Page 1

TECHNICAL MANUAL

Pulse Oximeter Tester

Model SRC-2

To contact Mallinckrodt’s representative: In the United States,

call 1-800-635-5267 or (314)-654-2000; outside of the United States,

call your local Mallinckrodt representative.

© 2000 Mallinckrodt Inc. All rights reserved. 060288A-1000

Page 2

Mallinckrodt Inc.

675 McDonnell Boulevard

P.O. Box 5980

St. Louis, MO 63134 USA

Telephone 314.654.2000

Toll Free 1.800.635.5267

Mallinckrodt

Europe BV

Hambakenwetering 1

5231 DD’s-Hertogenbosch

The Netherlands

Tel +31.73.6485200

Nellcor Puritan Bennett

4280 Hacienda Drive

Pleasanton, CA 94588 USA

Nellcor Puritan Bennett is a wholly owned subsidiary of Mallinckrodt Inc.

Nellcor is a trademark of Mallinckrodt Inc. C-Lock is a trademark of Mallinckrodt Inc.

To obtain information about a warranty, if any, for this product, contact Mallinckrodt

Technical Services or your local Mallinckrodt representative.

Covered by one or more of the following U.S. Patents and foreign equivalents: 4,621,643;

4,700,708; 4,770,179.

Page 3

CONTENTS

Figures

Tables

Introduction ............................................................................. 1

Electromagnetic Interference ............................................. 1

Unpacking and Inspection .................................................. 2

Manual Introduction ............................................................ 2

Tester Description .............................................................. 3

Guide to Operation.................................................................. 5

Front Panel ......................................................................... 5

Switches and Indicators ..................................................... 6

Basic Operation with Oximeter........................................... 7

Test 1 ........................................................................... 7

Test 2 ........................................................................... 7

Test 3 ........................................................................... 8

Test 4 ........................................................................... 8

Test 5 ........................................................................... 8

Test 6 ........................................................................... 10

Circuit Analysis ....................................................................... 11

Introduction......................................................................... 11

Input Rectifier and Power Circuit........................................ 12

Light Amplitude and Modulation Circuits ............................ 12

Oscillator and Pulse Generator .......................................... 13

ECG Trigger Output (not used by N-20 series) .................. 14

Calibration Resistor ............................................................ 14

Routine Maintenance .............................................................. 15

Service................................................................................ 15

Cleaning Instructions .......................................................... 15

Technical Assistance .......................................................... 15

Returning the SRC-2 .......................................................... 16

Environmental Statement ................................................... 16

iii

Page 4

Contents

Troubleshooting...................................................................... 17

Disassembly Guide ................................................................. 19

Testing and Verification ......................................................... 23

Spare Parts .............................................................................. 35

Specifications .......................................................................... 37

Schematic Diagram ................................................................. 41

Introduction......................................................................... 17

Introduction......................................................................... 19

Disassembly Procedure...................................................... 19

Assembly Procedure .......................................................... 21

Introduction......................................................................... 23

Test Equipment Required................................................... 23

Connector Continuity Test .................................................. 24

Calibration Resistor Test .................................................... 26

Power Distribution Tests .................................................... 27

Oscillator Circuit Tests ....................................................... 28

Gain/Modulation Verification .............................................. 29

ECG Trigger Output Tests.................................................. 33

Overview............................................................................. 35

Controls .............................................................................. 37

Input/Output Connectors .................................................... 38

Calibration Resistors .......................................................... 38

Accuracy............................................................................. 38

Signal Output...................................................................... 38

Emissions Compliance ....................................................... 39

Environmental..................................................................... 39

Mechanical ......................................................................... 39

Overview............................................................................. 41

iv

Page 5

FIGURES

1 Front Panel........................................................................ 5

2 Overall Block Diagram ...................................................... 11

3 SRC-2 Exploded View....................................................... 20

4 Ten-Position Header Connector (P2)................................ 24

5 Nine-Position Oximeter D-Connector................................ 24

6 Main PCB Component Location........................................ 41

S-1 Schematic, PCB ................................................................ 43

