Page 1

SERVICE MANUAL

NPB-40

Handheld Pulse Oximeter

Caution: Federal law (U.S.) restricts this device to sale by or on the order of a physician.

To contact Nellcor Puritan Bennett’s representative: In the United States, call 1-800-635-5267 or

925-463-4000; outside of the United States, call your local Nellcor Puritan Bennett representative.

© 2001 Nellcor Puritan Bennett, Inc. All rights reserved. 036048D-0601

0123

Page 2

Nellcor Puritan Bennett Inc.

4280 Hacienda Drive

Pleasanton, CA 94588 USA

Telephone Toll Free 1.800.NELLCOR

Tyco Healthcare UK LTD

Fareham Road

Gosport

PO13 0AS

U.K.

Tel: +44.1329.224000

To obtain information about a warranty, if any, for this product, contact Nellcor

Puritan Bennett Technical Services Department, or your local Nellcor Puritan

Bennett representative.

Notice: Purchase of this instrument confers no express or implied license under any

Nellcor Puritan Bennett patent to use the instrument with any sensor that is not

manufactured or licensed by Nellcor Puritan Bennett.

Oxisensor II is a trademark of Nellcor Puritan Bennett, Inc.

Covered by one or more of the following U.S. Patents and foreign equivalents:

4,621,643; 4,653,498; 4,700,708; 4,770,179; 4,869,254; 4,928,692; 4,934,372; 5,078,136;

5,351,685; 5,368,026; and Re. 35,122.

Page 3

TABLE OF CONTENTS

List of Figures

List of Tables

Section 1: Introduction................................................................................. 1-1

1.1 Manual Overview............................................................................ 1-1

1.2 Equipment Description ................................ ................................ ... 1-1

Section 2: Routine Maintenance ................................................................ 2-1

2.1 Maintenance Overview ................................................................... 2-1

2.2 Battery Maintenance ...................................................................... 2-1

2.3 Cleaning ................................ ................................ ............................ 2-2

Section 3: Performance Verification .......................................................... 3-1

3.1 Performance Verification ................................................................... 3-1

Section 4: Troubleshooting ................................................................ ......... 4-1

4.1 Introduction..................................................................................... 4-1

4.2 Who Should Perform Repairs......................................................... 4-1

4.3 Repair Level Supported.................................................................. 4-1

4.4 How to Use This Section ................................ ................................ 4-1

4.5 Obtaining Replacement Parts ........................................................ 4-1

4.6 Troubleshooting Guide ................................................................... 4-2

Section 5: Disassembly Guide .................................................................... 5-1

5.1 Introduction..................................................................................... 5-1

5.2 System Disassembly and Reassembly .......................................... 5-1

Section 6: Spare Parts.................................................................................. 6-1

6.1 Introduction..................................................................................... 6-1

Section 7: Packing for Shipment................................................................. 7-1

7.1 General Instructions........................................................................ 7-1

7.2 Packing NPB-40 in Original Carton ................................ ................ 7-1

7.3 Packing in a Different Carton ......................................................... 7-1

Section 8: Specifications ................................................................ ............. 8-1

8.1 Performance ................................................................................... 8-1

8.2 Electrical ......................................................................................... 8-2

8.3 Environmental................................................................................. 8-2

8.4 Physical ......................................................................................... 8-3

Technical Supplement.................................................................................. S-1

S1 Introduction..................................................................................... S-1

S2 Pulse Oximetry Principles of Operation .......................................... S-1

S3 Circuit Analysis ............................................................................... S-2

S4 Schematic Diagrams ................................ ................................ ...... S-17

2.2.1 Battery Replacement ......................................................... 2-1

2.2.2 Battery Disposal ................................................................ 2-2

S2.1 Overview ................................................................ ........... S-1

S2.2 Functional Versus Fractional Saturation............................ S-1

S2.3 Measured versus Calculated Saturation............................ S-2

S3.1 Overall Unit Block Diagram Analysis ................................ . S-3

S3.2 CPU PCB Theory of Operation.......................................... S-5

S3.3 LCD PCB Theory of Operation .......................................... S-11

iii

Page 4

Table of Contents

LIST OF FIGURES

1-1 NPB-40 Handheld Pulse Oximeter ................................................ 1-1

1-2 NPB-40 Front Panel....................................................................... 1-2

2-1 NPB-40 Battery Installation ........................................................... 2-2

3-1 NPB-40 Self-Test Front Panel Display ................................ .......... 3-1

3-2 Printer Interface Setup................................................................... 3-3

3-3 Typical Average Data Print Out ..................................................... 3-4

3-4 Typical Data Print Out ................................................................... 3-5

4-1 Typical Error Code Display ............................................................ 4-2

5-1 Opening the NPB-40 Case ............................................................ 5-2

5-2 Top Case Removal ........................................................................ 5-2

5-3 Unlocking CPU PCB Connector J3 ............................................... 5-3

5-4 Separating LCD PCB from CPU PCB............................................ 5-3

6-1 NPB-40 Expanded View ................................................................ 6-2

7-1 Repacking the NPB-40 .................................................................. 7-2

S2-1 Oxyhemoglobin Dissociation Curve .............................................. S-2

S3-1 NPB-40 Block Diagram ................................................................. S-4

S3-2 CPU PCB Block Diagram .............................................................. S-6

S3-3 LCD PCB Block Diagram............................................................... S-12

S4-1 CPU PCB Parts Locator Diagram.................................................. FO-1

S4-2 LCD PCB Parts Locator Diagram .................................................. FO-2

S4-3 CPU PCB Schematic Diagram ...................................................... FO-3

S4-4 LCD PCB Schematic Diagram....................................................... FO-4

S4-5 Front Panel Keypad Schematic Diagram ...................................... FO-5

LIST OF TABLES

4-1 Troubleshooting Guide .................................................................. 4-2

4-2 NPB-40 Error Codes ..................................................................... 4-5

iv

Page 5

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 Equipment Description

1.1 MANUAL OVERVIEW

This manual contains information for servicing the NPB-40 handheld pulse

oximeter. Only qualified service personnel should service this product. Before

servicing the NPB-40, read the operator’s manual carefully for a thorough

understanding of how to operate the NPB-40.

1.2 EQUIPMENT DESCRIPTION

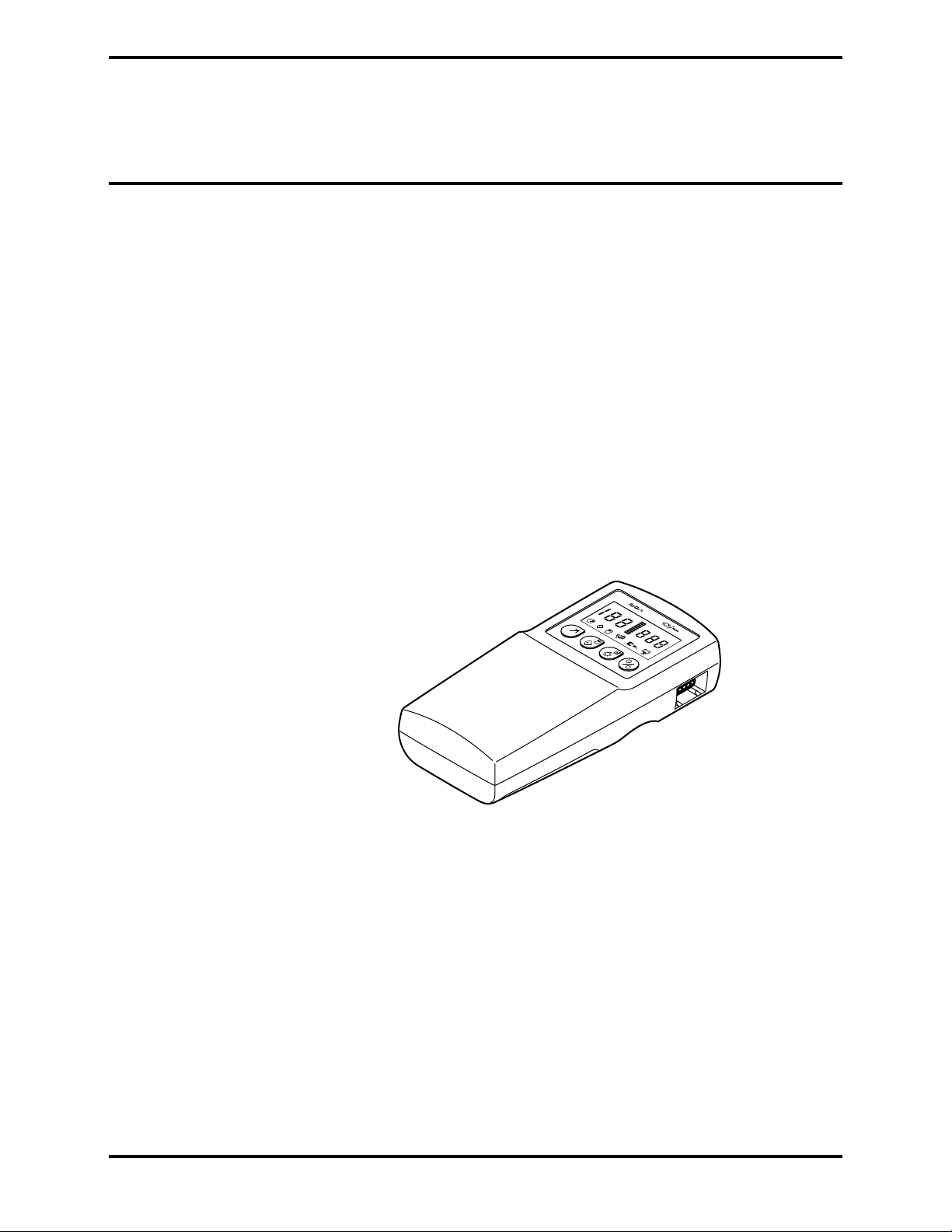

The Nellcor Puritan Bennett NPB-40 handheld pulse oximeter is used for

noninvasive spot-check measurement of functional oxygen saturation of

arterial hemoglobin (SpO2) and pulse rate (measured by the SpO2 sensor).

The NPB-40 is for attended monitoring only, and must be used in the

continuous presence of a qualified healthcare provider. The NPB-40 can be

used on adult, pediatric, and neonatal patients. It can be used in mobile

environments when protected from excessive moisture such as direct rainfall.

The NPB-40 is powered by four “AA” cell alkaline batteries. An external

Hewlett-Packard HP82240B printer can be used with the NPB-40 to printout

readings stored in the NPB-40 memory. This printer is available from Nellcor

Puritan Bennett. The NPB-40 handheld pulse oximeter is illustrated in

Figure 1-1.

