MAX809, MAX810

3-Pin Micropr ocessor

Reset Monitors

The MAX809 and MAX810 are cost–effective system supervisor

circuits designed to monitor VCC in digital systems and provide a reset

signal to the host processor when necessary. No external components

are required.

The reset output is driven active within 20 µsec of V

through the reset voltage threshold. Reset is maintained active for a

minimum of 140msec after V

rises above the reset threshold. The

CC

MAX810 has an active–high RESET output while the MAX809 has

an active–low RESET output. The output of the MAX809 is

guaranteed valid down to VCC = 1V. Both devices are available in a

SOT–23 package.

The MAX809/810 are optimized to reject fast transient glitches on

the V

line. Low supply current of 17µA (V

CC

= 3.3V) makes these

CC

devices suitable for battery powered applications.

Features

• Precision V

Monitor for 3.0V, 3.3V, and 5.0V Supplies

CC

• 140msec Guaranteed Minimum RESET , RESET

Output Duration

• RESET Output Guaranteed to V

= 1.0V (MAX809)

CC

• Low 17µA Supply Current

• V

Transient Immunity

CC

• Small SOT–23 Package

• No External Components

• Wide Operating Temperature: –40°C to 85°C

Typical Applications

• Computers

• Embedded Systems

• Battery Powered Equipment

• Critical µP Power Supply Monitoring

falling

CC

http://onsemi.com

SOT–23

(TO–236)

