Page 1

N-65

Page 2

Nellcor Puritan Bennett Incorporated is an affiliate of Tyco Healthcare. Nellcor, Oxiband, Durasensor,

OxiCliq, Dura-Y, MAX-FAST, and O

XIMAX are trademarks of Nellcor Puritan Bennett Incorporated or an

affiliate.

Cet appareil ISM est conforme à la norme NMB-001 Canada.

To obtain information about a warranty, if any, contact Nellcor’s Technical Services Department, or your

local representative.

Purchase of this instrument confers no express or implied license under any Nellcor Puritan Bennett patent to

use the instrument with any sensor that is not manufactured or licensed by Nellcor Puritan Bennett.

Covered by one or more of the following U.S. Patents and foreign equivalents: 4,802,486; 4,869,254; 4,928,692;

4,934,372; 4,960,126; 5,078,136; 5,485,847; 5,743,263; 5,865,736; 6,035,223; 6,298,252; 6,463,310; 6,591,123;

6,675,031; 6,708,049; 6,801,797; and Re.35,122.

Page 3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Description of OXIMAX N-65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Front Panel Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rear Panel Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Label Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Menu Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Set Menu Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Set Time/Date Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Periodic Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Equipment Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Power-On-Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Operational Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Setting the Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Operation with a Live Subject . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pulse Oximetry Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Test 1: BPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Test 2: SpO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Test 3: Modulation Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

OXIMAX N-65 Service Manual i

Page 4

Contents

Test 4: Light Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

How To Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Who Should Perform Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Disassembly Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Replacement Level Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Prior to Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Separating the Front and Back Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

SpO2 PCB or User Interface PCB Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Front Case Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Rear Case Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Battery Compartment Door Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Obtaining Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Parts List and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Packing for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Returning the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Repacking in Original Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Packing in a Different Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Manufacturer’s Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Technical Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

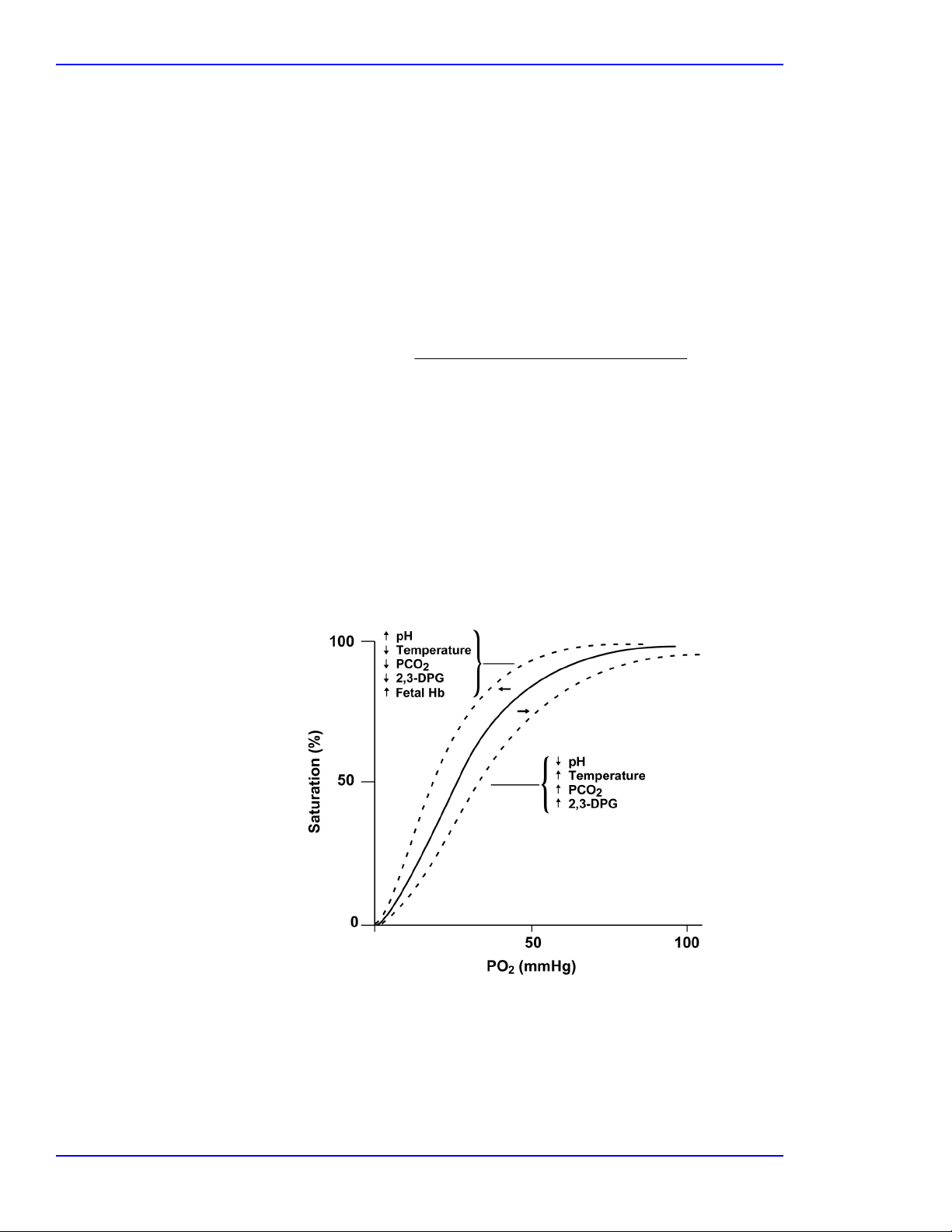

Oximetry Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Functional versus Fractional Saturation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Measured versus Calculated Saturation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

OXIMAX Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

ii OXIMAX N-65 Service Manual

Page 5

Contents

Block Diagram Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

2 Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

SpO

Patient Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Power Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

User Interface Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

CPU and Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

IrDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Power Supply Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

OXIMAX N-65 Service Manual iii

Page 6

Contents

Blank Page

iv OXIMAX N-65 Service Manual

Page 7

Introduction

Warnings

Warnings are identified by the WARNING symbol shown above.

Warnings alert the user to potential serious outcomes (death, injury, or adverse

events) to the patient or user.

WARNING: The sensor uses the date and time provided by the OXIMAX N-65

handheld pulse oximeter when the sensor event record is recorded by the

sensor. The accuracy of the date/time is dependent on the date/time already

set in and provided by the monitor.

WARNING: Explosion hazard. Do not use the OXIMAX N-65 in the presence

of flammable anesthetics mixed with air, oxygen, or nitrous oxide.

WARNING: Do not spray, pour, or spill any liquid on the OXIMAX N-65, its

accessories, connectors, switches, or openings in the enclosure as this may

damage the monitor.

WARNING: Chemicals from a broken LCD display panel are toxic when

ingested. Use caution when the OXIMAX N-65 has a broken display panel.

WARNING: The use of accessories, sensors, and cables other than those

specified may result in increased emission and/or create invalid readings of

the OXIMAX N-65.

WARNING: Do not silence the OXIMAX N-65 audible alarm or decrease its

volume if patient safety could be compromised.

WARNING: To ensure patient safety, do not place the monitor in any

position that might cause it to fall on the patient.

OXIMAX N-65 Service Manual 1

Page 8

Introduction

Cautions

WARNING: As with all medical equipment, carefully route patient cabling

to reduce the possibility of patient entanglement or strangulation.

WARNING: To ensure accurate performance and prevent device failure, do

not expose the monitor to extreme moisture such as rain.

Cautions are identified by the CAUTION symbol shown above.

Cautions alert the user to exercise care necessary for the safe and effective use of

the O

XIMAX N-65.

Notes

Caution: Observe ESD (electrostatic discharge) precautions when working

within the unit.

Caution: Observe ESD (electrostatic discharge) precautions when

disassembling and reassembling the O

XIMAX N-65 and when handling any of

the components of the monitor.

Caution: When reassembling the O

XIMAX N-65, tighten the screws that hold

the cases together to a maximum of ten inch-pounds. Over-tightening could

strip out the screw holes in the front case, rendering it unusable.

Notes are identified by the Note symbol shown above.

Notes provide useful helpful information.

2 OXIMAX N-65 Service Manual

Page 9

Manual Overview

Introduction

This manual contains information for service personnel who will service the

Nellcor model O

XIMAX N-65 handheld pulse oximeter, herein referred to as the

monitor. Only qualified service personnel should service this product. Read the

operator's manual carefully and thoroughly understand the operation of the

monitor.

OXIMAX N-65 Service Manual 3

Page 10

Introduction

Description of OXIMAX N-65

The OXIMAX™ N-65 handheld pulse oximeter is indicated for continuous or spot

check monitoring of functional arterial oxygen saturation (SpO

adult, pediatric and neonatal patients in hospital, hospital-type facilities, transport

and mobile environments as well as in the homecare environment.

Front Panel Description

This section identifies the symbols, controls, displays, and indicators on the

XIMAX N-65.

O

2) and pulse rate of

Refer to the O

XIMAX N-65 Operator’s Manual for a complete description of all

buttons, symbols, controls, displays and indicators.

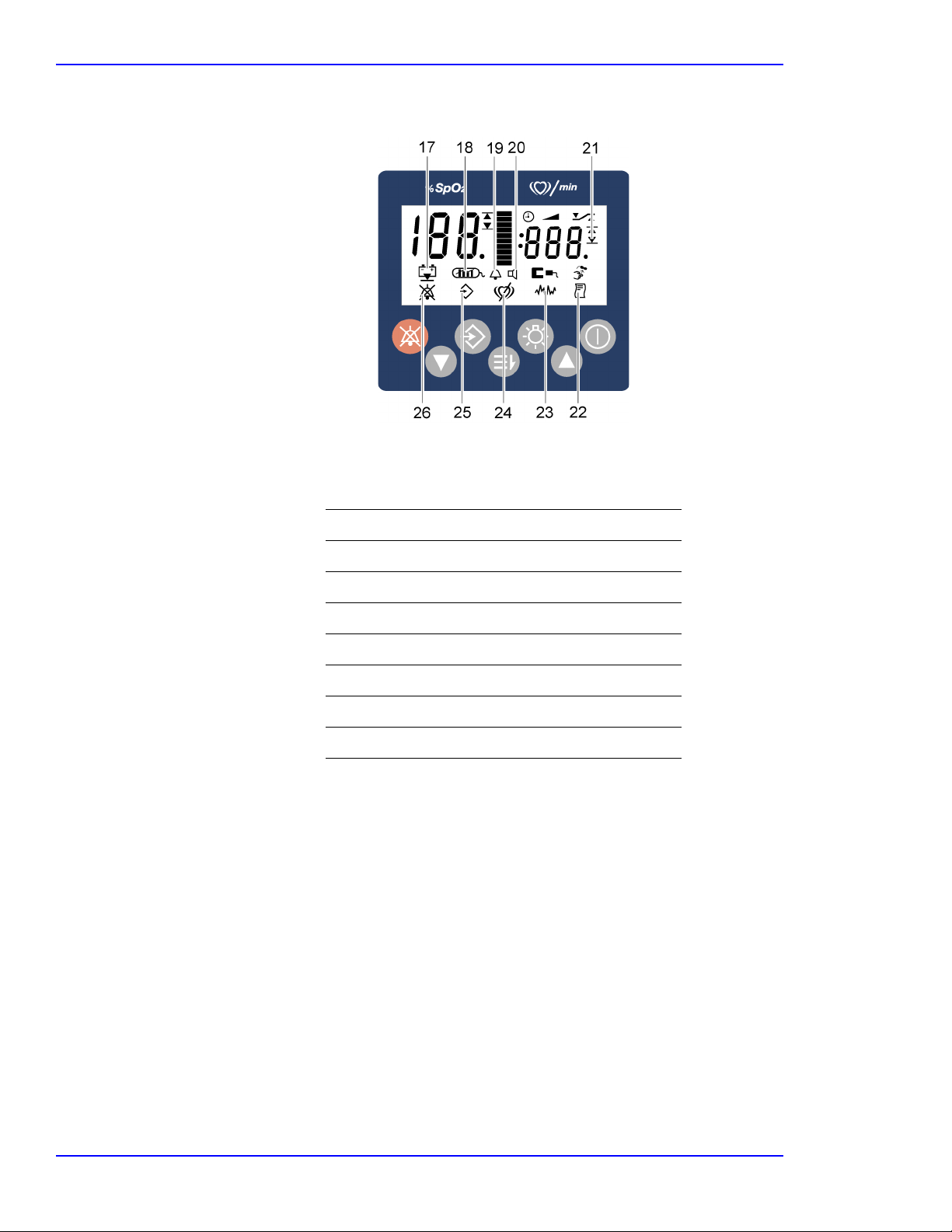

1 — %SpO2 area of display

2 — Measured %SpO2

3 — Pulse beats per minute (BPM) area of display

4 — Measured BPM

4 OXIMAX N-65 Service Manual

Page 11

5 — %SpO2 Lower Alarm Limit indicator

Introduction

6 — %SpO

2 Upper Alarm Limit indicator

7 — Pulse Amplitude indicator (Blip bar)

