Page 1

QUICK REFERENCE INDEX

GENERAL INFORMATION GI

MAINTENANCE MA

PICKUP

MODEL D22 SERIES

FOREWORD

This supplement contains information concerning necessary service

procedures and relevant data for the

model D22 series.

All information, illustrations and specifications contained in this supplement are based on the latest product

information available at the time of

publication. If your NISSAN model

differsfromthespecificationscontained in this supplement, consult your

NISSAN distributor for information.

ENGINE MECHANICAL EM

ENGINE LUBRICATION &

COOLING SYSTEMS

LC

ENGINE CONTROL SYSTEM EC

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

FE

CLUTCH CL

MANUAL TRANSAXLE MT

TRANSFER TF

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

PD

FRONT AXLE & FRONT SUSPENSION FA

REAR AXLE & REAR SUSPENSION RA

The right is reserved to make changes in specifications and methods at

any time without notice.

BRAKE SYSTEM BR

STEERING SYSTEM ST

RESTRAINT SYSTEM RS

BODY & TRIM BT

HEATER & AIR CONDITIONER HA

Edition: October 2003

Printing: November 2003 (01)

PublicationNo.:SM3E00-1D22E0E

Reference No.: 7711347050

ELECTRICAL SYSTEM EL

ALPHABETICAL INDEX IDX

NISSAN EUROPE S.A.S.

© 2003 NISSAN EUROPE S.A.S. Printed in the Netherlands

Not to be reproduced in whole or in part without the prior written permission of Nissan Europe S.A.S., Paris, France.

Page 2

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

PICKUP, model D22 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not specifically recommended by NISSAN must

first completely satisfy himself that neither his safety nor the vehicle’s

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering Section

Paris, France

Page 3

<SUPPLEMENT-V>

BRAKE SYSTEM

MODIFICATION NOTICE:

Wiring diagrams have been changed.

Service data and specifications (SDS) have been changed.

