Page 1

GRAPHIC OPERATION TERMINAL

GOT SIMPLE Series

User's Manual

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury or

physical damage.

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING" and "CAUTION".

Note that the caution level may lead to a serious accident according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forward it to the end user.

[DESIGN PRECAUTIONS]

WARNING

● Some failures of the GOT or cable may keep the outputs on or off. Some failures of a touch panel

may cause malfunction of the input objects such as a touch switch. An external monitoring circuit

should be provided to check for output signals which may lead to a serious accident. Not doing so

can cause an accident due to false output or malfunction.

● Do not use the GOT as the warning device that may cause a serious accident. An independent and

redundant hardware or mechanical interlock is required to configure the device that displays and

outputs serious warning. Not doing so can cause an accident due to false output or malfunction.

● When the GOT detects its backlight failure, the GOT disables the input operation on the touch

switch(s). Thus, operators cannot operate the GOT with touches. The GOT backlight failure can be

checked with a system signal of the GOT.

● Even when the display section has dimmed due to a failure of the liquid crystal section or the

backlight on the GOT, the input operation of the touch switches may still be enabled. This may cause

an incorrect operation of the touch switches. For example, if an operator assumes that the display

section has dimmed because of the screen save function and touches the display section to cancel

the screen save, a touch switch may be activated.

A - 1

Page 4

[DESIGN PRECAUTIONS]

WARNING

● The display section of the GOT is an analog-resistive type touch panel. Simultaneous pressing of

two or more areas on the display section may activate the switch between those areas. Do not press

two or more areas simultaneously on the display section. Doing so may cause an accident due to

incorrect output or malfunction.

● When programs or parameters of the controller (such as a PLC) that is monitored by the GOT are

changed, be sure to shut off the power of the GOT promptly and power on the GOT again. Not doing

so can cause an accident due to false output or malfunction.

● If a communication fault (including cable disconnection) occurs during monitoring on the GOT,

communication between the GOT and PLC CPU is suspended and the GOT becomes inoperative. A

system where the GOT is used should be configured to perform any significant operation to the

system by using the switches of a device other than the GOT on the assumption that a GOT

communication fault will occur. Not doing so can cause an accident due to false output or

malfunction.

CAUTION

● Do not bundle the control and communication cables with main-circuit, power or other wiring. Run

the above cables separately from such wiring and keep them a minimum of 100mm apart. Not doing

so noise can cause a malfunction.

● Do not press the GOT display section with a pointed material as a pen or driver. Doing so can result

in a damage or failure of the display section.

● When the GOT is connected to the Ethernet network, the available IP address is restricted according

to the system configuration.

• When multiple GOTs are connected to the Ethernet network:

Do not set the IP address (192.168.3.18) for the GOTs and the controllers in the network.

• When a single GOT is connected to the Ethernet network:

Do not set the IP address (192.168.3.18) for the controllers except the GOT in the network.

Doing so can cause the IP address duplication. The duplication can negatively affect the communication of the

device with the IP address (192.168.3.18). The operation at the IP address duplication depends on the devices

and the system.

● Turn on the controllers and the network devices to be ready for communication before they

communicate with the GOT. Failure to do so can cause a communication error on the GOT.

● When the GOT is subject to shock or vibration, or some colors appear on the screen of the GOT, the

screen of the GOT might flicker.

[MOUNTING PRECAUTIONS]

WARNING

● Be sure to shut off all phases of the external power supply used by the system before mounting or

removing the GOT main unit to/from the panel. Not doing so can cause the unit to fail or malfunction.

A - 2

Page 5

[MOUNTING PRECAUTIONS]

CAUTION

● Use the GOT in the environment that satisfies the general specifications described in this manual.

Not doing so can cause an electric shock, fire, malfunction or product damage or deterioration.

● When mounting the GOT to the control panel, tighten the mounting screws in the specified torque

range (0.36N

GOT to drop, short circuit or malfunction. Overtightening can cause a drop, short circuit or

malfunction due to the damage of the screws or the GOT.

● Remove the protective film of the GOT. When the user continues using the GOT with the protective

film, the film may not be removed.

● Operate and store the GOT in environments without direct sunlight, high temperature, dust, humidity,

and vibrations.

● Do not use the GOT in an environment with oil or chemicals. Doing so may cause failure or

malfunction due to the oil or chemical entering into the GOT.

·m to 0.48N·m) with a Phillips-head screwdriver No.2. Undertightening can cause the

[WIRING PRECAUTIONS]

WARNING

● Be sure to shut off all phases of the external power supply used by the system before wiring. Failure

to do so may result in an electric shock, product damage or malfunctions.

CAUTION

● Please make sure to ground FG terminal of the GOT power supply section by applying 100Ω or less

which is used exclusively for the GOT. Not doing so may cause an electric shock or malfunction.

● Correctly wire the GOT power supply section after confirming the rated voltage and terminal

arrangement of the product. Not doing so can cause a fire or failure.

● Tighten the terminal screws of the GOT power supply section in the specified torque range (0.5N

to 0.6N

short circuit or malfunction due to the damage of the screws or the GOT.

● Exercise care to avoid foreign matter such as chips and wire offcuts entering the GOT. Not doing so

can cause a fire, failure or malfunction.

● Plug the communication cable into the GOT interface or the connector of the connected unit, and

tighten the mounting screws and the terminal screws in the specified torque range. Undertightening

can cause a short circuit or malfunction. Overtightening can cause a short circuit or malfunction due

to the damage of the screws or unit.

·m). Undertightening can cause a short circuit or malfunction. Overtightening can cause a

·m

A - 3

Page 6

[TEST OPERATION PRECAUTIONS]

WARNING

● Before performing the test operations of the user creation monitor screen (such as turning ON or

OFF bit device, changing the word device current value, changing the settings or current values of

the timer or counter, and changing the buffer memory current value), read through the manual

carefully and make yourself familiar with the operation method. During test operation, never change

the data of the devices which are used to perform significant operation for the system. False output

or malfunction can cause an accident.

[STARTUP/MAINTENANCE PRECAUTIONS]

WARNING

● When power is on, do not touch the terminals. Doing so can cause an electric shock or malfunction.

● Before starting cleaning or terminal screw retightening, always switch off the power externally in all

phases.

Not doing so can cause the unit to fail or malfunction.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or unit.

CAUTION

● Do not disassemble or modify the unit. Doing so can cause a failure, malfunction, injury or fire.

● Do not touch the conductive and electronic parts of the unit directly. Doing so can cause a unit

malfunction or failure.

● The cables connected to the unit must be run in ducts or clamped. Not doing so can cause the unit or

cable to be damaged due to the dangling, motion or accidental pulling of the cables or can cause a

malfunction due to a cable connection fault.

● When unplugging the cable connected to the unit, do not hold and pull from the cable portion. Doing

so can cause the unit or cable to be damaged or can cause a malfunction due to a cable connection

fault.

● Do not drop the module or subject it to strong shock. A module damage may result.

● Before touching the unit, always touch grounded metals, etc. to discharge static electricity from

human body, etc. Not doing so can cause the unit to fail or malfunction.

A - 4

Page 7

[TOUCH PANEL PRECAUTIONS]

CAUTION

● For the analog-resistive film type touch panels, normally the adjustment is not required.

However, the difference between a touched position and the object position may occur as the period

of use elapses. When any difference between a touched position and the object position occurs,

execute the touch panel calibration.

● When any difference between a touched position and the object position occurs, other object may be

activated. This may cause an unexpected operation due to incorrect output or malfunction.

[PRECAUTIONS WHEN THE DATA STORAGE IS IN USE]

WARNING

● If the SD card mounted on drive A of the GOT is removed while the GOT is accessed, processing for

the GOT might be interrupted about for 20 seconds. The GOT cannot be operated during this period.

The functions that run in the background including a screen updating, alarm, logging, scripts, and

others are also interrupted. Since this interruption makes an impact to the system operation, it might

cause failure. After inhibiting access to the SD card on the GOT utility screen, check that the SD card

access LED is off and remove the SD card.

[PRECAUTIONS WHEN THE DATA STORAGE IS IN USE]

CAUTION

● If the data storage mounted on the GOT is removed while the GOT is accessed, the data storage

and files are damaged. To remove the data storage from the GOT, check that the access to the data

storage in SD card access LED, the system signal, and others is not performed.

● When removing the SD card from the GOT, make sure to support the SD card by hand as it may pop

out. Failure to do so may cause the SD card to drop from the GOT, resulting in a failure or break.

● Before removing the USB device from the GOT, follow the procedure for removal on the utility screen

of the GOT. After the successful completion dialog is displayed, remove the USB device by hand

carefully. Failure to do so may cause the USB device to drop from the GOT, resulting in a failure or

break.

[DISPOSAL PRECAUTIONS]

CAUTION

● When disposing of this product, treat it as industrial waste.

A - 5

Page 8

[TRANSPORTATION PRECAUTIONS]

CAUTION

● Make sure to transport the GOT main unit and/or relevant unit(s) in the manner they will not be

exposed to the impact exceeding the impact resistance described in the general specifications of this

manual, as they are precision devices. Failure to do so may cause the unit to fail. Check if the unit

operates correctly after transportation.

● When fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine are

used for disinfecting and protecting wooden packaging from insects, they cause malfunction when

entering our products. Please take necessary precautions to ensure that remaining materials from

fumigant do not enter our products, or treat packaging with methods other than fumigation (heat

method). Additionally, disinfect and protect wood from insects before packing products.

A - 6

Page 9

INTRODUCTION

Thank you for choosing Mitsubishi Graphic Operation Terminal (Mitsubishi GOT).

Read this manual and make sure you understand the functions and performance of the GOT thoroughly in

advance to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS .........................................................................................................................A - 1

INTRODUCTION ...................................................................................................................................... A - 7

CONTENTS ..............................................................................................................................................A - 7

About Manual.......................................................................................................................................... A - 13

Quick Reference ..................................................................................................................................... A - 14

Abbreviations and Generic Terms ..........................................................................................................A - 15

1. OVERVIEW

1.1 Features........................................................................................................................................... 1 - 2

1.1.1 Rough procedure.................................................................................................................. 1 - 3

2. SYSTEM CONFIGURATION

2.1 Overall Configuration ....................................................................................................................... 2 - 1

2.2 Component List................................................................................................................................ 2 - 1

2.2.1 GOT...................................................................................................................................... 2 - 2

2.2.2 Option................................................................................................................................... 2 - 2

3. SPECIFICATIONS

3.1 General Specifications..................................................................................................................... 3 - 1

3.2 Performance Specifications ............................................................................................................. 3 - 2

3.3 Power Supply Specifications ........................................................................................................... 3 - 3

3.4 GOT Connector Specifications ........................................................................................................ 3 - 4

3.4.1 RS-232 interface................................................................................................................... 3 - 4

3.4.2 RS-422 interface................................................................................................................... 3 - 4

4. PART NAME

4.1 Front Panel ...................................................................................................................................... 4 - 1

4.2 Back Panel....................................................................................................................................... 4 - 2

4.3 Bottom ............................................................................................................................................. 4 - 3

5. EMC DIRECTIVE

5.1 Overview.......................................................................................................................................... 5 - 1

5.1.1 Conforming standards in the EMC Directive ........................................................................ 5 - 1

5.2 EMC Directive Requirements .......................................................................................................... 5 - 2

5.2.1 Installing the GOT on the control panel ................................................................................ 5 - 2

5.2.2 Installing a noise filter (power supply line filter) .................................................................... 5 - 3

5.2.3 System configuration ............................................................................................................ 5 - 4

5.2.4 Connection of power cables and ground cables................................................................... 5 - 4

5.2.5 Fabricating a connection cable............................................................................................. 5 - 5

A - 7

Page 10

5.2.6 Grounding a cable ................................................................................................................ 5 - 7

6. INSTALLATION

6.1 Control Panel Inside Dimensions for Mounting GOT ....................................................................... 6 - 1

6.2 Panel Cutting Dimensions ............................................................................................................... 6 - 2

6.3 Mounting Position ............................................................................................................................ 6 - 2

6.4 Control Panel Temperature and Mounting Angle ............................................................................ 6 - 3

6.5 Installation Procedure ...................................................................................................................... 6 - 4

7. WIRING

7.1 Power Supply Wiring ....................................................................................................................... 7 - 2

7.1.1 Cable types and wire end processing................................................................................... 7 - 2

7.1.2 Wiring example ..................................................................................................................... 7 - 3

7.1.3 GOT's ground ....................................................................................................................... 7 - 3

7.1.4 The cause of malfunctions related wiring/Remedy ............................................................... 7 - 4

7.2 Wiring Inside and Outside the Panel ............................................................................................... 7 - 6

7.2.1 Wiring inside ......................................................................................................................... 7 - 6

7.2.2 Outside the panel.................................................................................................................. 7 - 6

7.2.3 Attaching surge killers to control equipment ......................................................................... 7 - 7

8. OPTION

8.1 SD Card ........................................................................................................................................... 8 - 1

8.1.1 Applicable SD card ............................................................................................................... 8 - 1

8.1.2 Installation/removal procedure of SD card............................................................................ 8 - 1

9. UTILITY FUNCTION

9.1 Utility Execution ............................................................................................................................... 9 - 1

9.2 Utility Function List........................................................................................................................... 9 - 2

9.3 Utility Display ................................................................................................................................... 9 - 3

9.3.1 Display operation of main menu ........................................................................................... 9 - 5

9.3.2 Utility basic configuration ...................................................................................................... 9 - 7

9.3.3 Basic operation of settings change....................................................................................... 9 - 8

10. LANGUAGE SETTING (LANGUAGE)

10.1 Display language setting................................................................................................................ 10 - 1

10.1.1 Display language setting function....................................................................................... 10 - 1

10.1.2 Language setting operation ................................................................................................ 10 - 1

11. COMMUNICATION INTERFACE SETTING (COMMUNICATION SETTING)

11.1 Standard I/F Setting....................................................................................................................... 11 - 1

11.1.1 Standard I/F functions......................................................................................................... 11 - 1

11.1.2 Standard I/F display operation............................................................................................ 11 - 1

11.1.3 Display contents of standard I/F .........................................................................................11 - 2

11.1.4 Detail information setting operation .................................................................................... 11 - 4

11.1.5 Channel setting operation................................................................................................... 11 - 7

11.1.6 Driver setting operation....................................................................................................... 11 - 8

11.2 GOT IP Address Setting ................................................................................................................ 11 - 9

11.2.1 Standard ............................................................................................................................. 11 - 9

A - 8

Page 11

11.2.2 Display operation of GOT IP address................................................................................. 11 - 9

11.2.3 Setting operation .............................................................................................................. 11 - 10

11.3 Ethernet Communication ............................................................................................................. 11 - 11

11.3.1 Setting function for Ethernet communication.................................................................... 11 - 11

11.3.2 Display operation of Ethernet communication .................................................................. 11 - 11

11.3.3 Display contents of Ethernet setting ................................................................................. 11 - 12

11.4 Communication Monitor............................................................................................................... 11 - 15

11.4.1 Communication monitor functions .................................................................................... 11 - 15

11.4.2 Communication monitor display operation ....................................................................... 11 - 15

11.4.3 Screen display content ..................................................................................................... 11 - 16

11.5 Ethernet Check ............................................................................................................................ 11 - 18

11.6 Setting the Transparent Mode ..................................................................................................... 11 - 20

11.7 Keyword....................................................................................................................................... 11 - 21

11.7.1 Keyword functions ............................................................................................................ 11 - 21

11.7.2 Keyword display operation ............................................................................................... 11 - 21

