Nellcor N550B Service manual

Nellcor Puritan Bennett Inc. is an affiliate of Tyco Healthcare. Nellcor, Oxiband, Durasensor, OxiCliq,

OxiBand, Dura-Y, Max-Fast, and O

XIMAX are trademarks of Nellcor Puritan Bennett Inc.

T o obtain information about a warranty, if any , contact Nellcor’ s Technical Services Department, or your local

representative.

Purchase of this instrument confers no express or implied license under any Nellcor Puritan Bennett patent to

use the instrument with any sensor that is not manufactured or licensed by Nellcor Puritan Bennett.

Covered by one or mor e of the foll owing U.S. Patents and for eign equivalents: 4,653,498; 4,802,486; 4,869,254;

4,928,692; 4,934,372; 5,078,136; 5,351,685; 5,485,847; 5,533,507; 5,577,500; 5,803,910; 5,865,736; 6,463,310;

6,708,049; Re.35, 122; and foreign equivalents.

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warnings ...................................... ....... ...... ....... ...... ... ....... ...... ....... ...... ...... ....... .....1

Cautions .................................... ...... ....... ...... ....... ... ...... ....... ...... ....... ...... ....... ...... ..1

Notes ....................................................................................................................1

Manual Overview ..................................................................................................2

Description Of N-550B Pulse Oximeter ................................................................2

Related Documents ..............................................................................................4

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning ....................................... ....... ...... ....... ...... ... ....... ...... ....... ...... ...... ....... .....5

Periodic Safety Checks .........................................................................................5

Functional Checks ........................................... ... ... ... ... .... ... ... ...............................5

Battery ..................................................................................................................6

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction .................................. ................................................................. ........7

Equipment Needed ...............................................................................................7

Performance Tests ............ .... ... ... ... .......................................... .... ... ... ... ...............8

Battery Charge .........................................................................................8

Power-Up Performance .................................. .... ... ... ... .... ........................8

Power-On Self-Test (POST) .......................................................9

Power-On Defaults and Alarm Limit Ranges ............................11

General Operation .............................................. ... ................................16

LED Excitation Test ..................................................................16

Operation with a Live Subject ...................................................17

Alarm Volume Control ...............................................................18

Pulse Tone Volume Control ......................................................19

Pulse Oximetry Functional Tests ...........................................................19

Introduction ...............................................................................20

Initial Setup ...............................................................................20

Test #1: BPM ............................................................................21

Test #2: SpO2 ...........................................................................22

Test #3: Modulation Level .........................................................23

Test #4: Light ............................................................................25

Safety Tests ........................................................................................................26

Audible Alarm Settings and Service Functions . . . . . . . . . . . . . . . . . . . . 29

Introduction .................................. ................................................................. ......29

Audible Alarm Settings ....................... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ................29

Alarm Silence State ...............................................................................29

Alarm Silence Duration ..........................................................................30

Alarm Volume ........................................................................................30

N-550B Menu ......................................................................................................30

Operator's Menu Options ................ .... ... ... .......................................... ... ... .... ... ...32

N-550B i

Contents

Accessing Menu Items ...........................................................................33

Menu Item 1 (Trend Print) ......................................................................33

Menu Item 2 (Trend Clear) ....................................................................34

Menu Item 3 (Language Selection) ........................................................34

Menu Item 4 (Baud Rate) ......................................................................34

Menu Item 5 (EPP Mode) ......................................................................34

Service Menu Options ........... ... ... ... .... ... ... .......................................... ... ... .... ... ...35

Menu Item 6 (In-Sensor Trend Mode) ...................................................35

Menu Item 7 (RS-232 Nurse Call Polarity) ............................................35

Menu Item 8 (Time Set) .........................................................................36

Menu Item 9 (Save Current Values as Power-On Defaults) .................. 37

Menu Item 10 (Restore Factory Default Settings as Power-On Default) ...

38

Menu Item 11 (Alarm Silence Restrictions) ...........................................39

Menu Item 12 (Silence Alarms) .............................................................40

Menu Item 13 (All Display Off) ...............................................................40

Menu Item 14 (Alarm Sound Style Select) .............................................40

Setting Institutional Defaults (Sample) ................................................................41

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Introduction .................................. ................................................................. ......43

How To Use This Section ...................................................................................43

Who Should Perform Repairs ............. ... ... ... .... ......................................... .... ... ...43

Troubleshooting Guide ................... .... ... ... ... .... ... ... ... ... .... ...................................43

Power ..................................... ......... .......... .......... ......... .......... ...... ..........44

Buttons ................................... ......... .......... .......... ...... .......... ......... ..........46

Display/Alarms ....................................... ................................................47

Operational Performance .......................................................................48

Data Port ................................................................................................49

Error Codes ........................................................................................................49

Disassembly Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Introduction .................................. ................................................................. ......53

Replacement Level Supported ...........................................................................54

Prior to Disassembly ...........................................................................................54

Separating Top and Bottom Cases .....................................................................54

Front Case Disassembly .....................................................................................57

MP-506 Removal ................................................................................................59

Main PCB Removal ............................................................................................60

Power Supply Removal ......................................................................................63

Fan Removal ......................................................................................................64

Battery Removal .................................................................................................66

Equipotential Terminal Removal .........................................................................68

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Introduction .................................. ................................................................. ......71

Obtaining Replacement Parts .............................................................................71

Parts List and Accessories .................................................................................71

Packing for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Introduction .................................. ................................................................. ......75

Returning the N-550B .........................................................................................75

General Instructions ............................... ... ... .... ......................................... .... ... ...75

Repacking in Original Carton ..............................................................................75

ii

Contents

Repacking in a Different Carton ..........................................................................77

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Performance ....................................................................................................... 79

Electrical ............................................................................................................. 82

Environmental Conditions .. .......................................... .... ... ... ... .... ... ... ... ... .... ... ...83

Physical Characteristics ......................................................................................84

Compliance .................................. .................................... ...................................85

Manufacturer’s Declaration .................................... ... ... .... ... ... ... .... ... ... ... ... .... ......86

Safety Tests ........................................................................................................92

Ground Integrity ........ ... .......................................... ... ... .... ... ... ... ... .... ......92

Earth Leakage Current ..........................................................................92

Enclosure Leakage Current ...................................................................92

Patient Risk Applied Current ............................... ............. ............ ..........93

Patient Isolation Risk Current .......................................... ... ... ... ... .... ... ...93

Data Port Interface Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Introduction .................................. ................................................................. ......95

Enabling The Data Port ......................................................................................95

Protocol ..................................... .......... ......... .......... .......... ...... .......... ......95

Baud Rate ..............................................................................................96

Connecting To The Data Port ................ .............................................................97

Nurse Call Polarity Settings ...................................................................99

Nurse Call Relay Pin States ........ ... .... ... ... ... ... .......................................99

Nurse Call Relay Rating ........ ... ... ... .......................................... ... .... ... ...99

Real-Time Printout ............................................................................................100

Column Heading ..................................................................................100

Printout Source ....................................................................................101

Software Revision Level ..................................... ... ... ... .... ... ... ... ...........101

Alarm Limits .........................................................................................101

Column Headings ................................................................................101

Time Tag ..............................................................................................102

Patient Data .......... .... .......................................... ... ... ... ........................102

Operating Status .......................................... ... .... ... ... ... .... ... ... ... ... .... ....102

Technical Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Oximetry Overview ...... ... ... .... ... ... ... .......................................... .... ....................105

Automatic Calibration ...........................................................................106

Functional versus Fractional Saturation ..............................................106

SatSeconds Alarm Management ......................................................................107

Reads Through Motion ....................................................... ... ... .... ... ... ... ... .... ... .107

OXIMAX Technology ........................................................................................108

MP-506 Interface ..............................................................................................108

Circuit Analysis .................................................................................................110

Block Diagram Theory ......................................................................................111

AC Input ....... .......................................... .......................................... ... ..............111

Power Supply PCB Theory Of Operation .........................................................112

Battery ..............................................................................................................112

Main PCB ..........................................................................................................112

Regulated DC Power Supply ............................................................... 113

Controlling Hardware ...........................................................................113

CPU ..................................................................................................... 113

Charging Circuits .................................................................................114

Real-Time Clock (RTC) .......................................................................114

N-550B iii

Contents

Storage of Patient Data ............... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ...........114

Front Panel PCB and Controls .........................................................................115

Front Panel Display .............................................................................115

Button Interface .............. ... .... ... ... ... .... ... ... .......................................... .115

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

iv

Figures

Contents

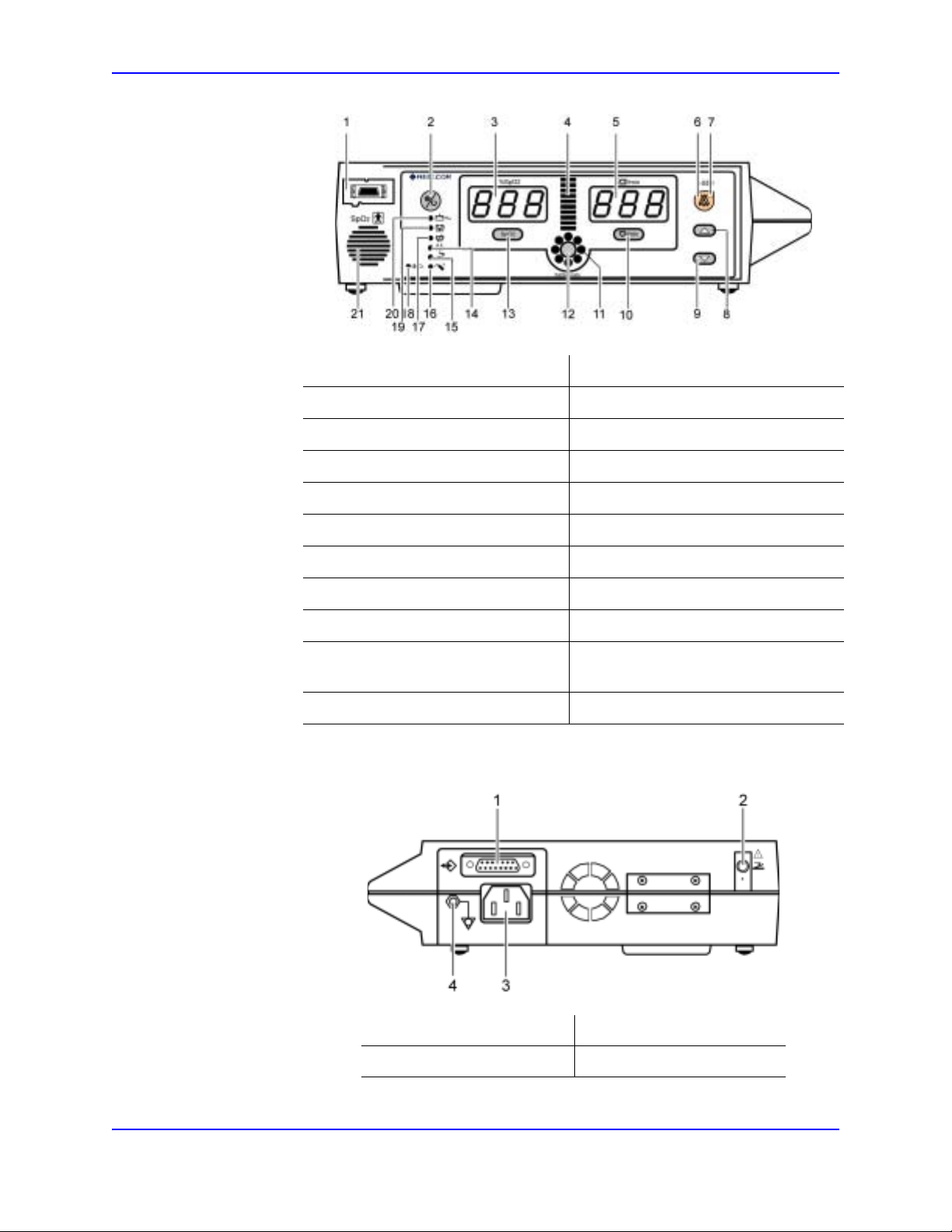

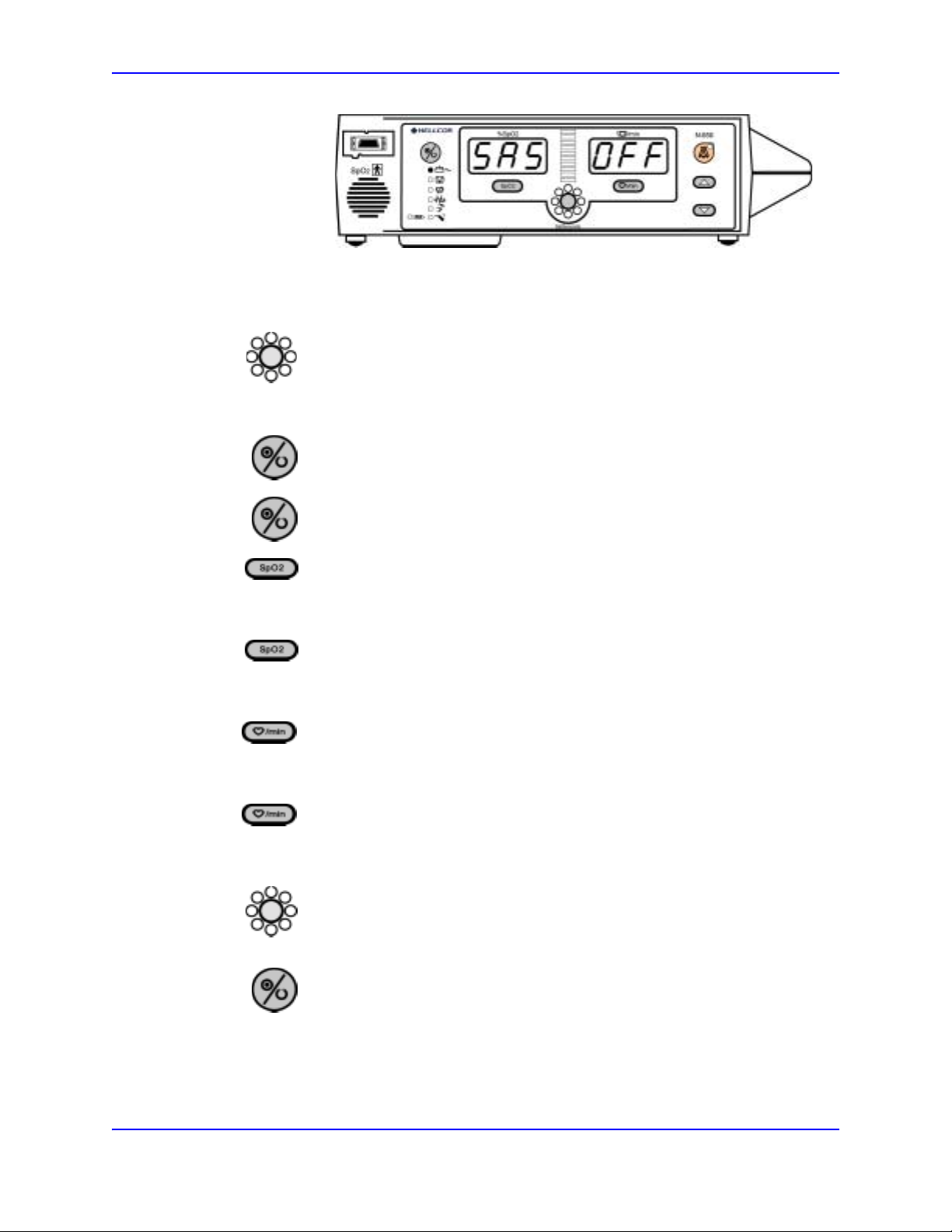

Figure 1: N-550B Front Panel ...........................................................................3

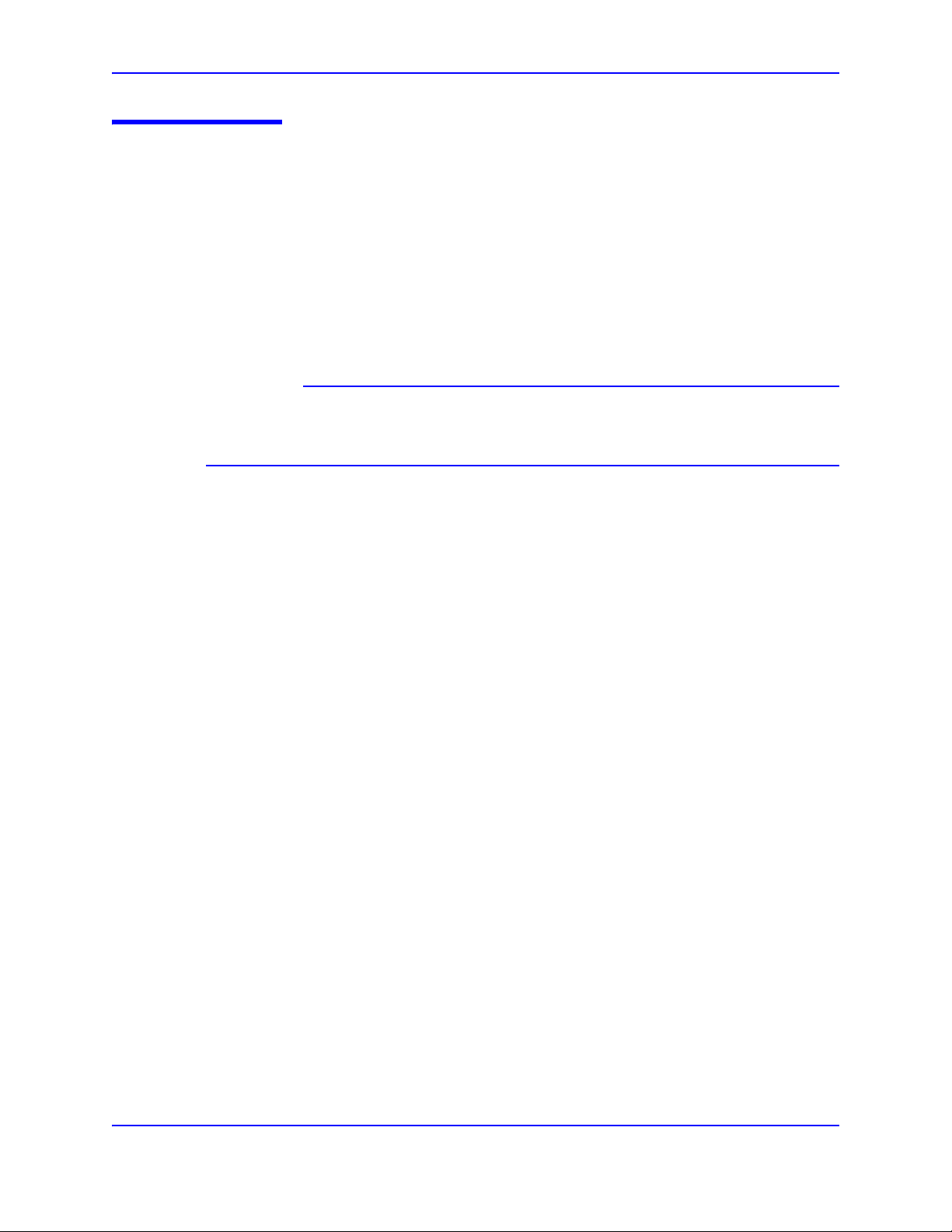

Figure 2: N-550B Rear Panel ............................................................................3

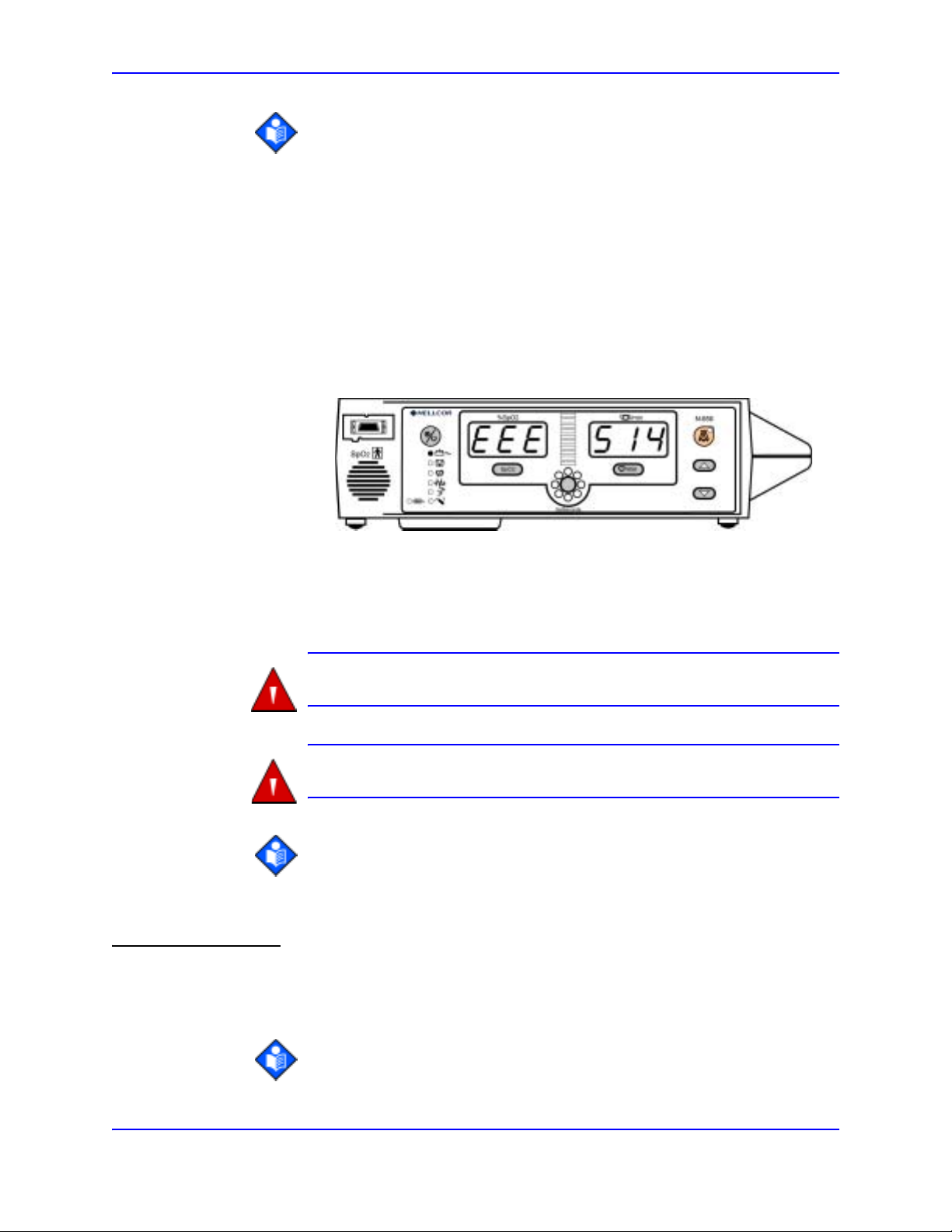

Figure 3: N-550B Controls ................................................................................9

Figure 4: Adjusting High %SpO2 Alarm Limit .................................................12

Figure 5: Adjusting Low %SpO2 Alarm Limit .................................................. 13

Figure 6: Adjusting High Pulse Rate Alarm Limit ............................................13

Figure 7: Adjusting Low Pulse Rate Alarm Limit ... ... .... ... ... .............................14

Figure 8: Adjusting SatSeconds Alarm Limit ...................................................15

Figure 9: N-550B Controls ..............................................................................29

Figure 10: Year Month Display ..........................................................................36

Figure 11: Day Hour Display .............................................................................36

Figure 12: Minute Second Display .................................................................... 37

Figure 13: N-550B Rear Panel Screws .............................................................55

Figure 14: N-550B Case Screws .......................................................................55

Figure 15: Top Case Removal ..........................................................................56

Figure 16: Separated Cases .............................................................................56

Figure 17: Front case Wiring .............................................................................57

Figure 18: Front Case Mounting Screws ...........................................................58

Figure 19: Front Case Bracket .......................................................................... 58

Figure 20: Speaker Removal ............................................................................59

Figure 21: Front PCB Removed ........................................................................59

Figure 22: MP-506 Cable Connections .............................................................60

Figure 23: MP-506 Removal .............................................................................60

Figure 24: Front case Wiring .............................................................................61

Figure 25: Front Case Mounting Screws ...........................................................61

Figure 26: Main PCB Removal ..........................................................................62

Figure 27: Main PCB Removed ........................................................................62

Figure 28: Power Supply Wiring ........................................................................63

Figure 29: Power Supply Screws ......................................................................64

Figure 30: Power Supply Removed ..................................................................64

Figure 31: Fan Wires .........................................................................................65

Figure 32: Fan Bracket Removal ......................................................................65

Figure 33: Fan and Bracket Removal ...............................................................66

Figure 34: Fan Screws ......................................................................................66

Figure 35: Battery Screws .................................................................................67

Figure 36: Battery Cover ...................................................................................67

Figure 37: Battery Connector .................................................................. ..........67

Figure 38: Battery Removal ..............................................................................68

Figure 39: Ground Wire .....................................................................................69

Figure 40: Equipotential Ground Terminal ........................................................69

Figure 41: Equipotential Ground Terminal Removed .................................. ...... 70

Figure 42: Exploded View .................................................................................73

Figure 43: Packing ............................................................................................76

Figure 44: Data Port Pin Layout ........................................................................98

Figure 45: Real-Time Printout .........................................................................100

Figure 46: Oxyhemoglobin Dissociation Curve ....................... ........................ 107

Figure 47: MP-506 Interface ...........................................................................109

Figure 48: Block Diagram ................................................................................111

N-550B v

Contents

Figure 49: Main PCB Battery Charger Schematic Diagram ............................117

Figure 50: Main PCB Isolation for MP-506 Schematic Diagram .....................119

Figure 51: Main PCB Isolation for External Interface Schematic Diagram ......121

Figure 52: Main PCB DC Battery Input and DC/DC Converter Schematic Diagram

123

Figure 53: Main PCB Interface and Speaker Control Schematic Diagram .....125

Figure 54: Main PCB MCU and Storage Control Schematic Diagram ............127

Figure 55: Main PCB Parts Locator Diagram .............................. .................... 129

Figure 56: Front Panel PCB 7-Segment Display Schematic Diagram ............131

Figure 57: Front Panel PCB LED Display and Buttons Schematic Diagram ...133

Figure 58: Front Panel PCB Interface and LED Drivers Schematic Diagram .135

Figure 59: Front Panel Parts Locator Diagram ...............................................137

Figure 60: Power Supply Schematic Diagram ................................................139

Figure 61: Power Supply Parts Locator Diagram ........................... ................. 141

vi

Tables

Contents

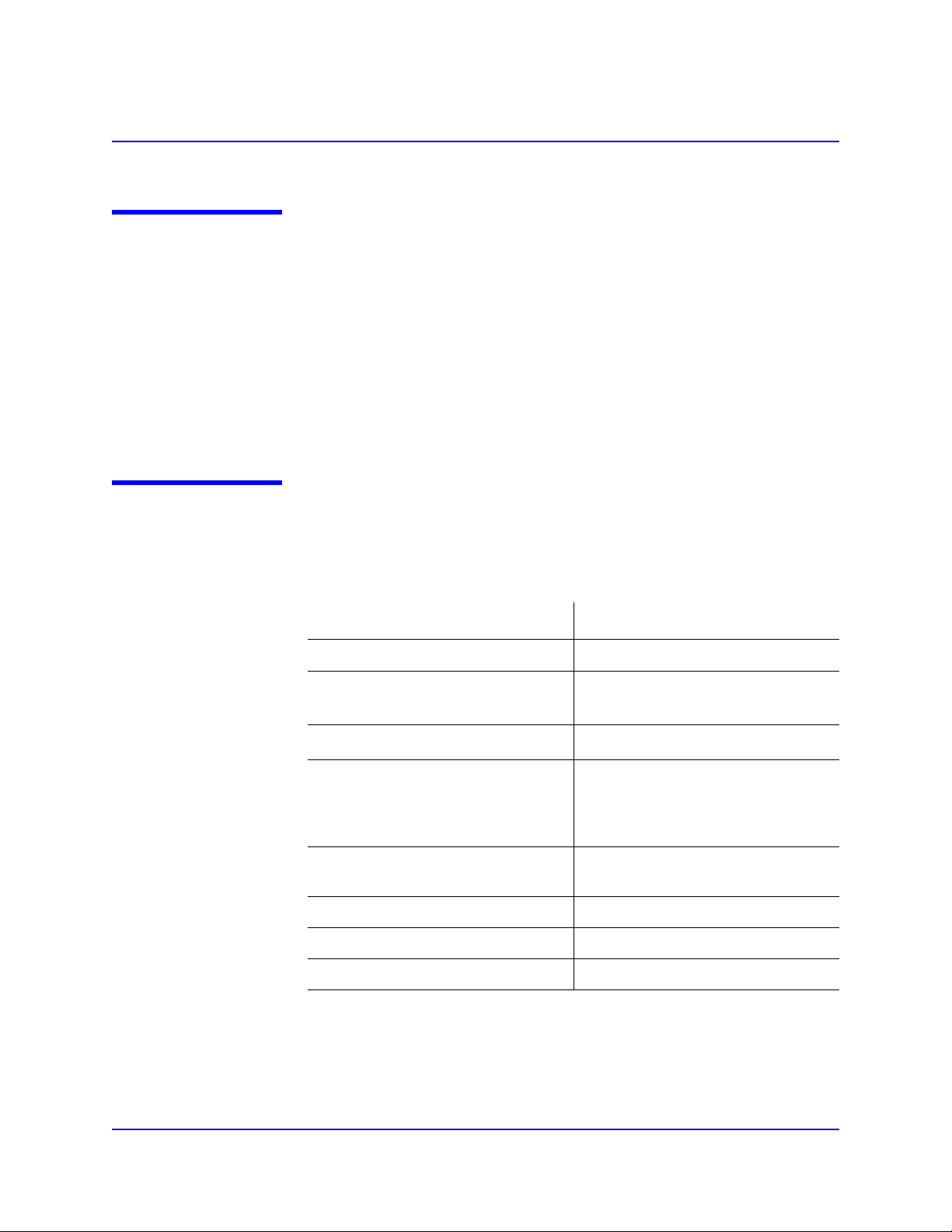

Table 1: Equipment Needed ........................................ ... ... ... .... ... ... ... ... ............7

Table 2: N-550B Menu Selections ..................................................................30

Table 3: Institutional Default Values ...............................................................37

Table 4: Factory Default Settings ...................................................................38

Table 5: Problem Categories ....................................................................... ...44

Table 6: Power Problems ..... ... ... .......................................... .... ... ... ... .............45

Table 7: Button Problems .................................. ... ... .... ... ... ... ..........................46

Table 8: Display/Alarms Problems ..................... ... ... .... ... ... ... .... ... ... ... ... .... ......47

Table 9: Operational Performance Problems ....................................... .... ... ...48

Table 10: Data Port Problems ...... .... ... ... .......................................... ... ... .... ... ...49

Table 11: Error Codes ......... ... .......................................... ... ... .... ... ... ... ... .... ......50

Table 12: Spare Parts and Accessories ...........................................................71

Table 13: Tone Definition ..................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ......80

Table 14: Cable Compliance ............................................................................86

Table 15: Electromagnetic Emissions ...............................................................88

Table 16: Electromagnetic Immunity .......................................... ... ... ... ... .... ... ...88

Table 17: Electromagnetic Immunity .......................................... ... ... ... ... .... ... ...90

Table 18: Recommended Separation Distances Between Portable and Mobile RF

Communication Equipment and the N-550B 91

Table 19: Data Port Pinouts .................... .......................................... ... ... .... ... ...97

Table 20: Status Codes ................................. ... ... ... ... .... .................................103

Table 21: MP-506 J1 Pinouts .........................................................................109

Table 22: MP-506 J2 Pinouts .........................................................................110

N-550B vii

Blank Page

Introduction

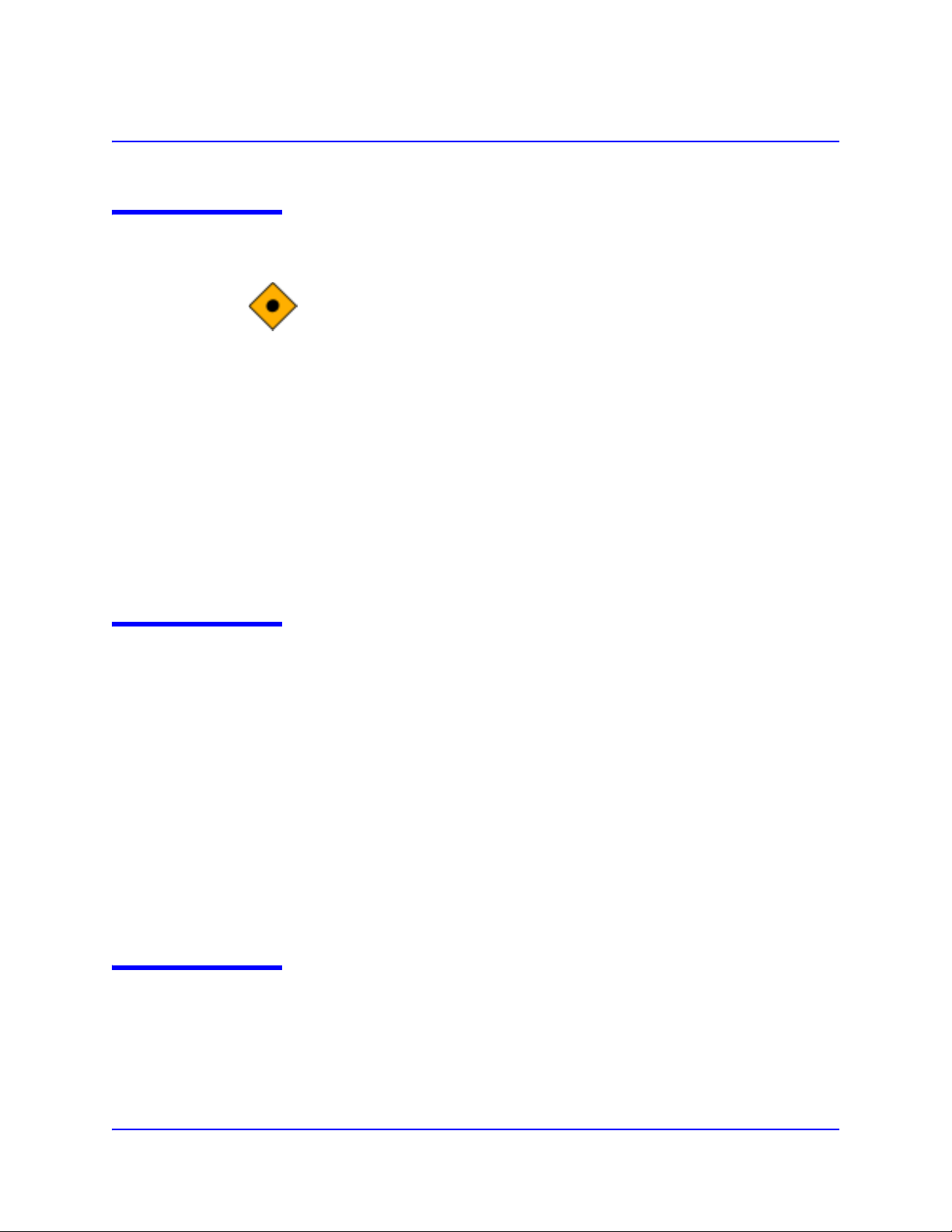

Warnings

Warnings are identified by the WARNING symbol shown above and a line

above and below the warning text. The word WARNING and all warning text

are boldfaced.

W arnings alert the user to potential serious outcomes (death, injury, or adverse

events) to the patient or user.

Cautions

Notes

Cautions are identified by the CAUTION symbol shown above. The word

CAUTION and the caution text are boldfaced.

Cautions alert the user to exercise care necessary for the safe and effective use

of the N-550B.

Notes are identified by the Note symbol shown above.

Notes provide additional useful information.

N-550B 1

Introduction

Manual Overview

This manual contains information for servicing the Nellcor® model N-550B

pulse oximeter. Only qualified service personnel should service this product.

Before servicing the N-550B, read the operator's manual carefully for a

thorough understanding of operation.

WARNING: Explosion hazard. Do not use the N-550B pulse oximeter in

the presence of flammable anesthetics.

Description Of N-550B Pulse Oximeter

The N-550B Pulse Oximeter is indicated for the continuous noninvasive

monitoring of functional oxygen saturation of arterial hemoglobin (SpO

pulse rate. The N-550B is intended for use with neonatal, pediatric, and adult

patients during both no-motion and motion conditions and for patients who

are well or poorly perfused in hospitals, hospital-type facilities, intra-hospital

transport, and home environments. For prescription use only.

2) and

Note: Hospital use typically covers such areas as general care floors,

operating rooms, special procedure areas, intensive and critical care

areas, within the hospital plus hospital-type facilities. Hospital-type

facilities include physician office based facilities, sleep labs, skilled

nursing facilities, surgicenters, and subacute centers.

Intra-hospital transport includes transport of a patient within the

hospital or hospital-type facility.

Use with any particular patient requires the selection of an appropriate oxygen

transducer as described in the N-550B Operator's Manual.

Motion performance claims are applicable to models MAX-A, MAX-AL,

MAX-P, MAX-N, and MAX-I Nellcor O

XIMAX

TM

oximetry sensors.

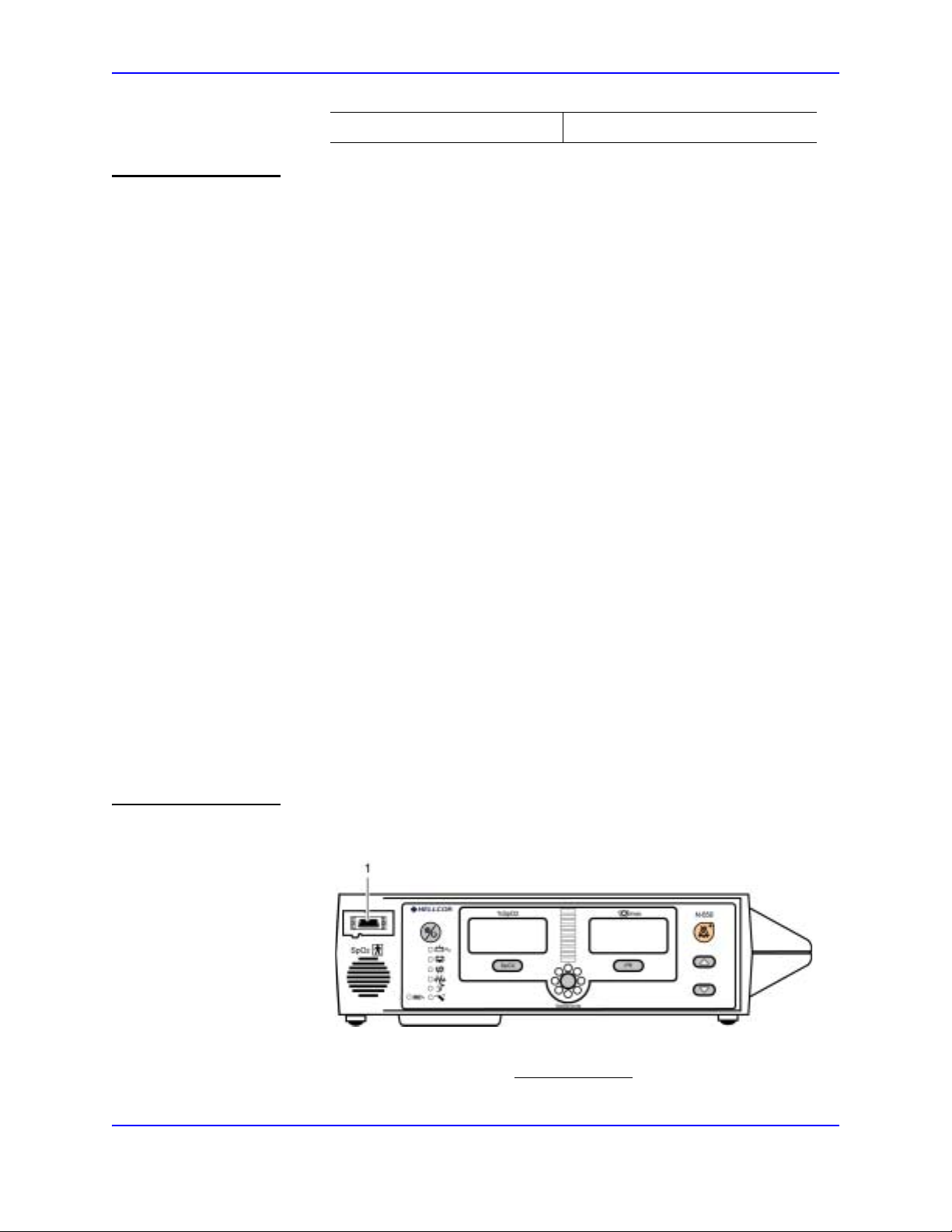

Digital displays are provided for oxygen saturation and pulse rate, and a

10-segment light-emitting diode (LED) bar indicates pulse amplitude. The

controls and indicators for the N-550B are illustrated and defined in Figure 1

and Figure 2 on page 3.

2

Introduction

1 — SpO2 Sensor Port 12 — SatSeconds Alarm Limit Button

Power On/Off Button 13 — SpO2 Alarm Limit Button

2 —

3 —

% SpO2 Display 14 — Motion Indicator

4 —

Pulse Amplitude Indicator 15 — Sensor Off Indicator

5 —

Pulse Rate Display 16 — Sensor Message Indicator

6 —

Alarm Silence Button 17 — Pulse Search Indicator

7 —

Alarm Silence Indicator 18 — Data In Sensor Indicator

8 —

Adjust Up Button 19 — Low Battery Indicator

9 —

Adjust Down Button 20 — AC Power Indicator

10 —

Pulse Rate Alarm Limit

Button

SatSeconds Display

11 —

21 — Speaker

Figure 1: N-550B Front Panel

1 — Data Port Connector 3 — AC Power Connector

2 — Foot Switch Connector 4 — Equipotential Terminal

Figure 2: N-550B Rear Panel

N-550B 3

Introduction

Related Documents

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/ProductManuals.html

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/Apartweb/main/PartAcceMenu.html

To perform test and troubleshooting procedures and to understand the

principles of operation and circuit analysis sections of this manual, you must

know how to operate the N-550B. Refer to the N-550B operator's manual. To

understand the various Nellcor sensors that work with the N-550B, refer to the

individual sensor's directions for use.

The latest versions of the operator’s manual and the service manual are posted

on the Internet at:

Spare parts and accessories are posted on the Internet at:

4

Routine Maintenance

Cleaning

CAUTION: Do not spray, pour, or spill any liquid on the N-550B, its

accessories, connectors, switches, or openings in the chassis.

For surface-cleaning and disinfecting follow your institution's procedures or:

• The N-550B may be surface-cleaned by using a soft cloth dampened

with either a commercial, nonabrasive cleaner or a solution of 70%

alcohol in water, and lightly wiping the surfaces of the N-550B.

• The N-550B may be disinfected using a soft cloth saturated with a

10% solution of chlorine bleach in tap water .

Before attempting to clean an SpO

enclosed with the sensor. Each sensor model has cleaning instructions specific

to that sensor.

Periodic Safety Checks

The N-550B requires no routine service or calibration other than changing the

battery at least every two years. See Battery Removal on page 66. The

following checks should be performed at least every two years by a qualified

service technician.

1. Inspect the equipment for mechanical and functional damage.

2. Inspect safety labels for legibility. If the labels are damaged, contact

Nellcor’s Technical Services Department, 1.800.635.5267, or your local

Nellcor representative.

2 sensor, read the directions for use

Functional Checks

1. If the N-550B has been visibly damaged or subjected to mechanical shock

(for example, if dropped), perform the performance tests. See

Performance Tests on page 8.

N-550B 5

Routine Maintenance

Battery

2. Perform the electrical safety tests detailed in Safety Tests on page 26. If

the N-550B fails these electrical safety tests, refer to Troubleshooting on

page 43.

3. Inspect the fuses for proper value and rating (F1 and F2 = 2 amp,

250 volts).

Nellcor recommends replacing the N-550B's battery every two years. When

the N-550B is going to be stored for two months or more, remove the battery

prior to storage. To replace or remove the battery, refer to Disassembly Guide

on page 53.

If the N-550B has been stored for more than 30 days, charge the battery as

described in Battery Charge on page 8. A fully discharged battery requires

6 hours to receive a full charge. The battery is being charged whenever the

N-550B is plugged into an AC power source.

6

Performance Verification

Introduction

This section discusses the tests used to verify performance following repairs

or during routine maintenance. All tests can be performed without removing

the N-550B cover. All tests except the battery char ge and battery performance

tests must be performed as the last operation before the N-550B is returned to

the user.

If the N-550B fails to perform as specified in any test, repairs must be made to

correct the problem before the N-550B is returned to the user.

Equipment Needed

Table 1: Equipment Needed

Equipment Description

Digital multimeter (DMM) Fluke Model 87 or equivalent

Durasensor

(sensor)

O

XIMAX

Pulse oximeter tester SRC-MAX (must meet current EN

Safety analyzer Must meet current AAMI ESI/1993 &

Pulse oximetry cable DOC-10

Data interface cable EIA-232 cable (optional)

Stopwatch Manual or electronic

®

oxygen transducer

oxygen transducer

DS-100A

MAX-A

61326-1, FCC Part 15, and UL 1010-1,

or IEC 61010-1, or CSA 22.2 No.

1010-1 specifications)

IEC 60601-1/1998 specifications

N-550B 7

Performance Verification

Performance Tests

Battery Charge

Note: This section is written using Nellcor factory-set defaults. If your

institution has preconfigured custom defaults, those values will be

displayed. Factory defaults can be restored. See Menu Item 10

(Restore Factory Default Settings as Power-On Default) on page 38.

Perform the following procedure to fully charge the battery.

1. Connect the N-550B to an AC power source.

2. Verify that the N-550B is off and that the

3. Charge the battery for at least 6 hours in standby.

Power-Up Performance

The power-up performance tests verify the following N-550B functions:

• Power-On Self-Test (POST) on page 9

• Power-On Defaults and Alarm Limit Ranges on page 11

AC Power indicator is lit.

8

Performance Verification

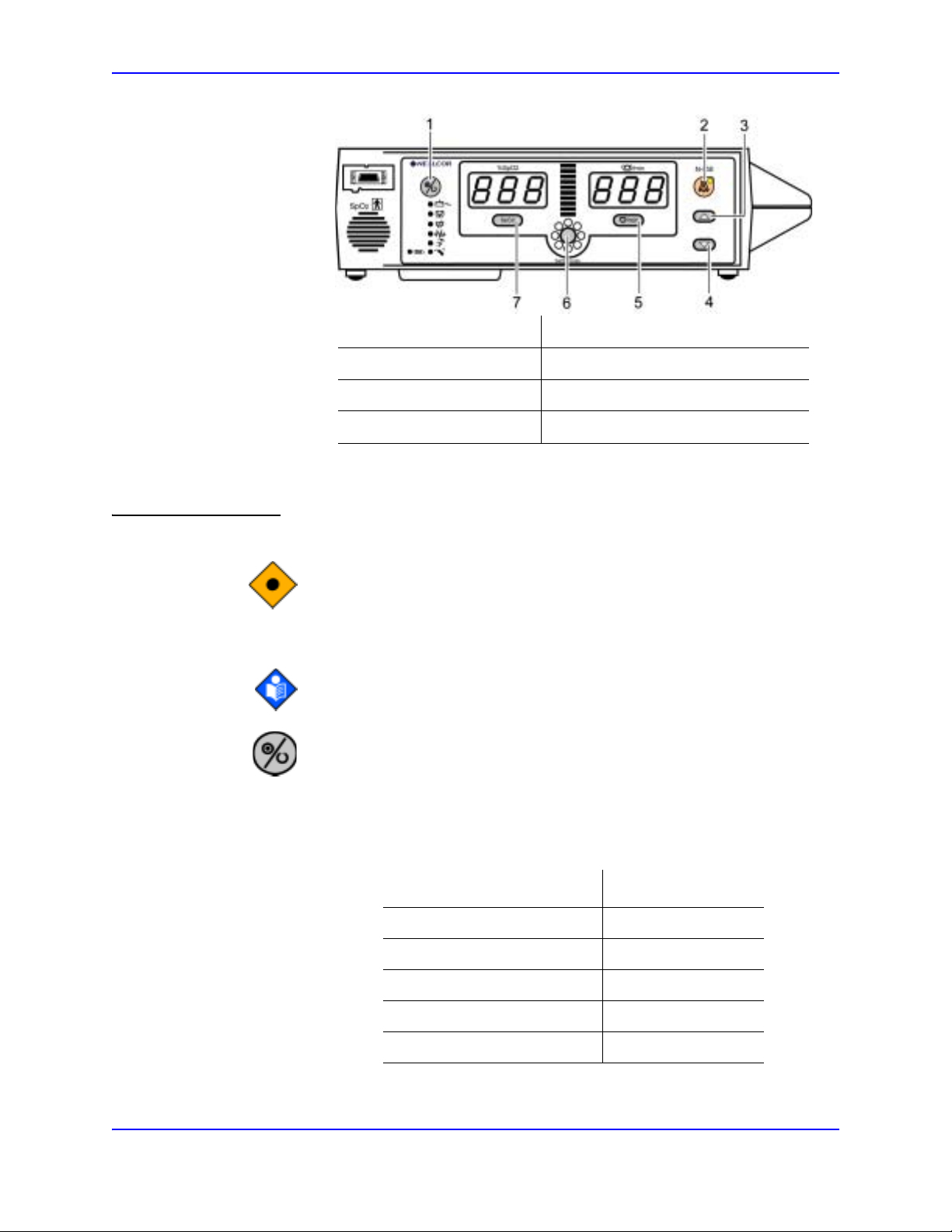

1 — Power On/Off Button 5 — Pulse Rate Alarm Limit Button

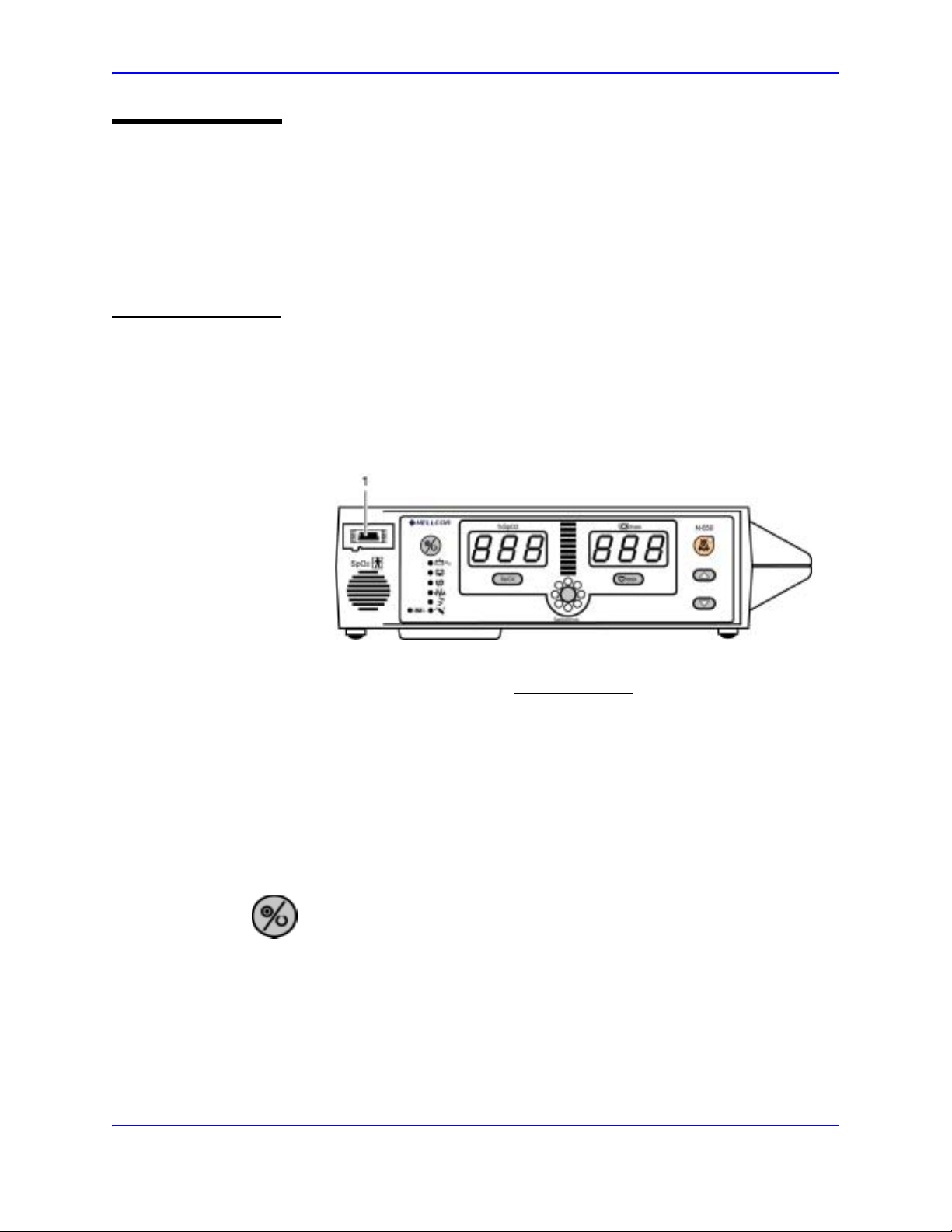

Power-On Self-Test (POST)

CAUTION: If any indicator or display element does not light, or the

speaker does not sound, do not use the N-550B. Instead, contact qualified

service personnel, your local Nellcor representative, or Nellcor's

Technical Services Department, 1.800.635.5267.

Note: The N-550B should complete the POST function within 12 seconds.

1. Turn on the N-550B by pressing the

2 —

Alarm Silence Button

Adjust Up Button 7 — SpO2 Alarm Limit Button

3 —

4 —

Adjust Down Button

6 — SatSeconds Alarm Limit Button

Figure 3: N-550B Controls

Power On/Off button for greater

than 0.5 seconds.

2. The N-550B displays/sounds:

Display Sound

5 (in pulse rate left window) low priority alarm

5 (in pulse rate center window) medium priority alarm

0 (in pulse rate right window) high priority alarm

n (in SpO

n (in SpO

N-550B 9

2 left window)

2 center window)

Performance Verification

3. The N-550B automatically starts the Power-On Self-Test (POST), which

tests N-550B circuitry and functions.

CAUTION: During POST (immediately after power-up), confirm that all

display segments and indicators light, and the speaker sounds a

one-second pass tone.

4. While performing POST, the self-test display appears for approximately

five seconds. During this time:

• All indicators illuminate

• All segments of all numeric digits light and change from red to green

• All segments of the Pulse Amplitude Display light

• All segments of the

SatSeconds indicator light

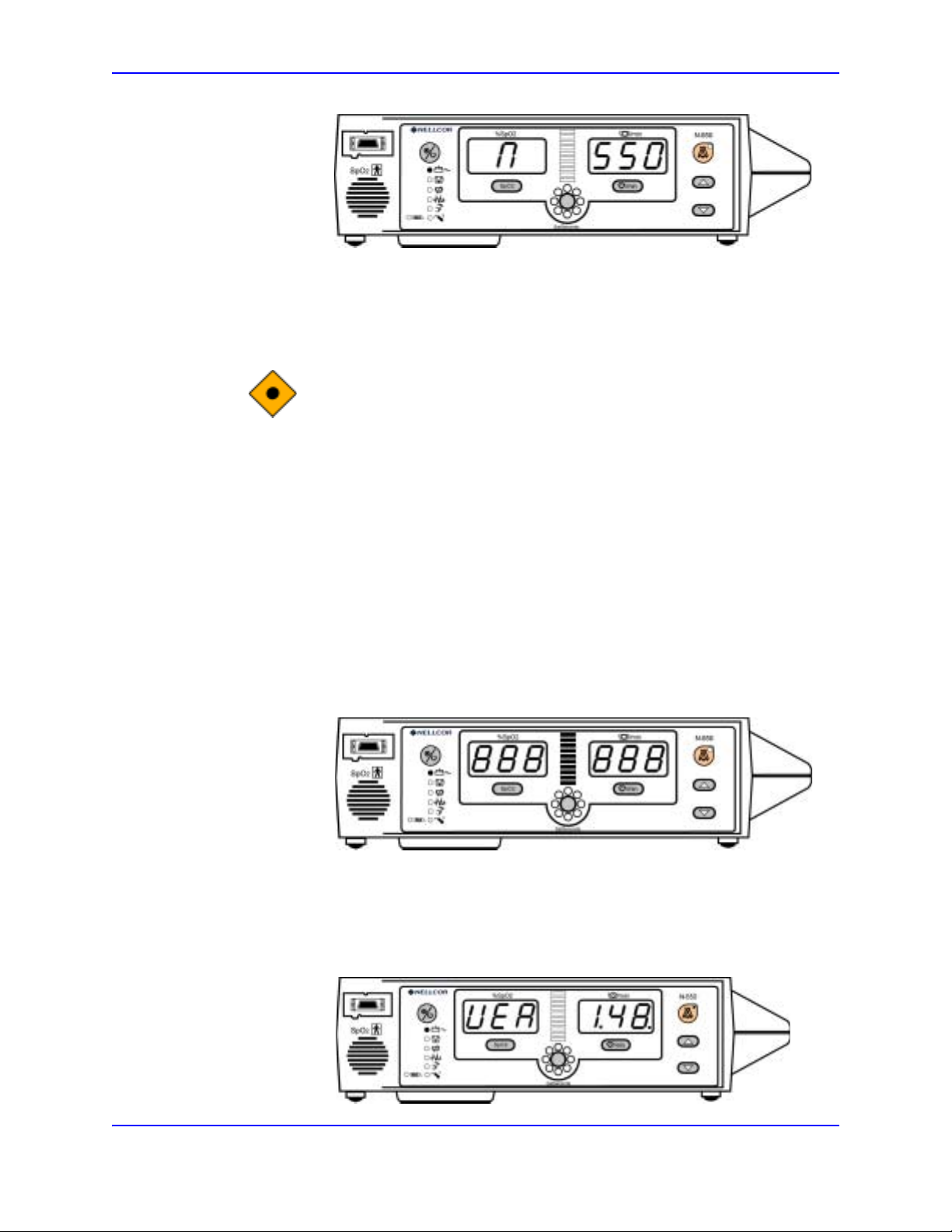

5. Once the display test portion of POST is complete, the N-550B version is

displayed for approximately two seconds.

10

Performance Verification

Note: The version above is only a sample. Check your N-550B for the

current version installed.

The version number is needed when calling Nellcor's Technical

Services Department, 1.800.635.5267, or your local Nellcor

representative for technical assistance. Write down the number and

have it available prior to requesting technical assistance.

6. If the N-550B detects an internal problem during the POST, an alarm tone

sounds and the N-550B displays an Error Code and corresponding

number. See Troubleshooting on page 43.

7. Upon successful completion of the POST, the N-550B sounds a

one-second tone indicating that the N-550B has passed the test.

WARNING: If you do not hear the POST pass tone, do not use the

N-550B.

WARNING: Ensure that the speaker is clear of any obstruction. Failure

to do so could result in an inaudible alarm tone.

Note: In addition to serving as the POST pass verification, the POST pass

tone also functions as an audible confirmation that the speaker is

performing properly. If the speaker does not function, the alarm

sounds cannot be heard.

Power-On Defaults and Alarm Limit Ranges

See Figure 3 on page 9 for the location of the N-550B controls.

Note: When observing or changing default limits, a three-second time-out is

in effect. That is, if no action is taken within three seconds, the

N-550B automatically returns to the normal mode.

N-550B 11

Performance Verification

1. Turn the N-550B on by pressing the Power On/Off button.

2. Wait for POST to be completed.

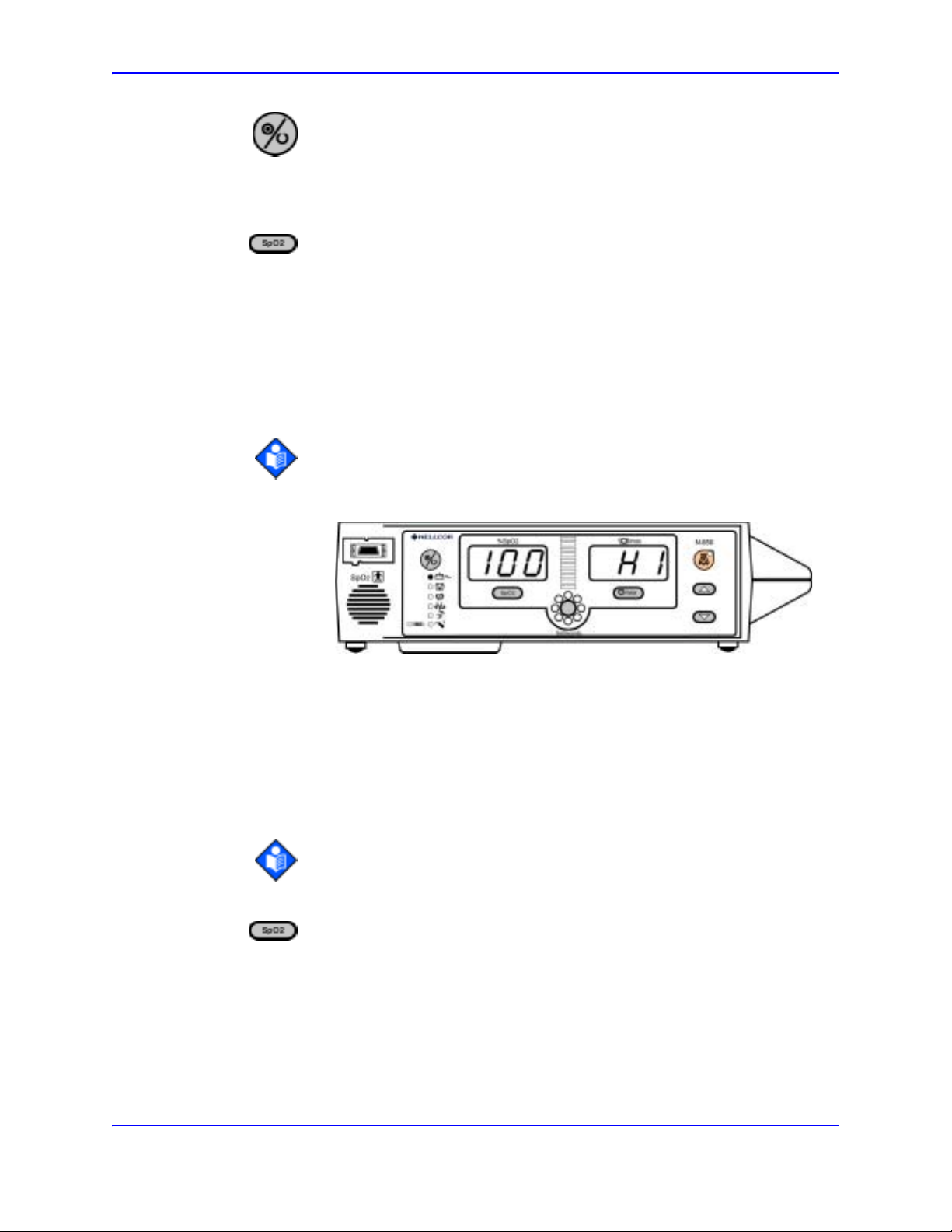

3. Press and release the

4. Verify that the N-550B emits a single beep and the %SpO

SpO2 Alarm Limit button.

2 display

indicates an upper alarm limit of “100” for about three seconds.

5. Verify that “HI” is displayed in the

Pulse Rate display.

Note: “HI” in the display window indicates an upper alarm limit that is

being adjusted, and a “LO” in the window indicates that a low alarm

limit is being adjusted.

Figure 4: Adjusting High %SpO2 Alarm Limit

12

6. Press the SpO2 Alarm Limit button. Within 3 seconds, press and hold

the Adjust Down button. Verify that the %SpO2 display reduces to a

minimum of one point above the %SpO

2 low alarm limits setting.

Note: A decimal point to the right of the value in either window display

indicates that the alarm limits are not power-on default values.

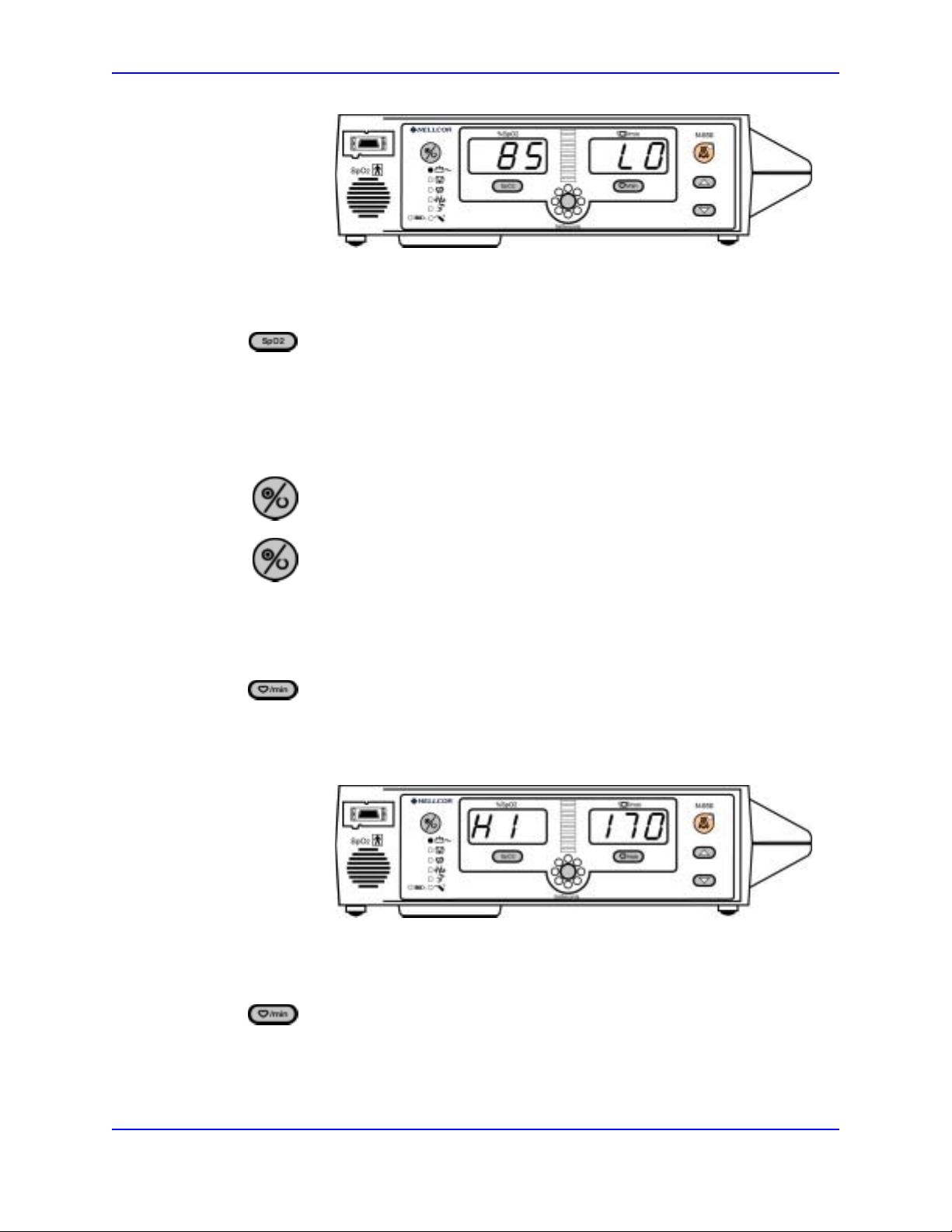

7. Press the

seconds). Verify that the N-550B emits two beeps and that the %SpO

SpO2 Alarm Limit button two times rapidly (twice within three

2

display indicates “85” for three seconds. Verify that “LO” is displayed in

the pulse rate window.

Performance Verification

Figure 5: Adjusting Low %SpO2 Alarm Limit

8. Press the SpO2 Alarm Limit button two times rapidly. Within three

seconds, press and hold the

%SpO2 display reduces to a minimum of “20.” Press and hold the Adjust

Up

button and verify that the %SpO2 display cannot be raised past the

upper alarm limit setting minus one point.

Adjust Down button and verify that the

9. Turn the N-550B off by pressing the

10. Turn the N-550B on by pressing the

Power On/Off button.

Power On/Off button.

11. Wait for POST to be completed. The %SpO

will be reset to the default values.

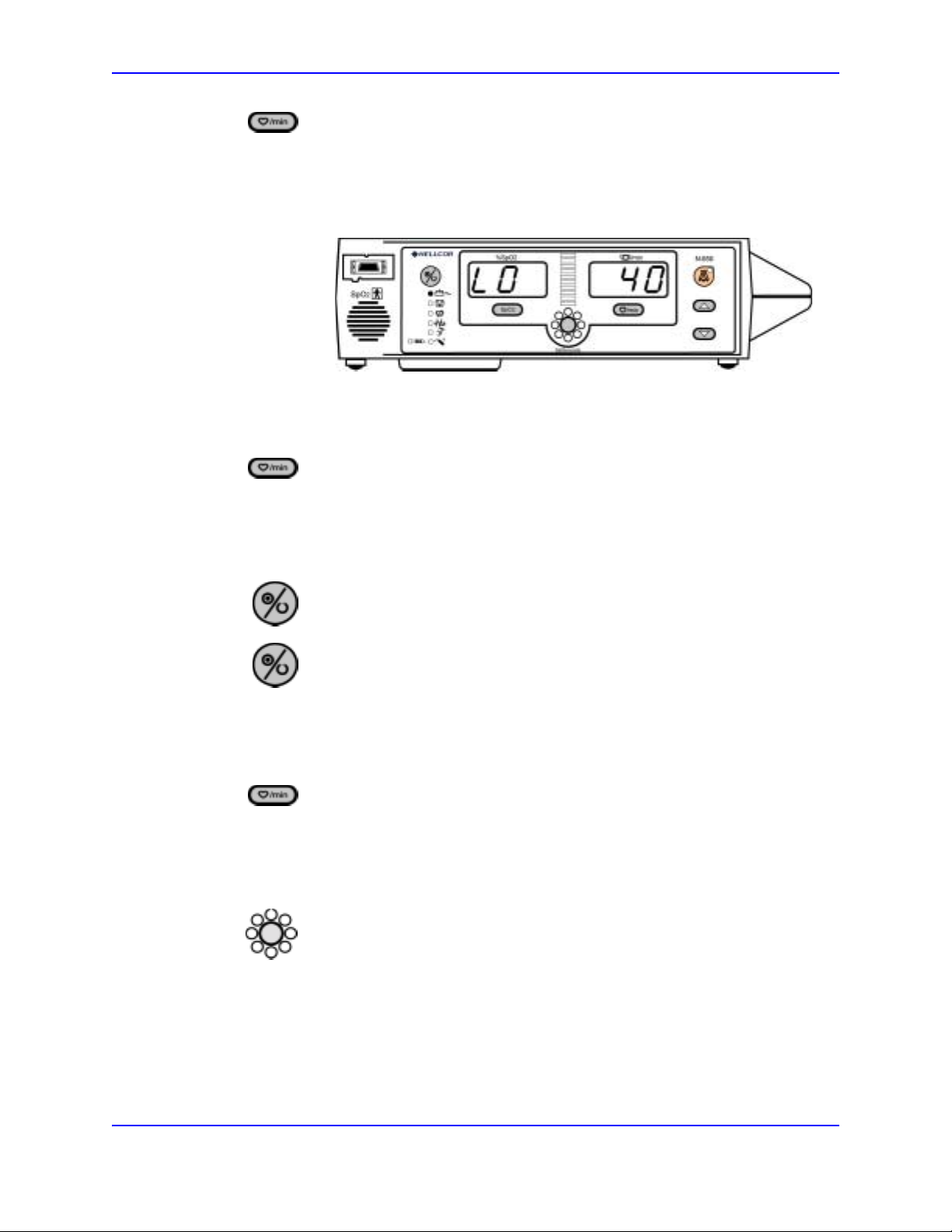

12. Press the

a single beep, the

and that the %SpO

Pulse Rate Alarm Limit button. V erify that the N-550B emits

Pulse Rate display indicates an alarm limit of “170”

2 display window shows “HI” for about 3 seconds.

2 and pulse rate alarm limits

Figure 6: Adjusting High Pulse Rate Alarm Limit

13. Press the Pulse Rate Alarm Limit Button. Within 3 seconds press and

hold the

reduces to a minimum of one point above the pulse rate low limit alarm

setting.

N-550B 13

Adjust Down button. Verify that the Pulse Rate display

Performance Verification

14. Press the Pulse Rate Alarm Limit button two times (twice within 3

seconds). Verify that the N-550B emits two beeps and that the

Rate

display indicates an alarm limit of “40” for 3 seconds. Verify that

“LO” is displayed in the %SpO

2 display.

Pulse

Figure 7: Adjusting Low Pulse Rate Alarm Limit

15. Press the Pulse Rate Alarm Limit button two times rapidly. Within 3

seconds press and hold the

Rate

display cannot be raised past the upper alarm limit setting minus

one point.

Adjust Down button. Verify that the Pulse

16. Turn the N-550B off by pressing the

17. Turn the N-550B on by pressing the

18. Wait for POST to be completed. The %SpO

Power On/Off button.

Power On/Off button.

2 and pulse rate alarm limits

will be reset to the default values.

19. Press the

three seconds press and hold the

Rate

Pulse Rate Alarm Limit button two times rapidly. Within

Adjust Up button. Verify that the Pulse

display cannot be adjusted above the upper alarm limit setting

minus one point.

20. Press the SatSeconds Alarm Limit button. Verify that the N-550B emits a

single beep and that the

“OFF” for three seconds. Verify that “SAS” is displayed in the %SpO

Pulse Rate display indicates an alarm limit of

2

display.

14

Performance Verification

Figure 8: Adjusting SatSeconds Alarm Limit

21. Press the SatSeconds Alarm Limit button. Within three seconds press the

Adjust Up button or the Adjust Down button. Verify that the Pulse

Rate

display changes between 10, 25, 50, 100, and OFF.

22. Press the

23. Press the

24. Press and release the

display indicates an alarm limit of “100.”

25. Press the

%SpO2 display indicates an alarm limit of “85.”

26. Press and release the

Power On/Off button to turn the N-550B off.

Power On/Off button to turn the N-550B on.

%SpO2 Alar m Limit button. Verify that the %SpO2

%SpO2 Alarm Limit button two times rapidly. Verify that the

Pulse Rate Alarm limit button. Verify that the

Pulse Rate display indicates an alarm limit of “170.”

27. Press the

the Pulse Rate display indicates an alarm limit of “40.”

28. Press the SatSeconds Alarm Limit button. Verify that the

display indicates an alarm limit of “OFF.”

Pulse Rate Alarm Limit button two times rapidly. Verify that

Pulse Rate

29. Press the

N-550B 15

Power On/Off button to turn the N-550B off.

Performance Verification

General Operation

LED Excitation Test

The following tests are check overall system performance:

• LED Excitation Test below.

• Operation with a Live Subject on page 17.

This procedure uses normal system components to test circuit operation. A

Nellcor O

XIMAX oxygen transducer (sensor), model MAX-A, is used to

examine LED intensity control. The red LED is used to verify intensity

modulation caused by the LED intensity control circuit.

1. Sensor Port

1. Connect the N-550B to an AC power source.

2. Connect a DOC-10 pulse oximetry cable to the N-550B sensor port (1).

3. Connect a MAX-A sensor to the sensor-input cable.

4. Press the

Power On/Off button to turn the N-550B on.

5. Leave the sensor open with the LEDs and photo detector visible.

6. After the N-550B completes its normal power-up sequence, verify that

the sensor LED is brightly lit.

16

Performance Verification

7. Slowly move the sensor LED in proximity to the photo detector element

of the sensor (close the sensor slowly). Verify, as the LED approaches the

optical sensor, that the LED intensity decreases.

8. Open the sensor and notice that the LED intensity increases.

9. Repeat step 7 and the intensity will again decrease. This variation is an

indication that the microprocessor is in proper control of LED intensity.

10. Press the

Operation with a Live Subject

Patient monitoring involves connecting the sensor to a live subject for a

qualitative test.

1. Ensure that the N-550B is connected to an AC power source.

Power On/Off button to turn the N-550B off.

1. Sensor Port

2. Connect a DOC-10 pulse oximetry cable to the N-550B sensor port (1).

3. Connect a Nellcor Durasensor oxygen transducer (sensor), model

DS-100A, to the sensor cable.

4. Clip the DS-100A to the subject as recommended in the sensor's

directions for use.

5. Press the

Power On/Off button to turn the N-550B on and verify that the

N-550B is operating.

N-550B 17

Performance Verification

Alarm Volume Control

6. The N-550B should stabilize on the subject's physiological signal in about

15 to 30 seconds. Verify that the oxygen saturation and pulse rate values

are reasonable for the subject.

1. Press and hold the Alarm Silence button for more than three seconds.

Verify the following:

• “Alarm Silence Duration Time” is displayed for approximately three

seconds.

• After three seconds:

• a steady tone is heard at the default volume setting

• the %SpO2 dis play indicates “VOL”

•the

2. Press the

button, until an alarm volume setting of “1” is displayed. Verify that the

alarm volume has decreased but is still audible.

3. Press the

increase the alarm volume setting to a maximum value of “10.” Verify

that the volume increases.

4. Press the

button, until a comfortable audio level is obtained.

Pulse Rate display indicates the default setting of “4”

Adjust Down button, while holding the Alarm Silence

Adjust Up button, while holding the Alarm Silence button, to

Adjust Down button, while holding the Alarm Silence

18

5. Release the

Alarm Silence button. The tone stops.

Pulse Tone Volume Control

1. When a valid pulse is acquired, press the Adjust Up button and verify

Performance Verification

that the sound level of the beeping pulse tone increases.

2. Press the

Adjust Down button and verify that the beeping pulse tone

decreases until it is no longer audible.

3. Press the

Adjust Up button to return the beep volume to a comfortable

level.

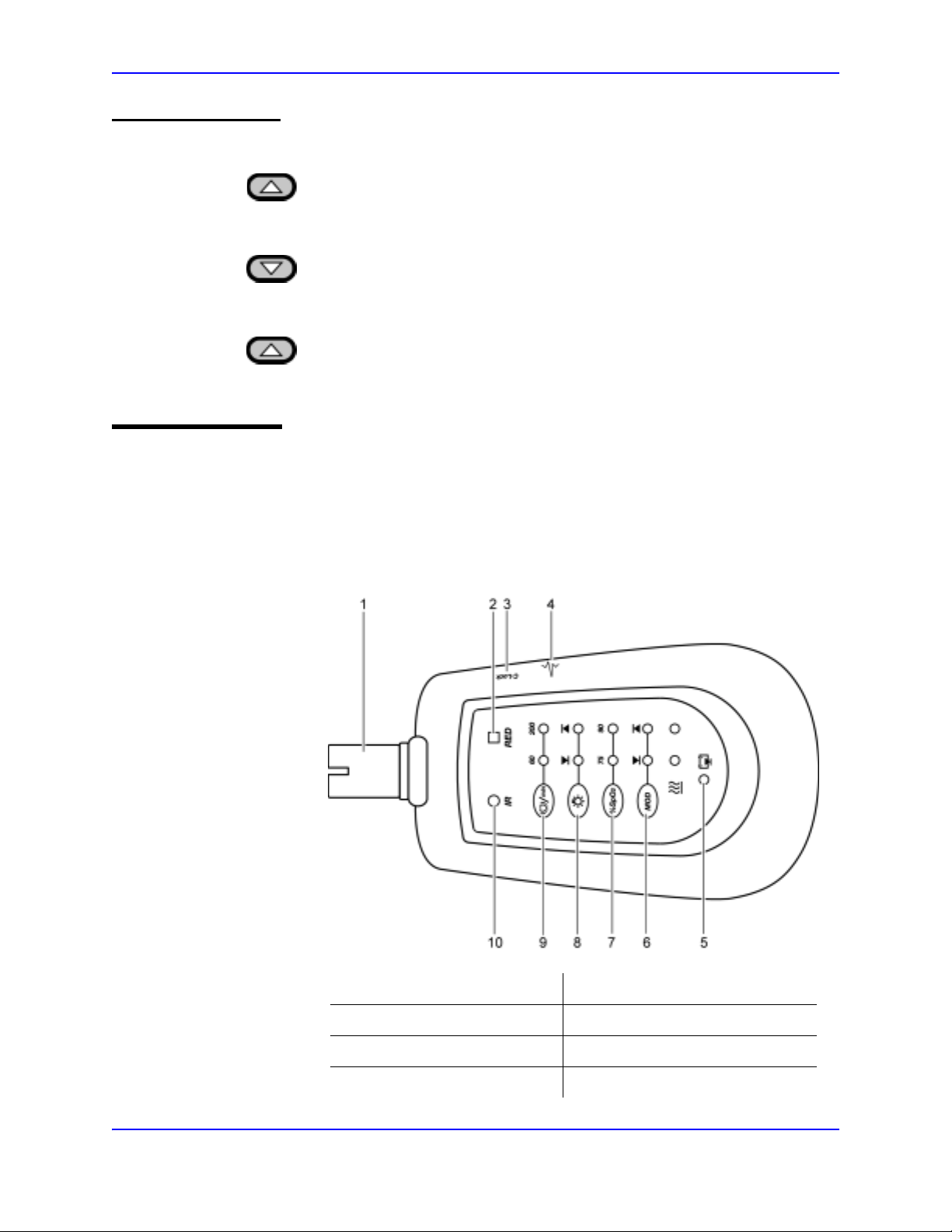

Pulse Oximetry Functional Tests

These tests utilize the pulse oximetry functional tester (SRC-MAX) to verify

the performance of the N-550B pulse oximeter.

All of these tests should be done in sequence.

1 — DOC-10 Cable Connector 6 — % Modulation Select Button

2 — Red LED Drive Indicator 7 — % SpO

3 — Not Used For N-550B 8 — Light Level Selection Button

4 — Not Used For N-550B 9 — Pulse Rate Selection Button

N-550B 19

2 Select Button

Performance Verification

Introduction

5 — Battery Low Indicator 10 — Infrared LED Drive Indicator

The SRC-MAX functional tester allows qualified technicians to functionally

test Nellcor O

XIMAX technology-based pulse oximeters and OEM OXIMAX

technology-based monitors. The technician must perform the test setup

procedure before performing tests 1 through 4. The following is a brief

description of each test:

• Test Setup — This procedure establishes the baseline for all the other

tests. The T est Setup procedure must be performed before performing

any or all of the SRC-MAX tests.

Initial Setup

• Test #1: BPM — This procedure simulates an O

XIMAX sensor

attached to a patient indicating 60 bpm and 200 bpm. The test setup

procedure sets up Test 1 for 60 bpm.

• Test #2: SpO

2 — This procedure simulates an OXIMAX sensor

attached to a patient, indicating 75 percent blood oxygen saturation

and 90 percent blood oxygen saturation. The test setup procedure sets

up Test 2 for 75 percent blood oxygen saturation.

• Test #3: Modulation — This procedure simulates an O

XIMAX sensor

attached to a patient indicating low and high pulse strength. The test

setup procedure sets up Test 3 for low pulse strength.

• Test #4: Light — This procedure simulates an O

XIMAX sensor

attached to a patient indicating low and high light level passing

through the patient at the sensor site. The test setup procedure sets up

Test 4 for low light level.

20

1. Sensor Port

Loading...

Loading...