Page 1

SERVICE

&

PARTS

MANUAL

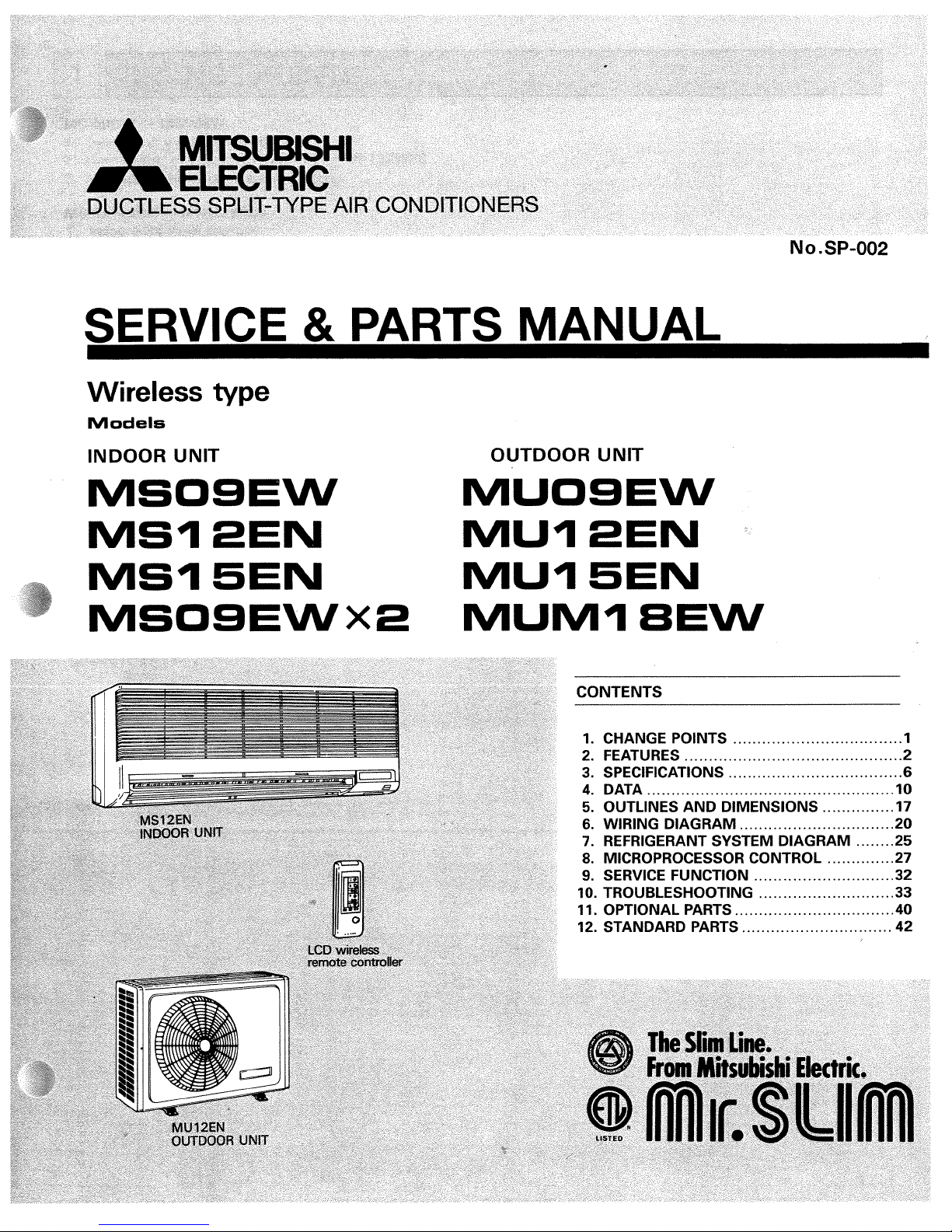

Wireless type

Models

INDOOR UNlT

MSOSEW

MS12EN

OUTDOOR UNlT

Page 2

MS-O9DW + MSOSEW

1 . lndoor unit model changed.

2. Compressor changed. KH-122WEV

-+

KH-122WES

3.

New model has Auto restart function.

/

1

1

MS-12/15DN

-+

MS12/15EN

1

.

lndoor front panel changed.

2. Suction line changes from 1 /2

0.

D. to 5/8

0.

D

.

3.

Compressor of MS15EN changed. RH207NAB

-t

RH-207NFL

4.

New model has Auto restart function. Cut the jumper wire to work the function.

I

CHANGE

POINTS

MSMI 8EW

1

.

lndoor unit model changed.

2. Compressor changed. KH-122WEV

-.

KH-122W ES

3.

New model has Auto restart function. Cut the jumper wire to work the function.

Model indication of wiring diagram and spec. name plate etc. chanegd.

Page 3

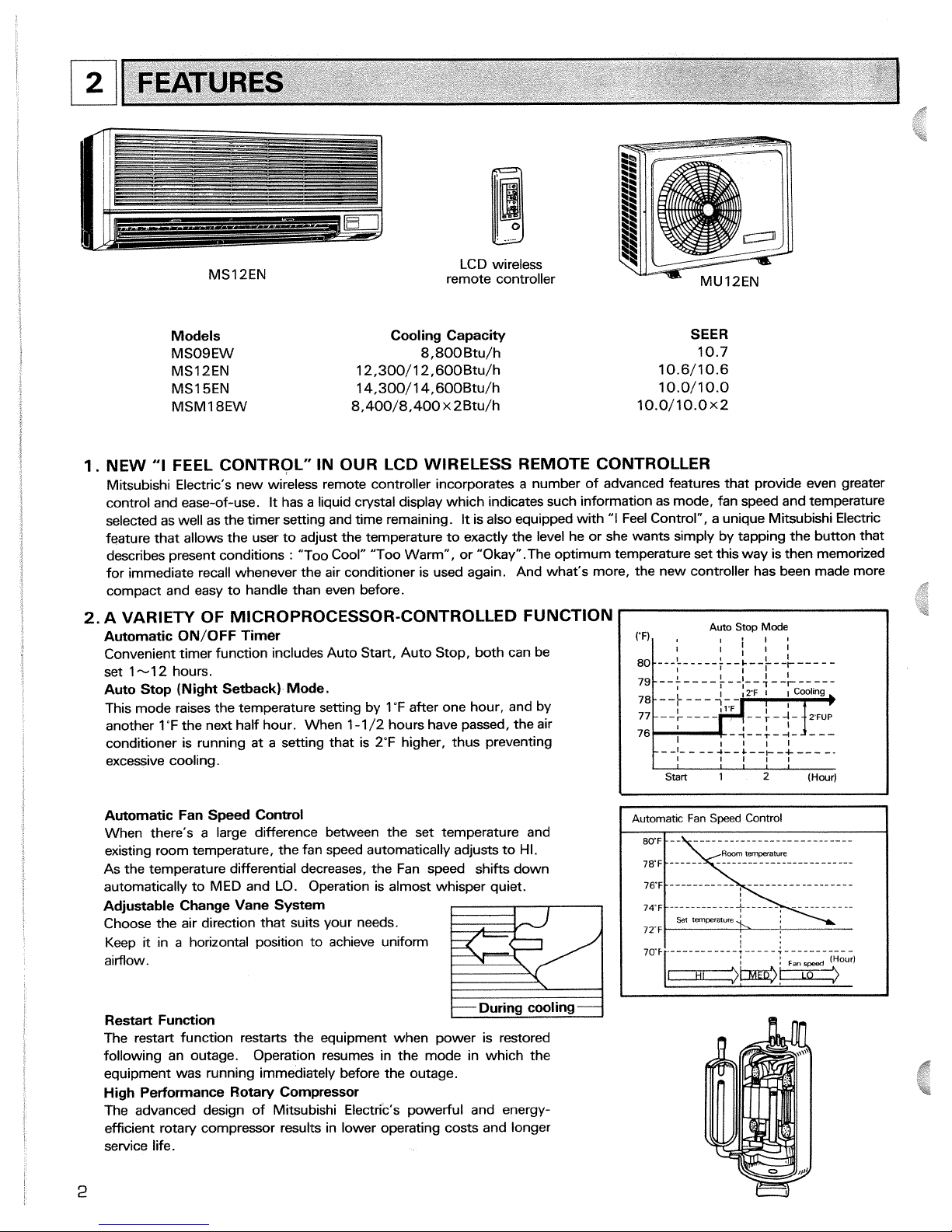

FEATURES

LCD wireless

remote controller

Models Cooling Capacity

MSOSEW 8,800 Btu/h

MS12EN 12,300/12,600Btu/h

MS15EN 14,300/14,600Btu/h

MSMI 8EW 8,400/8,400 x 2Btu/h

1.

NEW

"I

FEEL CONTROL" IN OUR LCD WIRELESS RER

SEER

10.7

10.6/10.6

10.0/10.0

10.0/10.0x2

dOTE CONTROLLER

Mitsubishi Electric's new wireless remote controller incorporates a number of advanced features that provide even greater

control and ease-of-use.

It

has a liquid crystal display which indicates such information as mode, fan speed and temperature

selected as well as the timer setting and time remaining.

It

is also equipped with

"I

Feel Control", a unique Mitsubishi Electric

feature that allows the user to adjust the temperature to exactly the level he or she wants simply by tapping the button that

describes present conditions

:

"Too Cool" "Too Warm", or "Okay" .The optimum temperature set this way is then memorized

for immediate recall whenever the air conditioner is used again. And what's more, the new controller has been made more

compact and easy to handle than even before.

2.

A VARIETY OF MICROPROCESSOR-CONTROLLED FUNCTION

Automatic ON/OFF Timer

Convenient timer function includes Auto Start, Auto Stop, both can be

set 1-12 hours.

Auto Stop (Night Setback) Mode.

This mode raises the temperature setting by 1 "F after one hour, and by

another 1

"F the next half hour. When 1-1 /2 hours have passed, the air

conditioner is running at a setting that is 2°F higher, thus preventing

excessive cooling.

Automatic Fan Speed Control

When there's a large difference between the set temperature and

existing room temperature, the fan speed automatically adjusts to HI.

As the temperature differential decreases, the Fan speed

shifts down

automatically to MED and LO.

Operation is almost whisper quiet.

Adjustable Change Vane System

Choose the air direction that suits your needs.

Keep it in a horizontal position to achieve uniform

aimow.

During cooling

Restart Function

The restart function restarts the equipment when power is restored

following an outage.

Operation resumes in the mode in which the

equipment was running immediately before the outage.

High Performance Rotary Compressor

The advanced design of Mitsubishi Electric's powerful and energy-

efficient rotary compressor results in lower operating costs and longer

service life.

76

I I

Start

1

2

(Hour)

Page 4

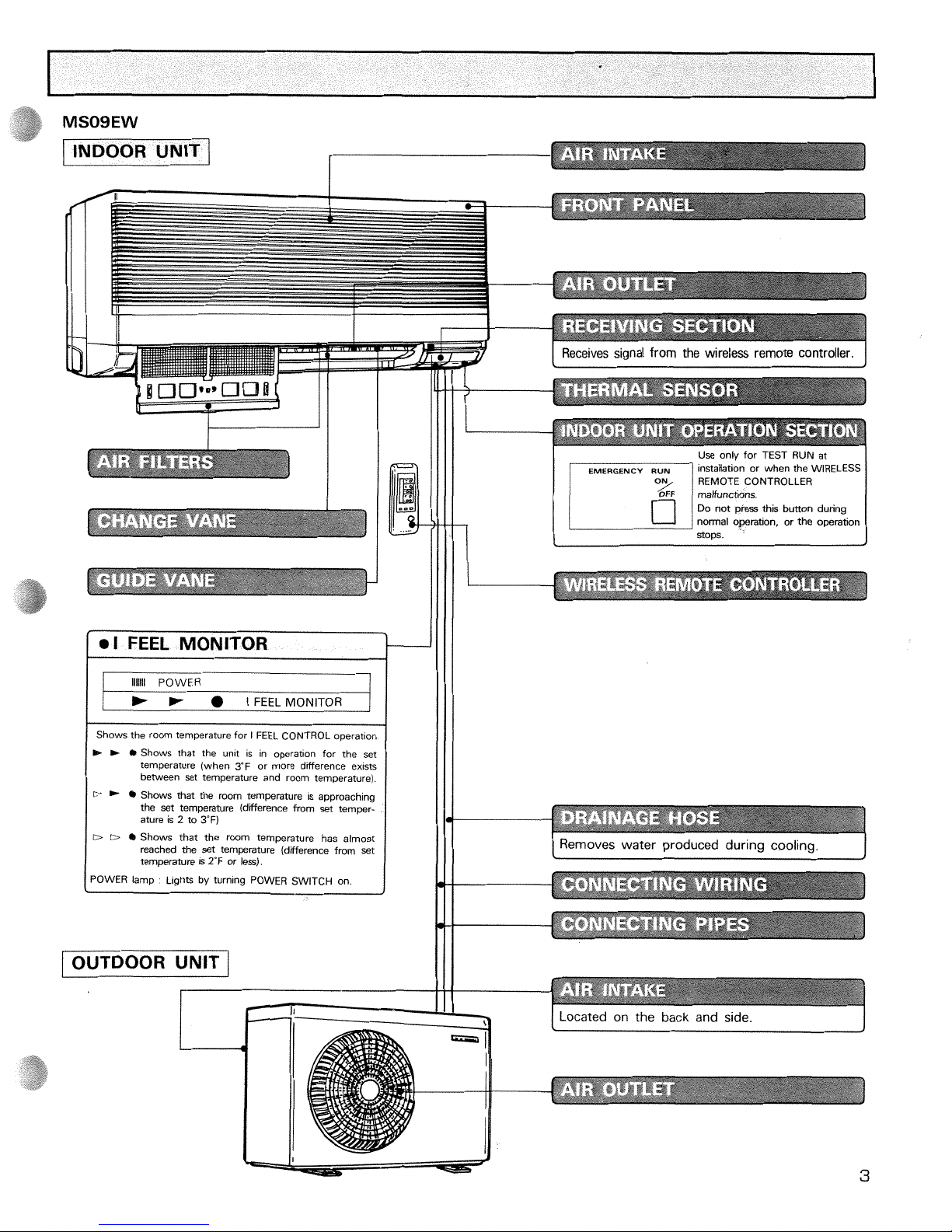

1

INDOOR UNIT

1

ll i 'ii

I

1

Shows the room temperature for I FEEL CONTROL

operation

R- R-

0

Shows that the unlt is in operation for the set

temperature (when 3'F or more difference exlsts

between set temperature and room temperature).

