Page 1

Run / Standby Panel

PANEL_RS2

FOR INSTALLERS

INSTALLATION MANUAL

Version 1.02

For safe and correct use, please read this installation manual thoroughly before installing the PANEL_RS2.

Page 1 of 25

MITSUBISHI ELECTRIC

Page 2

1

[Fig. 1]

A

B

A 3 x PAC-SA89TA

B 3 x PAC-SF40RM

Page 2 of 25

Page 3

2

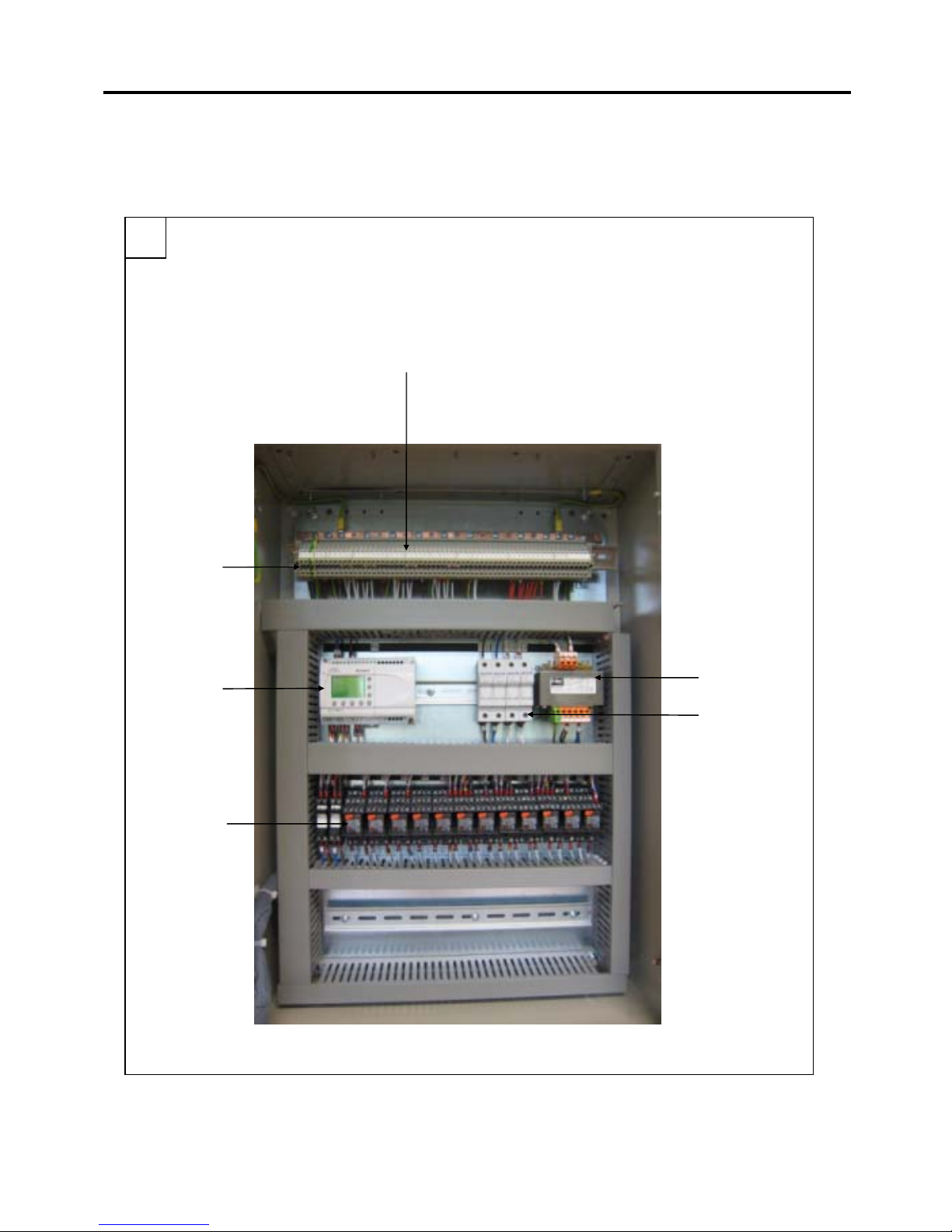

[Fig. 2]

