Page 1

SWEEPER

SR 1100 P/B SR 1200 P/B

SR 5110 P/B SR 5120 P/B

Manual for use and maintenance

FORM No. S31NUK5120(3)2001-04

Page 2

INDEX

Model:

Serial No.:

Power:

Tot weight:

Tot weight:

(w/o battery)

Type G&E Floor cleaning machine.

MADE IN ITALY

Prod. No.:

Max axel rear:

Max axel front:

Noise level:

Voltage:

Nilfisk-Advance Italia

Località Novella terza

26862 Guardamiglio (Italia)

S31NUK5120(3)2001-04

INTRODUCTION / GENERAL INFORMATION ............................................................................. 1

UNPACKING .................................................................................................................................. 2

TECHNICAL DATA ........................................................................................................................ 3

DESCRIPTION OF COMMANDS AND CONTROL PANEL.......................................................... 4

PRELIMINARY OPERATIONS ...................................................................................................... 5-7

USE ................................................................................................................................................ 8-13

USE OF THE WORKING PROGRAMS .................................................................................... 9

FURTHER PERFORMANCES OF THE MACHINE

WITH PETROL ENGINE ........................................................................................................... 13

SIDE BRUSHES ADJUSTMENT AND REPLACEMENT .............................................................. 14

MAIN BRUSH REPLACEMENT .................................................................................................... 15-16

FILTER CLEANING AND REPLACEMENT .................................................................................. 17-18

MAINTENANCE ............................................................................................................................. 19-22

BATTERIES: CONTROL AND RECHARGE............................................................................ 19

BRAKES ADJUSTMENT.......................................................................................................... 20

FRONT LAMP REPLACEMENT............................................................................................... 20

MAINTENACE OF THE PETROL ENGINE .............................................................................. 21-22

SUMMARY OF MAINTENANCE CONTROLS (battery version) ............................................ 23

SUMMARY OF MAINTENANCE CONTROLS (petrol version) .............................................. 24

OPTIONAL ITEMS ......................................................................................................................... 25

SAFETY FUNCTIONS AND TROUBLE-SHOOTING .................................................................... 26

SERVICE ADDRESSES................................................................................................................. 27

Page 3

INTRODUCTION / GENERAL INFORMATION

This manual will help you get the most from your Nilfisk SR1100 - SR1200. Read it thoroughly before operating the

machine. Specifications and details are subject to change without prior notice.

SPARE PARTS AND MAINTENANCE

Repairs, when required, should be performed by Nilfisk-Advance service personnel using Nilfisk-Advance original

replacement parts and accessories. Any “left,, or “right,, indication are always defined with reference to the machine

forward movement direction.

When calling Nilfisk-Advance for repair parts or service, please specify the Model and the Serial Number when

discussing your machine.

CHANGES AND IMPROVEMENTS

Our company constantly improves its products and reserves the right to make changes and improvements at its

discretion without being obliged to apply such benefits to the machine that were previously sold.

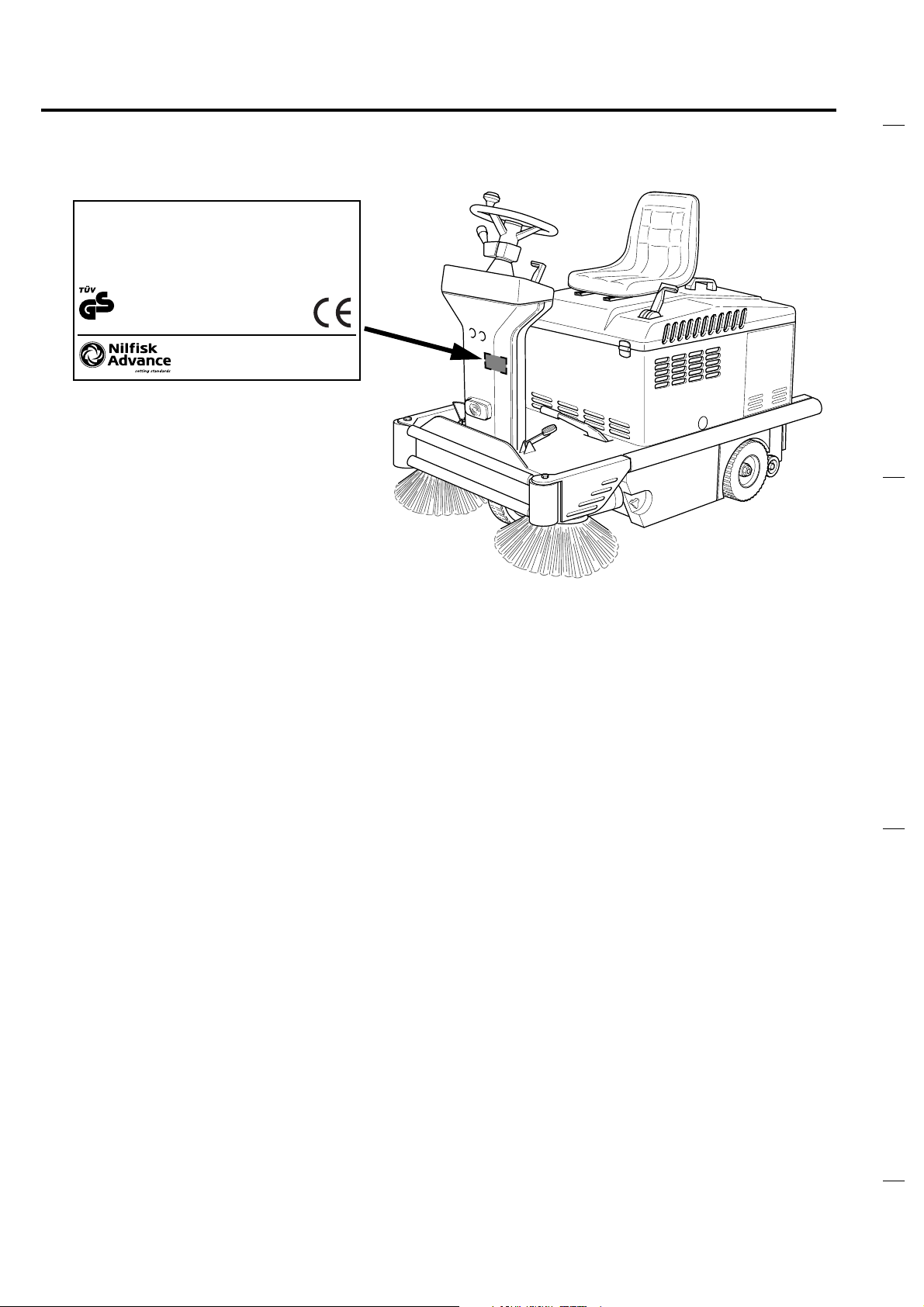

NAME PLATE

The Model and the Serial Number of your machine are shown on the Name plate located on the steering column.

This information is needed when ordering repair parts for the machines. Use the space below to note the Model and

the Serial Number of your machine for future reference.

MODEL_________________________________________

SERIAL NUMBER_________________________________

S31NUK5120(3)2001-04

GENERAL SAFETY RULES

Carefully follow the rules described below to avoid injury to the operator and damage to the machine.

Carefully read the labels on the machine, do not cover them for any reason and replace them immediately if they

become worn or damaged.

- The machine storage temperature range should be between 32˚F and 104˚F

- The machine working temperature is from +32°F to +104°F

- Humidity range should be between 30% and 95%.

- Do not use the machine in an explosive atmosphere environment

- Do not use the machine as a transport vehicle.

- Do not allow the brushes to operate while the machine is stationary to avoid damaging the floor.

- In case of fire, use a powder extinguisher.

- Do not bump into shelves or scaffolding where there is a risk of falling objects.

- Adjust the operating speed to the floor conditions.

- Do not exceed the declared slope limit to avoid an unstable condition.

- When the machine is parked, remove the key and engage the parking brake.

- When machine-operating malfunction occur, make sure that they are not caused by a lack of routine maintenance.

If not, request assistance from the service centre.

- If parts must be replaced, request ORIGINAL spare parts from a dealer or Authorised Retailer.

- Before any maintenance operations, disconnect the electric power supply from the batteries.

- Do not remove guards which require the use of tools to be disassembled.

- Do not wash the machine with pressurised water, or with corrosive substances.

- A service centre should inspect the machine every 200 hours of operation.

- The machine must be disposed of properly, because of the presence of toxic-harmful materials (battery acid, oil,

etc.) which are subject to standards that require disposal in special centres.

- The machine will not generate damaging vibration.

SAFETY- ACCIDENT PREVENTION

No accident prevention program is effective without the complete co-operation of the person directly responsible for

operating the machine. Most of the accidents that may occur in a company, on the job or during transfers are caused

by not-observing fundamental safety rules. A careful and cautious user is the best guarantee against accidents and

is more effective than any type of prevention program. While using the machine pay attention to your surroundings

and people nearby, especially to children.

SAVE THESE INSTRUCTIONS !!

