SR 2000

Kullanim Talimatlari

Instructions for Use

Nilfi sk Models: Models 56516750(Gas), 56516755(LPG), 56516753(Diesel)

10/08

FORM NO. 56041749

A-English

B-Türkçe

Printed in USA

A-2 / ENGLISH

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................A-3

MACHINE OPERATION ............................................................................................A-3

CAUTIONS AND WARNINGS ...................................................................................A-4

OPERATION OF CONTROLS AND GAUGES .............................................. A-5 – A-11

WATER TEMPERATURE GAUGE ..................................................................A-5

HOUR METER .................................................................................................A-5

FUEL GAUGE .................................................................................................. A-5

OIL PRESSURE GAUGE ................................................................................ A-5

VOLT METER .................................................................................................. A-5

BROOM & FAN SWITCH .................................................................................A-6

SHAKER MOTOR SWITCH .............................................................................A-6

TIMED SHAKER MOTOR SWITCH (OPTION) ................................................ A-6

HYDRAULIC FLUID SIGHT GLASS ................................................................ A-6

RIGHT SIDE BROOM LIFT AND POWER CONTROL ..................................... A-6

IGNITION SWITCH ..........................................................................................A-7

WET-SWEEP BYPASS SWITCH - (OPTION) .................................................A-7

TURN SIGNALS - 4 WAY (OPTION) ...............................................................A-7

FOOT BRAKE .................................................................................................. A-7

ACCELERATOR and DIRECTIONAL CONTROL PEDAL ...............................A-8

BACKUP ALARM (OPTION) ............................................................................A-8

SEAT ADJUSTMENT .......................................................................................A-8

PARKING BRAKE ............................................................................................A-8

CIRCUIT BREAKERS ...................................................................................... A-9

GLOW PLUG (DIESEL) .................................................................................... A-9

HOPPER LIFT/SIDE BROOM LEVER .............................................................A-9

HOPPER DUMP/RETURN CONTROL LEVER ................................................ A-9

THROTTLE CONTROL .................................................................................. A-10

CHECK ENGINE LIGHT ................................................................................. A-10

LEFT SIDE BROOM LIFT AND POWER CONTROL (OPTION) ....................A-10

MAIN BROOM LIFT ....................................................................................... A-10

WORK LIGHT SWITCH - (OPTION) ..............................................................A-11

LIGHT SWITCH - (OPTION) ........................................................................... A-11

HORN BUTTON ............................................................................................A-11

CAB - (OPTION) - NOT SHOWN ..................................................................A-11

LOW OIL SHUTDOWN .................................................................................. A-11

OPERATING INSTRUCTIONS ...................................................................A-12 – A-15

PRE-START CHECK LIST .............................................................................A-12

TO START ENGINE .......................................................................................A-12

POST-START CHECK LIST ..........................................................................A-12

TO OPERATE SWEEPER ............................................................................. A-12

TO STOP SWEEPER ....................................................................................A-12

POST-OPERATION CHECK LIST ................................................................. A-14

TO EMPTY DEBRIS HOPPER ....................................................................... A-14

TOWING INSTRUCTIONS ............................................................................. A-15

DUST FILTERS ............................................................................................. A-15

DUST CONTROL SYSTEM ............................................................................ A-15

GENERAL MACHINE MAINTENANCE ....................................................... A-16 – A-20

TECHNICAL SPECIFICATIONS ..............................................................................A-21

A-2 - FORM NO. 56041749 - SR 2000

ENGLISH / A-3

INTRODUCTION

This manual will help you get the most from your Nilfi sk SR 2000. Read it thoroughly before operating the machine. References to “right” and “left”

in this manual mean right or left as seen from the driver’s seat.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk Service Center, who employs factory trained service personnel, and

maintains an inventory of Nilfi sk original replacement parts and accessories.

Call the NILFISK INDUSTRIAL DEALER named below for repairs or service. Please specify the Model and Serial Number when discussing your

machine.

NAMEPLATE

The Model Number and Serial Number of your machine are shown on the Nameplate, located on the wall of the operator’s compartment. This

information is needed when ordering repair parts for the machine. Use the space below to note the Model Number and Serial Number of your

machine for future reference.

MODEL ________________________________________________

SERIAL NUMBER ________________________________________

Note: Reference the separately supplied engine manufacture’s maintenance and operator manual for more detailed engine specifi cation and service

data.

UN-CRATING

Upon delivery, carefully inspect the shipping crate and the machine for damage. If damage is evident, save all parts of the shipping crate so that they

can be inspected by the trucking company that delivered the machine. Contact the trucking company immediately to fi le a freight damage claim.

MACHINE OPERATION

YOUR SWEEPER HAS BEEN SHIPPED COMPLETE, BUT DO NOT ATTEMPT TO OPERATE WITHOUT READING THE FOLLOWING

INSTRUCTIONS:

1. Uncrate the machine and carefully remove from skid to prevent damage.

2. Connect and tighten battery cables.

3. Fill tank with UNLEADED gasoline or Diesel Fuel.

WARNING!

Never fi ll fuel tank while the engine is running. Always be sure gasoline container and sweeper are electrically connected before pouring gas. This

can be easily done by providing an insulated wire (permanently attached to the container) with battery clip on the other end.

4. Check engine crankcase oil level. Although properly lubricated at factory, check before starting engine. No special break-in oil is used and

recommended number of operating hours before the initial oil change is the same as normal. See Nilfi sk Service Manual.

5. Check radiator coolant level. Permanent type antifreeze is added at the factory to provide protection to approximately -35° F (-37° C). To

retain this protection level, always add one part water to one part antifreeze.

6. Check oil level in the hydraulic reservoir located at center of machine beside the engine. The hydraulic reservoir is full, if oil can be seen in

the sight glass with the hopper in “DOWN” position. If oil is required, add HYDRAULIC FLUID ONLY, automatic transmission fl uid FORD type

“F” ATF.

NOTE

After the fi rst 50 operating hours, service must be performed on your engine to insure future high performance and trouble free operation. See

Maintenance.

FORM NO. 56041749 - SR 2000 - A-3

A-4 / ENGLISH

SYMBOLS

Nilfi sk uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the necessary steps to protect personnel

and property.

DANGER !

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING !

Is used to call attention to a situation that could cause severe personal injury.

CAUTION !

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

WARNING!

This machine shall be used only by properly trained and authorized persons.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while ascending (driving up)

the ramp.

To avoid hydraulic oil injection or injury always wear appropriate clothing and eye protection when working with or near hydraulic system.

Turn the key switch off (O) and disconnect the battery before servicing electrical components.

Never work under a machine without safety blocks or stands to support the machine.

Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable liquids exist.

Do not clean this machine with a pressure washer.

This machine emits exhaust gases (carbon monoxide) that can cause serious injury or death, always provide adequate ventilation when using machine.

Do not dump the hopper over an open pit or dock. Do not dump the hopper when positioned on a grade (ramp). The machine must be level (horizontal).

Operate only when lids, doors, and access panels are securely closed.

Never travel with the hopper in the raised position.

Watch out for obstructions, especially overhead.

Carry no passengers on the machine.

Report damage or faulty operation immediately. Do not operate the machine until repairs have been completed.

Maintenance and repairs must be done by authorized personnel only.

Never manually depress the electrical switch on the left lift arm when the hopper is raised.

To Maintain The Stability Of This Sweeper In Normal Operation, The Counterweights, Overhead Guard, Rear Bumper Guard, Or Any Similar Equipment

Installed By The Manufacturer As Original Equipment, Should Never Be Removed. If It Becomes Necessary To Remove Such Equipment For Repair Or

Maintenance, It Must Be Reinstalled Before The Sweeper Is Placed Back In Operation.

Wheel Assembly May Explode Causing Serious Personal Injury Or Death. Wheel Assembly Must Be Serviced By Properly Trained And Qualifi ed Personnel

In Accordance With Federal Osha Standard 29 Cfr Part 1910.177.<D>

Do Not Add Air To Tire And Rim Assemblies That Have Been Operated In A Serious Underinfl ated Or Flat Condition. The Tire And Rim Components Can

Explode Causing Serious Or Fatal Injuries.

CAUTION!

This machine is not approved for use on public paths or roads.

This machine is not suitable for picking up hazardous dust.

When operating this machine, ensure that third parties, particularly children, are not endangered.

Before performing any service function, carefully read all instructions pertaining to that function.

Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the parking brake.

Turn the key switch off (O) before changing the brushes, and before opening any access panels.

Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

A-4 - FORM NO. 56041749 - SR 2000

SAVE THESE INSTRUCTIONS

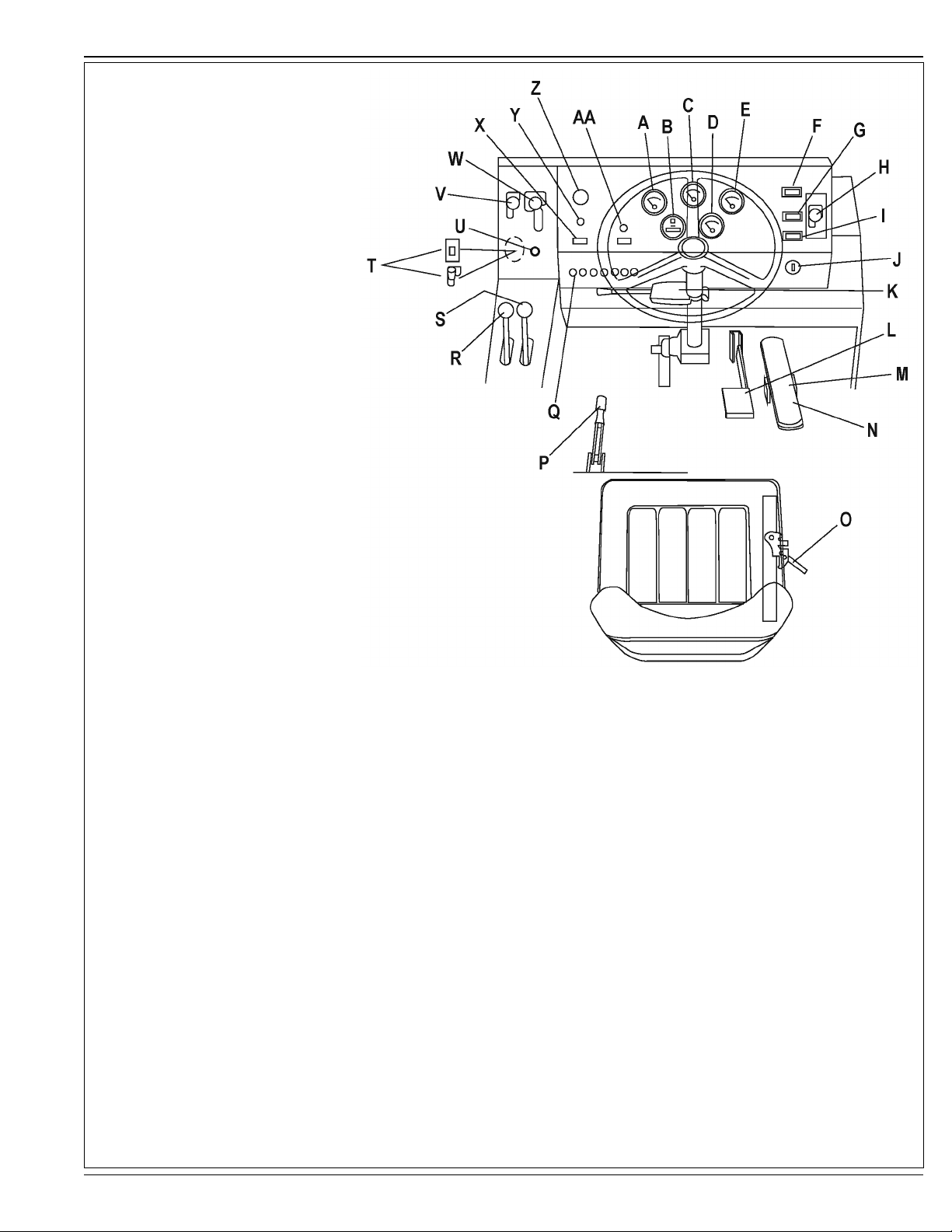

OPERATIONS OF CONTROLS AND GAUGES

A Water Temperature Gauge

B Hour Meter

C Fuel Gauge

D Oil Pressure Gauge

E Volt Meter

F Broom and Fan Switch

G Shaker Motor Switch

H Right Side Broom Lift

I Wet Sweep Bypass (option)

J Ignition Switch

K Turn Signal (option)

L Foot Brake

M Accelerator and Directional Control Pedal

N Backup Alarm Switch (option)

