Page 1

Safety

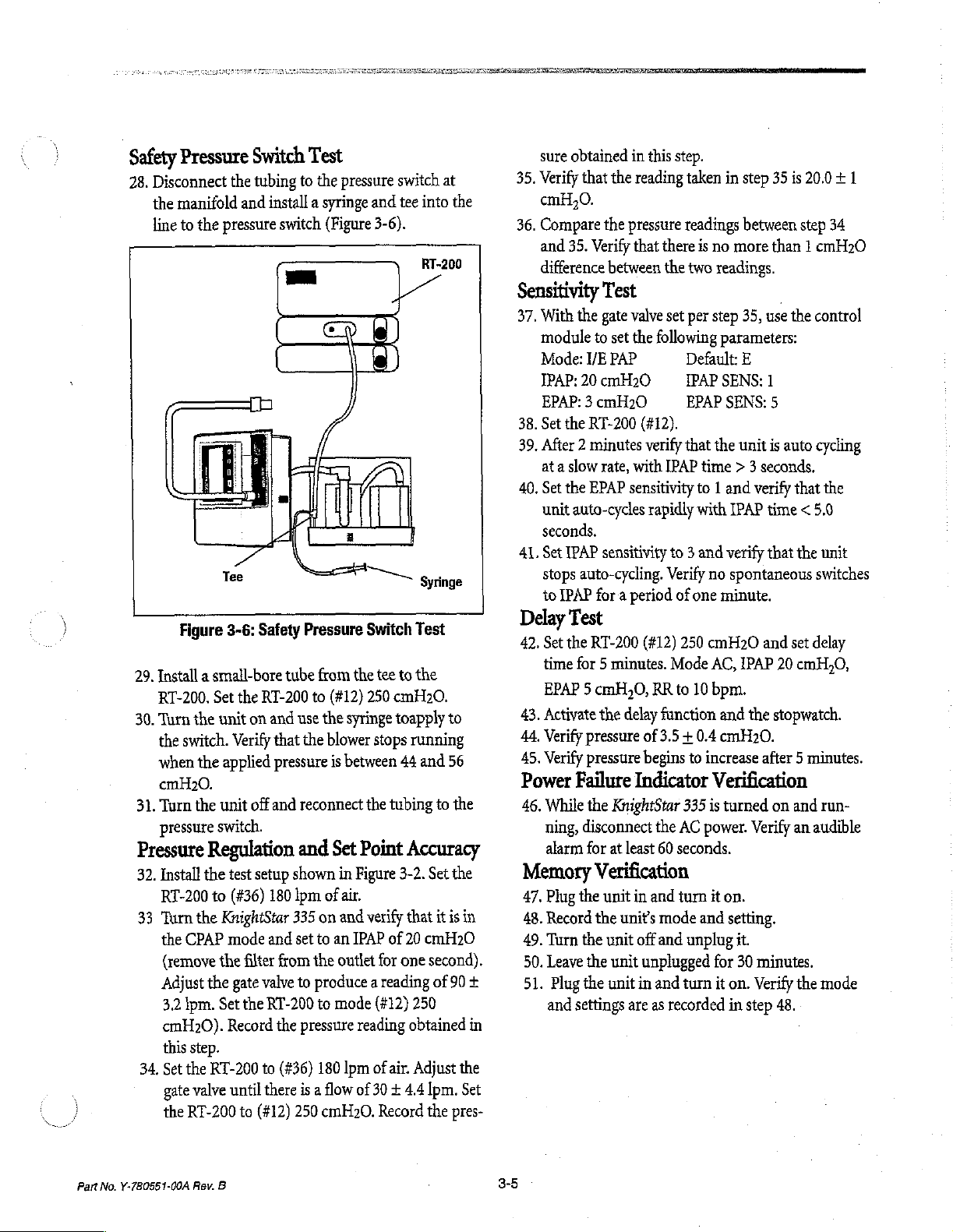

28.

Pressure

Disconnect

the

manifold

line

to

the

pressure

the

29.

Install a small-bore

RT-200.

30.

Turn

the

when

cmH20.

31.

Turn

pressure

Pressure

32.

Install

RT-200

33

Turn

the

(remove

Adjust

3.2

cmH20).

this

34,

Set

gate

the

Tee

Figure

3-6:

Set

the

unit

switch.

the

applied

the

unit

switch.

Verify

Regulation

the

test

to

(#36)

the

KnightStar

CPAP

mode

the

the

gate

Ipm.

Set

Record

step.

the

RT-200

valve

until

RT-200

Switch

tubing

and

Safety

the

on

off

Test

to

the

install a syringe

switch

Pressure

tube

from

RT-200

to

and

use the

that

the

pressure

and

reconnect

and

setup

shown

180

lpm

335

on

and

set

to

filter

from

the

valve

to

produce a reading

the

to

there

to

(#12)

RT-200

to

the

pressure

(#36)

is a flow

250

180

pressure

and

(Figure

blower

of

Switch

the

(#12)

250

syringe

is

between

the

Set

Point

in

Figure

air.

and

verify

an

IPAP

outlet

mode

reading

lpm

3-6).

stops

(#12)

of

of 30 + 4.4

cmH20.

switch

tee

into

RT-200

Syringe

Test

tee

to

the

cmH20.

toapply

running

44

and

tubing

Accuracy

3-2.

Set the

that

of

20

cmH20

for

one

second).

250

obtained

air.

Adjust

Ipm.

Record

the

at

the

to

56

to

the

it

is

of

90

pres-

in

+

in

the

Set

sure

35,

Verify

cmH,0.

36.

Compare

and

difference

Sensitivity

37,

With

module

Mode:

IPAP:

EPAP: 3 cmH20

38.

Set

39.

After 2 minutes

at a slow

40.

Set

unit

seconds.

41. Set

stops

to

IPAP

Delay

42,

Set

time

EPAP 5 cmH,0,

43,

Activate

44.

Verify

45.

Verify

Power

46.

While

ning,

alarm

Memory

47.

Plug

48.

Record

49.

Turn

50.

Leave

51.

Plug

and

obtained

that

35.

in

the

reading

the

pressure

Verify

that

this

there

between

Test

the gate

20

the

the

auto-cycles

IPAP

auto-cycling.

valve

to

set

the

following

I/E

PAP

cmH20

RT-200

EPAP

(#12).

verify

rate,

with

sensitivity

rapidly

sensitivity

for a period

Test

the

RT-200

for 5 minutes.

(#12)

RR

the

delay

function

pressure

pressure

Failure

the

disconnect

for

of

3.5 + 0.4

begins

Indicator

KnightStar

the

at

least

60

Verification

the

unit

in

and

the

units

mode

the

unit

off

and

the

unit

unplugged

the

unit

in

and

settings

are

as

step.

taken

in

readings

is

no

the

two

readings.

set

per

step

parameters:

Default:

IPAP

SENS:

EPAP

SENS:

that

the

IPAP

time > 3

to 1 and

with

IPAP

to 3 and

Verify

of

Mode

to

one

250

10

verify

no

spontaneous

minute.

cmH20

AC,

bpm.

and

cmH20.

to

increase

Verification

335

is

turned

AC

power.

seconds.

turn

it

on.

and

setting.

unplug

for

turn

it

on.

recorded

in

step

35

is

20.0 + 1

between

more

35,

E

unit

IPAP

the

Verify

step

than 1 cmH20

use

the

1

5

is

auto cycling

seconds.

verify

that

time

< 5,0

that

the

and

set

delay

20

cmH,0,

stopwatch.

after 5 minutes.

on

and

an

audible

it.

30

minutes.

Verify

the

step

48.

34

control

the

unit

switches

run-

mode

Part

No.

Y-780551-00A

Rev.

B

3-5

Page 2

Assembled

52.

Disconnect

equipment

base

through

53.

Connect

using

54.

Connect

MAINS

55.

Turn

powered

and

56.

Verify

panel

57.

Toggle

control

58,

Enable

pushing

PLAY

59.

Install

NASAL

the

with

+0.5

60.

Repeat

TIDAL

lowing

mode:

61.

Simultaneously

ARROW

log

62.

Simultaneously

ARROW

mal

63.

Connect a bacteria

tube,

outlet

64.

Turn

the

and

65.

Set

Adjust

+

66.

Set

pressure

Tests

unit

and

unit

per

ae.

the

the

6-foot

the

ON

the

unit

up,

the

three

the

green

is

illuminated.

through

module

the

calibration

the

key

until a “C”

the

analog

PRESSURE

control

the

fluke

to

0.0

step

VOLUME

outputs

Output

key

outputs

key

operation.

pressure

of

the

the

unit

mode

to

remove

the

RT-200

the

4.4

lpm.

the

RT

indicated

from

AC

the

bacteria

section

control

unit

light

and

indicator

DOWN

4,

procedure

module

cable.

to

an

AC

is

illuminated.

on.

Verify

the

control

LEDs

POWER

all

selectors

to

verify

outputs

ARROW

is

displayed.

output

analog

module.

