Page 1

Model

PU(H)Y-P250YGM-A

PUHY-P500YGM-A

PFD-P250VM-E

PFD-P500VM-E

DATA BOOK

AIR CONDITIONERS

Page 2

CONTENTS

1. Specifications

1-1 Main Features

1-2

List of Possible Combinations of Indoor and Outdoor Units

1-3 Unit Specifications

2. Capacity Curves

2-1 Cooling Capacity

2-2 Cooling Input

2-3 SHF Curves

2-4 Correction by refrigerant piping length

2-5 Operation limit

3. Sound Levels

3-1 Noise Level

3-2 NC Curves

3-3 Fan Characteristics Curves

4. External Dimensions

5. Electrical Wiring Diagrams

6. Refrigerant Circuit Diagram And Thermal Sensor

7. System Design

7-1 Refrigerant Piping System

7-2 Control Wiring

7-3 Types of switch settings and setting methods

7-4 Sample System Connection

7-5 External input/output specifications

8. Air Conditioning the Computer Room

8-1 Main Features of the Floor-Duct Air Conditioners

8-2 Features of air-conditioner for computer room

8-3

Step-by-Step Plan for the Implementation of the Air-Conditioning

8-4

Conditions for the Installation of Computer-Room Air Conditioners

8-5 Setting the Air conditioners

8-6 Automatic Control of the Computer Room

9. Maintenance/Inspection

9-1 Maintenance/Inspection Schedule

1

1

2

3

4

4

4

5

6

6

7

7

8

8

10

14

18

20

20

21

22

24

29

33

33

33

34

35

36

38

39

39

Close control

PU(H)Y-P-YGM-A

PFD-P-VM-E

······························································

······························································

·····

·························································

·························································

·························································

·························································

·························································

····························

·························································

···································································

···································································

···································································

···········································

···········································

·································································

······················································

···

··············································

·································································

················

············································

·······························

················

···

···

·························

··········

·············································

······················

···············································

·······························

Page 3

Page 4

1. Specifications

1-1.Main Features

1

(1) List of Models

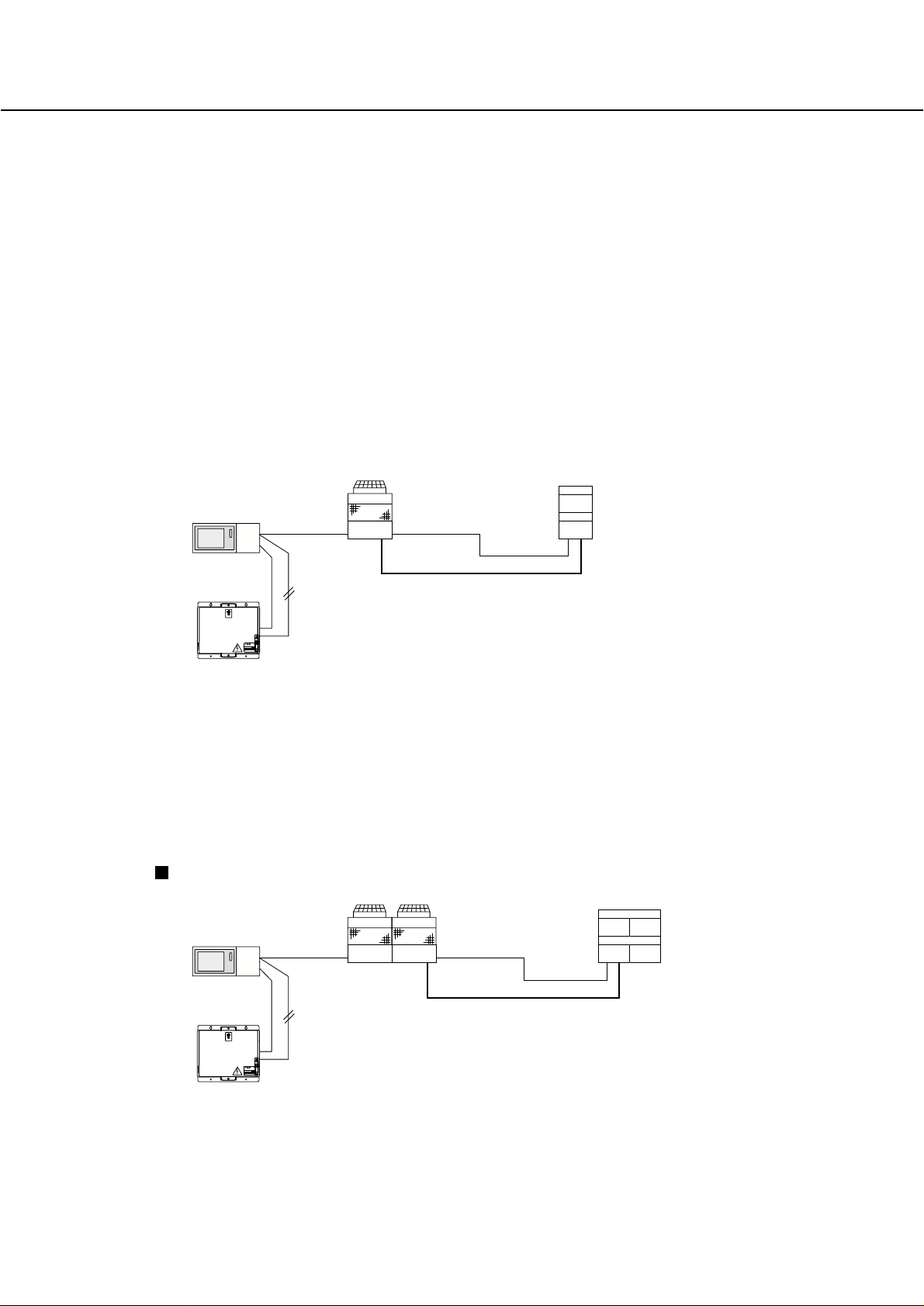

<10HP System>

<20HP System>

Single refrigerant circuit

PU(H)Y-P250YGM-A

PUHY-P500YGM-A

10HP(Down flow): PFD-P250VM-E

20HP(Down flow): PFD-P500VM-E

✻ PFD-type indoor units cannot be connected to outdoor units other than the ones specified above.

✻ It is necessary to rewrite the S/W on the control circuit board of the outdoor unit connected to

the PFD-type indoor units.

✻ PFD-type indoor units and other types of indoor units cannot coexist in the same refrigerant system.

✻ It is necessary to change pulley and V-belt when using it by the power supply frequency 60Hz.

✻ For restrictions when the PFD-type indoor units are connected (related to the system), see P21.

When using a PFD-P500VM-E as an indoor unit, connect an outdoor unit PUHY-P500YGM-A to

each indoor unit and operate with a built-in remote control for the indoor unit.

✻1: Bold line indicates refrigerant piping (gas/liquid). This system consists of single refrigerant circuit.

✻2: Indicates TB3-type transmission line that connects the indoor and outdoor units.

This system consists of single refrigerant circuit.

✻3: Indicates TB7-Type transmission line that allows the unit to communicate with the controller.

When using a PFD-P250VM-E as an indoor unit, connect an outdoor unit PU(H)Y-P250YGM-A to

each indoor unit and operate with a built-in remote control for the indoor unit.

✻1: Bold line indicates refrigerant piping (gas/liquid). This system consists of single refrigerant circuit.

✻2: Indicates TB3-type transmission line that connects the indoor and outdoor units.

This system consists of single refrigerant circuit.

✻3: Indicates TB7-Type transmission line that allows the unit to communicate with the controller.

} Outdoor Unit

} Indoor Unit

Outdoor Unit

G-50A

PU(H)Y-P250YGM-A

Indoor Unit

PFD-P250VM-E

TB7

TB3 ✻2✻3

✻1

12V DC

M-NET

PAC-SC50KUA

UP

POWER RATING

MODEL

WEIGHT

SERIAL No.

2.11kg

POWER SUPPLY UNIT

MITSUBISHI ELECTRIC CORPORATION

PAC-SC50KUA

Outdoor Unit Indoor Unit

TB7

TB3 ✻2

✻1

PUHY-P500YGM-A PFD-P500VM-E

G-50A

12V DC

M-NET

PAC-SC50KUA

UP

POWER RATING

MODEL

WEIGHT

SERIAL No.

2.11kg

POWER SUPPLY UNIT

MITSUBISHI ELECTRIC CORPORATION

PAC-SC50KUA

Page 5

2

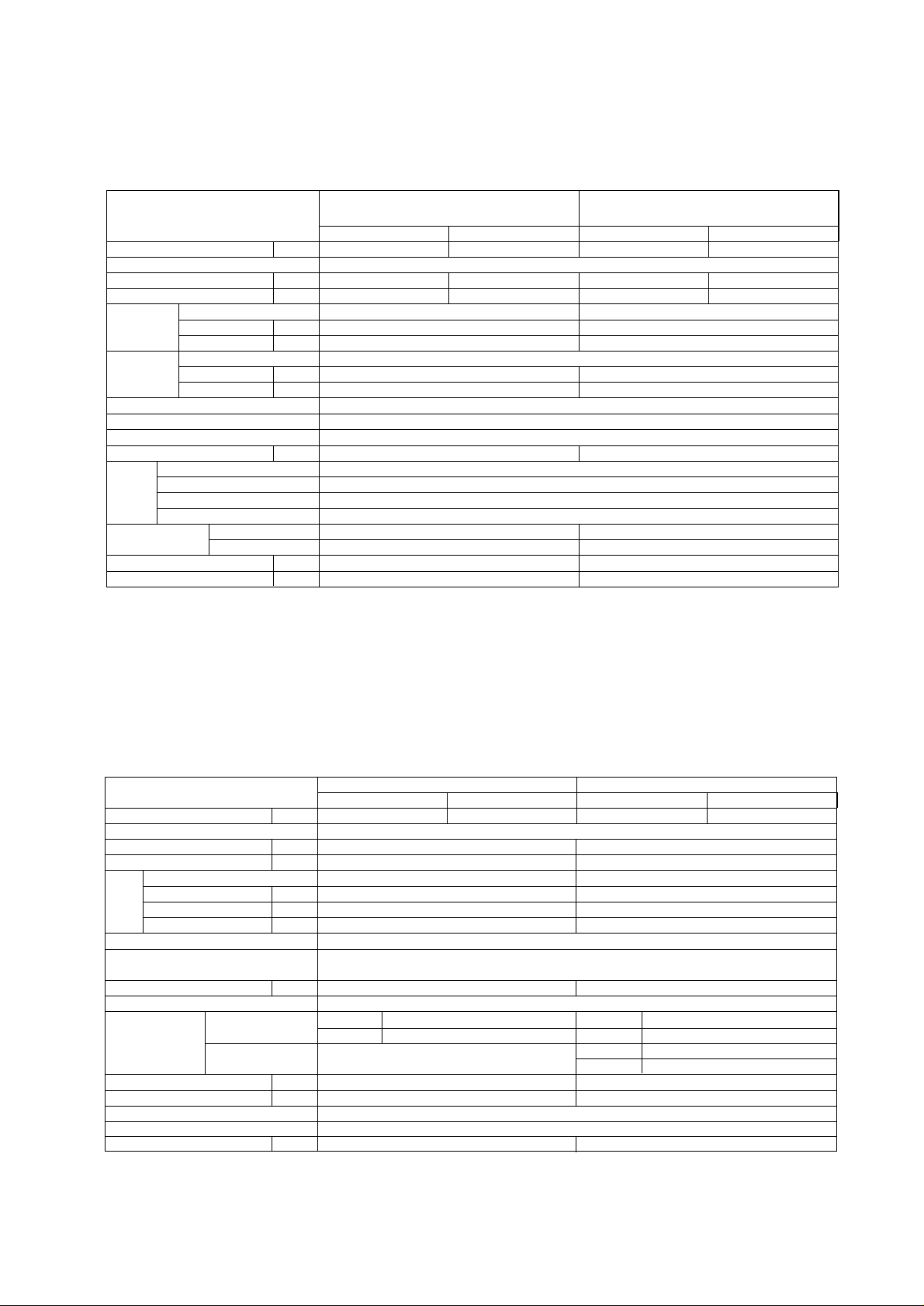

1-2. List of Possible Combinations of Indoor and Outdoor Units

✻1: Refer to the following pages for detailed specifications of each unit.