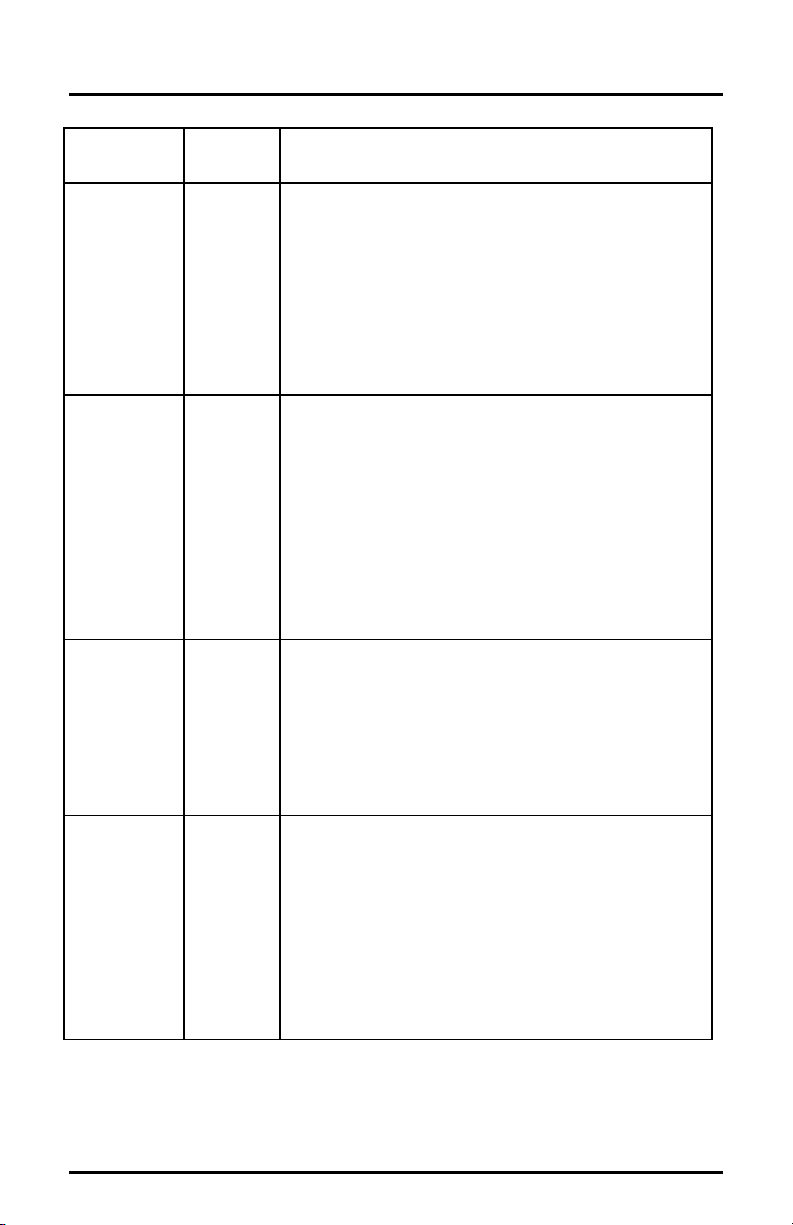

TABLES

1 Connector Pins.................................................................. 25

Contents

v

Page 6

THIS PAGE INTENTIONALLY LEFT BLANK

Page 7

INTRODUCTION

Electromagnetic Interference

Unpacking and Inspection

Manual Introduction

Tester Description

ELECTROMAGNETIC INTERFERENCE

This device has been tested and found to comply with the limits of

the Electromagnetic Compatibility Directive 89/336/EEC. These

limits are designed to provide reasonable protection against

harmful interference in a typical installation. However, because of

the proliferation of radio-frequency transmitting equipment and

other sources of electrical noise in the health-care and home

environments (for example, cellular phones, mobile two-way

radios, electrical appliances), it is possible that high levels of such

interference due to close proximity or strength of a source, may

result in disruption of performance of this device.

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference with other devices in

the vicinity. Disruption or interference may be evidenced by

erratic readings, cessation of operation, or other incorrect

functioning. If this occurs, the site use should be surveyed to

determine the source of this disruption, and actions taken to

eliminate the source.

The user is encouraged to try to correct the interference by one or

more of the following measures:

Turn equipment in the vicinity off and on to isolate the offending

equipment.

Reorient or relocate the other receiving device.

Increase the separation between the interfering equipment and

this equipment.

If assistance is required, contact Mallinckrodt’s Technical

Services Department or your local Mallinckrodt representative.

1

Page 8

Introduction

UNPACKING AND INSPECTION

Upon receipt, inspect the shipping container, if it is damaged,

immediately notify the carrier. The shipping container holds one

SRC-2, one ECG patch cord cable Type L, and one service

manual. Inspect each item, if the SRC-2, the patch cord cable, or

the service manual is missing or damaged, immediately contact

Mallinckrodt’s Technical Services Department or Mallinckrodt’s

local representative.

MANUAL INTRODUCTION

WARNING: Carefully read the operating instructions and all

precautionary information (set in boldface type) before use.

This manual provides service information for the Nellcor pulse

oximeter tester, model SRC-2. The SRC-2 is not intended for use

with Nellcor pulse oximeter models N-10, N-30, or the 4-button

N-100.

Note: This information is intended only for use by qualified

service personnel.

The first three sections describe the SRC-2, give instructions for

using it to test pulse oximeters, and provide a circuit description.

The remaining sections describe troubleshooting, disassembly,

test and calibration verification procedures, and provide a

schematic diagram and a spare parts lists.

2

Page 9

TESTER DESCRIPTION

The SRC-2 tests the light emitting diode (LED) drive circuits and

internal detect circuits of Nellcor pulse oximeters. The SRC-2 is

powered by the oximeter LED drive signals. Switches allow the

selection of RATE, LIGHT, and MODULATION levels, mode of

operation and RCAL. (RCAL is a parameter used to select the

calibration curve.) LEDs provide an indication that drive signals

from the oximeter are active.

Introduction

Note: This device is designed to verify the calculated SpO

2

value at 81% ±2, and not any other values.

Note: Due to the pulse wave shape generated by the SRC-2

tester and Nellcor’s oximetry sampling technique, the

pulse rate tolerance at high pulse rates slightly exceeds the

oximeter’s pulse rate accuracy specification. The

oximeter’s pulse rate specification is based on the clinical

performance with physiological pulses rather than the

square wave pulses generated by the SRC-2 tester.

Note: The SRC-2 is intended to be used to assist verification of

the operation of Nellcor oximeters and is not to be used to

verify calibration of these oximeters. Refer to the

oximeter’s service manual for calibration instructions, if

applicable.

