Page 1

CONTENTS

INTRODUCTION

VEHICLE IDENTIFICATION AND

GENERAL SPECIFICATIONS

GENERAL INFORMATION

Tools and equipment ............................................. 8

Safety .................................................................... 10

General repair procedures..................................... 11

........................................

.................

......................

5

7

8

LUBRICATION AND MAINTENANCE... 14

Specifications......................................................... 14

How to grease and oil change .............................. 14

Service schedule ................................................... 17

WHEELS AND TYRES

Specifications......................................................... 21

How to change a road wheel ................................ 21

Tire wear trouble shooting..................................... 22

Care and maintenance ......................................... 23

ENGINE TUNE-UP

Tune-up specifications ........................................... 25

Tune-up operations ............................................... 25

ROADSIDE TROUBLE SHOOTING

Trouble shooting.................................................... 32

To check ignition and electrical system ................ 33

To check fuel system ............................................ 34

To check mechanical system................................ 35

ENGINE

Specifications ........................................................ 37

Engine mechanical trouble shooting...................... 39

Description ............................................................ 41

Engine and transaxle assembly ........................... 42

Manifolds............................................................... 44

Camshaft, rocker arms and tappets..................... 48

Cylinder head ........................................................ 50

Engine sump and oil pump pickup pipe................ 54

Oil pump ............................................................... 55

Pistons, connecting rods and cylinder bores ........ 57

Crankshaft and bearings...................................... 60

Flywheel /drive plate............................................... 63

Engine mountings.................................................. 64

Exhaust system.................................................... 66

.......................................................

.............................

....................................

.......

21

25

32

37

COOLING AND HEATING SYSTEMS.... 68

Specifications ........................................................ 68

Cooling system trouble shooting ........................... 68

Heater and air conditioner trouble shooting ......... 69

Description ............................................................ 70

Radiator ................................................................ 70

Cooling fan ............................................................ 73

Thermostat............................................................ 75

Thermostat housing .............................................. 76

Water pump .......................................................... 76

Welch plugs .......................................................... 76

Heater unit, water valve and controls................... 77

Blower fan ............................................................. 80

Air conditioning ..................................................... 80

FUEL AND ENGINE MANAGEMENT ... 82

Specifications ........................................................ 82

Fuel and engine management trouble shooting... 82

Description............................................................ 84

Service precautions and procedures ..................... 86

System diagnosis and adjustments...................... 89

Fuel supply components ....................................... 92

Air flow components.............................................. 98

Electronic components.......................................... 104

EMISSION CONTROL

Introduction ........................................................... 117

Crankcase ventilation system............................... 117

Evaporate control system ..................................... 117

Air preheat system — 1.6 liter engines ................ 119

Exhaust control system........................................ 120

CLUTCH

Specifications........................................................ 121

Clutch trouble shooting......................................... 121

Description............................................................ 122

Clutch unit and release mechanism..................... 123

Clutch pedal ......................................................... 124

Clutch cable.......................................................... 124

Clutch adjustments............................................... 125

MANUAL TRANSAXLE AND

DRIVE SHAFTS

Specifications........................................................ 126

Manual transaxle and drive shaft trouble shooting 126

Description............................................................ 128

Transaxle assembly.............................................. 129

Differential and final drive assembly ..................... 135

Gear lever assembly ............................................ 136

Drive shafts .......................................................... 137

......................................................

.........................................

AUTOMATIC TRANSAXLE

Specifications........................................................ 140

Automatic transaxle trouble shooting.................... 140

Description............................................................ 141

Transaxle fluid ...................................................... 141

Brake band........................................................... 142

Kickdown cable .................................................... 142

Transaxle selector linkage ................................... 142

Neutral safety switch............................................ 142

Transaxle assembly .............................................. 143

STEERING

PART 1. STEERING TROUBLE SHOOTING....145

Faults, causes and remedies................................ 145

PART 2. MANUAL STEERING......................... 147

Specifications........................................................ 147

Description............................................................ 147

Steering wheel ...................................................... 147

Steering column.................................................... 148

Steering gear assembly ....................................... 149

PART 3. POWER STEERING .......................... 152

Specifications........................................................ 152

Description............................................................ 152

In car adjustments, checks and minor repairs..... 152

Steering wheel ...................................................... 153

Steering column.................................................... 153

Power steering pump ........................................... 153

Power steering gear assembly............................. 154

.................................................

.............................

.......................

117

121

126

140

145

Page 2

FRONT SUSPENSION

Specifications......................................................... 156

Front suspension trouble shooting ........................ 156

Description ............................................................ 157

Steering knuckle.................................................... 157

Suspension unit..................................................... 159

Control arm ........................................................... 161

Stabiliser bar ........................................................ 162

Suspension and steering angles .......................... 163

REAR SUSPENSION

Specifications ........................................................ 164

Rear suspension trouble shooting ........................ 164

Description ............................................................ 165

Rear hub............................................................... 166

Suspension unit .................................................... 167

Control arm ........................................................... 169

Knuckle assembly.................................................. 170

Stabiliser bar ........................................................ 170

Rear wheel alignment ........................................... 171

BRAKES

Specifications......................................................... 172

Brakes trouble shooting ........................................ 172

Description ............................................................ 174

Master cylinder...................................................... 175

Brake servo unit .................................................... 177

Front brakes ......................................................... 178

Rear disc brakes................................................... 181

Rear drum brakes................................................. 184

Handbrake cable and lever assembly ................... 186

Brake adjustments ................................................ 187

Brake pedal........................................................... 187

Hydraulic system................................................... 188

......................................................

............................

................................

156

164

172

ELECTRICAL SYSTEM

Specifications......................................................... 190

Battery and charging system trouble shooting....... 190

Battery and starting system trouble shooting ........ 191

Lighting system trouble shooting ........................... 192

Turn signal lamp trouble shooting ........................ 192

Test equipment and some applications................. 193

Battery................................................................... 194

Alternator ............................................................... 196

Starter motor......................................................... 201

Ignition system ...................................................... 206

Steering wheel ....................................................... 206

Switches and controls........................................... 206

Instrument cluster.................................................. 209

Blower fan.............................................................. 209

Radio/cassette...................................................... 209

lamp units............................................................ 210

Windscreen wiper ................................................. 213

Fuses, fusible links and relays............................. 215

Trailer wiring......................................................... 216

Wiring diagrams ................................................... 218

BODY

Windscreen and rear glass .................................. 225

Front doors........................................................... 225

Rear doors............................................................ 228

Engine bonnet ...................................................... 231

Tailgate and lock — hatchback ............................ 231

Luggage compartment lid and lock — sedan ........ 233

Radiator grille.............................................................. 234

Centre console...................................................... 234

Dashboard............................................................ 235

Scat belts ............................................................. 236

Seats .................................................................... 236

Vehicle cleaning ........................................................... 237

...........................................................

CONVERSION TABLES

............................

..........................

190

225

238

Page 3

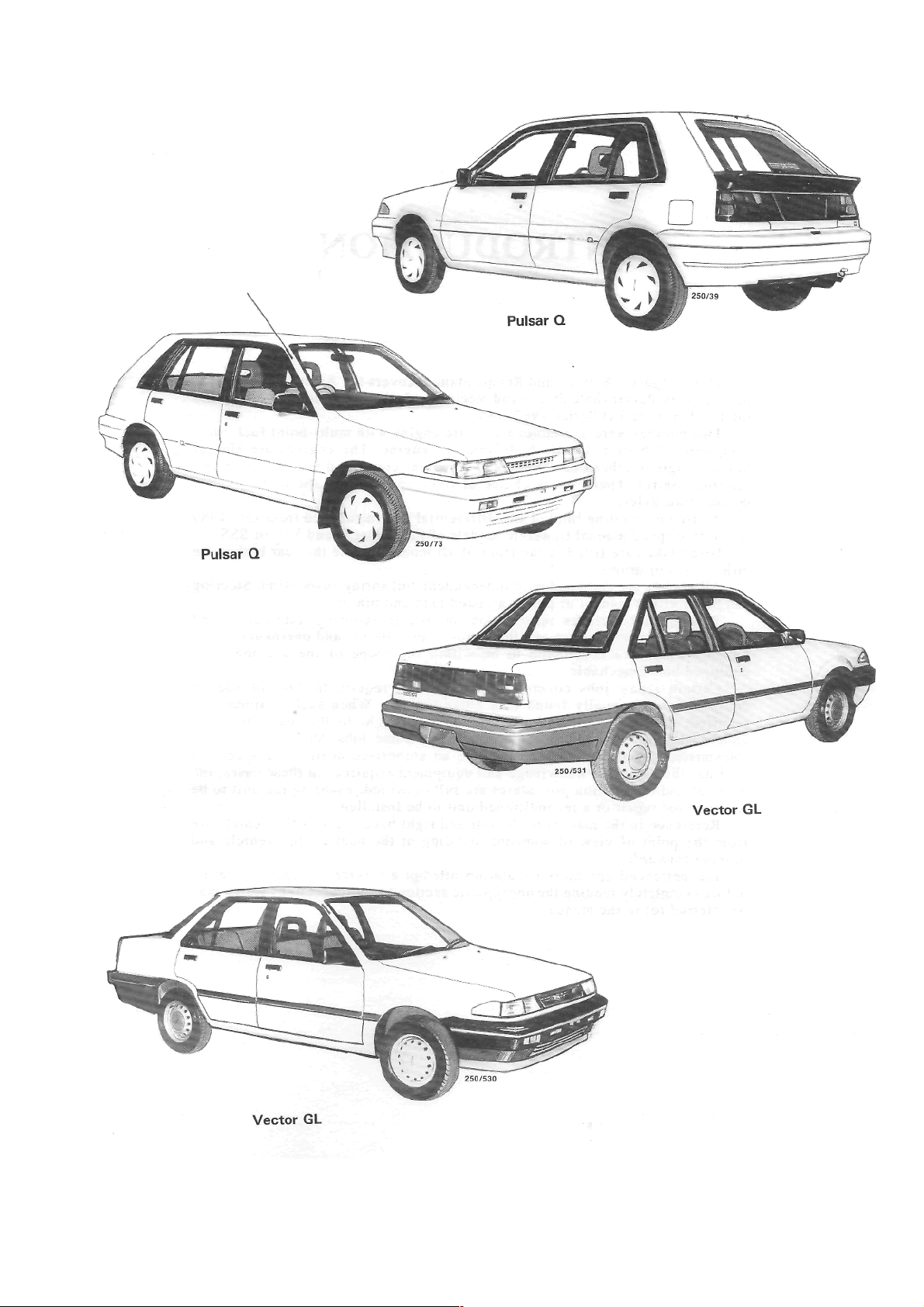

INTRODUCTION

This Service and Repair Manual covers the Australian manufac-

tured Nissan Pulsar (hatchback) and Vector (sedan) N13 Series 1

the Holden Astra LD Series 1987 - 89.

Two engines were available: a 1.8 l it er engine with multi-point fuel injection, and a 1.6 liter throttle body injected engine. The engines are similar

having single overhead camshafts and computer controlled fuel injection and

ignition control. There was a choice of three speed automatic or five speed

manual transaxles.

A viscous coupling limited sli p differential was introduced from July 1989

to the five speed manual transaxle models of the Pulsar Q and Vector SSS.

Disc brakes are fitted at the front of al l models, while the rear brakes are

either discs or drums.

All models are equipped with independent coil spring suspension. Steering

can be by either manual or power assisted rack and pinion.

This manual includes information on trouble shooting, lubrication and

maintenance, specifications and the removal, installation and overhaul of components which are considered to be within the scope of the average, well

equipped home mechanic.

Certain repair jobs covered in this manual require the use of special

equipment not normally found in a home tool kit. When such equipment is

required, the equipment and its function is brought to the users attention

underneath the heading for that component. Some jobs, such as automatic

transmission overhaul, should he left to an authorized dealer or a specialist

who has the extensive knowledge and equipment required. In these cases, the

removal and installation procedures are fully covered, enabling the unit to be

removed for repair or a reconditioned unit to be installed.

Reference in the manual to the left and right hand sides of the vehicle are

from the point of view of someone standing at the back of the vehicle and

looking forward.

Inexperienced operators should not attempt a service or repair operation

before completely reading the appropriate section (or other sections which may

be referred to) in the manual.

(

J87 - 91 and

Page 4

Page 5

VEHICLE IDENTIFICATION AND

GENERAL SPECIFICATIONS

1. VEHICLE IDENTIFICATION

When purchasing spare parts or when

registering

or insuring a vehicle, it may be necessary to quote

various vehicle identification codes. The location of

these codes are as follows:

The Engine Number is stamped on the front

face

of the engine block below No. 4 spark plug.

The Chassis Number is stamped on the bulkhead

above and to the right of the brake booster.

The Vehicle Identification Plate is located on the

bulkhead to the left of the MAP sensor and contains

codings relating to body style, engine capacity,

model,

transaxle type, engine number, paint, trim and build

date.

The Compliance Plate contains information on

the vehicle make, model, month and year of manufacture, chassis number, seating, capacity and the

Australian Design Rules (ADR) with which the vehicle complies. This plate is affixed to the bulkhead

above and to the left of the brake booster.

The Tire Placard, which is located on the inside

of the glove compartment, contains information

on

the tire size, rim size, tire pressure and load ratings.

2. GENERAL VEHICLE SPECIFICATIONS

Length:

Pulsar...................................................4 030 mm

Astra hatchback ..................................4 035 mm

Vector ..................................................4215 mm

Astra sedan..........................................4 255 mm

Width:

Nissan .................................................. 1 640 mm

Holden ................................................. 1 655 mm

Height ........................................................ 1 380 mm

Wheelbase..................................................2 430 mm

Wheel track:

Front .................................................... 1 435 mm

Rear ..................................................... I 430 mm

View of the engine compartment showing the location

of various vehicle identification information.

Minimum ground clearance:

Nissan.................................................... 128 mm

Holden................................................... 110 mm

Turning circle kerb to kerb .......................... 10.8 m

Fuel tank capacity:

Nissan.................................................... 47 liters

Holden................................................... 50 liters

Towing capacity:

Without trailer brakes............................ 400 kg

With trailer brakes................................. 900 kg

*Fuel consumption:

L/100km L/100km

(City) (Highway)

Manual transaxle 8.5 6.6

Automatic transaxle 9.0 7.2

*The fuel consumption information is based on

tests made according to Australian Standard 2877.

The actual fuel consumption will depend on many

factors including driving habits, vehicle condition

and equipment and the prevailing conditions.

Page 6

GENERAL INFORMATION

1. TOOLS AND EQUIPMENT

To successfully perform any maintenance or repair work on a motor vehicle, suitable hand tools are

essential. The use of tools for other than their intended purpose or the use of incorrectly fitting tools can

cause damage to the component and/or injury lo the

operator.

