Page 1

Field Service Manual

Basic and Field Level Test Procedures

iDEN

Digital Multi-Service,

Data-Capable Portable

Page 2

i580

Digital Multi-Service,

Data-Capable Portable

Field Service Manual

Basic and Field Level

Test Procedures

2006

68P80401P05 i

Page 3

Manual Revisions

Changes that occur after this manual is printed are described in the Field Manual Revisions (FMRs). The FMRs provide

the most current instructions and component information.

Copyright Information

The Motorola products described in this manual may include Motorola computer programs stored in semiconductor

memories or other media that are copyrighted with all rights reserved worldwide to Motorola. Laws in the United States

and other countries preserve for Motorola, Inc. certain exclusive rights to the copyrighted computer programs, including

the exclusive right to copy, reproduce, modify, decompile, disassemble, and reverse-engineer the Motorola computer

programs in any manner or form without Motorola’s prior written consent. Furthermore, the purchase of Motorola products shall not be deemed to grant either directly or by implication, estoppel, or otherwise, any license or rights under the

copyrights, patents, or patent applications of Motorola, except for a nonexclusive license to use the Motorola product

and the Motorola computer programs with the Motorola product.

Trademarks

MOTOROLA, the Stylized M Logo, Message Mail, VibraCall, and iDEN are registered trademarks of Motorola, Inc.

® Reg. U.S. Pat. & Tm. Off. All other product or service names are the property of their respective owners.

© Copyright 2006, Motorola, Inc. All rights reserved.

ii 68P80401P05

Page 4

SAFETY AND GENERAL INFORMATION

SAFETY AND GENERAL INFORMATION

IMPORTANT INFORMATION ON SAFE AND EFFICIENT OPERATION.

READ THIS INFORMATION BEFORE USING YOUR INTEGRATED

MULTI-SERVICE PORTABLE RADIO.

RF Operational Characteristics

Your radio product contains a radio frequency transmitter to

convey the information you wish to send as well as occasional

automatic signals used to sustain connection to the wireless

network, and a receiver which enables you to receive

communication and connection information from the network.

PORTABLE RADIO PRODUCT OPERATION

AND EME EXPOSURE

Your Motorola two-way radio complies with the following RF

energy exposure standards and guidelines:

• United States Federal Communications Commission, Code

of Federal Regulations; 47 CFR part 2 sub-part J

• American National Standards Institute (ANSI) / Institute of

Electrical and Electronics Engineers (IEEE). C95. 1-1992

• Institute of Electrical and Electronics Engineers (IEEE).

C95. 1-1999 Edition

• International Commission on Non-Ionizing Radiation

Protection (ICNIRP) 1998

• Ministry of Health (Canada). Safety Code 6. Limits of

Human Exposure to Radiofrequency Electromagnetic Fields

in the Frequency Range from 3 kHz to 300 GHz, 1999

• Australian Communications Authority

Radiocommunications (Electromagnetic Radiation - Human

Exposure) Standard 2001

• ANATEL, Brasil Regulatory Authority, Resolution 256

(April 11, 2001) “additional requirements for SMR, cellular

and PCS product certification.”

To assure optimal radio product performance and

make sure human exposure to radio frequency

electromagnetic energy is within the guidelines set forth in

the above standards, always adhere to the following

procedures:

Phone Operation

Two-way radio operation

When using your radio product as a

traditional two-way radio, hold the

radio product in a vertical position

with the microphone one to two

inches (2.5 to 5 cm) away from the

lips.

Body-worn operation

To maintain compliance with FCC RF exposure guidelines, if

you wear a radio product on your body when transmitting,

always place the radio product in a Motorola approved clip,

holder, holster, case or body harness for this product. Use of

non-Motorola-approved accessories may exceed FCC RF

exposure guidelines. If you do not use a Motorola approved

body-worn accessory and are not using the radio product in

the intended use positions along side the head in the phone

mode or in front of the face in the two-way radio mode, then

ensure the antenna and the radio product are kept the

following minimum distances from the body when

transmitting:

• Phone or Two-way radio mode: one inch (2.5 cm)

• Data operation using any data feature with or without

an accessory cable: one inch (2.5 cm)

Antenna Care

Use only the supplied or an approved replacement antenna.

Unauthorized antennas, modifications, or attachments could

damage the radio product and may violate FCC regulations.

DO NOT hold the antenna when the radio product is “IN

USE”. Holding the antenna affects call quality and may cause

the radio product to operate at a higher power level than needed.

Approved Accessories

For a list of approved Motorola accessories call 1-800-4530920, visit our website at www.mot.com/iden or look in the

accessory section of this manual.

When placing or receiving a phone call, hold your radio product

as you would a wireline telephone. Speak directly into the

microphone.

68P80401P05 iii

Page 5

SAFETY AND GENERAL INFORMATION

ALL MODELS WITH FCC ID AZ489FT5848 MEET THE

GOVERNMENT'S REQUIREMENTS FOR EXPOSURE TO

RADIO WAVES.

Your wireless phone is a radio transmitter and receiver. It is designed

and manufactured not to exceed the emission limits for exposure to

radiofrequency (RF) energy set by the Federal Communications

Commission of the U.S. Government. These limits are part of

comprehensive guidelines and establish permitted levels of RF energy

for the general population. The guidelines are based on standards that

were developed by independent scientific organizations through

periodic and thorough evaluation of scientific studies. The standards

include a substantial safety margin designed to assure the safety of all

persons, regardless of age and health.

The exposure standard for wireless mobile phones employs a unit of

measurement known as the Specific Absorption Rate, or SAR. The SAR

limit set by the FCC is 1.6 W/kg.* Tests for SAR are conducted using

standard operating positions specified by the FCC with the phone

transmitting at its highest certified power level in all tested frequency

bands. Although the SAR is determined at the highest certified power

level, the actual SAR level of the phone while operating can be well below

the maximum value. This is because the phone is designed to operate at

multiple power levels so as to use only the power required to reach the

network. In general, the closer you are to a wireless base station antenna,

the lower the power output.

Before a phone model is available for sale to the public, it must be tested

and certified to the FCC that is does not exceed the limit established by

the government-adopted requirement for safe exposure. The tests are

performed in positions and locations (e.g., at the ear and worn on the

body) as required by the FCC for each model. The highest SAR value

for this model phone when tested for use at the ear is 1.02 W/kg and

when tested on the body, as described in the user guide, is 1.30 W/kg

during packet data transmission. (Body-worn measurements differ

among phone models, depending upon available accessories and FCC

requirements.) While there may be differences between the SAR levels

or various phones and at various positions, they all meet the government

requirement for safe exposure.

The FCC has granted an Equipment Authorization for this model phone

with all reported SAR levels evaluated as in compliance with the FCC

RF exposure guidelines. SAR information on this model phone is on file

with the FCC and can be found under the Display Grant section of

http://www.fcc.gov/oet/fccid after searching on FCC ID

AZ489FT5848.

Additional information on Specific Absorption Rates (SAR) can be

found on the Cellular Telecommunications Industry Association (CTIA)

web-site at http://www.wow-com.com.

Facilities

To avoid electromagnetic interference and/or compatibility

conflicts, turn off your radio product in any facility where

posted notices instruct you to do so. Hospitals or health care

facilities may be using equipment that is sensitive to external RF

energy.

Aircraft

When instructed to do so, turn off your radio product when on

board an aircraft. Any use of a radio product must be in

accordance with applicable regulations per airline crew

instructions.

Medical Devices

Pacemakers

The Advanced Medical Technology Association (AdvaMed)

recommends that a minimum separation of 6 inches (15 cm) be

maintained between a handheld wireless radio product and a

pacemaker. These recommendations are consistent with those of

the U.S. Food and Drug Administration.

Persons with pacemakers should:

• ALWAYS keep the radio product more than 6 inches

(15 cm) from their pacemaker when the radio product is

turned ON.

• Not carry the radio product in a breast pocket.

• Use the ear opposite the pacemaker to minimize the

potential for interference.

• Turn the radio product OFF immediately if you have any

reason to suspect that interference is taking place.

Hearing Aids

Some digital wireless radio products may interfere with some

hearing aids. In the event of such interference, you may want to

consult your hearing aid manufacturer to discuss alternatives.

Other Medical Devices

If you use any other personal medical device, consult the

manufacturer of your device to determine if it is adequately

* In the United States and Canada, the SAR limit for mobile phones used by

the public is 1.6 watts/kg (W/kg) averaged over one gram of tissue. The

standard incorporates a substantial margin of safety to give additional

protection for the public and to account for any variations in measurements.

shielded from RF energy. Your physician may be able to assist

you in obtaining this information.

Use While Driving

Check the laws and regulations on the use of radio products in

Electro Magnetic Interference/

Compatibility

NOTE: Nearly every electronic device is susceptible

to electromagnetic interference (EMI) if

inadequately shielded, designed or

otherwise configured for electromagnetic

compatibility.

the area where you drive. Always obey them. When using the

radio product while driving, please:

• Give full attention to driving and to the road.

• Use hands-free operation, if available.

• Pull off the road and park before making or answering a call

if driving conditions so require.

iv 68P80401P05

Page 6

Operational Warnings

P

SAFETY AND GENERAL INFORMATION

Operational Cautions

F

For Vehicles Equipped with an Air Bag

Do not place a portable radio product in the area over the air bag

or in the air bag deployment area. Air bags inflate with great

force. If a portable radio is placed in the air bag deployment area

and the air bag inflates, the radio product may be propelled with

great force and cause serious injury to occupants of the vehicle.

Potentially Explosive Atmospheres

Turn off your radio product prior to entering any area with a

potentially explosive atmosphere, unless it is a radio product type

especially qualified for use in such areas as “Intrinsically Safe”

(for example, Factory Mutual, CSA, or US approved). Do not

remove, install, or charge batteries in such areas. Sparks in a

potentially explosive atmosphere can cause an explosion or fire

resulting in bodily injury or even death.

NOTE: The areas with potentially explosive atmospheres

referred to above include fueling areas such as

below decks on boats; fuel or chemical transfer or

storage facilities; areas where the air contains

chemicals or particles, such as grain, dust or

metal powders; and any other area where you

would normally be advised to turn off your vehicle

engine. Areas with potentially explosive

atmospheres are often, but not always, posted.

Blasting Caps and Areas

To avoid possible interference with blasting operations, turn off

your radio product when you are near electrical blasting caps, in a

blasting area, or in areas posted: “Turn off two-way radio”. Obey

all signs and instructions.

Antennas

Do not use any portable radio product that has a damaged

antenna. If a damaged antenna comes into contact with your skin,

a minor burn can result.

Batteries

All batteries can cause property damage and/or bodily injury, such

as burns if a conductive material, such as jewelry, keys, or beaded

chains touches exposed terminals. The conductive material may

complete an electrical circuit (short circuit) and become quite hot.

Exercise care in handling any charged battery, particularly when

placing it inside a pocket, purse, or other container with metal

objects.

If the radio product does not work after following the steps

listed above, contact your dealer for servicing information.

Clean the external surfaces of the radio product with a damp

cloth, using a mild solution of dishwashing detergent and water.

Some household cleaners may contain chemicals that could

seriously damage the radio product. Avoid the use of any

petroleum-based solvent cleaners. Also, avoid applying liquids

directly on the radio product.

Accessory Safety Information

IMPORTANT: SAVE THESE ACCESSORY SAFETY

INSTRUCTIONS

Cleaning and Drying Considerations

Using a leather carry case may help protect the surfaces and help

prevent liquids (e.g., rain) from entering into the interior of the

radio product. This product is not water proof, and exposing the

unit to liquids may result in permanent damage to the unit.

If your radio product interior gets wet, then do not try to

accelerate drying with the use of an oven or a dryer as this will

damage the radio product and void the warranty. Instead, do the

following:

1. Immediately power off the radio product.

2. Remove Battery and SIM card (if so equipped) from radio

product.

3. Shake excess liquid from radio product.

4. Place the radio product and battery in an area that is at room

temperature and has good air flow.

5. Let the radio product, battery, and SIM card dry for 72 hours

before reconnecting the battery and/or powering on the radio

product.

• Before using any battery or battery charger, read all the

instructions for and cautionary markings on (1) the battery,

(2) the battery charger, which may include a separate wallmounted power supply or transformer, and (3) the radio

product using the battery.

• Do not expose any battery charger to water, rain, or snow as

they are designed for indoor or in-vehicle use only.

WARNING: To reduce the risk of

injury, charge only the rechargeable

P

batteries listed in the Accessories

section of this manual. Other types

of batteries may burst, causing

personal injury and damage.

• To reduce the risk of damage to the cord or plug, pull by the

plug rather than the cord when you disconnect the battery

charger from the power source outlet.

• Do not operate any battery charger with a damaged cord or

plug — replace them immediately.

• Battery chargers may become warm during operation, but

not hot. If it becomes hot to the touch, unplug it from the

power outlet immediately and discontinue its use.

68P80401P05 v

Page 7

SAFETY AND GENERAL INFORMATION

• Use of a non-recommended attachment to a battery charger

may result in a risk of fire, electric shock, or injury to

persons.

• Make sure the battery charger power cord is located so that

it will not be stepped on, tripped over, or subjected to

damage or stress.

• An extension cord should not be used with any battery

charger unless absolutely necessary. Use of an improper

extension cord could result in a risk of fire and electric

shock. If an extension cord must be used, make sure that:

• The pins on the plug of the extension cord are the same

number, size, and shape as those on the plug of the

charger.

• The extension cord is properly wired and in good

electrical condition.

• The cord size is 18AWG for lengths up to 100 feet and

16AWG for lengths up to 150 feet.

• Do not operate any battery charger if it has received a sharp

blow, has been dropped, or has been damaged in any way;

take it to a qualified service technician.

• Do not disassemble a battery charger; take it to a qualified

service technician when service or repair is required.

Incorrect reassembly may result in a risk of electric shock or

fire.

• Maximum ambient temperature around the power supply or

transformer of any battery charger should not exceed 40°C

(104°F).

• The output power from the power supply or transformer

must not exceed the rating given on the Desktop DualPocket Charger.

• The disconnection from the line voltage is made by

unplugging the power supply from the AC receptacle.

• To reduce risk of electric shock, unplug any battery charger

from the outlet before attempting any maintenance or

cleaning.

For optimum charging performance, turn off the radio product

while charging it in any battery charger.

vi 68P80401P05

Page 8

MODEL INFORMATION

This manual applies to the following iDEN i580 Digital Portable models:

H83XAH6RR4AN 806-940 MHz, Multi-Service, Data-Capable Portable

MODEL NUMBERING SYSTEM

Typical Model Number: H 8 3 X A H 6 R R 4 A N

Position: 123456789101112

Position 1 - Type of Unit

H = Hand-Held Portable

M = Mobile Product

MODEL INFORMATION

Positions 2 and 3 - Model Series Position 12 - Unique

40 = i85s/i55sr/i50sx Products

41 = i90c Products

45 = i265 Products

48 = i80s Products

56 = i30sx/i30s Products

57 = i95cl Products

58 = i88s/i58sr Products

59 = i60c Products

62 = i205/i305 Products

63 = i530/i730/i710 Products

68 = i325pro Products

69 = i315plus Products

73 = i860 Products

74 = i830 Products

75 = i285 Products

72 = i930 Products

85 = i870 Products

83 = i580 Products

Position 4 - Frequency Band Position 11 - Version

U = 806 to 870 MHz Version Letter (Alpha) X = 806 to 941 MHz Major Change

*Values given represent range only; they are not absolute.

