Page 1

Note

z Read thoroughly this manual before using the product.

z Keep this document along with the product in a safe place.

Built-in DAT

User’s Guide

Safety Precautions

This operation manual uses the symbols shown below to enable you to use the product safely

and correctly and to prevent injury and property damage.

WARNING

CAUTION

The following symbols are used to indicate danger or caution in handling the product.

This symbol indicates that using the product improperly in defiance of

this symbol may result in death or serious injury.

This symbol indicates that using the product improperly in defiance of

this symbol may result in injury or only damage to property.

Indicates that carelessness may invite danger.

Indicates a certain action is prohibited.

Indicates an action that the user must execute.

Indicates that you should not disassemble the unit.

Indicates that you should unplug the power code for safety.

– 1 –

Page 2

WARNI NG

" Never attempt to disassemble the unit such as opening the unit

cover.

Doing so may cause an electric shock or fire.

" Do not pour water or put anything into the unit.

If anything gets into the unit, turn the power off immediately and

disconnect the power plug from the outlet to avoid a short-circuit or

an electric shock.

" If the unit is damaged, or smoke, odor, or abnormal sound is

emitted, immediately turn off the POWER switch and disconnect the

power plug from the outlet to avoid a short-circuit or an electric

shock.

" Disconnect the power plug from the outlet when a thunderstorm is

likely to avoid an electric shock.

CAUTION

" Do not install the unit in a place where it is exposed to direct

sunlight or the temperature rises abnormally.

" Do not block the ventilation hole.

" Do not install the unit in a dusty or humid place.

" To avoid an electric shock, do not disconnect/connect the plug

while your hands are wet.

" Insert the power plug into the outlet as far as it will go to avoid an

electric shock or a fire.

" When connecting cables or wiring, observe the instruction in this

manual.

" Before connecting/disconnecting of the host computer or peripheral

devices, turn off the power and disconnect the power plug from the

outlet.

If the power plug is kept connected, you may get an electrical

shock.

" Do not install the unit in an unstable place.

It may cause the unit to fall down leading a human injury.

" Confirm that the connector is not damaged, the connector pin is not

bent or stained before connecting the cable. The damaged

connector, or stained or bent connector pin may cause a shortcircuit resulting in a fire.

" Use only the specified cable for connecting with the processing unit,

and confirm the destination connector. Using any other cables

than specified or connecting to incorrect connector may cause a

short-circuit resulting in a fire.

– 2 –

Page 3

CAUTION

" Do not use a handy telephone or a communication device near the

unit.

Doing so may cause an unexpected operation of the unit.

" .When disconnecting the power plug, do not pull the cable.

– 3 –

Page 4

CONTENTS

Safety Precautions ........................................................................................................................................ 1

Getting Started ........................................................................................................................................................ 5

Contents of the Package .......................................................................................................................................... 6

Unpacking .............................................................................................................................................. 6

Built-In DAT Hardware........................................................................................................................................... 7

Names and Functions of Built-In DAT and Setup Procedures (SCSI ID etc.).......................................... 7

Installing to the Basic Processing Unit.................................................................................................. 12

Using Built-In DAT.............................................................................................................................. 13

Cleaning ............................................................................................................................................... 14

Precautions........................................................................................................................................... 15

4mm Data Cartridge...................................................................................................................................... 16

Structure of the 4mm Data Cartridge..................................................................................................... 16

Specifications and Requirements for Storage and Shipment .................................................................. 16

Labeling ............................................................................................................................................... 17

Write-protection ................................................................................................................................... 17

Precautions on Handling ....................................................................................................................... 18

Standards for Prohibited Use................................................................................................................ 19

Cartridge Life....................................................................................................................................... 20

Preserving Critical Data........................................................................................................................ 20

Three-Generation Data Management .................................................................................................... 20

Appendix............................................................................................................................................................... 21

Major Specifications............................................................................................................................. 21

List of LED Indications......................................................................................................................... 22

Addendum............................................................................................................................................................. 24

For WindowsNT

TM

3.5/3.51 Users ....................................................................................................... 24

TRADEMARKS

WindowsNT™ is a registered trademark of Microsoft Corporation of the U.S. in the

U.S.A. and other countries.

– 4 –

Page 5

GETTING STARTED

This document is the user’s guide for Built-In DAT.

For operations of the basic processing unit, please refer to its attached manual.

