Page 1

DLP

TM

Data Display Cube

PH50 series (SXGA+ models)

XL50, XL21 series

(XGA models)

Set-up and Installation Manual

March 09, 2007 (REV 2.4)

Page 2

Table of Contents

1. SET-UP AND INST ALLATION......................................................................................................5

1.1. Overview...............................................................................................................................

1.1.1. Product lineup ................................................................................................................

1.1.2. Flowchart........................................................................................................................5

Start..................................................................................................................................................5

1.2. Cube installation....................................................................................................................

1.2.1. Safety precaution ...........................................................................................................6

1.2.2. Preparation.....................................................................................................................6

1.2.3. Input board installation (optional)....................................................................................

1.2.4. Unlocking (for XXLL2211 ).....................................................................................................8

1.2.5. Cube stacking (for RReeaarr ).............................................................................................10

1.2.6. Cube stacking (for FFrroonntt ) ............................................................................................13

1.2.7. Screen open/close (for FFrroonntt ) .....................................................................................21

1.3. Connecting..........................................................................................................................23

1.3.1. Control signal connection .............................................................................................

1.3.2. Image signal connection...............................................................................................23

1.3.3. Internal cabling (for FFrroonntt ) ...........................................................................................24

1.4. Initial set up .........................................................................................................................25

1.4.1. Menu operat ion ............................................................................................................25

1.4.2. Dipswit ch setting...........................................................................................................28

1.4.3. Picture outline adjustment ............................................................................................

1.5. System memory setting.......................................................................................................37

1.5.1. System set up...............................................................................................................37

1.5.2. Color balance adjustment.............................................................................................

1.5.3. Image set up.................................................................................................................48

1.6. Input memo ry setting (for th e main input).............................................................................51

1.6.1. Input port selecting.......................................................................................................

1.6.2. Automatic input signal scanning...................................................................................

1.6.3. Signal adjustment.........................................................................................................52

1.6.4. Image quality adjustment..............................................................................................

1.6.5. Input memory saving....................................................................................................

1.6.6. Input memory calling/delet ing.......................................................................................

1.7. Input memory setting (for the input board)...........................................................................

1.7.1. Input port selecting.......................................................................................................57

1.7.2. Expansi o n setting.........................................................................................................57

1.7.3. Automatic input signal scanning...................................................................................

1.7.4. Signal adjustment.........................................................................................................58

1.7.5. Image quality adjustment..............................................................................................63

1.7.6. Input memory saving....................................................................................................

1.7.7. Input memory calling/delet ing.......................................................................................65

1.8. Display memory s etting (for the inpu t board) .......................................................................

1.8.1. INPUT ME MORY..........................................................................................................

1.8.2. H.DISPLAY POS, V. DISPLAY POS..............................................................................

1.8.3. CROP...........................................................................................................................66

1.8.4. DISPLAY......................................................................................................................

5

5

6

7

23

28

44

51

51

55

56

56

57

57

65

66

66

66

67

PH50, XL50, XL21 series Set-up and Installation Manual

2

Page 3

1.8.5. DIGITAL OUT...............................................................................................................

67

1.8.6. SCREEN MODE...........................................................................................................67

1.8.7. Display memory saving ................................................................................................68

1.8.8. Display memory calling/deleting ...................................................................................

68

1.9. Setting as daisy cha in connection (for the input board)........................................................69

2. REGULAR MAINTENANCE.......................................................................................................

2.1. Lamp repla c ement...............................................................................................................

71

71

2.1.1. Safety precautions........................................................................................................71

2.1.2. Procedure.....................................................................................................................

72

2.1.3. Auto-lamp changing function (for CChhaannggeerr ).................................................................78

2.2. Condenser lens adjustment (for SSiinnggllee)..............................................................................81

2.3. Focus adjustment................................................................................................................82

2.4. Cleaning..............................................................................................................................

2.4.1. Screen front surface.....................................................................................................

83

83

2.4.2. Cabinet.........................................................................................................................83

2.4.3. Dust filter (for FFrroonntt )....................................................................................................83

2.5. For delivery..........................................................................................................................85

2.5.1. 6-axis adjuster fixing.....................................................................................................85

2.5.2. Color wheel locking (for XXLL2211 )....................................................................................85

2.5.3. Lamp cushion inserting (for XXLL2211 CChhaannggeerr )...............................................................85

2.5.4. Screen-fixing bolt tightening (for 5500””FFrroonntt ) .................................................................86

2.5.5. Screen-holding arm locking (for 6677””FFrroonntt)...................................................................86

3. FUNCTION................................................................................................................................. 87

3.1. Memories.............................................................................................................................

3.2. Menu trees..........................................................................................................................

87

87

3.2.1. Input memory ...............................................................................................................87

3.2.2. Display memory............................................................................................................88

3.2.3. System memory ...........................................................................................................

89

3.2.4. Memory list display.......................................................................................................90

3.3. Test pattern list ....................................................................................................................

3.4. Control panel.......................................................................................................................

91

91

3.5. LED displa y......................................................................................................................... 91

3.6. Terminal functions................................................................................................................93

3.6.1. RS-232C te rminal.........................................................................................................

93

3.6.2. CONTROL terminal......................................................................................................93

3.7. Available input signal list......................................................................................................94

3.8. Motorized adjustment tool, S-AXL50E specific ation.............................................................

3.8.1. Applicable product........................................................................................................

3.8.2. Outline drawing............................................................................................................

3.8.3. Accessory.....................................................................................................................

96

96

96

96

3.8.4. Terminals......................................................................................................................97

3.8.5. Recovery procedure from error.....................................................................................98

3.8.6. Trouble shooting...........................................................................................................

98

4. ADJUSTMENT SOFTWAR E, “WALLABY”...............................................................................

4.1. General................................................................................................................................

4.2. Installation ...........................................................................................................................

REV 2.4

3

99

99

99

Page 4

4.2.1. Software Installation.....................................................................................................

4.2.2. Connecting...................................................................................................................

4.2.3. Dipswit ch setting...........................................................................................................99

4.2.4. Starting the applic ation.................................................................................................99

4.3. Initial set-up.........................................................................................................................

4.3.1. Model selecting ............................................................................................................99

4.3.2. System configuration sett ing.......................................................................................100

4.3.3. Panel ID defining........................................................................................................

4.3.4. Serial port setting........................................................................................................100

4.3.5. Serial port opening.....................................................................................................101

4.3.6. Turning on..................................................................................................................

4.3.7. Picture mute off..........................................................................................................101

4.3.8. Data reading...............................................................................................................

4.4. Adjustment ........................................................................................................................

4.4.1. Service tab (for system memory)................................................................................

4.4.2. Input tab (for input mem ory) .......................................................................................

4.4.3. Display t ab (for display m e mory) ................................................................................

4.4.4. Memory tab ................................................................................................................110

4.4.5. Informatio n tab ...........................................................................................................110

4.4.6. Memory copy..............................................................................................................

4.5. Memory backup.................................................................................................................112

4.5.1. Cube data saving........................................................................................................112

4.5.2. Data sending to cubes................................................................................................

4.6. Main window......................................................................................................................113

4.6.1. Panel selection area...................................................................................................113

4.6.2. Serial Port ..................................................................................................................

4.6.3. Power and Mute.........................................................................................................113

4.6.4. Information .................................................................................................................113

4.7. Menu bar...........................................................................................................................

4.7.1. File menu...................................................................................................................

4.7.2. Edit menu...................................................................................................................115

4.7.3. System Con f ig menu..................................................................................................

4.7.4. Test Patterns menu ....................................................................................................

4.7.5. Serial Port menu.........................................................................................................

4.7.6. Special me nu..............................................................................................................

4.7.7. Help menu..................................................................................................................117

99

99

99

100

101

101

101

102

106

109

111

112

113

114

114

116

116

117

117

5. ABOUT TRADEMARKS ..........................................................................................................

6. REVISION HISTORY................................................................................................................

PH50, XL50, XL21 series Set-up and Installation Manual

4

118

119

Page 5

1. Set-up and installation

1.1. Overview

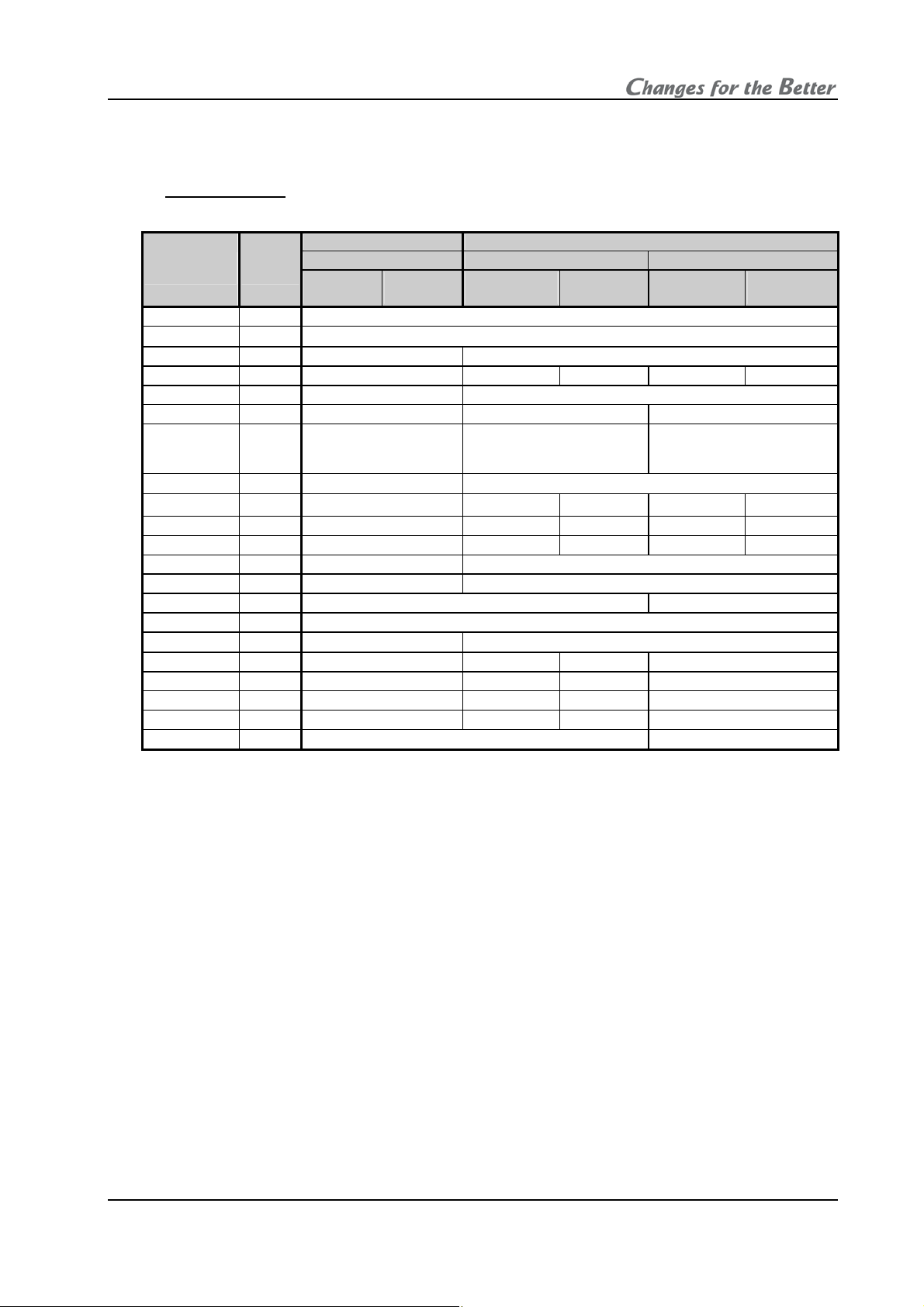

1.1.1. Product lineup

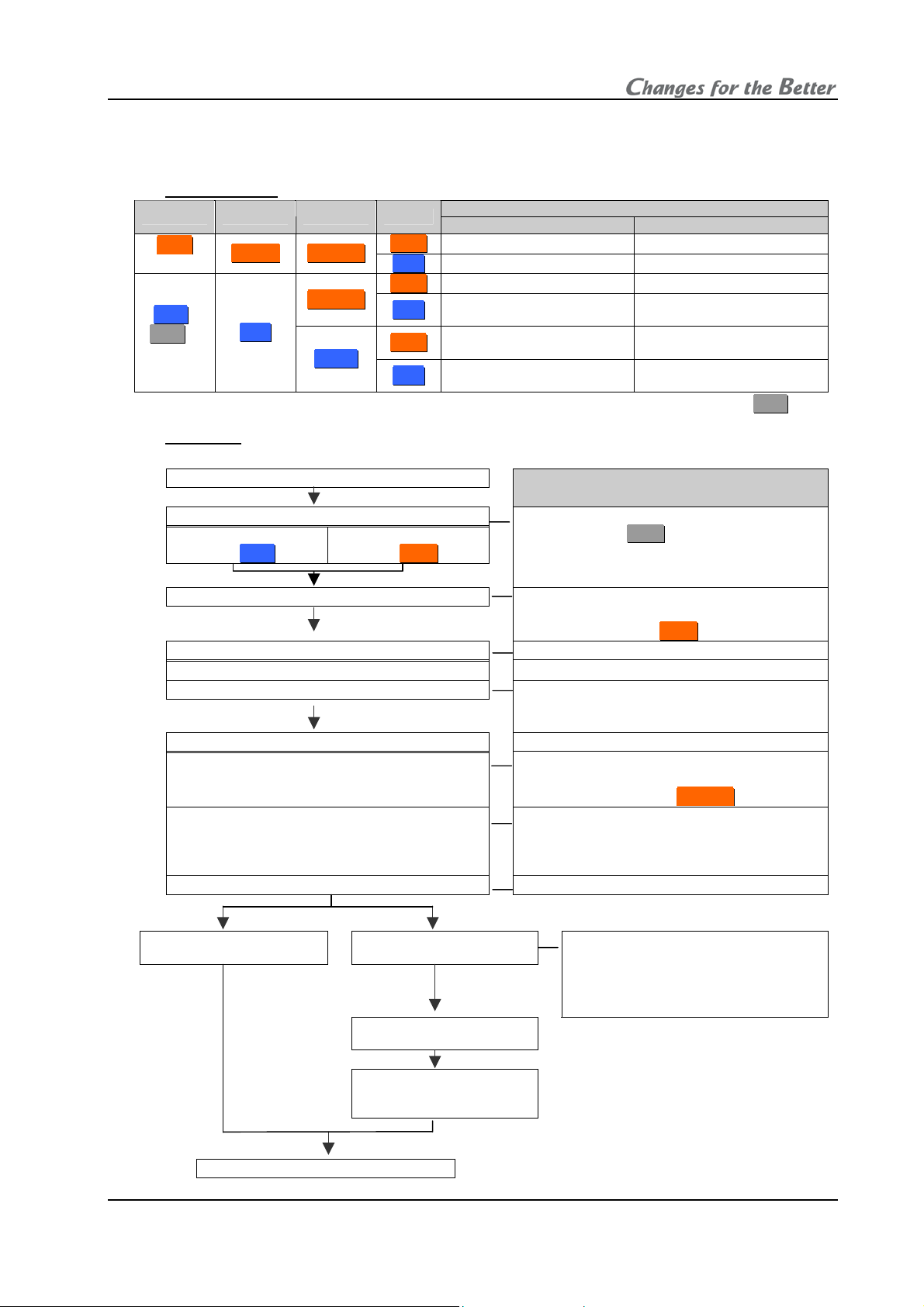

Lineup Resolution Lamp Access

e

FFrroonntt

RReeaar

FFrroonnt

r

RReeaar

FFrroonnt

RReeaar

PPHH550

series

XXLL550

(XXLL2211)

series

0

0 /

SSXXGGAA++ CChhaannggeerr

(*1)

XXGGA

A

CChhaannggeer

SSiinngglle

r

t

r

t

r

(VS-50XL21U, VS-50XL20U)

50” 67”

– VS-67PHF50U

VS-50PH50U VS-67PH50U

VS-50XLWF50U VS-67XLWF50U

VS-50XLW50U

(VS-50XLW20U)

VS-50XLF50U

(VS-50XLF20U)

VS-50XL50U

(*1) Parenthesized products are XXLL2211 series.

