NIKON D2HS REPAIR MANUAL

VBA10601-R.3665.A

M

サービス

計画課

作成承認印 配布許可印

VBA10601

REPAIR MANUAL

Printed in Japan March 2005

Copyrighc2005 by Nikon Corporation.

All Rights Reserved.

無断転載を禁ず

!!

Specications

VBA10601-R.3665.A

Type

Effective pixels 4.1 million

Image sensor 23.3 × 15.5 mm; total pixels: 4.26 million

Image size (pixels) 2464 × 1632 (large), 1840 × 1224 (medium)

Lens mount Nikon F mount (with AF coupling and AF contacts)

Single-lens reex digital camera with interchangeable lenses

Compatible lenses*

Type G or D AF Nikkor All functions supported

Micro Nikkor 85 mm

F2.8D

Other AF Nikkor † All functions supported except 3D color matrix metering and 3D

AI-P Nikkor All functions supported except 3D color matrix metering, 3D

Non-CPU Can be used in exposure modes A and M; electronic range nder can

* IX Nikkor lenses can not be used † Excluding lenses for F3AF

Picture angle Equivalent in 35-mm format is approximately 1.5 times lens focal

All functions supported except autofocus and some exposure modes

multi-sensor balanced ll-ash for digital SLR

multi-sensor balanced ll-ash for digital SLR, and autofocus

be used if maximum aperture is f/5.6 or faster;color matrix metering,

multi-sensor balanced ll-ash for digital SLR, and aperture value

display supported if user provides lens data

length

Viewnder Optical xed eye-level pentaprism

Diopter adjustment –3 – +1 m–1

Eyepoint 19.9 mm (–1.0 m–1)

Focusing screen Type B Brite View clear-matte Mark III screen provided

Fame coverage Approximately 100% of lens (vertical and horizontal)

Magnication Approximately 0.86× (50-mm lens at innity; –1.0 m–1)

Reex mirror Quick return

Lens aperture Instant return with depth-of-eld preview

Focus-area selection Single area or group can be selected from 11 focus areas

Lens servo Instant single-servo AF (S); continuous-servo AF (C); manual (M);

predictive focus tracking automatically activated according

to subject status in single- and continuous-servo AF

- M1 ・ -

VBA10601-R.3665.A

Autofocus TTL phase detection by Nikon Multi-CAM2000 autofocus module

Detection range

(ISO 100 at 20 °C / 68 °F)

–1 – +19 EV (0 – +19 EV for focus areas at left and right edges of

frame)

AF-area mode Single-area AF, dynamic-area AF, group dynamic-AF, dynamic-area

AF with closest subject priority

Focus lock Focus can be locked by pressing shutter-release button halfway

(single-servo AF) or by pressing AE-L/AF-L button

Exposure

Metering Three-mode through-the-lens (TTL) exposure metering

Matrix 3D color matrix metering supported with type G and D lenses;

color matrix metering available with other CPU lenses and with

non-CPU lenses if user provides lens data

Center-weighted Weight of 75% given to 6, 8, 10, or 13-mm circle in center of

frame, or weighting based on average of entire frame

Spot Meters 3-mm circle (about 2% of frame) centered on selected

focus area (on center focus area when non-CPU lens is used)

Range

(ISO 100 equivalent,

0 – 20 EV (3D color matrix or center-weighted metering)

2 – 20 EV (spot metering)

f/1.4 lens, 20 °C/68 °F)

Exposure meter coupling Combined CPU and AI

Exposure control

Exposure modes Programmed auto with exible program; shutter-priority auto;

aperture priority auto; manual

Exposure compensation

–5 – +5 EV in increments of 1/3, , or 1 EV

Bracketing Exposure and / or ash bracketing (2–9 exposures in increments

of 1/3, , 2/3, or 1 EV)

Exposure lock Luminosity locked at detected value with AE-L/AF-L button

Shutter Electronically-controlled vertical-travel focal-plane shutter

Speed

Sensitivity

30 – 1/8000 s in steps of 1/3, , or 1 EV, bulb

200 – 1600 in steps of 1/3, , or 1 EV, 3200, 6400; auto gain to 1600

(ISO equivalent)

White balance Auto (TTL white-balance with main image sensor, 1,005 pixels

RGB sensor, and ambient light sensor), six manual modes with

ne-tuning, color temperature setting

Bracketing 2–9 exposures in increments of 1, 2, or 3

- M2 ・ -

VBA10601-R.3665.A

Flash

Sync contact X-contact only; ash synchronization at up to 50 s

Flash contrrol

TTL TTL ash control by combined ve-segment TTL multi sensor with

single-component IC and 1,005-pixel AE sensor

• SB-800, 600: i-TTL balanced ll-ash for digital SLR and

standard i-TTL ash for digital SLR

• SB-80DX, 28DX, or 50DX with type G or D lens: 3D multi-sensor

balanced-ll ash for digital SLR

• SB-80DX, 28DX, or 50DX with other lens: multi-sensor balanced-

ll ash for digital SLR

• SB-80DX, 28DX, or 50DX with spot metering: standard TTL ash

for digital SLR

Auto aperture Available with SB-800, 80DX, or 28DX and CPU lens

Non-TTL auto Available with such Speedlights as SB-800, 28, 27, and 22s

Range-priority manual Available with SB-800

Sync modes Front curtain sync (normal), slow sync, rear-curtain sync, redeye

reduction, red-eye reduction with slow sync

Flash-ready indicator Lights when SB-series Speedlight such as 800, 600, 80DX,

28DX, 50DX, 28, 27, or 22s is fully charged; blinks for 3 s

after ash is red at full output

Accessory shoe Standard ISO hot-shoe contact with safety lock

Creative Lighting

System

With SB-800 and 600, supports Advanced Wireless Lighting

(SB-600 only supports AWL when used as remote ash), Auto

FP High-Speed Sync, Flash Color Information Communication,

modeling illumination, and FV Lock

Storage

Media Type I and II CompactFlash memory cards; Microdrives

File system Compliant with Design Rule for Camera File System (DCF) and

Digital Print Order Format (DPOF)

Compression • Compressed 12-bit NEF (RAW): approximately 50–60%

• JPEG: JPEG baseline-compliant, can be selected from Fixed size

and Optimal quality

Self-timer Electronically controlled timer with 2 – 20s duration

Depth-of-eld preview Lens aperture stopped down when depth-of- eld preview button is

pressed

Monitor 2.5

brightness adjustment

″ ,

232,000-dot, low-temperature polysilicon TFT LCD with

- M3 ・ -

VBA10601-R.3665.A

Video output Can be selected from NTSC and PAL

External interface USB 2.0

Tripod socket ″ (ISO)

Firmware User upgradeable

Supported languages Chinese (Simplied), Dutch, English, French, German, Italian,

Japanese, Korean, Spanish, Swedish

Power source • One 11.1V EN-EL4 rechargeable Li-ion battery

• EH-6 AC adapter (available separately)

Dimensions (W × H × D) Approximately 157.5 × 149.5 × 85.5 mm (6.2″ × 5.9″ × 3.4″)

Weight Approximately 1070 g (2 lb 6 oz) without battery, memory card,

body cap, or monitor cover

Operating environment

Temperature 0 – 40 °C (32 – 104 °F)

Humidity Less than 85% (no condensation)

• Unless otherwise stated, all gures are for a camera with a fully-charged batteryoperating at an

ambient temperature of 20 °C (68 °F).

• Nikon reserves the right to change the specications of the hardware and software described in this

manual at any time and without prior notice. Nikon will not be held liable for damages that may

result from any mistakes that this manual may contain.

- M4 ・ -

Precautions for disassembly/(re)assembly

VBA10601-R.3665.A

Notes

: ①

②

③

④

⑤

⑥

⑦ All wires are special parts (supporting UL), so be sure to use specied wires.

Points to notice for Lead-free solder products

・Lead-free solder is used for this product.

・For soldering work, the special solder and soldering iron are required.

・Do NOT mix up lead-free solder with traditional solder.

・Use the special soldering iron respectively for lead-free solder and lead solder. They

In disassembly/(re)assembly, be sure to use conductive mat (J5033) and wrist strap (J5033-5), in order to

protect electric parts from static electricity.

Before disassmbling, be sure to remove batteries, AC power cord, and battery for clock (CR1616).

In disassembling, be sure to memorize the processing state of wires and FPC, screws to be xed and their

types, etc.

The low-pass lter of the image PCB is easily damaged. Handle it very carefully.

In the chapter of Disassembly, sometimes a large assembly unit is removed. In case such a unit is further

disassembled , refer to the exploded technical drawings.

In Disassembly/(re)assembly chapters, the dip-proof sponge is not mentined. In case parts are replaced, be

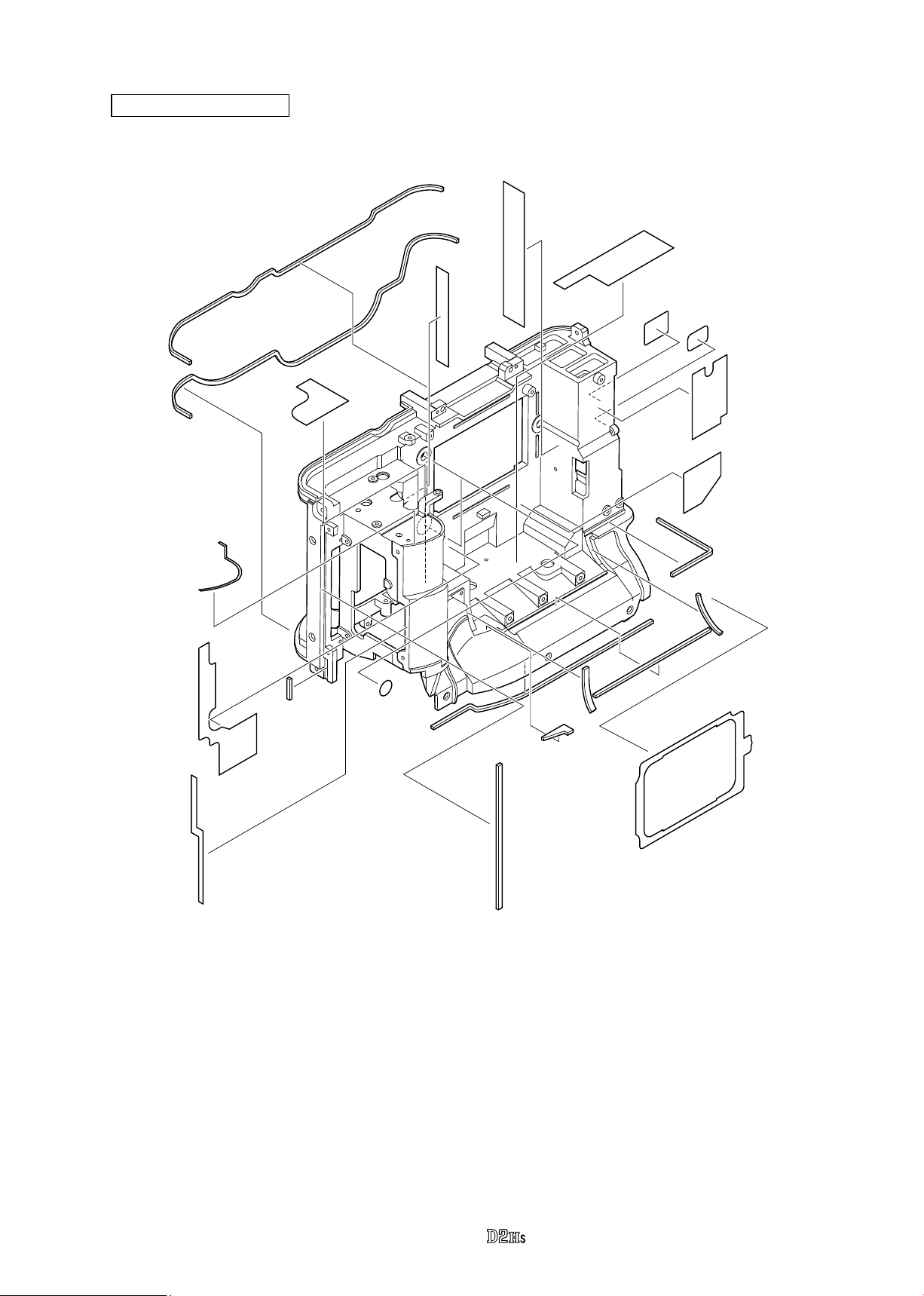

sure to attach the dip-proof sponge by referring to the exploded technical drawings.

cannot be used in common.

Disassembly

1. External units and Imaging-related PCBs

Note 1: Before disassembling a camera, of which the main FPC should be replaced, be sure to read and note down the

adjustment value of the environment light sensor by adjustment software for the camera unit.

read out from the camera, replace the top cover unit, too. (Refer to Page A28 for the details when replaced.)

Note 2: When "Seprating Front and Rear bodies", "Disassembling Image PCB", and "Disassembling Bayonet", be sure to perform

"Reset of AF defocus compensation amount" by D2Hs adjustment software after reassembly.

