Page 1

Mikon

Speedlight

INSTRUCTION MANUAL

Page 2

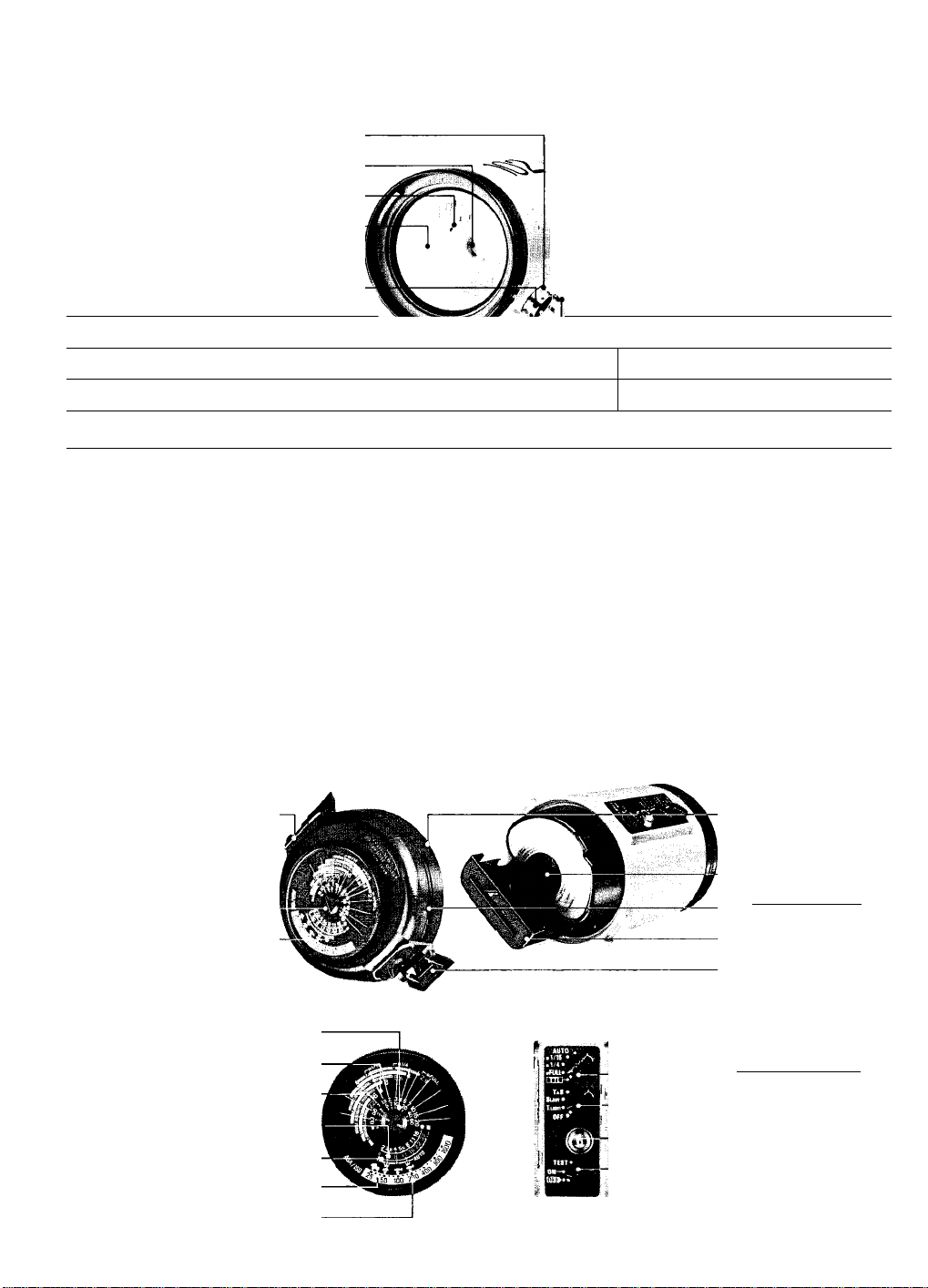

NOMENCLATURE

0 Synchro socket index

) Sensor socket index

> Target-iight lamp

) Slave sensor

I Firing tube

Wide-Fiash Adapter

) SW-102

) Sensor socket

I Synchro socket

(D Synchro socket cover

® Sensor socket cover

(D) Spare target-light lamp

(!|) Speedllght plug and locking ring

) Sync cord

1 Camera piug and locking ring

) Sensor hoider socket

) Sensor hoider positioning pin

I Bracket slot

I Bracket screw

Joint coilar

Flash head positioning index

Joint plate

"0.3m" position mark

"0.6m” position mark

"Normai” position mark

Arm positioning index

Joint iever

Arm positioning screw ®

Joint @

I

_________________________

M

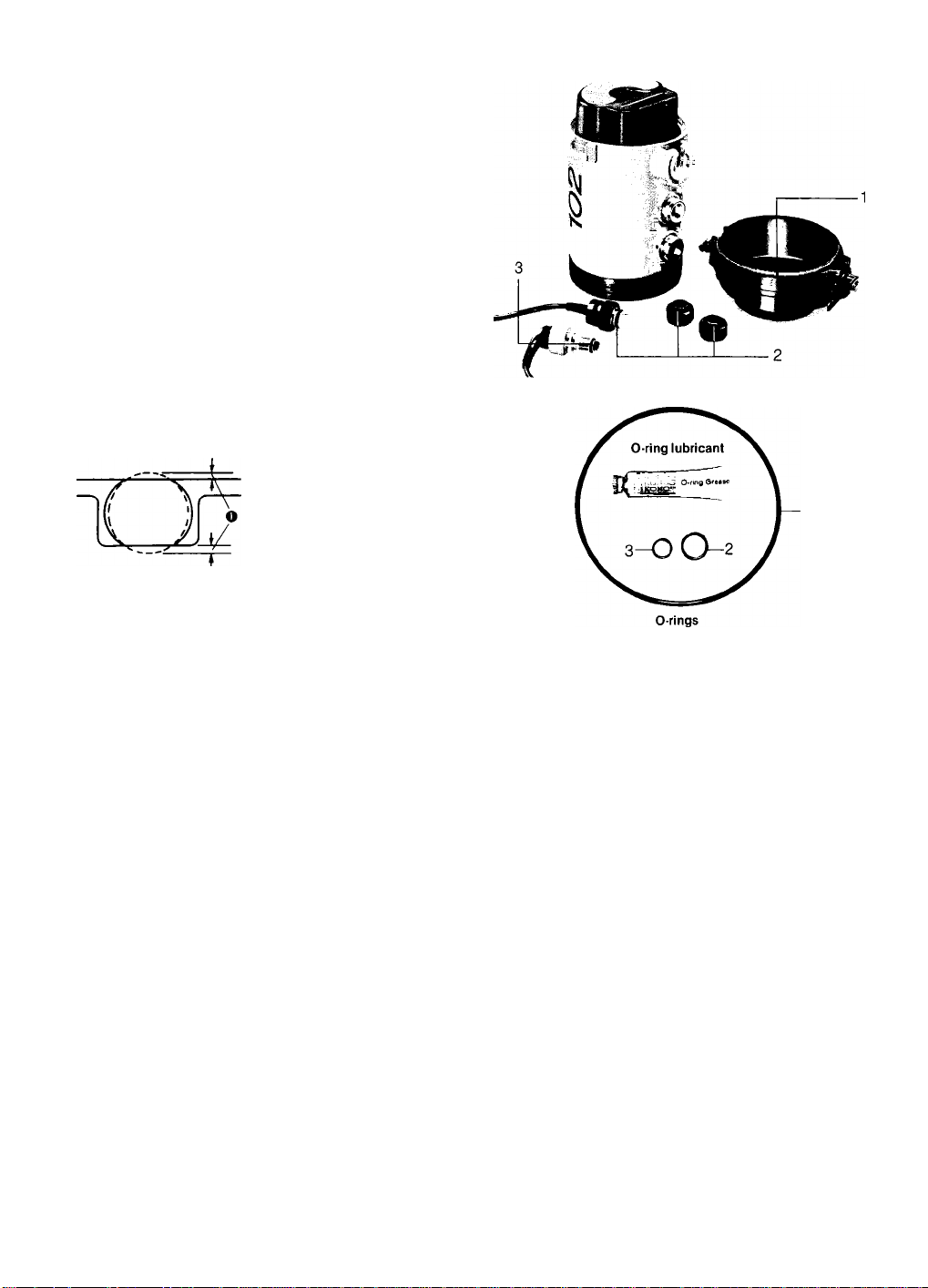

0-rings and iubricant

fJW Arm ®

Grip

o

I Tripod socket

I Cord fastening hanger

) Bracket

) Buckie iock/reiease iatch

) Exposure caicuiation diai screw

) Exposure caicuiation dial

Exposure calculation dial

@ Distance scaie

) Aperture scale

) Distance iines

) Non-TTL auto shooting aperture scale

) Non-TTL auto shooting aperture index

) Shooting situation marks

) ASA/ISO film speed scale

Arm knob

Battery chamber cap index

Target-light holder

Battery chamber cap

C-type battery cartridge

Buckle

Shooting mode selector

T-S switch

Ready-light

Power switch

Page 3

CONTENTS

NOMENCLATURE

FOREWORD...................................................................... 4

PREPARATION........................................................... 4—6

Examining and iubricating the O-rings

The O-rings and their sealing method

TIPS ON SPEEDLIGHT CARE

BASIC OPERATIONS

CONTROLS IN DETAIL..............................................17-30

Bracket

.....................................................................

Arm............................................................................ 17

Joint

..........................................................................

Close-Up Shooting in the Non-TTL

Automatic Mode

Synchro Socket

Sensor Socket.......................................................... 19

Sensor Unit SU-101 (Optional]

Synchronization Speed

Shooting Mode Selector

Exposure Calculation Dial

TTL Automatic Flash Control

Non-TTL Automatic Flash Control

Manual Flash Control........................................25—26

Exposure Compensation..................................26—27

Ready-Light........................................................27—28

Test Firing................................................................. 28

Cord Fastening Flanger........................................... 29

Wide-Flash Adapter SW-102

Target-Light........................................................29—30

Multiple Flash Photography

Daylight Fill-In Flash Photography......................... 30

TIPS ON SPEEDLIGHT PHOTOGRAPHY

OPTIMUM BATTERY PERFORMANCE

ACCESSORIES

Sensor Unit SU-IOI

Sensor Fielder (for SB-102]

Extension Arm.......................................................... 33

Double Flash Bracket............................................... 33

Double Sync Cord

Protectors.................................................................. 34

Speedlight Case SS-101 (Provided]........................ 34

O-rings and Lubricant.............................................. 34

SPECIFICATIONS............................................................ 35

...........................................................

__________

............................................................

...................

.....................

.........................................

..................................................

....................................................

.......................................................

...............................

...........................................

.........................................

......................................

...........................

.........................

...................................

....................................

.....................

.........................

..................................................

.....................................

....................................................

22—23

33-34

8-16

17

18

18

19

20

20

21

22

24

29

30

31

32

33

33

34

2

5

6

7

Speedlight Case SS-101

Page 4

FOREWORD

The Nikonos Speedlight SB-102, an amphibious high

performance electronic flash unit with a silicon-con

trolled rectifier and series circuitry, is designed for use

with the Nikonos-V, Nikonos IV-A, and Nikonos III. The

SB-102 can be submerged to a depth of 50 meters

(160 feet) and withstand pressure of up to 6kg/cm^

(85 Ib/in^), enabling it to be used in environments where

regular speedlights could not be taken.