£0.1

60

at

Verify

87

in

the

min/max

VDC.

for

EST

PATIENT

analog

with

the

of

0.5

to

press

the

until a “0”

0.0

+ 0.1

press

the

to

return

the

filter,

tee

gate

valve,

KnighiStar

on

and

use

CPAP

with a pressure

filter

from

to

the

180

gate

valve

to

to

(#12)

250

on

RT-200

source,

that

ON

that

cable

outputs.

fluke

-0.5

DISPLAY

is

Remove

filter.

Assemble

|,

steps

to

the

KnighiStar

source

and

verify

when

the

unit

panel

DELAY

momentarily

LED

on

the

and

fields

on

they

are

operational.

by

simultaneously

key

and

the

into the

output

the

following

on

EST

the

mode:

FLOW

Verify

87

in

the

£0.1

VDC.

and

displayed.

Verify

all

the

o

is

LED

light.

front

the

DIS-

back

outputs

Output

and

the

min/max

DOWN

volts.

DISPLAY

analog

the

335

the

outlet

Ipm

produce a reading

cmH,0.

and

outputs

6-foot

and

RT-200

as

shown

control

of

for

one

air

range

Verify

is

20

UP

to

smooth

to

in

figure

module

20

cmH20

second.

(#36).

of

that

+0.1

cmH,0.

test

335

the

first

of

of

EST

fol-

all

ana-

nor-

bore

the

3-2.

to

set

30

the

67.

Remove

unit.

68.

Verify

ed

69.

Set

DELAY

nated.

control

Current

Test

70.

Connect

rear

that

Disconnect

source.

71.

Connect

tester.

O.lohms

and

72.

Turn

rent

both

Remote

73.

Set

and

74,

Connect

power

75.

From

KnightStar

using

76.

Remove

the

the

77,

From

remote

KnightStar

be

control

78.

Move

module

position.

79.

Return

80.

Disconnect

the

circuit

assembly

that

the

LEAK

indication

within

60

to

80

seconds.

the

delay

interval

button

Turn

the

module

to 5 minutes.

and

verify

KnightStar

from

the

Leakage/Ground

the

AC

power

panel

receptacle

the

rear

panel

the

the

AC

Verify

that

between

the

KnightStar

on

the

KnightStar

leakage

normal

is

and

Control

the

data

rate

the

IR

module

the

IR

switch

approximately

335

the

remote

the

IR

data

rate

switches

remote

activated

control

approximately

control

335.

by

buttons.

the

data

and

the

Repeat

the

switches

unit

and

AC

KnightStar

power

ground

the

power

335’s

less

than

reverse

Test

switches

in

opposite

module

of

the

base

15

can

not

control.

module

to

15

toward

Verify

pressing

rate

switches,

remote

step

75.

to

from

from

the

LED

DELAY

base

cord

to

indicator

cord

line

metal

335

100

LED

335

off

and

unit.

Line

Resistance

to

the

KnightStar

an

AC

source.

is

illuminated.

335

from

to

the

resistance

cord

grounding

chassis.

and

verify

micro

amperes

polarity.

(If

Remote

in

the

remote

positions.

to

the

base

unit

in

the

feet

away,

verify

be

activated

from

the

base

on

both

the

IR

the

same

data

feet

away,

point

the

IR

Module

that

the

KnightStar

the

appropriate

on

both

control,

their

AC

to

original

source.

outlet

of

the

is

illuminat-

Press

the

is

illumi-

disconnect

335

Verify

the

AC

electrical

is

less

that

the

safety

than

pin

cur-

for

is

Used)

control

unit.

Place

the

ON

position.

that

the

or

deactivated

unit

and

set

module

rate

and

position.

the

on

the

335

can

remote

the

IR

the

opposite

settings.

Part

No.

Y-780551-00A

Rev.

B

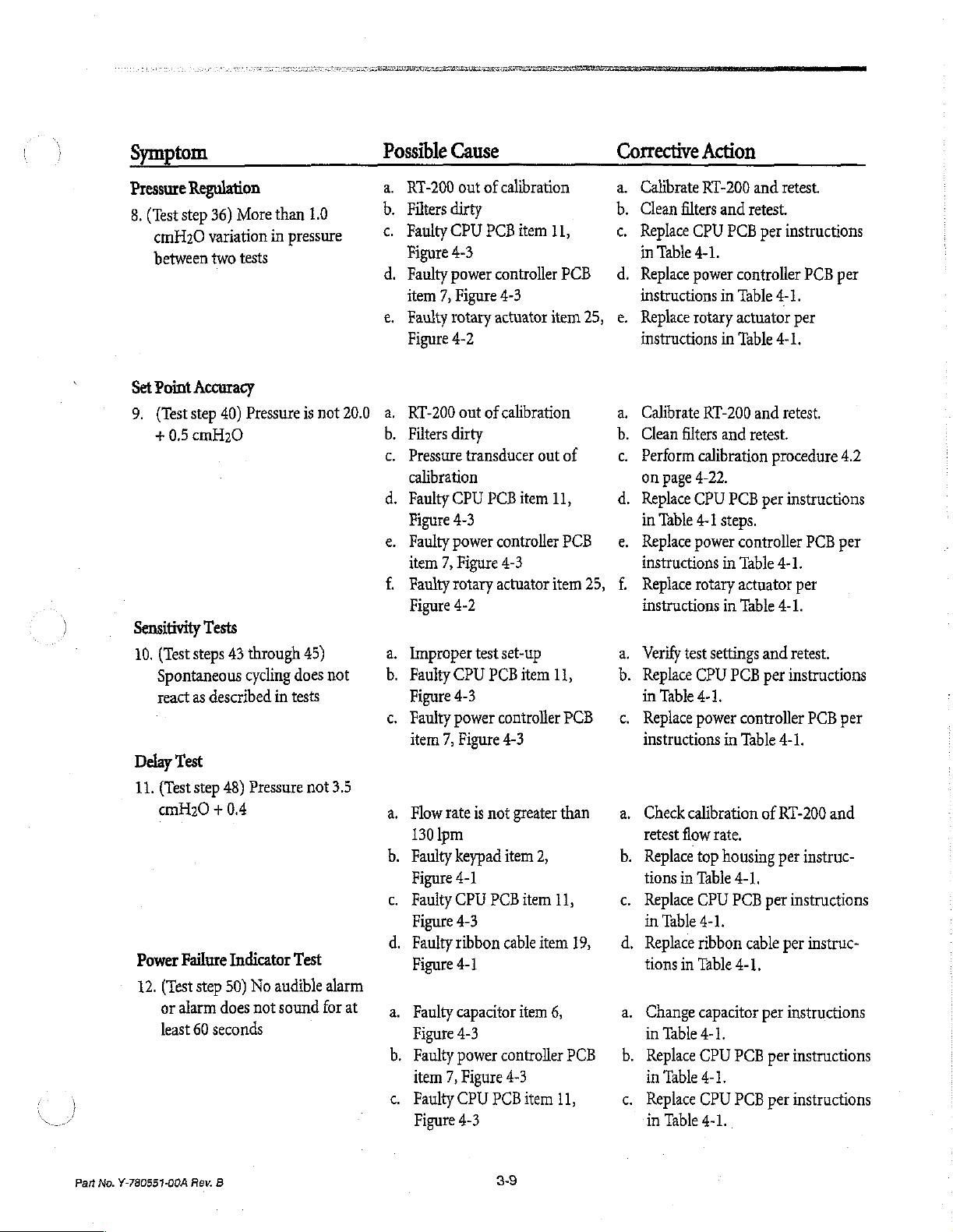

Page 3

Table

3-3

Troubleshooting

Troubleshooting

sented

is

not

all-inclusive

formance

tive

verification

actions.

For

operational

WARNING:

If

any

operational

Bennnett.

NOTE:

|

When

more

than

one

likely

reasons

Symptom

for

failure.

procedures

but

procedure.

troubleshooting,

problem

cannot

possible

Guide

for

the

is

intended

This

be

solved,

cause

is

KnightStar

to

table

identified, the

Possible

335

serve

as a general

describes

refer

to

do

not

use

possible

Cause

system

symptoms,

the

are

outline

Patient

the

KnightStar

causes

presented

identifies

Guide

are

in

for

solving

possible

located

335

on a patient:

listed.in

Corrective

Table

3-3.

problems

causes

in

Section 1 of

Contact

order

of

The

information

found

and

suggests

this

Nellcor

most

likely

Action

pre-

during

the

correc-

manual.

Puritan

to

the

least

per-

Maximum

1.

(Test

step

KnightStar

102

pm

2.

(Test

step

greater

Flow

10)

335

13)

than

Test

Flow from

is

not

greater

Current

2.475

amps

the

draw

than

is

a.

Flow

tester

calibration

b.

Tubing

c.

Leaks

in

d.

Faulty

item

15,

e.

Faulty

item

25,

Е

Faulty

item

7,

a.

