Page 1

Portable Bedside Capnograph/Pulse Oximeter

Service Manual

CI05225E

Page 2

Notice: Purchase of this instrument confers no express or implied license under any Oridion

Medical patent or Nellcor Puritan Bennett patent to use the instrument with any accessory that is

not manufactured or licensed by Oridion Medical 1987 Ltd.

Capnography is covered by one or more of the following United States patents: 6,491,643;

6,656,127; 6,168,958; 5,300,859 and 4,755,675 and their foreign equivalents

この製品は、次の日本における特許、1980816と海外での同等のものによって保護されて

居ります。

Microstream

Smart BiteBloc™ and NIV Line™ are trademarks of Oridion Medical 1987 Ltd.

Nellcor Puritan Bennett Incorporated is an affiliate of Tyco Healthcare.

The following are trademarks of Nellcor Puritan Bennett Incorporated: Oxiband

OxiCliq

Pulse Oximetry is covered by one or more of the following US patents and foreign equivalents:

4,802,486; 4,869,254; 4,928,692; 4,934,372; 5,078,136; 5,485,847; 5,743,263; 5,865,736;

6,035,223; 6,298,252; 6,463,310; 6,591,123; 6,675,031; 6,708,049; 6,801,797; Re 35,122.

®

and FilterLine® are registered trademarks and Smart CapnoLine™, CapnoLine™,

®

; Dura-Y®; and OXIMAX®.

.

®

; Durasensor®;

Page 3

TABLE OF CONTENTS

List of Figures

List of Tables

Section 1: Introduction........................................................................ 1-1

Section 2: Required Equipment.......................................................... 2-1

Section 3: Cleaning ........................................................................... 3-1

Section 4: Service Mode...................................................................... 4-1

Section 5: Troubleshooting................................................................. 5-1

Section 6: Flow Calibration Check ..................................................... 6-1

Section 7: Disassembly Guide............................................................ 7-1

1.1 Manual Overview ............................................................... 1-1

1.2 Warnings, Cautions, and Notes ......................................... 1-1

1.2.1 Warning.............................................................. 1-1

1.2.2 Caution...............................................................1-1

1.2.3 Note.................................................................... 1-1

1.3 Product Description ...........................................................1-2

2.1 Required Equipment .......................................................... 2-1

3.1 Cleaning ........................................................................... 3-1

3.1.1 Procedure........................................................... 3-1

4.1 Introduction ........................................................................ 4-1

4.2 Service Level 1 .................................................................. 4-1

4.2.1 Information Screen............................................. 4-1

4.2.2 Event Messages Screen .................................... 4-1

4.2.3 Interface Test Screen......................................... 4-2

4.2.4 Accessing Service Mode and Service Level 1 ... 4-3

4.3 Service Level 2 .................................................................. 4-5

4.3.1 Default Alarm Limits ........................................... 4-7

4.3.2 Default Settings.................................................. 4-9

4.3.3 Flow Calibration ............................................... 4-10

5.1 Introduction ........................................................................ 5-1

5.2 Who Should Perform Repairs ............................................ 5-1

5.3 Repair Level Supported ..................................................... 5-1

5.4 How to Use This Section ...................................................5-1

5.5 Obtaining Replacement Parts............................................ 5-1

5.6 Troubleshooting Guide ......................................................5-2

6.1 Introduction ........................................................................ 6-1

6.2 Flow Rate Check ...............................................................6-1

6.3 Flow Calibration Process ................................................... 6-2

7.1 Introduction ........................................................................ 7-1

7.2. Opening the Monitor Case.................................................7-2

7.3 Replacing the CO

7.4 Replacing the SpO

2 Board .................................................. 7-4

2 Board................................................. 7-5

7.5 Replacing the Pump ..........................................................7-6

7.6 Replacing the Flow System ...............................................7-7

7.6.1 Replacing the lines to the pump.........................7-8

7.6.2 Replacing the lines to the solenoid ....................7-9

7.7 Replacing LCD and LED Display..................................... 7-11

7.7.1 Replacing the LCD ........................................... 7-11

7.7.2 Replacing the LED Display .............................. 7-11

iii

Page 4

Table of Contents

7.8 Replacing Housing Components ..................................... 7-12

7.8.1 ON-OFF Button and Gas Outlet....................... 7-12

7.8.2 Keypads ...........................................................7-12

7.8.3 Front Cover ......................................................7-13

7.8.4 SpO

Connector Latch, Rear Cover and

2

SpO

Insulation Plate .......................................7-13

2

7.9 Updating Software Version .............................................. 7-14

Section 8: Electrical Safety Tests.......................................................8-1

8.1 Electrical Safety Tests ....................................................... 8-1

Section 9: Periodic Maintenance ........................................................ 9-1

9.1 Periodic Maintenance ........................................................ 9-1

Section 10: Performance Verification............................................... 10-1

10.1 Flow System Leak Check ................................................ 10-1

10.1.1 Flow System Leak Check Procedure ............... 10-1

10.2 Performance Verification Procedure................................ 10-2

Section 11: Packing For Shipment ................................................... 11-1

11.1 General Instructions......................................................... 11-1

11.2 Packing Monitor in Original Carton .................................. 11-1

11.3 Packing in a Different Carton........................................... 11-1

Section 12: Specifications................................................................. 12-1

12.1 Physical ......................................................................... 12-1

12.1.1 Size .................................................................. 12-1

12.1.2 Weight.............................................................. 12-1

12.1.3 Noise Emission ................................................ 12-1

12.2 Environmental..................................................................12-1

12.2.1 Temperature.....................................................12-1

12.2.2 Relative Humidity ............................................. 12-1

12.2.3 Pressure and Altitude....................................... 12-1

12.3 Safety Standards ............................................................. 12-1

12.4 Performance .................................................................... 12-2

12.4.1 Capnograph ..................................................... 12-2

12.4.2 Pulse Oximeter................................................. 12-3

12.5 Power Specifications ....................................................... 12-4

12.5.1 External Power Source .................................... 12-4

12.5.2 Internal Power Source...................................... 12-4

12.6 Components and User interface ...................................... 12-4

12.6.1 Displays............................................................ 12-4

12.6.2 Controls and Indicators .................................... 12-4

12.6.3 Connections ..................................................... 12-4

Section 13: Spare Parts..................................................................... 13-1

13.1 Spare Parts List ............................................................... 13-1

Glossary of Terms

iv

Page 5

Table of Contents

LIST OF FIGURES

LIST OF TABLES

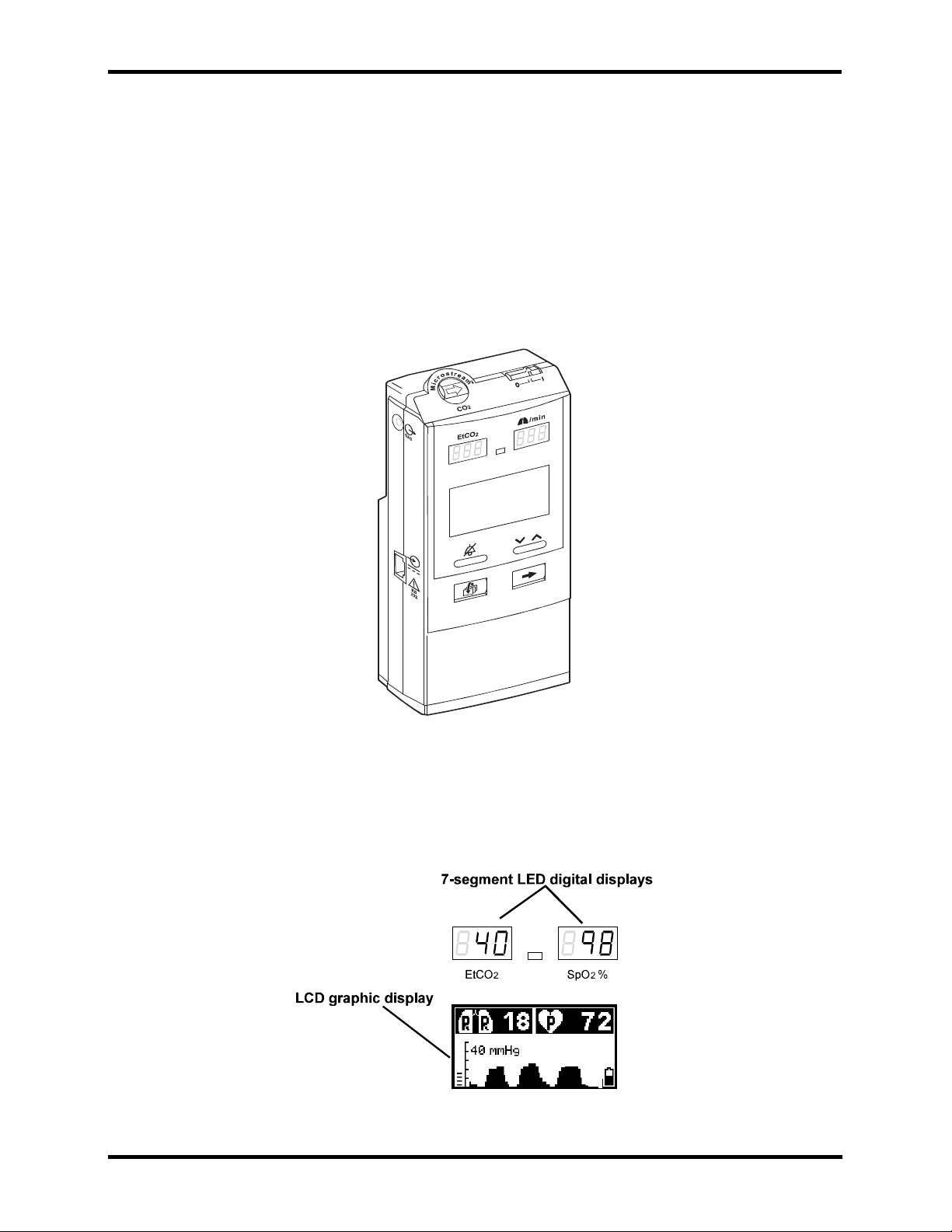

1-1 Handheld Capnograph/Pulse Oximeter............................. 1-2

1-2 LCD Graphic Display and 7 Segment Digital Displays ......1-2

7-1 Removing the Battery Pack ............................................... 7-2

7-2 Removing Mounting Screws.............................................. 7-3

7-3 Separating Rear and Front Covers.................................... 7-3

7-4 Replacing CO

7-5 Replacing SpO

2 Board and Housing Components.............. 7-4

2 Board....................................................... 7-5

7-6 Replacing the Pump .......................................................... 7-6

7-7 Flow System ......................................................................7-7

7-8 Main Line ........................................................................... 7-8

7-9 Exhaust Line...................................................................... 7-8

7-10 Lines to Solenoid (Zero line, Input line 1, Input line 2........ 7-9

7-11 Zero line........................................................................... 7-10

7-12 Replacing LCD and LED Display.....................................7-11

7-13 Replacing SpO

2 Connector Latch.................................... 7-13

7-14 Replacing EPROM........................................................... 7-14

10-1 Leak Test Jig Connection ................................................10-1

10-2 Initialization Screen.......................................................... 10-2

10-3 Self-Test Screen .............................................................. 10-2

10-4 Measuring Mode .............................................................. 10-2

10-5 Quick Guide ..................................................................... 10-3

10-6 Connecting the monitor to Printer/PC with

Communication Adapter Kit ............................................. 10-9

11-1 Packing the Monitor in Original Packing .......................... 11-2

4-1 Accessing Service Mode and Changing Parameter

Settings................................................................... 4-3

4-2 Accessing Service Level 2................................................. 4-5

4-3 Changing Default Alarm Limits .......................................... 4-7

4-4 Changing Default Settings................................................. 4-9

4-5 Accessing Flow Calibration.............................................. 4-10

5-1 Troubleshooting Guide ...................................................... 5-2

5-2 Advisory Messages Guide.................................................5-4

5-3 Event Messages ................................................................ 5-5

6-1 Flow Calibration................................................................. 6-2

10-1 CO

2 Calibration Check..................................................... 10-4

10-2 Calibration Process.......................................................... 10-6

10-3 Calibration Process -Troubleshooting.............................. 10-7

10-4 Plethysmograph Waveform ............................................. 10-8

10-5 Accessing Monitor’s Print Functions.............................. 10-10

13-1 Spare Parts List ............................................................... 13-1

v

Page 6

Table of Contents

Page 7

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 Warnings, Cautions, and Notes

1.3 Product Description

1.1 MANUAL OVERVIEW

This manual contains information for servicing the handheld capnograph/

pulse oximeter (the monitor). Only authorized service personnel should

service this product. The Handheld Capnograph/Pulse Oximeter

Operator’s Manual (the operator’s manual) is an integral part of the

service procedures. Before servicing the monitor, read the operator’s

manual carefully for a thorough understanding of how to operate the unit.

