Page 1

SERVICE MANUAL

Nellcor Puritan Bennett

™

NPB-3900 Patient Monitor

To contact Nellcor Puritan Bennett’s representative: In the United States, call 1-800-NELLCOR or 510 463-4000;

outside the United States, call your local Nellcor Puritan Bennett representative.

Caution: Federal law (U. S.) restricts this device to sale by or on the order of a physician.

© 1998 Nellcor Puritan Bennett Inc. All Rights Reserved 047940A-0398

0123

Page 2

Corporate Headquarters

Regional/Local Offices

Nellcor Puritan Bennett Inc.

4280 Hacienda Drive

Pleasanton, California 94588

U.S.A.

Tel. 510 463-3900 or

1-800-NELLCOR

U. S. Service Repair Center

Nellcor Puritan Bennett Inc.

2200 Faraday Avenue

Carlsbad, California 92008

U.S.A.

Tel. 619 482-5000

European Office

Nellcor Puritan Bennett Europe BV

Hambakenwetering 1

5231 DD ’s-Hertogenbosch

The Netherlands

Tel. +31.73.6485200

Asia/Pacific Office

Nellcor Puritan Bennett HK Ltd.

Room 1602 Evergo House

38 Gloucester Road

Wanchai

Hong Kong

Tel. +852.2529.0363

Nellcor Puritan Bennett UK Ltd.

10, Talisman Business Centre

London Road

Bicester, Oxfordshire OX6 0JX

United Kingdom

Tel. +44.1869.322700

Nellcor Puritan Bennett Belgium NV/SA

Interleuvenlaan 62/8, Zone 2

B-3001 Heverlee

Belgium

Tel. +32.16.400467

Nellcor Puritan Bennett France

3 avenue du Canada, Bâtiment Sigma

LP851 Les Ulis

91975 Courtaboeuf Cedex

France

Tel. +33.1.69.82.14.66

Nellcor Puritan Bennett Germany GmbH

Black-&-Decker-Strasse 28

65510 Idstein

Germany

Tel. +49.6126.5930

Nellcor Puritan Bennett Italia S.r.L.

Via Edison 6

20090 Assago (MI)

Italy

Tel. +39.2.4577161

Nellcor Puritan Bennett Finland Oy

Kappelitie 8

02200 Espoo

Finland

Tel. +358.9.270.92.900

To obtain information about a warranty, if any, for this product, contact Nellcor Puritan Bennett

Technical Services or your local Nellcor Puritan Bennett representative.

Nellcor Puritan Bennett, Durasensor, Oxisensor II, Oxichip, C-Lock, and the Nellcor Puritan Bennett

knob configuration are trademarks of Nellcor Puritan Bennett Incorporated.

SureTemp is a trademark of Welch Allyn, Inc.

Covered by one or more of the following U. S. Patents and foreign equivalents: 4,621,643; 4,653,498;

4,700,708; 4,770,179;,4,869,254; 4,928,692; 4,934,372; 5,078,136; 5,368,224; 5,632,555; Re.35,122.

Page 3

TABLE OF CONTENTS

List of Figures

List of Tables

List of Figures..................................................................................................v

List of Tables..................................................................................................vi

Section 1: Introduction....................................................................................1-1

1.1 Manual Overview..................................................................................1-1

1.2 Warnings, Cautions, and Notes ........................................................... 1-1

1.3 NPB-3900 Patient Monitor Description................................................1-1

1.4 P-3900 Introduction.............................................................................. 1-2

1.5 Related Documents..............................................................................1-2

Section 2: Routine Maintenance .................................................................... 2-2

2.1 Cleaning............................................................................................... 2-2

2.2 Periodic Safety and Functional Checks...............................................2-2

2.3 Battery..................................................................................................2-2

2.4 Environmental Protection..................................................................... 2-3

Section 3: Performance Verification..............................................................3-1

3.1 Introduction .......................................................................................... 3-1

3.2 Equipment Needed .............................................................................. 3-1

3.3 Performance Tests...............................................................................3-2

3.4 Safety Tests.......................................................................................3-15

Section 4: Power-Up Defaults Menu and Diagnostic Mode......................... 4-1

4.1 Introduction .......................................................................................... 4-1

4.2 Power-Up Defaults Menu..................................................................... 4-1

4.3 Restoring Factory Settings................................................................... 4-4

4.4 Diagnostic Mode .................................................................................. 4-4

Section 5: Troubleshooting ............................................................................ 5-1

5.1 Introduction .......................................................................................... 5-1

5.2 How to use This Section ...................................................................... 5-1

5.3 Who Should Perform Repairs .............................................................. 5-1

5.4 Replacement Level Supported............................................................. 5-1

5.5 Obtaining Replacement Parts..............................................................5-2

5.6 Troubleshooting Guide......................................................................... 5-2

5.7 Troubleshooting the Oximetry Function.............................................5-11

5.8 P-3900 Troubleshooting Guide..........................................................5-17

Section 6: Disassembly Guide........................................................................6-1

6.1 Introduction .......................................................................................... 6-1

6.2 How to use This Section ...................................................................... 6-2

6.3 Disassembly Flow Charts.....................................................................6-2

6.4 Closed Case Disassembly...................................................................6-7

6.5 Front Case Disassembly.................................................................... 6-16

6.6 Rear Case Disassembly.....................................................................6-20

6.7 Main PCB Disassembly......................................................................6-22

Section 7: Spare Parts.....................................................................................7-1

7.1 Introduction .......................................................................................... 7-1

7.2 Top Level Assembly............................................................................. 7-1

7.3 Front Case Assembly........................................................................... 7-2

7.4 Rear Case Assembly ........................................................................... 7-2

7.5 Main PCB Assembly ............................................................................ 7-3

Table of Contents

iii

Page 4

Table of Contents

7.6 P-3900 Printer...................................................................................... 7-4

Section 8: Packing For Shipment................................................................... 8-1

8.1 General Instructions............................................................................. 8-1

8.2 Repacking In Original Carton............................................................... 8-1

8.3 Repacking In a Different Carton........................................................... 8-1

Section 9: Specifications ................................................................................ 9-1

9.1 General ................................................................................................9-1

9.2 Safety Standards..................................................................................9-1

9.3 Electrical...............................................................................................9-2

9.4 Environmental......................................................................................9-2

9.5 Measuring Parameters.......................................................................... 9-2

9.6 Trends.................................................................................................. 9-7

9.7 P-3900 Printer (Optional).....................................................................9-7

Section 10: RS-232 Interface.........................................................................10-1

10.1 Serial Interface Connection.............................................................. 10-1

10.2 Nurse Call ........................................................................................ 10-1

10.3 Exporting Trend Data....................................................................... 10-2

Appendix - Technical Supplement..................................................................A-1

A-1 General................................................................................................A-1

A-2 Block Diagram.....................................................................................A-1

A-3 Isolated Patient Connection Section....................................................A-2

A-4 Temperature Measurement Circuit......................................................A-4

A-5 ECG Inputs..........................................................................................A-7

A-6 On/Off Power Control..........................................................................A-9

A-7 Audio Volume and Speaker Drive .....................................................A-11

A-8 Power Supplies..................................................................................A-12

A-9 NIBP Section.....................................................................................A-17

A-10 System A/D......................................................................................A-20

A-11 Buttons And Lights ..........................................................................A-22

A-12 SpO

2................................................................................................A-22

A-13 Microcontroller.................................................................................A-28

A-14 Program Storage/Execution ............................................................A-32

A-15 Dram Control...................................................................................A-33

A-16 Real Time Clock (RTC) ...................................................................A-34

A-17 Uart Operation.................................................................................A-36

A-18 FPGA Glue Logic.............................................................................A-37

iv

Page 5

LIST OF FIGURES

Table of Contents

Figure 5-1: Preamplifier and PGA Outputs......................................................5-12

Figure 5-2: Filter Outputs and ADC Input ...................................................... 5-513

Figure 5-3: SpO

Figure 5-4: SpO

Figure 5-5: SpO

2 Module with an SRC-2......................................................... 5-14

2 Module with SRC-2 Drive Current Test at TP7....................5-15

2 Module with SRC-2.............................................................. 5-16

Figure 6-1: Top Level Disassembly Flow Chart.6-Error! Bookmark not defined.

Figure 6-2: Front Case Disassembly Flow Chart...............................................6-4

Figure 6-3: Rear Case Disassembly Flow Chart................................................6-5

Figure 6-4: Main Board Disassembly Flow Chart .............................................. 6-6

Figure A-1: NPB-3900 Block Diagram...............................................................A-2

Figure A-2: Temperature Measurement Circuit .................................................A-6

Figure A-3: ECG Processing Circuitry, First Stage............................................A-8

Figure A-4: ECG Processing Circuitry, Second Stage.......................................A-9

Figure A-5: Power ON/OFF Circuitry...............................................................A-10

Figure A-6: Watchdog Circuitry........................................................................A-11

Figure A-7: Audio Volume Circuitry..................................................................A-12

Figure A-8: Buck Power Regulator, Simplified Schematic & Waveforms........A-13

Figure A-9: Battery Charger Circuitry...............................................................A-14

Figure A-10: 3.3V Regulated Supply................................................................A-15

Figure A-11: 5V Regulated Supply Circuitry....................................................A-15

Figure A-12: LCD Bias Supply Circuitry...........................................................A-16

Figure A-13: LCD Backlight Supply Circuitry...................................................A-16

Figure A-14: Isolated ±5V Supply Circuitry......................................................A-17

Figure A-15: NIBP Power Sourcing Circuitry...................................................A-17

Figure A-16: NIBP Pump Control Circuitry.......................................................A-18

Figure A-17: NIBP Pressure Sensors Processing Circuitry.............................A-19

Figure A-18: Proportional Valve Powering Circuitry.........................................A-20

Figure A-19: A/D Circuitry................................................................................A-21

Figure A-20: Interfacing with SpO2 Processing...............................................A-23

Figure A-21: Microcontroller Signal Assignments............................................A-29

