Nissan ZD30 Y Service Manual

ENGINE MECHANICAL

B ENGINE

A

EM

SECTION

CONTENTS

KA24DE

PRECAUTIONS .......................................................... 5

Precautions for Drain Coolant .................................. 5

Precautions for Disconnecting Fuel Piping .............. 5

Precautions for Removal and Dis as sembly .............5

Precautions for Inspection, R epair and Replace-

ment ......................................................................... 5

Precautions for Assembly and Installation ...............5

Parts Requiring Angular Tightening ......................... 5

Precautions for Liquid Gasket .................................. 6

REMOVAL OF LIQUID GASKET SEALING .......... 6

LIQUIDG ASKETAPPLICATIONPROCEDURE..... 6

PREPARATION ........................................................... 7

Special Service Tools ...............................................7

Commercial Service Tools ........................................ 8

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 10

NVH Troubleshooting —Engine Noise ................... 10

Use the Chart Below to Help You Find the Caus e

of the Symptom. ......................................................11

ENGINE ROOM COVER .......................................... 12

Removal and Installation of Engine Room Right

Side ........................................................................ 12

REMOVAL ........................................................... 12

INSTALLTION ..................................................... 12

Removal and Installation of Engine Room Rear

Cover ...................................................................... 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 13

DRIVE BELTS ........................................................... 14

Checking Drive Belts .............................................. 14

Tension Adjustment ................................................ 14

POWER STEERING PUMP BELT ...................... 14

AIR CONDITIONER COMPRESSOR BELT ....... 14

ALTERNATOR AND WATER PUMP BELT ......... 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

AIR CLEANER AND AIR DUCT ............................... 16

Removal and Installation ........................................ 16

ENGINE MECHANICAL

REMOVAL ...........................................................1 6

INSTALLATION ...................................................17

Changing Air Cleaner Element ...............................1 8

REMOVAL ...........................................................1 8

INSTALLATION ...................................................18

THROTTLE BODY ....................................................1 9

Removal and Installation ........................................19

REMOVAL ...........................................................1 9

INSPECTION AFTER REMOVAL .......................20

INSTALLATION ...................................................20

Disassembly and Assembly ....................................20

DISASSEMBLY ...................................................20

ASSEMBLY .........................................................2 0

INTAKE MANIFOLD .................................................2 1

Removal and Installation ........................................21

REMOVAL ...........................................................2 1

INSPECTION AFTER REMOVAL .......................22

INSTALLATION ...................................................22

EXHAUST MANIFOLD .............................................23

Removal and Installation ........................................23

REMOVAL ...........................................................2 3

INSPECTION AFTER REMOVAL .......................24

INSTALLATION ...................................................24

INSPECTION AFTER INSTALLATION ................24

OIL PAN AND O IL STRAINER .................................25

Removal and Installation ........................................25

REMOVAL ...........................................................2 5

INSPECTION AFTER REMOVAL .......................25

INSTALLATION ...................................................25

INSPECTION AFTER INSTALLATION ................26

SPARK PLUG (CONVENTIONAL) ........................... 2 7

Removal and Installation ........................................27

REMOVAL ...........................................................2 7

INSPECTION AFTER REMOVAL .......................27

INSTALLATION ...................................................27

FUEL INJECTOR AND FUEL TUBE ........................28

Removal and Installation ........................................28

REMOVAL ...........................................................2 8

INSTALLATION ...................................................29

INSPECTION AFTER INSTALLATION ................29

C

D

E

F

G

H

I

J

K

L

M

EM-1

ROCKER COVER .....................................................30

Removal and Installation ........................................30

REMOVAL ...........................................................30

INSTALLATION ....................................................30

CAMSHAFT ............................................................... 32

Removal and Installation ........................................32

REMOVAL ...........................................................32

INSTALLATION ....................................................34

INSPECTION AFTER REMOVAL........................35

Valve Clearance ......................................................38

INSPECTION .......................................................38

ADJUSTMENT ....................................................38

SECONDARY TIMING CHAIN ..................................41

Removal and Installation ........................................41

REMOVAL ...........................................................41

INSPECTION AFTER REMOVAL........................44

INSTALLATION ....................................................45

PRIMARY TIMING CHAIN ........................................49

Removal and Installation ........................................49

REMOVAL ...........................................................50

INSPECTION AFTER REMOVAL........................51

INSTALLATION ....................................................51

CYLINDER HEAD .....................................................55

On-Vehicle Service .................................................55

CHECKING COMPRESSION PRESSURE .........55

Removal and Installation ........................................56

REMOVAL AND INSTALLATION .........................56

Disassemblyand Assembly ....................................57

DISASSEMBLY ...................................................57

ASSEMBLY .........................................................58

INSPECTION AFTER DISASSEMBLY ................58

ENGINE ASSEMBLY ................................................63

Removal and Installation ........................................63

REMOVAL ...........................................................64

INSTALLATION ....................................................65

INSPECTION AFTER INSTALLATION ................66

CYLINDER BLOCK ...................................................67

Disassemblyand Assembly ....................................67

DISASSEMBLY ...................................................68

ASSEMBLY .........................................................70

How to Select Piston and Bearing ..........................74

DESCRIPTION ....................................................74

HOW TO SELECT PISTON .................................75

HOW TO SELECT CONNECTING ROD BEAR-

ING ......................................................................75

HOW TO SELECT MAIN BEARING ....................76

Inspection After Disassembly .................................78

CRANKSHAFT SIDE CLEARANCE ....................78

CONNECTING ROD SIDE CL EARANCE ...........78

PISTON AND PISTON PIN CLEARANCE ..........78

PISTON RING SIDE CLEARANCE .....................79

PISTON RING END GAP ....................................79

CONNECTING ROD BEND AND TORSION .......80

CONNECTING R OD BEARING (BIG END) ........80

CONNECTING R OD BUSHING OIL CLE AR-

ANCE (SMALL END) ...........................................80

CYLINDER BLOCK DISTORTION ......................81

INNERDIAMETER OF MAINBEARING HOUS-

ING .......................................................................81

PISTON TO CYLINDER BORE CLEARANCE ....82

OUTER DIAMETER OF CRANK SHAFT JOUR-

NAL ......................................................................83

OUTER DIAMETER OF CRANKSHAFT PIN ......83

OUT-OF-ROUND A ND TAPER OF CRA NK-

SHAFT ................................................................. 83

CRANKSHAFT RUNOUT ....................................83

OIL CLEARANCE OF CONNECTING RO D

BEARING .............................................................84

OIL CLEARANCE OF MAIN BEARING ...............84

CRUSH HEIGHT OF MAIN BEARING ................85

OIL JET ................................................................85

OIL JET RELIEF VALVE ......................................85

FLY WHEEL RUNOUT ........................................86

SERVICE DATA AND SPECIFICATIONS (SDS) ......87

Standard and Limit ..................................................87

GENERAL SPECIFICATIONS .............................87

DRIVE BELTS ......................................................87

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD ...................................................................87

SPARK PLUG ......................................................88

SECONDARY TIMING CHAIN ............................88

CYLINDER HEAD ................................................88

VALVE ..................................................................88

CAMSHAFT AND CAMSHAFT BEARING ...........92

CYLINDER BLOCK ..............................................92

PISTON,PISTON RING AND PISTON PIN ........93

CONNECTING ROD ............................................94

CRANKSHAFT .....................................................94

MAIN BEARING ...................................................95

CONNECTING ROD BEARING ...........................95

FLYWHEEL ..........................................................96

Tightening Torque ...................................................96

ZD30DD

PRECAUTIONS .........................................................98

Precautions for Drain Coolant ................................. 98

Precautions for Disconnecting Fuel Piping ............. 98

Precautions for Removal and Disassembly ............98

Precautions for Inspection, Repair and Replace-

ment ........................................................................98

Precautions for Assembly and Installation ..............98

Parts Requiring Angular Tightening ........................98

Precautions for Liquid Gasket ................................. 99

REMOVAL OF LIQUID GASKET SEALING ........99

LIQUIDGASKETAP PLICATIONPROCEDURE...99

PREPARATION .......................................................100

Special Service Tools ............................................100

Commercial Service Tools ....................................102

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ............................................103

NVH Troubleshooting —Engine Noise ..................103

Use the Chart Below to Help You Find the Cause

of the Symptom. ....................................................104

ENGINE ROOM CO VER .........................................105

Removal and I ns tallation of Engine Room Right

EM-2

Side ...................................................................... 105

REMOVAL ......................................................... 105

INSTALLATION ................................................. 105

Removal and Installation of Engine Room Rear

Cover .................................................................... 105

REMOVAL ......................................................... 105

INSTALLATION ................................................. 106

DRIVE BELTS ......................................................... 107

Checking Drive Belt .............................................. 107

Tension Adjustment .............................................. 107

Removal and Installation ...................................... 107

WATER PUMP, ALTERNATOR AND A/C COM-

PRESSOR BELT ............................................... 107

Drive Belt Auto Tensioner ..................................... 109

REMOVAL ......................................................... 109

INSPECTION AFTER REMOVAL ..................... 109

INSTALLATION ................................................. 109

Dummy Pulley ...................................................... 109

REMOVAL ......................................................... 109

INSPECTION AFTER REMOVAL ..................... 109

INSTALLATION ................................................. 109

AIR CLEANER AND AIR DUCT ..............................110

Removal and Installation .......................................110

REMOVAL ..........................................................110

INSTALLATION .................................................. 111

Changing Air Cleaner Element ..............................112

REMOVAL ..........................................................112

INSTALLATION ..................................................112

INTAKE MANIFOLD COLLECTOR AND INTAKE

MANIFOLD ..............................................................113

Removal and Installation .......................................113

REMOVAL ..........................................................113

INSPECTION AFTER REMOVAL ......................115

INSTALLATION ..................................................115

EXHAUST MANIFOLD ............................................117

Removal and Installation .......................................117

REMOVAL ..........................................................117

INSPECTION AFTER REMOVAL ......................118

INSTALLATION ..................................................118

INSPECTION AFTER INSTALLATION ..............118

OIL PAN AND OIL STRAINER . ...............................119

Removal and Installation .......................................119

REMOVAL ..........................................................119

INSTALLATION ................................................. 120

INSPECTION AFTER INSTALLATION ............. 120

GLOW PLUG .......................................................... 121

Removal and Installation ...................................... 121

REMOVAL ......................................................... 121

INSTALLATION ................................................. 122

VACUUM PUMP ..................................................... 123

Removal and Installation ...................................... 123

REMOVAL ......................................................... 123

INSTALLATION ................................................. 123

INSPECTION AFTER INSTALLATION ............. 123

INJECTION TUBE AND INJE CT ION NOZZLE ......125

Removal and Installation ......................................125

REMOVAL .........................................................125

INSPECTION AFTER REMOVAL .....................127

INSTALLATION .................................................127

INSPECTION AFTER INSTALLATION ..............128

ELECTRONIC CO NTRO LFUEL INJECTIONPUMP.129

Removal and Installation ......................................129

REMOVAL .........................................................129

INSTALLATION .................................................132

INSPECTION AFTER INSTALLATION ..............134

ROCKER COVER ...................................................135

Removal and Installation ......................................135

REMOVAL .........................................................135

INSTALLATION .................................................136

CAMSHAFT ............................................................138

Removal and Installation ......................................138

REMOVAL .........................................................139

INSPECTION AFTER REMOVAL .....................139

INSTALLATION .................................................141

Valve Clearance ...................................................142

INSPECTION ....................................................142

ADJUSTMENTS ................................................144

TIMING CHAIN ........................................................147

Removal and Installation ......................................147

REMOVAL .........................................................147

INSPECTION AFTER REMOVAL .....................149

INSTALLATIO N .................................................149

TIMING GEAR .........................................................151

Removal and Installation ......................................151

REMOVAL .........................................................152

INSPECTION AFTER REMOVAL .....................155

INSTALLATIO N .................................................157

CYLINDER HEAD ...................................................160

On-Ve hicle Service ...............................................160

CHECKING COMPRESSION PRESSURE .......160

Removal and Installation ......................................161

REMOVAL .........................................................161

INSPECTION AFTER REMOVAL .....................162

INSTALLATIO N .................................................163

Disassembly and Assembly ..................................166

DISASSEMBLY .................................................166

ASSEMBLY .......................................................167

INSPECTION AFTER DISASSEMBLY ..............167

ENGINE ASSEMBLY ..............................................172

Removal and Installation ......................................172

REMOVAL .........................................................172

INSTALLATIO N .................................................174

INSPECTION AFTER INSTALLATION ..............175

CYLINDER BLOCK ................................................176

Disassembly and Assembly ..................................176

DISASSEMBLY .................................................177

ASSEMBLY .......................................................181

How to Select Piston ............................................184

DESCRIPTION ..................................................184

SELECTIVE PISTON COMBINATION ..............184

INSPECTION AFTER DISASSEMBLY ..............185

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-3

SERVICE DATA AND SPECIFICATIONS (SDS ) ....194

Standard and Limit ................................................194

GENERAL SPECIFICATIONS ...........................194

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD .................................................................194

DRIVE BELTS ...................................................194

CYLINDER HEAD .............................................195

VALVE ................................................................195

CAMSHAFT AND CAMSHAFT BEARING ........199

CYLINDER BLOCK ............................................199

PISTON,PISTON RING AND PISTON PIN ......200

CONNECTING ROD ..........................................201

CRANKSHAFT ...................................................201

AVAILABLE MAIN BEARING .............................202

AVAILABLE CONNECTING ROD BEARING .....202

MISCELLANEOUS COMPONENTS ..................202

Tightening torque ..................................................203

EM-4

PRECAUTIONS

[KA24DE]

[KA24DE]

PRECAUTIONS PFP:00001

Precautions for Drain Coolant

● Drain coolant when engine is cooled.

Precautions for Disconnecting Fuel Piping

● Before starting work, make sure no fire or spark producing items are in the work area.

● Release fuel pressure before disassembly.

● After disconnecting pipes, plug openings to stop fuel leakage.

EBS007JS

EBS007JT

A

EM

C

Precautions for Removal and Disassembly

● When instructed to use special service tools, use the specified tools. Always be careful to work safely,

EBS007JU

avoid forceful or uninstructed operations.

● Exercise maximum care to avoid damage to mating or sliding surfaces.

● Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

● Mark and arrange disassembly parts in an organized way for easy troubleshooting and re -assembly.

● When loosening nuts and bolts, as a basic rule, s tart with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loos ening is specified, do exactly as specified.

Precautions for Inspection, Repair and Replacement

● Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way,

EBS007JV

and replace if necessary.

Precautions for Assembly and Installation

● Use torque wrench to tighten bolts or nuts.

● When tightening nuts and bolts, as a basic rule, equall y tighten in several different steps starting with the

EBS007JW

ones in center, then ones on inside and outs ide diagonally in this orde r. If the order of tightening is specified, do exactly as specified.

● Replace with new ga sket, packing, oil seal or O-ring.

● Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction

and blockage.

● Avoid damaging sliding or mating surfaces. Completely remove foreign materials suc h as cloth lint or dust.

Before assembly, oil sliding surfaces well.

● Release air within route after draining coolant.

● After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems

for leakage.

D

E

F

G

H

I

J

K

L

Parts Requiring Angular Tightening

● Use an angle wrench for the final tightening of the following engi ne parts:

– Cylinder head bolts

– Connecting rod cap nuts

● Do not use a torque value for final tightening.

● The torque value for these parts are for a preliminary step.

● Ensure thread and seat su rfaces are clean and coated with engine oil.