CASE 318

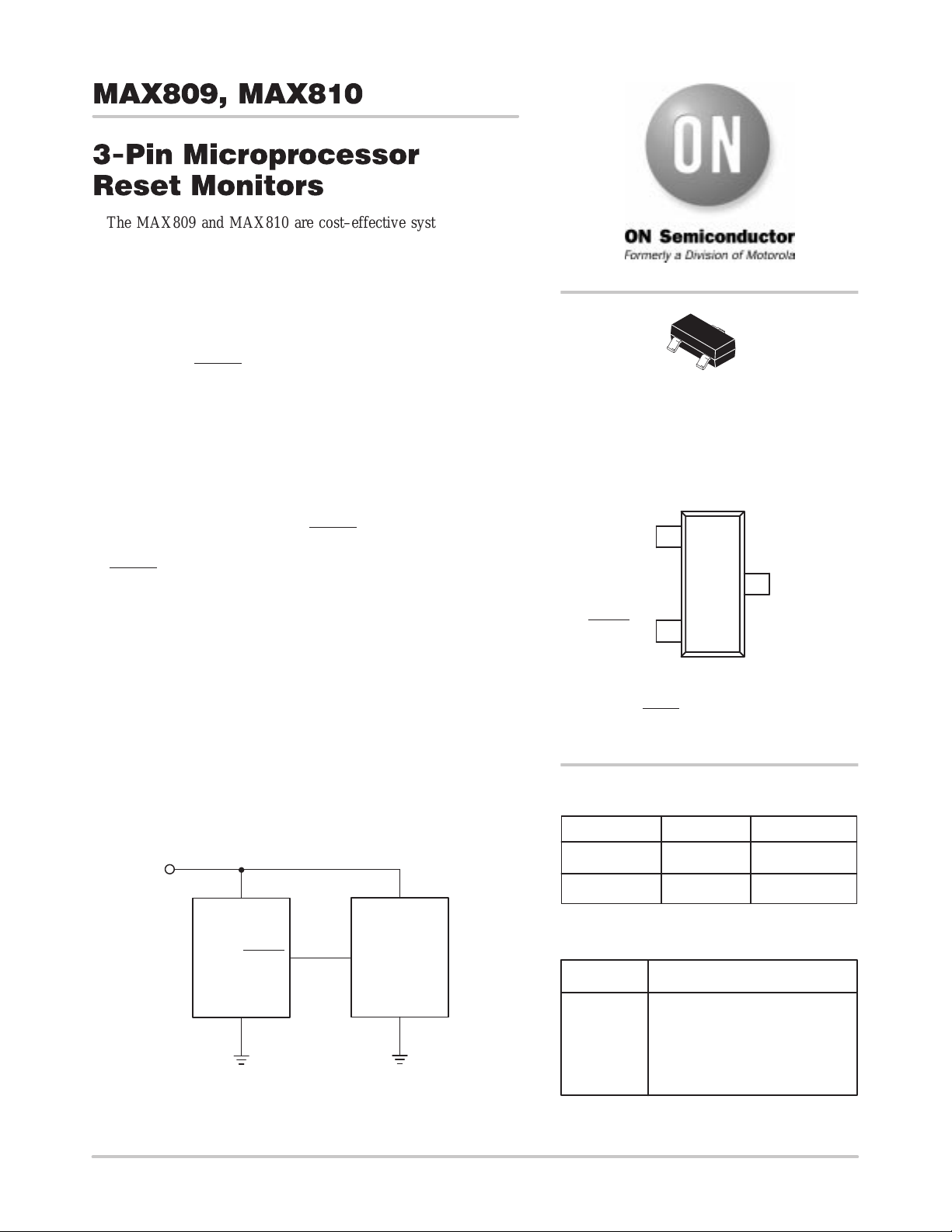

PIN CONFIGURATION

(Top View)

1

GND

V

3

CC

RESET

(RESET)**

NOTE: *SOT–23 is equivalent to JEDEC (TO–236)