Only use the tools and test equipment as specified in this manual. Only

use original spare parts available from your local distributor.

Warning: Incorrect procedures may harm the patient, or

damage the monitor.

1.2 WARNINGS, CAUTIONS, AND NOTES

1.2.1 Warning

1.2.2 Caution

1.2.3 Note

A warning precedes an action that may result in injury or death to the

patient or user. Warnings are boxed and highlighted in boldface type.

A caution precedes an action that may result in damage to, or malfunction

of, the monitor. Cautions are highlighted in boldface type.

A note gives information that requires special attention.

1-1

Page 8

Section 1: Introduction

1.3 PRODUCT DESCRIPTION

The handheld capnograph/pulse oximeter is used to continuously monitor

end-tidal carbon dioxide (EtCO

2), and pulse rate. The monitor is for attended monitoring only and

(SpO

must be used in the continuous presence of a qualified healthcare

provider. The monitor can be used on adult, pediatric, and infant/neonatal

patients. It is intended for use where continuous, noninvasive monitoring

of these parameters is desired, including hospital and mobile use (when

protected from excessive moisture such as direct rainfall). The monitor

operates on AC power or a rechargeable Nickel Metal Hydride battery

pack.

2), respiratory rate, oxygen saturation

1-2

Figure 1-1: Handheld Capnograph/Pulse Oximeter

The monitor is operated using a four-key keypad. Measurements are

displayed on the front panel on the 7-segment LED digital displays (LED)

and on the LCD graphic display (LCD) as shown in Figure 1-2. Refer to the

operator’s manual for complete operating instructions.

Figure 1-2: LCD Graphic Display and 7-Segment Digital Displays

Page 9

SECTION 2: REQUIRED EQUIPMENT

2.1 Required Equipment

2.1 REQUIRED EQUIPMENT

You will need the following equipment to disassemble, replace parts,

check, adjust, or calibrate the monitor.

For disassembly and replacement:

• Phillips-head screwdriver (medium)

• Flat-head screwdriver (small)

• IC Extractor for PLCC socket

• Threadlocker glue e.g. Loctite

For checks, adjustments and calibration:

®

222 super screw lock

• Calibration Gas (5% CO

2 in air)

• FilterLine or FilterLine H and a connecting means

• DS-100A - O

XIMAX Durasensor

®

, Nellcor

• Leak Test Jig

• Vacuum manometer with a range of 0-500 mBar

e.g. MPL-3200-DM, Digital Manometer MicroPneumatic Logic, Inc.

• Communication Adapter Kit (only necessary to verify print functions)

• Seiko DPU-414 printer (only necessary to verify print functions)

• External power supply

• Handheld Capnograph/Pulse Oximeter Operator’s Manual

• Flow Meter (range 0-50 ml/min) e.g. Top Track Mass Flow Meter,

model: 822-13-OV1-PV1-V1, Sierra Instruments, Inc.

Warning: Observe ESD (electrostatic discharge) precautions

when handling, adjusting or performing any procedure with

the monitor’s internal components.

2-1

Page 10

SECTION 3: CLEANING

3.1 Cleaning

3.1 CLEANING

Always clean the outer surface of the monitor before servicing.

Warning: Always wear latex or surgical gloves when cleaning

or servicing the monitor after hospital use.

Warning: Do not allow liquids to drip inside the housing.

Warning: Do not clean internal components.

Warning: Do not use preparations based on: phenols, halogen

producing compounds, strong organic acids, or oxygen

producing compounds.

3.1.1 Procedure

1. Unplug the unit from AC power.

2. With a damp cloth, gently wipe the outer case of the monitor with a

disinfectant based on aldehyde, alcohol or quaternary ammonium

producing compounds.

3-1

Page 11

SECTION 4: SERVICE MODE

4.1 Introduction

4.2 Service Level 1

4.3 Service Level 2

4.1 INTRODUCTION

The monitor supports a service mode built into the instrument’s firmware.

To access the service mode, refer to Table 4-1: "Accessing Service Mode

and Changing Parameter Settings".

The architecture of the monitor’s service mode divides the service mode

into two levels as described in the sections below.

• Service Level 1

• Service Level 2

4.2 SERVICE LEVEL 1

The Service Level 1 provides information and tools on three service

screens to test and calibrate specific functions without disassembling the

monitor.

• Information Screen

• Event Messages Screen

• Interface Test Screen

From these display screens the service technician can check the operating

hours counter and event messages, test the Human Interface functions

(HMI), set the light detection threshold, adjust the LCD contrast middle

point and do a calibration check and a calibration process, if necessary.

Refer to Table 4-1: "Accessing Service Mode and Changing Parameter

Settings".

4.2.1 Information Screen

The information screen displays the monitor’s main board serial number,

the number of operating hours, and the SpO

versions.

4.2.2 Event Messages Screen

The monitor automatically performs a series of built-in tests (BITs) at

start-up and during operation to check sub-systems and modules for

errors. The event messages screen lists the last five event messages, the

time each occurred relative to the unit’s operating hours, and a

recommended service action. There are three event messages and each

has a specific response as follows:

2 and CO2 boards’ software

Event Message: Action:

2 board Replace CO2 board

CO

2

board Replace SpO2 board

SpO

Flow Replace CO

2 board

4-1

Page 12

Section 4: Service Mode

Note: To exit the service mode and save event messages, turn off the

4.2.3 Interface Test Screen

The interface test screen shows four parameters (listed below) that

provide tools for the user to test, adjust, and calibrate the unit’s

interfacing systems.

•HMI Test

• Light Detector

• Contrast Cal. (Calibration)

monitor. Event messages will be erased when exiting the service

mode by a long press of .

•CO

2 Calib. (Calibration)

4.2.3.1 HMI Test

When the HMI Test is turned on, the monitor performs a self-test of the

following sub-systems:

• Buzzer (sounds for one second)

• LCD graphic display (screen shows a checkerboard pattern)

• 7-segment digital display (8s scroll left to right)

• Alarm bar (lights red, yellow, off)

• Backlight (turns on and off)

• Alarm silence indicator (light turns on and off)

When the HMI test is completed the status field returns automatically to

OFF.

4.2.3.2 Light Detector

The Light Detector parameter allows the service technician to set the

threshold value of the phototransistor. The default value is 1 and the

range is from 1 to 5 with 1 as the most sensitive (backlight on at all times)

and 5 as the least sensitive (backlight off). The threshold value should be

set according to the lighting conditions of the working environment. A

higher threshold value saves on battery power consumption.

4-2

4.2.3.3 Contrast Cal. (calibration)

The Contrast Cal. gives the service technician the option to change the

middle point default value of the contrast intensity of the LCD. Refer to

Table 4-1: "Accessing Service Mode and Changing Parameter Settings".

4.2.3.4 CO

The CO

2 Calib. (calibration)

2 Calib. allows the service technician to perform a calibration

check and calibration process to ensure the accuracy of the monitor.

Section 10: Performance Verification describes the calibration check

procedure.

