Nissan Maxima 2001 User Manual

ENGINE MECHANICAL

GI

MA

CONTENTS

PRECAUTIONS ...............................................................3

Parts Requiring Angular Tightening.............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION ...............................................................4

Special Service Tools ..................................................4

Commercial Service Tools...........................................6

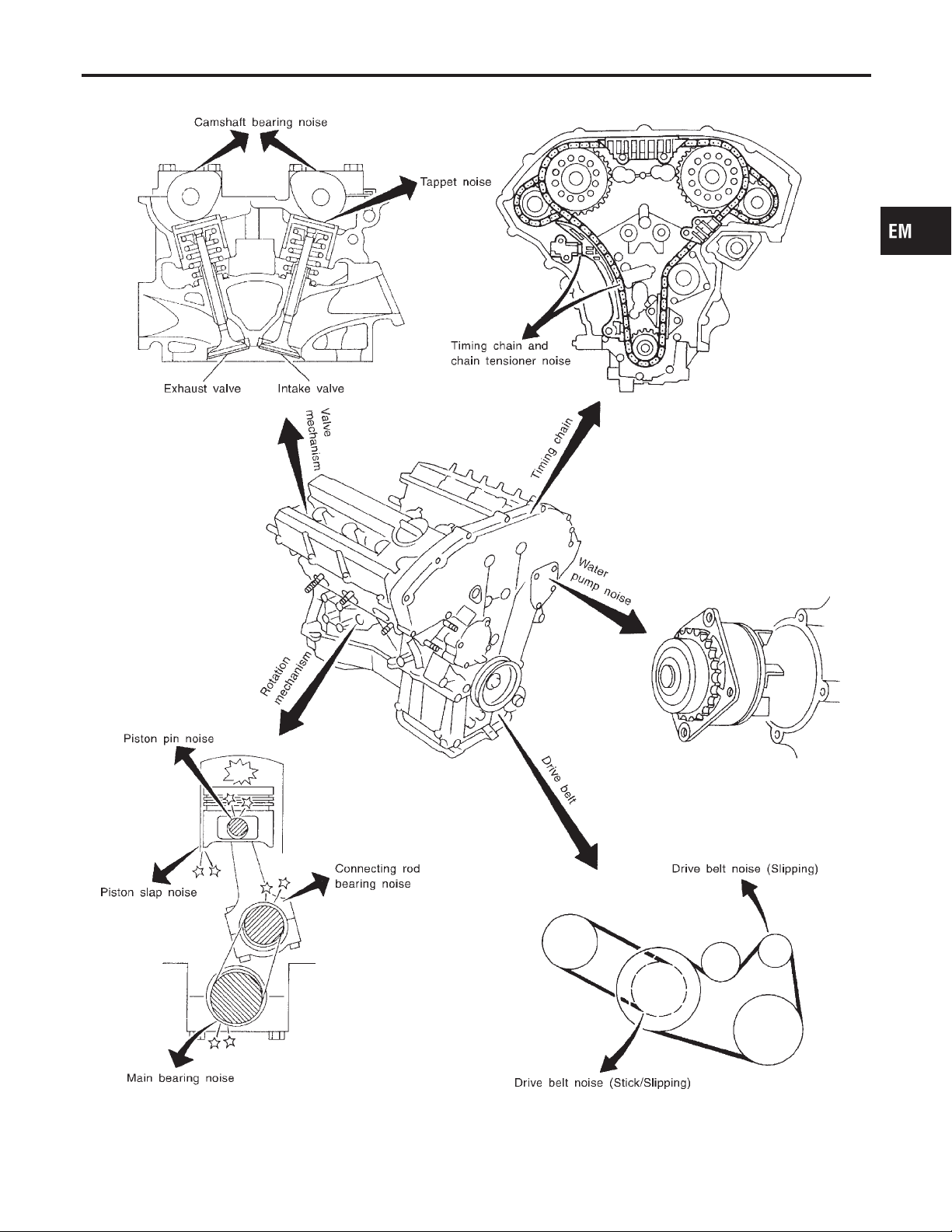

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................7

NVH Troubleshooting — Engine Noise.......................8

OUTER COMPONENT PARTS.......................................9

Removal and Installation.............................................9

TIGHTENING PROCEDURES

MEASUREMENT OF COMPRESSION PRESSURE....12

OIL PAN.........................................................................13

Components...............................................................13

Removal.....................................................................13

Installation..................................................................16

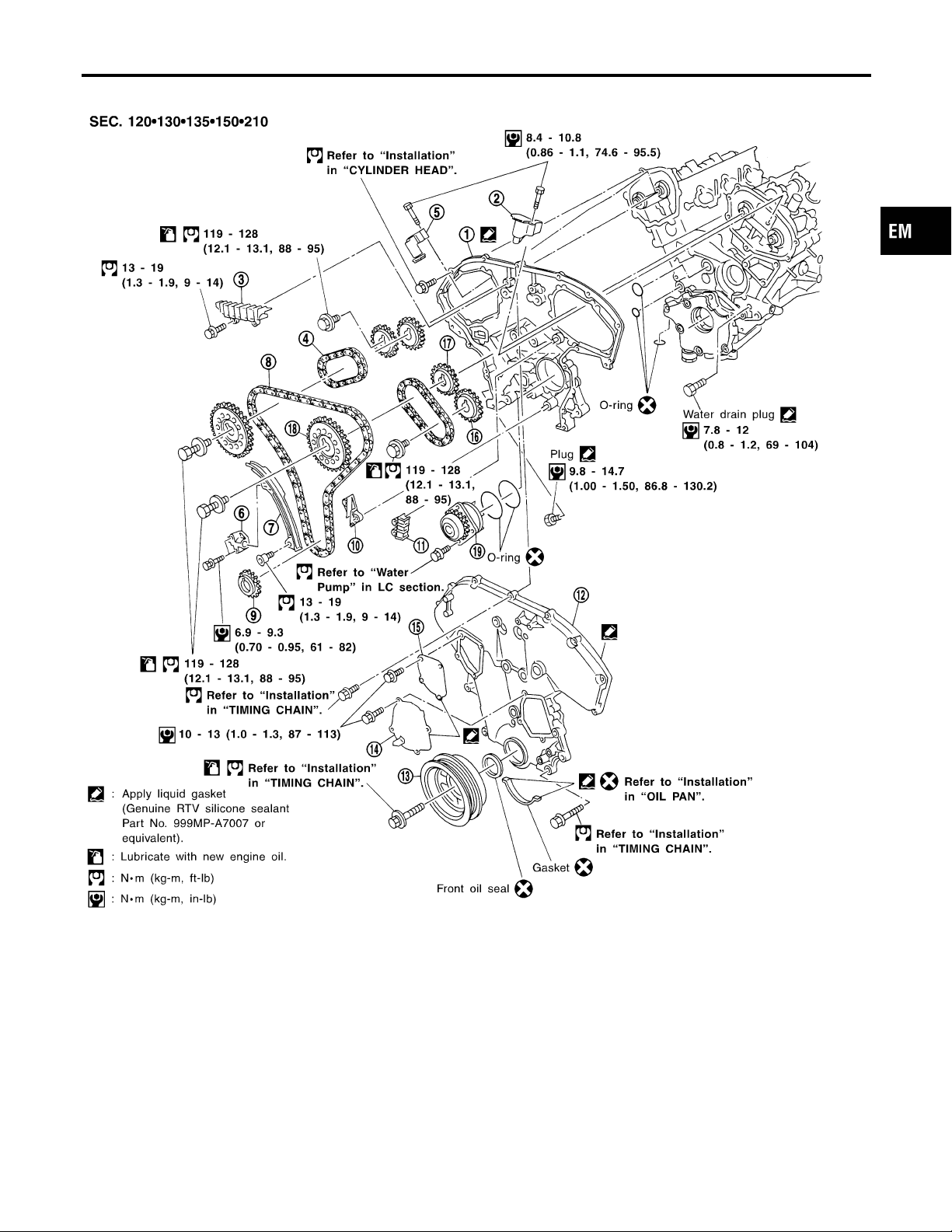

TIMING CHAIN ..............................................................19

Components...............................................................19

POSITION FOR APPLYING LIQUID GASKET

Removal.....................................................................22

Inspection...................................................................29

Installation..................................................................29

OIL SEAL.......................................................................35

Replacement..............................................................35

VALVE OIL SEAL

OIL SEAL INSTALLATION DIRECTION

FRONT OIL SEAL

REAR OIL SEAL

CYLINDER HEAD..........................................................38

Components...............................................................38

Removal.....................................................................39

Disassembly...............................................................39

Inspection...................................................................41

CYLINDER HEAD DISTORTION

CAMSHAFT VISUAL CHECK

CAMSHAFT RUNOUT

CAMSHAFT CAM HEIGHT

CAMSHAFT JOURNAL CLEARANCE

CAMSHAFT END PLAY

.....................................................35

....................................................36

......................................................37

...................................11

............20

.....................36

...............................41

....................................41

..............................................41

.......................................41

........................42

............................................42

SECTION

CAMSHAFT SPROCKET RUNOUT

VALVE GUIDE CLEARANCE

VALVE GUIDE REPLACEMENT

VALVE SEATS

REPLACING VALVE SEAT FOR SERVICE PARTS

VALVE DIMENSIONS

VALVE SPRING

VALVE LIFTER

Assembly ...................................................................46

Installation..................................................................46

Valve Clearance.........................................................51

CHECKING

ADJUSTING

ENGINE ASSEMBLY.....................................................56

Removal and Installation...........................................56

REMOVAL

INSTALLATION

CYLINDER BLOCK.......................................................59

Components...............................................................59

Cylinder Block Heater................................................60

Removal and Installation...........................................60

Disassembly...............................................................60

PISTON AND CRANKSHAFT

Inspection...................................................................61

PISTON AND PISTON PIN CLEARANCE

PISTON RING SIDE CLEARANCE

PISTON RING END GAP

CONNECTING ROD BEND AND TORSION

CYLINDER BLOCK DISTORTION AND WEAR

PISTON-TO-BORE CLEARANCE

CRANKSHAFT

BEARING CLEARANCE

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

REPLACEMENT OF CONNECTING ROD

BUSHING (SMALL END)

FLYWHEEL/DRIVE PLATE RUNOUT

Assembly ...................................................................68

PISTON

CRANKSHAFT

.........................................................44

........................................................45

.............................................................51

............................................................53

...............................................................57

........................................................58

.........................................................64

..........................................................67

..................................................................68

.........................................................69

EM

...........................42

....................................43

................................43

....44

...............................................45

.......................................................45

....................................60

..................61

............................61

..........................................62

...............62

...........63

..............................63

...........................................65

..........................................68

........................68

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS (Cont’d)

REPLACEMENT OF PILOT BUSHING (M/T) OR

PILOT CONVERTER (A/T)

SERVICE DATA AND SPECIFICATIONS (SDS).........72

General Specifications...............................................72

Compression Pressure..............................................72

Cylinder Head............................................................72

Valve ..........................................................................73

....................................................................73

VALVE

VALVE CLEARANCE

AVAILABLE SHIMS

VALVE SPRING

VALVE LIFTER

VALVE GUIDE

Valve Seat..................................................................76

Camshaft and Camshaft Bearing..............................77

.......................................................75

........................................................75

.........................................................76

........................................71

................................................73

..................................................73

Cylinder Block............................................................78

Piston, Piston Ring and Piston Pin ...........................79

AVAILABLE PISTON

PISTON RING

PISTON PIN

Connecting Rod.........................................................80

Crankshaft..................................................................81

Available Main Bearing..............................................82

UNDERSIZE

Available Connecting Rod Bearing............................83

CONNECTING ROD BEARING

UNDERSIZE

Miscellaneous Components.......................................83

BEARING CLEARANCE

............................................................80

............................................................82

............................................................83

................................................79

.........................................................80

.................................83

...........................................83

EM-2

PRECAUTIONS

Parts Requiring Angular Tightening

Parts Requiring Angular Tightening

I Use an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap nuts

d) Crankshaft pulley bolt

I Do not use a torque value for final tightening.

I The torque value for these parts are for a preliminary step.

I Ensure thread and seat surfaces are clean and coated with

engine oil.