3

Page 10

THIS PAGE INTENTIONALLY LEFT BLANK

Page 11

GUIDE TO OPERATION

Front Panel

Switches and Indicators

Basic Operation with Oximeter

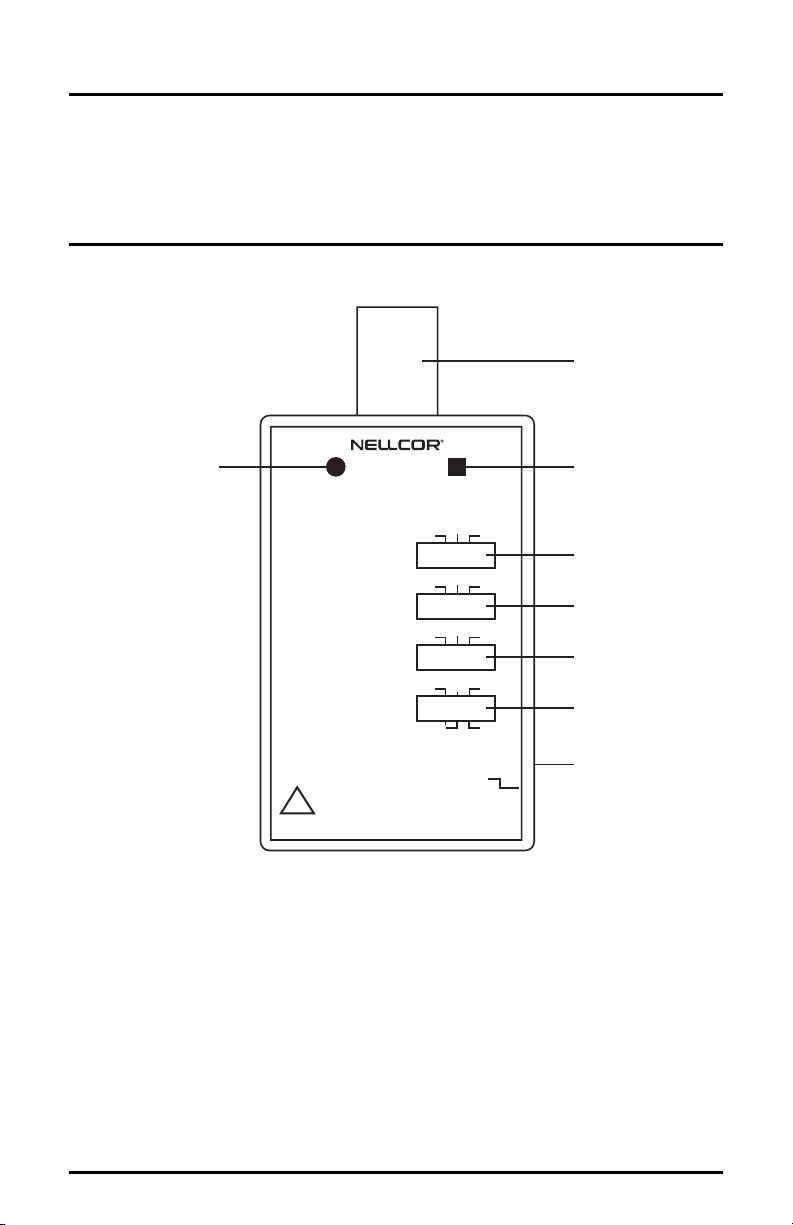

FRONT PANEL

2

1

IR

RED

112

20138

RATE

HIGH 1

LOW

HIGH 2

LIGHT

LOW

HIGHOFF

MODULATION

RCAL/MODE

RCAL 63RCAL 64

LOCALREMOTE

C-LOCK TEST

!

MODELS N-10, N-30, OR 4-BUTTON N-100

MODEL SRC-2

NOT FOR USE WITH NELLCOR

Figure 1: Front Panel

1. IR LED drive input indicator.

2. Standard oximeter connector.

3. RED LED drive input indicator.

4. Pulse RATE selector switch (38, 112, 201)

5. LIGHT output switch (low, high 1, high 2)

6. MODULATION selector switch (off/low/high)

7. RCAL/MODE selector switch

3

4

5

6

7

8

8. C-Lock® TEST input connector

5

Page 12

Guide to Operation

SWITCHES AND INDICATORS

The SRC-2 front panel has four switches and two LED indicators.

• The IR LED drive indicator (1) and the RED LED drive

indicator (3) illuminate when the OXIMETER is switched

ON and the SRC-2 is connected to it. The LEDs indicate that

the oximeter LED drive circuit signals are functional.

• The RATE switch (4) sets internally generated pulse rates: 38

beats/minute (bpm), 112 bpm, and 201 bpm.

• The LIGHT switch (5) has three positions (low, high 1, and

high 2). Low simulates a condition of dark-colored skin or

thick tissue between the sensor LEDs and the photo detector.

The two high settings simulate conditions of light-colored

skin or thin tissue between the sensor LEDs and the photo

detector.

• The MODULATION switch (6) has three positions (off, low,

and high) and controls amplitude of modulation. The high

setting is equivalent to strong pulse signals detected by an

oxygen transducer, and low setting is equivalent to weak

pulse signals.

• The RCAL/MODE switch (7) selects SRC-2 controlled pulse

rates, light level, and modulation when set to LOCAL, while

also testing the RCAL 63 resistor. When set to REMOTE,

local functions are disabled. When set to RCAL 64, this

resistor is selected.

Note: REMOTE mode is reserved for future use. Do not

use this mode with test procedures in this manual.

6

Page 13

BASIC OPERATION WITH OXIMETER

1. Turn the oximeter off.

2. Connect the SRC-2 to the sensor connector.

3. Turn the oximeter on.

Ensure that the SRC-2 IR and RED LED drive indicators are

both lit.

4. Set the RCAL/MODE switch to RCAL 63/Local.

5. Set the LIGHT and MODULATION switches as required by

test procedures 1–4 listed on the following page. Allow the

oximeter a few seconds to obtain a steady reading.

6. Observe and record the OXIMETER SpO

saturation and pulse rate. These readings should be within the

specifications defined in each of the tests listed below.

Test 1

1. Set the LIGHT switch to HIGH 1.

Guide to Operation

readings for

2

Test 2

2. Set the MODULATION switch to HIGH.

3. Set the RATE switch to 112.

4. Verify the following readings on the oximeter:

Saturation (%): 81 ±2

Rate (bpm): 112 ±2% (110 to 114)

1. Set the LIGHT switch to LOW.

2. Set the MODULATION switch to LOW.

3. Set the RATE switch to 201.

4. Verify the following readings on the oximeter:

Saturation (%): 81 ±2

Rate (bpm): 201 ±3% (195 to 207)

7

Page 14

Guide to Operation

Test 3

1. Set the LIGHT switch to HIGH 2.

Note: For the N-100C oximeter, use the high 1 setting.

2. Set the MODULATION switch to LOW.

3. Set the RATE switch to 38.

4. Verify the following readings on the oximeter:

Saturation (%): 81 ±2

Rate (bpm): 38 ±2% (37 to 39)

Test 4

1. Set the LIGHT switch to LOW.

2. Set the MODULATION switch to HIGH.

3. Set the rate switch to 201.

4. Verify the following readings on the oximeter:

Test 5

8

Saturation (%): 81 ±2

Rate (bpm): 201 ±3% (195 to 207)

1. Set the modulation switch to OFF.

2. Set the RCAL switch to RCAL 63.

3. On the oximeter, locate the applicable memory location:

Page 15

Guide to Operation

Oximeter

N-20 Series

N-100C

N-200

N-180/N-185

N-1000/

N-2500

N-6000/

N-6000B

Memory

Location

9

9

3

9

Service

Screen

SpO2

board

Procedure for finding correct

memory location.

Note: The RCAL value cannot be displayed on

N-20 series oximeters.

1. On the oximeter, press the high sat and audio

alarm off buttons simultaneously.

2. Rotate the control knob until “9” (“3” for the

N-180/N-185) appears in the SAT display field.

3. Note the RCAL value displayed in the Rate

display field.

1. From the main menu, press SETUP.

2. Press OFFLINE MENU.

3. Move the curser to ENGINEERING MENU,

then press EXECUTE.

4. Move the cursor to EXAMINE SAT MEMORY,

then press EXECUTE.

5. Rotate the control knob clockwise to reach item

#9.

6. Note the displayed RCAL value.

1. On the monitor, press the FREEZE button.

2. Press unlabeled menu soft keys 2 and 4

simultaneously.

3. Press “Service” soft key.

4. Press “SpO2” soft key.

5. Note displayed “CALIB. INDEX” RCAL value.

N-3000 Service

Menu,

item #30

1. While simultaneously holding down the upper

and lower limit buttons and the print button,

turn the oximeter on.

