DATA SHEET

PHOTOCOUPLER

PS9513,PS9513L1,PS9513L2,PS9513L3

1 Mbps, OPEN COLLECTOR OUTPUT, FOR GATE DRIVE INTERFACE

INTELLIGENT POWER MODULE

8 mm CREEPAGE 8-PIN DIP HIGH-SPEED PHOTOCOUPLER

DESCRIPTION

The PS9513, PS9513L1, PS9513L2 and PS9513L3 are optically coupled isolators containing a GaAlAs LED on the

input side and a photo diode and a signal processing circuit on the output side on one chip.

The PS9513 is designed specifically for high common mode transient immunity (CMR) and low pulse width

distortion with operating temperature. It is suitable for IPM drive.

The PS9513L1 is lead bending type for long creepage distance.

The PS9513L2 is lead bending type for long creepage distance (Gull-wing) for surface mount.

The PS9513L3 is lead bending type (Gull-wing) for surface mounting.

FEATURES

• Long creepage distance (8 mm MIN. : PS9513L1, PS9513L2)

• High common mode transient immunity (CM

• High-speed response (t

• Maximum propagation delays (t

• Pulse width distortion ( | t

PHL = 500 ns MAX., tPLH = 750 ns MAX.)

PLH − tPHL = 270 ns TYP.)

PHL − tPLH | = 270 ns TYP.)

H, CML = ±15 kV/

μ

s MIN.)

• Open collector output

• Ordering number of tape product : PS9513L2-E3 : 1 000 pcs/reel

: PS9513L3-E3 : 1 000 pcs/reel

• Pb-Free product

• Safety standards

• UL approved: File No. E72422

• CSA approved: No. CA 101391

• BSI approved: No. 8937, 8938

• SEMKO approved: No. 615433

• NEMKO approved: No. P06207243

• DEMKO approved: No. 314091

• FIMKO approved: No. FI 22827

• DIN EN60747-5-2 (VDE0884 Part2) approved (Option)

APPLICATIONS

• IPM Driver

• General purpose inverter

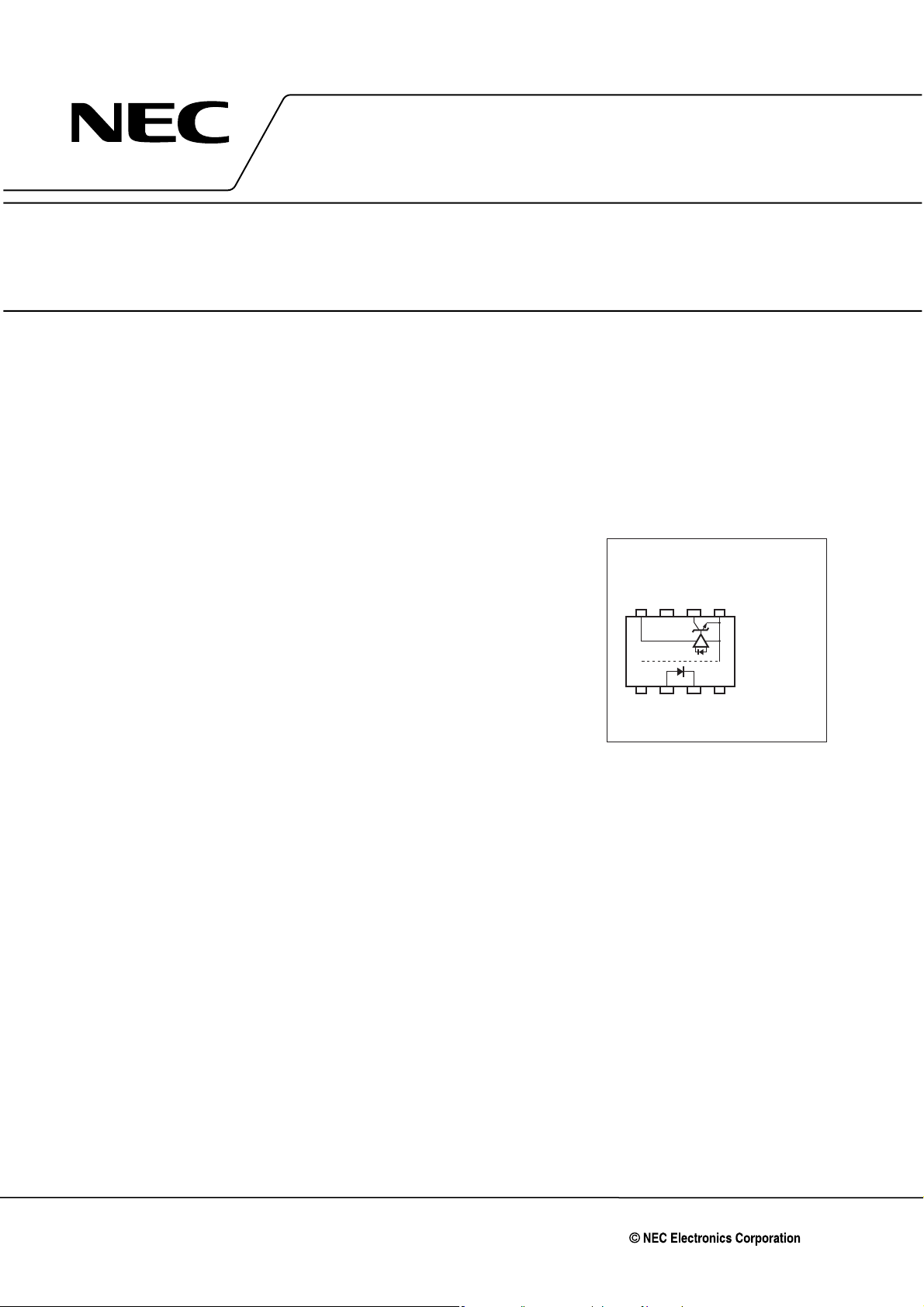

PIN CONNECTIONS

(Top View)

8

7

243

1

5

6

−NEPOC Series−

1. NC

2. Anode

3. Cathode

4. NC

5. GND

6. V

O

7. NC

8. V

CC

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all products and/or types are available in every country. Please check with an NEC Electronics

sales representative for availability and additional information.

Document No. PN10679EJ02V0DS (2nd edition)

Date Published August 2008 NS

Printed in Japan

The revised points can be easily searched by copying an "<R>" in the PDF file and specifying it in the "Find what:" field.

The mark <R> shows major revised points.

