Page 1

SG79Y756H01

SPLIT-TYPE AIR CONDITIONERS

English

Models

MS-GA50VB

MSH-GA50VB

INSTALLATION MANUAL

[FLARE CONNECTION TYPE]

1. THE FOLLOWING SHOULD ALWAYS BE

OBSERVED FOR SAFETY

Be sure to read “THE FOLLOWING SHOULD ALWAYS BE OBSERVED FOR

•

SAFETY” before installing the air conditioner.

Be sure to observe the cautions specifi ed here as they include important items

•

related to safety.

The indications and meanings are as follows.

•

WARNING

Could lead to death, serious injury, etc.

CAUTION

Could lead to serious injury in particular environments when operated incorrectly.

After reading this manual, be sure to keep it together with the OPERATING

•

INSTRUCTIONS in a handy place on the customer’s site.

WARNING

Q Do not install the unit by yourself (customer).

Incomplete installation could cause injury due to fi re, electric shock, the unit

falling or leakage of water. Consult the dealer from whom you purchased the

unit or special installer.

Install the unit securely in a place which can bear the weight of the unit.

Q

When installed in an insuffi cient strong place, the unit could fall causing injury.

Q Use the specifi ed wires to connect the indoor and outdoor units securely

and attach the wires fi rmly to the terminal block connecting sections so

the stress of the wires is not applied to the sections.

Incomplete connecting and fi xing could cause fi re.

Q Do not use intermediate connection of the power cord or the extension

cord and do not connect many devices to one AC outlet.

It could cause a fi re or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

Q Check that the refrigerant gas do not leak after installation has

completed.

If refrigerant gas leaks indoors, and comes into contact with the fi re of a fan

heater, space heater, stove, etc., harmful substances will be generated.

Q Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fi re, electric shock,

the unit falling or leakage of water.

Q Perform electrical work according to the installation manual and be sure

to use an exclusive circuit.

If the capacity of the power circuit is insuffi cient or there is incomplete electrical

work, it could result in a fi re or an electric shock.

Q Attach the electrical cover to the indoor unit and the service panel to the

outdoor unit securely.

If the electrical cover in the indoor unit and/or the service panel in the outdoor

unit are not attached securely, it could result in a fi re or an electric shock due

to dust, water, etc.

Q Be sure to use the part provided or specifi ed parts for the installation

work.

The use of defective parts could cause an injury or leakage of water due to a

fi re, an electric shock, the unit falling, etc.

Q Be sure to cut off the main power in case of setting up the indoor electronic

control P.C. board or wiring works.

It could cause an electric shock.

Q The appliance shall be installed in accordance with national wiring

regulations.

Q When installing or relocating the unit, make sure that no substance other

than the specifi ed refrigerant (R410A) enters the refrigerant circuit.

Any presence of foreign substance such as air can cause abnormal pressure

rise or an explosion.

HFC

utilized

R410A

Series

When installing an MXZ series

outdoor unit, refer to the MS

and MSH type manual for

indoor unit set up.

Q Earth the unit.

Do not connect the earth to a gas pipe, water pipe, lightning rod or telephone

earth. Defective earthing could cause an electric shock.

Q Do not install the unit in a place where an infl ammable gas leaks.

If gas leak and accumulate in the area surrounding the unit, it could cause an

explosion.

Q Install an earth leakage breaker depending on the installation place (Where

it is humid).

If an earth leakage breaker is not installed, it could cause an electric shock.

Q Perform the drainage/piping work securely according to the installation

manual.

If there is a defect in the drainage/piping work, water could drop from the unit

and household goods could be wet and damaged.

Q Fasten a fl are nut with a torque wrench as specifi ed in this manual.

When fastened too tight, a fl are nut may broken after a long period and cause

a leakage of refrigerant.

IMPORTANT NOTES

TO COMPLY WITH THE REQUIREMENT

OF AUSTRALIAN STANDARD AS/NZS 3000

ELECTRICAL INSTALLATIONS (Wiring Rules),

THE ELECTRICAL WIRING REQUIRED

BETWEEN THE INDOOR AND OUTDOOR

UNITS MUST BE INSTALLED BY A LICENCED

ELECTRICAL CONTRACTOR.

CAUTION

2. SELECTING THE INSTALLATION LOCATION

2-1 INDOOR UNIT

Where airfl ow is not blocked.

•

Where cool air spreads over the entire room.

•

Maximum refrigerant piping length between indoor unit and outdoor unit is 25 m and

•

the difference of height of both units is 10 m.

Rigid wall without vibration.

•

Where it is not exposed to direct sunshine.

•

Where easily drained.

•

At a distance 1 m or more away from your TV and radio. Operation of the air conditioner

•

interferes with radio or TV reception in areas where reception is weak.

An amplifi er may be required for the affected device.

In a place as far away as possible from fl uorescent and incandescent lights (so the

•

infrared remote control can operate the air conditioner normally).

Where the air fi lter can be removed and replaced easily.

•

2-2 OUTDOOR UNIT

Where it is not exposed to strong wind.

•

Where airfl ow is good and dustless.

•

Where it is not exposed to rain and direct sunshine.

•

Where neighbours are not annoyed by operation sound or hot air.

