Page 1

NAD

SERVICE MANUAL

M22

STEREO

M22

STEREO

AMPLIFIER

AMPLIFIER

Page 2

TABLE OF CONTENTS

DESCRIPTION P A G E

SERVICE CAUTION…………………………………………………………....3-4

SPECIFICATIONS………………………………………………………….... 5

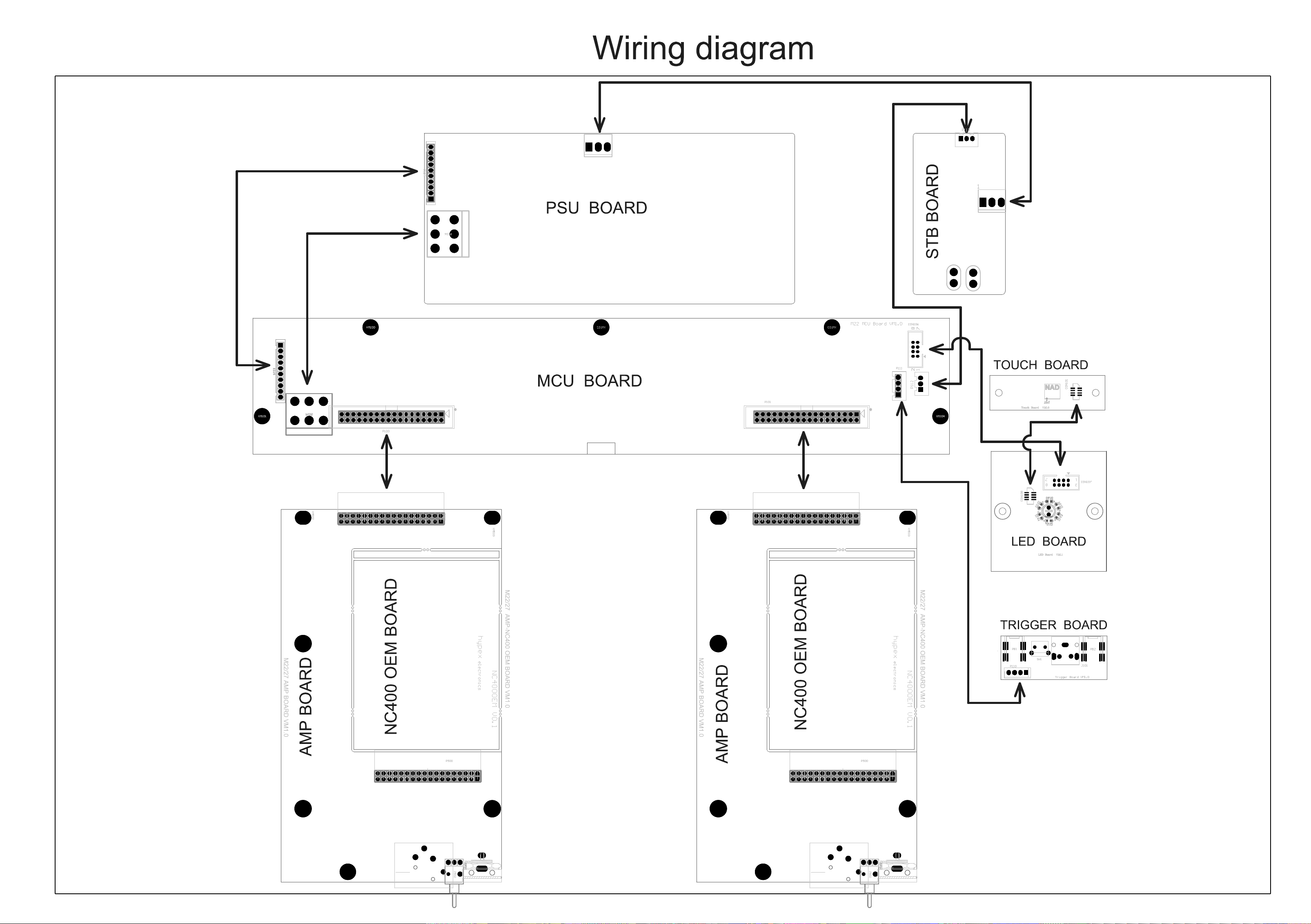

WIRING DIAGRAM…………………………………………………………….....6

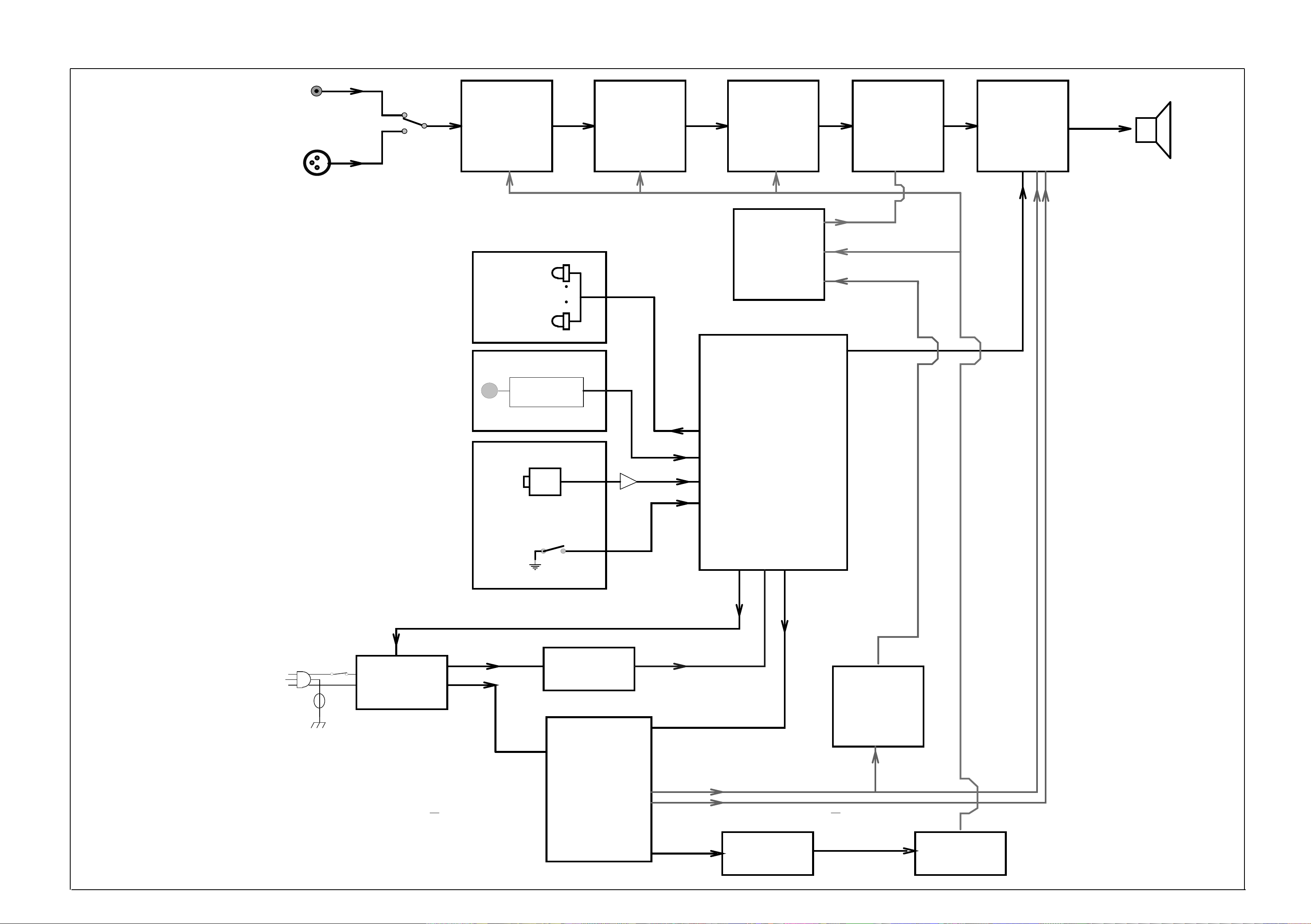

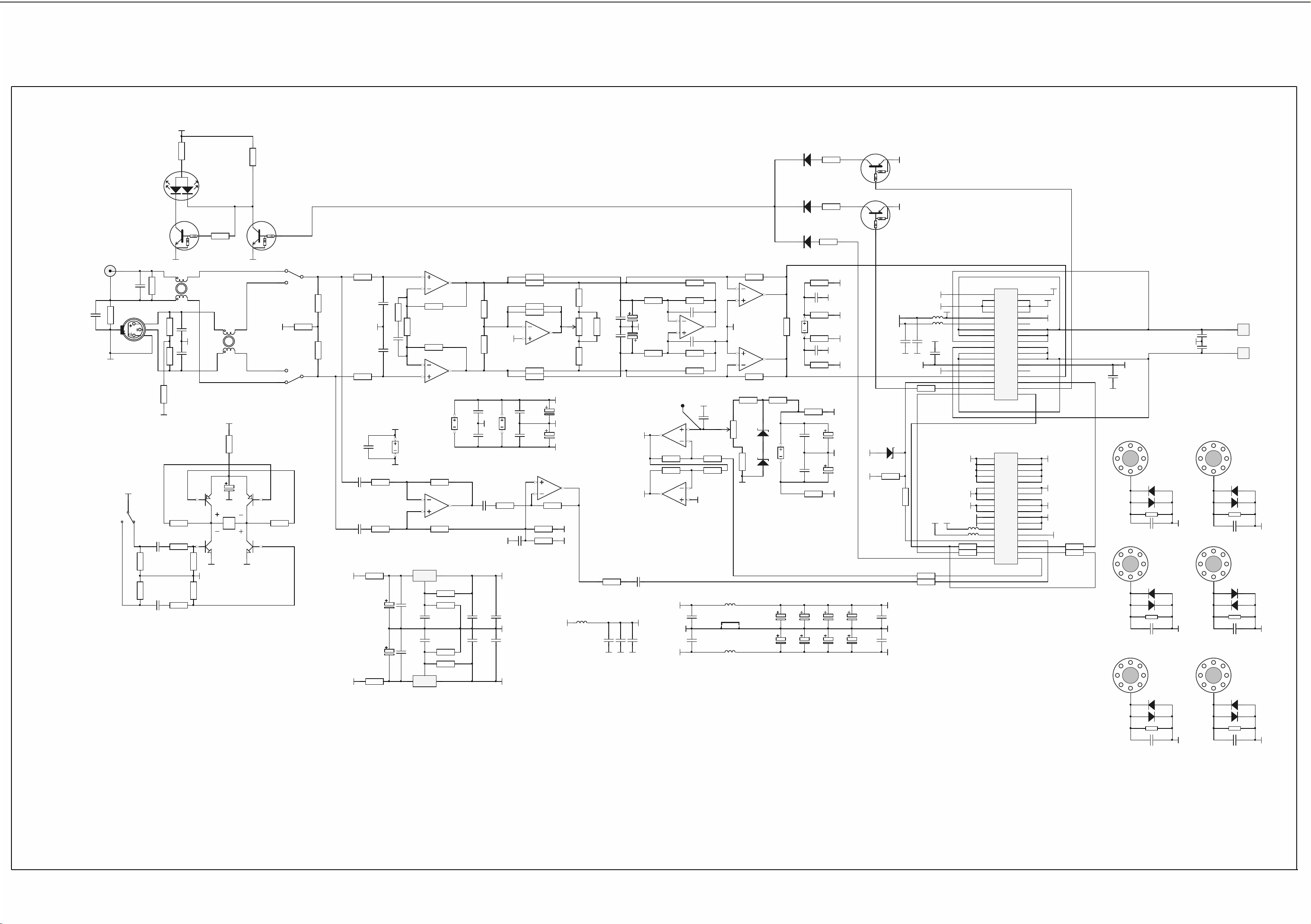

BLOCK DIAGRAM…………………………………………………….. ….......7-9

TROUBLE SHOOTING A GUIDE…………………......................................10

TROUBLE SHOOTING B GUIDE…………………......................................11

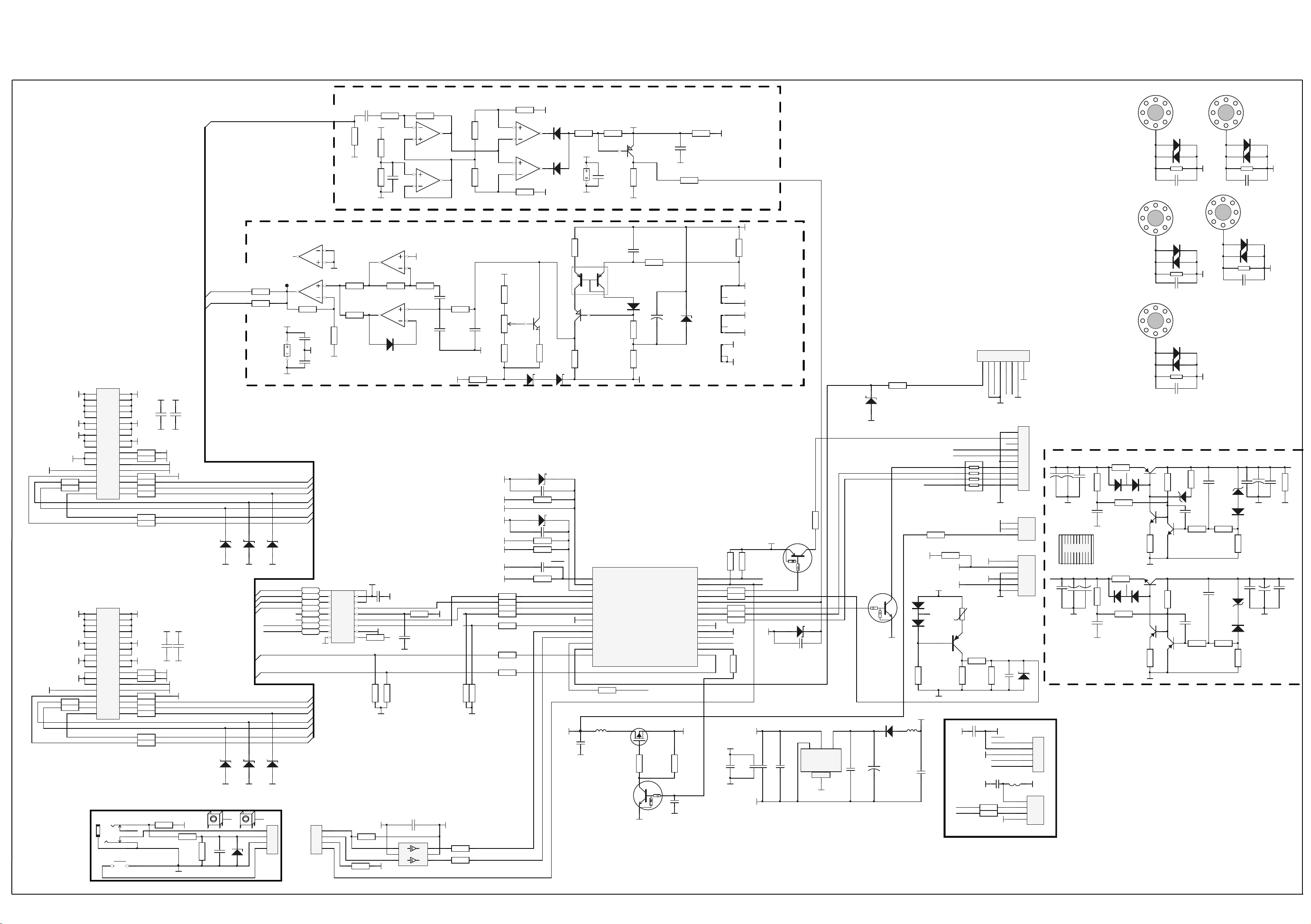

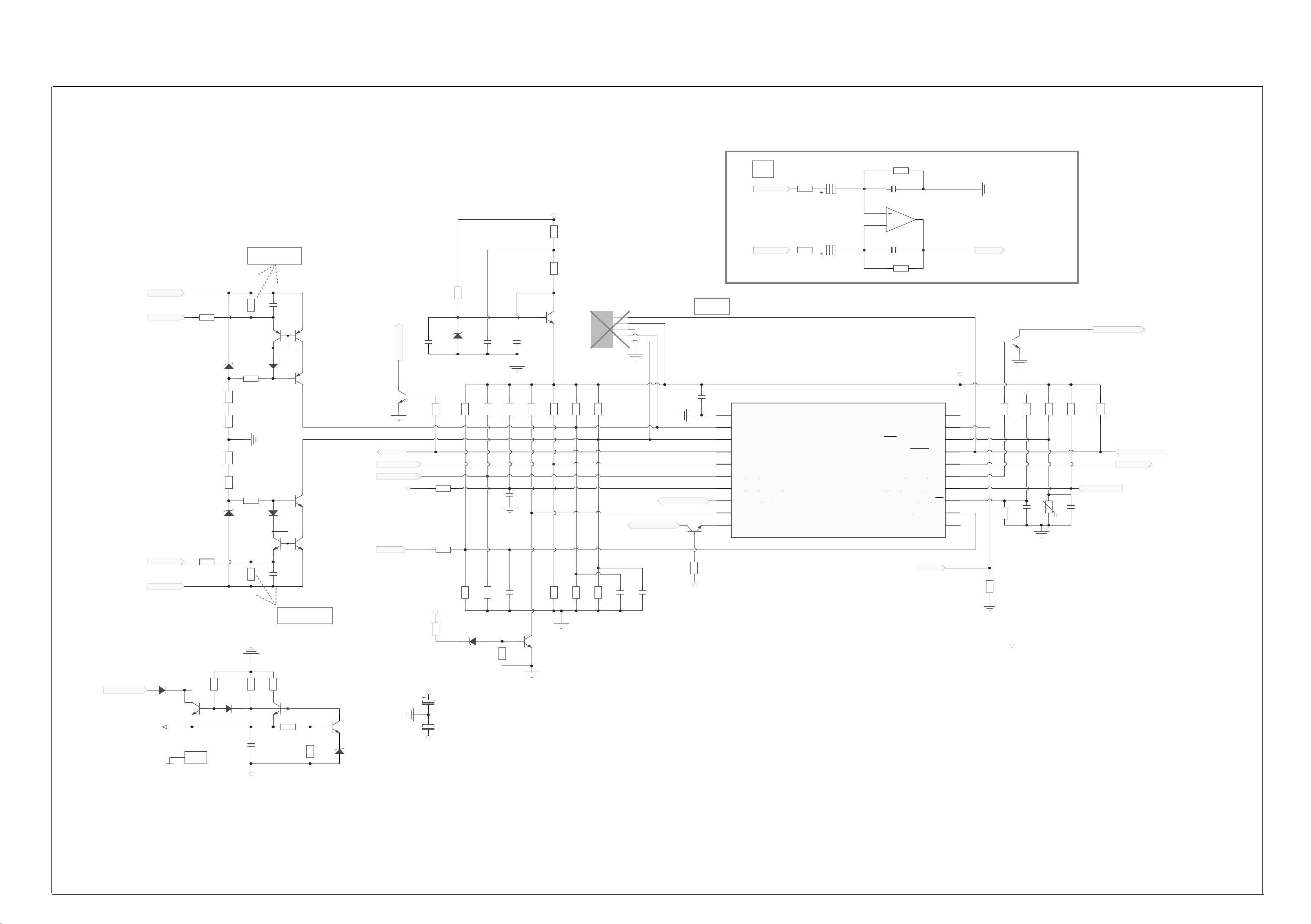

CIRCUIT DIAGRAMS

PCB LAYOUT………………………………………………………………..25-30

ELECTRICAL PARTS LIST…………………………………………......31-50

EXPLODED VIEW…………………………………………………………. 51-54

EXPLODED VIEW PARTS LIST……………………………………………....55

………………………………………………..…......12-24

Page 3

SUBJECT: GRAPHIC SYMBOLS

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METALPART

CAUTION : DO NOT ATTEMPT TO MODIFY THIS

PRODUCT IN ANY WAY, NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S

APPROVAL. UNAUTHORIZED MODIFICATIONS WILL

NOT ONLY VOID THE WARRANTY, BUT MAY LEAD TO

YOUR BEING LIABLE FOR ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY

AFTER YOU ARE THOROUGHLY FAMILIAR WITH ALL

OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,INCREASES

THE RISK OF POTENTIAL HAZARDS AND INJURY TO

THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINESHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS

BEEN CORRCTED. A CHECK SHOULD BE MADE OF

THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1.BE SURE THAT ALL COMPONENTS ARE POSI-

TIONED IN SUCH A WAY AS TO AVOID POSSIBILITY

OF ADJACENT COMPONENT SHORTS.THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH

ARE TRANSPORTED TO AND FROM THE REPAIR

SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULATORS, BARRIERS,

COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVEBEEN REINSTALLED PER ORIGINAL DESIGN. BE

SURE THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER

POSSIBLE COLD SOLDER JOINTS, SOLDER

SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE

OR DETERIORATION TO PARTS AND COMPONENTS.

FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD). AND REPLACE IF NECES-

5. NO LEAD OR COMPONENT SHOULD TOUCH A

RECIVING TUBE OR A RESISTOR RATED AT 1 WATT

OR MORE. LEAD TENSION AROUND PROTRUNING

METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC.

MUST BE REPLACED WITH EXACT FACTORY TYPES,

DO NOT USE REPLACEMENT COMPONENTS OTHER

THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C. LEAKAGE TEST ON ALL EXPOSED

METALLIC PARTS OF THE CABINET, (THE CHANNEL

SELECTOR KNOB, ANTENNA TERMINALS. HANDLE

AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A

1500 OHM 10 WATT RESISTOR, PARALLELED BY A

.15 MFD. 150.V A.C TYPE CAPACITOR BETWEEN A

KNOWN GOOD EARTH GROUND (WATER PIPE,

CONDUIT,ETC.) AND THE EXPOSED METALLIC

PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE

A.C. PLUG AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75 VOLTS

R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C

ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A

POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED

TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE LITERATURE.

Page 4

SERVICING PRECAUTIONS

CAUTION

this service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS. NOTE: if unforeseen

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this publication,

always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the Stereo amplifier AC power cord from the

AC power source before:

(1) Removing or reinstalling any component, circuit board,

(2) Disconnecting or reconnecting any internal electrical

(3) Connecting a test substitute in parallel with an electrolytic

Caution: A wrong part substitute or incorrect polarity

2. Do not spray chemicals on or near this Stereo amplifier or

any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cottontipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this Stereo amplifier and/or any

of its electrical assemblies unless all solid-state device heat

sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground lead

last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter (500V) to the

blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1 M-ohm.

Note 1: Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

: Before servicing the Stereo amplifier covered by

module, or any other assembly.

plug or other electrical connection.

capacitor.

installation of electrolytic capacitors may result in an

explosion hazard.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical Es devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handing any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reason prior to applying power to

the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8.Minimize bodily motions when handing unpackaged

replacement ES devices. (Normally harmless motion such as

the brushing together of your clothes fabric or the lifting of

your foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

Page 5

FRANÇAIS ESPAÑOL ITALIANO DEUTSCH NEDERLANDS SVENSKA РУССКИЙ

SPECIFICATIONS

OVERALL SPECIFICATIONS

Continuous output power into 8 ohms and 4 ohms ≥ 250 W (ref. rated THD, 20 Hz – 20 kHz, both channels driven)

Rated THD (250 mW to rated power, CCIF IMD, DIM 100) ≤0.005 % (ref. 20 Hz - 20 kHz)

IHF dynamic power 8 ohms : 355 W

4 ohms :640 W

2 ohms : 620 W

Damping factor >800 (ref. 8 ohms, 50 Hz and 1 kHz)

Input sensitivity 1.6 V (ref. rated power)

Signal-to-noise ratio, A- weighted > 98 dB (ref. 1W)

Signal-to-noise ratio, A- weighted > 120 dB (ref. rated power)

Frequency response ± 0.1 dB (ref. 20 Hz - 20 kHz)

- 2.5 dB at 3 Hz and 100 kHz

Time to go to Standby mode at no input signal ≤ 30 minutes

POWER CONSUMPTION

Rated power 640 W (120V 60Hz, 230V 50Hz)

Standby power < 0.5 W

Idle power < 40 W

DIMENSION AND WEIGHT

Unit dimensions (W x H x D) * 435 x 103 x 379 mm

17 1/8 x 4 1/16 x 14 15/16 inches

Shipping weight 15.0 kg (33.1 lbs)

* - Gross dimension include feet, front panel and rear panel extensions (knobs, buttons, speaker terminals, sub fascia, etc.)

NAD SHALL NOT BE HELD LIABLE FOR ANY TECHNICAL OR USER INTERFACE DISCREPANCIES IN THIS MANUAL. THE M22 SERVICE MANUAL MAY BE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE. CHECK OUT WWW.NADELECTRONICS.COM FOR THE LATEST VERSION OF THE M22 SERVICE MANUAL.