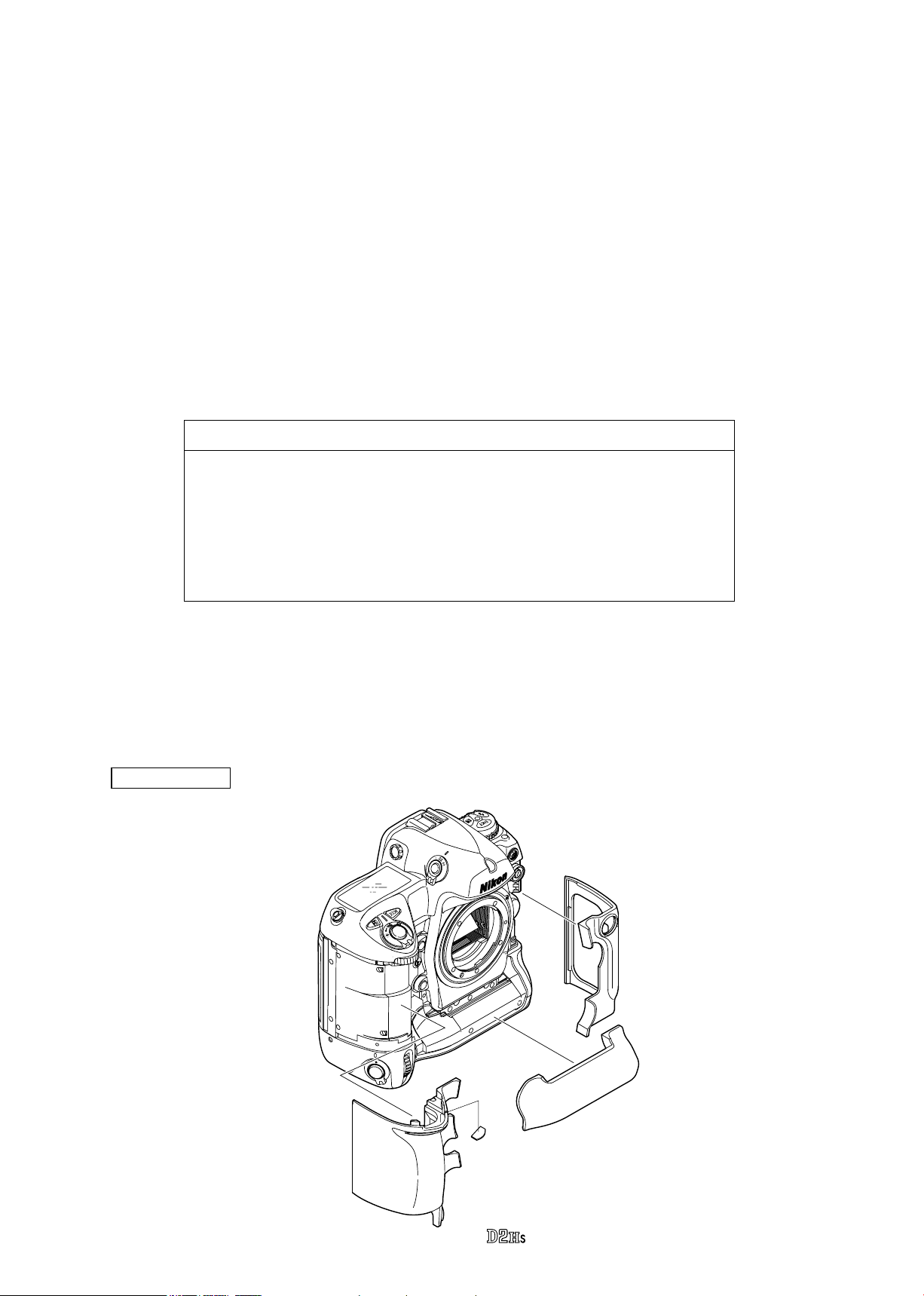

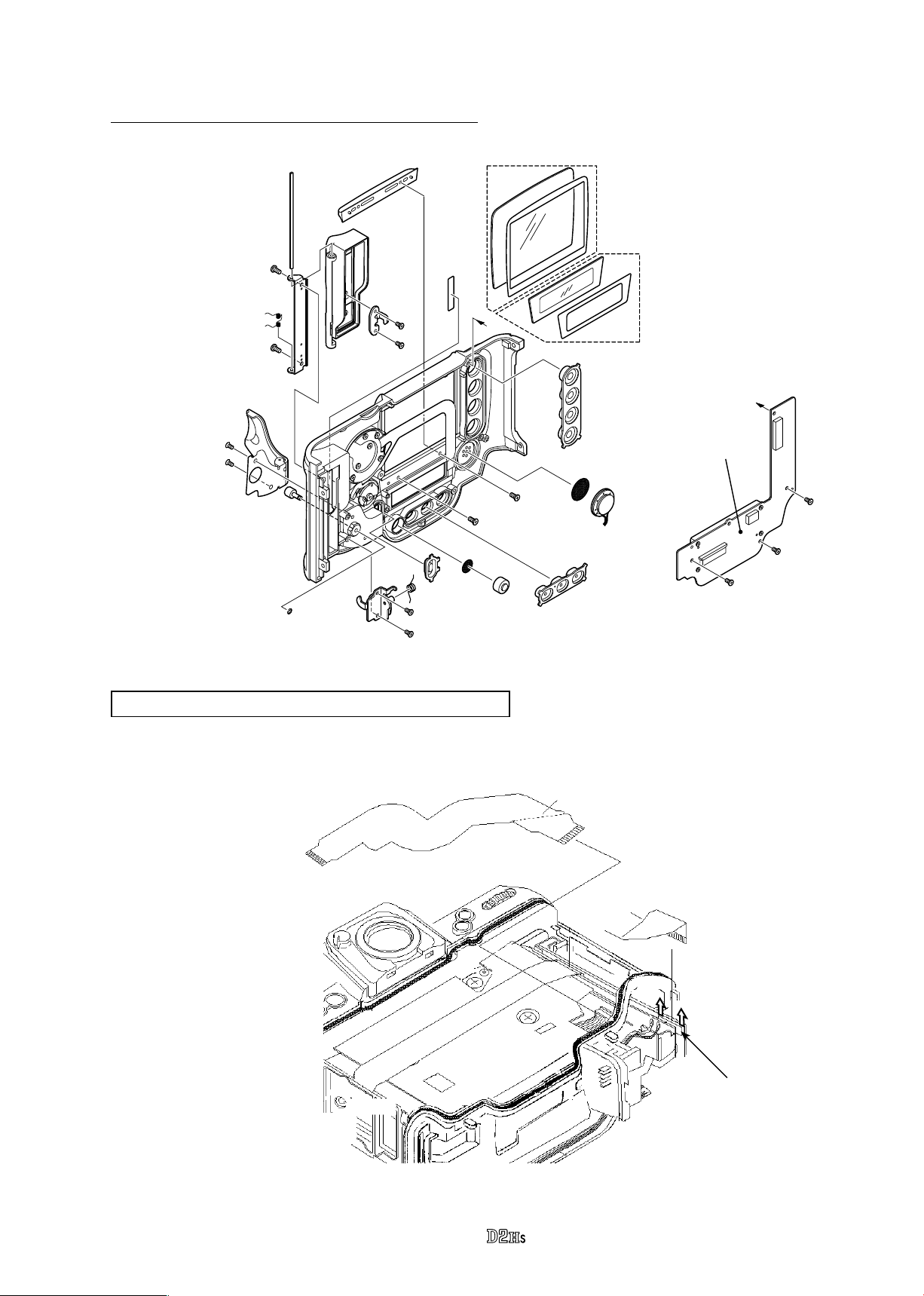

External rubber

Remove the grip rubber (#B60-1), apron lower rubber (#B66), and rubber at the lm rewind side (#B61).

・

#B61

If the value cannot be

#729

#B60-1

- D1 ・ -

#B66

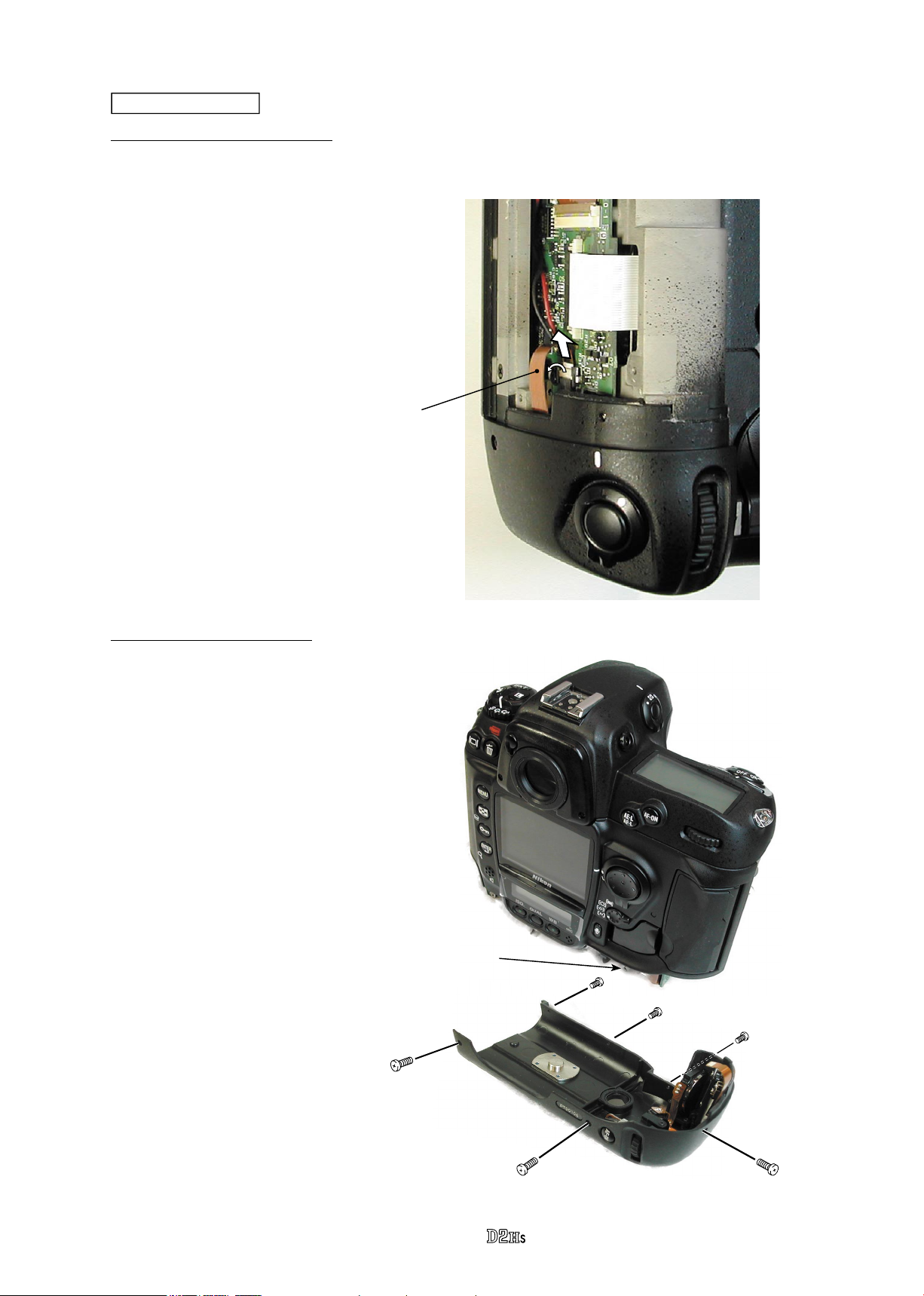

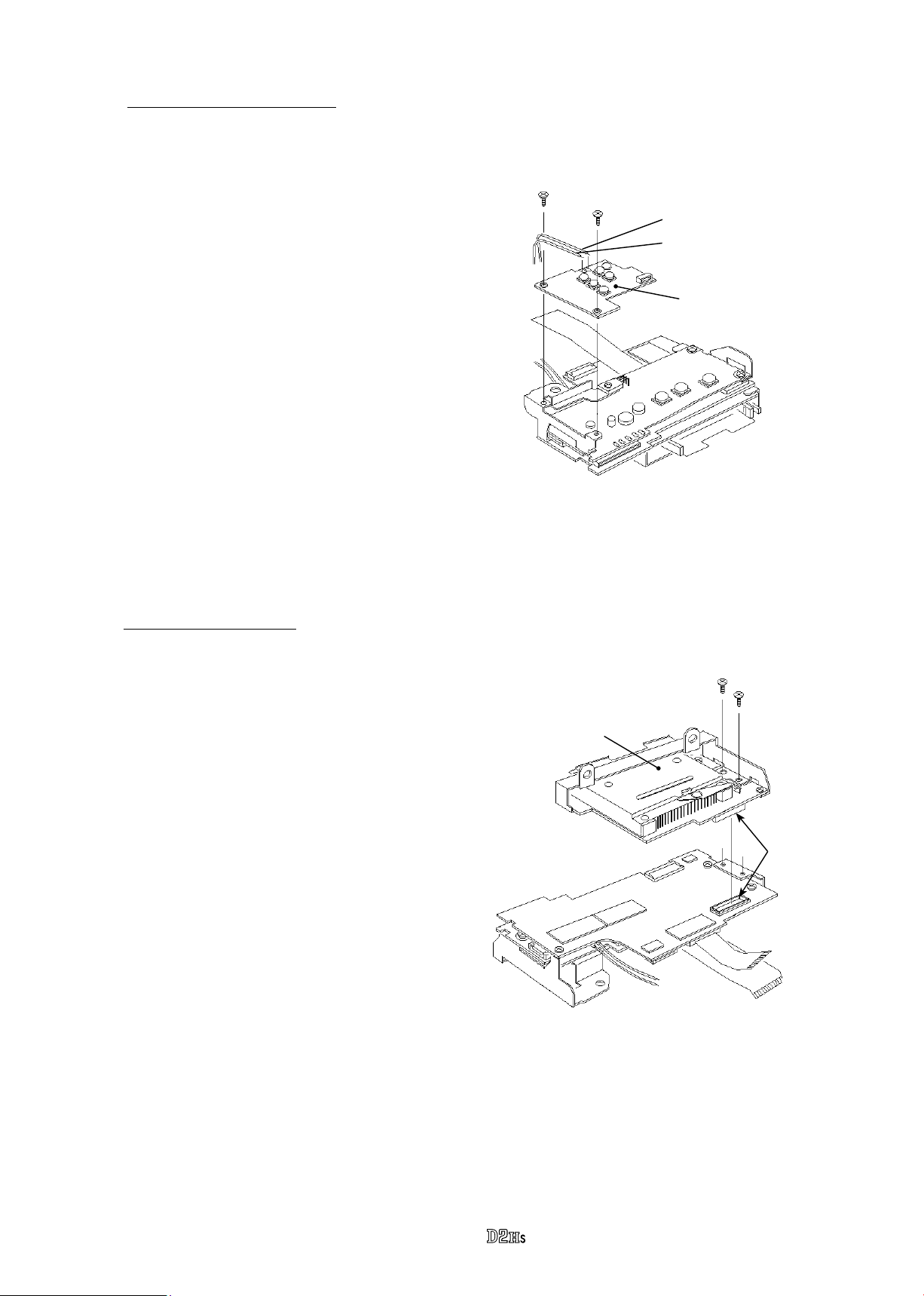

I/F Block

Take out 3 screws (#1589) and detach the I/F block.

・

VBA10601-R.3665.A

#1589×3

Grip Cover

Take out 2 screws (#1534) and 2 screws (#1510) to detach the grip cover.