CONTENTS

TROUBLE DIAGNOSES .....................................5002

Schematic/4 Wheel Sensors Models...............5002

Wiring Diagram - ABS -/4 Wheel Sensors LHD

Models..............................................................5003

Wiring Diagram - ABS -/4 Wheel Sensors

RHD Models.....................................................5006

SERVICE DATA AND SPECIFICATIONS

(SDS)....................................................................5009

SECTION

General Specifications.....................................5009

BR

BR

Page 4

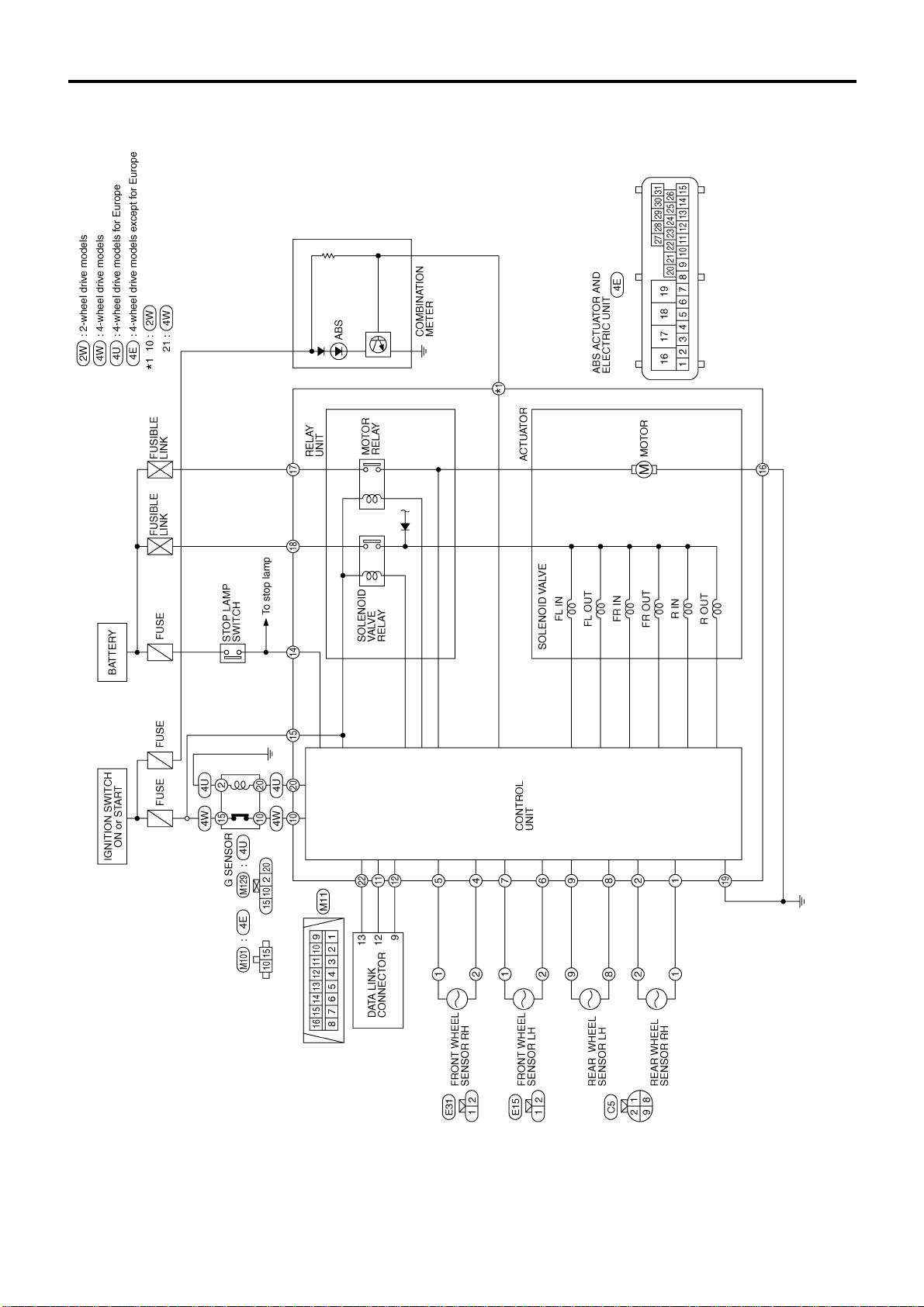

TROUBLE DIAGNOSES

Schematic/4 Wheel Sensors Models

BR-5002

GBR060A

Page 5

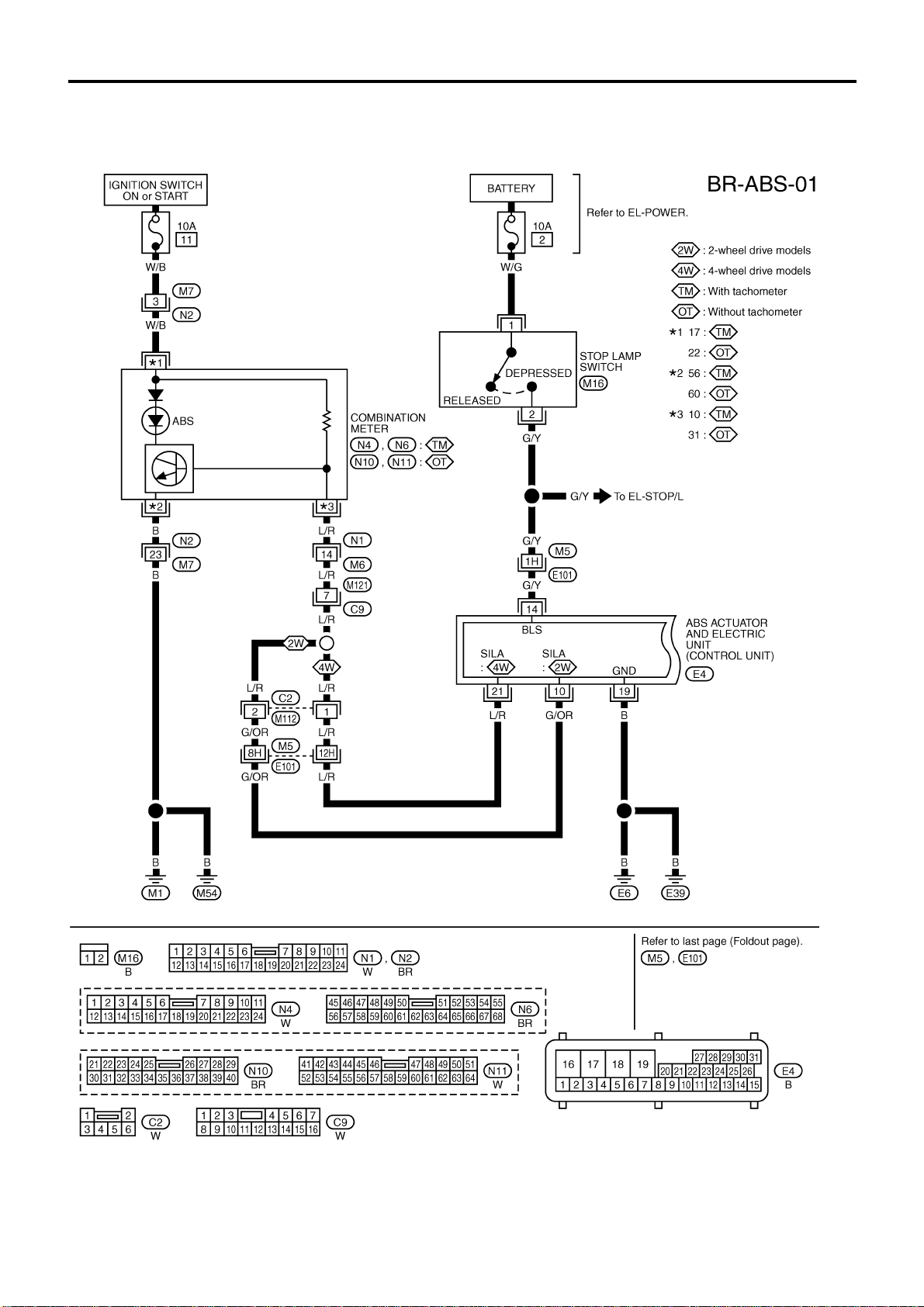