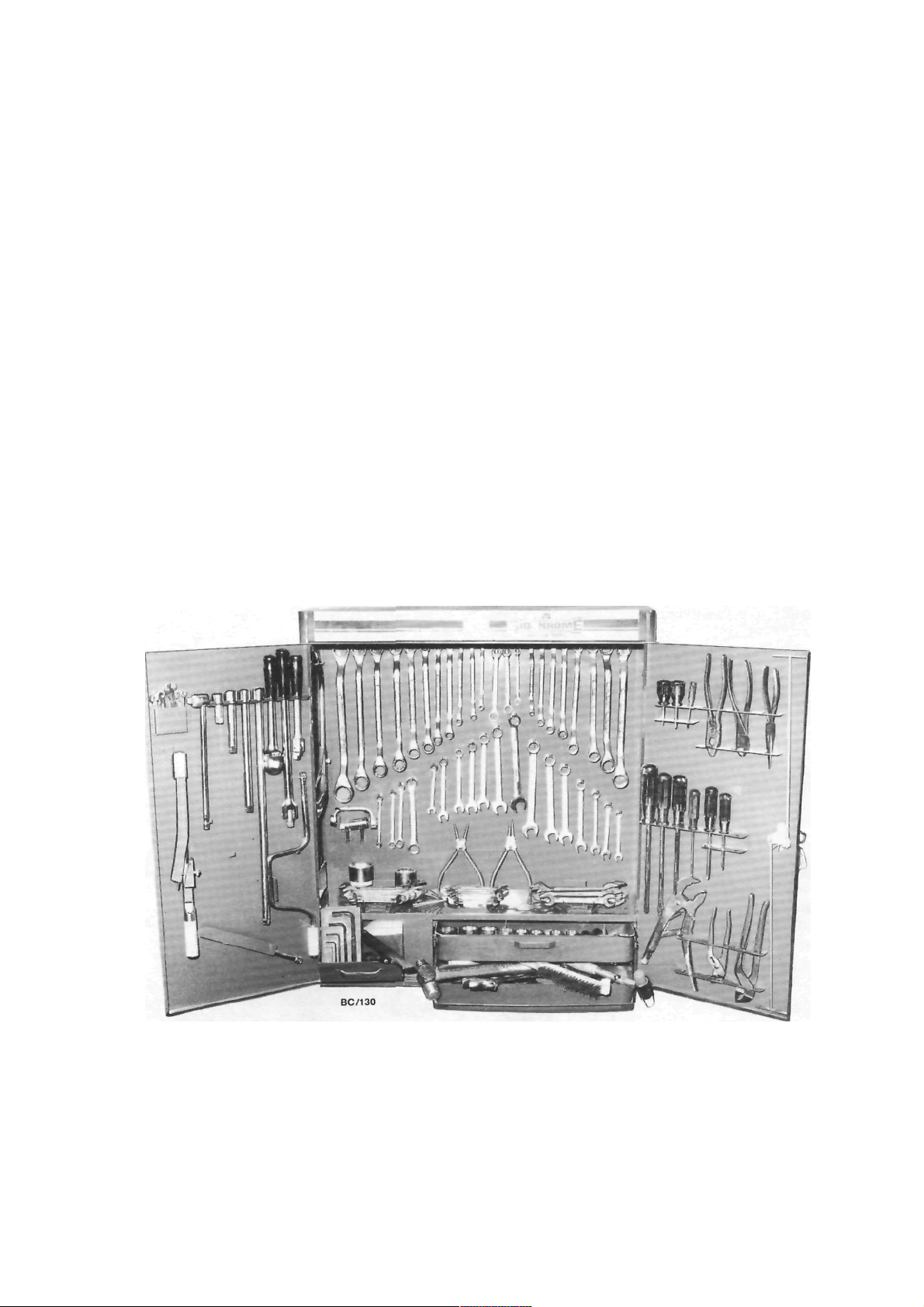

BASIC TOOL KIT

equipment for the majority of the maintenance and

repair procedures described in this manual. Of course,

not all of the tools are required for all the jobs, so it is

wise to purchase tools on an 'as needed' basis.

The following is a suggested list of tools and

Set of open ended spanners.

Set of ring spanners.

Set of socket spanners.

Spark plug spanner.

Assorted bladed screwdrivers.

Assorted Philips screwdrivers.

Assorted pliers — combination, long nose, multigrip, vice grip, snap ring (internal and external).

Assorted adjustable spanners.

Ball pein hammer.

Cold chisels.

Pin punches and centre punch.

Assorted files.

Scraper.

Feeler gauges.

Torque wrench.

Hydraulic jack.

Chassis stands.

Car ramps.

Grease gun.

Oil can.

Oil gun.

Oil filter removal tool.

Funnel.

Containers for draining oil and washing components.

A comprehensive tool kit showing a wide range of general hand tools.

Page 7

General Information

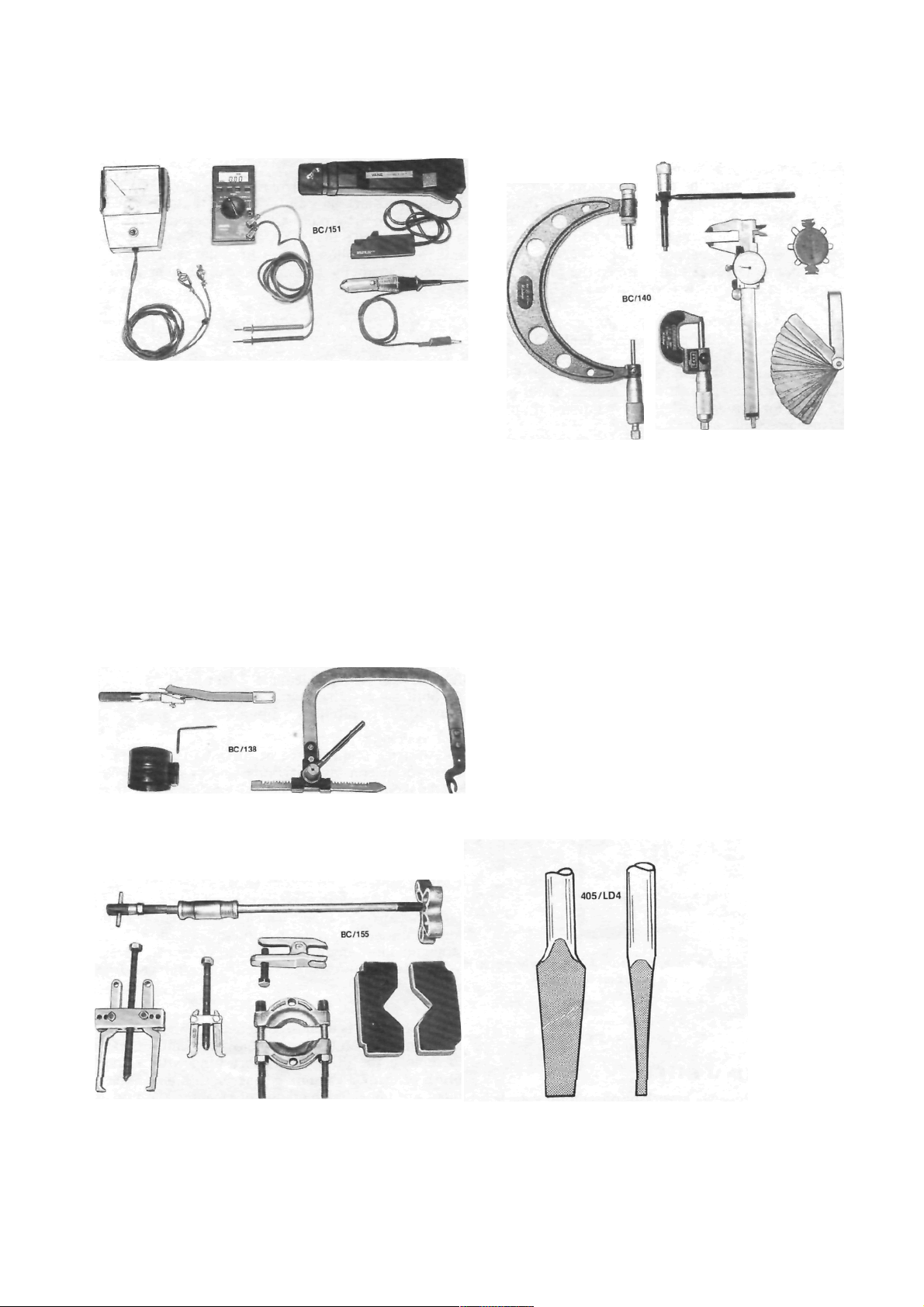

Assorted test equipment — dwell tachometer, digital

multimeter, timing light and test lamp.

Inspection lamp.

Test lamp.

Tachometer.

Timing light.

Digital multimeter.

Piston ring compressor.

Valve spring compressor.

Micrometer — inside, outside, multi range.

Vernier calipers.

Assorted pullers.

When purchasing tools, it is sound advice to select

the highest quality that can be afforded, as the

working life of cheaper tools is often very short.

Assorted measuring devices — inside and outside

micrometers, vernier calipers, wire gauges and feeler

Ensure that the tools are suitable for the system of

bolt and nut sizing on the vehicle. The range of

vehicles covered by this manual use metric sizes.

TOOL CARE

To ensure the longest possible life for hand tools,

it is important that time be spent maintaining them.

At the conclusion of each job. all tools used should

be washed thoroughly in kerosene or similar cleaning

solvent. Ensure that all dirt and grease is removed,

particularly from tools with moving parts such as

pliers and adjustable spanners. The tools should then

be wiped dry with a clean cloth.

Measuring devices should be given particular

attention as their accuracy can be affected if not

properly maintained. Feeler gauges should be kept

clean at all times and the blades should be wiped with

an oily cloth after use to prevent rusting.

gauges.

Tension wrench, piston ring compressor and valve

spring compressor.

Slide hammer, ball joint puller, assorted pullers and

press plates.

Views showing the correct tip profiles for a bladed

screwdriver. Bladed screwdrivers should not be

ground to a sharp point.

Page 8

10

General Information

If tools are to be stored for any length of time, it is

good policy to wipe them with an oily cloth.

Bladed screwdrivers should be checked for damage to the tip. If necessary, the tip can be returned to

its original profile by careful grinding. Do not grind

screwdriver tips to a sharp point.

Hammer heads should be secure on their handles

and should be regularly checked for cracking or other

damage.

Chisels and punches should be checked for damage or 'mushrooming' of the head. Any faults should

be rectified by grinding.

Hydraulic jacks should be regularly checked for

fluid leaks. Chassis stands and car ramps should be

checked for damage and cracks. Any equipment that

is suspect should not be used.

STORES

For routine maintenance, stores of automotive

oils, greases and additives should be kept on hand.

The following is a suggested list.

Engine oil.

Brake fluid.

Manual transmission or automatic transmission

oil — automatic transmission oil is also used in

the power steering system.

Rear axle oil.

Cooling system corrosion inhibitor/antifreeze.

Chassis grease.

High melting point grease, for hub bearings etc.

Penetrating oil or spray.

Kerosene or similar cleaning solvent.

Methylated spirits.

Oils and greases are available in handy pack size for

do-it-yourself lube jobs.

2. SAFETY

PERSONAL SAFETY

Safety when working on a motor vehicle is basically a matter of commonsense. Some safety precautions

to prevent personal injuries are as follows.

Raising a Vehicle

Always jack a vehicle on firm, level ground and at

the specified jacking points. Ensure that the wheels

remaining on the ground are fully chocked.

After raising the vehicle, place chassis stands

underneath and allow the weight of the vehicle to rest

on them. Do not use bricks, blocks of wood or similar

material.

NOTE: Never work under a vehicle which is

only supported by a jack.

Electrical System

Always disconnect the negative battery terminal

when working on any electrical components. Avoid

wearing metal watches, rings and chains which may

short across live terminals.

As battery gases are explosive, keep naked flames

and sparks clear of the work area. When connecting

and disconnecting jumper leads, use extreme caution

to avoid sparking.

Electronic Ignition Systems

Electronic ignition systems produce dangerous

high tension voltages in both the primary and secondary circuits which can be fatal. Exercise extreme

caution when working on or near any ignition system

components. Do not disconnect high tension leads

while the engine is running.

Work Area

Do not run the engine in a confined space. Ensure

that the work area is adequately ventilated.

Spilt oil or water should be cleaned immediately

to avoid the possibility of slipping.

Fuel System

Always disconnect the negative battery terminal

when working on any fuel components. Do not smoke.

Keep naked flames and sparks clear of the work area.

Do not siphon fuel using the mouth. Use a hand

pump or suitable siphon.

Do not attempt to repair a fuel tank by welding it.

This is an extremely hazardous procedure and should

be entrusted to a specialist.

Cooling System

To avoid scalding, use caution when releasing the

radiator cap on an engine which is at normal operating

temperature. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to release.

When the pressure is released, remove the cap from

the radiator.

Brakes

As asbestos is used in some brake lining material,

avoid inhaling brake dust. Do not use compressed air

to remove the dust. Gentle brushing with a small

brush or using a vacuum cleaner with a hose attachment are the safest methods of cleaning the brakes.

The above precautions also apply to the clutch plate

lining material.

Page 9

General Information

11

Lifting Equipment

When using lifting equipment to lift heavy components such as the engine and/or transmission, use

metal slings or chain in preference to rope. If rope

must be used, ensure that it is not placed against sharp

edges on the component.

Automotive Lubricants and Solvents

Avoid prolonged skin contact with oils, greases

and solvents as some can cause skin irritations and

dermatitis.

Exercise caution when using cleaning solvents as

many are inflammable. Do not smoke. Keep naked

flames and sparks clear of the work area.

Compressed Air

Never point an air hose at another person or allow

compressed air to blow onto your skin. High pressure

air forced against the skin can enter the bloodstream

and prove fatal.

Suspension and Steering Components

Damaged suspension and steering components

should not be welded. Many of these components are

fabricated from toughened metals. If welded they may

lose their strength or become brittle. Damaged components should be renewed.

Air Conditioning

Avoid disconnecting air conditioning hoses as

escaping refrigerant can cause frostbite. The refrigerant is highly flammable and when burnt, a poisonous

gas is produced.

VEHICLE SAFETY

To prevent damage to the vehicle during servicing

or repair work, note the following precautions.

Brake Fluid

If spilt on the vehicle paintwork, brake fluid

should be immediately washed away with clean water

and allowed to dry naturally, not wiped with a cloth.

Catalytic Converter

The following should be observed to prevent

damage to the catalytic converter:

Do not operate the vehicle on leaded fuel.