D

*

Shows that the room temperature

is

approaching

the set temperature (diierence from set temperature

is

2

to

3'F)

D

D

0

Shows that the room temperature has almost

reached the set temperature (difference from set

temperature

is

2°F or less).

I

POWER lamp

L~ghts by turning POWER SWITCH on

2

(

OUTDOOR UNIT

/

I

Receives signal from the wireless remote controller.

Use only for TEST RUN at

installation or when the WIRELESS

REMOTE CONTROLLER

maVunctlons

Do not press thls button dunng

normal

operanon,

or

the operahon

SODS.

Removes water produced during cooling.

J

I

Located on the back and side.

I

Page 5

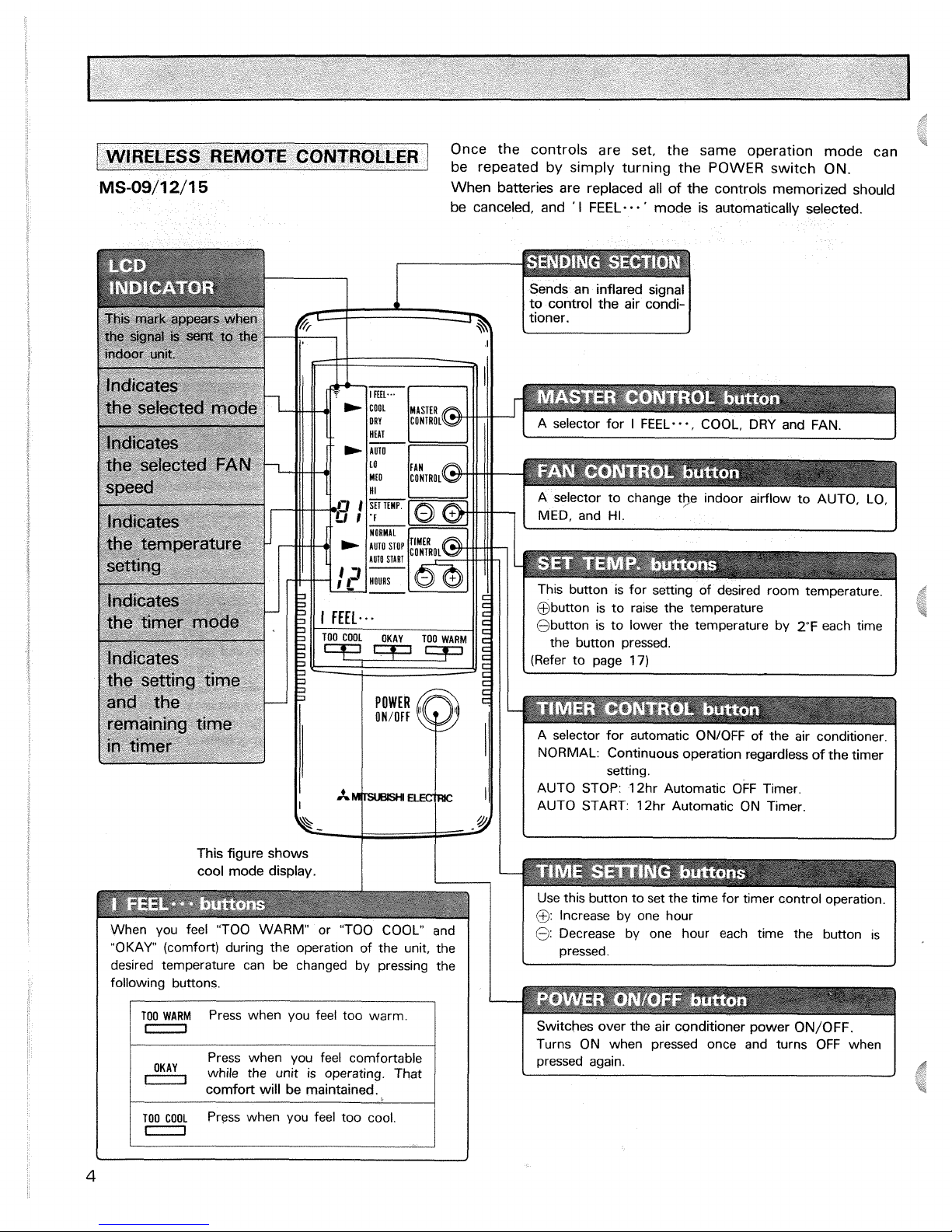

--

Once the controls are set, the same operatlon mode can

coNTRoLLE~

be repeated by s~mply turning the POWER sw~tch ON

-

--

When batteries are replaced all of the controls memorized should

be canceled, and

'

I

FEEL-.

-

'

mode is automatically selected.

Sends an inflared signal

to control the air

condi-

tioner.

1

This button is for setting of desired room temperature.

@button is to raise the temperature

@button is to lower the temperature by 2°F each time

the button pressed.

(Refer to page

17)

This figure shows

cool mode display.

When you feel "TOO WARM" or "TOO COOL" and

"OKAY (comfort) during the operation of the unit, the

desired temperature can be changed by pressing the

following buttons.

I

I

TO0

WARM

Press when you feel too warm.

0

while the unit is operating. That

-

comfort will be maintained.

TOO COOL

Press when you feel too cool.

I

in

A selector for automatic ON/OFF of the air conditioner.

NORMAL: Continuous operation regardless of the timer

setting.

AUTO STOP: 12hr Automatic OFF Timer.

AUTO START:

12hr Automatic ON Timer.

--

Switches over the air conditioner power ON/OFF.

Turns ON when pressed once and turns OFF when

pressed again.

Use this button to set the

tme for timer control operatlon

@

Increase by one hour

@

Decrease by one hour each tme the button is

pressed

Page 6

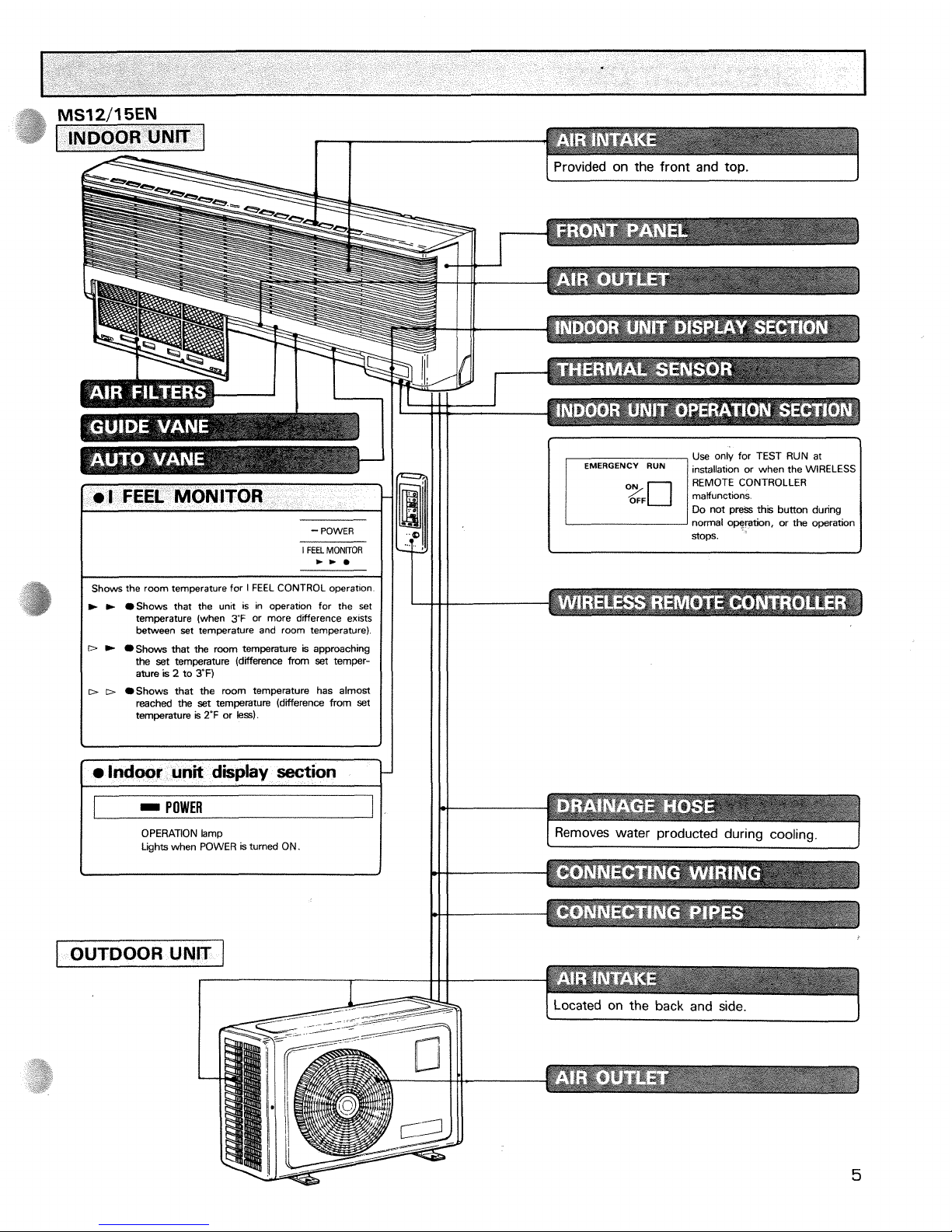

I

INDOOR UNIT

]

A

Provided on the front and top.

I

FEEL

MONFTOR

/

Shows the room temperature for I FEEL CONTROL operatton

I

m

b

Shows that the unit is in operation for the set

temperature (when

3'F

or more difference exists

between set temperature and room temperature)

D

Shows that the room temperature k approaching

the set temperature (difference from set temperature

is

2

to

TF)

I

I

D D

Shows that the room temperature has almost

reached the set temperature (difference from set

temperature

is

2'F

or

less).

-

POWER

OPERATION lamp

Lights when POWER

is

turned ON.

I

OUTDOOR UNIT

]

Use only for TEST RUN at

REMOTE CONTROLLER

Do not

pres;

th~s button dunng

normal operabon, or the operation

stops

I

Removes water producted during

cool in^.

I

Located on the back and side.

I

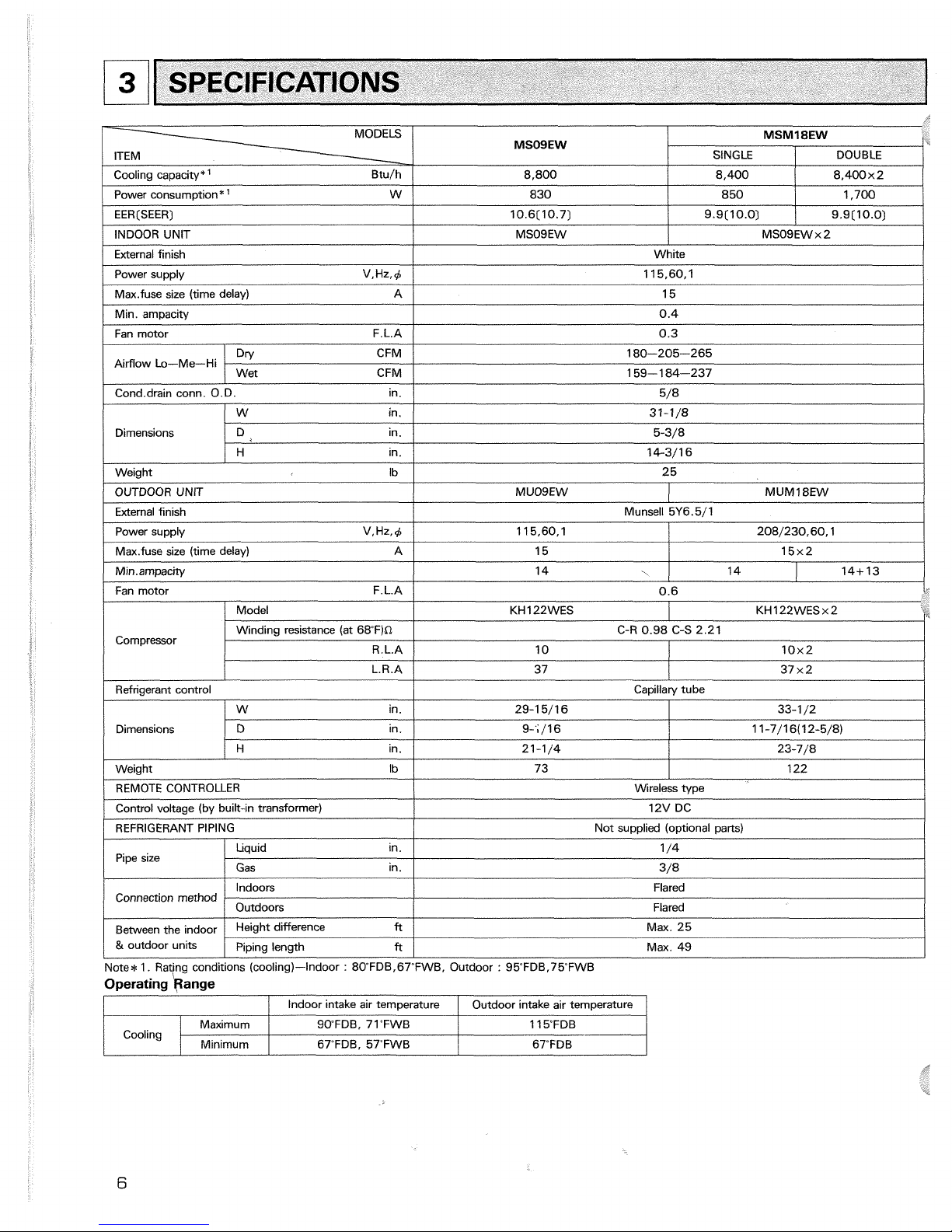

Page 7

-

MODELS

ITEM

Cool~na cawacitv*

'

Btu/h

-.

