Page 1

NAD

SERVICE MANUAL

C 165BEE

STEREO

C 165BEE

STEREO

PREAMPLIFIER

PREAMPLIFIER

Page 2

TABLE OF CONTENTS

DESCRIPTION P A G E

SERVICE CAUTION…………………………………………………………..3-4

REAR PANEL/FRONT PANEL VIEW………………………………………..5

SPECIFICATIONS…………………………………………… ……… … …6

WIRING DIAGRAM………………………………………………………………7

BLOCK DIAGRAM……………………………………………………. …….8-12

ALIGNMENT PROCEDURE........................................................13

SCHEMATICS……………………………………………………………....14-16

PCB LAYOUT……………………………………………………………….17-20

TROUBLE SHOOTING GUIDE…………………......................................21

ELECTRICAL PARTS LIST…………………………………………….22-34

EXPLODED VIEW……………………………………………………………..35

EXPLODED VIEW PARTS LIST……………………………………………....36

C725BEE PACKING ACCESSORY AND PARTS LIST.............................37

Page 3

PRODUCT SAFETY SERVICING GUIDELINES

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN

ANY WAY. NEVER PERFORM CUSTOMIZED INSTALLATIONS

WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED

MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT

MAY LEAD TO YOUR BEING LIABLE FOR ANY RESULTING

PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU

ARE THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING

SAFETY CHECKS AND SERVICING GUIDELINES. TO DO

OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS

AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR

PROTECTION FROM AC LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN

CORRECTED. A CHECK SHOULD BE MADE OF THE

FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN

SUCH A WAY AS TO AVOID POSSIBILITY OF ADJACENT

COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND

FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE

DEVICES SUCH AS INSULATORS, BARRIERS, COVERS,

SHIELDS, STRAIN RELIEFS, POWER SUPPLY CORDS, AND

OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE THAT THE SAFETY PURPOSE

OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE

COLD SOLDER JOINTS, SOLDER SPLASHES OR SHARP

SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR

DETERIORATION TO PARTS AND COMPONENTS. FOR

FRAYED LEADS, DAMAGED INSULATION (INCLUDING AC

CORD). AND REPLACE IF NECESSARY FOLLOW ORIGINAL

LAYOUT, LEAD LENGTH AND DRESS

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING

TUBE OR A RESISTOR RATED AT 1 WATT OR MORE. LEAD

TENSION AROUND PROTRUDING METAL SURFACES MUST

BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC. MUST BE

REPLACED WITH EXACT FACTORY TYPES, DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE

SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT

MODIFICATIONS

.

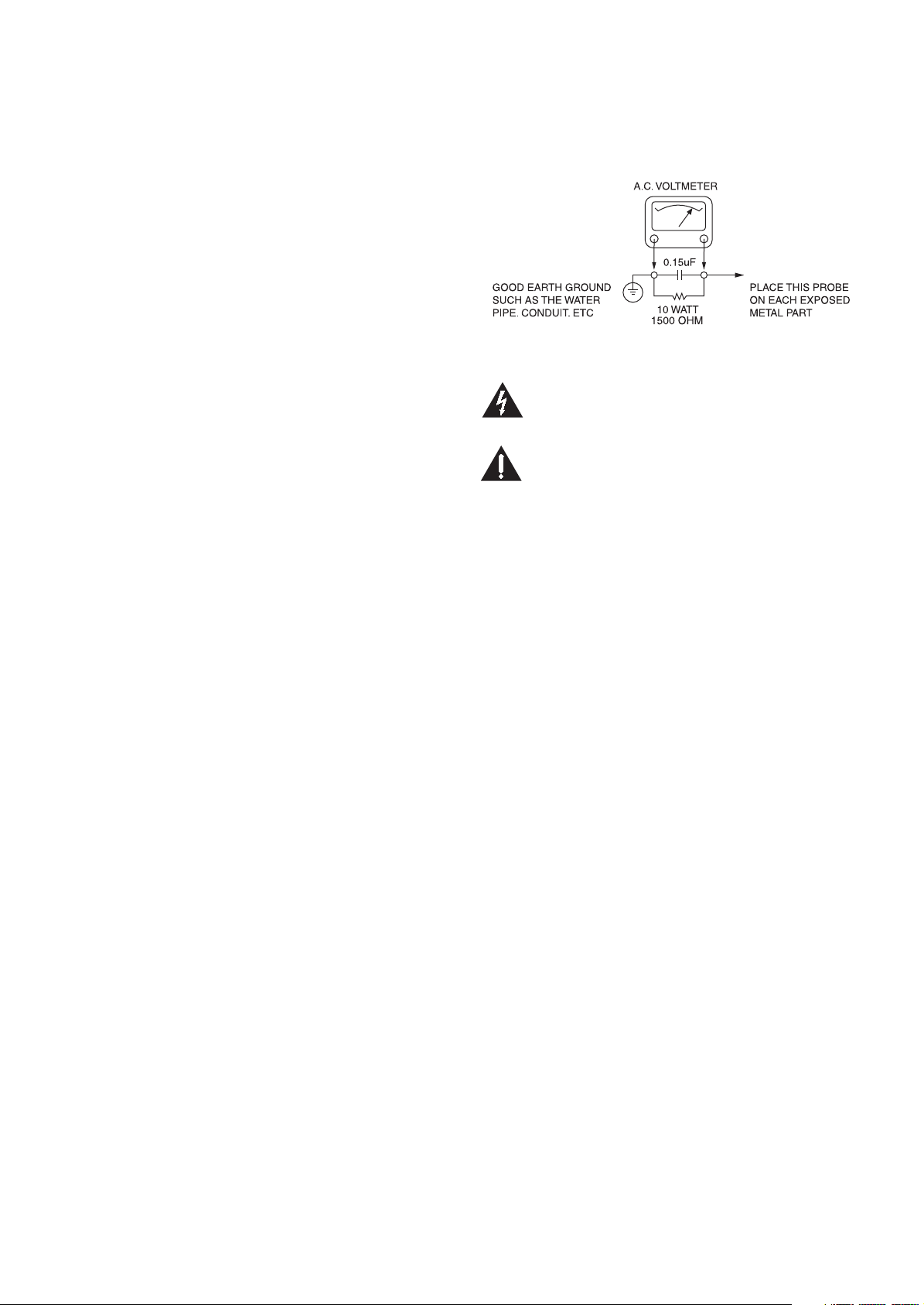

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN

AC LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF

THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA

TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET

IS

SAFET TO OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER

DURING THIS TEST USE AN AC VOLTMETER, HAVING 5000

OHMS PER VOLT OR MORE SENSITIVITY, IN THE

FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT

RESISTOR,

PARALLELED BY A .15 MFD, 150V AC TYPE

CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND

(WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED

METALLIC PARTS, ONE AT A TIME.

MEASURE THE AC VOLTAGE ACROSS THE COMBINATION

OF 1500 OHM RESISTOR AND .15 MFD CAPACITOR.

REVERSE THE AC PLUG AND REPEAT AC VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART.

.

VOLTAGE MEASURE MUST NOT EXCEED 75 VOLTS R.M.S.

THIS CORRESPONDS TO 0.5 MILLIAMP AC ANY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY

.

SUBJECT : GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” WITHIN THE

PRODUCT’S

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE

INTENDED TO ALERT THE USER TO THE PRESENCE OF IMPORTANT

OPERATING AND MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

ENCLOSURE THAT MAY BE OF SUFFICIENT MAGNITUDE TO

EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS,

CUBBYHOLE

OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED

AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS:

OUTDOOR PATIO INSTALLATIONS WHERE DEW IS A

FACTOR, NEAR STEAM RADIATORS WHERE STEAM

LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT

REAR VENTING. THE CUSTOMER SHOULD ALSO AVOID THE

USE OF DECORATIVE SCARVES OR OTHER COVERINGS

WHICH MIGHT OBSTRUCT VENTILATION

WALL AND SHELF MOUNTED INSTALLATIONS USING A

4.

COMMERCAL MOUNTING KIT MUST FOLLOW THE FACTORY

APPROVED MOUNTING INSTRUCTIONS A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS

ORIGINAL

SPACERS)

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM

LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5.

CAUTION CUSTOMERS AGAINST THE MOUNTING OF A

PRODUCT

UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE

ON ITS MOUNTING TO THE CART. CAUTION THE

CUSTOMER

SMALL CASTERS ACROSS THRESHOLDS OR DEEP

WITH

PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR

STAND WHICH HAS NOT BEEN LISTED BY UNDERWRITERS

LABORATORIES,

MODEL

APPROVED FOR USE WITH T.V.’S OF THE SAME OR

LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION

CORDS, EXPLAIN THAT A FOREST OF EXTENSIONS

ROUTING FROM A SINGLE OUTLET CAN LEAD TO

SP

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

OR CLOSELY FITTING SHELF SPACE. OVER

.

FEET (OR THE EQUIVALENT THICKNESS IN

TO PROVIDE ADEQUATE AIR FLOW ACROSS

ON SLOPING SHELF OR A TILTED POSITION,

ON THE HAZARDS OF TRYING TO ROLL A CART

INC. FOR USE WITH THEIR SPECIFIC

OF TELEVISION RECEIVER OR GENERICALLY

Page 4

SERVICING PRECAUTIONS

CAUTION : Before servicing the A/V Receiver covered by this

service data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances

create conflict between the following servicing precautions and any

of the safety precautions in this publication, always follow the safety

precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the A/V Receiver AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical plug or

other electrical connection.

(3) Connecting a test substitute in parallel with an electrolytic

capacitor.

Caution : A wrong part substitution or incorrect polarity installation

of electrolytic capacitors may result in an explosion hazard.

2. Do not spray chemicals on or near this A/V Receiver or any of its

assemblies.

3. Unless specified otherwise in this service data, clean electrical

contacts by applying an appropriate contact cleaning solution to

the contacts with a pipe cleaner, cottontipped swab, or

comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with which

instruments covered by this service manual might be equipped.

5. Do not apply AC power to this A/V Receiver and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

6. Always connect test instrument ground lead to the appropriate

ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

on. Connect an insulation resistance meter(500V) to the

power

blades of the attachment plug. The insulation resistance between

each blade of the attachment plug and accessible conductive parts

(Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input

terminals, Earphone jacks, etc

.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by

static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical Es

devices are integrated circuits and some field effect transistors and

semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed for

potential

test

2. After removing an electrical assembly equipped with ES devices,

place the assembly on a conductive surface such as aluminum

foil,

assembly

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices

4. Use only an antistatic solder removal device. Some solder

removal

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package

replacement

shorted together by conductive foam, aluminum foil, or

comparable conductive material).

7. lmmediately before removing the protective material from the

leads

the chassis or circuit assembly into which the device will be

installed.

Caution

observe all other safety precautions

8. Minimize bodily motions when handing unpackaged replacement

ES

together of your clothes fabric or the lifting of your foot from a

carpeted

an ES device.)

shock reasons prior to applying power to the unit under

.

to prevent electrostatic charge buildup or exposure of the

.

.

devices not classified a “anti-static” can generate

until immediately before you are ready to install it. (Most

ES devices are packaged with leads electrically

of a replacement ES device, touch the protective material to

: Be sure no power is applied to the chassis or circuit, and

devices. (Normally harmless motion such as the brushing

floor can generate static electricity sufficient to damage

assembly, drain off any electrostatic

.