EM-5

EBS007JX

M

PRECAUTIONS

[KA24DE]

Precautions for Liquid G asket

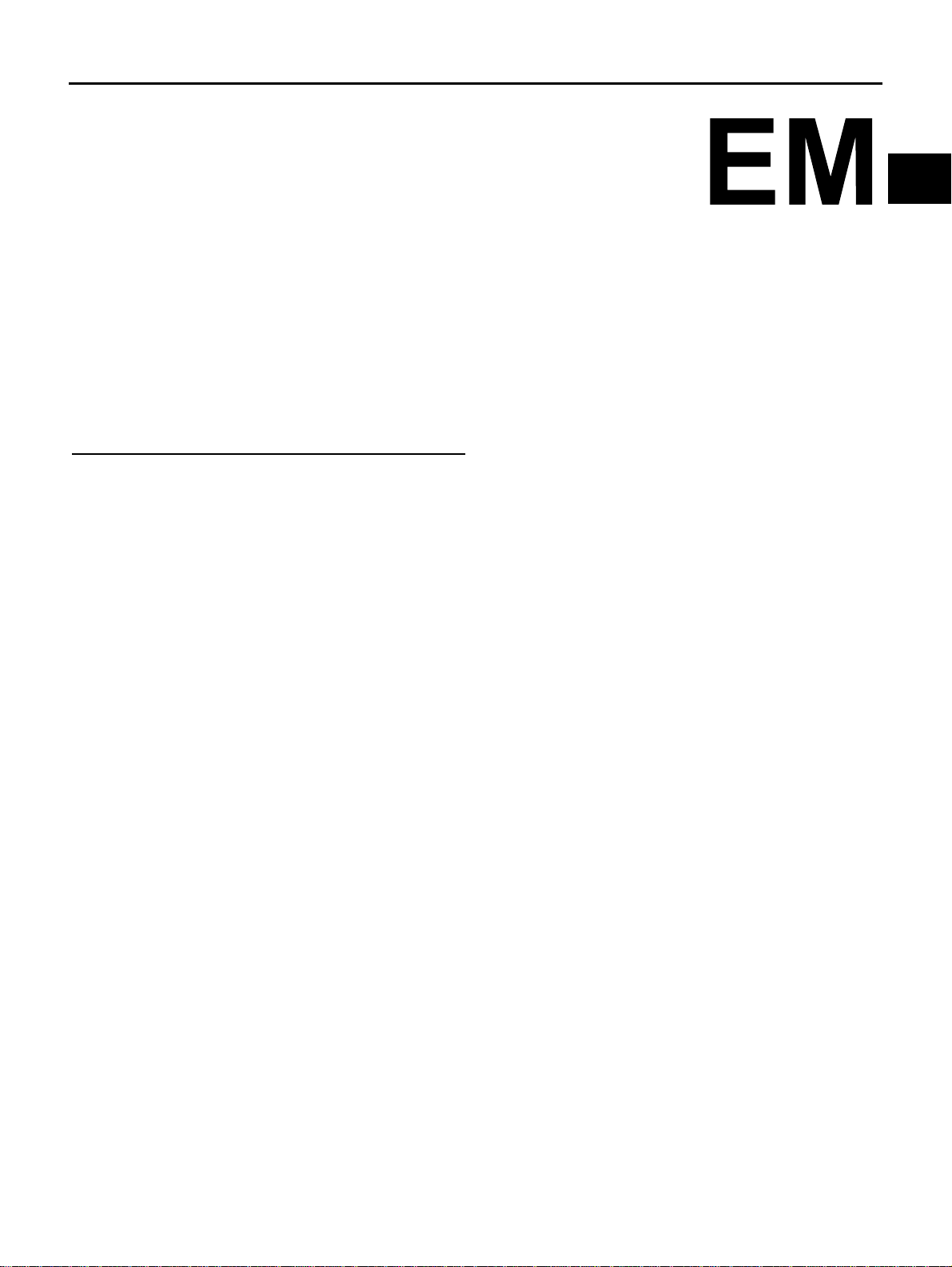

REMOVAL OF LIQUID GASKET SEALING

● After removing the mounting bolts and nuts, disconnect and

remove the liquid gasket se aling using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

● In areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

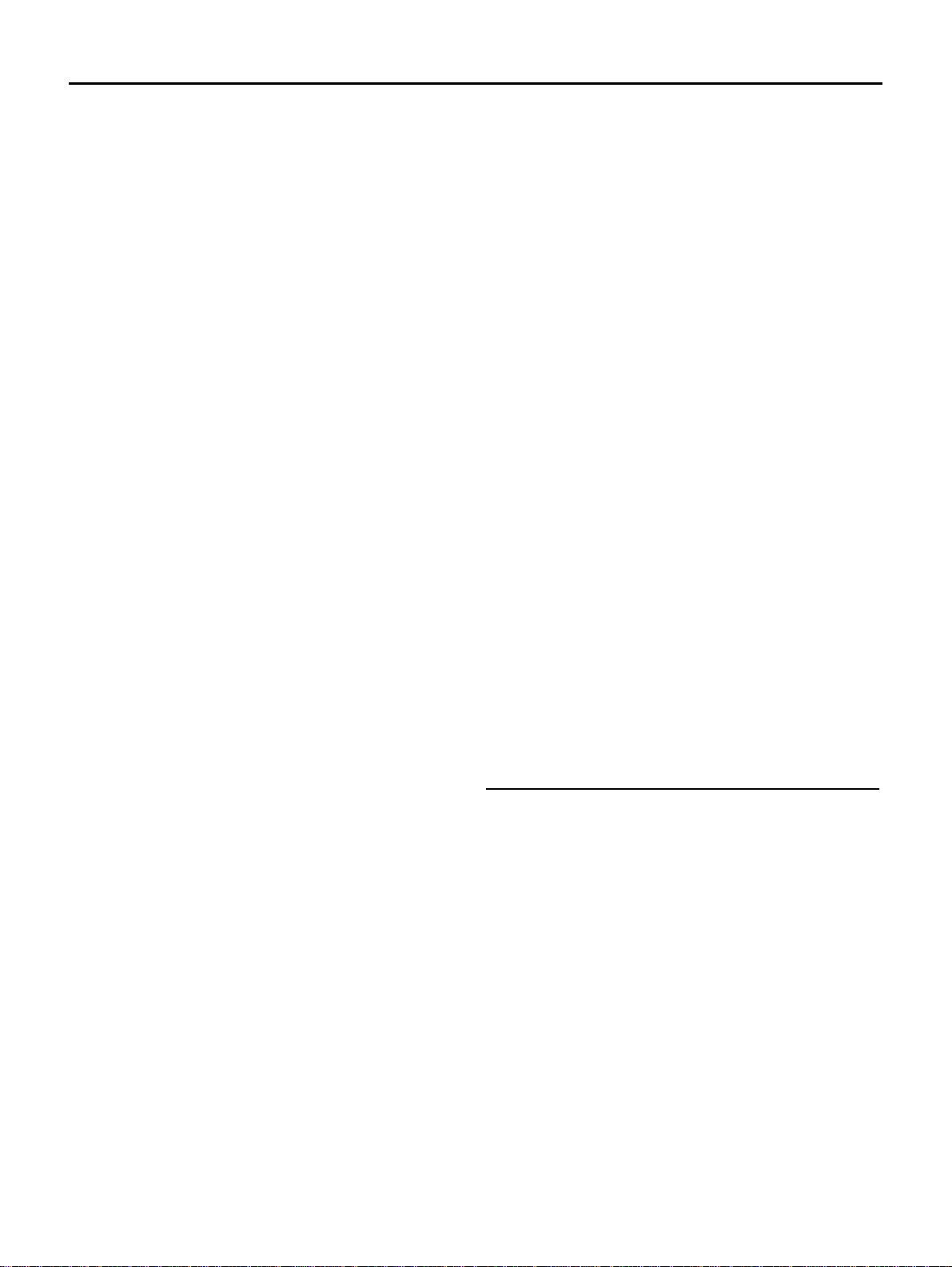

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

● Remove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lig hting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

EBS007JY

PBIC0275E

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

● If there is a groove for the liquid gasket application, apply the

gasket to the groove.

● As for the bolt holes, normally apply the gasket inside the hole s.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

● Within five minutes of gasket applica tion, install the mating com-

ponent.

● If the liquid gasket protrudes, wipe it off immediately.

● Do not retighten after the installation.

● After 30 minutes or more have passed from the installation, fill the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe them.

PBIC0003E

EMA0622D

EM-6

PREPARATION

[KA24DE]

PREPARATION PFP:00002

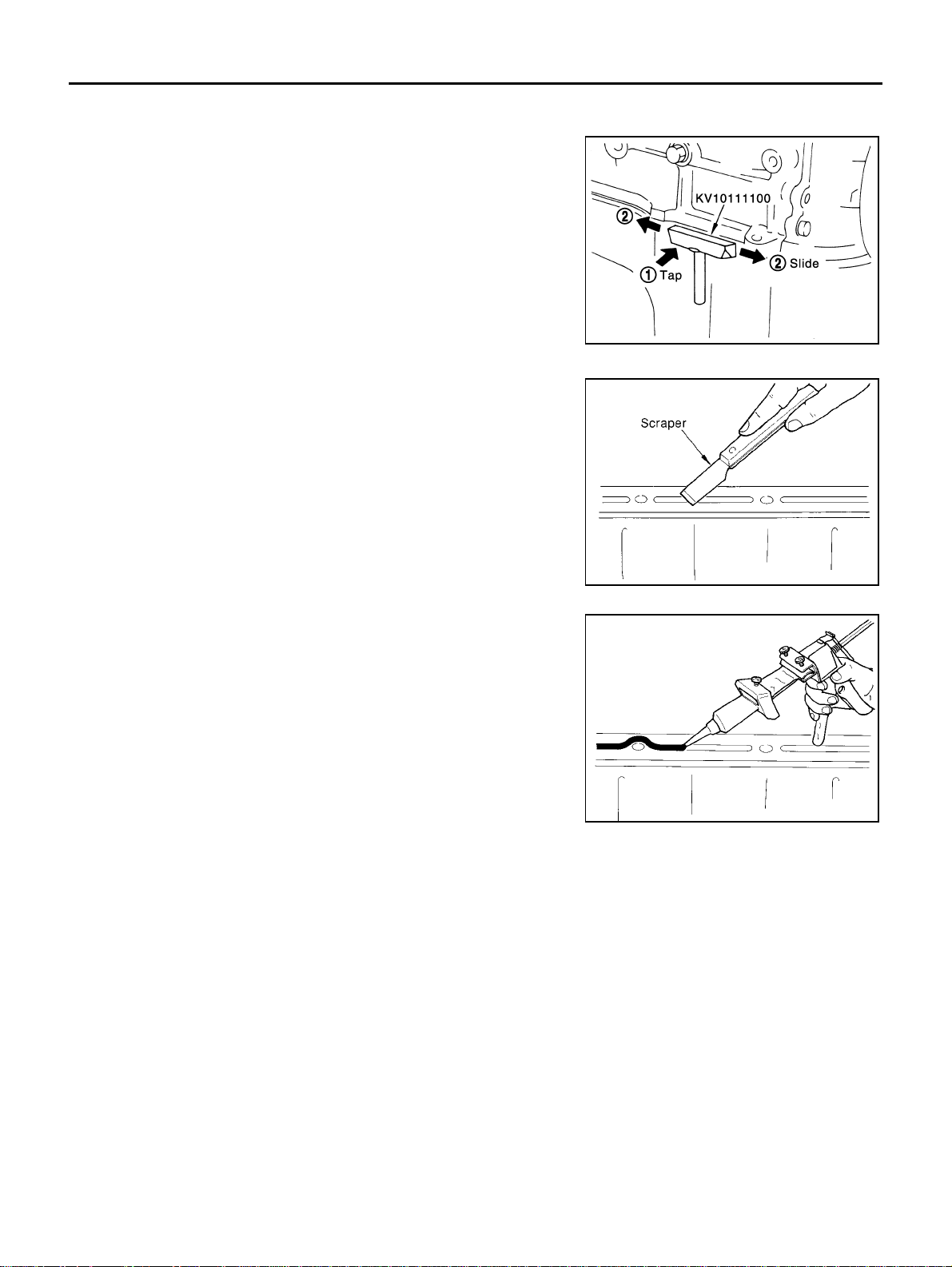

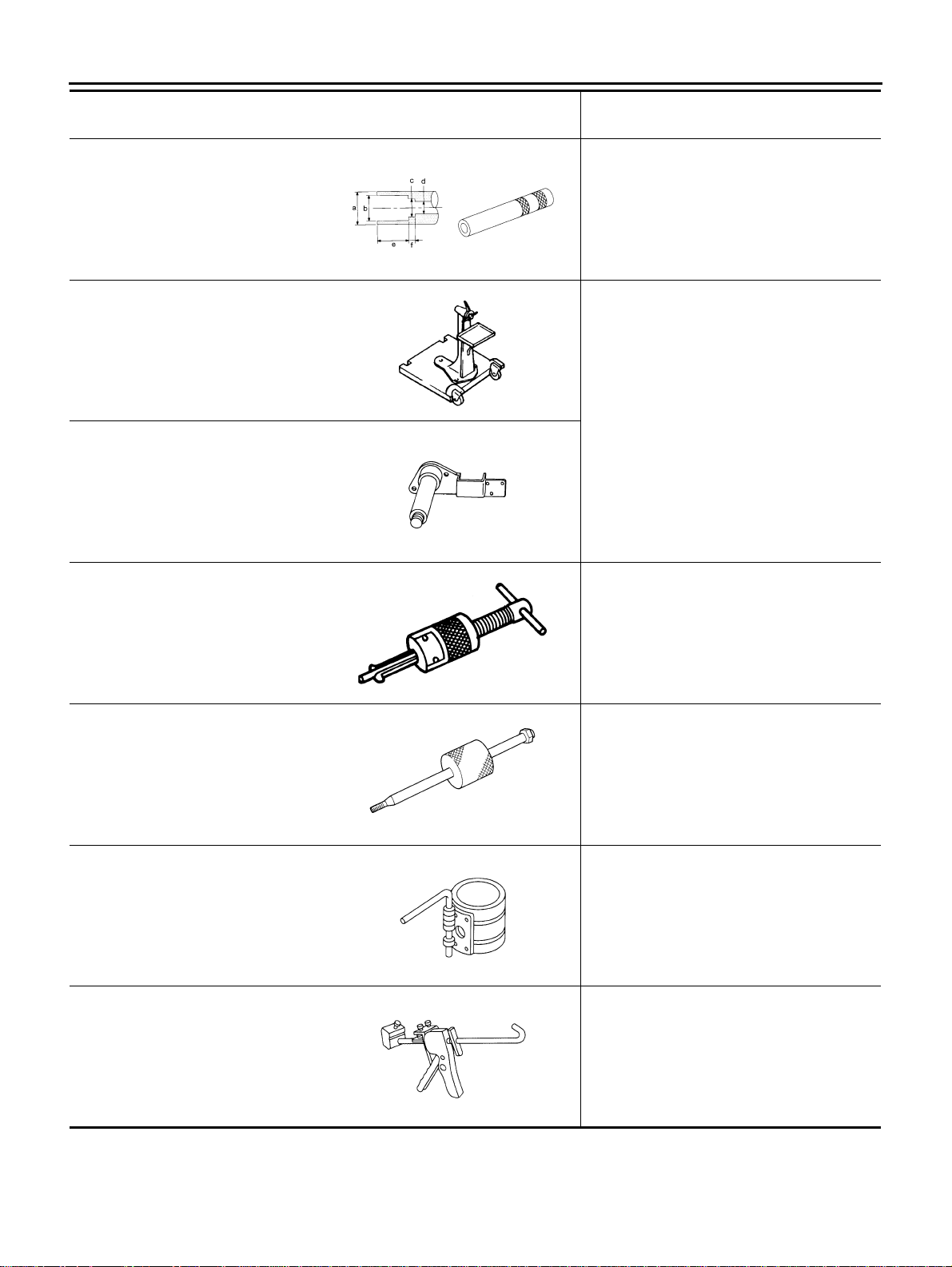

Special Service Tools

EBS007JZ

A

Tool number

Tool name

KV10111100

Seal cutter

KV10117100

Heated oxygen sensor wrench

KV10105800

Timing chain stopper

KV101151S0

Lifterstopper set

1 KV10115120

Lifter stopper

2 KV10115110

Camshaft pliers

ZZA0013D

ZZA1007D

ZZA1006D

Description

Removing steel oil pan and rear timing chain

case

Loosening or tightening heated oxygen

sensorswith 22 mm (0.87in) hexagon nut

Removingand installing idler sproket

Changing valve lifter shims

EM

C

D

E

F

G

H

I

J

KV10112100

Angle wrench

KV10116200

Valve spring compressor

KV10111200

Adapter

KV10116100

Valve oil seal puller

ZZA0103D

ZZA0120D

ZZA0993D

ZZA0015D

K

Tightening bolts for bearing cap, cylinder

head, etc.

L

M

Disassembling and assembling valve

components

Removing valve oil seal

EM-7

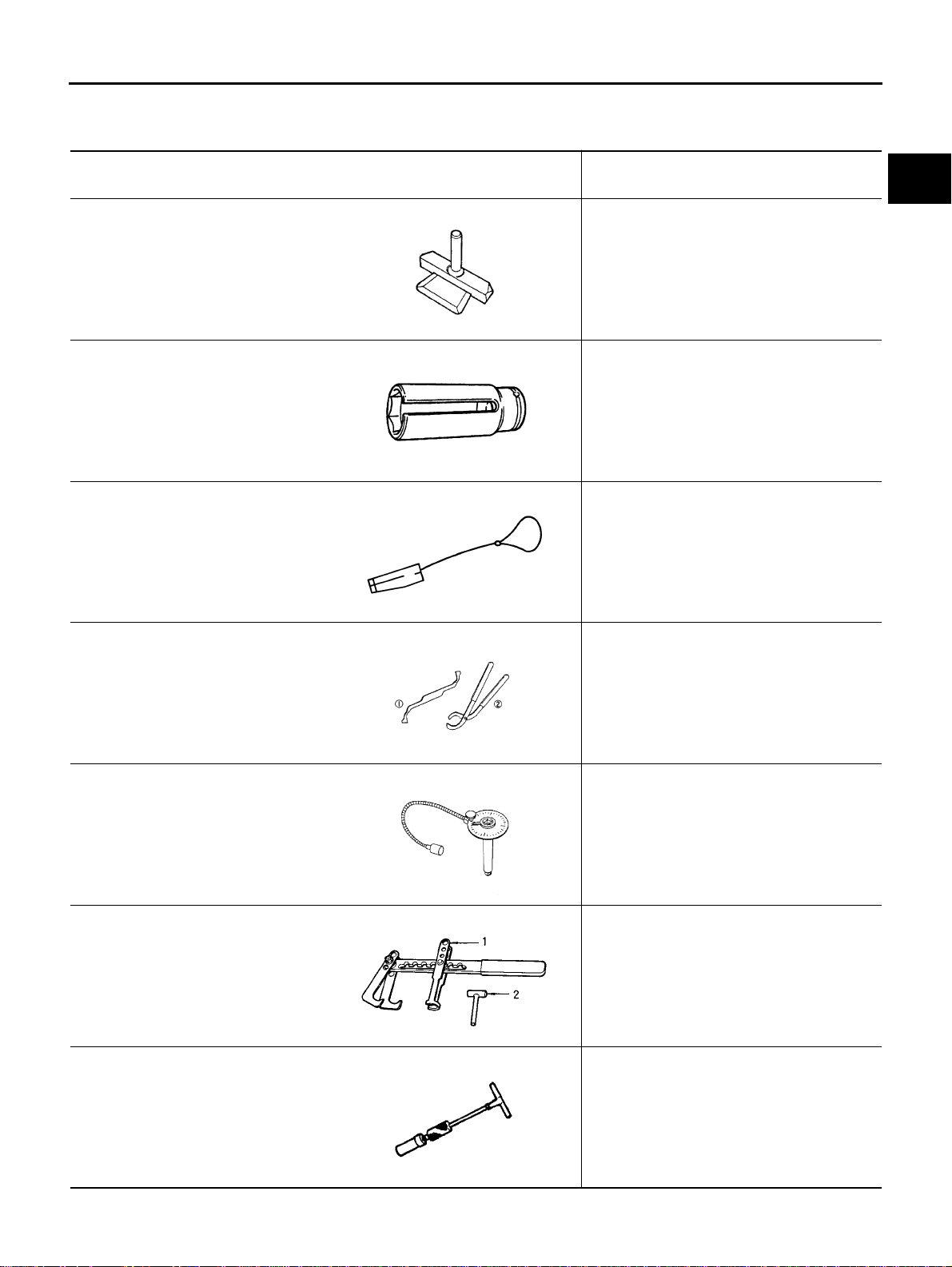

PREPARATION

[KA24DE]