•

Where rigid wall or support is available to prevent the increase of operation sound

•

or vibration.

Where there is no risk of combustible gas leakage.

•

When installing the unit at a high level, be sure to fi x the unit legs.

•

Where it is at least 3 m away from the antenna of TV set or radio. Operation of the

•

air conditioner interferes with radio or TV reception in areas where reception is weak.

An amplifi er may be required for the affected device.

Install the unit horizontally.

•

Please install it in an area not affected by snowfall or blowing snow. In areas with

•

heavy snow, please install a canopy, a pedestal and/or some baffl e boards.

Note:

It is advisable to make a piping loop near outdoor unit so as to reduce vibration

transmitted from there.

CAUTION

Avoid the following places for installation where air conditioner trouble is liable

to occur.

Where fl ammable gas could leak.

•

Where there is much machine oil.

•

Salty places such as the seaside.

•

Where sulfi de gas is generated such as a hot spring.

•

Where there is high-frequency or wireless equipment.

•

2-3 WIRELESS REMOTE CONTROLLER MOUNTING

Place of mounting

•

• Where it is easy to operate and easily visible.

• Where children can not touch.

Mounting

•

Select a position about 1.2 m above the fl oor, check that signals from the remote

controller are surely received by the indoor unit from that position (‘beep’ or

‘beepbeep’ receiving tone sounds). After that, attach remote controller holder 3 to

a pillar or wall and set the wireless remote controller 6.

In rooms where inverter type fl uorescent lamps are used, the signal from the wireless

remote controller may not be received.

Page 2

3.

INSTALLATION DIAGRAM & ACCESSORIES

FLARED CONNECTIONS

This unit has fl ared connections on both indoor and outdoor sides.

•

Remove the outdoor units valve cover, then connect the pipe.

•

Refrigerant pipes are used to connect the indoor and outdoor units.

•

Be careful not to crush or bend the pipe in pipe bending.

•

Limits

Pipe length 25 m max.

Height difference 10 m max.

No. of bends 10 max.

Refrigerant adjustment ... If pipe length exceeds 7 m, additional refrigerant

•

(R410A) charge is required.

(The outdoor unit is charged with refrigerant for pipe length up to 7 m.)

Up to 7 m No additional charge is required.

Pipe length

Refrigerant to

be added

Exceeding 7 m

20 g/m × (refrigerant piping length (m) -7)

ACCESSORIES

Check the following parts before installation.

<Indoor unit>

Installation plate 1

1

Installation plate fi xing screw 4 × 25 mm 7

2

Remote controller holder 1

3

4 Fixing screw for 3 3.5 × 16 mm (Black)

Battery (AAA) for remote controller 2

5

Wireless remote controller 1

6

Felt tape (Used for left or left-rear piping) 1

7

Air Cleaning fi lter 2

8

Additional charge is required.

(Refer to the table below.)

2

PIPING PREPARATION

1 Specifi cations

Use the refrigerant pipes that meet the following specifi cations.

Pipe

For liquid 6.35 8

For gas 12.7 8

• Use a copper pipe or a copper-alloy seamless pipe with a thickness of 0.8 mm.

Never use any pipe with a thickness less than 0.8 mm, as the pressure resistance

is insuffi cient.

2 Ensure that the 2 refrigerant pipes are insulated to prevent condensation.

3 Refrigerant pipe bending radius must be 100 mm or more.

Be sure to use the insulation of specifi ed thickness. Excessive thickness may

cause incorrect installation of the indoor unit and lack of thickness may cause dew

drippage.

1

2

0 mm

or more

72 mm or more

100 mm or more for left and left

back piping (using spacer)

Outside diameter Insulation thickness

mm mm

Insulation material

Heat resisting

foam plastic 0.045

specifi c gravity

CAUTION

Decide the installation position using mark on the installation

plate indicating the indoor unit size as reference.

Be careful the

drain hose is not

raised.

1

PART TO BE PROVIDED AT YOUR SITE

Optional extension pipe

Indoor/outdoor unit connecting wire

A

(2-core 1.0 mm

Extension pipe

B

Wall hole sleeve

C

Wall hole cover

D

Pipe fi xing band

E

(The quantity depends on the pipe length.)

Fixing screw for E 4 × 20 mm

F

(The quantity depends on the pipe length.)

Piping tape

G

Putty

H

Drain hose

I

(or soft PVC. hose, 15 mm inner dia.)

Refrigeration oil

J

Power supply cord (See the table in 5

INDOOR/OUTDOOR WIRE CONNECTION

K

AND OUTDOOR POWER SUPPLY CORD

CONNECTION for the cord size.)

mm

0

9

2

2

-2.0 mm2)

850mm

Air outlet

500mm

mm01

Slot

4-10 mm × 21 mm

Note:

When operating the air conditioner in low outside temperature,

be sure to follow the instructions described below.

Never install the outdoor unit in a place where its air inlet/outlet

•

side may be exposed directly to wind.

To prevent exposure to wind, install the outdoor unit with its

•

air inlet side facing the wall.

To prevent exposure to wind, it is recommended to install a

•

baffl e board on the air outlet side of the outdoor unit.

1

1

1

1

2 to 5

2 to 5

1

1

1

1

1

mm

8

1

mm013

mm81

8

5

1

00 mm or more

2

00 mm or m

5

6

4

ore

Note: Do not obstruct

the air outlet.