,

I

I

I

/

power supply V.Hz,C

/

11 5,60, 1

1

MSOSEW

8.800

Power consumption*

'

W

/

830

EER[SEER)

INDOOR UNIT

External finish

/

Fan motor F.L.A

/

0.3

1

MSMISEW

850

10.6[10.7)

MSO9EW

Max.fuse size (time delay) A

/

15

SINGLE

1,700

Min. amoacity

I

Cond.drain conn. O.D. in.

1

5/8

1

DOUBLE

White

9.9(10.0)

0.4

Airflow Lo-Me-Hi

Dimensions

9.9[10.0)

IW

in.

I

31-11'8

I

8.400

MSO9EWx2

Dn/ CFM

8.400~2

180-205-265

/

H in.

1

14-3/16

I

Wet CFM

I

159-1 84-237

I

D ~n.

5-3/8

Weight Ib

I

25

/

Fan motor F.L.A

/

0.6

i-

OUTDOOR UNIT

External finish

Power supply V.Hz,C

Max.fuse size (time delay) A

I

1

/

Model KH 122WES KH 122WES x 2

MUOSEW

Munsell 5Y6.5/1

MUM18EW

11 5,60, 1

Compressor

/

REMOTE CONTROLLER

I

Wireless type

1

208/230,60,1

Winding resistance (at 68F)n

R.L.A

Refrigerant control

15

Capillary tube

Dimensions

Control voltage (by built-in transformer)

15x2

C-R 0.98 C-S 2.21

29-1 5/16

9-';/I 6

21-1/4

73

W in.

D

ln.

H in.

12V DC

Pipe size

10

33-1 /2

1 1-7/16(12-5/8)

23-7/8

122 Weight

Ib

Connection method

Note*

I.

Rating conditions (cooling)-Indoor : 8OFDB,67'FWB, Outdoor : 95FDB.75FWB

Operating kange

10x2

REFRIGERANT PIPING

Liquid in.

Gas in.

Between the indoor

&

outdoor units

I

/

Indoor intake air temwerature

I

Outdoor intake air temoerature

/

Not supplied (optional parts)

1 /4

3/8

Indoors

Height difference

ft

1

Max. 25

Piping length

ft

/

Max.

49

Flared

Outdoors

Cooling

Flared

SO'FDB, 71"FWB

67"FDB. 57"FWB

Maximum

Minimum

11 5FDB

67"FDB

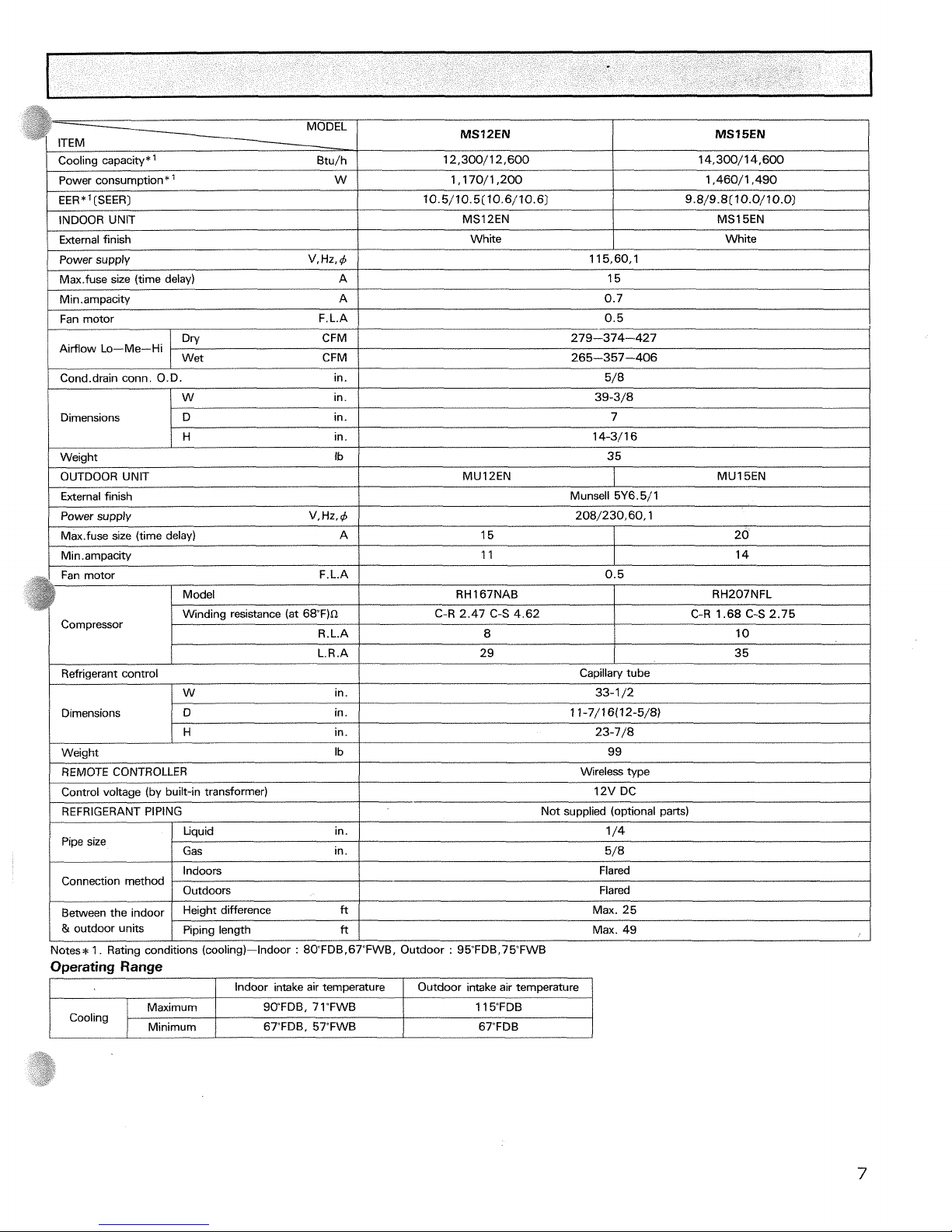

Page 8

I

Cooling capacity*' Btu/h

/

12,300/12,600

/power consumption*

'

w

I

1,170/1,200

I

1,460/1,490

1

EER

*

'

(SEER)

I

I

/

Fan motor F.L.A

/

0.5

I

10.5/10.5(10.6/10.6)

External finish

Power supply V, Hz, 4

Max.fuse size (time delay) A

Min

.

ampacity A

9.8/9.8(10.0/10.0)

115,60,1

15

0.7

MS15EN

INDOOR UNIT

White

I

Dimensions

1

D in.

I

7

MS12EN

White

DW CFM

Cond.drain conn. O.D. in.

279-374-427

5/8

/W

in.

1

39-3/8

H

in.

Airflow Lo-Me-Hi

14-3/16

-

I

/

Max.fuse size (time delay) 15

1

20

1

Wet CFM

/

265-357-406

Weiqht Ib

/

35

OUTDOOR UNIT

External finish

Munsell 5Y6.5/1

MUl2EN

Power supply V,Hz,4

1

208/230,60,1

L.R.A

Refrigerant control

/W

in.

MU15EN

Dimensions

29

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

35

D in.

H

in.

Wireless type

12V DC

Not supplied (optional parts)

Pipe size

Notes*

1. Rating conditions (cooling)-Indoor

:

80"FDBr67"FWB, Outdoor : 95FDB.75FWB

Capillary tube

33-1 /2

1 1-7/16(12-5/8)

23-7/8

Weight Ib

Connection method

Between the indoor

&

outdoor units

Operating Range

/

Indoor intake air temperature I Outdoor intake air temperature

1

99

Liquid in.

1 /4

Indoors

Outdoors

Height difference

ft

Piping length

ft

Gas in.

I

5/8

Flared

Flared

Max. 25

Max. 49

Cooling

SWFDB, 71"FWB

67"FDB. 57TWB

Maximum

Minimum

11 5FDB

67"FDB

Page 9

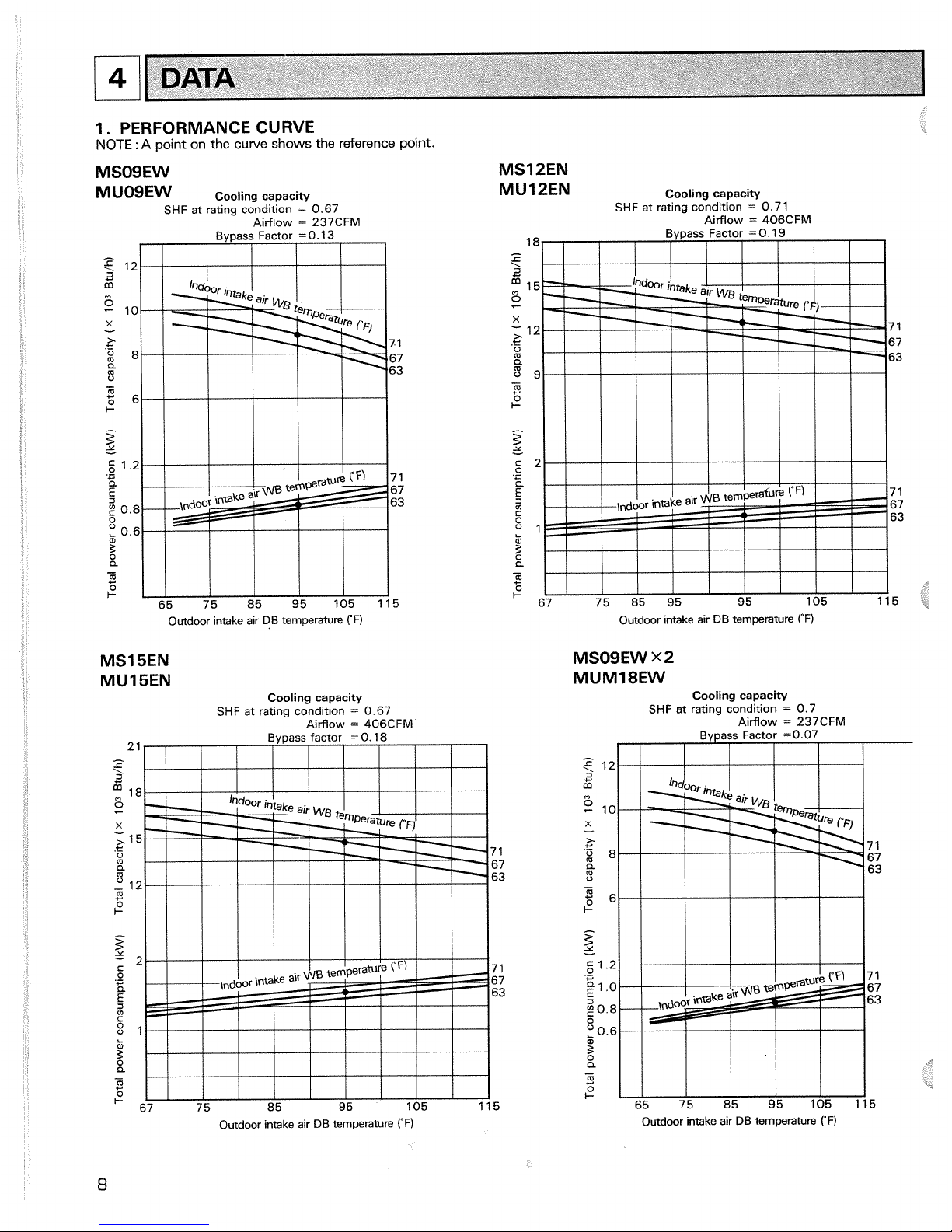

1. PERFORMANCE CURVE

NOTE

:

A

point on the

curve

shows

the

reference point.

1

Outdoor intake air DB temperature

rF)

DATA

MS15EN

MU15EN

Cooling capacity

SHF

at rating condition

=

0.67

Airflow

=

406CFM

MS12EN

MU12EN

Cooling capacity

SHF

at ratlng condition

=

0.7

1

Airflow

=

406CFM

18

e

i!

fj

15

Et

X

;

12 7 1

+

.-

0

67

m

a

63

5

9

-

m

C

2'

z

-

c

2

E!

C

e

7 1

2

67

63

81

k

3

a

-

m

C

I-

67 75 85 95 95 105 115

Outdoor intake air DB temperature

("F)

MSOSEW

x2

MUM18EW

Cooling capacity

SHF

st rating condition

=

0.7

Airflow

=

237CFM

Bypass Factor

=0.07

I

I

I

I

I I

I

Outdoor mtake air DB temperature

rF)

Outdoor ~ntake air DB temperature

("F)