Tool number

Tool name

KV10116300

Valv e o il se al drift

ST0501S000

Enginestand assembly

KV10105001

Engineattachment

Description

Installing valve oil se al

a: 25 mm (0.98 in) dia.

b: 14.4 mm (0.567 in) dia.

c: 11.8 mm (0.465 in) dia.

d: 10 mm (0.39 in) dia.

e: 11mm (0.43 in)

f: 9 mm (0.35 in)

NT602

Engine overhaul

ZZA0022D

ZZA1061D

ST16610001

Pilot bushing puller

KV10114700

Main bearing cap remover

EM03470000

Piston ring compressor

WS39930000

Tube presser

Removingcrankshaft pilot bushing

(M/T model only)

ZZA0046D

ZZA0023D

Installing piston assembly into cylinder bore

S-NT04 4

Pressing the tube of liquid gasket

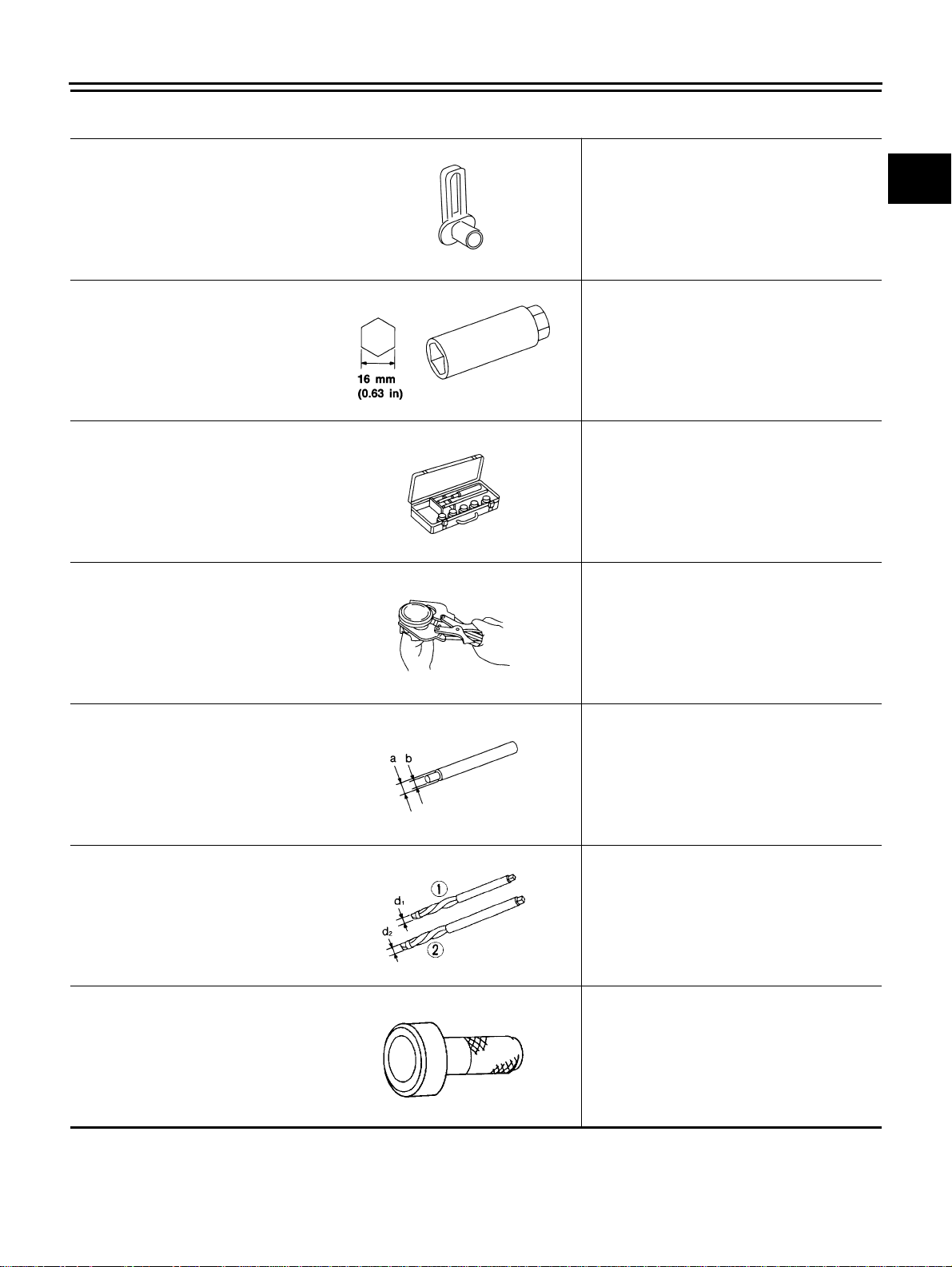

Commercial Service Tools

S-NT05 2

EBS007K0

EM-8

PREPARATION

[KA24DE]

Tool number

Tool name Description

Quick connector release Removingfuel tube quick connectorsin

engine room

(Available in SEC. 164 of PARTS

CATALOG: Part No. 16441 6N210)

PBIC0198E

Spark plu g wrench Removing a nd installing spark plug

S-NT04 7

Valve seat cutter set Finishing valve seat dimensions

S-NT04 8

Piston ring expander Removingand installing piston ring

A

EM

C

D

E

F

G

H

S-NT03 0

Valve guide drift Removingand installing valve guide

Intake & Exhaust:

a: 109.5 mm (0.413 in) dia.

b: 6.6 mm (0.260 in) dia.

S-NT01 5

Valve guide reamer 1: Reaming valve guide inner hole

2: Reaming hole for oversize valve guide

Intake & Exhaust:

1 : 7 .0 mm (0.276 in) dia.

d

2 : 11.175 mm (0.440 in) dia.

d

S-NT01 6

Rear oil seal drift Installing rear oil seal

I

J

K

L

M

ZZA0025D

EM-9

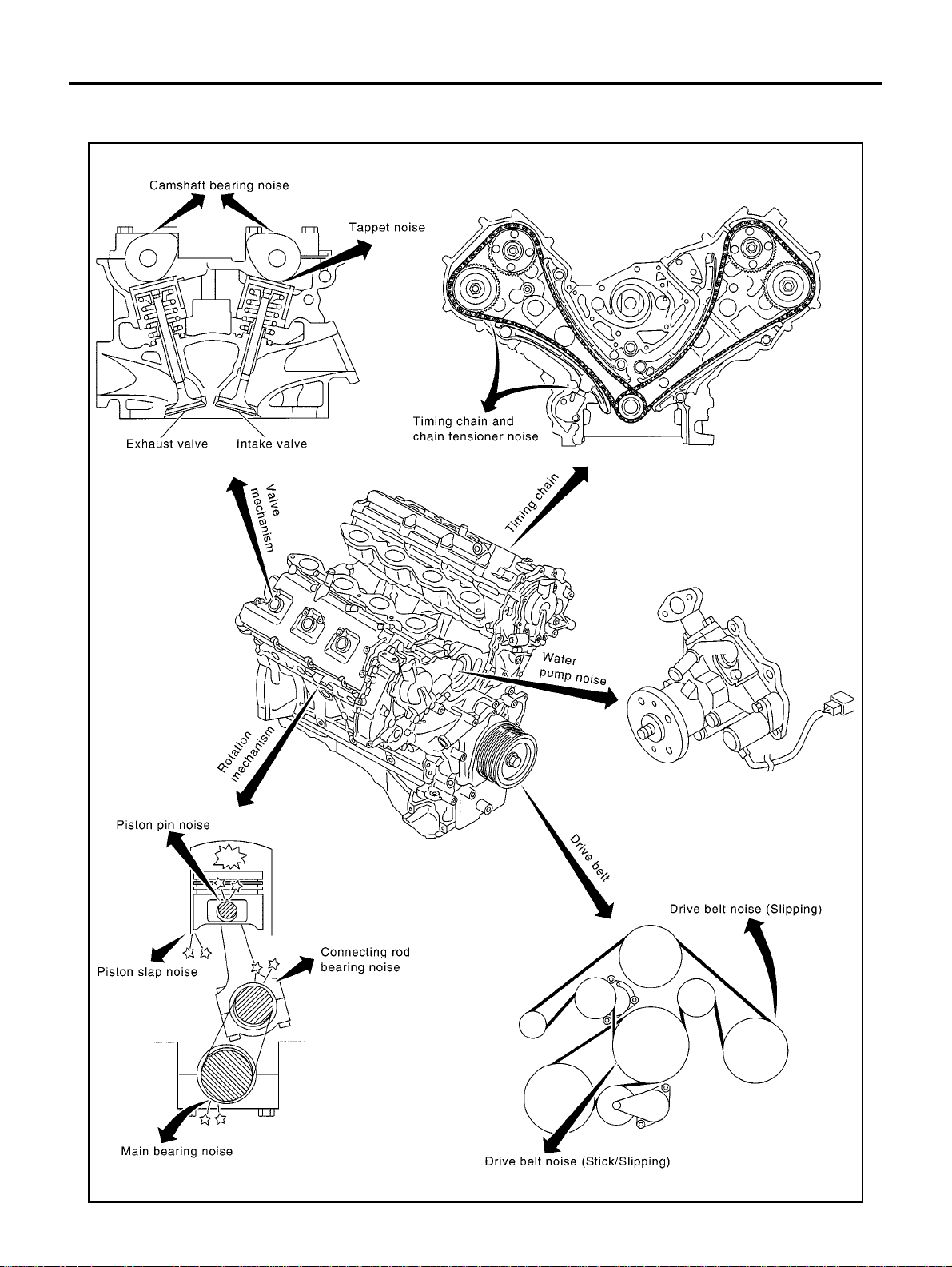

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[KA24DE]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting —Engine Noise

PFP:00003

EBS007K1

EM-10

PBIC0192E

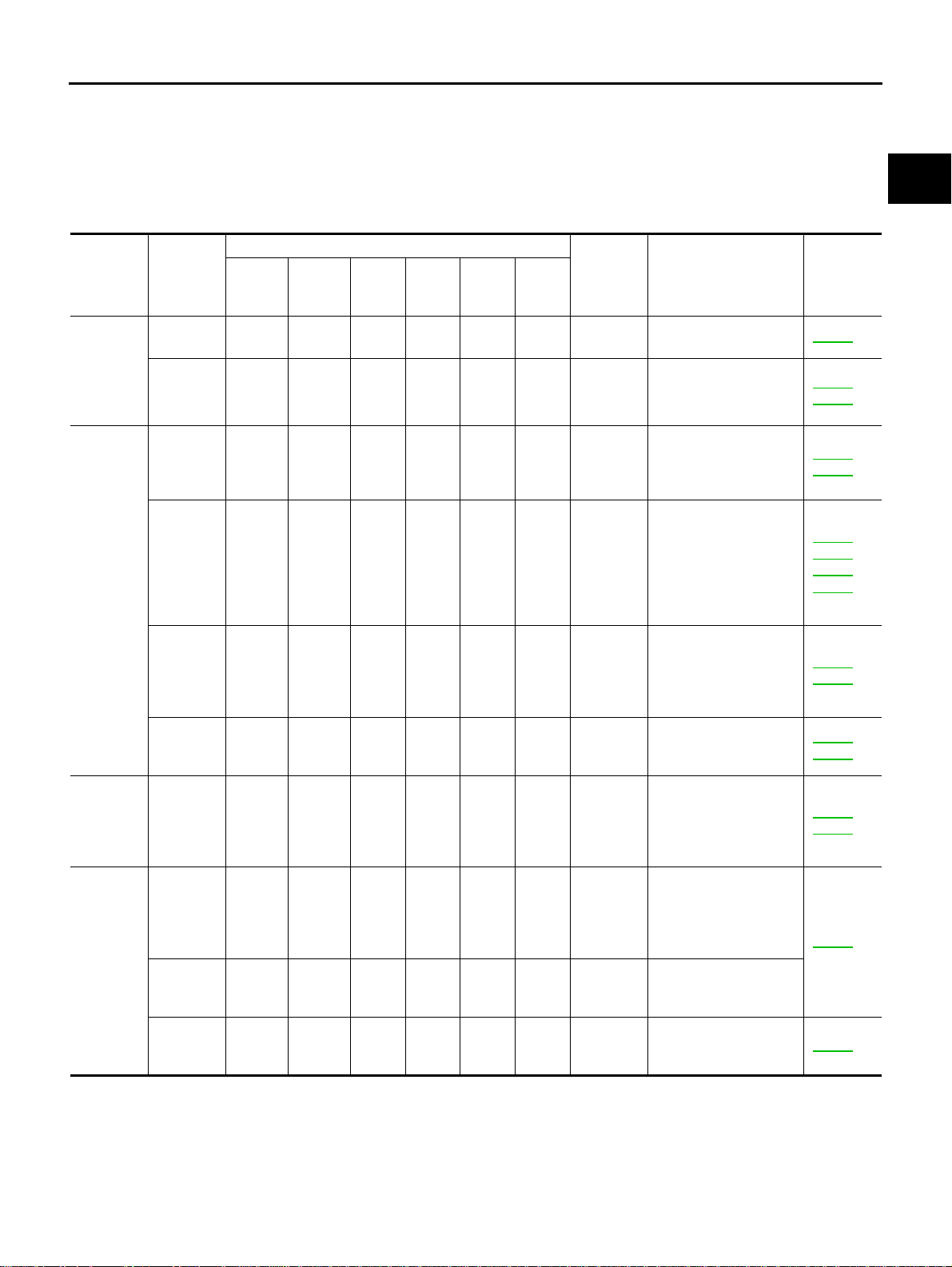

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[KA24DE]

Use the Chart Below to Help You Find the Cause of the Symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Operating condition of engine

Location

of noise

Top of

engine

Rocker

cover

Cylinder

head

Crankshaft pulley

Cylinder

block

(Side of

engine)

Oil pan

Front of

engine

Timing

chain

cover

Front of

engine

A: Closelyrelated B: Related C: Sometimes related —: Not related

Type of

noise

Ticking or

clicking

Rattle C A — A B C

Slap or

knock

Slap or

rap

Knock A B C B B B

Knock A B — A B C

Tappingor

ticking

Squeaking or fizzing

CreakingA B ABAB

Squall

Creak

Before

warm-

up

CA—AB—

—A—BB—

A ——BBA

A A—BBB

AB—B—C

A B—BAB

After

warm-

up

When

start-

ing

When

idling

When

racing

While

driving

Sourceof

Tappet

noise

Camshaft

bearing

noise

Pistonpin

noise

Piston

slap noise

Connecting rod

bearing

noise

Main

bearing

noise

Timing

chain and

chain tensioner

noise

Other

drivebelts

(Sticking

or slipping)

Other

drivebelts

(Slipping)

Water

pump

noise

noise

Checkitem

Valve clearance EM-38

Camshaftjournal clearance

Camshaft runout

Pistonand piston pin

clearance

Connecting rod bushing clearance

Piston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend

and torsion

Connecting rod bushing clearance (Small

end)

Connecting rod bearing clearance (Big end)

Main bearing oil clearance

Crankshaft runout

Timing chain cracks

and wear

Timing chain tensioner

operation

Drive belts deflection

Idler pulley bearing

operation

Water pump operation CO-21

EBS007K2

Refer-

ence page

EM-36

EM-35

EM-80

EM-80

EM-80

EM-79

EM-79

EM-80

EM-80

EM-80

EM-84

EM-83

EM-44

EM-51

EM-14

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-11

ENGINE ROOM COVER

[KA24DE]

ENGINE ROOM COVER

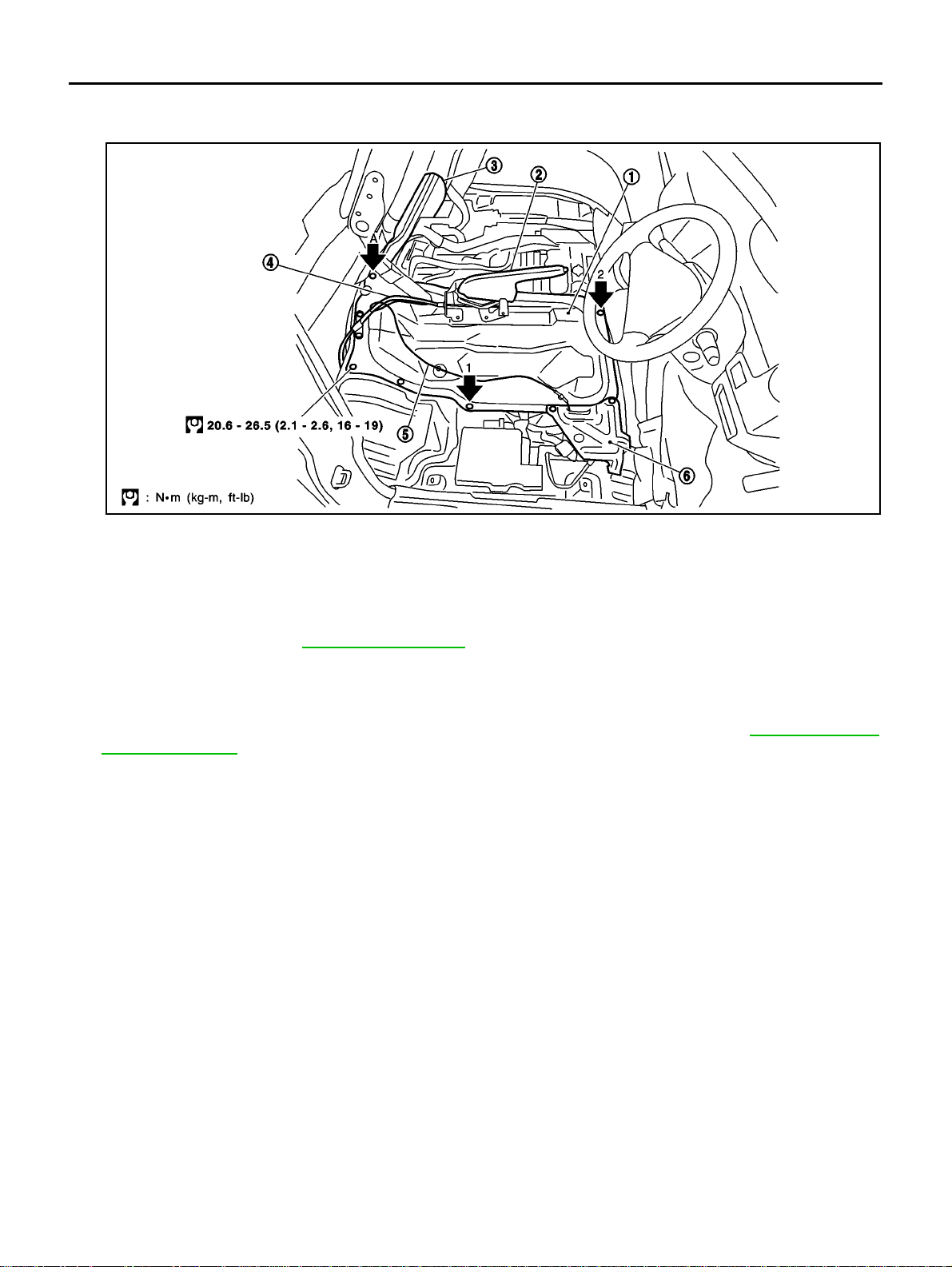

Removal and Installation of Engine Room Right Side

1. Engine room right side cover 2. Parking brake lever 3. Engineroom left side cover

4. Parking brake cable 5. Harness 6. Harness protector

PFP:14049

EBS00ALX

KBIA0741E

REMOVAL

1. Open engine compartment LH cover and secure it.

2. Remove RH seat. Refer to SE-4, "

FRONT SEAT" .