B

C

A Input / output terminal

B 240VAC terminal

C Time clock

A

D Relays

E Control fuses

F Transformer

F

E

D

Page 3 of 25

Page 4

3

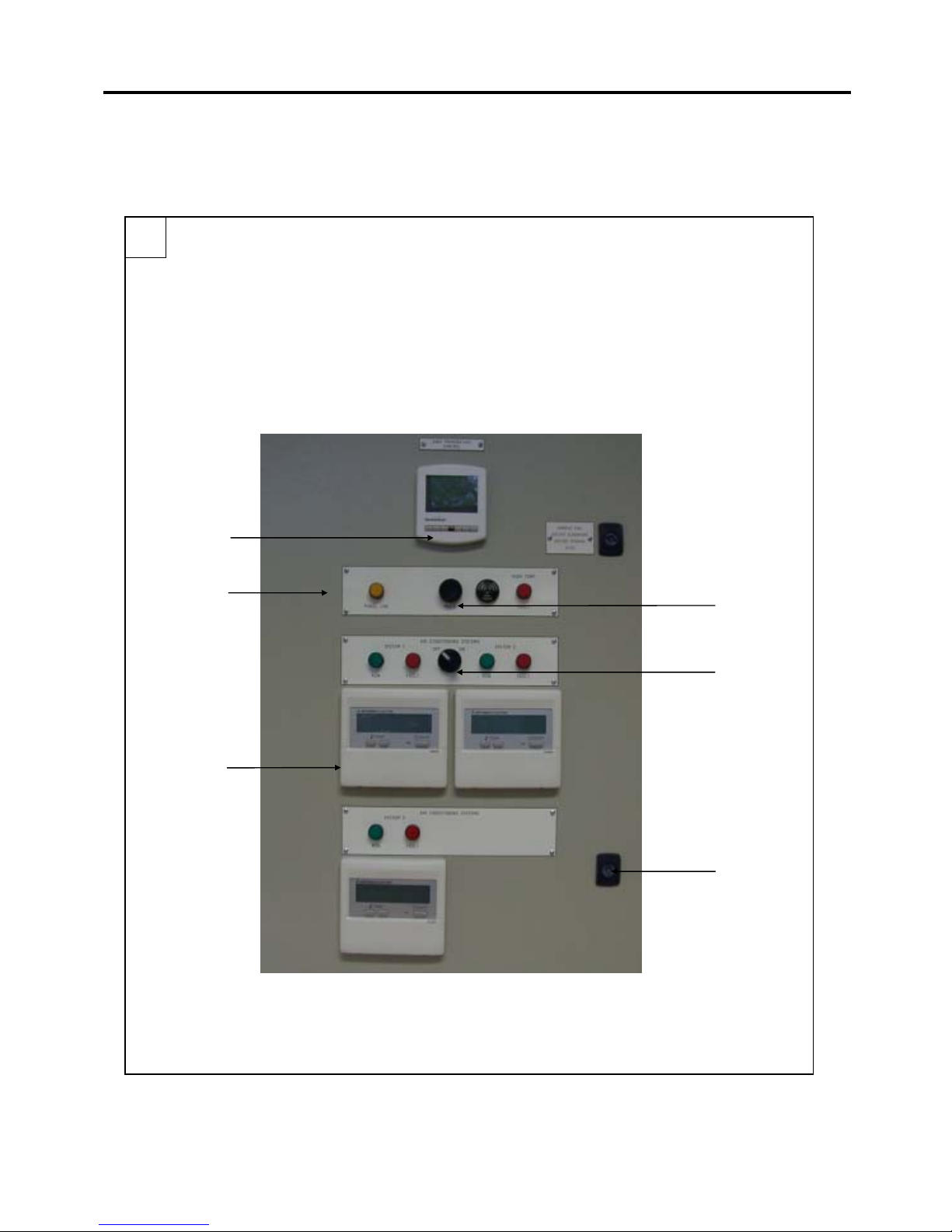

A Thermostat

[Fig. 3]