Position 5 - Power Level Position 10 - Feature level

A = 0 to 0.7 Watts 1 = Basic 6 = Standard Plus

B = 0.7 to 0.9 Watts 2 = Limited Pkg 7 = Expanded Pkg

C = 1.0 to 3.9 Watts 3 = Limited Plus 8 = Expanded Plus

D = 4.0 to 5.0 Watts 4 = Intermediate 9 = Full Feature/

E = 5.1 to 6.0 Watts 5 = Standard Pkg Programmable

F = 6.1 to 10.0 Watts

Position 6 - Physical Packages Position 9 - Primary System Type

F = Limited Keypad - With Display R = iDEN Shared

H = Full Keypad - With Display

N = Enhanced Controls - Enhanced Display

Model Variations

N = Standard Package

Position 7 - Channel Spacing Position 8 - Primary Operation

1 = 5 kHz 5 = 15 kHz N = Digital Dispatch

2 = 6.25 kHz 6 = 25 kHz Q = Low Profile - Basic Display

3 = 10 kHz 7 = 30 kHz R = Digital Multi-Service

4 = 12.5 kHz 9 = Variable Programmable J = TDMA Digital Dual Mode

68P80401P05 vii

Page 9

MODEL SPECIFICATIONS

MODEL SPECIFICATIONS

GENERAL RECEIVER TRANSMITTER

FCC Designation: AZ489FT5848 Receiver Type: Direct Conversion Transmitter Type Single Conversion

Operational Modes:

800 MHz Band only:

Temperature Range:

Operating –10°C to +60°C

Storage (w/o battery) –40°C to +85°C

Power Supply:

Battery Type Lithium Ion

Recommended

Battery: SNN5744B

Battery Voltage:

Nominal

Range

Dimensions (HxWxD):

w/750mAh 94 x 57

battery door x 34 mm

w/500mAh 94 x 57

battery door x 31 mm

Phone

Private

Group

Circuit Data

Packet Data

MotoTalk

SNN5769A

3.6 Vdc

3.0 to 4.2 Vdc

Frequency Range: 851-870 MHz

935-940 MHz

902-928 MHz

Channel Spacing:

iDEN

MotoTalk

Frequency Stability:

Referenced to base

station 0.4 ppm

Sensitivity (10%) BER:

(M-16 QAM)

MotoTalk (3%)BER

(FSK)

Spurious Response

Immunity: -51 dBm

Spurious Radiation:

Above 960 MHz

216–960 MHz

88–216 MHz

30–88 MHz

25 kHz

50 kHz

–111 dBm

–119 dBm

<500 µV/m.

<200 µV/m.

<150 µV/m.

<100 µV/m.

Frequency Range: 806-825 MHz

896-901 MHz

902-928 MHz

Emission Designator: 18K3D7W

Modulation Types: Quad 16QAM

Quad 64QAM

Quad QPSK

FSK

Frequency Stability:

Referenced to base

station 0.4 ppm

Spurious Emissions:

Conducted

Radiated

MotoTalk Radiated

RF Pulse Avg Power:

iDEN (dynamically

adjusted)

MotoTalk

22.6 to +28.82 dBm

–13 dBm

–13 dBm

–41.2 dBm

–6 to +28 dBm

Weight:

(without battery)

viii 68P80401P05

112.5 g

Audio Output Power

and Speakerphone

Rating:

(Private and Group

Modes only) into

8 ohms at maximum

volume (nominal

battery voltage) 500 mW

Distortion at Rated

Audio:

Electrical

Acoustical

Specifications subject to change without notice.

5% Max.

10% Max.

Adjacent Channel

Power:

iDEN (at ±25 kHz in

18 kHz BW)

MotoTalk

(at ±50 kHz in 26 kHz

BW)

-55 dB

-55 dB

Page 10

Contents

SAFETY AND GENERAL INFORMATION ....................................... iii

MODEL INFORMATION...................................................................... vii

MODEL SPECIFICATIONS ................................................................ viii

PREFACE................................................................................................... v

Who Should Use This Manual ................................................................................ v

How This Manual Is Organized............................................................................... v

Conventions Used in This Manual ......................................................................... vi

Related Publications .............................................................................................. vi

CHAPTER 1 OVERVIEW............................................................................................... 1

i DEN Digital Modulation Technology...................................................................... 1

i DEN Voice Compression Technology ................................................................... 3

RF Transmission Bursts ........................................................................................................... 3

Calling Area Coverage.............................................................................................................. 4

Global Positioning System (GPS) Section.............................................................. 5

MOTOtalk ............................................................................................................... 5

Bluetooth® Wireless System .................................................................................. 5

SIM Cards............................................................................................................... 6

Removing and Inserting a SIM Card......................................................................................... 6

CHAPTER 2 FEATURES, ICONS, AND INDICATORS............................................ 8

i 580 Features ..................... ................................................. ................................... 8

Display Icons .......................................................................................................... 9

Main Menu Icons ...................................................................................................................... 9

Status Icons ............................................................................................................................ 10

CHAPTER 3 DISPLAYS, MESSAGES, AND ALERTS............................................ 11

Power-Up Sequence............................................................................................. 11

Power-Down Sequence ........................................................................................ 12

Messages ............................................................................................................. 12

Self-Test Errors....................................................................................................................... 12

Self-Test Reset Errors ............................................................................................................ 12

Service Messages .................................................................................................................. 13

Alert Tones ........................................................................................................... 14

Using the Optional Vibrate Function ..................................................................... 17

PREPARING FOR BASIC LEVEL TESTING.................................... 19

Test Equipment..................................................................................................... 19

Reference Unit........................................................................................................................ 19

Reference Accessories ........................................................................................................... 19

CHAPTER 5 BASIC LEVEL CHECKS AND SELF TESTS..................................... 20

Customer Care ..................................................................................................... 20

Test Conditions..................................................................................................... 20

Antenna Condition .................................................................................................................. 20

Reset Condition ...................................................................................................................... 20

Basic-Level Test Checklist.................................................................................... 21

68P80401P05 i

Page 11

Preventive Maintenance ...................................................................................... 21

Mechanical and Electrical Checks ....................................................................... 22

SIM Card Swap Test............................................................................................................... 22

Accessory Swap Test ............................................................................................................. 23

Lockup Test ............................................................................................................................ 23

Battery Connections Test ....................................................................................................... 24

Testing the GPS Receiver ...................................................................................................... 24

Voltage Recognition Test........................................................................................................ 25

Self-Test Procedures ........................................................................................... 25

Passcode Test ........................................................................................................................ 26

Programming Menu Settings Check ....................................................................................... 26

Call Performance Test ............................................................................................................ 31

CHAPTER 6 BASIC LEVEL TEST MODES AND PROCEDURES........................ 33

Test Modes .......................................................................................................... 33

Entering Debug Mode ............................................................................................................. 33

Trace Mode Display Screens.................................................................................................. 34

Entering Test Mode ................................................................................................................ 36

Test Mode Test Procedures................................................................................. 36

Audio Loopback Test .............................................................................................................. 36

ESN and IMEI Matching Test ................................................................................................. 37

Debug Check .......................................................................................................................... 37

Technician Test Procedures ................................................................................ 40

Programming the i580 Unit .................................................................................. 41

Connecting the Unit to the RSS Workstation ....................................................... 41

Codeplug Help ........................................................................................................................ 42

Codeplug Troubleshooting...................................................................................................... 42

CHAPTER 7 PREPARING FOR FIELD LEVEL TESTING.................................... 43

Preparing Equipment for Testing ......................................................................... 43

Calibrating Equipment ............................................................................................................ 43

Checking the RF Cable........................................................................................................... 43

Strong-Signal Environments................................................................................................... 43

Protecting Static-Sensitive Devices ........................................................................................ 43

Using RSS ........................................................................................................... 44

Connecting an i DEN Unit to the R-2660.............................................................. 44

Operating the R-2660 .......................................................................................... 46

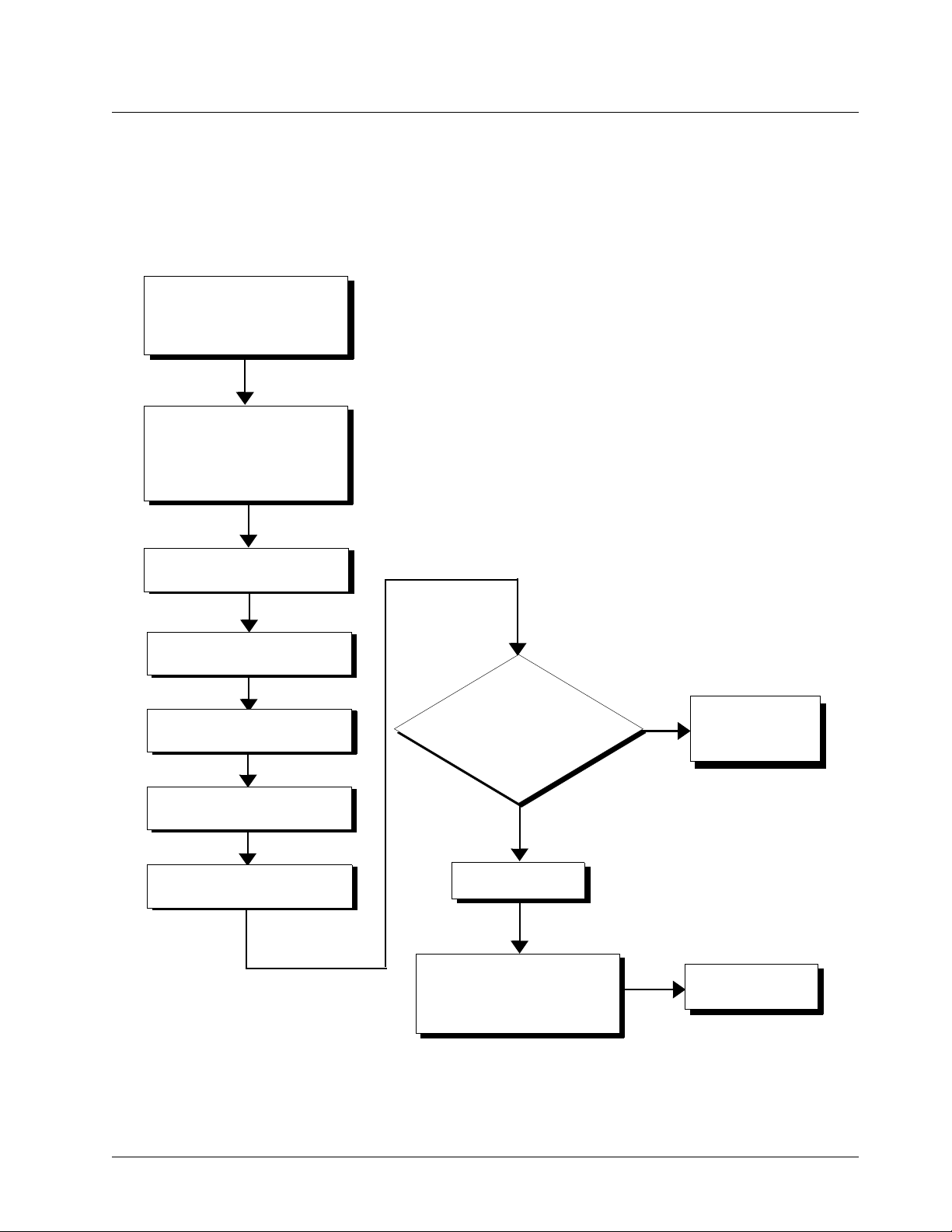

Disassembling and Reassembling the Unit ......................................................... 47

Disassembly Sequence Flowchart ....................................................................... 47

Assembly/Disassembly Procedures..................................................................... 47

Remove Battery Cover......................................................................................... 48

Remove: ................................................................................................................................. 48

Install: ..................................................................................................................................... 48

Remove Battery ................................................................................................... 49

Remove: ................................................................................................................................. 49

Remove SIM Card ............................................................................................... 50

Remove: ................................................................................................................................. 50

Remove Antenna ................................................................................................. 50

Remove Back Housing ........................................................................................ 52

Remove: ................................................................................................................................. 52

Install: ..................................................................................................................................... 52

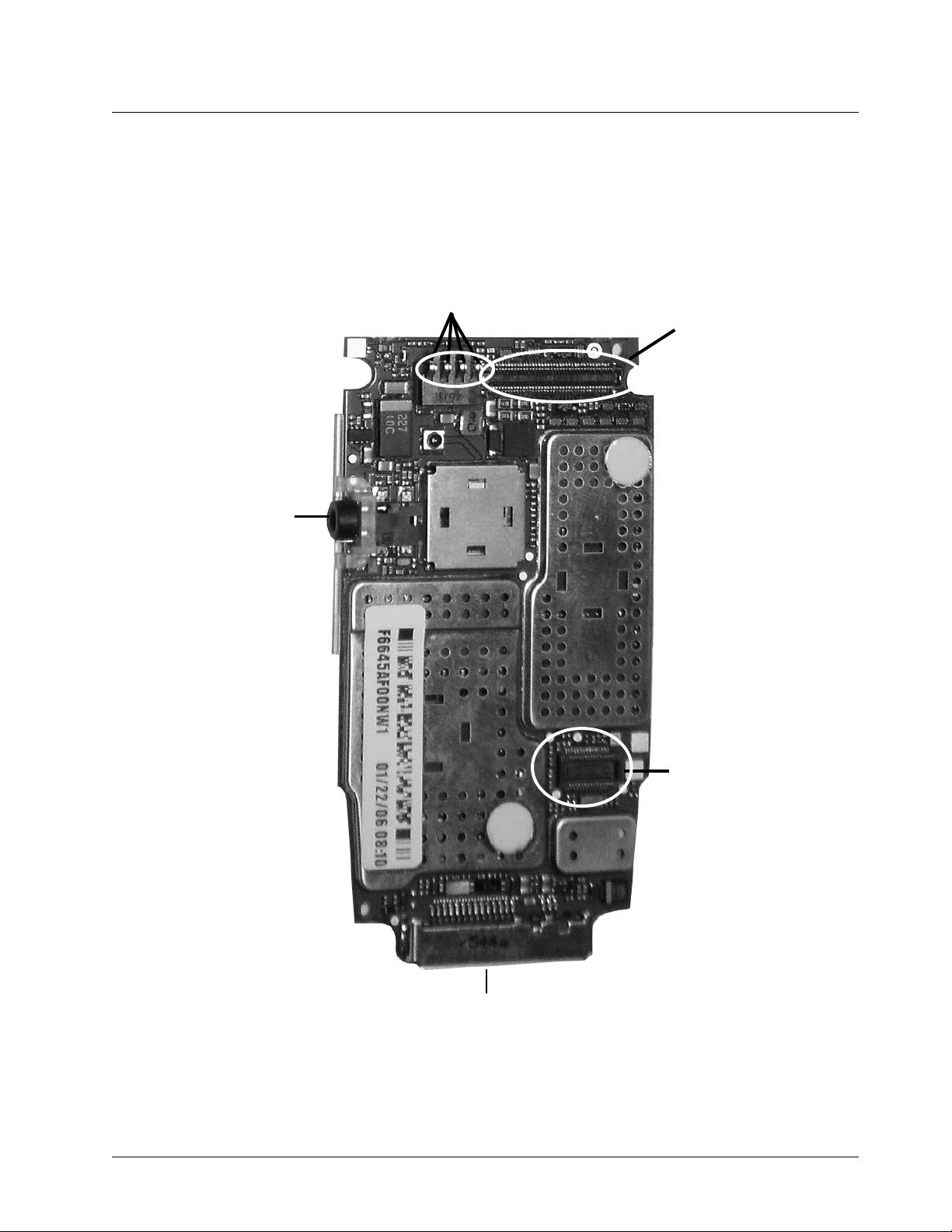

Remove Main Board, Keypad .............................................................................. 53