3. Partially remove floor carpet.

4. Disconnect harness protector secured together at front right. Disconnect harness connector to move harness routed on top of engine compartment RH cover aside.

5. Move parking brake lever and cable from engine compartment RH cover. Refer to PB-3, "

PARKING

BRAKE SYSTEM" .

6. Remove mounting bolts, and remove engine compartment RH cover.

CAUTION:

When taking it out of vehicle, do not allow it to interfere with vehicle.

INSTALLTION

● Install in reverse order of removal following instructions below.

1. Temporarily tighten bolt No. 1 shown in the figure.

2. Tighten bolt No. 2 shown in figure to specified torque.

3. Tighten other bolts except bolt “A” shown in the figure (bolt No. 1 is included) to specified torque in any

given order.

4. Close engine compartment LH cover.

5. Tighten bolt “A” shown in the figure to specifi ed torque.

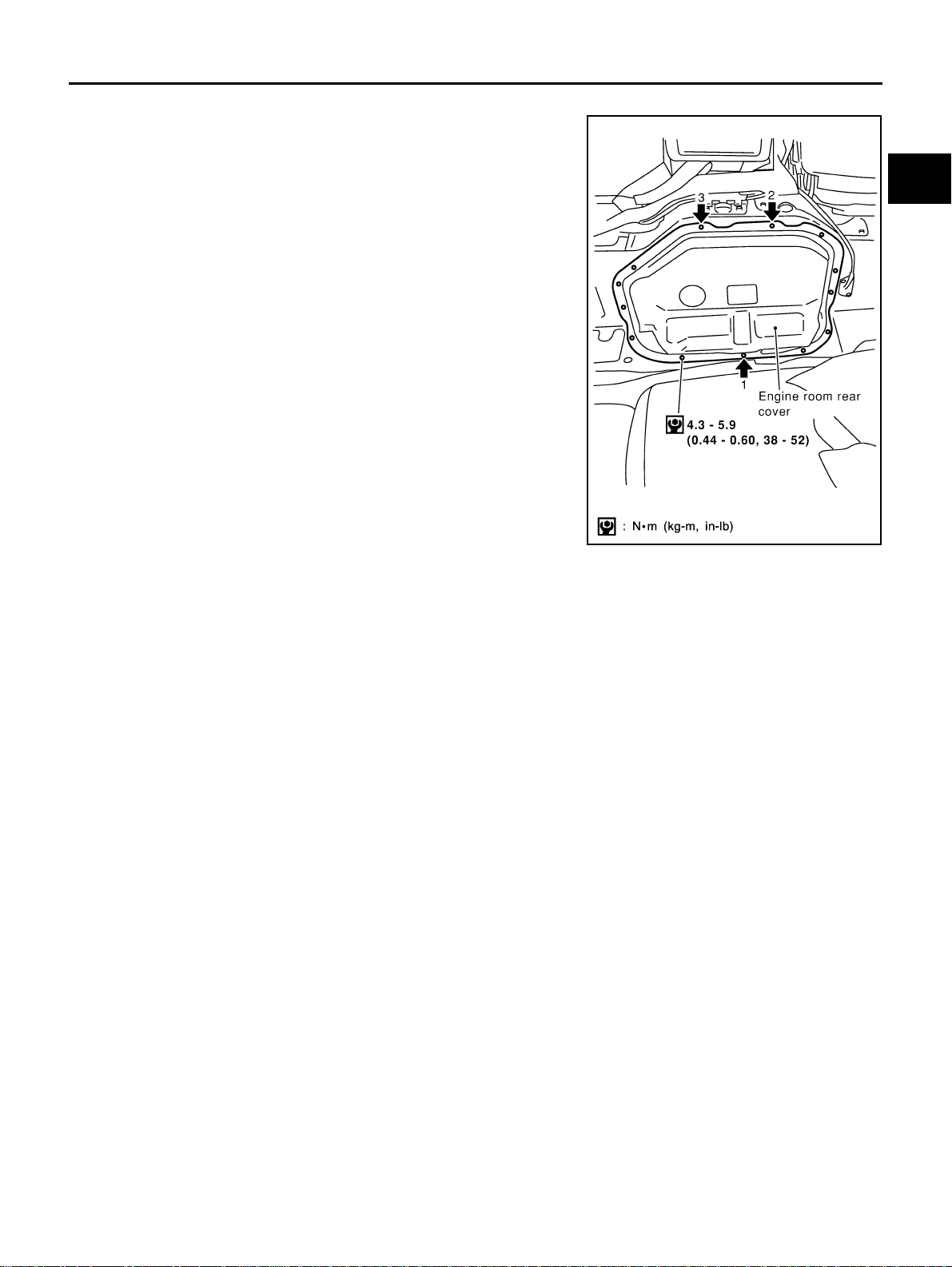

Removal and Installation of Engine Room Rear Cover

EBS00ALY

REMOVAL

1. Move folded seat on engine c ompartment rear cover side rearward, if applicable.

2. Partially remove floor carpet.

3. Remove mounting bolts, and remove engine compartment rear cover.

EM-12

ENGINE ROOM COVER

INSTALLATION

Following inst ruc tions below, install in reverse order of removal.

1. Tighten bolts No. 1 to No. 3 shown in the figure to specified

torque in this order.

2. Tighten other bolts to specified torque in any given order.

[KA24DE]

A

EM

C

D

E

F

G

KBIA0742E

H

I

J

K

L

M

EM-13

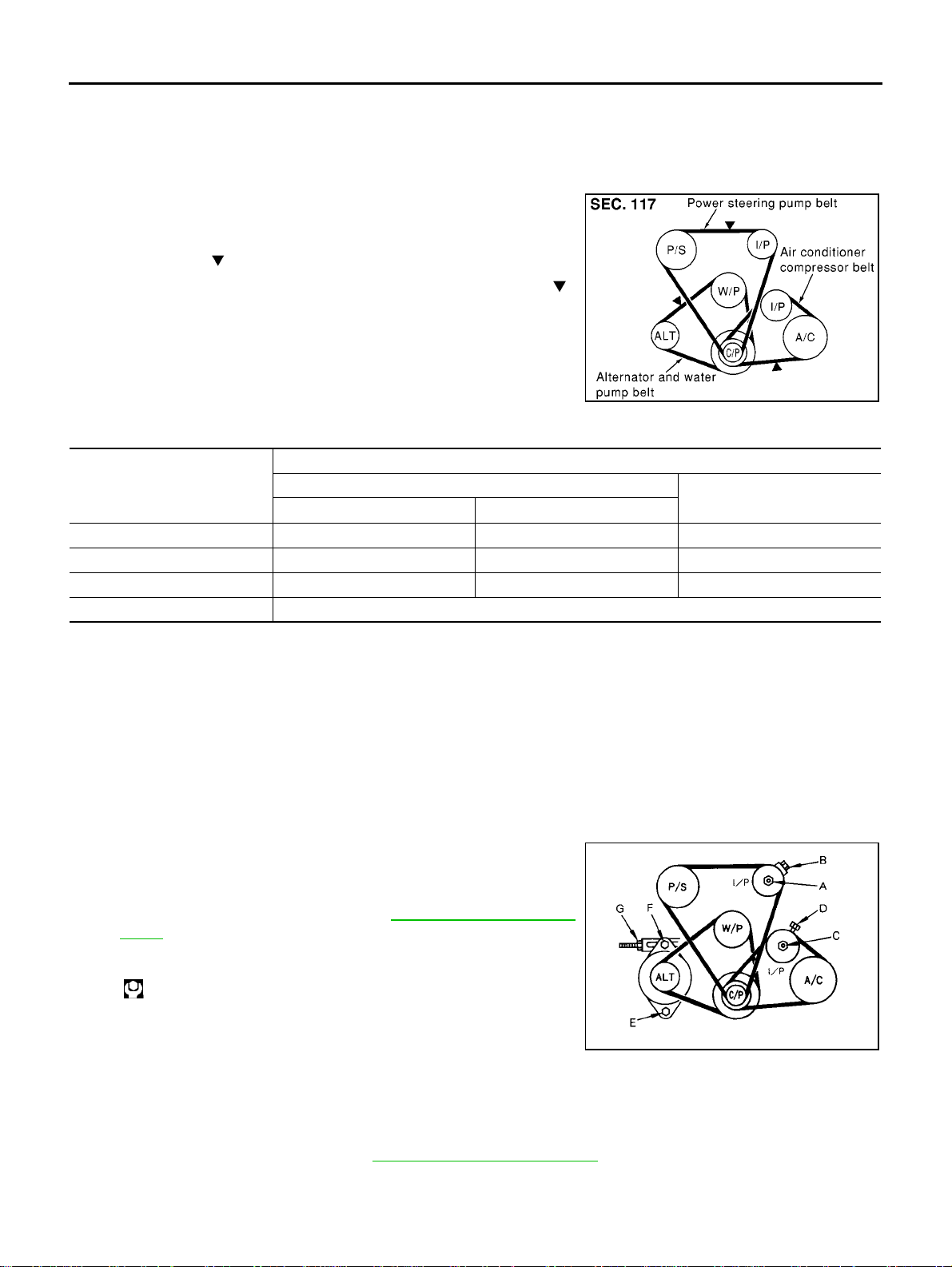

DRIVE BELTS

[KA24DE]

DRIVE BELTS

Checking Drive Belts

WARNING:

Be sure to perform when the engine is stoppe d.

● Inspection should be done only when engine is cold, or over 30

minutes after engine is stopped.

● Measure belt tension with tension meter (special service tool) at

points marked shown in the figure.

● Measure belt deflection by applying load of 98.1 N {10 kg} to .

Unit: mm (in)

Deflection adjustment

Used belt

Limit After adjustment

Alternator 11 (0.43) 7 - 8 (0.28 - 0.31) 6 - 7 (0.24 - 0.28)

Air conditioner compressor 13 (0.51) 8 - 10 (0.31 - 0.39) 7 - 8 (0.28 - 0.31)

Powersteering oil pump 13 (0.51) 8 - 10 (0.31 - 0.39) 7 - 8 (0.28 - 0.31)

Appliedpushing force 98 N (10 kg, 72 lb)

New belt

PFP:02117

EBS007K4

PBIC0422E

Tension Adjustment

EBS00AM2

CAUTION:

● When belt is replaced with a new one, tighten it a little stronger than current one to accommodate

for insufficient adaptability with pulley grooves.

● When tension of belt being used exceeds ″Retightening limit″, adjust it to value for ″Used belt″.

● When installing belt, make sure that it is correctly engaged with pulley groove.

● Keep oil and water away from belt.

● Do not twist or bend belt excessively.

POWER STEERING PUMP BELT

1. Open and fix engine compartment LH cover.

2. Loosen idler pulley lock nut (A) and adjust tension by turning

adjusting bolt (B).

● For specified belt tension, refer to EM-14, "Checking Drive

Belts" .

3. Tighten nut (A ).

: 25.5 - 32.4 N·m (2.6 - 3.3 kg-m, 19 - 23 ft- lb)

EMK0571D

AIR CONDITIONER COMPRESSO R BELT

1. Open and fix engine compartment LH cover (passenger side for RHD models or driver-side for LHD models).

2. Loosen idler pulley lock nut (C) and adjust tension by turning adjusting bolt (D).

● For specified belt tension, refer to EM-14, "Checking Drive Belts" .

3. Tighten nut (C).

EM-14

DRIVE BELTS

[KA24DE]

: 25.5 - 32.4 N·m (2.6 - 3.3 kg-m, 19 - 23 ft-lb)

ALTERNATOR AND WATER PUMP BELT

1. Remove front-side under cover.

2. Remove RH seat. Refer to SE-4, "

3. Remove engine compartment RH cov er. Refer to EM-12, "

FRONT SEAT" .

ENGINE ROOM COVER" .

4. Loosen alternator mounting bolt (E) and adjuster lock bolt (F) , and adjust tension by turning adjusting nut

(G).

● For specified be lt tension, refer to EM-14, "Checking Drive Belts" .

5. Tighten bolts (E), (F) and (G).

: 45.1 - 59.8 N·m (4.6 - 6.1 kg-m, 34 - 44 ft-lb) for E bolt

: 15.7 - 20.6 N·m (1.6 - 2.1 kg-m, 12 - 15 ft-lb) for F bolt

: 6.5 - 7.6 N·m (0.67 - 0.77 kg-m, 58 - 67 in-lb) for G bolt

Removal and Installation

EBS007K6

REMOVAL

● Loosen each belt while referring to "Adjustment", and re m ove them one by one starting from the one in

front.

INSTALLATION

1. Install belts to pulley in reverse order of removal.

2. Adjust belt tension.

CAUTION:

● When checking belt tension immediately after installation, first, adjust to specified value. Then,

after turning crankshaft more than two turns, re-adjust to specified value to avoid variation in

deflection between pulleys.

● Tighten idler pulley lock nut by hand and measure tension without looseness.

3. Tighten each adjusting bolt and nut to the specified torque.

4. Make sure that tension of each belt is within the standard.

A

EM

C

D

E

F

G

H

I

J

K

M

L

EM-15

AIR CLEANER AND AIR DUCT

[KA24DE]

AIR CLEANER AND AIR DUCT

Removal and Installation

PFP:16500

EBS007K8

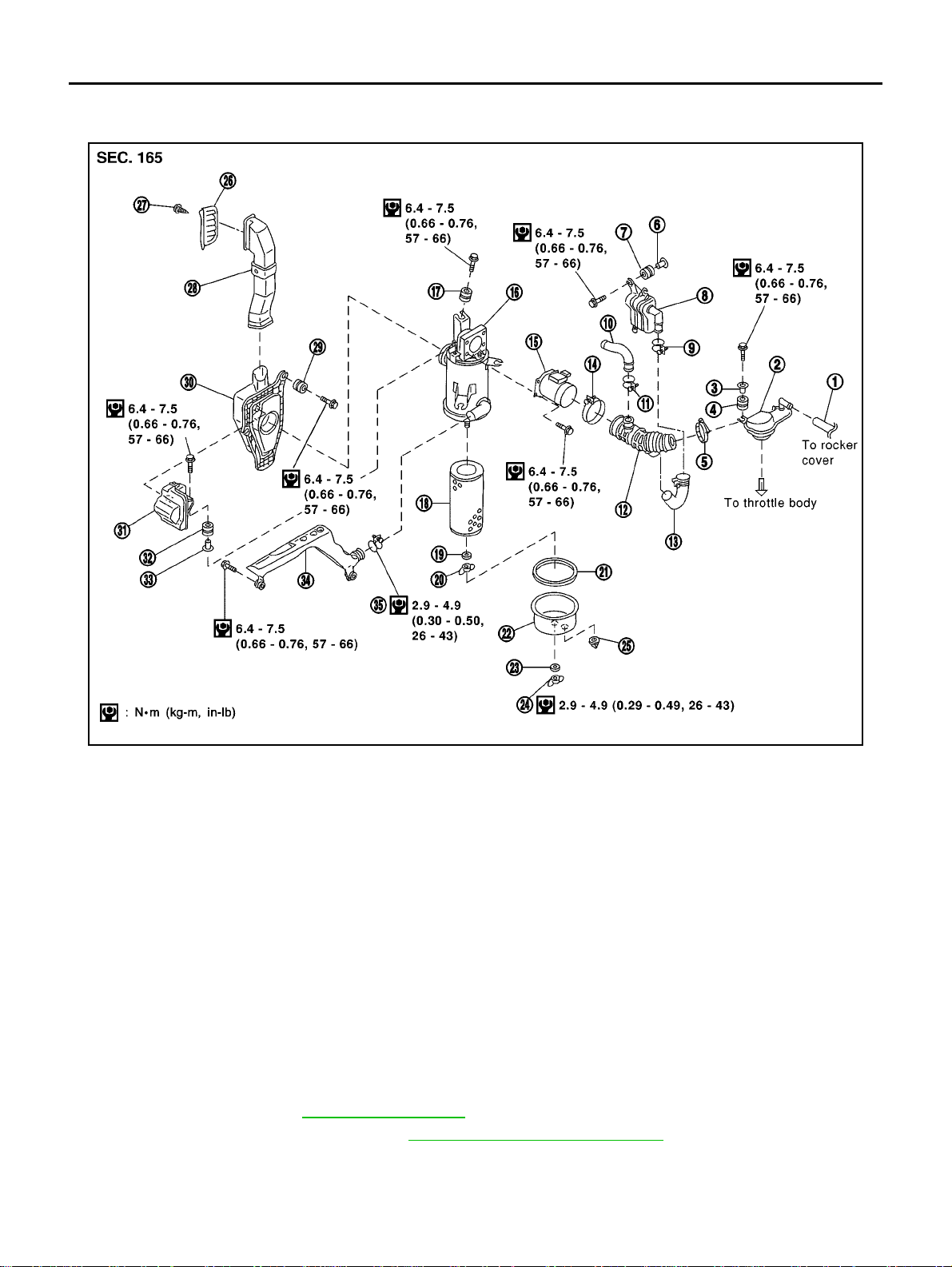

1 PCV hose 2 Air duct 3 Collar

4Grommet 5Clamp 6Collar

7 Grommet 8 Resonator 9 Clamp

10 Resonator 11 Clamp 12 Air hose

13 Resonator 14 Clamp 15 Mass air flow meter

16 Air cleanercase 17 Grommet 18 Air cleaner element

19 Washer 20 Wing nut 21 Seal ring

22 Dust pan 23 Washer 24 Wing nut

25 Dust exhaust valve 26 Grille 27 Screw

28 Air duct 29 Grommet 30 Air duct

31 Resonator 32 Grommet 33 Collar

34 Resonator 35 Clamp

REMOVAL

1. Remove rear-side u nder cover.

2. Open and fix engine room LH cover.

3. Remove RH seat. Refer to SE-4, "

4. Remove engine room RH cover. Refer to EM-12, "

5. Remove floor cover behind RH seat.

6. Disconnect harness connector from airflow sensor.

FRONT SEAT" .

