Page 1

EP350

Portable Radios

Detailed Service Manual

Page 2

Page 3

Technical Information Updates

As we continue to make engineering enhancements to our products, the information in our

Service Manuals need to be updated accordingly. If you wish to be informed of these

updates, kindly fill in and fax us your details.

Fax to: 6-04-6124944

The Technical Publications Coordinator,

Global Customer Documentation,

R&D Department,

Motorola Penang.

Your Details

N a m e / C o n t a c t P e r s o n :

Company Name:

Address:

Telephone No. :

Fax No.:

Email Address:

How would you like to receive the update notification?

Through: mail email fax

Manual No.: 6878422A01

Kindly complete the Service Manual Feedback Form on the next page to help us ensure

that you receive the most accurate and complete information.

Page 4

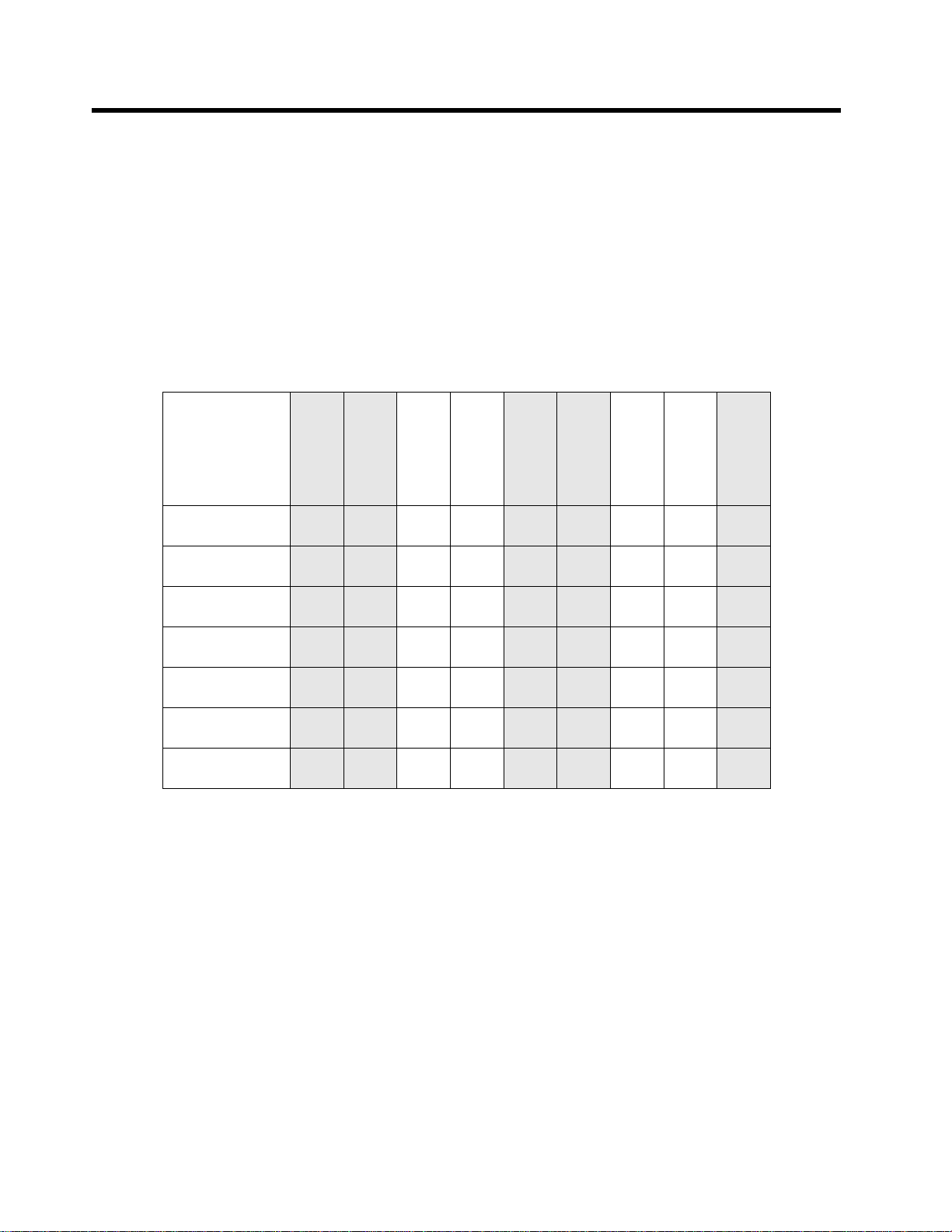

Service Manual Feedback Form

We believe that reports from users provide valuable information for producing quality

manuals. Kindly take a few moments to provide feedback on this manual. Thank you for

your cooperation.

Fax to: 6-04-6124944

The Technical Publications Coordinator,

Global Customer Documentation,

R&D Department,

Motorola Penang.

1. Please check all the appropriate boxes:

Complete

Disassembly

Procedures

Alignment

Procedures

Exploded

Views

Schematic

Diagrams

Circuit Board

Details

Electrical Parts

List

Exploded View

Parts List

Incomplete

Correct

Incorrect

Clear

Confusing

Size

Adequate

Size

Too Small

Not Covered

in this Manual

2. How do you rate this particular Service Manual?

excellent very good good fair poor

3. Did this Service manual provide you with the information necessary to service and

maintain the specific equipment?

very much so generally yes to some extent no

4. We would appreciate any corrections or recommendations for improving this manual.

Please include the specific page number(s) of the diagram or procedure in question.

5. General comments/suggestions:

Manual No.: 6878422A01

Page 5

COPYRIGHT

Copyrights

© 2009 by Motorola, Inc. All rights reserved.

No part of this manual may be reproduced, transmitted, stored in a retrieval system, or translated into

any language or computer language, in any form or by any means, without the prior written

permission of Motorola Inc.

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted Motorola computer

programs stored in semiconductor memories or other media. Laws in the United States and other

countries preserve for Motorola certain exclusive rights for copyrighted computer programs including,

but not limited to, the exclusive right to copy or reproduce in any form the copyrighted computer

program. Accordingly, any copyrighted Motorola computer programs contained in the Motorola

products described in this manual may not be copied, reproduced, modified, reverse-engineered, or

distributed in any manner without the express written permission of Motorola. Furthermore, the

purchase of Motorola products shall not be deemed to grant either directly or by implication, estoppel,

or otherwise, any license under the copyrights, patents or patent applications of Motorola, except for

the normal non-exclusive royalty-free license to use that arises by operation of law in the sale of a

product.

i

Trademarks

MOTOROLA and the Stylized M Logo are registered in the U.S.Patent and Trademark Office. All

other product or service names are the property of their respective owners.

Page 6

ii

SAFETY INFORMATION

Product Safety and RF Energy Exposure Compliance

These servicing instructions are for use by qualified personnel only. To

reduce the risk of electric shock, do not perform any servicing other than that

contained in the Operating Instructions unless you are qualified to do so.

Refer all servicing to qualified service personnel.

Before using this product, read the operating instructions for safe usage

contained in the Product Safety and RF Exposure booklet enclosed with your

radio.

ATTENTION!

This is restricted to occupational use only to satisfy ICNIRP RF energy exposure

requirements. Before using this product, read the RF energy awareness information and

operating instructions in the Product Safety and RF Exposure booklet enclosed with your

(Motorola Publication part number 68007024010) to ensure compliance with RF energy

exposure limits.

For a list of Motorola-approved antennas, and other accessories, visit the following web site

which lists approved accessories: http://www.motorola.com/radiosolutions

Page 7

DOCUMENT HISTORY

The following major changes have been implemented in this manual since the previous edition:

Edition Description Date

6878422A01-A Initial edition Mar, 2009

iii

6878422A01-B Added VHF and UHF1 band information (Chapter 8,

9, 10, 11, 12, 13)

August, 2009

Page 8

iv

Notes

Page 9

Table of Contents v

Table of Contents

Copyright ........................................................................................................ i

Safety Information......................................................................................... ii

Document History ........................................................................................ iii

Chapter 1 Maintenance ........................................................................ 1-1

1.1 Preventive Maintenance ................................................................................................................ 1-1

1.2 Inspection ...................................................................................................................................... 1-1

1.3 Cleaning......................................................................................................................................... 1-1

1.4 Safe Handling of CMOS and LDMOS............................................................................................ 1-2

1.5 General Repair Procedures and Techniques ................................................................................ 1-2

Chapter 2 Test Equipment, Service Aids, and Service Tools........... 2-1

2.1 Test Equipment.............................................................................................................................. 2-1

2.2 Service Aids................................................................................................................................... 2-2

Chapter 3 DC Power Distribution........................................................ 3-1

3.1 DC Regulation and Distribution ..................................................................................................... 3-1

Chapter 4 Controller Theory of Operation.......................................... 4-1

4.1 RX Audio Circuit ............................................................................................................................ 4-1

4.1.1 Audio processor IC (U102) ............................................................................................... 4-1

4.1.1.1 RX Audio Processing......................................................................................... 4-1

4.1.1.2 RX Tone PL/Digital PL Decode Filtering............................................................ 4-2

4.1.2 Audio Amp ........................................................................................................................ 4-2

4.1.3 Internal and External Speaker .......................................................................................... 4-2

4.2 TX Audio Circuit............................................................................................................................. 4-3

4.2.1 MIC and External MIC ...................................................................................................... 4-3

4.2.2 4-order 4 kHz Low-Pass Filter (U501-C, D) ...................................................................... 4-3

4.2.3 Audio processor IC (U102) ............................................................................................... 4-3

4.2.3.1 TX Audio Processing ......................................................................................... 4-3

4.2.3.2 Tx Tone PL/Digital PL Encode Filtering............................................................. 4-4

4.2.4 TX audio amplifier and 6 order 3 kHz Low-Pass filter....................................................... 4-4

4.2.5 TX modulation Adjustment................................................................................................ 4-4

4.3 Microprocessor Circuitry ................................................................................................................ 4-4

4.3.1 Memory Usage ................................................................................................................. 4-5

4.3.2 Control and Indicator Interface ......................................................................................... 4-5

4.3.3 Interface to USB programming ......................................................................................... 4-5

4.3.4 Storage of Customer-Specific Information........................................................................ 4-5

4.3.5 Sensing of VOX operating ................................................................................................ 4-5

4.3.6 Microprocessor Power-on reset Routine .......................................................................... 4-5

4.3.7 Microprocessor 7.3728 MHz Clock................................................................................... 4-5

Page 10

vi Table of Contents

4.3.8 Battery indicator ................................................................................................................ 4-5

Chapter 5 435 – 480 MHz UHF2 Theory Of Operation ....................... 5-1

5.1 Introduction .................................................................................................................................... 5-1

5.2 UHF2 Receiver .............................................................................................................................. 5-1

5.2.1 Receiver Front End ...........................................................................................................5-2

5.2.2 Receiver Back End ........................................................................................................... 5-2

5.3 UHF2 Transmitter .......................................................................................................................... 5-3

5.3.1 Power Amplifier................................................................................................................. 5-3

5.3.2 Antenna Switch ................................................................................................................. 5-3

5.3.3 Harmonic Filter..................................................................................................................5-3

5.3.4 Auto Power Control........................................................................................................... 5-4

5.4 UHF2 Frequency Generation Circuitry........................................................................................... 5-4

5.4.1 Reference Oscillator (12.8 MHz VCTCXO)....................................................................... 5-4

5.4.2 PLL IC Prescaler and Comparator.................................................................................... 5-5

5.4.3 Voltage Doubler and Charge Pump .................................................................................. 5-5

5.4.4 Loop Filter ......................................................................................................................... 5-5

5.4.5 Dual VCO.......................................................................................................................... 5-5

5.5 Keypad........................................................................................................................................... 5-6

Chapter 6 UHF2 Troubleshooting Tables........................................... 6-1

6.1 Troubleshooting Table for Receiver (UHF2) .................................................................................6-1

6.2 Troubleshooting Table for Synthesizer (UHF2) ............................................................................ 6-2

6.3 Troubleshooting Table for Transmitter (UHF2) .............................................................................6-3

6.4 Troubleshooting Table for Board and IC Signals (UHF2) ............................................................. 6-4