Do not push or tow start the vehicle.

Do not allow the engine to idle for prolonged

periods.

Do not switch the ignition off while the vehicle is

in motion and the transmission is in gear.

Do not 'prime' the engine by pouring fuel into the

inlet manifold.

Do not operate the vehicle if the engine is

misfiring.

Avoid running the vehicle out of fuel.

Ensure that the engine oil is formulated to contain

low phosphorus levels.

Electronic Components

The electronic components of the ignition and

fuel injection systems can be damaged by the use of

incorrect testing equipment.

It is essential in all tests where voltage or resistance is to be measured that a digital display multimeter with a minimum 10 megohm input impedance

be used.

Some types of tachometers, timing lights and

ignition system analyzers are not compatible with

certain engine electronic systems. It is therefore

recommended that the manufacturer of the test equipment be consulted before using the equipment.

Jump starting, or being jump started by another

vehicle can cause damage to the electronic components of the vehicle. Refer to the Roadside Trouble

shooting section for the correct jump starting procedure.

3. GENERAL REPAIR PROCEDURES

SEIZED FASTENERS

Seized bolts, nuts or screws should first have a

liberal amount of penetrating oil applied. The fastener

should be left for a period of time to allow the oil to

penetrate and soften the corrosion which is causing

the binding.

Often, a sharp hammer blow to the head of the

fastener can dislodge the corrosion and permit it to be

loosened.

An impact driver, which can be fitted with a

socket or screwdriver bit, can be used to loosen a

seized fastener.

Another method is to heat the component in

which the fastener is seized. However, extreme caution should be exercised when heating aluminum

alloy components as the melting point is much lower

than that of steel.

If the above methods fail to free a seized nut,

carefully hacksaw through one side of the nut until it

can be split. Care should be taken that the threads of

the bolt or stud are not damaged.

Should a bolt or stud break below the surface of

the component, it will be necessary to use a screw

extractor to remove the remaining part. Follow the

screw extractor manufacturers instructions.

Tap and die set and assorted screw extractors.

Page 10

12

General Information

Damaged threads can be repaired using a die nut

on studs and bolts, and a tap on nuts and threaded

holes in castings. If the threads of a threaded hole are

damaged beyond repair, it will be necessary to drill

and tap the hole to a larger size. Alternatively, a

Helicoil insert can be used to Testore the hole to the

original thread size.

STUDS

The simplest method for removing studs is to lock

two nuts together on the threaded section. The stud

should then be able to be removed by applying an

unscrewing action to the lower nut.

Alternatively, there are various makes of stud

extracting tools available.

similar levers between the components in an attempt

to lever them apart. This can cause severe damage to

the sealing surfaces, particularly if the components are

made of alloy compounds.

The components can be separated by tapping

along the joint with a soft faced hammer or piece of

wood. Before installing a new gasket, the mating

surfaces should be cleaned of all traces of old gasket

material and sealant.

Check that the new gasket is correct by comparing

the bolt holes and passages on the component face

with the openings in the gasket.

Cork and paper gaskets which have been stored

for some time may suffer from shrinkage. This can be

rectified by soaking the gasket in water.

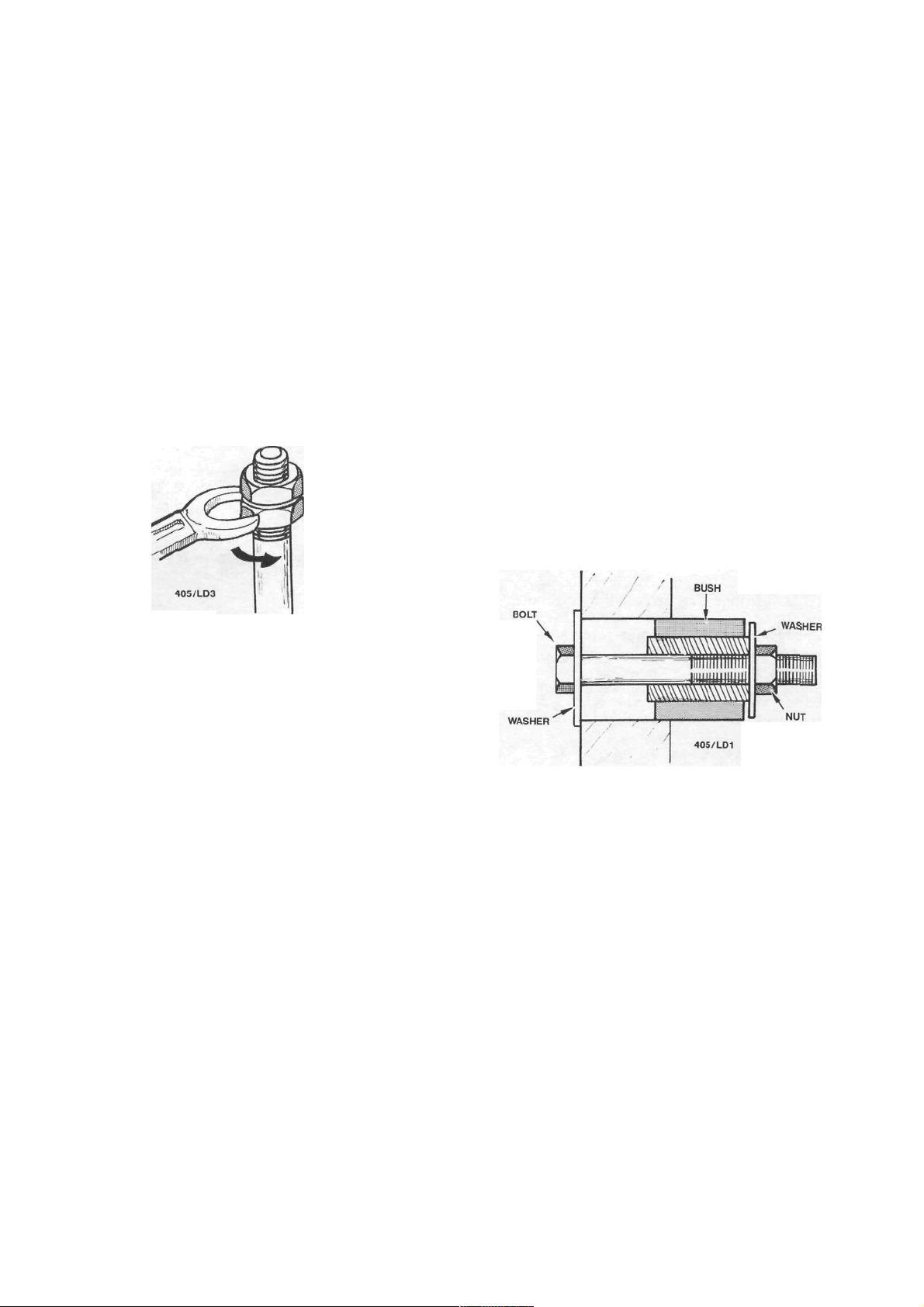

BEARINGS AND BUSHES

If the correct equipment is not available when

removing and installing bearings and bushes, it is

often possible to improvise.

Bearings can often be removed from shafts by

tapping alternately on opposite sides with a hammer

and drift.

Using two nuts locked together to remove a stud.

OIL SEALS

Oil seals can usually be removed by levering out

with a flat screwdriver or other suitable lever. Care

should be taken not to damage the surface of the

component which the seal lip runs on.

Seals can also be removed by inserting a number

of self tapping screws into the seal body. The seal can

then be withdrawn using pliers gripping the self

tapping screws.

Always apply a smear of grease or oil to the seal lip

prior to installation to provide initial lubrication.

Unless otherwise stated, oil seals should always be

installed with the lip facing inwards or towards the

substance to be sealed. During installation, the seal lip

should be protected from damage from sharp components such as shaft splines by wrapping tape around

the sharp edges.

Install the new seal using a wooden block, or a

socket or length of tube of the appropriate diameter.

Ensure that the seal is installed squarely or distortion

and subsequent leakage may occur. If an installation

depth is not specified, the seal should be installed

flush with the component surface.

GASKETS

When separating mating components (i.e.

cylinder

head and cylinder block), do not insert screwdrivers or

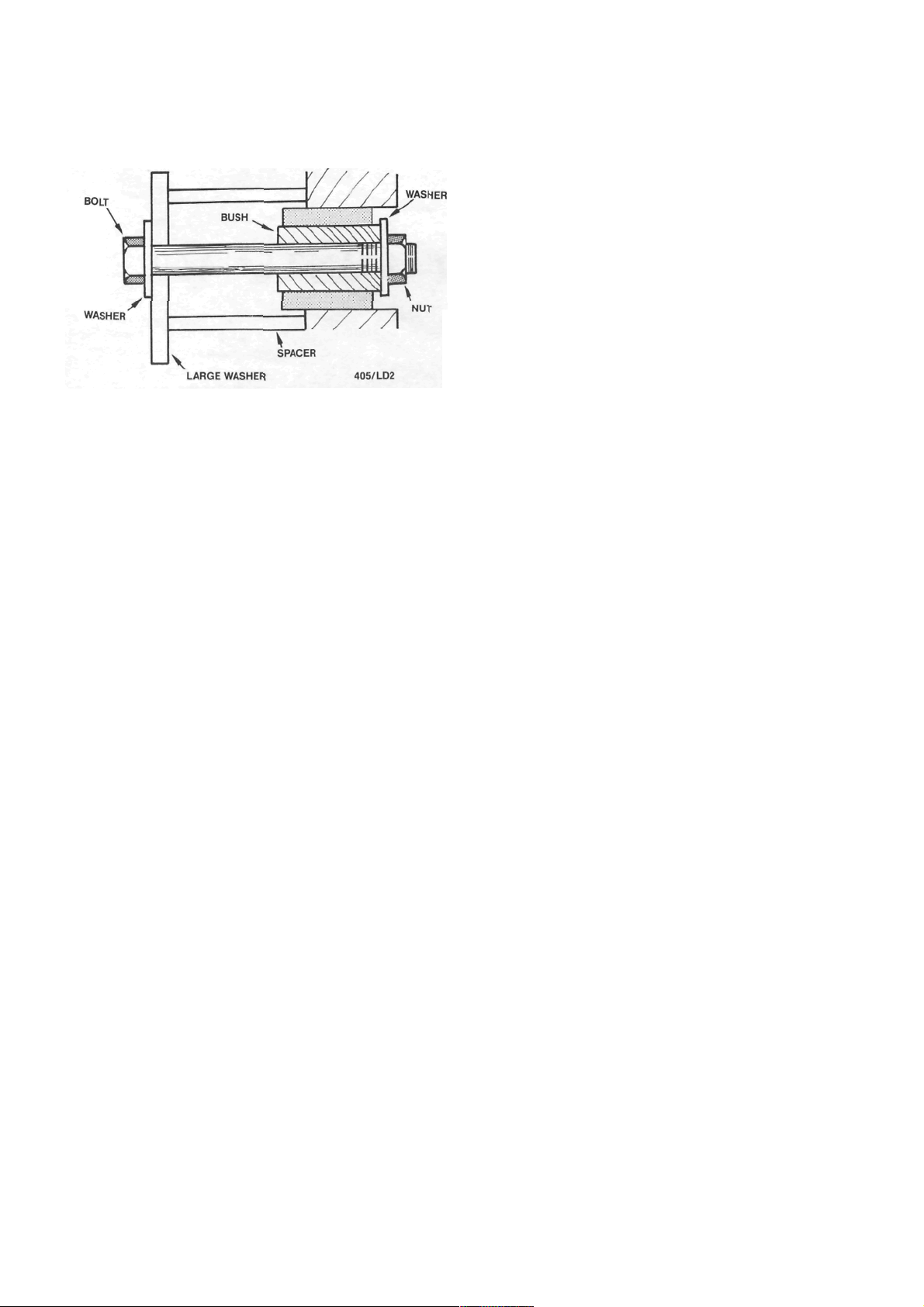

A simple bush installing tool using a bolt, nut and two

washers.

If a press is unavailable, bushes can be installed by

placing the bush and component between the jaws of a

vice and screwing the jaws together until the bush is

fully inserted. A vice can also be used to remove

bushes by using suitably sized spacers against either

vice jaw, one bearing on the bush and the other on the

component. This method can also be used with a G

clamp.

A simple removing and installing tool can be

made using a long bolt, large and small washers, a nut

and a tubular spacer. Refer to the illustrations for the

method and applications.

Rubber bushes and bushes in blind holes can be

removed using an expanding type masonry bolt

(Rawlbolt Loxin). Install a neat fitting masonry bolt to

the bush. Install and tighten the bolt until it grips the

bush. The bolt and bush can then be removed using a

slide hammer or levers.

Page 11

General Information

13

A simple bush removing tool using a bolt, nut, suitable

spacer and large and small washers.

Bushes in blind holes can also be removed using

hydraulic force. With the hole packed with grease,

insert a neat fitting drift and tap the drift into the hole.

The pressure of the grease on the rear of the bush

should force it from the hole.

ROTATING THE CRANKSHAFT

There are many occasions when it is necessary to

rotate the crankshaft to a certain position. These

include timing and valve adjustment and checking

valve timing.

To make the engine easier to rotate, remove the

spark plugs. This will relieve compression pressure.

The simplest method is to use a socket or ring

spanner on the crankshaft pulley nut and turn the

engine in the normal direction of rotation.

On vehicles with manual transmission, the engine

can be turned by selecting top gear and rolling the

vehicle forward. A variation of this method is to raise

one of the driving wheels and, with top gear selected,

rotate the driving wheel in a forward direction to turn

the engine.

Alternatively, the engine can be brought to the

desired position by briefly actuating the starter motor.

Page 12

14

LUBRICATION AND MAINTENANCE

SPECIFICATIONS

CAPACITY AND GRADE

Engine:

Lubricant........................................... 15W-50 SF

Sump capacity including filter ........... 3.3 liters

Cooling system capacity............................ 6.0 liters

Manual transaxle:

Lubricant.......................................80W-90 GL-4

Capacity ............................................... 2.7 liters

Automatic transaxle:

Lubricant.............................................. Dexron II

Capacity ............................................... 6.0 liters

Power steering:

Lubricant.............................................. Dexron II

Capacity ............................................... 1.0 liters

Manual steering lubricant........ Castrol EPLl grease

Brake fluid type ................................................ Dot 4

1. HOW TO GREASE AND OIL CHANGE

(1) Run the front of the vehicle onto car ramps

and stop the engine. Chock the front wheels.

(2) Raise the rear of the vehicle and place

chassis stands under the rear jacking points.

NOTE: It is best if the vehicle is kept as level

as possible to avoid false readings when

checking the lubricant levels.

