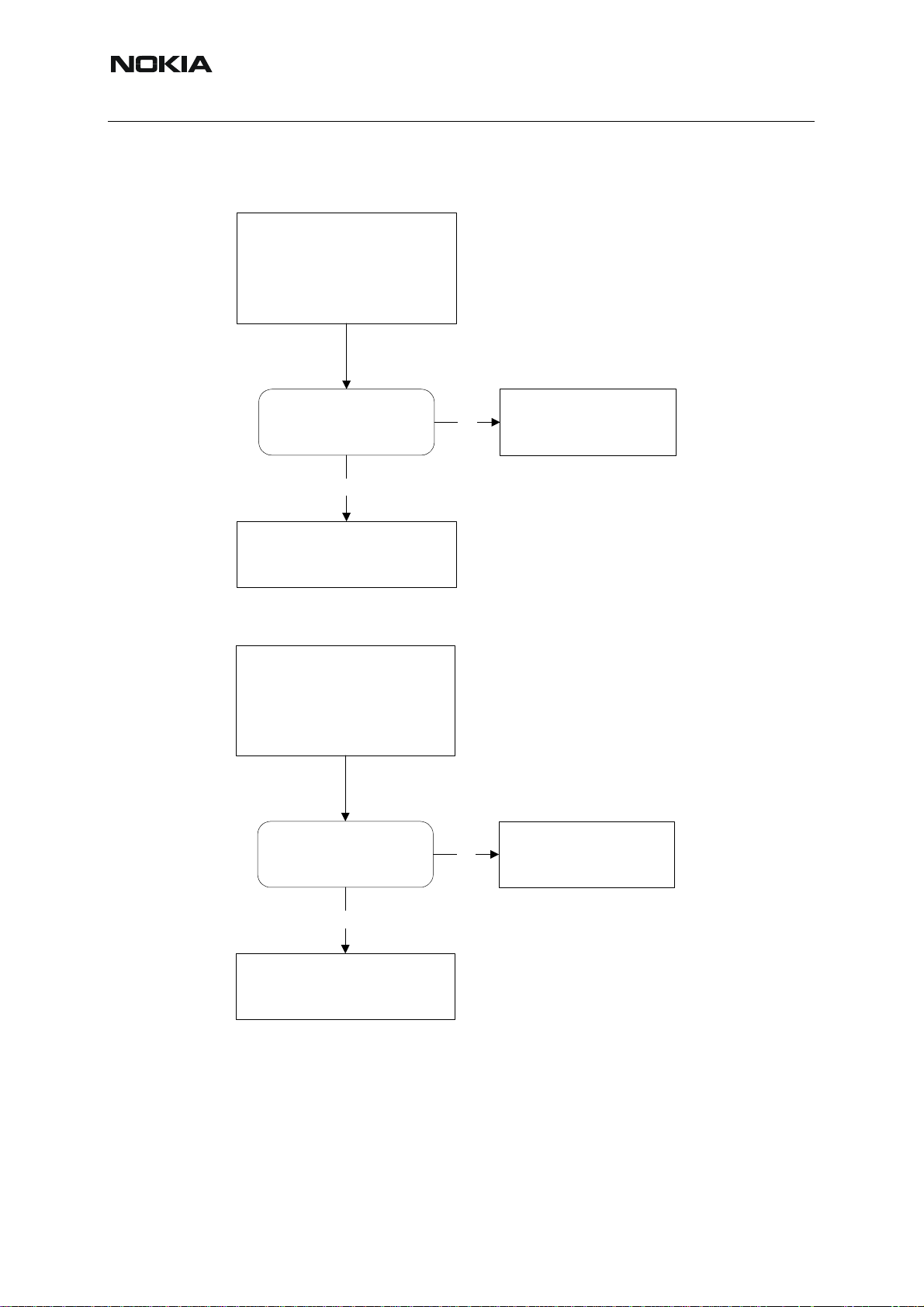

■ Charging troubleshooting

Figure 8:Phone is OFF:no current from charger

Phone is OFF - battery is

completely empty

(<=3,1VDC)

and no current from

charger when connected

RH-53/54

L100

VCHAR > 2,1VDC

Yes

Defective D200*

Phone is ON or OFF - battery

nominal voltage (~3,6VDC)

and no current from

charger when connected

L100

VCHAR > 3,6VDC

No

No

Check :

F100, L100, V100, C100,

R200, System-connector.

Check :

F100, L100, V100, C100,

R200, System-connector.

Yes

Defective

D200 or D400*

14 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 15

RH-53/54

Nokia Customer Care

Figure 9:Display info:charger connected, not charging

Display info when

charger is connected :

"Not charging"

R206

Voltage on R206 towards

D200 is ~0,8VDC

when power is connected.

Yes

R207

Voltage (use scope) on R207

towards D200 is ~0,9VDC at

peak.

No

No

Check :

X105, R202, R206, C240.

Check :

X105, R202, R207, C220.

Yes

R200

Voltage on R200 towards

D200 same as VBAT voltage

Yes

R200

Voltage rises slowly on

R200 towards D200 when

charger is connected.

Yes

Check :

PWB

No

No

Check :

R200, PWB.

Else defective D200*v

Check :

PWB.

Else defective D200*

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 15

Copyright © 2004 Nokia. All Rights Reserved.

Page 16

Nokia Customer Care

■ Audio troubleshooting 1, 2

Figure 10:Microphone does not work

Microphone do not work and

the isn't any mechanical

problem

RH-53/54

Z100

Check Z100 is

working correctly

(no short/open-circuit)

No

Replace :

Mic and micboot

Error still present

R165

Check voltage level on

R165 towards UEM (bias)

= 2,1V

Yes

No

R165, C168, PWB.

Else defctive D200*

R153

Check voltage level on

R153 towards mic-lines (bias)

= 1,0V - 1,4V

No

R153, R157,C151, C152,

C153, C154,R171, PWB.

Figure 11:Top: Earpiece does not work

Headset earpiece do not

work and the isn't any

mechanical problem

Replace :

Z100

Check :

Check :

R183, Z102

Check R183, Z102 is

working correctly

(no open-circuit)

No

Replace :

C183 and/or Z102

Defective D200*

16 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 17

RH-53/54

■ Audio troubleshooting 3: Headset does not work

Figure 12:Headset does not work

Headset microphone do not

work and the isn't any

mechanical problem

Nokia Customer Care

Z101

Check Z101 is working

correctly

(No short/open circuit)

Yes

R151

Check voltage level on R151

towards UEM (bias)

= 1,0V - 1,4V

Yes

R151

Check voltage level on R151

towards UEM (bias) = 1,0V -

1,4V

Check XMIC line to UEM

(D200)

Error still present

Defective D200*

No

No

No

Replace :

Z101

Check :

R166, R151, C171

Check :

R156, C170, C174, C172,

R169

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 17

Copyright © 2004 Nokia. All Rights Reserved.

Page 18

RH-53/54

Nokia Customer Care

Upper block failures

All checks can be done while the phone is partially disamsembled (no need for full reasembly

inbetween debugging steps):

SIM failure (including insert SIM faults)

1. Flex B2B connector pressed in?

2. Change LCD can assembly (for new flex) works?

3. C314 (VSIM cap) short circuitting?

4. C313 (SIMIO cap) short circuitting?

5. Voltages (SIM startup sequence)? Board to Board connector pin17

6. Change main PWB (UEM)?

The hardware of the SIM interface from UEM (D200) to the SIM co nnector can be teste d wit hout a SIM card. When the power is switched on the phone first check for a 1,8V SIM card and

then a 3V SIM card. The phone will try this four times, whereafter it will display ”Insert SIM

card”.