2. After the tone, release the three buttons.

3. Press the print button again to confirm that you

are in the service mode.

4. Rotate the control knob to reach item #30.

5. Press the upper limit key.

6. Note displayed RCAL value.

9

Page 16

Guide to Operation

4. Verify displayed value to be 63.

5. Change the SRC-2 RCAL switch to RCAL 64.

6. On the monitor, verify that the displayed value changes to 64

within 10 seconds.

Test 6

Note: Test 6 is used only on the N-200, N-1000/N-2500, and

N-6000 series monitors.

1. Use the PC-L cord to connect the SRC-2 C-Lock

connector to the oximeter C-Lock or ECG IN connector.

2. Power up the oximeter.

3. Set the LIGHT switch to LOW.

4. Set the MODULATION switch to LOW.

5. Set the RATE switch to 201.

6. Set the RCAL switch to RCAL 63.

7. Verify the following readings on the oximeter:

®

TEST

10

Saturation (%): 81 ±2

Rate (bpm): 201 ±3% (195 to 207)

8. Ensure that the “C-Lock” or “ECG in Use” indicator lights up

on the oximeter.

Page 17

CIRCUIT ANALYSIS

Introduction

Input Rectifier and Power Circuit

Light Amplitude and Modulation Circuits

Oscillator and Pulse Generator

ECG Trigger Output (not used on N-20 series)

Calibration Resistor

INTRODUCTION

This section discusses SRC-2 operation at the block diagram

level. Refer to Figure 2 and the schematic diagram.

Simulated sensor

output to oximeter

LED drives

from oximeter

Amplifier

Rectifier

and power

circuit

Light switch

Modulation

switch

+Vcc

Remote

Pulse

conditioning

Pulse

rate

generator

38

112

201

Local

ECG

generator

ECG

trigger

63

RCAL

64

Crystal

Figure 2: Overall Block Diagram

This section is divided into the following circuit subsections:

• Input rectifier and power circuit

• Light amplitude and modulation circuits

• Oscillator, divider, and pulse generator

• ECG trigger output.

• Calibration resistor (RCAL)

11

Page 18

Circuit Analysis

INPUT RECTIFIER AND POWER CIRCUIT

Schottky diodes CR4 and CR5 shunt the LED drive signal at J1–5

and J1–6 to ground, and provide a power source of approximately

4.5 V. The full wave bridge rectifier (DS1, DS2, CR2, CR3, and

the parallel load resistors R4 and R5) transforms the LED drive

signal to an offset unipolar signal, which is sensed at the

differential amplifier U4.

The output, measured at U4–14, is 5 mV per mA of input current.

The output of the following amplifier U4–1, measured at (TP4),

has a gain of four. The output waveform at U4–1 corresponds to

the absolute value of the incoming LED drive current, with a

resultant voltage output to current input conversion ratio of 20

mV/mA.

The LED drive signal may be sent directly to the output connector

through S4–3, 2 (REMOTE) to J2–1; or, it may be routed through

the light amplitude and modulation circuitry to create pulses

before being sent to the output connector through S4–1, 2

(LOCAL) to J2–1.

LIGHT AMPLITUDE AND MODULATION CIRCUITS

The signal at U4–1 is routed through S2–6 and R12 to voltage

follower U4–5, 6, 7. When Q1 is off (Q1 gate/TP5 low), both R13

and R14 are out of the circuit and the signal passes straight to the

output at U4–7. This allows the relative light level to be selected

using S2–1.

The HIGH light level signal from U4–7 passes through R8 in

HIGH 2 setting and through the series combination of R8 and R30

in HIGH 1 setting. The signal is routed to S2–3 with a scale factor

of 267 nA/mA or 100 nA/mA of LED drive, respectively.

12

Page 19

The LOW light level signal is created by dividing the HIGH light

level signal by 11 through voltage divider R19 and R20. The

LOW light level signal from U4–8 passes through R7, and is

routed to S2–3 at a scale factor of 7 nA/mA.

The signal at U4–1 is modulated when Q1 is switched on by the

oscillator circuitry (TP5 high) to create a voltage divider.

R14 in conjunction with R12 creates a reduction in signal level

corresponding to the HIGH modulation setting.

R13 in conjunction with R12 creates a reduction in signal level

corresponding to the LOW modulation setting.

The shape of the modulating wave is modified from a square wave

by high pass network C12 and R36.

OSCILLATOR, DIVIDER, AND PULSE GENERATOR

The pulse rate signal used to switch the gate of Q1 is derived from

the oscillator and divider circuits consisting of U1, U2, U3, Y1,

and RATE switch S1.

Circuit Analysis

The oscillator circuit consists of the 32.768 kHz crystal Y1, the

fourteen stage counter U3, and the NAND gate U1. U3 is used to

divide down the high frequency. It does this by combining the

outputs Q13 (4096), Q12 (2048), Q10 (512), Q9 (256) and Q6

(32) in a four-bit word at U1, which resets the counter at the

required frequency.

This frequency is determined by the RATE switch S1 pins 1, 2 &

4. The 32,768 Hz crystal input signal is divided by 4896 to 6.6928

Hz (201), 4384 to 7.4745 Hz (112) and 6432 to 5.0945 Hz (38),

which is provided as the input to the U2 ripple counter.

The U2 ripple counter divides the oscillator signal to achieve the

selected pulse generator output RATE, via S1 pins 5, 7, & 8,

which drives the modulator circuitry.

13

Page 20

Circuit Analysis

With the RATE setting of 201, U2 divides the 6.6928 Hz signal

by 2 to 3.3464 Hz, which equals 200.784 bpm. With the RATE

setting of 112, U2 divides the 7.4745 Hz signal by 4 to 1.8686 Hz,

which equals 112.1175 bpm. And, with the RATE setting of 38,

U2 divides the 5.0945 Hz signal by 8 to 0.6368 Hz, which equals

38.20875 bpm. These signals are selected by the RATE switch S1

and routed from S1–6 to the gate of Q1 for modulating the U4–1

signal output.

The Pulse Generator circuit is disabled when the MODULATION

switch S3 is placed in the OFF position. In the OFF position, U2

is placed in the RESET state when Vcc is applied to pin U2-2 via

S3-6 and S3-8.

ECG TRIGGER OUTPUT

Note: ECG Trigger Outpug is used only on the N-200,

N-1000/N-2500, and N-6000-series monitors.