1

Page 4

1

2

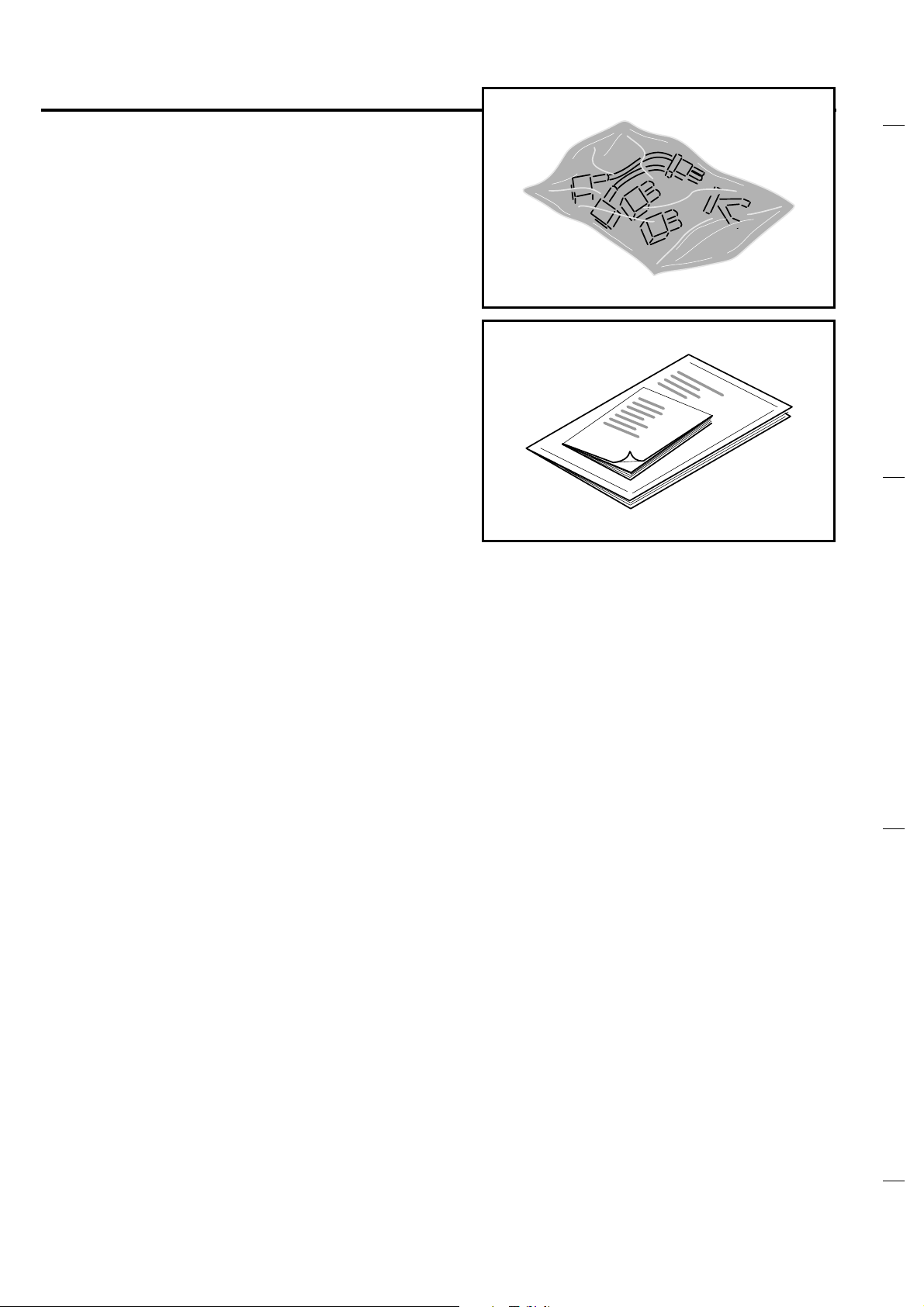

UNPACKING

Please check that the following items are

supplied with the machine:

- envelope with cables for batteries and

connector for battery-charger.

- technical documents (Spare Parts Catalogue,

Manual for Use and Maintenance and - for the

petrol version only - Use and Maintenance

Manual of the engine).

S31NUK5120(3)2001-04

2

Page 5

TECHNICAL DATA

S31NUK5120(3)2001-04

VERSION SR 1100B - SR 5110B SR 1100P - SR 5110P SR 1200B - SR 5120B SR 1200P - SR 5120P

Voltage 24V 24V 24V 24V

Engine model / Honda G150 -K1 144 cc / Honda G150 -K1 144 cc

Nominal Power at 3600

RPM

Power at 3200 RPM

setting

Start / Electric / Electric

Drive electric motor 450W - 120 RPM 450W - 120 RPM 550W - 330 RPM 550W - 330 RPM

Main brush electrical

motor

Suction electric motor 200W - 3300 RPM 200W - 3300 RPM 200W - 3300 RPM 200W - 3300 RPM

Side brush electric motor 60W - 120 RPM 60W - 120 RPM 90W - 120 RPM 90W - 120 RPM

Forward speed max 7 km/h max 7 km/h max 9 km/h max 9 km/h

Reverse speed max 3,5 km/h max 3,5 km/h max 4 km/h max 4 km/h

Max slope 20% 20% 20% 20%

Main brush Ø 300 mm x 700 mm Ø 300 mm x 700 mm Ø 300 mm x 800 mm Ø 300 mm x 800 mm

Side brush Ø 430 mm Ø 430 mm Ø 460 mm Ø 460 mm

Cleaning width with 1

side brush

Cleaning width with 2

side brushes

Front wheel (NR 1) Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm

Rear drive wheels (NR 2) Ø 250 mm Ø 250 mm Ø 250 mm Ø 250 mm

Container capacity 70 lt 70 lt 100 lt 100 lt

Panel filte r 2,95 m

Electric filter shaker 90W - 6000 RPM 90W - 6000 RPM 90W - 6000 RPM 90W - 6000 RPM