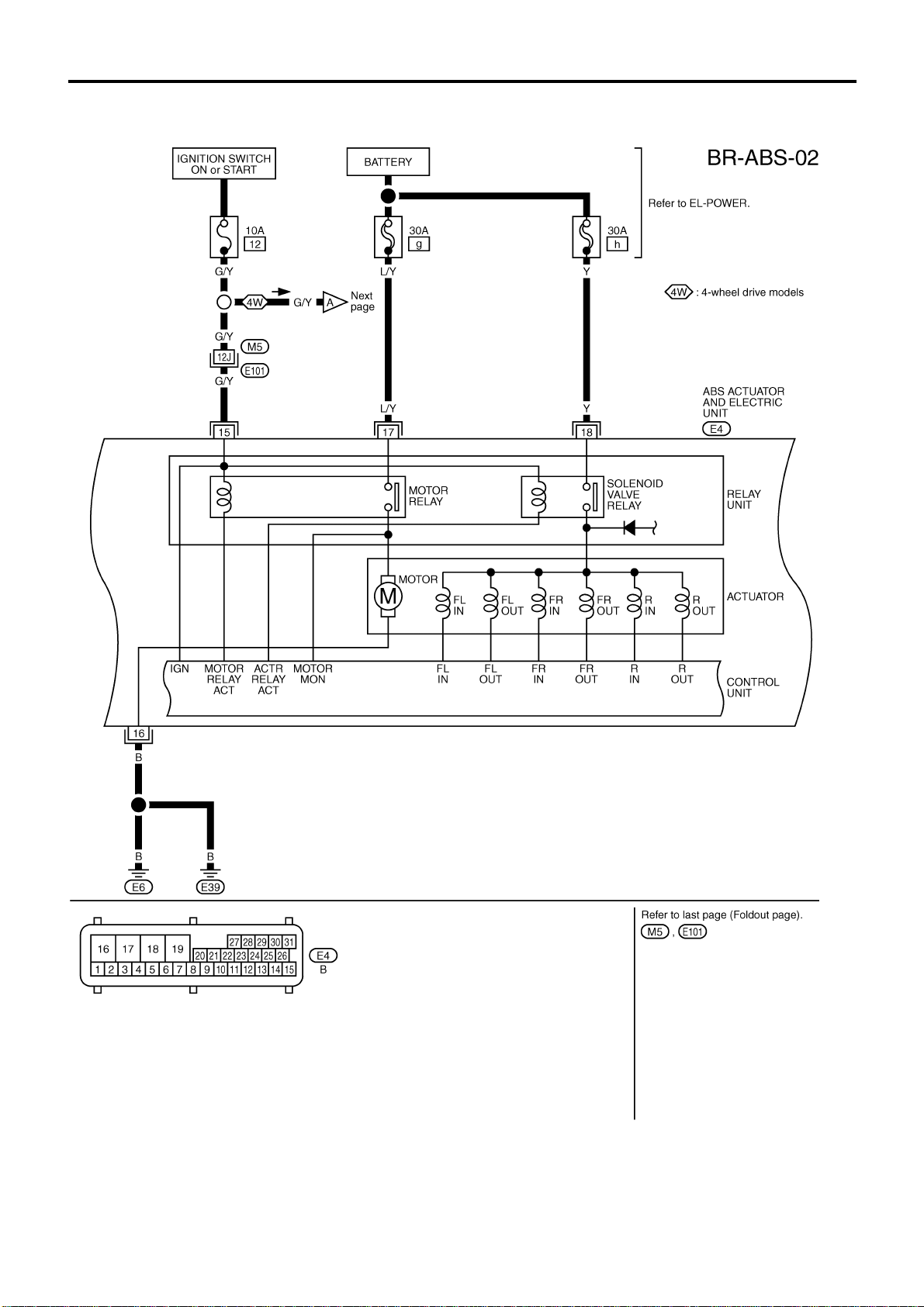

TROUBLE DIAGNOSES

Wiring Diagram — ABS —/4 Wheel Sensors

LHD Models

BR-5003

GBR061A

Page 6

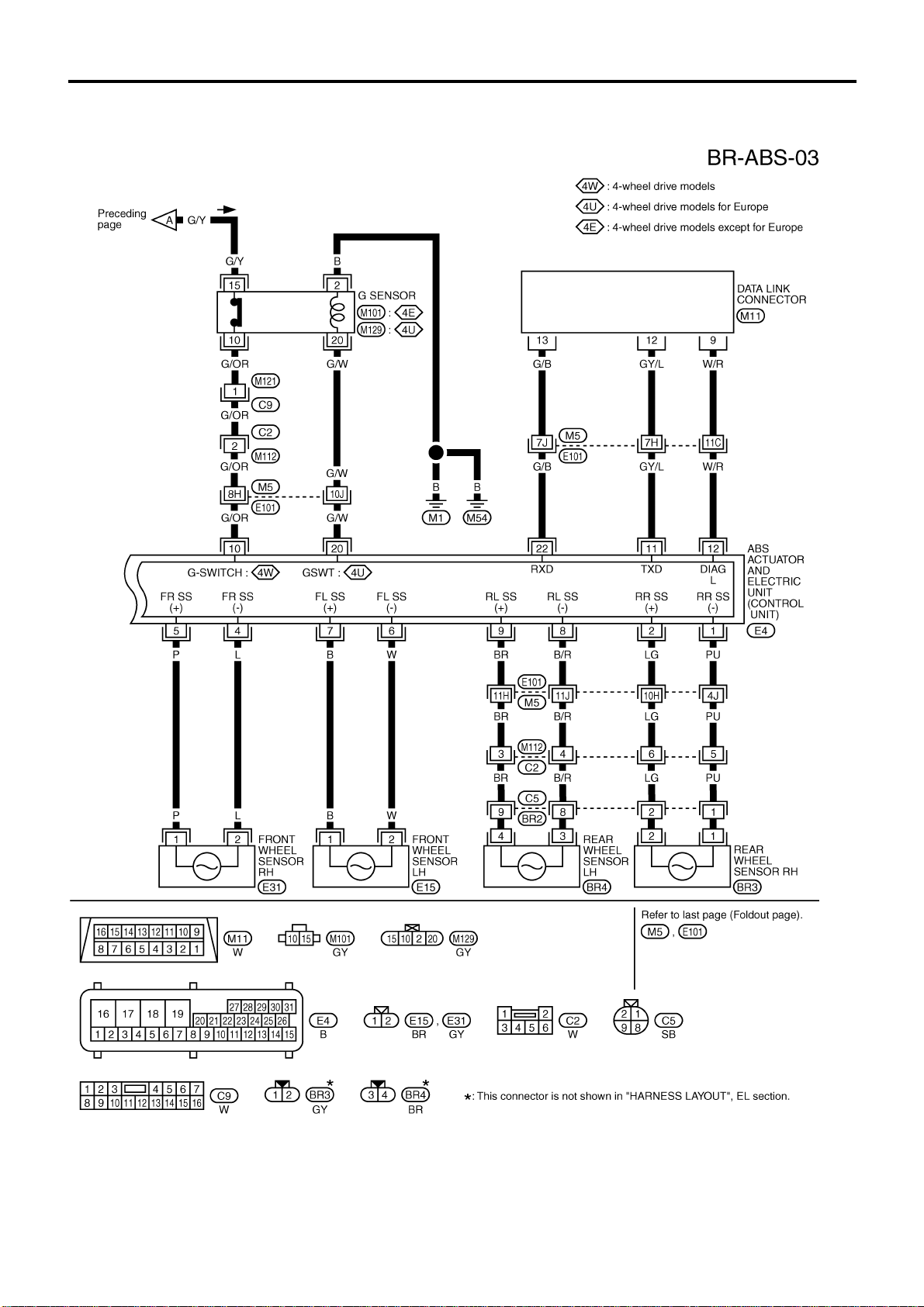

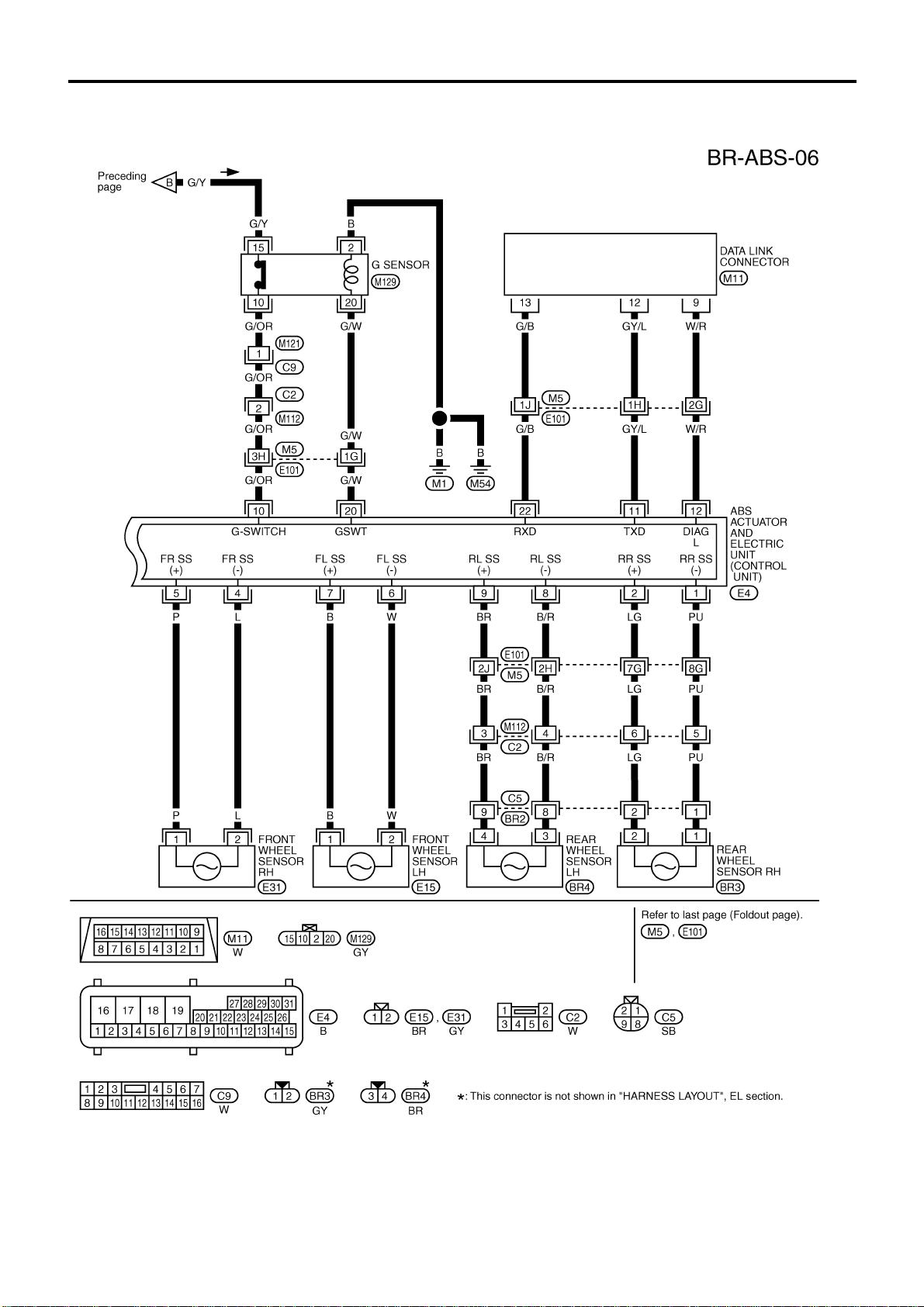

TROUBLE DIAGNOSES

Wiring Diagram — ABS —/4 Wheel Sensors

LHD Models (Cont’d)

BR-5004

GBR062A

Page 7

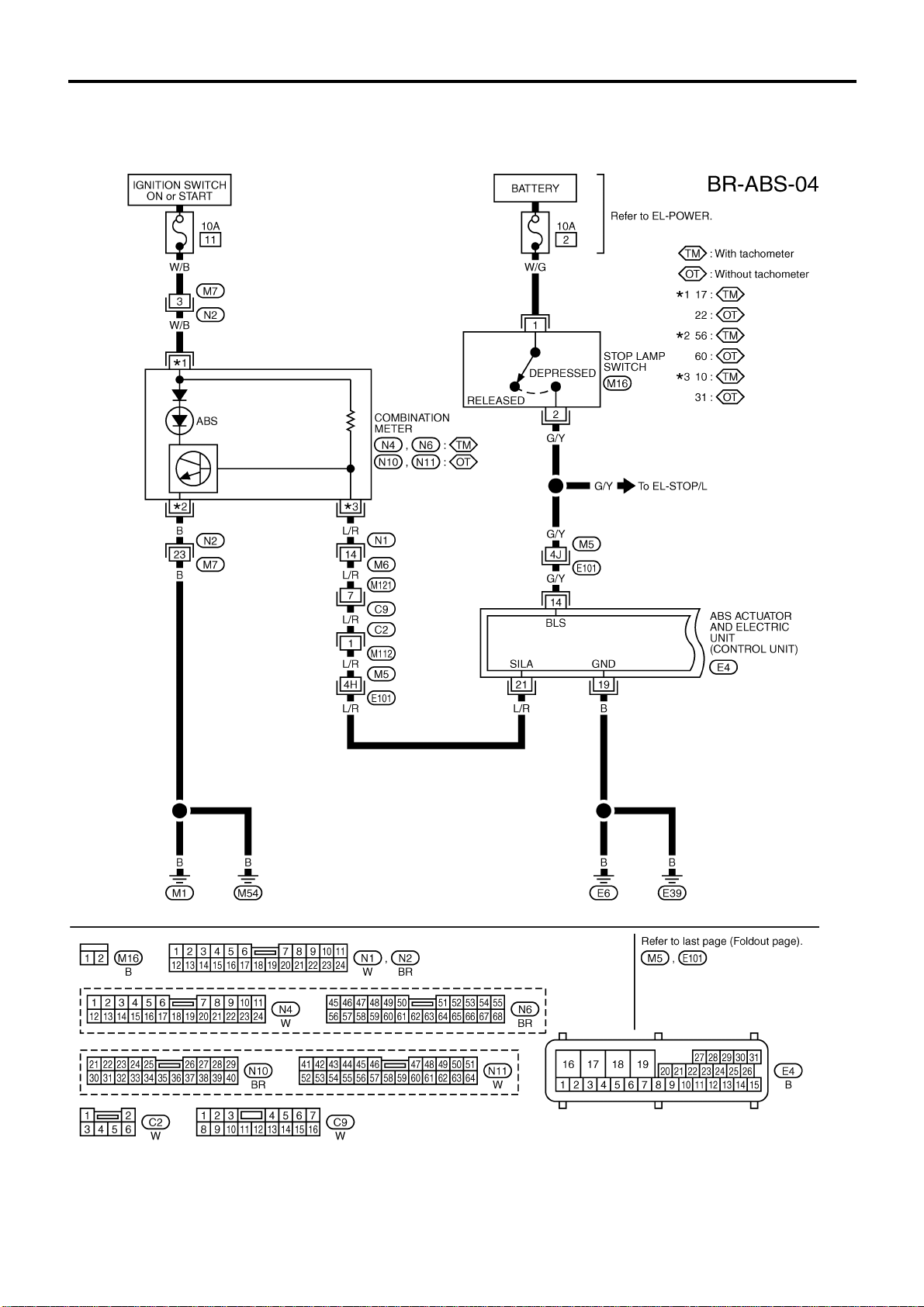

TROUBLE DIAGNOSES

Wiring Diagram — ABS —/4 Wheel Sensors

LHD Models (Cont’d)

BR-5005

GBR063A

Page 8

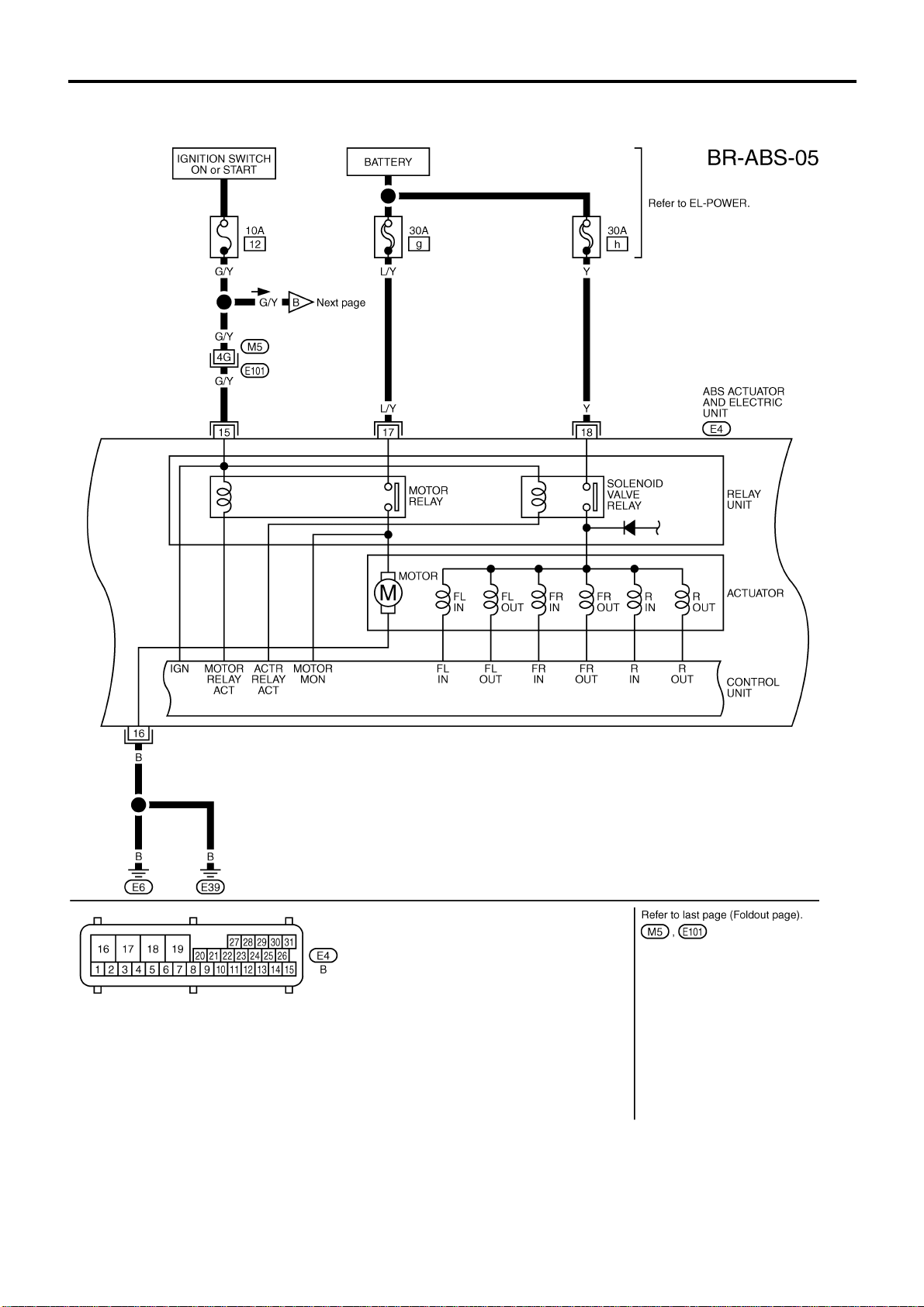

TROUBLE DIAGNOSES

Wiring Diagram — ABS —/4 Wheel Sensors

RHD Models

BR-5006

GBR064A

Page 9

TROUBLE DIAGNOSES

Wiring Diagram — ABS —/4 Wheel Sensors

RHD Models (Cont’d)

