Page 1

SERVICE MANUAL

NPB-190 Pulse Oximeter

Caution: Federal law (U.S.) restricts this device to sale by or on the order of a physician.

To contact Mallinckrodt’s representative: In the United States, call 1.800.635.5267 or 314.654.2000; outside of the United

States, call your local Mallinckrodt representative.

1999 Mallinckrodt Inc. All rights reserved. 033925E-0599

0123

Page 2

Mallinckrodt, Inc.

675 McDonnell Boulevard

P.O. Box 5840

St. Louis, MO 63134

Tel 314.654.2000

Toll Free 1.800.635.5267

Nellcor Puritan Bennett

4280 Hacienda Drive

Pleasanton, CA 94588 USA

Mallinckrodt

Europe BV

Hambakenwetering 1

5231 DD’s-Hertogenbosch

The Netherlands

Tel +31.73.6485200

Nellcor Puritan Bennett is a wholly owned subsidiary of Mallinckrodt Inc. Nellcor and Nellcor Puritan Bennett are trademarks of

Mallinckrodt Inc.

To obtain information about a warranty, if any, for this product, contact Mallinckrodt Technical Services or your local Mallinckrodt

representative.

Purchase of this instrument confers no express or implied license under any Mallinckrodt patent to use the instrument with any sensor

that is not manufactured or licensed by Mallinckrodt.

Durasensor, and Oxisensor II, are trademarks of Mallinckrodt Inc.

Covered by one or more of the following U.S. Patents and foreign equivalents: 4,621,643; 4,653,498; 4,700,708; 4,770,179; 4,869,254;

Re.35.122; 4,928,692; 4,934,372; 5,078,136; and 5,368.224.

Page 3

TABLE OF CONTENTS

List of Figures

List of Tables

Table Of Contents ....................................................................................... iii

List Of Figures......................................................................................... v

List Of Tables .......................................................................................... vi

Section 1: Introduction............................................................................... 1-1

1.1 Manual Overview.......................................................................... 1-1

1.2 NPB-190 Pulse Oximeter Description.......................................... 1-1

1.3 Power-On Self Test...................................................................... 1-2

1.4 Related Documents...................................................................... 1-3

Section 2: Routine Maintenance................................................................ 2-1

2.1 Cleaning ....................................................................................... 2-1

2.2 Periodic Safety and Functional Checks ....................................... 2-1

2.3 Battery.......................................................................................... 2-1

Section 3: Performance Verification ......................................................... 3-1

3.1 Introduction .................................................................................. 3-1

3.2 Equipment Needed ...................................................................... 3-1

3.3 Performance Tests....................................................................... 3-1

3.4 Safety Tests ................................................................................. 3-9

Section 4: Audible Alarm Settings & Service Menu................................. 4-1

4.1 Introduction .................................................................................. 4-1

4.2 Audible Alarm Settings ................................................................. 4-1

4.3 Service Menu ............................................................................... 4-2

Section 5: Troubleshooting ....................................................................... 5-1

5.1 Introduction .................................................................................. 5-1

5.2 How To Use This Section............................................................. 5-1

5.3 Who Should Perform Repairs ...................................................... 5-1

5.4 Replacement Level Supported ..................................................... 5-1

5.5 Obtaining Replacement Parts ...................................................... 5-1

5.6 Troubleshooting Guide ................................................................. 5-2

5.7 Error Codes.................................................................................. 5-7

Section 6: Disassembly Guide................................................................... 6-1

6.1 Introduction .................................................................................. 6-1

6.2 Prior to Disassembly .................................................................... 6-1

6.3 Fuse Replacement ....................................................................... 6-2

6.4 Monitor Disassembly .................................................................... 6-3

6.5 Monitor Reassembly .................................................................... 6-4

6.6 Battery Replacement.................................................................... 6-5

6.7 Power Entry Module (PEM) Removal/Installation ........................ 6-6

6.8 Power Supply Removal/Installation.............................................. 6-7

6.9 Display PCB Removal/Installation................................................ 6-9

6.10 UIF PCB Removal/Installation...................................................... 6-10

6.11 Alarm Speaker Removal/Installation............................................ 6-11

Section 7: Spare Parts ................................................................................ 7-1

7.1 Introduction .................................................................................. 7-1

Section 8: Packing For Shipment .............................................................. 8-1

8.1 General Instructions ..................................................................... 8-1

iii

Page 4

Table of Contents

8.2 Repacking in Original Carton ....................................................... 8-1

8.3 Repacking in a Different Carton................................................... 8-3

Section 9: Specifications............................................................................ 9-1

9.1 General ........................................................................................ 9-1

9.2 Electrical....................................................................................... 9-1

9.3 Physical Characteristics ............................................................... 9-2

9.4 Environmental .............................................................................. 9-2

9.5 Alarms .......................................................................................... 9-2

9.6 Factory Default Settings ............................................................... 9-2

9.7 Performance ................................................................................ 9-3

Appendix (Serial Port Interface Protocol)................................................. A-1

A1 Introduction .................................................................................. A-1

A2 Enabling the Serial Port................................................................ A-1

A3 Connecting to the Serial Port ....................................................... A-1

A4 Real-Time Printout ....................................................................... A-2

A5 Nurse Call .................................................................................... A-5

Technical Supplement................................................................................ S-1

S1 Introduction .................................................................................. S-1

S2 Oximetry Overview....................................................................... S-1

S3 Circuit Analysis............................................................................. S-3

S4 Functional Overview..................................................................... S-3

S5 AC Input ....................................................................................... S-3

S6 Power Supply PCB Theory of Operation...................................... S-4

S7 Battery.......................................................................................... S-5

S8 User Interface PCB (UIF) ............................................................. S-5

S9 Front Panel Display PCB and Controls ........................................ S-8

S10 Schematic Diagrams .................................................................... S-9

iv

Page 5

LIST OF FIGURES

Table of Contents

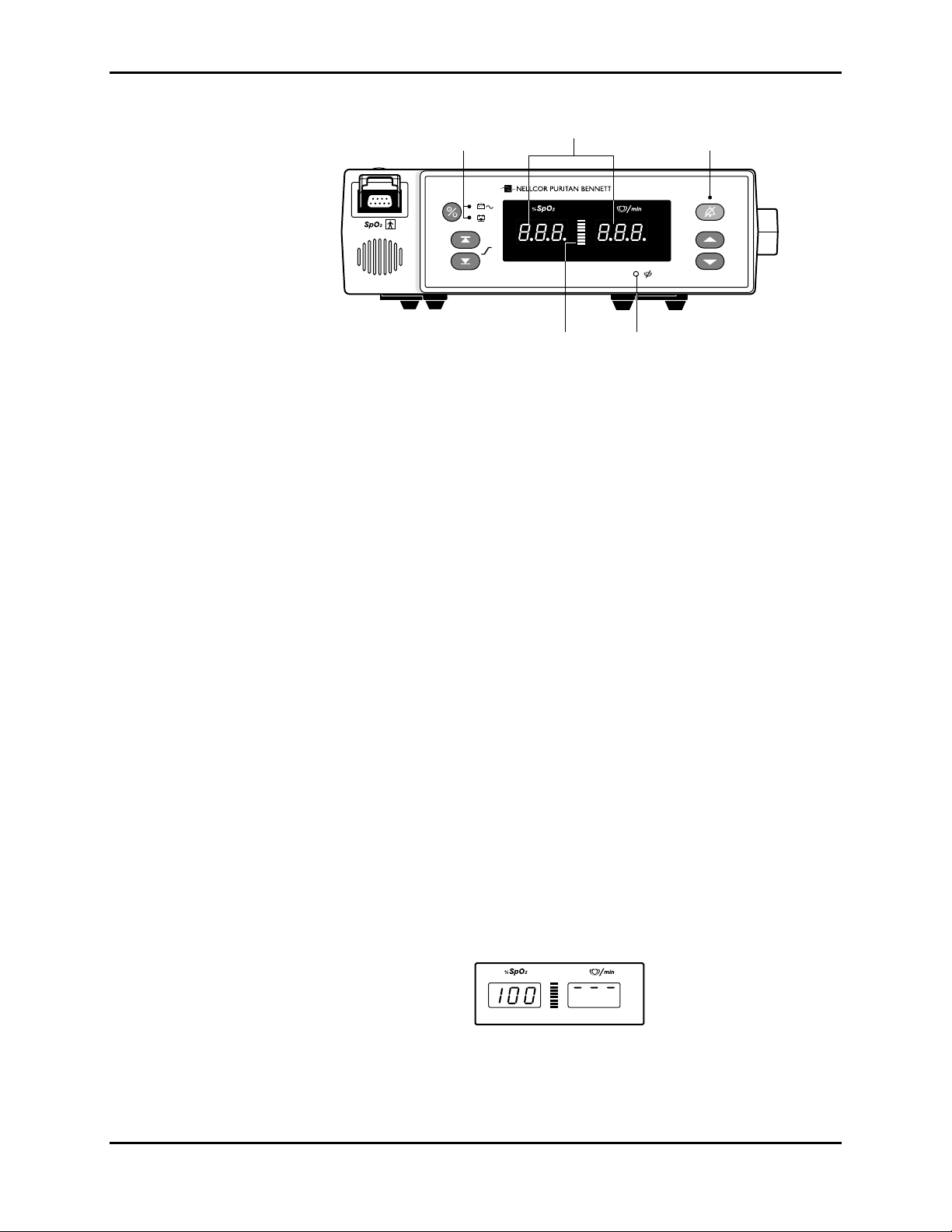

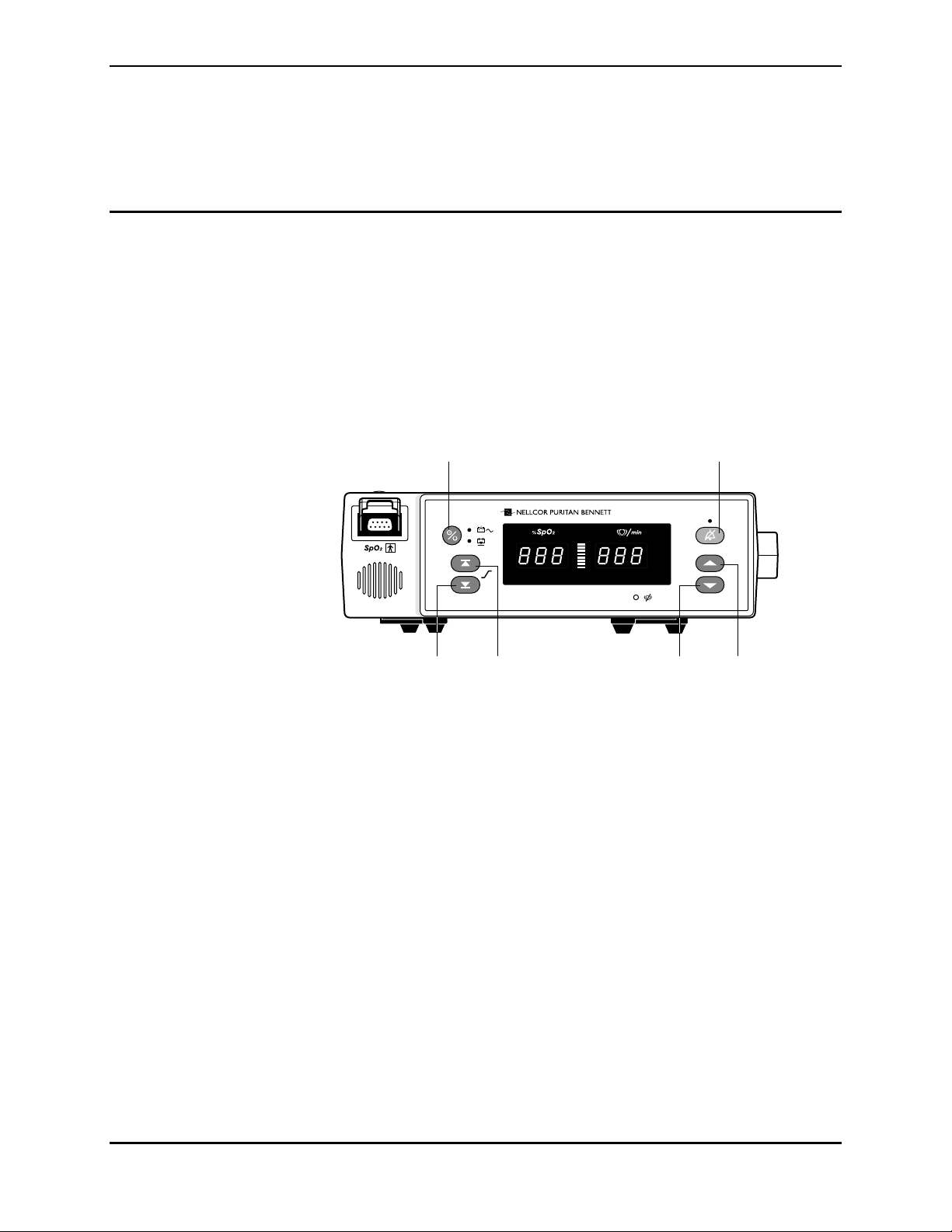

Figure 1-1: NPB-190 Front Panel.................................................................. 1-2

Figure 1-2: NPB-190 Rear Panel .................................................................. 1-2

Figure 3-1: NPB-190 Controls....................................................................... 3-2

Figure 3-2: Self-Test Display......................................................................... 3-3

Figure 3-3: Adjusting High %SpO2 Alarm Limit ............................................ 3-3