2007, 2008

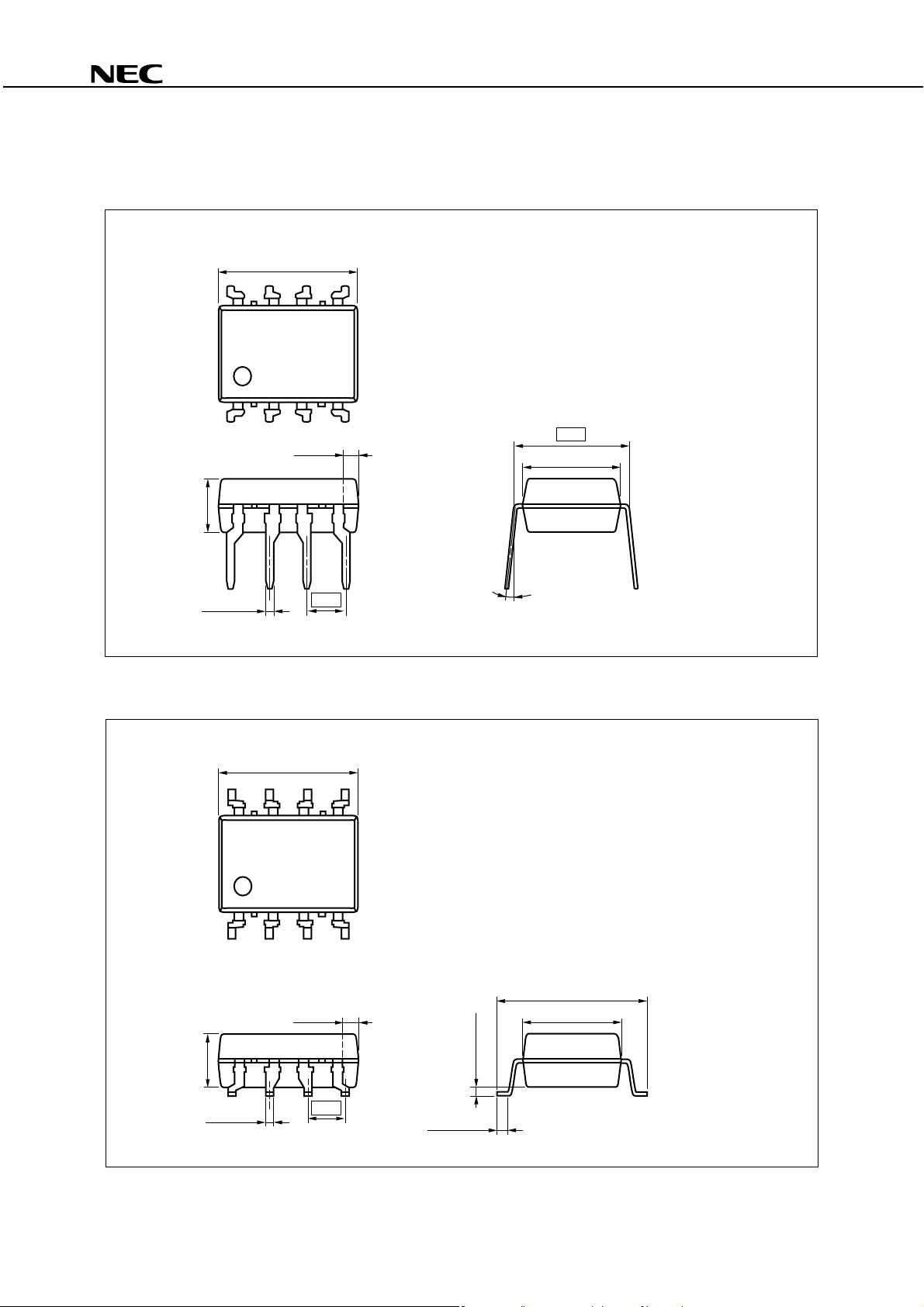

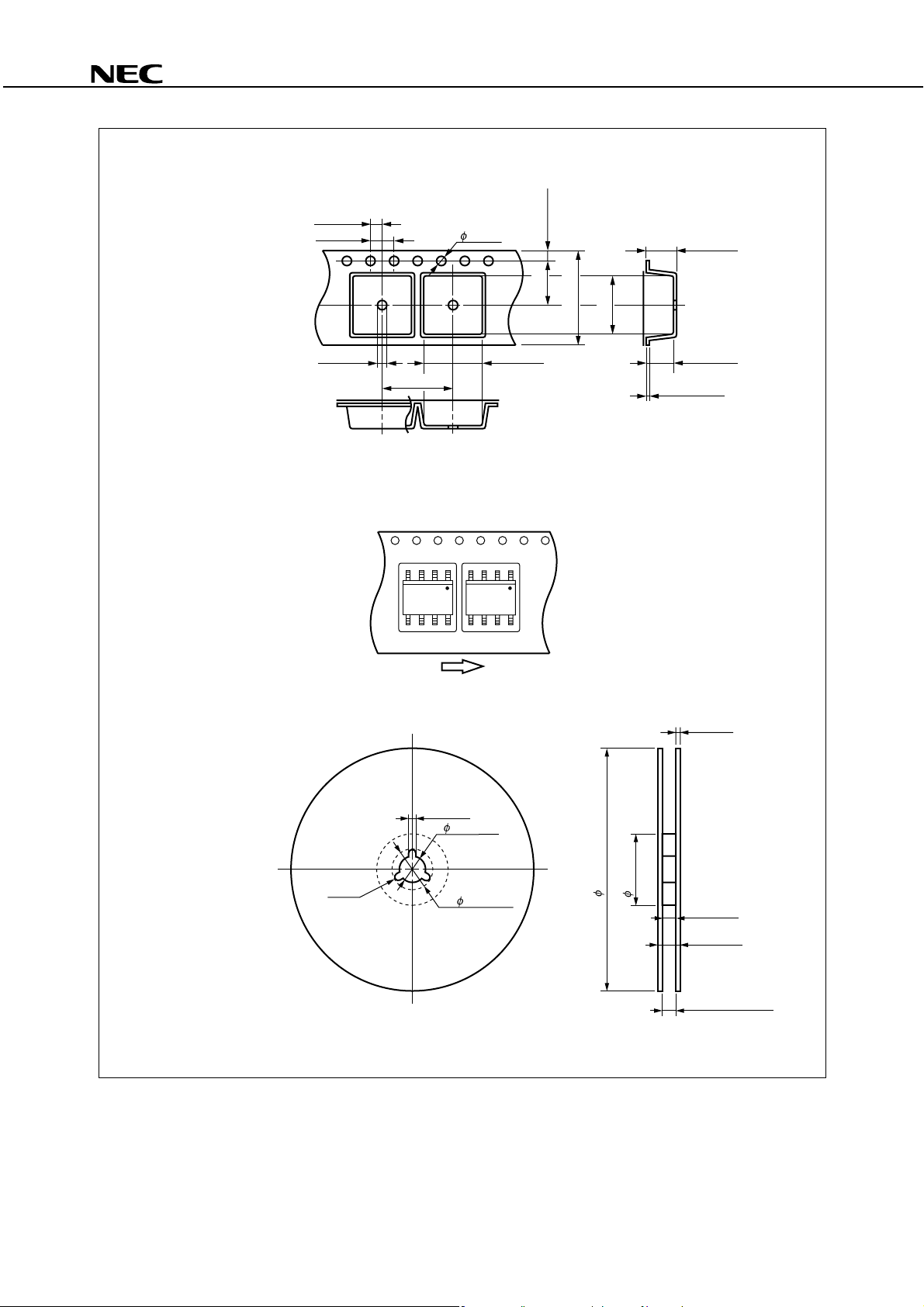

PACKAGE DIMENSIONS (UNIT: mm)