Page 10

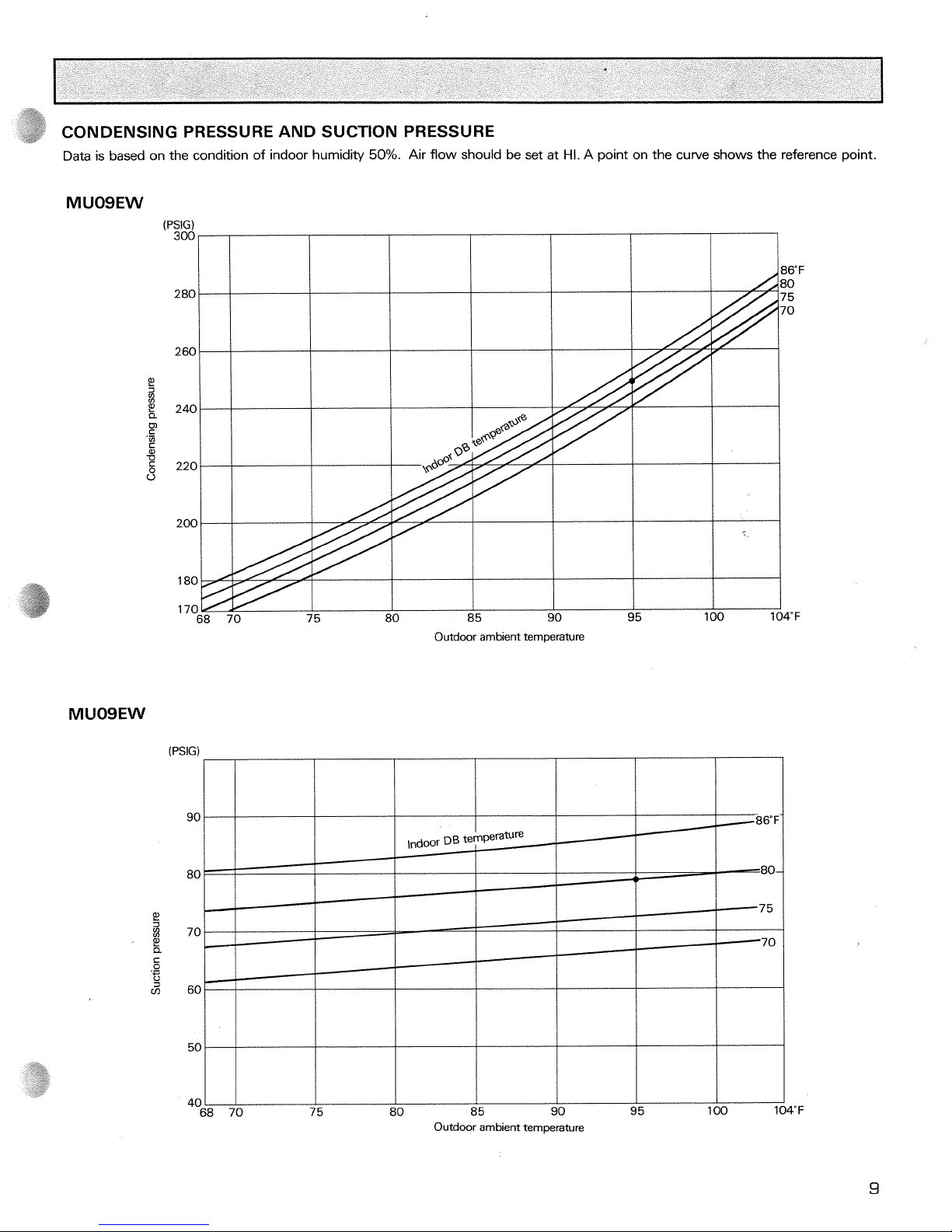

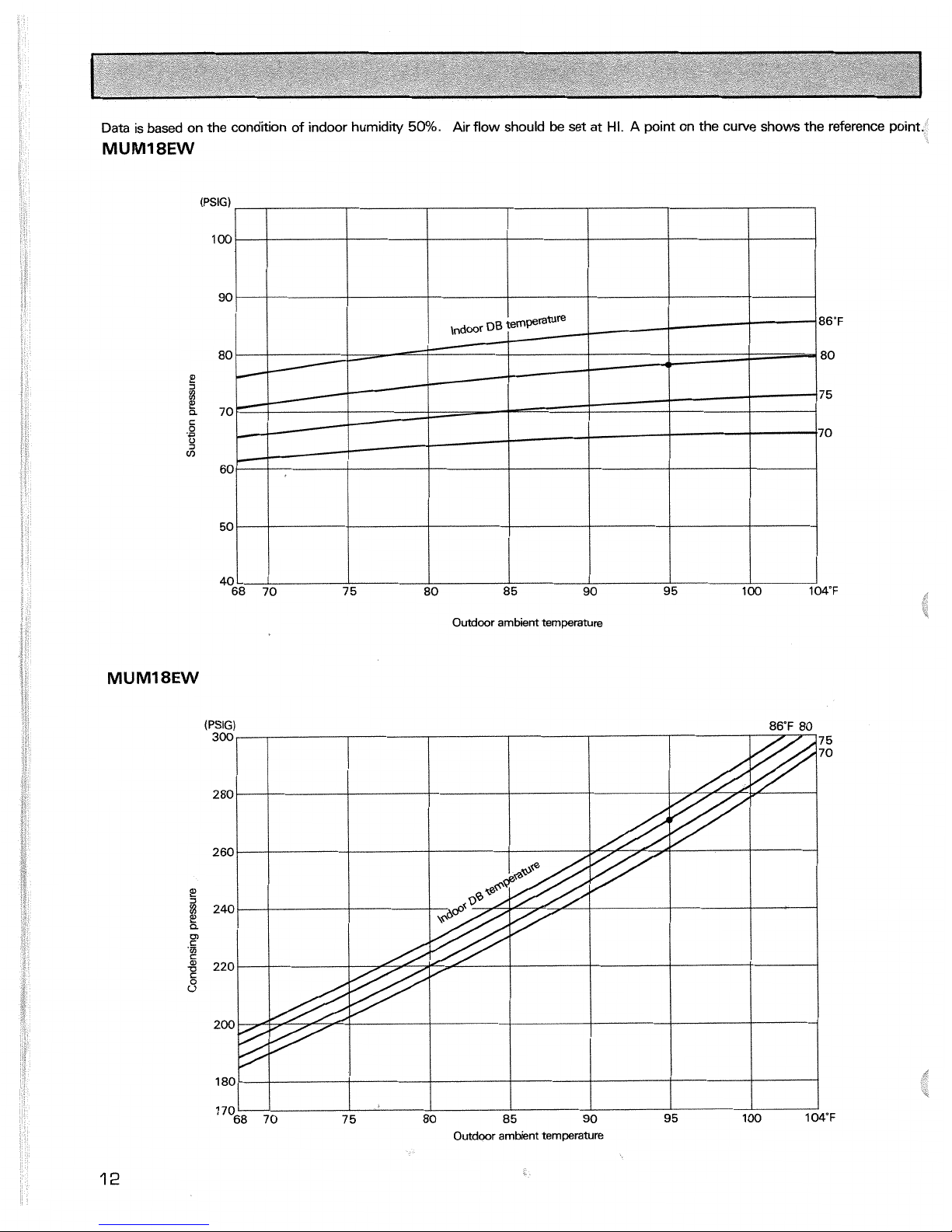

CONDENSING PRESSURE AND SUCTION PRESSURE

Data is based on the condition of indoor humidity

50%.

Air flow should be set at

Hi.

A point on the curve shows the reference point.

P!

I

,

P!

a

c

.-

I-'

3

m

85

90

95

100 1

Outdoor ambient temperature

Outdoor ambient temperature

Page 11

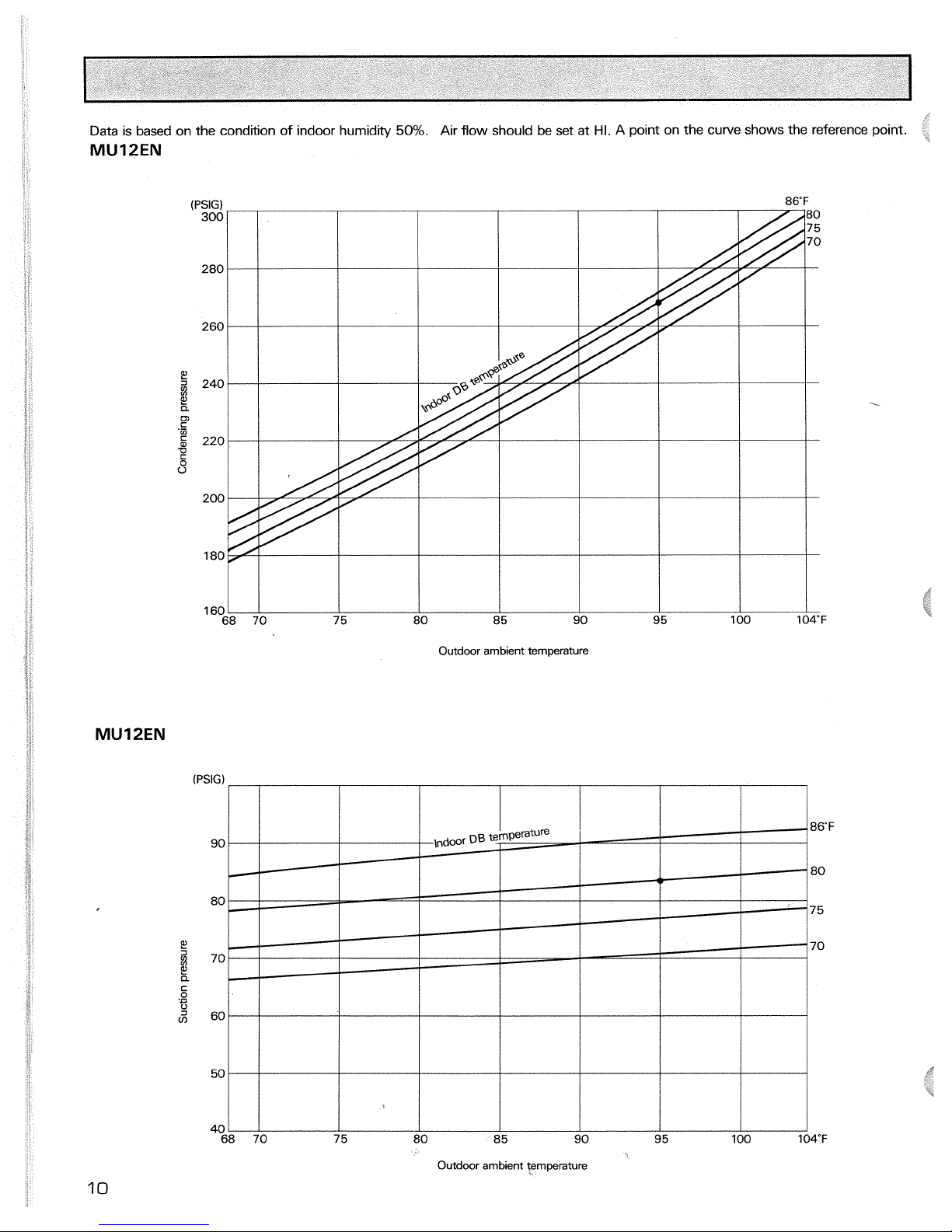

Data

is based on the condition of indoor humidity

50%.

Air flow should be set at

HI.

A point on the curve shows the reference point.

MU12EN

(PSIG)

Outdoor

ambient

temperature

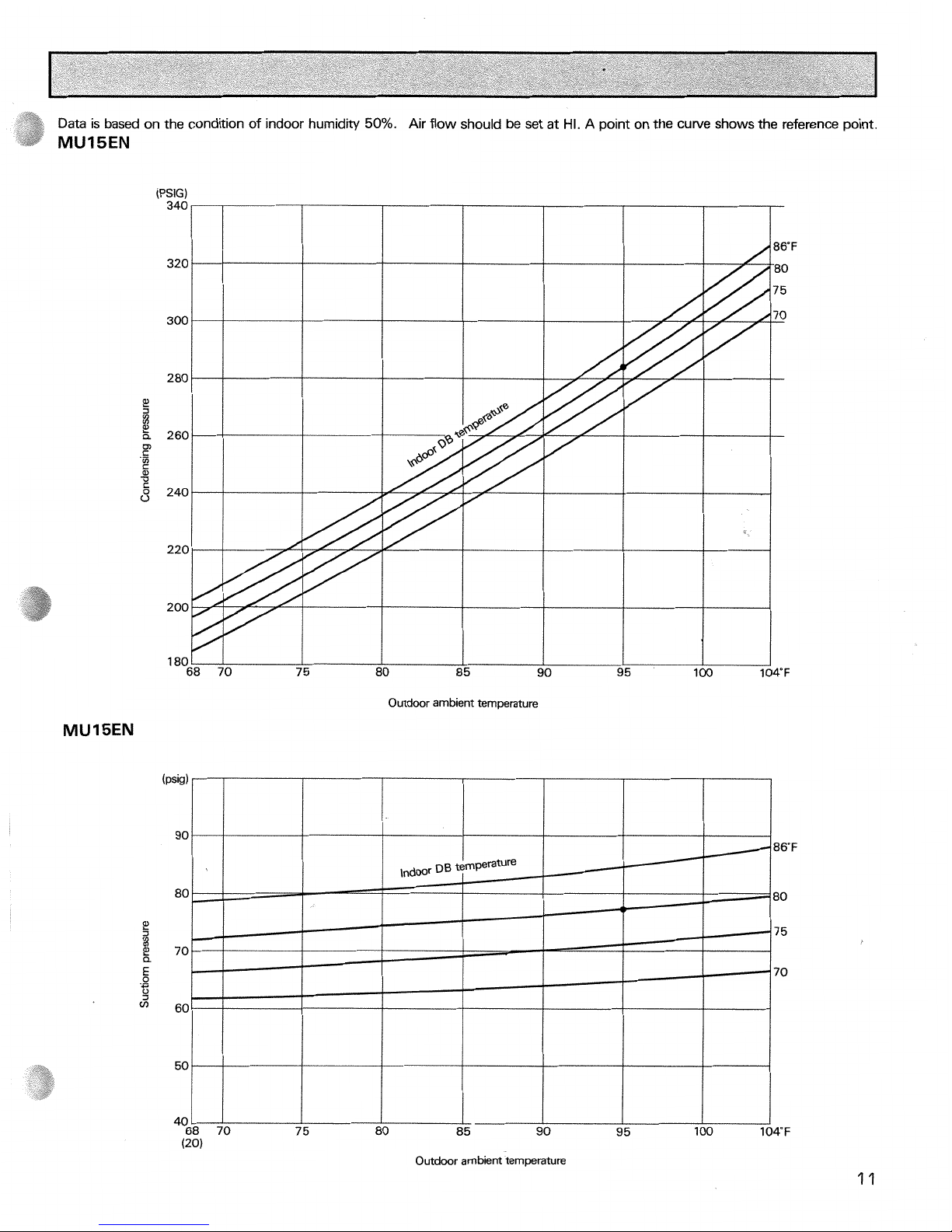

Page 12

Data

is based on the condition of indoor humidity

50%.

Air flow should be set at

HI.

A point on the curve shows the reference point.

MUISEN

Outdoor ambient temperature

Page 13

Data

is based on the condition of indoor humidity

50%.

Air flow should

be

set at

HI.

A

point on the curve shows the reference point.