Page 13

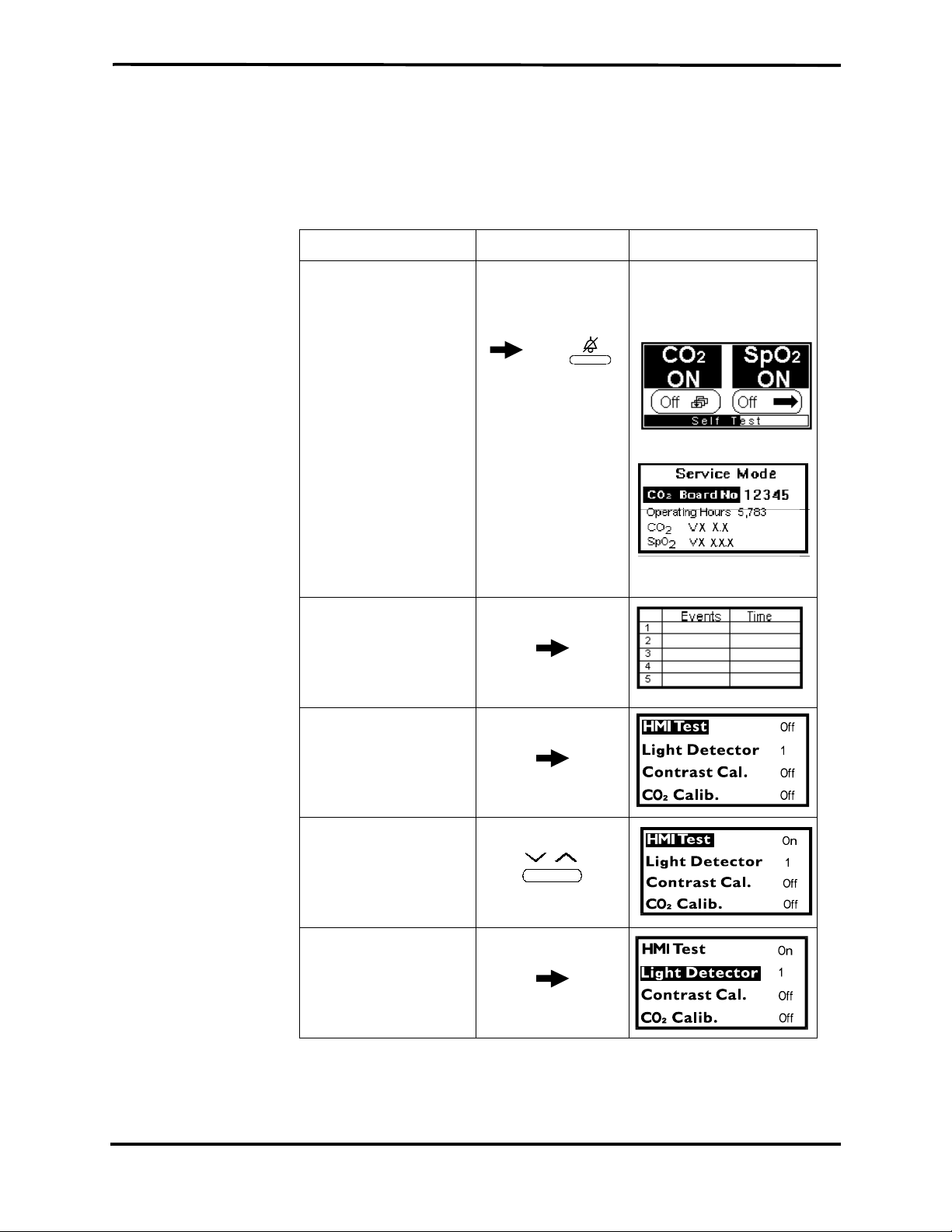

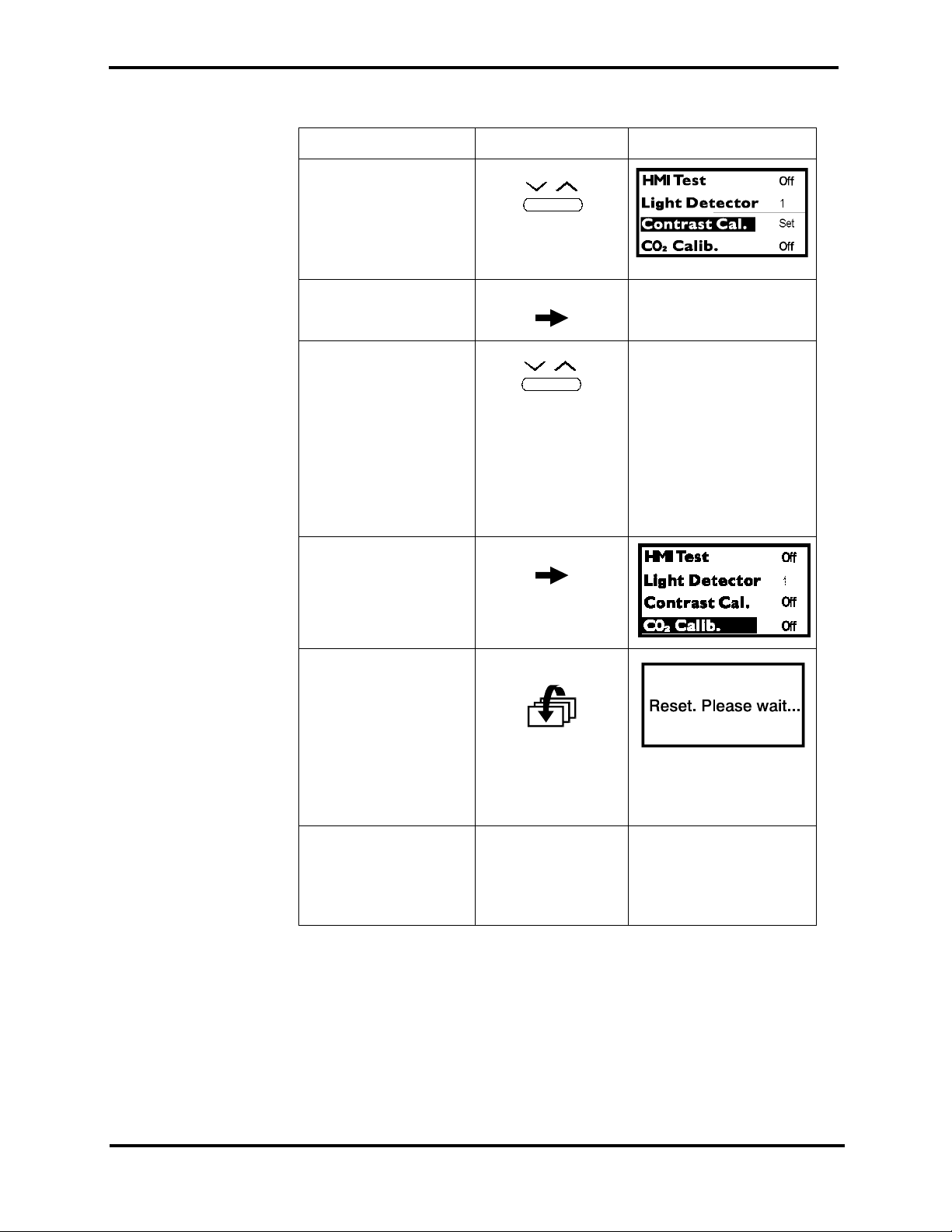

4.2.4 Accessing Service Mode and Service Level 1.

Table 4-1: "Accessing Service Mode and Changing Parameter Settings"

describes the process to access the service mode, change parameter

settings and how to change Contrast Cal. settings.

Table 4-1: Accessing Service Mode and

Changing Parameter Settings

Objective Action Response

Section 4: Service Mode

To access Service Mode During self-test,

long press

simultaneously

and

To access Event

Messages screen

To access Interface

Test screen

long press

long press

Self-test occurs and the

Information Screen

appears:

To change the

parameter setting or

value

To move to the next

parameter

short press

short press

4-3

Page 14

Section 4: Service Mode

Table 4-1: Accessing Service Mode and

Changing Parameter Settings (Continued)

Objective Action Response

To change Contrast

short press

Cal. setting to set

To start Contrast Cal. short press “Contrast Cal.” flashes.

To adjust Contrast

Cal. middle point

press

Screen lightens or

darkens

until desired setting is reached. (Pressing on the left lightens the screen, and pressing on the right darkens the screen.)

To accept new setting short press

To reset and return to

measuring mode

(automatically erasing

the event messages

memory)

To exit service mode

from any service

screen without erasing

the event messages

memory

long press

Note: Reset time is

approximately one

minute.

Turn off the

monitor.

4-4

Page 15

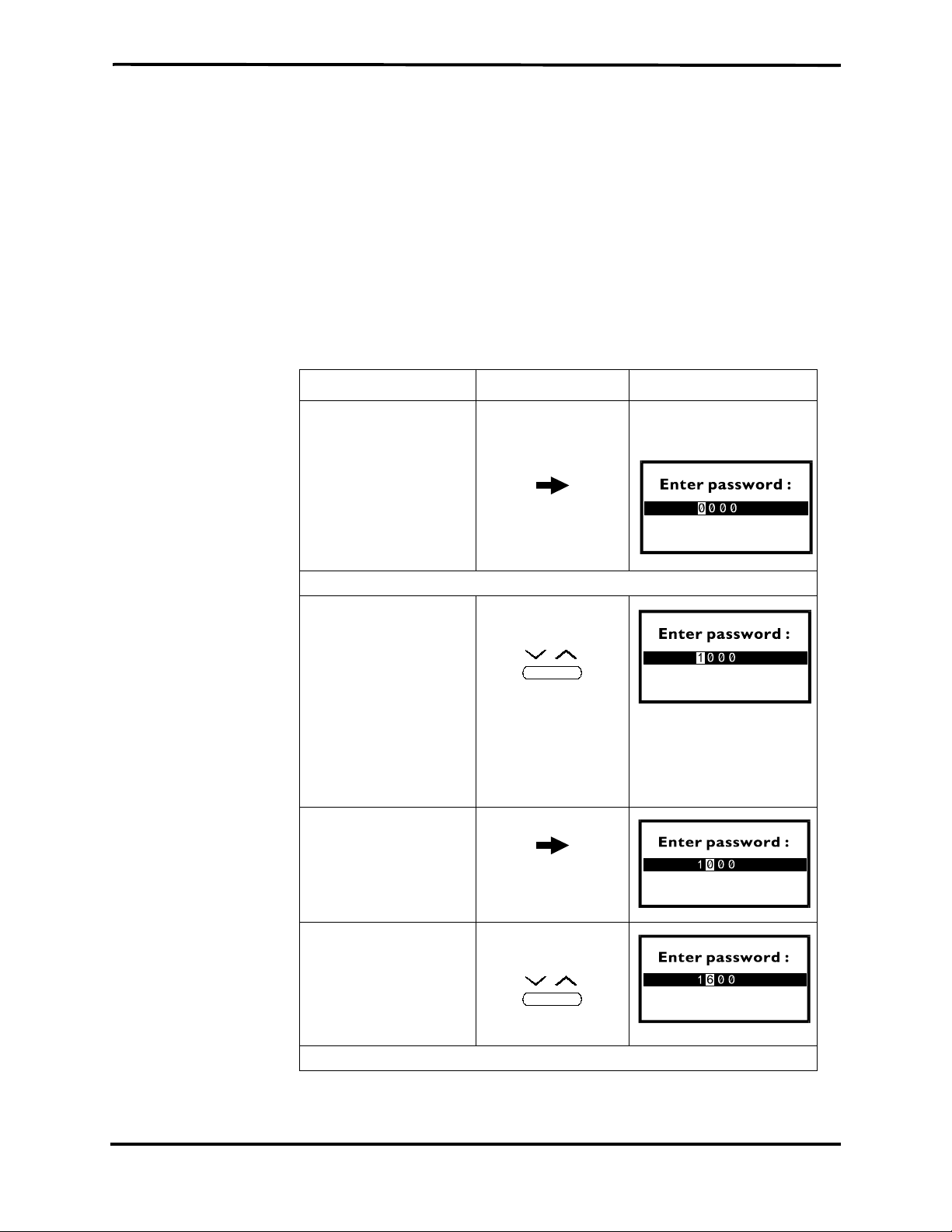

4.3 SERVICE LEVEL 2

Section 4: Service Mode

The Service Level 2 gives the service technician tools on three service

screens:

• Default Alarm Limits

• Default Settings

• Flow Calibration

To access this service level, the service technician must enter a valid

password (1627), refer to Table 4-2: "Accessing Service Level 2".

Note: The password should not be disclosed to avoid unauthorized setting

of parameters.

Table 4-2: Accessing Service Level 2

Objective Action Response

To access

Service Level 2

Enter Password: 1627

Enter the 1st digit short press (right)

Move to the next digit short press

After entering the service mode

long press (x3)

(x1)

Pressing on the right arrow scrolls the numbers up, the left arrow scrolls the numbers down.

Password Screen

appears

Enter the 2nd digit short press (right)

x6

Repeat the same procedure as above for the next two digits (2, 7).