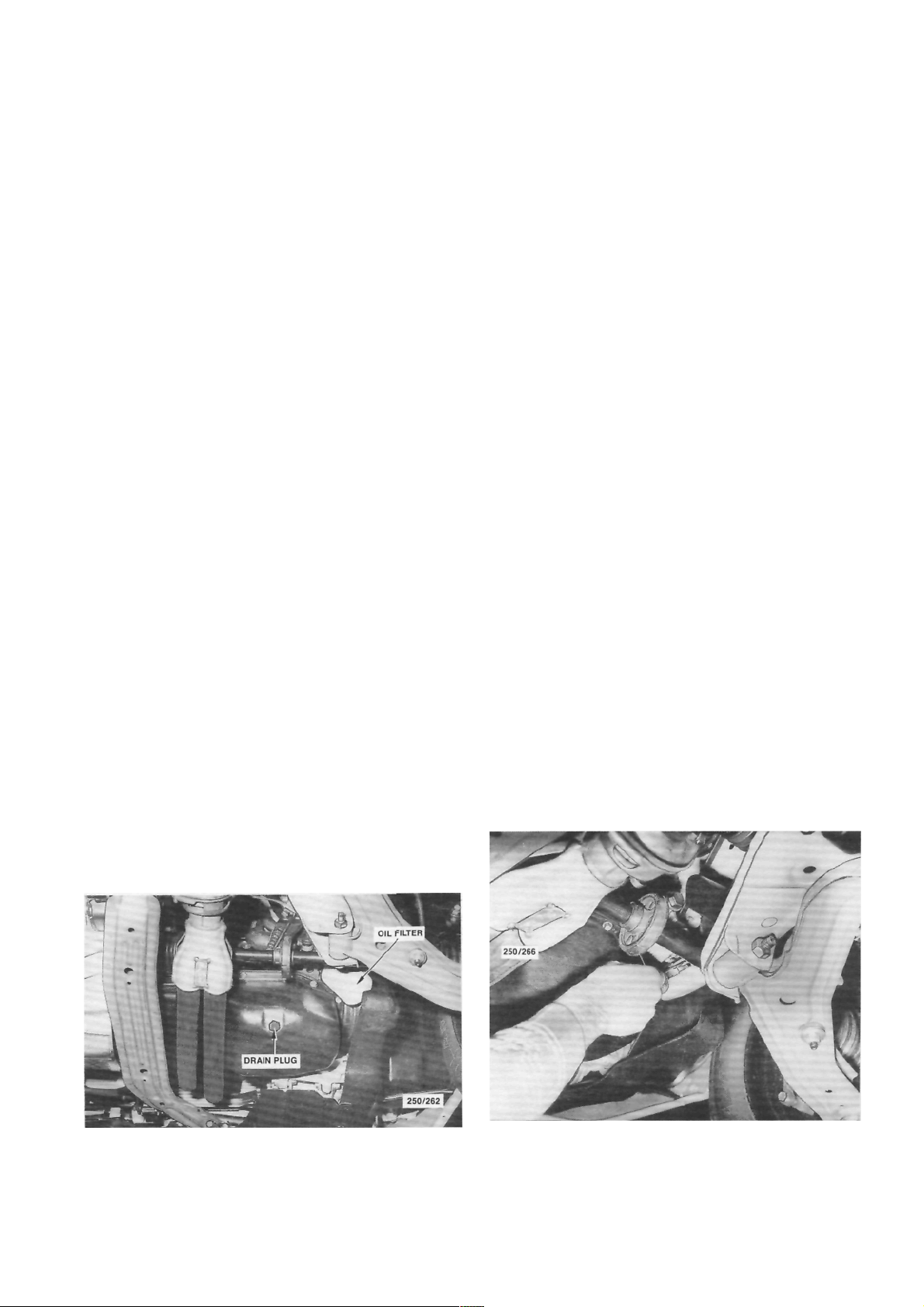

(3) Clean around the engine sump drain plug.

(4) Place a drain tin under the engine sump,

remove the engine sump drain plug and allow the

engine sump to completely drain.

NOTE: It is best to drain the engine sump

with the oil at operating temperature. However, if the oil is hot take care to avoid

scalding.

(5) Check that the sealing gasket on the sump

plug is in a serviceable condition.

(6) When the engine sump has completely

drained, install and firmly tighten the sump drain plug.

Wipe around the plug after installation.

(7) Place the drain tin under the oil filler,

remove the oil filter using a filter removal tool and

allow the residual engine oil to drain. Smear the

scaling ring of the new filter with engine oil and

lighten the filter by hand as per the instructions

supplied with the new filter.

NOTE: Before installing the new filter, ensure that the sealing gasket from the old

filter has not adhered to the filter sealing

surface on the engine.

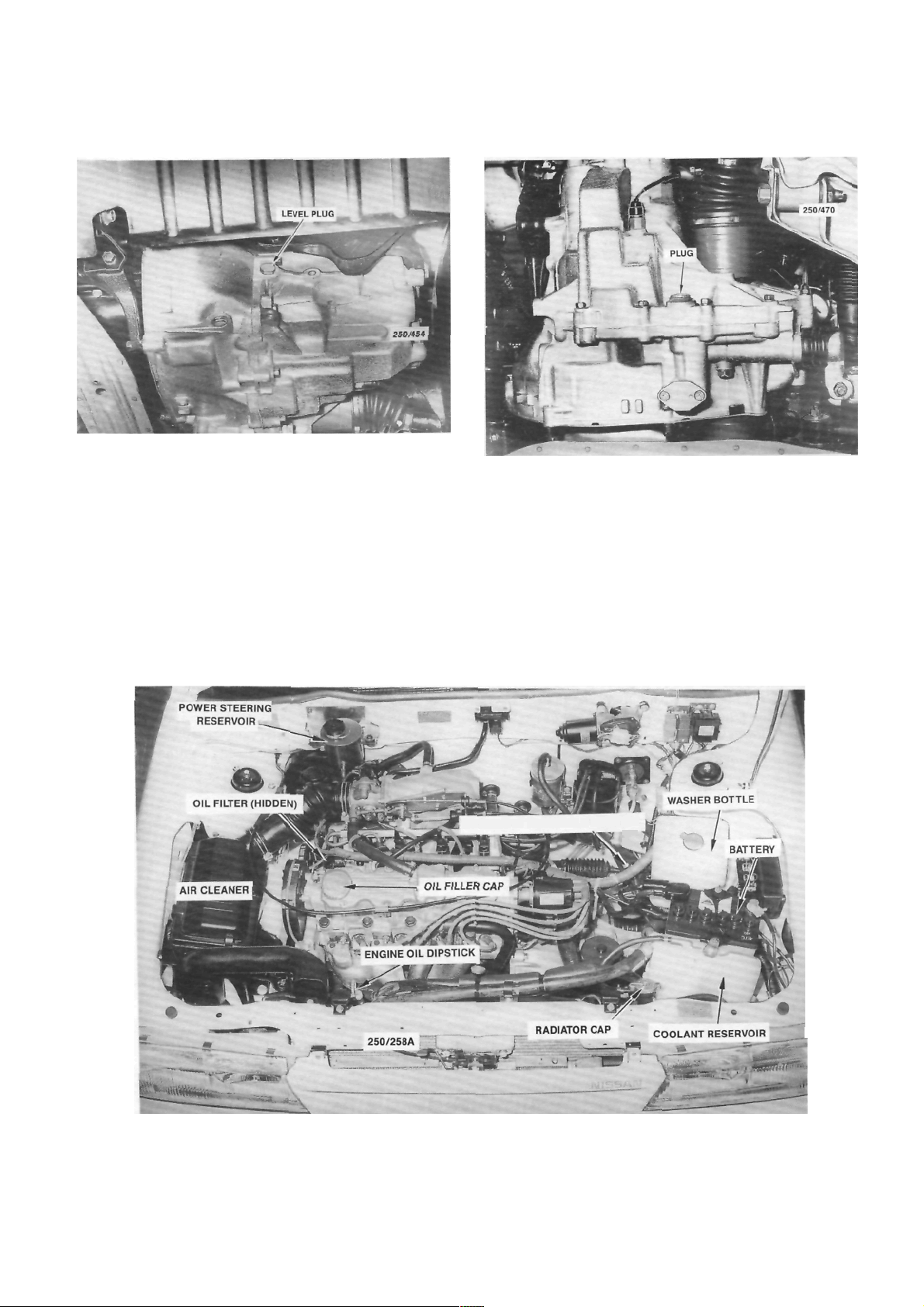

(8) Rem o v e t he level check i n g p lug from the

Location of the engine sump drain plug.

Removing the engine oil filter using a filter removal tool.

Page 13

Lubrication and Maintenance

Location of the manual transaxle level plug.

manual transaxle. Using a finger, check that the oil is

level with the bottom of the plug hole. Overfilled units

should be drained to the correct level.

If the oil level is low, use an oil gun to fill the

transaxle to the correct level.

When satisfied that the oil level is correct, install

the plug and tighten firmly. Wipe around the plug

after installation.

NOTE: On automatic transaxle vehicles,

refer to the Automatic Transaxle section for

the checking and topping up procedure.

Location of the manual transaxle drain plug.

(9) Using a funnel, fill the engine with the

specified amount and grade of engine oil. start the

engine and run it for a few minutes. Ensure that the

oil light goes out. Stop the engine, wait for a few

minutes and check the engine oil on the dipstick. If

necessary add oil to bring the level to the full mark on

the dipstick.

NOTE: To prevent overfilling the engine

initially, it is good policy not to pour all the

15

AUTOMATIC TRANSAXLE DIPSTICK

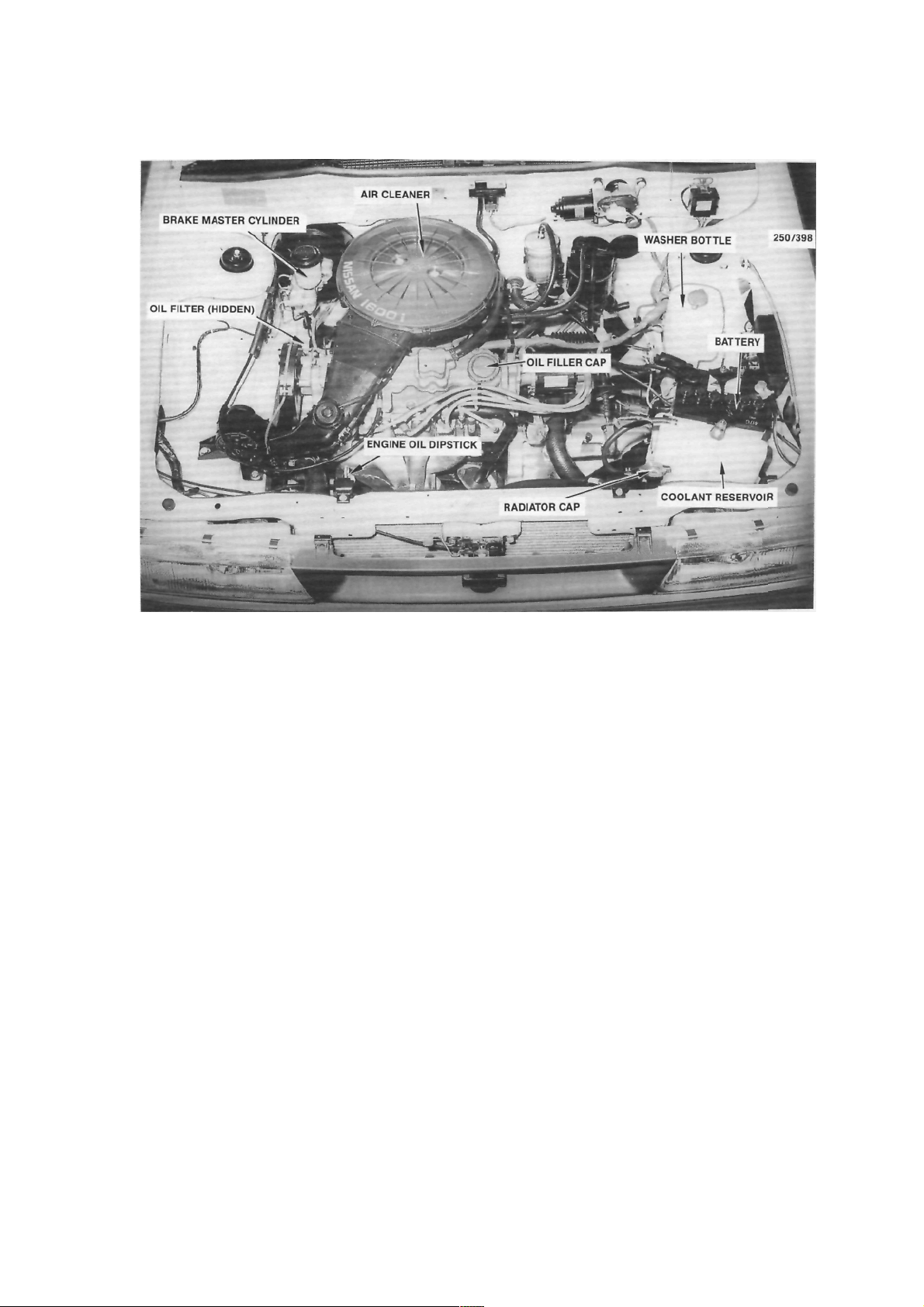

Underbonnet view of the 1.8 liter engine. Automatic transaxle model.

r

Page 14

16

Lubrication and Maintenance

Underbonnet view of the 1.6 liter engine. Manual transaxle model.

oil into the engine in one go as sometimes

the amounts specified are only approximate.

If is best to hold back at least half a liter and

top up the level after the engine has been run

for a few minutes.

(10) Check thoroughly for oil leaks at the engine

sump drain plug and oil filter if a new filter was

installed.

(11) Referring to the service schedule, lubricate

and check all other items which coincide with the

grease and oil change intervals.

(12) Lower the vehicle to the ground.

Page 15

Lubrication and Maintenance 17

2. SERVICE SCHEDULE

This Section Removed

Page 16

18

Lubrication and Maintenance

This Section Removed

Page 17

Lubrication and Maintenance

19

This Section Removed

Page 18

20

Lubrication and Maintenance

This Section Removed

Page 19

WHEELS AND TYRES

SPECIFICATIONS

TYRES PRESSURES

Front:

Normal load ............................................ 200 kPa

Heavy load or high speed ......................230 kPa

Rear:

Normal load ............................................ 180 kPa

Heavy load or high speed ...................... 210 kPa

NOTE: The above pressures are measured

cold and are meant as a guide only. Always

refer to the tire placard positioned on the

inside of the glove compartment lid and the

tire manufacturers recommendations first.