Remove: ................................................................................................................................. 53

ii 68P80401P05

Page 12

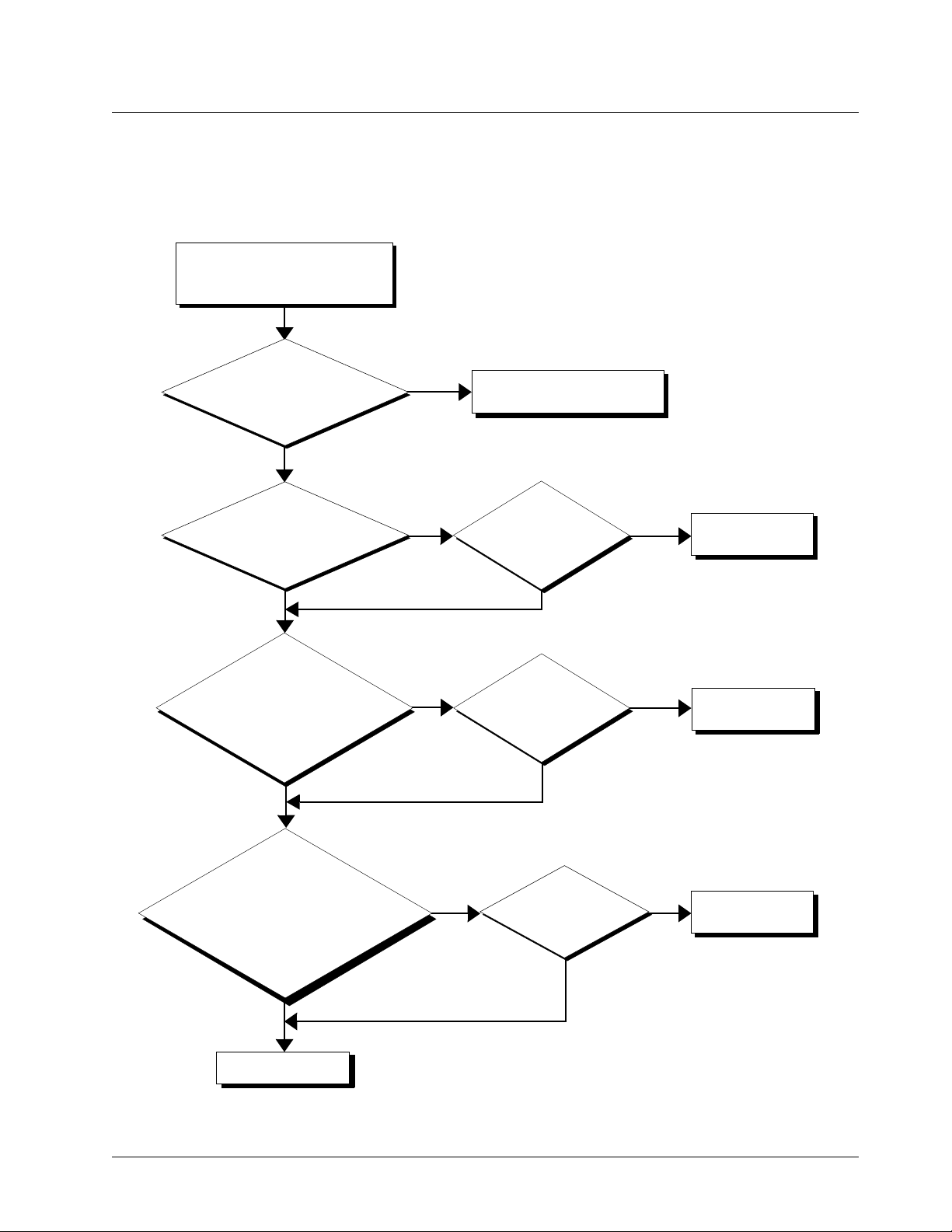

Remove Flip Assembly ......................................................................................... 54

Procedure to remove flip assembly: ....................................................................................... 54

Install Flip Assembly ............................................................................................. 56

Procedure to install flip assembly: .......................................................................................... 56

Exploded View and Parts List ............................................................................... 58

i580 Component Parts List ..................................................................................................... 58

i580 Exploded View ................................................................................................................ 59

CHAPTER 8 FIELD LEVEL TEST MODES AND PROCEDURES........................ 60

Test Modes ........................................................................................................... 60

Entering Test Mode ................................................................................................................ 60

Required Test Equipment ..................................................................................... 61

Field-Level Test Checklist..................................................................................... 61

Registration/Call Test ........................................................................................... 63

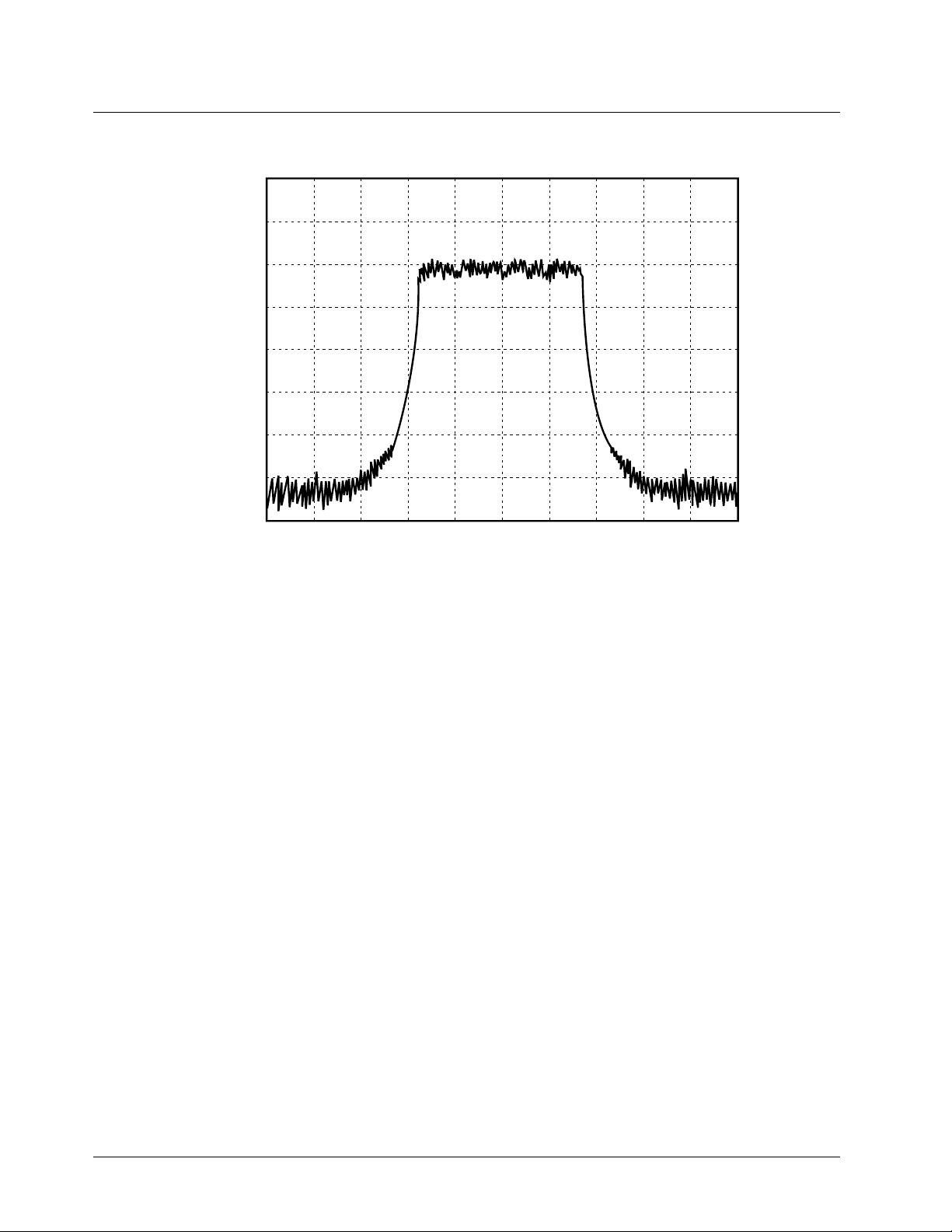

Signal Quality Error (SQE) Test............................................................................ 64

TX Power Test ...................................................................................................... 65

Bit Error Rate (BER) Test ..................................................................................... 66

Power-Up Test...................................................................................................... 67

Keypad Test.......................................................................................................... 68

Audio Test............................................................................................................. 69

Reset Test ............................................................................................................ 70

Reset Log Test ..................................................................................................... 71

Model Assembly (MA) Test Mode Test................................................................. 72

GPS (Global Positioning System) Receiver Test.................................................. 73

MOTOtalk ............................................................................................................. 74

Bluetooth Test....................................................................................................... 75

CHAPTER 9 MECHANICAL PARTS REWORK AND REPAIR ........................... 77

Recommended Equipment ................................................................................... 77

Hot Air Machine ...................................................................................................................... 77

Preheater................................................................................................................................ 77

High Performance Soldering Station ...................................................................................... 77

Microscope ............................................................................................................................. 77

Magnifier Lamp ....................................................................................................................... 77

Fume Absorber ....................................................................................................................... 77

Recommended Tools............................................................................................ 78

Nozzles ................................................................................................................................... 78

Heat Shields ........................................................................................................................... 78

Tweezers ................................................................................................................................ 78

Probe/Pick .............................................................................................................................. 78

Vacuum Pick........................................................................................................................... 78

Recommended Supplies....................................................................................... 78

Rework/Repair Requirements:.............................................................................. 78

Temperatures: ........................................................................................................................ 78

Board Preparation:.................................................................................................................. 79

Components Identification ...................................................................................................... 79

Mechanical Parts Rework Procedure ................................................................... 80

Removal Procedure................................................................................................................ 80

Land Preparation Procedure................................................................................................... 80

Installation Procedure ............................................................................................................. 80

J600 RF Connector................................................................................................................. 81

J752 Audio Jack ..................................................................................................................... 81

68P80401P05 iii

Page 13

J401 (30 Pin Board-to-Flex Connector) .................................................................................. 81

J400 (80 Pin Board-to Flex Connector) .................................................................................. 82

M002 (SIMM Connector) ....................................................................................................... 82

M105 (Battery Contact ............................................................................................................ 82

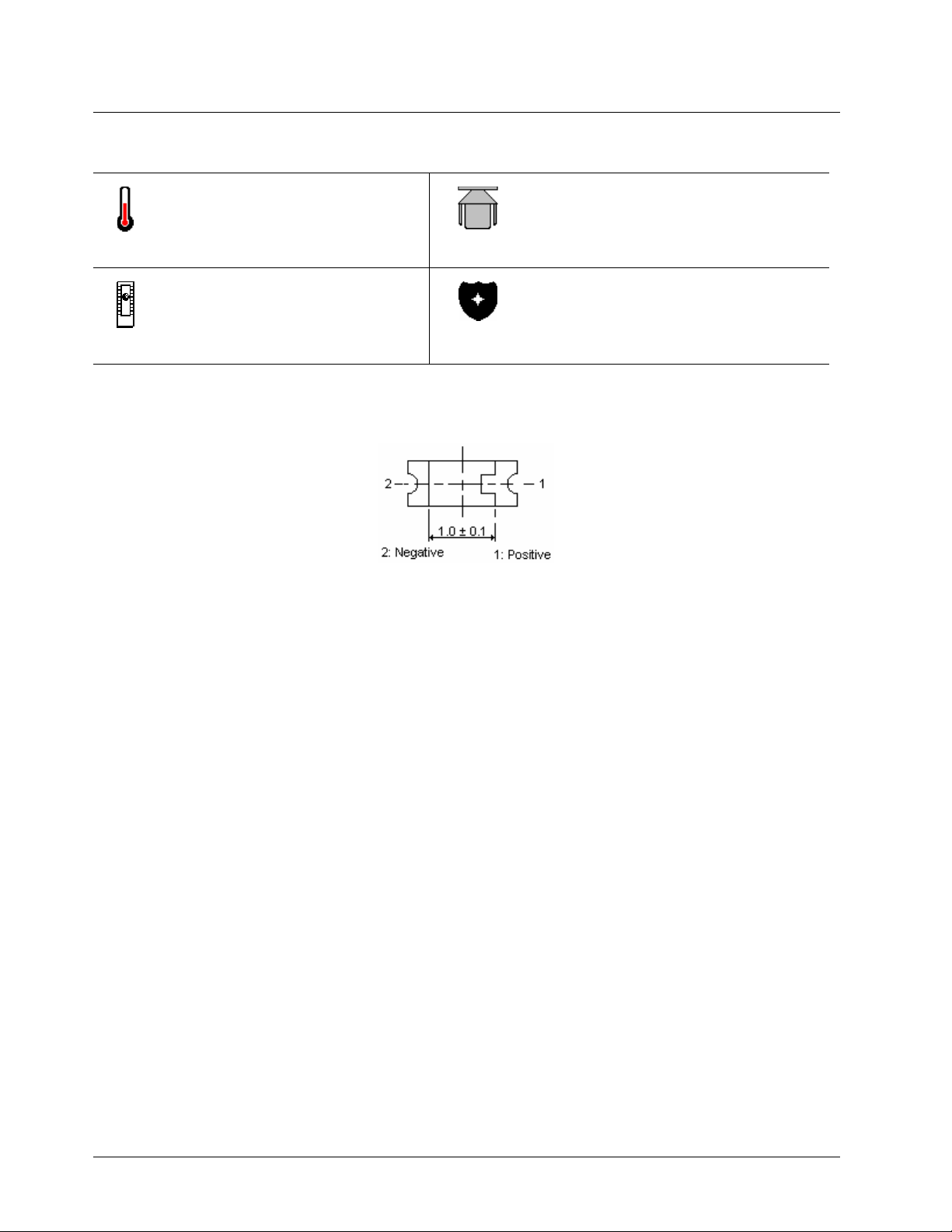

M2 (2 Pin-Contact).................................................................................................................. 83

J753 (Microphone Socket)...................................................................................................... 83

SW-all (Key/Switch) ................................................................................................................ 83

D401 through D412 (LED) ...................................................................................................... 84

APPENDIX A ORDERING REPLACEMENT PARTS AND KITS........................... 85

Customer Service ................................................................................................ 85

Replacement Parts .............................................................................................. 85

Domestic Orders .................................................................................................. 85

International Orders ............................................................................................. 85

Replacement Kits................................................................................................. 86

Recommended Test Equipment and Tools.......................................................... 90

Recommended Programming Equipment............................................................ 90

iv 68P80401P05

Page 14

PREFACE

The iDEN i580 Digital Multi-Service, Data-Capable Portable Field Service Manual contains the

information necessary to identify and fix problems in the Motorola i580 Digital Portable. This unit

is based on digital technology and is designed to operate on iDEN systems.

Basic and field-level service for the this unit as described in this manual includes troubleshooting,

testing, board swapping, and maintenance.

Service for this unit is based on the substitution method: a faulty part is replaced by a working one,

providing quicker service to the customer. For example, if the battery is faulty, it is replaced. If the

unit requires more complete testing or service than is available at the basic level, it is sent to the

field-level service facility, serviced, and returned to the iDEN Customer Care Center (ICC).

NOTE: Before operating or testing this unit, please read the Safety and General Information

section in the front of this manual.

1.1 Who Should Use This Manual

PREFACE: Who Should Use This Manual

This manual is intended for service technicians who should be familiar with the test equipment

recommended in Appendix A. To help pinpoint basic problems with the unit, first perform the

mechanical checks and self tests as described in Chapter 5; then proceed to field level

troubleshooting and testing.

1.2 How This Manual Is Organized

This manual contains the following chapters and appendices:

Chapter 1 presents the theory and technology used by the iDEN system and the unit.

Chapter 2 describes the unit’s features, icons, and indicators.

Chapter 3 describes displays, messages, and alerts.

Chapter 4 describes preparing for basic level testing.

Chapter 5 describes basic mechanical checks and self test procedures to be performed.

Chapter 6 describes basic test modes and technician test procedures.

Chapter 7 describes how to prepare and operate field level test equipment. It also contains

disassembly and reassembly instructions.

Chapter 8 describes field level test modes and procedures.

Chapter 9 describes large component repair and rework procedures.

Appendix A provides information on ordering kits and replacement parts. It also contains lists of

recommended test equipment.