– 5 –

Page 6

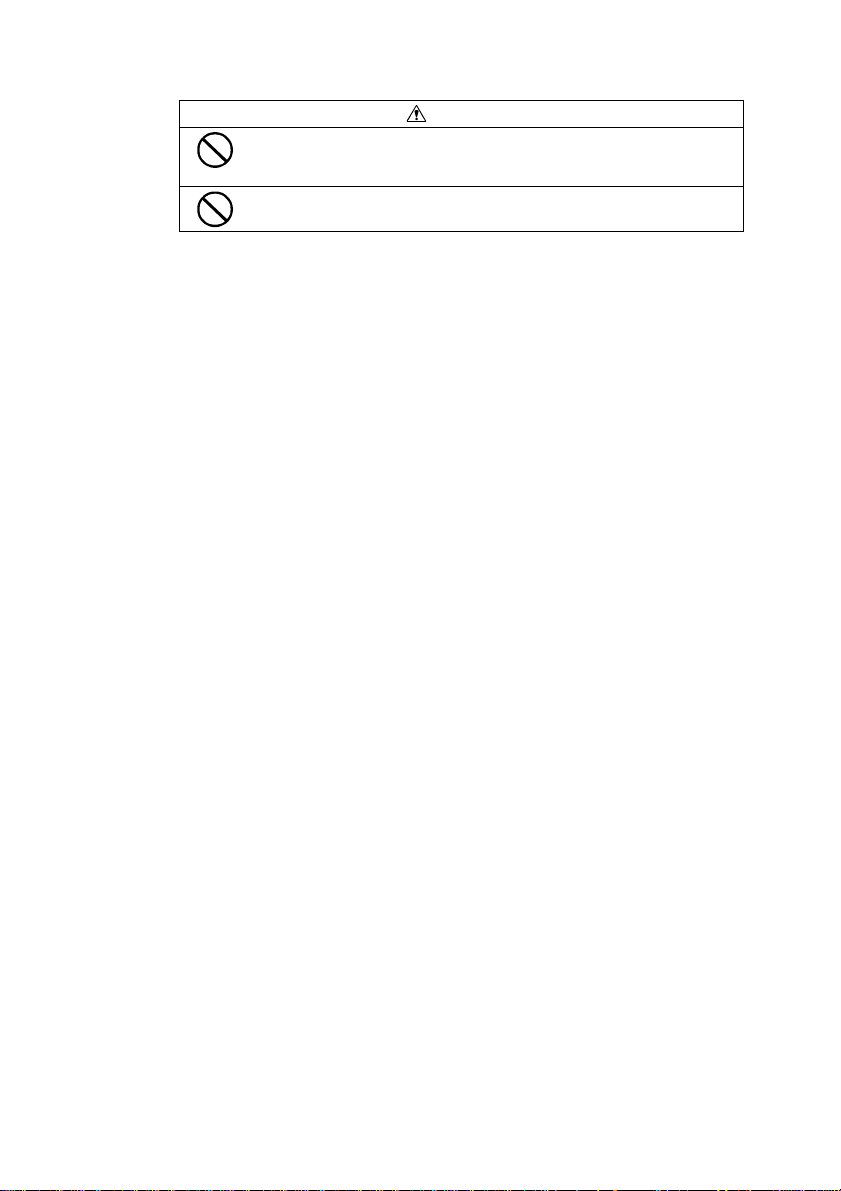

CONTENTS OF THE PACKAGE

Unpacking

Open the package and make sure everything including accessories is in it.

Built-In DAT

User’s GuideCleaning Cartridge

4 M3 Mounting Screws

DAT Handling Information

Data Cartridge

Make sure to attach this manual to the Built-in DAT when you transfer it to

someone else.

