Page 1

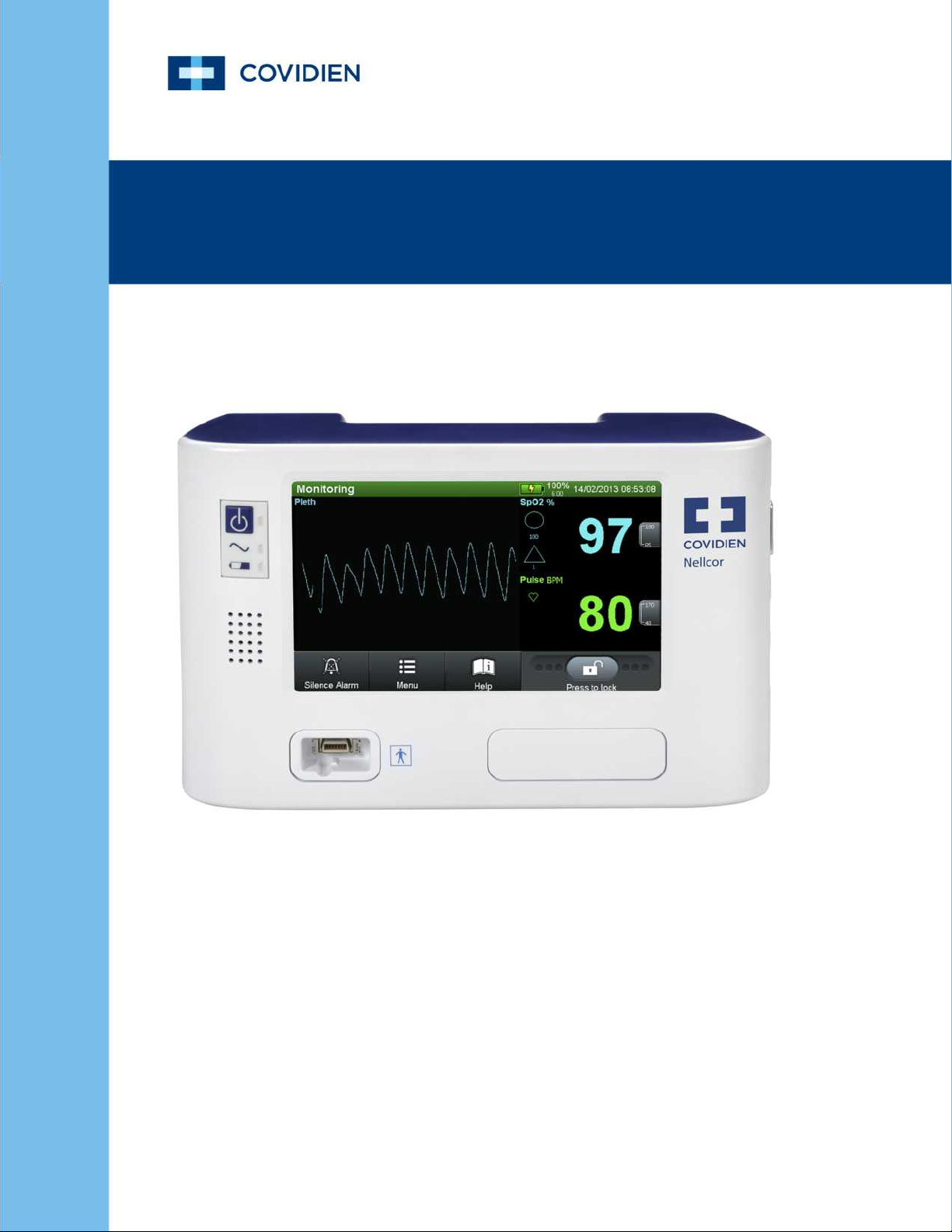

Service Manual

Nellcor™

Bedside Respiratory Patient Monitoring System

Page 2

COVIDIEN, COVIDIEN with logo, the Covidien logo and positive results for life are U.S. and

internationally registered trademarks of Covidien AG. Other brands are trademarks of a Covidien company.

©2013 Covidien. All rights reserved.

Microsoft and Windows EC are registered trademarks of Microsoft Corporation in the United

States and other countries.

The information contained in this manual is the sole property of Covidien and may not be

duplicated without permission. This manual may be revised or replaced by Covidien at any time

and without notice. It is the responsibility of the reader to have the most current applicable

version of this manual. If in doubt, contact Covidien Technical Services.

While the information set forth herein is believed to be accurate, it is not a substitute for the

exercise of professional judgment.

The equipment and software should only be operated and serviced by trained professionals.

Covidien’s sole responsibility with respect to the equipment and software, and its use, is as

stated in the limited warranty provided.

Nothing in this manual shall limit or restrict in any way Covidien’s right to revise or otherwise

change or modify the equipment and software described herein, without notice. In the

absence of an express, written agreement to the contrary, Covidien has no obligation to

furnish any such revisions, changes, or modifications to the owner or user of the equipment

and software described herein.

Page 3

Table of Contents

1 Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.1 Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.2 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.3 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 Obtaining Technical Assistance . . . . . . . . . . . . . . . . . . . . 1-5

1.4.1 Technical Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.2 On-Screen Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 Product Specifications

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.3 Rating of Nurse Call Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.1 Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.2 Transport and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5 Sensor Accuracy and Ranges . . . . . . . . . . . . . . . . . . . . . . 2-4

2.6 Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.7 Product Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.8 Manufacturer’s Declaration and Guidance . . . . . . . . . . . 2-6

2.8.1 Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . 2-6

2.8.2 Ground Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.8.3 Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3 Theory of Operations

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Theoretical Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Service Manual i

Page 4

3.5 Functional Testers and Patient Simulators . . . . . . . . . . . 3-3

3.6 Unique Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.6.1 Functional versus Fractional Saturation . . . . . . . . . . . . . . . . . 3-4

3.6.2 Measured versus Calculated Saturation . . . . . . . . . . . . . . . . . 3-4

3.6.3 Data Update Period, Data Averaging, and Signal Processing . 3-5

3.7 System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.7.1 Nellcor™ Sensor Technology . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.7.2 SatSeconds™ Alarm Management Parameter . . . . . . . . . . . . 3-7

3.7.3 OxiMax SPD™ Alert Parameter . . . . . . . . . . . . . . . . . . . . . . 3-11

3.7.4 Pulse Rate Delay Alarm Management Parameter . . . . . . . . . 3-13

4 Product Overview

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Indications for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.4 List of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.5 Synopsis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.6 Product Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.6.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.6.2 Monitoring Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6.3 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7 Labeling Symbology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

5 Installation

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Product Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.1 Mounting Options and Transport Considerations . . . . . . . . . 5-3

5.3.2 Connection to an AC Power Source . . . . . . . . . . . . . . . . . . . 5-3

5.3.3 Battery Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.4 Battery Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.5 Battery Power Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4 Connection to Nellcor™ Sensors . . . . . . . . . . . . . . . . . . . 5-7

6 Operation

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

ii Service Manual

Page 5

6.2.2 Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.3 Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.4 System Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.2.5 Automatic Shutdown and Power Off . . . . . . . . . . . . . . . . . . 6-6

6.3 Nellcor™ Sensor Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.1 Sensor Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.2 Sensor Detection Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.4 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.4.1 Default Monitoring Screen and Trend Data . . . . . . . . . . . . . . 6-9

6.4.2 Status Messages and Alarms in the Monitoring Status Field . 6-9

6.4.3 Alarm Management and Status Messages . . . . . . . . . . . . . . 6-10

6.4.4 Audible Alarm Management . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.4.5 Visual Alarm Management . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.6 HELP Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.5 Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.5.1 Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5.2 Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.5.3 Logs Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.5.4 Covidien Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.5.5 Parameter Activation Menu . . . . . . . . . . . . . . . . . . . . . . . . 6-33

6.5.6 About Monitor Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

7 Trend Data Access

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Trend Data Management . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2.1 Trend Data Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 Data Port Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.3.2 Typical Equipment Used for Connectivity . . . . . . . . . . . . . . . 7-3

7.3.3 Data Port Configuration Information . . . . . . . . . . . . . . . . . . . 7-3

7.3.4 Data Port Communications . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.4 Using the Nurse Call Interface . . . . . . . . . . . . . . . . . . . . 7-14

7.4.1 Nurse Call Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.4.2 Setting Nurse Call RS-232 Polarity . . . . . . . . . . . . . . . . . . . . 7-16

7.5 Calculating the Analog Voltage Output . . . . . . . . . . . . 7-17

8 Performance Considerations

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Oximetry Considerations . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Service Manual iii

Page 6

8.2.1 Monitoring System Constraints . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2.2 Nellcor™ Sensor Performance Considerations . . . . . . . . . . . . 8-1

8.3 Patient Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.4 Reducing EMI (Electromagnetic Interference) . . . . . . . . . 8-4

9 Product Maintenance

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.3 Periodic Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.4 Service and Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.5 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.5.1 Monitoring System Transport and Storage . . . . . . . . . . . . . . 9-2

9.5.2 Removed Battery Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

10 Modification and Testing

10.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Setting Institutional Defaults . . . . . . . . . . . . . . . . . . . . . 10-5

10.3 Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.3.2 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.4 Safety Testing Standards . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.5 Battery Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.5.1 Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.5.2 Battery Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.6 Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.6.1 Power-On Defaults and Alarm Ranges . . . . . . . . . . . . . . . 10-11

10.6.2 Operational Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

10.6.3 Overall Performance Check . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.6.4 Pulse Oximetry Functional Tests . . . . . . . . . . . . . . . . . . . . 10-24

10.6.5 Setting Nurse Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

10.7 Test Data Sheet Form . . . . . . . . . . . . . . . . . . . . . . . . . . 10-42

10.8 Monitoring Screen Calibration . . . . . . . . . . . . . . . . . . . 10-44

10.9 Software and Firmware Upgrades . . . . . . . . . . . . . . . . 10-45

11 Troubleshooting

11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.2 System Condition Categories . . . . . . . . . . . . . . . . . . . . . 11-1

11.3 User Prompts and Messages . . . . . . . . . . . . . . . . . . . . . . 11-4

iv Service Manual

Page 7

11.4 Alarms and Error Conditions . . . . . . . . . . . . . . . . . . . . . . 11-4

11.4.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

11.4.2 Correctable error conditions . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.5 Power Failure Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

11.6 Monitoring Screen Issues . . . . . . . . . . . . . . . . . . . . . . . 11-13

11.7 Alarm Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

11.8 Communication Issues . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

11.9 Operational Performance Issues . . . . . . . . . . . . . . . . . . 11-17

11.10 Hardware Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-17

11.11 System Errors and Software issues . . . . . . . . . . . . . . . 11-19

11.12 Non-correctable Failures . . . . . . . . . . . . . . . . . . . . . . . . 11-19

11.13 Product Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-20

12 Repair

12.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.2 Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.3 Repair Prerequisites and Required Equipment . . . . . . . 12-5

12.4 Basic Preventive Maintenance . . . . . . . . . . . . . . . . . . . . 12-6

12.4.1 Fuse Removal and Replacement . . . . . . . . . . . . . . . . . . . . . 12-7

12.4.2 Battery or Battery Access Door Replacement . . . . . . . . . . . . 12-7

12.4.3 Rubber Feet Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12.5 Chassis Disassembly and Reassembly . . . . . . . . . . . . . 12-10