B Lamp status

C Remote controllers

D Door lock

Air conditioning On/Off

E

F Buzzer switch

switch

B

C

A

F

E

D

Page 4 of 25

Page 5

4

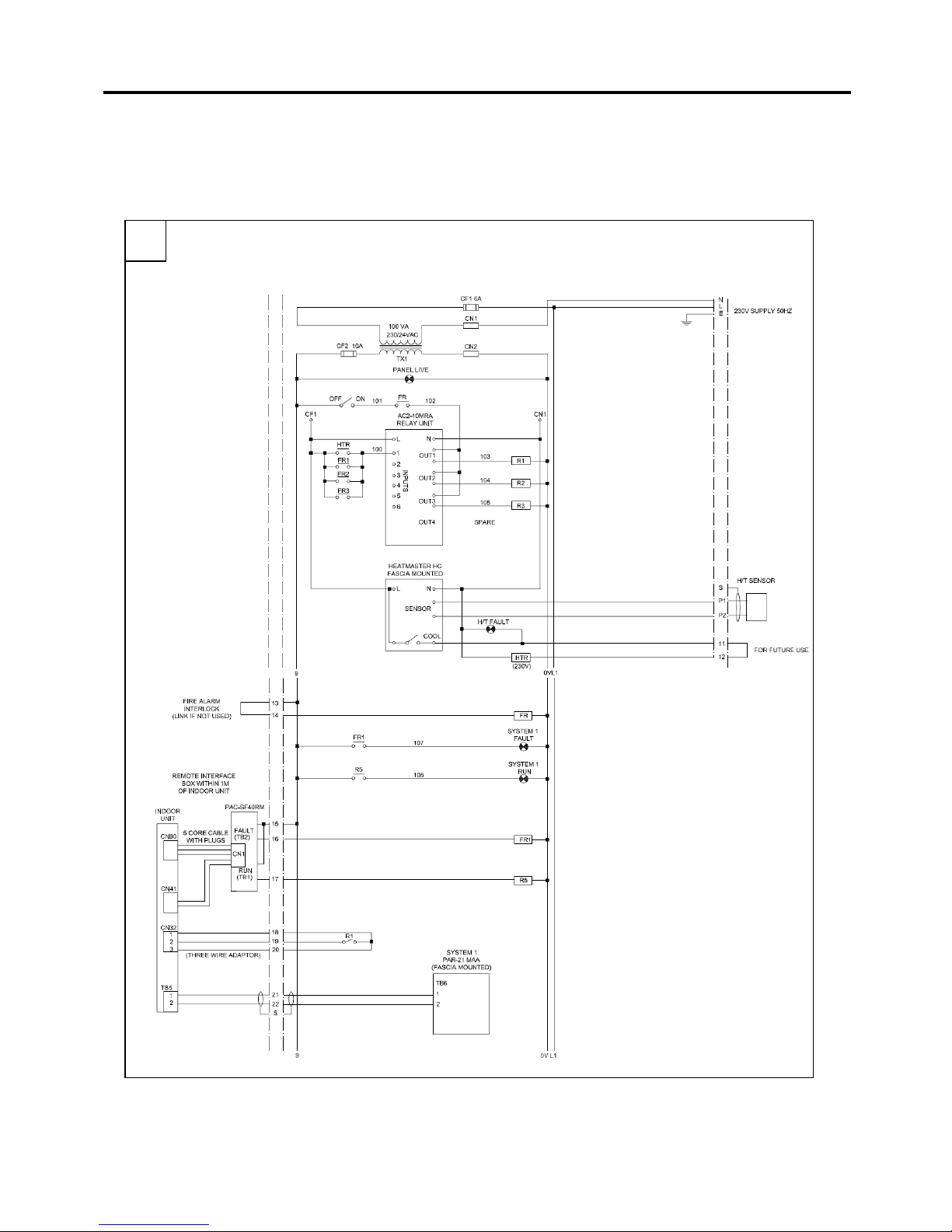

[Fig. 4]

Page 5 of 25

Page 6

5

[Fig. 5]

Page 6 of 25

Page 7

5

[Fig. 5]

Page 7 of 25

Page 8

Contents

1.

Safety precautions ....................................................................................................................................................9

2.

Overview ..................................................................................................................................................................10

3.

Panel size and weight .............................................................................................................................................11

4.

Selecting an installation site..................................................................................................................................12

5.

Installation ...............................................................................................................................................................13

5.1.

System diagram 1 – Connected to Mr Slim units .......................................................................................... 13

5.2. System diagram 2 – Connected to City Multi PFD units................................................................................ 14

6.

Electrical wiring.......................................................................................................................................................15

6.1.

Precautions on electrical wiring...................................................................................................................... 15

6.2. Types of control cables .................................................................................................................................. 15

6.3. Connecting wiring ........................................................................................................................................... 15

6.3.1. Power supply wiring................................................................................................................................... 15

6.3.2. Connecting PAC-SA89TA ......................................................................................................................... 15

6.3.3. Connecting PAC-SF40RM (for Mr Slim) ................................................................................................... 15

6.3.4. Connecting optional PAR-21MAA ............................................................................................................. 15

7.

Applicable Air Conditioning models.....................................................................................................................16

8.

Important notes .......................................................................................................................................................17

9.

Additional information............................................................................................................................................18