✻2: They were measured at operation under the following conditions:

<Cooling> Indoor:27˚CDB/19˚CWB Outdoor:35˚CDB

<Heating> Indoor:20˚CDB Outdoor: 7˚CDB/6˚CWB

Pipe length:7.5m, Height difference:0m

Model Name Indoor unit

Outdoor unit

Cooling Heating

System capacity kW 28.0 31.5

System Power input kW 9.3 9.1

System current A 16.7/15.9/15.4 16.4/15.5/15.1

10HP system

PFD-P250VM-E

PU(H)Y-P250YGM-A

Cooling Heating

56.0 63.0

18.6 18.2

32.3/30.8/29.7 31.7/30.0/29.1

20HP system

PFD-P500VM-E

PU(H)Y-P250YGM-A x 2

or PUHY-P500YGM-A

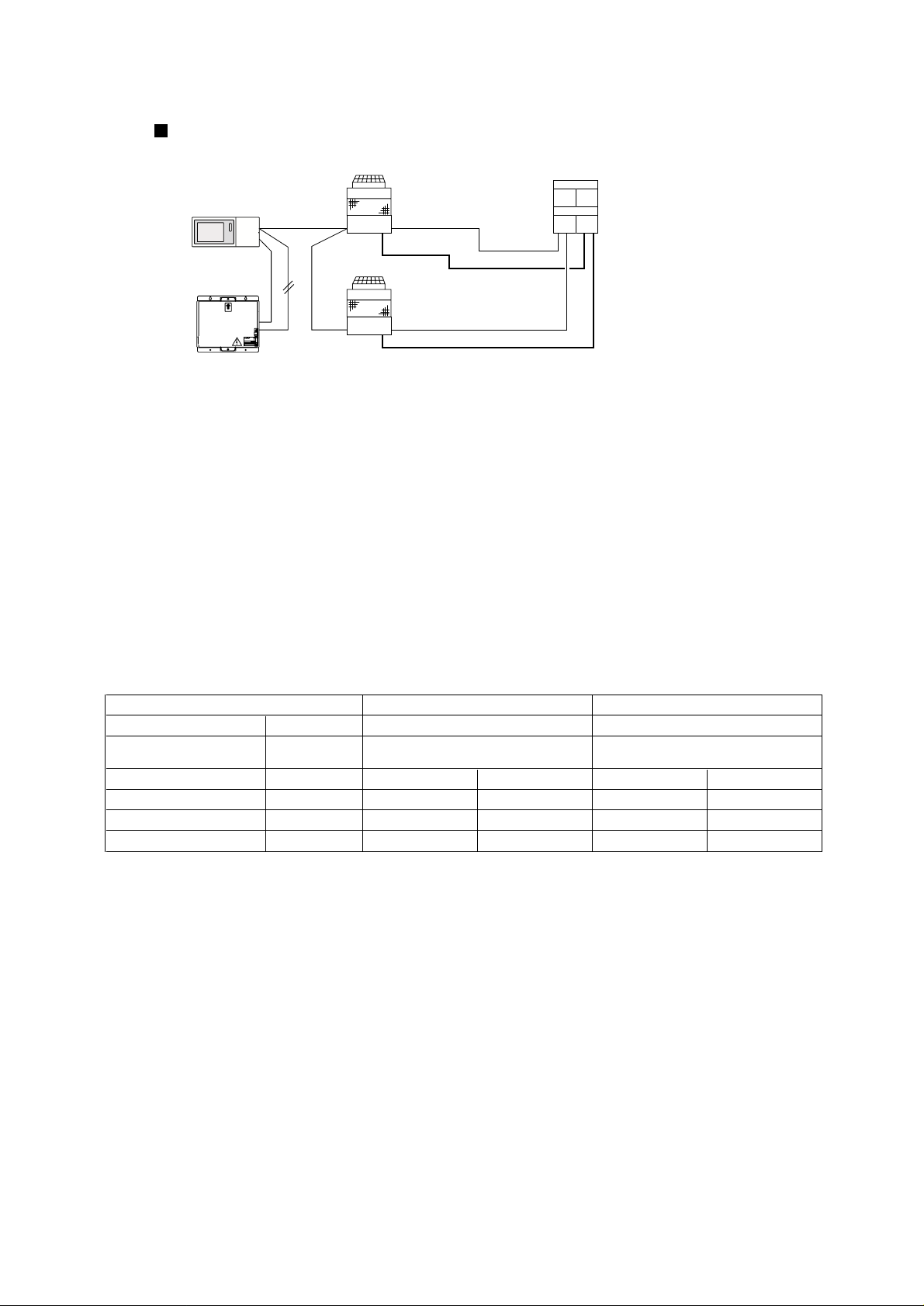

When using a PFD-P500VM-E as an indoor unit, connect 2 PU(H)Y-P250YGM-A outdoor units to

each indoor unit and operate with a built-in remote control for the indoor unit.

At factory shipment, this model of indoor unit is designed and set to accommodate a single refrigerant circuit.

Connection of two refrigerant circuits to the indoor unit requires setting change and pipe work.

✻1: Bold line indicates refrigerant piping (gas/liquid). This system consists of two refrigerant circuits.

✻2: Indicates TB3-type transmission line that connects the indoor and outdoor units.

This system consists of two refrigerant circuits.

✻3: Indicates TB7-type transmission line that allows the unit to communicate with the controller.

Outdoor Unit

PU(H)Y-P250YGM-A

Indoor Unit

PFD-P500VM-E

TB7

TB3 ✻2

✻1

TB3

PU(H)Y-P250YGM-A

TB7

✻3

G-50A

12V DC

M-NET

PAC-SC50KUA

UP

POWER RATING

MODEL

WEIGHT

SERIAL No.

2.11kg

POWER SUPPLY UNIT

MITSUBISHI ELECTRIC CORPORATION

PAC-SC50KUA

Two refrigerant circuits

Page 6

(2) Indoor Unit

3

1-3. Unit Specifications

28.0 31.5

3N ~ 380/400/415V 50/60Hz

Capacity

Model name

kW

Power source

✻

1

✻

2

kW

A

m

3

/min

kW

kW

kW

mm

dB(A)

kg

Power input

Current

Fan

Airflow rate

Type ✕ Quantity

Motor output

Type

Motor output

Crankcase heater

Compressor

Refrigerant / Lubricant

External finish

High pressure protection

Inverter

Compressor

Fan

External dimension HxWxD

Protection

devices

Refrigerant

piping diameter

High press. pipe

Low press. pipe

Noise level

Net weight

1,840 x 990 x 840

Propeller fan x 1

200

0.38

Hermetic

6.7

0.045 x 1

R410A/MEL32

Heat exchanger Salt resistant fin

Over current protection / Thermal protection

ø9.52 Flare (ø12.7 for over 90m)

ø22.2 Brazed

Pre-coated galvanized sheets (+ powder coating for -BS type) <MUNSEL 5Y 8/1 or similar>

4.15MPa

233

6.66.8

11.1/10.5/10.211.4/10.9/10.5

PU(H)Y-P250YGM-A (-BS)

connected with PFD series

PUHY-P500YGM-A (-BS)

connected with PFD series

Over current protection / Over heat protection

Thermal switch

57/57

56.0 63.0

Cooling Heating Cooling Heating

1,840 x 1,990 x 840

Propeller fan x 2

400

0.38 x 2

8.2+5.3

0.045 x 2

ø15.88 Flare

ø28.58 Brazed

455

13.6 13.2

22.2/21.0/20.422.8/21.8/21.0

60/61

Note: *1. Cooling/Heating capacity indicates the maximum value at operation under the following condition.

*2. It is measured in anechoic room.

** Installation/foundation work, electrical connection work, duct work, insulation work, power source switch,

and other items shall be referred to the Installation Manual.

Indoor : 27

˚CDB / 19˚CWB

Indoor : 20

˚CDB

Pipe length : 7.5m

Outdoor :

Outdoor :

Height difference : 0m

35

˚CDB

7

˚CDB

/ 6

˚CWB

<Cooling>

<Heating>

3N~380/400/415V(50Hz), 400/415V(60Hz)

PFD-P500VM-E

5.0

Power source

kW

-

Power input

System capacity

A

m

3

/min

Pa

kg

dB(A)

m

mm

Current

Heat exchanger

Fan

Refrigerant

External finish

Type x Quantity

Airflow rate

External static pressure

kW

Motor Output

Air filter

Refrigerant

piping diameter

✻2

Refrigerant piping allowable length

Gas pipe

Liquid pipe

Cross fin (Aluminum plate fin and copper tube)

Sirocco fan x 2Sirocco fan x 1

ø

9.52 Brazed (ø 12.7 for over 90m)

ø 22.2 Brazed

Single refrigerant

circuit

Two refrigerant

circuit

320

1,950 x 1,380 x 780

9.5/9.0/8.7

PFD-P250VM-E

2.5

kW 28.0 31.5 56.0 63.0

5.3/5.0/4.9

160

120120

4.42.2

380

59

150

Gas pipe

Liquid pipe

ø

15.88 Brazed

ø 28.58 Brazed

Gas pipe

Liquid pipe

ø

9.52 Brazed (ø 12.7 for over 90m)

ø 22.2 Brazed

520

63

150

R410A

Galvanized steel plate (with polyester coating)

<MUNSEL 2.9GY 8.6/0.3(White) 7.2GB 3.2/5.3(Blue) or similar>

PP Honeycomb fabric (washable)

Thermal switch

1,950 x 1,980 x 780

Protection devices (Fan)

External dimensions

HxWxD

Model name

Noise level

Net weight

Cooling Heating ✻1 ✻1Cooling Heating

Note: *1. Heating can be used only by the indoor warming-up.

*2. At factory shipment, this model of indoor unit is designed and set to accommodate a single refrigerant circuit.

Connection of two refrigerant circuits to the indoor unit requires setting change and pipe work.

** Installation/foundation work, electric connection work, duct work, insulation work, power source switch and other items are

not specified in the specifications.

(1) Outdoor Unit

Page 7

4

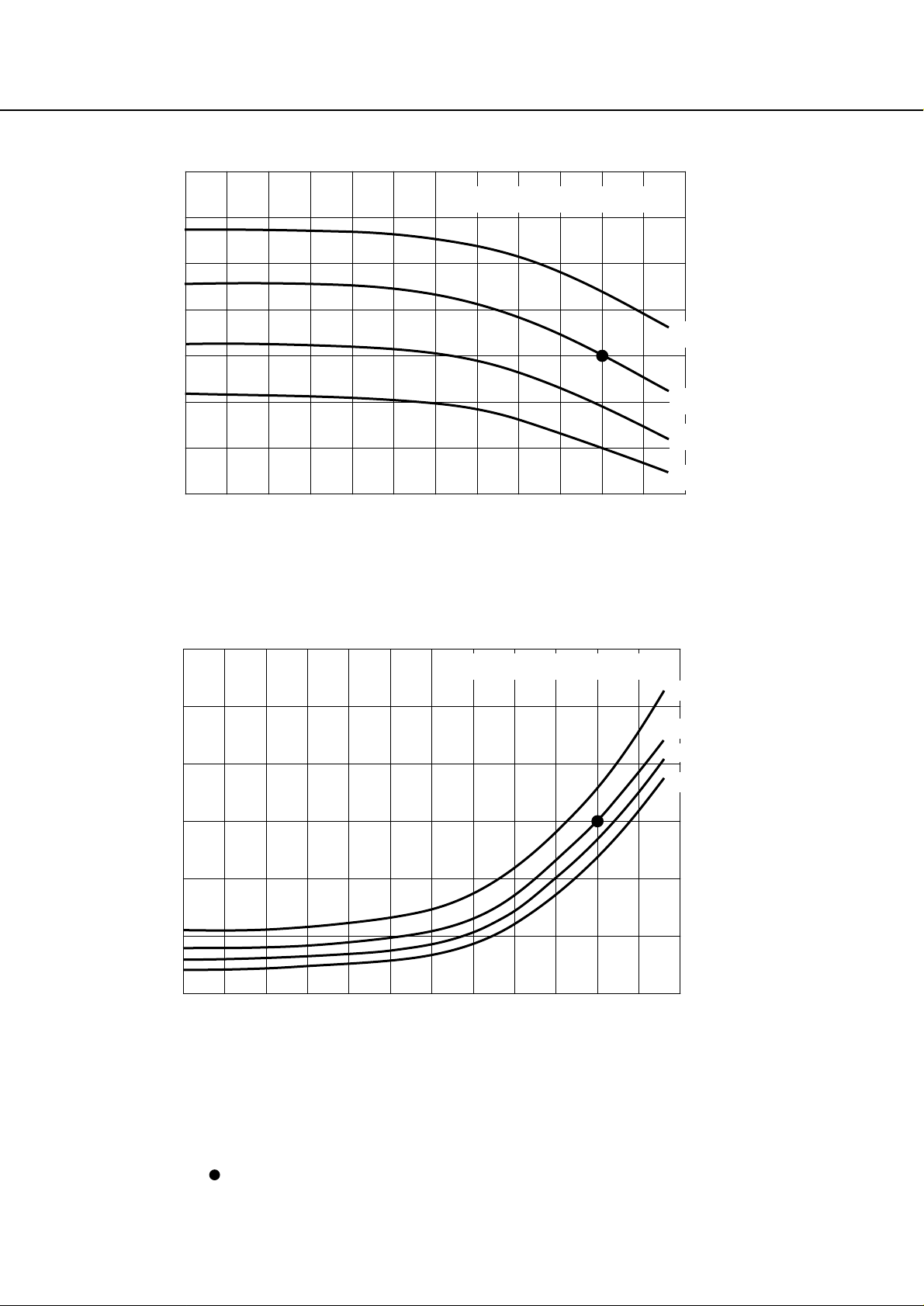

2. Capacity Curves

2-1. Cooling Capacity

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

-15 -10 -5 0 5 10 15 20 25 30 35 40 45

Indoor unit inlet temperature (˚CWB)

Indoor unit inlet temperature (˚CWB)

19

15

12

24

0.7

0.8

0.9

1.0

1.1

1.2

1.3

19

24

15

12

-15 -10 -5 0 5 10 15 20 25 30 35 40 45

Capacity correction coefficientInput Correction Coefficient

Outdoor unit inlet temperature (˚CDB)

Outdoor unit inlet temperature (˚CDB)

2-2. Cooling Input

✻ The correction curves indicate the values measured at the point where the compressor was

operated at its maximum capacity.