68P80401P05 v

Page 15

PREFACE: Conventions Used in This Manual

1.3 Conventions Used in This Manual

The following conventions are used throughout this manual:

italics Used for emphasis and new terms

bold Defines menu items, fields, and buttons

code Used for sample input and output

1.4 Related Publications

The following publications are available separately:

iDEN i580 Digital Multi-Service Data-Capable Phone User’s Guide NNTN6775A

R-2660 Digital Communications System Analyzer Operator’s Manual 68P80386B72

vi 68P80401P05

Page 16

CHAPTER 1

OVERVIEW

To achieve a high spectrum efficiency, the i580 digital multi-service, data-capable portable uses a

unique modulation technology and sophisticated voice-compression algorithm. The voice of the

person speaking into the microphone is converted into a digital bit stream consisting of zeros (0)

and ones (1). The stream then is modulated into a radio-frequency (RF) signal, which is transmitted

over the air to another unit. This process is called digital modulation.

1.1 i DEN Digital Modulation Technology

The i580 digital portable is a dual band 806-870 MHz and 896-940 MHz unit that can operate in

multiple modes: phone, private, data, and group. It uses three digital modulation technologies:

Quad QAM, Quadrature Phase Shift Keying (QPSK), and Time Division Multiple Access (TDMA).

Quadrature Amplitude Modulation (QAM) is a modulation technique that transmits information by

altering the amplitude and phase of the radio frequency (RF) signal. Data is converted into complex

symbols, which alter the RF signal and transmit the information. When the signal is received, the

amplitude and phase are converted back into symbols and then into the original data.

OVERVIEW: i DEN Digital Modulation Technology

There are three different QAM modes that are used for different applications: 64QAM, 16QAM, and

4QAM. In voice applications, 16QAM is used, while in data applications, 64QAM, 16QAM, and

4QAM are used.

NOTE: The 900 MHz band operates only in 16QAM modulation.

In 64QAM, 64 possible combinations of 6 bits are converted into a unique amplitude and phase. In

16QAM, there are 16 possible combinations of 4 bits, while in 4QAM, there are 4 possible

combinations of 2 bits.

The traditional 25 kHz channel used for two-way radios is split into four QAM signals (subcarriers)

that are transmitted simultaneously. This technique can transmit 64 Kbps in a single 25 kHz

channel.

The iDEN system requires approximately 10 Kbps to transmit a compressed voice; therefore, 64

Kbps can accommodate 6 voice channels or 3 voice channels in enhanced systems.

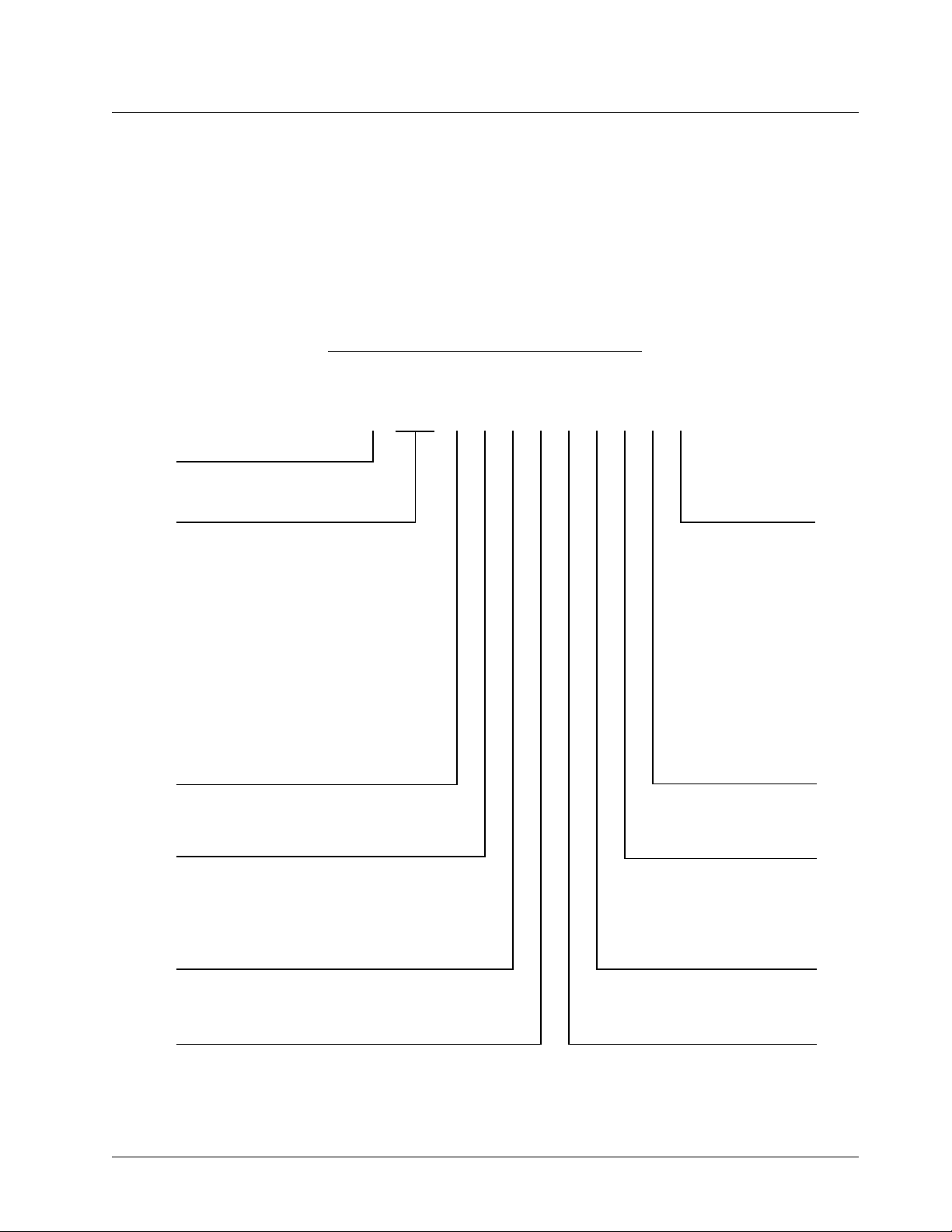

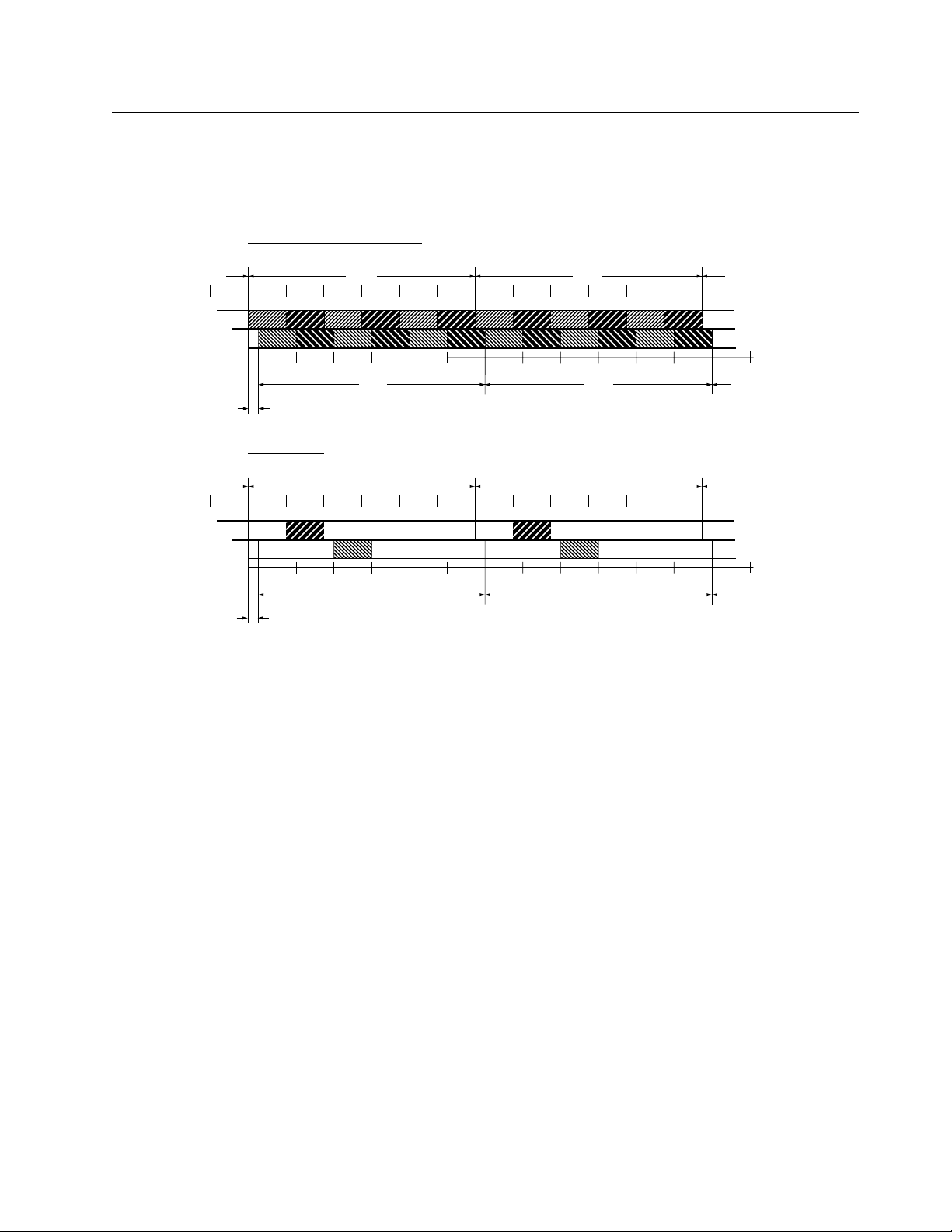

The signal spectrum of the Quad 16QAM is shown in Figure 1-1.

68P80401P05 1

Page 17

OVERVIEW: i DEN Digital Modulation Technology

RL 0dBm 10 dB/

-10

-20

-30

Power

-40

(dB)

-50

-60

-70

0-10-20 10 20

Frequency from Desired Channel Center

(kHz)

Figure 1-1. Spectrum of i DEN Quad 16QAM

Quadrature Phase Shift Keying (QPSK) is one of the most common modulation techniques for

satellite communications. In QPSK, a digital data stream is taken two bits at a time to generate four

possible phase states of the transmitted carrier. A characteristic of this technique is its resistance to

noise.

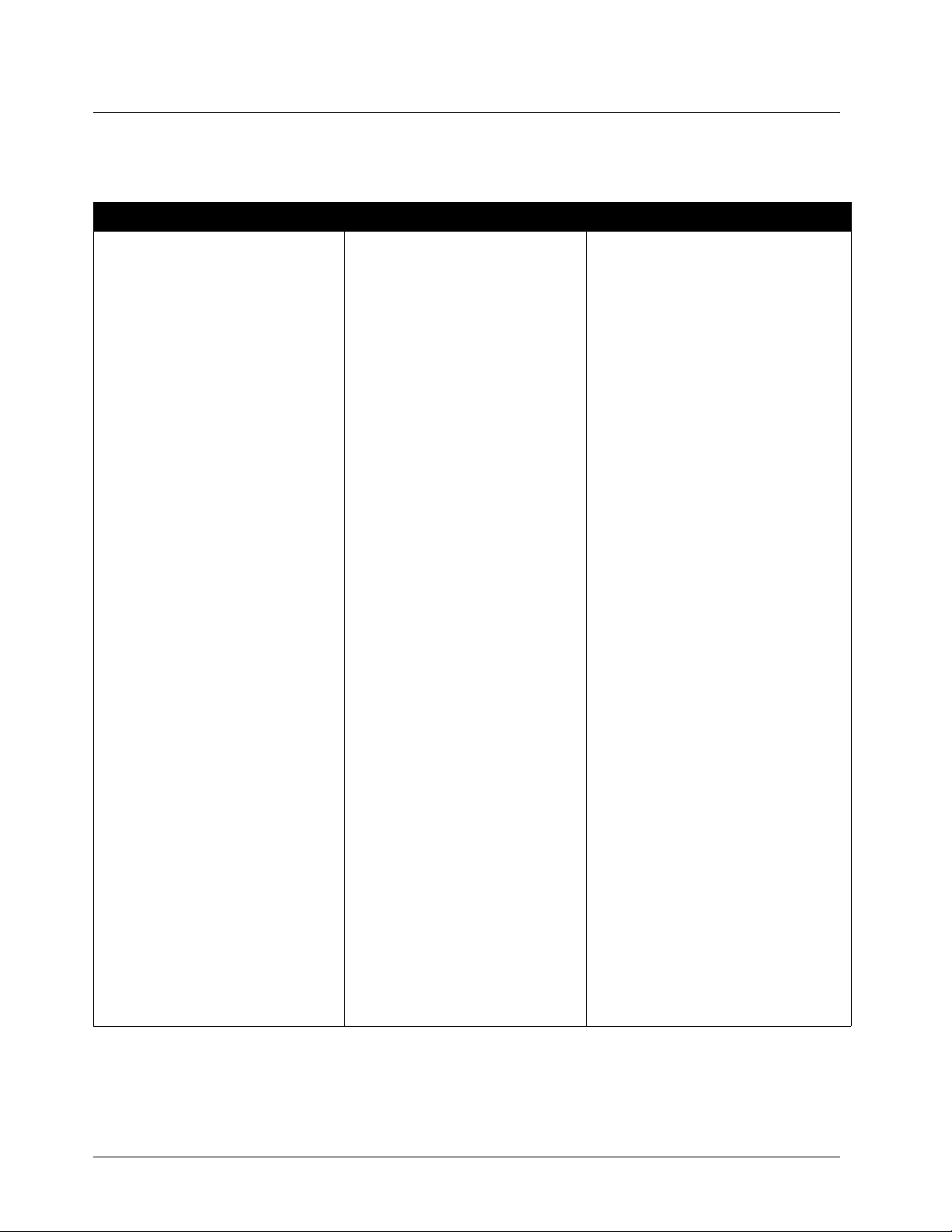

Time Division Multiple Access (TDMA) is used to allocate portions of the RF signal by dividing

time into 6 slots, one for each unit. Time allocation enables each unit to transmit its voice

information without interference from another unit’s transmission.

Transmission from a unit or base station is accommodated in time-slot lengths of 15 milliseconds

and frame lengths of 90 milliseconds (see Figure 1-2).

Note that Rx (outbound) indicates base-to subscriber transmissions; Tx (inbound) indicates

subscriber-to-base transmissions. The slots are paired and have a fixed offset of 19 milliseconds;

their timings are synchronized by the iDEN system. The TDMA technique requires sophisticated

2 68P80401P05

Page 18

OVERVIEW: i DEN Voice Compression Technology

algorithms and one digital-signal processor (DSP) to perform voice compression/decompression

and RF modulation/demodulation.

Base Station Control Channel

Transmitting 6 of 6 slots continually.

90ms 90ms

15ms

Tx

Rx

15ms

90ms 90ms

Receiver 4ms delayed

Portable Unit

When turned on, scans for control station, then transmits one slot every six slots.

90ms 90ms

15ms

Rx

Tx

15ms

90ms 90ms

Transmitter 4ms delayed

Figure 1-2. i DEN TDMA Format

1.2 i DEN Voice Compression Technology

15ms15ms 15ms15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms

15ms15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms

15ms15ms 15ms15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms

15ms15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms 15ms

Voice is converted into a digital bit stream by sampling the voice signal at a high rate and converting

the samples into numbers, which are represented by bits. A sample consists of 8 bits. Approximately

8000 samples per second (64 Kbps) are required to maintain a reasonable quality.

Voice compression reduces the number of bits per second while maintaining the voice at an

acceptable quality level. The iDEN system uses a coding technique called Vector Sum Excited

Linear Prediction (VSELP) to compress voice to 4.2 or 8.0 Kbps. The compressed voice-data bits

modulate the RF signal. The compression rate is based on the type of call (dispatch or interconnect)

and the network configuration established by the local service provider.

Adding error-correction bits to the coded-voice bits increases the required RF-transmission bit rate

to approximately 7.4 Kbps for the 4.2 Kbps voi ce coder and 14.8 Kbps for the 8.0 Kbps voice coder.

