Nikon D200 Repair Manual

作成承認印 配布許可印

VBA13001-R.3677.A

VBA13001

Copyrighc2005 by Nikon Corporation.

All Rights Reserved.

無断転載を禁ず

!!

Printed in Japan November 2005

Recycled paper

再生紙を使用しています

REPAIR MANUAL

M

サービス

計画課

VBA13001-R.3677..A

- M1 ・ -

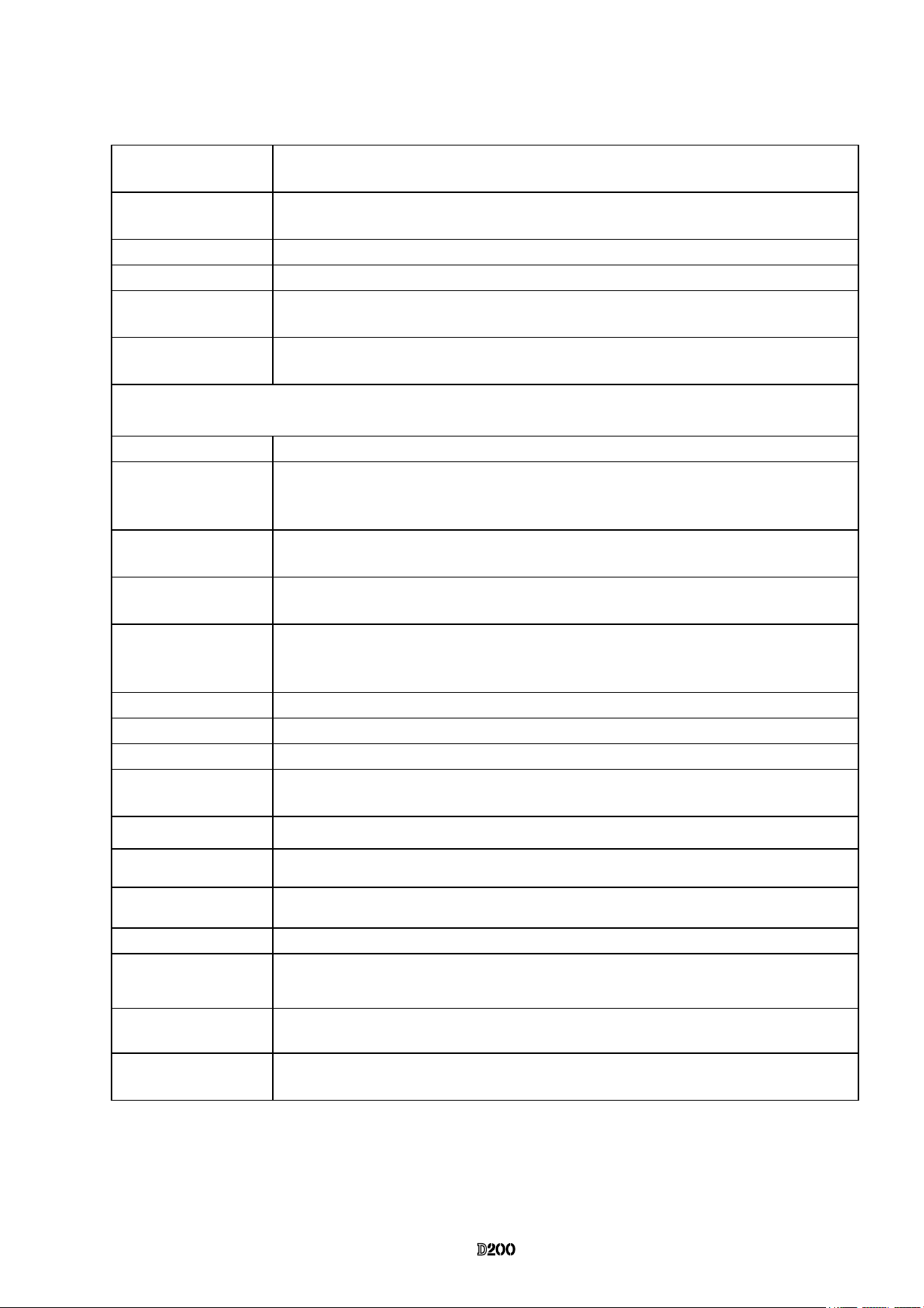

Specications

Type Single-lens reex digital camera with interchangeable lenses

Effective pixels 10.2 million

LBCAST image sensor 23.6× 15.8 mm; total pixels: 10.92 million

Image size (pixels) 3872× 2592 (L), 2896× 1944 (M), 1936× 1296 (S)

Lens mount Nikon F mount (with AF coupling and AF contacts)

Compatible lenses

Type G or D AF Nikkor All functions supported (except IX Nikkor)

Micro Nikkor 85 mm F2.8D All functions supported except autofocus and some exposure modes

Other AF Nikkor All functions supported except 3D color matrix metering Ⅱ and 3D multi-sensor

balanced ll-ash for digital SLR

AI-P Nikkor All functions supported except 3D color matrix metering Ⅱ , 3D multi-sensor

balanced ll-ash for digital SLR, and autofocus

Non-CPU

Can be used in exposure modes A and M; electronic range nder can be used if

maximum aperture is f/5.6 or faster; color matrix metering, multi-sensor balanced

ll-ash for digital SLR, and aperture value display supported if user provides lens

data (Non-Ai lens cannot be used.)

Picture angle Equivalent in 35-mm format is approximately 1.5 times lens focal length

Viewnder Fixed eyelevel pentaprism

Diopter adjustment - 2 ~+ 1 m

- 1

Eyepoint 19.5 mm (-1.0 m

- 1

)

Focusing screen Type B BriteView clear matte screen Mark Ⅱ provided (Focus frame; grid line

display for composition)

Frame coverage Approximately 95% of lens (vertical and horizontal)

Magnication Approximately 0.94× (50-mm F1.4 lens at innity; -1.0 m

- 1

)

Reex mirror Quick return

Lens aperture Instant return with depth-of-eld preview

VBA13001-R.3677..A

- M2 ・ -

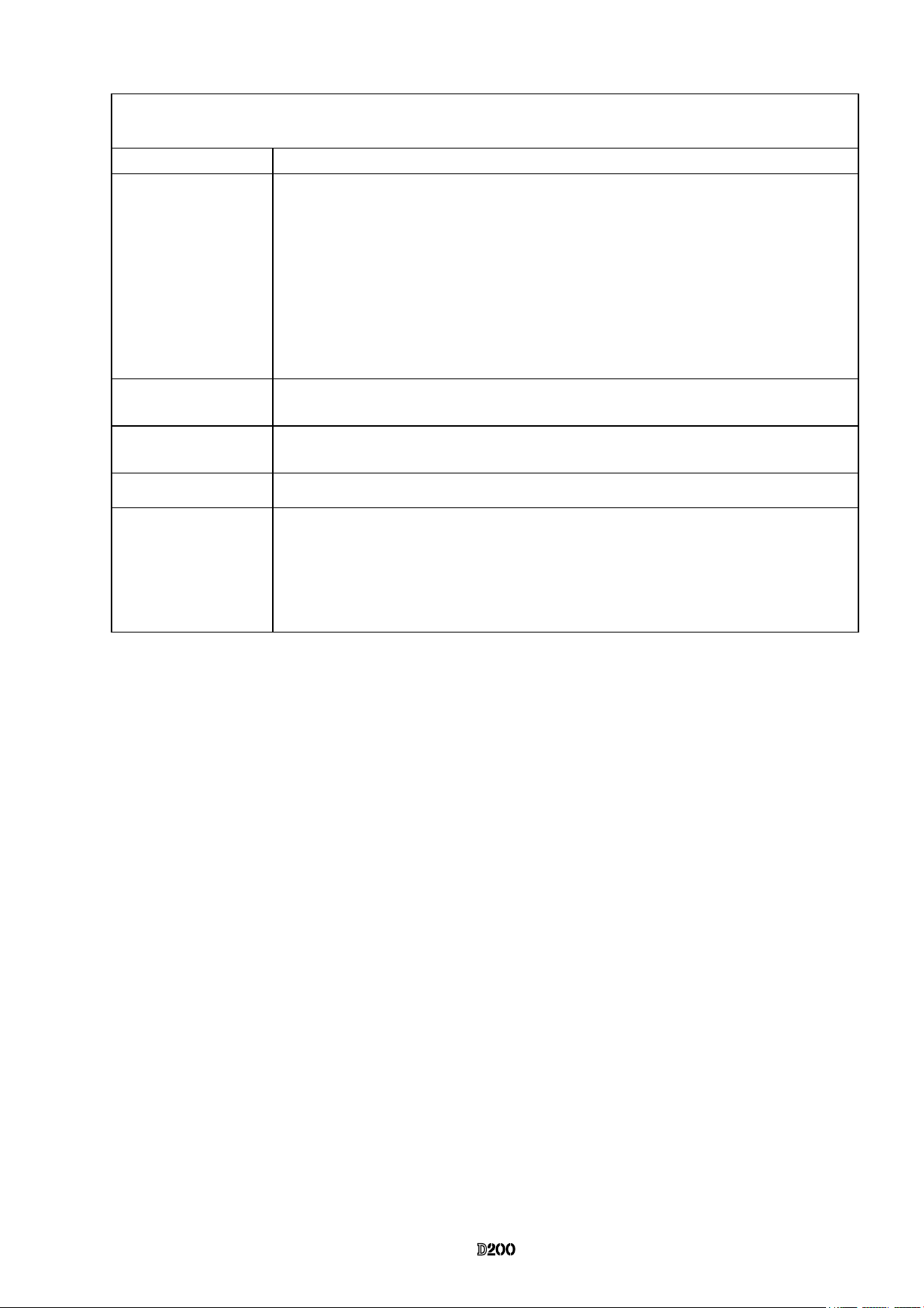

Focus-area selection Normal frame (11 focus areas): Single area or group can be selected from 11 focus areas

Wide frame (7 focus areas): Single area can be selected from 7 focus areas

Lens servo Instant single-servo AF (S); continuous-servo AF (C); manual (M); predictive focus tracking

automatically activated according to subject status in continuous-servo AF (C)

Autofocus TTL phase detection by Nikon Multi-CAM2000 autofocus module

Detection range -1- +19 EV (ISO 100, room temperature 20 °C/68 °F)

AF-area mode Single-area AF, dynamic-area AF, group dynamic-AF, dynamic-area AF with closest subject

priority

Focus lock Focus can be locked by pressing shutter-release button half-way (single-servo AF) or by

pressing AE-L/AF-L button

Exposure

Metering Three-mode through-the-lens (TTL) exposure metering

Matrix 3D color matrix metering Ⅱ supported with type G and D lenses; color matrix metering Ⅱ

available with other CPU lenses; and color matrix metering available with non-CPU lenses if

user provides lens data

Center-weighted Weight of 75% given to 6, 8, 10, or 13-mm circle in center of frame, or weighting based on

average of entire frame

Spot Meters 3-mm circle (about 2% of frame); metered area linked to selected focus area (with

non-CPU lens, xed in center)

Range EV0 ~ 20 (3D color matrix or center weighted metering)

EV2 ~ 20 (spot metering)

(ISO 100 equivalent, f/1.4 lens, 20℃ /68°F)

Exposure meter coupling

Combined CPU and AI

Exposure modes Programmed auto with exible program; shutter-priority auto; aperture priority auto; manual

Exposure compensation ±5EV in increments of 1/3, 1/2, or 1 EV

Bracketing Exposure and/or ash bracketing (2-9 exposures in increments of 1/3, 1/2, 2/3, or 1EV)

WB (2-9 exposures in increments of 1- 3EV)

Exposure lock Luminosity locked at detected value with AE-L/AF-L button

Shutter

Electronically-controlled vertical-travel focal-plane shutter

Speed

30- 1/8000 in steps of 1/3, 1/2, or 1EV, bulb

Sensitivity

100 -1600 (in steps of 1/3, 1/2, or 1EV), auto gain to ISO 1600 equivalent

White balance

Auto (TTL white-balance control with 1,005 pixels RGB sensor), six manual modes with

ne-tuning, color temperature setting, preset, white balance bracketing

Built-in Speedlight

Pop-up Speedlight with button release

Guide number (at 20°

C/68°F)