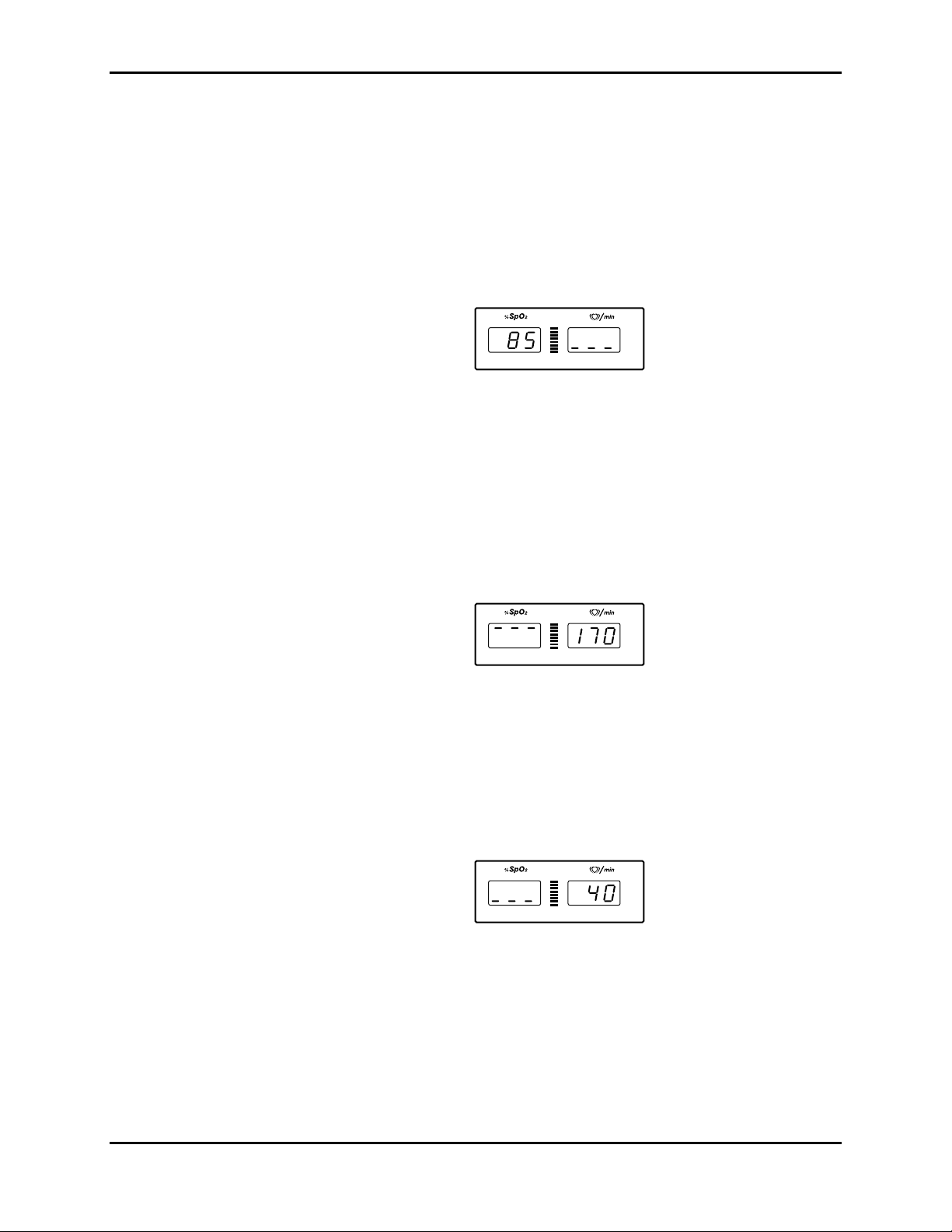

Figure 3-4: Adjusting Low %SpO2 Alarm Limit ............................................. 3-4

Figure 3-5: Adjusting High Heart Rate Alarm Limit ....................................... 3-4

Figure 3-6: Adjusting Low Heart Rate Alarm Limit ........................................ 3-4

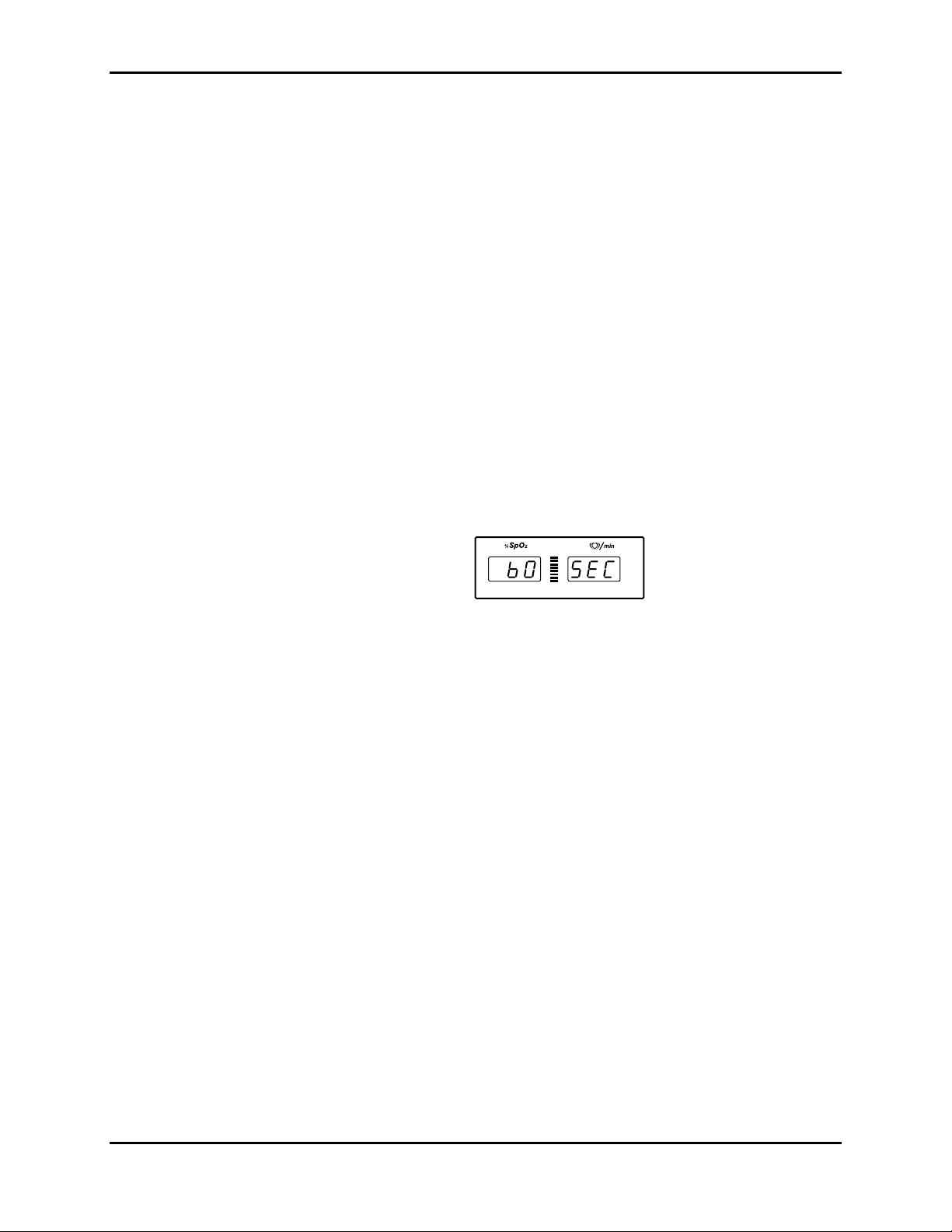

Figure 3-7: Alarm Silence Duration ............................................................... 3-6

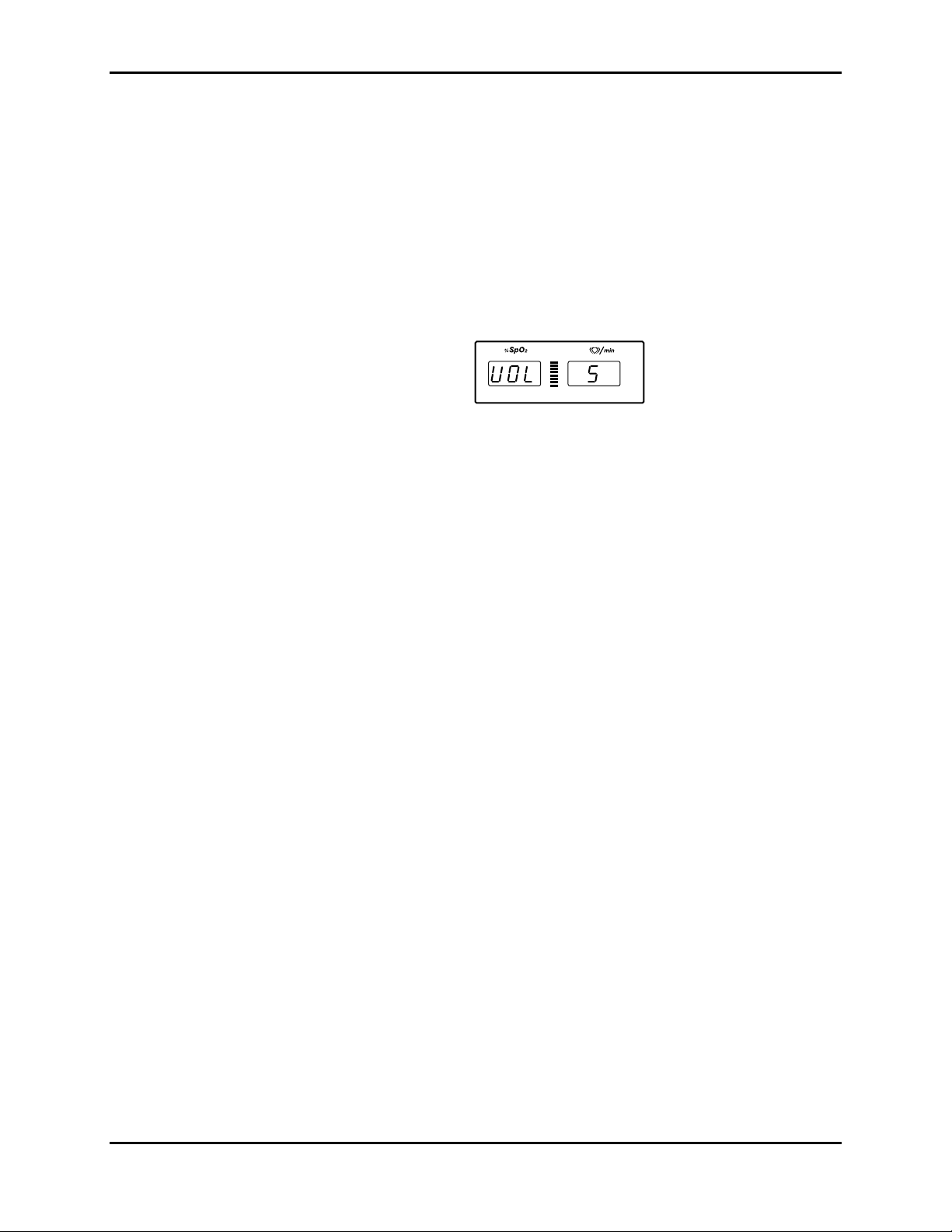

Figure 3-8: Alarm Volume Display ................................................................ 3-7

Figure 4-1: NPB-190 Controls....................................................................... 4-1

Figure 6-1: Fuse Removal............................................................................. 6-2

Figure 6-2: NPB-190 Corner Screws ............................................................ 6-3

Figure 6-3: Separating Case Halves ............................................................. 6-4

Figure 6-4: Battery Removal ......................................................................... 6-5

Figure 6-5: Power Entry Module.................................................................... 6-6

Figure 6-6: Power Supply Leads Connections .............................................. 6-7

Figure 6-7: Power Supply.............................................................................. 6-8

Figure 6-8: Display PCB................................................................................ 6-9

Figure 6-9: UIF PCB...................................................................................... 6-10

Figure 6-10: Alarm Speaker .......................................................................... 6-12

Figure 7-1: NPB-190 Exploded View............................................................. 7-2

Figure 8-1: Repacking the NPB-190 ............................................................. 8-2

Figure A-1: Serial Port Pin Layout................................................................. A-2

Figure A-2: Real-Time Printout ..................................................................... A-2

Figure S-1: Oxyhemoglobin Dissociation Curve ........................................... S-2

Figure S-2: NPB-190 Functional Block Diagram ........................................... S-3

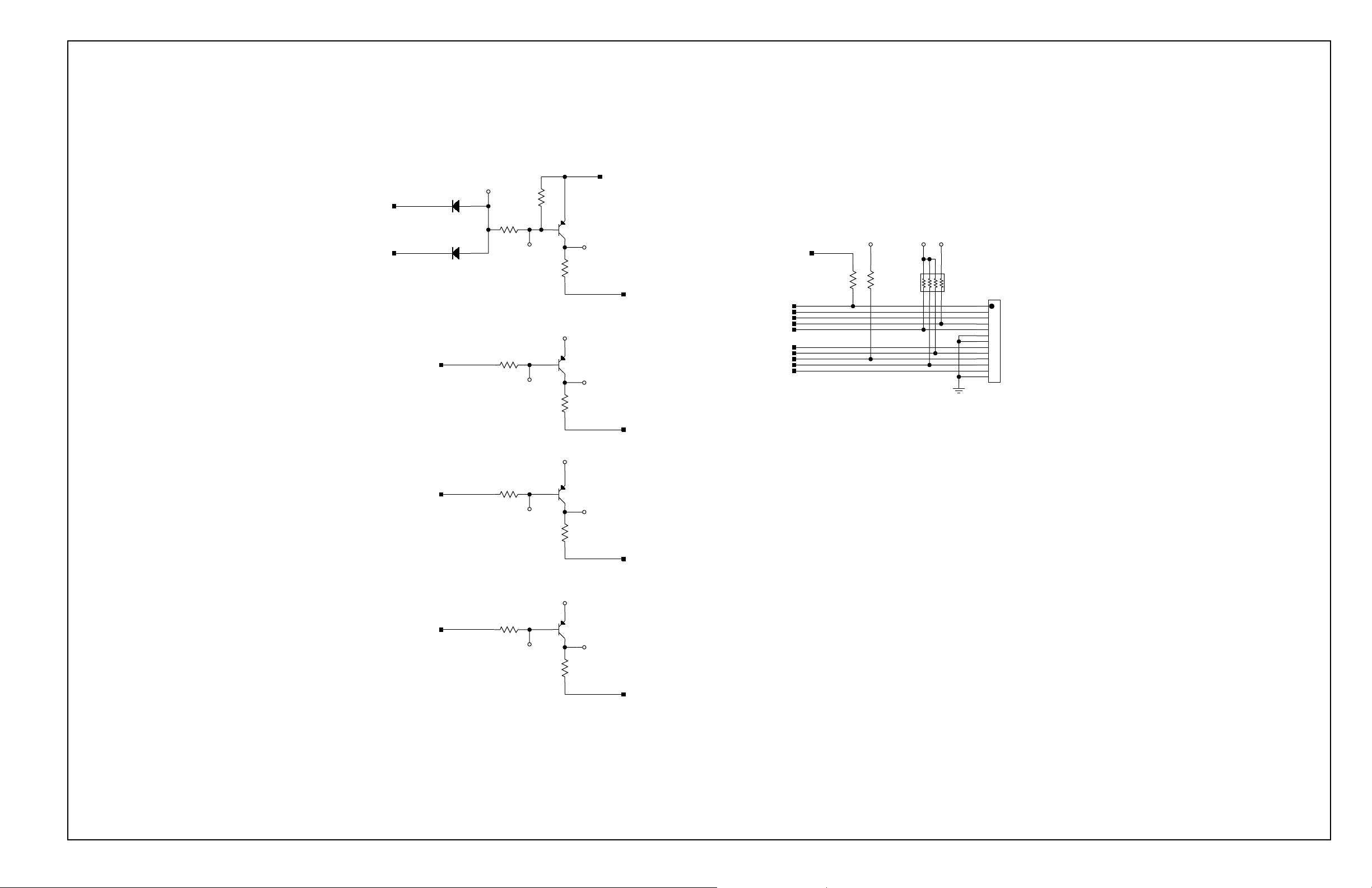

Figure S-3 Front End Red/IR Schematic Diagram ....................................... S-11