Machine length 1376 mm 1376 mm 1489 mm 1489 mm

Width 910 mm 910 mm 1020 mm 1020 mm

Height 1193 mm 1193 mm 1251 mm 1251 mm

Weight (without batteries) 240 kg 280 kg 300 kg 350 kg

Fuel tank capacity / 2,5 lt / 2,5 lt

Engine oil tank capacity / 0,7 lt / 0,7 lt

500W - 1600 RPM 500W - 1600 RPM 500W - 1600 RPM 500W - 1600 RPM

/ 3,8 Hp - 2,8 Kw / 3,8 Hp - 2,8 Kw

/3 Hp - 2,2 Kw / 3 Hp - 2,2 Kw

900 mm 900 mm 1050 mm 1050 mm

1100 mm 1100 mm 1250 mm 1250 mm

2

2,95 m

2

2,95 m

2

2,95 m

2

3

Page 6

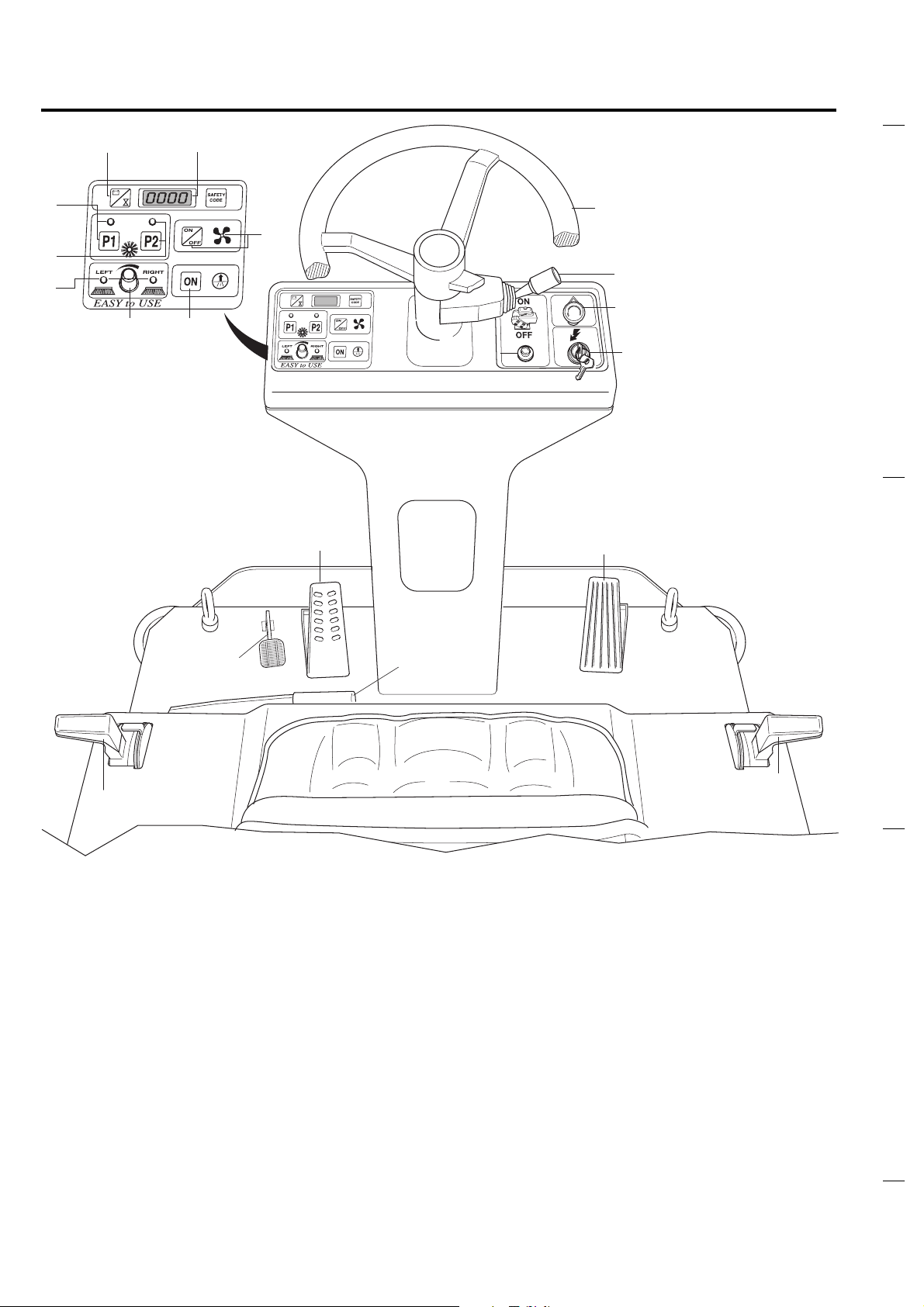

19

1

2

3

4

5

6

7

8

9

4 10

11

12

13

14

15

16

17

18

19

DESCRIPTION OF COMMANDS AND

CONTROL PANEL

1

2

3

5

4

7

6

8

11

S31NUK5120(3)2001-04

13

12

9

10

15

14

18

- Voltmeter/hourmeter push button

- Display

- Button for selection/indicator of working

program P1

- Button for selection/indicator of working

program P2

- ON/OFF button and indicator of suction

motor

- Knob for the speed adjustment of the

side brushes

- Indicator of the operation of left/right side

brushes

- ON button of filter-shaker motor

- Emergency stop push button

16

17

19

- ON/OFF main key switch

- Start/Stop push button for petrol engine

- Selection of forw./reverse speed, light ON/

OFF, horn

- Steering wheel

- Pedal for flap lifting

- Brake pedal

- Accelerator

- Parking brake lever

- Lever for left side brush command

- Lever for right side brush command

Page 7

1

2

3

1

1a

1b

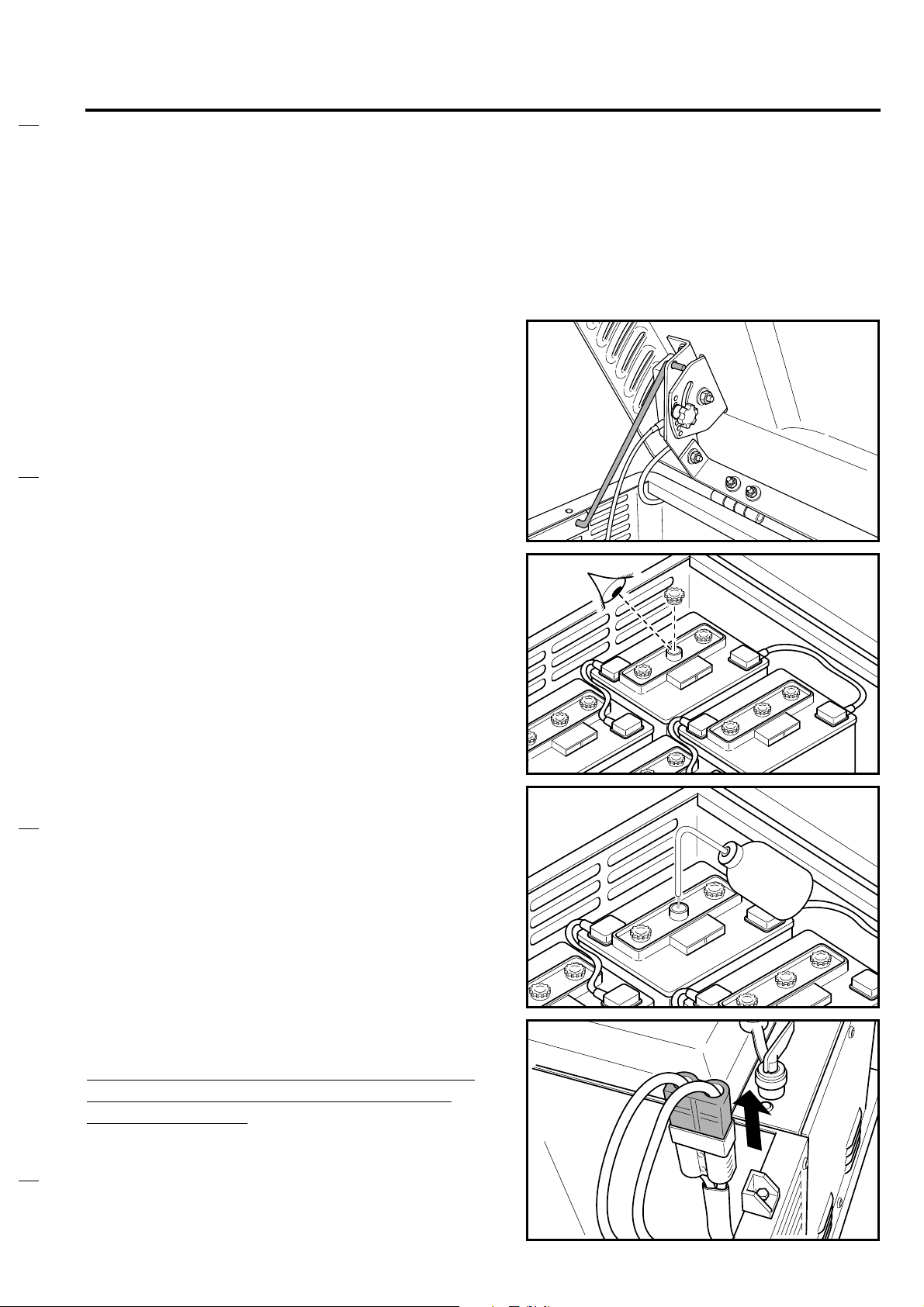

PRELIMINARY OPERATIONS

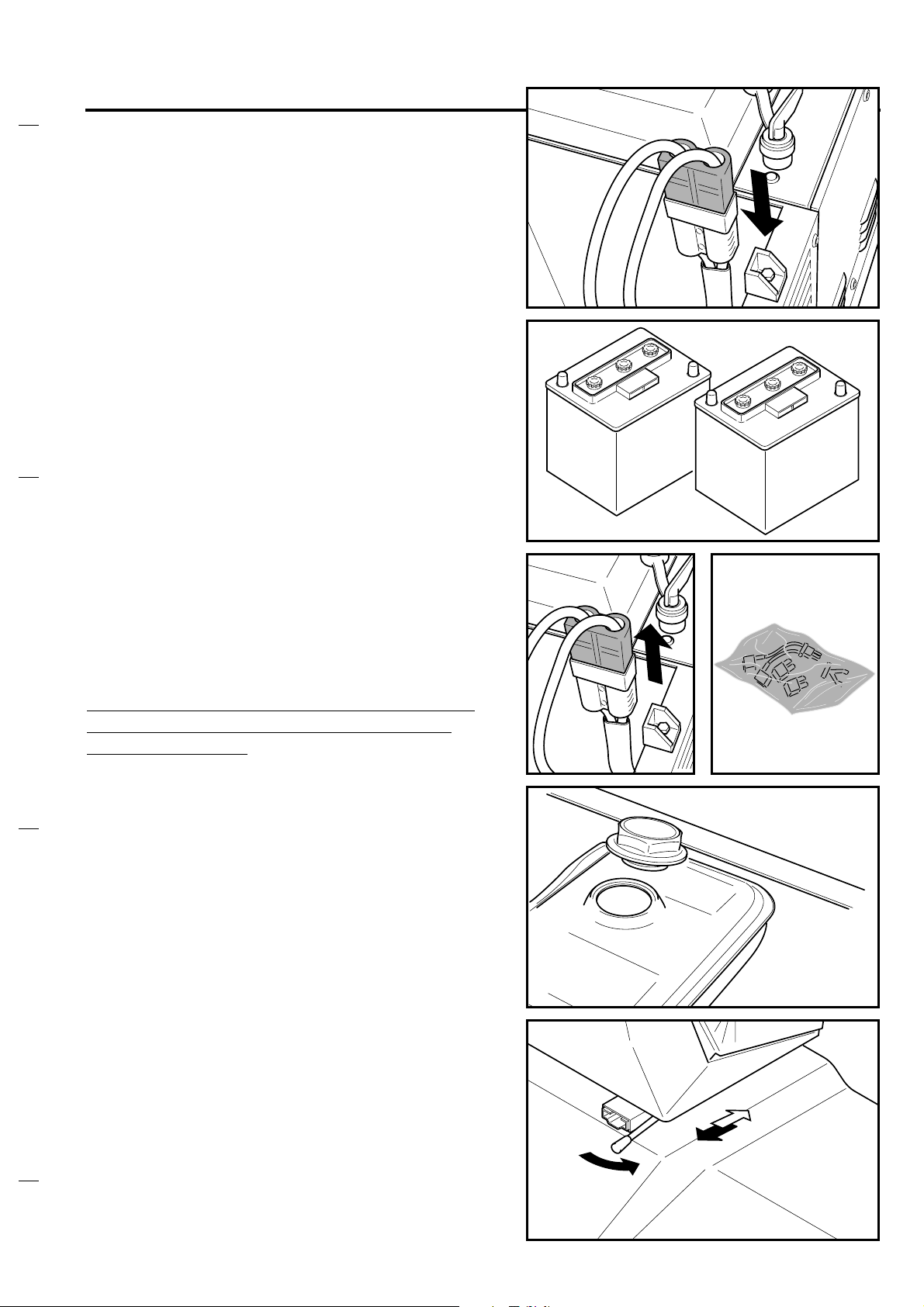

Both versions of the machine, petrol and battery,

require a 24 V battery set.