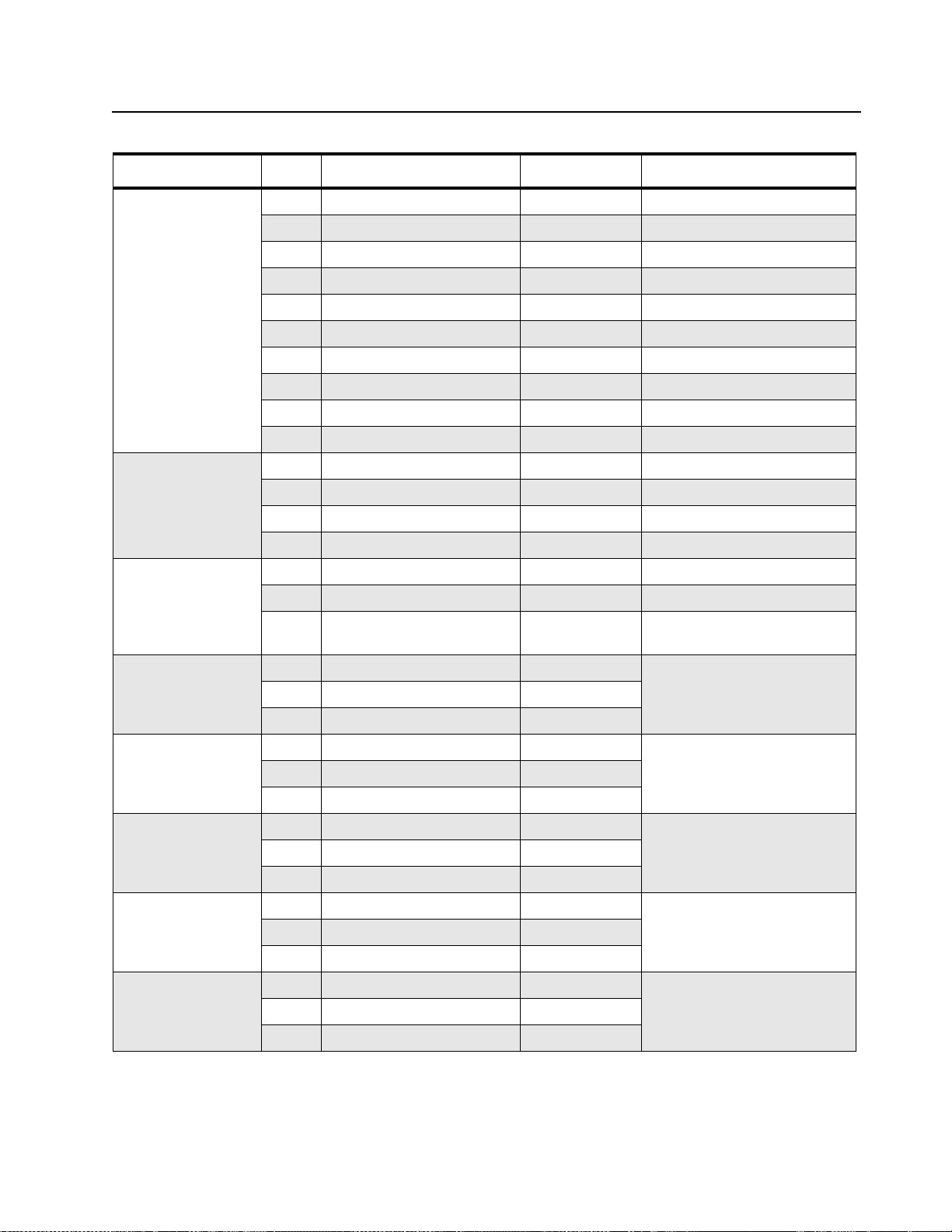

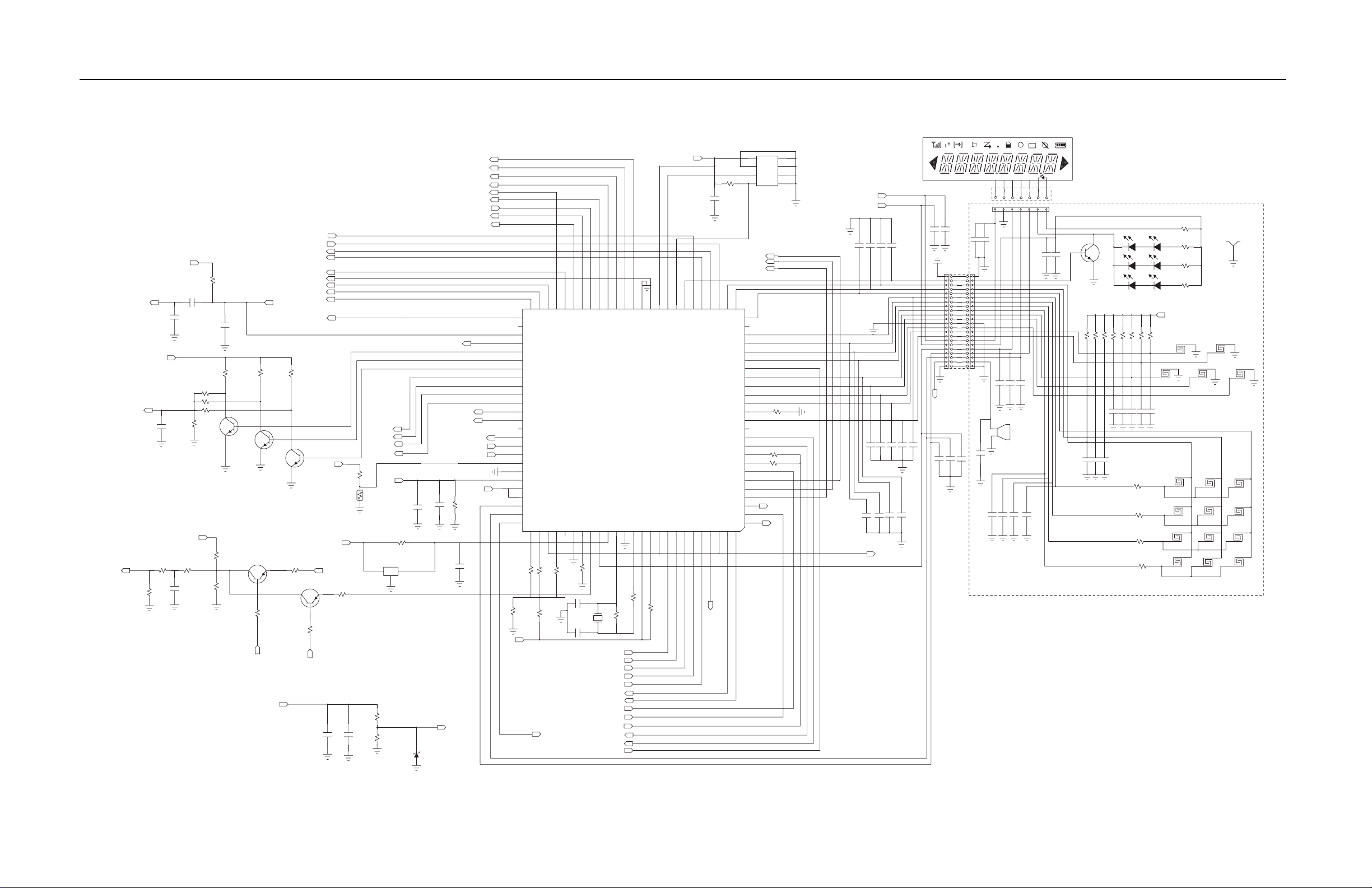

Chapter 7 UHF2 Schematic Diagrams, Overlays, and Parts Lists ... 7-1

7.1 Introduction .................................................................................................................................... 7-1

7.1.1 Notes For All Schematics and Circuit Boards ...................................................................7-1

7.1.2 Four Layer Circuit Board...................................................................................................7-3

7.2 Speaker and Microphone Schematic .............................................................................................7-3

7.2.1 Speaker and Microphone Parts List.................................................................................. 7-3

7.3 Circuit Board/Schematic Diagram and Parts List (UHF2: 435–480 MHz)...................................... 7-4

7.3.1 Parts List ......................................................................................................................... 7-16

Chapter 8 136 – 174 MHz VHF Theory Of Operation.......................... 8-1

8.1 Introduction .................................................................................................................................... 8-1

8.2 VHF Receiver................................................................................................................................. 8-1

8.2.1 Receiver Front End ...........................................................................................................8-2

8.2.2 Receiver Back End ........................................................................................................... 8-2

8.3 VHF Transmitter............................................................................................................................. 8-3

8.3.1 Power Amplifier................................................................................................................. 8-3

8.3.2 Antenna Switch ................................................................................................................. 8-3

8.3.3 Harmonic Filter..................................................................................................................8-3

8.3.4 Auto Power Control........................................................................................................... 8-4

8.4 VHF Frequency Generation Circuitry............................................................................................. 8-4

8.4.1 Reference Oscillator (12.8 MHz VCTCXO)....................................................................... 8-4

8.4.2 PLL IC Prescaler and Comparator.................................................................................... 8-5

Page 11

Table of Contents vii

8.4.3 Voltage Doubler and Charge Pump.................................................................................. 8-5

8.4.4 Loop Filter......................................................................................................................... 8-5

8.4.5 Dual VCO.......................................................................................................................... 8-5

8.5 Keypad........................................................................................................................................... 8-6

Chapter 9 VHF Troubleshooting Tables ............................................. 9-1

9.1 Troubleshooting Table for Receiver (VHF) ................................................................................... 9-1

9.2 Troubleshooting Table for Synthesizer (VHF) .............................................................................. 9-2

9.3 Troubleshooting Table for Transmitter (VHF) ............................................................................... 9-3

9.4 Troubleshooting Table for Board and IC Signals (VHF) ............................................................... 9-4

Chapter 10 VHF Schematic Diagrams, Overlays, and Parts Lists.... 10-1

10.1 Introduction.................................................................................................................................. 10-1

10.1.1 Notes For All Schematics and Circuit Boards ................................................................. 10-1

10.1.2 Four Layer Circuit Board................................................................................................. 10-3

10.2 Speaker and Microphone Schematic........................................................................................... 10-3

10.2.1 Speaker and Microphone Parts List................................................................................ 10-3

10.3 Circuit Board/Schematic Diagram and Parts List (VHF: 136–174 MHz)...................................... 10-1

10.3.1 Parts List....................................................................................................................... 10-14

Chapter 11 403 – 447 MHz UHF1 Theory Of Operation ..................... 11-1

11.1 Introduction.................................................................................................................................. 11-1

11.2 UHF1 Receiver ............................................................................................................................ 11-1

11.2.1 Receiver Front End......................................................................................................... 11-2

11.2.2 Receiver Back End .........................................................................................................11-2

11.3 UHF1 Transmitter ........................................................................................................................ 11-3

11.3.1 Power Amplifier............................................................................................................... 11-3

11.3.2 Antenna Switch............................................................................................................... 11-3

11.3.3 Harmonic Filter ............................................................................................................... 11-3

11.3.4 Auto Power Control......................................................................................................... 11-4

11.4 UHF1 Frequency Generation Circuitry ........................................................................................ 11-4

11.4.1 Reference Oscillator (12.8 MHz VCTCXO) .................................................................... 11-4

11.4.2 PLL IC Prescaler and Comparator.................................................................................. 11-5

11.4.3 Voltage Doubler and Charge Pump ................................................................................ 11-5

11.4.4 Loop Filter....................................................................................................................... 11-5

11.4.5 Dual VCO........................................................................................................................ 11-5

11.5 Keypad......................................................................................................................................... 11-6

Chapter 12 UHF1 Troubleshooting Tables......................................... 12-1

12.1 Troubleshooting Table for Receiver (UHF1) ............................................................................... 12-1

12.2 Troubleshooting Table for Synthesizer (UHF1) .......................................................................... 12-2

12.3 Troubleshooting Table for Transmitter (UHF1) ........................................................................... 12-3

12.4 Troubleshooting Table for Board and IC Signals (UHF1) ........................................................... 12-4

Chapter 13 UHF1 Schematic Diagrams, Overlays, and Parts Lists . 13-1

13.1 Introduction.................................................................................................................................. 13-1

Page 12

viii Table of Contents

13.1.1 Notes For All Schematics and Circuit Boards ................................................................. 13-1

13.1.2 Four Layer Circuit Board................................................................................................. 13-3

13.2 Speaker and Microphone Schematic........................................................................................... 13-3

13.2.1 Speaker and Microphone Parts List ................................................................................ 13-3

13.3 Circuit Board/Schematic Diagram and Parts List (UHF1: 403–447 MHz).................................... 13-1

13.3.1 Parts List ....................................................................................................................... 13-13

Appendix A Warranty, Service Support, and Replacement Parts .......A-1

A.1 Scope of Manual ............................................................................................................................A-1

A.2 Warranty ........................................................................................................................................A-1

A.2.1 Warranty Period and Return Instructions..........................................................................A-1

A.2.2 After Warranty Period .......................................................................................................A-1

A.2.3 Piece Parts........................................................................................................................A-2

Page 13

List of Figures ix

List of Figures

Figure 2-1. Programming/Test Cable (PMDN4077_R)....................................................................... 2-3

Figure 2-2. Cloning Cable (PMDN4076_R) ........................................................................................ 2-3

Figure 2-3. Wiring of the Connectors.................................................................................................. 2-3

Figure 3-1. DC Power Distribution Block Diagram.............................................................................. 3-1

Figure 4-1. RX Audio Circuit ............................................................................................................... 4-1

Figure 4-2. TX Audio Circuit ............................................................................................................... 4-3

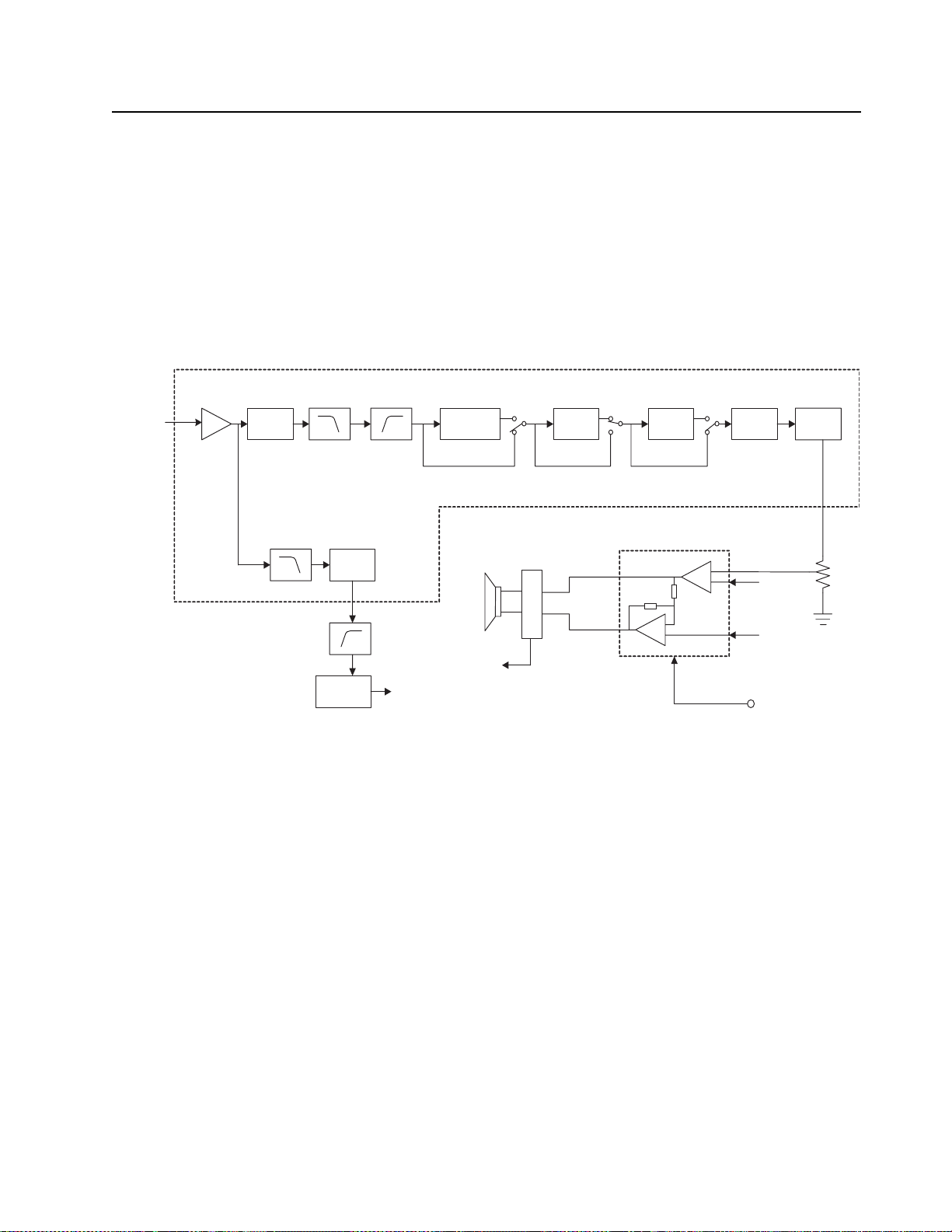

Figure 5-1. UHF2 Receiver Block Diagram ........................................................................................ 5-1