ISO 100: approximately 12 (Manual full-ash: approx. 13)

VBA13001-R.3677..A

- M3 ・ -

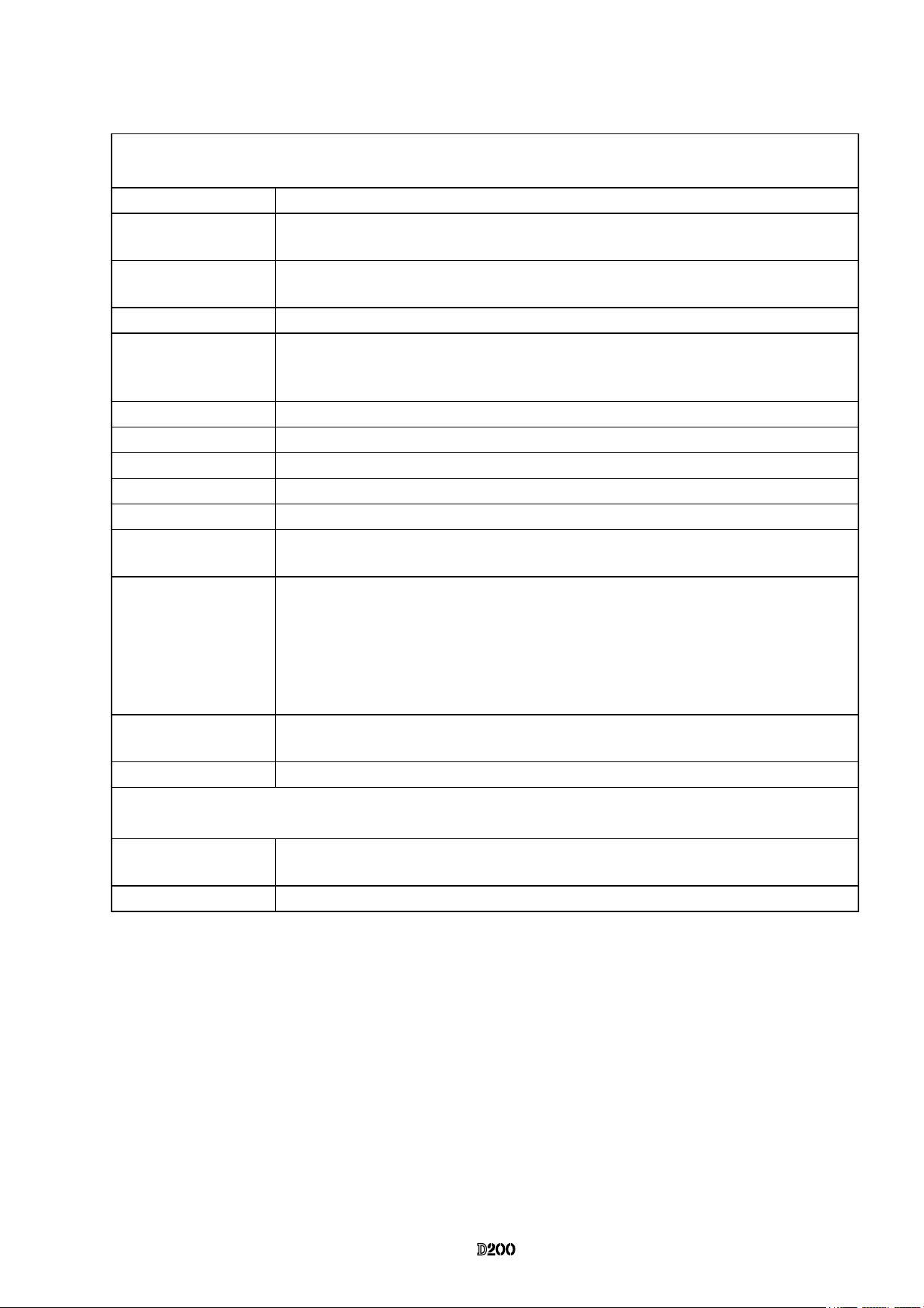

Flash

Sync contact

X-contact only; ash synchronization at up to 1/250 s

Flash control

TTL ash control by 1005-segment RGB sensor:

- i-TTL balanced ll-ash for digital SLR (built in Speedlight or SB-800/SB-600 with other

meterings than spot metering)

- Standard i-TTL balanced ll-ash for digital SLR (built in Speedlight or SB-800/SB-600

with spot metering)

(Can be set on speedlight when SB-800/SB-600 is used)

Auto aperture is available with CPU lenses and SB-800

Non-TTL auto is available with SB-800, SB-80DX,SB-28DX, SB-27, SB-22S, etc

Range-priority manual is available with SB-800

Sync modes

Front curtain sync (normal), slow sync, rear-curtain sync, red-eye reduction, red-eye

reduction with slow sync

Flash-ready indicator

Lights when B-800, SB-600, SB-80DX, SB-28DX, SB-50DX, SB-28, SB-27, B-22S, etc,

is fully charged; blinks for 3 sec. after ash is red at full output

Accessory shoe

Standard ISO hot-she contact with safety lock

Creative Lighting System

- with SB-800, SB-600, or SB-R200, supports Advanced Wireless Lighting (with SB-600

and SB-R200, remote only)

Setting Comand mode can control built-in Speedlight as Master ash

- Supports Auto FP High-Speed Sync, Flash Color Information Communication, modeling

illumination, and FV lock

VBA13001-R.3677..A

- M4 ・ -

Storage

Media Type I and II CompactFlash memory cards; Microdrives

File system Compliant with DCF2.0 (Design Rule for Camera File Systems) and DPOF (Digital Print

Order Format)

Compression

- Compressed NEF (RAW): 12-bit (about 50%~ 60% ) compression

- JPEG baseline-compliant (size priority, image priority can be selected)

Self-timer Electronically controlled timer with 2, 5, 10, and 20 sec. duration

Depth-of-eld preview Lens aperture stopped down when depth-of-eld preview button is pressed.

Stopped down up to set aperture value with A・M mode; up to control aperture value with P・S

mode.

Monitor 2.5”, 230,000-dot, low-temperature polysilicon TFT LCD with brightness adjustment

Video output Can be selected from NTSC and PAL

External interface USB 2.0 Hi-Speed

Tripod socket 1/4 (ISO 1222)

Firmware updates Can be updated by users

Language German, English, Spanish, French, Korean, Italian, Dutch, Portuguese, Russian, Swedish,

simplied Chinese, and Japanese

Power source

- One rechargeable Nikon EN-EL3e lithium-ion battery

Voltage 7.4V DC[Quick charger MH-18a]is used

- MB-D200 multi-power battery pack (available separately) with one or two rechargeable

Nikon EN-EL3e lithium-ion batteries or six (LR6 (AA) alkaline, ZR6 nickel-manganese, or

HR6 nickel-metal-hydride) batteries

- EH-6 AC adapter (available separately)

Dimensions

(W× H×D)

Approximately 147×113× 74 mm

Weight Approximately 830g without battery, memory card, body cap, or LCD monitor cover

Operating environment

Temperature 0 ~ 40℃

Humidity Less than 85% (no condensation)

● Unless otherwise stated, all gures are for a camera with a fully-charged battery operating at an ambient temperature of 20°C (68°

F).

● Nikon reserves the right to change the specications of the hardware and software described this manual at any time without prior

notice. Nikon will not be held liable for damages that may result from any mistakes that this manual may contain.

- D1 ・ -

VBA13001-R.3677.A

Points to notice for Disassembly and Assembly

�

内部に高電圧部あり。カバーを外す 時は感電に注意すること。

カバーを外した後は、修理指針の指 示に従ってメインコンデン

サーの放電を必ず行うこと。

警告

Caution:

① In disassembly/(re)assembly, be sure to use conductive mat (J5033) and wrist strap (J5033-5), in

order to protect electric parts from static electricity.

② Before disassembling, be sure to remove batteries or AC power cord.

③ In disassembling, be sure to memorize the processing state of wires and FPC, screws to be xed and

their types, etc.

④ The low-pass lter of the image PCB is easily damaged. Handle it very carefully.

Points to notice for Lead-free solder products

・Lead-free solder is used for this product.

・For soldering work, the special solder and soldering iron are required.

・Do NOT mix up lead-free solder with traditional solder.

Caution:

When "Separation of Front body from Rear body", "Disassembly of CCD/FPC unit" and

"Disassembly of Bayonet" are performed, be sure to carry out "RESET AF-DEFOCUS

COMPENSATION" of the D200 adjustment software after assembly.

WARNING

Take extra care not to get an electric shock when detaching

covers.

After removing covers, be sure to discharge the main

condenser according to the instructions of repair manuals

.

- D2 ・ -

VBA13001-R.3677.A

Disassembly

1. Separate Front and Rear bodies

External rubber

WB

Q

U

A

R

I

S

O

#B60

#B447

#B61

#B63

・

Remove the external rubbers

(#B63,#B60,#B61,and #B447).

Bottom cover

・

Remove the battery lid (by tilting and pulling it).

・

Take out two screws (#1556), six screws (#1549) and two screws (#1547).

・

Remove the bottom cover.

#1547

#1549×6

#1556

Bottom cover

#1556

#1547

- D3 ・ -

VBA13001-R.3677.A

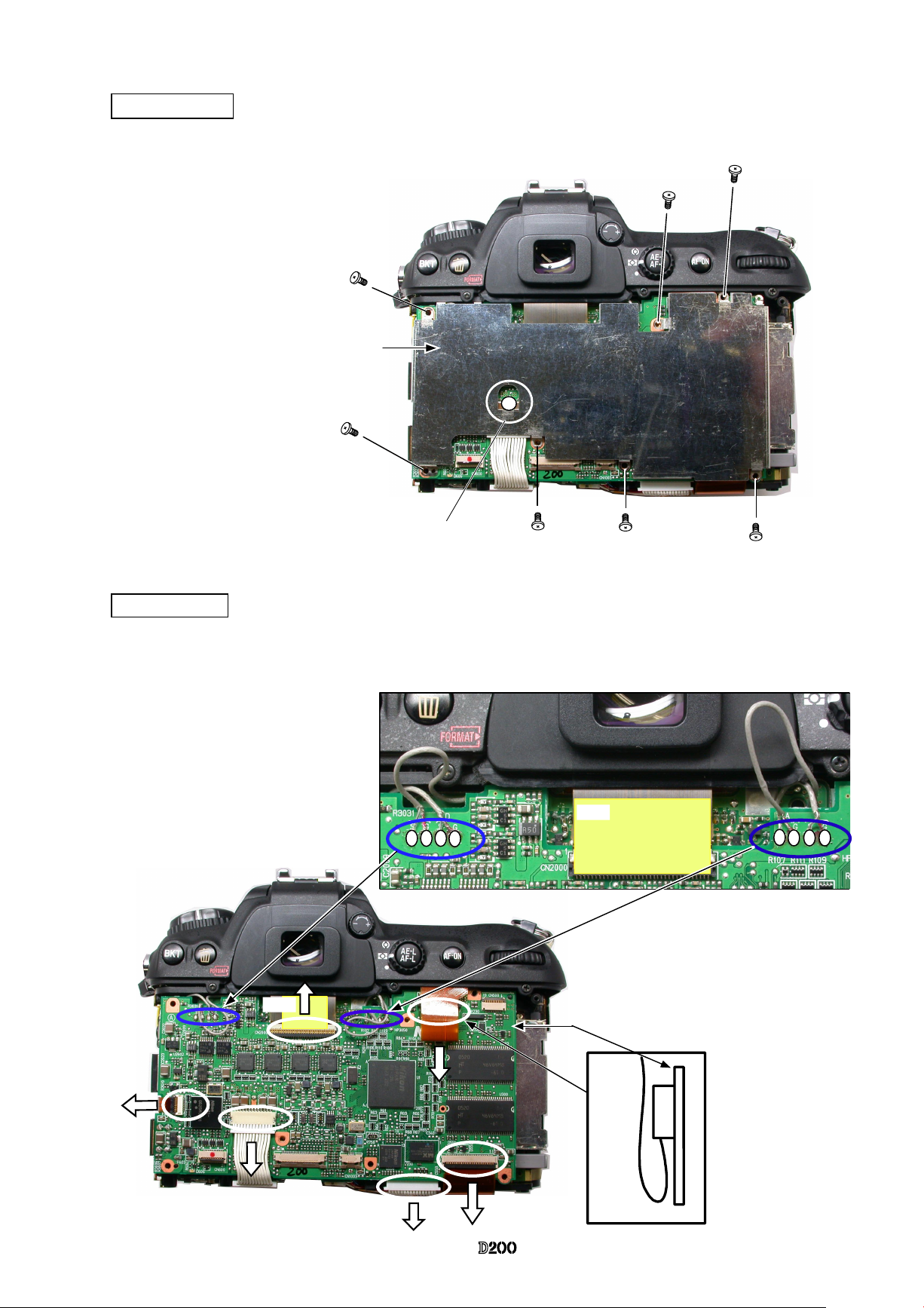

・

Remove the three TFT-PCB connection FPCs from the connector.