Figure A-22: Flash Timing Parameters............................................................A-32

Figure A-23: DRAM Timing Parameters..........................................................A-33

Figure A-24: RAS and CAS Timing..................................................................A-34

Figure A-25: Read Timing................................................................................A-35

Figure A-26: Write Timing................................................................................A-35

Figure A-27: Data Signal..................................................................................A-37

Figure A-28: Control Signal..............................................................................A-37

Figure A-29: NPB-3900 Top Assembly Drawing (Sheet 1 of 2).......................A-43

Figure A-29: NPB-3900 Top Assembly Drawing (Sheet 2 of 2).......................A-45

Figure A-30: NPB-3900 Front Case Assembly Drawing (Sheet 1 of 2)...........A-47

Figure A-30: NPB-3900 Front Case Assembly Drawing (Sheet 2 of 2)...........A-49

Figure A-31: NPB-3900 Rear Case Assembly Drawing...................................A-51

Figure A-32: P-3900 Assembly Drawing..........................................................A-53

Figure A-33: NPB-3900 Interconnect Diagram................................................A-55

Figure A-34: Main PCB Schematic Diagram (Sheet 1 of 5).............................A-57

Figure A-34: Main PCB Schematic Diagram (Sheet 2 of 5).............................A-59

Figure A-34: Main PCB Schematic Diagram (Sheet 3 of 5).............................A-61

Figure A-34: Main PCB Schematic Diagram (Sheet 4 of 5).............................A-63

Figure A-34: Main PCB Schematic Diagram (Sheet 5 of 5).............................A-65

Figure A-35: NPB-3900Patient Connector PCB Schematic Diagram..............A-67

v

Page 6

Table of Contents

LIST OF TABLES

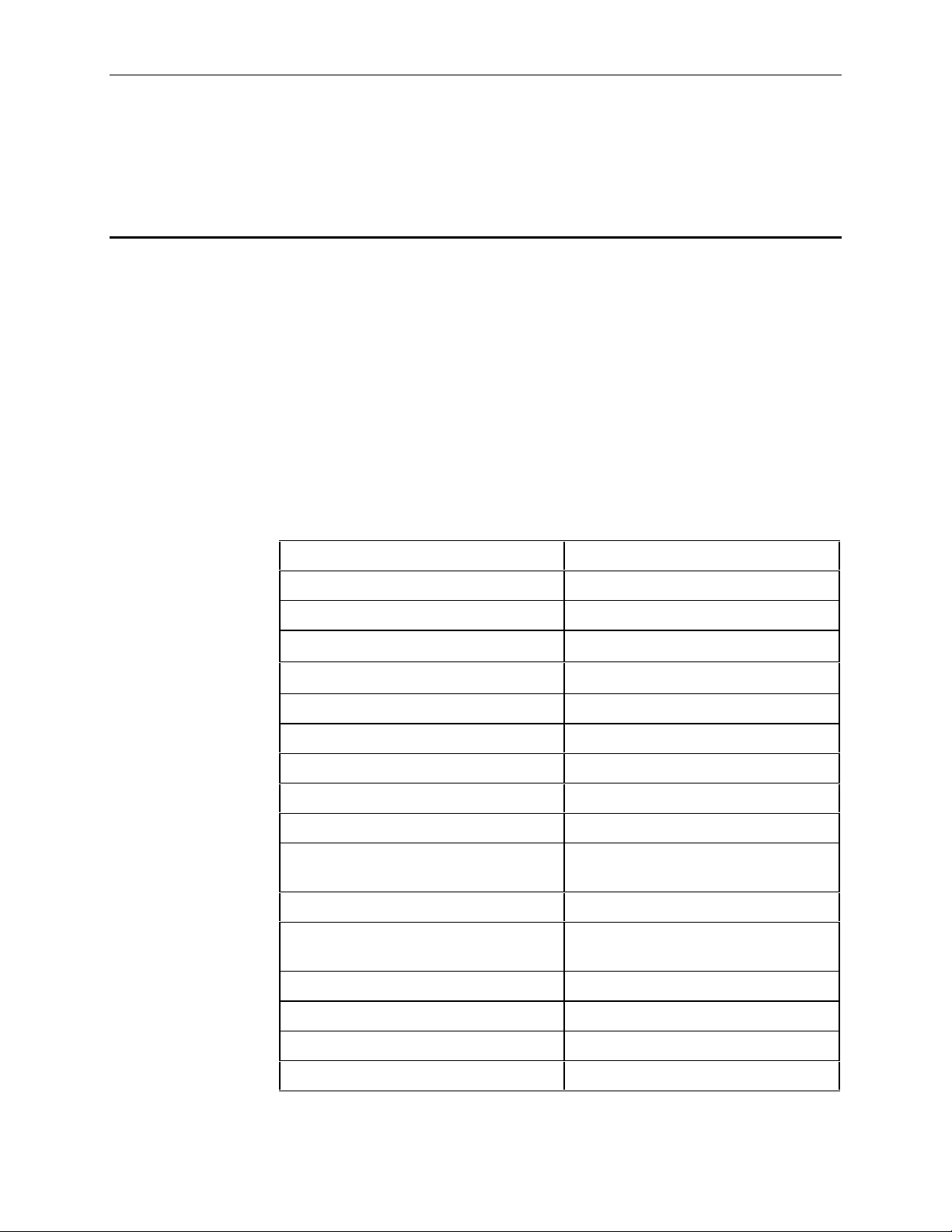

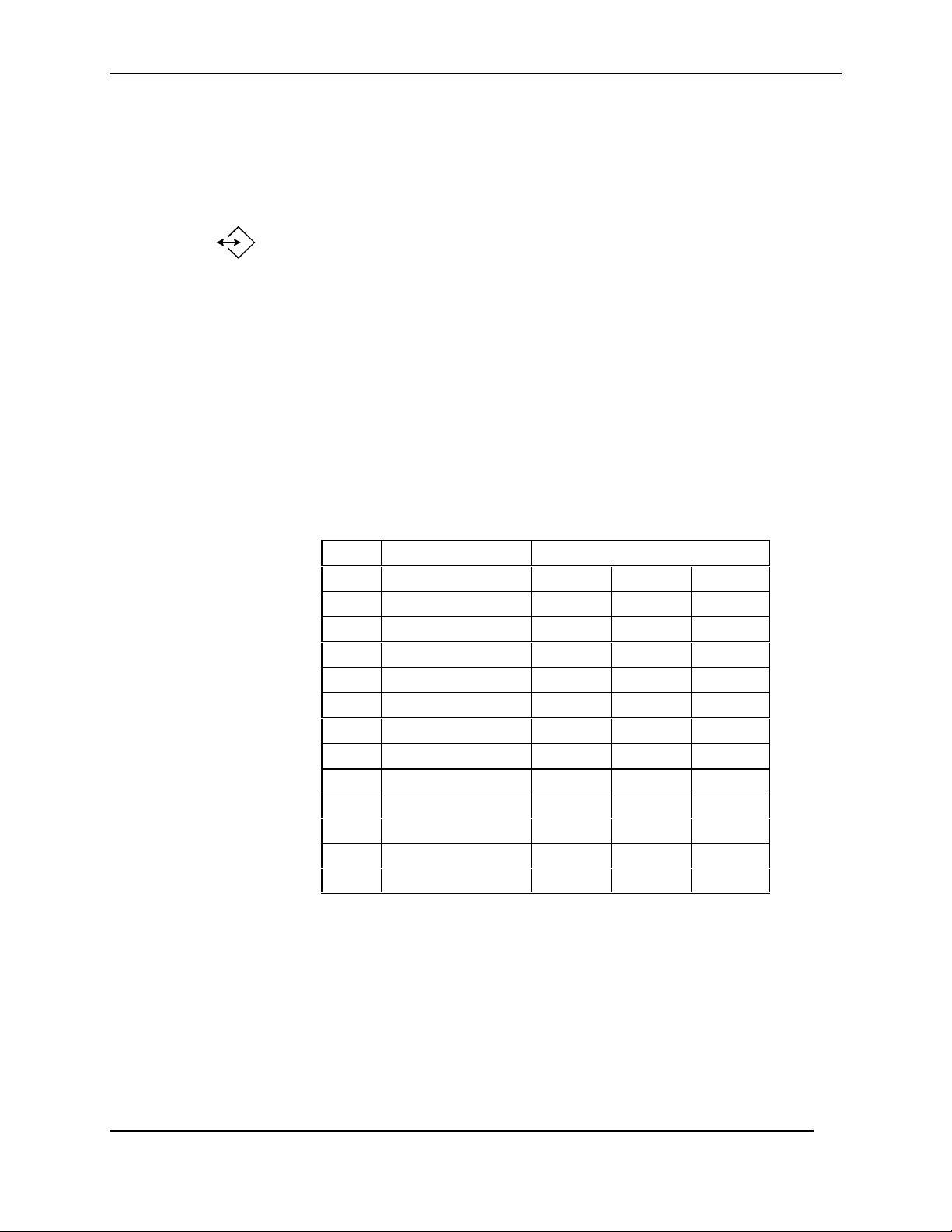

Table 1-1: Model Configuration..........................................................................1-2

Table 3-1: Required Test Equipment................................................................. 3-1

Table 3-2: SRC Settings and NBP-3900 Indications.........................................3-6

Table 3-3: Serial Interface Measurements....................................................... 3-13

Table 3-4: Current Test....................................................................................3-16

Table 3-5: Leakage Current............................................................................. 3-16

Table 4-1: Power-Up Defaults Menu..................................................................4-1

Table 4-2: A/D Channel Designators.................................................................4-7

Table 5-1: Problem Categories.......................................................................... 5-2

Table 5-2: Power Problems ............................................................................... 5-3

Table 5-3: Serviceable Hardware Error Codes..................................................5-5

Table 5-4: Error Code Categories...................................................................... 5-8

Table 5-5: Buttons/Knob Problems.................................................................... 5-9

Table 5-6: Display/Audible Tones Problems...................................................... 5-9

Table 5-7: Operational Performance Problems ............................................... 5-10

Table 5-8: Fault Evaluation.............................................................................. 5-11

Table 5-9: P-3900 Troubleshooting Guide....................................................... 5-17

Table 7-1: Top Level Assembly ......................................................................... 7-1

Table 7-2: Front Case Assembly ....................................................................... 7-2

Table 7-3: Rear Case Assembly........................................................................ 7-2

Table 7-4: Main Board Assembly....................................................................... 7-3

Table 7-5: Main PCB Jumper Configuration......................................................7-3

Table 7-5: P-3900 Printer...................................................................................7-4

Table 10-1: RS-232 Serial Interface Connections.............................................7-1

Table A-1:

Oxichip

Circuit Pin Descriptions.....................................................A-23

vi

Page 7

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 Warnings, Cautions, and Notes

1.3 NPB-3900 Patient Monitor Description

1.4 P-3900 Introduction

1.5 Related Documents

1.1 MANUAL OVERVIEW

This manual contains information for servicing the NPB-3900 series of patient

monitors. Only qualified service personnel should service this product. Before

servicing the NPB-3900, read the operator’s manual carefully for a thorough

understanding of operation.