ENGINE ROOM COVER" .

KBIA0821E

EM-16

AIR CLEANER AND AIR DUCT

7. For correct installation, m ake matching marks on each connec tion.

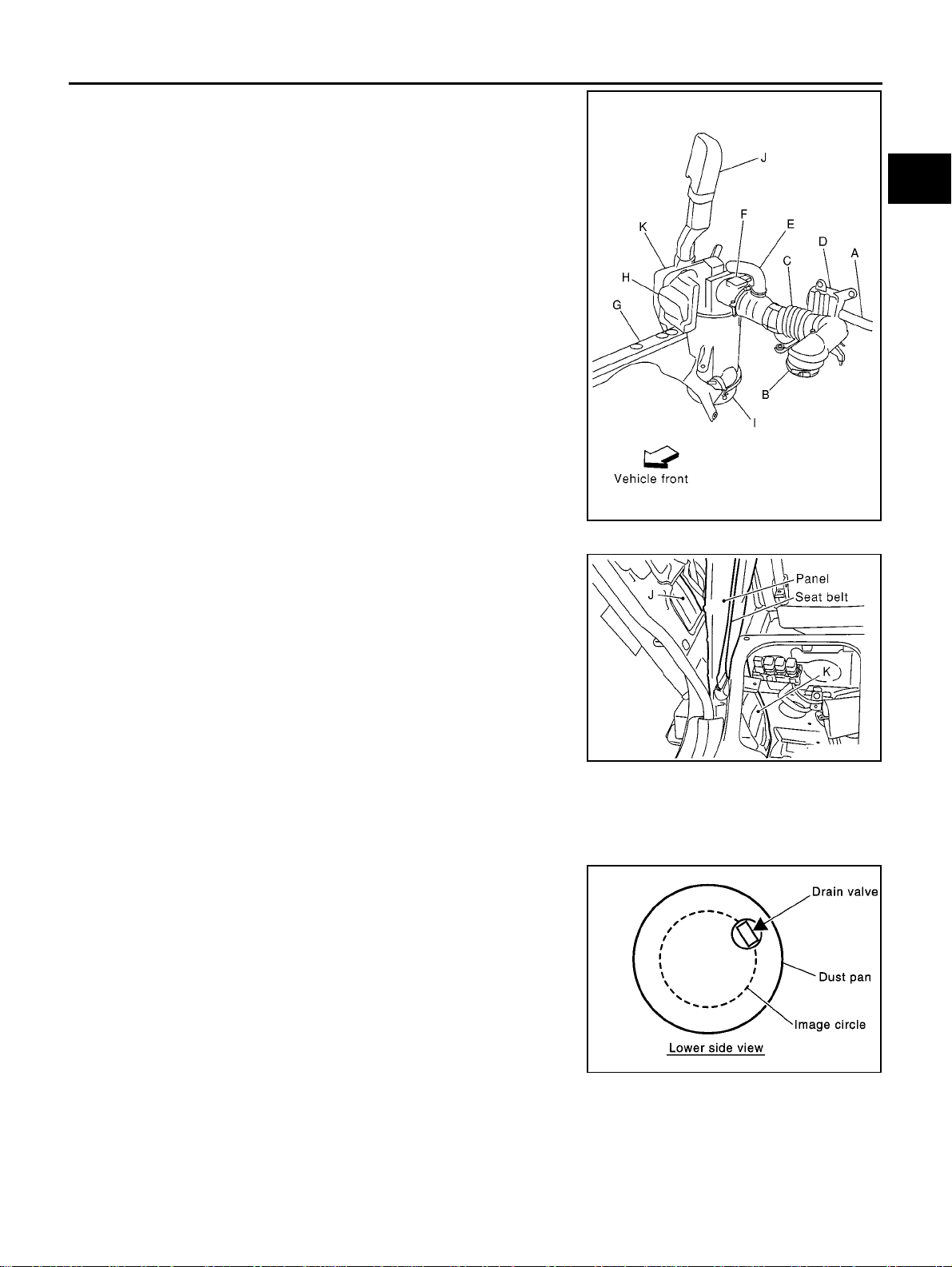

8. Remove from engine side after separating the s ystem with the

following procedure.

a. Remove PCV hose (A).

b. Remove air duct (B).

c. Separate air hose (C) and resonator (D).

d. Remove resonator (E).

e. Remove air hose (C).

f. Remove resonator (D).

g. Remove mass ai r flo w sensor (F).

CAUTION:

● Handle with care, avoiding any shocks.

● Do not disassemble it.

● Do not touch sensor part.

h. After removing mud flap of front RH wheel, remove resonator

(G).

i. When removing following parts, remove EVAP canister, and set

it aside.

j. Remove resonator (H).

k. Remove air cleaner case (I).

9. When removing components inside vehicle on right-hand,

remove them with the following procedure.

a. Remove components up to air cleaner case (I), referring to step

8.

b. Remove intake grille from outside of vehicle.

c. Remove kicking plate on RH side, and lift up panel under RH

side seat belt anchor.

d. Lift up air duct (J) from vehicle opening, and separate it from a ir

duct (K).

e. Pull and remove air duct (K).

f. Remove air duct (J) from mounting hol e of air duct (K).

[KA24DE]

KBIA0822E

KBIA0902E

A

EM

C

D

E

F

G

H

I

J

K

INSTALLATION

Install in reverse order of removal, paying attention to points below.

● After aligning matching marks marked when rem oving, install each connection, and firmly tighten clamps.

● Install dust drain valve so that its opening is along circumfer-

ence.

KBIA0819E

EM-17

L

M

AIR CLEANER AND AIR DUCT

[KA24DE]

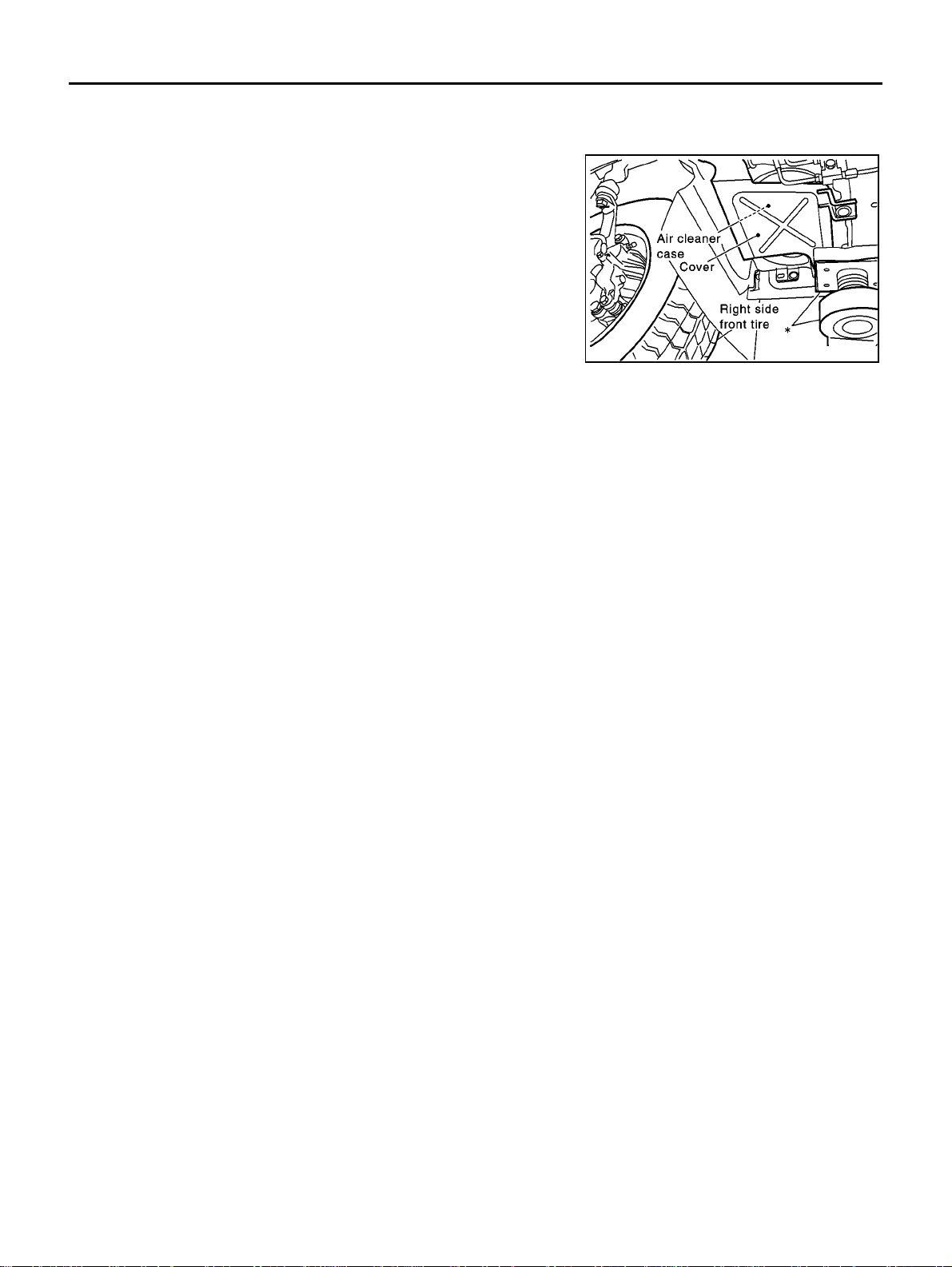

Changing Air Cleaner Element

REMOVAL

NOTE:

● Mark ″*″ in the figure shows part of lift arm.

● For replacement of air cleaner e lement, it is not necessary to lift

up vehicle.

1. Remove brake pipe protector under vehicle, behind front RH

wheel.

2. Remove 3 clips, and the cover at the bottom of air c leaner case.

3. Remove wing nut, dust pan under air cleaner case, and then air

cleaner element.

INSTALLATION

Install in the reverse order of removal.

EBS0096T

KBIA0749E

EM-18

THROTTLE BODY

[KA24DE]

THROTTLE BODY PFP:16298

Removal and Installation

EBS008X7

A

EM

C

D

E

F

G

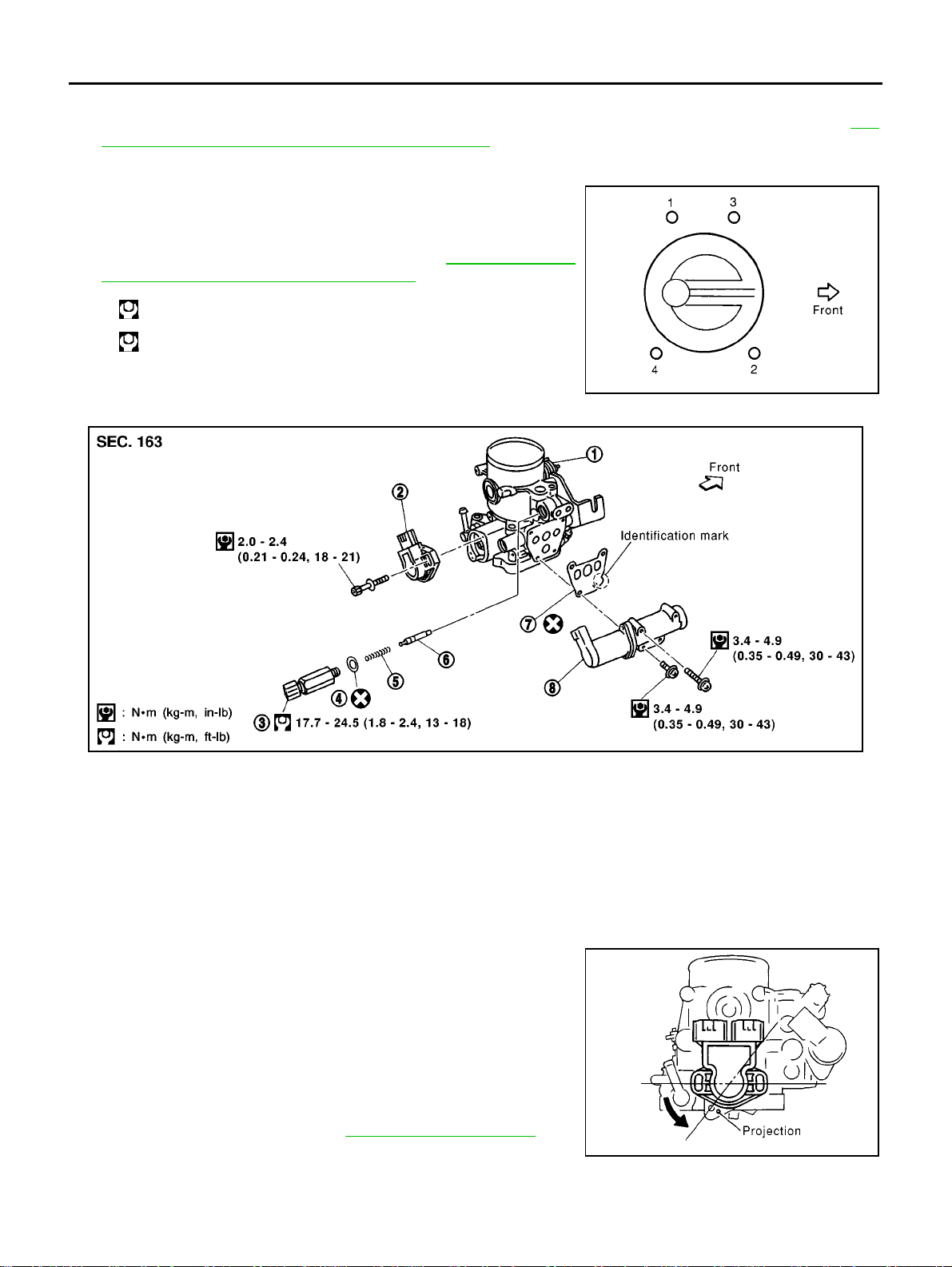

1 Bracket 2 Throttle position sensorharness 3 Waterhose

4 Throttle body 5 Bracket 6 Water hose

7 Gasket 8 Intake manifold

REMOVAL

1. Remove RH seat. Refer to SE-4, "FR ONT SEAT" .

2. Remove engine compartment RH cov er. Refer to EM-12, "

3. Remove air duct on throttle body. Refer to EM-16, "

AIR CLEANER AND AIR DUCT" .

4. Disconnect accelerator cable, and set it aside.

5. Disconnect harness connector.

6. Disconnect water hose.

● After disconnection, plug the hose to prevent cool ant leaks.

7. Loosen mounting bolts in reverse order shown in the figure, and

remove throttle body.

ENGINE ROOM COVER" .

H

I

KBIA0823E

J

K

L

M

EM-19

PBIC0424E

THROTTLE BODY

[KA24DE]

INSPECTION AFTER REMOVAL

● If idle is rough when engine is cold or warmed up, check and adjus t the fas t idle cam (FIC). Refer to EC-

28, "Fast Idle Cam (FIC) Inspection and Adjustment" .

INSTALLATION

Install in reverse order of removal, paying attention to points below.

● For throttle body, tight en mounting bolts in two steps in the

numerical order shown in the figure.

● For adjustment of acce lerator cable, refer to ACC-3, "ACCEL-

ERATOR CON TRO L SYSTEM (KA24DE)" .

1st step : 8.8 - 10.8 N·m (0.9 - 1.1 kg-m, 78 - 95 in-lb)

2nd step : 17.7 - 21.6 N·m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

PBIC0424E

Disassembly and Assembly

1 Throttle body 2 Throttle position sensor 3 IACV-FICD solenoidvalve

4 Washer 5 Spring 6 plunger

7 Gasket 8 IACV-AAC valve

DISASSEMBLY

Disassemble referring to the component illustration.

EBS008X8

PBIC0425E

ASSEMBLY

Assemble in reverse order of disassembly, paying attention to points below.