(PSIG)

100

I

I I

I

0

85

90

95

100

Outdoor

ambient

temperature

Outdoor ambient temperature

Page 14

Indoor unit MS12EN

I

MS15EN

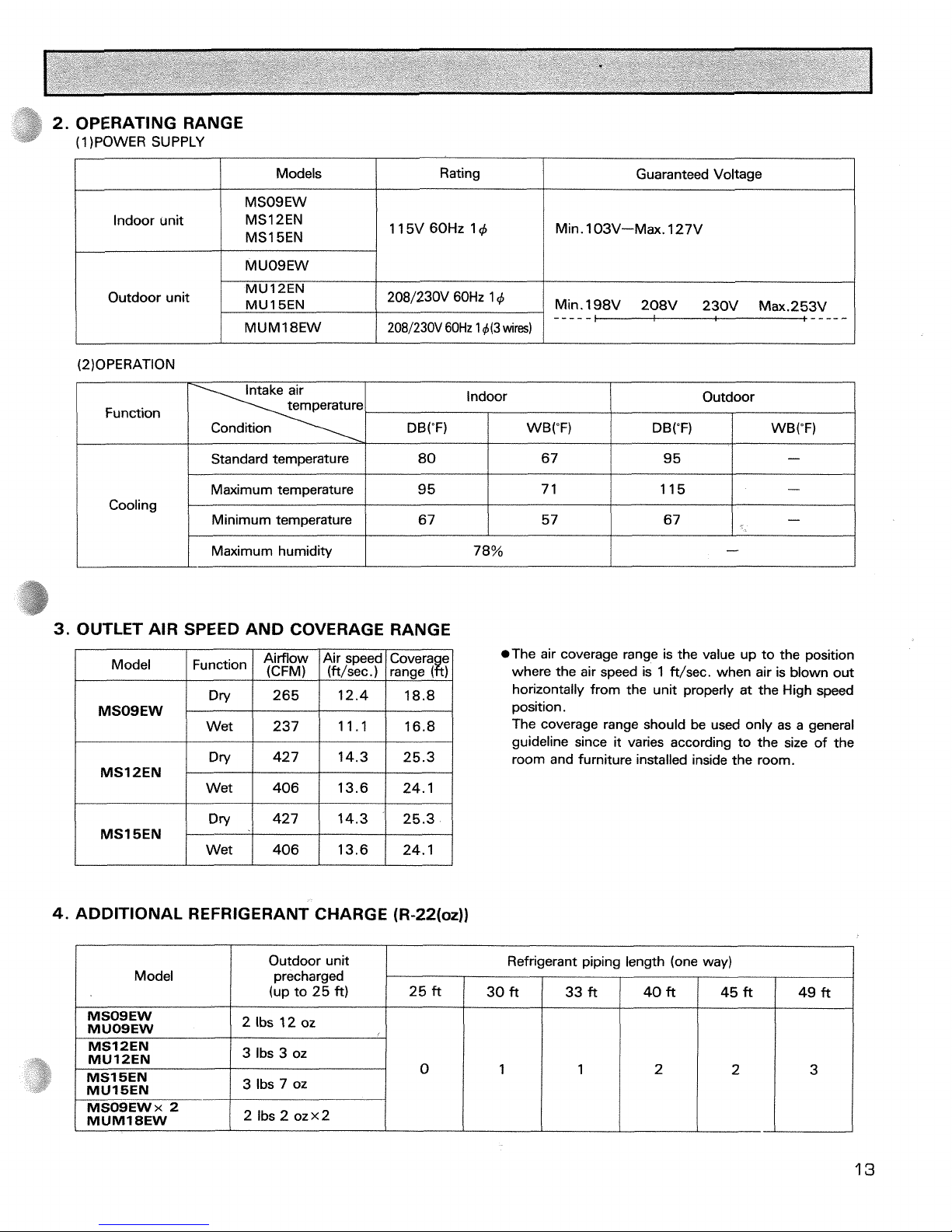

2. OPERATING RANGE

(1 )POWER SUPPLY

Min. l03V-Max. 127V

Models

Rating

Outdoor unit

Guaranteed Voltage

MUM1 8EW

Function

Min. 198V 208V 230V Max.253V

MU

12EN

MU1

5EN

2081230V 60Hz

1

d(3

wires)

Standard temperature

Maximum

tern~erature

2081230V 60Hz 14

-----

Cooling

3.

OUTLET AIR SPEED AND COVERAGE RANGE

Outdoor

DB("F)

i

WB("F)

Indoor

80

9

5

I

Maximum humidity

Model

Airflow Air speed Covera e

I I

(CFM) I ift/sec.) I ranae

I

DB("F)

I

I

I I

MSOSEW

14.3 25.3

MSl SEN

Wet 406 13.6 24.1

WB("F)

67

7

1

78%

4.

ADDITIONAL REFRIGERANT CHARGE (R-22(oz))

Minimum temperature

-

*The air coverage range is the value up to the position

where the air speed is 1 ft/sec. when air is blown out

horizontally from the unit properly at the High speed

position.

The coverage range should be used only as a general

guideline since

it

varies according to the size of the

room and furniture installed inside the room.

9 5

115

5 7 67

Model

-

-

67

-

Outdoor unit

precharged

(up to 25

ft)

I

I

I

I

I

I

I

/

3 lbs 7 oz

Refrigerant piping length (one way)

MSOSEW

MUOSEW

MS12EN

MU12EN

25 ft

2 Ibs

12

oz

3

Ibs 3 oz

30 ft

49 ft

33 ft 40 ft

45 ft

Page 15

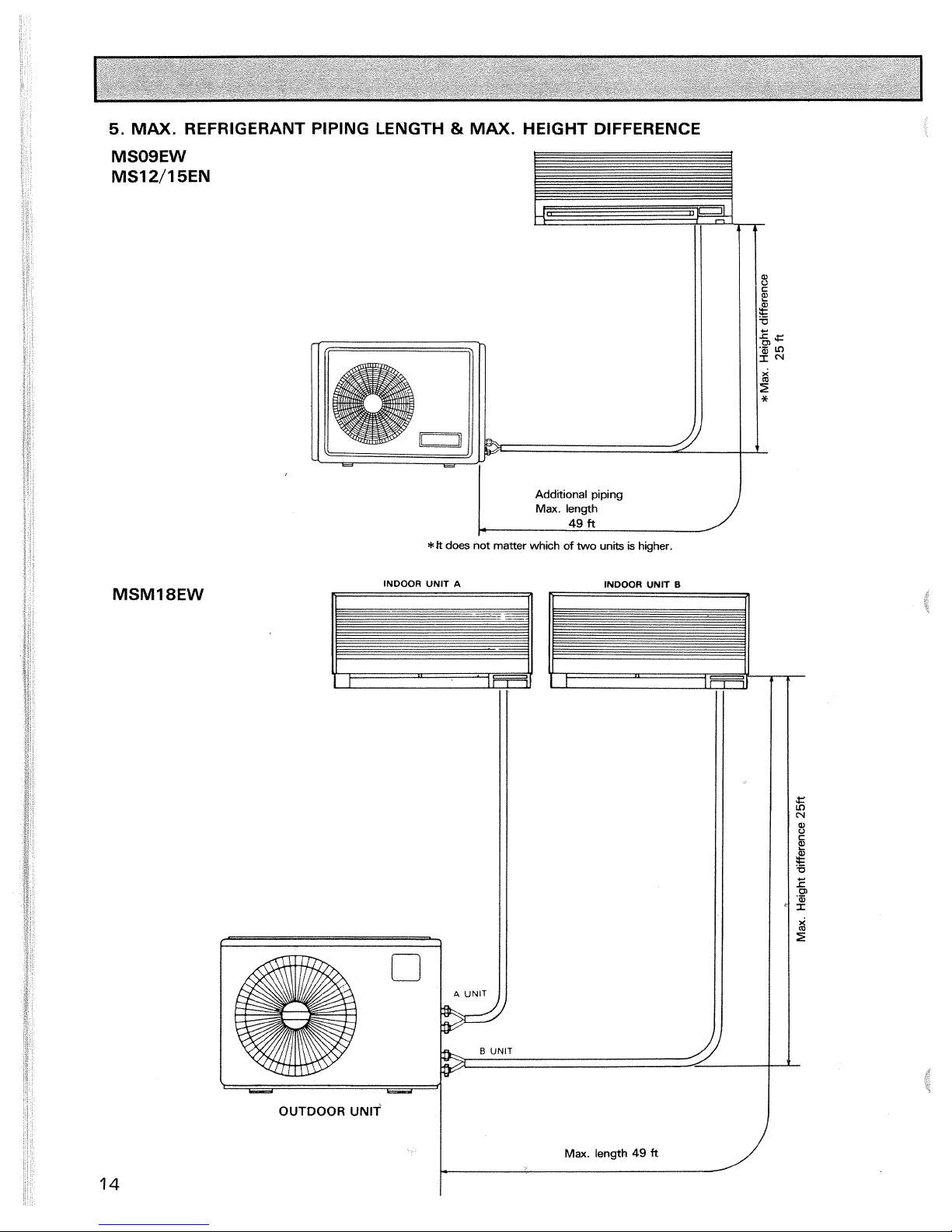

5.

MAX.

REFRIGERANT PIPING LENGTH & MAX.

HEIGHT DIFFERENCE

Additional piping

Max.

length

r

49

ft

*Jt

does not

matter

which

of

two units

is

higher.

INDOOR UNIT

A

INDOOR UNIT

I3

OUTDOOR UNlT

-

Page 16

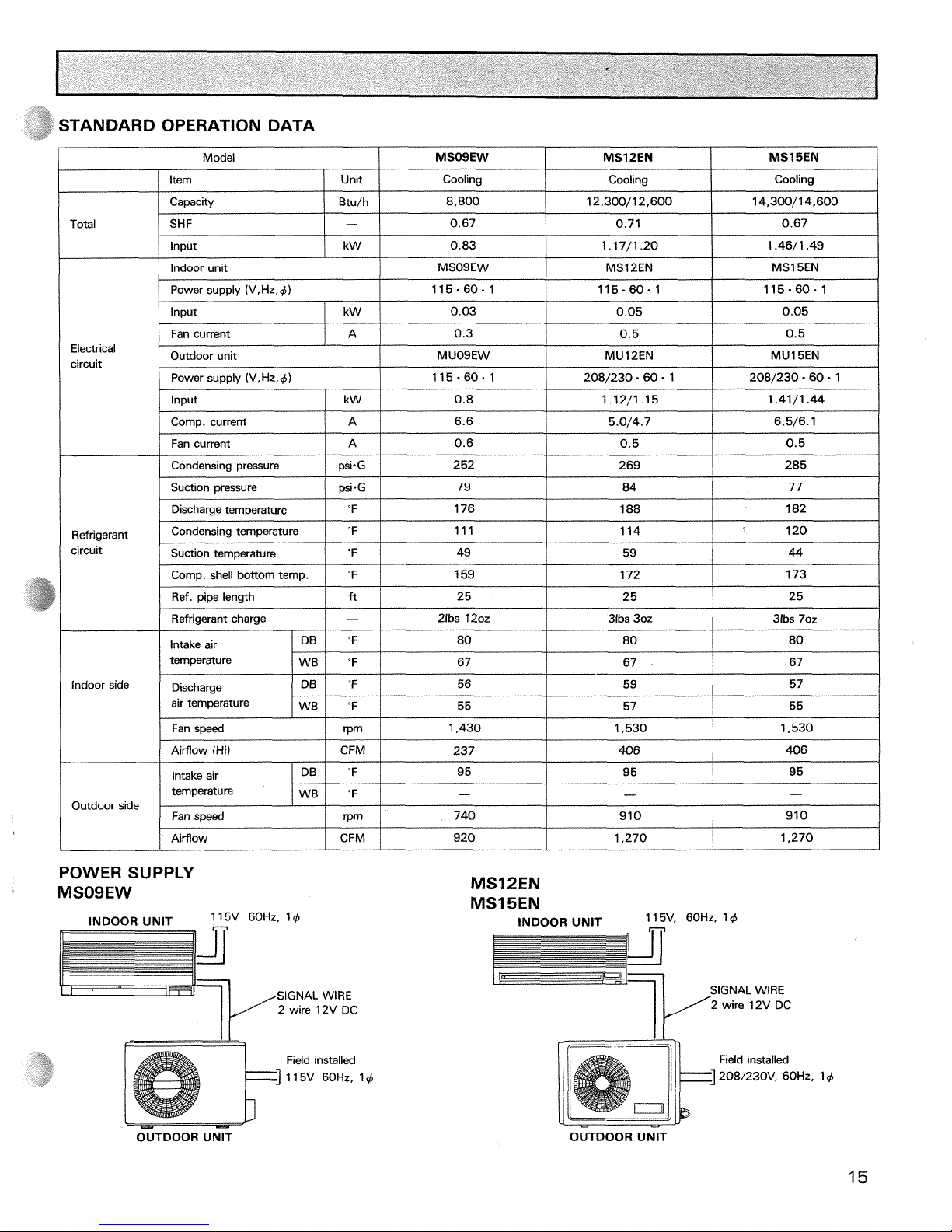

TANDARD OPERATION DATA

I

[tern

/

Unit

1

Cooling

1

Cooling

I

Cooling

I

Model

MSOSEW MSl

PEN

Total

MSl

BEN

Input

Capacity

SHF

Power supply (V,Hz,+)

kW

Electrical

circuit

I

Fan current

IAl

0.6

1

0.5

I

0.5

1

Btu/h

-

/

Indoor unit

115.60.1

Input

0.83

Input

I

kW

/

0.03 0.05

Fan current

/

Discharge temperature

I

%

I

176

1

188

I

182

I

8,800

0.67

MSO9EW

115.60.1

0.05

Power supply (V,Hz,d)

k W

Condensing pressure

Suction pressure

1.17/1.20

115-60.1

A

12,300/12,600

0.71

1.46/1.49

MSl2EN

Outdoor unit

115.60.1

0.8

6.5/6.1

Comp. current

/

A

/

6.6

psi.G

psi-G

Refrigerant

circuit

/

Refrigerant charge

1-1

2ibs 120z

1

31bs 30z

1

31bs 70z

I

14,300/14,600

0.67

MS1 SEN

0.3

5.0/4.7

Comp. shell bottom temp.