1.2 WARNINGS, CAUTIONS, AND NOTES

This manual uses three terms that are important for proper operation of the

monitor: Warning, Caution, and Note.

1.2.1 Warning

A warning precedes an action that may result in injury or death to the patient or

user. Warnings are boxed and highlighted in boldface type.

1.2.2 Caution

A caution precedes an action that may result in damage to, or malfunction of, the

monitor. Cautions are highlighted in boldface type.

1.2.3 Note

A note gives information that requires special attention.

1.3 NPB-3900 PATIENT MONITOR DESCRIPTION

The purpose and function of the NPB-3900 series of patient monitors is to

monitor: ECG; heart rate; noninvasive blood pressure (systolic, diastolic, and

mean arterial pressures); functional arterial oxygen saturation; and temperature

for adult and pediatric patients in all hospital areas and hospital-type facilities.

They may be used during hospital transport and in mobile, land-based

environments, such as ambulances.

Refer to the NPB-3900 operator’s manual for a description of the NPB-3900

controls, indicators, and operation. The physical and operational characteristics

of the monitors are described in the operator’s manual and Section 9,

Specifications, of this manual.

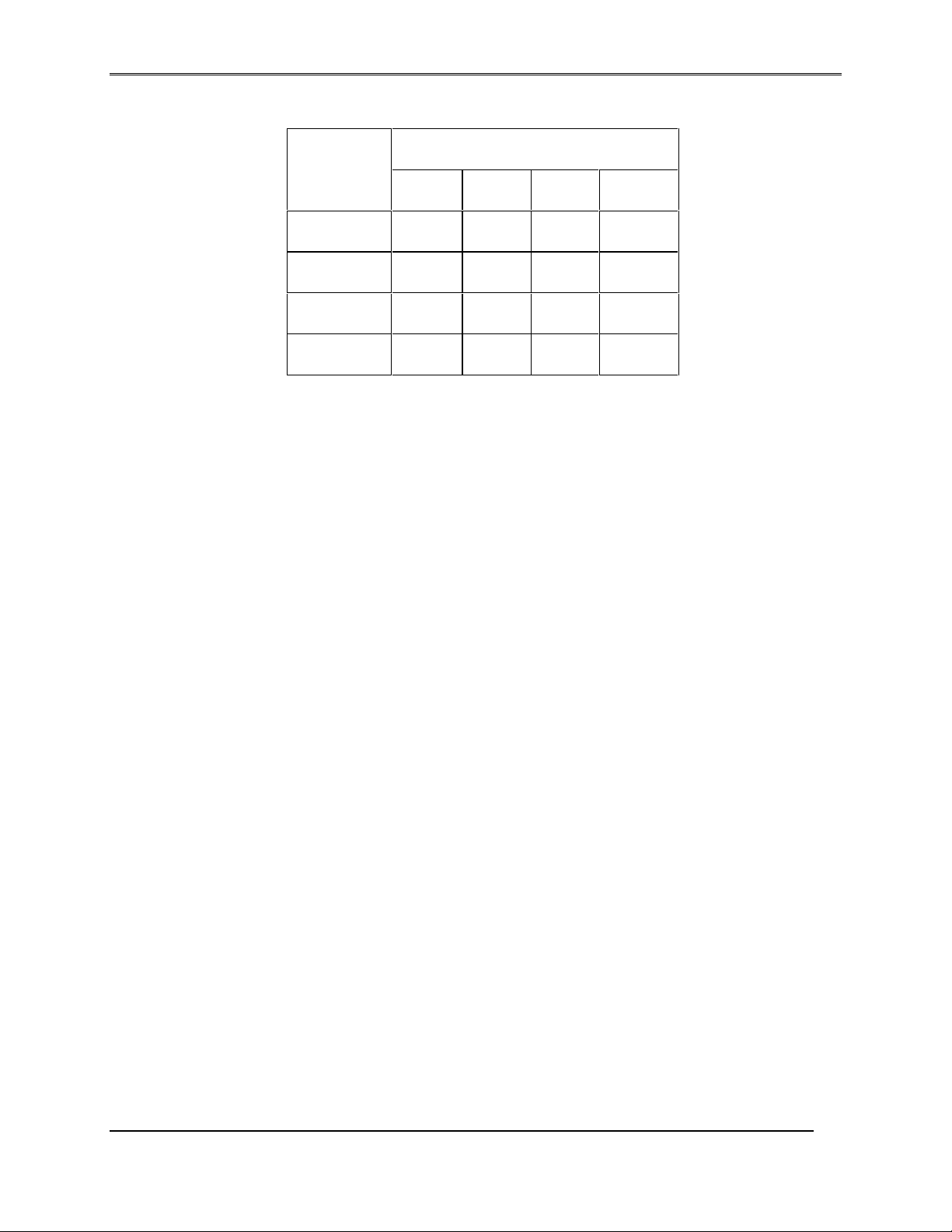

The parameter measurements for each model in the NPB-3900 series are

indicated in Table 1-1.

1-1

Page 8

Section 1: Introduction

Model Parameter

NPB-3910 X X

NPB-3920 X X X

NPB-3930 X X X

NBP-3940 X X X X

1.4 P-3900 INTRODUCTION

The P-3900 is an optional, standalone printer designed for use with the

NPB-3900 patient monitor. The P-3900 communicates with the monitor using a

null-modem cable connected between each device’s RS-232 connector. The

P-3900 contains an internal battery, which, when fully charged, will operate the

printer for 3 hours (typical, at 25°C, producing fifteen 20-second printouts per

hour). The P-3900 can be connected to AC power using an external power

supply. The P-3900 uses the same type power supply as the NPB-3900 monitor,

the PS-120V or PS-240V.

Table 1-1: Model Configuration

NIBP SpO2 TEMP ECG

The P-3900 does not have an On/Off switch. The printer can sense when it has

an established communications link with the monitor. At that time, the green

LINKED indicator on the front panel lights, indicating that the printer is ready

for operation. See the NPB-3900 operator’s manual for more information

regarding use of the printer.

1.5 RELATED DOCUMENTS

To perform test and troubleshooting procedures and to understand the principles

of operation and circuit analysis sections of this manual, you must know how to

operate the monitor. Refer to the NPB-3900 operator’s manual. To understand

the various Nellcor Puritan Bennett sensors, ECG leads, blood pressure cuffs,

and temperature probes that work with the monitor, refer to the operator’s

manual and individual directions for use that accompany these accessories.

1-2

Page 9

Page 10

SECTION 2: ROUTINE MAINTENANCE

2.1 Cleaning

2.2 Periodic Safety and Functional Checks

2.3 Battery

2.4 Environmental Protection

2.1 CLEANING

WARNING: Do not spray, pour, or spill liquid on the NBP-3900, its

accessories, connectors, switches, or openings in the chassis. Do not immerse

the NPB-3900 or its accessories in liquid or clean with caustic or abrasive

cleaners.

To clean the NPB-3900, dampen a cloth with a commercial, nonabrasive cleaner

and wipe the exterior surfaces lightly. Do not allow any liquids to come in

contact with the power connector or switches. Do not allow any liquids to

penetrate connectors or openings in the instrument. For cables, sensors, and

cuffs, follow the cleaning instructions in the directions for use that accompany

these accessories.

2.2 PERIODIC SAFETY AND FUNCTIONAL CHECKS

Nellcor Puritan Bennett recommends that the following checks be performed at

least every 2 years by a qualified service technician.

1. Inspect the exterior of the NPB-3900 for damage.

2. Inspect labels for legibility. If the labels are not legible, contact Nellcor

Puritan Bennett’s Technical Services Department or your local Nellcor

Puritan Bennett representative.

3. Verify that the unit performs properly as described in paragraph 3.3.

4. Perform the electrical safety tests detailed in paragraph 3.4. If the unit fails

these electrical safety tests, do not attempt to repair. Contact Nellcor Puritan

Bennett’s Technical Services Department or your local Nellcor Puritan

Bennett representative.

2.3 BATTERY

If the NPB-3900 has not been used for a long period of time, the battery will

need charging. To charge the battery, connect the NPB-3900 to an AC source as

described in the Setup & Use section of the operator’s manual.

NOTE: Storing the NBP-3900 for a long period without charging the battery

may degrade the battery capacity. A complete battery recharge when

not using the monitor requires 8 hours. The battery may be recharged

while the monitor is in use; in which case, the battery will require 14

hours to be recharged. The battery may require a full charge/discharge

cycle to restore normal capacity.

2-1

Page 11

Nellcor Puritan Bennett recommends that the NPB-3900’s sealed, lead-acid

battery be replaced at 2-year intervals. Refer to Section 6, Disassembly Guide.

2.4 ENVIRONMENTAL PROTECTION

Follow local governing ordinances and recycling plans regarding disposal or

recycling batteries and other device components.