4-5

Page 16

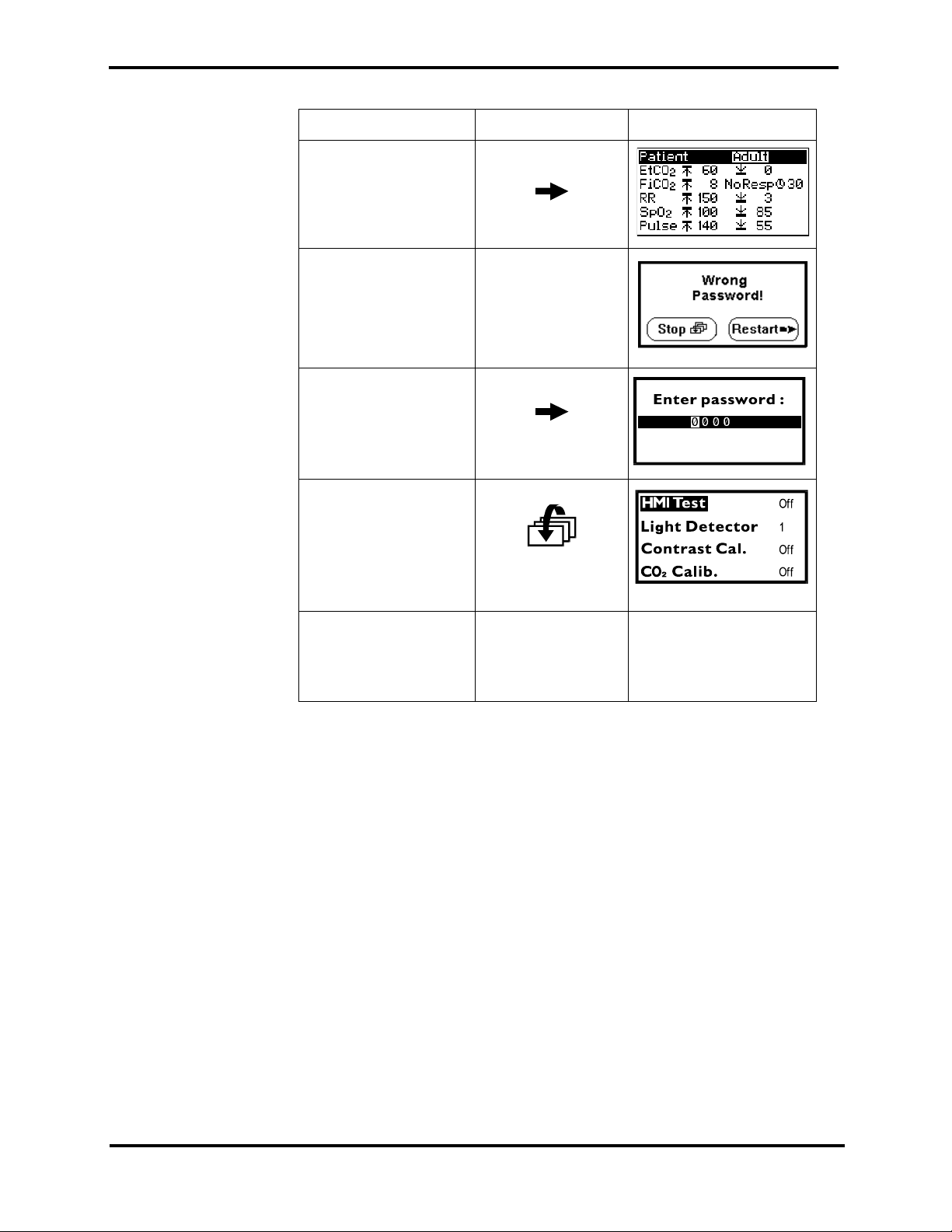

Section 4: Service Mode

Table 4-2: Accessing Service Level 2 (Continued)

Objective Action Response

To accept the last digit

and access the Default

Alarm Limits menu

In case you entered a

wrong digit:

To restart password

validation process

To return to the

Interface Test Screen

short press

long press

long press

To exit service mode

and save event

messages

Turn off the

monitor.

4-6

Page 17

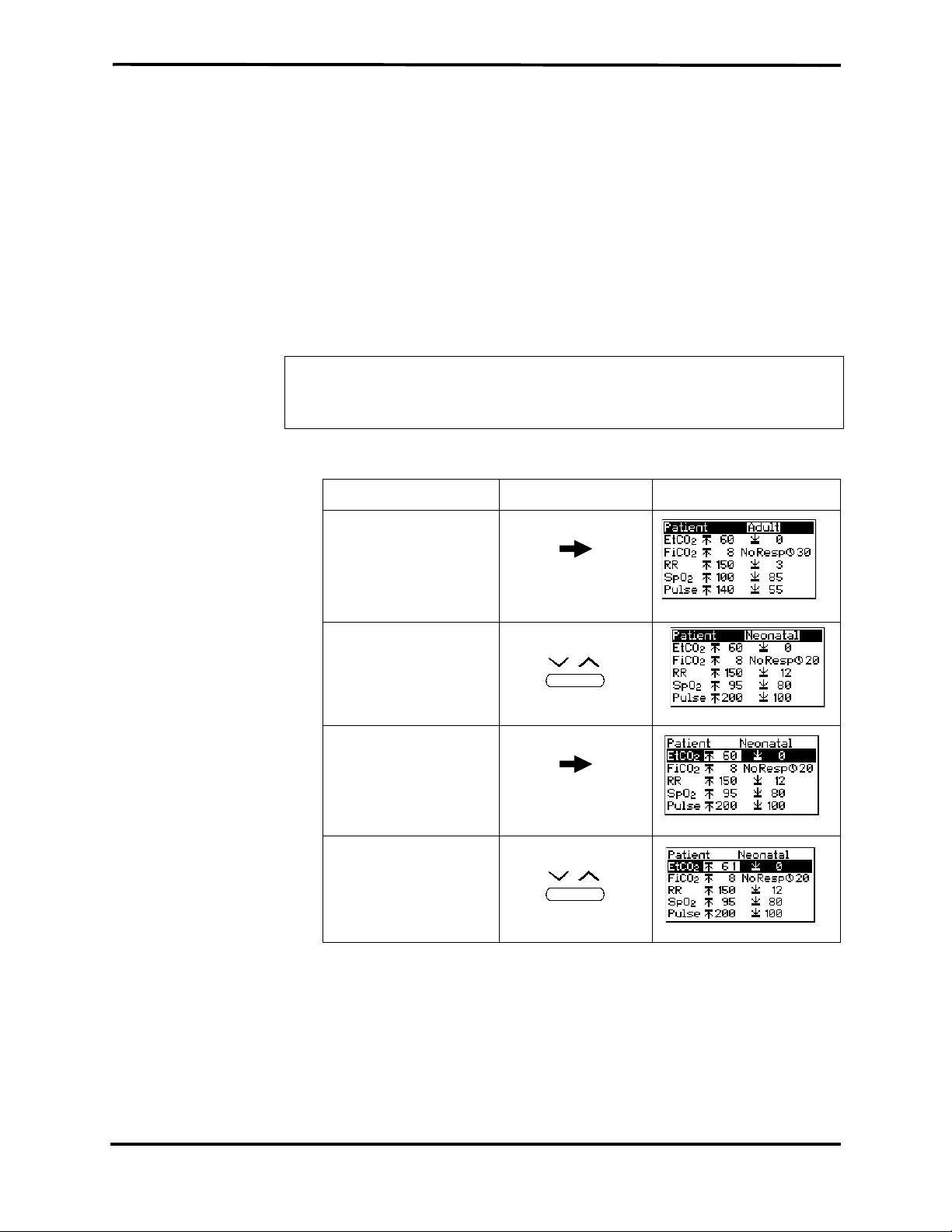

4.3.1 Default Alarm Limits

The service technician can change the default alarm limits for either

patient mode (Adult or Neonatal) as described in Table 4-3: "Changing

Default Alarm Limits".

The monitor has the following alarms with adjustable level settings:

Section 4: Service Mode

•EtCO

•FiCO

•SpO

2 high and low levels (mmHg)

2 high level (mmHg)

2 high and low levels (%)

• Pulse rate high and low levels (bpm)

Warning: Changing default settings will permanently change the

user’s start-up value and should be verified with the responsible

clinical personnel.

Table 4-3: Changing Default Alarm Limits

Objective Action Response

To access the Default

short press Alarm Limits menu after entering last password digit

To change the patient

short press

mode

To access a new

short press

parameter

To change the value short press

4-7

Page 18

Section 4: Service Mode

Table 4-3: Changing Default Alarm Limits (Continued)

Objective

To reset to measuring

mode (automatically

erasing event

messages)

To exit service mode

and save event

messages

Action

long press

then long press

Turn off the

monitor.

Response

4-8

Page 19

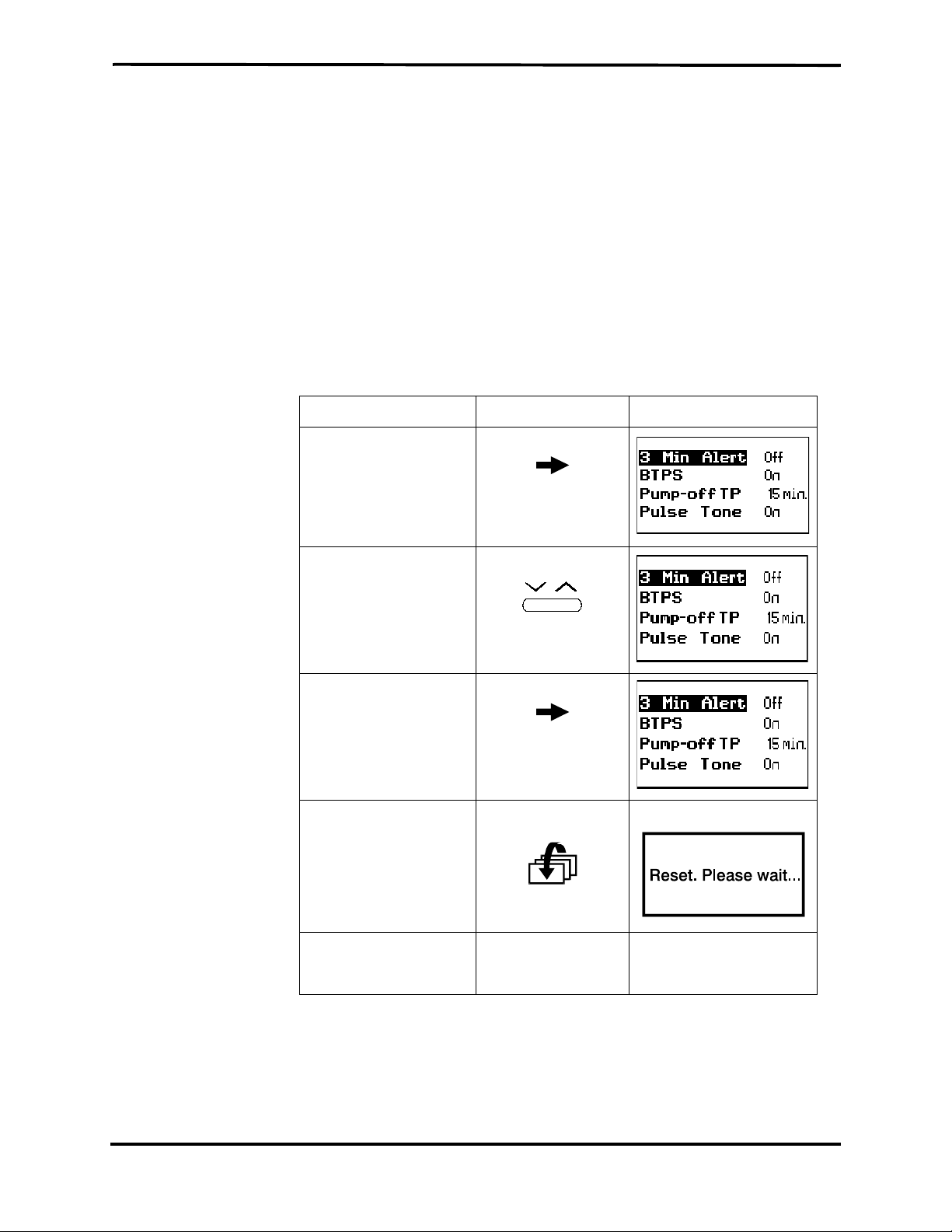

4.3.2 Default Settings

Section 4: Service Mode

The service technician can change two default settings (refer to Table 4-4:

"Changing Default Settings"):

•3 Min Alert

When the 3 Min Alert is ON, the unit will beep every three minutes

to remind the user that an alarm (or all alarms) are set to OFF.

• BTPS (body temperature, pressure, saturation)

When BTPS is ON, the CO

2 value is corrected for this factor

• Pulse Tone

Pulse Tone default is ON. When changed to OFF, the Pulse Tone

default is silent (as indicated on screen).

.