O Seat Adjustment

P Parking Brake

Q Circuit Breakers

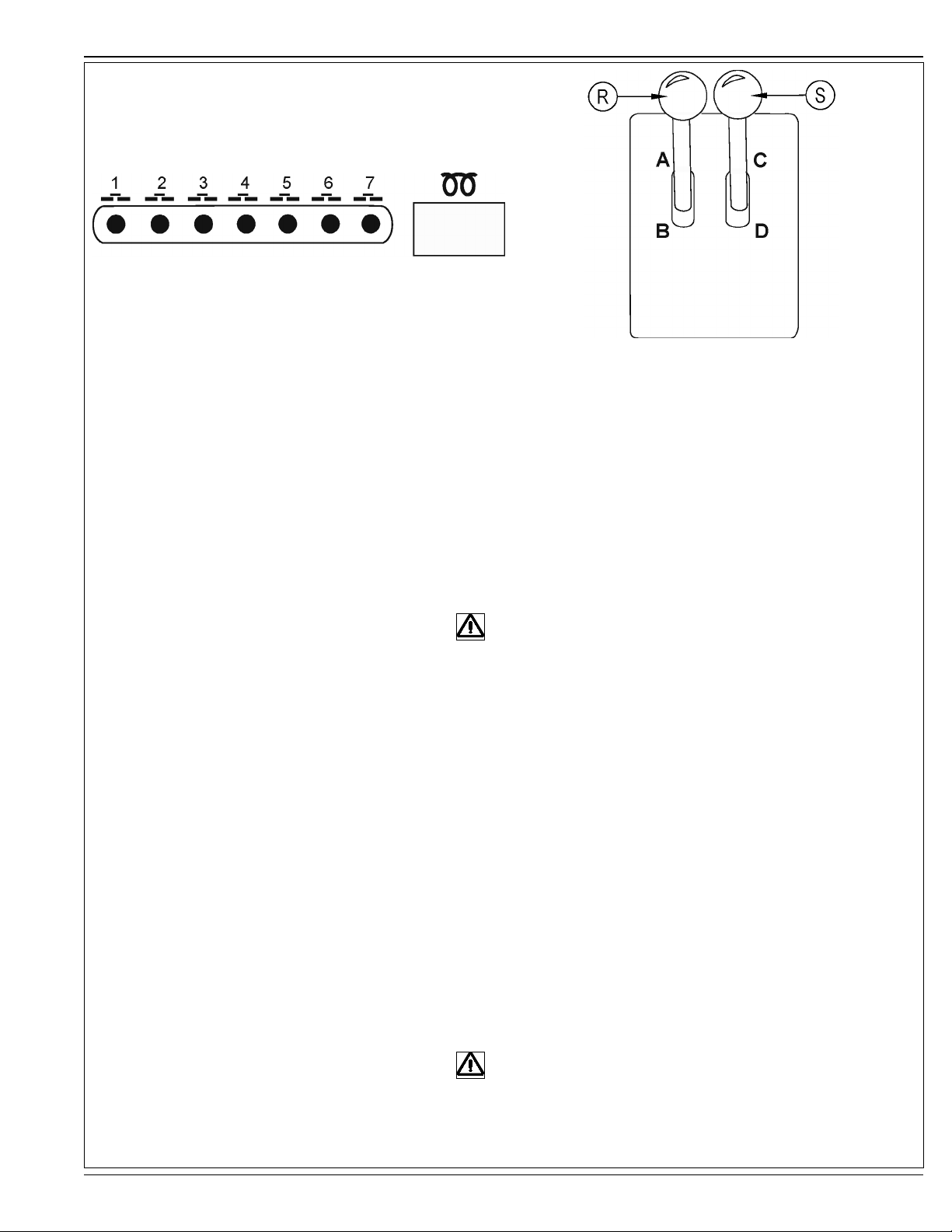

R Hopper Lift

S Hopper Rotate and Dump

T Throttle Control

U Check Engine Light (Gas/LPG)

V Left Side Broom Lift

W Main Broom Lift

X Work Light Switch (option)

Y Light Switch (option)

Z Horn

AA Glow Plug (Diesel)

ENGLISH / A-5

FIGURE 2

WATER TEMPERATURE GAUGE (See Figure 2)

The water temperature gauge (A) is located on the instrument panel to the left of the fuel gauge. The gauge is activated by a sender in the

engine. It displays the engine water temperature in °F.

HOUR METER (See Figure 2)

This meter (B) is located to the left of the oil pressure gauge on the instrument console. This meter is activated when the engine begins running.

The meter indicates actual “run” time of the machine. The meter can be used to indicate when maintenance should be done to the machine.

FUEL GAUGE (See Figure 2)

The fuel gauge (C) is located between the water temperature gauge and the volt meter on the instrument panel, and indicates the level of fuel

contained in the fuel tank.

OIL PRESSURE GAUGE (See Figure 2)

The oil pressure gauge (D) is located on the instrument panel to the right of the hour meter. The gauge is mechanical and activated by a sender

in the engine. It displays the engine oil pressure in PSI.

VOLT METER (See Figure 2)

The volt meter (E) is located on the control panel to the left of the fuel gauge. The meter indicates the charging or discharging of the battery.

When the key is in the accessory position the gauge will register approx. 12 volts. The meter will indicate approximately 13 to 14.5 volts when the

engine is running. This indicates that the alternator is working correctly.

FORM NO. 56041749 - SR 2000 - A-5

A-6 / ENGLISH

OPERATIONS OF CONTROLS AND GAUGES

FIGURE 3 FIGURE 4

BROOM & FAN SWITCH (See Figure 2)

The broom and fan switch (F) is located to the left of the right side broom lever. This switch “powers” the brooms and the vacuum fan system. It

has on-off positioning.

SHAKER MOTOR SWITCH (See Figure 2)

The shaker motor switch (G) is located below the broom and fan switch. This is a momentary switch that will activate the fi lter shaker motors.

Hold the switch for 20 to 30 seconds to activate the shaker motors. When the shaker motors have been activated, the brooms and impeller fan

will stop. The shaker motors will only operate with the hopper in the “SWEEP” position. The switch is not on the control panel if the machine is

equipped with the CDC Dust Control Filter Option.

TIMED SHAKER MOTOR SWITCH (OPTION) (See Figure 2)

The shaker motor switch (G) is located below the broom and fan switch. This is a momentary switch that will activate the fi lter shaker motors for

20 to 30 seconds after it has been pushed. When the shaker motors have been activated, the brooms and impeller fan will stop. The shaker

motors will only operate with the hopper in the “SWEEP” position.

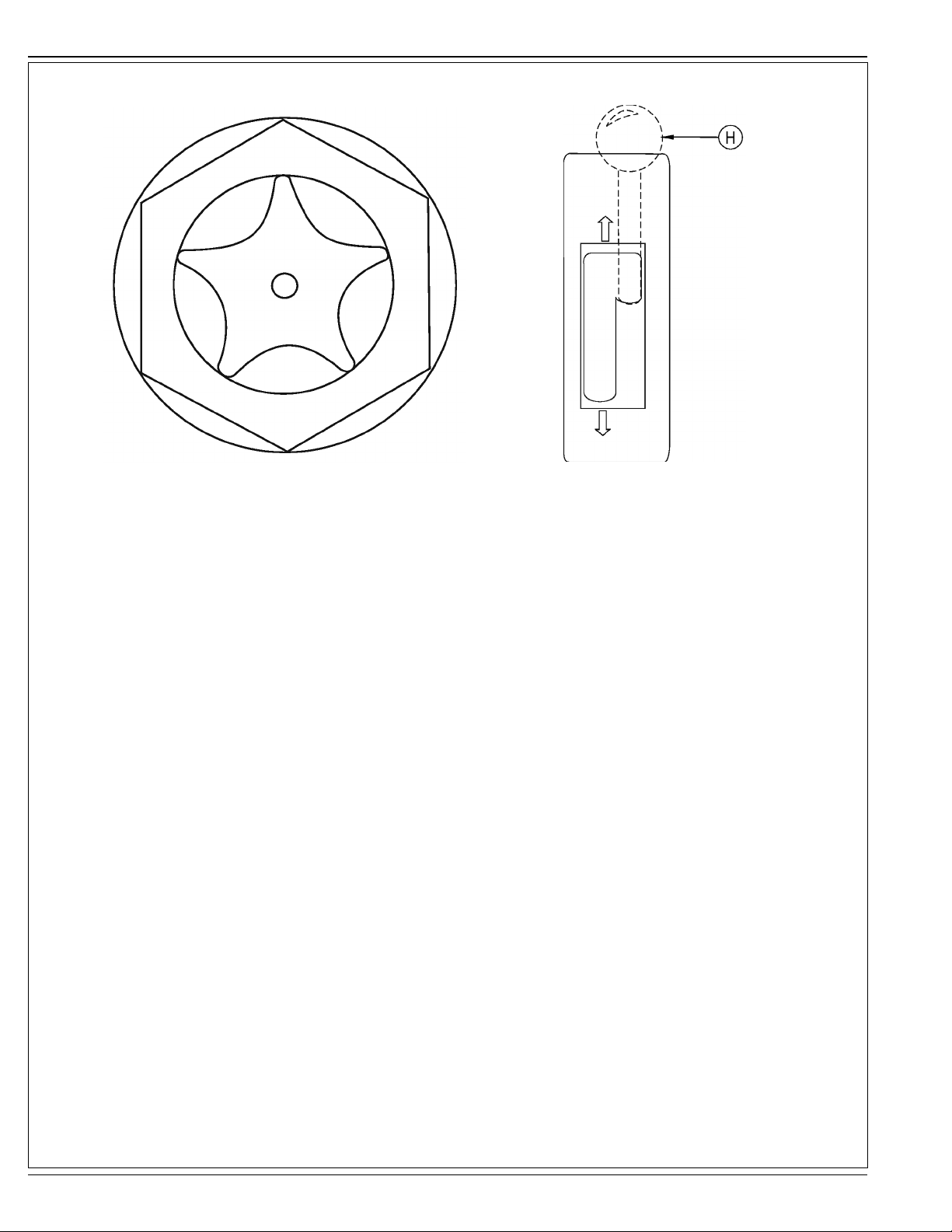

HYDRAULIC FLUID SIGHT GLASS (See Figure 3)

The sight glass is located on the side of the hydraulic oil reservoir.

The sight glass indicates the level of the hydraulic oil in the reservoir.

Fluid level must be visible in the sight glass when the hopper is in the down position. If the sight glass is completely full, then there is too much

fl uid in the reservoir.

RIGHT SIDE BROOM LIFT AND POWER CONTROL (See Figure 4)

The right side broom lift (H) and power control is located on the right side of the instrument panel. To raise and stop the side broom, grasp the

lever and push the lever to the locking notch, marked with the “UP” arrow. To lower the side broom, grasp the lever, push it up and to the left,

away from the locking notch. Let the lever lower -until it rests by the “DOWN” arrow. The broom will automatically begin rotating as it is lowered.

To turn “ON” the side brooms, move the Hopper Lift/Side Broom Lever forward to the “ON” position (See Figure 9).

A-6 - FORM NO. 56041749 - SR 2000

ENGLISH / A-7

OPERATIONS OF CONTROLS AND GAUGES

FIGURE 5 FIGURE 6

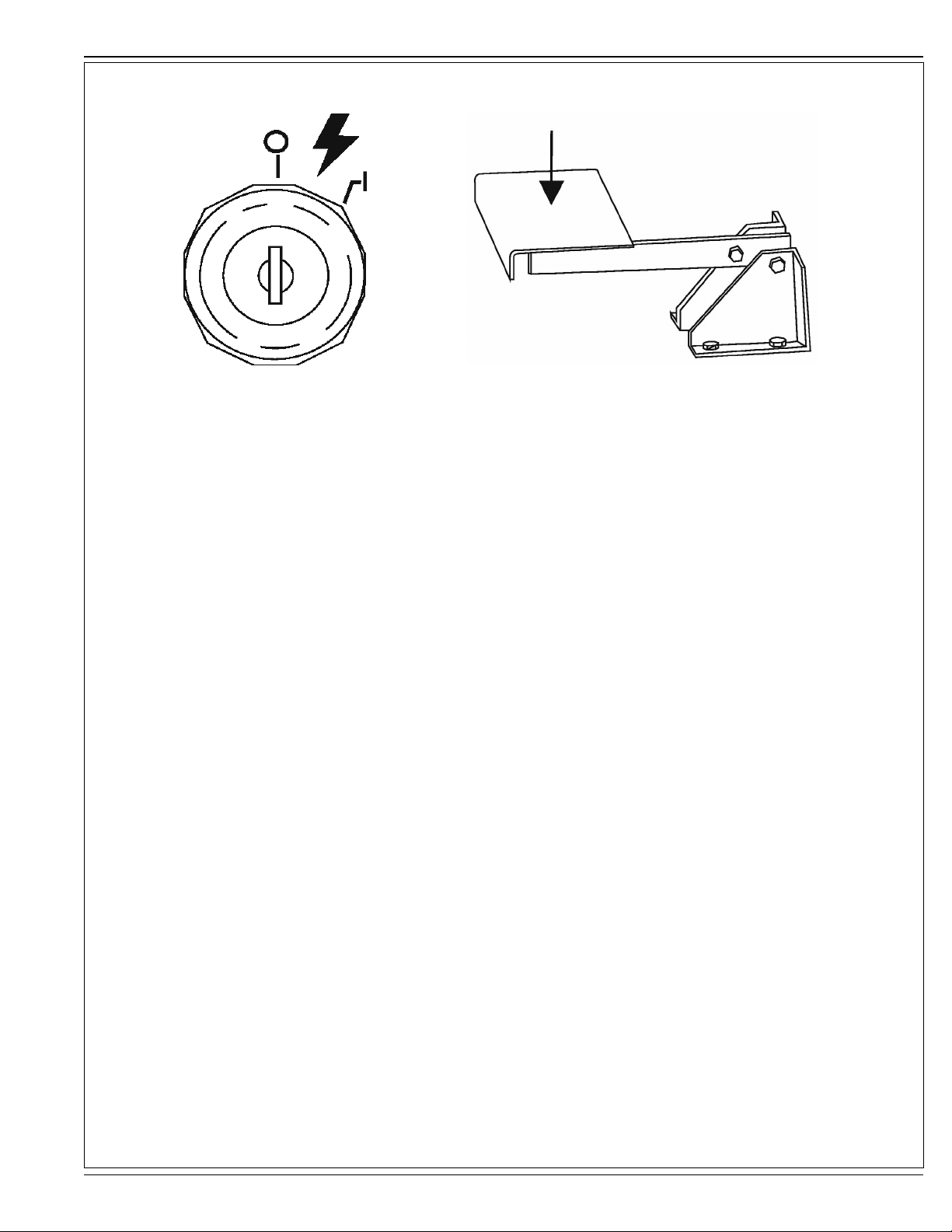

IGNITION SWITCH (See Figure 5)

The keyed ignition switch is located to the right of the steering column on the front face of the instrument console. It has four positions.