VSIM – Board to board connector pin 17

Reset – Board to board connector pin 29

Clock – Board to board connector pin 20

Data – Board to board connector pin 19

Check for SIM voltage during power-up

Ch1 : VSIM

Ch2 : RESET

Ch3 : CLOCK

Ch4 : DATA

18 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 19

RH-53/54

Nokia Customer Care

The error ”SIM card rejected” means that the A TR message received from SIM card is corrupted, e.g. data signal levels are wrong. The first data is always ATR and it is sent from card to

phone.

For reference a picture with normal SIM power-up is shown below.

Normal SIM power-up sequence

Ch1 : VSIM

Ch2 : RESET

Ch3 : CLOCK

Ch4 : DATA

Vibra failure

1. Flex B2B connector pressed in?

2. Change C2 cover assembly(new vibra)/Vibra works?

3. Change LCD can assembly (new flex) works?

4. Change main PWB (UEM)?

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 19

Copyright © 2004 Nokia. All Rights Reserved.

Page 20

Nokia Customer Care

Figure 13:Vibra troubleshooting

Start

Wrong setting or

software error.

Contact problem.

Mechanical problem

Is there any

vibration?

Yes

No

- counterweight is

blocked

Defective o r missing

vibra.

Defective UEM.

RH-53/54

Is there

sufficient

vibration?

Yes

Vibra is

constantly

switched

on?

No

Intermittent

vibration?

No

Acoustical

noise?

No

Yes

Yes

Software error

Contact problem.

Defective vibra.

Defective UEM.

Software error.

Defective UEM.

Short circuit.

Yes

Bad connection.

Defective vibra.

Defective vibra.

Mechanical problem

- counterweight hits

LCD can/C2 cover

Loose parts in

phone.

Speaker failure

1. Flex B2B connector pressed in?

20 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 21

RH-53/54

Display failure

Nokia Customer Care

2. C2 cover mounted correct (red snap not vissible)?

3. Check if system connector is misplaced slightly?

4. Check for ”headset inserted symbol” in display?

5. Change speaker chamber/antenna works?

6. Change LCD can assembly (for new flex) works?

7. Change main PWB (UEM)?

1. Flex B2B connector pressed in?

2. Display B2B connector pressed in (press through hole in C2 cover assembly)?

3. Change display works?

4. Change LCD can assembly (for new flex) works?

5. R316 (LCDRESETX) missing?

Fold detection failure

1: Check if magnet is mounted on bottom side of C2 cover assembly

(with a spare screw)

2: Check if N306 (Hall IC) is mounted?

Note:

Don’t try and rework flex!! Handling is likely to cause the solder pads to brake or disconncect

from track, which cannot be repaired in a reliable wa y by resoldering. Only reliable repair option

is to change the flex (LCD can assembly)!

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 21

Copyright © 2004 Nokia. All Rights Reserved.

Page 22

Nokia Customer Care

RH-53/54

[This page intentionally left blank]

22 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 23

RH-53/54

Nokia Customer Care

Introduction to RH-53/54 RF Troubleshooting

Three types of measurements are used in the following. It will be specified if the measurement

type is "RF" “RF test” or "LF".

• RF measurements should be done with a GSM tester and a suitable connector to

the general RF input/output. That connection is for tun ing a nd te sting the whole RF

in the phone.

• RF test measurements should be done with a Spectrum Analyzer and a high-frequency 500ohm passive probe, for example HP54006A. Use some sort of DC blocking device, to avoid loading the circuit or the SPA with DC. (Note that when

measuring with the 500ohm probe, the signal will be around 20 dB attenuated. The

values in the following will have these 20 dB subtracted and represent the real value

seen on the spectrum analyzer).

• LF (Low frequency) and DC measurements should be done with a 10:1 probe and

an oscilloscope. The probe used in the following is 10MΩ/8pF passive probe . If using another probe then bear in mind that the voltages displayed may be slightly different.

Always make sure the measurement set-up is calibrated when measuring RF parameters on

the antenna connector. Remember to in clude the loss in the module rep air jig and the coaxial

cable when realigning the phone.

Most RF semiconductors are static discharge sensitive. So ESD prot ection must be taken

during repair (ground straps an d ESD soldering irons). Mjoelner is mo isture sensitive so parts

must be pre-baked prior to soldering.

Apart from key-components described in this document there are a lot of discrete components

(resistors, inductors and capacitors) for which troubleshooting is done by checking if soldering

of the component is done properly or checking if the component is missing from PCB. Capacitors can be checked for short-circuit and resistors for value by means of an ohmmeter, but be

aware in-circuit measurements should be evaluated carefully.

In the following both the name “low band” will be used to describe both GSM850 - EGSM and

GSM900, while “high band” will be used for both PCN and GSM1800.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 23

Copyright © 2004 Nokia. All Rights Reserved.

Page 24

RH-53/54

Nokia Customer Care

General description of the RF circuits

In the following general desriptions different colours are used in the block diagram. The Lowband signal route is shown in red, the Highband route in green and the common signal lines

are shown in blue.

■ Receiver signal path

The signal from the antenna pad is routed to the Front End Module (FEM - N700). The FEM

contains a diplexer and a switch system controlling the direction of the signals, either routing

the TX signal from the Power Amplifier (P A) to the anten na or routing the received signal from

the antenna to either the Lowband (850/900 MHz) or the Highband (1800/1900 MHz) input on

the RF IC (N600).

Figure 14:Receiver signal path

Rx

Ant

Diplexer

RX/TX switch

PA and detector

GSM RX

PCS RX

supply

F

X

R

D

D

V

LNA

Bias

INMH

INPL

INML

INPM

INMM

INPH

ASIC

LNA

LNA

LNA

Pre-gain

Pre-gain

SAW

RX850/

900

SAW

RX1800/

1900

filter

222

2

1/2 1/4

Mjølner

BBAMP

BBAMP

B

B

X

R

D

D

V

BIQUAD

DCN1

LPF1

DCN1

LPF1

AGC

AGC

LPF2

BIQUAD

LPF2

DCN2

DCN2

VRX

RXIP

RXIM

RXQP

RXQM

VR6

1/4

1/2

The Lowband signal from the FEM is routed to the SAW filter (Z602). The purpose of the SA W

filter is to provide out-of band blocking imummity and to provide the LNA in Mjoelner (N600)

with a balanced signal. The front end of Mjoelner is divided into a LNA and Pre-Gain amplifier

before the mixers.

The output from the mixer is fed to Baseband part of Mjoelner where the signals amplified in

the BBAMP aand low pass filteret in LPF1 before the DC compensation circuits in DCN1. The

DCN1 output is followed by a controlled attenuator and a se cond lowp ass filter LPF2. The ou tput from LPF2 is DC centeret in DCN2 before being feed to the BB for demodulation.

The Highband signal chain is similar to the lowband.