DIP Type

+0.5

9.25

–0.25

PS9513,PS9513L1,PS9513L2 PS9513L3

PS9513

+0.4

1.01

–0.2

3.5±0.2

0.5±0.15

2.54

Lead Bending Type (Gull-wing) For Surface Mount

PS9513L3

9.25

+0.5

–0.25

7.62

6.5

0 to 15˚

+0.5

–0.1

2

3.5±0.2

0.5±0.15

1.01

+0.4

–0.2

2.54

0.635±0.15

0.74±0.25

Data Sheet PN10679EJ02V0DS

9.65±0.4

+0.5

6.5

–0.1

PS9513,PS9513L1,PS9513L2 PS9513L3

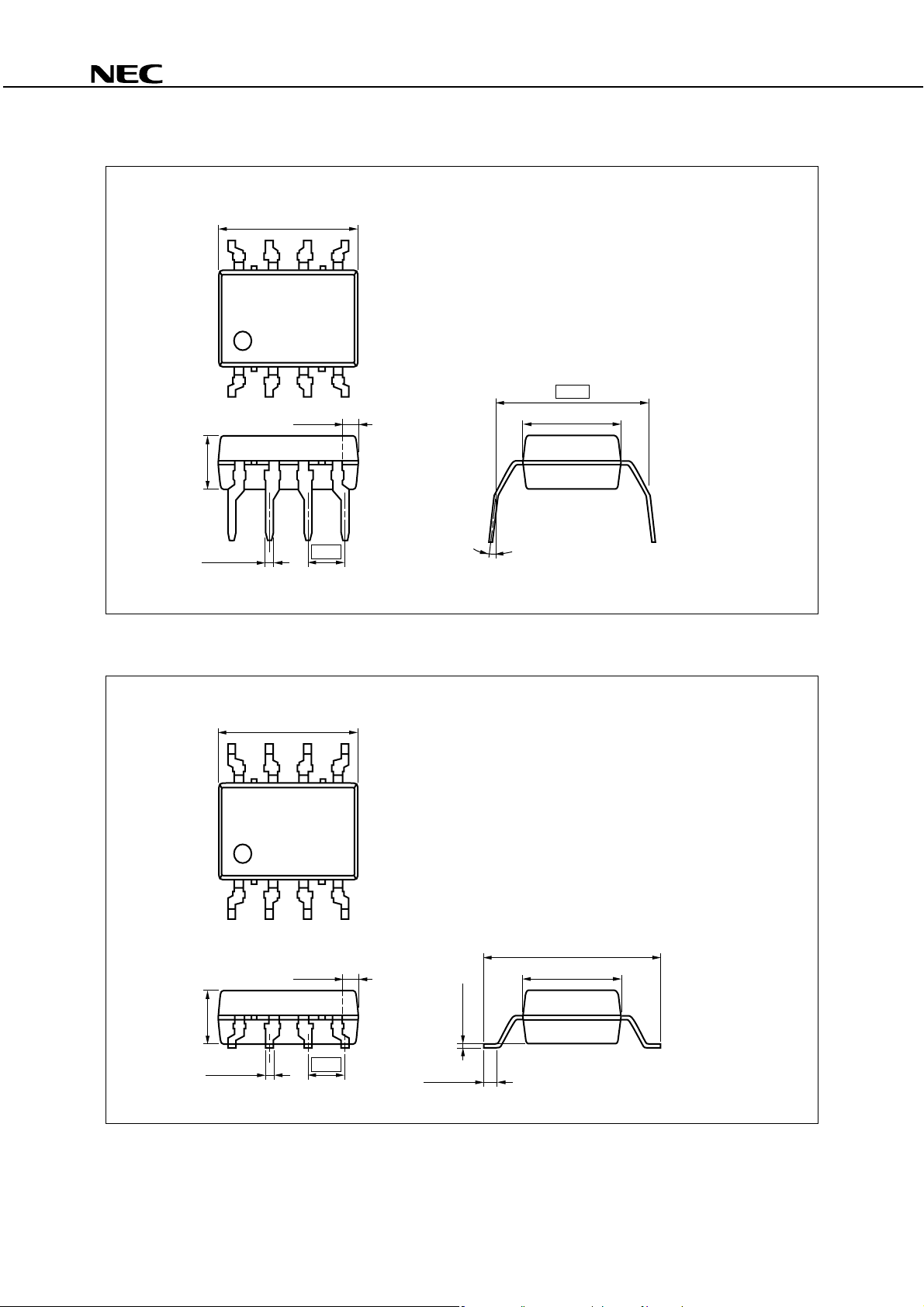

Lead Bending Type For Long Creepage Distance

PS9513L1

+0.5

9.25

–0.25

+0.4

1.01

–0.2

3.5±0.2

10.16

6.5

+0.5

–0.1

0.5±0.15

2.54

0 to 15˚

Lead Bending Type For Long Creepage Distance (Gull-wing) For Surface Mount

PS9513L2

11.8±0.4

+0.5

6.5

–0.1

9.25

+0.5

–0.25

1.01

+0.4

–0.2

3.5±0.2

0.5±0.15

2.54

0.25±0.2

0.9±0.25

Data Sheet PN10679EJ02V0DS

3

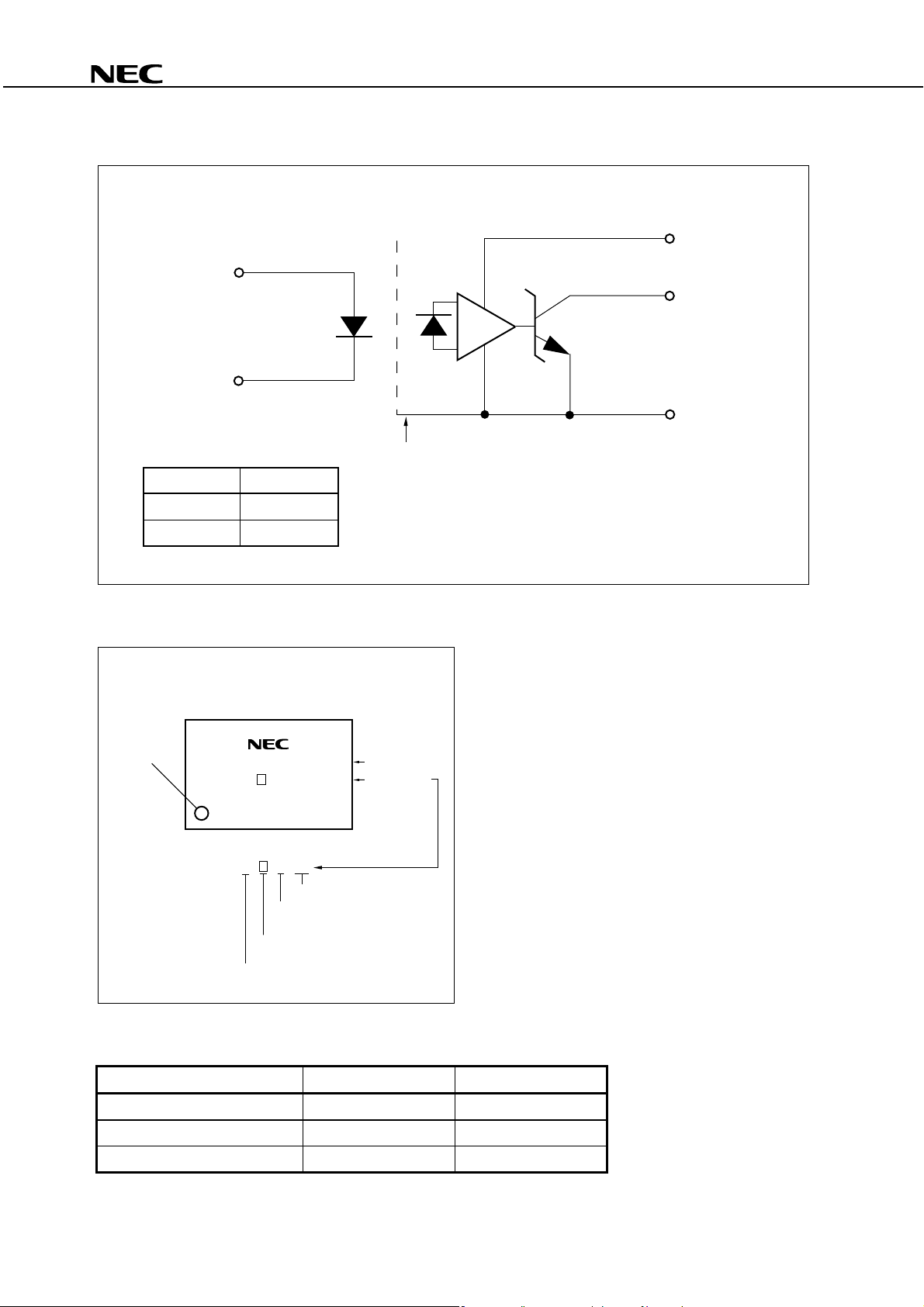

PS9513,PS9513L1,PS9513L2 PS9513L3

FUNCTIONAL DIAGRAM

8

2

6

3

5

Shield

<R>

LED

ON L

OFF

MARKING EXAMPLE

No. 1 pin

Mark

N 831

N

Output

H

9513

8

31

Year Assembled

(Last 1 Digit)

In-house Code

(L or T)

Rank Code

Type Number

Assembly Lot

Week Assembled

PHOTOCOUPLER CONSTRUCTION

Parameter PS9513, PS9513L3 PS9513L1, PS9513L2

Air Distance (MIN.) 7 mm 8 mm

Outer Creepage Distance (MIN.) 7 mm 8 mm

Isolation Distance (MIN.) 0.4 mm 0.4 mm

4

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

ORDERING INFORMATION

Part Number Order Number Solder Plating

Specification

PS9513 PS9513-AX Pb-Free Magazine case 50 pcs Standard products PS9513

PS9513L1 PS9513L1-AX (Ni/Pd/Au) (UL, CSA, BSI, PS9513L1

PS9513L2 PS9513L2-AX SEMKO, NEMKO, PS9513L2

PS9513L3 PS9513L3-AX DEMKO, FIMKO PS9513L3

PS9513L2-E3 PS9513L2-E3-AX Embossed Tape 1 000 pcs/reel approved) PS9513L2

PS9513L3-E3 PS9513L3-E3-AX PS9513L3

PS9513-V PS9513-V-AX Magazine case 50 pcs DIN EN60747-5-2 PS9513

PS9513L1-V PS9513L1-V-AX (VDE0884 Part2) PS9513L1

PS9513L2-V PS9513L2-V-AX Approved (Option) PS9513L2

PS9513L3-V PS9513L3-V-AX PS9513L3

PS9513L2-V-E3 PS9513L2-V-E3-AX

PS9513L3-V-E3 PS9513L3-V-E3-AX PS9513L3

Embossed Tape 1 000 pcs/reel PS9513L2

*1 For the application of the Safety Standard, following part number should be used.