✻ indicates the standard value.

Page 8

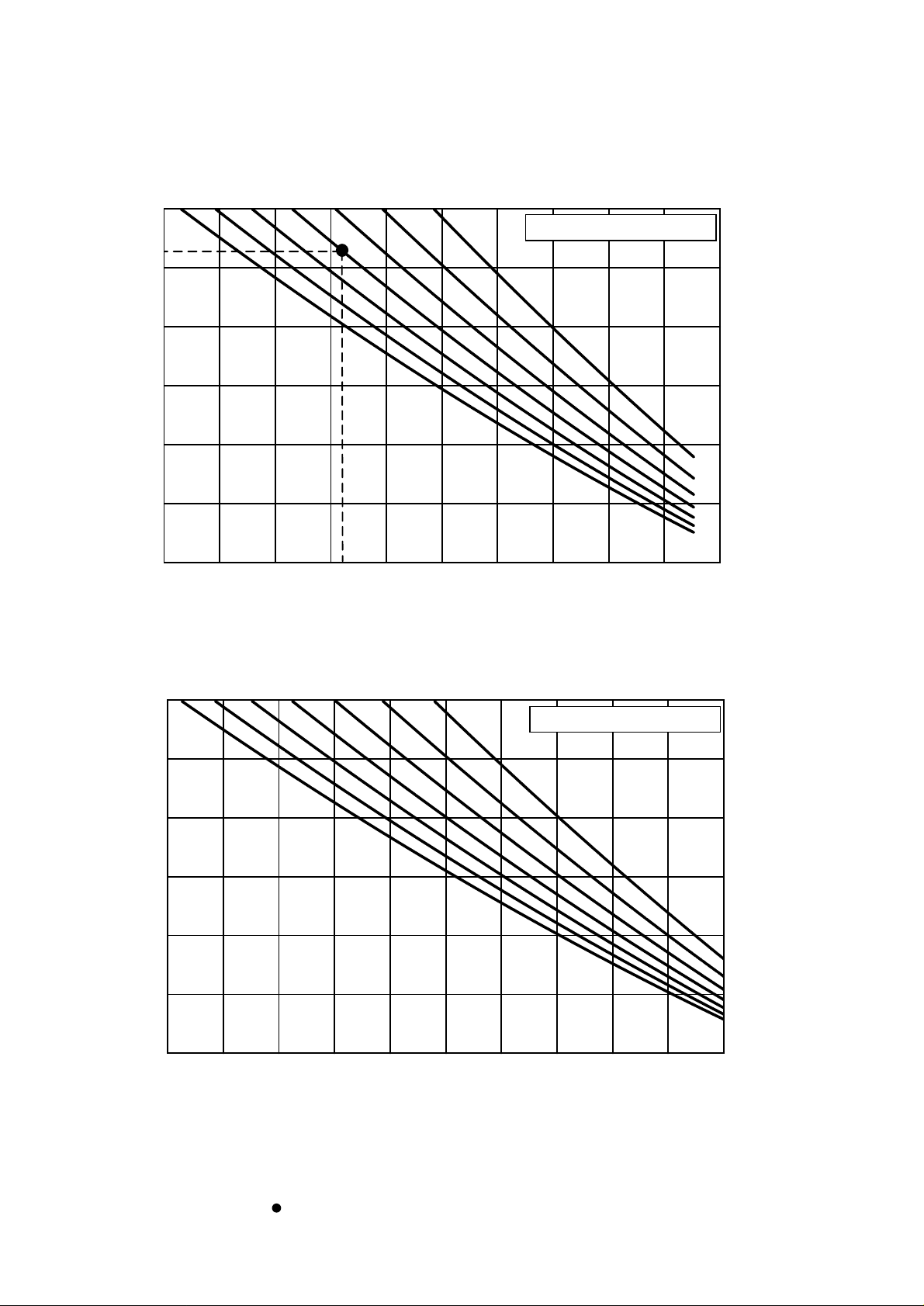

5

2-3. SHF Curves

Operation Temparature Range: Indoor : 12˚CWB~24˚CWB

Outdoor: -15˚CDB~43˚CDB

(RH : 30~80%)

Standard Point " " : Indoor : 27˚CDB/19˚CWB

Outdoor: 35˚CDB/-

0.4

0.5

0.6

0.7

0.8

0.9

1

30 40 50 60 70 80

RH (%)

SHF

130% 120%110%100% 90% 80% 70%

Standard Capacity Ratio

Standard Capacity Ratio

0.93

0.4

0.5

0.6

0.7

0.8

0.9

1

30 40 50 60 70 80

RH (%)

SHF

130% 120%110%100% 90% 80% 70%

35 45 55 65 75

Indoor Temperature 27˚CDB

35 45 55 65 75

Indoor Temperature 24˚CDB

Page 9

6

2-4. Correction by refrigerant piping length

To obtain a decrease in cooling/heating capacity due to refrigerant piping extension, multiply by the capacity

correction factor based on the refrigerant piping equivalent length in the table below.

• Cooling

Equivalent length = (Actual piping length to the farthest indoor unit) + (0.50 ✕ number of bent on the piping)m

• How to obtain piping equivalent length

Piping equivalent length (m)

Capacity correction coefficient

0.7

0.8

0.9

1

0 20 40 60 80 100 120 140 160 180

2-5. Operation limit

Indoor temperature (˚CWB)

-15 0-5-10 5 1015202530354045

10

12

15

20

25

30

* The height between the Outdoor PU(H)Y-P-YGM-A and Indoor could make the running

temperature range narrow. For details refer to P20, 7-1 Refrigerant Piping System.

Outdoor temperature (˚CDB)

• Heating

Outdoor temperature (˚CWB)

Indoor temperature (˚CDB)

30

25

20

15

10

5

-20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50

Page 10

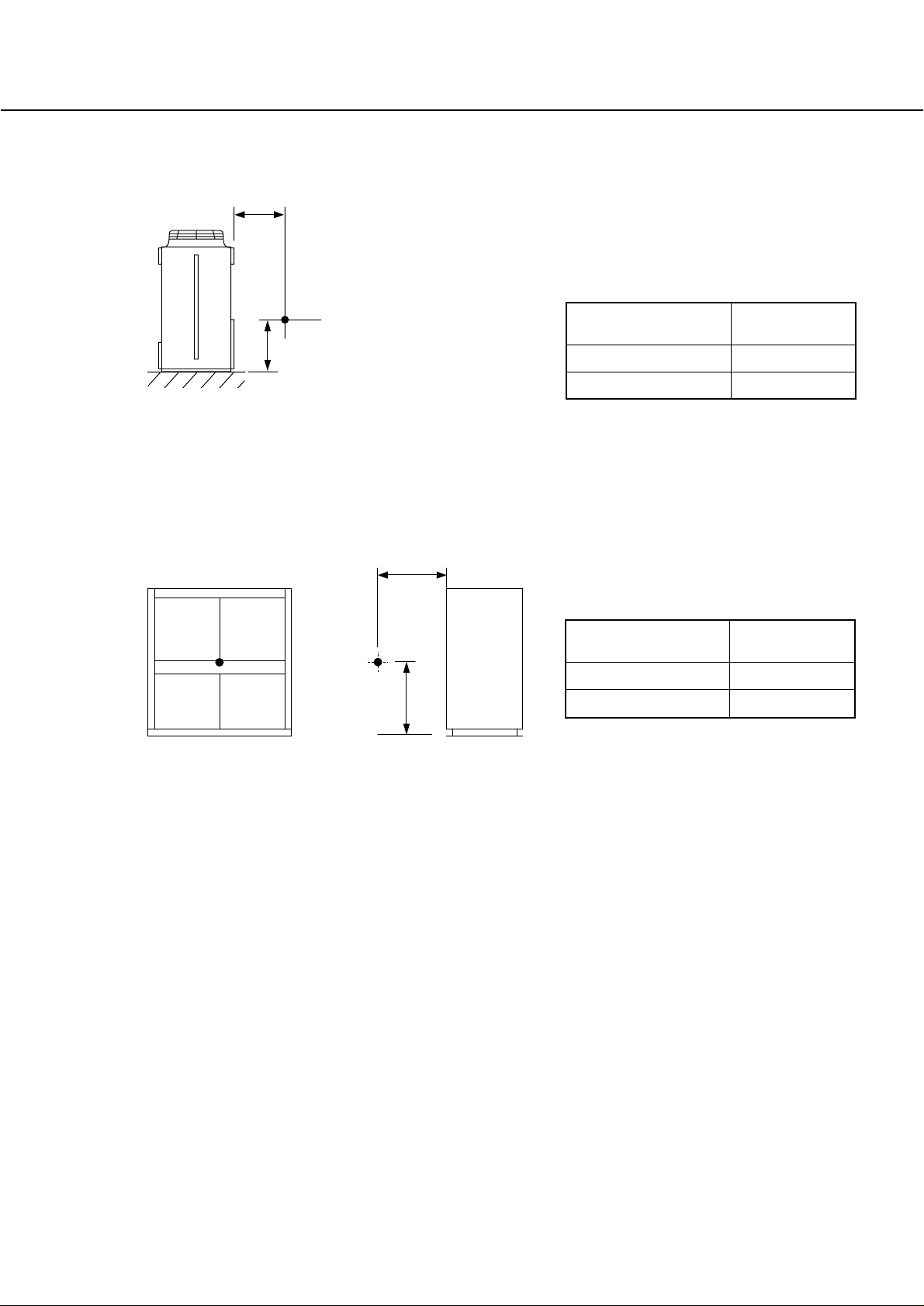

3. Sound Levels

3-1. Noise Level

7

1m

1m

Measured

point

Series

Noise Level

(dB [Type A])

PFD-P250VM-E 59

PFD-P500VM-E 63

(1) Outdoor Unit

(2) Indoor Unit

Measured

point

1m

1m

Series

Noise Level

(dB [Type A])

PU(H)Y-P250YGM-A 57

PUHY-P500YGM-A 60/61

(50Hz/60Hz)

Page 11

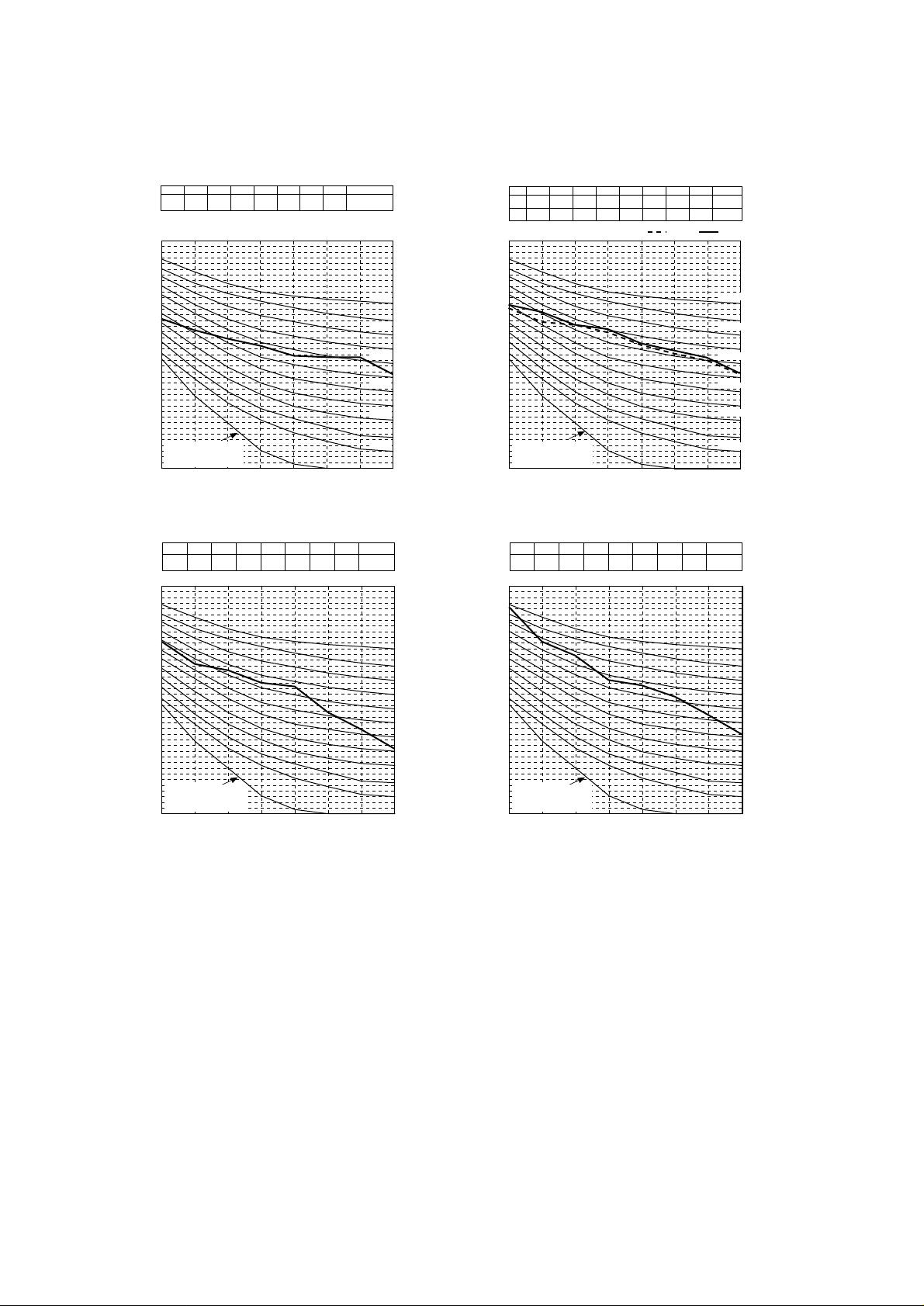

8

3-2. NC Curves

PU(H)Y-P250YGM-A

(External static

pressure 0Pa)