9.1. Heatmiser thermostat ..................................................................................................................................... 18

9.1.1. Overview.................................................................................................................................................... 18

9.1.2. Wiring diagram .......................................................................................................................................... 18

9.1.3. Technical Details ....................................................................................................................................... 18

9.2. Inlec transformer............................................................................................................................................. 19

9.2.1. Overview.................................................................................................................................................... 19

9.3. Mitsubishi Electric AL2-14MR-A alpha controller .......................................................................................... 20

9.3.1. Overview.................................................................................................................................................... 20

9.3.2. Setup.......................................................................................................................................................... 20

9.4. Mitsubishi Electric PAR-21MAA remote controller ........................................................................................ 21

9.4.1. Overview.................................................................................................................................................... 21

9.4.2. Lock the buttons ........................................................................................................................................ 22

9.4.3. Error codes ................................................................................................................................................ 23

Page 8 of 25

Page 9

g

1. Safety precautions

¾ Before installing the unit, make sure you read all the

“Safety precautions”

¾ The “Safety precautions” provide very important points

re

arding safety. Make sure you follow them

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Warning:

Carefully read the labels affixed to the main unit

Warning:

• Ask the dealer or an authorised technician to install the unit

- Improper installation by the user may result in water leakage, electric shock, or fire

• Use the specified cables for wiring. Make the connections securely so that any outside forces acting on the cables are

not applied to the terminals

- Inadequate connection and fastening may generate heat and cause a fire

• Never repair the unit. If the controller must be repaired, consult the dealer

- If the unit is repaired improperly, electric shock, or fire may result

• When handling this product, always wear protective equipment. EG: Gloves, full arm protection and safety glasses

- Improper handling may result in injury

• Have all electric work done by a licensed electrician according to "Electric Facility Engineering Standard", "Interior Wire

Regulations" and the instructions given in this manual and always use a special circuit