1.2.1 RF Transmission Bursts

All RF transmissions within an iDEN system occur in 15-millisecond blocks called bursts. An

iDEN base station transmits bursts continuously on each RF frequency it uses. Transmission bursts

from the stations are synchronized in time by signals received from the global positioning satellite

68P80401P05 3

Page 19

OVERVIEW: i DEN Voice Compression Technology

(GPS) system. Each burst is numbered; the number is referred to as the slot number. All bursts

occurring at a given time carry the same slot number.

Inbound transmission bursts (sent from the unit) are offset 19 milliseconds from the outb ound burst;

the inbound burst begins 4 milliseconds after the end of the outbound burst (see Figure 1-2 on

page 1-3). This offset in time allows the unit to appear capable of transmitting and receiving at the

same time (it actually is switching rapidly back and forth between receiving and transmitting).

In current iDEN systems, outbound transmissions in the 800 MHz band range from 851–870 MHz;

inbound transmissions are 45 MHz lower in frequency. For the 900 MHz band, outbound

transmissions range from 935-940 MHz; inbound transmissions are 39 MHz lower in frequency.

An iDEN channel is created by grouping bursts so that their slot numbers differ by a number referred

to as the repetition rate. The unit uses two repetition rates for interconnect voice calls: 6:1 and 3:1. A

single frequency can handle 6 calls using a 6:1 repetition rate with the 4.2 Kbps coder.

Dispatch calls always use this rate. However, the audio quality of the 3:1 repetition rate with the 8.0

Kbps coder is superior to the 6:1 rate with the 4.2 Kbps coder . Most service providers configure the

system and unit to allow only the 3:1 rate for interconnect calls.

Calls are set up on a primary control channel (PCCH) in response to a request from a unit or a

regular telephone connected to the Public Switch Telephone Network (PSTN). The PCCH is

established by the base station equipment; typically, it is a 6:1 channel.

The outbound PCCH carries system information and “pages” to specific subscriber units and asks

them to respond if they are available for a call. Inbound PCCH transmissions carry responses to the

“pages” and requests by subscriber units to set up calls. Inbound transmissions on the primary

control channel only take 7.5 milliseconds and can be timed to occur in either half of a 15millisecond burst.

The dual band unit will power up in the 800 MHz band and will use these channels for control

channels—Primary Control Channel (PCCH) and Broadcast Control Channel (BCCH). The 900

MHz mode will be used only during 3:1 interconnect calls. Every attempt will be made to assign the

unit to 900 MHz carriers during new 3:1 interconnect calls, handov ers into a cell, and inter-cell

handovers. If no resources are available, or if available resources have insufficient channel quality

(in the case of a handover), then 800 MHz carriers will be evaluated.

Using the above techniques, the iDEN system can operate 6 voice channels simultaneously in

dispatch mode or 3 voice channels simultaneously in interconnect mode on a single RF carrier at

25 kHz bandwidth.

1.2.2 Calling Area Coverage

Area coverage is obtained by dividing the area into a mosaic of cells. Coverage is controlled so that

frequencies can be reused with less distance between sites. Each cell is covered by a base station,

which is classified as Omni or Sectored. An Omni station connects base transceivers to antennas that

have a circular pattern centered at the site. A Sectored station connects base transceivers to

directional antennas that point in particular directions. Units that operate in a multi-site system must

4 68P80401P05

Page 20

OVERVIEW: Global Positioning System (GPS) Section

be able to “handoff” from one coverage area to another as the user moves about during a call.

Handoff is controlled by the iDEN system.

1.3 Global Positioning System (GPS) Section

The U.S. Department of Defense (DoD) has built a 24-satellite constellation for the purpose of

pinpointing locations anywhere on the planet. The satellites circle the earth every 12 hours,

transmitting radio signals at a fixed frequency of 1575.42 MHz. The satellites share the 1575.42

MHz spectrum with each other through the use of CDMA modulation.

To determine a location on earth, a receiver must be built that can receive the simultaneous signals

from the satellites that are in view of the receiver and use that information to calculate the location

of the receiver. The receiver must pick up the signals from 4 satellites. Once the 4 satellites are

located, the receiver measures the time it took for the satellite signals to arrive. From this timing

information, the distance between the receiver and each satellite can be calculated. The four

satellites’ ephemeris data provide the satellite’s X, Y, and Z positions. The range, R, is the receiver

measurement made by calculating the time it took for the signal to reach the receiver. The user’s

position, (Ux, Uy, Uz), and the clock bias, Cb, is then calculated.

To use the GPS, a receiver that can receive the spread-spectrum signals must be built. The detected

signals are then converted from RF signals into appropriate digital input formats. These digital

inputs are processed and converted into position information. Once the position coordinates are

determined, they are communicated to the handset microprocessor and displayed on the screen or

transmitted to the base station as required.

1.4 MOTOtalk

The purpose of the MOTOtalk feature is to allow simple, direct, simplex two-way radio-to-radio

communications between subscriber units. It is a PTT (Push-To-Talk)- based feature that operates

like most any two-way radio might. A good basic model for operation is that of the Motorola

Talkabout product. What makes it quite different, however, is that it is digital in operation, which

allows for superior range and voice quality. It is also asynchronous in nature, and requires no

external source of synchronization for connections between units to be made.

1.5 Bluetooth® Wireless System

Bluetooth technology is used for short range wireless communications that do not require high data

rates. The original usage models included telephone, headsets, low-data rate access point, file

transfer, and automatic synchronization. The newer usage models have added human interface

devices, remote control, print capability, cable replacements, and personal area networks.

Bluetooth devices use GFSK modulation in the 2.4 to 2.4835 GHz ban d. The channels have a

bandwidth of 1MHz. Frequency hopping is used to provide immunity to interference. The master

unit in a pico-net dictates the hopping sequence at a rate of 1600 hops per second. This translates to

a 625 uS transmission. The maximum data rate through a Bluetooth device is 1Mb per second.

68P80401P05 5

Page 21

OVERVIEW: SIM Cards

1.6 SIM Cards

This unit is designed to work with a mini Subscriber Identity Module (SIM). The SIM card contains

all of the personal data required to access iDEN services. Data held by the SIM card includes:

• Temporary Mobile Subscriber Identity

• Services to which the user subscribes

• PIN and unblocking codes

• Call barring codes

The SIM card is also capable of storing phone numbers and names.

Available SIM cards for this unit are 64 kB and prepaid.

1.6.1 Removing and Inserting a SIM Card

NOTE: When a SIM card is defective and must be replaced with a new one, the following

information will be erased:

• The recent calls list

• Call forwarding settings

• Net alerts

• Mobile originated text messages, drafts, and quick notes

• Information stored in Memo

• 3 most recent GPS enabled locations

• Voice records

• Voice names

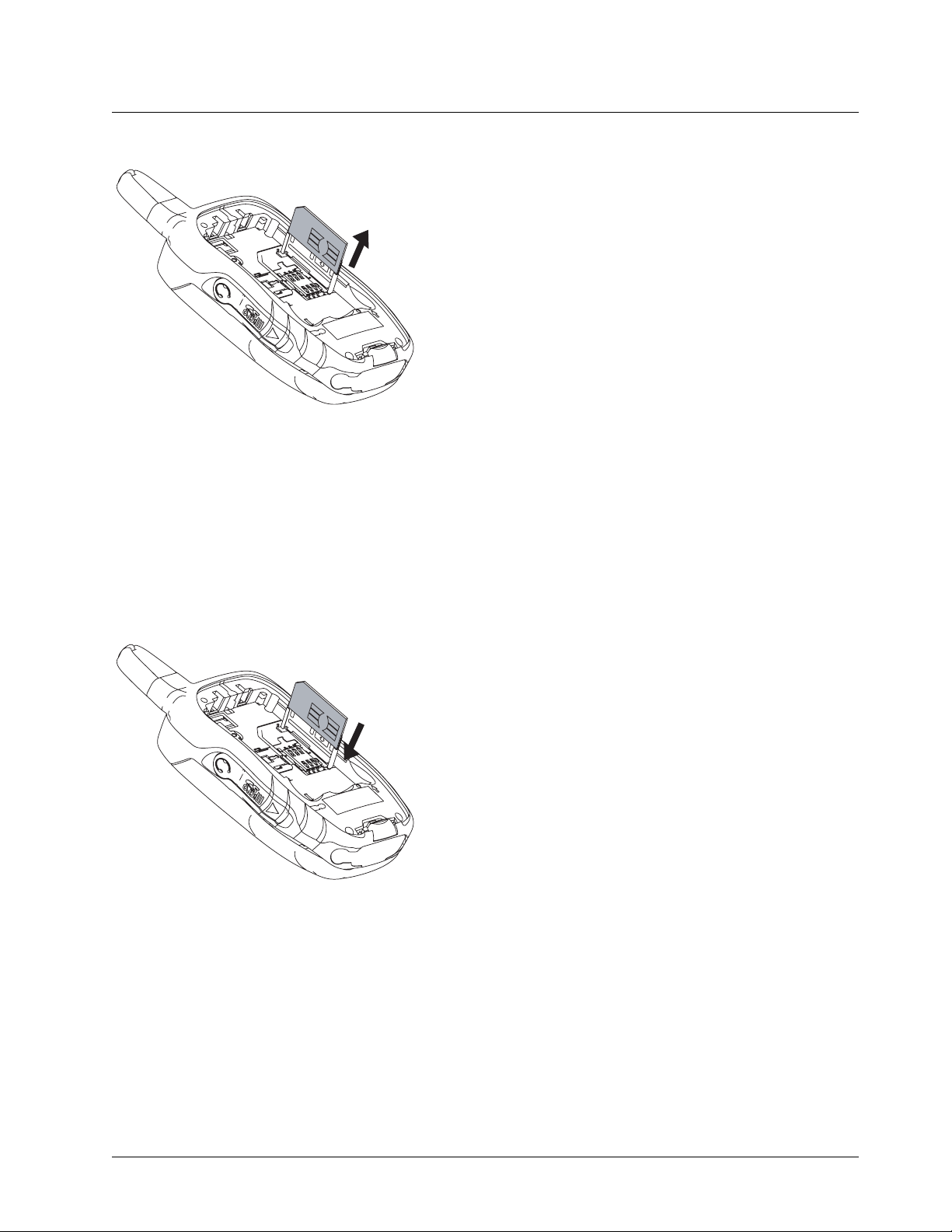

To remove a SIM card (Figure 1-3):

F

1. Power off the unit and remove the battery cover and battery.

2. Turn the unit face down so that the antenna is at the upper left corner.

3. Slide open latch.

4. Open the SIM card holder (see Figure 1-3).

5. Grasp SIM card from one side and pull out.

CAUTION: Do not touch the gold-colored area of the SIM card.

6 68P80401P05

Page 22

Figure 1-3. Removing a SIM Card

To insert a SIM card (Figure 1-4):

1. Open the SIM card holder.

OVERVIEW: SIM Cards

2. Carefully slide the SIM card into the holder (see Figure 1-4). Position SIM card as shown.

3. Close SIM door, slide latch to shut.

4. Reinstall the battery, and reattach the battery cover.

Figure 1-4. Inserting a SIM Card

68P80401P05 7

Page 23

FEATURES, ICONS, AND INDICATORS: i 580 Features

CHAPTER 2

FEATURES, ICONS, AND INDICATORS

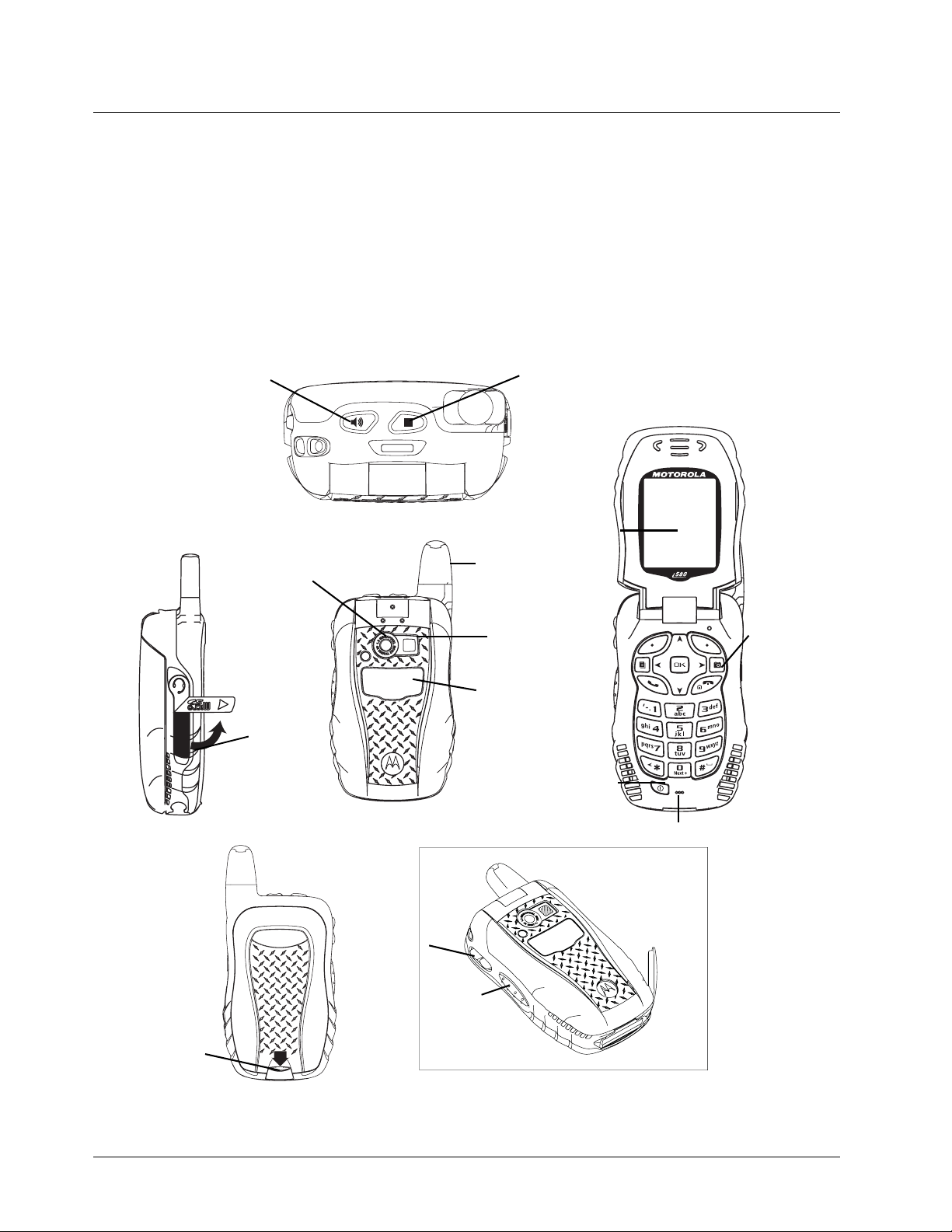

To conduct basic troubleshooting and maintenance of the i580 unit, you must become familiar with

the components, display icons, and status indicators associated with the unit.

2.1 i 580 Features

Speaker Key;

Send Calls to Voicemail

Answer Calls

Right Side

Transflash

Card Slot

Camera

Lens

Top View

Front View

Closed

End Calls;

Send Calls

to Voicemail

Display

Retractable Antenna

Mirror

External Display

Power Button

Front View

Open

Camera

Key

Microphone

Release

Button

Back View

Left Side

Vol ume

Controls

Walkie-Talkie Button

Controls

Figure 2-1. i580 Feature Views

8 68P80401P05

Page 24

2.2 Display Icons

Icons for this unit provide information that is useful for troubleshooting and testing purposes. All

features can be accessed through the main menu. When using a feature, the icon for that feature

appears in the upper left corner of the display. Depending upon features and options chosen, the

following icons can appear on the unit’s display.

NOTE: Feature icons may appear in various places within the display. Check the specific User’s

Guide for more information about the unit’s icons and indicators.