BR-5007

GBR065A

Page 10

TROUBLE DIAGNOSES

Wiring Diagram — ABS —/4 Wheel Sensors

RHD Models (Cont’d)

BR-5008

GBR066A

Page 11

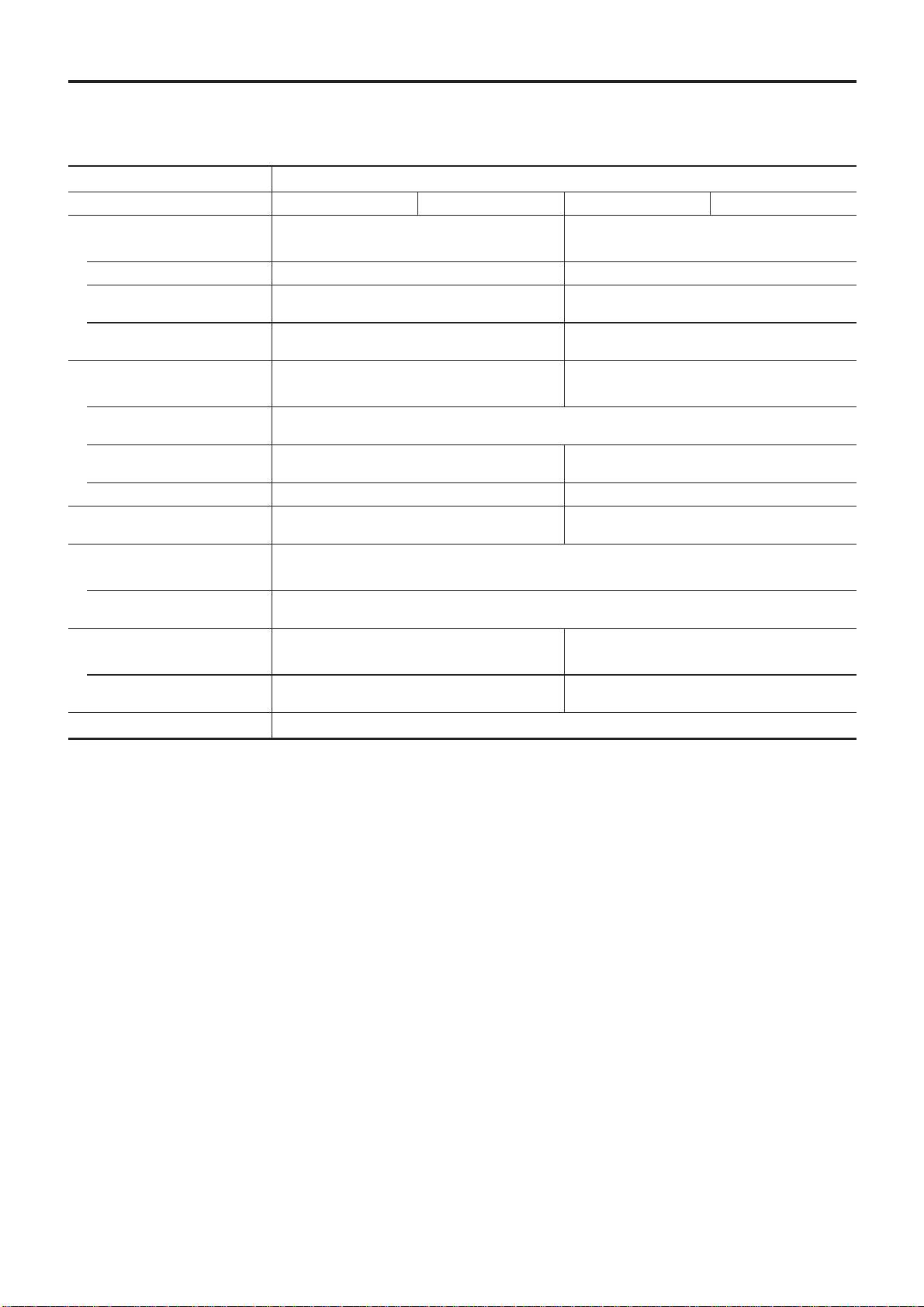

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

2WD MODELS

Destination Europe

Applied model KA24DE YD25 KA24DE YD25

Front brake

Type CL28VD CL33VD

Cylinder bore diameter mm (in) 42.8 (1.685) x 2 46.4 (1.827) x 2

Pad dimension mm (in)

Length x width x thickness

Rotor outer diameter x thickness

Rear brake

Type LT26B LT30A

Wheel cylinder bore diameter

Lining dimension mm (in)

Length x width x thickness

Drum inner diameter mm (in) 260.0 (10.24) 295.0 (11.61)

Master cylinder bore diameter

Control valve

Type LSV

Split point x reducing ratio

kPa (bar, kg/cm

Brake booster

Model M195T M215T

Diaphragm diameter mm (in)

Recommended brake fluid DOT 3 or DOT 4

mm (in)

mm (in)

mm (in)

2

, psi)

249.6 x 40 x 5.5 (9.83 x 1.57 x 0.217) 296 x 50 x 6.1 (11.65 x 1.97 x 0.240)

146.6 x 48.5 x 10

(5.77 x 1.909 x 0.39)

260 x 26 (10.24 x 1.02) 283 x 28 (11.14 x 1.10)

22.22 (7/8)

With ABS: 23.81 (15/16)

Without ABS: 25.4 (1)

(Variable) x 0.15

Primary: 205 (8.07)

Secondary: 180 (7.09)

132.0 x 52.5 x 11 (5.20 x 2.067 x 0.43)

25.4 (1)

Primary: 230 (9.06)

Secondary: 205 (8.07)

BR-5009

Page 12

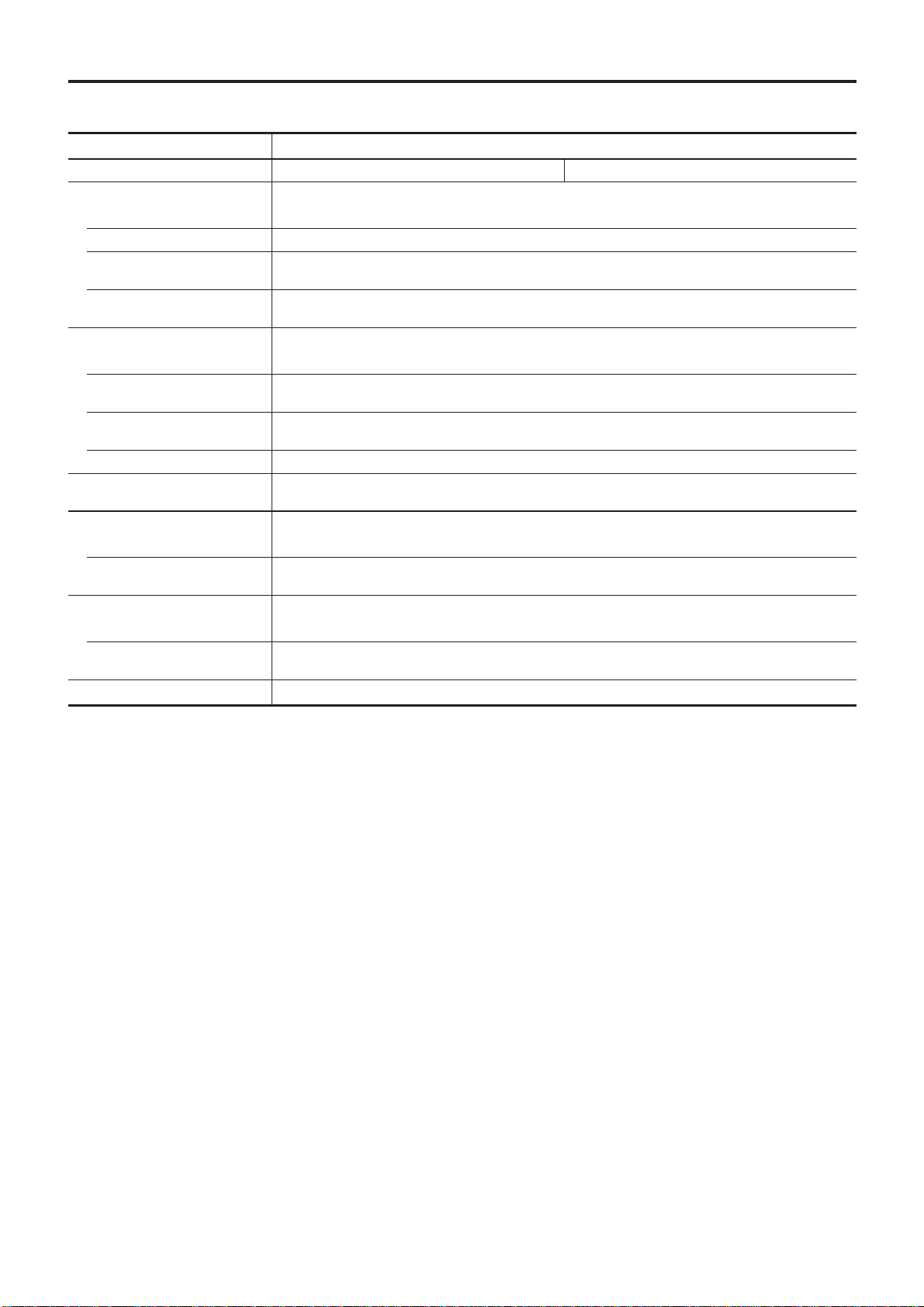

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications (Cont’d)

4WD MODELS

Destination Europe

Applied model KA24DE YD25

Front brake

Type CL33VD

Cylinder bore diameter mm (in) 46.4 (1.827) x 2

Pad dimension mm (in)

Length x width x thickness

Rotor outer diameter x thickness

Rear brake

Type LT30A

Wheel cylinder bore diameter

Lining dimension mm (in)

Length x width x thickness

Drum inner diameter mm (in) 295 (11.61)

Master cylinder bore diameter

Control valve

Type LSV

Split point x reducing ratio

kPa (bar, kg/cm

Brake booster

Model M215T

Diaphragm diameter mm (in)

Recommended brake fluid DOT 3 or DOT 4

mm (in)

mm (in)

mm (in)

2

, psi)

132.0 x 52.5 x 11 (5.20 x 2.067 x 0.43)

283 x 28 (11.14 x 1.10)

22.22 (7/8)

296.0 x 50.0 x 6.1 (11.65 x 1.969 x 0.240)

25.4 (1)

(Variable) x 0.15

Primary: 230 (9.06)

Secondary: 205 (8.07)

BR-5010

Page 13

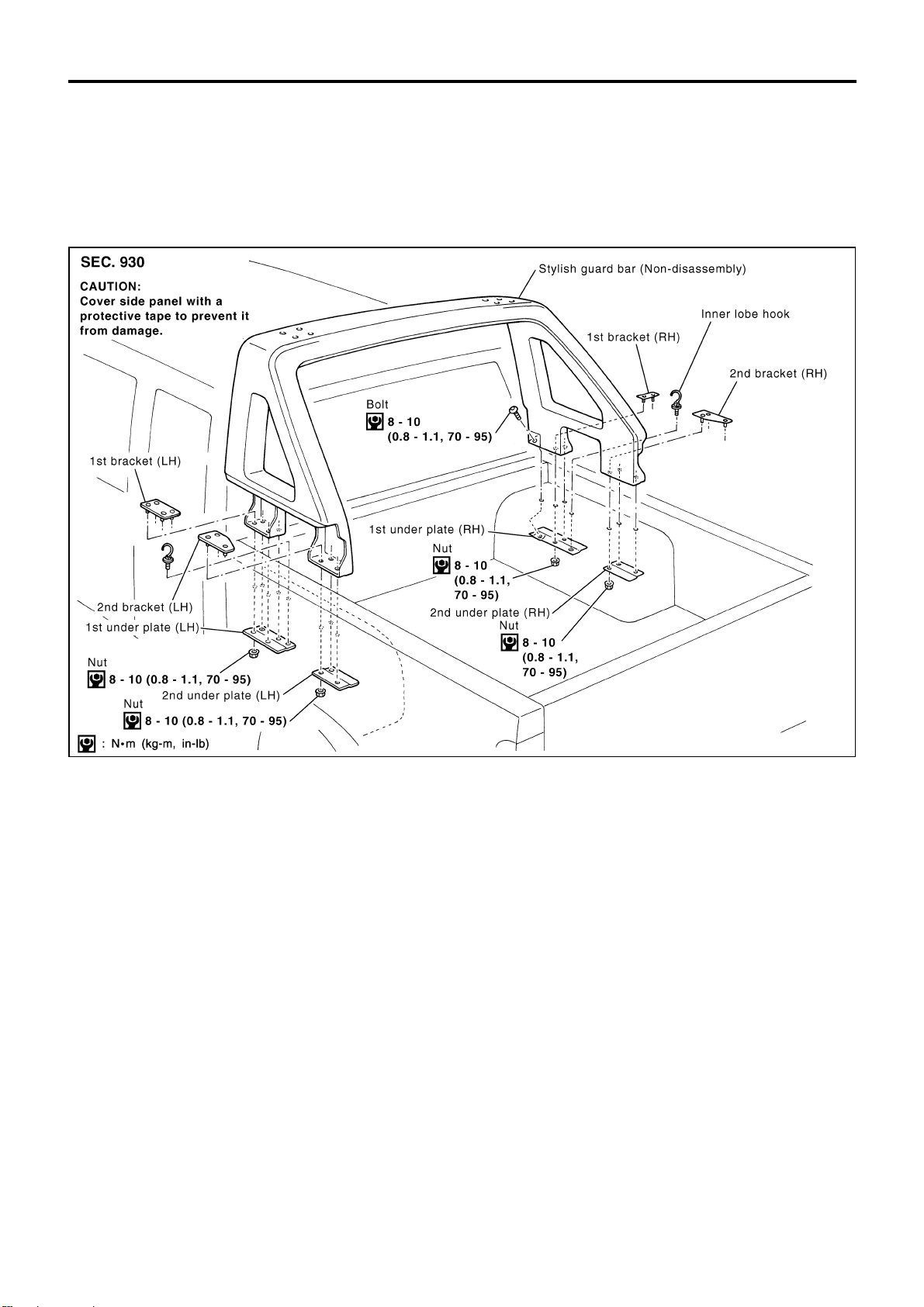

<SUPPLEMENT-V>

BODY & TRIM

MODIFICATION NOTICE:

Stylish guard bar has been added.