PUHY-P500YGM-A

(External static

pressure 0Pa)

PFD-P250VM-E

(External static

pressure 120Pa)

PFD-P500VM-E

(External static

pressure 120Pa)

63Hz 125Hz 250Hz 500Hz 2000Hz1000Hz 4000Hz 8000Hz

dB(A)

82.8 70.5 65.6 57,0 55.1 51.1 44.7 37.9 63

63Hz 125Hz 250Hz 500Hz 2000Hz1000Hz 4000Hz 8000Hz

dB(A)

70.6 62.7 60.5 56.1 54.8 45.7 39.7 32.9 59

10

20

30

40

50

60

70

80

90

63Hz 125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

10

20

30

40

50

60

70

80

90

63Hz 125Hz 250Hz 500Hz 1000Hz 2000Hz 4000Hz 8000Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPaOCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

OCTAVE BAND CENTER FREQUENCIES (Hz)

63 125 250 500 1000 2000 4000 8000

10

20

30

40

50

60

70

80

90

Approximate minimum

audible limit on

continuous noise

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

63Hz 125Hz 250Hz 500Hz 2000Hz1000Hz 4000Hz 8000Hz

dB(A)

62.5 58.5 55.5 53 49.5 49 49 43 57

50Hz 60Hz

OCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPaOCTAVE BAND PRESSURE LEVEL (dB) 0dB = 20µPa

OCTAVE BAND CENTER FREQUENCIES (Hz)

OCTAVE BAND CENTER FREQUENCIES (Hz)

63 125 250 500 1000 2000 4000 8000

10

20

30

40

50

60

70

80

90

Approximate minimum

audible limit on

continuous noise

Approximate minimum

audible limit on

continuous noise

Approximate minimum

audible limit on

continuous noise

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

63Hz 125Hz 250Hz 500Hz 2000Hz1000Hz 4000Hz 8000Hz

dB(A)

67

50Hz

60Hz

61.5 60.5 58 53.5 50.5 48 43 60

68 65 60.5 59 54 51.5 49 43.5 61

Page 12

9

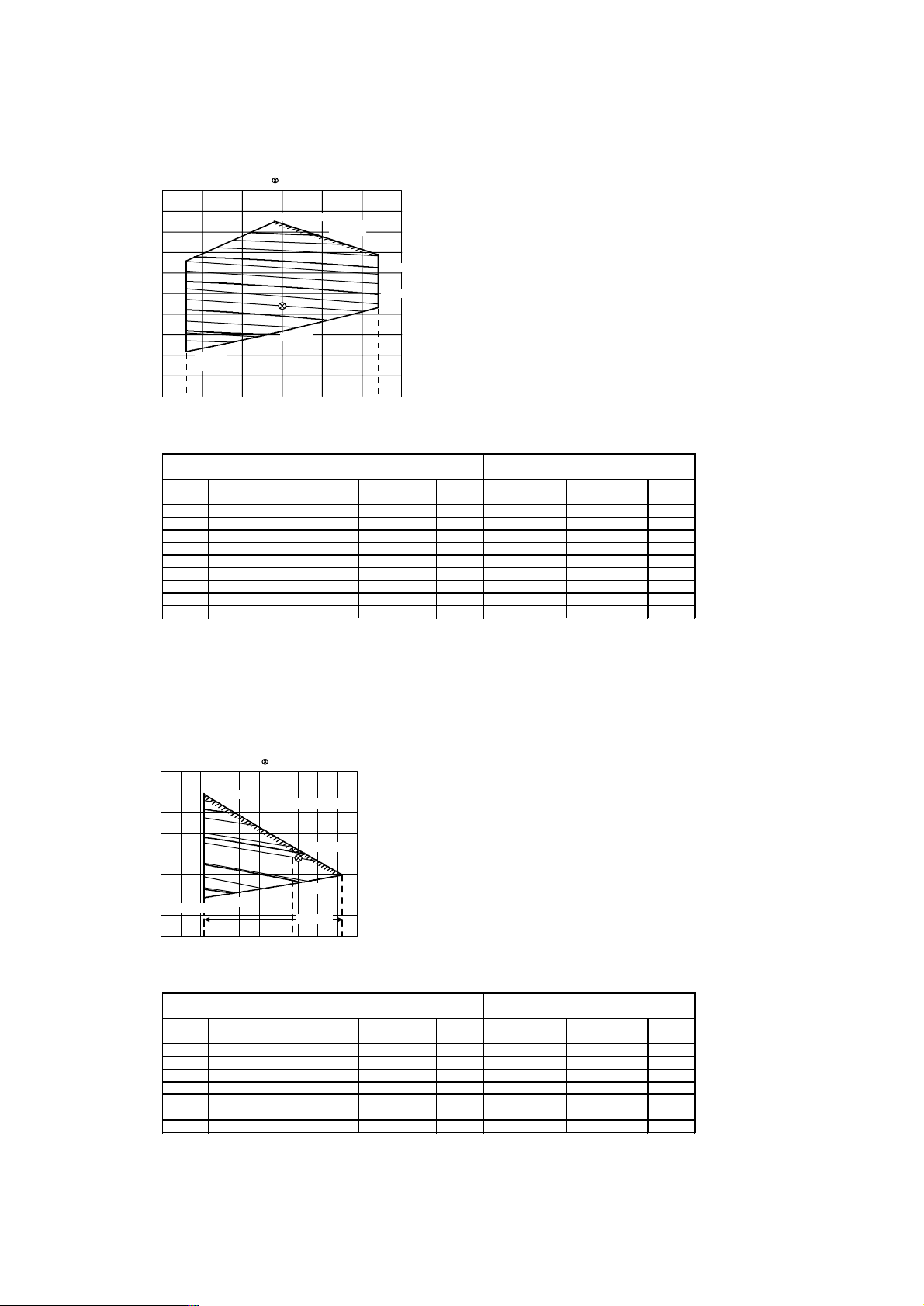

3-3. Fan Characteristics Curves

PFD-P250VM-E

PFD-P500VM-E

: 50/60Hz, standard

: 50/60Hz, standard

0

100

200

300

400

500

600

700

800

900

1000

130 140 150 160 170 180 190

)aP(erusserpcitatsla

t

oT

Fan rotation speed

Internal

resistance

1200rpm

1100rpm

1000rpm

900rpm

800rpm

Output 3.7kW

136 184

Air volu me (m3/min)

Air volu me (m3/min)

✻ Pulley and V-belt is procured on site.

✻ Pulley and V-belt is procured on site.

290 310 330 350

318 345

250

0

100

200

300

400

500

600

700

800

270

)aP(erusserpcitatslatoT

272

800rpm

800rpm

Internal resistance

Fan rot ation speed

Output

5.5kW

StandardStandard

1000rpm

1100rpm

1000rpm

900rpm

900rpm

1

2

3

4

5

6

7

8

9

3

4

5

6

7

8

9

2

6

No.

3

4

5

6

7

8

9

No.

1

3

4

5

7

8

9

1170

1140

1080

1040

973

930

845

797

748

Rotational

speed

(rpm)

1135

1070

1015

978

905

850

803

Rotational

speed

(rpm)

ø315-B-2-42

ø315-B-2-42

ø250-B-2-42

ø250-B-2-42

ø280-B-2-42

50Hz

Motor pulle y Fan pulley

ø170-B-2-38

ø180-B-2-38

ø170-B-2-38

ø180-B-2-38

ø180-B-2-38

ø160-B-2-38

ø170-B-2-38

ø236-B-2-42

ø250-B-2-42

50Hz

Motor pulle y Fan pulley

ø160-B-2-28

ø160-B-2-28

ø170-B-2-28

ø165-B-2-28

ø165-B-2-28

ø165-B-2-28

ø165-B-2-28

ø170-B-2-28

ø160-B-2-28

ø315-B-2-42

ø280-B-2-42

ø200-B-2-42

ø212-B-2-42

ø224-B-2-42

ø236-B-2-42

ø280-B-2-42

ø315-B-2-42

ø250-B-2-42

B48

B49

B50

B51

B52

B54

B53

B56

B56

V-belte

B51

B51

B51

B50

B53

B56

B55

V-belte

60Hz

Motor pulle y Fan pulle y

ø280-B-2-42

ø165-B-2-28

ø165-B-2-28

ø165-B-2-28

ø180-B-2-28

ø170-B-2-28

ø355-B-2-42

ø250-B-2-42

ø280-B-2-42

ø280-B-2-42

-

ø160-B-2-28

ø160-B-2-28

ø170-B-2-28

ø300-B-2-42

ø315-B-2-42

ø355-B-2-42

-

ø300-B-2-42ø180-B-2-38

ø355-B-2-42

ø355-B-2-42ø160-B-2-38

60Hz

Fan pulleyMotor pulle y

ø160-B-2-38 ø250-B-2-42

ø280-B-2-42

ø300-B-2-42

ø170-B-2-38

ø160-B-2-38

ø160-B-2-38

ø160-B-2-38 ø315-B-2-42

B52

B56

B54

B54

B55

B56

B59

B59

-

V-belte

B50

B55

B52

B54

B55

B58

B58

V-belte

Page 13

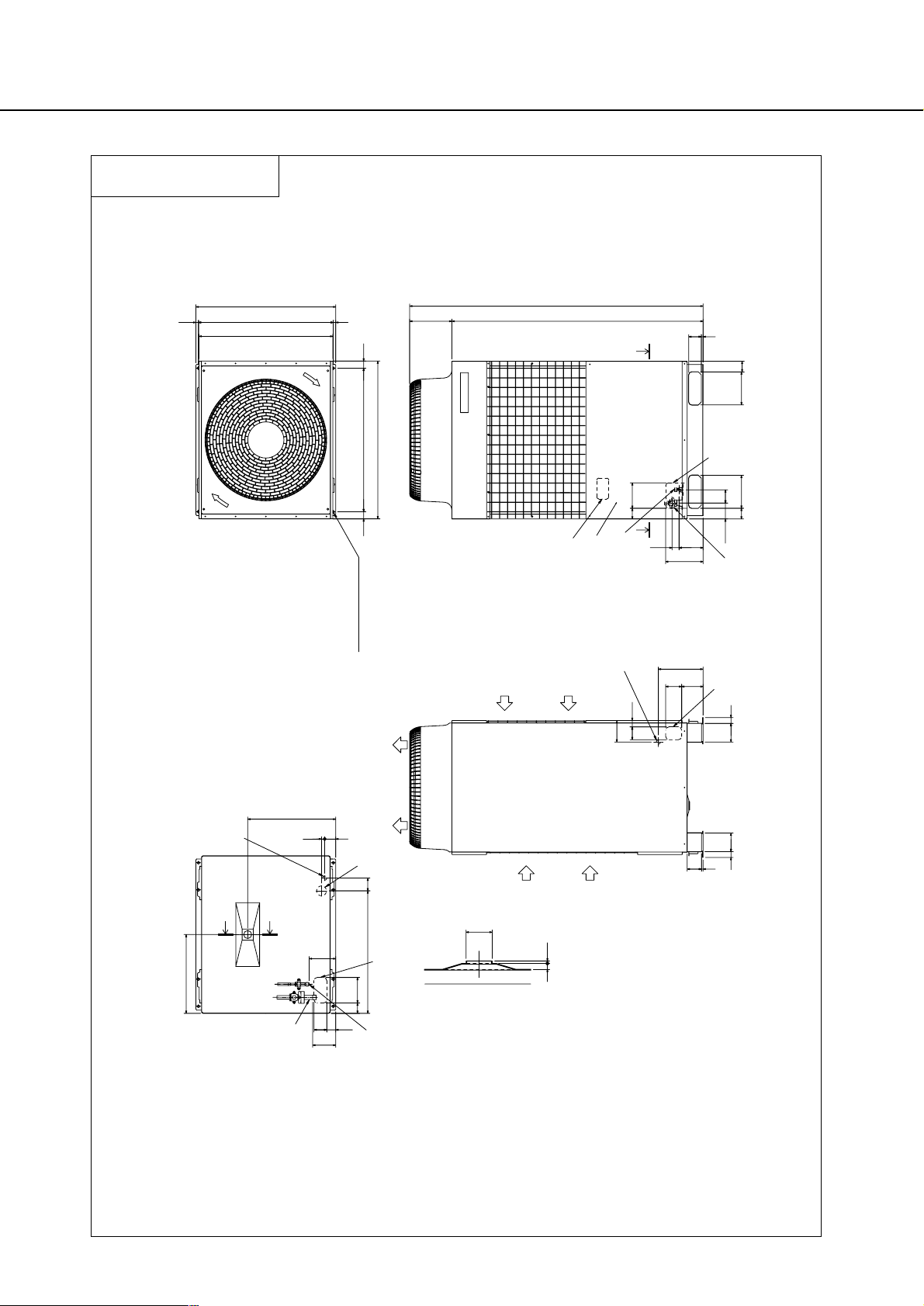

10

4. External Dimensions

PU(H)Y-P250YGM-A

Unit : mm

Note1.Use the opening at the bottom of the unit

when running the power supply line from

the front or from the side of the unit.