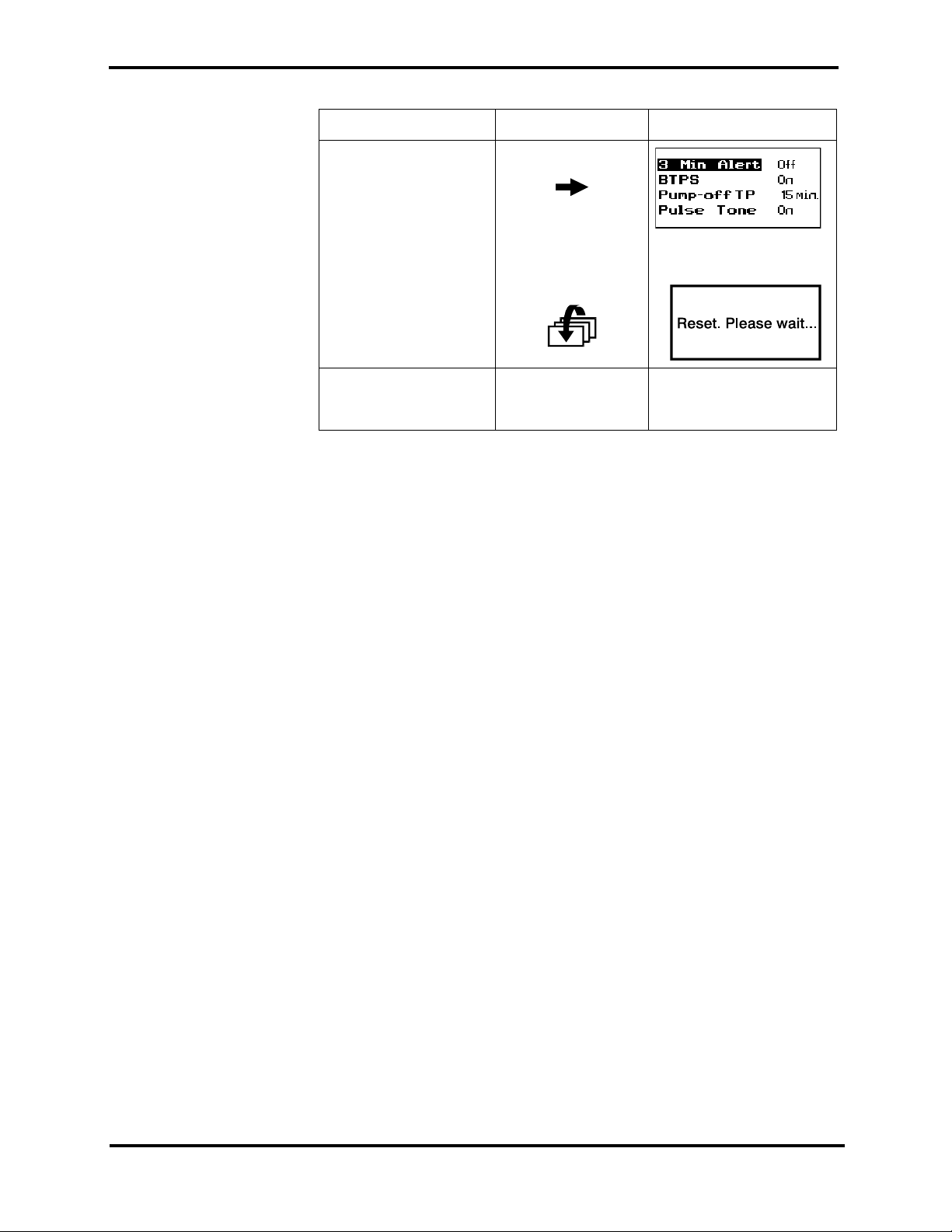

Table 4-4: Changing Default Settings

Objective Action Response

To access the Default

Settings menu (after

accessing the Default

Alarm Limits menu)

To change the setting short press

To access BTPS

parameter (and save

the changed setting for

3 Min Alert)

To reset and return to

measuring mode

(automatically erasing

event messages

memory)

long press

short press

long press

To exit service mode

and save event

message

Turn off the

monitor.

4-9

Page 20

Section 4: Service Mode

4.3.3 Flow Calibration

The Flow Calibration screen allows the service technician to perform flow

calibration after flow adjustment and/or pump or flow system

replacement, refer to Table 4-5: "Accessing Flow Calibration"

Note: When changing the pump voltage setting, refer to

Flow Calibration Check

Table 4-5: Accessing Flow Calibration

Objective Action Response

To access the Flow

Calibration screen

To change the

parameter setting or

value

To move to the next

parameter (and save

the changed setting)

At any screen after

the password

long press

simultaneously

for change guidelines.

and

short press

short press

Section 6:

4-10

Page 21

SECTION 5: TROUBLESHOOTING

5.1 Introduction

5.2 Who Should Perform Repairs

5.3 Repair Level Supported

5.4 How to Use This Section

5.5 Obtaining Replacement Parts

5.6 Troubleshooting Guide

5.1 INTRODUCTION

This section provides information for troubleshooting the monitor and

isolating a failure on the unit.

5.2 WHO SHOULD PERFORM REPAIRS

Only qualified service personnel should remove and replace components

of the monitor. If your facility does not have qualified service personnel,

contact your local distributor.

5.3 REPAIR LEVEL SUPPORTED

The monitor has the following replaceable components: CO2 board, SpO2

board, Flow System, Pump Assembly, Housing Components, LCD graphic

display (LCD), 7-segment LED digital displays (LED display) and

Software Assembly.

The procedures for disassembling and replacing the mentioned parts are

described in Section 7: Disassembly Guide.

5.4 HOW TO USE THIS SECTION

Failures of the Housing Components; Front Cover, Rear Cover, Gas

Outlet, External SpO

are determined by visually inspecting these components for cracks or

deformations, and checking for mechanical failures.

Refer to Table 5-1: “Troubleshooting Guide”to isolate failures of the

boards, Flow System, Pump Assembly, LCD and LED displays. Once a

failure has been isolated, refer to Section 7: Disassembly Guide for

instructions for removing and replacing a component of the monitor.

5.5 OBTAINING REPLACEMENT PARTS

Your local distributor provides technical assistance information and

replacement parts. Refer to parts by the part name listed in Section 13:

Spare Parts.

2 Connector Latch, ON/OFF button and Keypads,

5-1

Page 22

Section 5: Troubleshooting

5.6 TROUBLESHOOTING GUIDE

If you encounter a problem that cannot be resolved through a visual

inspection, refer to Table 5-1: “Troubleshooting Guide” which provides a

list of symptoms, probable causes, and recommended actions to take to

correct the problem. It is recommended that corrective actions be

performed in the order presented. For a symptom that is not listed in

Table 5-1: “Troubleshooting Guide”, contact your local distributor.

If a Caution or Advisory message is displayed on the LCD, refer to

Table 5-1: “Troubleshooting Guide”for the indicated failure and corrective

action. Caution messages appear on the display screen followed by !! and

Advisory messages are followed by !.

Check in the Service Mode for any Error Code and refer to Table 5-3:

“Event Messages”for the indicated failure and corrective action.

Symptom Probable Cause Corrective Action

Table 5-1: Troubleshooting Guide

The unit does not

turn on when the

ON/OFF button

is switched

ON

when the unit is

operated with

batteries.

The unit does not

turn on when the

ON/OFF button

is switched

ON

when the

monitor is

connected to

mains power.

The battery pack is

missing or is installed

incorrectly.

The battery pack’s

charge is low.

The battery pack’s

contacts are defective.

The contacts for the

battery pack on the CO

board are defective or a

CO

2 board component

has failed.

The ON/OFF button has

a mechanical defect.

Check if there is a

battery pack in the

monitor, if not, place

one in the monitor. Be

sure the battery pack

is installed correctly.

Install a fully charged

battery pack; charge

the empty battery

pack.

Install a new battery

pack and check the

monitor functions.

Connect the monitor

to mains line power

2

and if the monitor

functions, replace the

CO

2 board.

Inspect the button for

cracks, deformations

or other damage.

Replace with a new

button.

5-2

A CO

2 board component

has failed.

Replace with a new

CO

2 board.

Page 23

Section 5: Troubleshooting

Table 5-1: Troubleshooting Guide (Continued)

Symptom Probable Cause Corrective Action

The unit does not

turn on when the

ON/OFF button

is switched

ON

when the

monitor is

connected to

main lines

power.

One or more

buttons on the

upper or lower

keypad do not

work.

The wall socket is not

receiving power or is

defective.

Check the wall socket

for power supply or

mechanical defects. If

necessary, use a

different wall socket.

The AC adapter is

defective.

A CO

2 board component

is defective.

Replace with new AC

adapter.

Replace with a new

CO

2 board.

The keypad is defective. Inspect the keypad for

cracks, deformations

or other damage.

Replace with a new

keypad.

A CO

2 board component

has failed.

Replace with a new

CO

2 board.

No information

is displayed on

the LCD.

LCD Backlight

does not come on

when the unit is

placed in a dark

environment.

The contrast default

value is set too low or

high.

An LCD component has

failed.

A CO

2 board component

has failed.

The Power

Management option is

set at

LOW.

An LCD component has

failed.

A CO

2 board component

has failed.

Check the contrast

value in the Service

Mode using the

Contrast Cal.

option and correct

accordingly.

Replace with a new

LCD.

Replace with a new

CO

2 board.

Refer to the monitor’s

operator’s manual to

change the Power

Management option

to

NORMAL or

HIGH.

Replace with a new

LCD.

Replace with a new

CO

2 board.

5-3

Page 24

Section 5: Troubleshooting

Table 5-1: Troubleshooting Guide (Continued)

Symptom Probable Cause Corrective Action

LED display

does not light

when the unit is

functioning.

Beeper does not

beep.

The Power

Management option is

set at

LOW.

An

LED display has

failed.

A CO

2 board component

has failed.

The Pulse Tone option

on the Alarm Silence

menu has been

disabled.

One or more of the

Alarm Silence options

has been turned

A CO

2 component has

OFF.

failed.

Refer to the monitor’s

operator’s manual to

change the Power

Management option

to

NORMAL or

HIGH.

Replace with new

LED Display.

Replace with a new

CO

2 board.

Turn the Pulse Tone

ON. Refer to the

monitor’s operator’s

manual.

Turn the respective

alarm

ON. Refer to

the monitor’s

operator’s manual.

Replace with a new

CO

2 board.

Table 5-2: Advisory Messages Guide

Message Probable Cause Corrective Action

Check Unit

!

A CO2 board component

has failed.

Check Event

Messages screen in

Service Mode.

Check CO

Check SpO2 !

2 !

An SpO2 board

component has failed.

Replace with a new

SpO

2 board.

5-4

Page 25

Section 5: Troubleshooting

Table 5-3: Event Messages

Event Message Probable Cause Corrective Action

CO

2 board A CO2 board component

failed.

2 board Replace with a new

SpO

Replace with a new

CO

2 board.

SpO

2 board.

Flow - Loose connections

- Kinks or twists in

tubing

- Flow system blocked

- Pump Malfunction - Replace pump

- A CO

2 board

component failed

- Inspect all tubing

ends for loose

connections and

ensure tight

connections

- Straighten kinks

and undo any twists

in the tubing.

- Check flow rate and

if necessary change

Flow System.

- Replace with a new

CO

2 board

5-5

Page 26

SECTION 6: FLOW CALIBRATION CHECK

6.1 Introduction

6.2 Flow Rate Check

6.3 Flow Calibration Process

6.1 INTRODUCTION

Perform a Flow Calibration Check after replacing the Flow System and/or

Pump. Flow Calibration Check includes Flow Rate Check and Flow

Calibration Process.

6.2 FLOW RATE CHECK

To perform the Flow Rate Check, follow the steps below:

1. Connect the FilterLine to the Handheld Capnograph/Pulse

Oximeter.