11.7.3 Regist ............................................................................................................................... 11 - 22

11.7.4 Delete ............................................................................................................................... 11 - 25

11.7.5 Clear................................................................................................................................. 11 - 27

11.7.6 Protect .............................................................................................................................. 11 - 29

12. DISPLAY AND OPERATION SETTINGS (GOT SET UP)

12.1 Display Settings ............................................................................................................................. 12 - 1

12.1.1 Display setting functions..................................................................................................... 12 - 1

12.1.2 Display operation of display setting .................................................................................... 12 - 2

12.1.3 Display setting operations .................................................................................................. 12 - 3

12.2 Operation Setting (Settings for Operation) .................................................................................... 12 - 5

12.2.1 Operation setting functions................................................................................................. 12 - 5

12.2.2 Display operation of operation setting ................................................................................ 12 - 6

12.2.3 Setting operation of operation ............................................................................................ 12 - 7

12.2.4 Position correction of the touch panel (touch panel calibration setting) ............................. 12 - 9

12.2.5 Setting the utility call keys ................................................................................................ 12 - 11

12.3 Inherent Information..................................................................................................................... 12 - 13

12.3.1 Setting function for inherent information........................................................................... 12 - 13

12.3.2 Display operation of inherent information ......................................................................... 12 - 13

12.3.3 Setting operation for inherent information ........................................................................ 12 - 13

12.4 GOT internal device monitor........................................................................................................ 12 - 14

12.4.1 Setting the GOT internal device monitor .......................................................................... 12 - 14

12.4.2 GOT internal device monitor display operation ................................................................ 12 - 14

12.4.3 GOT internal device monitor setting operation ................................................................. 12 - 15

13. SECURITY LEVEL AND OPERATOR SETTINGS (SECURITY SETTING)

13.1 Security Level Authentication ........................................................................................................ 13 - 1

13.2 Operator Authentication................................................................................................................. 13 - 3

13.2.1 Operator information management..................................................................................... 13 - 3

13.2.2 Password change............................................................................................................. 13 - 13

13.2.3 Function setting ................................................................................................................ 13 - 15

13.3 Login/Logout ................................................................................................................................ 13 - 17

A - 9

Page 12

14. CLOCK SETTINGS AND BATTERY STATUS DISPLAY

(TIME SETTING AND DISPLAY)

14.1 Time Setting and Display............................................................................................................... 14 - 1

14.1.1 Time setting and display functions...................................................................................... 14 - 1

14.1.2 Clock synchronization method............................................................................................ 14 - 2

14.1.3 Time setting ........................................................................................................................ 14 - 3

14.1.4 Adjusting the clock.............................................................................................................. 14 - 5

14.1.5 Local time ........................................................................................................................... 14 - 9

15. CONTROL OF VARIOUS DATA (DATA CONTROL)

15.1 Data Storage Location ................................................................................................................... 15 - 1

15.1.1 Data type and storage location...........................................................................................15 - 1

15.1.2 Checking version of basic system application .................................................................... 15 - 3

15.2 OS information ............................................................................................................................... 15 - 4

15.3 Resource Data Information............................................................................................................ 15 - 6

15.3.1 Alarm information................................................................................................................ 15 - 6

15.3.2 Recipe information............................................................................................................ 15 - 12

15.3.3 Logging information .......................................................................................................... 15 - 21

15.3.4 Image file management ....................................................................................................15 - 28

15.4 SD Card Access .......................................................................................................................... 15 - 33

15.4.1 Functions of SD card access............................................................................................ 15 - 33

15.4.2 Display operation of SD card access................................................................................ 15 - 33

15.4.3 Operation of SD card access............................................................................................ 15 - 33

15.5 SD Card Format........................................................................................................................... 15 - 34

15.6 Clear data .................................................................................................................................... 15 - 36

15.6.1 Clear data functions.......................................................................................................... 15 - 36

15.6.2 Clear data display............................................................................................................. 15 - 36

15.6.3 Clear data operation ......................................................................................................... 15 - 36

15.7 Data Copy.................................................................................................................................... 15 - 37

15.7.1 Display operation of data copy ......................................................................................... 15 - 37

15.7.2 Operation of data copy ..................................................................................................... 15 - 38

15.8 BACKUP/RESTORE.................................................................................................................... 15 - 40

15.8.1 BACKUP/RESTORE......................................................................................................... 15 - 40

15.8.2 System configuration ........................................................................................................ 15 - 41

15.8.3 Access range.................................................................................................................... 15 - 46

15.8.4 Precautions....................................................................................................................... 15 - 46

15.8.5 Security and password ..................................................................................................... 15 - 49

15.8.6 Operation of backup/restore ............................................................................................. 15 - 55

15.8.7 Operation of backup ......................................................................................................... 15 - 56

15.8.8 Operation of restore.......................................................................................................... 15 - 58

............................................................... 15 - 60

15.8.9 Operation of keyword......................................

...

15.9 Errors and Corrective Actions ...................................................................................................... 15 - 61

16. GOT SELF CHECK (DEBUG)

16.1 Device Monitor Function ................................................................................................................ 16 - 1

16.1.1 System configuration .......................................................................................................... 16 - 1

16.1.2 Devices that can be monitored ........................................................................................... 16 - 2

16.1.3 Precautions......................................................................................................................... 16 - 2

A - 10

Page 13

16.1.4 Display operation of device monitor ................................................................................... 16 - 3

16.1.5 Information displayed on the device monitor screen and key functions ............................. 16 - 4

16.1.6 Basic operation of device monitor ...................................................................................... 16 - 6

16.1.7 Device registration .............................................................................................................. 16 - 7

16.1.8 Quick test.......................................................................................................................... 16 - 10

16.2 FX List Editor ............................................................................................................................... 16 - 14

16.2.1 Display operation of FX list editor..................................................................................... 16 - 14

16.2.2 Specifications ................................................................................................................... 16 - 16

16.2.3 Access range.................................................................................................................... 16 - 17

16.2.4 Precautions....................................................................................................................... 16 - 17

16.2.5 Display operation.............................................................................................................. 16 - 18

16.2.6 Operation procedures....................................................................................................... 16 - 20

16.2.7 Selection and operation of modes .................................................................................... 16 - 22

16.2.8 Displaying sequence programs ........................................................................................ 16 - 23

16.2.9 Searching commands/devices.......................................................................................... 16 - 25

16.2.10 Writing commands............................................................................................................ 16 - 27

16.2.11 Changing operands, set values ........................................................................................ 16 - 30

16.2.12 Deleting commands.......................................................................................................... 16 - 31

16.2.13 Sequence program all clear..............................................................................................16 - 32

16.2.14 PLC diagnostics................................................................................................................ 16 - 33

16.2.15 Parameter setting ............................................................................................................. 16 - 35

16.2.16 Keyword............................................................................................................................ 16 - 37

16.2.17 List monitor ....................................................................................................................... 16 - 39

16.2.18 Action for an incorrect key input .......................................................................................16 - 40

16.2.19 Error messages and corrective actions ............................................................................ 16 - 41

16.3 FX3U-ENET-ADP Communication Setting Function ................................................................... 16 - 42

16.3.1 Specifications ................................................................................................................... 16 - 42

16.3.2 Display operation of FX3U-ENET-ADP communication setting function .......................... 16 - 43

16.3.3 Setting operation .............................................................................................................. 16 - 44

17. MAINTENANCE

17.1 Touch Panel Calibration ................................................................................................................ 17 - 1

17.2 Touch Panel Check ....................................................................................................................... 17 - 3

17.3 Clean ............................................................................................................................................. 17 - 5

18. BootOS and System Application Installation Using Data Storage

18.1 Installing when starting the GOT ................................................................................................... 18 - 2

18.2 Installing using the data control function (Utility) ........................................................................... 18 - 2

19. INSTALLATION OF Boot OS AND BASIC SYSTEM APPLICATION

19.1 Boot OS and Basic System Application to be Installed ................................................................. 19 - 1

19.2 Prior Preparations for Installing Boot OS and System Application ................................................ 19 - 2

20. ERROR MESSAGE LIST

21. MAINTENANCE AND INSPECTION

21.1 Daily Inspection ............................................................................................................................. 21 - 2

21.2 Periodic Inspection ........................................................................................................................ 21 - 2

21.3 Cleaning Method............................................................................................................................ 21 - 3

A - 11

Page 14

21.4 Backlight Shutoff Detection............................................................................................................ 21 - 4

21.4.1 Backlight shutoff detection and external alarm ................................................................... 21 - 4

22. TROUBLESHOOTING

22.1 GOT Restoration Sheets ............................................................................................................... 22 - 1

23. CONNECTION

24. APPENDIX

Appendix.1External Dimensions................................................................................................................. 24- 1

REVISIONS

WARRANTY

A - 12

Page 15

About Manual

The following manuals related to this product are available.

Refer to each manual in accordance with the intended use.

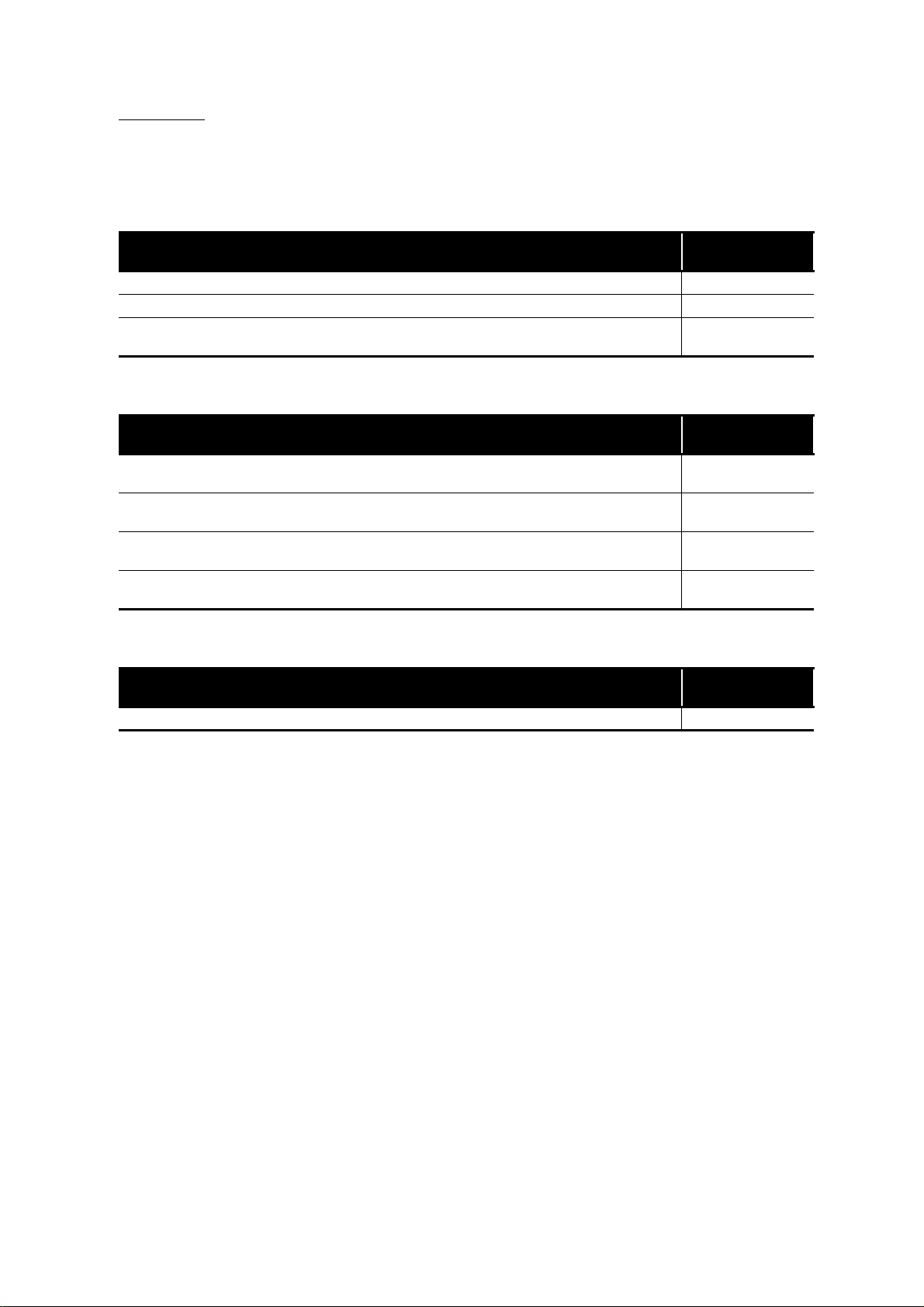

Screen creation software manuals

Manual name

GT Works3 Installation Instructions -

GT Designer3 (GOT2000) Help -

GT Converter2 Version3 Operating Manual for GT Works3

Manual number

(Model code)

SH-080862ENG

(1D7MB2)

Connection manuals

Manual name

GOT2000 Series Connection Manual (Mitsubishi Product) For GT Works3 Version1

GOT2000 Series Connection Manual (Non Mitsubishi Product 1) For GT Works3 Version1

GOT2000 Series Connection Manual (Non Mitsubishi Product 2) For GT Works3 Version1

GOT2000 Series Connection Manual (Microcomputer, MODBUS Products, Peripherals) For GT Works3 Version1

Manual number

(Model code)

SH-081197ENG

(1D7MJ8)

SH-081198ENG

(1D7MJ9)

SH-081199ENG

(1D7MK1)

SH-081200ENG

(1D7MK2)

GOT SIMPLE series manuals

Manual name

GOT SIMPLE Series User's Manual JY997D52901

Manual number

(Model code)

