Page 1

TW 300 CAR

Anhang zur Betriebsanleitung

Annex to Operating Instructions

Supplément aux Instructions de Service

Aanhangsel bij de gebruiksaanwijzing

Supplemento alle istruzioni sull’uso

Vedlegg til bruksveiledning

Bilaga till bruksanvisningen

Bilag til driftsvejledningen

Käyttöohjeen liite

Dodatek k navodilu za uporabo

Privitak uz uputstvo za upotrebu

Dodatok k prevádzkovému návodu

Dodatek k návodu k obsluze

Załącznik do instrukcji obsługi

Függelék a kezelési utasításhoz

Apéndice a las instrucciones de uso

Anexo do manual do usuário

ΠαράρΠαράρ

Παράρ

ΠαράρΠαράρ

Ýþletme kýlavuzuna ek

τηµα στις οδηγίετηµα στις οδηγίε

τηµα στις οδηγίε

τηµα στις οδηγίετηµα στις οδηγίε

ς λς λ

ς λ

ς λς λ

ειτειτ

ειτ

ειτειτ

οο

υρυρ

γίαγία

γία

γίαγία

ςς

ς

ςς

ο

υρ

οο

υρυρ

Page 2

EG - Konformitätserklärung

Déclaration de conformité CE

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Erzeugnis:

Typ:

Beschreibung:

Die Bauart des Gerätes entspricht

folgenden einschlägigen

Bestimmungen:

Angewendete harmonisierte

Normen:

Angewendete nationale Normen

und technische Spezifikationen:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Prüfungen und Zulassungen

Sprühextraktionsgerät

ALTO TW 300 CAR

220-230 V~, 50 Hz

EG-Maschinenrichtlinie 98/37 EG

EG-Niederspannungsrichtlinie 73/23/EWG

EG-Richtlinie EMV 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

EU Declaration of Conformity Dichiarazione di conformità CE

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Product:

Type:

Description:

The design of the unit corresponds

to the following pertinent

regulations:

Applied harmonised standards:

Applied national standards and

technical specifications:

Spray extraction cleaner

ALTO TW 300 CAR

220-230 V~, 50 Hz

EC Machine Directive 98/37/EWG

EC Low-voltage Directive 73/23/EWG

EC EMV Directive 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Bellenberg, 23.01.2001

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produit:

Type:

Description:

La construction de l’appareil est

conforme aux réglementations

afférentes suivantes:

Normes harmonisées appliquées:

Normes nationales et spécifications

techniques appliquées:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Controles et homologations

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Prodotto:

Tipo:

Descrizione:

La costruzione dell' apparecchio è

conforme alle seguenti direttive

specifiche:

Norme armonizzate applicate:

Norme nazionali applicate e

specifiche tecniche:

Injecteur/extracteur

ALTO TW 300 CAR

220-230 V~, 50 Hz

EC-Machine Directive 98/37 EG

EC-Low-Voltage Directive 73/23/EWG

EC EMV Directive 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Apparecchio per estrazione e spruzzo

ALTO TW 300 CAR

220-230 V~, 50 Hz

Direttiva CE sulle macchine 98/37/EWG

Direttiva CE sulla bassa tensione 73/23/EWG

Direttiva CE sulla compatibilità

elektromagnetica 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Bellenberg, 23.01.2001

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Tests And Approvals

EG-Verklaring van overeenstemming

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beschrijving:

De constructie van het apparaat

voldoet aan de volgende van

toepassing zijnde voorschriften:

Toegepaste geharmoniseerde

normen:

Toegepaste nationale normen en

technische specificaties:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Keuringen en vergunningen

Sproei-/extractietoestel

ALTO TW 300 CAR

220-230 V~, 50 Hz

EG-machinerichtlijn 98/37/EWG

EG-laagspanningsrichtlijn 73/23/EWG

EG-richtlijn EMV 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Bellenberg, 23.01.2001

Bellenberg, 23.01.2001

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Controlli e omologazioni

Atestado de conformidad de la UE

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Producto:

Modelo:

Descripción:

La construcción de la máquina

corresponde a las siguientes normas

específicas:

Normas armonizadas aplicadas:

Normas nacionales aplicadas y

especificaciones técnicas:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Pruebas y homologaciones

Máquina de limpieza por aspersión/aspiración

ALTO TW 300 CAR

220-230 V~, 50 Hz

R. de la UE para máquinas 98/37/EWG

R. de la UE para baja tensión 73/23/EWG

R. de la UE para la compatibilidad electromagnética 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Bellenberg, 23.01.2001

Bellenberg, 23.01.2001

Page 3

Atestado de

conformidade da UE

∆ήλωση ανταπόκρισης ΕΟΚ

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produto:

Modelo:

Descrição:

A construção da máquina

corresponde às seguintes normas

específicas:

Normas harmonizadas aplicadas:

Normas nacionais aplicadas e

especificações técnicas:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Testes e homologações

aparelho de extração e pulverização

ALTO TW 300 CAR

220-230 V~, 50 Hz

Directiva UE para máquinas 98/37/EWG

Directiva UE para baixa tensão 73/23/EWG

Directiva para a compatibilidade

electromagnética 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

EF-konformitetserklæring

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beskrivelse:

Sprøjteekstraheringsapparat

ALTO TW 300 CAR

220-230 V~, 50 Hz

Bellenberg, 23.01.2001

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Προϊόν:

Τύπος:

Περιγραφή:

Ο κατασκευαστικός τύπος της

συσκευής ανταποκρίνεται στους

ακόλουθους σχετικούς

κανονισµούς:

Εφαρµοσθείσες εναρµονισµένες

προδιαγραφές:

Εφαρµοσθείσες εθνικές

προδιαγραφές και τεχνικοί

προσδιορισµοί:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP ΕΛΕΓΧΟΙ ΚΑΙ Α∆ΕΙΕΣ

ΣυσκΣυσκ

εε

Συσκ

ε

ΣυσκΣυσκ

εε

ALTO TW 300 CAR

220-230 V~, 50 Hz

Οδηγία περί µηχανών ΕΟΚ 98/37/ΕΟΚ

Οδηγία χαµηλών τάσεων ΕΟΚ 73/23/ΕΟΚ

Οδηγία περί ηλεκτροµαγνητικής

συµβατότητας 89/336/ΕΟΚ

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

EG-försäkran om

överensstämmelse

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Typ:

Beskrivning:

Sprutextraktionsapparat

ALTO TW 300 CAR

220-230 V~, 50 Hz

υή ψεκυή ψεκ

υή ψεκ

υή ψεκυή ψεκ

αα

σµού ανσµού αν

α

σµού αν

αα

σµού ανσµού αν

αρρόφησηςαρρόφησης

αρρόφησης

αρρόφησηςαρρόφησης

Bellenberg, 23.01.2001

Apparatets konstruksjonstype er i

samsvar med følgende gjeldende

bestemmelser:

Anvendte harmoniserte standarder:

Anvendte nasjonale standarder og

tekniske spesifikasjoner:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Prøver og godkjennelser

EF-maskindirektiv 98/37/EEC

EF-lavspenningsdirektiv 73/23/EEC

EF-direktiv elektromagnetisk

kompatibilitet 89/336/EEC

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

EF-overensstemmelsesattest

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beskrivelse:

Konstruktionen af dette apparat

opfylder følgende gældende

bestemmelser:

Anvendte harmoniserede

standarder:

Anvendte tyske standarder og

tekniske specifikationer:

Sprøyte- og ekstraksjonsrenser

ALTO TW 300 CAR

220-230 V~, 50 Hz

EF-maskindirektiv 98/37/EØF

EF-lavspændingsdirektiv 73/23/EØF

EF-direktiv vedr. elektromagnetisk

fordragelighed 89/336/EØF

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Bellenberg, 23.01.2001

Apparatens konstruktion motsvarar

följande tillämpliga bestämmelser:

Tillämpade harmoniserade normer:

Tillämpade nationella normer och

tekniska specifikationer:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Provningar och koncessioner

EG-maskindirektiv 98/37/EWG

EG-lågspänningsdirektiv 73/23/EWG

EG-direktiv EMK 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

EY-Vaatimustenmukaisuusvakuutus

ALTO Deutschland GmbH

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tuote:

Tyyppi:

Kuvaus:

Tämän laitteen rakenne vastaa

seuraavia määräyksiä:

Käytetyt harmonisoidut normit:

Käytetyt kansalliset normit ja

tekniset spesifikaatiot:

Suihkepuhdistuslaite

ALTO TW 300 CAR

220-230 V~, 50 Hz

EY-konedirektiivi 98/37/EWG

EY-pienjännitedirektiivi 73/23/EWG

EY-direktiivi EMV 89/336/EWG

EN 292

EN 60335-1, EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2,

EN 61000 3-3

DIN EN 60335-1

DIN EN 60335-2-10

DIN EN 60335-2-68

Bellenberg, 23.01.2001

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Afprøvninger og godkendelser

Bellenberg, 23.01.2001

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Tarkastukset ja hyväksymiset

Bellenberg, 23.01.2001

Page 4

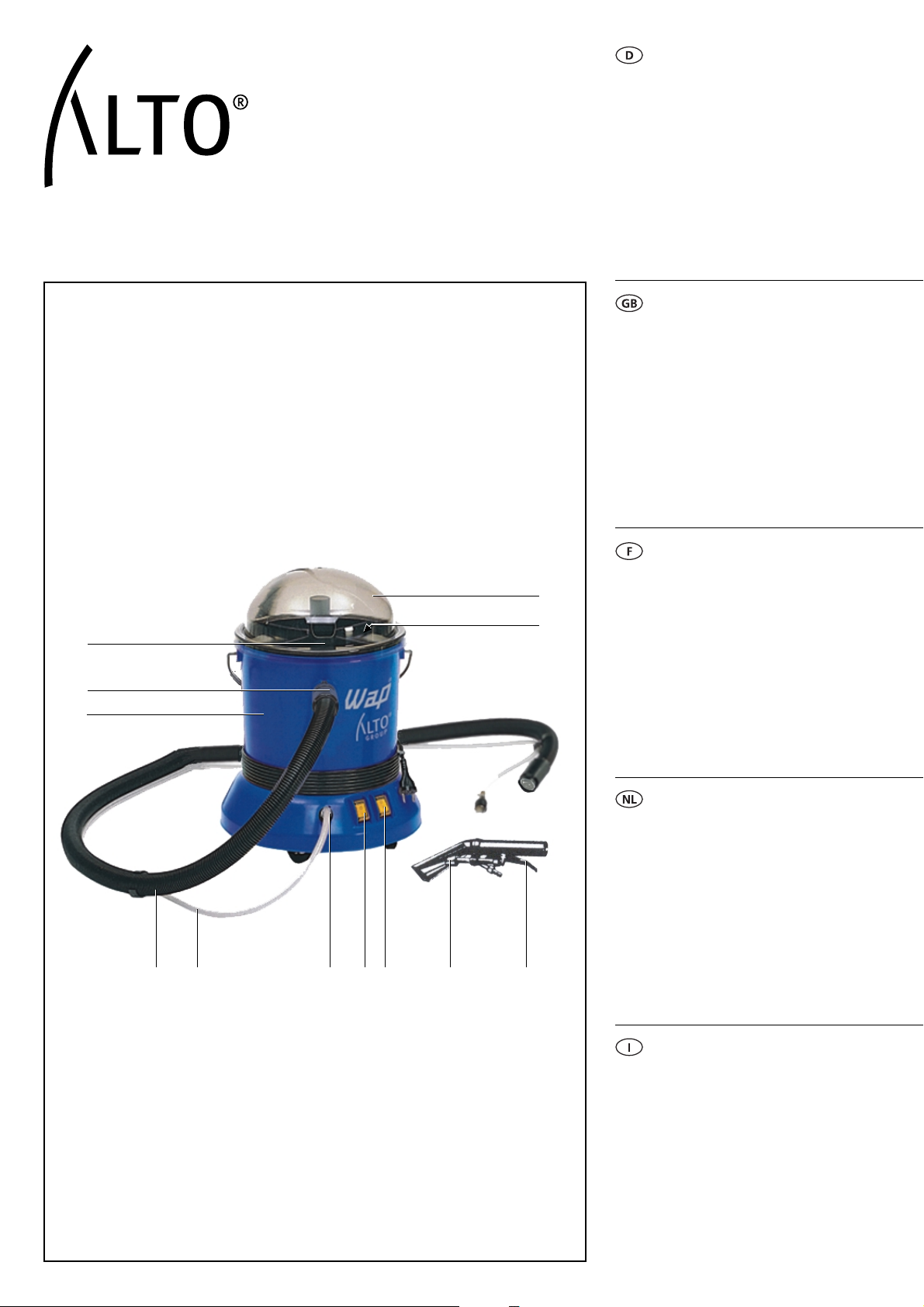

Anhang zur Betriebsanleitung

BETRIEBSANLEITUNG LESEN UND

SICHERHEITSHINWEISE BEACHTEN!