2. Turn on the monitor.

3. Connect the other end of the FilterLine to the Flow meter gas

outlet.

4. Access the Flow Calibration screen of the Service Mode, refer to

Table 6-1: "Flow Calibration".

5. Check that the Flow Meter reading is 50 ±5 ml/min. (at sea level)

If the Flow Meter reading is 50 ±5 ml/min:

5a Perform Flow Calibration Process, refer to section 6.3 "Flow

Calibration Process".

If the Flow Meter reading is not 50 ±5 ml/min:

5b Change the pump voltage value until the flow rate displayed

in the flow meter is 50 ±5 ml/min, refer to Section 4: Service

Mode, Table 4-5: "Accessing Flow Calibration".

5c Perform Flow Rate Check

5d Perform Flow Calibration Process, section 6.3 "Flow

Calibration Process".

If you cannot set the flow rate to 50 ±5 ml/min after adjusting the

pump voltage value:

5e Change the Flow System, refer to section 7.6 "Replacing the

Flow System".

5f Perform Flow Rate Check

5g Perform Flow Calibration Process.

If after changing the Flow System you still cannot set the flow rate

display in the flow meter to 50 ±5 ml/min:

5h Change the Pump, refer to section 7.5 "Replacing the Pump".

5i Perform Flow Rate Check

5j Perform Flow Calibration Process.

6-1

Page 27

Section 6: Flow Calibration Check

6.3 FLOW CALIBRATION PROCESS

To perform the Flow Calibration Process, refer to Table 6-1: "Flow

Calibration".

Objective Action Response

Table 6-1: Flow Calibration

To access Flow

Calibration screen

To change the

parameter setting or

value

To move to the next

parameter (and save

the changed setting)

To select Flow Cal. short press

Simultaneously

long press

and

short press

short press

6-2

To start Calibration short press

short press

Wait until either a Pass or Fail message is displayed.

Page 28

Section 6: Flow Calibration Check

Table 6-1: Flow Calibration (Continued)

Objective Action Response

If Fail is displayed Replace Flow

System and/or

Pump

Pump volt.

(refer to Section 5:

Troubleshooting)

and repeat above

procedure

If Pass is displayed Exit Service Mode

2.0

To reset and return to

measuring mode

To exit service mode

and save event

messages

long press

Turn off the

monitor

Pump volt.

2.0

6-3

Page 29

SECTION 7: DISASSEMBLY GUIDE

7.1 Introduction

7.2 Opening the Monitor Case

7.3 Replacing the CO

7.4 Replacing the SpO

7.5 Replacing the Pump

7.6 Replacing the Flow System

7.7 Replacing the LCD and LED Display

7.8 Replacing the Housing Components

7.9 Updating the Software Version

7.1 INTRODUCTION

The monitor can be disassembled and the following components can be

replaced:

2 Board

2 Board

•CO

•SpO

2 Board

2 Board

• Pump Assembly

• Flow System

• Housing components

•EPROM

• LCD graphic display (LCD)

• 7-segment LED digital displays (LED Display)

Caution: Observe ESD (electrostatic discharge) precautions when

disassembling and reassembling the monitor and when handling

any of the components of the monitor.

Use the following procedures to disassemble the monitor and replace

parts as needed. Reassemble the monitor in reverse order. The

manufacturer recommends that you follow the disassembly procedure in

the order presented.

Note: After replacing the Flow System and/or Pump, perform a flow

calibration check as described in Section 6: Flow Calibration

Check.

Note: After reassembling any part of the monitor, be sure to complete

the performance verification as described in Section 10:

Performance Verification.

7-1

Page 30

Section 7: Disassembly Guide

7.2 OPENING THE MONITOR CASE

1. Be sure the monitor is disconnected from mains power and

remove the battery pack from the monitor; press the release

button at the bottom of the monitor and pull out the battery pack

as shown in Figure 7-1: Removing the Battery Pack.

7-2

Figure 7-1: Removing the Battery Pack

Page 31

Section 7: Disassembly Guide

2. Place the monitor on a clean, dry, nonabrasive surface with the

back of the monitor facing up.

3. Remove the two Bottom Mounting and two Back Mounting

Screws from the rear panel of the monitor as shown in

Figure 7-2: Removing Mounting Screws.

.

Figure 7-2: Removing Mounting Screws

4. Carefully lift the rear case cover up and remove the 14-pin flat

cable from the CO

2 Board as shown in Figure 7-3: Separating

Rear and Front Covers.

Figure 7-3: Separating Rear and Front Covers

7-3

Page 32

Section 7: Disassembly Guide

7.3 REPLACING THE CO2 BOARD

Refer to Figure 7-4: Replacing CO2 Board and Housing Components

1. Open the monitor case as described in section 7.2 "Opening the

Monitor Case".

2. Remove the two CO

2 Board Mounting Screws.

3. Remove the CO2 Connector Screw from the CO2 Input

Connector.

4. Remove the ON-OFF Button and save for reassembly.

5. Pull out and remove the Gas Outlet and save for reassembly.

6. Remove the CO

2 Board and replace with a new CO2 Board and

reassemble in reverse order.

Note: When replacing the keypads, be sure the icons are facing the correct

direction. (Refer to Figure 1-1: Handheld Capnograph/Pulse

Oximeter.)

7-4

Figure 7-4: Replacing CO2 Board and Housing Components

Page 33

7.4 REPLACING THE SPO2 BOARD

(Refer to Figure 7-5: Replacing SpO2 Board.)

1. Open the monitor case as described in section 7.2 "Opening the

Monitor Case".

Section 7: Disassembly Guide

2. Pull out the Internal SpO

3. Remove the three SpO

2 Connector Lock.

2 Board Mounting Screws and Washers.

4. Remove the SpO2 Board with attached cables and replace with a

new SpO

Internal SpO

2 Board. Be sure to reattach the cables and use the new

2 Connector Lock. Be sure the SpO2 Insulation

Plate is placed correctly over the three screw mounts.

Caution: When replacing the SpO

2 Mounting Screws, be sure you

use the plastic washers supplied with the original unit.

Caution: When replacing the SpO

2 Board, carefully hand-tighten

the Mounting Screws. Overtightening can strip the screw-holes.

Figure 7-5: Replacing SpO2 Board

7-5

Page 34

Section 7: Disassembly Guide

7.5 REPLACING THE PUMP

Refer to Figure 7-6: Replacing the Pump.

1 Open the monitor case described in section 7.2 "Opening the

2 Remove the Damping cover from the Pump.

3 Locate the two tubings, Main line and Exhaust line, connected to

4 Locate the purple Main line restrictor and the green Exhaust line

5 Disconnect both tubings from their restrictors.

Monitor Case".

the Pump, refer to Figure 7-7: Flow System.

restrictor, refer to Figure 7-7: Flow System.

Note: Both restrictors must remain with their flow system lines

attached to the CO

2 Board.

6 Disconnect the Pump connector from it’s CO

7 Remove the CO

2 Board from the Front Cover, refer to section 7.3

2 Board socket.

"Replacing the CO2 Board".

8 Unscrew and remove the Pump mounting screws.

9 Remove the Lower damping and Damping holder.

10 Remove the Pump and the Upper damping.

11 Place the new Pump.

12 Reassemble the unit, using the new assembly parts, in reverse

order.

Note: Before replacing the pump mounting screws, first dip them into

®

Loctite

glue or any other threadlocker glue. Carefully twist the

screws into the Lower damping, gently pressing against the

2 Board.

CO

7-6

Figure 7-6: Replacing the Pump

Page 35

7.6 REPLACING THE FLOW SYSTEM

1. Open the monitor case as described in section 7.2 "Opening the

Monitor Case".

The Flow System has 5 lines, refer to Figure 7-7: Flow System.

Two lines go from the pump:

•Main line

•Exhaust line

Three lines go from the solenoid:

• Zero line

• Input line 1

• Input line 2 (not viewed in Figure 7-7)

Section 7: Disassembly Guide

Figure 7-7: Flow System

7-7

Page 36

Section 7: Disassembly Guide

7.6.1 Replacing the lines to the pump

7.6.1.1 Replacing the Main line

(Refer to Figure 7-8: Main line and Figure 7-9: Exhaust line)

1. Locate the purple restrictor.

2. Carefully disconnect the Main line from the tubing connected to the Pump, leaving the purple restrictor on the Main line.

3. Remove the tubing from the Sensor.

4. Remove the tubing from the Pressure sensor.

5. Reassemble the new Main line in reverse order.

Note: In order to fit the Main line on the board without twists and

kinks, coil

the tubing around the Pressure sensor.

Figure 7-8: Main line

7.6.1.2 Replacing the Exhaust line

(Refer to Figure 7-9: Exhaust line)

1. Locate the green restrictor.

2. Carefully disconnect the Exhaust line, at the green restrictor,

from the tubing connected to the pump. Leave the green

restrictor on the Exhaust line.

3. Reassemble the new Exhaust line in reverse order.

7-8

Figure 7-9: Exhaust line

Page 37

7.6.2 Replacing the lines to the solenoid

Refer to:

Figure 7-10: Lines to Solenoid (Zero line, Input line 1, Input line 2)

7.6.2.1 Removing the lines to the solenoid

1. Carefully disconnect the Zero line from the solenoid.

Warning: The scrubber on the Zero line is filled with a

lithium based compound. Follow local governing

ordinances for disposal.

2. Remove Input line 1 from the solenoid connector and the other

end from the FilterLine input connector.

3. Remove Input line 2 from the solenoid connector and the other

end from the sensor connector.

Section 7: Disassembly Guide

Figure 7-10: Lines to Solenoid (Zero line, Input line 1, Input line 2)

7-9

Page 38

Section 7: Disassembly Guide

7.6.2.2 Reassembly of the lines to Solenoid

1. Connect the new Input line1 to the line 1 solenoid connector.

2. Connect the new Input line 2 to the line 2 solenoid connector.

3. Bring the Input line 2 tubing over Input line 1, and connect to

4. Lead the Input line 1 under the FRS cables (connected to the

5. Connect the Zero line to the Zero line solenoid connector. Place

Refer to Figure 7-10: Lines to Solenoid (Zero line, Input line 1,

Input line 2) and Figure 7-11: Zero line

the sensor connector.

FilterLine input connector, not viewed in Figure 7-10) and

connect to the FilterLine input connector.

the scrubber close to the pump under the coiled Main line

tubing (not viewed in Figure 7-11: Zero line) around the

pressure sensor.

Figure 7-11: Zero

line

7-10

Page 39

7.7 REPLACING LCD AND LED DISPLAY

(Refer to Figure 7-12: Replacing LCD and LED display)

7.7.1 Replacing the LCD

1. Remove the CO2 Board as described in Figure 7-4: Replacing CO2

Board and Housing Components.

2. Unscrew and remove the four LCD mounting screws.

3. Carefully remove the LCD and replace with a new LCD.

7.7.2 Replacing the LED Display

1. Remove the CO2 Board as described in section 7.3 "Replacing the

CO2 Board".

2. Carefully remove the faulty LED Display from its socket and

replace with a new LED Display. Note the correct orientation of

the LED Display when replacing it.

Section 7: Disassembly Guide

Figure 7-12: Replacing LCD and LED display

7-11

Page 40

Section 7: Disassembly Guide

7.8 REPLACING HOUSING COMPONENTS

The Housing kit includes the following replaceable components:

• Front Cover

• Rear Cover

• ON-OFF Button

• Upper Keypad (Alarm Silence/Alarm Silence Menu Button and

Contrast/Value Change Button)

• Lower Keypad (Event/Home Button and Next/Menu Button)

•Gas Outlet

•SpO

• External SpO

• Internal SpO

2 Insulation Plate

2 Connector Latch

2 Connector Lock

•Screws

•Washers

Note: When reassembling the monitor after replacing any part, be sure

to follow the disassembly steps in reverse order.

