DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD4726

RS-232 LINE DRIVER/RECEIVER

The µPD4726 is a high-voltage silicon gate CMOS line driver/receiver conforming to EIA/TIA-232-E Standards.

It contains a DC/DC converter and can operate with a +5 V single power supply. In addition, it is also provided with

ancillary functions such as a standby function.

This IC is equipped with four driver circuits and seven receiver circuits and can configure a simple RS-232 interface

circuit with only four external capacitors.

FEATURES

Conforms to EIA/TIA-32-E (old RS-232C) Standards

•

+5 V single power supply

•

A standby mode can be set by making the standby pin low to reduce the power dissipation. At this time, the driver

•

outputs go into a high-impedance state.

Two receiver circuits can operate as inverters without a hysteresis width even in the standby mode. The remaining

•

five receiver circuits are fixed to the high level.

ORDERING INFORMATION

Part Number Package Quality Grade

µ

PD4726GS-BAF 36-pin plastic SSOP (300 mil) Standard

Please refer to "Quality grade on NEC Semiconductor Devices" (Document number IEI-1209) published by NEC

Corporation to know the specification of quality grade on the devices and its recommended applications.

Document No. IC-3413 (1st edition)

(O.D.No. IC-8923)

Date Published March 1997 P

Printed in Japan

©

1994

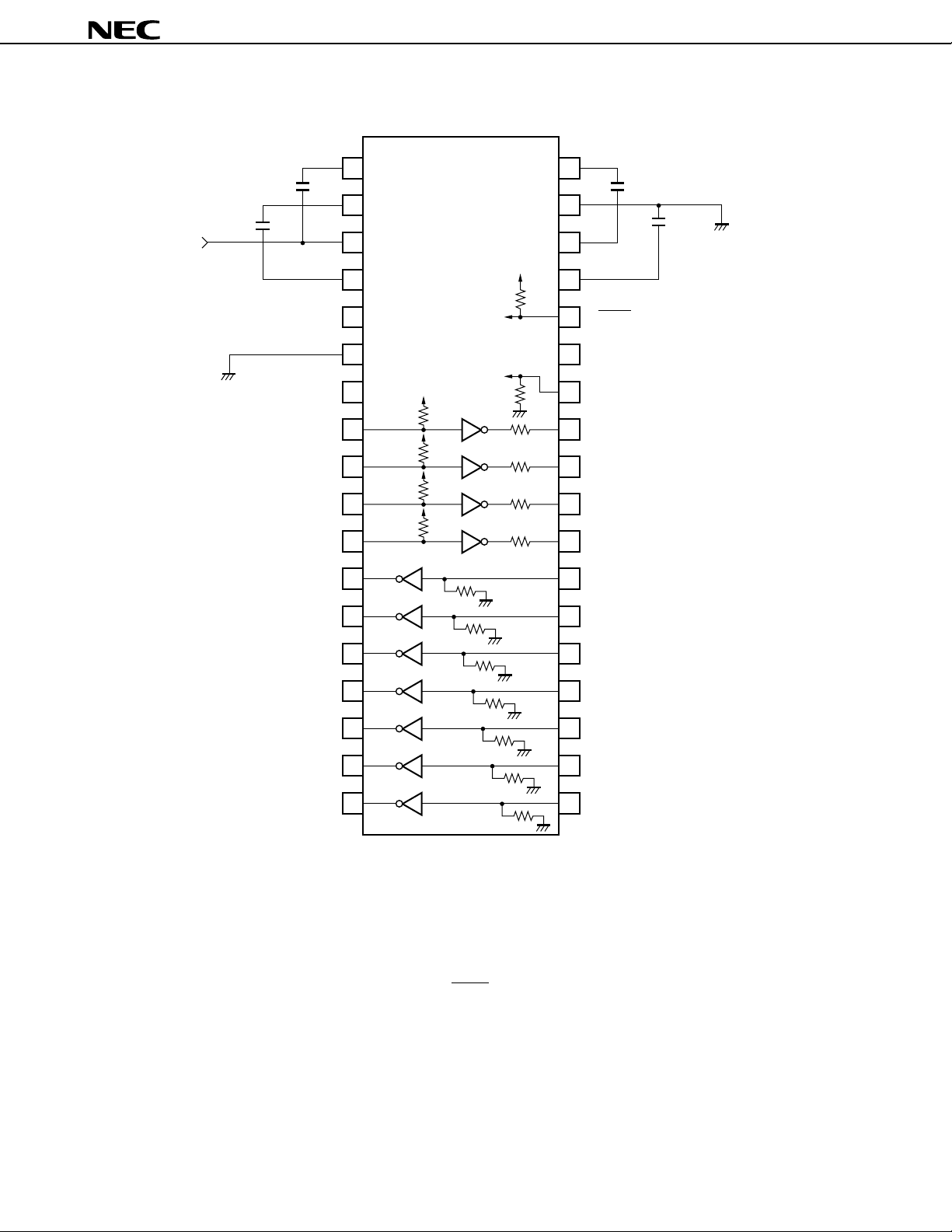

BLOCK DIAGRAM/PIN CONFIGURATION (Top View)

µ

PD4726

+5 V

+10 V

1

V

10

11

12

DD

+

2

C

1

3

V

CC

-

4

C

1

5

N.C.

6

GND

N.C.

7

To internal

circuit

To internal

circuit

8

9

+

C

3

+

C

1

D

IN1

D

IN2

D

IN3

D

IN4

R

OUT1

C

GND

C

V

+

36

4

35

-

34

4

33

SS

32

31

30

29

28

27

26

25

STBY

GND

EN

D

OUT1

D

OUT2

D

OUT3

D

OUT4

R

IN1

+

C

4

+

C

2

−10 V

24

R

23

22

21

20

19

IN2

R

IN3

R

IN4

R

IN5

R

IN6

R

IN7

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

13

14

15

16

17

18

R

R

R

R

R

R

Notes1. VDD and VSS output internally boosted voltages. Do not connect a load directly to these pins.

2. It is recommended that capacitors having a breakdown voltage of 20 V or higher be used as C

5. Inserting a bypass capacitor of 0.1 to 1

C

µ

F in between VCC and GND is also recommended.

3. Be sure to connect all the GND pins. Especially, make sure that pin 31 is connected; otherwise, the

µ

PD4726 will not operate normally. Be sure to leave the NC pins (pins 5 and 7) open.

4. The pull-up resistors for D

IN1 through DIN4 and STBY and the pull-down resistor for EN are active resistors.

