Page 1

Operator's

Order Parts Here:

www.ivie-ent.com/parts

Ph:(918)254-5161

3DS

Manual

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this

book prior to operating or attempting any service or maintenance procedure to your ALTO machine could

result in injury to you or to other personnel; damage to the machine or to other property could occur as

well. You must have training in the operation of this machine before using it. If you cannot read English,

have this manual explained fully before attempting to operate this machine.

Si Ud. o sus operadores no pueden leer el Inglés, se hagan explicar este manual completamente antes

de tratar el manejo o servicio de esta máquina.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

For new books write to: ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

Form No. 74845A 3/01 AMERICAN SANDERS TECHNOLOGY Printed in the U.S.A.

Page 2

Contents of this Book

Operator Safety Instructions........................................................3

Explanation of Hazard Symbols ...................................................4

Introduction and Machine Specifications ......................................5

Instructions On Connection To Power Supply 230 Volt................6

Machine Breakdown/Transportation ............................................7

Machine Set-Up ...........................................................................9

Operating Instructions................................................................10

Maintenance ..............................................................................11

User Maintenance................................................................11

Service Maintenance............................................................11

Section II Parts and Service Manual

Troubleshooting .........................................................................14

Sanding Cuts and Sandpaper ....................................................15

Accessories ...............................................................................16

Assembly Drawing #1 ................................................................18

Assembly Parts List #1..............................................................19

Assembly Drawing #2 ................................................................20

Assembly Parts List #2..............................................................21

Electrical Schematic ..................................................................22

Page 2 AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS

Page 3

OPERATOR SAFETY INSTRUCTIONS

WARNING AVERTISSEMENT ADVERTENCIA

DANGER means: Severe bodily injury or death can or will occur to you or other personnel if

the DANGER statements found on this machine or in this Operator's Manual

are ignored or are not adhered to. Read and observe all DANGER state-

ments found in this Operator's Manual and on your machine.

WARNING means: Severe injury can occur to you or to other personnel if the WARNING

statements found on your machine or in this Operator's Manual are ignored

or are not adhered to. Read and observe all WARNING statements found in

this Operator's Manual and on your machine.

CAUTION means: Minor personnal injury, property damage, or damage to machine can occur if

the CAUTION statements found on your machine or in this Owner's Manual

are ignored or are not adhered to. Read and observe all CAUTION state-

ments found in this Operator's Manual and on your machine.

DANGER: Failure to read the Operator's Manual prior to operating or servicing your machine could

result in injury to you or to other personnel; damage to the machine or to other property could

occur as well. You must have training in the operation of this machine before using it. If you

cannot read English, have this manual explained fully before attempting to operate

this machine.

DANGER: Operating a machine that is not completely or fully assembled can result in injury to the

operator or property damage. Do not operate this machine until it is completely assembled.

Keep all fasteners tight. Keep adjustments according to machine specifications.

DANGER: Explosive materials, severe bodily injury or death can occur. Sanding/finishing wood floors

can create an explosive or combustible environment. Do not operate this machine around

solvents, thinners, alcohol, fuels, floor finishes, wood dust or any other flammable materials.

Vapors and wood dust generated by sanding or finishing wood flooring can create an

explosive environment. Cigarette lighters, pilot lights, electrical sparks and all other sources

of ignition should be extinguished or avoided. Keep work area

well ventilated.

DANGER: Dust generated from sanding wood floors can spontaneously ignite or explode. Promptly

dispose of any sanding dust in a metal container clear of any combustibles. Do not dispose

in a fire.

DANGER: Electrocution could occur if the machine is being serviced while the machine is connected

to a power source. Disconnect the power supply before servicing. Always remove the

electrical plug from the power source before changing the brush pad or other attachment.

Always disconnect the power supply before leaving the machine.

DANGER: Electrocution or fire could occur if the machine is being operated with a damaged power

cord. Keep the power cord clear of the pad. Always lift the cord over the machine. Do not

move the machine by the power cord.