5

Page 6

6

Page 7

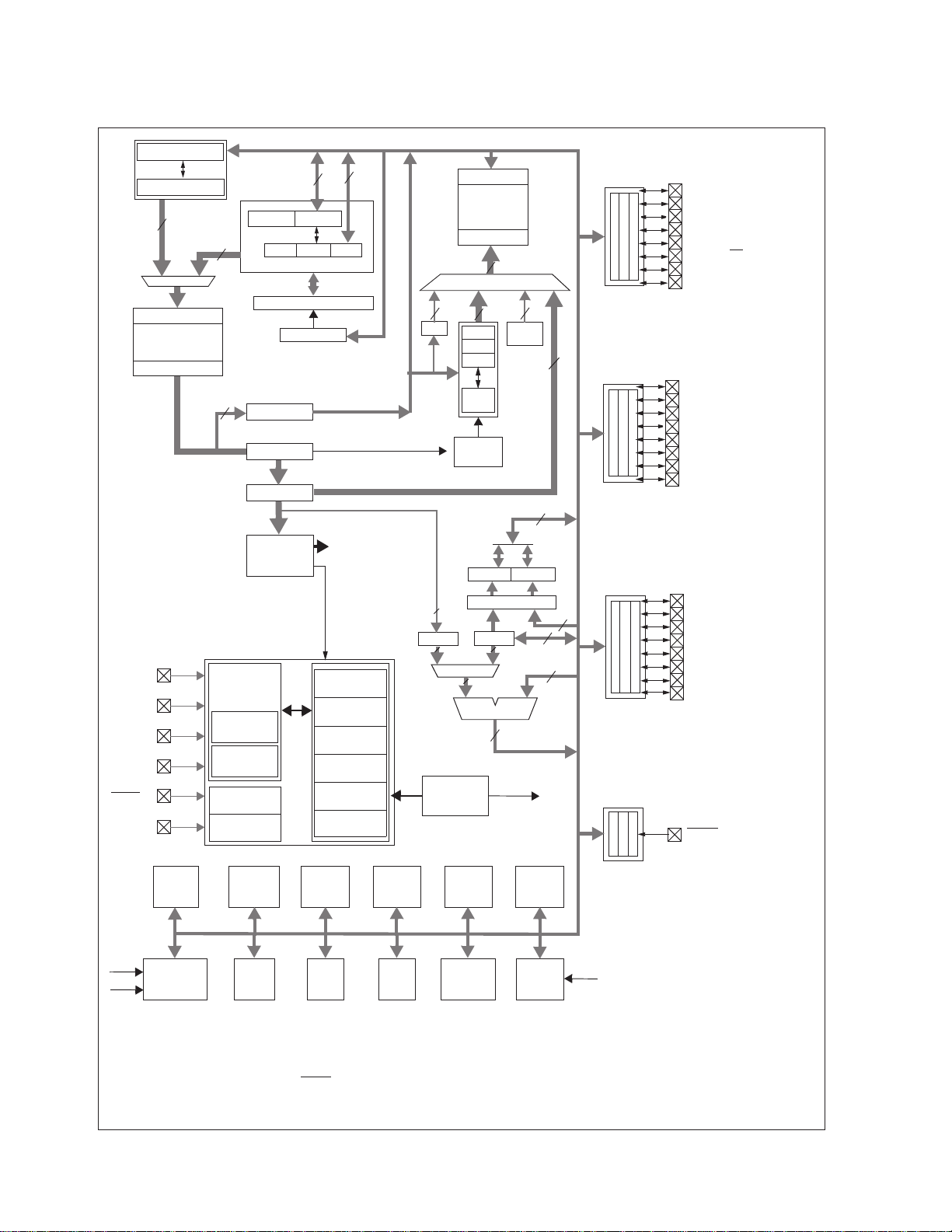

unbalanced

Block diagram

Analog Input

balanced

Relay

OP

LM E49720

LED

CM R

TL072

DC servo

TL072

Clipping controler

OPA2134

OP

LM E49720

Hypex

NC400 OEM M odule

TOUCH

CY8CM BR2044

TRIGGER

3.5mm

Audio sense on/off

IIC

M icro controller

IIC/SPI/GPIO

PIC18F26K20

100-120V A C

220-240V A C

STB PSU

5V

AC

LDO

M AIN PSU

STB

3V3

Current sensor

ENABLE

+/-VB

+/-VDR

7

+/-VAUX

Regulated supply

LM 317/LM 337

TL084CN

+/-17.5V

+/-14.5V

Regulated supply

LM 317/LM 337

7

Page 8

PIC18F26K20

MCU BOARD

Table Pointer<21>

inc/dec logic

21

Address Latch

Program Memory

(8/16/32/64Kbytes)

Data Latch

Instruction Bus <16>

(3)

OSC1

(3)

OSC2

T1OSI

T1OSO

(2)

MCLR

V

VDD,

SS

PCLATU

20

8

Table Latch

ROM Latch

Instruction

Decode and

Control

Internal

Oscillator

Block

LFINTOSC

Oscillator

16 MHz

Oscillator

Single-Supply

Programming

In-Circuit

Debugger

8

PCLATH

PCH PCL

PCU

Program Counter

31-Level Stack

STKPTR

IR

State machine

control signals

Power-up

Oscillator

Start-up Timer

Power-on

Watchdog

Brown-out

Fail-Safe

Clock Monitor

Data Bus<8>

8

Timer

Reset

Timer

Reset

Data Latch

Data Memory

Address Latch

Data Address<12>

4

BSR

FSR0

FSR1

FSR2

inc/dec

logic

Address

Decode

3

BITOP

8

Precision

Band Gap

Reference

12

12

Access

Bank

PRODLPRODH

8 x 8 Multiply

W

8

8

ALU<8>

8

FVR

PORTA

4

12

PORTB

8

PORTC

8

8

8

PORTE

RA0/AN0

RA1/AN1

RA2/AN2/VREF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

RA5/AN4/SS

OSC2/CLKOUT

OSC1/CLKIN

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

RB3/AN9/CCP2

RB4/KBI0/AN11

RB5/KBI1/PGM

RB6/KBI2/PGC

RB7/KBI3/PGD

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

RC2/CCP1

RC3/SCK/SCL

RC4/SDI/SDA

RC5/SDO

RC6/TX/CK

RC7/RX/DT

MCLR/VPP/RE3

/HLVDIN/C2OUT

(3)

/RA6

(3)

/RA7

(1)

(1)

(2)

BOR

HLVD

FVR

CVREF

Note 1: CCP2 is multiplexed with RC1 when Configuration bit CCP2MX is set, or RB3 when CCP2MX is not set.

2: RE3 is only available when MCLR

3: OSC1/CLKIN and OSC2/CLKOUT are only available in select oscillator modes and when these pins are not being used as digital I/O.

Refer to Section 2.0 “Oscillator Module (With Fail-Safe Clock Monitor)” for additional information.

Data

EEPROM

ECCP1

CCP2

functionality is disabled.

MSSP

Timer2Timer1 Timer3Timer0

FVR

EUSARTComparator

ADC

10-bit

8

Page 9

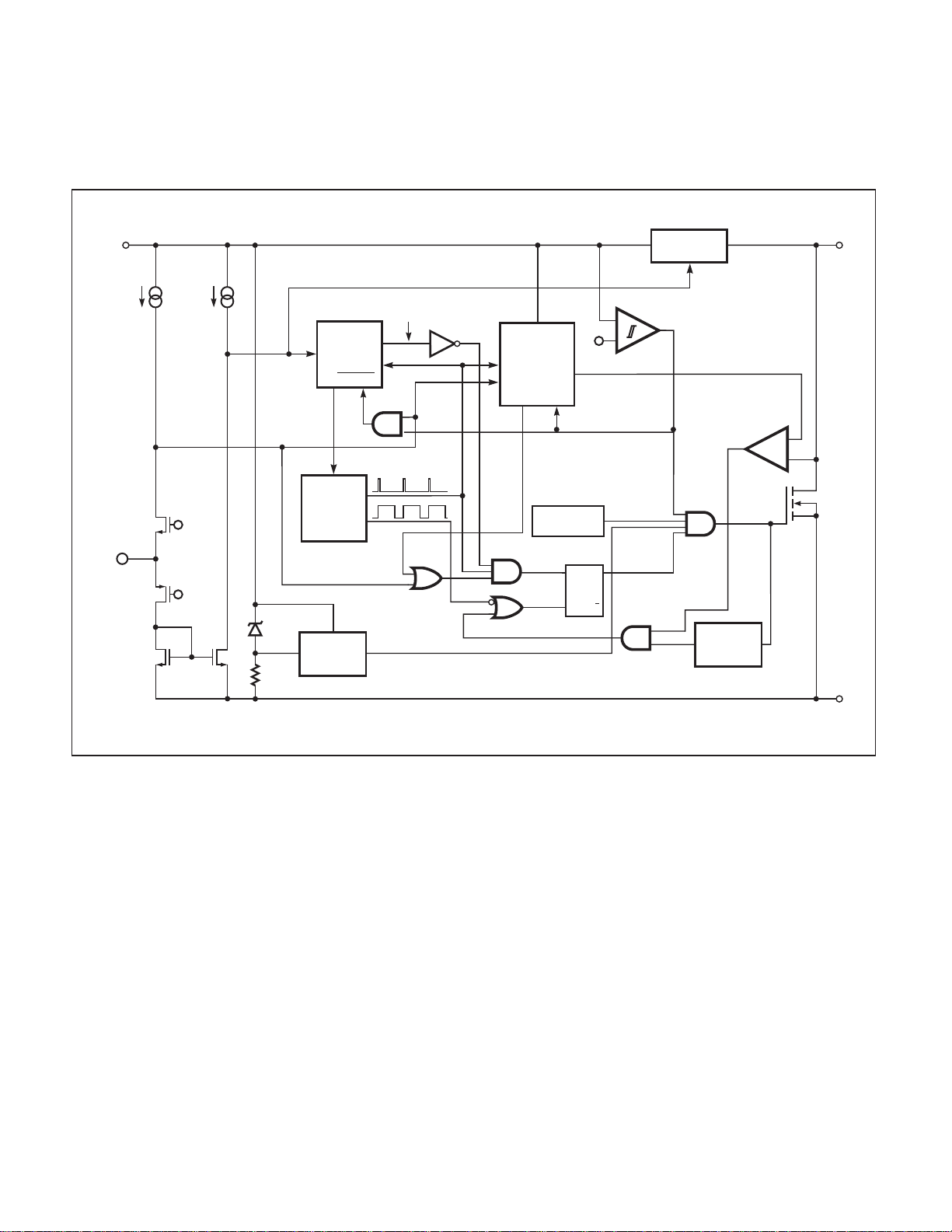

TNY274

SMPS STB BOARD

BYPASS/

MULTI-FUNCTION

(BP/M)

115 μ

A 25 μ

ENABLE/

UNDER-

VOLTAGE

(EN/UV)

A

ENABLE

1.0 V + V

1.0 V

DRAIN

REGULATOR

5.85 V

(D)

LINE UNDER-VOLTAGE

6.4 V

AUTORESTART

COUNTER

RESET

FAULT

PRESENT

BYPASS

CAPACITOR

SELECT AND

CURRENT

LIMIT STATE

MACHINE

5.85 V

4.9 V

BYPASS PIN

UNDER-VOLTAGE

+

-

V

I

LIMIT

CURRENT LIMIT

COMPARATOR

+

JITTER

CLOCK

T

DC

MAX

THERMAL

SHUTDOWN

OSCILLATOR

SRQ

Q

LEADING

OVP

LATCH

EDGE

BLANKING

SOURCE

(S)

9

Page 10

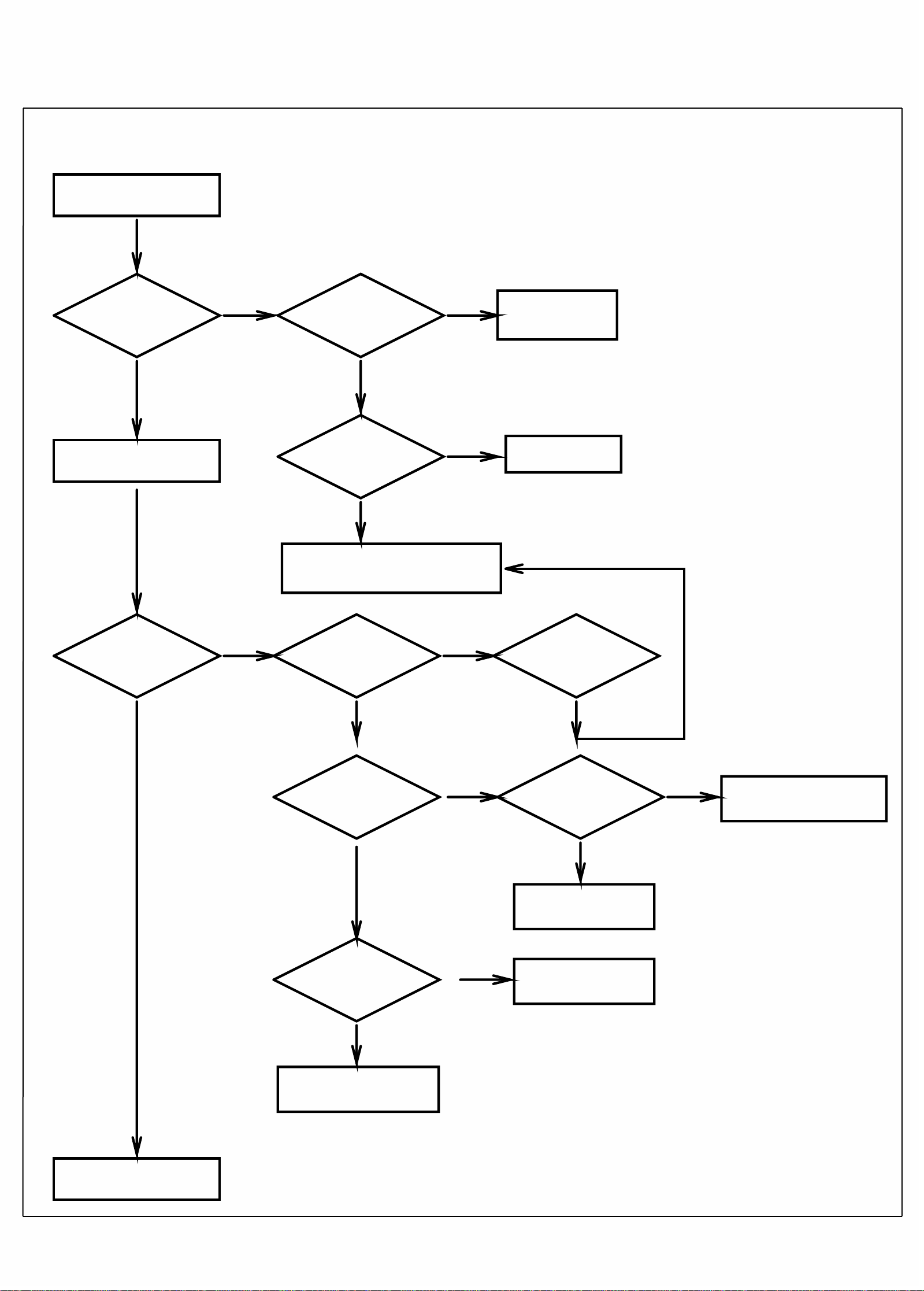

No Power or Power shuts off

immediately

TROUBLESHOOTING A GUIDE

Logo Amber LED on?