– 6 –

Page 7

BUILT-IN DAT HARDWARE

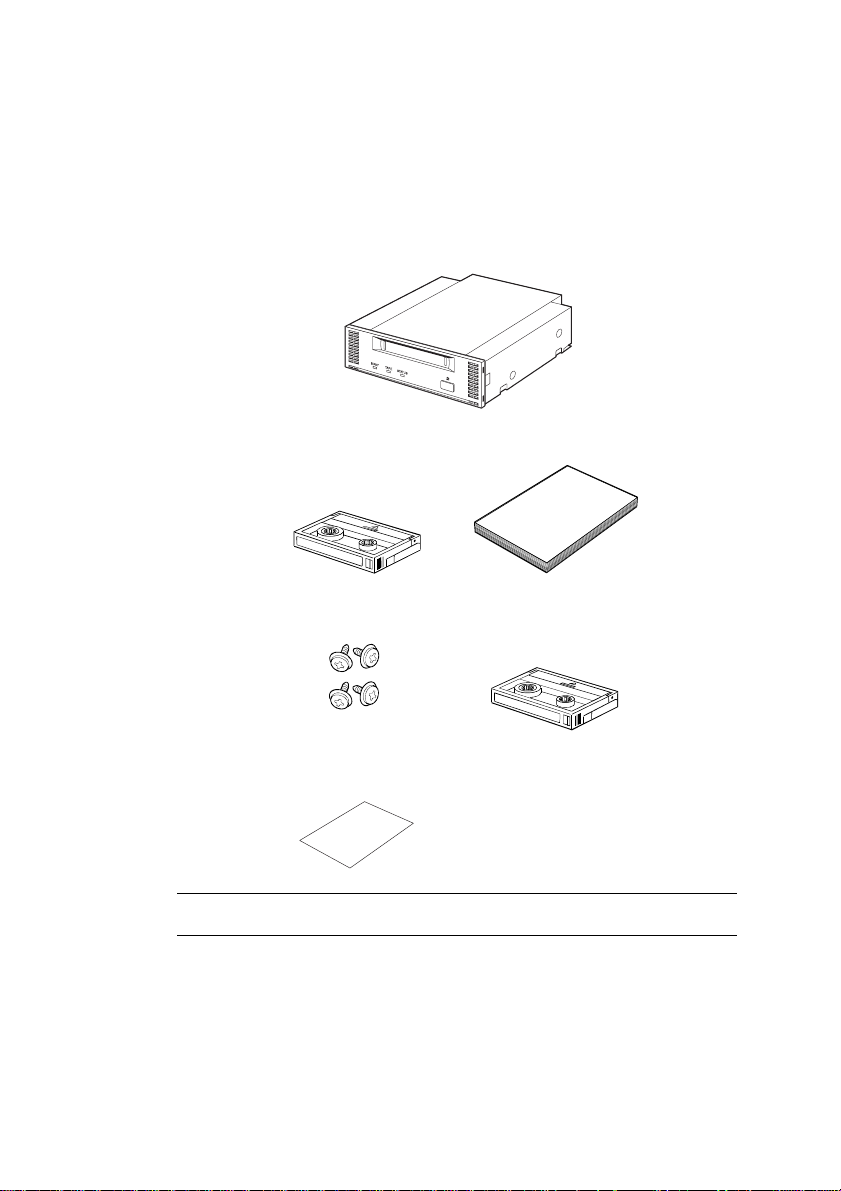

Names and Functions of Built-In DAT and Setup Procedures (SCSI ID etc.)

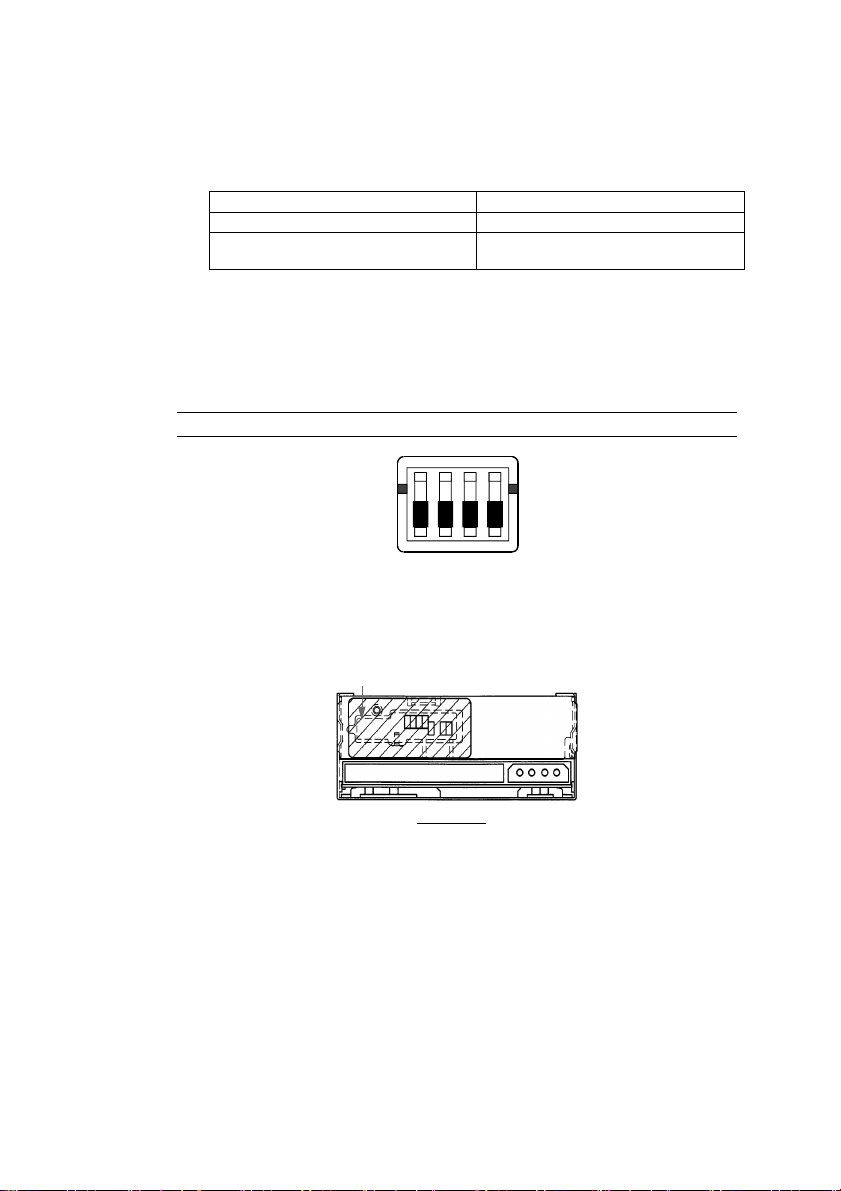

■Front Side

1

2 3 4 5

1 4mm Data Cartridge Slot

Insert the 4mm data cartridge into the slot. For procedures for inserting and ejecting

the cartridge, see the sections, “Inserting 4mm Data Cartridge” and “Ejecting 4mm

Data Cartridge”, respectively.