TW 300 CAR

Diese Betriebsanleitung ist ein

Anhang zur Betriebsanleitung

TW 300 S und enthält alle Informationen über die technischen Unterschiede der Geräte.

Annex to Operating Instructions

PLEASE READ THE OPERATING

INSTRUCTIONS AND OBSERVE THE

SAFETY INSTRUCTIONS!

These operating instructions are a

supplement to the TW 300 S

operating instructions and they

contain all the information on the

Supplément aux Instructions

de Service

12

11

10

1

2

3456789

VEUILLEZ LIRE LES INSTRUCTIONS

DE SERVICE ET RESPECTER LES

CONSIGNES DE SECURITE!

Ces instructions de service sont un

supplément aux instructions de

service du TW 300 S et contiennent

toutes les informations nécessaires

Aanhangsel bij de

gebruiksaanwijzing

GEBRUIKSAANWIJZING LEZEN EN

DE VEILIGHEIDSINSTRUCTIES

OPVOLGEN!

Deze gebruiksaanwijzing is een

aanhangsel bij de gebruiksaanwijzing TW 300 S en bevat alle

informatie over de technische

verschillen tussen de apparaten.

Supplemento alle istruzioni

sull’uso

SI PREGA LEGGERE LE ISTRUZIONI

SULL’USO E LE INDICAZIONI DI

SICUREZZA

Queste istruzioni sull’uso sono un

supplemento alle istruzioni sull’uso

del TW 300 S e danno tutte le

informazioni necessarie che

Page 5

Beachten Sie alle Vorschriften und

Nutzungshinweise sowie

Sicherheitsbestimmungen der

vorgenannten Betriebsanleitung.

BESCHREIBUNG

1 Deckel

2 Schmutzwassereimer

3 Hebelventil

4 Polsterdüse (Sprüh-Saugdüse)

5 Schalter für Saugaggregat

6 Schalter für Reinigungsmittelpumpe

7 Kupplung

8 Sprühschlauch

9 Saugschlauch

10 Gehäuse

11 Anschluss für Saugschlauch

12 Sprühbogen

technical differences between the

devices.

Please observe all regulations and

operating notes as well as the

safety regulations for the

previously mentioned operating

instructions.

DESCRIPTION

1 Cover

2 Dirty water tank

regardant les différences techniques des appareils.

Veuillez respecter toutes les prescriptions et remarques d’utilisation

ainsi que les consignes de sécurité

des instructions de service susmentionnées.

DESCRIPTION

1 Couvercle

2 Cuve à eau sale

3 Valve operating lever

4 Upholstery nozzle (Spray/suction

nozzle)

5 Switch for suction unit

6 Switch for cleansing agent pump

7 Coupling

8 Spray hose

9 Suction hose

10 Housing

11 Connection for suction hose

12 Spray siphon

3 Vanne à levier

4 Buse pour rembourrages (Buse de

pulvérisation/aspiration)

5 Interrupteur pour groupe d’aspiration

6 Interrupteur pour pompe à détergent

7 Accouplement

8 Flexible de pulvérisation

9 Flexible d’aspiration

10 Boîtier

11 Raccord pour flexible d’aspiration

12 Coude de pulvérisation

Neem alle voorschriften en gebruiksinstructies in acht alsmede de

veiligheidsbepalingen van de

bovengenoemde gebruiksaanwijzing.

BESCHRIJVING

1 deksel

2 vuilwateremmer

3 hefboomafsluiter

4 bekledingszuigmond (sproei-/

zuigmond)

riguardano le differenze tecniche

tra gli apparecchi.

Si prega osservare tutte le

precauzioni ed informazioni d’uso

come pure le indicazioni di

sicurezza delle suddette istruzioni

sull’uso.

DESCRIZIONE

1 Coperchio

2 Recipiente dell’acqua sporca

5 schakelaar voor zuigaggregaat

6 schakelaar voor reinigingsmiddel-

pomp

7 koppeling

8 sproeislang

9 zuigslang

10 huis

11 aansluiting voor zuigslang

12 sproeiboog

3 Leva azionatrice

4 Ugello per imbottiture (Ugello di

spruzzo/aspirazione)

5 Interruttore del gruppo aspirante

6 Interruttore della pompa del

detergente

7 Giunto

8 Tubo di spruzzo

9 Tubo d’aspirazione

10 Involucro

11 Attacco del tubo d‘aspirazione

12 Gomito di spruzzo

Page 6

INTERNET

http://www.alto-online.com

ALTO HEADQUARTERS

Incentive International A/S

Kongens Nytorv 28

P.O.Box 2064

DK 1013 Copenhagen K

Tel.: (+45) 33 11 11 42

Fax: (+45) 33 93 46 36

e-mail: incentive@incentive-dk.com

SUBSIDIARIES

AUSTRALIA

ALTO Overseas Inc.

1B/8 Resolution Drive

P.O.Box 797

AUS-Caringbah, N.S.W. 2229

Tel: (++61) 295 24 61 22

Fax: (++61) 295 24 52 56

AUSTRIA

Wap Reinigungssysteme GmbH

Metzgerstr. 68

A-5101 Bergheim/Salzburg

Phone: (+43) 662 45 64 00-14

Fax: ( +43) 662 45 64 00-55

BRASIL

Wap do Brasil Ltda.

Rua 25 de Agosto, 608

CEP 83323-260 Pinhais/Paraná

BR-Brasil

Tel./Fax (++55) 4 18 67 40 26

CANADA

ALTO Canada

24 Constellation Road

Rexdale

C-Ontario M9W 1K1

Tel: 1 41 66 75 58 30

Fax: 1 41 66 75 69 89

CZECH REPUBLIC

Wap čistící systémy s.r.o.

Zateckých 9

CZ-140 00 Praha 4

Tel. (+420) 2 42 78 38

Fax (+420) 2 42 19 25

DENMARK

ALTO Danmark A/S

Industrikvarteret

DK-9560 Hadsund

Tel: (+45) 72 18 21 00

Fax: (+45) 72 18 21 05

ALTO Danmark A/S

Blytækkervej 2,

DK-9000 Aalborg

Tel: (+45) 72 18 21 00

Fax: (+45) 72 18 20 99

FRANCE

ALTO France S.A.