The ECG trigger output is formed by wave-shaping the rising

edge of the gate drive pulse output from S1–6. This signal is

capacitively coupled through C10 to R23 where it exponentially

decays at a time constant of 25 ms. This 4.2 V peak signal is then

divided by two through R24 and R25 and presented at the base of

Q2.

Q2 is an emitter follower, supplied by an approximate 0.6 V

supply consisting of R28 and forward-biased CR6. This limits the

positive peak of the output signal to approximately 0.5 V once the

saturation voltage of Q2 is subtracted. This signal at output

(TP10) is approximately 25 ms wide.

CALIBRATION RESISTOR (RCAL)

R9 is a 768Ω resistor that notifies the oximeter that an SRC-2 is

attached (RCAL 63), and allows the oximeter diagnostics to be

activated. R31 is a 6.04 kΩ resistor used when RCAL/MODE

switch is set to RCAL 64.

14

Page 21

ROUTINE MAINTENANCE

Service

Cleaning Instructions

Technical Assistance

Returning the SRC-2

Environmental Statement

SERVICE

WARNING: Carefully read the operating instructions and all

precautionary information (set in boldface type) before use.

The SRC-2 requires no routine service other than that which is

mandated by your local institution.

CLEANING INSTRUCTIONS

Caution: Do not immerse the SRC-2 in liquid or use caustic or

abrasive cleaners.

To clean the SRC-2 surfaces, dampen a cloth with a commercial,

nonabrasive cleaner and wipe the surfaces lightly. Do not spray or

pour any liquid directly on the SRC-2. Do not allow any liquid to

penetrate switches, connectors, or openings in the chassis.

TECHNICAL ASSISTANCE

For technical information and assistance or to order parts, contact

Mallinckrodt’s Technical Services Department or Mallinckrodt’s

local representative.

15

Page 22

Routine Maintenance

RETURNING THE SRC-2

If it is necessary to return the SRC-2, call Mallinckrodt’s

Technical Services Department for shipping instructions.

Pack in the original shipping carton. If the carton is not available,

use a suitable box with an appropriate amount of packing material.

ENVIRONMENTAL STATEMENT

Follow local governing ordinances and recycling plans regarding

disposal or recycling of device components.

16

Page 23

TROUBLESHOOTING

Introduction

INTRODUCTION

This section describes troubleshooting for the SRC-2. If questions

arise, contact Mallinckrodt’s Technical Services Department or

your local Mallinckrodt representative.

1. No saturation or pulse rate readings.

• Ensure that the MODE switch is in the LOCAL/RCAL

63 position.

• MODULATION switch is in the OFF position. Select

LOW or HIGH setting.

• Try the SRC-2 on another oximeter.

• Refer to test and calibration procedures.

2. Saturation or pulse rate readings are too high or too low.

• Ensure that the MODE switch is in the LOCAL/RCAL

63 position.

• Try the SRC-2 on another oximeter.

• Refer to the applicable oximeter service manual for

further troubleshooting information.

3. No C-Lock

• Ensure PC-L cable is plugged in at both ends.

• Check cable for continuity.

• Try another oximeter.

17

Page 24

THIS PAGE INTENTIONALLY LEFT BLANK

Page 25

DISASSEMBLY GUIDE

Introduction

Disassembly Procedure

Assembly Procedure

INTRODUCTION

This section describes how to disassemble the SRC-2 for

troubleshooting or testing. An assembly procedure is also

included. Figure 3 shows the SRC-2 exploded view.

DISASSEMBLY PROCEDURE

1. Slide all switches fully toward the center of the top cover.

2. Using a No. 2 Phillips screwdriver, remove the screw from

the back of the case.

3. Hold the SRC-2 together and turn it topside up. Separate the

two halves of the case by pulling gently on the top and the

bottom covers. Set the top cover assembly aside.

4. Remove the printed circuit board assembly from the bottom

cover’s PCB locating pins by pulling gently straight up.

5. Disconnect the cable from the PCB.

6. To replace the oximeter connector cable, remove the cable

assembly from the bottom cover by lifting straight up.

7. To replace the bottom cover, the end plug may be removed

from the bottom cover by pulling upward.

8. To replace the switch caps:

• Remove the top cover.

• Slide the switch cap toward the outer edge of the top

cover.

• Lift out the end of the cap that points toward the center.

19

Page 26

Disassembly Guide

10

1

2

3

4

5

20

9

Figure 3: SRC-2 Exploded View

1. Switch label 6. Bottom cover

2. Switch caps 7. Product Label

3. Top cover 8. Pan head screw

4. Main PCB assembly 9. End plug

5. Oximeter D-connector assembly 10. Ten-position header

connector

6

7

8

Page 27

ASSEMBLY PROCEDURE

1. Refer to Figure 3 for proper orientation of the parts within the

final assembly.

2. Slide the end plug into the bottom cover at the end nearest the

small half-round cutout C-Lock test jack in the cover side

edge.

3. To install the oximeter connector cable assembly, ensure that

the

9-pin D-connector is aligned with the row of five pins at the

top. Align the slot in the bottom cover between the ribs on the

connector and push downward.

4. Loop the cable around the molded screw boss so that the

cable lies in the center of the cover. Plug the 10-position

connector end into J2 on the PCB.

5. Position the PCB such that the LEDs are at the same end as

the

D-connector. Then press the PCB gently down over the three

locating pins.

6. Carefully align and apply the top cover label.

Disassembly Guide

7. With the top cover outer surface facing up, install the four

switch caps in the slots by tipping them into the slots. Slide

the caps fully toward the outside edge of the cover before

pressing them into place. Note that the slot closest to the halfround cutout in the cover edge is left empty.

8. Position the four switches (S1, S2, S3, S4) on the PCB in the

center location. Position S5 in the Right location.

9. Position the switch caps toward the center of the switch slot.

10. Place the top cover assembly over the bottom cover

assembly, ensuring that the switches (S1–S4) on the PCB are

in the center position, and aligned with the switch caps.

11. Press the top and bottom covers together. Turn over the

assembly and replace the screw. Using a No. 2 Phillips

screwdriver, tighten until firm (about 8–9 in-lb torque).

12. Reapply bottom cover label.

21

Page 28

THIS PAGE INTENTIONALLY LEFT BLANK

Page 29

TESTING AND VERIFICATION

Introduction

Test Equipment Required

Connector Continuity Test

RCAL Resistor Test

Power Distribution Tests

Oscillator Circuit Tests

Gain/Modulation Verification

INTRODUCTION

This section outlines procedures for testing SRC-2 operation.

Testing involves disassembling the unit to gain access to test

points on the PCB and pins on J2.