・

#1534×2

Grip cover

#1510×2

I/F Block

- D2 ・ -

VBA10601-R.3665.A

- D3 ・ -

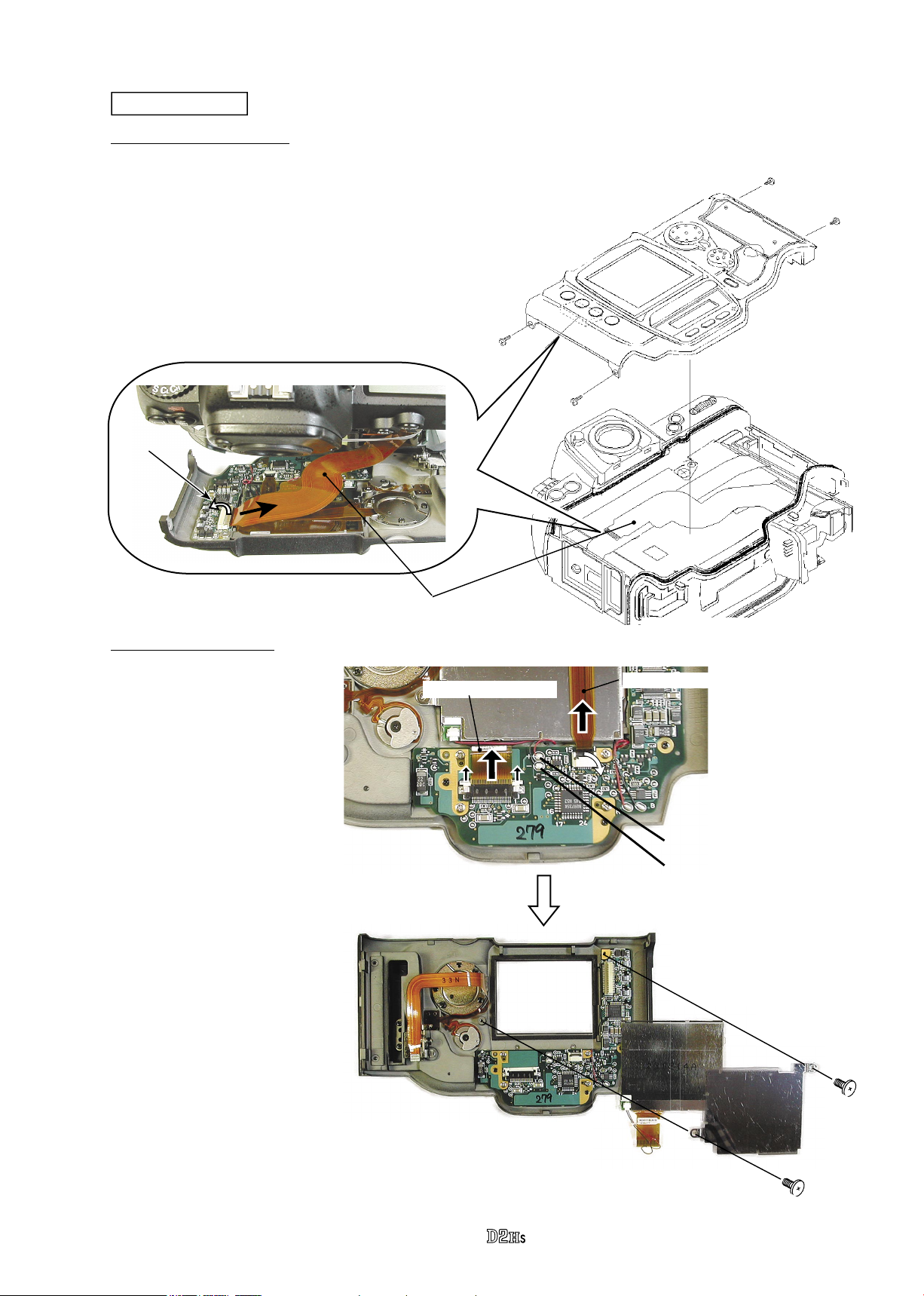

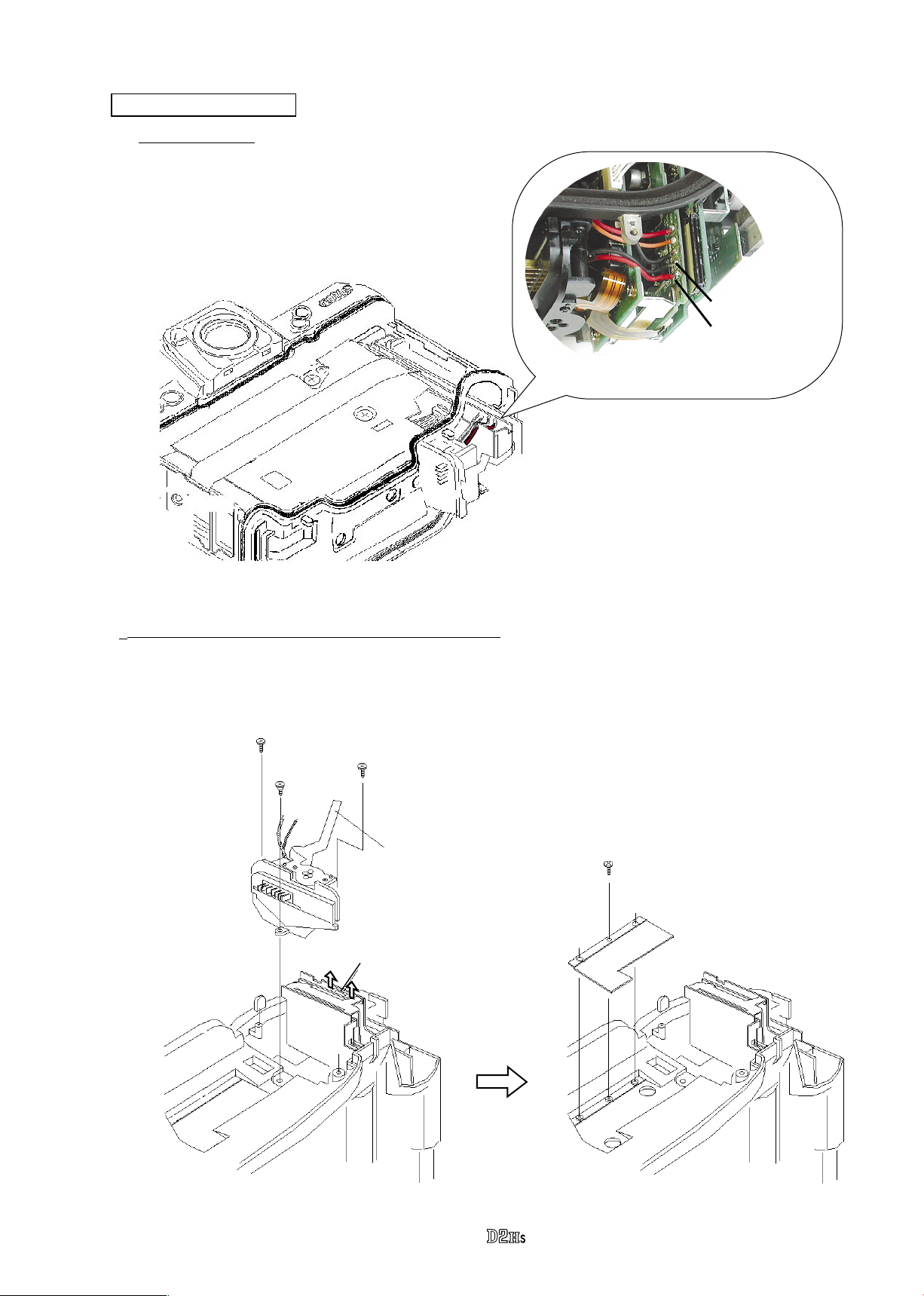

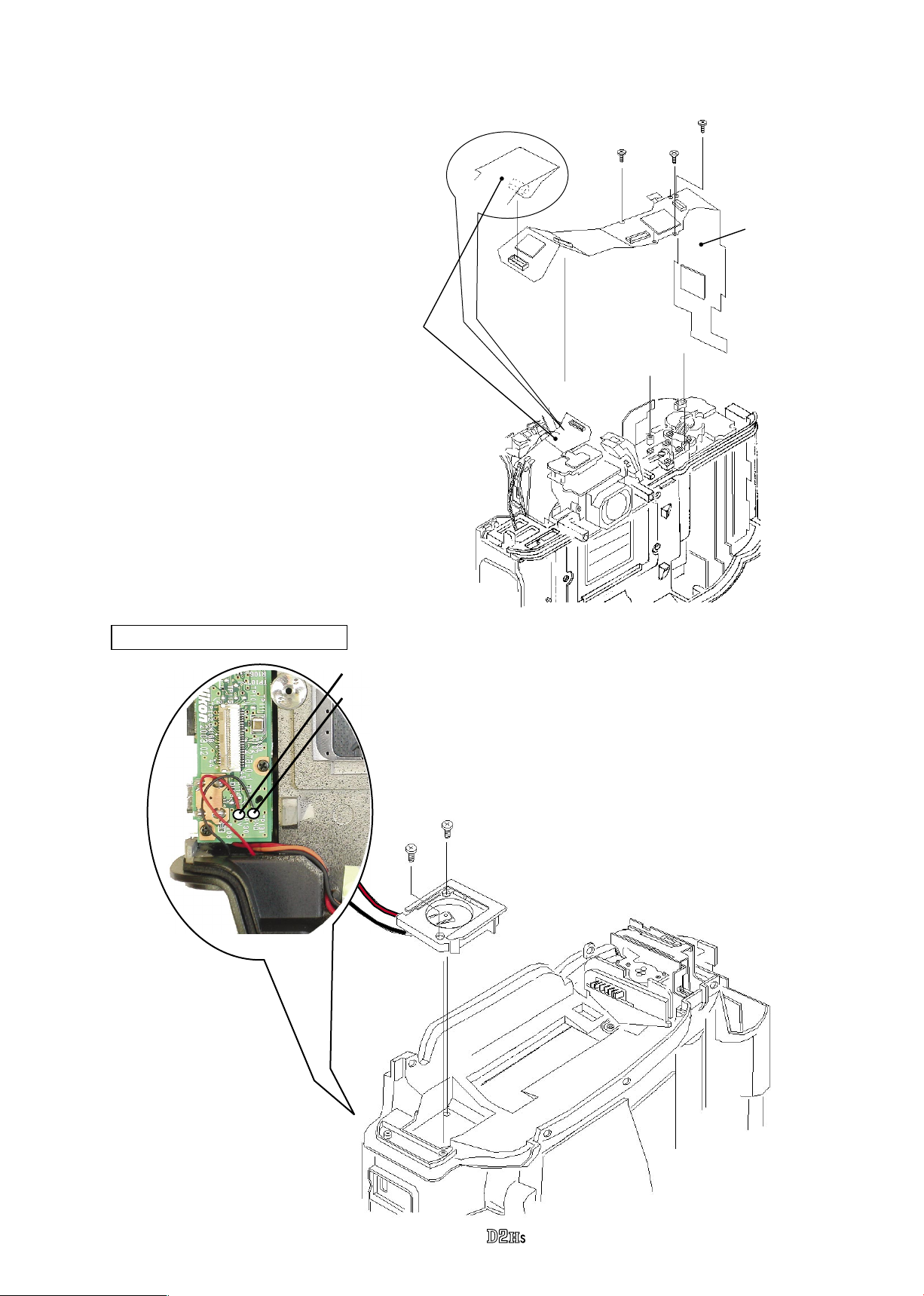

1. Remove Vertically position FPC

Bottom Cover Unit

2. Remove Bottom cover unit

Vertically position FPC

Bottom cover unit

・

Remove the vertically position FPC from

the connector.

・

Take out 3 screws (#1512) and 3 screws

(#1517).

・

Remove the bottom cover unit from the

camera body.

#1512×3

#1517×3

Note: Between the bottom cover and

the body (i.e. A part), there is the

washer (T=0.3) inserted.

When assembling, be sure to put

it back into the original position.

(This measure is for lling in a

gap between the back door and

bottom cover.)

A part

VBA10601-R.3665.A

- D4 ・ -

Back door unit

1. Remove Back door unit

2. Remove TFT Monitor

・

Take out 4 screws (#1514) and detach the

back door unit slowly.

・

Remove the TFT (Memory compression PCB

connection-FPC: #5041) from the connector.

(ref. Fig.1

)

Fig.1

#5041

Connector

#1514×4

Back door unit

・

Remove the red and black

wires of the TFT back light

harness.

・

Remove the TFT monitor

FPC and AF area FPC from

the connector.

・

Take out 2 screws (#436)

and remove the TFT

retaining (#432) and TFT

monitor (#5043).

#436×2

#432

#5043

Red: TFT back light

Black: TFT back light

TFT monitor FPC

AF area FPC

3. TFT-PCB, Speaker, Microphone, other small parts

�

�

VBA10601-R.3665.A

#B428

#1522×2

#1513×2

#437

#425

#453

#427

#442

#445

#460

#467

Microphone

TFT PCB

#463

Speaker

#1560×2

#1508×3

#456

#B439

#1531×2

TFT & Memory compression PCB connection-FPC

Remove the TFT & Memory compression PCB connection-FPC (#5041) from the connector.

・

#5041

- D5 ・ -

Connector

Battery contacts unit

1. Remove wires

Remove the red and black wires that connect from

・

the battery contacts.

VBA10601-R.3665.A

Black : Battery contact

Red : Battery contact

2. Remove Battery contacts and Battery case upper unit

Remove the battery contacts connection-FPC from the connector.

・

Take out 2 screws (#1515) and 1 screw (#812) and detach the battery contact unit (#B801).

・

Take out 1 screw (#1520) and remove the battery case upper unit (#B823), (which is attached by the

・

both-sided adhesive tape).

