Page 1

Service Manual

Nellcor

TM

Portable SpO2 Patient Monitoring System

Page 2

COVIDIEN, COVIDIEN with logo, the Covidien logo and positive results for life are U.S. and

internationally registered trademarks of Covidien AG. Other brands are trademarks of a Covidien company.

©2014 Covidien. All rights reserved.

Microsoft and Windows CE are registered trademarks of Microsoft Corporation in the United

States and other countries.

The information contained in this manual is the sole property of Covidien and may not be

duplicated without permission. This manual may be revised or replaced by Covidien at any time

and without notice. It is the responsibility of the reader to have the most current applicable

version of this manual. If in doubt, contact Covidien Technical Services.

While the information set forth herein is believed to be accurate, it is not a substitute for the

exercise of professional judgment.

The equipment and software should only be operated and serviced by trained professionals.

Covidien’s sole responsibility with respect to the equipment and software, and its use, is as

stated in the limited warranty provided.

Nothing in this manual shall limit or restrict in any way Covidien’s right to revise or otherwise

change or modify the equipment and software described herein, without notice. In the

absence of an express, written agreement to the contrary, Covidien has no obligation to

furnish any such revisions, changes, or modifications to the owner or user of the equipment

and software described herein.

Page 3

Table of Contents

1 Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 Explosion, Shock, and Toxicity Hazards . . . . . . . . . . . . . . . . . . . . 1-2

1.2.3 Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.4 Monitoring System Operation and Service . . . . . . . . . . . . . . . . . . 1-4

1.2.5 Patient Monitoring and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.6 Monitoring System Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.7 Sensors, Cables, and Other Accessories . . . . . . . . . . . . . . . . . . . . 1-6

1.2.8 Electromagnetic Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.2.9 Connections with Other Equipment . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.2.10 Monitoring System Storage, Transport, and Disposal . . . . . . . . . . 1-9

1.3 Obtaining Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.3.1 Technical Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.3.2 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.4 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2 Data Management

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 External Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Real-Time Data Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Monitoring History Download . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3 Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3 Modification and Testing

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 System Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Power-On Self-Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.2 Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.3 Patient Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.4 Homecare Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.5 Sleep Study Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.6 Dynamic Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.7 Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.8 Wireless Network Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4 Operational and Functional Tests . . . . . . . . . . . . . . . . . . . . . . 3-15

3.4.1 General Operation Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

iii

Page 4

3.4.2 Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

3.5 Verification Check Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3.5.1 Performance, Operation, and Functional Test Results . . . . . . . . . 3-53

4 Troubleshooting

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Error Conditions by Category . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.2 System Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

5 Repair

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4.1 Remove the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4.2 Replace the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5 Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.1 Front and Rear Assembly Replacement . . . . . . . . . . . . . . . . . . . . 5-7

5.5.2 NELL1SR Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5.3 Main Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.5.4 Coin Cell Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.5 Wireless Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.5.6 LCD Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.5.7 PI Cable and Cable Housing Replacement . . . . . . . . . . . . . . . . . 5-16

iv

Page 5

List of Figures

Figure2-1. Communication Settings—Oxinet ............................................. 2-3

Figure2-2. Remote Connectivity Selections ................................................. 2-4

Figure2-3. New Connection Settings .......................................................... 2-5

Figure2-4. Wi-Fi On/Off Setting ................................................................. 2-6

Figure2-5. Wi-Fi On/Off Setting ................................................................. 2-7

Figure2-6. Mini-USB Port ........................................................................... 2-9

Figure2-7. Transfer Data Type .................................................................. 2-10

Figure2-8. Transfer Data by USB .............................................................. 2-10

Figure2-9. Sample Monitoring History Printout ........................................ 2-11

Figure2-10. Bridge Driver Installer Window ................................................ 2-13

Figure2-11. New Hardware Wizard Screen ................................................. 2-14

Figure2-12. Device Manager Button, Hardware Tab ................................... 2-15

Figure2-13. Hardware List in Device Manager Window .............................. 2-16

Figure2-14. Sample Initial USB to UART Bridge Properties Window ............ 2-17

Figure2-15. Baud Rate List, Port Settings Tab ............................................. 2-18

Figure2-16. Firmware Upgrade Mode ........................................................ 2-19

Figure2-17. Firmware Upgrade, PCSync Utility ........................................... 2-20

Figure2-18. Firmware Upgrade Process ...................................................... 2-21

Figure2-19. POST Screen and Firmware Version ......................................... 2-21

Figure3-1. Power-On Self-Test Sequence ................................................... 3-3

Figure3-2. Change Patient Mode Menu ..................................................... 3-4

Figure3-3. Homecare Mode Menu Item ..................................................... 3-6

Figure3-4. Homecare Mode Monitoring Screen .......................................... 3-7

Figure3-5. Sleep Study Mode Menu Item ................................................... 3-8

Figure3-6. Service Menu ............................................................................ 3-9

Figure3-7. Dynamic Password Menu (Homecare to Standard Example) ....... 3-9

Figure3-8. Password Set or Reset (Homecare to Standard Example) .......... 3-10

Figure3-9. Date/Time Settings .................................................................. 3-11

Figure3-10. Communications Settings ....................................................... 3-12

Figure3-11. Add New Connection Menu ................................................... 3-13

Figure3-12. Device Settings Menu ............................................................. 3-14

Figure3-13. Sensor Port ............................................................................. 3-15

Figure3-14. Sensor Port ............................................................................. 3-17

Figure3-15. Low SpO

Figure3-16. Low Pulse Alarm Limit of 160BPM ........................................... 3-18

Figure3-17. Alarm Audio Paused Setting of 30 Seconds ............................. 3-19

Figure3-18. Permission to Mute Alarm ....................................................... 3-20

Figure3-19. Confirmation for Muted Alarm ............................................... 3-21

Figure3-20. Alarm Volume Default Setting of 2 ......................................... 3-22

Figure3-21. Key Beep Volume Default Setting of 0 .................................... 3-23

Figure3-22. Pulse Volume Default Setting of 0 ........................................... 3-24

Figure3-23. Brightness Setting ................................................................... 3-25

Figure3-24. “Spot Reading Saved” Message .............................................. 3-26

Figure3-25. Monitoring History Spot Data .................................................. 3-27

2 Alarm Limit of 99% ................................................ 3-17

v

Page 6

Figure3-26. Sensor Disconnect Alarm Priority Setting ................................. 3-28

Figure3-27. Sensor Off Alarm .................................................................... 3-29

Figure3-28. Screen Saver Time Setting ....................................................... 3-30

Figure3-29. Auto Power Off Time Setting .................................................. 3-32

Figure3-30. SRC-MAX OxiMax Oximetry Tester .......................................... 3-35

Figure3-31. SRC-MAX Tester-Generated Waveform ................................... 3-36

Figure3-32. SRC-MAX Increase to 200 BPM ............................................... 3-37

Figure3-33. SRC-MAX Decrease to 60 BPM ............................................... 3-38

Figure3-34. SRC-MAX %SpO

Figure3-35. SRC-MAX %SpO

2 Increase to 90 ............................................ 3-39

2 Decrease to 75 ........................................... 3-40

Figure3-36. SRC-MAX High Modulation .................................................... 3-41

Figure3-37. BPM of 200 with High Modulation .......................................... 3-42

Figure3-38. BPM of 60 with High Modulation ............................................ 3-43

Figure3-39. %SpO

Figure3-40. %SpO

Figure3-41. %SpO

2 of 90 with High Modulation ....................................... 3-44

2 of 75 with High Modulation ....................................... 3-45

2 of 75 with Low Modulation ........................................ 3-46

Figure3-42. High Light Condition ............................................................... 3-47

Figure3-43. BPM of 200 with High Light Condition .................................... 3-48

Figure3-44. BPM of 60 with High Light Condition ...................................... 3-49

Figure3-45. %SpO

Figure3-46. %SpO

2 of 90 with High Light Condition ................................. 3-50

2 of 75 with High Light Condition ................................. 3-51

Figure3-47. High Modulation and High Light Condition ............................. 3-52

Figure4-1. Return Packaging .................................................................... 4-10

Figure5-1. Exploded View .......................................................................... 5-2

Figure5-2. Standard Cover (3 Shown) and Ambulatory Cover .................... 5-4

Figure5-3. Battery Replacement ................................................................. 5-5

Figure5-4. Front and Rear Assembly Replacement ...................................... 5-8

Figure5-5. NELL1SR Board Replacement ................................................... 5-10

Figure5-6. Main Board Replacement ........................................................ 5-11

Figure5-7. Coin Cell Battery Replacement ................................................ 5-13

Figure5-8. Wireless Board Replacement ................................................... 5-14

Figure5-9. LCD Replacement ................................................................... 5-15

Figure5-10. PI Cable and Cable Housing Replacement ............................... 5-17

vi

Page 7

List of Tables

Table1-1. Safety Symbol Definitions......................................................... 1-2

Table2-1. Monitoring Status Codes ........................................................ 2-12

Table3-1. Required Test Equipment ......................................................... 3-2

Table3-2. Patient Modes ........................................................................... 3-5

Table3-3. Wireless Status Icon................................................................. 3-14

Table3-4. Functional Tests with SRC-MAX ............................................. 3-33

Table4-1. Error Conditions and Resolutions............................................. 4-2

Table4-2. System Error Codes.................................................................... 4-6

Table5-1. Spare Parts List by Callout Number .......................................... 5-3

Table5-2. Monitoring System Accessories ................................................ 5-4

vii

Page 8

Page Left Intentionally Blank

viii

Page 9

1 Introduction

1.1 Overview

This manual contains information for servicing the Nellcor™ Portable SpO2

Patient Monitoring System.