A - 13

Page 16

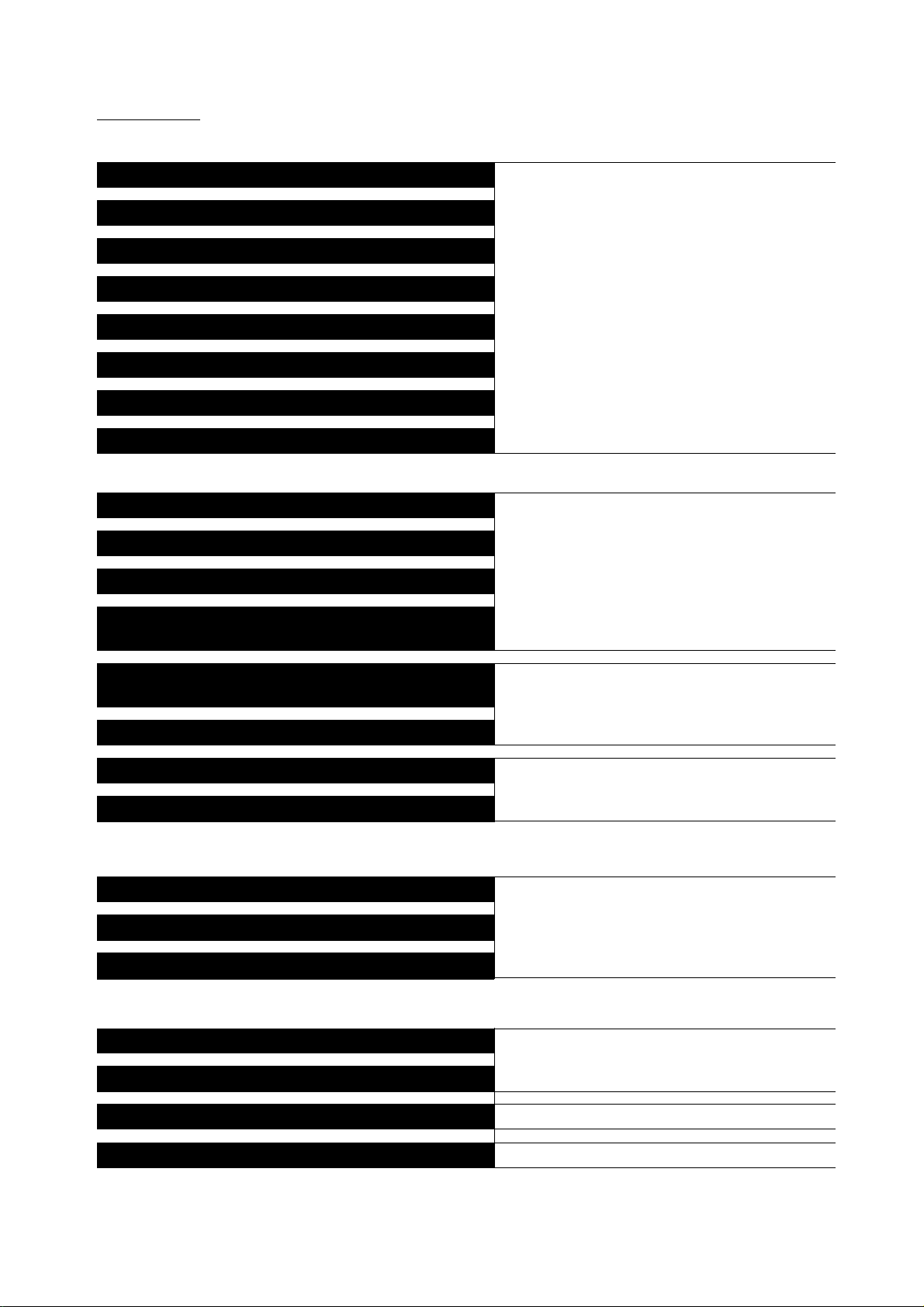

Quick Reference

Creating projects

Obtaining the specifications and operation methods of GT Designer3

Setting available functions on GT Designer3

Creating a screen displayed on the GOT

Obtaining useful functions to increase efficiency of drawing

Setting details for figures and objects

Setting functions for the data collection or trigger action

Setting functions to use peripheral devices

Simulating a created project on a personal computer

Connecting a controller to the GOT

Obtaining information of Mitsubishi products applicable to the GOT

Connecting Mitsubishi products to the GOT

Connecting multiple controllers to one GOT (Multi-channel function)

GT Designer3 (GOT2000) Help

GOT2000 Series Connection Manual (Mitsubishi Product)

For GT Works3 Version1

Establishing communication between a personal computer and a

controller via the GOT (FA transparent function)

Obtaining information of Non-Mitsubishi products applicable to the

GOT

Connecting Non-Mitsubishi products to the GOT

Obtaining information of peripheral devices applicable to the GOT

Connecting peripheral devices including a bar code reader to the GOT

Transferring data to the GOT

Writing data to the GOT

Reading data from the GOT

Verifying an editing project to a GOT project

Others

Obtaining the specifications and operation methods of GT Designer3

Setting available functions on GT Designer3

• GOT2000 Series Connection Manual (Non Mitsubishi

Product 1) For GT Works3 Version1

• GOT2000 Series Connection Manual (Non Mitsubishi

Product 2) For GT Works3 Version1

GOT2000 Series Connection Manual (Microcomputer,

MODBUS Products, Peripherals) For GT Works3 Version1

GT Designer3 (GOT2000) Help

GOT SIMPLE Series User's Manual

Creating a screen displayed on the GOT

Obtaining useful functions to increase efficiency of drawing

A - 14

GOT SIMPLE Series User's Manual

GT Designer3 (GOT2000) Help

Page 17

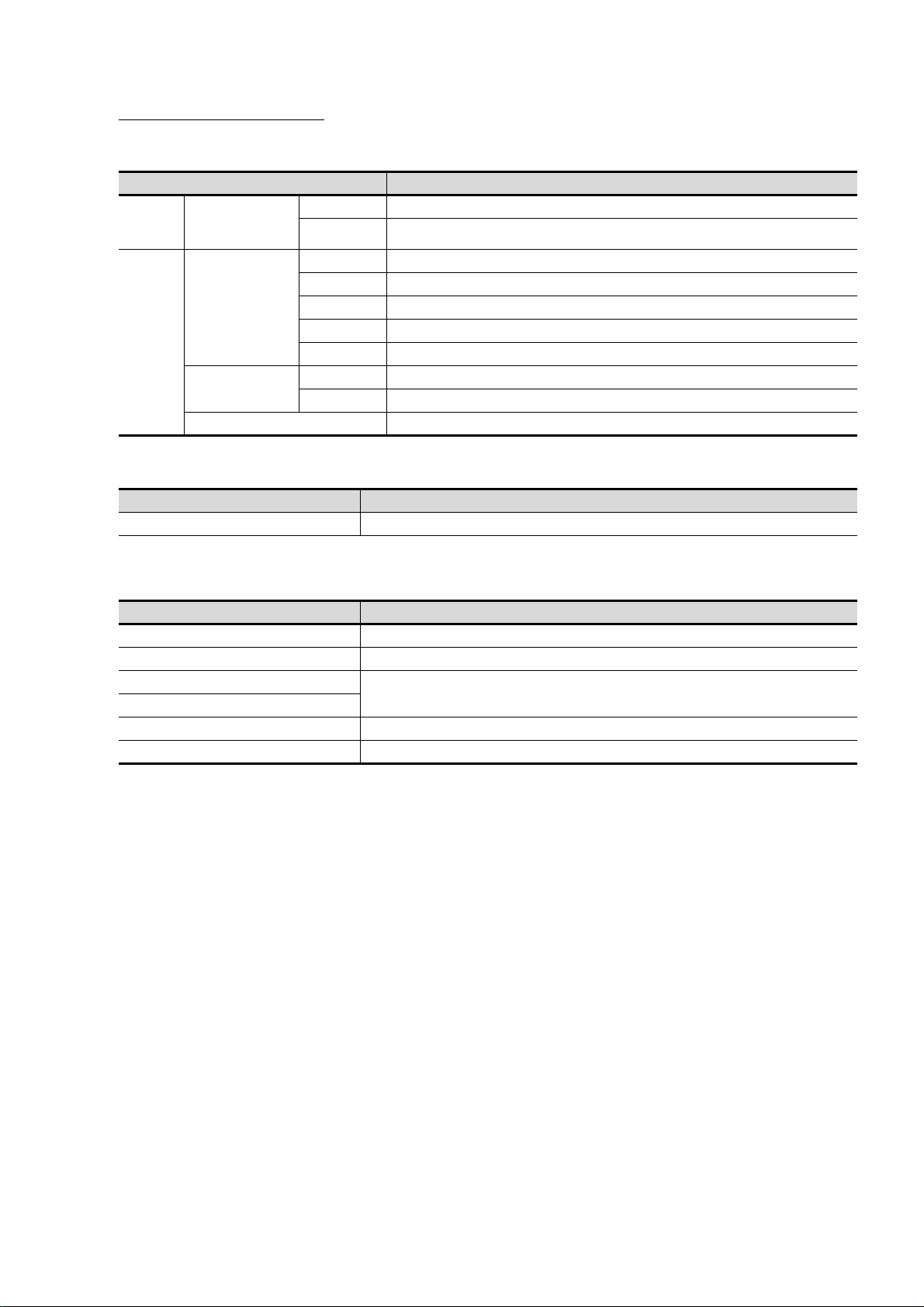

Abbreviations and Generic Terms

GOT

Abbreviations and generic terms Description

GOT

SIMPLE

Series

GOT2000

Series

GS21

GT27

GT23

GT SoftGOT2000 GT SoftGOT2000 Version1

GS2110-W GS2110-WTBD

GS2107-W GS2107-WTBD

GT2712-S GT2712-STBA, GT2712-STWA, GT2712-STBD, GT2712-STWD

GT2710-S GT2710-STBA, GT2710-STBD

GT2710-V GT2710-VTBA, GT2710-VTWA, GT2710-VTBD, GT2710-VTWD

GT2708-S GT2708-STBA, GT2708-STBD

GT2708-V GT2708-VTBA, GT2708-VTBD

GT2310-V GT2310-VTBA, GT2310-VTBD

GT2308-V GT2308-VTBA, GT2308-VTBD

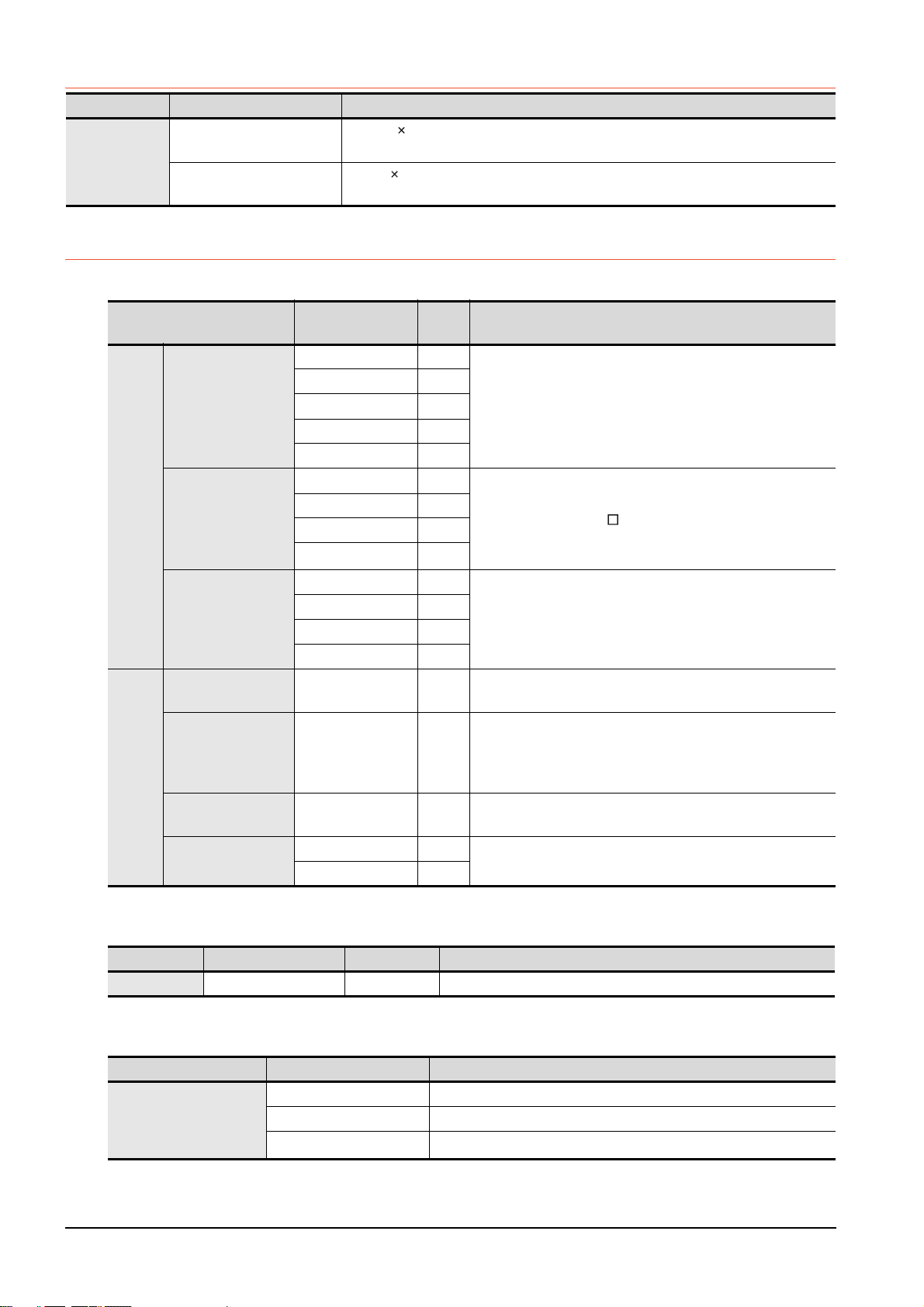

Option

Abbreviations and generic terms Description

SD card L1MEM-2GBSD, L1MEM-4GBSD

Software

(1) Software related to GOT

Abbreviations and generic terms Description

GT Works3 SW1DNC-GTW3-J, SW1DND-GTW3-J, SW1DNC-GTW3-E, SW1DND-GTW3-E, SW1DND-GTW3-C

GT Designer3 Version1 Screen drawing software GT Designer3 for GOT2000/GOT1000 series

GT Designer3

GT Designer3 (GOT2000)

GT Designer3 (GOT1000) Screen drawing software for GOT1000 series included in GT Works3

GT Simulator3 Screen simulator GT Simulator3 for GOT2000/GOT1000/GOT900 series

Screen drawing software for GOT2000 series included in GT Works3

A - 15

Page 18

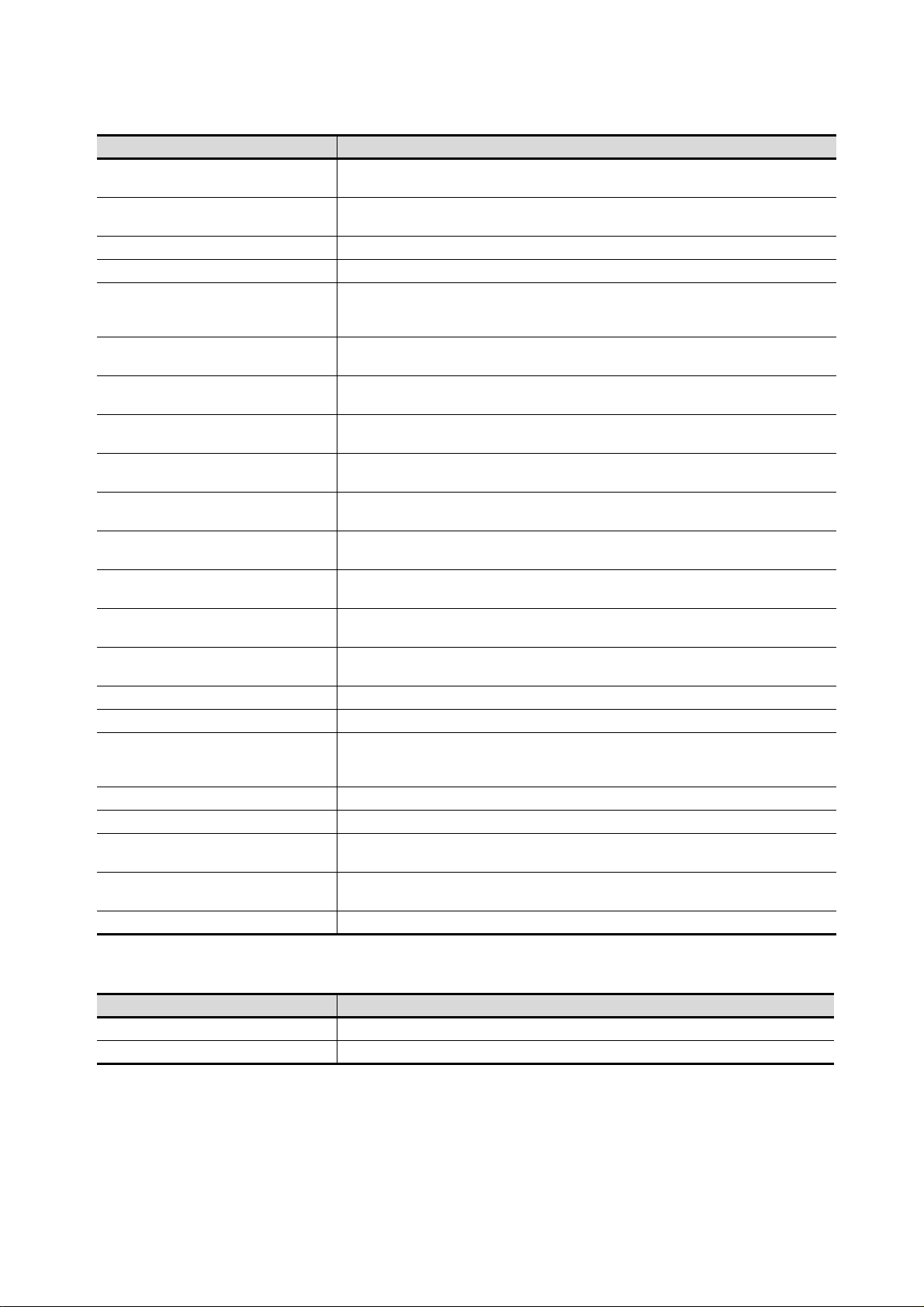

(2) Other software

Abbreviations and generic terms Description

GX Works3

GX Works2

GX Simulator3 Simulation function of GX Works3

GX Simulator2 Simulation function of GX Works2

GX Simulator

GX Developer

GX LogViewer

PX Developer

MT Works2

MT Developer

CW Configurator

MR Configurator2

MR Configurator

FR Configurator

NC Configurator2 CNC parameter setting support tool (FCSB1221)

NC Configurator CNC parameter setting support tool

FX Configurator-FP

FX3U-ENET-L Configuration tool FX3U-ENET-L type Ethernet module setting software (SW1D5-FXENETL-E)

RT ToolBox2 Robot program creation software (3D-11C-WINE)

MX Component

MX Sheet

CPU Module Logging Configuration Tool CPU module logging configuration tool (SW1DNN-LLUTL-E)

SW□DND-GXW3-E (-EA) type programmable controller engineering software

(□ indicates a version.)