In combination with the Nikonos-V, the SB-102 features

automatic through-the-lens (TTL) flash exposure con

trol. This means the silicon photodiode (SPD) in the

Nikonos-V’s shutter box reads the light passing through

the lens and then automatically signals the speedlight

to turn itself off when the exposure is correct. Because

TTL flash offers a wide range of useable apertures and

shooting distances, depth of field is easy to control and

shooting as close as 0.3 m (1 ft) is possible.

With the optional Sensor Unit SU-101, the SB-102 can

be used for non-TTL automatic flash photography in

combination with the Nikonos-V, Nikonos IV-A, and

Nikonos III. In this mode, flash output is automatically

controlled by the SU-101.

This speedlight has the same area of coverage as a

28mm lens. When the Wide-Flash Adapter SW-102

(provided) is used, the area of coverage increases to

that of a 15mm lens.

The SB-102 also features manual control with three

power settings (“FULL," “M1/4,” and “M1/16”), slave

firing capability for wireless multiple flash photography,

and a target-light for close-up shooting. The target-light,

positioned in the center of the flash head, shoofs a

beam of light at the subject to help you aim the flash

head at the subject. In addition to the equipment men

tioned, a variety of optional accessories is available to

increase the versatility of the SB-102.

Even though this speedlight is extremely easy to oper

ate, you should still familiarize yourself wifh the pre

paratory steps and basic operations explained in the

first two sections of this manual. For more detailed

information, refer to “CONTROLS IN DETAIL” and

“TIPS ON FLASH PHOTOGRAPHY A few minutes

wisely invested now will pay off later in years of reward

ing photographic experiences.

PREPARATION

STOP! READ THIS NOTICE BEFORE USING YOUR SB-102. THE 0-RING SEALS

MUST BE EXAMINED AND LUBRICATED BEFORE USE TO AVOID DAMAGING

THE SPEEDLIGHT.

This Nikonos Speedlight SB-102 uses 0-rings to seal

and waterproof the junctions between parts. Your

Nikonos Speedlight SB-102 should not be considered

waterproof until you have examined the user-service

able 0-rings (one each for the battery chamber cap®,

the sync cord's ® camera and speedlight plugs, and

the synchro socket and sensor socket covers (|) @).

They must be in perfect, undamaged condition and

properly lubricated prior to each use. Read the follow

ing instructions thoroughly to familiarize yourself wifh

the maintenance of fhe 0-rings.

Because fhe outer surface of your Nikonos Speedlight

SB-102 has been specially treated to make it water

proof, it must be protected from impacf. If it becomes

damaged, send it to a qualified technician for service

before the next use.

Your Nikonos Speedlight SB-102 is watertight only when

In perfectly serviced condition, when all 0-ring seals

are in perfect condition, and when all components are

properly assembled and closed.

Pay special attention to the instructions for installing

the O-rings because they are what make the Nikonos

Speedlight SB-102 watertight. For the O-rings to per

form properly, fhey must be in perfect condition (with

no cuts, tears, or other imperfections) and properly

lubricated. If fhey are nof, they will not perform properly

and may allow water to enter your flash unif. To prevent

the accidental use of a defective 0-ring, always discard

old rings.

The channels into which the O-rings fit must be free of

anyforeign matter and in their original, smoothly finished

condition. If they are not, the O-rings will not seat pro

perly and may allow water to enter your flash unit. If any

channel in your Nikonos Speedlight SB-102 becomes

damaged, send the unit to a qualified technician for

service before the next use.

Your Nikonos Speedlight SB-102 contains a series of

O-rings. Some are factory-installed and cannot be

serviced by you. Once each year, send your fiash unit

to a qualified technician so that these O-rings can be

serviced. Do not attempt to disassemble the unit and

service these O-rings yourself.

All of the O-rings in your Nikonos Speedlight SB-102

that can be serviced by you must be examined at the

end of each dive day and, if possible, after each dive.

Page 5

PREPARATION —continued

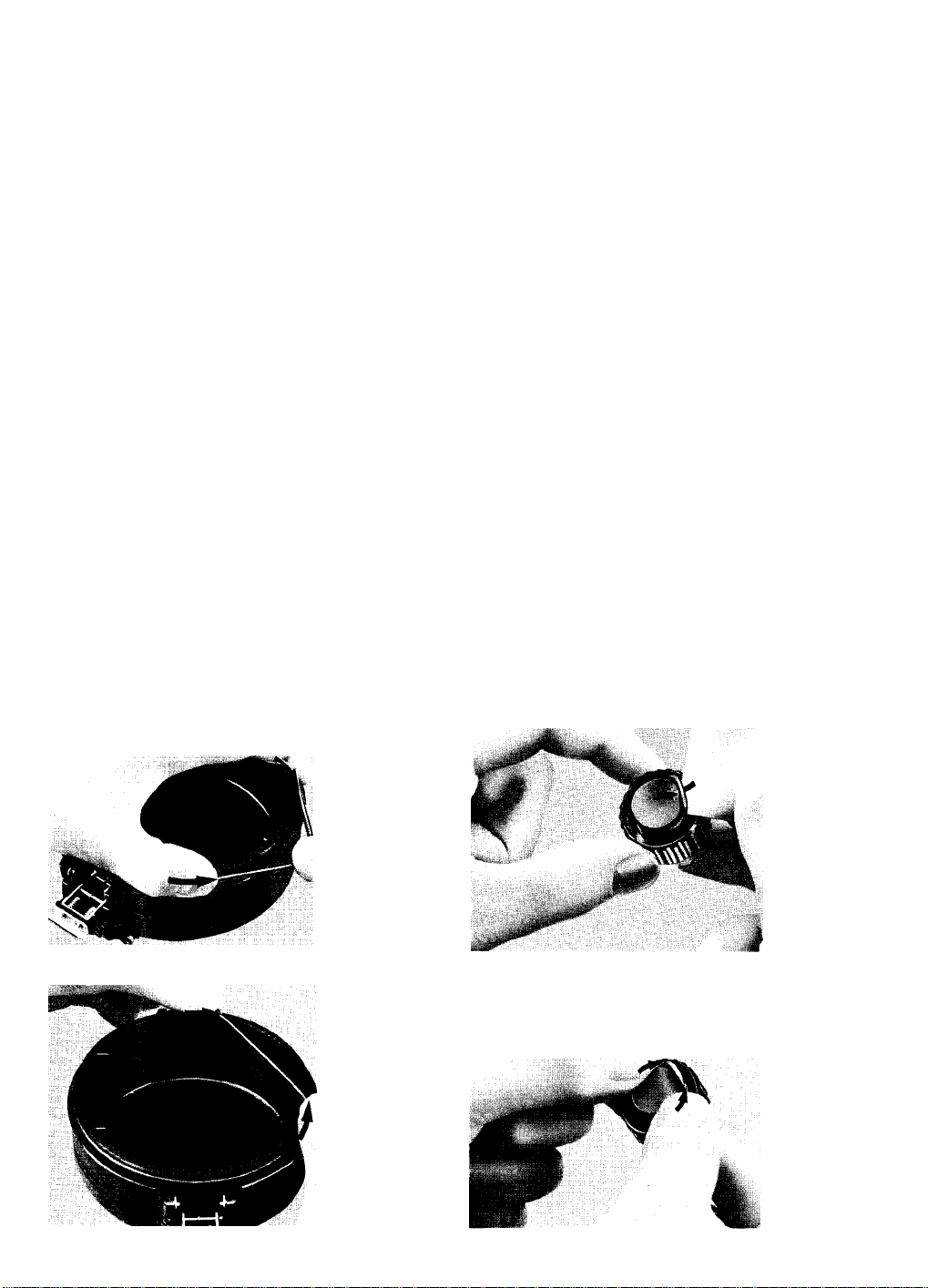

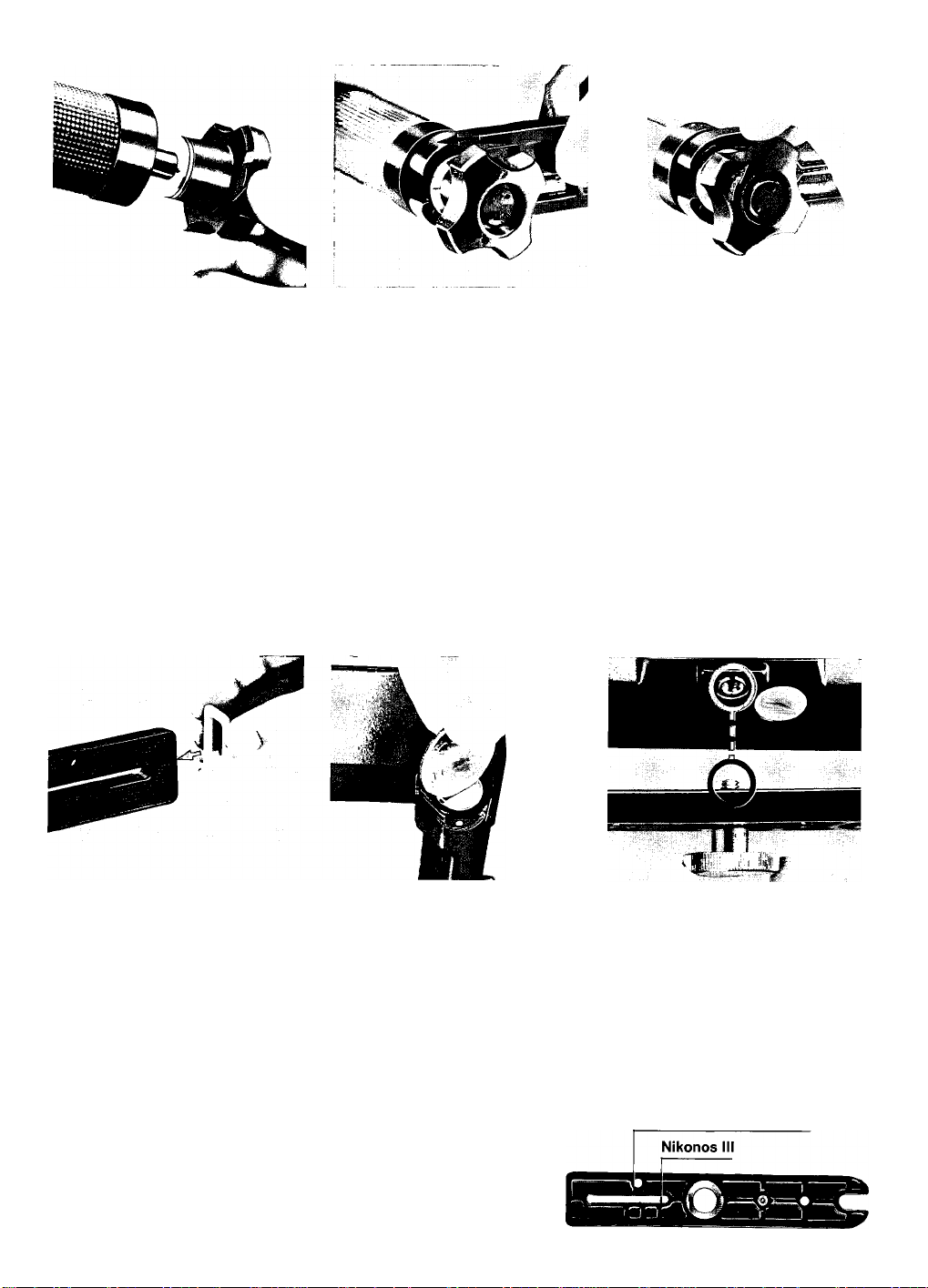

Examining and lubricating the 0-rings:

1. To remove the 0-rings, except those in the synchro

socket and sensor socket covers, grasp the ring be

tween your thumb and forefinger. Pinch your fingers

together as you slide them in the direction of the

arrow to create slack in the 0-ring. Then grasp the

slack portion with your other hand and pull the ring

off (see Fig. 1).