Depending on the country where the machine is

sold three possibilities can occur:

- the battery is supplied with the machine and it

is set, complete with acid solution

- the battery is supplied with the machine and it

is set, but not complete with acid solution

- the battery is not supplied.

The battery compartment is under the seat: lift

the compartment lid, towards the steering wheel,

and verify which one of the three possibilities is

applied to your machine.

S31NUK5120(3)2001-04

If the batteries are installed open one of the caps

of every battery and check if they are filled with

electrolyte.

- If the battery is filled:

. Check the electrolyte level in every cell and -

if necessary- fill up with distilled water.

. Proceed with a battery recharge according to

the MAINTENANCE paragraph and to the

Battery User Manual.

WARNING: before starting the recharge the

battery connector must be disconnected

from the machine.

After the recharge plug the battery connector to

the machine.

5

Page 8

2

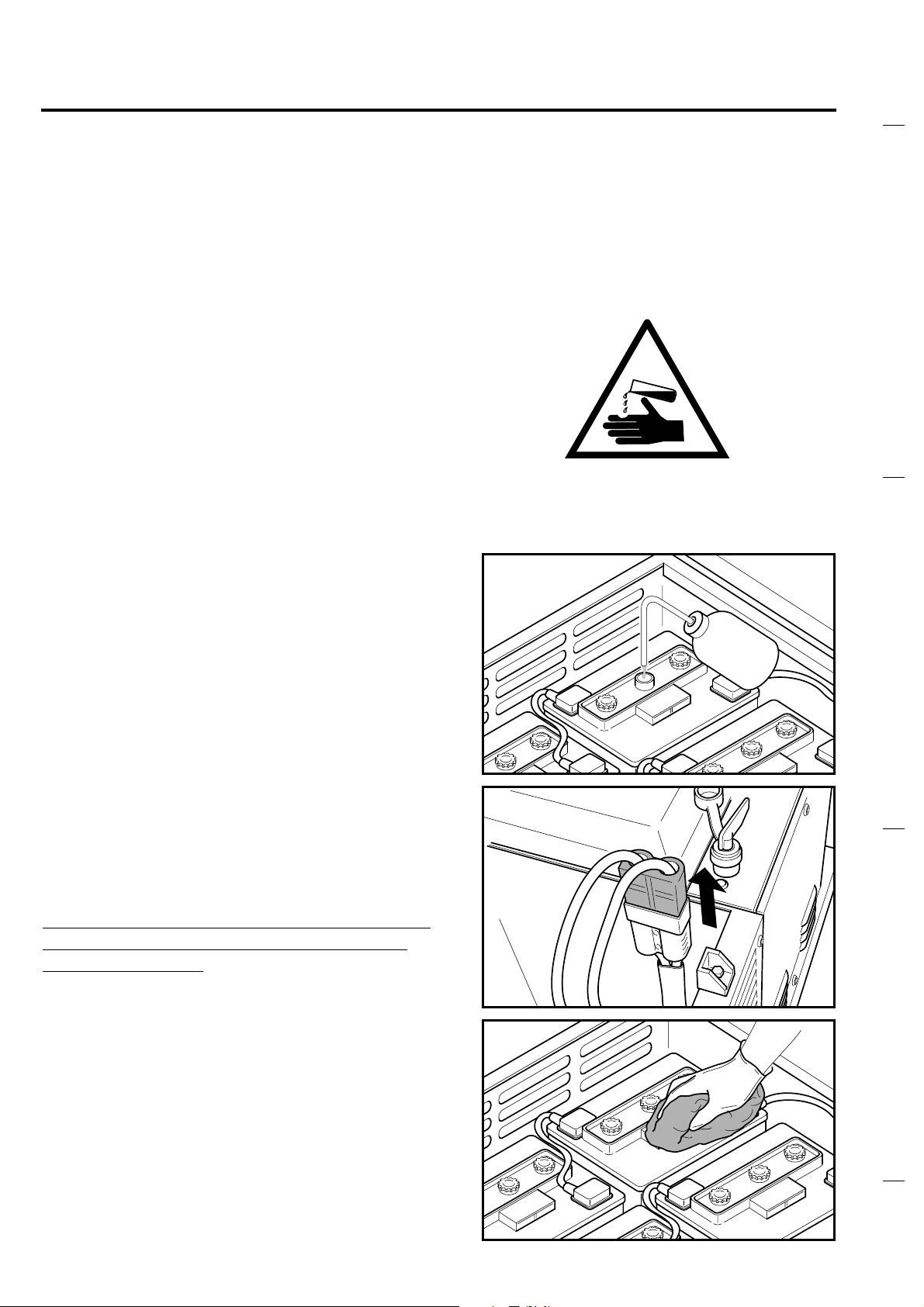

PRELIMINARY OPERATIONS

- If the batteries are installed but not filled with

acid solution they must be filled with a solution

of sulphuric acid (density between 1,270 Kg

and 1,290 Kg at 25°C temperature) according

to the instructions specified below and in the

Battery User Manual.

BATTERY FILLING UP WITH ACID SOLUTION

Warning: the battery acid is corrosive; if it

comes in contact with the skin or eyes rinse

thoroughly with water and consult a

physician.

The batteries must be filled in a well

ventilated area.

S31NUK5120(3)2001-04

Fill every battery cell with acid; the right level is

specified in the Battery User Manual.

After one hour fill up with acid, if necessary.

Let batteries rest for a further hour; then proceed

with a recharge according to the instructions

specified in the Battery User Manual and in the

MAINTENANCE paragraph. During the recharge

the battery caps must be open.

WARNING: before starting the recharge the

battery connector must be disconnected

from the machine.

After the recharge close all the cell caps and

clean the top of the battery from any acid

remains.

6

Page 9

3

PRELIMINARY OPERATIONS

Connect the battery connector to the machine.

- If the machine is not equipped with batteries

they must be procured and mounted. It is

recommended to get the assistance of

qualified personnel to choose and set the

batteries.

S31NUK5120(3)2001-04

The electric cables supplied with the machine

can be used for the connection of the four

batteries.

WARNING: before starting the recharge the

battery connector must be disconnected

from the machine.

Fill the fuel tank with UNLEADED PETROL and

close the engine compartment.

Check the engine oil level according to what

specified in chapter “Maintenance”

After having set the batteries, climb onto the

machine and adjust the seat to find the most

comfortable position.

Now the machine is ready to be used.

7

Page 10

)

)