1 through

2

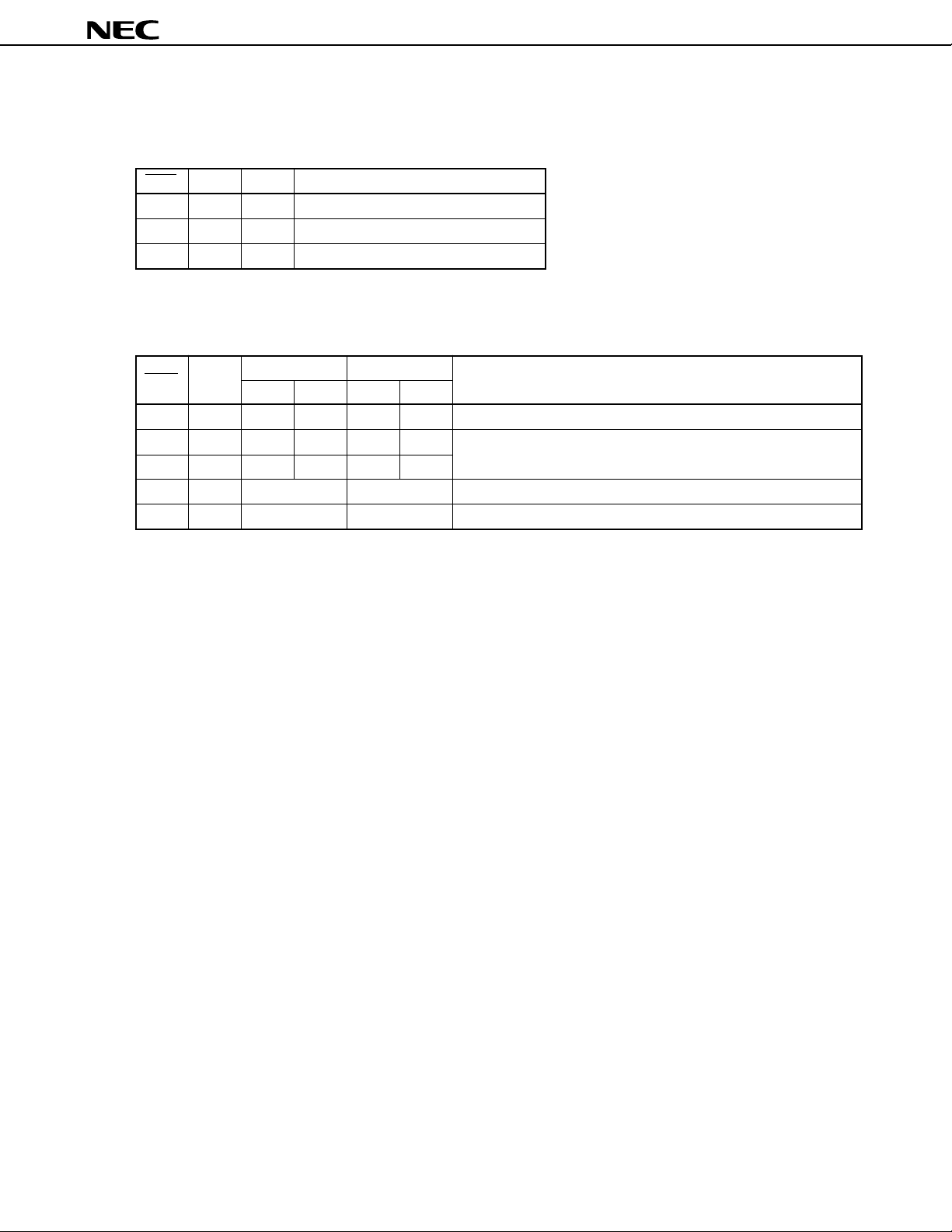

TRUTH TABLE

Drivers

STBY DIN DOUT Remarks

L × Z Standby mode (DC/DC converter stops.)

H L H Space level output

H H L Mark level output

Receivers

µ

PD4726

STBY EN

LL××H H Standby mode 1 (DC/DC converter stops.)

LHL×H H Standby mode 2 (DC/DC converter stops. R6 and R7 operate.)

LHH×LH

H× L H Mark level input

H × H L Space level input

H: high level

L : low level

Z : high impedance

× : H or L

RIN ROUT

R6 - R7 R1 - R5 R6 - R7 R1 - R5

Remarks

3

ABSOLUTE MAXIMUM RATING (Ta = 25 °C)

Parameter Symbol Ratings Unit

Supply voltage VCC −0.5 to +7.0 V

Driver input voltage DIN −0.5 to V CC + 0.5 V

Receiver input voltage RIN −30.0 to +30.0 V

Control input voltage VIN −0.5 to VCC + 0.5 V

(STBY, EN)

Driver output voltage DOUT −25.0 to +25.0

Receiver output voltage ROUT −0.5 to VCC + 0.5 V

Input current (DIN, STBY, EN) IINI ±20.0 mA

Operating ambient temperature Topt. −40 to +85 °C

Storage temperature Tstg. −55 to +150 °C

Permissible package power PT 0.5 W

dissipation

Note 5. Pulse width: 1 ms, duty cycle: 10 % MAX.

Note 5

µ

PD4726

V

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol MIN. TYP. MAX. Unit

Supply voltage (VCHA = L) VCC 4.5 5.0 5.5 V

Input voltage, high (DIN)VIH 2.0 V CC V

Input voltage, low (DIN)VIL 0 0.8 V

Input voltage, high (STBY, EN) VIH 2.4 VCC V

Input voltage, low (STBY, EN) VIL 0 0.8 V

Receiver input voltage RIN −30 +30 V

Operating ambient temperature Topt. −40 +85 °C

External capacitance (nominal value) Note 6 1 4.7

Note 6. Use capacitors whose capacitance fluctuation is within ±50 % including fluctuations due to temperature

µ

and tolerance (effective value: 0.5 to 7.05

F).

Use of capacitors with excellent high-frequency characteristics (such as multilayer ceramic capacitors,

tantalum capacitors, and aluminum electrolytic capacitors for switching power supply) is recommended.

Keep the wiring length between a capacitor and an IC pin as short as possible.