2

SOT–23*

** RESET

** RESET is for MAX810

ORDERING INFORMATION

is for MAX809

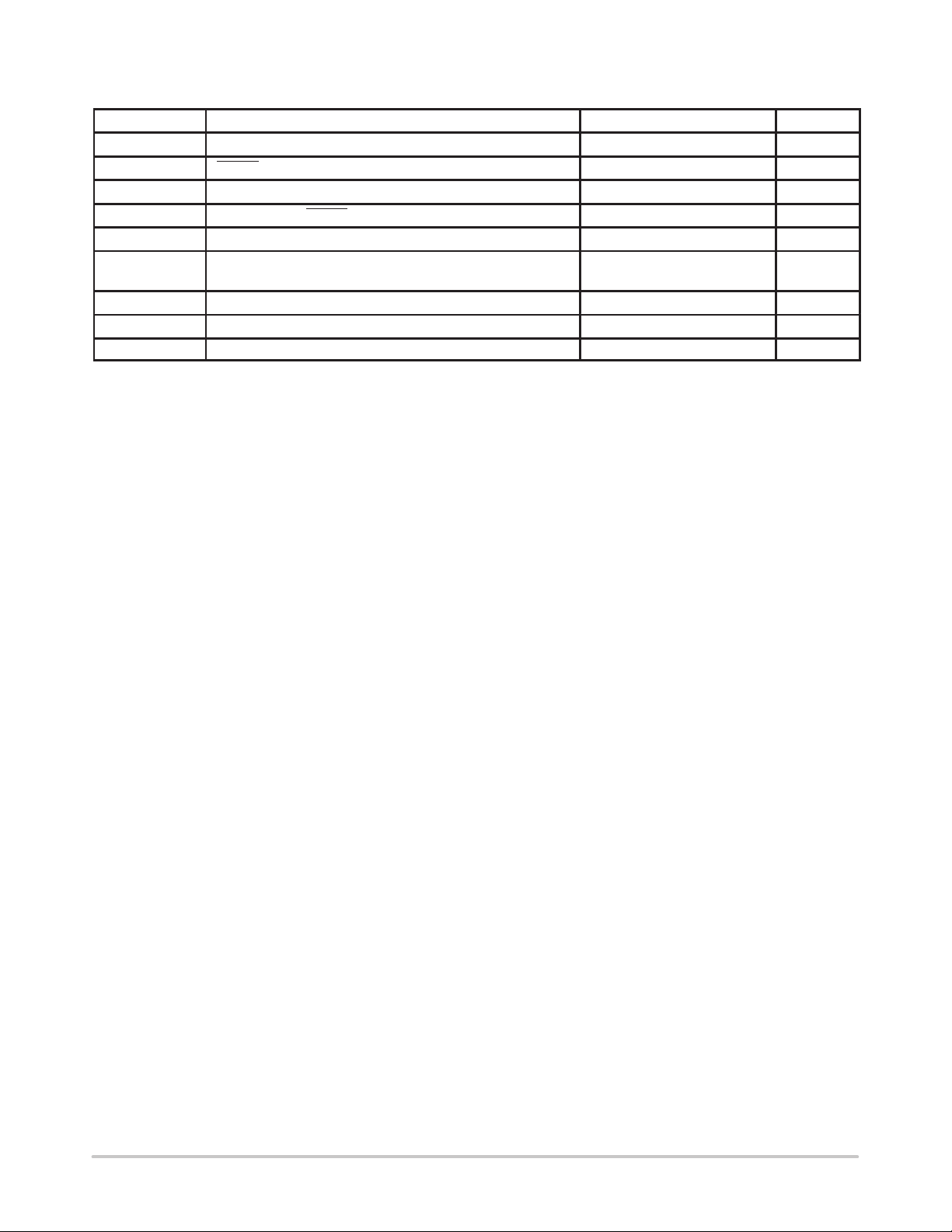

TYPICAL APPLICATION DIAGRAM

V

CC

V

CC

MAX809

RESET

GND GND

Semiconductor Components Industries, LLC, 1999

February , 2000 – Rev. 2

V

CC

PROCESSOR

RESET

INPUT

Device Package Shipping

MAX809xTR SOT–23 3000 Tape/Reel

MAX810xTR SOT–23 3000 Tape/Reel

NOTE: The ”x” denotes a suffix for VCC threshold –

see table below

Suffix Reset VCC Threshold (V)