Packing Style Safety Standard

Approval

Application Part

Number*

1

Data Sheet PN10679EJ02V0DS

5

PS9513,PS9513L1,PS9513L2 PS9513L3

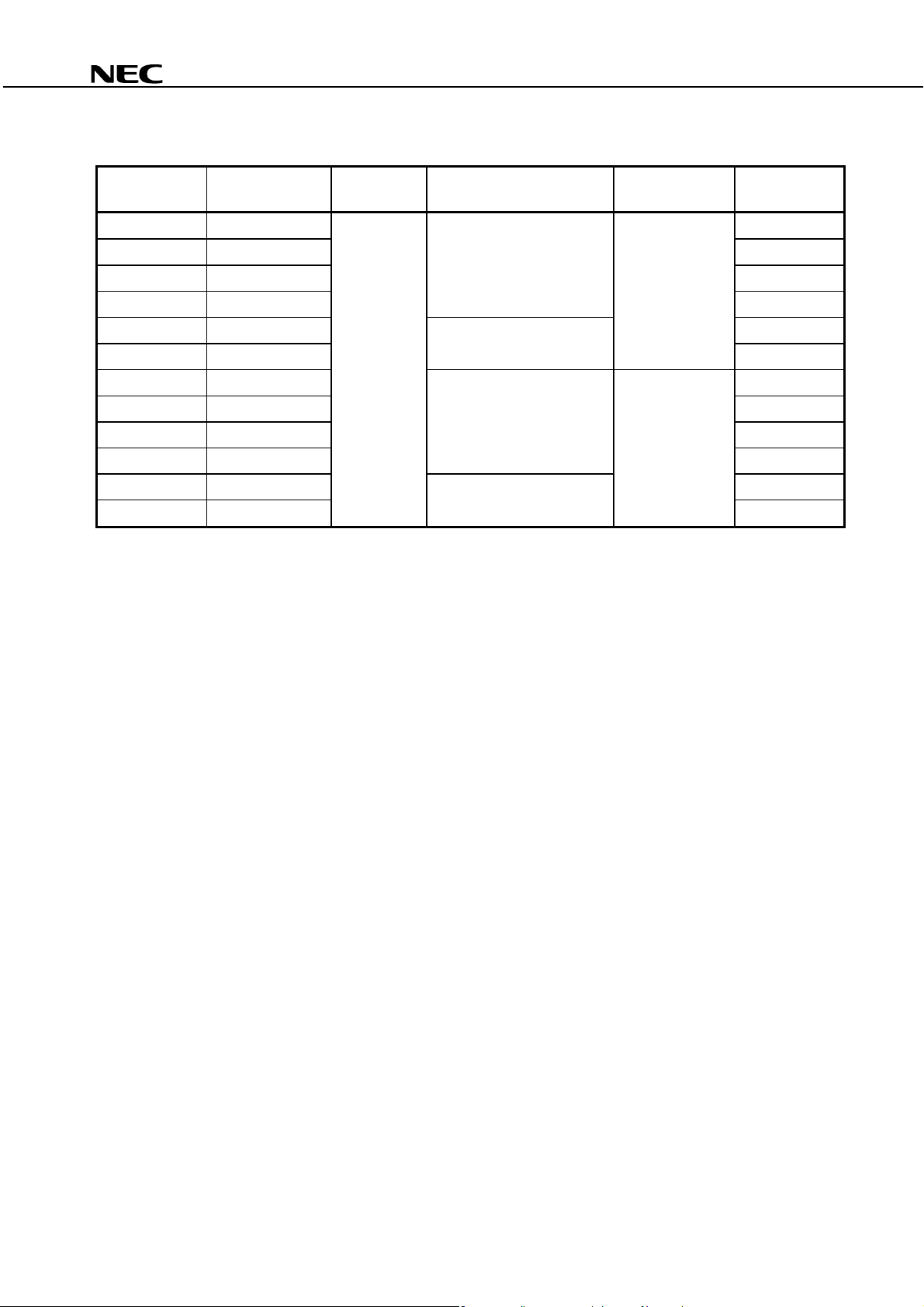

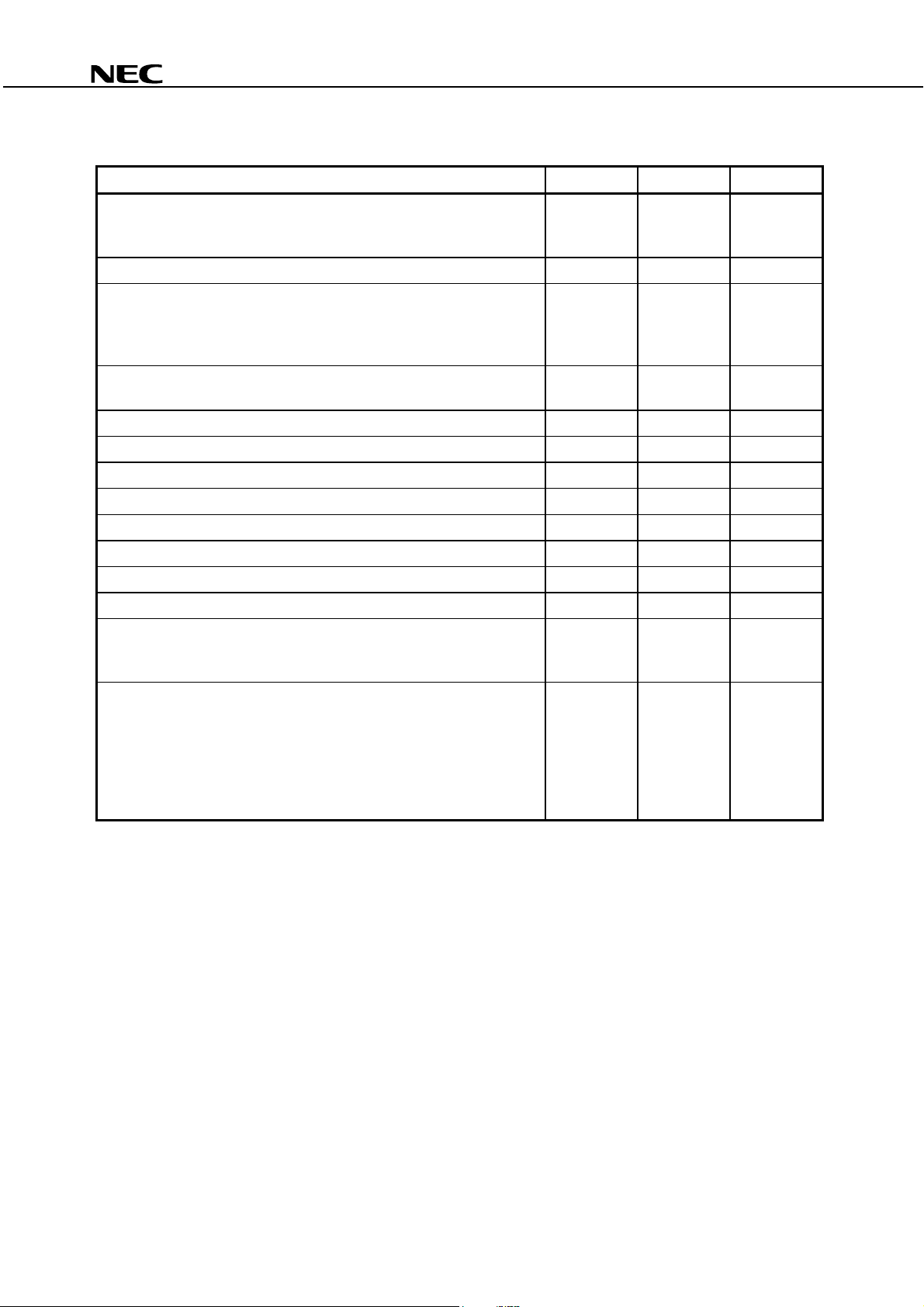

ABSOLUTE MAXIMUM RATINGS (TA = 25°C, unless otherwise specified)

Parameter Symbol Ratings Unit

Diode Forward Current

Reverse Voltage VR 5.0 V

Detector

Output Voltage VO −0.5 to +35 V

Output Current IO 15 mA

Power Dissipation

Isolation Voltage

Operating Ambient Temperature TA −40 to +100 °C

Storage Temperature Tstg −55 to +125 °C

Supply Voltage VCC −0.5 to +35 V

*3

BV 5 000 Vr.m.s.

*1 Reduced to 0.33 mA/°C at T

*2 Reduced to 2.0 mW/°C at T

*3 AC voltage for 1 minute at T

Pins 1-4 shorted together, 5-8 shorted together.

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol MIN. TYP. MAX. Unit

*1

IF 25 mA

*2

PC 100 mW

A = 70°C or more.

A = 70°C or more.

A = 25°C, RH = 60% between input and output.