8 — Time Colon time/date field separator

9 — Adjust Time mode indicator

10 — Adjust Volume mode indicator

11 — Set Limit mode indicator

12 — BPM Upper Alarm Limit

indicator

13 — BPM Limit Changed indicator

14 — Sensor Off Patient indicator

15 — Sensor Disconnected indicator

16 — %SpO

2 Limit Changed indicator

OXIMAX N-65 Service Manual 5

Page 12

Introduction

17 — Low Battery indicator

18 — Data In-Sensor indicator

19 — Alarm Volume Adjust indicator

20 — Pulse Beep Tone Volume Adjust indicator

21 — BPM Lower Alarm Limit indicator

22 — Print indicator

23 — Interference indicator

24 — Pulse Search indicator

25 — Data indicator

26 — Alarm Silenced indicator

6 OXIMAX N-65 Service Manual

Page 13

27 — Power button

28 — Up Arrow button

29 — Backlight button

Introduction

30 — Menu button

31 — Data (Record/Print) button

32 — Down Arrow button

33 — Alarm Silence button

OXIMAX N-65 Service Manual 7

Page 14

Introduction

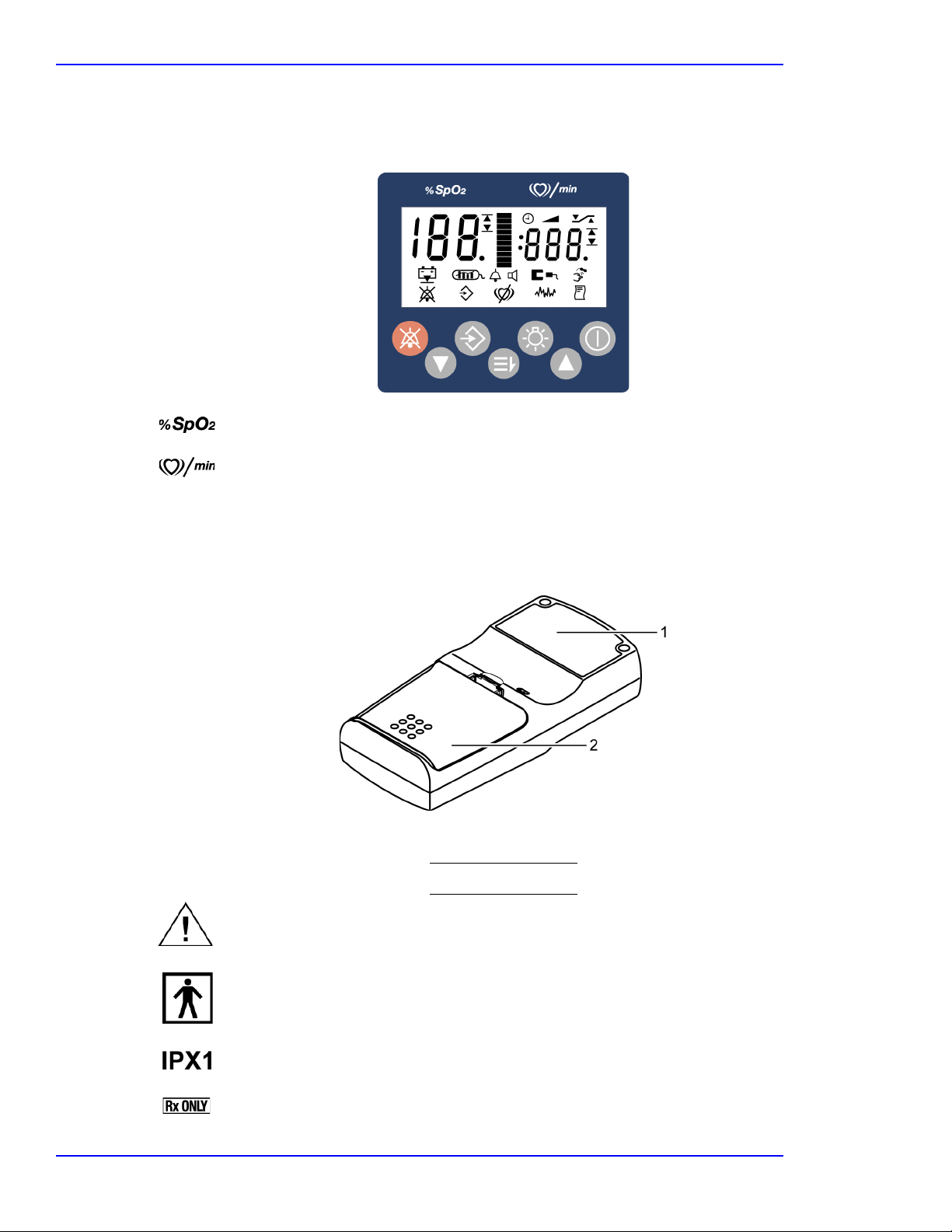

Front Panel Symbols

The follow two symbols are located on the front panel of the monitor.

Displays the measured percent of oxygen saturation.

Displays the measured pulse beats per minute.

Rear Panel Symbols

The following symbols are located on the rear panel of the monitor.

See Instructions for Use

1 — Label

2 — Battery Cover

Type BF Applied Part - Not defibrillator proof

Resistant to liquid ingress

Prescription only

8 OXIMAX N-65 Service Manual

Page 15

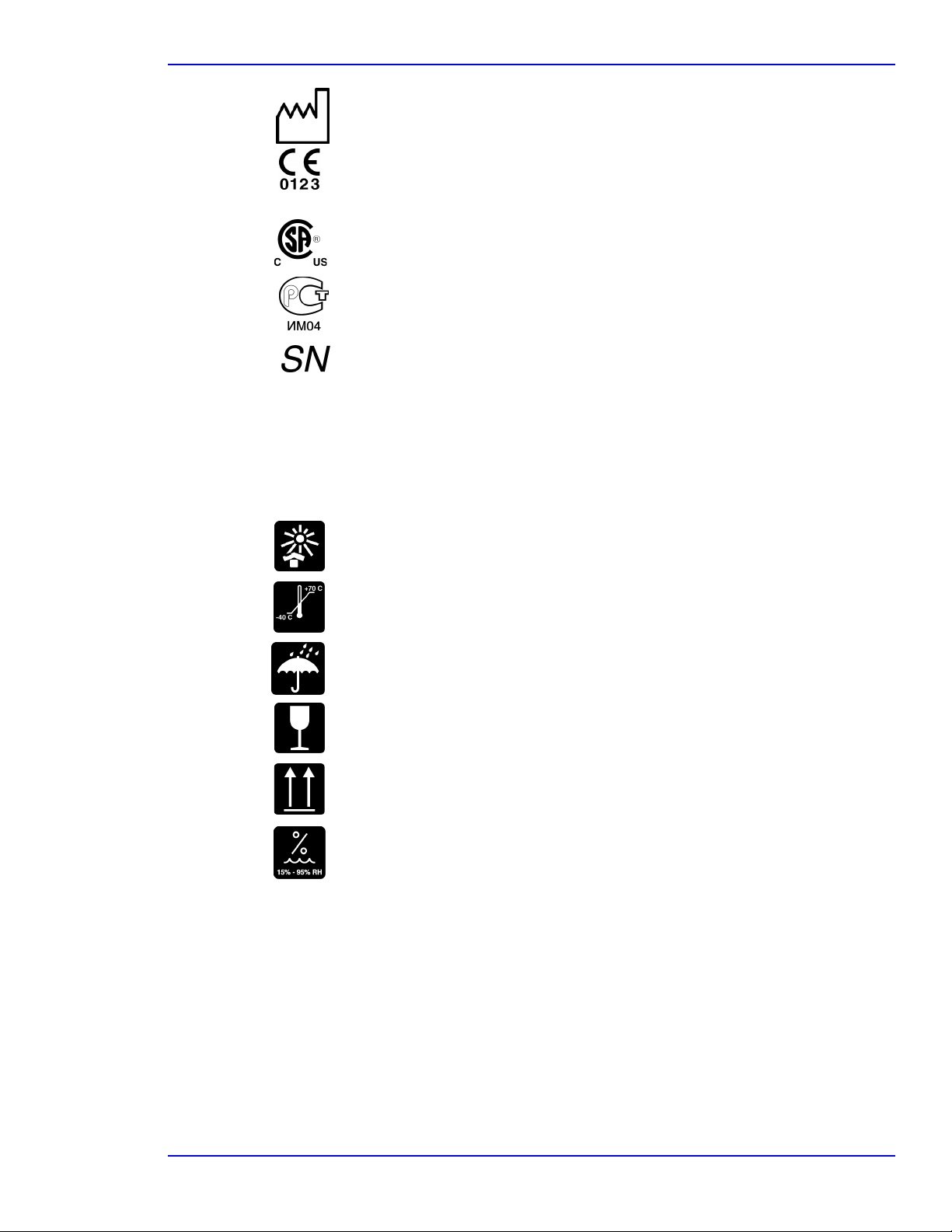

Label Symbols

Introduction

Date of Manufacture

European union approval

Canadian/USA certification mark (electrical safety)

Russian regulatory approval

Serial number

These symbols display on the monitor’s labels.

Keep away from heat

Temperature limitation

Protect from moisture

Fragile

Keep upright

Humidity limitation

OXIMAX N-65 Service Manual 9

Page 16

Introduction

Menu Parameters

This section contains information on how to set monitor parameters and limits

using the menu structure.

See Set Menu Parameters on page 11 to set the following parameters:

• high and low SpO

2 limits

• high and low BPM limits

• alarm volume

• pulse beep volume

• data printing

See Set Time/Date Parameters on page 12 to set the following parameters:

•Hour

•Minute

•Day

•Month

• Year

10 OXIMAX N-65 Service Manual

Page 17

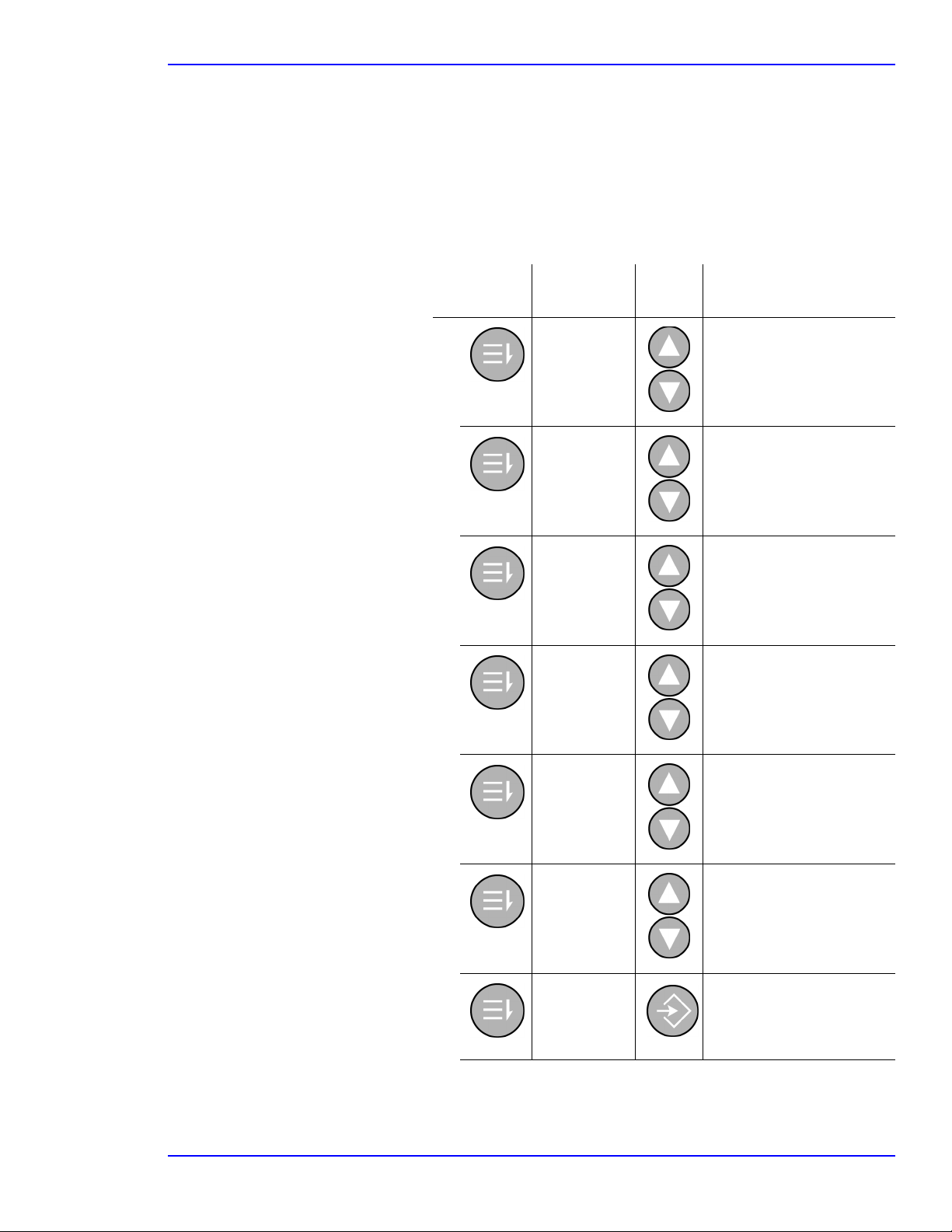

Introduction

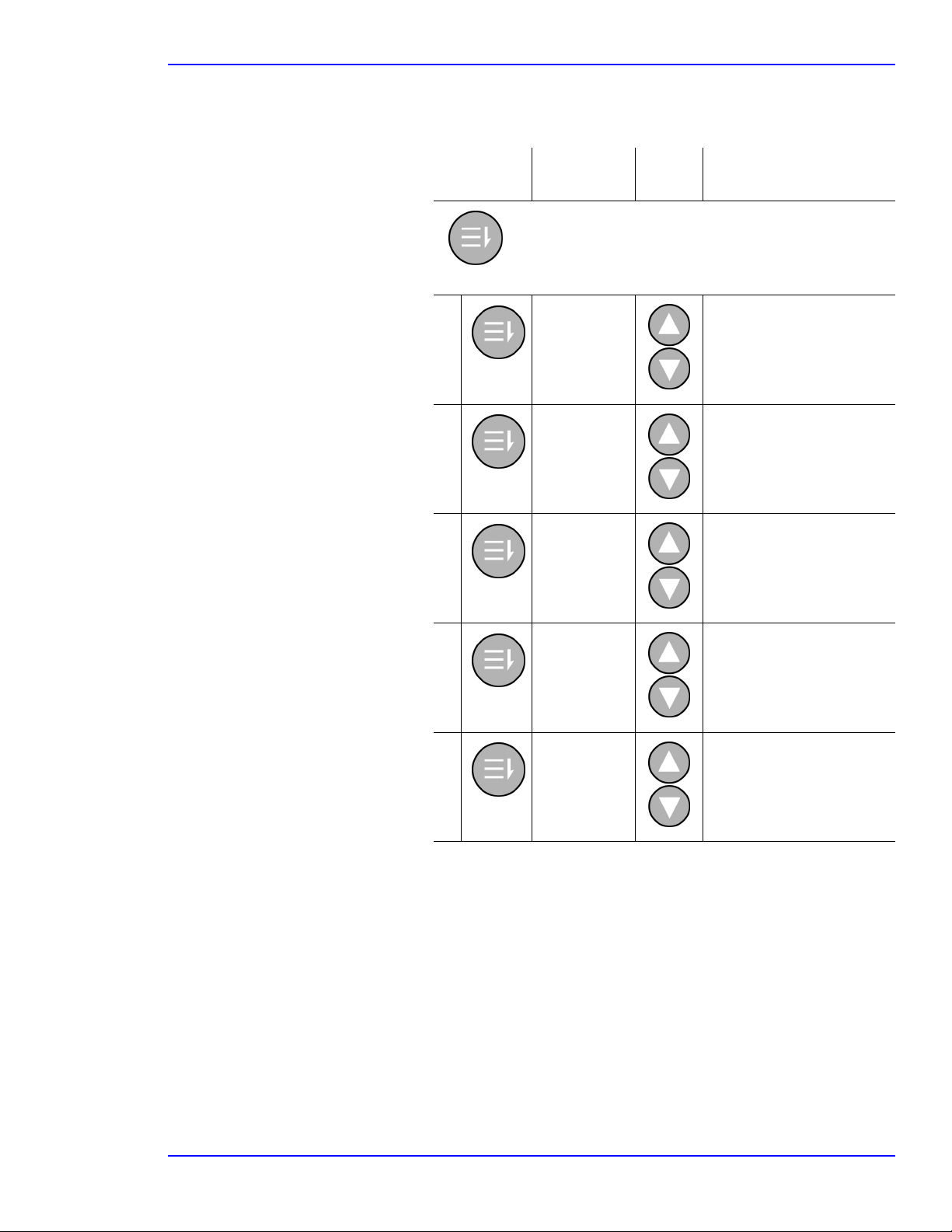

Set Menu Parameters

To set menu parameters, press the Menu button repeatedly during normal

operation to display the parameters to set. Use the Up Arrow button or Down

Arrow button to adjust the parameter limit. Press the Menu button to return to the

default monitoring display.

Table 1: Menu Structure

# of

Presses

1

2

3BPM Low

4 BPM High

Parameter Press Function

%SpO2 Low

Limit

%SpO2 High

Limit

Limit

Limit

Adjust limit

Adjust limit

Adjust limit

Adjust limit

5 Pulse Beep

Vo l u m e

6Alarm

Vo l u m e

7 Print Data Print summary and/or

OXIMAX N-65 Service Manual 11

Adjust volume. Indications

on blip bar.

Adjust volume. Indications

on blip bar.

stored snap-shot and

sensor-event data.

Page 18

Introduction

WARNING: Do not silence the OXIMAX N-65 audible alarm, or decrease its

volume, if patient safety could be compromised.

Set Time/Date Parameters

To access the Time/Date settings menu, press the Menu button during start-up

Power-On-Self-Test (POST). Press the Menu button repeatedly to display the

time/date parameters to set. Use the Up Arrow button and Down Arrow button to

adjust time/date settings. Press the Menu button to return to the POST display.

When the month entry is made, the monitor checks the day selection to see if it is

valid. If the day selection is not valid for the month selected the menu display

returns to the day selection display.

When the year entry is made, the monitor checks the day and month selections to

see if they are valid. If the day or month selection is not valid for the year selected

the menu display returns to the day selection display.

Examples of invalid dates are:

• 30 February

• 31 February

•31 April

•31 June

• 31 September

•31 November

• 29 February on a non-leap year

12 OXIMAX N-65 Service Manual

Page 19

Table 2: Time Set Menu

Introduction

# of

Presses

Parameter Press Function

The Menu button must be pressed during the

POST.

1 Hour Adjust 1 to 23

2 Minute Adjust 1 to 59

3 Day Adjust 1 to 31

4 Month Adjust 1 to 12

5 Year Adjust 2003 to 2099

OXIMAX N-65 Service Manual 13

Page 20

Introduction

Related Documents

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/Apartweb/main/PartAcceMenu.html

To perform test and troubleshooting procedures and to understand the principles

of operation and circuit analysis sections of this manual, you must know how to

operate the O

understand the various Nellcor approved O

monitor, refer to the individual O

XIMAX N-65. Refer to the OXIMAX N-65 Operator's Manual. To

XIMAX sensors that work with the

XIMAX sensor's Directions For Use.

The latest version of the operator’s manual and the service manual are posted on

the Internet at:

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/ProductManuals.html

Spare Parts and Accessories are posted on the Internet at:

14 OXIMAX N-65 Service Manual

Page 21

Routine Maintenance

Cleaning

WARNING: Do not spray, pour, or spill any liquid on the OXIMAX N-65 its

accessories, connectors, switches, or openings in the enclosure as this may

damage the monitor.

For surface-cleaning and disinfecting follow your institution's procedures or:

•The O

dampened with either a commercial, nonabrasive cleaner or a solution of

70 percent alcohol in water, and lightly wiping the surfaces of the

monitor.

• The monitor may be disinfected using a soft cloth saturated with a ten

percent solution of chlorine bleach in tap water.

Before cleaning an SpO

with the O

that sensor.

Periodic Safety Checks

The OXIMAX N-65 does not require calibration.

A qualified service technician should perform the following safety checks every

24 months.

To perform periodic safety checks:

1. Inspect the equipment for mechanical and functional damage.

XIMAX N-65 may be surface-cleaned by using a soft cloth

2 OXIMAX sensor, read the Directions For Use enclosed

XIMAX sensor. Each sensor model has cleaning instructions specific to

2. Inspect safety labels for legibility. If the labels are damaged, contact Nellcor’s

Technical Services Department, 1.800.635.5267, or your local Nellcor

representative.

Functional Checks

If the monitor has been visibly damaged or subjected to mechanical shock (for

example, if dropped), immediately perform the performance tests. See

Performance Tests on page 17.

Every two years a qualified service technician should perform the electrical safety

tests detailed in Safety Tests on page 37. If the unit fails these electrical safety

tests, refer to Troubleshooting on page 39.

OXIMAX N-65 Service Manual 15

Page 22

Routine Maintenance

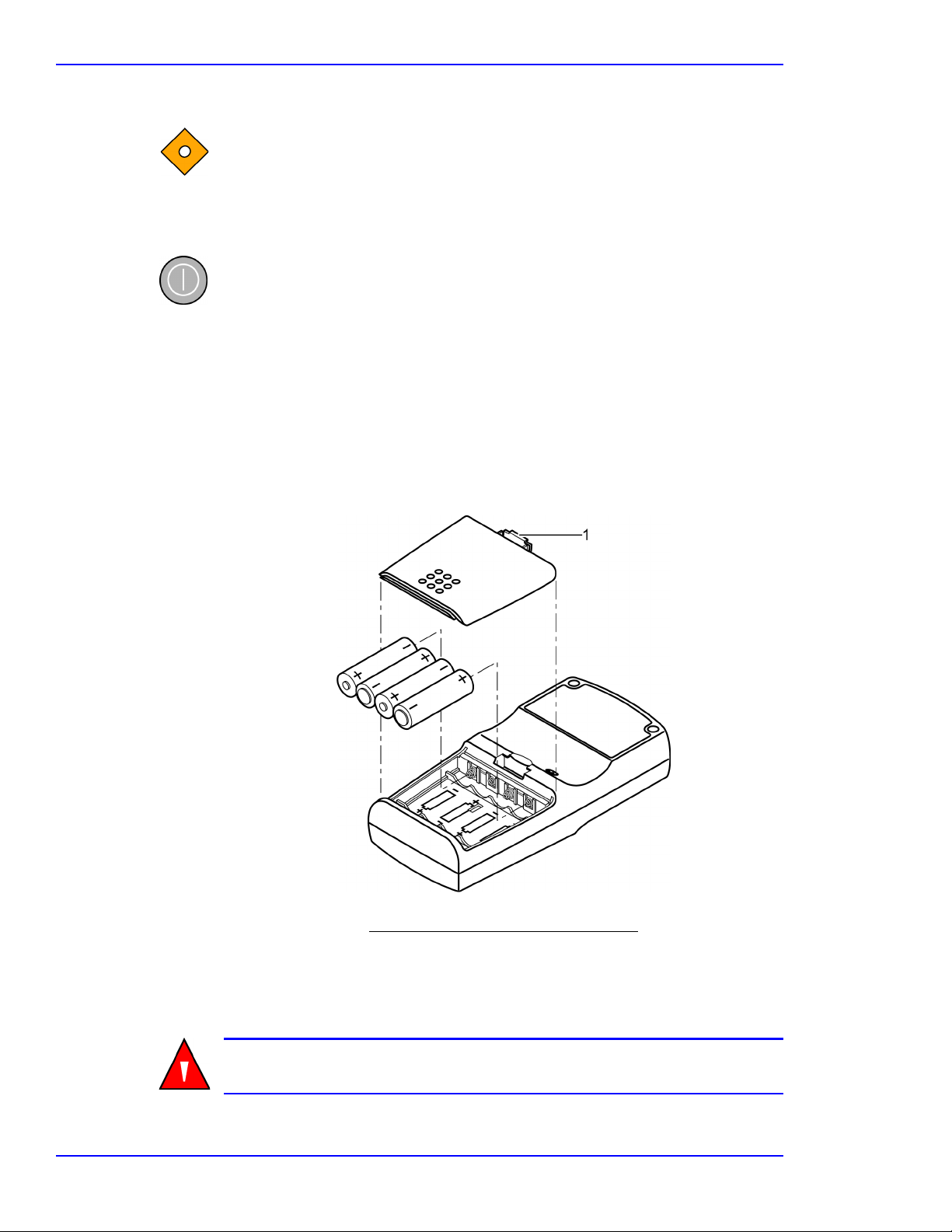

Battery Installation

Caution: The monitor does not operate with dead batteries. Install new

batteries.

To install new batteries:

1. Press the Power button to turn the monitor off.

2. Pull the battery compartment latch downward, toward the bottom of the

3. Install four “AA” size batteries, orientated as shown in Figure 1.

4. Replace the battery access door.

monitor, and remove the battery access door. See Figure 1.

1 — Battery compartment latch

Figure 1: Installing Batteries

WARNING: Explosion hazard. Do not use the OXIMAX N-65 in the presence

of flammable anesthetics mixed with air, oxygen, or nitrous oxide.