L 4.63

M 4.38

J* 4.00

T 3.08

S 2.93

R 2.63

NOTE: *J version is available for MAX809 only

1 Publication Order Number:

MAX809/D

MAX809, MAX810

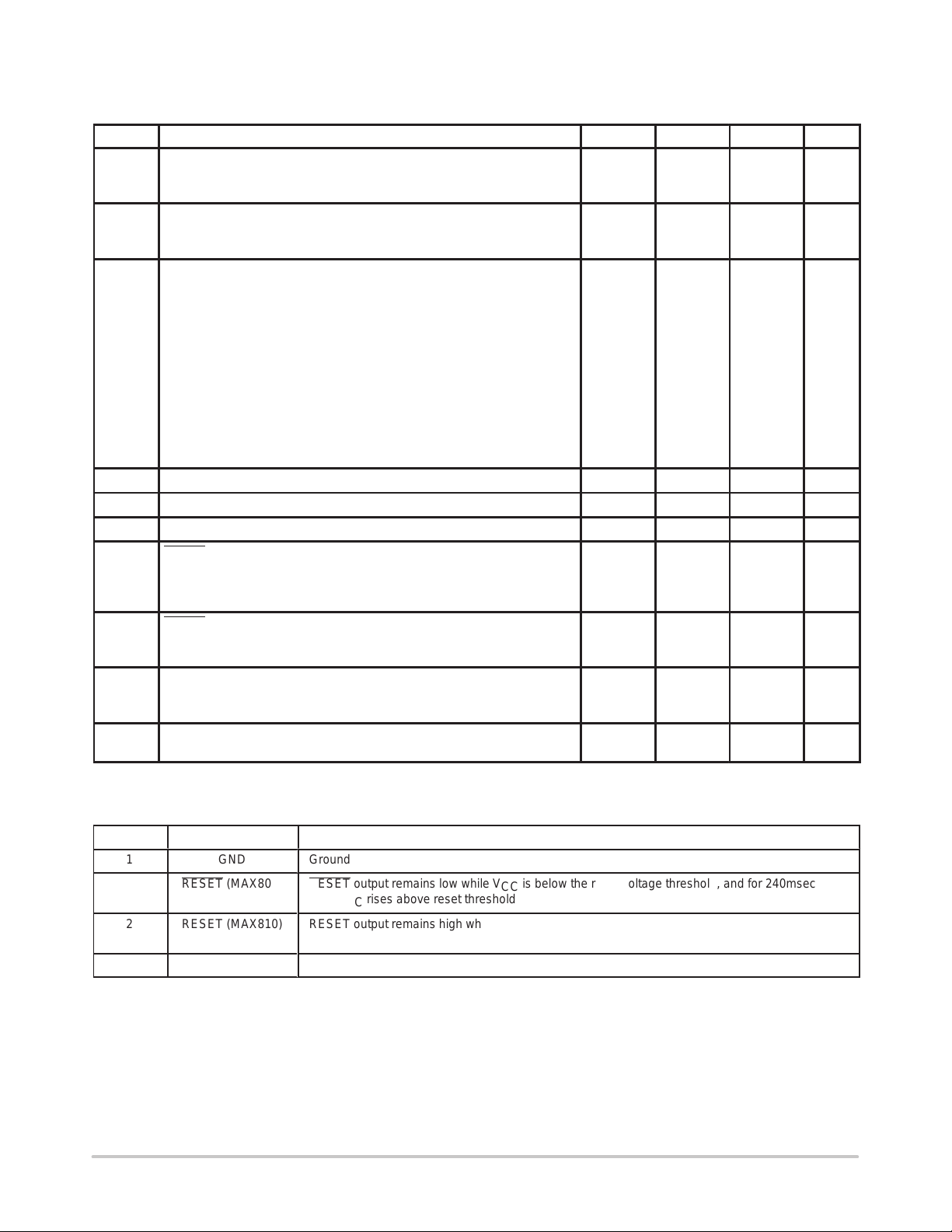

ABSOLUTE MAXIMUM RATINGS*

Symbol Parameter Value Unit

Supply Voltage (VCC to GND) 6.0 V

RESET, RESET –0.3 to (VCC + 0.3) V

Input Current, V

Output Current, RESET, RESET 20 mA

dV/dt (VCC) 100 V/µsec

P

D

T

A

T

stg

T

sol

* Maximum Ratings are those values beyond which damage to the device may occur.

Power Dissipation (TA ≤ 70°C)

SOT–23 (derate 4mW/°C above +70°C)

Operating Temperature Range –40 to +85 °C

Storage Temperature Range –65 to +150 °C

Lead Temperature (Soldering, 10 Seconds) +260 °C

CC

20 mA

230

mW

http://onsemi.com

2

MAX809, MAX810

ББББББ

Á

ББББББ

Á

Á

Á

ББББББ

ББББББ

ELECTRICAL CHARACTERISTICS (VCC = Full Range, TA = –40°C to +85°C unless otherwise noted. typical values are at T

= 1.2mA

= 3.2mA

= 500µA

= 800µA

= 1.2mA

= 3.2mA

(Note NO TAG)

1.0

1.2

—

—

4.56

4.50

4.31

4.25

3.93

3.89

3.04

3.00

2.89

2.85

2.59

2.55

—

—

—

0.8 V

CC

VCC – 1.5

—

—

0.8 V

CC

—

—

24

17

4.63

—

4.38

—

4.00

—

3.08

—

2.93

—

2.63

—

—

—

—

—

—

—

—

— —

5.5

5.5

µA

60

50

4.70

4.75

4.45

4.50

4.06

4.10

3.11

3.15

2.96

3.00

2.66

2.70

0.3

0.4

0.3

—

—

0.3

0.4

= +25C, VCC = 5V for L/M/J, 3.3V for T/S, 3.0V for R)

Symbol

VCC Range

TA = 0°C to +70°C

TA = –40°C to +85°C

I

CC

Supply Current

MAX8xxL/M/J: VCC < 5.5V

MAX8xxR/S/T: VCC < 3.6V

V

TH

Reset Threshold (Note NO TAG)

MAX8xxL: TA = 25°C

TA = –40°C to +85°C

MAX8xxM: TA = 25°C

TA = –40°C to +85°C

MAX809J: TA = 25°C

TA = –40°C to +85°C

MAX8xxT: TA = 25°C

TA = –40°C to +85°C

MAX8xxS: TA = 25°C

TA = –40°C to +85°C

MAX8xxR: TA = 25°C

TA = –40°C to +85°C

Reset Threshold Temperature Coefficient — 30 — ppm/°C

VCC to Reset Delay VCC = VTH to (VTH – 100mV) — 20 — µsec

Reset Active Timeout Period 140 240 560 msec

V

OL

RESET Output Voltage Low (MAX809)