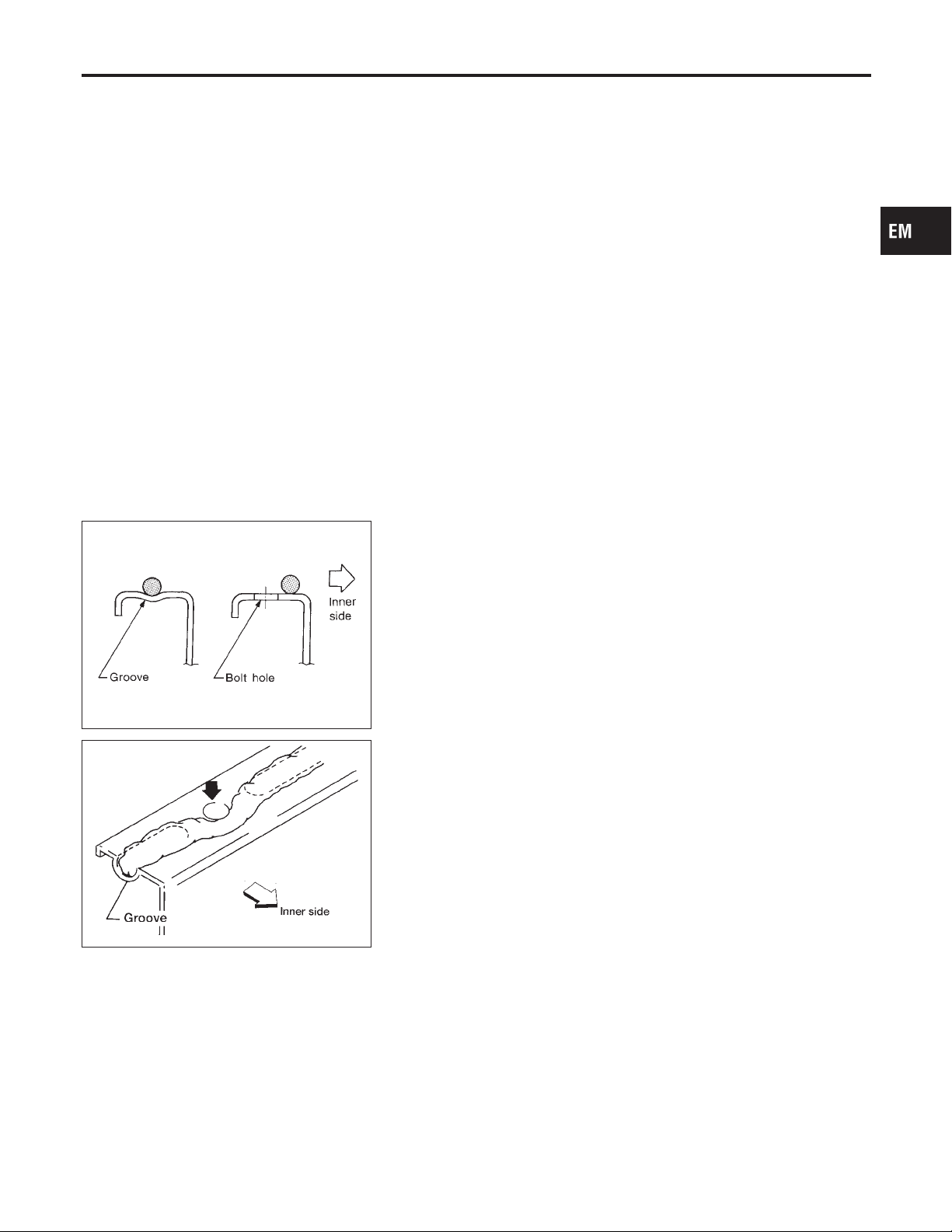

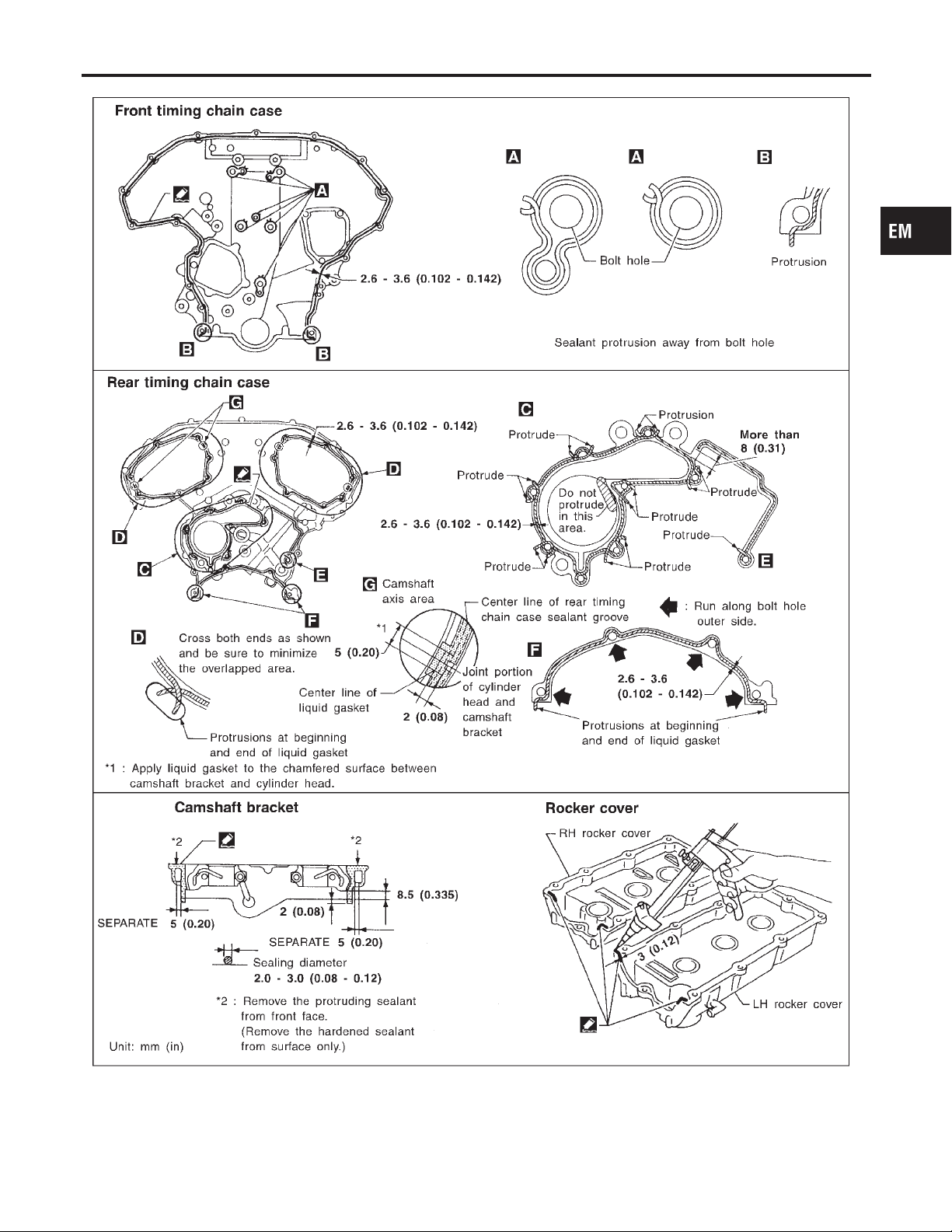

Liquid Gasket Application Procedure

1. Use a scraper to remove all traces of old liquid gasket

from mating surfaces and grooves. Also, completely clean

any oil from these areas.

2. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine RTV silicone sealant Part No. 999MP-

A7007 or equivalent.)

I Be sure liquid gasket diameter is as specified.

NFEM0001

NFEM0002

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

SEM164F

AEM080

3. Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and

engine coolant.

BR

ST

RS

BT

HA

SC

EL

IDX

EM-3

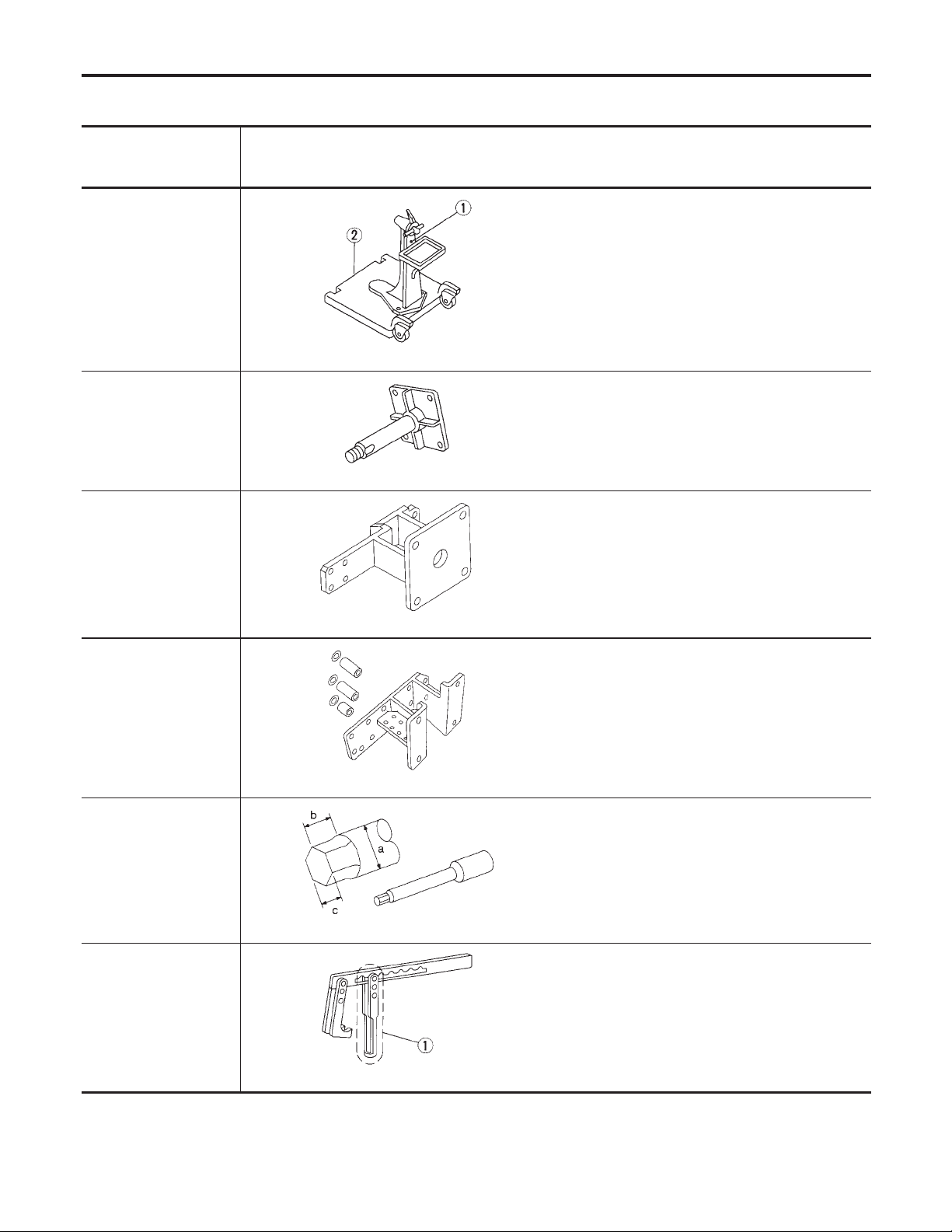

Special Service Tools

PREPARATION

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST0501S000

(—)

Engine stand assembly

1 ST05011000

(—)

Engine stand

2 ST05012000

(—)

Base

KV10106500

(—)

Engine stand shaft

KV10117000

(J41262)

Engine sub-attachment

Description

Disassembling and assembling

NT042

NT028

KV10117000 has been replaced with KV10117001

(KV10117000 is no longer in production, but it is

usable).