Figure S-4 Front End LED Drive Schematic Diagram.................................. S-13

Figure S-5 Front End Output Schematic Diagram ....................................... S-15

Figure S-6 Front End Power Supply Schematic Diagram ............................ S-17

Figure S-7 Isolation Barrier EIA-232 Port Schematic Diagram .................... S-19

Figure S-8 CPU Core Schematic Diagram .................................................. S-21

Figure S-9 PIC and Speaker Schematic Diagram ....................................... S-23

Figure S-10 Indicator Drive Schematic Diagram.......................................... S-25

Figure S-11 Core Power Supply Schematic Diagram .................................. S-27

Figure S-12 Parts Locator Diagram for UIF PCB ......................................... S-29

Figure S-13 Display PCB Schematic Diagram............................................. S-31

Figure S-14 Parts Locator Diagram for Display PCB ................................... S-33

Figure S-15 Power Supply Schematic Diagram ........................................... S-35

Figure S-16 Parts Locator Diagram for Power Supply PCB......................... S-37

v

Page 6

Table of Contents

LIST OF TABLES

Table 3-1: Dynamic Operating Range.......................................................... 3-8

Table 3-2: Earth Leakage Current Limits ..................................................... 3-10

Table 3-3: Enclosure Leakage Current Limits.............................................. 3-11

Table 3-4: Patient Leakage Current Limits .................................................. 3-12

Table 3-5: Patient Leakage Current Test Configurations - Mains

Voltage on the Applied Part ........................................................ 3-12

Table 4-1: Factory Default Settings.............................................................. 4-3

Table 5-1: Problem Categories .................................................................... 5-2

Table 5-2: Power Problems.......................................................................... 5-3

Table 5-3: Button Problems ......................................................................... 5-4

Table 5-4: Display/Alarms Problems............................................................ 5-4

Table 5-5: Operational Performance Problems ........................................... 5-5

Table 5-6: Serial Port Problems ................................................................... 5-6

Table 5-7: Error Codes................................................................................. 5-7

Table A-1: Serial Port Pin Outs .................................................................... A-1

Table A-2: Status Codes .............................................................................. A-4

vi

Page 7

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 NPB-190 Pulse Oximeter Description

1.3 Power-On Self Test

1.4 Related Documents

1.1 MANUAL OVERVIEW

This manual contains information for servicing the Nellcor model NPB-190

Pulse Oximeter. Only qualified service personnel should service this product.

Before servicing the NPB-190, read the operator’s manual carefully for a

thorough understanding of operation.

Warning: Explosion hazard. Do not use the NPB-190 pulse oximeter in the

presence of flammable anesthetics.

1.2 NPB-190 PULSE OXIMETER DESCRIPTION

The Nellcor NPB-190 portable pulse oximeter is intended for continuous,

noninvasive measurement of functional oxygen saturation of arterial hemoglobin

(SpO

2), and pulse rate (measured by SpO2 sensor).

The monitor is intended for use on adult, pediatric, and neonatal patients in all

hospital-type facilities and in the home environment. It may be used during intrahospital transport when powered by its internal battery.

Digital displays are provided for oxygen saturation and pulse rate, and a 10segment LED bar indicates pulse amplitude. High and low alarm limits for

saturation and pulse rate can be adjusted by the operator. The NPB-190 can

operate on AC or a rechargeable internal battery power. The controls and

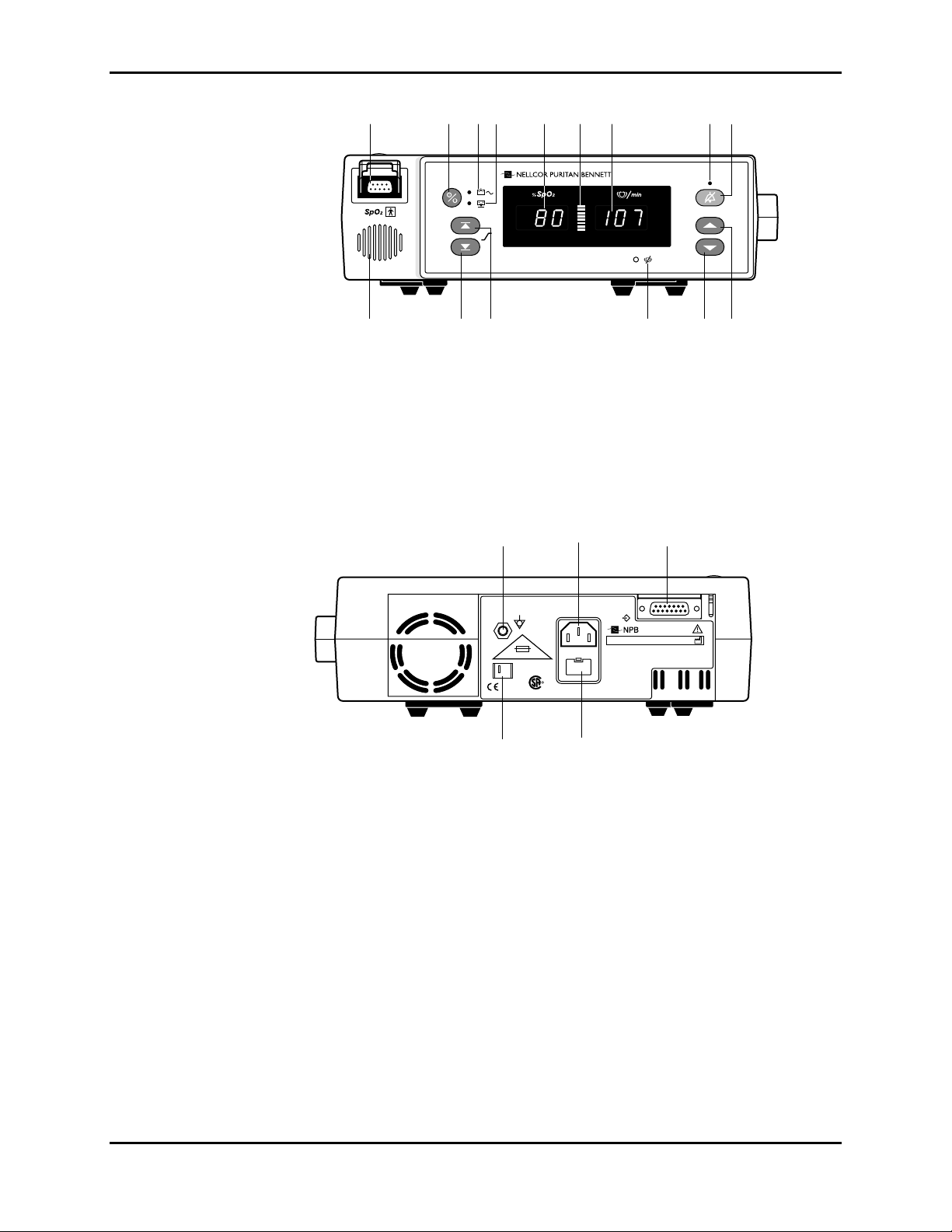

indicators for the NPB-190 are illustrated in Figures 1-1 and 1-2.

1-1

Page 8

Section 1: Introduction

1 2 3 4 5 6 7 8 9

NPB190

101112131415

Figure 1-1: NPB-190 Front Panel

1. SpO2 Sensor Port 9. Alarm Silence Button

2. Power On/Standby Button 10. Adjust Up Button

3. AC/Battery Charging Indicator 11. Adjust Down Button

4. Low Battery Indicator 12. Pulse Search Indicator

5. %SpO2 Display 13. Upper Alarm Limit Button

6. Pulse Amplitude Indicator 14. Lower Alarm Limit Button

7. Pulse Beats per Minute Display 15. Speaker

8. Alarm Silence Indicator

1. Equipotential Terminal 4. Fuse Drawer

2. AC Connector 5. Voltage Selector Switch

3. Serial Port

1.3 POWER-ON SELF TEST

When the NPB-190 is turned on it will perform a POST (Power On Self Test).

During POST the following sequence should occur:

0123

1

2X

T 0.50A 250V

IPX1

5

CISPR 11

Group 1

Class B

NRTL/C

R

100-120 V~ 200-240 V~

50/60Hz

2

20 VA

4

SN

NELLCOR PURITAN BENNETT, INC.

PLEASANTON, CA 94588, U.S.A.

NELLCOR PURITAN BENNETT EUROPE BV,

's-HERTOGENBOSCH, THE NETHERLANDS

U.S. PATENTS:

4,621,643; 4,653,498;

4,700,708; 4,770,179;

4,869,254; Re. 35,122;

4,928,692; 4,934,372;

5,078,136

TM

3

NPB-190

MADE IN IRELAND

Figure 1-2: NPB-190 Rear Panel

036400-1098

1-2

• All indicator lights illuminate

• All segments of the numeric digits light

• All segments of the Pulse Amplitude Display light

Page 9

Section 1: Introduction

Upon completion of the POST display test, the software versions will be

displayed for approximately 2 seconds. Two versions are displayed:

• The first version is indicated by the numeral “1” in the leftmost segment of

the %SpO

2 display. The series of digits and decimal points displayed to the

right of the “1” represent the main processor software version.

• The second version is indicated by the numeral “2” in the leftmost segment

of the %SpO

2 display. The number(s) appearing to the right of the “2”

represent the subprocessor software version.

The software version numbers are often needed when calling Mallinckrodt’s

Technical Services Department or your local Mallinckrodt representative for

technical assistance. Record the numbers and have them available prior to

requesting technical assistance.

Upon successful completion of POST, the NPB-190 sounds a 1-second tone

indicating that the monitor has passed the test.

If the start-up sequence is not completed as described above do not use the

monitor.

1.4 RELATED DOCUMENTS

To perform test and troubleshooting procedures and to understand the principles

of operation and circuit analysis sections of this manual, you must know how to

operate the monitor. Refer to the NPB-190 operator’s manual. To understand the

various Nellcor sensors that work with the monitor, refer to the individual sensor

directions for use.

1-3

Page 10

Page 11

SECTION 2: ROUTINE MAINTENANCE

2.1 Cleaning

2.2 Periodic Safety and Functional Checks

2.3 Battery

2.1 CLEANING

Caution: Do not immerse the NPB-190 or its accessories in liquid or clean

with caustic or abrasive cleaners. Do not spray or pour any liquid on the

monitor or its accessories.

To clean the NPB-190, dampen a cloth with a commercial, nonabrasive cleaner

and wipe the exterior surfaces lightly. Do not allow any liquids to come in

contact with the power connector, fuse holder, or switches. Do not allow any

liquids to penetrate connectors or openings in the instrument cover. Wipe sensor

cables with a damp cloth. For sensors, follow the individual directions for use.

2.2 PERIODIC SAFETY AND FUNCTIONAL CHECKS

The following checks should be performed at least every 2 years by a qualified

service technician:

2.3 BATTERY

1. Inspect the exterior of the NPB-190 for damage.

2. Inspect safety labels for legibility. If the labels are not legible, contact

Mallinckrodt’s Technical Services Department or your local Mallinckrodt

representative.

3. Verify that the unit performs properly as described in paragraph 3.3.

4. Perform the electrical safety tests detailed in paragraph 3.4. If the unit fails

these electrical safety tests, do not attempt to repair.

5. Inspect the fuses in the Power Entry Module for proper value and rating.

The fuses are slow blow, 0.5 amp, and 250 volt.

Mallinckrodt recommends replacing the instrument battery every 2 years. When

the NPB-190 is going to be stored for 3 months or more remove the battery. To

replace or remove the battery, refer to Section 6, Disassembly Guide.

If the NPB-190 has been stored for more than 30 days, charge the battery as

described in paragraph 3.3.1. A fully discharged battery requires 14 hours to

receive a full charge. The battery is being charged anytime the instrument is

plugged into AC.

2-1

Page 12

Page 13

SECTION 3: PERFORMANCE VERIFICATION

3.1 Introduction

3.2 Equipment Needed

3.3 Performance Tests

3.4 Safety Tests

3.1 INTRODUCTION

This section discusses the tests used to verify performance following repairs or

during routine maintenance. All tests can be performed without removing the

NPB-190 cover. All tests except the battery charge and battery performance tests

must be performed as the last operation before the monitor is returned to the

user.

If the NPB-190 fails to perform as specified in any test, repairs must be made to

correct the problem before the monitor is returned to the user.

3.2 EQUIPMENT NEEDED

Equipment Description

Digital multimeter (DMM) Fluke Model 87 or equivalent

Durasensor oxygen transducer

Oxisensor II oxygen transducer

Pulse oximeter tester SRC-2

Safety analyzer Must meet current AAMI specifications

Sensor extension cable EC-4 or EC-8

Serial interface cable EIA-232 cable (optional)

Stopwatch Manual or electronic

DS-100A

D-25

3.3 PERFORMANCE TESTS

The battery charge procedure should be performed before monitor repairs

whenever possible. It should also be performed before and after performing the

battery performance test (paragraph 3.3.2).

Note: This section is written using Mallinckrodt factory-set defaults. If your

institution has preconfigured custom defaults, those values will be

displayed. Factory defaults can be reset using the configuration

procedure described in paragraph 4.3.3.

3.3.1 Battery Charge

Perform the following procedure to fully charge the battery.

1. Connect the monitor to an AC power source.

3-1

Page 14

Section 3: Performance Verification

2. Verify that the monitor is off and that the AC Power/Battery Charging

indicator is lit.