#812

#1515×2

Battery contacts connection FPC

#B801

Connector

#1520

#B823

- D6 ・ -

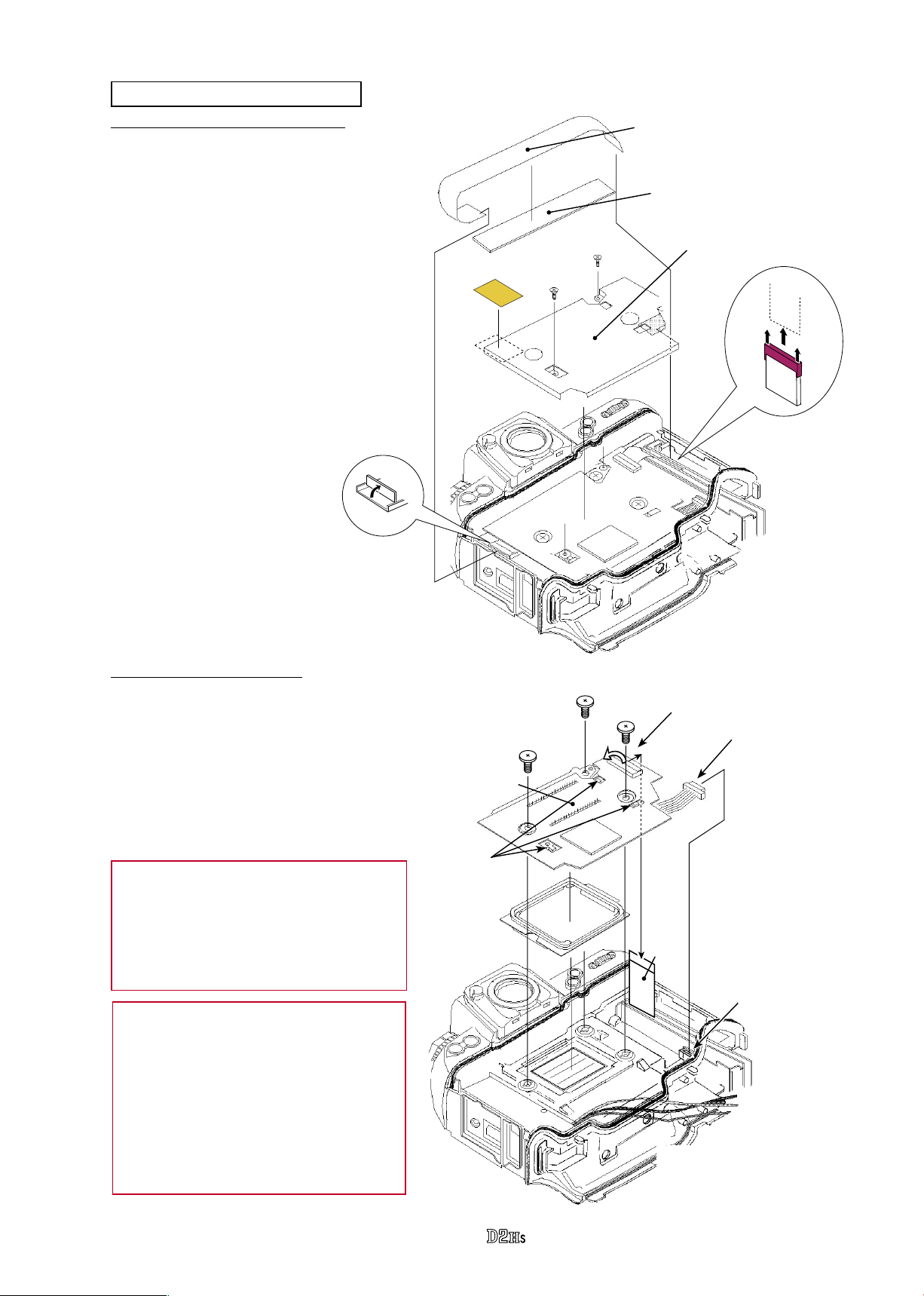

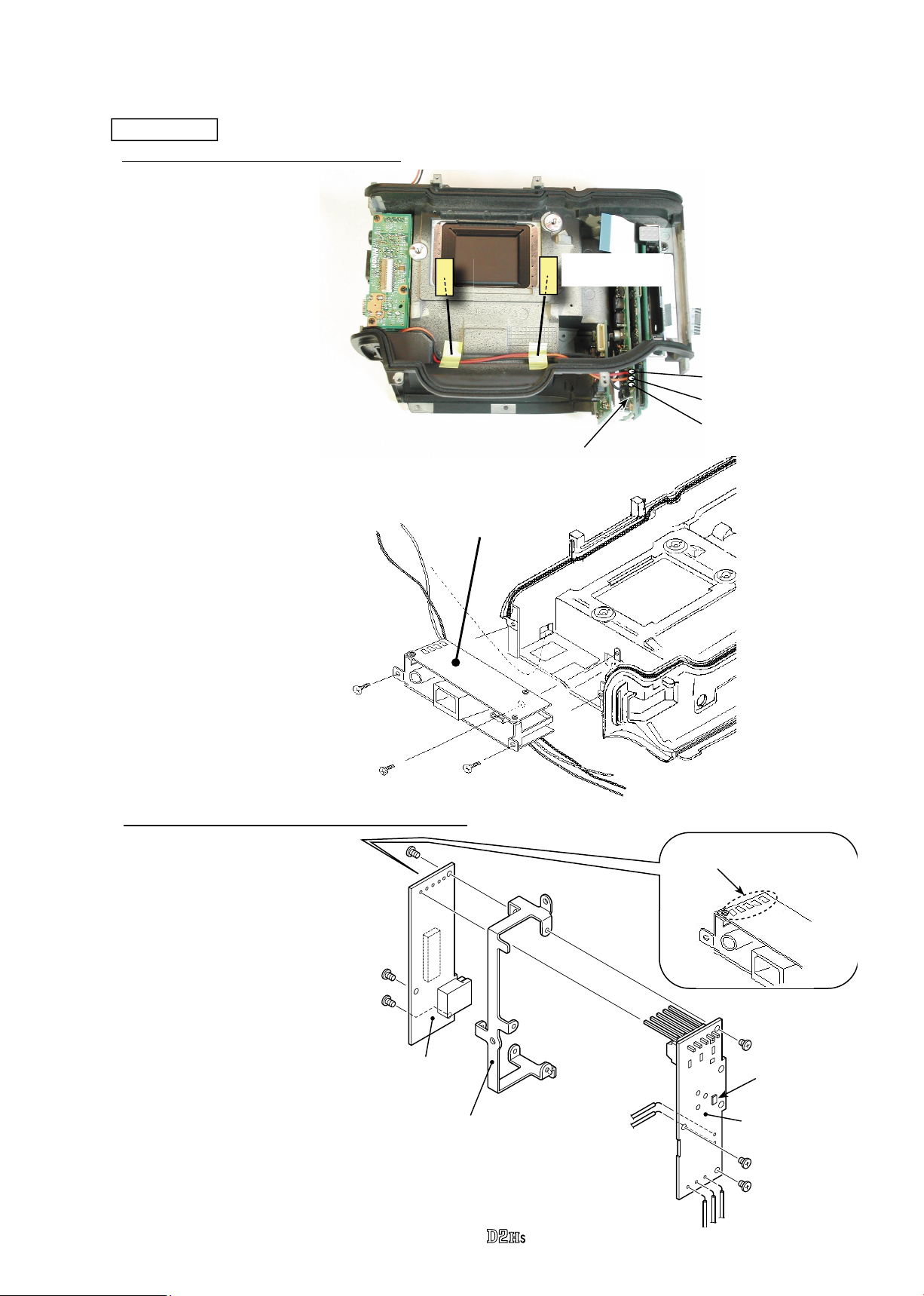

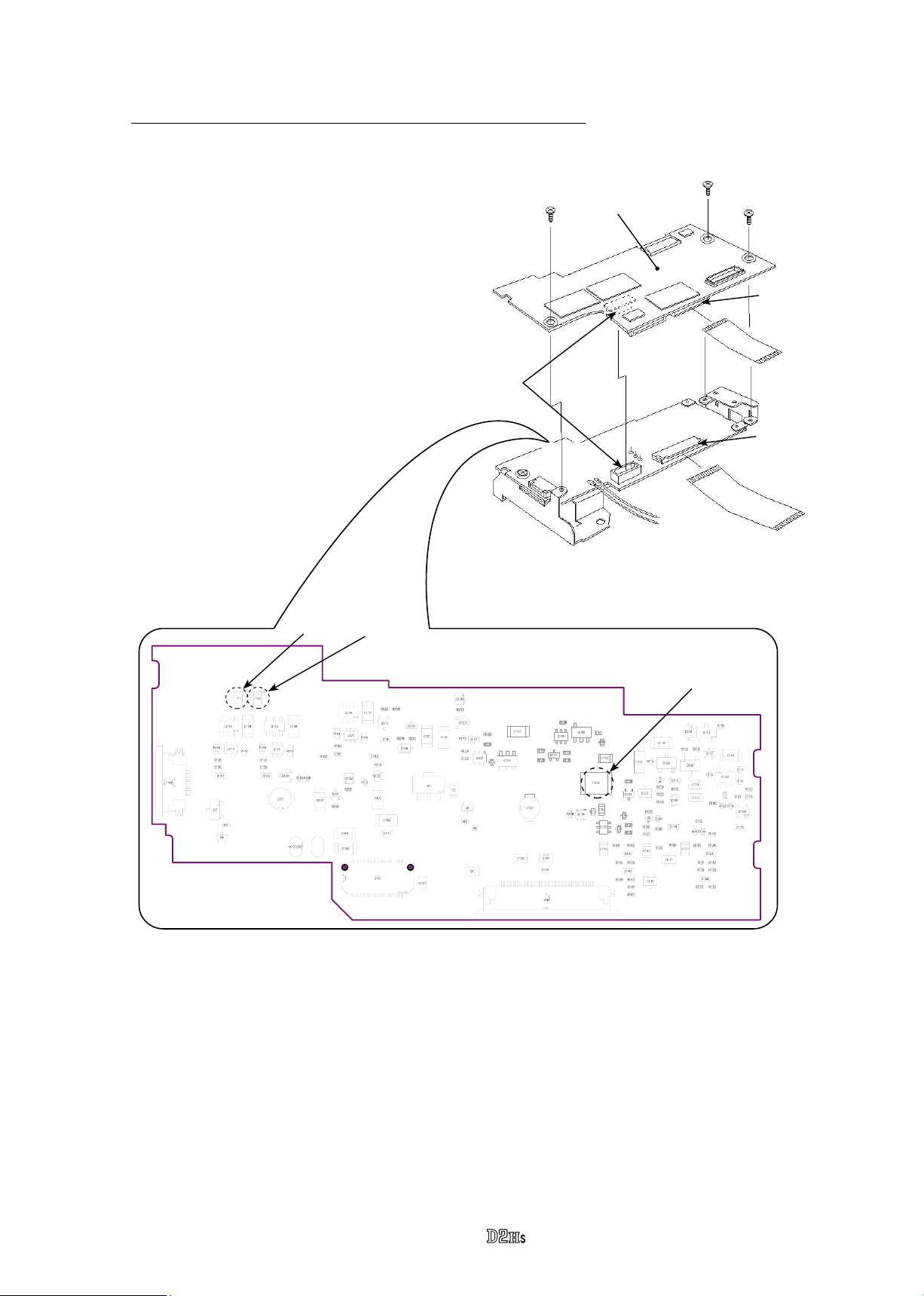

Imaging (LBCAST) PCB unit

VBA10601-R.3665.A

1. Remove Image PCB cover plate

Detach the both ends of the connection-

・

FPC of the memory compression

PCB & USB PCB (#5040) from the

connector.

(The EMI (electromagnetic interference)

prevention sheet (#592) is attached on

the connection-FPC.

Take out 2 screws (#1530).

・

Remove the image PCB cover plate.

・

)

#596

#5040

#592

Image PCB cover plate

#1530×2

2. Remove Image PCB unit

Remove the connection-FPC of the

・

image PCB & memory compression

PCB (#5038) from the connector.

Remove the image PCB harness

・

from the connector.

Take out 3 screws (#525).

・

Remove the image PCB unit.

・

Remove the screen frame (#529).

・

Note 1: For some bodies, the washer

is already put on the attaching face of

the image PCB. There is an indication

of the mark in red with magic marker.

Refer to Page A25 in the Assembly chapter

for the details.

*Note 2: For some bodies, there are L-shaped

washers attached at 3 parts of A-part on the

image-PCB.

On such PCB, there is red-marked indication

on its attachment side, so if the washers

come off, reattach them.

In case the PCB is replaced with the one

without red marking, the washers are NOT

necessary.

Image PCB unit

*A part

#529

#525×3

Connector

Image PCB harness

#5038

Connector

- D7 ・ -

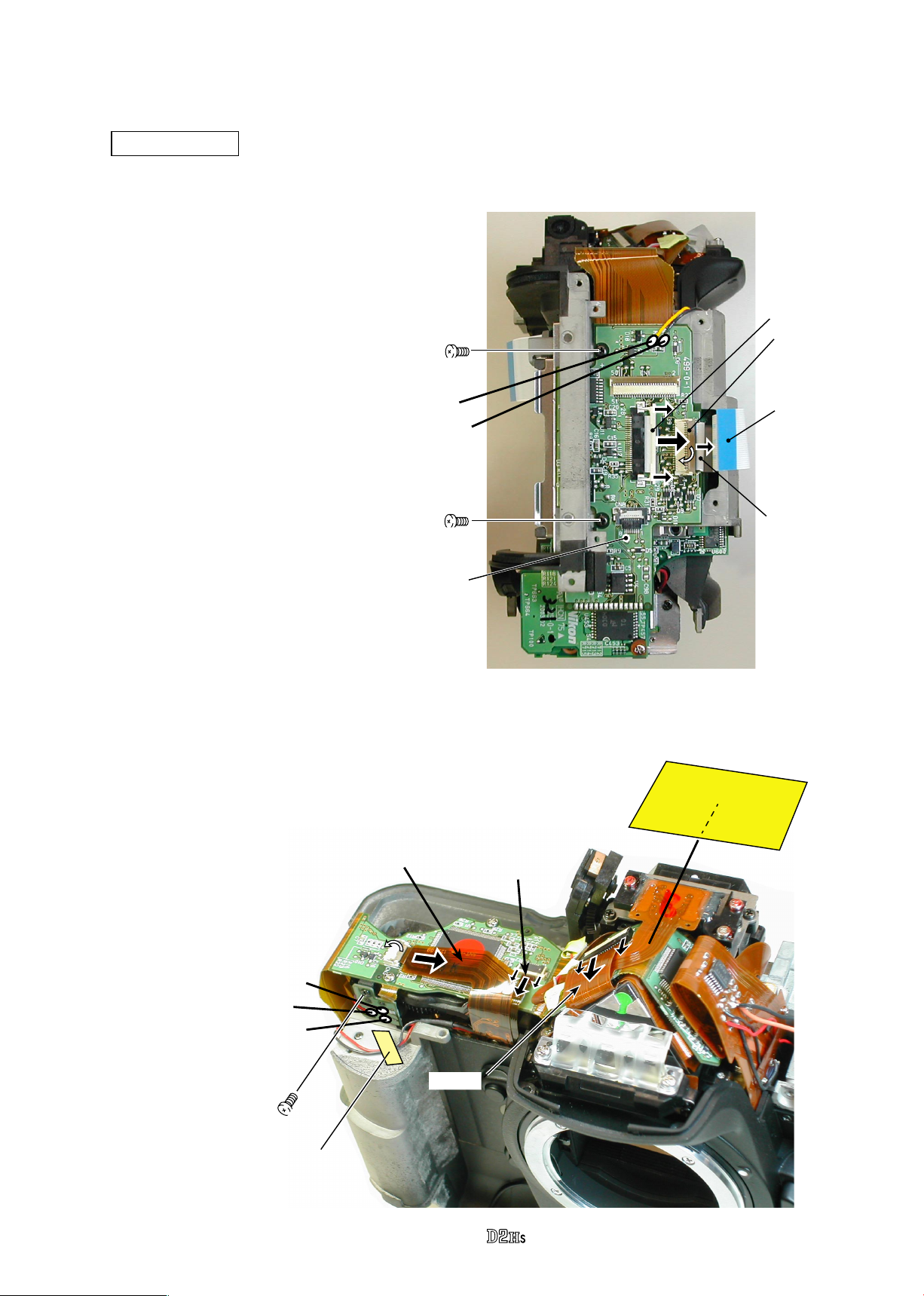

Top cover unit

1. Remove Top cover FPC connection and EL wires

Remove the red and black wires

・

on the main PCB.