SW□DNC-GXW2-□ type programmable controller engineering software

(□ indicates a version.)

SW□D5C-LLT-E (-EV) type ladder logic test tool function software package

(SW5D5C-LLT (-V) or later versions)

(□ indicates a version.)

SW□D5C-GPPW-E (-EV)/SW□D5F-GPPW (-V) type software package

(□ indicates a version.)

SW□DNN-VIEWER-E type software package

(□ indicates a version.)

SW□D5C-FBDQ-E type FBD software package for process control

(□ indicates a version.)

Motion controller engineering environment MELSOFT MT Works2 (SW□DNDMTW2-E)

(□ indicates a version.)

SW□RNC-GSV type integrated start-up support software for motion controller Q series

(□ indicates a version.)

C Controller module configuration and monitor tool (SW1DND-RCCPU-E)

(□ indicates a version.)

SW□DNC-MRC2-E type servo configuration software

(□ indicates a version.)

MRZJW□-SETUP type servo configuration software

(□ indicates a version.)

Inverter setup software (FR-SW□-SETUP-WE)

(□ indicates a version.)

Parameter setting, monitoring, and testing software packages for FX3U-20SSC-H

(SW□D5CFXSSCE)

(□ indicates a version.)

MX Component Version□ (SW□D5C-ACT-E, SW□D5C-ACT-EA)

(□ indicates a version.)

MX Sheet Version□ (SW□D5C-SHEET-E, SW□D5C-SHEET-EA)

(□ indicates a version.)

Others

Abbreviations and generic terms Description

SIEMENS Siemens AG

PLC Programmable controller manufactured by each corporation

A - 16

Page 19

1. OVERVIEW

PLC

Connector for

program

GOT

■1. About GOT

A GOT is installed on the panel surface of a control panel or operating

panel and connects to the PLC within the control panel. The GOT carries

out switch operation, lamp display, data display, message display, etc.

1

For the display screen, two kinds of screens are available: user screen and

utility screen.

(1) User screen

The user screen is a screen drawn by drawing software.

The objects "Touch switch", "Lamp display", "Comment display", and

"Numeric display" can be arbitrarily arranged on the display.

Moreover, multiple screens created within drawing software can be

individually selected or overlapped for the display.

For details, refer to the following.

➠ GT Designer3 (GOT2000) Help

(2) Utility Screen

The utility screen is a factory drawn horizontal screen that cannot be edited.

The utility screen can be displayed on the GOT by installing the standard monitor OS from drawing software or an SD

card to the GOT.

Such as [Brightness] and [Time setting] can be set from the utility screen.

For details, refer to the following.

➠ 9. to 22.

OVERVIEW

1 - 1

Page 20

1.1 Features

Monitoring for turning on or off bit devices of a PLC, forcibly turning on or off the bit devices of a PLC, monitoring the word

device set value/current value and changing that numeric values are easily made.

(1) The display unit is used for engineers' stage replacement, setting change and troubleshooting or

for operation guidance to an operator.

• Monitor

• Forcibly turning on or off

• Set value change

•Trouble check

(2) Improved monitoring performance and connectivity to FA devices

• Multiple languages are displayed using the Unicode2.1-compatible fonts and beautiful characters are drawn using

the TrueType and high quality fonts

• Two types of display modes are available: 65536-color display and monochrome

A fine and beautiful full-color display which shows even small characters clearly, is enabled in the 65536-color

display by adopting the high intensity, wide viewing angle and high definition TFT color liquid crystal display.

(Also compatible with digital screen displays with 65536 colors, BMP, etc.)

High speed monitoring through high speed communication at maximum of 115.2kbps

• High speed display and high speed touch switch response

• The operation performance is improved by the analog touch panel.

(3) More efficient GOT operations including screen design, startup, adjustment, management and

maintenance works

• The 9MB built-in flash memory is included as standard.

• SD card interface is included as standard.

• RS-232 interface is included as standard.

• RS-422 interface is included as standard.

• USB interface (device) is included as standard.

• Ethernet interface is included as standard.

• System font types are increased by the adoption of the font installation system.

• Four types of alarms (system alarm, user alarm, alarm history and alarm popup display) are integrated, and

realizing an efficient alarm notification.

(4) Enhanced support of FA setup tools

• Transferring or monitoring the sequence programs using the personal computer connected to GOT, during

connection to L, Q, QnA, or FX series PLC CPU (FA transparent function)

1 - 2

1.1 Features

Page 21

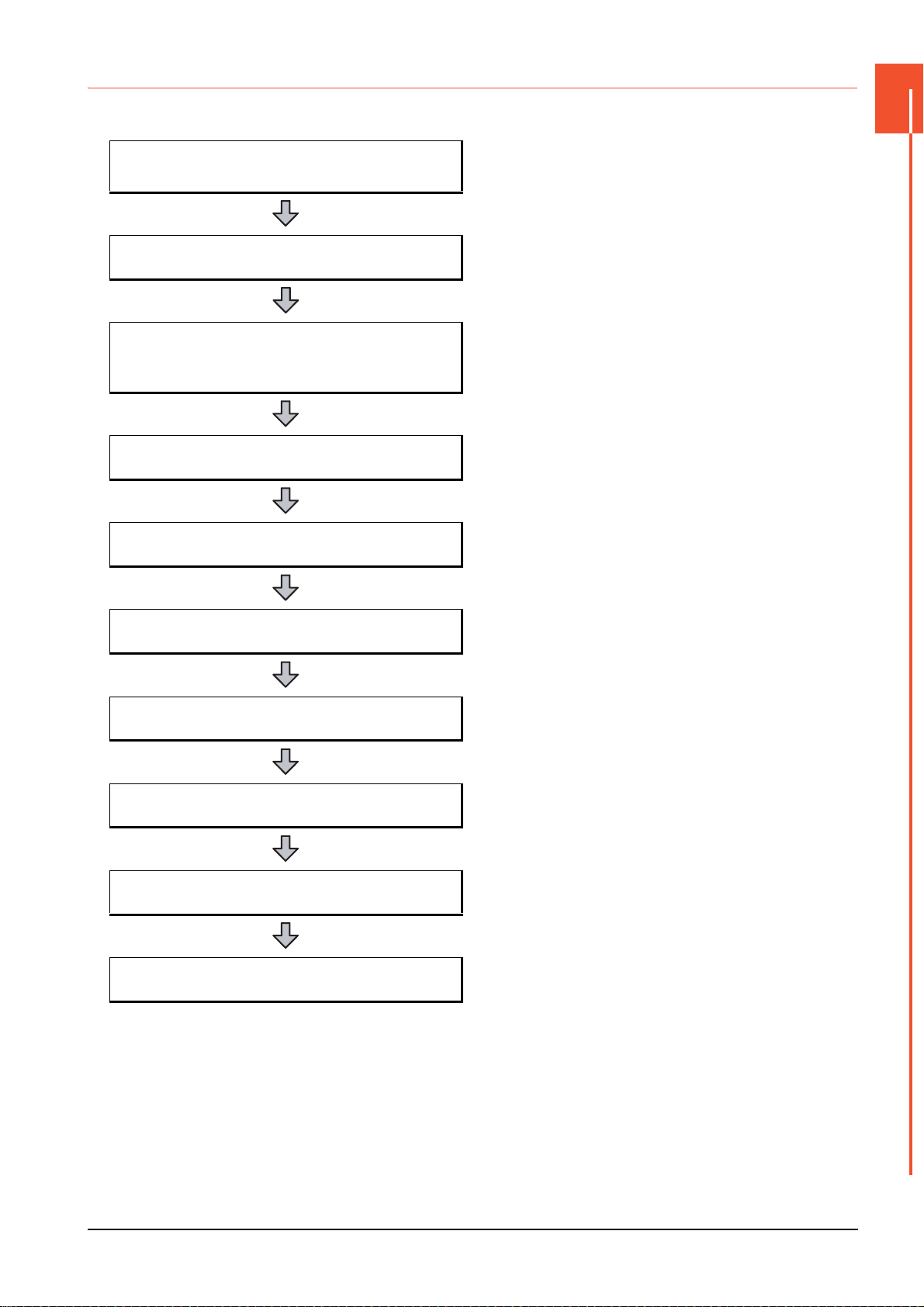

1.1.1 Rough procedure

The following shows the procedures before operating a GOT and the descriptions of each item.

1

Install GT Designer3 in a personal computer.

Create project data.

Wire for the GOT power supply and the controller.

Wire for the controller power supply and I/O.

Turn on the power of the GOT and controller.

➠ Refer to the setting method of GT Works3.

➠ Refer to GS21 GOT General Description.

OVERVIEW

➠ Refer to GT Designer3 (GOT2000) Help.

➠ 7. WIRING

➠ Refer to GOT2000 Series Connection Manual for GT Works3

Version1.

➠ Controller manuals

Install the OS to the GOT.

Check that the OS is installed to the GOT.

Download project data.

Turn on the controller power and check that the GOT

recognizes the controller.

Check that the monitoring is normal.

➠ Refer to GT Designer3 (GOT2000) Help.

➠ Refer to GT Designer3 (GOT2000) Help.

1.1 Features

1 - 3

Page 22

1 - 4

1.1 Features

Page 23

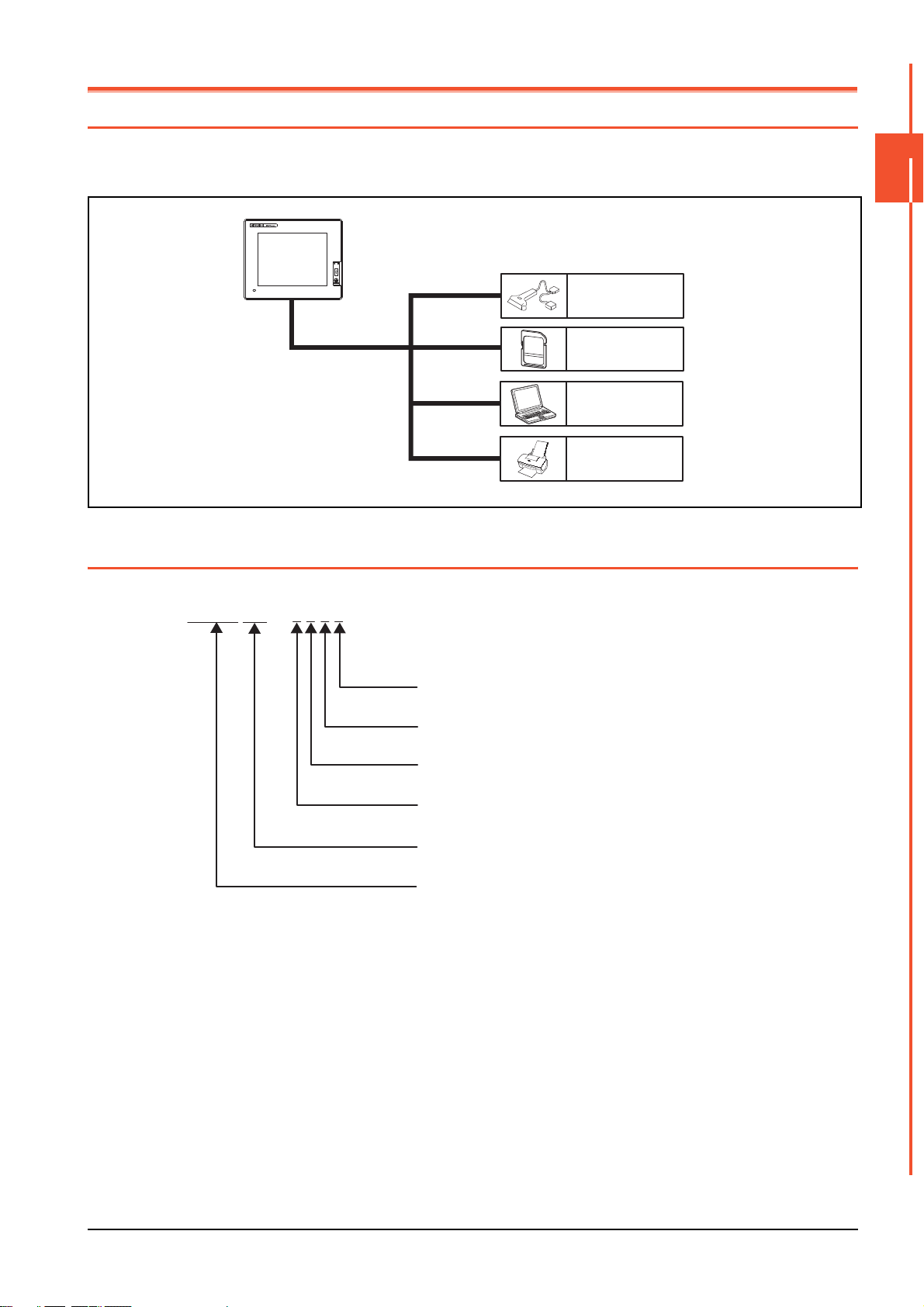

2. SYSTEM CONFIGURATION

Bar code reader

(Commercially available)

Personal computer

(Commercially available)

Printer

*1

(Commercially available)

SD card

2.1 Overall Configuration

The overall configuration of GOT is as follows.

For the connection methods applicable to GS series and cable, refer to the following.

➠ GOT2000 Series Connection Manual For GT Works3 Version1

*1 Only hard copy of the screen can be printed.