Figure 1-1: NPB-40 Handheld Pulse Oximeter

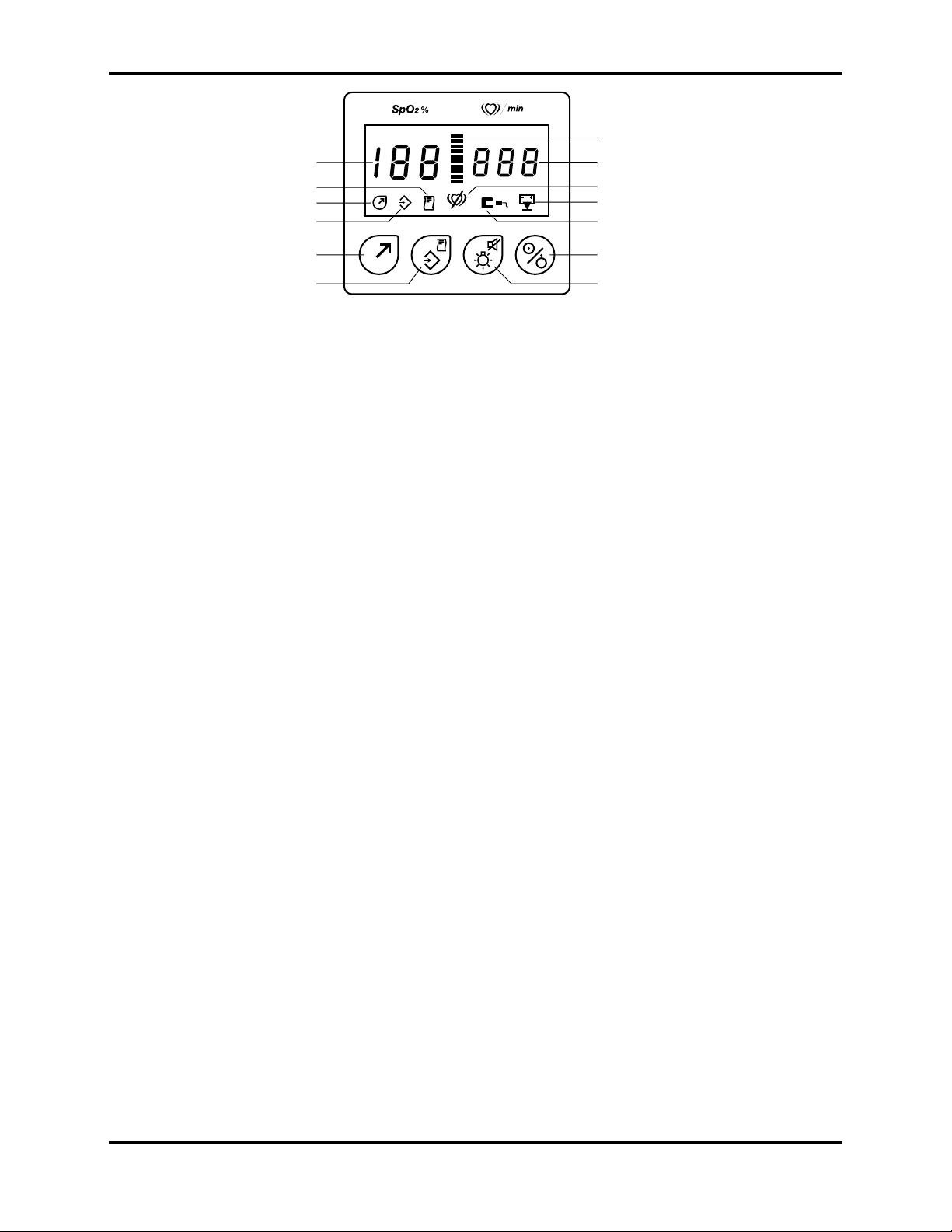

The NPB-40 is operated using a four-key keypad and an LCD display on the

front panel as shown in Figure 1-2. Refer to the NPB-40 operator’s manual

for complete operating instructions.

1-1

Page 6

Section 1: Introduction

13

12

11

10

1

Pulse Amplitude indicator

2

1

2

3

4

5

9

8

6

7

Pulse Rate display

3

Pulse Search display

4

Low Battery indicator

5

Sensor disconnect indicator

6

Power On/Off key

7

Display Light/Beep On/Off key

8

Store Data/Print key

9

Shift key

10

Store Data icon

11

Shift icon

12

Print icon

13

SpO2% display

Figure 1-2: NPB-40 Front Panel

1-2

Page 7

SECTION 2: ROUTINE MAINTENANCE

2.1 Maintenance Overview

2.2 Battery Maintenance

2.3 Cleaning

2.1 MAINTENANCE OVERVIEW

The NPB-40 requires no routine service or calibration. The performance

verification tests in Section 3, Performance Verification, may be used

following repairs or during routine maintenance (if required by your local

institution).

2.2 BATTERY MAINTENANCE

Warning: The NPB-40 uses four “AA” cell alkaline batteries for

operation. If batteries are not replaced when recommended or are

not disposed of properly, serious personal injury or damage to the

NPB-40 could result.

Caution: When inserting the positive end of each battery, exercise

caution to not damage the small coiled spring contact.

Nellcor Puritan Bennett recommends that you comply with the following

guidelines for battery replacement and battery disposal as a minimum.

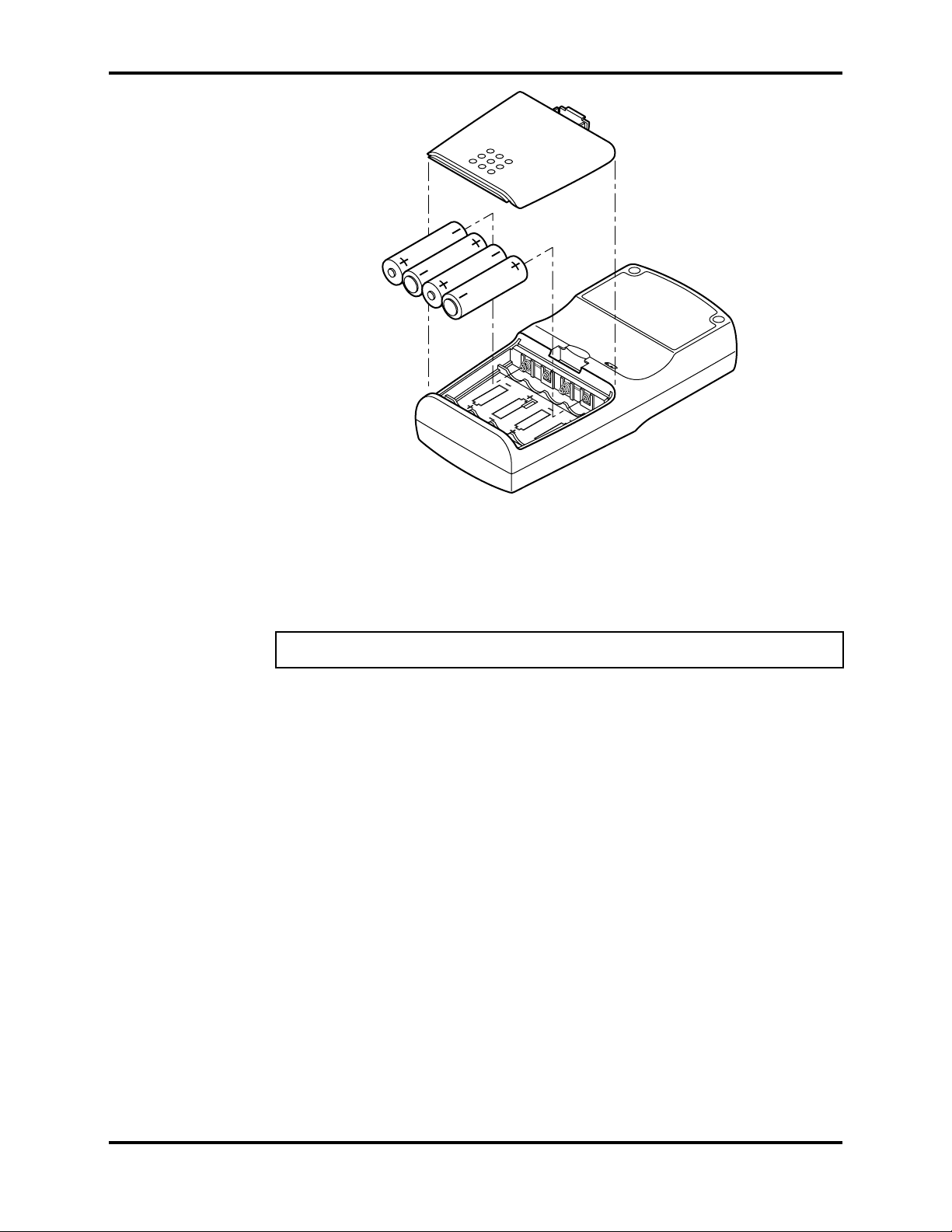

2.2.1 Battery Replacement

Caution: The NPB-40 could be damaged by batteries that are left

unused in the unit and begin to leak. Never store the NPB-40 with

the batteries installed for a prolonged period of time.

NPB-40 batteries should be replaced whenever a low battery indication is

observed on the unit. Remove the batteries if you will be storing the NPB-40

for longer than one month. Refer Figure 2-1 for replacing the batteries.

Note: For easier battery installation, insert the negative end of the battery

first when installing each battery.

2-1

Page 8

Section 2: Routine Maintenance

2.2.2 Battery Disposal

2.3 CLEANING

Figure 2-1: NPB-40 Battery Installation

When NPB-40 batteries have been replaced, dispose of the old batteries.

Always follow local ordinances when disposing of the NPB-40 batteries.

Warning: Never dispose of NPB-40 batteries by burning. The

batteries could explode in fire and cause serious personal injury.

Caution: Do not immerse the NPB-40 or accessories in liquid or use

caustic or abrasive cleaners.

To clean the NPB-40, dampen a soft cloth with a commercial nonabrasive

cleaner and wipe the unit with the cloth.

2-2

Page 9

SECTION 3: PERFORMANCE VERIFICATION

3.1 Performance Verification

3.1 PERFORMANCE VERIFICATION

The performance of the NPB-40 can be verified using the following procedure.

Before performing this procedure, the NPB-40 must have fresh batteries

installed. If any of the required observations cannot be obtained, do not

return the NPB-40 to service before referring to Section 4, Troubleshooting.

You will need an SRC-2 pulse oximeter tester to perform this procedure. If

the performance of the printing function will be verified, you will need an

HP82240B printer.

The NPB-40 is to be turned off and any sensors disconnected before

performing this procedure.