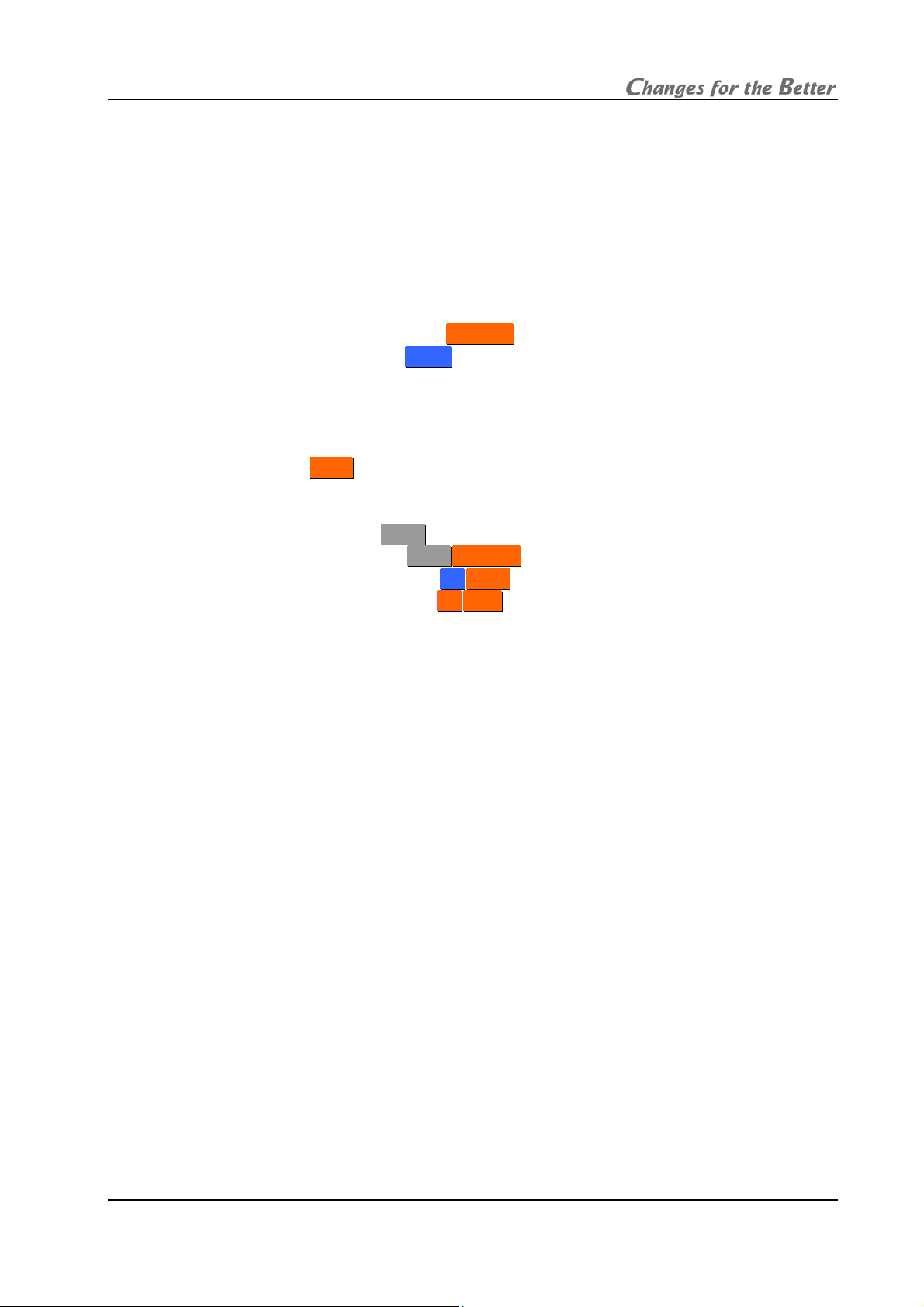

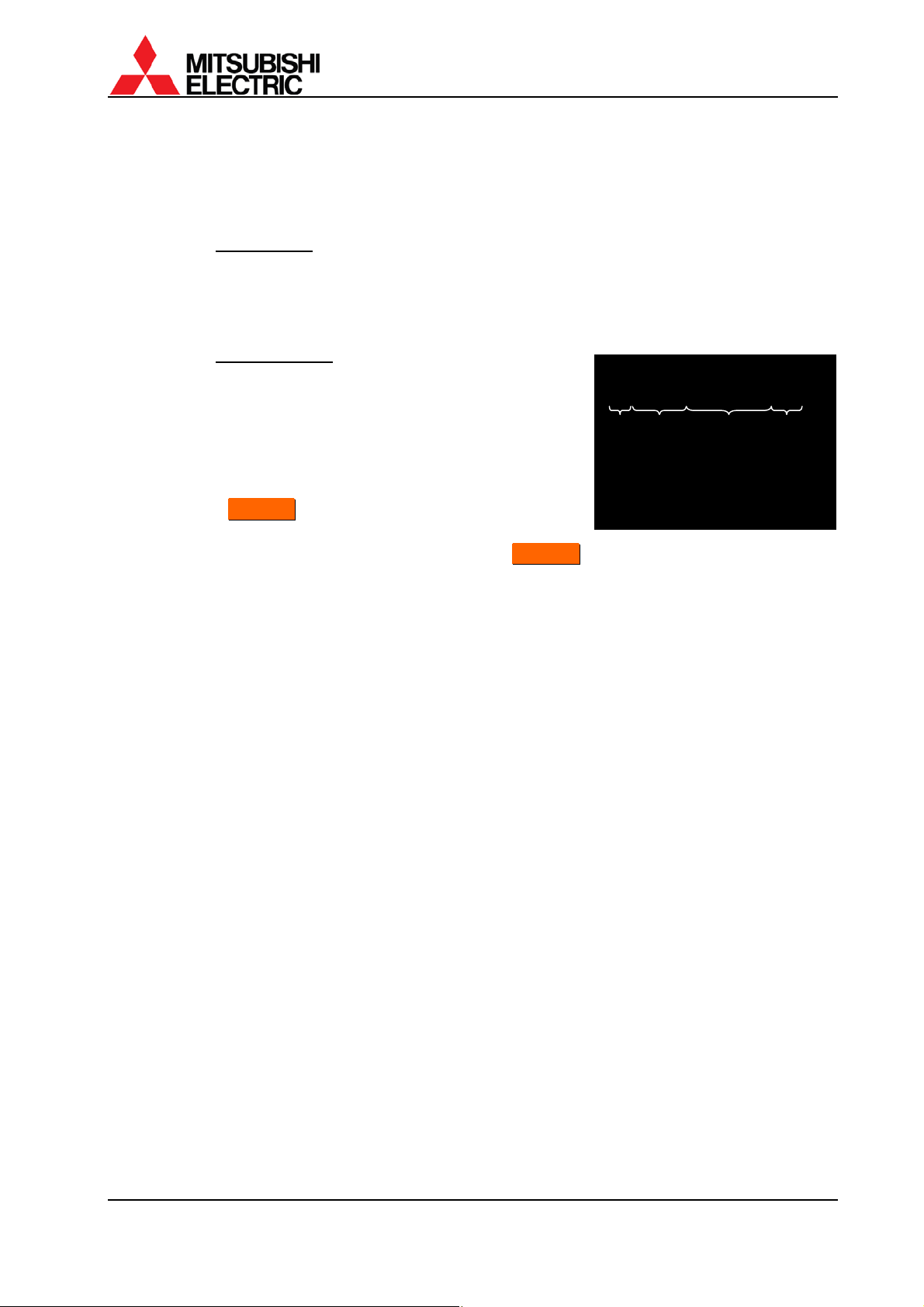

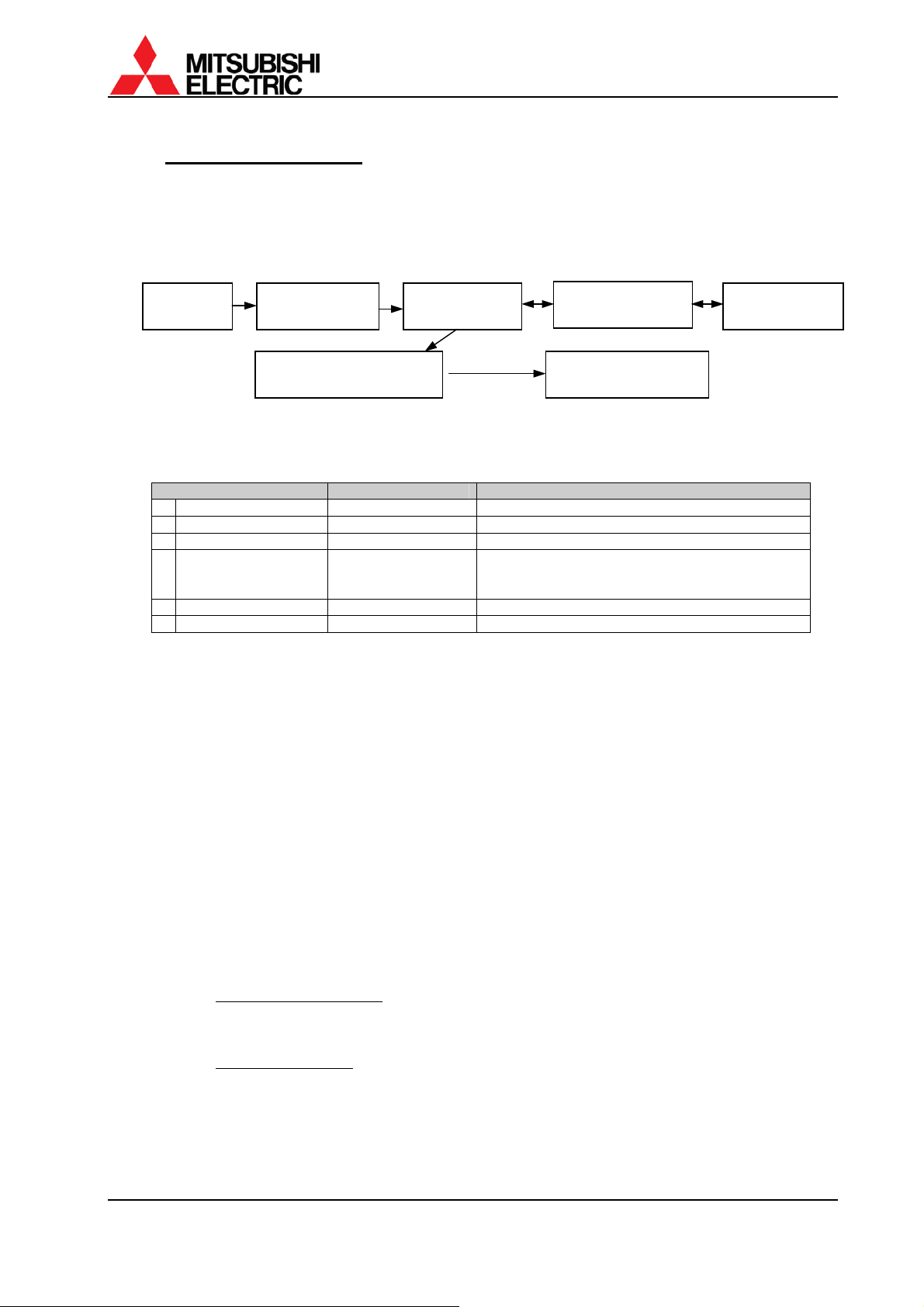

1.1.2. Flowchart

1.2 Cube installation

1.2.5 Cube stacking

(for RReeaarr )

1.3 Connecting

1.4 Initial set up

1.5 System memory setting

1.6 Input memory setting

(for the main input)

Finish

1.4.2 Dipswitch setting

1.4.3 Picture outline adjustment

1.5.1 System set up

1.5.2 Color balance adjustment

Start

1.2.6 Cube stacking

(for FFrroonntt )

1.5.3 Image set up

1.7 Input memory setting

(for the input board)

1.8 Display memory setting

(for the input board)

1.9 Setting as daisy chain

connection (for the input

board)

Input board installation (optional)

•

• Unlocking (for XXLL2211 )

• Control signal connection

•

Image signal connection

• Internal cabling (for FFrroonntt )

•

Operation mode (to advanced mode)

•

Displaying internal test pattern

• 6-axis adjustment

• Mirror adjustment

•

LAMP POWER

•

SYSTEM SYNC

• HOT EXCHANGE (for CChhaannggeerr)

•

CSC

•

GRADA TION

• TARGET COLOR

•

SENSOR

(When necessary)

5

Screen size

Major setting items

• Input port selecting

•

Automatic input signal scanning

• H.POSITION, V.POSITION

• FINE

• AMP GAIN

VS-67XLW50U

(VS-67XLW20U)

VS-67XLF50U

VS-67XL50U

(VS-67XL21U, VS-67XL20U)

REV 2.4

Page 6

1.2. Cube installation

1.2.1. Safety precaution

• This product requires a special installation to prevent falling or toppling. This should be done

by installation specialists.

• Be sure to read this manual and the user ’s manual for your safety before starting assembly

or installation.

• Be sure to use supplied accessories for assembly or installation.

• Attach all the screws and fixtures specified in this manual securely.

• Reinforce the wall surface an d floor so that it can support the total weights of the products

for a long time and resist earthquakes, possible vibrations, and external forces.

• Ensure that the safety factor is more than 10 (or ensure that the total bolts can bear ten

times the weight of products and the brackets).

• Do not use the product near a heater or in a humid, dusty or smoky location.

• Unless otherwise specified, do not install the product with its intakes, exhaust slots and

ventilation holes blocked. The unit may overheat and cause a fire or breakdown.

• Be sure that a lighting or sunlight does not leak into the screens.

• Inspect the mounting fixings more than once in a year as needed.

1.2.2. Preparation

• Before installation, remove the desiccant(s) taped on the top of the product.

• Make sure that all of the following are supplied.

Supplied accessories (per unit) Q’ty Necessary tools

1. Hexagon socket head bo l t (M6) 8

2. Flat washer (for M6) 8

3. Spring w asher (for M6) 8

4. Joint hole seal 1

5. Power cord (1.8m) for North America and Europe

(in VS-50XL20U and VS-67XL20U)

6. Control cable 1

7. User’s manual 1

8. Plastic cable tie (for FFrroonntt)

Optional products Others

1. Wireless/wired remote control: R-XL50TX

2. RGB input board:

VC-B50KA (for PPHH5500, XXLL5500), VC-B20KA (for PPHH5500, XXLL2211)

3. Video input board:

VC-B50KV (for PPHH5500, XXLL5500), VC-B20KV (for PPHH5500, XXLL2211)

4. Power cord (3m):

JC-PC3MA (for North America)

JC-PC3ME (for Europe)

JC-PC3MC (for China)

5. External AC fan (for 5500””SSiinngglleeFFrroonntt):

JC-AF115R (for AC115V)

JC-AF230R (for AC230V)

6. Motorized adjustment tool: S-AXL50E

7. Spare lamp:

S-PH50LA (for CChhaannggeerr)

S-XL50LA (for SSiinnggllee)

8. Spare color wheel:

S-PH50CW (for PPHH5500)

S-XL50CW (for XXLL5500), S-XL20CW (for XXLL2211)

2

6 (5500””),

10 (6677””)

1. Allen wrench

2. Phillips screw drive r #0 , #2

3. Level

4. Stepladder

5. Spacer (for suitable screen

6. Wrench (for base stand level

1. Base stand

2. Base stand level adjuster

3. Base stand level adjuster

4. Wall fixing metal part

5. Anchor bolt

6. Hexagon socket head cap

2mm, 2.5mm, 4mm, 5mm

gaps)

adjuster)

fixing metal part

screw (M6)