This manual applies to the following products:

Note:

Before use, carefully read this manual, the Operator’s Manual, accessory Instructions

for Use, and all precautionary information and specifications.

PM10N

PM10N-W

Reference the Operator’s Manual for the following information:

• Intended Use statement

• Operations-related warnings and cautions

• Overviews of the display and operating buttons

• Descriptions of product and packaging symbols

• Installation instructions

• Alarms management

• Preventive maintenance

• Performance considerations

• Accessories

• Theory of operations

• Clinical studies

1-1

Page 10

Introduction

1.2.1 Safety Symbols

1.2 Safety Information

This section contains important safety information related to general use of the

Nellcor™ Portable SpO2 Patient Monitoring System. Other important safety

information appears throughout the manual. The Nellcor™ Portable SpO2

Patient Monitoring System is referred to as the “monitoring system” throughout this manual.

Table1-1.Safety Symbol Definitions

Symbol Definition

WARNING

Alerts users to potential serious outcomes (death, injury, or adverse events) to

the patient, user, or environment.

Caution

Identifies conditions or practices that could result in damage to the equipment

or other property.

Note

Provides additional guidelines or information.

1.2.2 Explosion, Shock, and Toxicity Hazards

WARNING:

Explosion hazard — Do not use the monitoring system in the presence of

flammable anesthetics.

WARNING:

Shock hazard—Do not pour or spill liquids onto the monitoring system.

WARNING:

Shock hazard—Firmly close the battery cover to prevent moisture from

entering the monitoring system.

1-2 Service Manual

Page 11

WARNING:

The LCD panel (display) contains toxic chemicals. Do not touch broken LCD

panels. Physical contact with a broken LCD panel can result in transmission or

ingestion of toxic substances.

1.2.3 Service Procedures

WARNING:

To avoid possible injury, do not attempt to service the monitoring system if

there are any signs of burning or smoking coming from the monitoring

system.

WARNING:

Before attempting to service the monitoring system, disconnect it from the

patient to avoid possible injury to the patient.

Safety Information

WARNING:

Before attempting to disassemble the monitoring system, remove the

batteries to prevent possible injury.

WARNING:

Ensure that conductive portions of the electrodes, leads, and cable do not

come into contact with any other conductive parts.

WARNING:

High voltage is generated by the LCD backlight driver. Exercise caution when

operating the monitoring system with covers open.

WARNING:

Extreme care must be taken in modifying default or other settings to ensure

they are appropriate to the intended use.

WARNING:

Make sure to complete all performance and safety tests outlined in Chapter

3, Modification and Testing before placing the monitoring system into

operation after repair or maintenance. Failure to perform all tests could result

in erroneous monitoring system readings.

Service Manual 1-3

Page 12

Introduction

WARNING:

WARNING:

1.2.4 Monitoring System Operation and Service

Any connections between this monitoring system and other devices must

comply with applicable medical systems safety standards such as IEC 60601-1.

Failure to do so could result in unsafe leakage current and grounding

conditions.

To ensure accurate performance and prevent device failure, do not expose

the monitoring system to extreme moisture, such as direct exposure to rain.

Such exposure may cause inaccurate performance or device failure. Reference

the Operator’s Manual for fluid ingress specifications.

WARNING:

Inspect the monitoring system and all accessories before use to ensure there

are no signs of physical damage or improper function. Do not use if damaged.

WARNING:

To ensure accurate performance and prevent device failure, do not expose

the monitoring system to extreme moisture, such as direct exposure to rain.

Such exposure may cause inaccurate performance or device failure. Do not

immerse in water, solvents, or cleaning solutions, since the monitoring

system and pulse oximetry sensors and connectors are not waterproof.

WARNING:

Do not sterilize the monitoring system

oxide.

WARNING:

The monitoring system should not be used adjacent to or stacked with other

equipment. If adjacent or stacked use is necessary, observe the monitoring

system to verify normal operation in the desired configuration.

by irradiation, steam, or ethylene

WARNING:

The only user-serviceable parts inside the monitoring system are the four AA

batteries. While users can open the battery cover to change the batteries,

1-4 Service Manual

Page 13

only qualified service personnel should remove the cover or access internal

components for any other reason. Users should not modify any components

of the monitoring system.

WARNING:

Do not spray, pour, or spill any liquid on the monitoring system, its

accessories, connectors, switches, or openings in the casing, since this may

cause damage to the monitoring system. Never place fluids on the monitoring

system. If fluid spills on the monitoring system, remove batteries, wipe all

components dry immediately, and have the monitoring system serviced to

ensure no hazard exists.

WARNING:

Do not damage the batteries by applying pressure. Do not throw, hit, or drop

or impact the batteries.

Safety Information

WARNING:

Keep the monitoring system and batteries out of reach of children to avoid

any accidents.

Caution:

The monitoring system may not operate properly if it is operated or stored at

conditions outside the ranges stated in this manual, or if it is subjected to

excessive shock or dropping.

1.2.5 Patient Monitoring and Safety

WARNING:

Always disconnect and remove the monitoring system and sensors during

magnetic resonance imaging (MRI) scanning. Attempting to use the

monitoring system during an MRI procedure could cause burns or adversely

affect the MRI image or the monitoring system's accuracy.

WARNING:

Keep patients under close surveillance when monitoring. It is possible,

although unlikely, that radiated electromagnetic signals from sources

external to the patient and the monitoring system can cause inaccurate

measurement readings.

Service Manual 1-5

Page 14

Introduction

WARNING:

WARNING:

1.2.6 Monitoring System Readings

WARNING:

As with all medical equipment, carefully route patient cabling to reduce the

possibility of patient entanglement or strangulation.

Do not lift or carry the monitoring system by the pulse oximetry sensor or

pulse oximetry interface cable. The cable may disconnect and cause the

monitoring system to drop on a patient or cause damage to monitoring

system surfaces.

The monitoring system may remain attached to the patient during

defibrillation or during use of an electrosurgical unit; however, the

monitoring system is not defibrillator-proof, and readings may be inaccurate

during defibrillation and shortly thereafter.

WARNING:

Check the patient's vital signs by alternate means should there be any doubt

about the accuracy of any measurement. Request a qualified service

technician confirm the monitoring system is functioning correctly.

WARNING:

For best product performance and measurement accuracy, use only

accessories supplied or recommended by Covidien. Use accessories according

to their respective Instructions for Use.

1.2.7 Sensors, Cables, and Other Accessories

WARNING:

Before use, carefully read the pulse oximetry sensor Instructions for Use,

including all warnings, cautions, and instructions.

1-6 Service Manual

Page 15

WARNING:

Use only the Covidien-approved pulse oximetry sensors, interface cables, and

accessories. Use of other sensors, cables, and accessories can result in

inaccurate readings and increased monitoring system

WARNING:

Do not use any other cables to extend the length of the Covidien-approved

interface cable. Increasing the length will degrade signal quality and may lead

to inaccurate measurements.

WARNING:

To prevent damage, avoid undue bending of the sensor cable.

WARNING:

The sensor disconnect error message and associated alarm indicate the pulse

oximetry sensor is either disconnected or has faulty wiring. Check the

connection and, if necessary, replace the sensor, the pulse oximetry cable, or

both.

Safety Information

emissions.

1.2.8 Electromagnetic Interference

WARNING:

Any radio frequency transmitting equipment or other nearby sources of

electrical noise may result in disruption of the monitoring system.

WARNING:

The monitoring system is designed for use in environments in which the

signal can be obscured by electromagnetic interference. During such

interference, measurements may seem inappropriate or the monitoring

system may not seem to operate correctly.

WARNING:

Large equipment using a switching relay for its power on/off may affect

monitoring system operation. Do not operate the monitoring system in such

environments.

Service Manual 1-7

Page 16

Introduction

Caution:

Caution:

Caution:

This device has been tested and found to comply with the limits for medical

devices related to IEC 60601-1-2: 2007. These limits are designed to provide

reasonable protection against harmful interference in a typical medical

installation.

This monitoring system generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to other devices in the vicinity. If interference is

suspected, move pulse oximetry cables away from the susceptible device.

Be aware of possible interference from sources of electromagnetic

interference, such as cellular phones, radio transmitters, motors, telephones,

lamps, electrosurgical units, defibrillators, and other medical devices. If pulse

oximetry readings are not as expected for the patient’s condition, remove the

sources of possible interference.

1.2.9 Connections with Other Equipment

Caution:

Accessory equipment connected to the monitoring system's data interface

must be certified according to IEC 60950-1 for data-processing equipment. All

combinations of equipment must be in compliance with IEC 60601-1:2005

Requirements for Medical Electrical Systems. Anyone who connects

additional equipment to the signal input or signal output port configures a

medical system and is therefore responsible for ensuring the system complies

with the requirements of IEC 60601-1:2005 and IEC 60601-1-2:2007.

Caution:

When connecting the monitoring system to any instrument, verify proper

operation before clinical use.

Caution:

Anyone who connects a PC to the data output port configures a medical

system and is therefore responsible for ensuring that the system complies

1-8 Service Manual

Page 17

with the requirements of IEC 60601-1-1 and the electromagnetic compatibility

IEC 60601-1-2.

1.2.10 Monitoring System Storage, Transport, and Disposal

Caution:

Remove the batteries from the monitoring system

or when not using it for a long period.

before placing it in storage

Caution:

Do not short-circuit the batteries, as they may generate heat. To avoid shortcircuiting, do not let the batteries come in contact with metal objects at any

time, especially during transport.