DANGER: Electrocution could occur if the machine is used on an ungrounded electrical circuit. Always

use a three-wire electrical system connected to the electrial ground. Never remove or

disable the grounding supply conductor on the electrical cord. Consult an electrician if the

grounding conductor is missingf or if you suspect your circuit is not grounded properly.

WARNING: Always use a three-wire electrical system connected to the electrical ground. For maximum

protection against electric shock, use a circuit that is protected by a ground fault interrupter.

Consult your electrical contractor.

AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS Page 3

Page 4

DANGER: To avoid injury keep hands, feet, and loose clothing away from all moving parts on the

machine. Disconnect the power cord before replacing the pad, changing the abrasive, or

when servicing. Do not operate the machine unless all guards are in place. Never leave

the machine unattended while connected to a power source.

WARNING: Shock hazard. Electrical components of this machine can “short-out” if exposed to water

or moisture. Keep the electrical components of the machine dry. Wipe the machine down

after each use. For storage, keep the machine in a dry building.

WARNING: Injury can occur if protective clothing or equipment is not used while sanding. Always wear

safety goggles, protective clothing, and dust mask while sanding.

WARNING: Any alterations or modifications of this machine could result in damage to the machine or

injury to the operator or other bystanders. Alterations or modifications not authorized by the

manufacturer voids any and all warranties and liabilities.

WARNING: Operating a machine without observing all labels and instructional information could result

in injury to the operator or damage to the machine. Read all machine labels before

attempting to operate the machine. Make sure all of the labels and instructional information

are attached or fastened to the machine. Get replacement labels and decals from your

authorized distributor.

WARNING: The machine is heavy. Injury could occur to the operator or other bystanders unless proper

lifting procedures are used. Get help to lift the machine.