B.P. 44, 4 Place d’Ostwald

F-67036 Strasbourg Cedex 2

Tel: (++33) 3 88 28 84 00

Fax: (++33) 3 88 30 05 00

GERMANY

Wap KundenCenter

Tel. (+49) 0180 / 5 37 37 37

Fax (+49) 0180 / 5 37 37 38

e-mail: center@wap-online.de

Besuchen Sie uns im Internet:

http://www.wap-online.com

Wap ALTO Group

Wap Reinigungssysteme GmbH

& Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tel. (+49) 07306 / 72-0

Fax (+49) 07306 / 7 22 00

RegionalCenter Frankfurt

Moselstraße 2b

D-63452 Hanau

Tel. (+49) 06181 / 18 72-0

Fax (+49) 06181 / 18 72-11

e-mail: rcffm@wap-online.de

RegionalCenter

Hamburg/Hannover

Storchenweg 8A

D-21217 Seevetal–Meckelfeld

Tel. (+49) 040 / 79 09 06 60

Fax (+49) 040 / 79 09 06 66

e-mail: rchann@wap-online.de

RegionalCenter Köln

Kaiserstraße 127

D-51145 Köln-Porz

Tel. (+49) 02203 / 9 22 99-0

Fax (+49) 02203 / 9 22 99-25

e-mail: rckoeln@wap-online.de

RegionalCenter Leipzig

Wachau/Gewerbegebiet

Südring 16

D-04416 Markkleeberg

Tel. (+49) 034297 / 4 87 25

Fax (+49) 034297 / 4 93 57

e-mail: rcleip@wap-online.de

RegionalCenter München

Furtweg 11

D-85716 Unterschleißheim

Tel. (+49) 089 / 32 15 02-0

Fax (+49) 089 / 32 15 02-40

e-mail: rcmuen@wap-online.de

RegionalCenter Stuttgart

Dornierstraße 7

D-71069 Sindelfingen

OT Darmsheim

Tel. (+49) 07031 / 76 70-0

Fax (+49) 07031 / 76 70-20

e-mail: rcstut@wap-online.de

RegionalCenter Ulm

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tel. (+49) 07306 / 72-195

Fax (+49) 07306 / 3 41 29

e-mail: rculm@wap-online.de

GREAT BRITAIN

Wap ALTO Cleaning

Systems(UK)Ltd.

Gilwilly Industrial Estate

GB-Penrith, Cumbria CA11 9BN

Tel: (+44) 1 7 68 86 89 95

Fax: (+44) 1 7 68 86 47 13

Telex: 64309 kewg

HONG KONG

ALTO Hong Kong

RM 602, Tower B, Regent Ctr.

79, Ta Chuen Ping Street

Kwai chung

HK-Hong Kong

Tel. (+852) 26 10 10 42

Fax (+852) 26 10 10 47

Att. Mr. Dereck Lee

JAPAN

ALTO Danmark A/S Japan

Representative Office

Naruse-build 4F

7-2 Shinbashi 1-Chome, Minato-Ku

J-Tokyo 105-004

Tel: (+81) 3 35 69 38 07

Fax: (+81) 3 35 69 38 08

e-mail: alto-jpn@aqua.famille.ne.jp

CROATIA

Wap sistemi za čišćenje, d.o.o.

Florijana Andrašeca 14

HR-10000 Zagreb

Tel. (++385) 01 / 3 09 49 07

(++385) 01 / 3 09 49 09

Fax (++385) 01 / 3 09 49 06

e-mail: admin.wap@wap-sistemi.hr

NETHERLANDS

Wap ALTO Nederland

Postbus 65

NL-3370 AB HardinxveldGiessendam

Tel. (+31) 01846 / 67 72 00

Fax (+31) 01846 / 67 72 01

NORWAY

ALTO Norge AS

Bjørnerudveien 24

N-1266 Oslo

Tel: (+47) 22 75 17 70

Fax: (+47) 22 75 17 71

SINGAPORE

ALTO Danmark A/S

Representative Office

No. 17 Link Road Road

SG-Singapore 619034

Tel: (+65) 2 68 10 06

Fax: (+65) 2 68 49 16

SLOWAKIA

Wap čistiace systémy spol. s.r.o.

Vajnorská 135

SK-83237 Bratislava

Tel. (+421) 7 44 25 96 64

Fax (+421) 7 44 25 79 44

SLOVENIA

Wap čistilni sistemi, d.o.o.

Letališka 33

SLO-1110 Ljubljana

Tel. (++0368) 61 44 23 42

Fax (++0368) 61 1 40 42 94

SPAIN

Hidrolimpia, S.L. (ALTO

Iberica)

Ronda de Valdecarrizo 9

– Modulo 5 –

E-28760 Tres Cantos Madrid

Tel. (+34) 091 / 804 62 56

Fax (+34) 091 / 804 64 63

SWEDEN

ALTO Sverige AB

Aminogatan 18, Box 40 29

S-431 04 Mölndal

Tel: (+46) 3 17 06 73 00

Fax: (+46) 3 17 06 73 41

SWITZERLAND

Wap Reinigungssysteme

Schweiz AG

Allmendstr. 14

CH-5612 Villmergen

Tel.: (+41) 56 618 85 00

Fax: (+41) 56 618 85 10

USA

ALTO U.S.Inc

390 South Woods Mill Road

Suite 300

Chesterfield

USA-Missouri 63017-3433

Tel: (+1) 314 205 1220

Fax: (+1) 314 205 1544

ALTO U.S.Inc

2100 Highway 265

Springdale

USA-Arkansas 72764

Tel: (+1) 50 17 50 10 00

Fax: (+1) 50 17 56 07 19

ALTO U.S.Inc

1100 Haskins Road

Bowling Green

USA-Ohio 43402

Tel: (+1) 41 93 52 75 11

Fax: (+1) 41 93 53 71 87

ALTO U.S.Inc

P.O.Box 4369

1500 North Belcher Road

Clearwater

USA-Florida 33765

Tel: (+1) 72 74 61 45 55

Fax: (+1) 72 74 61 51 93

303000010 / 010401

Page 7

TW 300 S

TW 350

Betriebsanleitung ............................... 2

Operating Instructions ........................ 7

Notice d'utilisation ............................ 12

Gebruiksaanwijzing ........................... 17

Istruzioni sull'uso ............................... 22

Driftsinstruks...................................... 27

Bruksanvisning................................... 32

Driftsvejledning ................................. 37

Käyttöohje.......................................... 42

Navodilo za uporabo .............................