● Insert throttle position sensor into throttle body, with connectors

positioned as shown in the figure. Then rotate it in the direction

shown by arrow and temporarily tighten mounting screws.

● While they are turned in direction shown by arrow, circumfer-

ence of sensor hits projection. Avoid hitting projection by giving

slight space, and insert projection into inside of mounting screw

long hole. (It is temporarily held in place by c ounter-action of

spring.)

● After adjustment on vehicle, tighten mounting screws.

For adjusting procedure, refer to EC-45, "

Basic Inspection" .

EM-20

PBIC0426E

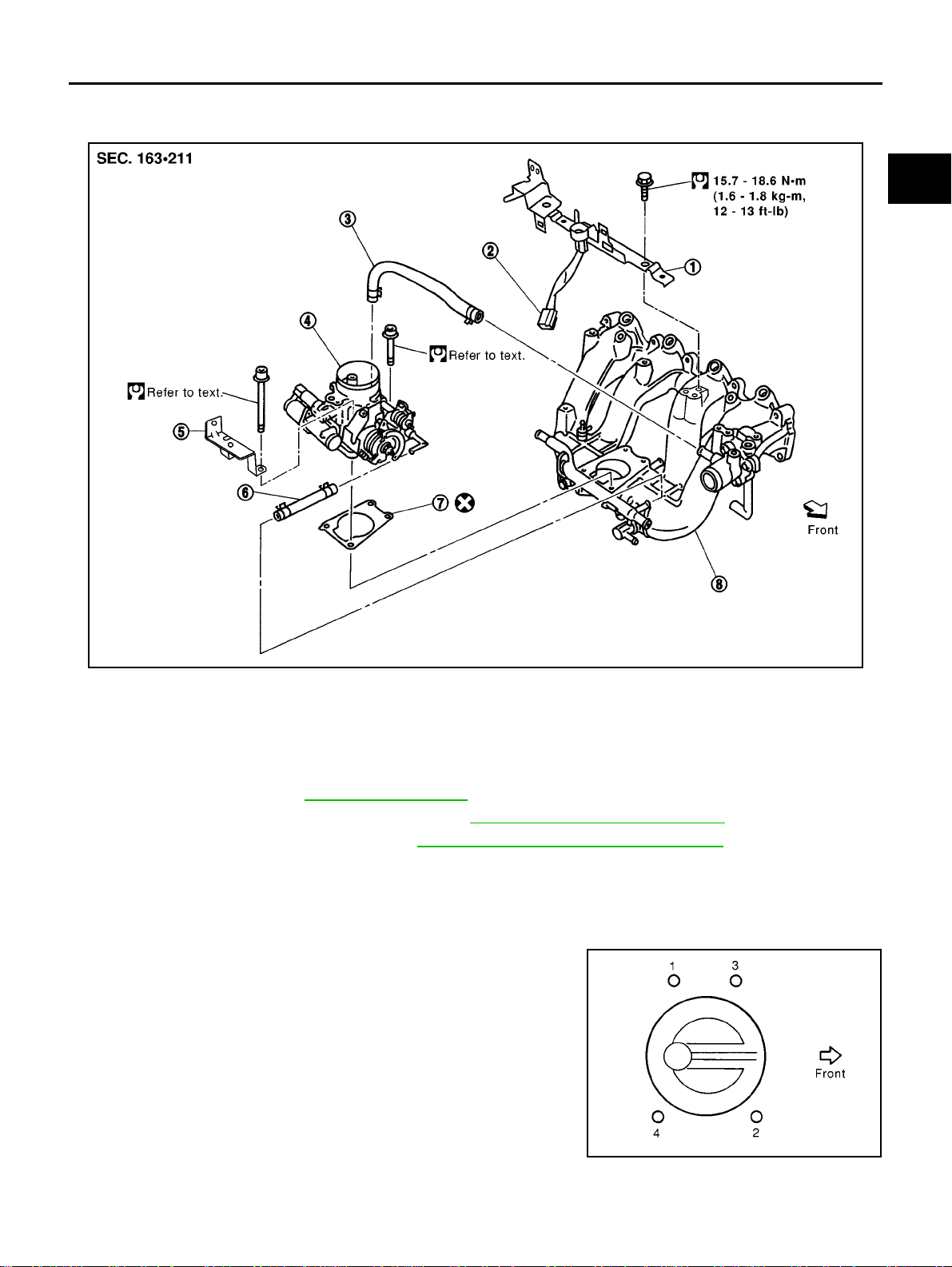

INTAKE MANIFOLD

[KA24DE]

INTAKE MANIFOLD PFP:14003

Removal and Installation

EBS007K9

A

EM

C

D

E

F

G

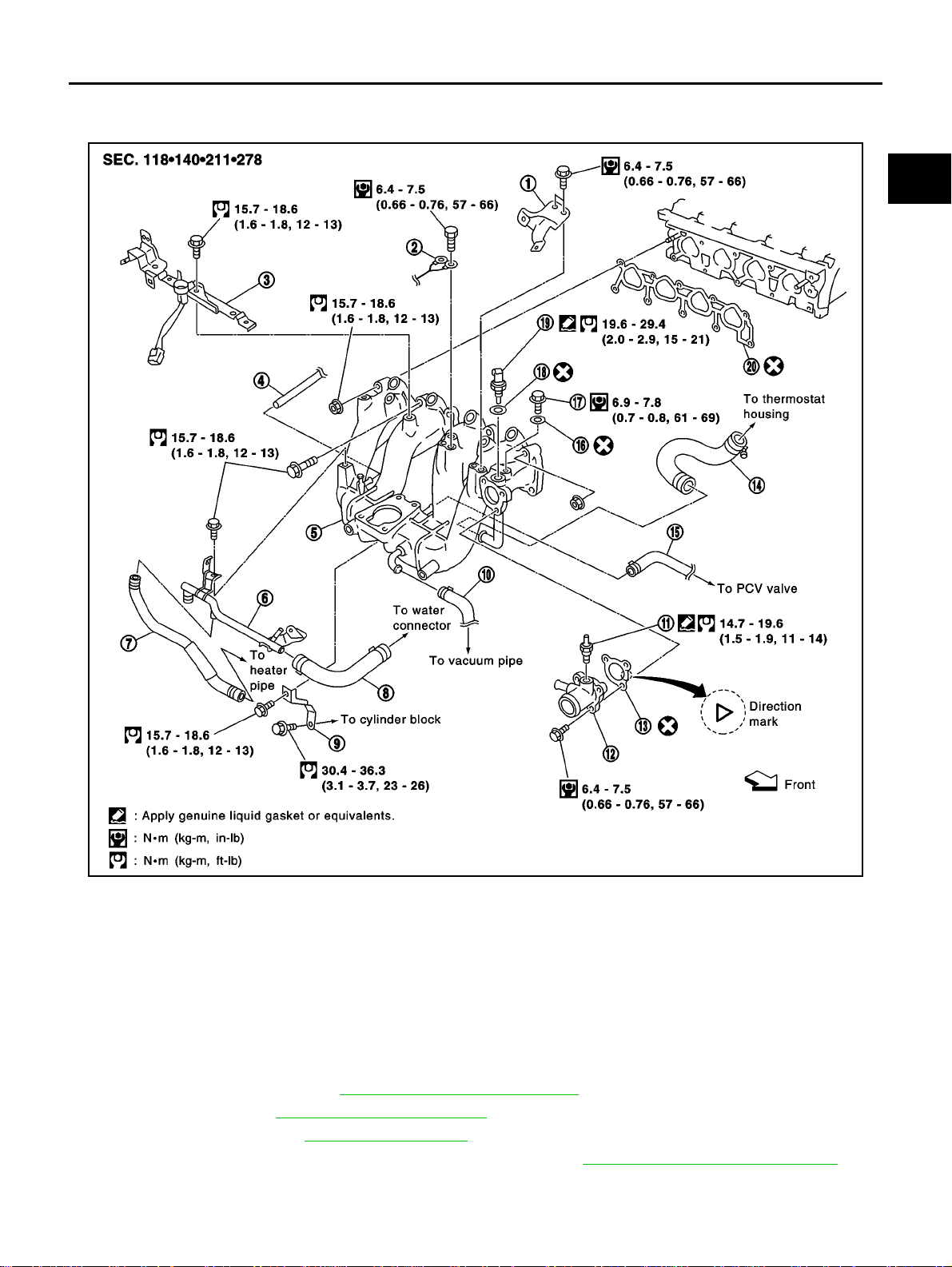

1 Bracket 2 Grounding wire 3 Bracket

4 Vacuum hose 5 Intake manifold 6 Heater pipe

7 Waterhose 8 Water hose 9 Intake manifold support

10 Vacuum hose 11 Thermal transmitter 12 Water outlet

13 Gasket 14 Water hose 15 PCV hose

16 Gasket 17 Air relief plug 18 Gasket

19 Engine coolanttemperature sensor 20 Gasket

H

I

J

K

L

PBIC0427E

M

REMOVAL

1. Release fuel pressure. Refer to EC-27, "Fuel Pressure Release" .

2. Drain coolant. Refer to CO-9, "

3. Remove RH seat. Refer to SE-4, "

ENGINE COOLANT" .

FRONT SEAT" .

4. Remove engine compartment RH cov er and rear cover. Refer to EM-12, "

5. Remove floor cover behindRH seat.

EM-21

ENGINE ROOM COVER" .

INTAKE MANIFOLD

6. Move aside main harnes s above intake manifold.

7. Disconnect PCV hose between rocker cover and air duct.

8. Remove air duct between throttle body a nd mass air flow sensor. Refer to EM-16, "

AIR DUCT" .

9. Remove throttle body. Refer to EM-19, "

10. Remove fuel tube and injector assembly. Refer to EM-28, "

11. Disconnect radiator hose (upper).

12. Disconnect hoses connected to intake manifold.

NOTE:

Separate water hose and PCV hose behind intake manifold when removing intake manifold.

13. Remove intake manifold with the following procedure.

a. Loosen mounting bolts and nuts in reverse order shown in the

figure.

b. Pull out stud bolts on rear.

c. Di sconnect water hose and PCV hose on back side, and remove

intake manifold.

THROTTLE BODY" .

FUEL INJECTOR AND FUEL TUBE" .

[KA24DE]

AIR CLEANER AND

PBIC0428E

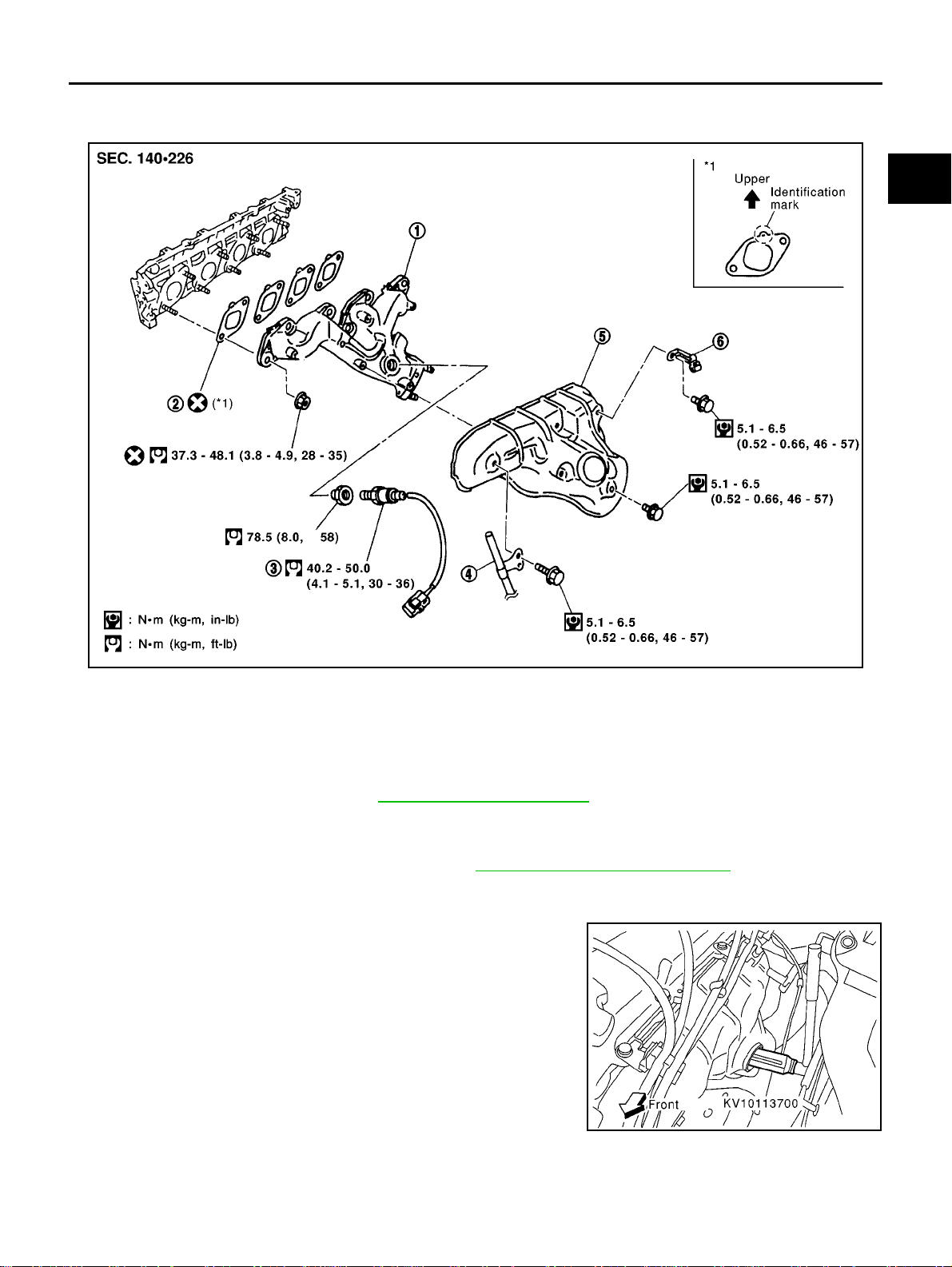

INSPECTION AFTER REMOVAL

Surface Distortion

● Using straightedge and feeler gauge, inspect surface d istortion

of intake manifold.

Limit : 0.1 mm (0.004 in)

INSTALLATION

Assemble in reverse order of removal, paying attention to the following.

Intake Manifold Bolts

● Tighten in numerical or der as shown in the figure.

: 15.7 - 18.6 N·m (1.6 - 1.8 kg-m, 12 - 13 ft-

lb)

PBIC0429E

Water Outlet

● Install ga sket so that identification mark face as shown in component parts drawing.

EM-22

PBIC0428E

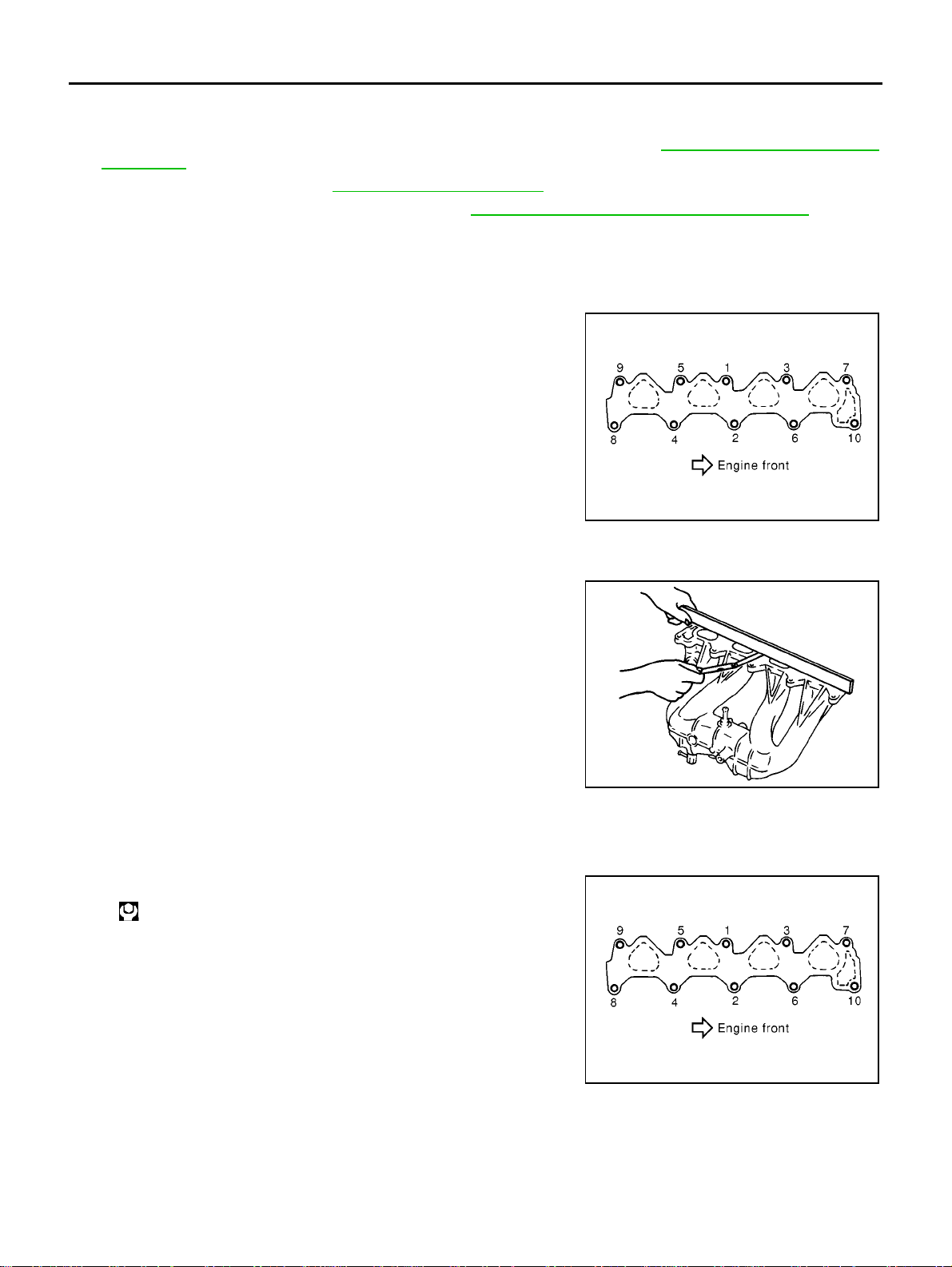

EXHAUST MANIFOLD

[KA24DE]

EXHAUST MANIFOLD PFP:14004

Removal and Installation

EBS008RQ

A

EM

C

D

E

F

G

KBIA0825E

1 Exhaust manifold 2 Gasket 3 Heated oxygen sensor

4 Oil level gauge guide 5 Exhaust manifold cover 6 Bracket

REMOVAL

1. Remove under cover on rear side.

2. Remove exhaust front tube. Refer to EX-2, "

3. Open and fix engine compartment LH cover.

4. Remove heated oxygen sensor with the following procedure.

a. Remove engine compartment rear cover. Refer to EM-12, "

b. Disconnect heated oxygen s ensor harness connector from bracket on intake manifold No. 4 port, and

remove all harness clamps.

c. Using socket for heated oxygen sensor removal and installation

(special service tool), remove heated oxygen sensor.