Figure 5-2. UHF2 Transmitter Block Diagram .................................................................................... 5-3

Figure 5-3. UHF2 Frequency Generation Unit Block Diagram ........................................................... 5-4

Figure 5-4. Keypad Block Diagram..................................................................................................... 5-6

Figure 7-1. Four–Layer Circuit Board: Copper Steps in Layer Sequence .......................................... 7-3

Figure 7-2. Speaker and Microphone Schematic ............................................................................... 7-3

Figure 7-3. UHF2 (435–480 MHz) Receiver Schematic Diagram....................................................... 7-4

Figure 7-4. VCO and PLL Schematic Diagram................................................................................... 7-5

Figure 7-5. Transmitter Schematic Diagram....................................................................................... 7-6

Figure 7-6. Microprocessor and Keypad Schematic Diagram ............................................................ 7-7

Figure 7-7. Audio Power Amplifier and External Audio Schematic Diagram ...................................... 7-8

Figure 7-8. Switches and Battery Schematic Diagram ....................................................................... 7-9

Figure 7-9. Transmitter Audio Filter and Sub-tone Schematic Diagram ........................................... 7-10

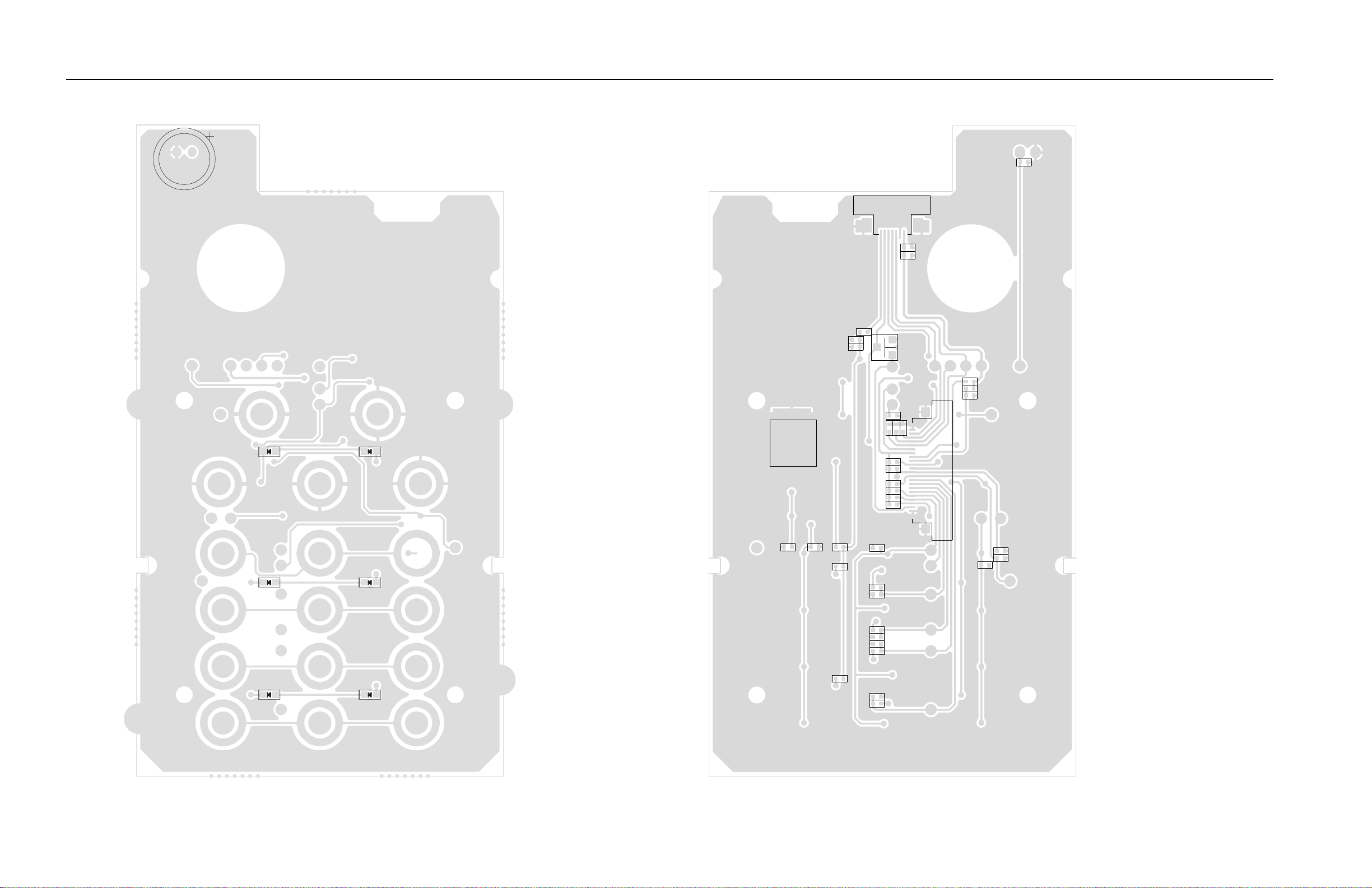

Figure 7-10. UHF2 (435–480 MHz) Mainboard Top Side: PCB No. 8431BEACON200..................... 7-11

Figure 7-11. UHF2 (435–480 MHz) Mainboard Bottom Side: PCB No. 8431BEACON200 ............... 7-12

Figure 7-12. UHF2 (435–480 MHz) Sub Circuit Board Top View: PCB No. 8421BEACON100......... 7-13

Figure 7-13. UHF2 (435–480 MHz) Sub Circuit Board Bottom View: PCB No. 8421BEACON100.... 7-14

Figure 7-14. UHF2 (435–480 MHz) Keypad Board: PCB No. 8422BEACON100 .............................. 7-15

Figure 8-1. VHF Receiver Block Diagram...........................................................................................8-1

Figure 8-2. VHF Transmitter Block Diagram....................................................................................... 8-3

Figure 8-3. VHF Frequency Generation Unit Block Diagram.............................................................. 8-4

Figure 8-4. Keypad Block Diagram..................................................................................................... 8-6

Figure 10-1. Four–Layer Circuit Board: Copper Steps in Layer Sequence ........................................ 10-3

Figure 10-2. Speaker and Microphone Schematic ............................................................................. 10-3

Figure 10-3. VHF (136–174 MHz) Receiver Schematic Diagram....................................................... 10-1

Figure 10-4. VCO and PLL Schematic Diagram................................................................................. 10-2

Figure 10-5. Transmitter Schematic Diagram..................................................................................... 10-3

Figure 10-6. Microprocessor and Keypad Schematic Diagram .......................................................... 10-4

Figure 10-7. Audio Power Amplifier and External Audio Schematic Diagram .................................... 10-5

Figure 10-8. Switches and Battery Schematic Diagram ..................................................................... 10-6

Figure 10-9. Transmitter Audio Filter and Sub-tone Schematic Diagram ........................................... 10-7

Figure 10-10. Receiver Audio Filter and Sub-tone Schematic Diagram ............................................... 10-8

Figure 10-11. VHF (136–174 MHz) Mainboard Top Side: PCB No. 8431BEACON400....................... 10-9

Figure 10-12. VHF (136–174 MHz) Mainboard Bottom Side: PCB No. 8431BEACON400................ 10-10

Figure 10-13. VHF (136–174 MHz)Sub Circuit Board Top View: PCB No. 8421BEACON100 .......... 10-11

Figure 10-14. VHF (136–174 MHz)Sub Circuit Board Bottom View: PCB No. 8421BEACON100 ..... 10-12

Figure 10-15. VHF (136–174 MHz) Keypad Board: PCB No. 8422BEACON100 .............................. 10-13

Figure 11-1. UHF1 Receiver Block Diagram ...................................................................................... 11-1

Figure 11-2. UHF1 Transmitter Block Diagram .................................................................................. 11-3

Figure 11-3. UHF1 Frequency Generation Unit Block Diagram ......................................................... 11-4

Figure 11-4. Keypad Block Diagram................................................................................................... 11-6

Figure 13-1. Four–Layer Circuit Board: Copper Steps in Layer Sequence ........................................ 13-3

Figure 13-2. Speaker and Microphone Schematic ............................................................................. 13-3

Figure 13-3. UHF1 (403–447 MHz) Receiver Schematic Diagram..................................................... 13-1

Page 14

x List of Figures

Figure 13-4. VCO and PLL Schematic Diagram ................................................................................. 13-2

Figure 13-5. Transmitter Schematic Diagram ..................................................................................... 13-3

Figure 13-6. Microprocessor and Keypad Schematic Diagram .......................................................... 13-4

Figure 13-7. Audio Power Amplifier and External Audio Schematic Diagram .................................... 13-5

Figure 13-8. Switches and Battery Schematic Diagram ..................................................................... 13-6

Figure 13-9. Transmitter Audio Filter and Sub-tone Schematic Diagram ........................................... 13-7

Figure 13-10. UHF1 (403–447 MHz) Mainboard Top Side: PCB No. 8431BEAUHF300 .....................13-8

Figure 13-11. UHF1 (403–447 MHz) Mainboard Bottom Side: PCB No. 8431BEAUHF300 ................13-9

Figure 13-12. UHF1 (403–447 MHz) Sub Circuit Board Top View: PCB No. 8421BEACON100 ....... 13-10

Figure 13-13. UHF1 (403–447 MHz) Sub Circuit Board Bottom View: PCB No. 8421BEACON100.. 13-11

Figure 13-14. UHF1 (403–447 MHz) Keypad Board: PCB No. 8422BEACON100 ............................ 13-12

Page 15

List of Tables xi

List of Tables

Table 1-1. Lead Free Solder Wire Part Number List ......................................................................... 1-3

Table 1-2. Lead Free Solder Paste Part Number List ....................................................................... 1-3

Table 2-1. Recommended Test Equipment....................................................................................... 2-1

Table 2-2. Service Aids ..................................................................................................................... 2-2

Table 3-1. Voltage Regulators........................................................................................................... 3-2

Table 4-1. Radio Memory Requirements........................................................................................... 4-4

Table 6-1. Troubleshooting Table for Receiver (UHF2) .................................................................... 6-1

Table 6-2. Troubleshooting Table for Synthesizer (UHF2)................................................................ 6-2

Table 6-3. Troubleshooting Table for Transmitter (UHF2) ................................................................ 6-3

Table 6-4. Troubleshooting Table for Board and IC Signals (UHF2)................................................. 6-4

Table 9-1. Troubleshooting Table for Receiver (VHF)....................................................................... 9-1

Table 9-2. Troubleshooting Table for Synthesizer (VHF) .................................................................. 9-2

Table 9-3. Troubleshooting Table for Transmitter (VHF)................................................................... 9-3

Table 9-4. Troubleshooting Table for Board and IC Signals (VHF)................................................... 9-4

Table 12-1. Troubleshooting Table for Receiver (UHF1) .................................................................. 12-1

Table 12-2. Troubleshooting Table for Synthesizer (UHF1).............................................................. 12-2

Table 12-3. Troubleshooting Table for Transmitter (UHF1) .............................................................. 12-3

Table 12-4. Troubleshooting Table for Board and IC Signals (UHF1)............................................... 12-4

Page 16

xii Notations Used in This Manual

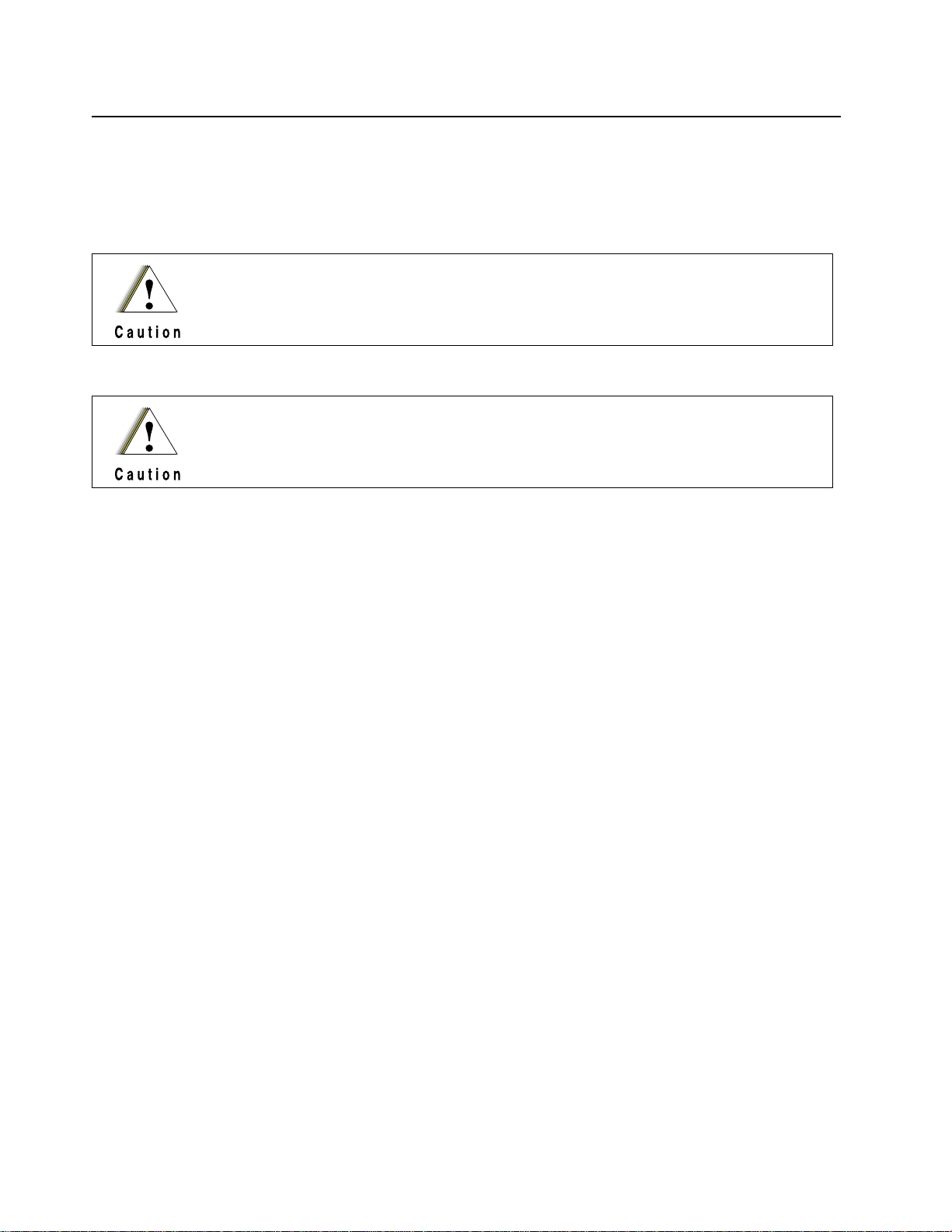

Notations Used in This Manual

Throughout the text in this publication, you will notice the use of the following notations. These notations are

used to emphasize that safety hazards exist, and due care must be taken and observed.