7 mm or more

3

00 mm or more

100 mm or more

1

7

200 mm or more

D

H

C

Piping can be directed towards rear,

right, downward, left or left-rear

directions.

Rear side

Right

Rear

Downward Left-rear

Lock the catch.

from the fl oor

1800 mm or more

Front

Left

B

G

Separate the 2 connecting pipes and

F

E

A

K

I

350 mm or more

apply insulation individually.

8 mm thickness thermal insulation

plastic

When the piping is to be attached to

a wall containing metals (tin plated)

or metal netting, use a chemically

treated wooden piece 20 mm or

thicker between the wall and the piping

or wrap 7 to 8 turns of insulation vinyl

tape around the piping.

Units should be installed by licensed contractor according

to local code requirement.

Page 3

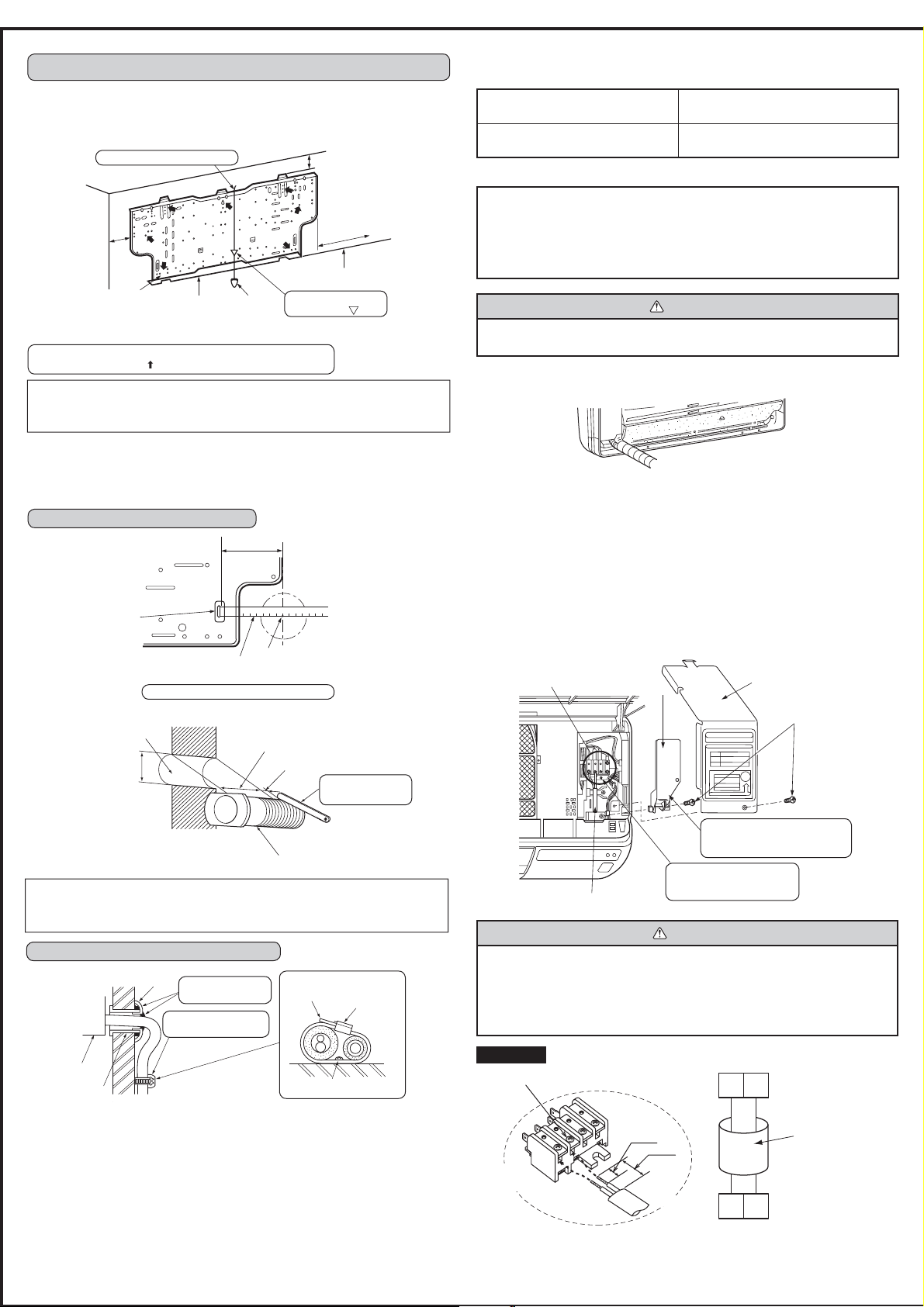

4. INDOOR UNIT INSTALLATION

4-1 FIXING OF INSTALLATION PLATE

Find a structural material (such as a stud) in the wall and fi x installation plate

•

horizontally.

Bind the line to the center hole.

0 mm or more

12

(off the wall)

Installation

plate fi xing

screw 2

4 × 25 mm

To prevent the installation plate from vibrating, be sure to fi x the holes

as indicated by the arrows .