To remove the 0-rings in the synchro socket and

sensor socket covers, use the edge of a credit card

or dive card or some thin, blunt, instrument. Never

use a knife or other sharp-edged object. Push up

on the center of the cover with a fingertip (or pointed

object), insert the card under the ring, and puli it up

to lift the 0-ring out (see Fig. 2). Do not scratch the

0-ring in the process.

2. Visually examine each 0-ring for imperfections. If

any 0-ring is damaged (by tears, cuts, or other im

perfections), discard it immediately. If any 0-ring has

dirt, sand, hair, or foreign matter on it, rinse the 0-ring

in fresh water to remove it.

3. When lubricating the various parts of your flash unit,

use only the special non-water-soluble silicone

lubricant supplied with the speedlight. Never use

other lubricants (such as Vaseline) which are watersoluble.

4. To lubricate the 0-rings, smear a small amount of the

special silicone lubricant on your fingertips and then

gently run each 0-ring between your fingertips.

Never use a brush or similar object to apply the lubri

cant; small hairs may fall into the channel and allow

water to enter the flash unit. While lubricating each

0-ring, examine it with your fingertips for imperfec

tions. If an 0-ring is properly lubricated, it will glisten

and will not have "gobs” of lubricant on it.

To ensure the longest possible flash unit life, apply

lubricant whenever necessary. Lubrication protects

the 0-rings from excessive wear; it also makes it

easier to attach or remove other parts.

5. Visually examine the channels into which the 0-rings

fit to determine that each is clean and smooth. If any

channel is dirty, clean it with a non-lint-bearing mate

rial. Coat each channel with a thin film of lubricant

while being careful not to apply too much.

6. Reseat all of the 0-rings with your fingertips by insert

ing one side of the ring into the channei and holding it

in position while rolling the other side of the ring into

piace (Fig. 3). To insert the 0-rings into the channels

of the synchro socket and sensor socket covers,

push up on the center of the cover with a fingertip

(or pointed object), piace the ring over the channel,

then press it down into place. Check that the 0-ring

is not twisted and that each of its edges is properly

seated (see Fig. 4).

7. Check the surfaces which are opposite the 0-rings

to determine that each is clean, smooth, and free of

foreign matter. Clean and lubricate the surfaces in

the same manner as the channels.

8. When reattaching the parts with 0-rings, be sure that

each 0-ring seats properly and securely. All of the

0-rings must be properly aligned and not “pinched."

Fig. 1

Fig. 3

V

Fig. 2

Fig. 4

Page 6

PREPARATION —continued.

The preceding instructions must be performed on each

user-serviceable 0-ring prior to each dive day and, if

possible, prior to each dive. By following these pro

cedures and all other procedures in this instruction

manual, you will be able to enjoy using your Nikonos

Speedlight SB-102 for many years.

Reminder; An extra set of 0-rings and a tube of lubri

cant are supplied with the flash unit. Additional 0-rings

and lubricant are available from authorized Nikon

dealers and service centers.

The 0-rings and their seaiing method

The method used by the 0-rings to seal and waterproof

the flash unit is shown in the following illustrations.

When a low level of pressure exists (for instance, just

under the water’s surface), each 0-ring seals its groove

by its own elastic force (see Chart A). When the pres

sure increases (at greater depths), the 0-ring’s shape

is altered and its sealing ability is increased to withstand

the greater pressure. The pressure changes the ring

from its original “0” shape (when looking at a cross

sectional view) to a ','D” shape (see Chart B).

Pressure

Chart A

O Slight compression

Chart B

Page 7

TIPS ON SPEEDLIGHT CARE

1. After using the speedlight and camera under

water, rinse them both as soon as possibie in

fresh running water with the sync and sensor

cords attached. When the speediight/camera

assembly gets dirty, rinse it thoroughly in fresh

water. Immediately after using it in salt water,

rinse it thoroughly in fresh water to remove any

residue. Otherwise, corrosion may occur in

minute places like small holes or the junctions

of parts. To prevent this, soak the speedlight/

camera assembly overnight in a basin of fresh

water, then rinse it vigorously in running water

while paying special attention to the joint @, arm

@, bracket screw®, buckles®, and similar parts

where it is very difficult to remove mud or salt.

Finally, dry the speediight/camera assembly with

a soft cloth—never by heating—before removing

the sync and sensor cords. Be sure to wipe away

any drops of water that may have speeded in

past the 0-ring.

When the unit is completely dry, check the

0-rings. If any of them is scratched or damaged,

immediately replace it with a new one by follow

ing the procedures in “PREPARATION.”

All moving parts should be lubricated to prevent

corrosion and facilitate attachment. Apply lubri

cant sparingly and be sure to wipe off any excess.

When the speedlight will not be used for some

time, store it in a cool, dry, clean place with the

batteries and battery chamber cap removed.

2. Never submerge the speedlight in water with

the sync or sensor socket cover removed, or

get the sync or sensor cord plugs wet. Always

make sure the sync cord and sensor cord plugs

are securely attached before entering the water.

3. Never pick up or suspend the speedlight by the

sync or sensor cords.

4. If an 0-ring with dust, scratches, or damage is

used, water may enter the flash unit and damage

the electrical circuitry. Before and after diving,

check the 0-rings by following the procedures

in PREPARATION

5. Do not allow the speedlight to be exposed to

direct sunlight for long periods. And never place

the speedlight in an area where the temperature

is or may rise to 60°C (140°F) such as in a

closed car or car trunk during warm weather.

6. Fligh-voltage circuitry may cause electrical

shock if water enters the flash unit. Should water

get inside the flash unit, take it—with the bat

teries and battery chamber cap removed—to

an authorized Nikon dealer or service center

immediately.

If you experience difficulty of an electrical nature

with the unit, never attempt to disassemble or

service it yourself. Instead, take the unit to an

authorized Nikon dealer or service center.

7. As much as possible, avoid removing the battery

chamber cap near salty wind or splashing water

because either may damage the unit’s electrical

circuitry. If the battery chamber cap must be

removed in one of these situations, for instance,

to exchange batteries, use a vinyl bag to prevent

water or salt from entering the unit.

8. When not using the speedlight, remove batteries

to prevent damage from battery leakage. Leaking

batteries may also cause dangerous combustible

gases to be trapped inside the battery chamber.

If the battery chamber becomes corroded by

leakage, take the unit to an authorized Nikon

dealer or service center.

9. To remove dirt or fingerprints, wipe with a soft,

dry or silicon-treated cloth. Never use thinner,

benzine, or alcohol because they may damage

plastic parts. To clean the Wide-Flash Adapter

SW-102, wash it with soap and water. Never

use a brush.

10. If this speedlight is frequently used underwater

(especially in salt water or dirty water), take it to

an authorized Nikon dealer or service center for

inspection on a regular basis.

11. If the speedlight is dropped or bumped against

a hard surface, take it to an authorized Nikon

dealer or service center for inspection even if

there is no surface damage.

12. After using the speedlight, attach the dust-proof

plastic caps to the sync and sensor cord plugs

to protect them from damage.

Page 8

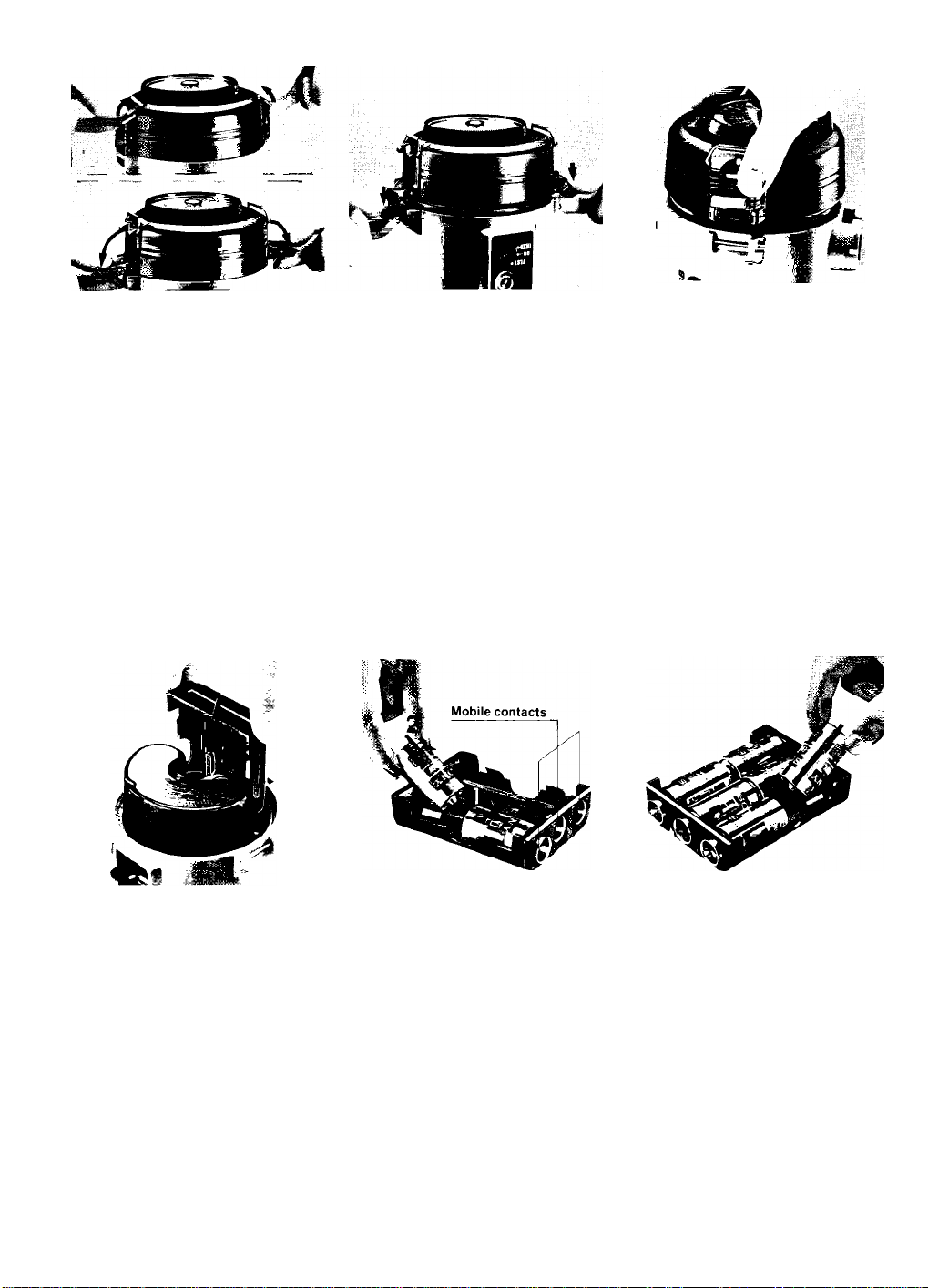

BASIC OPERATIONS

^ Unlock the buckle

" lock/release latches

® and unlock the

buckles ®.

Pull up the buckle lock/release latch

and push the buckles outward and

downward.

Note: The small numbers In circles identify

parts of the speedlight as listed in the

NOMENCLATURE section.

2 Remove the battery

■ chamber cap ®.