PH50, XL50, XL21 series Set-up and Installation Manual

6

Page 7

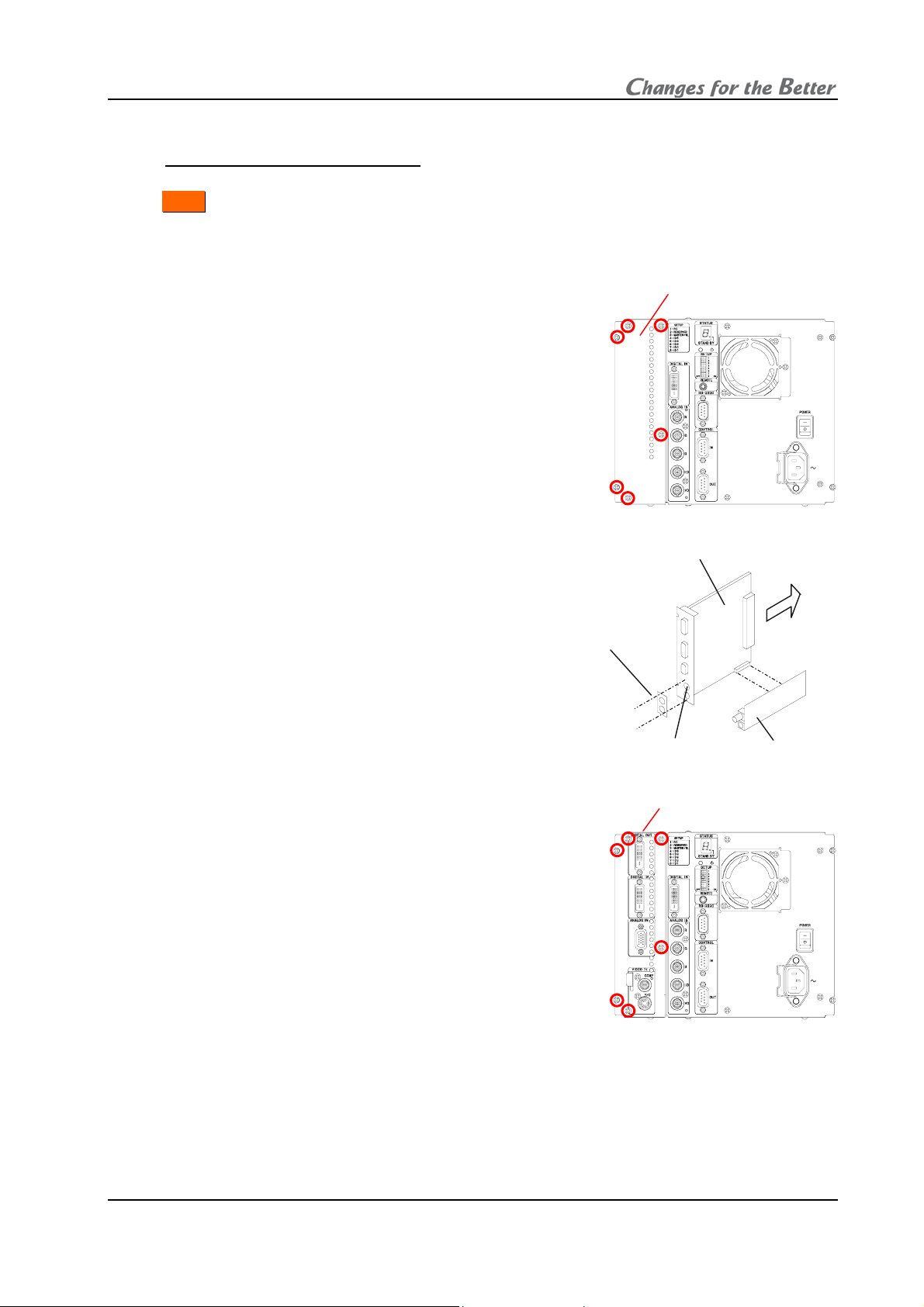

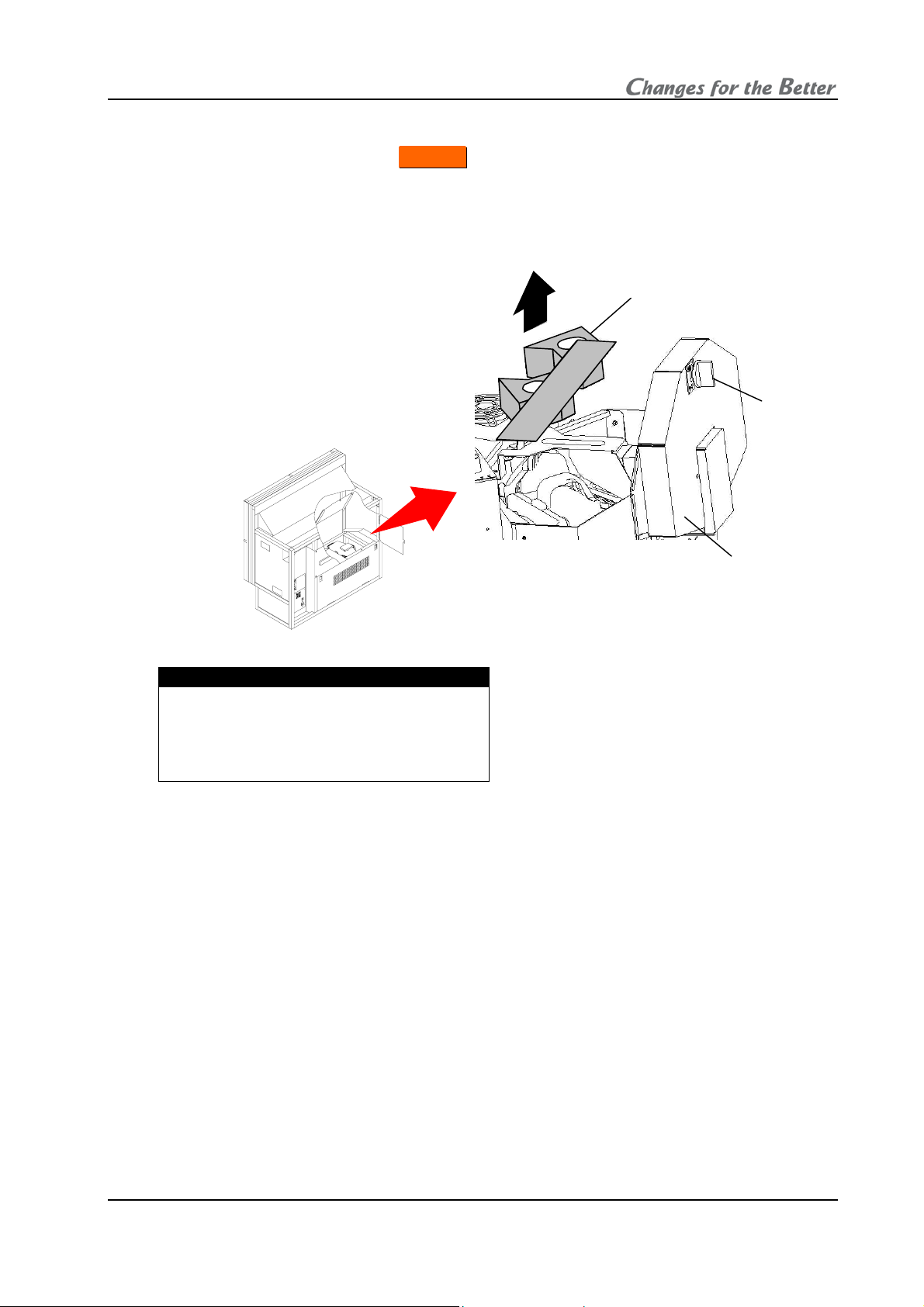

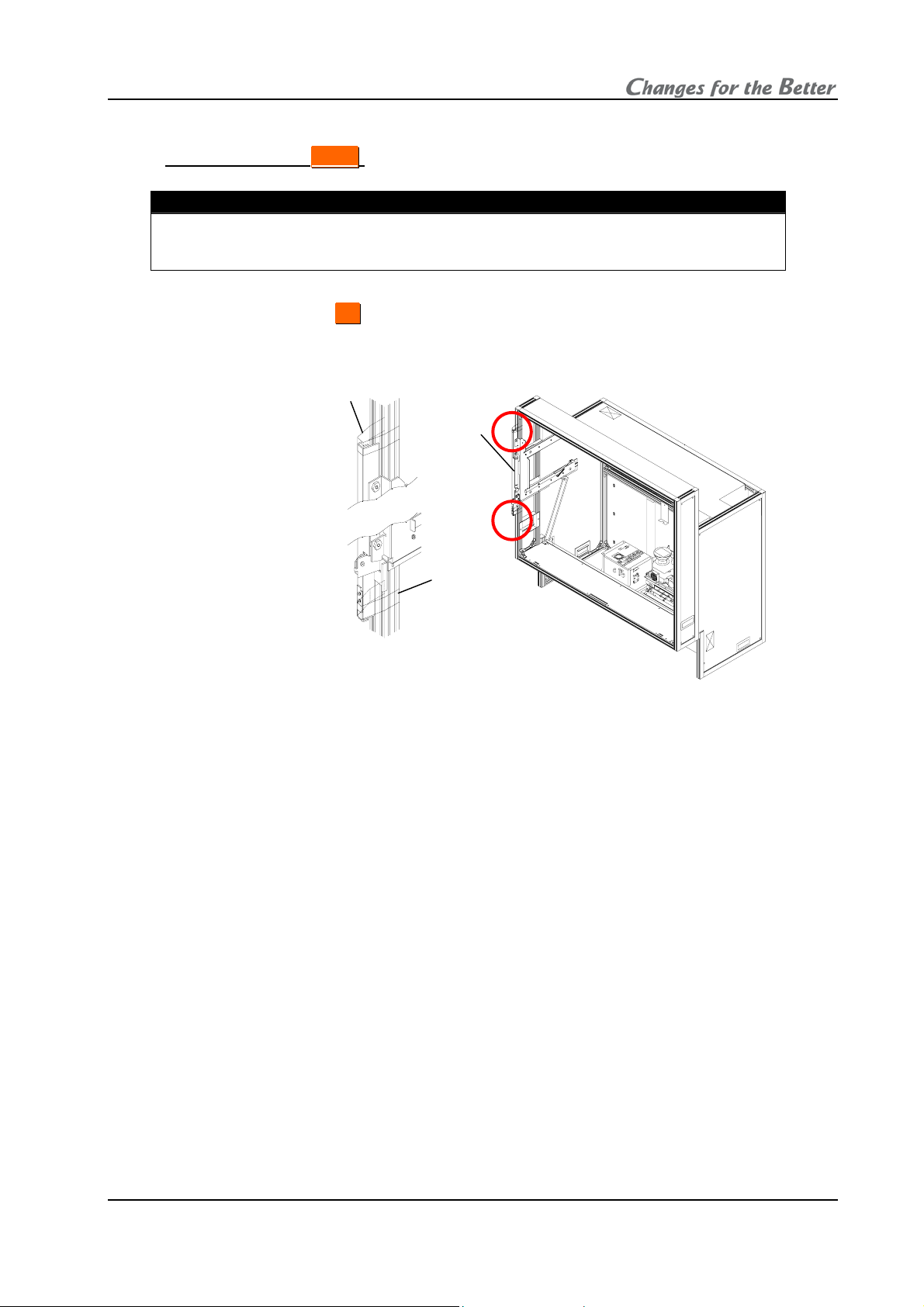

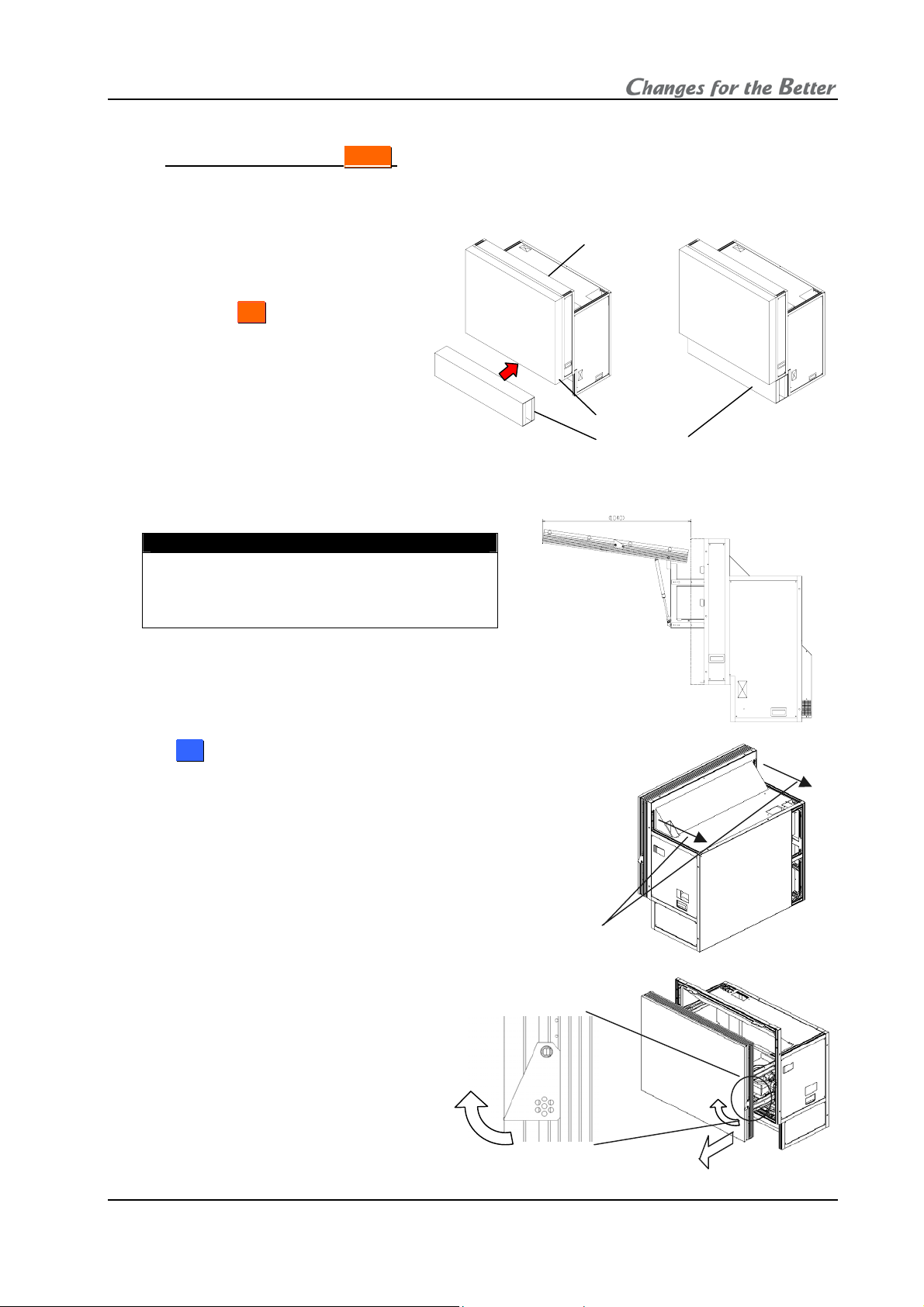

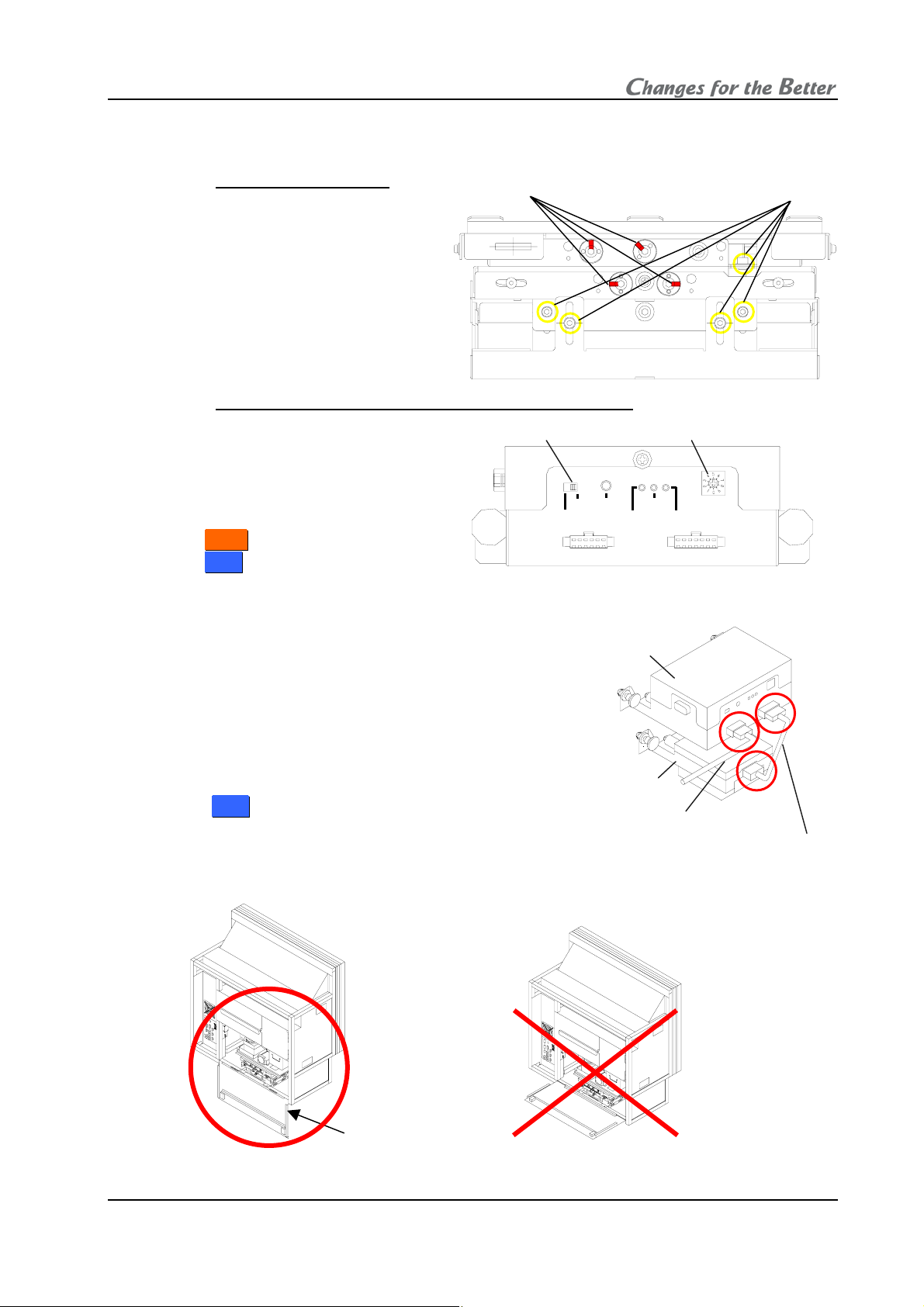

1.2.3. Input board installation (optional)

When using the optional input board, install it into the product according to the following steps.

In FFrroonntt, a slot for the board is located inside the cube. Open the screen unit before installation

according to the chapter 1.2.7 on page 21.

When you attach it, be sure to turn off the main power switch.

1. Remove a panel cover on the control panel by removing 6

Panel cover

screws at the positions shown in the figure.

2. When you use the video input board, attach

it as right figure. Stick a supplied terminal

name label on the RGB input board, and

combine the boards with supplied 2 screws.

2. Stick the supplied

terminal name label,

and then combine

the boards with 2

supplied screws.

RGB input board

3. Firmly insert the input board into the board

slot along guide rails till the end.

1. Remove 2 hole-stoppers.

Video input board

Input board

4. Firmly fix the input board with the 6 screws that have been

removed in the step 1.

Insert

REV 2.4

7

Page 8

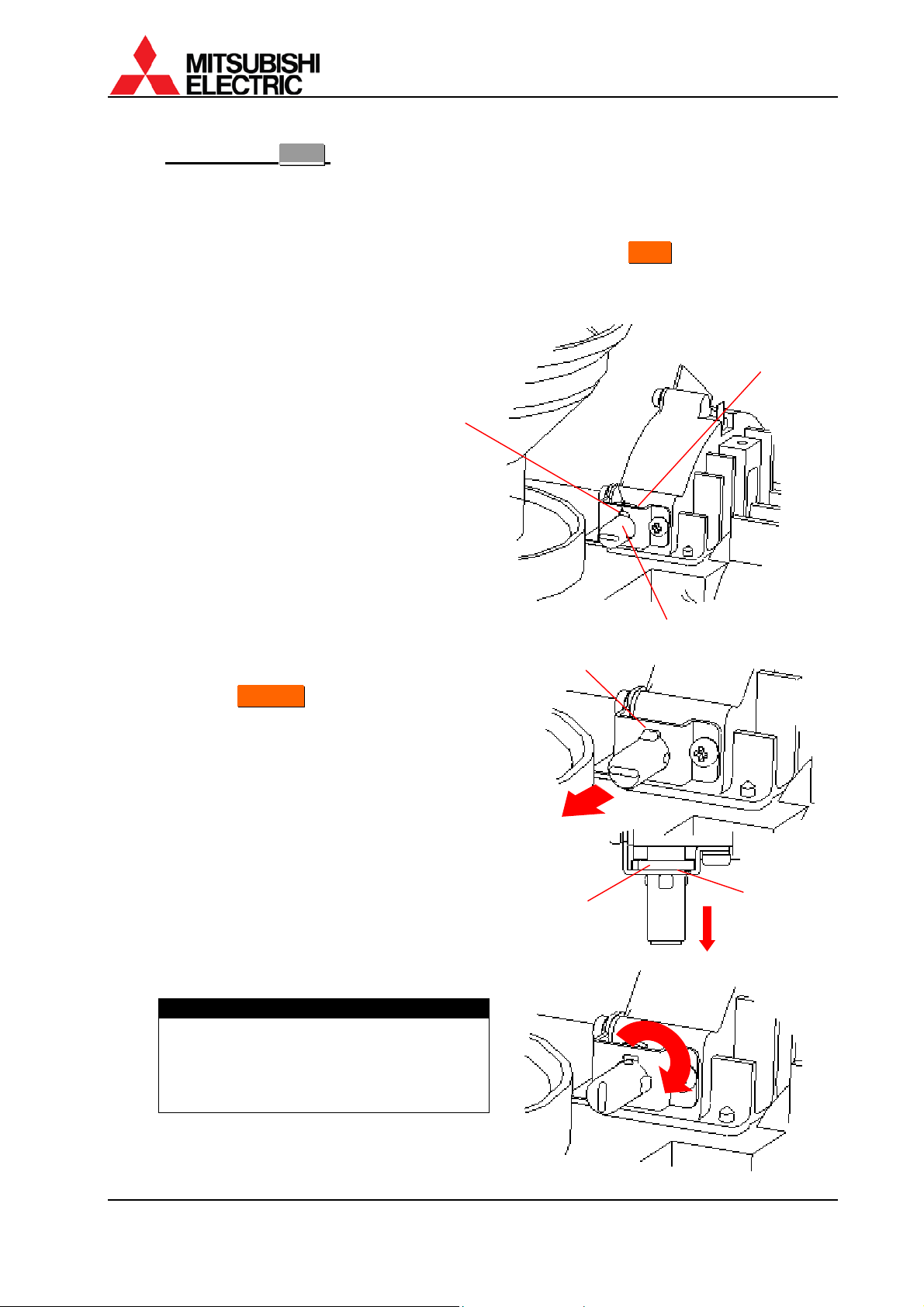

1.2.4. Unlocking (for XXLL2211 )

Surely release following locks before turning on the main power switch. Turning on without

releasing may cause damage.

1.2.4.1. Color wheel unlocking

The color wheel is located on the optical unit inside the cube. In FFrroonntt, open the screen unit

according to the chapter 1.2.7 on page 21 before unlocking. Turning on without unlocking may

cause damage.

1. Make sure a key slot on the

color wheel cushion faces

the top as you begin the

procedure.

Key slot

2. Pull the color wheel cushion till the flange hits

Stopper

Color wheel cushion

the metal part.

• For CChhaannggeerr, pliers are recommended to

use since it is hard to access with fingers.

Flange

Metal

3. Turn it 90 degrees clockwise.

Caution

Before shipment, be sure to lock the color

wheel in the reverse order of unlocking

(chapter

2.5.2, on page 85). Shipping the

product without locking may cause

breakage.

Metal

PH50, XL50, XL21 series Set-up and Installation Manual

8

Page 9

r

1.2.4.2. Lamp cushion removing (for CChhaannggeerr)

Remove a lamp cushion before turning on the main power switch. Turning on without removing

may cause smoking and catching fire.

• It should be remembered to lock the lamp cover after removing. If you neglect to lock it, the

lamp changer may not work correctly.

Lamp cushion

Lock

Lamp cove

Caution

Before shipment, be sure to insert the

cushion in the reverse order of removing

(chapter

2.5.3, on page 85). Shipping the

product without inserting may cause

breakage.