Uputstvo za rad ......................................

Prevádzkový návod ................................

Provozní návod .......................................

Instrukcja obs³ugi ..................................

Kezelési utasítás ....................................

Instrucciones de manejo .................... 77

Instruções de operação...................... 82

ПдзгЯет лейфпхсгЯбт .........................

Ýþletme kýlavuzu ................................. 92

47

52

57

62

67

72

87

Page 8

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Erzeugnis:

Typ :

Beschreibung:

Die Bauart des Gerätes entspricht

folgenden einschlägigen

Bestimmungen:

Angewendete harmonisierte

Normen:

Angewendete nationale Normen

und technische Spezifikationen:

EG - Konformitätserklärung

Sprühextraktionsgerät

TW 300 S, TW 350

230 V~, 50 Hz

EG-Maschinenrichtlinie 98/37 EG

EG-Niederspannungsrichtlinie 73/23/EWG

EG-Richtlinie EMV 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Déclaration de conformité CE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produit:

Type:

Description:

La construction de l’appareil est

conforme aux réglementations

afférentes suivantes:

Normes harmonisées appliquées:

Normes nationales et spécifications

techniques appliquées:

Injecteur/extracteur

TW 300 S, TW 350

230 V~, 50 Hz

EC-Machine Directive 98/37 EG

EC-Low-Voltage Directive 73/23/EWG

EC EMV Directive 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Prüfungen und Zulassungen

EU Declaration of Conformity Dichiarazione di conformità CE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Product:

Type:

Description:

The design of the unit corresponds

to the following pertinent

regulations:

Applied harmonised standards:

Applied national standards and

technical specifications:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Tests And Approvals

Spray extraction cleaner

TW 300 S, TW 350

230 V~, 50 Hz

EC Machine Directive 98/37/EWG

EC Low-voltage Directive 73/23/EWG

EC EMV Directive 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

EG-Verklaring van overeenstemming

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beschrijving:

De constructie van het apparaat

voldoet aan de volgende van

toepassing zijnde voorschriften:

Toegepaste geharmoniseerde

normen:

Toegepaste nationale normen en

technische specificaties:

Sproei-/extractietoestel

TW 300 S, TW 350

230 V~, 50 Hz

EG-machinerichtlijn 98/37/EWG

EG-laagspanningsrichtlijn 73/23/EWG

EG-richtlijn EMV 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Bellenberg, 18.07.2000

Bellenberg, 18.07.2000

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Controles et homologations

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Prodotto:

Tipo:

Descrizione:

La costruzione dell' apparecchio è

conforme alle seguenti direttive

specifiche:

Norme armonizzate applicate:

Norme nazionali applicate e

specifiche tecniche:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Controlli e omologazioni

Apparecchio per estrazione e spruzzo

TW 300 S, TW 350

230 V~, 50 Hz

Direttiva CE sulle macchine 98/37/EWG

Direttiva CE sulla bassa tensione 73/23/EWG

Direttiva CE sulla compatibilità

elektromagnetica 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Atestado de conformidad de la UE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Producto:

Modelo:

Descripción:

La construcción de la máquina

corresponde a las siguientes

normas específicas:

Normas armonizadas aplicadas:

Normas nacionales aplicadas y

especificaciones técnicas:

Máquina de limpieza por aspersión/aspiración

TW 300 S, TW 350

230 V~, 50 Hz

R. de la UE para máquinas 98/37/EWG

R. de la UE para baja tensión 73/23/EWG

R. de la UE para la compatibilidad electromagnética 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Bellenberg, 18.07.2000

Bellenberg, 18.07.2000

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Keuringen en vergunningen

Bellenberg, 18.07.2000

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Pruebas y homologaciones

Bellenberg, 18.07.2000

Page 9

conformidade da UE

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produto:

Modelo:

Descrição:

A construção da máquina

corresponde às seguintes normas

específicas:

Normas harmonizadas aplicadas:

Normas nacionais aplicadas e

especificações técnicas:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Testes e homologações

aparelho de extração e pulverização

TW 300 S, TW 350

230 V~, 50 Hz

Directiva UE para máquinas 98/37/EWG

Directiva UE para baixa tensão 73/23/EWG

Directiva para a compatibilidade

electromagnética 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Atestado de

Bellenberg, 18.07.2000

ДЮлщуз бнфбрьксйузт ЕПК

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Рспъьн:

Фэрпт:

РесйгсбцЮ:

П кбфбукехбуфйкьт фэрпт фзт

ухукехЮт бнфбрпксЯнефбй уфпхт

бкьлпхипхт учефйкпэт

кбнпнйумпэт:

ЕцбсмпуиеЯует енбсмпнйумЭнет

рспдйбгсбцЭт:

ЕцбсмпуиеЯует еинйкЭт

рспдйбгсбцЭт кбй фечнйкпЯ

рспудйпсйумпЯ:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP ЕЛЕГЧПЙ КБЙ БДЕЙЕУ

УхукехЮ шекбумпэ бнбссьцзузт

TW 300 S, TW 350

230 V~, 50 Hz

ПдзгЯб ресЯ мзчбнюн ЕПК 98/37/ЕПК

ПдзгЯб чбмзлюн фЬуещн ЕПК 73/23/ЕПК

ПдзгЯб ресЯ злекфспмбгнзфйкЮт

ухмвбфьфзфбт 89/336/ÅÏÊ

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Bellenberg, 18.07.2000

EF-konformitetserklæring

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beskrivelse:

Apparatets konstruksjonstype er i

samsvar med følgende gjeldende

bestemmelser:

Anvendte harmoniserte standarder:

Anvendte nasjonale standarder og

tekniske spesifikasjoner:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Prøver og godkjennelser

Sprøjteekstraheringsapparat

TW 300 S, TW 350

230 V~, 50 Hz

EF-maskindirektiv 98/37/EEC

EF-lavspenningsdirektiv 73/23/EEC

EF-direktiv elektromagnetisk

kompatibilitet 89/336/EEC

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

EF-overensstemmelsesattest

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Type:

Beskrivelse:

Konstruktionen af dette apparat

opfylder følgende gældende

bestemmelser:

Anvendte harmoniserede

standarder:

Anvendte tyske standarder og

tekniske specifikationer:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Afprøvninger og godkendelser