1. The key turned to the center “OFF” position will shut off the engine. The following items can be activated in the “OFF” position.

(A.) Horn

(B.) Light Options

2. The key turned to the right “IGN/ON” position will allow all the following items to be activated (but will NOT start the engine):

(A) Horn

(B) Light Options

(C) Turn Signals

(D) Instrument Panel Gauges

3. The key turned to the far right “START” position will start the engine. This position is a momentary position. The key will revert to the “IGN/

ON” position when it is released.

WET-SWEEP BYPASS SWITCH (OPTION) (See Figure 2)

The wet-sweep bypass switch (I) is located to the right of the steering wheel under the shaker motor switch. The switch activated will shut off the

vacuum motor. This will keep the dust fi lters from being ruined by the water pickup from sweeping water.

4-WAY TURN SIGNALS (OPTION) (See Figure 2)

The turn signal option (K) is located on the steering column and works as automotive turn signals work, forward on the lever for right and back on

the lever for left. The 4 way fl asher will activate when the turn signal lever is pulled out.

FOOT BRAKE (See Figure 6)

The foot brake pedal (L) is located to the right of the steering column on the fl oor of the driver compartment. The foot brake on front wheels is a

mechanical system actuated by the brake pedal.

FORM NO. 56041749 - SR 2000 - A-7

A-8 / ENGLISH

OPERATIONS OF CONTROLS AND GAUGES

FIGURE 7 FIGURE 8

ACCELERATOR & DIRECTIONAL CONTROL PEDAL (See Figure 7)

The accelerator and directional control pedal is located on the fl oor of the operator’s area, to the right of the brake pedal. The accelerator and

directional control pedal controls the machine direction and travel speed.

1. Put foot pressure on the upper portion (A) of the pedal. The machine will move forward.

2. Increase the foot pressure on the upper portion (A) of the pedal to increase the forward speed.

3. Put foot pressure on the lower portion (B) of the pedal. The machine will move in reverse.

4. Increase the foot pressure on the lower portion (B) of the pedal to increase the reverse speed.

5. To stop the machine, put light foot pressure on the opposite end of the accelerator and directional control pedal. If the machine is moving

forward, put light foot pressure on the lower portion of the pedal. If the machine is moving in reverse, put light foot pressure on the upper

portion of the pedal.

BACK UP ALARM (OPTION) (See Figure 2)

The back up alarm (N) is operated by a switch that is located under the lower section of the Accelerator and directional control pedal. The alarm

makes a loud audible noise when the machine is being driven in

reverse.

SEAT ADJUSTMENT (See Figure 2)

This lever (O) is located on the right of the seat. This lever allows the seat to be adjusted forward or back when the lever is moved.

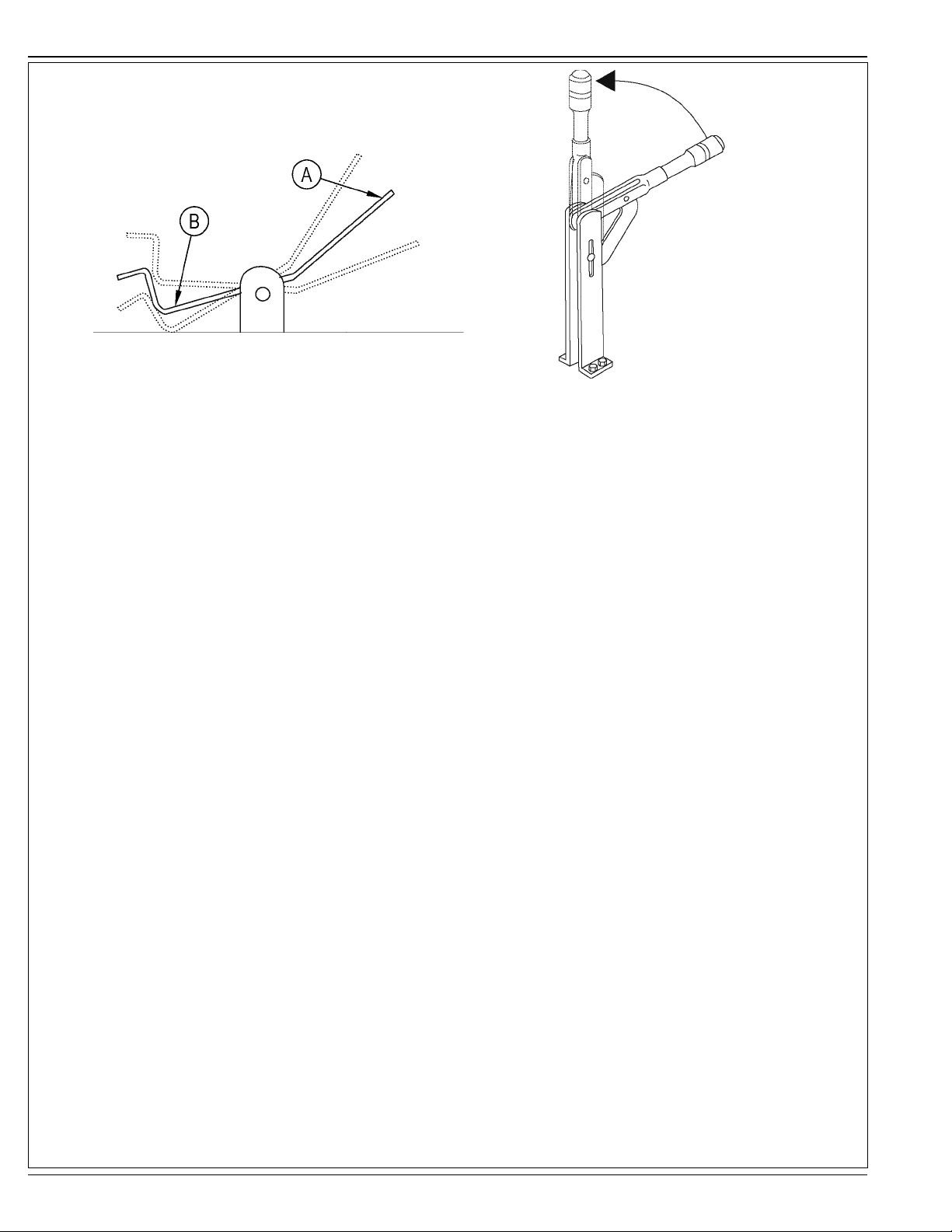

PARKING BRAKE (See Figure 8)

The parking brake lever (P) is located in the left side of the driver compartment fl oor. This lever when raised to the upright position will “lock” the

foot brake pedal in the down position.

A-8 - FORM NO. 56041749 - SR 2000

ENGLISH / A-9

OPERATIONS OF CONTROLS AND GAUGES

FIGURE 8a FIGURE 9

CIRCUIT BREAKERS (See Figures 2 & 8a)

The circuit breakers (Q) are located to the left of the steering wheel. When a circuit breaker “pops” out, this is an indication of an electrical problem that must be

corrected before the breaker can be reset.

There can be up to seven circuit breakers in the row. They control the following circuits, beginning with number 1 on the left:

CB-1 = Filter shaker motors

CB-2 = Horn

CB-3 = Starter relay

CB-4 = Ignition

CB-5 = Accessory

CB-6 = Options

CB-7 = Cab Options

GLOW PLUG - DIESEL (See Figure 8a)

WARNING!

It is advised that in no circumstances should either or any other unauthorized starting aids be used at the same time as the Glow Plugs.

To operate the glow plugs, the following procedure should be adopted.

1. Before operating he starter motor, press the “GLOW PLUG” button for approximately 20 to 30 seconds.

2. With the “GLOW PLUG” button still depressed, engage the starter motor until the engine starts.

3. Continue to press the “GLOW PLUG” button for a few seconds after the engine has started until even running has been obtained.

4. If the engine does not start, disengage the starter motor but keep the “GLOW PLUG” button depressed for a further 10 to 15 seconds. When a further

attempt is made to start the engine, keep the glow plugs energized while starting and for a few seconds after the engine has fi red until it is running smoothly.

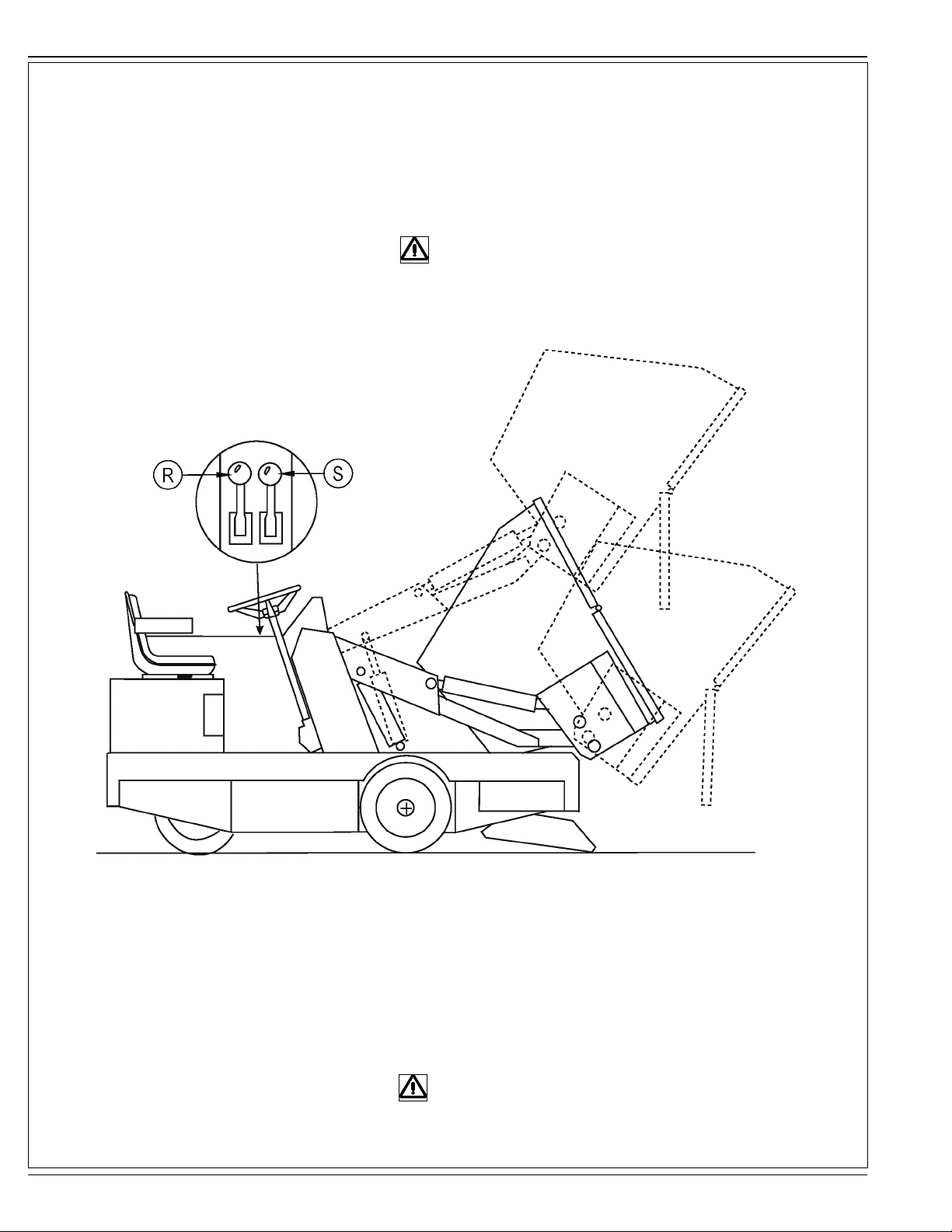

HOPPER LIFT / SIDE BROOM LEVER (See Figure 9)

The Hopper Lift/Side Broom lever (R) is located to the left side of the drive compartment. The lever is a three position control that operates the hopper lift, side

broom and optional left side broom.

NOTE

The hopper lift lever will not function until the hopper has been rotated to clear the body of the sweeper.

The lever is spring centered from the rear position. The center position turns OFF the side broom (or brooms) and is the HOLD position when dumping the hopper.

The lever is detonated in the forward position. Move the lever forward to turn ON the side broom when sweeping or to LOWER (A) the hopper when dumping the

hopper. Move the lever back to RAISE (B) the hopper when dumping. Release the lever when the hopper has reached the desired height. The lever will return to

the center HOLD position.