Forward Current IF 10 20 mA

Output Voltage VO 0 30 V

Supply Voltage VCC 4.5 15 30 V

Input Voltage VF 0 0.8 V

6

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

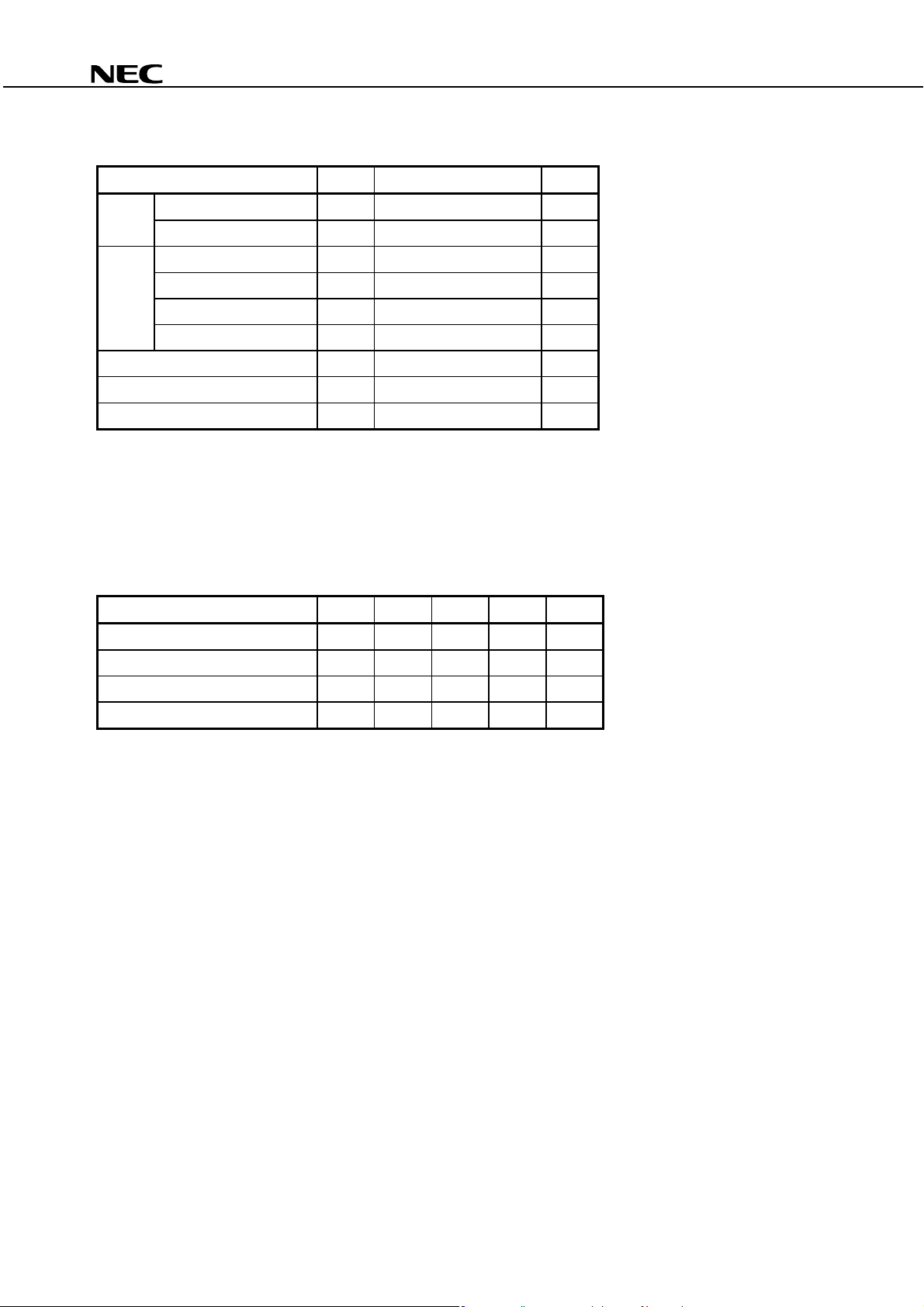

ELECTRICAL CHARACTERISTICS (TA = −40 to +100°C, VCC = 15 V, unless otherwise specified)

Parameter Symbol Conditions MIN. TYP.*1 MAX. Unit

Diode Forward Voltage VF IF = 10 mA 1.3 1.65 2.1 V

Reverse Current IR VR = 3 V 200

Terminal Capacitance Ct V = 0 V, f = 1 MHz, TA = 25°C 30 pF

Detector Low Level Output Voltage VOL IF = 10 mA, IOL = 2.4 mA 0.13 0.6 V

High Level Output Current IOH VCC = 30 V, VF = 0.8 V 1.0 50

High Level Supply Current ICCH VCC = 30 V, VF = 0.8 V, VO = open 0.6 1.3 mA

Low Level Supply Current ICCL VCC = 30 V, IF = 10 mA, VO = open 0.6 1.3 mA

Coupled Threshold Input Current

IFHL VO = 0.8 V, IO = 0.75 mA 0.86 5.0 mA

(H → L)

Current Transfer Ratio (IC/IF) CTR IF = 10 mA, VO = 0.6 V 44 110 %

11

Isolation Resistance RI-O VI-O = 1 kVDC, RH = 40 to 60%,

A = 25°C

T

10

Isolation Capacitance CI-O V = 0 V, f = 1 MHz, TA = 25°C 0.7 pF

Propagation Delay Time

Propagation Delay Time

(H → L)

(L → H)

*2

*2

Maximum Propagation

t

PHL IF = 10 mA, RL = 20 kΩ, CL = 100 pF,

THHL = 1.5 V, VTHLH = 2.0 V

V

t

PLH

tPLH−tPHL −200 270 650

250 500 ns

520 750

Delays

Pulse Width Distortion

(PWD)

*2

Common Mode

Transient Immunity at High

Level Output

*3

Common Mode

Transient Immunity at Low

Level Output

*3

|t

PHL−tPLH| 270 650

H TA = 25°C, IF = 0 mA, VO > 3.0 V,

CM

CM = 1.5 kV, RL = 20 kΩ,

V

L = 100 pF

C

L TA = 25°C, IF = 10 mA, VO < 1.0 V,

CM

CM = 1.5 kV, RL = 20 kΩ,

V

L = 100 pF

C

15 kV/

15 kV/

μ

A

μ

A

Ω

μ

s

μ

s

Data Sheet PN10679EJ02V0DS

7

*1 Typical values at TA = 25°C.

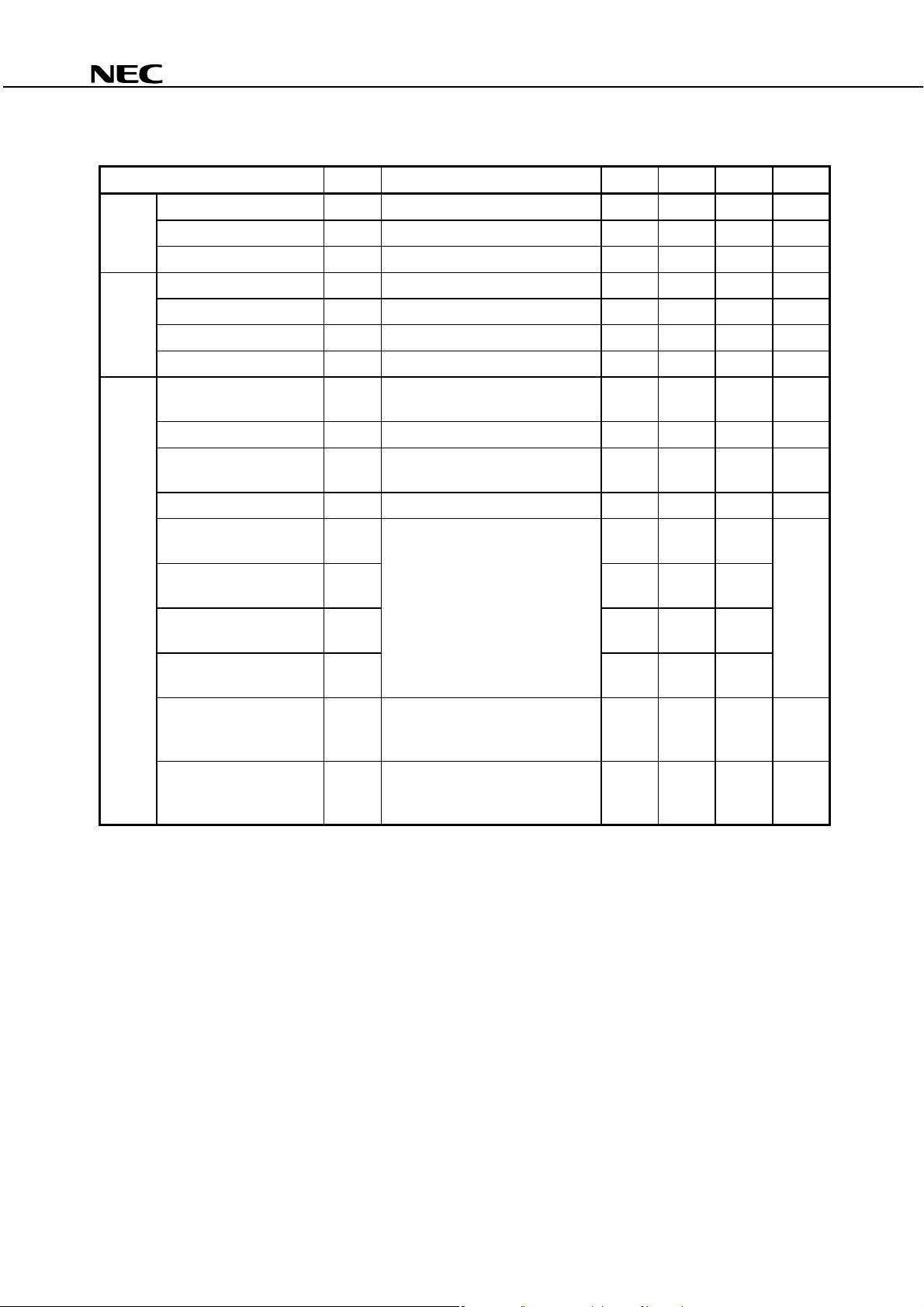

*2 Test circuit for propagation delay time

Pulse input (I

(PW = 10 s,

Duty cycle = 1/10)

Input

(monitor)

F

μ

= 10 mA)

47 Ω

GND

μ

0.1 F

PS9513,PS9513L1,PS9513L2 PS9513L3

CC

= 15 V

V

RL = 20 kΩ

V

O

CL = 100 pF

(monitor)

THHL

= 1.5 V

V

Input

Output

t

PHL

t

PLH

50% I

IF (ON)

F

(ON)

15 V

V

THLH

OL

V

= 2.0 V

CL includes probe and stray wiring capacitance.

*3 Test circuit for common mode transient immunity

V

CC

F

SW I

BA

GND

0.1 F

μ

R

L

= 20 kΩ

CL = 100 pF

= 15 V

VO (monitor)

VCM 90%

10%

t

V

O

(Switch A: IF = 0 mA)

O

V

(Switch B: IF = 10 mA)

r

t

f

1.5 kV

0 V

V

3.0 V

1.0 V

V

CL includes probe and stray wiring capacitance.

USAGE CAUTIONS

1. This product is weak for static electricity by designed with high-speed integrated circuit so protect against static

electricity when handling.