Safety Information

Caution:

Follow local government ordinances and recycling instructions regarding

disposal or recycling of the monitoring system

batteries and accessories.

and its components, including

Service Manual 1-9

Page 18

Introduction

1.3.1 Technical Services

1.3 Obtaining Technical Assistance

For technical information and assistance, contact Covidien or a local Covidien

representative.

Covidien Technical Services: Patient Monitoring

15 Hampshire Street

Mansfield, MA 02048 USA

1.800.635.5267, 1.925.463.4635,

or contact a local Covidien representative

www.covidien.com

When calling Covidien or a local Covidien representative, have the monitoring

system serial number available. The serial number label is located on the

bottom of the monitoring system. Provide the firmware version number displayed during the power-on self-test (POST).

1.3.2 Related Documents

Nellcor™ Portable SpO2 Patient Monitoring System

Operator’s Manual —

system and troubleshooting errors or malfunctions.

Nellcor™ Pulse Oximetry Sensor Instructions for Use — Guides sensor selection

and usage. Before attaching any of the various Covidien-approved pulse oximetry

sensors to the monitoring system, refer to the individual Directions for Use.

Saturation Accuracy Grid — Provides sensor-specific guidance related to desired

2 saturation accuracy measurements. Available online at www.covidien.com.

SpO

Provides basic information for operating the monitoring

1-10 Service Manual

Page 19

1.4 Revision History

The documentation part number and revision number indicate its current edition. The revision number changes when Covidien prints a new edition. Minor

corrections and updates incorporated at reprint do not cause a change in the

revision number. Extensive changes may require a new document part number.

1.5 Warranty Information

The information contained in this document is subject to change without

notice. Covidien makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Covidien shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

Revision History

Service Manual 1-11

Page 20

Introduction

Page Left Intentionally Blank

1-12 Service Manual

Page 21

2 Data Management

2.1 Overview

This chapter contains information for accessing, transmitting, and downloading patient monitoring data and history. This chapter also contains instructions

for upgrading firmware for the Nellcor™ Portable SpO2 Patient Monitoring

System. The monitoring system supports the following types of data viewing

and transmission:

• Transmit real-time data — Real-time patient data transmission by Wi-Fi to the

Oxinet III Remote Patient Monitoring System or the Vital Sync Virtual Patient Monitoring System. Reference the Operator’s Manual.

• Access stored monitoring history — Monitoring history (trend data) can be

viewed anytime it is stored in the monitoring system. Reference the Operator’s

Manual.

• Download stored monitoring history — Monitoring history can be down-

loaded to a PC using HyperTerminal or other data transmission and analysis tools.

• Upgrade the monitoring system’s firmware — Occasionally, Covidien will

provide upgrades to the firmware for the monitoring system, which must be

loaded via the mini-USB port.

Note:

The Wi-Fi feature is an option and does not exist on all Portable SpO

Monitoring Systems.

2.2 External Data Communication

WARNING:

Any connections between this monitoring system and other devices must

comply with applicable medical systems safety standards such as IEC 60601-1

and applicable collaterals. Failure to do so may result in unsafe leakage

current and grounding conditions.

2 Patient

2-1

Page 22

Data Management

Caution:

Do not attach any cable intended for computer use to the sensor port

connector.

Caution:

Connect the monitoring system to a medical grade PC that is on an isolated

AC circuit.

Note:

Reference the manuals for the Covidien Nellcor™ Oxinet III Remote Monitoring

System and Vital Sync™ System 2.0 or above for operation information and

recommendations for the placement of the monitoring system relative to the

distributed alarm system.

The monitoring system supports the following types of data communication:

• Real-time data transmission — Real-time data transmission by Wi-Fi to the

Covidien Nellcor™ Oxinet III Remote Monitoring System or the Vital Sync™

System 2.0 (or above) Virtual Patient Monitoring System.

• Monitoring history (trend data) download — Monitoring history downloads

by mini-USB connection to a PC using data transmission and analysis tools.

Note:

To use the Wi-Fi feature (if available), a qualified service technician must first configure

the monitoring system to connect to a wireless network, as described in the following

sections.

2.2.1 Real-Time Data Transmission

Transfer real-time monitoring data to Covidien Nellcor™ Oxinet III or Vital

Sync™ System

the monitoring system to one of these applications.