REV 2.4

9

Page 10

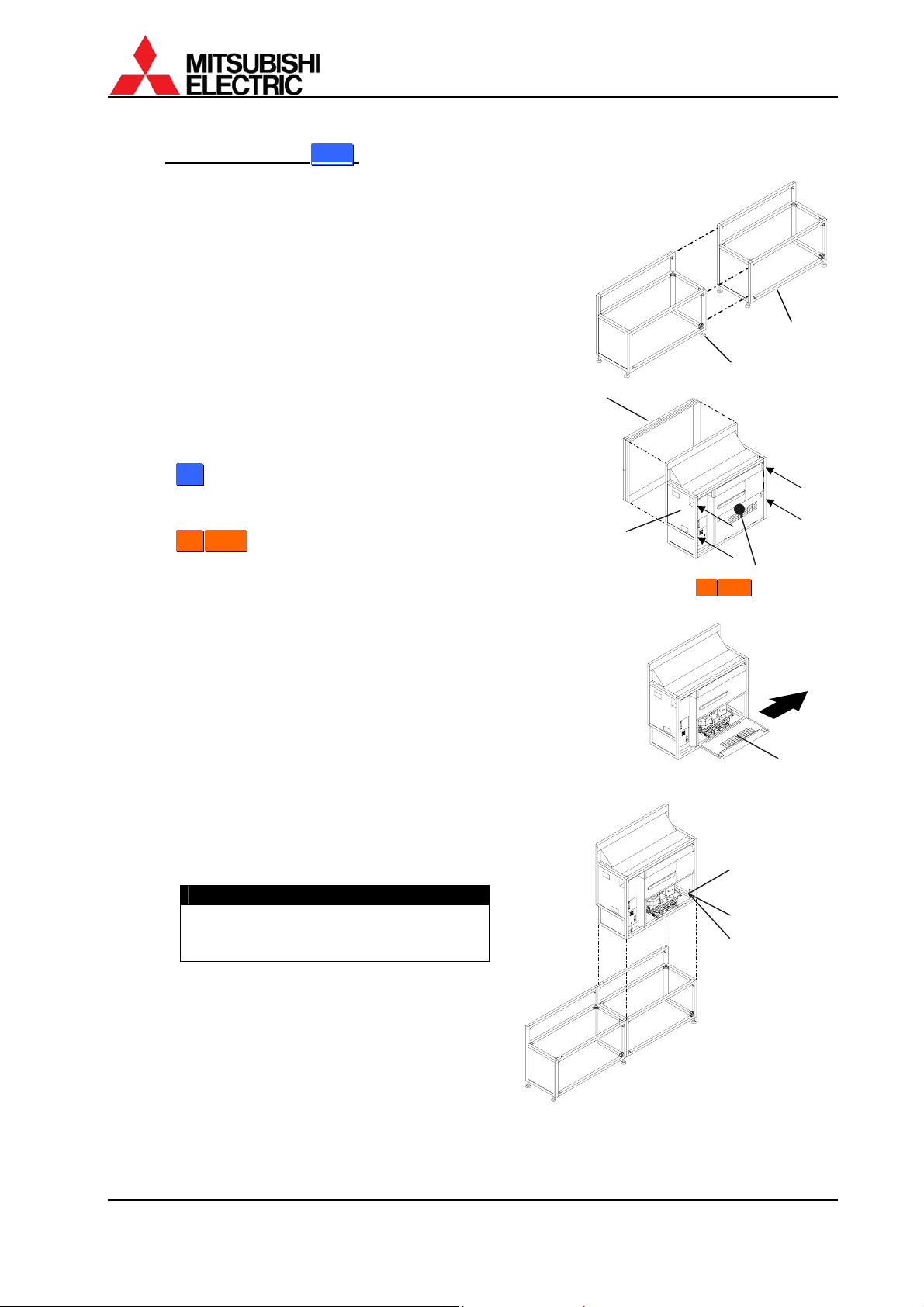

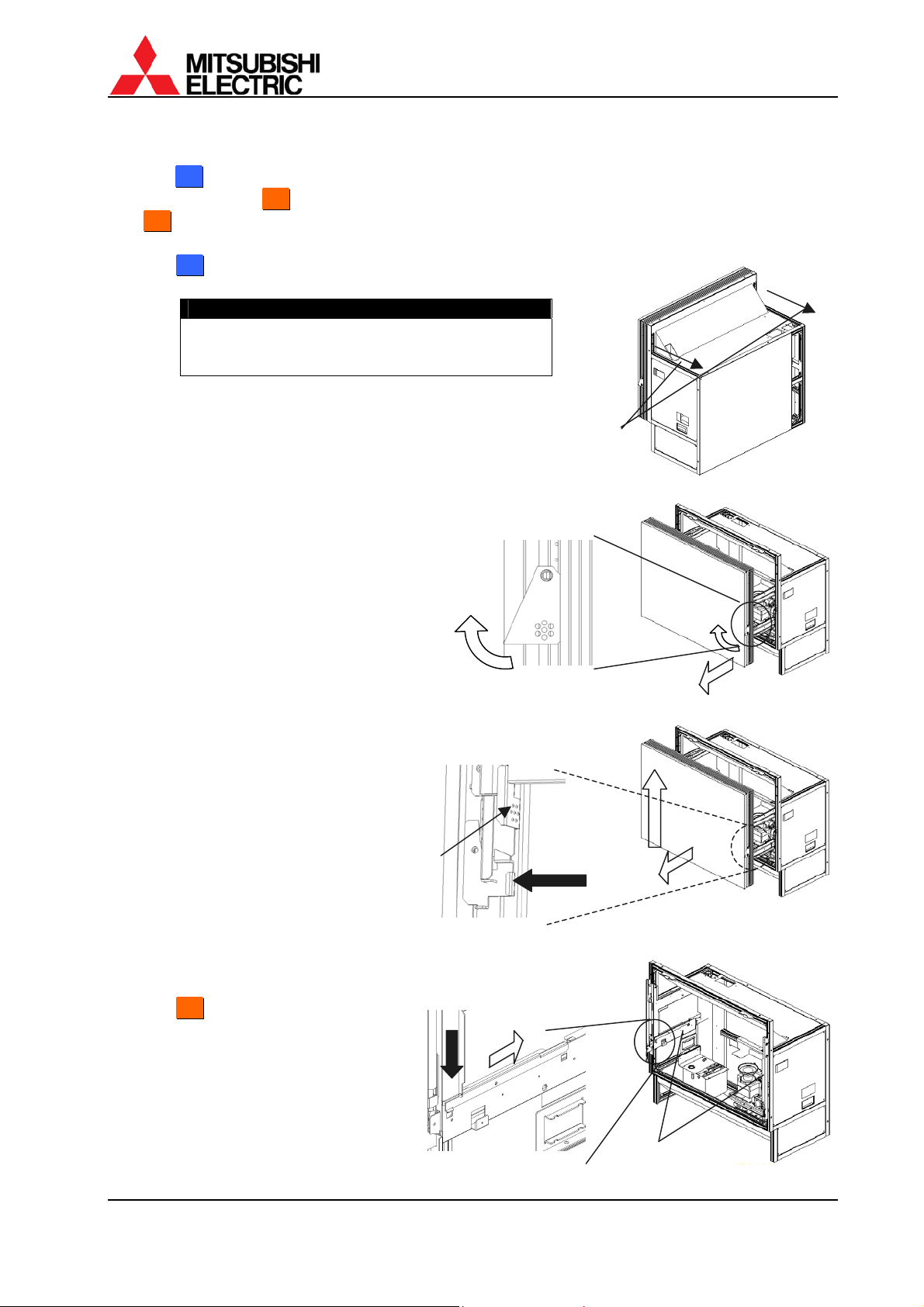

1.2.5. Cube stacking (for RReeaarr )

1.2.5.1. Assembling the base stands and cubes

1. Assemble base stands.

2. Adjust level adjusters to make the base stand both level

and plumb by means of a spirit level.

3. Loosen 4 screen-fixing screws per unit shown

with arrow lines in the right figure with an Allen

wrench (5 mm) to remove the screen units

from all cubes to be installed. (This applies to

”, which is supplied with the screen fitted).

5500”

4. 6677””PPHH5500: Turn a center screw in the lower

door 90 degrees anti-clockwise to unlock with

an Allen wrench (4mm).

5. Open the lower door 90 degrees by pushing

down the handles. And then slide it to right to

detach. The door cannot be detached other

than 90 degrees opening position.

6. Place a cube on the base stand.

7. Fix the cube at 4 points with supplied hexagon

socket head bolts, spring washers and flat

washers.

Caution

When holding up a cube, be careful not

to put your hand between the cube and

the base stand.

Screen unit

Cube unit

Level adjusters

Center screw

(6677””PPHH5500)

Lower door

Hexagon socket

head bolt

Spring washer

Flat washer

Base stands

Screen-fixing

screws

PH50, XL50, XL21 series Set-up and Installation Manual

10

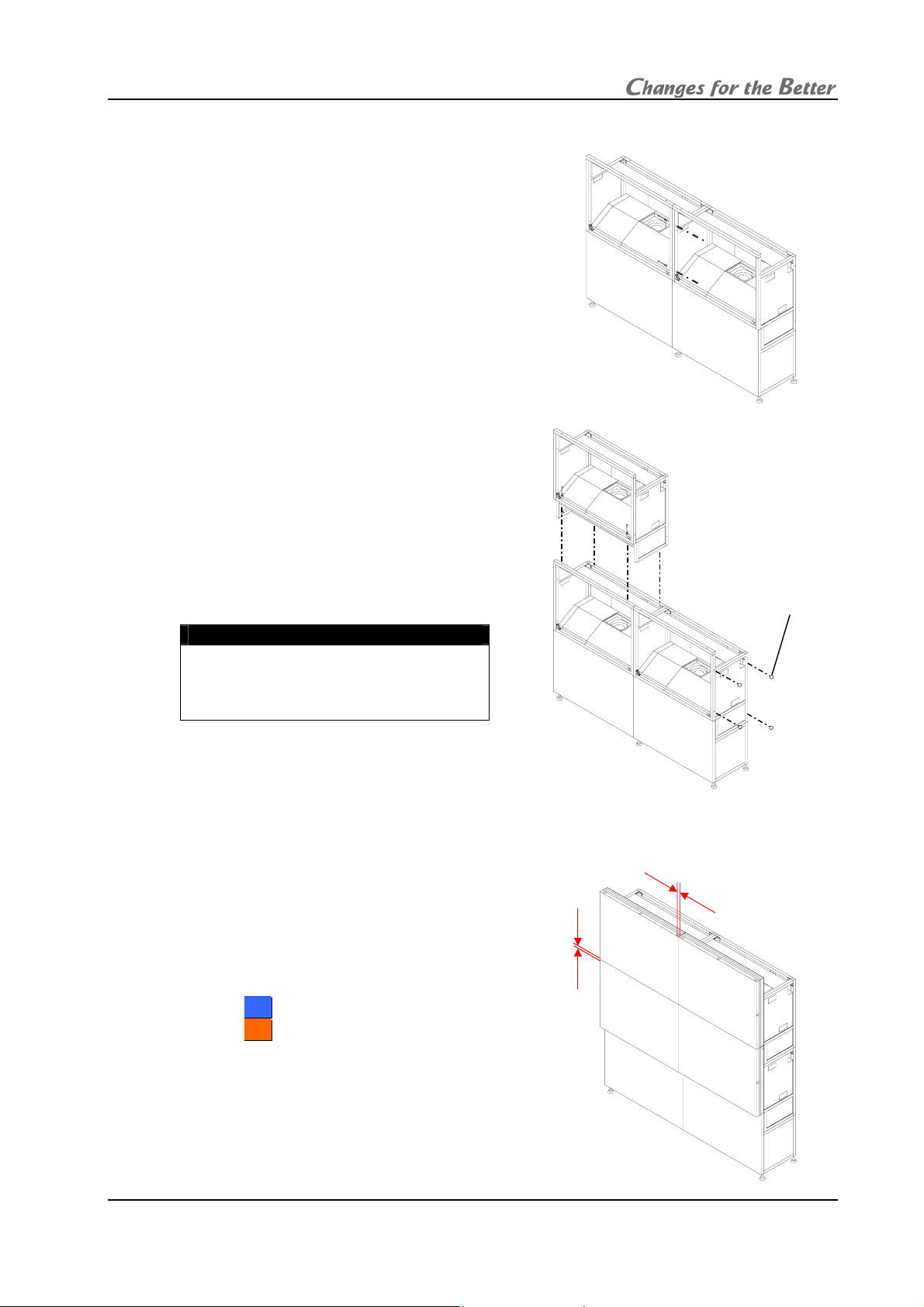

Page 11

8. Place the next bottom row cube on the base stand

and fix it in the same way.

9. Join right and left cubes at 4 points with supplied

hexagon socket head bolts, spring washers and flat

washers.

10. Place cubes for the upper row on the

assembled units.

11. Fix them vertically and horizo ntally at 4 points

each with supplied hexagon socket head bolts,

spring washers and flat washers.

12. Stop up the holes on both sides with supplied

joint hole seals, which holes are not used for a

display wall.

Caution

To avoid units from falling, measure

horizontal and vertical degrees with a

level etc. to make sure the units are

stably assembled.

Joint hole seals

1.2.5.2. Screen gap adjustment

1. Temporarily attach the screen units, which

were detached in the previous step. (For

67-inch models, the screens were supplied

separately).

2. Put spacers between screens and adjust the

screen gaps to be:

1 mm for 5500”” or

2 mm for 6677””.

3. Tighten the 4 screen-fixing screws. Be

careful not to tighten with an excessive

torque (suggested torque: 3.9Nm).

1mm

(2mm)

1mm

(2mm)

REV 2.4

11

Page 12

A

A

1.2.5.3. Fixing to the wall and floor

You don’t have to attach the lower door in this chapter since picture outlines have yet to be

adjusted as explained in the next chapter.

After the picture outline adjustment, attach the door in the reverse order of detaching.

1. Attach floor-fixing brackets on 4 level adjusters below the base stand and fix them to the

floor with anchor bolts.

2. Fix the upper back part of the display wall to the back wall with wall-fixing brackets as shown

in the following figure.

Hexagon socket head

cap screws (M6)

Wall-fixing brackets

nchor bolts

Adjusters

nchor bolts

Floor-fixing brackets

Caution

Make sure the whole set is assembled firmly and installed stably. To prevent the set

from falling due to unpredictable events such as earthquakes and shocks, fix the set

firmly to the wall and floor. Furthermore, carefully confirm the strength of the fixing area

of the installation place (wall and floor). The wall and floor fixing method differs

according to the number of assembled units.

PH50, XL50, XL21 series Set-up and Installation Manual

12

Page 13

1.2.6. Cube stacking (for FFrroonntt )

Caution

Take heed of appropriate surrounding space for ventilation (except rear surface) such

as not to pool the hot air on the top of the display walls so that the ambient

temperature doesn’t exceed the product environmental requirements.

1.2.6.1. Tape peeling off (for 6677””)

The screen-holding arms in both sides are taped at each end for transportation. Peel them off

before installation.

Tape

Screen-

holding arm

Tape

REV 2.4

13

Page 14

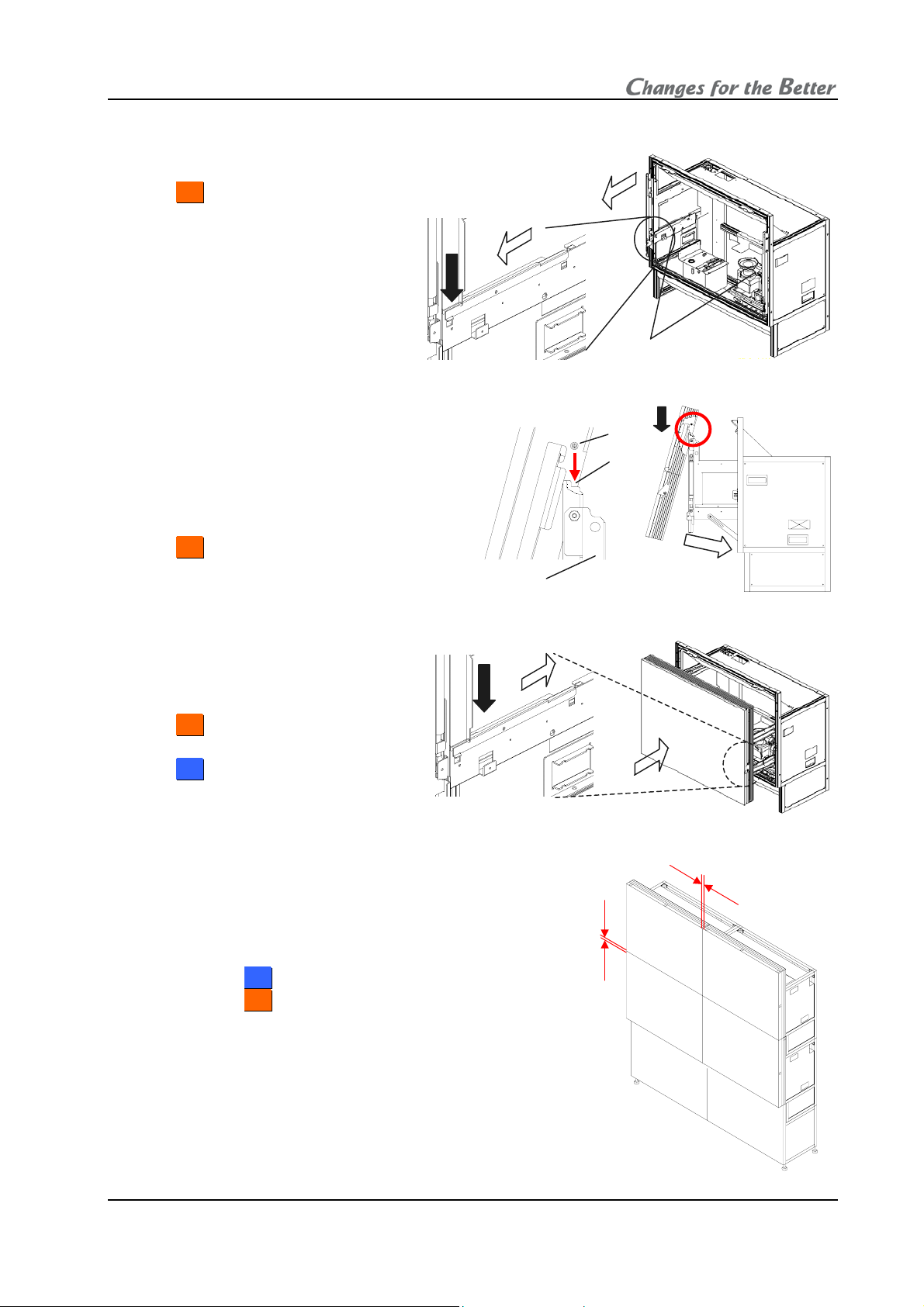

1.2.6.2. Screen detaching

For 5500”” which is supplied with the screen fitted, the screen unit should be detached before

installation. (For 6677””, the screens are provided separately.)

”: Screen attaching/detaching work should be done by two or more people.

6677”

Be careful not to trap your fingers when you slide its arms during detaching/attaching work.

1. 5500””: Remove two screen-fixing bolts (M6 – 45mm,

gold hexagon socket).

Caution

Before shipment, be sure to tighten the bolts (see

chapter

2.5.4, on page 86). Shipping the product

without tightening may cause breakage.

Screen-fixing

bolts

2. Pull screen-drawing handles in both sides to draw the screen

till locked.

Screen-drawing handle

3. Lift up and detach the screen unit with pushing

screen-detaching levers located inside the screen unit in

both sides. Be careful not to

push the adjacent flip-up lock

lever.

(Flip-up lock lever)

Push

Screen-detaching lever (inside the screen unit)

4. Press down the slide lock levers in both sides to unlock, and

put back the screen-holding arms.

”: The levers can be

6677”

unlocked respectively.