■ Transmitter signal path

The I/Q signal from the BB is routed two the modulators for both Lowband and Highband. The

output of the modulators is either terminated in a SA W filte r (Z603) for the Lowb and or a balun

for the Highband. The signals from the SAW and Balun are then amplified in the Power Amplifier (PA) located in the Front End Module (FEM - N700) where the gain control t akes place. In

24 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 25

RH-53/54

Nokia Customer Care

order to control the TX level a sample of the signal is taken in the FEM and used in the power

loop amplfier in Mjoelner to establish the right output power. The selection of which amplifier

chain in the FEM to be active is controlled through the 4 controllines VC1, VC2, BS and Vtx.

Figure 15:Transmitter signal path

Ant

Diplexer

RX/TX switch

PA and detector

Vapc

Vsense

VC1 (TX/RX GSM)

VC2 (TX/RX DCS)

VTX

Band sel

PCN/PCS

GSM

PCN/PCS

Balun

VTX

SAW

PW-loop

filter

VPCTRL_G

VANTL

VANTM

VANTH

VB_DET

VTXLOL

VTXLOH

VTXBH

VTXBL

OUTHP

OUTHM

OUTLP

OUTLM

DET

PLFB1

PLFB2

ASIC

RF Controls

RF Controls

Open collector

Open collector

VDDDIG

VDDRXBB

PWC

TXP

Mjølner

1/2

1/2

2

TXC

VDDTX

Supply

filter

1/4

1/4

2

2

2

2

2

VTX

TXQP/TXQM

VBATTRF

VR2

TXC

TXP

TXIP/TXIM

■ PLL

The PLL supplies Local Oscillator (LO) signals for the RX and TX-mixers. In order to be able

to generate LO-frequencies for the required EGSM and PCN channels a regular synthesizercircuit is used. All blocks for the PLL except for the VCO, reference X-tal and loopfilter is lo cated

in the Mjoelner IC, N600.

The reference frequency is generated by a 26MHz V olt age Controlled X-tal Oscillator (VCXO)

located in the Mjoelner IC. Only the X-tal is external. 26MHz is supplied to BB where a divideby-2 circuit (located in the UPP IC) generates the BB-clock at 13MHz. The reference frequency

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 25

Copyright © 2004 Nokia. All Rights Reserved.

Page 26

RH-53/54

Nokia Customer Care

is supplied to the reference divider (RDIV) where the frequency is divided by 65. The output of

RDIV (400kHz) is used as reference clock for the Phase Detector (ϕ).

The PLL synthesizer is a feedback control system controlling the phase and frequency of the

LO-signal. Building blocks for the PLL are: Phase detector, Charge Pump, Voltage Controlled

Oscillator (VCO), N-Divider and loopfilter. As mentioned earlier only the VCO and loopfilter is

external to the Mjoelner IC.

The VCO (G600) is the component that actually generates the LO-frequency. Based on the

control voltage input the VCO generates a signal, which is made differential through a balun.

This signal is fed to the Prescaler and N-divider in Mjoelner, these 2 block together divide the

frequency by a ratio based on the selected channel. The divider output is supplied to the phase

detector which compares the frequency and phase to the 400kHz reference clock. Based on

this comparison the phase detector controls the charge pump to either charge or discharge the

capacitors in the loopfilter . By charging/discharging the loop filter the control voltage to the VCO

changes and the LO-frequency will change. Therefore the PLL will make the LO-frequency stay

locked to the 26MHz VCXO frequency.

The loopfilter consists of the following components: C639-C641 and R618-R619.

The PLL is operating at twice the channel center frequency when transmitting or receiving in

the PCN band. For the EGSM band the PLL is operating at 4-times the channel frequency.

Therefore divide-by-2 and divide-by-4 circuits are inserted between the PLL output and LO-inputs to the PCN and EGSM mixers.

The frequency plan is shown in the figure below:

Table 1: Frequency table

Frequency

Band

GSM

850

EGSM

900

GSM

1800

Channel #

RX 128 – 251 869.2 – 893.8 3476.8 – 3575.2

TX 824.2 – 848.8 3296.8 – 3395.2

RX 975 – 1023

1 – 124

TX 880.2 – 914.8 3520.8 – 3659.2

RX 512 – 885 1805.2 – 1879.8 3610.4 – 3759.6

TX 1710.2 – 1784.8 3420.4 – 3569.6

System Frequency Band

[MHz]

925.2 – 959.8 3700.8 – 3839.2

PLL Frequency Band

[MHz]

PCN RX 512 – 810 1930.2 – 1989.8 3860.4 – 3979.6

TX 1850.2 – 1909.8 3700.4 – 3819.6

According to the figures above the PLL must be able to cover the f requency range 3420.4MHz

to 3839.2MHz for the GSM900/1800 and 3296.8 to 3979.6MHz for the GSM850/1900.

26 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 27

RH-53/54

To PCN RX

mixer

ASIC

2 22

2

To GSM RX

mixer

Nokia Customer Care

Figure 16:Frequency plan

1/2

1/2

222

2

To PCN

Modulator

Mjoelner

N600

1/4

1/4

To GSM

Modulator

VDDRXBB

Resistor Ext/R2H/R2

VBEXT

Ref.

filte

r

1

VREF

RFCONV_0(9)

Main Bias

Circuit

VDDLO

VDDPLL

VDDPRE

Buffer

VDDCP

CPOUT

VDDXO

VDDBBB

REFOUT

XTALM

XTALP

INPLO

INMLO

VDDDIG

VDDDL

SELADDR

RESETX

RF_EN

RF_CLK

RF_DATA

RESETX

VCOSENSE

3

Charge

Pump

Lock

Detect

1/2

level

shift

I/O

64/

65

RBEXT

2,7k

LOCNT

REFCNT

NDIV

ADIV

VCXO Bias

VDDRXBB

SENSE

Rpa

PA vendor

indication

33k : Hitachi

82k : RFMD

RDIV

R2H/R2

VDDTX

Sensor

BIST / Temp.

ϕ

AFC/CAL

Control

Buf/

AGC

Digital

Control

Synth

supply

filter

Vcp

supply

filter

PLL

loop

filter

VCXO

supply

filter

26MH

z

3

VPLL

VXO

REFOUT

VVCO

VBB (1.8V)

Ref clk set

RESET_X_M

RFBUSX

RFBUSDA

RFBUSCLK

VR5

VR3

VR7

VR2

VIO

VIO

GENIO6

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 27

Copyright © 2004 Nokia. All Rights Reserved.

Page 28

Nokia Customer Care

■ RF Key component placement

Figure 17:RF key component placement

RH-53/54

Table 2: Key component placement tABLE

N600 Mjoelner RF IC

Z601 PCN RX SAW High band RX SAW filter

Z602 EGSM RX SAW Low band RX SAW filter

Z603 EGSM TX SAW Low band TX SAW filter

B600 26 MHz crystal

G600 VCO ( 3.6 GHZ VCO )

N700 Front End Module (FEM)

X700 RF connector

28 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 29

RH-53/54

Nokia Customer Care

Troubleshooting

■ Common circuit

The power supply and the synthesiser is common for RH53/54, except for the synthesiser ranges.

Power Supply Configuration

All power supplies for the RF Unit are generated in the UEM IC (D200). All power outputs from

this IC have a decoupling capacitor at which the supply voltage can be checked.