Installation

plate 1

Plumb

When bolts recessed in the concrete wall are to be utilized, secure the installation plate

1 using 11 × 20 · 11 × 26 oval hole (450 mm pitch).

If the recessed bolt is too long, change it for a shorter one available in the market.

4-2 WALL HOLE DRILLING

1 Determine the wall hole position.

2 Drill a 75 mm hole so that outside can be lower than inside.

3 Insert the wall hole sleeve C.

Positioning of the holes on the wall

Installation plate 1

Insert the scale.

Align the scale with the line.

Repeat the same procedure for the left hole.

Wall hole

75 mm dia.

(Indoor side)

(Wall hole cross section)

Be sure to use wall hole sleeve C to prevent the outdoor connecting wires from

contacting with metal part in the wall and to prevent damage by rat in case the wall

is hollow.

Wall hole sealing and fi xing pipe to wall

Wall hole cover D

Seal the wall hole

gap with putty H.

Fix the pipe to wall with

pipe fi xing band E.

100 mm

Hole of dia.

75 mm

Wall thickness

Wall hole sleeve C

72 mm or more

100 mm or more for left

and left back piping (using

spacer)

00 mm or more

2

the wall)

(off

1800 mm or more

from the fl oor

Align the plumb line

with the mark .

One scale

Cut with 1 extra

scale length.

Cut off the

extra length. Pipe fi xing

band E

4-3 CONNECTING WIRE SPECIFICATIONS

Use special room air conditioning circuit.

•

Power supply cord length

(Lead to left/Lead to right)

Indoor/outdoor unit connecting

wire Specifi cation

Take out power supply cord from the left or right bottom corner of the indoor unit.

•

Cable 2-core 1.0 mm

Design 60245 IEC 57.

1 m/2 m

2

, in conformity with

Connect to the power switch which has a gap of 3 mm or more when open to

interrupt the source power phase.

(When the power switch is shut off, it must interrupt all phases.)

(Rated Voltage/Frequency : 230 V/50 Hz)

(Input capacity Main switch/Fuse : 10 A)

(This plug has to be the one meets the Standards.)

WARNING

Never cut the indoor and outdoor unit connecting wire and connect it to other wires.

It may cause a fi re.

Do not bundle the spare wire, but put it as shown below.

4-4 INDOOR AND OUTDOOR CONNECTING WIRE

CONNECTION

You can connect indoor/outdoor lead wire without removing the front panel.

1 Open the front panel.

2 Remove one screw holding the electrical cover, then remove the cover.

3 Remove the VA clamp and the cord clamp.

4 Pass the indoor/outdoor unit connecting wire from the back of the indoor unit and

process the end of the wire, then connect it to the terminal block.

5 Replace the fi xture and electrical cover securely.

Indoor

terminal block

Indoor/outdoor unit connecting wire A

VA clamp

Never fail to hook the left claw on

the wire fi xture to secure indoor/

outdoor unit connecting wire A.

Securely push the wire into

the terminal block until no

part of its core is appeared.

WARNING

O

Use the indoor/outdoor unit connecting wire that meets the Standards to connect

the indoor and outdoor units and fi x the wire to the terminal block securely so

that no external force is conveyed to the connecting section of the terminal block.

Incomplete connection or fi xing of the wire could result in a fi re.

O

Attach the VA clamp securely. If it is attached incorrectly, it could result in a fi re

or an electric shock due to dust, water, etc.

ELECTRICAL COVER

Fixing screws

Indoor unit

Wall hole

sleeve C

Fixing screw F

MSH type

Loosen terminal

screw.

Terminal

block

15 mm

<Connection details>

35 mm

Lead wire

3 N

3

N

Indoor terminal block

Indoor/outdoor unit

connecting wire A

2-core 1.0 mm

Outdoor terminal block

2

Page 4

MS type

Loosen terminal

screw.

15 mm

35 mm

Terminal

block

<Connection details>

O

Be careful not to make mis-wiring.

O

Firmly tighten the terminal screws to prevent them from loosening.

O

After tightening, pull the wires lightly to confi rm that they do not move.

O

If the connecting wire is incorrectly connected to the terminal block, the unit does

not operate normally.

O

If an earth is incorrect, it may cause an electric shock.

O

Make earth wire a little longer than the others. (more than 35 mm)

Lead wire

CAUTION

Indoor terminal block

Indoor/outdoor unit

connecting wire A

2-core 1.0 mm

Outdoor terminal block

2

4-5 AUTO RESTART FUNCTION

These models are equipped with an auto restart function. If you do not want to use

•

this function, please consult the service representative because the setting of the unit

needs to be changed.

When the indoor unit is controlled with the remote controller, the operation mode, the

•

set temperature, and the fan speed are memorized by the indoor electronic control P.C.

board. The auto restart function sets to work the moment the power has restored after

power failure, then, the unit will restart automatically. If the unit is operated in “I FEEL...”

or “AUTO” mode before power failure, the operation mode (COOL, DRY or HEAT) is not

stored in the memory. When the main power is turned on, the unit decides the operation

mode by the initial room temperature at restart and starts operation again.

Insert the piping and the drain hose into the wall hole sleeve C, and hook the upper

•

part of the indoor unit on the installation plate 1.

