Page 1

Instructions and warnings for the fitter

Istruzioni ed avvertenze per l’installatore

Instructions et recommandations pour l’installateur

Anweisungen und Hinweise für den Installateur

Instrucciones y advertencias para el instalador

Instrukcje i uwagi dla instalatora

Aanwijzingen en aanbevelingen voor de installateur

For projecting

and non-projecting

up-and-over doors,

and sectional doors

Spin10KCE

Spin11KCE

Page 2

2

Spin10KCE

Spin11KCE

Table of contents: page

1 Warnings 3

2 Product description 3

2.1 Operating limits 4

2.2 Typical system 5

2.3 List of cables 5

3 Installation 6

3.1 Preliminary checks 6

3.2 Fitting SPIN 6

3.2.1 Assembly of guide supplied with SPIN10KCE 7

3.2.2 SNA11 guide assembling 8

3.2.3 Mounting the gearmotor to the guide 8

3.2.4 Mounting the gearmotor to the ceiling 8

3.3 Installation of the Various Devices 9

3.4 Electrical connections 10

3.5 Description of the electrical connections 11

4 Final checks and start up 11

4.1 Power Supply Connection 11

4.2 Recognition of the door opening and

closing positions 12

4.3 Checking door movements 12

4.4 Pre-set functions 12

4.5 Radio receiver 12

4.5.1 Memorization of Radio Transmitters 13

4.5.2 Memorization Mode I 13

4.5.3 Memorization Mode II 13

4.5.4 “Remote” memorization 14

4.5.5 Deleting the Radio Transmitters 14

5 Testing and commissioning 14

5.1 Testing 14

5.2 Commissioning 15

6 Maintenance and Disposal 15

6.1 Maintenance 15

6.2 Disposal 15

7 Additional information 16

7.1 Programming keys 16

7.2 Programming 16

7.2.1 Level one functions (ON-OFF functions) 16

7.2.2 Level one programming (ON-OFF functions) 17

7.2.3 Level two functions (adjustable parameters) 18

7.2.4

Level two programming (adjustable parameters)

18

7.2.5 Level one programming examples

(ON-OFF functions) 19

7.2.6 Examples of Level 2 programming 20

7.3 Adding or Removing Devices 21

7.3.1 STOP Input 21

7.3.2 Photocells 22

7.3.3 Electric block 22

7.4 Special functions 23

7.4.1 “Always open” Function 23

7.4.2 “Move anyway” Function 23

7.5 Connection of other devices 23

7.6 Troubleshooting 23

7.7 Diagnostics and Signals 24

7.7.1 Signalling with flashing light and courtesy light 24

7.7.2 Signals on the control unit 24

7.8 Accessories 25

8 Technical characteristics 26

Instructions and Warnings for users of SPIN gearmotor 29

Page 3

3

GB

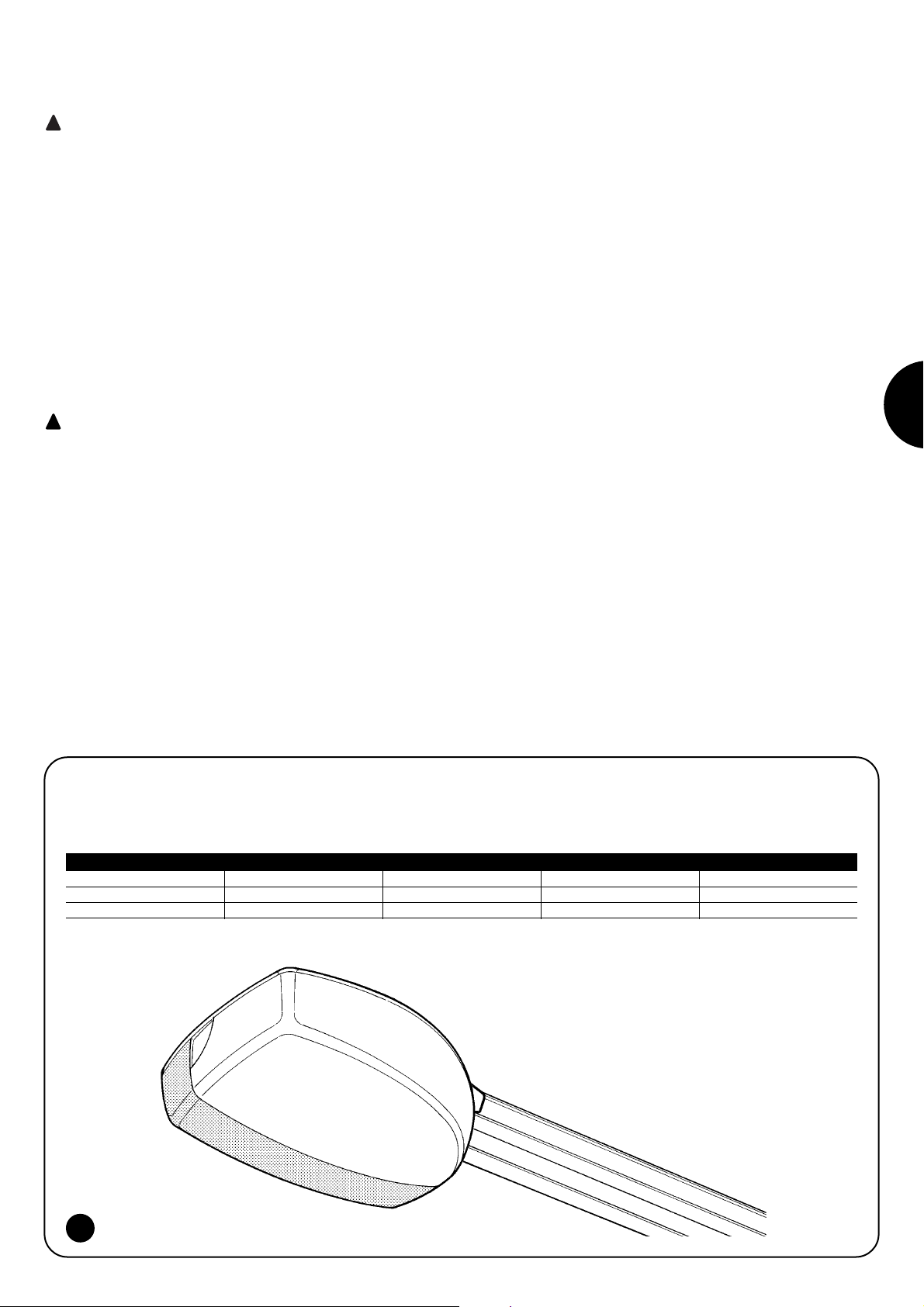

SPIN is a range of gearmotors designed for the automation of sectional doors and, in combination with accessory SPA5 (supplied separately), protruding or non-protruding spring or counterweight overhead doors.

SPIN operates with electric power. In the event of a power failure, the

gearmotor can be released in order to move the door manually.

The products described in tables 1 belong to the SPIN range.

* see paragraph “4.5 radio receiver” for the types of transmitters that can used.

1) Warnings

Important instructions for installation safety

Incorrect installation may cause serious injury.

Carefully follow all installation instructions.

This manual contains important information regarding safety; before you

start installing the components, it is important that you read all the information contained herein. Store this manual safely for future use.

In this manual when all data, warnings and other information related to

all products are stated, the range name “SPIN”. The description of individual products can be found in chapter “2 Product description”

Considering the hazards that may exist during the installation and operation of SPIN, installation must be carried out in strict compliance with

current legislation, standards and regulations. This chapter provides

details of general warnings. Other, more specific warnings are detailed in

Chapters “3.1 Preliminary Checks” and “5 Testing and commissioning”.

According to the most recent European legislation, the

production of automatic doors or gates is governed by the

provisions listed in Directive 98/37/EC (Machine Directive)

and, more specifically, to provisions: EN 12445; EN 12453 and

EN 12635, which enable manufacturers to declare the presumed conformity of the product.

Please access “www.niceforyou.com” for further information, and guidelines for risk analysis and how to draw up the Technical Documentation.

• This manual has been especially written for use by qualified fitters.

Except for the enclosed specification “Instructions and Warnings for

Users of the SPIN gearmotor” which is to be removed by the installer,

none of the information provided in this manual can be considered as

being of interest to end users!

• Any use or operation of SPIN which is not explicitly provided for in

these instructions is not permitted. Improper use may cause damage

and personal injury.

• Risk analysis must be carried out before starting installation, to include

the list of essential safety requisites provided for in Enclosure I of the

Machine Directive, indicating the relative solutions employed. N.B. Risk

analysis is one of the documents included in the “Technical Documentation” for this automation.

• Check whether additional devices are needed to complete the

automation with SPIN based on the specific application requirements

and dangers present. The following risks must be considered: impact,

crushing, shearing, dragging, etc. as well as other general dangers.

• Do not make modifications to any components unless such action is

specified in this manual. Operations of this type are likely to lead to

malfunctions. NICE disclaims any liability for damage resulting from

modified products.

• During installation and use, ensure that solid objects or liquids do not

penetrate inside the control unit or other open devices. If necessary,

please contact the NICE customer service department; the use of

SPIN in these conditions can be dangerous.

• The automation system must not be used until it has been commissioned as described in chapter 5: “Testing and commissioning”.

• The packing materials of SPIN must be disposed of in compliance with

local regulations.

• If a fault occurs that cannot be solved using the information provided

in this manual, refer to the NICE customer service department.

• In the event that any automatic switches are tripped or fuses blown,

you must identify the fault and eliminate it before resetting the switches or replacing fuses.

• Disconnect all the power supply circuits before accessing the terminals

inside the SPIN cover. If the disconnection device is not identifiable,

post the following sign on it: “WARNING: MAINTENANCE WORK IN

PROGRESS”.

!

!