Page 5

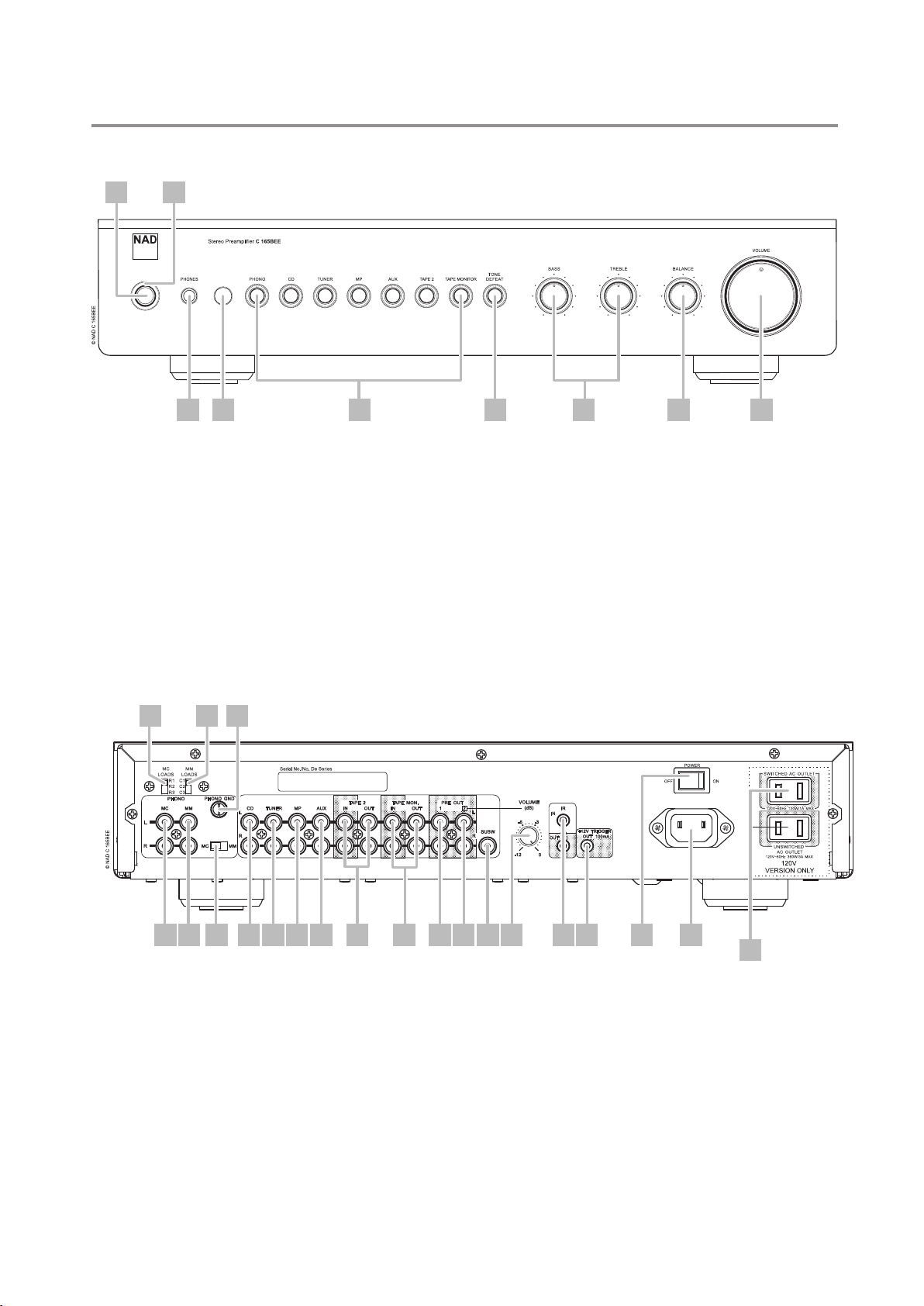

*%&/5*'*$"5*0/0'$0/530-4

'30/5 1"/&-

45"/%#:

45"/%#: -&%

1)0/&4

3&.05&4&/403

*/1654&-&$5034

50/& %&'&"5

50/& $0/530-4

#"-"/$&

70-6.&

3&"3 1"/&-

.$ -0"%43 3 3

.. -0"%4$ $ $

.$ */165

.. */165

1)0/0 (306/% $0//&$503

.$..48*5$)

$% */165

56/&3 */165

.1 */165

"69 */165

5"1&*/065

5"1& .0/ */065

13& 065

13& 065

46#8

70-6.&

*3 */065

7 53*((&3 065

108&348*5$)

"$ ."*/4*/165

"$ 065-&57WFSTJPOPOMZ

Page 6

OVERALL SPECIFICATIONS

LINE LEVEL INPUT

Input impedance (R and C) 100 kΩ+ 320 pF

Input sensitivity 158 mV (ref. 500 mV out)

Maximum input signal >9 V

Signal/Noise ratio, A-weighted >108 dB (ref. 500 mV in 500 mV out, volume set to unity gain)

>106 dB (ref. 2V out, Volume maximum)

Channel Separation >80 dB (ref. 1 kHz/10 kHz)

Frequency response ± 0.1 dB (ref. 20 Hz - 20 kHz, Tone defeat ON)

± 0.5 dB (ref. 20 Hz - 20 kHz, Tone defeat OFF)

Frequency response (subwoofer out) 100 Hz (ref. -3 dB)

OUTPUT

Output impedance - Pre out 75 Ω

Tape out Source Z + 440 Ω

Sub out 100 Ω

Headphones 10 Ω

Maximum output level - Pre out >10 V into 600 Ω

Tape out >10 V into 10 kΩ load

Sub out >7 V into 1 kΩ load

Headphones >5 V into 600 Ω

>2 V into 32 Ω

THD (CCIF IMD, DIM 100) >0.001 % dB (ref. 20 Hz – 20 kHz, 2 Vout)

TONE CONTROLS

Treble ± 5 dB at 10 kHz (ref. 2V in 500 mV out)

Bass ± 5 dB at 100 Hz (ref. 2V in 500 mV out)

POWER CONSUMPTION

Normal operation 21 W

Standby mode <0.8 W

PHONO INPUT

Input impedance - MC 40,100,600 Ω (R)

1 nF (C)

MM 47 kΩ (R)

220,300,400 pF (C)

Input sensitivity - MC 0.15 mV (ref. 1 kHz 500 mV out)

MM 2.63 mV (ref. 1 kHz 500 mV out)

Input overload - MC 1 mV/10 mV/100 mV (20 Hz/1 kHz/20 kHz)

MM 16 mV/147 mV/1.4 (20 Hz/1 kHz/20 kHz)

Gain - MC in - Tape out 59.8 dB1 (ref. 1 kHz, 10 kΩ load)

MM in - Tape out 36.5 dB (ref. 1 kHz, 10 kΩ load)

THD (CCIF IMD, DIM 100) <0.009 % (ref. 20 Hz – 20 kHz, 5 Vrms Tape out)

Signal/Noise ratio, IHF A-weighted - MC >78 dB2 (ref. 0.5 mV)

MM >86 dB3 (ref. 0.5 mV)

RIAA response accuracy ± 0.5 dB (ref. 20 Hz – 50 Hz)

± 0.3 dB (ref. 50 Hz – 20 kHz)

Infrasonic lter 10 Hz (at -3 dB)

5 Hz (at -14 dB)

Channel Separation - MC >60 dB (ref. 1 kHz/10 kHz)

MM >60 dB (ref. 1 kHz/10 kHz)

DIMENSION AND WEIGHT

Dimensions (W x H x D) 435 x 80 x 286 mm (Net)