TORQUE WRENCH SETTINGS

Wheel nut torque .............................................98 Nm

1. HOW TO CHANGE A ROAD WHEEL

(4) Apply the handbrake firmly and chock the

front and rear of the wheel diagonally opposite the

wheel being changed.

(5) Remove the spare wheel, tool kit and jack

located in the luggage compartment.

(6) On vehicles equipped with full wheel covers,

remove the trim from the wheel.

(7) Using the wheel spanner, loosen the wheel

nuts progressively in a diagonal sequence half a turn.

(8) Position the jack under the jacking point

closest to the wheel being removed and raise the jack

until the head of the jack contacts the jacking point.

(9) Raise the vehicle slightly and check that the

jack is stable and vertical.

(1) Ensure that the vehicle is on level firm

ground and clear of any passing traffic.

(2) If necessary, switch on the hazard

flashers.

(3) Switch off the engine and place the transaxle

in the (P) Park position on automatic transaxle

models or in reverse gear on manual transaxle models.

Chock the front and rear of the wheel diagonally

opposite the wheel being changed.

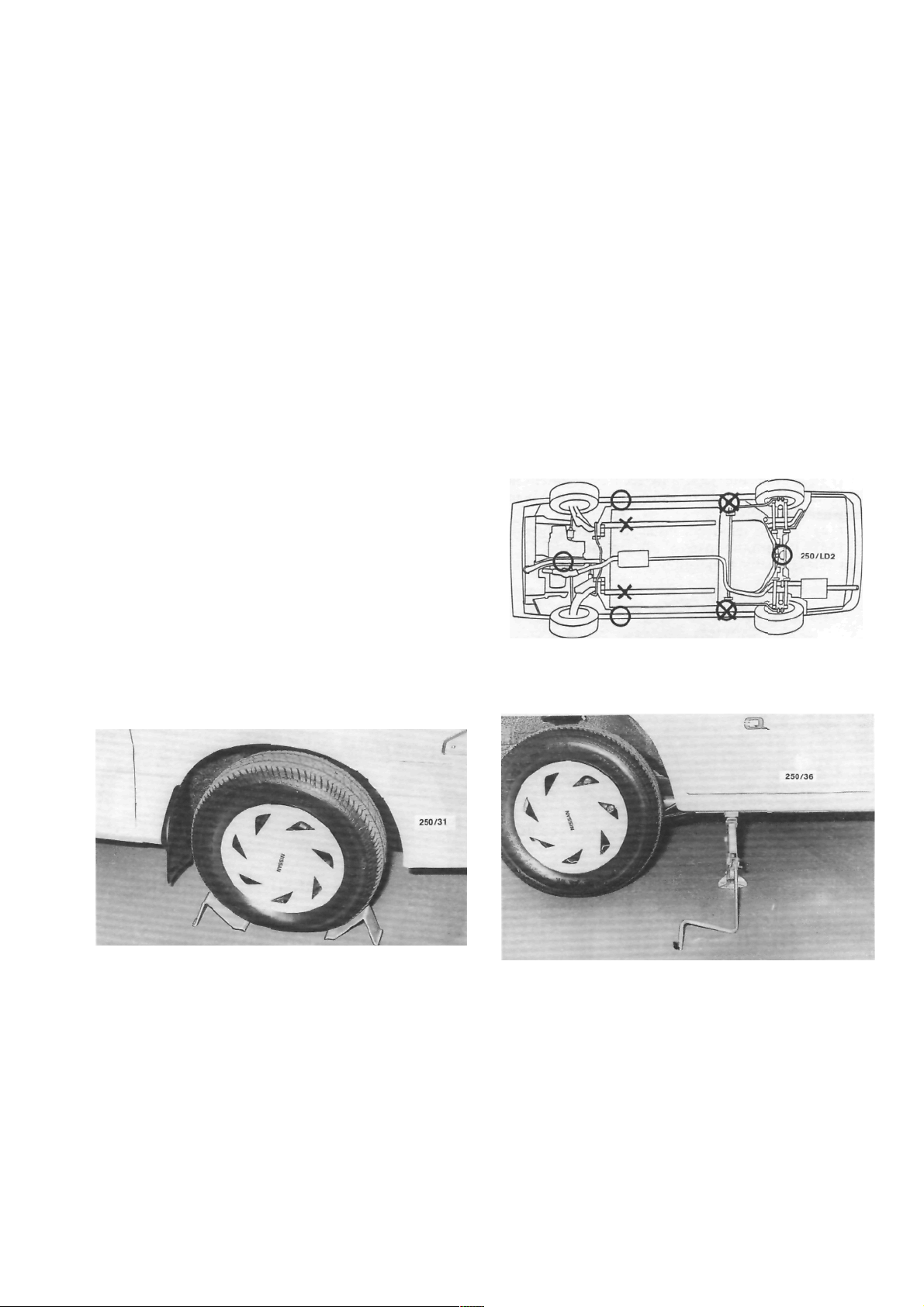

Underbody view showing the jacking and supporting

points. O indicates the jacking points and X indicates

the supporting points.

View of the jack correctly installed to the rear jacking

point.

Page 20

22

View of the jack correctly installed to the front jacking

point

.

Wheels and Tires

(10) Continue to raise the jack until the tire

clears the ground sufficiently to allow the spare wheel

to be installed.

(11) Remove the wheel nuts and lift the wheel

off the hub.

NOTE: Under no circumstances get under

the vehicle while the jack is the only means

of support.

(12) Install the spare wheel and install the wheel

nuts with the chamfered ends contacting the wheels.

Tighten the wheel nuts as much as possible by hand.

(13) Lower the jack and securely tighten the

wheel nuts progressively in a diagonal sequence using

the wheel spanner.

(14) Where removed, install the wheel cover.

(15) Return the spare wheel, jack and tool kit to

their relevant storage positions.

ABNORMAL WEAR ON CENTRE OF TREAD

(1) Over inflation of tires: Check and reduce to

the recommended pressure.

ABNORMAL WEAR ON INSIDE OF TREAD

(1) Excessive negative camber angle: Check the

wheel alignment.

(2) Sagging coil springs: Check and renew the

coil springs as a pair.

(3) Loose or worn hub bearing assembly: Check

and renew the hub bearing assembly.

(4) Bent, loose or worn suspension components:

Check and renew any faulty components.

Tighten the wheel nuts in a diagonal sequence using

the wheel spanner.

2. TYRE WEAR TROUBLE SHOOTING

ABNORMAL WEAR ON BOTH SIDES OF

TREAD

(1) Under inflation of tires: Check and inflate to

the recommended pressure.

(2) Overloading: Reduce the maximum loading.

ABNORMAL WEAR ON OUTSIDE OF TREAD

(1) Excessive positive camber: Check the front

wheel alignment.

(2) Excessive speed when cornering: Revise driv-

ing habits.

(3) Bent, loose or worn suspension components:

Check and renew any faulty components.

FLAT SPOTS ON TREAD OR IRREGULAR

WEAR

(1) Static or dynamic unbalance of the wheel

and tire assembly: Check the balance of the wheel and

tire assembly.

(2) Lateral run out of the wheel: Check and (rue

up or renew the wheel.

Page 21

(3) Excessive play in the front suspension ball

joints: Check and renew the ball joints.

(4) Excessive play in the hub bearing assembly:

Check and renew the hub bearing assembly.

Wheels and Tires

23

WORN SPOTS ON CENTRE OF TREAD

(1) Static unbalance of the wheel and tire asem-

bly: Check the balance of the wheel and tire assembly

(2) Radial run out (eccentricity) of the wheel:

Check and renew the wheel.

FEATHERED EDGES ON TREAD PATTERN

(1) Excessive speed when cornering: Revise driv-

ing habits.

(2) Excessive toe-in or toe-out: Check and adjust

the wheel alignment.

(3) Bent, loose or worn suspension components:

Check and renew any faulty components.

NOTE: To preserve tire life it is good policy

to periodically have the front wheel balanced

and the steering geometry checked on a

reliable wheel alignment machine.

Under no circumstances mix radial ply

and conventional ply tires. Install only tires

of the same construction to all four wheels.

3. CARE AND MAINTENANCE

STEEL WHEELS

Steel wheels should be regularly cleaned of all

foreign matter, such as dirt and mud. If foreign matter

is allowed to build up it will affect the balance of the

wheel and may cause vibrations and uneven tire wear.

If the paint has been chipped or scratched it should be

touched up as soon as possible to prevent rust.

Any minor damage to the wheel rim can usually

be repaired using a suitable hammer after the wheel

has been removed from the vehicle. However, any

major rim damage or buckling of the wheel will

necessitate the renewal of the wheel. It is good policy

to occasionally remove the wheels from the vehicle

and inspect them for damage, cracks or corrosion.

ALLOY WHEELS

Alloy wheels should be regularly cleaned of all

foreign matter such as dirt and mud. If foreign matter

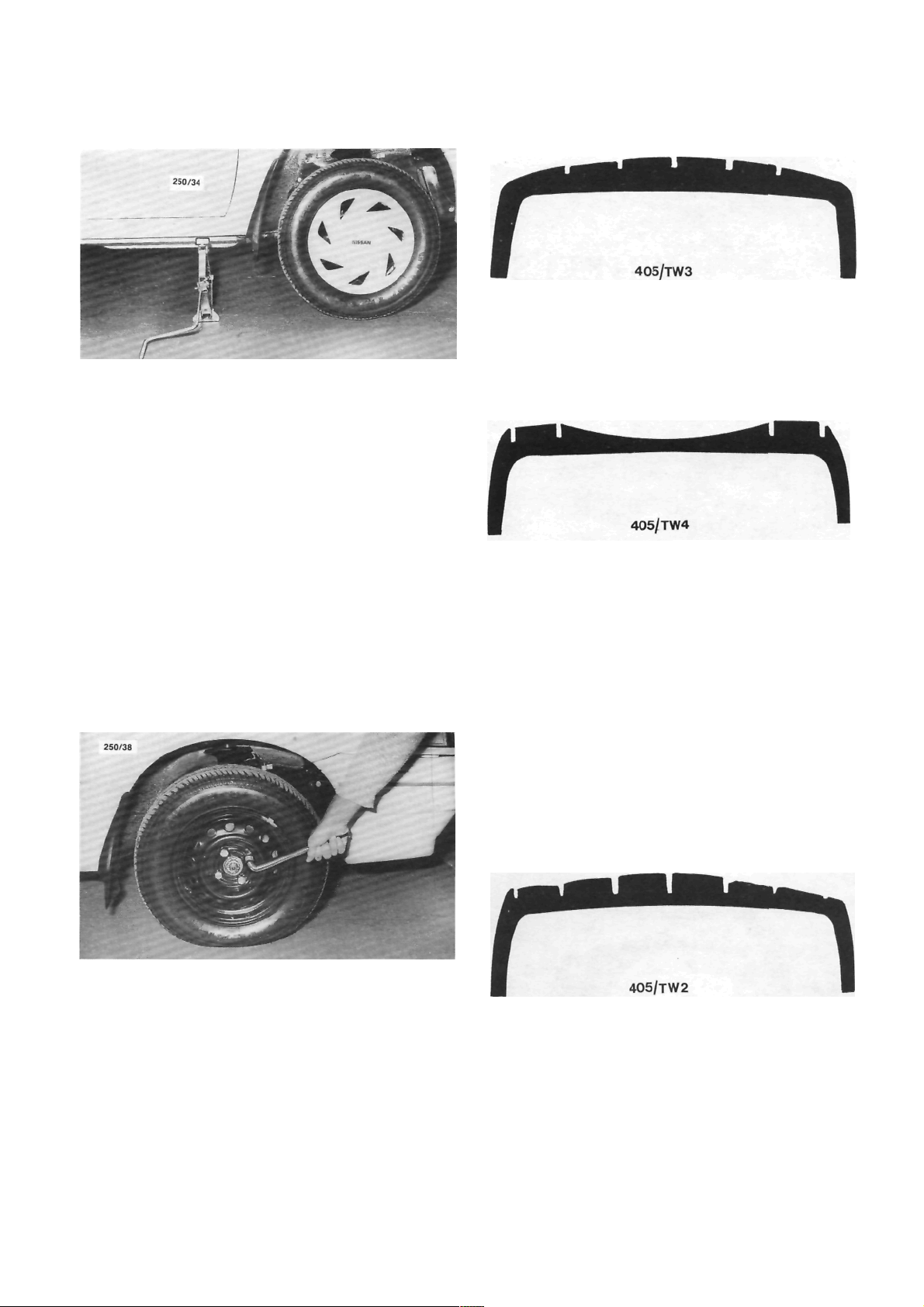

Wheels should be cleaned regularly of dirt and mud.

is allowed to build up it will affect the balance of the

wheel and may cause vibrations and uneven tire wear.

The alloy wheels are coated with a clear protective

finish. Do not use abrasive cleaner, polishing compounds, steel wool etc. when cleaning the wheels. Only

mild soap and warm water are recommended. Alloy

wheels are particularly susceptible to corrosion damage particularly if exposed to salt water.

Alloy wheels being relatively soft in comparison to

steel are easily scuffed, however, this will not affect the

serviceability of the wheel. Where heavy damage has

been sustained to the wheel it should be renewed.

Buckling or cracking of an alloy wheel cannot be

repaired.

TYRES

The depth of the tire tread grooves should never

be allowed to be less than 1.5 mm before the tires are

renewed. The tires should also be renewed when any

damage, whether it be internal or external, is evident.

Minor punctures or leaks should be properly repaired.

Refer the tire to a tire specialist if there is any doubt

about the serviceability of the tire.

The tread, tread grooves and sidewalls should be

regularly inspected for foreign matter i.e. nails, stones

etc. Where foreign matter is detected it should be

removed from the tire and if necessary, the puncture

repaired.

The tire valves should always have the caps

installed, be regularly cleaned of dirt or dust and be

inspected for leakage and damage every time the tire

pressures are checked.

Regularly inspect the tread of the tires for signs of

uneven wear. If uneven wear is apparent, refer to the

heading Tire Wear Trouble Shooting in this section

for possible causes and cures. If the uneven tire wear

is noticed early enough, the cause correctly identified

and the necessary cure carried out, the life of the tire

should be extended.