Note2.Please refer to the next page for information

regarding necessary spacing around the

unit and foundation work.

166

83100

44150

Y

Y

20

70

80

100

90

10

4080

135

280

134

553

494

8057

16065

768

37 117 117 37

1575

1840

11

235

16067

990

16

840

67 207

207

67

78

X

X

877

845(mounting pitch)16

45900(mounting pitch)45

265

ø53

12 5

Conn. pipe(Liquid)

ø9.52 <Flare>

Conn. pipe(Gas)

ø22.2 <Brazed>

(Mounting hole)

Air outlet

Air

inlet

Air

inlet

ø62 Knockout hole

<Hole for power supply>

Changeable to ø27,ø33 by using

attached conduit mounting plate <Accessory>

ø27 Knockout hole

<Bottom hole for

control wiring>

Knockout hole

<Bottom piping hole>

Left side view

ø27 Knockout hole

<Left side hole for

control wiring>

Knockout hole

<Left piping hole>

<Accessories>

• Refrigerant (Gas) conn. pipe......1 pc.

(Already installed on the unit)

• Packing for conn. pipe................1 pc.

(Attached near the ball valve)

• Conduit mounting plate

ø33, ø27..............................1 pc.Each

• Tapping screw M4......................2 pcs.

Cross section Y – Y

Cross section X – X

2X2-14X20 0val hole

Top view

Front view

Knockout hole

Service panel

Refrig. service

valve (Liquid)

<Flare>

Refrig. service

valve(Gas)

<Flange>

Knockout hole

<Front piping

hole>

136

Page 14

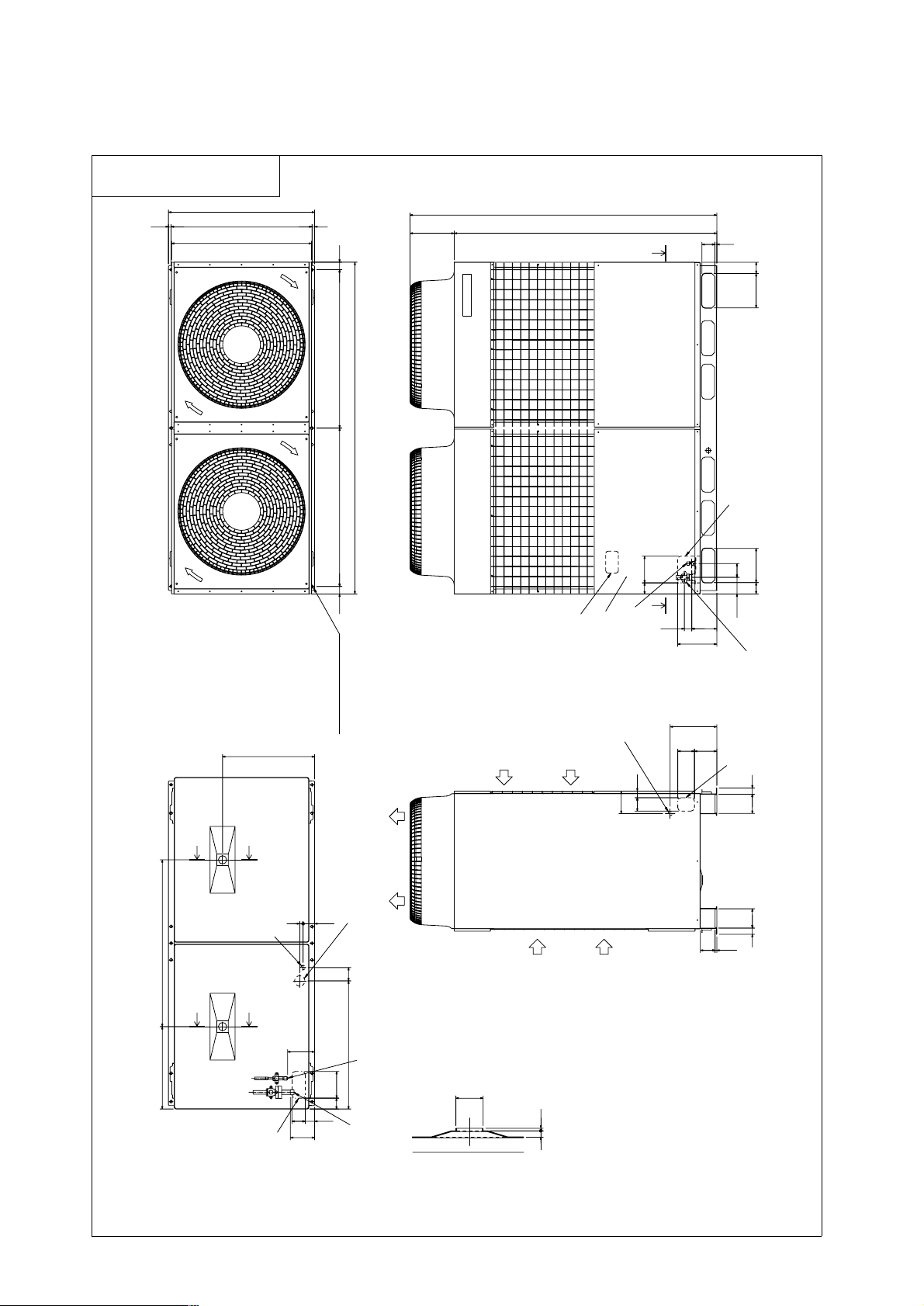

11

PUHY-P500YGM-A

Unit : mm

Note1.Use the opening at the bottom of the unit

when running the power supply line from

the front or from the side of the unit.

Note2.Please refer to the next page for information

regarding necessary spacing around the

unit and foundation work.

44150

83

162

135

40

8910

37 115 115 37

134 100

280

80

80

20

70

494

145

553

1000

768

80

57

160

65

1840

1575

11

68

68 205 205

100

235

16067

78

265

45

1990

45950(mounting pitch)

877

840

16 16

845(mounting pitch)

950(mounting pitch)

512

ø53

Conn. pipe(Gas)

ø28.58<Brazed>

Conn. pipe(Liquid)

ø15.88<Flare>

YY

YY

X

X

(Mounting hole)

Knockout hole

<Bottom piping hole>

ø27 Knockout hole

<Bottom hole for

control wiring>

ø62 Knockout hole

<Hole for power supply>

Changeable to ø46,ø53 by using

attached conduit mounting plate <Accessory>

<Accessories>

• Refrigerant (Gas) conn. pipe....1 pc.

(Already installed on the unit)

• Packing for conn. pipe......1 pc.

(Attached near the ball valve)

• Conduit mounting plate

ø53, ø46......1 pc.Each

• Tapping screw M4...2 pcs.

Air

inlet

Air

inlet

Air outlet

Cross section X – X

Cross section Y – Y

ø27 Knockout hole

<Left side hole for

control wiring>

Knockout hole

<Left piping hole>

Left side view

Front view

Knockout hole

Service panel

Knockout hole

<Front piping hole>

Refrig. service

valve (Liquid)

<Flare>

Refrig. service

valve(Gas)

<Flange>

Top view

3X2-14X20 Oval hole

Page 15

12

PFD-P250VM-E

Unit : mm

390

50

50

100

Note1. Be sure to set up a trap for Emergency

drain piping.

(Trap height:beyond 100mm)

(Trap is not necessary for main drain piping.)

2. Approve this figure because it is refused

for the improvement and specification

subject to change without notice.

3. Amputate a gas pipe/liquid pipe in the

fixed height at the time of 2 refrigerant

circuit connection, and connect it with

the local pipe.

Drain piping connection

for humidifier

Air inlet

500 or more200 or more

400 or more

800 or more

Indoor unit

Service space

Unit surface

figure

Pipe execution

space

Unit front

figure

Indoor unit

Service space

Hole for the control wiring

Lifting bolts

<2-ø32 knock out

hole>

Hole for the power

supply(Body)

<Nomal/Local>

1380

Remote controller

A

Refrig. piping <gas> ø22.2 braze

Power supply:White

Operating :Green

Check :Yellow

Failure :Red

(Accessory)

Filter

Lamp

<view from A>

320

220

1950

20

100

462

580

Panel

<ø32 knock out hole>

Air inlet

Control box

50

140

Hole for the control wiring <ø32 knock out hole>

Main drain piping connection <Rp1-1/4>

<Accessory>

· Lifting bolts ······4pc.

· Front panel opening and closing key ······1pc.

100

Air outlet

Refrig. piping <liquid> ø9.52 braze

Hole for the power supply <ø32 knock out hole>

260

68

100

1180

780

1340

Hole for the control wiring(ø60)

410

68

Hole for the power supply(ø60)

321

220

Hole for gas pipe connecting(ø42)

Air outlet

20

Bolt holes:8-ø18

140

305

100

518

Hole for liquid pipe connecting(ø24)

65

<Rp1-1/4>

Hole for liquid pipe connecting(ø24)

87

186

20

Emergency drain piping connection <Rp1-1/4>

Hole for gas pipe connecting(ø42)

Changeover switch

340

100

150

260

171

20

401

740

Page 16

13

PFD-P500VM-E

Unit : mm

50100

140

50

50390

100

68

124

135

Note1. Be sure to set up a trap for Emergency

drain piping.

(Trap height:beyond 100mm)

(Trap is not necessary for main drain piping.)

2. Approve this figure because it is refused

for the improvement and specification

subject to change without notice.

3. Amputate a gas pipe/liquid pipe in the

fixed height at the time of 2 refrigerant

circuit connection, and connect it with

the local pipe.

Refrig. piping <liquid> in 2 refrig. circuit system ø 9.52 braze No.1

Refrig. piping <gas> in 2 refrig. circuit system

type P450:ø 19.05 braze, type P560:ø 22.2 braze No.1

Refrig. piping <liquid> ø 15.88 braze

Refrig. piping <gas> ø 28.58 braze

Hole for No.2 gas pipe

connecting(ø 42) in 2

refrig. circuit system

Hole for No.2 liquid pipe

connecting(ø 24) in 2

refrig. circuit system

Hole for liquid pipe connecting(ø 34)

Hole for No.1 liquid pipe connecting

(ø 24) in 2 refrig. circuit system

Bolt holes:8-ø 18

Hole for No.1 gas pipe connecting(ø 42)

in 2 refrig. circuit system

Hole for gas pipe connecting(ø 48)

Main drain piping connecting<Rp1-1/4>

Drain piping connection

for humidifier

<Accessory>

· Lifting bolts ······4pc.

· Front panel opening and closing key ······1pc.

Air inlet

Service space

Indoor unit

Pipe execution

space

Panel opening

and closing

dimension

Indoor unit

Unit surface

figure

Service space

400 or more

Unit front

figure

1000 or more ✻1

200 or more

✻1. It is necessary for the removal

of the panel beyond 600mm.