435 x 99 x 315 mm (Gross

Net weight 6 kg

Shipping weight 7.8 kg

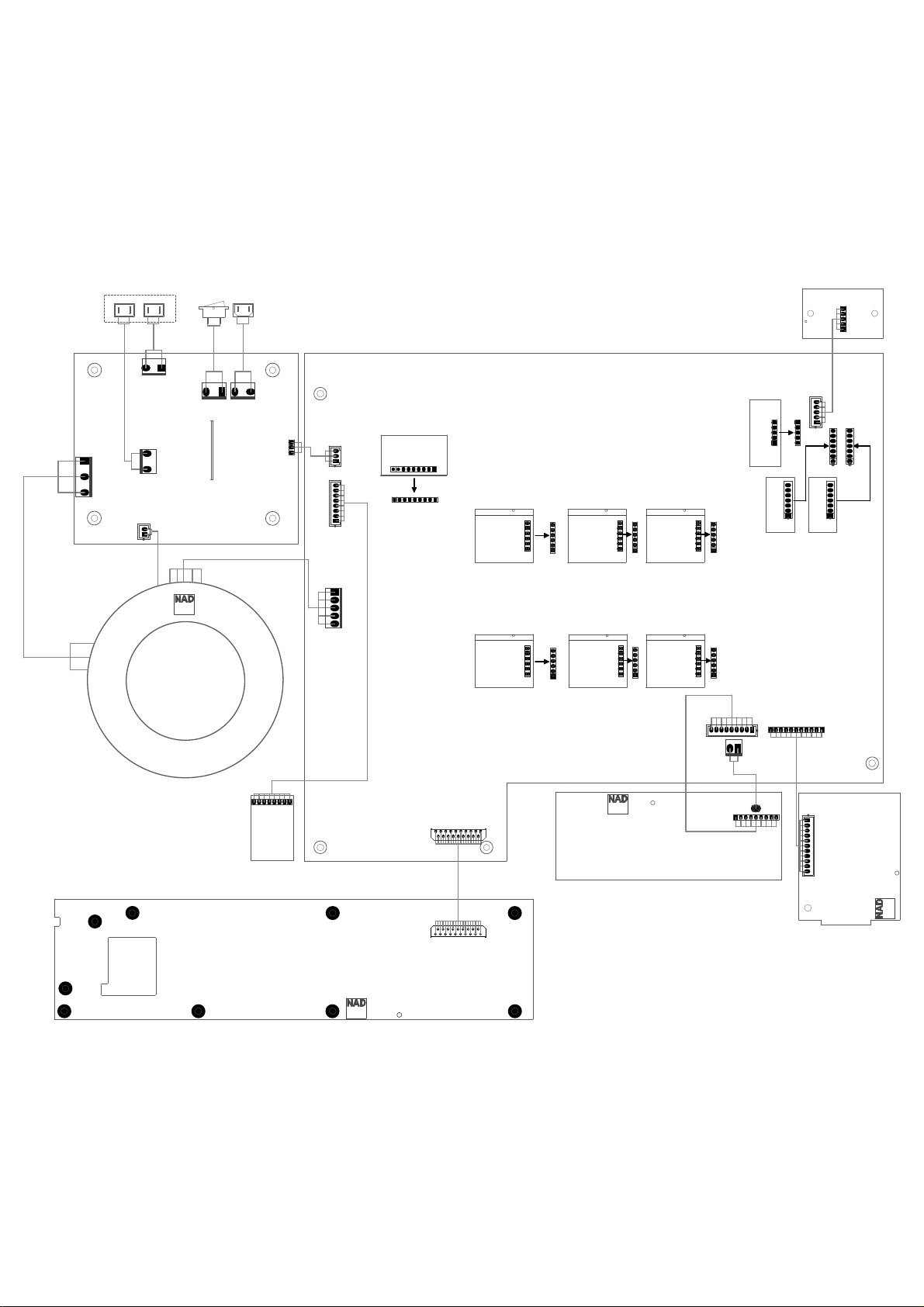

Page 7

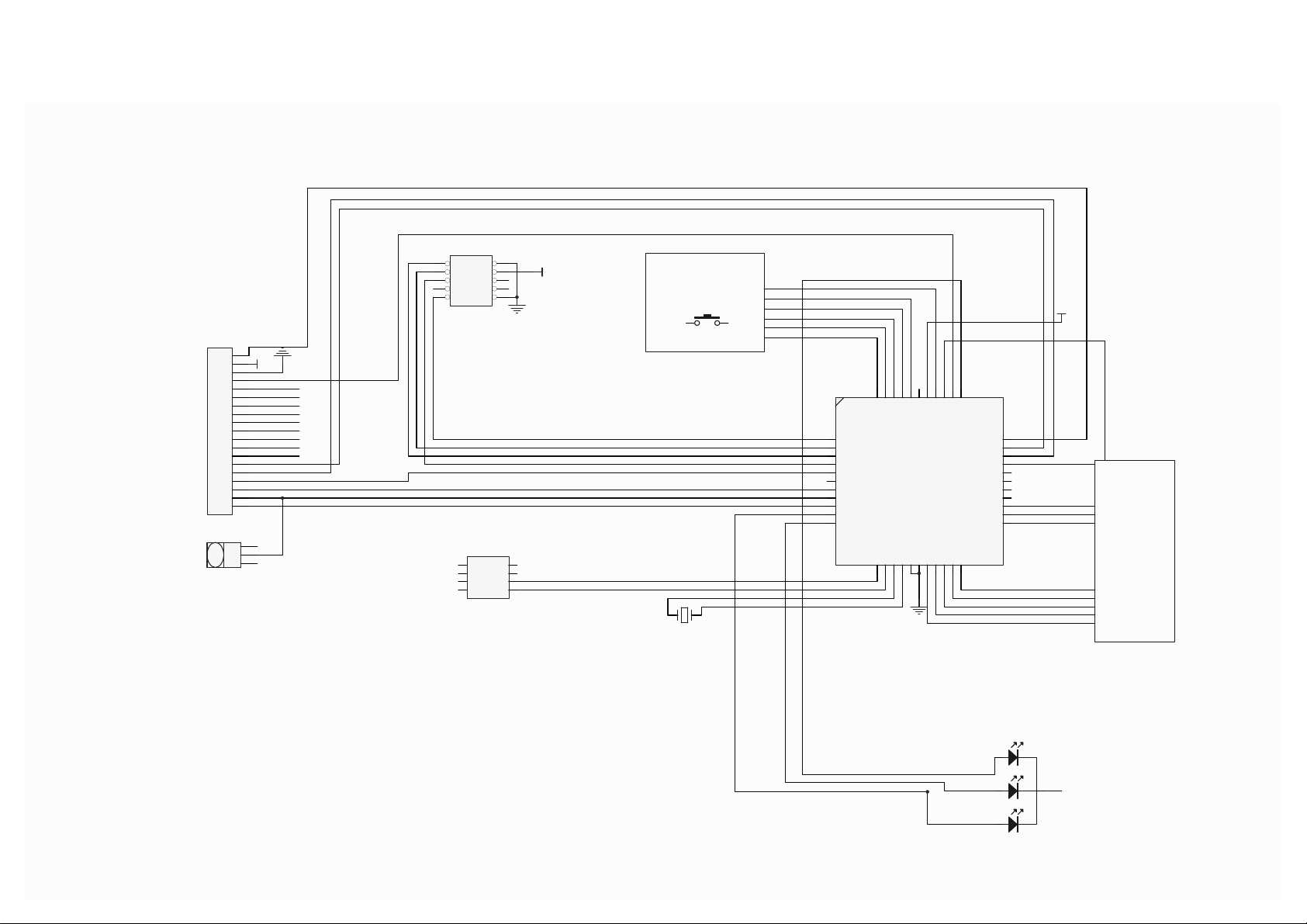

120V VERSION ONLY

WIRING DIAGRAM

CZ107

PHONO SWITCH

UL1672#18AWG

CB54

UL1672#18AWG

CB57

TO SWITCHED AC OUTLET

CZ58

CB52

UL1672#18AWG

UL1672#18AWG

CB55

TO AC INLET

CB56

CZ109

CB53

UL2468#26AWG

CB104

CB102

HEADPHONE Vm1.0

C165BEE PHONE AMP Vm1.0

CZ108

INSERT

CB108

UL2468#26AWG

LINE MODULE

M303

INSERT

CZ113

LINE MODULE

M302

INSERT

CZ115

MM MODULE

CZ117

MM INPUT Vm1.0

M301

INSERT

MC INPUT L

Vm1.0

UL2468#26AWG

INSERT

CB107

INSERT

CB111

CB110

INSERT

CZ111

MC INPUT R

Vm1.0

CB109

CZ110

UL3266 AWG#22

UL3266 AWG#18

CB103

UL1672 AWG#22

C165 BEE MAINBOARD

LINE MODULE

M403

INSERT

CZ114

LINE MODULE

M402

INSERT

CZ116

MM MODULE

M401

INSERT

CZ118

NAD C165 TRANSFORMER

HEADPHONE Vm1.0

CZ102

CB101

FPC2.5-19 S=1.25mm

CZ701

NAD C165 KEY BOARD Vm1.0

COPYRIGHT C 2008 NAD ELECTRONICS

CB106

P101

NAD C165BEE T ONE BOARD Vm1.0

COPYRIGHT C 2008 NAD ELECTRON ICS

UL2468#26AWG

CZ106

CB105

UL1015#16AWG

UL2468#26AWG

P100

CZ105

NAD C165BEE POT BOARD Vm1.0

COPYRIGHT C 2008 NAD ELE CTRONICS

Page 8

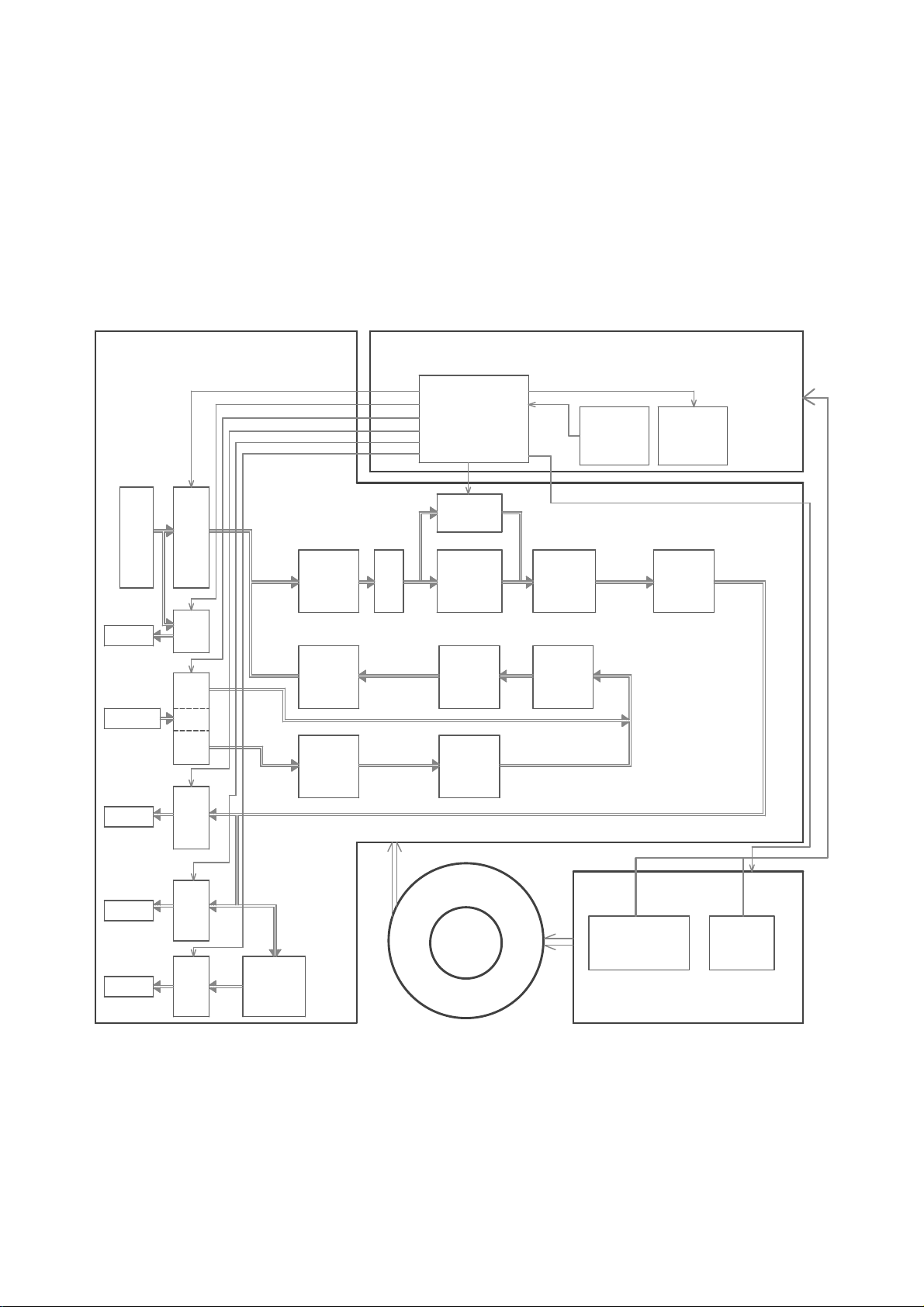

BLOCK DIAGRAM

MCU

IC73

KEY

STANDBY

TONE DEFEAT

KEYBOARD SECTION

LED

CD

TUNER

DISC

AUX

TAPE

MP

REC OUT

PHONO IN

SUBOUT

PREOUT

HP OUT

OUTPUT

MM

INPUT

SW1

MC

INPUT

2SK363

RELAYRELAY

INPUT RELAY

RELAY

Q109

RL110 RL109

PHONE AMP

MODULE

M403

LINE

MODULE

M302

M402

RIAA

CIRCUIT

INPUT RES

SELECTOR

S101

RV14

BALANCE

TONE

DEFEAT

RL111

TONE

CONTROL

RV11&RV12

MM INPUT CAP

MODULE

M301 S102

M401

MC AMP

CIRCUIT

TRANSFORMER

VOLUME

CONTROL

RV13

SELECTOR

LINE

MODULE

M303

M403

POWERBOARD SECTION

SWITCHING POWER

+5.5V

MAINBOARD SECTION

+5.5V

LINEAR

Page 9

MCU CONNECTION DIAGRAM

J202

CZ701

19

18

17

16

15

14

13

12

11

10

CON19

IS1U60L

IC703

9

8

7

6

5

4

3

2

1

V

S

G

+5.5V

HEADPHONE DET

PHONE MUTE

TONE D

TP1

TP2

AU

M

TU

C

PHO

1 2

3 4

5 6

7 8

9 10

ISP

1

2

3

IC71

NC

NC

NC

Vss4SDA

24C01

SCL

Vcc

NC

+5.5V

8

7

6

5

Y71

11.0592MHz

KEY

AT89S52-TQFP

IC73

1

P1.5(MOSI)

2

P1.6(MISO)

3

P1.7(SCK)

4

RST

5

P3.0(RXD)

6

NC

7

P3.1(TXD)

8

P3.2(INT0)

9

P3.3(INT1)

10

P3.4(T0)

11

P3.5(T1)

44

41

38

37

40

39

NC

P1.242P1.343P1.4

VCC

P1.0(T2)

P1.1(T2 EX)

P3.6(WR)12P3.7(RD)13XTAL214XTAL115GND16GND17P2.0(A8)18P2.1(A9)19P2.2(A10)20P2.3(A11)21P2.4(A12)

P0.3(AD3)34P0.2(AD2)35P0.1(AD1)36P0.0(AD0)

P0.4(AD4)

P0.5(AD5)

P0.6(AD6)

P0.7(AD7)

EA/VPP

ALE/PROG

PSEN

P2.7(A15)

P2.6(A14)

P2.5(A13)

22

+5.5V

33

32

31

30

29

28

NC

27

26

25

24

23

TO LED

AND CONTROL SIGNAL

TO MAINBOARD

1

1

RED

3

AMBER

4

BLUE

D707

3LED

2

3

2

4

Page 10

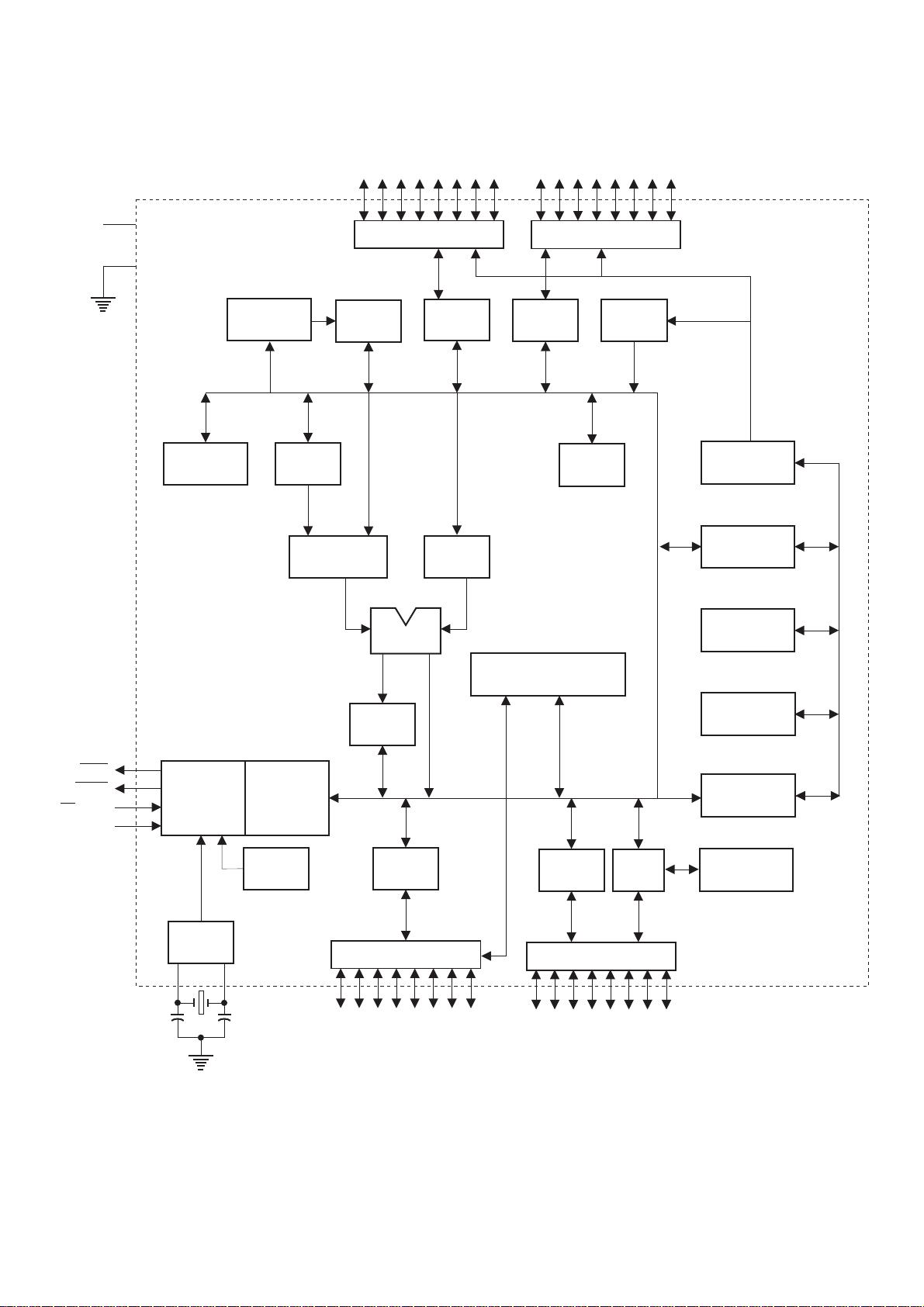

AT89S52

KEY BOARD IC73

V

CC

GND

B

REGISTER

RAM ADDR.