CONTENTS

EXTERIOR...........................................................5002

Stylish Guard Bar.............................................5002

SECTION

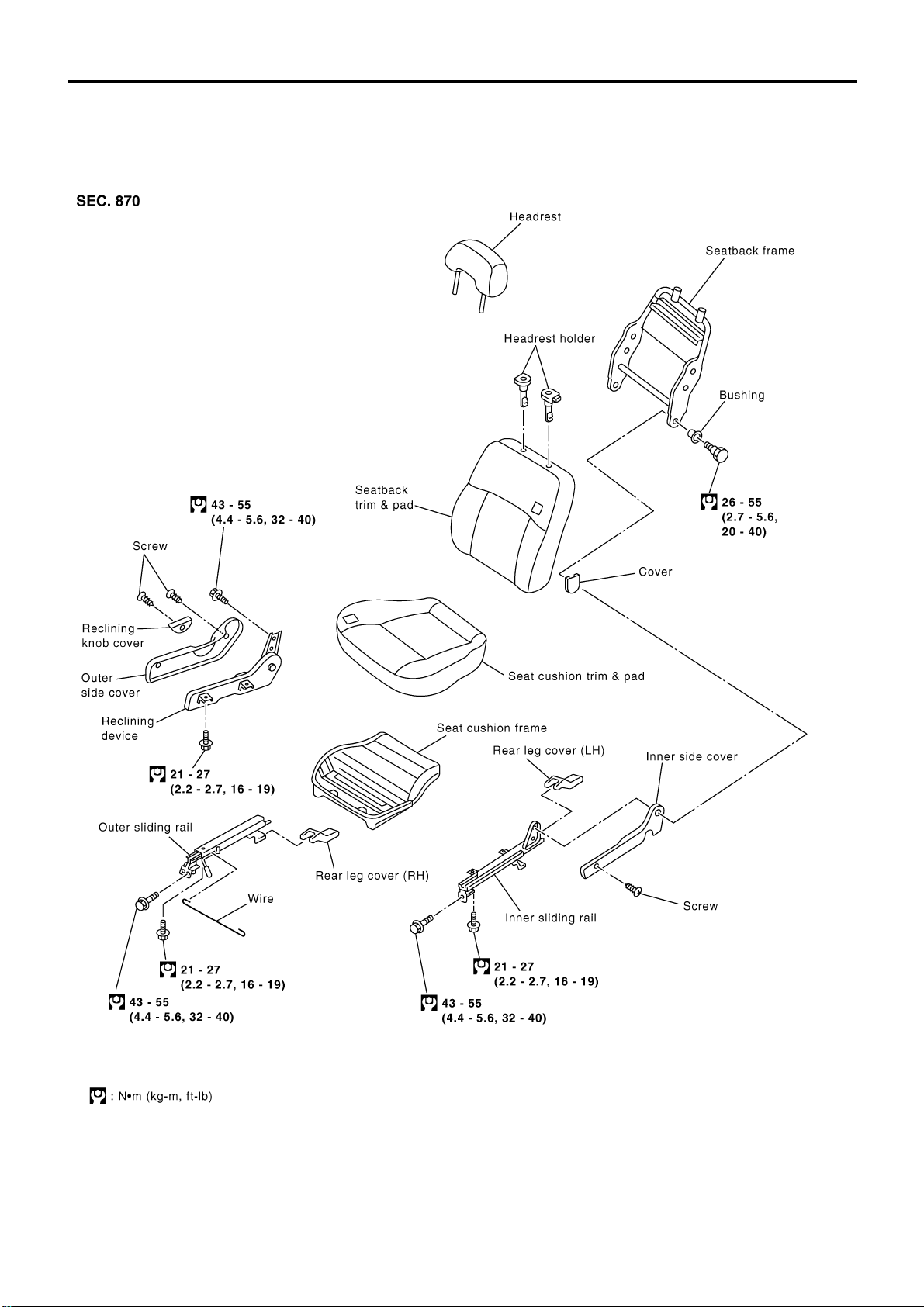

Front Seat ........................................................5003

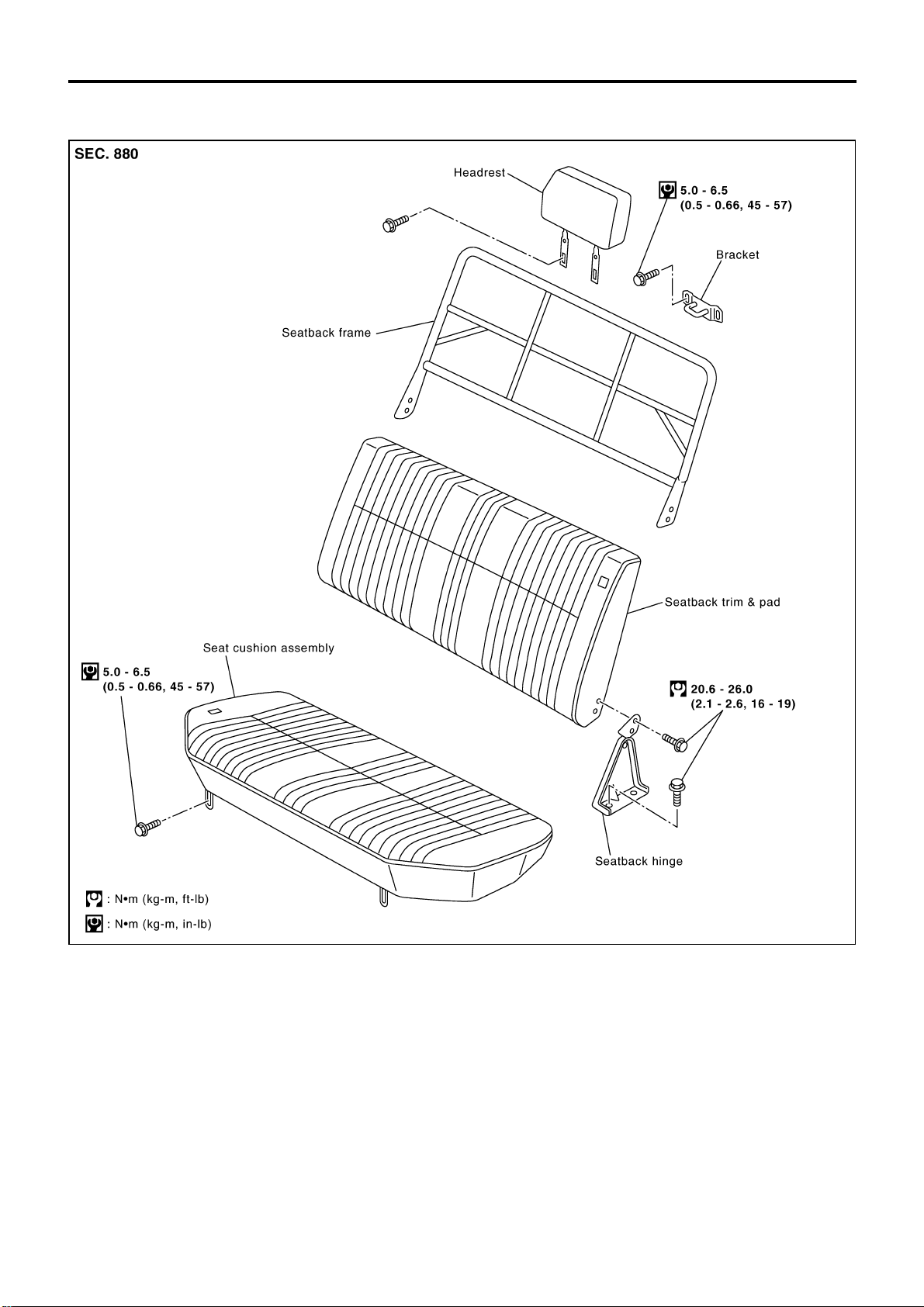

Rear Seat.........................................................5004

BT

BT

Page 14

EXTERIOR

Stylish Guard Bar

REMOVAL — Stylish guard bar assembly

1

Remove nuts of guard bar (left).

V

2

Remove nuts of guard bar (right).

V

3

Remove bolt of guard bar (right).

V

4

Remove stylish guard bar assembly.

V

PIIA6340E

BT-5002

Page 15

EXTERIOR

● When removing or installing the seat trim, carefully handle it to keep dirt out and avoid damage.

Front Seat

BT-5003

PIIB0901E

Page 16

EXTERIOR

Rear Seat

BT-5004

PIIB0902E

Page 17

<SUPPLEMENT-V>

ELECTRICAL SYSTEM

MODIFICATION NOTICE:

● Wiring diagrams have been changed.

● Harness layouts have been changed.

CONTENTS

INTERIOR ROOM LAMP.....................................5002

Wiring Diagram - ROOM/L -............................5002

ILLUMINATION....................................................5003

Wiring Diagram - ILL -/LHD Models................5003

POWER WINDOW...............................................5005

Schematic/With Interruption Detection

Function ...........................................................5005

Wiring Diagram - WINDOW -/With Interruption

Detection Function...........................................5006

SECTION

THEFT WARNING SYSTEM ...............................5010

Wiring Diagram - PRWIRE -............................5010

HARNESS LAYOUT............................................5012

Main Harness...................................................5012

Engine Room Harness.....................................5018

Room Lamp Harness/LHD Models..................5026

EL

EL

Page 18

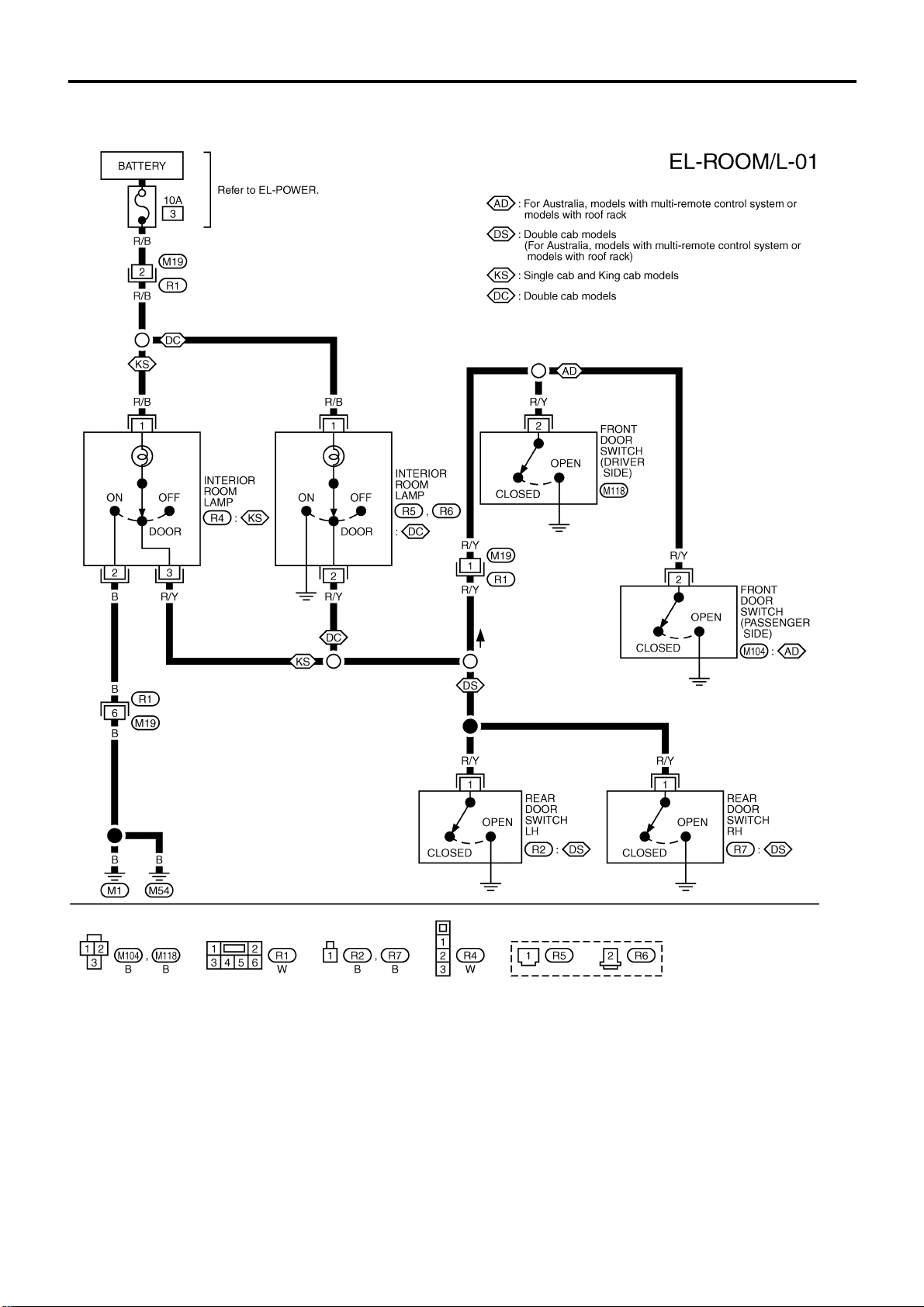

INTERIOR ROOM LAMP

Wiring Diagram — ROOM/L —

EL-5002

GEL924A

Page 19

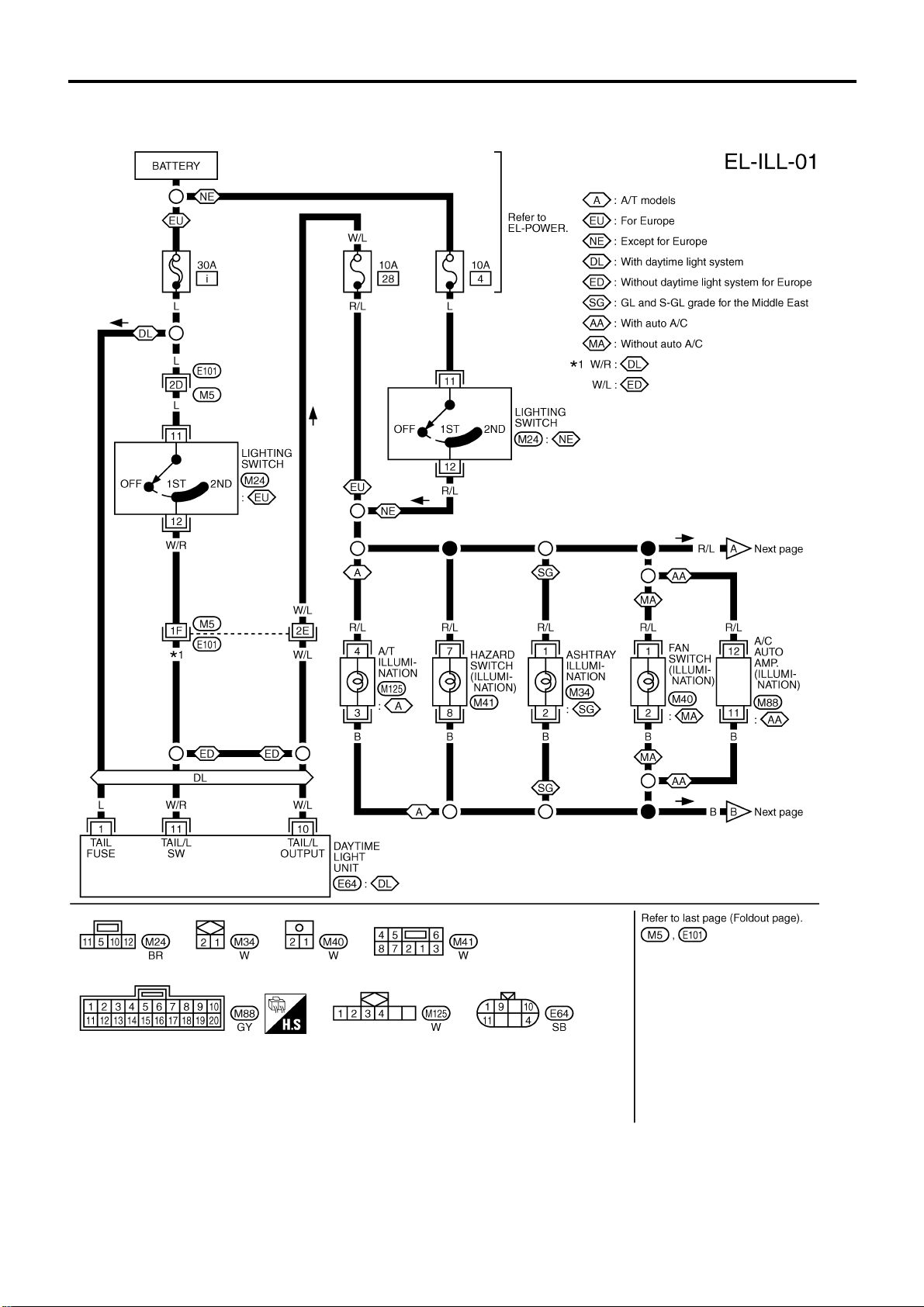

ILLUMINATION

Wiring Diagram — ILL —/LHD Models

EL-5003

GEL675A

Page 20

ILLUMINATION

Wiring Diagram — ILL —/LHD Models

(Cont’d)