1. Press the On/Off key on the front panel keypad.

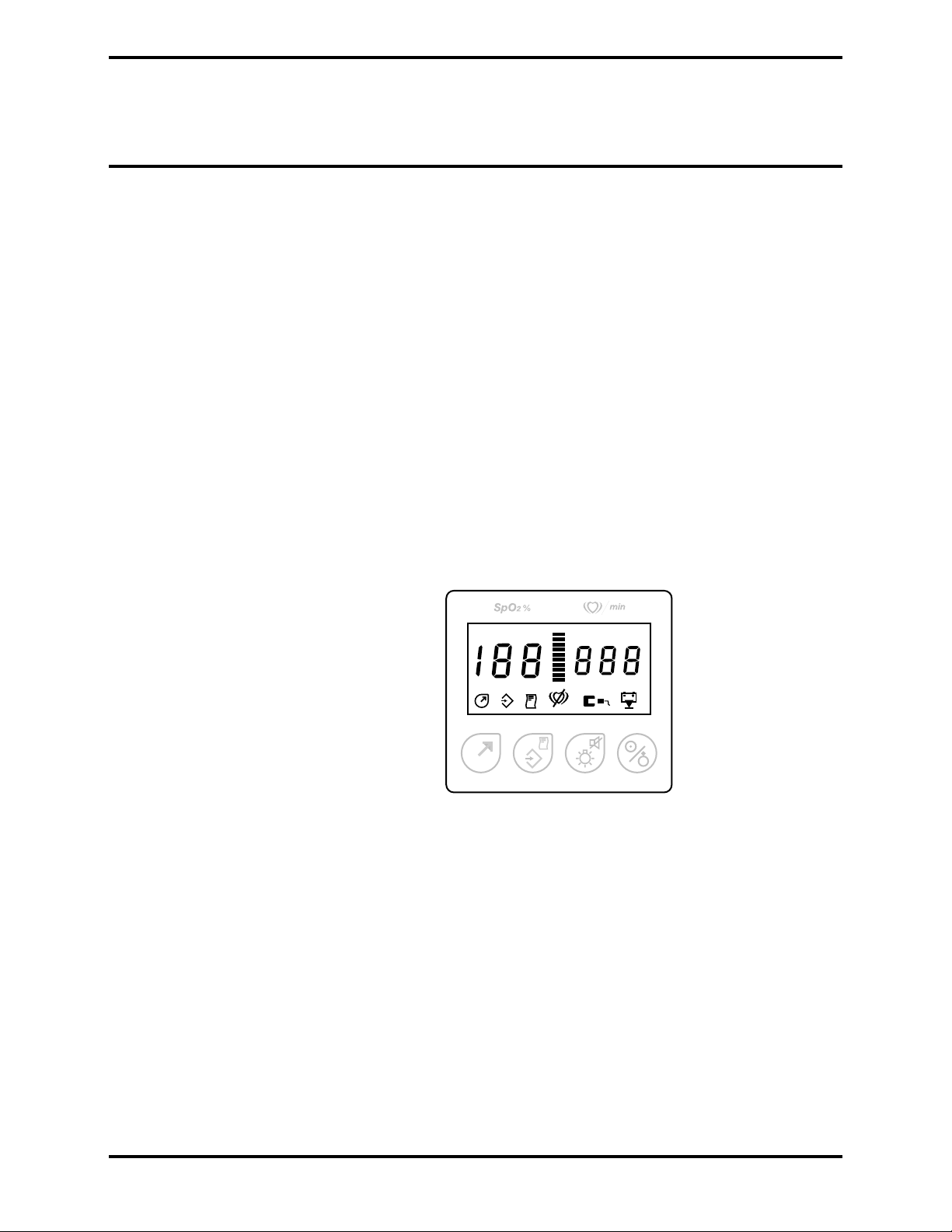

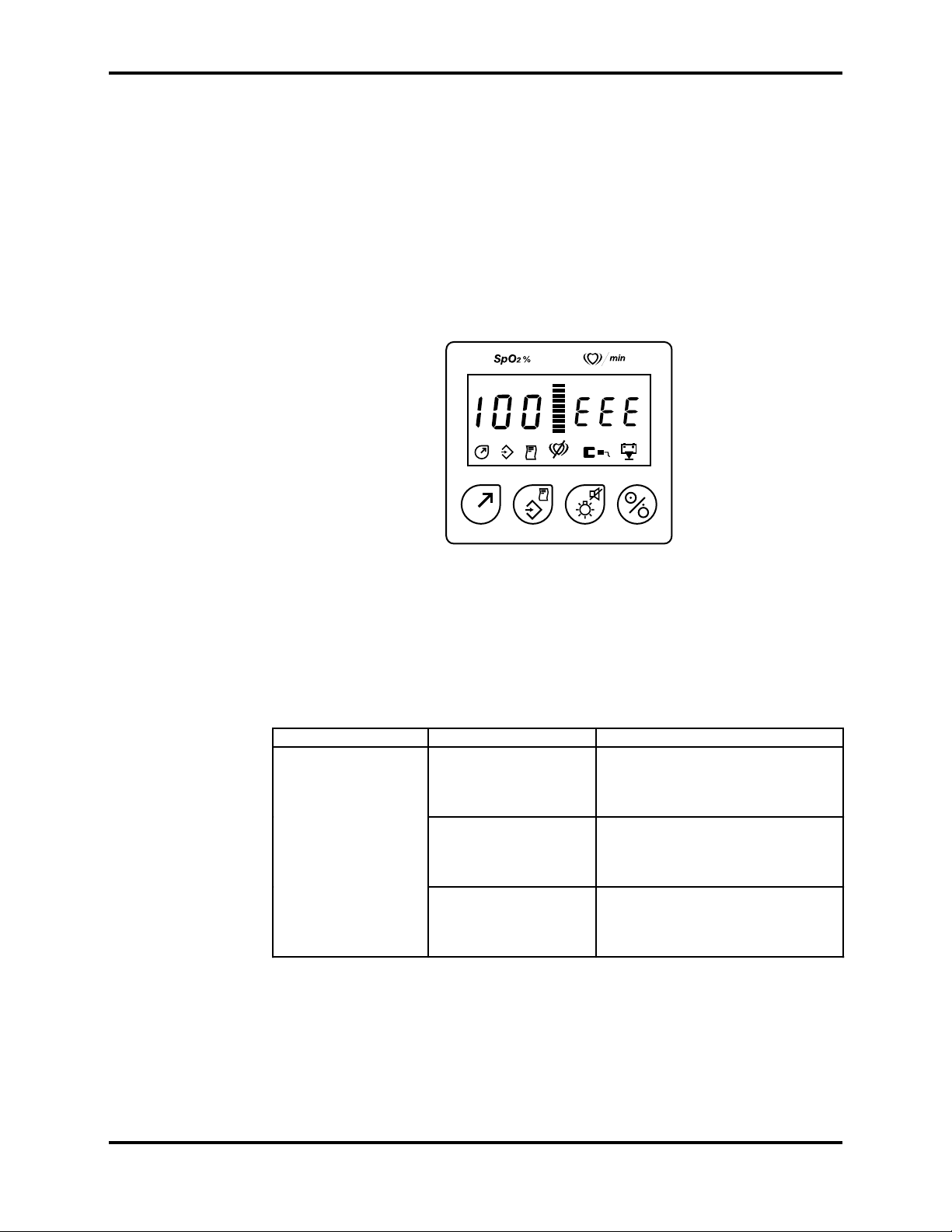

2. The NPB-40 will perform a self-test. Verify that all display segments

are lit during the self-test as shown in Figure 3-1. Also verify that a low

pitched audio tone is heard at the end of the self test. Also verify that

you then hear a high, a low, and a high pitch error tone indicating that

a sensor is not connected. Verify that dashes are shown on the display

and the SENSOR DISCONNECT indicator is flashing.

Figure 3-1: NPB-40 Self-Test Front Panel Display

3. Wait for 20 to 40 seconds. Verify that two triple beeps are heard. Verify

that the NPB-40 then shuts itself off.

4. Connect an SRC-2 pulse oximeter tester to the NPB-40 sensor

connector.

Note: If the SRC-2 is connected directly to the NPB-40 sensor

connector, its controls will be facing the opposite direction of

the NPB-40 controls. Connecting the SRC-2 through a sensor

extension cable, such as the Nellcor Puritan Bennett model EC4 or EC-8, will make it easier to perform this procedure.

3-1

Page 10

Section 3: Performance Verification

Set the SRC-2 controls as follows:

RATE 112

LIGHT HIGH 1

MODULATION HIGH

LOCAL/REMOTE/RCAL LOCAL

5. Press the On/Off key on the NPB-40 front panel keypad.

6. When the self-test is complete, verify that the PULSE SEARCH

indicator illuminates momentarily and verify that the NPB-40 is

displaying a pulse rate of 112 (±3 bpm), that the pulse amplitude

indicator is displaying properly, that the SpO2% indicator is displaying

81 (±2 %), that a pulse beep can be heard, and that the PULSE

SEARCH indicator is off.

7. Set the following SRC-2 controls as indicated:

RATE 38

LIGHT HIGH 2

MODULATION LOW

Wait 30 seconds and verify that the NPB-40 is displaying a pulse rate of

38 (±3 bpm), that the pulse amplitude indicator is displaying properly,

that the SpO2% indicator is displaying 81 (±2 %), that a pulse beep can

be heard, and that the PULSE SEARCH indicator is off.

8. Set the following SRC-2 controls as indicated:

RATE 201

LIGHT LOW

Wait 30 seconds and verify that the NPB-40 is displaying a pulse rate of

201 (±3 bpm), that the pulse amplitude indicator is displaying properly,

that the SpO2% indicator is displaying 81 (±2 %), that a pulse beep can

be heard, and that the PULSE SEARCH indicator is off.

9. Set the following SRC-2 control as indicated:

MODULATION HIGH

Wait 30 seconds and verify that the NPB-40 is displaying a pulse rate of

201 (±3 bpm), that the pulse amplitude indicator is displaying properly,

that the SpO2% indicator is displaying 81 (±2 %), that a pulse beep can

be heard, and that the PULSE SEARCH indicator is off.

10. Press the Shift key followed by the Display Light/Beep On/Off key.

Verify that the SHIFT indicator illuminates when the Shift key is

pressed then verify that the pulse beep stops and the SHIFT indicator

extinguishes when the Display Light/Beep On/Off key is pressed.

11. Press the Shift key followed by the Display Light/Beep On/Off key and

verify that the pulse beep can be heard again at a low level.

3-2

Page 11

Section 3: Performance Verification

12. Press the Shift key followed by the Display Light/Beep On/Off key and

verify that the pulse beep can again be heard again at a higher level.

13. Press and release the Display Light/Beep On/Off key on the front panel

keypad and verify that the LCD backlight comes on, remains on and the

LCD is adequately illuminated.

14. Press the Display Light/Beep On/Off key on the front panel keypad and

verify that the LCD backlight is off.

15. Set the following SRC-2 control as indicated:

LOCAL/REMOTE/RCAL REMOTE

16. On the NPB-40, verify that the PULSE SEARCH indicator illuminates

after a few seconds and that the number “0” is displayed in the SpO2%

and pulse rate displays.

17. Set the following SRC-2 control as indicated:

LOCAL/REMOTE/RCAL LOCAL

18. On the NPB-40, verify that the PULSE SEARCH indicator illuminates

momentarily and verify that the NPB-40 is displaying a pulse rate of

201 (±3 bpm), that the pulse amplitude indicator is displaying properly,

that the SpO2% indicator is displaying 79 to 83, that a pulse beep can

be heard, and that the PULSE SEARCH indicator is off.

Note: If an HP82240B printer is not available, skip steps 19 through

27 and proceed to step 28.

19. Refer to the printer operator’s manual as needed. Verify that paper is

properly installed in the printer and turn the printer on.

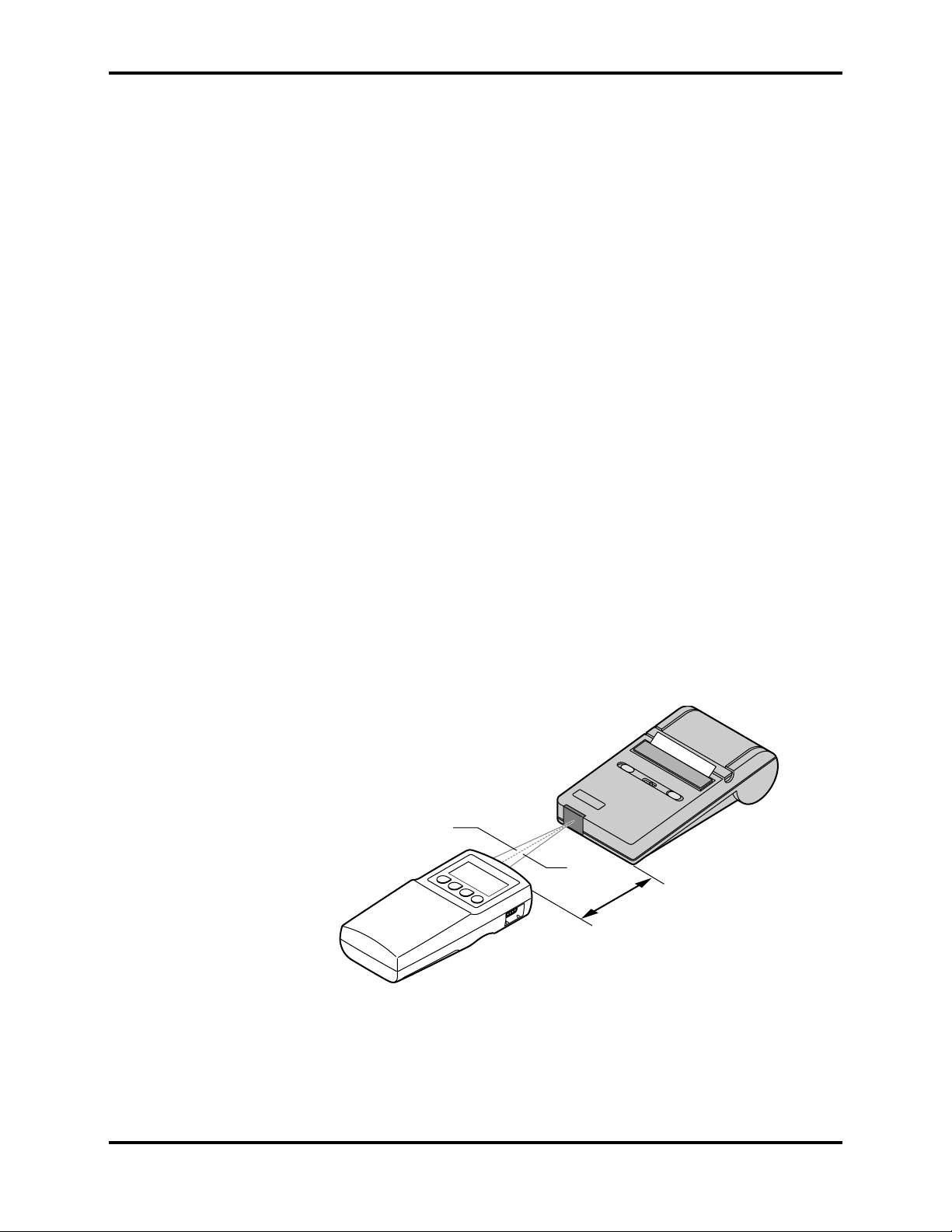

20. Align the NPB-40 with the printer as shown in Figure 3-2.

0°–5°

0°–5°

1"–2" (2.5–5.1 cm.)