3. Charge the battery for at least 14 hours.

3.3.2 Performance Tests

The power-up performance tests (3.3.2.1 and 3.3.2.2) verify the following

monitor functions:

• Power-On Self-Test

• Factory Power-On Defaults and Alarm Limit Ranges

On/Standby Alarm Silence

NPB-190

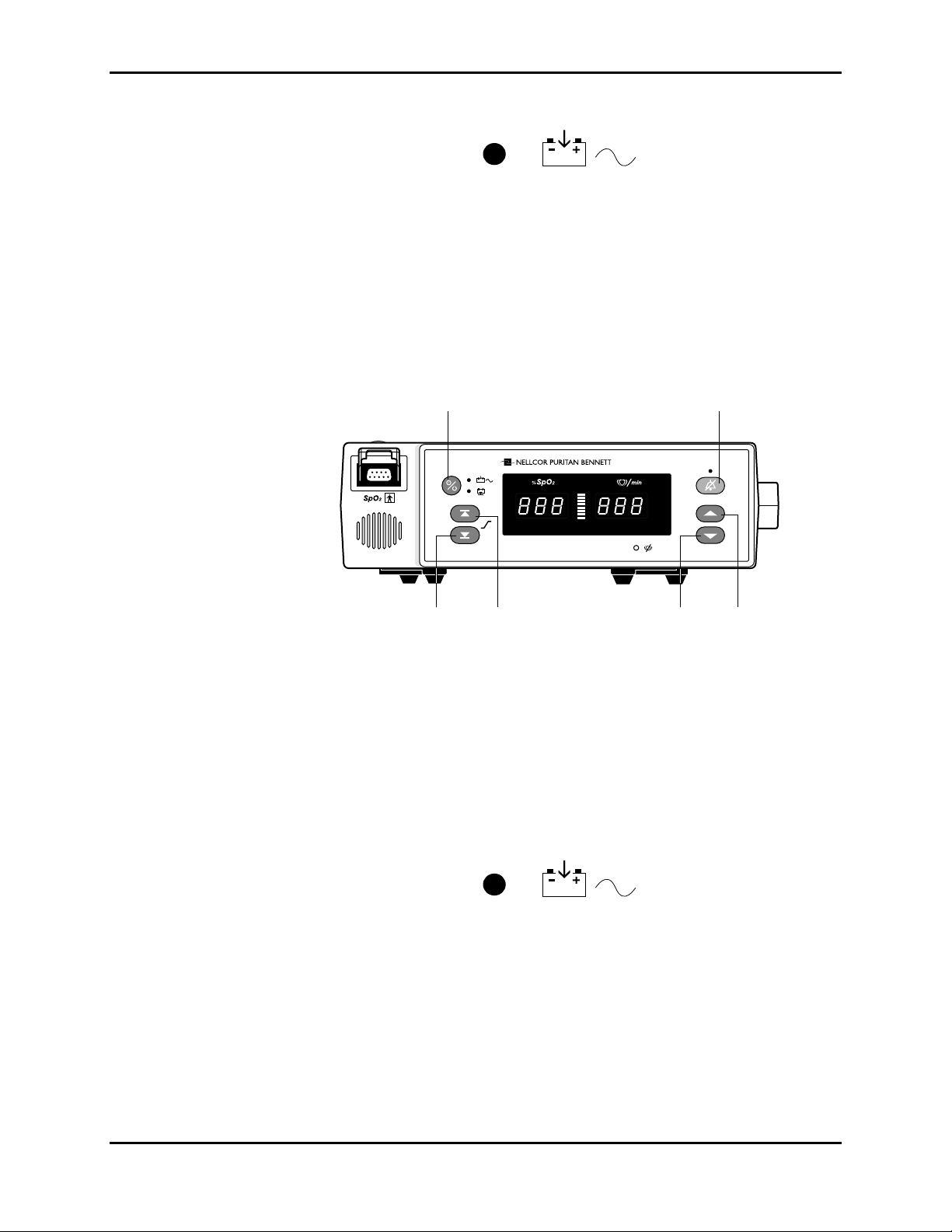

Note: Refer to Figure 3-1, NPB-190 Controls, when following the instructions

3.3.2.1 Power-On Self-Test

1. Connect the monitor to an AC power source. Verify that the AC

Power/Battery Charging indicator is lit.

2. Do not connect any input cables to the monitor.

3. Observe the monitor front panel. With the monitor off, press the Power

On/Standby button. Verify that the monitor performs the following

sequence:

Lower Alarm

listed below.

Limit

Upper Alarm

Limit

Figure 3-1: NPB-190 Controls

Adjust

Down

Adjust

Up

3-2

Page 15

Section 3: Performance Verification

a. All indicators light for a few seconds as illustrated in Figure 3-2.

LEDs

illuminated

888 displayed

10 segments

illuminated

NPB190

LED

illuminated

LED

illuminated

Figure 3-2: Self-Test Display

b. The software version is displayed and the AC Power/Battery Charging

indicators remain on.

c. When a sensor is connected a zero is displayed in each window, a 1-

second Power-On Self-Test (POST) beep sounds and the Pulse Search

LED is illuminated.

If no sensor is connected a 1 second POST beep sounds, 3 dashes are

displayed in each window and the Pulse Search LED is off.

d. The NPB-190 begins normal operation if a sensor is connected.

Without a sensor the monitor will be in the idle mode (3 dashes in each

window).

3.3.2.2 Factory Power-On Defaults and Alarm Limit Ranges

Note: When observing or changing default limits, a 3-second timeout is in

effect, that is, if no action is taken within 3 seconds, the monitor

automatically returns to the normal mode.

1. Turn the monitor on by pressing the Power On/Standby button. Wait for

POST to be completed. Press and release the Upper Alarm Limit button.

Verify that the monitor emits a single beep and the %SpO

a high alarm limit of “100” for about 3 seconds. Verify that three dashes are

displayed at the top of the pulse rate display window.

Note: The location of the three dashes indicates the type of alarm limit that is

being adjusted. Three dashes in the top of the display window indicate a

high alarm limit and three dashes in the bottom of the display window

indicate a low alarm limit.

2 display indicates

Figure 3-3: Adjusting High %SpO2 Alarm Limit

Normal monitoring is resumed after 3 seconds.

3-3

Page 16

Section 3: Performance Verification

2. Press the Upper Alarm Limit button. Press and hold the Adjust Down

button. Verify that the %SpO

Note: A decimal point to the right of the value in either display indicates that

3. Press the Lower Alarm Limit button. Verify that the monitor emits a single

beep and that the %SpO

seconds. Verify that three dashes are displayed at the bottom of the pulse

rate display window.

4. Press the Lower Alarm Limit button. Press and hold the Adjust Down

button and verify that the %SpO

Press and hold the Adjust Up button and verify that the %SpO

cannot be raised past the upper alarm limit setting of “85”.

2 display reduces to a minimum of “85”.

the alarm limits are not power-on default values.

2 display indicates an alarm limit of “85” for 3

Figure 3-4: Adjusting Low %SpO2 Alarm Limit

2 display reduces to a minimum of “20”.

2 display

5. Press the Upper Alarm Limit button two times rapidly (twice within 3

seconds). Verify that the monitor emits two beeps, the pulse rate display

indicates an alarm limit of “170”, and that the %SpO

2 display window

shows three dashes at the top for about 3 seconds.

Figure 3-5: Adjusting High Heart Rate Alarm Limit

6. Press the Upper Alarm Limit button two times rapidly. Press and hold the

Adjust Down button. Verify that the pulse rate display reduces to a

minimum of “40”.

7. Press the Lower Alarm Limit button two times rapidly. Verify that the pulse

rate display indicates an alarm limit of “40” and that the %SpO

2 display

window shows three dashes at the bottom for 3 seconds.

Figure 3-6: Adjusting Low Heart Rate Alarm Limit

3-4

8. Press the Lower Alarm Limit button two times rapidly. Press and hold the

Adjust Down button. Verify that the pulse rate display reduces to a

minimum of “30”.

9. Press the Lower Alarm Limit button two times rapidly. Press and hold the

Adjust Up button and verify that the pulse rate display cannot be adjusted

above “40”.

Page 17

Section 3: Performance Verification

10. Press the Power On/Standby button to turn the unit off. Turn the unit back

on.

11. Press and release the Upper Alarm Limit button. Verify that the %SpO

display indicates an alarm limit of “100”.

12. Press and release the Lower Alarm Limit button. Verify that the %SpO

display indicates an alarm limit of “85”.

13. Press the Upper Alarm Limit button two times rapidly. Verify that the pulse

rate display indicates an alarm limit of “170”.

14. Press the Lower Alarm Limit button two times rapidly. Verify that the pulse

rate display indicates an alarm limit of “40”.

15. Press the Power On/Standby button to turn the monitor off.

3.3.3 Hardware and Software Tests

Hardware and software testing include the following tests:

• Operation with a Pulse Oximeter Tester

• General Operation

3.3.3.1 Operation with a Pulse Oximeter Tester

Operation with an SRC-2 pulse oximeter tester includes the following tests:

• Alarms and Alarm Silence

• Alarm Volume Control

• Pulse Tone Volume Control

• Dynamic Operating Range

• Nurse Call

2

2

3.3.3.1.1 Alarms and Alarm Silence

1. Connect the SRC-2 pulse oximeter tester to the sensor input cable and

connect the cable to the monitor. Set the SRC-2 as follows:

SWITCH POSITION

RATE 38

LIGHT HIGH

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

2. Press the Power On/Standby button to turn the monitor on. After the normal

power-up sequence, verify that the pulse rate initially indicates zeroes.

Note: The pulse bar may occasionally indicate a step change as the

monitor is in the pulse search mode.

3. Set the modulation switch on the SRC-2 to HIGH.

4. Verify the following monitor reactions:

3-5

Page 18

Section 3: Performance Verification

a. The pulse blip bar begins to track the artificial pulse signal from the

b. The pulse tone is heard.

SRC-2.

c. Zeroes are displayed in the %SpO

2 and pulse rate displays.

d. After about 10 to 20 seconds, the monitor displays oxygen saturation

and pulse rate as specified by the tester. Verify that the values are

within the following tolerances:

Oxygen Saturation Range 79% to 83%

Pulse Rate Range 37 to 39 bpm

e. The audible alarm sounds and both the %SpO

2 and pulse rate displays

flash. This is an indication that both parameters have violated the

default alarm limits.

5. Press and hold the Alarm Silence button on the front of the monitor for less

than 3 seconds. Verify that the pulse rate display indicates “SEC” and the

%SpO

2 display indicates “60” while the Alarm Silence button is pressed.

The alarm is silenced when the button is released.

Figure 3-7: Alarm Silence Duration

6. Release the Alarm Silence button. Verify the following:

a. The alarm remains silenced.

b. The Alarm Silence indicator lights.

c. The %SpO

2 and pulse rate displays resume flashing.

d. The pulse tone is still audible.

e. The audible alarm returns after approximately 60 seconds.

7. While pressing the Alarm Silence button, press the Adjust Down button

until the %SpO

2 display indicates “30”. Press the Adjust Up button and

verify that the displays indicate 60 SEC, 90 SEC, 120 SEC, and OFF.

Release the button when the display indicates “OFF”. Press the Alarm

Silence button again and verify that the Alarm Silence indicator flashes.

8. Wait approximately 3 minutes. Verify that the alarm does not return. After 3

minutes ± 10 seconds, the alarm silence reminder beeps three times, and

continues to do so at 3-minute intervals.

3-6

Page 19

3.3.3.1.2 Alarm Volume Control

After completing the procedure in paragraph 3.3.3.1.1:

1. Press and hold the Alarm Silence button for more than 3 seconds. Verify the

following:

a. “OFF” is displayed for approximately 3 seconds.

b. After 3 seconds, a steady tone is heard at the default alarm volume

setting, the %SpO

indicates the default setting of 5.

2. Press the Adjust Down button until an alarm volume setting of 1 is

displayed. Verify that the volume of the alarm has decreased but is still

audible.

Section 3: Performance Verification

2 display indicates “VOL”, and the pulse rate display

Figure 3-8: Alarm Volume Display

3. Press the Adjust Up button to increase the alarm volume setting to a

maximum value of 10. Verify that the volume increases. Press the Adjust

Down button until a comfortable audio level is attained.

4. Release the Alarm Silence button. The tone stops.

3.3.3.1.3 Pulse Tone Volume Control

1. When a valid pulse has been acquired, press the Adjust Up button and

verify that the beeping pulse tone sound level increases.

2. Press the Adjust Down button and verify that the beeping pulse tone

decreases until it is no longer audible. Press the Adjust Up button to return

the beep volume to a comfortable level.

3.3.3.1.4 Dynamic Operating Range

The following test sequence verifies proper monitor operation over a range of

input signals:

1. Connect the SRC-2 to the NPB-190 and turn the NPB-190 on.

2. Place the SRC-2 in the RCAL 63/LOCAL mode.

3. Set the SRC-2 as indicated in Table 3-1. Verify that the NPB-190 readings

are within the indicated tolerances. Allow the monitor several seconds to

stabilize the readings.

Note: A (*) indicates values that produce an alarm. Press the Alarm Silence

button to silence the alarm.