USE

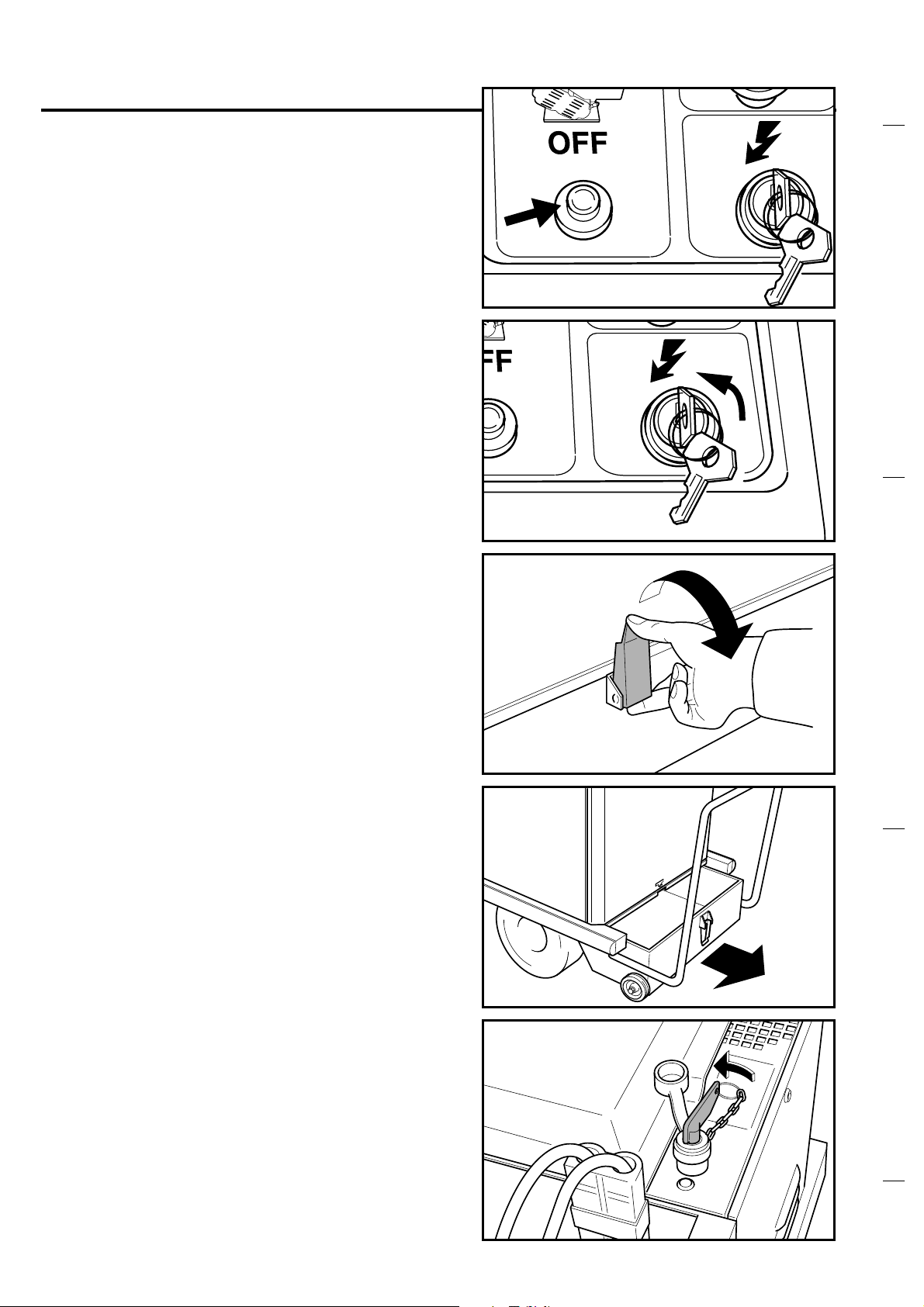

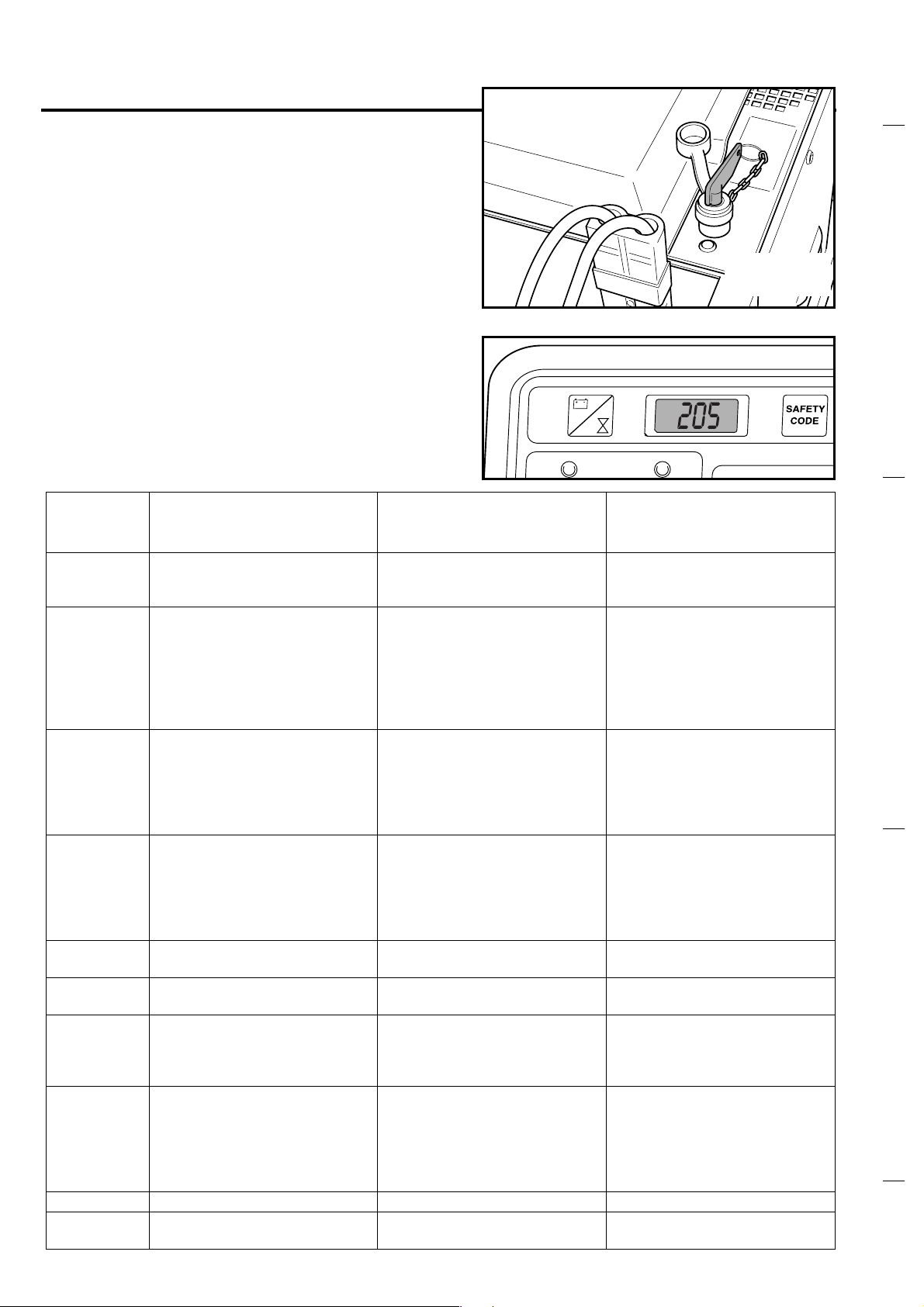

Insert the ignition key into the panel and turn it

clockwise: the display will show all zeros and after

about three seconds the battery voltage will appear.

Note : the temporary lighting of the two side brush

indicators and the short sound from the reverse

speed acoustic indicator are to be considered a

normal behaviour.

Wait not less than three seconds before restarting the

machine after switching Off.

Check the charge status of the batteries on the

display.

Six different data/functions can be shown on the

display.

The six functions are described in the following table

Displayed datum/function

1. Voltmeter : the battery voltage is normally shown on the

display. A block function will be activated in case of battery

undervoltage: when battery voltage will be about 20V all

machine functions will stop, except traction; in this case the

display will show 0205; proceed then with a battery recharge

(see Maintenance paragraph)

2. & 3. Hourmeter : to read the machine working time - in

hours - press once the yellow display button. By pressing the

button a second time the working minutes will appear. Just

waiting ten seconds the display will show the battery voltage

again

4. Total swept surface (m

each 1000 m

5. Daily swept surface (m

each 10 m

6. Productivity : sweeping rate m

instantaneous machine working speed

2

2

2

: the displayed value will increase

2

: the displayed value will increase

2

/hour: it depends on the

Display

reading

Normally fixed.

(battery voltage)

Flashing when

0205 appears.

Fixed

Fixed

Fixed

Flashing

S31NUK5120(3)2001-04

.

Notes :

- to pass to the next function press the yellow display

button once, 10 seconds after choosing one of the

possible data/functions

- the display will return automatically to the battery

voltage from every function

- data 2 and 3 will increase just using the traction

function (accelerator pedal)

- data 4, 5 and 6 will increase only if main broom is

turning AND traction function is used

- when datum 5 is displayed you can reset it just by

keeping the yellow display button pressed 5

seconds.

- If the batteries are charged enough, now it is

possible to start the job (in battery mode).

If the machine is equipped with the gasoline engine,

proceed with the start of the engine itself.

START/STOP OF THE PETROL ENGINE

To start the gasoline engine press the red button

shown in the figure; to stop the engine press the

same button again.

8

Page 11

P1

P2

USE

USE OF THE WORKING PROGRAMS

Once the machine has been turned on and

eventually after starting the petrol engine,

choose one of the two working programs P1 and

P2 according to your cleaning need and press

the relevant button:

is the “light cleaning program” (for internal

environment, i.e. smooth floor, moquette, small

debris etc.)

is the “hard cleaning program” (for external

environment, i.e. asphalt, uneven floor, big

debris etc.).

P1

S31NUK5120(3)2001-04

P2

After having pressed the preferred button the

relevant light indicator will turn on, together with

the suction motor indicator.

The temporary activation of the main brush and

suction electric motors will also occur; (the

relevant light indicators will flash).

Note : the working parameters of programs P1

and P2 are pre-set by the manufacturer of

the machine: if you want to change the

pre-set values call the customer service

personnel of your supplier.

Lower the side brush/es by pressing the top of

the relevant lever and moving it forward.

Note : on the control panel the corresponding

light indicators will turn on.

To lift the side brush/es press the top of the

levers and move them backwards.

Note : the side brush/es, the main brush and the

suction fan will start automatically when

the accelerator pedal will be pressed

(AUTO POWER-ON).

9

Page 12

USE

It is possible to adjust the side brush/es turning

speed by means of the dedicated knob.

Select the forward speed by means of the

command lever.

Press the accelerator pedal to start the job.

S31NUK5120(3)2001-04

Note : by releasing the accelerator pedal (or

setting the command lever to the neutral

position) the automatic switch off of all

functions will occur within 8 seconds (Auto

Power Off); the light indicators of the

selected working program and of the

suction fan will start flashing. The

automatic restart of all functions will

automatically occur as soon as the

accelerator pedal will be pushed again

(Auto Power ON).

In order to enable the selection of a

different working program first disable the

previously selected one.

When it is necessary to sweep on a wet floor

stop the suction fan pressing the relevant button,

in order to prevent the damage of the paper

panel filter.

In order to get an efficient cleaning function the

panel filter must always be clean.

Press the filter-shaker button, even if the

machine is working.

This operation must be repeated every 10 to 15

minutes, depending on the kind of rubbish to be

swept; before emptying the dirt container and, in

any case, at the end of the work.

10

Page 13

USE

To collect light and bulky debris lift the front flap

using the left pedal (do not press the pedal down

for a long time, not to reduce the suction

capability of the machine).

The machine gets an automatic breaking

function when the accelerator pedal is released;

when necessary the service brake can also be

used (see the figure).

S31NUK5120(3)2001-04

When driving in reverse gear an intermittent

acoustic signal will be heard and all the functions

will remain active.

