Page 1

SERVICE

MANUAL

PULSE

Caution:

NELLCOR®

OXIMETER

Federal

to

sale

by

MODEL

law

or

on

the

ULTRA

AND

N-6000

(U.S.)

order

CAP™

CAPNOGRAPH,

restricts

of a physician.

this

device

©

1993

Nellcor

Incorporated

Nellcor

25495

Hayward,

Incorporated

Whitesell

California

510

887-5858

1-800-NELLCOR

.

Street

94545

U.S.A.

028065A-0193

Page 2

Corporate

Headquarters

European

Office

Asia/Pacific

Headquarters

Nellcor

25495

Hayward,

Whitesell

USA

Tel

510-887-5858

Incorporated

Street

California

94545

Nelleor

Hambakenwetering

5231

The

Tel.

European

Northwest

Nellcor

Hambakenwetering

5231

The

Tel.

Middle

Nelleor

Black-&-Decker-Strasse

W-6270

Germany

|

Tel.

Southern

Nellcor

3,

78353

France

Tel.

BV

DD

’s-Hertogenbosch

Netherlands

+31.73.426565

Regional

Europe

Europe

DD

‘s-Hertogenbosch

Netherlands

+31.73.426565

and

GmbH

Idstein

+49

6126.5930

Sarl

rue

du

Petit

Jouy-en-Josas

+33.1.39.46.96.58

BV

Central

Europe

Robinson

1

Offices

1

Europe

.

28

Cedex

Nellcor

Suite

Admiralty

18

Hong Kong

Tel.

Limited

1204C

Harcourt

+852.529.0363

Centre,

Road

Tower

1

European

Nellcor

University

Science

Coventry

United

Tel.

Nelleor

Interleuvenlann

B-3001

Belgium

Tel.

Local

(UK)

Limited

of

Park

CV4

7EZ

Kingdom

+44.203.690220

(Belgium)

Leuven

+32.16.400467

Offices

Warwick

NV/SA

62/8

.

ii

Page 3

TABLE

OF

CONTENTS

11

12

13

2.1

2.2

2.3

2.4

2.5

3.1

3.2

3.3

3.4

Symbols

We

Introduction...

Introduction.........................

Warnings,

Description..................,..,............,...

1.8.1

13.2

13.3

13.4

1.3.5

1.3.6

1.3.7

18.8

1.3.9

1.3.10

1.3.11

13.12

Principles

Overview.........................

PulseOximetrySubsystem.......................

2.2.1

2.2.2

2.2.8

2.2.4 - Measured

Capnography

N20/02

24.1

2.4.2

2.4.3.

2.4.4

2.4.5

2.4.6

2.4.7

.

Factory

Circuit

Introduction.................

CO2

3.2.1

3.2.2

3.2.3

8.2.4

3.2.5

3.2.6

3.2.7

8.2.8

3.2.9

3.2.10

Oximetry

©

8.8.1

Detailed

3.4.1

AAA

Cautions,

Visible

Audible

Visible

StatusMessages..............................

Automatic

On-Screen

N-6000

Trend

Automatic

Battery

Noninvasive

C-LOCK™

C-LOCK

Automatic

Functional

Standard

Pressure

N20

O2

Water

BTPS/ATPS

Summary:

Calibrated

Analysis

Module

Sensor

CO2

Default

Memory......:...,...............,,,,,......

of

Subsystem

Compensation

Collision

Collision

Circuit

Module

bDigital.....................

Motor

Signal

Heater

Source....

Barometer...

StatusLEDs....................

Status

OximetryModule........................

Oximetry

Control........

Module

Oximetry

and Notes

and

Audible

Indicator.......................

and

Operation

Broadening

Vapor

Operation.........

22220

Audible

Self-Test

Menus..................,...,,,.......

and

Calibration..…..............,........,.,.......ss

..................

Oximetry

ECG

Synchronization

Operation.

ECG

Calibration..................

versus

versus

Gas

Reported

Amplifier..

LED

Module

Calculated

............................

............

Conditions

Broadening...........

Broadening.........................,.,...........ss

Effect...

Compensation.

Sensor

Details.

Hardware

Summary............

Block

Diagram

Module

...

Indicators.

Alarms.

and

Warm-Up

Custom

Synchronization

Fractional

CO2

μμ

Default

Sensors.........................

Saturation

Compensation...

Values...

ΕΟΟ

....

Analysis

Circuit

Analysis

Time..

Set-Up

for

Pulse

Saturation...

...

…

.

.

Oximetry..

....

...

...

レレ

くく

レト

issues

ニュ

レッ

くく

トー トト ャ ッッ て と

と ャ

て て と て て

ss

ρου

sense

とく

나

…

…

..

„12

..

..

…

....

ここ

..

‚...

„21

„22

ーー

.

..

..

.

..

..

..

..

..

..

…

..

..

…

...

…

...

ας

.

.

1-1

1-1

1-2

1-2

12

1-2

1-3

13

13

13

13

13

1-4

2-1

21

2-1

2-3

2-5

25

2-5

2-6

2-6

2-6

2-6

2-6

2-7

3-1

3-2

3-2

3-2

3-2

3-3

3-8

3-8

3-3

3-3

BA

3-4

3-4

3-6

3-6

Page 4

TABLE

OF

CONTENTS

(continued)

3.5

3.6

4.1

4.2

4.3

4.4

5.1

5.2

5.3

6.1

6.2

”Disassempbly

7.1

7.2

7.3

8.1

8.2

8.3

9.1

Main

8.5.1

8.5.2

3.5.3

3.5.4

8.5.5

8.5.6

3.5.7

8.5.8

8.5.9

3.5.10

3.5.11

3.5.12

3.5.13

Power

3.6.1

3.6.2

3.6.3

3.6.4

Routine

Introduction............

Cleaning

Changing

Replacing

Packing

Överview...........................

Repacking

Repacking

Disassembly

Introduction............

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

Testing

Description.....................

COs

7.2.1

7.2.2

Calibration

Troubleshooting........................

Introduction.......

Advisory

Status

Spare

In

Processor

Microprocessor

Power.

Reset

Battery

Internal

Graphical

BEPROM..............

FLASH

Real

Time

Audio

Charging

Patient

Front

Supply-Charger

Power

AC

Rectifier

+5

Volt

C-LOCK

Maintenance

Instructions............

Mains

or

Changing

and

PCB

Control.........

and

Watehdog......................

Backup

and

Display

Memory.

Clock....

Generation

Indicator................

Isolation

Panel

Supply

and

Logic

QRS

Voltage

Shipping......

Circuit

Section.......,...............,....,......,

and

Memory

External

..................,....,,.....,..,.

....

Power

Display

and

Sync

Controller..

PCB

Charger

+12

volt

Display

Input

......................

Input

the

Fuse...

Details.

Retention............

Serial

Supply...

Communications..

Circuit

Theory

Battery

Power

Circuit...

....

In

Original

In

New

Guide........

Procedure

RemovinginstrumentCover...........................

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

and

Calibration

Carton..

Carton

Front Panel

Power

Transformer..........

.......

了

attery.

Oximetry

Main

Pull-Out

Speaker............................

............

and

C02

Processor

Assembly

Card

Supply-Charger

Display

ConventionS

Service

Breath

and

Screen

Detection

Accuracy

and

Display

and

Check

Conventions...................

Display

of

Messages.

Messages.....

Parts........

го

ас

6101...

sise

ーー

...

essences

Details.........

of

Charger...........

Supply

Subassembly..

PCB...........................

.............................,................,.....

Tray...

Assembly.

0

End-Tidal

Operation..

....

…

<

scccrcre*

CO2

ui

iii

Values..

…

ees

enten

ennen

eker

0040000400000

000000e0

..

nernnse

„

en

…

..

.

.

..

..

..

72

7-6

8-1

8-1

8-6

8-7

9-1

9-1

iv

Page 5

TABLE

OF

CONTENTS

(continued)

10

10.1

1

11.1

11.2

113

114

185

11.6.

11.7.

¡ACA

Overview.........

Specifications.............

Physical/Environmental.........

Components

Controls

Connectors................

Performance.

Calibration.....

Airway

and

Adapter

11.8 再 jectrical.

2

12.1

2-1

2-2

3-1

3-2

3-3

3-4

3-5

8-6

8-7

4-1

4-2

6-1

7-1

Schematic

Introduction...................,......,.................

Oxyhemoglobin

Nondispersive

Overall

Oximetry

LRD

Input

Input

A:D

Support

North

European

Disassembly

Failed

Block

Module

Driver

Signal

Amplifier,

Conversion

American

LED

essences

and

User

Interface..

Indicators...........

EP O KO KO R O R K

0

0000

Koh

OK S KO

RS O O

Diagrams..

see

LIST

OF

FIGURES

Dissociation

Infrared

Diagram..........................

Overall

Cireuit に し に

Processing.

Synchronous

Circuits.......................,.......,,,...........

Circuits...................

Fuse

Аттапветейв.............

Fuse

Diagram..............

Атгапретейф...............

Digits

Curve..........................................

CO2

Block

に に に レート

Analyzer..

Diagram...

ーーー・

Detector,

and

Filter/Amplifier

линии

нии

ини

тни

KOK

KK P KKK

низине

ss

KK O RR

oP P een

K R

0.0000

öseeeeeea

PK O v

нение

наити

ek

6

εως

Kone

..

.

7-1

8-1

The

United

OXISENSOR;;

The

4,770,179;

Service

Troubleshooting

following

States

N-6000

Screen

are

trademarks

and

other

and

is

covered

4,802,486;

IndicatiomS

Guide

countries;

ULTRA

by

4,869,254; 4,928,692;

the

following

CAP,

of

Nellcor

C-LOCK,

which

レレ

ーー

patents:

トレ

ーー

トト

ーー

Incorporated:

which

is a

commercial

U.S.

4,934,372;

NELLCOR,

is

registered

Patent

and

スー

スト

ドー

くに

トー

which

in

the

trademark.

No.