2. By-pass capacitor of more than 0.1

distance between the leads of the photocoupler and capacitor is no more than 10 mm.

3. Avoid storage at a high temperature and high humidity.

μ

F is used between VCC and GND near device. Also, ensure that the

OH

OL

8

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

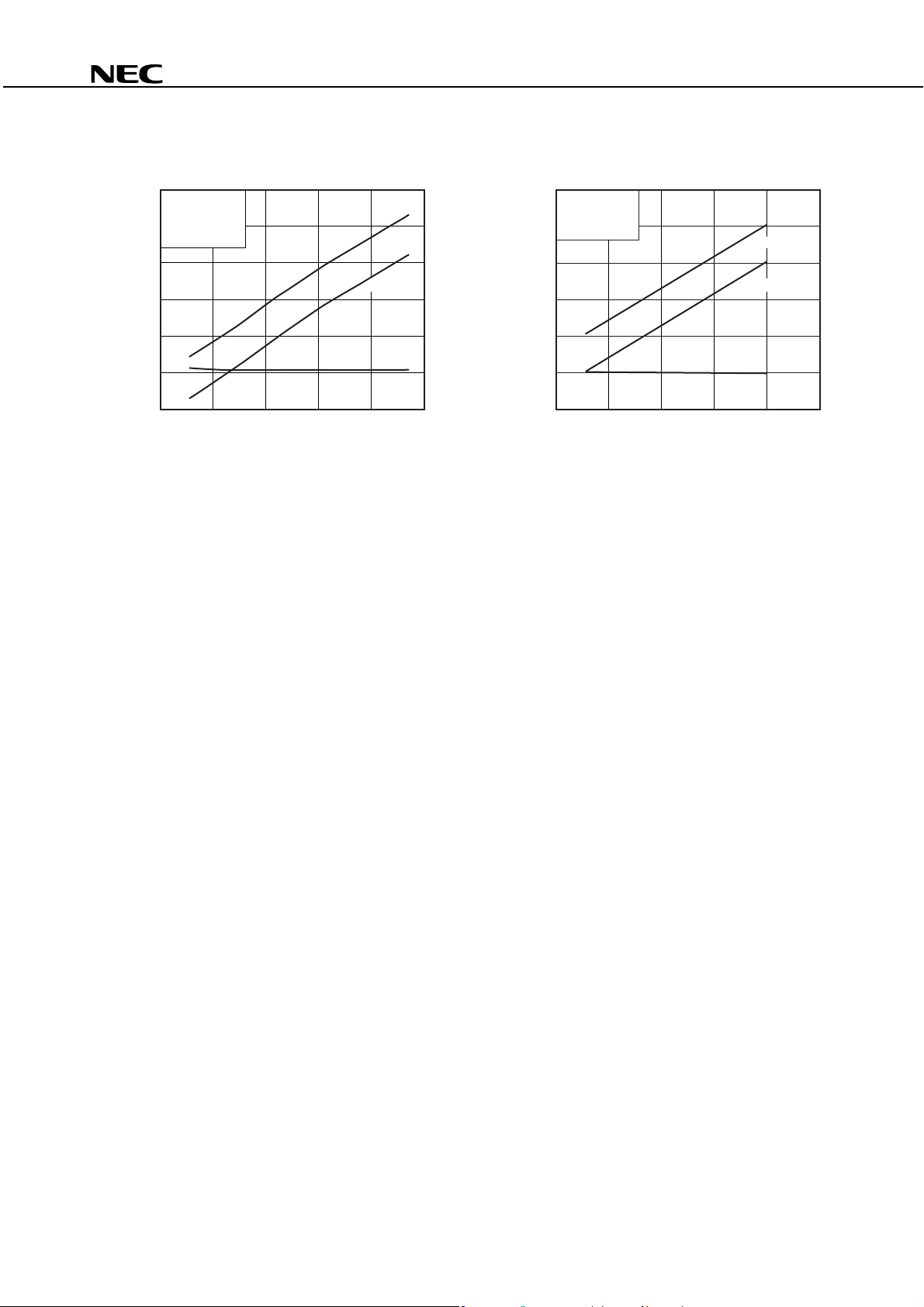

TYPICAL CHARACTERISTICS (TA = 25°C, unless otherwise specified)

MAXIMUM FORWARD CURRENT

vs. AMBIENT TEMPERATURE

40

35

30

25

20

DETECTOR POWER DISSIPATION

vs. AMBIENT TEMPERATURE

150

100

15

10

Maximum Forward Current IF (mA)

100

10

0.1

Forward Current IF (mA)

0.01

5

25 50 75 100 1250

Ambient Temperature TA (˚C)

FORWARD CURRENT vs.

FORWARD VOLTAGE

TA = +100˚C

+85˚C

1

1.0

1.2 1.4 1.6 1.8 2.0 2.2 2.4

Forward Voltage VF (V)

+50˚C

+25˚C

0˚C

–20˚C

–40˚C

50

Detector Power Dissipation PC (mW)

25 50 75 100 1250

Ambient Temperature TA (˚C)

SUPPLY CURRENT vs.

AMBIENT TEMPERATURE

1.20

1.00

CCL (mA)

0.80

0.60

0.40

0.20

High Level Supply Current ICCH (mA),

Low Level Supply Current I

0

–50 –25 0 25 50 75 100

Ambient Temperature TA (˚C)

V

V

CCH : VF = 0.8 V,

I

CCL : IF = 10 mA

I

CC = 30 V,

O = Open,

I

CCL

ICCH

THRESHOLD INPUT CURRENT vs.

AMBIENT TEMPERATURE

5

4

3

2

1

Threshold Input Current IFHL (mA)

0

–50 –25 0 25 50 75 100

Ambient Temperature TA (˚C)

Remark The graphs indicate nominal characteristics.

VCC = 15 V,

O = 0.8 V,

V

O = 0.75 mA

I

Data Sheet PN10679EJ02V0DS

LOW LEVEL OUTPUT VOLTAGE vs.

AMBIENT TEMPERATURE

0.6

0.5

0.4

0.3

0.2

0.1

Low Level Output Voltage VOL (V)

0

–50 –25

Ambient Temperature TA (˚C)

250 50 75 100

CC = 15 V,

V

F = 10 mA,

I

O = 2.4 mA

I

9

OUTPUT CURRENT vs. FORWARD CURRENT

14

A

= +100˚C

12

10

(mA)

O

T

+25˚C

8

6

–40˚C

4

Output Current I

2

0 5 10 15 20

Forward Current IF (mA)

O

V

= 0.6 V

PROPAGATION DELAY TIME,

MAXIMUM PROPAGATION DELAYS

vs. FORWARD CURRENT

700

(ns)

PHL

600

– t

(ns),

PLH

PLH

500

, t

PHL

400

t

PLH

t

PLH

– t

PHL

300

200

100

0 5 10 15 20

Maximum Propagation Delays t

Propagation Delay Time t

t

PHL

VCC = 15 V,

C

L

= 100 pF,

R

L

= 20 kΩ

Forward Current IF (mA)

PROPAGATION DELAY TIME,

PULSE WIDTH DISTORTION

vs. AMBIENT TEMPERATURE

700

(ns)

PLH

600

– t

(ns),

PHL

PLH

500

, t

PHL

400

300

200

V

CC

= 15 V,

I

F

= 10 mA,

100

L

= 100 pF,

C

R

L

= 20 kΩ

0

Pulse Width Distortion (PWD) t

Propagation Delay Time t

–40 –20 0 20 40 60 80 100

Ambient Temperature TA (˚C)

Remark The graphs indicate nominal characteristics.

t

PLH

PWD

PHL

t

PS9513,PS9513L1,PS9513L2 PS9513L3

OUTPUT CURRENT vs.

AMBIENT TEMPERATURE

1.10

F

= 10 mA,

I

V

O

1.05

1.00

0.95

0.90

(Value relative to 25˚C)

O

0.85

0.80

0.75

0.70

Output Current I

1 800

(ns)

PHL

1 600

– t

(ns),

1 400

PLH

PLH

, t

1 200

PHL

1 000

800

600

400

200

Maximum Propagation Delays t

Propagation Delay Time t

1 800

1 600

(ns)

PLH

1 400

, t

PHL

1 200

1 000

800

600

400

200

Propagation Delay Time t

= 0.6 V

–40 –20 0 20 40 60 80 100

Ambient Temperature TA (˚C)

PROPAGATION DELAY TIME,

MAXIMUM PROPAGATION DELAYS

vs. SUPPLY VOLTAGE

IF = 10 mA,

C

L

= 100 pF,

R

L

= 20 kΩ

t

PLH

t

PHL

t

PLH

– t

PHL

010203040

Supply Voltage VCC (V)

PROPAGATION DELAY TIME vs.