Section 3: Performance Verification

2-3

Page 12

Page 13

SECTION 3: PERFORMANCE VERIFICATION

3.1 Introduction

3.2 Equipment Needed

3.3 Performance Tests

3.4 Safety Tests

3.1 INTRODUCTION

This section discusses the tests used to verify performance following repairs or

during routine maintenance. All tests can be performed without removing the

NPB-3900 covers.

If the NPB-3900 fails to perform as specified in any test, repairs must correct the

problem before the monitor is returned to the user.

3.2 EQUIPMENT NEEDED

Table 3-1 lists the equipment required for performance verification.

Table 3-1: Required Test Equipment

Equipment Description

Digital multimeter (DMM) Fluke Model 87 or equivalent

Sensor extension cable EC-8

Durasensor® finger clip sensor

Oxisensor® II adhesive sensor

DS-100A

D-25

ECG cable CE-10

ECG electrodes Standard

ECG leads LE series

NIBP hose SHBP-10

NIBP cuff SCBP series

Temperature probe Welch Allyn SureTemp® (blue capped

probe)

Pulse oximeter tester Nellcor Puritan Bennett SRC-2

ECG simulator Dynatech Nevada medSim 300 or

equivalent

NIBP simulator Bio-Tek “BP Pump” or equivalent

Thermometer Calibrator Key Welch Allyn Model 767

Safety analyzer Bio-Tek 601 Pro or equivalent

Stopwatch Manual or electronic

3-1

Page 14

Section 3: Performance Verification

3.3 PERFORMANCE TESTS

The battery charge and battery performance tests should be performed before

monitor repairs whenever the battery is suspected as being a source of a problem.

All other tests should be performed following monitor repairs. Before

performing the battery performance test, ensure that the battery is fully charged

(paragraph 3.3.1).

This section is written using Nellcor Puritan Bennett factory-set power-up

defaults. If your institution has reconfigured custom defaults, those values will

be displayed.

3.3.1 Battery Charge

Perform the following procedure to fully charge the battery.

1. Connect the monitor to an AC power source using the PS-120 or PS-240

external power supply and power cord, if needed.

2. Verify that the EXTERNAL POWER indicator is lit.

3. Charge the battery for at least 8 hours. The battery may require a complete

charge/discharge cycle to restore its normal capacity.

4. To check for a full charge, perform the procedure in paragraph 3.3.2

“Battery Performance Test.”

3.3.2 Battery Performance Test

The monitor is specified to operate typically on battery power for a minimum of

4 hours, at 25°C, with one NIBP measurement every 15 minutes. Before

performing this test, ensure that the battery is fully charged (paragraph 3.3.1).

1. Connect the Nellcor Puritan Bennett SRC-2 pulse oximeter tester to the

monitor via the EC-8 sensor cable. Connect the NIBP simulator to the

monitor via the SHBP-10 hose.

2. Set the SRC-2 switches as follows:

SWITCH

POSITION

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

3- 2

3. Set the NIBP simulator to simulate a pressure setting of 120/80 mmHg

and heart rate of 80 bpm.

4. Ensure that the monitor is not connected to AC power.

Page 15

Section 3: Performance Verification

5. With the NPB-3900 turned off, press the ON/STANDBY button and

verify that the battery icon appears at the bottom of the display after the

power-on self-test is completed. The boxes in the battery icon should all

be filled, indicating the battery is charged.

6. Verify that the monitor is responding to the SpO2 simulator signal and

that the audible alarm is sounding. Use the knob to select the SpO

2

Menu and permanently silence the SpO2 audible alarm.

7. Use the knob to select the NIBP Menu and set the Automatic

Measurement Interval to 15 minutes. Exit the menu and press the front

panel NIBP button to manually initiate the first NIBP measurement.

Subsequent NIBP measurements will be taken automatically every 15

minutes.

8. The monitor must operate for at least 4 hours before the monitor

automatically powers down due to low battery condition.

9. Verify that the low battery alarm occurs 15-30 minutes before the battery

fully discharges.

10. Allow the monitor to operate until it automatically powers down due to

low battery condition. Verify that an audible alarm sounds when the

monitor automatically shuts down. Press the alarm silence button to

terminate this audible alarm.

11. If the monitor passes this test, immediately recharge the battery

3.3.3 Power-On Self-Test

1. Connect the monitor to an AC power source using the PS-120 or PS-240

2. Do not connect any input cables to the monitor.

3. Observe the monitor front panel. With the monitor off, press the

(paragraph 3.3.1, steps 1–3).

power supply and power cord, and verify that the EXTERNAL POWER

indicator is lit.

ON/STANDBY button. The monitor must perform the following sequence.

a. The monitor emits a beep.

b. A few seconds later, the display backlight illuminates, but the display

is blank.

c. The Nellcor Puritan Bennett logo then appears for a few seconds,

with the version numbers of the boot and operational software

displayed in the lower left corner of the display. (The upper version

number corresponds to the boot software, the lower version number

corresponds to the operational software.)

d. A beep signals the end of the power-on self-test. The power-on self-

test takes approximately 10 seconds to complete.

e. Upon successful completion of the power-on self-test, the display will

be in the normal monitoring screen configuration. No vital-sign

numeric values or trend values will be displayed.

3-3

Page 16

Section 3: Performance Verification

3.3.4 Hardware and Software Tests

Hardware and software testing includes the following tests applicable to the

indicated models in the series.

• 3.3.4.1 SpO

• 3.3.4.2 Operation with an ECG Simulator — NPB-3930, NPB-3940

• 3.3.4.3 Verification of Pneumatic System — NPB-3900

• 3.3.4.4 Operation with a Temperature Simulator — NPB-3920, NPB-3940

• 3.3.4.5 General Operation — NPB-3900

3.3.4.1 SpO

2 Testing (NPB-3900)

2 testing includes the following tests.

SpO

• 3.3.4.1.1 Alarms and Alarm Silence

• 3.3.4.1.2 Heart Rate Tone Volume Control

• 3.3.4.1.3 Dynamic Operating Range

• 3.3.4.1.4 LED Excitation Test

3.3.4.1.1 Alarms and Alarm Silence

1. Connect the SRC-2 pulse oximeter tester to the EC-8 sensor extension cable

and connect the cable to the monitor. Set the SRC-2 as follows:

2 Testing NPB-3900

SWITCH

POSITION

RATE 38

LIGHT LOW

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

2. Press the ON/STANDBY button to turn the monitor on. After the normal

power-up sequence, verify that the SpO

2% display initially indicates zero

or is blank.

NOTE: The pulse bar may occasionally indicate a step change as the monitor is

in the pulse search mode.

3. Move the modulation switch on the SRC-2 to LOW.

4. Verify the following monitor reaction:

a. The pulse bar begins to track the artificial pulse signal from the SRC-2.

b. Initially, zero is displayed in the SpO

2 frame, or it is blank.

c. After about 10 to 20 seconds, the monitor displays saturation and heart

rate as specified by the tester. Verify that the values are within the

following tolerances:

Oxygen Saturation Range 79% to 83%

Heart Rate Range 35 to 41 bpm

3- 4

Page 17

Section 3: Performance Verification

d. The audible alarm sounds and both the SpO2% and HEART RATE

displays flash, indicating both parameters have violated the default

alarm limits.

e. The heart rate tone is heard. (Heart rate tone source, found in the

Heart Rate Menu, should be set to “SpO2”.)

5. Press the ALARM SILENCE button on the front panel of the monitor. The

audible alarm is temporarily silenced.

6. Verify the following:

a. The audible alarm remains silenced.

b. The “slashed bell” icon appears in each numeric frame on the display.

c. The SpO

d. The heart rate tone remains audible.

e. The audible alarm returns in approximately

60 seconds.

3.3.4.1.2 Heart Rate Tone Volume Control

Connect the SRC-2 pulse oximeter tester to the EC-8 sensor extension cable and

connect the cable to the monitor. Set the SRC-2 as follows:

SWITCH

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

1. Power on the monitor and verify that the SpO2 and heart rate values are

correctly displayed. Press the ALARM SILENCE button on the front panel

of the monitor to temporarily silence the audible alarm.

2. Verify that the heart rate tone source, found in the Heart Rate Menu, is set

to “SpO

2”. Press the VOLUME button on the front panel of the monitor.

Within 3 seconds of having pressed the button, rotate the knob CW and

verify that the beeping heart rate tone sound level increases.

2% and HEART RATE displays continue flashing.

POSITION

3. Rotate the knob CCW and verify that the beeping heart rate tone decreases

until it is no longer audible. Rotate the knob CW to return the beep volume

to a comfortable level. (Note that 3 seconds after the last button-press or

rotation of the knob, function of the knob reverts to moving the highlight

on the display screen.)

3-5

Page 18

Section 3: Performance Verification

3.3.4.1.3 Dynamic Operating Range

The following test sequence verifies proper monitor operation over a range of

input signals.

1. Connect the SRC-2 to the NPB-3900 (using an EC-8) and turn the

NPB-3900 on.

2. Place the SRC-2 in the RCAL 63/LOCAL mode.

3. Set the SRC-2 as indicated in Table 3-2. Verify that the NPB-3900

readings are within the indicated tolerances. Allow the monitor several

seconds to stabilize the readings.

NOTE: A “*” indicates values that produce an alarm. Press the ALARM

SILENCE button to temporarily silence the audible alarm.

Table 3-2: SRC Settings and NBP-3900 Indications

RATE LIGHT MODULATION SpO2 Pulse Rate

38 HIGH2 LOW 79 - 83* 35 - 41*

112 HIGH1 HIGH 79 - 83* 109 - 115

201 LOW LOW 79 - 83* 195 - 207*

201 LOW HIGH 79 - 83* 195 - 207*

SRC-2 Settings NPB-3900 Indications

NOTE: For the pulse rate setting of 201 bpm, the pulse rate tolerance of 195 to

4. Turn the monitor off.

3.3.4.1.4 LED Excitation Test

This procedure uses normal system components to test circuit operation. A

Nellcor Puritan Bennett Oxisensor II adhesive sensor, model D-25, is used to

examine LED intensity control. The red LED is used to verify intensity

modulation caused by the LED intensity control circuit.