Slide lock lever (Inside the arm)

PH50, XL50, XL21 series Set-up and Installation Manual

14

Screen-holding arm

Page 15

A

r

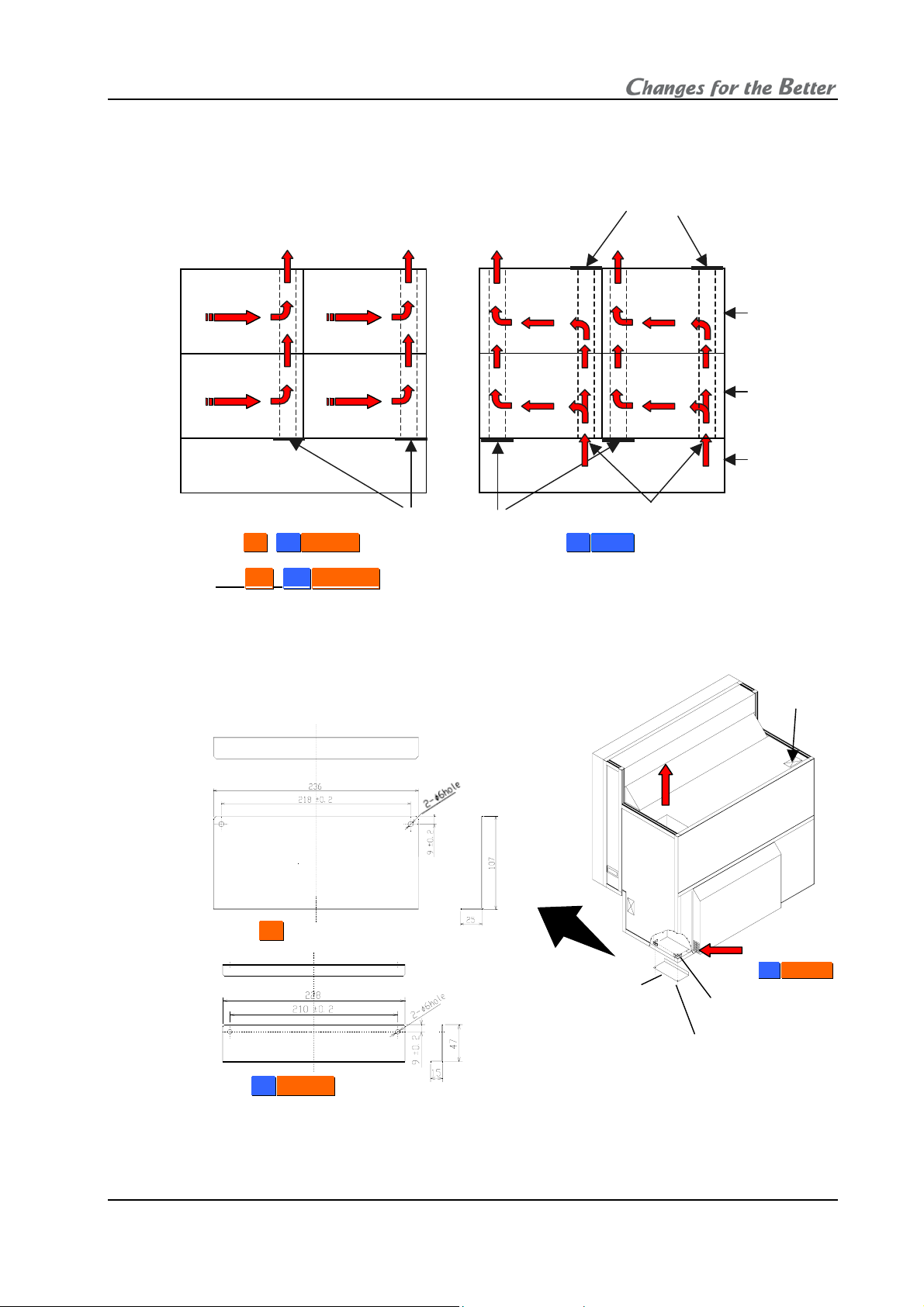

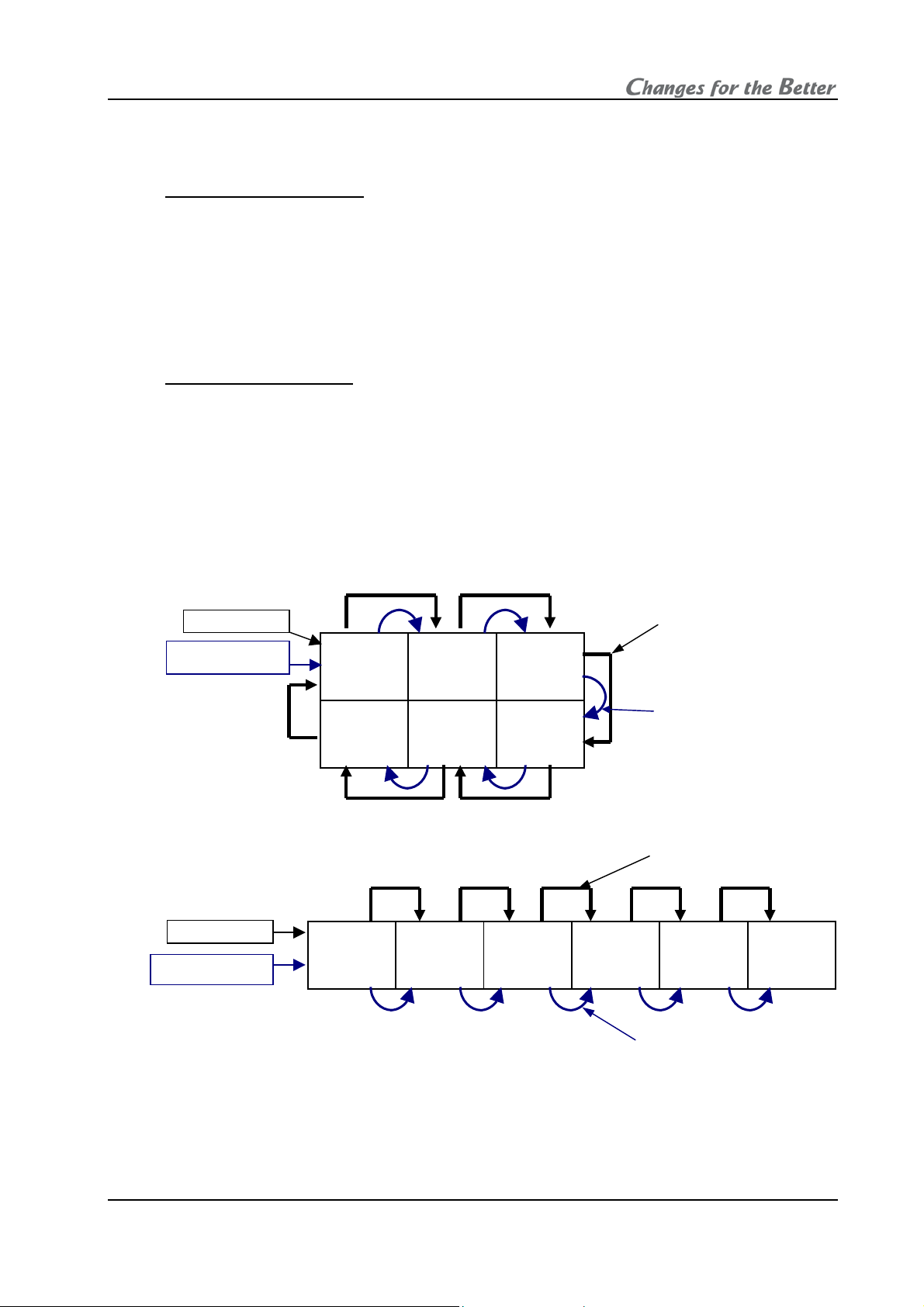

1.2.6.3. Ventilation

To ensure a proper airflow for cooling, you need to block some vents as the following figures.

Panel 1

(From rear)

Panel 3

(From rear)

Exhaust

(From rear)

(From rear)

Panel 2

Panel 4

Exhaust

Exhaust

Panel 1

Panel 3

Intake

Should be blocked

Exhaust

Panel 2

Panel 4

Intake

Top row

Bottom row

Base stand

For 6677””, 5500””CChhaannggeerr

Vents t o be b lo cke d

irflow concept

Vents t o be b lo cke d

For 5500””SSiinnggllee

External AC fans (occasional)

1.2.6.3.1. For 6677””, 5500””CChhaannggeerr

1. Block the vents in the bottom row. Prepare a cover material by yourself in reference to the

figures below. The covers can be fixed with two self-tapping screws (nominal diameter: 4mm,

length: 8 – 12mm) on the holes of the corner joint. Be sure this work is only for the cubes in

the bottom row.

Vent covers (example):

Material: aluminum or steel plate (thickness: 1mm)

Exhaust

For 6677””

For 5500””CChhaannggeerr

Unit [mm]

Vent cove

Intake

(from right side

in5500””CChhaannggeerr)

Holes of corner joint

Two self-tapping screws

(nominal diameter: 4mm,

length: 8 – 12mm)

2. To keep dust out, seal the cable holes on the top of the display wall. Prepare a cover

material by yourself. The size of the holes is 116.5mm x 63mm. Be sure this work is only for

the cubes in the top row.

Cable

hole

REV 2.4

15

Page 16

1.2.6.3.2. For 5500””SSiinnggllee

According to circumstances, attach the optional external AC fans (JC-AF115R or JC-AF230R) on

the intake vents in the bottom row (see “External AC fan attaching” on page 17).

• Prepare openings on base stands to ventilate.

• Keep enough base stand height not to inhale a coat of dust on a floor from the intake vents.

1. To block the bottom row, detach the bottom duct cover from inside the cube and attach it on

the bottom of the duct. Be sure this work is only for the cubes in the bottom row.

2. To block the top row, remove the cushion unit on the top at first. Then detach the top duct

cover from the top surface of the cube and attach it on the top of the duct. Be sure this work

is only for the cubes in the top row.

Tighten removed 3

screws to attach.

Detaching

Top duct cover

Cushion unit

Detaching

Tighten the duct screw

to attach with duct

panel.

Detaching

Bottom duct cover

0

XXLL550

1

XXLL221

Tighten removed screw

to attach.

3. To keep dust out, seal the cabl e holes on the top of the display

wall. Prepare a cover material by yourself. The size of the

holes is 116.5mm x 63mm. Be sure this work is only for the

cubes in the top row.

Cable hole

PH50, XL50, XL21 series Set-up and Installation Manual

16

Page 17

A

A

External AC fan attaching (

occasional)

When 4-high configuration with 5500””SSiinnggllee, attach the optional external AC fans (JC-AF115R or

JC-AF230R) on intake vents. Even in 3-high configuration, attach the AC fans as well, when

spaces are narrower than 50cm to the ceiling and 10cm to the wall behind. Narrow spaces tend

to rise the cube internal heat. Be sure this work is only for the cubes in the bottom row.

1. Attach a suitable plug to the bare end of the power

cord of the fan to correspond with an interface such

as a terminal block or a power strip. 2-meter AC

power cord is included in the fan.

2. Insert the fan into the intake vent till click.

3. Fix it to the lower part of cube with the screw supplied

with the fan.

Note:

• To avoid injuries and shock hazards, do not carry

Intake vent

External

C fan

electricity to the fan during this work. It must be done

by qualified personnel.

• Be sure to use the fan within the range of its power

rating.

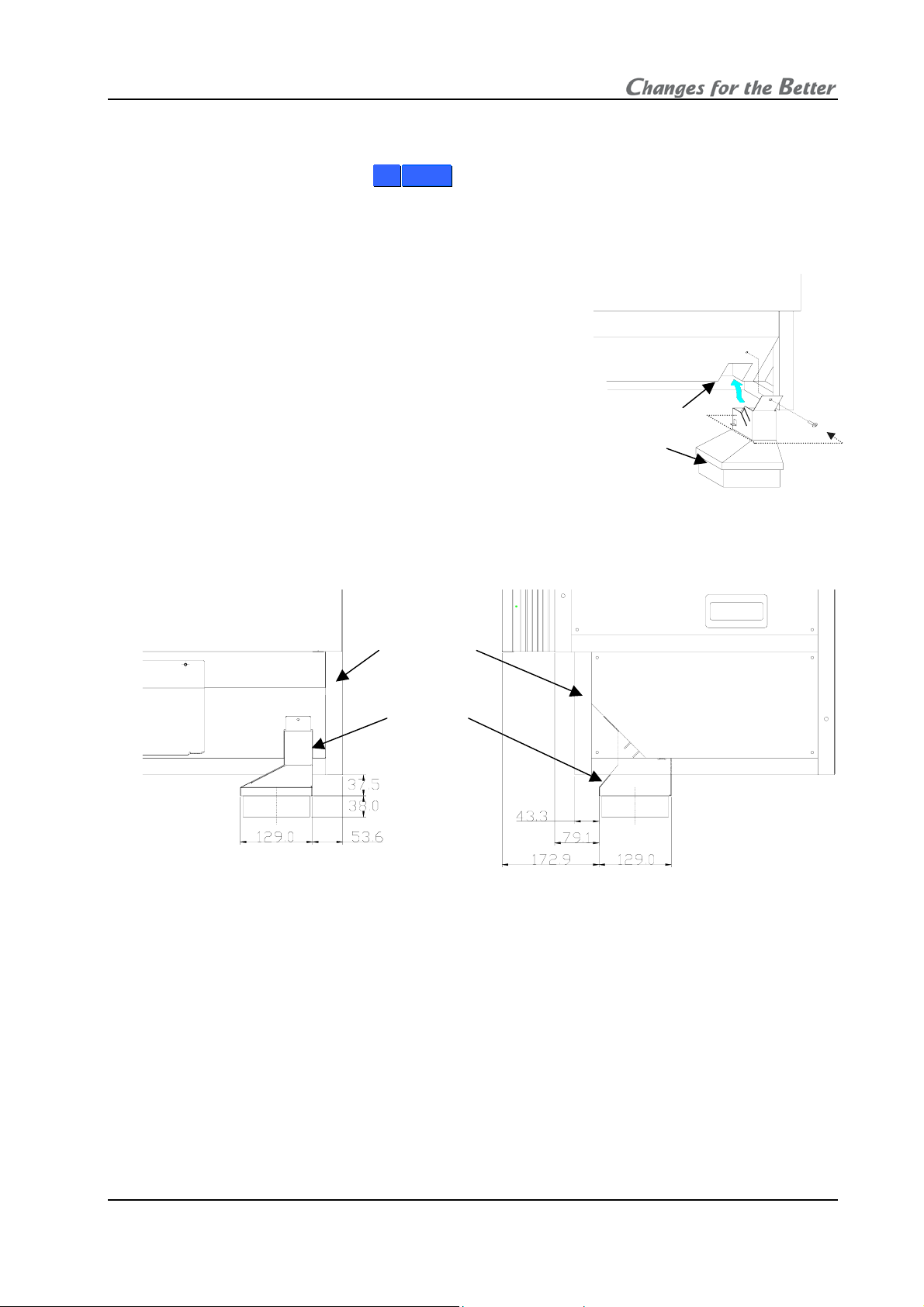

• The outline of the fan is shown below. Prepare a base stand which does not interfere with the

fan.

Front view

Lower part of cube

External

C fan

[Unit: mm]

Side view

REV 2.4

17

Page 18

r

r

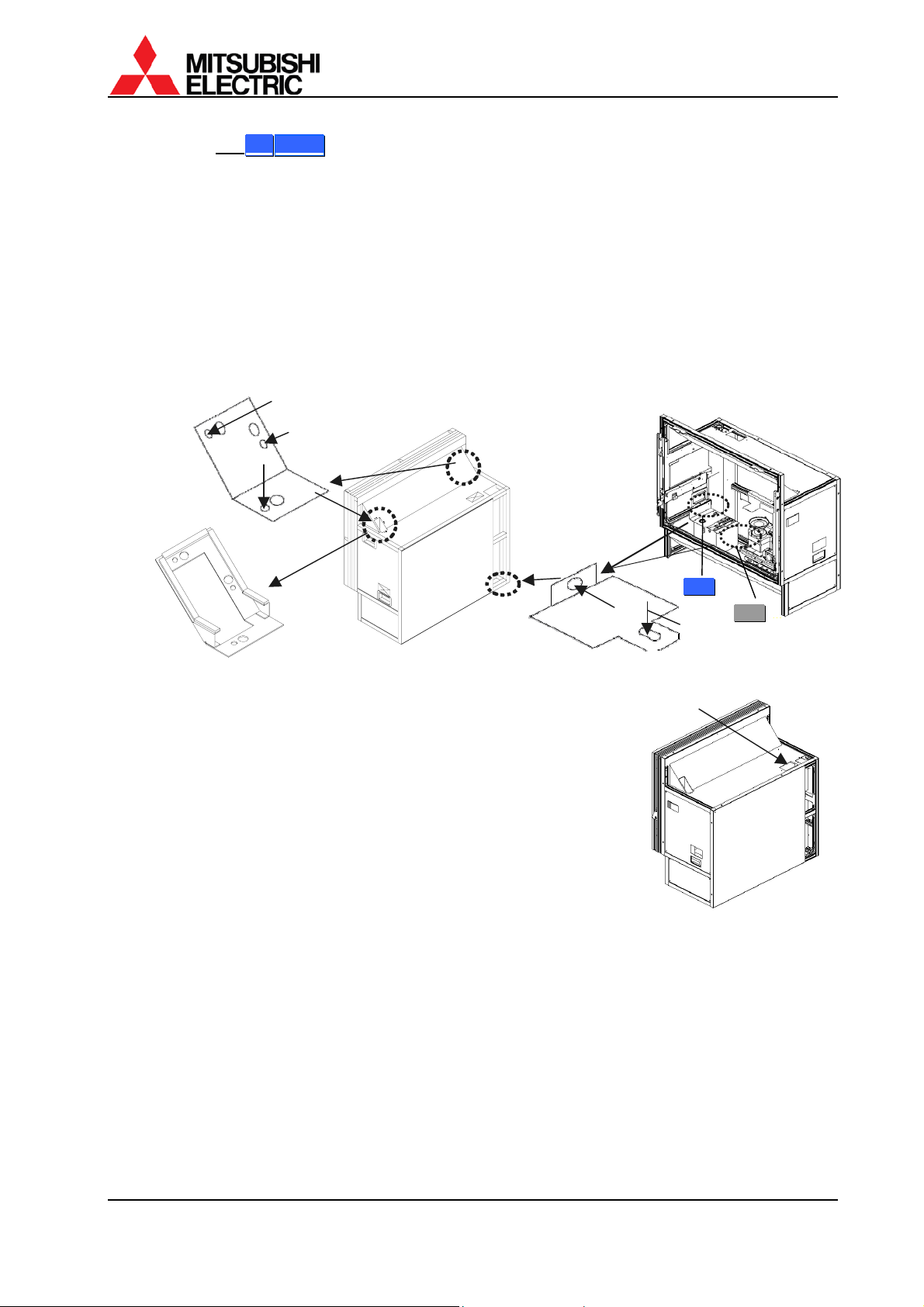

1.2.6.4. Assembling base stands and cubes

1. Assemble base stands.

2. Adjust level adjusters to make the base stand both level and

plumb by means of a spirit level.

3. Place a cube on the base stand.

Caution

Do not grip the screen-holding arms to

Hexagon socket

lift up a cube cabinet. It may cause

breakage.

4. Fix the cube at 4 points with supplied hexagon

Spring washe

socket head bolts, spring washers and flat

washers.

Caution

When holding up a cube, be careful not

to put your hand between the cube and

the base stand.

5. Place the next bottom row cube on the base stand and fix it in

the same way.

6. Join right and left cubes at 4 points with supplied hexagon

socket head bolts, spring washers and flat washers.

7. Place cubes for the upper row on the assembled units.

8. Fix them vertically and horizontally at 4 points each with

supplied hexagon socket head bolts, spring washers and

flat washers.