2.2 Component List

(1) Explanation of the GOT model name

2

SYSTEM CONFIGURATION

07 - W

TBDG S 2 1

Power type

Panel color type

Display device type

Resolution

Display color type

GS21 series

D : DC24V

B : Black

T : TFT color

W : 800×480

10 : 10"

07 : 7"

2.1 Overall Configuration

2 - 1

Page 24

2.2.1 GOT

Product name Model Specifications

GS2110-WTBD

GOT

GS2107-WTBD

10" [800 480 dots], TFT color liquid crystal, 65536 colors

24VDC, Memory capacity: 9MB, built-in Ethernet interface

7" [800 480 dots], TFT color liquid crystal, 65536 colors

24VDC, Memory capacity: 9MB, built-in Ethernet interface

2.2.2 Option

■1. Connection cables for MITSUBISHI PLCs (Sold separately)

Cable

length

For connecting FXCPU (MINI DIN 8 pins connector) and GOT

For connecting FXCPU expansion board (MINI DIN 8 pins

connector) and GOT

For connecting FXCPU (D-Sub 25 pins connector) and GOT

For connecting FA-CNV CBL and GOT

For connecting serial communication unit (AJ71QC24(N)-R4)

and GOT

For connecting computer link unit/serial communication unit and

GOT

For connecting FXCPU expansion board (D-Sub 9 pins

connector) and GOT

For connecting FXCPU special adaptor (D-sub 9 pins connector)

and GOT

For connecting FXCPU special adaptor (D-sub 25 pins

connector) and GOT

For connecting computer link unit/serial communication unit and

GOT

RS-422

Cable

RS-232

cable

Product name Model

GT01-C10R4-8P 1m

FXCPU direct

connection cable,

FX expansion board

connection cable

QnA/A/FXCPU direct

connection cable,

computer link

connection cable

Computer link

connection cable

QCPU direct

connection cable

FX expansion board

connection cable,

FX special adaptor

connection cable

FX special adaptor

connection

Computer link

connection cable

GT01-C30R4-8P 3m

GT01-C100R4-8P 10m

GT01-C200R4-8P 20m

GT01-C300R4-8P 30m

GT01-C30R4-25P 3m QnA/A motion controller (A series)

GT01-C100R4-25P 10m

GT01-C200R4-25P 20m

GT01-C300R4-25P 30m

GT09-C30R4-6C 3m

GT09-C100R4-6C 10m

GT09-C200R4-6C 20m

GT09-C300R4-6C 30m

GT01-C30R2-6P 3m For connecting QCPU and GOT

GT01-C30R2-9S 3m

GT01-C30R2-25P 3m

GT09-C30R2-9P 3m

GT09-C30R2-25P 3m

Description

■2. Connection cables for SIEMENS PLCs (Sold separately)]

Product name Model Cable length Description

RS-232 cable GT09-C30R20801-9S 3m For connecting SIEMENS HMI Adapter and GOT

■3. SD card (Sold separately)

Product name Model Description

L1MEM-2GBSD SD memory card 2GB

L1MEM-4GBSD SDHC memory card 4GB

-

Commercially-available SD card

2 - 2

SD card

*1 Some models with the operations checked by our company are usable. For the operation-checked models, refer to "Operation

Check Results of Third Party SD Cards on GT14 Model" (Hime-T-P-0089) separately available, or contact your local distributor.

2.2 Component List

*1

Page 25

■4. Drawing software (Sold separately)

Product name Model Description

SW1DND-GTWK3-J Standard license product

SW1DND-GTWK3-JC

GOT screen creation

software

MELSOFT GT

Works3 Version1

FA integration

engineering software

MELSOFT iQ Works

*3*4

*1 If you need two licenses or more, request the number of licenses. For details, consult your local Mitsubishi representative.

*2 Up to 200 licenses can be registered per site license product. However, this applies only to the same corporation or business

*3 Site license products, multiple-license products, and additional license products can be provided. For details, refer to MELSOFT

*4 This product includes the following software.

SW1DND-GTWK3-JA

SW1DND-GTWK3-JAZ

SW1DND-GTWK3-JV

SW1DND-IQWK-J

SW1DNC-IQWK-J CD-ROM product

facility where the product is purchased.

iQ Works catalog <L(NA)08232ENG>.

• System management software [MELSOFT Navigator]

• PLC engineering software [MELSOFT GX Works2]

• Motion controller engineering software [MELSOFT MT Works2]

• Servo setup software [MELSOFT MR Configurator2]

• GOT screen creation software [MELSOFT GT Works3]

• Robot programming software [MELSOFT RT ToolBox2 mini]

Site license product

Multiple-license product

Additional license product

Standard license product (For upgrading version)

(For upgrading version of user's GT Designer2/

GT Works2 to the latest one)

Standard license product

*2

*1

*1

2

DVD product

SYSTEM CONFIGURATION

■5. PC connection cable (Sold separately)

Product name Model Cable length Description

Project data transfer cable GT09-C30USB-5P 3m

■6. Bar code reader (Sold separately)

Product name Model Description

Bar code -

*1 Some models with the operations checked by our company are usable. For the operation-checked models, contact your local

distributor.

For connecting GOT (USB Mini-B) and personal computer

(USB)

Commercially-available bar code reader

*1

2.2 Component List

2 - 3

Page 26

2 - 4

2.2 Component List

Page 27

3. SPECIFICATIONS

3.1 General Specifications

Item Specifications

Operating ambient temperature 0 to 50°C

Storage ambient temperature -20 to 60°C

10 to 90%RH, non-condensing (The wet bulb temperature is 39°C)

Operating/Storage ambient humidity

Vibration resistance

Shock resistance

Operating atmosphere

Operating altitude

Overvoltage category

Pollution degree

Cooling method Self-cooling

Grounding

*1

*2

*3

*1 Do not use or store the GOT under pressures higher than the atmospheric pressure of altitude 0m (0ft.). Failure to observe this

instruction may cause a malfunction. When the air inside the control panel is purged by pressurization, the surface sheet may be

lifted by high pressure. As a result, the touch panel may be difficult to press, and the sheet may be peeled off.

*2 This indicates the section of the power supply to which the equipment is assumed to be connected between the public electrical

power distribution network and the machinery within the premises. Category II applies to equipment for which electrical power is

supplied from fixed facilities. The surge voltage withstand level for up to the raged voltage of 300V is 2500V.

*3 This index indicates the degree to which conductive pollution is generated in the environment where the equipment is used. In

pollution degree 2, only non-conductive pollution occurs but temporary conductivity may be produced due to condensation.

When the ambient temperature exceeds 40°C, maintain the absolute humidity at 40°C and

90%.

Conforms to

IEC 61131-2

Conforms to IEC 61131-2 (147m/s

Must be free of lamp black, corrosive gas, flammable gas, or excessive amount of electro

conductive dust particles.

Must be no direct sunlight. (Same as for saving)

2000m (6562ft) max.

II or less

2 or less

Class D grounding (100Ω or less), To be connected to the panel when grounding is not

possible.

Under

intermittent

vibration

Under

continuous

vibration

Frequency Acceleration

5 to 8.4Hz - 3.5mm 10times each

8.4 to 150Hz

5 to 8.4Hz - 1.75mm

8.4 to 150Hz

2

, 3times each in the X, Y, and Z directions)

9.8m/s

4.9m/s

Half

amplitude

2

-

2

-

Sweep Count

in X, Y and Z

directions

-

3

SPECIFICATIONS

3.1 General Specifications

3 - 1

Page 28

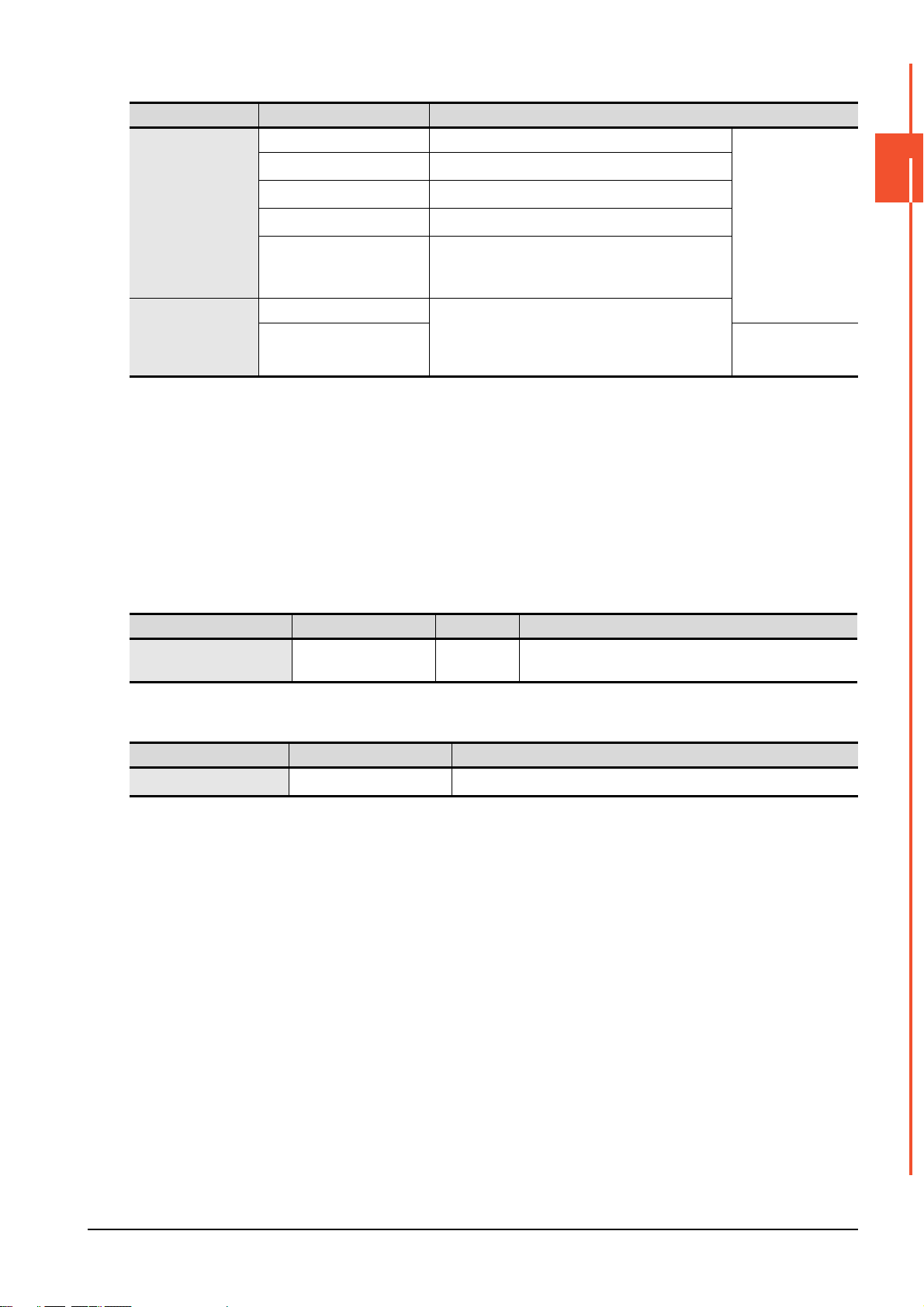

3.2 Performance Specifications

The following shows the performance specifications.

Item

Type TFT color liquid crystal

Screen size 10" 7"

Resolution

Display

*1

section

Backlight

Touch panel

Memory C drive

Built-in

interface

Buzzer output Single tone (LONG/SHORT/OFF adjustable)

Protective structure

External dimensions

Panel cutting dimensions

Weight Approx. 1.3kg (Excluding mounting fixtures) Approx. 0.9kg (Excluding mounting fixtures)

Compatible software package

(Version of GT Designer3)

Display size

Display character

Display color 65536 colors

Brightness 32-level adjustment

Type Analog-resistive film type

Key size

Number of points

*2

touched

simultaneously

Life 1 million times (operating force 0.98N max.)

RS-422

RS-232

Ethernet

USB

SD card

*3

800 480 [dots]

W222(8.74) H132.5(5.22) [mm](inch)

(Horizontal format)

16-dot standard font: 50 characters 30 lines (Horizontal format)

LED-type (no replacement required)

Backlight off/screen saving time can be set.

Minimum 2 2 [dots] (per key)

Simultaneous 2-point presses prohibited (Only one point can be touched.)

Flash memory (Internal) (9MB), for storing project data, OS

Life (Number of write times) 100,000times

RS-422, 1ch

Transmission speed: 115200/57600/38400/19200/9600/4800bps

Connector shape: D-sub 9 pins (Female)

Application: For communicating with controllers

Terminating resistor: 330Ω fixed

RS-232, 1ch

Transmission speed: 115200/57600/38400/19200/9600/4800bps

Connector shape: D-sub 9 pins (Male)

Application: For communication with controllers and a bar code reader

For PC connection (Project data read/write, FA transparent function)

Data Transfer method: 100BASE-TX, 10BASE-T, 1ch

Connector shape: RJ-45 (modular jack)

Application: For communication with controllers

For PC connection (Project data read/write, FA transparent function)

USB (Full Speed 12Mbps) 1ch

Connector shape: Mini-B

Application: For PC connection (Project data read/write, FA transparent function)

Conforms to the SD standard, 1ch

Supported memory card: SDHC memory card, SD memory card

Application: Project data read/write, logging data save

IP65F (only the front part of the panel)

W272(10.71) H214(8.43) D56(2.21)

[mm] (inch)

W258(10.16) H200(7.88) [mm] (inch)

(Horizontal format)

Version1.104J or later

GS2110-WTBD GS2107-WTBD

Specifications

W154(6.06) H85.9(3.38) [mm](inch)

(Horizontal format)

W206(8.11) H155(6.11) D50(1.97) [mm]

(inch)

W191(7.52) H137(5.40) [mm](inch)

(Horizontal format)

3 - 2

3.2 Performance Specifications

Page 29

*1 Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal display panel. It is impossible to completely avoid this

POINT

symptom, as the liquid crystal display comprises of a great number of display elements. Flickers and partial discoloration may be

generated on the liquid crystal display panel due to individual differences of panels. Please note that these phenomena appear

due to its characteristic and are not caused by product defect.

*2 The touch panel is an analog-resistive type. Simultaneous pressing of two or more areas on the touch panel may activate the

switch between those areas. Do not press two or more areas simultaneously on the touch panel.

*3 Note that this does not guarantee all users' operation environment. In addition, the product may not be used in environments

under exposition of oil or chemicals for a long period of time, or in environments filled with oil-mist.