2) Product description

1

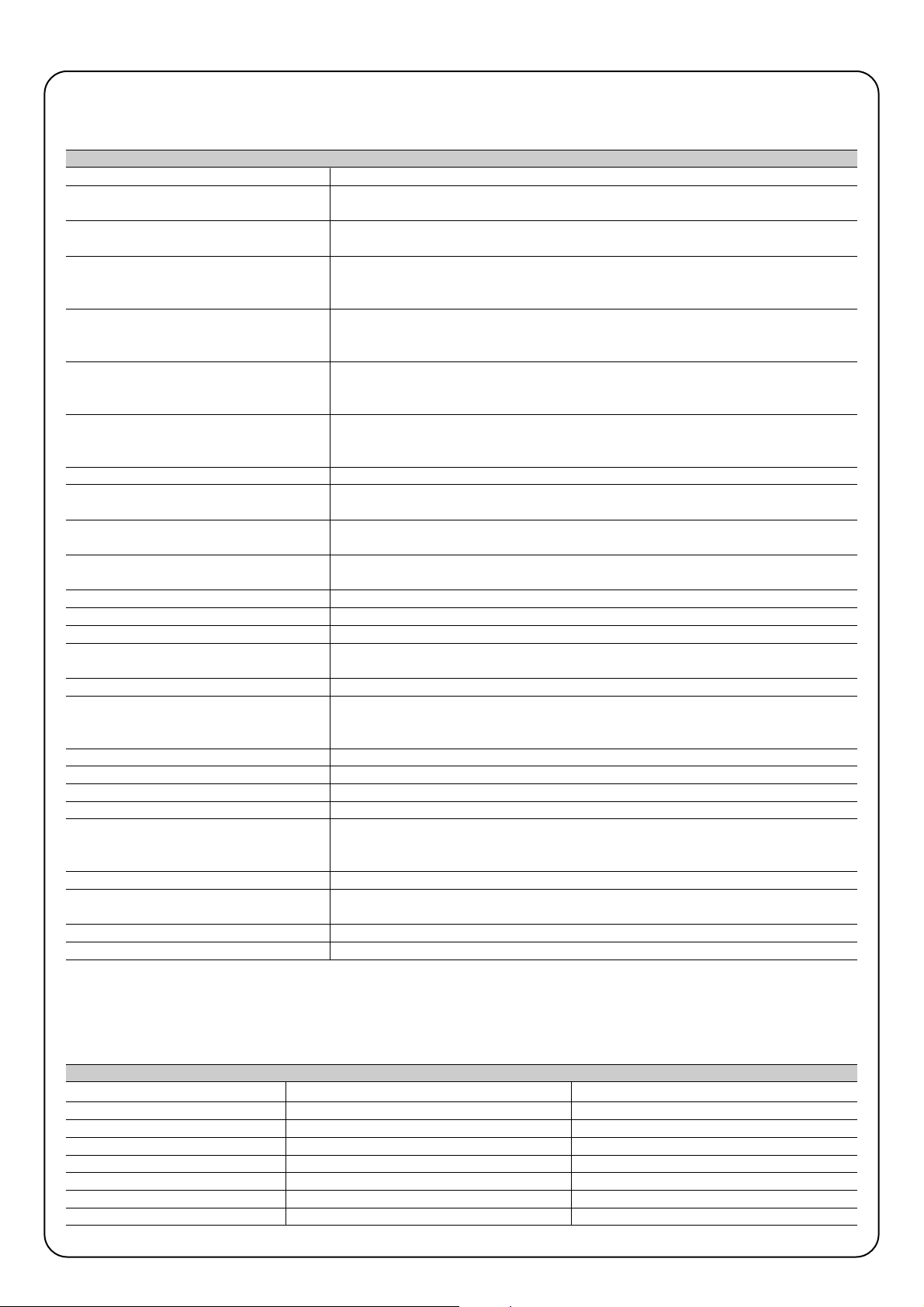

Model: Gearmotor Guide Radio receiver Radio Transmitter

SPIN10KCE SN6011 3x1m Incorporated FLO2R-S*

SPIN11KCE SN6011 3m Incorporated FLO2R-S*

Table 1: Description of the SPIN components

Page 4

4

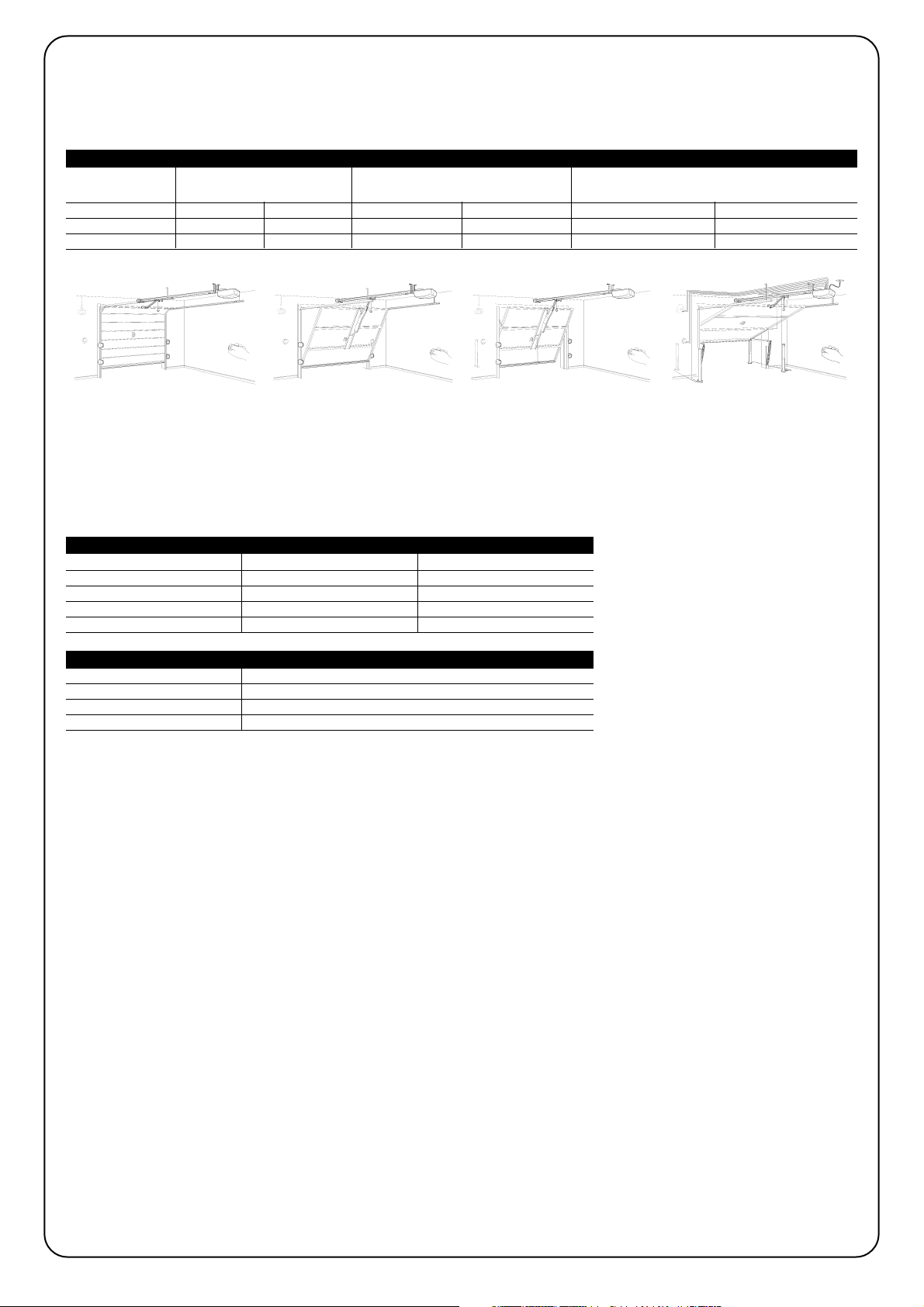

2.1) Operating limits

Chapter 8 “Technical Characteristics” provides the data needed to determine whether the products of the SPIN line are suitable for the intended application.

The structural characteristics of the SPIN products make it suitable for use on sectional and overhead doors within the limits shown in Tables

2, 3 and 4.

The measurements in table 2 are guideline only and can be used as a general estimate only. The effective suitability of SPIN for automating

a specific door depends on the degree of door leaf balancing, guide friction and other aspects, including occasional phenomena such as

wind pressure or the presence of ice, which could obstruct leaf movement.

To establish effective conditions, the force required to move the leaf throughout its stroke must be measured, to ensure that this value does

not exceed the “rated torque” specified in chapter “8 Technical specifications”; also, to calculate the number of cycles/hour and consecutive

cycles, the data in tables 3 and 4 must be taken into account.

The height of the door enables a calculation of the maximum number of cycles per hour and consecutive cycles, while the force required to

move the door enables a calculation of the percentage of cycle reduction; for example, if the leaf height is 2.2 m this would enable 12 cycles

per hour and 6 consecutive cycles, but if a force of 250N is required, these would have to be reduced to 70%, resulting therefore in 8 cycles

per hour and around 4 consecutive cycles.

To avoid overheating, the control unit has a limiter that is based on the motor operation and duration of cycles, and trips when the maximum

limit is exceeded.

Note: 1Kg = 9.81N, for example, 500N = 51Kg

Model: SECTIONAL door OVERHEAD door, non-protruding OVERHEAD door, protruding (with accessory

(with accessory SPA5) SPA5) or with springs (without SPA5)

Height Width Height Width Height Width

SPIN10KCE 2.4m 3.7m 2.2m 3.5m 2.8m 3.5m

SPIN11KCE 2.4m 3.7m 2.2m 3.5m 2.8m 3.5m

Table 2: SPIN gearmotor operating limits

Leaf height Max. no. of cycles/hour

Max. no. of consecutive cycles

Max. 2 16 8

2÷2,5 12 6

2,5÷3 10 5

3÷3,5 8 4

Table 3: limits related to leaf height

Force required to move leaf N

Cycle reduction percentage

Max. 200 100%

200÷300 70%

300÷400 25

Table 4: limits in relation to force required to move door leaf

Page 5

5

GB

2.2) Typical system

Figure 2 shows a typical system for automating a sectional door.

2

1 SPIN

2 Photocells

3 Photocells on post (fig. 3)

4 Main edge

5 Flashing light with incorporated

aerial

6 Key-operated selector switch

7 Radio-transmitter

Figures 3 and 4 show typical installations of a protruding and non-protruding overhead door.

For installations on overhead doors, the accessory SPA5 is required.

!

3 4

5

6

C

B

A

2

2

4

B

B

D

7

1

3

2.3) List of cables

Figure 3 shows the cables needed for the connection of the devices

in a typical installation; Table 5 shows the cable characteristics.

The cables used must be suitable for the type of installation. For example, an H03VV-F type cable is recommended for indoor applications

!

Note 1: A single 4x0.5mm2cable can be used instead of two 2x0.5mm2cables.

Note 2: special devices which enable connection even when the leaf is moving must be used to connect edges to the door.

Connection Cable type Maximum length allowed

A: Flashing light with aerial N°1 cable 2x0,5mm

2

20m

N°1 RG58 type shielded cable 20m (recommended less than 5 m)

B: Photocells N°1 2x0,25mm2cable for TX 30m

N°1 4x0.25mm2cable for RX 30m

C: Key-operated selector switch N°2 2x0,5mm2cables (note 1) 50m

D: Primary sensitive edge N°1 2x0,5mm2cable (note 2) 30m

Table 5: list of cables

B

Page 6

6

3.1) Preliminary checks

Before proceeding with the installation of SPIN you must:

• Verify and ensure after installation that no door parts obstruct pub-

lic roadways or pavements.

• Check that all the materials are in excellent condition, suitable for

use and that they conform to the standards currently in force.

• Make sure that the structure of the gate is suitable for automation.

• Make sure that the force and dimensions of the door fall within the

specified operating limits provided in chapter “2.1 Operating limits”.

• Check that the static friction (that is, the force required to start the

movement of the leaf) is less than half the “maximum torque”, and

that the dynamic friction (that is, the force required to keep the leaf

in movement) is less than half the "nominal torque”. Compare the

resulting values with those specified in Chapter 8 “Technical Characteristics”. The manufacturer recommends a 50% margin on the

force, as unfavourable climatic conditions may cause an increase

in the friction.

• Make sure that there are no points of greater friction in the open-

ing or closing travel of the door.

• Make sure that the mechanical stops are sturdy enough, and that

there is no danger of door derailing.

• Make sure that the door is well balanced: it must not move by itself

when it is placed in any position.

• Make sure that the mounting positions of the various devices (pho-

tocells, keys, etc.) are protected from impacts and that the mounting surfaces are sufficiently sturdy.

• Make sure that the minimum and maximum clearances specified

in fig. 5 and 6 are observed.

• Check and ensure that the manual release is fitted at a maximum

height of 1.8 m.

• Components must never be immersed in water or other liquids.

• Keep all components of SPIN away from heat sources and open

flames; these could damage the components and cause malfunctions, fire or dangerous situations.

• If the door includes an access door, make sure that it does not

obstruct normal travel. Mount a suitable interlock system if necessary.

• If the door to be automated is an overhead type, check the dis-

tance [E] in Figure 7, i.e. the minimum distance between the upper

side of the guide and the maximum point reached by the upper

edge of the door. Otherwise SPIN cannot be installed.

• Connect SPIN only to a power supply line equipped with safety

grounding system.

• The power supply line must be protected by suitable magneto-

thermal and differential switches.

7

3.2) Fitting SPIN

Fixture of the SPIN gearmotor comprises 3 stages.

• Guide assembly (see paragraph 3.2.1 for guides supplied with

SPIN10KCE and paragraph 3.2.2 for guide SNA11)

• Mounting the gearmotor to the guide (see paragraph 3.2.3)

• Mounting the gearmotor to the ceiling (see paragraph 3.2.4)

The installation of SPIN must be carried out by qualified

personnel in compliance with current legislation, standards and regulations, and the directions provided in this

manual.

!

3) Installation

5

6

200mm

300mm

380mm

E 65÷300 mm

C 2970mm D 380mm

B 0÷400mm

A 40÷400mm

200mm

Page 7

7

GB

B

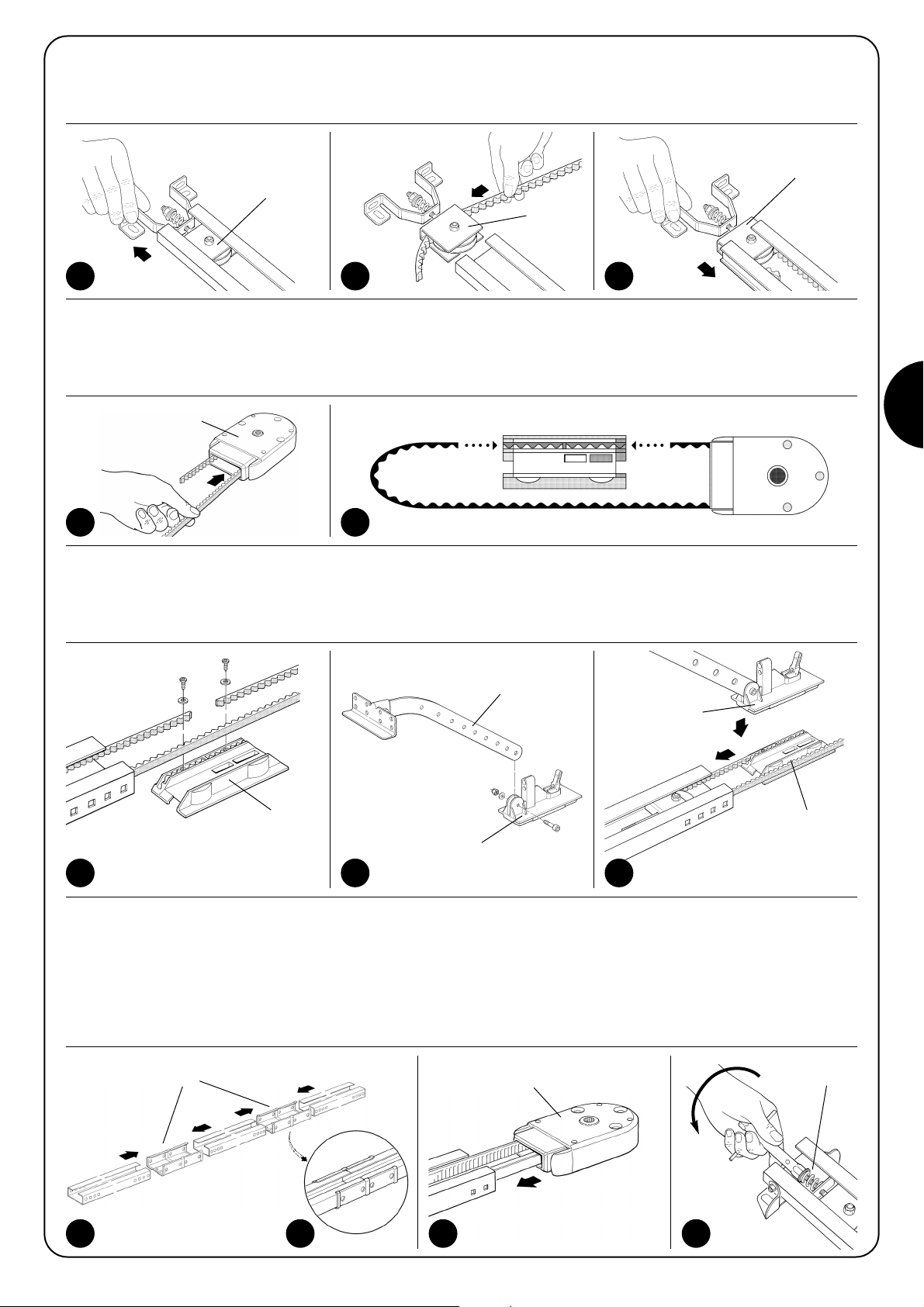

3.2.1) Assembly of guide supplied with SPIN10KCE

The guide that is supplied with SPIN10KCE must be assembled as follows:

1. Referring to figure 8, remove the belt tensioner device (8a); insert one end of the belt into the pulley (8b); reintroduce the belt tensioner

device into the guide (8c).

4. Position both ends of the belt into all of the shaped slots of the lower carriage (C). Secure the ends of the belt with the 2 screws (V4.2x9.5)

and 2 washers (R05), as in figure 11.

5. Fix the belt guide (D) to the upper carriage (E) with the V6x18 screw and related M6 nut, as in figure 12.

6. Insert the upper carriage (E)into the lower carriage (C) and place the entire carriage assembly inside the guide, as in figure 13.

7. With the aid of a hammer, assemble the three pieces of the guide engaging them into the connection brackets (F) with force, as in fig-

ures 14 and 15.

Important: the guides must slide into the brackets until they click into position.

8. Carefully position the belt into the guide, making sure that it is not twisted.

9. Fix the head (B) into the free end of the guide with force, as in figure 16.

10.Finally, tension the belt with the adjustment screw (H) of the belt tensioner device, as in figure 17.

Warning: the gearmotor could break if the belt is too taut and if it is too slack, it could cause unpleasant noise.

11 12 13

C

14 16 17

H

D

E

E

C

8A 8B 8C

10

A

B

9

A

A

2. Pass the same end of the belt through the head (B), as in figure 9.

Note: Make sure that the belt is correctly positioned: it must be with the teeth facing inwards, straight and without twists.

3. Turn the lower section of the carriage so that the grooves correspond with the two ends of the belt, as in figure 10.

F

15

Page 8

8

3.2.2) SNA11 guide assembling

The guide SNA11 guide is already assembled. The only operation

required is tensioning the belt by means of the M8 nut (H), as shown

in figure 17, until it is sufficiently taut.

3.2.3) Mounting the gearmotor to the guide

1. Join the SPIN gearmotor with the guide head (B); then secure by means of the four V6.3x38, screws, as shown in figure 18.

2. The motor can be rotated in three different positions, as shown in figure 19.

18 19

3.2.4) Fissaggio del motoriduttore al soffitto

1. On the basis of distances A and B in figure 5, trace the two fixing points of the front guide bracket at the centre of the door. On the basis

of the type of support surface, the front bracket can be fixed with rivets, plugs or screws (figures 20, 21). If distances A, and B (figure 5)

are sufficient, the bracket can be fixed directly onto the ceiling, as shown in figure 22.

2. After drilling the holes in the relative points, leaving the gearmotor on the ground, lift the guide from the front section and secure by means

of two screws, plugs or rivets, according to the installation surface.

3. Secure the brackets (I) by means of the M6x15 screws (L) and nuts M6 (M) selecting the hole most suited to ensure distance B, as shown

in figure 23.

4. Using a ladder, lift the gearmotor until the brackets are touching the ceiling. Trace the drilling points and then return the gearmotor to the

ground, as shown in figure 24.