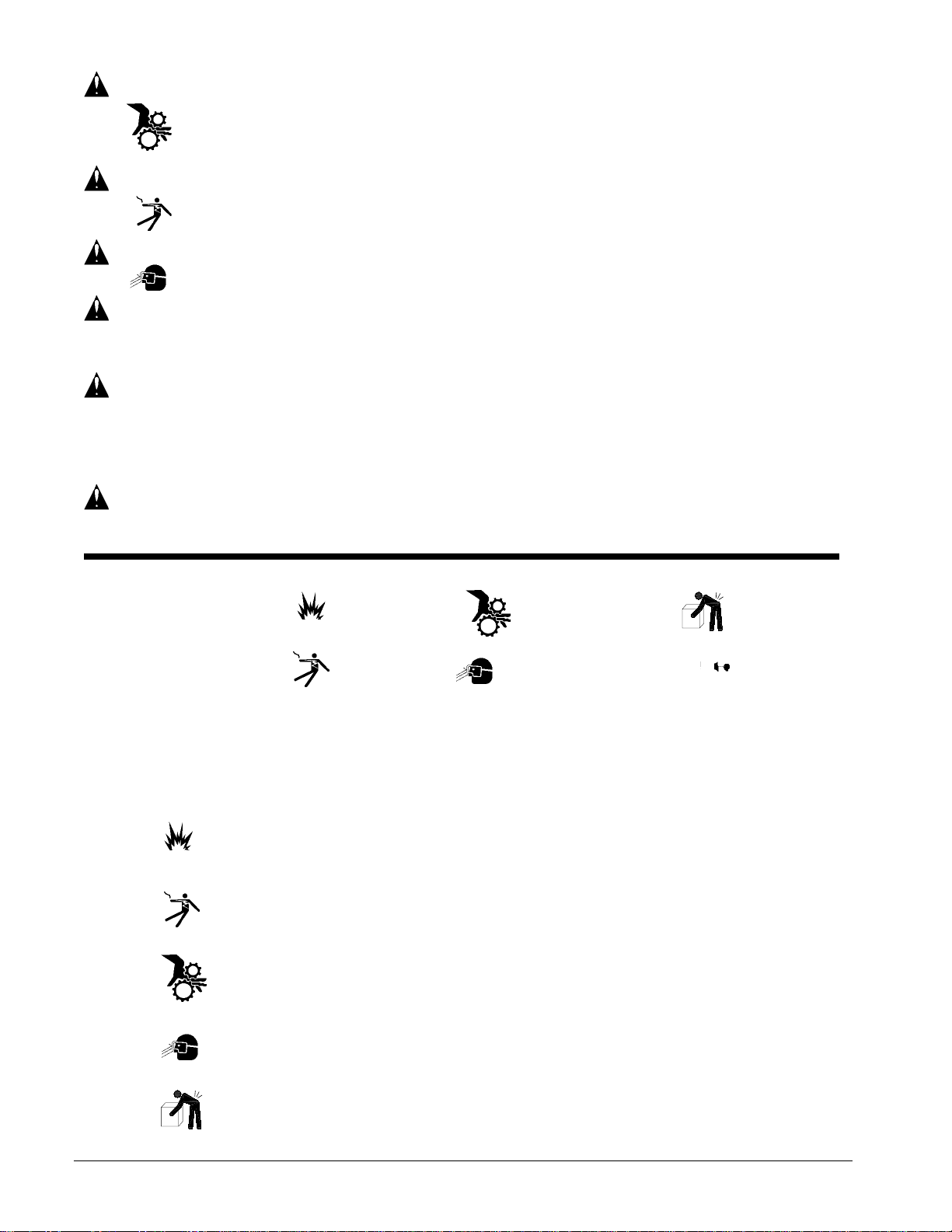

Explosion

Electrical Shock

Failure to read operator’s manual could result in injury to operator or damage to

machine.

The symbol of a flame shows that the material can ignite and burn you.

The symbol of a man with voltage going through him depicts electrocution

or shock. This can cause death or severe injury.

This symbol refers to the danger of moving parts. Injury can occur.

This symbol of a person wearing goggles warns of injuries to eyes.

Moving parts

Eye Protection

Heavy Object

Read Owner’s Manual

Explanation of Hazard Symbols

This symbol of a man lifting shows that injury could occur without proper

lifting procedures.

Page 4 AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS

Page 5

Introduction & Machine Specifications

The 3DS is a machine designed primarily for fine finish sanding of hardwood floors. The finish sanding process results

in a smoother and flatter floor and assists in removing imperfections created during the drum or belt sanding process.

This machine can not be used on wet surfaces.

PRODUCT SPECIFICA TIONS

Machine Code 07082C 07085C

Machine Type:

Motor:

Voltage:

Frequency:

Current:

Fuse:

Insulation Class:

Sanding Pad Diameter:

Speed of Sanding Pad: (rpm)

Speed of Sanding

Gear Housing: (rpm)

Weight of Sanding Unit:

Weight of Chassis:

To tal Weight (w/o vacuum):

To tal Weight (with vacuum):

Length:

Width:

Height (assembled):

Filter dimension (cloth):

Filter dimension (paper):

Filtration (cloth):

Filtration (paper):

Shipping Weight w/vacuum):

Shipping Weight w/o vacuum):

Noise Emission

(with vacuum unrestricted):

Noise Emission

(w/o vacuum unrestricted):

Working Diameter:

Power Cable

Rubber Jacketed

60 Hz 50Hz

8” 20.32cm

35” 88 cm

20” 51 cm

39.5” 100 cm

234 lbs. 106 kg

212 lbs. 96 kg

18.75” 48 cm

40’ 12-3 Cord 15 meters

3 Disc Dry Sanding

3 HP Single Phase

230 Volt

11.5 Amps

15 Amps

F

717 (Loaded)

170 (Loaded)

109 lbs. (49.44 kg.)

37 lbs.(16.78 kg.)

146 lbs.(66.36 kg.)

163 lbs.(74.09 kg.)

950 sq. cm.

5310 sq. cm.