Rear cover

・

Take out two screws (#1552), two screws (#1547) and one screw (#1549).

・

Remove the rear cover.

#1552×2

#1547×2

#1549

・

Be careful NOT to cut the TFT-PCB connection

FPC that is at the lower side of the rear cover.

- D4 ・ -

VBA13001-R.3677.A

Discharge of Main condenser

・

Discharge the main condenser .

�

内部に高電 圧部 あり 。カ バーを外す時は感電に注意す るこ と。

カバーを外 した 後は 、修 理指針の指示に従ってメイン コン デン

サーの放電 を必 ず行 うこ と。

警告

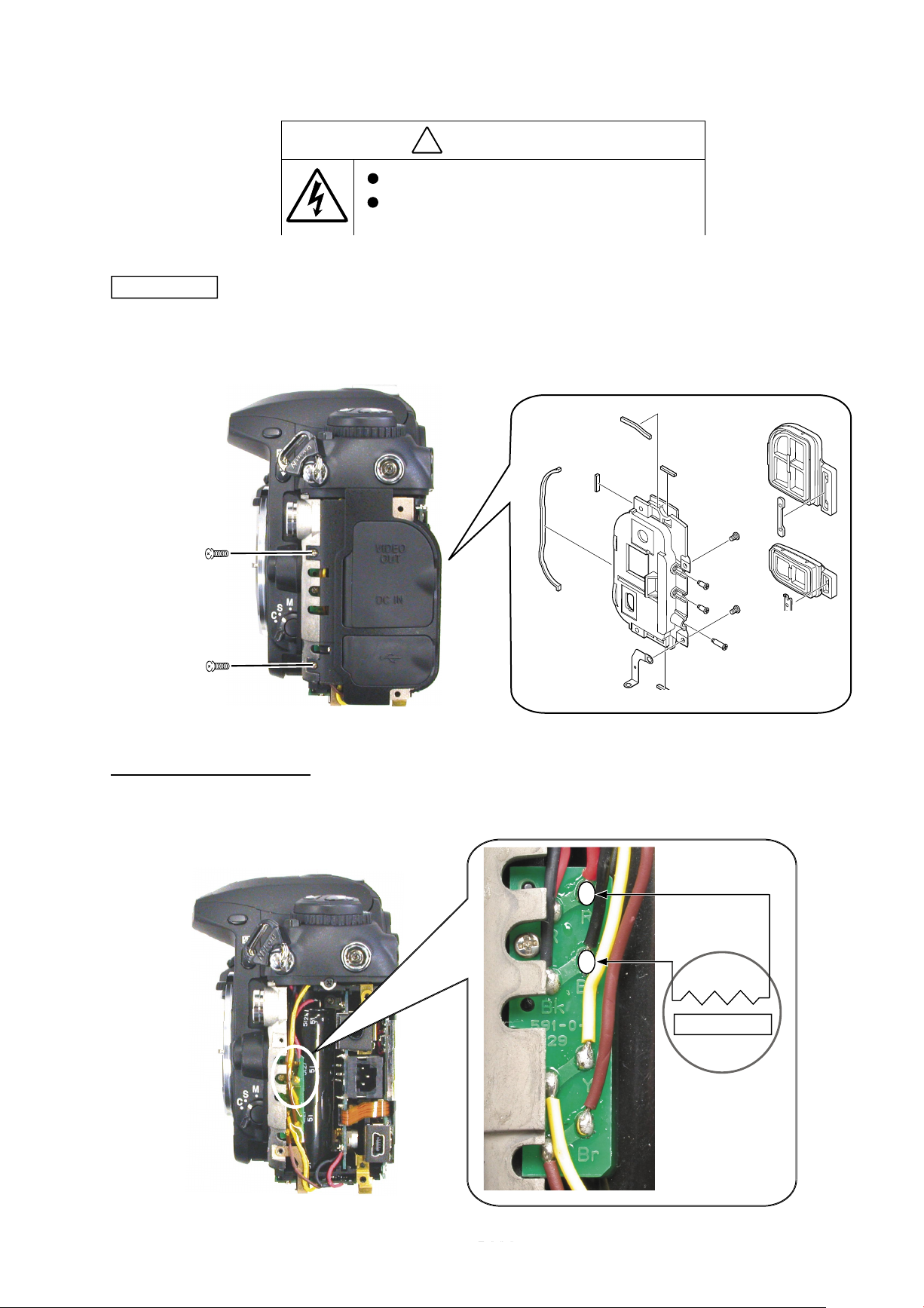

I/F cover

#1549×2

・

Take out two screws (#1549).

・

Remove the I/F cover unit.

#969

#969

#393

#395

#962×3

#965

#1643

#1642×2

#392

#394

WARNING

Take extra care not to get an electric shock when

detaching covers.

After removing covers, be sure to discharge the main

condenser according to the instructions of repair manuals

.