Note

An operational procedure, practice, or condition that isessential to emphasize.

CAUTION indicates a potentially hazardous situation which, if not avoided,

might result in equipment damage.

Page 17

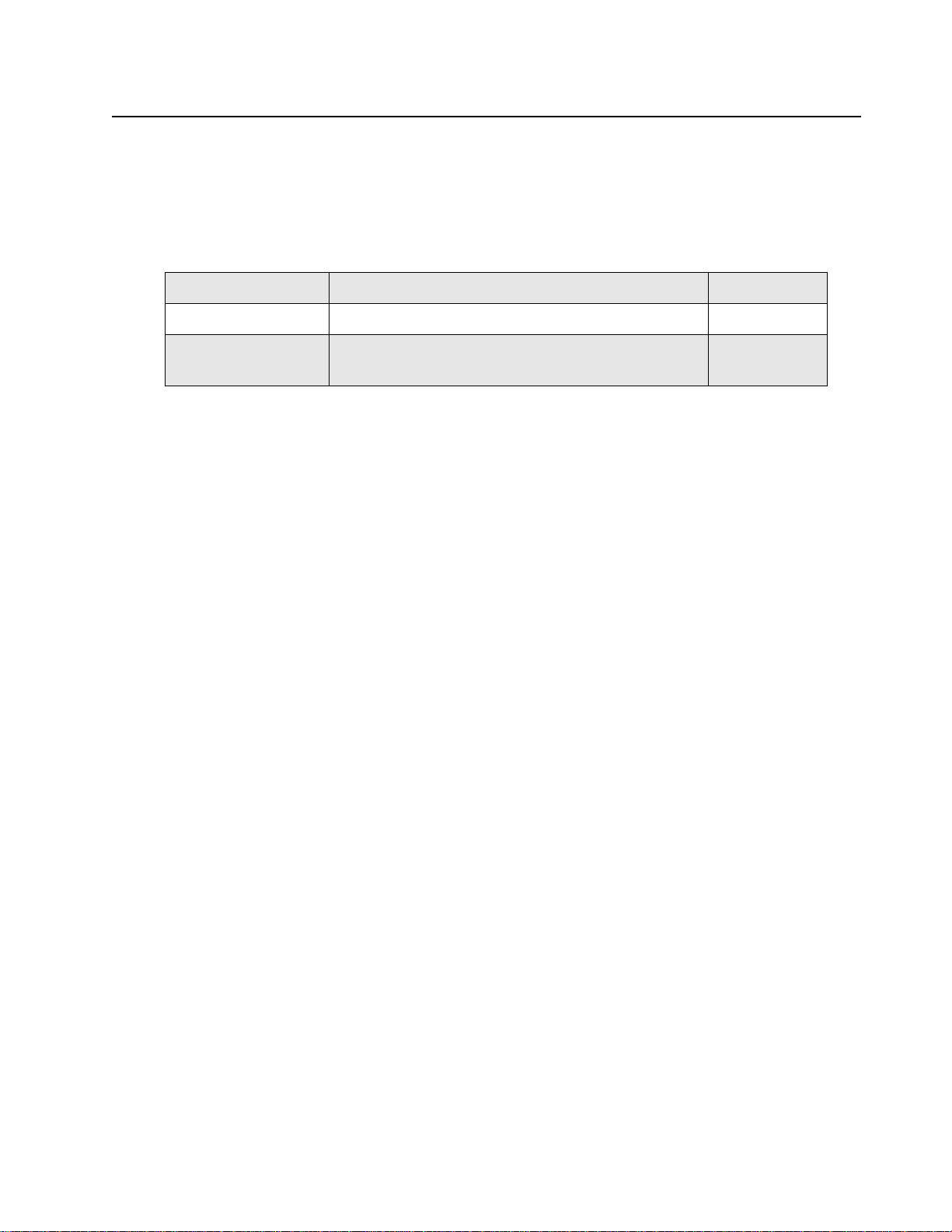

Summary of Printed Circuit Boards and Bands Available xiii

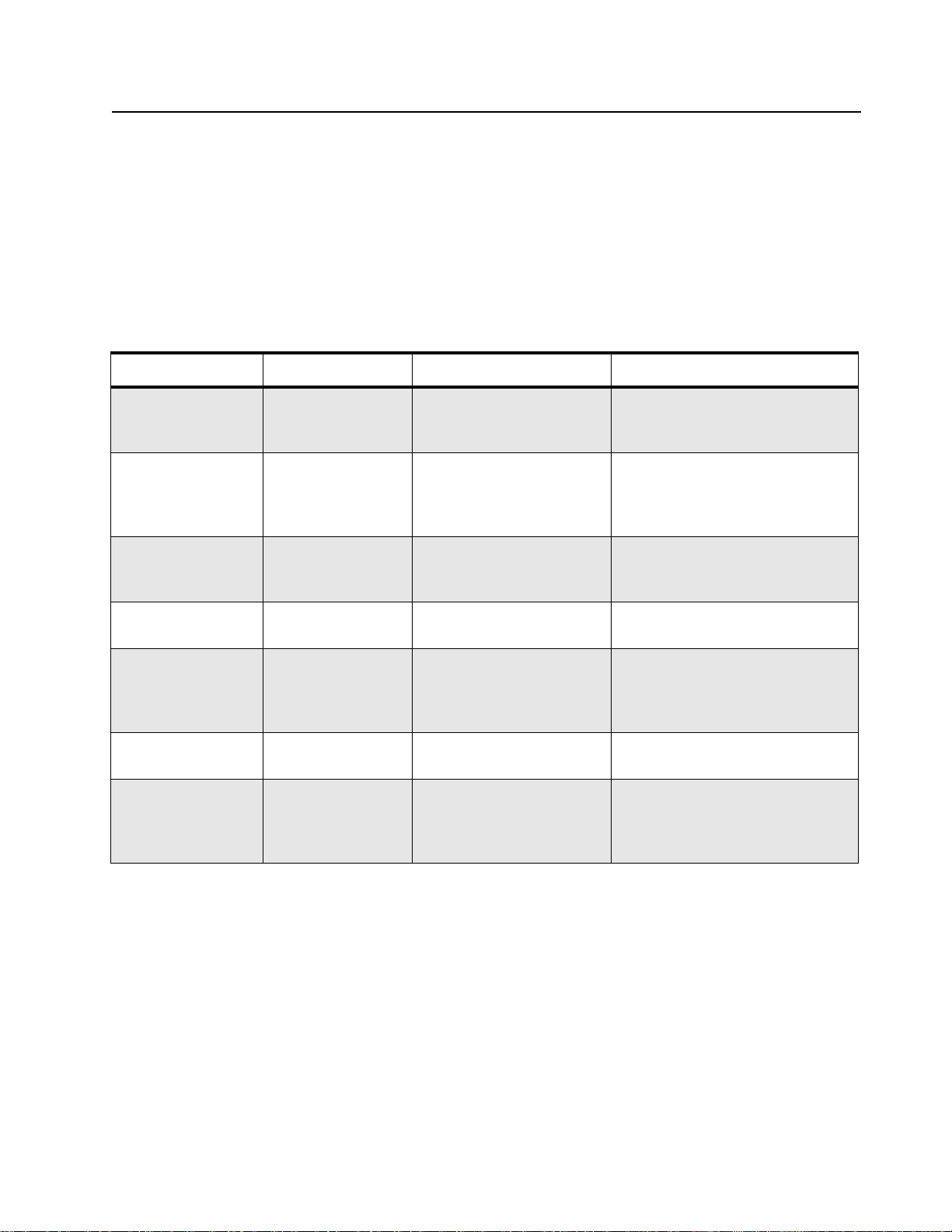

Summary of Printed Circuit Boards and Bands Available

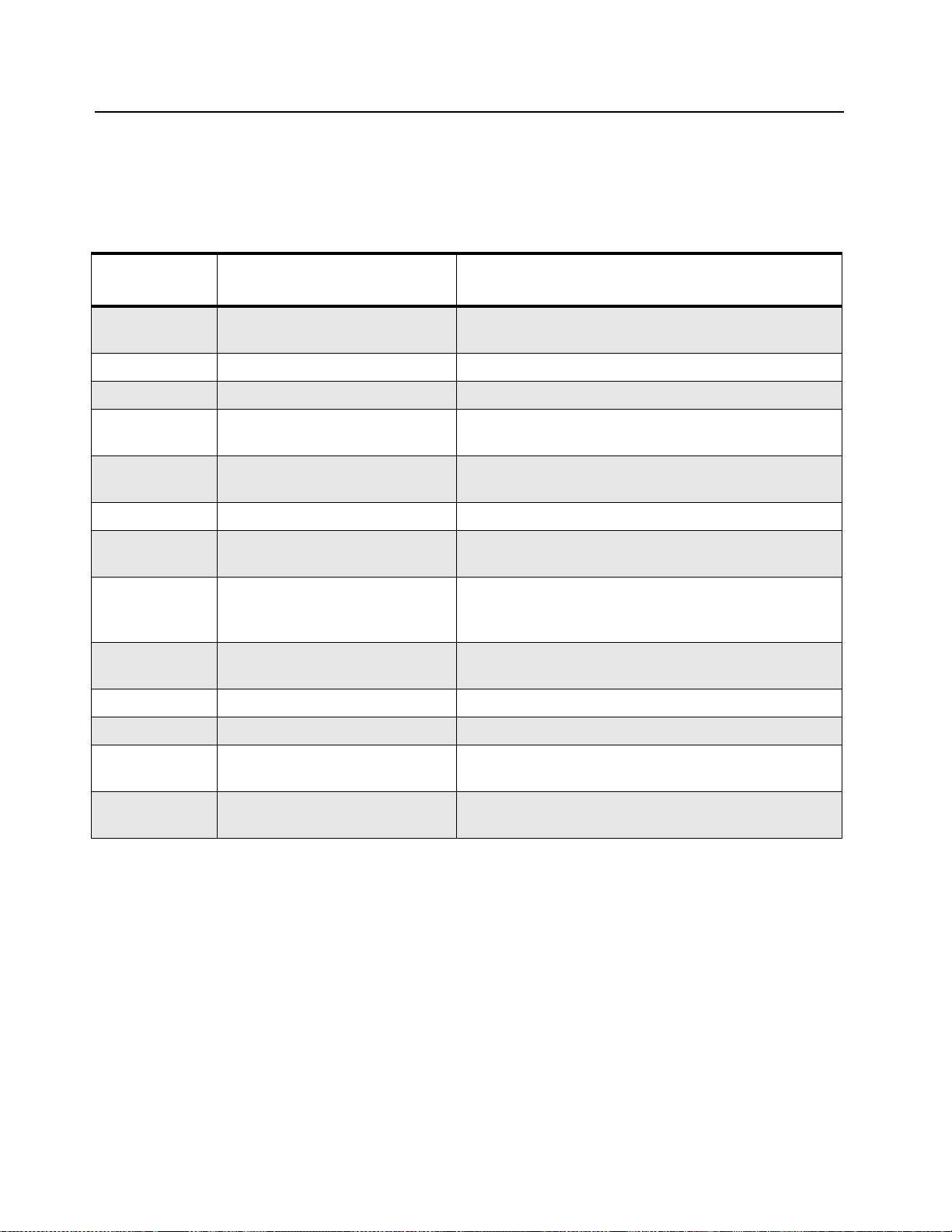

Table below lists all the bands available in this manual.

Frequency

Band

UHF2 435 – 480 MHz 1W or 4W

UHF2 – –

UHF2 – –

VHF 136 – 162 MHz 1W or 5W

VHF – –

VHF – –

UHF1 403 – 447 MHz 1W or 4W

UHF1 – –

UHF1 – –

Bandwidth Power Level PC Board Part Number Board

8431BEACON200

8421BEACON100

8422BEACON100

8431BEACON400

8421BEACON100

8422BEACON100

8431BEAUHF300

8421BEACON100

8422BEACON100

Chapter

Revision

27

1 7

17

4 10

110

1 10

313

1 13

113

Page 18

xiv

Notes

Page 19

Chapter 1 Maintenance

1.0 Introduction

This chapter of the manual describes:

• Preventive maintenance

• Safe handling of CMOS devices

• Repair procedures and techniques

NOTE

The Servicing of your Intrinsically Safe Radios.

In order to maintain compliance, radios that are FM Approved to intrinsically safe

standards MUST be repaired at FM audited service centers. See Further Assistance From

Motorola on page 1-2 for more information.

1.1 Preventive Maintenance

Periodic visual inspection and cleaning is recommended.

1.2 Inspection

Check that the external surfaces of the radio are clean, and that all external controls and switches

are functional. It is not recommended to inspect the interior electronic circuitry.

1.3 Cleaning

The following procedures describe the recommended cleaning agents and the methods to be

used when cleaning the external and internal surfaces of the radio. External surfaces include the

front cover, housing assembly, and battery case. These surfaces should be cleaned whenever a

periodic visual inspection reveals the presence of smudges, grease, and/or grime.