The power supply configuration used in the phone is shown in the block diagram below:

Figure 18:Power supply configuration

Internal Mjoelner

VR2

2.78 v +/-3%

@100 mA

TX modulator

VR3

VR5

UEM

VR1a

VrefRF01

VR6

VIO

VR7

Modulator loading

netwok

2.78 V +/-3%

@20 mA

2.78 V +/-3%

@50 mA

4.75 V +/-3%

@10 mA

1.35 V +/- 2%

< 100 uA

2.78 V +/-3%

@50 mA

1.8 V +/- 4.5%

@150 mA

2.78 V +/- 3%

@45 mA

Power Loop Amp

Digital control logic

VCXO Power Supply

Baseband clk buffer

Dividers & LO buffer

PLL Pre-scaler

PLL Counters

PLL charge pump

Ref. volt for Mjoelner

LNA and Pre-gain

BB Section

Digital com. interface

VCO module

VCO

VR4

Vbat

2.78 V+/- 3%

@50 mA

Not used

Front End Module

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 29

Copyright © 2004 Nokia. All Rights Reserved.

Page 30

Nokia Customer Care

The names to the left are the signal names used on the RF schematics

Table 3: Supply names

RH-53/54

Supply

name RF

Supply

name UEM

Min Typ Max Unit

VCP VR1A 4.54 4.75 4.9 V

VTX VR2 2.64 2.78 2.86 V

VXO VR3 2.64 2.78 2.86 V

VPLL VR5 2.64 2.78 2.86 V

VRX VR6 2.64 2.78 2.86 V

VVCO VR7 2.64 2.78 2.86 V

VBB VIO 1.72 1.8 1.88 V

VREF2 VrefRF01 1.334 1.35 1.366 V

VBATT BATTERY 3.1 3.6 5.2 V

See the picture below for measuring points at the UEM (D200).

Figure 19: UEM measuring points

VR2=VTX (C223)

VR6=VRX (C225) VR1A=VCP (C221)

VR7=VVCO (C224)

VR3=VXO (C227)

VR5=VPLL (C226)

VrefRF01=VREF1 (C231)

VIO=VBB (C218)

There is only one PLL synthesizer generating Local Oscillator frequencies for both RX and TX

in both bands (Lowband and Highband). The VCO frequency is divided by 2 for Highband operation or by 4 for Lowband operation inside the Mjoelner IC.

30 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 31

RH-53/54

Nokia Customer Care

■ General instructions for Synthesizer troubleshooting

Start the Phoenix-Service-Software and

Select:ProductRH53/54 or scan

Select:Testing

RF Controls

Band XX, se table below

Active UnitRX

Operation ModeContinuous

RX/TX ChannelYY se table below

The signal from the VCO is measured at R640 using a spectrum analysator and a 500ohm p assive probe. The frequency should be as found in the table below and the power should be

around –20dBm.

Table 4: Frequency table

ZZ XX YY PLL frequency [MHz]

RH-54 GSM850 189 3525.6

RH-53 GSM900 36 3768.8

RH-53 GSM1800 700 3685.6

RH-54 GSM1900 661 3920

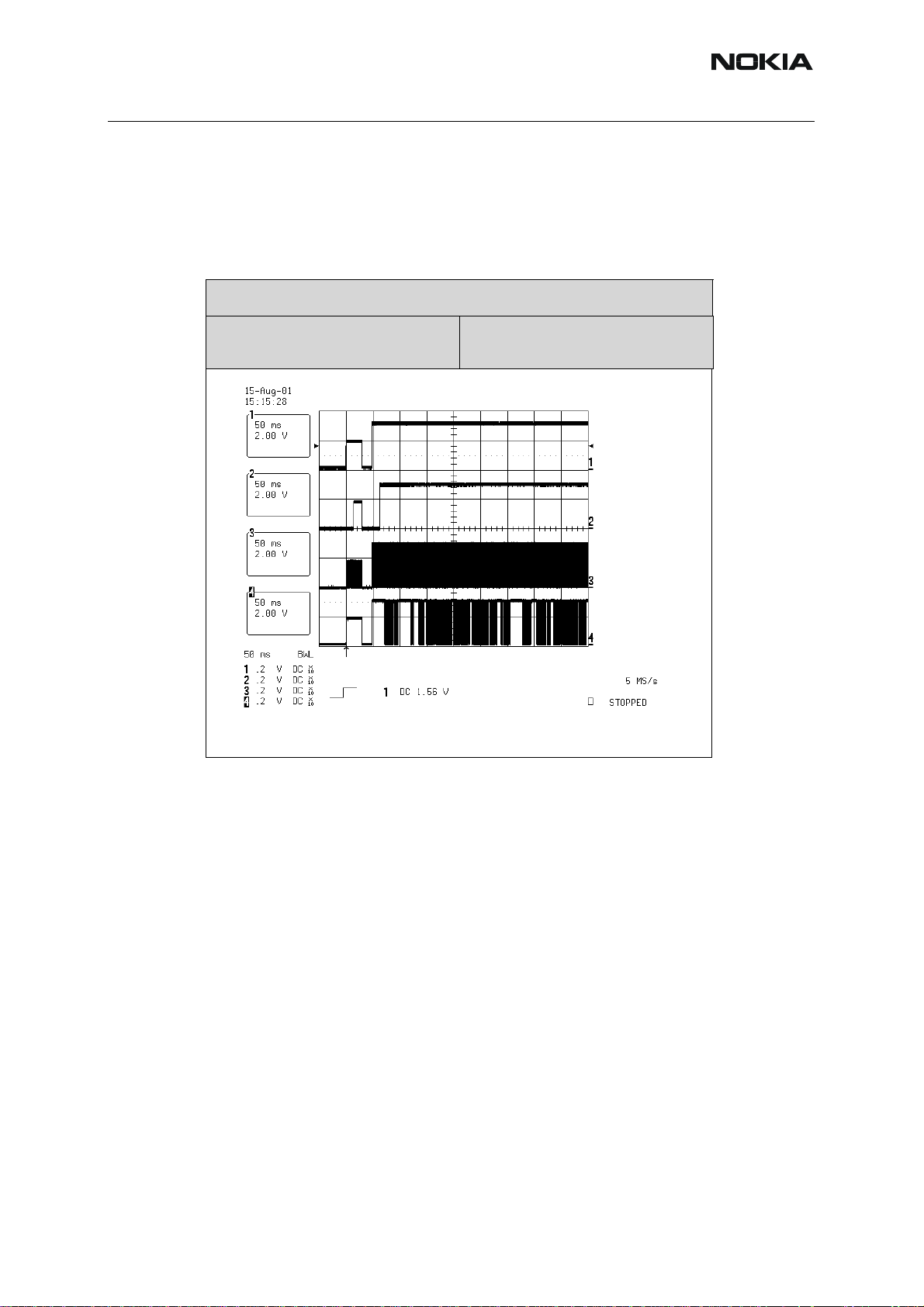

■ 26 MHz Reference Oscillator ( VCXO )

The 26 MHz oscillator is located in the Mjoelner IC (N600). The coarse frequency for this oscillator is set by an external crystal (B600). The reference oscillator is used as a reference frequency for the PLL synthesizer and as the system clock for BaseBand. The 26MHz signal is

divided by 2 to achieve 13MHz inside the UPP IC (D400). The 26 MHz signal from the VCXO

can be measured by probing R420 at the end towards the UPP, see “Measurement points for

the Synthesizer”. The level at this point is approx. 700mVpp. Frequency of this oscillator is adjusted by changing the AFC-register inside the Mjoelner IC. This is done via the Mjoelner serial

interface.