NFEM0003

KV10117001

(—)

Engine sub-attachment

ST10120000

(J24239-01)

Cylinder head bolt

wrench

KV10116200

(J26336-A)

Valve spring compressor

1 KV10115900

(J26336-20)

Attachment

NT373

Installing on the cylinder block

NT372

Loosening and tightening cylinder head bolt

a: 13 (0.51) dia.

b: 12 (0.47)

c: 10 (0.39)

Unit: mm (in)

NT583

Disassembling valve mechanism

NT022

EM-4

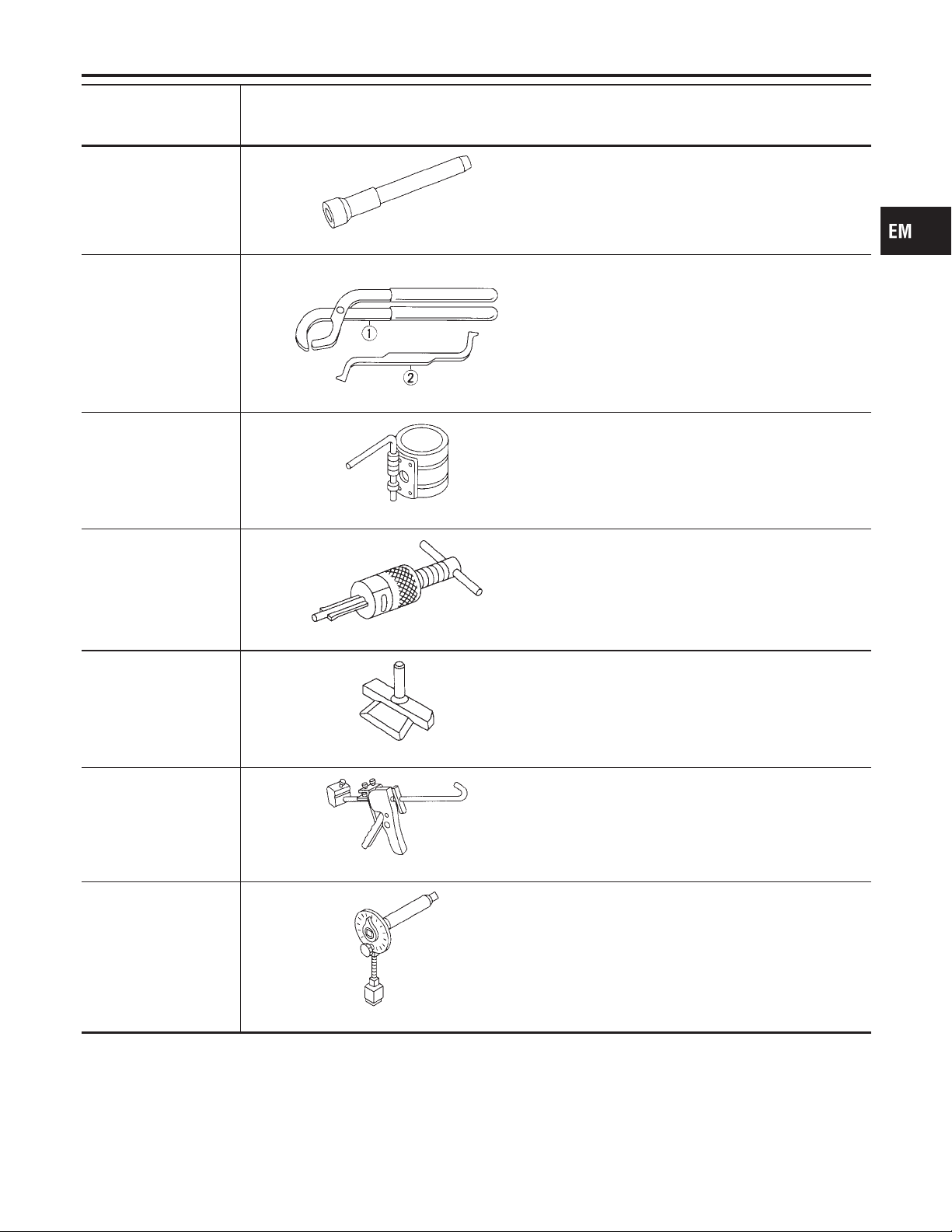

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Special Service Tools (Cont’d)

Description

GI

(J39386)

Valve oil seal drift

KV101151S0

(J38972)

Lifter stopper set

1 KV10115110

(J38972-1)

Camshaft pliers

2 KV10115120

(J38972-2)

Lifter stopper

EM03470000

(J8037)

Piston ring compressor

ST16610001

(J23907)

Pilot bushing puller

NT024

NT041

NT044

Installing valve oil seal

Changing shims

Installing piston assembly into cylinder bore

Removing crankshaft pilot bushing

MA

LC

EC

FE

CL

MT

AT

AX

KV10111100

(J37228)

Seal cutter

WS39930000

(—)

Tube presser

KV10112100

(BT8653-A)

Angle wrench

NT045

NT046

NT052

NT014

Removing steel oil pan and rear timing chain case

Pressing the tube of liquid gasket

Tightening bolts for bearing cap, cylinder head, etc.

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EM-5

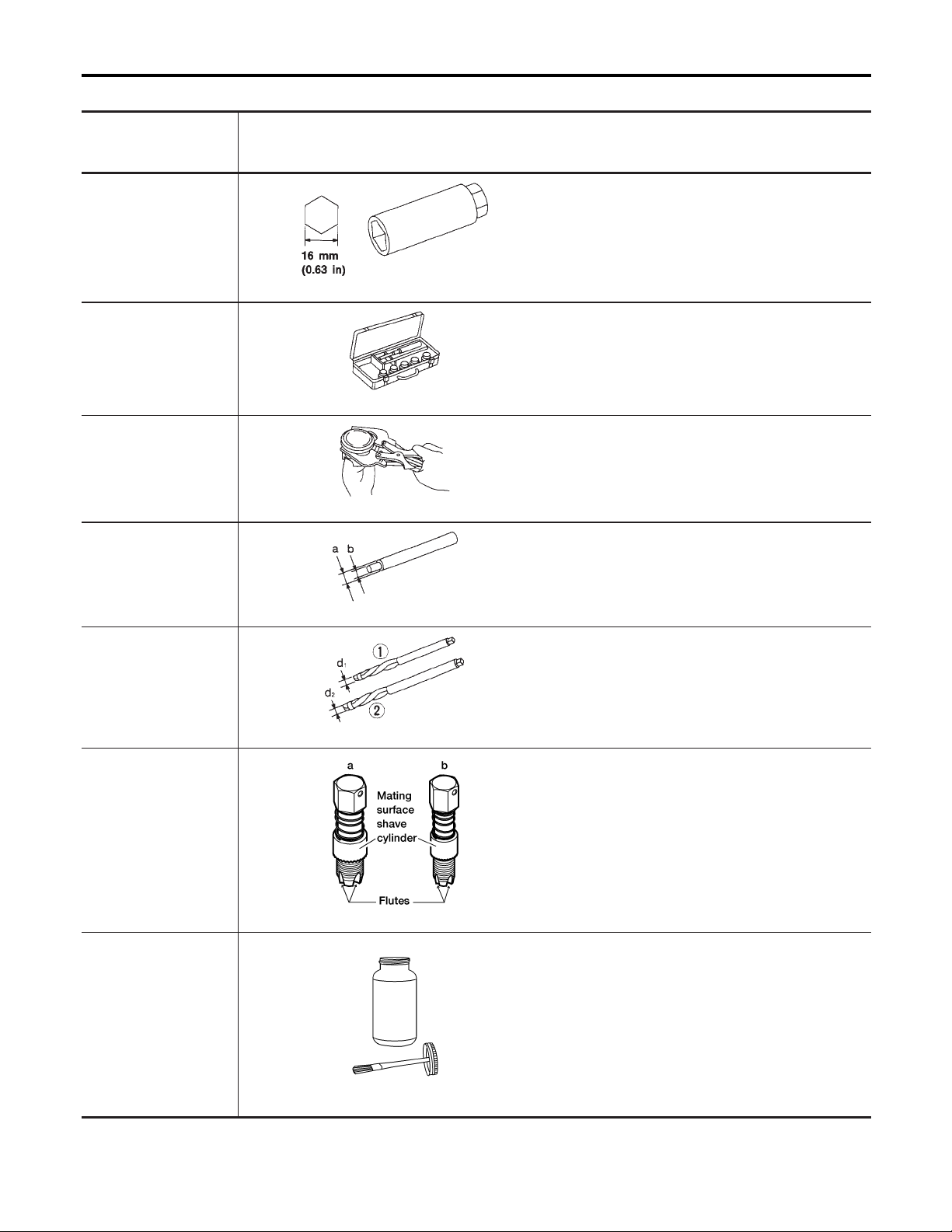

Commercial Service Tools

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

Spark plug wrench

Valve seat cutter set

Piston ring expander

Valve guide drift

Description

NT047

NT048

NT030

Commercial Service Tools

Removing and installing spark plug

Finishing valve seat dimensions

Removing and installing piston ring

Removing and installing valve guide

Intake & Exhaust:

a = 9.5 mm (0.374 in) dia.

b = 5.5 mm (0.217 in) dia.

NFEM0004

Valve guide reamer

(J-43897-18)

(J-43897-12)

Oxygen sensor thread

cleaner

Anti-seize lubricant

(Permatex 133AR or

equivalent meeting MIL

specification MIL-A-

907)

NT015

NT016

AEM488

Reaming valve guide 1 or hole for oversize valve

guide 2

Intake & Exhaust:

d

= 6.0 mm (0.236 in) dia.

1

d

= 10.2 mm (0.402 in) dia.

2

Reconditioning the exhaust system threads before

installing a new oxygen sensor (Use with anti-seize

lubricant shown below.)

a = J-43897-18 (18 mm dia.) for zirconia oxygen

sensor

b = J-43897-12 (12 mm dia.) for titania oxygen

sensor

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads

AEM489

EM-6

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NFEM0005

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EM-7

SC

EL

IDX

SEM646F

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting — Engine Noise

Location of

noise

Top of

engine

Rocker

cover

Cylinder

head

Crankshaft

pulley

Cylinder

block

(Side of

engine)

Oil pan

NVH Troubleshooting — Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Type of

noise

Ticking or

clicking

Rattle C A — A B C

Slap or

knock

Slap or

rap

Knock A B C B B B

Before

warm-up

C A —A B—

— A —B B—

A ——BBA

Operating condition of engine

After

warm-up

When

starting

When

idling

When

racing

While

driving

Source of

noise

Tappet

noise

Camshaft

bearing

noise

Piston pin

noise

Piston slap

noise

Connecting rod

bearing

noise

NFEM0005S01

Check item

Valve clearance EM-53

Camshaft journal clearance

Camshaft runout

Piston and piston pin

clearance

Connecting rod bushing clearance

Piston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend

and torsion

Connecting rod bushing clearance (Small

end)

Connecting rod bearing

clearance (Big end)

Reference

page

EM-41, 42

EM-61, 67

EM-61, 62,

62, 63

EM-67, 67

Knock A B — A B C

Front of

engine

Timing

chain

cover

Front of

engine

A: Closely related B: Related C: Sometimes related —: Not related

Tapping or

ticking

Squeaking

or fizzing

Creaking A B ABAB

Squall

Creak

A A—BBB

A B —B—C

A B—BAB

Main bearing noise

Timing

chain and

chain tensioner

noise

Other

drive belts

(Sticking

or slipping)

Other

drive belts

(Slipping)

Water

pump

noise

Main bearing oil clearance

Crankshaft runout

Timing chain cracks

and wear

Timing chain tensioner

operation

Drive belts deflection

Idler pulley bearing

operation

Water pump operation

EM-64, 65

EM-29, 19

MA section

(“Checking

Drive

Belts”,

“ENGINE

MAINTENANCE”)

LC section

(“Water

Pump

Inspection”,

“ENGINE

COOLING

SYSTEM”)