EL-5004

GEL676A

Page 21

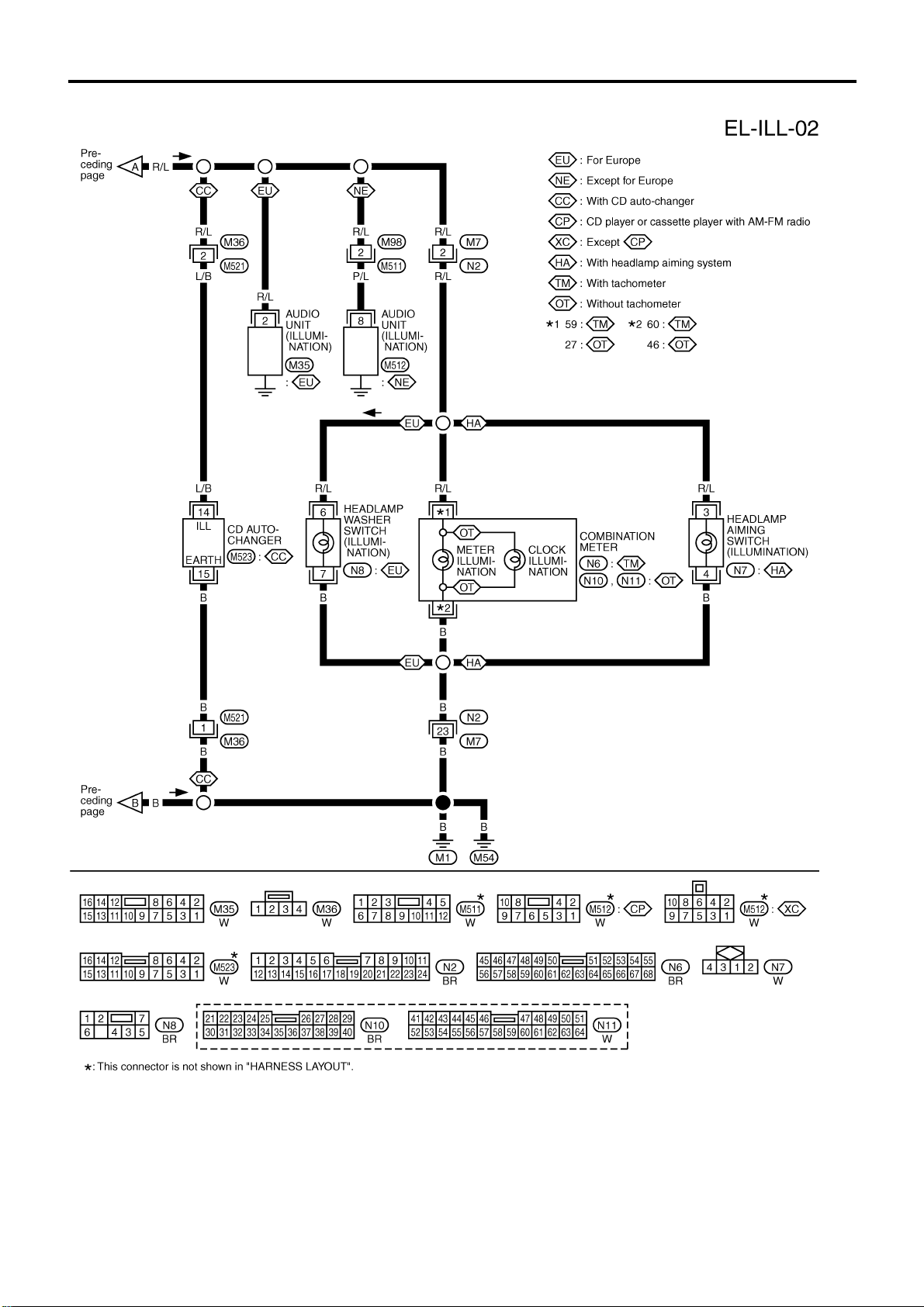

POWER WINDOW

Schematic/With Interruption Detection

Function

EL-5005

GEL925A

Page 22

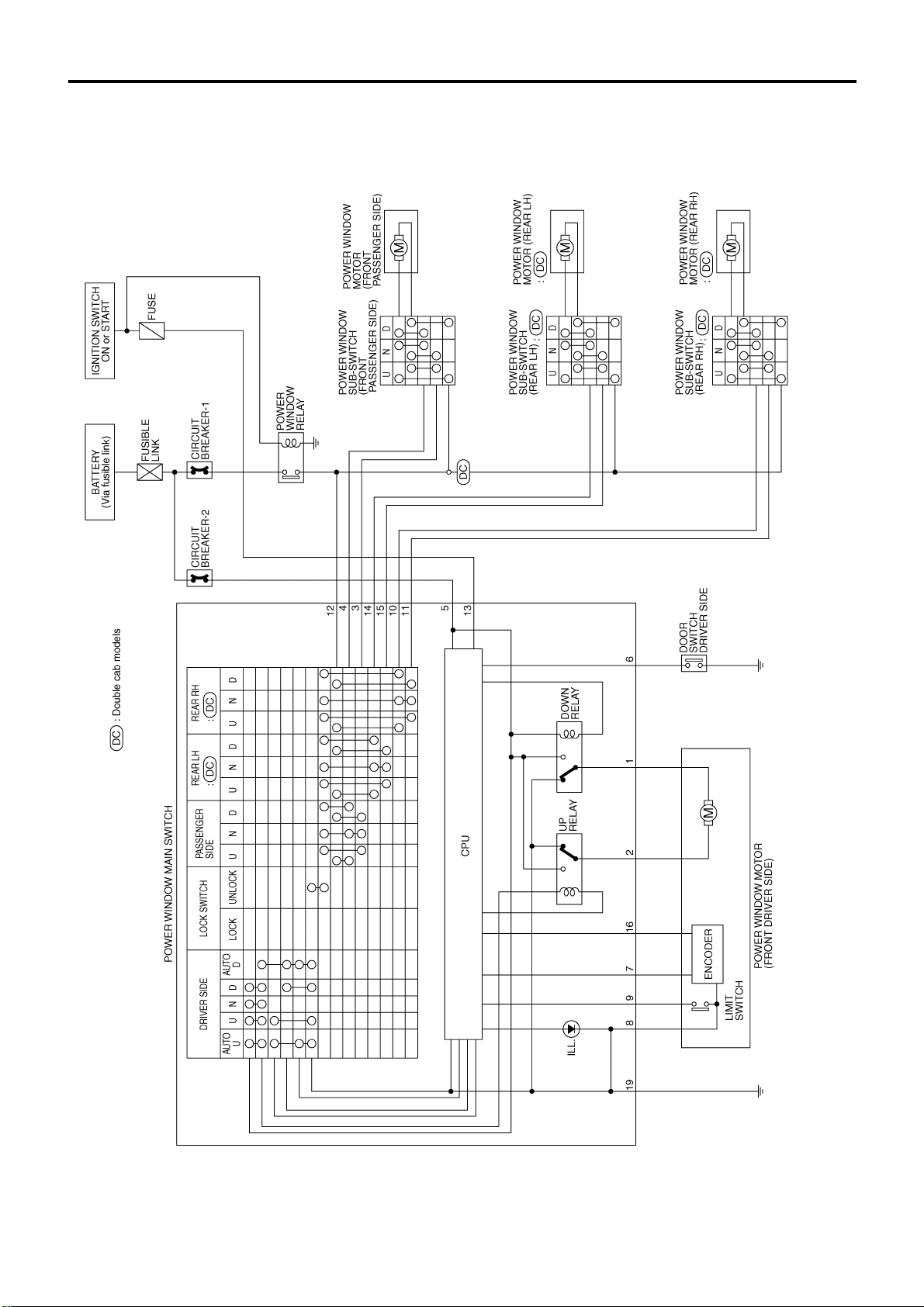

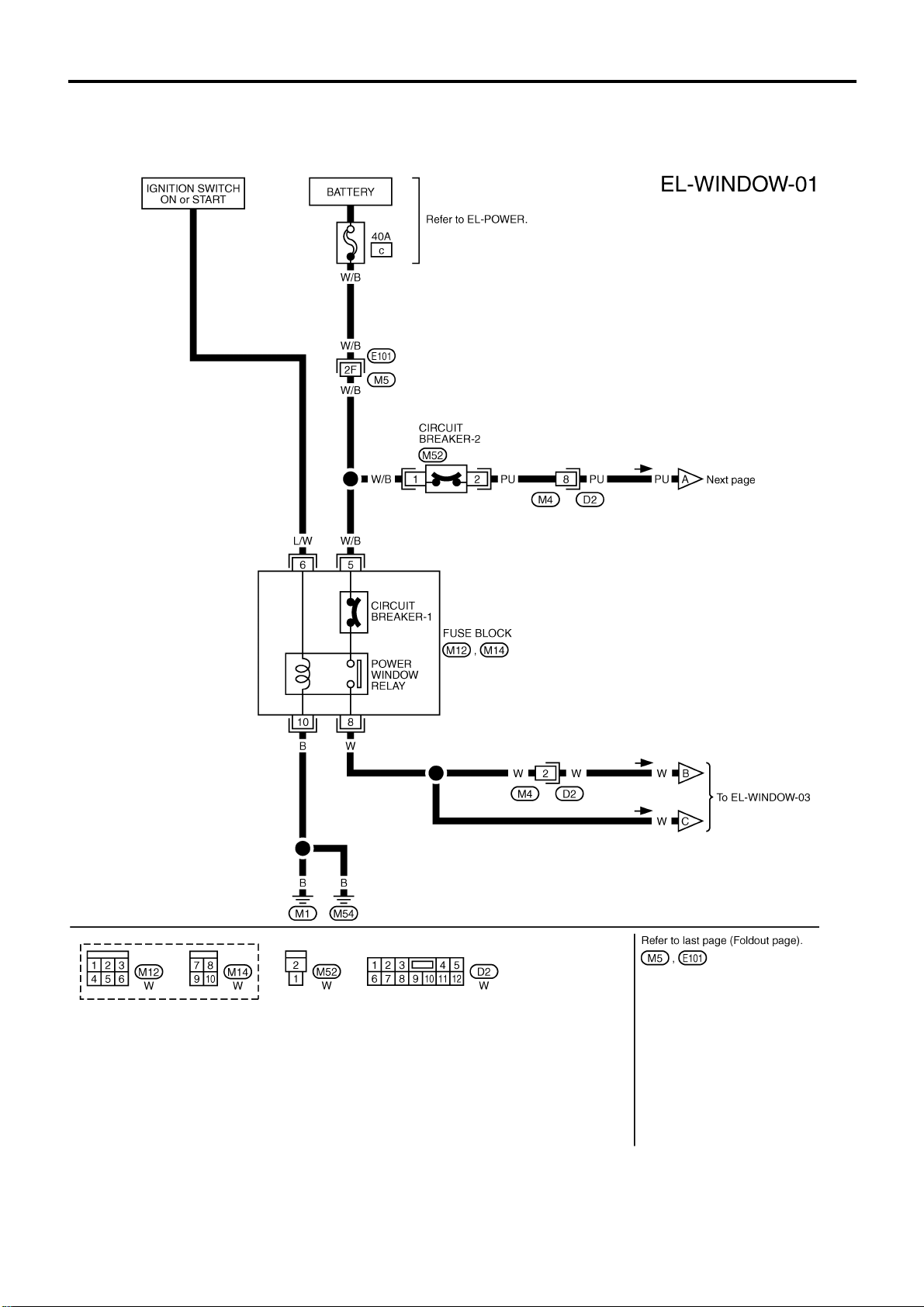

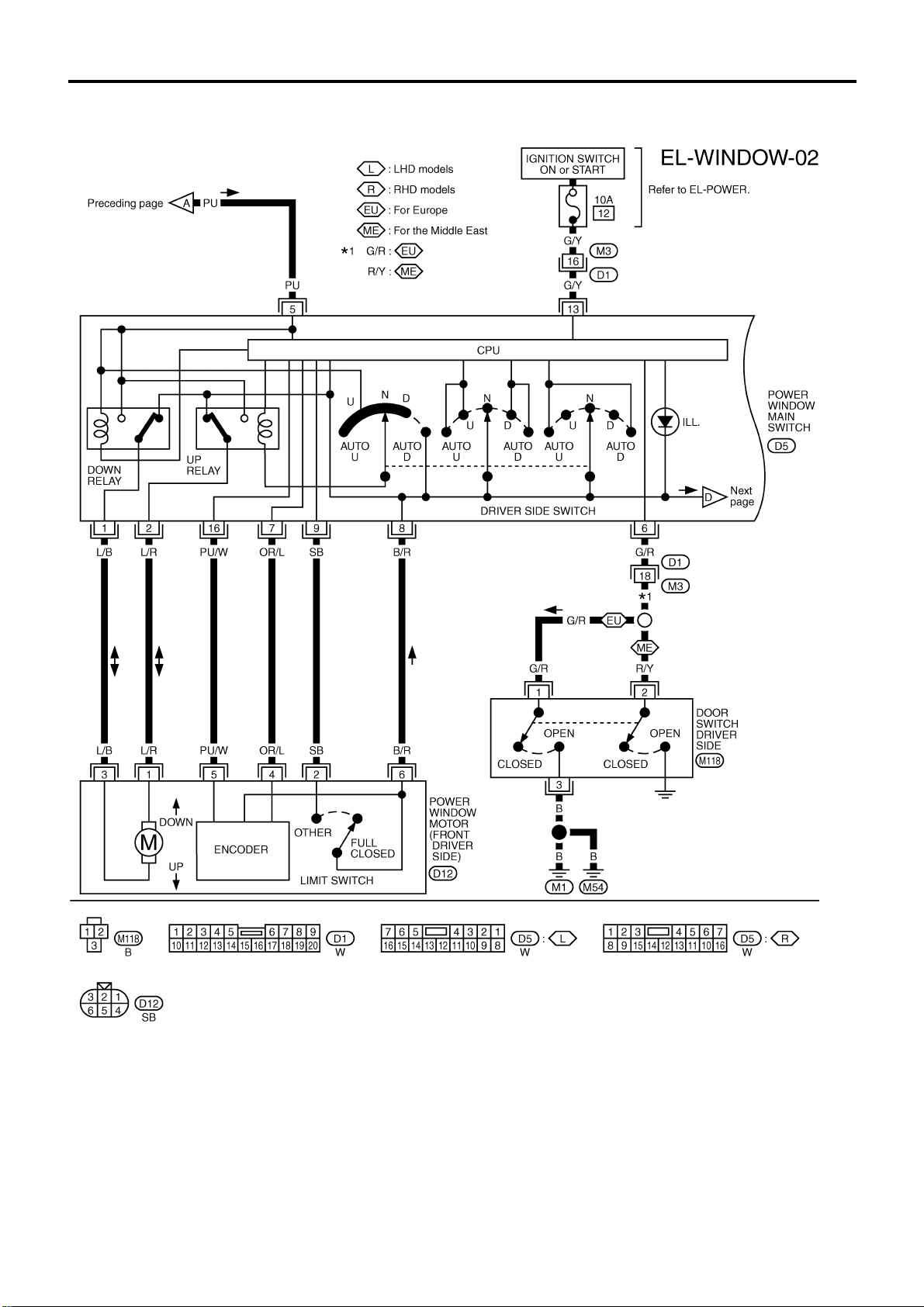

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function

EL-5006

GEL926A

Page 23

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function (Cont’d)

EL-5007

GEL927A

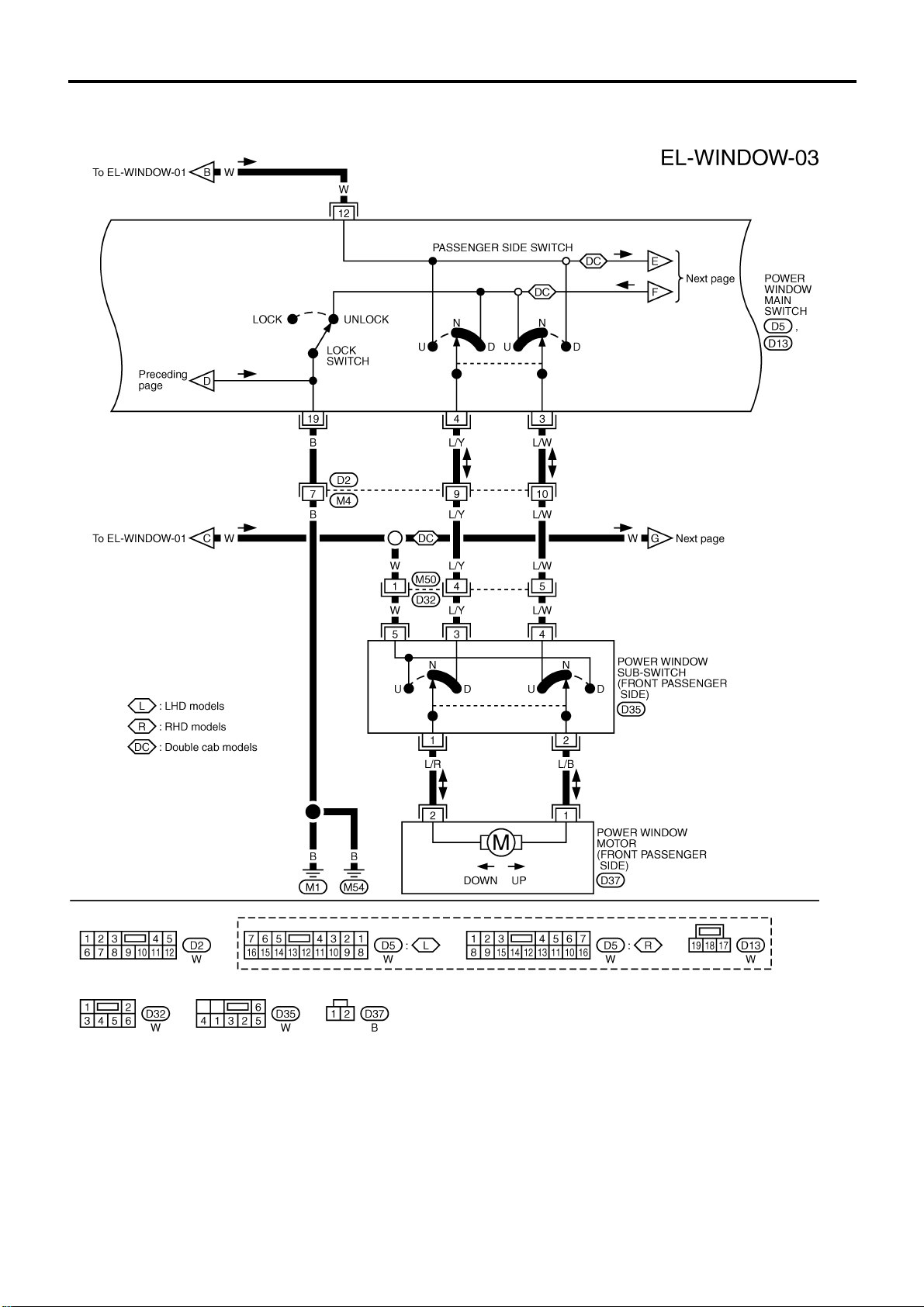

Page 24

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function (Cont’d)

EL-5008

GEL928A

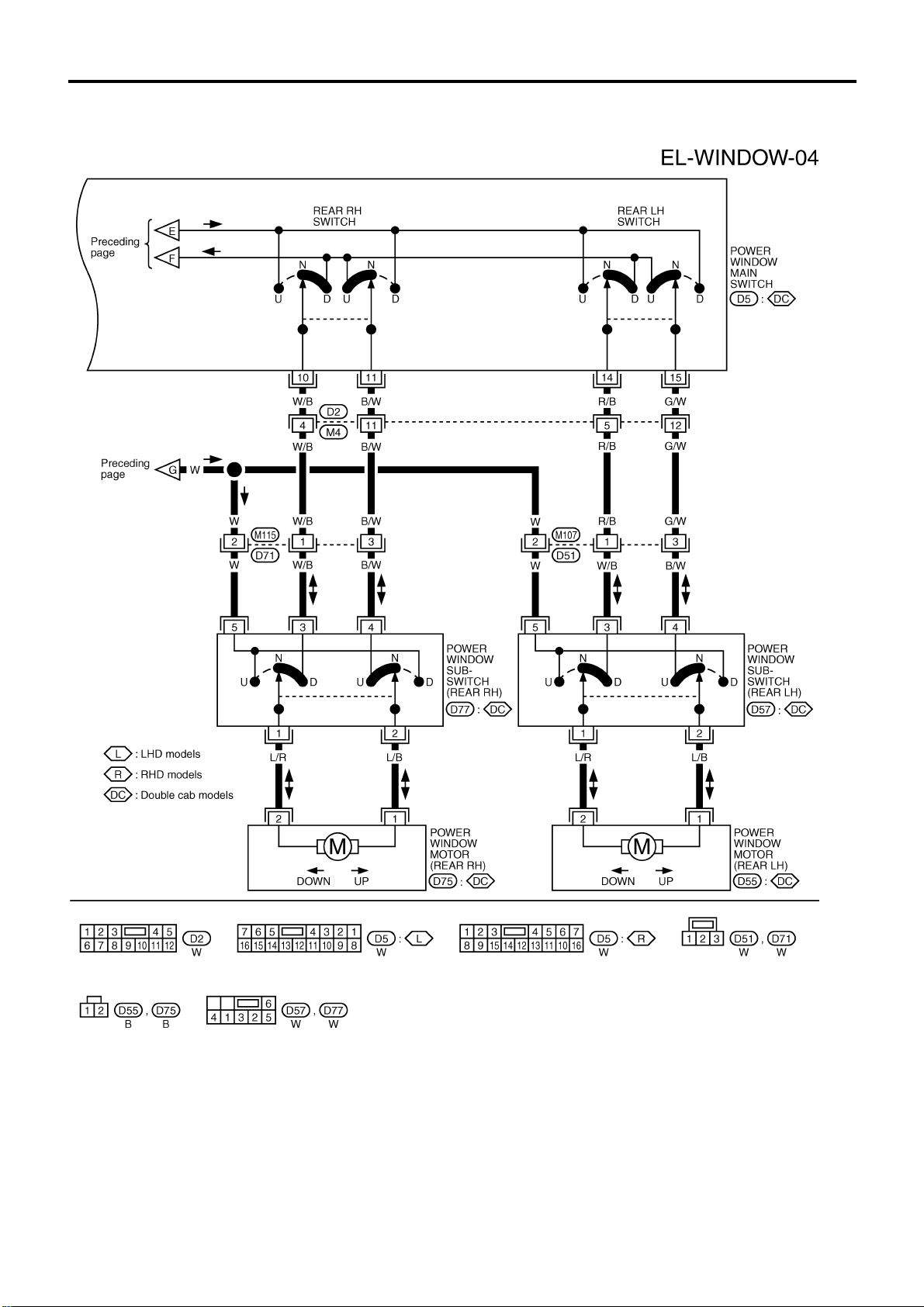

Page 25

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function (Cont’d)