1. Connect an EC-8 sensor extension cable to the monitor.

2. Connect a D-25 sensor to the sensor extension cable.

3. Press the ON/STANDBY button to turn the monitor on.

4. Leave the sensor open with the LED and photodetector visible.

5. After the monitor completes its normal power-up sequence, verify that the

207 bpm is greater than the ±3 bpm accuracy specification of the

monitor, due to the performance characteristics of the SRC-2 tester.

sensor LED is brightly lit.

3- 6

Page 19

6. Slowly move the sensor LED in proximity to the photodetector element of

the sensor. Verify, as the LED approaches the optical sensor, that the LED

intensity decreases.

7. Open the sensor and notice that the LED intensity increases.

8. Repeat step 6 and the intensity again decreases. This variation is an

indication that the microprocessor is in proper control of LED intensity.

9. Turn the NPB-3900 off.

3.3.4.2 Operation with an ECG Simulator (NPB-3930, NPB-3940)

1. With the monitor off, connect the ECG leads to the appropriate jacks on

the ECG tester.

2. Connect the leads to the CE-10 ECG cable. Connect the CE-10 to the ECG

input port on the NPB-3900. Set the ECG tester as follows:

Heart rate: 30 bpm

Amplitude: 1 millivolt

Lead select: II

Section 3: Performance Verification

Normal sinus rhythm

Adult mode

NOTE: The accuracy of the monitor’s ECG measurements is ±5 bpm. In the

procedure below, add the tolerance of the simulator to the acceptable

range of readings.

3. Press the ON/STANDBY button to turn the monitor on. After the normal

power-up sequence, verify the following monitor reactions:

a. After at least five heartbeats, the monitor displays a heart rate of

30 ±5 bpm.

b. The audible alarm sounds and the HEART RATE display flashes,

indicating the heart rate is below the default lower alarm limit.

4. Press the ALARM SILENCE button. Verify that the audible alarm is

silenced.

5. Increase the heart rate setting on the ECG simulator to 240 bpm.

6. After at least five heartbeats, verify that the monitor displays a heart rate

of 240 ±5 bpm.

7. Verify that the audible alarm sounds and the HEART RATE display

flashes, indicating that the heart rate is above the default upper alarm limit.

8. Press the ALARM SILENCE button to silence the alarm.

3-7

Page 20

Section 3: Performance Verification

9. Decrease the heart rate setting on the ECG simulator to 120 bpm.

10. After at least five heartbeats, verify that the monitor displays a heart rate

of 120 ±5 bpm.

11. Disconnect the LL lead from the ECG simulator. Verify that the “Leads

Off” alarm message appears, three dashes are displayed in the HEART

RATE display, and a low priority audible alarm sounds.

12. Reconnect the LL lead to the ECG simulator. Verify that the “Leads Off”

alarm message no longer appears and that the audible alarm is silenced.

13. Repeat steps 11 and 12 for the LA and RA leads.

14. Turn the monitor off.

3.3.4.3 Verification of Pneumatic System (NPB-3900)

Tests in paragraphs 3.3.4.3.1 through 3.3.4.3.5 verify the functionality of the

NPB-3900 pneumatic system. These tests were designed to use the Bio-Tek “BP

Pump” noninvasive blood pressure simulator. The internal test volume of the

Bio-Tek simulator is 250 cm

3

, which is used to calculated the inflation/deflation

rate periods. The Bio-Tek simulator, or any equivalent NIBP simulator, is

required to perform these tests.

The NPB-3900 must be placed in Diagnostic Mode, with the NIBP Test screen

active for each of the NIBP tests. For a detailed explanation of the Diagnostic

Mode, refer to Section 4, Power-up Defaults Menu and Diagnostic Mode.

Each of the tests described in paragraphs 3.3.4.3.1 through 3.3.4.3.5 must be

performed to verify pneumatic system functionality. These tests can be

performed individually (in any order) or sequentially. Prior to performing any of

these tests, perform the following setup procedure. If these tests are performed in

sequence, this procedure needs to be performed once prior to the first test.

1. Turn on the Bio-Tek simulator and press the MODE button to place the

simulator in test mode. The simulator screen will indicate “Internal Cuff”

and “Pressure Gauge”.

2. Connect the simulator hose to the NIBP connector on the NPB-3900.

3. Follow the procedure described in Section 4 to place the NPB-3900 in

Diagnostic Mode with the NIBP Test screen active.

3.3.4.3.1 Pressure Transducer Accuracy

The pressure transducer accuracy test verifies the pressure accuracy of the

NBP-3900 pressure transducer.

3- 8

Page 21

Section 3: Performance Verification

1. Confirm that the Bio-Tek simulator is in test mode. The simulator should

display “Pressure Gauge”. Confirm that the simulator is set up for the

internal cuff.

2. Confirm that the NIBP Test screen is active on the NPB-3900. Press, then

release, the SPEAKER button on the NPB-3900 to verify that the valve is

closed.

3. Press the CONTRAST button on the NPB-3900, then the ZERO button on

the simulator, to perform an offset adjustment so that the simulator and

NBP-3900 both display a pressure of 0 mmHg.

4. Press the SELECT button on the simulator until the simulator displays

“Pressure Source Set Test Pressure”. Use the UP/DOWN buttons on the

simulator to adjust for 250 mmHg.

5. Press the START PUMP button on the simulator. The simulator will begin

to pressurize. The current pressure in mmHg is displayed on both the

simulator and NPB-3900 displays.

6. Allow 15-20 seconds for the pressure to stabilize. The pressure displayed

on the NPB-3900 and the simulator should be within 5 mmHg of one

another to complete the test successfully.

7. Press the STOP PUMP button on the simulator to stop the test.

8. Press and hold the SPEAKER button until the NPB-3900 displays a

9. Additional NIBP tests may be performed at this time. If no further NIBP

3.3.4.3.2 Pneumatic Leakage

The pneumatic leakage test verifies the integrity of the pneumatic system. A

timer/stopwatch is required for this test.

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should

2. Ensure that the NIBP Test screen is active on the NPB-3900. Press, then

3. Press the CONTRAST button on the NPB-3900, then the ZERO button on

pressure of 0 mmHg.

tests are to be conducted, turn the NPB-3900 off. Normal monitoring

operation will return the next time the monitor is turned on.

display “Pressure Gauge”. Confirm that the simulator is set up for the

internal cuff.

release, the SPEAKER button on the NPB-3900 to verify that the valve is

closed.

the simulator, to perform an offset adjustment so that the simulator and

NBP-3900 both display a pressure of 0 mmHg.

3-9

Page 22

Section 3: Performance Verification

4. Press the NIBP button on the NPB-3900 to activate the pump. Hold the

5. Press and hold the SPEAKER button until the NPB-3900 displays a

6. Additional NIBP tests may be performed at this time. If no further NIBP

3.3.4.3.3 Inflation Rate

The inflation rate test verifies the inflation rate of the NPB-3900. A

timer/stopwatch is required for this test.

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should

button until the NPB-3900 displays a pressure of approximately 250 mmHg.

Allow 15-20 seconds for the pressure to stabilize. Record the pressure

displayed on the monitor, and initiate a 1-minute timer. After 1 minute,

again record the pressure displayed. The test is successfully completed if

the pressure has dropped by 6 mmHg, or less, during the 1-minute period.

pressure of 0 mmHg.

tests are to be conducted, turn the NPB-3900 off. Normal monitoring

operation will return the next time the monitor is turned on.

display “Pressure Gauge”. Confirm that the simulator is set up for the

internal cuff.

3.3.4.3.4 Deflation Rate

2. Ensure that the NIBP Test screen is active on the NPB-3900. Press, then

release, the SPEAKER button on the NPB-3900 to verify that the valve is

closed.

3. Press the CONTRAST button on the NPB-3900, then the ZERO button on

the simulator, to perform an offset adjustment so that the simulator and

NBP-3900 both display a pressure of 0 mmHg.

4. Press the NIBP button on the NPB-3900 to activate the pump, and

simultaneously start the timer. Hold the NIBP button until the monitor

displays a pressure of 280 mmHg. When a pressure of 280 mmHg is

reached, stop the timer. The test is successfully completed if the inflation

time is between 1 and 6 seconds.

5. Press and hold the SPEAKER button until the NPB-3900 displays a

pressure of 0 mmHg.

6. Additional NIBP tests may be performed at this time. If no further NIBP

tests are to be conducted, turn the NPB-3900 off. Normal monitoring

operation will return the next time the monitor is turned on.

The deflation rate test verifies the deflation rate of the NPB-3900. A timer/stop

watch is required for this test.

3- 10

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should

display “Pressure Gauge”. Confirm that the simulator is set up for the

internal cuff.

Page 23

Section 3: Performance Verification

2. Ensure that the NIBP Test screen is active on the NPB-3900. Press, then

release, the SPEAKER button to verify that the valve is closed.

3. Press the CONTRAST button on the NPB-3900, then the ZERO button on

the simulator, to perform an offset adjustment so that the simulator and

NBP-3900 both display a pressure of 0 mmHg.

4. Press the NIBP button on the NPB-3900 to activate the pump. Hold the

button until the NPB-3900 displays a pressure of 280 mmHg. Initiate a

1-minute timer, and simultaneously press and hold the ALARM SILENCE

button on the NPB-3900. This will cause the pneumatic system to deflate at

a rate of 3 mmHg/sec ±1.5 mmHg/sec. After 1 minute, record the pressure

displayed on the NPB-3900. The test is successfully completed if the

monitor displays a pressure reading of 10 mmHg to 190 mmHg.

5. Press and hold the SPEAKER button until the NPB-3900 displays a

pressure of 0 mmHg.

6. Additional NIBP tests may be performed at this time. If no further NIBP

tests are to be conducted, turn the NPB-3900 off. Normal monitoring

operation will return the next time the monitor is turned on.