3-7

Page 20

Section 3: Performance Verification

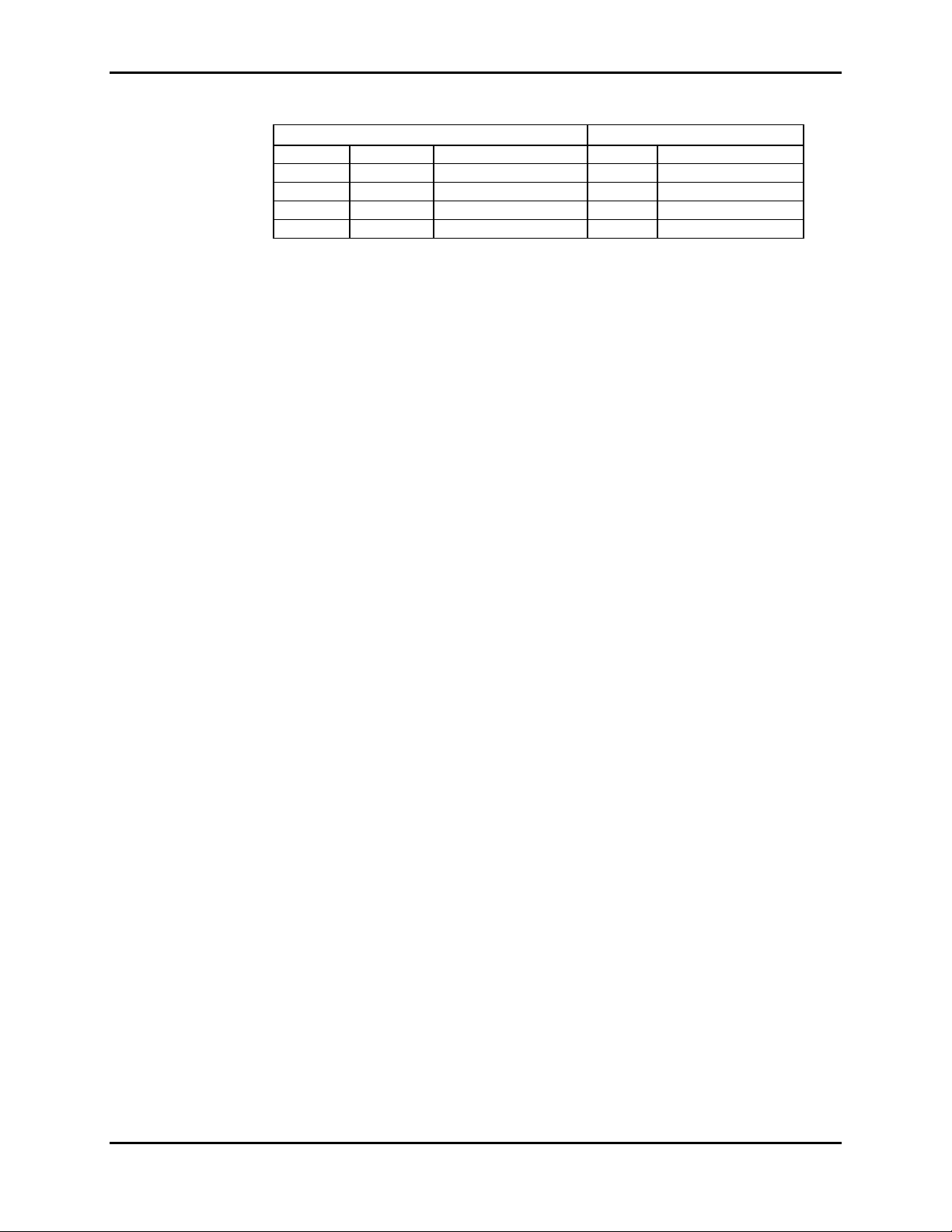

RATE LIGHT MODULATION SpO2 Pulse Rate

38 HIGH2 LOW 79 - 83* 37 - 39*

112 HIGH1 HIGH 79 - 83* 110 - 114

201 LOW LOW 79 - 83* 198 - 204*

201 LOW HIGH 79 - 83* 198 - 204*

3.3.3.1.5 Nurse Call

Note: The Nurse Call tests must be performed with the instrument operating

1. Connect the negative lead of a voltmeter to pin 10 and positive to pin 11 of

the serial port on the back of the instrument (Figure A-1 in appendix).

Ensure that the audible alarm is not silenced or turned off.

2. Set the SRC-2 to create an alarm condition. Verify an output voltage at pins

10 and 11 between +5 to +12 VDC.

3. Press the Alarm Silence button. With no active audible alarm, the output

voltage at pins 10 and 11 must be between -5 to -12 VDC.

Table 3-1: Dynamic Operating Range

SRC-2 Settings NPB-190 Indications

on AC power.

4. Turn the instrument off. Disconnect the voltmeter and the SRC-2.

3.3.3.1.6 Operation on Battery Power

1. Turn the instrument on using AC Power.

2. Disconnect the instrument from AC and verify that the AC Power Indicator

turns off.

3. Verify that the instrument continues monitoring normally and that the Low

Battery Indicator is not lit.

Note: If the Low Batter Indicator is illuminated, perform the procedure

outlined in step 3.3.1.

4. Connect the instrument to AC and verify that the AC Power Indicator turns

on and that the instrument is monitoring normally.

3.3.3.2 General Operation

The following tests are an overall performance check of the system:

• LED Excitation Test

• Monitor Operation with a Live Subject

3.3.3.2.1 LED Excitation Test

This procedure uses normal system components to test circuit operation. A

Nellcor Oxisensor II

intensity control. The red LED is used to verify intensity modulation caused by

the LED intensity control circuit.

3-8

â

oxygen transducer, model D-25, is used to examine LED

Page 21

Section 3: Performance Verification

1. Connect the monitor to an AC power source.

2. Connect an EC-4 or EC-8 sensor input cable to the monitor.

3. Connect a D-25 sensor to the sensor input cable.

4. Press the Power On/Standby button to turn the monitor on.

5. Leave the sensor open with the LEDs and photodetector visible.

6. After the monitor completes its normal power-up sequence, verify that the

sensor LED is brightly lit.

7. Slowly move the sensor LED in proximity to the photodetector element of

the sensor. Verify, as the LED approaches the photodetector, that the LED

intensity decreases.

8. Open the sensor and notice that the LED intensity increases.

9. Repeat step 7 and the intensity will again decrease. This variation is an

indication that the microprocessor is in proper control of LED intensity.

10. Turn the NPB-190 off.

3.3.3.2.2 Monitor Operation with a Live Subject

Pulse oximetry involves connecting the monitor to a live subject for a qualitative

test.

1. Ensure that the monitor is connected to an AC power source.

2. Connect an EC-4 or EC-8 sensor input cable to the monitor.

3. Connect a Nellcor Durasensor

sensor input cable.

4. Clip the DS-100A to an adult subject as recommended in the sensor

directions for use.

5. Press the Power On/Standby button to turn the monitor on and verify that

the monitor is operating.

6. The monitor should stabilize on the subject’s physiological signal in about

15 to 30 seconds. Verify that the saturation and heart rates are reasonable

for the subject.

3.4 SAFETY TESTS

â

oxygen transducer, model DS-100A, to the

NPB-190 safety tests meet the standards of, and are performed in accordance

with, IEC 601-1 (EN 60601-1, Second Edition, 1988; Amendment 1, 1991-11,

Amendment 2, 1995-03) and UL 2601-1 (August 18, 1994), for instruments

classified as Class 1 and TYPE BF and AAMI Standard ES1 (ANSI/AAMI ES1

1993).

3-9

Page 22

Section 3: Performance Verification

• Ground Integrity

• Electrical Leakage

3.4.1 Ground Integrity

This test checks the integrity of the power cord ground wire from the AC plug to

the instrument chassis ground. The current used for this test is < 6V RMS 50 or

60 Hz and 25 A.

1. Connect the monitor AC mains plug to the analyzer as recommended by the

analyzer operating instructions.

2. Connect the analyzer resistance input lead to the equipotential terminal

(grounding lug) on the rear panel of the instrument. Verify that the analyzer

indicates 100 milliohms or less.

3.4.2 Electrical Leakage

The following tests verify the electrical leakage of the monitor:

• Earth Leakage Current

• Enclosure Leakage Current

• Patient Leakage Current

• Patient Source Current (Mains on Applied Part)

Note: For the following tests, ensure that the AC switch on the rear of the

instrument is configured for the AC voltage being supplied.

3.4.2.1 Earth Leakage Current

This test is in compliance with IEC 601-1 (earth leakage current) and AAMI

Standard ES1 (earth risk current). The applied voltage for AAMI ES1 is 120

VAC 60 Hz, for IEC 601-1 the voltage is 264 VAC 50 to 60 Hz. All

measurements shall be made with the power switch in both the “On” and “Off”

positions.

1. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions.

2. The equipotential terminal is not connected to ground.

AC

POLARITY

Normal Closed Closed 500 µA

Reversed Closed Closed 500 µA

Normal Open Closed 1000 µA

Normal Closed Open 1000 µA

3.4.2.2 Enclosure Leakage Current

LINE CORD NEUTRAL

Table 3-2: Earth Leakage Current Limits

LEAKAGE

CORD

CURRENT

3-10

This test is in compliance with IEC 601-1 (enclosure leakage current) and AAMI

Standard ES1 (enclosure risk current). This test is for ungrounded enclosure

current, measured between enclosure parts and earth. The applied voltage for

Page 23

Section 3: Performance Verification

AAMI/ANSI is

120 VAC 60 Hz, and for IEC 601-1 the applied voltage is 264 VAC 50 to 60 Hz.

1. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions.

2. Place a 200 cm

is not in contact with any metal parts of the enclosure that may be grounded.

Measure the leakage current between the foil and earth.

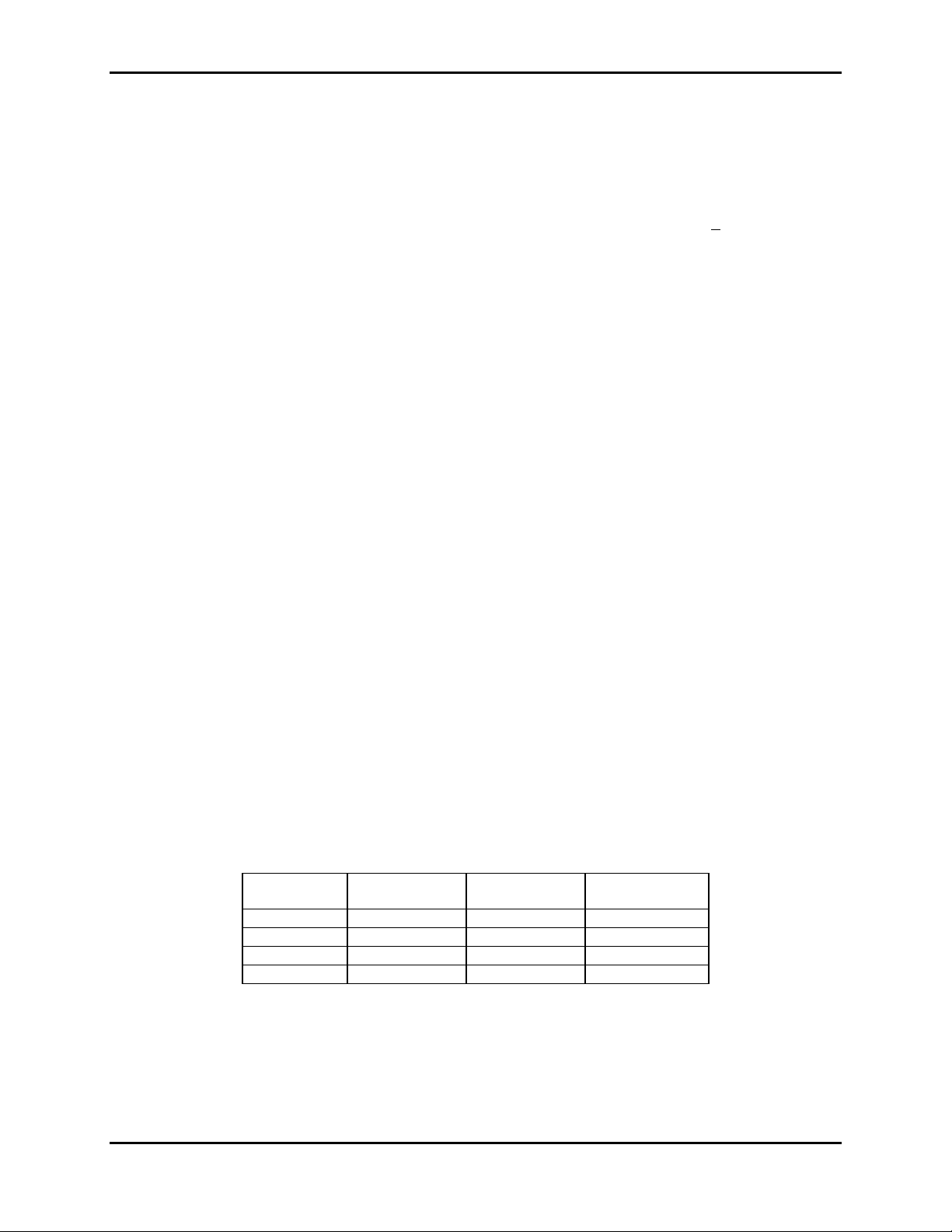

The analyzer leakage indication must not exceed values listed in the table below:

Table 3-3: Enclosure Leakage Current Limits

AC LINE

CORD

Closed Closed Closed 100 µA 100 µA

Closed Closed Open 500 µA 300 µA

Closed Open Closed 500 µA 300 µA

Open Closed Closed 500 µA 100 µA

Open Open Closed 500 µA 300 µA

Open Closed Open 500 µA 300 µA

3.4.2.3 Patient Applied Risk Current

NEUTRAL

LINE CORD

This test is in compliance with AAMI Standard ES1 (patient applied risk

current), and IEC 601-1 (patient auxiliary current). The leakage current is

measured between any individual patient connection and power (earth) ground.

The applied voltage for AAMI/ANSI is 120 VAC 60 Hz, and for IEC 601-1 the

applied voltage is 264 VAC 50 to 60 Hz.

2

foil in contact with the instrument case making sure the foil

POWER LINE

GROUND CABLE

IEC 601-1 AAMI/ANSI ES1

STANDARD

1. Configure the electrical safety analyzer as follows:

Function: Patient Leakage

Range: µA

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions for Patient Leakage

Current.

3. Connect the electrical safety analyzer patient leakage input lead to all pins

of the monitor's patient cable at the end of the cable.