HOPPER DUMP/RETURN CONTROL LEVER (See Figure 9)

The Hopper Dump/Return lever (S) is located to the left of the drive compartment. The lever is a two position control that operates the hopper dump system. The

lever is spring loaded to the center position which “STOPS” rotation of the hopper. To rotate the hopper, move the lever forward to the DUMP (C) position and

hold. Release the lever when the hopper reaches the desired position. The return the hopper after dumping, move the lever back to the RETURN (D) position.

The hopper will rotate back and the hopper will lower to the seated position. Release the lever once the hopper has been seated in the body of the sweeper.

WARNING!

Never turn off the engine with the hopper in the lifted position.

FORM NO. 56041749 - SR 2000 - A-9

A-10 / ENGLISH

OPERATIONS OF CONTROLS AND GAUGES

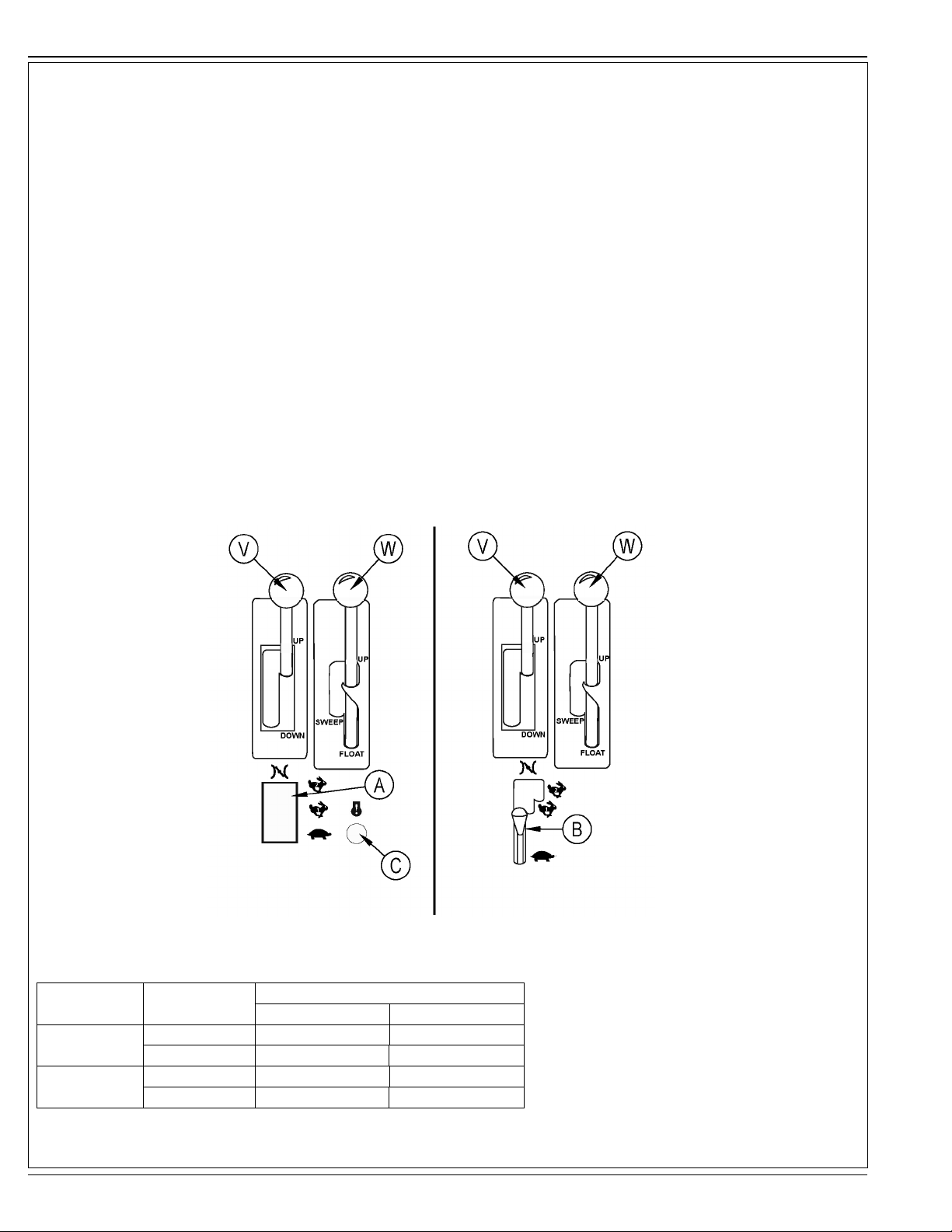

THROTTLE CONTROL (See Figures 10 & 10a)

The throttle control is located on the left side console. Gas and LP equipment have a throttle switch (A). Diesel versions have a lever (B). Both have 3 throttle

speed positions - IDLE, 1, and 2. To operate the diesel, grasp the lever and push up and right to desired locking notch. To reduce to idle, grasp the lever and push

up and to the left (away from both locking notches). Let the lever lower until it rests at the bottom of the slot. For the Gas/LP switch, the bottom position is idle, the

top position is top RPMs (2450 “no load”), and the middle is lower speed (2050 “no load” RPMs). “Load” (brooms and/or brushes and/or dust control operating)

and “No Load” (brooms, brushes & dust control off) RPMs are the same for gas and LP equipment; there will be a slight drop between “Load” and “No Load” RPMs

with diesels. Always return the throttle lever to the idle position before turning off the key to stop the engine.

CHECK ENGINE LIGHT (Gas, LP Only) (See Figure 10a)

The check engine light (MIL) (C) is located on the left side console. If the light comes on, it indicates a problem with the engine. Go to the GM Engine Service

Manual, Section 7, for directions on how to diagnose the problem.

LEFT SIDE BROOM LIFT AND POWER CONTROL (OPTION) (See Figure 10)

The left side broom lift control (V) is located on the left side of the instrument panel. To raise and stop the side broom, grasp the lever and push the lever to the

locking notch with the “UP” mark. To lower the side broom, grasp the lever and push it up to the right away from the locking notch. Let the lever lower until it rests

by the “DOWN” mark. To turn “ON” the side brooms, move the Hopper Lift/Side Broom Lever (R) FIGURE 9 forward to the “ON” position.

MAIN BROOM LIFT (See Figure 10)

The main broom lift control (W) is located to the left of the driver’s seat. To lower the main broom, grasp the lever and push up and to the left to clear the locking

notch. Move the lever down to the fi rst or second notch in the elongated slot. The fi rst notch, “SWEEP”, is for normal sweeper (2 to 3 in. or 5 to 8 cm. broom

pattern). The second notch, “FLOAT”, is for heavy sweeping (4 to 5 in. or 10 to 13 cm. broom pattern), To raise the main broom, push the lever up and slide into

the locking notch in the “UP” position. You may operate the main broom in either the “SWEEP” or “FLOAT” position. However, the “SWEEP” position should be

used for normal sweeping and will result in increased broom life. The “FLOAT” position should be used only when sweeping in extremely uneven areas.

FIGURE 10 FIGURE 10A

Engine Speeds RPMs

IDLE “NO LOAD”

Gas/LP 1st 950 2050

2nd 950 2450

Diesel 1st 950 2150

2nd 950 2550

A-10 - FORM NO. 56041749 - SR 2000

ENGLISH / A-11

OPERATIONS OF CONTROLS AND GAUGES

WORK LIGHT SWITCH (OPTION) (See Figure 2)

The work light switch (X) is located under the light switch to the left side of the steering wheel. It allows the operator to work the rear work light

option when the headlights are on.

LIGHT SWITCH (OPTION) (See Figure 2)

The light switch (Y) is located under the horn to the left side of the steering wheel. It will work various light options that are available for this

machine, such as:

- Head Lights

- Tail Lights

- Side Broom Lights

- Instrument Lights

All gauges with the exception of the hour meter can have an option internal instrument light.

HORN BUTTON (See Figure 2)

The horn button (Z) is located to the left of the steering column. The horn button is always active. Push the horn button to sound the horn.

CAB (OPTION)

The all-weather cab is available for this machine along with several “cab only” options:

- Windshield Wipers

- Defroster Fan

- Interior Light

- Pressurizer

These options have their controls located on the cab.

LOW OIL SHUTDOWN

This engine is equipped with a low oil pressure shutdown. If the engine oil pressure drops too low, the engine will shut down. Add engine oil until

the oil is brought up to the correct level.

FORM NO. 56041749 - SR 2000 - A-11

A-12 / ENGLISH

OPERATING INSTRUCTIONS

NOTE

Before starting the engine, perform these pre-start checks.

PRE-START CHECKLIST

1. Clean engine air fi lter element if needed

2. Check engine oil level

3. Check radiator coolant level

4. Check hydraulic fl uid level

5. Check fuel level

6. Check all systems for leaks

7. Check brakes and controls for proper operation

BEFORE STARTING ENGINE

1. Set Parking Brake.

2. Make sure all controls are in the “Off” position.

TO START ENGINE

1. Be sure accelerator and directional control pedal is in neutral.

2. Turn key to “On” position & release.

3. If engine fails to start after following the above procedures, refer to Engine Manual.

NOTE

When machine has been stored in below-freezing temperatures, run engine at not over 1/2 throttle with machine standing still for 5 to 10 minutes to

warm engine and hydraulic oil.

POST-START CHECKLIST (Engine Running)

1. Check main and side brooms to make sure they are free of debris which will inhibit rotation & pick-up.

NOTE: Always wear hand protection when cleaning debris from brooms and/or brushes.

2. Check squeegees to make sure there is no damage and they meet the fl oor.

TO OPERATE SWEEPER

Make sure parking brake is released.1.

Lower the side and main broom to the fl oor. (The main broom control may be placed in either the “FLOAT” or “SWEEP” position.)2.

Turn Broom Fan Switch on.3.

Pull engine throttle to “UP” position. (Engine must always be operated at full governed speed while sweeping to obtain recommended brush speed and dust 4.

control).

Push forward on directional control pedal to place machine in motion.5.

Vary your foot pressure on the directional control pedal to obtain desired travel speed.6.

TO STOP SWEEPER

Allow directional control pedal to return to neutral (centered) position. (Pedal will automatically return to neutral when foot pressure is released.) FOR 1.

NORMAL OPERATION, DEPRESS DIRECTIONAL CONTROL PEDAL WITH HEEL INTO NEUTRAL.

Depress the foot brake.2.

Turn Broom Fan Switch off.3.

Put the broom controls (Side and Main) in the “UP” position.4.

Push engine throttle down. Turn key to “OFF.”5.

Set parking brake.6.

A-12 - FORM NO. 56041749 - SR 2000

OPERATING INSTRUCTIONS

ENGLISH / A-13

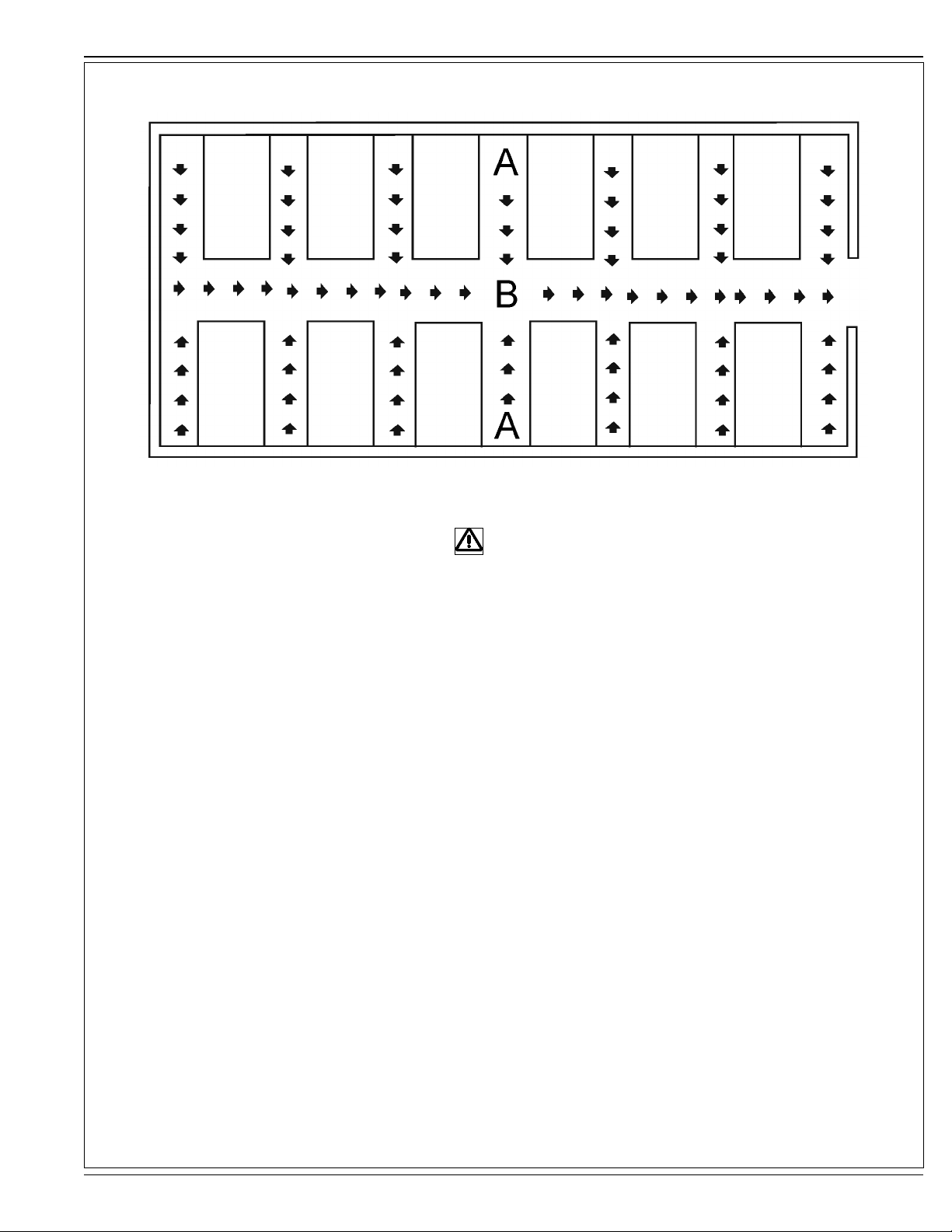

FIGURE 11

WARNING!