To set up a new connection for Oxinet or VitalSync

1. Start Oxinet III or VitalSync 2.0 or above.

2.0 or above. First, set up a new connection, and then connect

2. Turn on the monitoring system and go to the Service Menu (pass code required).

3. In the Service Menu, select Communication Settings.

2-2 Service Manual

Page 23

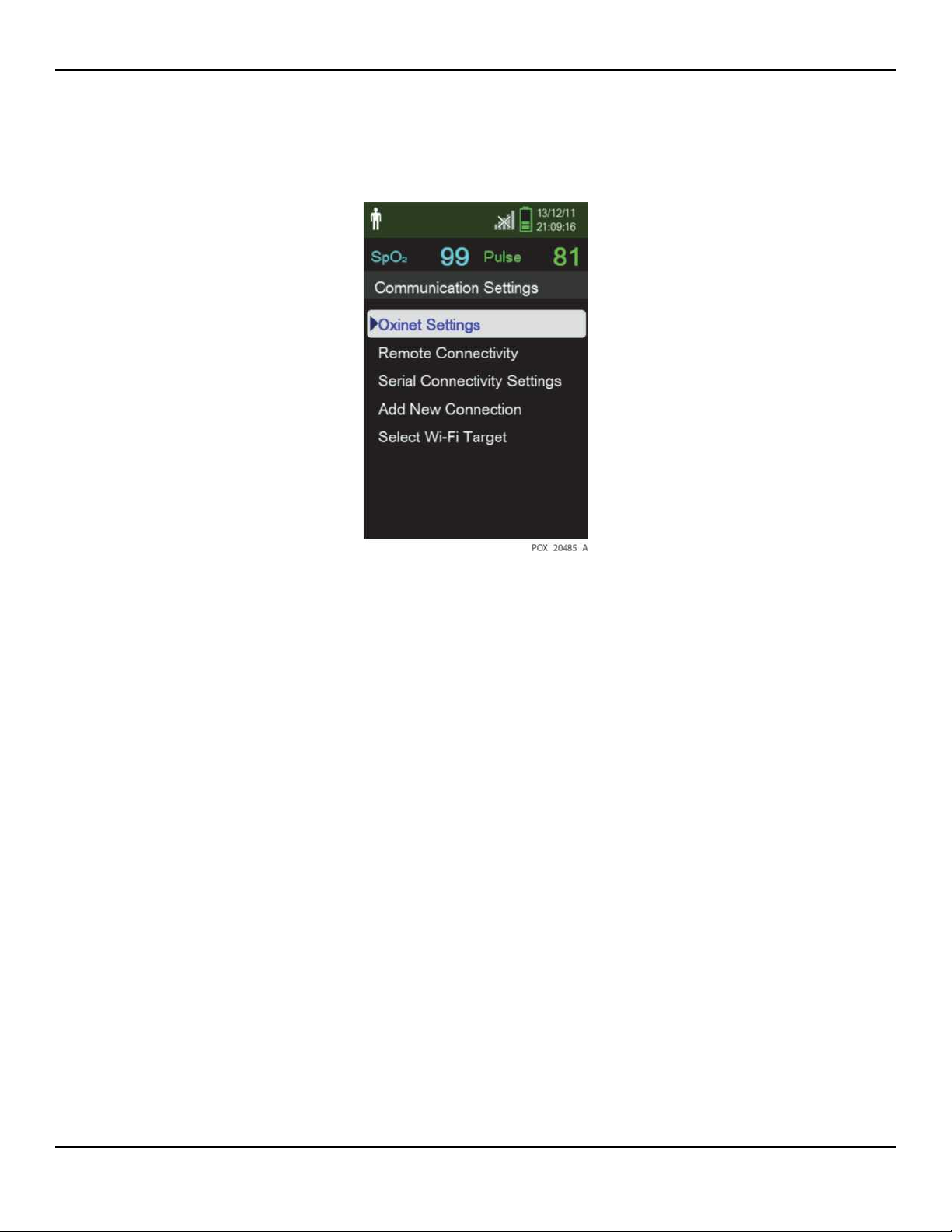

Figure2-1.Communication Settings—Oxinet

External Data Communication

4. Select Oxinet Settings and make the following settings:

• Destination IP Address — Set the IP address of the computer with the Oxinet or

VitalSync program installed

• Port — 18000 for Oxinet; 10001 for VitalSync

5. Select the data packet type (ASCII, SPDout) by selecting Remote Connectivity.

Service Manual 2-3

Page 24

Data Management

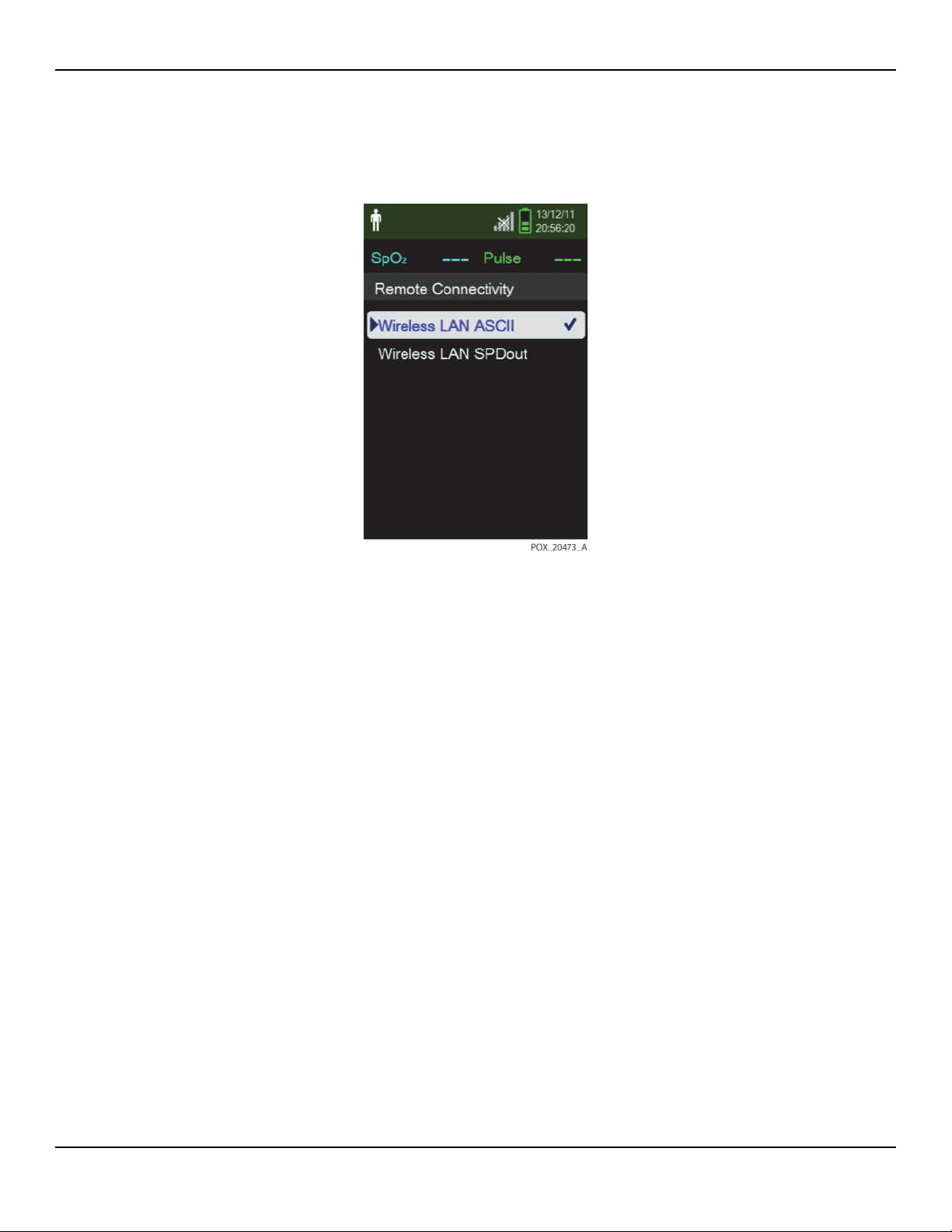

Figure2-2.Remote Connectivity Selections

6. Select Add New Connection and set as follows:

a. SSID: Enter the SSID name of the AP (access point).

b. Encryption: Select the encryption type of the current AP.

c. Encryption Type: Set the password for each encryption type.

d. DHCP: Turn DHCP On or Off. (When On, the IP Address, Subnet Mask, and

Gateway setting are automatically assigned using DHCP.)

e. IP Address: If DHCP is Off, set the IP address of the monitoring system.

f. Subnet Mask: If DHCP is Off, set the subnet mask of the monitoring system.

g. Gateway: If DHCP is Off, set the gateway of the monitoring system.

h. After setting the new connection, select Save Connection to add the settings

to the Wi-Fi Target.

2-4 Service Manual

Page 25

Figure2-3.New Connection Settings

External Data Communication

7. From the Select Wi-Fi Target menu, select the AP saved in the previous step.

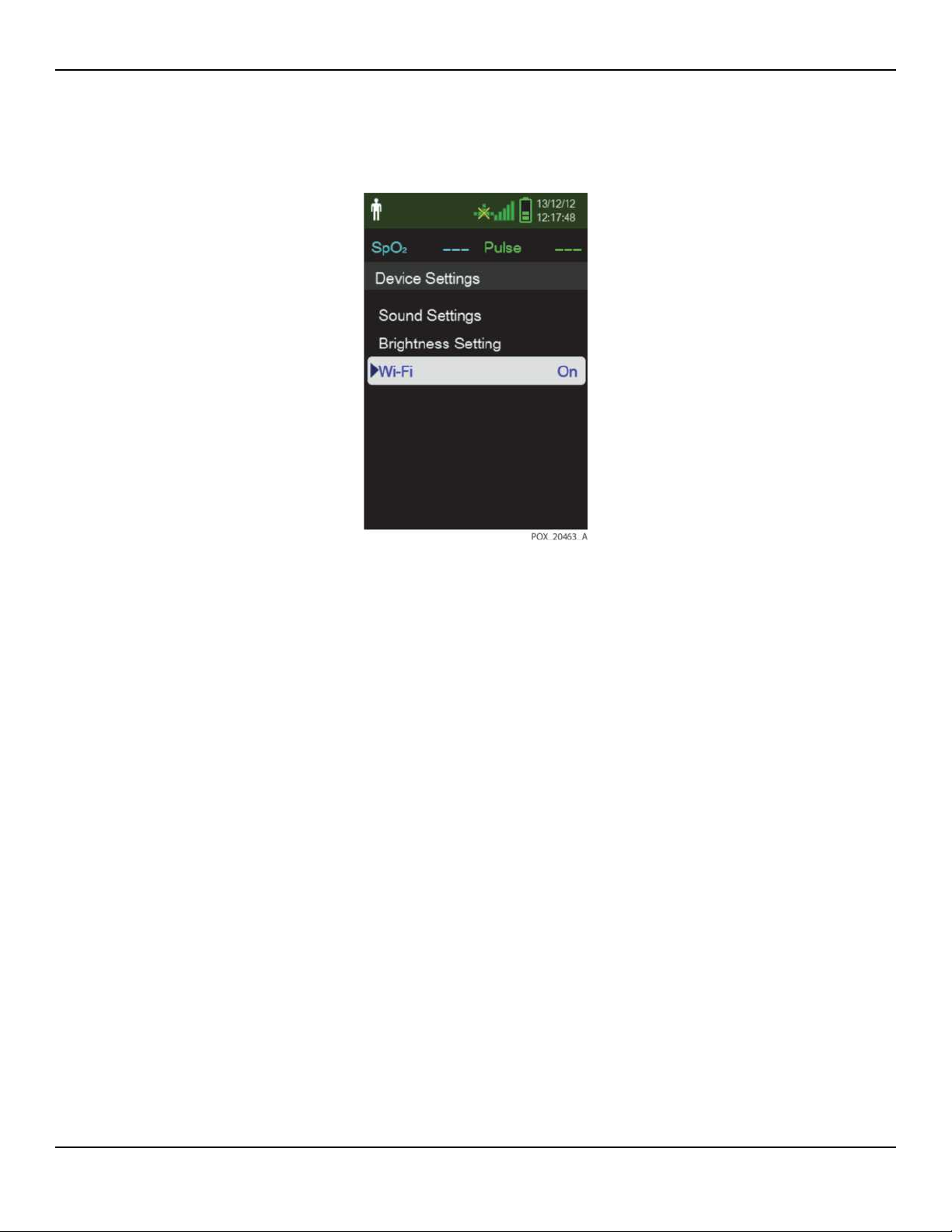

8. Exit the Service Menu and go to the Device Settings Menu.

To transfer real-time data to Oxinet

1. On the Device Settings menu, select Wi-Fi to activate the Wi-Fi connection.

Service Manual 2-5

Page 26

Data Management

Figure2-4.Wi-Fi On/Off Setting

2. On the Oxinet interface, click the Administration button at the bottom of the

screen and verify that the BEDs are connected. (When a connection is first established, a BED is displayed in an orange color.)

3. Select the connected BED and select the room number.

4. After verifying that the room is selected, register the patient information.

5. Click the Monitor button on the middle of the Oxinet screen and verify that the

selected room is displayed on the screen.

6. To confirm the settings of the monitoring system, select the measurement value

on the Oxinet screen. Then verify the following items:

a. The high and low limit values of the %SpO2 and pulse rate.

b. Patient type (Adult or Neonate).

c. Protocol: ASCII.

d. SatSeconds settings.

e. Model: NPSPMS (Nellcor™ Portable SpO2 Patient Monitoring System). To

check the model name, select the Addition Information window at the bottom

right of the Oxinet screen.