Page 22

24

Wheels and Tires

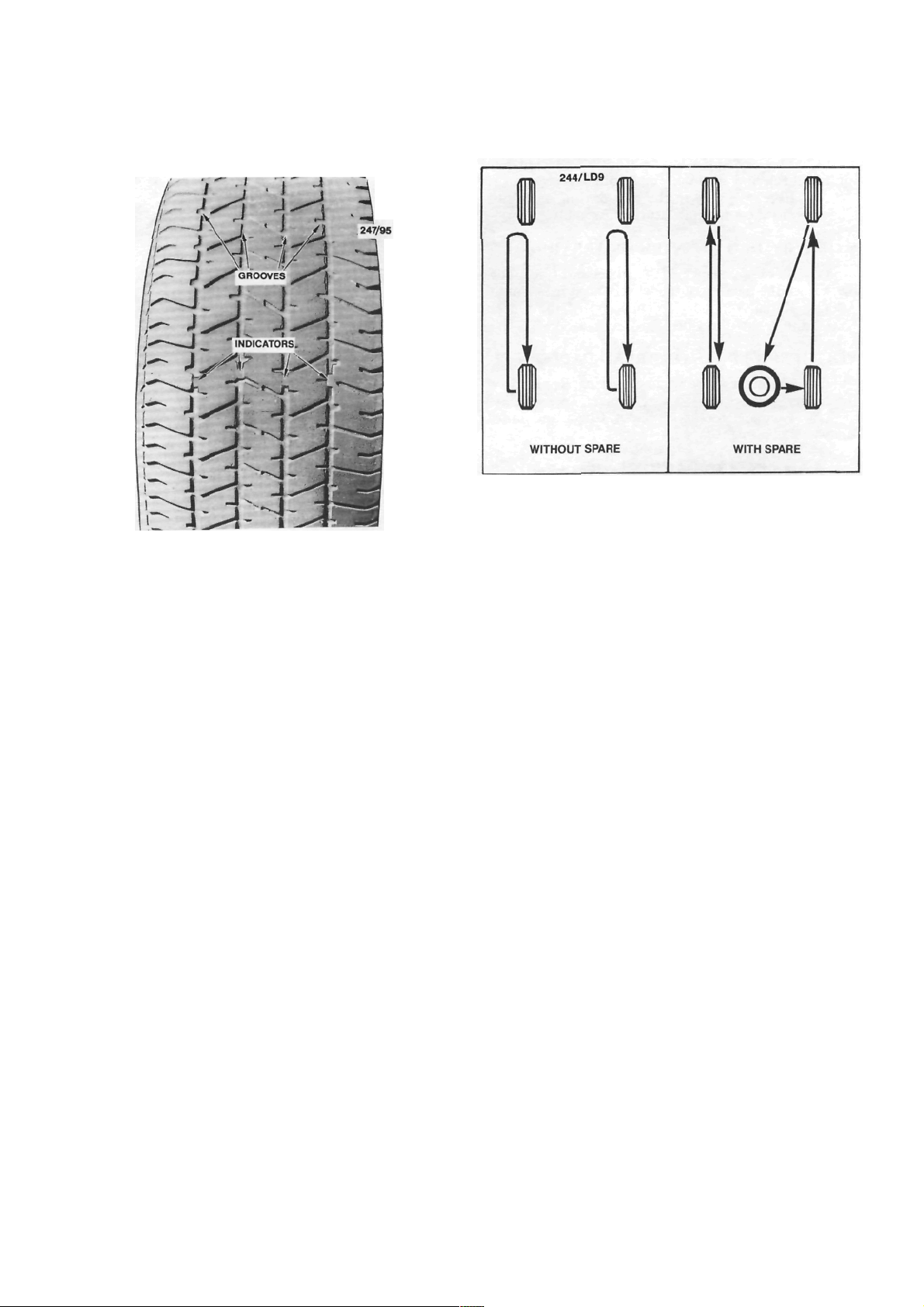

When the tire tread groove depth is less than 1.5

mm, or when the tire is worn to the point where the

tire wear indicators are level with the tread surface,

To preserve tire life it is good policy to periodically have the front wheels balanced and the front end

alignment checked on a reliable wheel alignment

machine.

The wheel and tire assemblies may be rotated at

20 000 km if desired. Rotation of the wheels and tires

will increase the period between tire renewal. Radial

tires should not be cross changed, they should be

changed from front to rear on the same side.

the tire should be renewed.

Tire rotation diagram. If desired, the wheel and tire

assemblies may be rotated every 20 000 km in the

manner shown. Vector SSS tire rotation not to include

spare wheel.

The air pressure in the tire is probably the single

most important aspect of tire care. Too little or too

much pressure in the tire can cause rapid wear or

complete failure through overheating. Where possible

the tire pressures should be checked and adjusted

when the tires are cold.

As a rule, different tire types, tread patterns or

sizes should never be used on the vehicle at one time.

All the tires on the vehicles, including the spare

should be a matched set to prevent the vehicle

behaving erratically under certain conditions. Under

no circumstances mix radial ply and conventional ply

tires.

Page 23

25

ENGINE TUNE-UP

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text for

precautionary notes.

1. TUNE-UP SPECIFICATIONS

Firing order................................................... 1 -3-4-2

Spark plugs:

Type ............................................. NGK BPR 6ES

Gap ...........................................................1.1 mm

Tightening torque...................................... 20 Nm

Ignition timing with diagnostic link

connector jumped...........................10 deg BTDC

Idle speed (ECU controlled):

Manual transaxle 1.8 liter............ 850 ± 50 rpm

Manual transaxle 1.6 liter............ 800 ± 50 rpm

Automatic transaxle

(Park or Neutral).......................... 825 ± 50 rpm

Drive belt deflection:

Alternator ........................................... 14-16 mm

Power steering pump......................... 14-16 mm

Air conditioner compressor .................. 9-11 mm

NOTE: When performing an engine tuneup, a/ways compare the above Specifications

with the emission control information label

inside the engine compartment.

1.8 Liter Engine

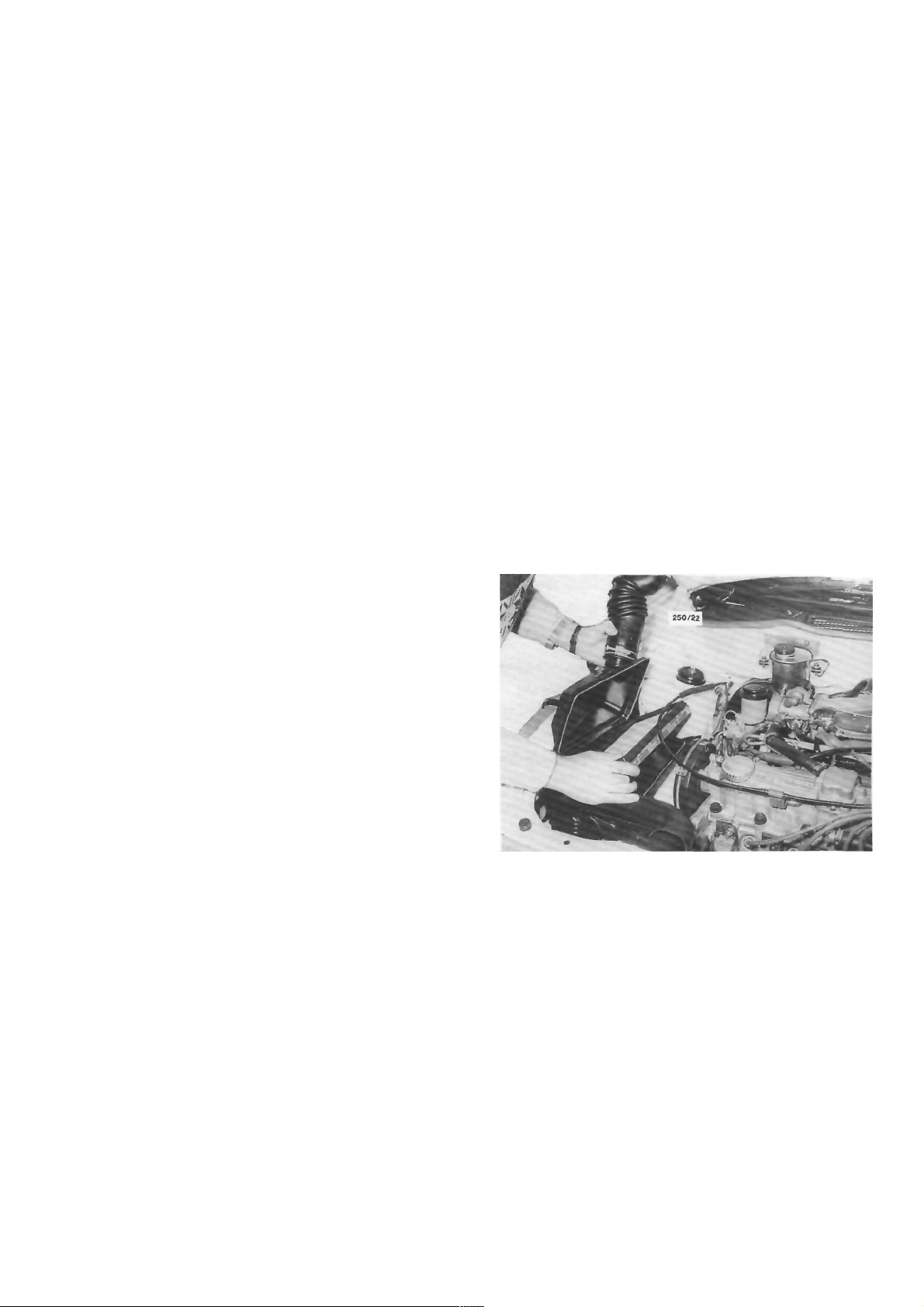

(1) Release the clamp securing the air intake

hose to the throttle body and disconnect the throttle

cable from the support bracket.

(2) Release the clips retaining the upper air

cleaner housing to the lower air cleaner housing and

raise the upper housing while disconnecting the air

intake hose from the throttle body. Remove the air

cleaner element.

2. TUNE-UP OPERATIONS

Special Equipment Required:

To Test Compression — Compression gauge

TO SERVICE AIR CLEANER

The air cleaner is equipped with a paper element.

The element should be regularly inspected but should

not be cleaned in service.

The element should be renewed every 40 000 km.

This distance is only a guide for normal operating

conditions and should be reduced accordingly if the

vehicle is operating under extremely dusty conditions.

NOTE: Paper air cleaner elements should

not be washed in petrol or any other type of

cleaning solvent. If the element has been

washed in solvent or has become oil soaked,

it should be discarded and a new element

installed.

The air cleaner element should be renewed at 40 000

km intervals. 1.8 liter engine.

(3) Clean the inside of the air cleaner housing

using a damp rag to remove all traces of dust and

check the upper housing and air inlet hose for cracks

and air leaks. Renew if necessary.

(4) Install a new air cleaner element to the lower

housing ensuring that the element is correctly seated

around the edges.

(5) Install the upper housing and lock the clips,

securing it to the lower housing. Connect the air

intake hose to the throttle body and the throttle cable

to the support bracket. Tighten the hose clamp

securely.

(6) Start the engine and check the air cleaner

assembly for air leaks.

Page 24

26

Engine Tune-up

1.6 Liter Engine

(1) Remove the nuts and washers securing the

upper air cleaner housing to the lower air cleaner

housing and release the retaining clips.

(2) Remove the air cleaner element.

(3) Clean the inside of the air cleaner housing

using a damp rag to remove all traces of dust.

(4) Install a new air cleaner element ensuring that

the element is correctly seated around the edges.

(5) Install the upper housing and secure the

retaining clips. Tighten the retaining nuts securely.

TO RENEW FUEL FILTER

filter should

The fuel

40 000 km.

be renewed every

(1) Depressurize the fuel system using the fol-

lowing procedure:

(a) Lift the front edge of the rear seat cushion

and remove the cushion from the vehicle.

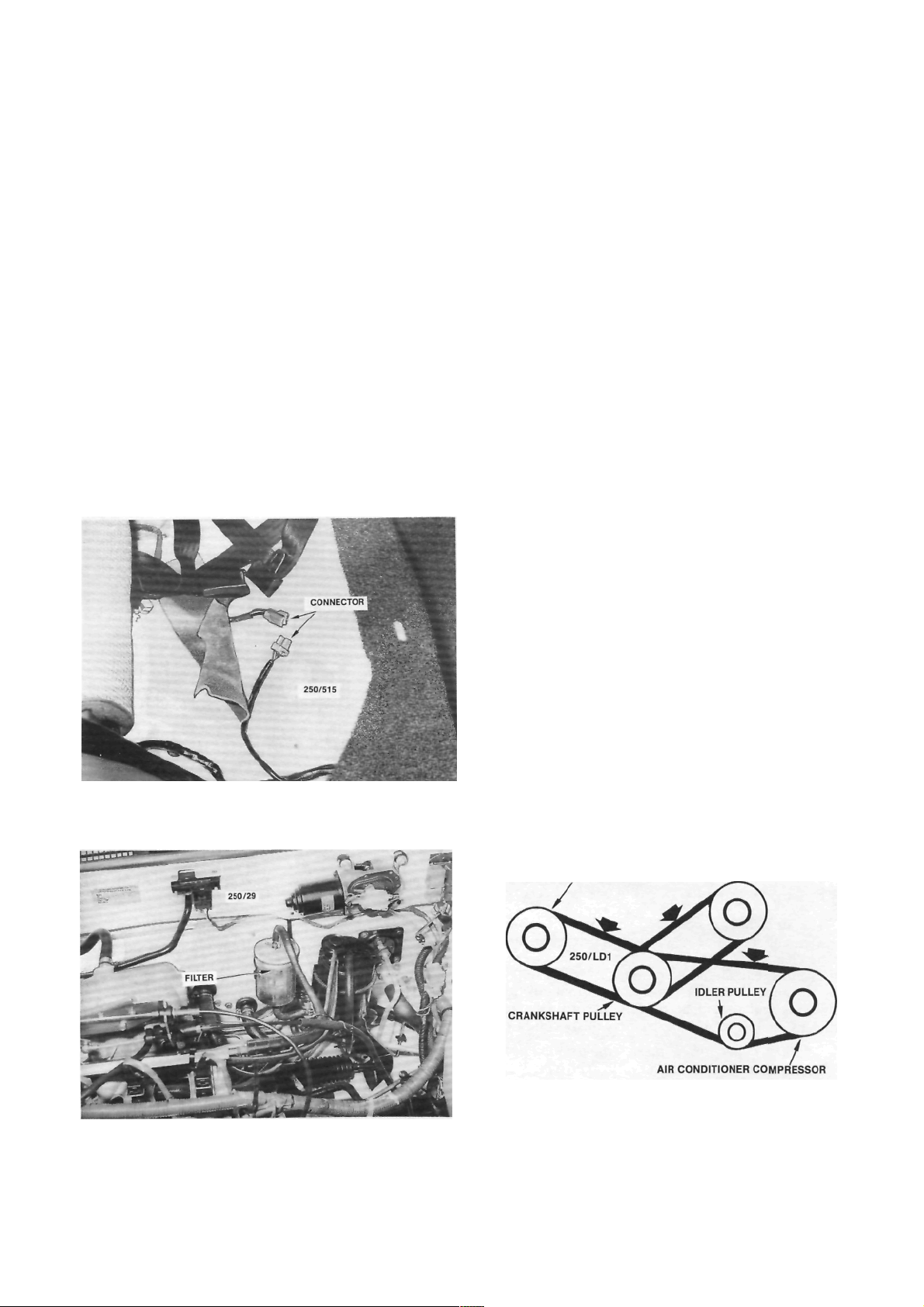

When depressurizing the fuel system, remove the rear

seat cushion and disconnect the fuel pump wiring

connector.