12.5.1 Parameter Module Replacement . . . . . . . . . . . . . . . . . . . . 12-10

12.5.2 Monitoring System Chassis Disassembly . . . . . . . . . . . . . . 12-17

12.5.3 Monitoring System Chassis Reassembly . . . . . . . . . . . . . . . 12-20

12.6 Power Components Replacement . . . . . . . . . . . . . . . . 12-21

12.6.1 Power Entry Module (PEM) Replacement . . . . . . . . . . . . . . 12-22

12.6.2 Right Power Cable Assembly Replacement . . . . . . . . . . . . 12-22

12.6.3 Battery Components Replacement . . . . . . . . . . . . . . . . . . 12-24

12.6.4 Left Power Cable Assembly Replacement . . . . . . . . . . . . . 12-31

12.7 Front Panel Components Replacement . . . . . . . . . . . . 12-32

12.7.1 Main PCB Components Replacement . . . . . . . . . . . . . . . . 12-33

12.7.2 LCD Assembly with Overlay Replacement . . . . . . . . . . . . . 12-39

12.8 Return Authorization and Shipment . . . . . . . . . . . . . . 12-41

12.8.1 General Instructions for Return . . . . . . . . . . . . . . . . . . . . . 12-41

12.8.2 Repackage in Original Carton . . . . . . . . . . . . . . . . . . . . . . 12-42

12.8.3 Repackage in an Alternate Carton . . . . . . . . . . . . . . . . . . 12-43

Index

Service Manual v

Page 8

Page Left Intentionally Blank

vi

Page 9

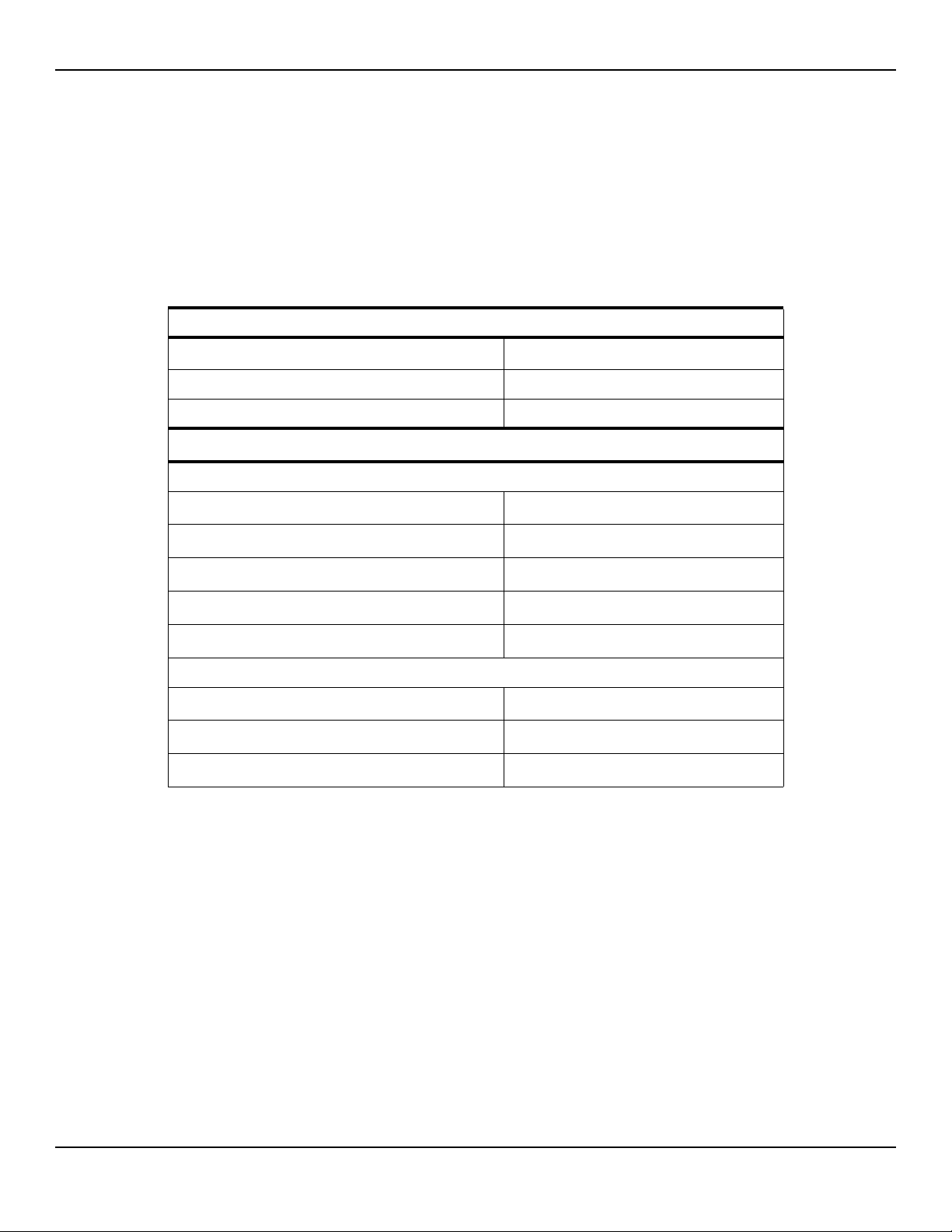

List of Tables

Table1-1. Safety Symbol Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table2-1. Nellcor™ Sensor Accuracy and Ranges . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table2-2. Nellcor™ Sensor Operating Range and Power Dissipation . . . . . 2-5

Table2-3. Sound Pressure in Decibels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table2-4. Frequency Band, Output Power, and Modulation Type . . . . . . . 2-6

Table2-5. Electromagnetic Emissions Guidelines and Compliance . . . . . . 2-7

Table2-6. Electromagnetic Immunity Guidelines and Compliance . . . . . . 2-8

Table2-7. Recommended Separation Distance Calculations . . . . . . . . . . . . 2-9

Table2-8. Recommended Separation Distances . . . . . . . . . . . . . . . . . . . . . . . 2-10

Table2-9. Sensor and Cable Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table2-10. Earth and Enclosure Leakage Current Specifications . . . . . . . . . 2-12

Table2-11. Patient Applied and Patient Isolation Risk Current . . . . . . . . . . . 2-13

Table4-1. Typical Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table4-2. Labeling Symbols and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table6-1. Battery Power Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Table6-2. Possible User Interface Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Table6-3. Possible Alarm Management Settings. . . . . . . . . . . . . . . . . . . . . . . 6-17

Table6-4. Possible Data Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Table6-5. Possible Service Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Table7-1. Input and Output Configuration Options . . . . . . . . . . . . . . . . . . . . 7-2

Table7-2. Sample Equipment Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Table7-3. DB-15 Signal Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Table7-4. RJ-45 Signal Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Table7-5. USB Signal Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Table7-6. Network Configuration Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Table7-7. Nurse Call Relay Pin States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Table7-8. Analog Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Table10-1. Possible User Interface Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Table10-2. Possible Alarm Management Settings. . . . . . . . . . . . . . . . . . . . . . . 10-3

Table10-3. Possible Data Interface and Service Settings . . . . . . . . . . . . . . . . 10-4

Table10-4. Equipment and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Table10-5. Functional Tests Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-26

Table10-6. Performance and Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . .10-42

Table10-7. Electrical Safety Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-43

Table11-1. Common User Prompts and Messages . . . . . . . . . . . . . . . . . . . . . . 11-4

Table11-2. Initial Alarm Priority for Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Table11-3. Common Correctable Problems and Resolutions . . . . . . . . . . . . 11-9

Table11-4. Power Failure Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-11

Service Manual vii

Page 10

Table11-5. Monitoring Screen Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Table11-6. Alarm Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

Table11-7. Common Prompts and Error Messages. . . . . . . . . . . . . . . . . . . . .11-16

Table11-8. Common Operational Performance Issues . . . . . . . . . . . . . . . . .11-17

Table11-9. Common Prompts and Error Messages. . . . . . . . . . . . . . . . . . . . .11-17

Table12-1. Available Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Table12-2. Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Table12-3. Main PCB Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19

Table12-4. Main PCB Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-33

viii Service Manual

Page 11

List of Figures

Figure 3-1. Block Diagram ............................................................................................. 3-1

Figure 3-2. Oxyhemoglobin Dissociation Curve ................................................... 3-5

Figure 3-3. Series of SpO2 Events ................................................................................ 3-7

Figure 3-4. First SpO2 Event: No SatSeconds Alarm ............................................. 3-8

Figure 3-5. Second SpO2 Event: No SatSeconds Alarm ......................................3-9

Figure 3-6. Third SpO2 Event: Triggers SatSeconds Alarm ..............................3-10

Figure 3-7. Clinically Significant Desaturation Patterns ...................................3-12

Figure 4-1. Front Panel ................................................................................................... 4-3

Figure 4-2. Sample Monitoring Screen Elements ................................................. 4-4

Figure 4-3. Rear Panel ..................................................................................................... 4-6

Figure 5-1. Sensor Cable insertion into Interface Cable .................................... 5-7

Figure 6-1. Sample POST Splash Screen ................................................................. 6-6

Figure 6-2. Sensor Type Message ............................................................................... 6-8

Figure 6-3. Default Monitoring Screen Layout ...................................................... 6-9

Figure 6-4. Sample user prompt message: READY ...........................................6-11

Figure 6-5. Sample status message: MONITORING ...........................................6-11

Figure 6-6. High priority alarm: BATTERY CRITICALLY LOW ..........................6-11

Figure 6-7. Medium priority alarm: SpO2 LOW ....................................................6-11

Figure 6-8. Low priority alarm: SENSOR OFF ........................................................6-12

Figure 6-9. Sample Alarm Limit Violations ............................................................6-13

Figure 6-10. Prompt to Enter SERVICE MODE .........................................................6-19

Figure 6-11. Default Monitoring Screen Layout ....................................................6-24

Figure 7-1. DB-15 Pin Layout ....................................................................................... 7-5

Figure 7-2. RJ-45 Receptacle ........................................................................................ 7-7

Figure 7-3. RJ-45 Pin Layout ......................................................................................... 7-7

Figure 7-4. USB Pin Layout ............................................................................................ 7-8

Figure 7-5. New Network Connection Windows ................................................7-11

Figure 7-6. New Network Connection Windows ................................................7-12

Figure 7-7. Nurse Call Polarity Screen .....................................................................7-16

Figure 10-1. Prompt to Enter SERVICE MODE .........................................................10-5

Figure 10-2. Sample: Configuring Alarms ............................................................. 10-18

Figure 10-3. Sample: Configuring Alarms with Silenced Alarm .................... 10-19

Figure 10-4. Sensor Identification ............................................................................ 10-24

Figure 10-5. SRC-MAX Functional Tester ..............................................................10-25

Figure 10-6. BPM Test: BPM 60 and SpO2 75 ........................................................ 10-27

Figure 10-7. BPM Test: BPM 200 and SpO

Figure 10-8. SpO2 Test: SpO2 75, BPM 60 ..............................................................10-29

2 75 ..................................................... 10-28

Service Manual ix

Page 12

Figure 10-9. SpO2 Test: SpO2 90, BPM 60 ..............................................................10-30

Figure 10-10. MOD Test: BPM 60, SpO2 75, and MOD Low ............................... 10-31

Figure 10-11. MOD Test: BPM 60, SpO

Figure 10-12. MOD Test: BPM 200, SpO

2 75, and MOD High .............................. 10-32

2 75, and MOD High ............................ 10-33

Figure 10-13. MOD Test: BPM 60, SpO2 90, and MOD High .............................. 10-34

Figure 10-14. LIGHT Test: BPM 60, SpO2 75, MOD low, Light low ................... 10-35

Figure 10-15. LIGHT Test: BPM 60, SpO2 75, MOD low, Light High ................10-36

Figure 10-16. LIGHT Test: BPM 200, SpO2 75, MOD low, Light High ..............10-37