2-6 Service Manual

Page 27

External Data Communication

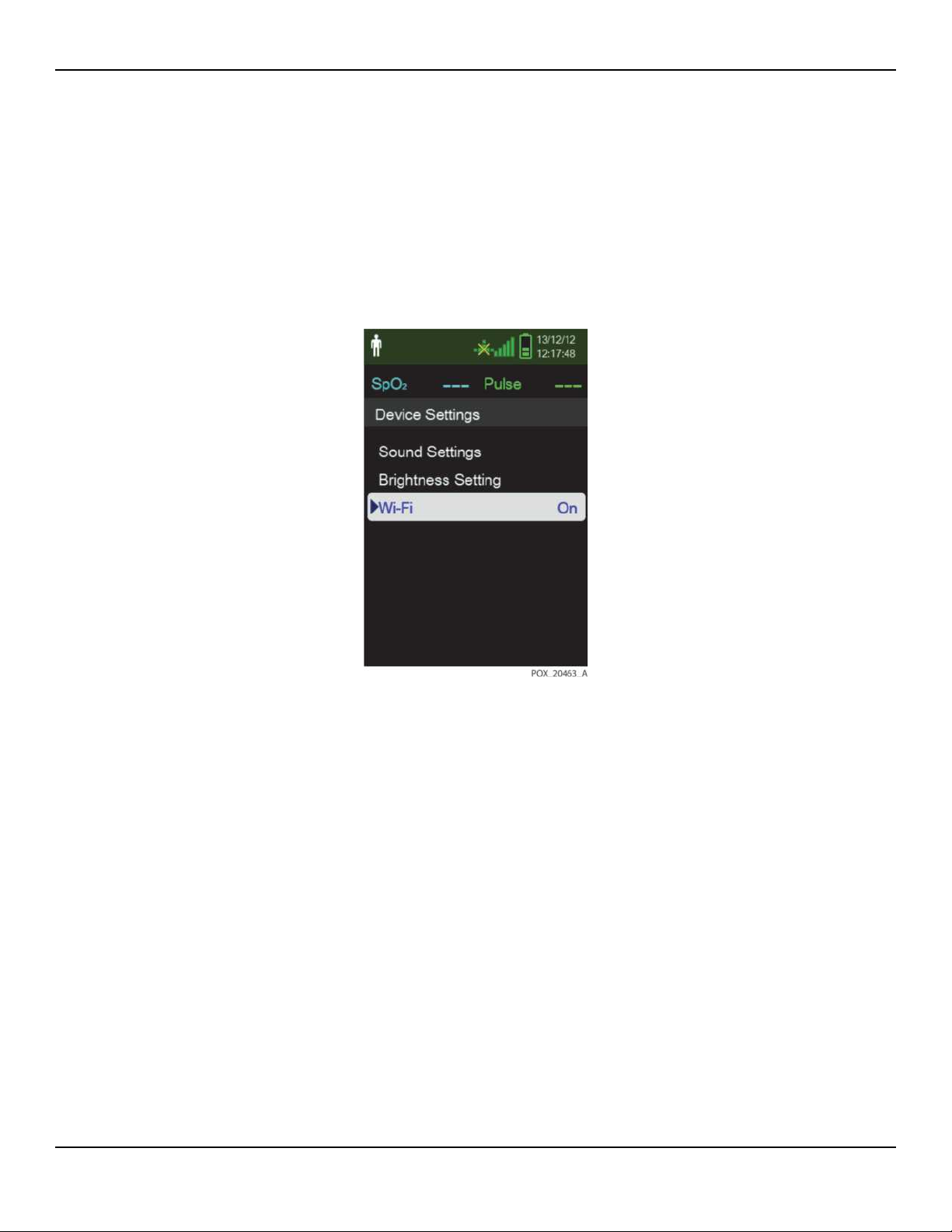

To transfer real-time data to Vital Sync 2.0 or above

1. Reference To set up a new connection for Oxinet or VitalSync, p. 2-2 to connect

to a wireless network.

2. On the Device Settings menu, select Wi-Fi to activate the Wi-Fi connection.

Figure2-5.Wi-Fi On/Off Setting

3. The real-time data displays on the Vital Sync screen.

2.2.2 Monitoring History Download

The monitoring system presents monitoring history (trend data) in tabular

format. The newest data values appear at the top.

WARNING:

Replacing the coin cell battery for the main board resets the monitoring

system’s date and time settings. Integrity of existing patient data will be

questionable. Reset the date and time after replacing this battery with a

known good battery.

Caution:

Anyone who connects a PC to the data output port configures a medical

system and is therefore responsible for ensuring that the system complies

Service Manual 2-7

Page 28

Data Management

with the requirements of IEC 60601-1-1 and the electromagnetic compatibility

IEC 60601-1-2.

Caution:

Signal artifacts, secondary to a variety of external factors, may compromise

the presence or accuracy of the displayed values.

Caution:

If the monitoring system does not contain its own isolation barrier, connect it

to a medical grade PC that is on an isolated AC circuit.

To download monitoring history (trend data), connect by mini-USB port to a

PC using HyperTerminal or other data transmission and analysis tools. Any PC

connected to the data port must be certified according to IEC 60950. All combinations of equipment must be in compliance with IEC 60601-1-1 system

requirements.

Note:

Users may choose to import patient monitoring history to a spreadsheet program. To

do so, export monitoring history using the ASCII format option. Have a qualified

service technician set this option prior to attempting a data download.

System Compatibility Prerequisites

• Windows-based PC

• HyperTerminal or equivalent software installed on PC

Hardware

• Mini-USB data download cable

• CD or thumb drive, if USB driver required

Data transfer by USB port relies on existing communication software drivers for

USB-based devices already on the computer, so should not require any modification of the drivers used by the USB interface. If, for some reason, the computer does not have the correct USB driver, use the device driver provided on

the product CD or from Technical Services. Reference COM port USB Driver

Alternatives, p. 2-13.

2-8 Service Manual

Page 29

Note:

Any monitoring history download relies on either factory default settings or

institutional default settings established by a qualified service technician prior to

usage. This includes baud rate and communication protocol selection.

To download monitoring history using HyperTerminal

1. Configure the monitoring system’s Serial Connectivity Settings appropriately.

2. Connect the monitoring system’s mini-USB port to the computer.

External Data Communication

Figure2-6.Mini-USB Port

3. Execute HyperTerminal.

Note:

If this is the first time the HyperTerminal program launches, it will prompt the user

to set it as the default Telnet program. Depending on institutional requirements,

choose Yes or No.

4. Set the appropriate values for HyperTerminal’s port settings:

a. Set the baud rate (bits per second) to match the monitoring system’s baud

rate.

b. Ensure the data bit is set to 8.

c. Ensure the parity bit is set to none.

d. Ensure the stop bit is set to 1.

e. Ensure the flow control is set to off.

5. From the monitoring system’s Transfer Data menu, select Spot Data or Continu-

ous Data.

Service Manual 2-9

Page 30

Data Management

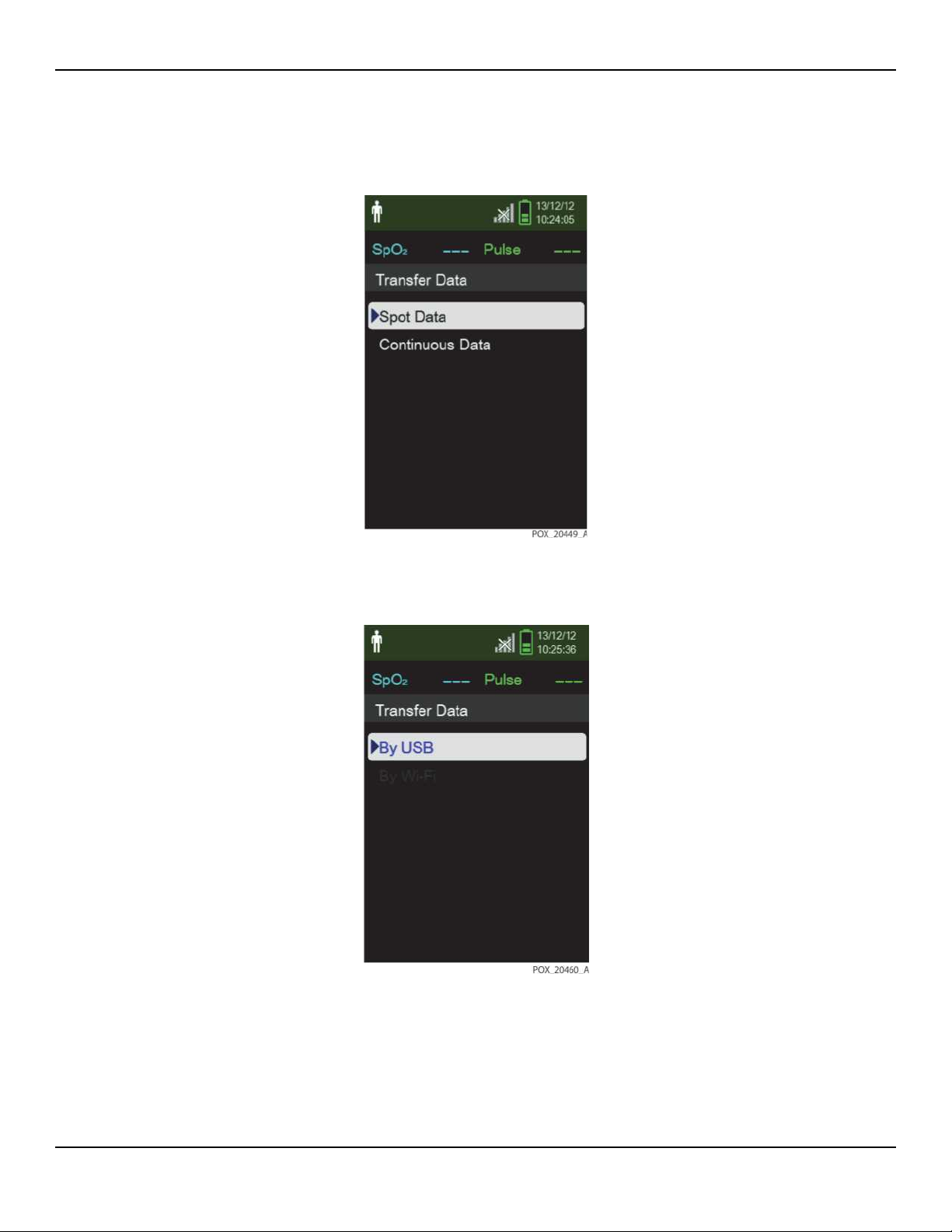

Figure2-7.Transfer Data Type

6. Select By USB.

Figure2-8.Transfer Data by USB

The data is transferred, and a progress bar is displayed. If desired, select Cancel to

abort the transmission.

2-10 Service Manual

Page 31

External Data Communication

The Output Complete message is displayed when the transmission is complete.