YES

Touch Power key

YES

Check STB board

5V RIGHT?

YES

Check LED board

5VL RIGHT?

YES

Check Q110 Q111 Q114 Q115 Q116 circuit

Check PWM signal

Change LED board

NO

check IC301 circuitNONO

change STB board

Check L104 C175 C176

Logo led turn white?

YES

NO

Logo led turn red?

YES

Check PSU board

+/-VB +/-VAUX +/-VDR RIGHT?

YES

Check MCU Board

VPP VPI +/-17.5V +/-VDR RIGHT?

Check MCU Board

NO

NO

NO

Logo led turn off?

YES

Check STB board

STB 3V RIGHT?

YES

Check U1 U5 PWM circuit

Change PSU Board

Check Q123 Q124 circuit

Change MCU Board

NO

Check MCU board:Q131 circuit

Check STB Board:Q301 K301 circuit

YES

Check U104,

Check LED control signal

Change MCU board

B

10

Page 11

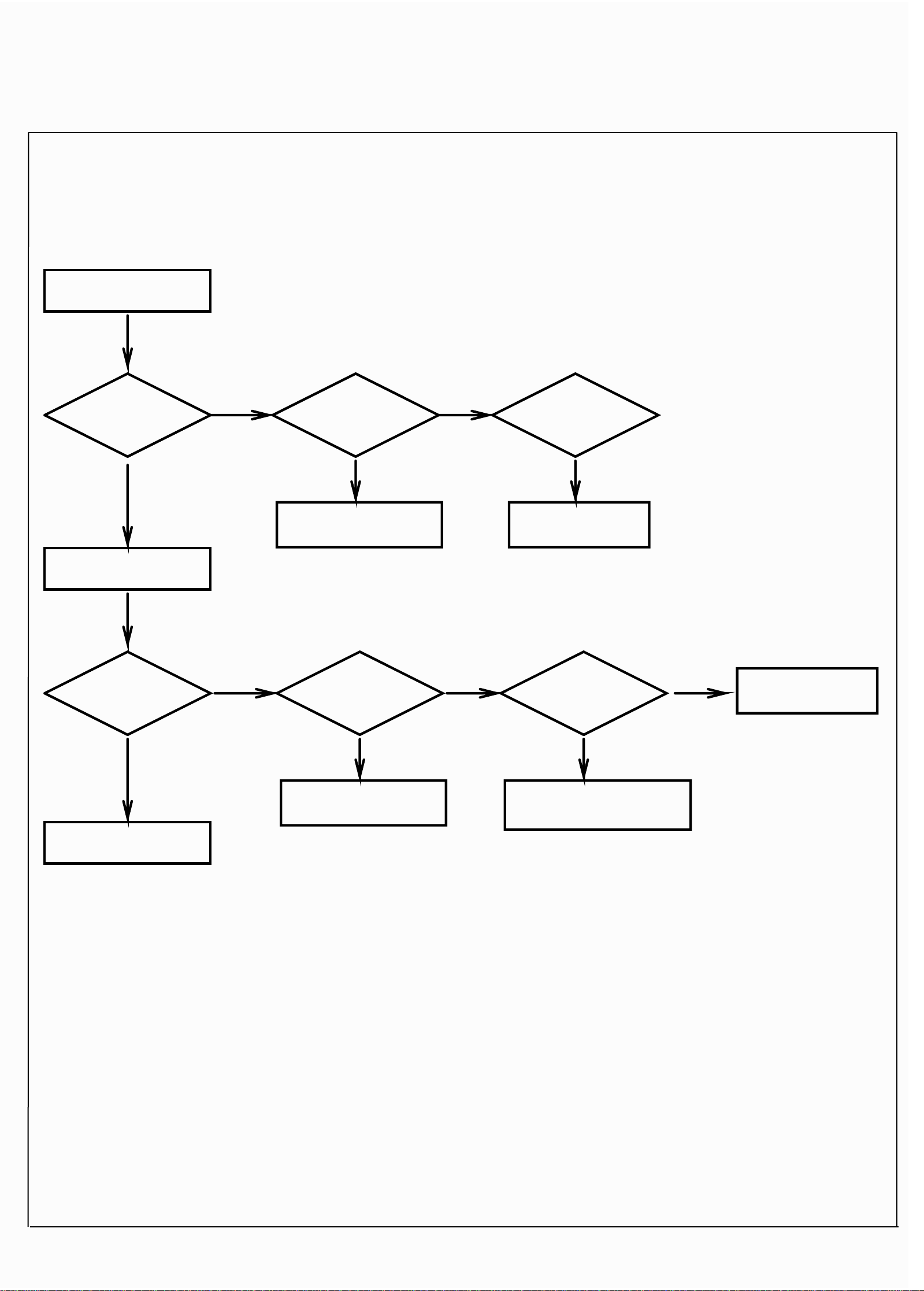

TROUBLESHOOTING B GUIDE

B

Rear panel led show green?

YES

Apply 1khz sinewave to DUT

Amplifier output correct?

NO

NO

YES

Check Q500 Q502 Q508 circuit

Change NC400 OEM BOARD

INC INH signal correct?

NO

NO

led turn off?Rear panel led show red?

YES

Check D500 U505 circuit,

check+/-14.5V,5V Right?

NO

checkQ505 Q506 Circuit

change AMP board

YES

F i n i sh

YES

Change NC400 OEM BOARD

YES

checkU500 U501 U502 U503 Circuit

checkQ503 Q504 Circuit

change AMP board

11

Page 12

CIRCUIT DIAGRAM

1.MCU VM1.0

0.22u/16v

AudioS

100K

GND

U102C

TL084

12K

C116

2N2

C117

2N2

100R

100R

100R

100R

100R

100R

100R

100R

P111

TO MAIN

GND

1

2

3

4

GND

9

10

12

13

1

2

3

4

5

6

7

GND

1K

GND

U104

q1

q2

q3

q4

q5

q6

q7

gnd8q'h

74HC595

R151

10K

R167

10K

R176

16

vcc

15

q0

14

ser

13

/g

12

rck

11

sck

10

/sclr

9

10R

8

U102D

TL084

i d l i n g 0 V

TP1

VCLIP0

VCLIP1

P100 TO AMP board A

GND

VPPi

VPNi

S

GPOb0

GPI0

5VS

GPOb1

GPI1

GND

0R

0R

GND

VPPi

VPNi

GND

0R

0R

R130

R131

R172

R174

AMP MODUL E1

5V

AMP MODUL E2

3536

3334

3132

2930

2728

2526

2324

2122

1920

1718

1516

1314

1112

910

78

56

34

12

P101 TO AMP board A

3536

3334

3132

2930

2728

2526

2324

2122

1920

1718

1516

1314

1112

910

78

56

34

12

trig in

17-02001-55

J101A

SW1

2 1

SW(TOUCH)