REGISTER

P0.0 - P0.7

PORT 0 DRIVERS

RAM

ACC

TMP2 TMP1

PORT 0

LATCH

PORT 2 DRIVERS

PORT 2

LATCH

POINTER

P2.0 - P2.7

FLASH

STACK

PROGRAM

ADDRESS

REGISTER

BUFFER

PSEN

ALE/PROG

EA / V

RST

PC

ALU

RUPT, SERIAL PORT,

INTER

AND TIMER BLOCKS

PSW

TIMING

AND

PP

CONTROL

OSC

INST

RUCTION

REGISTER

WATCH

DOG

PORT 3

LATCH

PORT 3 DRIVERS

P3.0 - P3.7

PORT 1

LATCH

RT 1 DRIVERS

PO

P1.0 - P1.7

ISP

PORT

INCREMENTER

PROGRAM

COUNTER

DUAL DPTR

PROGRAM

LOGIC

Page 11

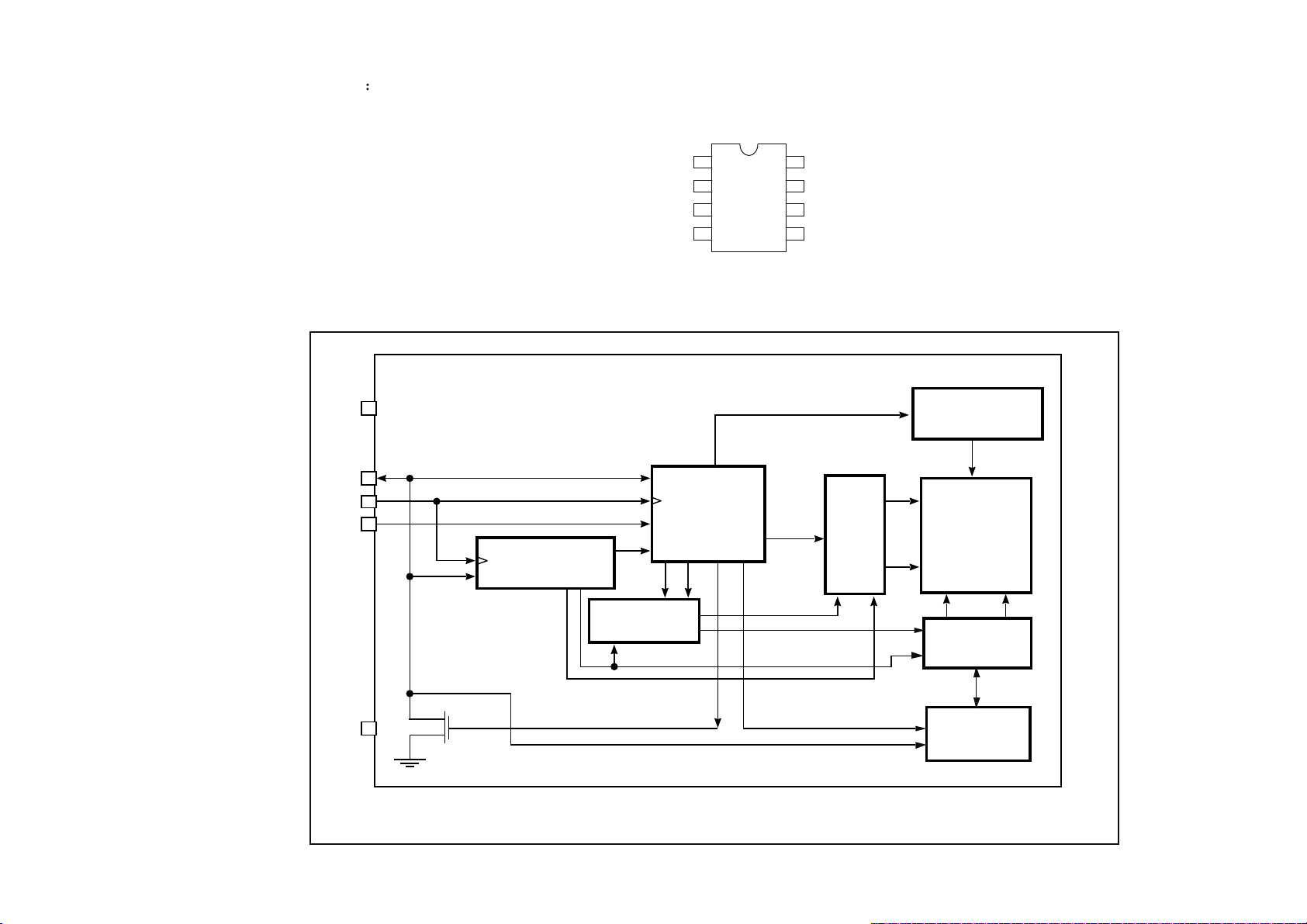

24C01

KEY BOARD IC71

PIN CONFIGURATION

FUNCTIONAL BLOCK DIAGRAM

8

Vcc

5

SDA

6

SCL

7

WP

SLAVE ADDRESS

REGISTER &

COMPARATOR

1

NC

2

NC

3

NC

4 5

VSS

CONTROL

LOGIC

8

VCC

7

NC

6

SCL

SDA

HIGH VOLTAGE

GENERATOR,

TIMING & CONTROL

REDOC

X

E

D

EEPROM

ARRAY

GND

WORD ADDRESS

COUNTER

Y

DECODER

4

ACK

nMOS

Clock

DI/O

DATA

>

REGISTER

Page 12

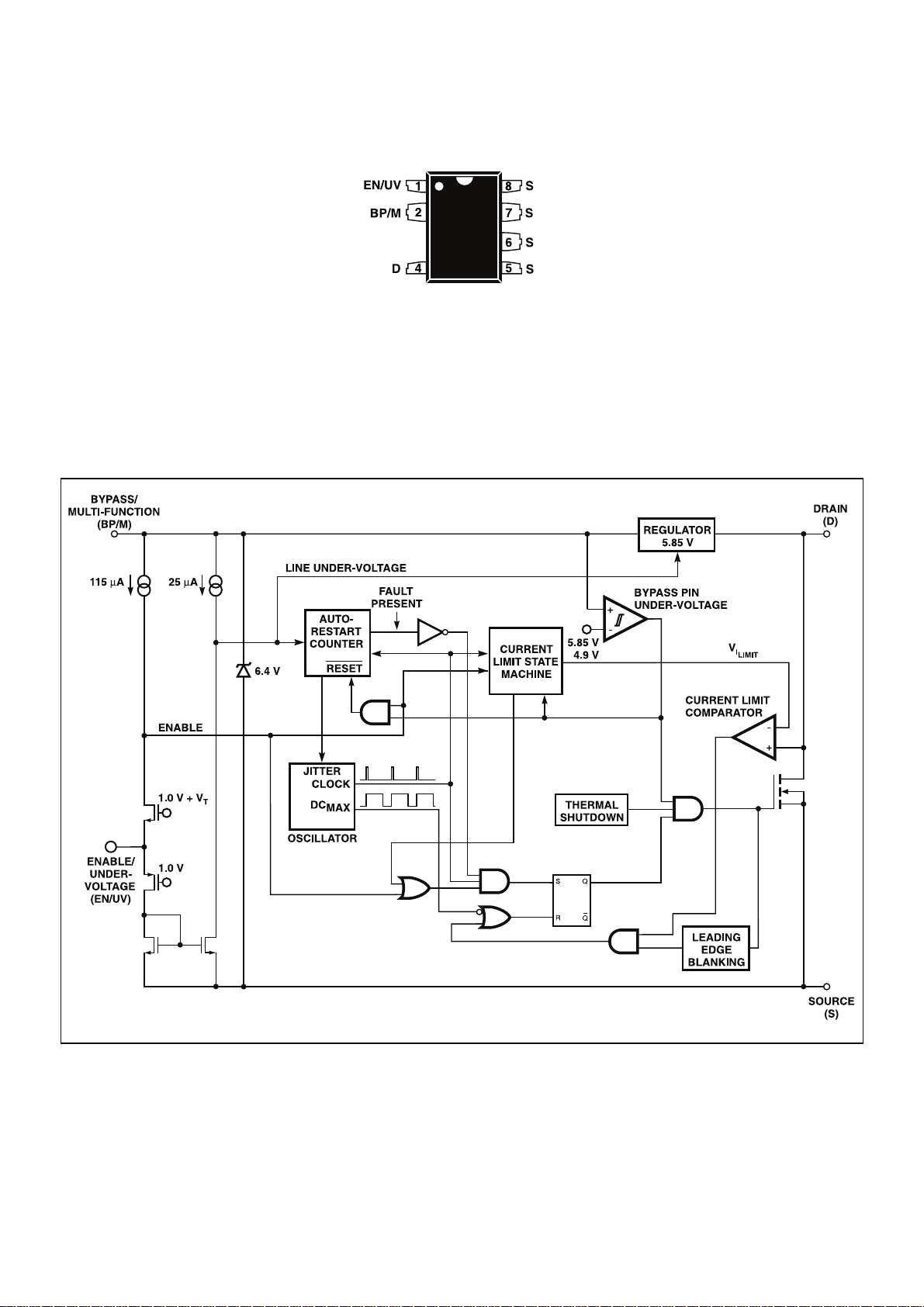

TNY274

POWERBOARD:IC51

PIN CONNECTION :

BLOCK DIAGRAM:

Page 13

Page 14

+5.5V

0.33,1/4W FS

CB53

CON3

+5.6V

C165 BEE POWERBOARD(1/3)

C56

2.2nF/250V,Y1

R570

DGND

R577

4K7

D59

C59

330uF/10V

100

D57

4V3

DGND

SR540

IC53

R578

10K

C515

4700u/25V

T51

EE16

PC817

+5.5V

DGND

R579

1K

Q501

C1815

C55

10nF/1KV

FR107/UF4006

R574

D510

DB104

D58

R572

100K/1W

1

2

C52

0.1uF/16V

PGND

Relay-SPST

D533

1N4148

1K

C511

10nF

R575

1K

F52

T0.5A/250V

R576

1

2

3

C513

0.1u

+5.6V

Standby

DGND

+5.5V

0.1uF

C514

10uF

L52

10uH

C54

C58

330uF/10V

R571

510

IC52

LM7805

IN

D51

1N4148

DGND

IC51

8

UV

S

7

BP

S

6

S

5

D4S

TNY274

PGND

+5.5V

RL51

Q522

C1815

DGND

To Main Board

C53

10uF/400V

C510

CB52

1

2

CON2

4N7/400V

+

CZ51

CON5

CZ52

CON2

!

!

!

!

!

!

!

!

AC POWER CORD

1

1

AC OUTLET˄UN SW ITCHED ˅

2

(120V Version)

2

SW52

POWER SWITCH

1

1

AC OUTLET 2˄SWITCHED˅

2

(120V Version)

2

CB55

S2

D52

-

AC

V+

V-

AC

DB105

S1

L51

FILTER INDUCTOR,48mH

1

2

3

4

5

2

1

RD

BK

RD

OR

OR

Blue

Blue

!

BK

WH

BL

C165 Transformer

(120V Version)

C57

4n7/400V

(120V Version)

F51

T2AL/250V For 120VAC

T1.6AL/250V For 230VAC

C51

0.22uF

CB58

1

2

3

4

5

CON5

CZ58

CON5

1

2

3

4

5

CB54

CB56

CB57

1 2

120V Version

1 2

230V Version

CZ55

1

2

3

1

2

3

1

2

3

1

2

3

3

2

1

CZ54

3

2

1

CZ56

1

2

3

CZ57

3

2

1

J52

J51

Page 15

C165 KEYBOARD(2/3)

A1015

R728

1K

C74

10n

PHONO

CZ701

CON19

+5.5V

Q710

LD501

PHONO

R726

4K7

R727

4K7

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R730

4K7

Q701

C1815

+5.5V

HEADPHONE DET

PHONE MUTE

TONE D

TP1

TP2

AU

M

TU

C

PHO

R729

MUTE LED

10K

LD502

CD

C75

10n

Q702

C1815

R724

4K7

R725

4K7

CD

VOL+

VOL-

STANDBY

LD503

TUNER

C76

10n

R722

4K7

R723

4K7

TUNER

1N4148

Q703

C1815

D722

+5.5V

R797

R798

C77

10n

MP

C717

10uF,16V

R778

10K

LD504

MP

R720

4K7

R721

4K7

J202

1 2

3 4

5 6

7 8

9 10

ISP

+5.5V

V

S

G

IS1U60L

IC703

10k

+5.5V

+5.5V

4k7

+5.5V

IR OUT

IR IN

C72

0.1uF

IC71

1

2

3

24C01

BLUEBLUEBLUE BLUE BLUE

LD505

AUX

NC

NC

NC

SCL

Vss4SDA

BLUE

LD506

TAPE2

R772

10K

8

Vcc

7

NC

6

5

+5.5V

AUPHO C TU M TP2 TP1 TONE D

Q704

C1815

C78

10n

R716

4K7

R719

4K7

AUX

Q705

C1815

C711

10n

R714

4K7

R715

4K7

TAPE2

Q706

C1815

R707

1K

C712

10n

TAPE1

+5.5V

C73

10u

AMBER

LD507

TAPE1

R709

4K7

R708

4K7

R771

10K

Q707

C1815

R703

10K

+5.5V

+5.5V

R704

10K

K704

TONE DEF

K701 Phono

R787

1K

BLUE

LD508

TONE DEFEAT

C713

10n

R711

4K7

R710

4K7

TONE DEF

11.0592MHz

Q708

C1815

R705

10K

K708 CD

K705 AUX

K702

Y71

C79

27p

PHONE MUTE

C514

10n

R713

4K7

R712

4K7

MUTE 2

TUNER

Q709

C1815

R706

10K

K707

K706 TAPE1

K703 TAPE2

C710

27p

+5.5V

R717

100

Q711

C1815

C714

R791

100nF

100

R795

10K

MP

STANDBY

IR MUTEIR MUTE

+5.5V

R744

220

R783

1K

Q712

R784

C1815

10K

C715

R792 10 R793 10

R785

1K

R786

10K

AT89S52-TQFP

IC73

1

2

3

4

5

6

7

8

9

10

11

+5.5V

R788

220

Q713

C1815

100nF

R782 1K

P1.5(MOSI)