9. Stop up the holes on both sides with supplied joint hole

seals, which holes are not used for a display wall.

Caution

To avoid units from falling, measure horizontal and

vertical degrees with a level etc. to make sure the units

are stably assembled.

10. Run cables through the internal cabinets according to the

chapter

1.3.3 on page 24 before attaching the screen unit.

Base stands

Level adjusters

head bolt

Flat washe

Joint hole seals

PH50, XL50, XL21 series Set-up and Installation Manual

18

Page 19

11. Pr ess down the slide lock levers in both sides to unlock, and

draw the screen-holding ar ms till locked.

”: The levers can be unlocked respectively.

6677”

Slide lock lever (Inside the arm)

12. Reinstall the screen unit in its original

cabinet. Put the pins inside the screen

unit on the retainers at the top of the

screen-holding arms, following which

make the screen upright. Make sure it

will be locked securely .

”: Screen attaching/detaching work

6677”

should be done by two or more

people.

screen-holding arm

13. Press down the slide lock

levers in both sides to unlock,

and push the screen unit along

the rail till the end.

”: The levers can be

6677”

unlocked respectively.

”: You don’t have to tighten

5500”

the removed two screen-fixing

bolts.

Slide lock lever (Inside the arm)

Screen-holding arm

Pin

Retainer

1.2.6.5. Screen gap adjustment

This adjustment is normally unnecessary.

As needed, you can adjust the screen gaps.

1. Estimate a distance to move the screens so that

the screen gaps will approximately be:

2 mm for 5500”” or

3 mm for 6677””.

2. Open the screen units (chapter 1.2.7.1, on page

21).

2mm

(3mm)

2mm

(3mm)

REV 2.4

19

Page 20

A

A

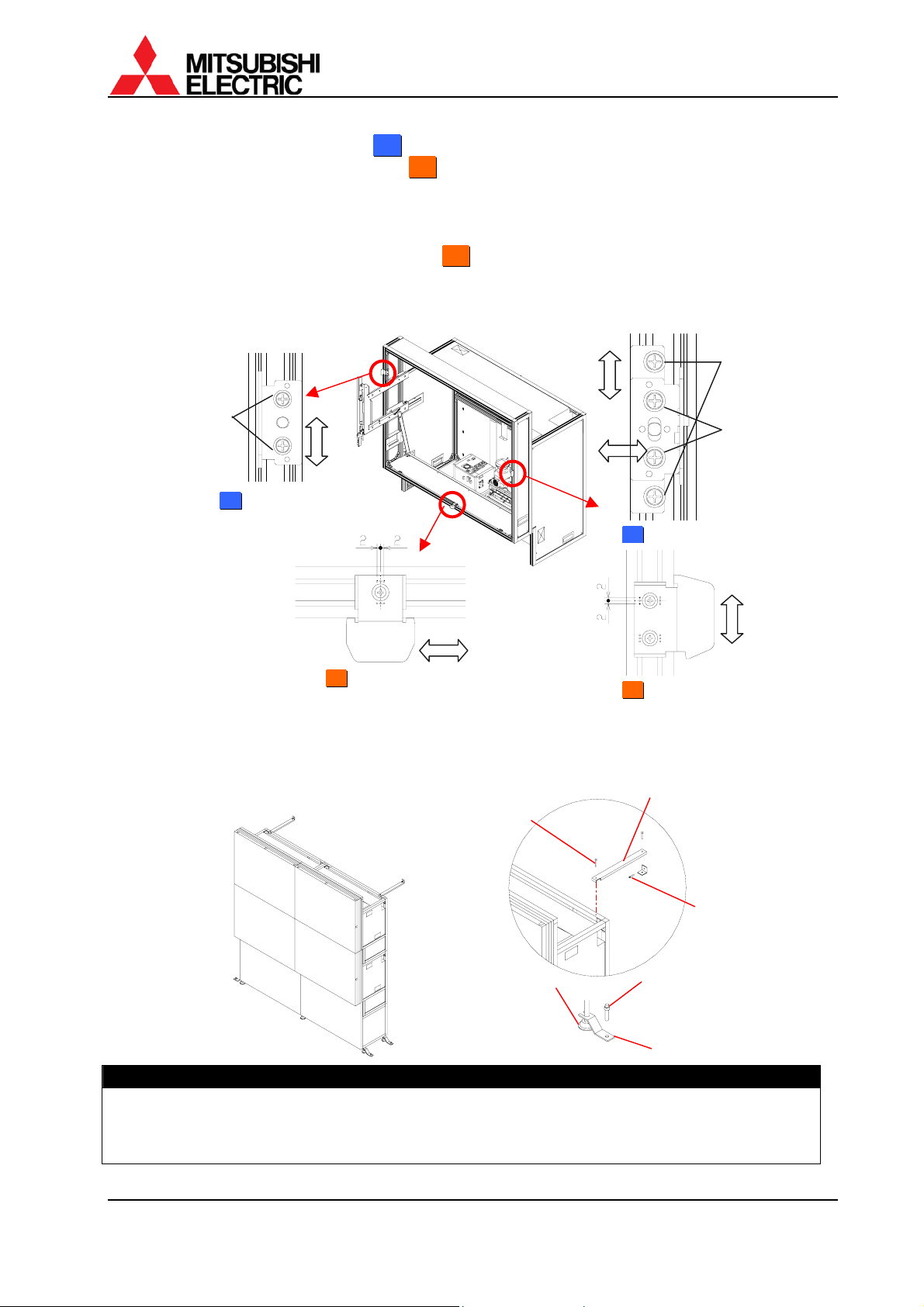

A

3. For horizontal adjustment: 5500””: Loosen two screws in the right screen guide to adjust its

horizontal position and fix them. 6677””: Loosen the screw in the bottom screen guide to adjus t

its horizontal position and fix it. The screen guide has punch marks at the adjustable range

(+/- 2mm) and its center.

4. For vertical adjustment: Loosen two screws each in the left and right screen guides to adjust

their vertical positions and fix them. 6677””: The screen guides have the punch marks at the

same position as described above.

5. Close the screen units (chapter 1.2.7.2, on page 22).

6. Check the screen gaps and repeat the steps until you get reasonable gaps.

For vertical

adjustment

For vertical

adjustment

For horizontal

adjustment

” Left screen guide

5500”

” Right screen guide

5500”

” Bottom screen guide

6677”

For horizontal

adjustment

” Screen guide (both side)

6677”

For vertical

adjustment

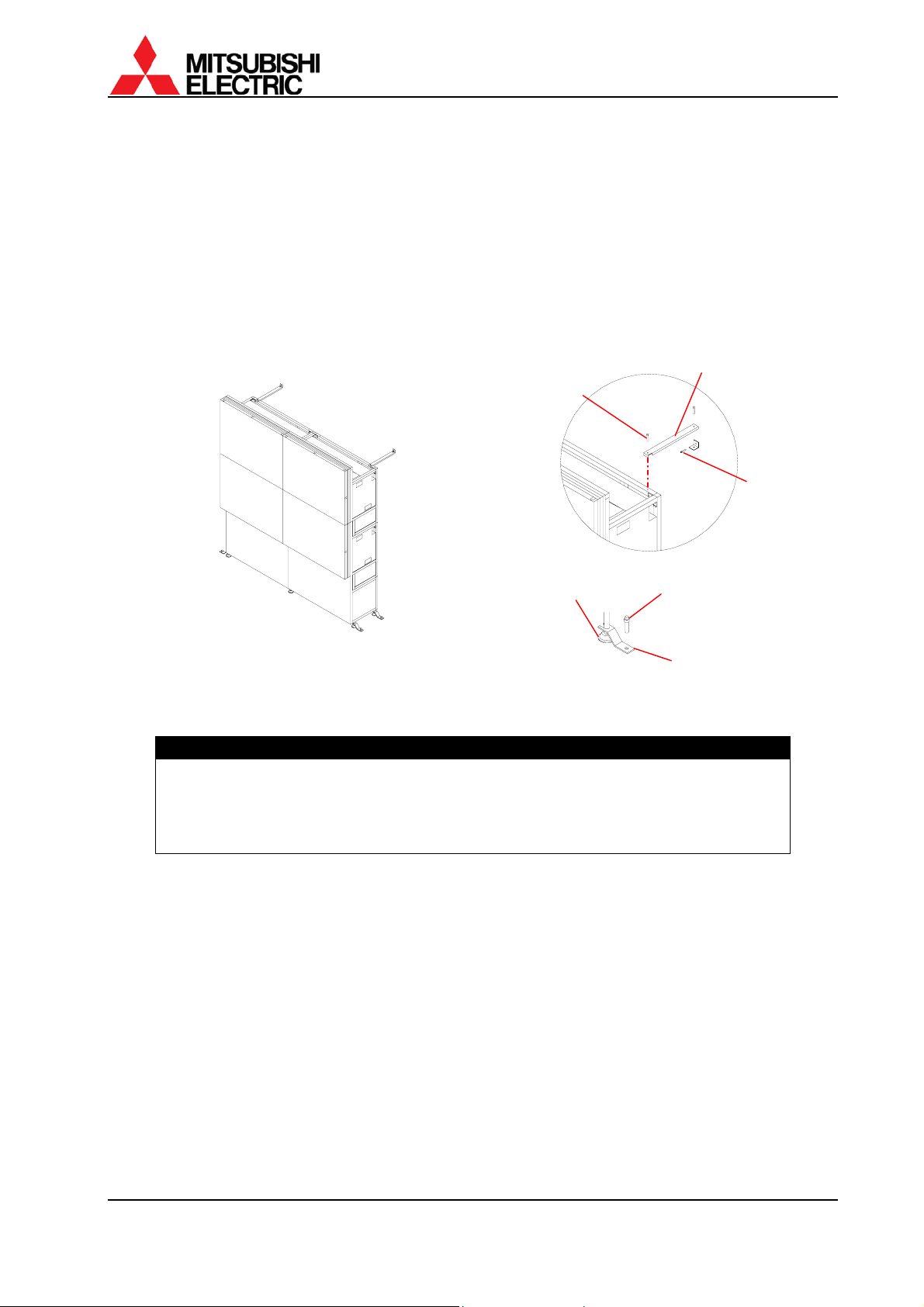

1.2.6.6. Fixing to the wall and floor

1. Attach floor-fixing brackets on 4 level adjusters below the base stand and fix them to the

floor with anchor bolts.

2. Fix the upper back part of the display wall to the back wall with wall-fixing brackets as shown

in the following figure.

Hexagon socket head

cap screws (M6)

Wall-fixing brackets

nchor bolts

djusters

nchor bolts

Floor-fixing brackets

Caution

Make sure the whole set is assembled firmly and installed stably. To prevent the set from falling

due to unpredictable events such as earthquakes and shocks, fix the set firmly to the wall and

floor. Furthermore, carefully confirm the strength of the fixing area of the installation place (wall

and floor). The wall and floor fixing method differs according to the number of the assembled units.

PH50, XL50, XL21 series Set-up and Installation Manual

20

Page 21

1.2.7. Screen open/close (for FFrroonntt )

Cabling or lamp replacement, etc. requires opening the screen unit. Be careful not to trap your

fingers during the work.

The open/close should be

performed on a one-by-one basis in

Cube unit

a display wall so as not to shift the

center of gravity much.

In particular, 6677”” may cause topple

down due to wide shifting of the

center of gravity. When you

open/close the screen units on

stand-alone cubes without fixing to

a base stand or other cubes, be

sure to use the support base which

Screen unit

Support base

is contained in the cube carton box.

1.2.7.1. Screen opening

Caution

About one-meter space in front of the screens

is needed for the opening. Prior to work, make

sure that there is no object such as steps in the

working space.

1. 5500””: Make sure that the two screen-fixing bolts (M6 –

45mm, gold hexagon socket) have been removed.

Screen-fixing bolts

2. Pull the screen-drawing handles in both sides to draw the

screen till locked.

Screen-drawing handle

REV 2.4

21

Page 22

3. Pull up the bottom of the screen unit to rotate 90

degrees with pushing flip-up lock levers located inside

the screen unit in both sides.

”: The levers can be unlocked

6677”

respectively.

Be careful not to push the

adjacent screen-detaching lever.

(Screen-detaching lever)

Flip-up lock lever (inside the screen unit)

1.2.7.2. Screen closing

Be careful not to trap your fingers during the work.

1. Push down the bottom of the screen slowly till locked.

2. Press down the slide lock levers in both sides to unlock,

and push the screen unit along the rail till the end.

”: The levers can be

6677”

unlocked respectively.

Slide lock lever (inside the arm)

Note:

Depending on the screen gap

adjustment (chapter

1.2.6.5, on page

19), the screen unit may touch the top

edge of the lower screen. In this case,

slightly lift the upper screen to close

without touching.

Push

PH50, XL50, XL21 series Set-up and Installation Manual

22

Page 23

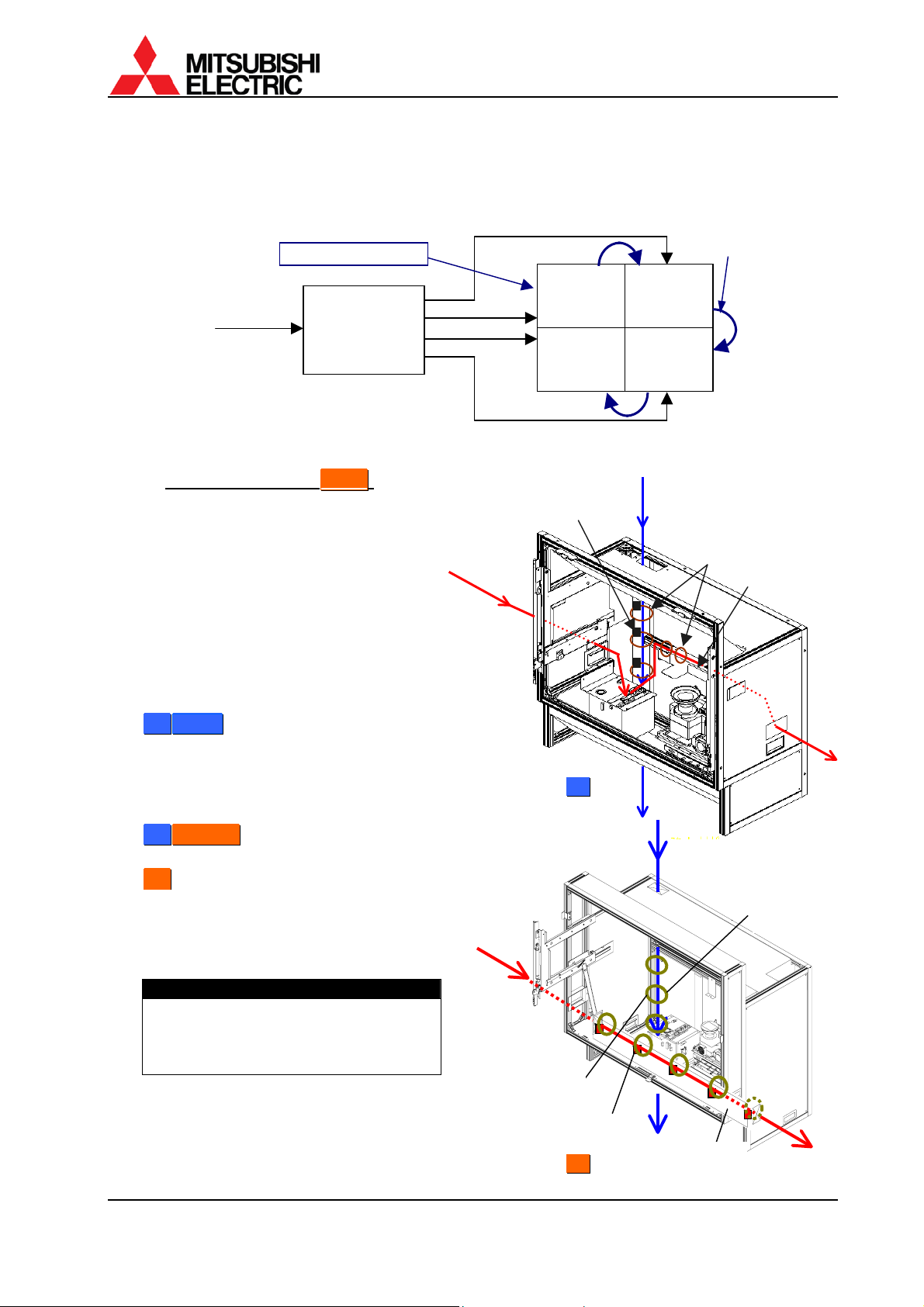

1.3. Connecting

1.3.1. Control signal connection

An external controller such as a personal computer etc. can control cubes through RS-232 format

communication. In the case of a display wall, connect the external controller to a MASTER cub e

set by dipswitch (chapter

and CONTROL OUT terminals between cubes with supplied control cables. Do not connect to a

loop.

Allocating ID numbers by dipswitch, each cube can be controlled separately by one controller. Up

to 64 cubes can be chained in one control line.

1.4.2, on page 28) with RS-232 cross cable, and connect CONTROL IN

1.3.2. Image signal connection

Connect (an) image input source(s) with cubes adequately.

1.3.2.1. In the case of daisy chain

In the case of an enlarged image displaying with digital daisy chain connection, install the

optional input boards (chapter 1.2.3, on page 7) and connect DIGITAL IN and DIGITAL OUT

terminals between cubes with digital cables (DVI-D) that are supplied with the boards. The digital

image signal can be chained up to 16 cubes.

In the case of 3 by 2

Video device

External controller

ID 1

MASTER

ID 4

SLAVE

ID 2

SLAVE

ID 5

SLAVE

ID 3

SLAVE

ID 6

SLAVE

Supplied digital cables

(6 pcs)

Supplied control cables

(5 pcs)

In the case of 6 by 1

(In this case, an image signal cannot be connected to a loop.)

Supplied digital cables (5 pcs)

Video device

External controller

ID 1

MASTER

ID 2

SLAVE

ID 3

SLAVE

ID 4

SLAVE

ID 5

SLAVE

SLAVE

ID 6

Supplied control cables (5 pcs)

REV 2.4

23

Page 24

1.3.2.2. For other than daisy chain

Connecting with a multiple-output device, an enlarged image can be displayed as well as daisy

chain connection.

Input image

External controller

Multiple-output

device

ID 1

MASTER

ID 3

SLAVE

ID 2

SLAVE

ID 4

SLAVE

Supplied

control cables

Connecting with a multiple-output device (example)

1.3.3. Internal cabling (for

Run cables through the holes located on

both sides and top/bottom.

FFrroonntt

)

Mount bases

Horizontal

cabling

For the vertical cabling: Thread the

supplied plastic cable ties through the

holes in 3 mount bases to fix on the rear

surface of the back panel, and fasten

the cables with the ties.

For the horizontal cabling:

5500””SSiinngglle

e: Route the cables through

the guide below the mirror and fasten

them with supplied cable ties as

appropriate not to shade picture images

For 5500””

from the optical unit.

5500””CChhaannggeer

r: Run the cables through

the cable guide behind the mirror.

”: Thread the supplied cable ties

6677”

through the holes in 5 mount bases to fix

Horizontal

on the rear surface of the skirt part, and

cabling

fasten the cables with the ties.

Caution

For the safety reason, do not allocate a

power strip inside the cube cabinet. It is

recommended to use the optional

3-meter power cord.