Check if the indoor unit is hooked securely on the installation plate 1 by moving the

•

unit to left and right.

Thrust the lower part of the indoor unit into the installation plate 1.

•

FOR LEFT OR LEFT-REAR PIPING

Pipe arrangement

•

Put the refrigerant piping and the drain hose together, then apply felt tape 7 to them.

Be careful drain

hose is not heaved.

Felt tape 7

Firmly apply felt tape 7 from the end.

(Felt tape 7 overlap width should be 1/3

the tape width.)

REATTACHING DRAIN HOSE

Be sure to reattach the drain hose and the drain cap in case of left or left-rear piping.

Otherwise, it could cause drops of water to drip down from the drain hose.

Cut off in case of left piping.

Use a bandage stopper at

the end of felt tape 7.

Operation

1 If the main power (230V AC) has been cut, the operation settings remain.

2 When three minutes have passed after power was restored, the unit will restart

automatically according to the memory.

Notes:

• The operation settings are memorized when 10 seconds have passed after the remote

controller was operated.

• If the main power is turned off or a power failure occurs while AUTO START/STOP timer

is active, the timer setting is cancelled. As these models are equipped with an auto

restart function, the air conditioner starts operating with timer cancelled at the same

time that power is restored.

• If the unit has been off with the remote controller before power failure, the auto restart

function does not work as the power button of the remote controller is off.

• To prevent breaker off due to the rush of starting current, systematize other home

appliances not to turn on at the same time.

4-6 PIPE FORMING

Place the drain hose below the refrigerant piping.

•

Make sure that the drain hose is not heaved or snaked.

•

Do not pull the hose to apply the tape.

•

When the drain hose passes the room, be sure to wrap insulation material (obtainable

•

at a store) around it.

Wrap the felt tape 7 around the pipe and the drain hose, then put the pipe in the back

•

space of the indoor unit.

Liquid pipe

Gas pipe

Indoor/outdoor unit

connecting wire A

Felt tape 7

Drain cap

1

Pull out the drain cap at the rear right of the indoor unit.

Hold the convex section at the end and pull the drain cap.

Drain cap

2

Pull out the drain hose at the rear left of the indoor unit.

Hold the claw marked by the arrow and pull out the drain hose forward.

Drain hose

FOR REAR, RIGHT OR DOWNWARD PIPING

Pipe arrangement

•

Put the refrigerant piping and the drain hose together, then apply felt tape

Be careful drain

hose is not heaved.

Cut off in case of left piping.

Cut off in case of downward piping.

Firmly apply piping tape G

from the end.

G to them.

3

Put the drain cap into the section to which the drain hose is to be

attached at the rear of the indoor unit.

Insert the screwdriver, etc. (not sharp-edged tool) into the hole at the end of the cap

and insert the cap fully into the drain pan.

Drain cap

Page 5

4

Insert the drain hose into the section to which the drain hose is

to be attached at the rear right of the indoor unit.

Insert the drain hose fully into the drain pan. Check if the hose is hooked securely to

the projection of its inserting part at the drain pan.

Drain hose

INDOOR UNIT INSTALLATION

Insert the drain hose into the wall hole sleeve C, and hook the upper part of indoor

•

unit on the installation plate 1. Then, move the unit to the very edge of the left side

for putting the piping easily in the back space of the indoor unit. After that, cut the part

of packing material (spacer assembly) to hook it on the back rib and lift the indoor

unit as shown in the fi gure below.

Cut part of packing material (spacer assembly) to

hook it on the back rib.

Spacer assembly

Securely attach the spacer assembly

in the concave part of the rib, taking

care its direction is correct as shown

in the fi gure right.

Connect the refrigerant piping with the extension pipe B.

•

Thrust the lower part of the indoor unit into the installation plate 1.

•

Spacer

4-7 DRAIN PIPING

The drain hose should point downward for easy drain fl ow. (Fig. 1)

•

Do not make drain piping as shown in Fig. 2 to 5.

If the extension drain hose has to pass through a room, be sure to wrap it with

•

commercially sold insulation.

Downward

slope

Do not raise.

Accumulated

drain water

Air

5. OUTDOOR UNIT INSTALLATION

INDOOR/OUTDOOR UNIT CONNECTING WIRE CONNECTION AND OUTDOOR POWER SUPPLY CORD CONNECTION

Connect the indoor/outdoor unit connecting wire A from the indoor unit correctly on

•

the terminal block.

For future servicing, give extra length to connecting wire.

•

Rated

Voltage

230 V 15 A

O

When too long, or connected by cutting off the middle,

peel off power supply wire to the size as shown in the

O

O

(more than 35 mm)

For the power supply cord and the indoor/outdoor unit connecting wires, be sure to

•

Be sure to push the core until it is hidden and pull each cable to make sure that it is

•

Power supply cord

Specifi cation

Indoor and Outdoor

connecting wire

Specifi cation

Indoor

terminal

block

Outdoor

terminal

block

Breaker

capacity

Connect to the supply terminals and leave a contact

separation of at least 3 mm at each pole to disconnect the

source power pole. (When the power switch is shut off, it

must disconnect all poles.)

Peel off both ends of connecting wire (extension wire).

right.

Be careful not to contact connecting wire with piping.

Make earth wire a little longer than the others.