20 21 22

23 24

L

M

I

B

Page 9

9

GB

5. Drill at the outlined points and then, using a ladder, lift the gearmotor until the brackets are placed against the drilled holes and secure by

means of screws and plugs suited to the support surface, as shown in figure 25.

6. Ensure that the guide is perfectly horizontal, then cut off the excess section of the brackets with a saw, as shown in figure 26.

7. With the door closed, pull the cord to release carriage (E), as shown in figure 27.

8. Slide the carriage until the leaf connecting bracket (D) on the upper edge of the door is perfectly perpendicular to the guide (G). Then

secure the leaf connecting bracket (D) with rivets or screws, as shown in figure 28. Use screws or rivets suited to the leaf material, and

ensure that they are able to withstand the maximum force required for leaf opening and closing.

9. Loosen the screws of the two mechanical stops, then move the front mechanical stop (O) in front of the carriage, as shown in figure 29.

Push the carriage in the closing direction and, on reaching the position, tighten the screw (N) fully down.

10.Manually open the door to the required opening position, move the rear mechanical stop (Q) next to the carriage, as shown in figure 30

and tighten the screw (P) fully down.

11.Try to move the door manually. Ensure that the carriage slides easily without friction on the guide and that manual movement does not

require excessive force.

25 26

27 28

29 30

E

G

D

O

N

Q

P

3.3) Installation of the Various Devices

If other devices are needed, install them following the directions provided in the corresponding instructions. Check this in paragraph “3.5

Description of electrical connections” and the devices which can be

connected to the SPIN in Figure 2.

Page 10

10

3.4) Electrical connections

Before you proceed to make any electrical connections

make sure that the power supply is disconnected.

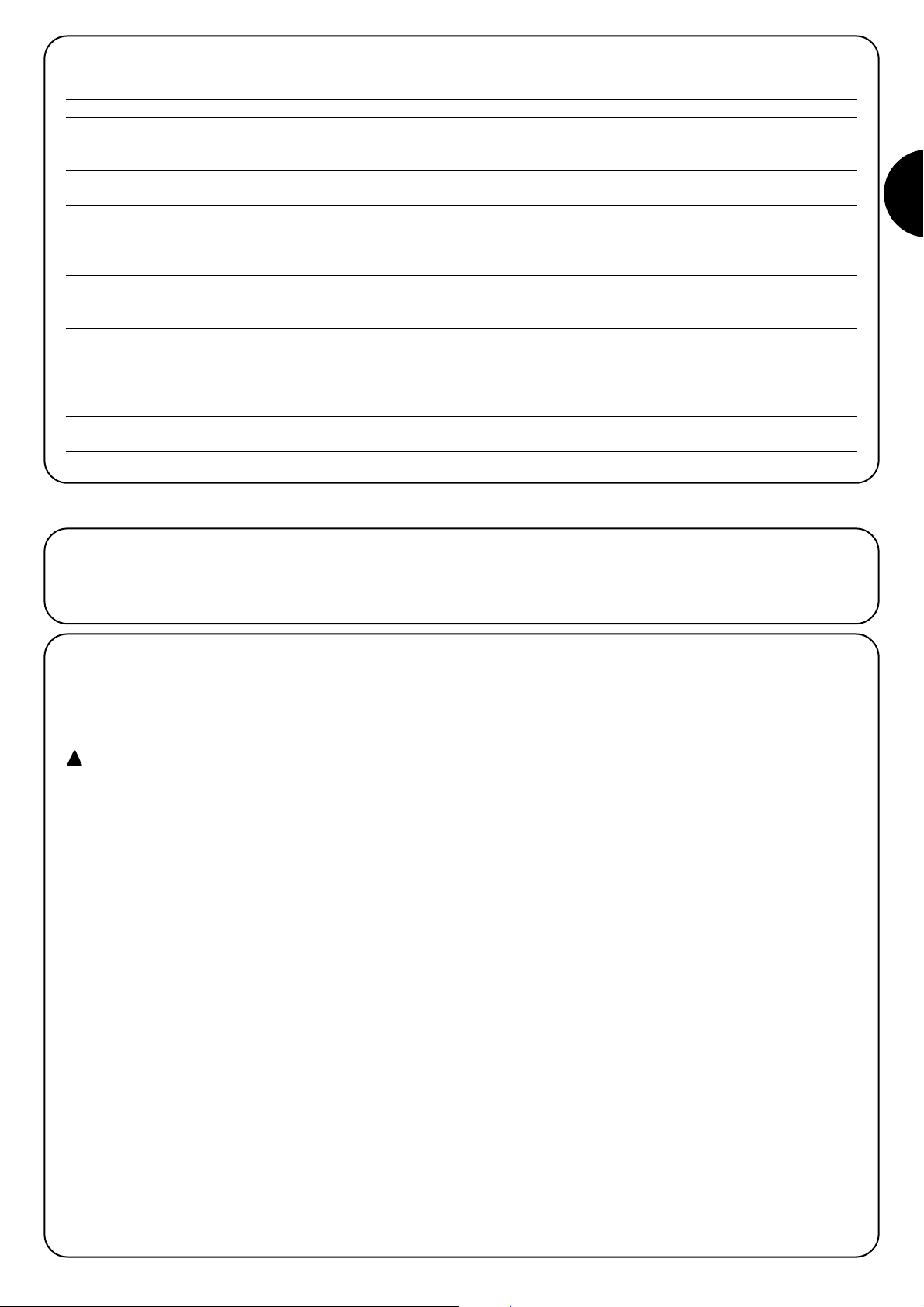

1. Open the protection cover in order to access the electronic con-

trol unit of the SPIN. To do this, press the side and rotate as

shown in figure 31.

2. Insert all the connection cables towards the various devices

through the hole, leaving a length of 20÷30 cm longer than necessary. See Table 5 for information regarding the type of cables

and Figure 2 for the connections.

3. Connect up the cables according to the diagram in Figure 33.

!

31 32

33

LUCYB

MOSE

Page 11

11

GB

The manufacturers recommend you unhook the carriage and position the leaf at approximately half travel before starting the checking

and start up phase of the automation. This will ensure the leaf is free

to move both during opening and closure.

4) Final checks and start up

4.1) Power Supply Connection

To power SPIN just insert the plug in a power outlet. If necessary, use

a commercial adapter if the plug on the SPIN unit does not correspond to the socket available.

Never cut or remove the cable supplied with SPIN.

If not already available, the power socket for SPIN connection must be made by qualified and experienced personnel in strict observance of current legislation, standards and regulations.

The power supply line must be protected from short circuits and ground leakage; a device must be provided to

enable the disconnection of the power supply during the

installation and maintenance of SPIN (the plug with outlet

are suitable for this purpose).

As soon as SPIN is energized, you should check the following:

1. Make sure that the “OK” LED flashes regularly, with about one

flash per second.

2. Check that the motor does not control the movement of the door

and that the courtesy light is off.

If the above conditions are not satisfied, you should immediately

switch off the power supply to the control unit and check the electrical connections more carefully.

For more useful information about finding and analysing failures see

also chapter “7.6 Troubleshooting”

!

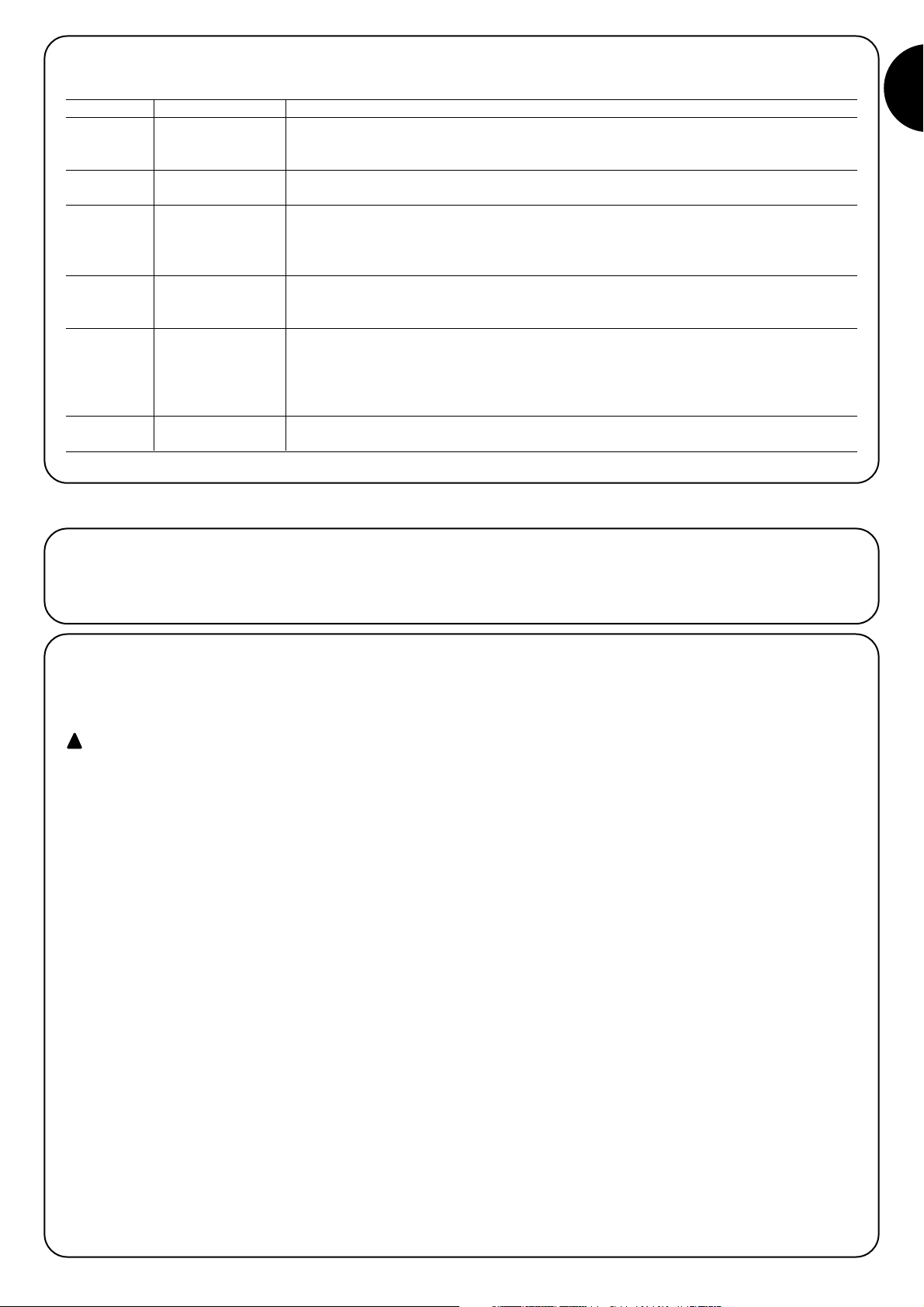

3.5) Description of the electrical connections

The following is a brief description of the electrical connections; for further information please read “7.3 Adding or Removing Devices” paragraph.

Terminals Function Description

1 – 2 Aerial connection input for the radio receiver aerial. The aerial is incorporated in LUCY B; alternatively

an external aerial can be used or leave a section of wire already present on the terminal, to serve

as an aerial.

3 – 4 Step-by-step input for devices which control movement. It is possible to connect “Normally Open” devices

up to this input.

5 – 6 Stop input for the devices which block or eventually stop the manoeuvre in progress. Contacts like

“Normally Closed”, “Normally Open” or constant resistance devices can be connected up

using special procedures on the input. Please refer to Paragraph “7.3.1 STOP Input” for

further information about STOP.

3 - 7 Photo Input for safety devices such as photocells. Cut-in during closure, reversing the manoeuvre.

“Normally closed “ type contacts can be connected. Further PHOTO information on the can be

seen in paragraph “7.3.2 PHOTO input”

6 – 8 Phototest Whenever a manoeuvre is begun, the relative safety devices are checked and only if everything is in

order will the manoeuvre start.

All this is only possible if a special configuration of the connections is used; in practice, the “TX”

photocell transmitters are powered separately from the “RX” receivers. Please refer to Paragraph

“7.3.2 PHOTO Input” for further information about the connection.

9 – 10 Flashing light a NICE “LUCY B” flashing light can be connected on this output with a car type 12 V 21 W lamp.

During the manoeuvre the unit flashes at intervals of 0.5 s.

Page 12

12

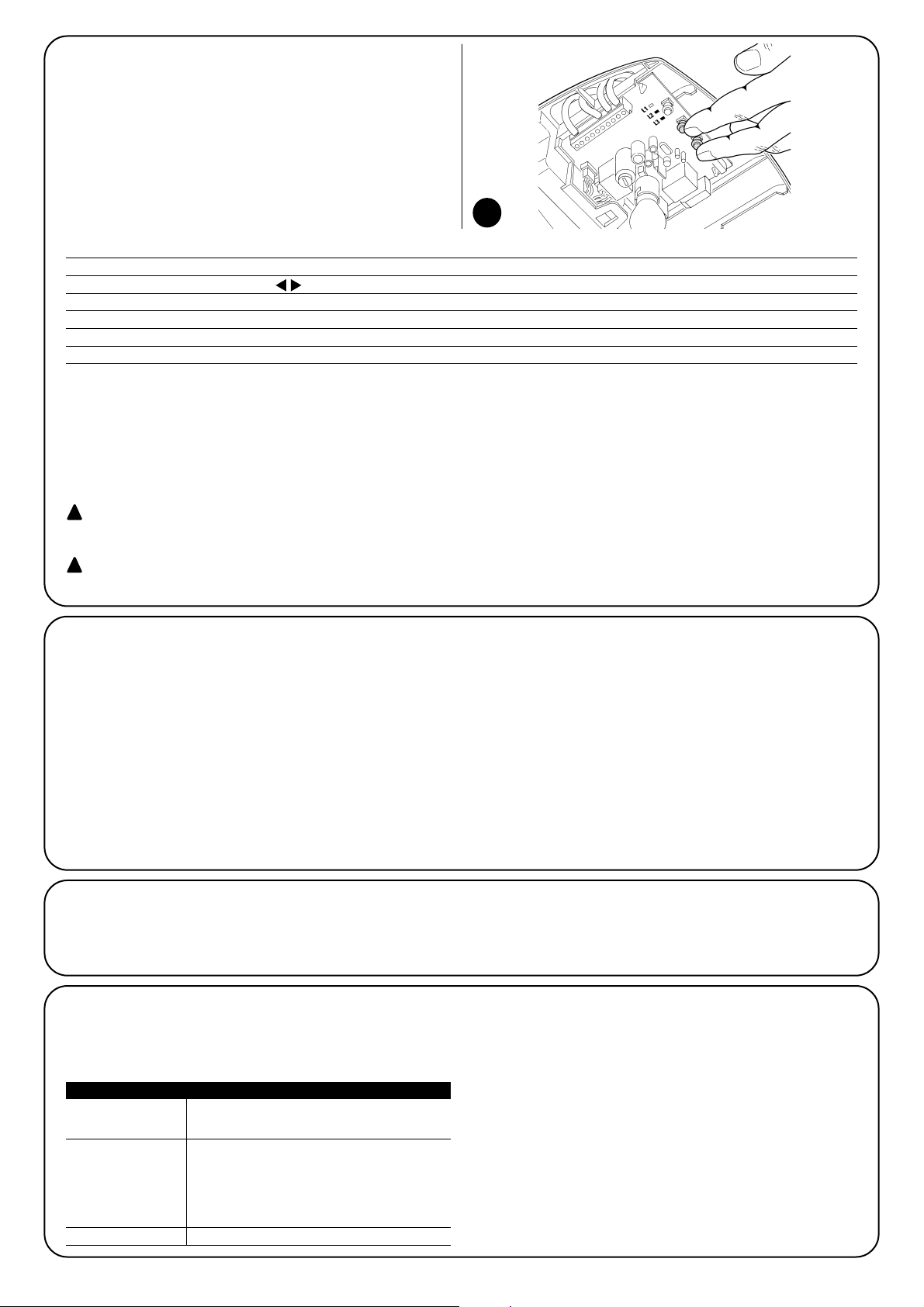

4.2) Recognition of the door opening and closing

positions

The control unit must be made to recognize the opening and closing

positions of the door. In this phase, the door stroke from the closing

mechanical stop to the opening mechanical stop is detected. In

addition to position, the STOP input configuration is detected and

memorised in this phase as well as the existence or non-existence

of the PHOTO input “Phototest”.