7.8.1 ON-OFF Button and Gas Outlet

(Refer to Figure 7-4: Replacing CO2 Board and Housing Components)

7.8.2 Keypads

(Refer to Figure 7-4: Replacing CO2 Board and Housing Components)

1. Open the monitor as described in section 7.2 "Opening the

Monitor Case".

2. Remove the Gas Outlet from the tubing and replace with a new

Gas Outlet.

2

3. Remove the ON-OFF Button from the CO

board as described in

section 7.3 "Replacing the CO2 Board", and replace with a new

button.

1. Open the monitor as described in section 7.2 "Opening the

Monitor Case".

2. Remove the CO

2 Board as described in section 7.3 "Replacing the

CO2 Board".

3. Remove the old keypad. When replacing the new keypad, be sure

the icons are facing the correct direction. (Refer to Figure 1-1:

Handheld Capnograph/Pulse Oximeter.)

7-12

Page 41

7.8.3 Front Cover

(Refer to Figure 7-4: Replacing CO2 Board and Housing Components)

Section 7: Disassembly Guide

1. Open the monitor as described in section 7.2 "Opening the

Monitor Case".

2. Remove the CO

2 Board as described in section 7.3 "Replacing the

CO2 Board".

3. Remove the keypad and ON-OFF Button. Place them in the new

Front Cover. When replacing the keypad, be sure the icons are

facing the correct direction. (Refer to Figure 1-1: Handheld

Capnograph/Pulse Oximeter.)

4. Place the CO

2 board in the new cover.

7.8.4 SpO2 Connector Latch, Rear Cover and SpO2 Insulation Plate

(Refer to Figure 7-5: Replacing SpO2 Board, Figure 7-12: Replacing LCD and LED

display and Figure 7-13: Replacing SpO2 Connector Latch)

1. The External SpO

2 Connector Latch can be removed without

opening the monitor casing. Carefully pull the latch out of its

hinges by squeezing the hinge and pulling the SpO

Latch to the side. Replace with a new SpO

2. To replace the Rear Cover, open the monitor as described in

section 7.2 "Opening the Monitor Case".

3. Remove the SpO

2 board and cables as described in section 7.4

"Replacing the SpO2 Board".

4. Remove the SpO

2 Insulation Plate and replace with a new plate

(if needed). Be sure to place the plate over the three screw

mounts.

2 Connector

2 Connector Latch.

5. Place the SpO

new Internal SpO

2 board and cables in the new back cover using a

2 Connector Lock.

Figure 7-13: Replacing SpO2 Connector Latch

7-13

Page 42

Section 7: Disassembly Guide

7.9 UPDATING SOFTWARE VERSION

Warning: Observe ESD (electrostatic discharge) precautions

when disassembling and reassembling the monitor and when

handling any of the components of the monitor.

1. Open the monitor as described in section 7.2 "Opening the

Monitor Case".

2. Remove the EPROM from its socket (on the CO

2 board) using an

IC extractor. (Refer to Figure 7-14: Replacing EPROM.)

3. Insert the new EPROM.

Note: When replacing the EPROM, be sure it is positioned correctly.

Note: When operating the monitor for the first time after updating the

software version, the warm-up and the self-test periods will be

longer than the usual.

7-14

Figure 7-14: Replacing EPROM

Page 43

SECTION 8: ELECTRICAL SAFETY TESTS

8.1 Electrical Safety Tests

8.1 ELECTRICAL SAFETY TESTS

Do not return the monitor to the user until the conditions are met in the

following “Warning” statement.

Warning: After servicing the monitor, always verify product

performance per the procedures in Section 10: Performance

Verification and perform any safety tests required by local

regulatory bodies or mandated by your institution.

8-1

Page 44

SECTION 9: PERIODIC MAINTENANCE

9.1 Periodic Maintenance

9.1 PERIODIC MAINTENANCE

Periodic maintenance is recommended according to operating hours (refer

to section 4.2 "Service Level 1"):

The Pump and Flow System should be replaced every 7,000 operating

hours.

For replacing the pump, refer to section 7.5 "Replacing the Pump".

For replacing the flow system, refer to section 7.6 "Replacing the Flow

System".

The monitor should be returned to the manufacturer for periodic

maintenance every 21,000 operating hours.

9-1

Page 45

SECTION 10: PERFORMANCE VERIFICATION

10.1 Flow System Leak Check

10.2 Performance Verification Procedure

The performance of the monitor must be verified after all service procedures. Perform all

procedures in this section to verify the correct functioning of the monitor.

10.1 FLOW SYSTEM LEAK CHECK

Perform the Flow System Leak Check after all service procedures

described in this manual.

10.1.1 Flow System Leak Check Procedure

1. Connect the vacuum manometer to the Leak Test Jig as shown in

Figure 10-1: Leak Test Jig Connection.

Figure 10-1: Leak Test Jig Connection

2. Open the Leak Test Jig clamp and empty the syringe’s contents.

3. Connect the open-ended tubing (as shown in Figure 10-1: Leak Test

Jig Connection) of the Leak Test Jig to the Gas Outlet of the

monitor.

4. Connect the other open-ended tubing of the Leak Test Jig to the

input connector.

CO

2

5. Pull the syringe valve out until the pressure drops (as displayed on

the vacuum manometer) to approximately -350 mBar

(or equivalent) and close the clamp.

6. Wait for pressure to drop to 300 mBar.

7. Wait 30 seconds.

8. The change in reading should be less than 20 mBar (or equivalent).

10-1

Page 46

Section 10: Performance Verification

9. If the reading drops more than 20 mBar, there is a leak in the flow

system.

• Open the unit.

• Check for loose fittings and if any are found, reconnect

them.

• Repeat the above process (steps 1-8).

• If the reading continues to show more than 20 mBar, replace

the Flow System, refer to section 7.6 "Replacing the Flow

System".

10.2 PERFORMANCE VERIFICATION PROCEDURE

Verify the performance of the monitor using the following procedure.

1. Connect the monitor to main power using the AC adapter.

2. Connect the FilterLine and the DS-100A - Durasensor

monitor.

3. Turn ON the monitor.

4. The initialization screen appears. (Refer to

Figure 10-2: Initialization Screen.)

5. Verify that an audio tone sounds. This

verifies proper operation of the Alarm

interfacing. Check that the LEDs on the

alarm bar turn red, yellow and then off. The

Figure 10-2:

Initialization Screen

LED display shows 8s moving from left to

right.

6. As the monitor continues to test its internal

subsystems, the Self-Test Screen appears.

(Refer to Figure 10-3: Self-Test Screen.).

Figure 10-3: Self-

Test Screen

7. After the Self-test, the monitor

automatically goes to Measuring

Mode. The message CO

2

Warmup appears on the Silent

Advisory Message area. (Refer to

Figure 10-4: Measuring Mode.)

Figure 10-4: Measuring

Note: If BTPS is on, the message will

read BTPS ON-Ready

®

to the

Mode

10-2

8. After CO

2 Warmup, verify that the message changes to Ready.

9. Disconnect the FilterLine and verify that the message FilterLine

is displayed on the Silent Advisory Message Area and verify that

the pump stops.

Page 47

Section 10: Performance Verification

10. Reconnect the FilterLine and verify that the message FilterLine

disappears and the pump is operating.

11. Disconnect the DS-100A - O

XIMAX Durasensor

®

and verify that the

message

2 Sensor is displayed in the Silent Advisory Message area.

SpO

12. Reconnect the DS-100A - O

XIMAX Durasensor

®

and verify that the

message

2 Sensor disappears.

SpO

13. Verify that all buttons on the unit work properly. Refer to the

monitor’s Quick Guide for their applications. (See Figure 10-5:

Quick Guide.)

Figure 10-5: Quick Guide

14. Verify the CO

2 Calibration Check process functions. Follow the

procedure as described below. When completed, return to the

Measuring Mode screen.

Note: Calibration must be performed annually or every 4000 operating

hours , whichever comes first, regardless of the CO

Calibration

2

Check results

10-3

Page 48

Section 10: Performance Verification

CO2 Calibration Check

Caution: Do not check CO

2 values from the measuring mode if the

BTPS setting is ON (factory default). This mode corrects the CO

value for BTPS. The calibration check mode disables this

correction automatically.

In order to ensure accuracy, a CO

2 calibration check needs to be done once

a year. Calibration gas and a FilterLine are needed for this procedure.

Start the process from the Interface Test screen (refer to Table 4-1:

"Accessing Service Mode and Changing Parameter Settings") as follows in

“Table 10-1: CO

Note: Connect the FilterLine to the monitor before starting CO

2 Calibration Check”.

2

Calibration Check. Use the calibration kit (5% gas in air and

connecting means) approved by Oridion Medical 1987 Ltd.

Note: If the CO

2 Calibration Check is performed on a battery powered

device, ensure that the battery is fully charged prior to

calibration.

Table 10-1: CO2 Calibration Check

Objective Action Result

Access CO

Calib.

2

short press

3 times

2

Change option

to Start.

Prepare for Cal.

Check.

short press

No action

required

No action

required

Connect the

FilterLine to the

calibration gas.

10-4

Page 49

Section 10: Performance Verification

Table 10-1: CO

2 Calibration Check (Continued)

Objective Action Result

Check the

measured

values shown in

Vol% in the

EtCO

2 digital

Press the gas

valve for 15

seconds until the

readings stabilize

display.

Calibration is not required if the measured value is the same

as the concentration of the calibration gas (±0.3 Vol%) e.g.

Concentration of calibration gas used is 5% (CO

2); the

measured value should be between 4.7%-5.3%, therefore,

calibration is not required.

To reset and

long press

return to

measuring

mode

(automatically

erasing event

messages)

To exit service

mode and save

Turn off the

monitor

event messages

If the reading is outside these limits, calibration is required.

Refer to Table 10-2: "Calibration Process" for the calibration

process procedure.

10-5

Page 50

Section 10: Performance Verification

Calibration Process

If calibration is required, perform the Calibration Process (after

performing CO

Process".

Objective Action Result

2 Calibration Check) as shown in Table 10-2: "Calibration

Table 10-2: Calibration Process

To start

calibration.

To start

calibration

process after

calibration check.

To activate

calibration

process.

Adjust the

display value to

the gas

concentration you

are using.

Press the gas

valve and

long press

No action

required.

long press

short press

10-6

Monitor performs

an internal

calculation.

Calibration

succeeded.

Return to

calibration check

mode.

Continue

pressing the gas

valve until the

message

Disconnect

Gas appears.

Disconnect Gas

from the

FilterLine.

No action

required.

long press

Page 51

Section 10: Performance Verification

Table 10-2: Calibration Process (Continued)

Objective Action Result

To reset and

return to

measuring mode

To exit service

mode and save

event messages

long press

Turn off the

monitor.

Calibration Errors

Table 10-3: "Calibration Process - Troubleshooting" describes calibration

problems that can occur, the message displayed and the appropriate

corrective action.

Table 10-3: Calibration Process - Troubleshooting

Message Possible Causes Action

• Gas concentration

does not match the

concentration value

selected in the first

calibration screen.

• Problems with gas

sampling

•Flow system

problems (purging,

blockage or no

FilterLine)

Check setup,

correct

probable

causes, and

recalibrate

unit as

above.