2 BUSY Indicator

Lights up when the data is being transmitted through the SCSI interface.

It blinks when read or write of the data in the inserted 4mm data cartridge is

successfully in progress.

Make sure not to power on/off the device while this lamp is lit. It may cause a read

error or critical damage to the 4mm data cartridge; or cause to write inappropriate

data.

3 TAPE Indicator

Lights up while the 4mm data cartridge is seated in the slot. It blinks under the

following conditions.

When inserting or ejecting the cartridge. Blinks at the same intervals.

When the cartridge is worn off. Repeats long turning-on and short turning-off.

– 7 –

Page 8

4 STATUS Indicator

5 EJECT Button

■Bottom Side

Do not change the initial setup of the dip switches as illustrated below.

■Rear Side

An anti-dust seal is applied to the back side of built-in DAT. Remove this seal when you

need to change the jumper settings, then replace it after the jumper settings have been

changed.

Lights up when the 4mm data cartridge inserted is write-protected. It blinks under

the following conditions.

When cleaning is required. Repeats long turning-on and short turning-off.

When tape cleaning completes. Blinks at the same intervals.

When the drive is out of order. Repeats short turning-on twice and long

turning-off.

Press this button to eject the cartridge out of the device.

N

O

1

2

3

4

Anti-dust seal

Built-In DAT

– 8 –

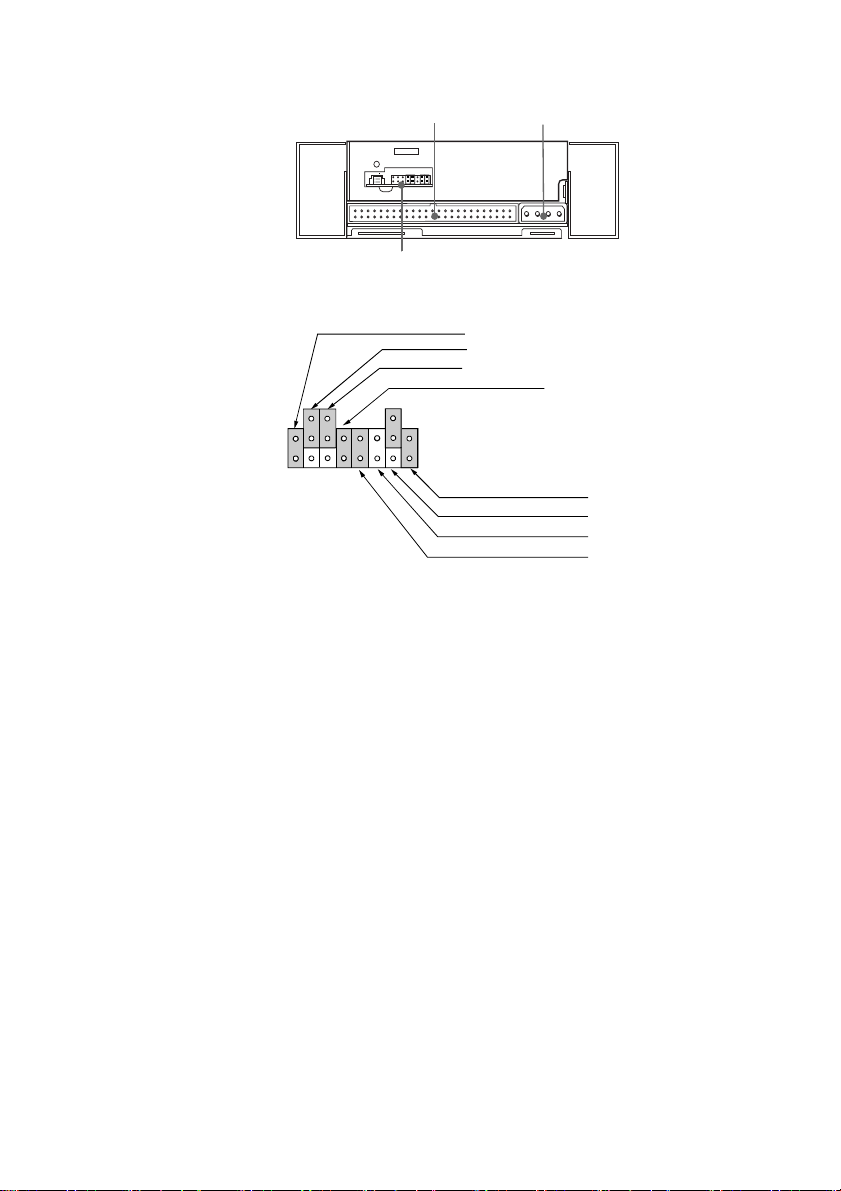

Page 9

12

3

Jumper Positions upon Shipment

SCSI ID 2

SCSI ID 1

SCSI ID 0

No Data Compression (DC)

Terminator Power Supply (TMP)

Terminator (TMON)

RSV

SCSI Parity (PAR)

1 Signal Connector

SCSI signal connector for control over Built-In DAT.