P1.6(MISO)

P1.7(SCK)

RST

P3.0(RXD)

NC

P3.1(TXD)

P3.2(INT0)

P3.3(INT1)

P3.4(T0)

P3.5(T1)

R789

1K

R790

10K

C716

44

MUTE LED

41

38

37

40

39

NC

P1.242P1.343P1.4

VCC

P1.0(T2)

P1.1(T2 EX)

P3.6(WR)12P3.7(RD)13XTAL214XTAL115GND16GND17P2.0(A8)18P2.1(A9)19P2.2(A10)20P2.3(A11)21P2.4(A12)

22

100nF

R781

10k

P0.3(AD3)34P0.2(AD2)35P0.1(AD1)36P0.0(AD0)

P0.4(AD4)

P0.5(AD5)

P0.6(AD6)

P0.7(AD7)

EA/VPP

ALE/PROG

PSEN

P2.7(A15)

P2.6(A14)

P2.5(A13)

+5.5V

K709

STANDBY

R796

10K

NC

R748

1

3

4

1

RED

3

AMBER

4

BLUE

10K*8

R794

10K

+5.5V

+5.5V

+5.5V

C71

0.1u

+5.5V

R779

R780

VOL-

VOL+

10K

10K

33

32

31

30

MUTE 2

29

28

27

26

25

24

23

R701

+5.5V

10K

TONE DEF

TAPE1

TAPE2

TUNER

AUX

MP

CD

PHONO

R702

10K

+5.5V

123456789

D707

3LED

2

2

Page 16

1

S101A

SS-23D03

432

R390

R391

120

43

C165 BEE MAINBOARD(3/3)

C165 PHONO LOADS SWITCH BOARD

CZ107

CON5

12345

5

1

5

S101B

MM IN R

MM OUT R

CB107

CON5

PREOUT1-L

PREOUT1-R

PREOUT2-R

PREOUT2-L

SS-23D03

S102A

SS-23D03

432

876

C392

R39443R393

120

180P

12345

MC IN R

MM OUT R

4

RL102B

5V

4

4

RL103B

5V

RL101B

5V

4

RL104B

5V

4

RL105B

5V

4

DGND

RL106B

5V

RL107B

5V

4

4

RL108B

R161

5V

100K

1

RL102A

5V

1

RL103A

5V

1

RL104A

5V

1

RL105A

5V

1

RL106A

5V

RL107A

5V

1

1

RL108A

R261

5V

100K

RL101A

1

MC IN R

R401

604

1% MF

S102B

SS-23D03

876

C393

C390

C391

82P

82P

180P

RCA1A

PHONO MC

SW1A

MM/MC

CB109

123

1

2

3

4

5

RCA1C

PHONO MM

CON5

6

R103

220 MF

5

CD

C102

R104

RCA2A

100p

1M

6

R105

220 MF

5

TUNER

C103

R106

RCA2C

100p

1M

6

R107

220 MF

5

MP

C104

R108

RCA3A

100p

1M

6

R109

220 MF

5

AUX

C105

R110

RCA3C

100p

1M

6

R111

220 MF

5

TAPE2

C106

R112

RCA4A

100p

1M

6

R113

220 MF

5

REC2

C107

R114

RCA4C

100p

1M

6

R115

220 MF

5

TAPE1

C108

R116

RCA5A

100p

1M

R117

C109

220 MF

100p

REC1

RCA5C

RCA6A

RCA6B

PREOUT 1

PREOUT1

RCA6C

RCA6D

PREOUT 2

PREOUT 2

3

R203

220 MF

2

CD

C202

R204

RCA2B

100p

1M

3

R205

220 MF

2

TUNER

C203

R206

RCA2D

100p

1M

3

R207

220 MF

2

MP

C204

R208

RCA3B

100p

1M

3

R209

220 MF

2

AUX

C205

R210

RCA3D

100p

1M

3

R211

220 MF

2

TAPE2

C206

R212

RCA4B

100p

1M

3

R213

220 MF

2

REC2

C207

R214

RCA4D

100p

1M

3

R215

220 MF

2

TAPE1

C208

R216

RCA5B

100p

1M

R217

C209

220 MF

REC1

100p

RCA5D

RCA1B

PHONO MC

SW1B

MM/MC

456

RCA1D

P18

PHONO MM

CHASSIS

C165 MC INPUT R BOARD

CB110

CON5

6

5

R168 10

L1 100uH

C158

0.1uF

C258

0.1uF

DGND

3

2

CB111

CON5

CZ111

CON7

C401

120P

1

2

4

R317

10K

C315

43p

4

2

1

R2 N.I.

C2 N.I.

R140

C148 N.I.

C112

C5 10n

1234567

1234567

R441

3K3 MF

L401

100uH

R402

R301

604

1% MF

+27V

M302

OPAMP

5 6

-27V

-27V

56

M402

OPAMP

+27V

N.I.

N.I.

2k

CZ110

CON7

1234567

R341

3K3 MF

L301

100uH

R302

C301

2k

120P

C165 MC INPUT L BOARD

1234567

C331

0.1u

R312

7K15

C307

Q316

2SC3324

1000u/10V

C304

R304

R303

N.I.

1K

820P

C332

47u

C395

R344

N.I.

2K74

C333

0.1u

12K

RV31

100

R345

R346 499

RL111B

5

3

6

5V

R327

430 1% MF

2

R320

P101

1

499 1% MF

GND

RL111A

R420

3

499 1% MF

2

C441

470P

R427

430 1% MF

3

C432

47u

C494

N.I.

C433

0.1u

R444

2K74

R446

R445

499

12K MF

RV41

100

MM OUT RMM IN R

C402

0.22u

C403

100u/16V

C165 MM INPUT BOARD

C302

0.22u

R315

1% MF

220

C303

100u/16V

C305

10u/25V

R398

C341

470P

4

1

R498

30K

C312

C311

39P

R308

1K

C306

1% MF

470u/25V

R306

3K3

1% MF

Q302

2SA970

C308

Q301

68P

2SC3324

R307

11

30K

R363 2.2

CB106

1

2

3

4

5

6

7

8

9

CON9

R463

2.2

C405

10u/25V

R412

7K15

C407

1000u/6.3V

C404

R404

R403

N.I.

820P

1K

1K

R186

680

R184

680

R178

10u/50V

DGND

2SA1015

D102

1N4148

D105

1N4148

Q305

2SA1015

C128

75/FS 0.5W

PREOUT2-L

75/FS 0.5W

RV06703-27-20-B13

PREOUT2-R

D114

2SC1815

R157

1K

Q314

R119 680

680

IN

IC104

LM7812M

R125

4K7

R353

R354

2K

R453

R454

2K

RV15B

R455

1N4148

8

RL111C8RL110C

R152 10K

R153 10K

Q315

+5.5V

R169

2.2,1W

+38V

C122

10uF/50V

R118

C117

100

5V

8

Q308

A1015

R155

330

R175

R174 22K

1000u/35V

RV15A

RV06703-27-20-B13

A1

R129

2K2

R131

2K2

VOL-

22K

C124

PREOUT1-L

PREOUT1-R

3300u/50V

B102

RS507L

S1

+

AC

+

C113

224/100V

S2

AC

-

R127

150K

C121

C118

10uF/50V

3300u/50V

-38V

S16V

B103

RS507L

S1

+

AC

+

S2

AC

-

R218

22K

R151

150K

IR MUTE

-15VA

D106

1N4148

PHONE IN 2

R139

10K

PHONE IN 1

R356

5K6

R395

4K7

R456 5K6

R495

4K7

C259

47uF/50V

DGND

R138

Q313

0.68/1W,FS

KSC2690A

D120

D119

1N4148

1N4148

D103 1N4148

C396

10uF

+15VP

1

2

3

4

5

6

7

8

9

-15VP

CB108

C496

PHONE AMP BOARD

10uF

-15VP

+15VP

+5.5V

R130

2K2

Q309

A1015

VOLUME +VOLUME -

R132

C138

C139

2K2

4u7

4u7

R133

R134

2K2

2K2

Q310

Q311

C1815

C1815

VOL+

R136

R135

N.I.

N.I.

DGND

TO CZ72

PHONE1B

IR IN

PHONE1A

IR OUT

R159

+12V

75,2W,5%

PHONE2

+12V Trigger

+5.5V

HEADPHONE DET

DGND

PHONE MUTE

TONE DEF

TAPE1

TAPE2

AUX

MP

TUNER

CD

PHONO

VOL+

VOLSTANDBY

IR MUTE

IR OUT

IRIN

R347

R350

1K

2K74 MF

C336

C339

R349

C338

18n

N.I.

22n

0.15u

RV11A

10KA

TREBLE

BASS

RV12A

10KA

A1

A1

C340

1u

C337

C335

0.1u

6n8

R348

R351

499MF

120

DGND

V-IN

R801

2M2

5

4

3

2

1

CB103

5PIN

C114

Standby

224/100V

D201

1N4001

3

DGND

2

+5.5V

1

CB104

CON3

R219

10K

R221

Q201

C1815

1K

R220

10K

R137

0.68/1W,FS

+15V-15V

D118

D117

1N4148

1N4148

1K2

R128

S16V

RL110B

6

4

R360

5

C353

5V

10,1W

2n2

C111

10n

CHASSIS

51

R222

-15VA

R223 51

+15VA

R460

2

RL110A

1

10,1W

3

C453

5V

2n2

CB101

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CON19

PREOUT1-L

PREOUT1-R

CZ106

CON9

123456789

DGND

R447

1K

P100

GND

C436

18n

RV11B

10KA

TREBLE

A1

20K MN

BALANCE

RV14A

Q103

A970

Q110

A1015

R172

22K

R173 22K

Q111

C1815

Q106

R176

C2240

100

R177

2.2,1W

C125

0.1u

DGND

220

R123

+27V

18K

R122

+5.5V

R126

4K7

RL109C

Q306

2SC1815

Q307

2SC1815

DGND

RL109B

5

5V

4

6

C345

220P

R355

330

RL109A

2

5V

1

3

C445

220P

A2

330

+5.5V

D115

1N4148

+5.5V

R154 10K

C145

10n

DGND

R158

33

R150

10

C146

DGND

0.1uF

C165 MODULE Board

MM module:We need populate Q802 and the R802 needn`t be populated.

LINE module:We need populate R802 and the Q802 needn`t be populated.

R817

R813

R803

100K

470

1K5

Q809

2SC3324

Q801

2SK932

R811

220

C805

220pF

VGND

Q802

2SA1312

+15VA

Q312

KSA1220A

R149

10K

PHONE IN 2

PHONE IN 1

Q109

2SK363

1

IC107A

NE5532N

3

C166

330nF

R144

10K

8

+15VA -15VA

R141 10K

R142 10K

Q808

R815

2SA1015

68

C806

Q803

N.I.

2SA1312

C809

33p

R812

C801

470

33p

VGND

R816

C810

100K

1uF

R802

Vf

0

V-IN

Vf

V_OUT

VGND

VGND

-27V

+27V

C802

0.1uF

+15VA

CZ108

1

2

3

4

5

6

7

8

9

-15VA

CON9

HEADPHONE DET

CB102

1

2

3

4

5

6

7

8

7PIN

RCA

RCA35

SUB-OUT

C149

100pF

D315

R188

10M

1N4148

C165

N.I.

R147

100

C142

68nF

2

R143

R146

11K

11K,MF,1%

R145

11K,MF,1%

7

IC107B

C143

C144

0.1uF

0.1uF

4

NE5532N

5

6

C165 TUNE BOARD

R450

2K74 MF

R449

C438

C439

22n

0.15u

N.I.