Test

equipment

tion

b.

Inlet

filters

c.

Faulty

item

15,

4.

Faulty

item

7,

e.

Faulty

Figure

ЕЁ

Faulty

Figure

is

out

of

kinked

tubing

motor/blower

Figure

rotary

actuator

Figure

power

controller

Figure

4-2

4-2

4-3

out

assembly

valve

of

calibra-

occluded

motor/blower

Figure

power

controller

Figure

power

supply

4-3

CPU

PCB

4-3

4-2

4-3

item

assembly

item

11,

PCB,

PCB

26,

a.

Calibrate

b.

Verify

no

outlet

of

tester.

с.

Verify

no

rotary

actuator

d.

Replace

per

instructions

—e.

Replace

instructions

£

Replace

instructions

a.

Calibrate

retest.

b.

Clean

inlet

c.

Replace

per

procedure

4-1.

ἆ,

Replace

procedure

e.

Replace

dure

outlined

f.

Replace

outlined

flow

tester

and

retest.

kinks

in

tubing

rotary

actuator

leaks

from

to

motor/blower

in

rotary

actuator

in

Table

power

controller

in

Table

test

equipment

filter

and

motor/blower

outlined

power

controller

outlined

power

supply

in

CPU

PCB

in

Table

outlet

the

flow

assembly

Table

valve

4-1.

4-1.

retest.

assembly

in

in

Table

per

Table

4-1.

per

procedures

4-1.

to

4-1.

from

flow

of

tester.

per

PCB

per

and

Table

PCB

per

4-1.

proce-

Part No.

Y-780551-00A

Rev.

B

3-7

Page 4

Symptom

Flow

Transducer

3.

(Test

step

than

0.00 + 0.049

4,

(Test

step 20)

not

5.00 + 0.2

Front

Panel

5,

(Test

step

LED

does

60

to

80

Check

17)

Voltage

VDC

Voltageon

VDC

Indicator

25)

LEAK

indication

not

illuminate

seconds

is

greater

DVMis

within

Possible

a.

b.

Cause

DVMconnectedincorrectly

Ports on

flow

transducer

capped

c.

Faulty

CPU

PCB,

item

Figure

4-3

d.

Faulty

power

controller

item

7,

Figure

4-3

a.

Polarity

connected

b.

RT-200

flow

limits

c.

Faulty

Figure

4.

Faulty

item

a.

Flow

130

b.

Faulty

Figure

c.

Faulty

Figure

d.

Faulty

Figure

is

is

out

range

CPU

4-3

power

7,

Figure

rate

is

jpm

keypad

4-1

CPU

4-3

ribbon

4-1

reversed

to

is

not

ontubing

flow

transducer

of

calibration

not

within

PCB

item

controller

4-3

greater

item

2,

PCB

item

cable

item

not

11,

PCB

test

11,

PCB

than

11,

19,

Corrective

a.

Verify

and

—_b.

Cap

с.

Replace

in

d.

Replace

instructions

a.

Verify

flow

b.

Zero

c.

Replace

in

d.

Replace

procedure

a.

Check

retest

b.

Replace

tions

c.

Replace

in

d.

Replace

tions

Action

proper

retest.

ports

of

CPU

Table

4-1,

power

proper

transducer.

the

RT-200

CPU

Table

4-1.

power

in

calibration

flow

rate.

top

in

Table

CPU

Table

4-1.

ribbon

in

Table

connection

transducer

PCB

controller

in

Table

tubing

and

PCB

controller

Table

housing

4-1.

PCB

cable

and

per

instructions

4-1.

connection

retest.

per

instructions

4-1.

of

RT-200

per

per

instructions

per

4-1.

of

DVM

retest.

PCB

per

to

PCB

per

and

instruc-

instruc-

6.

(Test

LED

onds

Safety

Pressure

7.

(Test step

blower

and

step

26)

did

not

Switch

30

assembly

off

at

proper

INOPERATIVE

illuminate

and

in

Tests

31)

Motor/

not

turning

pressure

15

a.

sec-

b.

on

Faulty

Figure

Faulty

Figure

с.

Faulty

Figure

a.

RT-200

b.

Faulty

Figure

с.

Faulty

item

CPU

4-3

display

4-5

connector

4-5

out

pressure

4-3

power

7,

Figure

3-8

PCB

item

11,

board

item

PCB

item

of

calibration

switch

item

controller

4-3

8,

PCB

14,

2,

a.

Replace

in

b.

Replace

tions

c.

Replace

instructions

a.

Check

Ob.

Change

CPU

Table

4-1.

display

in

Table

connector

calibration

pressure

instructions

c.

Replace

instructions

power

PCB

per

board

4-1.

PCB

in

Table

4-1.

and

switch

in

Table

4-1.

controller

in

Table

4-1.

Part

No.

Y-780551-00A

instructions

per

instruc-

per

retest.

per

PCB

per

Rev.

B

Page 5

|

2

Symptom

Pressure

8.

Set

9,

Sensitivity

10,

Delay

11.

Power

12.

Regulation

(Test

step 36)

cmH20

between

Point

(Test

+

variation

Accuracy

step

0.5

cmH20

two

40)

Tests

(Test

steps

Spontaneous

react

as

described

Test

(Test

step 48)

cmH20 + 0.4

Failure

(Test

step 50)

or

alarm

does

least

60

seconds

More

than

1.0

in

pressure

tests

Pressure

43

through

cycling

Pressure

Indicator

No

not

is

not

45)

does

in

tests

not

Test

audible

sound

for

20.0

not

3.5

alarm

at

Possible

a.

RT-200

b.

Filters

с.

Faulty

Figure

d.

Faulty

item

e.

Faulty

Figure

a.

RT-200

b.

Filters

c.

Pressure

calibration

d.

Faulty

Figure

e.

Faulty

item

f.

Faultyrotary

Figure

a.

Improper

b.

Faulty

Figure

с.

Faulty

item

a.

Flowrateis

130

b.

Faulty

Figure

c.

Faulty

Figure

d.

Faulty

Figure

a.

Faulty

Figure

b.

Faulty

item

с.

Faulty

」

Figure

Cause

out

of

dirty

CPU

PCB

4-3

power

controller

7,

Figure

rotary

actuator

4-2

out

of

dirty

transducer

CPU

PCB

4-3

power

controller

7,

Figure

actuator

4-2

test

CPU

PCB

4-3

power

controller

7,

Figure

not

Ipm

keypad

4-1

CPU

PCB

4-3

ribbon

4-1

capacitor

4-3

power

7,

Figure

CPU

PCB

4-3

calibration

item

11,

PCB

4-3

item

25,

calibration

out

of

item

11,

PCB

4-3

item

25,

set-up

item

11,

PCB

4-3

greater

item

cable

controller

4-3

than

2,

item

11,

item

item

6, a.

PCB

item

11,

19,

Corrective

a.

Calibrate

b.

Clean

c.

Replace

in

Od.

Replace

instructions

e.

Replace

instructions

a.

Calibrate

b.

Clean

c.

Perform

on

d.

Replace

in

e.

Replace

instructions

f.

Replace

instructions

a.

Verify

b.

Replace

in

c.

Replace

instructions

a.

Check

retest

b.

Replace

tions

c.

Replace

in

d.

Replace

tions

Change

in

b.

Replace

in

c.

Replace

in

Action

RT-200

filters

and

CPU

Table

4-1.

power

in

rotary

in

RT-200

filters

and

calibration

page

4-22.

CPU

Table

4-1

steps.

power

rotary

test

settings

CPU

Table

4-1.

power

calibration

flow

rate,

top

housing

in

Table

CPU

Table

4-1.

ribbon

in

Table

capacitor

Table

4-1.

CPU

Table

4-1.

CPU

Table

4-1.

and

retest.

retest.

PCB

per

instructions

controller

Table

4-1.

actuator

Table

per

4-1.

and

retest.

retest.

procedure

PCB

per

instructions

controller

in

Table

4-1.

actuator

in

Table

PCB

controller

in

Table

per

4-1.

and

retest.

per

instructions

4-1.

of

RT-200

per

4-1.

PCB

per

instructions

cable

per

4-1.

per

instructions

PCR

per

instructions

PCB

per

instructions

PCB

per

4.2

PCB

per

PCB

per

and

instruc-

instruc-

Part No.

Y-780551-00A

Rev.