1. Ensure that the drive belt is correctly tensioned and that the two mechanical stops are fully secured.

2. Engage the carriage.

3. Press keys []and [ Set ] and hold them down.

4. Release the keys when the manoeuvre starts (after approx. 3 s)

5. Wait for the control unit to complete the recognition stage: closing, opening and closing again of the door.

6. Push the [Step-by-Step] key to perform a complete opening manoeuvre.

7. Push the [Step-by-Step] key to close.

During these manoeuvres, the control unit memorises the force required for opening and closing.

If at the conclusion of the self-learning process the L2 and L3 flash, it means that an error has occurred; see paragraph 7.6 “Troubleshooting”.

It is important that these manoeuvres are not interrupted, e.g. by a STOP command.

If this occurs, the learning process described in point 1 must be repeated.

The recognition stage of the positions, and of the STOP and PHOTO input configuration can be repeated again at any time, even after the

installation (for example, if one of the mechanical stops is removed); just repeat the procedure starting from step

During the position search process, if the belt is not sufficiently tensioned, it may slip on the pinion. If this occurs,

press the [Stop] key to interrupt self-learning; tension the belt by tightening the M8 nut (D) as shown in figure 11, then

repeat self-learning from point 1.

Self-learning of the door opening and closing positions is only possible after the radio transmitter memorisation and

deletion time interval has elapsed (see paragraph 4.5 Radio receiver).

!

!

34

4.3) Checking door movements

On completion of the recognition of the opening and closing positions, it is advisable to carry out a number of manoeuvres in order to

check the door travels properly.

1. Press the [Step-by-Step] key to open the door. Check that

door opening occurs regularly, without any variations in speed;

the door must only slowdown and stop when it is between 30

and 20 cm from the opening mechanical stop. Then, at 2÷3 cm

from the mechanical opening stop the limit switch will trigger.

2. Press the [Step-by-Step] key to close the door. Check that door

closing occurs regularly, without any variations in speed; the door

must only slowdown and stop when it is between 30 and 20 cm

from the closing mechanical stop. A brief opening manoeuvre is

then performed to release belt tension.

3. During the manoeuvre, check that the flashing light (if any) flashes at a speed of 0.5 seconds on and 0.5 seconds off.

4. Open and close the gate several times to make sure that there

are no points of excessive friction and that there are no defects in

the assembly or adjustments.

5. Check that the fastening of the gearmotor, the guide and the

mechanical stops are solid, stable and suitably resistant, even if

the door accelerates or decelerates sharply.

4.4) Pre-set functions

The SPIN control unit has a number of programmable functions. These

functions are set to a configuration which should satisfy most automations. However, the functions can be altered at any time by means of a

special programming procedure. Please refer to paragraph “7.2 Programming” for further information about this.

4.5) Radio receiver

A radio receiver is incorporated in the control unit of SPIN for remote

control, operating at a frequency of 433.92 MHz compatible with the

following types of transmitter:

Since the type of coding is different, the first transmitter that is introduced also determines the type introduced afterwards. Up to 160

transmitters can be memorised.

Memorisation and deletion of transmitters must be performed within the first 10 seconds after powering up the

unit. In this time interval, the control unit key [RADIO] is

used for radio memorisation and deletion functions. 10

seconds after the last flash of led L1 or after the last key

is pressed, the key is disabled and led L1 is dedicated to

programming. The courtesy light flashes once to indicate

the end of the interval in which radio memorisation functions are enabled.

FLO FLO1 – FLO2 – FLO4

VERY VE

FLOR FLOR1 – FLOR2 – FLOR4

VERY VR

ERGO1 – ERGO4 – ERGO6

PLANO1 – PLANO4 – PLANO6

OPERA range transmitters

SMILO SM2 – SM4

Table 6: Transmitters

Page 13

13

GB

1 “Step-by-step” command

2 “Partial opening” command

3 “Open” command

4 “Close” command

Table 8: commands available in Mode II

4.5.1) Memorization of Radio Transmitters

Each radio transmitter is recognised by the radio receiver by means of a “code” which is different from that of any other transmitter. A “memorisation” phase must therefore be performed in order to allow the receiver to recognise each single transmitter. Transmitters can be memorised in 2 modes:

Mode I: in this mode the function of the transmitter keys is fixed and

each key corresponds to the command in the control unit shown in

Table 7; a single memorisation phase is carried out for each transmitter, during which all the transmitter keys are memorised. It doesn’t matter which key is pressed and just one memory sector is occupied. A transmitter can normally only control a single automation in

Mode I.

Mode II: In this mode, each transmitter key can be associated with

one of the 4 possible control unit commands shown in Table 8; only

one key is memorised for each stage, namely the one which was

pressed during memorisation. One memory section is occupied for

each key.

In Mode II, different keys on the same transmitter can be used in

order to give the same automation more than one command or to

control more than one automation. For example, in Table 9, only

automation “A”, is controlled, and the T3 and T4 keys are associated with the same command. Alternatively, three automations are

controlled in the example shown in Table 10, namely “A” (keys T1

and T2), “B” (key T3) and “C” (key T4).

Since the memorization procedures are timed (10s),

you must read the instructions in the following paragraphs

before you proceed with their execution.

!

T1 Key “Step-by-step” command

T2 Key “Partial opening” command

T3 Key “Open” command

T4 Key “Close” command

Table 7: Memorisation mode I

T1 Key “Open” command Automation A

T2 Key “Close” command Automation A

T3 Key “Partial opening” command Automation A

T4 Key “Partial opening” command Automation A

Table 9: 1st example of memorization in Mode II

T1 Key “Open” command Automation A

T2 Key “Close” command Automation A

T3 Key “Step-by-step” command Automation B

T4 Key “Step-by-step” command Automation C

Table 10: 2nd example of memorization in Mode II

Note: single-channel transmitters only have a T1 key, two channel

transmitters only have T1 and T2 keys.

1. Press the radio key on the control unit and hold it down (approx. 4 s)

4s

2. Release the key when the radio LED on the control unit lights up

3. Within 10s, press any key on the radio transmitter to be memorized and hold it down for at least 3s

3s

4. If the memorization procedure is successful, the radio LED on the control unit will flash 3 times.

x3

If there are other transmitters to memorise, repeat step 3 within another 10s seconds.

The memorisation phase finishes if no new codes are received for 10 seconds.

Table 11: to memorize a transmitter in mode I Example

4.5.2) Memorization Mode I

35

1. Press the radio key on the control unit as many times as the number corresponding to the desired

command, according to the table 8 1....4

2. Make sure that the radio LED on the control unit makes as many flashes as the number corresponding

to the desired command 1....4

3. Within 10s, press any key on the radio transmitter to be memorized and hold it down for at least 3s

3s

4. If the memorization procedure is successful, the LED on the receiver will flash 3 times.

x3

If there are other transmitters to memorise for the same type of command, repeat step 3 within another 10 seconds.

The memorisation phase finishes if no new codes are received for 10 seconds.

Table 12: to memorize the key of a transmitter in mode II Example

4.5.3) Memorization Mode II

Page 14

14

1. Press the key on the new radio transmitter and hold it down for at least 5s, then release it.

5s

2. Press the key on the previously memorized transmitter slowly 3 times.

1s 1s 1s

3. Press the key on the new radio transmitter once slowly.

1s

At this point the new radio transmitter will be recognized by the receiver and will assume the characteristics of the previously memorized

one. If there are other transmitters to be memorized, repeat all the steps above for each new transmitter.

Table 13: for the “Remote” memorization of a transmitter Example

4.5.4) “Remote” memorization

A new radio transmitter can be memorized without directly operating

the keys on the receiver. You need to have a pre-memorized operational radio transmitter. The “new” radio transmitter will inherit the characteristics of the old one, i.e. if the old radio transmitter was memorized in Mode 1, the new one will also be memorized in Mode 1. In this

case, during the memorization stage you can press any key on the

transmitters. If, on the other hand, the old transmitter was memorized

in Mode II, the new one will also be memorized in Mode II: you must

press the key on the old transmitter which corresponds to the

desired command, and the key on the new transmitter to which you

wish to associate that command.

Programming via radio may be done on all the receivers

within the range of the transmitter; therefore, only the one

involved in the operation should be kept switched on.

!

Holding the two transmitters, position yourself within the operating range of the automation and perform the following operations:

1. Press the radio key on the control unit and hold it down

2.

Wait until the radio LED lights up, then wait until it goes off, then wait until it has flashed 3 times

x3

3. Release the radio key precisely upon the third flash.

4. If the procedure is successful, after a few moments the LED will flash 5 times.

x5

Table 14: to delete all the radio transmitters Example

4.5.5) Deleting the Radio Transmitters

This is the most important stage in the automation system installation procedure in order to ensure the maximum safety levels.

Testing can also be adopted as a method of periodically checking

that all the various devices in the system are functioning correctly.

Testing of the entire system must be performed by qualified and experienced personnel who must establish which

tests to conduct on the basis of the risks involved, and verify the compliance of the system with applicable regulations, legislation and standards, in particular with all the

provisions of EN standard 12445 which establishes the test

methods for automation systems for gates and doors.

!

5) Testing and commissioning

5.1) Testing

Each component of the system, e.g. safety edges, photocells, emergency stop, etc. requires a specific testing phase. We therefore recommend observing the procedures shown in the relative instruction

manuals.

To test SPIN proceed as follows:

1. Make sure that the provisions contained in chapter 1 «WARNINGS» have been carefully observed.

2. Release the door by pulling the release cord downwards. Check

that the door can be manually manoeuvred with a force no

greater than 225N.

3. Engage the carriage again.

4. Using the selector switch or the radio transmitter, test the opening and closing of the door and make sure that the door moves

in the intended direction.

5. The test should be carried out a number of times to make sure

that the gate moves smoothly, that there are no points of excessive friction and that there are no defects in the assembly or

adjustments.

6. Check the proper operation of all the safety devices, one by one

(photocells, sensitive edges, etc.).

In particular, each time a device is activated the “OK” LED on the

control unit flashes 2 times quickly, confirming that the control unit

recognizes the event.

7. To check the photocells and make sure that there is no interference with other devices, pass a 5 cm diameter, 30 cm long cylinder on the optical axis, first near TX, then near RX and finally at

the mid-point between them and make sure that in all these cases the device is triggered, switching from the active to the alarm

status and vice-versa; finally, that it causes the intended action in

the control unit; for example that it causes the reversal of the

movement during the closing manoeuvre.

8. If the dangerous situations caused by the movement of the door

have been safeguarded by limiting the force impact, the user

must measure the impact force according to EN Standard 12445.

If the adjustment of the “speed” and control of the “motor force”

are used to assist the system for the reduction of the impact

force, try to find the adjustment that gives the best results

Page 15

15

GB

5.2) Commissioning

Commissioning can take place only after all testing phases have been

terminated successfully. It is not permissible to execute partial commissioning or to enable use of the system in makeshift conditions.

1. Prepare and store for at least 10 years the technical documentation for the automation, which must include at least: assembly

drawing of the automation, wiring diagram, analysis of hazards

and solutions adopted, manufacturer’s declaration of conformity

of all the devices installed (for SPIN use the annexed CE declaration of conformity); copy of the instruction manual and maintenance schedule of the automation.

2. Post a permanent label or sign near the door detailing the operations for the release and manual manoeuvre (refer to the figures in

“Instructions and warnings for users of the SPIN gearmotor”).

3. Post a permanent label or sign near the door containing this picture (min. height 60 mm).

4. Post a label on the door providing at least the following data: type

of automation, name and address of manufacturer (person

responsible for the “commissioning”), serial number, year of manufacture and “CE” marking.

5. Prepare the declaration of conformity of the automation system

and deliver it to the owner.

6. Prepare the “Installation instructions and warnings” of the

automation system and deliver it to the owner.

7. Prepare the maintenance schedule of the automation system and

deliver it to the owner; it must provide all directions regarding the

maintenance of all the automation devices.

Before commissioning the automation system inform the owner in

writing regarding dangers and hazards that are still existing (e.g.

in the “Installation instructions and warnings”).

36

This chapter provides information about how to draw up a maintenance schedule, and the disposal of SPIN.

6) Maintenance and Disposal

6.1) Maintenance

The automation must be subjected to maintenance work on a regular basis, in order to guarantee it lasts.

The maintenance operations must be performed in

strict compliance with the safety directions provided in

this manual and according to the applicable legislation

and standards.

If other devices are present, follow the directions provided in the corresponding maintenance schedule.

1. SPIN requires scheduled maintenance work every 6 months or

3,000 manoeuvres after previous maintenance.

2. Disconnect the power supply

3. Check for any deterioration of the components which form the

automation, paying special attention to erosion or oxidation of the

structural parts. Replace any parts which are below the required

standard.

4. Check the wear and tear on the moving parts: belt, carriage, pinions and the door components; if necessary replace them.

Connect the electric power sources up again, and carry out all

the tests and checks described in paragraph 5.1 “Testing”.

!

6.2) Disposal

SPIN is constructed of various types of materials, some of which can

be recycled: steel, aluminium, plastic, electric cables; while others

must be disposed of (batteries and electronic boards).

Some electronic components may contain polluting

substances; do not pollute the environment. Enquire

about the recycling or disposal systems available in compliance regulations locally in force.

1. Disconnect the power supply of the automation system.

2. Disassemble all the devices and accessories, following in reverse

order the procedures described in chapter 3 “Installation”.

3. Wherever possible, separate any parts which can or must be

recycled or disposed of in different ways, e.g. metal parts must

be disposed of separately from plastic ones, as must the electronic cards etc.

4. Sort the various materials and consign them to local licensed

firms for recovery and disposal.

!

Page 16

16

This chapter deals with the options for programming, personalisation, diagnostics and troubleshooting for the SPIN gearmotor.