500 or more

710

Refrig. piping <gas> in 2 refrig. circuit system

type P450:ø 19.05 braze,

type P560:ø 22.2 braze No.2

680

<2-ø 32 knook out

hole>

<ø 32 knook out hole>

Air outlet

Air inlet

Power supply:White

Operating :Green

Check :Yellow

Failure1 :Red

Failure2 :Red

<Normal/Local>

(Accessory)

<view from A>

<Rp1-1/4>

Air

outlet

Hole for liquid side pipe connecting

or No.1 gas side pipe connecting(ø 42)

in 2 refrig. circuit system

Hole for No.2 gas side pipe connecting(ø 42)

in 2 refrig. circuit system

100 1001780

1940

100

2020

20

65

321

100

410

359 241

740

359

580

305

320

220

370

20

Emergency drain piping connection <Rp1-1/4>

Hole for No.1 liquid side pipe connecting

(ø 24) in 2 refrig. circuit system

Hole for the power supply(ø 60)

1950

780

Hole for gas side pipe connecting or

No.2 liquid side pipe connecting(ø 48)

in 2 refrig. circuit system

440

Air

outlet

185

379

135

Refrig. piping <liquid> in 2 refrig. circuit

system ø 9.52 braze No.2

68

120

Hole for the control wiring <ø 32 knook out hole>

Hole for the power supply <ø 32 knook out hole>

220

150

81

Hole for the control wiring(ø 60)

Panel

68

Lifting bolts

171

A

Control box

Lamp

Filter

Remote controller

838

Hole for the control wiring

1980

124

68

Hole for the power

supply(Body)

Changeover switch

Page 17

14

5. Electrical Wiring Diagrams

PU(H)Y-P250YGM-A (Connected with PFD series)

–

+

+

+

X01

Radiator panel temp. detect(Fan)

THHS5

CNCT

yellow

orange

red

brown

A2A1

TH11

TH5

TH6

TH7

TH8

Z20

DC Current Sensor

DCCT

1 2 3 4

Power selection

connector

CN41CN40

1 2 3 41 2 3 4

1 2 3 4

DCCT

591

1

2

234

1

6

5

CNINV

LED1 operation

LED2 error

Compressor ON/OFF

Trouble

Low pressure sensor

CNRS3A

High pressure sensor

CN3S

red

CNVCC1

CN3D

SW1

Earth terminal

SW2SW3

SW4

LD1

ON

ON

ONOFFOFF

ONOFF ONOFF OFF

SW5

1

Radiator panel temp. detect

(Compressor)

Control circuit board

10

21569

13

14

SWU2

Address setting

SWU1

CN52C

yellow

green

red

X09

CNS2

blue

CNS1

blue

3

CN20

CN21

blue

13

F02

250VAC

6.3A T

1 2 3 4 5

1 2 3

3

TB1

(Terminal Block)

Power source

3N~

380/400/415V

50/60Hz

black

red

52C1

DCL

C2

red

14

DS1

(Diode stack)

white

black

10

CNDC2

N

IPM

P

C4

MC1

Gate amp board 1

ACCT

-W

9

ACCT

ACCT-U

X52

U V W

FAN control board

CNVDC

10

C1

R4

R3

R1

R2

ACNF1

(Noise Filter)

E

Filter board

CNFG

blue

L2

CNL1CNL2

CNOUT

green

CNIN

blue

C5

ZNR4

SWU3

012

CN15V1

CNDC1

black

CNDR1

bypass outlet temp.detect

at Sub-cool coil

CNVCC1

CNAC2

MF1

CNFAN

red

SW2SW1

1 4

1 6

CNAC3

LED1 operation

LED2 error

CNFG

blue

CNCT2

blue

black

CNTH

green

THHS1

red

7

CNRS1

Power circuit board 1

CNDC2

CN15V2

CNDR2

TB3

(Terminal Block)

M1

M2

SM2M1

TB7

(Terminal Block)

1

1 2

shield

F02

700VDC

2A T

red

white

black

blue

red

white

black

blue

red

black

Motor

(Compressor)

F01

250VAC

2A T

Refer to the service handbook

about the switch operations.

CENTRAL CONTROL

TRANSMISSION LINE

CNRS2

Inverter controller box

Function device

liquid outlet temp.detect

at Sub-cool coil

Discharge pipe temp. detect

OA temp.detect

Pipe temp.detect(Hex outlet)

Choke coil(Transmission)

Thermistor

High pressure switch

4-way valve

Electronic expansion valve

(SC coil)

Solenoid valve

(Heat exchanger capacity control)

Solenoid valve

(Discharge-suction bypass)

Magnetic contactor

(Inverter main circuit)

Crank case heater(Compressor)

Z20

L1,L2

63LS

DC reactor

(Power factor improvement)

63HS

63H1

THHS1

TH5

CN35

<Symbol explanation>

TH11

TH8

LEV1

1

THHS5

L3

L2

CNTH

green

1 2

2

3

2

1

1 2

ON

OFF

4

ON

OFF

1 2

4

8

3

L1

1

1

L3L2L1

2

1

122

1 2

3

1 2 3 4 5

1

9

1

N

123

4

12341

9

2

132

1

CNRS3B

CNTR

Symbol

CN38

black

SV5b

21S4a,b

CH11

MF1

52C1

DCL

SV1

ACCT

1

Name

3

63H1

INDOOR/OUTDOOR

TRANSMISSION LINE

CN04

AC Current Sensor

1

12V

CN51

2

1

W

3

2

V

Function setting

5

1

2

3

1 2 3

4

3

CH11

X03

X08

CN32

X02

CN33

CN36

SV

5b

2

1

21S

4a

21S

4b

2

7

1

78131

1

10

1

10

1

10

1

1103

2

N

L3

F01

250VAC

6.3A T

red

white

black

CNTYP5

CNH

CNTYP4

CN01

CNL

black

CNTYP1

red

CN02

1

R23

63HS

R22

63LS

7

2 1

632 1 3 2 12 1

2 1

U

CNLVB

red

detection

circuit

LEV1

7

L1

5412

2

332

1

black

white

red

Function setting

detection

circuit

65413

LD2

Maintenance

setting

8

N

red

white

blue

4

2

4 3

2

3

1

8 7 6 5

white

detection

circuit

MF

Fan motor

(Heat exchanger)

W

132

TH7

SV1

shield

PE

L1

TH6

8

1

1

V

U

X11

123

NOTE:The broken lines indicate field wiring.

X01

1

52

C1

2

Fan motor (Radiator panel)

T01

(Transformer)

black

NIGHT MODE

SNOW

1

L2

1

Page 18

15

PUHY-P500YGM-A (Connected with PFD series)

black

white

red

LEV1

NOTE:The broken lines indicate field wiring.

Gas pipe temp.detect

(Hex outlet)

TH2

Magnetic contactor(Fan motor)

52F

Overload relay(No.2Compressor)

51C2

Magnetic contactor(No.2Compressor)

52C2

DC Current Sensor

DCCT

<Symbol explanation>

Symbol Name

ACCT

DCL

52C1

MF3

CH11,12

21S4a,b,c

SV1,3

SV5b,c

LEV1

TH11,12

TH5

TH6

TH7

TH8

THHS1

63H1,2

63HS

63LS

L1,L2

Z20

AC Current Sensor

DC reactor

(Power factor improvement)

Magnetic contactor

(Inverter main circuit)

Solenoid valve

(Discharge-suction bypass)

Solenoid valve

(Heat exchanger capacity control)

Electronic expansion valve

(SC coil)

Fan motor (Radiator panel)

Crank case heater(Compressor)

4-way valve

Thermistor

Discharge pipe temp. detect

Pipe temp.detect(Hex outlet)

OA temp.detect

liquid outlet temp.detect

at Sub-cool coil

bypass outlet temp.detect

at Sub-cool coil

Radiator panel temp. detect

(Compressor)

High pressure switch

High pressure sensor

Low pressure sensor

Choke coil(Transmission)

Function device

Earth terminal

THHS5

Radiator panel temp. detect(Fan)

Motor

(Compressor)

Fan motor

(Heat exchanger)

Fan motor

(Heat exchanger)

black

white

red

Motor

(Compressor)

black

white

red

white

blue

white

red

power selection

connector

detection

circuit

detection

circuit

detection

circuit

Inverter controller box

red

white

black

CNHCNL

black

1

63HS

63LS

332

black

white

red

2

2

3

1

123

1

black

red

DS

(Diode stack)

black

white

red

Function setting

LED1 operation

LED2 error

Power circuit board

Gate amp board

Filter

board

T01

(Transfomer)

LED1 operation

LED2 error

FAN control board

Compressor ON/OFF

Trouble

NIGHT MODE

SNOW

Refer to the service handbook

about the switch operations.

Address setting

Function setting

Maintenance

setting

Control circuit board

TB3

(Terminal Block)

TB7

(Terminal Block)

TB1

(Terminal Block)

ACNF

(Noise Filter)

M2

M1

M2

M1

shield

shield

CENTRAL CONTROL

TRANSMISSION LINE

INDOOR/OUTDOOR

TRANSMISSION LINE

Power source

3N~

380/400/415V

50/60Hz

L3NL1

L2

blue

black

white

red

blue

N

1

921

9

1

5

6109

14

13

101413

96512

black

red

red

black

10

1

SW5

OFFOFF ONOFF ON

OFF OFF ON

ON

ON

LD1

SW4

SW3 SW2 SW1

10

1

10

1

10

1

10

1

DCCT

L3

L2

1

2

S

F12

AC660V

50A F

F11

AC660V

50A F

red

white

black

U

17

W

V

MC2

1

1

321

F01

250VAC

2A T

CNAC2CNCT

12

N

R2

C1

C2

R1

R4

R3

CNDC1

black

CN15V1

CNDR1

CNDC2

ACCT-W

ACCT-U

ACCT

CNDR2

F02

700VDC

2A T

CN15V2

THHS1

CNTH

green

CNFG

blue

CNDC2

CNCT2

blue

CNVCC1

CNFAN

red

CNRS1

CNL1CNL2

CNFG

blue

CNIN

blue

CN41

CNOUT

green

CNINV

CN21

blue

CNS1

blue

CN20

F02

250VAC

6.3A T

CN40

F01

250VAC

6.3A T

CNVDC

CNS2

blue

CNRS3B

CNVCC1

CNRS3A

CN51

CN3S

red

8

210

SWU3

SWU1SWU2

CN52C

yellow

CN32

CN33

CN34

red

CN36

CN35

green

CNTYP5

CNTYP4

R23

R22

CN01

TH11

CNTYP1

red

black

CNTR

CNRS2

4

Z20

L3

3

2

8

1

1

8

51C2

642

red

3412

U

43

MF2

3

X09

L1

52C1

DCL

N

IPM

P

C4

MC1

V

X52

U

E

C5

ZNR4

X01

1

8

W

2

3

2

X07

1

CNRT1

1

CN13

TH12

52

C1

5

132

1

7

321456

12V

4

3

1

2132121

2

7

154312 321

1

L3

L2

4

45312

CN3D

231

3

1

X03

132

123

X02

X08

W

V

L1 U

L2

L3

63H1

52F

51C2

234

132

L1

12

12

1

8

561

X05

X06

946

314

2

1

144

SW1

OFF

243

1

ON

6

3412

2

W

SW2

OFF

1

ON

4

V

1

253412

2

1

3

4

1

1

4

L2

3

CN02

21

78

CNOUT2

56

3

2

CNRT2

CNCH

CN52F

CN51C2

45321

5432

2

11

7

6

X2

X3

5

4

X1

1

1

13227

CN52C2

blue

3

5

4

3

2

52

C2

1

312

52C2

TH5

TH6

TH7

21S

4a

SV1

SV3

PE

A1 A2

gray yellow

CH12

A2 A1

13 14

brown purple

red

orange

63H2

red

95 96

white black

52C2

21S

4c

V

W

6

CNOUT1

yellow

21321

3

321

CN05

SV

5c

CN04

52F

blue

A2

L1

L2

3

21

Relay board

orange

yellow

red

brown

THHS5

4

A1

741

CNTH

green

4

2

1

321

X01

+

+

–

+

black

MF3

CNLVB

red

SV

5b

CNAC3

2

1

TH8

red

white

21S

4b

CH11

321

MF1

WVU

321

1

3

2

LD2

1

U

CN38

5

3

black

2

2

yellow

L1

Page 19

16

PFD-P250VM-E

Note:1. The dotted lines show field wiring.

2. The address setting of the indoor unit should always be odd.

3. The outdoor unit to which the indoor unit is connected with the transmission line,

the address of the outdoor unit should be the indoor unit +50.

4. Mark indicates terminal bed, connector, board insertion connector

or fastening connector of control board.

0

F

E

D

C

B

A

9

0

9

8

7

6

5

4

3

2

1

9

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

2121

7123456

CN7V

CN24 CN25

X11

SW8

SW4

SW11

(1st digit)

SW12

(2nd digit)

SW14

SW7 SW2 SW1SW3

SWC SW5

Address

(odd)

1234561232121212112

T

CN3T

3

CN28 CN31CN29CN20 CN21 CN60CN22

Z3

33P1

97513131311

CNT CND

CN90CN33

CNP

5432

1

65432

CN51

1

CN52

Dehumidify

ZNR901

DSA1

CN3A

ZNR1

F901

X06 X05

X04

321

2

CN32

321

X01

CN2M

I.B.

1

X07

Z1

Inside section of control box

RC

2

1

2

1

TB15

Failure output

Distant location on/off

<no voltage or current>

Status output

Distant location on/off

<with voltage and current>

Power supply DC30V, AC100/200V

Switch(normal/local)

Power supply DC12~24V

Power supply

380/400/415V(50Hz)

400/415V(60Hz)

DC24~30V

Indoor unit

Control wiring

LED display(failure)

LED display(status)

LED display(power supply)

3N~

LED display(check)

SW9

234515432

1

B2B1BCA2A1

AC

54321

C

IFB

3

L3

A1SB1

L2

L1

X11

1

2

216

5

1

2

PE

N

F1

345

6

3

1

ZNR1

3

1

CN1

DSA1

PE

TB23

TB21

L

L

TB22

CN53

TB2

S.B.