The figure shows the functions of the command

lever:

1- forward gear

2- reverse gear

3- horn

4- front light On/Off.

The machine is equipped with an emergency

stop button; by pressing this button (red light On)

a sudden stop of the machine will occur and all

functions will turn off, the petrol engine too.

To restart the machine turn the red button

clockwise (according to the arrow shown on the

button itself).

4

1

3

2

To restart the normal operation re-select one of

the two working programs P1 or P2.

A safety device is located inside the operator

seat: the drive function - either forward or

reverse - is disabled as soon as the operator will

stand up or leave the seat.

11

Page 14

USE

At the end of the job turn off the selected working

program (P1 or P2) and switch the petrol engine

off by pressing the button shown in the figure.

Before leaving the machine make sure that the

side brushes are lifted, the parking brake

engaged and the master key in the OFF position.

(counter clockwise)

S31NUK5120(3)2001-04

At the end of the job or whenever it is necessary

empty the rear dirt container.

In the event that the machine must be pushed

when switched Off turn the proper red key

counter-clockwise (see the figure), in order to

disengage the electric drive motor and disable

the self-breaking function. Turn and eventually

remove the red key that can be seen after lifting

the lid of the battery compartment.

12

Page 15

USE

FURTHER PERFORMANCES OF THE

MACHINE WITH PETROL ENGINE

The machine equipped with the petrol engine is

able to work with full performance even if the

petrol engine is turned Off; this could occur just

because the machine run out of the fuel or when

it is necessary to work in a closed environment.

In this case the available working time will

depend on the capacity (amper.hours) of the

batteries installed on the machine; on the

intensity of the selected working program; on the

charge status of the batteries.

On this machine, in order to guarantee the

reliability of the batteries, two safety features are

envisaged:

S31NUK5120(3)2001-04

1- protection against the deep discharge of the

battery: when the battery voltage drops down to

about 20 Volt the automatic stop of all function

will occur - except the traction function. When it

is in this condition, it is necessary to proceed with

the recharge of the battery or to start the petrol

engine.

2- Protection against the excessive recharge. If

the battery voltage will be over 29 Volt the

automatic stop of the petrol engine will occur.; in

any case the machine will still be able to operate

only with batteries. The petrol engine can be

restarted when the battery voltage will be low

enough (at about 24 Volt).

13

Page 16

SIDE BRUSHES ADJUSTMENT AND

REPLACEMENT

Warning: the following operations must be done

with the machine in Off condition and master key

out, on a flat floor.

When the side brush is worn its height must be

adjusted.

Loosen the knob. Turn the adjusting disk and

move its position of one hole.

And tighten the knob.

S31NUK5120(3)2001-04

To check the adjustment of the brush start it and

verify that the contact with the floor is as shown

in the figure. If necessary repeat the adjustment

sequence.

When the brush is remarkably worn out, it is

necessary to replace it. Just press the two tabs

inwards and remove the brush. Reinstall the new

brush by carrying out the reverse operation;

apply a light pressure to the brush with your

hands.

Note: when the brush is replaced set the

adjusting devices to their original position

(corresponding to brush new, with no

wear).

14

Page 17

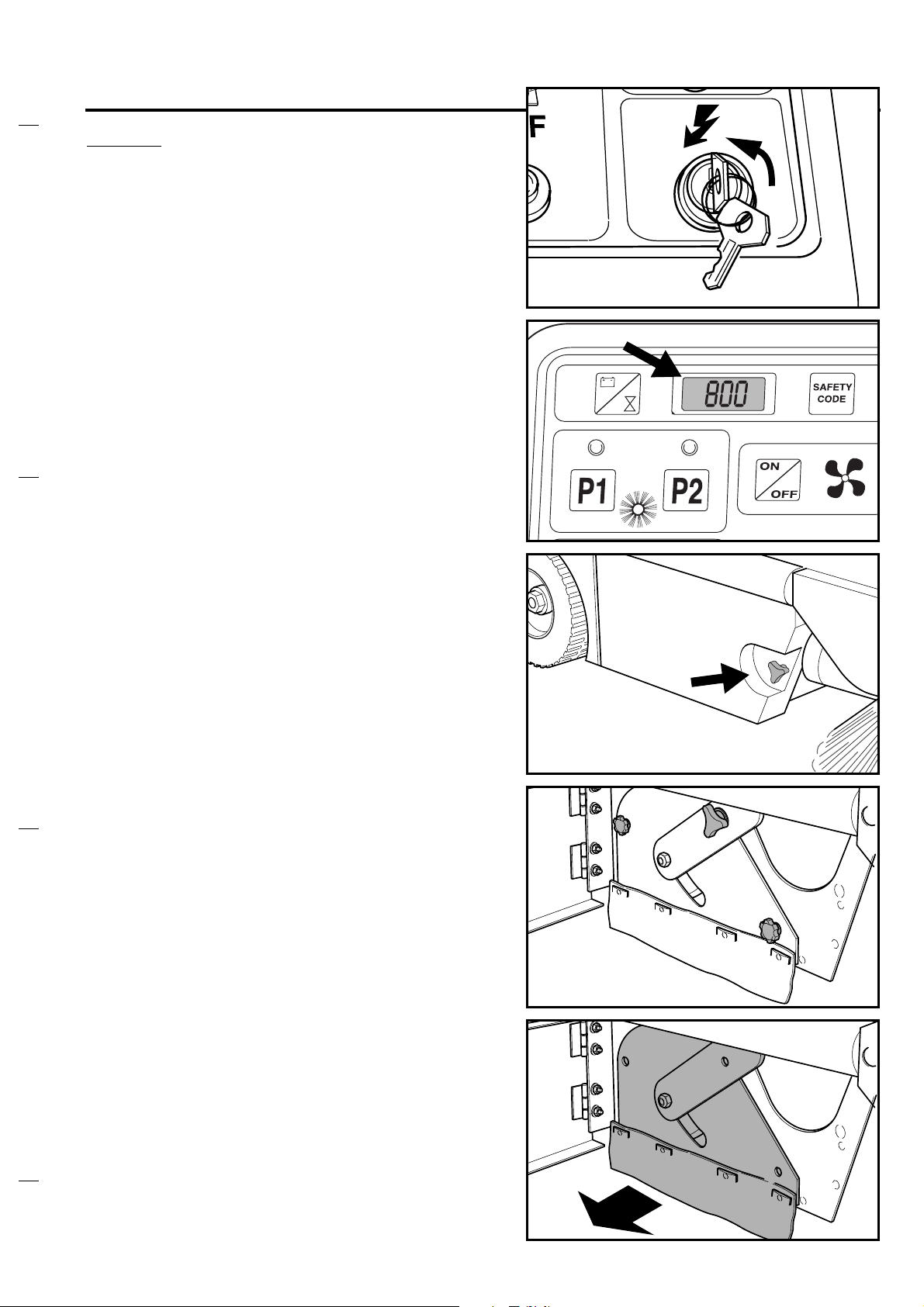

MAIN BRUSH REPLACEMENT

Warning: the following operations must be done

with the machine in Off condition and master key

out.

This machine is equipped with an automatic

control of the main brush pressure; this also

means that the position of the main brush is

automatically adjusted (no need of manual

adjustment).

The complete wear out of the main brush - and

therefore the need to replace it - is notified with

code 800 on the display.

S31NUK5120(3)2001-04

Please meet the following procedure for the main

brush replacement.

Open the side door on the right side of the

machine, unscrewing the knob shown in the

figure.

Remove the three knobs used to fix the lid of the

main brush compartment.

Remove the lid.

15

Page 18

MAIN BRUSH REPLACEMENT

Remove the worn out brush.

Fit the new brush in its compartment, paying

attention to the engagement of the plastic

adapter with the hub on the opposite side of the

compartment.

S31NUK5120(3)2001-04

Fit the lid of the main brush compartment using

the three knobs previously removed.

16

Page 19

FILTER CLEANING AND REPLACEMENT

The panel filter requires a regular cleaning.

Lift the lid.

Remove the lid of the filter compartment.

S31NUK5120(3)2001-04

Disconnect the electric cable of the filter-shaker

motor (the machine must first be switched off

and the key out).

Loosen the two screws with butterfly head on the

two sides of the metal frame fixing the panel

filter; it is not necessary to remove the screws

completely.

Remove the metal frame and take the panel filter

out.

Clean the filter shaking, blowing it with

compressed air - pressure not higher than 6 barfrom the side where the metal protection net is

mounted, to avoid damaging to the paper.

17

Page 20

FILTER CLEANING AND REPLACEMENT

After cleaning, fit the filter and the relevant fixing

frame.

Tighten the two screws with butterfly head and

reconnect the filter shaker electric cable.

If the filter is damaged or can not be properly

cleaned replace it with a new one.

Ask to your supplier for the new spare parts list.

Polyester panel filters are also available.

S31NUK5120(3)2001-04

18

Page 21

MAINTENANCE

BATTERIES: CONTROL AND RECHARGE

Make a frequent check of the electrolyte level

inside every battery cell. The battery

compartment is under the operator seat; lift the

lid and open the caps of all the battery cells:

when necessary fill up the cells with distilled

water.

The proper electrolyte level is specified in the

Manual for use and maintenance of the battery.

S31NUK5120(3)2001-04

Warning

battery level check must be done every week.

After filling close all the cell caps and clean the

top of the battery from any acid remains.

Warning: the battery acid is corrosive; if it comes

in contact with the skin or eyes rinse thoroughly

with water and consult a physician.