5. Remove exhaust manifold cove r.

EXHAUST SYSTEM" .

ENGINE ROOM COVER" .

H

I

J

K

L

M

EM-23

KBIA0826E

EXHAUST MANIFOLD

6. Loosen m ounting nuts in reverse order shown in the figure, and

remove exhaust manifold.

INSPECTION AFTER REMOVAL

● Using straightedge and feeler gauge, inspect surface d istortion

of intake manifold.

Limit : 0.3 mm (0.012 in)

[KA24DE]

PBIC0430E

INSTALLATION

Install in the reverse order of removal, paying attention to the following.

● Tighten in numerical or der as shown in the figure.

: 37.3 - 48.1 N·m (3.8 - 4.9 kg-m, 28 - 35 ft-lb)

INSPECTION AFTER INSTALLATION

Start engine , and ch eck for exhaust gas leakage and unusual noise by increasing engine speed.

PBIC0431E

PBIC0430E

EM-24

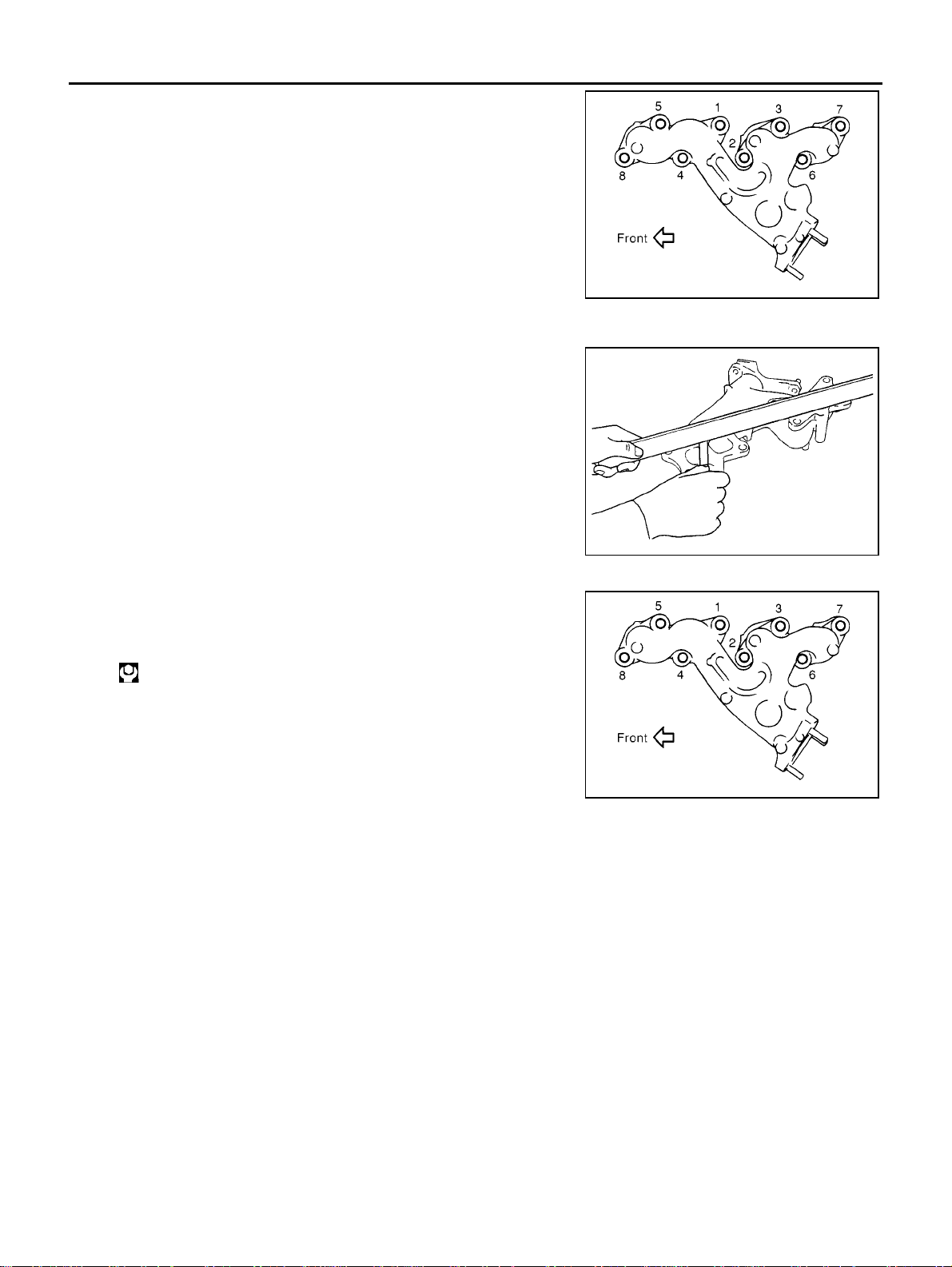

OIL PAN AND OIL STRAINER

[KA24DE]

OIL PAN AND OIL STRAINER PFP:11110

Removal and Installation

EBS007KB

A

EM

C

D

E

F

1 Gasket 2 Oil strainer 3 Oil pan drain plug washer

4 Oil pan drain plug 5 Oil pan

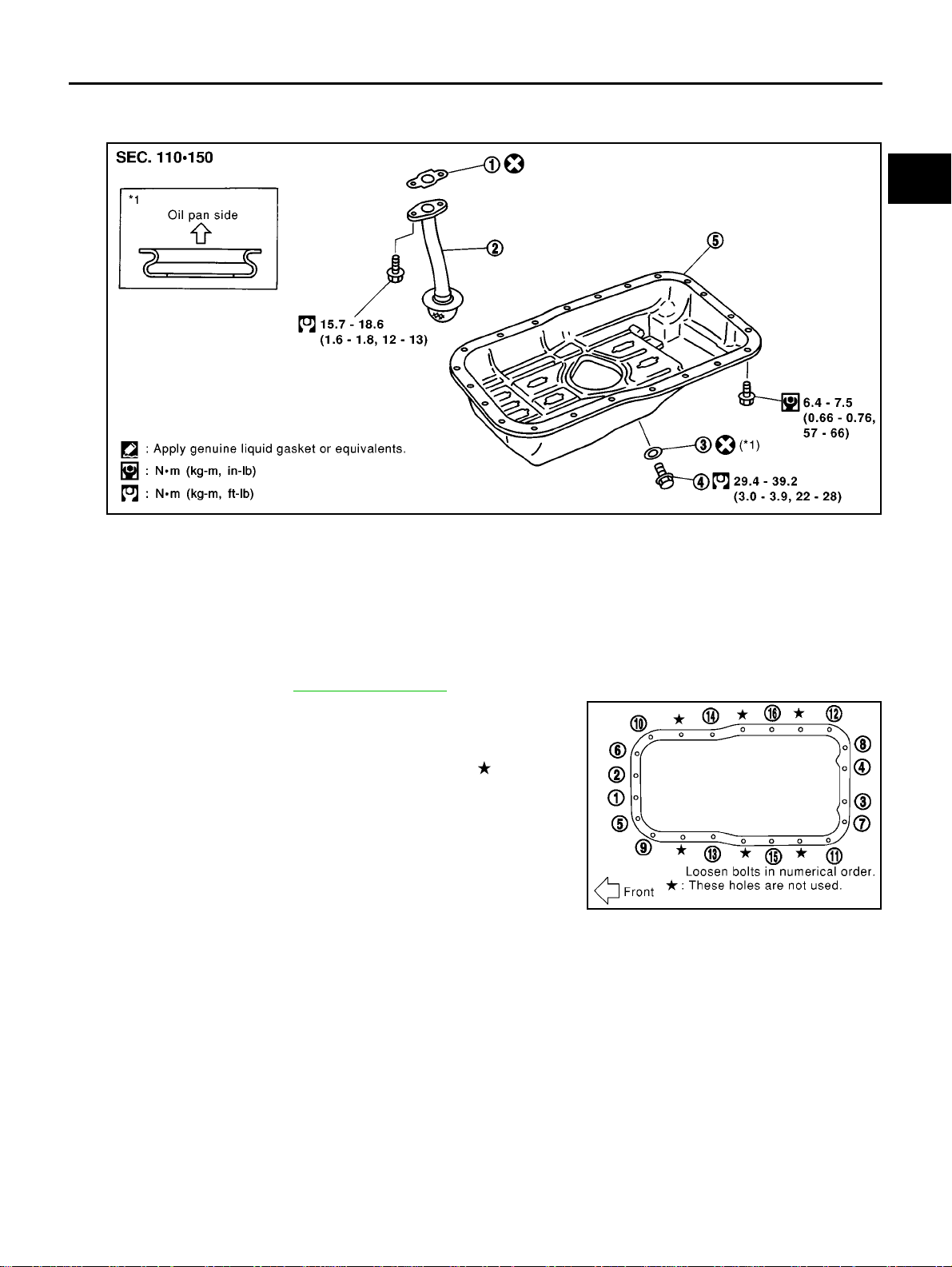

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

1. Remove under covers on front-side, and rear-side.

2. Drain engine oil. Refer to LU-5, "

ENGINE OIL" .

3. Loosen mounting bolts in reverse order shown in the figure, and

remove them.

NOTE:

There are no screw holes in the area marked with on cylinder

block. (No mountin g bolts.)

4. Using a s eal cutter (special service tool), separate liquid gaske t,

and remove oil pan.

5. Remove oil strainer.

INSPECTION AFTER REMOVA L

Check oil strainer and clean it if any object attached.

PBIC0432E

SEM980F

G

H

I

J

K

L

M

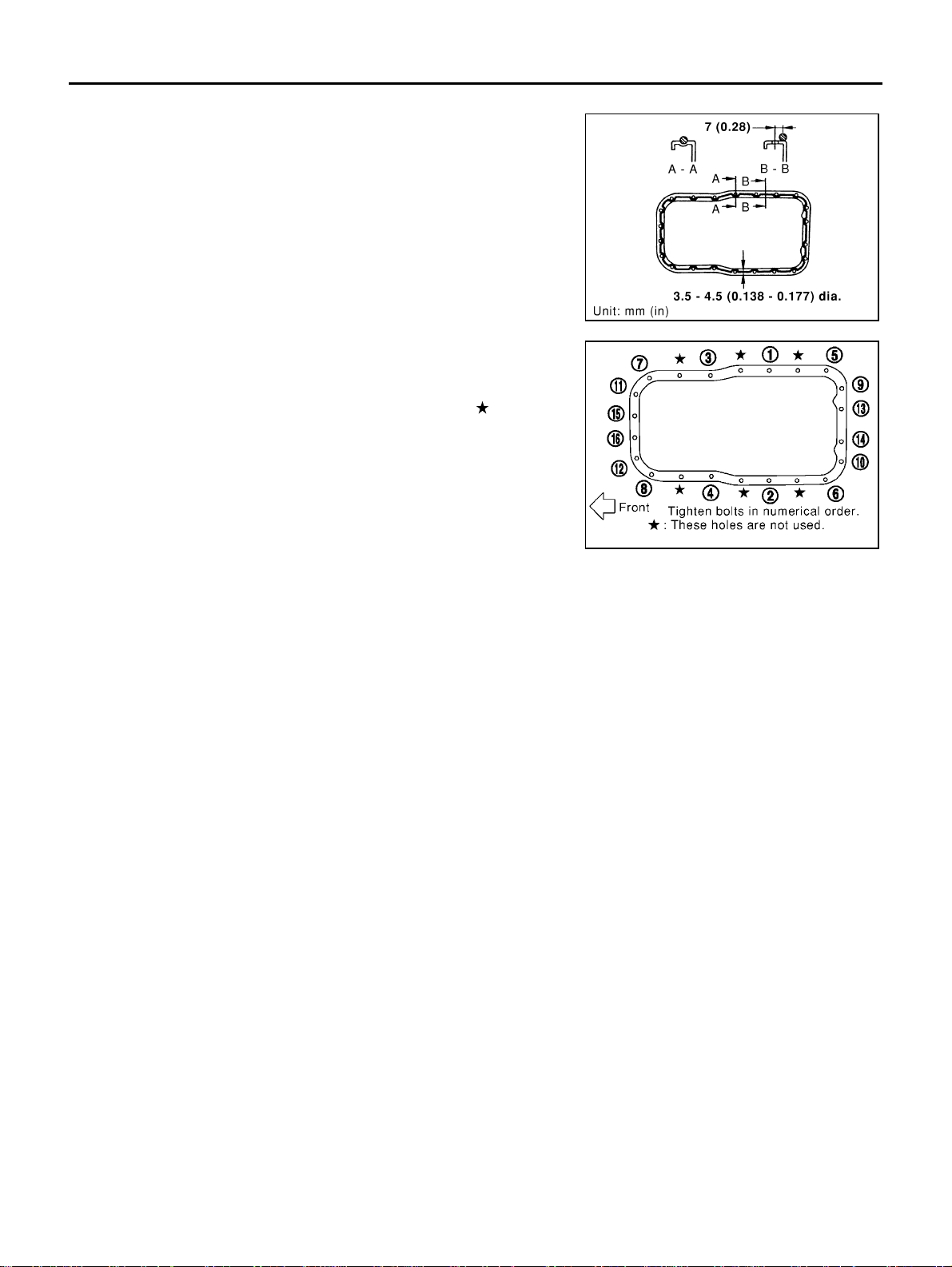

INSTALLATION

Install in the reverse order of removal paying attention to the following.

EM-25

OIL PAN AND OIL STRAINER

Installing Oil Pan

1. Apply liquid gasket thoroughly as shown in illustration.

● Use Genuine Liquid Gasket or equiv alent.

2. Tighten mounting bolts in numerical order as shown in the figure.

NOTE:

There are no sc rew holes in the area marked with on cylinder

block. (No mounting bolts.)

[KA24DE]

PBIC0433E

Installing Drain Plug Washer

Refer to illustration of com ponent parts for installation direction.

INSPECTION AFTER INSTALLATION

Check for leakage of engine oil when engine is warmed.

SEM985F

EM-26

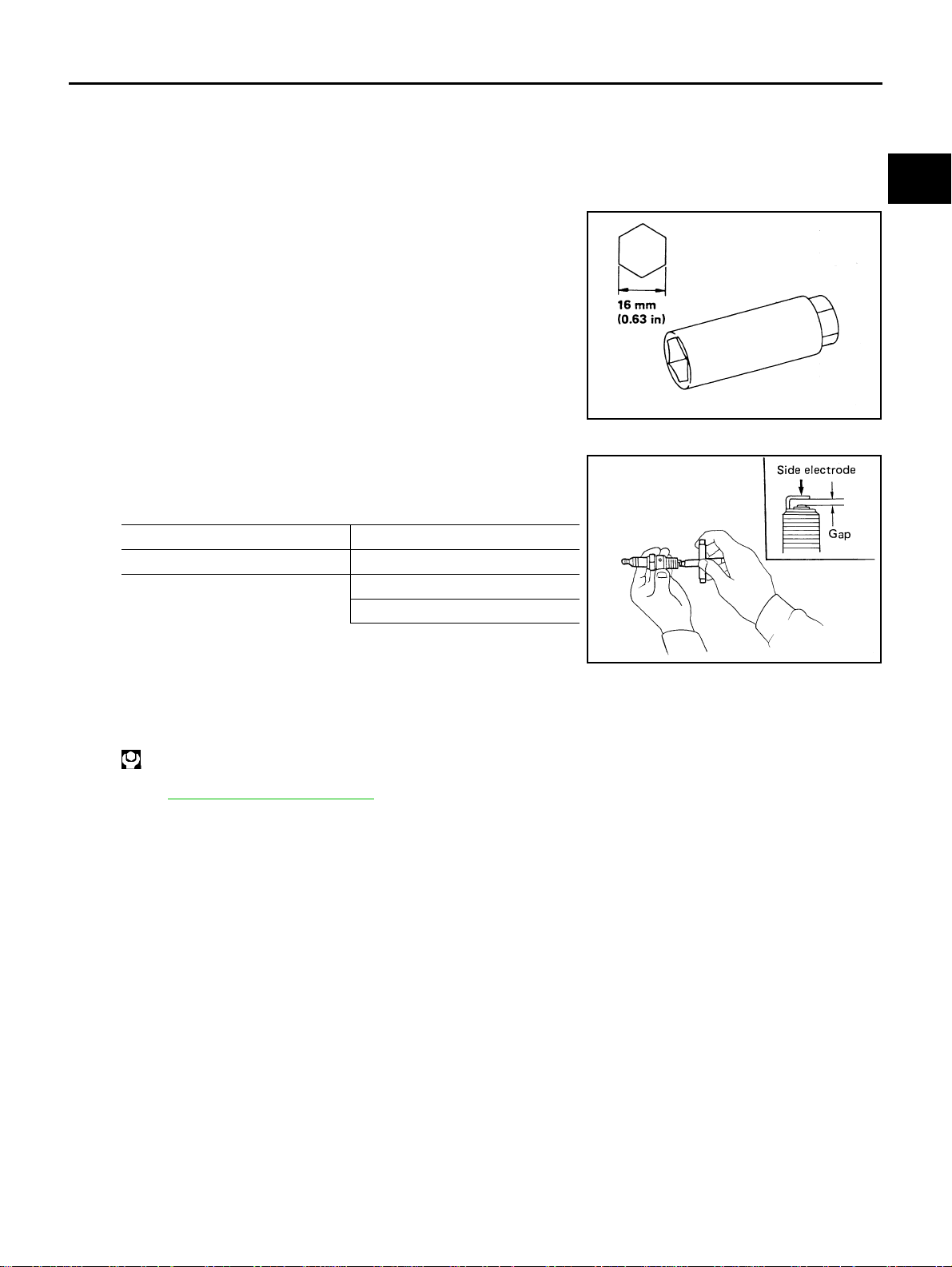

SPARK PLUG (CONVENTIONAL)

[KA24DE]

SPARK PLUG (CONVENTIONAL) PFP:22401

Removal and Installation

REMOVAL

1. Open and fix engine compartment LH cover.

2. Disconnect high-tension cables from rocker cover.

3. Remove spark plugs with a spark plug wrench (comme rcial service tool).

● Remove and i nstall No. 4 cylinder by conne cting exte nsion

bar of 75 mm and universal socket to spark plug wrench.