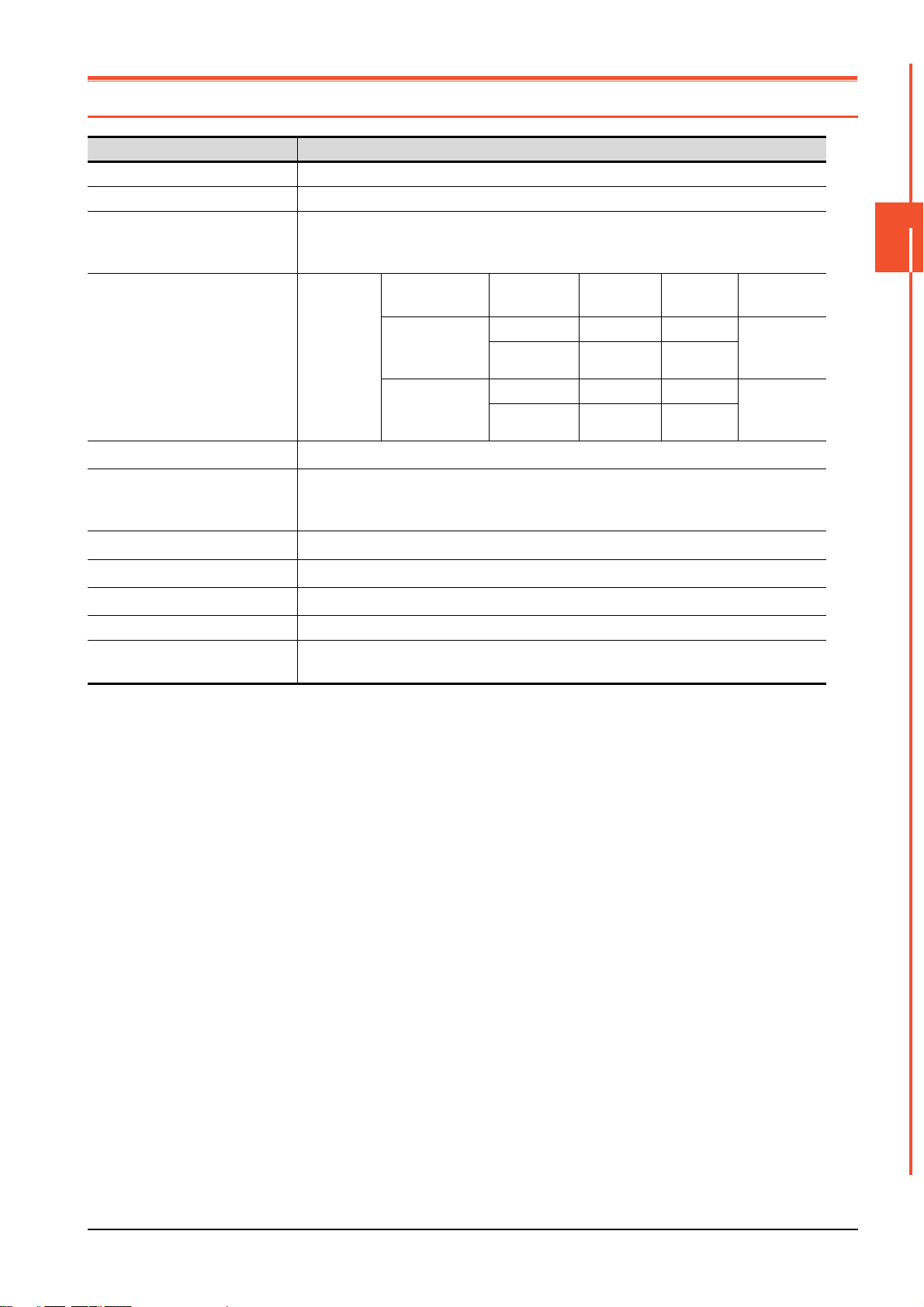

3.3 Power Supply Specifications

Item

Input power supply voltage 24VDC (+10% -15%), ripple voltage 200mV or less

Power consumption 7.6W (317mA/24V) or less 6.5W (271mA/24V) or less

At backlight off 3.8W (158mA/24V) or less 3.8W (158mA/24V) or less

Inrush current 17A or less (6ms, 25°C, at the maximum load)

Permissible instantaneous

power failure time

Noise immunity Conforms to IEC61000-4-4, 2kV (power supply line)

Dielectric withstand voltage 350VAC for 1 minute (across power supply terminals and earth)

Insulation resistance 500VDC across power terminals and earth, 10 MΩ or more by an insulation resistance tester

Within 5ms

POINT

POINT

GS2110-WTBD GS2107-WTBD

Operation at momentary power failure

The GOT continues to operate even upon 5ms or shorter instantaneous power failure.

The GOT stops operating if there is extended power failure or voltage drop, while it automatically

resumes operation as soon as the power is restored.

Specifications

3

SPECIFICATIONS

3.3 Power Supply Specifications

3 - 3

Page 30

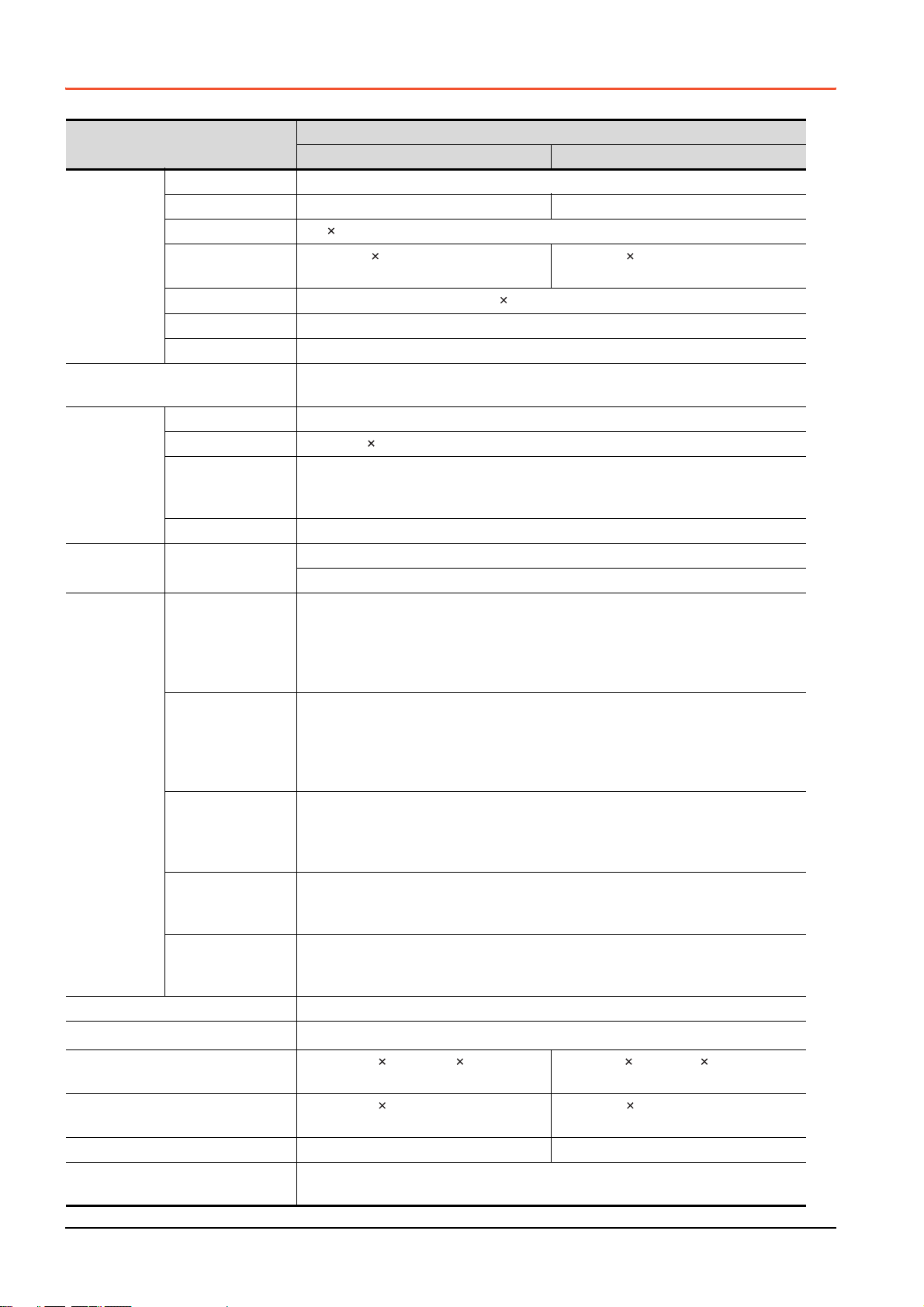

3.4 GOT Connector Specifications

D-Sub 9pin male

GOT main part connector

see from the front

15

69

D-Sub 9pin female

GOT main part connector

see from the front

51

96

The following shows the specifications of connectors for the GOT.

Refer to this section for creating a connection cable by the user.

3.4.1 RS-232 interface

The following shows the connector for the RS-232 interface of the GOT. For the connection cable connector of the GOT

side, use a connector and a connector cover which can be connected to the GOT connector.

■1. Connector specifications

GOT Connector type Connector model Manufacturer

GS series

■2. Connector pin arrangement

D-sub 9 pins (Male)

Inch screw type

17LE-23090-27(D3CC) DDK Ltd.

3.4.2 RS-422 interface

The following shows the connector for the RS-422 interface of the GOT.

For the connection cable connector of the GOT side, use a connector and a connector cover which can be connected to the

GOT connector.

■1. Connector model

GOT Connector type Connector model Manufacturer

GS series

■2. Connector pin arrangement

D-sub 9 pins (Female)

M2.6 mm screw type

17LE-13090-27(D3AC) DDK Ltd.

3 - 4

3.4 GOT Connector Specifications

Page 31

4. PART NAME

4.1 Front Panel

(1)(2)

No. Name Specifications

(1) Display section Displays the utility screen and the user creation screen.

(2) Touch panel For operating the touch switches in the utility screen and the user creation screen

4

PART NAME

4.1 Front Panel

4 - 1

Page 32

4.2 Back Panel

GS2110-WTBD

(6) (10)

(7)

(8)

(4)

(2)(1)(3)(9) (5)

GS2107-WTBD

(6) (7) (8)

(10)

(4)

(1)(3)(9)

No. Name Specifications

(1) RS-232 interface

(2) RS-422 interface For communicating with controller (PLC, microcomputer board, etc) (D-sub 9-pin female)

(3) Ethernet interface For Ethernet communication with controller (PLC, microcomputer board, etc) (RJ-45 connector)

(4) USB interface USB interface (host) for data transfer and saving

Hole for preventing the USB

(5)

cable from unplugging

(6) Rating plate (nameplate)

(7) SD card interface Interface for mounting an SD card to the GOT

(8) SD card access LED ON: SD card is accessed, OFF: SD card is not accessed

(9) Power terminal Power terminal and FG terminal (for power supply (24VDC) to GOT and grounding)

Ethernet communication

(10)

status LED

For communicating with controller (PLC, microcomputer board, RFID, etc) or personal computer

(OS installation, project data download, FA transparent) (D-sub 9-pin male)

Hole for preventing the USB cable from unplugging with a banding band

Model name, current consumption, production number, hardware version, and Boot OS version are

described.

SD RD: Green light while data are being sent or received, 100M: Green light when the transmission

speed is 100Mbps

(5)(2)

4 - 2

4.2 Back Panel

Page 33

4.3 Bottom

GS2110-WTBD

(1)

GS2107-WTBD

(1)

No. Name Specifications

Hole for unit installation

(1)

fittings

Hole for the inserting installation fittings (accessory) during the GOT installation to the panel

(4 holes at top and bottom)

4

PART NAME

4.3 Bottom

4 - 3

Page 34

4 - 4

4.3 Bottom

Page 35

5. EMC DIRECTIVE

5.1 Overview

For the products sold in European countries, the conformance to the EMC Directive, which is one of the European

Directives, has been a legal obligation since 1996.

Manufacturers, who recognize that their products comply with the EMC Directive must declare that their products comply

with the Directives and put a CE mark on the products.

■1. Sales representative in Europe

The sales representative in Europe is as shown below.

Company name: Mitsubishi Electric Europe BV

Address: Mitsubishi-Electric-Platz 1, 40882 Ratingen, Germany

5.1.1 Conforming standards in the EMC Directive

The GOT complies with the following standards in the EMC Directive.

Applied

standard

EN61131-2

: 2007

Test standard Test details Standard value

CISPR16-2-3

Radiated noise

IEC61000-4-2

Electrostatic immunity

IEC61000-4-3

Radiated electromagnetic

field, amplitude modulation

IEC61000-4-4

Fast transient burst noise

IEC61000-4-5

Surge immunity

IEC61000-4-6

Conducted RF immunity

IEC61000-4-8

Power supply frequency

magnetic field immunity

*1 The GOT is an open type device (designed to be integrated in equipment).

*2 QP: Quasi-peak value, Mean: Average value

*3 This test item is conducted in the following conditions.

*1

*1

*1

Make sure to install the GOT on a control panel.

This test item is conducted in the condition where the GOT is installed on a control panel and combined with the MITSUBISHI

PLC.

• 30 MHz to 230 MHz

QP: 40 dBμV/m (measured at 10 m)

• 230MHz to 1000MHz

QP: 47 dBμV/m (measured at 10 m)

Test for measuring electromagnetic

emissions from the product

Immunity test in which static electricity

is applied to the cabinet of the

equipment

Immunity test in which an electric field

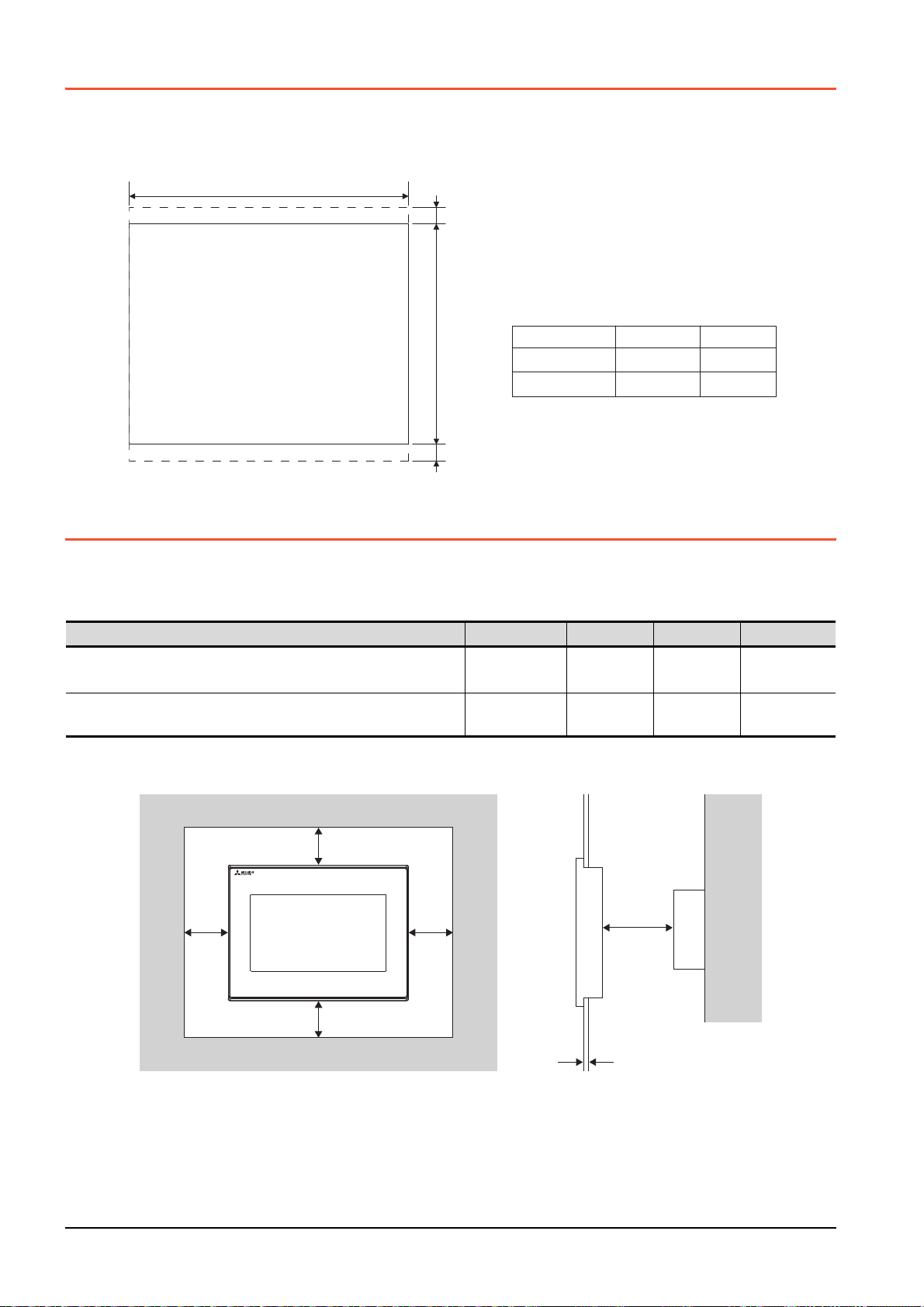

is applied to the product

*1

Immunity test in which burst noise is

applied to the power cables and the

*1

signal lines

Immunity test in which lightening surge

is applied to the product

Immunity test in which a noise

inducted on the power cable and the

*1

signal lines is applied

Test for checking normal operations

under the circumstance exposed to the

ferromagnetic field noise of the power

supply frequency (50/60 Hz)

• 30 MHz to 230 MHz

QP: 30 dBμV/m (measured at 30 m)

• 230 MHz to 1000 MHz

QP: 37 dBμV/m (measured at 30 m)

• Contact discharge: ±4 kV

• Aerial discharge: ±8 kV

80 MHz to 1000 MHz: 10 V/m

1.4 GHz to 2 GHz: 3 V/m

2.0 GHz to 2.7 GHz: 1 V/m

(80% amplitude modulation at 1 kHz)

Power cable: 1 kV

Digital I/O: 1 kV

Analog I/O: 1 kV

Signal cable: 1 kV

• AC power type

Power cable (between cable and ground): ±2

kV

Power cable (between cables): ±1 kV

Data communication port: ±1 kV

• DC power type

Power cable (between cable and ground):

±0.5 kV

Power cable (between cables): ±0.5 kV

Data communication port: ±1 kV

Power cable: 10 V

Data communication port: 10 V

30 A/m

*2*3

*2*3

5

EMC DIRECTIVE

5.1 Overview

5 - 1

Page 36

5.2 EMC Directive Requirements

The EMC Directive requires the following.