CN54

L3

TB5

SHIELD

L2

L1

L4

FAN

over current

detection

51F

Z1

ZNR2

52F

Z3

51F 52F

MF

TH24

TH21

TH22

TH23

65432

1

LEV

SYMBOL

NAME

DSA1

Surge absorber

LED display (power supply)

F901

ZNR1, ZNR2, ZNR901

MF

I.B.

S.B.

IFB

TB2

TB5

TB15

TB21

TB22

TB23

F1

T

LEV

52F

51F

33P1

RC

L4

L3

L2

L1

Z3

Z1

X11

SWC(I.B.)

SW14(I.B.)

SW12(I.B.)

SW11(I.B.)

SW9

SW4(I.B.)

SW3(I.B.)

SW2(I.B.)

SW1(I.B.)

Surge absorber board

Switch (outlet/inlet temp.control)

Float switch

Fuse<6-3/6A>

Varistor

Transformer

Electronic linear expan.valve

Contactor(fan I/D)

Over current relay (fan I/D)

Fuse<5A>

Thermistor (inlet temp.detection)

Switch (connection No.set)

Switch (for mode selection)

Switch (for capacity code)

Switch (for mode selection)

Switch (for model selection)

Auxiliary relay(check)

LED display (failure)

LED display (status)

LED display (check)

Switch (normal/local)

TH24

TH23

TH22

TH21

Switch (1st digit address set)

Switch (2nd digit address set)

Fan motor

Indoor controller board

Power source terminal bed

Transmission terminal bed

External input/output board

Transmission terminal bed

MA Remote controller

Terminal bed for distant location on/off

<With voltage and current>

Terminal bed for distant location on/off

<No voltage or current>

Auxiliary relay(fan failure detection)

Auxiliary relay(fan)

Thermistor (piping temp.detection/gas)

Thermistor (piping temp.detection/liquid)

Thermistor (outlet temp.detection)

Terminal bed for distant location display

External input adapter

(PAC-SA88HA)

CN52

5(green)

1(brown)

Z

Indoor unit

control board

Relay circuit

The signal input of the dehumidify order is to

connect wiring referring to the bottom figure.

SW

Power

Distant control panel

SW:Defumidify order

(field supply

and construction)

Z

Z:Relay (Contact : Minimum applicable load

DC12V 1mA or less)

Page 20

17

PFD-P500VM-E

1.The dotted lines show field wiring.

2.It is wiring for 1 refrigerant system at the time of shipping.

Change wiring and SW2, 3, 4 (No.1&No.2) as this figure in field

when you change it to 2 refrigerant circuit

3.Set up the address of No.1 board in the odd number, and set up the

address of No.2 board in the even number.

But, set up the address of the No.2 board in the No.1 board +1.

4.The outdoor unit to which the indoor unit is connected with the

transmission line, the address of the outdoor unit should be the

indoor unit +50.

5.Set up the zone No. (SW14) from 1 to 5 when you connect a concentration

controller.

(Install an indoor unit within 20 units in the all 5 zone.)

6.Mark indicates terminal bed, connector, board insertion connector

or fastening connector of control board.

Note:

SW8

SW4 SW7 SW2

SWC SW5

0

F

E

D

C

B

A

9

0

9

8

7

6

5

4

3

2

1

9

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

657 4321CN24 CN25

1

2

2

1

X11

CN7V

Address

(odd)

SW11

(1st digit)

SW12

(2nd digit)

SW14

No.1

CN51

CN52

Dehumidify

13

45

1

2

3

45

2

ZNR901

DSA1

ZNR1

F901

X06 X05 X04X01 X07

CN3A

CN32

CN2M

I.B.1

3212321

1

591513731

CNT

CND

CN90

13

CN33CNP

31

Z1

T

CN3T

31

CN28

21

CN31

12321

CN29

3222

1

11

CN20

CN21

CN60

CN22

21 654

Z3

33P1

SW1SW3

TH24-1

TH21-1

TH22-1

TH23-1

LEV2

LEV1

12345

6654321

AD.B.

6543 126543 12

6543 12

LEV1A

LEV1B

LEV1

2

1

Inside section of control box

RC

2

1

TB15

A1SB1

216

5

DC24~30V

No.1 Indoor unit

Control wiring

LED display(No.1 failure)

LED display(status)

TB5-1

SHIELD

L3

L1

1

3

ZNR1

3

1

CN1

DSA1

S.B.

3

L3

L2

L1

1

2

N

F1

Power supply

3N~

380/400/415V(50Hz)

400/415V(60Hz)

LED display(power supply)

PE

TB2

L5

345

6

Switch(normal/local)

SW9

No1.Failure output

Distant location on/off

<no voltage or current>

No1.Status output

Distant location on/off

<with voltage and current>

No2.Status output

No2.Failure output

Power supply DC30V, AC100/200V

Power supply DC12~24V

LED display(No.2 failure)

DC24~30V

No.2 Indoor unit

Control wiring

LED display(check)

L4

L2

L

L

L

L

54321

S

A2

B2

B2B1BCA2A1

AC

54321

C

IFB

CN54

TB22

CN53

TB21

TB23

SHIELD

TB5-2

3

4

X11

1

2

PE

X12

<note2>

CN3A1CN2M

123

CN32

213

2

123

1

I.B.2

54321

CN52

54321

CN51

Dehumidify

ZNR901

F901

ZNR1

DSA1

X01

X07

X04X05X06

CNP CN33

CN90

CND

CNT

CN3T

12

CN22 CN21CN20

1122

CN29

12321

CN31

12

CN28

531

CN60

1234563113 731 51139

Z2

<note2>

33P2

T

Z3

CN25CN24

12 CN7V

1234567

21

X12

SW5

SWC

SW12

(2nd digit)

SW11

(1st digit)

SW8

Address

(odd)

SW3 SW1SW2SW7SW4

SW14

0

F

E

D

C

B

A

9

0

9

8

7

6

5

4

3

2

1

9

1

2

3

4

5

6

7

8

0

8

7

6

5

4

3

2

1

No.2

FAN

over current

detection

51F

Z1

ZNR2

Z2

52F

Z3

TH24-2

TH21-2

TH22-2

TH23-2

51F

52F

MF

NAME

SYMBOL

Surge absorber

DSA1

L5

ZNR1, ZNR2, ZNR901

LED display (No.2 failure)

LED display (status)

LED display (check)

LED display (power supply)

MA Remote controller

RC

TB21

TB15

TB5-1, -2

TB2

IFB

S.B.

AD.B.

I.B.1, I.B.2

MF

Surge absorber board

Switch (outlet/inlet temp.control)

Float switch

Varistor

Transformer

Electronic linear expan.valve

Contactor(fan I/D)

Over current relay (fan I/D)

Thermistor (inlet temp.detection)

Switch (connection No.set)

Switch (for mode selection)

Switch (for capacity code)

Switch (for mode selection)

Switch (for model selection)

Auxiliary relay(check)

LED display (No.1 failure)

Switch (normal/local)

TH24-1, TH24-2

SW1(I.B.)

SW2(I.B.)

SW3(I.B.)

SW4(I.B.)

SW11(I.B.)

SW12(I.B.)

SW14(I.B.)

SWC(I.B.)

X11, X12

Z1, Z2Z3L1L2L3

L4

SW9

TH23-1, TH23-2

TH22-1, TH22-2

TH21-1, TH21-2

33P1, 33P2

51F

52F

LEV1, 2

T

F1

F901

TB23

TB22

Switch (1st digit address set)

Switch (2nd digit address set)

Fan motor

Indoor controller board

Adapter board

Power source terminal bed

Transmission terminal bed

External input/output board

Transmission terminal bed

Terminal bed for distant location on/off

<With voltage and current>

Terminal bed for distant location on/off

<No voltage or current>

Auxiliary relay(fan failure detection)

Auxiliary relay(fan)

Thermistor (piping temp.detection/gas)

Thermistor (piping temp.detection/liquid)

Thermistor (outlet temp.detection)

Terminal bed for distant location display

Fuse <6.3/6A>

Fuse <5A>

(field supply

and construction)

Power

SW

Indoor unit

control board

Z

1(brown)

5(green)

CN52

The signal input of the dehumidify order is to

connect wiring referring to the bottom figure.

Relay circuit

External input adapter

(PAC-SA88HA)

SW:Defumidify order

Z:Relay (Contact : Minimum applicable load

DC12V 1mA or less)

Distant control panel

Z

How to connect in case of 2 refrigerant circuit.

Remove the LEV1B connector

from AD.B. board, and

connect it to CN60 of

I.B.2 board.

Connect a connector to

CN3A, CN2M of I.B.2

board.

<note2>

65432

1

CN60

654321

CN3A

CN2M

I.B. 2

12321

LEV2

<note2>

How to set up to SW2, 3, 4.

(In case of 2 refrigerant circuit)

PFD-P500VM-E

(at the time of shipping)

ON

654321

ON

65432110987

ON

54321

ON

5432110987

ON

654321

ON

654321

2 refrigerant

circuit

1 refrigerant

circuit

SW2 SW3 SW4

External input-output

board (IFB)

The case of with-voltage input

...

A

The case of no-voltage input

....

B

When using the external input function on the indoor unit

that is connected to a two-refrigerant circuit, connect the

short-circuit plate that is supplied with the unit to the

appropriate terminals on the external input-output board.

ACA1A2BCB1

B2

A

B

TB23

TB21

Page 21

18

6. Refrigerant Circuit Diagram And Thermal Sensor

PU(H)Y-P250YGM-A

21S4a

21S4b

COMP

O/S

CJ1

CJ2

63HS

63LS

63H

SV1

HEX F HEX B

SV5b

TH8

TH11

TH5

TH6

TH7

CP2 ST8

LEV1

SCC

ST4

ST3

CP1

Drier

ST7

ST6

ACC

BV1

BV2

ST1

ST2

TH23

TH22

Page 22

19

PUHY-P500YGM-A

21S4a21S4c21S4b

TH6

CP2

CP1

TH11

TH12

COMP

2

Oil

Tank

COMP

1

O/S O/S

CJ3

CJ1

63H2

63H1

63HS

ST7

ST6

ST5

SV1

SV3

CV1 CV2

HEX2b

(B)

HEX1b

(F)

TH5

TH8

SCC

CP3

TH7

ST9

Drier

LEV1 ST8

SV5c

SV5b

HEX2a

(B)

HEX1a

(F)

ST2

ST13 ST12 ST11 ST10

CJ2

63LS

BV2

ACC

BV1

ST1

TH23-1

TH22-1

TH23-2

TH22-2

Page 23

20

7. System Design

7-1.Refrigerant Piping System

■ Sample connection

■ Pipe selection

■ Amount of refrigerant charge

Refrigerant for extension piping is not included at factory shipment. Add an appropriate amount of refrigerant for each

system on site. Write down the size and the length of the piping in each system as well as the amount of added

refrigerant on the outdoor unit as a reference for servicing.

■ Calculating the amount of refrigerant to be added

• The amount of refrigerant that is necessary for extension piping is calculated based on the size and the length of the

liquid piping.

• Use the following formula to figure out the amount of refrigerant to be added.

• Round up the calculation result to the nearest 0.1 kg. (e.g., If the result is 16.08 kg, round up the .08 to .1 , which

yields 16.1 kg.)

Caution

Charge Liquid Refrigerant

Filling the equipment with gas refrigerant will result in a power loss due to transformation of refrigerant in the tank.

500 model indoor unit :

When ø 15.88 pipes are used and the piping length is 150 m

150(m) x 0.2(kg/m)+4.0kg=34.0kg

✻ Refrigerant charge

calculation

✻ Amount of charged

refrigerant at factory shipment

✻Sample calculation

Outdoor unit

model

Charged

refrigerant

amount(

kg)

9.5P250

22.0P500

Outdoor unit

L

L

H

A

Outdoor unit

L

H

A

Indoor unit Indoor unit

Liquid pipe size

Total length of the

ø 15.88 pipes x 0.2

Liquid pipe size

Total length of the

ø 9.52 pipes x 0.06

(m) x 0.2(kg/m)

+

(m) x 0.06(kg/m)

+

Total capacity of

connected indoor units

Amount for the indoor unit

P250 model

2.0kg

✻ 2 kg x 2 when connected to a

system with two outdoor units

P500 model

4.0kg

<Connection to a system with one outdoor unit>

500 model indoor unit : When ø 9.52 pipes are used and the piping length is 80 m

80(m) x 0.06(kg/m)+2.0kg=6.8kg

(Amount for the extension pipe to each outdoor unit)

<Connection to a system with two outdoor unit>

Farthest piping length(L)

Height difference between indoor

and outdoor units (H)

50 m or less (40 m if outdoor unit is below indoor unit,

15 m if outside temperature is 10

˚C or below)

150 m or less in actual length

Allowable piping

length

Allowable height

difference

<Refrigerant system with one outdoor unit>

<Amount of refrigerant to be added>

<Refrigerant system with two outdoor units>

Outdoor unit model

Liquid pipe size Gas pipe size

P250

P500

✻1 Use ø 12.7 pipes when the pipe

length exceeds 90 m.