16 OXIMAX N-65 Service Manual

Page 23

Performance Verification

Introduction

This section discusses the tests used to verify performance following repairs or

during routine maintenance. All tests can be performed without removing the

O

XIMAX N-65 cover. All tests, except the battery charge and battery performance

tests, must be performed as the last operation before the monitor is returned to the

user.

If the monitor fails to perform as specified in any test, repairs must be made to

correct the problem before the monitor is returned to the user.

Equipment Needed

Equipment Description

Durasensor® OXIMAX oxygen sensor

XIMAX

oxygen sensor

O

Extension cable DEC-4

Nellcor model SRC-MAX Tester Provides testing for O

DS-100A

MAX-A

XIMAX compatible monitors

Performance Tests

The Power-On-Self-Test (POST) performance test verifies that the OXIMAX N-65

is ready for patient monitoring.

Power-On-Self-Test

Discussion

Before using the monitor, you must verify that it is working properly and is safe to

use. Proper working conditions are verified each time the monitor is turned on as

described in the following procedure. The POST verification procedure takes

approximately 10 seconds to complete.

Caution: If any indicator or display element does not light when the monitor

is turned on, do not use it. Instead, contact qualified service personnel, your

local Nellcor representative, or Nellcor’s Technical Services Department.

Note: Physiological conditions, medical procedures, or external agents that may

interfere with the monitor’s ability to detect and display accurate measurements

include: dysfunctional hemoglobin, arterial dyes, low perfusion, dark pigment,

and externally applied coloring agents, such as nail polish, dye, or pigmented

cream.

Note:The O

XIMAX N-65 automatically starts POST, which tests the monitor

circuitry and functions.

OXIMAX N-65 Service Manual 17

Page 24

Performance Verification

Caution: During POST (immediately after power-up), confirm that all

display segments and icons are shown, and the monitor speaker sounds a

one-second tone.

When the monitor is turned on, the backlight remains on. The display displays the

following sequence, in order, as POST takes place:

• All display graphics are shown for three seconds and the backlight is

turned on.

• The display goes blank (all display elements off) for one second.

• The software version number displays for three seconds as a three digit

number in the right number field (with leading zeros if the version

number is less than 100) and two dashes in the left number field.

• The current time of day is shown in 24-hour format.

• Successful completion of POST is announced by a POST pass tone. A

failed POST is announced by a high-priority alarm tone.

Procedure

To run POST:

1. Press the Power button to turn on the monitor.

Note: Do not have a sensor connected to the monitor.

The backlight remains on during POST.

All display numbers and icons are shown for three seconds. The backlight is

turned on.

18 OXIMAX N-65 Service Manual

Page 25

Performance Verification

2. The display goes blank for one second.

3. The software version number displays. The software version is identified by

two dashes in the %SpO

2 area of the display.

Note: The software version 001 is an example. Check the monitor for

the software version installed. Write down the software version number

and have it available prior to requests for technical assistance.

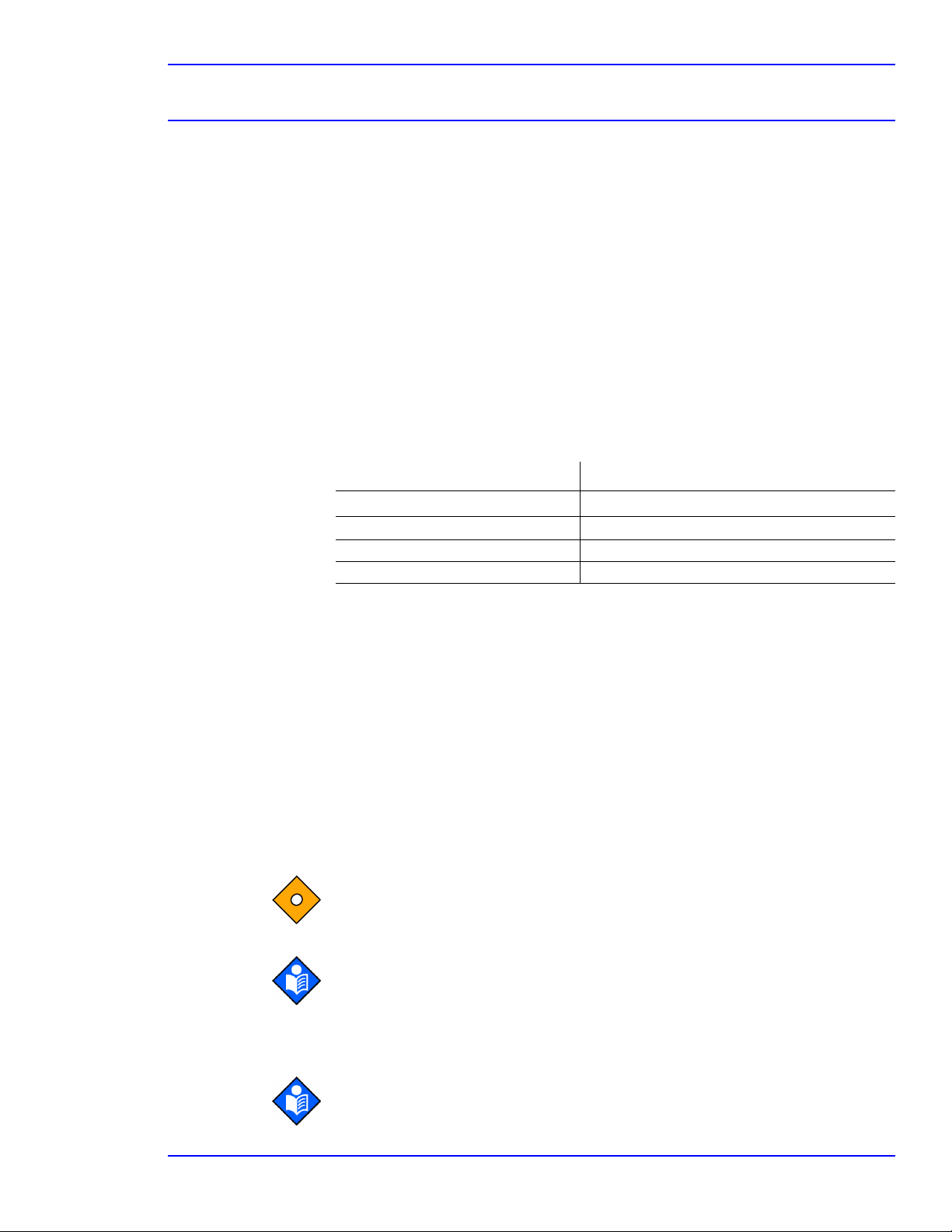

4. The current time displays in a 24-hour format.

OXIMAX N-65 Service Manual 19

Page 26

Performance Verification

Note: If the time has never been set, do not continue until you set the

time. See Operator’s Manual.

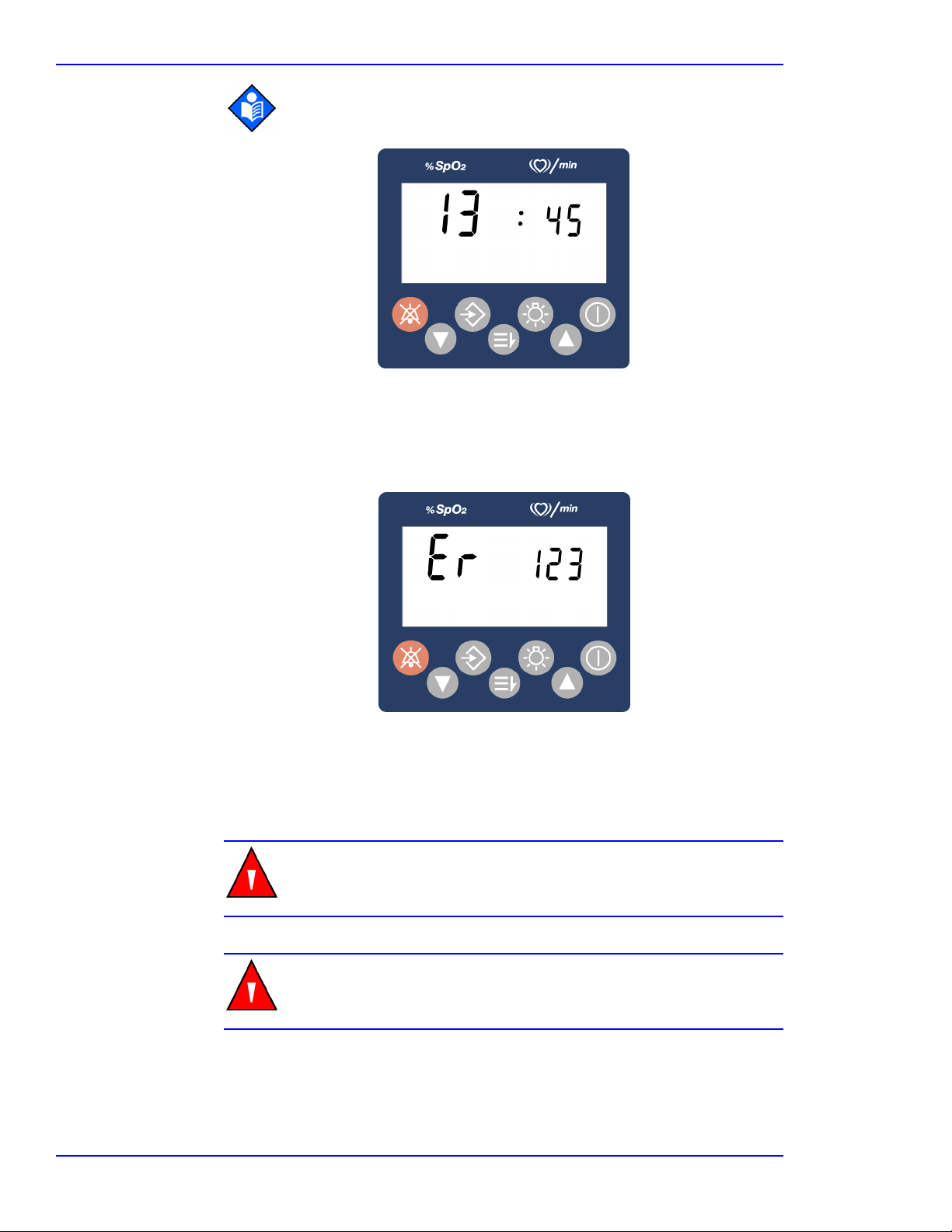

5. If the monitor detects a problem, an error tone sounds and an error code (Er)

and the error number display. See Troubleshooting on page 39.

6. Upon successful completion of POST, the monitor sounds a one-second tone

to indicate it has passed the test.

WARNING: If you do not hear the POST pass tone, do not use the

monitor.

WARNING: Ensure that the speaker is clear of any obstructions

and that the speaker holes are not covered. Failure to do so could

result in an inaudible alarm tone.

20 OXIMAX N-65 Service Manual

Page 27

Performance Verification

Note: In addition to serving as the POST pass verification, the POST

pass tone also functions as audible confirmation that the speaker is

performing properly. If the speaker does not function, the alarm warning

sounds cannot be heard.