Figure 10-17. LIGHT Test: BPM 60, SpO2 90, MOD low, Light High ................10-38

Figure 10-18. LIGHT Test: BPM 60, SpO2 90, MOD High, Light High .............. 10-39

Figure 10-19. Initial Calibration Screen .................................................................... 10-44

Figure 11-1. Ready Prompt ...........................................................................................11-2

Figure 11-2. Sensor Disconnected Message and Help Screen .........................11-2

Figure 11-3. Stacked Alarm/Alerts ..............................................................................11-3

Figure 11-4. Sample Speaker Failure Message .......................................................11-8

Figure 11-5. System Error ............................................................................................ 11-19

Figure 12-1. Exploded View of Removable Components ..................................12-3

Figure 12-2. Exploded View of Internal Components .........................................12-4

Figure 12-3. External Fuse Removal ...........................................................................12-7

Figure 12-4. Battery Removal .......................................................................................12-8

Figure 12-5. Rubber Feet Replacement ....................................................................12-9

Figure 12-6. Parameter Module Screw Removal ................................................ 12-11

Figure 12-7. Parameter Module Tab Release ....................................................... 12-12

Figure 12-8. Parameter Module Assembly Removal ......................................... 12-12

Figure 12-9. Parameter Module Disassembly ...................................................... 12-14

Figure 12-10. Parameter Board PCB and Oximetry Module Removal .......... 12-16

Figure 12-11. Corner Chassis Screws Removal ...................................................... 12-18

Figure 12-12. Initial Chassis Disassembly ................................................................ 12-20

Figure 12-13. Right Power Cable Assembly Replacement ................................ 12-23

Figure 12-14. Battery Cradle Removal ...................................................................... 12-25

Figure 12-15. Power Supply PCB Removal .............................................................. 12-27

Figure 12-16. Battery Interconnect PCB Removal ............................................... 12-29

Figure 12-17. Cooling Fan Removal .......................................................................... 12-30

Figure 12-18. Left Power Cable Assembly Replacement ................................... 12-31

Figure 12-19. Main PCB Connectors .......................................................................... 12-34

Figure 12-20. Antennae PCB and UFL Connectors Removal ............................ 12-36

Figure 12-21. Single Board Computer (SBC) Removal ........................................ 12-37

Figure 12-22. LCD Assembly Removal ...................................................................... 12-40

Figure 12-23. Components to Repackage in Original Carton .......................... 12-42

x Service Manual

Page 13

1 Introduction

1.1 Overview

This manual, for use by qualified personnel only, contains instructions for

servicing, testing, and maintaining the Nellcor™ Bedside Respiratory Patient

Monitoring System.

This manual applies to the following products:

GR101704

GR101704-RR

PM1000N

PM1000N-RR

1.2 Intended Audience

This manual provides information to professionals acting as trained and qualified service technicians in a hospital or hospital-type setting for maintenance

and service or repair of the monitoring system. Refer to the institution for any

additional training or skill requirements beyond those identified here for maintenance and repair of the monitoring system. Before servicing, thoroughly read

this manual.

1-1

Page 14

Introduction

1.3.1 Safety Symbols

1.3 Safety Information

Table1-1.Safety Symbol Definitions

Symbol Definition

WARNING

Warnings alert users to potential serious outcomes (death, injury, or adverse

events) to the patient, user, or environment.

Caution

Cautions alert users to exercise appropriate care for safe and effective use of

the product.

Note

Notes provide additional guidelines or information.

1.3.2 Warnings

WARNING:

Explosion hazard — Do not use in the presence of flammable anesthetics.

WARNING:

Shock hazard — Use only when connected to a grounded outlet to avoid

electric shock.

WARNING:

Before attempting to open or disassemble, disconnect the power cord to

avoid possible injury.

WARNING:

Use only Covidien-approved internal batteries.

WARNING:

The monitoring system is not defibrillator-proof. It may remain attached to

the patient during defibrillation or during use of an electrosurgical unit,

1-2 Service Manual

Page 15

however, readings may be inaccurate during use in this environment and

shortly thereafter.

WARNING:

Supplemental oxygen will attenuate patterns of desaturation. A patient’s

respiratory compromise can be proportionally more severe before patterns

appear in the saturation trend. Remain vigilant when monitoring a patient on

supplemental oxygen.

WARNING:

Do not silence or disable audible alarms or decrease the volume of the audible

alarm if patient safety could be compromised. Do not dim or disable visual

alarms if patient safety could be compromised.

WARNING:

Ensure the monitoring system is clear of any obstructions that prevent

awareness of visual or audible alarms. Failure to do so may result in

inadvertently missing a visual alarm or an inaudible alarm tone.

Safety Information

WARNING:

Do not use any monitoring system, sensor, cable, or connector that appears

damaged. Remove any damaged equipment from service for inspection by a

qualified service technician.

WARNING:

Do not lift by the sensor or interface cable. The cable may disconnect,

potentially dropping the monitoring system on a patient or damaging

surface.

WARNING:

When installing the AC power cord, ensure the cord is carefully positioned to

prevent tripping and entanglement.

WARNING:

Do not spray, pour, or spill any liquid on the monitoring system, its accessories,

connectors, switches, or openings in the chassis, since this may cause damage

to the monitoring system.

Service Manual 1-3

Page 16

Introduction

WARNING:

WARNING:

WARNING:

1.3.3 Cautions

To ensure accurate performance and prevent device failure, do not subject to

extreme moisture, such as direct exposure to rain. Such exposure may cause

inaccurate performance or device failure.

The monitoring screen contains toxic chemicals. Do not touch a broken

enclosure or monitoring screen. Physical contact with a broken enclosure or

monitoring screen can result in transmission or ingestion of toxic substances.

No user serviceable parts inside.

Caution:

Federal law (U.S.A.) restricts this device to sale by or on the order of a

physician.

Caution:

When connecting the monitoring system to any instrument, verify proper

operation before clinical use. Both the monitoring system and the instrument

connected to it must utilize a grounded outlet. Any equipment connected to

the data interface must be certified according to the latest IEC/EN 60950 -1

standard for data-processing equipment, the latest IECEN 60601-1 standard

for electromedical equipment, or the latest IEC/EN safety standards relevant

to that equipment. All combinations of equipment must be in compliance

with Requirements for Medical Electrical Systems IEC Standard

60601-1:2007and the electromagnetic compatibility IEC/EN Standard

60601-1:2005. Anyone who connects equipment to the data interface is

configuring a medical system and, therefore, is responsible for ensuring that

the system complies with the Requirements for Medical Electrical Systems

IEC/EN Standard 60601-1-1:2007 and the electromagnetic compatibility IEC/

EN Standard 60601-1-2:2007. Accuracy may degrade if it is connected to

secondary I/O devices when the equipment is not connected to earth

reference.

1-4 Service Manual

Page 17

Caution:

Observe electrostatic discharge (ESD) precautions prior to opening the chassis

or handling any internal components.

Caution:

Observe the required torque for tightening screws. Over-tightening can strip

out screw holes, rendering them useless.

1.4 Obtaining Technical Assistance

1.4.1 Technical Services

For technical information and assistance, if unable to correct a problem while

using the monitoring system, to order parts, or to order an Operator’s or

Service Manual, contact Covidien or a local Covidien representative.

Obtaining Technical Assistance

Covidien Technical Services: Patient Monitoring

15 Hampshire Street

Mansfield, MA 02048 USA

1.800.635.5267, 1.925.463.4635 (toll)

or contact a local Covidien representative

www.covidien.com

When calling Covidien or a local Covidien representative, have the serial

number, as well as the code versions available.

To locate the serial number and code versions

1. Press MENU.

2. Press ABOUT THE MONITOR.

3. Locate the serial number under Monitor Information and code versions under

Software Information.

Service Manual 1-5

Page 18

Introduction

1.4.2 On-Screen Help

The monitoring system provides users with an on-screen help system for

various help topics. Reference To access on-screen help topics, p. 6-16.

1.5 Related Documents

Documentation is available online at www.covidien.com. Covidien makes available all appropriate information relevant to servicing monitoring system parts

designated as repairable in this manual. For further assistance, contact Covidien.

• Nellcor™ Bedside Respiratory Patient Monitoring System Operator’s

Manual — Provides basic information on operating the monitoring system and

troubleshooting errors or malfunctions. Before using the monitoring system, thoroughly read this manual.

• Nellcor™ Sensor Instructions for Use — Guides sensor selection and usage.

Before attaching any of the various Covidien-approved Nellcor™ sensors to the

monitoring system, refer to their Instructions for Use.

• Nellcor™ Oxygen Saturation Accuracy Specification Grid — Provides

sensor-specific guidance related to desired SpO2 saturation accuracy measure-

ments.

1.6 Warranty Information

To obtain information, contact Covidien or a local Covidien representative.

Purchase of this instrument confers no express or implied license under any

Covidien patent to use that instrument with any sensor not manufactured or

licensed by Covidien llc.

1-6 Service Manual

Page 19

2 Product Specifications

2.1 Overview

This chapter contains physical and operational specifications of the

Nellcor™ Bedside Respiratory Patient Monitoring System. Ensure all product

requirements are met prior to installation.

2.2 Physical Characteristics

Weight 7.5 lbs. (3.4 kg)

Dimensions 10 in. x 6.5 in. x 5 in. (252 mm x 163 mm x 122 mm)

2.3 Electrical Requirements

2.3.1 Power

Power Requirements Rated at 80-263 volts AC (nominal 120-230 VAC), 30 VA

Input Frequency 47/63 Hz

Fuses Slow-blow 1.5 amp, 250 volts, IEC (5 x 20 mm)

Quantity: 2 external

2-1

Page 20

Product Specifications

2.3.2 Battery

Note:

The battery provides approximately seven hours of battery life when new and fully-charged

with no alarms, no serial data, no analog output, no nurse call output, with backlight on

while using a pulse simulator set for 200 bpm, high light and low modulation.