ø 9.52 ✻1

ø 15.88

ø 22.2

ø 28.58

Page 24

21

7-2.Control Wiring

Restrictions when the PFD-type indoor units are connected (related to the system)

(1) Specifications of control wiring and maximum length of wiring

Transmission line is a type of control line.When the source of noise is located adjacent to the unit, the use

of shield cable as well as moving the unit as far away from the noise source are recommended.

1 Transmission line (M-NET transmission line)

For multiple-refrigerant system

Length of transmission line

Facility type

(noise level measurement)

No. of cable 2-core cable

Diameter Over 1.25mm

2

Wiring specifications

All types of facilities

n/a

Shield cable

CVVS · CPEVS · MVVS

System component

Maximum length: 200m

Maximum length of centralized control transmission line and Indoor/Outdoor

transmission line via indoor/outdoor units: 500m maximum

Total length of indoor/outdoor transmission line

Cable type

(1) It is necessary to rewrite the S/W on the control circuit board of the outdoor unit connected to the

PFD-type indoor units to the dedicated S/W.

If the S/W is rewritten incorrectly, the PFD-type indoor units do not work properly.

· When it is necessary to replace the control circuit board at servicing, the control circuit board

must be replaced with the dedicated control circuit board.

(2) The outdoor units on which the S/W is rewritten to the dedicated S/W cannot be connected to the

indoor units other than the PFD-type indoor units.

(3) The PFD-type indoor units cannot be connected to the ME remote controller.

(4) The address settings must be made on this system.

(5) The following functions cannot be selected on the PFD-type indoor units.

1) Switching between automatic power recovery Enabled/Disabled (Fixed to "Enabled" in the PFDtype indoor units)

2) Switching between power source start/stop (Fixed to "Disabled" in the PFD-type indoor units)

(6) The PFD-type indoor units and other types of indoor units cannot be grouped.

(7) The following functions are limited when the system controller (such as G-50A) is connected.

1) To perform group operation in the system with two refrigerant circuits (combination of two outdoor units and one indoor unit: P500 model only), the addresses of the controller boards No.1

and No.2 on a indoor unit must be set within a group.

2) The local operation cannot be prohibited with the system controller.

3) When the switches of the PFD-type indoor units are set as follows, the unit ON/OFF operation

cannot be made with the system controller.

· When the Normal/Local switching switch is set to "Local"

· When the DipSW1-10 on the control circuit board is set to "ON"

4) The PFD type indoor units cannot be grouped with other types of indoor units.

Page 25

22

(1) Address setting

7-3.Types of switch settings and setting methods

Whether a particular system requires switch settings depends on its components. Refer to the section

“7-4 Sample System Connection” before conducting electrical work.

Keep the power turned off while setting the switches. If settings are changed while being powered, the

changed settings will not register, and the unit may malfunction.

Symbol

Outdoor unit OC

Indoor unit

✻ 10HP has only the main controller

Main/sub controllers ✻ IC

Turn off the power to

Outdoor unit

Indoor and outdoor units

Unit

2 Remote control wiring

MA remote controller ✻ 1

No. of cable 2-core cable

Diameter

0.3

~1.25mm

2

(0.75~1.25mm2)

✻ 2

✻ 3

Wiring specifications

VCTF · VCTFK · CVV · CVS · VVR · VVF · VCT

Maximum length: 200 m

Total Length

✻ 1: “MA remote controller” includes MA remote controller, Simple MA controller, and wireless remote controller.

✻ 2: Cables with a diameter of 0.75mm2 or smaller recommended for easier handling.

✻ 3: When connecting to Simple MA controller terminal, use a cable with a diameter within the range shown in

the parenthesis.

Cable type

The need for address settings and the range of address setting depend on the configuration of the system. Refer to “Sample System Connection”.

Symbol

Unit or controller

Main

· SubIndoor unit

MA remote controller

Address

setting range

IC

01~50

(Note 1)

Address setting method

Factory setting

No address setting required.

00

00

MA

Outdoor unit OC

Main

51~100

Model

In case of 10HP system or 20 HP system with one

refrigerant circuit, assign an odd number starting with "01

".

In case of 20HP system with two refrigerant circuits, assign

a sequential odd number starting with "01" to the upper

indoor controller, and assign "the address of the upper

indoor controller + 1" to the lower indoor controller.

(For the system with one refrigerant circuit, the lower circuit

board is not used.)

Add 50 to the address assigned to the indoor unit connected

the system with one outdoor unit.

(The main/sub switch must be configured if

two remote controllers are connected to the

system or if the indoor units are connected

to different outdoor units.)

(Note1) If a given address overlaps any of the addresses that are assigned to other outdoor units, use a different, unused address

within the setting range.

Page 26

23

(5)

Connection of two refrigerant circuits

When two refrigerant circuits are connected on site, make the switch settings on the controller circuit

board following the instructions described in the installation manual for the indoor unit.

(4) Setting the MA “Sub” controller

When using two remote controllers or running two indoor units as a group, one of the controllers must be

set to “Sub” controller.

✻ No more than two remote controllers can be connected to a group.

(Factory setting:“Main”)

Set the controller according to the following procedure.Refer also to the instructions manual supplied with

the MA remote controller.

Remote controller bodyDip switches

1ON234

Screwdriver

Remove the cover on the remote controller

Set Dip Switch No.1 on the remote

controller to “OFF” (Main to Sub)

Insert a flat-head screwdriver in the

groove shown in the picture, and

move the screwdriver in the direction

shown in the arrow.

(3)

Choosing the temperature detection spot by indoor unit (Factory Setting: SWC “Standard”)

When using the suction temperature sensor, set SWC to “Option.”

(The discharge temperature sensor is supplied as standard specification.)

(2)

Power supply switch connector connection on the outdoor unit

(Factory setting:The male power supply switch connector is connected to CN41.)

System

configuration

Power supply switch connector connection

Not connected

Not grouped

Grouped

Required

Grouped

/Not grouped

Grouped

/Not grouped

Grouped

/Not grouped

Not required

Leave the male connector on CN41 as it is.

(Factory setting)

Leave the male connector on CN41 as it is.

(Factory setting)

System in which indoor

units connected to one

outdoor unit

Connection to

the system

controller

With connection

to indoor-outdoor

transmission line

With connection

to transmission

line for centralized

control

Power supply unit

for transmission

lines

Not required

(Powered from

the outdoor unit)

Grouping the indoor

units connected to

different outdoor

units

System in which indoor

units connected to

multiple outdoor units

Disconnect the male connector from the female

power supply switch connector (CN41) and connect

it to the female power supply switch connector

(CN40) on only one of the outdoor units (OC).

*Connect the S (shielded) terminal on the terminal

block (TB7) on the outdoor unit whose male

connector on CN41 was disconnected and

connected to CN40 to the earth terminal ( ) on

the control box.

✻ When the system controller is connected to the indoor/outdoor transmission line and the power is supplied from the outdoor unit,

do not to turn off the outdoor unit. If its power supply is cut, the power is not supplied to the system controller, and the functions

will not work.

Page 27

7-4.Sample System Connection

24

(1) An example of a system to which an MA remote controller is connected

Control Wiring Diagram

Notes

Maximum Allowable Length

Wiring and Address Setting

OC

TB3

TB7

M1 M2 M1 M2

S

51

IC

TB5-1

A1B1S

01

TB5-2

A2 B2

S

02

AB

TB15

1

2

MA

NO

L1

Leave the male connector

on CN41 as it is.

1.

Leave the male connector on the female power supply switch connector (CN41) as it is.

2. Grounding to S terminal on the terminal block for transmission line for centralized

control (TB7) is not required.

3. Although two indoor controllers (controller circuit boards) are equipped inside the

indoor unit (20HP), the board on No.2 side (lower side) is not used. Do not connect

wiring to the lower controller circuit board.

4. The outdoor unit cannot be connected to the units other than the PFD series indoor

units.

<a. Indoor/Outdoor transmission line>

Connect M1, M2 terminals of the indoor/outdoor transmission line terminal block (TB3) on the outdoor unit (OC) and A1, B1 terminals of the

indoor/outdoor terminal block (TB5-1) on the indoor unit (IC). (Non-polarized 2-core cable) *Only use shielded cables.

[Shielded cable connection]

Connect the earth terminal of the OC and S terminal of the IC terminal block (TB5-1).

<b. Switch setting>

Address setting is required as follows.

Main Controller

Sub Controller

Settings to be made with the sub/main switch

IC

IC

OC

1

2

Notes

3

MA

MA

51~100

01

~50

01

~50

00

00

Setting not required.

Sub Controller

✻ One indoor controller (controller circuit board)

is equipped in the indoor unit (10HP), and two

indoor controllers (controller circuit boards)

are equipped in the indoor unit (20HP).

<a. Indoor/Outdoor transmission line>

Maximum Length (1.25mm

2

or more)

L1 200m

Steps

Unit or controller

Main

Sub

Indoor

unit

MA

remote

controller

Address

setting range

Address setting method

Outdoor unit

Factory

setting

Main

Assign a sequential odd number starting with

"01" to the upper indoor controller.

Add 50 to the address assigned to the indoor unit

connected to the system with one outdoor unit.

Assign sequential numbers starting with the

address of the main unit in the same group.

(Main unit address +1)

1 System connected to one outdoor unit

Page 28

25

Control Wiring Diagram

Notes

Maximum Allowable Length

Wiring and Address Setting

NO

NO

Leave the male connector

on CN41 as it is.

1. Assign a sequential number to the outdoor unit.

2. Do not connect the terminal blocks (TB5) of the indoor units connected to different

outdoor units.

3. Disconnect the male connector on the controller board from the female power supply

switch connector (CN41), and connect it to the female power supply switch connector

(CN40) on only one of the outdoor units.

4. Provide grounding to S terminal on the terminal block for transmission line for

centralized control (TB7) on only one of the outdoor units.

5. When the power supply unit is connected to the transmission line for centralized

control, leave the male connector on the female power supply switch connector

(CN41) as it is at factory shipment.

6.

The outdoor unit cannot be connected to the units other than the PFD series indoor units.

<a. Indoor/Outdoor transmission line>

Connect M1, M2 terminals of the indoor/outdoor transmission line terminal block (TB3) on the outdoor unit (OC) and A1, B1 terminals of the

indoor/outdoor terminal block (TB5-1) on the indoor unit (IC). (Non-polarized 2-core cable) *Only use shielded cables.

[Shielded cable connection]

Connect the earth terminal of the OC and S terminal of the IC terminal block (TB5-1).

<b. Transmission line for centralized control>

Daisy-chain terminals M1 and M2 on the terminal block for transmission line for centralized control (TB7) on each outdoor unit (OC).

Disconnect the male connector on the controller board from the female power supply switch connector (CN41), and connect it to the female power

supply switch connector (CN40) on only one of the outdoor units. *Only use shielded cables.

[Shielded cable connection]

To ground the shielded cable, daisy-chain the S-terminals on the terminal block (TB7) on each of the outdoor

units. Connect the S (shielded) terminal on the terminal block (TB7) on the outdoor unit whose male connector

on CN41 was disconnected and connected to CN40 to the earth terminal ( ) on the electric box.

<c. Switch setting>

Address setting is required as follows.

Main Controller

Sub Controller

Settings to be made with the sub/main switch

IC

IC

OC

1

2

Notes

3

MA

MA

51~100

01

~50

01

~50

00

00

Setting not required.

Sub Controller

✻ One indoor controller (controller circuit board)

is equipped in the indoor unit (10HP), and two

indoor controllers (controller circuit boards)

are equipped in the indoor unit (20HP).

<a. Indoor/Outdoor transmission line>

Maximum Length (1.25mm

2

or more)

L1, L2 200m

<b. Transmission line for centralized control>

Maximum Length via outdoor unit (1.25mm2 or more)

L1 + L31 + L2 500m

Steps

Unit or controller

Main

Sub

Indoor

unit

MA

remote

controller

Address

setting range

Address setting method

Outdoor unit

Factory

setting

Main

Assign a sequential odd number starting with

"01" to the upper indoor controller.

Add 50 to the address assigned to the indoor unit

connected to the system with one outdoor unit.

Assign sequential numbers starting with the

address of the main unit in the same group.

(Main unit address +1)

OC

TB3

TB7

M1M2

M1M2

S

51

IC

TB5-1

A1 B1

S

01

TB5-2

A2B2

S

02

OC

TB3

TB7

M1M2

M1M2

S

52

AB

TB15

1

2

MA

L31

L1

L2

Connection

Disconnect the male power supply

connector from CN40 and connect

it to CN41.

(1) An example of a system to which an MA remote controller is connected

2 System connected to two outdoor units

Page 29

26