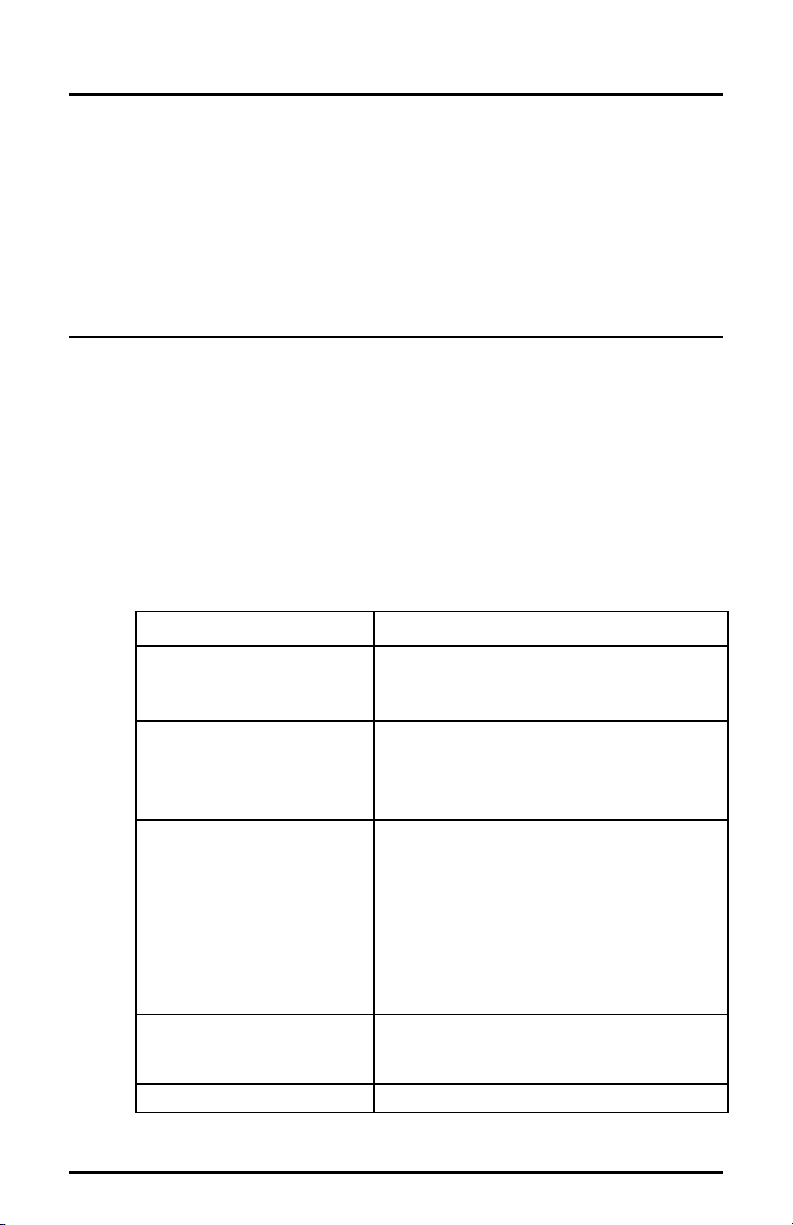

TEST EQUIPMENT REQUIRED

Testing the SRC-2 requires the following commercially available

test equipment.

Equipment Characteristics

Oscilloscope:

Tektronix Model 465,

or equivalent

Frequency Counter:

Hewlett-Packard

Model 5314A,

or equivalent

Digital Multimeter:

FLUKE Model 8840A, or

equivalent

(Note: two meters are

required.)

DC Power Supply:

Topward Model

TPS-4000D, or equivalent.

Variable Resistor:

• Bandwidth: 15 MHz.

• Input impedance: >10 MΩ

• Vertical sensitivity: 10 mV/div.

• Frequency: 1 MHz, minimum.

• Input impedance: > 1 MΩ.

• Minimum sensitivity:

• 100 mV p–p.

• Accuracy: ± 0.5%.

• DC voltage measurement range:

200 mV to 10 V, full scale.

• Resolution: 4 digits.

• DC current measurement range:

200 µA to 1 A, full scale.

• Resistance measurement range 200 Ω

to 20 MΩ, full scale.

• Output: 0 to 5 V, 0 to 100 mA.

• Resistance: 0 to 100 Ω.

23

Page 30

Testing and Verification

CONNECTOR CONTINUITY TEST

Measure continuity from the nine-position oximeter D-connector

to the ten-position header P2 on the SRC-2. (Refer to Table 1.)

Verify resistance at 0.5 ohms maximum, between connector pins.

Refer to the illustrations below for connector and header pin

locations. Note that these views are looking into the cable

connector at each respective end.

Key

2 4

1 3 5 7 9

Figure 4: Ten-Position Header Connector P2

6 8

10

24

12345

6789

Figure 5: Nine-Position Oximeter D-Connector

Note: One version of the SRC-2 has a D–connector with only

seven pins present, as compared to nine pins on the older

version. Determine the connector type and use the

information in the following table to test continuity, as

appropriate, between the oximeter D–connector pins and

the pins on 10–position header connector P2.

Page 31

Table 1: Connector Pins

Nine-Position Oximeter

D-connector Pins

12

26

35

∗

4

51

63

7 9, 10 (inner, outer shield)

8

*

9 No connection

No connection 4 (key)

Header Connector P2 Pins

Testing and Verification

Ten-Position

7

8

∗

These pins are not present in newer connectors. If all nine pins are present and

the sockets or holes for pins 4 and/or 9 are not present in your cable, contact

Mallinckrodt’s Technical Services Department or your local Mallinckrodt

representative for further instructions.

25

Page 32

Testing and Verification

CALIBRATION RESISTOR TEST

1. Orient the Printed Circuit Board Assembly (PCBA) with the

component side up and connectors J1 and J2 on the left hand

side.

2. Set the actuators (contacts) on the switches as follows:

S1 FAR RIGHT (RATE = 201 BPM)

S2 FAR RIGHT (LIGHT = HIGH 2)

S3 FAR RIGHT (MODULATION = HIGH)

S4 FAR RIGHT (LOCAL/ RCAL 63)

S5 RIGHT (CONTACT not used)

3. On the PCBA, connect a digital multimeter between J2,

pins 2 and 3. Verify that the resistance is between 760 Ω

and 776 Ω.

4. Slide the actuator on S4 to the middle position (REMOTE).

Verify that the resistance is between 760 Ω and 776 Ω

5. Slide the actuator on S4 to the far left position (RCAL 64).

Verify the resistance is between 5.98 kΩ and 6.10 kΩ.