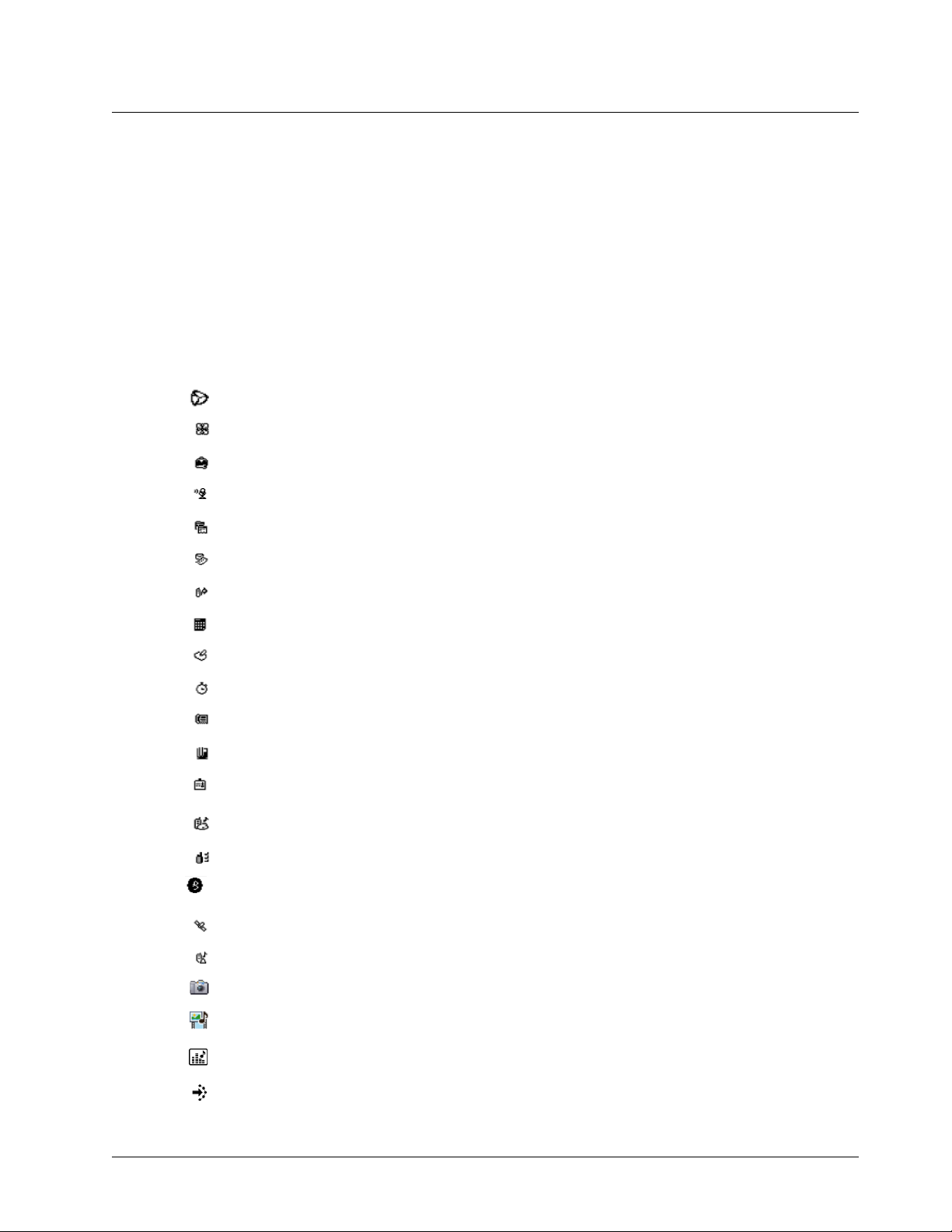

2.2.1 Main Menu Icons

Browser Browse the W e b.

Java Apps Use Java applications on your phone.

Settings Customize your phone.

VoiceRecord Record and play audio messages.

Contacts Create, view, store, edit contacts.

FEATURES, ICONS, AND INDICATORS: Display Icons

.

Messages Access messages.

Call Forward Set call forwarding options.

Datebook Schedule appointments.

Memo Store a number to access later.

Call Timers Phone usage information.

Recent Calls Access information about recent calls.

Shortcuts Create sh ortcuts to screens.

My Info View personal phone information, including phone

number and Private ID.

Profiles Apply groups of settings together.

Call Alert Access information about call alerts.

Bluetooth Connect to a device with Bluetooth.

GPS Find your approximate geographical location.

Ring Tones Assign ring tones and turn ringer off.

Camera Image in camera lens shows on the main display.

Media Center Edit captured images.

Audio Player Access the MP3 audio player.

Quick PTT Access private ID’s and Selective Dynamic Groups

(SDG). (Carrier optional feature.)

68P80401P05 9

Page 25

FEATURES, ICONS, AND INDICATORS: Display Icons

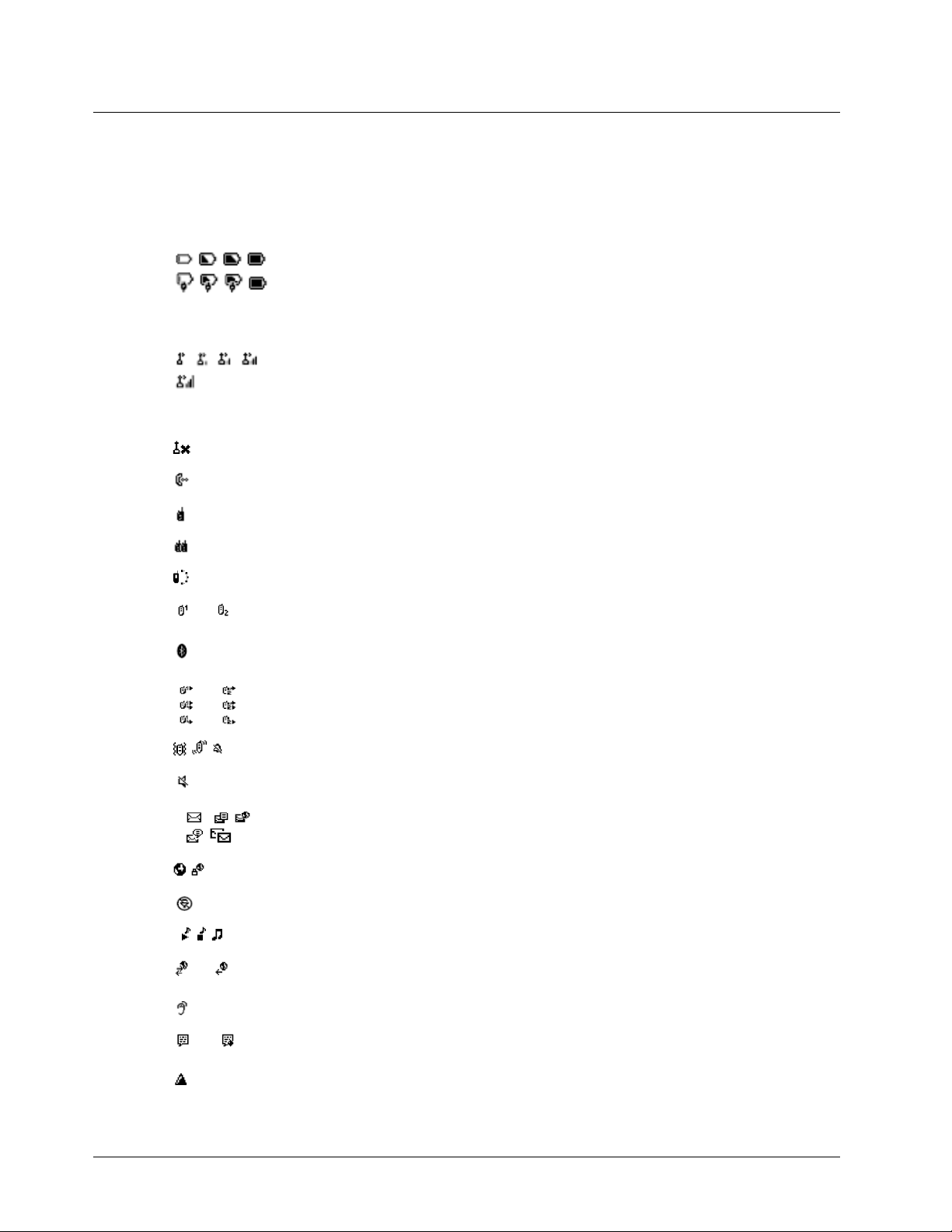

2.2.2 Status Icons

Status icons appear in the two rows at the top of the display. Some appear at all times. Others appear

only when your phone is engaged in certain activities or when you have activated certain features.

Battery Strength—Indicates the battery’s stored level of charge.

The Battery Strength icon exhibits a darkened area inside the simulated battery image to in dicate

the level of stored charge. The levels of charge are shown in the display with or without the

charger attached. A depleted battery has little or no darkened area. As the battery is charged, the

levels of darkened area increase until the ba ttery is fully charged . As the battery is depleted, the

darkened area decreases.

Signal Strength—Indicates the device is registered and the strength of the network signal. The

antenna portion of the icon is always displayed. Up to 4 bars are displayed next to the antenna.

The more bars depicted, the stronger the signal. One bar = approx. 19 SQE and >-103 RSSI, 4

bars = approx. 29 SQE and >-88 RSSI. When the unit is in a no-service state, or the signal is less

than 19 SQE or <-103 RSSI, no bars appear next to the antenna.

No Service — your phone is without service. You cannot make or receive any type of call.

Phone In Use — your phone is active on a phone call.

Private In Use — your phone is active on a Private call.

Talkgroup In Use — your phone is active on a Group Connect call.

SDG Call In Use — unit active on an SDG call.

Active Phone Line — 1 indicates phone line 1 is ready to make calls; 2 indicates phone line 2 is

ready to make calls.

Bluetooth in Use — your phone is using Bluetooth. If this icon is blinking, then your phone is in

discoverable mode. If this icon is static, your phone is active in a Bluetooth connection.

Call Forward — your phone is set to forward calls.

Ringer Off — your phone is set not to ring.

Speaker Off — Sounds associated with Private calls and group calls are set to come through the

earpiece rather than through the speaker.

Messages — you have one or more messages.

Internet — you are ready to browse the internet or are browsing the internet.

Transmitters — your phone is set not to receive calls and other transmissions.

Audio Player — The audio player is active.

Packet Data — you are ready to transfer packet data or are transferring packet data using a data

cable.

Hearing Aid — your phone is set for use with a hearing aid.

TTY— Indicates that unit is connected to a TTY device and TTY mode is enabled. You can

select either VCO (voice-carry-over) or HCO (hearing-carry-over) mode.

Roaming — You are using your phone outside your carrier’s network.

10 68P80401P05

Page 26

DISPLAYS, MESSAGES, AND ALERTS: Power-Up Sequence

CHAPTER 3

DISPLAYS, MESSAGES, AND ALERTS

To conduct basic troubleshooting and maintenance of the i580 unit, you must become familiar with

the display screens, messages, and alert tones associated with the unit.

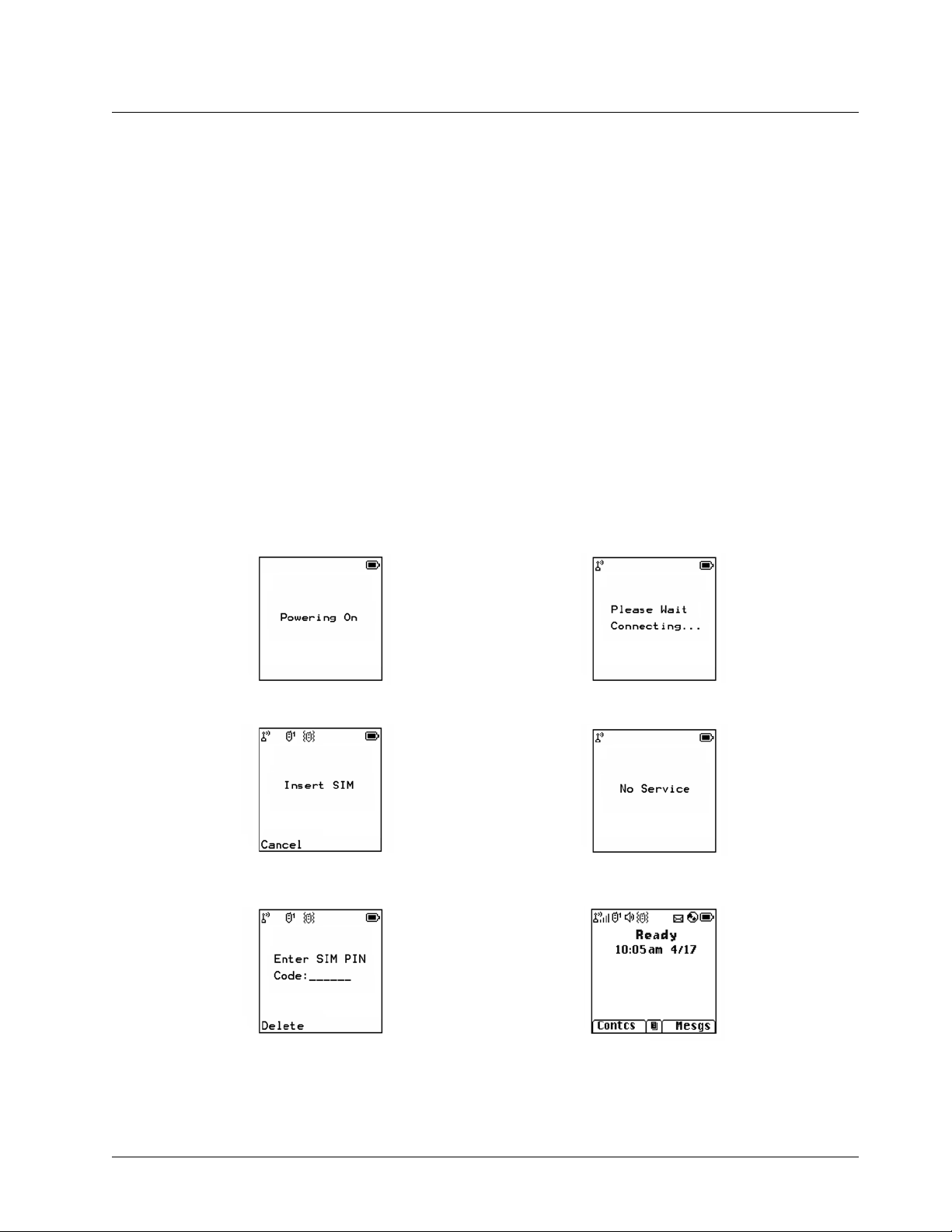

3.1 Power-Up Sequence

Extend the antenna whip and press the Power key until the power-up sequence begins. The powerup sequence initiates a series of displays on the unit. Each display reflects a stage in the sequence.

If the last display shows the idle screen, the power up was successful; if the last display shows No

Service, the unit is out of range or there is a hardware or software problem. If the vibrate function is

enabled for incoming phone calls, voice mail, or message mail, the power-up sequence includes a

500ms vibrate cycle.

Depending upon the service provider, the power-up sequence screens may differ from those shown.

1. Powering On 4. Connecting

2. Insert SIM

OR OR

3. Enter SIM

Note: SIM PIN feature can be

cancelled.

Figure 3-1. Power-Up Sequence Displays

5. No Service

6. Unit Ready Display (Idle

Note: Idle screens differ depending

68P80401P05 11

Page 27

DISPLAYS, MESSAGES, AND ALERTS: Power-Down Sequence

3.2 Power-Down Sequence

To power down the unit, press and hold the Power key until the unit begins powering down.