Plastic

cable ties

Mount bases

(for horizontal)

For 6677””

PH50, XL50, XL21 series Set-up and Installation Manual

24

Vertical

cabling

Plastic cable ties

Cable guide

Vertical cabling

Mount bases

(for vertical)

Skirt part

Page 25

1.4. Initial set up

1.4.1. Menu operation

1.4.1.1. Control button list

In normal mode In advanced mode

Remote

control

POWER ON Turn on -

POWER OFF - Turn off

DISPLAY - Statu s i n formation Statu s i n formation (Press-and-hold for detail informa ti on)

PIC MUTE - - - Picture mute - Picture mute

INPUT A - - Selective input signal list

MENU1 - - Input memory menu -

MENU2 - -

MEM LIST

R

G - - G raster on/off G input on/off G raster on/off G input on/off

B - - B raster on/off B input on/off B raster on/off B input on/off

TEST - - Test pattern on – pattern rounding – test pattern off

FUNC - - Remote ID setting mode on/off

NORMAL - Normal mode/advanced mode switching Initialize

ESC - Cancel, back or test pattern off, etc.

ENTER

UP - - - - Menu option and cursor up

DOWN - - - - Menu option and cursor down

LEFT

RIGHT

Number

In stand-

by state

- -

- -

- -

- - - -

- - - -

-

Menu OFF Menu OFF Menu ON

Test pattern

ON

Test pattern

OFF

Display memory calling

Test pattern

ON

Display memory menu

(Press-and-hold for system

R raster on/off R input on/off R raster on/off R input on/off

memory menu)

Input memory and di sp lay memory list

Test pattern

OFF

Test pattern

Define

Test pattern

ON

-

Va lue down

Va lue up

-

OFF

REV 2.4

25

Page 26

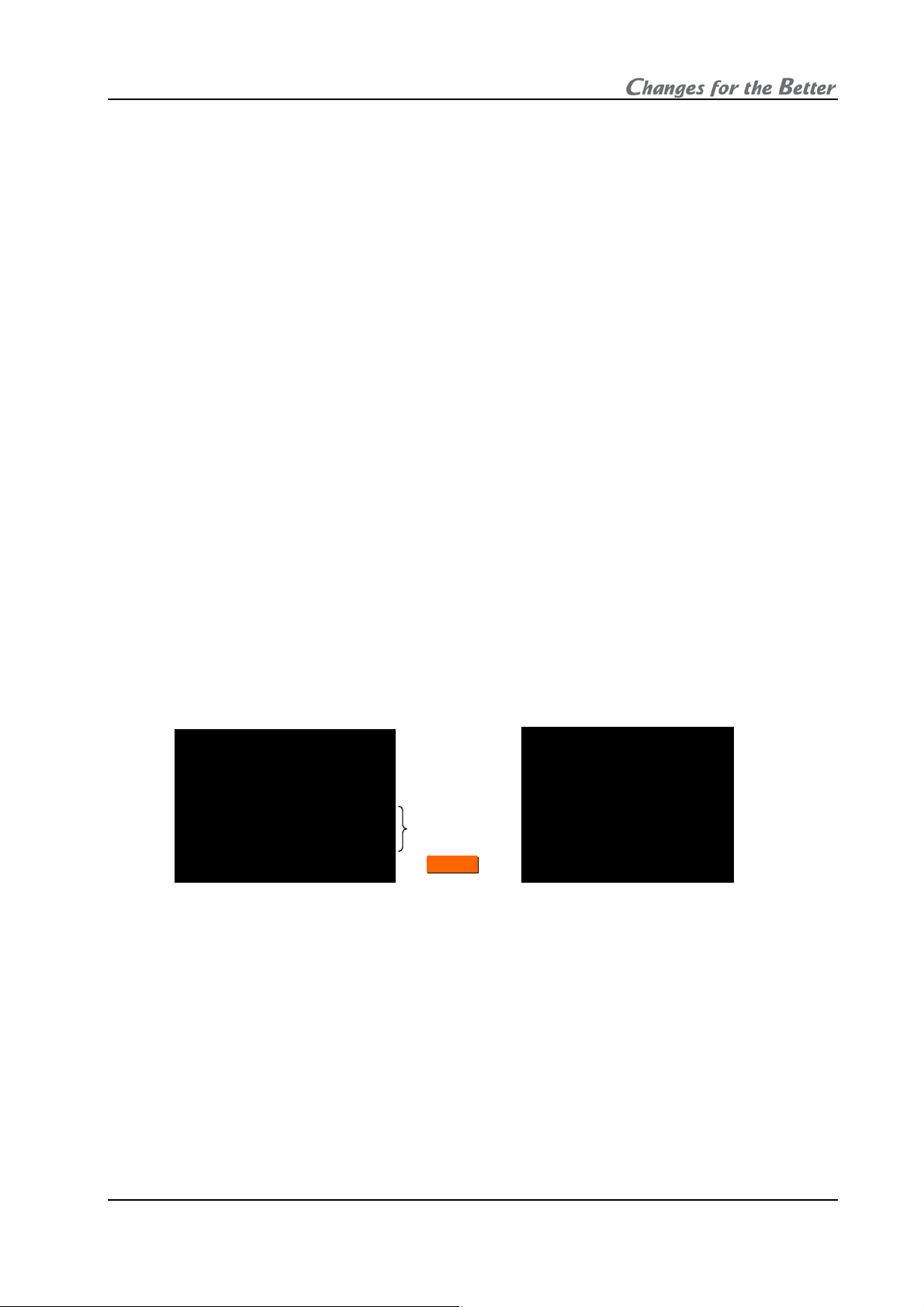

1.4.1.2. Operation mode

This product has two operation modes: “normal mode” and “advanced mode”. Use the normal

mode in usual operation. Switch to the advanced mode when you set up or adjust the product.

Two modes can be switched by [NORMAL] button when there is no adjustment menu on screen.

1.4.1.2.1. Normal mode The normal mode allows you to turn off the power by [POWER] button, to display status information by [DISPLAY] button, to change the operation mo de by [NORMAL] button and to cal l a display memory by number buttons. Adjustment menus cannot be called in the normal mode.

1.4.1.2.2. Advanced mode

In advanced mode, status information appears on screen as

described in right figure.

1. Status display:

! ANALOG NO SIGNAL ID01

Status Input port Comment Set ID

• “!” mark appears when values in a menu are

changed. It is also displayed when a value is

automatically changed by internal process.

• In CChhaannggeerr, “☀” mark appears when the status of

a spare lamp is other than “NEW”.

• During lamp position auto calibration (for CChhaannggeerr) and initial sensor value obtaining,

the operating status is noticed with figures such as “3”, “4” or “7”. When the function has

worked correctly, it disappears after 5-minute displaying.

2. Input port: Displaying current input port.

3. Comment:

• “NO SIGNAL” is displayed when any image signal is not input.

• “TEST *” is displayed during internal test patterns displaying.

• “MUTE” is displayed during picture mute.

4. Set ID: Displaying a set ID.

PH50, XL50, XL21 series Set-up and Installation Manual

26

Page 27

1.4.1.3. Basic menu operation

Adjustments should be conducted with the remote control in advanced mode.

(You can also use the adjustment software, “Wallaby” (chapter

4, on page 99)).

• [POWER ON] button: To turn on after main power switch on.

• [MENU1] button: To display the input memory menus.

• [MENU2] button: To display the display memory menus while the input board is attached.

• [MENU2] button (press and hold): To display the system memory menus.

• Up/down button: To select menu items.

• [ENTER] button: To enter each adjusting menu. Some items indicate the lower menu layer.

• Left/right button: To change an adjusting value.

• [ESC] button: To exit menus.

• [NORMAL] button: To reset an adjusting value. In reply to appeared “RESET OK?” message,

press [ENTER] button. You can exit the menu without resetting by [ESC] button.

[NORMAL] button also executes automatic input signal scanning during input memory

menus displaying.

• [FUNC] button: Remote ID setting (chapter

1.4.1.4).

• [TEST] button: To display test patterns (chapter 3.3, on page 91). Even while any menus

are displayed on screen, the test patterns on/off and selecting are available.

• [R][G][B] buttons: To switch muting/displaying of primary colors. It works regardless of

remote ID setting.

Press-and-hold the button can always display the selected color. This function is helpful

when you display the same color across a display wall, which mixes color displaying/muted

cubes. Just pressing may unintentionally mute the color in other cubes.

• Number buttons: To call a display memory directly with 3-digit number while there is no

menu on screen. For instance, press 001 to call the display memory 1.

• [DISPLAY] button: To show status information.

LAMP TIMER 99999H

INPUT ANALOG

SYSTEM ID 01

LAMP A NEW BUSY

LAMP B USED STANDBY

NO SIGNAL

Status information ([DISPLAY] button)

Lamp operating time

Input port

Set ID

Lamp status

Comment

(In CChhaannggeerr)

! ANALOG ID01

F/W VER P01.50A

H/W VER 12.19

SET TIMER 99999H

MASTER

L.SENSOR 125

Detail status information

([DISPLAY] button press-and-hold)

Firmware version

FPGA version

Set operating time

Master/slave setting

Luminous sensor value

1.4.1.4. Remote ID

Remote ID is used to operate remote control toward a specified screen in a display wall. Even

while any menus are displayed on screen, remote ID can be switched.

Specify a set ID by [FUNC] button and 2-digit number in advanced mode, which ID has been set

in the dipswitch. When you control only ID=1 cube, press [FUNC]+[0]+[1]. It can be also selected

by left/right button after the [FUNC] button. And then press [ENTER] button to confirm.

Pressing [FUNC]+[0]+[0] buttons enable remote control toward all cubes.

27

REV 2.4

Page 28

A

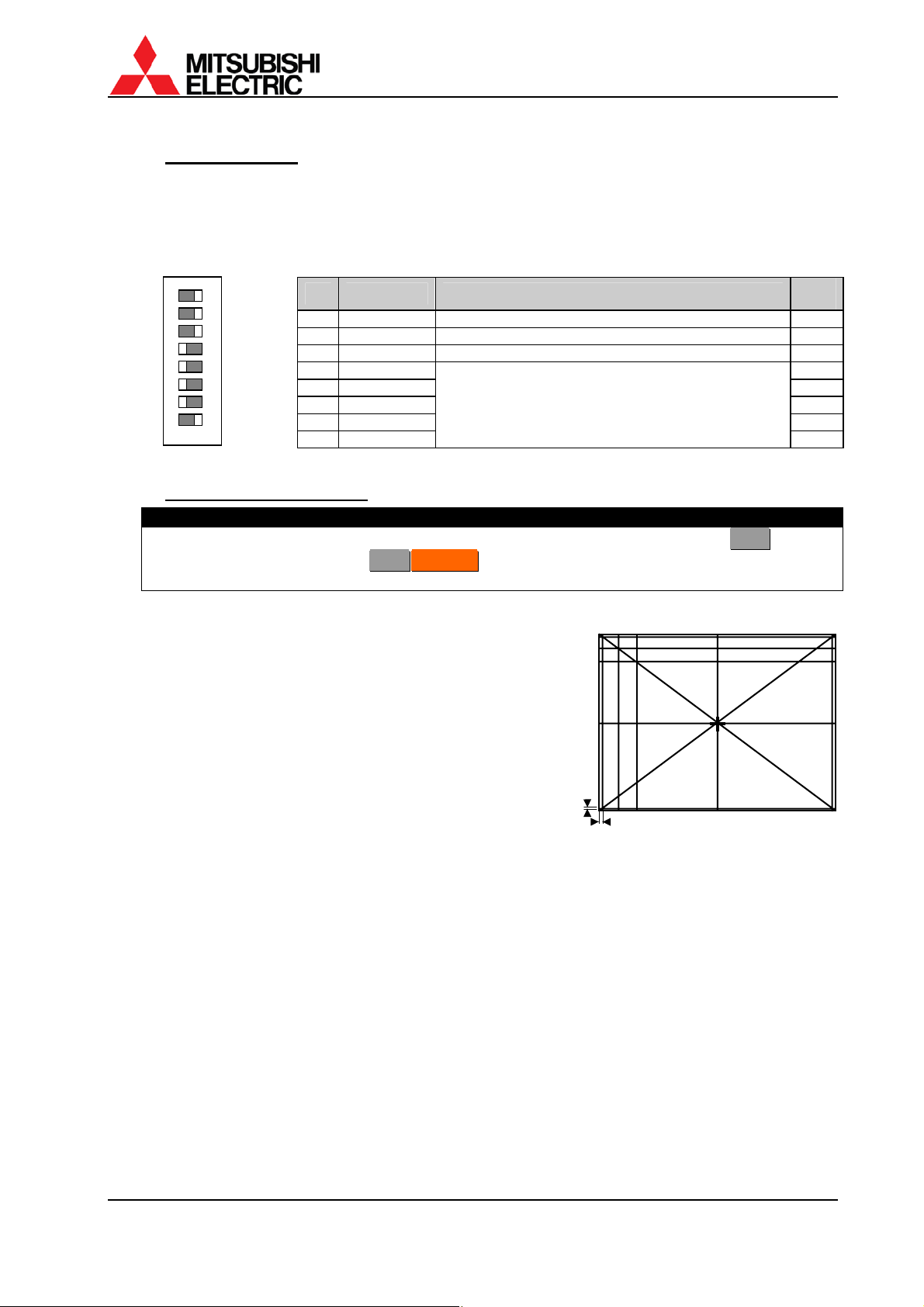

1.4.2. Dipswitch setting

Before turning on the main power switch, set the dipswitch correctly according to a system

configuration (see “

1.3 Connecting” on page 23). The set ID can be set up to 64 (see “1.5.1.14

EXTENDED ID” on page 41). Be sure to turn off the main power switch if you change the setting

in the middle of the operation. Turning on the main power switch will renew the setting.

OFF ON

1

2

3

4

5

6

7

8

RC

RESERVED

MASTER

ID5

ID4

ID3

ID2

ID1

No. Name Function

1 RC Enabling remote control (ON: enabled, OFF: disabled) ON

2 RESERVED Normally ON. ON

3 MASTER MASTER/SLAVE setting (ON: MASTER, OFF: SLAV E) ON

4 ID5 OFF

5 ID4 OFF

6 ID3 OFF

7 ID2 OFF

8 ID1

Designating set ID number (1 to 32) (ON: 1, OFF: 0)

ID No.=1×(ID1)+2×(ID2)+4×(ID3)+8×(ID4)+16×(ID5)

Example:

ID No.=1: ID1=ON, ID2, ID3, ID4 and ID5=OFF

ID No.=32 :ID1, 2, 3, 4 and 5=OFF

1.4.3. Picture outline adjustment

Caution

Before turning on, make sure again that the color wheel has been unlocked for XXLL2211 (chapter

1.2.4.1, on page 8) and, for XXLL2211CChhaannggeerr, the lamp cushion has been removed (chapter

1.2.4.2, on page 9).

Initial

setup

ON

1.4.3.1. Displaying internal test pattern

Display the internal crosshatch pattern for picture

outline adjustment by pressing [TEST] button

twice in advanced mode.

Adjust to align the outermost lines with screen

edges.

There are another adjustment lines for over-scan

inside the outermost lines. When OVERLAP

setting (chapter

1.5.1.6, on page 38) is ON,

adjust the picture outline so that these lines fit the

screen edges.

djustment lines for over-scan

PH50, XL50, XL21 series Set-up and Installation Manual

28

Page 29

R

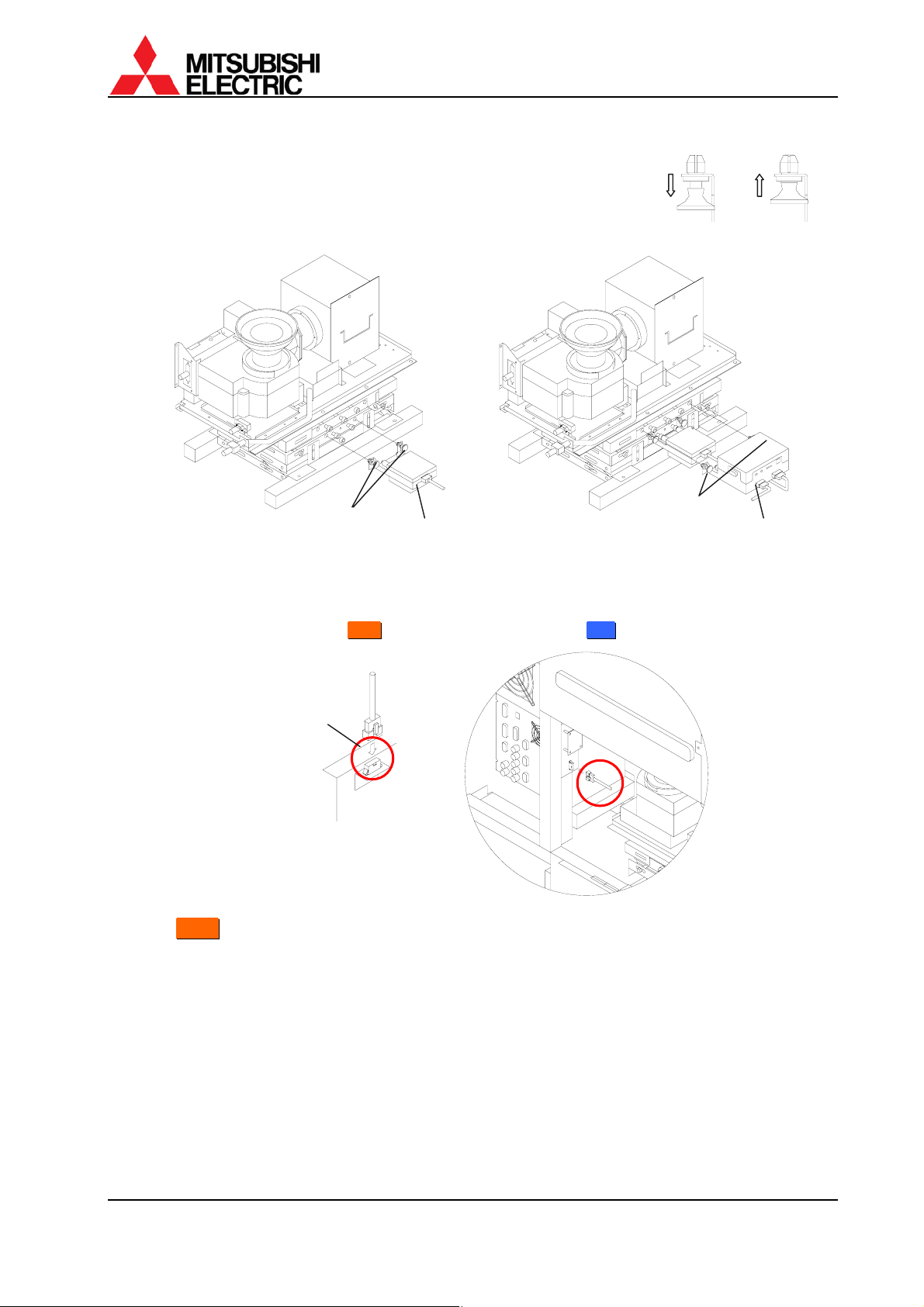

1.4.3.2. 6-axis adjustment

1.4.3.2.1. Release the lock screws

Before 6-axis adjustment, release locks

4 locking screws

in the adjuster. Loosen 4 locking screws

with an Allen wrench (2mm) and 5 fixing

screws with an Allen wrench (4mm).