26

6. Slide the actuator on S4 back to the far right position

(LOCAL/RCAL 63).

7. On the PCBA, connect the digital multimeter between J1,

pins 2 and 3. Verify that the resistance is between 760 Ω and

776 Ω.

8. On the PCBA, connect the digital multimeter between J1,

pins 7 and 8. Verify that the resistance is between 3.88 kΩ

and 3.92 kΩ.

9. On the PCBA, connect the digital multimeter between TP6

and TP11. Verify that the resistance is between 74.3 kΩ and

75.8 kΩ.

10. Move the actuator on S2 to the middle position (LIGHT =

HIGH).Verify that the resistance is between 197 kΩ and

201 kΩ.

Page 33

11. On the PCBA, connect the digital multimeter between TP3

and TP11.

12. Move the actuator on S2 to the far left position (LIGHT =

LOW) Verify that the resistance is between 198 kΩ and

202 kΩ.

13. On the PCBA, connect the digital multimeter between TP4

and TP11.

14. Move the actuator on S4 to the middle position (REMOTE).

Verify that the resistance is between 198 kΩ and 202 kΩ

15. On the PCBA, connect the digital multimeter between TP7

and TP11.

16. Move the actuator on S4 to the far left position (RCAL 64).

Verify that the resistance is between 198 kΩ and 202 kΩ.

POWER DISTRIBUTION TESTS

1. Orient the Printed Circuit Board Assembly (PCBA) with the

component side up and connectors J1 and J2 on the left hand

side.

Testing and Verification

2. Set the actuators (contacts) on the switches as follows:

S1 FAR RIGHT (RATE = 201 BPM)

S2 FAR RIGHT (LIGHT = HIGH 2)

S3 FAR RIGHT (MODULATION = HIGH)

S4 FAR RIGHT (LOCAL/ RCAL 63)

S5 RIGHT (CONTACT)

3. On the PCBA, connect the negative output from the power

supply to J2, pin 10.

4. Connect the positive output to J2, pin 6.

5. On the power supply, set the output to 4.5 volts.

6. On the PCBA, connect a digital multimeter between TP7 and

TP8. Verify that the voltage is greater than 4.2 volts.

27

Page 34

Testing and Verification

7. On the power supply, disconnect the lead from the positive

output.

8. Connect an ammeter in series between the power supply

positive output and J2, pin 6. Verify that the current is less

than 6 mA.

9. Remove the ammeter from the circuit.

10. On the PCBA, connect the positive output of the power

supply to J2, pin 5.

11. Connect a digital multimeter between TP7 and TP8. Verify

that the voltage is greater than 4.2 volts.

12. Disconnect the lead from the positive output on the power

supply.

13. Connect an ammeter in series between the power supply

positive output and J2 pin 5. Verify that the current is less

than 6 mA.

OSCILLATOR CIRCUIT TESTS

1. Orient the Printed Circuit Board Assembly (PCBA) with the

component side up and connectors J1 and J2 on the left hand

side.

28

2. Set the actuators (contacts) on the switches as follows:

S1 FAR RIGHT (RATE = 201 BPM)

S2 FAR RIGHT (LIGHT = HIGH 2)

S3 FAR RIGHT (MODULATION = HIGH)

S4 FAR RIGHT (LOCAL/ RCAL 63)

S5 RIGHT (CONTACT)

3. On the PCBA, connect the negative output from the power

supply to TP7.

4. Connect the positive output from the power supply to TP1.

5. On the power supply, set the output to 4.5 volts.

Page 35

6. On the PCBA, connect the input lead of a frequency counter

to TP2.

7. Connect the ground (shield) of this lead to TP7. Verify that

the oscillator frequency is between 32,728 and 32,808 Hz.

8. On the PCBA, connect the input lead of an oscilloscope to

TP5.

9. Connect the ground (shield) of this lead to TP7. Verify that

the signal, which approximates a square wave, has an

amplitude greater than 3.5 volts peak-to-peak.

10. Disconnect the frequency counter lead at TP2, and reconnect

it to TP5. Verify that the frequency is between 3.342 and

3.350 Hz.

11. Move the actuator on S1 to the middle position (112 BPM).

Verify that the frequency is between 1.867 and 1.871 Hz.

12. Move the actuator on S1 to the far left position (38 BPM).

Verify that the frequency is between 0.6361 and 0.6377 Hz.

GAIN/MODULATION VERIFICATION

Testing and Verification

1. Orient the Printed Circuit Board Assembly (PCBA) with the

component side up and connectors J1 and J2 on the left hand side.

2. Set the actuators on the switches as follows:

S1 FAR RIGHT (RATE = 201 BPM)

S2 FAR RIGHT (LIGHT = HIGH 2)

S3 FAR RIGHT (MODULATION = HIGH)

S4 FAR RIGHT (LOCAL/ RCAL 63)

S5 RIGHT (CONTACT)

29

Page 36

Testing and Verification

3. On the power supply, connect two test leads to the positive

output.

4. On the PCBA, connect one of the positive power supply leads

to TP1 and the other to TP9.

5. Connect the negative power supply output to TP7.

6. On the power supply, set the output voltage to 4.5 volts.

7. On the PCBA, verify that both LEDs are not illuminated.

8. Using the digital multimeter:

• connect the positive lead to TP5 on the PCBA, and

• connect the negative lead to TP7.

Verify that the voltage is 0 ± 0.25 volts.

9. On the PCBA, connect the positive lead of the multimeter to

J2, pin 1. Verify that the voltage is 0 ± 0.10 volts.

10. Connect the positive lead of the multimeter to TP4. Verify

that the voltage is less than 0.2 volts.

11. Disconnect the positive power supply lead from TP1. Only

TP9 should now have a positive power supply lead attached.

30

12. Connect a variable resistor and an ammeter in series between

TP1 and TP7.

13. Adjust the resistance to obtain a reading of 50 mA. Verify

that DS1 (left side LED) is illuminated.

14. Connect the positive lead of the multimeter to TP1 on the

PCBA. Verify that the voltage is greater than 2.0 volts.

15. Connect the positive lead of the multimeter to TP4 on the

PCBA. Verify that the voltage is between 0.94 and 1.10 volts.

16. Connect the positive lead of the multimeter to TP6 on the

PCBA. Verify that this voltage is the same voltage as TP4 ±

0.01 volts.

Page 37

Testing and Verification

17. Connect the positive lead of the multimeter to TP3 on the

PCBA. This voltage should equal 0.09 times the voltage at

TP6 ± 0.01 volts.