4. The equipotential terminal is not connected to ground.

5. All functional earth terminals are not connected to ground.

6. Measure the leakage current between the patient connector and earth.

3-11

Page 24

Section 3: Performance Verification

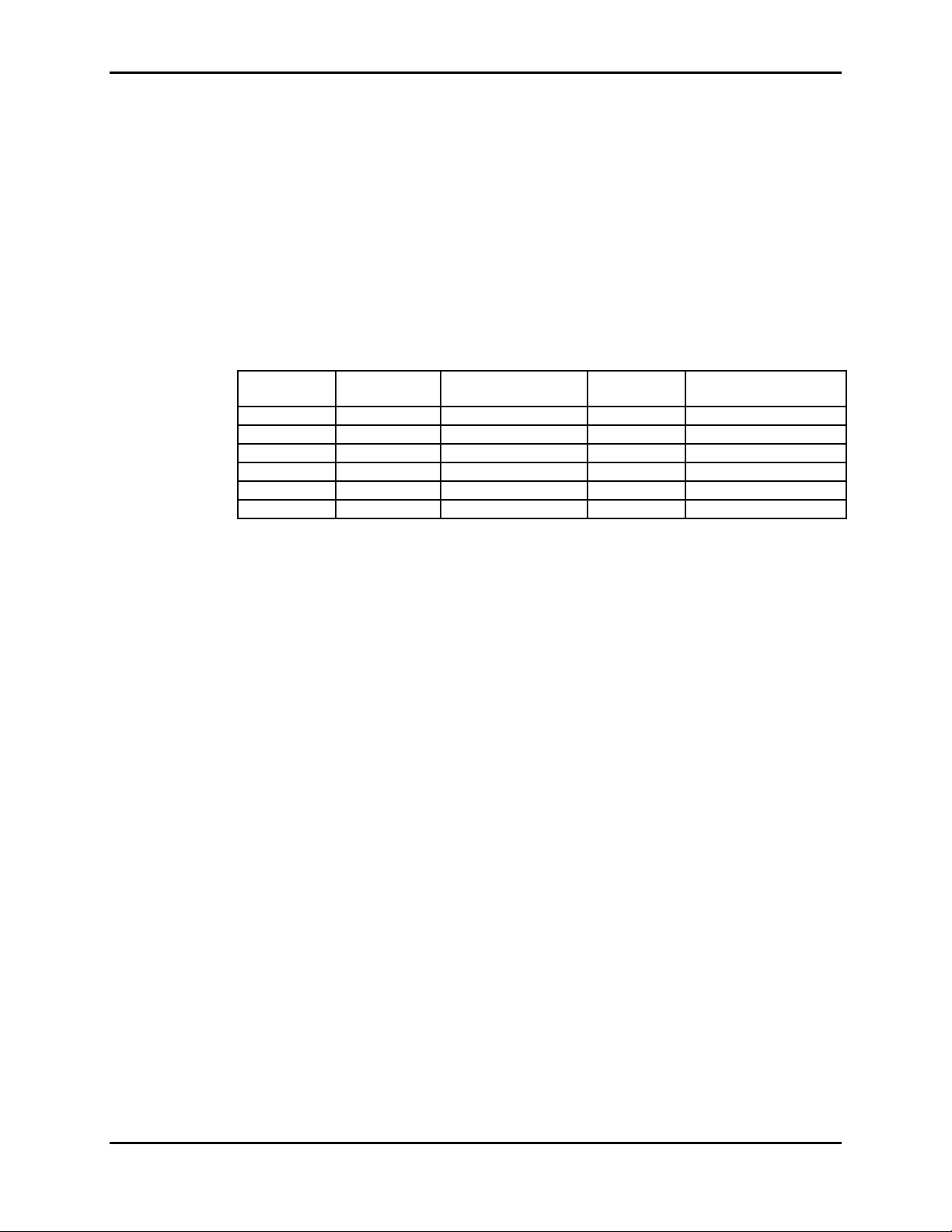

Table 3-4: Patient Leakage Current Limits

AC LINE

POLARITY

Normal Closed Closed 100 µA 10 µA

Normal Open Closed 500 µA 50 µA

Normal Closed Open 500 µA 50 µA

Reverse Closed Closed 100 µA 10 µA

Reverse Open Closed 500 µA 50 µA

Reverse Closed Open 500 µA 50 µA

3.4.2.4 Patient Isolation Risk Current - (Mains Voltage on the Applied Part)

NEUTRAL

LINE

POWER LINE

GROUND

CABLE

IEC 601-1 AAMI/ANSI

This test is in compliance with AAMI Standard ES1 (patient isolation risk

current [sink current]), and IEC 601-1 (patient leakage current). Patient Leakage

Current is the measured value in a patient connection if mains voltage is

connected to that patient connection. The applied voltage for AAMI/ANSI is 120

VAC 60 Hz, and for IEC 601-1 the applied voltage is 264 VAC 50 to 60 Hz.

Warning: AC mains voltage will be present on the patient applied part

terminals during this test. Exercise caution to avoid electrical shock hazard.

1. Configure the electrical safety analyzer as follows:

Function: Patient Leakage (Mains On Applied Part)

Range: µA

ES1

STANDARD

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the operating instructions for patient sink (leakage)

current.

3. Connect the electrical safety analyzer patient leakage input lead to all

connectors in the patient cable at the patient end of the cable.

4. The equipotential terminal is not connected to ground.

5. All functional earth terminals are not connected to ground.

6. The analyzer leakage current must not exceed the values shown in the table

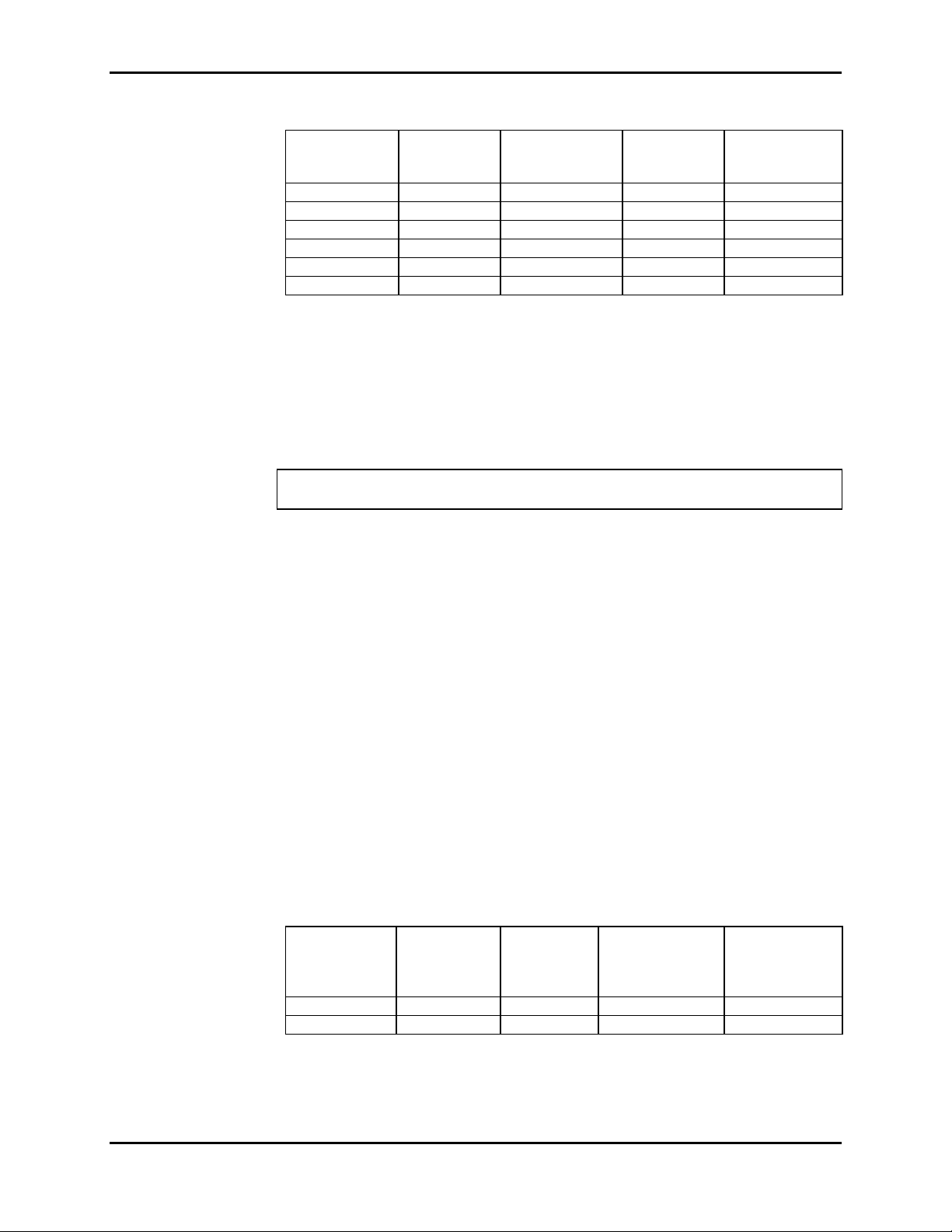

below.

Table 3-5: Patient Leakage Current Test Configurations -

Mains Voltage on the Applied Part

AC LINE

POLARITY

Normal Closed Closed 5 mA 50 µA

Reverse Closed Closed 5 mA 50 µA

NEUTRAL

LINE

POWER

LINE

GROUND

CABLE

IEC 601-1 AAMI/ANSI

ES1

STANDARD

3-12

Page 25

SECTION 4: AUDIBLE ALARM SETTINGS & SERVICE MENU

4.1 Introduction

4.2 Audible Alarm Settings

4.3 Service Menu

4.1 INTRODUCTION

This section discusses use of the service menu to reconfigure power-on default

values, and how to control the behavior of the audible alarm.

4.2 AUDIBLE ALARM SETTINGS

The following paragraphs describe how to change the behavior of the audible

alarm. Operators can select the volume of the alarm and the duration of alarm

silence. Controls for the NPB-190 are shown in Figure 4-1.

On/Standby Alarm silence

NPB190

4.2.1 Alarm Silence State

Press the Alarm Silence button to silence the alarm. Press the button a second

time to turn the alarm back on.

4.2.2 Alarm Silence Duration

1. Press and hold the Alarm Silence button for less than 3 seconds.

2. Before 3 seconds have passed the Adjust Up or Adjust Down button can be

used to change the duration of the alarm silence. The alarm’s duration can

be 30, 60, 90, 120 seconds, or the alarm can be turned off.

4.2.3 Alarm Volume

1. Press and hold the Alarm Silence button for more than 3 seconds.

Set lower

limit

Set upper

limit

Figure 4-1: NPB-190 Controls

Adjust

down

Adjust

up

4-1

Page 26

Section 4: Audible Alarm Settings & Service Menu

2. After 3 seconds, while still pressing the Alarm Silence button, the Adjust

Up or Adjust Down button can be used to select alarm volumes from 1 to

10. Select a level that is suitable for the monitor’s location.

4.3 SERVICE MENU

The menu items listed below should be accessed only by a qualified service

technician. Power-on default values can be changed for the behavior of the

audible alarm, alarm limits, and for the serial port.

4.3.1 Accessing Menu Items

1. Menu items can be accessed at any time by pressing the Upper and Lower

Alarm Limit buttons simultaneously for at least 3 seconds. The service

menu has been accessed when a 1 appears in the pulse rate display.

2. Pressing the Adjust Up or Adjust Down button selects the menu item

number. Menu numbers 5 and 6, have items within them that can be selected

by first pressing the Upper Alarm Limit button, and then pressing the Adjust

Up or Adjust Down key.

Note: Service menu items greater than 2 cannot be accessed if a sensor is

connected to the monitor.

3. Once adjustments have been made within a menu item the, Upper Alarm

Limit button can be used to initiate the current selection. Three tones will

sound to indicate that the change has been accepted, and the monitor will

return to normal monitoring.

4. The service menu can be exited without making changes by pressing the

Lower Alarm Limit button. If a period of 10 seconds passes with no button

presses, the instrument will exit the service menu, go to normal monitoring,

and no changes will have been made.

4.3.2 Menu Item 1 (Save Current Values as Power-On Default)

1. If menu item 1 is selected, the current values for alarm limits, alarm volume,

pulse beep volume, audible alarm silence duration, alarm silence behavior,

and baud rate will be saved as the power-on default settings. Some values

are not allowed to be saved as power on default values, they are; an Alarm

Silence Duration of Off, and low %SpO

invalid tone is heard instead of the triple beep the current settings were not

changed.

Note: Current values will not be stored in memory as defaults, if power is

interrupted before exiting this menu option.

Note: When the operator changes an alarm limit to a value other than a power

on default value, a decimal point will appear to the right of the parameter

whose alarm limit was changed.