Figure 3-2: Printer Interface Setup

3-3

Page 12

Section 3: Performance Verification

21. On the NPB-40, press the Shift key followed by the Store Data/Print

key on the front panel keypad.

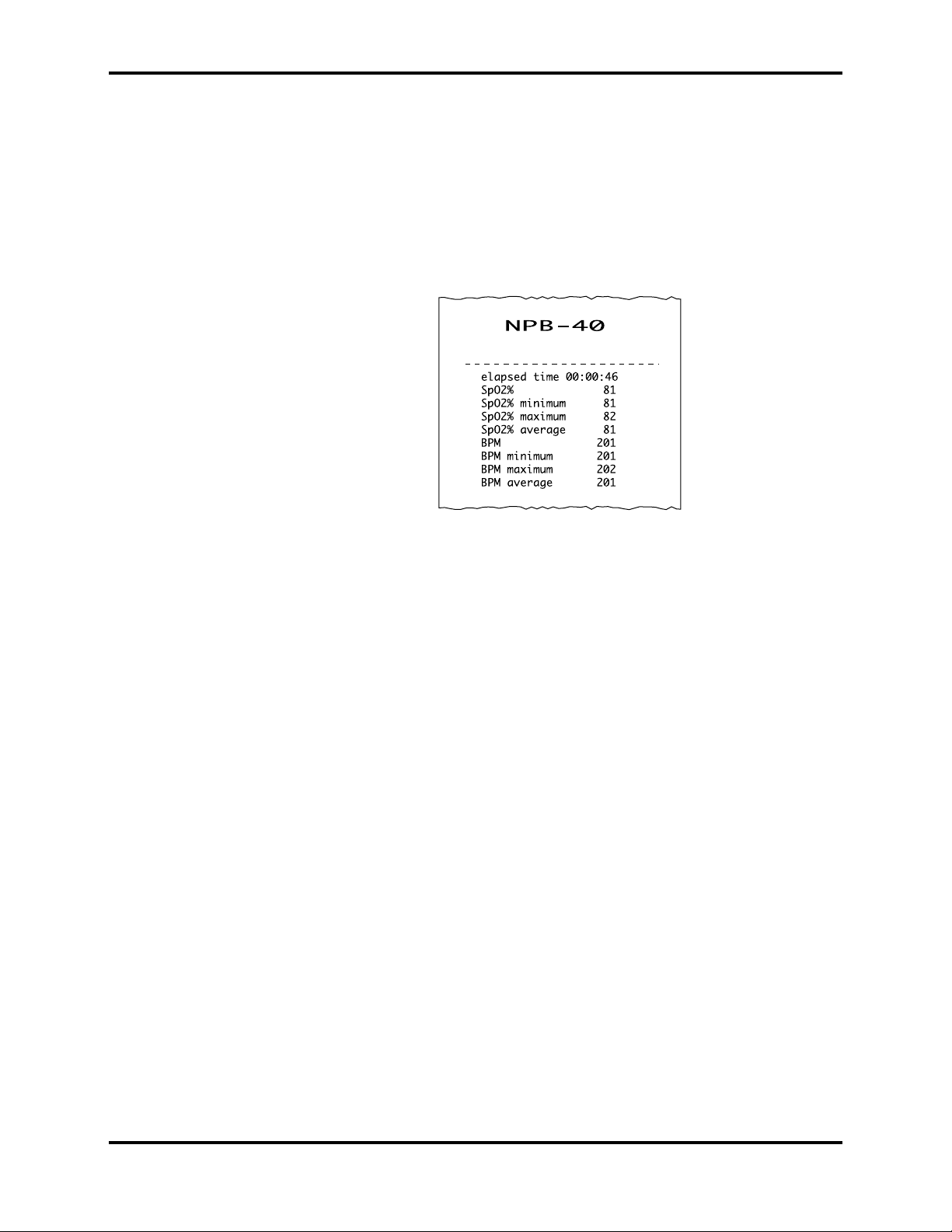

Note: In the following steps, printed SpO2% values will be 79 to 83

22. Verify that the PRINT icon is illuminated on the NPB-40 display, that

the printer begins printing and that the printer prints out a summary

report similar to that shown in Figure 3-3.

and pulse rate values will be 201, ±3 bpm. Figures 3-3 and 3-4

are examples of typical print outs. The NPB-40 will not display

pulse or SpO2% values while printing.

Figure 3-3: Typical Average Data Print Out

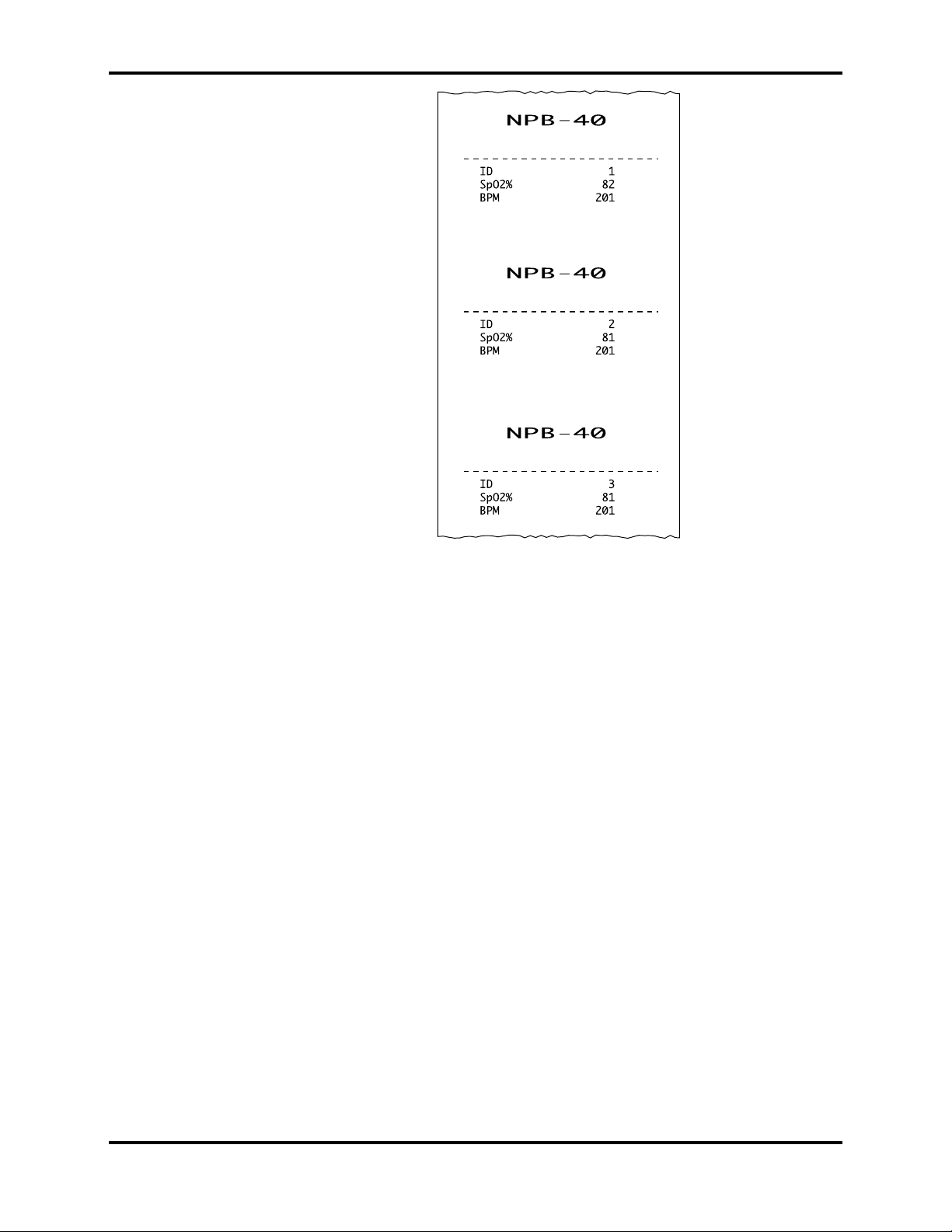

23. With the SRC-2 connected to the NPB-40 and still set up as in step 18,

press only the Store Data/Print key on the front panel keypad and

verify that the LCD display indicates “1-Id” and the STORE DATA icon

illuminates.

24. Press only the Store Data/Print key on the front panel keypad and

verify that the LCD display indicates “2-Id” and the STORE DATA icon

illuminates.

25. Press only the Store Data/Print key on the front panel keypad and

verify that the LCD display indicates “3-Id” and the STORE DATA icon

illuminates.

26. Align the NPB-40 with the printer as shown in Figure 3-2 and press the

Shift key on the NPB-40 front panel keypad, followed by the Store

Data/Print key.

27. Verify that the PRINT icon is illuminated on the NPB-40 display, that

the printer begins printing and that the printer prints out data similar

to that shown in Figure 3-4. As data stored in steps 24, 25, and 26 is

printed out, the NPB-40 display will indicate “1-Id”, “2-Id”, and “3-Id”,

respectively.

3-4

Page 13

Section 3: Performance Verification

Figure 3-4: Typical Data Print Out

28. Press the On/Off key on the front panel keypad.

29. Verify that the NPB-40 shuts off.

3-5

Page 14

(This page intentionally left blank)

Page 15

SECTION 4: TROUBLESHOOTING

4.1 Introduction

4.2 Who Should Perform Repairs

4.3 Repair Level Supported

4.4 How to Use This Section

4.5 Obtaining Replacement Parts

4.6 Troubleshooting Guide

4.1 INTRODUCTION

This section provides information for troubleshooting the NPB-40 and helping

you to isolate a failure to the front panel keypad, the CPU PCB, or the LCD

PCB. A troubleshooting guide is provided in Paragraph 4.6, “Troubleshooting

Guide” that lists possible difficulties, along with probable causes, and

recommended actions to correct each difficulty. The Technical Supplement at

the end of this manual provides information on how the components of the

NPB-40 function.

4.2 WHO SHOULD PERFORM REPAIRS

Only qualified service personnel should remove and replace components of

the NPB-40. Repairs to the NPB-40 are limited to the repair level identified

in Paragraph 4.3, “Repair Level Supported.” If your facility does not have

qualified service personnel, contact the Nellcor Puritan Bennett Technical

Services Department or your local Nellcor Puritan Bennett representative.

4.3 REPAIR LEVEL SUPPORTED

Besides the batteries, the NPB-40 has five replaceable components, the case

top with the front panel keypad, the case bottom, the CPU PCB, the LCD

PCB, and the battery compartment door.

4.4 HOW TO USE THIS SECTION

Failures of the case bottom, the battery compartment door, and the case top,

not including the front panel keypad, are determined by visually inspecting

these components for cracks or deformations and for mechanical failures such

as the screw holes stripping out in the case top. The case top and the front

panel keypad are replaced together. Use the troubleshooting guide provided

in Paragraph 4.6, “Troubleshooting Guide” to isolate failure to the front panel

keypad, the CPU PCB, or the LCD PCB. Once a failure has been isolated,

refer to Section 5, Disassembly Guide for instructions for removing and

replacing a component of the NPB-40.

4.5 OBTAINING REPLACEMENT PARTS

Nellcor Puritan Bennett Technical Services Department provides technical

assistance information and replacement parts. To obtain replacement parts,

contact the Nellcor Puritan Bennett Technical Services Department or your

local Nellcor Puritan Bennett representative. Refer to parts by the part

names and part numbers listed in Section 6, Spare Parts.