2 DC Connector (+5V/+12V)

Connector for power supply to Built-In DAT. Plug in the power cable located in the

basic processing unit.

3 Optional Jumper Switch

Optional jumper switch for setting up the SCSI ID number, data compression, SCSI

parity, terminator, and terminator power supply. The jumper positions of the

switches are illustrated above.

– 9 –

Page 10

SCSI ID Number Jumper

The SCSI ID number jumper sets the SCSI ID number. The following table lists available

SCSI ID numbers and their settings.

SCSI ID 2 1 0 DC PAR

0

1

2

3

4*

5

6

7**

× × × - - - - -

× × ○ - - - - -

× ○ × - - - - -

× ○ ○ - - - - -

○ × × - - - - -

○ × ○ - - - - -

○ ○ × - - - - -

○ ○ ○ - - - - -

----

TMON TMP

○: Wired with the jumper.

×: Not wired with the jumper.

* The SCSI ID number is set to 4 upon shipment.

** Do not set the SCSI ID number to 7.

Terminator Power Supply Jumper (TMP)

This jumper sets whether to supply the terminator power onto the SCSI Bus.

Term Power 2 1 0 DC PAR

Supplied

Not supplied

- - - - - - - ○

- - - - - - - ×

----

TMON TMP

○: Wired with the jumper.

×: Not wired with the jumper.

The terminator power is set to be supplied from the drive upon shipment. Leave

this setting as it is at shipment.

– 10 –

Page 11

Terminator Setup (TMON)

To connect this device to the end of the SCSI BUS, make sure the BUS is terminated.

Otherwise, the SCSI BUS should not be terminated.

Terminator 2 1 0 DC PAR

Terminated

Not terminated

○: Wired with the jumper.

×: Not wired with the jumper.

- - - - - - ○ -

- - - - - - × -

----

TMON TMP

The terminator is disabled upon shipment.

Parity Jumper (PAR)

The parity jumper sets the parity function.

SCSI Parity 2 1 0 DC PAR

Parity enabled

Parity disabled

○: Wired with the jumper.

×: Not wired with the jumper.

- - - - ○ - - -

- - - - × - - -

----

TMON TMP

The parity function is set enabled upon shipment.

Leave this setting as it is at shipment.

Data Compression (DC)

This jumper sets whether data compression is enabled or disabled. To disable the data

compression function, set the function disabled with this jumper and reset the device by

powering off and on.

Data Compression 2 1 0 DC PAR

Data compression disabled

Data compression enabled

○: Wired with the jumper.

×: Not wired with the jumper.

- - - ○ - - - -

- - - × - - - -

----

TMON TMP

The data compression is set enabled upon shipment.

Leave this setting as it is at shipment.

– 11 –

Page 12

Installing to the Basic Processing Unit

The following describes an installation example to the basic processing unit.

Before installing this unit, make sure you unplug the power plug for the

basic processing unit you are using (such as a server or workstation

basic processing unit). Leaving the power cord plugged in presents an

electrical shock hazard.

1 Mount Built-In DAT to the following position illustrated in the figure below.

2 Connect the interface cable as illustrated in the following figure.

CAUTION

Place it in either location.

DC Power Cable

(Spare connector in the

system)

SCSI Interface Cable

(Spare connector in the

system)

! Confirm that the SCSI ID, terminator, and others are appropriately set before

installation.

! The SCSI ID of this device is set to 4 upon shipment. Make sure to set its

SCSI ID not to conflict with another device.

– 12 –

Page 13

Using Built-In DAT

■Inserting 4mm Data Cartridge

1 Insert the 4mm data cartridge to the direction indicated by the arrow illustrated in the

following figure. When the 4mm data cartridge is inserted to certain extent, it is

automatically drawn into the slot.

■Ejecting 4mm Data Cartridge

1 Press the EJECT button.

The 4mm data cartridge is drawn out.

The cartridge is drawn out upon completion of rewinding the tape. It takes 2

minutes at longest before the 4mm data cartridge is drawn out.

2 Pull out the 4mm data cartridge.

– 13 –

Page 14

Cleaning

■Cleaning the Head

1 Insert the attached cleaning cartridge into Built-In DAT.

Cleaning starts automatically and the cleaning cartridge will be drawn out

approximately 30 seconds later.