NOTE

The only recommended agent for cleaning the external radio surfaces is a 0.5% solution of a mild

dishwashing detergent in water. The only factory recommended liquid for cleaning the printed

circuit boards and their components is isopropyl alcohol (100% by volume).

Internal surfaces should be cleaned only when the radio is disassembled for servicing or

repair.

CAUTION: The effects of certain chemicals and their vapors can have harmful results on

certain plastics. Aerosol sprays, tuner cleaners, and other chemicals should be avoided.

1. Cleaning External Plastic Surfaces

The detergent-water solution should be applied sparingly with a stiff, non-metallic, shortbristled brush to work all loose dirt away from the radio. A soft, absorbent, lintless cloth or

tissue should be used to remove the solution and dry the radio. Make sure that no water

remains entrapped near the connectors, cracks, or crevices.

Page 20

1-2 Introduction

2. Cleaning Internal Circuit Boards and Components

Isopropyl alcohol may be applied with a stiff, non-metallic, short-bristled brush to dislodge

embedded or caked materials located in hard-to-reach areas. The brush stroke should

direct the dislodged material out and away from the inside of the radio. Make sure that

controls or tunable components are not soaked with alcohol. Do not use high-pressure

air to hasten the drying process since this could cause the liquid to collect in unwanted

places. Upon completion of the cleaning process, use a soft, absorbent, lintless cloth to

dry the area. Do not brush or apply any isopropyl alcohol to the frame, front cover, or

back cover.

NOTE Always use a fresh supply of alcohol and a clean container to prevent contamination by

dissolved material (from previous usage).

1.4 Safe Handling of CMOS and LDMOS

Complementary metal-oxide semiconductor (CMOS) devices are used in this family of radios.

CMOS characteristics make them susceptible to damage by electrostatic or high voltage charges.

Damage can be latent, resulting in failures occurring weeks or months later. Therefore, special

precautions must be taken to prevent device damage during disassembly, troubleshooting, and

repair.

Handling precautions are mandatory for CMOS circuits and are especially important in low

humidity conditions. DO NOT attempt to disassemble the radio without first referring to the CMOS

CAUTION paragraph in the Disassembly and Reassembly section of the manual.

1.5 General Repair Procedures and Techniques

NOTE

Environmentally Preferred Products (EPP) (refer to the marking on the printed circuit

boards - examples shown below) were developed and assembled using environmentally

preferred components and solder assembly techniques that meet or exceed compliance

to the European Union’s ROHS and WEEE directives (Waste Electrical and Electronic

Equipment (WEEE) Directive 2002/96/EC and Restriction of Hazardous Subtances

(ROHS) Directive 2002/95/EC). To maintain product compliance and reliability, use only

the Motorola specified parts in this manual.

For the identification of lead (Pb) free assemblies, all EPP products will carry the EPP

Marking, shown below, on the printed circuit board (PCB). This marking provides

information to those performing assembly, servicing and recycling operation on this

product, adhering to the JEDEC standard #97. The EPP Marking takes the form of a

label or marking on the PCB.

Page 21

Introduction 1-3

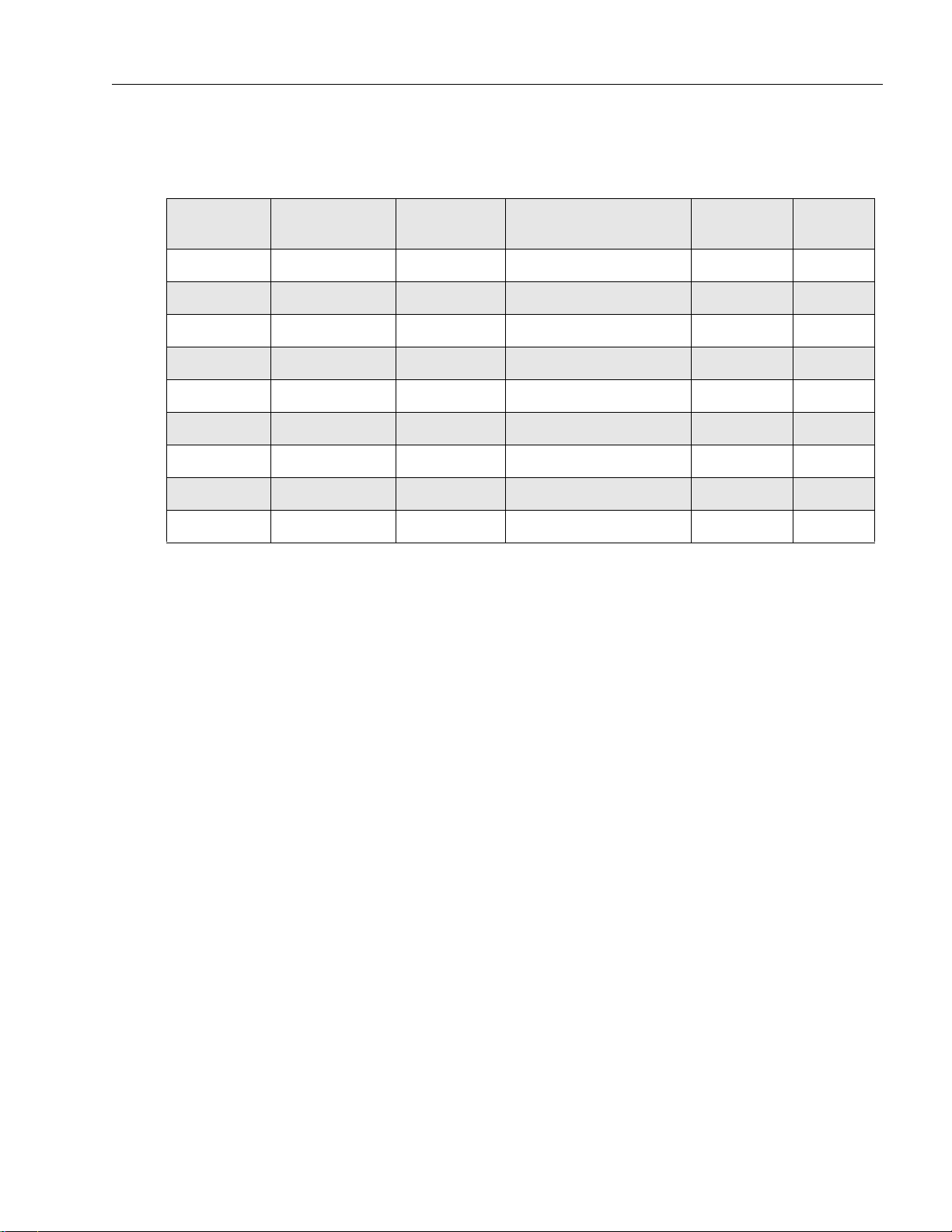

Any rework or repair on Environmentally Preferred Products must be done using the appropriate

lead-free solder wire and solder paste as stated in the following tables:

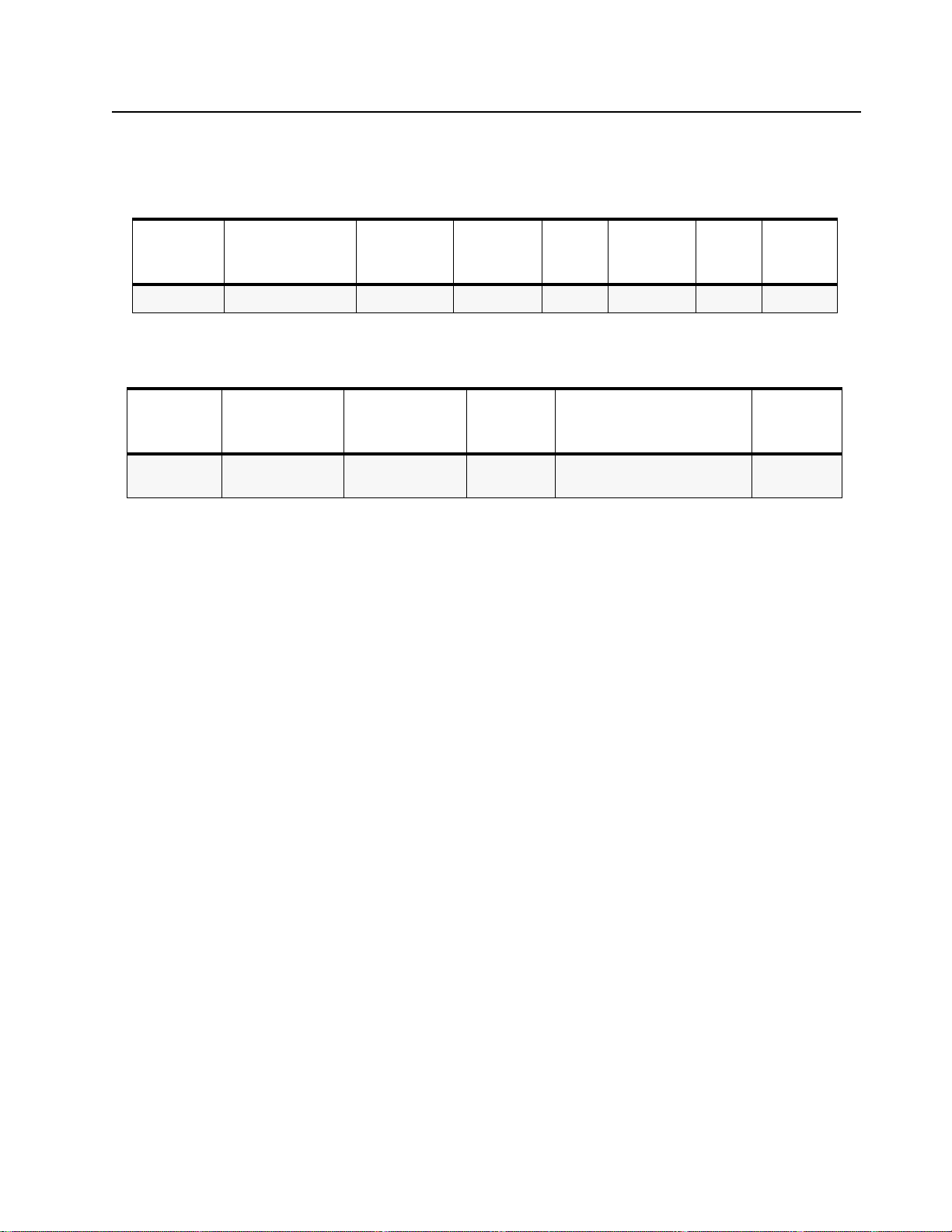

Table 1-1. Lead Free Solder Wire Part Number List

Motorola

Part

Number

1088929Y01 95.5Sn/3.8Ag/0.7Cu RMA Version 2.7-3.2% 217C 52171 0.015” 1lb spool

Alloy Flux Type

Flux

Content by

Weight

Melting

Point

Supplier

Part

number

Diamet

er

Weight

Table 1-2. Lead Free Solder Paste Part Number List

Motorola

Part Number

1085674C03 NC-SMQ230 900-1000KCPs

Manufacturer

Part Number

Viscosity Type Composition & Percent Metal

Brookfield (5rpm)

Type 3

(-325/+500)

(95.5%Sn-3.8%Ag-0.7%Cu)

89.3%

Liquid

Temperatur

e

217°C

Parts Replacement and Substitution

When damaged parts are replaced, identical parts should be used. If the identical replacement

component is not locally available, check the parts list for the proper Motorola part number and

order the component from the nearest Motorola Communications parts center listed in the “Piece

Parts” section of this manual.

Rigid Circuit Boards

The family of radios uses bonded, multi-layer, printed circuit boards. Since the inner layers are

not accessible, some special considerations are required when soldering and unsoldering

components. The through-plated holes may interconnect multiple layers of the printed circuit.

Therefore, care should be exercised to avoid pulling the plated circuit out of the hole.

When soldering near the connector pins:

• Avoid accidentally getting solder in the connector.

• Be careful not to form solder bridges between the connector pins

• Closely examine your work for shorts due to solder bridges.

Chip Components

Use the RLN4062 Hot-Air Repair Station for chip component replacement. Adjust the

temperature control to 390 °C (735 °F), and adjust the airflow to a minimum setting. Airflow can

vary due to component density.

• To remove a chip component:

1. Use a hot-air hand piece and position the nozzle of the hand piece approximately 0.3 cm

(1/8") above the component to be removed.

2. Begin applying the hot air. Once the solder reflows, remove the component using a pair

of tweezers.

3. Using a solder wick and a soldering iron or a power desoldering station, remove the

excess solder from the pads.

Page 22

1-4 Introduction

• To replace a chip component using a soldering iron:

1. Select the appropriate micro-tipped soldering iron and apply fresh solder to one of the

solder pads.

2. Using a pair of tweezers, position the new chip component in place while heating the

fresh solder.

3. Once solder wicks onto the new component, remove the heat from the solder.

4. Heat the remaining pad with the soldering iron and apply solder until it wicks to the

component. If necessary, touch up the first side. All solder joints should be smooth and

shiny.

• To replace a chip component using hot air:

1. Use the hot-air hand piece and reflow the solder on the solder pads to smooth it.

2. Apply a drop of solder paste flux to each pad.

3. Using a pair of tweezers, position the new component in place.

4. Position the hot-air hand piece approximately 0.3 cm (1/8”) above the component and

begin applying heat.

5. Once the solder wicks to the component, remove the heat and inspect the repair. All

joints should be smooth and shiny.

Shields

Removing and replacing shields is recommended to be done with the Air Blower,

BOSCH GHG 603 or equivalent.

• To remove the shield:

1. Place the circuit board in the circuit board holder.

2. Add solder paste flux around the base of the shield.

3. Position the heat-focus head onto the shield.

4. Turn on the heater and wait until the shield lifts off the circuit board.

5. Once the shield is off, turn off the heat, and grab the part with a pair of tweezers.

6. Remove the circuit board from the circuit board holder.

• To replace the shield:

1. Add solder to the shield if necessary, using a micro-tipped soldering iron.

2. Next, rub the soldering iron tip along the edge of the shield to smooth out any excess

solder. Use solder wick and a soldering iron to remove excess solder from the solder

pads on the circuit board.