15 mm

35 mm

use the ones in compliance with the standards.

not pulled up incomplete insertion may cause a risk of burning the terminal blocks.

2

3-core 1.5 mm

in conformity with Design 60245 IEC 57.

3-core 2.5 mm

in conformity with Design 60245 IEC 57.

Cable 2-core 1.0 mm

or more,

2

or more,

10 m or less

15 m or less

2

,

in conformity with Design 60245 IEC 57.

WARNING

O A means for disconnection of the supply with an isolation switch, or similar

device, in all active conductors shall be incorporated in the fi xed wiring.

O Never cut the power cord and connect it to other wires.

It may cause a fi re.

MS type MSH type

221

1

Indoor/outdoor unit

connecting wire A

2-core 1.0 mm

NL

Indoor

terminal

block

Outdoor

terminal

block

3 N

3

N

Indoor/outdoor unit

connecting wire A

2-core 1.0 mm

NL

Water

leakage

(Fig. 1) (Fig. 2) (Fig. 3)

Tip of drain

hose dipped

in water.

Water

leakage

(Fig. 4) (Fig. 5)

If the drain hose provided with the indoor unit is too short, connect it with drain hose

•

I that should be provided at your site. (Fig. 6)

When connecting the drain hose to the hard vinyl chloride pipe, be sure to insert it

•

securely into the pipe. (Fig. 7)

(Fig. 6) (Fig. 7)

Ditch

Less than

50 mm gap

Drain

hose

Soft hose

I.D.

15 mm

70 cm or

more

Differentdiameter joint

Water

leakage

Waving

Drain hose

Hard vinyl

chloride pipe

I.D. 30 mm

Be sure to insert

the drian hose

securely into the

pipe.

Power supply cord K

Power supply cord K

CAUTION

O Use care not to make mis-wiring.

O Firmly tighten the terminal screws to prevent them from loosening.

O After tightening, pull the wires lightly to confi rm that they do not move.

O If the connecting wire is incorrectly connected to the terminal block, the unit

does not operate normally.

Page 6

Be sure to fi x the indoor/outdoor unit

connecting wire A and power supply cord K

using this cord clamp.

Be sure to put the left portion

into the square hole of the

service panel.

Fixing screws

K

A

Service panel

Remove two fi xing

screws to open the

service panel.

WARNING

Be sure to attach the service panel of the outdoor unit securely. If it is not attached

correctly, it could result in a fi re or an electric shock due to dust, water, etc.

6. INDOOR/OUTDOOR UNIT CONNECTION

FINISHING AND TEST RUN

INSTALLATION INFORMATION FOR THE AIR

CONDITIONER WITH R410A REFRIGERANT

This room air conditioner adopts an HFC refrigerant (R410A) which will never destroy

•

the ozone layer.

Pay particular attention to the following points, though the basic installation

•

procedure is same as that for R22 air conditioners.

1 As R410A has a working pressure approx. 1.6 times as high as that of R22, some

special tools and piping parts / materials are required. (Refer to the table below.)

2 Take suffi cient care not to allow water and other contaminations to enter the

R410A refrigerant during storage and installation, since it is more susceptible to

contaminations than R22.

3 For refrigerant piping, use clean, pressure-proof parts / materials specifi cally

designed for R410A. (Refer to 2. Refrigerant piping.)

4 Composition change may occur in R410A since it is a mixed refrigerant. When

charging, charge liquid refrigerant to prevent composition change.

6-1 Tools dedicated for the air conditioner with R410A

refrigerant

The following tools are required for R410A refrigerant. Some R22 tools can be

substituted for R410A tools.

The diameter of the service port on the stop valve in outdoor unit has been changed to

prevent any other refrigerant being charged into the unit. (Cap size has been changed

from 7/16 UNF with 20 threads to 1/2 UNF with 20 threads.)

R410A tools

Gauge manifold No

Charge hose No

Gas leak detector No Dedicated for HFC refrigerant.

Torque wrench

Flare tool Yes

Flare gauge New

Vacuum pump

adaptor

Electronic scale

for refrigerant

charging

No: Not substitutable for R410A Yes: Substitutable for R410A

Can R22 tools

be used?

Yes 1/4

No 1/2

New

New

Description

R410A has high pressures beyond the

measurement range of existing gauges.

Port diameters have been changed to prevent

any other refrigerant from being charged into

the unit.

Hose material and cap size have been changed

to improve the pressure resistance.

Clamp bar hole has been enlarged to reinforce

the spring strength in the tool.

Provided for fl aring work (to be used with R22

fl are tool).

Provided to prevent the back fl ow of oil. This

adapter enables you to use existing vacuum

pumps.

It is diffi cult to measure R410A with a charging

cylinder because the refrigerant bubbles due to

high pressure and high-speed vaporization.

6-2 FLARING WORK

Main cause of gas leakage is defect in fl aring work.

•

Carry out correct fl aring work in the following procedure.

1

Pipe cutting

• Cut the copper pipe correctly with pipe cutter.

Good

Copper pipe

2

Burrs removal

• Completely remove all burrs from the cut cross section of pipe.

• Put the end of the copper pipe to downward direction as you remove burrs in order to

avoid to let burrs drop in the piping.