15 microns

12 microns

76 dBA

73 dBA

AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS Page 5

Page 6

Grounding Instructions - 230 V olt

230 VOLT MACHINES

INSTRUCTIONS FOR CONNECTION

TO THE POWER SUPPLY

AND THE ELECTRICAL GROUND

CAUTION: To avoid damage to the machine op-

erate only on AC frequency and electrical voltage shown on the nameplate. Make sure you have the correct frequency and voltage before

connecting the power cord to an outlet.

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the

risk of electric shock. This product is equipped with

a cord having an equipment-grounding conductor

and grounding plug. The plug must be inserted into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

WARNING: Improper connection of the equip-

ment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician

or service person if you are in doubt

as to whether the outlet is properly

grounded. Do not modify the plug

provided with the product - if it will

not fit the outlet, have a proper outlet installed by a qualified electrician.

This product is for use on a nominal 230 volt circuit

and has a grounding attachment plug that looks like

one of the plugs illustrated in Fig. 1. Make sure that

the product is connected to an outlet having the

same configuration as the plug. No adaptor should

be used with this product.

NEMA L6-20P

IEC-309 16A-6h/200-250 V ac

Figure 1

WARNING: To avoid electrical shock always use

this machine with an AC three-conductor electrical system connected

to the electrical ground. Replace

any worn, cut or damaged cords.

Replace any damaged plugs, receptacles, or connector bodies. Do

not move the machine over an electrical cord. Always lift the cord over

the machine.

EXTENSION CORDS

Use only an approved extension cord with two

main conductors and one earthing conductor. The

machine has a power cord with wire size 12 A WG

or 2.5mm2.

WARNING:To avoid motor burnout, if you use

an extension cord, use an extension

cord with minimum wire size of 10

AWG or 4.0mm2. Do not use an extension cord longer than 40 feet or

15 meters. Do not join two extension cords.

WARNING:T o avoid electrical shock, do not cut,

This machine must be connected to the electrical

ground to protect the operator from electrical shock.

The machine has a power cord with two main conductors and one earthing conductor. Connect the plug

to the receptacle. The green or green and yellow conductor in the cord is the ground wire. Never connect

this wire to any terminal other than the ground terminal.

Page 6 AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS

remove or break the ground terminal. Do not try to fit a three-terminal plug into a receptacle or connector body that does not fit the plug. If

the receptacle or connector body

does not fit the plug, see your authorized American Sanders T echnology dealer to get an authorized person to make the connection.

Page 7

Machine Breakdown/T ransportation

To break down the machine, follow this procedure:

1. Unplug machine from wall and wrap cord.

WARNING: Injury to the operator or bystanders

could occur if the power supply remains connected when servicing the

equipment, changing abrasive, or

empting the dust bag.

2. Unplug the power cord, motor cord, and vacuum

from electric box.

3. Disconnect the vacuum hose from the sanding unit.

Ü

Figure 2

4. Remove both hand knobs from the sanding unit

and separate sanding unit from truck frame.

(see Figure 2)

WARNING: The sanding unit is heavy (109 lbs.).

T o avoid injury to the operator or damage to the machine use a firm grip

and proper lifting technique. Get assistance if necessary.

5. To lift the sanding unit grasp the assembly at the

lifting sites. (see Figure 3)

6. Unwrap the vacuum power cord from the cleats on

the handle and place on vacuum head.

7. Disconnect the vacuum straps by unhinging the

draw latch. The vacuum strap will spring back and

the vacuum can be lifted off the truck frame. (See

Figure 4)

8. The handle may be taken off by removing the four

5/16-18 bolts and nuts that secure it to the truck

frame.

Ü

Ü

Figure 3

Ü

Figure 4

9. Secure all elements in cargo area when transport-

ing to avoid damage to the machine.

How to Move Machine (Room to Room)

When moving the machine short distances (room to room)

it may be moved by tilting it back until the 4” diameter wheels

contact the floor. With steady downward pressure on the

handle the machine can be pushed to the desired location.