Type Lithium Ion

Voltage 7.2 Volts DC, 11.6 Ah, 83 Wh

Recharge 8 hours with monitoring system turned off

Shelf Life Four months, if monitoring system runs on new, fully-charged battery

12 hours with monitoring system turned on

After four months storage, units run 33% of stated battery life

Compliance IEC 62133

2.3.3 Rating of Nurse Call Relay

Maximum Input Voltage 30 VAC or VDC (polarity is not important)

Load Current 120 mA continuous (peak 300 mA @ 100 ms)

Minimum Resistance 26.5 ohms to 50.5 ohms (40.5 ohms typical) during alarms

Ground Reference Isolated Ground

Electrical Isolation 1500 Volts

2-2 Service Manual

Page 21

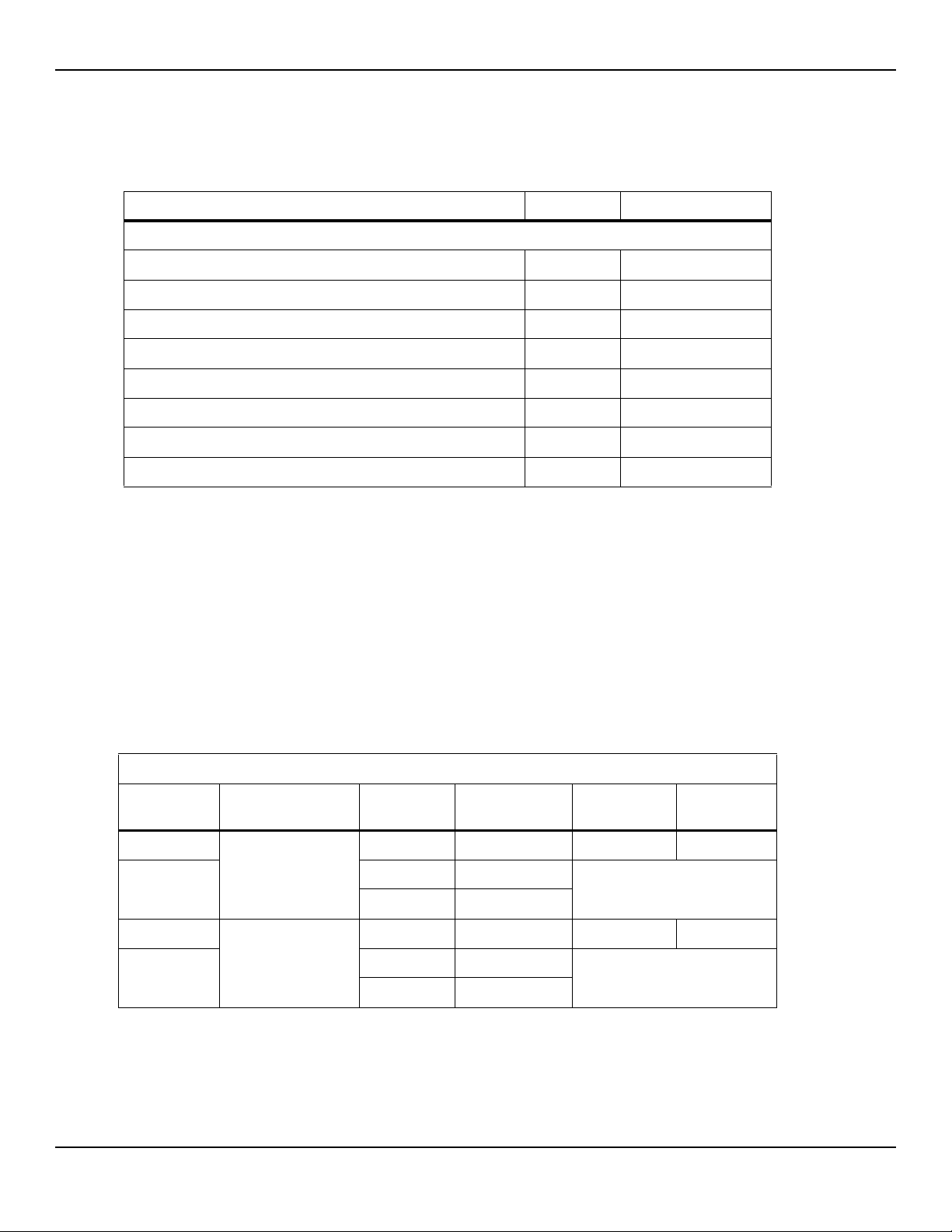

2.4 Environmental Conditions

2.4.1 Operating

Temperature 5 ºC to 40 ºC (41 ºF to 104 ºF)

Altitude -304.8 m to 4,572 m

(-1,000 ft. to 15,000 ft.)

Atmospheric Pressure 105 kPa to 57.2 kPa

(31.0 in. Hg to 16.89 in. Hg)

Relative Humidity 15% to 95% non-condensing

2.4.2 Transport and Storage

Environmental Conditions

Not in shipping container In shipping container

Temperature -20 ºC to 60 ºC

(-4 ºF to 140 ºF)

Altitude -390 m to 5,574 m (-1,254 ft. to 18,288 ft.)

Atmospheric Pressure 50 kPa to 106 kPa (14.7 in. Hg to 31.3 in. Hg)

Relative Humidity 15% to 95% non-condensing

-20 ºC to 70 ºC

(-4 ºF to 158 ºF)

Service Manual 2-3

Page 22

Product Specifications

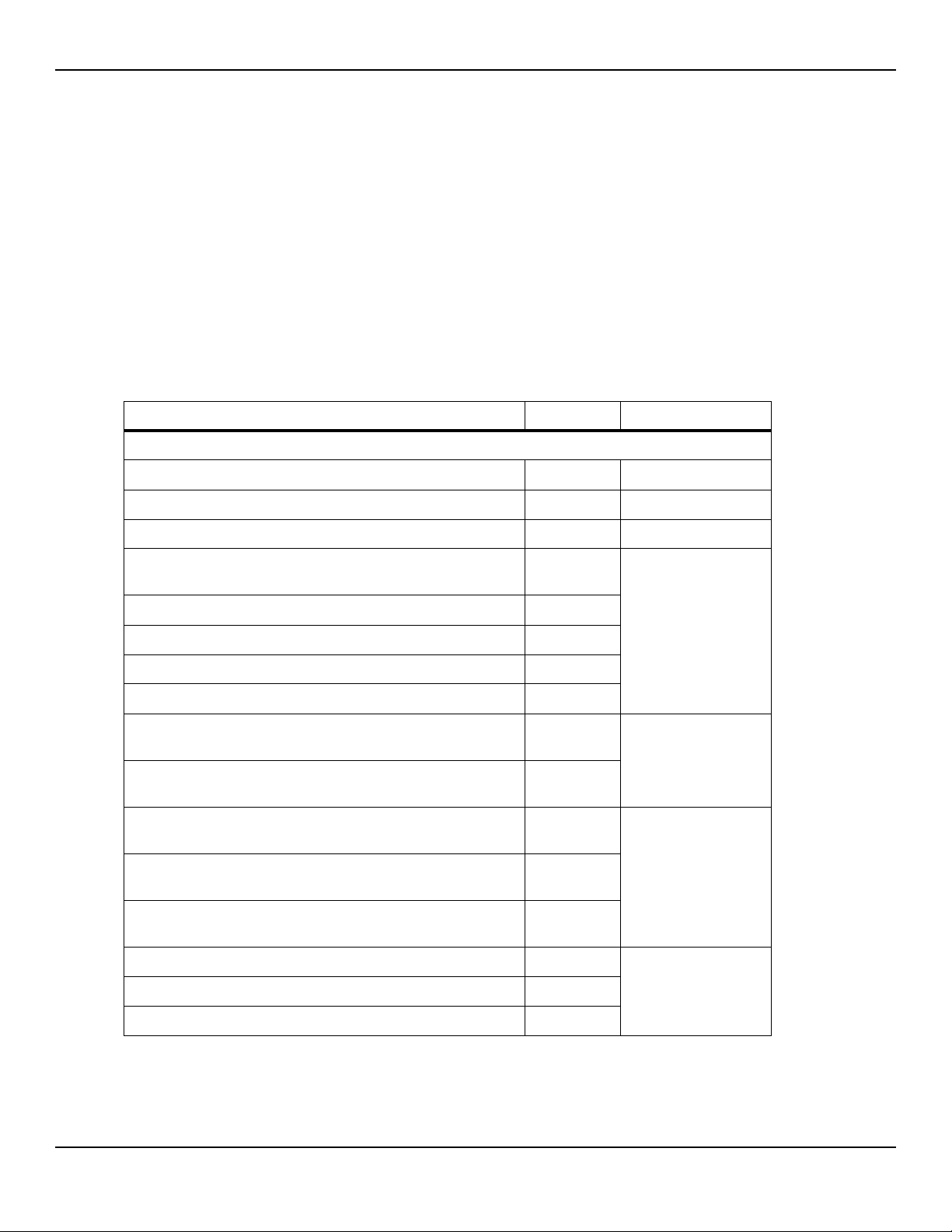

2.5 Sensor Accuracy and Ranges

This monitoring system has the capability to detect physiological alarm conditions using SpO2 accuracy, pulse rate accuracy and alarm limit conditions.

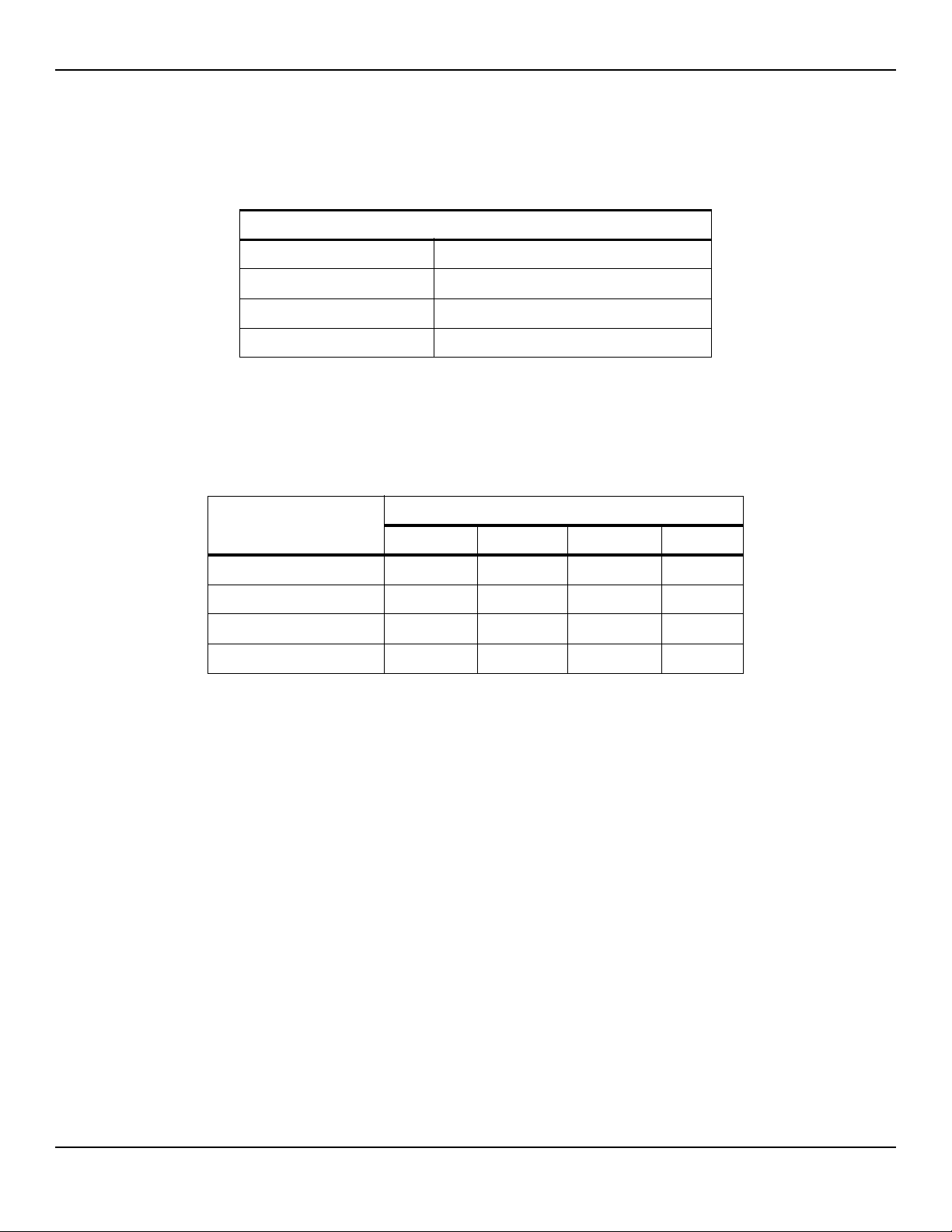

Table2-1.Nellcor™ Sensor Accuracy and Ranges

Measurement Range

SpO

2

1% to 100%

Pulse Rate 20 to 250 beats per minute (bpm)

Perfusion Range 0.03% to 20%

Accuracy

1

Saturation

2, 3

Adult

Adult and Neonate Low Sat

Neonate

Low Perfusion

4, 5

6

2, 3, 4

Adult and Neonate with Motion

2, 7

70 to 100% ±2 digits

60 to 80% ±3 digits

70 to 100% ±2 digits

70 to 100% ±2 digits

70 to 100% ±3 digits

Pulse Rate

Adult and Neonate

Low Perfusion

Adult and Neonate with Motion

1. Saturation accuracy varies by sensor type. Refer to the Nellcor™ Oxygen Saturation Accuracy Specification Grid at

www.covidien.com/rms.