4-1

Page 16

Section 4: Troubleshooting

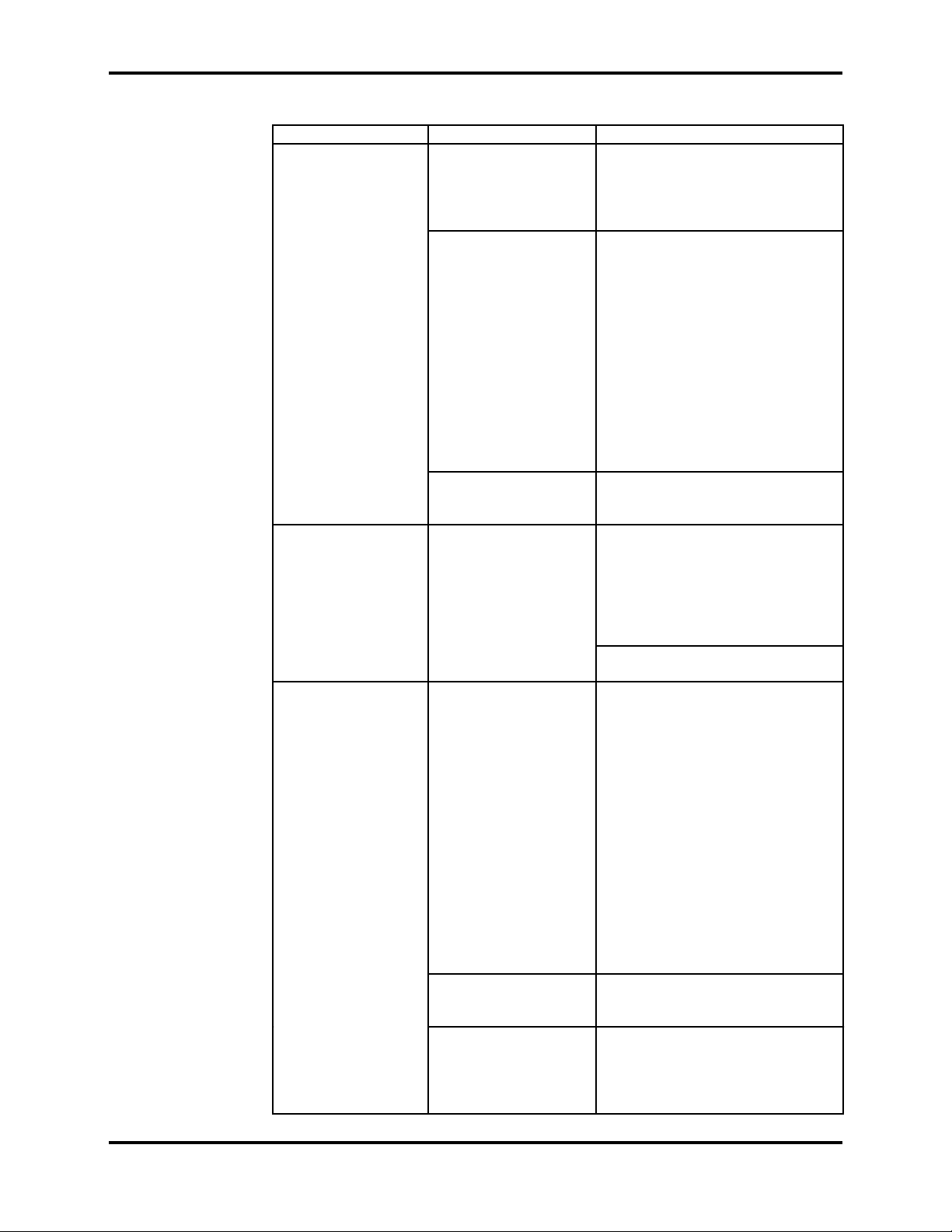

4.6 TROUBLESHOOTING GUIDE

If you encounter a problem that cannot be resolved through a visual

inspection, refer to Table 4-1 which provides a list of symptoms, probable

causes, and recommended actions to take to correct the problem. It is

recommended that corrective actions be performed in the order presented.

For a symptom that is not listed in Table 4-1, contact the Nellcor Puritan

Bennett Technical Services Department or your local Nellcor Puritan Bennett

representative.

If an error code is shown on the front panel LCD display, as shown in Figure

4-1, turn the NPB-40 off and back on again. If the error code still persists,

refer to Table 4-2 for the indicated failure and corrective action.

Figure 4-1: Typical Error Code Display

Once you have performed the recommended action, reassemble the NPB-40,

refer to Section 3, Performance Verification, and conduct a performance

verification before returning the NPB-40 to service. If the symptom persists,

continue troubleshooting.

Table 4-1: Troubleshooting Guide

Symptom Probable Cause Corrective Action

The unit does not

turn on when the

On/Off key is

The batteries are

missing.

Open the battery compartment

and if batteries are missing,

install new batteries.

pressed.

The batteries are

installed incorrectly

or are backwards.

Open the battery compartment

and if batteries are not installed

correctly, remove and reinstall

the batteries.

The batteries are at

Install new batteries.

or near a voltage too

(Continued on next

page)

low for the NPB-40 to

operate.

4-2

Page 17

Section 4: Troubleshooting

Table 4-1: Troubleshooting Guide (Continued)

Symptom Probable Cause Corrective Action

The unit does not

turn on when the

The sensor is

defective.

Replace the sensor.

On/Off key is

pressed.

(continued)

The front panel

keypad is defective.

Open the NPB-40, disconnect

the case top from J3 on the CPU

PCB and connect an ohmmeter

between the flex circuit

conductor for J3, pin 5 and the

conductor for J3, pin 3. Observe

a short when the On/Off key is

pressed and an open when not

pressed. If incorrect, replace

case top. If all keys function

correctly, replace CPU PCB.

Caution: Unlock J3 before

attempting to remove flex

circuit conductor.

Flex circuit between

front panel and CPU

PCB is disconnected.

A CPU PCB

component has

failed.

Inspect the flex circuit between

the front panel and the CPU

PCB and reconnect if loose.

Inspect the CPU PCB

components and circuit board

for cracking, burning, or

damage, and replace the CPU

PCB if any are found. If any

failed components are observed,

replace CPU PCB.

Replace the CPU PCB with a

known good PCB.

One or more keys

on the front panel

keypad does not

work.

The front panel

keypad is defective.

Open the NPB-40, disconnect

the case top from J3 on the CPU

PCB and connect an ohmmeter

lead to the flex circuit conductor

for J3, pin 3. Refer to the front

panel schematic diagram and

individually connect the other

ohmmeter lead to each

conductor for the other keys.

Observe a short when the key is

pressed and an open when not

pressed. If incorrect, replace

case top. If correct, replace the

CPU PCB.

Caution: Unlock J3 before

attempting to remove flex

circuit conductor.

Flex circuit between

front panel and CPU

PCB is disconnected.

A CPU PCB

component has

failed.

(Continued on next

page)

Inspect the flex circuit between

the front panel and the CPU

PCB and reconnect if loose.

Inspect the CPU PCB

components and circuit board

for cracking, burning, or damage

and replace the CPU PCB if any

are found.

4-3

Page 18

Section 4: Troubleshooting

One or more keys

on the front panel

keypad does not

work. (Continued)

One or more

display segments

does not work.

Beeper does not

beep for pulse

indication or no

sound can be heard

from the beeper.

Pulse rate or SpO2

value is not

displayed and the

unit is on.

LCD backlight does

not come on when

the Display Light

key is pressed.

The unit shuts off

when the LCD

backlight is turned

on.

Table 4-1: Troubleshooting Guide (Continued)

Symptom Probable Cause Corrective Action

CPU PCB has failed. Replace the CPU PCB with a

known good PCB.

An LCD PCB

component has

failed.

Inspect the LCD PCB

components and circuit board

for cracking, burning, or damage

and replace the LCD PCB if any

are found.

Flex circuit between

LCD and LCD PCB

has come loose.

Inspect the flex circuit between

the LCD and the LCD PCB has

come loose and replace the LCD

PCB if loose.

Replace the LCD PCB with a

known good PCB.

The beeper has been

Turn the beeper back on.

turned off or its

volume is turned

down too low to hear.

The holes for the

beeper on the back of

Clear the holes for the beeper on

the back of the NPB-40.

the NPB-40 are

blocked.

The external output

port on the CPU PCB

Replace the CPU PCB with a

known good PCB.

has failed.

The beeper on the

LCD PCB has failed

The SpO2 sensor is

not connected

Replace the LCD PCB with a

known good PCB.

Connect the SpO2 sensor to the

NPB-40.

properly.

The SpO2 sensor has

failed.

A component on the

LCD PCB has failed.

A component on the

CPU PCB has failed.

The Display Light

key on the front

panel keypad is

Replace the SpO2 sensor with a

known good SpO2 sensor.

Replace the LCD PCB with a

known good PCB.

Replace the CPU PCB with a

known good PCB.

See “One or more keys on the

front panel keypad does not

work,” above.

defective.

The backlight LEDs

on the LCD PCB

Replace the LCD PCB with a

known good PCB.

have failed.

The batteries are at

Install new batteries.

or near a voltage too

low for the NPB-40 to

operate.

4-4

Page 19

Section 4: Troubleshooting

Table 4-1: Troubleshooting Guide (Continued)

Symptom Probable Cause Corrective Action

Printer will not

print.

The printer is turned

off.

The Store Data key

on the front panel

keypad is defective.

Turn on the printer.

See One or more keys on the

front panel keypad does not

work, above.

The printer batteries

are at or near a

Install new batteries in the

printer.

voltage too low for it

to operate.

The NPB-40 and

printer are not

properly aligned.

A component on the

LCD PCB has failed.

A component on the

CPU PCB has failed.

The printer is

defective.

Refer to the operator’s manual

for instructions for aligning the

NPB-40 with the printer.

Replace the LCD PCB with a

known good PCB.

Replace the CPU PCB with a

known good PCB.

Attempt to print using another

known good NPB-40. If the

printer still does not print,

troubleshoot the printer

Table 4-2: NPB-40 Error Codes

Error Code Failure Indicated Corrective Action

100EEE Failure in the

1. Replace the sensor.

microprocessor

analog-to-digital

converter on the CPU

2. Replace the CPU PCB with a

known good PCB.

PCB.

150EEE Failure of the

microprocessor on

Replace the CPU PCB with a

known good PCB.

the CPU PCB.

151EEE Failure of the RAM

on the CPU PCB.

152EEE Failure of the ROM

on the CPU PCB.

153EEE Failure in the

microprocessor I/O

Replace the CPU PCB with a

known good PCB.

Replace the CPU PCB with a

known good PCB.

Replace the CPU PCB with a

known good PCB.

ports on the CPU

PCB.

154EEE Failure of the

watchdog circuit on

Replace the CPU PCB with a

known good PCB.

the CPU PCB.

155EEE Failure of the

memory on the CPU

Replace the CPU PCB with a

known good PCB.

PCB when storing an

event or when

printing.

4-5

Page 20

(This page intentionally left blank)

Page 21

SECTION 5: DISASSEMBLY GUIDE

5.1 Introduction

5.2 System Disassembly and Reassembly

5.1 INTRODUCTION

The NPB-40 can be disassembled into five assemblies:

• Case top/front panel keypad

• Case bottom

• CPU PCB

• LCD PCB

• Battery compartment door

Note: Some spare parts you receive will have a business reply card

attached. When you receive these spare parts, please fill out and

return the business reply card.

The only tool you will need to disassemble or reassemble the NPB-40 is a

Number 1 (medium) Phillips-head screwdriver.

Caution: Observe ESD (electrostatic discharge) precautions when

disassembling and reassembling the NPB-40 and when handling any

of the components of the NPB-40.

5.2 SYSTEM DISASSEMBLY AND REASSEMBLY

Use the following procedure to disassemble the NPB-40. Reassemble the

monitor in reverse order and, if the unit is to be returned to service, install

batteries when reassembly is complete and replace the battery compartment

door. Nellcor Puritan Bennett recommends that you follow this disassembly

procedure in the order presented.

Note: Before you begin to disassemble the NPB-40, remove the battery

compartment door and remove the batteries.

1. Place the NPB-40 on a nonabrasive surface so that the back of the unit

is up and the bottom of the unit is closest to you.

2. Remove the four screws holding the case together as indicated in Figure

5-1.

Note: The two screws at the top of the NPB-40 are longer than those

at the bottom. When reassembling the unit, be sure to install

the longer screws at the top and the shorter screws at the

bottom.

Caution: When reassembling the NPB-40, hand tighten the screws

that hold the NPB-40 case together to a maximum of 4 inch-pounds.

Over tightening could cause the screws to strip out the screw-holes

in the top case, rendering it unusable.

5-1

Page 22

Section 5: Disassembly Guide

Remove screws

Remove screws

Figure 5-1: Opening the NPB-40 Case

3. While holding the case together, turn the NPB-40 over with the front

panel up and the bottom of the unit closest to you.

4. Separate the case top from the bottom case on the right side of the unit

and rotate the case top to the left as shown in Figure 5-2.

J3

5-2

Figure 5-2: Top Case Removal

Page 23

Section 5: Disassembly Guide

Caution: Failure to unlock connector J3 on the CPU PCB before

attempting to remove the front panel flex circuit could damage the

flex circuit.

5. Unlock connector J3 on the CPU PCB as shown in Figure 5-3 and pull

the front panel keypad flex circuit out of J3.

Note: When reassembling the NPB-40, be sure to lock J3 after you

insert the front panel keypad flex circuit. See Figure 5-3.

Unlock

J3 Lock

Lock

CPU PCB

Figure 5-3: Unlocking CPU PCB Connector J3

Note: The battery connectors (spring assemblies) at the bottom of the

CPU PCB are held in slots in the battery compartment. In the

next step, observe how these connectors are engaged in these

slots when you remove the CPU PCB with the LCD PCB and

make sure the battery connectors are inserted back in these

slots when you reassemble the NPB-40.

6. Lift the CPU PCB and the LCD PCB together and remove them from

the case bottom.

7. To separate the CPU PCB and the LCD PCB, grasp the CPU PCB in

one hand and the LCD PCB in the other. Rotate the ends of the two

PCBs as shown in figure 5-4 until the two assemblies separate at the

connectors J1 and J2.

J1

LCD PCB

CPU PCB

J2

Figure 5-4: Separating LCD PCB from CPU PCB

Note: When reassembling the NPB-40, be sure to align all 20 pins of

both J1 and J2 on the CPU PCB with all 20 sockets of J1 and

J2 on the LCD PCB before pressing the two PCBs together.

5-3

Page 24

(This page intentionally left blank)

Page 25

SECTION 6: SPARE PARTS

6.1 Introduction

6.1 INTRODUCTION

Spare parts, along with corresponding Nellcor Puritan Bennett part numbers,

are shown below. Figure 6-1 shows the replaceable NPB-40 monitor

components with numbered callouts that correspond to item numbers in

parentheses in the spare parts list below.

In December, 1997, the external plastic parts of the NPB-40 were modified.

Plastic parts made after that date are incompatible with parts made before

that time.

To determine which part number to order, look at the back of the instrument.

To the right of center, just above the battery compartment door, there will be

either 3 holes or three slots for the speaker. If your instrument has three

slots, use part numbers from the “After 12/97” column. If the instrument has

three holes, use part numbers from the “Before 12/97” column.

Item Part Numbers

(Before 12/97)

(1) Case Top/Keypad 045691 048863

(2) CPU PCB 034311 034311

(3) LCD PCB 034835 034835

(4) Case Bottom 035097 035397

(5) Battery Compartment Door 033880 034975

Part Numbers

(After 12/97)

6-1

Page 26

Section 6: Spare Parts

1

2

3

Figure 6-1: NPB-40 Expanded View

4

5

6-2

Page 27

SECTION 7: PACKING FOR SHIPMENT

7.1 General Instructions

7.2 Packing NPB-40 in Original Carton

7.3 Packing in a Different Carton

7.1 GENERAL INSTRUCTIONS

To ship an NPB-40 handheld pulse oximeter or one of its components for any

reason, follow the instructions in this section.

Pack the NPB-40 or component carefully. Failure to follow the instructions in

this section may result in loss or damage not covered by any applicable

Nellcor Puritan Bennett warranty. If available, use the original carton and

packing materials and follow the instructions in “Packing in Original

Carton.” If the original shipping carton and material are not available, use

other suitable shipping materials and container and follow the instructions in

“Packing in a Different Carton.”

Prior to shipping the NPB-40 or component, contact Nellcor Puritan Bennett

Technical Services Department or your local Nellcor Puritan Bennett

representative for a Returned Goods authorization (RGA) number. Mark the

shipping carton and any shipping forms with the RGA number.

Caution: Observe ESD (electrostatic discharge) precautions when

packing any NPB-40 components.

7.2 PACKING NPB-40 IN ORIGINAL CARTON

If the original carton and packing materials are available, repack the NPB-40

as shown in Figure 7-1. Add packing material in the bottom of the carton as

needed so the NPB-40 will not be able to move during shipment.

7.3 PACKING IN A DIFFERENT CARTON

If the original carton and packing material are not available when shipping

an NPB-40 or one of its components:

1. Place the NPB-40 or component in a plastic bag.

2. Locate a corrugated cardboard shipping carton with at least 200 pounds

per square inch (psi) bursting strength.

3. Fill the bottom of the carton with at least 2 inches of packing material.

4. Place the bagged NPB-40 or component on the layer of packing material

and fill the box completely with packing material such that there is at

least 2 inches of packing material around all sides of the item.

5. Seal the carton with packing tape.

6. Label carton with shipping address, return address, and RGA number.

7-1

Page 28

Section 7: Packing for Shipment

7-2

Figure 7-1: Repacking the NPB-40

Page 29

SECTION 8: SPECIFICATIONS

8.1 Performance

8.2 Electrical

8.3 Environmental

8.4 Physical

8.1 PERFORMANCE

Measurement Range

SpO2

0–100%

Pulse Rate

20–250 beats per minute (bpm)

Accuracy

SpO2

Adults

70–100% ± 2 digits

0–69% unspecified

Neonates

70–100% ± 2 digits

0–69% unspecified

Note: Accuracies are expressed as plus or minus “X” digits (oxygen

saturation percentage points) between saturations of 70-100%. This

variation equals plus or minus one standard deviation (1SD), which

encompasses 68% of the population. All accuracy specifications are

based on testing the subject monitor on healthy adult volunteers in

induced hypoxia studies across the specified range. Adult accuracy is

determined with Oxisensor® II D-25 sensors. Neonatal accuracy is

determined with Oxisensor II N-25 sensors. In addition, the neonatal

accuracy specification is adjusted to take into account the theoretical

effect of fetal hemoglobin in neonatal blood on oximetry

measurements.

Pulse Rate

20–250 bpm ± 3 bpm

Note: Accuracy is expressed as plus or minus 3 bpm across the display

range. This variation equals plus or minus one standard deviation

(1SD), which encompasses 68% of the population.

8-1

Page 30

Section 8: Specifications

8.2 ELECTRICAL

Instrument

Power Requirements

6V, supplied by battery-power only

Patient Isolation

No electrical connection to patient (inherently insulated)

Battery

Type

Four 1.5V alkaline “AA” size batteries

Battery Capacity

Typically 19 hours with four new disposable alkaline batteries.

Note: Not all brands of off-the-shelf alkaline batteries provide the same

8.3 ENVIRONMENTAL

Operating Temperature

battery life.

Instrument

0 to 55°C

Sensor

Within physiologic range for specified accuracy

Transport/Storage Temperature (boxed)

-40 to 70°C, 15-95% RH

Humidity

Operating

15-95% noncondensing

Storage (unboxed)

15-95% noncondensing over a temperature range of -20° C to 60° C

Altitude

Operating

-1280 ft. to 12,000 ft (-390 m to 3,658 m) [650 to 1060 hPa]

Storage

-2330 ft. to 15,000 ft. (-457 m to 4,573 m) [572 to 1100 hPa]

8-2

Page 31

8.4 PHYSICAL

Section 8: Specifications

Weight (with batteries installed)

0.3 kg (11 oz.)

Size

15.75 cm high x 7.5 cm wide x 3.8 cm deep

(6.2 in. high x 2.95 in. wide x 1.5 in. deep)

Equipment Classification (IEC 601-1 / CSA 601.1 / UL 2601-1)

Type of Protection

Internally Powered

Degree of Protection

Type BF

Enclosure Degree Protection Class

IPX1

Mode of Operation

Continuous

8-3

Page 32

(This page intentionally left blank)

Page 33

TECHNICAL SUPPLEMENT

S1 Introduction

S2 Pulse Oximetry Principles of Operation

S3 Circuit Analysis

S4 Schematic Diagrams

S1 INTRODUCTION

This Technical Supplement provides a description of the principles of pulse

oximetry, a block diagram level theory of operation discussion, and a

schematic level theory of operation discussion. Part locator diagrams and

schematic diagrams are located at the end of this section as fold-out

drawings. These diagrams can be folded out for review while reading the

theory of operation.

S2 PULSE OXIMETRY PRINCIPLES OF OPERATION

S2.1 Overview

The NPB-40 is based on the principles of spectrophotometry and optical

plethysmography. Optical plethysmography uses light absorption technology

to reproduce waveforms produced by pulsatile blood. The changes that occur

in the absorption of light due to vascular bed changes are reproduced by the

pulse oximeter as plethysmographic wave forms.

Spectrophotometry uses various wavelengths of light to qualitatively measure

light absorption through given substances. Many times each second, the

NPB-40 passes red and infrared light into the sensor site and determines

absorption. The measurements that are taken during the arterial pulse,

reflect absorption by arterial blood, nonpulsatile blood, and tissue. The

measurements that are obtained between arterial pulses reflect absorption by

nonpulsatile blood and tissue.

By correcting "during pulse" absorption for "between pulse" absorption, the

NPB-40 determines red and infrared absorption by pulsatile arterial blood.

Because oxyhemoglobin and deoxyhemoglobin differ in red and infrared

absorption, this corrected measurement can be used to determine the percent

of oxyhemoglobin in arterial blood: SpO2 is the ratio of corrected absorption

at each wavelength.

S2.2 Functional Versus Fractional Saturation

The NPB-40 measures functional saturation, that is, oxygenated hemoglobin

expressed as a percentage of the hemoglobin that is capable of transporting

oxygen. It does not detect significant levels of dyshemoglobins. In contrast,

some instruments such as the IL282 Co-oximeter measure fractional

saturation, that is, oxygenated hemoglobin expressed as a percentage of all

measured hemoglobin, including dyshemoglobins.

Consequently, before comparing NPB-40 measurements with those obtained

by an instrument that measures fractional saturation, measurements must

be converted as follows:

functional

saturation

fractional

=

saturation

x

100-(% carboxyhemoglobin +%methemoglobin)

100

S-1

Page 34

Technical Supplement

S2.3 Measured versus Calculated Saturation

When saturation is calculated from a blood gas measurement of the partial

pressure of arterial oxygen (PaO2), the calculated value may differ from the

NPB-40 SpO2 measurement. This is because the calculated saturation may

not have been corrected for the effects of variables that can shift the

relationship between PaO2 and saturation.

Figure S2-1 illustrates the effect that variations in pH, temperature, partial

pressure of carbon dioxide (PCO2), and concentrations of 2,3-DPG and fetal

hemoglobin may have on the oxyhemoglobin dissociation curve.

S3 CIRCUIT ANALYSIS

This section provides an explanation of NPB-40 theory of operation using

block diagrams and schematic diagrams.

100

50

pH

Temperature

PCO

2

2,3-DPG

Fetal Hb

pH

Temperature

PCO

2

2,3-DPG

Saturation (%)

0

PO2 (mmHg)

Figure S2-1: Oxyhemoglobin Dissociation Curve

10050

S-2

The NPB-40 consists of three main functional components described in the

following paragraphs:

• The CPU PCB block diagram (Figure S3-2) and schematic diagram

(Figure S4-3).

• The LCD PCB block diagram (Figure S3-3) and schematic diagram

(Figure S4-4).

• The Front Panel PCB schematic diagram (Figure S4-5).

The relationship between these components and their interconnection is

illustrated in the NPB-40 block diagram (Figure S3-1).

Page 35

Technical Supplement

The following is a list of terms and definitions used in the following

paragraphs.

Analog to Digital (A/D) converter. The CPU has a 10-bit A/D converter on

board. Up to eight different analog inputs can be provided to the A/D for

measurement.

Central Processing Unit (CPU). An Intel 80C196KC 16-bit

microprocessor. The CPU sends and receives control signals to the SpO2

analog section, display, and printer infrared LED.

High Speed Outputs (HSO). The 6 HSO lines control most of the timing of

the LED signal pulse and the demodulation of the received signal.

Input and Output (I/O). Digital lines that are used by the CPU to read in

data and output data.

Light Emitting Diodes (LEDs). Two LEDs are used in Nellcor Puritan

Bennett oximetry sensors. Light is transmitted through body tissue and

received by a photodetector circuit that converts it to photocurrent. The two

wavelengths, which are used for calculation of pulse rate and oxygen

saturation in blood, are transmitted at the following frequencies:

• infrared (IR) light at ≈ 915 microns

• red light at ≈ 660 microns

Pulse Width Modulation (PWM). The three 8-bit PWM outputs can be

software controlled; their duty cycle can be changed from 0 TO 99.6 percent of

the total pulse duration. PWM frequency is the crystal frequency of the CPU

(10 MHz) divided by 1024. The PWMs control the gains within the analog

circuit.