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 31

Copyright © 2004 Nokia. All Rights Reserved.

Page 32

Nokia Customer Care

Example Signal Measured at VCXO output (R420)

Figure 20:Measured signal at VCXO output

RH-53/54

VCO

The VCO is generating frequencies in the range of 3420.4MHz – 3839.2 MHz for the RH-53

and in the range 3296.8 to 3979.6 MHz for RH-54 when the PLL is running. The output frequency from the VCO is led to the Local oscillator input of the Mjoelner IC (N600), where the frequency is divided either by 2 or 4 in order to generate all channels in EGSM and PCN

respectively . Frequency of the VCO is controlled by a DC-volt age (Vctrl) coming from the loopfilter. The loopfilter consists of the component s R618, R619 and C639-C641. Range of the Vctrl

when the PLL is running (locked) is 0.4V – 4.3V. Even if the PLL is not in locked state (Vctrl

out of range) there is some frequency at the output of the VCO (G600), which is between 3 and

4 GHz. This is true if the VCO is working and if the VCO power supply is at present (2.7V).

32 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 33

RH-53/54

■ Tr oubleshooting chart for the Synthesizer

Figure 21:Troubleshooting chart for synthesizer

From Phoenix chose:

File > product > RH-53/54

Maintenance > Testing > RF controls > band > RX >

continous > channel

Band and channel according to the previous table

Nokia Customer Care

Spectrum analyser

VCO frequency (R640)

MHz (see table)

No

Osciloskope

VXO Power supply

(C618)

2.78Vdc

Yes

Osciloskope

VXO Power supply

(C620)

2.78Vdc

Yes

Osciloskope

VCXO output

(R420) 26MHz

approx. 700mVpp

Yes

Yes

No

No

No

PLL block functional

Check UEM, SW

Phone not in function

Check R605, SW

Phone not in function

VCXO is not functional

Check crystal (B600)

Osciloskope

PLL Power supply

(C614, C634)

All 2.7Vdc

No

Check UEM, SW

Phone not in function

Yes

Osciloskope

PLL Charge pump

supply

(C616)

All 4.75Vdc

No

Check R603, C645, UEM,

SW

Phone not in function

N600 not functional

Yes

Spectrum analyser

VCO output (R640)

some signal between

3 and 4 GHz

No

VCO (G600) is not functional

Check Loop filter (R618,

R619, C639-C641)

YES

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 33

Copyright © 2004 Nokia. All Rights Reserved.

Page 34

RH-53/54

Nokia Customer Care

If the phone stops working a short time after the power is turned ON, a possible reason for this

might be the 26MHz system clock signal is not getting to the UPP clock-inpu t in BaseBand. In

this case check the following:

Turn on the phone and check

VCXO Power supply (C620) = 2.7V

VCXO output (R420 – end not connected to C420) is 26MHz and approx. 700mVpp

If this is not the case check the reference crystal (B600) and Mjolner (N600) as well as R420,

R426, C420, C426.

■ Measurement points for the Synthesizer

Figure 22:Measurement points for Synthesizer

Charge pump Supply C616)

VCXO Out (R420)

VPLL (C614, C634)

VXO (C620) VXO (C618)

34 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 35

RH-53/54

Nokia Customer Care

Figure 23:Measurement points for the VCO

Vctl

VVCO (C624)

VCO out (R640)

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 35

Copyright © 2004 Nokia. All Rights Reserved.

Page 36

Nokia Customer Care

RH-53/54

[This page left intentionally blank]

36 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 37

RH-53/54

Nokia Customer Care

Receiver Troubleshooting

■ Front End Module (FEM) control signals

Depending on the vendor of the Front End Module (FEM), dif ferent timing of the control signals

are present. The SW suppoerts both FEMs. R629 tells the SW which FEM control should be

active. Renesas FEM control is used when R629 is 18K and RFMD FEM control is used when

R629 is 82K.

If the FEM is exchanged with an other type, the R629 must be changed, too.

Renesa FEM logic

Table 5: Renesa FEM logic

Mode Vtx BS VC1 VC2

VTX_B_P VTX_B_P Vant1 Vant2

Low Band RX 0 0 0 0

Low Band TX 1 0 1 0

High Band RX 0 1 0 0

High Band TX 1 1 0 1

RFMD FEM logic

Mode VTX_B_P VTX_B_P Vant1 Vant2

Idle 0 0 0 0

Low Band RX 0 0 1 0

Low Band TX 1 0 1 0

High Band RX 0 1 1 0

High Band TX 1 1 1 0

Table 6: RFMD FEM logic

Vtx BS VC1 VC2

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 37

Copyright © 2004 Nokia. All Rights Reserved.

Page 38

Nokia Customer Care

■ Measurements points

Measurement points for the receiver

Figure 24:Measurement points for the FEM

RH-53/54

BS (C709)

RX1800

VC1 (C708)

RX900

VTX (J700)

VC2 (C730)

Figure 25:RX interface points between N600/SAW filters

L610/612 END

L602/603 END

Z601out

Z602out

38 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 39

RH-53/54

Nokia Customer Care

Figure 26:Serial Bus interface measurement points

RESETX

RFBUSDA

Mjoelner seriel interface

RFBUSSENX

RFBUSCLK

Figure 27:I/Q measurement points

RXQP RXQM

RXIP RXIM

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 39

Copyright © 2004 Nokia. All Rights Reserved.

Page 40

Nokia Customer Care

■ RH-54 Receiver

General Instructions for GSM850 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Select->File

->Scan for product->CTRL-R

Select->

Testing ->

RFcontrols

Select:

RH-53/54

Band: GSM850

Active Unit: RX

Operation Mode: Continuous

Rx/Tx Channel: 190

AGC: 9

The setup should now look like this:

Table 7: Band values

Figure 28:RF controls

40 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 41

RH-53/54

Apply -55dBm

881.6MHz

Offset 67.71kHz

from generator to X700

Osciloscope at

Signal 580mVpp

DC offset 1.35V

Freq. 67.71kHz

(ch 190)

RX I/Q.

No

Nokia Customer Care

Figure 29:Troubleshooting chart for GSM850 receiver

Yes

GSM850 OK

Spectrum analyser

RX level (FEM, N700) at

RX900/850 point

-56 dBm

Yes

Spectrum analyser

SAW filter Z602 output

-65dBm

Yes

Spectrum analyser

Check signal after inductors

L602 and L603

-65dBm

Yes

No

No

No

check VC1, VC2, Vtx and

BS, according to logic table

Check Z602

Check inductor

L602, L603

Osciloscope

at N700

Yes

No

Check FEM

N700

Check Mjoelner

N600

Osciloscope

VRX 2.78 Vdc (C225)

Check Mjoelner serial

interface

No

Check UEM, UPP

Yes

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 41

Copyright © 2004 Nokia. All Rights Reserved.