EM-8

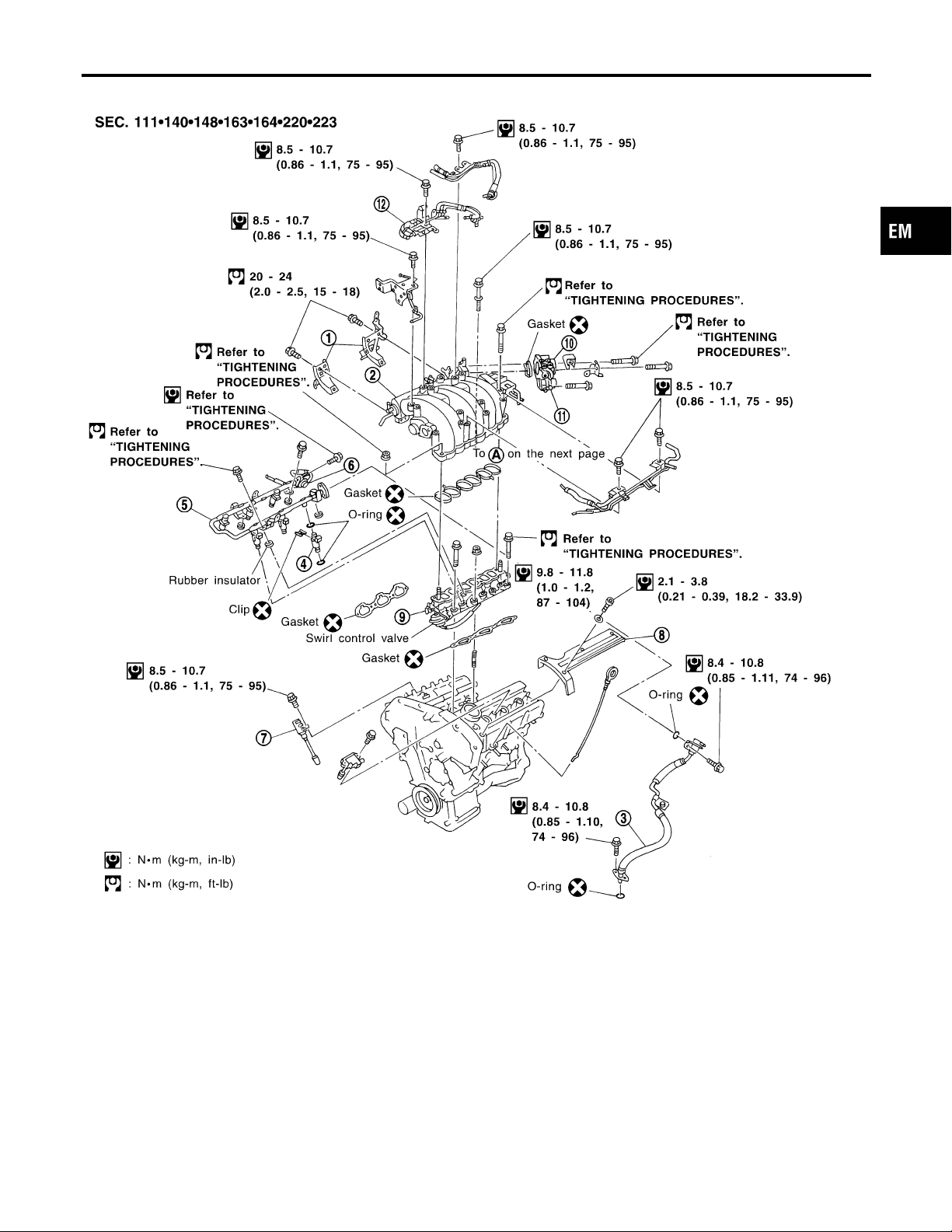

OUTER COMPONENT PARTS

Removal and Installation

Removal and Installation

NFEM0006

GI

MA

LC

EC

FE

CL

MT

1. Intake manifold collector support

2. Intake manifold collector

3. Fuel damper and fuel feed hose

assembly

4. Injector

5. Fuel tube assembly

6. Fuel pressure regulator

7. Ignition coil with power transistor

8. Ornament cover

SEM585G

9. Intake manifold

10. Throttle body

11. IACV-AAC valve

12. EVAP canister purge volume control solenoid valve

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

EM-9

IDX

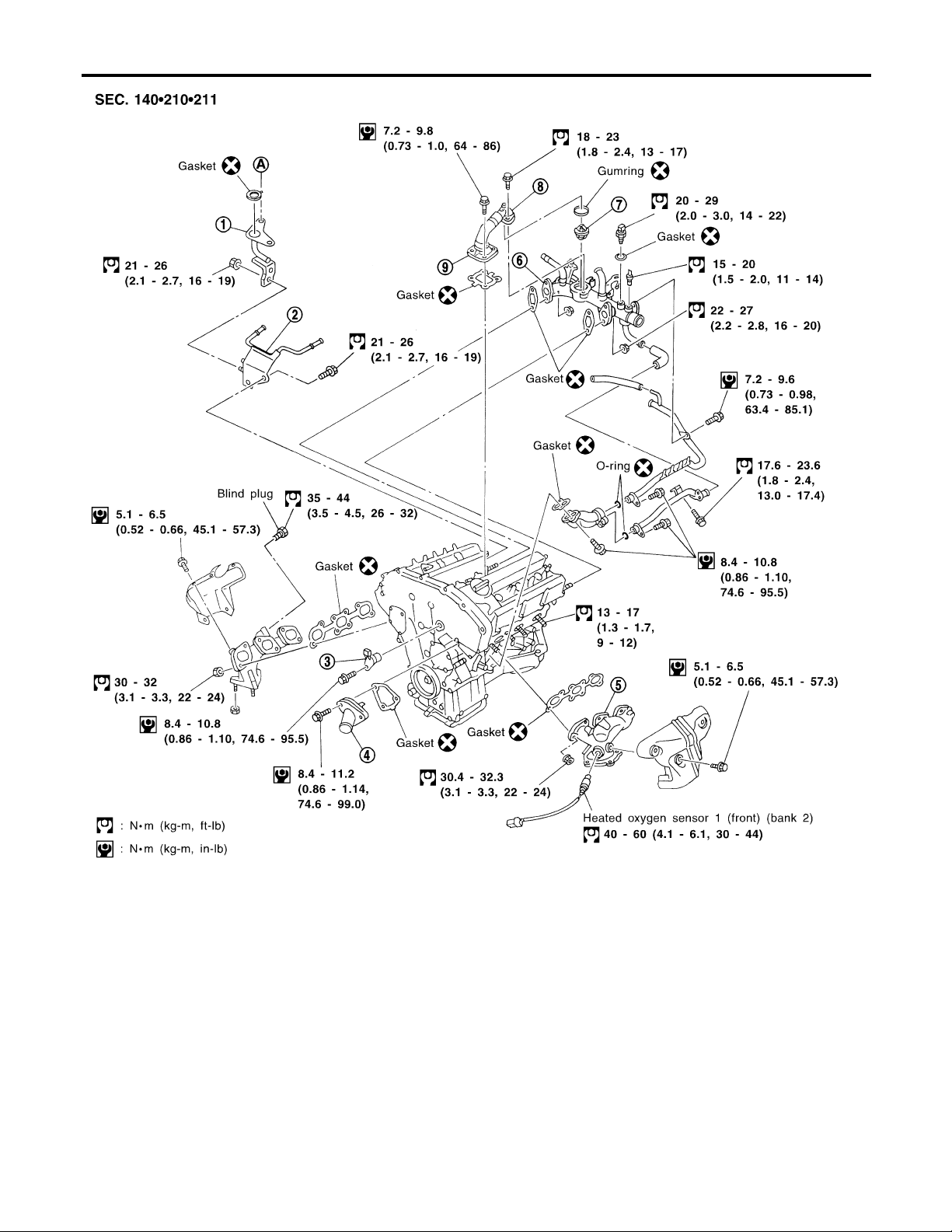

Removal and Installation (Cont’d)

OUTER COMPONENT PARTS

1. Intake manifold upper support

2. Intake manifold lower support

3. Camshaft position sensor

(PHASE)

4. Thermostat with water inlet

5. Exhaust manifold

6. Water outlet

EM-10

SEM586G

7. Water control valve

8. Water connector

9. Cylinder block water outlet

OUTER COMPONENT PARTS

Removal and Installation (Cont’d)

SEM950F

SEM951F

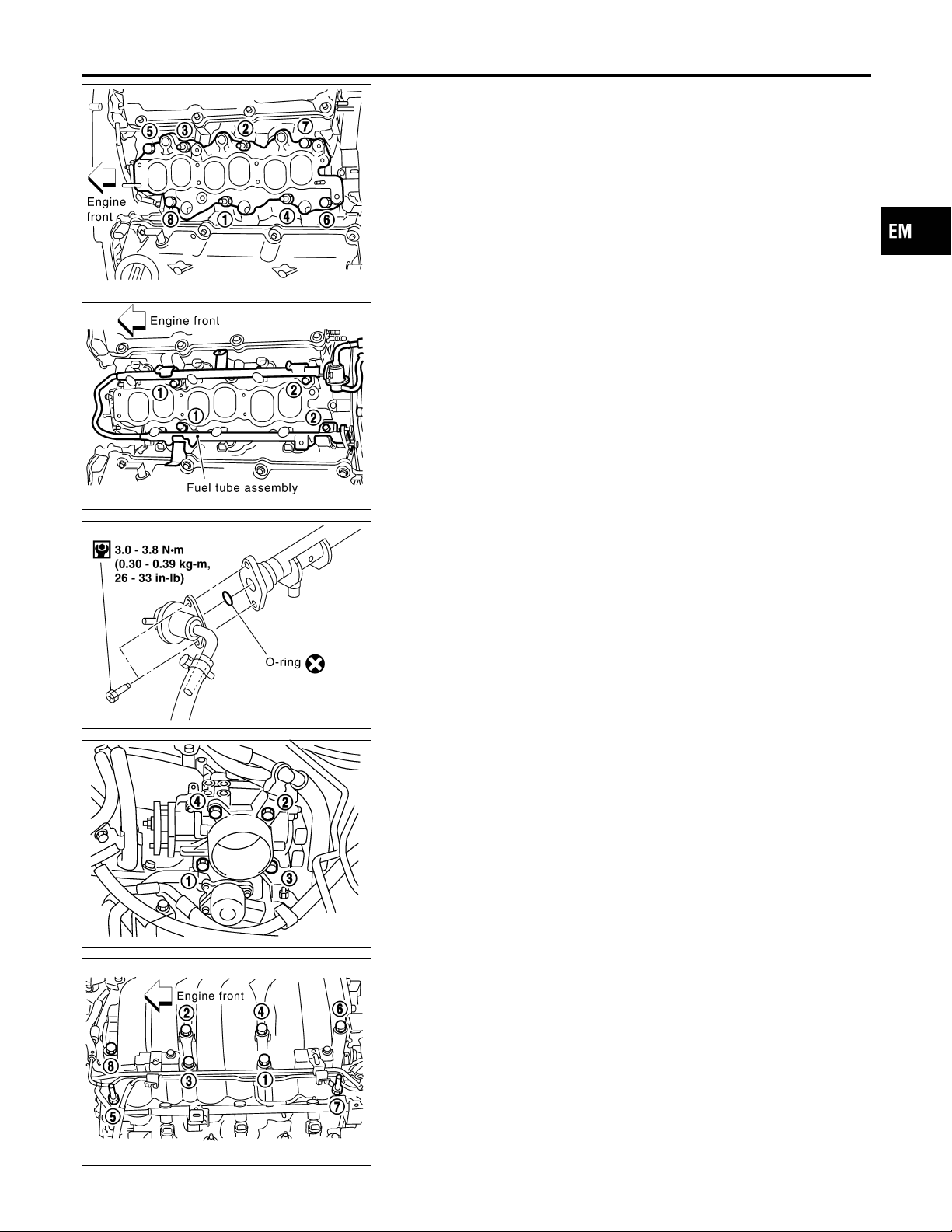

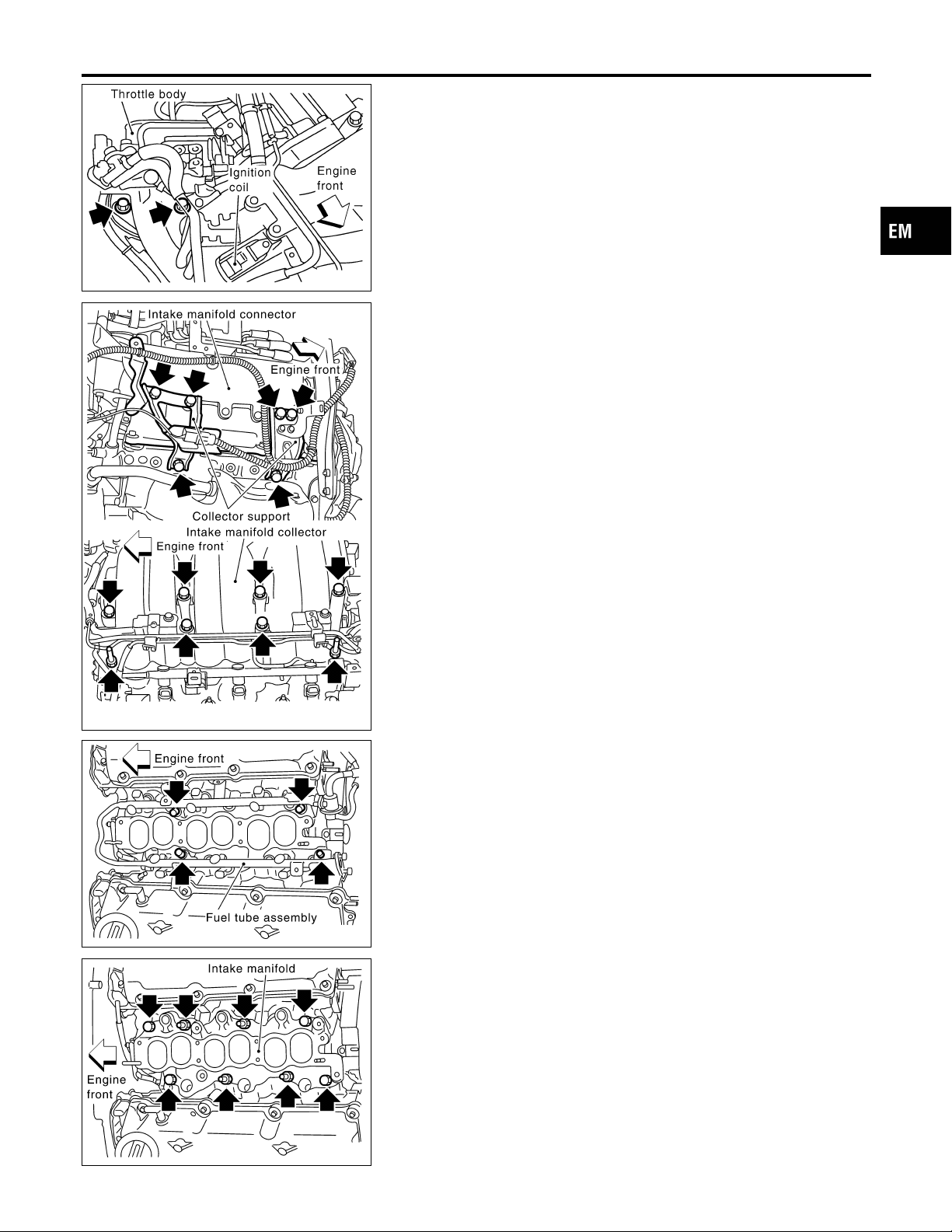

TIGHTENING PROCEDURES

Intake Manifold

I Tighten in numerical order shown in the figure.