B

3-9

Page 6

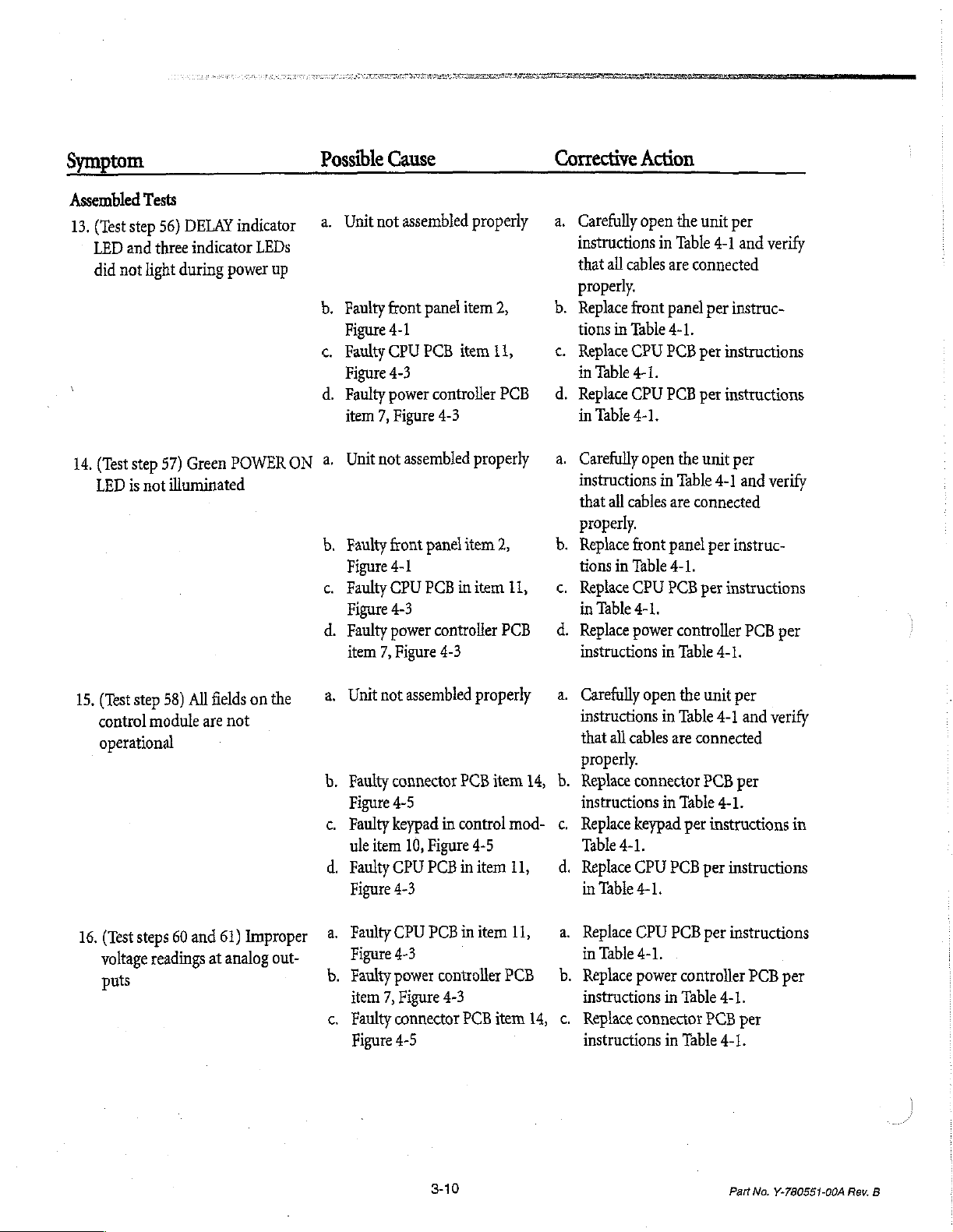

Symptom

Possible

Cause

Corrective

Action

Assembled

13.

(Test

step

LED

and

did

not

14,

(Test

step

LED

is

Tests

56)

DELAY

three

indicator

light

during

57)

Green

not

illuminated

indicator

LEDs

power

up

POWER

ON

a.

b.

c.

d.

a.

b.

с.

d.

Unit

Faulty

Figure

Faulty

Figure

Faulty

item

Unit

Faulty

Faulty

not

front

4-1

CPU

4-3

power

7,

Figure

not

front

Figure

4-1

CPU

Figure

4-3

Faulty

power

item

7,

Figure

assembled

panel

PCB

assembled

PCBinitemil,

properly

item

item

controller

4-3

properly

panel

item

controller

4-3

2,

11,

PCB

2,

РСВ

a.

Carefully

instructions

that

all

cables

properly.

b.

Replace

tions

<.

Replace

in

4.

Replace

in

κ.

Carefully

instructions

that

properly.

b.

Replace

tions

<

Replace

in

4.

Replace

instructions

front

in

Table

CPU

Table

4-1.

CPU

Table

4-1.

all

cables

front

in

Table

CPU

Table

power

4-1.

open

the

in

Table

are

panel

4-1.

PCB

PCB

open

the

in

Table

are

panel

4-1.

PCB

controller

in

Table

unit

per

4-1

and

verify

connected

per

instruc-

per

instructions

per

instructions

unit

per

4-1

and

verify

connected

per

instruc-

per

instructions

PCB

4-1.

per

15,

(Test

step

control

module

operational

16,

(Test

steps

voltage

readings

puts

58) All

are

60

and

fields

not

61)

Improper

at

analog

on

the

out-

a.

Unit

b.

Faulty

Figure

c,

Faulty

ule

4.

Faulty

Figure

a.

Fauliy

Figure

b.

Faulty

item

c.

Faulty

Figure

not

assembled

connector

4-5

keypad

item

10,

Figure

properly

PCB

in

control

4-5

CPUPCBinitem

4-3

CPU

PCBinitemli,

4-3

power

controller

7,

Figure

4-3

connector

4-5

PCB

item

14,

mod-

11,

PCB

item

14,

a.

Carefully

instructions

that

all

cables

properly.

=

Replace

instructions

c.

Replace

Table

4.

Replace

in

a.

Replace

in

b.

Replace

instructions

с.

Replace

instructions

keypad

4-1.

Table

Table

open

the

unit

in

Table

are

connected

connector

CPU

4-1.

CPU

4-1.

power

connector

PCB

in

Table

per

instructions

PCB

per

PCB

per

controller

in

Table

PCB

in

Table

per

4-1

and

verify

per

4-1.

in

instructions

instructions

PCB

per

4-1.

per

4-1.

3-10

Part

No.

Y-780551-00A

Rev.

B

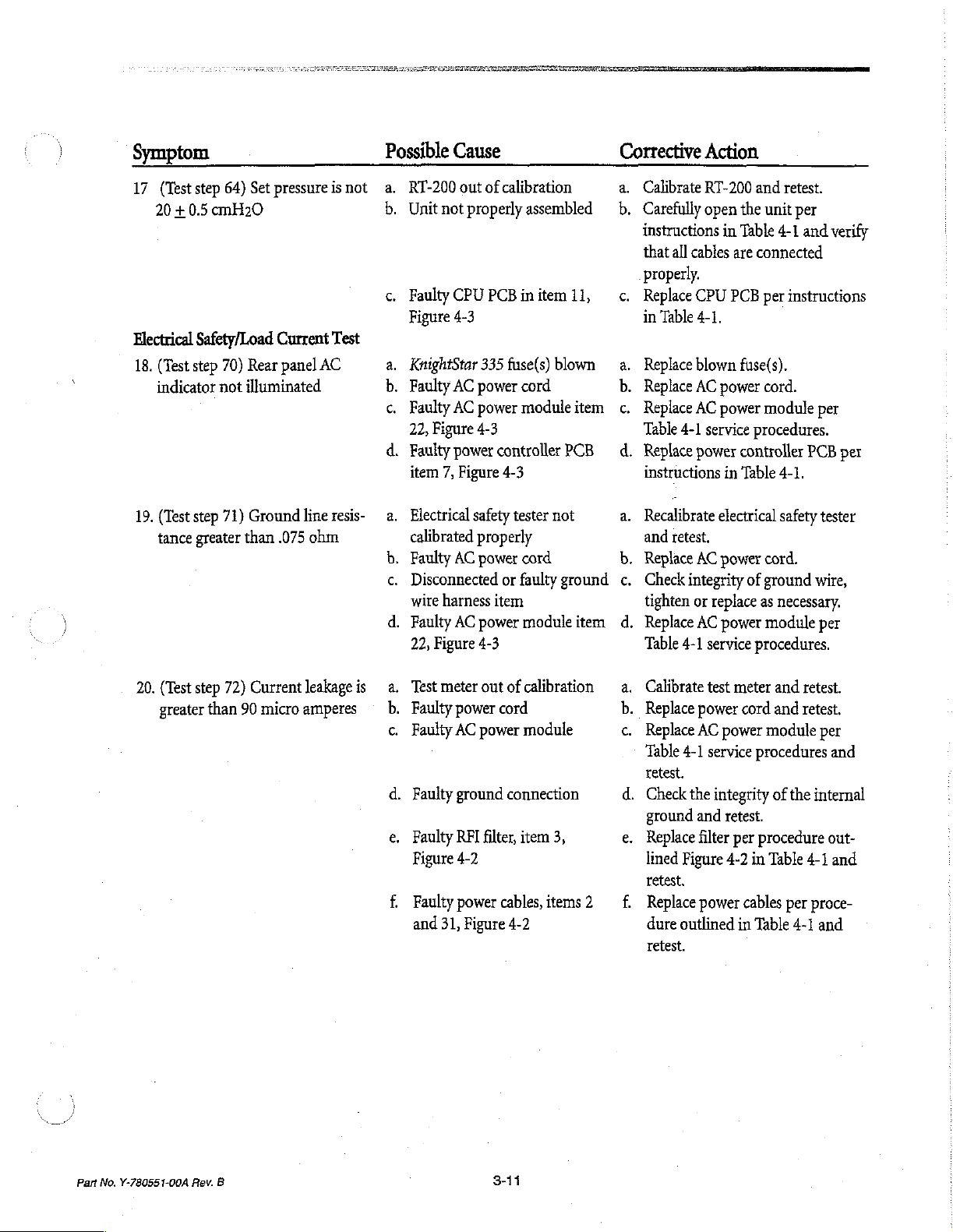

Page 7

neo

`

Symptom

17

(Test

step

20 + 0.5

Electrical

18.