Remove the top cover FPC from

・

the connector.

VBA10601-R.3665.A

Top cover FPC

Red: Back light for top LCD (EL)

Black: Back light for top LCD (EL)

2. Remove Top cover unit

Remove the eyepiece diopter knob cover

・

(#1130). Then take out the screw (#1568)

to remove the eyepiece diopter knob

(#1121).

Take out 8 screws in total (1 screw:#1543,

・

2 screws:#1537, 1 screw: #1519, 1

screw:#1510, 2 screws:#1516, and 1

screw: #1556).

#1537×2

#1130

#1543

#1568

#1121

#B1137

Top cover (#B23)

#1519

#1510

Detach the top cover (#B23) then the

・

eyepiece block unit (#B1171) comes off.

#1516×2

#1556

- D8 ・ -

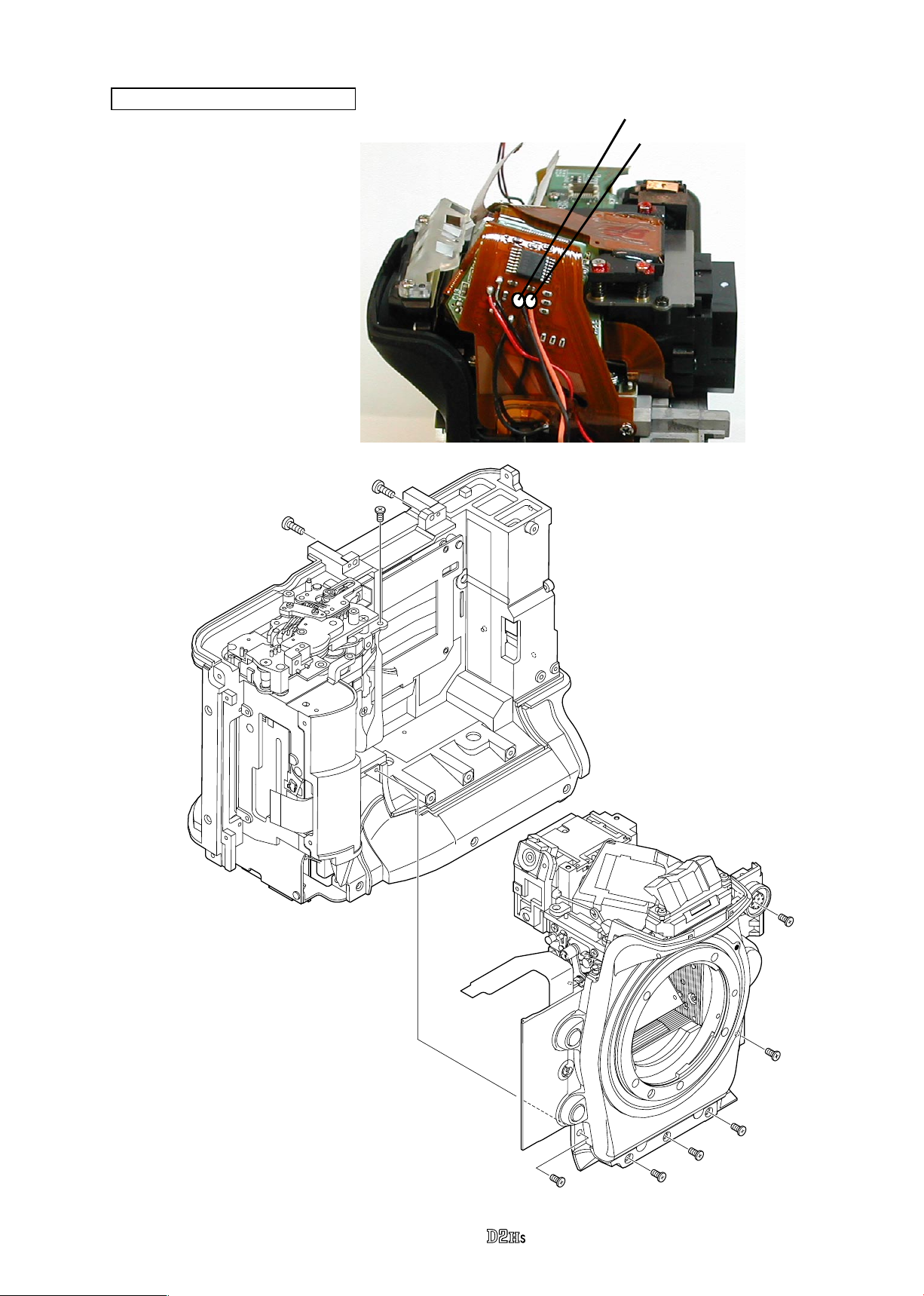

2. Separate Front and Rear bodies

Main FPC 1 unit

Remove the red and black wires on the main

・

FPC 1 side face.

Remove the connection-FPC of the main

・

FPC1 & DC/DC unit 2 (#5033) from the

connector.

Remove the connection-FPC of the main

・

FPC1 & memory compression PCB (#5035)

from the connector.

Take out 2 screws (#1532).

・

#1532×2

VBA10601-R.3665.A

Connector

Connector

Yellow: Charge motor

Black: Charge motor

Main FPC 1 unit

Remove the 3 wires (in red, brown and black) that connect from the charge SW.

・

Remove the P - F (Preview & function) FPC (#5027) from the connector.

・

Remove the shutter FPC (#5014) from the connector.

・

Remove the penta FPC (#B15005) from the connector.

・

Unscrew #1553.

・

#5033

#5035

#684

Brown: Charge SW

Red: Charge SW

Black: Charge SW

#1553

TA-0005

(6×12)

#5027

#B15005

- D9 ・ -

#5014

Remove the connecting connectors of

・

the main FPC 1 and main FPC 2.

Take out 3 screws (#1566) to detach

・

the main FPC 1.

Main FPC 2

VBA10601-R.3665.A

#1566×3

Main FPC 1

Back-up Battery Box Unit

Red: Back-up battery box

Black: Back-up battery box

#1533×2

#B818

Remove the red and black wires on the

・

USB PCB.

Take out 2 screws (#1533) and remove the

・

back-up battery box unit (#B818).

- D10 ・ -

Separate Front and Rear bodies

Remove the black and orange

・

wires that connect from the I/F

PCB.

Black: I/F PCB

Orange: I/F PCB

VBA10601-R.3665.A

#1590×2

#1535

#1514×6

Take out 2 screws (#1590) under the

・

eyepiece.

Unscrew #1535.

・

Take out 6 screws (#1514).

・

Separate the front body from the rear

・

body.

- D11 ・ -

VBA10601-R.3665.A

- D12 ・ -

3. Rear Body

I/F PCB unit

Red: I/F PCB

Orange: I/F PCB

Black: I/F PCB

・

Remove the 3 wires (in red,

orange and black) from the

DC/DC unit 2.

・

Remove 2 pieces of the tape

TA-0005(20×10).

2. Separation into DC-IN video PCB and USB PCB

1. Remove I/F PCB unit from Rear body

・

Take out 2 screws (#1510

and #1523) to remove

the I/F PCB unit from

the rear body.

#1510

#1523×2

I/F PCB unit

・

Remove 5 soldering

bridges.

・

Take out 3 screws (#1526)

to remove the USB PCB

from the IF-PCB locking

plate.

・

Take out 3 screws (#1526)

to the DC-IN video PCB

from the IF-PCB locking

plate.

Soldering bridge×5

DC-IN video PCB

IF-PCB locking plate

USB PCB

#1526×3

#1526×3

TA-0005

(20×10)×2

*FU1

* Fuse-FU1 is replaceable before separating

the DC-IN video PCB from the USB-PCB.

Phenomenon when fuse-FU1 is blown out:

In case of using DC-IN as power, the power

does NOT turn ON.

DC/DC unit 2

CF card PCB unit

1. Remove CF card PCB unit from Rear body

Take out 2 screws (#1531).

・

VBA10601-R.3665.A

#1531×2

Take out 2 screws (#1531).

・

Hold down 2 connection-FPCs

・

with ngers so that they are not

hooked to the rear body, then

remove the CF card PCB unit

from the lower holes of the rear

body.

#1531×2

CF card eject lever

CF card PCB unit

2 connection-FPCs

- D13 ・ -

2. Remove DC/DC PCB unit 1

Remove the red and black wires.

・

Take out 2 screws (#1530) to remove the

・

DC/DC PCB unit 1.

VBA10601-R.3665.A

#1530×2

Black: DC/DC PCB unit 2

Red: DC/DC PCB unit 2

DC/DC PCB unit 1

3. Remove CF Card PCB

Take out 2 screws (#1530).

・

Disconnect the connectors to remove the CF

・

card PCB.

#1530×2

CF card PCB

Connector

- D14 ・ -

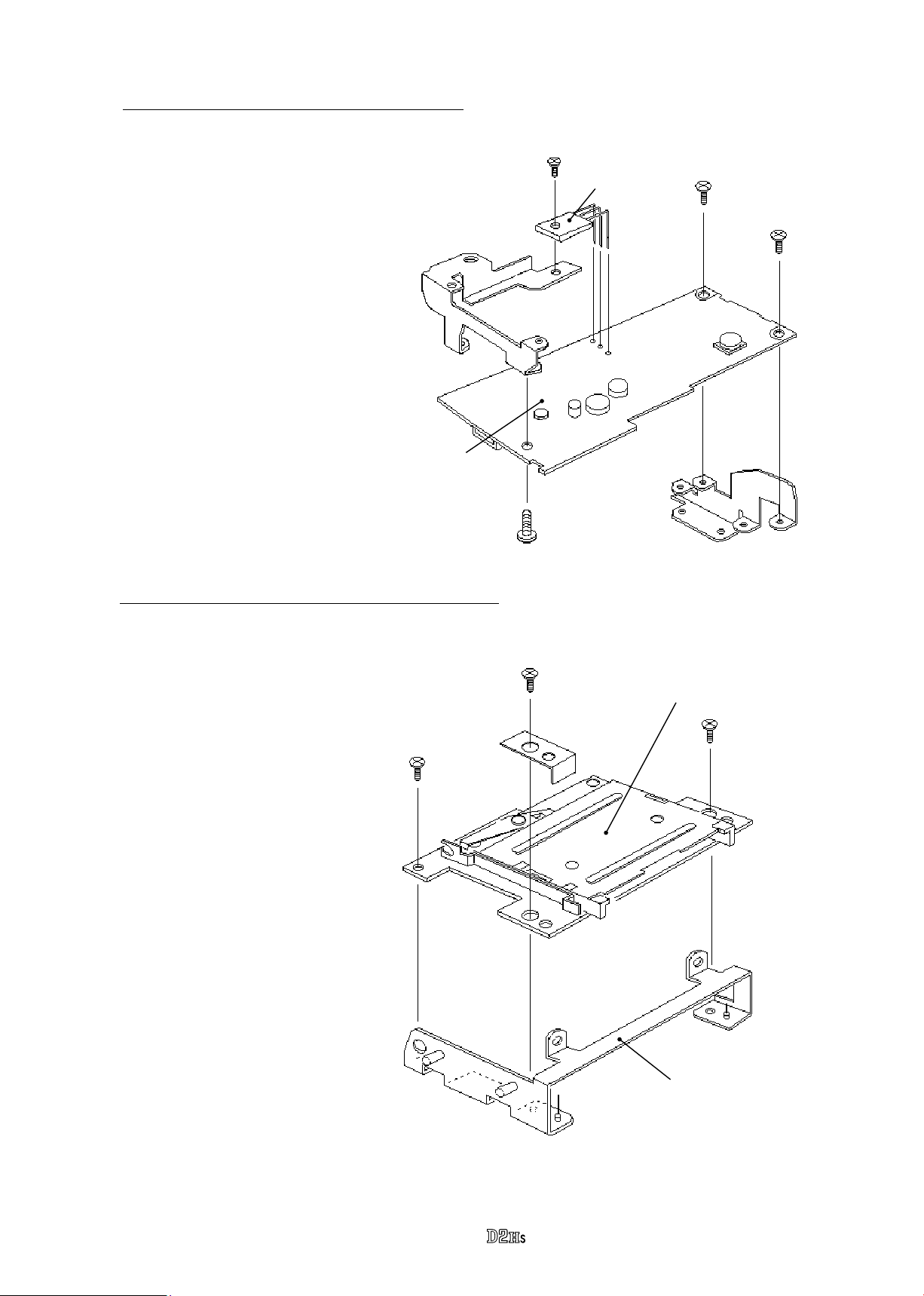

4. Separation of Memory compression PCB and DC/DC PCB unit 2

Take out 3 screws (#1530).

・

Me mory com pres sion

PCB

VBA10601-R.3665.A

#1530×3

Connector

①

Disconnect the connectors to separate

・

the memory compression PCB and

DC/DC PCB unit 2.

F1

F102

Connectors

DC/DC PCB unit 2

F104

#5035

Connector

#5033

②

*If the memory compression PCB is separated from DC/DC unit 2, the following fuses (except F104 Polyswitch) can be

replaced.