3.3.4.3.5 Over-pressure

The over-pressure test verifies the functionality of the over-pressure relief

system of the NPB-3900.

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should

display “Pressure Gauge”. Confirm that the simulator is set up for the

internal cuff.

2. Ensure that the NIBP Test screen is active on the NPB-3900. Press, then

release, the SPEAKER button on the NPB-3900 to verify that the valve is

closed.

3. Press the CONTRAST button on the NPB-3900, then the ZERO button on

the simulator, to perform an offset adjustment so that the simulator and

NBP-3900 both display a pressure of 0 mmHg.

4. Press the SELECT button on the simulator until the simulator displays

“Overpressure Test”. Press the START TEST button on the simulator. The

simulator will pressurize the system until the monitor’s over-pressure relief

system activates, including the warning display screen. The simulator will

display the pressure value that caused the NPB-3900 over-pressure relief

system to activate. The test is successfully completed if the simulator

displays a pressure reading of 280 mmHg to 330 mmHg.

5. Press and hold the SPEAKER button to ensure that the NPB-3900 displays a

pressure of 0 mmHg.

6. Additional NIBP tests may be performed at this time. If no further NIBP

tests are to be conducted, turn the NPB-3900 off. Normal monitoring

operation will return the next time the monitor is turned on.

3-11

Page 24

Section 3: Performance Verification

3.3.4.4 Operation with a Thermometer Calibration Key (Models 3920 and 3940)

1. Remove the probe from its holder.

2. Insert the calibration key in the temperature input port

3. Press the ON/STANDBY button to turn the monitor on. After the normal

power-up sequence, verify that the temperature reads 36.3 ±0.1 °C (or 97.3

±0.2 °F).

4. Turn the monitor off.

3.3.4.5 General Operation

The following tests provide an overall performance check of the system:

• 3.3.4.4.1 Operation with a Human Subject

• 3.3.4.4.2 Serial Interface Test

• 3.3.4.4.3 Printer Verification

3.3.4.5.1 Operation with a Human Subject

Patient monitoring involves connecting the monitor to a human subject for a

qualitative test.

1. Connect an EC-8 sensor extension cable to the monitor. Connect a

Nellcor Puritan Bennett Durasensor finger clip sensor, model DS-100A,

to the sensor extension cable. Clip the DS-100A to the subject as

described in the sensor directions for use.

T

on the NPB-3900.

2. Connect a CE-10 ECG cable to the NPB-3930 or NPB-3940. Connect

ECG leads to the cable. Connect ECG electrodes to the leads. Apply ECG

electrodes to the subject according to the lead’s and electrodes’ directions

for use.

3. Connect an SHBP-10 blood pressure hose to the monitor. Apply the

appropriate SCBP series blood pressure cuff to the subject according to

the cuff directions for use.

4. Connect a blue-capped SureTemp oral thermometer probe to the

NPB-3920 or NPB-3940. Place the probe in its holder in the module on

the rear of the monitor.

5. Press the ON/STANDBY button to turn the monitor on and verify that

the monitor is operating.

6. The monitor should stabilize on the subject’s physiological signals in

about 15 to 30 seconds. Verify that the saturation and heart rate are

reasonable for the subject.

7. Press the NIBP button on the front panel of the monitor. Verify that the

blood pressure values are reasonable for the subject.

3- 12

Page 25

8. Remove the temperature probe from its holder. Following the directions

3.3.4.5.2 Serial Interface Test

Perform the following procedure to test the serial port voltages. The test is

RS-232

qualitative and only verifies that the serial interface port is powered correctly,

and that the “nurse call” signal is operational. The serial connector is a male

DB-9 located on the monitor’s rear panel, identified with the RS-232 symbol.

1. Turn the monitor ON.

2. Set up the DMM with the function set to “VDC” at a range of 10 volts.

3. Connect the DMM negative lead to connector pin 5 (GND), or the shell of

4. Connect the DMM positive lead to the following pins, in turn, and verify

Section 3: Performance Verification

in the NPB-32900 operator’s manual, apply a new probe cover and take

the subject’s temperature. Verify that the temperature measurement is

reasonable for the subject.

the RS-232 connector.

the voltage values listed in Table 3-3. (Voltage for pin 9 is that listed for the

“no alarm” condition.)

Table 3-3: Serial Interface Measurements

Measurement (V)

Pin Signal Min Typical Max

1 not used -0.4 0.0 0.4

2 RXD <<< -0.4 0.0 0.4

3 TXD >>> -5.0 -9.0 -15.0

4 DTR >>> -5.0 -9.0 -15.0

5 GND -0.4 0.0 0.4

6 DSR <<< -0.4 0.0 0.4

7 RTS >>> -5.0 -9.0 -15.0

8 CTS <<< -0.4 0.0 0.4

9 Alarm Out >>>

(no alarm) -5.0 -9.0 -15.0

9 Alarm Out >>>

(alarm underway) 5.0 9.0 15.0

5. Connect the Nellcor Puritan Bennett SRC-2 pulse oximeter tester to the

monitor via the EC-8 sensor extension cable.

3-13

Page 26

Section 3: Performance Verification

6. Set the SRC-2 switches as follows:

SWITCH

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

7. Verify that the monitor is responding to the SpO2 simulator signal and the

audible alarm is sounding. If desired, press the ALARM SILENCE button

to temporarily silence the audible alarm.

8. Connect the DMM positive lead to pin 9 and verify the voltage value listed

in Table 3-3. (Voltage for pin 9 is that listed for the “alarm underway”

condition.)

3.3.4.5.3 Printer Verification (For Optional Printer)

Printer verification consists of connecting the printer to the monitor and the

monitor to a human subject for a qualitative test.

1. Connect the output of the appropriate power supply, PS-240V or PS-120V,

to the labeled connector in the rear of the printer. When the printer’s external

15V - 1A

power supply is connected, the printer front-panel charging LED is lighted.

POSITION

RS-232

2. Connect the serial cable between the labeled connectors in the rear panels of

the monitor and the printer.

3. The printer front-panel communication LED is lighted when the RS-232

communications link is completed.

4. Rotate the monitor knob to highlight the setup icon . Press the knob and

ensure Communications Selection is (Printer).

5. Connect an EC-8 sensor extension cable to the monitor. Connect a Nellcor

Puritan Bennett Durasensor oxygen transducer, model DS-100A, to the

sensor extension cable. Attach the DS-100A to the subject as described in

the sensor directions for use.

6. Press the ON/STANDBY button to turn the monitor on and verify that the

monitor is operating.

7. The monitor should stabilize on the subject’s physiological signal in about

15 to 30 seconds. Verify that the saturation and heart rate is reasonable for

the subject.

3- 14

Page 27

8. Press the printer CONTINUOUS BUTTON. Verify that the printout contains

vital signs across the top of the paper, and that aSpO

marks, occupies the center portion of the paper. Press the CONTINUOUS

BUTTON again to terminate printout.

9. Disconnect the sensor and shut off the monitor.

3.4 SAFETY TESTS

NPB-3900 safety tests consist of the following Leakage Currents elements,

performed in accordance with IEC 601-1.

3.4.1 Protective Ground Continuity

NOTE: The NPB-3900 does not require an isolated Earth Ground terminal,

neither is one installed. No Protective Ground Continuity check is

required.

3.4.2 Electrical Leakage

NPB-3900 leakage current tests consist of the following elements, performed in

accordance with IEC 601-1, clause 19:

Section 3: Performance Verification

2 waveform, with grid

• Patient Leakage Current

• Patient Leakage Current, with Mains Voltage on the Applied Part

3.4.2.1 Patient Leakage Current

This test measures patient leakage current in accordance with IEC 601-1, clause

19, for Class II, type CF equipment. Patient leakage current in this test is

measured from any individual patient connection to earth (power ground).

NOTE: This test requires a test cable for each patient connector. For example,

the ECG test cable consists of the ECG cable connector, with all the

conductors shorted together, connected to a test lead from the electrical

safety analyzer. Test cables for SpO

in a similar manner.

1. Configure the electrical safety analyzer as recommended by the analyzer

operating instructions.

2. Connect the appropriate external power supply input power cord to the

analyzer as recommended by the analyzer operating instructions. Connect

the external power supply output cord to the monitor.

3. Connect the ECG test cable to the ECG connector on the NPB-3930 /3940

and the appropriate input connector on the analyzer. Turn on the

NPB-3930/3940.

2 and temperature can be configured

4. Perform the test as recommended by the analyzer operating instructions.

Patient leakage current is measured under various conditions of the AC

mains. For each condition, the measured leakage current must not exceed

that indicated in Table 3-4.

3-15

Page 28

Section 3: Performance Verification

5. Repeat the test for the SpO2 and temperature patient connections, using the

appropriate test cables.