Do not turn the steering wheel sharply when the machine is in motion. The sweeper is very

responsive to movement of the steering wheel. Do not make sudden turns.

Sweep in straight paths. Do not bump posts. Do not scrape the sides of the machine.

When the machine is in motion, do not push the directional/speed control pedal all the way forward. This is the same as starting in “High” and will put

a strain on the motor and drive system.

1. Plan your sweeping in advance. Try to arrange long runs with minimum stopping and starting. Sweep debris from narrow aisles (A) out into

main aisle (B) ahead of time. Do an entire fl oor, or section at one time.

2. Pick up oversize debris before sweeping.

3. Don’t turn steering wheel too sharply when machine is in motion. The machine is very responsive to movement of the steering wheel - so

avoid sudden turns.

4. Try to follow as straight a path as possible. Avoid bumping into posts or scraping the sides of the machine.

5. When placing the machine in motion, avoid slamming the directional control pedal all the way forward quickly. This is equivalent to starting

out in “HIGH” and puts needless strain on the engine and drive system.

6. Always allow the machine to warm up before operating in cold temperatures.

7. Periodically turn sweeping (main) broom end for end to prevent the bristles from “setting” in one direction.

NOTE

Replace sweeping broom when bristles are worn to 3-inch (8-cm.) length.

FORM NO. 56041749 - SR 2000 - A-13

A-14 / ENGLISH

OPERATING INSTRUCTIONS

After stopping the engine, perform these post operation checks.

POST-OPERATION CHECK LIST

1. Clean debris hopper.

2. Check brooms for wear or damage.

3. Check all fl aps for wear, damage and adjustment.

4. Fill the fuel tank.

The gasoline tank access is located behind the driver’s seat.

DO NOT mistake the hydraulic reservoir for the fuel tank.

5. Check all systems for leaks.

NOTE

WARNING!

FIGURE 11a

TO EMPTY DEBRIS HOPPER

1. Set engine throttle to full throttle position.

2. Push the hopper rotate and dump lever (S) to the “DUMP” position. The hopper will begin to rotate.

3. Once the hopper rotation speed doubles, the hopper lift lever (R) will work. Raise the hopper to the desired level (MINIMUM OF 8” or 20 cm OF LIFT

REQUIRED) by pulling back the hopper lift lever (R) to the “RAISE” position.

4. Drive forward 12 to 18 inches slowly with the hopper up before completing the dump cycle.

5. Push the hopper rotation and dump lever (S) to the “DUMP” position to complete dump cycle.

6. Drive in reverse 12 to 18 inches or 30 to 46 cm. slowly with the hopper up to clear the dumpster before lowering the hopper.

7. Pull the hopper rotation and dump lever (S) to the “RETURN” position and the hopper will automatically rotate and lower to its proper position.

WARNING!

Never turn off the engine with the hopper in the lifted position.

A-14 - FORM NO. 56041749 - SR 2000

ENGLISH / A-15

OPERATING INSTRUCTIONS

View of drive pump from front of machine

FIGURE 12

The main broom and impellor fan will shut off automatically when the shaker motor is cycling.

TOWING INSTRUCTIONS

1. Locate tow control shaft extension (A) as shown in Figure 12. The tow control shaft is

located underneath the pump.

2. To open hydraulic circuit to wheel drive motor turn shaft 90°.

3. After towing, turn shaft 90° to its original position.

DUST FILTERS

The Filter Panel can be periodically removed from the hopper and blown off with compressed air

(not to exceed 100 P.S.I.) or cleaned with soap and water. (Do not attempt to use Filter Panels

that have not dried completely.)

THE DUST CONTROL SYSTEM

The baffl e system that is built into the debris hopper is designed minimize dust in the air while

the machine is sweeping.

The debris from sweeping is thrown into the hopper. The impeller vacuum fan pulls the lighter

dust up and through a baffl e system. The Pre-Clean Flap separates the heavier dust particles

to an area below the fi lter. The lighter dust particles are captured by the dust fi lter. This allows

the dust fi lter to remain cleaner and need less shaking to remove dust. When the dust fi lter

becomes clogged the fi lter shaker switch should be pushed to start the dust shaker cycle. This

will extend the life of the fi lter.

NOTE

FIGURE 13

FORM NO. 56041749 - SR 2000 - A-15

A-16 / ENGLISH

GENERAL MACHINE MAINTENANCE

FIGURE 14

HOW TO REPLACE THE MAIN BROOM (See Figure 14)

Replace the main broom when the bristles are worn to 2 inches in length.

Open the left broom chamber door 1. (A).

Put the main broom control in the “SWEEP” position.2.

Remove the retaining bolt 3. (B). (See Figure 14)

Remove the idler arm assembly 4. (C).

Remove the main broom 5. (D) and discard.

Put a new main broom in the broom chamber.6.

Rotate the new broom to the right on the drive hub 7. (E) until it engages the drive hub broom tabs.

Put the idler arm assembly 8. (C) in place.

Put the retaining bolt 9. (B) in place and tighten.

Close the broom chamber door 10. (A).

Start the engine.11.

Put the broom lever in the “SWEEP” position.12.

Let the broom sweep in place for 30 seconds.13.

Put the broom lever in the “UP” position.14.

Back the machine off the test spot.15.

Inspect the polished area where the broom swept, for broom bristle contact with the fl oor. The area of broom bristle contact with the fl oor should be 2 to 3 16.

inches or 5 to 8 cm. wide.

MAIN BROOM LEVEL ADJUSTMENT

The main broom level is factory set and should not need adjustment, if the level gets out of adjustment and the broom bristle contact pattern is not an even 2” to

3” wide, the broom arm lift frame will have to be adjusted. The frame is supported by two fl ange bearings. These bearings are located inside the broom doors. The

carriage bolts on the two end fl anges will have to be loosened. The frame can then be leveled and the bolts tightened.

A-16 - FORM NO. 56041749 - SR 2000

GENERAL MACHINE MAINTENANCE

ENGLISH / A-17

FIGURE 15

HOW TO ADJUST MAIN BROOM WEAR PATTERN

When the bristles of the broom begin to wear out the following adjustments may be made to keep a 2 inch (5 cm) broom pattern.

Loosen the wing nut located in the engine compartment.1.

Set the broom lever to the “Sweep” position and adjust the torque knob to obtain a 2 inch (5 cm) broom pattern. The torque knob will move 2.

the linkage rod that adjusts the sweeping pattern of the broom for wear.

Tighten the wing nut against the torque knob.3.

SIDE BROOM LEVEL ADJUSTMENT

As the side broom wears, simply loosen the two wear adjusting bolts and slide the broom-motor assembly into a position so that the broom

contacts the fl oor at a 3 degree angle when lowered.

SIDE BROOM REPLACEMENT

Put the side broom lift control in the “UP” position. Remove the retaining screw in the bottom middle of the side broom. Remove the side broom.

Transfer the side broom fl ange, spacer, screws, washers, and nuts to the replacement side broom. Put the replacement side broom on the shaft.

Put the retaining screw and washer in position and tighten.

BROOM FLAPS

The Urethane Flaps are susceptible to damage and should be inspected regularly and maintained in good condition. The side and hopper fl aps

(A) are adjustable and should be maintained even with the fl oor. The rear fl ap must be maintained 1/16” (1.6 mm.) above the fl oor. All fl aps should

be replaced when worn or damaged to such an extent that they cannot perform their normal function.

FORM NO. 56041749 - SR 2000 - A-17

A-18 / ENGLISH

GENERAL MACHINE MAINTENANCE

FIGURE 16

Perform the following lubrication procedures after every 50 hours of machine use:

Lubricate dump system pivot points 1. (A), with a good grade multipurpose grease. Do the following lubrication procedures after every 100

hours of machine use.

Lubricate drive wheel swivel bearing 2. (B), and the front wheel bearings (C) with a good multi-purpose grease.

The steering gear assembly has a grease fi tting, located on the front section of the steering gear housing. Use E.P. Lithium grease to 3.

lubricate the steering gear through the grease fi tting.

Lubricate all other moving joints 4. (D) of the machine with #10 oil.

Lubricate the clamp ends of the throttle cable 5. (E) with NAPA #765-1363 or equivalent anti-seize lubricant.

A-18 - FORM NO. 56041749 - SR 2000

GENERAL MACHINE MAINTENANCE

ENGLISH / A-19

FORM NO. 56041749 - SR 2000 - A-19

A-20 / ENGLISH

GENERAL MACHINE MAINTENANCE

MAINTENANCE SCHEDULE

EVERY 8 HOURS or DAILY operation check and clean/adjust if necessary:

1. Inspect panel fi lter for damage and clean.

2. Check engine oil level

3. Check hydraulic fl uid level

4. Check radiator core for blockage

5. Check all fl aps for wear or damage

6. Check brooms for wear or damage, adjust as required

7. Check panel fi lter (clean side) for leakage

8. Check brake pedal and parking brake

9. Check for LP/Diesel odor at connections

10. Check water separator (Diesel)

11. Clean engine air fi lter dust cap and check fi lter

12. Check hydraulic return fi lter

13. Check coolant level

EVERY 50 HOURS

14. Check tension on all belts

15. Check battery electrolyte level (If battery is not maintenance free)

16. Lubricate dump system

17. Check all hydraulic hoses for wear or cuts

18. Rotate main brush (end-to-end)

19. Clean or replace panel fi lter

Perform recommended engine maintenance (See engine manual)

EVERY 100 HOURS

20. Change crankcase oil

21. Change engine oil fi lter

22. Lubricate drive wheel swivel bearing

23. Lubricate front wheel bearings

24. Lubricate steering gear box

25. Lubricate all moving joints

26. Check brake pads for wear and adjust accordingly

27. Lubricate clamp ends of the throttle cable with NAPA #765-1363 or equivalent anti-seize lubricant.

Perform recommended engine maintenance (See engine manual)

EVERY 250 HOURS

29. Flush radiator coolant system

30. Remove spark plugs - clean or replace (Gas, LP)

31. Check distributor - service or replace (Gas, LP)

32. Clean and lubricate governor linkage (Diesel)

33. Replace fuel fi lter

34. Replace hydraulic return fi lter element

35. Check brass bushings & pins on hopper & lift arms

Perform recommended engine maintenance (See engine manual)

EVERY 500 HOURS

36. Clean hydraulic reservoir

37. Clean hydraulic intake strainer

38. Change hydraulic fl uid

Perform recommended engine maintenance (See engine manual)

A-20 - FORM NO. 56041749 - SR 2000

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model SR 2000 VD LPG

SR 2000 VD Petrol

SR 2000 VD Diesel

Model No. 56516755

56516750

56516753

Sound Pressure Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 11201) dB (A) 92.3

Sound Power Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 3744) dB (A) Lwa 112.1

Total Weight lbs/kg 3800 / 1724

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations at the Seat (EN 1032) m/s

Gradeability 21% (11.8°)

2

2

0.93 m/s

0.54 m/s

2

2

ENGLISH / A-21

FORM NO. 56041749 - SR 2000 - A-21

B-2 / TÜRKÇE

İÇİNDEKİLER

GİRİŞ ..................................................................................................................................................................................... B-3

MAKİNEYİ ÇALIŞTIRMA .....................................................................................................................................................B-3

ÖNLEMLER VE UYARILAR ................................................................................................................................................. B-4

KONTROLLER VE GÖSTERGELERİN KULLANIMI ................................................................................................B-5 – B-11

SU SICAKLIK GÖSTERGESİ ..................................................................................................................................... B-5

SAAT ÖLÇER ............................................................................................................................................................. B-5

YAKIT GÖSTERGESİ ................................................................................................................................................. B-5

YAĞ BASINCI GÖSTERGESİ .................................................................................................................................... B-5

VOLTMETRE .............................................................................................................................................................. B-5

SÜPÜRGE VE FAN ANAHTARI .................................................................................................................................B-6

SALLAMA MOTORU ANAHTARI .................................................................................................................................B-6

ZAMANLAMALI SALLAMA MOTORU ANAHTARI (OPSİYON)................................................................................... B-6

HİDROLİK SIVISI GÖZETLEME CAMI ......................................................................................................................B-6

SAĞ YAN SÜPÜRGE KALDIRMA VE GÜÇ KONTROLÜ ........................................................................................... B-6

KONTAK ANAHTARI .................................................................................................................................................. B-7

ISLAK SÜPÜRME BYPASS ANAHTARI (OPSİYON) ................................................................................................. B-7

DÖNÜŞ SİNYALLERİ - 4 YÖN (OPSİYON) .............................................................................................................. B-7

AYAK FRENİ ............................................................................................................................................................... B-7

GAZ PEDALI VE YÖN KONTROL PEDALI ................................................................................................................ B-8