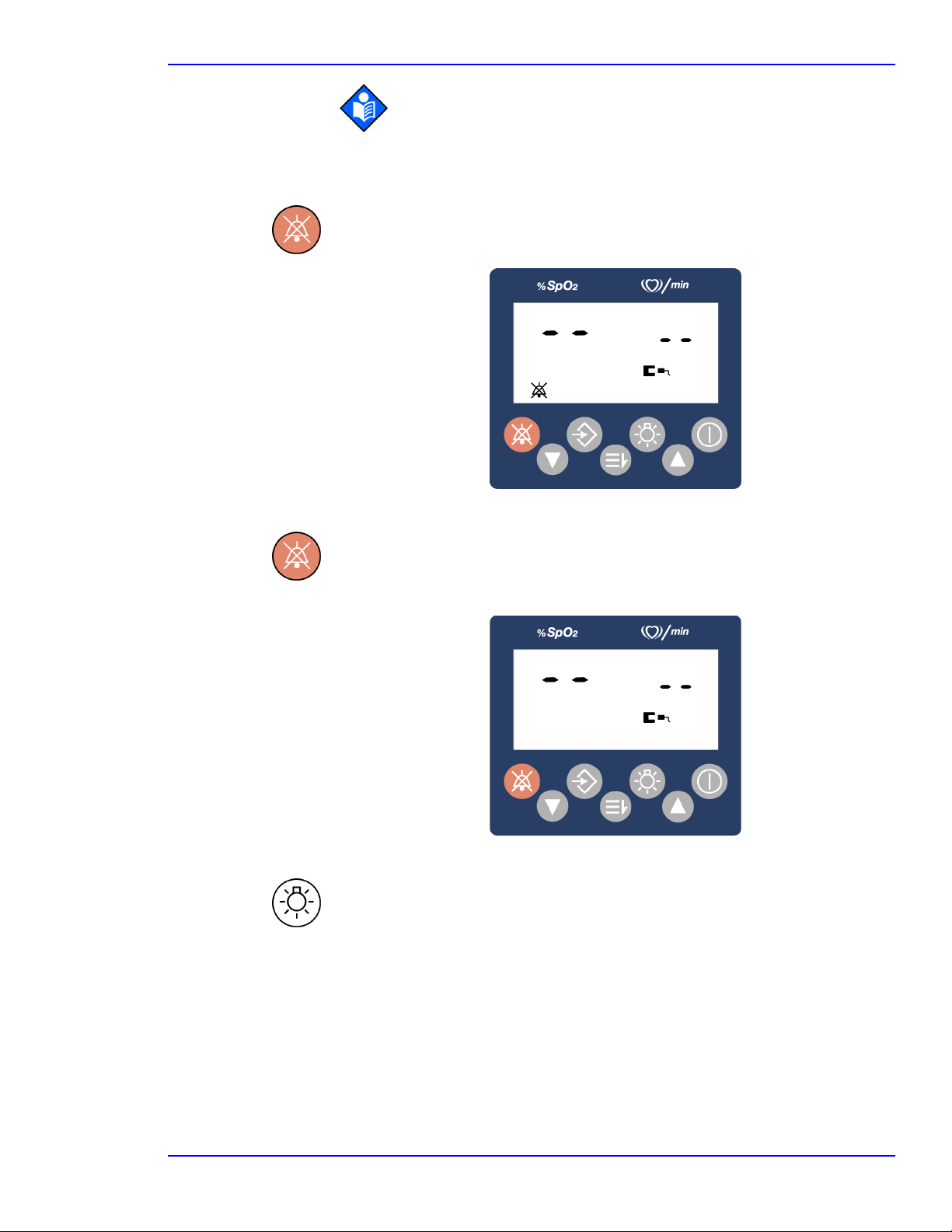

7. Press the Alarm Silence button. The Alarm Silenced indicator displays.

8. Press the Alarm Silence button. The Alarm Silenced indicator does not

display.

9. Press the Backlight button. The backlight turns on.

10. Press the Backlight button. The backlight turns off.

OXIMAX N-65 Service Manual 21

Page 28

Performance Verification

Operational Setup

The operational setup procedure sets the time and date into the monitor. Refer to

the O

monitor returns to the factory default settings when it is powered on: therefore,

individual parameter settings need to be set at that time.

Setting the Time and Date

Discussion

WARNING: The OXIMAX sensor uses the date and time provided by the

O

chip in the sensor. The accuracy of the date/time used for patient alarm

events depends on the date/time set in the monitor.

Note: When the monitor times-out in 30 seconds, the parameter is set and the

monitor display returns to the normal operation.

Normal operation means:

XIMAX N-65 Operator’s Manual for individual parameter settings. The

XIMAX N-65 when the patient alarm events are recorded to the memory

• the monitor is turned on

• a sensor is connected to the monitor

• the sensor is applied to the patient

• the patient’s %SpO

2 (oxygen saturation percentage) and pulse rate

readings (BPM) are being reported

• no error conditions exist

Procedure

To set the time and date:

1. With the monitor in normal operation, press the Power button to turn the

monitor off.

2. Press the Power button to turn the monitor on.

22 OXIMAX N-65 Service Manual

Page 29

Performance Verification

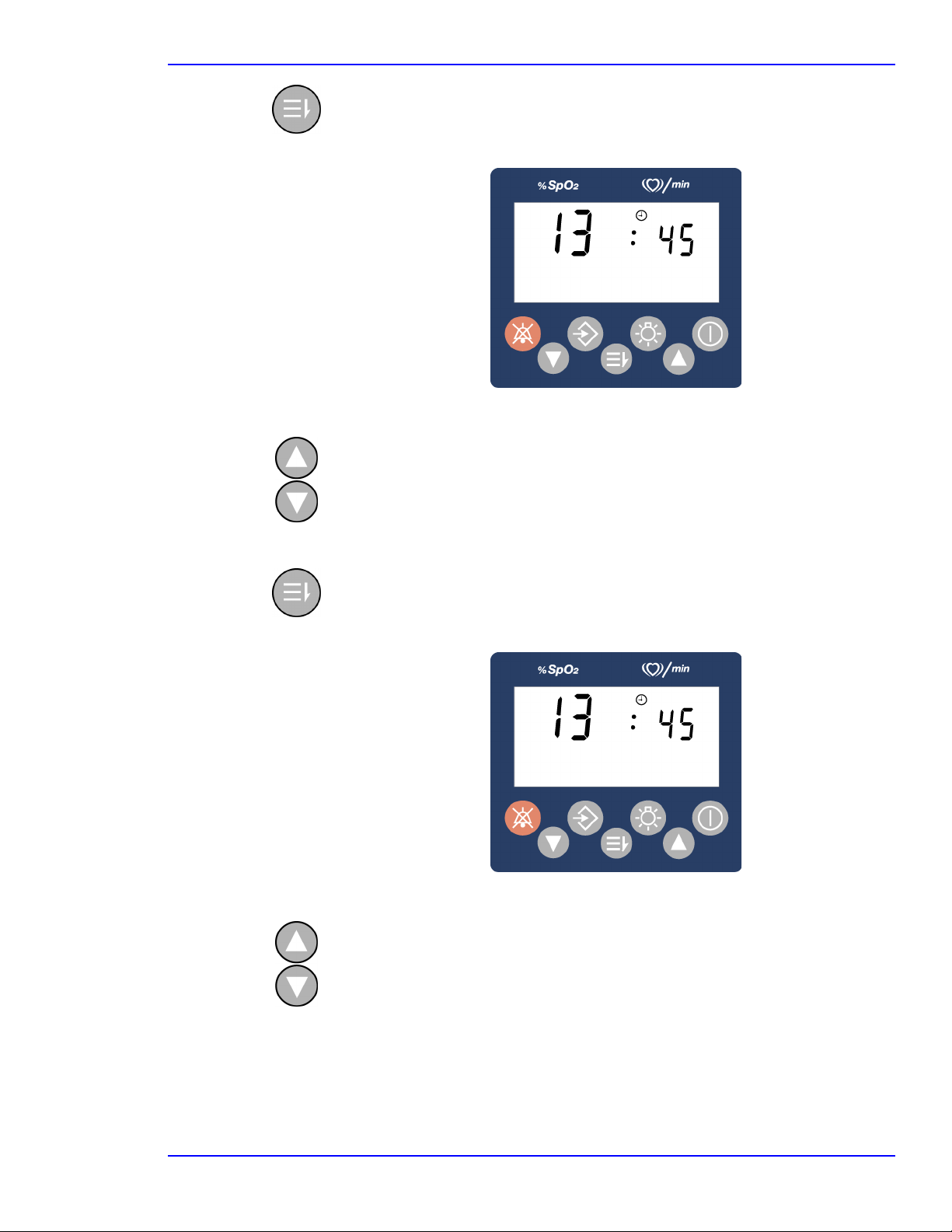

3. Press the Menu button during the POST operation until the set hours window

appears with the hours indication (13) flashing.

4. Press the Up Arrow button or the Down Arrow button until the desired hours

appear.

5. Press the Menu button to set the hours and show the minutes set display. The

minutes indication (45) flashes.

6. Press the Up Arrow button or the Down Arrow button until the desired

minutes appear.

OXIMAX N-65 Service Manual 23

Page 30

Performance Verification

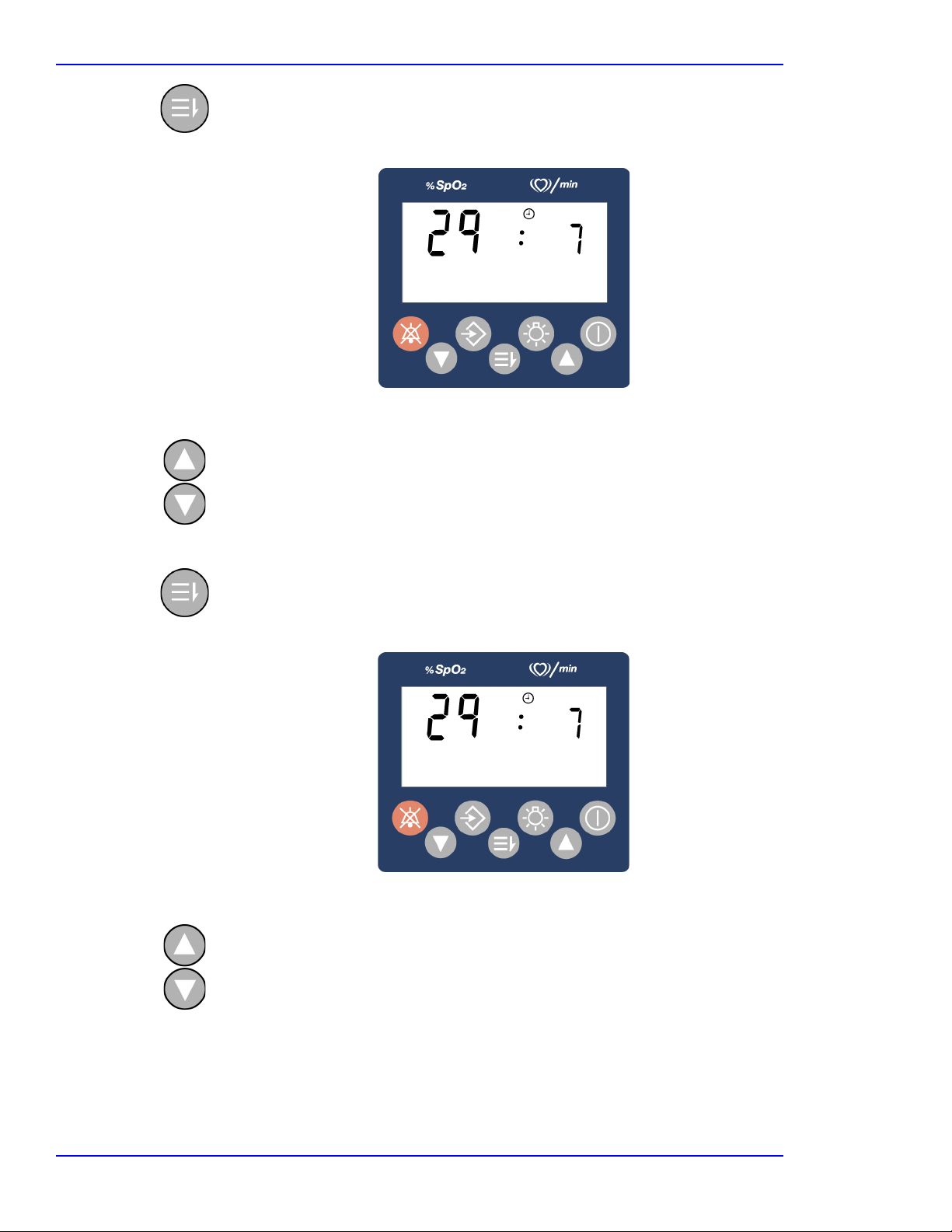

7. Press the Menu button to set the minutes and show the day set display. The

day indication (29) flashes.

8. Press the Up Arrow button or the Down Arrow button until the desired day

appears.

9. Press the Menu button to set the day and show the month set display. The

month indication (7) flashes.

10. Press the Up Arrow button or the Down Arrow button until the desired

month appears.

24 OXIMAX N-65 Service Manual

Page 31

Performance Verification

11. Press the Menu button to set the month and show the year set display. The

year indication (2004) flashes.

12. Press the Up Arrow button or the Down Arrow button until the desired year

appears.

13. Press the Menu button to set the year and return to normal operation.

OXIMAX N-65 Service Manual 25

Page 32

Performance Verification

General Operation

The Operation with a Live Subject test is an overall performance check of the

system.

Operation with a Live Subject

Patient monitoring involves connecting the OXIMAX sensor to a live subject for a

qualitative test.

.

1

— Sensor Port

To connect the OXIMAX sensor to a live subject for a qualitative test:

1. Connect a Nellcor O

2. Clip the MAX-A to the subject as recommended in the O

XIMAX MAX-A oxygen OXIMAX sensor to the monitor.

XIMAX sensor's

Directions For Use.

3. Press the Power button to turn the monitor on and verify that it is operating.

The monitor should stabilize on the subject's physiological signal in

approximately 30 seconds.

4. Verify that the oxygen saturation and pulse rate values are reasonable for the

subject.

5. Press the Data button.

26 OXIMAX N-65 Service Manual

Page 33

The monitor records snap-shot data.

6. Turn off the monitor.

Performance Verification

OXIMAX N-65 Service Manual 27

Page 34

Performance Verification

Pulse Oximetry Functional Tests

The Pulse Oximetry Functional Tests utilize the pulse oximetry functional tester

(Nellcor model SRC-MAX) to verify the performance of the monitor. See

Figure 2.