1. Tighten all bolts and nuts to 5 to 10 N·m (0.5 to 1.0 kg-m, 44

to 86 in-lb).

2. Finally tighten all bolts and nuts to 26 to 31 N·m (2.7 to 3.2

kg-m, 20 to 23 ft-lb).

I Tightenall bolts and nuts to the final torque, evenly dividing the

tightening into at least five steps.

Fuel Tube

I Tighten in numerical order shown in the figure.

1. Tighten all bolts to 9.3 to 10.8 N·m (0.95 to 1.1 kg-m, 83 to 95

in-lb).

2. Then tighten all bolts to 21 to 26 N·m (2.1 to 2.7 kg-m, 15 to

20 ft-lb).

Fuel Pressure Regulator

Tighten fuel pressure regulator to 2.9 to 3.8 N·m (0.3 to 0.39 kg-m,

26.0 to 33.9 in-lb).

I Tighten screws evenly several times to have the fuel pres-

sure regulator tightened at the specified torque.

I Always replace O-ring with new ones.

I Lubricate O-ring with new engine oil.

NFEM0006S01

NFEM0006S0101

NFEM0006S0102

NFEM0006S0103

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

SEM952F

SEM587G

Throttle Body

I Tighten in numerical order shown in the figure.

1. Tighten all bolts to 8.8 to 10.8 N·m (0.9 to 1.1 kg-m, 79 to 95

in-lb).

2. Then tighten all bolts to 17.7 to 21.6 N·m (1.8 to 2.2 kg-m, 13

to 16 ft-lb).

Intake Manifold Collector

Tightenbolts and nuts to 11 to 15 N·m (1.1 to 1.6 kg-m, 8 to 11 ft-lb)

in numerical order shown in the figure.

NFEM0006S0105

NFEM0006S0107

BR

ST

RS

BT

HA

SC

EL

IDX

SEM954F

EM-11

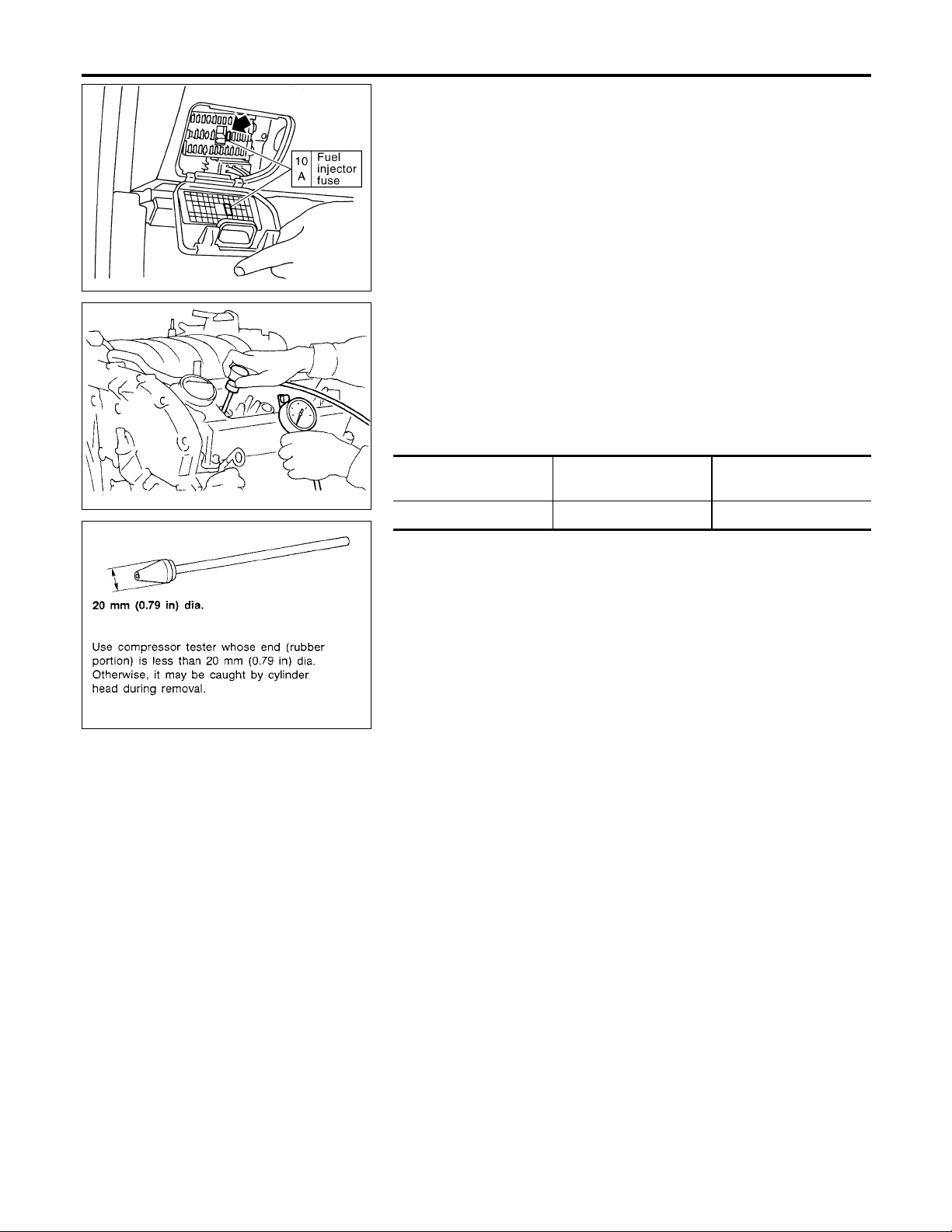

MEASUREMENT OF COMPRESSION PRESSURE

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC-49, “Fuel Pressure Release”.

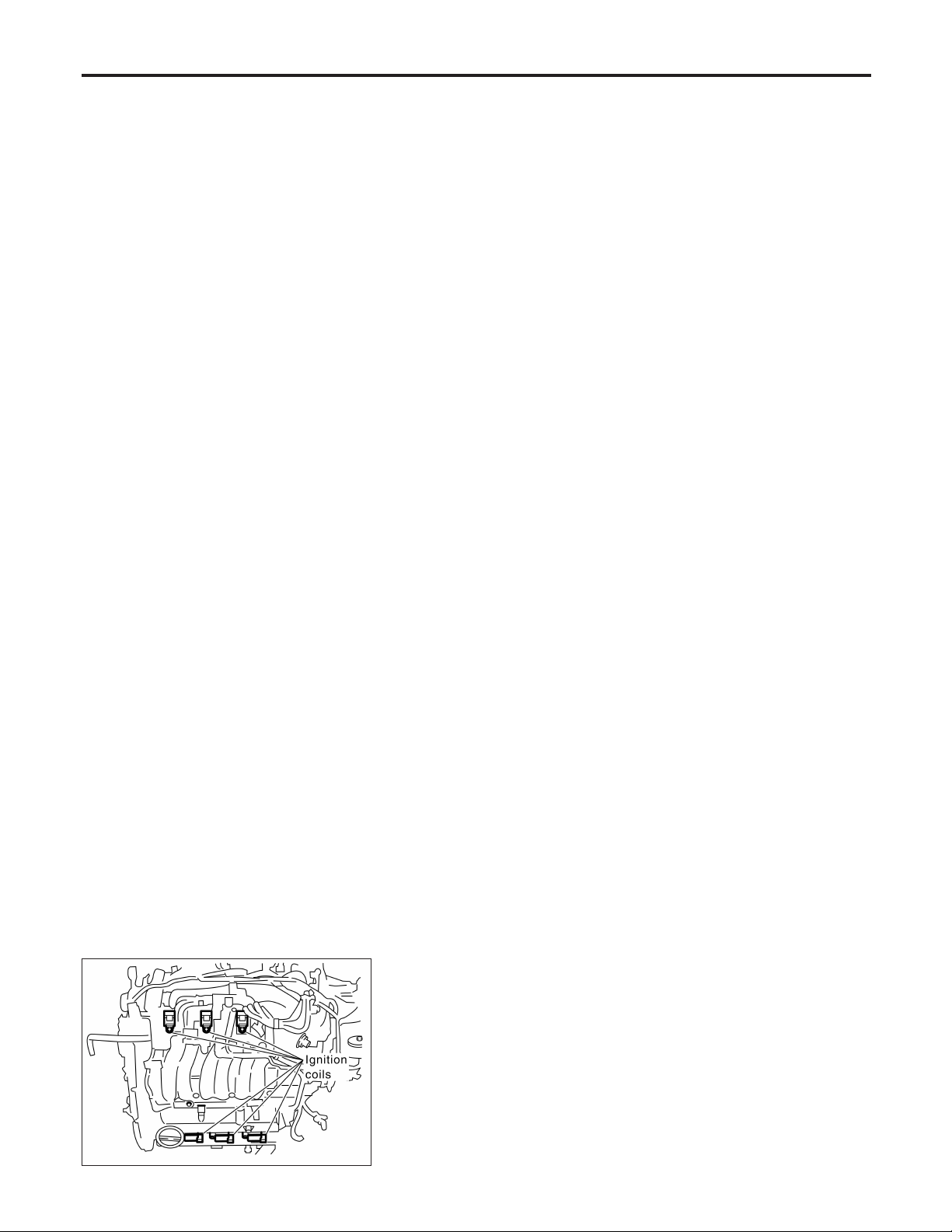

4. Disconnect ignition coil with power transistor harness

connectors, then remove ignition coils.

5. Remove all spark plugs.

6. Remove fuse for fuel injector.

SEM087G

7. Attach a compression tester to No. 1 cylinder.

8. Depress accelerator pedal fully to keep throttle valve wide

open.

9. Crank engine and record highest gauge indication.

10. Repeat the measurement on each cylinder as shown above.

I Always use a fully-charged battery to obtain specified

engine speed.

NFEM0007

Unit: kPa (kg/cm2, psi)/rpm

SEM909E

SEM387C

Standard Minimum

1,275 (13.0, 185)/300 981 (10.0, 142)/300 98 (1.0, 14)/300

Difference limit between

cylinders

11. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through spark

plug holes.

b. Retest compression.

I If adding oil helps compression, piston rings may be worn

or damaged. If so, replace piston rings after checking piston.

I If pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat. (Refer

to SDS, EM-73 and EM-76.) If valve or valve seat is damaged excessively, replace them.

I If compression stays low in two cylinders that are next to

each other:

a) The cylinder head gasket may be leaking, or

b) Both cylinders may have valve component damage. Inspect

and repair as necessary.