YEDEK ALARM (OPSİYON) ....................................................................................................................................... B-8

KOLTUK AYARI .......................................................................................................................................................... B-8

PARK FRENİ .............................................................................................................................................................. B-8

DEVRE KESİCİLER .................................................................................................................................................... B-9

ISITMA BUJİSİ (Dizel) ................................................................................................................................................. B-9

HUNİ KALDIRMA/YAN SÜPÜRGE KALDIRMA KOLU ................................................................................................ B-9

HUNİ BOŞAL

GAZ KONTROLÜ ...................................................................................................................................................... B-10

MOTOR KONTROL IŞIĞI ..........................................................................................................................................B-10

SOL YAN SÜPÜRGE KALDIRMA VE GÜÇ KONTROLÜ (OPSİYON) ...................................................................... B-10

ANA SÜPÜRGE KALDIRMA ..................................................................................................................................... B-10

ÇALIŞMA IŞIĞI ANAHTARI (OPSİYON) ....................................................................................................................B-11

IŞIK ANAHTARI (OPSİYON) ......................................................................................................................................B-11

KORNA DÜĞMESİ ....................................................................................................................................................B-11

KABİN (OPSİYON) - GÖSTERİLMİYOR ...................................................................................................................B-11

DÜŞÜK YAĞ KAPATMA ............................................................................................................................................B-11

KULLANIM TALİMATLARI ....................................................................................................................................B-12 – B-15

ÇALIŞTIRMA ÖNCESİ KONTROL LİSTESİ ............................................................................................................. B-12

MOTORU ÇALIŞTIRMAK İÇİN ................................................................................................................................. B-12

ÇALIŞTIRMA SONRASI KONTROL LİSTESİ .......................................................................................................... B-12

TEMİZLEYİCİYİ ÇALIŞTIRMAK İÇİN ....................................................................................................................... B-12

TEMİZLEYİCİYİ DURDURMAK İÇİN ........................................................................................................................ B-12

POST-OPERATION CHECK LIST ............................................................................................................................ B-14

ÇÖP HUNİSİNİ BOŞALTMA ...................................................................................................................................... B-14

ÇEKME TALİMATLARI .............................................................................................................................................. B-15

TOZ FİLTRELERİ ..................................................................................................................................................... B-15

TOZ KONTROL SİSTEMİ ..........................................................................................................................................B-15

GENEL MAKİNE BAKIMI .......................................................................................................................................B-16 – B-20

TEKNİK ÖZELLİKLER ........................................................................................................................................................B-21

TMA/DÖNÜŞ KONTROL KALDIRMA KOLU ......................................................................................... B-9

B-2 - FORM NO. 56041749 - SR 2000

TÜRKÇE / B-3

GİRİŞ

Bu kılavuz, Nilfi sk SR 2000’inizden en iyi verimi almanıza yardımcı olacaktır. Makineyi çalıştırmadan önce tamamını okuyun. Bu kılavuzdaki “sağ”

ve “sol” referansları, sürücü koltuğundan bakıldığında sağ veya sol anlamına gelmektedir.

YEDEK PARÇA VE SERVİS

Gerekli hallerde onarım işlemleri, fabrikada eğitilmiş servis personeli istihdam eden ve Nilfi sk orijinal yedek parçaları ve aksesuarlarını kullanan

Yetkili Nilfi sk Servis Merkeziniz tarafından gerçekleştirilmelidir.

Yedek parça veya servis ihtiyaçlarınız için aşağıda adı verilen NILFISK ENDÜSTRİYEL YETKİLİ SATICISINI arayın. Makinenizle ilgili işlem yaptırmak

için Modelini ve Seri Numarasını belirtin.

TANITMA LEVHASI

Makinenizin Model Numarası ve Seri Numarası, operatör bölümünün duvarında bulunan Tanıtma Levhasında gösterilir. Bu bilgiler, makinenin

onarım parçalarını sipariş ederken gereklidir. Gelecekte gerektiğinde kullanmak üzere makinenizin Model Numarası ve Seri Numarasını yazmak

için aşağıdaki boş alanları kullanın.

MODEL ________________________________________________

SERİ NUMARASI ________________________________________

Not: Daha ayrıntılı motor özellikleri ve servis verileri için ayrıca verilen motor imalatçısı bakım ve işletme kılavuzuna bakın.

SANDIĞI AÇMA

Makineyi teslim aldığınızda, hasar olup olmadığını kontrol etmek için nakliye sandığını ve makineyi dikkatlice inceleyin. Belirgin bir hasar varsa,

makineyi teslim eden taşıma şirketi tarafından kontrol edilebilmesi için sevkıyat sandığının tüm parçalarını saklayın. Tespit edilen navlun hasarını

bildirmek üzere derhal taşıma şirketi ile irtibata geçin.

MAKİNEYİ ÇALIŞTIRMA

TEMİZLEYİCİNİZ KOMPLE HALDE SEVK EDİLMİŞTİR ANCAK AŞAĞIDAKİ TALİMATLARI OKUMADAN MAKİNEYİ KULLANMAYA

ÇALIŞMAYIN.

1. Makineyi sandıktan çıkarın ve hasarı önlemek için dikkatlice paletten indirin.

2. Batarya kablolarını takın ve sıkın.

3. Depoyu KURŞUNSUZ benzinle ya da Dizel Yakıtla doldurun.

UYARI!

Motor çalışırken asla yakıt deposunu doldurmayın. Yakıt dökmeden önce benzin bölümü ve temizleyicinin elektrik bağlantısı olduğundan emin olun.

Diğer ucunda batarya klipsi olan izolasyonlu bir kablo (bölmeye kalıcı olarak takılmış) temin ederek bu işlem kolayca gerçekleştirilebilir.

4. Motor karteri yağ seviyesini kontrol edin. Fabrikada doğru yağlanmış olmasına karşın, motoru çalıştırmadan önce kontrol edin. Özel rodaj

yağı kullanılmamıştır ve ilk yağ değişimi öncesi tavsiye edilen çalışma saati, normal zamandaki ile aynıdır. Nilfi sk Servis El Kitabına bakın.

5. Radyatör soğutma suyu seviyesini kontrol edin. Yaklaşık -35° F (-37° C)’ye kadar koruma sağlayacak şekilde fabrikada kalıcı tip antifriz

eklenmektedir. Bu koruma seviyesini sürdürmek için, daima bir birim suya bir birim antifriz karıştırın.

6. Makinenin ortasında motorun yanında bulunan hidrolik haznesindeki yağ seviyesini kontrol edin. Huni “AŞAĞI” konumdayken gözetleme

camından yağ görülebiliyorsa, hidrolik haznesi doludur. Yağ gerekiyorsa, SADECE HİDROLİK SIVISI, otomatik şanzıman sıvısı FORD tipi

“F” ATF ekleyin.

NOT

İlk 50 saatlik çalışmanın ardından, gelecekte de yüksek performans ve sorunsuz çalışma sağlamak için makinenize servis yapılmalıdır. Bakım

bölümüne bakın.

FORM NO. 56041749 - SR 2000 - B-3

B-4 / TÜRKÇE

SİMGELER

Nilfi sk, potansiyel olarak tehlikeli koşulları işaretlemek üzere aşağıdaki simgeleri kullanmaktadır. Her zaman bu bilgileri dikkatlice okuyun ve can ve mal güvenliğini

korumak için gerekli önlemleri alın.

TEHLİKE!

Bu simge, ağır kişisel yaralanma veya ölüme sebep olacak ani tehlikelere karşı uyarı amacıyla kullanılır.

UYARI!

Bu simge, ağır kişisel yaralanmaya sebep olabilecek bir duruma dikkat çekmek üzere kullanılır.

DİKKAT!

Bu simge, hafi f yaralanma veya makine ya da başka mülkte zarara sebep olabilecek bir duruma dikkat çekmek için kullanılır.

Kullanmadan önce bütün talimatları okuyun.

GENEL GÜVENLİK TALİMATLARI

Özel Önlemler ve Uyarılar, makine hasarı veya fi ziksel yaralanmadan kaynaklanan potansiyel tehlikelere karşı uyarı amacıyla verilmektedir.

UYARI!

Bu makine sadece uygun eğitim almış ve yetkili kişilerce kullanılır.

Rampa üzerinde ve eğimli yerlerde, yüklü olduğunda ani durma hareketinden kaçının. Ani ve keskin dönüşlerden kaçının. Yokuş aşağı düşük hızda gidin.

Sadece rampadan tırmanırken (yukarıya doğru giderken) temizleyin.

Hidrolik yağı sıçraması veya yaralanmadan kaçınmak için, hidrolik sistemle veya hidrolik sistemin yanında çalışırken mutlaka uygun giysi ve göz koruması

kullanın.

Elektrikli parçaları çıkarmadan önce kontak anahtarını kapatın (O) ve bataryanın bağlantısını kesin.

Makineyi destekleyen emniyet blokları veya sehpaları olmadan makine altında asla çalışmayın.

Ya

nıcı temizlik maddelerini etrafa yaymayın, makineyi bu maddeler üzerinde veya yakınında ya da yanıcı sıvıların bulunduğu alanlarda çalıştırmayın.

Bu makineyi basınçlı yıkayıcı ile temizlemeyin.

Bu makine ciddi yaralanma veya ölüme sebebiyet verebilecek egzoz gazları (karbon monoksit) yaymaktadır; makineyi kullanırken mutlaka yeterli havalandırma

sağlayın.

Huniyi açık bir çukura ya da havuza boşaltmayın. Huniyi eğimli bir yerdeyken (rampa) boşaltmayın. Makine düz seviyede (yatay) olmalıdır.

Yalnızca kapaklar, kapılar ve erişim panelleri sıkıca kapalıyken çalıştırın.

Asla huni kaldırılmış konumdayken gezmeyin.

Özellikle üst tarafta tıkanıklıklara dikkat edin.

Makinede yolcu taşımayın.

Hasar ya da hatalı kullanımı hemen bildirin.

Bakım ve tamir işlemleri sadece yetkili personel tarafından gerçekleştirilmelidir.

Huni kaldırılmış durumdayken asla sol kaldırma kolundaki elektrik anahtarına elinizle basmayın.

Bu Temizleyicinin Normal Çalışmada Dengesini Korumak İçin, Denge Ağırlıkları, Üst Muhafaza, Arka Tampon Muhafazası Ya Da Üretici Tarafından Orijinal

Ekipman Olarak Monte Edilmiş Benzer Herhangi Bir Parça Asla Yerinden Çıkarılmamalıdır. Tamir Veya Bakım İçin Bu Ekipmanların Sökülmesi Gerekirse,

Makine Tekrar Çalışmaya Başlamadan Önce

Tekerlek Tertibatı Patlayarak Ciddi Yaralanmalara Veya Ölüme Neden Olabilir. Tekerlek Tertibatına Uygun Eğitim Almış Ve Yetkili Personel Tarafından Federal

Osha Standardı 29 Cfr Kısım 1910.177.<D>’ye Göre Servis Yapılmalıdır.

Ciddi Derecede Havası İnik Bir Konumda Ya Da Patlak Olarak Çalıştırılmış Lastik Ve Tekerlek Tertibatlarına Hava İlavesi Yapmayın. Lastik Ve Tekerlek

Parçaları Patlayarak Ciddi Ya Da Ölümcül Yaralanmalara Neden Olabilir.

Tamirat tamamlanmadan makineyi çalıştırmayın.

Yeniden Yerine Monte Edilmelidir.

DİKKAT!

Bu makine, halka açık yollar veya caddelerde kullanım için onaylı değildir.

Bu makine, zararlı tozları toplamak için uygun değildir.

Bu makineyi kullanırken, özellikle çocuklar olmak üzere üçüncü tarafl arın tehlikeye girmemesine dikkat edin.

Herhangi bir servis işlevi yerine getirmeden önce, söz konusu işleve ait tüm talimatları dikkatlice okuyun.

İlk önce kontak anahtarını kapatmadan (O), anahtarı çıkarmadan ve el frenini çekmeden makinenin yanından ayrılmayın.

Fırçaları değiştirmeden ve herhangi bir erişim panelini açmadan önce, kontak anahtarını kapatın (O).

Saç, takı veya bol giysilerin hareketli parçalara takılmasını engellemek için önlem alın.

B-4 - FORM NO. 56041749 - SR 2000

BU TALİMATLARI SAKLAYIN

KONTROLLER VE GÖSTERGELERİN KULLANIMI

A Su Sıcaklık Göstergesi

B Saat Ölçer

C Yakıt Göstergesi

D Yağ Basıncı Göstergesi

E Voltmetre

F Süpürge ve Fan Anahtarı

G Sallama Motoru Anahtarı

H Sağ Yan Süpürge Kaldırma

I Islak Süpürme Bypass (opsiyon)

J Kontak Anahtarı

K Dönüş Sinyali (Opsiyon)

L Ayak Freni

M Gaz Pedalı ve Yön Kontrol Pedalı

N Backup Alarm Switch (option)

O Koltuk Ayarı

P Park Freni

Q Devre Kesiciler

R Huni Kaldırma

S Huni Döndürme ve Boşaltma

T Gaz Kontrolü

U Motor Kontrol Işığı (Benzin/LPG)

V Sol Yan Süpürge Kaldırma

W Ana Süpürge Kaldırma

X Çalışma Işığı Anahtarı (opsiyon)

Y Işık Anahtarı (opsiyon)

Z Korna

AA Isıtma Bujisi (Dizel)

TÜRKÇE / B-5

ŞEKİL 2

SU SICAKLIK GÖSTERGESİ (Bkz Şekil 2)

Su sıcaklık göstergesi (A) yakıt göstergesinin solundaki gösterge panelinin üzerindedir. Gösterge motordaki bir vericiyle etkinleştirilir. Motor

suyu sıcaklığını Fahrenheit biriminde gösterir.