(see Figure 5)

Ü

Figure 5

AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS Page 7

Page 8

Machine Setup

Listed below are the tools needed for setup of the

machine: 1 - #2 Phillips screwdriver

To prepare the machine for use, follow this procedure:

2 - ½” open end wrenches or (2) adjustable

wrenches.

1. Remove all components of the machine from its

package and check for damaged or missing parts.

2. Read Operation and Parts Manual, including all

danger, warning, and caution statements before

operating the machine. If you or the operator are

unable to read the language this manual is printed

in, have the manual fully explained before attempting to operate this machine.

3. Attach the sanding unit to the truck frame by securing the two hand knobs through the truck frame

to the sanding unit. (see Figure 6). The eccentrics in the truck frame should be used for proper

alignment between the truck frame and sanding

unit. Match tick marks on spacers and frame;

one on right and two on left.

4. Route the motor power cable under the head pressure strap and vacuum support strap, then over

the tilt assist strap.

5. Secure the handle assembly to the truck frame by

bolting it on with the four 5/16-18 bolts and nyloc

nuts supplied and plug in motor power cord. (see

Figure 7) Tighten the nuts that hold on the tilt

wheels and attach the vacuum support straps as

per figure 7.

6. Put Dacron filter around the cloth filter. (See Figure 8)

7. Set the dry vacuum on the vacuum support straps

with the center bottom in the 2” diameter hole.

NOTE: The vacuum hose port should be facing

the sanding unit motor. Attach the vacuum strap

around the base of the vacuum. (See Figure 9)

Ü

Figure 6

Ü

Figure 7

Ü

Figure 8

3DS

8. An optional disposable paper bag (60711A) is

9. Wrap the vacuum cord around the cleats located

available. If you wish to use the paper bag, remove the vacuum head and install a paper dust

control bag by inserting the deflector on the

vacuum into the mounting shoe of the paper bag.

To ensure the bag is properly seated on the deflector, the rubber seal should rest in the groove

of the deflector. (See Figure 10)

NOTE: Check the paper bag for proper seating

after transport to avoid dust in the vacuum tank.

on the back of the handle. Leave enough slack in

the cord to plug into the electric box. Turn the

vacuum switch to the “ON” position. The vacuum

switch should remain in the “ON” position. (See

Figure 1 1 below)

Ü

Figure 9

Ü

Ü

Ü

Figure 11

Page 8 AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS

Figure 10

Page 9

Machine Setup (cont)

WARNING: Injury could occur to the operator or by-

standers if the machine should tip or fall

while replacing the pad or changing the

abrasive.

WARNING: Never allow the machine to be started

while tilted up. Severe injury could result if the machine is started while the

abrasive is being changed.

CAUTION: Damage to the sanding head will occur

if the unit is allowed to drop freely from

the tilted position.

CAUTION: Damage to the pad driver will occur if

the machine is operated without sandpaper or screen and pad. Damage to

the pad driver can also occur if the pad

is less than 1/8” thick.

10. Install or replace sandpaper or screen and pad. The

sandpaper, screen, and pad should be replaced if

there are any tears or if they have become worn and

dull. The pad should also be replaced if its thickness

is less than 1/8”. To inst all or replace the sandp aper ,

screen, or pad: (See Figure 12)

DANGER: Disconnect the power source. Electrocu-

tion could occur if the machine is connected to the power source while changing the abrasives, pads or empting the dust

bag.

Ü

Figure 12

Ü

Ü

Figure 13

a.) Unplug the machine from its power source and

move the power cord out of your way .

b.) Tilt the machine back by pressing on the tilt

assist strap with your foot while also pushing

down on the handle. (see Figure 13)

c.) Remove foot from tilt assist strap and con-

tinue to push down on the handle until the

machine rests in the up position on the handle

and tilt wheels. (see Figure 14)

d.) T o remove the existing paper or screen / pa d

stand to the side of the machine and pull from

one edge. The screen may have a plastic

pushpin in the center that will require removing prior to the screen’s removal.