Ref. pipe length

MUO9EW

208/230.60

-

1

1.12/1.15

252

79

Condensing temperature

Suction temperature

indoor side Discharge

air temperature

208/230.60

1

0.5

1.41/1.44

"F

ft

/

Fan speed

/

rpm

I

1,430

1

1,530

I

1,530

I

0.5

MU12EN

ppp

269

84

"F

'F

Intake air

temperature

MU1 SEN

285

77

159

25

"F

'F

DB

WB

/

Airflow

I

CFM

/

920

I

1,270

I

1,270

1

111

49

Outdoor side

POWER SUPPLY

MSOSEW

172

25

80

67

INDOOR UNlT

60Hz,

'4

n

n

II

1 14

59

173

25

SIGNAL

WIRE

2 wire 12V DC

120

44

80

67

Airflow (Hi)

Field installed

1

15V 60Hz, 14

80

67

CFM

"F

"F

rpm

Intake air

temperature

MS12EN

MS15EN

INDOOR UNlT

11 5V. 60Hz. 1 4

DB

WB

SIGNAL

WlRE

237

95

-

740

Fan speed

It'

2 wire 12V DC

OUTDOOR UNlT

406

95

-

910

OUTDOOR UNlT

406

95

-

910

Page 17

Model

Item

I

unit

Total

MSMI

8EW

Input

Single

Capacity

Input

Double

kW

Electrical

circuit

I

Condensing pressure

I

P+G

I

245

I

270

I

Cooling

SHF

-

0.7 0.7

!

Btu/h

Indoor unit model

Power supply

(V.Hz.4)

Fan current

/

A

/

0.3~2

k W

Comp. current

MSO9EW

115-60.1

0.85

0.03~2

I

Outdoor unit model

Power supply (V.Hz.4)

Input

I

kW

8,400

1.70

Fan current

IAl

1

.O

A

Suction pressure

Discharge temperature

/

Comp. shell bottom temp.

I

'F

1

166

I

8,400~2

MUM

18EW

208/230 60

.

1

(3-wire)

Refrigerant

circuit

0.82

6.5

psi-G

'F

Indoor side

1.64

7.2~2

Condensing temperature

Ref.

pipe length

Refrigerant charge

76

188

I

Airflow (Hi)

/

CFM

I

237

I

79

184

'F

ft

-

Intake air

temperature

Discharge

air temperature

Outdoor side

Suction temperature

1

'F

I

63

25

21bs

202 X 2

109

50

Fan soeed

I

rpm

I

1,430

DB

WB

DB

WB

119

Intake air

temperature

POWER

SUPPLY

'F

"F

"F

"F

Fan speed

INDOOR UNlT

DB

WB

INDOOR UNlT

n

80

67

Aifflow

/

CFM

/

1,150

rpm

-------

Field installed

208/230V,

60Hz,

56

55

'F

'F

900

i

OUTDOOR UNIT

56

55

95

-

Page 18

MSOSEW

INDOOR UNlT

4 holes 7/16 x 13/16

Wall holeb2-1/2

1

Air in

OUTLINES AND DIMENSIONS

111

2-3/16 3/4

Wireless remote controller

OUTDOOR UNlT

Air out

Air out

Drain

hoseO.D.5/8

Insulation 0.0.1

-

1 /8

REQUIRED SPACE

Unit

:

inch

Wiring hole

43-7/8

Refrigerant

pipe

(Flared)

0.

D.3/8

Note

:

The symbol 4 indicates diameter

Page 19

Installation plate

LiquidlineO.D.5/46-19-11/16

Flare joint 1 /4F

Gas line O.D.3/8-16-15/16

Insulation Flare joint 5/8F

0.D.2-3/16

O.D.l-1/8

--

--3

MODEL MS12EN

Unit : inch

MS15EN

INDOOR UNlT

3-1/2

32-1 /4

3-1 /2

INDOOR UNIT REQUIRED SPACE

-

-

4 In or more

4-3/8 In or more

OUTDOOR UNlT

b

i&------

q5-i

:

i

i i

-

-

I

-

7

-

-

- - -

- - -

-.

-

-

I

-

i

P.

-

L

i

Page 20

0DEL:MUM-18EW

OUTDOOR UNIT

REQUIRED SPACE

Unit

:

inch

Air in

4

Installation anchor holes

Air

out

Wiring hole

6

3-7/8

1

Refr~gerant

ppe(Flared)

#I

14

Refr~gerant Unit center

'

ppe(Flare4

@3/8

NOTE

:

The symbol # indicates diameter.

Page 21

MODEL

MSOSEW WIRING DIAGRAM

1

TO OUTDOOR

UNIT

--

CON N ECTl NG

DC12V

--

WIRING DIAGRAM

NOTES

:

1.

For outdoor electric wiring refer to the outdoor unit electric wiring diagram.

2.

Use copper conductors only. (For field wiring)

3.

Symbols below indicate.

Q

:

Terminal block,

:

Connector.

SYMBOL

C

DSAR

F

MF

NR

SYMBOL

RTl 1

RT12

T

TB1,2

Xl l-14

NAME

INDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE

(2A)

INDOOR FAN MOTOR (INNER THERMOSTAT)

VARISTOR

NAME

ROOM TEMPERATURE THERMISTOR

INDOOR COIL THERMISTOR

TRANSFORMER

INDOOR TERMINAL BLOCK

INDOOR FAN MOTOR RELAY

Page 22

MODEL MUOQEW WIRING DIAGRAM

POWER

--

--

SUPPLY L1

1

l5V

lphase

-

-

--

N

60Hz

:--'-'-A

I

IBLK:

;2

SLKn

+

GROUND

BLK

RED

MF

I

WHT

FROM INDOOR

UNIT

CONNECTING WIRES

----zFo,

----

52C

12VDC

I

MC I COMPRESSOR

/

52C / CONTACTOR

1

I

MF I OUTDOOR FAN MOTOR (INNER THERMOSTAT)

/

1

I

SYMBOL

C 1

C2

NOTE

:

Use

copper conductors only (For field wiring).

SYMBOL

TB1.2

51C

NAME

COMPRESSOR CAPACITOR

OUTDOOR FAN MOTOR CAPAClTOR

NAME

TERMINAL BLOCK

OVERCURRENT RELAY

Page 23

MS12EN

MSI~EN

WIRING DIAGRAM

WHT

SUPPLY

-

-

TO OUTDOOR

UNIT

--

CONNECTING

12VDC

--

NOTES

:

1.

For outdoor electric wiring refer to the outdoor unit electric wiring diagram.

2.

Use copper conductors only. (For field wiring)

3.

Symbols below indicate.

Q

:

Terminal block,

-1

:

Connector.

SYMBOL

C

DSAR

F

MF

NR

SYMBOL

RTl 1

RT12,14

T

TB1.2

Xll-14

NAME

INDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE (2A)

INDOOR FAN MOTOR

VARISTOR

NAME

ROOM TEMPERATURE THERMISTOR

INDOOR

COIL THERMISTOR

TRANSFORMER

INDOOR TERMINAL BLOCK

INDOOR FAN MOTOR RELAY

Page 24

MODEL

MU

12EN WIRING DIAGRAM

zL

ED

ol

T

WHT

;i

sqR

POWER SUPPLY NO COM

208/230V

1

phase

60Hz

---

BLU

RED

L2

ELK

+

-

RED

GROUND

MF

ORN

FROM INDOOR UNIT

CONNECTING WIRES

12VDC

2

I

I I

MC

/

COMPRESSOR

/

52C

/

CONTACTOR

I

/

MF

/

OUTDOOR FAN MOTOR (INNER THERMOSTATI

/

1

I

r

SYMBOL

C6 1

C65

NOTE

:

Use copper conductors only (For field wiring).

SYMBOL

TB1,2

51 C

NAME

COMPRESSOR CAPACITOR

OUTDOOR FAN CAPACITOR

MODEL MU l5EN WIRING DIAGRAM

NAME

OUTDOOR TERMINAL BLOCK

OVERCURRENT RELAY

---

POWER SUPPLY

208/230V

1

phase

60Hz

BLU

RED

ELK

-

GROUND

FROM INDOOR UNIT

CONNECTING WIRES

12VDC

52C

2

/

SYMBOL

I

NAME

/

SYMBOL

I

NAME

I

I

I

C61 I COMPRESSOR CAPACITOR

/

MF

I

OUTDOOR FAN MOTOR (INNER THERMOSTAT)

I

I

C65 I OUTDOOR FAN CAPACITOR

/

TBI

,2

I

OUTDOOR TERMINAL BLOCK

1

NOTE

:

Use copper conductors only (For field wiring).

Page 25

MODEL MUM18EW WIRING DIAGRAM

lphase

3wires

POWER

SUPPLY

WHT

2

1

MF

3

5

FROM INWOR

UNIT

No.

A

CONNECTING

WIRES

l2VDC

---

FROM UNIT No. INDOOR B

---

:-@

CONNECTING

WIRES

-

--

l2VDC

(-)

SYMBOL

C1,2

C3

MC1,2

J

NOTES

:

1.

Use copper conductors only. (For field wiring)

2.

Symbols below indicate.

0

:

Terminal block,

:

Connector.

NAME

COMPRESSOR CAPACITOR

OllTDOOR

FAN

MOTOR CAPACFOR

COMPRESSOR

SYMBOL

MF

TB1-3

XI ,2

NAME

WlWOR

FAN

MOmR

INNER

THERWAD

TERMINAL BLOCK

OUTDOOR FAN RELAY

SYMBOL

51C1.2

52C1.2

NAME

OVERCURRENT RELAY

CONTACTOR

Page 26

REFRIGERANT SYSTEM DIAGRAM

.

I

Indoorunit

1

Refngerant pipe 43/8

(Opt~on)

(with heat insulator)

connection

1

Unit:

inch

1

Outdoorunit

1

Strainer

i_

I

/I

connection

(I

I

Refrigerant pipe 4 1 /4 Ball valve

Capillary tube 0~0.12 x ID0.063 x47-1/4

(Option) with service

(with heat insulator) port

f

Indoor unit

1

Refnqerant pipe Q5/8

Room temperature

thermistor RTl1

b

I

Service

ared connectio

Accumulator

Muffler

rn

Compressor

I

Outdoor unit

1

Flared connection

MU12EN ODO. 12 xID0.063 X27-9/16

\

I/

MUISEN OD0.12X1D0.063X23-5/8

Refrigerant pipe41 /4

"

Ball valve

(Option) (with service port)

(wkh heat insulator)

+Flow of refrigerant

NOTE:

The symbol

d,

indicates diameter.

Page 27

MS09EW x2/MUMl8EW

Unit: inch

1

Indoor

unit

]

1

Outdoor

unit

1

Refrigerant pipe +3/8

(Option)

(with heat insulator)

'fE53

I-.+&

Flared

'

Ball valve

connection

ODO. 12

X

100.055 X23-5/8

bith heat insulator)

U

Room

I

I

11

temperature

Refrigerant pipe +3/8

IO~tion)

;!',--$t.a463m

C-

Indoor coil

I I

11

thermistor Refrigerant pipe 4 1

/4

Ball valve

Capillary tube Strainer

RT11 (Option) with service

port

I

Room

temperature

thermistor

RTl 1

-

Capillary tube Strainer

Refrigerant pipe

+

1

/4

Ball valve

(Option) with service

port

(with heat insulator)

--.

Flow of refrigerant

Page 28

MICROPROCESSOR CONTROL

Wireless Remote Controller

SENDING SECTION

I

LCD

INDICATOR

rooi

DRY

MASTER CONTROL

button

LO

FAN CONTROL

HI

bunon

St1 TEMP

SET TEMP.

bunons

AUTO

STOP

TIMER CONTROL

AUTO

SPRT

bunon

HOURS

TIME SETTING

bunons

TO0 COOL

OKAY

TOO

WARM

POWER

bunon

I

'I FEEL" CONTROL bunons

This figure shows

I

FEEL CONTROL mode display.

[

INDOOR UNIT DISPLAY SECTION

I

I

FEEL MONITOR

bb.

POWER

...

...

Once the controls are set, the same operation mode can

be

repeated by simply turning the POWER switch ON.

Indoor unit receives the signal with a beep tone.

When the system turns off,

"3

min. time-delay function" will

operate to protect system from over load and compressor will

not restart for

3

minutes.

1.

"I

FEEL

CONTROL" operation

(1 ) Press POWER button on the remote controller. Power

lamp of the indoor unit will tum on with a beep tone.

(2)

Press the MASTER CONTROL button to set

"I

FEEL

. . .

".

And I FEEL MONITOR lamp lights with a beep tone.

(3)

The operation mode is decided by the initial room

temp. at starting up the operation.

1

Initial Room Temp.

/

Mode

!

*Once the mode is fixed, the mode will not change by

room temp. afterwards.

*Under the AUTO START timer operation, the mode is

determined according to the room temperature

1

hour

before the set time.

When the system is stopped with the POWER button on

the remote controller, and restarted within

1

hour in

"I

FEEL CONTROL" mode, the system operates in previous

mode automatically regardless of the room temp.

When the system is restarted after 1 hour, the operation

mode is decided by the initial room temperature at start-up

of the operation.

Example

Previous operation

COOL mode of

"I FEEL CONTROL"

COOL mode of

or COOL mode

Page 29

(4)

The initial set temperature is decided by the initial room temperature for the first 2 min. after the system starts.

tG

UI

JTROL"

/

Less than 76°F

Initial room temperature

minus 2 deg("F)

Initial set temperature

Model

%

1

After the system restarts by the remote controller, the system operates with the previous set temperature regardless

of the initial set temperature.

Initial room temperature

(5)

1

FEEL CONTROL buttons

In

'I

FEEL CONTROL" mode, set temperature is decided by the microprocessor based on the room temperature. In

addition, set temperature is controlled by

I

FEEL buttons when you feel too cool or too warm, and when you feel

comfortable the button fixes the comfortable temperature.

When the

I

FEEL button is pressed, I FEEL MONITOR lamp on the indoor unit flickers for a second with beeps.

*Variable control

When the

TOO COOL

or

TOO

WARM

-

button is pressed, the set temperature is changed based on the room temperature. As the

set temperature range is variable, this is called "Variable control". The variable control operates only in

'I

FEEL

CONTROL" mode.

In DRY mode of

'I

FEEL CONTROL". the set temperature range is fixed

+

2

deg ("F).

:=!.-.To raise the set temperature by

2

deg.

--

3

deg.('F)

OKAY

--.To fix and memorize the comfortable present temperature

0

WARM--^^

lower the set temperature 2 deg.

--

3

deg. ('F)

0

-

I

FEEL

MONITOR

lamp

on the indoor unit

-

When I FEEL CONTROL button is pressed, I FEEL MONITOR lamp on the indoor unit flickers with beeps and shows the

temperature control condition.