To interpret downloaded monitoring history

1. Examine monitoring history on the HyperTerminal screen, in a spreadsheet, or on

a printout from the personal computer.

Figure2-9.Sample Monitoring History Printout

1 Product column headings Data source, firmware version, and system settings

2 Patient data column headings Lists appropriate time and data headings

3 Time column Real-time clock date and time stamp

4 Output Complete Message indicating completion of monitoring history down-

load

5 %SpO

6 PR Current pulse rate

7 PA Current pulse ampltitude

8 Status Operating status of the monitoring system

2. Ensure patient data settings coincide with expected settings. This would include

2 Current saturation value

the version of firmware and its CRC code, which should be all zeros; alarm limit

settings; patient mode; and SatSeconds setting.

3. Scan the time, SpO2, or PR column until reaching the events of interest.

Service Manual 2-11

Page 32

Data Management

4. Reference Table 2-1 on page 2-12 for descriptions of the operating status codes.

Table2-1.Monitoring Status Codes

Status

Description

Code

LM Loss of pulse, patient motion

LP Loss of pulse

CB Critically low battery

LB Low battery

SO Sensor off

SD Sensor disconnect

AO Alarm off

AS Alarm paused

MO Signal interference, patient motion

PS Pulse search

2-12 Service Manual

Page 33

External Data Communication

COM port USB Driver Alternatives

• Load the appropriate driver from the product CD into the connected computer.

• Contact Technical Services or a local Covidien representative.

To install a USB driver from the compact disc

1. Insert the Nellcor™ Portable SpO2 Patient Monitoring System compact disc (CD)

into the designated personal computer (PC).

2. Copy the Covidien USB to UART Bridge Driver zip file to the PC, installing it in the

desired program folder.

3. Right-click on the zipped folder.

4. Select Extract All.

5. Open the extracted folder.

6. Launch the Driver Installer executable file.

Note:

To change the location of the driver, select the desired mapping by clicking

Change Install Location.

7. Click Install.

8. Reboot the PC for changes to take effect.

Figure2-10.Bridge Driver Installer Window

9. Connect the monitoring system to the PC, firmly engaging the USB end to the PC

and the mini-USB to the monitoring system.

Service Manual 2-13

Page 34

Data Management

10. Allow the PC to sense the new hardware and load the InstallShield Wizard, which

guides users through the entire setup process. Do not click the Cancel button.

Figure2-11.New Hardware Wizard Screen

11. At the prompt from the InstallShield Wizard, click the Next button to copy the

driver to the PC.

12. When the InstallShield Wizard provides the end-user license agreement, read it

carefully, then click the button for accepting the terms of the license.

13. Click Next to formally accept the agreement.

14. Review the Destination Folder mapping. To change the destination, click Browse

and select the desired mapping.

15. Click Next to formally accept the Destination Folder mapping.

16. Click Install in the resulting driver installer window. Do not click the Cancel

button.

Note:

If Windows Security pops up, select the option to install the driver anyway.

2-14 Service Manual

Page 35

External Data Communication

17. Click OK to complete the installation in the resulting Success window.

18. Reboot the PC for changes to take effect.

19. From the Start menu, click the Settings menu option and select the Control Panel

option.

20. Select the System option to open the System Properties window.

21. Click the Hardware tab, then the Device Manager button.

Figure2-12.Device Manager Button, Hardware Tab

22. Select the Ports option from the resulting list.

Service Manual 2-15

Page 36

Data Management

Figure2-13.Hardware List in Device Manager Window

23. Double click the Silicon Labs CP210x USB to UART Bridge option.

Note:

The listed COM port should match the HyperTerminal COM port designation.

Reference To download monitoring history using HyperTerminal, p. 2-9.

2-16 Service Manual

Page 37

Figure2-14.Sample Initial USB to UART Bridge Properties Window

External Data Communication

24. Click the Port Settings tab.

25. Set the bits per second to one of the possible baud rates: 19200 or 115200. The

factory default is 19200 bps.

Service Manual 2-17

Page 38

Data Management

Figure2-15.Baud Rate List, Port Settings Tab

26. Click the OK button to complete the process.

27. Reference To download monitoring history using HyperTerminal, p. 2-9 to down-

load monitoring history. Or, use a different data transmission and analysis tool.

2.3 Firmware Upgrade

This section describes how to upgrade the firmware for the monitoring system.

Firmware updates occur periodically, and the monitoring system should be

kept up to date to ensure proper operation. Reference System Error Codes, p.

4-6 if errors occur during firmware upgrade.

2-18 Service Manual

Page 39

Caution:

To help prevent the loss of power during the upgrade, make sure to use new

batteries.

Caution:

Do not press buttons other than those specified in the following instructions.

The firmware upgrade can be interrupted or canceled by pressing any button.

Caution:

When the firmware version (.bin) is not matched with the correct version of

the resource file (.res), the monitoring system may not operate properly.

To upgrade firmware

1. Install and run the PCSync utility on the PC to be used for the upgrade.

Firmware Upgrade

2. Turn off the monitoring system.

3. Connect a mini-USB cable from the monitoring system to the PC.

4. On the monitoring system, press the Power On/Off button and Down button

together.

5. The monitoring system powers on in firmware update mode as shown in Figure

2-16.

Figure2-16.Firmware Upgrade Mode

6. Start the PC Sync utility.

Service Manual 2-19

Page 40

Data Management

7. Complete the connection between the monitoring system and PCSync by using

Figure2-17.Firmware Upgrade, PCSync Utility

the PC’s Device Manager to determine the serial port number for the USB to UART

Bridge.

Enter the port number in the Serial Port box at the top left of the dialog box, then

click Connect.

To verify the connection, click the Get Software Version on the PC Sync dialog

box. A pop-up window containing the current version of the monitoring system

firmware is displayed.

8. If the Resource file needs to be updated, click the Resource Update button and

select the appropriate .res file.

When the file is selected, the resource upgrade procedure begins automatically.

Upon completion of the resource update, the Complete message is displayed in

the PC Sync utility.

If the Resource file does not need to be updated, skip this step.

9. Click the Firmware Update button and select the appropriate .bin file.

When the file is selected, the firmware update begins automatically.

Upon completion of the firmware update, the Complete message is displayed in

the PC Sync utility.

The screen shown in Figure 2-18 on page 2-21 is displayed as the monitoring

system is updated. Then the monitoring system is automatically reset.

2-20 Service Manual

Page 41

Figure2-18.Firmware Upgrade Process

Firmware Upgrade

10. Verify the upgrade is complete by checking the POST screen and firmware version.

Figure2-19.POST Screen and Firmware Version

Service Manual 2-21

Page 42

Data Management

Note:

The monitoring system’s previous settings are not modified during the upgrade.

Reference the Operator’s Manual for power-on settings.

2-22 Service Manual

Page 43

3 Modification and Testing

3.1 Overview

This chapter provides information to trained service technicians on verifying

Nellcor™ Portable SpO2 Patient Monitoring System performance following

repairs or during preventive maintenance. When performing tests, follow

these guidelines:

• All tests can be performed without removing the covers from the monitoring

system.

• For many of the tests, the PCSync utility shown in Figure 2-17, p. 2-20 provides

an efficient way to change the monitoring system’s settings.

• All tests must be performed as the last operation before the monitoring system is

returned to the user.

• If the monitoring system fails to perform as specified in any test, repairs must be

made to correct the problem before the monitoring system is returned to the user.

WARNING:

Only qualified service personnel should open the monitoring system, remove

and replace parts, or make adjustments. If your medical facility does not have

a qualified service technician, please contact Covidien Technical Services or

your local Covidien representative.

Note:

Many of the tests outlined in this chapter require access to the monitoring system’s

Service Menu. Contact Covidien Technical Services for the pass code to this menu.

3-1

Page 44

Modification and Testing

3.2 Required Equipment

SpO

SpO

SpO

Stop watch Manual or electronic/For alarm audio paused and alarm

Note:

Contact Covidien Technical Services for pricing and ordering information of the

required equipment. Reference Technical Services, p. 1-10.

Table3-1.Required Test Equipment

Equipment Description/Use

2 sensor (durable) DS-100A Durasensor™ Adult Finger Clip Sensor

2 extension cable DEC-4

2 simulator Nellcor model SRC-MAX

reminder intervals

3.3 System Performance Tests

Caution:

If using the PCSync utility to change settings for the monitoring system, make

sure all the settings on the PCSync screen are correct before clicking Send.

Otherwise, unexpected settings will result.

3.3.1 Power-On Self-Test (POST)

To check the power-on self-test (POST)

1. With the monitoring system off, press and hold the Power On/Off button for

approximately 1 second.

While the monitoring system performs power-on self-test (POST), a progress bar

appears at the bottom of the display.Verify that the following steps occur:

a. The product name and software version number are displayed on the POST

screen.

b. When POST completes successfully, one pass tone sounds, and the monitoring

system displays the main monitoring screen.

3-2 Service Manual

Page 45

Figure3-1.Power-On Self-Test Sequence

System Performance Tests

Note:

POST takes approximately 10 seconds to complete.

Note:

If an error occurs during POST, the monitoring system displays an error message.

Reference Chapter 4, Troubleshooting.

3.3.2 Battery Status

To verify battery status:

1. Insert the batteries into the monitoring system.

2. Press and hold the Power On/Off button for approximately 1 second.

3. Verify the monitoring system is turned on and operating normally.

• Verify the Battery status icon on the display. The battery status icon displays

the remaining battery capacity.

• If the monitoring system is in a critically low battery condition, the high priority

alarm occurs for about 5 minutes before the monitoring system shuts down

automatically. Replace the batteries.