EM-12

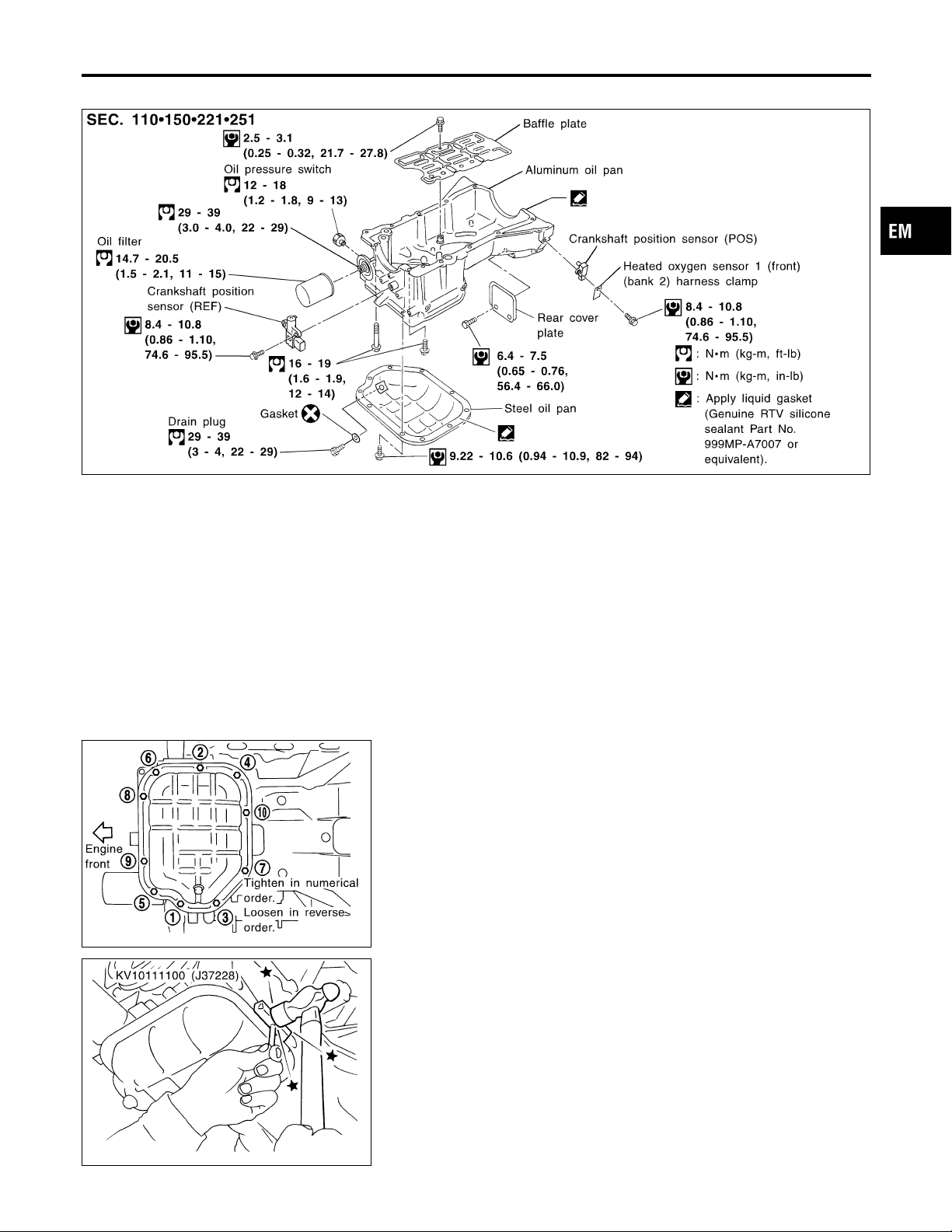

OIL PAN

Components

Components

Removal

CAUTION:

When removing the aluminum oil pan from engine, first

remove the crankshaft position sensors (POS and REF) from

the assembly.

Be careful not to damage sensor edges and signal plate teeth.

1. Remove engine undercover.

2. Drain engine oil.

NFEM0008

SEM574G

NFEM0009

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

SEM956F

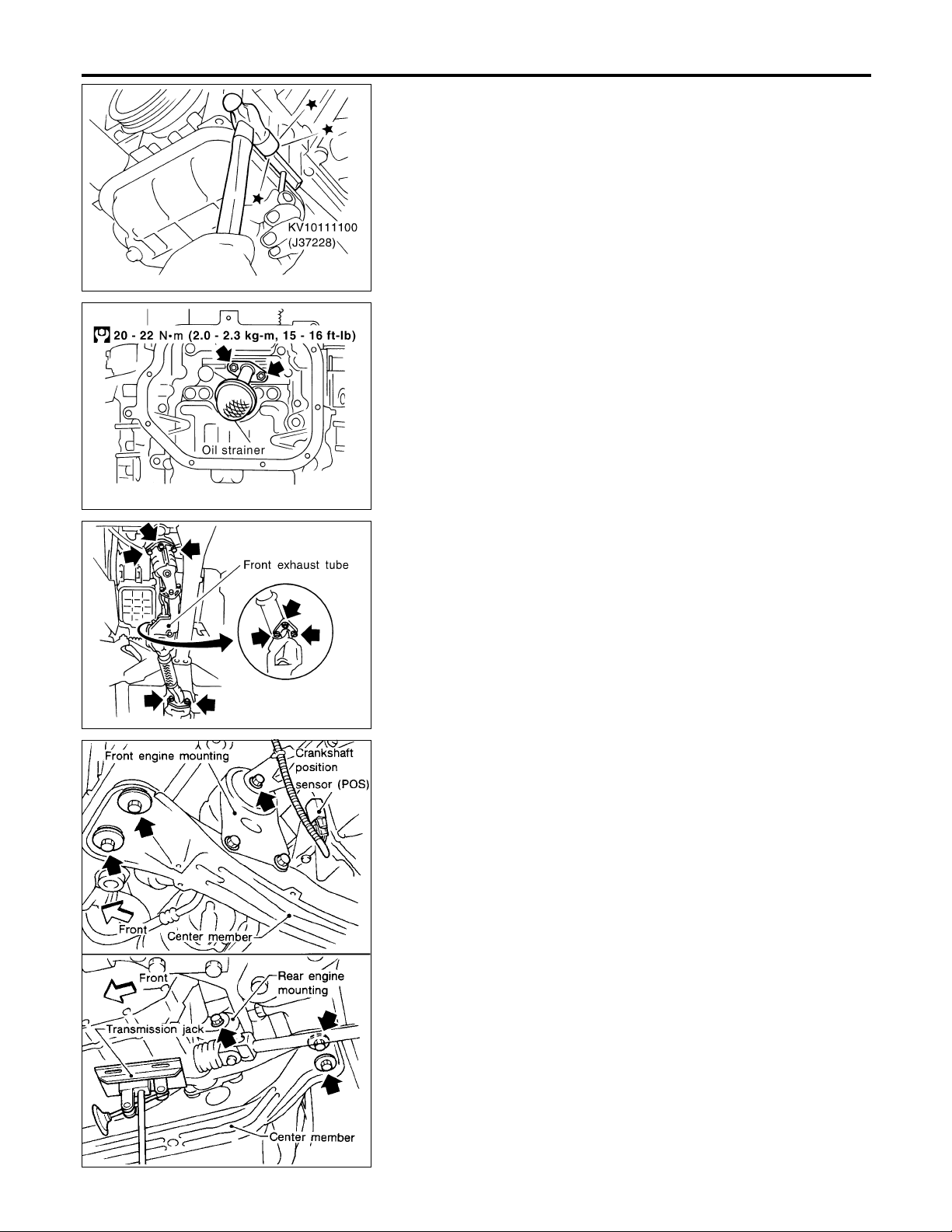

3. Remove steel oil pan bolts.

4. Remove steel oil pan.

a. Insert Tool between aluminum oil pan and steel oil pan.

I Be careful not to damage aluminum mating surface.

I Do not insert screwdriver, or oil pan flange will be

deformed.

BR

ST

RS

BT

HA

SC

EL

IDX

SEM957F

EM-13

Removal (Cont’d)

OIL PAN

b. Slide Tool by tapping on the side of the Tool with a hammer.

c. Remove steel oil pan.

SEM960F

5. Remove oil strainer.

SEM575G

SEM834FA

6. Remove front exhaust tube and its support.

Refer to FE-10, “Removal and Installation”.

7. Set a suitable transmission jack under transaxle and hoist

engine with engine slinger.

8. Remove crankshaft position sensors (POS and REF) from oil

pan.