I

FEEL MONITOR lamp

\,

\I

\I

b-b

Shows difference between set temperature and room temperature is more than 3 deg. ("F)

t\

I,

I

\

During this condition, I FEEL button is not available.

Wait for about 15 min.

D

Shows difference between set temperature and room temperature is 2 deg.

-3

deg. (OF)

\I

The buttons are available.

DD*

Shows room temperature has almost reached set temperature. The difference is less than 2°F.

The buttons are available.

NOTE

During

"I

FEEL CONTROL" operation, thermostat (SET TEMP.) is not available. Use

"I

FEEL CONVKN-"

buttons to set temperature

Once the set temperature is set, the microprocessor memorizes the temperature and the system restarts at

the same set temperature.

*The set temperature range is 61 to 88F in COOL

DRY mode of

'I

FEEL CONTROL".

When the main power is turned off, the settings are canceled. Initial set temperature will be decided as

shown in the above table.

Page 30

-

COOL mode of

"I

FEEL CONTROL"

-

ON ON

Compressor

&

OFF

1

OFF

Outdoor fan motor

I

ON

Runs all \he time in cooling mode

Indoor fan motor

NOTE Coil frost prevention during COOL mode of

'I

FEEL CONTROL".

There are two types of controls in coil frost prevention.

@

Temperature control

<MS09>

When the indoor coil thermistor RTI 2 reads 47°F or below for 5 min., the coil frost prevention starts. The compressor stops

and the indoor fan operates at set speed or AUTO speed for 5 min. After that if

RTI 2 still reads 47°F or below, this function

is prolonged until

RTI 2 reads over 47°F.

<MS12/15>

MS12/15 have two indoor coil thermistors RTI 2 and RTI 4. When RTI 2 (or RTI 4) reads 50°F or below for 5 min., the

coil frost prevention starts. The compressor stops and the indoor fan operates at set speed or AUTO speed for 5 min. After

that, if

RT12 (or RT14) still read(s) 50°F or below, this function is prolonged until RT12 (or RT14) read(s) over 50°F.

@

Time control

When the three conditions below have been satisfied for 1 hour and 45 minutes, the compressor stops for

3

minutes and

the coil frost prevention mode starts.

(a)The compressor is on continuously.

(b)The indoor fan speed is LO or MED.

(c)The room temperature is below 79°F.

If the compressor turns off half way, the accumulated time is cancelled.

Time counting starts from the beginning when the above three conditions are satisfied again.

If the indoor fan speed becomes

HI or the room temperature exceeds 79"F, time counting stops temporarily.

Time counting restarts from the stop point when the above three conditions are satisfied again.

The indoor fan operates at the set speed.

*Indoor fan operates at the set speed

by

FAN CONTROL switch.

Followings are' the fan speed in AUTO.

Room temperature minus set temperature

:

4 to 7 deg.("F) or over-.........--HI

-

- - - - - - - - -

-

Room temperature minus set temperature : 2 to 7 deg.("F)

..--.-....-.....--.-.

MED

----.-

t

4

deg. 7 deg

Room temperature minus set temperature : 2 to 3 deg.('F) or below -....-.LO

- - - - -

f

2deg.

3deg.

-

DRY

mode of

"I

FEEL CONTROL"

-

The system uses the same refrigerant circuit as the cooling circuit for dry operation.

The compressor and the indoor fan are controlled by both temperature and the microprocessor.

By such controls, indoor flow amounts will be reduced in order to lower humidity without much room temperature decrease.

The operation of the

comp. and indoor fan is as follows on the next page.

1.

When the room temperature is 73°F or over

Compressor operates by temperature control and time control.

For the first 2 min. the system is FAN mode and the indoor fan operates at very low speed.

Then 2 min. later, the room temperature is read as the initial temperature.

@Set temperature is controlled to fall by 2°F as initial set temperature.

Page 31

@When the thermostat is ON, the compressor repeats 8 rnin. ON/3 rnin. OFF cycle operation.

When the thermostat is OFF, the compressor repeats 4 rnin. OFF/1 min. ON cycle operation.

indoor and outdoor fans operate in the same cycle with compressor.

lndoor fan speed is very low.

2.

When the room temperature is under

73°F.

Compressor works in 2 min. ON/3 min. OFF cycle while the thermostat is on.

When the thermostat is OFF, the compressor repeats 4 rnin. OFF/1 min. ON cycle operation.

lndoor and outdoor fans operate in the same cycle with compressor.

lndoor fan speed is Very low

Operation Time

Chart

1st ON

Example

7

Thermostat

!

lndoor fan OFF

I

VLO

speed

Outdoor fan OFF

/

compressor

2

min.

j

I

OFF

I

OFF

, , , , , , ,

,

, , , ,

,

,

m,

ON

, ,

, ,

OFF

!

2

0

2,

NOTE *Coil frost prevention during DRY mode of

"I

FEEL CONTROL"

The operation is same as coil frost prevention during COOL mode of

"I

FEEL CONTROL" except the indoor

fan speed is VLo.

*In DRY mode of

"I

FEEL CONTROL", FAN CONTROL switch is not available.

2.

COOL

operation

(1 ) Press POWER button.

Power lamp of the indoor unit turns on with a beep tone.

lndoor fan continues to operate regardless of thermostat's OFF-ON.

Coil frost prevention is the same as COOL mode of

"I

FEEL CONTROL".

(2)

Select COOL mode.

(3) Set the SET TEMP. button.

F

The setting range is 61 to 88°F.

95.

*"I

FEEL CONTROL" buttons are not available.

(4) The indoor fan runs continuously to provide venti-

lation and prevent air stratification.

90-

3.

DRY

operation

85-

(1)

Press POWER ON/OFF button.

E.

Power lamp of the indoor unit turns on with a beep tone.

$

80:.

(2)

Select DRY mode.

8.1

(3)

lndoor fan operates at VLO speed.

E.

8-

(4)

After 2 rnin. the microprocessor reads the room temperature

5

75:

and decides the set temperature. Set temperature will be as

shown on the chart.

70-

Thermostat

(SET

TEMP.) is not available.

The other operations are same as DRY mode of

"I

FEEL CONTROL".

65.

30

65

70

75 80 85 90 95

100'F

Set temperature and ~nitial room temperature

/

/

/I

/

/

/

Page 32

4.

FAN

operation

(1) Press POWER ON/OFF button.

(2) Select FAN mode.

(3) Press SET TEMP. button to select the desired temperature.

The indoor fan stops when room temperature is lower than the set temperature

(4) Select the desired fan speed.

Followings are the fan speed in AUTO.

Room temperature minus set temperature

:

4 to 7 deg.("F) or over.....-...-..HI

- -

- - -

-

-

-

Room temperature minus set temperature : 2 to 7 deg.("F)

......-.....-.-.....-MED

- - -

-

-

Room temperature minus set temperature : -2 to 3 deg.("F)

..-...............

LO

---

Room temperature minus set temperature : -2 to 0 deg.("F) or below

..-...

Only indoor fan operates.

Outdoor unit does not operate.

SOFT SLEEP CIRCUIT

5.

TIMER

4

1 . AUTO STOP operation

AUTO STOP mode has "SOFT SLEEP" circuit which provides comfortable

temperature control for sleeping.

3

(1) Set the TIMER CONTROL to AUTO STOP.

2

4..

(2) Set the time. Time setting is in 1 hour units for up to 12 hours.

8

ti

2

(3) "SOFT SLEEP" circuit operates in COOL mode. By this circuit, system

operates at the set temperature for the first 1 hour. Then, in COOL mode

the set temperature rises by 1 deg. half-hourly to

2

deg. range.

1

In

"I

FEEL CONTROL and DRY mode, the circuit does not operate.

Set temperature

1 Hour

2

Hours

2.

AUTO START operation

(1) Set the TIMER CONTROL button to AUTO START.

(2) Set the time. Time setting is in 1 hour units for up to 12 hours.

NOTE

TIMER setting will be canceled by power failure or breaker functioning.

6.

EMERGENCY-TEST operation

When the remote controller is missing, has failed or the batteries run down, press the emergency run on/off switch on the

front of the indoor unit. The unit will start and the operation lamp will light.

The first 30 min. of operation will be the test run operation. This operation is for servicing. The indoor fan runs at high speed

and the system is in continuous operation.

The thermostat does not operate and the timer is reset to normal.

After 30 min. of test run operation the system shifts to emergency run operation with a set temperature of 75°F in cooling.

The fan shifts to MED speed.

This operation continues until the emergency run

on/off button is pressed or a button on the remote control is pressed, then

normal operation will start.

The coil frost prevention circuit operates in this mode.

EMERGENCY RUN

EMERG~NCY

ON/OFF

button

Page 33

1.

AUTO RESTART FUNCTION

When the indoor unit is controlled by the remote controller; the operation mode, set temperature, and the fan speed are

memorized by the indoor electronic control P.C. board. After power failure, the unit operates automatically when power is

restored. In case of unit operated in

'I

FEEL CONTROL"

mode before power failure, the operation is not memorized. In

'I

FEEL CONTROL" mode, the operation is decided

by

the initial temperature. Refer to page 28.

How to set AUTO RESTART FUNCTION

Cut the jumper wire JR84

Operation

a) If main power

(ACI 15V) is cut, the operation settings remain.

b)

When power is restored, the unit restarts in previous mode 3 minutes later without remote controller.

c) Even if power is cut for about 0.5 seconds, auto restart works.

Note

a) If main power is cut while AUTO START/STOP timer is set, the timer setting is cancelled when auto restart function

works.

b) If the unit was off by the remote controller before power failure, auto restart function does not work as the power button

of the remote controller is off.

[q

2.

How to reconstruct for individual operation

SERVICE FUNCTION

A

maximum of 4 units with wireless remote controllers can

be

used in a room. In this case, reconstruction of

P.C.

boards is needed

to operate each unit individually by each remote controller.

The transmission code is changed by the reconstruction.

1 . Reconstruction of the remote controller

P.

C.

board.

Remove batteries before reconstruction.

/-

&

I&

are printed on the board.

Originally, chip parts are fitted on J10/J20 side and there is no chip parts on the other side.

Remove the chip parts of

J

10/J20 side and connect Jumper wire to J11 /J21 side according to the number of the

individual control.

Either J 10 or J 1

1

/J20 or J2 1 should be attatched for normal operation.

Standard reconstrucion table

1

/

1 unit operation

1

2 units operation

1

3

units operation

1

4

units operation

1

/

No. 1 unit No construction

1

Same as left

I

Same as left

I

Same as left

I

Reconstruction of the indoor electronic control

P.

C

.

board.

JR05

JR06

is printed on the board. Refer to TEST POINT VOLTAGE in the manual for the print point.

Jumper wire are fitted to JR05 and JR06.

Reconstruct JR05 and JR06 to corespond to the remote controller board.

L

No.2 unit

No.3 unit

No.4 unit

I

I

1 unit operation

1

2 units operation

1

3

units operation

1

4

units operation

/

-

-

-

No. 1 unit

No.2 unit

/

No.4unit

1

-

I

-

I

-

I

Remove JR05, JR06

I

Same as left

Remove

J 1 0

Connect

to

J

1 1

-

Connect

to

~2

1

Remove

J20

-

-

No.3 unit

Same as left

Same as left

Remove

J10, J20

Connect

to

J

1 1 ,

J2

1

No construction

-

J

-

Same as left

Remove JR05

-

Same as left

Same as left

Same as left

Same as left

Remove JR06

Same as left

Page 34

Self

check

function

This function is to show defective point by lighting or flashing of the indoor unit power lamp, or

"I

FEEL

monitor lamp (monitor

LED). If trouble written in the below table occurs during operation, the self check result is indicated.

The abnormal cation

indication is reset by pressing the power on/off button of the remote controller and when the unit is on.

10

1I_;

*

Before taking measures make sure that the symptom reappears, for accurate troubleshooting.

TROUBLE

SHOOTING

Self Check Table

;m:

Flash

0

OFF

Abnormal point

indication

Symptom

Detect

methd

Cause

Repair

lndoor coil thermistor

,

POWER

D

~1.1

I

FEEL

MONITOR

lndoor unit power turns off.

Detects lndoor coil thermistor short or open circuit every

2

sec. during operation.

Thermistor defect

Connector disconnecting

0

Connector misconnecting

lndoor control P.C. board defect

Check thermistor calibration.

0

Reconnect connector.

0

Check indoor board.

Page 35

(I

)

Operation does not start

(Stan)

I

Check power supply voltage on indoor

terminal block.

Is there 1 15V AC between indoor

Turn on power supply

terminal block

[IT]

-

?

Yes

/

\

Does+signal mark appear for an instant

on Remote Controller when POWER button is

pressed

?

Yes

,

Is battery voltage

over 2.4V

?

Does emergency run start by

No

pressing EMERGENCY button

?

Yes Replace Remote controller

Check Electronic control P.C. board voltage.

a)

CN102

@ - @

:

12-20VAC

b) CN109@+

-

0-

:

5V

See the TEST POINT DIAGRAM VOLTAGE on page

37.

Replace Electronic

control P.C. board.

.

Does indoor unit receive signal

with a beep tone when POWER

Replace Receiver board.

button is pressed

?

Check power P.C. board

qvOltage.

CN204

0

-

@

:

Replace

Power P. C. board

Page 36

Compressor and outdoor fan do not operate (Only indoor fan operates)

Press EMERGENCY ON/OFF bunon

3 min

.

time-delay function operates.

Test mode operates for 30 min.

MS12/15EN

Is there 230V AC between

-

a

on

outdoor terminal block

?

No

L

Tum on outdoor

MSOSEW power supply.

Is there

1

15V AC between

-

m.

Yes

Check voltage to contactor 52C

Yes

Is there 1 2V DC between

(

+

'

-

2

-

1

of

c

Check Contactor 52C

outdoor term~nal block TB2

7

If defectwe replace.

*

No

is there 12V DC between.li(+)

-

211-1

of

Yes

Check

cont~nu~ty

of

Indoor term~nal block TB2

?

L

~ndoor and outdoor untt

control wiring.

J

Replace the power P. C. board.

Check resistance of room temp. thermistor RT1 1.

NO

e

Replace Room temp.