3. Place the circuit board back in the circuit board holder.

4. Place the shield on the circuit board using a pair of tweezers.

5. Position the heat-focus head over the shield.

6. Turn on the heater and wait for the solder to reflow.

7. Once complete, turn off the heat, raise the heat-focus head and wait approximately one

minute for the part to cool.

8. Remove the circuit board and inspect the repair. No cleaning should be necessary.

Page 23

Chapter 2 Test Equipment, Service Aids, and Service

Tools

2.1 Test Equipment

Table 2-1 lists test equipment required to service the radios.

Table 2-1. Recommended Test Equipment

Motorola Part No. Description Characteristics Application

R2600 series or

HP 8920A

*R1074A Fluke 87 digital

*R1377A AC voltmeter 1 mV to 300 mV, 10 mega-

R1611A Dual channel

S1339A RF millivolt meter 100 μV to 3V RF, 10 kHz to

*R1013B or

*R1370A

System analyzer This item will substitute for

items with an asterisk (*)

True RMS metering,

multi-meter

Fluke 85 RF probe 500 MHz, 30 VAC max Use with Fluke 87 digital

100 MHz

oscilloscope

(Agillent)

SINAD meter or

SINAD meter with

RMS

200 kHz frequency

counter, 32-segment bar

graph with backlit display

Ohm input impedance

Two-channel, 100 MHz

bandwidth, 200 M sample

rate/sec, 2 MB memory/

channel

1 GHz frequency range

Without RMS audio

voltmeter or

With RMS audio voltmeter

Frequency/Deviation meter and

signal generator for wide-range

troubleshooting and alignment

Digital voltmeter is recommended

for AC/DC voltage and current

measurements

multi-meter for RF voltage

measurements.

Audio voltage measurements

Waveform measurements

RF level measurements

Receiver sensitivity

measurements

Page 24

2-2 Test Equipment, Service Aids, and Service Tools: Service Aids

2.2 Service Aids

Table 2-2 lists the service aids recommended for working on the EP350 Series Radios. While all of

these items are available from Motorola, most are standard shop equipment items, and any

equivalent item capable of the same performance may be substituted for the item listed.

Table 2-2. Service Aids

Motorola Part

No.

PMDN4026_R Flat Ceramic Tuning Tools

(1.8mm)

PMDN4038_R Knob Remover/Chassis Opener Used to remove the front cover assembly.

PMDN4039_R Crab Eye Nut Opener Used to remove the crab eye nut.

1

PMDN4040_R

PMDN4041_R RF Adapter Adapts radio’s antenna port to BNC cabling of test

PMDN4044_R T-Head Ceramic Tuning Tool Used for tuning the VCO.

PMDN4053_R Flat Ceramic Tuning Tools

PMDN4076_R Radio to Radio Cloning Cable Allows a radio to be duplicated from a master radio by

PMDN4077_R Programming Cable Used to program the radio through Customer

PMDN4079_R GND Plate Interconnects radio’s chassis to RF Adaptor.

Radio Test Box Enables communication between the radio, test

(0.9mm)

Description Application

Used for tuning the VCO.

equipment and the computer's USB port.

equipment.

Used for tuning the VCO.

transferring programmed data from the master radio to

the other.

Programming Software and Radio Tuner.

PMDN4080_R Battery Eliminator Interconnects radio to power supply.

PMVN4161_ Customer Programming

Software on CD Rom

PMVN4165_ Tuner on CD Rom Only Motorola Service Centers or Authorized Motorola

Note: 1.Use PMDN4040BR or higher for tuning the EP350 Series radios as PMDN4040AR cannot be used to

perform this function.

Program customer option and channel data.

Service Dealers can perform this function.

Page 25

Test Equipment, Service Aids, and Service Tools: Service Aids 2-3

t

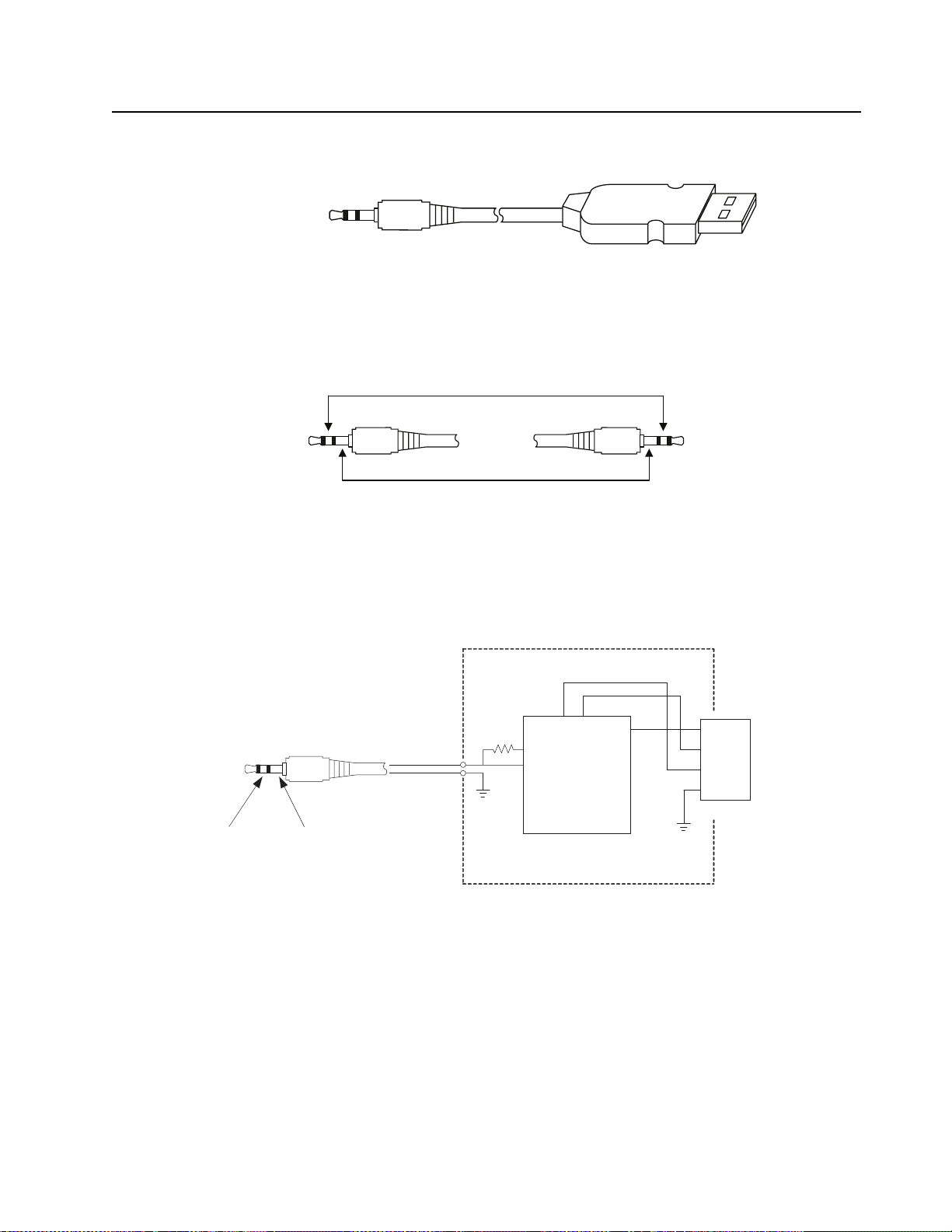

Programming/Test Cable

2.5mm stereo

USB connection

Figure 2-1. Programming/Test Cable (PMDN4077_R)

2.5mm stereo

2.5mm stereo >

12

RX / TX data GND

~

Figure 2-2. Cloning Cable (PMDN4076_R)

D-D+

VBUS

1

2

GND

TX_D

RX_D

IC : CP2102

2.5mm stereo

1

VBUS

2

D-

3

D+

GND

4, 5, 6

To Computor

USB_CONNECTOR

Figure 2-3. Wiring of the Connectors

Page 26

2-4 Test Equipment, Service Aids, and Service Tools: Service Aids

Notes

Page 27

Chapter 3 DC Power Distribution

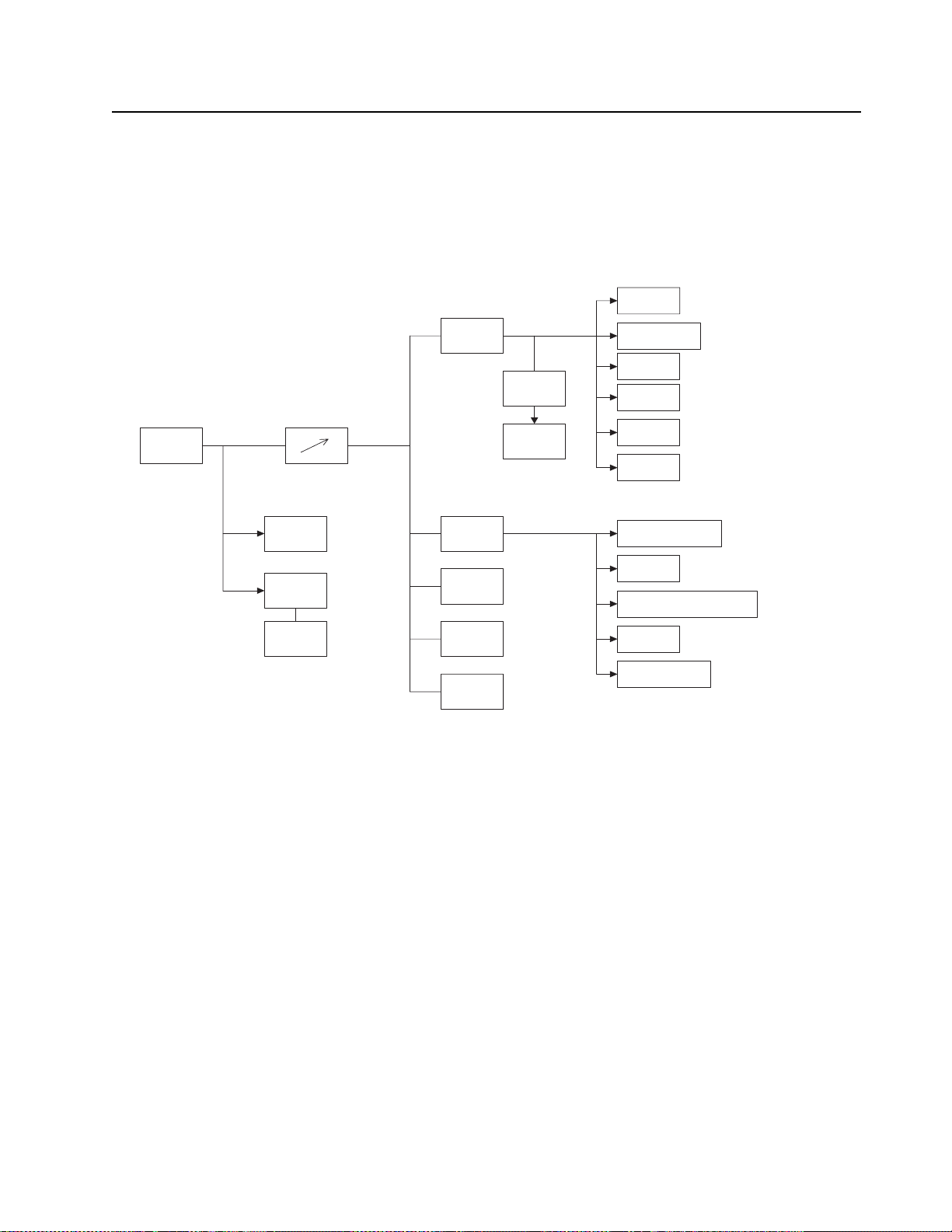

3.1 DC Regulation and Distribution

A block diagram of the DC power distribution throughout the radio is shown in Figure 3-1.

VCTCXO

Voltage

Doubler

10V

Charge

5V

Pump

3.3V

Audio filter

½ Vcc

VCO

RX B+

TXVB

MCU, EEPROM

PLL IC

Digital potent iometer

DTMF IC

LCD Driver

7.5V

Battery

Mech SW1

PA

APC

Driv er,

Pre-driver

SWB+

Vdd

Regulat or

Vdd

Regulat or

Key PC B

Low Batt.

detect or

Audio

Amplifier

Figure 3-1. DC Power Distribution Block Diagram

Battery voltage enters at connector J602 and is routed through SW/VOL1 to become SWB+.