When necessary proceed with a recharge of the

battery according to the following instructions

and taking also into account what is specified in

the Battery User Manual:

- switch the machine Off and remove the master

key.

Warning: before starting the recharge the

battery connector must be disconnected

from the machine.

: On the version with petrol engine the

- the recharge must be done in a well ventilated

area

- open all the cell caps

- connect the battery connector to the battery

charger connector

- connect the battery charger cable to the mains

(please check that the voltage and frequency of

the mains correspond to the data of the

charger)

At the end of the recharge disconnect the battery

from the charger and fit the battery connector to

the machine. Close all the cell caps and clean

the top of the battery from any acid remains.

Note: in any case refer to the instructions

specified in the Battery Use Manual.

19

Page 22

MAINTENANCE

BRAKES ADJUSTMENT

When the pedal brake and/or the parking brake

reach a low efficiency operation some

adjustments can be done on the front wheel

(models SR 1100 e SR 5110):

- loosen the locking nut A

- turn adjuster B

- tighten locking nut A.

On models SR 1200 and SR 5120 the two

brakes on the rear wheels can also be adjusted,

by means of the regulating devices located

under the foot board (under the brake pedal).

S31NUK5120(3)2001-04

B

A

FRONT LAMP REPLACEMENT

In order to replace the front lamp:

- remove the transparent cover

- push the lamp and turn it counter-clockwise to

remove it

- replace the lamp paying attention to the volt

and watt ratings

- fit the transparent cover.

20

Page 23

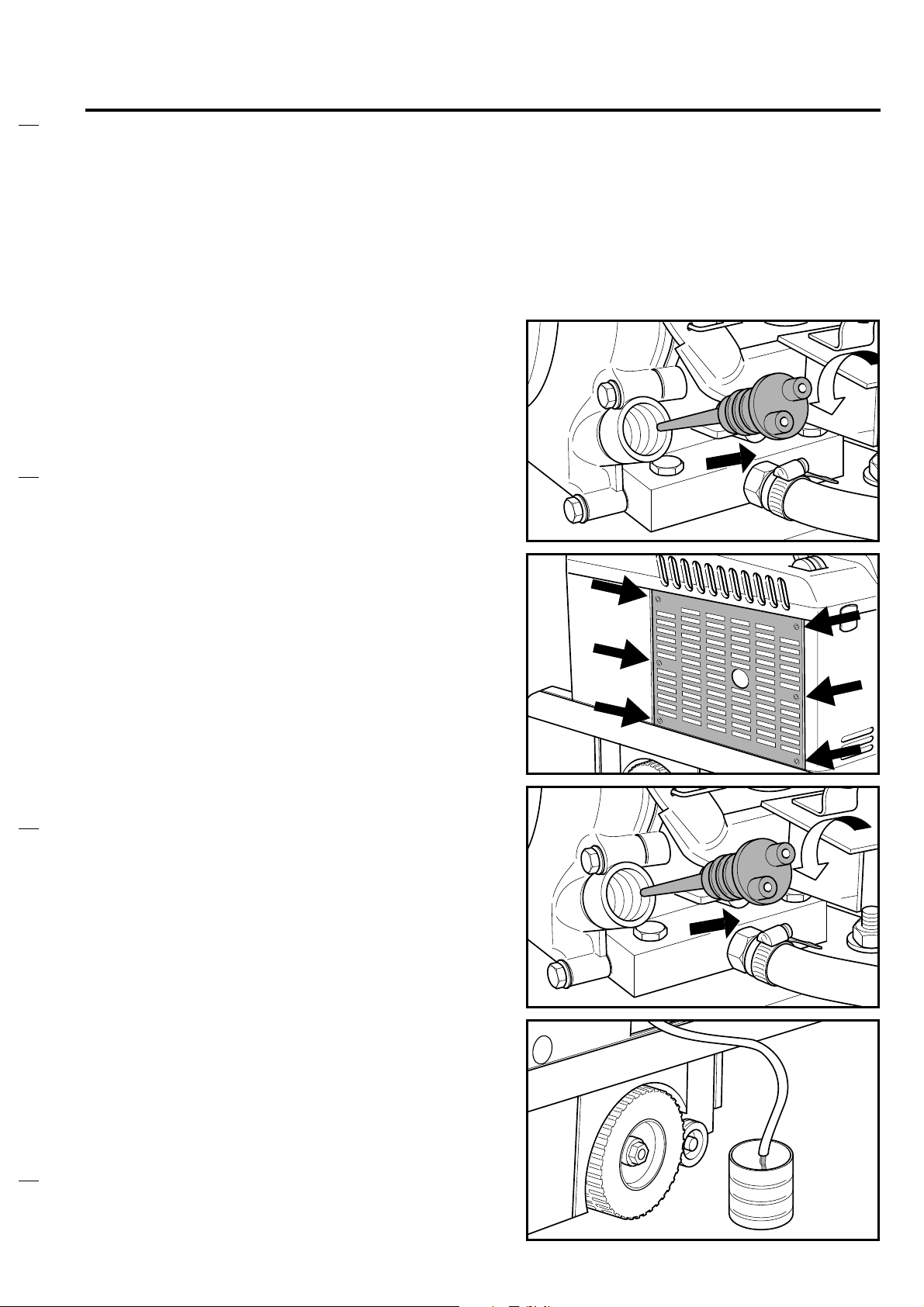

MAINTENANCE OF THE PETROL ENGINE

(HONDA)

MAINTENANCE OF THE PETROL ENGINE

(HONDA)

First: read thoroughly the Use and Maintenance

Manual of the engine.

Here below some recommendations are pointed

out.

Check the engine oil level at each working

session; for possible fill up read the oil type

specified on the engine Manual

Warning: the engine oil must be replaced the

first time after 20 working hours or, in

any case, not later that one month

since the receipt of the machine.

Afterwards it must be replaced every

100 hours or not later than 8 months

since the last replacement.

S31NUK5120(3)2001-04

The procedure for the replacement of the engine

oil is specified here below.

Remove the side panel from the machine.

Unhook the engine oil emptying hose.

Slip off the engine oil level check rod.

21

Page 24

MAINTENANCE

Remove the cap from the engine oil emptying

hose and let the oil come out.

Note: it is suggested to remove the oil when the

engine is warm.

Dispose of the used oil in proper special

containers.

S31NUK5120(3)2001-04

Note: keep the emptying hose lifted and open

during filling.

Take a funnel and pour in the new oil (type

indicated in the engine Use e Maintenance

booklet) from the hose of the rod for oil level

check. Fit the rod for oil level check and close the

emptying hose with its cap.

At the end of the filling sequence check the

engine oil level.

Make a periodic check of the engine air filter.

If necessary wash the engine air pre- filter (A)

with water and soap or any other detergent for

domestic use.

Squeeze it and dry it well.

B

A

Proceed by cleaning the filter B with compressed

air (pressure not higher than 6 bar).

If the filter can’t be completely cleaned, replace

it.

Fit the engine air filter in its compartment and the

relevant cover.

22

Page 25

SUMMARY OF MAINTENANCE

CONTROLS (battery version)

Warning: the following interventions must be

done with machine in Off condition and master

key out. All the periodic maintenance operations

must be performed by skilled personnel or by an

authorized service centre.

Note: the battery life will depend on a good

periodic maintenance (check of the level of the

electrolyte and of battery voltage). Besides it

must be taken into account that an unused

battery is submitted to a self-discharge

phenomenon. In the event that the machine is

not used for a long time (e.g. 3 or 4 weeks) it is

necessary TO RECHARGE THE BATTERY; in

fact the battery voltage MUST NEVER drop

down below 20 Volt.

S31NUK5120(3)2001-04

CONTROL

Battery liquid level and

voltage

check

UPON

DELIVERY

●

EVERY

30

HOURS

●

OR EVERY TWO

WEEKS

EVERY

50

HOURS

EVERY 100

HOURS

EVERY 400

HOURS

Check the carbon brushes

of all electrical motors and

●

replace them if worn

Belt tension ●●

Brake adjustment ●●

Filter shaker ●

Nut and screw tightness ●

Wear of main brush and

●

side brushes

Panel filter cleaning ●

Sealing of gaskets of filter

●●

compartment and of flaps

Clean the steering chain

and (SR 1200 - SR 5120

only) the traction wheels

chains with gas-oil or a

proper solvent.

23

●

Page 26

SUMMARY OF MAINTENANCE

S31NUK5120(3)2001-04

CONTROLS (petrol version)

Warning: the following interventions must be done with machine in Off condition and master key

out. All the periodic maintenance operations must be performed by skilled personnel or

by an authorized service centre.

Every maintenance intervention on the petrol engine must be performed in agreement with the

engine User Manual.

Note: the battery life will depend on a good periodic maintenance (check of the level of the

electrolyte and of battery voltage). Besides it must be taken into account that an unused

battery is submitted to a self-discharge phenomenon. In the event that the machine is not

used for a long time (e.g. 3 or 4 weeks) it is necessary TO RECHARGE THE BATTERY;

infact the battery voltage MUST NEVER drop down below 20 Volt.

CONTROL

Battery liquid level and voltage

check

Engine air filter cleaning ●

Panel filter cleaning ●

Engine oil level check 1st TIME ●

Engine oil replacement ● (+)

Engine RPM check and

adjustment (*)

Check the carbon brushes of all

electrical motors and replace

them if worn

Belt tension ●●

Brake adjustment ●●

Filter shaker ●

Nut and screw tightness ●

Wear of main brush and side

brushes

Sealing of gaskets of filter

compartment and of flaps

Clean the steering chain and

(SR 1200 - SR 5120 only) the

traction wheels chains with gasoil or a proper solvent.