See the thermistor resistance on page

37.

thermistor RT11.

i

Yes

Is there 12V DC between CN 1020-

-

@

+

NO

on the Indoor electronic control P.C. board

?

*

Replace the indoor electronic

control P.C. board

Yes

Page 37

RELAY OPERATION

NOTE : When the compressor is OFF,

"3

min. time-delay circuit" operates

MODE

COIL FROST PREVENTION mode are as follows

THERMOSTAT

]

52C CONTACTOR

1

INDOOR FAN RELAY

THERMOSTAT

Indoor

fan

relav mode

52C CONTACTOR

OFF for 5 min. After

that, OFF is prolonged

until indoor coil thermistor reads termina-

tion temp.

1

Indoor fan speed

I

Relay turning ON

1

HI

I

OFF

I

All fan relavs are off

I

XI4

LO

INDOOR FAN RELAY

Auto or set speed

Very low speed

XI

2

MED

VLO

XI

1

i

XI

3

I

Page 38

TEST POINT DIAGRAM AND VOLTAGE

MSOQEN

MS12/15EN

In/out signal circuit

Power supply

25-30V

AC

Ir

In/out siganl

output

24-OV

DC

Indoor electronic control

P.C.

board

I

Reconstruction of indoor

:;i

$

Defrost thermistor

-

"---Auto restart

function switch

Room temperature

thermistor

electronic control

P.

C. board

I

$.

Room temperature

Thermistor RTl 1

20

5

15

Y

-

E

E

'3

10

d

5

60 70 7780 90 100

Defrost

Thermistor RT12.RT14

Temperature

('F)

Temperature

('F)

Page 39

MSOSEW

Power P.C. board

Transformer

Output lnput Output

12-20V

AC

1 15V

AC

25-30V

AC

-,----.-

aQQIaB a

I

lnput

1 15V

AC

In/out signal

12-1 4V

DC

Indoor fan motor relay signal

Page 40

NIS12/15EN

Power

P.C.

board

Transformer

Output Input

12--20V AC 1 1 5V AC

In/out signal

~~2550 - LD2570

lnput

1

i5~

AC

12-16V DC

Page 41

OPTIONAL PARTS

1.

REFRIGERANT PIPES

The air conditioner has flared connections on its indoor and outdoor sides.

Please use the optional extension pipe as follows.

Applicable

Parts No. Pipe length

models

Pipe Size

0.

D

A.Gas (in.)

B.

Liquid (in.)

I

Additional

refrigerant

Page 42

THIS PAGE LEFT INTENTIONALLY BLANK.

Page 43

STANDARD PARTS

INDOOR UNIT PARTS

MSOSEW

Page 44

Parts Name

I

I

1 I T2W 901 000 / FRONT PANEL ASSEMBLY

Symbol

1

Q'tvhnit

1

in

Wiring Remarks

Diagram MSO9EW

1

Air filter wire is included

2 T2W 901 067 SCREW CAP 2

3 T2W 901 100 AIR FILTER 2

4

/

M21 K17 022 / AIR FILTER WIRE

1 1

2

I

5 1 T2W 901 004 / SWITCH DOOR

1 1

1

I

6 1 T2W 901 234 1 BOX ASSEMBLY

1 1

1

I

7 T2W 901 975 CORNER BOX 1

8 M21 BOO 970 INSTALLATION PLATE 1

9

1

T2W 901 081 1 ELECTRICAL BOX 1

10

1

T2W 901 339 1 TRANSFORMER T 1

11

/

T2W 901 443 1 SWITCH P.C. BOARD

1 1

1

I

12 T2W 712 781 LAMP HOLDER 1

13 T2W 901 329 DISPLAY P.C. BOARD 1

14

/

M21 534 375 1 INDOOR TERMINAL BLOCK

1

TB1

I

1

1

15 T2W 901 375 INDOOR TERMINAL BLOCK

TB2 1

16 T2W 901 450

ELECTRONIC CONTROL P.C. BOARD 1

17 T2W 901 440

POWER P.C. BOARD 1

18 T2W 901 300 INDOOR FAN MOTOR MF 1 RA4W11-

AA

19 / M21 BOO 302 / LINE FLOW FAN

I

1

1

1

20 M21 453 505 RUBBER MOUNT 2

21 T2W 41 6 382 FUSE (2A) F 1

22

1

T2W 901 235 1 NOZZLE ASSEMBLY

1 1

1

I

I

I

1

I

I

23 1 T2W 901 040 1 VANE 1

24

1

M21 BOO 041 1 VANE HOLDER

1

I

1

I

25 M21 B03 703 DRAIN HOSE 1

26 M21 NO0 468 RECEIVER P.C. BOARD 1

27

/

T2W 901 320

/.

SLIDE KNOB

1

I

1

1

28 T2W 723 307 ROOM TEMPERATURE THERMISTOR RTl

I

1

29

/

T2W

A04 308 INDOOR COIL THERMISTOR RT12 1

30

/

T2W 676 620 / INDOOR HEAT EXCHANGER

1

1

1

1

31

M21

BOO 509 BEARING MOUNT

1

32

M21

BOO 504 SLEEVE BEARING

1

Page 45

OUTDOOR UNIT PARTS

MUOSEW

1 2 1

M21 478 297 1 TOP PANEL

1 1

1

1

I

No.

1

Parts Name

CABINET ASSEMBLY

Parts No.

T2W 464 232

3

4

1 7 1

T2W 457 641 / CHARGE PLUG

I

1

2

I

I

5

6

1 8 1

T2W 416 642 1 FUSIBLE PLUG

I I

1

I

I

Symbol

Wiring

In

Diagram

T2W 41 6 521

M21

A00 245

T2W 41 6 630

T92 513 200

1

12 1 T2W 41 6 509 / OUTER NOZZLE

1

I

1

1

I

Q'ty/unit

MUO9EW

1

FAN GUARD

SERVICE PANEL

9

10

11

1

13 / T2W 464 290 / BASE ASSEMBLY

1

I

1

1

I

Remarks

1

1

OUTDOOR HEAT EXCHANGER

COMPRESSOR

1

14 1 T2W 679 301 / OUTDOOR FAN MOTOR

1

MF

I

1

/

SGW-26C-CB

I

M21 987 936

T2W 460 661

T2W 460 662

MC

CAPILLARY TUBE

VALVE (GAS)

VALVE (LIQUID)

15

16

19

1

T2W 679 350 / OUTDOOR FAN MOTOR CAPACITOR

I

C2

/

1

/

5,uF

250V

1

1

17

18

KH-122WES

1

1

1

M21 601 501

T2W 81

1

375

40.12~

40.063 x 126

M21 534 375

T2W 903 353

20

21

PROPELLER

OUTDOOR TERMINAL BLOCK

22

OUTDOOR TERMINAL BLOCK

COMPRESSOR CAPACITOR

T2W 464 340

T2W 382 342

TB

1

I

44

T2W 460 246

1

1

TB2

C1

OVERCURRENT RELAY+

CONTACTOR

VALVE COVER

1

1

51 C

52C

1

55,uF 220V

1

1

Page 46

OUTDOOR UNIT

MUM18EW

Refer

to

MSOSEW

for

PARTS

indoor unit

Parts No. Parts Name

I

I

1 I T2W 382 342 1 CONTACTOR

Symbol Q'tvhnit

in

Wiring

Remarks

Diagram MUM

18EW

52C1.52C2 2

2 T2W 462 232 CABINET 1

3 T2W 667 249 SIDE PANEL 1

4

/

T2W 739 245 1 SERVICE PANEL

1 1

1

I

1

5 T2W 466 509 OUTER NOZZLE 1

6 T2W 466 301 OUTDOOR FAN MOTOR MF 1 SGW-6OF-AC

7

/

R01 093 11 5 1 PROPELLER

1

I

1

1

I

7T2W 903 353 COMPRESSOR CAPACITOR

I

I

I

C1, C2 2 55j4 F 220V

1

9 / T2W 466 342 1 OUTDOOR FAN RELAY

I

x1,x2

/

2

1

I

800 375 OUTDOOR TERMINAL BLOCK TB 1 1

464 340 OVERCURRENT RELAY 51C1 ,51C2 2

OUTDOOR FAN CAPACITOR C3 1

1

8pF 220V

OUTDOOR HEAT EXCHANGER 1

14

/

T2W 457 641 1 CHARGE PLUG

1

I

4

I

I

15 T2W 416 642 FUSIBLE PLUG

*I

1

VALVE (LIQUID)

1

2

17 T2W 460 662 VALVE (GAS) 2

18 T92 513 200 COMPRESSOR

MCI, MC2 2 KH-122WES

19

1

T2W 739 246 1 VALVE COVER

I I

1

1

I

I

I

I

I I

20 T2W 233 936 CAPILLARY TUBE 2

I

dO.12~dO.055~43-5/16

21

1

M21 534 375 / TERMINAL BLOCK

1

TB2.3

I

2

I

I

22 T2W 359 378 TERMINAL BLOCK 1

23 T2W 739 290 BASE ASSEMBLY 1

Page 47

INDOOR UNITS PARTS

MS12EN

MSl5EN

1

Page 48

Parts Name

In

Wiring Remarks

Diagram MS12EN MS1 SEN

FRONT PANEL ASSEMBLY 1 1

Parts No.

AIR FILTER

2 2

SWITCH DOOR

1 1

SCREW CAP

1

13/31

BOX ASSEMBLY

I

~1~1~

INSTALLATION PLATE

1

~1~1~

INDOOR HEAT EXCHANGER

I

1

ELECTRICAL BOX 1 1

ELECTRONIC CONTROL P.C. BOARD

1

llll/

POWER P.C. BOARD

1

11/11

DISPLAY P.C. BOARD

-

1 1

LAMP HOLDER 1 1

LINE FLOW FAN

1

11 111

INDOOR FAN MOTOR MF 1 1 S4W-23 B-AA

RUBBER MOUNT 2 2

M21

BOO 504

M21 BOO 509

SLEEVE BEARING 1 1

BEARING MOUNT 1 1

INDOOR FAN CAPACITOR

/

C 11 11 14/.tF220V

SWITCH P.C. BOARD

1 1

RECEIVER P.C. BOARD 1 1

SWITCH HOLDER (KNOB SET)

1

/Ill/

ROOM TEMPERATURE THERMISTOR

RTl

I

1

1

INDOOR COIL THERMISTOR RT12,14 2 2

NOZZLE ASSEMBLY 1

1

INDOOR TERMINAL BLOCK TB2 1 1

INDOOR

TERMINAL

BLOCK

ITBIII~I

TRANSFORMER T 1 1

VANE

1

1

VANE SUPPORT SLEEVE SET

1

1

GUIDE VANE SET 16 16

DRAIN HOSE

1

11/11

PIPE SUPPORT 1 1

WATER SHIELD

1

1

Page 49

OUTDOOR UNIT PARTS

MU12EN

MU15EN

Symbol

No.

I

2

Q'tv/unit

4

I

Parts No.

T2W 708 301

R01 093 115

L

5

6

Parts Name

OUTDOOR FAN MOTOR

PROPELLER

I

M21 534 375

T2W 659 375

7

8

C6 1

C6

1

52C

T7W 966 723

T2W 913 353

T2W 359 340

C65

51

C

in

Wiring

Dgagram

MF

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

CONTACTOR

OUTDOOR TERMINAL BLOCK

OUTDOOR TERMINAL BLOCK

T2W 708 350

T2W 394 330

1

1

1

1

OUTDOOR FAN CAPACITOR

OVERCURRENT RELAY

TB

1

TB2

Remarks

S6N-50F-EC

MU12EN

1

1

1

1

1

MU1 5EN

1

I

25,uF 370V

30,uF 380V

1

1

3p F 440V

1

1

Page 50

OUTDOOR UNIT PARTS

MU12EN

MU15EN

No.

1

1

4 / T2W 521 509 / OUTER NOZZLE

1

111lI

I

2

3

Parts No.

T2W 510 232

T2W 521 245

T2W 521 249

5

6

Parts Name

CABINET ASSEMBLY

7

8

SERVICE PANEL

SIDE PANELASSEMBLY

T2W 708 290

T2W 911 515

9

10

Symbol

in

Wiring

Diagram

T2W 774 630

T92 650 452

T92 667 600

11

12

1

1

BASE ASSEMBLY

MOTORSUPPORT

T2W 457 641

T2W 41 6 642

13

1

M21

987 936

1

CAPILLARY TUBE

1

1

OUTDOOR HEAT EXCHANGER

COMPRESSOR

COMPRESSOR

T2W 460 662

R01 951 41 1

Remarks

Q'ty/unit

1

1

CHARGE PLUG

FUSIBLE PLUG

-When servicing, cut the tube to the proper length as shown in the REFRIGERANT SYSTEM DIAGRAM in MANUAL OB-099.

1

MU1 2EN

1

1

1

MC

MC

BALL VALVE (LIQUID)

BALL VALVE (GAS)

1

I

dO.12~dO.063~126

MU1 5EN

1

2

1

1

1

2

1

1

1

1

1

1

1

RH-167NAB

RH-207NFL

Page 51

ACCESSARY & REMOTE CONTROLLER PARTS

MSOSEN

MS12EN

MS15EN

-

/

Svmbol

1

Q'tv/unit

I

\lo

1

2

3

4

5

Parts No.

T2W 679 426

M21 N28 01 7

6

7

M21 N28 083

M21 478

919

M21 478

917

9

10

Parts Name

REMOTE CONTROLLER

BATTERY COVER

M21 480 708

M21 480

973

M21 480

977

M21 K50

977

REMOTE CONTROLLER HOLDER

PUrrY

PIPING TAPE

M21 480

703

M21 BOO 973

in

Wiring

Diagram

PIPE FIXING BAND

PIPE HOLE COVER

WALL HOLE SLEEVE

WALL HOLE SLEEVE

1

1

I

DRAIN HOSE

WALL HOLE COVER

1

1

I

3

1

1

Remarks

MSO9EW

1

I

3

I

1

1;;

::[

1

I

1

1

Page 52

3400 Lawrenceville Suwanee Road ● Suwanee, Georgia 30024

Toll Free: 800-433-4822 ● Toll Free Fax: 800-889-9904

Specifications are subject to change without notice.

www.mrslim.com

Loading...

Loading...