µ

F

4

µ

PD4726

ELECTRICAL SPECIFICATIONS (CHIP)

(Unless otherwise specified, Ta = −40 to +85 °C, C1 through C5 = 1 µF)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Circuit current ICC1 VCC = +5.0 V, no load, RIN pin open, 12 mA

STBY = H

Circuit current ICC2 VCC = +5.0 V, RL = 3 kΩ (DOUT), 38 mA

DIN = GND, RIN, ROUT pins open,

STBY = H

Circuit current in standby ICC3 VCC = +5.0 V, no load, 9 20

mode (standby mode 1) DIN, RIN pins open, STBY = L, EN = L,

Ta = 25 °C

VCC = +5.0 V, no load, 15

DIN, RIN pins open, STBY = L, EN = L,

Circuit current in standby ICC4 VCC = +5.0 V, no load, 9 20

mode (standby mode 2) DIN, RIN pins open, STBY = L, EN = H,

Ta = 25 °C

VCC = +5.0 V, no load, 15

DIN, RIN pins open, STBY = L, EN = H,

Ta = 25 °C

Input voltage, high VIH STBY, EN pins, 2.4 V

VCC = +4.5 to +5.5 V

Input voltage, low VIL STBY, EN pins, 0.8 V

VCC = +4.5 to +5.5 V

Input current, high IIH STBY pin, VCC = +5.5 V, VI = +5.5 V 1

Input current, low IIL STBY pin, VCC = +5.5 V, VI = 0 V −40

Input current, high IIH EN pin, VCC = +5.5 V, VI = +5.5 V 40

Input current, low IIL EN pin, VCC = +5.5 V, VI = 0 V −1

Input capacitance CIN Driver inputs and receiver inputs, 10 pF

VCC = +5.0 V, vs. GND, f = 1 MHz

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

Remark TYP. value is a reference value at Ta = 25 °C.

5

µ

ELECTRICAL SPECIFICATIONS (DRIVERS)

(Unless otherwise specified, Ta = −40 to +85 °C, VCC = +5.0 V ±10 %, C1 through C5 = 1 µF)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input voltage, low VIL 0.8 V

Input voltage, high VIH 2.0 V

Input current, low IIL −40

Input current, high IIH 1.0

Output voltage VDO VCC = +5.0 V, RL = ∞, Ta = 25 °C ±9.7 V

VCC = +5.0 V, RL = 3 kΩ, Ta = Topt. ±5.5 V

VCC = +4.5 V, RL = 3 kΩ, Ta = Topt. ±5.0 V

Output short current ISC VCC = +5.0 V, vs. GND ±40 mA

Slew rate SR C L = 10 pF, RL = 3 to 7 kΩ 4.0 30 V/µs

CL = 2 500 pF, RL = 3 to 7 kΩ 4.0 30 V/µs

Propagation delay time

Output resistance R0 VCC = VDD = VSS = 0 V 300 Ω

Standby output transition time tDAZ RL = 3 kΩ, CL = 2500 pF,

Standby output transition time tDZA RL = 3 kΩ, CL = 2500 pF,

Power-ON output transition time tPRA RL = 3 kΩ, CL = 2500 pF,

Note 8

tPHL RL = 3 kΩ, CL = 2 500 pF 2

tPLH

VOUT = ±2 V

Note 9

Note 9

Note 10

410

0.5 1 ms

0.5 1 ms

PD4726

µ

A

µ

A

µ

s

µ

s

Remark TYP. value is a reference value at Ta = 25 °C.

Note 8. Test point

V

CC

D

IN

0 V

+

V

DO

D

OUT

−

V

DO

−3 V

0.8 V

t

PLH

+5 V

+3 V +3 V

+

SR

2.0 V

t

PHL

−3 V

SR

−5 V

−

6

Note 9. Test point

µ

PD4726

V

CC

STBY

0.6 V

0 V

t

DAZ

+

V

DO

D

OUT

−

V

DO

+5 V

High impedance

−5 V

The driver output is undefined during the standby output transition time t

the standby output transition time t

DZA after the standby mode has been released.

Note 10. Test point

5 V

V

CC

0 V

4.5 V

2.4 V

t

DZA

+5 V

−5 V

DZA. Do not perform communication within

t

PRA

+

V

DO

−

DO

High impedance

D

OUT

V

+5 V

−5 V

The driver output is undefined during the power-ON output transition time t

within the power-ON output transition time t

PRA on power application.