7) Further information

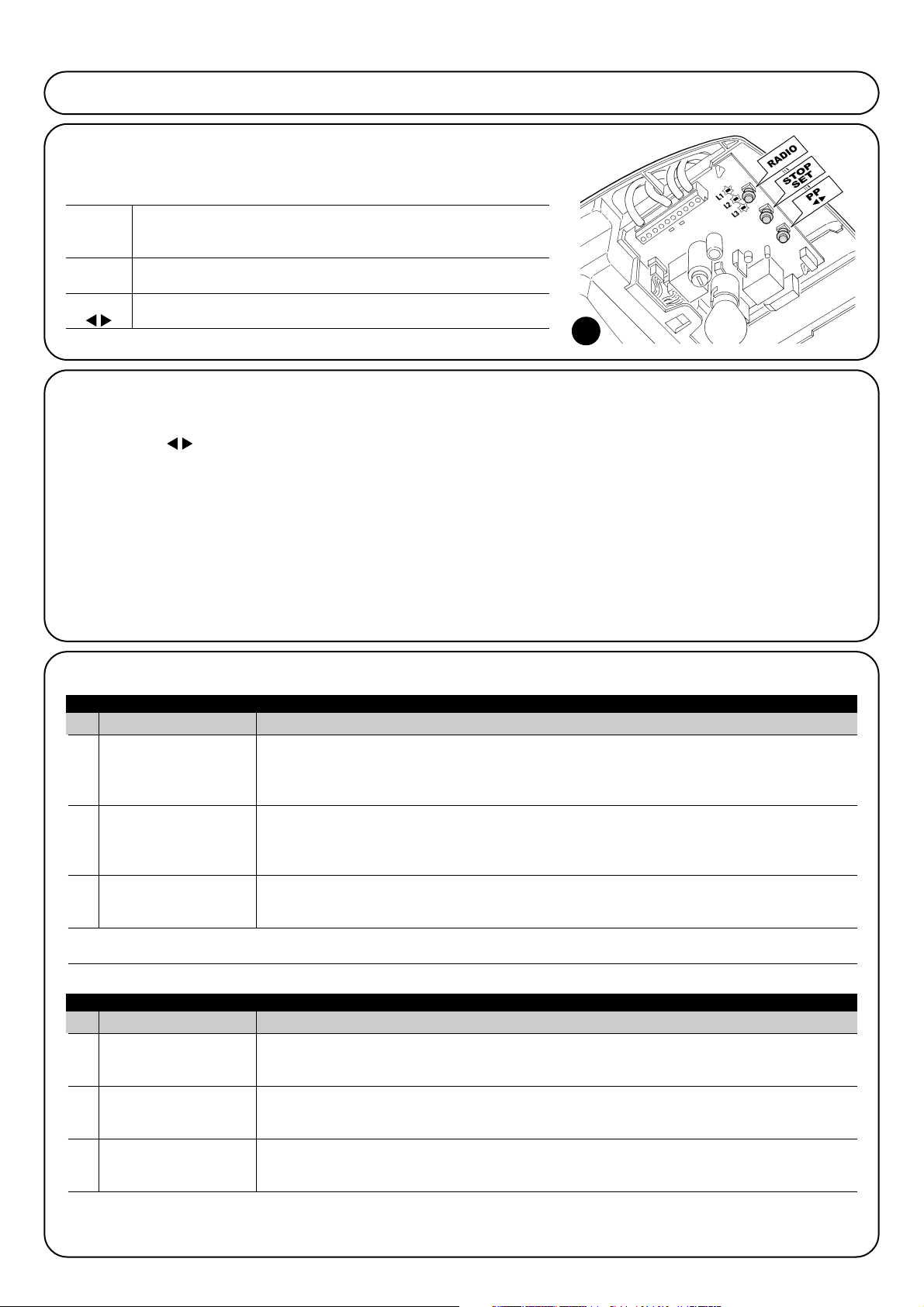

RADIO Within the first 10 seconds after power-up, perform the “RADIO” function to

enable memorisation and deletion of the radio transmitters used with SPIN.

After this time interval, the key is no longer used.

Stop The STOP key stops the manoeuvre; if pressed for more than 5 seconds,

SET it enables entry to programming mode as described below.

SS The SS key enables door opening and closing commands; otherwise this key

can be used to scroll up through the programming steps.

7.1) Programming keys

The SPIN control unit is fitted with 3 keys which can be used both for the control of

the unit during testing and the programming procedure:

7.2) Programming

The SPIN control unit is equipped with a number of programmable

functions; function settings are entered by means of the 2 keys on

the control unit: []and [Set] and are displayed by means of 3

leds: L1, L2, L3.

There are two types of programming:

Programming on power-up: This type of programming can be

performed only immediately after switching on SPIN. Press and hold

[Set] during power-up of the control unit to activate this programming mode.

Standard programming: This programming mode can be used at

any time and is activated by pressing and holding [Set].

For both modes, the programming and programmable functions

available are divided into 2 levels:

Level 1: functions settable in ON-OFF mode (enabled or disabled);

in this case leds L1, L2, and L3 indicate a function, if lit the function

is enabled, if off the function is disabled; see Tables 15 and 15a.

Level 2: parameters settable on a scale of values (from 1 to 3); in

this case each led L1, L2, L3 indicates a set value from the possible 3; see Tables 17 and 17a.

37

N° Description Example

L1 Variable Sensitivity This function enables the user to enable or disable sensitivity with which obstacles are detected.

The factory setting of sensitivity is variable (led L1 off): Greater sensitivity in the case of low motor force,

and less sensitivity where the motor force increases. All with the aim of ensuring optimal detection

precision. Variable sensitivity can be disabled, and 3 “fixed” levels of motor force remain (led L1 lit).

L2 Phototest/Electric block This function enables the user to enable output 8 of the terminal board for operation with Phototest or

with an Electric block. The factory setting of output 8 is with the “phototest” function enabled (led L2 off).

Alternatively the output can be programmed on the SPIN control unit for control of an electric block

(led L2 lit).

L3 Partial open This function enables the selection of a long or short partial opening interval. The factory setting for

partial open is long (approx. 1 m, led L3 lit). Alternatively partial open can be set to short (approx. 15cm,

led L3 off).

At the end of the “Programming on power-up” procedure, leds L1, L2 and L3 indicate the status of the functions in “Standard programming” mode.

Table 15: List of programmable functions in “Programming on power-up” mode

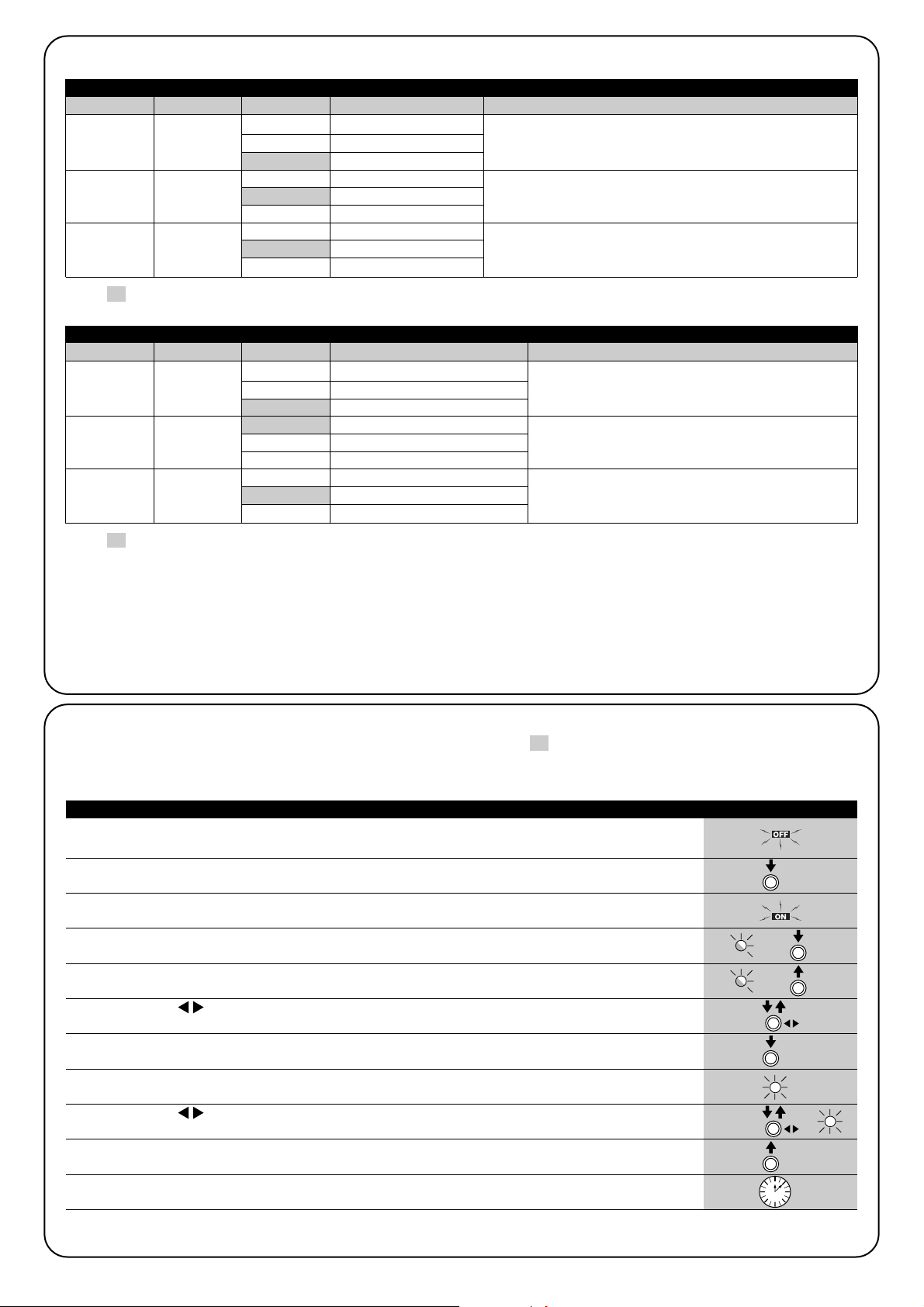

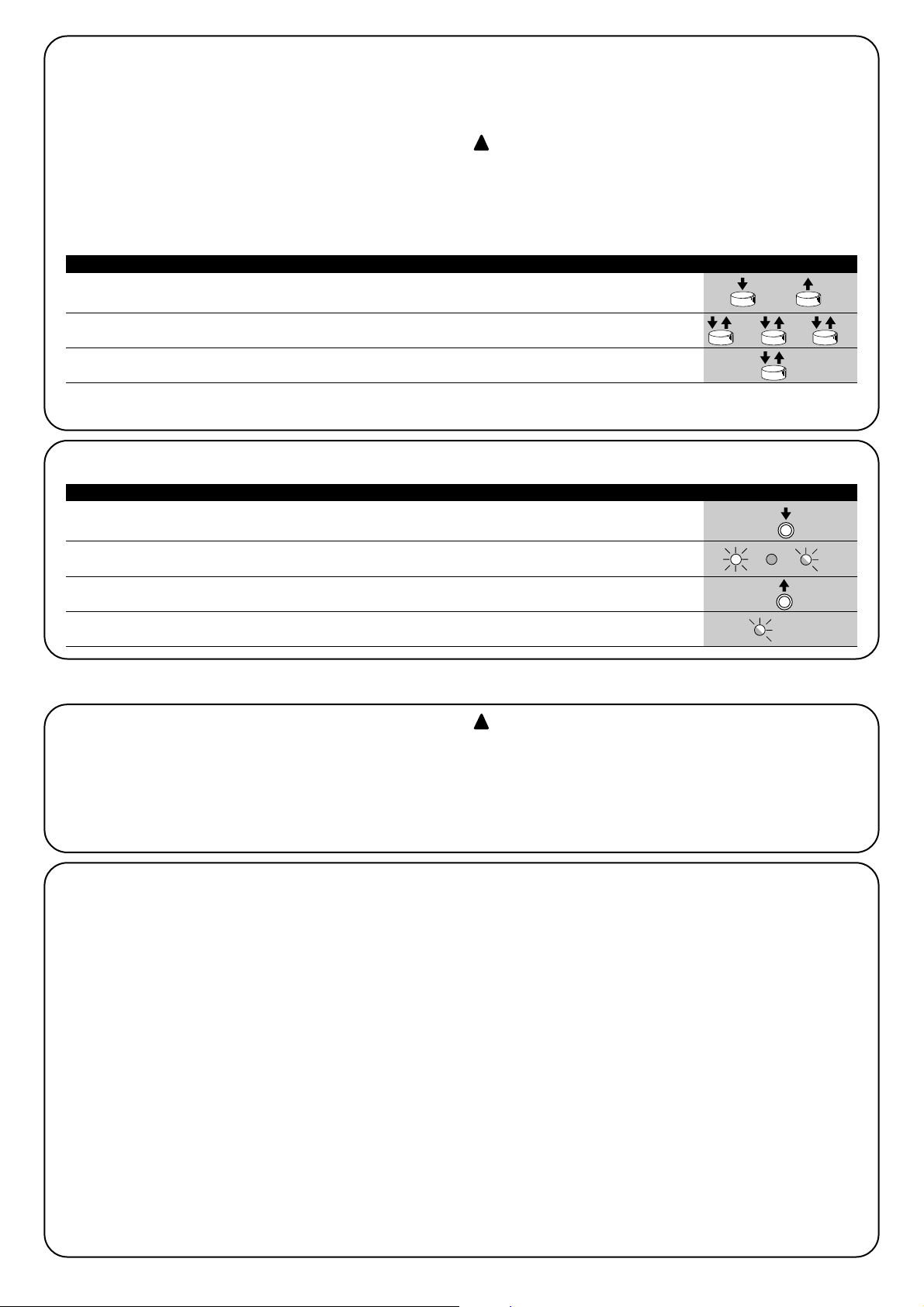

7.2.1) Level 1 functions (ON-OFF functions)

N° Description Example

L1 Closing speed This function enables the selection of the motor speed during the closing manoeuvre, from 2 levels:

“high” and “low”. The factory setting is “high” (led L1 lit). Alternatively the function can be disabled to set

the “low” speed (led L1 off).

L2 Opening speed This function enables the selection of the motor speed during the opening manoeuvre, from 2 levels:

“high” and “low”. The factory setting is “high” (led L2 lit). Alternatively the function can be disabled to set

the “low” speed (led L2 off).

L3 Automatic closure This function enables automatic closure of the door after a programmed pause; the default Pause Time

is set at 30 seconds but may be modified to 15 or 60 seconds. The factory setting is “semiautomatic”

as Automatic closure is disabled (led L3 off).

During normal operation of SPIN, leds L1, L2 and L3 are lit or off depending on the status of the associated function in Standard programming mode, for example L3 is lit if the function “Automatic closure” is enabled. L1 also displays the status of the “radio” function in

the first 10 seconds after power-up.