This voltage is routed to:

•SW/VOL1

• TX power amplifier Q403 (via R417)

• APC circuit U401

• RX audio power amplifier U601

• 5V regulator (U505)

• 3.3V regulator (U506)

• Voltage divider R153/R154, a microprocessor A/D input which measures battery voltage

•Key PCB

Page 28

3-2 DC Power Distribution: DC Regulation and Distribution

The following regulators are used:

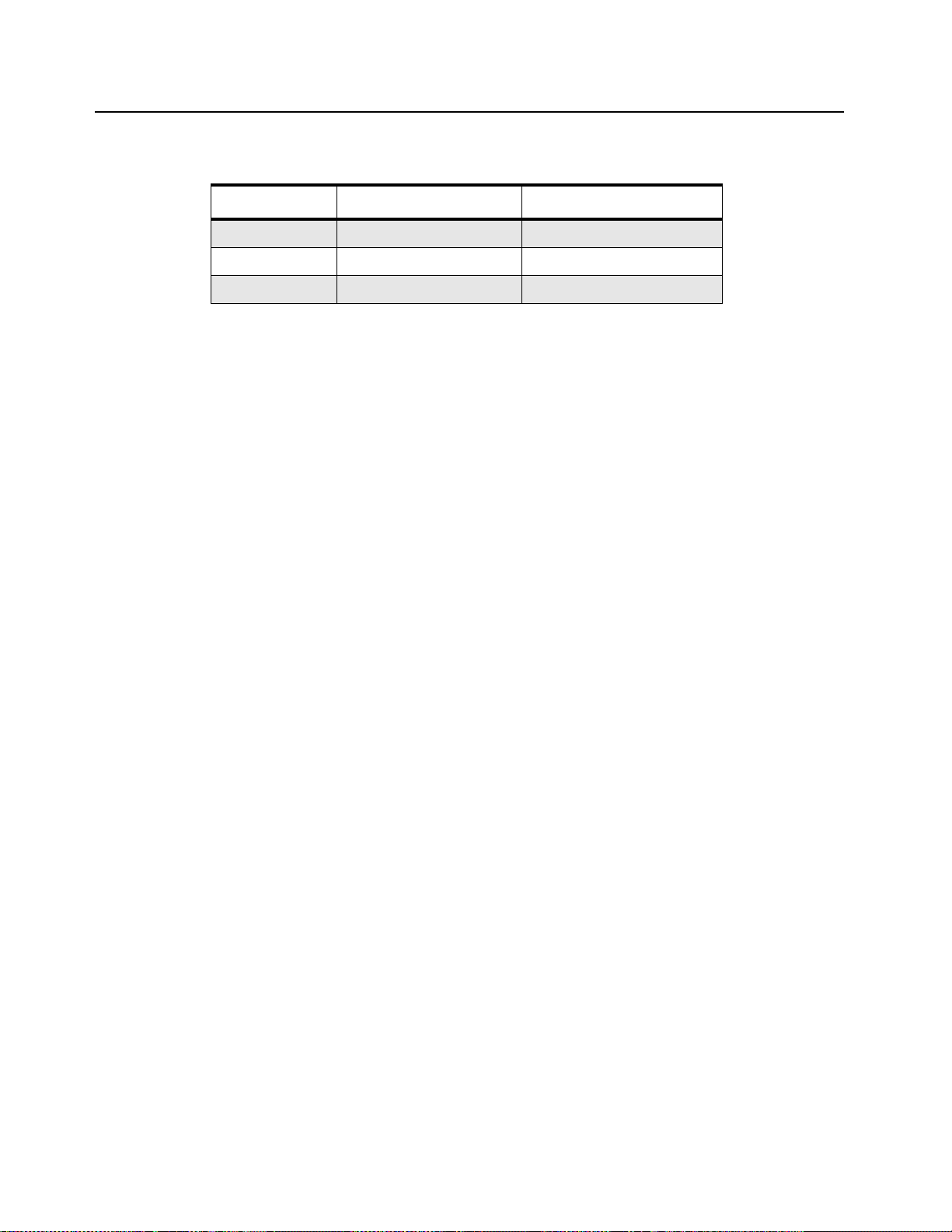

Table 3-1. Voltage Regulators

Reference No. Description Type

U505 5V regulator TK11250

U506 3.3V regulator TK11233

U507 Voltage Doubler (10V) TC12140

The 5 V source from U505 is applied to:

• RX back end circuitry

• RX/TX audio filters

• 1/2 VCC generator

• VCO power source (Q705, Q706)

• RX B+ (Q304)

• TXVB (Q407)

• VCTCXO

The 5 V source is also applied to transistor switches Q304 and Q407. Q304 is turned on by Q305

when RX_EN (from U101 Pin 71) is high, and supplies the source to mixer, IF IC and LNA. Q407 is

turned on by Q408 when TX_EN2 (from U101 Pin 85) is high, and supplies the "TXVB" source to the

first transmitter stage Q401 base, Q402 gate, APC power source (U401 Pin 8) and ANT switch

(CR401).

The 3.3 V regulated source from U506 is applied to:

• MCU IC U101

• EEProm IC U104

• DTMF IC U103

• Audio processor IC U102

• Microphone bias circuitry

• And applied to Key PCB (LCD driver power source)

The 10 V source from U507 is applied to Charge Pump.

Page 29

Chapter 4 Controller Theory of Operation

4.1 RX Audio Circuit

The RX audio circuit consists of Audio Processor IC, Audio Amplifier, Internal (INT)/External (EXT)

speaker and Sub-Audio Tones System.

Audio Processor IC (AK2347)

Audio IN

(from IF IC)

pin24

RXA1

VR3

-4 to +3.5dB/

0.5dB

Sub audio

Programmable

RX LPF TX/RX HPF

LPF

Sub audio

-6 to +6dB/

HPF

Comparator

U105-C

0.5dB

VR5

pin18

U105-A,B

(tone detect)

Figure 4-1. RX Audio Circuit

4.1.1 Audio processor IC (U102)

The RX audio from Pin 9 of U201 enters to Pin 24 of Audio processor IC.

To CPU

Scrambler/

Descrambler

U102

INT SPK.

EXT SPK.

J601

De-

emphasis

Expander VR4 SMF

-18, -4.5 to +4.5dB/

0.25dB

Audio Amp.

OUT-

OUT+

U601

IN-

IN+

SVR

Audio Mute

pin21

Vol1

control

• RX A: An operational amplifier used for gain adjustment of the receive demodulation signal

from Pin 9 of U201. The gain is unity and it acts as a buffer amplifier.

4.1.1.1 RX Audio Processing

•VR3: This circuit controls the volume for adjusting the input level of receive demodulation

signal. Adjustment range: -4.0dB to +3.5dB in 0.5dB steps.

• RX LPF: Low-pass filter to eliminate high-frequency components higher than 3 kHz which are

included in the receive demodulation signal.

• TX/RX HPF: High-pass filter to eliminate low-frequency components lower than 250 Hz which

are included in receive audio signal. This circuit is turned on and off by control register of Audio

processor IC.

• Descrambler: This circuit inverts the spectrum distribution of receive audio signals with respect

to the carrier frequency. The carrier frequency is 3.388 kHz or 3.290 kHz.

Page 30

4-2 Controller Theory of Operation: RX Audio Circuit

• De-emphasis: This circuit restores the original state of signal of which high-frequency

component has been emphasized by the pre-emphasis.

• Expander: This circuit expands the signal compressed twice by the Compressor in dB scale to

restore the original signal state.

•VR4: This circuit controls the volume for adjusting the RX output level.

Adjustment range: -18.0dB, -4.5dB to +4.5dB in 0.25dB steps.

•SMF: Smoothing filter to eliminate the high-frequency and clock components generated in the

Audio processor IC.

4.1.1.2 RX Tone PL/Digital PL Decode Filtering

• Sub-audio Programmable LPF: Low-pass filter to eliminate components of the RXA1 signal.

This circuit is controlled by the internal registers and by the audio processor IC for cut-off

frequency.

•VR5: This circuit controls the volume for adjusting the output level from the sub-audio LPF

signal. Adjustment range: -6.0dB, +6.0dB in 0.5dB steps

The sub-audio tone of U102 Pin 18 output pass through switchable high-pass filter U105. This filter

(U105-A, B) has 4 different high pass cut-off frequencies which can be selected accordingly to the

sub-tone audio. This filter (U105-A, B) filters the unwanted sub-tone. The tone of U105-B output

passed through U105-C comparator, which acts as a squaring circuit. This output signal is then sent

to microprocessor Pin 3. The micro-processor then decodes CTCSS and CDCSS from this square

signal.

4.1.2 Audio Amp

The de-emphasized audio signal from Pin 21 of audio processor IC passes through volume control

(SW/VOL1) and is amplified by U601BTL audio amplifier to a sufficient level to drive a loud speaker.

U601 has mute/un-mute function controlled by audio-mute control (Pin 83) of CPU. When U601

Pin 1 is low, the audio amp goes to active (un-mute) mode. When U601 Pin 1 is high, the audio amp

goes to mute mode.

4.1.3 Internal and External Speaker

When no external speaker is plugged into J601, the RX audio is passed through to the internal

speaker. When an external speaker is plugged into J601, the internal speaker is cut-off from the

rest of the circuit and RX audio is passed through the external speaker.

Page 31

Controller Theory of Operation: TX Audio Circuit 4-3

4.2 TX Audio Circuit

The TX audio circuit consists of MIC/External MIC, LPF, Audio processor IC, and TX Sub-tone

system. For UHF1 and UHF2, refer to Figure 4-2. For VHF, refer to Figure 4-3.

4 Order LPF

(Fc=4KHz)

Mic

(Audio IN)

U501-C,D

Audio Processor IC (AK2347)

pin4

TXA1

-6 to +4.5dB/

Tone IN

(from CPU)

4 Order LPF

(Fc=4KHz)

U501-C,D

VR1

(HPF)

1.5dB

Com-

pressor

pin19

Mic

(Audio IN)

TX/RX HPF

Pre-

Emphasis

Scrambler/

Descrambler

Limiter

Fc=300Hz

U102

DTA1

Sub audio

Programmable

LPF

-6 to +6dB/

0.5dB

2 Order LPF

(Fc=300Hz)

VR5

pin17

U502-A

To VCO &

VCTC XO

Figure 4-2. TX Audio Circuit (UHF1 and UHF2)

Audio Processor IC (AK2347)

-9.6 to +3dB/

6 Order LPF

(Fc=3KHz)

U501-A,B

VR2

0.2dB

Splatter SMF

Fc=2.55KHz/

3KHz

Mod.Adj,

U508

pin8

TX AF Amp.

U502-C

pin4

TXA1

-6 to +4.5dB/

(from CPU)

VR1

(HPF)

1.5dB

Tone IN

Com-

pressor

pin19

DTA1

TX/RX HPF

pin17

Scrambler/

Descrambler

U102

2 Order LPF

(Fc=300Hz)

U502-A

Pre-

Emphasis

Sub audio

Programmable

LPF

Fc=300Hz

-6 to +6dB/

0.5dB

VR5

Figure 4-3. TX Audio Circuit (VHF)

Limiter

To VCO &

VCTC XO

-9.6 to +3dB/

6 Order LPF

(Fc=3KHz)

U501-A,B

VR2

0.2dB

Splatter SMF

Fc=2.55KHz/

3KHz

U502-C

pin8

TX AF Amp.

Mod.Adj,

U508

Page 32

4-4 Controller Theory of Operation: TX Audio Circuit

4.2.1 MIC and External MIC

The TX audio enters the radio via the internal MIC or the external MIC jack. When using

the internal MIC, the audio passes through the external jack then rest of the circuits. When using the

external jack, the audio from the internal MIC is cut-off from the rest of the circuits and the external

MIC audio is passed to the rest of the circuits.

4.2.2 4-order 4 kHz Low-Pass Filter (U501-C, D)

4-order 4 kHz Low-pass filter to prevent aliasing noise of the ASIC switching cut-off frequency.

4.2.3 Audio processor IC (U102)

4.2.3.1 TX Audio Processing

Tx Audio from Pin 14 of U501-D enters the ASIC at Pin 3, 4 (Internal TX AMP).

• TX A1: Operational amplifier for gain adjustment of TX audio signal. R102, R103, C102, C103

are used to set the gain.

• VR1 (HPF): This circuit controls the volume for adjusting the input level of TX audio signal.

Adjustment range: -6.0dB, +4.5dB in 1.5dB steps

• Compressor: This circuit compresses the amplitude of transmit audio signal by 1/2 in dB scale.

• Pre-emphasis: This circuit emphasizes the high-pass frequency component of TX audio signal

to improve the S/N ratio of the modulation signal.

• TX/RX HPF: High-pass filter to eliminate low-frequency components lower than 250 Hz which

are included in transmitter audio signal. This circuit is turned on and off by control register of

Audio Processor IC.

• Scrambler: This circuit inverts the spectrum distribution of transmitter audio signals with

respect to the carrier frequency. The carrier frequency is 3.388 kHz or 3.290 kHz.

• Limiter: Amplitude limiting circuit to suppress frequency deviation in the modulation signal. The

limit level can be adjusted by applying a DC voltage the LIMLV Pin 7. When the pin is left open,

the level predetermined within the device is output.

• VR2: This circuit controls the volume for adjusting the output level on the MOD Pin 8.

Adjustment range: -9.6dB to +3.0dB in 0.2dB steps.

• Splatter: Low-pass filter to eliminate high-frequency components higher than 3 kHz which are

included in the limiter output signal. The cut-off frequency is 3 kHz.

• SMF: Smoothing filter to eliminate the high-frequency and clock components generated in the

ASIC.

4.2.3.2 Tx Tone PL/Digital PL Encode Filtering

The encode circuit of CTCSS and CDCSS mixes signals from 4 ports of microprocessor. This mixed

signal passes through ASIC Pin 19, 20 (U102).

• DTA1: Amplifier for gain adjustment of sub-audio signal which generated from CPU. Use

external resistor and capacitor to set the gain.

• Sub-audio Programmable LPF: Low-pass Filter to eliminate components of DAT1 signal in the

transmitter. This circuit is controlled cut-off frequency by the internal ASIC registers.

• VR5: This circuit controls the volume for adjusting the output level from the Sub-Audio LPF

signal. Adjustment range: -6.0dB to +6.0dB in 0.5 steps.

Page 33

Controller Theory of Operation: Microprocessor Circuitry 4-5

4.2.4 TX audio amplifier and 6 order 3 kHz Low-Pass filter

The TX audio signal from ASIC Pin 8 (UHF1, UHF2) or U508 Pin 4 (VHF) is linked by TX audio amp

(U502-C) to increase limiting range. The limited audio signal is adjusted to a proper level by U508

and passes through 6 order 3 kHz low pass filter (U501-A,B) before being modulated.

4.2.5 TX modulation Adjustment

TX audio signal from Pin 8 of U502-C (UHF1, UHF2) or Pin 8 of ASIC (VHF) is linked TX modulation

adjustment IC (U508). The TX modulation is tuned in the factory. If any of the TX part is replaced, the

TX modulation must be tuned using Tuner.

4.3 Microprocessor Circuitry

The microprocessor circuitry includes microprocessor (U101) and associated EEPROM.

Table 4-1. Radio Memory Requirements

Reference No. Description Size

U101 Microprocessor Flash ROM 128 Kbyte * 8

RAM 5 Kbyte * 8

U104 Serial EEPROM 8 Kbit * 8

4.3.1 Memory Usage

Radio operation is controlled by software that is stored in internal Flash ROM memory. Radio

parameters and customer specific information is stored in External EEPROM (U104). The operating

status of the radio is maintained in RAM located within the microprocessor. When the radio is turned

off, the operating status of the radio is written to EEPROM before operating voltage is removed from

the microprocessor.

4.3.2 Control and Indicator Interface

Ports Pin 35 and 36 are outputs which control the Sub-PCB mounted LED indicator. When Pin 35 is

high, the indicator is green. When Pin 36 is high, the indicator is red. When both are high, the

indicator is amber. When both are low, the indicator id is off.

Pressing the side-mounted PTT button (PB501) provides a low to port Pin 44, which indicates PTT is

asserted. Side-mounted function buttons 1 & 2 (PB502 and PB503) are connected to port Pin 21 and

Pin 32, respectively.