1 —OXIMAX N-65 Cable Connector 6 — % Modulation Select Button

2 — RED LED Drive Indicator 7 — % SpO

3 — Not Used For O

4 — Not Used For O

XIMAX N-65 8 — Light Level Selection Button

XIMAX N-65 9 — Pulse Rate Selection Button

2 Select Button

5 — Battery Low Indicator 10 — INFRARED LED Drive Indicator

Figure 2: SRC-MAX O

XIMAX Oximetry Tester

28 OXIMAX N-65 Service Manual

Page 35

Performance Verification

The SRC-MAX functional tester allows qualified technicians to functionally test

Nellcor O

XIMAX technology-based pulse oximeters and OEM OXIMAX

technology-based monitors.

The Pulse Oximetry Functional tests should be completed in the order shown:

•Test Setup

Note: The technician must complete Test Setup before performing tests

1 through 4 as follows.

•Test 1: BPM

•Test 2: SpO

2

• Test 3: Modulation

• Test 4: Light

See Table 3, "Pulse Oximetry Functional Tests", on page 30 for a brief

description of each test.

OXIMAX N-65 Service Manual 29

Page 36

Performance Verification

Table 3 shows the Pulse Oximetry Functional Tests you must perform and a

description of each.

Table 3: Pulse Oximetry Functional Tests

Test Description

Test S et u p This procedure establishes the baseline for all the other

Test 1: BPM This procedure simulates an OXIMAX sensor attached to a

Tes t 2 : Sp O2

Test 3: Modulation This procedure simulates an OXIMAX sensor attached to a

tests.

Test Setup must be performed before performing any or

all of the SRC-MAX tests.

See Test Setup on page 31.

patient indicating 60 bpm and 200 bpm.

The test sets up Test 1 for 60 bpm.

See Test 1: BPM on page 32.

This procedure simulates an OXIMAX sensor attached to a

patient, indicating 75 percent blood oxygen saturation and

90 percent blood oxygen saturation.

The test sets up Test 2 for 75 percent blood oxygen

saturation.

See Tes t 2: S p O2 on page 33.

patient indicating low and high pulse strength.

The test sets up Test 3 for low pulse strength.

See Test 3: Modulation Level on page 34.

Test 4: Light This procedure simulates an OXIMAX sensor attached to a

patient indicating low and high light level passing through

the patient at the sensor site.

The test sets up Test 4 for low light level.

See Test 4: Light Level on page 36.

30 OXIMAX N-65 Service Manual

Page 37

Test Setup

Performance Verification

You must complete Test Setup before performing any other pulse oximetry

functional tests.

To perform test setup:

1. Press the Power button to turn on the monitor.

2. After the monitor presents the monitoring screen, connect the SRC-MAX

tester to the monitor sensor port as shown.

Note: Use a DEC-4 extension cable between the SRC-MAX and the

monitor.

1 — Sensor Port

The SRC-MAX panel lights and in a few seconds the monitor tracks the

simulator.

After the monitor completes POST, the monitor:

•is in SpO

• displays an %SpO

2 alarm

2 of 75 (pass criteria is 73 to 77 %SpO2 inclusive)

• displays a pulse rate of 60 (pass criteria is 57 to 63 bpm inclusive)

OXIMAX N-65 Service Manual 31

Page 38

Performance Verification

Test 1: BPM

• Pulse Amplitude indicator - displays low level modulation (low

amplitude pulse amplitude indicator)

To p e rf or m Te s t 1 : B P M:

1. Press the SRC-MAX % Pulse Rate selection button.

The SRC-MAX Pulse Rate 200 LED lights.

The monitor bpm increases to 200 and stabilize at 200 bpm. The test pass

criteria is 197 to 203 bpm inclusive.

The monitor:

• displays 75 %SpO

2

• displays 200 bpm (pass criteria is 197 to 203 bpm inclusive)

•alarms

• Pulse Amplitude indicator displays low level modulation

32 OXIMAX N-65 Service Manual

Page 39

Performance Verification

2. Press the SRC-MAX Pulse Rate select button.

The SRC-MAX Pulse Rate 60 LED lights.

The monitor pulse rate decreases to 60 and stabilize at 60 bpm. The test pass

criteria is 57 to 63 bpm inclusive.

The monitor:

Test 2: SpO2

• displays 75 %SpO

2

• displays 60 bpm (test pass criteria is 57 to 63 bpm inclusive)

•alarms

• Pulse Amplitude indicator displays low level modulation

To p e rf or m Te s t 2 : S p O2:

1. Press the SRC-MAX %SpO2 select button.

The SRC-MAX %SpO

2 90 LED lights.

The monitor displays three dashes until the SRC-MAX stabilizes at 90

2. The test pass criteria is 88 to 92 %SpO2 inclusive.

%SpO

The monitor:

• displays 90 %SpO

2 (pass criteria is 88 to 92 %SpO2 inclusive)

• displays 60 bpm

• no alarms

• Pulse Amplitude indicator displays low level modulation

OXIMAX N-65 Service Manual 33

Page 40

Performance Verification

2. Press the SRC-MAX %SpO2 select button.

The SRC-MAX %SpO

The monitor displays two dashes until the SRC-MAX stabilizes at 75 %SpO

The test pass criteria is 73 to 77 %SpO

The monitor:

• displays 75 %SpO

• displays 60 bpm

•alarms

• Pulse Amplitude indicator displays low level modulation

Test 3: Modulation Level

To perform Test 3: Modulation Level:

1. Press the SRC-MAX % Modulation selection button.

The SRC-MAX % Modulation LED lights.

2 75 LED lights.

2.

2 inclusive.

2 (pass criteria is 73 to 77 %SpO2 inclusive)

The monitor pulse blip bar initially increases in amplitude and then stabilizes

at the higher level.

The monitor:

• displays 75 %SpO

2 (test pass criteria is 73 to 77 %SpO2 inclusive)

• displays 60 bpm (test pass criteria is 57 to 63 bpm inclusive)

•alarms

• Pulse Amplitude indicator displays high level modulation

34 OXIMAX N-65 Service Manual

Page 41

Performance Verification

2. Perform Test 1: BPM on page 32.

The Pulse Amplitude indicator should indicate high level modulation.

3. Perform Test 2: SpO2 on page 33.

The Pulse Amplitude indicator should indicate high level modulation.

4. Press the SRC-MAX % Modulation selection button.

The SRC-MAX % Modulation LED lights.

The monitor pulse blip bar decreases in amplitude.

The monitor:

• displays 75 %SpO

2

• displays 60 bpm

•alarms

• Pulse Amplitude indicator displays low level modulation

5. Perform Test 1: BPM on page 32.

The pulse amplitude indicator should indicate low level modulation.

6. Perform Test 2: SpO2 on page 33.

The pulse amplitude indicator should indicate low level modulation.

OXIMAX N-65 Service Manual 35

Page 42

Performance Verification

Test 4: Light Level

To perform Test 4: Light Level:

1. Press the SRC-MAX Light Level selection button.

The SRC-MAX Light Level LED lights.

The monitor pulse blip bar initially increases in amplitude and then reduces

and stabilizes at 3-5 bars.

The monitor:

• displays 75 %SpO

2 (test pass criteria is 73 to 77 %SpO2 inclusive)

• displays 60 bpm (test pass criteria is 57 to 63 bpm inclusive)

•alarms

• pulse amplitude indicator displays low level modulation

2. Perform Test 1: BPM on page 32.

The pulse amplitude should indicate low level modulation.

3. Perform Test 2: SpO2 on page 33.

The pulse amplitude should indicate low level modulation.

36 OXIMAX N-65 Service Manual

Page 43

Performance Verification

4. Press the SRC-MAX Light Level selection button.

The SRC-MAX Light Level LED lights.

The monitor pulse blip bar initially increases in amplitude and then reduces

and stabilizes at 3-5 bars.

The monitor:

Safety Tests

• displays 75 %SpO

2

• displays 60 bpm

•alarms

• pulse amplitude indicator displays low level modulation

5. Perform Test 1: BPM on page 32.

The pulse amplitude indicator should indicate low level modulation.

6. Perform Test 2: SpO2 on page 33.

The pulse amplitude indicator should indicate low level modulation.

7. Disconnect all equipment and turn off the monitor.

The monitor safety tests meet the standards of, and are performed in accordance

with, EN 60601-1: 1990 (A1 and A2), IEC 60601-1, UL 60601-1, and CAN/CSA

C22.2 No. 601.1. This product is categorized as internally powered type BF

equipment.

OXIMAX N-65 Service Manual 37

Page 44

Performance Verification

Blank Page

38 OXIMAX N-65 Service Manual

Page 45

Troubleshooting

Introduction

This section explains how to troubleshoot the OXIMAX N-65. Tables list possible

monitor difficulties, along with probable causes, and recommended actions to

correct the difficulty.

How To Use This Section

Use this section in conjunction with Performance Verification on page 17, and

Spare Parts on page 61. To remove and replace a part suspected of being

defective, follow the instructions in Disassembly Guide on page 47. The circuit

analysis section in the Technical Discussion on page 81, offers information on

how the monitor functions.

Who Should Perform Repairs

Only qualified service personnel should open the monitor housing, remove and

replace components, or make adjustments. If your medical facility does not have

qualified service personnel, contact Nellcor’s Technical Services or your local

Nellcor representative.

Troubleshooting Guide

Note: Follow the recommended actions discussed in this section to correct the

majority of problems you may encounter. However, problems not covered here

can be resolved by calling Nellcor’s Technical Services or your local Nellcor

representative.

If you encounter a problem that cannot be resolved through a visual inspection,

refer to Table 4: Troubleshooting Guide, on page 40. In the table, find the

condition that describes the problem and follow the corrective actions in the order

presented. For a symptom that is not listed in Table 4, contact the Nellcor

Technical Services Department at 1.800.635.5267 or your local Nellcor

representative.

OXIMAX N-65 Service Manual 39

Page 46

Troubleshooting

If an error code is shown on the monitor front panel display, see Figure 3. Turn

the monitor off, wait ten seconds, then turn it back on. This clears recoverable

errors encountered by the monitor. If the error code persists, refer to Table 5:

Error Codes, on page 43 for an explanation of the error code. Apply the action

specified.

Figure 3: Typical Error Code Display

Once you have performed the recommended action, reassemble the monitor, refer

to Performance Verification on page 17, and conduct a performance verification

before returning the monitor to service. If the symptom persists continue

troubleshooting.

Table 4: Troubleshooting Guide

Condition Recommended Action

The monitor does not turn on when you press the Power button.

• The Power button was not fully

depressed.

• The batteries are missing. Open the battery compartment. If the batteries are missing,

• The batteries are installed incorrectly. Open the battery compartment. If the batteries are not

• The batteries are at, or near, a voltage too

low for the monitor to operate.

• The flex circuit between the front panel

and the SpO

making a good connection.

• The front panel keypad is defective. Caution: Unlock J4 before attempting to

2 PCB is damaged, or not

Fully press the Power button.

install new batteries. Refer to the O

Manual.

installed correctly, remove and reinstall them. Make sure the

batteries are not installed backwards. Refer to the O

N-65 Operator’s Manual.

Install new batteries. Refer to the O

Manual.

Caution: Unlock J4 before attempting to

remove and reinsert the flex cable.

Inspect the flex cable for damage. Inspect the connection to

J4. If there is damage to the flex cable, replace the front

case. Otherwise, remove the cable from J4 and reconnect it.

Reassemble the monitor and retest. Refer to Separating the

Front and Back Cases on page 48 and Front Case Assembly

Replacement on page 54.

remove the flex circuit cable.

XIMAX N-65 Operator’s

XIMAX

XIMAX N-65 Operator’s

Replace the Front Case. Refer to Front Case Assembly

Replacement on page 54.

40 OXIMAX N-65 Service Manual

Page 47

Troubleshooting

Table 4: Troubleshooting Guide (Continued)

Condition Recommended Action

• Replacing the front case does not fix the

problem.

• Replacing the SpO

2 PCB does not fix the

problem.

One or more keys on the front panel keypad does not work.

• The flex circuit between the front panel

and the SpO

2 PCB is damaged, or not

making a good connection.

• The front panel keypad is defective. Caution: Unlock J4 before attempting to

• Replacing the front case does not fix the

problem.

• Replacing the SpO

2 PCB does not fix the

problem.

One or more display segments does not work.

• A User Interface PCB component has

failed.

• The User Interface PCB is defective. If damage is found, replace the User Interface PCB. See

Pulse rate and %SpO

• The SpO

2 sensor is not connected

2 value does not display when the monitor is turned on.

properly.

• The SpO

2 sensor has failed. Replace the SpO2 sensor.