LOAD CAPACITANCE

VCC = 15 V,

I

F

= 10 mA,

R

L

= 20 kΩ

0 100 200 300 400

Load Capacitance CL (pF)

t

PLH

PHL

t

500

10

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

PROPAGATION DELAY TIME,

MAXIMUM PROPAGATION DELAYS

vs. LOAD RESISTANCE

1 200

(ns)

VCC = 15 V,

PHL

I

F

800

= 10 mA,

C

L

= 100 pF

(ns),

PLH

, t

PHL

1 000

– t

PLH

600

400

200

010203040

Maximum Propagation Delays t

Propagation Delay Time t

Load Resistance RL (kΩ)

Remark The graphs indicate nominal characteristics.

t

PLH

t

PLH

– t

PHL

PHL

t

50

PROPAGATION DELAY TIME,

MAXIMUM PROPAGATION DELAYS

vs. LOAD RESISTANCE

600

(ns)

VCC = 5 V,

PHL

– t

(ns),

PLH

PLH

, t

PHL

Maximum Propagation Delays t

Propagation Delay Time t

F

= 10 mA,

I

500

C

L

= 15 pF

400

300

200

100

0 5 10 15 20

Load Resistance RL (kΩ)

t

PLH

t

PLH

– t

PHL

PHL

t

25

Data Sheet PN10679EJ02V0DS

11

TAPING SPECIFICATIONS (UNIT: mm)

Outline and Dimensions (Tape)

PS9513,PS9513L1,PS9513L2 PS9513L3

2.0±0.1

4.0±0.1

2.05±0.05

Tape Direction

12.0±0.1

+0.1

1.5

–0

10.7±0.1

PS9513L2-E3

1.75±0.1

11.5±0.1

24.0±0.3

4.5 MAX.

12.8±0.1

4.1±0.1

0.3±0.05

Pull-out direction

Outline and Dimensions (Reel)

2.0±0.5

13.0±0.2

R 1.0

Packing: 1 000 pcs/reel

21.0±0.8

330±2.0

100±1.0

2.0±0.5

25.5±1.0

29.5±1.0

23.9 to 27.4

Outer edge of

flange

12

Data Sheet PN10679EJ02V0DS

Outline and Dimensions (Tape)

PS9513,PS9513L1,PS9513L2 PS9513L3

Tape Direction

2.0±0.1

4.0±0.1

1.55±0.1

12.0±0.1

PS9513L3-E3

1.5

+0.1

–0

10.3±0.1

1.75±0.1

7.5±0.1

16.0±0.3

5.3 MAX.

10.4±0.1

4.75±0.1

0.35±0.05

Outline and Dimensions (Reel)

R 1.0

Packing: 1 000 pcs/reel

2.0±0.5

13.0±0.2

21.0±0.8

330±2.0

100±1.0

2.0±0.5

17.5±1.0

21.5±1.0

15.9 to 19.4

Outer edge of

flange

Data Sheet PN10679EJ02V0DS

13

PS9513,PS9513L1,PS9513L2 PS9513L3

RECOMMENDED MOUNT PAD DIMENSIONS (UNIT: mm)

D

CB

Part Number

PS9513L2

PS9513L3

A

Lead Bending

lead bending type (Gull-wing)

for long creepage distance (surface mount)

lead bending type (Gull-wing)

for surface mount

A

10.2

8.2

B

2.54

2.54

C

1.7

1.7

D

2.2

2.2

14

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

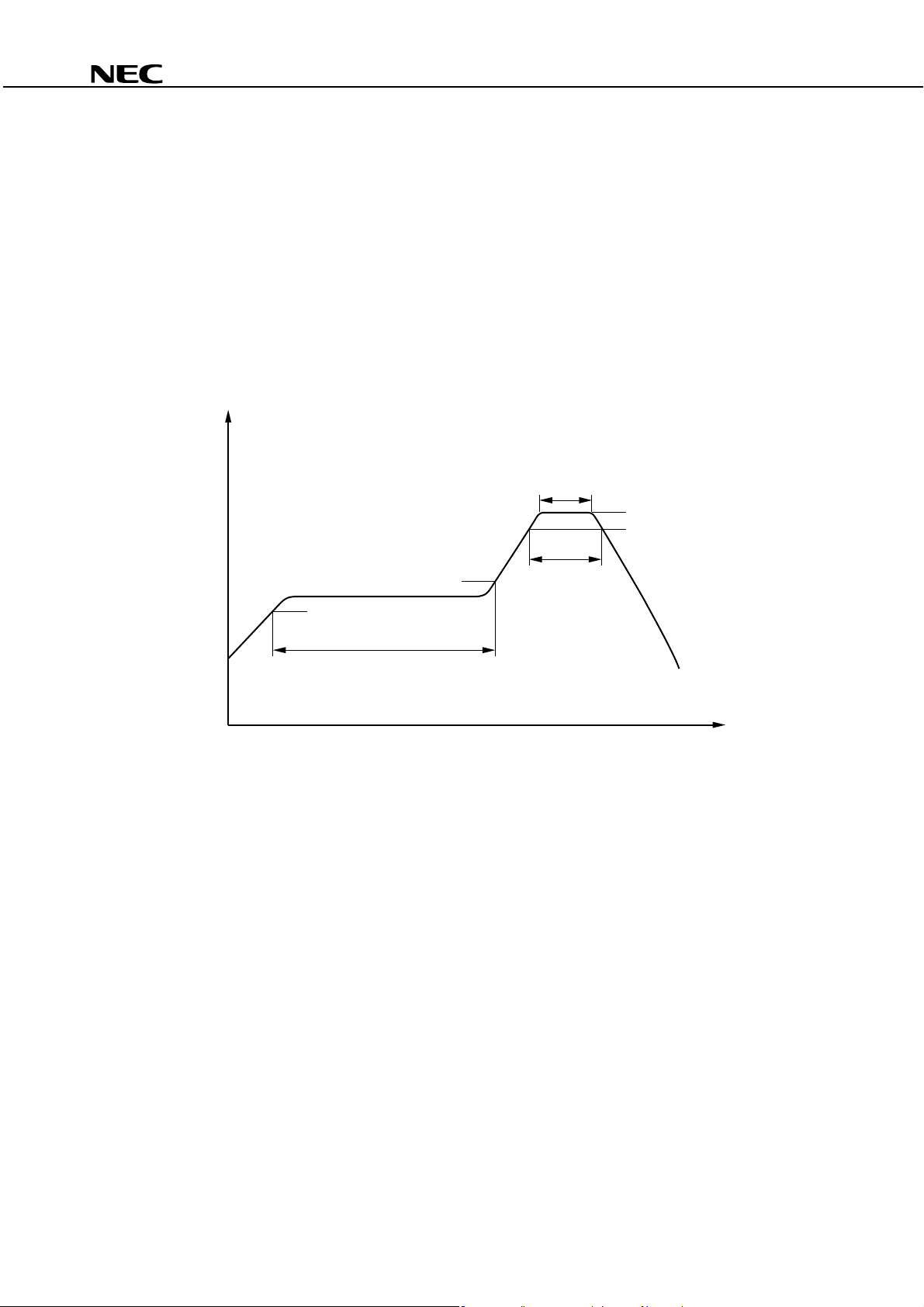

NOTES ON HANDLING

1. Recommended soldering conditions

(1) Infrared reflow soldering

• Peak reflow temperature 260°C or below (package surface temperature)

• Time of peak reflow temperature 10 seconds or less

• Time of temperature higher than 220°C 60 seconds or less

• Time to preheat temperature from 120 to 180°C 120±30 s

• Number of reflows Three

• Flux Rosin flux containing small amount of chlorine (The flux with a

maximum chlorine content of 0.2 Wt% is recommended.)

Recommended Temperature Profile of Infrared Reflow

(heating)

to 10 s

260˚C MAX.

220˚C

to 60 s

180˚C

120˚C

Package Surface Temperature T (˚C)

120±30 s

(preheating)

Time (s)

(2) Wave soldering

• Temperature 260°C or below (molten solder temperature)

• Time 10 seconds or less

• Preheating conditions 120°C or below (package surface temperature)

• Number of times One (Allowed to be dipped in solder including plastic mold portion.)

• Flux Rosin flux containing small amount of chlorine (The flux with a maximum chlorine

content of 0.2 Wt% is recommended.)

(3) Soldering by soldering iron

• Peak temperature (lead part temperature) 350°C or below

• Time (each pins) 3 seconds or less

• Flux Rosin flux containing small amount of chlorine (The flux with a

maximum chlorine content of 0.2 Wt% is recommended.)

(a) Soldering of leads should be made at the point 1.5 to 2.0 mm from the root of the lead.

(b) Please be sure that the temperature of the package would not be heated over 100°C.

Data Sheet PN10679EJ02V0DS

15

<R>

PS9513,PS9513L1,PS9513L2 PS9513L3

(4) Cautions

• Fluxes

Avoid removing the residual flux with freon-based and chlorine-based cleaning solvent.

2. Cautions regarding noise

Be aware that when voltage is applied suddenly between the photocoupler’s input and output or between

collector-emitters at startup, the output transistor may enter the on state, even if the voltage is within the absolute

maximum ratings.