3.3 Messages

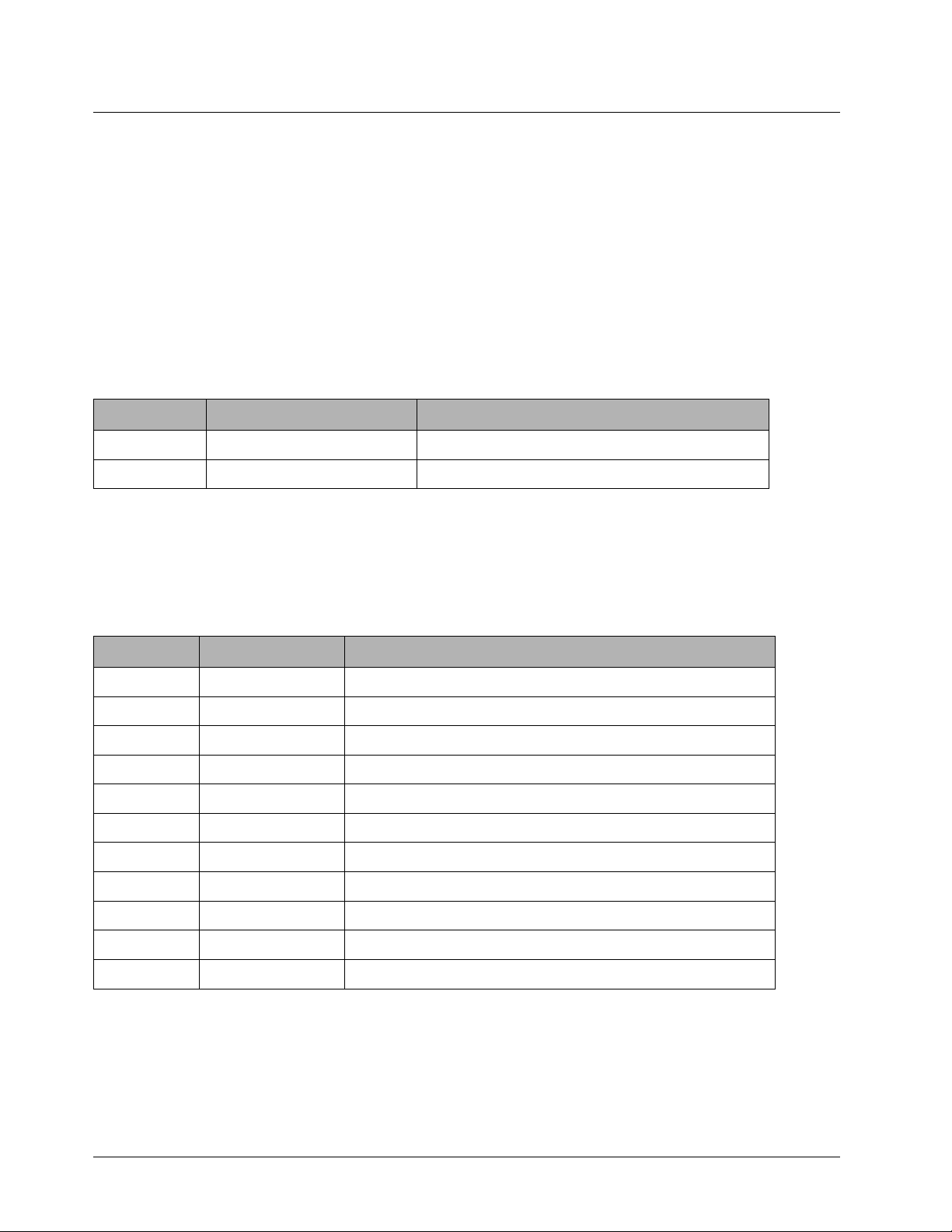

3.3.1 Self-Test Errors

The following table contains the list of self-test non-reset errors. These errors are displayed as SELF

CHECK ERROR YXXXX (YXXXX represents the identifier for that error).

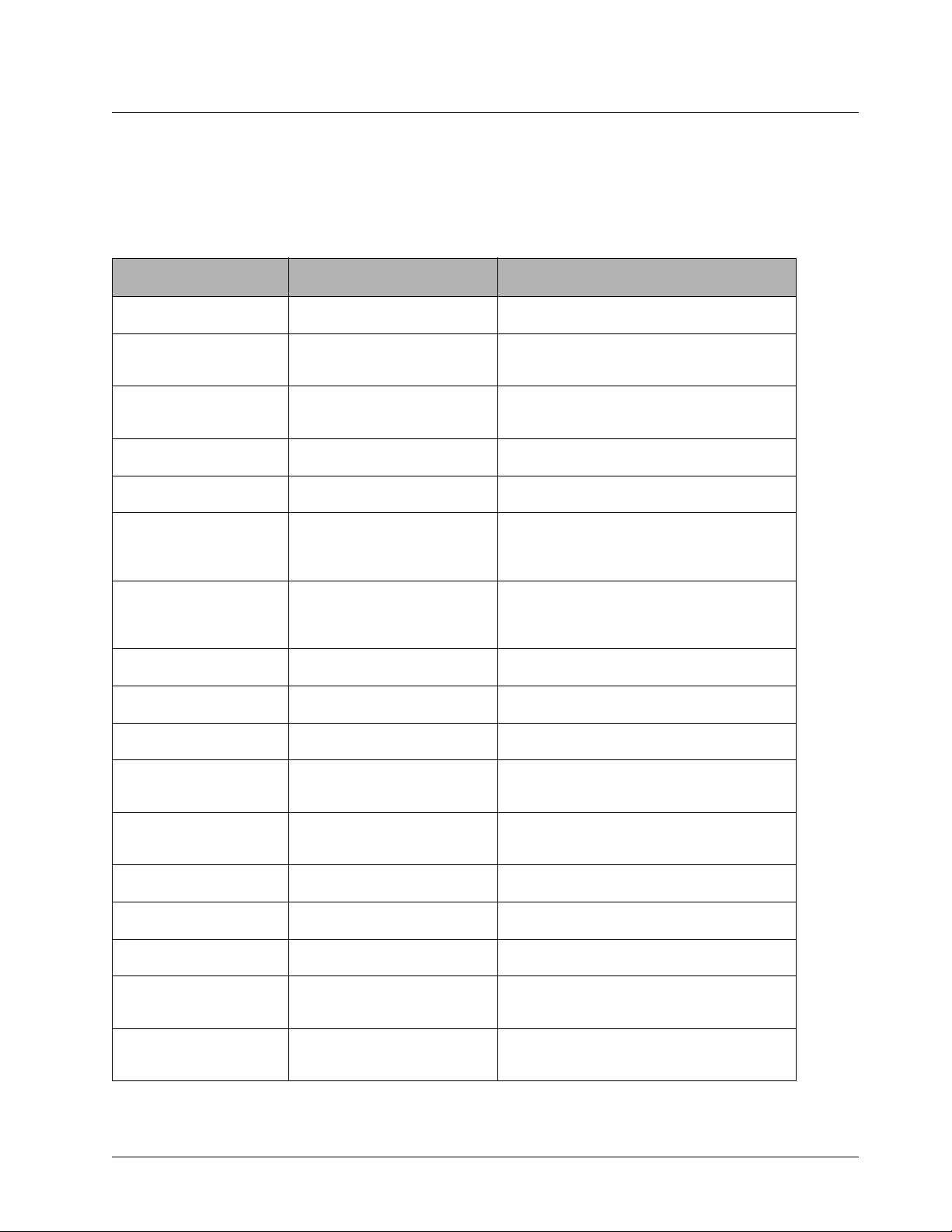

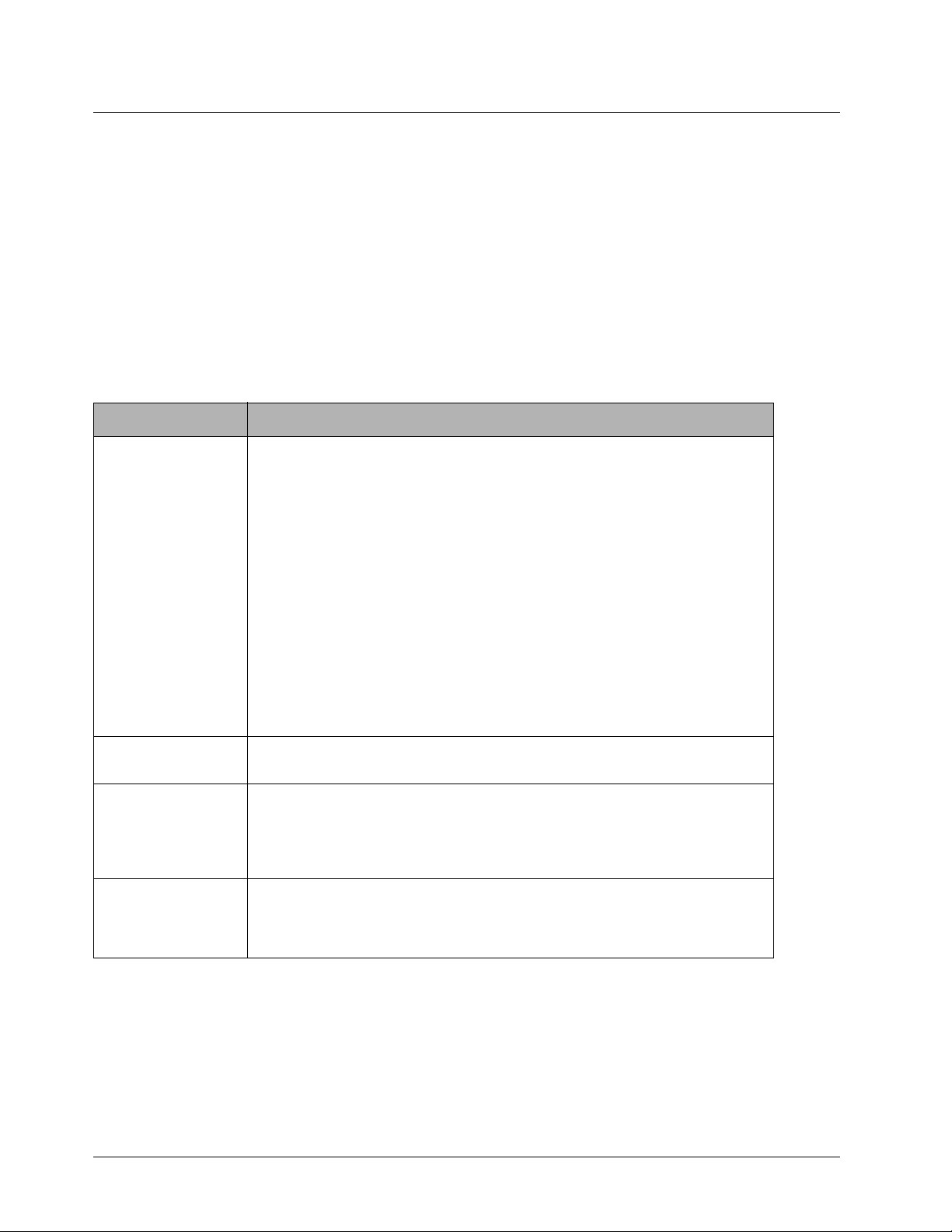

Table 3-1. Self-Test Errors

Y XXXX Description of Error

0 0001 Non-reset error log

0 0002 Codeplug error log

3.3.2 Self-Test Reset Errors

The following table contains the list of self-test reset errors. These errors are displayed as SELF

CHECK FAIL YXXXX (YXXXX represents the identifier for that error).

Table 3-2. Self-Test Reset Errors

Y XXXX Description of Error

0 0100 RAM failure

0 0200 Data lines failure

0 0400 Address line failure

0 0800 Codeplug corruption/invalid

0 1000 Flash checksum error

0 2000 Reset error logging

0 4000 Codeplug mismatch

F 4000 Ergo pre-self-test codeplug error

F 8000 Ergo pre-self-test invalid device or device failure

F 8002 Ergo pre-self-test invalid device or device failure

: 0800 FDI-related error

12 68P80401P05

Page 28

3.3.3 Service Messages

Service messages indicate the probable cause of a problem. The following table lists the messages,

their probable causes, and recommended corrective actions.

Table 3-3. Service Messages

Message Cause Action

Charger Attached While Power Down

DISPLAYS, MESSAGES, AND ALERTS: Messages

Device Attached 17-Pin connector plugged in while

Device Detached 17-Pin connector removed while

Device Not Compatible Incompatible with unit’s hardware Acquire compatible software or hardware

Error Unidentified error Report problem to your service provider

Invalid Number Invalid number entered or invalid

Low Battery Unable to

Locate Sats

No Entry No numbers in phone list Add phone numbers to list

No Service Phone unable to register Report problem to service provider

Number Not In Service Invalid target ID Re-enter ID or try a different ID

Please Try Again 1. Loss of service or system failure

powered up.

powered up.

voice-mail access number

received

Battery level is too low to obtain

fix but is able to perform dispatch

or interconnect communication

2. Network problem

Re-enter number or report problem to service

provider

Charge or replace battery

1. Ask provider how long problem will continue

2. Report problem to service provider

Service Conflict Current service conflicts with

previously activated service

Service Not Available Not currently available on system Ask provider when service will be available

Service Restricted Service not subscribed to Ask provider when service will be available

System Busy, Try Later System is currently busy Try call again later

Target Busy in Private Target unit in a Private Call or Call

Alert

Target Not Authorized Target unit not authorized to

receive call

68P80401P05 13

Deactivate previous service and try current service

again

Try call again later

Do not call unauthorized unit

Page 29

DISPLAYS, MESSAGES, AND ALERTS: Alert Tones

Table 3-3. Service Messages (Continued)

Message Cause Action

Technical Error Unable to

Locate Sats

Unable to locate Sats Unit does not have clear view of

Unknown User Unit unknown to system Report problem to provider

User Not Available Target unit in Private, Group, or

Problem detected with the GPS

circuitry

GPS satellites

Alert call, or is not in service

Reboot unit. If problem persists, contact Motorola

Make sure user is out in clear sky and stationary. If

problem persists, reboot unit.

Try call again later

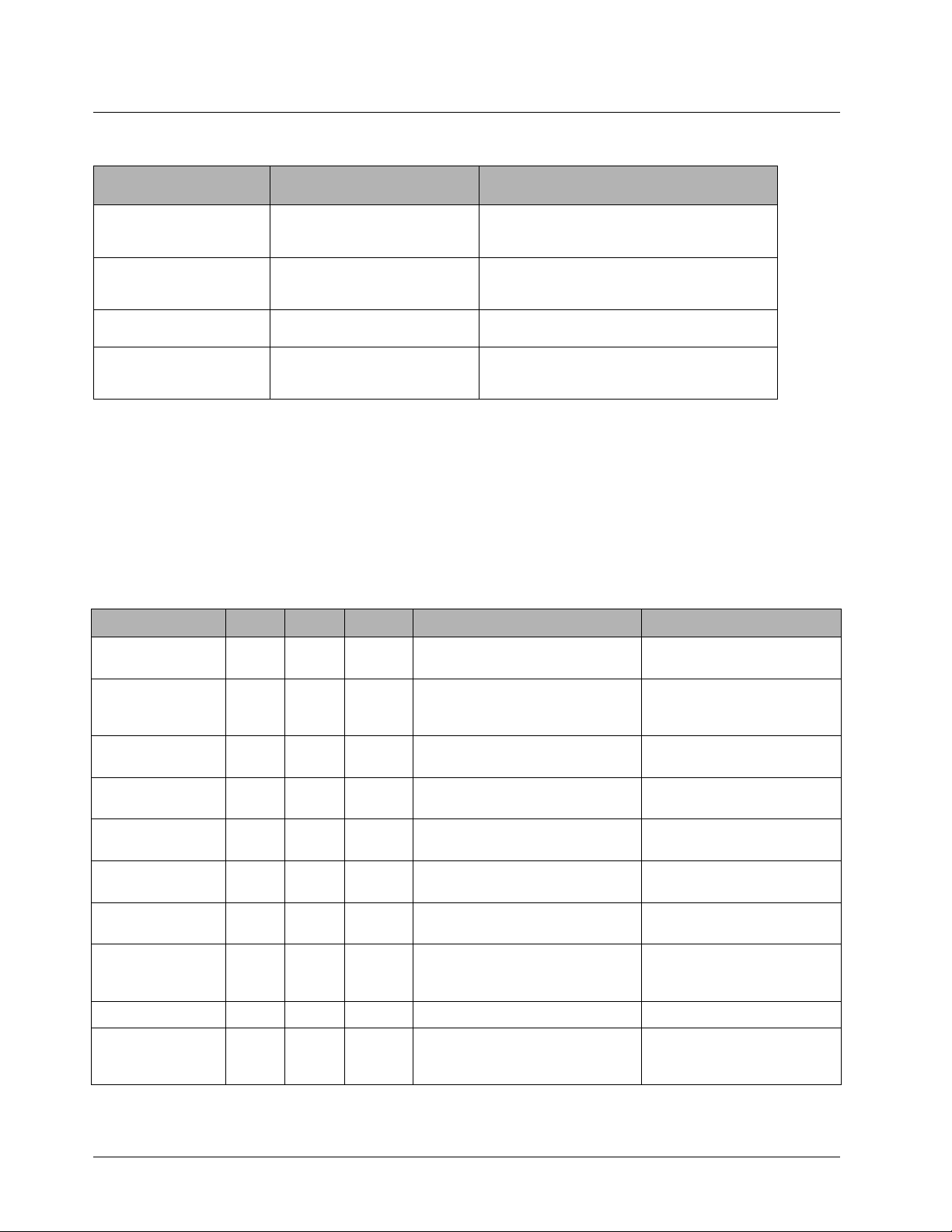

3.4 Alert Tones

This unit can send alert tones to the earpiece, speaker, or external speaker. Press the Mute key to

determine where some of the tones are sent.