Table 15a: List of programmable functions in “Standard programming” mode

Page 17

17

GB

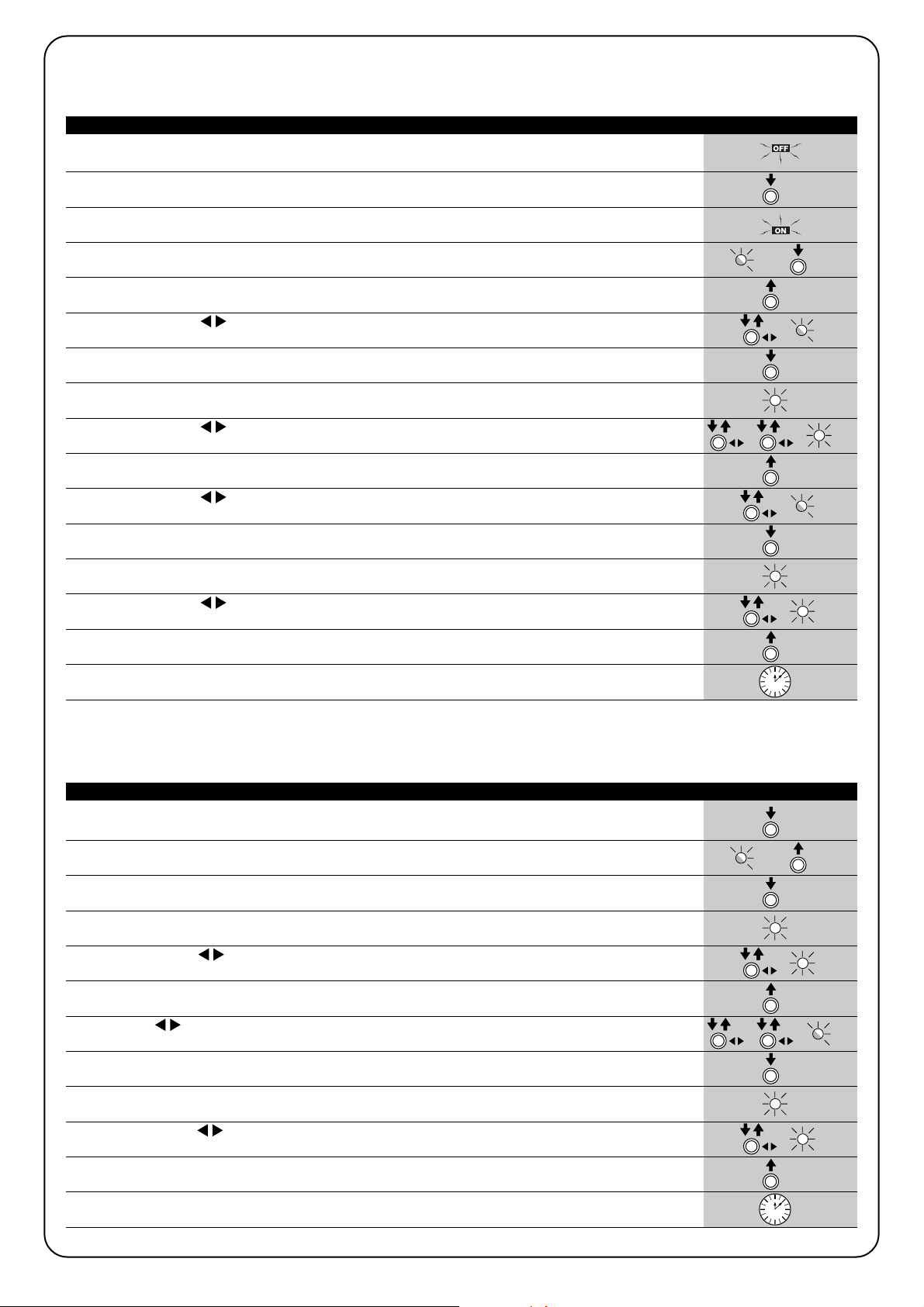

7.2.2) Level 1 programming (ON-OFF functions)

By default level 1 functions are set as shown in tables 15 and 15a, but can be modified at any time as shown in tables 16 and 16a. Take

care during modification procedures, as there is a maximum time interval of 10 seconds between pressing one key and another; otherwise

the system exits the procedure automatically memorising the changes made up to that time.

1. Switch off SPIN (for example by removing fuse F1)

2. Press and hold [Set]

3. Switch on SPIN (for example by inserting fuse F1)

4. Wait for the flashing signal indicating control unit start-up and keep [Set] pressed until L1 starts to

flash (approx. 6s) L1 6s

5. Release the key [Set] when led L1 starts to flash

L1

6. Press key []to move the flashing led to the led associated with the function to be modified

7. Press [Set] to change the status of the function (short flash = OFF; long flash = ON)

8. Wait 10s to exit the programming mode automatically after the maximum time interval.

10s

Note: points 6 and 7 can be repeated during the same programming phase to set other functions to ON or OFF.

Table 16: To modify the ON-OFF functions in “programming on power-up” mode Example

SET

SET

SET

SET

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

L1

3. Press key []to move the flashing led to the led associated with the function to be modified

4. Press [Set] to change the status of the function (short flash = OFF; long flash = ON)

5. Wait 10s to exit the programming mode automatically after the maximum time interval.

10s

Note: points 3 and 4 can be repeated during the same programming phase to set other functions to ON or OFF

Table 16a: To modify the ON-OFF functions in “standard programming” mode Example

SET

SET

SET

Page 18

18

Sensitivity

variable

Belt recovery

Closing

slowdown

High

Medium

Low

No recovery

Minimum recovery

Maximum recovery

Short

Medium

Long

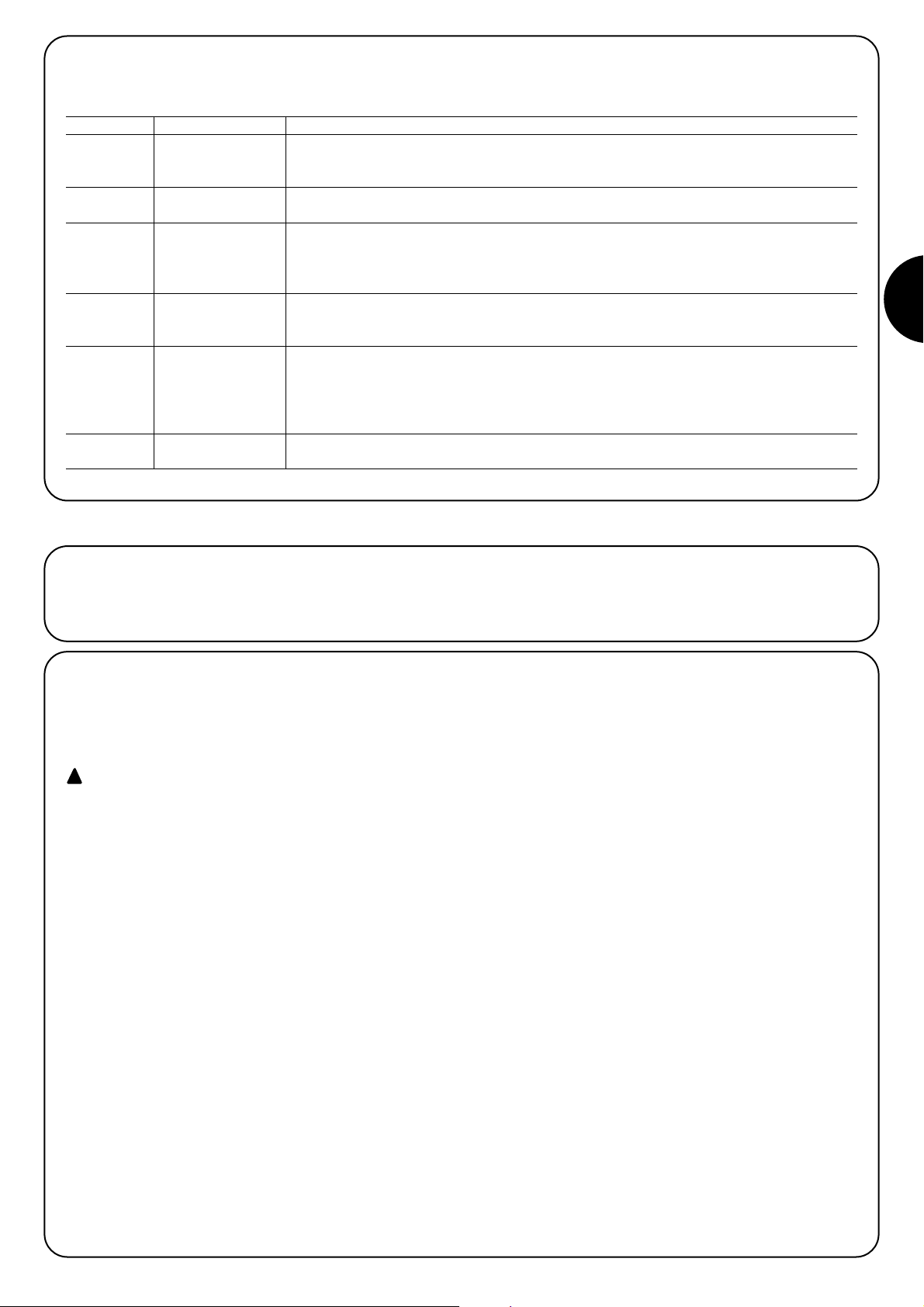

7.2.3) LEVEL 2 functions (adjustable parameters)

Table 17: List of level 2 programmable functions in “Programming on power-up” mode

Input leds Parameter Led (level) Value Description

When variable sensitivity is enabled, it can be set to three different activation thresholds. “High” variable sensitivity is most

suited to small size correctly balanced doors.

Sets the belt recovery value. After complete closure of the

door, a very brief opening manoeuvre is activated, settable

with this parameter.

Sets the slowdown time interval during the closing manoeuvre.

Note: “ ” Represents factory settings.

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

7.2.4) Level 2 programming (adjustable parameters)

By default the settable parameters are set as shown in Tables 17 and 17a with: “ “ but can be modified at any time as shown in Tables

18 and 18a. Take care during modification procedures, as there is a maximum time interval of 10 seconds between pressing one key and

another; otherwise the system exits the procedure automatically memorising the changes made up to that time.

1. Switch off SPIN (for example by removing fuse F1)

2. Press and hold [Set]

3. Switch on SPIN (for example by inserting fuse F1)

4. Wait for the flashing signal indicating control unit start-up and keep [Set] pressed until L1 starts to flash

(approx. 6s) L1 6s

5. Release the key [Set] when led L1 starts to flash

L1

6. Press key []to move the flashing led to the “input led” associated with the parameter to be

modified

7. Press and hold [Set] during steps 5 and 6

8. Wait approx. 3s after which the led associated with the current level of the parameter to be modified

will light up 3s

9. Press key []to move the led associated with the parameter value.

10. Release [Set]

11. Wait 10s to exit the programming mode automatically after the maximum time interval.

10s

Note: Points 6 to 10 can be repeated during the same programming phase to modify other parameters

Table 18: To modify the adjustable parameters in “programming on power-up” mode Example

SET

SET

SET

SET

Motor force

SS function.

Pause Time

Low

Medium

High

Open, Stop, Close, Open

Open, Stop, Close, Stop

Apartment block

15 seconds

30 seconds

60 seconds

Table 17a: List of level 2 programmable functions in “Standard programming” mode

Input leds Parameter Led (level) Value Description

Sets the maximum force generated by the motor to

move the door.

Adjusts the sequence of commands associated with

the SS input or the 1st radio command (see tables 7

and 8).

Adjusts the pause time, i.e. time before automatic reclosure. Is effective only if automatic closure is enabled

Note: “ ” Represents factory settings.

All parameters can be adjusted as required without any contraindications, only the “Motor force” setting may require special attention:

• Use of high force values are not recommended to compensate for the fact that the leaf has anomalous points of friction; excessive force

may impair the safety system and damage the leaf.

• If the “Motor force control” is used in support of the system for impact force reduction, after each adjustment the force measurement pro-

cedure must be performed, as envisaged by standard EN 12445.

• Wear and atmospheric conditions influence movement of the gate; force settings should be checked periodically.

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

SET

Page 19

19

GB

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

L1

3. Press key []to move the flashing led to the “input led” associated with the parameter to be

modified

4. Press and hold [Set] during steps 5 and 6

5. Wait approx. 3s after which the led associated with the current level of the parameter to be modified

will light up

6. Press key []to move the led associated with the parameter value.

7. Release [Set]

8. Wait 10s to exit the programming mode automatically after the maximum time interval.

10s

Note: Points 3 to 7 can be repeated during the same programming phase to modify other parameters

Table 18a: To modify the adjustable parameters in “standard programming” mode Example

SET

SET

SET

SET

7.2.5) LEVEL 1 programming examples (ON-OFF functions)

This example shows the sequence of operations required to change the factory setting of the functions to deactivate the function of “Variable Sensitivity” (L1) and activate “Short Partial Open” (L3).

1. Switch off SPIN (for example by removing fuse F1)

2. Press and hold [Set]

L1

3. Switch on SPIN (for example by inserting fuse F1)

4. Wait for the flashing signal indicating control unit start-up and keep [Set] pressed until L1 starts to flash

(approx. 6s) L1 6s

5. Release [Set]

6. Press [Set] once to change the status of the function associated with L1 (Variable Sensitivity) led L1

now emits long flashes L1

7. Press []twice to move the flashing led onto led L3

L3

8. Press [Set] once to change the status of the function associated with L3 (Partial open) led L3 now

emits long flashes L3

9. Wait 10s to exit the programming mode automatically after the maximum time interval

10s

On standby to exit programming mode, leds L1 and L3 must remain lit to indicate that the functions “Variable Sensitivity disabled” and “Short

Partial Open” are active.

Table 19: Example of LEVEL 1 programming in “Programming on power-up” mode Example

SET

SET

SET

This example shows the sequence of operations required to change the factory setting of the functions to activate the functions of “High

opening speed” (L2) and “Automatic Closure” (L3).

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

L1

3. Press the key [] once to move the flashing led onto led L2

L2

4. Press [Set] once to change the status of the function associated with L2 (Opening speed) led L2 now

emits long flashes L2

5. Press the key []once to move the flashing led onto led L3

L3

6. Press [Set] once to change the status of the function associated with L3 (Automatic closure) led L3

now emits long flashes L3

7. Wait 10s to exit the programming mode automatically after the maximum time interval

10s

At the end of these operations leds L2 and L3 must remain lit to indicate that the functions “High opening speed” and “Automatic closure” are

enabled.

Table 19a: Example of LEVEL 1 programming in “Standard programming” mode Example

SET

SET

SET

SET

SET

SET

Page 20

20

7.2.6) Examples of LEVEL 2 programming

This example shows the sequence of operations required to change the factory setting of the parameters and set the functions of “Belt

Recovery” to no recovery (input on L2 and level on L1) and set “Closing slowdown” to long (input on L3 and level on L3).

1. Switch off SPIN (for example by removing fuse F1)

2. Press and hold [Set]

3. Switch on SPIN (for example by inserting fuse F1)

4. Wait for the flashing signal indicating control unit start-up and keep [Set] pressed until L1 starts to flash

(approx. 6s) L1 6s

5. Release [Set]

6. Press the key []once to move the flashing led onto led L2

L2

7. Press and hold [Set] during steps 8 and 9

8. Wait approx. 3s until led L2 lights up, indicating the current level of “Belt recovery”

L2 3s

9. Press the key []once to move the illuminated led onto L1, to eliminate “Belt recovery”

L1

10. Release [Set]

11. Press the key []once to move the flashing led onto led L3

L3

12. Press and hold [Set] during steps 13 and 14

13. Wait approx. 3s until led L2 lights up, indicating the current level of “Closing slowdown”.

L2 3s

14. Press the key []once to move the illuminated led onto L3, indicating the new value of

“Closing slowdown”. L3

15. Release [Set]

16. Wait 10s to exit the programming mode automatically after the maximum time interval.

10s

Table 20: Example of LEVEL 2 programming in “Programming on power-up” mode Example

SET

SET

SET

SET

SET

SET

SET

This example shows the sequence of operations required to change the factory setting of the parameters and set the functions of “Motor

Force” to high (input on L1 and level on L3) and increase the “Pause Time” to 60s (input on L3 and level on L3).