Push down on the buckles until the

battery chamber cap is separated

from the speedlight case.

Unlock the silver buckle catches

from the pins on the speedlight

case and pull up on the battery

chamber cap.

•After using the speedlight underwater, rinse

it thoroughly in running water and wipe off

any droplets with a soft cloth before re

moving the battery chamber cap.

Remove the C-type

‘ battery cartridge @

from the battery

chamber.

Install the batteries.

" Install six 1.5V C-type alkalinemanganese batteries or six 1.2 V

NiCd batteries.

Make sure the positive and negative

(-1- and -) terminals are aligned as

shown in the diagram on the car

tridge. Make sure you always push

the first battery in each slot against

the mobile contact.

To remove

Remove the batteries installed in

the side slots first.

• Do not: Insert batteries improperly: leave

flash unit turned on when not in use. Any of

these may damage the flash unit. Also, do

not leave batteries installed when the flash

unit is not being used: it m ay cause the

batteries to explode.

• Do not drop or damage the battery cartridge.

• Use only one brand or type of battery at any

given time. When replacing batteries, re

place alt six at the same time.

•Warning: Batteries may be hot when you

remove them: handle carefully.

• Use of manganese batteries is not recom

mended.

• Check proper battery installation before

shooting. Turn flash unit on and make sure

the SB-102's ready-light lights up within 30

seconds.

• Please see “OPTIMUM BATTERY PER

FORMANCE." page 32.

Page 9

Replace the C-type

■ battery cartridge in

the battery chamber.

Be sure the speedlight power switch

® is in the “OFF” position, then

align the groove on the battery car

tridge with the notch on the inside

of the compartment and slide the

battery cartridge into the chamber.

Replace the battery

" chamber cap.

While holding the buckles away

from the battery chamber cap,

align the battery chamber cap

index @ with the index on the speed-

light case and replace the battery

chamber cap.

Check the 0-ring: Before replacing

the battery chamber cap, examine

its 0-ring for dust and scratches

and be sure it is properly seated

and lubricated.

Lock the buckles.

" Push the battery chamber cap

against the speedlight case so it is

fully seated, hook the silver buckle

catches onto the pins on the speedlight case, and pull the buckles In

ward and upward until they lock

into position,

• When locking the buckles, be sure the silver

buckle catches are hooked onto the pins on

the speedlight case.

A Lock the buckle lock/

■ release latches.

Push the buckle lock/release

latches over the edges of the

buckles to lock them.

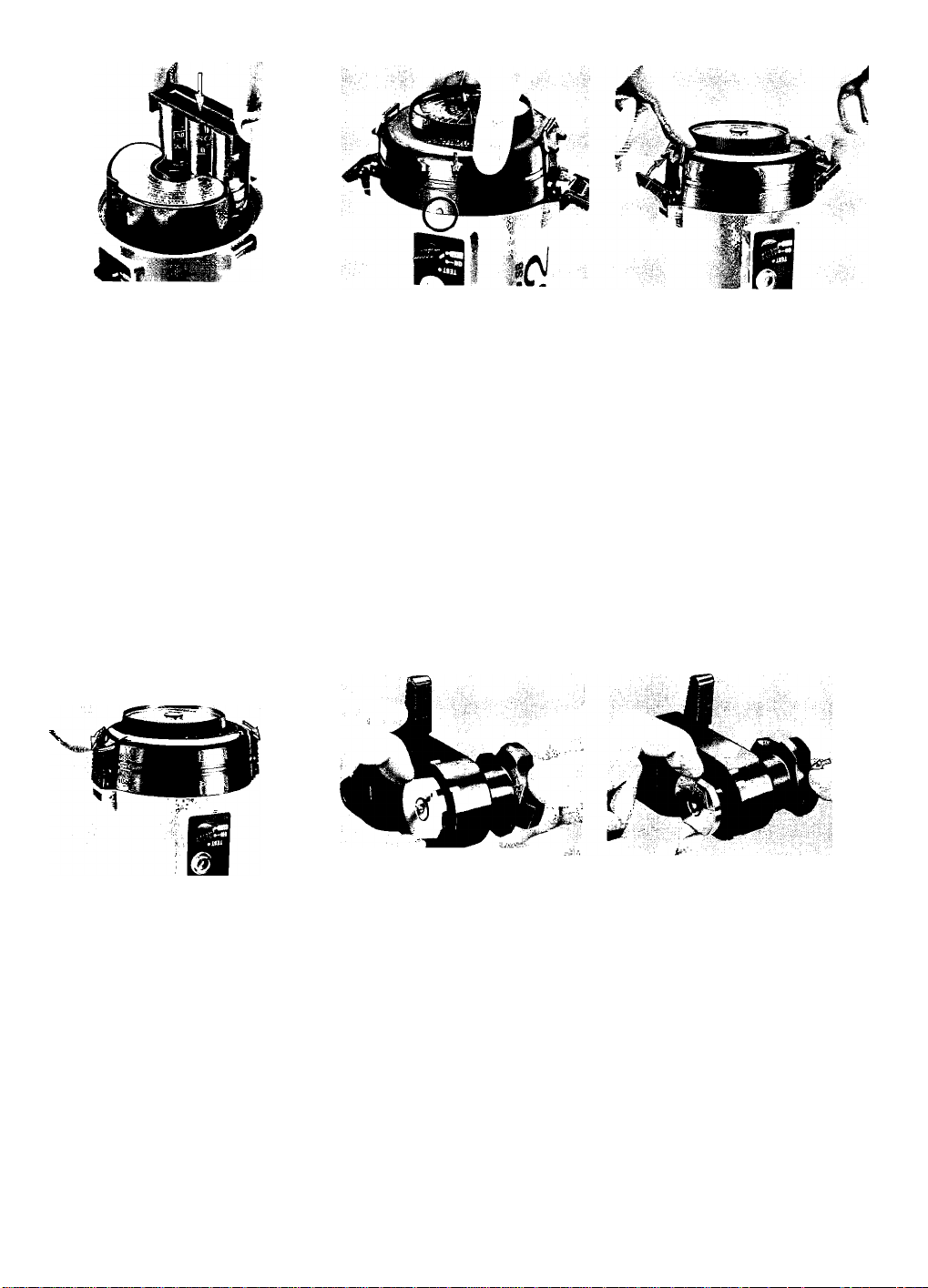

Loosen the joint

" knob ®.

To loosen the joint knob, turn it

counterclockwise while holding the

joint plate (g).

Properly position the

■ joint plate.

Turn the joint knob so the flat sides

of the joint plate are parallel with

the flat edges of the joint.

Page 10

BASIC OPERATIONS —continued.

A4 Insert the joint plate

■ into the joint collar®.

While holding the base of the joint

knob against the joint, slide the joint

plate into the joint collar until it is

fully seated.

• W hen in serting the joint plate into the joint

collar, be sure the flat edges of the joint plate

remain parallel to the flat edges of the joint.

AO Lock the joint.

Align the flash head position

ing index ®) with the "normal” posi

tion mark on the flash head posi

tioning scale, then turn the joint

knob clockwise until the joint is

locked in position.

•See page 18 lor information about removing

the joint.

40 Loosen the joint

" lever ®.

Turn the joint lever counterclock

wise as tar as it will go to loosen it.

A A Insert the arm ® into

the joint.

Insert the arm positioning screw @

into the slot in the joint. The arm

can be inserted from either side of

the joint. The normal position is

shown in the photo.

10

4C Position the arm.

Align the arm positioning

screw with the arm positioning

index ® on the joint by turning the

arm 90°.

4 A Lock the arm.

After aligning the arm posi

tioning screw with the arm position

ing index, turn the joint lever clock

wise as tar as it will go to lock the

arm into position.

• Normally, the joint is locked at the top of the

arm.

•Before diving, be sure the joint knob and

joint lever are locked tightly.

Page 11

Loosen the arm

■ knob®.

Turn the arm knob counterclock

wise as far as it will go to loosen it

(the two bracket positioning pins

on the bottom of the grip (g) will

be visible).

Attach the bracket

■ @) to the arm.

Slide the open end of the bracket

between the arm knob and the grip,

seat the two bracket positioning

pins in the two indentations on the

bracket, and turn the arm knob

clockwise as far as it will go to lock

the bracket into position.

• The correct arm/bracket position is with the

three washers on the underside of the

bracket, the rubber side of the bracket facing

up, and flat side of the grip perpendicular

to the bracket.

19. Attach the cord

■ fastening hanger <

to the bracket.

As shown in the photo, slide

cord fastening hanger onto

bracket.

2Q^ Remove the

■ camera’s flash sync

socket cover.

the

Turn the camera’s sync socket

the

cover counterclockwise with a coin

to remove it.

21. Attach the camera

' body to the bracket.

With the camera against the rubber

side of the bracket and the camera’s

tripod socket over the bracket

screw, screw the bracket screw

into the camera’s tripod socket

until the camera and bracket are

securely attached.

Nikonos-V or Nikonos IV-A

11

Page 12

BASIC OPERATIONS —continued.

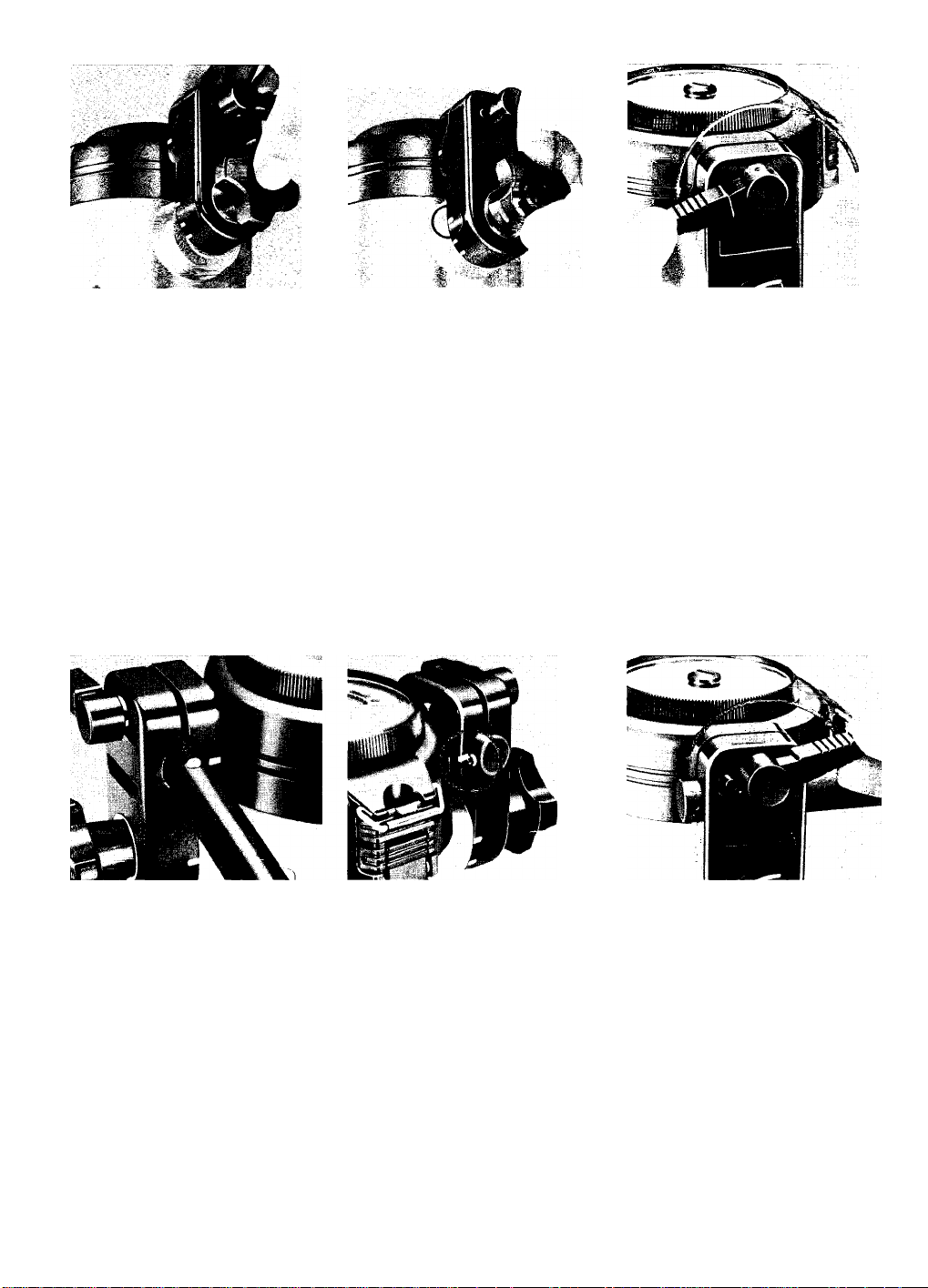

OO Connect the sync

■ cord® to the

camera.