2 alarm limits less than 80%. If an

4-2

Page 27

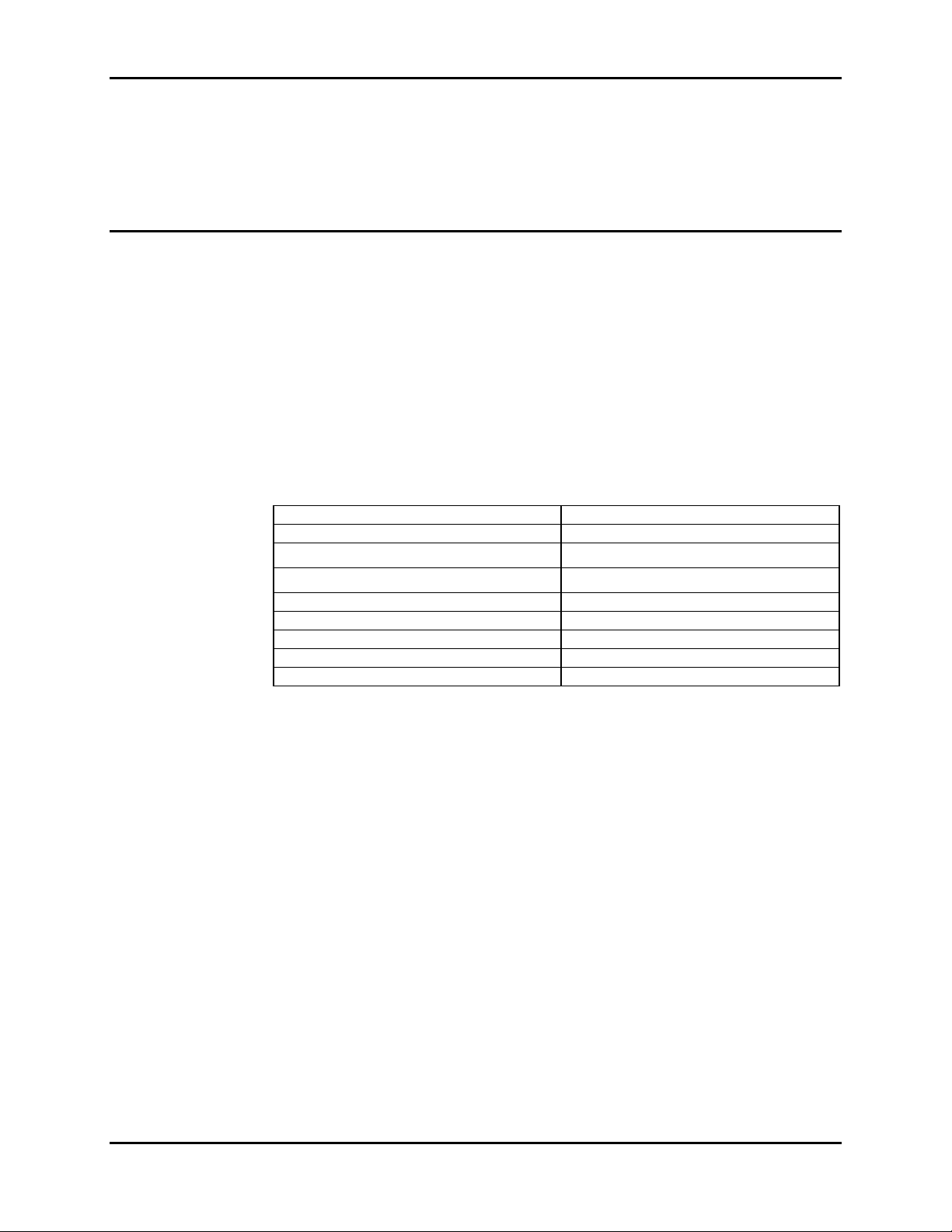

4.3.3 Menu Item 2 (Return to Default Settings)

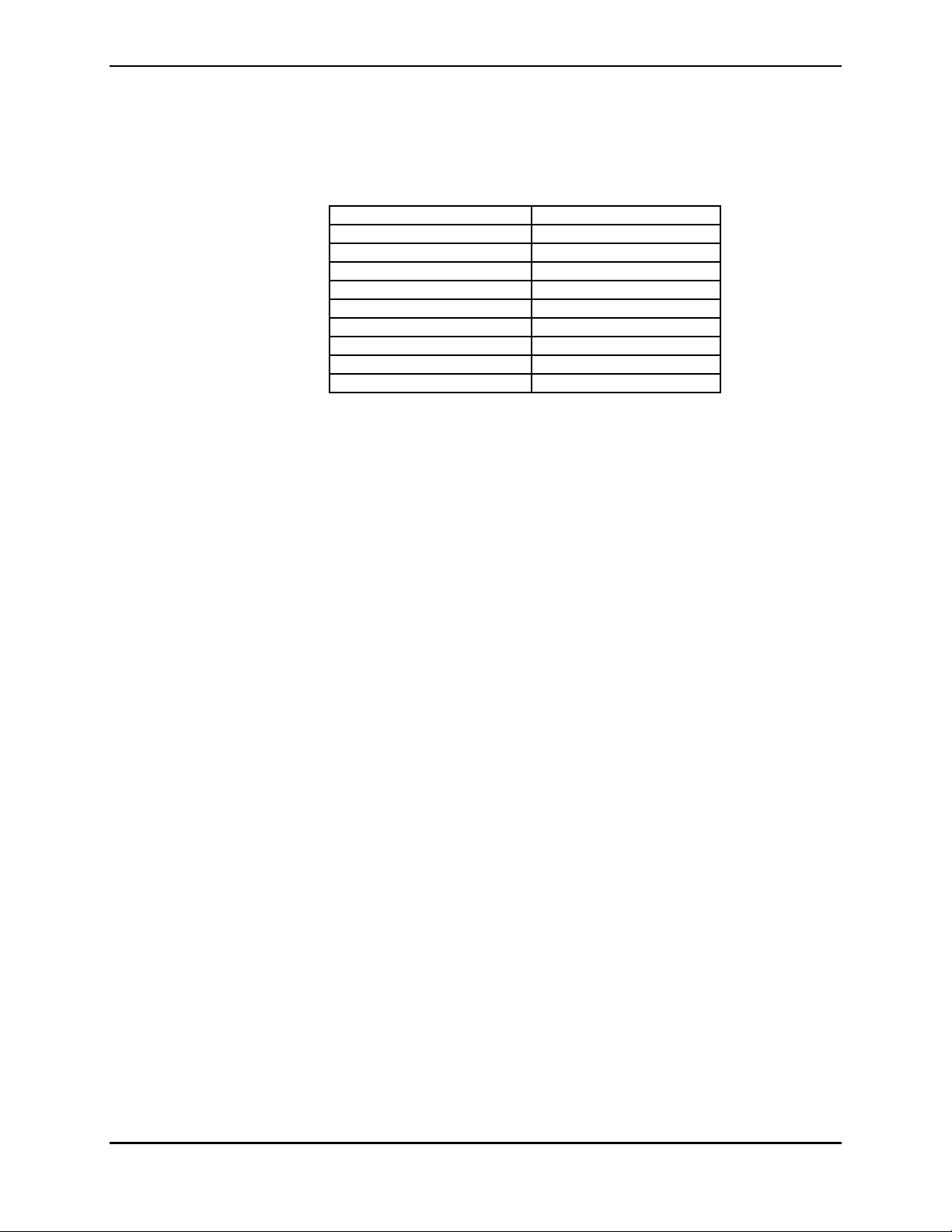

Menu item 2 resets the monitor to factory default settings as shown in table 4-1.

Table 4-1: Factory Default Settings

Parameter Default Value

SpO2 High 100%

SpO2 Low 85%

Pulse rate High 170 bpm

Pulse rate Low 40 bpm

Pulse beep volume Level 4

Alarm Volume Level 5

Alarm Silence Duration 60 seconds

Alarm Silence Behavior 0 (Off with reminder)

Baud Rate 9600

Note: Menu items greater than 2 cannot be accessed when a valid sensor is

plugged into the unit.

Note: To reach menu item 5 two invalid tones will be heard when passing

through menu items 3 and 4.

Section 4: Audible Alarm Settings & Service Menu

4.3.4 Menu Item 3 (Not Displayed)

4.3.5 Menu Item 4 (Not Displayed)

4.3.6 Menu Item 5 (Alarm Silence Behavior)

1. This menu item is used to change alarm silence behavior. Three options; 0,

1, or 2 can be accessed by first pressing the Upper Alarm Limit button, then

using the Adjust Up or Down button to scroll to the desired number.

2. Option “0” will allow the operator to select Alarm Silence, but there will be

a reminder tone every 3 minutes.

3. Option “1” allows the operator to select Alarm Silence and there will be no

reminder tone.

4. Option “2” will not allow the operator to select Alarm Silence.

5. When the desired option is indicated in the display, press the Upper Alarm

Limit button to save the current selection. Three tones will sound to indicate

that the change has been accepted

Note: The low battery audible alarm cannot be disabled.

4.3.7 Menu Item 6 (Baud Rate)

1. Baud rates of 2400, 9600, and 19200 can be selected by first pressing the

Upper Alarm Limit button, then using the Adjust Up or Adjust Down button

to select the desired baud rate. The baud rates will be displayed in the

%SpO

2 window as 24, 96, or 192.

4-3

Page 28

Section 4: Audible Alarm Settings & Service Menu

2. When the desired option is indicated in the display, press the Upper Alarm

Limit button to save the current selection. Three tones will sound to indicate

that the change has been accepted.

4.3.8 Menu Item 7

Do not use. For use by Mallinckrodt Customer Service Engineer.

4.3.9 Menu Item 8

Do not use. For use by Mallinckrodt Customer Service Engineer.

4.3.10 Menu Item 9

Do not use. For use by Mallinckrodt Customer Service Engineer.

4-4

Page 29

SECTION 5: TROUBLESHOOTING

5.1 Introduction

5.2 How to Use this Section

5.3 Who Should Perform Repairs

5.4 Replacement Level Supported

5.5 Obtaining Replacement Parts

5.6 Troubleshooting Guide

5.7 Error Codes

5.1 INTRODUCTION

This section explains how to troubleshoot the NPB-190 if problems arise. Tables

are supplied that list possible monitor difficulties, along with probable causes,

and recommended actions to correct the difficulty.

5.2 HOW TO USE THIS SECTION

Use this section in conjunction with Section 3, Performance Verification, and

Section 7, Spare Parts. To remove and replace a part you suspect is defective,

follow the instructions in Section 6, Disassembly Guide. The circuit analysis

section in the Technical Supplement offers information on how the monitor

functions.

5.3 WHO SHOULD PERFORM REPAIRS

Only qualified service personnel should open the monitor housing, remove and

replace components, or make adjustments. If your medical facility does not have

qualified service personnel, contact Mallinckrodt Technical Services or your

local Mallinckrodt representative.

5.4 REPLACEMENT LEVEL SUPPORTED

The replacement level supported for this product is to the printed circuit board

(PCB) and major subassembly level. Once you isolate a suspected PCB, follow

the procedures in Section 6, Disassembly Guide, to replace the PCB with a

known good PCB. Check to see if the symptom disappears and that the monitor

passes all performance tests. If the symptom persists, swap back the replacement

PCB with the suspected malfunctioning PCB (the original PCB that was installed

when you started troubleshooting) and continue troubleshooting as directed in

this section.

5.5 OBTAINING REPLACEMENT PARTS

Mallinckrodt Technical Services provides technical assistance information and

replacement parts. To obtain replacement parts, contact Mallinckrodt or your

local Mallinckrodt representative. Refer to parts by the part names and part

numbers listed in Section 7, Spare Parts.

5-1

Page 30

Section 5: Troubleshooting

5.6 TROUBLESHOOTING GUIDE

Problems with the NPB-190 are separated into the categories indicated in Table

5-1. Refer to the paragraph indicated for further troubleshooting instructions.

Note: Taking the recommended actions discussed in this section will correct

the majority of problems you will encounter. However, problems not

covered here can be resolved by calling Mallinckrodt Technical

Services or your local representative.

Problem Area Refer to Paragraph

1. Power

• No power-up on AC and/or DC

• Fails power-on self-test

• Powers down without apparent cause

2. Buttons

• Monitor does not respond properly to

buttons

3. Display/Alarms

• Displays do not respond properly

• Alarms or other tones do not sound

properly or are generated without apparent

cause

4. Operational Performance

• Displays appear to be operational, but

monitor shows no readings

• Suspect readings

5. Serial Port

• NPB-190 and PC not communicating

properly

• Nurse Call not functioning properly

Table 5-1: Problem Categories

5.6.1

5.6.2

5.6.3

5.6.4

5.6.5

5-2

All of the categories in Table 5-1 are discussed in the following paragraphs.

Page 31

5.6.1 Power

Section 5: Troubleshooting

Power problems are related to AC and/or DC. Table 5-2 lists recommended

actions to power problems.

Table 5-2: Power Problems

Condition Recommended Action

1. BATTERY LOW

indicator lights

steadily while NPB190 is connected to

AC and battery is

fully charged.

2. The NPB-190 does

not operate when

disconnected from

AC power.

3. BATTERY LOW

indicator on during

DC operation and

an alarm is

sounding.

1. Ensure that the NPB-190 is plugged into an operational AC

outlet and the AC indicator is on.

2. Check the fuses. The Power Entry Module contains the

fuses as indicated in paragraph 6.3 and Figure 6-3 of the

Disassembly Guide section. Replace if necessary.

3. Open the monitor as described in section 6. Verify power

supply’s output to the battery while on AC. Disconnect the

battery leads from the battery and connect a DVM to them.

The voltage measured should be 6.8 VDC + 0.15 and the

current should be 400 mA + 80 mA. Replace power supply

if above values are not met.

4. Check the cable connection from the bottom enclosure to

the UIF PCB, as instructed in paragraph 6.5 of the

Disassembly Guide section. If the connection is good,

replace the UIF PCB.

1. The battery may be discharged. To recharge the battery,

refer to paragraph 3.3.1, Battery Charge. The monitor may

be used with a less than fully charged battery but with a

corresponding decrease in operating time from that charge.

2. If the battery fails to hold a charge, replace the battery as

indicated in Section 6, Disassembly Guide.

There are 15 minutes or less of usable charge left on the

NPB-190 battery before the instrument shuts off. At this

point, if possible, cease use of the NPB-190 on battery

power, connect it to an AC source, and allow it to recharge.

The full recharge takes 14 hours. The NPB-190 may

continue to be used while it is recharging.

4. Battery does not

charge.

1. Replace battery if more than 2 years old.

2. Open the monitor as described in Section 6. Verify power

supply’s output to the battery while on AC. Disconnect the

battery leads from the battery and connect a DVM to them.

The voltage measured should be 6.8 VDC ± 0.15 and the

current should be 400 mA ± 80 mA. Replace power supply

if above values are not met.

5-3

Page 32

Section 5: Troubleshooting

5.6.2 Buttons

Table 5-3 lists symptoms of problems relating to nonresponsive buttons and

recommended actions. If the action requires replacement of a PCB, refer to

Section 6, Disassembly Guide.

Condition Recommended Action

1. The NPB-190 responds

to some, but not all

buttons.

Table 5-3: Button Problems

1. Replace Top Housing assembly.

2. If the buttons still do not work, replace the UIF PCB.

5.6.3 Display/Alarms

2. The NPB-190 turns on

but does not respond to

any of the buttons.

1. Check the connection between the membrane panel

and J5 of the UIF PCB.

2. Replace Top Housing assembly.

3. If the buttons still do not work, replace the UIF PCB.

Table 5-4 lists symptoms of problems relating to nonfunctioning displays,

audible tones or alarms, and recommended actions. If the action requires

replacement of a PCB or module, refer to Section 6, Disassembly Guide.

Table 5-4: Display/Alarms Problems

Condition Recommended Action

1. Display values are

missing or erratic.

1. Try another sensor or relocate the sensor to a

different site.

2. If the sensor is connected, replace the sensor

connector assembly.

3. If the condition persists, replace the sensor

extension cable.

4. If the condition still persists, replace the UIF

PCB.

5-4

2. All display segments

do not light during

POST.

3. All Front Panel LED

indicators do not light

during POST.

4. Alarm sounds for no

apparent reason.

1. Check the connection between the UIF PCB and

the Display PCB.

2. If the condition does not change, replace the

Display PCB.

3. If the condition still persists, replace the UIF

PCB.

1. Check the connection between the membrane

panel and J5 of the UIF PCB.

2. Replace Top Housing assembly.

1. Moisture or spilled liquids can cause an alarm to

sound. Allow the monitor to dry thoroughly

before using.

2. If the condition persists, replace the UIF PCB.

Page 33

Section 5: Troubleshooting

Table 5-4: Display/Alarms Problems (cont. from page 5-4)

Condition Recommended Action

5. Alarm does not sound. 1. Check speaker connection to UIF PCB.

2. Replace the speaker as described in Section 6,

Disassembly Guide.

3. If the condition persists, replace the UIF PCB.

Table 5-5 lists symptoms of problems relating to operational performance (no

error codes displayed) and recommended actions. If the action requires

replacement of a PCB or module, refer to Section 6, Disassembly Guide.

Table 5-5: Operational Performance Problems

Condition Recommended Action

1. The Pulse Amplitude

indicator seems to

indicate a pulse, but the

digital displays show

zeroes.

2. SpO2 or pulse rate values

change rapidly; Pulse

Amplitude indicator is

erratic.

1. The sensor may be damaged; replace it.

2. If the condition still persists, replace the UIF

PCB.

1. The sensor may be damp or may have been

reused too many times. Replace it.

2. An electrosurgical unit (ESU) may be

interfering with performance:

ñ Move the NPB-190 and its cables and

sensors as far from the ESU as possible.

ñ Plug the NPB-190 and the ESU into

different AC circuits.

ñ Move the ESU ground pad as close to the

surgical site as possible and as far away

from the sensor as possible.

3. Verify performance with the procedures

detailed in Section 3.

4. If the condition still persists, replace the UIF

PCB.

5-5

Page 34

Section 5: Troubleshooting

5.6.5 Serial Port

Table 5-6 lists symptoms of problems relating to the serial port and

recommended actions. If the action requires replacement of the PCB, refer to

Section 6, Disassembly Guide.

Condition Recommended Action

Table 5-6: Serial Port Problems

1. No printout is being

received.

2. The Nurse Call function

is not working.