2. Accuracy specifications were validated using measurements of healthy non-smoking adult volunteers during controlled

hypoxia studies spanning the specified saturation ranges. Subjects were recruited from the local population and comprised

both men and women ranging in age from 18-50 years old, and spanned a range of skin pigmentations. Pulse oximeter

SpO2 readings were compared to SaO2 values of drawn blood samples measured by hemoximetry. All accuracies are

expressed as ±1 SD. Because pulse oximeter equipment measurements are statistically distributed, about two-thirds of the

measurements can be expected to fall in this accuracy (A

3. Adult specifications are shown for OXIMAX MAX-A and MAX-N sensors with the Nellcor™ Bedside Respiratory Patient Monitoring System.

4. Neonate specifications are shown for OXIMAX MAX-N sensors with the Nellcor™ Bedside Respiratory Patient Monitoring System.

5. Clinical functionality of the MAX-N sensor has been demonstrated on a population of hospitalized neonate patients. The

observed SpO2 accuracy was 2.5% in a study of 42 patients with ages of 1 to 23 days, weight from 750 to 4,100 grams,

and 63 observations made spanning a range of 85% to 99% SaO2.

6. Specification applies to Nellcor™ Bedside Respiratory Patient Monitoring System oximeter performance. Reading accuracy

in the presence of low perfusion (detected IR pulse modulation amplitude 0.03% - 1.5%) was validated using signals

supplied by a patient simulator. SpO2 and pulse rate values were varied across the monitoring range over a range of weak

signal conditions and compared to the known true saturation and pulse rate of the input signals.

7. Motion performance was validated during a controlled hypoxia blood study. Subjects performed rubbing and tapping

movements 1-2 cm in amplitude with aperiodic intervals (randomly changing) with a random variation in frequency between

1-4 Hz. Applicability: OXIMAX MAX-A, MAX-AL, MAX-P, MAX-I, and MAX-N sensors.

2, 3, 4

6

2, 7

) range (refer to the Sensor Accuracy Grid for more details).

RMS

20 to 250 bpm ±3 digits

20 to 250 bpm ±3 digits

48 to 127 bpm ±5 digits

2-4 Service Manual

Page 23

Table2-2.Nellcor™ Sensor Operating Range and Power Dissipation

Red Light Wavelength Approximately 660 nm

Infrared Light Wavelength Approximately 900 nm

Optical Output Power Less than 15 mW

Power Dissipation 52.5 mW

2.6 Sound Pressure

Sound Pressure

Operating Range and Dissipation

Table2-3.Sound Pressure in Decibels

Volume Setting

Alarm Type

High Priority 88.1 dB 85.5 dB 80.6 dB 71.5 dB

Medium Priority 78.3 dB 75.4 dB 70.2 dB 61.2 dB

Low Priority 74.4 dB 71.1 dB 66.4 dB 57.6 dB

SPD Alarm (Low Priority) 74.4 dB 70.7 dB 65.7 dB 57.5 dB

2.7 Product Compliance

Equipment Classification IEC/EN 80601-2-61:2011

Protection Type Class I (Internally powered)

Degree of Protection Type BF - Applied part

Mode of Operation Continuous

Electromagnetic Compatibility IEC 60601-1-2:2007

High Med High Med Low Low

IEC/EN 60601-1:2005

CAN/CSA C22.2 No. 60601-1:08

ANSI AAMI ES 60601-1:2005

Liquid Ingress IPX1: Protected against harmful effects of dripping water

Degree of Safety Not suitable for use in the presence of flammable anesthetics

Service Manual 2-5

Page 24

Product Specifications

2.8 Manufacturer’s Declaration and Guidance

2.8.1 Electromagnetic Compatibility (EMC)

WARNING:

This monitoring system is intended for use by healthcare professionals only.

This monitoring system may cause radio interference or may disrupt the

operation of nearby equipment, regardless of whether it is CISPR compliant

or not. It may be necessary to take mitigation measures, such as re-orienting

or relocating the monitoring system or shielding the location.

WARNING:

The use of accessories, sensors, and cables other than those specified may

result in inaccurate readings of the monitoring system and increased EMI

emissions of the monitoring system.

The monitoring system is suitable for prescription use only in the specified electromagnetic environments, in accordance with the IEC 60601-1-2:2007 standard. The

monitoring system requires special precautions during installation and operation

for electromagnetic compatibility. In particular, the use of nearby mobile or portable communications equipment may influence monitoring system performance.

Frequency and Bandwidth for Wireless Connection

Table2-4.Frequency Band, Output Power, and Modulation Type

Frequency Band

(MHz)

2412 - 2462 0.088 BPSK, CCK, OFDM

5180 - 5240 0.018 OFDM

5260 - 5320 0.018 OFDM

5500 - 5700 0.028 OFDM

5745 - 5825 0.026 OFDM

Output Power

(Watts)

Modulation Type

2-6 Service Manual

Page 25

Manufacturer’s Declaration and Guidance

Electromagnetic Emissions

Table2-5.Electromagnetic Emissions Guidelines and Compliance

Guidance and Manufacturer’s Declaration—Electromagnetic Emissions

(IEC/EN 60601-1-2:2007, Table 1)

The monitoring system is intended for use in the electromagnetic environment specified below. The

customer or the user of the monitoring system should assure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment Guidance

RF emission

CISPR 11

EN 55011

Harmonic emissions

IEC/EN 61000-3-2

Voltage fluctuation/

flicker emissions

IEC/EN 61000-3-3

Group 1,

Class A

Class A N/A

Complies N/A

Not intended for use in a residential environment. If

used in a domestic environment, may not offer adequate protection to radio-frequency communication

services. The user may be required to take mitigation

measures, such as relocating or re-orienting the equipment.

Service Manual 2-7

Page 26

Product Specifications

Electromagnetic Immunity

The monitoring system is intended for use in the electromagnetic environment specified below. The

customer or the user of the monitoring system should assure that it is used in such an environment.

Table2-6.Electromagnetic Immunity Guidelines and Compliance

Guidance and Manufacturer’s Declaration—Electromagnetic Immunity

(IEC/EN 60601-1-2:2007, Table 2)

Immunity

Test

Electrostatic

discharge (ESD)

IEC/EN 61000-4-2

Electric fast

transient/burst

IEC/EN 61000-4-4

Surge

IEC/EN 61000-4-5

Voltage dips, short

interruptions and

voltage variations

on power supply

IEC/EN 61000-4-11

IEC/EN 60601-1-2

Test Level

± 6 kV contact

± 8 kV air

± 2 kV for power

supply lines

± 1 kV input/

output lines

± 1 kV differential

mode

± 2 kV common

mode

<5% U

T

(>95% dip in UT)

for 0.5 cycle

40% U

(60% dip in U

T

)

T

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

Compliance

Level

± 6 kV contact

± 8 kV air

± 2 kV for

power supply lines

± 1 kV input/

output lines

± 1 kV differential

mode

± 2 kV common

mode

<5% U

T

(>95% dip in UT)

for 0.5 cycle

40% U

(60% dip in U

T

)

T

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

Electromagnetic Environment

Guidance

Floor should be wood, concrete,

or ceramic tile. If floors are

covered with synthetic material,

the relative humidity should be at

least 30%.

Mains power quality should be

that of a typical commercial and/

or hospital environment.

Mains power quality should be

that of a typical commercial and/

or hospital environment.

Mains power quality should be

that of a typical commercial and/

or hospital environment.

If the user requires continued

operation during power mains

interruption, it is recommended

that the monitoring system be

powered from an uninterruptible

power supply or battery.

Power frequency

(50/60 Hz) magnetic

field

IEC/EN 61000-4-8

Note: U

is the AC main’s voltage prior to application of the test level.

T

<5% U

T

(>95% dip in UT)

for 5 seconds

3 A/m 3 A/m It may be necessary to position

<5% U

T

(>95% dip in UT)

for 5 seconds

further from the sources of

power frequency magnetic fields

or to install magnetic shielding.

2-8 Service Manual

Page 27

Manufacturer’s Declaration and Guidance

d 1.2 P=

d 1.2 P=

d 2.3 P=

Table2-7.Recommended Separation Distance Calculations

Guidance and Manufacturer’s Declaration—Electromagnetic Immunity

(IEC/EN 60601-1-2:2007, Table 4)

The monitoring system is intended for use in the electromagnetic environment specified below. The

customer or the user of the monitoring system should assure that it is used in such an environment.

Immunity

Test

IEC/EN 60601-1-2

Test Level

Compliance

Level

Electromagnetic

Environment Guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the monitoring

system, including cables, than the recommended separation distance calculated from the equation applicable to

the frequency of the transmitter.

Conducted RF

IEC/EN

61000-4-6

Radiated RF

IEC/EN

61000-4-3

3 Vrms

150 kHz to

80 MHz

3 V/m

80 MHz to

2.5 GHz

3 Vrms

150 kHz to

80 MHz

3 V/m

80 MHz to

2.5 GHz

Recommended Separation Distance

80 MHz to 800 MHz

800 MHz to 2.5 GHz

where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer and d is the recommended separation distance in

meters (m).

Field strengths from fixed RF transmitters, as determined

by an electromagnetic site survey

compliance level in each frequency range

Interference may occur in the vicinity of equipment

marked with the following symbol:

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects, and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile

radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should

be considered. If the measured field strength in the location in which the monitoring system is used exceeds the

applicable RF compliance level above, the monitoring system should be observed to verify normal operation. If

abnormal performance is observed, additional measures may be necessary, such as re-orienting or relocating the

monitoring system.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

a

, should be less than the

b

.

Service Manual 2-9

Page 28

Product Specifications

d 1.2 P=

d 1.2 P=

d 2.3 P=

Recommended Separation Distances Between Portable and Mobile RF Communications

The monitoring system is intended for use in an electromagnetic environment in which radiated RF

disturbances are controlled. The customer or the user of the monitoring system can help prevent elec-

tromagnetic interference by maintaining a minimum distance between portable and mobile RF com-

munications equipment (transmitters) and the monitoring system as recommended below, according

to the maximum output power of the communications equipment.

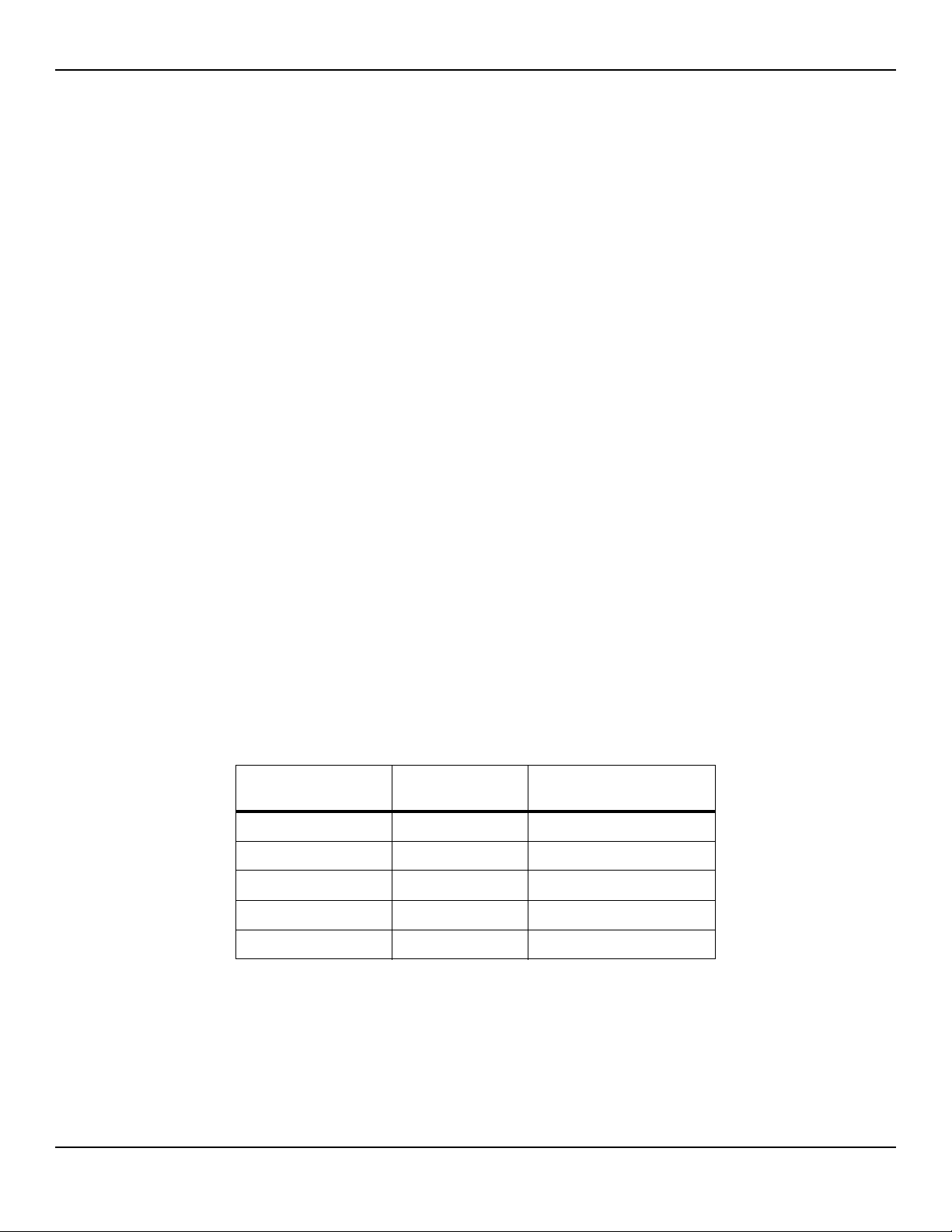

Table2-8.Recommended Separation Distances

Equipment and the Monitoring System

(IEC/EN 60601-1-2:2007, Table 6)

Rated Maximum

Output Power (P)

of Transmitter in

Watts

0.01 0.12 0.12 0.23

0.10 0.38 0.38 0.73

1.00 1.20 1.20 2.30

10.00 3.80 3.80 7.30

100.00 12.00 12.00 23.00

For transmitters rated at a maximum output power not listed above, the recommended separation

distance (d) in meters (m) can be estimated using the equation applicable to the frequency of the

transmitter, where P is the maximum output power rating of the transmitter in watts (W) according

to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects, and people.

Separation Distance According to Frequency of Transmitter in Meters

150 kHz to 80 MHz 80 MHz to 800 MHz 800 MHz to 2.5 GHz

2-10 Service Manual

Page 29

Sensor and Cable Compliance

WARNING:

The use of accessories, sensors, and cables other than those specified may

result in inaccurate readings of the monitoring system and increased emission

of the monitoring system.

Manufacturer’s Declaration and Guidance

Table2-9.Sensor and Cable Length

Item SKU Maximum Length

Sensors

Nellcor™ Adult SpO

Nellcor™ Adult XL SpO

Nellcor™ Forehead SpO

Nellcor™ Neonatal-Adult SpO

(Sterile, single-use only)

Nellcor™ Infant SpO

Nellcor™ Pediatric SpO

Nellcor™ Adult SpO

Nellcor™ Adult SpO

Nellcor™ Adult-Neonatal SpO

(Reusable with adhesive)

Nellcor™ Pediatric-Infant SpO

(Reusable with adhesive)

Nellcor™ Pediatric SpO

(Sterile, single-use only)

Nellcor™ Neonatal-Adult SpO

(Sterile, single-use only)

Nellcor™ Adult SpO

(Sterile, single-use only)

2 Sensor, Reusable (Nonsterile) DS100A 3.0 ft. (0.9 m)

2 Sensor (Sterile, single-use only) MAX-AL 3.0 ft. (0.9 m)

2 Sensor (Sterile, single-use only) MAX-FAST 2.5 ft (0.75 m)

2 Sensor (Sterile, single-use only) MAX-I

2 Sensor (Sterile, single-use only) MAX-P

2 Sensor (Sterile, single-use only) MAX-A

2 Nasal Sensor (Sterile, single-use only) MAX-R

2 Sensor, Two Piece

2 Sensor, Two Piece

2 Sensor

2 Sensor with Wraps

2 Sensor with Wraps

2 Sensor, Two Piece

MAX-N

OXI-A/N

OXI-P/I

P

N

A

1.5 ft. (0.5 m)

3.0 ft. (0.9 m)

OC-3 cable,

3.0 ft. (0.9 m)

Nellcor™ SpO

• Nellcor™ SpO2 Ear Clip, Reusable (Nonsterile) D-YSE

• Nellcor™ Pediatric SpO2 Clip, Reusable (Nonsterile) D-YSPD

Service Manual 2-11

2 Sensor, Multisite Reusable (Nonsterile) D-YS

4.0 ft. (1.2 m)

Page 30

Product Specifications

Power cord ---- 9.84 ft. (3 m)

DOC-10 interface cable 10.0 ft. (3 m)

Firmware download cable, RS-232 serial, 15 to 9 pin “D” 10.0 ft. (3 m)

Non-terminated cable, RS-232 analog, 15 pin “D” 3.3 ft. (1 m)

Printer cable, RS-232, 15 to 9 pin “D” 10.0 ft. (3 m)

Philips interface cable M1943 NL 3.3 ft. (1 m)

Oxinet™ III hardwire cable ---- 10.0 ft. (3 m)

Oxinet™ III data cable

Table2-9.Sensor and Cable Length (Continued)

Item SKU Maximum Length

Cables

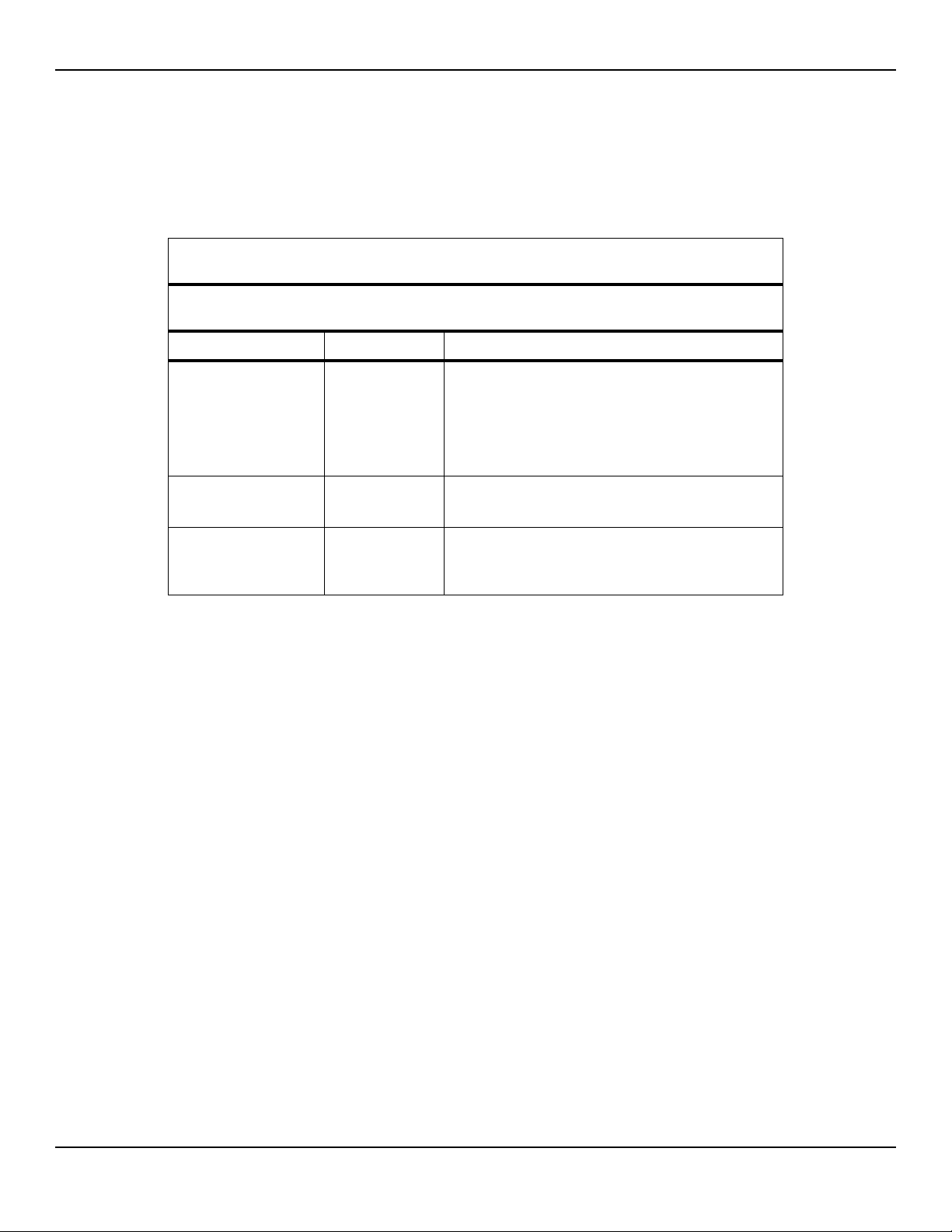

2.8.2 Ground Integrity

100 milliohms or less

2.8.3 Safety Tests

The following tables describe the maximum earth and enclosure leakage

current allowed, as well as patient leakage.

Table2-10.Earth and Enclosure Leakage Current Specifications

Earth Leakage Current

Neutral

Condition AC Line Polarity Line Cord

Normal Normal Closed Closed 500 μA 300 μA

Single Fault Open Closed 1000 μA

Closed Open

Normal Reversed Closed Closed 500 μA 300 μA

Single Fault Open Closed 1000 μA

Line Cord IEC 60601-1

ANSI/AAMI

60601-1

Closed Open

2-12 Service Manual

Page 31

Manufacturer’s Declaration and Guidance

Table2-10.Earth and Enclosure Leakage Current Specifications (Continued)

Enclosure Leakage Current

Neutral

Condition AC Line Polarity

Normal Normal Closed Closed 100 μA

Single Fault Open Closed 500 μA

Normal Reversed Closed Closed 100 μA

Single Fault Open Closed 500 μA

Table2-11.Patient Applied and Patient Isolation Risk Current

Condition AC Line Polarity Neutral Line

Normal Normal Closed Closed 100 μA

Single Fault Open Closed 500 μA

Line Cord

Closed Open

Closed Open

Patient Applied Risk Current

Closed Open

Power Line

Ground

Power Line

Ground Cable

IEC 60601-1

ANSI/AAMI 60601-1

IEC 60601-1

ANSI/AAMI 60601-1

Normal Reversed Closed Closed 100 μA

Single Fault Open Closed 500 μA

Closed Open

Patient Isolation Risk Current

Power Line

Condition AC Line Polarity Neutral Line

Single Fault Normal Closed Closed 5000 μA

Reversed Closed Closed

Ground Cable

IEC 60601-1

UL 60601-1

Service Manual 2-13

Page 32

Product Specifications

Page Left Intentionally Blank

2-14 Service Manual

Page 33

3 Theory of Operations

3.1 Overview

This chapter explains the theory behind operations of the

Nellcor™ Bedside Respiratory Patient Monitoring System.

3.2 Block Diagram

The functional block diagram provides a quick, visual overview of the monitoring system.

Figure3-1.Block Diagram

3-1

Page 34

Theory of Operations

3.3 Theoretical Principles

The monitoring system uses pulse oximetry to measure functional oxygen saturation in the blood. Pulse oximetry works by applying a Nellcor™ sensor to a

pulsating arteriolar vascular bed, such as a finger or toe. The sensor contains a

dual light source and a photodetector.

Bone, tissue, pigmentation, and venous vessels normally absorb a constant

amount of light over time. The arteriolar bed normally pulsates and absorbs

variable amounts of light during the pulsations. The ratio of light absorbed is

translated into a measurement of functional oxygen saturation (SpO2).

Ambient conditions, sensor application, and patient conditions can influence

the ability of the monitoring system to accurately measure SpO2. Reference

Performance Considerations, p. 8-1.

Pulse oximetry is based on two principles: oxyhemoglobin and deoxyhemoglobin differ in their absorption of red and infrared light (measured using spectrophotometry), and the volume of arterial blood in tissue (and hence, light

absorption by that blood) changes during the pulse (registered using plethysmography). A monitoring system determines SpO2 by passing red and infrared

light into an arteriolar bed and measuring changes in light absorption during

the pulsatile cycle. Red and infrared low voltage, light-emitting diodes (LED) in

the sensor serve as light sources; a photo diode serves as the photo detector.

Since oxyhemoglobin and deoxyhemoglobin differ in light absorption, the

amount of red and infrared light absorbed by blood is related to hemoglobin

oxygen saturation.

The monitoring system uses the pulsatile nature of arterial flow to identify the

oxygen saturation of arterial hemoglobin. During systole, a new pulse of arterial blood enters the vascular bed, and blood volume and light absorption

increase. During diastole, blood volume and light absorption reach their lowest

point. The monitoring system bases its SpO2 measurements on the difference

between maximum and minimum absorption (measurements at systole and

diastole). By doing so, it focuses on light absorption by pulsatile arterial blood,

eliminating the effects of nonpulsatile absorbers such as tissue, bone, and

venous blood.

3-2 Service Manual

Page 35

3.4 Automatic Calibration

Because light absorption by hemoglobin is wavelength dependent and

because the mean wavelength of LEDs varies, a monitoring system must know

the mean wavelength of the sensor's red LED to accurately measure SpO2.

During monitoring, the monitoring system’s software selects coefficients that

are appropriate for the wavelength of that individual sensor's red LED; these

coefficients are then used to determine SpO2.

Additionally, to compensate for differences in tissue thickness, the light intensity of the sensor's LEDs is adjusted automatically.

Note:

During certain automatic calibration functions, the monitoring system may briefly

display a flat line on the plethysmographic waveform. This is a normal operation and

does not require any user intervention.

Automatic Calibration

3.5 Functional Testers and Patient Simulators

Some models of commercially available bench top functional testers and

patient simulators can be used to verify the proper functionality of Covidien

Nellcor™ monitoring systems, sensors, and cables. Reference the individual

testing device's operator's manual for the procedures specific to the model of

tester used. While such devices may be useful for verifying that the sensor,

cabling, and monitoring system are functional, they are incapable of providing

the data required to properly evaluate the accuracy of a system's SpO2 measurements.

Fully evaluating the accuracy of the SpO

mum, accommodating the wavelength characteristics of the sensor and reproducing the complex optical interaction of the sensor and the patient’s tissue.

These capabilities are beyond the scope of known bench top testers. SpO2

measurement accuracy can only be evaluated in vivo by comparing monitoring

system readings with values traceable to SaO2 measurements obtained from

simultaneously sampled arterial blood using a laboratory CO-oximeter.

Many functional testers and patient simulators have been designed to interface with the monitoring system's expected calibration curves and may be suitable for use with monitoring systems and/or sensors. Not all such devices,

however, are adapted for use with the OxiMax™ digital calibration system.

2 measurements requires, at a mini-

Service Manual 3-3

Page 36

Theory of Operations

100 +–

---------------------------------

100=

While this will not affect use of the simulator for verifying system functionality,

displayed SpO2 measurement values may differ from the setting of the test

device. For a properly functioning monitoring system, this difference will be

reproducible over time and from monitoring system to monitoring system

within the performance specifications of the test device.

3.6 Unique Technologies

3.6.1 Functional versus Fractional Saturation

This monitoring system measures functional saturation where oxygenated

hemoglobin is expressed as a percentage of the hemoglobin that can transport

oxygen. It does not detect significant amounts of dysfunctional hemoglobin,

such as carboxyhemoglobin or methemoglobin. In contrast, hemoximeters

such as the IL482, report fractional saturation where oxygenated hemoglobin

is expressed as a percentage of all measured hemoglobin, including measured

dysfunctional hemoglobins. To compare functional saturation measurements

to those from a monitoring system that measures fractional saturation, fractional measurements must be converted using the listed equation.

functional saturation %carboxyhemoglobin

fractional saturation %methemoglobin

3.6.2 Measured versus Calculated Saturation

When calculating saturation from a blood gas partial pressure of oxygen (PO2),

the calculated value may differ from the SpO

2 measurement of a monitoring

system. This usually occurs when saturation calculations exclude corrections

for the effects of variables such as pH, temperature, the partial pressure of

carbon dioxide (PCO2), and 2,3-DPG, that shift the relationship between PO2

and SpO

3-4 Service Manual

2.

Page 37

Figure3-2.Oxyhemoglobin Dissociation Curve

Unique Technologies

1 % Saturation Axis 3 Increased pH; Decreased temperature, PCO2, and 2,3-DPG

2 PO2 (mmHg) Axis 4 Decreased pH; Increased temperature, PCO2, and 2,3-DPG

Data Update Period, Data Averaging, and Signal Processing

3.6.3

The advanced signal processing of the OxiMax™ algorithm automatically extends

2

the amount of data required for measuring SpO

and pulse rate depending on the

measurement conditions. The OxiMax™ algorithm automatically extends the

dynamic averaging time required beyond seven (7) seconds during degraded or difficult measurement conditions caused by low perfusion, signal artifact, ambient

light, electrocautery, other interference, or a combination of these factors, which

results in an increase in the dynamic averaging. If the resulting dynamic averaging

time exceeds 20 seconds for SpO2, the monitoring system displays the pulse search

indicator while continuing to update SpO2 and pulse rate values every second. If

the dynamic averaging time exceeds 25 seconds, a low-priority Extended Update

alarm also appears.

As such measurement conditions extend, the amount of data required may

continue to increase. If the dynamic averaging time reaches 40 seconds, and/

or 50 seconds for pulse rate, a high priority alarm state results: the monitoring

Service Manual 3-5

Page 38

Theory of Operations

system displays the Pulse Timeout alarm and reports a zero saturation indicating a loss-of-pulse condition.

3.7 System Features

3.7.1 Nellcor™ Sensor Technology

Use Nellcor™ sensors, which are specifically designed for use with the monitoring system. Identify Nellcor™ sensors by the Nellcor™ logo on the plug. All

Nellcor™ sensors contain a memory chip carrying information about the

sensor which the monitoring system needs for correct operation, including the

sensor’s calibration data, model type, troubleshooting codes, and error detection data.

This unique oximetry architecture enables several new features. When a Nellcor™ sensor is connected to the monitoring system, the monitoring system

reads the information from the sensor memory chip, ensures it is error free,

and then loads the sensor data prior to monitoring for new information. As the

monitoring system reads sensor information, it sends the sensor model

number to the monitoring screen. This process may take a few seconds. The

sensor model number disappears after the monitoring system starts tracking

the patient’s SpO2 and pulse rate.

Any monitoring system containing OxiMax technology uses calibration data

contained in the sensor in calculating the patient’s SpO2. With sensor calibration, the accuracy of many sensors is improved, since the calibration coefficients can be tailored to each sensor.

Contact Covidien or a local Covidien representative for a Nellcor™ Oxygen Sat-

uration Accuracy Specification Grid listing all of the sensors used with the monitoring system. Covidien retains a soft copy at www.covidien.com

.

The monitoring system uses the information in the sensor, tailoring messages

to better help the clinician troubleshoot client or data issues. The sensor automatically identifies its sensor type to the monitoring system when attached.

3-6 Service Manual

Page 39

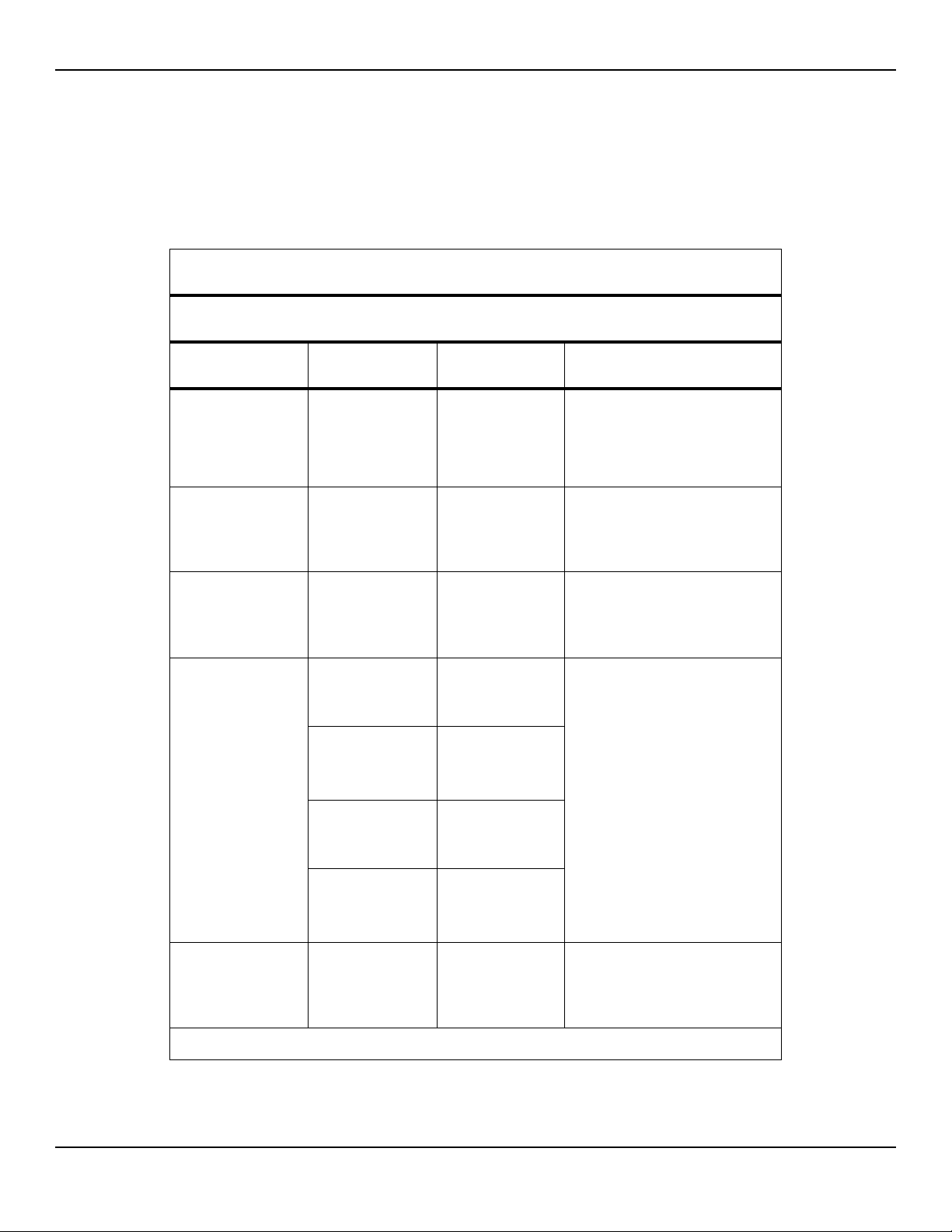

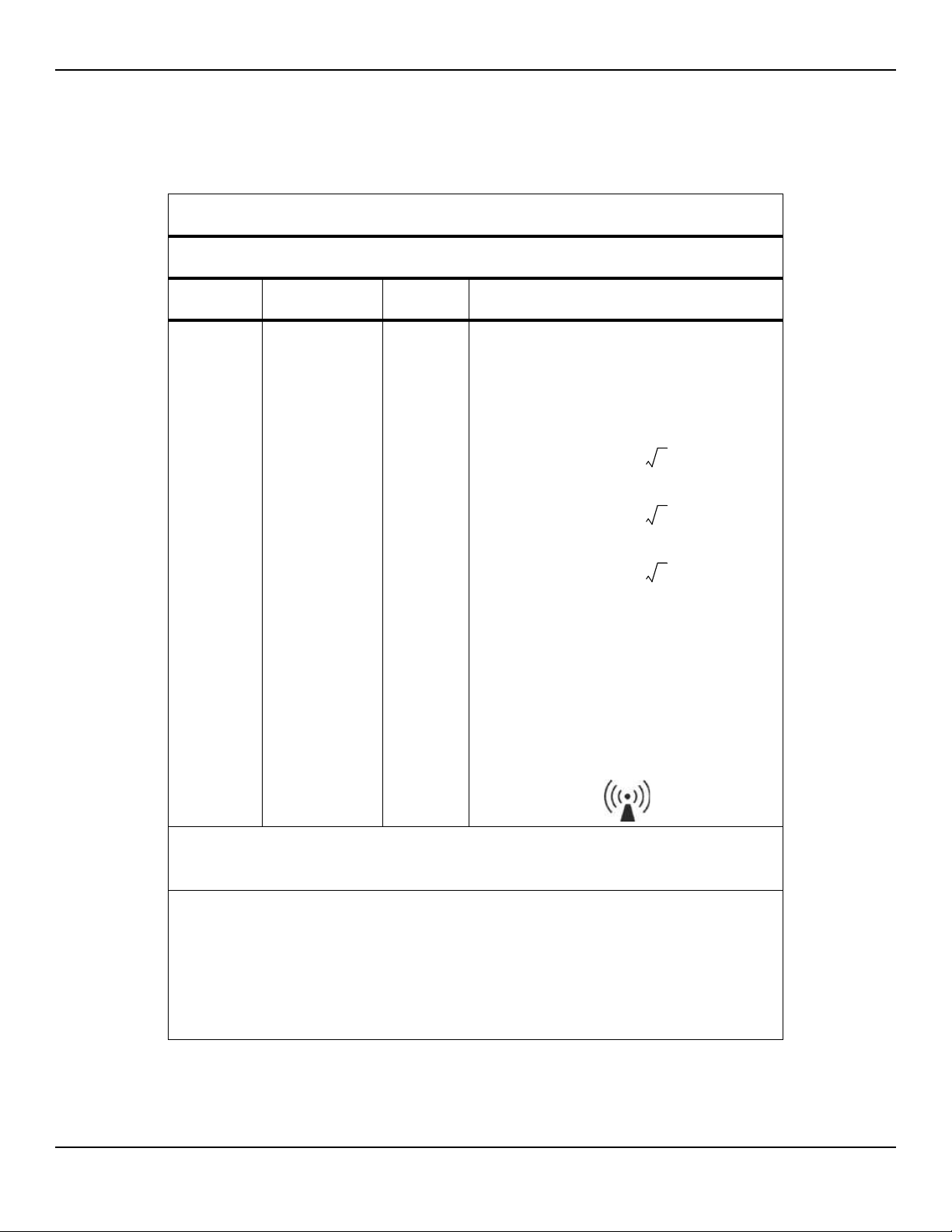

3.7.2 SatSeconds™ Alarm Management Parameter

The monitoring system monitors the percentage of hemoglobin binding sites

saturated with oxygen in the blood. With traditional alarm management, upper

and lower alarm limits are set to alarm at specific SpO

2

levels. When the SpO2

level fluctuates near an alarm limit, the alarm sounds each time it violates the

alarm threshold. SatSeconds monitors both degree and duration of desaturation

as an index of desaturation severity. Thus, the SatSeconds parameter helps distinguish clinically significant events from minor and brief desaturations that may

result in nuisance alarms.

Consider a series of events leading to a violation of the SatSeconds alarm limit.

An adult patient experiences several minor desaturations, then a clinically significant desaturation.

Figure3-3.Series of SpO2 Events

System Features

a First SpO

b Second SpO

cThird SpO

Service Manual 3-7

2 Event

2 Event

2 Event

Page 40

Theory of Operations

First SpO2 Event

Consider the first event. Suppose the SatSeconds alarm limit is set to 25. The

patient’s SpO2 drops to 79% and the duration of the event is two (2) seconds

before saturation again exceeds the lower alarm threshold of 85%.

Because the SatSeconds alarm limit is set to 25 and the actual number of

SatSeconds equals 12, there is no audible alarm.

6% drop below the lower alarm limit threshold

x 2 second duration below the lower threshold

12 SatSeconds; no alarm

Figure3-4.First SpO2 Event: No SatSeconds Alarm

3-8 Service Manual

Page 41

Second SpO2 Event

Consider the second event. Suppose the SatSeconds alarm limit is still set to

25. The patient’s SpO2 drops to 84% and the duration of the event is 15

seconds before saturation again exceeds the lower alarm threshold of 85%.

1% drop below the lower alarm limit threshold

x15 second duration below the lower threshold

15 SatSeconds; no alarm

Because the SatSeconds alarm limit is set to 25 and the actual number of

SatSeconds equals 15, there is no audible alarm.

Figure3-5.Second SpO2 Event: No SatSeconds Alarm

System Features

Service Manual 3-9

Page 42

Theory of Operations

Third SpO2 Event

Consider the third event. Suppose the SatSeconds alarm limit is still set to 25.

During this event, the patient’s SpO2 drops to 75%, which is 10% below the

lower alarm threshold of 85%. Since the patient’s saturation does not return

to a value over the lower alarm threshold within 2.5 seconds, an alarm sounds.

At this level of saturation, the event cannot exceed 2.5 seconds without invoking a SatSeconds alarm.

10% drop below the lower alarm limit threshold

x2.5 second duration below the lower threshold

25 SatSeconds; results in an alarm

Figure3-6.Third SpO2 Event: Triggers SatSeconds Alarm

3-10 Service Manual

Page 43

The SatSeconds Safety Net

The SatSeconds “Safety Net” is for patients with saturation levels frequently

below the limit, but not staying below the limit long enough for the SatSeconds time setting to be reached. When three or more limit violations occur

within 60 seconds, an alarm sounds even if the SatSeconds time setting has

not been reached.

3.7.3 OxiMax SPD™ Alert Parameter

WARNING:

Supplemental oxygen will attenuate patterns of desaturation. A patient’s

respiratory compromise can be proportionally more severe before patterns

appear in the saturation trend. Remain vigilant when monitoring a patient on

supplemental oxygen.

System Features

Caution:

Do not modify any other alarm settings while using the SPD parameter.

The OxiMax SPD™ Alert (SPD) method of detecting patterns of desaturation in

adults is a function of the software within the monitoring system, which

detects repetitive occurrences of desaturation followed by resaturation. These

patterns are indicative of repetitive reductions in airflow through the upper

airway and into the lungs. With the SPD parameter enabled, the default value

for SatSeconds alarms is 100.

Service Manual 3-11

Page 44

Theory of Operations

The SPD parameter detects patterns of desaturation in adults that are indicative of

repetitive reductions in airflow through a patient's upper airway into the lungs. Relative reductions in a patient's minute ventilation over a period of time may cause

a progressive drop in alveolar partial pressure of oxygen, leading to arterial desaturation. If these decreases in ventilation are repetitive, they generate distinct patterns in the saturation trend. Patterns of repetitive desaturation often develop

gradually over time, increasing in severity. Detection of patterns indicates that a

patient might be suffering progressively severe decrements in airflow that may

increase in acuity if left untreated.

Figure3-7.Clinically Significant Desaturation Patterns

Patterns of desaturation are multiple, sequential occurrences of a desaturation

followed by a resaturation. The SPD parameter qualifies patterns of desaturation resulting from such repetitive reductions in airflow based on specific characteristics.

The SPD parameter qualifies these patterns of desaturation over a period of six

(6) minutes. Depending on the sensitivity setting for SPD, patterns that persist

may result in an SPD alarm, alerting the caregiver to the condition.

• The severity of the desaturation event (the depth of the desaturation during the

event) and the extent of the following resaturation

• The regularity of the desaturation events (how often the pattern repeats)

• The slope of the desaturation/resaturation trends that form the events

The SPD parameter communicates information to the caregiver about these

patterns of desaturation in a variety of ways with icons and alarms and in trend

data.

3-12 Service Manual

Page 45

When the indicator reaches capacity, indicating the SPD limit has been

reached, an audible alarm sounds and an alarm warning flashes. The default

setting of one (1) is the most sensitive to desaturation patterns and results in

more frequent alarms. For less frequent alarms, use a less sensitive setting of

two (2) or three (3).

Note:

Unrecognized repetitive reductions in airflow through the upper airway occur in some

clinically significant scenarios. Patients exhibiting sleep apnea symptoms were used in

studies to validate the SPD™ Alert parameter. The presence of repetitive reductions

in airflow was scored using a standard diagnostic polysomnogram. Study results

indicate SPD is a sensitive marker in detecting repetitive reductions in airflow.

3.7.4 Pulse Rate Delay Alarm Management Parameter

System Features

The monitoring system also monitors pulse rate by determining the number of

pleth waves over unit time. With traditional alarm management, upper and

lower alarm limits are set for monitoring pulse rate. When pulse rates fluctuate

near an alarm limit, alarms trigger with each violation. Pulse Rate Delay allows

a period of threshold violation before the pulse rate alarm sounds. Thus, it distinguishes clinically significant events from minor and brief pulse rate limit violations that result in nuisance alarms.

To use Pulse Rate Delay, set the traditional alarm management upper and

lower pulse rate alarm limits. Then, set Pulse Rate Delay. The Pulse Rate Delay

limit controls the time the pulse rate level crosses either limit before an audible

alarm sounds.

Service Manual 3-13

Page 46

Theory of Operations