EL-5009

GEL929A

Page 26

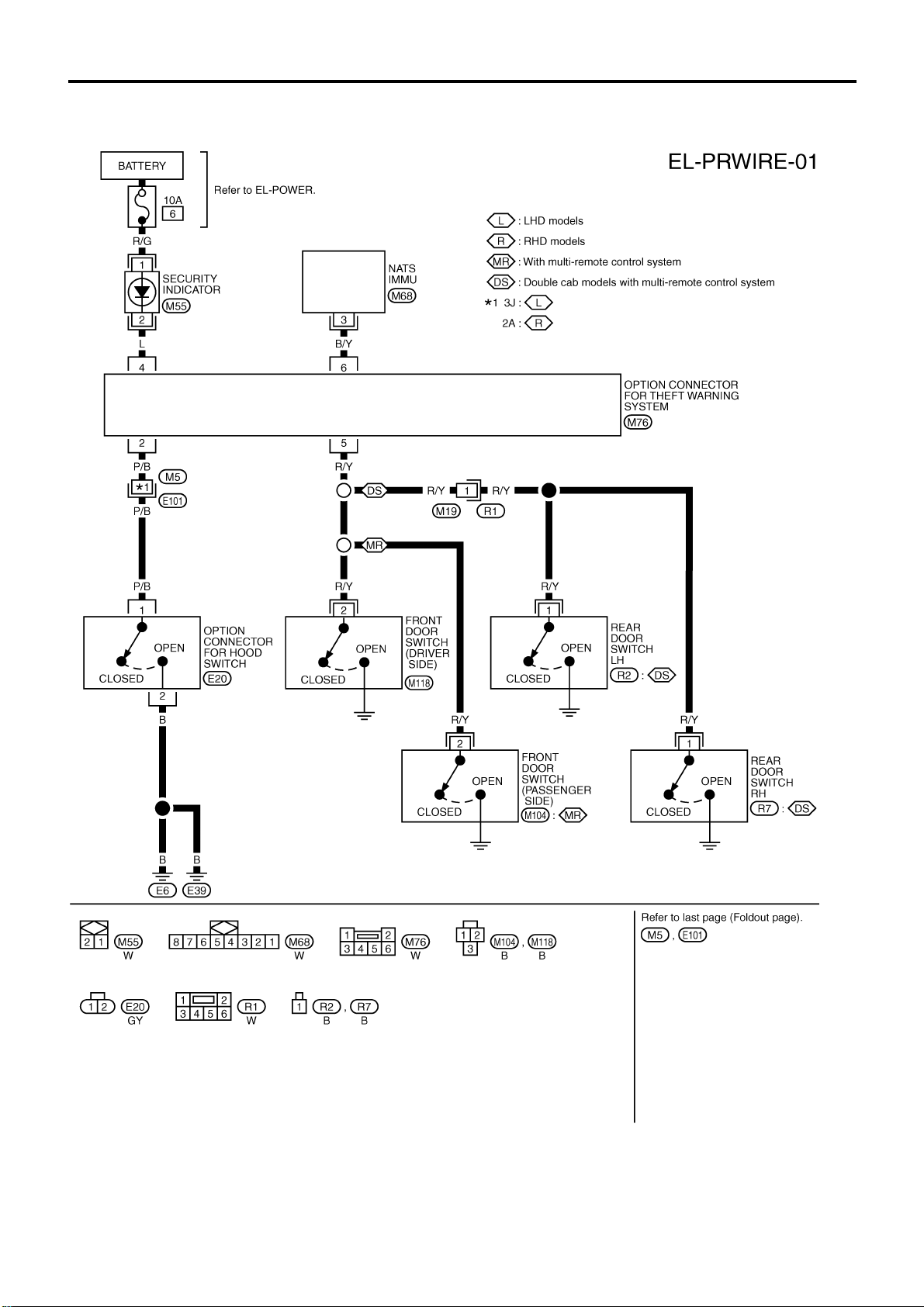

THEFT WARNING SYSTEM

Wiring Diagram — PRWIRE —

EL-5010

GEL930A

Page 27

NOTE

THEFT WARNING SYSTEM

EL-5011

Page 28

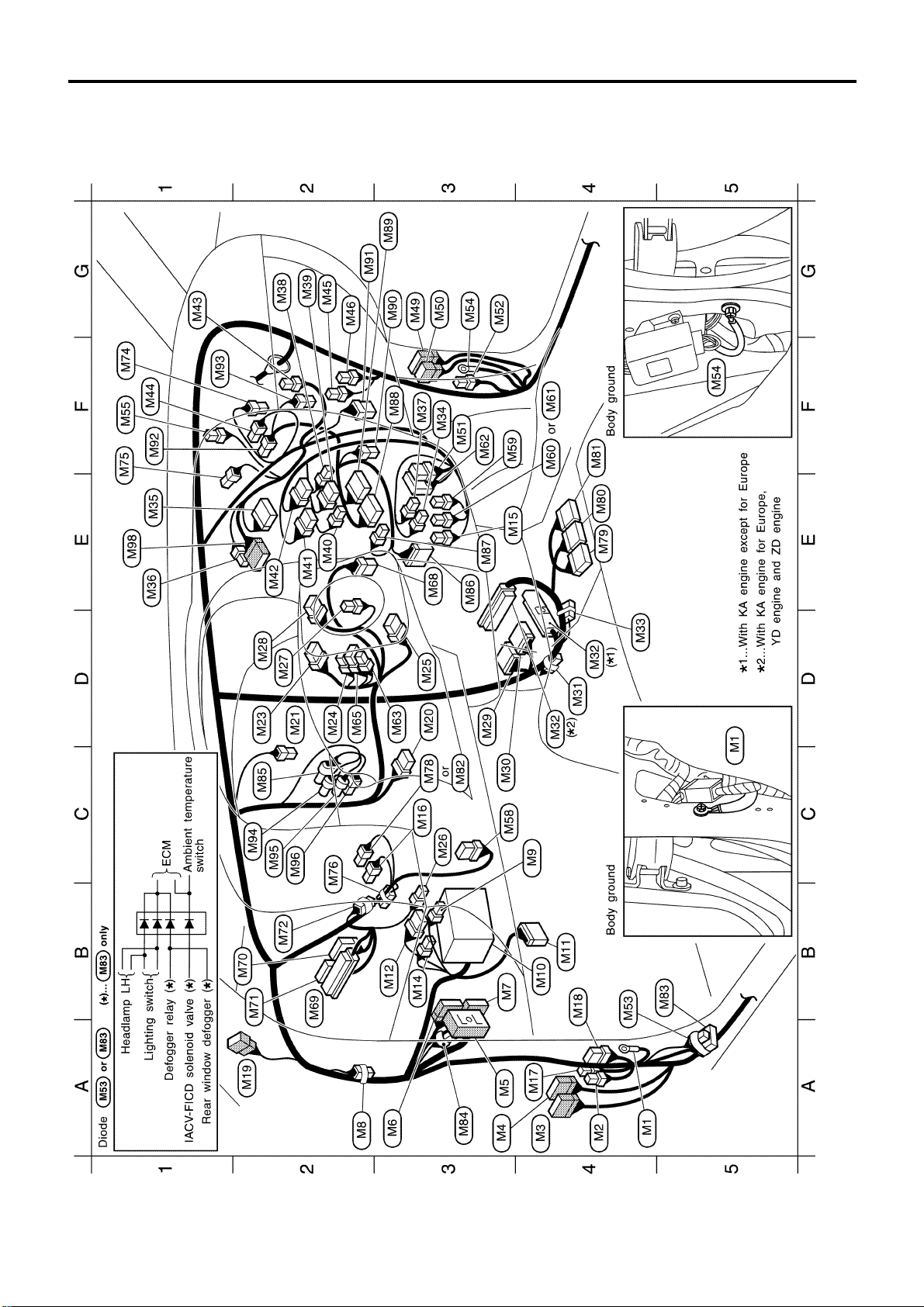

HARNESS LAYOUT

Main Harness

INSTRUMENT PANEL — LHD MODELS

EL-5012

HEL082C

Page 29

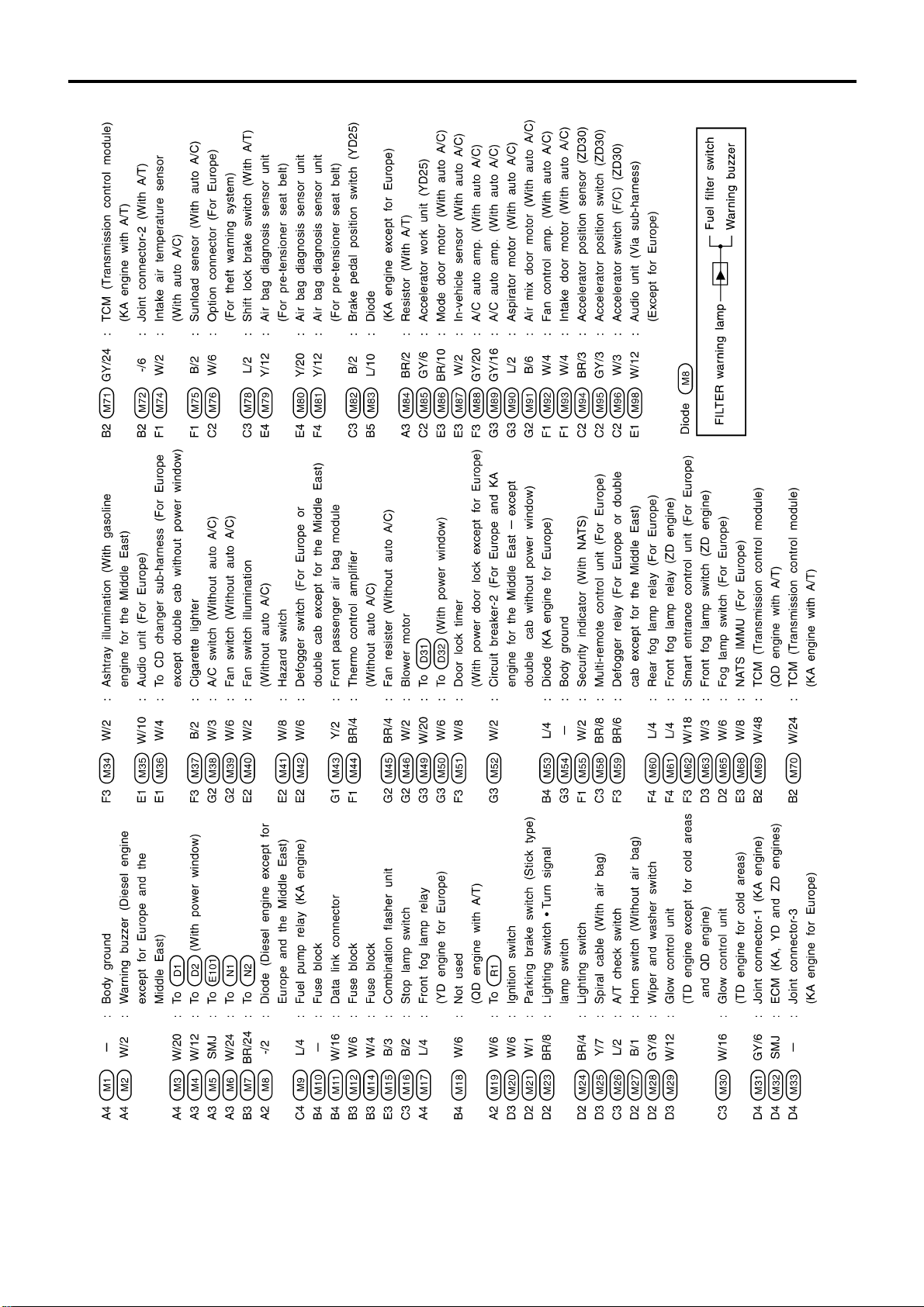

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5013

HEL083C

Page 30

HARNESS LAYOUT

Main Harness (Cont’d)

INSTRUMENT PANEL — RHD MODELS

EL-5014

HEL084C

Page 31

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5015

HEL085C

Page 32

BODY SIDE — LHD MODELS

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5016

HEL086C

Page 33

BODY SIDE — RHD MODELS

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5017

HEL087C

Page 34

HARNESS LAYOUT

LHD MODELS — GASOLINE ENGINE

Engine Room Harness

EL-5018

HEL088C

Page 35

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5019

HEL089C

Page 36

LHD MODELS — DIESEL ENGINE

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5020

HEL045C

Page 37

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5021

HEL090C

Page 38

HARNESS LAYOUT

RHD MODELS — GASOLINE ENGINE

Engine Room Harness (Cont’d)

EL-5022

HEL091C

Page 39

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5023

HEL092C

Page 40

RHD MODELS — DIESEL ENGINE

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5024

HEL968B

Page 41

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5025

HEL093C

Page 42

DOUBLE CAB

HARNESS LAYOUT

Room Lamp Harness/LHD Models

HEL094C

EL-5026

Page 43

WIRING DIAGRAM CODES (CELL CODES)

HARNESS LAYOUT

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

FICD EC IACV-FICD Solenoid Valve

GLOW EC Quick-glow System

ILL EL Illumination

PRWIRE EL Theft Warning System Pre-wire

ROOM/L EL Interior Room Lamp

SRS RS Supplemental Restraint System

WINDOW EL Power Window

EL-5027

Page 44

<SUPPLEMENT-V>

ELECTRICAL SYSTEM

MODIFICATION NOTICE:

● Wiring diagrams have been changed.

● Harness layouts have been changed.

CONTENTS

INTERIOR ROOM LAMP.....................................5002

Wiring Diagram - ROOM/L -............................5002

ILLUMINATION....................................................5003

Wiring Diagram - ILL -/LHD Models................5003

POWER WINDOW...............................................5005

Schematic/With Interruption Detection

Function ...........................................................5005

Wiring Diagram - WINDOW -/With Interruption

Detection Function...........................................5006

SECTION

THEFT WARNING SYSTEM ...............................5010

Wiring Diagram - PRWIRE -............................5010

HARNESS LAYOUT............................................5012

Main Harness...................................................5012

Engine Room Harness.....................................5018

Room Lamp Harness/LHD Models..................5026

EL

EL

Page 45

INTERIOR ROOM LAMP

Wiring Diagram — ROOM/L —

EL-5002

GEL924A

Page 46

ILLUMINATION

Wiring Diagram — ILL —/LHD Models

EL-5003

GEL675A

Page 47

ILLUMINATION

Wiring Diagram — ILL —/LHD Models

(Cont’d)

EL-5004

GEL676A

Page 48

POWER WINDOW

Schematic/With Interruption Detection

Function

EL-5005

GEL925A

Page 49

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function

EL-5006

GEL926A

Page 50

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function (Cont’d)

EL-5007

GEL927A

Page 51

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function (Cont’d)

EL-5008

GEL928A

Page 52

POWER WINDOW

Wiring Diagram — WINDOW —/With

Interruption Detection Function (Cont’d)

EL-5009

GEL929A

Page 53

THEFT WARNING SYSTEM

Wiring Diagram — PRWIRE —

EL-5010

GEL930A

Page 54

NOTE

THEFT WARNING SYSTEM

EL-5011

Page 55

HARNESS LAYOUT

Main Harness

INSTRUMENT PANEL — LHD MODELS

EL-5012

HEL082C

Page 56

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5013

HEL083C

Page 57

HARNESS LAYOUT

Main Harness (Cont’d)

INSTRUMENT PANEL — RHD MODELS

EL-5014

HEL084C

Page 58

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5015

HEL085C

Page 59

BODY SIDE — LHD MODELS

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5016

HEL086C

Page 60

BODY SIDE — RHD MODELS

HARNESS LAYOUT

Main Harness (Cont’d)

EL-5017

HEL087C

Page 61

HARNESS LAYOUT

LHD MODELS — GASOLINE ENGINE

Engine Room Harness

EL-5018

HEL088C

Page 62

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5019

HEL089C

Page 63

LHD MODELS — DIESEL ENGINE

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5020

HEL045C

Page 64

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5021

HEL090C

Page 65

HARNESS LAYOUT

RHD MODELS — GASOLINE ENGINE

Engine Room Harness (Cont’d)

EL-5022

HEL091C

Page 66

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5023

HEL092C

Page 67

RHD MODELS — DIESEL ENGINE

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5024

HEL968B

Page 68

HARNESS LAYOUT

Engine Room Harness (Cont’d)

EL-5025

HEL093C

Page 69

DOUBLE CAB

HARNESS LAYOUT

Room Lamp Harness/LHD Models

HEL094C

EL-5026

Page 70

WIRING DIAGRAM CODES (CELL CODES)

HARNESS LAYOUT

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

FICD EC IACV-FICD Solenoid Valve

GLOW EC Quick-glow System

ILL EL Illumination

PRWIRE EL Theft Warning System Pre-wire

ROOM/L EL Interior Room Lamp

SRS RS Supplemental Restraint System

WINDOW EL Power Window

EL-5027

Page 71

<SUPPLEMENT-V>

ENGINE MECHANICAL

SECTION

MODIFICATION NOTICE:

● YD25DDTi engine information has been added.

For information not included here, refer to information for YD25DDTi engine in D22 Supplement-VI 1st

Revision Service Manual (SM1E-1D22FG1).

EM

CONTENTS

EM

YD

CYLINDER HEAD................................................5002

Inspection.........................................................5002

CYLINDER BLOCK .............................................5003

Inspection.........................................................5003

SERVICE DATA AND SPECIFICATIONS

(SDS)....................................................................5005

Cylinder Head ..................................................5005

Cylinder Block..................................................5006

Piston, Piston Ring and Piston Pin..................5006

Page 72

SEM496G

CYLINDER HEAD

Inspection

CYLINDER HEAD DISTORTION

Clean surface of cylinder head. Use a reliable straightedge and

feeler gauge to check the flatness of cylinder head surface.

Check along six positions shown in the figure.

Head surface flatness: Limit 0.1 mm (0.004 in)

If beyond the specified limit, resurface or replace it.

The limit for cylinder head resurfacing is determined by the

cylinder block resurfacing.

Resurfacing limit:

Amount of cylinder head resurfacing is “A”.

Amount of cylinder block resurfacing is “B”.

The maximum limit:A+B=0.07 mm (0.0028 in)

After resurfacing cylinder head, check that camshaft rotates

freely by hand. If resistance is felt, cylinder head must be

replaced.

Nominal cylinder head height:

153.9 - 154.1 mm (6.059 - 6.067 in)

YD

EM-5002

Page 73

JEM206G

CYLINDER BLOCK

Inspection

PISTON-TO-BORE CLEARANCE

1. Using a bore gauge, measure cylinder bore in X and Y directions at A, B and C for wear, out-of-round and taper.

Cylinder bore inner diameter:

Standard

89.000 - 89.030 mm (3.5039 - 3.5051 in)

Wear limit

0.07 mm (0.0028 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder

block if necessary.

Out-of-round (Difference between X and Y):

Limit 0.015 mm (0.0006 in)

Taper (Difference between A and C):

Limit 0.010 mm (0.0004 in)

2. Check for scratches and seizure. If seizure is found, hone it.

YD

SEM899G

SEM258C

3. Measure piston skirt diameter.

Piston diameter “A”:

Standard

88.925 - 88.955 mm (3.5010 - 3.5022 in)

Measuring point “a” (Distance from the top):

59.0 mm (2.323 in)

4. Check that piston-to-bore clearance is within specification.

● Calculate the clearance by using outer diameter at piston

skirt and inner diameter of cylinder (direction of X, point B):

Piston-to-bore clearance = Cylinder bore − Piston

diameter “A”

Standard [at room temperature 20°C (68°F)]:

0.065 - 0.085 mm (0.0026 - 0.0033 in)

● If the value is out of the specified range, replace piston and

piston pin assembly.