4,621,643;

corresponding

トト

トト

トス

is

United

4,653,498;

patents

スレ

(レレ に レレ に トス

registered

States;

4,700,708;

in

other

countries,

レト

in

ストー

the

て

Page 6

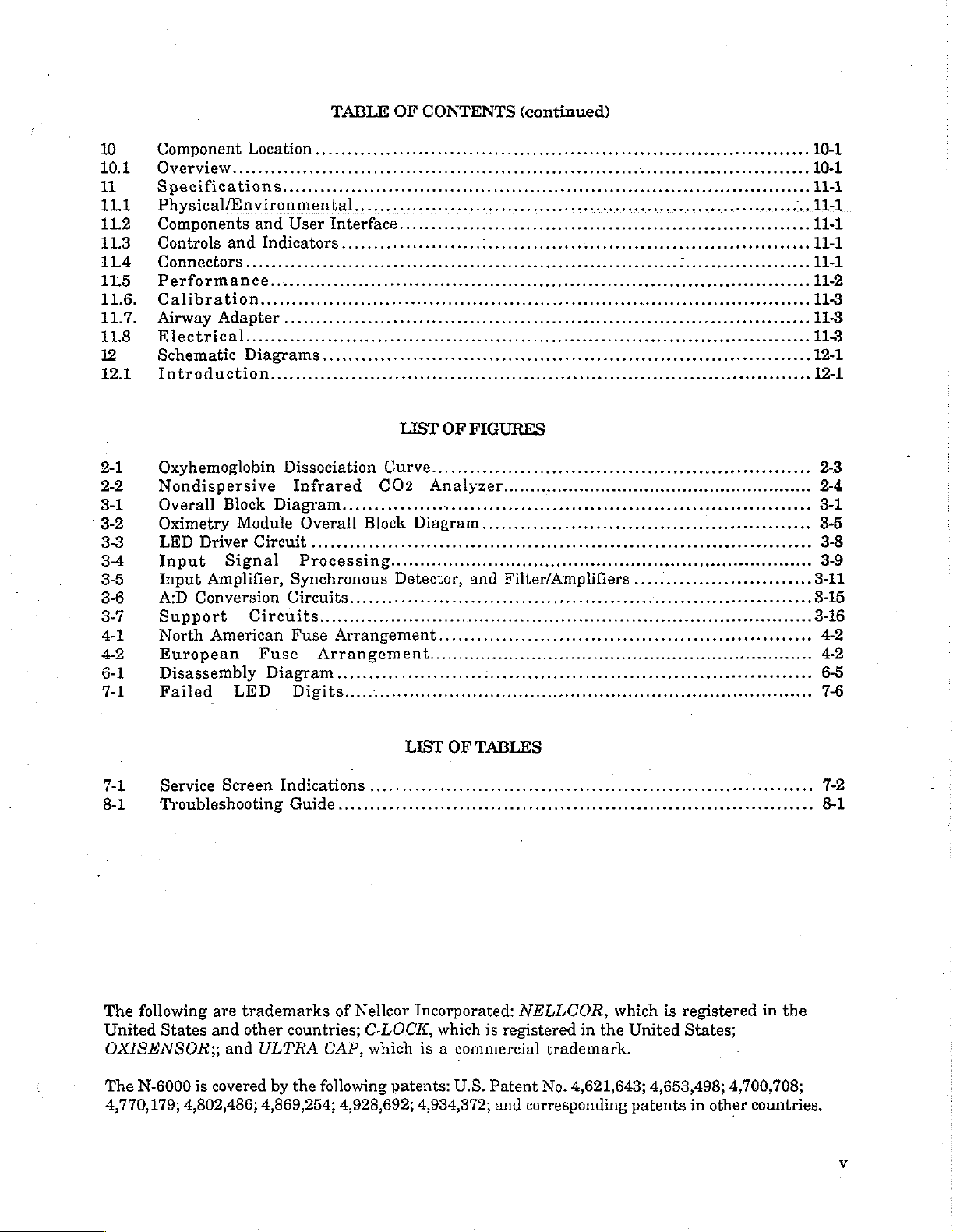

SYMBOLS

O/O

Sc

nx

el

On/Standby

Pulse

tone

volume

Audible

C-LOCK

Low

alarm

signal

battery

off

lost

FRONT

PANEL

eke

MENU

A

+

ni

Freeze

Menu

Audible

C-LOCK

Battery

alarm

in

in

use

on

use

κ

220/240V~

FRONT

PANEL

A

Battery

INSTRUMENT

Attention:

manual!

charging

ONLY

Refer

to

operator’s

Type

BF

equipment,

(patient

electrically

isolated)

vi

Page 7

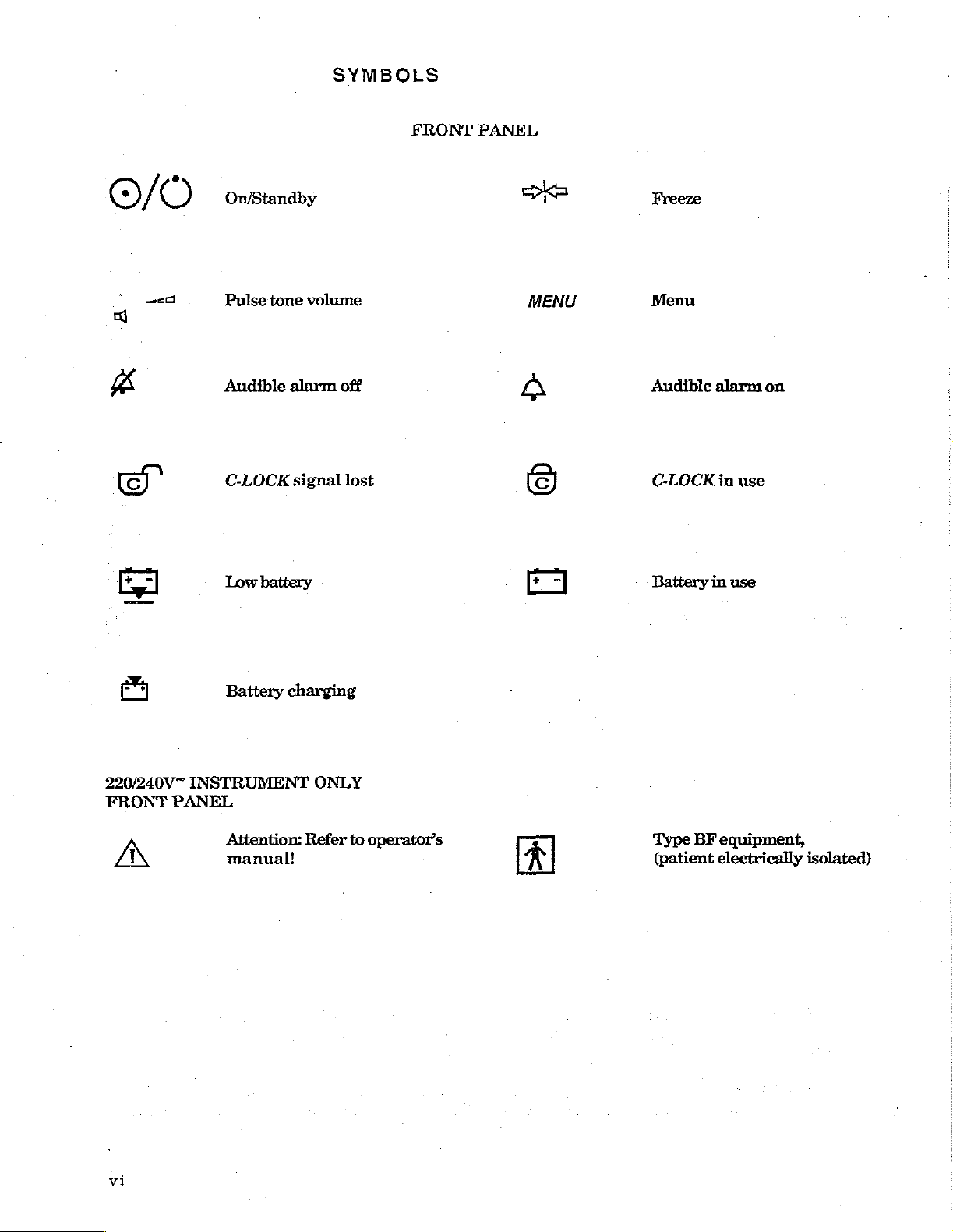

SYMBOLS

AS

=

MO

À

Battery

ECG

fuse

input

On/Off

BF

Type

(patient

equipment,

electrically

isolated)

BACK

PANEL

O

<>

RS232

Fuse

replacement

Eguipotential

RS232inputoutput

ground

port

110/120

BACK

VOLT

PANEL

INSTRUMENTS

Instrument

proof.

ONLY

not

anesthetic

VAN

Attention:

Refer

manual!

to

operator’s

vii

Page 8

WARNINGS

The

N-6000 contains

service

.

[For

The

from

connection,

must

be

protection

N-6000

is a patient-connected

potentially

the

no

performed

against

fire

dangerous

procedures

user-serviceable

by

qualified

hazard,

personnel.

replace

medical

electrical

and

potentials

part

specifications

parts.

fuses

device.

For

protection

only

Isolated

or

ground

contained

with

against

the

same

patient

paths.

in

this

electrical

type

and

connectors

To

protect

manual

rating.

protect

the

integrity

must

hazard,

the

be

adhered

all

patient

of

this

to.

viii

Page 9

1.1

INTRODUCTION

This

manual

and

capnograph,

personnel,

Note:

service

language

screen,

and

then

who

This

screens.

option

press

press

“LANGUAGE”

from

the

left.

or

“ENGLISCH.”

ㆍ

The

N-6000

time

monitoring

carbon

.

SpO2

SpO2

numerically,

shows

contains

information

model

have a technical

manual

the

If

to

Freeze

the

the

is

written

unit

English.

second

(LANGUE

Press

this

is a compact,

of

dioxide

is

noninvasively

sensors

(ETCO2),

which

while

the

patient’s

N-6000.

for

is

configured

To

reach

button

key

and

in

to

on

fourth

French

gain

oxygen

and

and

are

available

the

plethysmograph

relative

SECTION

I

Introduction

for

servicing

Service

of

this

background

an

N-6000

for

the

language

the

front

soft

keys

and

SPRACHE

access

microprocessor-controlled

saturation

respiratory

continuously

for a variety

pulse

strength

the

product

in

analog

configured

French

panel

from

to

the

language

(SpO2),

rate

measured

is

displayed

as

NELLCOR®

must

and

for

or

German,

selection

while

the

the

left

in

German)

pulse

(RR).

of

patient

measured

ULTRA

be

done

digital

by

electronics.

CAP™

qualified

English-language

the

technician

menu

main

at

selection

instrument

rate

using

from

monitoring

the

same

appears

(PR),

Nellcor's

sites.

the

time.

above

menu

and

used

for

inspired

reusable

SpO2

values

main

screen

The

CO2

as a waveform, A bar

by

the

pulse

oximetry

pulse

service

displays

must

and

change

monitoring

is

displayed,

legend

the

fourth

select

“ANGLAIS”

continuous

(ins.),

or

adhesive

are

displayed

graph

circuits.

oximeter

the

soft

key

real-

end-tidal

indicator

ㆍ

ETCOs

intubated

exhalation

This

manual

digital

N-6000

maintenance

12

Before

These

proper

WARNING:

service

Caution:

always

patient

operator’s

WARNINGS,

you

terms

operation

technician.

Cautions

in

boldface

Note: A note

is

determined

patient’s

is

is

intended

monitoring

or

repair.

read

the

identify

A

warning

gives

by

positioning

airway

displayed

for

(15

mm

numerically,

use

by

equipment.

manual

CAUTIONS,

N-6000

of

this

and

be

AND

service

information

instrument.

familiar

manual,

that

describes a condition

WARNINGS

are

describes a condition

type.

information

that

an

diameter).

while

authorized

Service

with

NOTES

it

pertains

that

always

warrants

that

in

may

infrared

The

CO2

is

service

personnel

instrument

is

important

to

technician

may

result

boldface

result

special

attention.

mainstream

amount

of

displayed

personnel,

must

have

operation

to

understand

and

in

injury

type

and boxed.

in

damage

CO2

sensor

CO2

present

as a waveform.

trained

read

patient

to

in

ahd

before

the

safety,

to the

the

instrument.

servicing

understood

attempting

following

patient,

across

at

the

and

an

end

of

analog

the

terms.

indicates

operator

Cautions

and

or

are

1-1

Page 10

1.3

DESCRIPTION

The

following

1.3.1

Visible

The

N-6000

.

C02

*

provides a qualitative

9

Trends

paragraphs

and

features

and

plethysmographic

are

displayed:

respiratory

ㆍ

When

the

switch, a battery

1.3.2

Audible

Indicator

describe

Audible

Indicators

numeric

displays

indication

acquired

SpO2

rate

for

trend

alone;

trends;

all

SpOz,

operator connects

charging

the

N-6000

of

SpO2,

waveform

of

pulse

parameters,

CO2

trend

CO2,

pulse

the

monitor

indicator

lights.

and

list

PR,

RR,

displays:

strength

and

the

alone;

rate,

to

AC

SpO2

and

power

important

and

ETCO2:

and a pulse

at

the

oximetry

following

and

CO2

respiratory

and turns

features.

amplitude

five

trend

trends;

rate

on

the

bar

sensor.

screens

pulse

trends.

rear-panel

graph,

can

rate

and

which

be

on/off

Pulse

pitch

decreases.

can

1.3.3

The

moves

apnea,

priority

the

button

ALARM

function

Note:

Note:

rate

of

this

watch

Visible

monitor

outside

or

of

alarm

alerts

SILENCE

disabled.

are

always

The

When

audible

1.3.4

A

Status

status

alarm

message

identified

and

tone

This. early

the

patient

and

has

when a sensor

the

alarm

temporarily. A flashing

the

operational.

SpO2

the

Messages

by a module

troubleshooting

oxygen

changes

warning

and

Audible

both

visible

an

adjustable

state.

operator

indicator

Visible

and

ETCO2

French

function

is

displayed

the

problem.

saturation

with

listen

are

indicated

variation

system

for

encourages

SpO2

in

changes

Alarms

and

limit

gets

disconnected.

Pressing

that

the

warns

alarms

numeric

language

audible

(operator-defined),

the

ALARM

alarm

that

appear

is

chosen

alarms.

The

ALARM

SILENCE

tone

one

on

indicators

and

disabled, a single tone

in

case

an

error

identifier

and

(See

an

error

section

VIII

audibly

SpO2,

tone

SILENCE

has

or

more

the

monitor

change

one

occurs

condition

code

for

with a tone

rising

prompt

as

saturation

corrective

simultaneously.

These

when

and

alarms

the

monitor

pattern

button

indicator

been

silenced

parameters

temporarily. A steady

sereen,

from

green

or

more

of

the

every

three

occurs.

number

more

that

information.)

that

increases

action

are

activated

detects

of

the

audible

turns

adjacent

have

had

and

unlike

to

red

parameters

minutes.

An

error

assists

signals

since

off

the

to

the

their

audible

when

condition

service

each

and

the

pulse.

falling

The

as

clinician

when a variable

loss

of

pulse

or

alarm

audible

ALARM

audible

depend

portion

SILENCE

ON

of

alarm

on

the

alarms,

an

alarm

have

had

personnel

the

will

occurs.

error

be

in

it

the

of

they

Page 11

1.3.5

Automatic

The

monitor

test

takes

that

the

allowing

45

seconds.

approximately

program

the

Self-Test

automatically

mainstream

If

an

error

“Troubleshooting,”

1.8.6

On-Screen

The

on-screen

at

the

bottom

function

MENU

1.8.7

The

Once

1.3.8

The

button

N-6000

N-6000

configured,

Trend

N-6000

memory

the

memory

memory

continues

key

can

can

while

Menus

menu

of

the

is

pressed,

to

display

Default

power-on

Memory

stores

be

viewed

is

full,

be

viewed

the

memory,

is

for

more

guides

screen

and

default

the

custom

up

to

in

the

oldest

on

trend

and

Warm-Up

performs a series

15

seconds

data

COz

after

memory,

sensor

to

detected, a status

information.)

the

operator

just

above

the

the

screen

the

top level

Custom

24

hours

30-minute,

the

data

displays a new

Default

settings

alarm

data

of

trend

are

limits

sereen

are

being

menu,

can

2-hour, 4-hour,

automatically

and

Time

of

the

operator

and

internal

warm.

The

message

—

through

four

function keys

or

to

Set-Up

be

customized

will

always

data

for

can

be

printed.

diagnostic

turns

circuitry

CO2

sensor

appears.

all

system

menu

return

with

to

according

be

CO2,

SpO2,

8-hour,

erased

printed

with a printer.

tests

when

on

the

are

warm-up

(Refer

functions.

that

are

additional

the

main

in

place,

pulse

12-hour,

as

new

turned

monitor.

These

functioning

time

to

Section

Menu

used

to

select

functions.

monitoring

to

institutional

even

after

rate,

and

or

24-hour

data

are

Patient

on.

The

system

tests

properly,

is

approximately

8,

items

an

are

item.

Press

screen.

requirements,

power-down.

respiratory

segments.

stored.

Data

monitoring

self-

confirm

while

displayed

When

the

rate.

Trend

When

stored

a

in

1.3.9

Automatic

The

SpO2

subsystem

the

system

is

turned

whenever a new

calibrated.

1.3.10

Battery

If

external

90

minutes

minutes

ㆍ

by

By

choosing

power

on

using

(including

w/BATTERY

displays

.

battery

When

AC

the

the

life.

the

MAINS

MENU

operator

Calibration

of

on

oximetry

Operation

is

lost

its

rechargeable

the

GRAPHICS

GRAPHICS

all

waveforms,

OFF,

only

the

numerical

GRAPHICS

power,

button

reapplies

the

N-6000

and

periodically

sensor

or

transportable

is

internal

w/BATTERY

messages,

the

display

values

w/BATTERY

the

display

to

turn

the

AC power

is

fully

thereafter.

connected.

operation

battery.

w/BATTERY

remains

of

option

will

only

GRAPHIC

to

the

self-calibrating.

It

Additionally,

The

capnography

is

necessary,

This

operating

power

ON

etc.)

will

blank

SpO2

is

blank

w/BATTERY

in

the

continue

during

and

ETCO2,

selected

when

saver

SYSTEM

battery

to

the

option

monitor.

is

calibrated

it

subsystem

the

N-6000

time

option.

menu,

to

operate.

This

allows

be

OFF

unit

transfers

ON.

automatically

is

recalibrated

of

can

can

be

extended

the

display

By

choosing

operation.

up

to

and

the

to

The

display

automatically

the

N-6000

operate

up

graphics

The

N-6000

180

minutes

unit

is

battery

returns

whenever

is

factory

up

to

to

180

GRAPHICS

of

operating

power.

Press

when

on

Page 12

1.3.11

Noninvasive

Oximetry

Sensors

Noninvasive

two

light-emitting

differences

infants,

1.3.12

children,

C-LOCK™

If a patient

quality

separate

signal

for

signals

from

synchronize

When

If

SIGNAL

N-6000

the

C-LOCK

ECG

LOST

is

not

NELLCOR

diodes

in

tissue

is

moving

thickness

and

adults.

ECG

Synchronization

or

measurements

that

reflect

the

ECG.

The

the

SpOz

measurements.

ECG

synchronization

signal

is

lost

symbol

being

used.

oximetry

(LEDs)

or

Refer

has

poor

of

oxygen

cardiac

N-6000

or

deteriorates

appears

on

sensors

as

light

sources.

skin

pigmentation.

to

specific

for

perfusion,

saturation.

activity:

uses

the

ECG

is

used,

to

the

the

display.

obtain

sensor

Pulse

C-LOCK

When

an

QRS

the

point

No

measurements

The

N-6000

Specific

directions

Oximetry

ECG

this

feature

optical

signal

complex

C-LOCK

that

symbol

it

IN

can

is

:

by

optical

adjusts

sensors

automatically

are

for

use

for

synchronization

is

used,

the

from

the

sensor

to

help

identify

USE

symbol

no

longer

displayed

be

if

used,

the

means

available

complete

can

enhance

N-6000

and

the

pulse

appears

the

C-LOCK

C-LOCK

alone,

using

for

for

neonates,

information.

signal

receives

an

electrical

and

on

the

display.

feature

of

two

the

Page 13

2.1

OVERVIEW

This

section

2.2

PULSE

The

N-6000

plethysmography.

sensor

photodetector.

920

nm).

The

photodetector

absorption.

With

each

hemoglobin

The

N-6000

hemoglobin

In

principle, a pulse

Absorption

both

wavelengths

describes,

OXIMETRY

oximetry

has two

When

low-voltage

One

the light

heartbeat, a pulse

differs

measures

that

is

also

in

subsystem

It

includes

LED

measures

from

red

is

saturated

oximeter

measured

results

general

SUBSYSTEM

light-emitting

emits

from

deoxygenated

and

in a value

terms,

is

based

an

‘electro-optical

red

light

the

LEDs

the

light

of

oxygenated

infrared

with

oxygen.

measures

when

pulsatile

SECTION

Principles

operating

on

the

diodes

(nominal

passes

that

hemoglobin

absorption

for

the

through

passes

arterial.blood

the

light

arterial

arterial

II

of

Operation

principles

principles

sensor

(LEDs)

through,

absorption

and a microprocessor-based

as

660

nm)

the

flows

in

its

to

determine

blood

oxygen

for

the

N-6000.

of

spectrophotometry

light

sources,

and

the

other

sensor

which

relative

is

saturation

to

by

tissues

in

the

the

site,

part

indicates

the

sensor

red

and

percentage

and

tissue.

(SpO2).

and

and

one

photodiode

emits

infrared

of

the

light

red

and

infrared

site.

Oxygenated

infrared

of

functional

nonpulsatile

The

ratio

module. The

as

(nominal

is

absorbed.

absorption.

blood.

of

absorption

a

at

2.2.1

C-LOCK

Through

identifying

during

When

an

complex

with

length

relationship

random

If

an

optical

C-LOCK

C-LOCK

patient

provided

optical

is

the

patient’s

of

the

motion.

ECG

pulse

ECG

signal

detected,

signal

ECG

Synchronization

ECG

the

pulse

and

movement

with

an

from

the

an

physiology

delay

is

relatively

is

used

to

identify

is

not

provided,

alone

is

used

synchronization

synchronization,

synchronizing

and

when

the

ECG

signal,

sensor

optical

and

to

determine

pulse

the

and

an

is

with

the

stable.

“good”

or

if

that

resumes

detected

Through

pulses

the

N-6000

SpO2

measurements.

patient’s

N-6000

electrical

at

location

and

signal

the

pulse

when

an

uses

an

perfusion

receives

signal

the

of

the

C-LOCK

reject

deteriorates

rate

adequate

is

two

from

sensor

sensor.

ECG

nonsynchronized

and

to

ECG

signal

This

poor.

signals

the

site.

The

However,

synchronization,

so

that

initiate

ECG

signal

as a reference

enhances

that

ECG. A short

length

it

can

saturation

is

signal

reflect

for a given

artifacts

no

cardiac

time

of

this

that

such

longer

measurements.

available.

point

quality

activity:

after a QRS

delay

varies

patient,

time

as

be

used,

for

the

-

the

2-1

Page 14

2.2.2

Automatic

The

oximetry

calibrated

connected.

differences

Each

sensor

determined

calibration

obtained

2.2.3

by

Functional

Calibration

subsystem

each time

Also,

the

in

tissue

is

calibrated

and

encoded

resistor

that

sensor.

versus

incorporates

it

is

turned

intensity

of

thickness

when

into a calibration

to

determine

Fractional

automatic

on,

at

periodic

the

sensors

and

pigmentation.

manufactured:

resistor.

the

appropriate

Saturation

calibration

intervals

LEDs

is

the

effective

calibration

thereafter,

adjusted

The

instrument’s

mechanisms.

and

automatically

mean

wavelength

coefficients

It

is

automatically

whenever a new

to

compensate

of

the

software

for

reads

the

measurements

red

this

sensor

for

LED

is

is

Because

those

expressed

N-6000

functional

the

N-6000

of

instruments

as a percentage

uses

two

SaO2.

carboxyhemoglobin

In

contrast,

Oximeter

measured

Measured

Consequently,

other

measurements

some

report

hemoglobin,

dysfunctional

to

instrument

can

functional

2.2.4

Measured

When

oxygen

saturation

(PaO2),

because

the

relationship

carbon

dioxide

the

versus

the

calculated

between

(PaCO2),

measures

that

measure

of

wavelengths,

It

does

not

or

methemoglobin.

laboratory

fractional

SaQ2-—~oxygenated

whether

hemoglobins

directly

must

measure

be

converted

compare

saturation

Calculated

is

calculated

calculated

saturation

PO2

the

functional

the

hemoglobin

it

measures

detect

instruments

or

not

N-6000

functional

using

=

100 — (%carboxyhemoglobin + %methemogiobin

SaO2,

fractional

SaO2.

that

oxygenated

significant

such

that

hemoglobin

are

included.

measurements

SaO2.

the

following

it

may

produce

Functional

is

capable

and

amounts

as

the

of

Instrumentation

hemoglobin

is

If

it

measures

equation:

fractional

measurements

SaQ2

of

transporting

deoxygenated.

dysfunctional

expressed

available

with

those

fractional

saturation

Saturation

from a blood

value

may

may

and

saturation

concentrations

not

gas

measurement

differ

from

have

been corrected

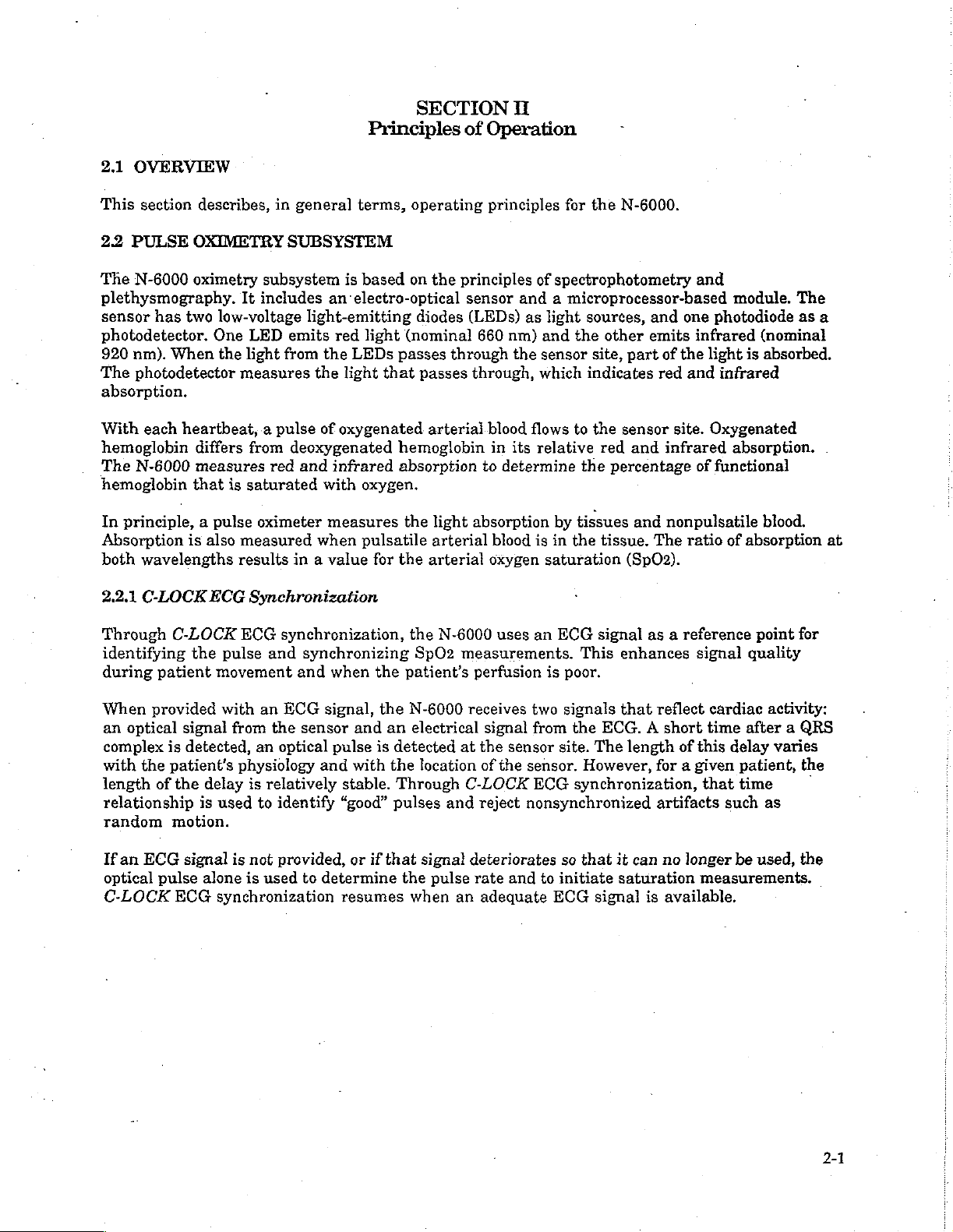

(Figure

of

2,3-DPG

the

N-6000

2-1):

temperature,

and

of

the

SpO2

for

fetal

is

oxygenated

oxygen.

hemoglobin,

hemoglobin,

Laboratory

as a percentage

for

oxygen

of

another

Sa02,

~

partial

pressure

measurement.

the

effects

pH,

of

the

hemoglobin.

that

differ

hemoglobin

Because

yielding

such

282

CO-

of

all

transport.

instrument,

those

x

of

arterial

This

variables

partial

that

pressure

from

the

as

that

is

shift

of

2-2

Page 15

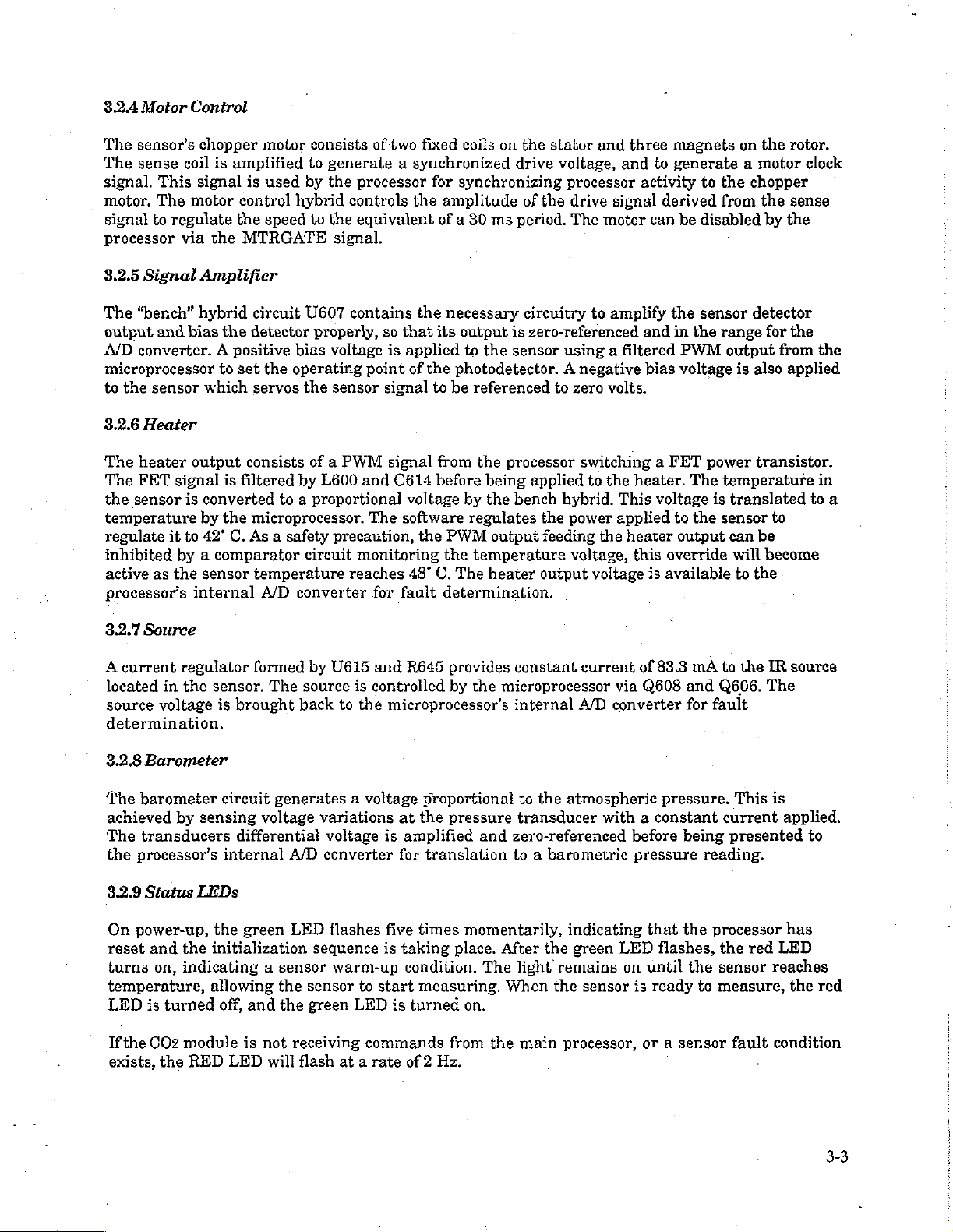

100

—

pH

t

Temperature

+

PCO2

+

+

2,3-DPG

=

ο

я

504

5

©

.

の

a

+

VA

0

ifs

4

+

+

nf.

+

7

の

;

+

4

e

+

+

“e

¿e

΄

+

7

+

.

e

+

e

è

>

e

.”

>.

+

„==

„>“

ㆍ

+

+

+

+

|

est

n°

pH

Temperature

PCO2

2,3-DPG

50

PO:

(mmHg)

=.

100

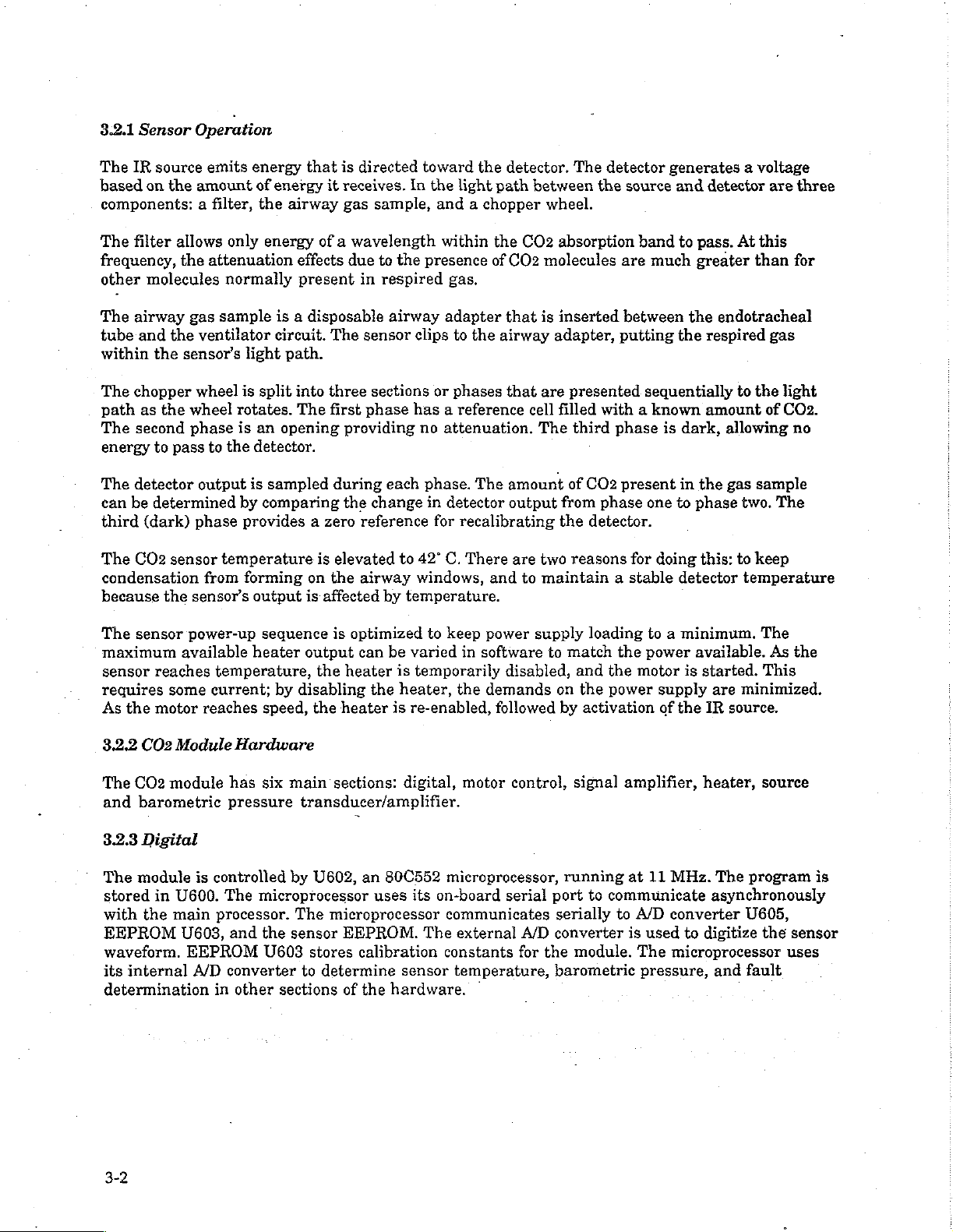

2.3

CAPNOGRAPHY

The

N-6000

present

sensor

ventilator

elbow

into

Infrared

infrared

specific

the

versus

have

at

the

that

circuit

and

the

contact

spectroscopy

light.

wavelengths

infrared

the

similar

proportional

determined

The

CO2

detection

“optical

bench”),

wavelengths

During

reaches

selectively

second.

monitoring,

the

absorbed

Three

uses

nondispersive

end

of

exhalation

attaches

to a disposable

either

patient

with

Of

the

respired

the

wye.

can

normally

of

spectrum

wavelength

spectra

to

by

that

the

concentration

comparing

mechanism

has

an

corresponding

light

narrow-band

by

measurements

Figure

2-1:

SUBSYSTEM

infrared

(ETCO2).

between

infrared

of a molecule

of

have

infrared

first

infrared

0602.

the

The

CO2

gases.

be

used

respired

light),

is

overlapping

the

absorbance

used

to

an

passes

It

then

are

to

light

of

source

absorption

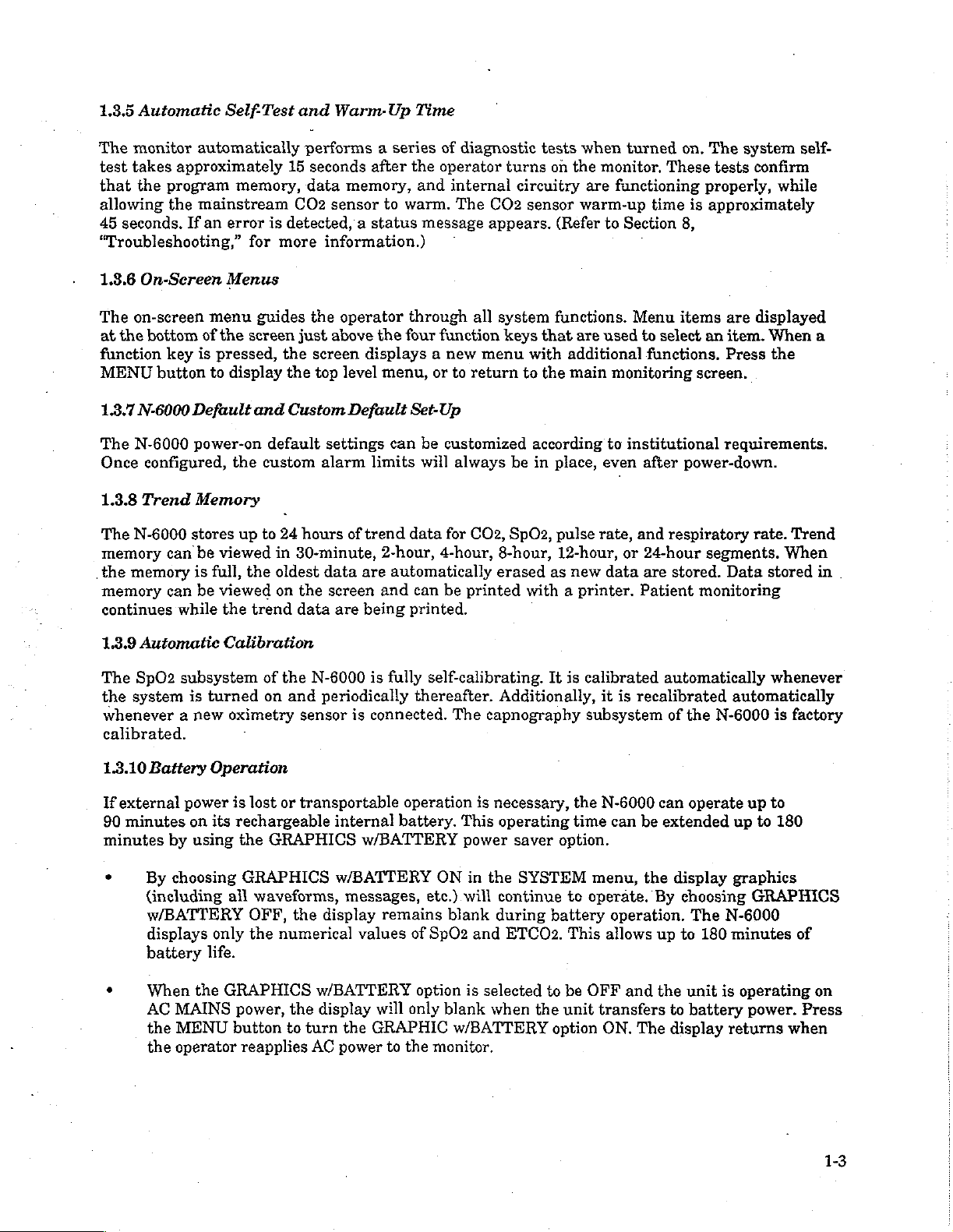

Oxyhemoglobin

spectroscopy

It

features a small

airway

adapter.

endotracheal

mainstream

measure

gases,

(i.e.,

have

(usually

unique

to.

absorption

the

absorbing

to

that

in

the

N-6000

that

peak

through

filter,

which

encounters

obtained

during

Dissociation

to

The

tube

sensor

the

concentration

only

CO2,

an

infrared

displayed

that

molecule.

molecule,

of a known

(commonly

is

optically

of

the

the

respiratory

was

selected

the

chopper

each

quantitatively

lightweight

airway

and

fits

as a graph

peaks.

filtered

CO2

rotation:

the

ventilator

on

top

N20,

and

spectrum).

However,

Because

an

standard.

referred

spectrum

gas

because

wheel,

adapter

of

of

any

of

unknown

to

in

Curve

measure

the

“mainstream”

is

inserted

circuit

the

adapter

molecule

water vapor

This

light

different

the

to

as

provide a narrow

(see

the

airway

it

passes

which

rotates

or

and

that

selectively

absorption

absorbed

molecules

absorption

concentration

the

CO2

Figure

adapter.

wavelengths

many

amount

of

CO2

into

the

between

by a molecule

sensor

2-2).

does

not

absorbs

pattern,

may

of

light

can

band

Next

times

the

absorb

be

or

of

that

CO2

come

is

it

are

each

ο

wheel

A

sample

and

measurement

then

reaches

the

is

made when

detector

(i.e.,

light

the

light

passes

passes

through

through

the

the

open

respiratory

area

gas).

of

the

chopper

Page 16

.

A

reference+sample

containing a known

respiratory

ㆍ

A

reaches

The

ratio,

determine

from

the

The

N-6000

assumed

N-6000.

expressed

are

assumed

is

being

to

fully

The

N-6000

dynamically

several

ETCO?

The

value

obtainable

simply

value

ETCO2.

patient.

gas

and

dark

measurement

the

detector).

“reference+sample/sample”,

the

CO2

analysis

measures

conditions

When

displayed

saturated

spontaneous

value,

average

of

ETCO2

This

units

as % dry

to

be

detects

from

the

of

ETCO2

from

the

all

seen

results

measurement

CO2

concentration

gas

in

the

is

concentration

of

the

CO2

the

partial

of

33° C and

of % (by

gas.

By

convention,

measured

on

the

conditions

and

maximum

breaths

N-6000

that best

patient

breaths

within

in a stable

from a patient

front

counts

with

accurately

during

together

the

is

obtained

and

reference

made when

in

waveform

airway

fully

volume)

panel

(BTPS ) before

breaths

and

minimum

low

estimates

last 8 seconds

ETCO2

cell).

light

is

then

respiratory

(capnograph).

pressure

saturated.

are

displayed

all

readings

and

LED

in

when

ETCO2

detects

the

forced

to-display

exhalations.

value

when

then

reaches

strikes a solid

used

in

gas.

Respiratory

of

CO2

Barometric

on

of

corrected

units

of

being

displayed.

the

COz2

level

CO2

values.

values

and

true

the

and

that

followed

counts

alveolar

ETCO2

displays

best

light

passes

the

detector

area

the

sensor-specific

rate

in

the

patient

pressure

the

front

panel

CO2

posted

to

body

mmHg

crosses a threshold,

Hence,

all

breaths.

CO2

Unlike

value,

that

approximates

on

temperature

or

kPa,

when a ventilated

by a mechanical

value

conventional

the

maximum

through a reference

(i.e.,

light

passes

of

the

is

determined

airway

is

measured

LEDs,

the

the

values

is

the

N-6000

the

arterial

wheel

front-panel

maximum

(1.9.,

calibration

adapter

the

measured

(37°

C).

are

which

breath

capnometers

looks

for

value

for

PaCO

gas

through

no

light

equation

by

the

N-6000

at

normal

directly

also

is

value

the

the

by

value

LED

display

When

patient

with a higher

PCO2

converted

set

has

that

maximum

true

value

in

cell

to

the

is

the

2-4

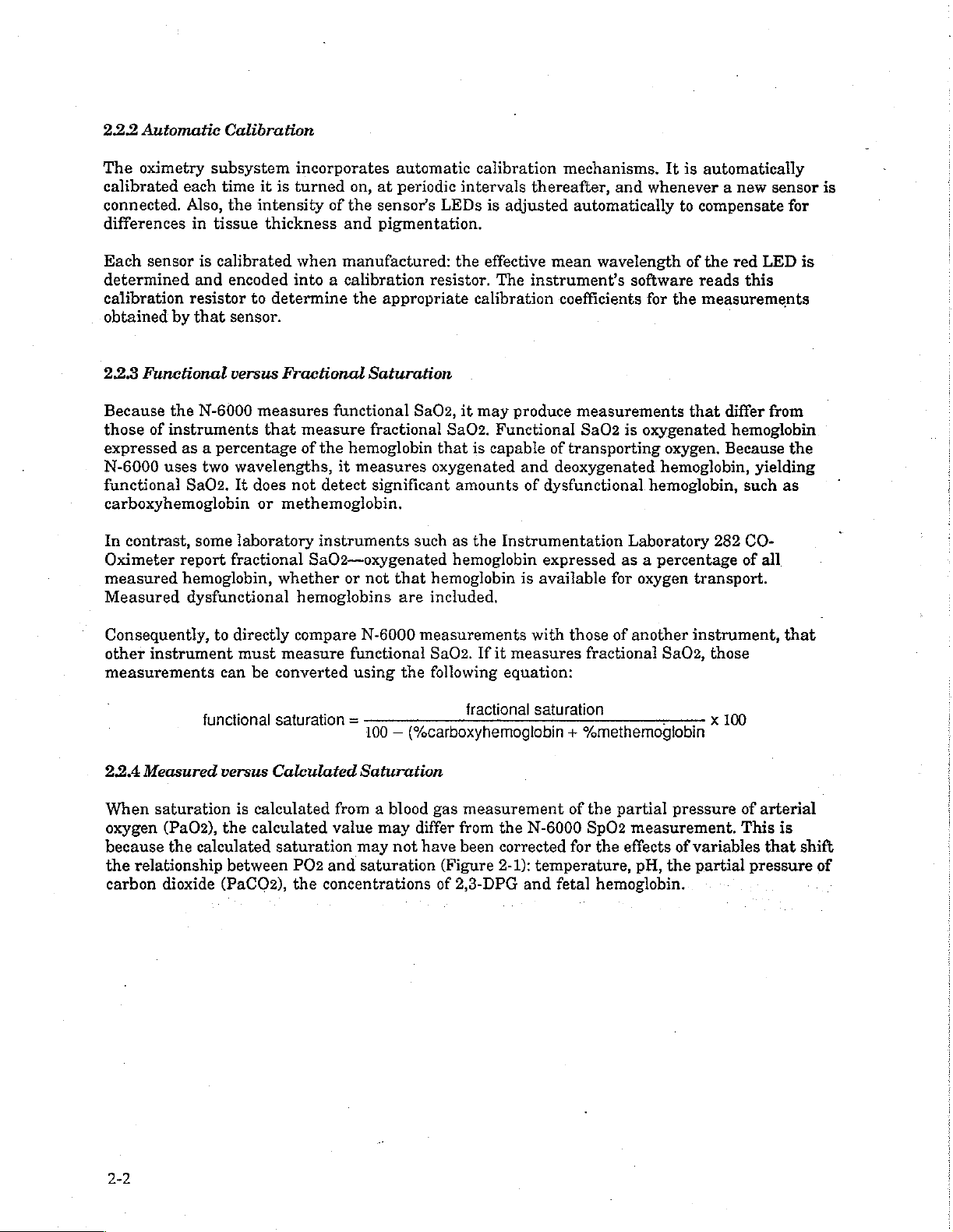

Light

source

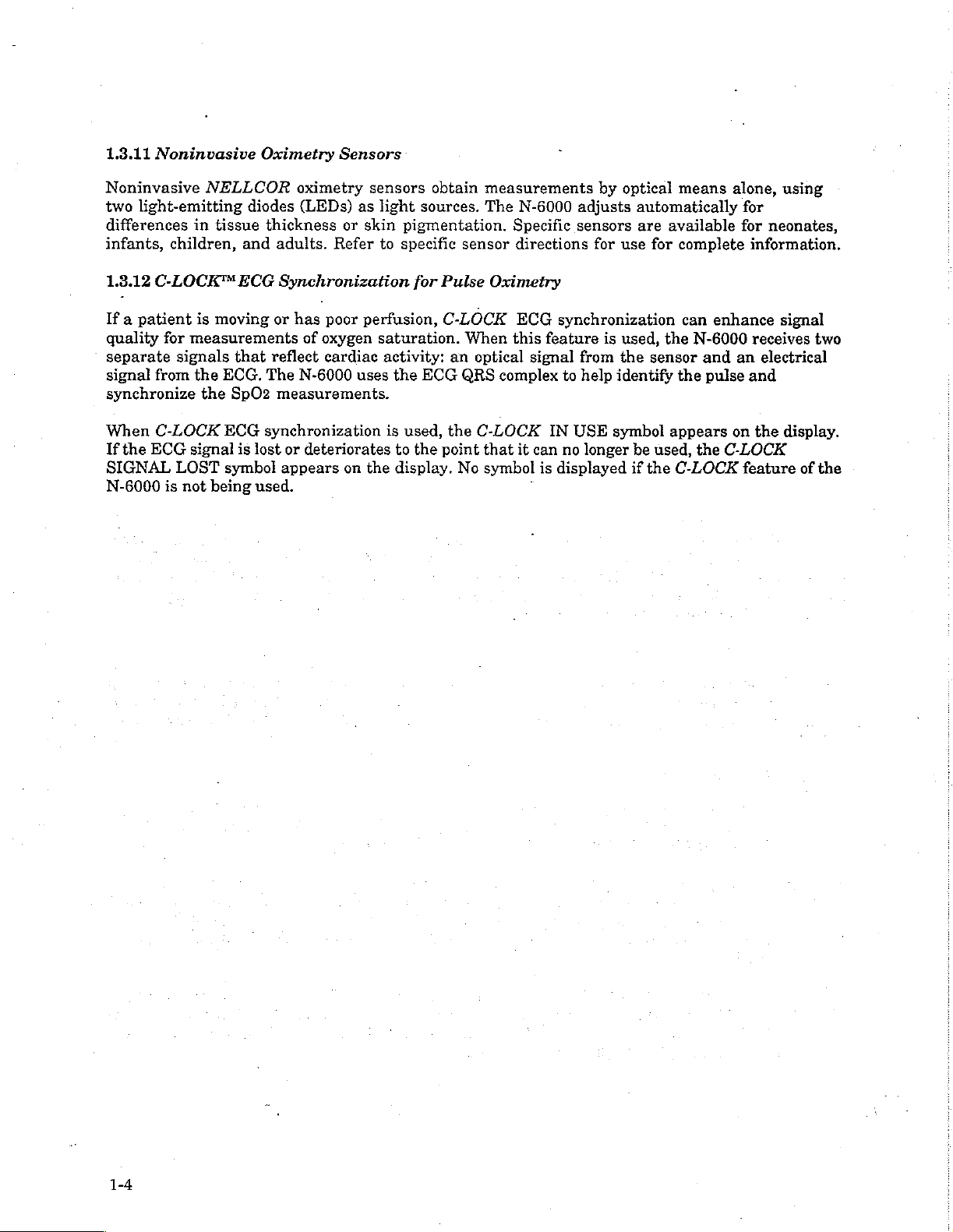

Figure

2-2:

!

Airway

adapter

Nondispersive

Infrared

filter

Chopper

wheel

Infrared

Reference

gas

cell

Open

area

Photodetector

CO2

Analyzer

Page 17

24

N20/O2

COMPENSATION

Unless

affect

To

oxide

screen

The

oxide

in

20%

for

The

provides

there

The

provides

there

Finally,

barometric

changes.

compensated

the

ensure

with

menu

N-6000

and

O2

beyond

of

increase

every

first

is

zero

second

is

zero

barometric

the

the

for,

measurement

accurate

oxygen; and

measurements,

selections.

is

calibrated

20%

oxygen.

the

reference

in

O2.

20%

increase

compensation

necessary

error

under

compensation

correction

error

under

pressure

pressure

require

elevated

of

the

concentration

(2)

high

for

low O2

This

is

the

state

An

increase

in

N20.

level

assumes

correction

these

level

factor

for

these

changes

no

levels

the

N-6000

oxygen.

compensation,

default

decreases

in

N20

50%

factor

assumed

assumes

high

levels

assumed

also

user

intervention;

of

oxygen

of

Compensation

mode

the

increases

nitrous

for

high

conditions,

0%

nitrous

conditions.

affect

(O2)

CO2

by a collision

provides

which

where

displayed

oxide

levels

of

O2.

Once

measured

the

and

nitrous

two

levels

levels

COMP. = OFF.

the

of

oxide

N-6000

are

assumes

CO2

value

displayed

and

50%

N20.

and

60%

again,

CO2

automatically

oxide

(N20)

broadening

of

compensation:

user

selectable

the

reference

In

the

by

1.5%

of

CO2

value

oxygen.

When

oxygen. Selecting

when

values.

Selecting

this

correction

this

correction

However,

adjusts

in

the

effect.

via

state

N-6000,

reading

by

1.6%

changes

airway

(1)

nitrous

display

of

0%

nitrous

an

increase

for

every

of

reading

COMP. = N20

is

applied,

COMP. = O2

is

applied,

in

for

these

The

following

conditions,

2.4.1

Standard

The

accuracy

CO2

in

balance

38

mmHg),

errors

2.4.2

Ambient

energy

barometric

CO2

additional

from

mmHg

are

Pressure

barometric

exchanged

values

the

standard

for

paragraphs

as

pertains

Gas

specifications

air

and a barometric

required

Broadening

pressure

reported

residual

every

to

Conditions

(21%

O2),

for

barometric

pressure

in

molecular

is

automatically

on

both

errors

reference

5000-foot

contain

N-6000

for

Compensation

may

change

further

operation.

the

N-6000

at

airway

pressure

pressure

affects

collisions

the

main

be

observed

state

of

in

in-depth

refer

conditions

of

760

(altitude),

measured

alters

measured

monitoring

when

760

mmHg

altitude.

discussion

to

the

following

of

33

°C,

fully

mmHg.

CO2

the

Additional

N20,

02,

by a “pressure

absorption

and a compensation

screen

testing

(sea

level).

spectrum

and

the

reference

These

of

compensation

standard

saturated

corrections

and

broadening”

service screen.

gases

amount

conditions:

(water

water

vapor.

of

is

automatically

at

to

and

standard

test

vapor

and/or

CO2.

pressures

approximately

residual

effect,

In

the

applied

However,

gas

is

pressure

in

which

N-6000,

to

different

+0.5

of

2-5

Page 18

2.4.3

N20

Collision

Broadening

Nitrous

“collision

absorption

eliminate

causes

standard

correct

both

mixture

2.4.4

Oxygen

exchanged

causes a decrease

Oxide

an

(N2O)

broadening”

spectrum

any

direct

increase

in

can

affect

effect

in

of

CO2.

The

absorption

measured

conditions. A software-selected

for

high

N20,

assuming a gas

the

N-6000

if

O2

Collision

(02)

the

02

can

in

molecular

main

monitoring

compensation

Broadening

affect

the

CO2

collisions

in

measured

conditions. A software-selected

high

O2,

assuming a gas

main

monitoring

compensation

2.4.5

Water

Water

vapor

respiratory

water

N-6000

are

to

vapor

is

calibrated

automatically

verify

calibration,

sereen

option

Vapor

also

has

gas

is

(with a vapor

composition

and

the

is

selected.

Effect

an

effect

at

standard

pressure

to

include

compensated,

CO2

values

airway

the

CO2

measurement

which

of

CO2

energy

infrared

infrared

of

approximately

exchanged

narrow

energy

(user-selectable)

composition

screen

option

measurement

alters

CO2

and

on

is

selected.

the

absorption

of

approximately

by a “collision

(user-selectable)

of

60%

O2

(0%

service

on

CO2

sereen

measurements.

conditions

of

38

mmHg)

this

effect,

while those

reported

and

on

CO2

on

the

by

bandpass

by

of

50%

the

service

-0.75%

02

compensation

N20).

are

compensated

of

33°C,

causes

values

the

service

service

both

in

filter

N20.

+0.8%

N20

N20

screen

spectrum

CO2

In

normal

fully

an

increase

reported

screen

screen

direct

absorption

molecular

used

in

However,

per

10%

increase

compensation

and

50%

are

compensated

broadening”

of

CO2.

per

10%

increase

option

values

for

use,

this

reported

it is

saturated.

in

on

the

are

not.

should

be

of

collisions

the

N-6000

N20

collision

in

option

O2.

CO2

values

effect

O2

collision

in

is

provided

on

gas

mixture

assumed

Under

measured

main

If

applying a dry

used

for

infrared

alters

is

chosen

the

broadening

N20

from

is

provided

reported

for

this

in

which

broadening

O2

from

to

correct

both

the

if

the

that

these

conditions,

CO2

of

6%.

monitoring

comparison.

and

by

to

on

gas

energy

standard

for

N-6000

O2

The

screen

test

gas

a

to

2.4.6

BTPS/ATPS

The

N-6000

temperature

adapter

barometric

conversion

fully

is

measured

pressure.

to

saturated

screen values

2.4.7

Summary:

CO2

water

a

dry

also

CO2

water

values

test

applied

values

reported

vapor

gas

reported

vapor,

Compensation

assumes

and

deep

that

measured

pressure

fully

at

33

°C,

By

convention,

lung conditions

with a water vapor

do

not

have

these

Reported

correction).

is

present

to

the

service

and,

if

CO2

on

the

That

in

the

screen

on

the

selected,

saturated

fully

saturated

of

pressure

corrections

Values

service

is,

CO2

airway

values.

main

monitoring

N20

and

respiratory

(ATPS).

with a water

CO2

values

body

temperature

of

47

applied.

on

the

Main

screen

are

values

adapter

reported

(at

screen

O2.

gases

are

That

is,

vapor

are

reported

and

mmHg,

at

Monitoring

uncorrected

on

the

25

°C).

Corrections

have

at

standard

it

is

assumed

pressure

on

the

pressure

ambient

and

for

BTPS/ATPS

service

all

corrections

airway

that

of

38

main

monitoring

fully

saturated

barometric

Service

screen

for

Screens

are

N20

applied:

conditions

the

gas

in

mmHg,

at

(BTPS):

pressure.

conditions

accurate

and

Oz,

if

BTPS/ATPS,

of

airway

the

airway

ambient

screen

after

37

Service

(including

assuming

selected,

°C,

are

Page 19

2.5

FACTORY

Each

CO2

sensor

temperatures.

components

calibrated

automatically

and

over

CALIBRATED

is

individually

The

N-6000

electronics

multiple

compensated

temperatures,

SENSOR

factory-calibrated

sensor

is

at a known

by

temperature

over

temperature-regulated

constant

so

that

temperature.

any

deviation

calibration

coefficients

multiple

to

42

°C,

Additionally,

from

gas

concentrations

which

the

42

°C

stored

keeps

the

the

sensor

set-point

with each

and

sensor

is

is

sensor

multiple

optical

factory-

unit.

Page 20

Page 21

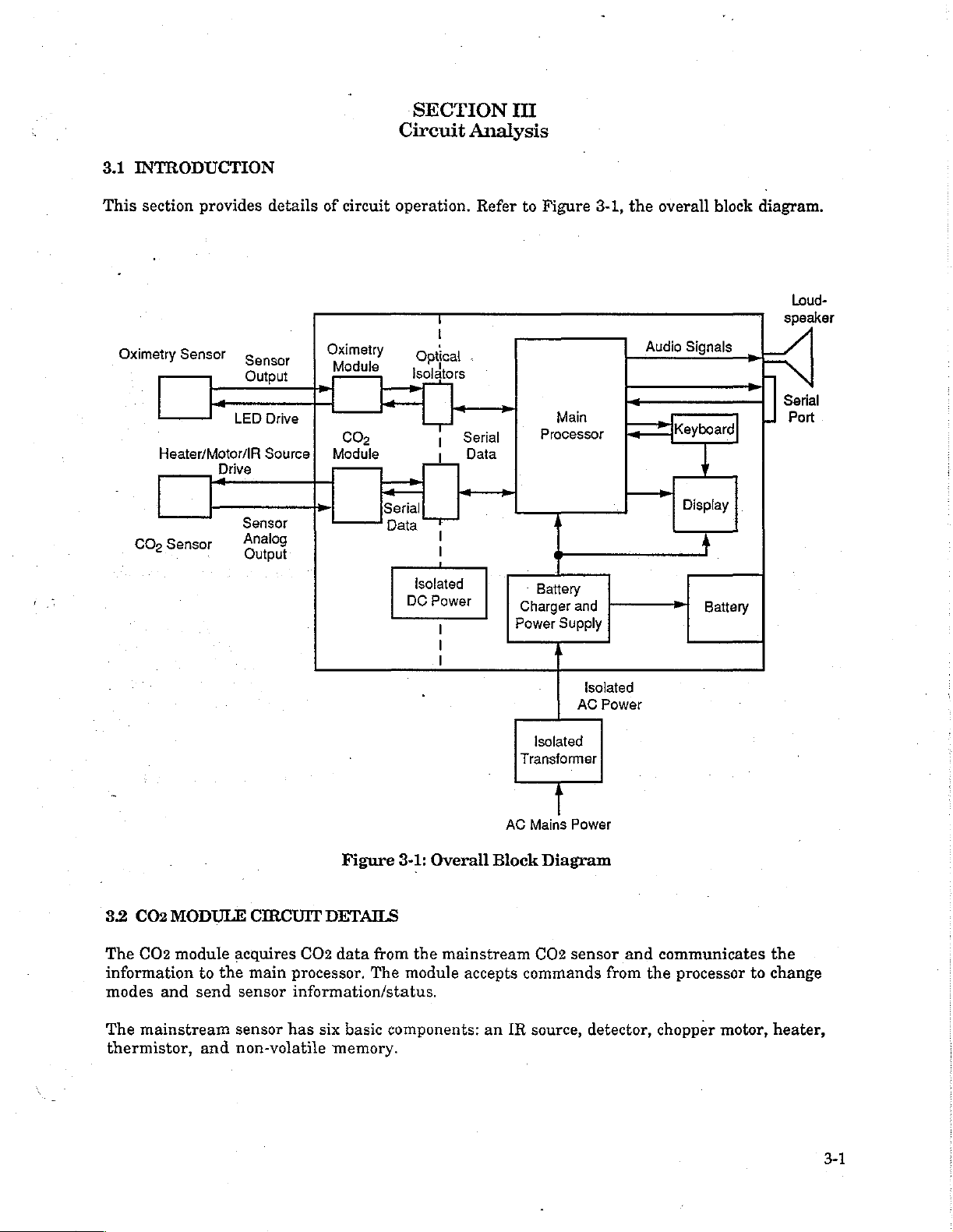

3.1

INTRODUCTION

This

section

provides

details

of

circuit

SECTION

Circuit

operation.

Analysis

Refer

HI

to

Figure

3-1,

the

overall

bleck

diagram.

i

Oximetry

Sensor

Heater/Motor/IR

CO,

Sensor

LED

Drive

Output

Sensor

Output

Drive

Source | Module

Sensor

Analog

Oximetr

>

>

Mo.

tule.

CO»

Optical

Isolators

»

Serial

Data

isolated

DC

T

i

・

Serial

|

1

|

Power

1

1

I

.

Data

>

Charger

Power

Transformer

Main

Processor

Battery

and

Supply

Å

AC

Isolated

Audio

isolated

Power

Signals

Keyboard

y

Display

—|

Battery

>

>

speaker

|

Serial

Loud-

Port

3.2

CO2

MODULE

The

CO2

module

information

modes

The

thermistor,

and

mainstream

acquires

to

the

send

sensor

sensor

and

non-volatile

Figure

CIRCUIT

main

DETAILS

CO2

data

processor,

information/status.

has

six

basic

memory.

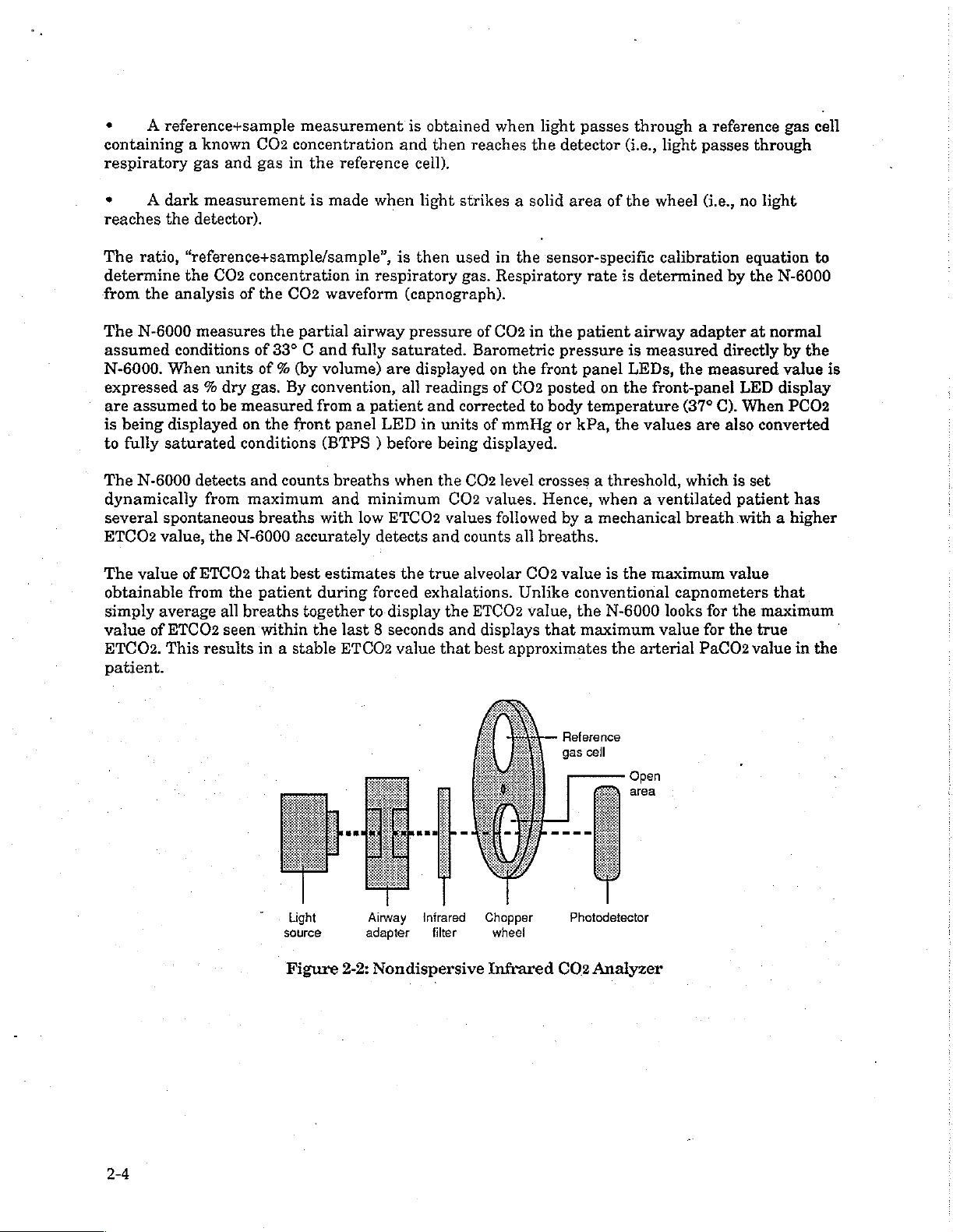

3-1:

Overall

from

the

The

module

components:

AC

Block

mainstream

accepts

an

IR

Mains

Power

Diagram

CO2

sensor

commands

source,

and

from

the

detector,

communicates

processor

chopper

motor,

the

to

change

heater,

Page 22

3.2.1

Sensor

Operation

The

IR

source

based

on

components: a filter,

The

filter

frequency,

other

molecules

The

airway

tube

and

within

The

path

The

energy

The

can

third

The

the

chopper

as

second

to

detector

be

determined

(dark)

CO2

condensation

because

the

allows

the

gas

the

sensor's

wheel

the

wheel

phase

pass

phase

sensor

the

sensor’s

amount

emits

energy

of

the

only

attenuation

normally

sample

ventilator

light

is

rotates.

is

an

to

the

detector.

output

is

by

provides a zero

temperature

from

forming

output

that

is

energy

energy

it

receives.

airway

gas

of a wavelength

effects

present

is a disposable

circuit.

The

path.

split

into

three

The

first

opening

sampled

comparing

during

is

elevated

on

the

is

affected

providing

the

directed

sample,

due

to

the

in

respired

airway

sensor

sections

phase

each

change

reference

to

airway

by

toward

In

the

the

light

path

and a chopper

within

presence

the

of

gas.

adapter

clips

or

to

phases

the

that

airway

has a reference

no

attenuation.

phase.

in

42°

windows,

temperature.

The

detector

for

recalibrating

C.

There

and

detector.

The

between

the

wheel.

CO2

absorption

CO2

molecules

is

inserted

adapter,

that

are

presented

cell

filled

The

third

amount

output

are

of

CO2

from

the

detector.

two

reasons

to

maintain a stable

detector

are

generates a voltage

source

band

and

to

much

between

putting

the

sequentially

with a known

phase

phase

is

present

one

for

doing

dark,

in

to

detector

detector

pass.

At

greater

the

endotracheal

respired

to

amount

allowing

the

gas

phase

this:

two.

to

temperature

are

this

than

for

gas

the

light

of

CO2.

no

sample

The

keep

three

The

sensor

maximum

sensor

requires

As

the

3.2.2

The

CO2

and

barometric

3.2.3

The

module

stored

with

EEPROM

waveform.

its

internal

power-up

available

reaches

some

motor

CO2

Module

module

Digital

in

U600.

the

main

U608,

EEPROM

A/D

determination

sequence

heater

temperature,

current;

reaches

speed,

Hardware

has

six

pressure

is

controlled

The

microprocessor

processor.

and

the

U603

converter

in

other

is

optimized

output

by

disabling

main

the

heater

the

heater

sections:

can

the

be

is

heater,

is

digital,

transducer/amplifier.

by

U602,

an

80C552

uses

The

microprocessor

sensor

sections

EEPROM.

stores

to

determine

of

calibration

sensor

the

hardware.

to

keep

power

varied

in

software

temporarily

the

demands

re-enabled,

motor

microprocessor,

its

on-board

communicates

The

external

constants

temperature,

©

supply

to

disabled,

followed

control,

serial

port

A/D

for

the

loading

match

on

by

the

and

the

the

power

activation

signal

amplifier,

running

te

communicate

serially

to

converter

module.

barometric

to a minimum.

power

motor

is

supply

of

the

available.

started.

IR

heater,

at

11

MHz.

A/D

converter

is

used

to

digitize

The

microprocessor

pressure, and

The

As

the

This

are

minimized.

source.

source

The

program

asynchronously

U605,

the

sensor

uses

fault

is

3-2

Page 23

3.2.4

Motor

The

sensor’s

The

sense

signal.

motor.

signal

processor

3.2.5

Signal

The

“bench”

output

A/D

converter. A positive

microprocessor

to

the

3.2.6

Heater

The

heater

The

FET

the

sensor

temperature

regulate

inhibited

active

processor’s

Control

chopper

coil

is

This

signal

The

motor

to

regulate

via

the

Amplifier

hybrid

and

bias

to

sensor

which

output

signal

is

converted

by

it

to

42°

by a comparator

as

the

sensor

internal

motor

amplified

is

control

the

MTRGATE

circuit

the

detector

used

hybrid

speed

consists

to

generate a synchronized

by

to

U607

properly,

bias

set

the

operating

servos

consists

is

filtered by

the

of a PWM

L600

to a proportional

the

microprocessor. The

C.

As a safety

circuit

temperature

A/D

converter

of

two

the

processor

controls

the

equivalent

signal.

contains

so

that

voltage

is

point

sensor

signal

signal

and

C614

software

precaution,

monitoring

reaches

for

fault

fixed

coils

for

synchronizing

the

amplitude

of a 30

the

necessary

its

output

applied

of

to

the

photodetector. A negative

to

be

from

before

voltage

by the

regulates

the

PWM

the

48°

C.

The

determination.

on

the

stator

drive

voltage,

of

the

ms

period.

circuitry

is

zero-referenced

the

sensor

referenced

the

processor

being

to

applied

bench

the

output

feeding

temperature

heater output

and

three

magnets

and

to

processor

drive

The

to

activity

signal

motor

amplify

derived

can

the

and

using a filtered

bias

zero

volts.

switching a FET

to

the

heater.

hybrid.

power

voltage,

This

applied

the

heater

this

voltage

voltage

override

is

available

on

the

rotor.

generate a motor

to

the

chopper

from

the

sense

be

disabled

sensor

in

the

PWM

voltage

power

The

is

to

the

output

by

the

detector

range

for

the

output

is

from

also

applied

transistor.

temperature

translated

sensor

can

will

to

to

be

become

the

clock

the

in

to

a

3.2.7

Source

A

current

located

source

regulator

in

the

voltage

determination.

3.2.8

Barometer

The

barometer

achieved

The

the

3.2.9

On

reset

turns

by

sensing

transducers

processor's

Status

LEDs

power-up,

and

the

on,

indicating a sensor

temperature,

LED

is

turned

Ifthe

CO2

module

exists,

the

RED

formed

sensor.

is

brought

circuit

by

The

source

back

generates a voltage

voltage

differential

internal

the

initialization

allowing

off,

LED

green

and

is

not

will

A/D

LED

sequence

the

sensor

the

green

receiving

flash

U615

and

is

controlled

to

the

microprocessor's

variations

voltage

is

converter

flashes

five

is

warm-up

to

start

LED

is

commands

at a rate

R645

provides constant

by the

proportional

at

the

pressure

amplified

for