- If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result

• Keep the electric parts away from any water - washing water etc…

- Contact may result in electric shock, fire or smoke

• Do not reconstruct or change the settings of the protection devices

- If the protection device is shorted or operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or

explosion may result

• To dispose of this product, consult your dealer

Caution:

• Ground the unit

- Do not connect the ground wire to gas or water pipes, lightning rods, or telephone ground lines. Improper grounding may result

in electric shock

• Install the power cable so that tension is not applied to the cable

- Tension may cause the cable to break and generate heat which may, in turn, cause fire

• Install a leak circuit breaker, as required

- If a leak circuit breaker is not installed, electric shock may result

• Use power line cables of sufficient current carrying capacity and rating

- Cables that are too small may leak, generate heat, and cause a fire

• Use only a circuit breaker and fuse of the specified capacity

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may result in a general unit failure or fire

• Be careful that the installation base is not damaged

- If the damage is left uncorrected, the unit may fall and cause personal injury or property damage

• Be very careful regarding product transportation

- Two people should be used to carry products of 20kg or more

- Some products use PP bands for packaging. Do not use any PP bands for a means of transportation

• Safely dispose of the packing materials

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries

- Tear apart and throw away plastic packaging bags so that children will not play with them - If children play with a plastic bag

which has not been torn apart, they face the risk of suffocation

Page 9 of 25

Page 10

2. Overview

The run/standby panel is used to automatically change over three Air Conditioning indoor units.

The panel will be fed with a 240VAC power supply.

The panel is fitted with a day time controller switch with battery back-up and latching relay to permit two indoor units to

run for instance 7 days, after this the panel will automatically change over to the next indoor unit for 7 days etc.

The panel is designed that if one indoor unit goes to fault while running it would automatically bring in the backup

indoor unit.

The high temperature thermostat option will allow the three indoor units to run together if a high temperature exists. A

high temperature warning lamp will indicate.

The sounder & mute option will allow any fault condition received by the control panel (i.e. unit fault, or high

temperature) to initiate a sounder on the panel door. A mute button is fitted to silence the sounder.

Volt free terminals are fitted to allow fault signals to be transmitted to any external monitoring system.

The panel is supplied with accessories to interface with the Air Conditioning indoor unit:

- 3 wire adaptor to control the On/Off

- PAC-SF40RM to monitor Run and Faults with Mr Slim indoor units

Figure 1 shows the accessories supplied with the panel.

Figure 2 shows the inside of the panel.

Figure 3 shows the front panel.