As shown in the following table, alert tones have specific frequencies and cadences/durations. They

are grouped according to function; grouped tones have the same tone specifications.

Table 3-4. Alert Tones

Tone Low High Freq Cadence When Tone Occurs

Automatic

Callback

Call Alert

Acknowledgment

Received

Call Alert No Ack

Received

Call Alert

Received

Call Alert Sent Ear Spkr 1800Hz2x (80ms off+80ms on) Call Alert acknowledged by

Call Waiting

Received

Clear to Send Ear Spkr 2300Hz1x50ms on Reception inhibited; clear to

Data Ringer Ear Spkr 2091/

DTMF (0-9, #, *) Ear Ear DTMF Continuous DTMF is transmitted

Earpiece Volume

Set

Ear Spkr 1800Hz2x (24ms on+24ms off) + 48ms on Voice channel for prior request

Ear Spkr 1800Hz2x (80ms off+80ms on) Call Alert successfully sent

Ear Spkr 900Hz 1x500ms on Call Alert fails

Spkr Spkr 2300Hz4x (150ms off+150ms on) every 10

seconds

Ear Ear 440Hz 2x(300ms off+300ms on) every 5

seconds

2823H

z

Ear Ear 1000HzContinuous Earpiece volume changed on

14x (80ms on 2091Hz + 100ms on

2823Hz + 2.5 seconds off

Call Alert received

FNE

Phone call received while

another call is active

transmit

Unit receives an incoming

circuit data call

quiet channel or in

Programming Menu (PRGM)

14 68P80401P05

Page 30

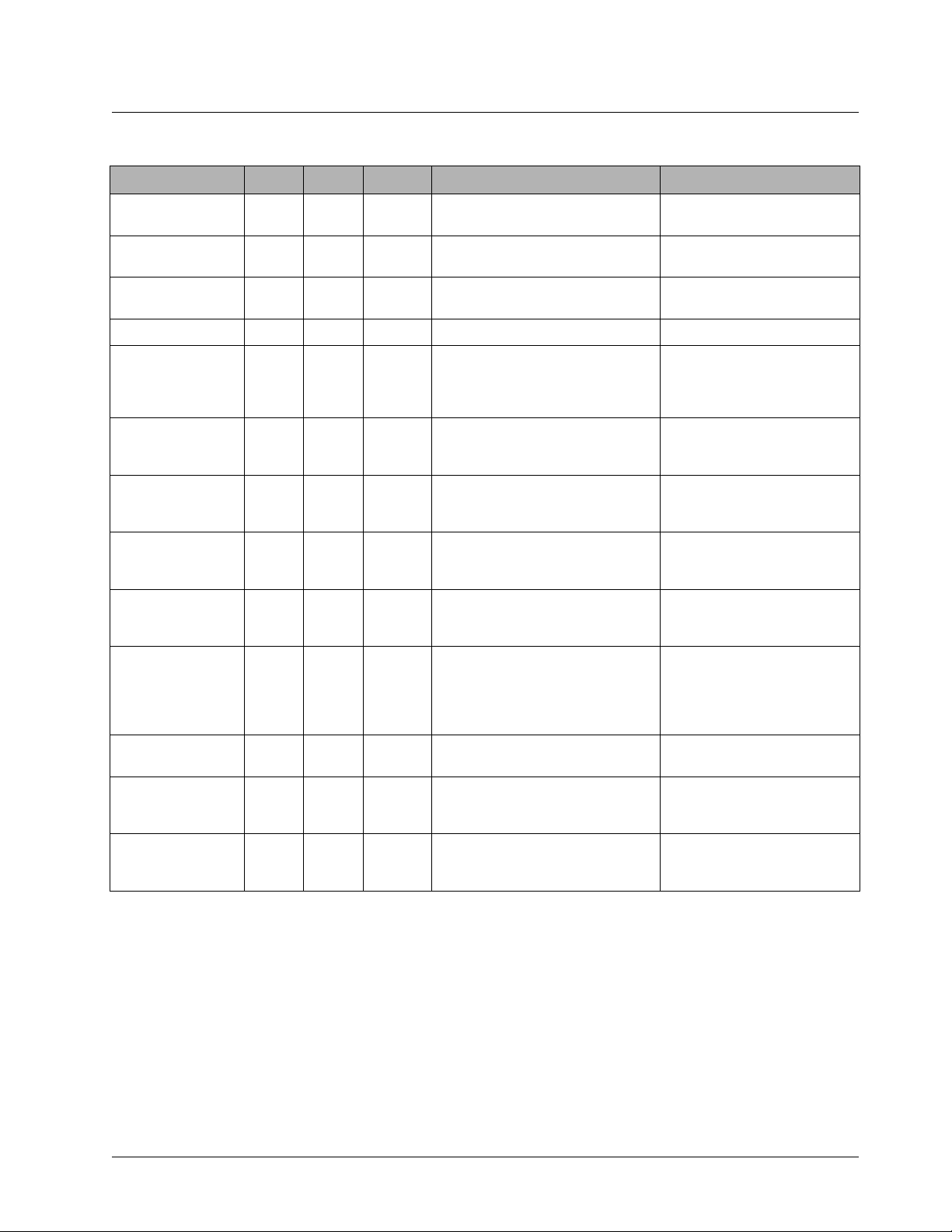

DISPLAYS, MESSAGES, AND ALERTS: Alert Tones

Table 3-4. Alert Tones (Continued)

Tone Low High Freq Cadence When Tone Occurs

Group Call Alert Spkr Spkr 2300H

z

In Service Spkr Spkr 2300H

z

Interconnect Busy Ear Ear 480/

Invalid Key Ear Ear 900Hz 1x80ms on Invalid key pressed

Low Battery in Idle Spkr Spkr 2300H

Keypad Volume

Set

Message Mail

Received in Idle

Msg Mail

Received in

Interconnect

Message Volume

Set

Net Alert Ear Spkr 880Hz,

One Minute Beep Ear Ear 2300H

Phone Fast Busy Ear Ear 480/

Phone Redial Alert Spkr Spkr 2091/

Ear Ear 1800HzContinuous Keypad volume changed on

Spkr Spkr 2400/

Ear Ear 2400/

Spkr Spkr 2400/

620Hz

z

2743H

z

2743H

z

2743H

z

1760H

z/

330Hz,

990Hz

z

620Hz

2556H

z

2x (150ms off+150ms on) Group call received

1x50ms on Entering in-service mode

1s off + 1s on 480Hz;

1s off +1s on 620Hz continuous

24ms on+24ms off + 24ms on+240

ms off + 24ms on+24ms off + 24ms

on+30ms off every 30 seconds

8x(64ms on 2400Hz + 64ms on

2743Hz)every 30 seconds

8x(64ms on 2400Hz + 64ms on

2743Hz) every 30 seconds

8x(64ms on 2400Hz + 64ms on

2743Hz) continuous

5x (50ms on 880Hz + 50ms on

1760Hz) 8x (50ms on 330Hz +

50ms on 990Hz) repeated every

750ms

1x 50ms on During interconnect calls

0.25s on+0.25s off 480Hz 0.25s

on+0.25s off 620Hz continuous

14x(24ms on 2091Hz + 24ms on

2556Hz)

Interconnect channel or line is

busy

Battery below preset value.

(Tone sounds from earpiece if

in low audio during a dispatch

or interconnect call.)

quiet channel or in

Programming Menu

Message mail received while

unit is idle

Message mail received while

unit is in interconnect mode

Message volume changed on

quiet channel or in

Programming Menu

Net alert received while in idle

Call failed (system busy, out of

service, or trouble with

network)

Phone redial successful

68P80401P05 15

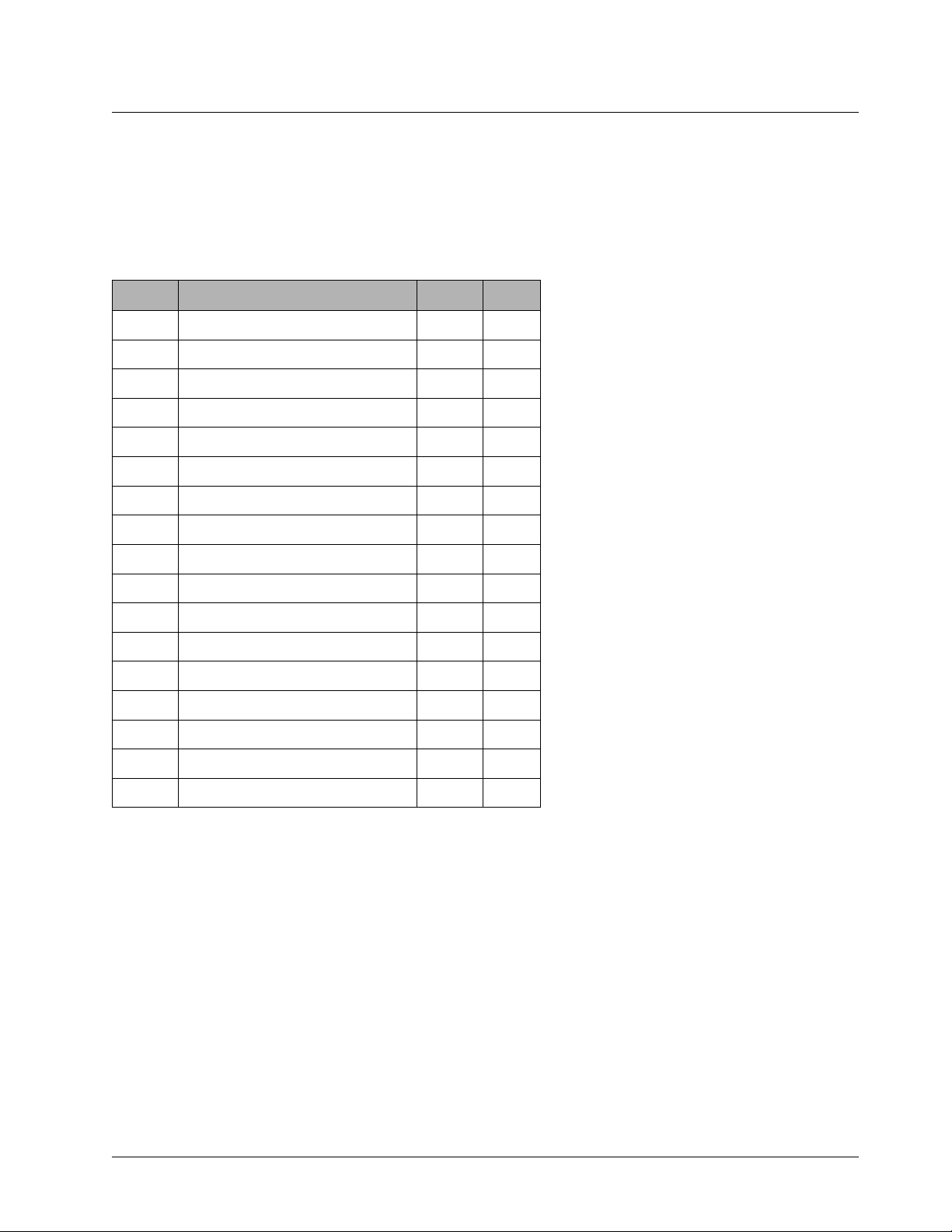

Page 31

DISPLAYS, MESSAGES, AND ALERTS: Alert Tones

Table 3-4. Alert Tones (Continued)

Tone Low High Freq Cadence When Tone Occurs

Phone Ring (U.S.) Spkr Spkr

2091/

2556H

z

2230/

2040H

z

2310/

2820H

z

3240/

2140H

z

3160/

1980/

2580H

z

2540/

2300/

2030H

z

2740/

3200H

z

2500H

z

Available ringer tones:

14x(24ms on 2091Hz + 24ms on

2556Hz) + 2.5s off

14x(64ms on 2230Hz + 64ms on

2040Hz) + 2.5s off

3x(400ms on 2310Hz + 400ms on

2820Hz) + 2.5s off

14x(38ms on 3240Hz + 38ms on

2140Hz) + 2.5s off

1x(200ms on 3160Hz + 100ms on

1980Hz + 200ms on 2580Hz) +

2.5s off

1x(200ms on 2540Hz + 200ms on

2300Hz + 200ms on 2030Hz) +

2.5s off

1x(150ms on 2740Hz + 150ms on

3200Hz + 150ms on 2740Hz) +

2.5s off

1x(200ms on 2500Hz + 200ms off +

200ms on 2500Hz + 200ms off

+ 200ms on 2500Hz) + 2.5s off

1x(200ms on 2580Hz + 200ms on

3200Hz + 200ms on 2040Hz)

+ 2.5s off

Phone call received

2580/

3200/

2040H

z

Phone Ring Back Ear Ear 440/

480Hz

Private Call

Received

Reject Ear Spkr 900Hz 1x500ms on Requested service denied or

Ringer Volume Set Spkr Spkr 2091/

Sat No Fix Spkr Spkr 900 Hz 1x500ms on Unable to fix on satellite

Self-Test Fail Spkr Spkr 900Hz 1x500ms on Self test fails on power up

16 68P80401P05

Spkr Spkr 2300Hz2x (88ms off+88ms on) Private call received

2556H

z

2s on+4s off 440Hz;

2s on+4s off 480Hz

24ms on 2091Hz + 24ms on 2556Hz

continuous

Called phone is ringing

failed

Ringer volume changed

Page 32

DISPLAYS, MESSAGES, AND ALERTS: Using the Optional Vibrate Function

Table 3-4. Alert Tones (Continued)

Tone Low High Freq Cadence When Tone Occurs

Speaker Volume

Set

System Busy Ear Spkr 480/

Talk Permit Ear Spkr 1800Hz2x (24ms on+24ms off) + 48ms on PTT transmission accepted

Talk Prohibit Ear Spkr 900Hz Continuous PTT transmission not allowed

TOT Warning Ear Spkr 900Hz 1x80ms on Transmission rights expiring

Valid Key Press Ear Ear 1800Hz 1x80ms on Valid key pressed or unit

Voice Mail

Received in Idle

Voice Mail

Received in

Interconnect

Spkr Spkr 1000HzContinuous Volume changed on quiet

channel or in Programming

Menu

620Hz

Spkr Spkr 2400/

2743H

z

Ear Ear 2400/

2743H

z

4x(0.25s on+0.25s off) 480Hz; 4x

(0.25s on+ 0.25s off) 620Hz

8x(64ms on 2400Hz + 64ms on

2743Hz) every 30 seconds

8x(64ms on 2400Hz + 64ms on

2743Hz) every 30 seconds

All channels are busy

powered up

Voice mail received while unit

is idle