SAAT ÖLÇER (Bkz Şekil 2)

Bu gösterge (B), gösterge konsolunun üzerinde yağ basıncı göstergesinin solunda bulunmaktadır. Bu sayaç, motor çalışmaya başladığında

etkinleşir. Saat ölçer, motorun kaç saat “çalıştığını” gösterir. Makinede bakımın ne zaman yapılacağını belirlemek için bu saat ölçer kullanılabilir.

YAKIT GÖSTERGESİ (Bkz Şekil 2)

Yak ıt göstergesi (C), gösterge panelinde su sıcaklık göstergesi ile voltmetre arasında bulunur ve yakıt deposundaki yakıt seviyesini gösterir.

YAĞ BASINCI GÖSTERGESİ (Bkz Şekil 2)

Yağ basıncı göstergesi (D), gösterge panelinde saat ölçerin sağında bulunur. Gösterge mekaniktir ve motordaki bir vericiyle etkinleştirilir. Motor

yağ basıncını PSI biriminde gösterir.

VOLTMETRE (Bkz Şekil 2)

Voltmetre (E) gösterge panelinin üstünde yakıt göstergesinin solundadır. Bu gösterge, bataryanın şarj olup olmadığını gösterir. Anahtar

aksesuar konumundayken gösterge yaklaşık 12 volt kaydeder. Motor çalışırken gösterge yaklaşık 13 ila 14.5 volt arasında bir değer gösterecektir.

Bu, alternatörün doğru çalıştığını belirtir.

FORM NO. 56041749 - SR 2000 - B-5

B-6 / TÜRKÇE

KONTROLLER VE GÖSTERGELERİN KULLANIMI

ŞEKİL 3 ŞEKİL 4

SÜPÜRGE VE FAN ANAHTARI (Bkz Şekil 2)

Süpürge ve fan anahtarı (F) sağ yan süpürge kaldırma kolunun solunda bulunur. Bu anahtar süpürgelere ve vakum fan sistemine “güç” sağlar.

Açık-kapalı konumu vardır.

SALLAMA MOTORU ANAHTARI (Bkz Şekil 2)

Sallama motoru anahtarı (G) süpürge ve fan anahtarının altındadır. Bu, fi ltre sallama motorlarını etkinleştiren anlık bir anahtardır. Sallama

motorlarını etkinleştirmek için anahtarı 20 ila 30 saniye tutun. Sallama motorları etkinleştirildiğinde, süpürgeler ve pervane fanı durur. Sallama

motorları sadece huni “SÜPÜRME” konumundayken çalışacaktır. Makinede CDC Toz Kontrol Filtre Opsiyonu varsa anahtar kontrol panelinde

değildir.

ZAMANLAMALI SALLAMA MOTORU ANAHTARI (Bkz Şekil 2)

Sallama motoru anahtarı (G) süpürge ve fan anahtarının altındadır. Bu, basıldıktan sonra fi ltre sallama motorlarını 20 – 30 saniyeliğine

etkinleştiren anlık bir anahtardır. Sallama motorları etkinleştirildiğinde, süpürgeler ve pervane fanı durur. Sallama motorları sadece huni

“SÜPÜRME” konumundayken çalışacaktır.

HİDROLİK SIVISI GÖZETLEME CAMI (Bkz Şekil 3)

Gözetleme camı, hidrolik yağı haznesinin yan tarafındadır.

Gözetleme camı, haznedeki hidrolik yağı seviyesini gösterir.

Huni aşağı konumdayken, gözetleme camından sıvı seviyesi görülebilmelidir. Gözetleme camı tamamen doluysa, haznede çok fazla sıvı var

demektir.

SAĞ YAN SÜPÜRGE KALDIRMA VE GÜÇ KONTROLÜ (Bkz Şekil 4)

Sağ yan süpürge kaldırma (H) ve güç kontrolü, gösterge panelinin sağ yanındadır. Yan süpürgeyi kaldırmak ve durdurmak için, kolu kavrayın ve

“YUKARI” oku ile işaretli kilitleme çentiğine doğru itin. Yan süpürgeyi indirmek için, kolu kavrayıp, yukarı ve sola kilitleme çentiğinden uzağa itin.

Kolu “AŞAĞI” okuna gelip durana kadar indirin. İndirildiğinde süpürge otomatik olarak dönmeye başlayacaktır. Yan süpürgeleri “AÇIK” konuma

getirmek için, Huni Kaldırma/Yan Süpürge Kaldırma Kolunu öne doğru “AÇIK” (ON) konumuna getirin (Bkz Şekil 9).

B-6 - FORM NO. 56041749 - SR 2000

TÜRKÇE / B-7

KONTROLLER VE GÖSTERGELERİN KULLANIMI

ŞEKİL 5 ŞEKİL 6

KONTAK ANAHTARI (Bkz Şekil 5)

Kontak anahtarı yuvası gösterge konsolunun ön yüzünde, direksiyon kolonunun sağında bulunur. Dört konumu bulunur.

1. Anahtar orta “KAPALI” konuma çevrildiğinde, motor kapanır. “KAPALI” konumdayken, aşağıdakiler etkinleştirilebilir.

(A.) Korna

(B.) Işık Seçenekleri

2. Anahtar sağa “IGN/ON” (Ateşleme/Açık) konumuna çevrildiğinde, aşağıdakiler etkinleştirilebilir (ancak motor ÇALIŞMAZ):

(A) Korna

(B) Işık Seçenekleri

(C) Dönüş Sinyalleri

(D) Gösterge Paneli Göstergeleri

3. Anahtar en sağdaki “START” (MARŞ) konumuna çevrildiğinde, motor çalıştırılır. Bu, anlık bir konumdur. Anahtar, bırakıldığında “IGN/ON”

konumuna geri dönecektir.

ISLAK SÜPÜRME BYPASS ANAHTARI (OPSİYON) (Bkz Şekil 2)

Islak süpürme bypass anahtarı (I) direksiyonun sağında sallama motoru anahtarının altındadır. Anahtar etkinleştirildiğinde, vakum motoru kapanır.

Böylece süpürge suyundan geri alınan su nedeniyle toz fi ltrelerinin bozulması önlenir.

4 YÖNLÜ DÖNÜŞ SİNYALLERİ (OPSİYON) (Bkz Şekil 2)

Dönüş sinyali opsiyonu (K) direksiyon kolonunda bulunmaktadır ve otomobil dönüş sinyali gibi çalışır, sağ için kolu ileri itin ve sol için kolu geri

çekin. Dönüş sinyali kolu dışarı çekildiğinde 4 yönlü fl aşör yanacaktır.

AYAK FRENİ (Bkz Şekil 6)

Ayak freni pedalı (L) sürücü bölmesinin zemininde direksiyon kolonunun sağında bulunur. Ön tekerleklerdeki ayak freni, fren pedalının kumanda

ettiği mekanik bir sistemdir.

FORM NO. 56041749 - SR 2000 - B-7

B-8 / TÜRKÇE

KONTROLLER VE GÖSTERGELERİN KULLANIMI

ŞEKİL 7 ŞEKİL 8

GAZ PEDALI VE YÖN KONTROL PEDALI (Bkz Şekil 7)

Gaz pedalı ve yön kontrol pedalı operatör bölmesinin zemininde, fren pedalının sağındadır. Gaz pedalı ve yön kontrol pedalı, makine yönünü ve

hareket hızını kontrol eder.

1. Pedalın üst kısmına (A) ayak basıncı uygulayın. Makine ileri hareket edecektir.

2. İleri doğru hızı arttırmak için pedalın üst kısmında (A) ayak basıncını arttırın.

3. Pedalın alt kısmına (B) ayak basıncı uygulayın. Makine geri hareket edecektir.

4. Geri doğru hızı arttırmak için pedalın alt kısmında (B) ayak basıncını arttırın.

5. Makineyi durdurmak için, gaz pedalının ve yön kontrol pedalının karşı ucuna hafi f ayak basıncı uygulayın. Makine ileri hareket ediyorsa,

pedalın alt kısmına hafi f ayak basıncı uygulayın. Makine geri hareket ediyorsa, pedalın üst kısmına hafi f ayak basıncı uygulayın.

YEDEK ALARM (OPSİYON) (Bkz Şekil 2)

Yedek alarm (N) Gaz Pedalı ve Yön Kontrol Pedalının alt kısmının altındaki bir anahtarla çalışır. Makine geri sürülürken alarm yüksek gürültüde

bir ses çıkarır.

KOLTUK AYARI ( Bkz Şekil 2)

Bu kaldırma kolu (O) koltuğun sağ tarafındadır. Bu kol hareket ettirildiğinde, koltuğun ileri veya geri ayarlanabilmesini sağlar.

PARK FRENİ (Bkz Şekil 8)

Park freni kolu (P) sürücü bölmesi zemininin sol tarafında bulunur. Bu kol dik konuma kaldırıldığında, ayak freni pedalını aşağı konumda

“kilitleyecektir”.

B-8 - FORM NO. 56041749 - SR 2000

TÜRKÇE / B-9

KONTROLLER VE GÖSTERGELERİN KULLANIMI

ŞEKİL 8a ŞEKİL 9

DEVRE KESİCİLER (Bkz Şekil 2 ve 8a)

Devre kesiciler (Q) direksiyonun solunda bulunur. Bir devre kesici “dışarı” çıkığında, devre kesici sıfırlanmadan önce düzeltilmesi gereken bir elektrik problemi

olduğunu gösterir.

Bir sırada yediye kadar devre kesici olabilir. Solda 1 numaradan başlayarak, aşağıdaki devreleri kontrol ederler:

CB-1 = Filtre sallama motorları

CB-2 = Korna

CB-3 = Marş rölesi

CB-4 = Kontak

CB-5 = Aksesuar

CB-6 = Opsiyonlar

CB-7 = Kabin Opsiyonları

ISITMA BUJİSİ - DİZEL (Bkz Şekil 8a)

UYARI!

Hiçbir durumda Isıtma Bujileri ile birlikte başka bir onaylanmamış marş yardımı kullanılmamalıdır.

Isıtma bujilerini çalıştırmak için, aşağıdaki prosedür uygulanmalıdır.

1. Marş motorunu çalıştırmadan önce, “ISITMA BUJİSİ” düğmesini yaklaşık 20 – 30 saniye basılı tutun.

2. “ISITMA BUJİSİ” düğmesi hala basılıyken, motor çalışana kadar motora marş yaptırın.

3. Motor çalıştıktan sonra, düzenli çalışma sağlanana kadar “ISITMA BUJİSİ” düğmesine birkaç saniye daha basmaya devam edin.

4. Motor çalışmazsa, marş motorunu bırakın ancak “ISITMA

ısıtma bujilerini marşa basarken ve motor çalıştıktan sonra düzgün çalışana kadar birkaç saniye daha çalıştırmaya devam edin

BUJİSİ” düğmesini 10 – 15 saniye daha basılı tutun. Motoru tekrar çalıştırmayı denediğinizde,

HUNİ KALDIRMA / YAN SÜPÜRGE KALDIRMA KOLU (Bkz Şekil 9)

Huni Kaldırma/Yan Süpürge Kaldırma Kolu (R) sürücü bölmesinin sol tarafında bulunur. Kaldırma kolu, huni kaldırmayı, yan süpürgeyi ve opsiyonlu yan süpürgeyi

çalıştıran üç konumlu bir kontroldür.

NOT

Huni, temizleyicinin gövdesini ortaya çıkarmak için döndürülene kadar huni kaldırma kolu çalışmayacaktır.

Kol, arka taraftan yayla ortalanmıştır. Orta konum yan süpürgeyi (ya da süpürgeleri) KAPALI konuma getirir ve huniyi boşaltırken TUTMA konumudur. Kaldırma

kolu, ileri konumdayken çalışır. Temizleme yaparken yan süpürgeyi AÇIK konuma getirmek için ya da huniyi boşaltırken huniyi ALÇALTMAK (A) için kaldırma

kolunu ileri hareket ettirin. Boşaltma yaparken huniyi YÜKSELTMEK (B) için kaldırma kolunu geri hareket ettirin. Huni istenen yüksekliğe ulaştığında kolu bırakın.

Kaldırma kolu ortadaki TUTMA konumuna geri dönecektir.

HUNİ BOŞALTMA / DÖNÜŞ KONTROL KALDIRMA KOLU (Bkz Şekil 9)

Huni Boşaltma/Dönüş Kontrol kaldırma kolu (S) sürücü bölmesinin solunda bulunur. Kaldırma kolu, huni boşaltma sistemini çalıştıran iki konumlu bir kontroldür.

Kaldırma kolu, huninin dönüşünü “DURDURAN” orta konumda yayla sabitlenmiştir. Huniyi döndürmek için, kolu BOŞALTMA (C) konumuna getirin ve tutun.

Huni istenen konuma ulaştığında kolu bırakın. Boşalttıktan sonra huniyi geri döndürmek için, kolu DÖNÜŞ (D) konumuna getirin. Huni dönerek geri gelecek ve

alçalarak yerine yerleşecektir. Huni, temizleyicinin gövdesine yerleştikten sonra kolu bırakın.