BASS

RV12B

10KA

A2

A2

C440

1u

C437

C435

6n8

0.1u

R448

R451

120

499 MF

A2

RV14B

20K MN

BALANCE

DGND

C803

0.1uF

VGND

C811

22p

Q804

2SC3324

KTC4373-Y

R804

1K

R807

C807

1K

1nF

CZ112

R808

1

750

2

3

4

5

R809

6

10K

CON6

C165 PHONE AMP BOARD

C397

100uF/25V

4

5

R364

560

-15VA

C354

+15VA

17

16

R464

560

-15VA

C454

330uF/6.3V

CZ102

8

7

6

5

4

3

2

1

8PIN

C165 PHONE BOARD

+15VA

R195

100K

Q411

A1015

R189

R192

220K

10M

R191

R190

200K

430K

C164

100p/63V

-27V

DGND DGND

+27V

Q805

V_OUT

R806

10

R805

10

1 2

R810

10

Q806

2SC3324

Q807

KTA1661-Y

-27V

+15VA

C349

100nF

31

IC1A

TPA6120A2

+

2

-

100uF

C398

/25V

100nF

C351

R358 2K

330uF/6.3V

R359 560

C347

100nF

1820

_1

IC1B

TPA6120A2

+

19

-

C348

100nF

R458 2K

R459 560

PJ1

6

5

4

2

3

7

8

9

1

PHONEJACK

IR MUTE

R194

5K1

Q39

C1815

R193

22K

CZ109

CON5

12345

R316

3K3 MF

L302

3.7mH

R314

C313

47K

180P

1% MF

+15V

Q304

2SD667A

R309

240

Q303

2SB647A

R310

200

1% MF

+27V

R311

M301

1K

R305

1

3K3

2

D316

C310

12V

100u/25V

5 6

4

-27V

C309

4u7/25V

R313

R330

1K

22K MF

C314

J5

R352

68K

VOLUME +

R328

499 1% MF

R319

1K

C318

1.8pF

R452

68K

C442

100nF

C431

0.1u

R408

1K

1% MF

C406

R406

3K3

470u/25V

1% MF

Q402

2SA970

C408

Q401

Q416

2SC3324

68P

2SC3324

R407

11

R416

R415

1% MF

220

L402

3.7mH

C412

C411

39P

3

OPAMP

C328

24n

C327

2% PE

2% PE

6n8

R332

R333 11K

R334 137K

1% MF

1% MF

75 MF

R335

R336

R318

8K2

7.15K

213

1% MF

C325

47u

10%

C317

C352

4u7

47u

20%

10%

CB105

11

10

9

8

7

6

5

4

3

2

1

CON11

+27V

M303

VOLUME -

OPAMP

C342

1

3

100nF

2

5 6

4

-27V

R329

430 1% MF

R429

430 1% MF

-27V

56

4

2

3

1

M403

OPAMP

+27V

R428

499 1% MF

D107

1N4148

8

RL101C

+15V

Q404

2SD667A

C493

0.1uF

R409

R411

240

1K5

R405

3K3

D416

C410

Q403

2SB647A

100u/25V

12V

C409

4u7/25V

R410

200

1% MF

R413

22K MF

R430

1K

+27V

3K3 MF

C120

C141

0.1u

10uF

R414

C413

47K

180P

1% MF

R171

220

C155

C119

0.1u

10uF

-27V

C350

C329

47u

0.1u

R338

R337

820 MF

51K MF

C330

2n2

PE

+15V

R162 110,MF

R163 1K2,MF

C129

C131

R164 150,MF

47uF

0.1u

R165 150,MF

C130

C132

R166 1K2,MF

0.1u

47uF

R167 110,MF

-15V

C165 VOLUME POT BOARD

RV13B

CZ105

11

10

9

8

7

6

5

4

3

RV13A 10KA

2

1

CON11

D108

D109

D110

1N4148

1N4148

1N4148

8

RL102C8RL103C8RL104C8RL105C8RL106C

+27V

M401

1

3

2

OPAMP

C427

2% PE

6n8

5 6

4

-27V

R432

R433 11K

1% MF

75 MF

R435

R418

8K2

213

1% MF

C414

C417

C452

J5

4u7

47u

20%

10%

D121

27V

R170

680

C154

10uF

IC108

LM317M

IC109 LM337M

10KA

B2

B1

+-

M

VOLUME CONTROL

D111

1N4148

R434 137K

1% MF

R436

7.15k

C425

47u

10%

C140

10uF

+12V

R160

330

IN

C428

24n

2% PE

Q101

R197

2SA1220

0

Q102

C1815

R196

R120

0

10K

C156

47p

R185

R121

Q104

680

C1815

680

R198

R181

C157

0

510

N.I.

R182

C152

N.I.

0

Q105

A1015

680

R183

C153

47p

R179

R199

10K

0

Q107

A1015

R187

0

Q108 2SA2690

C127

C126

D116

10uF

0.1u

1N4148

+27V

10uF

C133

0.1u

D104

C150

16V

C137

330u/25

C151

C134

0.1u

10uF

R124

DGND

-27V

0.22u

C343

C344 220u

C443 0.22u

220u

C444

D112

D113

1N4148

1N4148

8

RL107C8RL108C

C429

R438

47u

820 MF

C430

2n2

R437

51K MF

PE

R156

4.7K

C415

0.1u

Page 17

NAD C165BEE MAIN BOARD Vm1.0

R155

R150

C146

PHONE2

R156

Q315

R158

Q314

R157

R152

J1

J2

GND-1

C111

R159

J5

CB104

J12

CB102

J27

CB103

Q101

J3

Q109

J6

D315

C453

J82

C353

J26

J25

J24

R221

R219

C259

R220

R218

D201

C114

C113

B102

J46

R169

C122

Q110

R119

H1

C150

R164

C145

PHONE1

R153

R154

C166

C142

R147

C165

C144

IC107

J7

R188

Q411

R189

C164

R190

J13

R460

R222

J11

C496

R495

C137

R122

R123

J23

C128

R124

Q201

B103

J49

J48

R127

C117

R175

R172

R198

Q104

Q103

C157

R118

R171

C120

C141

R185

C156

R186

C140

R121

R196

R170

D121

R197

Q102

C133

IC108

H4

J45

R162

C129

R163

J44

R140

C148

RCA35

R455

R355

RV15

R141

R146

R142

R143

C143

R145

R195

R191

R192

CB108

J28

C396

R395

D105

Q306

D102

D104

J22

Q305

R128

D103

R151

J128

J127

J50

J51

R174

R182

C152

Q105

C119

C155

J47

R181

R120

C132

C131

C130

J42

J29

Q39

R144

J89

J88

J87

R194

R193

R360

R223

R356

R456

R160

C126

Q307

R126

R125

D116

J21

IC104

C124

H5

J55

C125

L1

J53

J52

C118

C121

R173

R176

Q111

Q106

R178

R183

R184

C153

C154

R179

R199

R187

Q107

C134

IC109

H3

R167

C151

R166

R165

CB101

J41

RCA6

C149

RL110

D115

J124

J14

J15

J16

J17

J18

J19

J20

C127

J54

R168

R177

Q108

H2

J40

J39

J121

J32(+27V)

J33(-27V)

J34 (GND)

J35

J36

J37

J38

J30

(-15V)

(+15V)

C445

C345

RL109

D106

J120

R453

(-27V)

J83

(+27V)

J111

J57

D117

D118

RCA5

R115

R116

R216

R117

C109

C209

R217

C108

C208

J123

D113

RL108

J118

J117

R161

J116

J112

M303

M403

R137

Q312

R149

J81

R354

R328

(GND)

J98

J99

J96

J97

R428

R138

D120

D119

R139

C340

R351

C338

C339

C440

R451

C438

C439

RCA4

R111

R212

R114

R214

R215

R113

RL107

J119

R261

R353

C344

C343

R329

C342

R319

J100

C444

C443

R454

R429

C442

J59

R112

R213

C106

C206

C107

C207

D112

RL106

COPYRIGHT C 2008 NAD ELECTRONICS

M302

J104

J101

J103

C318

M402

R346

RV31

J58

C341

R352

Q313

R398

R363

C395

COPYRIGHT C 2008 NAD ELECTRONICS

RV12

R350

R349

R348

R450

R449

R448

R211

R109

J115

J109

R345

R344

C337

C437

RCA3

R110

R210

C205

C105

R209

D111 D110

RL105

C158

(GND)J74

J102

J85

C258

C315

J60

J61

RL111

D114

J79

J56

C335

C435

R108

R208

R107

C104

C204

RL104

R320

R327

C333

C332

R317

J106

J126

J107

J125

R420

R427

C433

C432

R446

R445

R444

RV41

C441

R463

R498

J62

C494

J302

GND

RV11

C336

C436

RCA2

R205

R207

R105

R106

R206

R103

C103

C203

D108

D109

RL102

RL103

M301

C328

R334

MAIN-GND

J4

J108

M401

C428

R434

J68

J67

J66

J65

CB106

R452

J63

J64

P101

CZ106

J303

R347

RV14

GND

J301

R447

R104

R204

C102

C202

C329

R332

R318

C429

R432

R418

C417

J70

SW1

J95

GND LINE

P18

R203

D107

RL101

(GND)