(Test

indicator

19.

(Test

tance

cmH20

Safety/Load

step

70)

not

step

71)

greater

64)

Set

pressure

Current

Rear

panel

illuminated

Ground

than

.075

AC

line

ohm

isnot

Test

resis-

Possible

а.

s

с.

a.

b.

с.

d.

a.

Cause

RT-200

Unit

Faulty

Figure

KnightStar

Faulty

Faulty

22,

Faulty

item

Electrical

out

not

properly

CPU

4-3

AC

AC

Figure

power

7,

Figure

calibrated

b.

Faulty

AC

с.

Disconnected

wire

harness

d.

Faulty

AC

22,

Figure

of

calibration

assembled o b.

PCB

initem

335

fuse(s)

power

cord

power

module

4-3

controller

4-3

safety

tester

properly

power

cord

or

faulty

item

power

module

4-3

11,

blown

item

PCB

not

ground

item

Corrective

a.

Calibrate

Carefully

instructions

that

all

cables

Action

RT-200

open

in

properly.

с.

Replace

in

a.

Replace

b.

Replace

с.

Replace

Table

d.

Replace

instructions

a.

Recalibrate

and

b.

Replace

c.

Check

tighten

d.

Replace

Table

CPU

Table

4-1.

blown

AC

AC

4-1

service

power

retest.

AC power

integrity

or

replace

AC power

4-1

service

power

power

in

electrical

and

retest.

the

unit

per

Table

4-1

and

are

connected

PCB

per

instructions

|

fuse(s).

cord.

module

procedures.

controller

Table

of

procedures.

PCB

4-1.

safety

cord.

ground

as

necessary.

module

verify

per

per

tester

wire,

per

20.

(Test

greater

step

72)

than

Current

90

micro

leakage

is a.

amperes

Test

b.

Faulty

c.

Faulty

d.

Faulty

e.

Faulty

Figure

f.

Faulty

and

meter

power

AC

power

ground

RFI

4-2

power

31,

Figure

out

of

calibration

cord

module

connection

filter,

item

cables,

4-2

a.

Calibrate

b.

Replace

с.

Replace

Table

retest.

d.

Check

ground

3,

e.

Replace

lined

retest.

items 2 (Of

Replace

dure

retest.

test

meter

power

cord

AC

power

4-1

service

the

integrity

and

retest.

filter

per

Figure

4-2

power

cables

outlined

in

and

retest.

and

retest.

module

procedures

of

procedure

in

Table

Table

per

the

internal

4-1

per

proce-

4-1

and

out-

and

and

Part

No.

Y-780551-00A

Rev.

B

3-11

Page 8

3-12

(blank)

Part

No.

Y-780551-00A

Rev.

B

Page 9

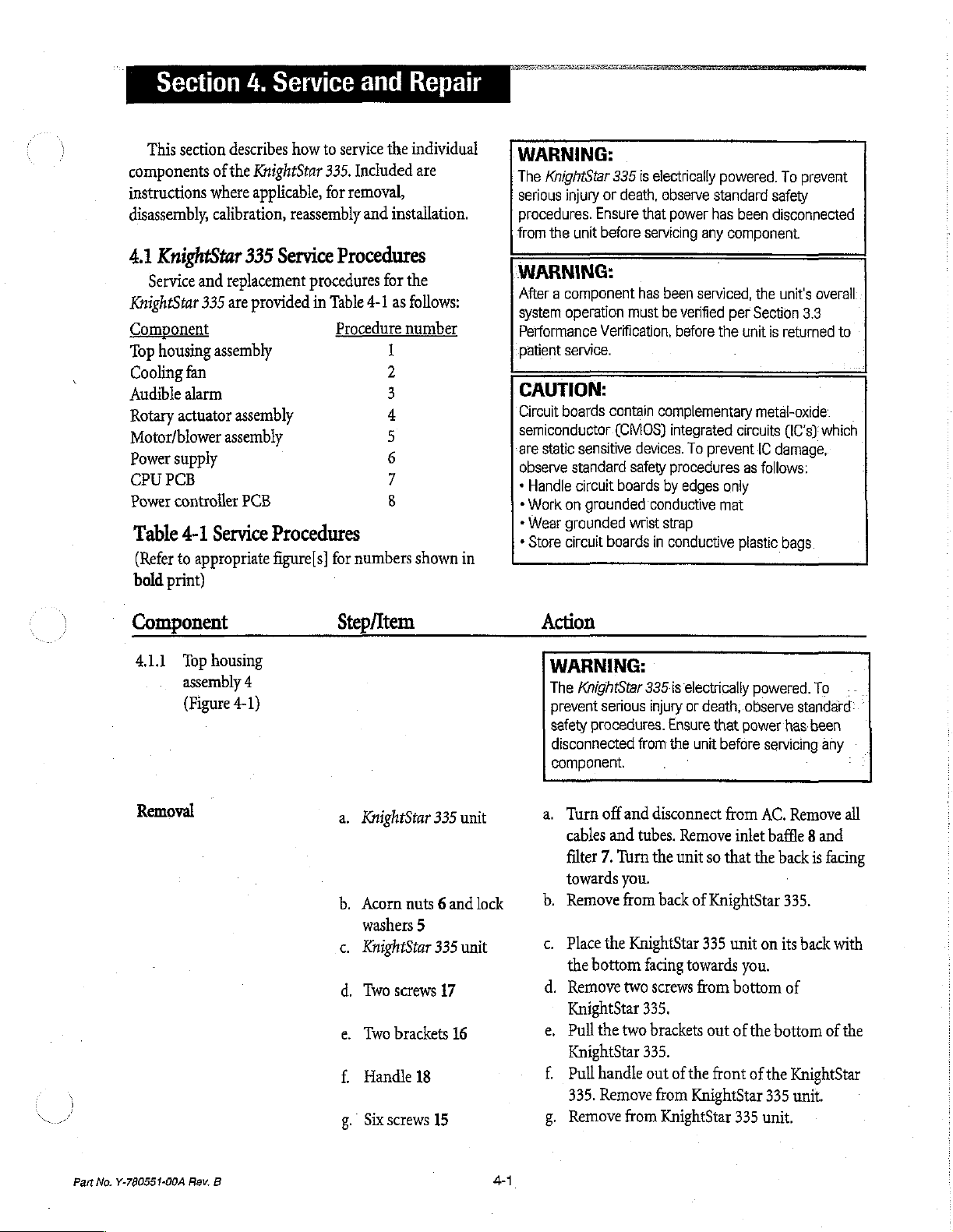

Section

4.

Service

and

Repair

[a

This

section

components

instructions

disassembly,

4.1

KnightStar

Service

KnightStar

Component

Top

housing

Cooling

Audible

Rotary

Motor/blower

Power

supply

CPU

PCB

Power

controller

Table

(Refer

bold

print)

actuator

4-1

to

describes

of

the

where

calibration,

and

replacement

335

are

assembly

fan

alarm

assembly

assembly

Service

appropriate

how

to

KnightStar

applicable,

335.

for

reassembly

335

Service

procedures

provided

PCB

in

Procedures

figure[s]

service

the

individual

Included

are

removal,

and

installation.

Procedures

for

the

Table

4-1

as

follows:

Procedure

for

numbers

number

1

NN

a

U qa

03d

shown

in

WARNING:

The

KnightStar

serious

procedures.

from

WARNING:

After a component

injury

the

system

operation

Performance

patient

service.

335

or

death,

Ensure

unit

before

Verification,

CAUTION:

Circuit

boards

semiconductor.

are

static

observe

*

Handle

*

Work

*

Wear

*

Store

contain

(CMOS)

sensitive

standard

circuit

boards

on

grounded

grounded

circuit

boards

ts

electrically

observe

that

power

servicing

has

been

must

be

verified

before

complementary

integrated

devices.

safety

wrist

To

procedures

by

edges

conductive

strap

in

conductive

powered.

standard

has

been

any

component.

serviced,

per

Section

the

unit

circuits

prevent

as

only

mat

plastic

To

prevent

safety

disconnected

the

unit's

overall

3.3

is

returned

metal-oxide

(IC's}

which

IC

damage,

follows:

bags

to

Component

4.1.1

Top

assembly

(Figure

Removal

housing

4

4-1)

Step/Item

a.