PRA. Do not perform communication

7

µ

ELECTRICAL SPECIFICATIONS (RECEIVERS)

(Unless otherwise specified, VCC = 4.5 to 5.5 V, Ta = −40 to +85 °C, C1 through C5 = 1 µF)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Output voltage, low VOL1 IOUT = 4 mA 0.4 V

(STBY = H)

Output voltage, high V OH1 IOUT = −4 mA VCC − 0.4 V

(STBY = H)

Output voltage, low VOL2 IOUT = 4 mA 0.5 V

(STBY = L)

Output voltage, high V OH2 IOUT = −4 mA VCC − 0.5 V

(STBY = L)

Propagation delay time tPHL RIN → ROUT, CL =150 pF 0.2

(STBY = H) tPLH VCC = +4.5 V,

Propagation delay time tPHL RIN → ROUT (R6, R7), CL =150 pF 0.1

(STBY = L, EN = H) tPLH VCC = +4.5 V,

Propagation delay time tPHA EN → ROUT (R6, R7), CL =150 pF 100 300 ns

(STBY = L) tPAH VCC = +4.5 V,

Input resistance RI 3 5.5 7 kΩ

Open voltage across input pins VIO 0.5 V

Input threshold voltage V IH VCC = +4.5 to +5.5 V 1.7 2.3 2.7 V

(STBY = H)

VIL VCC = +4.5 to +5.5 V 0.7 1.1 1.7 V

VH VCC = +4.5 to +5.5 V 0.5 1.2 1.8 V

(hysteresis width)

Input threshold voltage V IH VCC = +4.5 to +5.5 V, RIN6, RIN7 2.7 1.5 V

(STBY = L, EN = H)

VIL VCC = +4.5 to +5.5 V, RIN6, RIN7 1.5 0.7 V

Standby output transition time tDAH Note 13 0.2 3

Standby output transition time tDHA Note 13 0.3 1 ms

Power-ON output transition time tPRA Note 14 0.5 1 ms

Note 11

Note 11

Note 12

PD4726

µ

s

µ

s

µ

s

Remark TYP. value is a reference value at Ta = 25 °C.

Note 11. Test point

+3 V

R

IN

0 V

0.7 V

−3 V

t

PLH

V

OH

R

OUT

V

OL

2.0 V

8

2.7 V

t

PHL

0.8 V

Note 12. Test point

VCC

µ

PD4726

ROUT

Note 13. Test point

STBY

EN

0 V

VOH

VOL

V

0 V

V

CC

OH

STBY = L

2.4 V

0.6 V

t

DAH

0.8 V

0.6 V

tPAHtPHA

2.4 V

t

DHA

2.0 V

R

OUT

2.0 V

0.8 V

V

OL

The receiver output is undefined during the standby output transition time tDHA. Do not perform communication

within the standby output transition time t

DHA after the standby mode has been released.

Note 14. Test point

5 V

V

CC

0 V

V

OH

R

OUT

V

OL

The receiver output is undefined during the power-ON output transition time t

within the power-ON output transition time t

PRA on power application.