9. Remove front and rear engine mounting nuts and bolts.

10. Remove center member.

SEM811E

EM-14

OIL PAN

11. Remove drive belts.

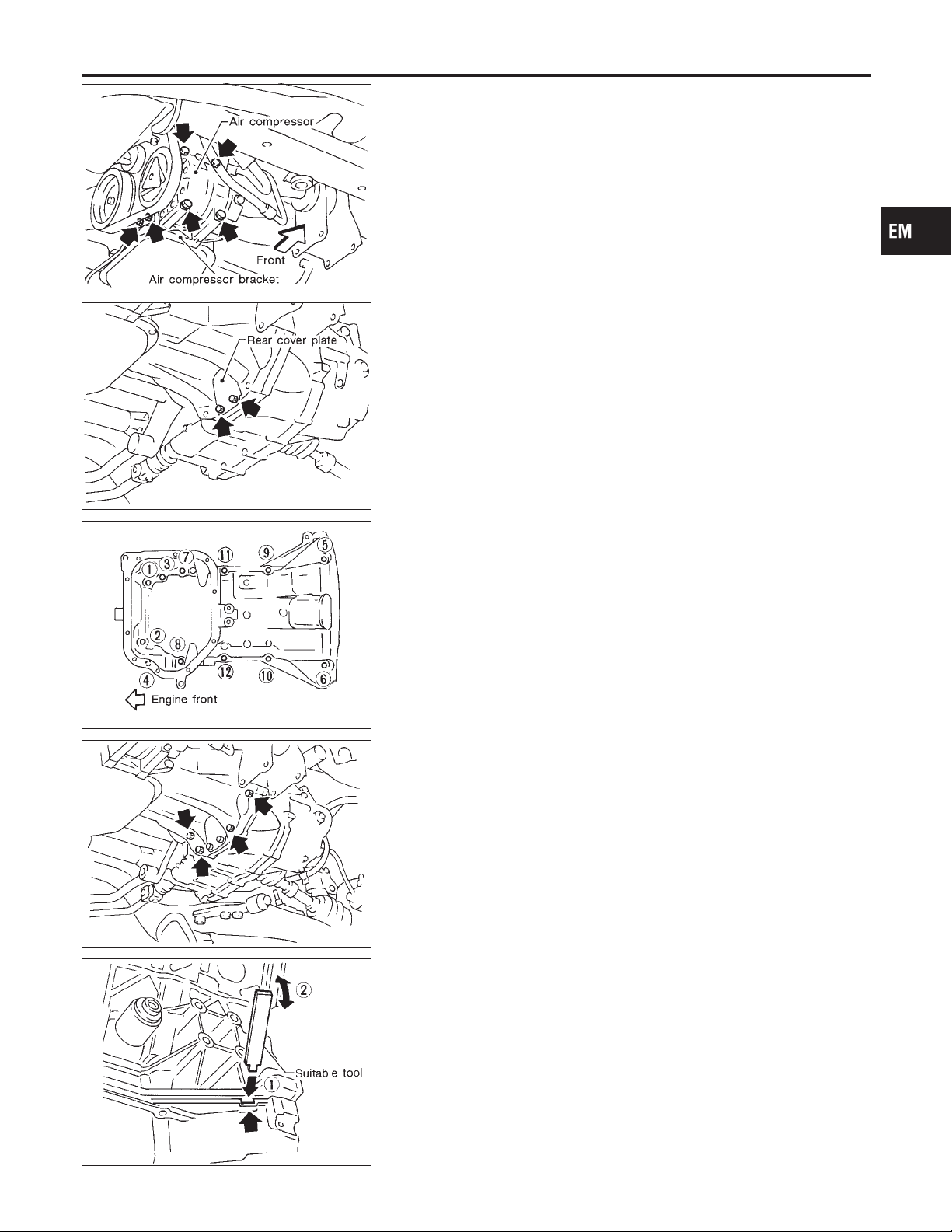

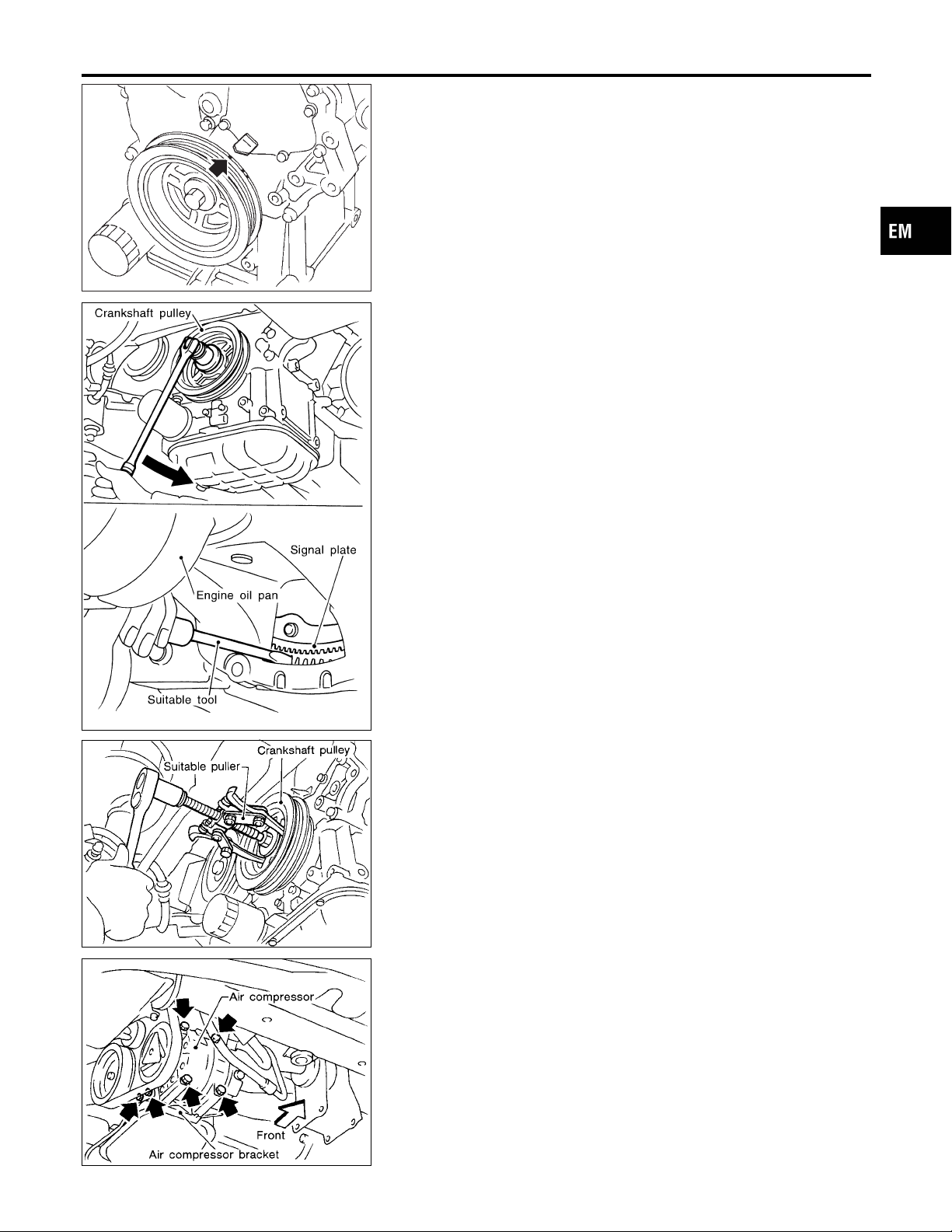

12. Remove air compressor and bracket.

Removal (Cont’d)

GI

MA

SEM812E

SEM813E

SEM184F

LC

13. Remove rear cover plate.

EC

FE

CL

MT

14. Remove aluminum oil pan bolts in numerical order.

AT

AX

SU

BR

15. Remove four engine-to-transaxle bolts.

ST

SEM815E

SEM155F

16. Remove aluminum oil pan.

a. Insert an appropriate size tool into the notch of aluminum oil

pan as shown in the figure.

I Be careful not to damage aluminum mating surface.

I Do not insert screwdriver, or oil pan flange will be

deformed.

b. Pry off aluminum oil pan by moving the tool up and down.

c. Remove aluminum oil pan.

EM-15

RS

BT

HA

SC

EL

IDX

Removal (Cont’d)

OIL PAN

17. Remove O-rings from cylinder block and oil pump body.

SEM819E

MEM108A

SEM964E

Installation

NFEM0010

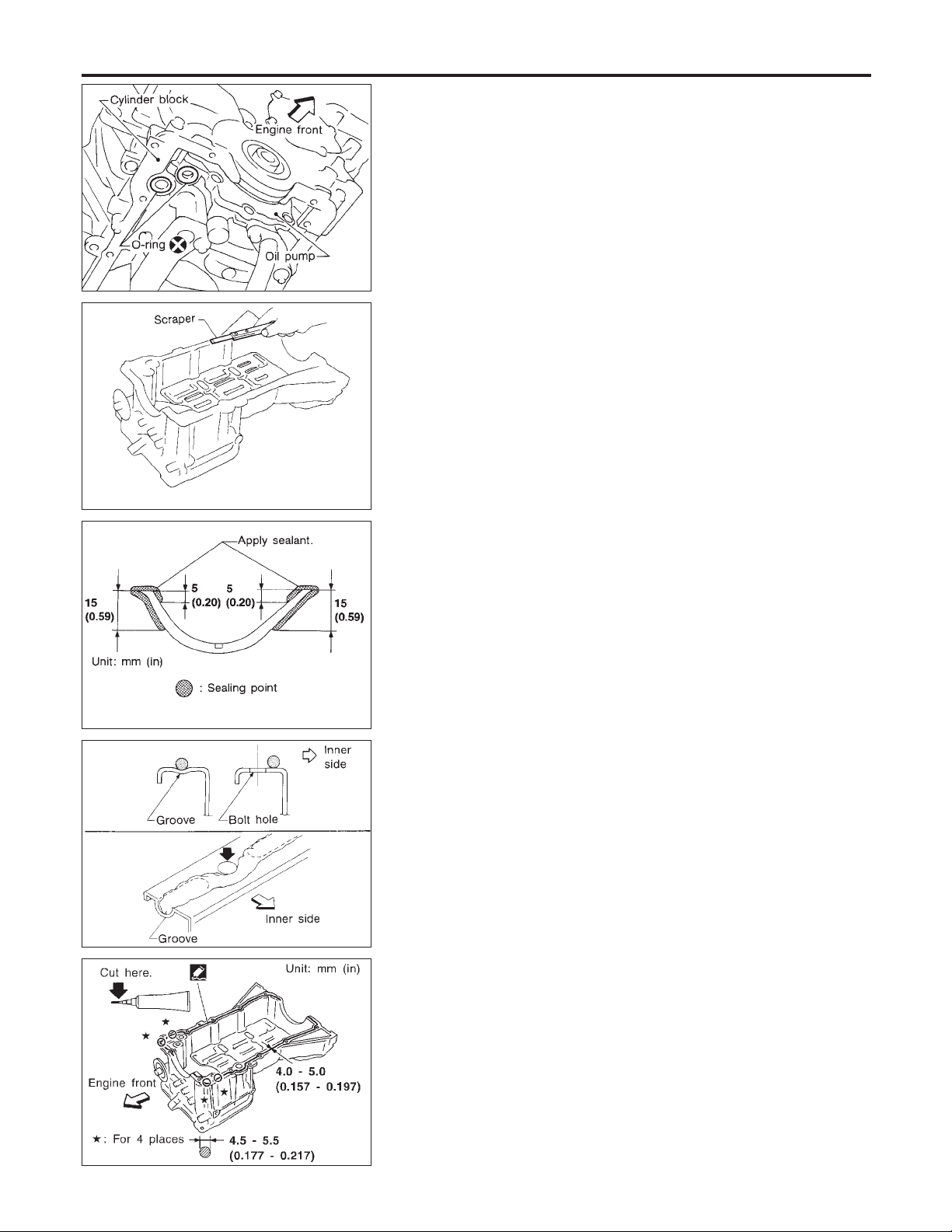

1. Install aluminum oil pan.

a. Use a scraper to remove old liquid gasket from mating sur-

faces.

I Also remove old liquid gasket from mating surface of cyl-

inder block, front cover and steel oil pan.

I Remove old liquid gasket from the bolt hole and thread.

b. Apply sealant to front cover gasket and rear oil seal retainer

gasket.

c. Apply a continuous bead of liquid gasket to mating surface of

aluminum oil pan.

I Use Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.

SEM159F

SEM185FA

d. Apply liquid gasket to inner sealing surface as shown in figure.

I Be sure liquid gasket is 4.0 to 5.0 mm (0.157 to 0.197 in)

or 4.5 to 5.5 mm (0.177 to 0.217 in) wide.

I Attaching should be done within 5 minutes after coating.

EM-16

OIL PAN

Installation (Cont’d)

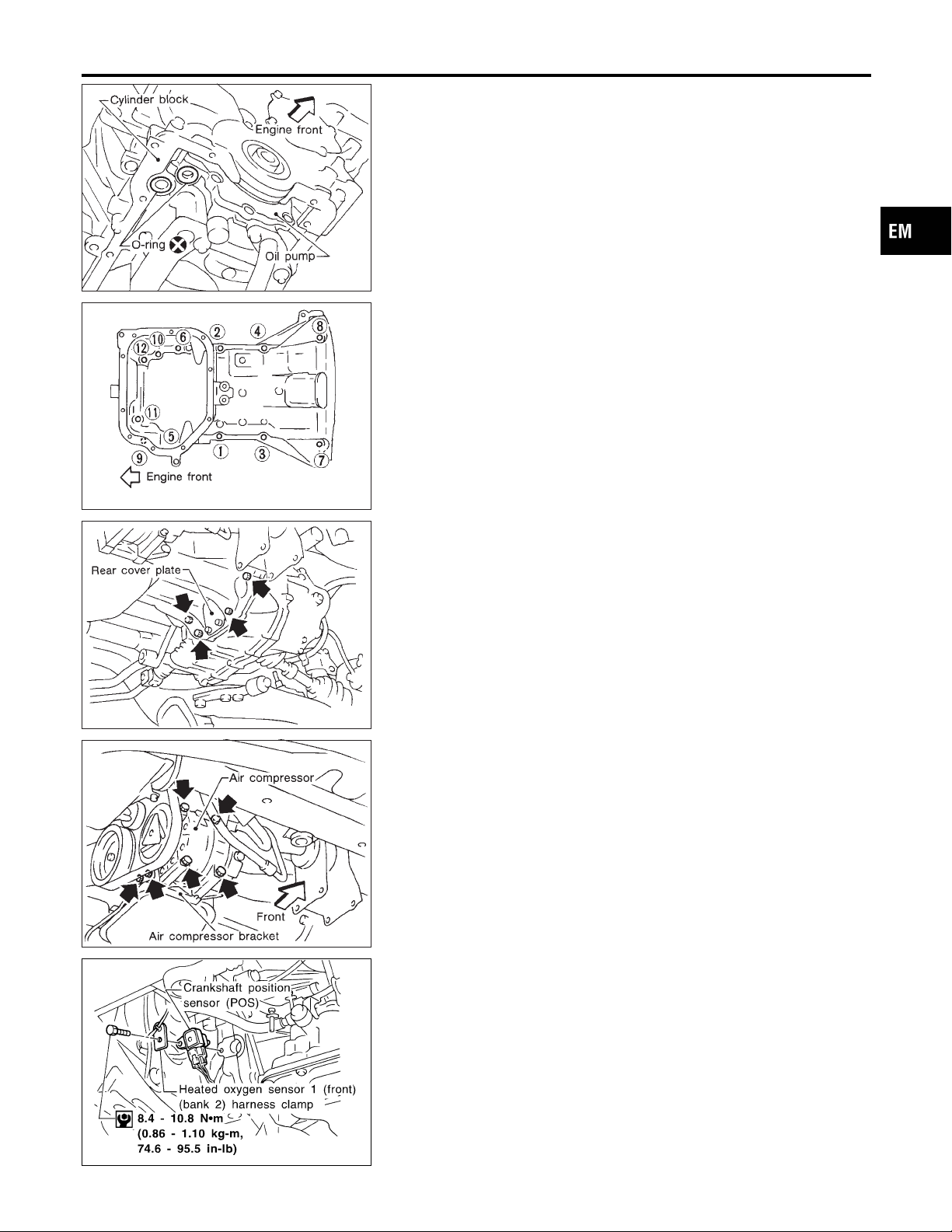

e. Install O-rings, cylinder block and oil pump body.

GI

MA

SEM819E

SEM186F

SEM822E

f. Install aluminum oil pan.

I Tighten bolts in numerical order.

I Wait at least 30 minutes before refilling engine oil.

2. Install the four engine-to-transaxle bolts. For tightening torque,

refer to MT-10 or AT-284, “Installation”.

3. Install rear cover plate.

4. Install air compressor and bracket.

RefertoHA-113, “REMOVALANDINSTALLATION”,“Compressor”.

5. Install drive belts.

6. Install center member.

7. Install front and rear engine mounting insulator nuts and bolts.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SEM812E

SEM222FD

8. Install crankshaft position sensors (POS and REF) and heated

oxygen sensor 1 (front) (bank 2) harness clamp.

I Make sure that crankshaft position sensor (POS) and

heated oxygen sensor 1 (front) (bank 2) harness clamp are

installed correctly as shown in figure.