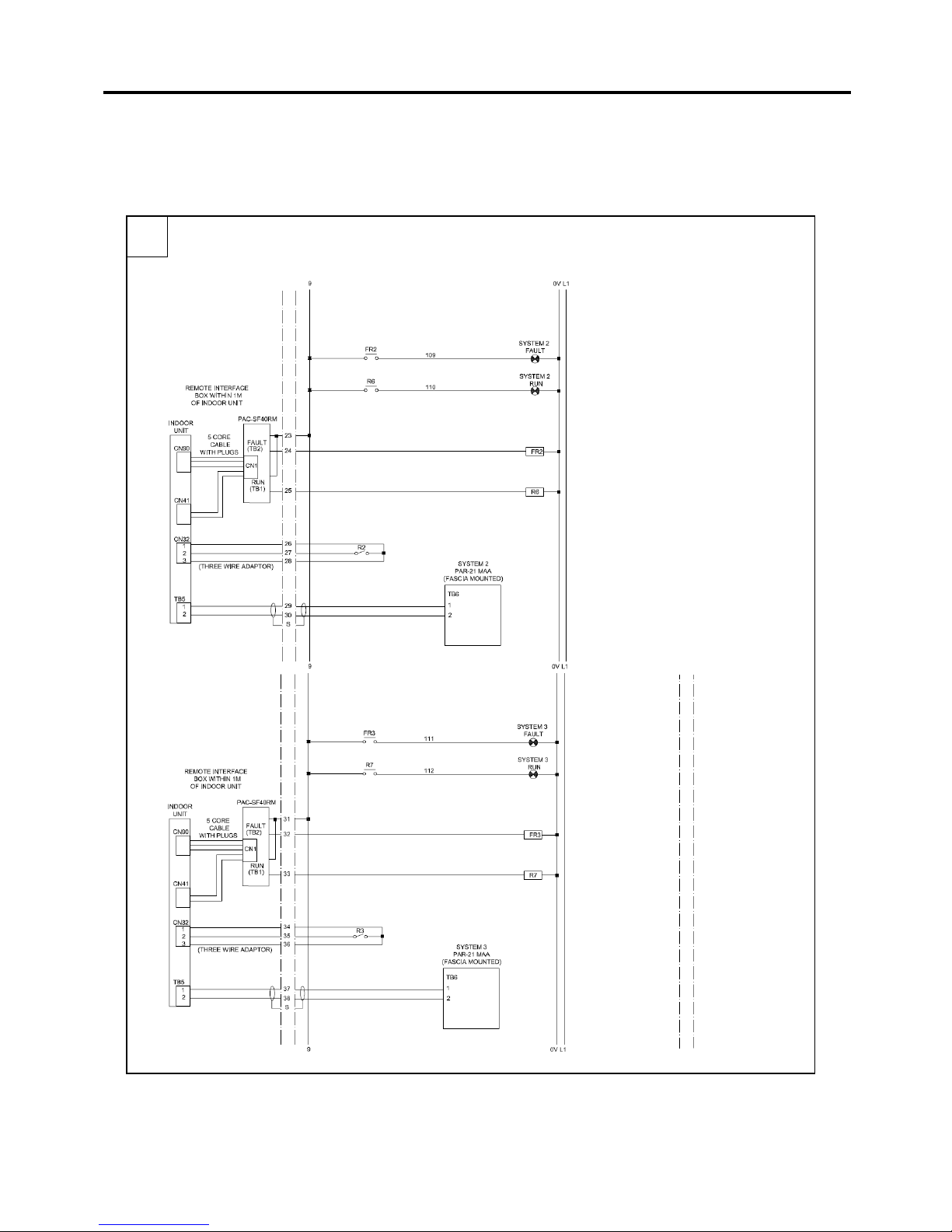

Figure 4 shows the wiring diagram of the panel.

Page 10 of 25

Page 11

3. Panel size and weight

The panel details are:

- Height 700mm

- Width 500mm

- Depth 210mm

- Weight 30Kg

Page 11 of 25

Page 12

4. Selecting an installation site

- Avoid locations in direct sunlight

- Avoid locations exposed to steam or oil vapour

- Avoid locations where combustible gas may leak, settle or be generated

- Avoid installation near machines emitting high-frequency waves

- Avoid places where acidic solutions are frequently handled

- Avoid places where sulphur-based or other sprays are frequently used

- Avoid areas of high humidity (when cooling operation is required)

- Install inside the building

- Install near the indoor units monitored and controlled

Page 12 of 25

Page 13

A

A

5. Installation

5.1. System diagram 1 – Connected to Mr Slim units

Three Mr Slim indoor units can be connected to the PANEL_RS2 via three PAC-SF40RM and three PAC-SA89TA.

POWER

SUPPLY

240VAC

HIGH

TEMP.