2KΩ / 5W

- D5 ・ -

VBA13001-R.3677.A

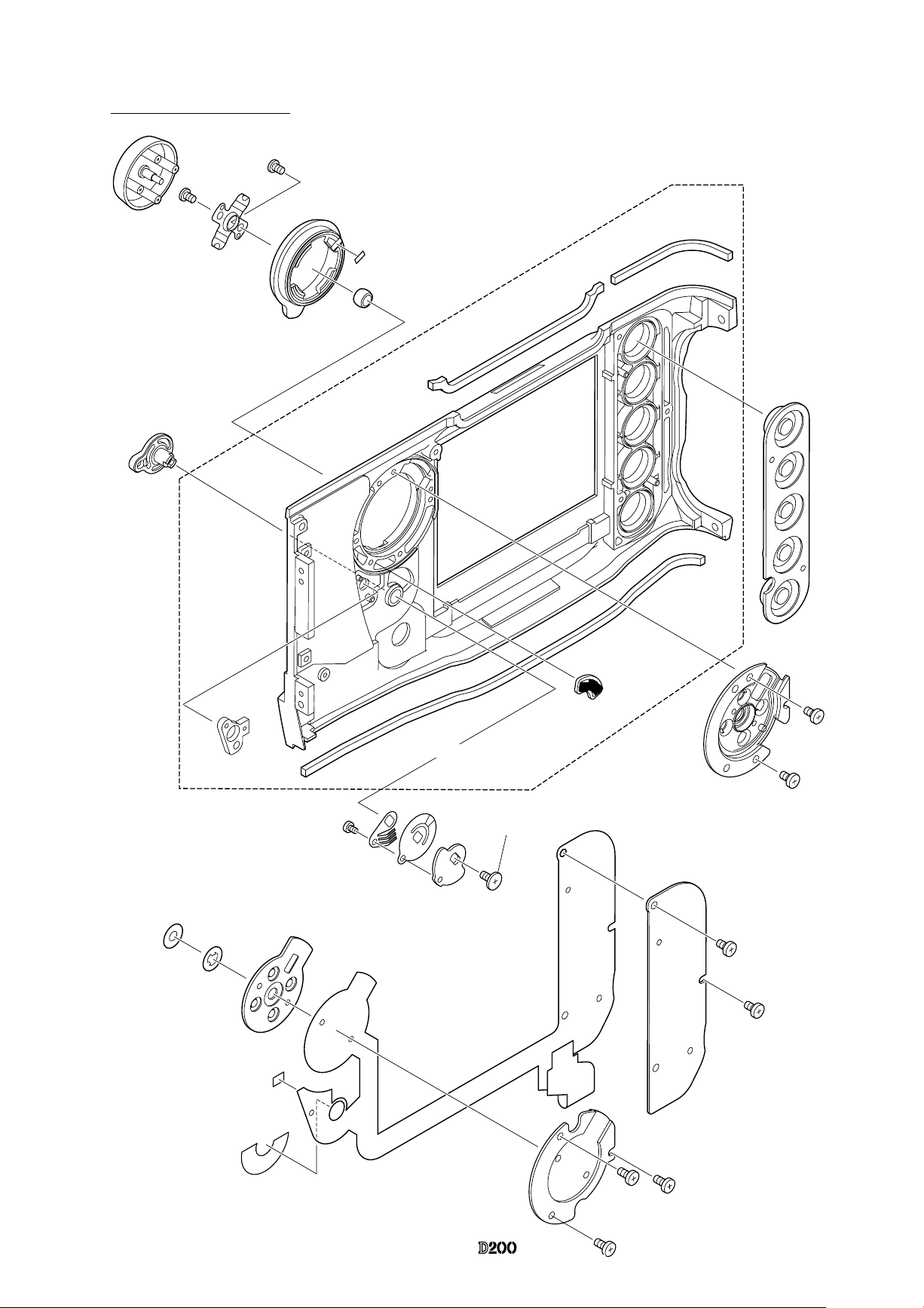

#426

#455

#467

#1538 × 2

#469

#468

#481

#474

#476

#986

#985

#924

#1631

#465

#1511 × 2

#1630

#479

#477

#478

#456

#1511 × 2

#1020

#1512 × 3

#422

#472

#473

#470

#430

#480

#RP00007

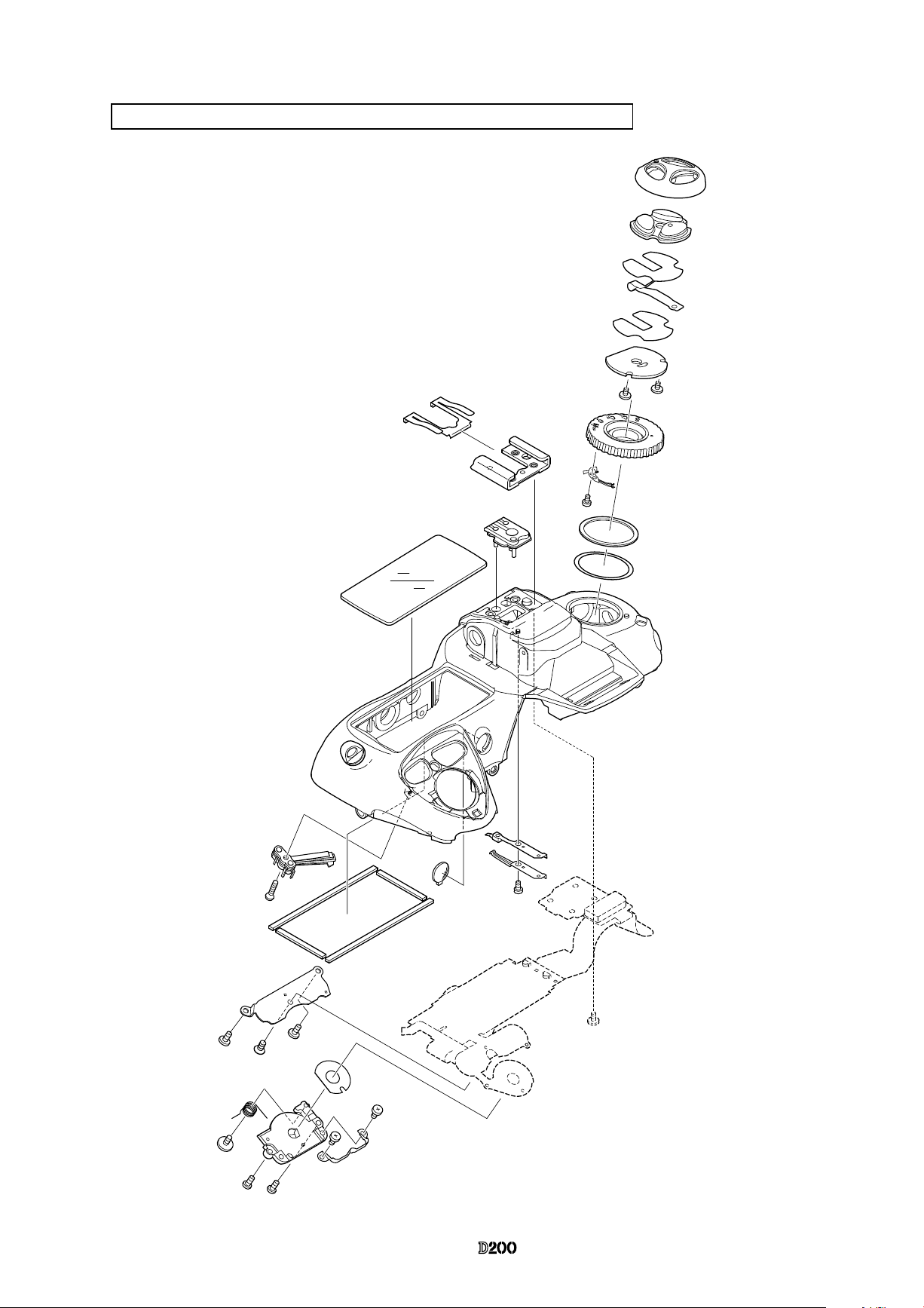

Disassemble Rear Cover

- D6 ・ -

VBA13001-R.3677.A

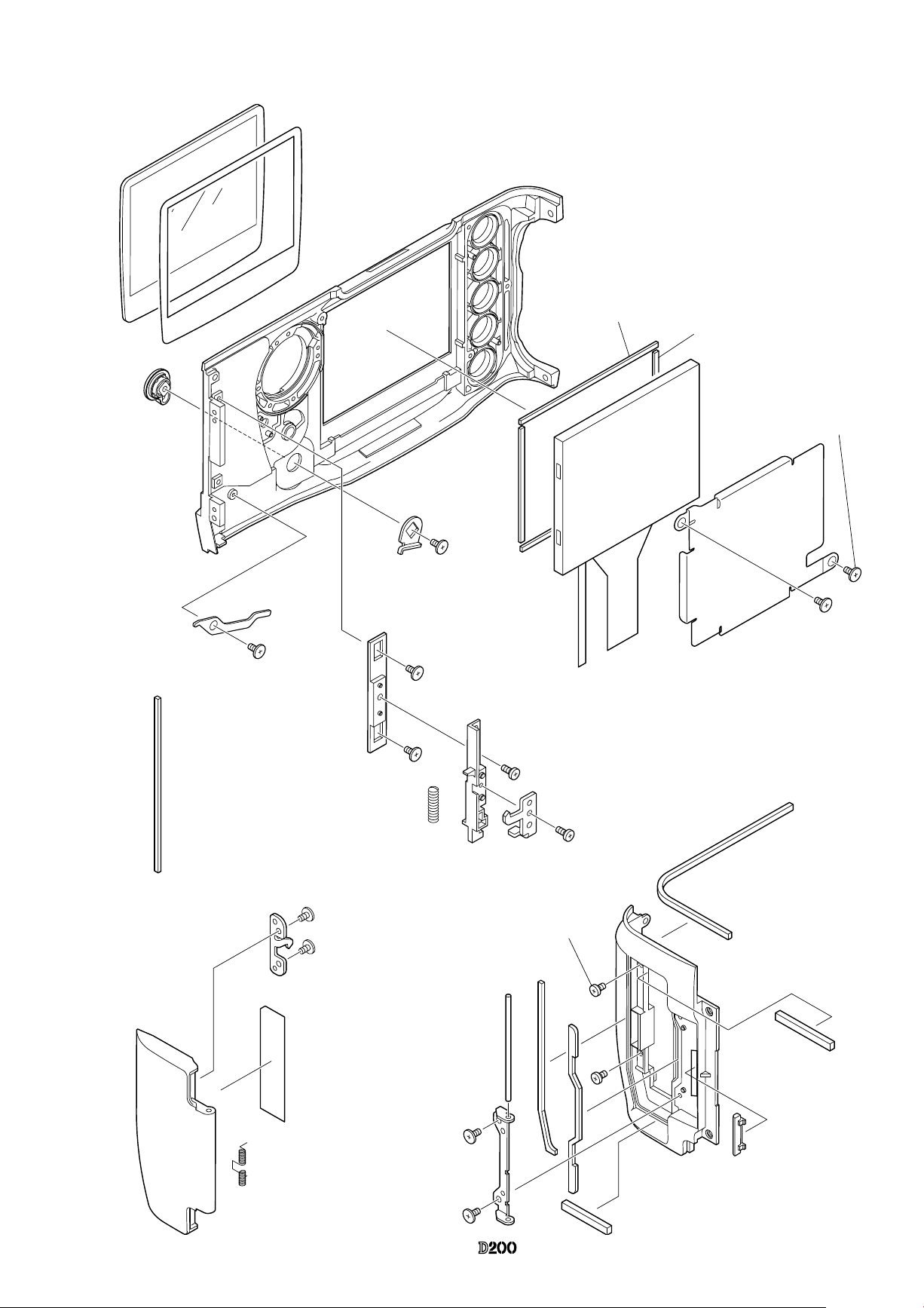

#431

#433

#488

#489

#1629

#434 × 2

#435 × 2

#1057

#1626

#1633

#432

#487

#492

#484

#483 × 2

#485

#1546

#491

#1571

#987

#922

#441

#443

#923

#442

#1628 × 2

#424

#921

#425

#1518 × 2

#486

#440

#1632 × 2

#427

#445

#429

#423

- D7 ・ -

VBA13001-R.3677.A

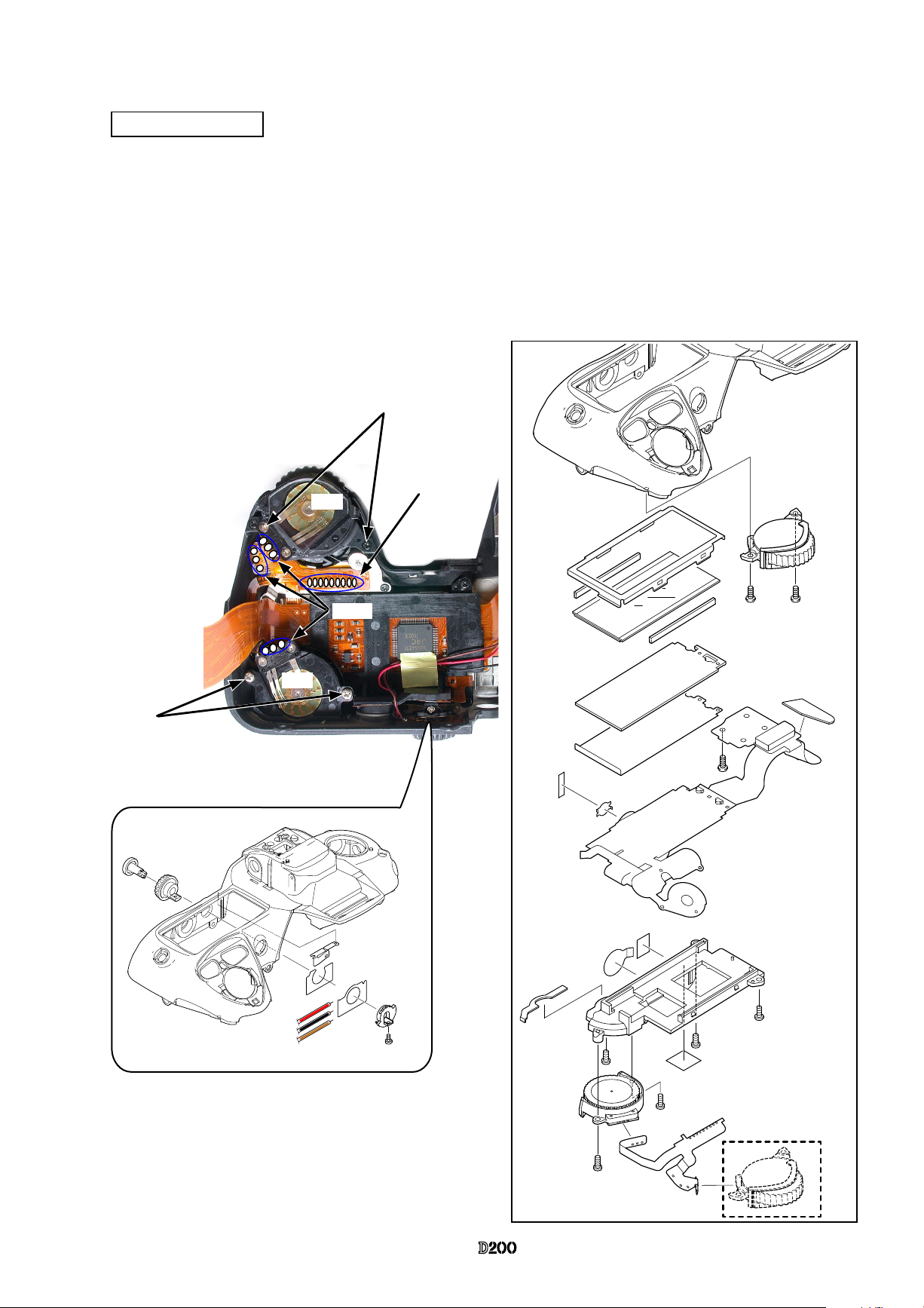

Soldering bridge

#1515

#1515

#1546×5

・

Take out ve screws

(

#1546) and two screws (#1515).

・

Remove the soldering bridge.

・

Remove the DG shield

plate unit

(#683, #696).

DG shield plate unit

DG-PCB unit

・

Remove the tape (#926).

・

Remove ve FPCs from the connector.

・

Remove the two harnesses from the

connector.

・

Unsolder the four wires.

・

Remove the DG-PCB unit (#B1017).

#B1017 DG-PCB unit

Harness

Harness

DG shield plate

#926

#926

- D8 ・ -

VBA13001-R.3677.A

・

Take out three screws (#1639) and remove the CCD/FPC unit (#B2032).

・

Take out three screws (#1543) and remove the CF card holder (#1018).

CCD/FPC unit

CF card holder

#1639×3

#B2032 CCD/FPC unit

#1543×3

#1018

CF card holder

・

Take out the screw (#1539) and remove the conductive plate (#691).

・

Take out four screws (#1539) and remove the conductive plates (#689, #690,and #688).

・

Remove the main connection FPC (#1035) from the connector of the power drive PCB (#1002).

#1543

Conductive plate

(

#691)

Power drive PCB (#1002)

Conductive plate

(#689)

Conductive plate

(

#690)

#1539

Conductive

plate (

#688)

#1539

#1539

M

サービス

計画課

JUL.7.2006

Change page

△

×1

△

(Addition

)

#1539

△

(Revice

)

#1539

- D9 ・ -

VBA13001-R.3677.A

・

Unsolder six wires.

・

Remove the harness of the back of the power drive PCB.

・

Take out two screws (#1541) and remove the power drive PCB.