Whi t e l ed br i ght ness ADJ

R119

R120

R121

R123

R126

R128

R158

R161

R165

R168

R169

R170

GND

C101

10N

VPPi

VPNi

0R

0R

0R

0R

0R

0R

0R

0R

GND

VPPi

VPNi

0R

0R

3K9

0R

0R

0R

0R

0R

5

4

3

2

1

10N

C109

R284

470R

+17.5V-17.5V

VDRVDR+

SCL

SDA

GPOa0

R133

R135

VDRVDR+

SCL

SDA

GPOa1

R177

R178

GNDGND

-17.5V

+17.5V

+17.5V-17.5V

GNDGND

-17.5V

+17.5V

R287

232 gnd

C102

10N

GND

VCLIP0

AudioS

C108

10N

GND

VCLIP1

AudioS

10KJ

232 gnd

R288

D107

4V7

GND

D114

4V7

GND

1

PB11PB2

C165

D138

6k8

100N

4v7

R136

200R

R137

200R

U102E

TL084

D106

4V7

GNDGND

GPOa0

GPOb0

GPOa1

GPOb1

A-LED

W/R-LED

SCL

SDA

D113

4V7

GNDGND

P110

TO MAIN

14

R163

+17.5V

4

11

-17.5V

D105

4V7

R209A

R209C

R209D

R213A

R213B

R213C

R213D

D112

4V7

1

2

3

4

C100

R117

R285

47KJ

3V3D

100R

R226

R107

GND

R290

5VA

R127

GND

1

U102A

TL084

U102B

TL084

7

C136

100N

3V3D

10K

3V3D

R100

100K

GND

1K

R116

100K

D111

ISS352

10K

C105

10U

R152

330K

GND

2

1

R108

2

3

12

13

3

2

5

6

10K

C140

100N

3V3S

C164

100n

U109

a23y2

gnd

a1

NC7WZ17

R101

47K

GND

R153

330K

vcc

y1

U100A

LM324

U100C

LM324

R214

4

5

6

1

14

-17.5V

GND

470N

C112

C114

1U

3V3S

R286

R164

120R

R289

120R

47K

R297

R319

1K5

NCK0R209B

NM OS I

NCS1

GPI0

GPI1

10k

3V3D

R115

15K

R125

15K

C115

10n

R219

R222

R225

R228

R231

R240

R244

10k

R296

GND

R16047K

R171

10K

GND

GND

GND

VAUXa

GND

GND

VHP1

GND

3V3S

TRIGON_OFF

TRIGIN

10

3

3

1

1

33K

100R

100R

100R

100R

100R

0R

0R

5

6

9

2

R325

D160

4v7

100K

R111

R129

100K

2

R201

R208

R210

R216

U100B

LM324

U100D

LM324

C137

NC

TRIGON_OFF

7

8

Q118

2SC3324

5K1

1k

10k

180k

22k

TRIGIN

5VA

GND

R175

4v7

D118

3V6

C125

100N

D119

3V6

C133

100N

D101

ISS352

D104

ISS352

D159

MCLR

LM324

GND

C174

R112

U100E

100R

3

2

7K5

22u/ 6v3

GND

5K6

5VA

GND

R139

R180

R245

10

11

12

13

14

411

Q117

2SA1312

U105

1

2

3

4

5

6

7

8

9

PIC18F26K20

R113

5K6

1

C104

2

100N

1

2

41

Q113

BCV62B

MCLR/VPP/RE3

RA0/AN0/C12IN0RA1/AN1/C12IN1RA2

RA3

RA4

RA5/HLVDIN

VSS

OSC1/CLKIN/RA7

OSC2/CLKOUT/RA6

RC0

RC1

RC2

RC3/SCK/SCL

PWM-LED

100R

Q135

DTC114E

Q132

APM2313

L101

742792662

5VA

GND

D

K A

Q104

2SA1312

R122

5K1

2N2

C107

D109

ISS352

R173

22K

R179

22K

GND

G

R239

10K

GND

GND

R141

100R

D110

15V

C113

10U/35V

06- 100 2 1 - 06

RB7/KBI3/PGD

RB6//KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0

RB3/AN9

RB2/INT2

RB0/INT0/FLT0/AN12

S

RB1/INT1

RC7/RX/DT

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

GND

R124

R241

10k

5VEN

C146

1N

R114

10R

C103

10U

100R

CLIPPING CONTROL

28

27

26

R223

25

R220

24

23

R229

22

R232

21

R233

20

VDD

19

VSS

18

17

16

15

3V3S3V3D

5VS

AUDIO SENSE

VPP

2.5mR

R144

1

VPPi1

JP100

2

2

3

JP101

JP102

R 33 1

3V3S

22u/ 6v3

GND

10 K

100R

100R

100R

100R

100R

GND

GND

R 33 0

GND

R235

100R

C139

100N

VPPi

VPNi

VPNi

10 K

PG D A T A

PG C LK

3V3S

GND

3

3V3S

RXD

TXD

C138

A udioSa

O V L

nA M P O N

G N D

3V 3S

STBY

C158

D TA 114

Q 131

100n

D 123

4V 7

C151

22N

C177

10U

R339

XM104

HOLE

100R

D166

CD4148WP

680

D169

16V

D167

CD4148WP

R346

680

XM101

HOLE

C126

GND

C184

10U

220U

GND

D146

ISS352

ISS352

-17.5VVAUX-

C130

D135

ISS352

ISS352

D147

100R

C168

22N

+17.5VVAUX+

C124

100N

D137

R283

C163 22N

GND

R293

GND

VAUXa

220U

C129

100R

R185

10K

100N

XM102

HOLE

D140

ISS352

D139

ISS352

100R

R291

GND

C166

22N

XM100

HOLE

D134

ISS352

D136

ISS352

R282

C162

GND

XM103

HOLE

D141

10K

C178

47P

R348

C179

47P

R347

680

R349

D170

15V

680

ISS352

D142

ISS352

100R

R292

GND

C167

22N

C182

1U

C181

1U

R338

680

R340

680

D168

16V

CON106

1

2

345

678

GND

Q105

GND

D124

ss12

C156

470U/6V3

R309

10K

e c

742792662

L102

VHP1

1

2

120K

5VS

nFATAL

OVL

nAMPON

AMPOFF

R186

D154

BAV99

3

R326

10n

C159

100

VPPi

GND

R203

180k

VPNi

VAUX+

VAUX-

8

7

6

5

STB_EN

VPP

Rt

GND

TXD

RXD

D EBU G

PS_EN

FB100

100M/600R

VDR+

VDR-

RT1

NTC

Q120

FMMT593TA

R327

120K

R328

4K3

C147

100N

GND

C152

GND

100R

100R

PWM-LED

GND

1

2

3

4

GND

5VS

GND

GND

10K

MCLR

PGDATA

PGCLK

100n

GND

POWER_ON

D158

4v7

R 20 2

0R

DTC114EKA

b

C 143

100N

3

1

2

G

IN

OUT

O

22u/6V3

4

3V3S

U108

ASM1117-3.3

C155

100n

R329

3V3S

R268

R269

A-LED

C173

100N

L103

FB

W/R-LED

3V3D

5VS

P103

10

9

8

7

6

5

4

3

2

1

FROM PSU

P112

1

2

3

FROM STB

P105

1

2

3

4

5

6

From PSU

D155

3V6

CON103

ICSP

3V3S

P109

4

3

2

1

Header 4

R323

0.47

1 2

22k

220U

C123

GND

R332

C122

100N

C127

220U

220U

GND

GND

C183

10U

22k

C180

10U

R334

D162

22k

R333

R324

0.47

D163 BAV99

22k

R335

C131

220U

C128

GND

HS1

H eatsin k

C132

100N

1

2

3

4

5

3

3

BAV99

Q121

BC846B

BC856B

Q126

Q124

A1220

R336

GND

Q123

12

C2690

GND

R341

3K9

Q122

BC846B

470

3K9

R342

BC856B

Q125

R337

470

12

Page 13

2.AMP VM1.0

+14.5V

INPUT

C569

100n

17-01001-12

J500

RCA

R586

100R

GND

C558

100P

J502

XLR3F

5V

2

1

S500Source

3

DTC114EKA

R511

SEBAL

C531

10U

22K

R568

22K

R573

10U

C534

6K8

R500

A

D500

REDGREEN

K2

K1

Q501

e c

GND GND

2 3

47K

1 4

R516

220K

220K

R530

R587

4.7MEG

GND

R556

10K

R564

6K8

R575

6K8

T500

C500

100P

GND

C512

100P

Q503

2SA1015

47K

R569

47K

R574

b

GND

R504

Q505

2SC1815

GND

10K

RL500C

1 4

2 3

7 8

5V

GND

10R

R543

C525

220U/10V

SET

RESET

T501

GND

33K

R502

Q504

2SA1015

Q506

2SC1815

Q502

DTC114EKA

2

3

GND

6

5

R557

10K

RL500A

R522

100R

RL500B

D516

10K

1SS352

D502

10K

S

S352

1

D503

1K

1SS352

1

47K

R517

47K

R531

4

R506

100R

R536

100R

C501

220P

GND

C509

220P

5V

C521

1U

R546

2.2MEG

R558

2.2MEG

3R3

R572

C532

3R3

R582

GND

+17.5V

-17.5V

C524

10n

C529

10n

100U/25V

C551

100U/25V

1n8

8

4

R594

1K2

845R

R527

C570

U504C

MCP6002

3

C533

100nZ

C552

100nZ

2

3

2

R523

6

5

2

3

IN

IN

R520

ADJ

OUT

1

1

OUT

2K43

2K43

U506

ADJ

U500A

LME49720

U500B

LME49720

R547

680K

U504A

MCP6002

R559

680K

2

U505

LM317M

309R

3K24

C538

10U/25V

C547

10U/25V

3K24

316R

LM337M

3

1

7

8

4

U500C

LME49720

1

R576

R577

R580

R581

10K

R521

10K

R529

84

C516

100nZ

GND

C520

100nZ

U502C

TL072

C526

R552

10K

1U

GND GND

C539

100nZ

C548

100nZ

GND

C530

10U

+14.5V

C540

10U/25V

GND

C543

10U/25V

-14.5V

2

3

R507

12K

4K75

10K

10K

R534

4K75

12K

R538

C515

100nZ

C519

100nZ

5

6

U504B

R560

100k

R562

100k

R508

R514

R518

TL072

U502A

R553

330K

2

1

+14.5V

C514

100U/25V

GND

C517

100U/25V

-14.5V

MCP60

7

5V

5VS

R513

4K64

3

R524

500R

R525

1

R532

4K64

0

2

L502

BMB2A0600RS2

C544

10U/10V

C504

100N

392R

C506

100N

R550

5K6

GND

GND

10U/10V

C545

47K

R510

10K

R515

C503

10U/16V

GND GND

C505

10U/16V

R528

10K

U503A

OPA2134

1

VCL

+

7

VCL

-

C555

10U/25V

5V

C571

10U/10V

GND

R512

220K

C502

1U

6

TL072

5

TP2

R544

10K2

10K2

R548

U503B

OPA2134

VPPi

GNDC GND

VPNi

U502B

C508

1U

220K

R533

R535

47K

GND

3

m2 2 6.2 v

2

m2 7

6

5

GND

C541

10N

C549

10N

7

10U/10V

C556

bi as

6.

R545

4K7

10K2

R549

250V

250V

5 v

744302015

JP500

COPPER

744302015

2

3

5

6

BAR

R540

4K12

R542

5k

GND

L501

L503

4K75

R509

U501A

LME49720

U501B

LME49720

R537

4K75

R593

13K

D518

D519

4v7

1

7

R595

1K

4v7

470K

R526

84

OPA2134

U503C

C535

100U/100V

C546

100U/100V

10R

C567

1U/25V

8

NC

U501C

LME49720

4

NC

C568

1U/25V

10R

R541

10R

C557

100nZ

C523

100nZ

R551

10R

C559

100U/100V

C562

100U/100V

R588

GND

R519

R583

GND

R589

+14.5V

GND

-14.5V

C560

100U/100V

C563

100U/100V

R590

R503

R505

VCL+

+14.5V

-14.5V

VCL-

C518

47U/ 25V

C522

47U/ 25V

Q508

c

c

DTA114

GND

GND

VCLIP

AudioS

C561

100U/100V

C564

100U/100V

b

b

b

b

eec

eec

VDR-

VDR+

C553

10N

200v

C554

10N

200v

R565

NC

VPP

C542

330n/200V

C550

330n/200V

VPN

+14.5V

Over cur re nt in di cat i on

+14.5V

DTA114

Q500

INC

VPP

L504

GND

L505

GND

C510

10U/25V

GND

GND

-14.5V +14.5V

INH

D515

NC

R585

GND

10K

R539

0R

+17.5V-17.5V

IIC add

SCL

SDA

GPO0

R570

0R

0R

R571

VPP VPP

GND

GND

VPN

GND GND

VPN VPN

VDR

OUTC

OUTC OUTC

FBH OUTH

OUTH

OUTH

VSN VSP

GND

INH

OPT nAMPON

CLIP SCPIND

SDA/RDY SCL/nFAL

GNDC

VPPi

VPNi

VDR-

VDR+

L507

L506

0R

0R

P500

AMP MODULE

P502

R561

R563

TO

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

35 36

33 34

31 32

29 30

27 28

25 26

23 24

21 22

19 20

17 18

15 16

13 14

11 12

9 10

7 8

5 6

3 4

1 2

Mother board

GND

GND

NC

OUTC

OUTCFBC

OUTH

OUTH

NC

I

NC

GPO1

GPI

GND

VPP

VPN

GNDC

VPPi

VPNi

GNDC

5VS

R566

NC

NC

R567

OUTC

OUTH

GND

C513

10U/25V

XM500

HOLE

XM502

HOLE

XM533

HOLE

22-01626-00

D504

1SS352

D505

1SS352

R554

100R

C527

22N

D508

1SS352

D509

1SS352

R578

100R

C536

22N

D501

1SS352

D513

1SS352

R501

100R

C565

22N

GND

GND

GND

GND

XM501

HOLE

XM503

HOLE

XM534

HOLE

C507

10N 200V

C511

10N 200V

100R

100R

100R

1

1

D506

1SS352

D507

1SS352

R555

C528

22N

D510

1SS352

D511

1SS352

R579

C537

22N

D512

1SS352

D514

1SS352

R584

C566

22N

CN501

SP-

CN502

SP+

GND

GND

GND

13

Page 14

3.NC400 OEM VM1.0(1/4)

CLIP

D29

BAS316

R1

4R7

SDA/READY

A1/OPTION

GND

OUTH

FBH

FBC

C3

OUTC

4n7

GND

J3

35 36

33 34

31

29 30

27 28

-Vop

VDR_EXT

-VB -VB

+VB

25 26

23 24

21 22

19 20

17 18

15

13

11 12

9 10

7

5

3 4

1 2

CON_2x18MH

32

16

14

8

6

SCL/nFATAL

SCCPIND

A0/nAMPON

-BNI+BNI

IOUT

+Vop

OUTH

OUTC

+VB

GND

GND

VDR_EXT

-VB

+VB

C1

100n

C2

100n

C4

100n

Mechanical

PCB

Bare

Mechanical

Assembly

Mechanical

SILPAD_TO220

Mechanical

SILPAD_TO220

Mechanical

Screw

Screw

M3

M3

M3

insulator

Mechanical

insulator

Mechanical

Mechanical

Mechanical

M3

M3

Mechanical

TO126

Mechanical

M3

Mechanical

M3

Mechanical

M3

Spacer

Mechanical

Spacer

Mechanical

Spacer ALU

Mechanical

Spacer

Mechanical

Spacer

3.5x6x7.3mm ALU Hansong

ALU

ALU 3.5

ALU 3.5

Mechanical

SAA6L8W0H2T1

Hsink

3.5

3.5

Spacer

Mechanical

Spacer

Mechanical

Spacer

3.5x6.3x5mm ALU Hansong

ALU

ALU

Spacer

Spacer

3.5x6x4.5mm ALU Hansong

Mechanical

ALU 3.5

Mechanical

Hsink

SGG8L6W2H0T1

INB+

INB-

FBH

FBC

Modulator

INH

INC

FBH

FBC

FBLH

FBLC

ENABLE

CLIPPOS

CLIPNEG

Control

PSRR+

PSRR-

CTRLH

CTRLC

Power Stage

+ISENSE+

+ISENSE-

-ISENSE+

-ISENSE-

CTRLH

CTRLL

SCCP

VSW

Mechanical

M3

Mechanical

M3

Mechanical

M3

OUTH

OUTC

GND

FBLH

FBLC

LSENSE+

LSENSE-

OUTH

OUTC

Mechanical

M3

Mechanical

M3

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3

Mechanical

M3

Mechanical

M3

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

Mechanical

M3x16

A1/OPTION

A0/nAMPON

SCL/nFATAL

SDA/READY

SCCPIND

VDR_EXT

CLIP

IOUT

ENABLE

CLIPPOS

CLIPNEG

A1/OPTION

A0/nAMPON

SCL/nFATAL

SDA/READY

SCCPIND

VDR_EXT

CLIPIND

IOUT

NC400OEM

V0.1

Sheet 4 -

-

+HVPS

+ISENSE

-ISENSE

-HVPS

SCCP

VOUT

VSW

LSENSE+

LSENSE-

uP.SchDoc

GND

GND

J1

1

Mounting

J4

1

Mounting

Hole

Hole

GND

GND

J2

1

Mounting

J5

1

Mounting

Hole

Hole

1

Page 15

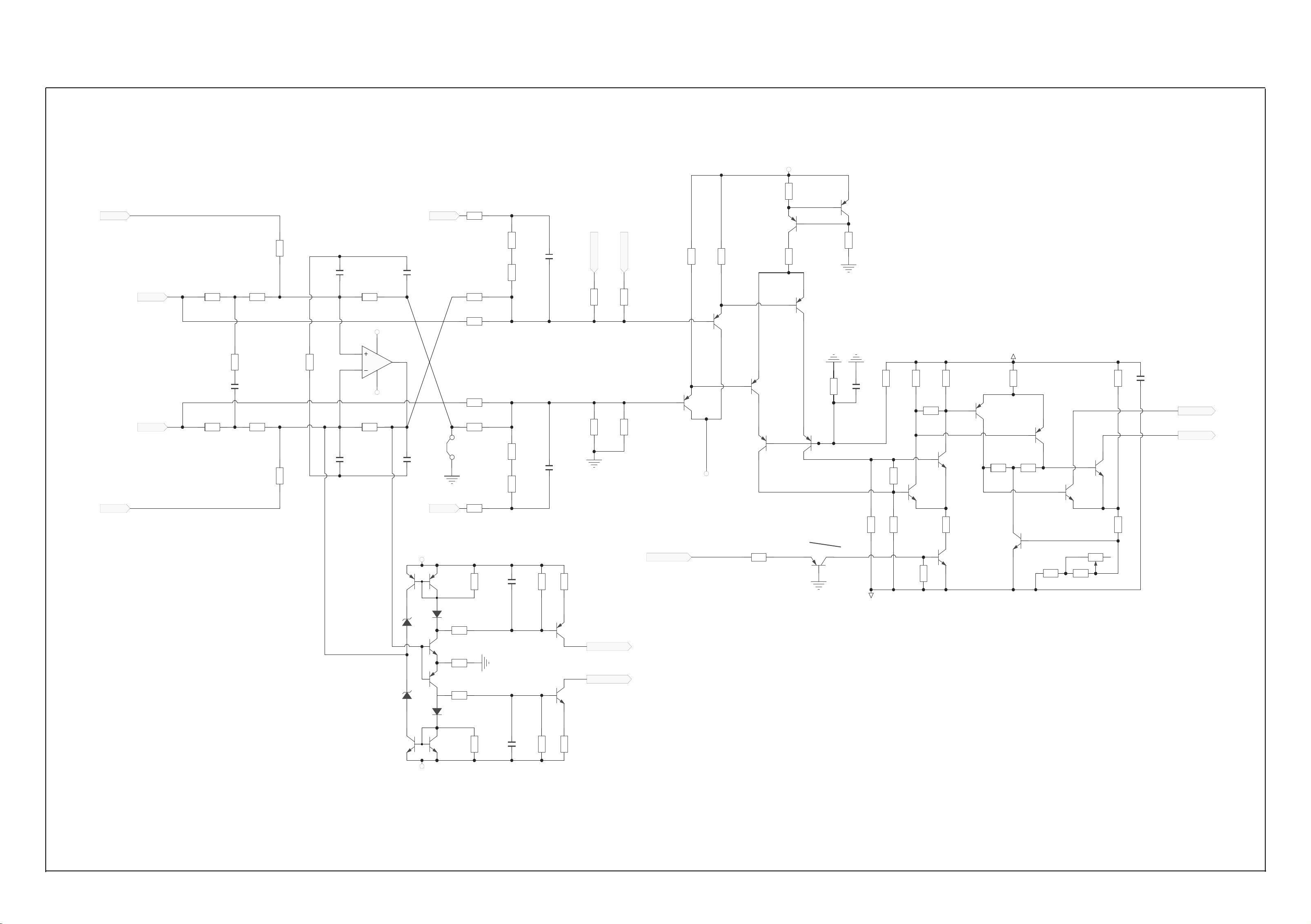

3.NC400 OEM VM1.0(2/4)