2 Take out the cleaning cartridge.

This completes cleaning. Use the device as usual.

! The attached cleaning cartridge is durable for 30 times of cleaning. Blinking of

the STATUS LED upon completion of cleaning indicates that the cleaning

cartridge is worn out. (See the section “STATUS Indicator” on page 4 for LED

indications.)

! Do not touch the tape surface of the cleaning cartridge nor rewind the tape for

re-use.

■Head Cleaning Period

Cleaning Tape Surface

Clean the head with the cleaning cartridge once a week before using the device. (The

cleaning period varies according to the environment where the device is used, i.e. amount of

dust, and frequency of use. To use the device everyday in the ordinary office, clean the

head once a week.)

– 14 –

Page 15

Precautions

■Precautions on the Storage and Operation Environment

! This device has a ventilation opening on its chassis to prevent the inside temperature

from rising. Do not cover the ventilation opening nor use the device in the place with

bad air flow. Also, do not store or operate this device in the place with extremely high

temperatures or sudden changes in temperature.

! Do not store or operate this device in the place exposed to the direct sunlight or the

place close to heat-generating equipment.

! Do not store or operate this device in the humid or dusty place.

! This device is composed of precision electronic parts. Do not apply any shock to the

device. Also do not store or operate this device in the place with vibration.

! It is dangerous to operate this device with water, liquid, or metal objects inside it.

Make sure no foreign material enter the device.

! Do not store or operate this device in the place filled with vaporized chemicals or the

place where it may come into contact with chemicals.

! Do not store or operate this device while it’s disassembled. It may cause an error or

electric shock.

! Do not store or operate this device with a heavy object on top of it.

■Other Precautions

When the outside of this device becomes dirty, gently wipe it with a soft cloth moistened

with water or a cleaning detergent. Use of volatile chemicals, such as thinner and

benzene, may cause deformation or discoloration. Applying insecticide may also cause

deformation or discoloration.

■Abnormality and Error

■Disposal

When you find any error or abnormality, such as smells and heat, plug out the power cable

and contact the authorized maintenance personnel or dealer.

When you dispose the unit, follow the rules and regulations in your country. Ask your

local government for details.

– 15 –

Page 16

4mm DATA CARTRIDGE

Structure of the 4mm Data Cartridge

Specifications and Requirements for Storage and Shipment

■Operation Requirements

Temperature

Humidity 20 to 80%

Holding Period If the 4mm data cartridge has been exposed to the environment that does not

■Storage Requirements

Temperature

Humidity 20 to 80%

Storage Place the 4mm data cartridge into the protection case and close the cover

■Shipment Requirements

Temperature

Humidity 20 to 80%

Temperature Gradient

Shipment Place the 4mm data cartridge into the protection case, then put the case into

10 to 35℃

The highest wet bulb temperature must be 26℃.

satisfy the operation and storage requirements, leave it in the operation

environment longer (max. 8 hours) than it has been in the above

environment before use. The temperature gradient must be 10℃/hour.

5 to 35℃

The highest wet bulb temperature must be 26℃.

for storage.

The case may be placed horizontally or vertically.

-30 to 35℃

The highest wet bulb temperature must be 26℃.

10℃/hour

a plastic bag and close the bag.

For shipment, pack the plastic bag containing the 4mm data cartridge in a

cardboard box to protect the cartridge against any force.

– 16 –

Page 17

Labeling

■Label Position

■Precautions on Labeling

! Use a label that is easy to remove and leaves no adhesive when removed to indicate

contents of the 4mm data cartridge.

! Do not use an eraser to erase indication of the contents for update. Replace the label

with a new one. (The INDEX labels come with the 4mm data cartridge.)

! Attach a label to the exact position illustrated in the previous section. Remove the old

label before replacing it with a new one.

! Use a label with the same size as the specified INDEX label when it is necessary to use

a non-specified one.

! On the attached INDEX label, there is a field to fill in the date of first use. Make sure

to fill it in. It will help determining the life of the 4mm data cartridge.

Write-protection

Placing the write-protection plug as illustrated in the right figure below protects contents of

the tape.

To prevent the written data from erasing, place the write-protection plug as illustrated in the

right figure below. Placing the write-protection plug as illustrated in the left figure below

allows the data to be written on the tape.

Label

Not write-protected Write-protected

– 17 –

Page 18

Precautions on Handling

■Precautions on Use

Before Use

! Do not use a 4mm data cartridge on which external damage, deformation, or bending is

found.

! To use the 4mm data cartridge stored in the environment that does not satisfy the

required temperature and humidity requirements, leave it in the operation environment

longer (max. 8 hours) than it has been in the above environment before use. If there is

an extreme difference in temperature between the storage and operation sites, do not

move the cartridge directly from the storage site to the operation site. Leave it in the

place with the temperature gradient of 10℃/hour and allow the 4mm data cartridge to

be accustomed gradually to the operation site.

In-device Period

Set the 4mm data cartridge as described in the section, “Inserting 4mm Data Cartridge”.

Tightly close the protection case after removing the 4mm data cartridge out of it, and store

it in the place with few dust.

After Use

Store the used 4mm data cartridge in the protection case and store it in the place with few

dust. It may be placed horizontally or vertically.

– 18 –

Page 19

■General Precautions

! Do not touch the tape. Also, do not open and close the tape cover.

! Do not place any magnetic objects close to the cartridge.

! Do not apply the direct sunlight to the cartridge or place it close to the heater.

! Do not apply any strong shock.

! Do not handle the cartridge while eating or smoking. Also keep it free from thinner or

alcohol.

! Keep the cartridge in the case for storage after use.

! Insert the cartridge gently into the equipment.

! Keep the 4mm data cartridge magnetic tape free from dust.

Standards for Prohibited Use

Replace the 4mm data cartridge with a new one if the following conditions fit.

! When the 4mm data cartridge receives any damage by applying strong shock such as

dropping it

! When the recording surface is exposed to any liquid (soft drinks, coffee, or tea), solvent,

metal powder, or cigarette ash

Remarks

Inserting the 4mm data cartridge in the above conditions into the equipment may place

damage or dirt to the head or equipment, causing an error of the equipment. Also inserting

the 4mm data cartridge into the equipment with the dirty or damaged head may place dirt or

damage to the cartridge, making the whole situation disastrous.

– 19 –

Page 20

Cartridge Life

Data cartridges are subject to wear during every read and write operation. Continuing to use

a cartridge eventually leads to errors, and further use could result in loss of stored data.

Cartridges should therefore be replaced periodically.

The useful life of a cartridge depends on the operating environment, but the following table

serves as an approximate guideline to cartridge life.

Usage Frequency Estimated Useful Life

Once per week One year

Two to three times per week Six months

Daily Three months

! The above estimates may be shortened by operating environment conditions

(temperature, humidity, dust, etc.)

To manage data cartridges for optimum useful life, we recommend the following steps:

! Assign control numbers to new data cartridges, and write the numbers on the labels.

! Maintain a tape control list, including the date of first use and the expected useful life of

each cartridge.

! Refer to the control list and tape labels to determine when cartridges are reaching the

end of their useful lives (or if read/write errors occur), and remove them from use.

The chemical compounds that compose the magnetic layer of the tape will deteriorate over

time. The rate of this deterioration is greatly influenced by the storage environment

(temperature and humidity), so even if never used, cartridges should be replaced about three

years after purchase.

Preserving Critical Data

To preserve critical data or programs, we recommend saving to two tapes: a main and a sub

copy.

Also, when writing the backup copies, we recommend confirming the copy by using the

verify function of the backup software. Please refer to the documentation for the backup

software regarding use of the verify function.

By taking these steps, even if read errors are encountered as a result of dirt or dust on the

tape, the other tape can be used for data recovery, preventing loss of critical data and

programs.

Three-Generation Data Management

We recommend using a three-generation data management system for backing up data

saved on disk.

This system uses three tapes (call them A, B and C), with the disk data saved in the order

A-B-C as follows: disk data is saved to tape A on the first day, tape B on the second day,

and tape C on the third day.

With this system, if, for example, a read error was found on tape C, most data could still be

restored from tape B, and even if a read error was found on tape B, important data could

still be restored from tape A.

– 20 –

Page 21

APPENDIX

Major Specifications

■Performance

Memory Capacity 12 G bytes (Compressed: 24 G bytes)

• The value for compressed use is estimated with double compressibility. The compressibility

varies according to the data pattern.

Bit Error Code 10

Data Transfer Speed (TAPE) 1,180K bytes / second (non-compressed)

Burst Data Transfer Speed (SCSI) 5M bytes / second (max., asynchronized)

Initializing Pe riod less than 3 seconds

Loading Period less than 24 seconds

Unloading Pe riod less than 20 seconds

Rewinding Pe riod less than 80 seconds (with the 125m tape in use)

■Environment Requirements

-15

or less

10M bytes / second (max., synchronized)

Operation

Shipment

Storage

■DC Power Specification

Voltage

Current (Typ.) 1.0A 0.21A

■Size and Weight

Ambie nt

Temperature

10 to 35℃

-30 to 40℃

-5 to 40℃

Relative

Humidity

20 to 80%

10 to 90%

10 to 90%

5V±5% 12V±10%

Width 149mm

Height 41.2mm

Depth 149.8mm

Weight 0.91kg or less

41.2mm

149mm 149.8mm

Maximum Wet Bulb

Temperature

26℃ with no condensation

26℃ with no condensation

26℃ with no condensation

– 21 –

Page 22

List of LED Indications

Tape

Condition

Normal Normal

Normal Normal

Normal Normal

Normal Normal

Normal Normal

Normal Normal

Normal Normal

Normal or

Abnormal

Device

Condition

Normal

BUSY Lit or unlit

TAPE Unlit

STATUS Unlit

BUSY Blinking at the

TAPE Lit

STATUS ***

BUSY Blinking at the

TAPE Blinking at the

STATUS ***

BUSY Lit, unlit, or

TAPE Lit

STATUS ***

BUSY ***

TAPE Lit

STATUS Lit

BUSY Unlit

TAPE Lit

STATUS Blinking at the

BUSY ***

TAPE ***

STATUS Repeats long

BUSY ***

TAPE Repeats long

STATUS ***

DAT Device

LED LED State Meaning

SCSI is a ctive while BUSY is

lit.

No data cartridge is inserted.

The data cartridge is under

same intervals

operation. Read/write or

write is in progres s.

The data cartridge is be ing

same intervals

inserted or ejected.

same intervals

The data cartridge is inserted. (Note)

blinks at the

same intervals.

The inserted data cartridge is

write-protected.

The cleaning cartridge is used

up.

same intervals

Cleaning the head is

requested.

turning-on and

short turningoff.

The data cartridge is inserted

and an error that exceeds the

turning-on and

short turningoff.

defined media warning

threshold occurs. “Warning

Only” (The data cartridge is

worn off. )

Measure

(Note)

Make sure not to power off in

these LED states.

(Note)

Make sure not to power off in

these LED states.

Make sure not to power off in

these LED states.

(Note)

Make sure not to power off in

these LED states.

• Replace the cleaning

cartridge with a new one.

Do not reuse the old

cleaning cartridge.

• Perform cleaning the

head.

• If the same error occurs

right after the cleaning,

use a new data cartridge.

• Clean the head with the

standard cleaning

cartridge. If the same

error occurs right after the

cleaning, use a new data

cartridge (or clean the

head again and use a new

data cartridge).

– 22 –

Page 23

Tape

Condition

Normal or

Abnormal

Device

Condition

Normal or

Abnormal

DAT Device

LED LED State Meaning

BUSY Repeats short

Reset awaiting state

turning-on and

long turningoff.

TAPE ***

STATUS ***

Measure

• Pressing the EJECT

button does not ejects the

data cartridge. There

may be a hardware error

in the DAT device.

• Restart the device by

powering off and on.

Persisting the same error

after the restart indicates a

hardware failure.

Replace the DAT device.

Normal or

Abnormal

Normal or

Abnormal

Abnormal Abnormal

BUSY ***

TAPE Repeats short

tuning-on and

long turningoff.

STATUS ***

BUSY ***

TAPE ***

STATUS Repeats short

turning-on

twice and long

turning-off.

Ejection awaiting state

The device is faulty.

• Eject the data cartridge.

Use a new data cartridge.

Persisting this error after

replacement of the data

cartridge indicates a

hardware failure.

Replace the DAT device.

• The DAT device has a

hardware failure.

• Replacement of the DAT

device is required. The

data in the data cartridge

in use may destroyed due

to the hardware failure.

use another data cartridge.

Do not reuse the DAT

device and data cartridge

that had this error.

***indic ate s that the LED stat e va ries according to the state of the DAT device but does not affect the meaning or

measure.

– 23 –

Page 24

ADDENDUM

For WindowsNTTM 3.5/3.51 Users

Using this device with NTBACKUP of WindowsNTTM requires the tape device driver

“4mm SONY Drive” to be installed.

Procedure for Adding the Tape Device Driver

Preparation

(1) Make the WindowsNTTM installation media (CD-ROM) ready to use.

Installation Procedure

(1) Select “ WindowsNTTM Setup ” in the WindowsNTTM main group.

(2) Select “ Add/Remove Tape Device ” from the “ Options ” menu of “ WindowsNT

Setup ”.

(3) Select Add on the “ Tape Device Setup ” window.

(4) Select “ 4millimeter SONY drive ” for the device name on the “ Select Tape Device

Option ” window and select the “ Install ” button.

(5) The tape device driver is installed from the WindowsNTTM installation media (CD-

ROM).

Confirm that the CD-ROM drive name is correct.

* Set the WindowsNTTM installation media (CD-ROM) in the CD-ROM drive.

(6) Select the “ Continue ” button.

(7) Confirm that “ 4millimeter SONY drive ” is included in the list of installed tape

devices and select “ Close ”.

(8) Exit “ WindowsNTTM Setup ” and restart the system.

* The installed tape device is not effective before the system is restarted.

TM

– 24 –

Page 25

Page 26

Page 27

Page 28

The contents of this guide are subject to revision without prior notice.

Built-in DAT

First Edition, August 2000

Second Edition, March 2001

Third Edition, August 2002

User’s Guide

Loading...

Loading...