RCal. Sensor RCal value is a resistance value specific to an individual

sensor. This value is used by the software during oxygen saturation

computations to maximize accuracy.

S3.1 Overall Unit Block Diagram Analysis

Exclusive of batteries covers, keys, and external connectors, the NPB-40

consists of three main functional components: the front panel keyboard, the

CPU PCB, and the LCD PCB as follows.

• CPU PCB — contains the CPU; power supply circuitry; support

memory circuits; sensor circuits for battery voltage; a serial data port;

LCD backlight control; pulsatile beeper drive circuits; and some display

control circuits.

• LCD PCB — contains the SpO2 analog circuitry and interface to the

external sensor; the power conditioning circuitry; the LCD display and

display driver circuits; the interface circuitry for the printer (which is

not used unless a printer is present); the LCD backlight; and audio

output hardware.

• Front Panel Keyboard — contains four membrane switches and a

line common to all four switches. This assembly connects to the CPU

PCB by a flex circuit.

Refer to Figure S3-1 for this NPB-40 block diagram. The CPU PCB and the

LCD PCB are each described in more detail in later paragraphs.

S-3

Page 36

Technical Supplement

The NPB-40 is powered by four AA-size replaceable alkaline batteries. A dc

voltage in the range of 3.6 to 6 Vdc is provided over the life of these batteries.

When the voltage from these batteries drops to a level too low to operate the

NPB-40, the unit will shut itself off. At that time, the batteries must be

replaced.

The front panel keypad contains four keys that provide discrete signals that

are monitored by the microprocessor on the CPU PCB. Refer to Figure S4-5

for a schematic diagram of the front panel keypad.

CPU PCB LCD PCB

Batteries

Front

panel

keypad

External

serial

interface

3.6-6 Vdc

On/off key

Function

keys

Power

down

External

output

control

Power

control

and PCB

power

CPU

Battery

voltage

sense

Raw power

Sensor

analog

signal

and

control

Printer

signal

LCD

enable

LCD

data

Power

condition

and PCB

power

Analog

sensor

circuits

Printer

IR LED

drive

LCD

Patient

sensor

input

S-4

External

output

port

Beeper

signal

Backlight

control

Beeper

backlight

Figure S3-1: NPB-40 Block Diagram

LCD

Page 37

Technical Supplement

Power from the batteries is controlled and filtered by the power control and

PCB power circuits on the CPU PCB. When the On/Off key is pressed on the

front panel keypad and the unit is turned off, the power control circuits will

turn on the unit. If the unit is on when the On/Off key is pressed, the unit

will be turned off. The PCB power circuits provide filtered power for the

circuits on the CPU PCB and raw power is passed to the LCD PCB where it is

conditioned for the circuits there.

A patient sensor connected to the NPB-40 contains a resistance that is a

calibration reference for the sensor. The analog sensor circuits on the LCD

PCB then measure the signal from a photodiode in the sensor that is different

based on the light absorption characteristics of each patient. That signal is

processed by the analog sensor circuits and measured by the CPU. The LED

drive signals are then adjusted by the CPU to obtain an optimum signal from

the photodiode.

The CPU provides a drive signal for an IR LED on the LCD PCB. When this

IR LED is aligned with a receiving photodiode on an external printer, patient

data stored in the NPB-40 can be printed.

An external output port on the CPU PCB is controlled by the CPU and sends

drive signals to the beeper and LCD backlight and display data to the LCD.

An external serial data interface, used during testing in manufacturing only,

is also controlled by the CPU. This interface is only accessible with a special

test fixture.

S3.2 CPU PCB Theory of Operation

Refer to Figure S3-2 for the CPU PCB block diagram and to Figure S4-3 for

the CPU PCB schematic diagram in the following description. The CPU PCB

hardware and related circuitry, which is illustrated in the following block

diagram, includes the following subsystems:

• CPU — A 16-bit microprocessor that includes: a serial port, watchdog

timer, A/D converter with an 8-input analog multiplexer, 3-pulse width

modulators, and a high speed I/O subsystem.

• System memory — External to the CPU and consists of an 8K x 8

static RAM and a 64K x 16 EPROM.

• Display control — The CPU provides drive and control signals for the

LCD driver and display on the LCD PCB.

• Audio output drive— Drives a piezoelectric ceramic beeper on the

LCD PCB for audio output.

• Printer drive— The CPU provides a printer drive signal that is

applied to an IR LED on the LCD PCB.

• Power supply/Power control circuitry — The NPB-40 receives

power from 4 "AA" cell batteries. The power control circuitry

discontinues power to the unit when the batteries are no longer

reliable.

S-5

Page 38

Technical Supplement

From

batteries

3.6-6 Vdc

From front

panel keypad

On/off

key

Shift

key

Display light/

beep on/off

key

Store data/

print

key

Battery power

Power

switch

circuit

Power

shut off

control

Battery power

feedback

Power on

Battery

voltage

sense

RD/WR

AD 0-7

WR

AD 0-15

ALE

Power

supply

circuit

RAM

RAM

enable

Address

decoding

Address

latch

To LCD PCB

Raw

+10 Vdc

Raw

-5 Vdc

VCC (+5 Vdc)

To CPU PCB circuits

ADDR

0-12

ADDR

9-15

EPROM enable

ADDR

1-15

VCC

monitor

and

watchdog

reset

circuit

10MHz

clock

circuit

WD

RST

Microprocessor

AD 0-7

External

output

port

Analog sensor voltage reference

Analog circuit control signal

External

output

enable

Beeper drive

LCD light enable

LCD CLK,

DATA, CE

LCD enable

Printer LED signal

Analog sensor signal

RD

AD 0-15

To/from LCD PCB

EPROM

Beeper

LCD

backlight

LCD

driver

Printer

interface

V ref

Sensor

circuits

S-6

Figure S3-2: CPU PCB Block Diagram

Page 39

S3.2.1 CPU

Technical Supplement

The Intel 80C196KC CPU is a 16-bit microprocessor with built-in peripherals

including: a serial port, watchdog timer, A/D converter with an 8-input

analog multiplexer, three pulse width modulators, two 16-bit counter/timers,

up to 48 I/O lines, and a high speed I/O subsystem.

The CPU is capable of running up to 16 MHz, but it is run at 10 MHz for

decreased power consumption. All unused inputs are tied to either Vcc or

ground through resistors—this prevents unused inputs floating to any

voltage and causing excess power drain. The READY input pin is tied high,

thereby disabling wait-state generation; all bus accesses are zero wait-state.

The EA pin is tied low to enable addressing of the external EPROM.

When the power supply is first switched on by the power control circuit, the

watchdog reset circuit holds the CPU RESET pin low for at least 20 ms, then

allows the internal pull-up resistor to bring it high; this assures a good CPU

reset.

An internal watchdog timer is enabled and runs continuously. The watchdog

timer provides a means of recovering from a software upset caused by ESD,

EMI, etc.. If the software does not clear the timer at least every 64K

state-times (13.1 ms), the CPU will drive RESET low, resetting the entire

unit. The reset output by the CPU is only 16 state-times long (3.2 µs).

The CPU has the ability to dynamically switch the data bus width—based on

the BUSWIDTH input pin. A low on BUSWIDTH tells the CPU to access

memory only 8 bits at a time. When accessing the static RAM, BUSWIDTH is

low, automatically reading the 8-bit wide RAM. Since BUSWIDTH is

connected to the active low RAM enable line (RAMEN-L), all other memory

and mapped I/O are read or written 16 bits at a time.

Eight analog inputs are measured by the CPU. Input from the SpO2 analog

section on the LCD PCB includes AC and DC signals for the oximeter sensor

red and infrared channels, and the sensor calibration resistor RSENS. The

battery voltage and reference voltage from the LCD PCB are also measured.

The CPU is configured as follows:

• Decoded AD0 and BHE generate separate WR write strobes for the low

and high bytes of a word. The signal WR (pin WRL) is the low-byte

write strobe.

• A standard address latch enable (ALE) is generated and used.

• HSO4 and HSO5 are configured as outputs. The HSO is used to

generate stable timing control signals to the SpO2 analog section,

display, and printer driver.

• External control pins: P2.2, P2.3, and P2.4 are configured to monitor

front panel keyboard keys Store Data/Print, Display Light/Beep On/Off,

and Shift keys, respectively.

• Pins HSI0 is configured for interrupt input. The CPU receives one

external interrupt (signal PHOTOI).

S-7

Page 40

Technical Supplement

• P2.0 and P2.1 are configured as a standard asynchronous serial

transmitter and receiver for a factory serial interface.

• P2.5, P1.3, and P1.4 are configured as pulse width modulator outputs.

They are used with outputs from P1.6 and P2.6 to control gains within

the SpO2 analog section.

S3.2.1.1 Address Demultiplexing

U10 and U11 are transparent latches that latch the address portion of the AD

bus data on the falling edge of ALE; the outputs are always enabled. The

outputs of U10 and U11 are always the address portion of the AD bus.

S3.2.1.2 Address Decoding

The CPU has a 64-Kbyte address range of 0-FFFF. RAM, EPROM, and I/O

ports share this space. The address decoding circuit splits up this space and

output enable lines to the RAM, EPROM, and external output ports.

When address lines A13, A14, A15 are all high, the output of U7C goes low,

enabling the RAM and generates the active low enable signal RAMEN-L.

This occurs for the 8K address range of E000-FFFF.

U8 is used to generate the output port active low enable signal EXOUTEN-L.

When address lines A15, A14, A11, and A10 are high, and A13 is low, U8

becomes enabled. With U8 enabled, the Y3 output is set low. The output to go

low is selected by pins A, B, and C. They form a 3-bit binary number with pin

C being the most significant bit. So when address line A12 is high, WR active

(low) and RD inactive (high), a binary 3 is produced on pins A, B, and C,

forcing output Y3 (EXOUTEN-L) low. This enables the output port for

writing. Note that in this condition, A15, A14, A12, A11, and A10 are high

and A13 is low.

S3.2.2 CPU Memory

The output port uses the address space of DE00-DFFF. When data is written

to that address, the output port enable signal EXOUTEN-L is activated.

Because the CPU is configured to use a 16-bit bus, except for RAM, any even

address in the DE00-DFFF range could be used for external port access. In

other words, reading or writing address DF00, DE02, DE04, etc., will all

produce the same results.

U7A generates the EPROMs active low enable signal, ROMEN-L. The active

low signals RAMEN-L and EXOUTEN-L are basically used as EPROM

disable signals. When RAMEN-L or EXOUTEN-L or the Y3 output of U8 are

low, the output of U7A, ROMEN-L, is forced high, disabling the ROM.

Therefore, the EPROM is disabled for the range DE00-FFFF and enabled for

the address range of 0-DFFF.

The memory system external to the CPU consists of an 8 K x 8 static RAM

(U12) and a 64 K x 16 EPROM (U5). The EPROM is 16 bits wide to enhance

CPU performance. Because RAM is infrequently accessed, it is only 8 bits

wide. U12 is a standard 8K x 8 static RAM.

S-8

Page 41

The program that the CPU runs is stored in U5. U5 is a 16-bit wide output,

one-time programmable (OTP) EPROM. During 16-bit wide bus accesses, the

CPU uses address line A0 for low/high byte selection, and is not used as a

normal address line. The CPU can only address 64K x 8 bytes or 32K x 16

bytes. Pin A15 of U5 is tied low, always selecting the lower half of the

EPROM. Signal ROMEN-L is then used to enable the EPROM for the proper

memory area.

The output port external to the CPU consists of an octal D latch, U9. The

output of U9 is always enabled. The output bits of U9 control the beeper

output, the LCD backlight, and the LCD display drive signals.

S3.2.3 Standard User Controls

The standard user controls consist of four momentary push-button switches

on the front panel keypad. These keys are metal dome membrane contact

switches.

The front panel switches Store Data/Print, Display Light/Beep On/Off, and

Shift are connected to the microprocessor, U4, input lines P2.2, P2.3, and

P2.4 and are normally pulled to the high state by R10, R8, and R18.

Whenever one of these keys is pressed, the U4 input line is pulled low. The

switch contacts are debounced in software.