1. The unit is running on battery power.

Connect to an AC source. If the AC indicator

is not on see section 5.6.1.

2. The monitor’s baud rate does not match the

printer. Change the baud rate of the monitor

following instructions in section 4.3.7.

3. Check connections between serial port and

printer (see section A3).

4. If the condition still persists, replace the UIF

PCB.

1. The unit is running on battery power.

Connect to an AC source. If the AC indicator

is not on see section 5.6.1.

2. Verify that connections are made between

pins 5 or 10 (GND) and 11 (Nurse Call) of

the serial port.

3. Verify that output voltage between ground

pin 5 or 10 and pin 11 is -5 to -12 VDC (no

alarm) and +5 to +12 VDC (during alarm).

4. If the condition still persists, replace the UIF

PCB.

5-6

Page 35

5.7 ERROR CODES

Section 5: Troubleshooting

An error code will be displayed when the NPB-190 detects a non-correctable

failure. When this occurs, the unit will stop monitoring, sound a low priority

alarm that cannot be silenced, clear patient data from the display, and display an

error code. Error codes will be displayed with EEE in the Saturation display and

the number of the code in the Pulse Rate display, i.e., EEE 1. Table 5-7 provides

a complete list of error codes and possible solutions.

Table 5-7: Error Codes

Code Meaning Possible Solutions

POST failure Replace UIF PCB

1

Battery dead 1. Check the voltage selector

4

switch.

2. Charge battery for 14 hours

3. Leads of battery reversed;

see paragraph 6.5

4. Replace battery

Too many microprocessor resets

5

within a period of time

Boot CRC error Replace UIF PCB

6

Error on UIF PCB 1. Cycle power to clear error.

7

1. Replace UIF PCB

2. Replace Power Supply

2. Check voltage selector

switch for proper setting.

3. Replace UIF PCB

Flash ROM corruption Replace UIF PCB

11

Error accessing EEPROM Replace UIF PCB

76

Institutional default values lost

80

Replace UIF PCB

and reset to factory default

values

Internal communications error Replace UIF PCB

84

5-7

Page 36

Page 37

SECTION 6: DISASSEMBLY GUIDE

6.1 Introduction

6.2 Prior to Disassembly

6.3 Fuse Replacement

6.4 Monitor Disassembly

6.5 Monitor Reassembly

6.6 Battery Replacement

6.7 Power Entry Module (PEM) Removal/Installation

6.8 Power Supply Removal/Installation

6.9 Display PCB Removal/Installation

6.10 UIF PCB Removal/Installation

6.11 Alarm Speaker Removal/Installation

6.1 INTRODUCTION

The NPB-190 can be disassembled down to all major component parts,

including:

• PCBs

• Battery

• Top and Bottom Housing

• Speaker

• Power Entry Module (PEM)

The following tools are required:

• Phillips-head screwdriver #1

• 10 mm open-end wrench

• Needle-nose pliers

• Torque wrench, 10 inch-pounds (1.13 newton-meters)

• Wire Cutters

WARNING: Before attempting to open or disassemble the NPB-190,

disconnect the power cord from the NPB-190.

Caution: Observe ESD (electrostatic discharge) precautions when working

within the unit.

Note: Some spare parts have a business reply card attached. When you receive

these spare parts, please fill out and return the card.

6.2 PRIOR TO DISASSEMBLY

1. Turn the NPB-190 off by pressing the Power On/Standby button.

2. Disconnect the monitor from the AC power source.

6-1

Page 38

Section 6: Disassembly Guide

6.3 FUSE REPLACEMENT

1. Complete the procedure in paragraph 6.2.

2. Disconnect the power cord from the back of the monitor.

3. Remove the fuse drawer from the Power Entry Module by pressing down on

the tab in the center and pulling the drawer out as shown in Figure 6-1.

Figure 6-1: Fuse Removal

4. Put new 0.5 amp fuses in the drawer and reinsert the drawer in the power

module.

6-2

Page 39

6.4 MONITOR DISASSEMBLY

Caution: Observe ESD (electrostatic discharge) precautions when

disassembling and reassembling the NPB-190 and when handling any of the

components of the

NPB-190.

1. Set the NPB-190 upside down, as shown in Figure 6-2.

Section 6: Disassembly Guide

Corner screws

Figure 6-2: NPB-190 Corner Screws

2. Remove the four corner screws.

3. Turn the unit upright. Separate the top case from the bottom case of the

monitor being careful not to stress the wire harnesses between the cases.

Place the two halves of the monitor on the table as shown in Figure 6-3.

4. Disconnect the Power Supply from J6 on the UIF PCB.

6-3

Page 40

Section 6: Disassembly Guide

J6

Power supply

harness

6.5 MONITOR REASSEMBLY

1. Place the two halves of the monitor on the table as shown in Figure 6-3 and

connect the Power Supply to J6 on the UIF PCB.

2. Place the top case over the bottom case and align the four outside screw

posts and close the monitor.

Caution: When reassembling the NPB-190, hand tighten the screws that

hold the cases together to a maximum of 10 inch-pounds. Over-tightening

could strip out the screw holes in the top case, rendering them unusable.

3. Install the four corner screws.

6-4

Figure 6-3: Separating Case Halves

Page 41

6.6 BATTERY REPLACEMENT

Removal

1. Follow procedure in paragraphs 6.2 and 6.4.

2. Remove the two screws from the battery bracket shown in Figure 6-4 and

lift the battery out of the bottom case.

3. Use needle-nose pliers to disconnect the leads from the battery.

Section 6: Disassembly Guide

Figure 6-4: Battery Removal

4. The lead-acid battery is recyclable. Do not dispose of the battery by placing

it in the regular trash. Dispose of properly according to state, local or other

applicable regulations, or contact Mallinckrodt Technical Services to return

for disposal.

Installation

5. Connect the leads to the battery. The red wire connects to the positive

terminal and the black wire goes to the negative.

6. Insert the new battery into the bottom case with the negative terminal

towards the bottom of the monitor. Install the bracket and grounding lead

with the two screws.

7. Complete the procedure in paragraph 6.5.

6-5

Page 42

Section 6: Disassembly Guide

8. Turn the monitor on and verify proper operation.

6.7 POWER ENTRY MODULE (PEM) REMOVAL/INSTALLATION

Removal

1. Complete the procedure in paragraphs 6.2 and 6.4.

2. While pushing the top of the PEM in from the outside of the case, gently

push the case to the outside and lift up on the PEM.

3. Use needle-nose pliers to disconnect the leads from the PEM (see Figure 6-

5).

N

G

L

6-6

Figure 6-5: Power Entry Module

Installation

4. Reconnect the three leads. The blue “N” wire, from the power supply goes

to the terminal labeled “N” on the PEM. The brown “L” wire, from the

power supply connects to the terminal labeled “L” on the PEM. The center

terminal at the top of the PEM is for the ground wire (Figure 6-6).

5. Install the PEM in the bottom case with the fuse drawer facing down. A tab

in the bottom case holds the PEM in place. Insert the bottom wing of the

PEM between the tab and the internal edge of the side wall of the bottom

case. Push the PEM down and towards the outside of the monitor until it

clicks into place.

Page 43

6. Position the ground line from the PEM so that it does not come into contact

with components on the Power Supply PCB.

7. Complete procedure in paragraph 6.5.

6.8 POWER SUPPLY REMOVAL/INSTALLATION

Removal

1. Complete the procedure described in paragraphs 6.2 and 6.4.

2. Disconnect the leads from the battery.

3. Follow the procedure in paragraph 6.7, steps 2 and 3.

4. Use a 10mm wrench to disconnect the Power Supply ground lead from the

equipotential lug (Figure 6-6).

5. Remove the seven screws shown in Figure 6-7.

Section 6: Disassembly Guide

6. Lift the Power Supply out of the bottom case.

W1

to

Equipotential

Lug

G

LN

Brown to

"L" on

PEM

W2

Equipotential

Lug

W3

Blue to

"N" on

PEM

W5

W4

Black

Red

Figure 6-6: Power Supply Leads Connections

6-7

Page 44

Section 6: Disassembly Guide

Figure 6-7: Power Supply

Installation

7. Reconnect the AC leads. The wire from the Power Supply labeled “N” goes

to the terminal labeled “N” on the PEM. The wire from the power supply

labeled “L” connects to the terminal labeled “L” on the PEM.

8. Place the Power Supply in the bottom case.

Caution: When installing the Power Supply, tighten the seven screws to a

maximum of 10 inch-pounds. Overtightening could strip out the inserts in

the bottom case, rendering them unusable.

9. Install the seven screws in the Power Supply and tighten.

10. Use a 10mm wrench to connect the power supply ground lead to the

equipotential lug. Tighten to 12 inch pounds.

11. Follow the procedure in paragraph 6.7, step 5.

12. Connect the ground wire to the PEM and position it so that it does not come

into contact with components on the Power Supply PCB.

6-8

13. Complete the procedure in paragraph 6-5.

Page 45

6.9 DISPLAY PCB REMOVAL/INSTALLATION

Removal

1. Complete the procedure described in paragraphs 6.2 and 6.4.

2. Lift the Display PCB up to remove it from the top case (Figure 6-8).

Grounding clip

Section 6: Disassembly Guide

J4

Figure 6-8: Display PCB

Installation

3. Slide the Display PCB into the grooves in the top case, being careful to

align the male pins from the Display PCB to connector J4 on the UIF PCB.

4. Complete the procedure in paragraph 6.5.

6-9

Page 46

Section 6: Disassembly Guide

6.10 UIF PCB REMOVAL/INSTALLATION

Removal

1. Complete the procedure described in paragraphs 6.2 and 6.4.

2. Lift the Display PCB up to remove it from the top case (Figure 6-8).

3. Disconnect the keypad ribbon cable from J5 of the UIF PCB (Figure 6-8).

J5 is a ZIF connector, lift up on the outer shell until it clicks, then remove

the ribbon cable from the connector.

4. Disconnect the speaker cable from J3 of the UIF PCB.

5. Remove the five screws in the UIF PCB (Figure 6-9).

J3

J5

6-10

Figure 6-9: UIF PCB

6. Remove the UIF PCB from the top case.

Page 47

Installation

Caution: When installing the UIF PCB, hand-tighten the five screws to a

maximum of 10 inch-pounds. Overtightening could strip out the inserts in

the top case, rendering them unusable.

7. Place the UIF PCB in the top case.

8. Install the five screws in the UIF PCB.

9. Lift up on the outer shell of J5 on the UIF PCB until it clicks. Insert the

keypad ribbon cable into J5 of the UIF PCB. Slide the outer shell of J5

down until it clicks.

10. Connect the speaker cable to J3 of the UIF PCB.

11. Slide the Display PCB into the grooves in the top case being careful to align

the male pins from the Display PCB to connector J4 on the UIF PCB.

12. Complete the procedure in paragraph 6.5.

6.11 ALARM SPEAKER REMOVAL/INSTALLATION

Removal

Section 6: Disassembly Guide

1. Complete the procedure described in paragraphs 6.2 and 6.4.

2. Disconnect the speaker wire harness for J3 on the UIF PCB (see Figure 6-

10).

3. Pull the holding clip towards the center of the monitor and lift the speaker

from the top housing.

6-11

Page 48

Section 6: Disassembly Guide

Connect speaker

wires to J3 connector

Figure 6-10: Alarm Speaker

Installation

4. Slide the speaker into the plastic holding clip provided in the top housing.

5. Connect the speaker wire harness to J3 on the UIF PCB.

6. Complete the procedure paragraph 6.5.

6-12

Page 49

SECTION 7: SPARE PARTS

7.1 Introduction

7.1 INTRODUCTION

Spare parts, along with part numbers, are shown below. Item numbers

correspond to the numbers called out in Figure 7-1.

Item Description Part No.

1 Top Case Assembly (Membrane Panel Included) 048428

2 Fuse Drawer 691500

3 Fuses 691032

4 Power Entry Module 691499

5 Power Supply 035200

6 Display PCB 035196

7 Battery 640119

8 Battery Bracket 035307

9 UIF PCB 035192

Sensor Lock (not shown) 022943

Alarm Speaker (not shown) 033494

Ground Clip (not shown) 035400

Rubber Feet (not shown) 4-003818-00

Power Cord (not shown) U.S. 071505

International 901862

U.K. 901863

Figure 7-1 shows the NPB-190 expanded view with item numbers relating to the

spare parts list.

Note: Some spare parts have a business reply card attached. When you receive

these spare parts, please fill out and return the card.

7-1

Page 50

Section 7: Spare Parts

1

9

NPB190

2

8

7

6

3

4

5

Figure 7-1: NPB-190 Exploded View

7-2

Page 51

SECTION 8: PACKING FOR SHIPMENT

8.1 General Instructions

8.2 Repacking in Original Carton

8.3 Repacking in a Different Carton

To ship the monitor for any reason, follow the instructions in this section.

8.1 GENERAL INSTRUCTIONS

Pack the monitor carefully. Failure to follow the instructions in this section may

result in loss or damage not covered by the Mallinckrodt warranty. If the original

shipping carton is not available, use another suitable carton; North American

customers may call Mallinckrodt Technical Services Department to obtain a

shipping carton.

Before shipping the NPB-190, contact Mallinckrodt Technical Services

Department for a returned goods authorization (RGA) number. Mark the

shipping carton and any shipping documents with the RGA number. European

customers not using RGA numbers, should return the product with a detailed,

written description of the problem.

8.2 REPACKING IN ORIGINAL CARTON

If available, use the original carton and packing materials. Pack the monitor as

follows:

1. Place the monitor in a plastic bag (not shown) and, if necessary, accessory

items in original packaging.

8-1

Page 52

Section 8: Packing for Shipment

8-2

Figure 8-1: Repacking the NPB-190

2. Place in shipping carton and seal carton with packaging tape.

3. Label carton with shipping address, return address and RGA number.

Page 53

8.3 REPACKING IN A DIFFERENT CARTON

If the original carton is not available, use the following procedure to pack the

NPB-190:

1. Place the monitor in a plastic bag.

2. Locate a corrugated cardboard shipping carton with at least 200 pounds per

square inch (psi) bursting strength.

3. Fill the bottom of the carton with at least 2 inches of packing material.

4. Place the bagged unit on the layer of packing material and fill the box

completely with packing material.

5. Seal the carton with packing tape.

6. Label the carton with the shipping address, return address, and RGA

number.

Section 8: Packing for Shipment

8-3

Page 54

Page 55

SECTION 9: SPECIFICATIONS

9.1 General

9.2 Electrical

9.3 Physical Characteristics

9.4 Environmental

9.5 Alarms

9.6 Factory Default Settings

9.7 Performance

9.1 GENERAL

Designed to meet safety requirements of: