MTD YM2BP User Manual

YM2BP

2-Cycle Backpack Blower

Operator’s Manual

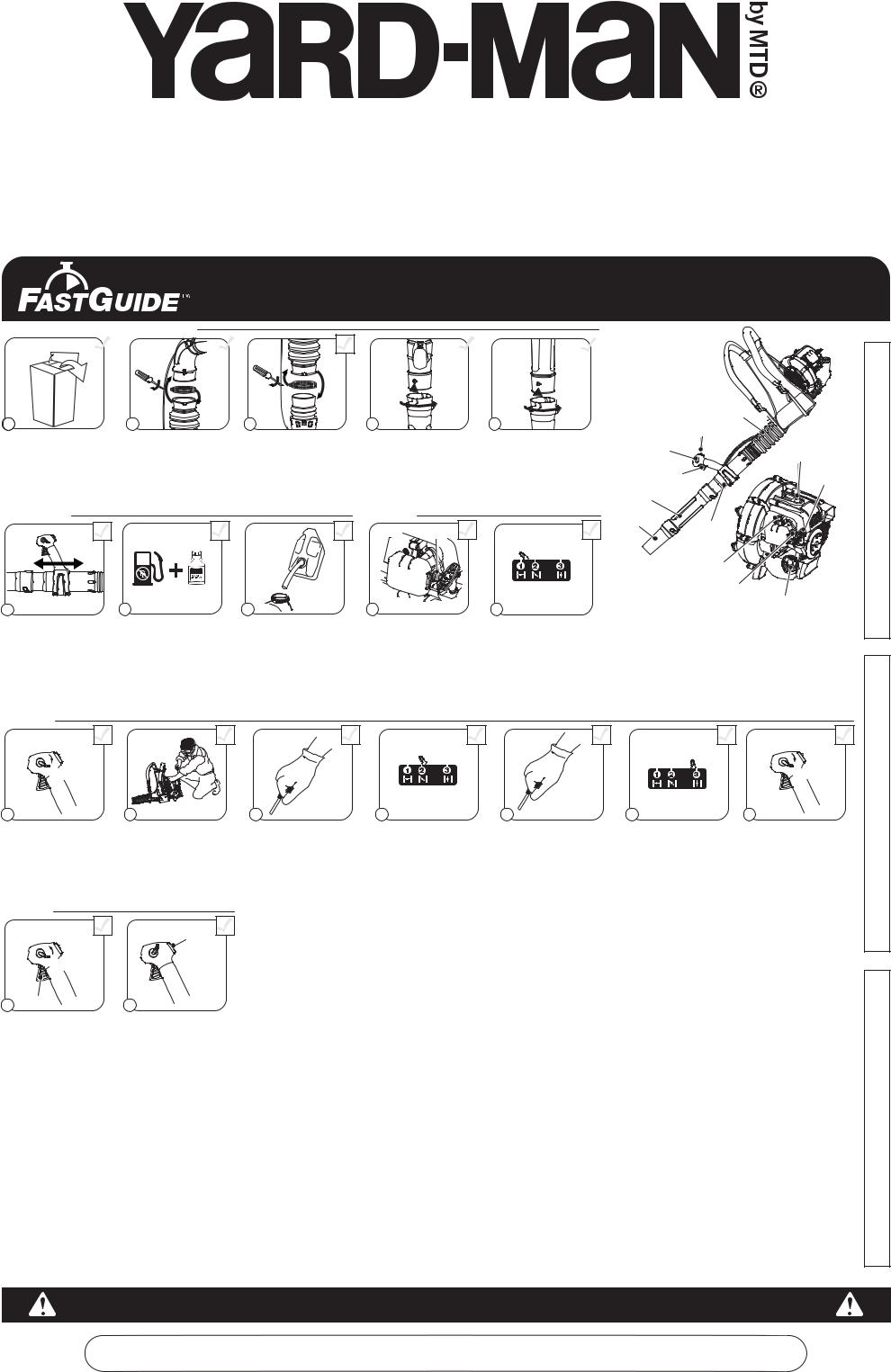

Remove Unit From Carton |

|

Assemble The Unit |

|

|

|

|

|

1 |

2 |

Remove all contents from |

Place a hose clamp over |

the carton. |

the end of the Flex Tube |

|

and slide the end of the |

|

with the clamp on it over |

|

the elbow tube. Tighten |

|

the clamp screw. |

Assemble The Unit |

|

3

Place a hose clamp over the other end of Flex Tube and slide the end over the top end of the upper blower tube. Tighten the clamp screw.

40:1

|

1 Gallon |

3.2 oz |

|

6 |

7 |

|

8 |

Loosen the 2 screws on |

Mix thoroughly in separate |

Place unit on a level |

|

the throttle control. Move |

fuel can: |

|

surface and fill fuel tank. |

the throttle control to the |

– 3.2 fl. oz. of 2-cycle |

DO NOT overfill. |

|

position that provides the |

engine oil |

|

|

best grip and tighten. |

– 1 gallon of unleaded |

|

|

gasoline

NOTE: Do not mix directly in fuel tank.

Start The Unit

|

|

|

|

|

|

4 |

|

|

5 |

|

|

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

Insert the upper blower |

Insert the lower blower |

||||

tube into the lower blower |

tube into the nozzle and |

||||

tube and twist the lower |

twist the nozzle clockwise |

||||

tube clockwise unit it locks |

until it locks into place. |

||||

into place. |

Zip tie the throttle cable to |

||||

|

|

|

the elbow tube. |

||

Start The Unit

Primer

Bulb

9 |

10 X |

|

Press primer bulb 10 times, or until fuel is visible

10

Move choke lever to

Position 1.

Tools Required-

Phillips Screwdriver

T-20 Torx® Screwdriver

Flex Tube

On/Off Switch

Cruise Control

Spark Plug

Trigger

Starter Rope

Lower Blower Tube

Nozzle |

Upper Blower |

Tube |

Choke Lever

Primer Bulb

Fuel Cap

DIDN’T START?

Repeat these instructions.

IF the engine hesitates, return the choke lever to

Position 2 and continue the warm-up.

IF the engine does not start, go back to step 9.

IF the unit fails to start after 2 attempts, move choke lever to Position 3 and pull rope until unit starts

|

SLOW |

|

|

|

|

|

SLOW |

|

FAST |

|

|

|

|

|

FAST |

|

|

|

5 X |

|

|

|

|

11 |

|

12 |

13 |

14 |

15 |

16 |

17 |

Press down cruise control |

Crouch in starting |

Pull rope 5 times. |

Move choke lever to |

Pull rope 3-5 times to |

Move choke lever to |

Continue to keep the |

|

to FAST position. |

position. |

|

Position 2 . |

start engine. Keep the |

Position 3. |

cruise control in FAST |

|

|

|

|

|

|

cruise control in FAST |

|

position and warm unit for |

|

|

|

|

|

position and allow unit to |

|

an additional 60 seconds |

|

|

|

|

|

warm up for 30 to 60 |

|

to complete warm-up. Unit |

|

|

|

|

|

seconds. |

|

may be used during this |

|

|

|

|

|

|

|

time. |

Stop The Unit |

|

|

|

|

|

|

|

|

SLOW |

On/Off |

|

|

|

|

|

|

Switch |

|

|

|

|

|

|

|

FAST |

|

|

|

|

|

|

18 |

Trigger |

19 |

|

|

|

|

|

|

|

|

|

|

|

||

Release your hand from |

Press the On/Off Switch |

|

|

|

|

|

|

the trigger or raise the |

in the OFF (O) position |

|

|

|

|

|

|

cruise control. Allow the |

and hold until the engine |

|

|

|

|

|

|

engine to cool down by |

comes to a complete |

|

|

|

|

|

|

idling. |

stop. |

|

|

|

|

|

|

ENGLISH — PAGE 1

FRANÇAIS — PAGE 5

ESPAÑOL — PAGE 9

IMPORTANT: READ OPERATOR’S MANUAL THOROUGHLY AND FOLLOW THE SAFE OPERATION PRACTICES WHILE OPERATING THE UNIT.

NEED HELP? Call 1-800-800-7310 in U.S. or 1–800–668–1238 in Canada

769-06206 P00 |

10/10 |

TABLE OF CONTENTS |

|

Safety Rules........................................................................................................................................... |

2 |

Oil and Fuel Information......................................................................................................................... |

3 |

Operating Instructions ........................................................................................................................... |

3 |

Maintenance and Repair Instructions .................................................................................................... |

3 |

Cleaning and Storage ............................................................................................................................ |

4 |

Troubleshooting Chart............................................................................................................................ |

4 |

Specifications ........................................................................................................................................ |

4 |

For service call 1-800-800-7310 in the United States, or 1-800-668-1238 in Canada to obtain a list of authorized service dealers near you. For more details about your unit, visit our website at www.yardman.com or www.yardman.ca.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

Service on this unit both within and after the warranty period should be performed only by an authorized and approved service dealer.

All information, illustrations, and specifications in this manual are based on the latest product information available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2010 MTD SOUTHWEST INC, All Rights Reserved.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and Washington require, by law that certain internal combustion engines operated on forest brush and/or grasscovered areas be equipped with a spark arrestor, maintained in effective working order, or the engine be constructed, equipped and maintained for the prevention of fire. Check with your state or local authorities for regulations pertaining to these requirements. Failure to follow these requirements could subject you to liability or a fine. This unit is factory equipped with a spark arrestor. If it requires replacement, ask your LOCAL SERVICE DEALER to install the Accessory Part #753-06418 Muffler Assembly

RULES FOR SAFE OPERATION

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT: Indicates danger, warning or caution. Attention is required in order to avoid serious personal injury. May be used in conjunction with other symbols or pictographs.

NOTE: Advises of information or instructions vital to the operation or maintenance of the equipment.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always follow the safety precautions to reduce the risk of fi re, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in injury to yourself and others. Always follow the safety precautions to reduce the risk of fi re, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

GENERAL SAFETY

WARNING: When using the unit, all safety rules must be followed. Please read these instructions before operating the unit in order to ensure the safety of the operator and any bystanders. Please keep these instructions for later use.

•Read the instructions carefully. Be familiar with the controls and proper use of the unit.

•Do not operate this unit when tired, ill, or under the influence of alcohol, drugs, or medication.

•Children and teens under the age of 15 must not use the unit, except for teens guided by an adult.

•All guards and safety attachments must be installed properly before operating the unit.

•Inspect the unit before use. Replace damaged parts. Check for fuel leaks. Make sure all fasteners are in place and secure. Replace parts that are cracked, chipped, or damaged in any way. Do not operate the unit with loose or damaged parts.

•Carefully inspect the area before starting the unit. Remove all debris and hard or sharp objects such as glass, wire, etc.

•Clear the area of children, bystanders, and pets. At a minimum, keep all children, bystanders, and pets outside a 50 feet (15 m.) radius; there still may be a risk to bystanders from thrown objects. Bystanders should be encouraged to wear eye protection. If you are approached, stop the unit immediately.

•Squeeze the throttle control and check that it returns automatically to the idle position. Make all adjustments or repairs before using unit.

•Never store the unit, with fuel in the tank, inside a building where fumes may reach an open flame (pilot lights, etc.) or sparks (switches, electrical motors, etc.).

•Allow the engine to cool before storing or transporting. Be sure to secure the unit while transporting.

•Store the unit in a dry place, either locked up or up high to prevent unauthorized use or damage. Keep out of the reach of children.

•Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean, and free from debris. Clean after each use, see Cleaning and Storage instructions.

•Keep these instructions. Refer to them often and use them to instruct other users. If you loan this unit to others, also loan these instructions to them.

•Wear safety glasses or goggles that are marked as meeting ANSI Z87.1–1989 standards and are marked as such. Wear ear/hearing protection when operating this unit.

•Never run the unit without the proper equipment attached.

•To reduce the risk of hearing loss associated with sound level(s), always wear ear/hearing protection when operating this unit.

•Wear heavy long pants, boots, gloves, and a long sleeve shirt. Do not wear loose clothing, jewelry, short pants, sandals or go barefoot. Secure hair above shoulder level.

•Use the unit only in daylight or good artificial light.

•Keep outside surfaces free from oil and fuel.

•Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator and unit must be in a stable position while starting. Refer to Starting/Stopping Instructions.

•Do not set unit on any surface except a clean, hard area while engine is running. Debris such as gravel, sand, dust, grass, etc. could be picked up by the air intake and thrown out by the discharge opening, damaging unit, property, or causing serious injury to bystanders or operator.

•Use the right tool. Only use this tool for its intended purpose.

•Do not force unit. It will do the job better and with less likelihood of injury at a rate for which it was designed.

•Do not overreach or use from unstable surfaces such as ladders, trees, steep slopes, rooftops, etc. Always keep proper footing and balance.

•Always hold the unit with a firm grip when operating.

•Keep hands, face, and feet away from all moving parts. Do not touch or try to stop the impeller when it is rotating. Do not operate without guards in place.

RULES FOR SAFE OPERATION

•Do not put any object into openings. Do not use with any opening blocked; keep free of dirt, debris, and anything that may reduce the air flow.

•Do not touch the engine or muffler. These parts get extremely hot from operation, even after the unit is turned off.

•Do not operate the engine faster than the speed needed to do the job. Do not run the engine at high speed when not in use.

•Always stop the engine when operation is delayed or when walking from one location to another.

•Use only genuine factory replacement parts and accessories for this unit. These are available from your authorized service dealer. Use of any unauthorized parts or accessories could lead to serious injury to the user or damage to the unit, and void your warranty.

•If you strike or come into contact with a foreign object, stop the engine immediately and check for damage. Do not operate before repairing damage. Do not operate the unit with loose or damaged parts.

•To reduce fire hazard, replace faulty muffler and spark arrestor. Keep the engine and muffler free from grass, leaves, excessive grease or carbon build up.

OIL AND FUEL SAFETY

WARNING: Gasoline is highly flammable and its vapors can explode if ignited. Take the following precautions:

•Store fuel only in containers specifically designed and approved for the storage of such materials.

•Always stop the engine and allow it to cool before fi lling the fuel tank. Never remove the fuel tank cap or add fuel when the engine is hot. Never operate the unit without the fuel cap securely in place.

•Always mix or add fuel in a clean, well-ventilated outdoor area where there are no sparks or flames. Do not smoke.

•Never Operate the unit without the fuel cap securely in place.

•Avoid creating a source of ignition for spilled fuel. Wipe up any spilled fuel from the unit immediately before starting the unit. Move the unit at least 30 feet (9.1 m) from the fueling source and site before starting the unit. Do not smoke.

•Never start or run the unit inside a closed room or building. Breathing exhaust fumes can be fatal. Operate this unit only in a well-ventilated outdoor area.

•Check the unit for fuel leaks.

•Loosen the fuel tank cap slowly to relieve any pressure in the tank.

•Never store the unit with fuel in the tank, inside a building where fumes may reach an open flame (pilot lights, etc.) or sparks (switches, electrical motors, etc.).

•To reduce fire hazard, replace a faulty muffler and spark arrestor. Keep the engine and muffler free from grass, leaves, excessive grease or carbon build up.

•Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator and unit must be in a stable position while starting. Refer to Starting/Stopping Instructions.

•Do not touch the engine, gear housing or muffler. These parts get extremely hot from operation, even after the unit is turned off.

•Turn the engine to off and disconnect the spark plug for maintenance or repair.

BLOWER SAFETY

•Stop the engine for maintenance, repair, to install or remove the blower tubes. The unit must be stopped and the impeller no longer turning to avoid contact with the rotating blades.

•Never point the blower in the direction of bystanders, animals, windows or automobiles.

SAVE THESE INSTRUCTIONS

• SAFETY & INTERNATIONAL SYMBOLS •

This operator’s manual describes safety and international symbols and pictographs that may appear on this product. Read the operator’s manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING

•SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other symbols or pictographs.

•READ OPERATOR’S MANUAL

WARNING: Read the operator’s manual(s) and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

•WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can cause severe eye injury and hearing loss. Wear eye protection meeting ANSI Z87.1-1989 standards and ear protection when operating this unit. Use a full face shield when needed.

•UNLEADED FUEL

Always use clean, fresh unleaded fuel

•DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing greater than 10% ethanol will likely damage this engine and void the warranty.

•ON/OFF CONTROL

ON / START / RUN

•ON/OFF CONTROL

OFF or STOP

• OIL

Refer to operator’s manual for the proper type of oil.

•PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• CHOKE CONTROL

1.• FULL choke position

2.• PARTIAL choke position

3.• RUN choke position

• THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high speed, causing injury. Keep away from the rotating rotor.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 50 feet (15 m.) from the operating area.

• HOT SURFACE

WARNING: Do not touch any metal engine components. The engine gets extremely hot from operation and may cause severe burns. Allow the unit to completely cool prior to any maintenance or servicing.

•BLOWERS – ROTATING IMPELLER BLADES CAN CAUSE SEVERE INJURY

WARNING: Stop the engine and allow the impeller to stop before opening the vacuum door, installing or changing tubes or bag, or before cleaning or performing any maintenance.

2

OIL AND FUEL

OIL AND FUEL MIXING INSTRUCTIONS

WARNING: Gasoline is extremely flammable. Ignited vapors may explode. Always stop the engine and allow it to cool before fi lling the fuel tank. Do not smoke while filling the tank. Keep sparks and open flames at a distance from the area.

WARNING: Add fuel in a clean, level and well ventilated outdoor area. Wipe up any spilled fuel immediately. Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

WARNING: Remove fuel cap slowly to avoid injury from fuel spray. Never operate the unit without the fuel cap securely in place.

Be sure to use fresh, clean unleaded fuel and follow instructions carefully for proper fuel/oil mixture.

Definition of Blended Fuels

WARNING: Fuel containing greater than 10% ethanol will likely damage the engine and void the warranty.

Today’s fuels are often a blend of gasoline and oxygenates such as ethanol, methanol, or MTBE (ether) which absorb water. Use fuel within 30 days of purchase. Blended fuels older than 30 days will affect the performance and life of the engine.

Using Blended Fuels

If the use of blended fuel is unavoidable, follow recommended precautions:

•Always use the fresh fuel mix explained in the operator’s manual

•Always agitate the fuel mix before fueling the unit

•Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

It is recommended to use the manufacturers 2-cycle oil with this unit. If unavailable, use a good 2-cycle oil designed for air-cooled engines along with a fuel additive, such as STA-BIL® Gas Stabilizer or an equivalent.

Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according to the instructions on the container. NEVER add fuel additives directly to the unit’s fuel tank.

Mixing The Fuel

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded fuel in a separate fuel can. Use a 40:1 fuel/oil ratio. Do not mix them directly in the engine fuel tank.

IF... |

the unit came with a bottle of 2-cycle oil; pour the entire bottle into 1 gallon of gas and mix |

|

thoroughly. |

NOTE: |

One gallon (3.8 liters) of unleaded fuel mixed with one 3.2 oz. (95 ml.) bottle of 2-cycle oil |

|

makes a 40:1 fuel/oil ratio. |

NOTE: |

Dispose of the old fuel/oil mix in accordance to Federal, State and Local regulations. |

OPERATION

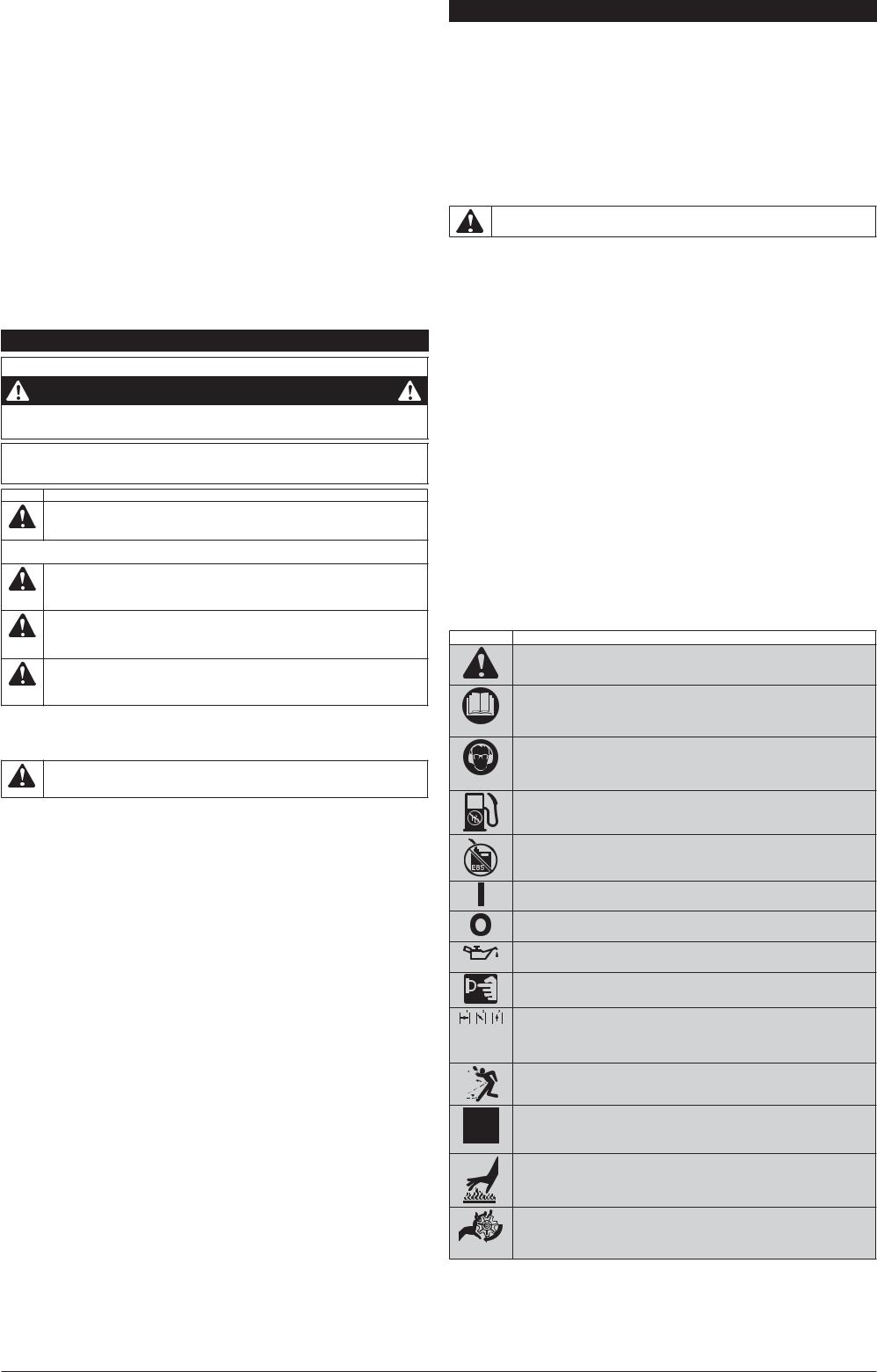

USING THE CRUISE CONTROL

1.Once the engine has been started and warmed up, squeeze the trigger to accelerate the unit as needed (Fig. 1).

2.For longer periods of operation and to eliminate possible finger fatigue, move the cruise control toward the

FAST position to incrementally increase or maintain the unit’s engine speed (Fig. 1). When the cruise control is pressed, the trigger will recede into the handle.

3.To decrease engine speed, move the cruise control to the SLOW position and the trigger will return to the idle position (Fig. 1).

PUTTING ON THE UNIT

1.Place the shoulder supports over the shoulders so that the engine rests on the operator’s back.

2.Pull the shoulder support straps down to tighten the shoulder supports (Fig. 2).

NOTE: The unit must be started prior to putting it on. See Starting/Stopping Instructions.

TAKING OFF THE UNIT

1.Pull up on the bottom tabs of the shoulder support buckles to loosen the shoulder supports (Fig. 3).

2.Remove the unit.

HOLDING THE BLOWER

Before operating the unit, stand in the operating position and check for the following (Fig. 4):

•The operator is wearing eye protection and proper clothing.

•If the conditions are dusty, the operator is wearing a dust mask.

•The unit is secure and comfortable on the operator’s back.

•The right arm is slightly bent and the right hand is gripping the throttle control.

OPERATING TIPS

•Never direct the unit at anyone while the unit is in operation.

•Always hold the unit securely when operating.

•To reduce the risk of hearing loss associated with sound level(s), hearing protection is required.

•Operate power equipment only at reasonable hours. Comply with times listed in local ordinances. Usual recommendations are 9:00 am to 5:00 pm, Monday through Saturday.

Cruise |

|

Control |

SLOW |

|

FAST |

Trigger |

|

|

Fig. 1 |

Shoulder |

Shoulder |

Support |

Supports |

Straps |

|

Fig. 2

Shoulder

Buckles

Fig. 3

Fig. 4

•To reduce noise levels, operate power blowers at the lowest possible speed to do the job and limit the total number of pieces of power equipment used at any one time.

•Check unit before operating, especially muffler, air intakes and air filters, for debri and possible blockages.

•Use rakes and brooms to loosen debris before blowing.

•In dusty conditions, slightly dampen surfaces.

•Conserve water by using power blowers instead of hoses for many lawn and garden applications, including cleaning debri from areas such as screens, patios, grills, porches, and gardens.

•Watch out for children, pets, open windows or freshly washed cars, and blow debris safely away.

•Use the full blower nozzle extension so the air stream can work closer to the ground.

•Clean up after using blowers and other equipment. Dispose of debris appropriately.

•Use the cruise control to make continuous operation easier.

APPLICATIONS

•Use the blower for trees, shrubs, flower beds and hard-to-clean areas.

•Use the unit around buildings and for other normal cleaning procedures.

•Use the blower around walls, overhangs, fences and screens.

MAINTENANCE

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. For these types of repairs call 1-800-800-7310 for more information.

NOTE: Please read the California/ EPA statement that came with the unit for a complete listing of terms and coverage for the emissions control devices, such as the spark arrestor, muffler, carburetor, etc

FREQUENCY |

MAINTENANCE REQUIRED |

SEE |

Every 10 hours |

Clean air filter |

p. 3 |

|

|

|

Every 25 hours |

Check the spark plug condition and gap |

p. 3 |

|

|

|

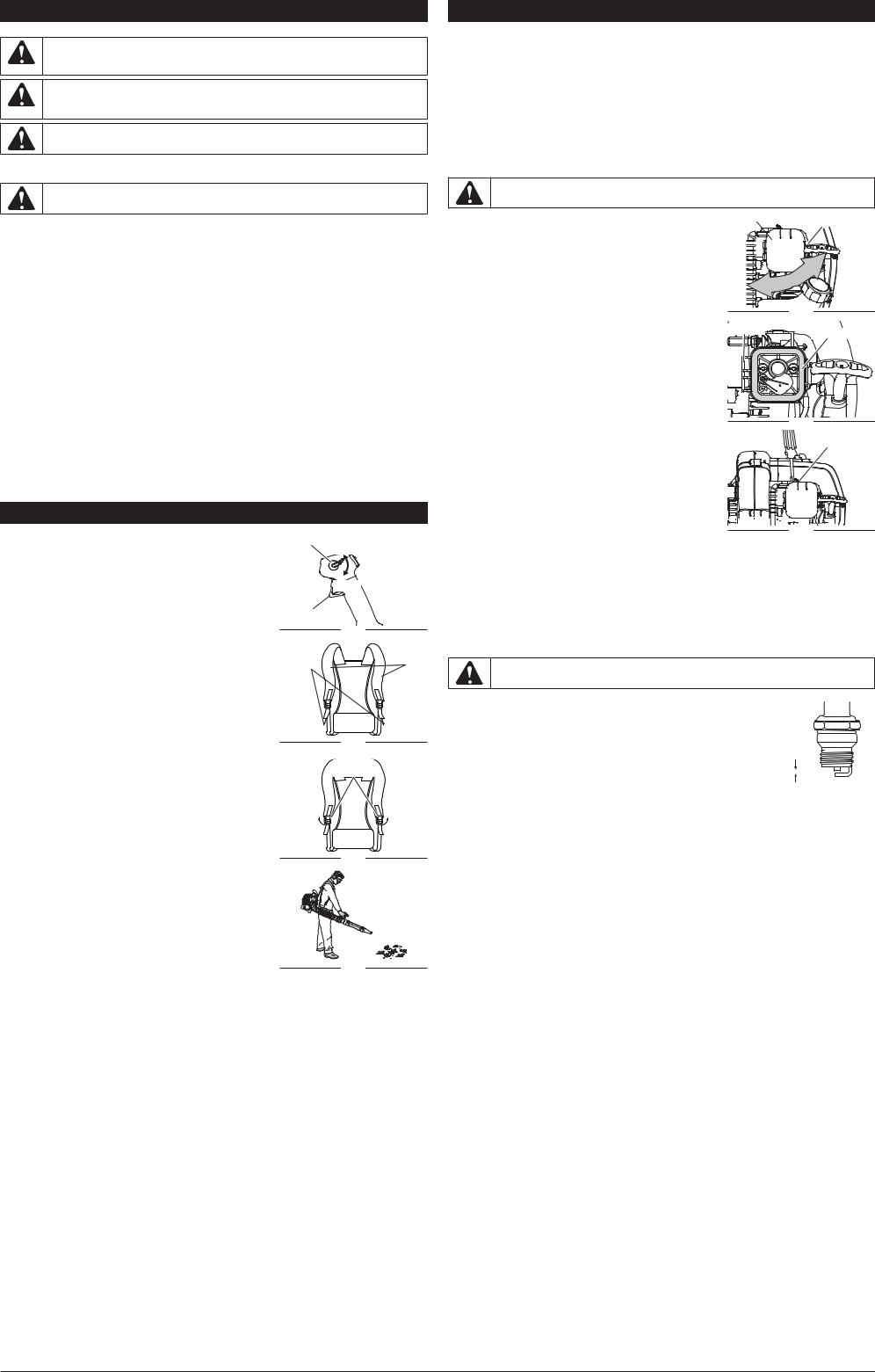

AIR FILTER MAINTENANCE

WARNING: To avoid serious personal injury, always turn the unit off and allow it to cool before cleaning or maintaining it.

Failure to maintain the air filter properly can result in poor performance or cause permanent damage to the engine.

1.Open the air filter cover and remove the air filter (Fig. 5).

2.Wash the fi lter in detergent and water. Rinse thoroughly and allow to dry.

3.Apply clean SAE 30 motor oil to filter.

4.Squeeze filter to spread and remove excess oil.

5.Replace air filter (Fig. 6).

NOTE: Operating unit without air filter WILL VOID warranty.

6.Reinstall the air filter cover and press down until it snaps into place (Fig. 5).

ADJUST IDLE SPEED SCREW

The idle speed of the engine is adjustable. An idle adjustment screw is between the air filter cover and the engine cover (Fig. 7).

NOTE: Careless adjustments can seriously damage your unit. An authorized service dealer should make carburetor adjustments.

Air Filter |

Tab |

|

Cover |

||

|

Fig. 5

Lock Tabs |

Air Filter |

If, after checking the fuel and cleaning the air filter, the engine still |

Fig. 6 |

will not idle, adjust the idle speed screw as follows: |

|

1. Start the engine and let it run at a high idle for a minute to |

|

warm up. Refer to Starting/Stopping Instructions. |

|

2. Move the cruise control to the SLOW position and let |

|

the engine idle. If the engine stops, insert a small Phillips |

|

screwdriver in between the air filter cover and the engine |

|

cover (Fig. 7). Turn the idle speed screw in, clockwise, 1/8 of a |

|

turn at a time (as needed) until the engine idles smoothly. |

|

Checking the fuel mixture, cleaning the air filter, and adjusting the

idle speed should solve most engine problems. If not and all of the Fig. 7 following are true:

idle speed should solve most engine problems. If not and all of the Fig. 7 following are true:

•engine will not idle

•engine hesitates or stalls on acceleration

•there is a loss of engine power

take the unit to a qualified service dealer.

REPLACING THE SPARK PLUG

Idle Adjustment

Screw

Use a replacement part number 753-06193 or Champion spark plug #RDJ7J. The correct spark gap is 0.025 in. (0.635 mm).

1.Stop the engine and allow it to cool.

2.Grasp plug wire firmly and pull.

WARNING: Do not sand blast, scrape or clean spark plug electrodes. Grit in the engine could damage the cylinder.

3.Clean around spark plug and remove using a 5/8-inch socket counterclockwise.

4. Set the air gap, according to specifications, using a feeler gauge (Fig. 8).

5. Install spark plug turning clockwise and torquing as stated:

• Torque to: 110-120 in.•lb. (12.3-13.5 N•m) Do not over |

0.025 in. |

|

|

|

|

|

tighten. |

|

|

|

|

|

|

|

|

|

|

|||

Do not over tighten. |

(0.635 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

6. Reconnect the spark plug wire. |

|

|

Fig. 8 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household cleaners that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can damage plastic housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

•Never store the unit with fuel in the tank where fumes may reach an open fl ame or spark.

•Allow the engine to cool before storing.

•Lock up the unit to prevent unauthorized use or damage.

•Store the unit in a dry, well-ventilated area.

•Store the unit out of the reach of children.

LONG TERM STORAGE

If you plan on storing the unit for an extended time, use the following storage procedure:

1.Remove all fuel from the fuel tank and dispose in accordance with federal, state and local regulations

2.Start the engine and allow it to run until it stalls. This ensures that all fuel has been drained from the carburetor.

3.Allow the engine to cool.

4.Remove the spark plug and put 3 - 5 drops of any high quality motor oil or 2-cycle oil into the cylinder. Pull the starter rope slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the cylinder before attempting to start the blower after storage.

5.Thoroughly clean the unit and inspect it for any loose or damaged parts. Repair or replace damaged parts and tighten loose screws, nuts or bolts. The unit is ready for storage.

TRANSPORTING

•Allow the engine to cool before transporting

•Drain fuel from unit before transporting

•Tighten fuel cap before transporting

•Secure the unit while transporting

3

TROUBLESHOOTING

PROBLEM |

SOLUTION |

|

|

|

|

ENGINE WILL NOT START, IDLE OR ACCELERATE |

||

|

|

|

Empty fuel tank |

Fill fuel tank with fuel |

|

|

|

|

Primer bulb wasn't pressed enough |

Slowly press primer bulb 10 times |

|

|

|

|

Old fuel |

Drain fuel tank and add fresh fuel mix |

|

|

|

|

Fouled spark plug |

Replace or clean the spark plug |

|

|

|

|

Air filter is plugged |

Replace or clean the air filter |

|

|

|

|

Improper idle speed |

Adjust according to the Idle Speed |

|

Adjustments section. |

||

|

||

|

|

|

ENGINE LACKS POWER OR STALLS |

|

|

|

|

|

Old fuel |

Drain fuel tank and add fresh fuel mix |

|

|

|

|

Fouled spark plug |

Replace or clean the spark plug |

|

|

|

|

|

SPECIFICATIONS |

|

|

|

|

UNIT* |

|

Engine Type............................................................................................................. |

Air-Cooled, 2-Cycle |

Displacement .................................................................................................................. |

............... 27 cc |

Idle Speed RPM........................................................................................................... |

3,200–4,400 rpm |

Operating RPM ............................................................................................................ |

6,900-7,200 rpm |

Spark Plug Gap.................................................................................................... |

0.025 inch (0.635 mm) |

Lubrication ..................................................................................................................... |

Fuel/Oil Mixture |

Fuel/Oil Ratio ................................................................................................................................... |

40:1 |

Fuel Tank Capacity............................................................................................................ |

20 oz. (591 ml) |

Approximate Unit Weight (No fuel)............................................................................. |

17.8 lbs. (8.07 kg) |

*All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any time without notice.

4

YM2BP

Souffleur à dos 2 temps Manuel de l’utilisateur

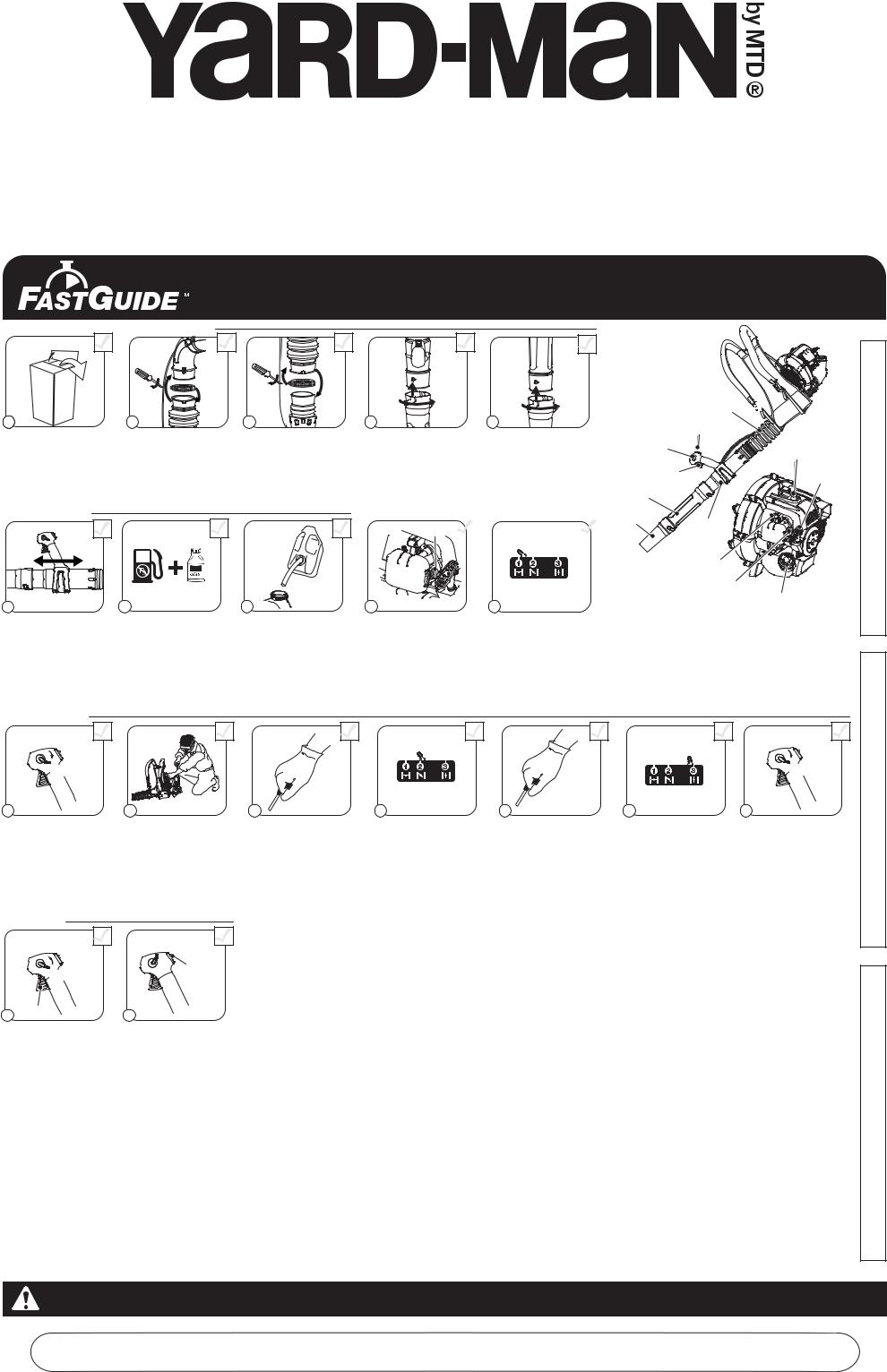

Retirer l’appareil du carton |

Assembler l’appareil |

Outils requis :

• Tournevis cruciforme

• Tournevis Torx® T-20

1

Retirez tous les éléments du carton.

Assembler l’appareil

6

Desserrez les 2 vis sur la manette des gaz. Placez la manette des gaz dans la position offrant la meilleure prise et resserrez.

Démarrer l’appareil

2 |

3 |

Placez un collier de |

Placez un collier de serrage |

serrage sur l’extrémité du |

à l’autre extrémité du tube |

tube flexible et faites |

flexible et faites glisser |

glisser l’extrémité du tube |

l’extrémité sur l’extrémité |

flexible muni du collier sur |

supérieure du tube de |

le tube coudé. Serrez la |

soufflage supérieur. Serrez |

vis de la bride. |

la vis de la bride. |

40:1

1 Gallon |

3.2 oz |

|

7 |

|

8 |

Mélangez soigneusement |

Placez l’appareil sur une |

|

dans un bidon d’essence : |

surface plane et |

|

– 0,09 litre (3,2 oz.) d’huile |

remplissez le réservoir de |

|

pour moteur 2 temps |

carburant. VEILLEZ À NE |

|

– 3,8 litres (1 gallon) |

PAS trop le remplir. |

|

d'essence sans plomb |

|

|

REMARQUE : ne faites pas le mélange directement dans le réservoir de carburant.

4 |

|

|

|

5 |

|

|

Insérez le tube de soufflage |

Insérez le tube de soufflage |

|||||

supérieur dans le tube de |

inférieur dans la buse et |

|||||

soufflage inférieur et |

pivotez la buse vers la droite |

|||||

pivotez le tube inférieur |

jusqu’à ce qu’elle soit |

|||||

vers la droite jusqu’à ce |

parfaitement en place. Fixez |

|||||

qu’il soit parfaitement en |

le câble de la manette des |

|||||

place. |

gaz sur le tube coudé à l’aide |

|||||

|

|

|

|

de l’attache autobloquante. |

||

Démarrer l’appareil |

|

|

|

|

||

|

|

|

|

|||

Poire |

|

|

|

|

||

d’amorçage |

|

|

|

|

||

|

|

|

|

|

|

|

9 |

10 X |

10 |

|

||

Pressez la poire |

Mettez le levier |

|

d’amorçage 10 fois ou |

d’étranglement en |

|

jusqu’à ce que le |

position 1. |

|

carburant soit visible. |

|

|

Tube flexible

Bouton marche/ arrêt (On/Off)

Régulateur

de vitesse

Bougie

Gâchette |

Cordon de |

|

démarrage |

Tube de soufflage |

|

inférieur |

|

Buse

Tube de soufflage supérieur

Levier d’étranglement

Poire d’amorçage

Bouchon du réservoir de carburant

L’APPAREIL NE DÉMARRE PAS ?

SI le moteur fait des accrocs, remettez le levier d’étranglement en position 2 et continuez de chauffer le moteur.

SI le moteur ne démarre pas, retournez à l’étape 9.

SI le moteur ne démarre pas après 2 tentatives, placez le levier d’étranglement en position 3 et tirez le cordon de démarrage jusqu’à ce que le moteur démarre.

|

LENT |

|

|

|

|

|

LENT |

|

RAPIDE |

|

|

|

|

|

RAPIDE |

|

|

|

5 X |

|

|

|

|

11 |

|

12 |

13 |

14 |

15 |

16 |

17 |

Appuyez sur le régulateur |

Placez-vous en position |

Tirez 5 fois sur le cordon. |

Mettez le levier |

Tirez sur le cordon 3 à 5 |

Mettez le levier |

Continuez de maintenir le |

|

de vitesse pour le placer |

de démarrage. |

|

d’étranglement en |

fois de suite pour |

d’étranglement en |

régulateur de vitesse en |

|

en position RAPIDE. |

|

|

position 2. |

démarrer le moteur. |

position 3. |

position RAPIDE et laissez |

|

|

|

|

|

|

Maintenez le régulateur |

|

le moteur chauffer |

|

|

|

|

|

de vitesse en position |

|

pendant encore 60 |

|

|

|

|

|

RAPIDE et laissez le |

|

secondes pour terminer le |

|

|

|

|

|

moteur chauffer pendant |

|

réchauffage. L’appareil |

|

|

|

|

|

30 à 60 secondes. |

|

peut être utilisé pendant ce |

|

|

|

|

|

|

|

temps. |

Arreter l’appareil |

|

|

|

|

|

|

|

|

LENT |

|

|

|

|

|

|

|

|

Bouton |

|

|

|

|

|

|

RAPIDE |

marche/arrêt |

|

|

|

|

|

|

(On/Off) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

Gâchette |

19 |

|

|

|

|

|

|

|

|

|

|

|

||

Relâcher la gâchette ou |

Appuyer et maintenir la |

|

|

|

|

|

|

régulateur de vitesse et |

commande Marche/Arrêt |

|

|

|

|

|

|

laisser le moteur refroidir |

enfoncée en position |

|

|

|

|

|

|

en le faisant tourner au |

ARRET (O) jusqu’à ce que |

|

|

|

|

|

|

ralenti. |

le moteur soit complète- |

|

|

|

|

|

|

|

|

ment arrêté. |

|

|

|

|

|

ENGLISH — PAGE 1

FRANÇAIS — PAGE 5

ESPAÑOL — PAGE 9

IMPORTANT : LISEZ ATTENTIVEMENT LE MANUEL DE L’UTILISATEUR ET CONFORMEZ-VOUS AUX INSTRUCTIONS POUR UNE UTILISATION DE L’APPAREIL EN TOUTE SÉCURITÉ.

BESOIN D’AIDE ? Appelez le 1-800-800-7310 aux États-Unis ou le 1–800–668–1238 au Canada

769-06206 P00 |

10/10 |

Loading...

Loading...