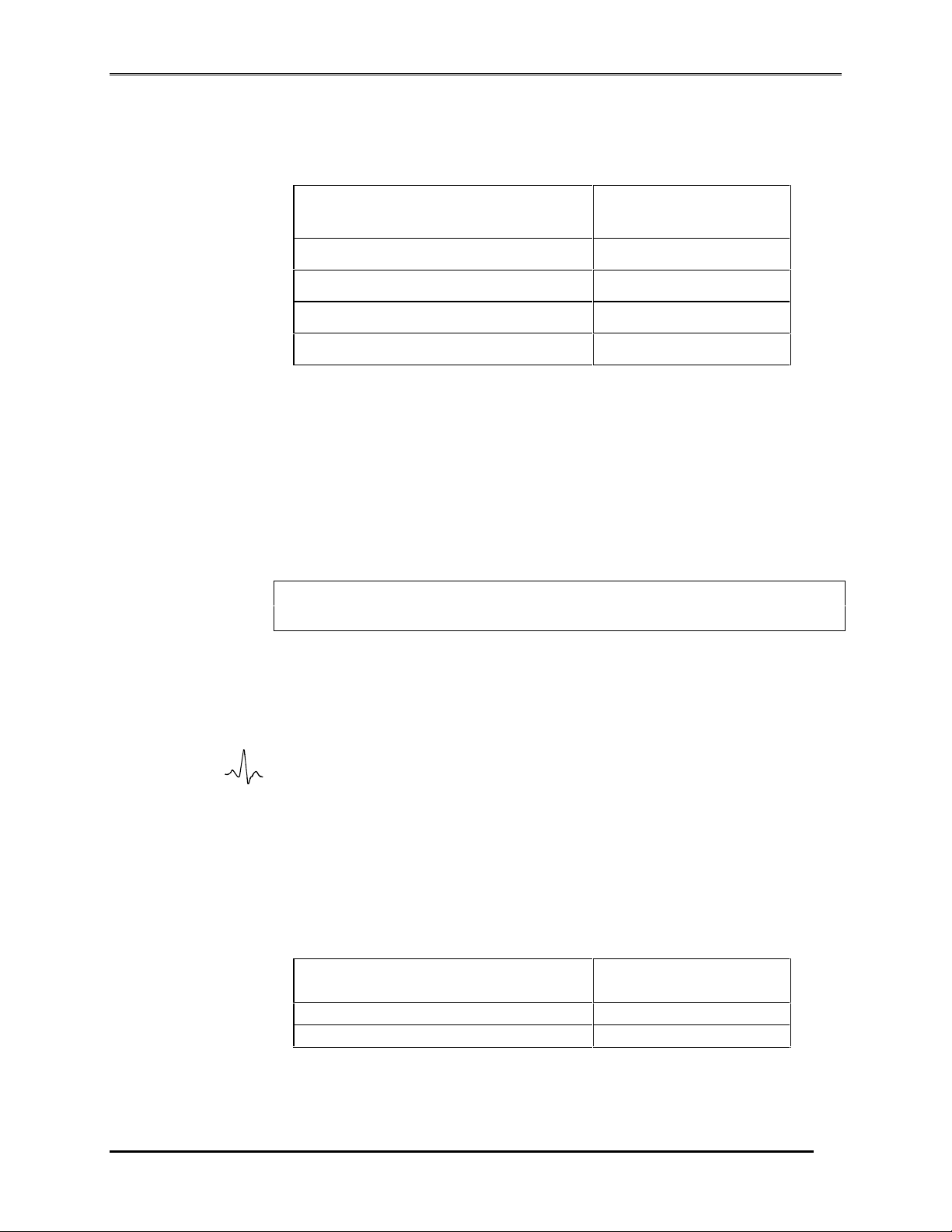

Table 3-4: Current Test

Allowable Leakage

Test Condition

Current (milliamps)

Normal polarity 0.01

Normal polarity; Neutral (L2) open 0.05

Reverse polarity 0.01

Reverse polarity; Neutral (L2) open 0.05

3.4.1.3 Patient Leakage Current, with Mains Voltage on the Applied Part

This test measures patient leakage current in accordance with IEC 601-1, clause

19, for Class II, type CF equipment. In this test, 110% of mains voltage is

applied between each patient connection and earth (power ground). Patient

leakage current is then measured from any individual patient connection to earth.

NOTE: This test requires the same test cables for each patient connector as

described in section 3.4.1.2.

WARNING: AC mains voltage will be present on the applied part

terminals during this test. Exercise caution to avoid electrical shock hazard.

1. Configure the electrical safety analyzer as recommended by the analyzer

operating instructions.

2. Connect the monitor’s appropriate external power supply input power cord

to the analyzer as recommended by the analyzer operating instructions.

Connect the external power supply output cord to the monitor.

3. Connect the ECG test cable to the ECG connector on the NPB-3930/3940

and the appropriate input connector on the analyzer. Turn on the

NPB-3930/3940.

4. Perform the test as recommended by the analyzer operating instructions.

Patient leakage current is measured with normal and reverse mains polarity.

For each condition, the measured leakage current must not exceed that

indicated in Table 3-5.

5. Repeat the test for the SpO2 and temperature patient connections, using the

appropriate test cables.

Table 3-5: Leakage Current

Allowable Leakage

Test Condition

Current (milliamps)

Normal polarity 0.05

Reverse polarity 0.05

3- 16

Page 29

SECTION 4: POWER-UP DEFAULTS MENU AND DIAGNOSTIC MODE

4.1 Introduction

4.2 Power-up Defaults Menu

4.3 Restoring Factory Settings

4.4 Diagnostic Mode

4.1 INTRODUCTION

This section discusses use of the Power-up Defaults Menu to configure power-on

default settings, and the Diagnostic Mode to obtain service-related information

about the monitor.

4.2 POWER-UP DEFAULTS MENU

The purpose of the Power-up Defaults Menu (Table 4-1) is to allow the

authorized user to create a “power-up default” for each setting in the NPB-3900.

Power-up defaults are the settings in effect each time the NPB-3900 is powered

on. Once the Power-up Defaults Menu is entered, physiological monitoring is

terminated. The screen layouts do NOT display any information associated with

normal monitoring operation.

Use the following procedure to configure the power-up default settings for the

NPB-3900 monitor.

1. While in normal monitoring mode, adjust each accessible setting on the

monitor as desired, using the techniques described in the operator’s manual.

Such settings include alarm limits, choice of display type for the graphic

frame, and ECG lead select.

2. Use the knob to invoke the Set-up Menu (choose the screwdriver icon found

along the bottom of the display).

3. Select the menu item “Enter Power-Up Defaults Menu”. Once selected, a

pop-up box appears with the text “Enter 3-Digit Passcode”. Use the knob to

enter the passcode, 2 1 5. This passcode is set at the factory and may not be

changed.

4. The Power-up Defaults Menu is now present. The available menu items are

explained in the table that follows. Make changes to these menu items as

desired.

Table 4-1: Power-Up Defaults Menu

MENU ITEM* CHOICES** EXPLANATION

Accept Current

Settings?

“Yes”

“No”

If “Yes” is chosen, the current

NPB-3900 settings become the

power-up defaults.

4-1

Page 30

Section 4: Power-up Defaults Menu and Diagnostic Mode

Table 4-1: Power-Up Defaults Menu - (Continued)

MENU ITEM* CHOICES** EXPLANATION

Permanent Audible

“Make Available”

Alarm Silence

“Deny Access”

Alarm Suspend “Make Available”

“Deny Access”

Auto-Set Limits

“Make Available”

“Deny Access”

If “Make Available” is chosen,

the caregiver may permanently

silence the audible alarm for a

particular parameter via the

Alarm/Limits Menu. Some

institutions may wish to prevent

audible alarms from being

permanently silenced. If so,

“Deny Access” should be

selected.

If “Make Available” is chosen,

the caregiver may invoke the

Alarm Suspend Mode by

pressing and holding the Alarm

Silence button for 2 seconds.

Some institutions may wish to

prevent Alarm Suspend from

being invoked. If so, “Deny

Access” should be selected.

If “Make Available” is chosen,

the caregiver may invoke the

Auto-Set Limits function via

the Alarm/Limits Menu. Some

institutions may wish to prevent

Auto-Set Limits from being

invoked. If so, “Deny Access”

should be selected.

4-2

Page 31

Section 4: Power-up Defaults Menu and Diagnostic Mode

Table 4-1: Power-Up Defaults Menu - (Continued)

MENU ITEM* CHOICES** EXPLANATION

Language

Enter Diagnostic

Mode

“English”

“Français”

“Deutsch”

“Español”

“Italiano”

“Portugués”

“Japanese”

“Chinese”

“Russian”

“Yes”

“No”

The language selected will be

used for all the text shown on

the display; the selected

language will be effective the

next time the monitor is

powered up.

If “Yes” is chosen, the Powerup Defaults Menu is exited and

the Diagnostic Menu appears.

Done When selected, the Power-up

Defaults Menu is immediately

exited and the user is instructed

to power down the monitor.

* The choice in effect at the time the screen is accessed is shown

in parentheses following the menu item.

** Bold type indicates the choice when the factory-set default menu

appears. The highlighting is displayed in reverse video.

5. After making any desired changes to the menu items, choose the menu item

“Accept current settings?”, select “YES”, then select “Done”.

6. Upon selecting “Done”, a Notice screen will appear, with the directions that

the monitor must be powered off, and that any changes made to the power-up

defaults will be in effect next time the unit is powered up.

4-3

Page 32

Section 4: Power-up Defaults Menu and Diagnostic Mode

Turn off the monitor at this time. Any changes

made to the power-up defaults will be in effect

the next time the monitor is turned on.

4.3 RESTORING FACTORY SETTINGS

CAUTION: In addition to restoring factory defaults, this procedure will

also clear the contents of trend memory.

NOTICE

NOTE: Read this procedure completely before performing the first step.

The following technique can be used to restore the monitor’s power-up default

settings which were originally established at the factory:

1. With the monitor powered off, simultaneously press the Volume and

2. While continuing to press the Volume and Contrast buttons, power-up the

3. Continue to keep the Volume and Contrast buttons depressed until the

4.4 DIAGNOSTIC MODE

The purpose of Diagnostic Mode is to allow factory, field-service, and hospital

biomedical technicians access to a series of test and system-related information

screens for the purpose of verifying NPB-3900 performance or troubleshooting

problems.

To access the Diagnostic Mode, first invoke the Power-up Defaults Menu as

described in section 4.2. Then, select the menu item, “Enter Diagnostic Mode”.

Choose “Yes”. The Power-up Defaults Menu will be exited and the Diagnostic

Menu will appear.

Contrast buttons on the front keypad.

monitor.

power-up diagnostic sequence is complete. When the normal monitoring

screen appears, release the two buttons.

4-4

Page 33

Section 4: Power-up Defaults Menu and Diagnostic Mode

DIAGNOSTIC MENU

Error Codes

System Information

System A/D Values

NIBP Test

Return

The Diagnostic Menu lists the test and system-related information screens.