SENSOR

FIRE

ALARM

INPUT

Normally

Closed

SYSTEM 1

CN90 CN4 1

CN1

PAC-SF40RM

TB2

TB2

TB1

INDOOR

MR SLIM

CN32

1 2 3

TB1

PAR-21MAA

Connection

(Option)

UNIT PCB

SYSTEM 2

CN90 CN41

CN1

PAC-SF40RM

TB2

TB2

TB1

MR SLIM

TB1

INDOOR

UNIT PCB

CN32

1 2 3

PAR-21MA

Connection

(Option)

SYSTEM 3

CN90 CN41

CN1

PAC-SF40RM

TB2

TB2

TB1

MR SLIM

TB1

INDOOR

UNIT PCB

CN32

1 2 3

PAR-21MA

Connection

(Option)

HIGH TEMP. OUTPUT Normally Opened

SYSTEM 1 FAULT OUTPUT Normally Opened

SYSTEM 3 FAULT OUTPUT Normally Opened

SYSTEM 2 FAULT OUTPUT Normally Opened

COMMON FAULT OUTPUT 240VAC

L

E

N

Page 13 of 25

11

12

13

14

15

16

17

P1

P2

SCR

18

19

20

21

22

23

24

25

26

27

28

29

SCR

30

RUN/STANDBY PANEL_RS2

SCR

47

48

49

50

51

31

32

33

34

35

36

37

38

SCR

52

58

53

54

57

Page 14

A

A

5.2. System diagram 2 – Connected to City Multi PFD units

Three City Multi PFD indoor units can be connected to the PANEL_RS2 via three PAC-SA89TA. The PAC-SF40RM

interfaces are not required.

POWER

SUPPLY

240VAC

L

N

HIGH

TEMP.

SENSOR

E

P1

P2

SCR

FIRE

ALARM

INPUT

Normally

Closed

11

12

13

SCR

INDOOR

SYSTEM 2

UNIT PCB

CITY MULTI PFD

TB22 2

TB22 1

TB22 C

23

CN32

1 2 3

PAR-21MA

Connection

(Option)

24

25

26

27

28

29

30

SCR

INDOOR

SYSTEM 3

UNIT PCB

CITY MULTI PFD

TB22 2

TB22 1

TB22 C

31

CN32

1 2 3

HIGH TEMP. OUTPUT Normally Opened

SYSTEM 3 FAULT OUTPUT Normally Opened

SYSTEM 1 FAULT OUTPUT Normally Opened

PAR-21MA

Connection

(Option)

32

33

34

35

36

37

38

SCR

SYSTEM 2 FAULT OUTPUT Normally Opened

47

48

49

50

51

COMMON FAULT OUTPUT 240VAC

COMMON FAULT OUTPUT 240VAC

52

53

54

58

57

INDOOR

SYSTEM 1

UNIT PCB

CITY MULTI PFD

TB22 2

TB22 1

TB22 C

14

15

CN32

1 2 3

PAR-21MAA

Connection

(Option)

16

17

18

19

20

21

22

Please note that DIP SWITCH SW1-9 and SW1-10 must be switched OFF to activate level input with CN32 instead of

pulse input.

Page 14 of 25

RUN/STANDBY PANEL_RS2

Page 15

6. Electrical wiring

6.1. Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers / electrician in accordance with "Engineering Standards for

Electrical Installation" and supplied installation manuals. Dedicated circuits should also be used. If the power circuit lacks

capacity or has an installation failure, it may cause a risk of electric shock or fire.

- Be sure to take power from the special branch circuit

- Be sure to install an earth leakage breaker to the power

- Install the unit to prevent any of the control circuit cables (MNET transmission cables) coming into direct contact with the power cable

outside the unit

- Ensure that there is no slack on all wire connections

- Never connect the power cable to leads for the transmission cables. This will damage the transmission cable

- Select control cables from the conditions given in “Type of control cables” section

6.2. Types of control cables

Wiring transmission cables

• Cable diameter: More than 1.25 mm

2

screened cable

6.3. Connecting wiring

6.3.1. Power supply wiring

Power supply cords of appliances shall not be lighter than design 245 IEC 57 or 227 IEC 57.

Caution:

Do not use anything other than the correct capacity breaker and fuse. Using fuse, wire or copper wire with too large capacity

may cause a risk of malfunction or fire.