4.3.3 Interface to USB programming

The radio can be programmed, or the programmed information can be read, using a computer with

CPS (Customer Programming Software) connected to the radio via a USB Programming cable

(PMDN4077A). Connection to the radio is made via the microphone connector (part of accessory

connector J601). The line connects the programming connect (J601 Pin 6) to port PRG/CLONE_RX

(data into uP, Pin 34) and PRG/CLONE_TX(data out of uP, Pin 33).

4.3.4 Storage of Customer-Specific Information

Information that has been programmed using CPS, such as channel frequencies or selective

signaling codes, etc, are stored in the external EEPROM, where it is retained permanently (unless

reprogrammed) without needing DC power applied to the microprocessor.

Page 34

4-6 Controller Theory of Operation: Microprocessor Circuitry

4.3.5 Sensing of VOX operating

Port PTT2 (Pin 68) is used to detect the presence of VOX operating when externally connected

accessories with VOX enabled. When port PTT2 is low, the VOX will start to operate.

4.3.6 Microprocessor Power-on reset Routine

On power-up, the microprocessor is held in reset until the digital 3.3V regulator (U506 Pin 4)

provides a stable supply voltage. Once the digital supply reaches steady state and releases the reset

line (U107 Pin 2), the microprocessor begins to start up. After reset release by all circuit, the software

within the microprocessor begins executing port assignment, RAM checking, and initialization.

4.3.7 Microprocessor 7.3728 MHz Clock

The 7.3728 MHz clock signal (Pin 13, X-in) is provided from the FL101.

4.3.8 Battery indicator

Various battery types are available having different capacities. The radio can select different battery

type by FPP (Front Panel Programming) or CPS. A voltage divided by R153 and R154. And

EEPROM have a data for each battery types.

Page 35

Chapter 5 435 – 480 MHz UHF2 Theory Of Operation

A

5.1 Introduction

This chapter provides a detailed theory of operation for the radio components. Schematic diagrams

for the circuits described in the following paragraphs are located in Chapter 7 of this manual.

5.2 UHF2 Receiver

The UHF2 receiver design covers the frequency range of 435 – 480 MHz and it is a double

conversion super heterodyne with 1st IF 45.1 MHz and 2nd IF 455 kHz. The receiver is divided into

two major blocks, Front End and Back End as shown in Figure 5-1.

Preselector

Filter

RF

Amp

Postselector

Filter

1st Mixer

Crystal

Filter

IF

Amp

RX from

ntenna Switch

Inj Filter

First LO

from Synthesizer

N/S_SW

Ceramic

Descriminator

455C24

Recovered Audio

LPF

Quadrature

Detector

Filter

IF

Amp

455FW

455HW

RSSI

Figure 5-1. UHF2 Receiver Block Diagram

Crystal

44.645MHz

Page 36

5-2 435 – 480 MHz UHF2 Theory Of Operation: UHF2 Receiver

5.2.1 Receiver Front End

Incoming RF signals from antenna are first routed through the harmonic filter (L409, L410, L411,

C426, C427, C428, C429, C445, C446) and antenna switch (CR301), part of the transmitter circuitry,

before being applied to the receiver front end. The receiver front end consists of preselector filter,

RF amplifier, post-selector filter and a single-balanced mixer.

The preselector filter is a varactor-tuned 2-pole design using discrete elements (L320, L324, C351,

C352, C353, C354, C355, C356, C357, C358, C359, C360, C361) in a series/shunt resonator

configuration. It is a band-shift filter and the frequency shift is controlled by varactor diodes CR314

and CR307, which are connected to the microprocessor. It is configured to provide steeper

attenuation above the passband for improved spurious rejection when low-side local injection is used.

The frequency is separated into 8 steps and controlled by CPU (435 – 480 MHz).

The output of this filter is matched to the base of RF amplifier Q301 which provides 13dB of gain.

The output of the RF amplifier is applied to the post-selector filter. The post-selector filter designed

using discrete elements (L322, L323, L328, C379, C354, C355) in a series/shunt resonator

configuration. It is a band-shift filter and the frequency shift is controlled by varactor diodes CR313,

CR304 and CR305, which are connected to the microprocessor. It is configured to provide steeper

attenuation above the passband for improved spurious rejection when low-side local injection is used.

The frequency is separated into 8 steps and controlled by CPU (435 – 480 MHz).

The output of the post selector is connected to the single-balanced mixer consisting of components

L329, L333, Q306 and Q307. 1st local signal generated from VCO is filtered by injection filter (L310,

L331, C325, C326, C327) to remove second harmonics. The converted 1st IF frequency at mixer

passes through L331 and matches the 45.1 MHz IF signal to pair crystal filter (FL301).

5.2.2 Receiver Back End

The 1st IF signal is amplified about 15 dB by IF amp Q303. The output of the IF amp is connected to

IF IC (U201). 1st IF frequency (45.1 MHz) and 2nd LO frequency (44.645 MHz) are mixed in U201.

The second mixer converts the 45.1 MHz high IF frequency to 2nd IF frequency (455 kHz).

Additional IF selectivity is provided by two ceramic filters (CF1, CF2). The wider filter 455 FW is used

for 25 kHz channel spacing, and the narrower filter 455 HW is used for 12.5 kHz channel spacing.

These two ceramic filters may eliminate undesired signal and demodulated by demodulator in U201.

N/S_SW which connected to microprocessor is used to select the wide and narrow band.

The mute (squelch) circuit switches off the audio amplifier when no audio is present. The squelch

circuit consists of U201 and U202 and their associated components. The noise signal from Pin 9 of

U201 is used to control the squelch circuit sensitivity of U202. The noise passes through filter, and is

amplified by internal amp of U201. The amplified noise act as a DC voltage to control the mute

system. So if the noise level is under the threshold voltage, the microprocessor (U101) un-mutes the

radio. If the noise level is over the threshold voltage, the microprocessor mutes the radio.

The squelch level is tuned in the factory. When a component or a part in the RX system is replaced,

the squelch must be re-tuned using the Tuner.

Page 37

435 – 480 MHz UHF2 Theory Of Operation: UHF2 Transmitter 5-3

5.3 UHF2 Transmitter

The UHF2 transmitter covers the range of 435 – 480 MHz. Depending on model, the output power of

the transmitter is switchable on a per-channel basis between high power (4 Watts) and low

power (1 Watt). The transmitter is divided into four major blocks as shown in Figure 5-2.

• Power Amplifier

• Harmonic Filter

• Antenna Matching Network

• Power Control.

From VCO

Attenuator

Circuit

5.3.1 Power Amplifier

The transmitter power amplifier has three stages of amplification – Pre Driver (Q401), Driver

Amp (Q402) and Final Amp (Q403). Signal from TX VCO is applied to the pre driver via an attenuator

circuit. The attenuator is pie style resistor attenuator, and is used as isolation between VCO and the

power amps. The -4dBm TX RF signal from attenuator is then amplified by pre driver and driver amp

to around +25dBm and is applied to the final amp. The final amp (Q403) is an enhancement-mode

N-channel MOSFET device providing a gain of 12dB. The device drain current is drawn directly from

the DC battery supply voltage input via L413. A matching network consisting of C416 to C420 and a

strip line, transforms the impedance to approximately 50 Ohm.

SWB+

Power Control

Pre Driver

Amp

Driver

Amp

BAT+

Current Detect

Strip Line

Final

Amp

To Receiver

Figure 5-2. UHF2 Transmitter Block Diagram

CR401

Antenna

Switch

Antenna

Harmonic

Filter

5.3.2 Antenna Switch

An antenna switch works mainly as a switching device between transmit and receive paths. In

transmit mode (PTT), Q407 is turned on and both PIN diodes (CR401, CR301) are forward biased

into conduction. This enables the RF signal to pass to the harmonic filter and then to the antenna. In

the receiver mode, both diodes are off. Signals applied to the antenna jack are routed via the LPF

(harmonic filter), through network L409 to L411, to the receiver input.

5.3.3 Harmonic Filter

The harmonic filter consists of components L409, L410, L411, C426, C427, C428, C429, C430, C445

and C446. The harmonic filter is a seven-pole Chebychev filter.

Page 38

5-4 435 – 480 MHz UHF2 Theory Of Operation: UHF2 Frequency Generation Circuitry

5.3.4 Auto Power Control

The APC keeps the current supply constant to the final amp (Q403). The drain current of Q403 (final

amp) is sensed across resistor R417. The voltage difference across R417 is amplified through U401

by the ratio of R423 to R417. The differential signal at the output of U401 (Pin 7) is passed to Q404

and Q405 that produces a constant power output to the antenna. If the current is changed due to

change of battery voltage or load, APC controls gate voltage of Q403 and collector voltage of Q401

and drain voltage of Q402 to keep TX power stable. This circuit stabilizes TX power at a

pre-determined level adjusted by U402. This bias voltage is tuned in the factory. If the transistor

(Q403) is replaced, the RF Output Power must be tuned. By tuning the RF output power, the bias

voltage will be tuned through U402. Extra care has to be taken during the tuning process. Do not

exceed the maximum allowed bias voltage.

5.4 UHF2 Frequency Generation Circuitry

The PLL synthesizer subsystem consists of the reference oscillator (VCTCXO), VCO, PLL IC, Charge

Pump and Loop Filter.

Modulating

Signal

FL701

12.8MHz

Ref.OSC.

Synthesizer

U701

PLL Data

from μP

Charge

Pump

Voltage

Doubler

Figure 5-3. UHF2 Frequency Generation Unit Block Diagram

5.4.1 Reference Oscillator (12.8 MHz VCTCXO)

The reference oscillator is powered by regulated 5V provided by U505. The reference frequency

12.8 MHz VCTCXO (Voltage Controlled Temperature Compensated Crystal Oscillator) is applied to

the PLL IC (U701) via Pin 1. Main frequency can be adjusted by chip trimmer of VCTCXO. This

frequency provides reference to the PLL IC and has a frequency stability of +/-2.5PPM (max) at the

temperature ranging from -30 to +60 Degree Celsius.

Loop

Filter

TX VCO

Circuit

TX Out

RX VCO

Circuit

RX Out

To PA Driver

To Mixer

Page 39

435 – 480 MHz UHF2 Theory Of Operation: UHF2 Frequency Generation Circuitry 5-5

5.4.2 PLL IC Prescaler and Comparator

The reference frequency from VCTCXO is divided to 6.25 kHz or 5 kHz by reference counter, R. The

RF signal input from the VCO is divided to by prescaler (1/64), divided by N and A counters in PLL IC

to determine frequency steps and then supplied to the comparator. The comparison frequency is

6.25/5 kHz. The internal phase comparator compares the phase difference between the reference

and VCO signal. When the phase of the reference frequency is leading, Pin15 (R) is the output.

When VCO frequency is leading, Pin 16 (P) is the output. When P=R, small pulses are the output of

the phase detector.

5.4.3 Voltage Doubler and Charge Pump

The voltage doubler (U507) converts 5V to 10V and is applied to the charge pump circuitry. The

charge pump is used for charging output signals P, R supplied by PLL IC from 0-3.3V to 0-10V. This

voltage is used to drive the VCO.

5.4.4 Loop Filter

The loop filter contains C751, C752, C753, C754, R726, R727, R728. It reduces the residual sideband noise to get the best signal-to-noise ratio. The output signal from loop filter is applied to VCO.

5.4.5 Dual VCO

The dual VCO module contains a RX VCO and a TX VCO. They are configured as colpitts oscillators

and connected to power up through transistor switches. Only one VCO is selected at a time. A

steering line voltage between 0.35V and 9.7V at varactor CR701 tunes the full RX frequency range

from 389.9MHz to 434.9MHz, and varactor CR702 tunes the full TX frequency range from 435MHz

to 480MHz.

In Receiver mode, high signal of RX_EN from Pin 71, U101 activates Q305. When Q305 is activated,

current flows through the base of Q304 and thus activates the Q705. The varactor CR701 sets the

resonance frequency. When there is a change in voltage supplied by loop filter, there is a change in

the resonance frequency. L703 is the resonating coil, which forms the tank circuit together with

variable cap C710.

In Transmit mode, high signal of TX_EN1 from Pin 84, U101 enables current flows through collector

of Q503 and thus activates Q706. The varactor CR702 sets the resonance frequency. When there is

a change in voltage supplied by loop filter, there is a change in the resonance frequency. L706 is the

resonating tuning coil, which forms the tank circuit together with variable cap C722.

Page 40

5-6 435 – 480 MHz UHF2 Theory Of Operation: Keypad

5.5 Keypad

Left, Right and P1 to P3 keys are directly connected to microprocessor via 22 pin connector. When

any of these keys is pressed, the voltage goes "low" and microprocessor detects it.

For full keypad models, the number keys are in matrix type which consisted of 3 rows and 4 columns.

When any of these keys is pressed, the voltage goes "low" and microprocessor interprets the voltage

for each key press.

KEYPAD

Left

Right

P1 P2 P3

NUMBERS

Key

detect

Key row

Keypad board

Key

22pin connector

column

Figure 5-4. Keypad Block Diagram

MCP

Main board

22pin connector

Page 41

Chapter 6 UHF2 Troubleshooting Tables

6.1 Troubleshooting Table for Receiver (UHF2)

Table 6-1. Troubleshooting Table for Receiver (UHF2)

Symptom Possible Causes Procedure Corrective Action

Radio Dead (no

turn–on beep, no

LED indication)

No RX Audio (with

LED indication)

1. Battery dead or

defective

2. Defective battery

contacts

3. Microprocessor not

starting up

4. Regulator fault Verify U506 Pin 4 is 3.3V

5. Flexible Cable fault Check connection of the 12 pin

1. Speaker dead or

defective

2. Audio Processor IC

not starting up

3. Audio Amp IC not

starting up

Substitute good battery or battery

eliminator

Inspect battery contacts for

corrosion or bent terminals

Verify clock input to U101 Pin 13 is

7.3728 MHz using high impedance

probe.

Verify U101 Pin10(reset) is high.

Verify U505 Pin 4 is 5.0V

flexible cable between J104 & J105

Substitute a good housing (with

speaker)

Verify J603 connection

Verify clock input U102 Pin 14 is

3.5795 MHz using high impedance

probe.

Verify U601 Pin 6 is battery voltage.

Change or replace battery.

Clean/Repair/Replace J602

Troubleshoot/Replace FL101.

If reset is Low, troubleshoot