Power drive PCB

#1075

Harness: DC/DC PCB

Power drive PCB (#1002)

Yellow: Main-PCB

Brown: Main-PCB

Blue:AF motor

Orange:AF motor

Red: Charge motor

Black: Charge motor

#1541

#1541

- D10 ・ -

VBA13001-R.3677.A

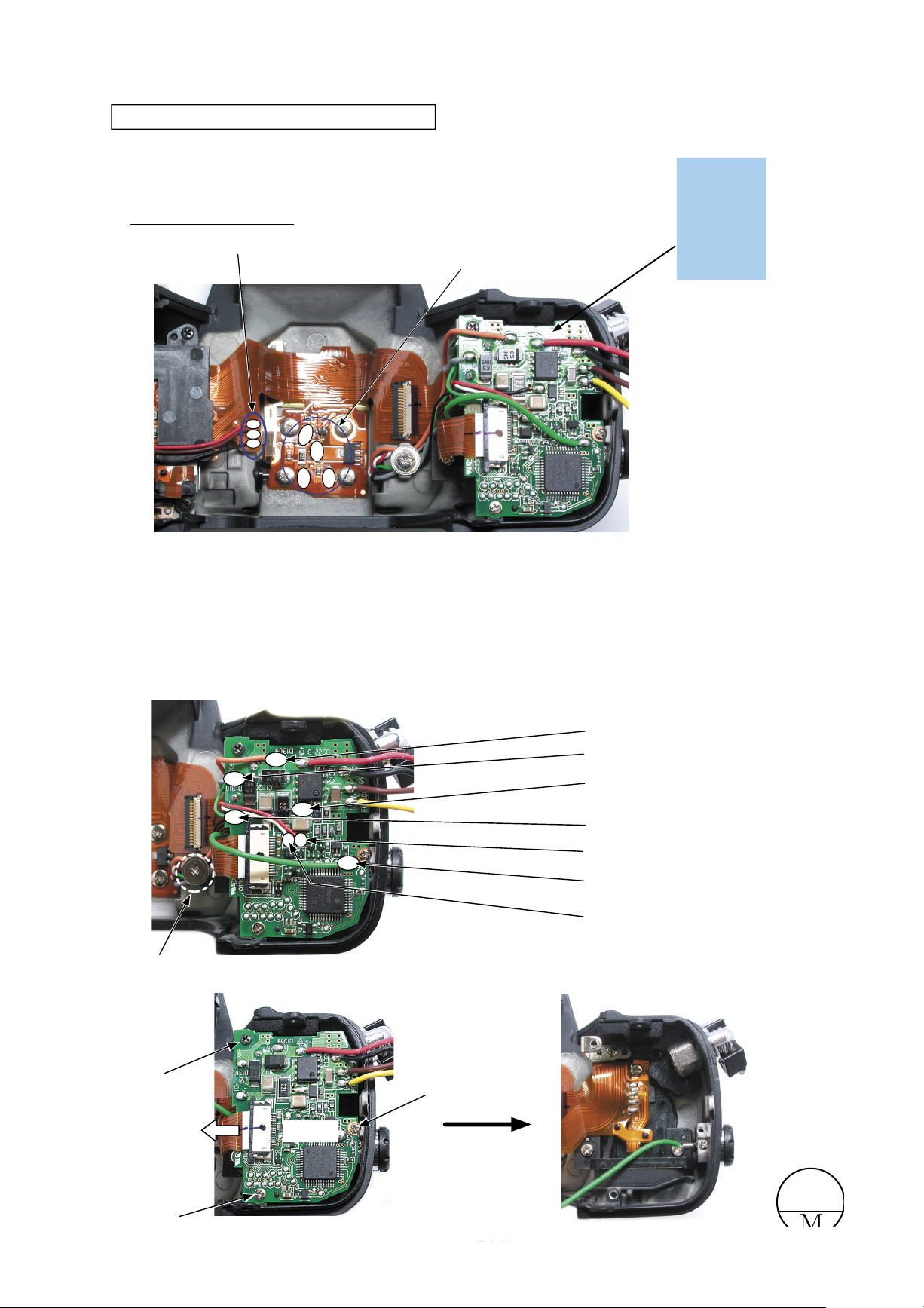

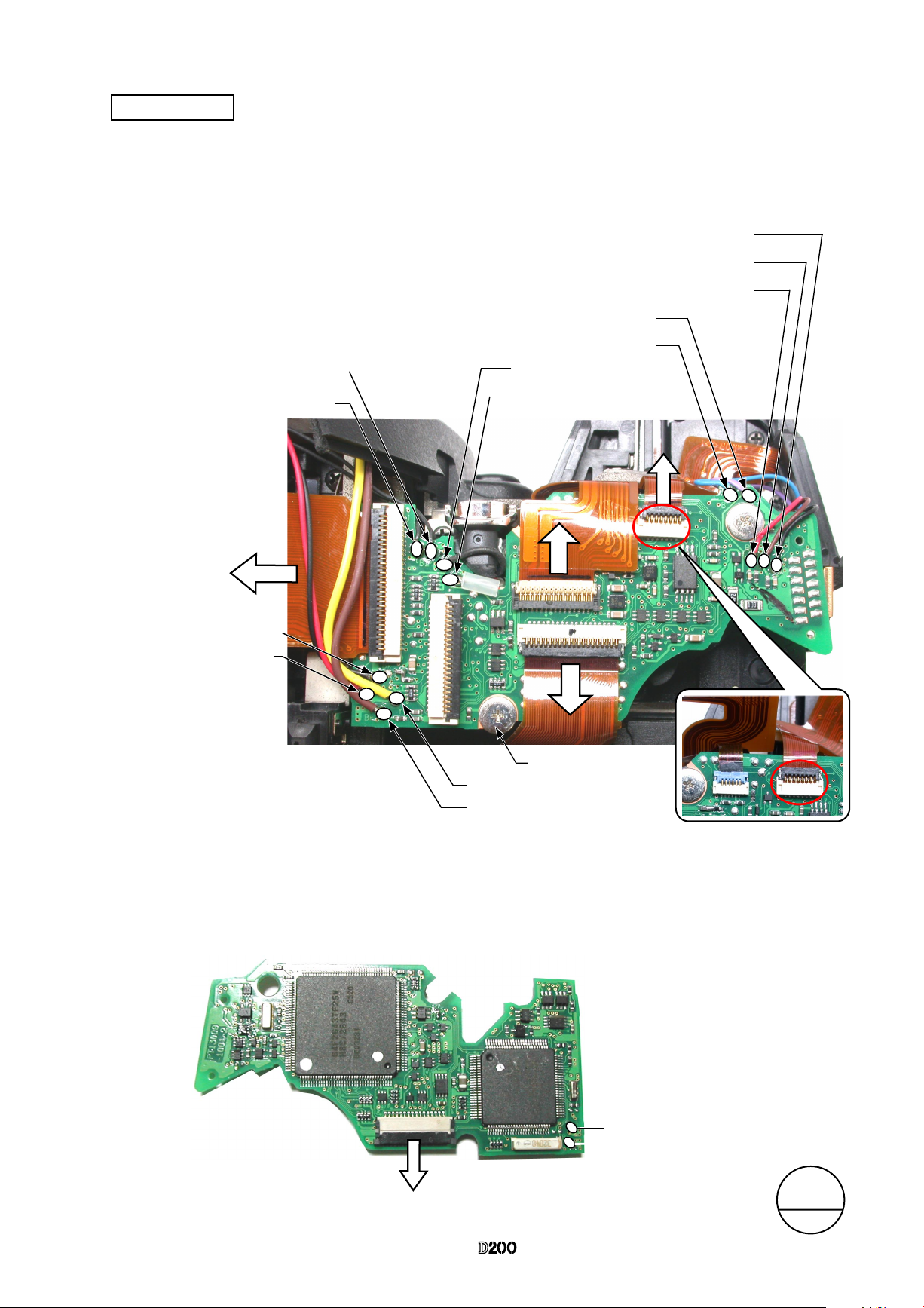

DC/DC PCB unit

・

Unsolder six wires.

・

Take out four screws (#1541) of the DC/DC-PCB (#1047).

・

Remove the harness (#1074) from the DC/DC-PCB (#1047).

・

Remove the harness (#1075) from the DC/DC-PCB (#1047) and from the connector of the power drive PCB

(#1002).

Harness: DG-PCB

#1074

Harness: Power drive PCB

#1075

M

サービス

計画課

JUL.7.2006

Change page

△

×1

Black: Battery contact

Red: Battery contact

Yellow:SBDI-PCB

Brown: SBDI-PCB

Red: IF-PCB

Black: IF-PCB

#1541

#1541

#1541

#1541

△(Addition)

#1047

- D11 ・ -

VBA13001-R.3677.A

Top cover

・

Remove the tape (#930).

・

Unsolder four wires.

・

Remove the top cover FPC (#1003) from the connector.

#1547

#1547

#1555

#1555

#1511

#1511

・

Remove the cover (#850). Take out the screw (#1622) , and

remove the diopter adjustment knob unit (#852, #857, #851).

・

Pop the SB up, and take out two screws (#1548).

・

Take out two screws (#1511), two screws (#1547) and two

screws (#1555).

・

Lift the top cover unit slowly not to cut the FPC.

#1548×2

Pop this up.

Tape (#930) Red: SB-PCB

Brown: SB-PCB

Yellow: SB-PCB

Black: SB-PCB

#1622

#852

#857

#851

#850

#1555

サービス

計画課

JUL.7.2006

Change page△×1

△

(Addition

)

#1003

- D12 ・ -

VBA13001-R.3677.A

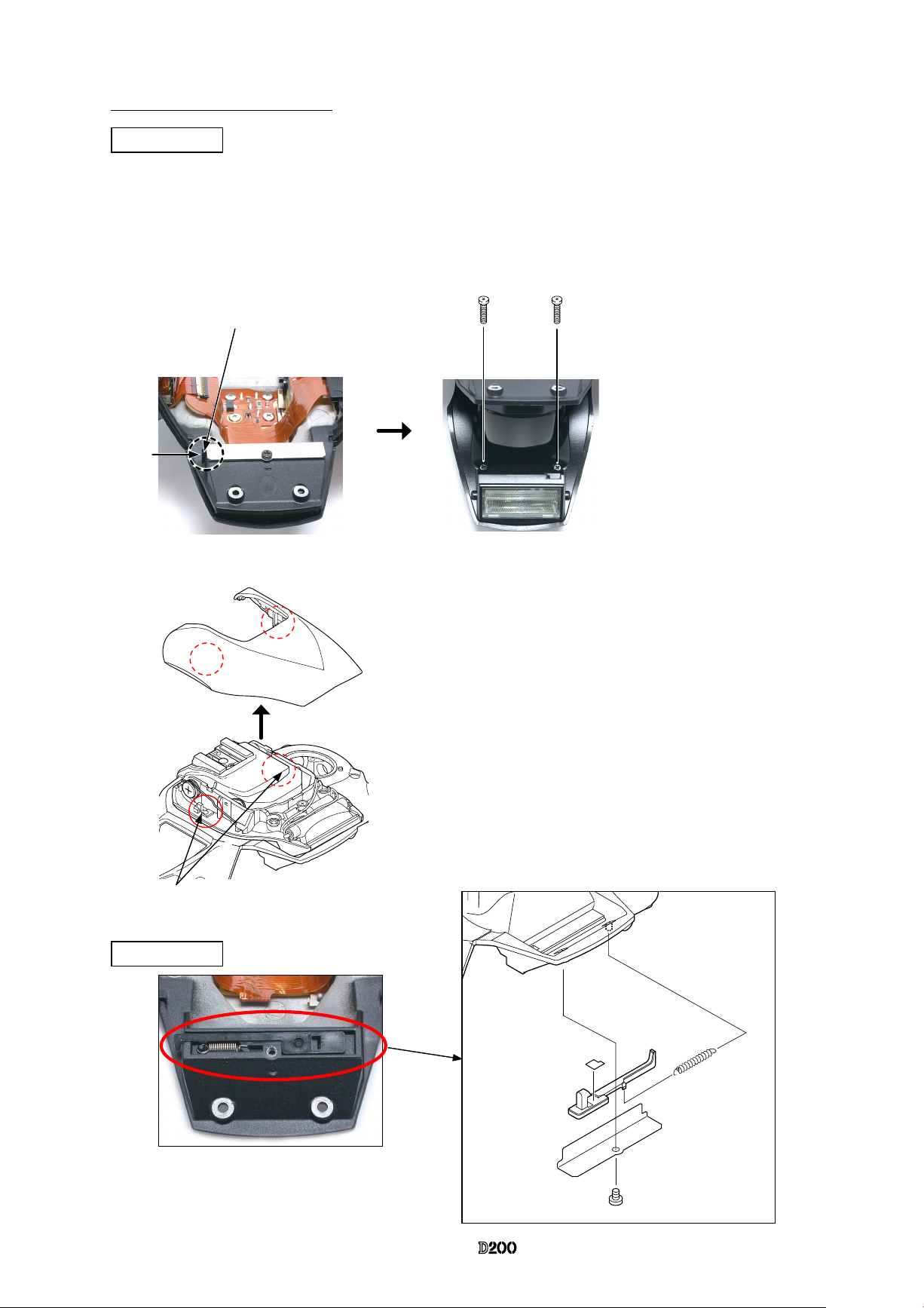

SB upper case

Disassembly of Top cover unit

・

Push the pop-up lever A-part of the top cover unit, and lift the built-in SB.