Burr

3

Putting nut on

• Remove fl are nuts attached to indoor and outdoor

units, then put them on pipe having completed

burr removal.

(not possible to put them on after fl aring work)

• Flare nut for R410A pipe differs from R22 pipe.

Refer to the following table for detail.

mm Inch R410A R22

ø6.35 1/4 17 17

ø12.7 1/2 26 24

4

Flaring work

• Carry out fl aring work using fl aring tool as shown below.

Flaring tool

Wing nut typeClutch type

Outside diameter

ø6.35 mm 0 to 0.5 1.0 to 1.5 1.5 to 2.0

ø12.7 mm 0 to 0.5 1.0 to 1.5 2.0 to 2.5

• Firmly hold copper pipe in a die in the dimension shown in the table above.

5

Check

• Compare the fl ared work with fi gure below.

• If fl are is noted to be defective, cut off the fl ared section and do fl aring work again.

Flare tool for R410A

Smooth all around

Even length

all around

Copper pipe

Die

clutch type

o

90

Spare

reamer

Pipe

cutter

Copper pipe

Clutch type Wing nut type

Inside is shining without any scratches.

No good

Tilted Uneven Burred

Flare nut

A

Flare nut

A (mm)

Conventional fl are tool

Copper pipe

Yor k

Die

Copper pipe

Page 7

6-3 PIPE CONNECTION

Note:

Fasten a fl are nut with a torque wrench as specifi ed in the table below.

When fastened too tight, a fl are nut may broken after a long period and cause a leakage

of refrigerant.

1 Indoor unit connection

Connect both liquid and gas pipings to indoor unit.

Apply a thin coat of refrigeration oil J on the seat surface of pipe.

•

For connection fi rst align the center, then tighten the fi rst 3 to 4 turns of fl are nut.

•

Use tightening torque table below as a guideline for indoor unit side union joint section,

•

and tighten using two wrenches. Excessive tightening damages the fl are section.

Pipe diameter Tightening torque

mm N·m kgf·cm

ø6.35 13.7 to 17.7 140 to 180

ø12.7 49.0 to 56.4 500 to 575

2 Outdoor unit connection

Connect pipes to stop valve pipe joint of the outdoor unit in the same manner applied for

indoor unit.

For tightening, use a torque wrench or spanner and use the same tightening torque

•

applied for indoor unit.

INSULATION AND TAPING

1 Cover piping joints with pipe cover.

2 For outdoor unit side, surely insulate every piping including valves.

3 Using piping tape G, apply taping starting from the entry of outdoor unit.

Stop the end of piping tape G with tape (with adhesive agent attached).

•

When piping have to be arranged through above ceiling, closet or where the temperature

•

and humidity are high, wind additional commercially sold insulation for prevention of

condensation.

6-4 PURGING PROCEDURES·LEAK TEST

PURGING PROCEDURES

Connect the refrigerant pipes (both liquid pipe and the gas pipe) between the indoor

and the outdoor unit.

Remove the service port cap of the stop valve on the side of the outdoor unit gas

pipe. (The stop valve will not work in it initial state fresh out of the factory (totally

closed with cap on).)

Connect the gauge manifold valve and the vacuum pump to the service port of the

stop valve on the gas pipe side of the outdoor unit.

Run the vacuum pump. (Vacuumize for more than 15 minutes.)

Check the vacuum with the gauge manifold valve, then close the gauge manifold

valve, and stop the vacuum pump.

Leave as it is for one or two minutes. Make sure the pointer gauge manifold valve

remains in the same position. Confi rm that the pressure gauge shows–0.101 Mpa

[Gauge] (–760 mmHg).

Stop valve

Close

Open

Hexagonal wrench

Precautions when using the control valve

Control Valve

Remove the gauge manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on

both sides of gas pipe and liquid pipe.

Operating without fully opening lowers the performance and this causes trouble.

A

Open

Close

Body

Pipe length up to 7 m

No gas charge is needed.

Tighten the cap to the service port to obtain the initial status.

Stop valve

Service port

Charge hose

Gauge manifold valve

Charge

hose

When attaching the control valve to the service port,

valve core may deform or loosen if excess pressure

is applied. This may cause gas leak.

When attaching the control valve to the service port,

make sure that the valve core is in closed position, and

then tighten part A. Do not tighten part A or turn the body

when valve core is in open position.

Retighten the cap.

Leak test

Vacuum pump

Pipe length exceeding 7 m

Charge the prescribed amount

of gas. (refer to 3)

Liquid pipe

Hexagonal

wrench

Stop valve

Service port

Gas pipe

Caps

Tightening torque

N·m kgf·cm

Cap for service port 13.7 to 17.7 140 to 180

Cap for stop valve 19.6 to 29.4 200 to 300

6-5 TEST RUN

MS type

• Before performing the test run, recheck for any wrong wiring.

Wrong wiring prevents normal operation or results in blown fuse disabling operation.

• The test run can be started by pressing EMERGENCY OPERATION switch. When

the EMERGENCY OPERATION switch is once pressed, the unit will start the test run

(continuous operation) for 30 minutes.

A thermostat does not work during this time. After 30 minutes the unit will start the

EMERGENCY OPERATION at a fi xed temperature setting of 24°C in COOL MODE.