・Phenomenon when fuse or *Polyswitch burns out.

F1: Both battery and DC-IN cannot be turned ON.

F102: Because there is no power except VBAT and VBT6, the LCD keeps the indications just before burnout of fuses,

and also other functions of camera cannot work.

*F104: Because there is no output from VCC12 and VCC23, the backlight of TFT cannot light up and TFT shows

indications but they can hardly be veried. At the same time, the control panel on top of the camera keeps the

indications just before burnout of fuses.

As for F104 (Polyswitch), however, if turning the main switch of camera to OFF for a few seconds and then turning

to ON, or if removing the battery once and then inserting it again, this Polyswitch recovers its function. So it does

not usually burn out (break) permanently, compared with other fuses.

- D15 ・ -

5. Remove Locking plate from DC/DC PCB unit 2

VBA10601-R.3665.A

#1540

#1530×2

#5086

Take out the screws (#1530 and

・

Locking plate

(#70)

#1540) to remove the locking

plate of the DC/DC unit 1 & 2

(#70).

Take out 2 screws (#1530) to

・

remove the locking plate of the

memory compression PCB &

DC/DC PCB unit 2 (#69).

Remove the solder of 3 legs of

・

the power transistor (#5086) to

detach it.

DC/DC unit 2

6. Remove CF locking plate unit from CF card PCB unit

#1530

Locking plate

(#69)

#1530×3

Take out 3 screws (#1530) to

・

detach the CF knob cover (#449)

and the CF locking plate unit.

CF card PCB unit

#449

CF locking plate unit

- D16 ・ -

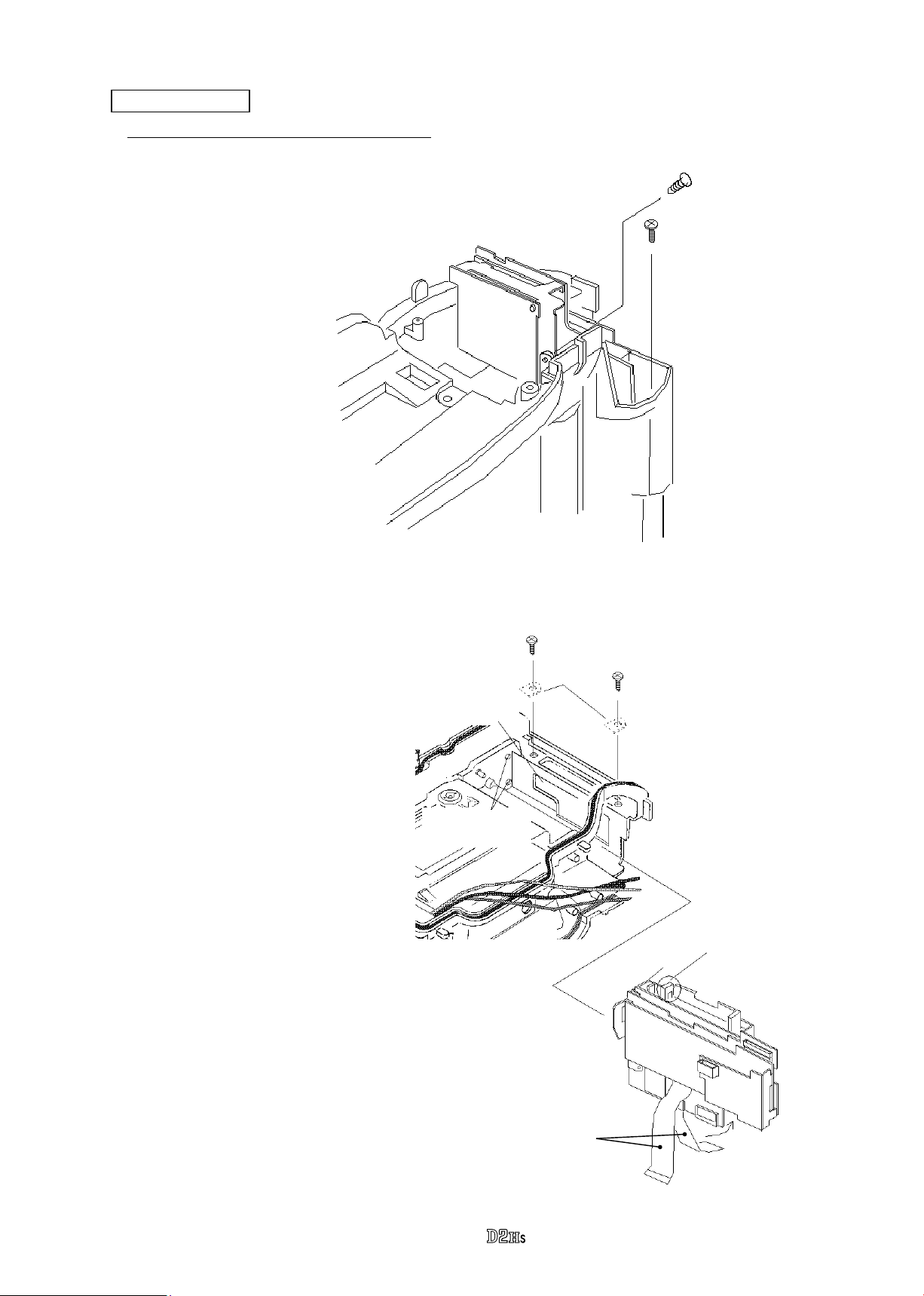

SQ (Sequence) PCB unit

VBA10601-R.3665.A

#1538×4

Unscrew #683 to remove the

・

shutter FPC from the SQ

PCB.

Take out 4 screws (#1538).

・

Remove the SQ PCB unit

・

from the rear body.

Shutter unit

SQ PCB unit

#683

Shutter FPC

#1704×3

Take out 3 screws (#1704) to

・

detach the shutter unit.

Note)The dust-proof sheet (#540)

is attached on the rear body

with the both-sided adhesive

tape.

Shutter unit

#540

- D17 ・ -

Rear body small parts

VBA10601-R.3665.A

#575

#566

#574

#571

#271

#567

#568

#573

#577-1

#576

#398

#397

#399

#572

#565

#564

#563

#569

#561

#595

#554

#562

#533

- D18 ・ -

4. Front Body

Adjustable diopter unit

Unscrew #1535 to detach the

・

adjustable diopter unit.

VBA10601-R.3665.A

Adjustable

dioptor unit

#1535

Main FPC 2

1. Remove wires, FPCs and soldering bridges

Remove the red and black wires

・

that connect from the AF motor

and the black wire that connects

from the lens contact FPC.

Remove the grey and black wires

・

that connect from the lens release

SW, and also remove the red, blue

and brown wires that connect

from SCM change-over.

Soldering bridges of 10

pin connectors

#1530

Red: AF motor

Black: AF motor

Black: Lens contact FPC

#1503

Lens contact FPC

Red: SCM change-over

Blue:

〃 〃

Brown:

Gray: Lens release SW

Black:

TTL FPC

〃 〃

〃 〃

Remove the soldering bridges

・

of 10 pin connectors.

Remove the lens contact

・

FPC and TTL FPC from the

connector.

Remove 5 soldering bridges

・

of AF-PI FPC.

Take out the screws (#1503

・

and #1530).

5 soldering bridges of AF-PI

FPC.

- D19 ・ -

VBA10601-R.3665.A

2. Remove Main FPC 2

Remove the screw (#283), press-contact plate (#282) and press-contact rubber (#285) to remove the main

・

FPC 2 from the front body.

#283

#282 #285

Main FPC 2

Prism Box

1. Separate Prism box unit from Front body

When the prism box is detached from

*

the front body, be sure to make the

inspection and adjustment of parallax

on Page A48.

#1188×4

Take out 4 screws (#1188).

・

Remove the prism box unit,

・

then the washers for alignment

& adjustment (#1180 and

#1181) come off.

#1180

#1181

- D20 ・ -

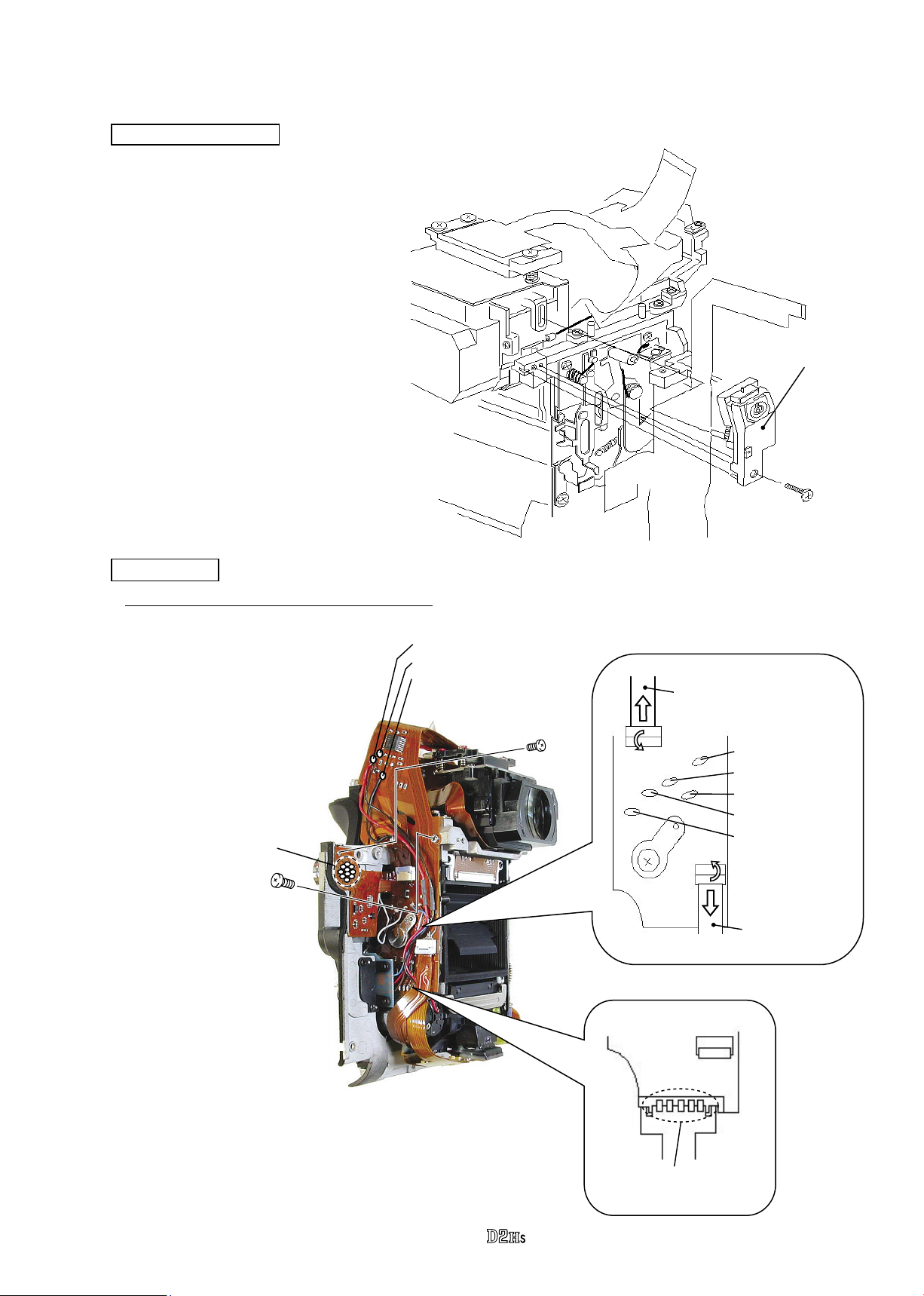

2. Remove S. I unit

Remove the penta

①

dust-proof tape

(#1205).

#1205

Remove 8 soldering bridges

②

of the penta FPC.