Technical Supplement

The fourth front panel switch, On/Off, is connected to the power switch

described Power Supply/Power Control Circuitry.

S3.2.4 Power Supply/Power Control Circuitry

The power supply and power control circuitry consists of the following

primary elements.

• Batteries — Four 1.5 V alkaline "AA" size batteries provide 3.6-6 Vdc

power.

• Power entry circuit — Components protect the NPB-40 from damage

if batteries are inserted incorrectly and provide reverse current limiting

and over-voltage or spike protection. In addition, a self-resetting fuse

protects the power supply from excessive current draw. The power

supply is also protected against electrostatic discharge and

electromagnetic interference.

• Power switch circuitry — This circuit controls power applied to the

power supply circuits. Power control circuitry is connected to the

batteries. It senses any press of the front panel keypad On/Off key and

switches the power supply circuit on or off. A control signal to this

circuit from the CPU will also shut off the NPB-40 when battery voltage

drops to an unusable level.

• Power supply circuits —consist of a power generation circuit that

provides +10Vdc, +5Vdc, and -5Vdc.

S-9

Page 42

Technical Supplement

S3.2.4.1 Power Entry Circuitry

Self-resetting fuse R22 protects the NPB-40 and will open when current in

excess of 0.75 Amps is drawn by the unit. R22 will close when the condition

causing excessive current has been eliminated. CR7 provides reverse current

protection and limits negative voltages (batteries reversed) to safe levels. In

either of these conditions, CR7 will conduct and cause fuse R22 to open. CR5

protects against large voltage transients caused by ESD, EMI, etc. and will

pass these undesirable transients to ground.

S3.2.4.2 Power Supply Feedback Circuitry

The power supply feedback circuit consists of Q1 and its associated

components. When batteries are installed and the NPB-40 is turned off, the

battery voltage (VBAT) is applied through resistor R2 at the collector of Q1

providing a logic 1 level voltage to the D input of flip-flop U1B in the power

switch circuit. When the NPB-40 is turned off, VCC is at 0 volts and Q1 is

turned off. When the NPB-40 is turned on (See “Power Switch Circuitry”), the

VCC potential is applied to the base of Q1, which turns it on. The voltage at

the D input of U1B then drops to a low voltage to provide a logic 0.

S3.2.4.3 Power Switch Circuitry

The power control circuit consists of U1B and its associated components. U1B

is a D flip/flop with asynchronous preset and clear; only the clear is used.

Battery voltage is applied to U1B whenever batteries are installed. The NPB40 is turned on and off by pressing the On/Off key on the front panel keypad.

The BTN PWR line is normally pulled up to the battery voltage by R3. When

battery voltage is at an acceptable level and the On/Off key on the front panel

keypad is pressed, the BTN PWR line is grounded and the resultant highgoing pulse from U2A toggles the CLK input of U1B and the high D input

logic level is transferred to the Q output. The logic state of the D input is

controlled by the power supply feedback circuitry (See “Power Supply

Feedback Circuitry”). When the NPB-40 is off the D input of U1B is high.

Pressing the front panel On/Off key sets the Q output and the PWR ON

signal high. This enables the power supply circuits, which then generate the

operating voltages for the NPB-40. The Q-not output of U1B is applied to U4

analog to digital converter input P0.6 through a battery voltage sensing

circuit consisting of U2B, R14, R17, and C14. When the battery voltage drops

below 3.6 Vdc, as measured by U4, the PWR DOWN line at U4 output HSO3

goes high and turns on Q2, which clears flip-flop U1B and the PWR ON

signal at the Q output goes low and turns off the power supply circuits.

When the NPB-40 is turned on, the D input of U1B is low (See “Power Supply

Feedback Circuitry”). When On/Off key on the front panel keypad is pressed,

the BTN PWR line is grounded and the resultant high going pulse from U2A

toggles the CLK input of U1B and the low D input logic level is transferred to

the Q output. This sets the Q output and the PWR ON signal low, which

turns off the power supply circuits.

S-10

Page 43

S3.2.5 Serial Interface

S3.2.6 Printer Control

Technical Supplement

S3.2.4.4 Power Supply Circuits

When the PWR ON signal at the S/S input of U3 is high, U3 generates a

square wave signal that drives the primary winding of transformer T1. The

three secondary windings of T1 are rectified and filtered to provide

RAW+10V, VCC (+5Vdc), and RAW-5V. The VCC signal is resistor divided by

R9 and R12 for a feedback voltage that U3 must see to continue operating.

VCC is used on the CPU and the LCD PCBs for operating circuit power.

RAW+10V and RAW-5V are supplied to the LCD PCB for backlight power

and for power conditioning for the SpO2 analog circuits.

The serial interface is only used for factory test purposes, and is not at the

RS-232 level, neither is it electrically isolated and, therefore, cannot be used

outside of the factory. The serial data port J5 is a TTL level serial interface.

RXD and TXD are configured as a standard asynchronous serial transmitter

and receiver at 19.2 Kbaud with 1 stop bit, 8 data bits, and no parity. The

serial interface can operate in full duplex mode. If no external serial data

device is connected, R19 pulls the RXD input high which prevents the input

from floating when it is not being used.

Microprocessor U4 provides a drive signal (IR OUT) at HSO5 that controls an

infrared LED on the LCD PCB which is used to interface with an external

printer.

S3.2.7 External VCC Monitor and Watchdog Timer

The external VCC monitor and watchdog timer circuit consists of U6 and

associated components. U6 provides two functions. If the VCC input voltage

drops below 4.0 Vdc, U6 will drive the RST-L line low, which resets

microprocessor, U4. U6 also periodically receives the WD RST pulse output

from U4. If U6 does not receive the WD RST signal at least every 500 ms, it

will drive the RST-L line low, which resets U4.

S3.3 LCD PCB Theory of Operation

Refer to Figure S3-3 for the LCD PCB block diagram and to Figure S4-4 for

the LCD PCB schematic diagram in the following description. This subsection

describes the SpO2 analog hardware. The analog circuitry has high signal

sensitivity and reduced susceptibility to noise. Its design allows for a wide range

of input signal levels and a broad range of pulsatile modulation. The SpO2 analog

circuitry consists of four subsections:

• Sensor output/LED control —The CPU controls the gain of both

LEDs so that signals received at the input amplifier are within an

acceptable dynamic range. Signal channel gain may also need to be

increased. The CPU uses Pulse Width Modulation (PWM) lines to

control LED current level or to amplify the signal channel.

• Input conditioning —Sensor output current is converted to voltage. A

demodulation circuit minimizes the effects of other light sources and

stray frequency inputs. Because the IR and RED signals are at different

current levels, the two LED signals are demultiplexed and separately

amplified, so they can be compared with each other. Two circuits handle

the demultiplexing by alternately selecting LED signals using switches.

S-11

Page 44

Technical Supplement

Filters then remove noise and smooth the signals before sending them

to the amplifiers.

• Signal gain —The separated LED signals are amplified so that their

current levels are within the A/D converter's acceptable range. The

signals are filtered to improve the signal-to-noise ratio, and clamped to

a reference voltage.

• AC ranging —DC offset is eliminated from each LED signal. An

analog switch sets the mean signal value to the mean of the A/D

converter range, and the AC modulation is superimposed on that DC

level. Then, each AC signal is amplified and filtered to eliminate

residual effects of the PWM modulations. Finally, these two signals are

input to the CPU A/D converter.

S-12

Page 45

Technical Supplement

The relationship between these subsections is shown in the LCD PCB block

diagram, Figure S3-3.

To/from CPU PCB

Raw +10 Vdc

Raw -5 Vdc

V ref

Printer

LED signal

LCD clock

LCD data

LCD enable

LCD light enable

Power

conditioning

LCD

driver

+10Vdc

-5 Vdc

Printer

IR LED

LCD

Beeper drive

Analog sensor

signal

Analog circuit

control signals

Red

channel

IR

channel

LED

drive

To/from patient sensor

LED drive

RSENS

Photodiode

LCD

backlight

Beeper

Sensor

D-connector

S3.3.1 Sensor Output/LED Control

The SpO2 analog circuitry provides control of the red and IR LEDs such that

the received signals are within the dynamic range of the input amplifier.

Because excessive current to the LEDs will induce changes in their spectral

output, it is sometimes necessary to increase the received signal channel

gain. To that point, the CPU controls both the current to the LEDs and the

amplification in the signal channel.

Figure S3-3: LCD PCB Block Diagram

S-13

Page 46

Technical Supplement

At initialization of transmission, the LEDs' intensity level is based on

previous running conditions, and the transmission intensity is adjusted until

the received signals match the range of the A/D converter. If the LEDs reach

maximum output without the necessary signal strength, the PWMs will

increase the channel gain. The PWM lines will select either a change in the

LED current or signal gain, but will not do both simultaneously.

The LED drive circuit switches between red and IR transmission and disables

both for a time between transmissions in order to provide a no-transmission

reference. To prevent excessive heat build-up and prolong battery life, each

LED is on for only a small portion of the duty cycle. Also, the frequency of

switching is well above that of motion artifact and not a harmonic of known

AC transmissions. The LED switching frequency is 1.485 kHz. The IR

transmission alone, and the red transmission alone, will each be on for about

one-fifth of the duty cycle; this cycle is controlled by the HSOs of the CPU.

The IR and red LEDs are separately controlled with their drive currents

multiplexed over two shared wires. Current to the IR LED is in the range of

4.3-50.0 mA; and, current to the red LED is in the range of 4.3 to 50 mA.

Currents are limited to less than 100 mA for two reasons: (1) slight excess

current can potentially change the emission characteristics of the LEDs, and

(2) large excess current could create excessive heat at the sensor site.

The IR/red LED transmission signal (HSO1 of the CPU) is fed into the select

inputs of the triple single-pole-double-throw (SPDT) analog multiplexing

switch U7, causing either the IR or the red LED transmission to be enabled.

PWM1, which is filtered by the network of R45, R35, C41, and C42, is input

to the LED drive circuit switch U7 and controls the magnitude of the IR LED

current supply.

PWM2, which is filtered by the network of R29, R39, C35, and C23, is also

input to U7 and controls the red LED current magnitude.

Two NPN transistors (Q8 and Q10) act as current sources for the IR and red

LED outputs. Two PNP transistors (Q9 and Q11) act as switches between the

IR and red LED output lines. Transistor Q12 acts as an LED drive current

limiter; it clamps the output of the current regulator circuit to the required

level. If any resistor in the LED drive circuit fails, current to the LED will

still be limited to a safe level.

The RSENS line senses the RCal value and enables the CPU to make the

proper calculations based on the type of sensor being used.

S3.3.2 Input Conditioning

Input to the SpO

photodiode. In order to condition the signal current, it is necessary to convert

the current to voltage.

A differential synchronous demodulation circuit is used to reduce the effects

of other light sources and stray frequency inputs to the system. Because the

IR and red signals are absorbed differently by body tissue, their received

signal intensities are at different levels. Therefore, the IR and red signals

must be demodulated and then amplified separately in order to compare

them to each other. Demultiplexing is accomplished by means of two circuits

that alternately select the IR and red signal. Selection of the circuits is

controlled by two switches that are coordinated with the IR and red

transmissions. A filter with a large time constant follows to smooth the signal

and remove noise before amplification.

2 analog circuit is the current output of the sensor

S-14

Page 47

Technical Supplement

Before the current from the photodetector is converted to voltage, any high

frequency noise is filtered by C9 and R21. The op-amp U5A is used in parallel

with the current-to-voltage converter U5B to cancel any DC voltage,

effectively AC coupling the output of U5B. The average value of the SpO

2

analog reference voltage (VREF) of U5B, 5 V, is measured at test point 6.

U3B, a single-pole-single-throw (SPST) analog switch, is controlled by the

same line that controls the on/off pulsing of the LEDs. When either of the

LEDs are on (the line is low and the switch is closed) U4B is used as a

noninverting amplifier. When the LEDs are both off, U4B is used an

inverting amplifier. The signal at the output of amplifier U4B is then

demultiplexed.

The CPU HSO lines SAMPRED and SAMPIR, which are both active low,

control SPST analog switches in U3A and U3C respectively. Switch U3A is

closed to sample the red signal; switch U3C is closed to sample the IR signal.

The sampling rate for both switches is 10 kHz. Switching is coordinated with