J43

C330

R337

C350

R338

C325

R336

R333

C327

R335

J90

C352

C317

C430

R437

C415

R438

C425

R436

R433

C427

R435

J122

J92

C452

J69

J71

J86

P100

RCA1

J78

J110

J91

CB109

Q304

R311

R305

D316

J84

J31

CB105

J114

J93

J113

CB107

CB111

CB110

R430

C304

R330

C307

C309

C308

Q302

J80

R306

R308

J76

C493

C404

R303

R313

Q316

Q416

R307

R407

J77

C5

Q303

R310

R410

R312

C331

R309

C305

C306

C310

C410

J75

Q310

R134

R135

C139

Q309

R130

R132

J72

J129

R2

C2

C407

R403

R413

Q401

J9

C409

C408

Q402

Q403

J10

R412

C431

R406

R409

R408

C405

J8

Q404

R411

R405

C406

D416

Q311

R133

R136

C138

Q308

J73

R129

R131

C112

MM INPUT Vm1.0

CZ109

C412

C413

C411

R414

R415

R416

L402

C312

C313

C311

R314

L302

R316

R315

NAD C165BEE TONE BOARD Vm1.0

Page 18

C165 BEE POWER BOARD

CZ58

TO UNSWITCHED AC OUTLET

L51

J55

J54

J52

120VAC Version

J51

230VAC Version

C510

J59

CB54

T1.6A/250V FOR 230V VERSION

C51

TO SWITCHED AC OUTLET

T2A/250V FOR 120V VERSION

J56

D52

CB57

Q522

C511

R575

J510

R572

R574

F51

C53

C55

R577

IC51

R579

D58

Q501

C52

J57

R578

C57

CB55

CB56

TO POWER SWITCH

TO AC INLET

NAD C165BEE POWER BOARD Vm1.0

COPYRIGHT C 2008 NAD ELECTRONICS

D57

D59

L52

C59

C54

C58

R576

C514

C513

J58

D51

T51

C52

IC53

C515

C56

R570

R571

DGND

STANDBY

DGND

+5V5

CB53

RL51

D533

D510

F52

CB52

T500mA/250V

C165 BEE POT BOARD

CZ105

RV13

J53

IC52

H501

NAD C165BEE POT BOARD Vm1.0

COPYRIGHT C 2008 NAD ELECTRONICS

Page 19

C165 BEE KEY+MODULE+MC INPUT+LOAD

SWITCH+HEADPHONE+PHONEJACK BOARD

TOPLAYER

R801

R811

LINE MODULE

R802

Q802

Q801

C805

R815

R813

Q804

R812

R817

Q803

C811

R816

R803

C810

Q809

R788

R784

Q711

R717

R783

D722

C717

D707

Q713

K709

C803

C802

R809

Q807

Q806

R808

Q805

C807

R807

R805

R810

R806

C809

C806

R804

C801

Q808

R792

C715

R790

R789

R778

R744

R786

R785

Q712

C73

C714

R791

J202

PHONO SWITCH

MC INPUT

LD501

LD502

LD503

LD504

GV

S

R703

R701

R796

TUNER

R748

PHONO

CD

MP

C79

Y71

C710

R772

R771

C72

C71

R801

R811

MM MODULE

Q801

C805

R813

R812

R817

Q803

R816

C810

Q809

MC INPUT R

L401

Vm1.0

C402

R402

R441

C401

C403

CZ111

R401

R390

R391

C803

C802

R809

R802

R803

Q807

Q802

Q806

R808

Q805

C807

R807

R815

Q804

R805

R810

R806

C811

C809

C806

R804

C801

Q808

Vm1.0

MC INPUT L

R302

R341

C301

R725

C75

R724

Q702

R727

C74

R726

Q701

IC703

K701

K708

CZ110

K702

K707

R721

C77

R720

Q704

R795

R705

R723

C76

R722

Q703

R301

TOP

S101

R394

C391

R393

C390

S102

C398

R458

C392

C393

COPYRIGHT C 2008 NAD ELECTRONICS

NAD C165 KEY BOARD Vm1.0

R719

C78

R716

Q705

R715

C711

R714

Q706

R704

R706

K705

K703

LD505

AUX

LD506

TAPE2

R780

R779

R702

R712

C514

R713

Q709

R794

R782

R781

HEADPHONE

CZ108

IC1

+5V5

GND

TAPE MONITOR

R728

Q710

R730

R729

LD507

LD508

TONE DEFEAT

R797

R798

R793

C716

R708

R358

C397

C712

R709

Q707

R707

R710

C713

R711

Q708

R787

K706

K704

HEADPHONE Vm1.0

CZ102

PJ1

Page 20

C165 BEE KEY+MODULE+MC INPUT+LOAD

SWITCH+HEADPHONE+PHONEJACK BOARD

BOTTOMLAYER

LINE MODULE

R801

R811

Q801

C805

R813

R812

R817

Q803

R816

C810

Q809

R802

CZ112

R803

C803

C802

R809

Q807

Q802

Q806

R808

Q805

C807

R807

R815

Q804

R805

R810

R806

C811

C809

C806

R804

C801

Q808

R788

R784

Q711

R717

R783

D722

C717

D707

Q713

K709

R792

C715

R790

R789

R778

R744

R786

R785

Q712

C73

C714

R791

J202

MM MODULE

C403

MC INPUT

R394

PHONO SWITCH

R393

HEADPHONE

L401

CZ111

R390

R391

S102

LD501

LD502

GV

S

R703

R701

R796

R748

PHONO

CD

C79

Y71

C710

IC73

R802

CZ112

R815

R803

C803

C802

R809

Q807

Q802

Q806

R808

Q805

C807

Q804

R807

R805

R810

R806

C811

C809

C806

R804

C801

Q808

Vm1.0

MC INPUT L

C303

C302

R302

R341

C301

L301

R725

C75

R724

Q702

R727

C74

R726

Q701

IC703

K701

K708

R801

R811

Q801

C805

R813

R812

R817

Q803

R816

C810

Q809

MC INPUT R

Vm1.0

C402

R402

R441

C401

CZ110

TUNER

R401

R301

R723

C76

R722

Q703

K702

LD503

R772

R771

C72

IC71

R721

C77

TOP

TOP

S101

R720

Q704

R795

R705

K707

LD504

MP

C71

C391

CZ107

C390

COPYRIGHT C 2008 NAD ELECTRONICS

C392

NAD C165 KEY BOARD Vm1.0

C393

C454

C398

C349

R458

C351

R464

CZ108

IC1

C165BEE PHONE AMP Vm1.0

C397

R459

R364

R359

R358

C348

C347

C354

R708

C712

R709

Q707

R719

C78

R716

Q705

R715

C711

R714

Q706

R704

R706

K705

K703

K706

LD505

LD506

LD507

AUX

TAPE2

TAPE MONITOR

R780

R779

R702

R712

C514

R713

Q709

R794

R782

R781

+5V5

GND

CZ701

R707

R710

C713

R711

Q708

R787

TONE DEFEAT

R728

Q710

R730

R729

LD508

R797

R798

R793

C716

K704

HEADPHONE Vm1.0

CZ102

PJ1

Page 21

PUSH THE POWER SWITCH TO ON

TROUBLESHOOTING GUIDE

IS THE 3-COLOUR-LED AMBER LIGHT?

YES

CAN PRESSING ANY KEY TO MAKE

THE UNIT WORK NOR MALLY?

YES YES

IS THE PRE-OUT NORMAL?

YES

NO

NO

NO

ARE ALL POWER SUPPLIES OK?

IS THE 3-COLOUR-LED RED AFTER

IS THERE SIGNAL OUTPUT?

IS IT RED FLASH?

YES

SHORT WORKING

YES

YES

NO

NO

NO

NO

IS THE INPUT NORMAL?

IS THE RELAY CONTROL HIGH LEVEL?

IS THE VOLUME CONTROL CIRC UIT

IS THE TONE DEFEAT CIRCUIT

IS THE LINE MODULE NORMAL?

IS IT BLUE

NORMAL?

NORMAL?

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

CHECK THE +5V SUPPLY

(POWER BOARD)

CHECK THE LED CONTROL CIRCUIT

AND POWER SUPPLY ON MAINBOARD

CHECK ALL POWER SUPPLIES

CHECK KEY CIRCUIT

CHECK THE MAIN TRANSFORMER AND

POWER SUPPLY ON MAINBOARD

CHECK THE PREAMP CIRCUIT SECTION

CHECK THE RELAY CONTROL CIRCUIT

CHECK THE VOLUME CONTROL CIRCUIT

CHECK THE TONE DEFEAT CIRCUIT

CHECK THE LINE MODULE

CHECK OTHER AMP CIRCUIT SECTION

IS THE PRE-OUT NORMAL W HEN

INPUT IS PHONO

YES

IS THE HEADPHONE OUTPUT OK?

IS THE REMOTE CONTROL OK?

YES

IS THE THD BAD?

IS THE IDLE CURRENT NORMAL?

NO

NO

NO

IS THE MM MODULE OK?

IS THE INPUT LOAD SELECT NORMAL?

IS THE MC AMP CIRCUIT NORMAL?

IS THE RIAA CIRCUIT NORMAL?

IS THE IR IN/OUT NORMAL?

IS THE REMOTE HANDSET ITSELF

YES

YES

YES

YES

YES

YES

NORMAL?

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

IS THE S/N BAD?

NO

YES

TURN THE TRANSFORMER

CHECK THE AMP CIRCUIT SECTION

ADJUST THE IDLE CURRENT OR

CHECK THE IDLE CURRENT CIRCUIT

CHECK OTHER PATRS OF THE

AMP SECTION

CHECK THE MM MODULE

CHECK THE INPUT SELECT CIR CUIT

CHECK THE M C AMP CIRCUIT

CHECK THE IR IN/OUT CIRCUIT

CHECK OTHER SECTION

CHECK THE HEADPHONE BOARD

CHECK THE IR IN/OUT CIRCUIT

CHECK THE HANDSET ITSELF

CHECK THE KEY BOARD AND MCU

IS THE +12V SUPPLY NORMAL?

YES

OK

NO

CHECK THE +12V SUPPLY CIRCUIT

(POWER BOARD)

Page 22

Designator HS P/N Part Type

MAINBOARD A16-16501-21 CEM-1

D201 33-24001-00 1N4001

D316, D416 33-11200-00 12V 0.5W

D104 33-11600-00 16V 0.5W

D121 33-12700-00 27V 0.5W

D102, D105, D106, D107, D108, D109, D110,

D111, D112, D113, D103, D116, D118, D117,

D120, D119, D115, D114, D315

B102, B103 33-30142-00 DB104

Q103, Q302, Q402 J31-00970-00 2SA970

Q106 J31-02240-00 2SC2240

Q301, Q316, Q401,Q416 J31-03324-00 2SC3324-GR

Q105, Q107, Q110, Q305, Q308, Q309, Q314,

Q411

Q101, Q312 31-01220-00 KSA1220A-Y

Q303, Q403 31-00647-00 2SB647A

Q39, Q102, Q104, Q111, Q201, Q306, Q307,

Q310, Q311, Q315

Q313, Q108 31-02690-00 KSC2690A-Y

Q304, Q404 31-00667-00 2SD667A

Q109 J31-00363-00 2SK363

IC104 03-07812-00 LM7812M

IC107 03-05532-00 NE5532N

IC108 03-00317-00 LM317M

IC109 03-00337-00 LM337M

R303, R330, R403 07-91001-01 1K,±1%,0805

R395 07-90472-01 4K7, 0805, ±5%

R336, R436 07-97151-01 7.15K,±1%,0805

R333, R433 07-91102-01 11K,±1%,0805

R313, R413 07-90223-01 22K, 0805, ±5%

R2, R135, R136, R140, R304, R404 NI

33-44148-00 1N4148

31-01015-00 2SA1015

31-01815-00 2SC1815

R182, R187, R196, R197, R198, R199 07-10000-50 0,1/6W

R363, R463 07-10229-50 2R2, 1/6W, ±5%

R150, R168 07-10100-50 10R, 1/6W, ±5%

R158 07-10330-50 33R, 1/6W, ±5%

R222, R223 07-10510-51 51R, 1/4W, ±5%

R118, R147, R176 07-10101-50 100R, 1/6W, ±5%

R171, R123 07-10221-50 220R, 1/6W, ±5%

R155 07-10331-50 330R, 1/6W, ±5%

R119, R121, R170, R178, R183, R184, R185,

R186

R124, R157, R221, R319 07-10102-50 1K, 1/6W, ±5%

R128 07-10122-50 1K2, 1/6W, ±5%

R354, R454 07-10202-50 2K, 1/6W, ±5%

R129, R130, R131, R132, R133, R134 07-10222-50 2K2, 1/6W, ±5%

R125, R126, R156, R495 07-10472-50 4K7, 1/6W, ±5%

07-10681-50 680R, 1/6W, ±5%

Page 23

R194 07-10512-50 5K1, 1/6W, ±5%

R356, R456 07-10562-50 5K6, 1/6W, ±5%

R141, R142, R144, R152, R153, R154, R219,

R220, R317

R143 07-10113-50 11K, 1/6W, ±5%

R345 07-10123-50 12K, 1/6W, ±5%

R122 07-10183-50 18K, 1/6W, ±5%

R172, R173, R174, R175, R193, R218 07-10223-50 22K, 1/6W, ±5%

R398, R498 07-10303-50 30K, 1/6W, ±5%

R352, R452 07-10683-50 RJ13, 68K, 1/6W, ±5%

R161, R195, R261 07-10104-50 100K, 1/6W, ±5%

R127, R151 07-10154-50 RJ13, 150K, 1/6W, ±5%

R191 07-10204-50 200K, 1/6W, ±5%

R192 07-10224-50 220K, 1/6W, ±5%

R190 07-10434-50 RJ13, 430K, 1/6W, ±5%

07-10103-50 10K, 1/6W, ±5%

R104, R106, R108, R110, R112, R114, R116,

R204, R206, R208, R210, R212, R214, R216

R188, R189 07-10106-50 10M, 1/6W, ±5%

R355, R455 07-10331-51 330R, 1/4W, ±5%

R139, R149 07-10103-51 10K, 1/4W, ±5%

R307, R407 07-21109-50 11R, 1/6W, ±1%

R332, R432 07-20750-50 75R, 1/6W, ±5%

R162, R167 07-21100-50 RJ13, 110R, 1/6W, ±1%

R164, R165 07-21500-50 150R, 1/6W, ±1%

R310, R410 07-22000-50 200R, 1/6W, ±1%

R318, R418 07-22130-50 RJ13, 213R, 1/6W, ±1%

R117, R217 07-20221-50 220R, 1/6W, ±5%

R309, R409 07-22400-50 240R, 1/6W, ±1%

R327, R329, R427, R429 07-24300-50 430R, 1/6W, ±1%

R320, R328, R346, R420, R428, R446 07-24990-50 RJ13, 499R, 1/6W, ±1%

R181 07-25100-50 RJ13, 510R, 1/6W, ±1%

R338, R438 07-20821-50 RJ13, 820R, 1/6W, ±5%

R308, R311, R408, R411 07-21001-50 1K, 1/6W, ±1%

R163, R166 07-20122-50 1K2, 1/6W, ±5%

R344, R444 07-22741-50 RJ13, 2K74, 1/6W, ±1%

R305, R306, R405, R406 07-20332-50 3K3, 1/6W, ±5%

R312, R412 07-27151-50 RJ13, 7K15, 1/6W, ±1%

R335, R435 07-20822-50 8K2, 1/6W, ±5%

R120, R179 07-21002-50 10K, 1/6W, ±1%

R145, R146 07-21102-50 11K, 1/6W, ±1%

R445 07-21202-50 12K, 1/6W, ±1%

R337, R437 07-20513-50 51K, 1/6W, ±5%

R334, R434 07-21373-50 RJ13, 137K, 1/6W, ±1%

07-10105-50 1M, 1/6W, ±5%

R103, R105, R107, R109, R111, R113, R115,

R203, R205, R207, R209, R211, R213, R215

R430 07-21001-51 1K, 1/4W, ±1%

07-20221-51 220R, 1/4W, ±5%

Page 24

R360, R460 07-30100-01 10R, 1W, ±5%

R160 07-30331-02 330, 1W, ±5%

R159 07-30750-02 75/2W,5%

R137, R138 07-50688-01 RF10, 0.68, 1W, ±5%

R169, R177 07-50229-01 2R2/FS 1W

R353, R453 07-50750-00 75/FS 0.5W

C2, C148, C165, C395, C494 N.I.