KnightStar

b.

Acorn

nuts 6 and

washers

с.

KnightStar

d.

Two

e.

Two

f.

Handle

g.

Six

5

screws

brackets

18

screws

335

335

17

16

15

unit

lock

unit

Action

WARNING:

The

KnightStar

prevent

safety

disconnected

component.

a.

>

c.

d.

e.

f.

g.

serious

procedures.

Turn

off

cables

and

filter

7.

Turn

towards

Remove

Place

the

the

bottom

Remove

KnightStar

Pullthe

KnightStar

Pull

handle

335.

Remove

Remove

335s

electrically

injury

or

Ensure

from

the

unit

and

disconnect

tubes.

Remove

the

unit

you.

from

back

of

KnightStar

facing

towards

two

screws

335.

two

brackets

335.

out

of

the

from

KnightStar

from

KnightStar

powered.

death,

observe

that

power

before

servicing any

from

AC.

inlet

so

that

the

KnightStar

335

unit

on

you.

from

bottom

cut

ofthe

front

of

the

335

335

unit.

To

standard

has-been

Remove

baffle 8 and

back

is

facing

335.

its

back

with

of

bottom

of

the

KnightStar

unit.

all

Part

No.

Y-780551-00A

Rev.

B

41

Page 10

Component

Installation

Step/Item

h.

KnightStar

i.

KnightStar

Wire

.

Flex

(Figure

KnightStar

.

Wire

.

Top

.

Top

.

Wire

.

Top

.

KnightStar

.

Flex

.

Wire

.

KnightStar

335

335

harness

tubing6

4-2)

harness

housing

housing

harness

housing

tube 6 (Figure

harness

unit

unit

19

335

unit

22

assembly

assembly

22

assembly

335

unit

19

335

unit

4-2)

Action

h.

Place

unit

the sides

housing

the

facing

assembly

front

CAUTION:

Forcing

at

or

i,

}.

k.

1.

m.

n.

o.

p.

q.

т.

s.

t.

u.

the

top

this

time.could

tubing.

Carefully

side

with

Reach

up

disconnect

keypad

Reach

disconnect

outlet

Place

of

housing

forward.

Disconnect

Figure

the

the

Slide

top

the

back

2.

up

3.

sides

assembly

4-3.

completely

unit.

Slide

top

KnightStar

Connect

CPU

PCB

Slide

the

KnightStar

access

to

Carefully

side

with

Reach

up

connect

Reach

up

harness

Place

position.

to

the

back

on

its

bottom

towards

about

of

the

machine.

housing

turn

the

bottom

into the

wire

into the

the

unit

facing

wire

housing

of

the

separated

housing

335

wire

(refer

top

335

connections

turn

the

inside

flex

tube 6 to

inside

keypad

KnightStar

assembly:too

cause

damage

the

KnightStar

facing

top

housing

harness

top

housing

flex

tube

in

an

upright

towards

another

harness

assembly

KnightStar

from

assembly

unit.

harness

housing

bottom

22

to

Figure

assembly

unit

leaving

inside

the

KnightStar

facing

of

the

machine

of

the

2.

335

feet

with

you.

Slide

the

two

inches

towards

far

forward

to

internal

335

unit

towards

you.

assembly

19

from

the

front

assembly

from

the

machine

position

you.

two

22

from

forward

335

the

partially

to

connector

4-4).

enough

of

towards

KnightStar

with

Slide

to

three

PCB

away

unit

until

KnightStar

onto

onto

the

room

the

unit.

335

unit

you.

335

outlet

unit

and

connect

unit

in

the

upright

one

of

top

cables

onto

its

and

and

one

the top

inches

11

on

from

it

is

335

J2

on

for

on

its

unit

and

3.

wire

4-2

Part

No.

Y-780551-00A

Rev.

B

Page 11

Component

4.1.2.

Removal

Cooling

(Figure

fan

4-3)

16

Step/Item

v.

Top

assembly

w.

Lock

washers

x.

KnightStar

y.

Six

screws

z.

Handle

aa.

Two

ab.

Two

ac.

KnightStar

ad.

Acorn

ae.

Filter 7 and

18

brackets

screws

nuts

4

5

335

unit

15

16

17

335

unit

6

inlet

baffle

8

Action

v.

Slide

unit.

NOTE:

It

may

be

the

top

housing

835

to

aid

the

KnightStar

w.

Place

nuts 6 nuts

the

back

this

time.

x.

Place

with

y.

Insert

and

tighten.

z.

Install

front

aa.

Orient

through

KnightStar

ab.

Insert

tighten.

ac.

Place

position.

ad.

Tighten

ae.

Reinstall

of

the

top

assembly

necessary

in

the

plate.

the

the

bottom

the

the

of

the

the

the

two

the

the

KnightStar

to

and

the

alignment

335.

lock

washers

on

the

Do

KnightStar

facing

six

screws

handle

top

housing

through

brackets

slots

in

335

unit.

screws

through

KnightStar

acorn

the

filter

335

onto

the

KnightStar

leave a small

back

of

the

of

posts 1 with

and

acorn

studs

protruding

not

tighten

335

unit

on

towards

through

the

the

assembly.

as

illustrated

the

bottom

the

335

unit

in

nuts.

and

inlet

baffle

unit.

335

gap

between

KnightStar

the

back

and

acorn

through

the

acorn

nut

its

back

side

you.

top

housing

two

holes

in

and

insert

of

the

brackets

the

upright

on

and

the

back

of

at

the

Part

Installation

No.

Y-780551-00A

Rev.

a.

Top

b.

Flex

c.

Cooling

housing

tube

assembly

10

fan

16

4

a.

Perform

(steps a through

b.

Disconnect

assembly

с.

Disconnect

four

screws

removal

flex

tube

15

(Figure

fan

harness

14b

and

procedure 1 (Figure

n)

Table

4-1.

from

motor/blower

4-2).

from

PCB

7.

nuts

17a.

and

fan

4-1)

Remove

guard

15b.

d.

Fan

guard

15a

е.

Fan

guard

15а

f.

Fan

guard

15b

B

4-3

d.

Remove

e.

Install

tighten

f.

Orient

screws

back

two

two

screws

to

fan

fan

guard

14b

through

plate

of

screws

14a

with

two

as

14a

and

through

nuts

shown

comers

KnightStar

335.

nuts

guard

17b.

and

of

fan

17b.

pass

guard

and

four

and

Page 12

Component

4.1.3.

Audible

(Figure

Removal

alarm

4-3)

24

Step/Item

Cooling

5.

Flex

Top

fan

tube

10

housing

16

assembly

4

Action

g.

Pass

cooling

fan

to

back

connect

h.

Connect

(Figure

i.

Follow

(steps o through

to

to

4-2).

installation

fan

over

four

screws

plate

with

four

nuts

PCB

7.

motor/blower

assembly

procedure 1 (Figure

ae).

14b,

17a

Secure

and

15

4-1)

installation

4.1.4,

Rotary

assembly

actuator

25

Removal

(Figure

4-2)

Top

housing

Audible

harness

Audible

Audible

Audible

Top

Top

Tubing

REI

alarm

alarm

alarm

housing

housing

29

filter

assembly

24

24

24

alarm

harness

assembly

assembly

and

30

3

4

4

4

a.

Perform

(Figure

b.

Disconnect

(Figure

c.

Remove

d.

Mount

KnightStar

e.

Connect

(Figure

Е

Follow

(steps o through

a.

Perform

(steps a through

b.

Remove

sure

removal

4-1)

4-4).

two

audible

4-4).

installation

tubes

to

mark

NOTE:

Before

c,

disconnecting

Disconnect

to

mark

the

connections.

procedure 1 removal

(steps a through

from

J8

on

screws

25.

alarm

to

335

with

two

to

J8

of

power

procedure 1 (Figure

ae)

Table

removal

procedure 1 (Figure

n)

Table

from

valve

the

original

tubing

wire

harness 2 and

original

location

n)

Table

power

controller

back

plate

of

screws

25.

controller

4-1.

4-1.

manifold

location.

mark

PCB

its

location.

31

being

of

the

4-1.

4-1)

4-1)

27

making

PCB

sure

Tie

wrap

A

Two

screws

o

Pitot

tube

KnightStar

va

32

5

335

1

unit

44

NOTE:

Before

disconnecting

Cut

tie

fu

mp

Remove

rh

ga

wrap

the

Disconnect

Place

the

the

internal

KnightStar

wiring

mark

and

discard.

two

screws

and

pitot

tube

from

335

unit

components

facing

its

location.

the

REI

valve

manifold.

on

its

towards

Part

filter.

back

with

you.