Page 42

RH-53/54

Nokia Customer Care

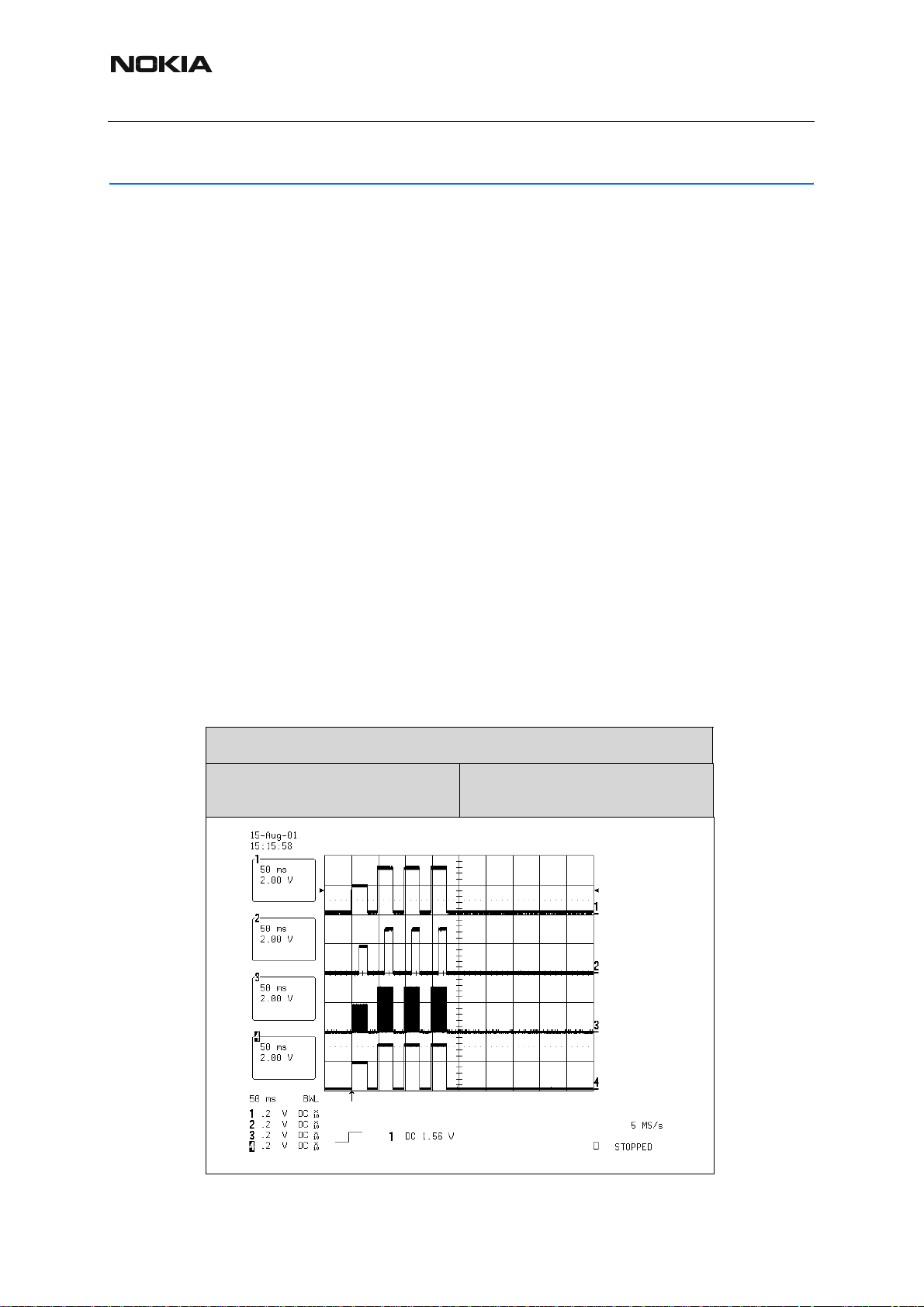

By measuring with an oscilloscope at RXIP or RXQP on a working GSM 850 receiver this picture should be seen

Signal amplitude peak-peak 588 mV

DC offset 1.33 V

Figure 30:Measuring with oscilloscope

42 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 43

RH-53/54

■ General Instructions for GSM1900 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Select->File

->Scan for product->CTRL-R

Select->

Testing ->

RFcontrols

Select:

Table 8: Band values

Nokia Customer Care

Band: GSM1900

Active Unit: RX

Operation Mode: Continuous

Rx/Tx Channel: 661

AGC: 9

The setup should now look like this:

Figure 31:Control values

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 43

Copyright © 2004 Nokia. All Rights Reserved.

Page 44

Nokia Customer Care

Figure 32:Troubleshooting chart for GSM1900 receiver

Apply -55dBm

881.6MHz

(ch 190)

Offset 67.71kHz

from generator to X700

Osciloscope at

RX I/Q.

Signal 580mVpp

DC offset 1.35V

Freq. 67.71kHz

No

Yes

RH-53/54

GSM850 OK

Spectrum analyser

RX level (FEM, N700) at

RX900/850 point

-56 dBm

Yes

Spectrum analyser

SAW filter Z602 output

-65dBm

Yes

Spectrum analyser

Check signal after inductors

L602 and L603

-65dBm

No

No

No

check VC1, VC2, Vtx and

BS, according to logic table

Check Z602

Check inductor

L602, L603

Osciloscope

at N700

Yes

No

Check FEM

N700

Check Mjoelner

N600

Yes

Osciloscope

VRX 2.78 Vdc (C225)

Check Mjoelner serial

interface

No

Check UEM, UPP

Yes

44 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 45

RH-53/54

Nokia Customer Care

By measuring with an oscilloscope at RXIP or RXQP on a working GSM1900 receiver this picture should be seen

Signal amplitude peak-peak 588 mV

DC offset 1.33

Figure 33:Measuring with the oscilloscope

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 45

Copyright © 2004 Nokia. All Rights Reserved.

Page 46

Nokia Customer Care

■ RH-53 Receiver

General Instructions for GSM900 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Select->File

->Scan for product->CTRL-R

Select->

Testing ->

RFcontrols

RH-53/54

Select:

Band: GSM900

Active Unit: RX

Operation Mode: Continuous

Rx/Tx Channel: 37

AGC: 9

The setup should now look like this:

Figure 34:Control values

Table 9: Band values

46 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 47

RH-53/54

Apply -55dBm

Offset 67.71kHz

from generator to

antenna pad

Osciloskope at

Signal 588mVpp

DC offset 1.35V

Freq. 67.71kHz

942.4 MHz

RX I/Q.

No

Nokia Customer Care

Figure 35:Troubleshooting chart for GSM900 receiver

Yes

GSM1800 OK

Check RX/TX

switch at RX900

Z700

-56 dBm

Yes

Spectrum analyser

SAW filt er Z 602 output

-65dBm

Yes

Spectrum analyser

Cehck signal after inductors

L602 and L603

-65dBm

No

No

No

check VC1 and VC2 at

Check Z602

Check inductor

L602, L603

Osciloskope

Z700

Signal=0Vdc

Yes

No

Check RX/TX

switch

Z700

Check Mjoelner

N600

Yes

Osciloskope

VRX 2.7 Vdc

Check Mjoelner serial

interface

No

Check Baseband

Yes

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 47

Copyright © 2004 Nokia. All Rights Reserved.

Page 48

RH-53/54

Nokia Customer Care

By measuring with an oscilloscope at RXIP or RXQP on a working GSM900 receiver this picture should be seen

Signal amplitude peak-peak 588 mV

DC offset 1.33 V

Figure 36:Measuring with oscilloscope

General Instructions for GSM1800 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Select->File

->Scan for product->CTRL-R

Select->

Testing ->

RFcontrols

48 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 49

RH-53/54

Select:

Band: GSM1800

Active Unit: RX

Operation Mode: Continuous

Rx/Tx Channel: 700

AGC: 9

The setup should now look like this:

Nokia Customer Care

Table 10: Band values

Figure 37:Rf controls

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 49

Copyright © 2004 Nokia. All Rights Reserved.