C318 05-18913-00 1.8pF,1KV±10%,F5.0

C315 05-43013-00 43pF,1KV±10%,F5.0

C153, C156 05-47013-00 47pF,1KV,±10%,F5.0

C308, C408 05-68013-00 68pF,1KV,±10%,F5.0

C102, C103, C104, C105, C106, C107, C108,

C109, C149, C164, C202, C203, C204, C205,

C206, C207, C208, C209

C345, C445 05-22113-01 220p, 1KV, ±10%

C341, C441 05-47113-00 470p,1KV, ±10%

C304, C404 05-82113-00 820p,1KV, ±10%

C353, C453 05-22213-01 2n2, 1KV, ±10%

C111, C145, C5 05-10313-02 10n, 1KV, 20%

05-10113-01 100p, 1KV, ±10%

C119, C120, C125, C126, C131, C132, C133,

C134, C143, C144, C146, C331, C431, C493

C330, C430 25-22251-01 2n2, 50V, ±5%

C327, C427 25-68261-03 6n8, 63V, ±5%

C328, C428 25-24361-02 24n, 63V, ±2%

C142 25-68361-00 68nF,±5%,63V

C342, C442 25-10461-07 0.1u/63V 5%

C166 25-33461-00 330nF,63V,±10%

C158, C258, C333, C350, C415, C433 25-10412-02 100V 0.1uF ±10%,

C343, C443 25-22461-01 220nF,63V,±10%,

C113, C114 25-22412-00 224, 100V, ±5%

C138, C139, C309, C317, C409, C417 06-47921-00 4.7uF,25V,±20%

C121, C122, C127, C128, , C140, C141, C150,

C151, C154, C155, C305, C405

C396, C496

C307, C407 06-10211-05 1000uF,10V,±20%

C325, C352, C425, C452 06-47051-09 47uF,50V,±10%

C332, C432 06-47011-09 47uF,16V,±20%

C129, C130, C259, C329, C429 06-47051-00 47uF,50V,±20%

C310, C410 06-10121-00 100uF,25V,±20%

C344, C444 06-22111-07 220uF,10V,±10%

C137 06-33121-03 330uF, 25V, ±20%

C306, C406 06-47121-00 470u, 25V, ±20%

C124 06-10231-07 1000uF, 35V, ±20%

C117, C118 06-33251-00 3300uF, 50V, ±20%

24-10412-01 0.1u, 100V, ±20%

06-10051-01 10uF,50V,±20%

06-10051-11 10uF,50V,20%

Page 25

J8, J9, J21, J22, J23, J26, J27, J28, J37,

J38, J45, J54, J58, J60, J61, J62, J64, J69,

J72, J73, J76, J77, J79, J82, J91, J92,

21-06500-00 Pitch=5mm

J103, J104, J122, J123, J124

J2, J3, J5, J10, J11, J18, J19, J41, J44, J56,

J57, J65, J66, J67, J68, J70, J75, J78, J80, J85,

J86, J93, J96, J101, J102, J112, J114

J6, J29, J31, J42, J63, J81, J90 21-06101-00 Pitch=10mm

J1, J24, J34, J47, J74, J84, J87, J88, J89, J95,

J110, J121

J13, J25, J55, J59, J71, J97, J98, J108, J109,

J113, J115, J116

J12, J17, J20, J46 21-06181-00 Pitch=18mm

J50, J51 21-10201-00 Pitch=18mm

J4, J7, J30, J32, J33, J35, J36, J39, J40, J83,

J106, J107, J125, J126

J14, J15, J16, J99, J100, J118, J119 21-06221-01 Pitch=22.5mm

J111, J117, J120 21-06251-00 Pitch=25mm

J48, J49, J52, J53 21-10251-00 Pitch=25mm

J43 21-10301-00 Pitch=30mm

L1 A08-01101-01 100uH,±20%

RV31, RV41 09-02101-00 100R

RV15 09-01102-02 RV06203F-26-25A-B1K

21-06750-00 Pitch=7.5mm

21-06121-01 Pitch=12.5mm

21-06151-00 Pitch=15mm

21-06201-00 Pitch=20mm

RL101, RL102, RL103, RL104, RL105, RL106,

RL107, RL108, RL109, RL110, RL111

SW1 11-05202-03 22F03-G10

RCA1, RCA2, RCA3, RCA4, RCA5, RCA6 17-01004-00

RCA35 17-01001-36 AV-8.4-14

PHONE1 J17-02002-02

PHONE2 17-07001-00 PY301-030-100-RS

P101 13-23902-00 VH 3.96A-2A

CB101 13-21219-00 FPC1.25 19PIN

CB102 13-22508-00 XHB2.5A-8A

CB103 13-23905-12 VH 3.96A-5A

CB104 13-22503-00 XHB2.5A-3A

CB107 13-22505-00 XHB2.5A-5A

P18---GND POINT ON REAR PANEL 14-30001-05 L=50mm, Multiple-Stranded, 26AWG

GND LINE 14-16501-01 UL1015#14AWG , 36mm/10mm length

CB105--CZ105 14-16511-00 UL2468#26AWG, L=80mm

CB106 13-22509-00 XHB2.5A-9A

GND-1 32-28042-00 GND-8

MAIN-GND 69-134001-0 H62, T=0.8mm

H4 N70-134005-0 HEATSINK

H3, H5 70-002005-0 HEATSINK

H1, H2 70-134006-0 6063 T5

12-02202-03 JRC-27F/005-S(555)

AV4-8.4-13, 4RCA, Ϟⱑϟ㑶

Page 26

H1, H2, H3, H4, H5 61-023206-0 BTB3X6

67-134008-0 SPCC,T=0.8mm,Tin plated

Self Taping Screws 61-022208-1 BTB2×8

Support CR Foam 79-134003-0 CR UL94V-0, 26×26×11

LINEAR AMP MODULE A16-16505-21 FR-4

Q801 J31-00209-00 2SK209

Q804, Q806, Q809 J31-03324-00 2SC3324-GR

Q808 31-01015-01 2SA1015-GR

Q803 J31-01312-00 2SA1312-GR

Q807 31-01661-00 KTA1661-Y

Q805 31-04373-00 KTC4373-Y

R802 07-90000-00 0

R815 07-90680-00 68 5%

R805, R806, R810 07-90100-00 10

R811 07-90221-00 220

R812, R813 07-94700-00 470 1%

R808 07-98200-00 820 1%

R804, R807 07-91001-00 1K 1%

R803 07-91501-00 1K5 1%

R809 07-90472-00 4K7

R816, R817 07-90104-00 100K

R801 07-90225-00 2M2

C811 26-22051-00

C801, C809 26-33051-00

C805 26-22151-00 220p

C807 26-10251-00 1nF

C802, C803 26-10451-00 0.1uF

C810 26-10521-01 1uK,25V,0805,X7R

22pˈNPO

33pˈNPO

CZ112(INSERTED TO M302/303/402/403 ON

THE MAIN BOARD)

Module Base 70-134002-0 6063 T5

Module Cover 70-134003-0 6063 T5

Self Taping Screws 61-062208-1 BTF2×8

Machine Screws 61-062507-1 MF2×7

MM AMP MODULE A16-16505-22 FR-4

Q801 J31-00209-00 2SK209

Q804, Q806, Q809 J31-03324-00 2SC3324-GR

Q808 31-01015-01 2SA1015-GR

Q802, Q803 J31-01312-00 2SA1312-GR

Q807 31-01661-00 KTA1661-Y

Q805 31-04373-00 KTC4373-Y

R815 07-90680-00 68 5%

R805, R806, R810 07-90100-00 10

R811 07-90221-00 220

R812, R813 07-94700-00 470 1%

R808 07-98200-00 820 1%

R804, R807 07-91001-00 1K 1%

13-12506-00 6pin

Page 27

R803 07-91501-00 1K5 1%

R809 07-90472-00 4K7

R816, R817 07-90104-00 100K

R801 07-90225-00 2M2

C811 26-22051-00

C801, C809 26-33051-00

C805 26-22151-00 220p

C807 26-10251-00 1nF

C802, C803 26-10451-00 0.1uF

C810 26-10521-01 1uK,25V,0805,X7R

CZ112(INSERTED TO M301/401 ON THE MAIN

BOARD)

Module Base 70-134002-0 6063, T5

Module Cover 70-134003-0 6063 T5

Self Taping Screws 61-062208-1 BTF2×8

Machine Screws 61-062507-1 MF2×7

PHONE AMP MODULE A16-16506-21 FR-4

IC1 J03-06120-01 TPA6120A2DWP

R358, R458 07-92001-01 2K, 1%

R359, R364, R459, R464 07-95600-00 560, 1%

C347, C348, C349, C351 26-10451-01 0.1uF

C354, C454

C397, C398

CZ108(INSERTED TO CB108 ON THE MAIN

BOARD)

MC INPUT BOARD L A16-16507-21 FR-4

R301 07-26040-50

R302 07-22001-50 2K, 1/6W, ±1%

R341 07-20332-50 3K3, 1/6W, ±5%

22pˈNPO

33pˈNPO

13-12506-00 6pin

06-33160-00

06-10121-02

13-12509-01 9pin

330uF,6.3V,±20%

100uF,25V,±20%

RJ13, 604, 1/6W, ±1%

C301 05-12113-01 CT8105aY5P121K1KVT, 120p, 1KV, ±10%

C302 25-22412-03 100V 0.22uF ±5%,

C303 06-10111-00 100uF,16V,±20%

L301 08-01101-00 100uH

CZ110(INSERTED TO CB110 ON THE MAIN

BOARD)

MC INPUT BOARD R A16-16507-22 FR-4

R401 07-26040-50

R402 07-22001-50 2K, 1/6W, ±1%

R441 07-20332-50 3K3, 1/6W, ±5%

C401 05-12113-01 120p, 1KV, ±10%

C402 25-22412-03 100V 0.22uF ±5%,

C403 06-10160-03 100uF,6.3V,±20%

L401 08-01101-00 100uH

CZ111(INSERTED TO CB111 ON THE MAIN

BOARD)

MM INPUT BOARD A16-16508-21 CEM-1

R315, R415 07-22200-50 220R, 1/6W, ±1%

R316, R416 07-20332-50 3K3, 1/6W, ±5%

13-12507-01 7pin

RJ13, 604, 1/6W, ±1%

13-12507-01 7pin

Page 28

R314, R414 07-20473-50 47K, 1/6W, ±5%

C311, C411 NI

C312, C412 05-39013-00 39p, 1KV, ±5%

C313, C413 05-18113-00 180p, 1KV, ±10%

L302, L402 08-01372-00 3.7mH

CZ109(INSERTED TO CB109 ON THE MAIN

BOARD)

POWER BOARD A16-16502-21 CEM-1

D51, D533 33-44148-00 1N4148

D58 33-20107-00 FR107

D58 or 33-24006-00 UF4006

D59 33-20540-00 SR540

D52, 33-30162-00 DB105

D510 33-30142-00 DB104

D57 33-14309-00 4V3 0.5W

Q501, Q522 31-01815-00 2SC1815

IC52 03-07805-00 LM7805

IC53 A03-00817-00 PC817

IC51 03-00274-00 TNY274

R570 07-10101-50 100R, 1/6W, ±5%

R571 07-10511-50 510R, 1/6W, ±5%

R574, R575, R579 07-10102-50 1K, 1/6W, ±5%

R577 07-10472-50 4K7, 1/6W, ±5%

R578 07-10103-50 10K, 1/6W, ±5%

R572 07-30104-05 100K, 1W, ±5%

R576 07-50338-00 0.33,1/4W FS

C52 26-10412-01 0.1uF/100V, X7R

C511 24-10351-03 10nF, 50V, ±20%

C58, C513 24-10412-01 0.1u, 100V, ±20%

C514 06-10011-00 10uF,16V,±20%

C53 06-10042-00 10U/400V

C59 06-33111-01 330uF/16V

C54 06-47111-09 470uF,10V,±20%

C515 06-47221-00 4700uF, 25V, ±20%

C56 A05-22242-00 2n2F, 250V, ±20%

C57, C510 A05-47242-00 4n7F, 400V, ±20%

C55 A25-10322-04 MKP64, X1,10nF,310V,±20%

C51 A25-22422-03 MKP62, 275V, 0.22uF 10%

C56, C57, C510 78-001001-1 Sleeve Boot

C56, C57, C510 or 78-001001-0 Sleeve Boot

J58 21-06500-00 Pitch=5mm

J52 21-06500-00 Pitch=5mm

J51 21-06500-00 Pitch=5mm

J53 21-06101-00 Pitch=10mm

J57, J59 21-06121-01 Pitch=12.5mm

J56, J510 21-06181-00 Pitch=18mm

J55 21-06201-00 Pitch=20mm

J54 21-06221-01 Pitch=22.5mm

13-12505-08 2.54mm, 5pin

Page 29

L51 A22-00025-10 FILTER INDUCTOR,48mH

L52 08-01100-00 LGB0810-10uH

T51 A18-72516-00 EE16

RL51 A12-02101-05

RL51 or A12-02101-01 Relay-SPST

CB52 13-22502-00 XHB2.5A-2A

CB55, CB56 13-23903-01 XHB3.96A-3A

CB54, CB57 13-23903-01 XHB3.96A-3A

CZ58 13-23905-13 XHB3.96A-5A

CB53--CB104 14-16503-00 UL2468#26AWG, L=60mm

H501 70-002005-0 HEATSINK

F52 A20-12501-00 T500mAL/250V

F51 A20-12162-01 T1.6AL/250V For 230VAC

F51 A20-12202-00 T2AL/250V For 120VAC

Fuse Holder 20-20000-00 HF-004

KEY BOARD PCB A16-16503-21 FR-4

D722 33-44148-00 1N4148