MAX809R/S/T: VCC = VTH min, I

MAX809L/M/J: VCC = VTH min, I

VCC > 1.0V, I

V

OH

RESET Output Voltage High (MAX809)

MAX809R/S/T: VCC > VTH max, I

SINK

= 50µA

MAX809L/M/J: VCC > VTH max, I

V

OL

RESET Output Voltage Low (MAX810)

MAX810R/S/T: VCC = VTH max, I

MAX810L/M/J: VCC = VTH max, I

V

OH

RESET Output Voltage High (MAX810)

1.8 < VCC < VTH min, I

1. Production testing done at TA = 25°C, over temperature limits guaranteed by design.

Characteristic Min Typ Max Unit

SINK

SINK

SOURCE

SOURCE

SINK

SINK

SOURCE

= 150µA

A

V

V

V

V

V

V

PIN DESCRIPTION

Pin No. Symbol Description

1

2

ÁÁÁ

2

3

GND

RESET (MAX809)

ÁÁÁÁ

RESET (MAX810)

V

CC

Ground

RESET output remains low while VCC is below the reset voltage threshold, and for 240msec (typ.)

after VCC rises above reset threshold

ББББББББББББББББББББББ

RESET output remains high while VCC is below the reset voltage threshold, and for 240msec (typ.)

after VCC rises above reset threshold

Supply Voltage (typ.)

http://onsemi.com

3

MAX809, MAX810

APPLICATIONS INFORMATION

VCC Transient Rejection

The MAX809/810 provides accurate V

monitoring and

CC

reset timing during power–up, power–down, and

brownout/sag conditions, and rejects negative–going

transients (glitches) on the power supply line. Figure 1

shows the maximum transient duration vs. maximum

negative excursion (overdrive) for glitch rejection. Any

combination of duration and overdrive which lies under the

curve will not generate a reset signal. Combinations above

the curve are detected as a brownout or power–down.

Transient immunity can be improved by adding a capacitor

in close proximity to the V

V

CC

400

TA = +25° C

m

320

240

160

90

MAX8xxR/S/T

0

1 10 100 1000

MAXIMUM TRANSIENT DURATION ( sec)

RESET COMPARATOR OVERDRIVE,

Figure 1. Maximum Transient Duration vs. Overdrive

for Glitch Rejection at 25° C

RESET Signal Integrity During Power–Down

pin of the MAX809/810.

CC

V

TH

Overdrive

Duration

MAX8xxL/M/J

(VTH – VCC (mV)

The MAX809 RESET output is valid to VCC = 1.0V.

Below this voltage the output becomes an ”open circuit” and

does not sink current. This means CMOS logic inputs to the

µP will be floating at an undetermined voltage. Most digital

systems are completely shutdown well above this voltage.

However, in situations where RESET

must be maintained

valid to VCC = 0V, a pull–down resistor must be connected

from RESET

to ground to discharge stray capacitances and

hold the output low (Figure 2). This resistor value, though

not critical, should be chosen such that it does not

appreciably load RESET

under normal operation (100k

W

will be suitable for most applications). Similarly, a pull–up

resistor to V

is required for the MAX810 to ensure a valid

CC

high RESET for VCC below 1.0V.

V

CC

V

CC

MAX809

RESET

GND

R1

100 k

Figure 2. Ensuring RESET Valid to VCC = 0 V

Processors With Bidirectional I/O Pins

Some µP’s (such as Motorola 68HC11) have

bi–directional reset pins. Depending on the current drive

capability of the processor pin, an indeterminate logic level

may result if there is a logic conflict. This can be avoided

by adding a 4.7kW resistor in series with the output of the

MAX809/810 (Figure 3). If there are other components in

the system which require a reset signal, they should be

buffered so as not to load the reset line. If the other

components are required to follow the reset I/O of the µP , the

buffer should be connected as shown with the solid line.