Page 50

Nokia Customer Care

Figure 38:Troubleshooting chart for GSM1800 receiver

Apply -55dBm

1842.8MHz

(ch 700)

Offset 67.71kHz

from generator to X700

Osciloscope at

RX I/Q.

Signal 580mVpp

DC offset 1.35V

Freq. 67.71kHz

No

Yes

RH-53/54

GSM1800 OK

Spectrum analyser

RX level (FEM, N700) at

RX1800/1900 point

-56 dBm

Yes

Spectrum analyser

SAW filter Z601 output

-65dBm

Yes

Spectrum analyser

Check signal after inductors

L610 and L612

-65dBm

No

No

No

check VC1, VC2, Vtx and

BS, according to logic table

Check Z601

Check inductor

L610, L612

Osciloscope

at N700

Yes

No

Check FEM

N700

Check Mjoelner

N600

Yes

Osciloscope

VRX 2.78 Vdc (C225)

Check Mjoelner serial

interface

No

Check UEM, UPP

Yes

50 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 51

RH-53/54

Nokia Customer Care

By measuring with an oscilloscope at RXIP or RXQP on a working GSM1800 receiver this picture should be seen

Signal amplitude peak-peak 588 mV

DC offset 1.33

Figure 39:Measuring with oscilloscope

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 51

Copyright © 2004 Nokia. All Rights Reserved.

Page 52

Nokia Customer Care

RH-53/54

[This page left intentionally blank]

52 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 53

RH-53/54

Nokia Customer Care

RH-53/54 Transmitter Troubleshooting

The troubleshooting of the transmitter for the different phones is similar, meaning that the low

band, 850/900 MHz, has similar values and the high band, 1800/1900 MHz, has simila r values.

The only differences are which selection of product done in Phoenix.

Measurement points for the transmitter

Figure 40:Front End Module FEM

R714 R711

VTX (J700)VPC (R712)

TXQ

VDET (R713)

BS (C709)

VC1 (C708)

VC2 (C730)

Figure 41:MjoelnerN600 test points

Z603 in Z603 Out

TXI

X700

VPC (C644)

T600 in

T600 Out

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 53

Copyright © 2004 Nokia. All Rights Reserved.

Page 54

Nokia Customer Care

RH-53/54

Figure 42:TXP and TXC test points

General instructions for TX troubleshooting

Apply an RF-cable to the RF-connector to allow the transmitted signal act as normal. RF-cable

should be connected to measurement equipment or to at least a 10-dB attenuator, otherwise

the PA may be damaged.

Start Phoenix Service Software and:

Establish a connection to the phone e.g. FBUS.

Select->File

->Scan for product->CTRL-R

Select->

Testing ->

RFcontrols

54 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 55

RH-53/54

Select:

Table 11: Band values

Band: XX

Active Unit: TX

Operation Mode: Burst

Rx/Tx Channel: YY

TX Power level ZZ

TX Data Type Random

Select ”XX” , ”YY” and ”ZZ” according to the table below

Nokia Customer Care

Phone XX YY ZZ

RH-54 GSM850 189 5

RH-53 GSM900 37 5

RH-53 GSM1800 700 0

RH-54 GSM1900 661 0

Your screen should look like this:

Table 12: Values

Figure 43:Control values

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 55

Copyright © 2004 Nokia. All Rights Reserved.

Page 56

RH-53/54

Nokia Customer Care

Measure the output power of the phone; it should be around 32.5 dBm for low band and 29.5

dBm for highband. Remember the loss in the jig; around 0 dB for the low band and 0.1 dB for

the high band.

Troubleshooting chart for GSM900 transmitter

For the spectrum analyzer measurements in the following chart use the 500ohm passive probe

giving an approximately 20 dB lower reading than indicate in the following figures. Since the

signal measured is bursted it is advised to set the analyzer to maxhold.

Figure 44:Troubleshooting chart for GSM900 transmitter

Signal ok on

GSM tester

SPA Burst

Power

No

Check PA input

power

No

Output power

Mjoelner

Yes Yes

Yes

Yes Yes

Check frequency,

TXC, PLL, Vdet, I/

Q

Signal ok on

GSM tester

No

Check I/Q

Yes

Change FEM

Power

laccording to

level

NoNo

TX Power

tuning working

No

Check DC

signals

No

Change FEM,

loop, Z603/T600

Yes

Yes

Check channels

and bands

Change FEM

(N700)

No

Check I/Q, PLL,

TXC, DC

Z603/R714

(T600/R711)

56 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 57

RH-53/54

32.5 dBm

(29.5 dBm)

Nokia Customer Care

Figure 45:Signals

+ 2 dBm + 4 dBm

FEM

N700

VC1 VC2 VTX BS

Det

Max PW: 1.13 vdc

Min PW: 0.22 Vdc

Names in () is for high band

All the red signals are pulsed with the burst

The Green "DC" signals are pulsed with the burst

In local mode random burst RF signals can be demodulated by a GSM

tester

Vpc R712

Max PW: 1.2 Vdc

Min PW: 0.65 Vdc

Logic signals for the Front End Module

Attenuator

R714

(R711)

TXC (R620) Max PW 1.6V

Min PW 0.6 V

TXP (C646) 2.7V

Opamp (C644) Max PW 1.2 V

Min PW 0.65

R610

R611

Z603

(T600)

Mjoelner

N600

Depending on the vendor of the Front End Module (FEM), dif ferent timing of the control signals

are at present:the SW supports both FEMS. R629 tells the SW which FEM control should be

active. Renesas FEM control is used when R629 is 18K and RFMD FEM control is used when

R629 is 82K.

If the FEM is exchanged with an other type, the R629 has to be changed, too.

Renesa FEM logic

Table 13: Renesa FEM logic

Mode Vtx BS VC1 VC2

VTX_B_P VTX_B_P Vant1 Vant2

Low Band RX 0 0 0 0

Low Band TX 1 0 1 0

High Band RX 0 1 0 0

High Band TX 1 1 0 1

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 57

Copyright © 2004 Nokia. All Rights Reserved.

Page 58

Nokia Customer Care

RFMD FEM logic

Table 14: RFMD FEM logic

Vtx BS VC1 VC2

Mode VTX_B_P VTX_B_P Vant1 Vant2

Idle 0 0 0 0

Low Band RX 0 0 1 0

Low Band TX 1 0 1 0

High Band RX 0 1 1 0

High Band TX 1 1 1 0

Analog Power control signals (TXC, VPC, VDET)

RH-53/54

The pictures in the following page show the typical shapes of the control signals low ba nd, right

side it for highest power – left side for lowest power . In all the pictures TXP is used a the trigger

point and is seen in the top of each picture. The difference between the high band and the low

band is that he high band signals looks the same with only small changes in level. The activating of high band Vdet starts 5us earlier than for low band.

58 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 59

RH-53/54

Nokia Customer Care

Figure 46:Power control signals

High Power Low Power

TXC TXC

VPC VPC

VDET VDET

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 59

Copyright © 2004 Nokia. All Rights Reserved.