Remove the dust-proof plastic cap

from the sync cord’s camera plug

(silver). Insert the camera plug in

the camera’s flash socket after

aligning the white index on the flash

sync socket with the red index on

the camera plug. When the camera

plug is inserted, turn its locking ring

clockwise as far as it will go to

secure the plug.

Check the 0-ring; Before con

necting the camera plug to the

camera, examine the plug’s 0-ring

for dust and scratches and be sure

it is properly seated and lubricated.

• Do not apply excessive force to the sync

cord's camera plug, and avoid twisting the

cord as much as possible.

23 Rernove the synchro

■ socket cover (D.

Turn the synchro socket cover

counterclockwise, then pull it up.

24 Connect the sync

cord to the SB-102.

Remove the dust-proof plastic cap

from the sync cord’s speedlight

plug (black). Insert the speedlight

plug into the synchro socket after

aligning the synchro socket index

© with the red index on the speed-

light plug. When the speedlight plug

is inserted, turn its locking ring

clockwise as far as it will go to

secure the plug.

12

Check the 0-ring: Before connect

ing the speedlight plug to the

speedlight, examine the plug’s

0-ring for dust and scratches and

be sure it is properly seated and

lubricated.

• To keep the sync cord out of the way while

shooting, attach it to the hook of the cord

fastening hanger.

25 Confirm the position

■ of thefiash head.

Confirm that the arm positioning

screw is aligned with the arm posi

tioning index, the flash head posi

tioning index is aligned with the

“normal” position mark on the flash

head positioning scale, and the

flash head is facing in the same

direction as the camera's lens. If

the arm positioning screw is not

properly aligned, loosen the joint

lever to reposition it. If the flash

head positioning index is not pro

perly aligned loosen the joint knob

to reposition it.

• See page 18 for information about position

ing the flash head for close-up shooting

within approximately 1m (3.3 ft).

Page 13

26 Set the ASA/ISO film

speed.

Turn the exposure calculation dial

@ until the correct shooting situa

tion mark ® is opposite the ASA/ISO

speed of the film in the camera.

Choose which mark to use accord

ing to the shooting situation:

^ : On-land photography

^ .■ On-land photography with the wide-flash

adapter

: Underwater photography

w* ; Underwater photography with the wide-

flash adapter

ASA/ISO film speed scale

-----------------

32 40 64 80

250

320

In the photograph, the shooting

situation mark (•<: underwater

photography) index is aligned with

ASA/ISO 100.

• For TTL operation with the Nikonos-V

camera, the useable film speed range is

from ASA/ISO 25 to 400.

• The ASA/ISO film speed settings are only for

determining shooting distances and useable

apertures: the exposure calculation dial is

not electrically connected to the flash unit.

• Intermediate ASA/ISO film speed settings

are indicated with dots:

m

500 \ 1000 I

640 1250

AU

m1/i6 •:

mFULL»X^

[HrH**

TaS», ,

SlAVi •!

Tlibht«"^

27. Set the shutter

■ speed on the

camera.

When using the Nikonos-V, set the

shutter speed/mode selector dial

to "A" or any shutter speed setting

from 1/1000 to 1/30sec.; when

using the Nikonos IV-A, set the

shutter speed dial to “A”; in the

case of the Nikonos III, set the

shutter speed dial to 1/60sec.

When using either the NikonoS-Vor

Nikonos IV-A, the proper synchroni

zation speed (1 /90sec.) will be auto

matically set when the SB-102’s

power switch is turned on.

.f/2.8)

• Step 28 is divided into two sections ac

cording to the camera and the shooting mode

in use.

The "A" steps are for TTL automatic opera

tion with the Nikonos-V camera: the "B" steps

are for non-TTL automatic operation with the

Nikonos-V, Nikonos IV-A, or III (the optional

Sensor Unit SU-101 is required for non-TTL

automatic operation).

For information about manual Hash operation,

see pages 25 to 26.

23A. Automatic

'Operation.

A-1. Set the shooting mode

selector switch ® to “TTL.”

A-2. Select an f/stop with the exposure calculation dial.

Select an aperture from the range

of apertures that can be used at the

existing flash-to-subject distance,

tance.

For example, when the shooting

situation mark (^4: underwater

photography) is set at ASA/ISO 100

and the flash-to-subject distance is

1 m (3.3ft), the useable aperture

range is from f/2.8 to f/16.

73

Page 14

BASIC OPERATIONS —continued.

A-3. Set the f/stop on the lens.

When you have determined which

f/stop to use, set this f/stop on the

lens. In the photograph, f/8 is set.

28B. Non-TTL Automatic

' Operation.

B-1. Attach the Sensor Unit

SU-101 to the camera’s acces

sory shoe.

Turn the sensor unit’s locking wheel

counterclockwise as far as it will

go, slip the unit's mounting foot into

the camera’s accessory shoe, and

turn the locking wheel clockwise to

tighten it.

• When a plastic frame finder or optical view

finder is mounted on the camera's accessory

shoe, use the optionai sensor holder to

attach the SU-101 to the speedlight bracket.

B-2. Remove the sensor socket

cover®.

Turn the sensor socket cover

counterclockwise, then pull it up.

14

B-3. Connect the sensor cord to

the SB-102.

Remove the dust-proof plastic cap

from the sensor cord’s speedlight

plug (black). Insert the speedlight

plug into the sensor socket after

aligning the sensor socket index ®

with the red index on the speedlight

plug. When the speedlight plug is

inserted, turn its locking ring clock

wise as far as it will go to secure

the plug.

Check the 0-ring: Before con

necting the speedlight plug to the

speedlight, examine the plug’s

0-ring for dust and scratches and

be sure it is properly seated and

lubricated.

B-4. Set the shooting mode

selector switch to “AUTO.”

Page 15

B-5. Select an f/stop with the exposure calculation dial.

Select an aperture by using the

non-TTL auto shooting aperture

scale # and non-TTL auto shooting

aperture index

For example, when the shooting

situation mark (^: underwater

photography) is set toASA/ISO 100,

the non-TTL auto shooting aperture

index is opposite the f/8 on the

green scale and the f/4 on the pink

one. These then are the useable

f/stops. At f/8, the useable flashto-subject distance range is from

0,6m (2ft) to 2m (6.6ft), At f/4, the

useable flash-to-subject distance

range is from 0.6 m (2ft) to 4 m (13ft).

• The closest shooting distance for non-TTL

automatic operation is 0.6m (2ft) regardless

of the film speed and whether or not the

wide-flash adapter Is being used.

TEST*^

GI»*- ^//'

B-6. Set the selector dial on

the Sensor Unit SU-101.

Set the index on the selector dial to

either the pink circle O or the green

squareO to correspond to the color

of the aperture selected in Step

B-5. For example, if you selected

f/4 in Step B-5, set the index to the

pink circle. If you chose f/8, set the

index to the green square.

B-7. Set the f/stop on the lens.

In the photograph, f/8 is set.

29 Turn on the flash unit.

‘ Turn power switch to “ON."

•As soon as you turn on the SB-102 when

using the Nikonos-V, the shutter speed LED

indicator inside the viewfinder will blink if

the shutter speed/mode selector dial is set

at "A," or at any shutter speed from 1/1000

to 1/30sec. As soon as you turn on the

SB-102 when using the Nikonos IV-A, the

viewfinder LED turns off.

• For normal shooting, the T-S switch should

be in the "OFF" position. For information

about the T-S switch, see pages 29 to 30.

Wait for the readylight® to light.

As soon as the flash ready-light

lights, the SB-102 is ready to fire.

Except for the Nikonos III, if the

camera you are using has a view

finder ready-light, it will light when

the SB-102 is completely recycled.

Note that with the Nikonos-V and

Nikonos IV-A, the exposure meter

must be turned on to activate the

viewfinder ready-light.

15

Page 16

BASIC OPERATIONS —continued.

F

•<

/000 500 250 125 60 30

• With a set of fully recharged NiCd batteries,

the ready-light will light in approximately 5

seconds: with a fresh set of alkalinemanganese batteries, it will light in approxi

mately 14 seconds.

•If either the SB-102’s or the camera's readylight does not light, check that: the batteries

are properly installed, the camera, sensor

unit, and flash unit are securely connected,

and the shutter speed/shooting mode and

ASA/ISO film speed setting on the camera

are correctly set.

•See pages 27 to 28 lor information about

ready-light exposure warning information.

F

J

04 Take the picture.

When the shutter is re

leased, the speedlight fires. After

you take the picture, watch either

the ready-light inside the camera’s

viewfinder or the one on the SB-102.

After a few seconds, it will light

again to indicate the flash unit is

fully recycled and ready for the

next shot.

•If the flash unit fires at its maximum output,

its ready-light will blink lor approximately

2 seconds after the shutter is released to

warn that the shot may have been under

exposed. In this case, recheck the shooting

distance/aperture combination selected

and use the wide-flash adapter or move

closer to the subject, if necessary. This

warning is also indicated by the viewlinder

ready-lights of the Nikonos-V and Nikonos

IV-A.

02 Turn off the flash unit.

between shooting sessions, turn

the power switch on the speedlight

to "OFF.”

16

To conserve battery power

• Turning the power switch off between ses

sions will also help prevent battery leakage.

Page 17

CONTROLS IN DETAIL

Nikonos

Bracket @

As indicated in the diagram there are two positions for

the bracket screw ®; one for Nikonos-V and Nikonos

IV-A and another for the Nikonos III. To reposition the

bracket screw, unscrew it, then screw it back into the

hole or the threaded end of the bracket slot ®. Once

screwed Into the bracket slot, the bracket screw can be

moved to any position.

The larger hole In the center allows the sync cord to be

connected through the bracket to the Nikonos III.

The small hole that goes completely through the bracket

is the sensor holder socket ®. When a plastic frame

finder or optical underwater viewfinder Is mounted on

the camera’s accessory shoe, the optional sensor

holder Is used to attach the Sensor Unit SU-101 to the

speedlight bracket. To attach, align the sensor holder

positioning pin ® on the top 6f the bracket with the hole

Sensor Unit SU-101

attached to the

bracket with the

sensor holder.

in the sensor holder; then screw the knob clockwise

until it is tight.

The small hole on the underside of the bracket is the

tripod socket @.