•CO

2 Sensor problem

• Calibration process

exceeds 3 minutes

•Contact

your local

distributor.

•Restart. If

problem

persists,

contact

your local

distributor.

10-7

Page 52

Section 10: Performance Verification

15. Advance to the Plethysmograph Display Screen as described in

Table 10-4: "Plethysmograph Waveform" below.

To View Action Screen

CO

2 waveform

(Measuring

Mode)

Plethysmograph short press (x4)

Table 10-4: Plethysmograph Waveform

No action

required.

16. Connect the DS-100A - O

the SpO

2 value appears on the LED digital display and the Pulse

XIMAX Durasensor

®

to your finger. Verify

rate appears on the LCD graphic display.

17. Disconnect the monitor from the AC power supply. Verify the unit

continues to work from its battery pack and the battery icon

appears on the lower right corner of the display.

18. Reconnect the monitor to main line power with the AC adapter.

Verify that the unit functions, and the plug icon appears.

Note: If the battery pack has a low charge level, the battery icon

will appear instead of the plug. The battery icon will fill indicating

the battery charging process.

10-8

Page 53

Section 10: Performance Verification

To verify printing functions:

19. Adjust the printer to the following communication settings:

Input Serial

Data Length 8 bits

Parity Settings None

Baud 9600 bps

20. Using the Communication Adapter Kit, connect the printer to the

monitor. (Refer to Figure 10-6: Connecting the monitor to Printer/

PC with Communication Adapter Kit)

Figure 10-6: Connecting the monitor to Printer/PC

with Communication Adapter Kit

21. Turn the printer ON and select on-line mode.

22. Access the monitor’s print functions as described in Table 10-5:

"Accessing Monitor’s Print Functions":

10-9

Page 54

Section 10: Performance Verification

Objective Action Result

Table 10-5: Accessing Monitor’s Print Functions

To access the

long press (x2)

Instrument Setup

menu (first access

the Alarm Limits

menu from any

measuring display)

To select Print short press (x4)

Be sure the Print

short press

option shows

Screen; if it doesn’t,

change to the

Screen option.

To return to

long press

Measuring Mode

To print long press

simultaneously

and

(printout)

10-10

Page 55

SECTION 11: PACKING FOR SHIPMENT

11.1 General Instructions

11.2 Packing Handheld Capnograph in Original Carton

11.3 Packing in a Different Carton

11.1 GENERAL INSTRUCTIONS

To ship a monitor or one of its components for any reason, follow the

instructions in this section. Failure to follow the instructions in this

section may result in loss or damage not covered by any applicable

manufacturer warranty.

Pack the monitor or component(s) carefully. If available, use the original

carton and packing materials and follow the instructions in “Packing

monitor in Original Carton.” If the original shipping carton and material

are not available, use other suitable shipping materials and container and

follow the instructions in “Packing in a Different Carton.”

Prior to shipping the monitor or a component, contact your local

representative for a Returned Material Authorization (RMA) number.

Mark the shipping carton and any shipping forms with the RMA and the

monitor’s serial number.

Caution: Observe ESD (electrostatic discharge) precautions when

packing any monitor components.

11.2 PACKING MONITOR IN ORIGINAL CARTON

If the original carton and packing material are available, repack the

monitor as follows. (Refer to Figure 11-1: Packing the Monitor in Original

Packing.)

1. Place the unit in a plastic bag. Place it into the corresponding

space, in the original foam padding, with the front panel facing up.

2. Place the foam padding cover over the top of the unit.

3. Seal the carton with packing tape.

4. Label the carton with the correct shipping address, return address

and RMA number.

11.3 PACKING IN A DIFFERENT CARTON

If the original carton and packing material are not available or if shipping

any monitor component not in its original carton:

1. Place the monitor in a plastic bag or component in a plastic antistatic bag.

2. Locate a corrugated cardboard shipping carton (approximately the

size of the monitor or component) with at least 200 pounds per

square inch (psi) bursting strength.

3. Fill the bottom of the carton with at least 2 inches of packing

material.

11-1

Page 56

Section 11: Packing For Shipment

4. Place the bagged monitor or component on the layer of packing

5. Seal the carton with packing tape.

6. Label carton with shipping address, return address and RMA

material and fill the box completely with packing material such

that there is at least 2 inches of packing material around all sides

of the item.

number.

Figure 11-1: Packing the Monitor in Original Packing

11-2

Page 57

SECTION 12: SPECIFICATIONS

12.1 Physical

12.2 Environmental

12.3 Safety Standards

12.4 Performance

12.5 Power Specifications

12.6 Components and User Interface

12.1 PHYSICAL

12.1.1 Size

206 mm H x 88 mm W x 52.5 mm D (8.11”H x 3.46” W x 2.06”D)

12.1.2 Weight

850 grams (1.87 lb.) (including battery pack)

12.1.3 Noise Emission

maximum 45 dB(a)

12.2 ENVIRONMENTAL

12.2.1 Temperature

Operating

o

C to 45oC (32oF to 113oF)

0

Storage

o

C to 70oC (-31oF to 158oF)

-35

12.2.2 Relative Humidity

10 to 95% (noncondensing)

12.2.3 Pressure and Altitude (for operating and storage)

Pressure

430 mmHg to 795 mmHg

Altitude

-380m to 4,570m (-1,250 ft. to 15,000 ft.)

12.3 SAFETY STANDARDS

The monitor was designed to comply with EN60601-1/1990, A1/1993, A2/

1995, UL2601-1, CSA C22.2 No. 601.1-M90, ISO 10993-1 (Sensors)

12-1

Page 58

Section 12: Specifications

12.4 PERFORMANCE

12.4.1 Capnograph

Sampling Rate

50 ±7.5 ml/min.

CO

0-99 mmHg (0-13.2 kPa and 0-13.0 Vol%) at sea level

Accuracy

From power-up until steady state is reached, the CO2 reading accuracy is:

0 - 38 mmHg: (+ 4 mmHg)

39 - 99 mmHg: (+ 12% of reading)

The CO2 reading reaches its steady state accuracy 20 minutes after power up.

0 - 38 mmHg: (+ 2 mmHg)

39 - 99 mmHg: (+5% of reading + 0.08% for every 1 mmHg above 40mmHg)

Equivalent values for kPa and Vol%Frequency Response:

EtCO

accuracy for respiration rate over 60 bpm, use the neonatal mode.) From

81 to 150 bpm accuracy is ±12%, if the EtCO

in neonatal mode.

2 Range

2 accuracy is maintained up to 80 breaths/min. (for maintaining

2 is higher than 18.8 mmHg

Respiration Rate

0-150 breaths/min.

Warm-up Time

30 seconds (typical)

Rise Time

190 msec for neonatal mode with low dead space endotracheal tube

adapter; 240 msec for adult mode with Microstream Airway Adapter

System Response Time

2.45 seconds (typical), 2.9 seconds maximum (includes delay time and rise

time)

Ambient Pressure

Compensated internally - automatic

Alarms

2 high, EtCO2 low, FiCO2 high, No Breath.

EtCO

12-2

Page 59

12.4.2 Pulse Oximeter

12.4.2.1 Display Ranges

SpO2 Saturation Range

0-100% SpO

2

Saturation Accuracy

(% SpO

2, ±1 SD)

Adults 70-100%±2 digits

0 - 69% Unspecified

Neonates 70-100%±3 digits

0 - 69% Unspecified

Pulse Rate Range

20-250 beats per minute (bpm)

Pulse Rate Accuracy

± 3 bpm

Note: Pulse rate accuracy is expressed as ±3 bpm across the

display range. This variation equals ±1 standard deviation

(1SD), which encompasses 68% of the population.

Section 12: Specifications

Alarms

2 high, SpO2 low, Pulse high, Pulse low

SpO

12-3

Page 60

Section 12: Specifications

12.5 POWER SPECIFICATIONS

12.5.1 External Power Source

12V DC Medical Grade Adapter

12.5.2 Internal Power Source

Ni-MH Rechargeable Battery Pack 7.2V 2100 mA/h (intended for

continuous operation)

Operating Time (fully charged)

Between 3 to 6 hours depending on power management. This spec reflects

the performance of a new battery; age and usage will degrade capacity.

Note: If the battery pack is stored for 6 months or longer, you must charge

and discharge it (leave the unit on, not connected to AC power, until

battery is empty) three times before use in order to ensure full

capacity.

Recharging Period

Approximately 4.5 hours internal recharging

Charger Type

Internal

12.6 COMPONENTS AND USER INTERFACE

12.6.1 Displays

LCD graphic display

(128 x 64 dots) with LED backlight dimension 75 mm x 53 mm.

Two numeric fields

3 digits each, using 7-segment LED graphic display dimension 22mm x 14

mm.

Two-color alarm bar

yellow, red

12.6.2 Controls and Indicators

Front Panel

ON/OFF switch; Alarm Silence/Alarm Menu button; Contrast/Value

Change button; Event/Home button; Next/Menu button.

12.6.3 Connections

Front Panel

2 Input connector

CO

Top Panel

2 Input socket

SpO

12-4

Rear Panel

Clamp connector, battery release button

Side Panel

Power Supply/Communication Adapter Port, Gas output connector

Page 61

SECTION 13: SPARE PARTS

13.1 Spare Parts List

13.1 SPARE PARTS LIST

Spare parts are shown below in Table 13-1. For spare part numbers

contact your local distributor.

Item Description

Table 13-1: Spare Parts List

1

CO

2 board - includes electronic board, sensor, pump

and scrubber, solenoid, LCD, 7-segment display, flow

system, CO

2 input connector, software EPROM and

screws.

2 Software Assembly - includes EPROM chip and last

updated software version.

3SpO

4SpO

Board

2

Kit - includes inter-board connection cable,SpO2

2

input cable, SpO

insulation plate and internal

2

connector lock

5 Housing Kit - includes front cover, rear cover,

ON/OFF button, keypads, gas outlet, screws, external

SpO

connector latch, SpO2 insulation plate and

2

internal SpO

connector lock

2

6 7-Segment Digital Display (x2)

7 LCD Assembly - Graphic Display Screen and PC

driver

8 Calibration Gas (5% CO

2 in air) and FilterLine

9 Leak Test Jig - vacuum test accessories

10 Communication Adapter Kit

11 Battery Pack

12 Pump Assembly

13 Flow System

13-1

Page 62

GLOSSARY OF TERMS

BIT: Built in Tests.

BTPS: Body Temperature, Pressure and Saturation

Compensation.

Where Body Temperature is assumed 37°C with

vapor pressure 47mmHg

The Calculations are made according to:

P

CO2

= F

x (Pb - 47)

CO2

Where:

F

is the Fractional concentration of CO2 in

CO2

Dry gas, F

= % CO2/100

CO2

Pb = the ambient pressure

P

= the partial pressure of CO2 at BTPS

CO2

EPROM: Erasable Programmable Read Only Memory.

ESD: Electrostatic Discharge.

EtCO

: End Tidal Carbon Dioxide: amount of CO2 present

2

at the end of the exhalation.

FiCO

: Fractional Inspired Carbon Dioxide: amount of

2

present during inhalation.

CO

2

FRS: FilterLine Recognition Safeguard.

LCD: Liquid Crystal Display.

HMI: Human Machine Interface.

Respiration Rate: Number of respiratory cycles (inhalation and

exhalation) per minute.

7-segments LED: Graphic display of seven segments of light emitter

diodes.

Solenoid: 2-way electro-pneumatic valve controlling the

directional flow either from the patient or from the

Scrubber (during Autozero).

CO

2

Scrubber: Lithium compound CO2 absorber.

Page 63

Loading...

Loading...