USAGE CAUTIONS

1. Protect against static electricity when handling.

2. Avoid storage at a high temperature and high humidity.

16

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

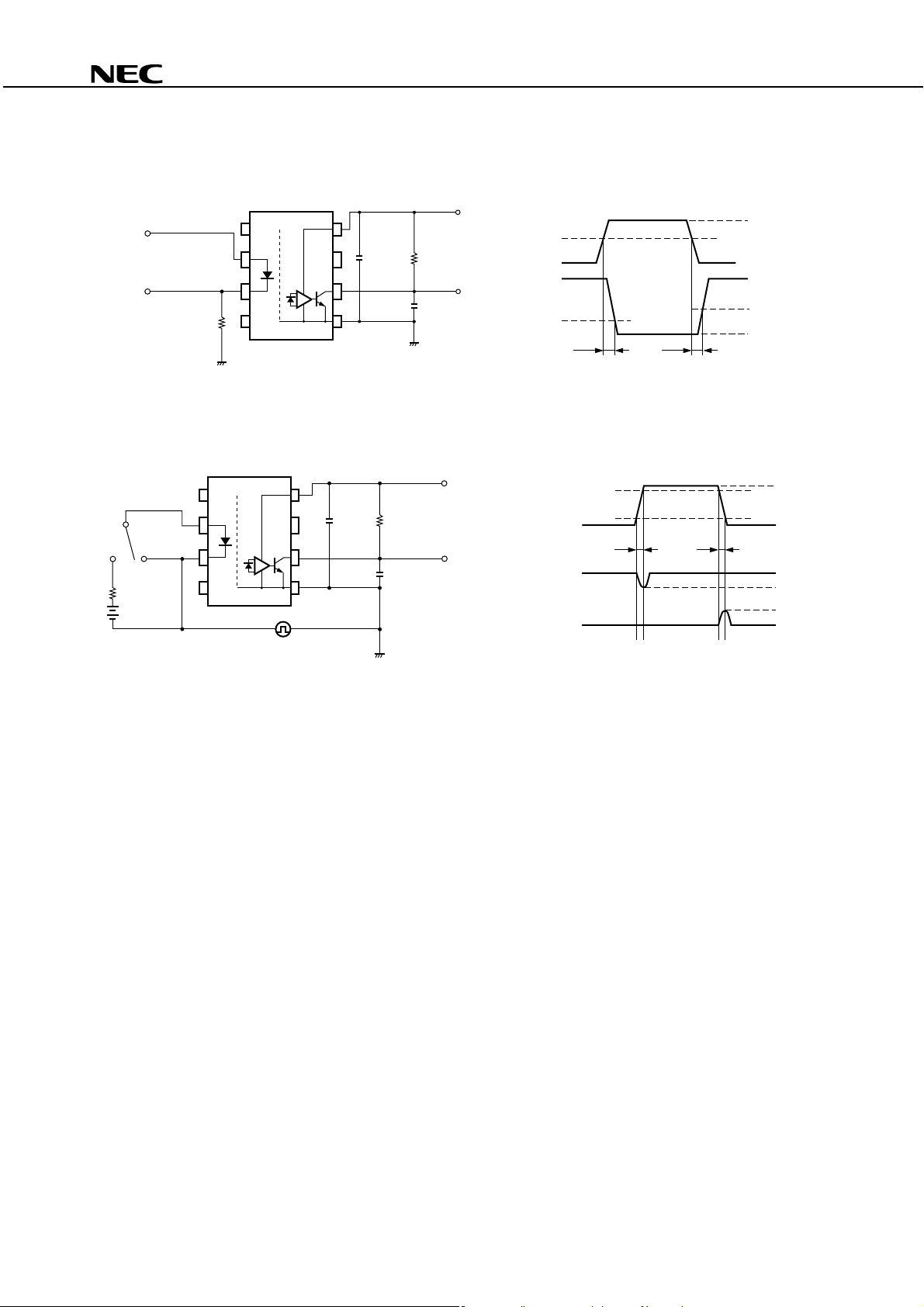

SPECIFICATION OF VDE MARKS LICENSE DOCUMENT

Parameter Symbol Speck Unit

<R>

Application classification (DIN EN 60664-1 VDE0110 Part 1)

for rated line voltages ≤ 300 Vr.m.s.

for rated line voltages ≤ 600 Vr.m.s.

IV

III

Climatic test class (DIN EN 60664-1 VDE0110) 55/100/21

Dielectric strength

maximum operating isolation voltage

Test voltage (partial discharge test, procedure a for type test and random test)

pr = 1.5 × UIORM, Pd < 5 pC

U

Test voltage (partial discharge test, procedure b for all devices)

pr = 1.875 × UIORM, Pd < 5 pC

U

IORM

U

Upr

U

pr 2 119 Vpeak

1 130

1 695

peak

V

Vpeak

Highest permissible overvoltage UTR 8 000 Vpeak

Degree of pollution (DIN EN 60664-1 VDE0110 Part 1) 2

Clearance distance >8.0 mm

Creepage distance >8.0 mm

Comparative tracking index (DIN IEC 112/VDE 0303 Part 1) CTI 175

Material group (DIN EN 60664-1 VDE0110 Part 1) III a

Storage temperature range Tstg –55 to +125 °C

Operating temperature range TA –40 to +100 °C

Isolation resistance, minimum value

IO = 500 V dc at TA = 25°C

V

IO = 500 V dc at TA MAX. at least 100°C

V

Safety maximum ratings (maximum permissible in case of fault, see thermal

derating curve)

Package temperature

Current (input current I

F, Psi = 0)

Power (output or total power dissipation)

Isolation resistance

V

IO = 500 V dc at TA = Tsi

Ris MIN.

Ris MIN.

Tsi

Isi

Psi

Ris MIN.

10

10

175

400

700

10

12

11

Ω

Ω

°C

mA

mW

9

Ω

Data Sheet PN10679EJ02V0DS

17

PS9513,PS9513L1,PS9513L2 PS9513L3

•

The information in this document is current as of August, 2008. The information is subject to

change without notice. For actual design-in, refer to the latest publications of NEC Electronics data

sheets or data books, etc., for the most up-to-date specifications of NEC Electronics products. Not

all products and/or types are available in every country. Please check with an NEC Electronics sales

representative for availability and additional information.

No part of this document may be copied or reproduced in any form or by any means without the prior

•

written consent of NEC Electronics. NEC Electronics assumes no responsibility for any errors that may

appear in this document.

•

NEC Electronics does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from the use of NEC Electronics products listed in this document

or any other liability arising from the use of such products. No license, express, implied or otherwise, is

granted under any patents, copyrights or other intellectual property rights of NEC Electronics or others.

Descriptions of circuits, software and other related information in this document are provided for illustrative

•

purposes in semiconductor product operation and application examples. The incorporation of these

circuits, software and information in the design of a customer's equipment shall be done under the full

responsibility of the customer. NEC Electronics assumes no responsibility for any losses incurred by

customers or third parties arising from the use of these circuits, software and information.

•

While NEC Electronics endeavors to enhance the quality, reliability and safety of NEC Electronics products,

customers agree and acknowledge that the possibility of defects thereof cannot be eliminated entirely. To

minimize risks of damage to property or injury (including death) to persons arising from defects in NEC

Electronics products, customers must incorporate sufficient safety measures in their design, such as

redundancy, fire-containment and anti-failure features.

•

NEC Electronics products are classified into the following three quality grades: "Standard", "Special" and

"Specific".

The "Specific" quality grade applies only to NEC Electronics products developed based on a customerdesignated "quality assurance program" for a specific application. The recommended applications of an NEC

Electronics product depend on its quality grade, as indicated below. Customers must check the quality grade of

each NEC Electronics product before using it in a particular application.

"Standard":

"Special":

"Specific":

Computers, office equipment, communications equipment, test and measurement equipment, audio

and visual equipment, home electronic appliances, machine tools, personal electronic equipment

and industrial robots.

Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support).

Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems and medical equipment for life support, etc.

The quality grade of NEC Electronics products is "Standard" unless otherwise expressly specified in NEC

Electronics data sheets or data books, etc. If customers wish to use NEC Electronics products in applications

not intended by NEC Electronics, they must contact an NEC Electronics sales representative in advance to

determine NEC Electronics' willingness to support a given application.

(Note)

(1)

"NEC Electronics" as used in this statement means NEC Electronics Corporation and also includes its

majority-owned subsidiaries.

(2)

"NEC Electronics products" means any product developed or manufactured by or for NEC Electronics (as

defined above).

M8E 02. 11-1

18

Data Sheet PN10679EJ02V0DS

PS9513,PS9513L1,PS9513L2 PS9513L3

Caution GaAs Products

This product uses gallium arsenide (GaAs).

GaAs vapor and powder are hazardous to human health if inhaled or ingested, so please observe

the following points.

• Follow related laws and ordinances when disposing of the product. If there are no applicable laws

and/or ordinances, dispose of the product as recommended below.

1. Commission a disposal company able to (with a license to) collect, transport and dispose of

materials that contain arsenic and other such industrial waste materials.

2. Exclude the product from general industrial waste and household garbage, and ensure that the

product is controlled (as industrial waste subject to special control) up until final disposal.

• Do not burn, destroy, cut, crush, or chemically dissolve the product.

• Do not lick the product or in any way allow it to enter the mouth.

Loading...

Loading...