• Perform test run in the following procedure.

PROCEDURE

• Press the EMERGENCY OPERATION switch.

1 Press it once, and after test run for 30 minutes the EMERGENCY COOL MODE

starts.

2 Press it once more, and the operation stops.

(The operation mode alternates between 1 and 2 every time the EMERGENCY

OPERATION switch is pressed.)

Operation Indicator lamp

Mode

COOL

1

(Light) (Off)

STOP

2

(Off) (Off)

EMERGENCY

OPERATION switch

MSH type

• Before performing the test run, recheck any wrong wiring.

Wrong wiring prevents normal operation or results in blown fuse disabling operation.

• The test run can be started by pressing EMERGENCY OPERATION switch. When

the EMERGENCY OPERATION switch is once pressed, the unit will start the test run

(continuous operation) for 30 minutes.

A thermostat does not work during this time. After 30 minutes the unit will start the

EMERGENCY OPERATION at a fi xed temperature setting of 24°C in COOL MODE or

HEAT MODE.

• Perform test run in the following procedure.

PROCEDURE

• Press the EMERGENCY OPERATION switch.

1 Press it once, and after test run for 30 minutes the EMERGENCY COOL MODE

starts.

If the left side lamp of the operation indicator blinks every 0.5 seconds, inspect the

indoor/outdoor unit connecting wire A for mis-wiring.

2 Press it once more, and the EMERGENCY HEAT MODE starts.

3 Press it once more, and the operation stops.

(The operation mode changes in order of 1 ~ 3 every time the EMERGENCY

OPERATION switch is pressed.)

Operation Indicator lamp

Mode

COOL

1

2

3

• In starting the heating operation, indoor unit fan may not operate to prevent blowing

cool air. Please wait for a few minutes until the temperature of heat exchanger rises

and warm air blows out.

(Light) (Off)

HEAT

(Off) (Light)

STOP

(Off) (Off)

EMERGENCY

OPERATION switch

MS type and MSH type

Checking the remote (infrared) signal reception

Press the ON/OFF button on the remote controller and check that an electronic sound is

heard from the indoor unit. Press the ON/OFF button again to turn the air conditioner off.

If the indoor unit is operated with the remote controller, both the test

run and the emergency operation are released by commands from

the remote controller.

• Once the compressor stops, the restart preventive device operates so the compressor

will not operate for three minutes to protect the air conditioner.

6-6 EXPLANATION TO THE CUSTOMER

• Using the OPERATING INSTRUCTIONS, explain the following to the customer, how

to control temperature, how to remove the air fi lters, how to remove or put the remote

controller in the remote controller holder, how to clean, precautions for operation, etc.

• Recommend the customer to read the OPERATING INSTRUCTIONS carefully.

Page 8

7. FOR MOVEMENT AND MAINTENANCE

7-1

REMOVING AND REINSTALLING THE FRONT PANEL

FRONT PANEL REMOVAL

4 Release the hooks.

Hold this concave section and pull the bottom

1 Remove the screw caps.

2 Remove three screws.

FRONT PANEL REINSTALLATION

Note:

Do not open the front panel up beyond the level position.

The panel may come off in order to prevent it from being damaged.

1 Set the horizontal vane to the position as below before reinstalling the front

panel.

1 Point the

horizontal

vane slightly

downward.

2 Attach the bottom of the front panel under the horizontal vane.

3 Fit in the top of the front panel.

4 Fit in the bottom of the front panel and tighten it using screws.

5 Push the section of the front panel marked by the arrow and fi t the panel into the

air conditioner.

forward to remove the front panel.

3 Pull the bottom.

5 Push

Horizontal vane

3

24

7-3 GAS CHARGE

1 Connect gas cylinder to the service port of stop valve (3-way).

2 Execute air purge of the pipe (or hose) coming from refrigerant gas cylinder.

3 Replenish specifi ed amount of the refrigerant, while operating the air conditioner

for cooling.

Note:

In case of adding refrigerant, comply with the quantity specifi ed for the refrigerating

cycle.

CAUTION

O

Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation,

reinstallation, or repairs to the refrigerant circuit.

O

When charging the refrigerant system with additional refrigerant, be sure

to use liquid refrigerant.

Adding gas refrigerant may change the composition of the refrigerant in the

system and affect normal operation of the air conditioner. Also, charge the

system slowly, otherwise the compressor will be locked.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm

water (under 40°C) during cold season. But never use naked fi re or steam.

Indoor unit

Refrigerant gas

cylinder

operating valve

Union

Liquid pipe

Gas pipe

Gauge manifold

valve (for R410A)

Charge hose (for R410A)

Refrigerant gas cylinder

for R410A with siphon

Refrigerant (liquid)

Electronic scale for

refrigerant charging

Stop valve

Outdoor unit

Service port

7-2 REMOVING THE INDOOR UNIT

Remove the bottom of the indoor unit from the installation plate.

1 Remove the front panel. (See FRONT PANEL REMOVAL shown above.)

2 Insert fl at screwdrivers into the square holes at the left and right bottom of the indoor

unit and push them up; the bottom of the indoor unit goes down and the hooks are

released.

Push

Go down

Square hole

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODAKU, TOKYO

100-8310, JAPAN

Loading...

Loading...