• The User Interface PCB is defective. Replace the User Interface PCB. See SpO2 PCB or User

• The SpO

2 PCB is defective. Replace the SpO2 PCB. See SpO2 PCB or User Interface

The display backlight does not come on when you press the Backlight button.

• The flex circuit between the front panel

and the SpO

2 PCB is damaged, or not

making a good connection.

Replace the SpO2 PCB. See SpO2 PCB or User Interface

PCB Replacement on page 50.

Replace the User Interface PCB. See SpO2 PCB or User

Interface PCB Replacement on page 50. If this does not fix

the problem, return the monitor to Nellcor.

Caution: Unlock J4 before attempting to

remove and reinsert the flex cable.

Inspect the flex cable for damage. Inspect the connection to

J4. If there is damage to the flex cable, replace the front

case. Otherwise, remove the cable from J4 and reconnect it.

Reassemble the monitor and retest. Refer to Separating the

Front and Back Cases on page 48 and Front Case Assembly

Replacement on page 54.

remove the flex circuit cable.

Replace the front case. Refer to Front Case Assembly

Replacement on page 54.

Replace the SpO

2 PCB. SpO2 PCB or User Interface PCB

Replacement on page 50.

Replace the User Interface PCB. See SpO2 PCB or User

Interface PCB Replacement on page 50. If this does not fix

the problem, return the monitor to Nellcor.

Inspect the User Interface PCB for cracking, burning, or

damage. If damage is found, replace the User Interface PCB.

See SpO2 PCB or User Interface PCB Replacement on

page 50.

SpO2 PCB or User Interface PCB Replacement on page 50.

Reconnect the SpO2 sensor to the monitor.

Connect the SpO

2 sensor to the patient. See the sensor

Directions for Use.

Interface PCB Replacement on page 50.

PCB Replacement on page 50.

Caution: Unlock J4 before attempting to

remove and reinsert the flex cable.

Inspect the flex cable for damage. Inspect the connection to

J4. If there is damage to the flex cable, replace the front

case. Otherwise, remove the cable from J4 and reconnect it.

Reassemble the monitor and retest. See Separating the Front

and Back Cases on page 48 and Front Case Assembly

Replacement on page 54.

OXIMAX N-65 Service Manual 41

Page 48

Troubleshooting

Condition Recommended Action

• The Backlight button on the front panel

keypad is defective.

• Replacing the SpO

problem.

• Replacing the SpO2 PCB does not fix the

problem.

• The Backlight LEDs on the User

Interface PCB have failed.

The monitor shuts off when you press the Backlight button.

• The batteries are, at or near, a voltage too

low for the monitor to operate.

The printer does not print.

• The IrDA between the printer and the

monitor is not properly aligned.

• The printer is turned off. Turn the printer on. See the printer documentation.

• The printer batteries are at, or near, a

voltage too low to operate.

• The Data button on the front panel

keypad is defective.

Table 4: Troubleshooting Guide (Continued)

Caution: Unlock J4 before attempting to

remove the flex circuit cable.

Replace the front case. See Front Case Assembly

Replacement on page 54.

2 PCB does not fix the

Replace the SpO2 PCB. See SpO2 PCB or User Interface

PCB Replacement on page 50.

Replace the User Interface PCB. See SpO2 PCB or User

Interface PCB Replacement on page 50. If this does not fix

the problem, return the monitor to Nellcor.

Replace the User Interface PCB. See SpO2 PCB or User

Interface PCB Replacement on page 50.

Install new batteries. See the O

Manual.

Align the printer and the monitor. See the O

Operator’s Manual for instructions.

Install new batteries in the printer. See the printer

documentation.

Caution: Unlock J4 before attempting to

remove the flex circuit cable.

XIMAX N-65 Operator’s

XIMAX N-65

• Replacing the Front Case does not fix the

problem.

• The printer is defective. See the printer documentation, or replace the printer.

Error Codes

Replace the Front Case. See Front Case Assembly

Replacement on page 54.

Replace the User Interface PCB. See SpO2 PCB or User

Interface PCB Replacement on page 50. If this does not fix

the problem, return the monitor to Nellcor.

An error code displays when the monitor detects a non-correctable failure. Table 5

provides a list of error codes for the monitor. However, you can turn the Power

off and on once (called “cycling” the power) to try removing the error code if one

of the following occurs:

• monitor sounds a low priority alarm

• measurements stop

• “Er” is shown in the %SpO

2 numeric display area

• Error code is shown in the right numeric display

If the error code remains, see Error Codes on page 43.

42 OXIMAX N-65 Service Manual

Page 49

Error

Code

Troubleshooting

Table 5 provides a list of error codes for the monitor.

Table 5: Error Codes

Scope of Action

Action Explanation

Clinician

Repair

Return

1 X Replace SpO2 board. SpO2 front end RAM error.

2 X Replace SpO

2 board. SpO2 front end ROM/code integrity

error.

3 X Replace SpO

4 X Replace SpO

2 board. SpO2 front end reported a bad CRC.

2 board. SpO2 front end reported FSP message

not allowed.

5 X Replace SpO

2 board. SpO2 front end reported illegal value

sent in FSP message.

6 X Replace SpO

2 board. SpO2 front end reports calibration

(offset) failure.

9 X Replace SpO

2 board. SpO2 front end reported syntax error

in FSP message.

10 1 2 1 — Check/replace sensor/

extension cable.

2 — Replace SpO

2 board.

11 1 2 1 — Replace batteries.

2 — Replace SpO

12 X Replace SpO

2 board.

2 board. SpO2 front end reports other hardware

2 front end reports over current

SpO

failure.

2 front end reports incorrect

SpO

system voltage.

problem.

14 X Replace SpO

2 board. SpO2 front end reports communication

channel overflow.

16 X Replace SpO

2 board. SpO2 front end reports watchdog time

out.

17 X Check/replace sensor/

extension cable.

18 X Replace SpO

2 board. SpO2 front end reports internal

SpO

2 front end reports that sensor

appears defective.

register appears modified from

expected value.

19 X Check/replace sensor/

extension cable.

48 X Replace SpO

2 board. SpO2 front end reports spurious

SpO

2 front end reports signal out-of-

range.

interrupt.

49 X Replace SpO

2 board. SpO2 front end reports internal buffer

overflow.

50 X Replace SpO

2 board. SpO2 front end reports intermittent

error.

51 X Replace SpO

2 board. SpO2 front end reports digital

communication error.

53 X Replace SpO

256 X Replace SpO

2 board. SpO2 front end data not received.

2 board. SpO2 back end reports beginning of

packet missing.

OXIMAX N-65 Service Manual 43

Page 50

Troubleshooting

Error

Code

Table 5: Error Codes (Continued)

Scope of Action

Action Explanation

Clinician

Repair

Return

257 X Replace SpO2 board. SpO2 back end reports packet start ID

(SID) missing.

258 X Replace SpO

2 board. SpO2 back end reports packet length

error.

259 X Replace SpO

2 board. SpO2 back end reports message length

error.

260 X Replace SpO

2 board. SpO2 back end reports packet contains

unsupported key.

261 X Replace SpO

2 board. SpO2 back end reports packet CRC

error.

262 X Replace SpO

2 board. SpO2 back end reports end of packet

missing.

263 X Replace SpO

2 board. SpO2 back end reports packet contains

unidentified key.

264 X Replace SpO

2 board. SpO2 back end reports corrupted

variable.

265 X Replace SpO

2 board. SpO2 back end reports memory

overflow.

266 X Replace SpO

267 X Replace SpO

2 board. SpO2 back end reports bad pointer.

2 board. SpO2 back end reports parameter

value out-of-range.

268 X Replace SpO

269 X Replace SpO

2 board. SpO2 back end reports reset detected.

2 board. SpO2 back end reports unexpected

value.

270 X Replace SpO

271 X Replace SpO

2 board. SpO2 back end reports time-out.

2 board. SpO2 back end reports not ready/not

initialized.

272 X Replace SpO

273 1, 2 3 1 — Restart the monitor.

2 — Set the time and date.

2 board. SpO2 back end reports double fault.

SpO

2 back end reports date out-of-

range error.

3 — Replace UI board.

274 X Return monitor for

reprogramming.

275 X Check/replace sensor/

extension cable.

276 X Replace with O

XIMAX sensor/

extension cable.

277 X Check/replace sensor/

extension cable.

280 X Check/replace sensor/

extension cable.

281 X Check/replace sensor/

extension cable.

282 X Check/replace sensor/

extension cable.

SpO

2 back end reports incompatible

software version.

SpO

2 back end reports incorrect

registration number.

SpO2 back end reports sensor read

failure.

SpO

2 back end reports sensor

signature verification fails.

SpO

2 back end reports does not

support feature required by sensor.

SpO

2 back end reports overflow/

underflow.

SpO

2 back end reports sensor

activation failure.

44 OXIMAX N-65 Service Manual

Page 51

Error

Code

Troubleshooting

Table 5: Error Codes (Continued)

Scope of Action

Action Explanation

Clinician

Repair

Return

512 X Replace UI board. Communication failure with real time

clock.

513 X Replace UI board. Real time clock oscillator control

problem.

514 X Replace UI board. Real time clock failed timing test.

515 X Replace UI board. LCD failed feedback test.

516 X Replace UI board. LCD failed feedback test.

518 X Return monitor for repair. Various system faults.

519 X Return monitor for repair. Unrecoverable software error.

520 X Replace UI board. Unrecoverable error verify real time

clock.

521 X Replace batteries. Battery power is critically low.

522 X Replace batteries. System power levels unacceptable for

continued operation.

523 1, 2 3 1 — Restart the monitor.

NVRAM failed consistency check.

2 — Set the time and date.

3 — Replace UI board.

524 X Replace UI board. NVRAM failed read-after-write

verification.

525 X X Restart, replace UI board. Time base discrepancy writing error

entry.

526 1, 2 1 — Replace SpO

2 board.

Fatal error for SpO2 communication.

2 — Replace UI board.

527 1, 2 1 — Replace SpO

2 — Replace UI board.

528 1 2 1 — Replace UI board

2 board.

Communication failure with SpO2

board.

Fatal error creating parser.

2 — Return monitor for repair.

529 1 2 1 — Replace UI board

Fatal error creating parser.

2 — Return monitor for repair.

530 1, 2 1 — Replace SpO

2 — Replace UI board.

531 1, 2 1 — Replace SpO

2 — Replace UI board.

532 1, 2 1 — Replace SpO

2 — Replace UI board.

533 1, 2 1 — Replace SpO

2 — Replace UI board.

534 1, 2 1 — Replace SpO

2 — Replace UI board.

535 1, 2 1 — Replace SpO

2 — Replace UI board.

2 board.

2 board.

2 board.

2 board.

2 board.

2 board.

Unrecoverable error with SpO2

communication.

Unrecoverable error with SpO2

communication.

Unrecoverable error with SpO2

communication.

Unrecoverable error with SpO2

communication.

Unrecoverable error with SpO2

communication.

Unrecoverable error with SpO2

communication.

536 X Replace UI board. Flash memory failed CRC check.

537 X Replace UI board. Fatal system error.

538 X Set the monitor time and date. Real time clock value bad.

OXIMAX N-65 Service Manual 45

Page 52

Troubleshooting

Error

Code

Table 5: Error Codes (Continued)

Scope of Action

Action Explanation

Clinician

539 1 2 1 — Restart the monitor.

540 X Replace UI board. Fatal system error reading memory.

541 X Return monitor for repair. Fatal software error.

542 1 2 1 — Replace UI board.

543 X Set time and date. Invalid time. Cannot snapshot.

544 X Replace UI board. Invalid register value.

545 X Replace SpO

546 X Replace UI board. IrDA failure.

997 X Replace UI board. RAM error.

998 X Replace UI board. Spurious Interrupt.

999 X Replace UI board. Watchdog protection activated.

Repair

Return

2 — Replace membrane

switch pad.

2 — Return monitor for repair.

2 board. SpO2 board in unexpected state.

Erroneous key press detected at start.

RAM corruption detected during

background check.

46 OXIMAX N-65 Service Manual

Page 53

Disassembly Guide

Introduction

The OXIMAX N-65 can be disassembled into all major component parts, including:

• Front case with front panel keypad

• Rear bottom

• User Interface PCB

•SpO

• Battery compartment door

Note: Some spare parts have a business reply card attached. Please fill out and

return the business reply card.

Caution: Observe ESD (electrostatic discharge) precautions when

disassembling and reassembling the monitor and when handling any

components of it.

2 PCB

Tools Required

The tools required to disassemble and reassemble the monitor are:

• Number one (medium) Phillips screwdriver

• Torque driver, four inch/pounds (10 cm/kg)

Replacement Level Supported

The replacement level supported for the monitor is at the printed circuit board

(PCB) and major subassembly level. When a PCB problem is identified, follow

the procedures in Disassembly Guide on page 47 to replace the PCB. Check to

ensure the symptom disappears and that the monitor passes all performance tests.