EBS008YM

SMA581C

A

EM

C

D

E

INSPECTION AFTER REMOVA L

Check spark plug gap. Adjust or replace if necessary.

Standard : 1.0 - 1.1 mm (0.039 - 0.043 in)

Spark plug:

Make NGK

Standard type BKR5E-11

Cold type

● Use a wire brush for cleaning, if necessary.

BKR6E-11

BKR7E-11

INSTALLATION

Install in the reverse order of removal, paying attention to the following.

Spark plug:

: 20 - 29 N·m ( 2.0 - 3.0 Kg-m, 14 - 22 ft-lb)

● Refer to EM-30, "ROCKER COVER" for installation of spark plug cap and high-tension cables.

F

G

H

I

SMA476

J

K

L

M

EM-27

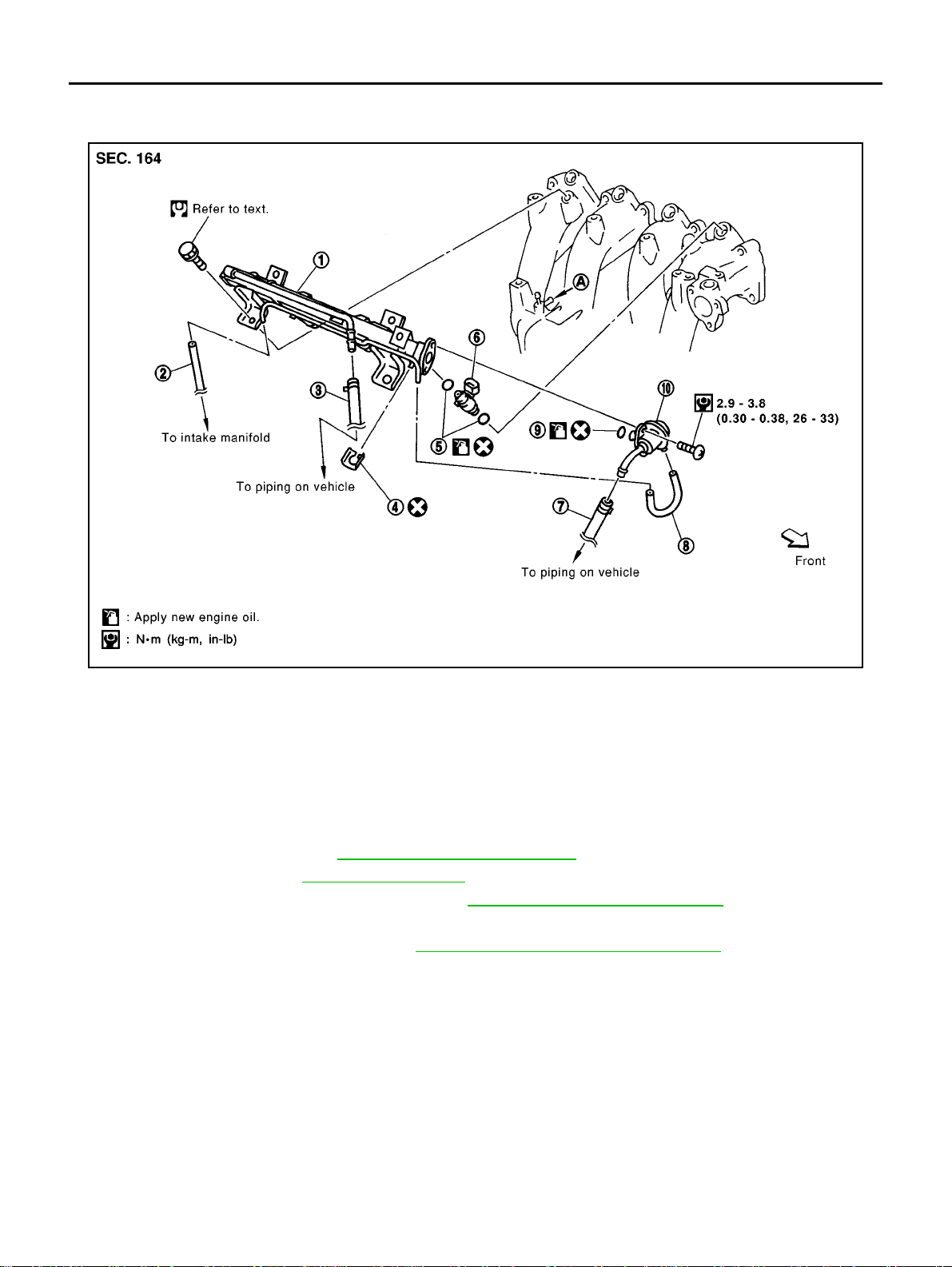

FUEL INJECTOR AND FUEL TUBE

[KA24DE]

FUEL INJECTOR AND FUEL TUBE

Removal and Installation

PFP:16600

EBS007KE

1 Fuel tube 2 Vacuum hose 3 Fuel feed hose

4 Clip 5 O-ring 6 Fuel injector

7 Fuel returnhose 8 Vacuum hose 9 O-ring

10 Fuel pressureregulator

CAUTION:

● Apply new engine oil when installing the parts that specified to do so in the figu re.

REMOVAL

1. Release fuel pressure. Refer to EC-27, "Fuel Pressure Release" .

2. Remove RH seat. Refer to SE-4, "

3. Remove engine compartment RH cover. Refer to EM -12, "

4. Disconnect PCV hose between rocker cover and air duct.

5. Remove air duct on throttle body. Refer to EM-16, "

6. Disconnect fuel injector harness connector.

7. Move aside main harnes s above intake manifold.

8. Disconnect vacuum hose from fuel tube.

9. Disconnect fuel feed hose and fuel return hose.

CAUTION:

Plug hoses to prevent fuel from draining.

10. Remove fuel tube and injector assembly.

CAUTION:

Do not incline it, or remaining fuel in pipes may drain from pipes.

FRONT SEAT" .

ENGINE ROOM COVER" .

AIR CLEANER AND AIR DUCT" .

KBIA0827E

EM-28

FUEL INJECTOR AND FUEL TUBE

[KA24DE]

11. Expand and remove clips securing fuel injectors.

12. Extractfuel injectors straight from fuel tubes.

● Be careful not to damage injector nozzles during

removal.

● Do not bump or drop fuel injectors.

● Do not disassemble.

PBIC0227E

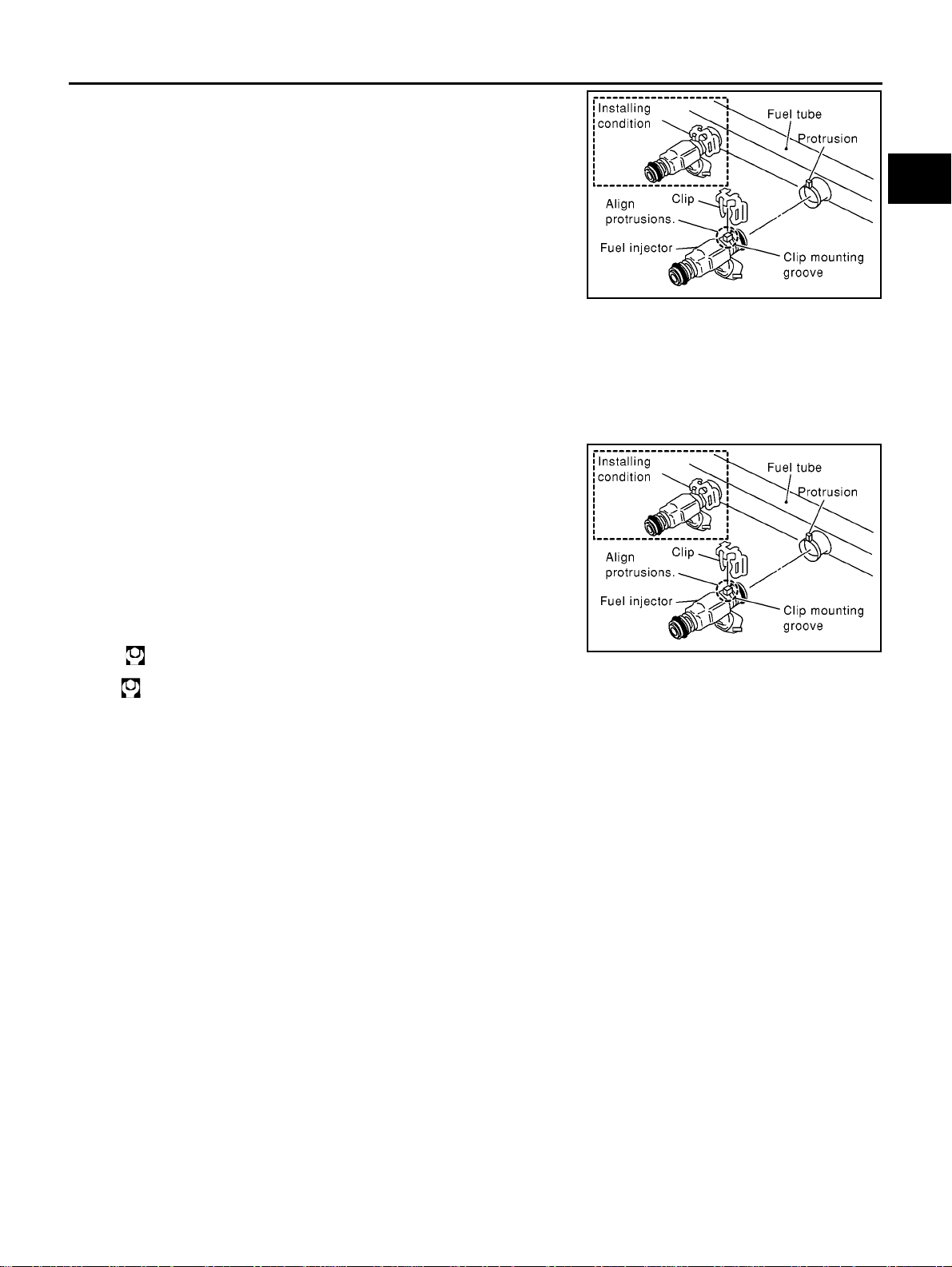

INSTALLATION

1. Careful ly install O-rings, including the one used with the pressure regulator.

● Lubricate O-rings by smearing new engine oil.

● Be careful not t o damage O-rings and surfaces for O-ring sealing with service tools, finger nails or

clips. Do not expand or twist O-rings.

● Discard old clips; replace with new ones.

2. Position clipsin grooves on fuel injectors.

● Make sure that p r otrusions of fuel injectors are aligned with

cutouts of clips after installation.

3. Align protrusions of fuel tubes with those of fuel injectors.

4. Do not incline it, or remaining fuel in pipes m ay drain from pipes.

● Insert hose until its end touches bulge on fuel tube. Install

clamp, avoiding bulge, and securely tighten i t.

5. Tighten fuel tube assembly mounting bolts alternatively in two

steps.

PBIC0227E

1st step : 7.8 - 10.8 N·m (0.8 - 1.1 kg-m, 69 - 95 ft-lb)

A

EM

C

D

E

F

G

H

I

2nd step :15.7 - 18.6 N·m (1.6 - 1.8 kg-m, 12 - 13 ft-lb)

6. Conne ct fuel feed nose and fuel return hose.

● Insert hose until its end touches bulge on fuel tube. Install clamp, avoiding bulge, and securely tighten

it.

7. Install all removed parts in the reverse o rder of removal.

INSPECTION AFTER INSTAL LATION

Check on Fuel Le akage

1. Start the engine, and run it for a few minutes with engine at idle.

2. Stop the engine, and check for fuel leakage both visually and by odor of gasoline.

NOTE:

Use mirrors for checking on invisible points.

CAUTION:

Do not touch the engine immediately after stopped, as engine becomes extremely hot.

J

K

L

M

EM-29

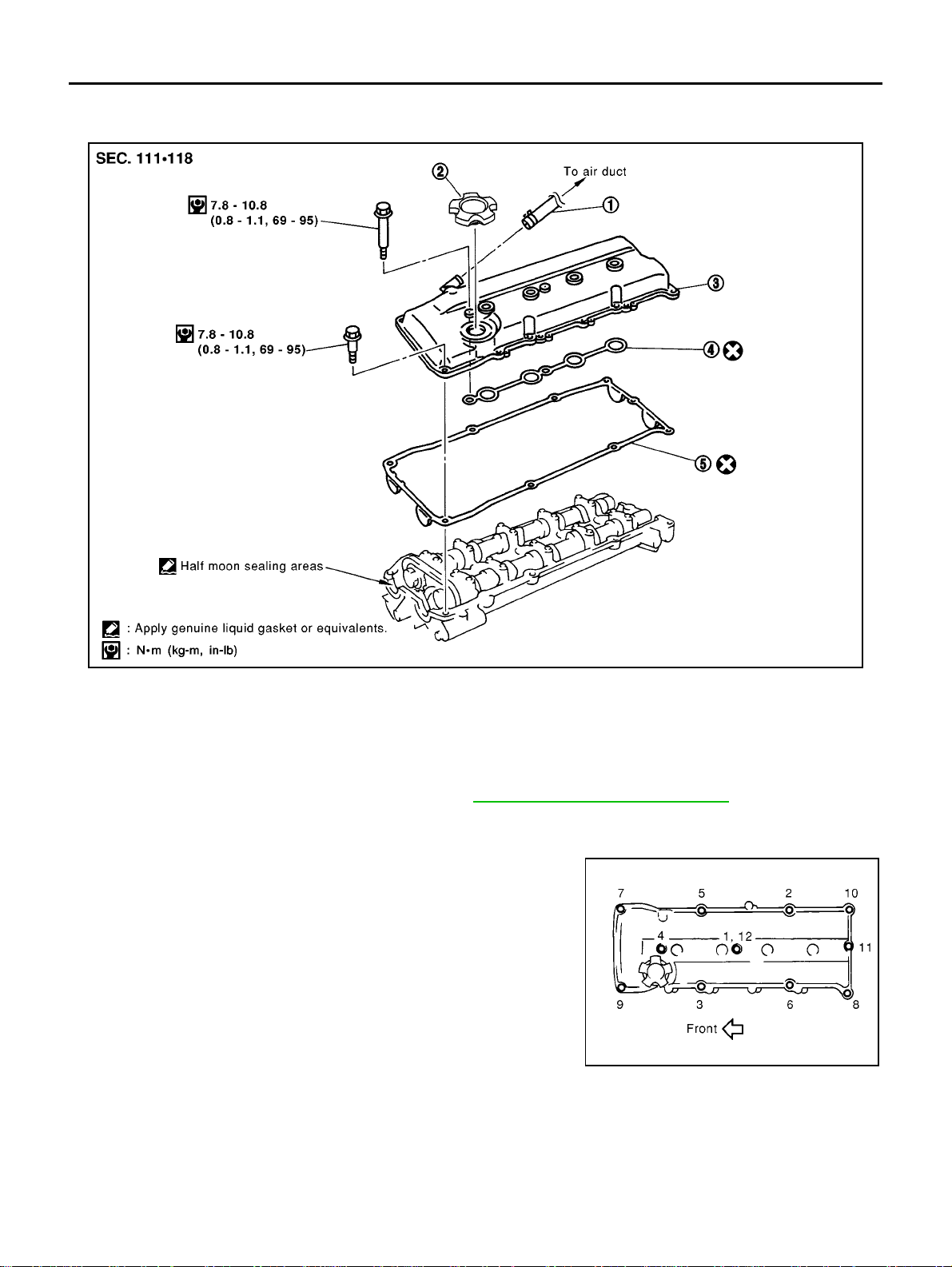

ROCKER COVER

[KA24DE]

ROCKER COVER

Removal and Installation

PFP:13264

EBS007KF

1 PCV hose 2 Oil filler cap 3 Rocker cover

4 Gasket 5 Gasket

REMOVAL

1. Open and fix engine compartment LH cover.

2. Remove engine compartment rear cover. Refer to EM-12, "

ENGINE ROOM COVER" .

3. Disconnect PCV hose.

4. Disconnect spark plug cap and high-tension cables, and set them aside.

5. Loosen mounting bolts in reverse order s hown in the figure, and

remove rocker cover.

INSTALLATION

Install in the reverse order of removal, paying attention to the following.

KBIA0828E

PBIC0434E

EM-30

Loading...

Loading...