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

L1

3. Press and hold [Set] during steps 4 and 5

4. Wait approx. 3s until led L2 lights up, indicating the current level of “Motor Force”

L2 3s

5. Press the key []once to move the illuminated led onto L3, indicating the new value of “Motor Force”

L3

6. Release [Set]

7. Press []twice to move the flashing led onto led L3

L3

8. Press and hold [Set] during steps 9 and 10

9. Wait approx. 3s until led L2 lights up, indicating the current level of “Pause Time”.

L2 3s

10. Press the key []once to move the illuminated led onto L3, indicating the new value of “Pause Time”.

L3

11. Release [Set]

12. Wait 10s to exit the programming mode automatically after the maximum time interval.

10s

Table 20a: Example of LEVEL 2 programming in “Standard programming” mode Example

SET

SET

SET

SET

SET

SET

Page 21

21

GB

7.3) Adding or removing devices

Devices can be added or removed at any time on an automation

using SPIN. In particular the inputs STOP and PHOTO can be connected to various types of device as indicated in paragraphs “7.3.1

STOP Input” and 7.3.2 Photocells. The figure shows the wiring diagram for connection of the various devices.

7.3.1) STOP input

STOP is the input that causes immediate shutdown of the movement followed by a brief inversion of the manoeuvre. This input can

be connected to devices with contact types Normally Open (NO),

Normally Closed (NC) or devices with a constant resistance of

8.2KΩ, such as sensitive edges.

The control unit recognises the type of device connected to the

STOP input during the self-learning phase (see paragraph “4.2 –

Learning the door opening and closing positions”); after which a

STOP command is activated whenever a variation with respect to

the learned status is detected.

When set accordingly, more than one device can be connected to

the STOP input, also different from one another:

• Several NO devices can be connected in parallel with no limit to

number.

• Several NC devices can be connected in parallel with no limit to

number.

• Several devices with a constant resistance of 8,2KΩ can be con-

nected “in cascade” with a single terminating resistance of 8,2KΩ

• It is possible to combine two NO and NC contacts, placing them

in parallel, taking care to place a resistance of 8,2KΩ in series with

the NC contact (this also enables the combination of 3 devices:

NO, NC and 8,2KΩ).

If the STOP input is used to connect devices with safety functions, only the devices with a constant resistance

of 8,2KΩ guarantee safety category 3 against faults in

accordance with the standard EN 954-1.

!

Page 22

22

7.3.2) Photocells

The SPIN control unit is equipped with the function “Phototest” which increases the reliability of the safety devices, enabling classification in

category 2 in compliance with the standard EN 954-1 regarding the combination of the control unit and safety photocells.

Each time a manoeuvre is started up, all safety devices are checked and only in the case of positive results can the manoeuvre be started.

If however the test fails (photocell “blinded “ by sun, cables shorted etc) the fault is identified and the manoeuvre is disabled.

For the “phototest” function, a specific connection is required of the photocell transmitters (see fig. 40 and 41).

The control unit recognises the connection in “phototest” mode during the self-learning phase (see paragraph “4.2 Learning the door opening and closing positions”)

• Connection without “Phototest” function (Figure 38 and 39)

Power the transmitters and receivers directly from the control unit services output (terminals 3 - 6).

• Connection without “Phototest” function (Figure 40 and Figure 41):

Power of the receivers comes directly from the services output (terminals 3 - 6), while that of the transmitters is from the “Phototest” output (terminals 8 – 6). The maximum admissible current on the “Phototest” output is 100mA.

If two pairs of photocells are used, which may interfere with the other, activate the synchronisation mechanism as described in the photocell

instructions.

38 39

40 41

7.3.3) Electric block

The factory setting of the “phototest” output is with the “Phototest”

function enabled.

Alternatively the output can be programmed on the SPIN control unit

for control of an electric block. On start-up of each opening manoeuvre, the output is activated for 2 seconds; in this way an electric

block device can be connected. The output is not activated during

the closing manoeuvre and therefore the electric block must have a

provision for mechanical reactivation.

The output can control the electric block directly, but only with loads

of 24Vac – 2W. The output must be interfaced with a relay, as shown

in the figure.

Page 23

23

GB

7.4.1) “Always open” Function

The “Always open” function is a control unit feature which enables

the user to control an opening manoeuvre when the “Step-by-step”

command lasts longer than 3 seconds. This is useful for connecting

a timer contact to the “Step-by-step” input in order to keep the door

open for a certain length of time, for example. This feature is valid

whatever the “Step-by-step” input programming may be (see the

“Step-by-step” properties in table 17).

7.4) Special functions

7.4.2) “Move anyway” Function

If one of the safety devices are out of order or malfunctioning, it is still

possible to control the door in “Man present” mode.

Please refer to the Paragraph “Control with safety devices out of

order” in the enclosure “Instructions and Warnings for users of the

SPIN gearmotor”.

7.5) Connection of other devices

If the user needs to feed external devices such as a proximity reader for transponder cards or the illumination light of the key-operated

selector switch, it is possible to tap power as shown in Figure 42.

The power supply voltage is 24Vac -30% +50% with a maximum

available current of 100mA.

24Vac

42

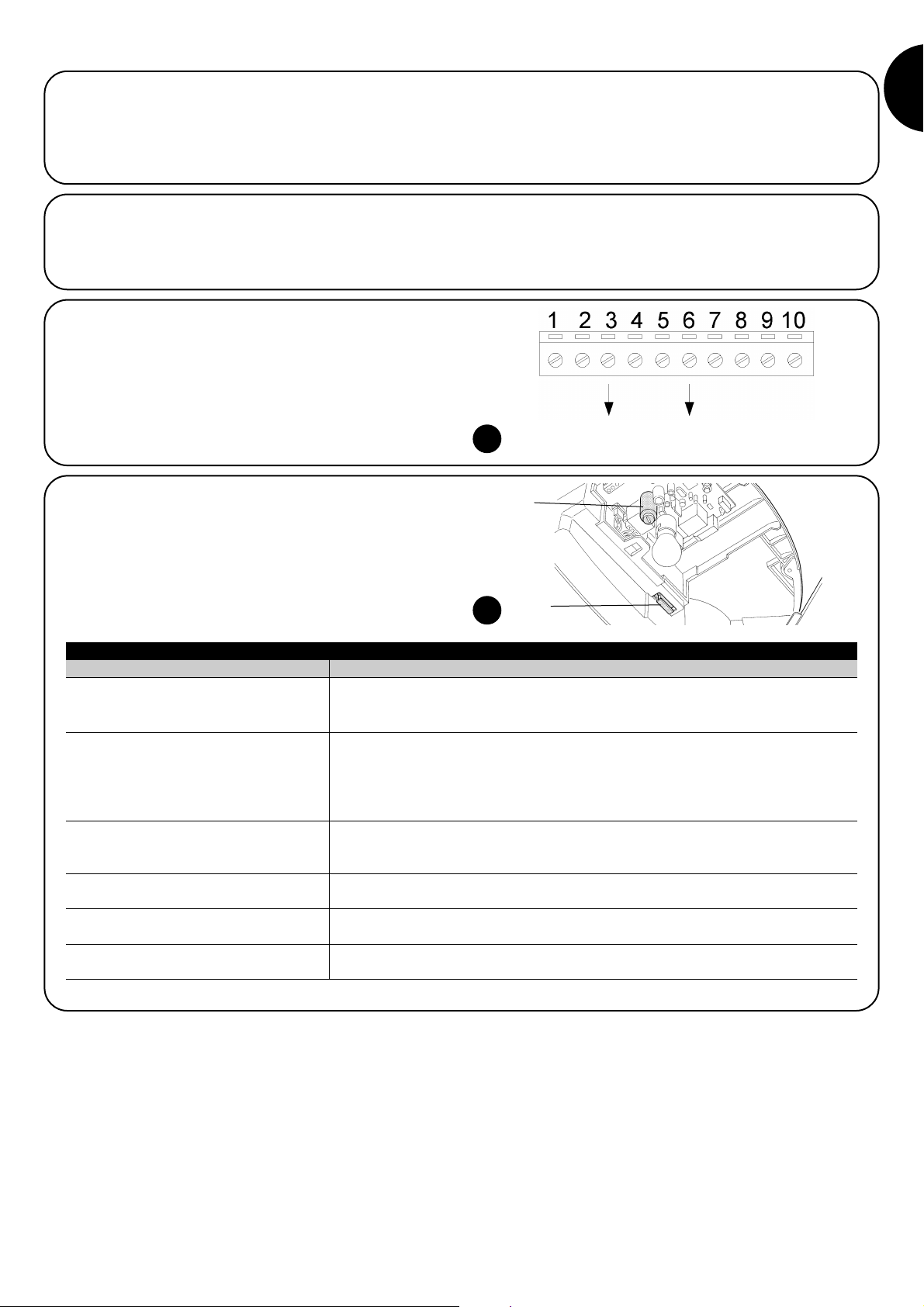

7.6) Troubleshooting

The following table contains instructions to help you solve malfunctions or errors that may occur during the installation stage or in case

of failure.

43

Table 21: Troubleshooting

Symptoms Probable cause and possible solution

The radio transmitter does not control the

door and the LED on the transmitter does

not light up

The radio transmitter does not control the

door and the LED on the transmitter lights up

No manoeuvre starts and the OK LED fails

to flash

No manoeuvre starts and the flashing light is

off

No manoeuvre starts and the flashing light

flashes a few times

The manoeuvre starts but it is immediately

followed by a reverse run

Check to see if the transmitter batteries are exhausted, if necessary replace them

Check to see if the transmitter has been memorised correctly in the radio receiver.

Check that the emission of the transmitters radio signal is correct by means of this empirical test: push a key and rest the LED on the aerial of a normal radio (ideally an economical

one) that is switched on and tuned in, as close as possible, to 108.5Mhz FM; a slight

crackling sound should be heard.

Check that SPIN is being fed 230 V voltage from the power supply. Check to see if the

fuses F1 and F2 are blown; if necessary, identify the reason for the failure and then replace

the fuses with others having the same current rating and characteristics.

Make sure that the command is actually received. If the command reaches the Step-byStep input, the OK led flashes twice indicating that the command has been received.

Count the flashes and check the corresponding value in table 22.

The selected force could be too low for this type of door. Check to see whether there are

any obstacles; if necessary increase the force.