Sprøyte- og ekstraksjonsrenser

TW 300 S, TW 350

230 V~, 50 Hz

EF-maskindirektiv 98/37/EØF

EF-lavspændingsdirektiv 73/23/EØF

EF-direktiv vedr. elektromagnetisk

fordragelighed 89/336/EØF

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Bellenberg, 18.07.2000

Bellenberg, 18.07.2000

EG-försäkran om

överensstämmelse

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Produkt:

Typ :

Beskrivning:

Apparatens konstruktion motsvarar

följande tillämpliga bestämmelser:

Tillämpade harmoniserade normer:

Tillämpade nationella normer och

tekniska specifikationer:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Provningar och koncessioner

Sprutextraktionsapparat

TW 300 S, TW 350

230 V~, 50 Hz

EG-maskindirektiv 98/37/EWG

EG-lågspänningsdirektiv 73/23/EWG

EG-direktiv EMK 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

EY-Vaatimustenmukaisuusvakuutus

Wap Reinigungssysteme GmbH & Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tuote:

Tyyppi:

Kuvaus:

Tämän laitteen rakenne vastaa

seuraavia määräyksiä:

Käytetyt harmonisoidut normit:

Käytetyt kansalliset normit ja

tekniset spesifikaatiot:

Johan Ley Dipl.Ing. W. Nieuwkamp

VP Tech-OP Tarkastukset ja hyväksymiset

Suihkepuhdistuslaite

TW 300 S, TW 350

230 V~, 50 Hz

EY-konedirektiivi 98/37/EWG

EY-pienjännitedirektiivi 73/23/EWG

EY-direktiivi EMV 89/336/EWG

EN 292

EN 60335-1, EN 60335-1-A6

EN 60335-2-10, EN 60335-2-68

EN 55014-1, EN 50014-2, EN 61000-3-2

DIN EN 60335-1

EN 60335-2-10

EN 60335-2-68

Bellenberg, 18.07.2000

Bellenberg, 18.07.2000

Page 10

1

1

2

4

3

5

1

4

2

3

6

5

Page 11

2

3

a

4

a

a

b

c

5

a

b

8 9

c

a

b

b

6

a

c

a

d

b

7

10

a

b

11

12

a

Page 12

READ THE OPERATING

INSTRUCTIONS AND

OBSERVE THE SAFETY

NOTES!

SAFETY NOTES

Do not pull the machine

along with the mains

lead. Take care not to

crush the mains lead or to

drag it over sharp corners.

Inspect the mains lead at

regular intervals. If the

mains lead is damaged,

the machine must not be

used until the lead has

been replaced with a lead

of the type specified in

the technical data.

If foam or fluid start to

escape from the machine,

switch off immediately.

Use only cleansing agents

approved by Wap/Alto.

INTENDED USE

The machines described in

these operating

instructions are intended

for use in cleaning textile

wall and floor coverings.

The machines are suitable

for commercial use, for

example in hotels,

schools, hospitals,

factories, shops, offices

and rental properties.

FUNCTION

Hot water, mixed with

cleansing agent, is

sprayed under pressure

down to the backing

fabric of the carpet / wall

covering and dissolves the

dirt.

At the same time, a

suction unit draws off the

water and the dirt flushed

to the surface out of the

carpet and into the dirty

water tank.

The pile becomes softer

and uniformly raised.

DESCRIPTION

(FIG. 1)

1 Metering valve

2 Suction / spray hose

3 Lid of dirty water tank

4 Suction / spray tube

5 ON/OFF switch

6 Lid for clean water

tank

ASSEMBLY

Before it is used for the

first time, the machine

has to be assembled:

• Push the suction tube

sections together.

• Push the suction hose

firmly into the spray

extraction cleaner and

the suction tube.

(TW 300 S: Fig. 2a, 4a

TW 350: Fig. 3a, 4a)

• Allow the pressure

hose to engage in the

coupling

(TW 300 S: Fig. 2b

TW 350: Fig. 5a)

• Allow the other end

of the pressure hose

to engage in the

metering valve.

(Fig. 4b)

• To remove the hose,

release the springloaded locking ring.

(Fig. 5a)

ELECTRICAL

CONNECTION

• The mains voltage

must correspond to

the voltage specified

on the rating plate!

(TW 300 S: Fig. 6a

TW 350: Fig. 7a)

• Connect the machine

only to a correctly

installed fused plug

socket with at least a

10 A fuse.

• Turn off the main

switch

(TW 300 S: Fig. 2c

TW 350: Fig. 5b)

• Insert the mains lead

plug into the plug

socket.

7

Page 13

FILL THE FRESH WATER

TANK

• Pour hot water (max.

40° C) into the fresh

water tank and mix

with cleansing agent.

(TW 300 S: Fig. 8

TW 350: Fig. 9a)

• Mixing ratio with

ALTO Top Wash

(liquid): 1% - 5%

Prespraying:

max. 10%

• Mixing ratio with

ALTO Top Wash P

(powder, alkaline):

0.3% - 1%

Prespraying: max. 5%

• TW 300 S only:

Observe mark for

maximum filling level

(210 mm under edge

of tank)! (Fig. 8a)

CAUTION!

Never use foaming

carpet shampoo. Use

only low-foam

cleansing agents which

are expressly approved

for use in spray

extraction cleaners.

PREVENTION OF FOAM

IN THE DIRTY WATER

TANK

When cleaning carpets

which have already been

shampooed several times,

excessive foaming can

occur in the dirty water

tank.

• ALTO Foam STOP

foam preventive agent

(0.05% in the dirty

water tank) effectively

prevents foaming.

PRECAUTIONARY

MEASURES

Use the spray

extraction method only

when the textile wall

or floor covering and

the wall or floor cannot

be damaged.

– Take care on wood or

floors sensitive to

water.

– Take care with carpets

which have been laid

using water-soluble

glue.

– Take care on carpets

with a backing fabric

sensitive to water (e.g.

jute).

– Take care on natural

fibre carpets.

– Observe the

manufacturer’s carpet

declaration.

– If in doubt about the

colour-fastness, apply

a small amount of

cleaning agent to the

carpet in an

inconspicuous place

using a white cloth. If

the cloth picks up the

colour, the carpet is

not colourfast.

CARPET PREPARATION

• Before starting the

spray extraction,

vacuum the carpet

thoroughly.

• Pretreat spots or

severe soiling with a

special cleanser or

spot remover.

USE FOR NORMAL

SOILING

• Start cleaning the

carpet in the corner

furthest from the door.

