Nellcor N-5500 Service manual

Patient Monitor

Service Manual

SERVICE MANUAL

For N5500 Patient Monitor

Tyco Healthcare

15 Hampshire Street Mansfield, MA02048, U.S.A.

Tyco Healthcare EMEA (Europe, Middle East and Africa)

Tyco Healthcare UK Ltd. 154 Fareham Road, Gosport PO13 OAS, U.K.

EU Representative

Tyco Healthcare UK Ltd. 154 Fareham Road, Gosport PO13 OAS, U.K.

Tel: (44) 1 329 224 114 Fax: (44) 1 329 224 390

Manufactured for Tyco Healthcare Mansfield, MA 02048, U.S.A.

Manufactured by Mediana Co.,Ltd. 231-6 Nonhyun-Dong, Kangnam-Ku, Seoul, Korea

Copyright © 2003 Tyco Healthcare. All rights reserved.

Notice

This document contains proprietary information which is protected by copyright. All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as

allowed under the copyright laws.

Warranty

The information contained in this document is subject to change without notice.

Tyco Healthcare makes no warranty of any kind with regard to this material, inclu ding, but not limited

to, the implied warranties or merchantability and fitness for a particular purpose.

Tyco Healthcare shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performa nce, or use of this material.

Revision/Printing History

The documentation printing date and part number indicate its current edition. The printing date changes

when a new edition is printed in accordance with the revision history of the documentation. Minor

corrections and updates which are incorporated at reprint do not cause the date to change. The

document part number changes when extensive technical changes are incorporated.

Contents

Figures

Tables

Introduction & Maintenance

Introduction....................................................................................................................................1

1.1 Manual Overview ................................................................................................................ 3

1.2 Related Documents.............................................................................................................. 3

1.3 Description of the N5500 Patient Monitor ............................................................................. 3

Routine Maintenance ......................................................................................................................7

2.1 Cleaning.............................................................................................................................. 7

2.2 Periodic Safety and Functional Checks .................................................................................. 7

2.3 Functional Checks ............................................................................................................... 8

2.4 Batteries.............................................................................................................................. 8

2.5 Environmental Protection ..................................................................................................... 8

Performance Verification

Performance Verification................................................................................................................9

3.1 Introduction......................................................................................................................... 9

3.2 Equipment Needed............................................................................................................... 9

3.3 Performance Tests...............................................................................................................10

3.4 Safety Tests........................................................................................................................23

Default Settings & Troubleshooting

Service Menu and Factory Default Settings .................................................................................. 29

4.1 Introduction........................................................................................................................29

4.2 Service Menu .....................................................................................................................29

4.3 Demo Mode .......................................................................................................................34

4.4 Factory Default Settings ......................................................................................................34

Troubleshooting............................................................................................................................37

5.1 Introduction........................................................................................................................37

5.2 How to Use This Section .....................................................................................................37

5.3 Who Should Perform Repairs ..............................................................................................37

5.4 Replacement Level Supported .............................................................................................37

5.5 Troubleshooting Guide ........................................................................................................38

Disassembly Guide & Spare Parts

Disassembly Guide ........................................................................................................................45

6.1 General..............................................................................................................................45

6.2 Replacement Level Supported .............................................................................................47

6.3 Prior to Disassembly ...........................................................................................................47

6.4 Fuse Replacement...............................................................................................................47

6.5 Battery Disassembly ...........................................................................................................49

6.6 Monitor Disassembly ..........................................................................................................50

6.7 Front Case Disassembly Procedures.....................................................................................51

6.8 Rear Case Disassembly Procedures......................................................................................56

6.9 Optional Printer Assembly/Disassembly Procedures .............................................................65

N5500 Service Manual i

Contents

Spare Parts ...................................................................................................................................67

7.1 Introduction .......................................................................................................................67

7.2 Obtaining Replacement Parts...............................................................................................67

7.3 Parts List............................................................................................................................67

Packing For Shipment ..................................................................................................................71

8.1 General Instructions ............................................................................................................71

8.2 Returning the N5500...........................................................................................................71

8.3 Repacking In Original Carton ..............................................................................................71

8.4 Repacking In a Different Carton ..........................................................................................72

Technical Information

Specifications ................................................................................................................................ 73

9.1 Display ..............................................................................................................................73

9.2 Controls .............................................................................................................................73

9.3 Alarms ...............................................................................................................................73

9.4 Physical.............................................................................................................................73

9.5 Electrical............................................................................................................................74

9.6 Environmental Conditions ...................................................................................................74

9.7 Measurement Parameters ....................................................................................................75

9.8 Trends................................................................................................................................77

9.9 Compliance........................................................................................................................78

System Processing Description......................................................................................................81

10.1 System Overview..............................................................................................................81

10.2 System Block Diagram......................................................................................................81

10.3 ECG Processing ................................................................................................................87

10.4 NIBP Processing ...............................................................................................................87

10.5 SpO2 Processing ...............................................................................................................89

10.6 Respiration Processing ......................................................................................................91

10.7 Temperature Processing.....................................................................................................92

ii N5500 Service Manual

Contents

Figures

Figure 1. N5500 Front Panel.............................................................................................................................................................4

Figure 2. N5500 Rear Panel..............................................................................................................................................................5

Figure 3. N5500 Right Side Panel .....................................................................................................................................................6

Figure 4. N5500 Left Side Panel........................................................................................................................................................6

Figure 5. The access of Service Menu via Set-up menu...................................................................................................................29

Figure 6. Service Menu....................................................................................................................................................................30

Figure 7. Disassembly Sequence Flow Chart..................................................................................................................................46

Figure 8. N5500 Exploded View ......................................................................................................................................................68

Figure 9. N5500 System Block Diagram 1.......................................................................................................................................81

Figure 10. N5500 System Block Diagram 2.....................................................................................................................................82

Figure 11. N5500 System Block Diagram 3.....................................................................................................................................82

Figure 12. Power Unit Block Diagram............................................................................................................................................83

Figure 13. Process Unit Block Diagram..........................................................................................................................................83

Figure 14. User-Control Unit Block Diagram.................................................................................................................................83

Figure 15. Sound Unit Block Diagram............................................................................................................................................84

Figure 16. Communication Unit Block Diagram.............................................................................................................................84

Figure 17. GUI Unit Block Diagram...............................................................................................................................................84

Figure 18. Thermal Printer Unit Block Diagram............................................................................................................................84

Figure 19. NIBP Unit Block Diagram.............................................................................................................................................85

Figure 20. ECG Unit Block Diagram..............................................................................................................................................85

Figure 21. Respiration Unit Block Diagram....................................................................................................................................85

Figure 22. SpO2 Unit Block Diagram.............................................................................................................................................85

Figure 23. Temperature Unit Block Diagram..................................................................................................................................86

Figure 24. Analog Control Unit Block Diagram.............................................................................................................................86

Figure 25. Oxyhemoglobin Dissociation Curve...............................................................................................................................90

Tables

Table 1. Required Test Equipments ....................................................................................................................................................9

Table 2. Parameter Alarm Limit Factory Defaults ..........................................................................................................................14

Table 3. Earth Leakage Current Values ...........................................................................................................................................24

Table 4. Enclosure Leakage Current................................................................................................................................................24

Table 5. Patient Leakage Current Values .........................................................................................................................................25

Table 6. Patient Leakage Current Values - Mains Voltage on Applied Part ....................................................................................26

Table 7. Test Lead Combinations .....................................................................................................................................................27

Table 8. Allowable Leakage Current................................................................................................................................................27

Table 9. Service menu......................................................................................................................................................................31

Table 10. NIBP Test Mode................................................................................................................................................................33

Table 11. System Information...........................................................................................................................................................33

Table 12. Factory Default Settings for the N5500 ...........................................................................................................................34

Table 13. Problem Categories..........................................................................................................................................................38

Table 14. Power Problems...............................................................................................................................................................39

Table 15. Display.............................................................................................................................................................................40

Table 16. Switches/Knob Problems..................................................................................................................................................41

Table 17. Alarms/Audible Tones Problems......................................................................................................................................41

Table 18. Operational Performance Problems ................................................................................................................................42

Table 19. Technical Error Codes......................................................................................................................................................43

Table 20. N5500 Parts List ...............................................................................................................................................................69

N5500 Service Manual iii

Section 1: Introduction

1.1 Manual Overview

1.2 Related Documents

1.3 Description of the N5500 Patient Monitor

Warnings

Warnings are identified by the WARNING symbol shown above.

Warnings alert the user to potential serious outcomes (death, injury, or adverse

events) to the patient or user.

WARNING: Explosion hazard. Do not use the N5500 in the presence of

flammable anesthetics or gases.

WARNING: Do not spray, pour, or spill any liquid on the N5500, its accessories,

connectors, switches, or openings in the chassis .

Maintenance, N5500

Introduction and

WARNING: Do not immerse the N5500 or its accessories in liquid or clean with

caustic or abrasive cleaners.

WARNING: Ensure that conductive portions of the electrodes, leads, and cable do

not come into contact with any other conductive parts.

WARNING: Before attempting to open or disassemble the N5500, disconnect the

power cord from the N5500

WARNING: The LCD panel contains toxic chemicals. Do not ingest chemicals

from a broken LCD panel.

WARNING: The use of accessories, transducers, and cables other than those

specified may result in increased emission and/or decreased immunity of the

N5500 patient monitor.

WARNING: Do not silence the N5500 audible alarm or decrease its volume if

patient safety could be compromised.

N5500 Service Manual 1

Introduction

Introduction and

Maintenance, N5500

WARNING: During the safety test, AC mains voltage will be present on the

applied part terminals. Exercise caution to avoid electrical shock hazard.

WARNING: Do not place the N5500 into operation after repair or maintenance

has been performed, until all Performance Tests and Safety Tests listed in section

3 of this service manual have been performed. Failure to perform all tests could

result in erroneous monitor readings.

WARNING: High voltage is generated by the LCD backlight driver. Exercise

caution when operating monitor with covers open..

Cautions

Cautions are identified by the Caution symbol shown above.

Cautions alert the user to exercise care necessary for the safe and effective use of

the N5500 monitor.

CAUTION: Observe ESD (electrostatic discharge) precautions when working

within the unit and/or when disassembling and reassembling the N5500 patient

monitor and when handling any of the components of the N5500 patient monitor.

CAUTION: When reassembling the N5500, over-tightening could strip out the

screw holes in the cases, rendering it unusable.

CAUTION: If any problem with N5500 built in an optional printer, check a

printer’s door is closed well. Operating error may be caused if the cover is not

closed correctly.

CAUTION: If internal battery cable has been disconnected, pay particular

attention to polarity of the cable before reattaching. If battery cable polarity is

reversed, it is likely that circuit damage will occur.

CAUTION: Ferrite Cores are used for electromagnetic compatibility. Please do

not remove Ferrite Cores while disassembling or reassembling, otherwise the

monitor can be affected by electromagnetic interference and measure inaccurate

data to be displayed or stored.

CAUTION: When reassembling, never forget that one of four screws on the back

bracket must be connected to green ground cable of the power inlet. This method

is for protecting dormant electrical shock hazards to operator or service engineer.

2 N5500 Service Manual

1.1 Manual Overview

This manual contains information for servicing the N5500 patient monitor .

The monitor subsequently referred to as N5500 throughout this manual. Only qualified

service personnel should service this product. Before servicing the N5500, read the

operator’s manual carefully for a thorough understanding of safe operation.

Read and understand all safety warnings and service notes printed in this service

manual and the operator ’s manual part number MDR05002-A7008.

1.2 Related Documents

To perform test and troubleshooting procedures and to understand the principles of

operation and circuit analysis sections of this manual, you must know how to operate

the monitor. Refer to the N5500 operator’s manual part number MDR05002-A7008.

To understand the various Nellcor sensors, ECG leads, blood pressure cuffs, and

temperature probes that work with the monitor, refer to the individual directions for

use that accompany these accessories.

1.3 Description of the N5500 Patient Monitor

The purpose and function of the Nellcor N5500 patient monitor is to monitor ECG,

heart rate, noninvasive blood pressure (systolic, diastolic, and mean arterial pressures),

functional arterial oxygen saturation, respiration, and temperature for adult, pediatric

and neonate patients in all hospital areas and hospital- type facilities. It may be used

during hospital transport and in mobile, land-based environments, such as ambulances,

within the specification of the environmental characteristics. It is not intended for home

use. Monitor users should be skilled at the level of qualified health care professionals ,

such as a technician, doctor, nurse or medical specialist.

Note: Hospital use typically covers such areas as general care floors, operating rooms,

special procedure areas, intensive and critical care areas, within the hospital plus

hospital-type facilities. Hospital-type facilities include physician office based

facilities, sleep labs, skilled nursing facilities, surgicenters, and sub-acutecenters.

Note: Intra-hospital transport includes transport of a patient within the hospital or

hospital-type facility.

Introduction

Maintenance, N5500

Introduction and

N5500 Service Manual 3

Introduction

The physical and operational characteristics of the monit or are described in the

operator’s manual and in the Specifications section of this manual.

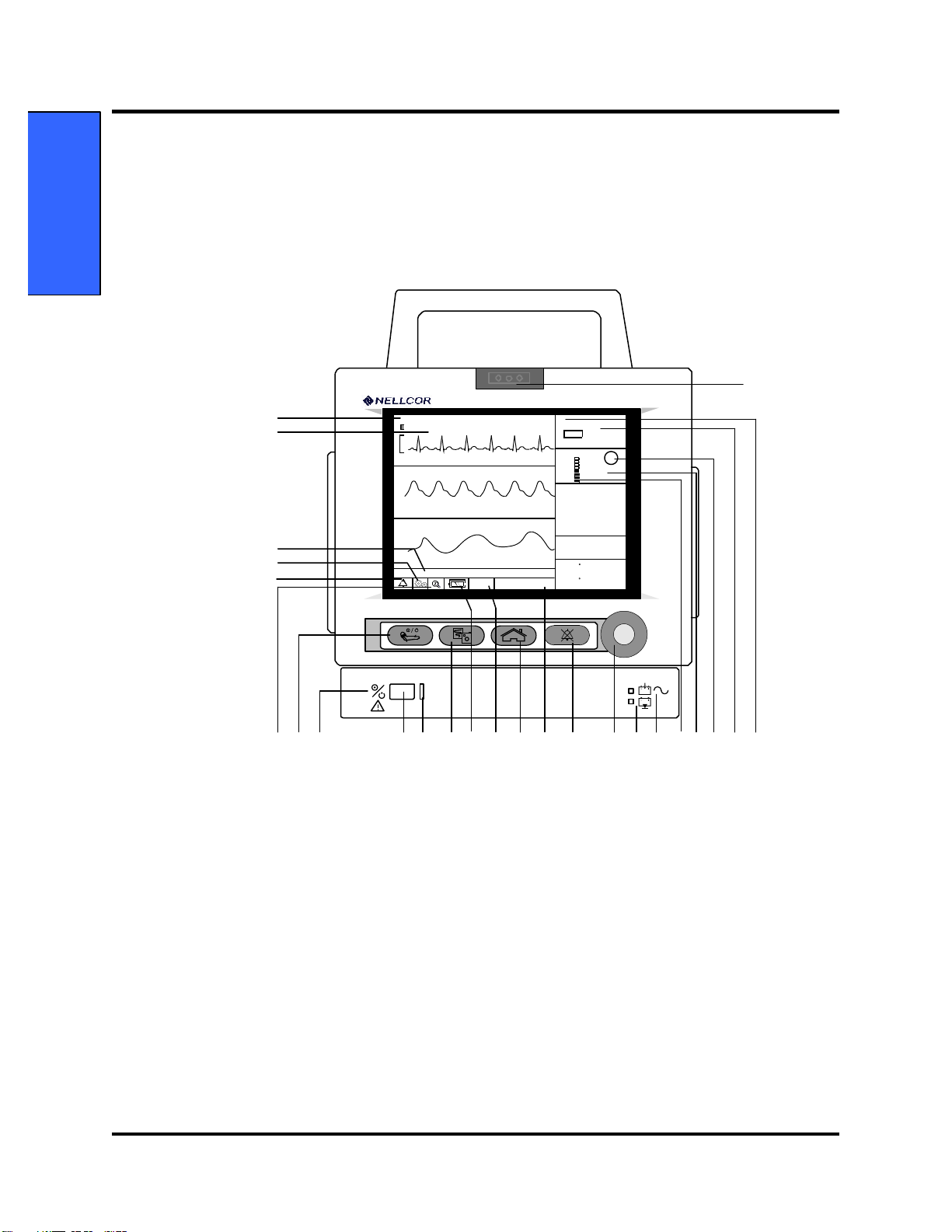

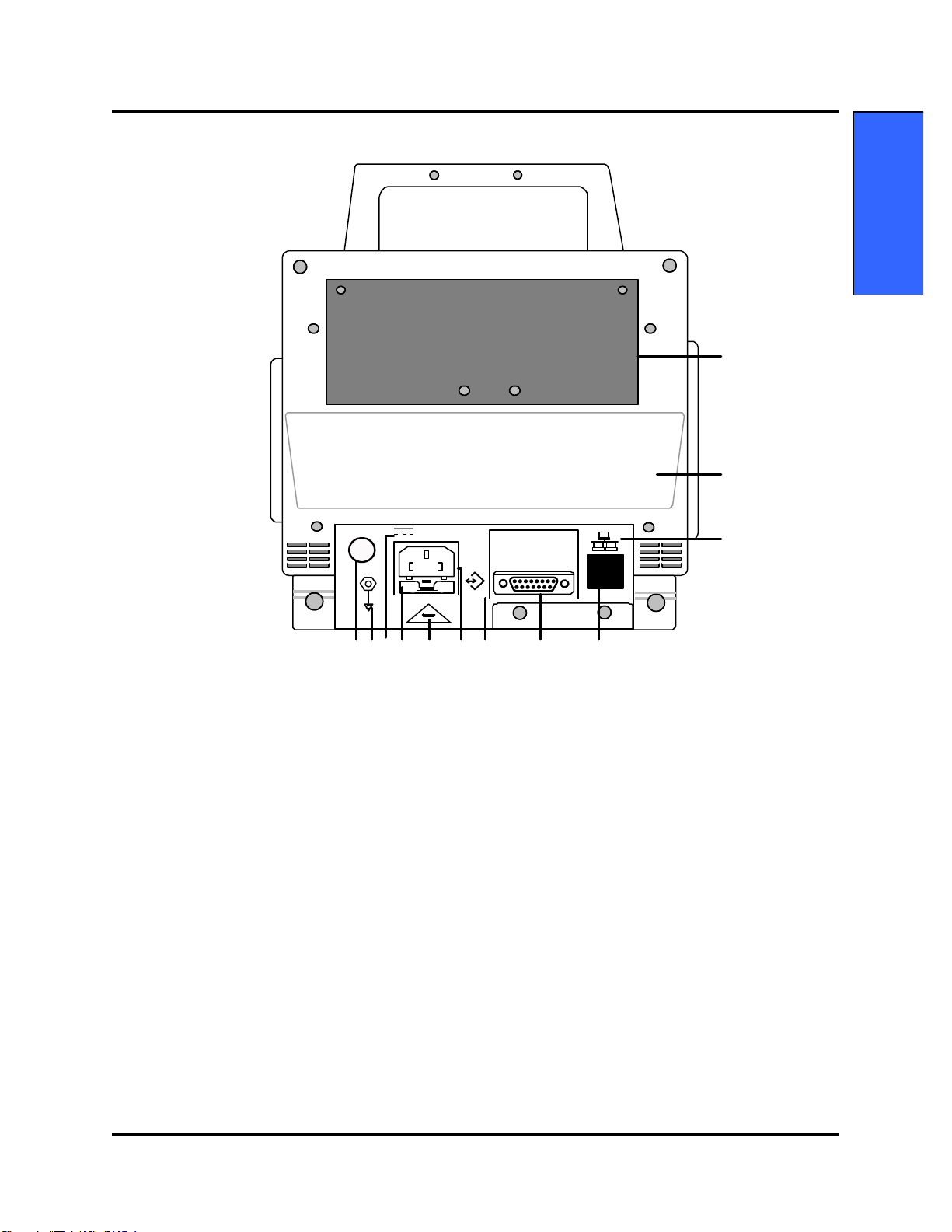

Figure 1 and 2 identify the displays, controls, indicators and symbols of the front and

Introduction and

Maintenance, N5500

rear panels.

25

1

2

3

4

5

6 7

ECG

mV

1mV

1.0

cm

SpO 2

SpO2

Resp

06/12/2002 08:12:23

Adult

8

10 11 12

9

13

HR

/min

ECG

120

120

SpO 2

%SpO 2

100

NIBP

mmHg

140/100

140/100

(120)

(120)

RR

/min

C

T1

37.0

T1

F

T2

T2

14

15 16 17 18 19

24

24

180

180

20

2122

23 24

1. Waveform Display Icon 14. Home Switch

2. Graphic Frame 15. Date and Time Display

3. Message Frame 16. Alarm Silence/Suspend Switch

4. Set-up Icon 17. Knob Switch

5. Alarm/Limits Icon 18. Low Battery Indicator

6. Big Numbers Icon 19. Battery Charging/ AC Power Indicator

7. NIBP Start/Stop Switch 20. Pulse Amplitude Indicator

8. Power On/Off Icon 21. Numeric Value Display

9. Power On/Off Button 22. SatSeconds Indicator

10. Power On/Off Indicator 23. Numeric Frame

11. Record Switch 24. Numeric Display Icon

12. Battery Icon 25. Alarm Indicator

13. Patient Mode Display

Figure 1. N5500 Front Panel

4 N5500 Service Manual

Introduction

Maintenance, N5500

Introduction and

12

11

10~16V 5A

RS232

2 X

T 4.0A 250V

1 2

3 4 5 7 86 9

10

1. External DC Power Connector 7. Data Interface Symbol

2. Equipotential Terminal (Ground) 8. Data Port Connector

3. External DC Power Symbol 9. Network Connector

4. Fuse Holder 10. Network Symbol

5. Fuse Replacement (Fuse Label) 11. Product Label

6. AC Power Connector 12. Heat Sink

Figure 2. N5500 Rear Panel

The N5500 patient monitor has a color liquid crystal display (LCD). The Numeric

frames on the screen contain five numeric values are displayed. The Graphic Frames

contain three equally sized graphic frames in which real-time physiological waveforms,

graphical trend, or tabular trend data are displayed.

Controlling is accomplished by using the knob to interact with the appropriate area or

icon on the screen.

N5500 Service Manual 5

Introduction

Introduction and

Maintenance, N5500

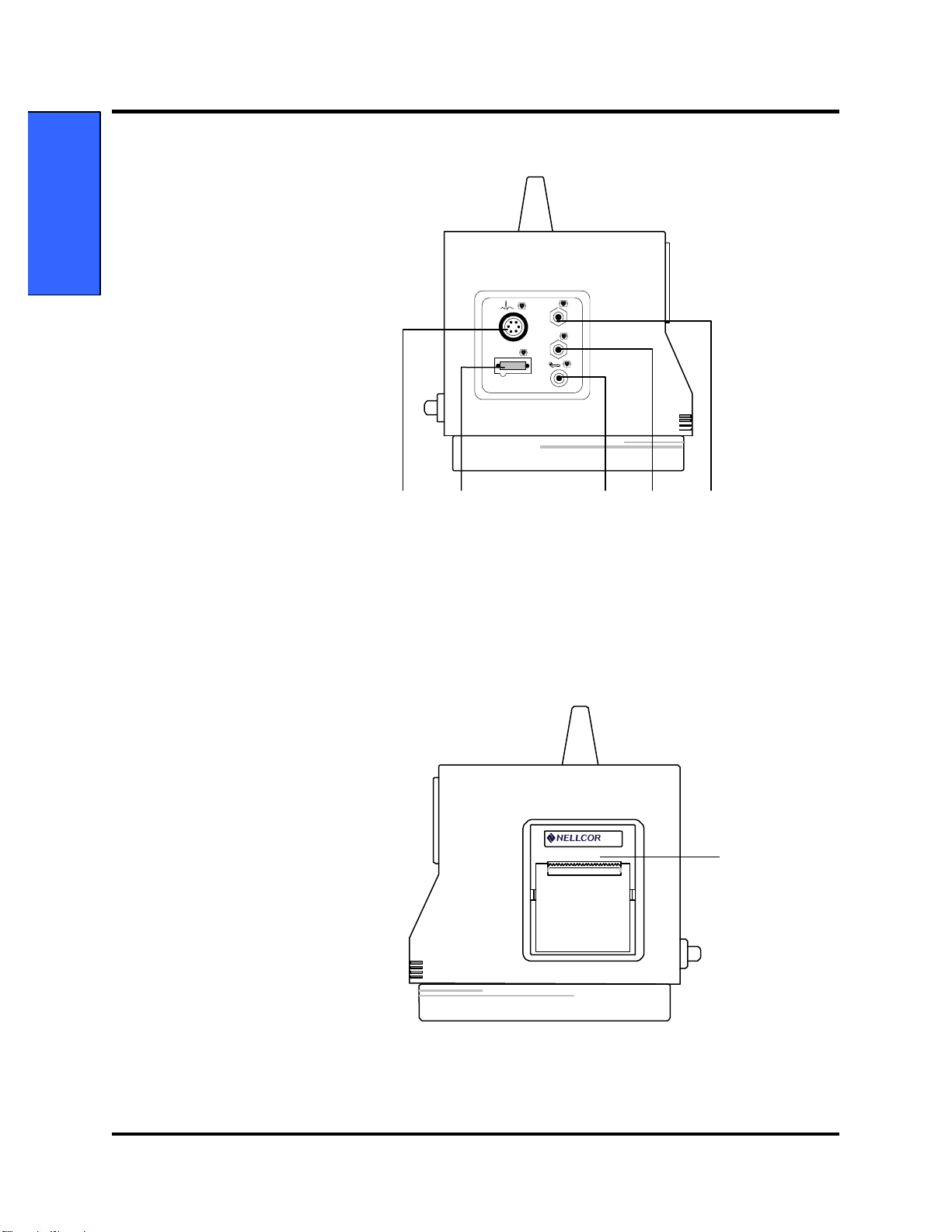

T1

T2

SpO2

1 2 3 4 5

1 ECG/Respiration Connector

2 SpO2 Connector

3 NIBP Connector

4 Temperature Connector (T2)

5 Temperature Connector (T1)

Figure 3. N5500 Right Side Panel

M4014-0

1

1 Optional thermal printer or Printer cover

Figure 4. N5500 Left Side Panel

6 N5500 Service Manual

Section 2: Routine Maintenance

2.1 Cleaning

2.2 Periodic Safety and Functional Checks

2.3 Functional Checks

2.4 Batteries

2.5 Environmental Protection

WARNING: Do not spray or pour any liquid on the monitor or its accessories. Do

not immerse the N5500 or its accessories in liquid or clean with caustic or

abrasive cleaners.

2.1 Cleaning

To clean the N5500, dampen a cloth with a commercial, nonabrasive cleaner and wipe

the exterior surfaces lightly.

CAUTION: Do not allow any liquids to come in contact with the power connector

or switches or to penetrate connectors or openings in the instrument.

Note: For cables, sensors and cuffs, follow the cleaning instructions in the directions

for use that accompany these accessories.

Note: If liquid is spilled on the monitor, clean and dry thoroughly before reuse.

Note: If in doubt about monitor safety, refer the unit to qualified service personnel.

For surface-cleaning, follow your institution’s procedures or:

l The N5500 may be surface-cleaned by using a soft cloth dampened with

either a commercial, nonabrasive cleaner or a solution of 70% alcohol in

water, and lightly wiping the top, bottom, and front surfaces of the monitor

lightly.

2.2 Periodic Safety and Functional Checks

The N5500 requires no routine service or calibration other than cleaning and battery

maintenance. The following performance verification tests may be used following

repair or during routine maintenance (if required by your local institution).

1. Inspect the exterior of the N5500 for damage.

2. Inspect labels for legibility. If the labels are not legible, contact Nellcor Technical

Services Department or your local Nellcor representative.

3. Verify that the unit performs properly as described in Performance Verification

section.

Maintenance, N5500

Introduction and

N5500 Service Manual 7

Routine Maintenance

2.3 Functional Checks

Introduction and

Maintenance, N5500

2.4 Batteries

2.5 Environmental Protection

4. Perform the electrical safety tests detailed in Performance Verification section. If

the unit fails these electrical safety tests, do not attempt to repair. Contact Nellcor

Technical Services Department or your local Nellcor representative.

The following checks should be performed at least every 2 years by a qualified service

technician .

1. If the monitor has been visibly damaged or subjected to mechanical shock (for

example, if dropped), perform the performance tests as described in Performance

Verification section.

2. Perform the electrical safety tests as described in Safety Tests section. If the unit

fails these electrical safety tests, refer to Troubleshooting section.

3. Inspect the fuses for proper value and rating (qty 2, 4.0 A, 250 volts).

If the N5500 has not been used for a long period of time, the battery will need charging.

To charge the battery, connect the N5500 to an AC outlet as described in Paragraph

3.3.1 in this service manual or the Battery Operation section of the operator’s manual.

Nellcor recommends replacing the instrument’s battery every 2 years. When the N5500

is going to be stored for 2 months or more, it is recommended to remove the battery

prior to storage. To replace or remove the battery, refer to Disassembly Guide.

Note: Storing the N5500 for a long period without charging the battery may degrade the

battery capacity. The battery may require a full charge/discharge cycle to restore

normal capacity. Nellcor recommends that the N5500’s sealed, Ni-MH batteries

be replaced at 2-year intervals. Refer to Disassembly Guide Section.

Note: The battery cannot be charged by an external DC power source.

Follow loc al governing ordinances and recycling plans regarding disposal or recycling

batteries and other device components.

8 N5500 Service Manual

Section 3: Performance Verification

3.1 Introduction

3.2 Equipment Needed

3.3 Performance Tests

3.4 Safety Tests

3.1 Introduction

This section discusses the tests used to verify performance following repairs or during

routine maintenance. All tests can be performed without removing the N5500 covers.

All tests except the battery charge and battery performance tests must be performed as

the last operation before the monitor is returned to the user.

If the N5500 fails to perform as specified in any test, repairs must be made to correct

the problem before the monitor is returned to the user.

3.2 Equipment Needed

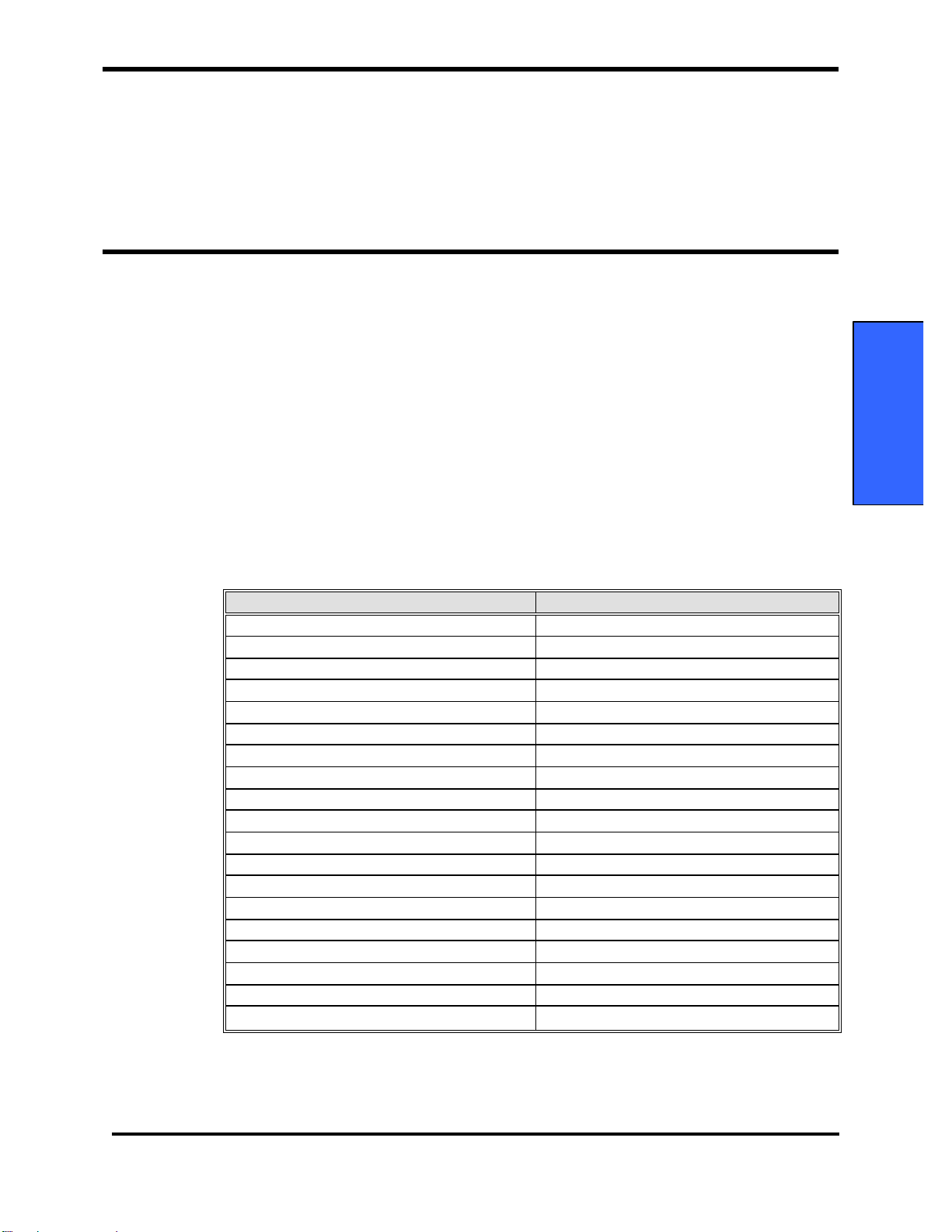

Table 1 lists the equipment required for performance verification.

Table 1. Required Test Equipments

Equipment Description

Digital multimeter (DMM) Fluke Model 87 or equivalent

ECG cable for 3-leadwires MDEC No.2

ECG cable for 5-leadwires (optional) MDEC No.4

ECG leads MDEL series (MDEL-3S, MDEL-3G)

ECG leads (optional) MDEL series (MDEL-5S, MDEL-5G)

NIBP hose Colin Hose No.1EM/No.3EM

NIBP cuff Colin Cuff series

Pulse oximetry cable DOC-10

OXIMAX Durasensor® oxygen transducer DS-100A

OXIMAX oxygen transducer MAX-A

Temperature probes Monotherm ™

SpO2 simulator Nellcor SRC-MAX simulator

ECG simulator METRON PS-420 or equivalent

NIBP simulator Bio-Tek “BP Pump 2” or equivalent

Respiration simulator METRON PS-420 or equivalent

Temperature simulator medSim 300 or equivalent

Safety analyzer METRON QA-90 or equivalent

Data interface cable RS-232 cable

Stopwatch Manual or electronic

Verification, N5500

Performance

N5500 Service Manual 9

Performance Verification

3.3 Performance Tests

3.3.1 Battery Charge

Performance

Verification, N5500

3.3.2 Battery Performanc e Test

The battery charge and battery performance test should be performed before monitor

repairs whenever the battery is suspected as being a source of the problems. All other

tests may be used following repairs or during routine maintenance (if required by your

local institution). Before performing the battery performance test, ensure that the battery

is fully charged. This section is written using Nellcor factory-set power-up defaults. If

your institution has preconfigured custom defaults, those values will be displayed.

1. Connect monitor to AC power source using proper power cord.

2. Verify AC Power indicator is lit.

3. Charge battery fully for at least 18 hours.

4. The only way to check for a full charge is to perform the procedure in paragraph

3.3.2 “Battery Performance Test.”

Note: The battery may require a complete charge/discharge cycle to restore its normal

capacity, depending on its previous usage.

1. The N5500 monitor is specified to typically operate on battery power a minimum of

1 hour, at 25°C, with no printing, and one NIBP measurement every 5 minutes.

Before performing this test, ensure that the battery is fully charged (paragraph 3.3.1).

2. Ensure monitor is not connected to AC power.

3. With N5500 turned off, press Power On/Off switch and verify battery icon appears at

bottom of display after power-on self -test is completed. Boxes in battery icon should

all be filled, indicating battery is charged.

4. Connect Nellcor SRC-MAX SpO 2 simulator to monitor via DOC-10 sensor cable.

5. Connect NIBP simulator to monitor via Colin -NO.EM hose.

6. Set SRC-MAX as follows: SpO2 of 75% and pulse rate of 60 bpm.

7. Set NIBP simulator to simulate pressure setting of 120/80 mmHg and heart rate of 80

bpm.

8. Verify monitor is responding to SpO 2 simulator signal and audible alarm is sounding.

Use knob to select SpO 2 Menu and silence SpO2 audible alarm (SpO2 alarm suspend

condition).

10 N5500 Service Manual

9. Use knob to select NIBP Menu and set Automatic Mode Interval to 5 minutes. Initial

NIBP measurement will be automatically taken in 5 minutes, then subsequent NIBP

measurements will be taken for 5 minutes, Automatic Mode Interval (from one

measurement completes to the next measurement starts).

10. N5500 monitor must operate for 1 hour with a full-charged battery. N5500 monitor

must operate for at least 5 minutes before monitor automatically powers down due to

low battery condition.

11. Verify low battery alarm occurs and the low battery indicator is lit about 5 minutes

before battery fully discharges.

12. Allow monitor to operate until it automatically powers down due to low battery

condition. Verify high priority alarm occurs 15 seconds before monitor automatically

shuts down.

13. If monitor passes this test, immediately recharge battery (3.3.1 Battery Charge ).

3.3.3 Power-On Self-Test

1. Connect monitor to AC power source and verify AC Power indicator is lit.

2. Observe monitor front panel. With monitor off, press Power On/Off switch. Monitor

must perform the following sequence.

a. Monitor emits three consecutively higher pitched beeps.

b. Nellcor logo appears for a few seconds, with version numbers of the software

displayed in lower left corner of display.

c. Alarm Indicator (red) on the top of the front panel, AC power indicator

(green) and Low battery indicator (green) on the right bottom of the front

panel are illuminated.

d. Upon successful completion of power-on self-test, display will be in normal

monitoring screen configuration.

Note: Power-on self -test takes approximately 3 seconds to complete.

Note: No vital signs numeric values or waveforms will be displayed.

3.3.4 General Operation Tests

3.3.4.1 Alarms and Alarm Silence

1. Press monitor Power On/Off switch to turn monitor on.

2. Connect SRC-MAX SpO2 simulator to sensor input cable and connect cable to

monitor.

3. Set SRC-MAX as follows: SpO2 of 75% and pulse rate of 60 bpm.

Performance Verification

Verification, N5500

Performance

N5500 Service Manual 11

Performance Verification

Performance

Verification, N5500

3.3.4.2 QRS Volume Control

4. Verify following monitor reaction:

a. Pulse bar begins to track artificial pulse signal from SRC-MAX.

b. After about 10 to 20 seconds, monitor displays saturation and pulse rate as

specified by simulator. Verify values are within following tolerances:

l Tolerance of Oxygen Saturation : ±2 % SpO 2

l Tolerance of Pulse Rate : ±3 bpm

c. Audible alarm sounds and “Low SpO2 limits violated” message will be

displayed and % SpO2 numeric area will flash, indicating the parameter ha s

violated default alarm limits.

5. Press Alarm silence/suspend switch on monitor front panel. Audible alarm is

temporarily silenced.

6. Verify the following:

a. An audible alarm remains silenced.

b. Alarm silence icon appears in each numeric frame on display.

c. %SpO2 display continue s flashing.

d. Audible alarm returns in approximately 60 seconds.

1. Press monitor Power On/Off switch to turn monitor on.

2. Connect SRC-MAX SpO2 simulator to sensor input cable and connect cable to

monitor.

3. Set SRC-MAX as follows: SpO 2 of 75% and pulse rate of 60 bpm.

4. Verify SpO 2 and pulse rate values are correctly displayed.

5. Press Alarm silence/suspend switch on front panel of the monitor to temporarily

silence audible alarm.

6. Verify heart rate tone source, found in ECG Menu, is set to “SpO 2”.

7. Select Setup icon on the screen to display Set-up menu.

8. Rotate knob to highlight QRS volume on Set-up menu and press knob to adjust QRS

volume.

9. Set QRS volume 1 to 7 and return to the monitoring screen. Verify beeping pulse

rate tone increases.

10. Set QRS volume 7 to 1 and return to the monitoring screen. Verify beeping pulse

rate tone decreases.

12 N5500 Service Manual

11. Set QRS volume to Off and return to the monitoring screen. Verify beeping pulse

rate tone is no longer audible.

12. Return QRS volume to a comfortable level.

3.3.4.3 LED Excitation Test

This procedure uses normal system components to test circuit operation. A Nellcor

OXIMAX oxygen transducer, model MAX-A, is used to examine LED intensity control.

The red LED is used to verify intensity modulation caused by the LED intensity control

circuit.

1. Connect the monitor to an AC power source.

2. Press the Power On/Off switch to turn the monitor on.

3. Connect DOC-10 pulse oximetry cable to the monitor.

4. Connect a MAX-A sensor to the pulse oximetry cable.

5. Leave the sensor open with the LEDs and photo detector visible.

6. After monitor completes its normal power-up sequence, verify that the sensor LED is

brightly lit.

7. Slowly move sensor LED in proximity of photodetector element of the sensor (close

the sensor slowly). Verify; as LED approaches the optical sensor, that the LED

intensity decreases.

8. Open the sensor and notice that the LED intensity increases.

9. Repeat step 7 and intensity will again decrease. This variation is an indication that

the microprocessor is in proper control of LED intensity.

10. Press the Power On/Off switch to turn the N5500 monitor off.

Performance Verification

Verification, N5500

Performance

N5500 Service Manual 13

Performance Verification

3.3.4.4 Restoring Power-On Default Settings

Performance

Verification, N5500

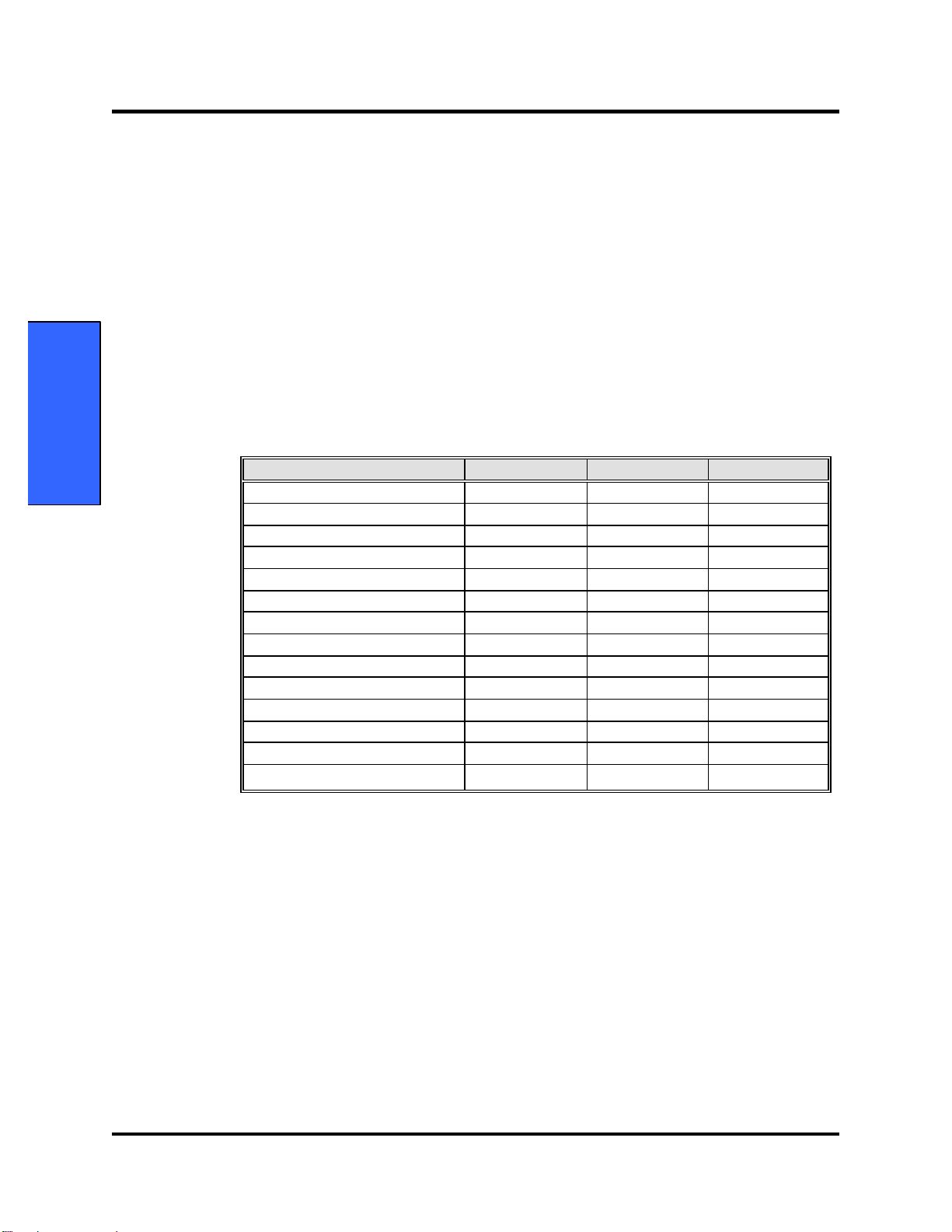

The following test procedures will verify that alarms are activated at the level of factory

default alarm limits and that any changed settings are saved and in effect when the user

changes alarm limit settings and saves the current settings as a power default .

1.Turn the monitor on at the factory default settings.

2.Select Alarm/limits icon to display Alarm/limits menu. Alarm/limits menu appears.

3.Verify alarm limits are set to as shown in Table 2.

4.Change Patient mode Adult to Pediatric/Neonatal, then verify alarm limits are set to as

shown in Table 2.

Table 2. Parameter Alarm Limit Factory Defaults

Factory Defaults Adult Pediatric Neonatal

Heart Rate Alarm Upper Limits 120 BPM 160 BPM 200 BPM

Heart Rate Alarm Lower Limits 50 BPM 75 BPM 100 BPM

NIBP SYS Alarm Upper Limits 160 mmHg 120 mmHg 90 mmHg

NIBP SYS Alarm Lower Limits 90 mmHg 70 mmHg 40 mmHg

NIBP DIA Alarm Upper Limits 90 mmHg 70 mmHg 60 mmHg

NIBP DIA Alarm Lower Limits 50 mmHg 40 mmHg 20 mmHg

NIBP MAP Alarm Upper Limits 110 mmHg 90 mmHg 70 mmHg

NIBP MAP Alarm Lower Limits 60 mmHg 50 mmHg 30 mmHg

%SpO2 Alarm Upper Limits 100 % 100 % 95 %

%SpO2 Alarm Lower Limits 90 % 90 % 80 %

RR Alarm Upper Limits 30 BPM 30 BPM 100 BPM

RR Alarm Lower Limits 8 BPM 8 BPM 30 BPM

T1/T2 Alarm Upper Limits 39.0ºC (102.2ºF) 39.0ºC (102.2ºF) 39.0ºC (102.2ºF)

T1/T2 Alarm Lower Limits 36.0ºC (96.8ºF) 36.0ºC (96.8ºF) 36.0ºC (96.8ºF)

5.Change alarm limit value via Alarm/limits menu.

6.Save the current changed alarm limit values as a power on default setting via Service

menu (see Service Menu and Factory Defaults section). Turn off the monitor.

7.Press Power On/Off switch to turn on the monitor.

8.Verify alarm limits are set to the current changed alarm limit values.

14 N5500 Service Manual

3.3.4.5 Printer Testing (Option)

If an optional printer is installe d in the N5500 monitor, the following test procedures

will verify the printer performance.

1. Turn the monitor on.

2. Connect all the necessary parameter simulator to the monitor.

3. Select Set-up icon to display Set-up menu. Set-up menu appears.

4. Test #1: One -shot printing

i. Set Print mode to One-shot.

ii. Press Record switch when all the parameter signals display normally.

iii. Verify the parameter values and waveforms are printed out for 20 seconds.

5. Test #2: Continuous printing

i. Set Print mode to Continuous.

ii. Press Record switch when all the parameter signals display normally.

iii. Verify the parameter values and waveforms are printed out continuously.

iv. Verify printing stops with pressing Record switch again.

6. Test #3: Print speed

i. Set Print speed to 25 mm/s.

ii. Press Record switch when all the parameter signals display normally.

iii. Verify the parameter values and waveforms are printed out with 25 mm/s.

iv. Verify printing stops with pressing Record switch again.

v. Set Print speed to 50 mm/s.

vi. Press Record switch when all the parameter signals display normally.

vii. Verify the parameter values and waveforms are printed out with 50 mm/s.

viii. Verify printing stops with pressing Record switch again.

7. Test #4: Print-on-alarm

i. Select Alarm/limits icon to display alarm/limits menu. Alarm/limits menu

appears.

ii. Set Print-on-alarm to ON in the Alarm/limits menu.

iii. Set Hear rate of ECG simulator to 30 bpm.

iv. Verify Heart rate low limits violated alarm is activated and the parameter

values and waveforms are printed out.

Note: If no printer is installed in the N5500 monitor, Print mode and Print speed will

not display in the Set-up menu.

Note: If there is no printer paper left or printer paper places improperly, the monitor

will display an error message and activate low priority alarm.

Note: If an optional printer connection is improper, the monitor will display an error

message and activate low priority alarm.

Performance Verification

Verification, N5500

Performance

N5500 Service Manual 15

Performance Verification

3.3.4.6 Serial Interface Test

Performance

Verification, N5 500

3.3.4.7 Network Test

Perform the following procedure to test the serial port. The serial connector is Dsub-15,

located on the monitor’s rear panel, identified with the data interface symbol (RS-232).

1.Connect a serial cable between the N5500 monitor and PC COM1.

2.Run “DSUB15 Test.exe ” on PC.

3.Set “BAUDRATE” to cbr57600.

4.Set “HEX” to Hex.

5.Press the OPEN button.

6.Turn the N5500 monitor on, then enter the service code, 916, in order. The monitor is

now set up to “Central Monitoring System (CMS)” mode.

7.Verify that first two transferred numbers are 55 and 01.

8.Press the CLOSE button to exit the program.

9.Enter the service code, 900, in order to exit CMS mode.

Perform the following procedure to test the Network. The Network connector is located

on the monitor’s rear panel, identified with the Network symbol.

1. Connect a network line to the N5500 monitor, then turn the N5500 monitor on.

2. Run “RJ45 Test.exe ” on PC connected the network line using the same gateway as

the N5500.

3. Press the PROBE button.

4. Verify that the number of N5500 connections to PC found is correct.

5. Press the EXIT button to close “RJ45 Test.exe ”.

CAUTION: Do not change any other settings of the test programs while performing

the serial test and the Network test.

16 N5500 Service Manual

3.3.5 Measurement Parameter Operation Tests

3.3.5.1 ECG Operation with an ECG Simulator

1. Press Power On/Off switch to turn monitor on.

2. Connect ECG leads to appropriate jacks on ECG simulator.

3. Connect leads to MDEC ECG cable.

4. Connect MDEC to ECG input port on N5500.

5. Set ECG simulator as follows:

l Heart rate: 30 bpm

l Amplitude: 1 millivolt

l Lead select: II

l Normal sinus rhythm

l Adult mode

6. After normal power-up sequence, verify the following monitor reactions:

a. After about 15 seconds , monitor displays a heart rate of 30 ±3 bpm.

b. Verify audible alarm will sound, “Low heart rate limits violated” message will

display and heart rate display will flash, indicating heart rate is below default

low alarm limit (medium priority alarm).

7. Increase heart rate setting on ECG simulator to 240 bpm.

a. After about 15 seconds , verify monitor displays heart rate of 240 ±3 bpm.

b. Verify audible alarm will sound, “High heart rate limits violated” message will

display and heart rate display will flash, indicating heart rate is above default

high alarm limit (medium priority alarm).

8. Decrease heart rate setting on ECG simulator to 120 bpm.

a. After about 15 seconds , verify monitor displays heart rate of 120 ±3 bpm.

9. Disconnect LL lead from ECG simulator.

a. Verify “ECG Leads Off” alarm message appears, three dashes are displayed in

HR(heart rate) display, and low priority audible alarm sounds.

b. Reconnect LL lead to ECG simulator. Verify “ECG Leads Off” alarm message

no longer appears and audible alarm is silenced.

c. Repeat this test for LA and RA leads.

Performance Verification

Verification, N5500

Performance

N5500 Service Manual 17

Performance Verification

Performance

Verification, N5500

3.3.5.2 Pneumatic System Operation with NIBP simulator

10. Connect all the leads to the monitor.

a. Select ECG menu and set ECG Lead selection to Lead I.

b. Verify the lead selection.

c. Repeat step 10-a for all the ECG Lead selections.

11. Set ECG Lead selection to Lead II.

12. Change ECG waveform size to all the selectable sizes and verify an appropriate size

of the waveform displays

13. Disconnect 3 ECG leads and connect 5 ECG leads.

14. Set ECG cable type to “5 Leads ” via Set-up Menu.

15. Repeat step 9 to 12.

16. Turn the monitor off.

Note: The accuracy of N5500 ECG measurements is ±3 bpm. In the procedure, add the

tolerance of the simulator to the acceptable range of readings.

These tests verify the functionality of the N5500 pneumatic system. The Bio-Tek

simulator or any equivalent NIBP simulator is required to perform these tests. Each of

the tests must be performed to verify pneumatic system functionality.

The N5500 must be placed in NIBP Test Mode. For a detailed explanation of the NIBP

Test Mode, refer to Service Menu and Factory Default Settings section.

Note: Before accessing the NIBP Test mode, ensure that current patient mode is proper

for the Pneumatic system to be test. You can set Patient mode; Adult/Pediatric or

Neonatal via Set-up menu.

Note: In the NIBP Test Mode, no function switch will have no effect except the knob.

All the tests will start to be performed by pressing or rotating the knob. If you

would like to stop the test during test progressing, press the knob.

1. Turn on Bio -Tek simulator and press “Pressure Test” button to place simulator in test

mode.

2. Connect simulator hose to NIBP connector on N5500.

3. Place N5500 in NIBP Test Mode with NIBP Test screen activ e. (See Table 10)

18 N5500 Service Manual

Performance Verification

3.3.5.2.1 Pressure Sensor Accuracy Test

The pressure sensor accuracy test verifies the pressure accuracy of the N5500 pressure

sensor.

1. Ensure Bio -Tek simulator is in Static pressure test mode.

2. NIBP Test screen is active on N5500 , then select “Pressure Sensor Accuracy Test”

by the knob.

3. Press Select button on simulator until simulator displays “Pressure Source Set Test

Pressure”. Adjust pressure on the simulator for 250, 150, 50 and 0 mmHg.

4. Press Start Pump button on simulator. The simulator will begin to pressurize. Allow

15-20 seconds for pressure to stabilize.

5. The current pressure in mmHg will be displayed on both the simulator and N5500

displays. Ensure N5500 pressure sensor accuracy meets the performance standard of

ANSI/AAMI SP-10:1992+A1:1996 (within the specification by more than ±3 mmHg

or 2 percent of reading, whichever is greater) to successfully complete the test.

3.3.5.2.2 Over Pressure Test

The over-pressure test verifies the functionality of the over-pressure relief system.

1. Ensure Bio -Tek simulator is in Pressure relief test mode.

2. Ensure NIBP Test screen is active on N5500, then select “Over Pressure Test ” by the

knob.

3. Press Start Test button on simulator. The simulator will pressurize the system until

the monitor’s over-pressure relief system activates.

4. Ensure the monitor activates over-pressure relief system at the point of protection

pressure.

Note: The test will have been successfully completed if the simulator displays a

pressure reading, approximately, of 320±10 mmHg in adult/pediatric mode and

160±5 mmHg in neonatal mode. However, the motor’s inflation pressure speed

may cause a slight difference between over-pressure relief values in test and the

specified relief values.

3.3.5.2.3 Air Leakage Test

The air leakage test verifies the integrity of the pneumatic system.

1. Ensure the monitor is set up with Rigid cuff can.

2. Ensure NIBP Test screen is active on N5500, then select “Air Leakage Test” by the

knob.

Verification, N5500

Performance

N5500 Service Manual 19

Performance Verification

Performance

Verification, N5500

3. The N5500 displays pressure of approximately 290 mmHg automatically.

4. The test result displays at the test completion. The initial pressure value at 1 minute

is displayed after the test start and the air leakage value at further 3 minutes after the

1 minute elapsed.

Note: The test will have been successfully completed if the pressure has dropped by 6

mmHg, or less, during the 1-minute period.

3.3.5.2.4 Inflation Time Measurement

The inflation time test verifies the inflation time of the N5500.

1. Ensure the monitor is set up with Rigid cuff can.

2. Ensure NIBP Test screen is active on N5500, then select “Inflation Time

Measurement” by the knob.

3. The N5500 displays pressure of approximately 290 mmHg automatically and

measures inflation time in seconds.

4. The test result displays at the test completion.

Note: The test will have been successfully completed if the inflation time is 4.0 to 7.5

seconds (to 250 mmHg).

3.3.5.2.5 Deflation Rate Measurement

The deflation time test verifies the deflation rate of the N5500.

1. Ensure the monitor is set up with Rigid cuff can.

2. Ensure NIBP Test screen is active on N5500, then select “Deflation Rate Test” by the

knob.

3. The N5500 displays pressure of approximately 290 mmHg automatically, then

measures deflation rate during reducing the pressure.

4. The test result displays 4 parts (from 260-180mmHg, 180-100mmHg, 100-60mmHg

and 60-30 mmHg) at the test completion.

5. Confirm the result is within the specification.

- 260-180mmHg : 4.8 ~ 6.0 mmHg/s

- 180-100mmHg : 4.8 ~ 6.0 mmHg/s

- 100-60mmHg: 3.5 ~ 5.0 mmHg/s

- 60-30 mmHg : 2.8 ~ 4.2 mmHg/s

20 N5500 Service Manual

3.3.5.3 Pulse Oximetry Operation with SpO 2 simulator

1. Connect the monitor to an AC power source.

2. Turn on the monitor by pressing the Power On/Off switch.

3. Connect the DOC-10 pulse oximetry cable after the monitor completes POST.

4. Connect the SRC-MAX simulator to the other end of the DOC-10 cable.

5. The monitor will:

- be in SpO2 alarm

- display an SpO 2 of 75 (Test pass criteria is 73 to 77 % SpO2)

- display a pulse rate of 60 (Test pass criteria is 57 to 63 bpm)

- display low level modulation

6. Test #1: SpO2

i. Press the SRC-MAX % SpO2 selection button. The SRC-MAX % SpO2

90 LED will light.

ii. The monitor will display three dashes until the SRC-MAX stabilizes at

90 % SpO 2. The test pass criteria is 88 to 92 % SpO2.

iii. The monitor will display:

- 90 % SpO 2

- 60 bpm

- no alarm

7. Test #2: Pulse rate (bpm)

i. Press the SRC-MAX PULSE RATE selection button. The SRC-MAX

PULSE RATE 200 LED will light:

ii. The monitor will increase to 200 bpm. The test pass criteria is 197 to 203

BPM.

iii. The monitor will display:

- 90 % SpO 2

- 200 bpm

-alarm: “High heart rate limits violated” message will display and heart

rate display will flash, indicating pulse rate is above default high alarm

limit (medium priority alarm) .

iv. Press the SRC-MAX PULSE RATE selection button. The SRC-MAX

PULSE RATE 60 LED will light.

v. The monitor will decrease to 60 and stabilize at 60 bpm. The test pass

criteria is 57 to 63 bpm.

vi. The monitor will display:

- 90 % SpO 2

- 60 bpm

- no alarm

- low level modulation

Performance Verification

Verification, N5500

Performance

N5500 Service Manual 21

Performance Verification

3.3.5.4 Respiration Operation with a Respiration Simulator

Performance

Verification, N5500

3.3.5.5 Temperature Operation with a Temperature Simulator

8. Test #3: Modulation Level

i. Press the SRC-MAX %MODULATION selection button. The SRC-

MAX %MODULATION LED will light.

ii. The monitor waveform display will spike and stabilizes at a higher

modulation level.

iii. The monitor will display:

- 90 % SpO 2

- 60 bpm

- no alarm

iv. Disconnect all equipments and turn off the monitor.

1. Press Power On/Off switch to turn monitor on.

2. Connect ECG leads to appropriate jacks on respiration simulator.

3. Connect ECG leads to MDEC ECG cable.

4. Connect MDEC to ECG input port on N5500.

5. Set simulator for respiration rate of 120 breaths per minute.

6. After normal power-up sequence, verify the following monitor reactions:

a. Monitor displays respiration rate of 120 ±3 breaths per minute.

b. Audible alarm will sound, “High respiration rate limits violated” message will

display and respiration rate display will flash, indicating respiration rate is

above default high alarm limits. (medium priority alarm)

7. Decrease respiration rate setting on respiration simulator to 20 breaths per minute.

a. Verify monitor displays respiration rate of 20 ±3 breaths per minute.

Note: The accuracy of N5500 ECG measurements is ±3 breaths per minute. In the

procedure below, add the tolerance of the simulator to the acceptable range of

readings.

1. Press Power On/Off switch to turn monitor on.

2. connect temperature probe (supplied with the temperature simulator) to appropriate

connector on temperature simulator.

3. Connect temperature probe to temperature input port on N5500.

22 N5500 Service Manual

4. Set temperature simulator as follows:

l Temperature: 37°C (98. 0°F)

l Probe type: Monotherm™ Temperature Probes (Probe accuracy: ±0.1°C)

5. After normal power-up sequence, verify temperature reads 37°C ±0.1°C (98.6°F

±0.2°F if Fahrenheit is selected as temperature units).

6. Turn monitor off.

Note: The accuracy of N5500 temperature measurements is ±0.1°C (±0.2°F) in the

range of 25°C to 45°C and ±0.2°C in the range of 15° C to less than 25° C as

specified in Specification section. In the procedure above, add the tolerance of

the simulator and the probe to the acceptable range of readings.

3.4 Safety Tests

N5500 safety tests meet the standards of, and are performed in accordance with, IEC

60601-1, Clause 19 (Second Edition, 1988; Amendment 1, 1991-11, Amendment 2,

1995-03), EN60601-1 for instruments classified as Class I and Type CF.

3.4.1 Protective Earth Continuity

This test checks the integrity of the power cord ground wire from the AC plug to the

instrument chassis ground. The current used for this test is less than or equal to 4 Volts

RMS, 50 to 60 Hz, and 25 Amperes.

1. Connect the monitor AC mains plug to the analyzer as recommended by the analyzer

operating instructions.

2. Connect the analyzer resistance input lead to the equipotential terminal (ground lug)

on the rear of the instrument. Verify that the analyzer indicates 100 milliohms or less.

3.4.2 Electrical Leakage

The following tests verify the electrical leakage of the monitor.

3.4.2.1 Earth Leakage Current

This test is in compliance with IEC60601-1 earth l eakage current. The applied voltage

for IEC60601-1 the voltage is 264 Volts AC, 50 to 60 Hz. All measurements shall be

made with the power switch in both “On” and “Off” positions.

1. Connect the monitor AC plug to the electrical safety analyzer as recommended by the

analyzer operating instructions.

2. Perform test as recommended by analyzer operating instructions.

Performance Verification

Verification, N5500

Performance

N5500 Service Manual 23

Loading...

Loading...