1.4.3.2.2. When adjusting with motorized adjustment tool, S-AXL50E

5 fixing screws

Attaching

Slide switch Rotary Dial

1. Set the rotary dial in the upper unit

of the adjustment tool according to

the product (chapter

page 97). The initial setting is 0.

•

•

FFrroonnt

r: Set it 1.

RReeaar

t: Set it 0.

3.8.4.2, on

FACTORY

2. Make sure the slide switch is set

OPE (right side).

3. Connect the upper and lower units with a supplied

unit-connecting cable.

4. Connect a su pplied cube-connecting cable with uppe r

unit.

5. Open the screen (chapter 1.2.7.1, on page 21) or rear

panel to access the 6-axis adjuster .

Note:

For RReeaarr, open the rear panel 180 degrees or

remove it to perform the adjustment. Adjustment with

half-open panel may cause breakage due to

interference with the adjustment tool.

OPE

Upper unit

Lower unit

POWER

RESET

ERRO

Cube-connecting cable

FW-EN

0 : FRONT

1 : REAR

9 : TEST

Unit-connecting cable

Rear panel

REV 2.4

29

Page 30

r

6. Make sure that latches on the units are released before the

attaching the units.

7. Attach the units on the adjuster in order of the lower and upper

unit.

8. Push the two latches each till click to fix the units.

Latch

Release Lock

Latches

Lower unit Upper unit

Latches

9. Connect the other end of the cube-connecting cable with a connector inside the cube as

following figures. The cable can be connected under operating conditions.

For Front For RReeaarr

Connecto

(in the circuit box)

10.

t: Close the screen (chapter 1.2.7.2, on page 22).

FFrroonnt

PH50, XL50, XL21 series Set-up and Installation Manual

30

Page 31

Adjustment

Perform the picture outline adjustment with remote control.

1. Make sure to release the locks in the adjuster (chapter

1.4.3.2.1 on page 29).

2. Display the internal crosshatch pattern for picture outline adjustment by pressing [TEST]

button twice in advanced mode. (Refer to the chapter

1.4.1.2 on page 26).

3. Press-and-hold [MENU2] button to display the system memory menu.

4. Select MECH ALIGNMENT in MAINTENANCE in the system menu.

5. Select an axis menu by up/down buttons and adjust it by right/left buttons. The bird icon

moves its beak on screen during communication with the remote control. Also arrow mark

appears to indicate the direction of button pressing.

Note:

When you reach the end of the adjustment range,

mark appears on screen and the picture

outline doesn’t move ahead. In this case, turn back and readjust combining with other axes. If

you cannot turn the axis due to adjusting tool locking, follow the chapter

3.8.5, on page 98 to

recover from the error.

Seen from front (screen side)

Axis menu (left button) (right button)

ZOOM

H-KEYSTONE

V-KEYSTONE

TILT

H-POSITION

V-POSITION

Detaching

After the adjustment, pull the latches to release the locks and detach the units in the reverse

order of attaching. Be careful not to load an excessive force to the adjuster.

31

REV 2.4

Page 32

)

A

1.4.3.2.3. When adjusting by manual Perform the picture outline adjustment with an Allen wrench (5mm).

: H position C: Tilt

B: V keystone

A: H position

Seen from front (screen side

F: Zoom D: V position

E: H keystone

B: V keystone

C: Tilt

D: V position

E: H keystone

F: Zoom

PH50, XL50, XL21 series Set-up and Installation Manual

32

Page 33

A

A

A

A

1.4.3.2.4. Adjusting procedure

1. After making an image size smaller than the outline of

screen with the zoom axis, adjust Tilt, V position and H

position so that upper and lower spaces and right and left

spaces will be almost equalized respectively.

A=A’, B=B’

2. Correct the horizontal keystone distortion, and adjust the

image position to the center of the screen with “H position”.

Correct the horizontal

keystone distortion.

djust the horizontally shifted

image to the center of the screen.

3. Correct the vertical keystone distortion, and adjust the image position to the center of the

screen with “V position”.

Correct the vertical

keystone distortion.

djust the vertically shifted image

to the center of the screen.

4. Adjust the image size to fit the outline of the screen.

5. Adjust all screens roughly, and tweak so that each image will link seamlessly in a multi

screen.

1.4.3.2.5. Fixing the adjuster Fix the 5 fixing screws in the reverse order of “1.4.3.2.1 Release the lock screws” on page 29. Before shipment, in addition to above, be sure to fix the 4 lock screws of the adjuster (chapter on page 85).

’

B

B’

2.5,

REV 2.4

33

Page 34

p

1.4.3.3. Mirror adjustment

1.4.3.3.1. Parallelogram distortion correction When a parallelogram distortion cannot be corrected with the 6-axis adjuster, correct it according to the following procedure.

1. Allign top, bottom and right lines of the crosshatch pattern

with the screen edge by the 6-axis adjustment.

Parallelogram distortion

2. RReeaarr: Loosen screws in the rear panel and upper

door. And then open the upper door and lift the rear

panel to remove.

t: Open the screen unit (chapter

FFrroonnt

1.2.7.1, on

page 21).

Rear

anel

PPHH5500RReeaar

r: Pull 3 latches on the bottom edge of the

rear panel to release. It is no necessary to loosen 3

screws on the top edge. Lift the panel to remove.

Upper door

Latches

Note: Make sure that the latches are released before

Latch

reattaching the panel. The panel cannot be attached with

latches locked. For reattaching, attach the panel and push

the latches till click to lock.

Release Lock

PH50, XL50, XL21 series Set-up and Installation Manual

34

Page 35

3. Loosen a mirror fixing screw located in the right seen from the rear. (Or in the left seen from

the front in FFrroonntt.)

Mirror fixing screw (rear)

For 5500””XXLL2211

(Seen from top)

Mirror fixing screw (side)

For other models

4. Turn the mirror adjusting screw.

For FFrroonntt:

• When the lower left image is smaller: turn the screw anti-clockwise

• When the lower left image is larger: Turn the screw clockwise

For RReeaarr:

• When the lower left image is smaller: Turn the screw clockwise

• When the lower left image is larger: Turn the screw anti-clockwise

For 5500””XXLL2211RReeaarr: move a lower part of the mirror up or down.

Mirror adjusting

screw

Mirror fixing

screw

For FFrroonntt

For RReeaarr

For 5500””XXLL2211

5. Tighten the mirror fixing screw.

6. After the correcting, tweak the picture outline with 6-axis adjuster.

(Mirror adjusting

screw)

Mirror

When the lower left image is smaller.

When the lower left image is larger.

REV 2.4

35

Page 36

A

A

1.4.3.3.2. Pincushion distortion correction (for 5500””)

When pincushion distortion appears and it cannot be

corrected with 6-axis adjuster, you can correct it

according to the following procedure.

Even after cube stacking, you can reach the following

Pin cushion

screws for the correction through holes in the upper cube.

Detach a screen from the upper cube to access the

screws.

Note: In XXLL2211RReeaarr, this correction should be done before cube stacking. You cannot access the

adjusting screws after the stacking.

1. Align the top corners of the crosshatch pattern with the screen corners by the 6-axis adjustment.

2. Loosen fixing screw(s) and turn the adjustment screw to correct the distortion.

djustment screw

Fixing screws (2pcs)

For XXLL5500RReeaarr and PPHH5500

Fixing screw

djustment screw

For XXLL5500FFrroonntt and XXLL2211RReeaarr

3. After the adjustment, tighten the fixing screw(s).

4. After the adjustment, fix the 6-axis adjuster (chapter

1.4.3.2.5, on page 33).

PH50, XL50, XL21 series Set-up and Installation Manual

36

Page 37

1.5. System memory setting

Set the system memory as shown below to suit a configuration. The parameters are effective for

all input memories and display memories.

Press and hold [MENU2] button to display the system memory menus. You can exit the menu by

[ESC] button.

1.5.1. System set up

1.5.1.1. LAMP POWER

Used to set brightness mode. The initial setting is NORMAL.

BRIGHT mode can make cubes brighter. The lamp life becomes shorter than NORMAL mode.

[Procedure]

1. Select LAMP POWER in MISC FUNCTION in the system menu.

2. Set NORMAL or BRIGHT.

1.5.1.2. LAMP MODE (for XXLL2211)

This adjustment is normally unnecessary.

Used to set lamp-driving system. The initial setting is F-REDUCTION.

• F-REDUCTION: It drives with lamp flicker reduction.

• LONG LIFE: It drives with longer lamp life t han F-REDUCTIO N mode even th ough the flickers

may occur .

• NORMAL: it automatically change F-REDUCTION and LONG LIFE mode.

[Procedure]

1. Select LAMP MODE in MISC FUNCTION in the system menu.

2. Set F-REDUCTION, LONG LIFE or NORMAL.

1.5.1.3. TERMINATE This adjustment is normally unnecessary.

Used to select the termination of analog synchronizing signal in the main input. The initial setting

is 1K (1KΩ termination). If the synchronization is lost while 5-line (separate sync) analog input in

the main input, set this item to 75 (75Ω termination). The image may be displayed correctly.

[Procedure]

1. Select TERMINATE in MISC FUNCTION in the system menu.

2. Set 75 or 1K.

1.5.1.4. S.TERMINATE (for the input board) This adjustment is normally unnecessary.

Used to select the termination of analog synchronizing signal in the input board. The initial setting

is 1K (1KΩ termination). If the synchronization is lost while 5-line (separate sync) analog input in

the input board, set this item to 75 (75Ω termination). The image may be displayed correctly.

[Procedure]

1. Select S.TERMINATE in MISC FUNCTION in the system menu.

2. Set 75 or 1K.

REV 2.4

37

Page 38

1.5.1.5. START MEMORY This adjustment is normally unnecessary.

Used to designate a display memory number that is loaded at start-up. The initial setting is OFF.

To display a designated image source, set a registered display memory number (chapter

on page 68), or a registered input memory number when the mai n input port is selected. If it is

set OFF, the product starts up with a last loaded memory.

[Procedure]

1. Select START MEMORY in MISC FUNCTION in the system menu.

2. Set 1 – 256 or OFF.

1.8.7,

1.5.1.6. OVERLAP (for the input board)

This adjustment is normally unnecessary.

Over scan area

Used to set the overlap mode that can automatically

calculate the output size so as to fit the screen size in

consideration of an over scan area. The initial setting is

OFF.

Effective output

area

ON setting creates the over scan area. Even if a

displayed image unexpectedly shifts in a daisy-chained

display wall, a black pixel-lacking area in fringe of a

screen would be hard to see.

For this mode, adjust the picture outline so that the lines

for over-scan fit the screen edges in advance (chapter

1.4.3.1, on page 28).

In the case of an enlarged image displaying with a multiple-output device or a single screen, this

mode may make small characters blurred. Normally set OFF.

[Procedure]

1. Select OVERLAP in MISC FUNCTION in the system menu.

2. Set ON or OFF.

1.5.1.7. OFFSET (for the input board) This adjustment is normally unnecessary.

Used to tweak horizontal/vertical positions and size if the picture outline is shifted after the final

6-axis adjustment.

[Procedure]

1. Select OFFSET in MISC FUNCTION in the system menu.

2. H.POSITION: to adjust horizontal position.

3. V.POSITION: to adjust vertical position.

4. H.SIZE: to adjust horizontal size.

5. V.SIZE: to adjust vertical size.

PH50, XL50, XL21 series Set-up and Installation Manual

38

Page 39

1.5.1.8. BAUD RATE

Used to select the transmission speed of RS-232 in accordance with an external controller

setting. The initial setting is 19200 (19,200bps). You can select 9,600bps or 19,200bps.

[Procedure]

1. Select BAUD RATE in MISC FUNCTION in the system menu.

2. Set 9600 or 19200.

1.5.1.9. SYSTEM SYNC

Used to set a vertical synchronizing frequency in accordance with a moving pictures signal to be

mainly displayed. The initial setting is 60 (60Hz). Set 60Hz for NTSC signal or 50Hz for PAL

signal. All cubes in a display wall should be the same setting.

[Procedure]

1. Select SYSTEM SYNC in MISC FUNCTION in the system menu.

2. Set 60 or 50.

1.5.1.10. IMAGE FLIP This adjustment is normally unnecessary.

Used to invert the displayed image vertically or horizontally. RReeaarr should be set S/W for the

normal image.

• S/W: Normal image

• S/E: Vertically flipped image

• N/W: Horizontally flipped image

• N/E: Vertically/horizontally flipped image

[Procedure]

1. Select IMAGE FLIP in MISC FUNCTION in the system menu.

2. Set S/W, S/E, N/W or N/E.

REV 2.4

39

Page 40

1.5.1.11. INDICA TION This adjustment is normally unnecessary.

Used to set how to indicate the status information.

1.5.1.11.1. WARNING (for CChhaannggeerr)

This is to set the indication of a warning mark on screen to induce to replace the spare lamp after

auto-lamp changing or pre-announcement of the changing (“ 2.1.3.5 Warning indication”, on page

80).

• OFF: No indication.

• MESSAGE, ☀: To display both pre-announcement of auto-lamp changing and a warning

mark to induce to replace the spare lamp.

• ☀: To display only the warning mark.

[Procedure]

1. Select WARNING in INDICATION in MISC FUNCTION in the system menu.

2. Set OFF, MESSAGE ☀ or ☀.

1.5.1.11.2. STANDBY This is to set a blue LED indication on screen (“

3.5 LED display”, on page 91) at stand-by state.

• LED: To light the blue LED on screen.

• OFF: No indication.

[Procedure]

1. Select STANDBY in INDICATION in MISC FUNCTION in the system menu.

2. Set LED or OFF.

1.5.1.11.3. ERROR This is to set a blue LED indication on screen (“3.5 LED display”, on page 91) at shutdown due to errors.

• LED: To blink the blue LED on screen.

• OFF: No indication.

[Procedure]

1. Select ERROR in INDICATION in MISC FUNCTION in the system menu.

2. Set LED or OFF.

1.5.1.11.4. BLOWOUT (for

1

or when the input board is selected in

XXLL221

PPHH550

0

and

XXLL550

0

This is to set a blue LED indication on screen (“3.5 LED displ ay”, on page 91) at lamp blowout

when BLOWOUT (chapter

1.5.1.13, on page 41) is set OPERATE.

• LED: To blink the blue LED on screen.

• OFF: No indication.

[Procedure]

1. Select BLOWOUT in INDICATION in MISC FUNCTION in the system menu.

2. Set LED or OFF.

)

PH50, XL50, XL21 series Set-up and Installation Manual

40

Page 41

1.5.1.12. AUTO POWER ON

Used to set automatic turning on when the main power is supplied. The initial setting is OFF.

• ON: Automatic turning on when the main power is supplied.

• OFF: When the main power is supplied, t he product takes over the last memory status. For

instance, it becomes stand-by state if the main power was turned off in stand-by state.

Likewise, if it was turned off in the state of power on, it automatically turns on.

[Procedure]

1. Select AUTO POWER ON in MISC FUNCTION in the system menu.

2. Set ON or OFF.

1.5.1.13. BLOWOUT (for XXLL2211 or when the input board is attached in PPHH5500 and XXLL5500)

This adjustment is normally unnecessary.

Used to select digital output status after lamp blowout. The initial setting is OPERATE.

• OPERATE: After lamp blowout, it maintains the digital output function. Set OPERATE when

the digital out is used for the digital daisy chain connection.

• SHUTDOWN: After lamp blowout, the product starts shutdown. Set SHUTDOWN for a single

screen or a display wall without digital daisy chain connections.

[Procedure]

1. Select BLOWOUT in MISC FUNCTION in the system menu.

2. Set OPERATE or SHUTDOWN.

1.5.1.14. EXTENDED ID

Used to set the ID number 33 or higher. The initial setting is NORMAL.

• NORMAL : The set ID can be set 1 to 32 by dipswitch (chapter

1.4.2, on page 28).

• ID:33–64 : The set ID can be set 33 to 64. When the ID is set 1 by the dipswitch, it is

automatically recognized as 33 in this mode.

[Procedure]

1. Select EXTENDED ID in MISC FUNCTION in the system menu.

2. Set NORMAL or ID:33–64.

REV 2.4

41

Page 42

1.5.1.15. CABLE LENGTH (for PPHH5500 and XXLL5500)

Used to set it according to a digital cable length of image inputs. The initial setting is NORMAL.

Set LONG when image noise is noticeable due to a transmission attenuation through a long

digital cable such as over 5 meters. As needed, CUSTOM menu can be selected for more

detailed adjustment.

[Procedure]

1. Select CABLE LENGTH in MISC FUNCTION in the system menu.

2. Select DIGITAL or S.DIGITAL according to the input port.

3. Set NORMAL, LONG or CUSTOM.

4. When selecting the CUSTOM menu, adjust the LEVEL value so that the noise on images will

be minimized. The adjusting range is 0 – 15. The initial value is 13.

1.5.1.16. RESOLUTION (for PPHH5500)

This adjustment is normally unnecessary.

Used to switch SXGA and SXGA+ reso lution. The initial setting is SXGA+.

• SXGA: SXGA resolution image (1280 x 1024 pixels) is displayed with black outer margins on

SXGA+ screen.

• SXGA+: SXGA+ resolution image (1400 x 1050 pixels) is displayed.

[Procedure]

1. Select RESOLUTION in MISC FUNCTION in the system menu.

2. Set SXGA or SXGA+.

1.5.1.17. DIRECTION This adjustment is normally unnecessary.

Used to set when you substitute an optical unit of RReeaarr for FFrroonntt and vice versa.

• REAR: Select for RReeaarr.

• FRONT: Select for FFrroonntt. FILTER RESET and FILTER TIME menus (on page 84) will be

active in the system menu. The filter time is counted up even during REAR mode. Reset the

filter time (chapter 2.4.3.3, on page 84) when switch to FRONT.

[Procedure]

1. Select DIRECTION in INSTALLATION in the system menu.

2. Set REAR or FRONT.

PH50, XL50, XL21 series Set-up and Installation Manual

42

Page 43

1.5.1.18. LAMP CHANGE (for CChhaannggeerr)

1.5.1.18.1. CALIBRATION

This adjustment is normally unnecessary. It is automatically set at auto-lamp changing

(chapter

2.1.3, on page 78).

It adjusts the lamp position optimally to maximize the brightness.

[Procedure]

1. Select CALIBRATION in LAMP CHANGER in MAINTENANCE in the system menu.

2. Press [ENTER] button in reply to “SET OK?” message to adjust the lamp to the suitable

position automatically.

1.5.1.18.2. CHANGE MODE

This adjustment is normally unnecessary.

Used to set auto-lamp changing due to brightness deterioration (chapter

2.1.3.2, on page 78).

The initial setting is NORMAL.

• OFF: It does not perform the auto-lamp changing due to brightness deterioration.

• NORMAL: The auto-lamp changing starts when the brightness becomes 50% of the initial

value.

• LONG: The auto-lamp changing starts when the brightness becomes 30% of the initial value.

[Procedure]

1. Select CHANGE MODE in LAMP CHANGER in MAINTENANCE in the system menu.

2. Set OFF, NORMAL or LONG.

1.5.1.18.3. HOT EXCHANGE Used to allow spare lamp replacement during the main lamp lighting. The initial setting is FORBID.

• FORBID: The product automatically shuts down when you open the lamp cover.

• ALLOW: You can open the lamp cover during the main lamp lighting.

[Procedure]

1. Select HOT EXCHANGE in LAMP CHANGER in MAINTENANCE in the system menu.

2. Set FORBID or ALLOW.

REV 2.4