9. Install front exhaust tube and its support.

10. Install oil strainer.

EM-17

HA

SC

EL

IDX

Installation (Cont’d)

OIL PAN

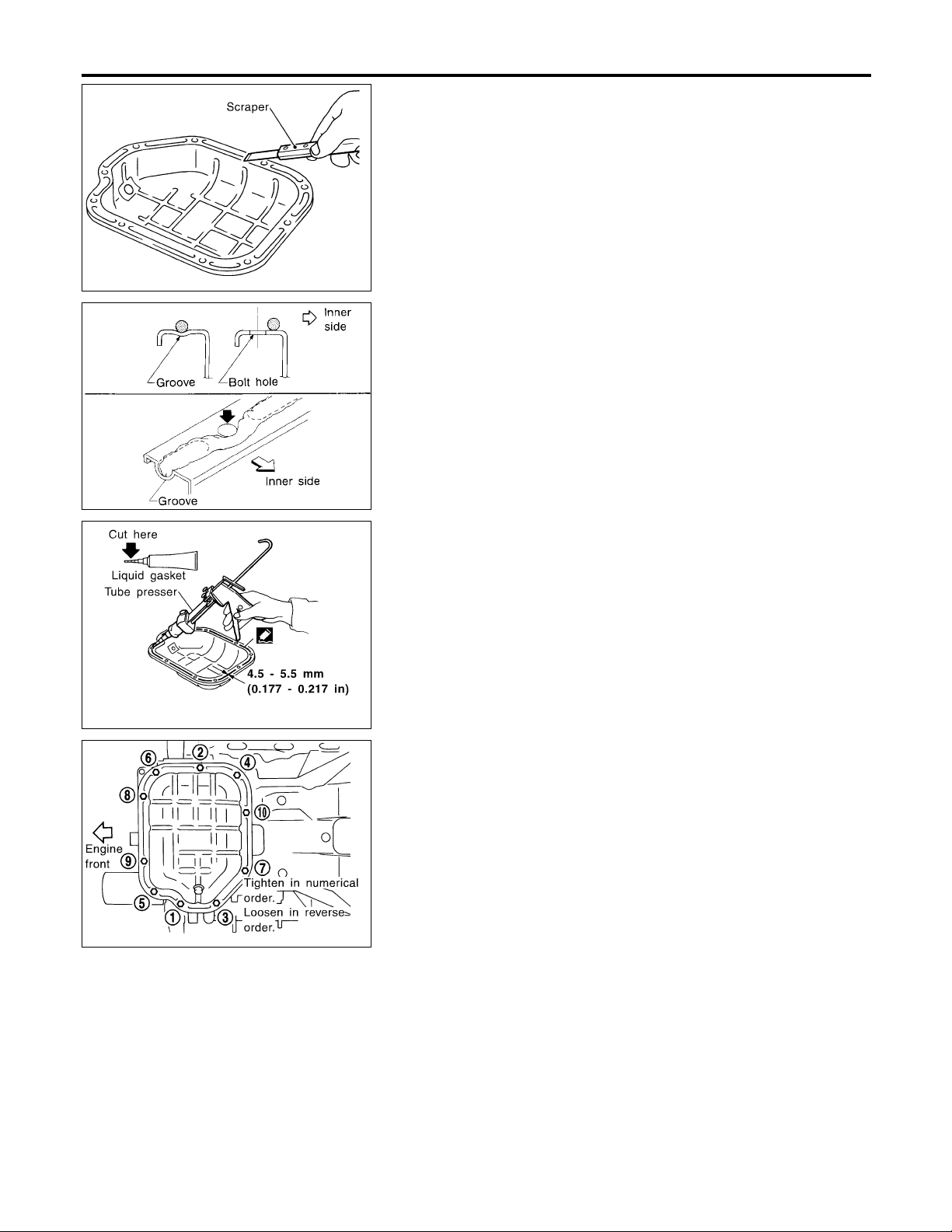

11. Install steel oil pan.

a. Use a scraper to remove old liquid gasket from mating sur-

faces.

I Also remove old liquid gasket from mating surface of alu-

minum oil pan.

SEM958F

b. Apply a continuous bead of liquid gasket to mating surface of

steel oil pan.

I Use Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.

SEM159F

SEM959F

SEM956F

I Be sure liquid gasket is 4.5 to 5.5 mm (0.177 to 0.217 in)

wide.

I Attaching should be done within 5 minutes after coating.

c. Install steel oil pan.

I Tighten in numerical order shown in the figure.

I Wait at least 30 minutes before refilling engine oil.

EM-18

TIMING CHAIN

Components

Components

NFEM0011

GI

MA

LC

EC

FE

CL

MT

1. Rear timing chain case

2. Left camshaft chain tensioner

3. Internal chain guide

4. Camshaft chain

5. Right camshaft chain tensioner

6. Timing chain tensioner

7. Slack side chain guide

8. Timing chain

9. Crankshaft sprocket

10. Lower chain guide

11. Upper chain guide

12. Front timing chain case

13. Crankshaft pulley

SEM277GB

14. Water pump cover

15. Chain tensioner cover

16. Exhaust camshaft sprocket 2ND

17. Intake camshaft sprocket 2ND

18. Camshaft sprocket 1ST

19. Water pump

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EM-19

Components (Cont’d)

TIMING CHAIN

POSITION FOR APPLYING LIQUID GASKET

Refer to “Installation” in “OIL PAN”, EM-16.

I Before installation, wipe off the protruding sealant.

=NFEM0011S01

EM-20

TIMING CHAIN

Components (Cont’d)

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EM-21

SC

EL

IDX

SEM443FA

Components (Cont’d)

TIMING CHAIN

CAUTION:

I After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

I When installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

I Apply new engine oil to bolt threads and seat surfaces

when installing cylinder head, camshaft sprockets, crankshaft pulley, and camshaft brackets.

I Before disconnecting fuel hose, release fuel pressure.

Refer to EC-49, “Fuel Pressure Release”.

I When removing the oil pans, oil pump assembly and tim-

ing chain from engine, first remove the camshaft position

sensor (PHASE) and the crankshaft position sensors

(REF)/(POS) from the assembly.

Be careful not to damage sensor edges.

I Do not spill engine coolant on drive belts.

Removal

NFEM0012

1. Drain engine oil.

2. Release fuel pressure.

Refer to EC-49, “Fuel Pressure Release”.

3. Drain coolant by removing cylinder block drain plugs. Refer to

MA-14, “Changing Engine Coolant”.

4. Remove left side ornament cover.

5. Remove air duct to intake manifold, collector, blow-by hose,

vacuum hoses, fuel hoses, wires, harness, connectors and so

on.

6. Remove the following.

I Vacuum hoses

I Water hoses

I EVAP canister purge hose

I Blow-by hose

7. Remove RH and LH ignition coils.

SMA040D

EM-22

TIMING CHAIN

8. Remove intake manifold upper support bolts.

Removal (Cont’d)

GI

MA

SEM588G

SEM962F

9. Remove intake manifold collector supports and intake manifold

collector (RH cylinder head only).

10. Remove fuel tube assembly. Referto EC-51, “InjectorRemoval

and Installation”.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

SEM963F

SEM964F

11. Remove intake manifold in reverse order of installation. Refer

to “TIGHTENING PROCEDURES”, EM-11.

EM-23

RS

BT

HA

SC

EL

IDX

Removal (Cont’d)

TIMING CHAIN

12. Remove RH and LH rocker covers from cylinder head.

SEM910E

13. Remove engine undercover.

14. Remove front RH wheel and engine side cover.

15. Remove drive belts and idler pulley bracket.

SEM911E

16. Remove power steering oil pump belt and power steering oil

pump assembly.

17. Remove camshaft position sensor (PHASE) and crankshaft

position sensors (REF)/(POS).

SEM912E

EM-24

TIMING CHAIN

Removal (Cont’d)

18. Set No. 1 piston at TDC on the compression stroke by rotating crankshaft.

GI

MA

SEM913E

SEM965F

19. Loosen crankshaft pulley bolt. (At this time remove oil pan rear

cover plate and set a suitable tool to ring gear so that crankshaft cannot rotate.)

I Be careful not to damage the signal plate teeth.

20. Remove crankshaft pulley with a suitable puller.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

SEM915E

SEM812E

21. Remove air compressor and bracket.

22. Remove front exhaust tube and its support.

23. Hang engine at right and left side engine slingers with a suitable hoist.

24. Remove right side engine mounting, mounting bracket and

nuts.

25. Remove center member assembly.

26. Remove upper and lower oil pans.

I For procedures described in steps 21 through 26, refer to

“Removal”, EM-13.

EM-25

RS

BT

HA

SC

EL

IDX

Removal (Cont’d)

TIMING CHAIN

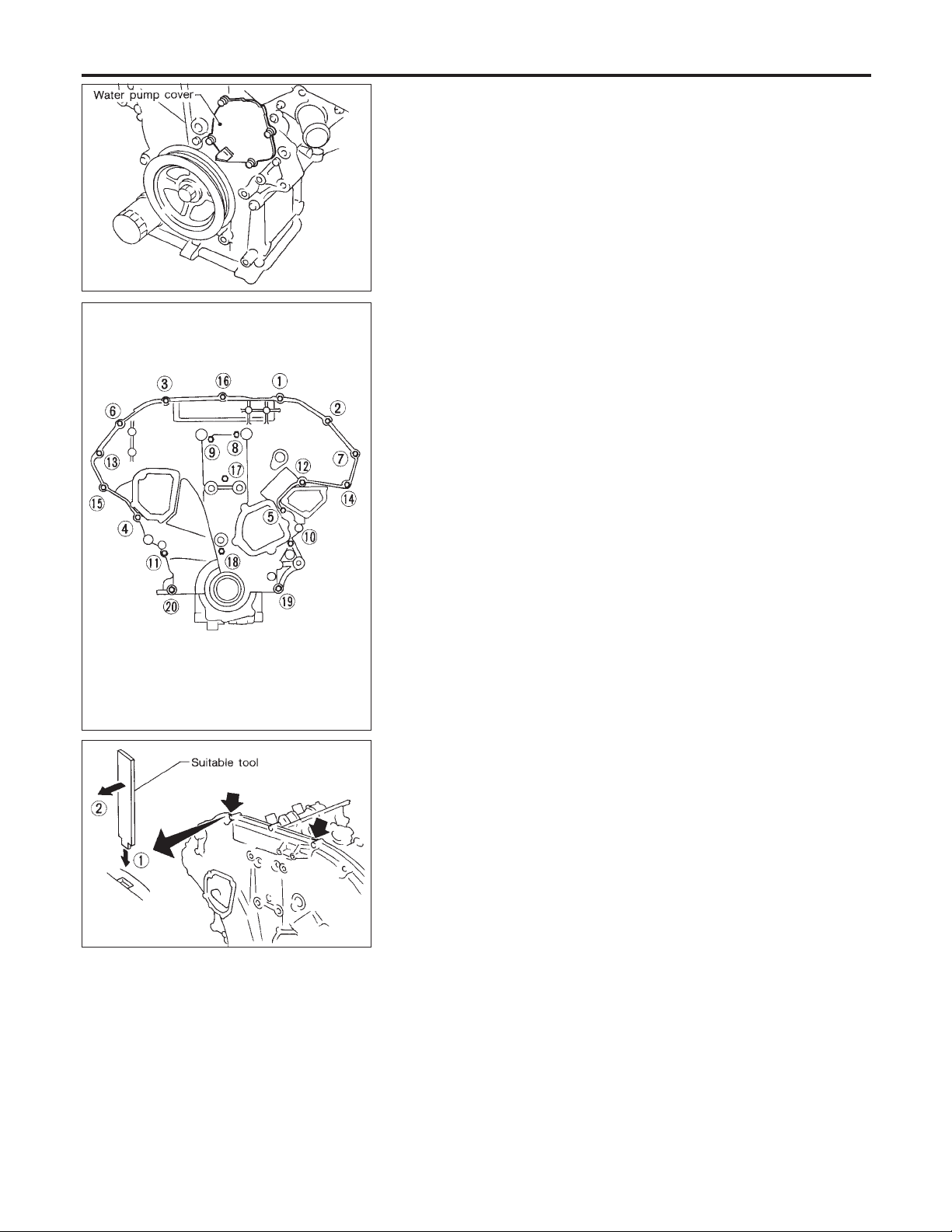

27. Remove water pump cover.

SEM916E

28. Remove front timing chain case bolts.

I Loosen bolts in numerical order as shown in the figure.

SEM917EA

SEM156F

29. Remove front timing chain case.

I Do not scratch sealing surfaces.

EM-26

Loading...

Loading...