• When the bracket and arm are attached to the Nikonos IV-A, certain

optical tinder models for older UW-Nikkor 15mm 1/2.8 lenses cannot

be attached. If this presents a problem tor you. authorized Nikon

dealers and service centers can perform the necessary modification.

Arm ®

To attach the arm to the joint @, insert the arm position

ing screw ® into the slot in the joint from either side.

Align the arm positioning screw with the arm positioning

index @ on the joint by turning the arm 90°. After align

ing the arm positioning screw with the arm positioning

index, turn the joint lever (§) clockwise as far as it will go

to lock the arm into position. When the arm is attached

in this manner, the speedlight’s axis will always inter

sect with the lens's optical axis, even if the flash head is

moved up or down on the arm. (Normally, the joint is

locked at the top of the arm.) Before diving, be sure the

joint knob ® and joint lever are locked tightly.

To attach the arm to the bracket, turn the arm knob ®

counterclockwise as far as it will go to loosen it (the two

bracket positioning pins on the bottom of the grip @ will

be visible). Slide the open end of the bracket between

the arm knob and the grip, seat the two bracket posi

tioning pins in the two indentations on the bracket, and

turn the arm knob clockwise as far as it will go to lock

the bracket into position. The correct arm/bracket posi

tion is with the two washers on the underside of the

bracket, the rubber side of the bracket facing up, and

the flat side of the grip perpendicular to the bracket.

17

Page 18

CONTROLS IN DETAIL —continued

Joint

The joint connects the arm to the speedlight and allows

the flash head to be positioned as required for various

shoofing situations.

The arm can be inserted from either side of the joint,

the normal position is shown in the photo. When using

two SB-102 Speedlights and the optional Double Flash

Bracket, insert the arm that is next to the camera’s film

advance lever into the joint from the direction opposite

that shown in the photo. (Flash head positioning scales

are provided on both sides of the joint.)

The joint lever allows the flash head to be turned on the

arm's axis and moved up or down the arm as required.

The joint knob is used to adjust the angle of fhe flash

head (the angle of intersection between the speedlight’s

axis and the lens’s optical axis): The normal angle of the

flash head is with the flash head positioning index ® at

the “normal” positioning mark @ on the flash head posi

Close-Up Shooting in the Non-TTL Automatic Mode

When using the SB-102 in the non-TTL automatic mode

for close-up shooting within approximately 1 m (3.3ft) to

0.3m (1ft), the flash head should be pointed directly at

the subject. Exposure compensation will be necessary,

though, to prevent the subject from being overexposed.

As a rule of thumb, choose an aperture 1/2 to 1 step

smaller (numerically larger f-numbers) than indicated

by the exposure calculation dial. Of course, the exact

amount of exposure compensation depends upon the

shooting situation, so additional compensation may be

required.

To determine the exact amount of exposure compensa

tion required before going to the actual shooting loca

tion, test-shoot in a location with conditions similar to

those of the actual situation (similar water quality, sur

roundings, subjects, and so on). If the conditions

change, the amount of the exposure compensation will

need to be changed correspondingly. Naturally, data

calculated on land will not be applicable to underwater

photography.

To detach

tioning scale. The “normal” position is used for shooting

between 1m (3.3ft) and infinity. For close-up shooting

within approximately 1m (3.3ft), loosen the joint knob,

point the flash head toward the subject, then tighten the

joint knob. In addition to the “normal” position mark on

the flash head positioning scale, "0.6m (2ft)” and “0.3 m

(1ft)” position marks®) ® are provided for use when

shooting subjects at these distances. Flowever, when

the flash head is not in the “normal” position, the joint

must be attached to the top of the arm.

For information about using the target-light to position

the flash head, see page 29.

To detach the joint from the speedlight, turn the joint

knob counterclockwise and slide the joint plate out of

the joint collar while pulling the joint knob.

18

Page 19

Synchro Socket (D

To connect the sync cord ® to the speedlight, remove

the synchro socket cover (D by turning it counterclock

wise and pulling it up. Remove the dust-proof plastic

cap from the sync cord’s speedlight plug (@ (black).

Insert the speedlight plug into the synchro socket after

aligning the synchro socket index © with the red index

on the speedlight plug. When the speedlight plug is

inserted, turn its locking ring clockwise as far as it will

go to secure the plug.

Never submerge the speedlight in water with the

synchro socket cover removed or get the sync cord

plugs wet. Always make sure either the synchro socket

cover or the sync cord plugs are securely attached

before entering the water.

After shooting underwater, wipe off any water droplets

with a soft cloth before removing the plug to prevent

water from entering the socket. Whenever the sync

cord is not being used or the speedlight is being washed

with the sync cord removed from the synchro socket,

attach the synchro socket cover to protect the socket.

To attach the socket cover press it against the socket to

seat the 0-ring, then turn the locking ring clockwise as

far as it will go.

• To simplify identification, both the tip of the sync cord's speedlight plug

and the inside of the synchro socket are color-coded yellow.

Sensor Socket @

To connect the sensor cord to the speedlight for nonTTL automatic flash control, remove the sensor socket

cover ® by turning it counterclockwise and pulling it up.

Remove the dust-proof plastic cap from the sensor

cord’s speedlight plug (black). Insert the speedlight

plug into the sensor socket after aligning the sensor

socket index @ with the red index on the speedlight

plug. When the speedlight plug is inserted, turn its lock

ing ring clockwise as far as it will go to secure the plug.

Never submerge the speedlight in water with the

sensor socket cover removed or get the sensor cord

piugs wet. Always make sure either the sensor socket

cover or the sensor cord plugs are securely attached

before entering the water.

After shooting underwater, wipe off any water droplets

with a soft cloth before removing the plug to prevent

water from entering the socket. Whenever the sensor

cord is not being used or the speedlight is being washed

with the sensor cord removed from the sensor socket,

attach the sensor socket cover to protect the socket.

To attach the socket cover, press it against the socket to

seat the 0-ring, then turn the locking ring clockwise as

far as it will go.

• To simplifty identification, both the tip of the sensor cord's speedlight

plug and the inside of the sensor socket are color-coded black.

19

Page 20

CONTROLS IN DETAIL —continued.

Sensor UnitSU-101 (Optional)

In combination with the optional Sensor Unit SU-101,

the SB-102 provides non-TTL automatic flash exposure

control. With the SB-102’s shooting mode selector

switch @1 at “AUTO,” the Sensor Unit SU-101 reads the

light reflected back from the subject while the speed-

light is firing and fells the speedlight to turn itself off

when the light output is sufficient for correct exposure.

The selector dial on the back of the SU-101 allows one

of two aperture settings to be selected.

Normally, the SU-101 is attached to the camera’s

accessory shoe. However, when a plastic frame finder

or optical underwater viewfinder is mounted on the

camera’s accessory shoe, the optional sensor holder is

used to attach the Sensor Unit SU-101 to the speedlight

bracket.

Synchronization Speed

The shutter speed at which the SB-102 synchronizes with

a camera depends upon the camera being used. The

table shows the flash sync speeds of various cameras.

Both the Nikonos-V and Nikonos IV-A cameras auto

matically switch to the proper synchronization speed

when the SB-102’s power switch is turned on; when the

switch is turned off, fhe automatic switchover function is

canceled. For convenience, the SB-102 provides infor

mation and warnings through these cameras’ viewfinder

ready-lights.

• Aperture-priority automatic exposure mode ("A") operation on the

Nikonos-V and Nikonos IV-A is canceled when the SB-102 is turned on.

To determine the correct aperture, use the SB-102's exposure calcula

tion dial (see page 22).

Mounting the SU-101 on the camera: Turn the sensor

unit’s locking wheel counterclockwise as far as it will

go, slip the unit’s mounting foot into the camera’s

accessory shoe, and turn the locking wheel clockwise

to tighten it.

Mounting the SU-101 on the bracket: Insert the

sensor holder positioning pin ® on the bracket into the

sensor holder, then screw the sensor holder’s screw

into the sensor holder socket ® on the bracket. To

attach the SU-101 to the sensor holder, follow the same

procedures as when attaching the SU-101 to the

camera’s accessory shoe.

Operating the SU-101: The two-position selector dial

on the back of the sensor unit must be set according to

the instructions in Step B-6 (page 15). To obtain the

correct exposure, position the sensor as close to the

lens as possible.

• For more information about non-TTL automatic operatio n, see page 24.

Camera

Nikonos-V* 1/90 sec, or slower

Nikonos IV-A* 1/90 sec. or slower

Nikonos III

* When batteries in the Nikonos-V or Nikonos IV-A are exhausted, reset the Nikonos-V's shutter speed/mode selector dial to M90 (1/90 sec.) or B

(Bulb), or the Nikonos IV-A's shutter speed dial to M (1/90 sec.) or B (Bulb). TTL automatic flash control is not possible when the Nikonos-V is

in the M90 or B modes.

* This indicates the correct shutter speed as determined by the subject's brightness and the aperture setting. Although this is not a speedlight

function, it is helpful when using daylight fill-in flash shooting.

Sync Speed Camera Setting Operable Shutter Speed Viewfinder Information

A 1/90 sec.

1/60 sec. or slower

1/1000 to 1/125 sec. 1/90 sec.

1/60 to 1/30 sec. as set

M90 or B as set —

A 1 /90 sec.

M (1/90 sec.) or B as set

—

as set

Correct shutter speed blinks**

LED does not light

—

—

20

Remarks

TTL operable

TTL inoperable

Page 21

AUTO ,

«1/16 • и 1/4*; >

«FULL*

ШЕЗ-*

T»S • .А,

Slave • ' ^

T.II6HT* ^

TEST*

ON-*

Eü^eîT

r\\v-

Shooting Mode Selector ®

The shooting mode selector @ has five click-stop set

tings. The shooting modes that can be used with specific

cameras are listed on page 28.

“TTL” position—TTL (through-the-iens) Automatic Fiash Mode

This mode, which can be used only in conjunction with

the Nikonos-V camera, automatically controls the flash

exposure Through-The-Lens (TTL). In this mode, the

Nikonos-V’s SPD (silicon photodiode) reads the light

passing through the lens and automatically signals the

SB-102 to turn itself off when the exposure is correct.

Because the range of useable apertures is larger (from

f/2.8 to f/22 when using ASA/ISO 100 film) than with

non-TTL flash, you can shoot at a variety of flash-to-

subject distances. The farther the subject, the more

light emitted by the flash unit; the closer the subject,

the less light given off. In addition, the TTL mode makes

daylight fill-in fiash and close-up photography easier

than ever.

• The useable film speed range for TTL operation is from ASA/ISO 25 to

400. For information about the apertures that can be used at various

fiim speeds, see page 23.

• TTL operation is not possibie with the Nikonos IV-A or Hi or when the

Nikonos-V’s shutter speed/mode selector dial is set at M90 ( 1/90sec.)

or В (Bulb).

•Even if the Nikonos-V's shutter speed/mode selector dial is set from

1/30 to 1/IOOOsec., TTL operation is not possible when: the sync cord

is not securely connected, the ASA/ISO film speed is set beyond

ASA/ISO 400, or the batteries are completely exhausted.

“AUTO”—Non-TTL Automatic Flash Mode

When the optional Sensor Unit SU-101 is used, this

mode provides non-TTL automatic flash operation. In

this mode, the sensor unit reads the light reflected back

from the subject while the speedlight is firing and tells

the speedlight to turn itself off when the light output is

sufficient for correct exposure. The selector dial on the

back of the SU-101 allows one of two aperture settings

to be selected according to the flash-to-subject distance

and the shooting situation.