VBA10601-R.3665.A

Take out 2 screws (#1577) to detach the

③

S. I. unit.

#1577×2

S. I. unit

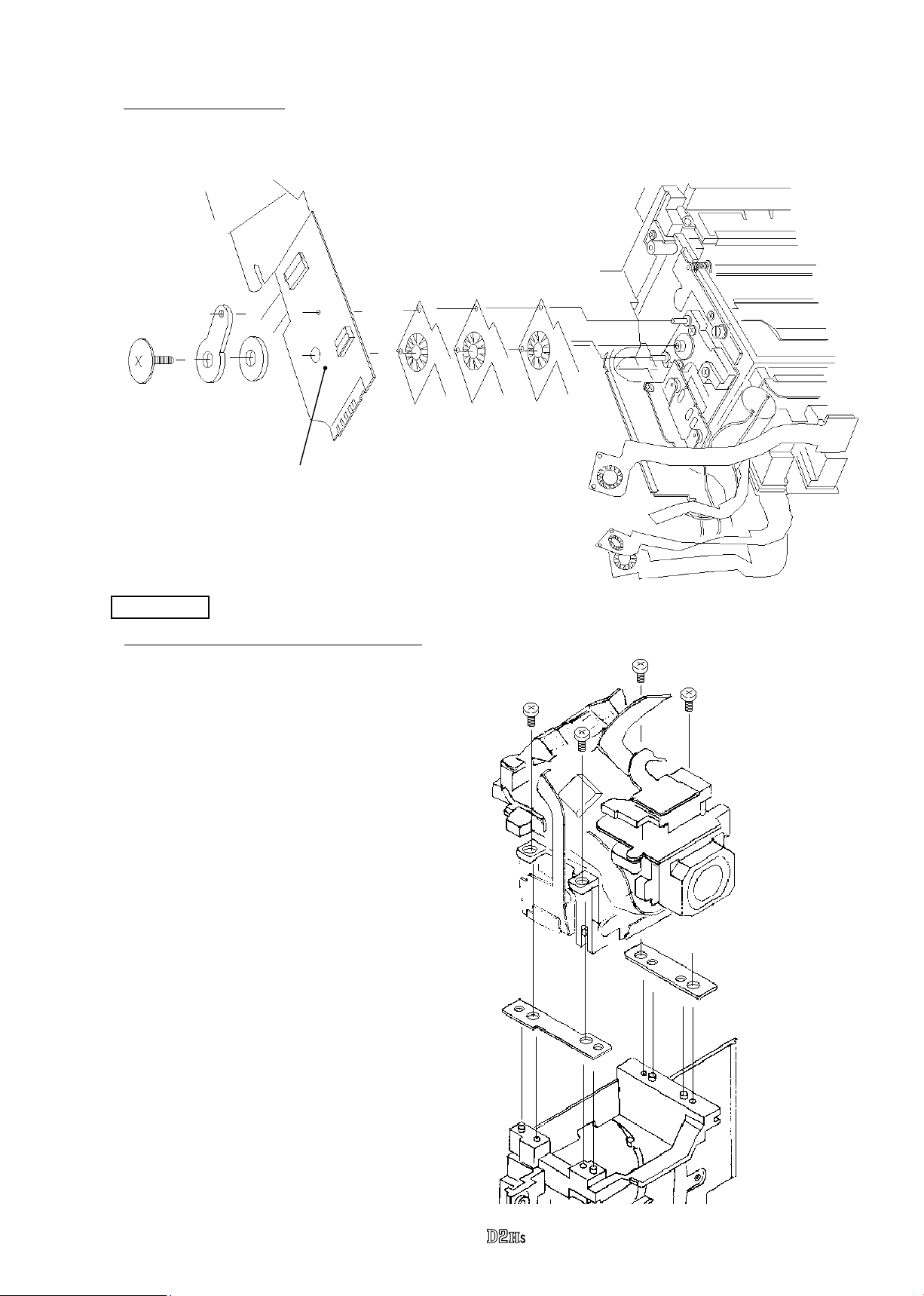

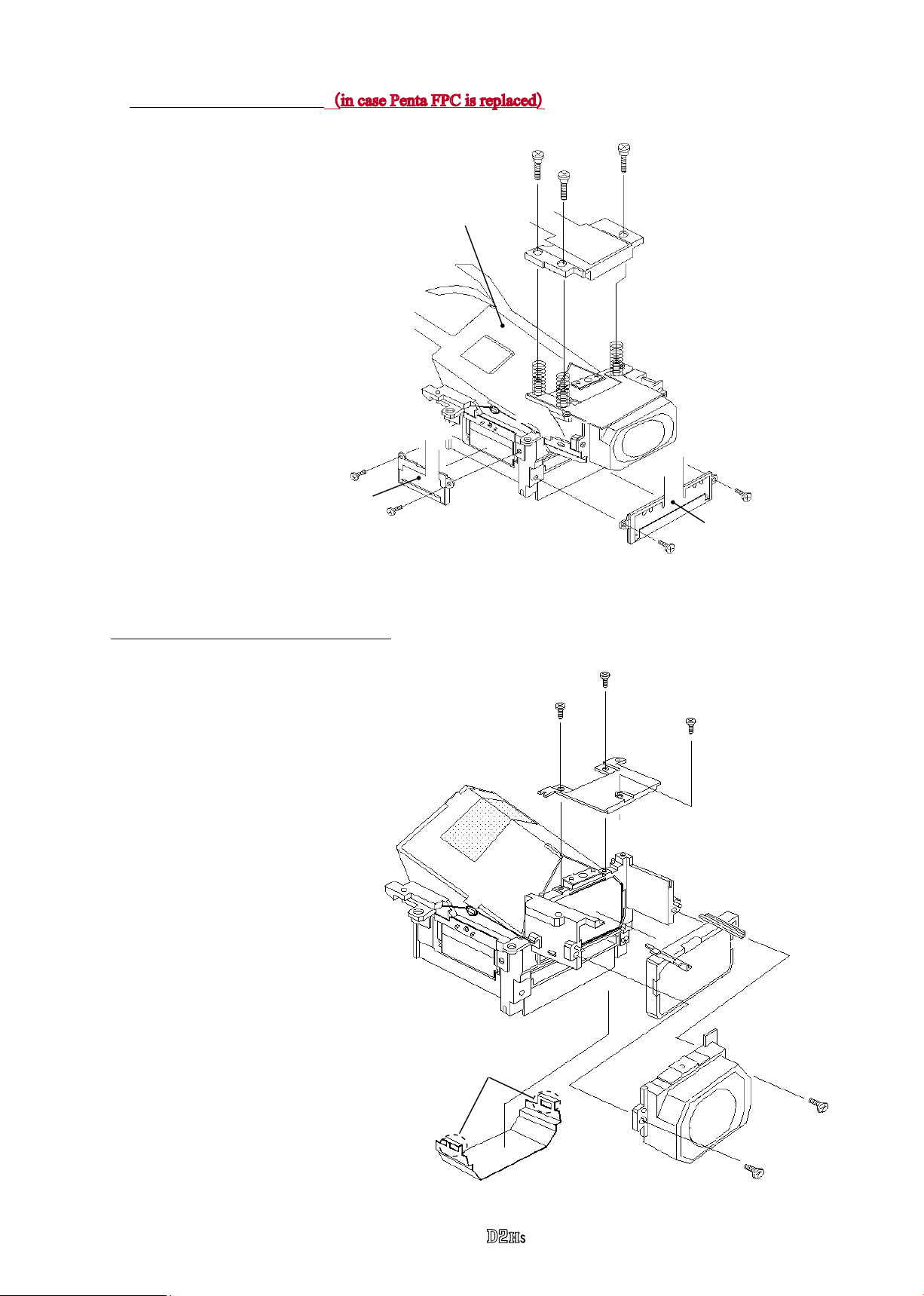

3. Remove Penta FPC unit (in case Penta FPC is NOT replaced

Take out 2 screws (#1551) to

・

detach the right-display LCD

unit.

Take out 2 screws (#1551)

・

Penta FPC unit

to detach the bottom-display

LCD unit.

Take out 2 screws (#1565) to

・

detach the AE sensor holder

unit attached to the penta FPC.

Detach the penta FPC from the

・

penta, (which is attached with

the both-sided adhesive tape.)

Right-display LCD unit

#1551×2

)

#1565×2

AE sensor holder unit

Bottom - d i s p l a y

LCD unit

#1551×2

- D21 ・ -

VBA10601-R.3665.A

3-1. Remove Penta FPC unit(in case Penta FPC is replaced

Take out 2 screws (#1551) to

・

detach the right-display LCD

unit.

Take out 2 screws (#1551) to

・

Penta FPC unit

detach the bottom-display LCE

unit.

Take out 3 screws (#1133) to

・

detach the AE sensor holder.

Remove 3 springs for AE

・

device adjustment (#1134).

Detach the penta FPC unit from

・

the penta, (which is attached

with the both-sided adhesive

tape.)

Right-display LCD unit

#1551×2

)

#1133×3

#1134×3

Bottom-display LCD unit

4. Remove Eyepiece holder unit C and B

Detach the 2 hooking parts of

・

the eyepiece cover (#1104) by

loosening them.

Take out 3 screws (#1544) to

・

detach the eyepiece top cover

(#1120).

Take out 2 screws (#1567) to

・

detach the eyepiece holder unit C

(#B1119).

Detach the eyepiece holder unit B

・

(#B1118).

#1551×2

#1544×3

#1120

#B1118

Hooking part×2

#1104

- D22 ・ -

#B1119

#1567×2

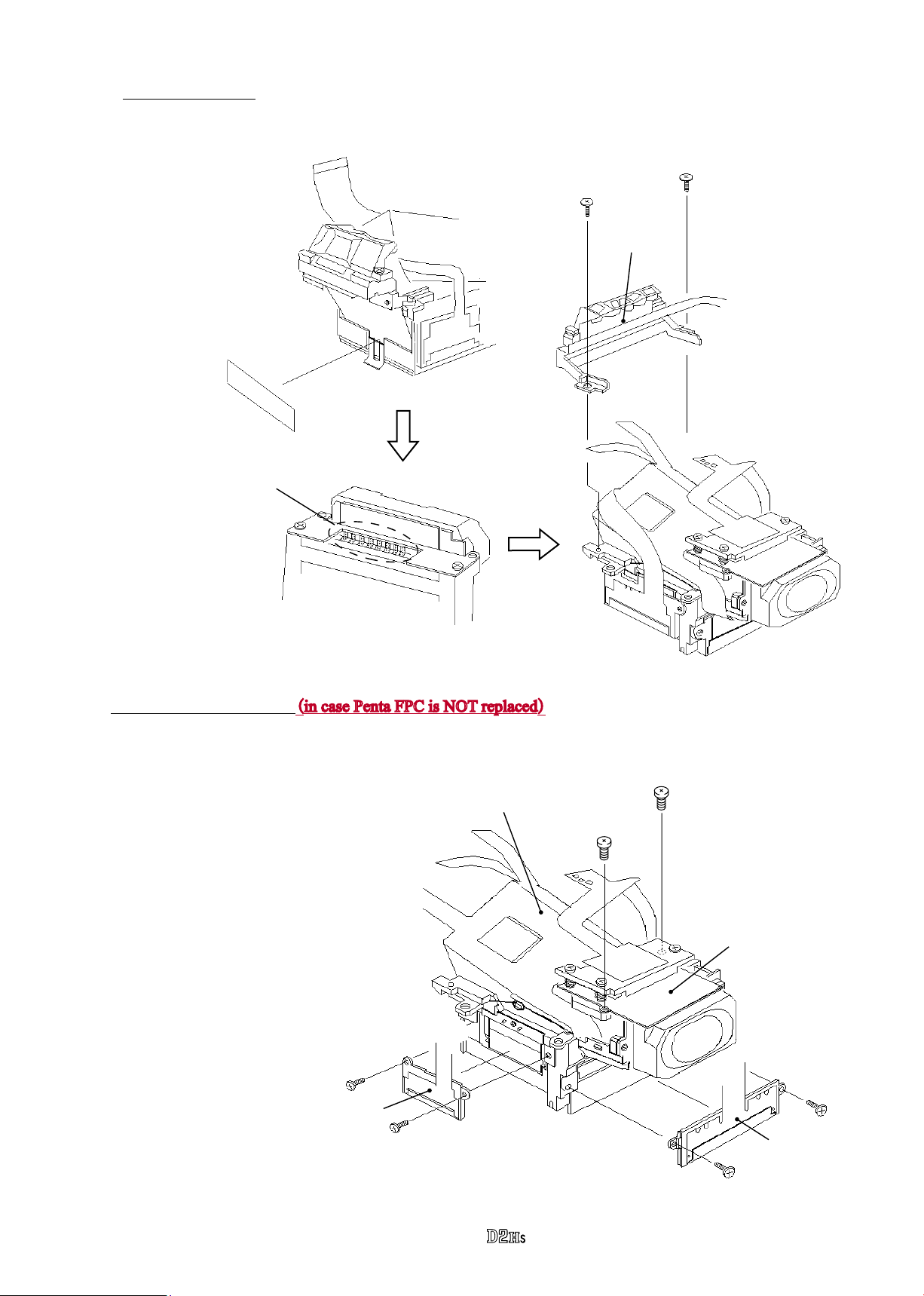

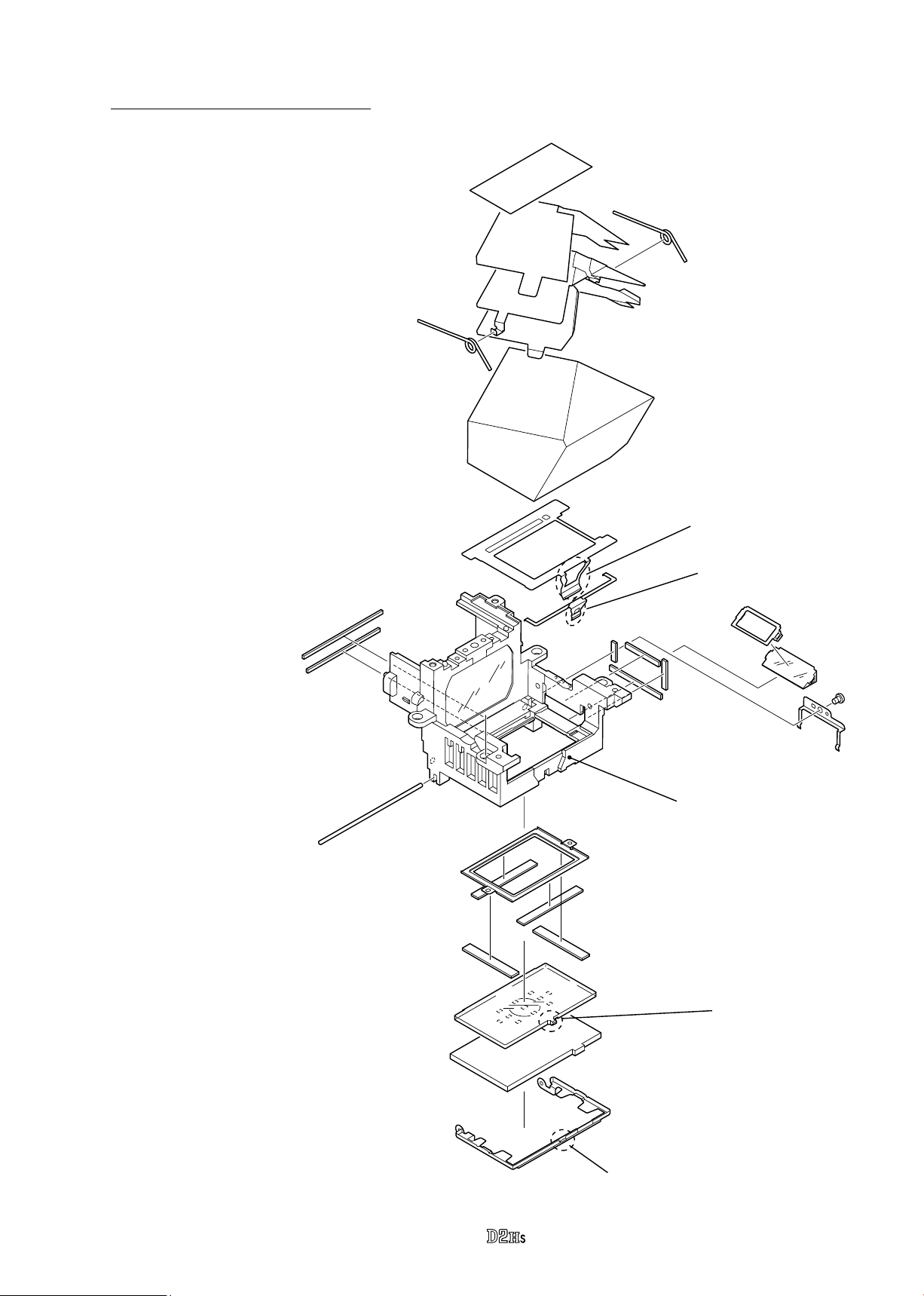

5. Screen, Prism, and other small parts

Unscrew #1562 to remove the retaining

・

spring (#1170).