・

Take out two screws (#1623). (Fig.1)

・

Fold down #301 of the SB lower case on the top cover. Then while holding the hooks of the SB upper case

from both sides by hand, release them from the two holes by sliding/tilting, then remove #301. (Fig.2)

Pop-up lever A-part

Push

#1623×2

Fig.1

SB lower case unit

SB upper case

Fig.2

Holes

Hooks

#301

SB lock cover

#310

#312

#1565

#309

#917C

・

Remove the spring (#310).

・

#309 comes off.

- D13 ・ -

VBA13001-R.3677.A

Removal of Top cover FPC / Wires / SB-PCB

・

Unsolder the three metering mode FPC lead wires.

・

Unsolder the accessory shoe contact at four locations.

・

Unsolder the seven lead wires of the SB-PCB.

・

Take out the screw (#1601).

・

Remove the FPC of SB-PCB (#B1013).

・

Take out the screw (#1511).

・

Take out the screw (#1535).

・

Take out the screw (#1541).

Metering mode FPC lead wire

Red×1, Brown×1, Black×1

Red, Brown, Black

△(Revice)

Accessory shoe contact×4

#1541

#1535

#1511

FPC

#B1013

#1601

SB(Black)

SB(Gray)

SB (Green)

SB(Red)

SB(White)

SB(Orange)

Sync terminal(Green)

サービス

計画課

JUL.7.2006

Change page

△× 2

△(Addition)

・It demounts tapes.

- D14 ・ -

VBA13001-R.3677.A

・ Pull each wire from the holes.

・ While releasing the two hooks of the collar (#308), remove #308.

・ Remove the rotation axes (#306 and #307).

・ Remove the SB lower case unit (#B302) from the top cover.

・

Remove the SB-up spring (#305) from the hooking part.

・

Take out the screw (#1601) and remove the SB-up spring (#305).

・

Remove #796, #322, and #325.

SB-up spring

SB lower case unit

#305

Hooking part

#796

#325

#322

#796

#306

#308

#307

#B302

Be careful of the direction of assembling.

Pull six wires out from the holes.

Hooks

#1601

#305

M

サービス

計画課

JUL.7.2006

Change page

△× 1

△(Revise)

#796×2

M/DFPC unit

Remove the FPC soldering bridges of #1025 and #1026.

Take out the screw (#1569).

Detach #1025 from the bosses.

Unsolder the lead wire (#1094).

Remove the solder of the lead wire (#1094).

Lift the FPC, and take out the screw (#1572).

Remove B502 and B504 (Trefoil button unit).

Soldering

bridge

#1026

#1569

#1569

Boss

#1025

#1094 Green

Trefoil button unit

Screw (#1572)

Use the Hexagonal wrench

of 5-mm diameter

#B502

#509

#B505

#50

#B43

#1532

#1572

#46

#1569

#513

#508

#510

#1544×2

Q

U

A

R

I

S

O

#1569

#1569

#B504

#514

#515

When removing the solder

on the synchro-terminal

unit, unsolder within 2 sec.

△

(Addition

)

Changed page △×2

△

(Addition

)

M

サービス

計画課

Aug.8.2006

- D16 ・ -

VBA13001-R.3677.A

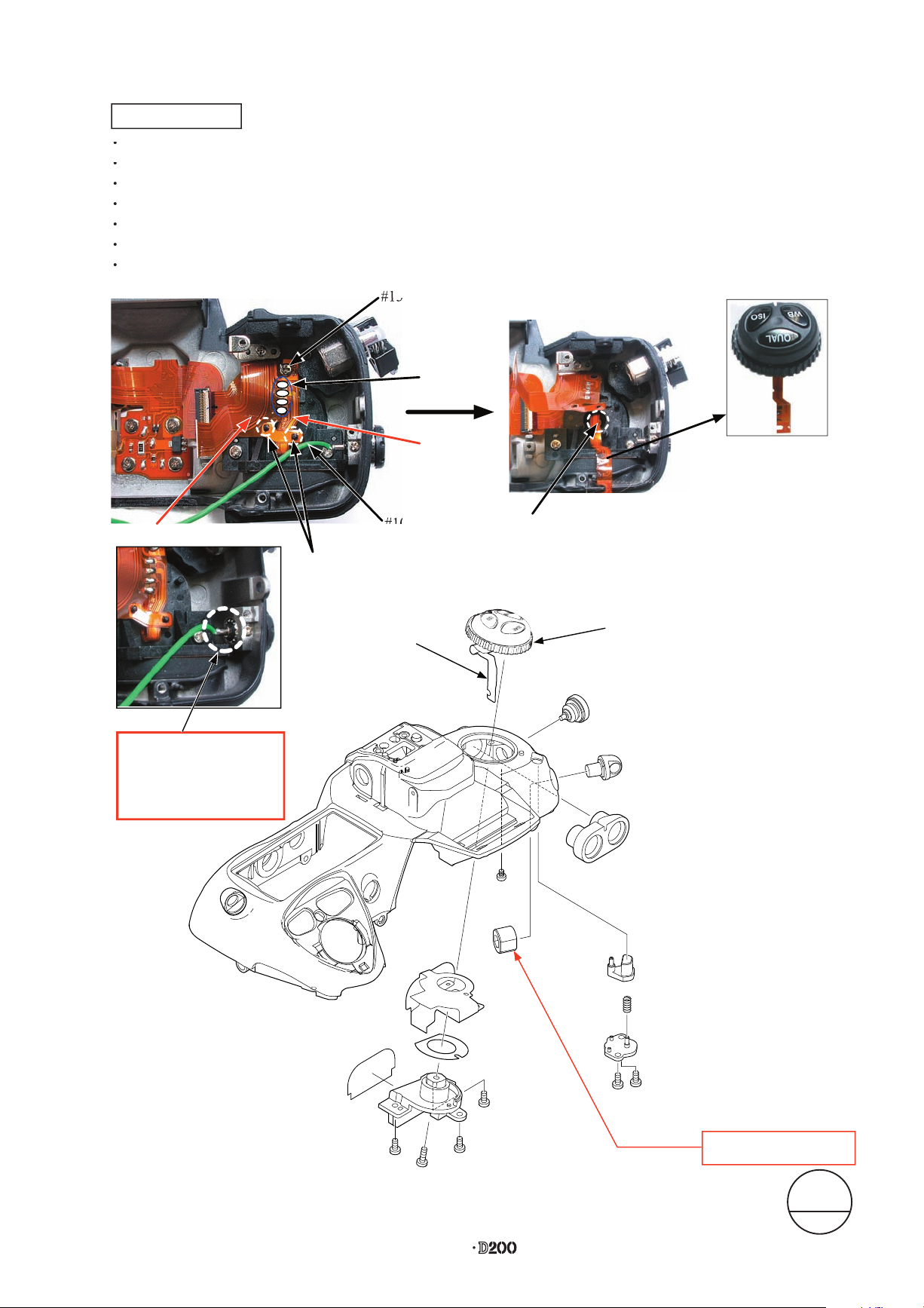

・

Remove the soldering bridges .

・

Unsolder the SUB dial command unit (B725) .

・

Take out two screws (#1544).

・

Remove the SUB command dial unit (B725).

・

Unsolder the MAIN command dial unit (B726) .

・

Take out two screws (#1571).

・

Remove the MAIN command dial unit (B726).

・

Remove the relies SW unit .

Top cover FPC unit

#39

#965

#B725

#703

#1003

#705

#321×4

#704

#1033

#913

#1053

#912

#974

#706

#973

#1544×2

#1571×2

#B726

#707×2

#1544×3

#929

#1544

×2

#1571

Soldering bridge × 9

Solder

B726

B725

#784

#1535

#1119(Black)

#781

#1028

#780

#1117(Red)

#1118(Brown)

#B782

#914

- D17 ・ -

VBA13001-R.3677.A

Release button / Other small parts

#742

#743

#24

#1608×2

#733

#732

#911

#730

#734

#1604

#1557×2

#1652

#749

#748×2

#701

#787

#B43

#1659

#RP5

#966

- D18 ・ -

VBA13001-R.3677.A

Outer LCD window / Shoe mold unit / Accessory shoe / Other small parts

W

B

Q

U

A

R

I

S

O

#323

#324

#1565

#701

#B317

#316

#318

#746

#1533

#507

#504

#512

#1606

#747

#1547×2

#750

#B735

#327

#511

#1605

#516

#1026

#501

#503

#1560

#731

#753

#1540×2

#502

#765×2

#766×2

#1640×2

#1537×2

- D19 ・ -

VBA13001-R.3677.A

Main PCB unit

・

Unsolder thirteen wires.

・

Remove ve FPCs from the connector.

・

Take out three screws (#1616) and remove the main PCB unit (#B1001).

Brown:

Lens contact FPC

Black:

10-pin

FPC

Red:

10-pin FPC

Yellow: Lens contact

FPC

Black:

Buzzer

Black: Buzzer

Gold

: AF-assist illuminator

Black: AF-assist

illuminator

Blue:FG-ID

Purple: Battery contact

Red: Charge

SW

Brown: Charge

SW

Black: Charge

SW

・

Unsolder the two wires of the back of the main PCB unit (#1001).

・

Remove the main connection FPC (#1035) from the connector of the back of the main PCB unit (#1001).

Back of Main PCB (#1001)

Yellow: Power drive PCB

FPC (#1035)

Brown: Power drive PCB

M

サービス

計画課

JUL.7.2006

Change page

△

×1

△(Addition)

#1616×3

- D20 ・ -

VBA13001-R.3677.A

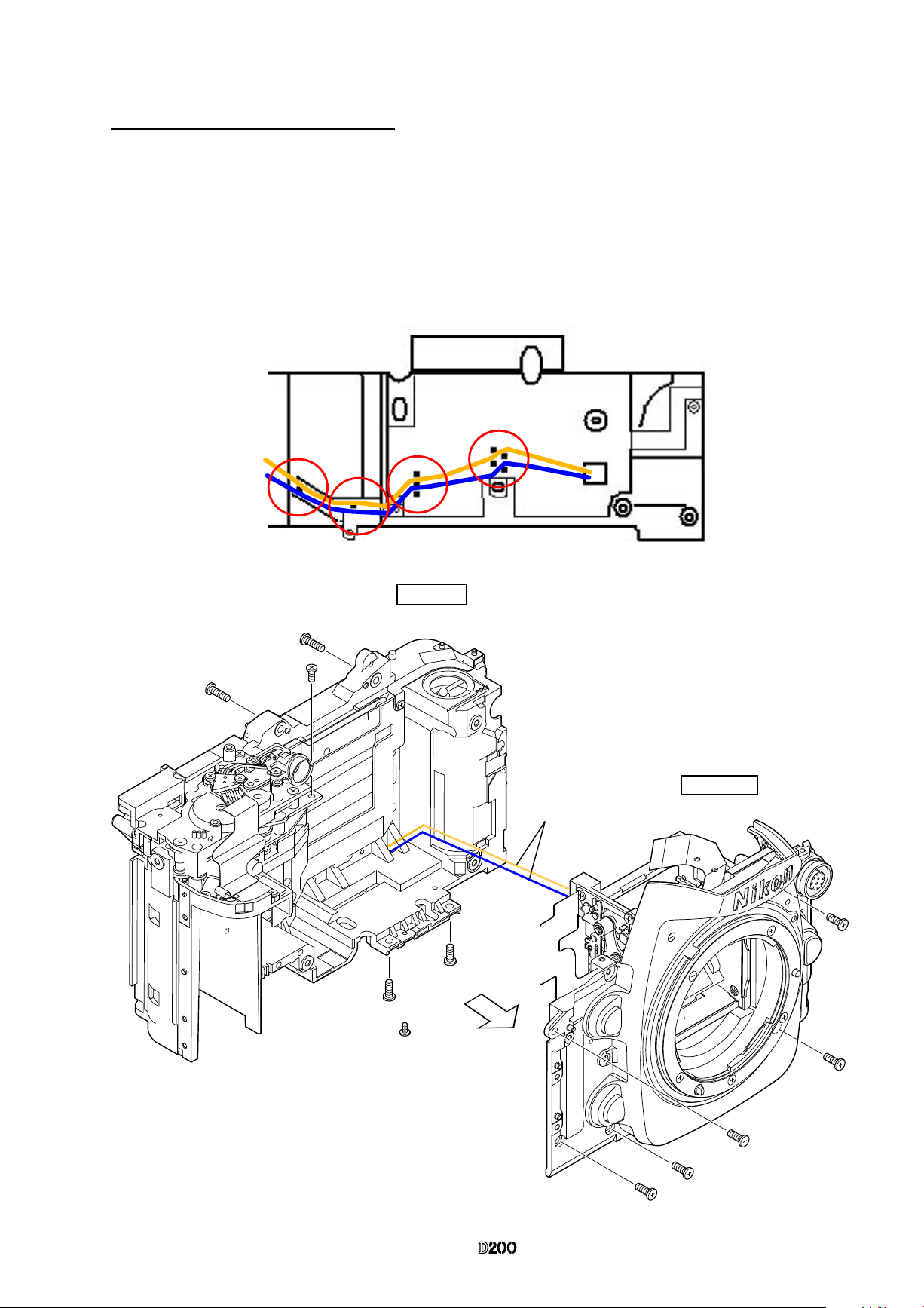

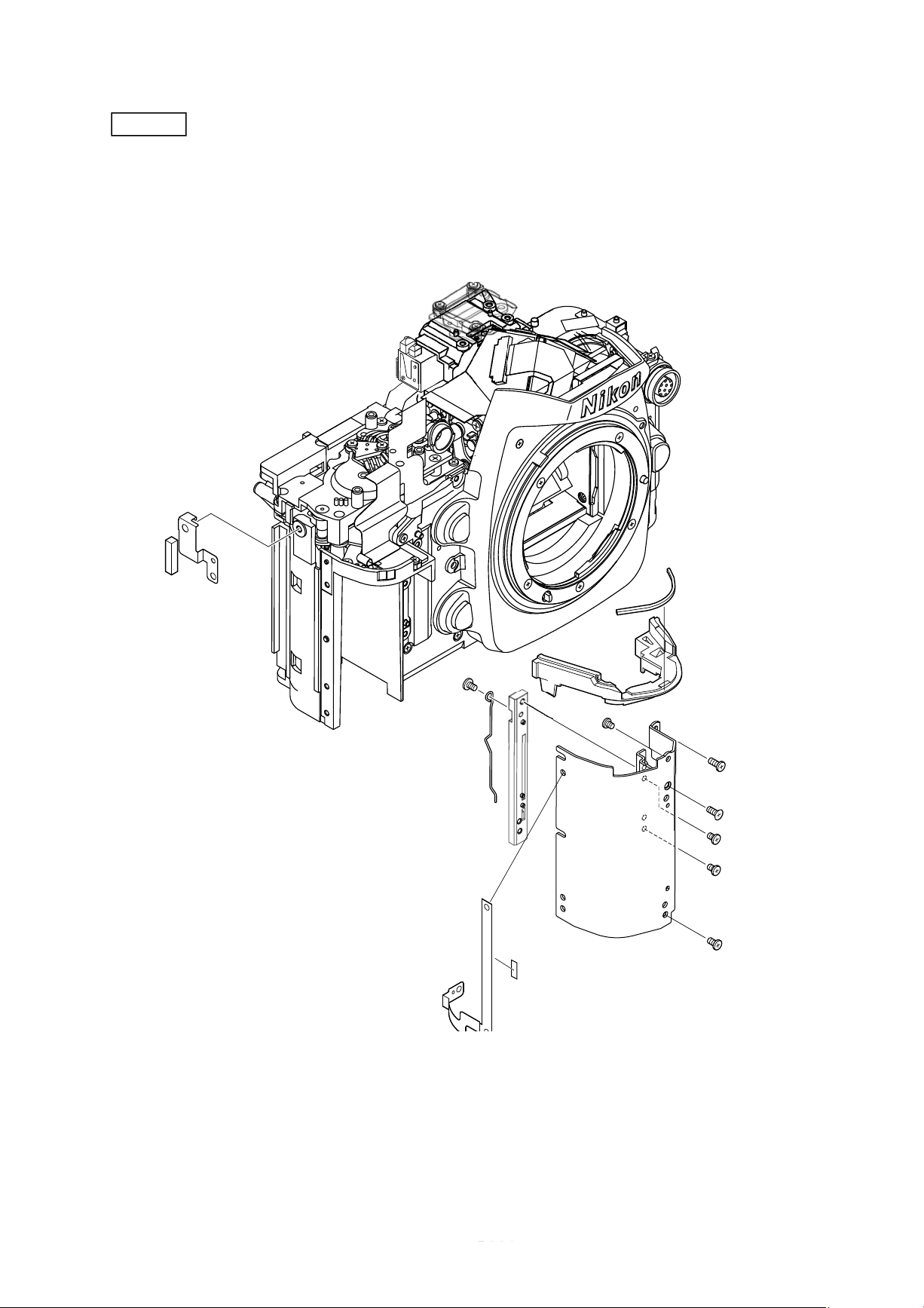

Separation of Front body from Rear body

・

Take out two screws (#1529), one screw (#67), two screws (#1531), one screw (#1525) and ve screws

(#1575).

・

Release the AF motor wires from the bosses, and while pulling them slowly from the holes of the rear

body, remove the front body.

#1575×5

Front body

#1529×2

#67

#1531×2

#1525

Rear body

AF motor wires

AF motor wires

- D21 ・ -

VBA13001-R.3677.A

#439

#1517

#828

#829

#58

#57

#1559

#1515

#952

#1541

#1509

#769

#826

#952

#1509

Grip unit

・

Remove the grip (#57) with the screw (#1515) and two screws (#1509).

- D22 ・ -

VBA13001-R.3677.A

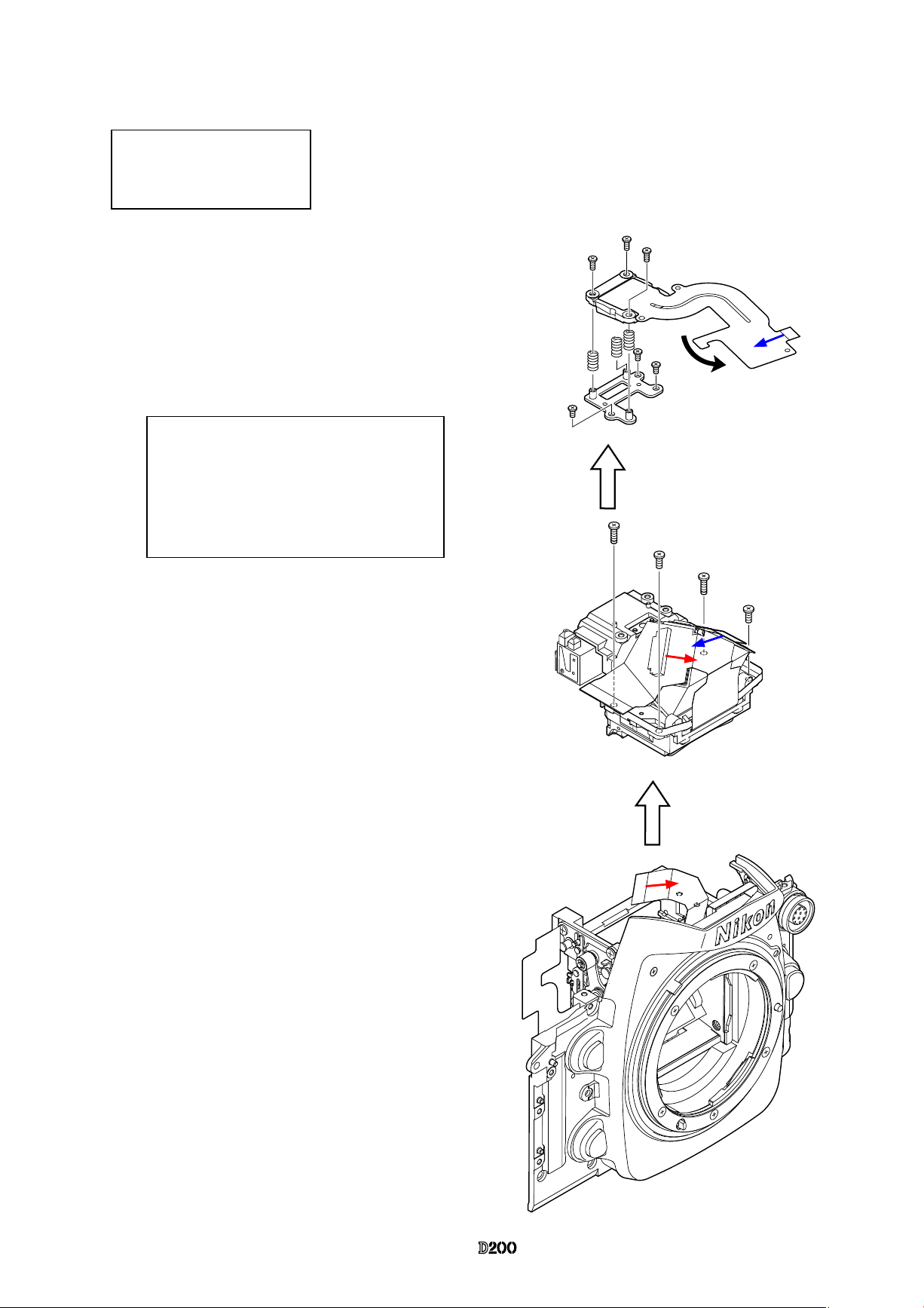

2. Front body

Metering FPC unit

Prism box unit

(with prism and eyepiece)

・

Remove the metering FPC from the connector of the SI-

FPC (#1005).

・

Take out three screws (#883), and remove the metering

FPC unit (#B10006).

・

Three springs (#884) come off.

・

Take out two screws (#1617) and remove the metering

FPC unit pedestal (#B882).

Caution:

The screw (#883) is attached with the

adhesive.

In case the screw (#883) is moved, the

AECCD positioning adjustment (ref.

Assembly) becomes necessary.

#1617×3

#883×3

#B1006

#884×3

#B882

#1005

#1525

#1525

#1528

#1528

・

Remove the lens contact FPC unit (#B1008) from the

connector of the SI-FPC (#1005).

・

Take out two screws

(

#1525) and two screws

(

#1528), and

remove the prism box unit from the front body.