18. Disconnect the ammeter and variable resistor from TP1.

19. Disconnect the power supply lead from TP9 and connect it to

TP1.

20. Connect the ammeter and variable resistor in series between

TP9 and TP7.

21. Adjust the resistance to obtain a current of 50 mA. Verify

that DS2 (right side LED) is illuminated.

22. Connect the positive lead of the multimeter to TP9 on the

PCBA. Verify that the voltage is greater than 2.0 volts.

23. Connect the positive lead of the multimeter to TP4 on the

PCBA. Verify that the voltage is between 0.94 and 1.10 volts.

Record this measurement. This is the base voltage used to

calculate modulation.

24. Orient the printed circuit board assembly (PCBA) with the

component side up and connectors J1 and J2 on the left- hand

side.

25. Set the actuators on the switches as follows:

S1 FAR RIGHT (RATE = 201 BPM)

S2 FAR RIGHT (LIGHT = HIGH 2)

S3 FAR RIGHT (MODULATION = HIGH)

S4 FAR RIGHT (LOCAL/ RCAL 63)

S5 RIGHT (CONTACT)

26. Connect the oscilloscope input to TP6 on the PCBA.

27. Connect the oscilloscope ground to TP7 on the PCBA.

31

Page 38

Testing and Verification

28. Set the oscilloscope as follows:

• Vertical Gain = 20mV/div.

• AC coupled

• Bandwidth Limit = ON

• Horizontal Sweep = 20 mS/div.

29. Measure the peak of the positive pulse. Record the

measurement.

30. Calculate the % modulation from the formula:

%Modulation =

Voltage at TP6 (recorded in step 29)

X 100%

Voltage at TP4 (recorded in step 23)

Verify that the modulation is between 9% and 11%.

31. Move the actuator on S3 to the middle position

(MODULATION = LOW).

32. Change the Vertical Gain on the oscilloscope to 5mV/div.

33. Measure the peak of the positive pulse and record the

measurement.

34. Verify that the peak negative voltage is, at least, 9mV.

35. Calculate the % modulation from the formula:

%Modulation =

Voltage at TP6 (recorded in step 33)

X 100%

Voltage at TP4 (recorded in step 23)

Verify that the modulation is between 0.8% and 1.2%

32

Page 39

ECG TRIGGER OUTPUT TESTS

1. Orient the Printed Circuit Board Assembly (PCBA) with the

component side up and connectors J1 and J2 on the left hand side.

2. Set the actuators on the switches as follows:

S1 FAR RIGHT (RATE = 201 BPM)

S2 FAR RIGHT (LIGHT = HIGH 2)

S3 FAR RIGHT (MODULATION = HIGH)

S4 FAR RIGHT (LOCAL/ RCAL 63)

S5 RIGHT (CONTACT)

3. On the PCBA, connect the negative output from the power

supply to TP7.

7. Connect the positive output of the power supply to TP1.

8. On the power supply, set the output to 4.5 volts.

9. Connect the oscilloscope input to TP10 on the PCBA.

Testing and Verification

10. Set the oscilloscope as follows:

• Vertical Gain = 0.1V/div.

• DC coupled

• Bandwidth Limit – ON

• Horizontal Sweep = 20 mS/div.

8. Verify that the pulse is positive with a peak amplitude

between 0.3 to 0.7 Volts.

9. Verify that the pulse decays to 0 volts between positive

peaks.

11. Verify that at 50% of the peak voltage, the pulse at TP10 is

between 20 to 50 mS wide.

33

Page 40

THIS PAGE INTENTIONALLY LEFT BLANK

Page 41

SPARE PARTS

Overview

OVERVIEW

This section contains a list of spare parts for the SRC-2. Refer to

the SRC-2 exploded view shown in Figure 3.

Key

Number Description Part No.

1 Switch label 040868

2 Switch caps 028997

3 Top cover 024381

4 Main PCB assembly 029318

5 Oximeter D-connector assembly 044207

6 Bottom Cover 024380

7 Product Label Not Available

8 Pan head screw, 6-32 x 7/8 802088

9 End plug 024382

10 Cable/10-Position Header Connector 044207

Accessory ECG patch cord, Type L PC-L

35

Page 42

THIS PAGE INTENTIONALLY LEFT BLANK

Page 43

SPECIFICATIONS

Controls

Input/Output Connectors

Calibration Resistor

Accuracy

Signal Output

Environmental

Mechanical

CONTROLS

RATE Switch

Three positions:

38, 112, 201 beats per minute

LIGHT Switch

Three positions:

Detected LED light level simulation

Low, High 1, and High 2

MODULATION Switch

Three positions:

Output signal modulation

Off, Low, and High

RCAL/MODE Switch

Three positions:

Local for internally generated rate, signal level, modulation, and

RCAL 63

Remote for testing the SRC-2

RCAL: 64

37

Page 44

Specifications

INPUT/OUTPUT CONNECTORS

Oximeter Input/Output

Nine-pin D-connector

CALIBRATION RESISTORS

768 Ω (RCAL 63)

6.04 kΩ (RCAL 64)

ACCURACY

Rate

38 ±2% (37 to 39)

112 ±2% (110 to 114)

201 ±3% (195 to 207)

SIGNAL OUTPUT

High 2 Light Switch Setting

~267 nA/mA of input current from oximeter

High 1 Light Switch Setting

~100 nA/mA of input current from oximeter

Low Light Switch Setting

~9 nA/mA of input current from oximeter

Modulation Switch Setting

10% in high position

1% in low position

ECG Trigger Output

0.5 V peak; at least 20 ms wide at 50% amplitude; less than 50 ms

wide after pulse rising edge

38

Page 45

EMISSIONS COMPLIANCE

Emissions Classification: CISPR II, Group 1, Class B

ENVIRONMENTAL

Temperature

32 to 104°F (0 to 40°C)

Humidity

Non-condensing

Elevation

0 to 20,000 ft. (0 to 6,100 m)

MECHANICAL

Size

5.0 in. (130 mm) long

2.6 in. (66 mm) wide

1.4 in. (36 mm) deep

Specifications

Weight

4.3 oz (123 g)

39

Page 46

THIS PAGE INTENTIONALLY LEFT BLANK

Page 47

SCHEMATIC DIAGRAM

Overview

OVERVIEW

This section contains the SRC-2 component location drawing

(Figure 6) and the SRC-2 schematic diagram (Figure S-1).

Figure 6: Main PCB Component Location

41

Page 48

Loading...

Loading...