4.5 V

t

PRA

0.8 V

PRA. Do not perform communication

9

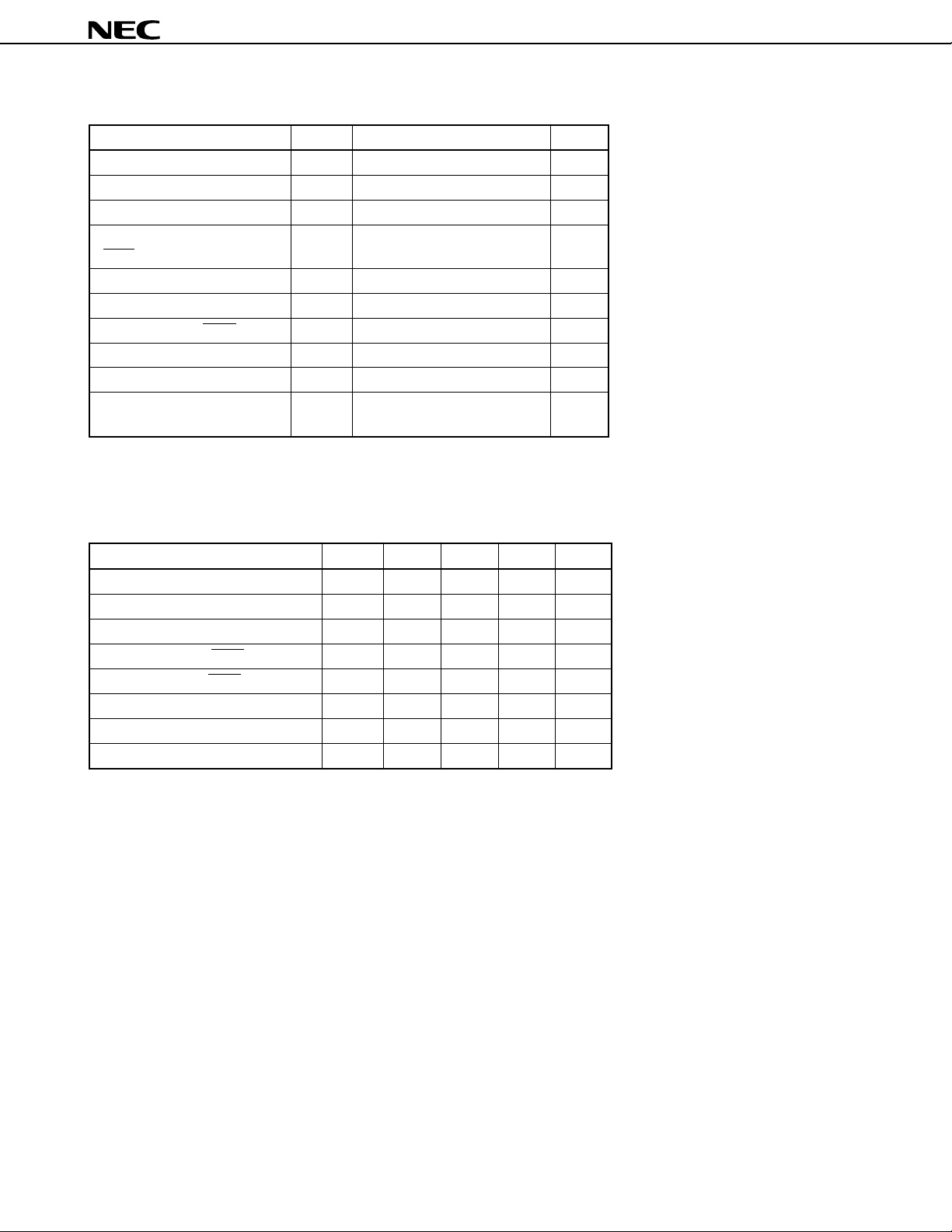

36 PIN PLASTIC SHRINK SOP (300 mil)

µ

PD4726

118

A

G

F

E

C

MD

N

M

NOTE

Each lead centerline is located within 0.10

mm (0.004 inch) of its true position (T.P.) at

maximum material condition.

1936

detail of lead end

5°±5°

H

I

K

L

B

P36GM-80-300B-3

ITEM MILLIMETERS INCHES

M

A

B

C

D

E

F

G

H

I

J

K

L

15.54 MAX.

0.97 MAX.

0.8 (T.P.)

+0.10

0.35

–0.05

0.125±0.075

1.8 MAX.

1.55

7.7±0.3

5.6

1.1

+0.10

0.20

–0.05

0.6±0.2

0.10

0.612 MAX.

0.039 MAX.

0.031 (T.P.)

+0.004

0.014

–0.003

0.005±0.003

0.071 MAX.

0.061

0.303±0.012

0.220

0.043

+0.004

0.008

–0.002

+0.008

0.024

–0.009

0.004

N 0.10 0.004

J

10

µ

PD4726

RECOMMENDED SOLDERING CONDITIONS

Solder and mount the µPD4726 under the following recommended conditions.

Consult NEC for conditions other than those recommended.

µ

PD4726GS-BAF

Soldering method Soldering conditions Symbol

Infrared ray reflow Peak temperature of package surface: 235 °C, IR35-00-2

Reflow time: Within 30 sec (210 °C or higher),

Number of reflow process: 2, Exposure limit: None

VPS Peak temperature of package surface: 215 °C, VP15-00-2

Reflow time: Within 40 sec (200 °C or higher),

Number of reflow process: 2, Exposure limit: None

Wave soldering Solder temperature: 260 °C or lower, Reflow time: Within 10 sec, WS60-00-1

Number of reflow process: 1, Exposure limit: None

Partial heating Pin temperature: 300 °C or lower, Time: Within 10 sec,

Exposure limit: None

Note

Note

Note

Note

Note Exposure limit before soldering after dry-package is opened. Storage condition: 25 °C and relative humidity

at 65 % or less.

Caution Do not use two or more soldering methods in combination (except the partial heating method).

REFERENCE

Document name Document No.

Semiconductor Device Mounting Technology Manual IEI-1207

Quality grade on NEC Semiconductor Devices IEI-1209

NEC Semiconductor Device Reliability/Quality Control system IEI-1212

11

µ

PD4726

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96.5

Loading...

Loading...