Service Manual 3-3

Page 46

Modification and Testing

• When the monitoring system is in a low battery condition, the remaining

battery power is only enough for 15 minutes of operation. Replace the batteries.

4. Press and hold the Power On/Off button for approximately 1 second and verify

that the monitoring system turns off.

3.3.3 Patient Modes

To verify that patient modes can be selected

1. Select the Change Patient Mode Menu.

A check mark appears next to the selected patient mode.

Figure3-2.Change Patient Mode Menu

2. Press the Down button to highlight each patient mode and press OK to verify that

the correct patient mode icon appears.

Pass codes are required to change to Homecare Mode, Sleep Study Mode, and

back to Standard (Adult or Neonatal) Mode.

Table 3-2 on page 3-5 lists the patient modes and their icons. The icon for the

current patient mode setting appears in the upper left of the monitoring system’s

display.

3-4 Service Manual

Page 47

Note:

To change to Homecare Mode or Sleep Study Mode requires a unique pass code

for each mode. Contact Covidien Technical Services for these pass codes.

System Performance Tests

Table3-2.Patient Modes

Icon Patient Mode

Adult

Neonatal

Homecare

(requires Homecare pass code)

Sleep Study

(requires Sleep Study pass code)

3.3.4 Homecare Mode

To verify Homecare Mode:

1. Connect a sensor to the monitoring system and to a live subject.

2. Access the Change Patient Mode menu.

3. Press the Up or Down button to highlight Homecare Mode, then press OK to

select Homecare Mode.

Service Manual 3-5

Page 48

Modification and Testing

Figure3-3.Homecare Mode Menu Item

4.

Enter the four-digit pass code for Homecare Mode.

Use the Up and Down buttons to change the value for each digit, then press OK to

select the value.

5.

After entering the four digits, select Confirm to enter Homecare Mode.

6.

Verify that the Homecare Mode screen appears. The Homecare Mode icon appears at

top left of the screen, and the monitoring screen’s appearance is different from the

Standard Mode and Sleep Study Mode screens.

3-6 Service Manual

Page 49

Figure3-4.Homecare Mode Monitoring Screen

System Performance Tests

Sleep Study Mode

3.3.5

To verify Sleep Study Mode

1. Access the Change Patient Mode menu.

2. Press the Up or Down button to highlight Sleep Study Mode, then press OK to

select Sleep Study Mode.

Service Manual 3-7

Page 50

Modification and Testing

Figure3-5.Sleep Study Mode Menu Item

3.

Enter the four-digit pass code for Sleep Study Mode.

Use the Up and Down buttons to change the value for each digit, then press OK to

select the value.

4.

After entering the four digits, select Confirm to enter Sleep Study Mode.

5.

Verify that the Sleep Study Mode icon appears at top of screen.

3.3.6 Dynamic Passwords

The Dynamic Password menu allows a user to set new pass codes for switching

between care modes. The menu is accessible in Standard Mode, and requires

access to the Service Menu. Contact Technical Services to obtain the default

Service Menu pass code.

To change a dynamic password:

1. Select the Service Menu.

2. Enter the default pass code obtained from Technical Services.

3-8 Service Manual

Page 51

System Performance Tests

3. From the Service Menu, use the down button to highlight Dynamic Password,

then press OK.

Figure3-6.Service Menu

4. Highlight the mode transition for which the password is being changed, then

press OK.

Figure3-7.Dynamic Password Menu (Homecare to Standard Example)

Service Manual 3-9

Page 52

Modification and Testing

5. Perform one of the following to set a new dynamic password or to reset the exist-

ing one to the factory default:

• Enter a new password by pressing the Up and Down buttons to change the

value for each digit, then select Confirm.

• Select Reset to revert to the factory default password.

Figure3-8.Password Set or Reset (Homecare to Standard Example)

3.3.7

Date and Time

To verify the date and time are accurate:

1. Select the Service Menu.

2. From the Service Menu, use the Down button to select the Date/Time Settings

menu.

3-10 Service Manual

Page 53

Figure3-9.Date/Time Settings

System Performance Tests

3.

Set the correct year, month, day, hour, and minute.

4.

Use the Up button and Down button to scroll through the Date Format options. The

options allow for changes in the date format (yy/mm/dd, mm/dd/yy, dd/mm/yy).

5. Verify that the selected year, month, day, hour, and minute appear at top of

screen

.

Note:

The time format is 24 hours only.

3.3.8 Wireless Network Connectivity

The wireless network feature is an option and does not exist on all monitoring

systems.

To verify the wireless network connectivity:

1. Select the Service Menu.

2. From the Service Menu, use the Down button to select the Communication Set-

tings menu.

Service Manual 3-11

Page 54

Modification and Testing

Figure3-10.Communications Settings

3.

Select the Oxinet Settings menu.

4.

Set the IP address and Port for access to the server.

5.

Select Add New Connection to set the access point (AP) and IP address for accessing

the monitoring system.

•

Select the SSID menu and enter the SSID for the AP

• Select the Encryption Type menu and enter the security type of the current AP.

• Unless the security type is Disable, set the Password in the Encryption Type

.

menu.

• Set the desired setting in the IP Address menu, Subnet Mask menu, or

Gateway menu.

• Select the Save Connection menu.

3-12 Service Manual

Page 55

Figure3-11.Add New Connection Menu

System Performance Tests

6.

Select the Select Wi-Fi Target menu and choose the desired settings.

7.

To exit the Communication Settings menu, select Return.

8.

From the Service Menu, select the Device Settings menu.

9.

Use the Down button to activate the Wi-Fi.

Service Manual 3-13

Page 56

Modification and Testing

Figure3-12.Device Settings Menu

10.

Verify that the wireless status icon appears at the top of the screen and that the icon

matches the current state of the wireless connection.

Note:

If the monitoring system does not contain the wireless option, the wireless status

icons will not appear on the screen.

Table3-3.Wireless Status Icon

Icon Description

Wi-Fi On, access point (AP) disabled

or

Wi-Fi Off

Unable to connect to the host

Active wireless connection

3-14 Service Manual

Page 57

Operational and Functional Tests

Table3-3.Wireless Status Icon

Icon Description

Wireless signal strength

3.4 Operational and Functional Tests

3.4.1 General Operation Tests

To perform general operation tests:

1. Set the monitoring system to Factory Defaults, which removes institutional default

settings.

For more information about factory defaults and options for saving monitoring

system settings, reference the Operator’s Manual.

2. Use a durable, adult finger sensor as specified in Table 3-1 on page 3-2.

LED Excitation Test

The LED excitation test uses normal system components to test circuit operation. The test uses the red sensor LED to verify intensity modulation controlled

by the LED intensity control circuit. Use an adult finger sensor to examine LED

intensity control.

Figure3-13.Sensor Port

To test the circuit operation:

1. Open the sensor port cover.

2. Connect a DEC-4 pulse oximetry cable to the sensor port.

3. Connect the adult finger sensor to the DEC-4 cable.

Service Manual 3-15

Page 58

Modification and Testing

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. Pinch the ends of the finger sensor to open the sensor to its widest point.

6. After the monitoring system completes POST, verify the finger sensor LED is

brightly lit.

7. Allow the sensor clip to close slowly.

8. Verify the LED intensity decreases as the LED approaches the optical sensor.

9. Open the sensor again and verify that the LED intensity increases.

10. Repeat step 7 and verify the intensity continues to decrease. This variation is an

indication the microprocessor is in proper control of LED intensity.

11. Leave the monitoring system on for the next test.

Operation with a Live Subject

Use the same finger sensor used in the LED Excitation Test, p. 3-15 to perform

the following test with a live subject.

To test using a live subject:

1. Attach the finger sensor to a live subject as recommended in the OxiMax pulse

oximetry sensor's directions for use.

2. If not already done, press and hold the Power On/Off button to turn the moni-

toring system on and verify the monitoring system is operating.

3. The monitoring system should stabilize on the subject's physiological signal in

about 15 to 30 seconds. Verify the oxygen saturation and pulse rate values are

reasonable for the subject.

Alarms and Alarm Paused

Access these settings from the Service Menu by using the pass code provided

by Technical Services. Reference Technical Services, p. 1-10.

To adjust the audio (alarms and alarm paused) options:

1. Connect the DEC-4 pulse oximetry cable to the monitoring system’s sensor port.

3-16 Service Manual

Page 59

Operational and Functional Tests

Figure3-14.Sensor Port

2. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

3. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

Alarm Audio Paused

1. Verify the SpO2 and pulse rate appear.

2. Select the Alarm Limits Menu.

3. Select Low SpO2.

4. Change Low SpO2 to 99%.

Figure3-15.Low SpO2 Alarm Limit of 99%

Service Manual 3-17

Page 60

Modification and Testing

5. Select Low Pulse.

6. Change Low Pulse to 160 BPM.

Figure3-16.Low Pulse Alarm Limit of 160BPM

7. Confirm the following results:

• The waveform tracks the pulse rate.

• The pulse tone is audible.

• SpO2 and pulse rate values have flashing yellow highlights behind them.

Note:

Depending on the live subject, an alarm might not be triggered using the Low

SpO

• The audible alarm sounds.

• The following messages alternately appear in the display: Pulse Rate Low and

SpO

8. Access the Service Menu and set Alarm Audio Paused to 30 seconds.

2 alarm limit of 99%.

2 Low.

3-18 Service Manual

Page 61

Figure3-17.Alarm Audio Paused Setting of 30 Seconds

Operational and Functional Tests

9. Exit the Service Menu.

10. As soon as the SpO2 Low alarm and Pulse Rate Low alarms sound, press the

Audio Paused button to immediately pause the alarm tone.