(b) Disconnect the fuel pump wiring connector.

(c) Start and run the engine until it stalls.

Operate the starter motor for 10 seconds to ensure

that the fuel pressure has dissipated.

(2) Disconnect the negative battery terminal.

(3) Release the hose clamps and disconnect the

fuel hoses from the filter. Remove the filter from the

retaining clamp noting the direction of the arrow on

the filter body.

On some models it will be necessary to remove the

screw from the side of the clamp to allow the filler to

be removed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the fuel filter with the arrow facing the

direction noted on removal, that is, in the direction of

fuel flow.

(2) Ensure that the hose clamps are tightened

securely.

(3) Connect the fuel pump wiring connector and

install the rear seat cushion.

(4) Start the engine and check for fuel leaks.

Rectify as necessary.

TO ADJUST DRIVE BELTS

It is essential that all drive belts are adjusted to

the correct tension to prevent slippage or premature

wear of the bearings in the alternator and, if equipped,

the power steering pump and air conditioner compressor.

(1) P u sh do w n on t h e dri v e belt w ith a 10 k g

force midway between the pulleys of the drive belt

concerned.

On models with air conditioning, push down on

the upper section of the drive belt between the

compressor and crankshaft pulleys.

If the drive belt deflection is not within Specifications it will require adjustment as follows.

(2) Loosen the alternator and, if equipped, the

power steering pump pivot and adjusting bolts and

ALTERNATOR

POWER STEERING PUMP

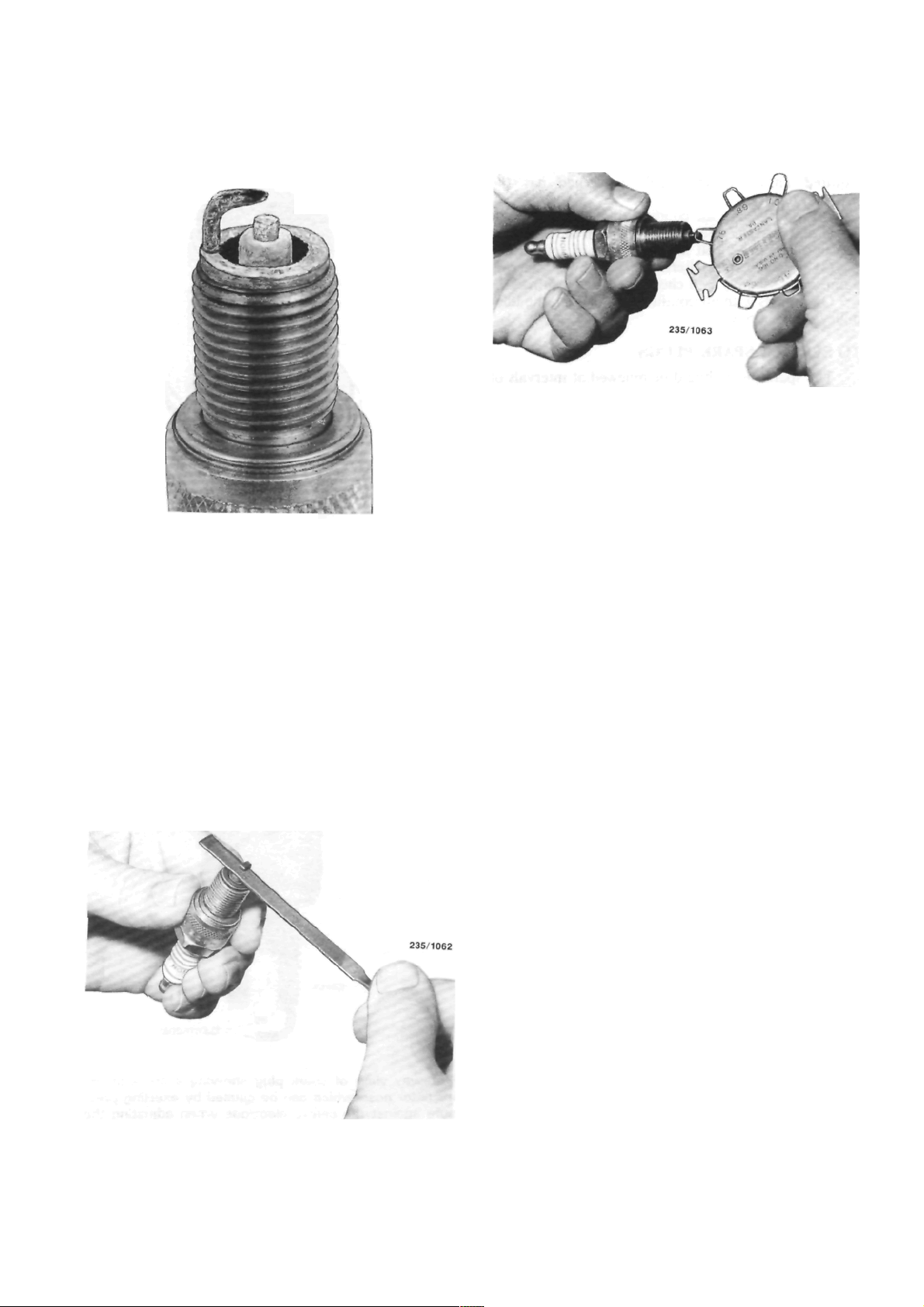

Installed view of the fuel filter. Note the direction of the

arrow on the filter prior to removal.

Illustration of the alternator, power steering pump and

air conditioner compressor drive belts. The arrows

indicate the deflection measuring points.

Page 25

Engine Tune-up

move the alternator or power steering pump as

required until the drive belt concerned has the

specified deflection.

On models with air conditioning, loosen the nut

in the centre of the idler pulley and turn the adjusting

bolt until the drive belt has the specified deflection.

(3) Tighten the alternator or power steering

pump bolts securely and check the belt tension.

On models with air conditioning, tighten the idler

pulley nut securely.

TO SERVICE SPARK PLUGS

The spark plugs should be renewed at intervals of

40 000 km.

Before removing the spark plugs ensure that the

area around each plug is clean to prevent foreign

matter entering the cylinder when the plugs are

removed.

Spark plugs removed from an engine in good

mechanical condition should have a light powdery

deposit ranging from light brown to grayish tan in

color. After considerable service the electrodes will

show signs of wear or normal burning. Spark plugs

showing a thick black oily deposit indicate an engine

in poor mechanical condition or possibly, that a plug

with too low a heat range has been installed.

Spark plugs showing a white or yellowish deposit

indicate sustained high speed driving or possibly that

plugs with too high a heat range have been installed,

particularly when these deposits are accompanied by

blistering of the porcelain and burning of the electrodes.

If the spark plugs are to be cleaned, use a

sandblasting machine and blow clean with compressed air. Ensure that all traces of abrasive grit are

removed from the spark plug threads and from the

well in the plug body. Carefully open the electrode gap

a little, by bending the side electrode, and lightly file

the electrodes flat with a points file.

27

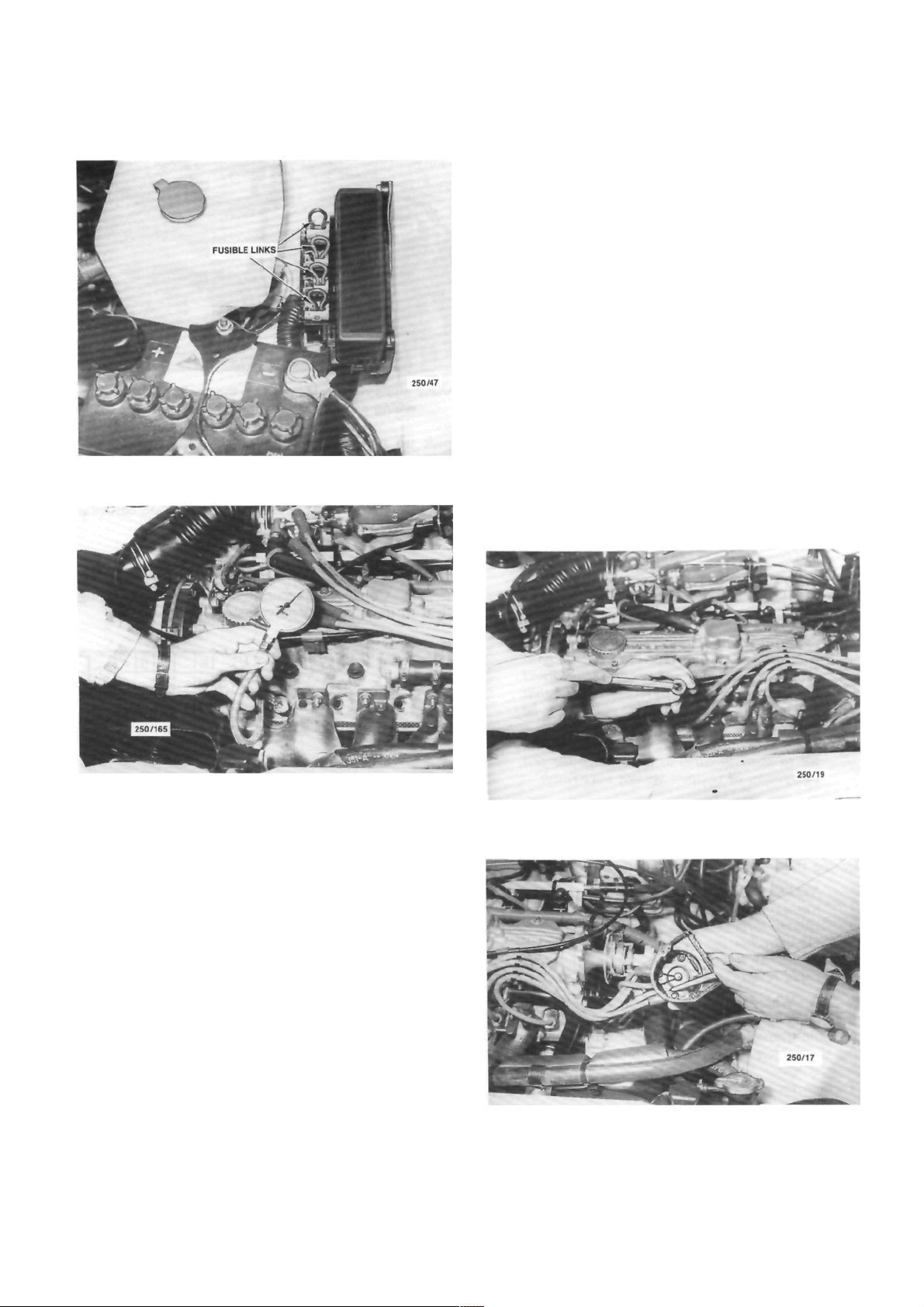

Black damp deposits can be caused by excessive oil

consumption or incorrect plug type. Spark plugs in this

condition are usually not firing.

CRACK

When plug electrodes are eroded to this degree the

spark can be considered worn out and should be

renewed using a plug of the recommended heat range

.

Cutaway view of spark plug showing a crack in the

insulator nose which can be caused by exerting pressure against the centre electrode when adjusting the

gap. The other crack shown on the insulator is caused

by tilting the plug spanner.

Page 26

Engine Tune-up

Spark plug with burnt electrodes and white blistered

appearance, possibly due to incorrect plug type, loose

plug or motor running too hot.

NOTE: Never attempt to alter the electrode

gap by bending the centre electrode as

damage to the porcelain insulator will

result.

Before installing any spark plugs measure the gap

between the electrodes, preferably with clean wire

gauges. If wire gauges are unavailable, use clean feeler

gauges. Move the side electrode towards or away from

the centre electrode to obtain the correct gap-

Screw the plugs into the cylinder head ringer tight,

then use a torque wrench to tighten the plugs lo the

specified torque.

Checking the spark plug electrode gap with a wire

gauge.

NOTE: If a torque wrench is unavailable,

extreme care must be taken when tightening

the spark plugs as over tightening may lead

to stripping of the thread from the cylinder

head. If the plugs are tightened with the

fingers and then taken up an additional 1/4

of a turn with a spark plug wrench, they will

be tight enough.

TO TEST COMPRESSION

(1) With the engine at operating temperature.

disconnect the high tension leads from the spark

plugs.

(2) Ensure that the area around each spark plug

is clean to prevent foreign matter entering the cylinders and remove the spark plugs.