No.

Y-780551-00A

Rev.

B

Page 13

Component

Installation

Step/Item

h.

Upper

and

lower

manifold

Valve

manifold

KnightStar

Rotary

assembly

KnightStar

.

Sound

Flex

Rotary

assembly

RnightStar

Rotary

assembly

Rotary

assembly

Flex

Sound

KnightStar

Valve

335

actuator

25

335

bracket

tube

10

actuator

25

actuator

25

actuator

tube

10

bracket

manifold

335

335

27

unit

unit

8

unit

8

unit

27

Action

h.

Remove

bracket.

1.

Separate

assembly

}

Place

position

k.

Disconnect

hatness

(Figure

L

Turn

is

m.

Remove

Remove

η,

Disconnect

assembly

actuator

housing

o.

Remove

NOTE:

As

screws 9 are

actuator

the

p.

Place

of

9.

Place

four

Carefully

the

from

4-4).

the

facing

assembly

PCBs.

the

the

sides

one

actuator

the

screw.

tighten

г.

Connect

harness

s.

Pass

11.

assembly

all

flex

Connect

motor/blower

t.

Place

sound

screws 7 in

u.

Place

the

components

v.

Place

upper

manifold.

actuator

screws

28

remove

valve

manifold

25.

KnightStar

with

the

KnightStar

towards

six

screws 7 from

sound

flex

15.

Disconnect

assembly.

11.

Remove

the

rotary

unit

facing

screw 9 in

assembly

Install

335

the

front

rotary

J11

on

power

335

you.

bracket

tube

from

Remove

four

actuator

being

loosened

to

prevent

in

an

upright

towards

position

with

remaining

four.

to

11

on

power

PCB

(Figure

tube

flex

25.

Connect

4-4).

through

tube

assembly

bracket

sound

unit

facing

bracket.

on

its

you.

in

back

manifold

Place valve

assembly.

from

each

each

bracket.

from

rotary

unit

in

an

facing

towards

actuator

from

assembly

controller

unit

so

that

sound

bracket.

housing

motor/blower

flex

tube

flex

tube

screws

9.

assembly.

hold:the.rotary

it

from

falling

position

you.

and

screw.

Partially

screws 9 and

controller

hole

in

side

to

rotary

actuator

flex

tube

to

15.

housing

bracket

manifold

with

26

11.

the

on

brackets

26

actuator

upright

you.

wire

PCB

the

back

11.

from

rotary

from

onto

with

one

align

rotary

tighten

wire

of

housing

Tighten

internal

on

valve

rotary

six

Part No.

Y-780551-00A

Rev.

B

4-5

Page 14

Component

4.1.5.

Motor/blower

assembly

(Figure

Removal

15

4-2)

Step/Item

w.

Manifold

x.

KnightStar

y.

REI

z.

Wire

aa.

Tubing

ab.

Pitot

ac.

Tie

ad.

Top

bracket

335

Filter

3

harness 2 and

29

and

tube

5

wrap

32

housing

26

unit

31

30

assembly

4

Action

w.

Place

bottom

manifold

the

manifold

28.

NOTE:

Alternately

eight

are

x.

Place

KnightStar

with

the

y.

Place

one

and

align

actuator

Place

second

both

of

z.

Reconnect

aa.

Reconnect

ab.

Reconnect

ac.

Install

ad.

Follow

(steps o through

manifold

27.

Place

four

brackets.

tighten

each

of

completely

left

screw 1 in

it

assembly.

335

side

facing

with

the

tight.

screw

hole

Partially

screw 1 in

them.

to

RFI

filter.

tubing

to

valve

pitot

tube

new

tie

wrap.

installation

procedure 1 (Figure

ae)

Table

bracket

screws

Tighten

the

screws

unit

in

upright

towards

hole

in

the

tighten

RFI

filter

manifold

to

valve

1-1.

on

valve

28

in

each

all

eight

until

all

position

you.

in

RFI

filter

rotary

the

screw.

and

tighten

27.

manifold

27.

of

screws

4-1)

a.

Top

housing

b.

Flex

tube

с.

Motor/blower

d.

Connector

e.

KnightStar

£

Motor/blower

15

assembly

10

assembly

tube

12

335

unit

assembly

4

a.

Follow

removal

(steps a through

b.

Disconnect

assembly

c.

Disconnect

power

controller

d.

Cut

tie

wraps

12

from

e.

Place

the

the

bottom

NOTE:

Secure

the

proceeding

£

While

holding

remove

21.

Remove

KnightStar

procedure 1 (Figure

n)

Table

flex

tube

from

outlet.

harness

motor/blower

KnighiStar

facing

motor/blower

to

prevent

four

335

from

PCB

(Figure

13

and

discard.

assembly.

335

unit

towards

assembly

it

from

the

motor/blower

acorn

nuts

22

motor/blower

unit.

4-1)

4-1,

motor/blower

J1

wire

harness

4-4).

Disconnect

on

its

back

with

you.

before

falling.

assembly

and

lock

washers

assembly

from

on

tube

the

4-6

Part

Na.

Y-780551-00A

Rev.

B

Page 15

Component

Step/Item

Action

Installation

4.1.6.

Removal

Power

supply

26

(Figure

PCB

4-3)

$.

Bracket

.

Vibration

Vibration

Brackets

.

Motor/blower

15

Motor/blower

.

Connector

.

Flex

tube

.

Top

housingassembly4

17

mounts

mounts

17

tube

10

20

20

assembly

assembly

12

g.

Remove

Separate

Remove

from

h.

Remove

from

i.

Place

in

j.

Pass

holes

motor/blower

bracket

two

bolts

bracket

nuts

14

motor/blower

nut

16

bracket.

vibration

place

with

nut

bolts

19

and

in

bracket.

with

nuts

NOTE:

The

90°

angle

on

center

of

the

&

Align

bottom

washers

mount

oo | Connect

power

m.

Connect

assembly

n.

Connect

motor/blower

vibration

plate

of

21

and

studs

and

wire

harness

controller

tube

15.

Install

to

outlet

15.

o.

Followinstallation

(steps o through

19

and

lock

washers

from

motor/blower

and

separate

second

assembly.

and

separate

mount

16.

Jock

Tighten

assembly

14.

each

bracket

mount

KnightStar

acorn

tighten.

PCB

to

outlet

new

of

motor/blower

vibration

on

bracket

washer

nuts

to

(Figure

18

bolts

in

15.

Connect

should

assembly.

studs

with

335

unit.

22

on

Jl

on

wire

4-4).

of

motor/blower

tie

wraps

procedure 1 (Figure

ae)

Table

4-1.

18.

assembly.

bracket

mount

and

secure

through

second

point

to

the

holes

in

Place

lock

vibration

harness

13.

assembly

4-1)

Part

Installation

No.

Y-780551-00A

Rev.

.

Top

housing

.

Wire

harness 2 and

(Figure

»

KnightStar

.

Power

assembly4

4-2)

335

supply

PCB

23

unit

26

a,

Perform

(steps a through

b,

Disconnect

c.

Place

the

facing

towards

d.

Remove

removal

n)

from

unit

on

you.

four

screws

procedure I (Figure

Table

4-1.

power

supply

its

back

with

27.

PCB,

the

bottom

4-1)

CAUTION:

Use

anti-static

beginning

B

47

procedures

of

Section

4.

outlined

at

the

Page 16

Component

4.1.7.

CPUPCB

(Figure

Removal

11

4-3)

Step/Ttem

e.

Power

supply

£

Wire

harness 2 and

g.

Top

housing

PCB

26

23

assembly

4

Action

e.

Place

one

with

hole

tighten

three

then

£

Connect

(Figure

g.

Follow

screw

screws

four

to

4-4),

installation

(steps o through

CAUTION:

Circuit

boards

semiconductor

which

are

static

damage,

follows:

*

+

Work

*

Wear

+

Handle

on

grounded

Store

circuit

observe

circuit

grounded

screw

27

in

power

27

to

27

through

screws.

power

ae)

contain

(CMOS)

sensitive

standard

boards

conductive

wrist strap

boards

in

bottom

supply

keep

supply

procedure 1 (Figure

Table

complementary

integrated

devices.

by

in

conductive

PCB.

PCB

the

case

PCB

4-1.

safety

edges

case

and

Partially

in

place.

and

into

(Figure

metal-oxide

circuits

To

prevent

procedures

only

mat

plastic

align

Install

4-2)

(IC's)

bags

PCB

4-1)

IC

as

Installation

a.

Top

housing

b.

Rotary

assembly

c.

Housing

d.

Capacitor

e.

Pressure

Е

Wire

(Figure

g.

CPUPCB

h.

CPU

i.

Pressure

assembly

actuator

25

II

(Figure

6

switch

harness

19

4-1)

11

PCB

Il

switch

4-2)

plate

1

plate

1

4

a.

Perform

(steps a through

b.

Perform

removal

removal

(steps a through

c.