11. With the alarm paused, verify the following:

• Alarm remains silent for 30 seconds before the alarm tone is audible.

• Audio Paused indicators light, and the Alarm Audio Paused messages appears

in the display.

• SpO2 and pulse rate values have flashing yellow highlights behind them.

• Pulse tone is audible.

Permission to Mute Alarm

1. Use the same values for Low SpO2 and PR Alarm Limit as described in “Alarm

Audio Paused” on page 17.

2. Confirm the following results:

• The Pulse Tone is audible.

• The SpO2 and pulse rate values are highlighted by flashing yellow boxes.

Service Manual 3-19

Page 62

Modification and Testing

• The Audible Alarm sounds.

• The following messages alternately appear in the display: Pulse Rate Low and

SpO

3. In the Service Menu, select the Permission to Mute Alarm.

2 Low.

Figure3-18.Permission to Mute Alarm

A confirmation message for the muted alarm setting appears.

4. Select Yes.

3-20 Service Manual

Page 63

Figure3-19.Confirmation for Muted Alarm

Operational and Functional Tests

5. Exit the Service Menu.

6. Access the Device Settings menu.

7. In the Device Settings Menu, access the Sound Settings menu.

8. In the Sound Settings menu, change the alarm volume to 0.

9. Verify the following:

• Alarm audio is silent.

• Audio Paused indicators appear.

• Pulse tone is audible.

Alarm Volume Control

After testing the Alarm Audio Paused and Alarm Audio Reminder settings,

perform the following alarm volume test procedure.

Note:

Turn the alarm audio back on for both SpO

procedure.

2 and pulse rate before performing this

Service Manual 3-21

Page 64

Modification and Testing

To test the alarm volume

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system off.

2. Connect the DEC-4 pulse oximetry cable to the sensor port.

3. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. Access the Device Settings menu.

6. In the Device Settings menu, access the Sound Settings menu.

7. Press the Down button to highlight Alarm Volume, then press OK.

8. Press the Up or Down button to adjust the alarm volume.

The Alarm Volume setting controls the volume (1-4) of alarms. The default setting

is 2.

9. To mute the alarm, change the Permission to Mute Alarm to Yes in the Service

Menu. Reference Permission to Mute Alarm, p. 3-19.

Figure3-20.Alarm Volume Default Setting of 2

3-22 Service Manual

Page 65

Operational and Functional Tests

Key Beep Volume Control

A beep sounds each time a button is pressed, unless the Key Beep Volume

setting is 0.

To test the Key Beep volume

1. Access the Device Settings menu.

2. In the Device Settings menu, access the Sound Settings menu.

3. Press Down button to highlight Key Beep Volume, then press OK.

4. Press Up or Down button to adjust the key beep volume.

The Key Beep Volume setting controls the volume (0-4) of key beeps. The default

setting is 0.

Figure3-21.Key Beep Volume Default Setting of 0

Pulse Volume Control

A pulse tone sounds with each detected heart beat.

To set the pulse volume

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system off.

Service Manual 3-23

Page 66

Modification and Testing

2. Connect the DEC-4 pulse oximetry cable to the monitoring system Sensor Port.

3. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. Access the Device Settings menu.

6. In the Device Settings menu, access the Sound Settings menu.

7. Press Down button to highlight Pulse Volume, then press OK.

8. Press Up or Down button to adjust the pulse volume.

The Pulse Volume setting controls the volume (0-4) of the pulse rate indicator. The

default setting is 0.

Brightness Control

Figure3-22.Pulse Volume Default Setting of 0

Adjust the brightness of the display.

To adjust the Brightness:

1. Access the Device Settings menu.

3-24 Service Manual

Page 67

Operational and Functional Tests

2. In the Device Settings menu, press the Up or Down button to highlight the Bright-

ness Setting menu and then press OK to select the Brightness Setting menu.

Figure3-23.Brightness Setting

Press Down button to decrease the brightness.

•

• Press Up button to increase the brightness.

3. Press OK to save the desired brightness.

Save Spot Reading

The Save Spot Reading function saves a point in time of the patient’s data.

To save a spot reading:

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system off.

2. Connect the DEC-4 pulse oximetry cable to the monitoring system Sensor Port.

3. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. Press Menu.

Service Manual 3-25

Page 68

Modification and Testing

6. Highlight Save Spot Reading and press OK.

The message “Spot Reading Saved” appears.

Figure3-24.“Spot Reading Saved” Message

7. Access the Monitoring History menu.

8. In the Monitoring History menu, select View Spot Data.

9. Verify the saved spot readings.

3-26 Service Manual

Page 69

Figure3-25.Monitoring History Spot Data

Operational and Functional Tests

Sensor Alarm Priority Settings

Access the Sensor Alarm Priority Settings menu to change the alarm priority to

Low, Medium, or High for:

• Sensor Disconnect alarm

• Sensor Off alarm

• Sensor Failure alarm

To change the Alarm Priority Setting for Sensor Disconnect:

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system off.

2. Connect the DEC-4 pulse oximetry cable to the monitoring system’s sensor port.

3. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. When the SpO2 saturation and pulse rate are displayed, disconnect the sensor

from the monitoring system’s sensor port.

Service Manual 3-27

Page 70

Modification and Testing

6. Verify that the Sensor Disconnect alarm occurs.

7. Access the Service Menu.

8. In the Service Menu, select the Sensor Alarm Priority Settings menu.

9. Set the Sensor Disconnect priority to High.

Figure3-26.Sensor Disconnect Alarm Priority Setting

10. Observe the monitoring screen.

11. Verify the following:

• The SpO2 and pulse rate values are highlighted by flashing red boxes.

• The High priority alarm sounds.

• The message “Sensor Disconnect” appears.

To change the Alarm Priority Setting for Sensor Off:

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system off.

2. Connect the DEC-4 pulse oximetry cable to the monitoring system’s sensor port.

3. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

3-28 Service Manual

Page 71

Operational and Functional Tests

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. When the monitoring system is powered on, disconnect the sensor from the

finger.

6. Verify that the Sensor Off alarm occurs.

Figure3-27.Sensor Off Alarm

7. Access the Service Menu.

8. In the Service Menu, Select the Sensor Alarm Priority Settings menu.

9. Set the High in the Sensor Off menu.

10. Go to the monitoring screen.

11. Verify the following:

• The SpO2 and pulse rate values are highlighted by flashing box boxes.

• The High priority alarm sounds.

• The message “Sensor Off” appears.

Service Manual 3-29

Page 72

Modification and Testing

Screen Saver

Screen Saver saves power by darkening the screen.

The Screen Saver functions during periods when no alarm condition exists and

the buttons are not pressed.

To set the Screen Saver:

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

2. Access the Service Menu.

3. In the Service Menu, Select the Power Saving Settings menu.

4. Select Screen Saver Time. The factory default is 3 minutes.

5. Set the desired number of minutes.

Screen Saver Time selections include Never and from 1 minute to 10 minutes.

Figure3-28.Screen Saver Time Setting

6. In the Power Saving Settings menu, select the Screen Saver Brightness menu.

7. Change the brightness to 0. The factory default is 20%.

3-30 Service Manual

Page 73

Operational and Functional Tests

8. After 1 minute, verify the following:

• The screen of the monitoring system is darkened.

• The LED is flashing green.

9. After pressing any button or when an alarm occurs, verify the following:

• The screen of the monitoring system is brightened.

• The LED lights green.

Power Saving

Power Saving turns the screen off after 10 minutes of inactivity.

Power Saving functions when no alarm condition exists and the buttons are

not pressed.

To test the Power Saving:

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system off.

2. Connect the DEC-4 pulse oximetry cable to the monitoring system’s sensor port.

3. Connect the OxiMax DS-100A sensor to the DEC-4 cable, then to a finger.

4. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

5. After 10 minutes, verify the following:

• The screen of the monitoring system is turned off.

• The LED is flashing at 2.5-second intervals.

6. After pressing any button except the Power On/Off or Alarm Paused button,

verify the following:

• The brightness of the screen is set to the desired brightness.

• The LED lights green.

Service Manual 3-31

Page 74

Modification and Testing

Auto Power Off

Auto Power Off turns the monitoring system off after the specified period of

inactivity.

Auto Power Off functions when no alarm condition exists, the buttons are not

pressed for the specified period, the sensor is disconnected, and the sensor

signal is lost.

To test Auto Power Off:

1. Press and hold the Power On/Off button for approximately 1 second to turn the

monitoring system on.

2. Access the Service Menu.

3. In the Service Menu, select the Power Saving Settings menu.

4. Select the Auto Power Off Time menu. The factory default is 3 minutes.

5. Set 1 minute in the Auto Power Off Time menu.

Auto Power Off selections include Never and from 1 minute to 10 minutes.

Figure3-29.Auto Power Off Time Setting

6. After 1 minute, verify the following:

3-32 Service Manual

Page 75

• The LED is off.

• The monitoring system turns off automatically.

3.4.2 Functional Tests

To perform functional tests:

1. Read SRC-MAX Overview, p. 3-33 to become familiar with the pulse oximetry

functional tester (Nellcor model SRC-MAX).

Note:

For the waveform tests, the display will show a pulse waveform of approximately

1/2-inch peak to peak (P-T-P) amplitude. Actual amplitude may vary but will be a

reference for low pulse amplitude/low light patients.

Operational and Functional Tests

2. Once the SRC-MAX is attached to the DEC-4 cable and the SRC-MAX and moni-

toring system are turned on, complete all of the tests in sequence, beginning with

BPM (PR), then %SpO