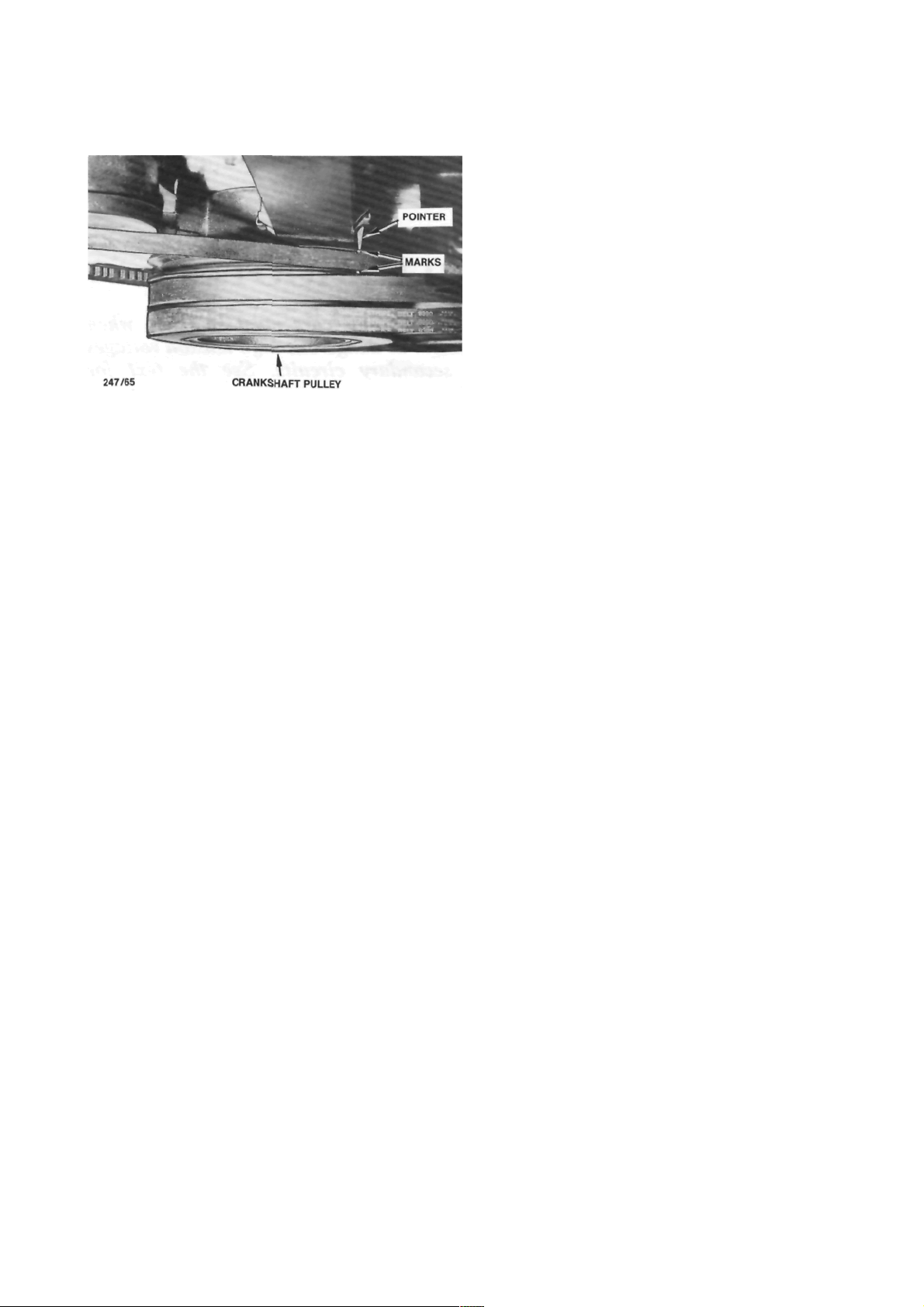

(3) Remove the fusible link that is positioned

third from the front of the fusible link connecting

block, located at the rear of the battery. Disconnect

the coil high tension lead from the coil.

NOTE: Failure to remove the fusible link

can result in an explosion.

Lightly file the plug electrodes flat with a points file

(4) Install a compression gauge to number one

spark hole according to the gauge manufacturers

instructions.

(5) Have an assistant fully open the throttle and

operate the starter switch to rotate the engine. Observe the compression gauge and stop the engine when

the gauge has reached the highest reading, usually

after 3 or 4 compression strokes.

(6) Record the reading and check the compres-

sion of the remaining cylinders in the same manner.

(7) Compare all the readings taken. Variation

between the highest and lowest reading cylinders

should not exceed 100 kPa.

(8) If a low reading is recorded on one or more

cylinders the trouble may be isolated as follows :

Page 27

Engine Tune-up

29

View showing the location of the fusible links.

Refer to the Fuel and Engine Management section

for Specifications and Trouble Shooting.

NOTE: When working on or near electronic

ignition systems, care should be taken as

dangerous high voltages are present in both

the primary and secondary circuits.

The ignition switch should be turned off

before removing or installing any electrical

connections otherwise damage to the ignition system as well as severe electrical shock

could result.

TO SERVICE HIGH TENSION LEADS

Check the leads for perishing or cracking and

renew as required. Never attempt to repair defective

carbon impregnated core leads.

The lead may be carefully cleaned, using cloth

moistened with kerosene and then wiped completely

dry.

If an ohmmeter is available the electrical resis-

tance of the leads may be checked as follows:

Check the cylinder compressions using a compression

gauge.

(a) Inject a small amount of engine oil into the

spark plug hole of the cylinder concerned ensuring

that the oil is evenly distributed within the cylinder by

rotating the engine.

(b) Repeat the compression test on the cylinder

concerned.

A substantial increase of compression pressure

indicates faulty or worn piston rings, pistons or

cylinder.

No increase of compression pressure indicates

burnt, obstructed or sticking valves, or a leaking or

blown cylinder head gasket.

(9) Install the fusible link and connect the high

tension lead to the coil.

TO SERVICE THE DISTRIBUTOR

The electronic ignition system requires virtually

no maintenance except for checking of the distributor

cap. rotor and high tension leads as described below.

Check the spark plug high tension leads for cracks and

burnt or corroded terminals.

Check the distributor cap for cracks or tracking

between the terminals

.

Page 28

30

Engine Tune-up

(1) With the distributor cap and leads removed

as an assembly, test one lead at a time, connecting the

meter probes at the spark plug end of the lead and at

the corresponding terminal inside the cap. Resistance

should be less than 15 000 ohms.

(2) If the resistance is more than 15 000 ohms

remove the lead from the distributor cap and check

(he resistance in the lead only. The lead should be

renewed if the resistance is still more than 15 000

ohms.

(3) High distributor cap resistance may be due

to corrosion deposits on the cap terminals. These

deposits should be removed with a small scraper or

emery cloth.

Check the distributor cap for cracks or tracking

between the high tension terminals on both the inside

and outside of the cap. Renew the cap if cracks or

tracking are evident.

Check the carbon brush in the centre of the

distributor cap for evidence of arcing and renew as

necessary.

Check the condition of the rotor and renew if

arced excessively or cracked.

View showing the location of the tachometer pickup

wiring connector with the resistor installed

.

pick up wiring connector which is located on the

ignition coil wiring harness, and connect the positive

lead of an accurate tachometer to the brown wire

terminal in the wiring connector.

(3) Connect the negative lead to a good earthing

point.

HOW TO CONNECT ELECTRICAL TEST

EQUIPMENT

NOTE: Some types of tachometers, timing

lights and ignition system analysers are not

compatible with this type of electronic ignition system and may result in incorrect

readings. It is therefore recommended that

the manufacturer of the test equipment be

consulted before using the equipment.

Do not allow the tachometer lead connector to short to earth as damage to the test

equipment or ignition system may result.

Timing Light

(1) Connect the timing light to the engine fol-

lowing the instrument manufacturers instructions.

NOTE: Do not connect or disconnect the

timing light with the engine running as

voltage surges could damage the alternator.

Do not allow the high tension leads to open

circuit as damage to the ignition system

could result.

(2) Where necessary, connect the power leads of

the timing light to an external power source to prevent

possible transient voltages in the timing light damaging the vehicle alternator.

Tachometer

(1) Ensure that the tachometer is compatible

with the vehicle ignition system.

(2) Disconnect the resistor from the tachometer

TO CHECK AND ADJUST IGNITION TIMING

(1) Connect an accurate tachometer and timing

light to the engine as previously described.

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

Inset shows the diagnostic link connector terminal

identification.

(2) Start the engine and allow it to reach normal

operating temperature.

(3) Connect a jumper lead between terminals A

and B on the diagnostic link connector.

(4) With the engine idling at the specified speed,

check the ignition timing with the timing light.

Correct timing exists when the marks on the

crankshaft pulley are aligned with the pointer on the

inner timing cover.

Page 29

Engine Tune-up

(5) If adjustment is necessary, loosen the distrib-

utor body retaining nuts and turn the distributor body

until the correct setting is obtained.

(6) Tighten the distributor body retaining nuts

and ensure that the timing is still correct.

(7) Remove the jumper lead from the diagnostic

link connector.

(8) Disconnect the timing light from the engine.

View of the engine timing marks showing the 10 deg

BTDC crankshaft notch aligned with the pointer on the

front of the engine.

TO ADJUST IDLE SPEED AND MIXTURE

The idle speed and mixture are not adjusted as

normal service procedure. However, should the performace of the vehicle indicate that the mixture is

incorrect, refer to the Fuel and Engine Management

section for the procedures to test for faulty components in the engine management system.

Page 30

32

ROADSIDE TROUBLE SHOOTING

CAUTION: To prevent severe electrical shock extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text for

precautionary notes.

This section deals with the common causes of

engine failure to start, as inevitably there will come a

time when every driver will experience this problem

and will therefore need to call upon his own resources

to rectify the trouble. Roadside breakdowns other

than engine failure can be identified by reference to

the Trouble Shooting section on the particular component affected.

Trouble shooting is only a process of elimination

and provided the procedure is carried out correctly

and systematically an accurate diagnosis of the trouble

can be made in the minimum amount of time.

For an internal combustion engine to run there

are three basic requirements, these are ignition, fuel

and compression. There are other factors of course

but as a rule an engine's failure to start can be

attributed to a fault in one of these three systems.

Reports from field engineers of motoring organisations prove that the biggest percentage of engine

breakdowns are in the order of ignition or electrical

failure first, followed by fuel, with mechanical or

compression failure the least common.

Should the engine fail to start, first check that

there is adequate fuel in the tank and if so. carry out

the following checking procedures in the order described.

1. TROUBLE SHOOTING

jump starting, or being jump started by

another vehicle. If available use jumper

leads equipped with a surge protection device and follow the lead manufacturers instructions carefully, particularly regarding

the connection and disconnection of the

leads.

(1) Ensure that the booster battery is 12 volts

and the negative terminal is earthed.

(2) Ensure that the vehicles are not touching and

that the ignition and all accessories on both vehicles

are switched Off.

(3) Ensure that the transmissions on both vehi-

cles are in Park or Neutral and the handbrakes are

firmly applied.

(4) Remove the vent caps from the battery and

check the electrolyte level. Replenish with distilled

water as necessary.

TO JUMP START A VEHICLE

NOTE: Jump starting a vehicle can be

dangerous if the procedure described below

is not performed correctly. If any doubt

exists, it is recommended that the services of

a competent mechanic be obtained.

The vehicles covered by this manual are

equipped with complex electronic circuitry

which can be damaged by voltage surges.

These voltage surges can be generated when

View showing the correct jumper lead connections for

jump starting a vehicle. The leads shown are equipped

with a surge protection device.

Page 31

Roadside Trouble Shooting

(5) Place the vent caps loosely over the cell

apertures.

(6) Connect one en d of t h e red j umper l ead t o

the positive ( + ) battery terminal of the booster

battery and the other end of the red lead to the

positive (+) battery terminal of the discharged battery.

NOTE: The battery emits hydrogen gas

which is explosive. Do not expose the battery

to naked /lames or sparks.

Do not lean over the battery when con-

necting the jumper leads.

Do not allow the ends of the jumper leads

to touch one another or any part of the

engine.

(7) Connect one end of the black juniper lead to

the negative (-) battery terminal of the booster

battery and the other end of the black lead to a good

earthing point on the engine of the vehicle with the

discharged battery.

NOTE: Do not connect the jumper lead

directly to the negative (-) battery terminal

of the discharged battery.

(8) Start the engine on the vehicle with the

booster battery and run the engine at a moderate

speed.

(9) Start the engine on the vehicle with the

discharged battery.

(10) If possible, leave the engines of both vehi-

cles running for 10 minutes.

(11) Disconnect the jumper leads in the reverse

order of the sequence in which they were connected.

2. TO CHECK IGNITION AND ELECTRICAL

SYSTEM

Ensure that the battery posts and terminals are clean.

(d) Where necessary carry out repairs to (b) and

(c).

Repeat the check procedure. Should the starter

motor still not operate, or the lamps not illuminate,

one or more of the following faults may be the cause:

No starter motor operation or lamps: Battery flat

or defective.

Lamps illuminate but no starter operation: Starter

motor drive jammed in mesh with flywheel ring gear.

Starter motor or solenoid defective. Ignition/starter

switch faulty. On automatic transaxle models, faulty

neutral safety switch.

Lamps dim and starter operation sluggish: Dis-

charged battery or fault in starter motor. Battery flat

due to broken fan belt or defective alternator. Faulty

battery due to cell breakdown.

NOTE: Electronic ignition systems can produce dangerously high voltages in both the

primary and secondary circuits. For this

reason, extreme care must be taken when

performing these checks. When disconnect-

(1) Switch on the ignition and check for warning

lamp illumination on the dashboard.

(2) Operate the starter and check that the starter

rotates the engine at a steady speed.

(3) Switch on the headlamps and check for good

light intensity.

Should the lamps not illuminate or the starter

motor not turn the engine, carry out the following

steps:

(a) Remove the battery terminals and clean both

terminals and posts. Connect the terminals and where

applicable tighten firmly but not excessively.

(b) Check that the earth lead from the battery to

the engine or body frame is not broken and that the

connections are clean and secure.

. (c) Check that the lead from the battery to the

starter motor or starter solenoid is intact and has a

clean and secure connection.

Securely earth the body of a test spark plug to check

for sparks at the spark plug leads.

Page 32

Roadside Trouble Shooting

ing the wiring from any component, ensure

that the ignition switch is off and the

negative battery terminal is disconnected to

prevent damage to the solid state circuitry.

(4) Open the electrode gap of a serviceable spark

plug to 6 mm. Securely earth the plug using a jumper

lead or by tying the plug to an earthed engine

component.

(5) Disconnect the high tension lead from a

spark plug and connect it to the test spark plug.

(6) Have an assistant operate the starter motor.

(7) Check that a spark, if any, jumps the gap on

the test spark plug.

If the spark is satisfactory, proceed to operation

(8).

If there is no spark, proceed as follows:

(a) Check the high tension leads to ensure that

they are dry and that the insulation is not cracked or

perished. Check the ends of the leads for burning.

Using an ohmmeter, measure the resistance in

each high tension lead. The resistance should be no

more than 15 000 ohms per lead.

Check the spark plug high tension leads for cracks and

burnt or corroded terminals.

(b) Check the distributor cap to ensure that it is

dry and clean. Examine both the inside and outside of

the cap for cracks or tracking, particularly between the

high tension lead segments.

Check that the carbon brush in the centre of the

distributor cap interior face is clean and dry and

ensure that the brush moves freely in and out of its

locating hole.

(c) Check the rotor arm for cracks, deposits and

burning on the metal arm.

(d) Ensure that the high tension leads have dry.

clean and secure connections on the distributor cap.

(8) If the above checks result in a good spark at

the spark plug high tension leads but the engine is still

not operating satisfactorily, remove all the spark plugs

and check the condition and electrode gap as described in the Engine Tune-up section under the

appropriate heading.

3. TO CHECK FUEL SYSTEM

Due to the complex nature of the EFI system, it is

recommended that should the following checks prove

satisfactory but the engine fail to start, reference be

made to the Fuel and Engine Management section of

this manual or a Nissan workshop be consulted.

(1) Check that the fuel tank contains a reasonable amount of fuel.

(2) Have an assistant switch the ignition on and

off while squeezing the fuel supply hose with the

fingers. If the fuel pump is operating it should be

possible to feel the fuel pressure increase for approximately two seconds.

NOTE: When conducting the above test it

should be possible to hear the fuel pump and

ignition relays clicking when the ignition is