• Strong electromagnetic waves are not emitted to the outside.: Emission (Electromagnetic interference)

• The product is not affected by the electromagnetic waves from the outside.: Immunity (Electromagnetic sensitivity)

To comply with the EMC Directive, this section explains the precautions for configuring equipment integrating the GOT.

The data described herein are produced with our best, based on the regulation requirements and standards obtained by

Mitsubishi. However, the data do not guarantee that the whole equipment produced according to the data comply with the

above directive.

The manufacturer of the equipment must determine the method to comply with the EMC Directive and conformance to the

directive.

5.2.1 Installing the GOT on the control panel

The GOT is an open type device (designed to be integrated in equipment).

Make sure to install the GOT in a control panel.

This restriction ensures safety and also has a large effect of suppressing noise generated from the GOT by using the control

panel.

■1. Control panel

• The control panel must be conductive.

• When fixing a top or bottom plate of the control panel with bolts, do not coat the plate and bolt surfaces so that they

contact each other.

Connect the door and the box using a thick grounding cable to ensure the low impedance under high frequency.

• To ensure electric conductivity in the large area as much as possible between an inner plate and the control panel,

do not coat the fixing bolt area of the inner plate and the control panel.

• Ground the control panel using a thick grounding cable to ensure the low impedance under high frequency.

• The diameter of cable holes on the control panel must be 10 cm or less.

If the diameter of the hole is 10 cm or more, radio waves may leak.

To reduce the chance of radio waves leaking out, ensure that the space between the control panel and its door is as

small as possible.

Pasting the following EMI gasket directly on the painted surface seals the space, reducing the leak of electric waves.

Manufacturer Series name Contact

KITAGAWA INDUSTRIES CO., LTD. RFSG series (Recommended Product) 0587-34-3651

Our test has been carried out on a panel having the damping characteristics of 37 dB max. and 30 dB mean (measured

by 3m method with 30 to 300 MHz).

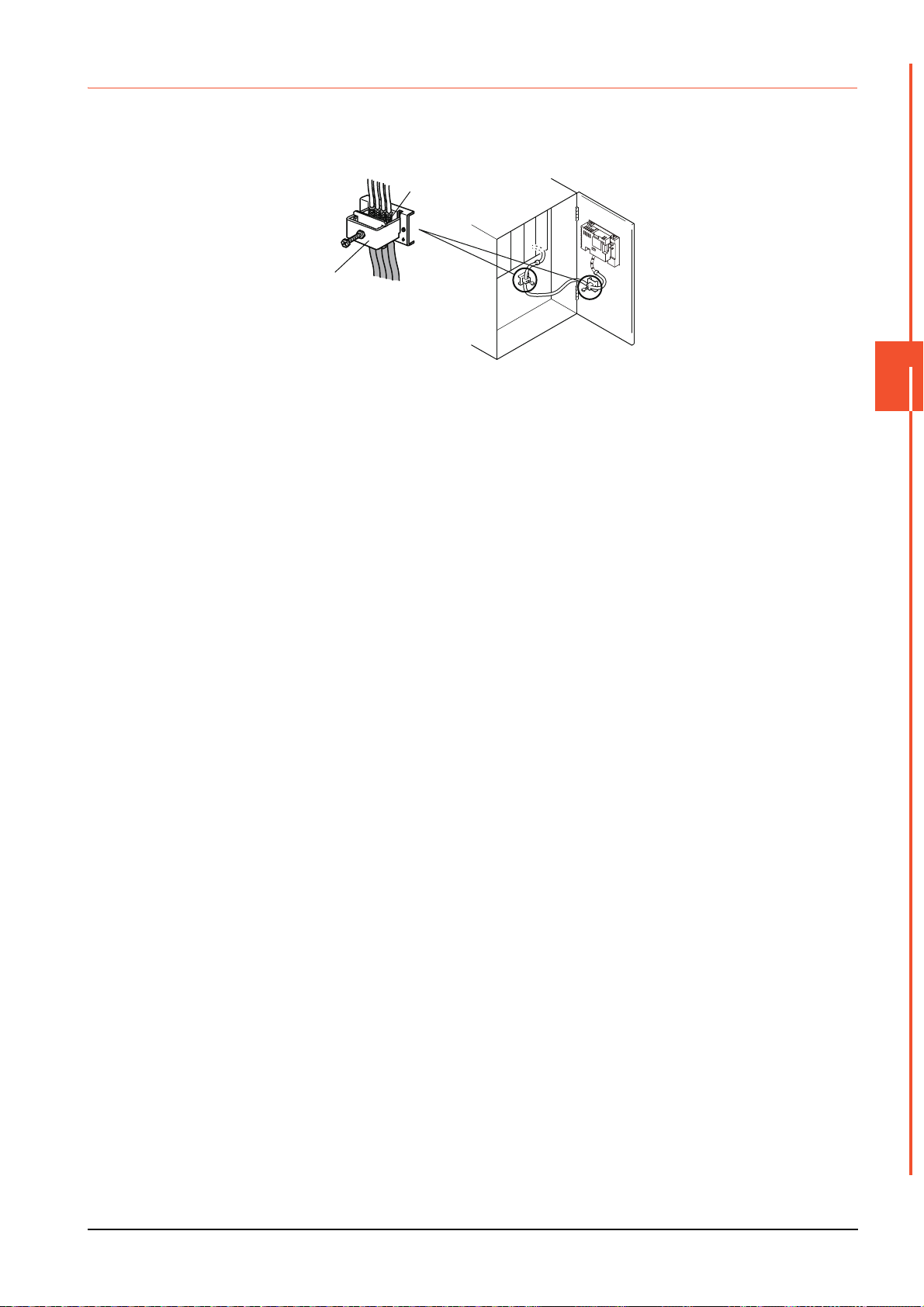

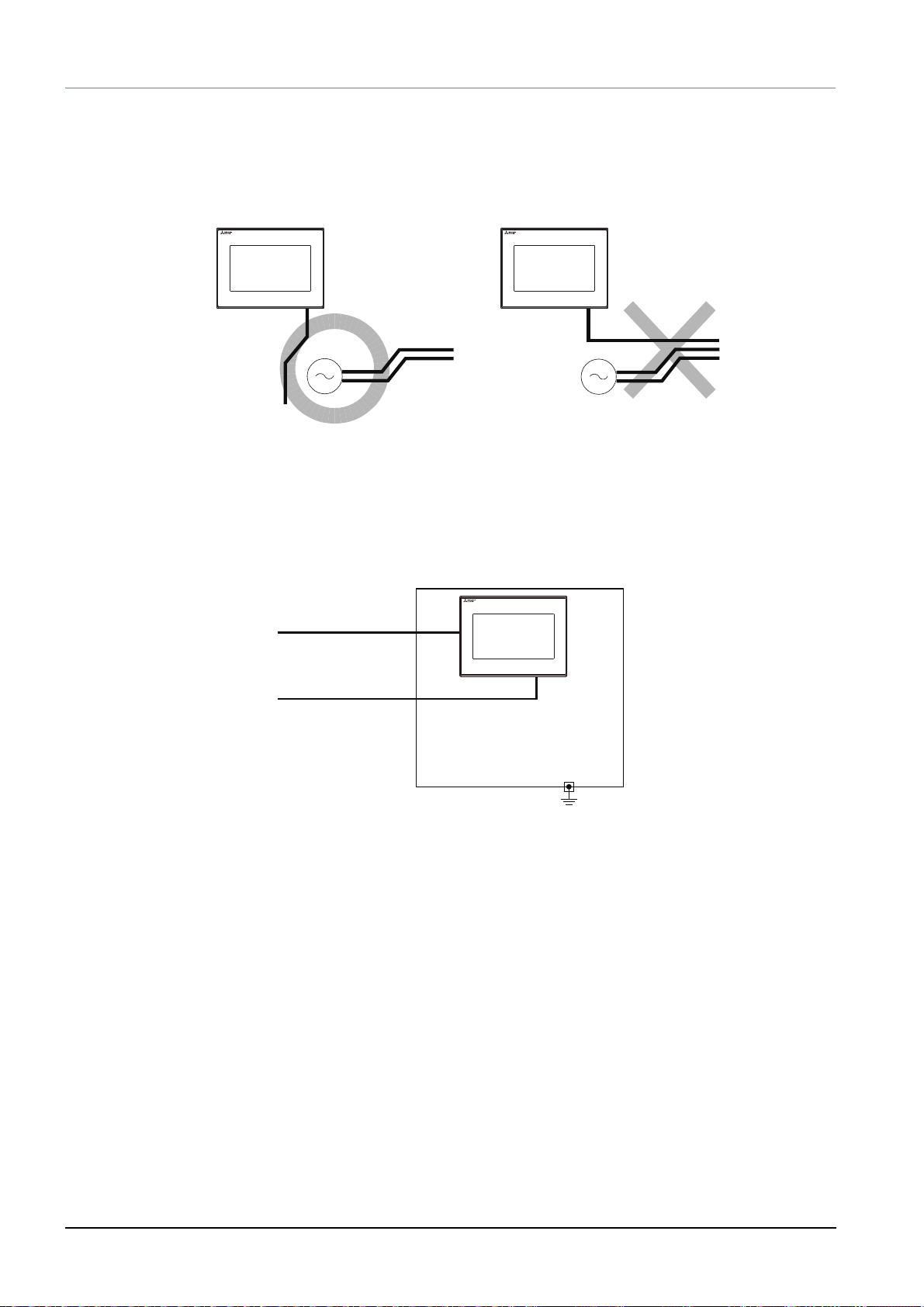

■2. Connection of power and ground cables

Ground the GOT and connect power supply cables as shown below.

(1) Wiring the ground cable

Provide a ground point near the GOT.

Ground the frame ground terminal (FG terminal) of the GOT with the thickest and shortest cable as possible.

(2) Ground cable length

The ground cable length must be 30 cm or shorter.

The FG terminals pass the noise generated in the PLC system to the ground.

Therefore, ensure an impedance as low as possible.

Since the ground cables relieve the noise, the cables themselves carry a large noise.

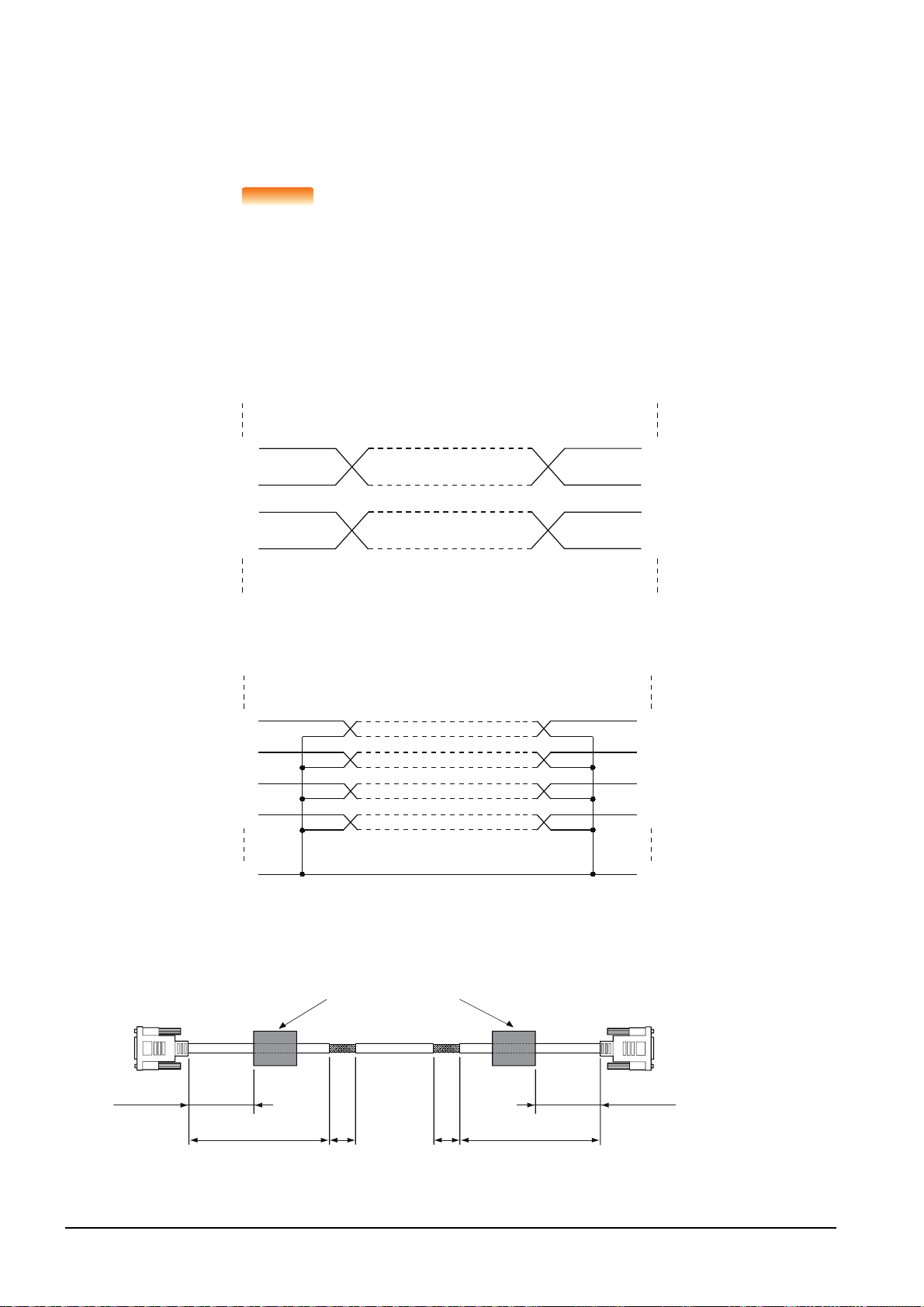

Thus, short wiring prevents the cable from acting as an antenna.