• Turn on both ON/OFF

switches for the suction

unit and the pump

(TW 300 S: Fig. 2c

TW 350: Fig. 5b)

• Position the spray

nozzle at the edge of

the carpet and actuate

the metering valve.

• Pull the nozzle

gradually backwards

(1 m in 5 seconds),

apply slight pressure

to the hand tube.

• Shortly before

reaching the end of a

stroke, close the

metering valve and

pick up the water last

sprayed.

• The next working

stroke should overlap

the previous stroke by

approx. 2 cm.

• The drying time can

be shortened if the

carpet is sucked off

again with the spray

extraction unit.

8

Page 14

USE FOR SEVERE

SOILING

• Prespray the cleansing

agent with the

metering valve open

and the suction motor

switched off.

• Allow the cleansing

agent to act, but do

not allow to dry.

• Carry out cleaning as

described in the

section “Use for

normal soiling”.

• Repeat the cleaning

process, preferably at

right angles to the

previous working

direction. Carry out

this second cleaning

process only when the

carpet has dried

completely.

AFTER WORK

• TW 350 only:

Draw all the water out

of the clean water tank

using the suction hose.

TW 300 S, TW 350:

• Turn off the ON/OFF

switch.

• Remove the mains

lead plug from the

plug socket.

• Inspect the filter in the

clean water tank and

clean, if necessary

(TW 300 S: Fig. 8b

TW 350: Fig. 9c)

• Empty and clean the

dirty water tank.

• TW 350 only:

Close the drain hose

(Fig. 10b).

SERVICE /

MAINTENANCE

Carry out only work

described in the operating

instructions.

Remove the mains lead

plug from the plug socket

before working on the

machine.

Leave service and repair

work, in particular the

remedying of electrical

faults, to the Wap/Alto

service or an authorised

specialist.

GUARANTEE

Our general terms and

conditions apply to the

guarantee and warranty.

CHECKS DURING WORK

• If the suction power

decreases, empty the

dirty water tank.

• Always empty the

dirty water tank

(TW 300 S: Fig. 9b

TW 350: Fig. 10a)

when refilling the

clean water tank

(TW 300 S: Fig. 8

TW 350: Fig. 9a)

STORAGE

• Coil up the mains

lead.

• Protect the machine

and accessories

against frost.

9

Page 15

TROUBLESHOOTING

Fault

‡ Motor not running

‡ Weak spraying force

‡ Weak suction force

Cause

> Power supply

interrupted

> Spray nozzle clogged

(Fig. 11a)

> Filter in fresh water

tank clogged (Fig. 8b,

9c)

> Fresh water tank

empty

> Pressure pump

defective

> Lid not fitted correctly

on dirty water tank

(air leaks)

> Nozzle clogged

> Suction hose

connections not

correctly fitted (air

leaks)

> Dirty water tank is full,

float switch interrupts

power supply (Fig. 12)

> Air filter clogged

(TW 300 S: Fig. 8c

TW 350: Fig. 9d)

> TW 350 only:

Dirty water drain hose

not closed (Fig. 10b)

Remedy

• Check mains lead,

plug socket, fuse

• Clean and/or descale

nozzle

• Clean

• Refill

• Call Alto technician or

authorised specialist

• Fit lid tightly; check

gasket

• Clean

• Check

• Empty dirty water tank

• Clean

• Close

10

Page 16

CLEANSING AGENTS AND CARE PRODUCTS

Product Brief description

Alto Top Wash

Alto Top Wash P

Neutral surface cleansing agent

Powdery alkaline surface

cleansing agent

Alto Foam STOP

Foam preventive agent

ACCESSORIES

Product Brief description

Upholstery

adapter

Carpet adapter

– Plastic with inner nozzle

– Aluminium with outer nozzle

1-nozzle adapter

4-nozzle adapter

Spray hose

Spray lance

pH value

7

10

7

TW 300 S

x

x

x

Package

size

6 x 1l

10 l

6 x 1 kg

10 kg

6 x 1 l

10 l

Order

No.

8467

80937

81100

81033

8469

80938

TW 350 Order

No.

x

x

x

x

x

x

6696

7335

7310

7330

7311

11553

TECHNICAL DATA

TW 300 S TW 350

Voltage Volt 230 230

Mains frequency Hz 50 50

Total installed load / fuse Watt/A 1200/10 1200/10

Protection class and type of protection KL/IP I / X4 I / X4

Suction motor power Watt 1000 1000

Vacuum max. Pa 22000 22000

Air volume l/min 3000 3000

Pump motor power Watt 100 180

Pump pressure, water volume bar / l/min 2 / 2 2,5 / 2,5

Interference suppression class EN 55014-1 EN 55014-1

Mains lead (H07 RN-F 3G1,5) m 7.5 7.5

Sound pressure level to EN 60704-1 dB(A) 74 76

Fresh water tank / max. temperature l / °C 7 / 40 14 / 40

Dirty water tank l 7 14

Weight kg 9.5 16

Dimensions L x W x H mm 390x390x520 440x360x460

Working width mm 260 260

11

Page 17

INTERNET

http://www.alto-online.com

ALTO HEADQUARTERS

Incentive International A/S

Kongens Nytorv 28

P.O.Box 2064

DK 1013 Copenhagen K

T el.: (+45) 33 11 11 42

Fax: (+45) 33 93 46 36

e-mail: incentive@incentive-dk.com

SUBSIDIARIES

AUSTRALIA

ALTO Overseas Inc.

1B/8 Resolution Drive

P.O.Box 797

AUS-Caringbah, N.S.W. 2229

Tel: (++61) 295 24 61 22

Fax: (++61) 295 24 52 56

AUSTRIA

Wap Reinigungssysteme GmbH

Metzgerstr. 68

A-5101 Bergheim/Salzburg

Phone: (+43) 662 45 64 00-14

Fax: ( +43) 662 45 64 00-55

BRASIL

Wap do Brasil Ltda.

Rua 25 de Agosto, 608

CEP 83323-260 Pinhais/Paraná

BR-Brasil

Tel./Fax (++55) 4 18 67 40 26

CANADA

ALTO Canada

24 Constellation Road

Rexdale

C-Ontario M9W 1K1

Tel: 1 41 66 75 58 30

Fax: 1 41 66 75 69 89

CZECH REPUBLIC

Wap čistící systémy s.r.o.