UYARI!

Huni kaldırılmış konumdayken asla motoru kapatmayın.

FORM NO. 56041749 - SR 2000 - B-9

B-10 / TÜRKÇE

KONTROLLER VE GÖSTERGELERİN KULLANIMI

GAZ KONTROLÜ (Bkz Şekil 10 ve 10a)

Gaz kontrolü sol konsolda bulunur. Benzinli ve Gazlı ekipmanın gaz anahtarı (A) vardır. Dizel versiyonlarda bir kol (B) bulunur. Her ikisinde de 3 gaz

hızı konumu bulunmaktadır - RÖLANTİ, 1 ve 2. Dizeli çalıştırmak için, kolu kavrayın ve istenen kilitleme çentiğine doğru yukarı ve ileri itin. Rölantiyi

düşürmek için, kolu kavrayıp yukarı ve sola (her iki kilitleme çentiğinden uzağa) itin. Kanalın tabanında durana kadar kolu indirin. Gaz/LP anahtarı

için, taban konumu rölanti, üst konum en üst devir (2450 “yüksüz”) ve orta konum ise düşük hızdır (2050 “yüksüz” devir). “Yüklü” (süpürgeler ve/veya

fırçalar ve/veya toz kontrolü çalışırken) ve “Yüksüz” (süpürgeler, fırçalar ve toz kontrolü kapalıyken) devirler benzinli ve gazlı ekipman için aynıdır;

dizellerde “Yüklü” ve “Yüksüz” devirler arasında hafi f bir düşüş olacaktır. Anahtarı çevirerek motoru kapatmadan önce daima gaz kolunu rölanti

konumuna getirin.

MOTOR KONTROL IŞIĞI (Gaz, yalnızca LP) (Bkz Şekil 10a)

Motor kontrol ışığı (MIL) (C) sol taraftaki konsolda bulunur. Işık yanarsa, motorda bir sorun olduğunu belirtir. Sorunun nasıl tespit edilebileceğine

ilişkin talimatlar için GM Motor Servis Kitapçığı, Bölüm 7’ye bakınız.

SOL YAN SÜPÜRGE KALDIRMA VE GÜÇ KONTROLÜ (OPSİYON ) (Bkz Şekil 10)

Sol yan süpürge kaldırma kontrolü (V) gösterge panelinin sol tarafında bulunur. Yan süpürgeyi kaldırmak ve durdurmak için, kolu kavrayın ve “YUKARI” oku ile

işaretli kilitleme çentiğine doğru itin. Yan süpürgeyi indirmek için, kolu kavrayıp, yukarı ve sağa kilitleme çentiğinden uzağa itin. Kolu “AŞAĞI” okuna gelip durana

kadar indirin. Yan süpürgeleri “AÇIK” konuma getirmek için, Huni Kaldırma/Yan Süpürge Kaldırma Kolunu (R) ŞEKİL 9 öne doğru “AÇIK” (ON) konumuna getirin.

ANA SÜPÜRGE KALDIRMA (Bkz Şekil 10)

Ana süpürge kaldırma kontrolü (W) sürücü koltuğunun solunda bulunur. Ana süpürgeyi indirmek için, kolu kavrayıp yukarı ve sola kilitleme çentiğini ortaya

çıkaracak şekilde itin. Kolu uzunlamasına kanalda aşağı doğru birinci veya ikinci çentiğe getirin. Birinci çentik “SÜPÜRME” normal süpürme içindir (2 – 3 inç ya

da 5 – 8 cm süpürme düzeni). İkinci çentik, “ASILI” konum, ağır süpürme içindir (4 - 5 inç ya da 10 - 13 cm süpürme düzeni). Ana süpürgeyi kaldırmak için, kolu

yukarı itin ve “YUKARI” konumundaki kilitleme çentiğine kaydırın. Ana süpürgeyi “SÜPÜRME” veya “ASILI” konumunda kullanabilirsiniz. Ancak “SÜPÜRME”

konumu normal süpürme için kullanılmalıdır ve daha uzun süpürge ömrü sağlayacaktır. “ASILI” konumu sadece son derece pürüzlü alanları süpürürken

kullanılmalıdır.

ŞEKİL 10 ŞEKİL 10A

Motor Hızlar Devir

RÖLANTİ “YÜKSÜZ”

Benzin/Gaz 1. 950 2050

2. 950 2450

Dizel 1. 950 2150

2. 950 2550

B-10 - FORM NO. 56041749 - SR 2000

TÜRKÇE / B-11

KONTROLLER VE GÖSTERGELERİN KULLANIMI

ÇALIŞMA IŞIĞI ANAHTARI (OPSİYON) (Bkz Şekil 2)

Çalışma ışığı anahtarı (X) direksiyonun solunda ışık anahtarının altında bulunur. Ön farlar açıkken operatörün arka çalışma ışığı opsiyonunu

çalıştırmasına olanak sağlar.

IŞIK ANAHTARI (OPSİYON) (Bkz Şekil 2)

Işık anahtarı (Y) direksiyonun solunda kornanın altında bulunur. Bu makinede bulunan çeşitli ışık seçeneklerini çalıştıracaktır, örneğin:

- Ön Farlar

- Stop Işıkları

- Yan Süpürge Işıkları

- Gösterge Işıkları

Saat ölçer dışındaki tüm göstergelerde opsiyonel dahili gösterge lambası bulunabilir

KORNA DÜĞMESİ (Bkz Şekil 2)

Korna düğmesi (Z) direksiyon kolonunun solunda bulunur. Korna düğmesi daima aktiftir. Kornayı çalmak için korna düğmesine basın.

KABİN (OPSİYON)

Her havada kullanıma uygun kabin, birkaç “yalnızca kabin” opsiyonu ile birlikte bu makine için mevcuttur:

- Cam Silecekleri

- Buz Çözücü

- İç Işık

- Basınçlandırıcı

Bu opsiyonların kontrolleri kabin üzerindedir.

DÜŞÜK YAĞ KAPATMA

Bu motor, bir düşük yakıt kapatma sistemine sahiptir. Motor yağ basıncı çok düşerse, motor kapanacaktır. Yağ miktarı doğru seviyeye gelene

kadar motor yağı ekleyin.

.

FORM NO. 56041749 - SR 2000 - B-11

B-12 / TÜRKÇE

KULLANIM TALİMATLARI

NOT

Motoru çalıştırmadan önce, bu çalıştırma öncesi kontrolleri yapın.

ÇALIŞTIRMA ÖNCESİ KONTROL LİSTESİ

1. Gerekiyorsa motor hava fi ltresi elemanını kontrol edin

2. Motor yağı seviyesini kontrol edin

3. Radyatör soğutma suyu seviyesini kontrol edin

4. Hidrolik yağı seviyesini kontrol edin

5. Yakıt seviyesini kontrol edin

6. Tüm sistemlerde kaçak olup olmadığını kontrol edin

7. Frenler ve kontrollerin doğru çalışıp çalışmadığını kontrol edin

MOTORU ÇALIŞTIRMADAN ÖNCE

1. Park Frenini ayarlayın.

2. Tüm kontrollerin “Kapalı” (Off) konumda olduğundan emin olun.

MOTORU ÇALIŞTIRMAK İÇİN

1. Gaz pedalı ve yön kontrol pedalının boşta olduğundan emin olun.

2. Anahtarı “Açık” (On) konumuna çevirin ve bırakın.

3. Yukarıdaki prosedürleri izledikten sonra motor çalışmazsa, Motor Kitapçığına bakınız.

NOT

Makine donma sıcaklığının altında muhafaza edilmişse, motor ve hidrolik yağını ısıtmak için makine sabitken motoru yarım gazdan fazla olmayacak

şekilde 5-10 dakika çalıştırın.

ÇALIŞTIRMA SONRASI KONTROL LİSTESİ (Motor Çalışır Durumda)

1. Ana ve yan süpürgelerde, dönmeyi önleyecek çöp olmadığından emin olun.

NOT: Süpürgelerden ve/veya fırçalardan çöpleri temizlerken daima koruyucu eldiven takın.

2. Lastik sileceklerde hasar olup olmadığını ve yere temas edip etmediklerini kontrol edin.

TEMİZLEYİCİYİ ÇALIŞTIRMAK İÇİN

Park freninin bırakılmış olduğundan emin olun.1.

Yan ve ana süpürgeleri zemine indirin. (Ana süpürge kontrolü “ASILI” ya da “SÜPÜRME” konumunda olabilir.)2.

Süpürge Fan Anahtarını açın.3.

Motor gazını “YUKARI” konuma çekin. (Tavsiye edilen fırça hızını ve toz kontrolünü elde etmek için motor her zaman tam hakimiyetli hızda çalıştırılmalıdır).4.

Makineyi harekete geçirmek için yön kontrol pedalını ileri bastırın.5.

İstenilen hareket hızını elde etmek için yön kontrol ayak pedalına uygulanan basıncı değiştirin.6.

TEMİZLEYİCİYİ DURDURMAK İÇİN

Yön kontrol pedalının boş (orta) konuma geri dönmesini bekleyin. (Ayak basıncı kalktığında, pedal otomatik olarak boşa geri dönecektir.) NORMAL 1.

ÇALIŞMA İÇİN, YÖN KONTROL PEDALINA TOPUK BOŞA GELECEK ŞEKİLDE BASIN.

Ayak frenine basın.2.

Süpürge Fan Anahtarını kapatın.3.

Süpürge kontrollerini (Yan ve Ana) “YUKARI” konuma getirin.4.

Motor gazını aşağı bastırın. Anahtarı “KAPALI” (OFF) konuma çevirin.5.

Park frenini ayarlayın.6.

B-12 - FORM NO. 56041749 - SR 2000

KULLANIM TALİMATLARI

TÜRKÇE / B-13

ŞEKİL 11

UYARI!

Makine hareket halindeyken direksiyonu keskin şekilde çevirmeyin. Temizleyici, direksiyon

hareketlerine son derece duyarlıdır. Ani dönüşler yapmayın.

Düz yollarda süpürün. Direklere çarpmayın. Makine kenarlarını sürtmeyin.

Makine hareket halindeyken, yön/hız kontrol pedalına sonuna kadar basmayın. Bu “Yüksek” çalıştırma ile aynıdır ve motorla tahrik sistemini

zorlayacaktır.

1. Süpürmenizi önceden planlayın. Minimum durma ve çalışmayla uzun mesafeler ayarlamaya çalışın. Dar koridorlardan (A) pislikleri önceden

ana koridora (B) süpürün. Bir zeminin veya bölümün tamamını bir seferde temizleyin.

2. Süpürmeden önce büyük çöpleri toplayın.

3. Makine hareket halindeyken direksiyonu keskin şekilde çevirmeyin. Makine, direksiyonun hareketine çok hassastır, ani dönüşler yapmayın.

4. Bir yolu mümkün olduğunca düz izleyin. Direklere çarpmaktan ya da makinenin kenarlarını sürtmekten kaçının.

5. Makineyi hareket ettirirken, yön kontrol pedalına hızlı bir şekilde sonuna kadar basmayın. Bu “YÜKSEK” çalıştırma ile aynıdır ve motorla

tahrik sistemini gereksiz zorlayacaktır.

6. Soğuk havalarda kullanıma başlamadan daima makineyi ısıtın.

7. Fırçaların bir yönde “kalmasını” önlemek için periyodik olarak (ana) fırçayı uçtan uca çevirin.

NOT

Kıllar 3 inç (8 cm) uzunluğa kadar aşındığında süpürme fırçalarını değiştirin.

FORM NO. 56041749 - SR 2000 - B-13

B-14 / TÜRKÇE

KULLANIM TALİMATLARI

NOT

Motoru durdurduktan sonra, aşağıdaki kullanım sonrası kontrolleri gerçekleştirin.

KULLANIM SONRASI KONTROL LİSTESİ

1. Çöp hunisini temizleyin.

2. Süpürgelerde hasar veya aşınma olup olmadığını kontrol edin.

3. Tüm kapaklarda aşınma, hasar ve ayar bozukluğu olup olmadığını kontrol edin.

4. Yakıt deposunu doldurun.

Benzin deposunun kapağı sürücü koltuğunun arkasındadır.

Hidrolik haznesini yakıt deposu ile KARIŞTIRMAYIN.

5. Tüm sistemlerde kaçak olup olmadığını kontrol edin.

UYARI!

ŞEKİL 11a

ÇÖP HUNİSİNİ BOŞALTMA

1. Motor gazını tam gaz konumuna getirin.

2. Huni döndürme ve boşaltma kolunu (S) ittirerek “BOŞALTMA” konumuna getirin. Huni dönmeye başlayacaktır.

3. Huninin dönme hızı iki katına çıktığında, huni kaldırma kolu (R) çalışacaktır. Huni kaldırma kolunu (R) “KALDIRMA” konumuna çekerek huniyi istenen

seviyeye yükseltin (MİNİMUM 8 inç ya da 20 cm KALDIRMA GEREKLİDİR).

4. Boşaltma turunu tamamlamadan önce huni yukarı konumdayken 12-18 inç kadar yavaşça ileri sürün.

5. Boşaltma turunu tamamlamak için huni döndürme ve boşaltma kolunu (S) ittirerek “BOŞALTMA” konumuna getirin.

6. Huniyi indirmeden önce çöpü temizlemek için huni yukarı konumdayken makineyi 12-18 inç ya da 30-46 cm kadar geri sürün.