F2

F1

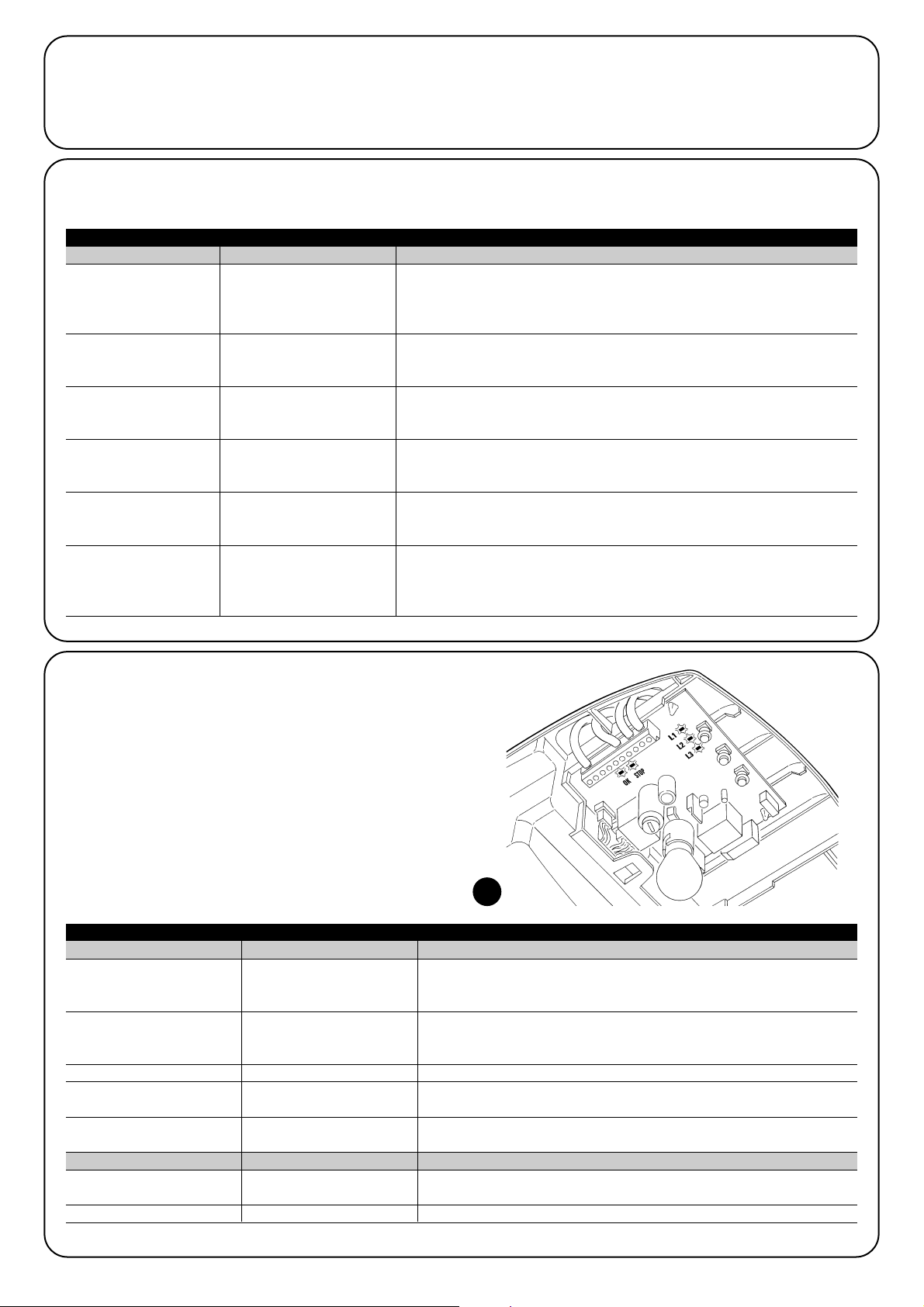

Page 24

24

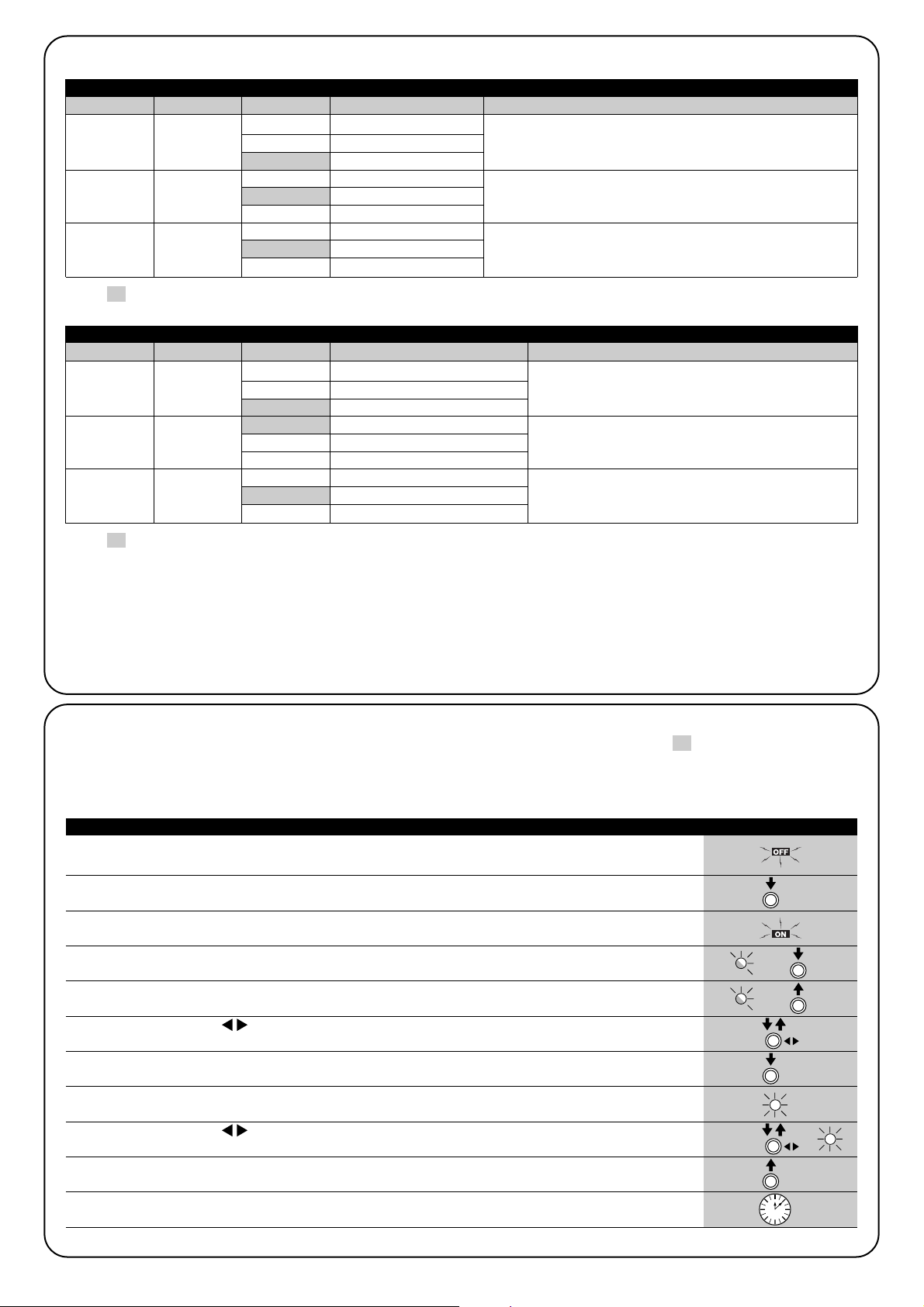

OK LED Cause ACTION

STOP LED Cause ACTION

Off

7.7.2) Signals on the control unit

On the SPIN control unit there is a set of LED’s each of which can

give special indications both during normal operation and in case of

malfunctions.

Table 23: LED’s on the control unit’s terminals

Malfunction

Make sure there is power supply; check to see if the fuses are blown; if

necessary, identify the reason for the failure and then replace the fuses with

others having the same characteristics.

On Serious malfunction

There is a serious malfunction; try switching off the control unit for a few

seconds; if the condition persists it means there is a malfunction and the

electronic board has to be replaced.

One flash every second Everything OK Normal operation of control unit

2 Quick flashes

The status of the inputs has

changed

This is normal when there is a change in one of the inputs: Step-by-Step,

STOP, triggering of photocells or the radio transmitter is used

Series of flashes separated by

a second’s pause

Miscellaneous It corresponds to the flashing light or the courtesy signal. See Table 22

Off Activation of the STOP input Check the devices connected to the STOP input

On Everything OK STOP Input active

44

7.7) Diagnostics and Signals

A few devices issue special signals that allow you to recognize the

operating status or possible malfunctions.

7 flashes

1 second’s pause

7 flashes

At the starting of the manoeuvre, one or more photocells do not enable it;

check to see if there are any obstacles.

This is normal when there is an obstacle impeding the closing movement.

7.7.1) Signalling with flashing light and courtesy light

During the manoeuvre the flashing light, if connected, flashes once every second. When something is wrong the flashes are more frequent;

the light flashes twice with a second’s pause between flashes. The courtesy light gives the same diagnostics signals.

Table 22: FLASH flashing light signalling

Quick flashes Cause ACTION

2 flashes

1 second’s pause

2 flashes

Triggering of a photocell

3 flashes

1 second’s pause

3 flashes

Activation of the “motor force”

limiting device

During the movement, the door experienced excessive friction; identify the

cause.

4 flashes

1 second’s pause

4 flashes

Activation of the STOP input During the movement the STOP input was activated; identify the cause

5 flashes

1 second’s pause

5 flashes

Error in the internal

parameters of the electronic

control unit

Wait at least 30 seconds, then try giving a command; if the condition persists it

means there is a serious malfunction and the electronic board has to be

replaced.

6 flashes

1 second’s pause

6 flashes

The maximum manoeuvre

limit/hour has been exceeded

Wait for a few minutes until the manoeuvre limiting device drops to under the

maximum limit.

There is an error in the

internal electric circuits

Disconnect all the power circuits for a few seconds and then try giving a

command again; if the condition persists it means there is a serious fault on the

electronic board or the motor cabling. Check and replace as necessary.

Page 25

25

GB

L1 LED Description

• Function programming in progress.

• If it flashes together with L2 it means that the user must carry out the recognition of the door opening and

closing positions (refer to Paragraph “4.2 Recognition of the door opening and closing positions”).

L3 LED Description

L2 LED Description

Off

Table 24: LED’s on the control unit’s keys

Correct during normal functioning.

Indicates that a radio code that is not in the memory, has been received during normal functioning.

• Function programming in progress.

• Memorising or Deleting the Radio Transmitters

On

It flashes

Off Indicates the slow “Motor speed” during normal functioning.

Indicates the fast “Motor speed” during normal functioning.

• Function programming in progress.

• If it flashes together with L3 it means that the user must carry out the recognition of the door opening and

closing positions (refer to Paragraph “4.2 Recognition of the door opening and closing positions”).

On

It flashes

Off During normal operation the device indicates “Automatic Closing” is inactive.

During normal operation the device indicates “Automatic Closing” is active.On

It flashes

7.8) Accessories

The following optional accessories are available for SPIN. For information on the complete range of accessories, refer to the Nice s.p.a.

product catalogue.

For all versions

• SPA2 Mechanical release with metal cord. For use in systems

which envisage only the automated door as point of access.

For all versions

• SPA5 Oscillating arm. Required if the door to be automated is an

overhead type with springs or counterweights.

Page 26

26

Emergency power supply No

Flashing Light Output For 1 LUCYB flashing light (12V, 21 W)

SPIN Courtesy Light

SPIN/V1 Courtesy Light

12V-21W BA15 socket

12V-21W BA15 socket

Use in acid, saline or potentially explosive

atmosphere

225 x 330 h 100 / 3,3Kg

Nice S.p.a., in order to improve its products, reserves the right to modify their technical characteristics at any time without prior notice. In

any case, the manufacturer guarantees their functionality and fitness for the intended purposes.

All the technical characteristics refer to a room temperature of 20°C (±5°C).

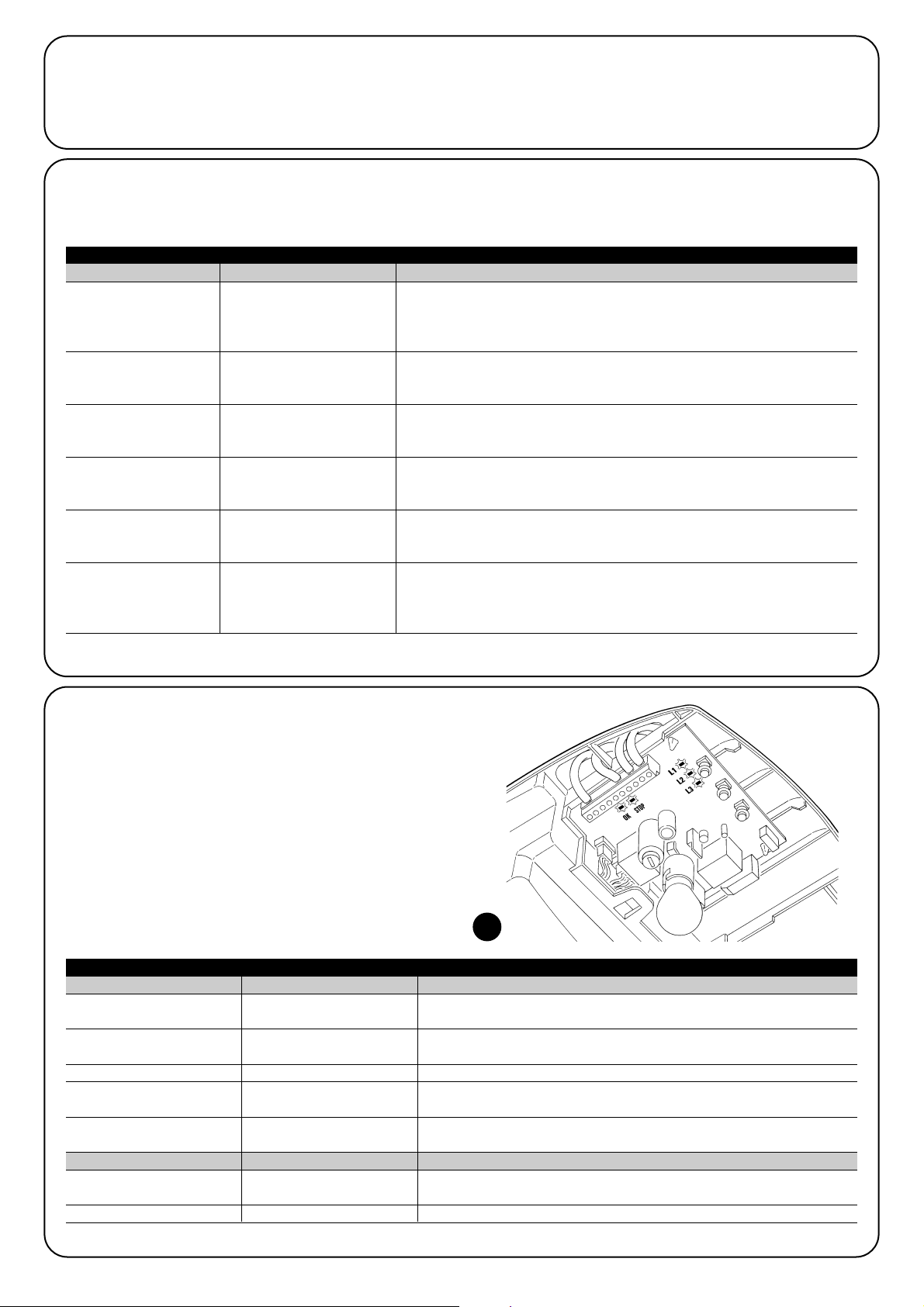

8) Technical characteristics

Ty pe

Technical characteristics: SPIN

Electromechanical gearmotor for the automatic movement of garage doors for residential

use, complete with electronic control unit

Pinion Diameter 9.5 mm, 28 teeth; for guides SNA11 and guides supplied with SPIN10KCE

Model: SN6011

Peak thrust

[corresponds to the force necessary to start

a leaf]

9.9Nm

[550N]

4.95Nm

[275N]

Nominal torque

[corresponds to the force necessary to keep

a leaf moving]

Speed under no load

[corresponds to if “Fast” speed is

programmed]

103 rpm

[0,14m/s]

The control unit enables programming 2 speeds equal to approx. 100% - 60% approx.

Nominal torque speed

[corresponds to if “Fast” speed is

programmed]

52 rpm

[0,07m/s]

Maximum frequency of operating cycles 30 cycles per day (the control unit allows up to the maximum described in tables 3 and 4)

Maximum continuous operating time

3 minutes (the control unit limits the continuous operation up to the maximum described in

tables 3 and 4)

Operating limits

In general, SPIN is suitable for the automation of sectional or overhead doors which remain

within the dimensions stated in table 2 and limits specified in Tables 3 and 4.

Max. absorbed power 200W

Insulation class 1 (a safety grounding system is required)

STOP Input

For normally close or normally open contacts or for constant resistance

8,2KΩ with self-recognition (any variation from the memorized status causes the “STOP”

command)

Step-by-step Input

For normally open contacts (the closing of the contact causes the “STEP-BY-STEP” command)

Radio AERIAL Input 52Ω for RG58 or similar type of cable

Radio receiver Incorporated

SPIN Power Supply

SPIN/V1 Power supply

230Vac (±10%) 50/60Hz.

120Vac (±10%) 50/60Hz.

Programmable functions 6 ON-OFF functions and 6 adjustable functions (see tables 15, 15a and 17, 17a)

Operating temperature -20°C ÷ 50°C

No

Protection class IP 40 use only in indoor or protected environments

Dimensions and weight

Recognition functions

Recognition of the type of “STOP” device (NO or NC contact or 8,2KΩ resistance).

Recognition the door opening and closing positions and calculation of the slowdown and

partial opening points.

Model: Guide in SPIN10KCE SNA11

Type 3-piece profile in galvanised steel single profile in galvanised steel

Guide length 3.15m 3.15m

Guide height 35mm 35mm

Useful stroke 2.6m 2.6m

Belt width 6m 6m

Belt height 6mm 6mm

Resistance to traction 730N 730N

Guide technical characteristics

Page 27

27

GB

Technical characteristics incorporated radio receiver

Type 4 channel receiver for incorporated radio command

Frequency 433.92MHz

Coding Digital Fixed code with 12 Bit code, FLO type

Digital Rolling code with 52 Bit code, FLOR type

Digital Rolling code with 64 Bit code, SMILO type

Transmitter compatibility (1) FLO, VERY VE

FLOR, VERY VR; only single group: ERGO, PLANO,

SMILO

Transmitters memorized Up to 160 if memorized in mode 1

Input impedance 52Ω

Sensitivity better than 0.5µV

Range of the transmitters From 100 to 150 m. The range can vary if there are obstacles or electromagnetic disturbances,

and is affected by the position of the receiving aerial

Outputs /

Operating temperature -20°C ÷ 55°C

Note 1: the first transmitter that is introduced also determines the type introduced afterwards.

Type 2 channel transmitter for radio command

Frequency 433.92MHz

Coding Fixed Code with Digital Rolling code with Digital Rolling code with

12 Bit code, FLO type 52 Bit code, FLOR type 64 Bit code, SMILO type

Keys 2

Power supply 12Vdc with 23A battery

Absorption 25mA

Battery life 1 year, estimated on the basis of 20 commands/day, each lasting 1s at 20°C

(at low temperatures the efficiency of the batteries decreases)

Irradiated power 100µW

Dimensions and weight 72 x 40 h 18mm / 30g 72 x 40 h 18mm / 30g Diameter 48 h14mm / 19g

Protection class IP40 (suitable for use indoors or in protected environments)

Operating temperature -40°C ÷ 85°C

Technical characteristics transmitter: FLO2 transmitter: FLO2R-S transmitter: SM2

Page 28

Page 29

29

GB

Congratulations on your purchase of a Nice automa-

tion. Nice S.p.a. produces components for the automation

of gates, doors, shutters, rolling shutters and sun

awnings: gearmotors, control units, radio controls, flashing lights, photocells and accessories. Nice uses exclusively top quality materials and processes, and by vocation researches into the most innovative solutions to

ensure the utmost simplicity of equipment use, with special attention to technical solutions, aesthetics and

ergonomics: given the vast range of Nice products, your

installer will certainly find the ideal product for your requirements. However, Nice is not the manufacturer of your