Zateckých 9

CZ-140 00 Praha 4

Tel. (+420) 2 42 78 38

Fax (+420) 2 42 19 25

DENMARK

AL TO Danmark A/S

Industrikvarteret

DK-9560 Hadsund

Tel: (+45) 72 18 21 00

Fax: (+45) 72 18 21 05

AL TO Danmark A/S

Blytækkervej 2,

DK-9000 Aalborg

Tel: (+45) 72 18 21 00

Fax: (+45) 72 18 20 99

FRANCE

ALTO France S.A.

B.P. 44, 4 Place d’Ostwald

F-67036 Strasbourg Cedex 2

Tel: (++33) 3 88 28 84 00

Fax: (++33) 3 88 30 05 00

GERMANY

Wap KundenCenter

Tel. (+49) 0180 / 5 37 37 37

Fax (+49) 0180 / 5 37 37 38

e-mail: center@wap-online.de

Besuchen Sie uns im Internet:

http://www.wap-online.com

Wap ALTO Group

Wap Reinigungssysteme GmbH

& Co.

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tel. (+49) 07306 / 72-0

Fax (+49) 07306 / 7 22 00

RegionalCenter Frankfurt

Moselstraße 2b

D-63452 Hanau

Tel. (+49) 06181 / 18 72-0

Fax (+49) 06181 / 18 72-11

e-mail: rcffm@wap-online.de

RegionalCenter

Hamburg/Hannover

Storchenweg 8A

D-21217 Seevetal–Meckelfeld

Tel. (+49) 040 / 79 09 06 60

Fax (+49) 040 / 79 09 06 66

e-mail: rchann@wap-online.de

RegionalCenter Köln

Kaiserstraße 127

D-51145 Köln-Porz

Tel. (+49) 02203 / 9 22 99-0

Fax (+49) 02203 / 9 22 99-25

e-mail: rckoeln@wap-online.de

RegionalCenter Leipzig

Wachau/Gewerbegebiet

Südring 16

D-04416 Markkleeberg

Tel. (+49) 034297 / 4 87 25

Fax (+49) 034297 / 4 93 57

e-mail: rcleip@wap-online.de

RegionalCenter München

Furtweg 11

D-85716 Unterschleißheim

Tel. (+49) 089 / 32 15 02-0

Fax (+49) 089 / 32 15 02-40

e-mail: rcmuen@wap-online.de

RegionalCenter Stuttgart

Dornierstraße 7

D-71069 Sindelfingen

OT Darmsheim

Tel. (+49) 07031 / 76 70-0

Fax (+49) 07031 / 76 70-20

e-mail: rcstut@wap-online.de

RegionalCenter Ulm

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Tel. (+49) 07306 / 72-195

Fax (+49) 07306 / 3 41 29

e-mail: rculm@wap-online.de

GREAT BRITAIN

Wap ALTO Cleaning

Systems(UK)Ltd.

Gilwilly Industrial Estate

GB-Penrith, Cumbria CA11 9BN

Tel: (+44) 1 7 68 86 89 95

Fax: (+44) 1 7 68 86 47 13

Telex: 64309 kewg

HONG KONG

ALTO Hong Kong

RM 602, Tower B, Regent Ctr.

79, Ta Chuen Ping Street

Kwai chung

HK-Hong Kong

Tel. (+852) 26 10 10 42

Fax (+852) 26 10 10 47

Att. Mr. Dereck Lee

JAPAN

ALTO Danmark A/S Japan

Representative Office

Naruse-build 4F

7-2 Shinbashi 1-Chome, Minato-Ku

J-T okyo 105-004

Tel: (+81) 3 35 69 38 07

Fax: (+81) 3 35 69 38 08

e-mail: alto-jpn@aqua.famille.ne.jp

CROATIA

Wap sistemi za čišćenje, d.o.o.

Florijana Andrašeca 14

HR-10000 Zagreb

Tel. (++385) 01 / 3 09 49 07

(++385) 01 / 3 09 49 09

Fax (++385) 01 / 3 09 49 06

e-mail: admin.wap@wap-sistemi.hr

NETHERLANDS

Wap ALTO Nederland

Postbus 65

NL-3370 AB HardinxveldGiessendam

Tel. (+31) 01846 / 67 72 00

Fax (+31) 01846 / 67 72 01

NORWAY

AL TO Norge AS

Bjørnerudveien 24

N-1266 Oslo

Tel: (+47) 22 75 17 70

Fax: (+47) 22 75 17 71

SINGAPORE

AL TO Danmark A/S

Representative Office

No. 17 Link Road Road

SG-Singapore 619034

Tel: (+65) 2 68 10 06

Fax: (+65) 2 68 49 16

SLOWAKIA

Wap čistiace systémy spol. s.r.o.

Vajnorská 135

SK-83237 Bratislava

Tel. (+421) 7 44 25 96 64

Fax (+421) 7 44 25 79 44

SLOVENIA

Wap čistilni sistemi, d.o.o.

Letališka 33

SLO-1110 Ljubljana

Tel. (++0368) 61 44 23 42

Fax (++0368) 61 1 40 42 94

SPAIN

Hidrolimpia, S.L. (ALTO

Iberica)

Ronda de Valdecarrizo 9

– Modulo 5 –

E-28760 Tres Cantos Madrid

Tel. (+34) 091 / 804 62 56

Fax (+34) 091 / 804 64 63

SWEDEN

AL TO Sverige AB

Aminogatan 18, Box 40 29

S-431 04 Mölndal

Tel: (+46) 3 17 06 73 00

Fax: (+46) 3 17 06 73 41

SWITZERLAND

Wap Reinigungssysteme

(Schweiz) AG

Holzikerstraße 488

CH-5042 Hirschthal / AG

Tel. (+041) 062 / 7 39 32 50

Fax (+041) 062 / 7 39 32 51

USA

ALTO U.S.Inc

390 South Woods Mill Road

Suite 300

Chesterfield

USA-Missouri 63017-3433

Tel: (+1) 314 205 1220

Fax: (+1) 314 205 1544

ALTO U.S.Inc

2100 Highway 265

Springdale

USA-Arkansas 72764

Tel: (+1) 50 17 50 10 00

Fax: (+1) 50 17 56 07 19

ALTO U.S.Inc

1100 Haskins Road

Bowling Green

USA-Ohio 43402

Tel: (+1) 41 93 52 75 11

Fax: (+1) 41 93 53 71 87

ALTO U.S.Inc

P.O.Box 4369

1500 North Belcher Road

Clearwater

USA-Florida 33765

Tel: (+1) 72 74 61 45 55

Fax: (+1) 72 74 61 51 93

65532 010800

Loading...

Loading...