CTRLH

CTRLL

SCCP

R38

1k

12

MMBT5401

T12

GND

D9

BAW56W

3

D10

5V6

R40

2k2

T7

BC856BW

T13

BC846BW

R39

1k

R34

1k

VDR

R29

10k

D14

5V6

+VB

R24

2R2

C15

22u

GND

T5

BF622

T10

BC846BW

C34

470n

-VB

R7

1R

C16

100n

GND

L4

600R/0.2A

GND

C33

100n

R41

1R

L1

1u/8A

D1

1 2

3

BAV99W

D7

1

3

BAV99W

C31

470n

GND

C35

22u

C76

100n

R144

1R

C5

100n

R2

1R

C6

100n

R3

1R

C7

100n

R4

1R

C8

100n

R5

1R

+PS

C10

R8

33k

D2

12

R10

10k

D6

15V

R11

470R

12

D4

BAV70W

3

C21

C22

220u

470n

T1T6:fmmt618;T4T11fmmt718

2

R30

10k

C32

470n

L6

1u/8A

R31

470R

12

D12

BAV70W

3

BAV99W

3

D8

12

BAV99W

3

C17

15p

T3A

MBT3906

C28

18p

T9A

MBT3906

R17

1k

R37

1k

D3

BAS316

D11

BAS316

R12

220R

T4

BC807W

T3B

MBT3906

R32

220R

T9B

MBT3906

GND

T6 BC817W

BC807W

T11

T1

BC817W

C19

470n

D5

2V4

R22

6R8

0.5W

C30

470n

D13

2V4

100u

GND

R13

2R2

FDP42AN15

R16

100k

C24

330p

R33

2R2

FDP42AN15

R36

100k

GND

C36

100u

C41

100n

R43

1R

R9

2.5m

C18

150p

T2

R15

12R

GND

R25

1M

C29

150p

T8

R35

12R

T2,T8:FDP52N20

R42

2.5m

-PS

C11

100u

GND

GND

C12

100u

GND

C18 L2 R15:NC

L2

33n

VDR

GND

R18

L3

33k

10u

C23

4n7

R23

GND

VSW

L5

33n

GND

4R7

GND

C29 L5 R35 :NC

GND

GND

C37

100u

C42

100n

R44

1R

C38

100u

C43

100n

R45

1R

GND

C39

100u

C44

100n

R46

1R

C13

100u

R14

10R

C20

100p

TUOWSV

GND

GND

C40

100u

C45

100n

R47

1R

C9

100n

R6

1R

C14

100u

R19

1R

C25

680n

R26

1R

+ISENSE+

+ISENSE-

-ISENSE+

-ISENSE-

LSENSE+

LSENSE-

R20

1R

C26

680n

R27

1R

GND

GND

J8

1

Mounting

R21

1R

C27

680n

R28

1R

J9

1

Mounting

FBLH

OUTH

OUTC

FBLC

Hole

Hole

1

GNDGNDGNDGNDGND

Page 16

3.NC400 OEM VM1.0(3/4)

FBH

INC

INH

FBC

R57

1k2

R74

1k2

R64

47R

C50

2n2

R58

1k2

R75

1k2

R52

10k

R84

10k

R65

1k8

C47

1n8

C52

1n8

+Vop

R48

220R

GND

R49

820R

R60

1k5

R63

1k5

R72

1k5

R77

1k5

J10

Jumper

R86

820R

R50

3k

R56

2k7

R80

2k7

R85

3k

C46

560p

C54

560p

GND

PSRR+

R61

360k

R78

360k

PSRR-

R62

360k

R79

360k

R53

6k8

T20B

BCM856S

-Vop

R54

6k8

T20A

BCM856S

T15B

BCM856S

T16A

BC856S

FBLH

C48

R59

47k

+Vop

84

V+

3

2

V-

-Vop

R76

47k

1n8

U1A

NE5532

1

C53

1n8

FBLC

T14B

BC856S

R55

1k

T15A

BCM856S

T16B

BC856S

MMST5401

+Vop

D16

3V3

D18

3V3

T24

BCV62B

D15

BAS316

T26

BC846BW

T28

BC856BW

D19

BAS316

T30

BCV61B

R98

10k

R99

100R

R101

10k

R96

10k

R102

10k

GND

C67

1n

C75

1n

R97

22k

R100

22k

ENABLE

R91

4k7

R103

1k

T25

BC856BW

CLIPPOS

CLIPNEG

T29

BC846BW

R128

1k

BC856BW

T23

GND

GND

GND

R71

47k

T14A

BC856S

R51

100k

GND

C51

100n

-VB

R87

1k

R66

47k

R83

560R

R88

1k

R67

2k7

R73

560R

T19A

BC846S

R95

4k7

R68

2k7

T19B

BC846S

R89

560R

T22

BC846BW

T17B

BC856S

R81

270R

VDR

R69

560R

R82

270R

T17A

BC856S

T21

BC846BW

R93

47R

T18A

BC846S

R94

82R

R92

200R

T18B

BC846S

R70

10k

R90

120R

C49

100n

CTRLH

CTRLC

-Vop

1

Page 17

3.NC400 OEM VM1.0(4/4)

R

G

OSC2/C

OU

V

R

C

OSC

R

C

V

A

C

OU

B

C

S

RC7/

O

+HVPS

+ISENSE

R112

82R

R111

390R

D21

12V

R114

10k

R125

10k

R126

10k

R129

10k

D23

12V

R113

150k

R131

150k

R111 NC

C59

10n

D22

BAS316

GND

D24

BAS316

T32

BCV62B

T33

MMBT5401

T35

MMBT5551

SCCPIND

GND

SCCP

CLIPPOS

CLIPNEG

-VB

C60

2u2

T34

BC846BW

R115

1k

R130

390k

R110

2k2

D20

3V9

R116

27k

C61

2u2

R127

10k

GND

GND

R117

10k

C64

10n

C62

2u2

+Vop

R118

10k

R106

330R

R109

330R

T31

BC846BW

R119

R151

8k2

12k

J11

1

2

3

4

placed

5

Not

CON_1x5MV

R120

2k2

GND

SCL/nFATAL

GND

SDA/READY

Reset

T36

C63

2u2

NC

LSENSE+

LSENSE-

U2

20

Vss

Vss

19

RA0/AN0/C1IN+/ICSPDAT/ULPWU

RA0/AN0/ C1IN+/I CSPDAT/ ULPWU

18

RA1/AN1/C12IN0-/VREF/ICSPCLK

RA1/AN1/ C12IN0-/ V REF/I CSPCLK

17

RA2/AN2/T0CKI/INT/C1OUT

RA2/AN2/T0 CKI/INT/ C1OUT

16

RC0/AN4/C2IN+

RC0/AN4/ C2IN+

15

RC1/AN5/C12IN-

RC1/AN5/ C12IN-

14

RC2/AN6/C12IN2-/P1D

RC2/AN6 /C12IN2- /P1D

13

RB4/AN10/SDI/SDA

RB4/AN10/SDI/SD A

12

RB5/AN11/RX/DT

RB5/AN11 /RX/DT

11

RB6/SCK/SCL

R105

2k4

R107

2k4

C55

10u

C57

10u

R104

10M

C56

1n5

5

6

U1B

NE5532

7

C58

1n5

R108

10M

KI/

RA5/T1CKI/OSC1/CLKIN

A5/T1

RA4/AN3/T1G/OSC2/CLKOUT

A4/AN3/T1

RC3/AN7/C12IN3-/P1C

RC3/AN7/C12IN3-/P1

1/CLKIN

/

RA3/MCLR/VPP

RC4/C2OUT/P1B

R

LK

LR/

A3/M

RC5/CCP1/P1A

RC5/CCP1/P1

4/C2

T/P1

RC6/AN8/SS

RC6/AN8/S

RC7/AN9/SDO

AN9/SD

RB7/TX/CK

RB7/TX/CKRB6/SCK/SCL

DD

VDD

PP

GND

IOUT

CLIPIND

T38

BC846BW

3VPIC

+VB

R133

R122

1

2

3

T

4

5

6

7

8

9

10

R121

1k

R140

10k

390k

C66

10n

1k8

R132

10k

R123

27k

C65

100p

R124

27k

A1/OPTION

A0/nAMPON

ENABLE

VDR_EXT

-ISENSE

-HVPS

D25

BAS316

VDR

GND

R135

82R

T39

BCP56

J12

1

Mounting

R146

47k

Hole

D26

BAS316

GND

-VB

R137

330R

R147

47k

C74

470n

T37

BCV61B

C68

10n

R137 NC

R148

68R

T40

BD139

R149

18k

R150

13k

T41

BC846BW

D27

5V6

VOUT

GND

VOUT

+Vop

+Vop

-Vop

R134

1M

R152

10k

C72

22u

C73

22u

R139

27k

D28

10V

R145

12k

C69

1u

R153

10k

T42

BC846BW

GND

R141

10k

GND

R142

1k2

R143

1k8

C70

100p

C71

100p

BC846BW

R136

4k7

3VPIC

PIC16F690

VSW

GND

R138

100k

-VB

17

Page 18

.LED&TRIGGER&TOUCH VM1.0

22 0R

R10 4

12

D 10 3

DTC114EKA

DGN D

DTC114EKA

R

BE

AM

Q 116

5V L

Q 111

5V L

Q114

DTA 114

R34 7

4K 7

R10 3

D 16 3

12

RE D

R34 8

12

D 16 4

RE D

A -L ED

D 15 0

22 0R

22 0R

R31 2

12

RE D

DGN D

22 0R

Q 10 9

D

TC114 EKA

D 10 2 W H I T E

D 15 6 W H I T E

3V 3D

DGN D

R320

D 15 7 W H I T E

4K 7

R10 2

Q 112

DTC114EKA

12

750

750

R322

12

750

R321

12

DGN D

DGN D

Q 110

DTC114EKA

Q 115

DTC114EKA

W/R-L ED

LED

I nd i c at or

PW M -L ED

C1 75

10 0 N

C1 76

2U 2

3V 3D

DGN D

W/

PWM -L ED

5V S

R-L ED

A -L ED

ouch

t

5V S

on

5V L

L104

FB

CON 108

CO N 1 07

8

7

6

5

4

3

2

1

4

3

2

1

n

trig i

J 10 1A

17 - 02 0 01- 5 5

5

4

3

2

1

SW1

2 1

SW(T OUCH

Wh i t e l e d br i gh t n e s s ADJ

)

R284

47 0 R

232 gnd

10 K J

R2 87

232 gnd

R2 88

6k 8

C165

100N

DGN D

1

PB11PB2

D138

4v7

TO

P110

M AIN

DGN D

LED

V CC

CON 10

L100

C174

.