JEM208G

● If cylinder block or pistons are replaced with new ones, select

piston as follows:

When using a new cylinder block:

● Identify the cylinder bore grade (No. 1, 2, or 3) on LH surface

at the rear of cylinder block and select a piston of the same

grade.

● The part No. of piston is specified together with the piston pin

as an assembly.

EM-5003

Page 74

SEM508GB

CYLINDER BLOCK

Inspection (Cont’d)

When re-using a removed cylinder block:

● Measure the inner diameter of the cylinder block bore.

● Determine the bore grade by comparing the measurement

with the values under “Cylinder bore ID” of the table below.

Choose a piston of the same grade.

Selective fitting for piston:

Unit: mm (in)

Grade (punched) 1 2 3

Cylinder bore ID

Piston OD

89.000 - 89.010

(3.5039 - 3.5043)

88.925 - 88.935

(3.5010 - 3.5014)

5. Determine piston oversize according to amount of cylinder

wear.

● For oversize pistons, 0.25 and 0.5 OS [0.25 mm (0.0098

in), 0.5 mm (0.0197 in) oversize] are available as service

parts. Refer to SDS, EM-5006. When using an oversize

piston, hone cylinder so that the clearance between piston and cylinder becomes the specified value. Be sure to

use appropriate oversize piston ring for the oversize piston.

6. Cylinder bore size is determined by adding piston-to-bore

clearance to piston diameter “A”.

Rebored size calculation:D=A+B−C

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston-to-bore clearance

C: Honing allowance 0.02 mm (0.0008 in)

7. Cut cylinder bores.

● When any cylinder needs boring, all other cylinders

must also be bored.

● Do not cut too much out of cylinder bore at a time. Cut

only 0.05 mm (0.0020 in) or so in diameter at a time.

8. Hone cylinders to obtain specified piston-to-bore clearance.

9. Measure finished cylinder bore for out-of-round and taper.

● Measurement should be done after cylinder bore cools

down.

89.010 - 89.020

(3.5043 - 3.5047)

88.935 - 88.945

(3.5014 - 3.5018)

89.020 - 89.030

(3.5047 - 3.5051)

88.945 - 88.955

(3.5018 - 3.5022)

YD

EM-5004

Page 75

SERVICE DATA AND SPECIFICATIONS (SDS)

Cylinder Head

Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.1 (0.004)

YD

Unit: mm (in)

JEM204G

EM-5005

Page 76

SERVICE DATA AND SPECIFICATIONS (SDS)

Cylinder Block

Surface flatness

Cylinder bore Inner diameter

Out-of-round (Difference between X and Y) Less than 0.015 (0.0006)

Taper (Difference between A and C) Less than 0.010 (0.0004)

Standard Less than 0.03 (0.0012)

Limit 0.1 (0.004)

Grade No. 1 89.000 - 89.010 (3.5039 - 3.5043)

Standard

Wear limit 0.07 (0.0028)

Grade No. 2 89.010 - 89.020 (3.5043 - 3.5047)

Grade No. 3 89.020 - 89.030 (3.5047 - 3.5051)

YD

Unit: mm (in)

SEM899G

Piston, Piston Ring and Piston Pin

AVAILABLE PISTON

Grade No. 1 88.925 - 88.935 (3.5010 - 3.5014)

Grade No. 2 88.935 - 88.945 (3.5014 - 3.5018)

Piston skirt diameter “A” Standard

“a” dimension 59.0 (2.323)

Piston clearance to cylinder block 0.065 - 0.085 (0.0026 - 0.0033)

Grade No. 3 88.945 - 88.955 (3.5018 - 3.5022)

0.25 (0.0098) oversize (Service) 89.175 - 89.205 (3.5108 - 3.5120)

0.50 (0.0197) oversize (Service) 89.425 - 89.455 (3.5207 - 3.5218)

Unit: mm (in)

SEM882E

EM-5006

Page 77

SUPER MULTIPLE JUNCTION (SMJ)

Terminal Arrangement

GEL314A

Page 78

CONTROL UNITS

Terminal Arrangement

GEL852A

Page 79

<SUPPLEMENT-V>

CONTENTS

CONSULT-II CHECKING SYSTEM.....................5002

Function and System Application ....................5002

Nickel Metal Hydride Battery Replacement.....5002

Checking Equipment........................................5003

GENERAL INFORMATION

SECTION

CONSULT-II Data Link Connector (DLC)

Circuit...............................................................5003

Model Variation................................................5004

Identification Number.......................................5006

GI

GI

This modification has been included in production starting with the following vehicle identification numbers

(Chassis number):

For Israel

JN1CPGD224X560201

JN1CPUD224X570401

For Europe

JN1APGD22U0056701

JN1APUD22U0037101

JN1BPGD22U0033201

JN1BPUD22U0090001

JN1CPGD22U0048001

JN1CPUD22U0088401

JN1ADGD22U0021601

JN1BDGD22U0031601

JN1BDUD22U0031801

JN1CDUD22U0031701

Page 80

CONSULT-II CHECKING SYSTEM

Function and System Application

Diagnostic test

mode

Work support

Self-diagnostic

results

Trouble diagnostic record

ECU discriminated No.

Data monitor

DTC work support

Active test

ECU (ECM) part

number

Function test

x: Applicable

Function ENGINE A/T ABS AIR BAG

This mode enables a technician to

adjust some devices faster and more

accurate by following the indications

on CONSULT-II.

Self-diagnostic results can be read

and erased quickly.

Current self-diagnostic results and all

trouble diagnostic records previously

stored can be read.

Classification number of a replacement ECU can be read to prevent an

incorrect ECU from being installed.

Input/Output data in the ECU (ECM)

can be read.

This mode enables a technician to

set operating conditions to confirm

self-diagnosis status/results.

Diagnostic Test Mode in which CONSULT-II drives some actuators apart

from the ECMs and also shifts some

parameters in a specified range.

ECU (ECM) part number can be

read.

Conducted by CONSULT-II instead

of a technician to determine whether

each system is “OK” or “NG” (No

Good).

Nickel Metal Hydride Battery Replacement

xx——

xxxx

——— x

——— x

xxx—

—x——

x—x—

xxx—

xxxx

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another battery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

GI-5002

Page 81

CONSULT-II CHECKING SYSTEM

Checking Equipment

When ordering the below equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

1

CONSULT-II unit (Tester internal soft:

V

Resident version 3.3.0) and accessories

2

Program card AED01C for diagnostic,

V

AEN00A/00B for NATS.

To confirm the best combination of

those softwares, refer to CONSULT-II

Operation Manual.

SGI083A

NOTE:

● The CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialization) procedure.

● Be sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II Data Link Connector (DLC)

Circuit

INSPECTION PROCEDURE

If the CONSULT-II cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT-II cannot access

any system.

CONSULT-II cannot access

individual system. (Other systems can be accessed.)

● CONSULT-II DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4)

(For detailed circuit, refer to EC section “MIL & Data Link Connectors”.)

● CONSULT-II DDL cable

● CONSULT-II program card (Check the appropriate CONSULT-II program card for the system.

Refer to “Checking Equipment” above.)

● Power supply and ground circuit for the control unite of the system

(For detailed circuit, refer to wiring diagram for each system.)

● Open or short circuit between the system and CONSULT-II DLC

(For detailed circuit, refer to wiring diagram for each system.)

SOM801

GI-5003

Page 82

C200

IDENTIFICATION INFORMATION

CONSULT-II CHECKING SYSTEM

Model Variation

Transfer

Engine Transmission Differential carrier

KA24DE FS5W71C

—

AVLGLCFD22UQL YD25DDTi FS5R30A

AVLGLDFD22UQL AVLGRDFD22UQL YD25DDTi FS5R30A

ABGGLCFD22EQL

ABGGLDFD22EQL — KA24DE FS5W71C

DX

STD

DX BBGGLDFD22EQN — KA24DE FS5W71C

DX BVLGLDFD22UQN BVLGRDFD22UQN YD25DDTi FS5R30A

DX BVLGLDFD22UQG —

YD25DDTi FS5R30A

ST BVLGLEFD22UQG —

Differential carrier

Engine Transmission

YD25DDTi FS5R30A

ST CVLGLEFD22UQG —

DX CVLGLDFD22UQG —

R180 C200 TX10

YD25DDTi FS5R30AST BVLULEFD22UQN BVLUREFD22UQN

YD25DDTi FS5R30A

Class Model

Cab Wheelbase Grade LH drive RH drive

Destination

PICKUP (2WD)

Single Cab

Long

King Cab

Europe

4WD appearance

4WD appearance

Double Cab DX CVLGLDFD22UQN CVLGRDFD22UQN

Class Model

Destination

PICKUP (4WD)

BBGULDFD22EQN — KA24DE FS5W71C

DX AVLULDFD22UQL AVLURDFD22UQL

STD AVLULCFD22UQL AVLURCFD22UQL

Cab Wheelbase Grade LH drive RH drive Front Rear

Single Cab

GI-5004

BVLULDFD22UQN BVLURDFD22UQN

DX

King Cab

CBGULDFD22EQN — KA24DE FS5W71C

SE BVLULFFD22UQN BVLURFFD22UQN

Long

Europe

CVLULDFD22UQN CVLURDFD22UQN

ST CVLULEFD22UQN CVLUREFD22UQN

SE CVLULFFD22UQN CVLURFFD22UQN

DX

SS CVLULGFD22UQN CVLURGFD22UQN

Double Cab

Page 83

IDENTIFICATION INFORMATION

CONSULT-II CHECKING SYSTEM

Model Variation (Cont’d)

Prefix and suffix designations

(Pickup)

A BG G L C F D22 E W L

Q: Europe

E: Multiport fuel injection system engine

U: Turbocharged engine with intercooler

F: 5-speed floor shift manual transmission

B: 4-speed column shift automatic transmission

A: 4-speed floor shift automatic transmission

C: STD model D: DX model E: GL, ST model F: SE model G: SS model

L: LH drive R: RH drive

G: Long wheelbase (2WD)

U: Long wheelbase (4WD)

BG: KA24DE engine VL: YD25DDTi engine

A: Single Cab B: King Cab C: Double Cab

L: Regular rear body

N: Smooth rear body

G: 4WD appearance model (2WD)

GI-5005

Page 84

IDENTIFICATION INFORMATION

CONSULT-II CHECKING SYSTEM

VEHICLE IDENTIFICATION NUMBER

Prefix and suffix designations

For Israel

JN1 C P G D22 4 X XXXXXX

Model

G: Long wheelbase (2WD) U: Long wheelbase (4WD)

P: YD25DDTi engine

C: Double Cab

JN1: Japan produced vehicle

Identification Number

Vehicle serial number

Manufacturing plant

X: Hiratsuka

Model year

4: 2004, 5: 2005 after November, ’03 production

For Europe

JN1 B P U D22 U O XXXXXX

JN1: Japan produced vehicle

Vehicle serial number

O: Stopgap (no meaning)

U: For Europe

Model

G: Long wheelbase (2WD) U: Long wheelbase (4WD)

D: KA24DE engine P: YD25DDTi engine

A: Single Cab B: King Cab C: Double Cab

GI-5006

Page 85

<SUPPLEMENT-V>

HEATER &

AIR CONDITIONER

SECTION

MODIFICATION NOTICE:

● Wiring diagrams have been changed for LHD models with KA, YD and ZD engines. (manual A/C)

HA

CONTENTS

MANUAL

TROUBLE DIAGNOSES .....................................5002

Circuit Diagram - A/C, M -...............................5002

Wiring Diagram - A/C, M -/LHD Models with

KA, YD and ZD Engines..................................5003

HA

Page 86

TROUBLE DIAGNOSES

Circuit Diagram — A/C, M —

MANUAL

HA-5002

GHA132A

Page 87

TROUBLE DIAGNOSES

Wiring Diagram — A/C, M —/LHD Models

with KA, YD and ZD Engines

MANUAL

HA-5003

GHA056A

Page 88

TROUBLE DIAGNOSES

Wiring Diagram — A/C, M —/LHD Models

with KA, YD and ZD Engines (Cont’d)

MANUAL

HA-5004

GHA057A

Page 89

TROUBLE DIAGNOSES

Wiring Diagram — A/C, M —/LHD Models

with KA, YD and ZD Engines (Cont’d)

MANUAL

HA-5005

GHA133A

Page 90

<SUPPLEMENT-V>

ALPHABETICAL INDEX

SECTION

IDX

IDX

Page 91

ALPHABETICAL INDEX

A

ABS-Wiringdiagram...........................BR-5003

A/Ctroublediagnoses(manualA/C)....HA-5002

A/C,M-Wiringdiagram.......................HA-5003

Anti-lock brake system - Wiring

diagram.............................................BR-5002

C

Cylinderblock.......................................EM-5003

Cylinderhead.......................................EM-5002

E

Exterior..................................................BT-5002

F

Frontseat..............................................BT-5003

H

P

Pistontoboreclearance......................EM-5003

Powerwindow.......................................EL-5005

R

Rearseat...............................................BT-5004

ROOM/L-Wiringdiagram.....................EL-5002

S

Seat,front..............................................BT-5003

Seat,rear...............................................BT-5004

SMJ (super multiple junction) ................. Foldout

SRS-Wiringdiagram...........................RS-5002

Supplemental restraint system - Wiring

diagram.............................................RS-5002

T

THEFT-Wiringdiagram.......................EL-5010

Theftwarningsystem............................EL-5010

Harnesslayout.......................................EL-5012

I

ILL-Wiringdiagram..............................EL-5003

Illumination.............................................EL-5003

Interiorlamp...........................................EL-5002

M

Modelvariation.......................................GI-5004

V

Vehicleidentificationnumber.................GI-5006

W

WiringDiagram(Cellcode)list.............EL-5027

IDX-5002

Page 92

<SUPPLEMENT-V>

RESTRAINT SYSTEM

MODIFICATION NOTICE:

Air bag system wiring diagram has been changed.

CONTENTS

TROUBLE DIAGNOSES - Supplemental

Restraint System (SRS).....................................5002

SECTION

Wiring Diagram - SRS -...................................5002

RS

RS

Page 93

TROUBLE DIAGNOSES — Supplemental Restraint System (SRS)

Wiring Diagram — SRS —

RS-5002

GRS006A

Page 94

TROUBLE DIAGNOSES — Supplemental Restraint System (SRS)

Wiring Diagram — SRS — (Cont’d)

RS-5003

GRS026A

Loading...

Loading...