Remove the right-display prism (#3012)

・

and the prism mask (#1166).

Remove the screen by unhooking the

・

convexity A of the screen frame from

the hooked part of the nder eld frame

A.

Remove the screen frame (#1102) by

・

detaching the supporting shaft for the

screen frame (#1103).

Remove the S. I. display plate by

・

unhooking the convexity A of the S.

I. display plate from the xed frame

(#1105).

#1114

#B1111

VBA10601-R.3665.A

Both-sided adhesive tape (#1194)

#1112×2

#1113

Prism

Finder eld

frame A

Hooked part of Finder

eld frame A

Remove 2 penta retaining springs

・

(#1112).

Remove the penta retaining plate

・

(#B1111) and penta insulating

sheet (#1114), (which are attached

in one with the both-sided adhesive

tape.)

Remove the penta retaining sheet

・

(#1113).

Remove the prism.

・

Remove the nder eld frame A.

・

Remove the xed frame (#1105).

・

Detach 2 sponges (#1199) and

・

remove the nder eld frame B.

#1196

#1197

#1103

#1105

#1193

Finder eld frame B

#1198×2

#1199×2

#1191

#1195

S. I. display plate

Screen

Screen frame

Hooked part of #1105

#1192

Prism box

Convexity B

#1166

#3012

#1562

#1170

- D23 ・ -

Convexity A

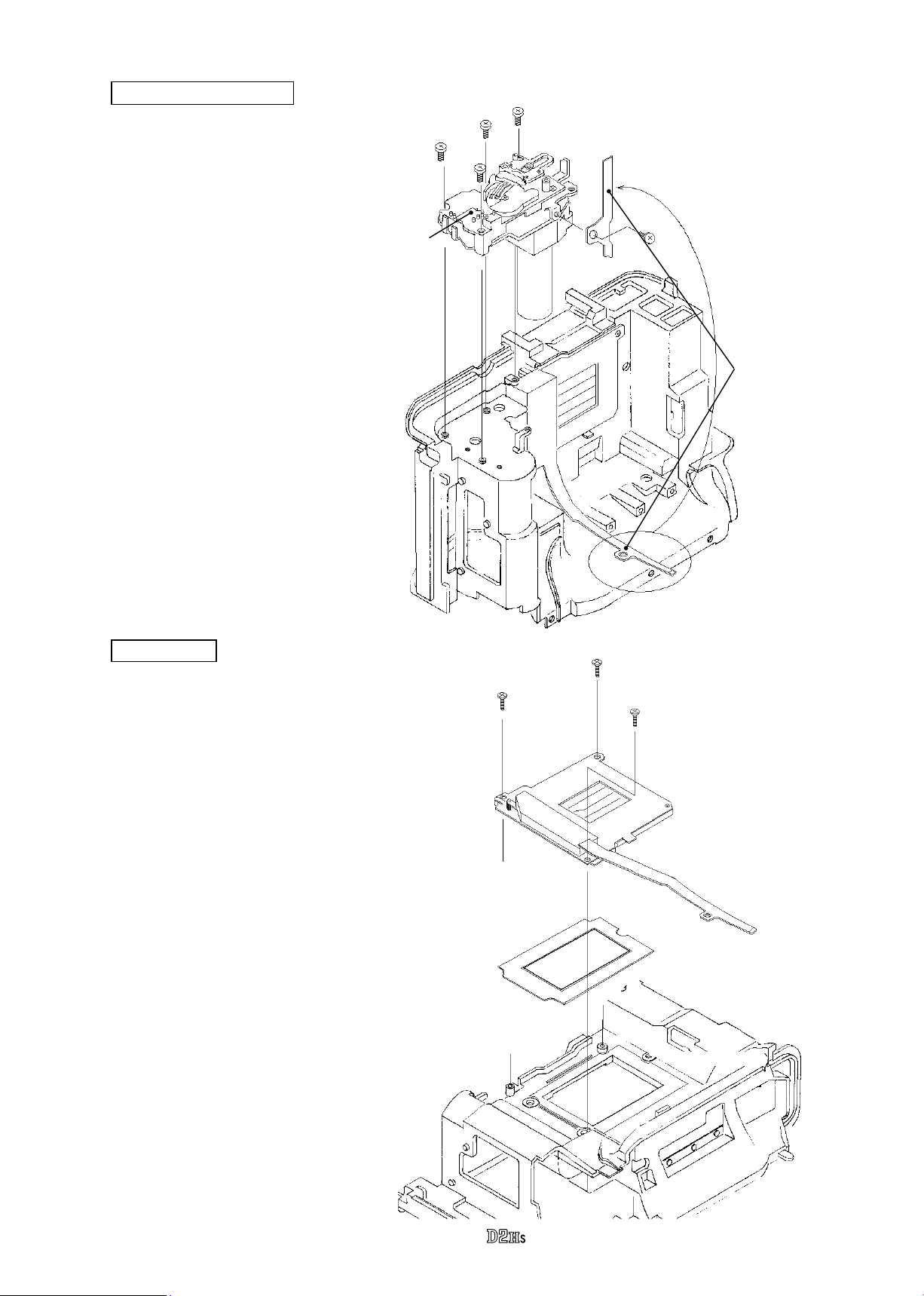

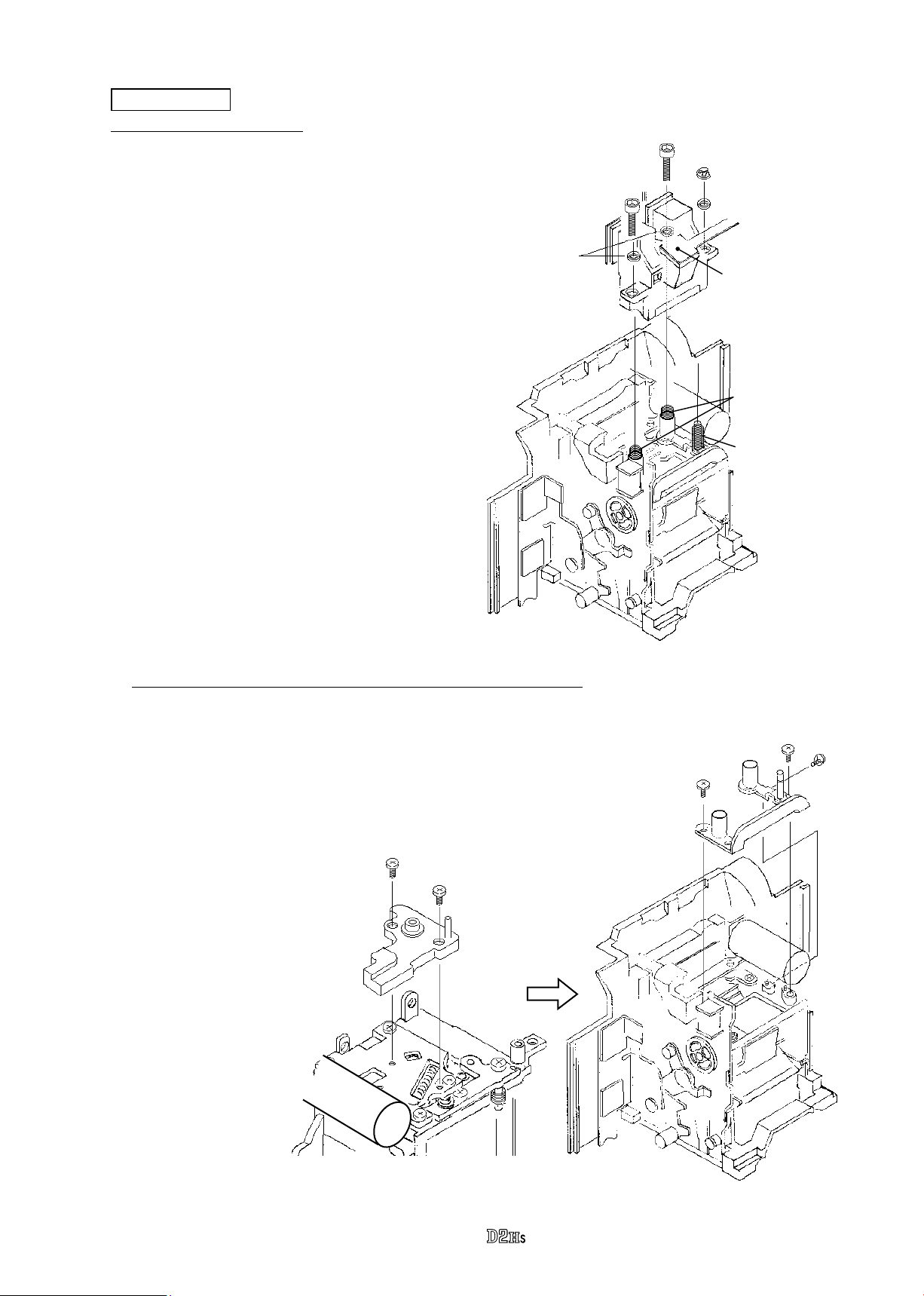

AF detector unit

1. Remove AF detector unit

VBA10601-R.3665.A

#295×2

Detach the E ring (#298) to remove the

・

washer (#294).

By using the Hexagonal wrench (φ1.5mm),

・

take out 2 screws (#295) and 2 washers

(#300).

Remove the AF detector unit.

・

Remove one spring (#293) and 2 springs

・

(#296).

* Even in case the AF detector unit is

not replaced, by going to the below 2

instruction without removing the above E

ring and 2 screws, it is possible to remove

the AF detector unit attached to the AF

detector installing plate.

#298

#294

#300×2

AF detector unit

#296×2

#293

2. Remove Press-contact base plate and AF detector installing plate

Take out 2 screws (#1530) to remove

・

the press-contact base plate (#281).

Take out one screw (#1523) and 2

・

screws (#1588) to remove the AF

detector installing plate (#B297).

#1530×2

#281

#1588×2

#1523

#B297

- D24 ・ -

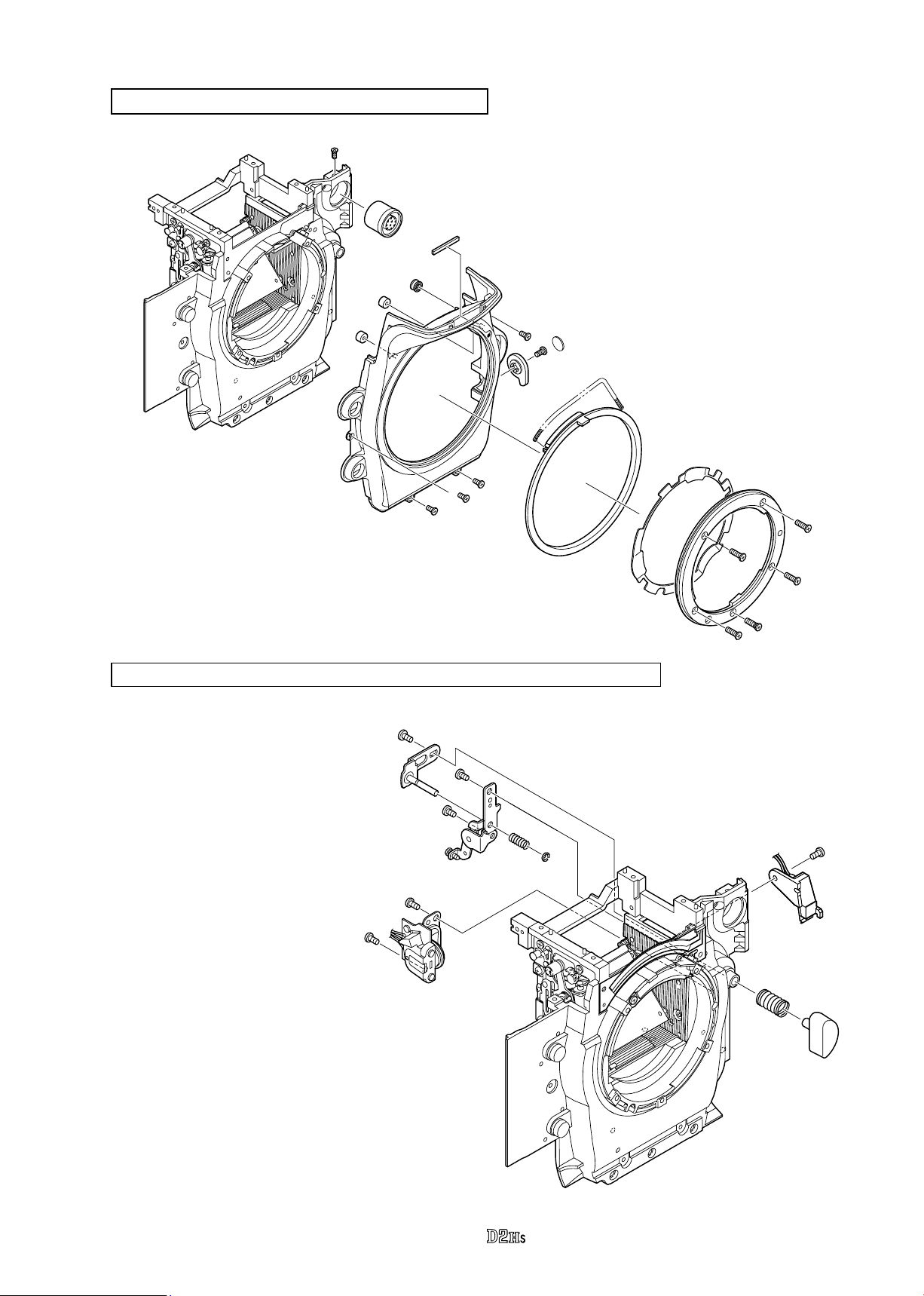

Bayonet mount, Apron, Remote connector (10 pins)

#47

#41

#555

VBA10601-R.3665.A

#410×2

#B22

#407

#1508×4

#387

#383

#B388

#406

Lens release SW unit, SCM change unit, Lens release button, Vertical lever unit

#B404

#402

#401

#1572×4

#1573

Unscrew #1532 to remove

・

the lens release SW unit

(#B378).

Take out 2 screws (#1508) to

・

remove the SCM change unit

(#B10384).

Unscrew (#379) to remove

・

the lens release button

(#376) and spring (#380).

Take out 2 screws (#1512) to

・

remove the vertical lever unit

(#B356).

#B371

#379

#1512×2

#1508×2

#B10384

#B356

#1532

#374

#1604

#B378

#380

#376

- D25 ・ -

Loading...

Loading...