6.3.2. Connecting PAC-SA89TA

Connect the PAC-SA89TA to the CN32 terminal on the indoor unit. The other end of the wire must be connected to the

panel (18, 19 and 20 for system 1, 26, 27 and 28 for system 2 and 34, 35 and 36 for system 3).

6.3.3. Connecting PAC-SF40RM (for Mr Slim)

Connect the PAC-SF40RM to the CN90 and CN41 terminals on the Mr Slim indoor unit. The TB1 and TB2 terminals

must be connected to the panel (15, 16 and 17 for system 1, 23, 24 and 25 for system 2 and 31, 32 and 33 for system

3).

6.3.4. Connecting optional PAR-21MAA

Connect the optional PAR-21MAA to the MA remote controller terminal on the indoor unit. The other end of the wire

must be connected to the panel (21 and 22 for system 1, 29 and 30 for system 2 and 37 and 38 for system 3). A CN22

connector is required for each wall mounted indoor unit.

Page 15 of 25

Page 16

7. Applicable Air Conditioning models

Below is a list of Air Conditioning models that can be connected to this panel:

- Mr Slim product range

- PFD City Multi VRF product range

Please note that:

- A CN22 connector is required for each wall mounted indoor unit

- The PAC-SF40RM is not required for the PFD units

Page 16 of 25

Page 17

8. Important notes

Please note that:

- If the internal fuse fails on the panel all systems stop

- If the internal fuse fails on the panel the volt free contacts for remote alarm does not operate

- If the panel is switched off all indoor units stop

- If the panel is switched off the volt free contacts for remote alarm does not operate

- When the panel is first energised all indoor units start together

- If the power of the indoor unit is switched off, the panel will not automatically change over

Page 17 of 25

Page 18

9. Additional information

9.1. Heatmiser thermostat

9.1.1. Overview

Set Temperature

This is the temperature the thermostat is currently controlling to. At any time, you can press the Up/Down arrow key

and the display will show the set Temperature for 30 seconds.

9.1.2. Wiring diagram

9.1.3. Technical Details

Large display

Automatic blue back-light (Turns off after 30 seconds)

Flush mounting

Self Learning Optimum Start (Heating Mode only)

°C / °F Selectable

Heating, Cooling and Automatic modes available

30 minute timing increments

5 day/2 day Program

(Weekday/Weekend programming)

Up to 4 changes in room temperature

Fan speed: Auto, High, Medium, Low

Heating Output, Cooling Output, Frost protection

Easily increase or decrease the required temperature

Temperature range 05°C - 35°C

Supply: 230v / 110v

Outputs: 230v / 110v

Page 18 of 25

Page 19

9.2. Inlec transformer

9.2.1. Overview

Page 19 of 25

Page 20

9.3. Mitsubishi Electric AL2-14MR-A alpha controller

9.3.1. Overview

9.3.2. Setup

The Alpha controller is used to switch other the systems every 7 days. The switch over timing (7) can be changed but

special programming software is required. Please contact your sales office for more details.

Page 20 of 25

Page 21

9.4. Mitsubishi Electric PAR-21MAA remote controller

9.4.1. Overview

Page 21 of 25

Page 22

9.4.2. Lock the buttons

Page 22 of 25

Page 23

9.4.3. Error codes

Control Error Codes (E)

Page 23 of 25

Page 24

A-Control Error Codes (F/P)

A-Control Error Codes (U)

Page 24 of 25

Page 25

This product is designed and intended for use in the residential, commercial and light-

industrial environment.

The product at hand is based on the following EU regulations:

• Low Voltage Directive 73/23/EEC

• Electromagnetic Compatibility Directive 89/336/EEC

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

MITSUBISHI ELECTRIC UK

MITSUBISHI ELECTRIC UK, TRAVELLERS LANE, HATFIELD HERTFORDAHIRE, AL10 8XB

Page 25 of 25

Loading...

Loading...