(See Figure 15)

e.) Center the new paper or screen / pad over the

pad driver and press against the pad driver until

the hooks on the driver hold them in position.

WARNING: The machine is heavy . Keep others away

from the machine because of possible injury if the machine should tip or fall. When

replacing the pad or changing the abrasive use caution when tilting the machine.

The operator or other bystanders could be

injured.

f.) Return the machine to upright position by

standing behind the handle and raising it from

the floor until the caster wheels contact the

floor. Place your foot on the tilt assist strap

and ease the sanding unit to the floor.

Ü

Figure 14

Ü

Figure 15

11. Connect the vacuum hose to the sanding unit and

12. Connect the power cord to the electric box.

AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS Page 9

vacuum.

Page 10

Operating Instructions - Sanding

To operate the machine, follow this procedure:

1. Move machine to work location. When sanding the area, work so that you are moving

away from the power supply. This will help

to avoid damaging the power cord and reduce the need to move the power cord as

frequently.

NOTE: For sanding cuts and sandpaper, see

page 13.

WARNING: Injury can occur if the machine is

connected to a power source

while installing or replacing the

abrasives. Disconnect the machine before installing the abrasives.

2. Install the abrasive. Use the same procedure outlined in MACHINE SETUP for installing the sandpaper or screen / pad.

(See Page 5)

DANGER: Electrocution could occur if the

machine is used on an ungrounded electrical circuit. Always use a three-wire electrical

system connected to the electrical ground. Never remove or disable the grounding supply conductor on the electrical cord.

Consult an electrician if the

grounding conductor is missing

or if you suspect your circuit is

not grounded properly .

3. Koosen the head pressure until the rubber foot

is not touching the mainframe. (See Figure

16) Tighten until the rubber foot touches the

main frame. Adjust to suit by running the machine, then making adjustments either up or

down to get sanding action desired.

Ü

Figure 16

4. Connect machine’s power cord to an appropriately fused and grounded circuit.

5. Stand behind the handle, place the rocker

switch to “Automatic” and press the green

start switch. To stop the machine, press the

red stop button. (See Figure 17)

CAUTION: To prevent possible damage to

the flooring and to reduce heat

buildup, keep the machine in motion while the motor is running.

6. The operator must be moving the machine

when the machine is running. The operator

may move the machine in any direction when

sanding the floor.

Page 10 AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS

Auto

Manual

Ü

Handle

Figure 17

Start

Stop

Page 11

Maintenance

User Maintenance:

The paper bags should be replaced after every 3 hours

of use, minimum. Paper bags may need to be replaced

more often with heavy cutting and softer wood types.

NOTE: Before paper bags are replaced, the machine

must be vacuumed to remove all dust and the cloth filter

must be cleaned to remove accumulated dust. (See the

DTV-7 Operator’s Manual for instructions on how to

clean the cloth filter)

When changing the sanding paper or screen, the foam

and dual lock “velcro” on the sanding pads should be

checked for any frays, wear, or damage.

Service Maintenance:

The 3DS Sander must be serviced after every 600

hours of use. Contact an authorized Alto Service

Center/Person for service. (The Service Centers are

listed on the inside back cover of the Operator’s

Manual).

The following service should include:

1. Check and/or change the brushes and commutator in the vacuum motor (See DTV-7

operator’s manual).

2. Check the rubber grommets on the sanding

pads for wear and tear; replace if damaged.

3. Check foam on sanding pads for wear and tear;

replace if damaged.

4. Check the drive mechanisms for wear, i.e. belts,

pulleys, motor shaft.

5. Blow accumulated dust out of vacuum motor.

6. Clean cloth filter on vacuum.

In addition to the above the following service should

be done:

1. After 1500 hours the drive belt should be

replaced.

2. After 3000 hours the bearings on the drive

pulleys should be replaced.

AMERICAN SANDERS TECHNOLOGY Operator’s Manual - 3DS Page 11

Loading...

Loading...