If the symptom persists, swap the replacement PCB with the malfunctioning PCB

(the original PCB that was installed when you started troubleshooting) and

continue troubleshooting.

OXIMAX N-65 Service Manual 47

Page 54

Disassembly Guide

Prior to Disassembly

The monitor batteries must be removed prior to disassembly.

To remove the batteries:

1. Press the Power button to turn the monitor off.

2. Remove the battery cover.

3. Pull the battery cover latch downward toward the bottom of the monitor case

and lift the battery cover. See Figure 4, item 1.

4. Remove the batteries.

1 — Batteries

2 — Battery cover

3 — Battery cover latch

Figure 4: Removing Batteries

Separating the Front and Back Cases

To separate the monitor front and back cases:

1. Do the procedure in paragraph Prior to Disassembly on page 48.

48 OXIMAX N-65 Service Manual

Page 55

Disassembly Guide

2. Remove the four screws holding the monitor front and rear cases together. See

Figure 5, items 1 through 4.

Figure 5: Monitor Case Screws

Caution: A flex cable runs between the monitor front and rear case

assemblies. Use care when separating the cases. Do not apply stress

to the flex cable.

3. Separate the monitor front and rear case assemblies. See Figure 6.

1 — Connector J4

Figure 6: Cases Separated

Caution: Failure to unlock connector J4 on the SpO

2 PCB before

removing the front case flex circuit could damage the flex circuit.

OXIMAX N-65 Service Manual 49

Page 56

Disassembly Guide

4. Unlock connector J4 on the SpO2 PCB. See Figure 6 and Figure 7.

1 — SpO2 PCB .

2 — J4 lock

3 — Lock direction

4 — Unlock direction

Figure 7: SpO

5. Disconnect the ribbon cable from SpO

2 PCB Connector J4 Lock

2 PCB connector J4.

SpO2 PCB or User Interface PCB Replacement

To replace the SpO2 PCB or the User Interface PCB:

1. Complete the procedure in Prior to Disassembly on page 48.

2. Complete the procedure in Separating the Front and Back Cases on page 48.

Caution: The battery connectors (spring assemblies) at the bottom

of the SpO

Observe how the connectors are engaged in the slots when you

remove the SpO

battery connectors are inserted back into these slots when you

reassemble the monitor.

2 PCB are held in slots in the battery compartment.

2 PCB and User Interface PCB. Ensure that the

50 OXIMAX N-65 Service Manual

Page 57

Disassembly Guide

3. Pull the SpO2 PCB and User Interface PCB to the left to free the case from the

DB-9 connector. Lift the combined SpO

2 and User Interface PCBs from the

case. See 8.

Figure 8: User Interface PCB and SpO

Caution: Do not force the User Interface PCB and SpO

This may damage the boards. To separate the User Interface PCB

from the SpO

the SpO

2 PCB, grasp the User Interface PCB in one hand and

2 PCB in the other. Rotate the ends of the two PCBs as

shown in Figure 9 until the two PCBs separate at the connection

points. Gently work the boards apart.

4. Separate the User Interface PCB from the SpO

and Figure 9 as follows.

2 PCB Removal

2 PCB apart.

2 PCB. See the Caution above

1 — Left Connection (J8 on SpO2, J4 on User Interface)

2 — User Interface PCB

3 — Right Connection ( J1 on SpO

4 — SpO

2 PCB

Figure 9: Separating the User Interface PCB and SpO

OXIMAX N-65 Service Manual 51

2, J5 on User Interface)

2 PCB

Page 58

Disassembly Guide

5. Place the defective PCB to the side.

6. Align the replacement PCB with the other PCB at the connectors. When both

rows of the connectors are aligned, gently press the PCBs together. See

Figure 10.

1 — Left Connection (J8 on SpO2, J4 on User Interface)

2 — User Interface PCB

3 — Right Connection (J1 on SpO

4 — SpO

2 PCB

2, J5 on User Interface)

Figure 10: Connecting PCBs

7. Install the User Interface PCB and SpO

2 PCB into the monitor case. Ensure

that the battery springs are aligned properly in their slots. See Figure 11.

Figure 11: Battery Spring Alignment

52 OXIMAX N-65 Service Manual

Page 59

Note: The longer screws install at the top of the case. See Figure 12,

items 1 and 4.

8. Align the front and rear cases. See Figure 12.

Figure 12: Installing The Case Screws

Disassembly Guide

9. Install the four screws (Figure 12, items 1 through 4).

10. Install the batteries and battery cover. See Figure 13.

1 — Batteries

2 — Battery cover

3 — Battery cover latch

Figure 13: Battery Installation

OXIMAX N-65 Service Manual 53

Page 60

Disassembly Guide

11. Perform the performance verification tests before placing the monitor into

service. See Pulse Oximetry Functional Tests on page 28.

Front Case Assembly Replacement

The front case assembly contains the keypad.

To replace the front case assembly:

1. Remove the batteries from the monitor. See Prior to Disassembly on page 48.

2. Separate the front and rear case assemblies. See Separating the Front and

Back Cases on page 48.

3. Dispose of the front case assembly in accordance with local regulations.

4. Connect the new front case assembly ribbon cable to the SpO

J4. See Figure 14.

1 — J4

Figure 14: Front Case Ribbon Cable Connection

2 PCB connector

54 OXIMAX N-65 Service Manual

Page 61

5. Lock the ribbon cable connector. See Figure 15.

1 — SpO2 PCB

2 — J4 lock

3 — Lock direction

4 — Unlock direction

Disassembly Guide

Figure 15: Locking SpO

2 PCB Connection to J4

6. Place the front and rear cases together and install the four screws. See

Figure 16, items 1 through 4.

Figure 16: Installing The Case Screws

OXIMAX N-65 Service Manual 55

Page 62

Disassembly Guide

7. Install the batteries and battery cover as shown in Figure 17.

1 — Batteries

2 — Battery cover

3 — Battery cover latch

Figure 17: Battery Installation

8. Perform the performance verification tests before placing the monitor into

service. See Pulse Oximetry Functional Tests on page 28.

56 OXIMAX N-65 Service Manual

Page 63

Rear Case Assembly Replacement

To replace the rear case assembly:

1. Remove the batteries from the monitor. See Prior to Disassembly on page 48.

2. Separate the front and rear case assemblies. See Separating the Front and

Back Cases on page 48.

Caution: The battery connectors (spring assemblies) at the bottom

of the SpO

Observe how these connectors are engaged in these slots when you

remove the SpO

battery connectors are inserted back in these slots when you

reassemble the monitor.

2 PCB are held in slots in the battery compartment.

Disassembly Guide

2 PCB and User Interface PCB and ensure that the

3. Lift the SpO

Figure 18: User Interface PCB and SpO

2 PCB and User Interface from the case. See 18.

2 PCB Removal

4. Discard the rear case assembly in accordance with local regulations.

OXIMAX N-65 Service Manual 57

Page 64

Disassembly Guide

5. Install the User Interface PCB and SpO2 PCB into the monitor case. Ensure

that the battery springs slip into place. See Figure 19.

Figure 19: Battery Spring Alignment

Note: The longer screws install at the top of the case. See Figure 20,

items 1 and 4.

6. Place the front and rear cases together and install the four screws. See

Figure 20.

Figure 20: Installing The Case Screws

58 OXIMAX N-65 Service Manual

Page 65

7. Install the batteries and battery cover. See Figure 21.

Figure 21: Battery Installation

Disassembly Guide

8. Perform the performance verification tests before placing the monitor into

service. See Pulse Oximetry Functional Tests on page 28.

Battery Compartment Door Replacement

To replace the battery compartment door:

1. Press the battery door latch (Figure 22, item 1) and lift the batter door from

the monitor rear case.

Figure 22: Battery Compartment Door Latch

2. Insert the new battery compartment door in the case and close until the battery

door latch snaps in place.

OXIMAX N-65 Service Manual 59

Page 66

Disassembly Guide

Blank Page

60 OXIMAX N-65 Service Manual

Page 67

Spare Parts

Introduction

The latest version of this manual is available on the Internet at:

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/ProductManuals.html

Spare parts are shown in Table 6. Item numbers correspond to the callout numbers

in Figure 23.

Obtaining Replacement Parts

Nellcor's Technical Services provides technical assistance information and

replacement parts. To obtain replacement parts, contact Nellcor's Technical

Services or your local Nellcor representative. Refer to parts by the part names and

part numbers.

Spare parts and accessories for the O

http://mallinckrodt.com/respiratory/resp/Serv_Supp/Apartweb/main/PartAcceMenu.html

Parts List and Accessories

Table 6: Parts and Accessories List

Figure 23

Reference

Spare Parts

1

2SpO

3 User interface (UI)

4 Bottom enclosure

5 Battery cover

XIMAX N-65 are listed on the Internet at:

Description

Top enclosure with membrane panel

2 PCB

-- Membrane switch panel

-- LCD assembly

-- Battery, alkaline, 1.5V, type AA

-- Screw, PH, 4 X /16 inch

-- Screw, PH, 4 X 3/16 inch

OXIMAX N-65 Service Manual 61

Page 68

Spare Parts

Table 6: Parts and Accessories List

Figure 23

Reference

-- Product data label

-- Quick guide label

Accessories

-- Boot, protective, silicone, yellow

-- Case, carry, fabric, black with shoulder strap

-- DEC-4 sensor extension cable

-- Jacket, water resistant, clear, plastic

-- Transport Boot

-- CD, operator and service manuals

-- Home Use Guide, English

-- Operator’s manual, Arabic

-- Operator’s manual, Chinese

-- Operator’s manual, Czechoslovakian

Description

-- Operator’s manual, Danish

-- Operator’s manual, Dutch

-- Operator’s manual, English

-- Operator’s manual, Finnish

-- Operator’s manual, French

-- Operator’s manual, German

-- Operator’s manual, Greek

-- Operator’s manual, Hungarian

-- Operator’s manual, Italian

-- Operator’s manual, Japanese

-- Operator’s manual, Norwegian

-- Operator’s manual, Polish

-- Operator’s manual, Portuguese (Brazilian)

-- Operator’s manual, Russian

-- Operator’s manual, Spanish (Latin American)

-- Operator’s manual, Swedish

-- Operator’s manual, Turkish

62 OXIMAX N-65 Service Manual

Page 69

Spare Parts

Figure 23 shows the monitor exploded view with numbers relating to the spare

parts list.

Figure 23: Exploded View

OXIMAX N-65 Service Manual 63

Page 70

Spare Parts

Blank Page

64 OXIMAX N-65 Service Manual

Page 71

Packing for Shipment

Introduction

To ship the OXIMAX N-65, follow the instructions in this section.

Returning the Monitor

Contact Nellcor’s Technical Services Department for shipping instructions,

including a Returned Goods Authorization (RGA) number. Unless otherwise

instructed by Nellcor's Technical Services Department, it is not necessary to

return the O

monitor in its original shipping carton. If the original carton is not available, use a

suitable carton with appropriate packing material to protect it during shipping.

Return the monitor by any shipping method that provides proof of delivery.

Repacking in Original Carton

If available, use the original carton and packing materials. See Figure 24. Pack the

monitor as follows:

XIMAX sensor or other accessory items with the monitor. Pack the

OXIMAX N-65 Service Manual 65

Page 72

Packing for Shipment

To repackage the monitor in the original carton:

1. Place the monitor in original packaging.

Figure 24: Packing

2. Place in shipping carton and seal carton with packing tape.

3. Label carton with shipping address, return address, and RGA number.

66 OXIMAX N-65 Service Manual

Page 73

Packing in a Different Carton

If the original carton is not available, repackage the monitor in a different carton.

To repackage the monitor in a different carton:

1. Place the monitor in a plastic bag.

2. Locate a corrugated cardboard shipping carton with a bursting strength of at

least 200 pounds per square inch (psi).

3. Fill the bottom of the carton with at least two inches of packing material.

4. Place the bagged unit on the layer of packing material and fill the box

completely with packing material.

Packing for Shipment

5. Seal the carton with packing tape.

6. Label the carton with the shipping address, return address, and RGA number.

OXIMAX N-65 Service Manual 67

Page 74

Packing for Shipment

Blank Page

68 OXIMAX N-65 Service Manual

Page 75

Specifications

Performance

Measurement Range

SpO

2

Pulse Rate 20 beats per minute (bpm) to 250

Perfusion Range 0.03% to 20%

Accuracy Tolerance

Saturation

1

Adult

Neonate

Low Perfusion

Pulse Rate

Adult and Neonate

Low Perfusion

1

Adult specifications are shown for OXIMAX MAX-A and MAX-N sensors

with the N-65. Neonate specifications are shown for O

sensors with the N-65. Saturation accuracy will vary by sensor type. Refer

to the Sensor Accuracy Grid. The Sensor Accuracy Grid is shipped with

the N-65. The latest version of the Sensor Accuracy Grid is available on