2N F

GND

U101

8

11

10K

1

2

3

4

GPO

R

1

GPO 1

2

GPO 0

3

TOGGL E/FS

4

DEL A Y

0

0

R132

R318

2

16

15

G PO 2

CS05CS1

6

C110

10 U

C111

10 0N

13

14

V D D

G PO 3

CM O D

SCA N R/SLEEP

X RES

S

CS3

ARST

CS2

V SS

7

8

GND

12

11

10

9

GPO

0

R154

FB

FB

L105

GND

GND

0

R311

1

4

3

2

1

Trigger

1

GND

GNDGND

0

6

5

R155

CY 8CM BR204

GND

4

GND

CS0

TOUCH

Page 19

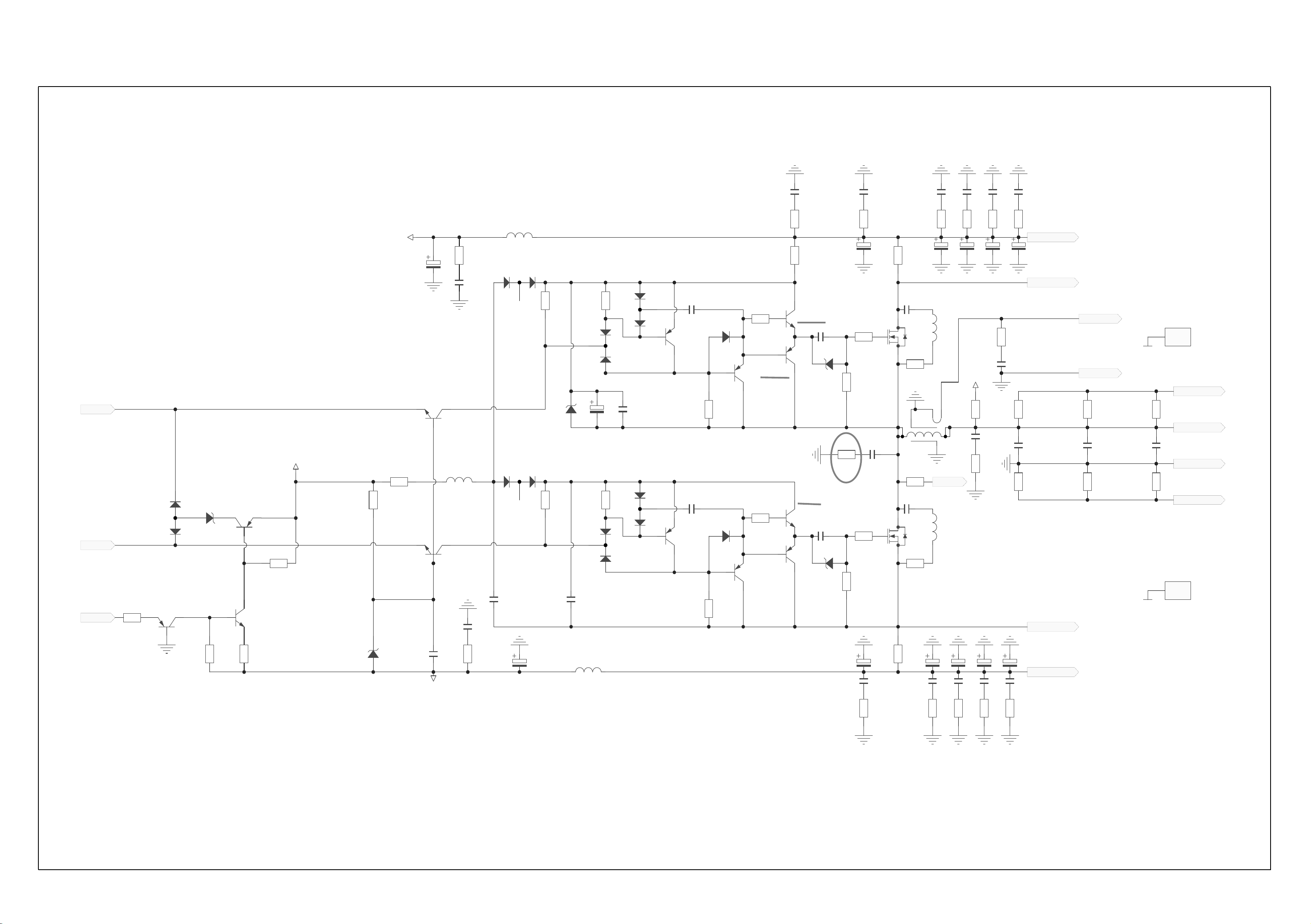

5.SMPS VM1.0(1/5)

J1

1

2

JST_B2P3_VH

F1

T12AH

Sheet2

L

N

-

Input Voltage

Selection.SchDoc

ACDET

PVAUX

PVSTART

PVBUS

PSVAUX

Sheet4

Sheet3

-

ACDET +VB

PVAUX

PVSTART

PVBUS

PSVAUX

- Standby

Main

SMPS.SchDoc

SMPS.SchDoc

-VB

+VDR

-VDR

PSEN

+VAUX

-VAUX

nFATAL

OVL

nAMPON

AMPOFF

+5VSB

+5VSB

+5VSB

J2

1

2

3

4

5

6

B06P-VL

S

J3

1

2

3

4

5

6

7

8

9

10

Sheet7

- Mechanical.SchDoc

PVBUS

PSVAUX

C36

100n

S

B10B-EH-A

+5VSB

S

MH1MH2

C35

100n

S

Page 20

5.SMPS VM1.0(2/5)

C70

10n

R102

D39

BAS316

10k

L

N

PVAUX

PSVAUX

BC846BW

R103

2k2

PSVAUX

T39

1M

1M

R54

R55

100k

180k

R97

R96

R50

1M

R51

1M

D44

SS16

T37

BC856BW

C71

220n

HV

HV

i

i

C14

470n

180k

100k

AC2

R100

R101

C15

1n

2

4

180k

BC846BW

R95

T38

HV

i

AC1

1

C8

TR3

2mH/8A

3

AC2

i

HV

PVSTART

P

BC846BW

T42

S

TL431

AC2AC1

U6

220n

6

3

10R

12V

K2B

R1

10k

R120

390k

R91

HV

i

D3

BYT79X-600

D4

7

4

5

8

i

HV

390k

10k

BYT79X-600D2BYT79X-600

R119

84

3

2

D40

BAT54J

R115

U7A

LM393

D1

BYT79X-600

1

R107

10k

3

6

R112

100k

12V

K1B

6

5

C9

22u

8

5

4

7

U7B

LM393

C1

1000u

C2

1000u

R108

R109

7

D41

BAS316

10k

10k

K1A

12V

C3

1000u

C4

1000u

1 2

i

HV

T43

BC807W

C5

1000u

C6

1000u

R81

2k2

D32

12V

R122

1M

R123

1M

BCP56

2

4

T36

R113

R114

P

100k

BC856BW

100k

T41

BC846BW

C73

100n

VDC

1

TR1

2mH/8A

3

VDC

C74

100n

T44

P

R116

390k

R111

100k

R106

100k

C7

470n

D36

12V

PVBUS

R110

390k

R105

47k

K2A

10k

12V

R104

D43

BAS316

1 2

T40

BC817W

P

P

P

PSVAUX

MAINS AC Detection

P

P

R124

2k2

P

U3C

3

LTV827S-V

4

PVBUS

PSVAUX

P

R38

5k6

C28

100u

C17

470n

P

U1

1

NCP1014

P

VCC

P

C32

220u

DRAIN

GND

P

D8

SS16

FB

C48

10n

Automatic

3

2

4

P

P

D10

P4SMA200A

D11

BYG20J

C41

1n

D38

BAT54J

MAINS Voltage

P S

HV

i

1

HV

i

2

4

3

P

R25

12R

D17

15V

P P

PP

Selection

1n

TR5

SBY

6

5

7

D13

6

C42

180p

R45

10k

U4D

LTV827S-V

P

C45

100n

S

15MQ040N

R29

10R

R49

220R

34

U4C

LTV827S-V

U2

TL431

S

C53

100n

S

P

L5

65R/7A

C23

1500u

D37

BAT54J

+5VSB

C31

1500u

S

R43

10k

R44

10k

S

PP

P

Inrush Current Limiter

D34

BAS316

P

R90

1k

P

ACDET

2

Page 21

5.SMPS VM1.0(3/5)

TR4A

TCT15

TR4B

TCT15

PVBUS

HV

i

2

3

1

3

3

4

PVAUX

12

D42

BAW56W

R118

1k

12

D22

BAW56W

R64

1k

R121

10R

R65

10R

C76

10n

P

T45

BC807

R117

100R

T22

BC807

R63

100R

HV

i

Sheet5

C75

10n

P

T46

BC817

T21

BC817

- Main

i

P

SMPS

T1

SPW32N50

T2

SPW32N50

ISEN

R69

0R018

C11

220u

P

Control.SchDoc

C72

220p

R99

68R

R98

68R

C69

220p

R86

68R

R79

68R

P

D35

SS16

C10

470n

C12

470n

P

HV

HV

C30

220u

C33

220u

+VB

C39

100n

S

S

C37

100n

-VB

PSEN

nAMPON

AMPOFF

nFATAL

OVL

+VB

R26

47k

S

S

R4

47k

-VB

L1 1u/8A

P

C16

1n

TR2

i

1

i

3

7

6

5

14

12

13

11

10

9

8

S

TCT15

TR4E

S

TCT15

S

TR4G

L2

R40

12

C20

220u

C21

220u

S

C22

220u

T3

FDP61N20

T5

FDP61N20

L10

330R/1.5A

L11

330R/1.5A

L12

330R/1.5A

L13

330R/1.5A

10R

D21

12

BAW56W

T20

BC807

R41

1k

R17

3

13

1

10R

D9

BAW56W

8

3

2

R19

9

R48

12R

1k

D18

MURA220T3

C50

1n

R46

12R

D19

MURA220T3

R47

12R

D20

MURA220T3

T17

BC807

C51

1n

C52

1n

C54

220p

R42

68R

R39

68R

C43

220p

R28

68R

R18

68R

+VDR

-VDR

+VAUX

S

-VAUX

TR4F

TCT15

TR4D

TCT15

C25

220u

C26

220u

C27

220u

3

11

10

3

7

9

+VDR

-VDR

+VAUX

-VAUX

1

D14

BAW56W

2

R36

1k

12

D5

BAW56W

R11

1k

R35

10R

R10

10R

T19

BC807

T11

BC807

T4

FDP61N20

T6

FDP61N20

+5VSB

VSW

C49

220p

R37

68R

R34

68R

C38

220p

R2

68R

R3

68R

Sheet6

1u/8A

C18

220u

S

S

C29

220u

L9

L8

1u/8A

Seconday

-

+5VSB

VSW

1u/8A

L3

1u/8A

L4

1u/8A

C19

220u

S

C34

220u

1u/8A

L7

L6

1u/8A

Control.SchDoc

PSEN

nAMPON

AMPOFF

nFATAL

OVL

S

SS

PSVAUX

PVSTART

ACDET

PSVAUX PTC

PVCTRL

PROT

ISEN

ISEN

TCT57

VSW

S

S

21

Page 22

5.SMPS VM1.0(4/5)

C

C

E

N

PSVAUX

U4B

8 7

LTV827S-V

R61

1k

T24

BCP56

D27

12V

PVCTRL

C13

22u

R92

47k

PTC

T28

BC856BW

R94

10k

D33

BAS316

C63

100n

PROT

C68

100n

P P

D31

BAS316

R85

100k

P

R93

100k

R72

10k

T35

BC846BW

PROT

R56

47k

D26

BAS316

D25

BAS316

R71

1k

R66

10k

T23

BC846BW

C58

1u

R58

220k

R68

100k

R67

1M

C61

100n

T27

C57

100n

C62

1u

R59

47k

R60

22k

R89

47k

BC856BW

R73

1M

C67

1n

R82

1k

PROT

T31

BC846BW

T32

BC856BW

C65

1u

R76

47k

P

R52

47k

R88

2k2

16

15

14

REF

1

1IN+

1I

2

1IN-

1IN-II

2IN+

2IN+II

2IN-

2I

R EF

II

N+

II

N-

P

4

DTC

D TC

3

FB

FB

CT

C T

R77

47k

R87

1k2

D30

BAS316

5

C64

470p

P

13

OPCTL

O PC T L

RT

R T

6

R75

18k

VCTRL

R74

10R

12

VCC

C1

E1

C2

E2

GND

7

U5

TL494

R78

10R

5

TCT15

P

C60

1u

D24

BAT54J

D23

BAT54J

R53

1k

T26

6

T25

P

R62

C55

1u

8

1

9

1

11

2

10

2

T29

BC817W

T30

BC807W

1k

D28

BAT54J

TR4C

C56

1u

D29

BAT54J

P

ISEN

P

R80

3k3

T34

BC846BW

R70

10k

P

C59

1n

P

P

R83

2k2

R84

10k

P

P

VCTRL

C66

1n

P

P

R57

2k2

12

T33

BC846BW

P

P

U3A

LTV827S-V

P

P

P

P

P

P

P

2

Page 23

5.SMPS VM1.0(5/5)

R30

VSW

+5VSB

1k

R31

47k

C44

220n

12

D16

3

BAW56W

S S

SMPS_ON

T15

BC856BW

S

R33

1M

D12

BAS316

C47

1u

S

R32

1M

D15

5V6

C46

100n

S

R27

47k

T16

BC856BW

C40

100n

R21

47k

T18

BC846BW

S

R24

47k

R20

47k

S S

T14

BC846BW

R22

R23

47k

47k

S

S

nAMPON

T13

BC846BW

AMPOFF

Assembly

Ass1

Bare PCB

PCB1

Heatsink to PCB

Mechanical

M3x12

Mechanical

M3x12

Heatsink to L-Profile

Mechanical

M3x6

Mechanical

M3x6

Mechanical

M3x6

Mechanical

M3x6

PCB to L-Profile

Mechanical

M3x16

Mechanical

M3x16

Mechanical

Springwasher M3

Mechanical

Springwasher M3

Mechanical

3x5x7,5mm

Mechanical

M3x6

Mechanical

M3x6

Mechanical

M3

Mechanical

M3

Mechanical

3x5x7,5mm

HS2

SBA19L12W5H3T1

Mechanical

3x5x10mm

Mechanical

3x5x10mm

HS1

SAA19L3W0H8T1

Mechanical

M3

Mechanical

M3

Mechanical

M3x6

ST1

ST3

ST2

R15

220R

12

U4A

LTV827S-V

S

T9

BC856BW

S

R8

10k

R9

22k

T10

BC846BW

D7

BAS316

S

R5

22k

R6

47k

PSEN

nFATAL

D6

BAS316

S

R13

1k

R7

2k2

C77

100n

T8

BC846BW

C78

100n

S

T12

BC856BW

R14

2k2

R16

1k

S

65

S

R12

10k

87

U3D

LTV827S-V

U3B

LTV827S-V

S S

T7

BC846BW

OVL

FETs/Diodes to Heatsink

Mechanical

Spring Clamp

Mechanical

Spring Clamp

Mechanical

Spring Clamp

Mechanical

Spring Clamp

FETs

Mechanical

25x20

Mechanical

25x20

Mechanical

Copper tape 19mm

Mechanical

Copper tape 19mm

Mechanical

Spring Clamp

Mechanical

Spring Clamp

Mechanical

Copper tape 19mm

Mechanical

Copper tape 19mm

Mechanical

Spring Clamp

Mechanical

Spring Clamp

Mechanical

Copper tape 19mm

Mechanical

Copper tape 19mm

Mechanical

Spring Clamp

Mechanical

Spring Clamp

Mechanical

58x55

Mechanical

49x55

Mechanical

30x55mm

23

Page 24

6.SMPS STB VM1.0

P301

AC-L

1

2

D301

B6S

F301

FUSE1

4

120-- 240VAC :T1.25AL/250V

3

C301

400V/10UF

TH301

SCK10054

5R/4A

100PF/1KV

C311

5

S

6

S

7

S

8

S

BYG20J 600V/1

IC301TNY274

D

BP

UV

.