A

A

B

B

- D23 ・ -

VBA13001-R.3677.A

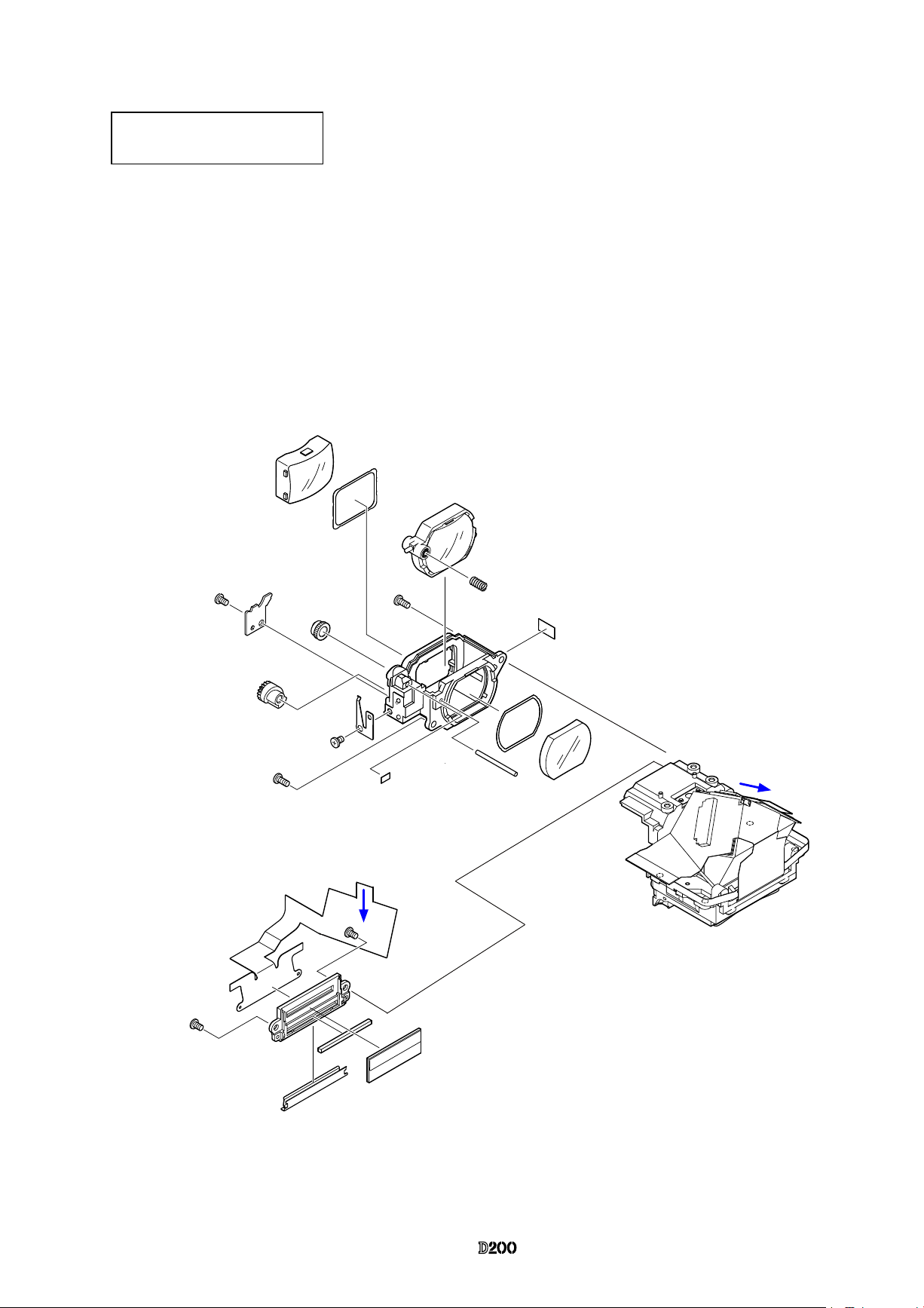

Eyepiece lens-barrel unit

Inner LCD unit

#7

#847

#B846

#844

#849

#841

#845

#5

#842

#858

#854

#853

#848

#856

#1539

#1539

#1619x2

・

Take out two screws (#1619), and remove the eyepiece lens-barrel unit.

・

Remove the nder-display FPC (#1004) from the connector of the SI-FPC.

・

Take out two screws (#1618), and remove the nder-display LCD unit.

#1618×2

#1054

#1004

#1056

#879

#878

#1005

A

A

- D24 ・ -

VBA13001-R.3677.A

Penta unit

#8

#832

#1619x2

#875x2

#876

#833

#1055

#834

#901

#838x2

#839

#837

#904

#840

#955

#B1005

#954

#953

#835

#873x2

#872x2

#874x2

#902

#3

#877A~B

#836A~C

#877C×2

*

*

- D25 ・ -

VBA13001-R.3677.A

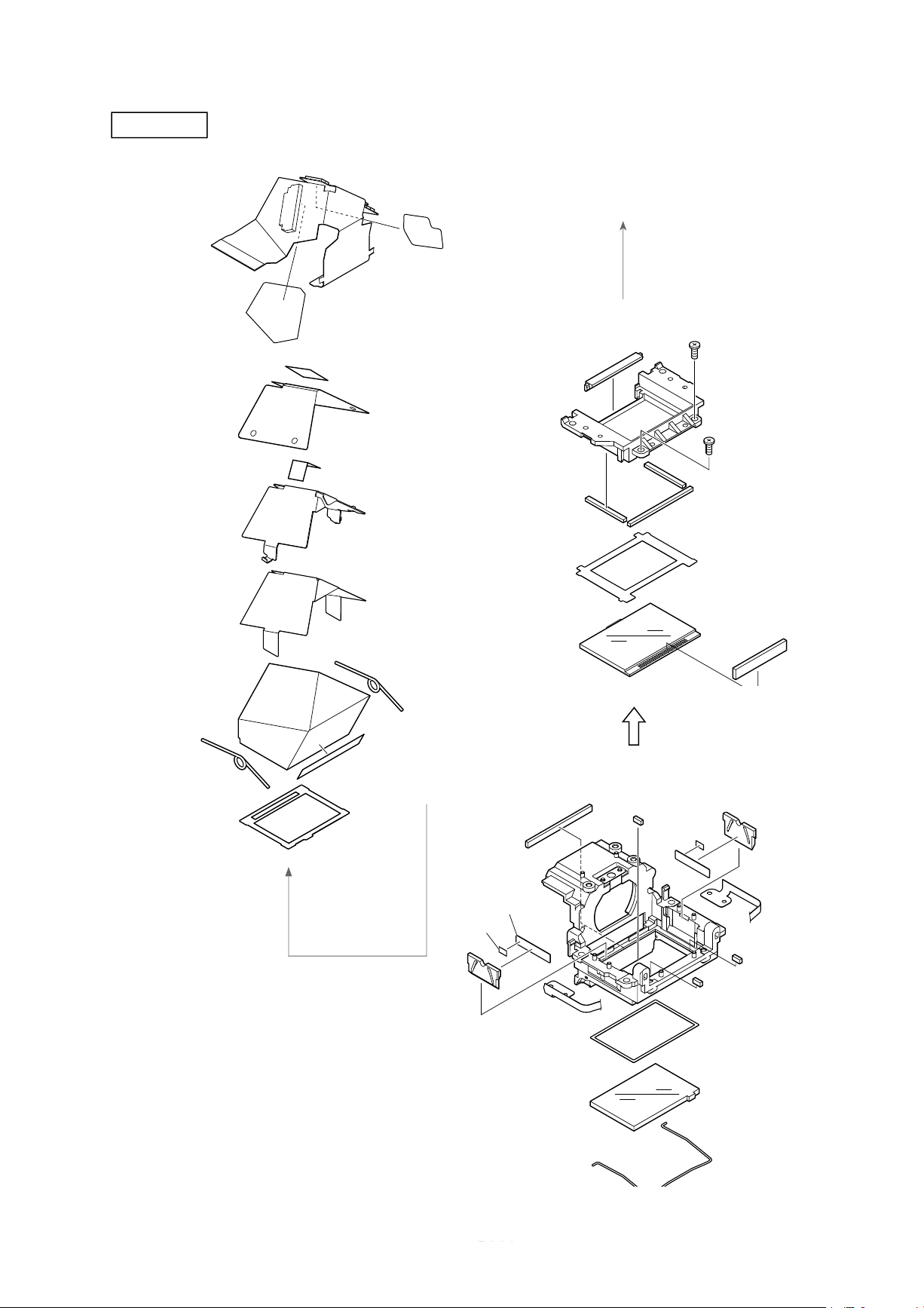

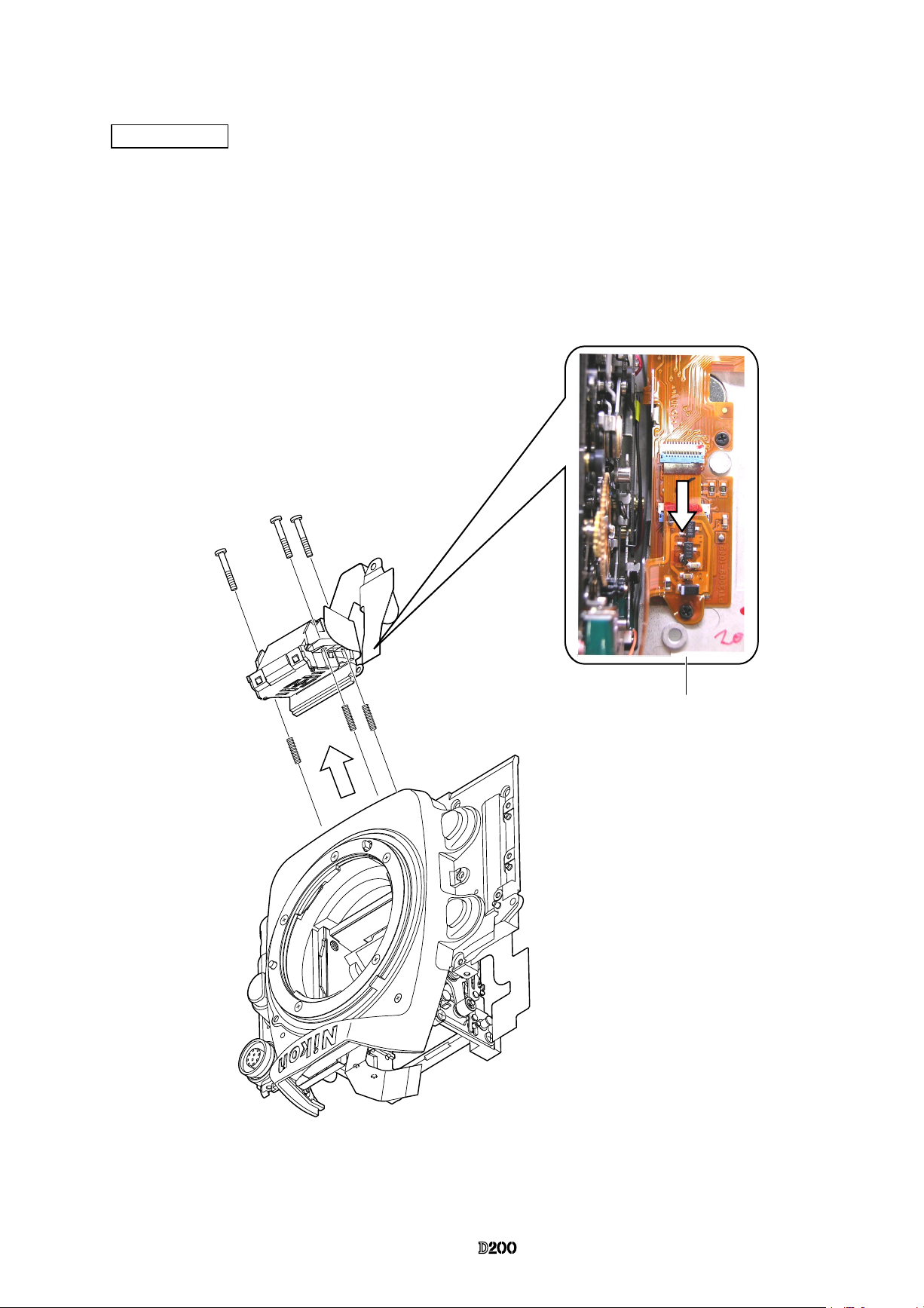

AF-PCB unit

・

Take out the screw (#1507).

・

Remove the AF-PCB FPC from the connector.

・

Take out the three screws (#295) with the Hexagonal wrench, and remove the AF-PCB unit (#B1007).

・

Three springs (#293) come off.

#1507

#295×3

#B1007

#293×3

Loading...

Loading...