Selection of an item in the menu will invoke that test or information screen. The

test and information screens that appear in the Diagnostic Menu are as follows:

• Error Codes

4.4.1 Error Codes

• System Information

• System A/D Values

• NIBP Test

• Return

This screen displays the 10 most recent error code types, logged by the

NPB-3900. After 10 error code types have been logged, the oldest error code

type will be deleted as new error code types are added. Adjacent to each error

code will be an entry which is the number of occurrences of that error. This

means that if there are many occurrences of one type of error code, that one error

code won’t “overwrite” the other 9 error codes.

Next to the occurrence field is the time and date of the most recent occurrence of

the error code. Error codes may not be changed or reset in this screen. When in

the Error Code screen, the “Return” item is always highlighted; a press of the

knob will return the user to the Diagnostic Menu. Rotating the knob while in the

Error Code screen will have no effect.

NOTE: Refer to Section 5.6.2 for more detail on error codes.

4-5

Page 34

Section 4: Power-up Defaults Menu and Diagnostic Mode

4.4.2 System Information

SYSTEM INFORMATION

Monitor On-Time 1563

Backlight On-Time 871

Battery Deep

Discharges

152

System Software

Version

2 Software Version Nellcor MP204/205

SpO

Return

V 2.01

V1.1.0.6 10/06/95

This screen displays several system-related items:

• Monitor On-time: Displays the number of hours, rounded to the nearest

hour, that the Main PCB has been operational. This value may not be reset.

(See Note 1.)

NOTE 1: Monitor on-time, backlight on-time, and battery deep

discharge values are stored in nonvolatile memory.

When a new Main PCB is installed, this value will be

set at zero.

• Backlight On-time: Displays the number of hours, rounded to the nearest

hour, that the LCD Backlight has been operational. This value may be reset

to zero, for instance, when a technician changes the backlight or installs a

new LCD. (See Note 1.)

• Battery Deep Discharges: Displays the number of deep-discharge cycles

seen by the battery. The monitor records a deep discharge cycle when the

battery voltage reaches 5.6 V, the voltage at which a “Low Battery” alarm is

issued. This value may be reset to zero, for instance, when a technician

installs a new battery. (See Note 1.)

4-6

• System software version: Displays the revision level of the system

software. This revision level is also momentarily shown on the LCD as part

of the Copyright screen. This value may not be changed by the user.

• SpO

2 software version: Displays the revision level of the software of the

SpO

2 EEPROM module. This value may not be changed by the user.

When in the System Information screen, the knob may be rotated to select any of

the “changeable” items. If one of those items is selected, a press of the knob will

cause a pop-up menu to appear. The first item in the pop-up will read “Make no

change”; the second item in the pop-up will read “Reset to zero”. Exiting the

screen is accomplished in the normal manner, by selecting “Return”.

Page 35

4.4.3 System A/D Values

g

s

R

R

Section 4: Power-up Defaults Menu and Diagnostic Mode

SYSTEM A/D VALUES

1. 1.478 12. 1.478

2. 0.235 13. 0.235

3. 3.652 14. 3.652

4. 0.782 15. 0.782

5. 4.012 16. 4.012

6. 0.045 17. 0.045

7. 2.149 18. 2.149

8. 1.025 19. 1.025

9. 0.478 20. 0.478

10. 1.369 21.

11. 0.702

2 S1 S018 SpO2 S2 S0010

SpO

Return

This screen displays the current value of each analog-to-digital (A/D) channel, in

volts. Some of the channels are for AC-coupled signals (such as ECG input), so

the numbers on the screen will be constantly changing when an input signal is

present. These AC-coupled values indicate whether basic functionality of the

channel is present, but no significance can be derived from the values of the

numbers displayed. However, other A/D channels read DC voltages, (for

example, power supply voltages and battery voltage) so those voltage values

provide useful diagnostic information.

The Primary and Secondary Status messages from the SpO

2 module will be

displayed and updated at the rate of about once per second. Presence of the

correct SpO

the SpO

2 message indicates that, at a basic level, communication between

2 module and the main monitor processor is working correctly. None of

the displayed values may be changed or reset in this screen. When in the System

A/D screen, the “Return” item is always highlighted; a press of the knob will

return the user to the Diagnostic Menu. Rotating the knob while in the System

A/D screen will have no effect. The A/D channel designators are shown in

Table 4-2.

Table 4-2: A/D Channel Desi

A/D CHANNEL DESIGNATO

1. ECG 12. (BATTERY VOLTAGE) X 0.5

A/D CHANNEL DESIGNATO

nator

2. RWAVE 13. TEMP PROBE <=0=ORAL,

1=RECTAL,2=CAL KEY, >=3 NONE)

3. PACEMAKER 14. +3.3VDC POWER SUPPLY

4. TEMP 1(93° TO 112°) 15. (NIBP VOLTAGE REF) X 0.8

4-7

Page 36

Section 4: Power-up Defaults Menu and Diagnostic Mode

Table 4-2: A/D Channel Designators - (Continued)

5. PRESSURE XDUCER 1 16. GROUND REFERENCE

6. PRESSURE XDUCER 2 17. (+5 VDC POWER SUPPLY) X 0.8

7. NIBP OSCILLATORY 18. ADC MID-SCALE VALUE

8. ECG LEADS OFF 19. ADC FULL-SCALE VALUE

9. TEMP 2(59° TO 93°) 20. ADC ZERO-SCALE VALUE

10. ISOLATED VOLTAGE REF 21. (NOT USED)

11. ISOLATED VOLTAGE ZERO

SpO2 S1 S018 SpO2 S2 S010

4.4.4 NIPB Test

WARNING: Never apply an attached blood pressure cuff to a patient while

the monitor is in Diagnostic Mode. Injury could result.

NIBP TEST

Pressure

179

(mmHg)

Valve: OPEN

Press “NIBP” to activate pump;

release to stop pump.

Press “Volume” to open valve; release

to close valve.

Press “Alarm Silence” to open

proportional valve and deflate at 3

mmHg/s; release to close valve.

Press “Contrast” to perform offset

adjust.

Return

4-8

An NIBP Test screen is provided to facilitate troubleshooting problems and

perform verification testing for the NIBP subsystem. Typically, when these tests

are performed, the pneumatic system is connected to an external pressure-

Page 37

Section 4: Power-up Defaults Menu and Diagnostic Mode

reading device and a closed reference volume. The NIBP Test screen provides a

real-time numeric display of the pressure in the pneumatic system, means for

controlling the pump and valve, and a display indicating whether the valve is

open or closed.

The NIBP Test screen elements are described below.

• Pressure Display: The real-time value of the system pneumatic pressure is

displayed in mmHg. The value is updated at the rate of approximately two

times per second.

• Valve Display: A display indicates whether the valve is open or closed.

• Activate pump: While the NIBP button is pressed, the pump will run. If

system pressure reaches the hardware over-pressure protection point (280 to

330 mmHg), the safety valve will open and the pump will be disabled, until

the pressure falls below the safety threshold.

• Deflate: For as long as the Alarm Silence button is pressed, the valve will

open and bleed off pressure at the rate of 3 ±1.5 mmHg/sec. It is useful to

control the bleed rate to 3 mmHg/sec to facilitate certain AAMI SP10 tests.

Any time the bleed rate falls below 3 mmHg/sec, the valve will open and

remain at maximum as long as the button is pressed.

• Open Valve: While the Volume button is pressed, the valve opens and

remains at maximum as long as the button is pressed.

• Offset Adjust: A momentary press of the Contrast button will invoke the

“zero calibration” routine that is performed immediately prior to each blood

pressure measurement. This routine looks at the pressure in the system, and

if the pressure is non-zero, an offset is applied which causes the system

pressure to be displayed as “zero”.

When in the NIBP Test screen, the “Return” item is always highlighted; a press

of the knob will return the user to the Diagnostic Menu. Rotating the knob while

in the NIBP Test screen will have no effect.

4-9

Page 38

Page 39

SECTION 5: TROUBLESHOOTING

5.1 Introduction

5.2 How to Use this Section

5.3 Who Should Perform Repairs

5.4 Replacement Level Supported

5.5 Obtaining Replacement Parts

5.6 Troubleshooting Guide

5.7 Troubleshooting the Oximetry Function

5.8 P-3900 Troubleshooting Guide

5.1 INTRODUCTION

This section explains how to troubleshoot the NPB-3900 if problems arise.

Tables are supplied that list possible monitor difficulties, along with probable

causes, and recommended actions to correct the difficulty.

5.2 HOW TO USE THIS SECTION

Use this section in conjunction with Section 3, Performance Verification, and

Section 7, Spare Parts. To remove and replace a part you suspect is defective,

follow the instructions in Section 6, Disassembly Guide. The circuit analysis

section in the Technical Supplement offers information on how the monitor

functions.

5.3 WHO SHOULD PERFORM REPAIRS

Only qualified service personnel should open the monitor housing, remove and

replace components, or make adjustments. If your medical facility does not have

qualified service personnel, contact Nellcor Puritan Bennett Technical Services

or your local Nellcor Puritan Bennett representative.

5.4 REPLACEMENT LEVEL SUPPORTED

The replacement level supported for this product is to the printed circuit board

(PCB) and major subassembly or component level. Once you isolate a suspected

PCB, follow the procedures in Section 6, Disassembly Guide, to replace the PCB

with a known good PCB. Check to see if the trouble symptom disappears and

that the monitor passes all performance tests. If the trouble symptom persists,

swap back the replacement PCB with the suspected malfunctioning PCB (the

original PCB that was installed in the monitor before you started

troubleshooting) and continue troubleshooting as directed in this section.

5-1

Page 40

Section 5: Troubleshooting

5.5 OBTAINING REPLACEMENT PARTS

Nellcor Puritan Bennett Technical Services provides technical assistance

information and replacement parts. To obtain replacement parts, contact Nellcor

Puritan Bennett or your local Nellcor Puritan Bennett representative. Refer to

parts by the part names and part numbers listed in Section 7, Spare Parts.

5.6 TROUBLESHOOTING GUIDE

Problems with the NPB-3900 are separated into the categories indicated in Table