D302

4

2

1

DW301

18V/3W

5A

SMA

D303

TVS

SMAJ200A

R301

D304

BAS321

R305

22K

C307

100nF/50V

10R

C302

10uF/50V

GNDP

T301

1

3

4

5

EE16E

CY301

1nF/AC250V

SS36

D305

10

9

60V/3A

OP301 PC817

C303

1000uF/10V

2 3

R306

100R

IC302

TL431

C305

100nF/50V

R307

1k

10k

1

L301

Comment: 10UH

R308

C308

100nF/50V

C304

1000uF/10V

R309

2.2K 1%

R310

2.2K

C306

100nF/50V

1%

5VDS

DSGND

1

R302

180k

AC90V/230v±10%

P302

AC-N

8

M AI N I N

ZV301

14D471K

CX301

1UF/275VAC

NC

R303

330K NC

NC

1

6

7

D2

D1

2

D2

D1

3

R304

180k

5

43

NC

IC303

NC

4

CAP017DG

1

L302

4mH/9A

2

CX302

470nF/275VAC

43

12

L303

8mH/9A

CX303

100nF/275VAC

5VDS

DSGND

STB

J302

3

2

1

CON3

1

CY302

1nF/AC250V

XM301

HOLE

CY303

1nF/AC250V

1

2

J303

TO-PSU1

K301

JQX-105F DC5V

34

12

L304

Comment: 550UH

LN

3

5VDS

CE

DSGND

D306

1N4148

Q301

Comment: 2SC2878

B

C309

100P

R311

STB

220R

R312

4.7K 1%

24

Page 25

PCB LAYOUT

1.MCU VM1.0 BOARD

Top Layer

Bottom Layer

25

Page 26

2.AMP VM1.0 BOARD

Top Layer

Bottom Layer

2

Page 27

3.NC400 OEM VM1.0 BOARD

Top Layer

Bottom Layer

2

Page 28

4.TRIGGER VM1.1 BOARD

Top Layer

5.TOUCH VM1.1 BOARD

Top Layer

Bottom Layer

Bottom Layer

6.LED VM1.1 BOARD

Top Layer

Bottom Layer

Page 29

5.SMPS VM1.0 BOARD

Top Layer

Bottom Layer

Page 30

6.SMPS STB VM1.0 BOARD

Top Layer

Bottom Layer

3

Page 31

ELECTRICAL PARTS LIST

PCB-1: MCU BOARD

NOITPIRCSED.ON TRAP.ON TIUCRIC

A16-62201-21 MCU Board VM1.0,FR-4,1.6mm,2Layers,2oz,TG130

D166, D167 33-44148-16 Switch Diode SMD CD4148WP

D101, D104, D109, D111, D134,

D135, D136, D137, D139, D140,

D141, D142, D146, D147

D105, D106, D107, D112, D113,

D114, D123, D158,D159,D160

D154,D162,D163 33-40099-02 Switch Diode BAV99-7-F

D168,D169

D118, D119, D155 33-13609-03 Zener Diode BZT52C3V6,3.6V,350mW

D110, D170 33-11500-06 Zener Diode BZT52C15,15V,350mW

Q105, Q135 31-00114-05 Digital transistor DTC114EKA

Q125,Q126

Q121,Q122

Q104, Q117 31-01312-00 Transistor 2SA1312GR(TE85L,F) TO-236MOD

R119, R120, R121, R123, R126,

R128, R130, R131, R133, R135,

R158, R161, R168, R169, R170,

R172, R174, R177, R178, R202,

R240, R244

R114, R290 07-91009-00 Chip resistor

R124,R139, R141, R186, R219,

R220, R222, R223, R225, R226,

R228, R229, R231, R232, R233,

R235, R245, R268, R269

R286, R289 07-91200-00 Chip Resistor 120Ω,0603,1/10W,±1%

R136, R137 07-92000-00 Chip Resistor

R100, R176, R201 07-91001-00 Chip Resistor

DIODES

33-40352-01 Switch Diode 1SS352(TPH3,F),1SS355TE-17

33-14709-09 Zener Diode BZT52C4V7,4.7V,350mW

33-11600-02

Zener Diode BZT52C16-7-F,16V,500mW,6%

Surface Mount Schottky

10-21002-33421D

Barrier Rectifier

SS12 SMA

TRANSISTORS

AKE411ATDrotsisnart latigiD10-41100-13131Q

epaT ,32TOS ,CAC1032MPATEFSOM HC-P10-10320-13231Q

31-00856-01

31-00846-01

Transistor BC856B,SOT23

Transistor BC846B,SOT23

B341TOS B26VCBrotsisnarT00-26000-13311Q

V001,PNP,395TMMF,RTSXrotsisnarT00-39500-13021Q

ICS

RDA423MLpmApO dauQ rewoP woL10-42300-30001U

RDC480LT/DC480LTPMAPO dauQ30-48000-30201U

SS/I-02K62F81CIPUCM10-62810-30501U

effuB10-71700-30901U

7111SMArotalugeR60-71110-30801U -3.3

X6P71ZW7CNr

811,D595CH47retsigeR tfihS10-59500-30401U

RESISTOR

07-90000-00 Chip Resistor 0Ω, 0603, ±5%

rotsiser pihC00-30819-70012R,302R

07-91000-00 Chip Resistor

180KΩ,0603,1/10W,±1%,RC0603FR07180KL

10Ω,0603,1/10W,±1%,RC0603FR0710RL

100Ω,0603,1/10W,±1%,RC0603FR07100RL

200Ω,0603,1/10W,±1%,RC0603FR07200RL

1KΩ,0603,1/10W,±1%,RC0603FR071KL

DOM632-OT )F,L58ET(RG-4233CS2rotsisnarT00-42330-13811Q

margorp 1.2V 22M(SS/I-02K62F81CIPUCMB62-62810-30501U )

31

Page 32

rotsiseR pihC00-10579-70081R

rotsiseR pihC00-20219-70361R

R165, R341,R342 07-93901-00 Chip resistor 3.9KΩ,0603,1/10W,±1%,

R338,R339,R340,R346, R347,

R348

R107, R108, R151, ,R167, R185,

R208, R214, R239, R241, R296,

R297, R309, R329, R330, R331,

R349

R122, R175 07-95101-00 Chip Resistor

R112, R113 07-95601-00 Chip resistor

R115, R125 07-91502-00 Chip Resistor

R173, R179,

R216,R333,R335,R332,R334

R101, R160,R164,R285 07-94702-00 Chip Resistor

R111, R116, R117, R127, R129 07-91003-00 Chip resistor

R326, R327 07-91203-00 Chip resistor

R152, R153 07-93303-00 Chip resistor

R282, R283, R291, R292, R293 07-90101-01 Chip Resistor

R209, R213 07-90101-10 Chip Resistor NET 100Ω, ±5% R0603X4

JP100, JP101, JP102 69-047001-0 Bus Bar

INSTALL COPPER

210mm*3

07-96800-00 Chip Resistor 680Ω,0603,1/10W,±1%,

07-91002-00 Chip Resistor

rotsiser pihC00-10519-70913R

07-92202-00 Chip resistor

elbairaV50-30120-90171R Ω,±10%,3362P-1-103LF

85-000002-0 Moveable Bushing KG-010N, 260mm

7.5KΩ,0603,1/10W,±1%,RC0603FR077K5L

12KΩ,0603,1/10W,±1%,RC0603FR0712KL

K3.4rotsiser pihC00-10349-70823R Ω,0603,1/10W,±1%,

74.0rotsiseR pihC30-70749-70423R,323R Ω, 1210, ±1% RL1210FR-070R47L

10KΩ,0603,1/10W,±1%,RC0603FR0710KL

074rotsiseR pihC00-00749-70733R,633R Ω,0603,1/10W,±1%,

1.5KΩ,0603,1/10W,±1%,RC0603FR071K5L

5.1KΩ,0603,1/10W,±1%,RC0603FR075K1L

5.6KΩ,0603,1/10W,±1%,RC0603FR075K6L

15KΩ,0603,1/10W,±1%,RC0603FR0715KL

22KΩ,0603,1/10W,±1%,RC0603FR0722KL

K33rotsiser pihC00-20339-70523R Ω,0603,1/10W,±1%,

47KΩ,0603,1/10W,±1%,RC0603FR0747KL

100KΩ,0603,1/10W,±1%,RC0603FR07100KL

120KΩ,0603,1/10W,±1%,RC0603FR07120KL

330KΩ,0603,1/10W,±1%,RC0603FR07330KLT

100Ω,0805,1/8W,±5%,RC0805JR07100RL

K01rotsiseR

m5.2,AEF005L23RSWrotsiseR pihC70-50529-70441R Ω, ±1%,3W

CAPACTIOR

C178, C179 26-47051-01 Ceramic Chip Capacitor

C107, C116, C117 26-22251-00 Ceramic Chip Capacitor 2n2K,50V,0603,X7R

C101, C102, C108, C109,

C115,C159

26-10351-00 Ceramic Capacitor SMD

47PJ,50V,0805,NPO,C2012C0G1H470J

T

10nK,50V,0603,X7R,C2012X7R1H103K

T

R7X,3060,V05,Kn1roticapaC pihC cimareC00-15201-62641C

R5X,5080,V61,Ku01roticapaC pihC cimareC12-11601-62381C,081C

R7X,5080,V52,Ku1roticapaC pihC cimareC10-12501-62281C,181C

%1±,W3,Rm5.2,0501SRLrotsiseR pihCrO441R

32

Page 33

C104, C122, C124, C125, C129,

C132, C133, C136, C139, C140,

C143, C147, C152, C155, C158,

C164, C173

C103, C105 26-10611-10 Ceramic Chip Capacitor

C162, C163, C166, C167, C168 26-22351-01 Ceramic Chip Capacitor 22nK,50V,0805,X7R

C138, C151, C174 26-22660-11 Ceramic Chip Capacitor 22uF, 6.3V, X5R, 0805

C123, C126, C127, C128, C130,

C131

26-10451-10 Ceramic Chip Capacitor 100nK,50V,0603,X7R

R7X,3060,V61,Ku1DMS roticapaC cimareC02-11501-62411C

10uK,10V,0603,X7R

ECJ1VB1C106J/ECJ1VB1H106J/ECJ1

VB1E106J/C0603C106K8RAC/C0603C

106K4RAC/C0603C106K3RAC/C0603C

106K5RAC

10uF, 25V, X5R, 1206,

roticapaC pihC cimareC21-12601-62481C,771C

C3216X5R1E106KT

06-22131-05 Alu Electrolytic Capacitor

CD289,220uF,35V,20%,D=8mm,Pitch=3

.5mm

CD287,470uF,10V,±20%,Pitch=3.5mm

roticapaC citylortcelE ulA01-11174-60651C

D=8mm

3060 ,R7X ,V61,Fn022roticapaC pihC cimareC01-11422-62001C

INDUCTOR

106-U4-906123ABCdaeB01-10640-80001BF

L101, L102, L103 08-04102-31 Chip Ferrite Bead

742792662,

1000ohm@100MHz,Imax=600mA

TRANSISTORS

621-OT,SYA0221ASKrotsisnarT rewoP00-02210-13421Q

621-OT SYA0962CSKrotsisnarT00-09620-13321Q

CONNECTORS

rotcennoc CDI50-80022-31601NOC

rotcennoC81-50521-31301NOC

rotcennoC 45.240-63522-31

rotcennoC 45.2ro

retcennoC00-60262-31501P

INSTALLQ123, Q124 70-048004-0 Small Heatsink 6063 T5 TBD

INSTALLQ123, Q124 61-023206-0 Self Tapping Screw BTB3×6,black zinc plated

INSTALLQ123, Q124 61-023208-0 Self Tapping Screw BTB3×8,black zinc plated

2mmPitch,2*4Pin,CNT-B200-2*4-GS-

2.8-N

A3-A5.2BHXtekcoS rotcennoC00-30522-31211P

2.54Pitch,5Pin,CNT-M254-1*5-GS-6/2.5N

2.54mmPitch,2*18Pin,gold-plating

5u'',BHA2900P18CCA01

2.54mmPitch,2*18Pin,gold-plating

,TSS-118-01-L-D,

2X3P MV 6.2mm PCB JST,JST VLseries

A4-3CJT/A4-A5.2 BHXtekcoS rotcennoC00-40522-31111P

01-2311-TNCrotcennoC32-01522-31301P

PCB-2: AMP BOARD

NOITPIRCSED.ON TRAP.ON TIUCRIC

R5X ,%01,3060,V61,Fn074DMS roticapaC cimareC00-11174-62211C

501,%02±,V53,Fu01,H07DCroticapaC citylortcelE ulA10-13001-60311C ℃,F2.5

N-3/6-SG-SG-1*1-452M-TNCniP tseT22-10001-311PT

A4PIS detalp dloG ,A4-A5.2BHXtekcoS rotcennoC02-40522-31901P

A16-62202-21 AMP PCB