Page 60

RH-53/54

Nokia Customer Care

I/Q signals

The following diagrams show different situations of TX IQ measurements. Depending on the

time the modulation may cause the signal to look different.

60 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 61

RH-53/54

Nokia Customer Care

Alignment

■ Manual alignment with Phoenix

The alignment/calibration is the same in both GSM900/850 and GSM1800/1900 except for the

channels and frequencies. Only the the procedures for GSM900/GSM1800 are shown.

In Phoenix select connection Fbus scan product. If you power up the board before selecting

Fbus, it works without any error messages. Use Jig or other device for RF and bus connection.

Attenuation in the probe alone is 0dB for 900 and 0.1dB for 1800. Use CMD55,CMU200 or other suitable device. Default channels are 37 for GSM900 and 700 for GSM1800 (Ch 190 and

661 for GSM850/1900). The alignments and calibrations mu st be performed in the order shown

to give reliable results.

The way to save data to the phone and to load data from the phone is made different in the

various tunings. Always look what is shown in the windows regarding these issues and act accordingly . In some windows the saving is done without any warning or secon d approval as soon

as you stop or end.

To vary a selected parameter you can use + and – key or in some cases directly type the new

value. + and – steps the value for every press. Repeat function seems not to work. In I/Q you

can use the side arrows.

■ RX calibration

Select Tuning, RX Calibration

Select band GSM900

Press start

Figure 47:RX calibration

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 61

Copyright © 2004 Nokia. All Rights Reserved.

Page 62

Nokia Customer Care

Follow the description in Phoenix, setting up the signal generator as described

Figure 48:Calibration tuning

RH-53/54

Press the OK button

Figure 49:Calibration tuning

Press the Save&Continue botton.

62 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 63

RH-53/54

Nokia Customer Care

Follow the description in Phoenix, setting up the signal generator as described

Figure 50:Calibration tuning

Press the OK button

Figure 51:Calibration tuning

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 63

Copyright © 2004 Nokia. All Rights Reserved.

Page 64

Nokia Customer Care

Press the Save&Continue botton

Note! You have to follow the shown procedure. It is not possible to tune the high band alone.

You need to make a tuning of the low band first to come to the high band. You can stop at any

time by switching off the menu. If the values are outside internal specs, you can not save them

and have to leave the tuning without saving.

■ RX Band Filter Response

Normally not needed in repair.

■ Tx Power tuning

Select Tuning, Tx Power Level Tuning

Figure 52:TX tuning

RH-53/54

Press start and follow the instructions in the pop-up window

Figure 53:TX tuning

64 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 65

RH-53/54

Nokia Customer Care

Set the spectrum analyser or GSM tester for the required settings and press “OK” If a GSM

tester is used, set the TX data type to random so that the tester can trig on the signal.

Figure 54:TX tuning

Tune the highlighted values to the wanted power (Use average burst power)

Tune the base level to –25dBm

When done press Save&Continue and Phoenix will automatically shif t from lowband t o

highband. At the same time the intermidiate values are calculated, but that is firs t seen

next time you start a tuning.

Figure 55:TX tuning

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 65

Copyright © 2004 Nokia. All Rights Reserved.

Page 66

RH-53/54

Nokia Customer Care

Set the spectrum analyser or GSM tester for the required settings and press “OK” . If a GSM

tester is used, set the TX data type to random so that the tester can trig on the signal.

Figure 56:TX tuning

Tune the highlighted values to the wanted power (Use average burst power).

Tune the base level to –25dBm.

When done press Save&Continue. The intermediate results are then calculated.

The procedure has to be followed. First low band tuning and then high band tuning. You do not

need to change anything.

■ I/Q tuning

Select Tuning, Tx IQ tuning, TX Data Type “random” for a GSM tester like CMU200 or 1/0 for

SPA measuring.

CMD55 shows the same as a spectrum analyzer when I/Q tuning is selected. CMU200 shows

the carrier and sideband supression directly as figures in the modulation mode.

66 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 67

RH-53/54

Nokia Customer Care

Figure 57:i/Q tuning

Press Start

Figure 58:I/Q tuning

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 67

Copyright © 2004 Nokia. All Rights Reserved.

Page 68

Nokia Customer Care

Set the spectrum analyser or GSM tester for the required settings and press “OK”

Figure 59:I/Q tuning

RH-53/54

Begin tuning with data from selected place.

Tune DC offset values to lowest carrier. Use Side arrows or +, - .

Tune Amplitude and phase to lowest sideband.

When satisfied with the result, press Next. (The sidebands should hardly be visible).Or for

CMU200 the supression should be better than -40dBc.

Figure 60:I/Q tuning

68 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 69

RH-53/54

Nokia Customer Care

Set the spectrum analyser or GSM tester for the required settings and press “OK”

Figure 61:I/Q tuning

Press Start to begin tuning with data from selected place.

Tune DC offset values to lowest carrier. Use Side arrows or +, - .

Tune Amplitude and phase to lowest sideband.

When satisfied with the result, press Finish. (The sidebands should hardly be visible).

■ RF control

The purpoase is to check the receiver or transmitter without going in call. It works very much

like a call, but you have control via the PC and not via the tester . If you want to tune or calibrat e

at other channels or levels than the default for that function, you can activate RF control at the

same time and change the wanted parameters.

Figure 62:RF controls

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 69

Copyright © 2004 Nokia. All Rights Reserved.

Page 70

RH-53/54

Nokia Customer Care

Autotune (RH-53 with CMU200)

■ File adjustments

Edit the file RH_53_tunings.ini and save it in the product folder under Phoenix with the right

name. It defines the target values for the tu nings which need targets or can be a general one

that only needs small updates for the values that might change (e.g. the base target).

Edit the file autotune_RH-53.ini and save it in the product folder under Phoenix with the right

name.

Change the Baselevel init values so that the expected base coefficient is among them. It is not

absolutely needed but it speeds up the tuning. Larger steps can be used but with lower accuracy.

Eventually, change also the Coeff init values if the tuning deviates too much from the target.

The lowest coefficient must be very close to 0. Check how the power tuning goes an d try with

some changes.

In case of edge capability, copy from RH-12 and make some changes. RH-12 is for Gemini engine, RH-53 is for Mjoelner engine.

For autotuning, please see also TB “Autotuning function in Phoenix”.

■ Phoenix setup

In Phoenix tools-options-gpib card select the type of card used.

Press start to check if the equipment can be found.

Figure 63:Phoenix-GPIB card

70 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 71

RH-53/54

Nokia Customer Care

With a PKD-1NS dongle the loss in cables and jigs has to be set, and the jig type must be defined to the product. When that is done the PKD-1 donkle can be used, and the losses can not

be changed with that dongle.

Figure 64:Set loss

Select or add a jig and define the losses

Figure 65:Set loss 2

ISSUE 1 09/2004 COMPANY CONFIDENTIAL 71

Copyright © 2004 Nokia. All Rights Reserved.

Page 72

RH-53/54

Nokia Customer Care

Make sure the product has the right type of jig. (At the moment new products like RH-54 can

not be added)

Figure 66:Set loss 3

Note! CMU200:

Remember that CMU200 is left as it was set in the autotune. Attenuation settings are at 0.

72 COMPANY CONFIDENTIAL ISSUE 1 09/2004

Copyright © 2004 Nokia. All Rights Reserved.

Loading...

Loading...