BUFFER

V

CC

V

CC

MAX809

RESET

GND GND

47 k

RESET

Figure 3. Interfacing to Bidirectional Reset I/O

BUFFERED RESET

TO OTHER SYSTEM

COMPONENTS

V

CC

m

P

http://onsemi.com

4

MAX809, MAX810

35

30

P

–UP

S

U

)

TYPICAL CHARACTERISTICS

30

m

25

20

15

10

SUPPLY CURRENT ( A)

5

0

–40 –20 0 20 40 60 85

TEMPERATURE (C°)

Figure 4. Supply Current vs Temperature

(No Load, MAX8xxR/S/T)

100

m

80

60

40

20

POWER–DOWN RESET DELAY ( sec)

0

–40 –20 0 20 40 60 85

VOD = 200 mV

TEMPERATURE (C°)

VOD = VTH – V

Figure 6. Power–Down Reset Delay vs

T emperature and Overdrive (MAX8xxR/S/T)

VCC = 5 V

VCC = 3 V

VCC = 1 V

VOD = 10 mV

VOD = 10 mV

VOD = 100 mV

CC

25

m

20

15

10

SUPPLY CURRENT ( A)

5

0

–40 –20 0 20 40 60 85

TEMPERATURE (C°)

Figure 5. Supply Current vs Temperature

(No Load, MAX8xxL/M/J/)

140

120

m

100

80

60

40

20

POWER–DOWN RESET DELAY ( sec)

0

–40 –20 0 20 40 60 85

VOD = 200 mV

TEMPERATURE (C°)

Figure 7. Power–Down Reset Delay vs

T emperature and Overdrive (MAX8xxL/M/J)

VCC = 5 V

VCC = 3 V

VCC = 1 V

VOD = VTH – V

VOD = 10 mV

VOD = 20 mV

VOD = 100 mV

CC

250

245

T (msec

240

ET TIMEO

235

RE

230

OWER

225

–40 –20 0 20 40 60 85

TEMPERATURE (C°)

MAX8xxL/M/J

MAX8xxR/S/T

Figure 8. Power–Up Reset Timeout vs

T emperature

1.003

1.002

1.001

1.000

0.999

NORMALIZED THRESHOLD

0.998

0.997

http://onsemi.com

5

–40 –20 0 20 40 85

TEMPERATURE (C°)

60

Figure 9. Normalized Reset Threshold vs

T emperature

TAPING FORM

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

БББББББББББ

MAX809, MAX810

Component Taping Orientation for 3L SOT–23 (JEDEC–236) Devices

USER DIRECTION OF FEED

DEVICE

MARKING

PIN 1

Standard Reel Component Orientation

(Mark Right Side Up)

Tape & Reel Specifications Table

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

SOT–23

8 mm 4 mm 3000 7 inches

MARKING DIAGRAM

SOT–23

xxYW

YW = Date Code

MARKING

ON Semiconductor Part # Reset Threshold or Address Marking

MAX809L

MAX809M

MAX809T

MAX809S

MAX809R

MAX809J

MAX810L

MAX810M

MAX810T

MAX810S

MAX810R

YW = Date code

4.63

4.38

3.08

2.93

2.63

4.00

4.63

4.38

3.08

2.93

2.63

J1YW

J2YW

J3YW

J4YW

J5YW

J6YW

K1YW

K2YW

K3YW

K4YW

K5YW

http://onsemi.com

6

MAX809, MAX810

P ACKAGE DIMENSIONS

SOT–23

PLASTIC PACKAGE (TO–236)

CASE 318–08

ISSUE AF

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

A

L

3

1

2

S

B

GV

C

D

H

K

J

3. MAXIMUM LEAD THICKNESS INCLUDES LEAD

FINISH THICKNESS. MINIMUM LEAD THICKNESS

IS THE MINIMUM THICKNESS OF BASE

MATERIAL.

INCHES

DIMAMIN MAX MIN MAX

0.1102 0.1197 2.80 3.04

B 0.0472 0.0551 1.20 1.40

C 0.0350 0.0440 0.89 1.11

D 0.0150 0.0200 0.37 0.50

G 0.0701 0.0807 1.78 2.04

H 0.0005 0.0040 0.013 0.100

J 0.0034 0.0070 0.085 0.177

K 0.0140 0.0285 0.35 0.69

L 0.0350 0.0401 0.89 1.02

S 0.0830 0.1039 2.10 2.64

V 0.0177 0.0236 0.45 0.60

MILLIMETERS

http://onsemi.com

7

MAX809, MAX810

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse T ime)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

8

MAX809/D

Loading...

Loading...