UPON

DELIVERY

●●

●●

TWO

TIMES PER

WEEK

ONE

TIME PER

WEEK

EVERY

20

HOURS

1st TIME

EVERY

50

HOURS

●

EVERY

100

HOURS

● (++)

●

●

EVERY

400

HOURS

●

For SR1100: 3200 engine shaft RPM with no function working and battery voltage higher than 27

Volt

For SR 1200: 3300 engine shaft RPM with no function working and battery voltage higher than 27

Volt

(+) 20 hours or not more than 1 month

(++) 100 hours or not more than 8 months

24

Page 27

OPTIONAL ITEMS

High capacity batteries both for the petrol version

and for the battery version.

Battery charger

S31NUK5120(3)2001-04

Different types of main bushes and side brushes

Polyester panel filter (it can be washed)

-Mini containers

-Flashing beacon on support

-Rollbar

-Flashing beacon on rollbar

-Front rollers and side bumpers

-Non marking wheels

For further information on all accessories get in

touch with your supplier

25

Page 28

SAFETY FUNCTIONS AND TROUBLESHOOTING

The machine is equipped with many safety

devices and functions which have been

described in the USE paragraphs (both for petrol

and electrical versions). For instance the

automatic stop of all functions to avoid the deep

discharge of the battery has been mentioned;

and also the availability of a special red key for

the disengagement of the self-breaking function

has been notified: this is to be operated when the

machine must be pushed in Off condition.

Besides the intervention of other safety functions

is notified by means of dedicated safety codes

appearing on the display. These safety codes

are described in the following table.

S31NUK5120(3)2001-04

TO PUSH

TO DRIVE

SEE SAFETY CODE 333

SAFETY

CODE

205

301 Stop of all functions and traction Overtemperature of the drive motor

302

305 The machine functions will stop

306 Stop of all functions and traction

307 The machine does not start Wrong start sequence

308 The machine does not start

333 The machine does not start

800 Display flashing Main brush worn -Replace the main brush

E10 Flashing display

MACHINE BEHAVIOUR

Stop of all functions except

traction

The machine does not start or, in

the event it was working, will stop

DESCRIPTION OF THE

MALFUNCTION

The battery is empty

Possible problem with traction

control electronic circuit

High temperature on the electronic

control circuits (95 °C)

High temperature on the electronic

control circuits (105 °C)

Damage of the cable of

potentiometer for traction control

-Off status of the red key for the

disabling of the self braking

function (see the picture on the

top page)

-Possible trouble of motor kables

(short circuit or open circuit)

Main broom is blocked Remove the main broom and clean

POSSIBLE INTERVENTION

Recharge the battery according to

the instructions given in the

Maintenance paragraph

-If the machine run on a long ramp it

could be normal: let the machine

cooling 20 minutes

-Check the efficiency of the front

and rear brakes

-Check the rotation of the rear drive

wheels

-Check carbon brushes of traction

motor

-Check connection cables of

traction motor

-If the above is OK replace the

power electronic board

-If the ambient temperature is high

let the machine cool down 20

minutes

-If the problem will remain call the

technical service to check the

electrical motors

-Make the same checks as per code

305

-Release the accelerator pedal

before turning the key On

-Check the cable connections of the

potentiometer for traction control

- Check the potentiometer for

traction control

-Insert the red key and turn it

clockwise

-Check the motor cables

all dirty parts

26

Page 29

SERVICE ADDRESS

S31NUK5120(3)2001-04

AUSTRALIA

Nilfisk-Advance Pty. Ltd.

ACN 003 762 623

Head office: 17 Leeds Street, Rhodes, N. S. W. 2138

Tel.(02) 9736 1244 - Fax (02) 9736 3910

Customer Responce Centre:

Tel.1 800 011 013

BELGIQUE/BELGIË/LUXEMBOURG

Nilfisk-Advance s.a./n.v.

Doornveld/Sphere Business Park

Industrie Asse 3, nr 11- bus 41

1731 Zellik-Asse

Tel.(02) 467.60.50 Fax (02) 463.44.16

CANADA

Nilfisk-Advance Ltd

396 Watline Avenue

Mississauga, Ontario L4Z 1X

Tel.(905) 712-3260 - Fax (905) 712-3255

DANMARK

Nilfisk-Advance Nordic A/S

Myntevej 3, 8900 Randers

Tel.86 42 84 33 - Fax 86 41 19 55

DEUTSCHLAND

Nilfisk-Advance AG

Siemensstraße 25-27

25462 Rellingen

Tel.(04101) 3990 - Fax ( 04101) 399191

Zentraler Kundenservice / Customer Hotline

Tel.0180 53 56 797

ESPAÑA

Nilfisk-Advance, S.A.

Torre D’Ara

Passeig del Rengle, 5 -PI.10

E-08302 Mataró (Barcelona)

Spain

Tel.: 93 741 2400

Fax: 93 757 8020

nilfisk@nilfisk-advance.es

Teléfono nacional de servicio Comercial: 902 200 201

Teléfono nacional de servicio Técnico: 902 300 301

Delegaciones, Distribuidores y Servicio Técnico a domicilio en todas las regiones

de Espagña.

FINLAND/ SUOMI

Oy Tecalemit AB

Hankasuontie 13, 00390 Helsinki

Tel.(89) 547 701- Fax (89) 547 1779

FRANCE

Nilfisk-Advance S.A

BP 246

91944 Courtaboeuf Cedex

Tel.(01) 69.59.87.00 Télécopie (01) 69.59.87.01

PORTUGAL

Nilfisk-Advance Lda.

Rua Cândido de Figueiredo, 91-i, 1500-133 LISBOA

Tel.01/7784142-Fax0l/7785613

Porto 02/526766 - Fax 02/520739

Açores 096/628092/3 - Fax 096/628129

Madeira 091/228965 - Fax 091/228796

SCHWEIZ / SUISSE

Nilfisk-Advance AG

Ringstrasse 19, 9533 Kirchberg/Wil

Tel.719 23 52 83 - Fax 719 23 84 44

SINGAPORE

Nilfisk-Advance Pte. Ltd.

10, Woodlands Loop

Singapore 738388

Tel.(65) 759 9100 - Fax (65) 759 9133

SVERIGE

Nilfisk-Advance AB

Sjöbjörnsvägen 5, 117 67 Stockholm

Tel.085 55 944 00 - Fax 085 55 944 30

TAIWAN

Nilfisk-Advance Ltd

1 F, No.23, Lane 132, Sec. 2

Ta An Road, Taipei

Tel.700 22 68 - Fax 784 08 43

UNITED KINGDOM

Nilfisk-Advance Limited

Newmarket Road

Bury St. Edmunds

Suffolk IP 33 3SR

Tel.(01284) 763163 - Fax (01284) 750562

USA

Nilfisk-Advance Inc.

14600 21st Avenue North

Plymouth, MN 55447-3408

Tel. +1763 475 2235 - Fax 1763 473 1764

Nilfisk-Advance of America, Inc.

300 Technology Drive

Malvern, PA 19355

Tel.(610) 647 647-6427

ÖSTERREICH

Nilfisk-Advance GmbH

Vorarlberg Allee 46

1230 Wien

Tel.1616 58 30 - Fax 1616 58 30 40

HONG KONG

Nilfisk-Advance Ltd

2001, 20/F HK Worsted Mills

Industrial Building

31-39 Wo Tong Tsui Street

Kwai Chung, N.T.

Tel.2427 59 51- Fax 2487 5828

IRELAND

Nilfisk-Advance Ltd

28 Sandyford Office Park

Dublin 18

Tel. +353 12943838 - Fax +353 12943845

ITALIA

Nilfisk-Advance Italia SPA

Località Novella Terza

26862 Guardamiglio ( LO) I

Tel. + 39 (0377) 451124 – Fax + 39 (0377) 51443

JAPAN

Nilfisk-Advance Inc.

3-4-9 Chigasaki Minami

Tsuzuki-Ku Yokohama 224

Tel.045-942-7741- Fax 045-942-6545

MALAYSIA

Mlfisk-Advance Sdn Bhd

Lot 2, 1st. Floor

Lorong l9/1A

46300 Petaling Jaya

Selangor Darul Ehsan

Tel.03-7568188/03-7568189/03-7568388-Fax03-7566828

NEDERLAND

Nilfisk-Advance B.V.

Flevolaan 7, Postbus 341

1380 AH Weesp

Tel.0294-462121- Fax 0294-430053

NEW ZEALAND

Nilfisk-Advance Limited

477 Great South Road, Penrose

Auckland

Tel.(09) 525 0092 - Fax (09) 525 6440

NORGE

Nilfisk-Advance AS

Enebakkvn, 119, 0680 Oslo, Postboks 196, Manglerud, 0612 Oslo

Tel.22 08 63 50 - Fax 22 08 63 63

Distriktsrepresentanter over hele landet

27

Page 30

Graphic project VISUAL DIVISION Milan Italy

COD.S31NUK5120(3)2001-04

Nilfisk-Advance Italia S.p.A

Località Novella Terza

26862 Guardamiglio (Lodi) Italia

www.nilfisk-advance.com

Phone: +39 0377 451124

Fax: +39 0377 51443

Printed in Italy

Loading...

Loading...