Pull

housing

unit.

d.

Do

not

disconnect

of

your

working

clamp

4.

e.

Disconnect

7.

Remove

out

of

KnightStar

f,

Disconnect

11.

Remove

g.

Remove

bag.

h.

Remove

CPU

screws

i

Place

CPU

CPU

PCB

10.

switch

nut 5 only.

procedure 1 (Figure

n)

Table

procedure 2 (Figure

o)

Table

out

of

back

of

the

capacitor,

area.

Remove

pressure

nut 5 and

wire

five

with

plate

switch 2 from

take

335

unit.

harness

screws

PCB

and

PCB

from

five

standoffs 9 and

over

10.

store

anti-static

studs

4-1.

4-1.

KnightStar

move

nut 5 and

J10

pressure

from

switch

J1

on

CPU

in

an

anti-static

bag.

install

29.

Install

4-1)

4-2)

335

it

clear

nylon

on

PCB

plate

PCB

Align

five

rear

4-8

Part

No.

Y-780551-00A

Rev.

B

Page 17

Component

4.1.8.

Power

PCB 7 (Figure

Removal

controller

4-3)

Step/Item

j.

Capacitor

k.

Pressure

L

Housing

m.

Rotary

assembly

n.

Top

6

switch

11

actuator

25

housing

2

assembly

4

Action

j.

Place

nylon

clamp 4 on front

capacitor 6 through

nut 5 on

k.

Connect

Insert

m.

Follow

front

switch

housing

installation

(steps p through

n.

Follow

CAUTION:

Circuit

semiconductor

which

damage,

follows:

«

Handle

*

Work

»

Wear

*

Store

installation

(steps o through

boards

contain

(CMOS)

are

static

sensitive

observe

circuit

boards

on

grounded

grounded

circuit

boards

stud

nylon

clamp

stud.

harness

in

ab)

ae)

standard

wrist

to

J10

back

plate

of

procedure 2 (Figure

Figure

4-2.

procedure 1 (Figure

Figure

4-1.

complementary

integrated

devices.

safety

procedures

by

edges

only

conductive

strap

in

conductive

mat

29.

Slide

and

install

on

PCB

7.

KnightStar

4-2)

4-1)

metal-oxide

circuits

To

plastic

(IC's)

prevent

bags

IC

as

335.

Installation

a.

Top

housing

b.

Rotary

assembly

c.

CPU

d.

Motor/blower

e.

f.

g.

h.

i.

j.

k

1

actuator

25

PCB

11

15

Cooling

harness

Audible

harness

Power

harness

fan

16

alarm

supply

wire

23

Capacitor 6 harness

Wire

harness

(Figure

Four

screws

20

Five

standoffs

Power

31

4-2)

30

controller

assembly

wire

24

wire

and

nuts

9

PCB

7

a.

Perform removal

(Figure

b.

Perform

4-1,

removal

(steps a through

c.

Perform

through

d.

Disconnect

wire

e.

Disconnect

7.

Disconnect

7.

g.

Disconnect

controller

h.

Disconnect

7.

Disconnect

7.

Remove

k

Remove

removal

g).

harness

PCB

four

five

PCB7.

Remove

anti-static

power

procedure 1 assembly

steps a through

procedure 2 (Figure

o)

Table

4-1.

procedure 6 (steps

from

J1

on

power

controller

from

from

from

7.

from

from

screws

standoffs

controller

bag.

J9

J8

J3

J5

J4

on

on

on

on

on

and

from

PCB

power

power

power

power

power

nuts

PCB

n)

Table

4-1.

4-2)

a

(Figure

7.

controller

controller

(Figure

controller

controller

from

power

4-2)

4-2)

chassis.

controller

and

store

4

PCB

PCB

PCB

PCB

in

an

Part

No.

Y-780551-00A

Rev.

B

4-9

Page 18

Component

Step/Item

m.

Power

controller

n.

Motor/blower

15

(Figure

o.

Audible

harness

p.

Cooling

q.

Wire

(Figure

г.

Capacitor 6 harness

s.

CPU

t.

Rotary

assembly

u.

Top

4-2)

alarm

fan

16

harness

4-2)

PCB

Il

actuator

25

housing

assembly

PCB

7

assembly

harness

24

harness

31

4

Action

m.

Remove

bag.

transistors.

of

Install

n.

Connect

ο.

Connect

Connect

|

q.

Connect

Connect

rt

s.

Follow

through

t

Follow

(steps p through

u.

Follow

(steps o through

power

Apply

KnightStar

four

to

to

to

to

to

installation

n).

installation

installation

controller

heat

sink

Place

power

335

unit.

screws

Jl

J8

J9

J4

J5

on

on

on

on

on

30

PCB

PCB

PCB

PCB

PCB

procedure 6 (steps

procedure 2 (Figure

ac).

procedure 1 (Figure

ae).

PCB

to

the

back

controller

Install

and

nuts

7.

7.

7.

7.

7.

from

anti-static

of

the

PCB

five

standoffs

20.

inside

9.

h

4-2)

4-1)

410

Part

No.

Y-780551-00A

Rev.

B

Page 19

Part No.

Y-780551-00A

Rev.

B

4-11

(blank)

Page 20

Parts

List

Item

1

2

3

4

5

6

7

8

9

10

ll

12

13

14

15

16

17

18

19

20

21

22

23

24

(Figure

PartNumber

Included

Included

Included

S-290601-US

S-290601-CA

S-290601-00

S-290601-FC

4-1)

in

4

in

4

in

4

S-290601-IN

S-290601-FR

§-290601-GE

S-290601-1T

S-290601-SP

Included

Included

in

in

23

23

S-645023-00

S-290600-00

S-232161-03

S-232161-02

$-232161-01

S-232161-00

Included

Included

S-290619-00

S-290619-01

S-290618-00

Includedin24

Includedin23

Included

Included

in24

in

23

in

18

in

23

S-290624-00

S-231850-04A*

Includedin23

Includedin23

S-231850-03A*

S-290625-00

S-290623-00

Description

7

W"

Spacer

Control

Outlet

Spare,

Spare,

Spare,

Spare,

Spare,

Spare,

Spare,

Spare,

Spare,

Lock

Acorn

Inlet

Spare

Power

Cord,

Power

Power

Panel

Connector

Cover

Assembly

Cover

Assembly

Cover

Assembly

Cover

Assembly

Cover

Assembly

Cover

Assembly

Cover

Assembly

Cover

Assembly

Cover

Assembly

Washer

Nut

#8

8-32

Filter

Inlet

Baffle

Cord

Assembly

AC

PWR

Cord

Assembly

Cord

Assembly(U.K.)

Bumper

6-32x.5"

Spare,

Spare,

Spare,

Rubber

Screw

2.0

Amp

3.15

Amp

Fuse

Foot

Drawer

Screw8-32x.437"

Handle

Screw 8 -

Spare

Keypad

Jack

Bracket

32 x .25"

Handle

Harness

Screw

Nut

Cable

Assembly

Spare,

Cover

Hardware

Spare

Feet

Kit

KS335

KS335

(Cont.

(Italian)

Fuses

Fuses

Kit

Cable

(included

(not

shown)

(U.S.)

(Used

on

Product P/N

(FR

CDN)

(Used

on

(U.S.)

(Used

on

Product P/N

(FR

CDN)

(Used

on

(International)

(French)

(German)

(Italian)

(Spanish)

(U.S.)

EUR)

Assembly,

Kit

in

35,

(not

Control

Figure

4-2)

shown)

Product

Product

Panel

Y-126812-00E)

P/N

Y-126812-FCB)

$-126812-00D)

P/N

$-126812-FCA)

*

These

items

are

available

to

Nellcor

Puritan

Bennett

4-12

service

centers

only.

Part

No.

Y-780551-00A

Rev.

B

Page 21

8

NO

VOD

USSORLA

‘ON

Hey

Page 22

Parts

List

Item

re

SA Mh WN

(Figure

Part

Included

Included

S-867558-00A*

S-611641-00A*

4-2)

Number

in

in

33

35

S-616394-00A*

S-611637-00A*

Included

S-425512-00A*

S-614541-13A

5-614541-00А.

S-614541-01A

Included

S-611638-00A*

S-290599-00A

S-611634-00A*

Included

Included

S-290576-00A

Included

Included

Included

Included

Included

Included

Included

Included

S-425511-00A*

$-290587-00

Included

S-616479-00

Included

S-611636-00A*

S-611635-00A*

Included

Included

in

in

in

in

in

in

in

in

in

in

in

in

in

in

in

in

33

33

4

34

4

34

34

34

34

34

34

35

33

33

35

33

S-290621-00

S-290620-00

S-290622-00

Description

Screw 6 -

Wire

REI

Coupling/Tubing

Tee

Tubing

Screw

Sound

Sound

Sound

Sound

Screw

Tubing

Spare,

32x.25"

Harness

Filter

Conector

Smooth

Bracket

Foam

Foam