• In both the TTL and non-TTL automatic fiash modes, the SB-102 emits

amounts of tight sufficient for subiects having average reflectivity.

Therefore, correct exposure may not be obtainable if the subject's

reflectivity is extremely low or high.

“MFULL”, “M1/4” and “M1/16”-Manual Flash Modes

Manual control is very convenient when the correct

exposure cannot be obtained through non-TTL auto

matic operation. The SB-102 has three manual control

modes for selection according to the flash-to-subject

distance and the shooting situation. The guide numbers

are GN 32 (16) at the “MFULL” position, GN 16 (8) at

“M1/4,” and GN 8 (4) at “M1/16” (when using ASA/ISO

100 film. The guide numbers in parentheses are for

underwater photography). To determine the correct

aperture, use the exposure calculation dial or perform

the calculations yourself (see pages 25 to 26).

21

Page 22

CONTROLS IN DETAIL —continued.

Exposure Calculation Dial

In flash photography, which apertures can be used is

closely related to the flash-to-subject distance. To deter

mine the useable apertures, align the shooting situation

mark on the exposure calculation dial with the ASA/ISO

film speed in use, find the flash-to-subject distance on

the distance scale, then follow the corresponding dis

tance line up to the aperture scale.

The dots on the ASA/ISO film speed scale indicate the

following intermediate settings:

ASA/ISO film speed scale

25 50 100 200 400 800 1600

32 40 64 80

• The exposure calculation dial can be removed to clean sand or other

foreign m atter from behind it.

125 j

160

250 I

320

500 I

640

1000 j

1250

Removing the Exposure Calculation Dial:

Remove the exposure calculation dial screw @ by turn

ing it counterclockwise with a coin, then pull up on the

dial.

To re-attach the dial, correctly align its center notches

with the mounting notches on the back of the flash

head and push down on the dial. Insert the exposure

calculation dial screw and turn it clockwise as far as it

will go.

TTL Automatic Flash Control

In TTL automatic flash photography, the useable aper

tures are from f/2.8 to f/22 (when using ASA/ISO 100

film), although the actual range tor a specific shooting

situation depends upon the flash-to-subject distance.

The actual ranges for specific situations can be easily

determined with the exposure calculation dial.

22

Example 1:

When the shooting situation mark is opposite the

100 on the ASA/ISO film speed scale and you want to

shoot at f/5.6, you can take pictures of subjects located

between 1 m (3.3ft) and 5.6m (I8.4ft).

When the shooting situation mark «m is opposite the

400 on the ASA/ISO film speed scale and you want to

use f/5.6, you can shoot subjects located between 0.7m

(2 3ft)and 4m (13.1 ft).

Before you select an aperture to use, always take the

flash-to-subject distance into consideration. To increase

the flash-to-subject coupling distance as much as pos

sible, select a larger f/stop (a numerically smaller

f-number). In the opposite case, close-up shooting,

select a smaller f/stop (a numerically larger f-number).

Page 23

Example 2:

When shooting a subject underwater at 4m (13ft) with

the wide-flash adapter while usihg ASA/ISO 100 film,

you must use f/2.8.

When several f/stops are useable at a specific flashto-subject distance, make your seiection by taking the

desired depth of fieid and speedlight recycling time into

consideration.

Example 3:

When shooting a subject on iand at 2m (6.6ft) without

the wide-flash adapter while using ASA/ISO 100 film

and you want the largest depth of field possible, select

f/16. If you want to minimize recyciing time as much as

possible, select f/2.8.

In the TTL automatic mode, the SB-102’s useable

ASA/ISO film speed range is from ASA/ISO 25 to 400,

its useable aperture range is from f/2.8 to f/22, and its

fiash-to-subject coupiing distance range is from 0.3m

(1 ft) to 22m (72.2ft). However, the reiationship between

the useabie aperture range and the fiash-to-subject

coupiing distance range varies according to the

ASA/iSO speed of the fiim in use, the type of photo

graphy (on iand or underwater), and whether or not the

wide-fiash adapter is being used.

TTL Auto Shooting Range

On land

400 25

2.8

— — — — 4 to 22 (13 to 72) 3 to 16 (9.8 to 52) 2 to 11 (6.6 to 36)

4

2.8 — — — 3 to 16 (9.8 to 52)

4

5.6

8 5.6 4

11

8 5.6 4 2,8

16 11 8

22 16 11

— 22 16

— —

* These figures should only be used as a guide because flash-to-subject coupling distance ranges are affected by the existing conditions

(water quality, surroundings, subjects, and so on). For best results, test-fire the flash before actually shooting.

_

2.8

2.8

5.6

8 5.6 0.5 to 2.8 (1,6 to 9.2) 0.3 to 2(1 to 6.6) 0.3 to 1.4 (1 to 4.6)

11

22

16

Without adaptor

—

2 to 11 (6.6 to 36)

—

1.4 to 8 (4.6 to 26) 1 to 5.6 (3.3 to 18)

1 to 5.6 (3.3 to 18) 0.7 to 4 (2.3 to 13) 0.5 to 2,8 (1.6 to 9.2) 0.3 to 2 (1 to 6.6)

4

0.7 to 4 (2.3 to 13) 0.5 to 2.8 (1.6 to 9.2)

8 0.3 to 2 (1 to 6.6)

11

0.3 to 1.4(1 to 4.6) 0.3 to 1 (1 to 3.3)

On land

With adaptor

2 to 11 (6.6 to 36) 1.4 to 8 (4,6 to 26) 1 to 5.6 (3.3 to 18)

1.4 to 8 (4.6 to 26) 1 to 5.6 (3.3 to 18) 0.7 to 4 (2.3 to 13)

0.3 to 1.4(1 to 4.6) 0.3 to 1 (1 to 3.3) 0.3 to 0.7 (1 to 2.3)

Underwater*

Without adaptor

0.7 to 4 (2.3 to 13)

0.3 to 2 (1 to 6.6)

0.3 to 0.7 (1 to 2.3) 0.3 to 0.5(1 to 1.6)

Unit: m (ft)

Underwater*

With adaptor

1.4 to 8 (4.6 to 26)

0.5 to 2.8 (1.6 to 9.2)

0.3 to 1.4 (1 to 4.6)

0.3 to 1 (1 to 3.3)

23

Page 24

CONTROLS IN DETAIL —continued.

Non-TTL Automatic Flash Control

When using the optional Sensor Unit SU-101, you can

select one of two useable apertures.

The useable apertures vary according to the ASA/ISO

speed of the film in use, but they can be easily deter

mined with the exposure calculation dial.

When the correct shooting situation mark is aligned

with the correct speed on the ASA/ISO film speed scale,

the non-TTL auto shooting aperture index ® above the

shooting situation mark indicates the useable apertures

(color-coded green and pink) on the non-TTL auto

shooting aperture scale.

To obtain the correct exposure, choose one of the two

useable f/stops and set the index on the sensor unit’s

selector dial to either the pink circle or the green square

to correspond to the color of the aperture selected.

Before doing this remember to take the flash-to-subject

distance into consideration.

• When the shooting situation mark index is aligned with an intermediate

setting on the ASA/ISO film speed scale (for example, ASA/ISO 64).

the non-TTL auto shooting aperture index indicates two useable inter

mediate apertures on the non-TTL auto shooting aperture scate. In this

situation, set one of the two intermediate apertures on the lens.

• In non- TTL automatic operation, the minimum fiash-to-subject coupling

distance is always 0.6m (2ft). The maximum flash-to-subject coupling

distance is determined by your choice of shooting situation marks

regardless of the ASA/ISO speed of the film in use. The coupling ranges

that correspond to the four shooting situation marks are shown in the

chart.

Example:

When shooting underwater«<while using ASA/ISO 100

film, the useable f/stops indicated on the non-TTL auto

shooting aperture scale are f/4 and f/8. Using the aper

ture scale, distance lines, and distance scale, the

flash-to-subject coupling distance ranges are deter

mined to be from 0.6m (2ft) to 4m (13.1ft) for f/4 and

from 0.6m (2ft) to 2m (6.6ft) for f/8. Therefore, when

the subject is beyond 2m (6,6ft), you must select f/4.

When the subject is within 2m (6.6ft), you can choose

either f/4 and f/8. If larger depth of field is desired, use

f/8; if shorter recycling time is preferable, select f/4.

Remember to set the sensor unit’s selector dial to the

same color-coded position as the aperture on the

exposure calculation dial you have selected.

Non-TTL Auto Shooting Range

Shooting

Situation Mark

w

SU-101’s Selector

Dial Setting

0(pink circle)

□ (green square)

0(pink circle)

□ (green square)

0(pink circle)

□ (green square)

w 0(pink circle)

□ green square)

Coupling Distance

0.6 to 8 (2 to 26)

0.6 to 4 (2 to 13)

0.6 to 5.6 (2 to 18)

0.6 to 2.8 (2 to 8.9)

0.6 to 4 (2 to 13)

0.6 to 2 (2 to 6.6)

0.6 to 2.8 (2 to 8.9)

0.6 to 1.4 (2 to 4.3)

Unit: m (ft)

24

Page 25

AUTO ,

«1/16 • .

«1/4

«FUIL*»V ''

mo*

SUVE •/ j

Tuoht« '

OFF

Manual Flash Control

Manual flash operation allows you to control the light

output of the SB-102 by setting the shooting mode

selector to one of three positions: “MFULL,” “M1/4,”

or “M1/16.”

To determine which setting to use, begin by aligning the

correct shooting situation mark with the correct speed

on the ASA/ISO fiim speed scale. Next, locate the

flash-to-subject distance on the distance scale and

follow the corresponding distance line up as it crosses

the aperture scale. At each intersection between the

distance line and an f/stop iine on the aperture scale,

one of four conditions will be present: 1) the distance

line will intersect the extreme right-hand edge of the

f/stop line (the “MFULL” mark), 2) the distance iine will

intersect a semicircle (the “M1/4" mark), 3) the dis

tance line wiil intersect a triangle (the "M1/16” mark),

or 4) the distance line will intersect an unmarked portion

of the f/stop line. The first three conditions indicate the

manuai flash mode that can be used at those particular

f/stops.

Before shooting, set the shooting mode selector to

correct position and set the correct aperture on the lens.

Example 1:

When shooting a subject underwater at 1 m (3.3ft) with

out using the wide-flash adapter while using ASA/ISO

100 film, you can select one of three aperture/mode

settings: f/16 at “MFULL,” f/8 at “M1/4,” or f/4 at

“M1/16.”

If the shooting distance changes to 5m (16.4ft) but you

still want to use “MFULL,” you should use an inter

mediate aperture setting between f/2.8 and f/4.

To determine the correct f/stop without using the expo

sure calculation dial, divide the GN (from the chart on

page 26) by the flash-to-subject distance (in meters).

Example 2:

When shooting a subject underwater at 4 m (13.1ft)

without using the wide-flash adapter while using

ASA/ISO 100 film and “MFULL,” divide the GN (16) by

the shooting distance [4m (13ft)] to get the correct

aperture (f/4).

25

Page 26

CONTROLS IN DETAIL —continued.

Example 3:

Shooting a subject on land at 8m (26.2ft) without using

the wide-flash adapter while using ASA/ISO 100 film

and “MFULL”: The GN for "MFULL” at ASA/ISO 100

on land is 32 (from the chart below). Divide the GN of

32 by the flash-to-subject distance of 8m to get the

correct aperture, f/4. Because water absorbs a great

deal of light, however, you cannot use the same GN

underwater as on land or your shot will be underexposed.

Instead, multiply the on-land GN by 1/2 to 1/3 for under

water photography. (The underwater GNs shown in the

following chart are 1/2 of the corresponding on-land

GNs.)

Guide Numbers in the Manual Mode

Film

speed

(ASA/

ISO)

1600 128(90)

800 90 (64)

400

200 45 (32)

100 32 (22)

50 22(16)

25

• The values in parentheses are when the Wide-Flash Adaptor

SW-102 is being used.

• The full amount of light is emitted when the shooting mode selector

is at "MFULL" and, even if not synchronized, at "AUTO."

On-land shooting

“MFULL” “M1/4”

64 (45) 32 (22) 16(11)

16(11)

“M1/16” “MFULL”

64 (45) 32 (22)

45 (32)

22(16)

16(11) 8 (5.6)

8(5.6) 4 (2.8) 8 (5.6)

22(16) 45 (32)

11 (8) 5.6 (4)

11 (8)

Underwater shooting

64 (45) 32 (22)

32 (22) 16(11)

22 (16)

16(11) 8(5.6)

11 (8)

“M1/4” “M1/16”

16(11)

22(16)

5.6 (4)

4 (2.8) 2(1.4)

11 (8)

11 (8)

8(5.6)

5.6 (4)

4 (2.8)

2.8 (2)

Exposure Compensation

When the Nikonos-V is used with the SB-102 in the TTL

or non-TTL flash mode, exposure compensation is re

quired for over- or underexposing the picture to match

subject or shooting conditions. Each procedure is dif

ferent, so read the following instructions carefully be

fore shooting.

In addition, if you photograph a subject with very high

reflectivity, such as a mirror or metallic surface, under

exposure is almost certain to occur. To prevent this, use

manual flash control.

TTL Exposure Compensation

When using TTL automatic flash control with the

Nikonos-V camera, you can use its ASA/ISO film speed

dial to make an exposure compensation for the shooting

situation or to create intentionally over- or underexposed

photos.

The relationship between the exposure compensation

value and ASA/ISO film speed dial setting is shown in

the following chart:

Exposure Compensation Value

(New ASA/ISO Setting)

ASA/ISO Film

Speed in use

25

50 — 25 50

100 25 50 100 200

200

400 100 200 400

4-2

4-1 0 -1 -2

— — 25 50 100

100 200

400

50 100 200 400 —

— —

The useable aperture range for TTL automatic flash

photography changes according to the exposure com

pensation value being used. Before using the exposure

calculation dial to determine the useable aperture

range, align the correct shooting situation mark with

new (compensation) setting on the ASA/ISO film speed

scale.

For example, to make a -F2 exposure compensation

when using ASA/ISO 100 film, reset the ASA/ISO film

speed scale to ASA/ISO 25, then read the modified

shooting distance from the dial.

•Positive (-F) exposure compensation cannot be made at some film

speeds, and negative (-) exposure compensation cannot be made at

other film speeds. In these cases, make the necessary compensation

in the non-TTL automatic mode (see page 24) or use one of the manual

flash modes.

• When you finish making the exposure compensation, be sure to reset

the ASA/ISO film speed dial on the Nikonos-V and the ASA/ISO film

speed scale on the speedlight.

26

Page 27

Non-TTL Automatic Flash Exposure Compensation

When shooting in the non-TTL automatic flash exposure

mode, exposure compensation can be made by stop

ping down or opening up the lens. To compensate for

a dark subject, use a 1/2- to 2-step smaller aperture

(a numerically larger f-number). To compensate for a

light subject, use a 1/2- to 2-step larger aperture (a

numerically smaller f-number).

• The ready-light will light up when the SB-102 has recycled to 80% of

its full capacity. Therefore, if you want to shoot a subject at either the

minimum or maximum camera-to-subject coupling distance in the

non-TTL automatic mode or one of the manual modes, it is best to wait

until a few seconds after the ready-light has lighted.

•/As the voltage of the batteries decreases with use, the GN of the flash

unit decreases slightly.

• The voltage of NiCd batteries decreases rapidly when their power is

almost exhausted, increasing the recycling time. When this occurs,

stop using them immediately and recharge them or they may be

damaged.

• When using alkaline-manganese batteries, if recycling takes 30

seconds or longer, replace the batteries with a fresh set.

• The ready-light goes out when the flash unit is turned off.

• W hen the exposure meters of the Nikonos-V and Nikonos IV-A are not

activated, the cameras' viewfinder ready-lights will not light even if the

speedlight is turned on (except when the shutter speed/mode selector

dial or shutter speed dial is set at M90 or M). Always confirm that the

viewfinder ready-light is lighted before shooting.

• When the shutter speed/mode selector dial or shutter speed dial of the

Nikonos-Vor Nikonos IV-A is set at M90 or M, the viewfinder ready-light

lights when the flash unit's ready-light lights.

Ready-Light

After its power switch is turned on, the ready-light on

the SB-102 will light to indicate that the SB-102 has re

cycled and is ready to fire. If you are using either a

Nikonos-Vor Nikonos IV-A camera, its viewtinder readylight will also light at the same time to let you know the

flash unit is ready for the next shot.

In addition, the viewfinder ready-lights of the Nikonos-V

and Nikonos IV-A blink to warn of improper settings. If

this happens, check that the camera and flash unit are

securely connected, and the shutter speed/shooting

mode and ASA/ISO film speed on the camera are

correctly set.

Warning Function: Beyond Auto Shooting Range

In the TTL and non-TTL automatic modes, the readylights on the flash unit and in the camera’s viewfinder

blink for approximately 2 seconds if the flash unit has

fired at its maximum output to indicate that the light

output may not have been sufficient for correct expo

sure. If this happens, recheck the flash-to-subject dis

tance. If it is beyond the coupling distance range, use

a larger aperture (a numerically smaller f-number), if

possible, or move closer to the subject.

Because the voltage of batteries (especially alkalinemanganese batteries) decrease rapidly with use, the

GN of the flash unit will decrease slightly. The flash

output of the SB-102 also varies according to the

amount of ambient light and the subject's reflectivity.

27

Page 28

CONTROLS IN DETAIL —continued.

Because of these three factors, the ready-light may

blink to indicate that the light output was insufficient

for correct exposure even if the subject was within the

coupling distance range.

Camera and Speediight Ready-Lights'

Camera Shutter Speed Setting (sec.)

A, 1/1000 to 1/30 TTL Lights Lights or biinks' Does not light

Nikonos-V

Nikonos IV-A

Nikonos iii

1. When the speediight has recycled.

2. When the ASA/ISO film speed dial is set to beyond ASA/ISO 400.

3. In the auto mode, the optional Sensor Unit SU-101 is required.

4. Speeds of 1/500 second, 1/250 second, and 1/125 second cannot be used because the sync shutter speed is 1/90 second or slower.

I 1= Proper flash synchronization is not possible because the shutter speed/shooting mode is improperly set.

• When the camera is set at M90 or M. the camera's exposure meter will not operate even if the shutter release button is depressed.

A, 1/1000 to 1/30 MFULL, M1/4, M1/16, AUTO' Lights Lights

M90(1/90), B

M90 (1/90), B

A TTL

A

M(l/90), B

M (1/90), B

1/500 to 1/30"

1/500 to 1/30"

Shooting mode

TTL Lights

MFULL, M1/4, M1/16, auto' Lights

MFULL, M1/4, M1/16, AUTO' Lights Lights Does not light

TTL Lights — Biinks

MFULL, M1/4, M1/16, AUTO'

TTL

MFULL, M1/4, M1/16, AUTO' Lights

Other Warning Functions:

1. When the shutter speed/mode selector dial of the

Nikonos-V is set to M90 (l/90sec.) or B (Bulb), or

when the shooting mode selector switch of the flash

unit is set to "TTL” when using the Nikonos IV-A.

2. When the sync cord is not securely connected to the

Nikonos-V.

3. When the ASA/ISO film speed setting dial of the

Nikonos-V is set to beyond ASA/ISO 400.

SB-102 ready-light

Lights Biinks Does not light

Lights

Lights — —

Camera ready-light

Meter ON 1 Meter OFF

— Blinks

—

—

— —

Does not light

Lights

Lights

Test Firing

To determine whether or not the flash illumination is

sufficient for a correct exposure, especially when using

the non-TTL automatic mode with distant subjects or

when using bounce-flash photography, test-fire the

flash unit. To test-fire the SB-102, turn its power switch

to “TEST” after the ready-light on thé flash unit lights. If

the ready-light on the flash unit begins blinking after

test-firing, switch to a larger aperture (a numerically

smaller f-number), if possible, or move closer to the

subject before shooting.

This setting also enables you to repeatedly fire the flash

manually with the camera set at B (open-flash firing) to

create multiple-exposure stroboscopic effects or

“paint” the scene with light. When doing this, discon

nect the speediight from the camera or the flash unit

will not fire, even if its power switch is set at “TEST.”

(Remove the sync cord and replace the camera’s flash

28

socket and the flash unit’s sync socket cover before

entering the water.)

•After test firing or open-flash firing, reset the speediight's power switch

to "ON"or "OFF."

In the TTL mode, the shutter must be released to test-fire the flash

unit, but if there is no film in the camera, the ready-light will blink even

if the light output was sufficient for correct exposure.

To avoid this, place a strip of cut film (provided it is not too old) or a

piece of gray paper under the camera's film pressure plate, then

release the shutter.

• Even if two speedlights are connected by the optional Double Sync Cord,

only the speediight tha t is being test-fired will fire.

Page 29

Cord Fastening Hanger

This hanger secures the sync cord to the bracket to

keep it out of the way while shooting.

To use the cord fastening hanger, attach it to the speedlight bracket as shown in the photo, then attach the

sync cord to the hook.

Wide-Flash Adapter SW-102 (D

Designed specifically for use with this flash unit, the

Wide-Flash Adapter SW-102 increases the SB-102’s

angle of coverage from that of a 28mm lens (on land

and underwater) to that of a 15mm lens (underwater).

When the adapter is attached, the SB-102’s GN is re

duced to 22 on land and 11 underwater (when using

ASA/ISO 100 film at “MFULL”),

• When the SW -102 is attached, be sure to use the correct shooting

situation marks {«¡m for underwater or ^ for on-iand shooting) when

setting the exposure calculation dial.

• To prevent overexposure during close-up shooting within approxim ately

0.6m (2ft), attach the adapter even if using a lens other than the

UW-Nikkor 15mm f/2.8N.

• To prevent the loss of the SW-102 and to enable it to be attached

quickly, tie one end of a piece of string to its hole and tie the other end

to the speedlight.

Attaching the SW-102

To attach the adapter, align the adapter’s mounting

notches with the adapter mounting catches on the flash

head, push the adapter onto the flash head as shown in

the photo, then turn the adapter clockwise as far as it

will go.

To remove: Turn the adapter counterclockwise and pull

it off.

Target-Light Function

The SB-102’s target-light enables the flash head to be

accurately positioned for close-up shooting regardless

of whether or not the speedlight is mounted on the

joint/arm. When the speedlight’s power switch is turned

on and the T-S switch ® is turned to "T.LIGFIT” or

“T&S,” the target-light will emit a beam of light to

indicate the direction of the flash head. To accurately

position the flash head, reset it by using the joint and

arm until the beam of light falls on the center of the

subject.

•Although you can shoot while the target-light is on, it is better to turn

the T-S switch to "OFF" or "SLAVE" before shooting to conserve

battery power.

• if the target-light is on when the flash is fired, the target-light will flicker

for a few moments. This does not indicate a malfunction.

• Recycling takes slightly longer when the target-light is being used.