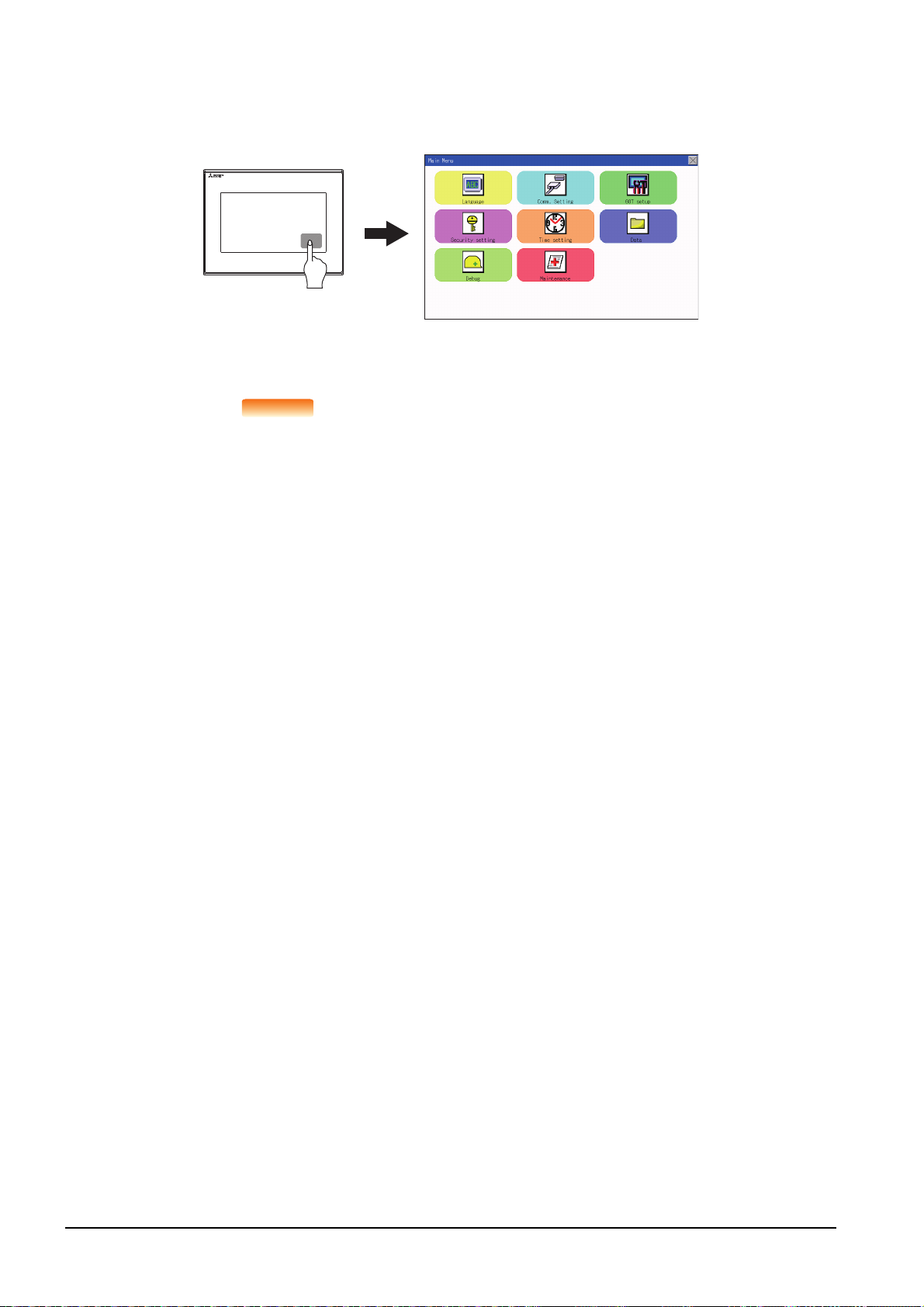

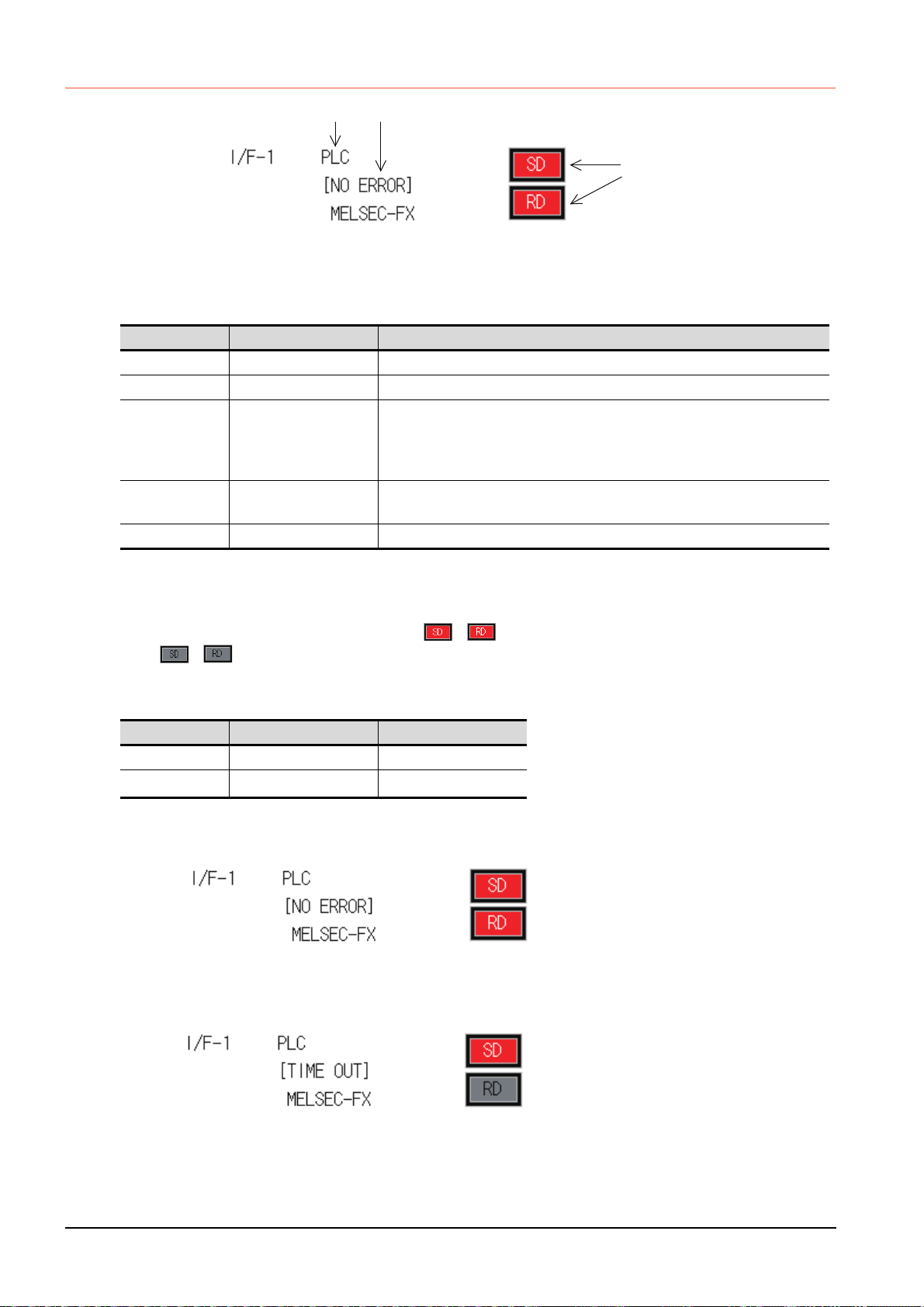

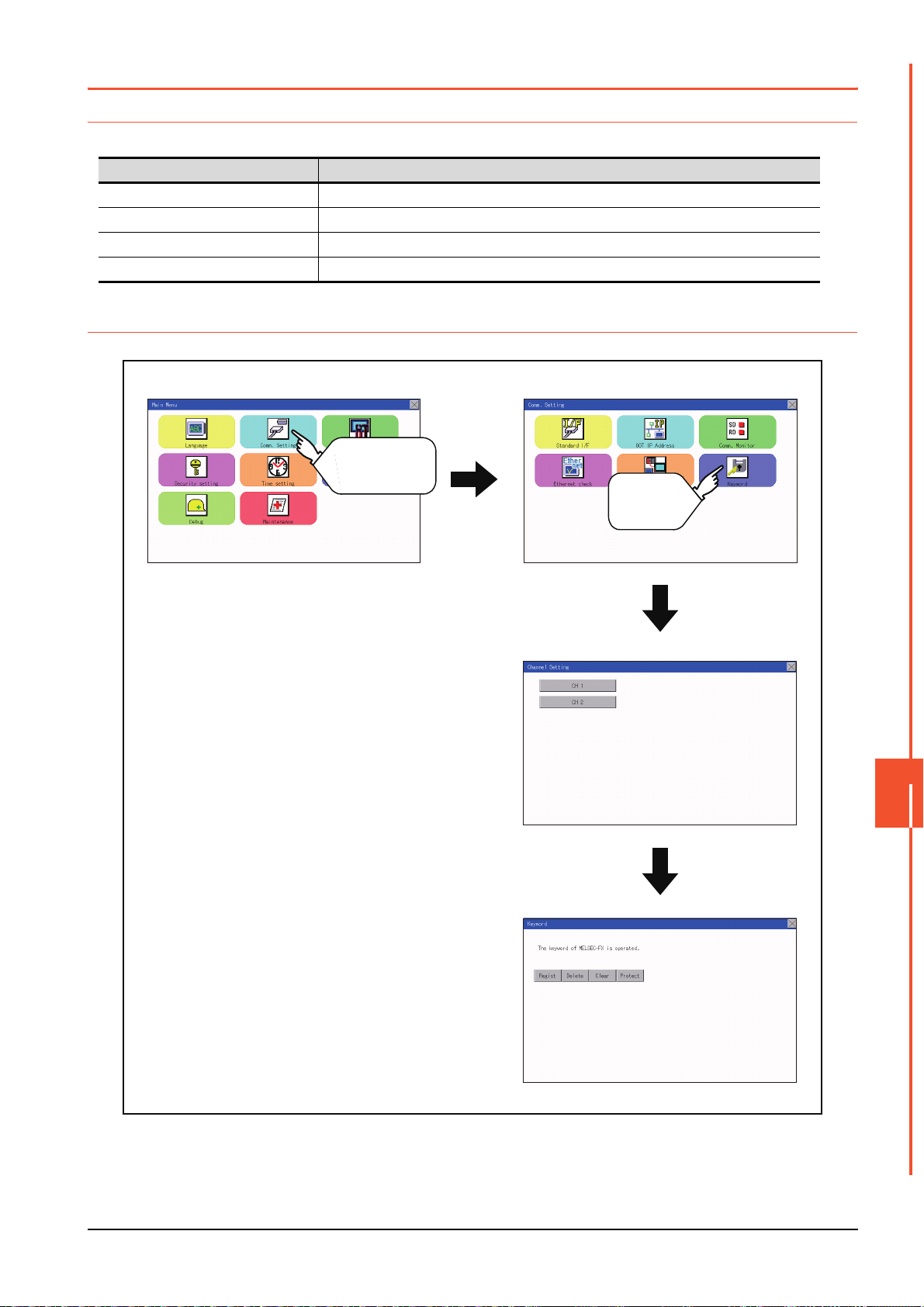

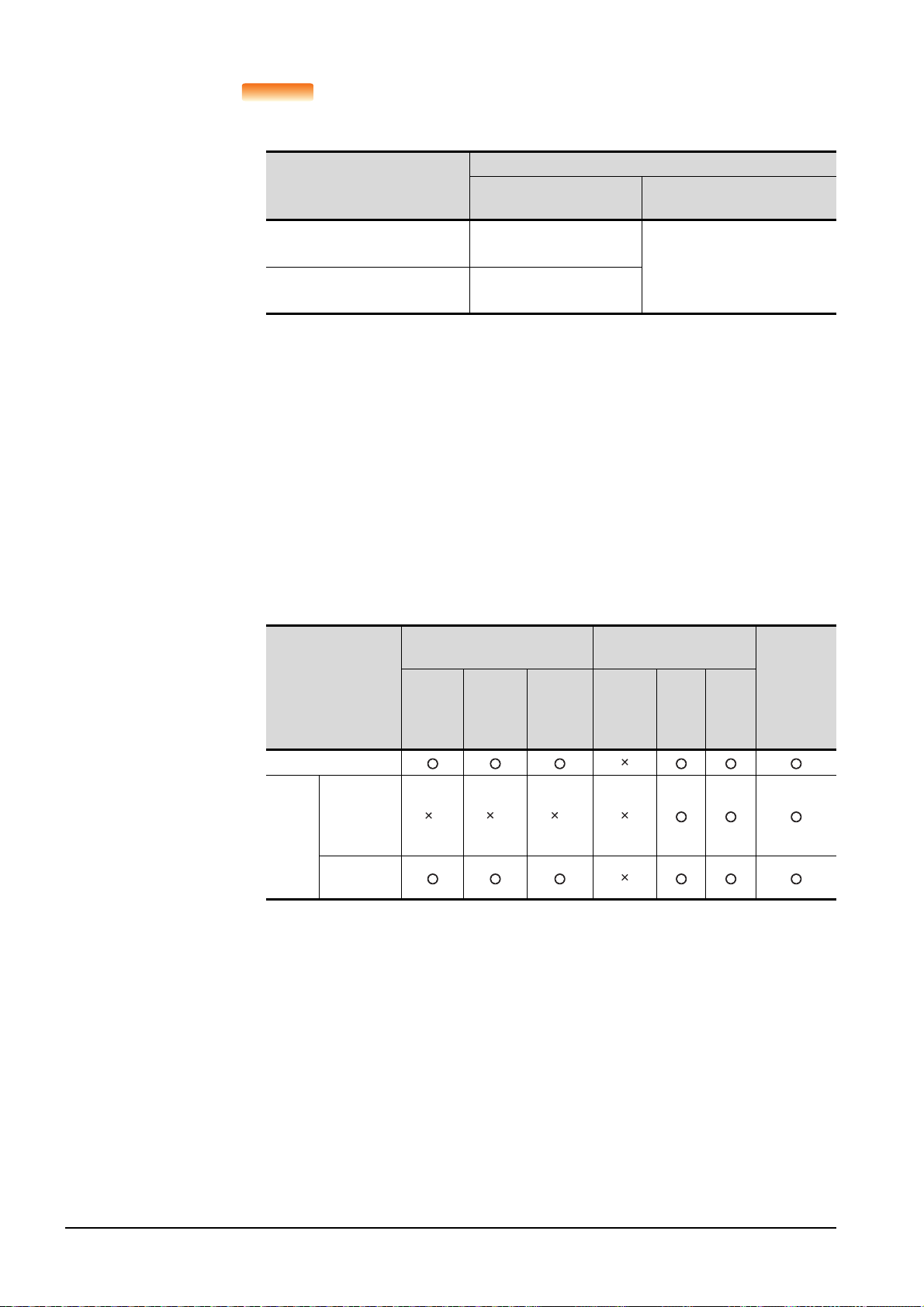

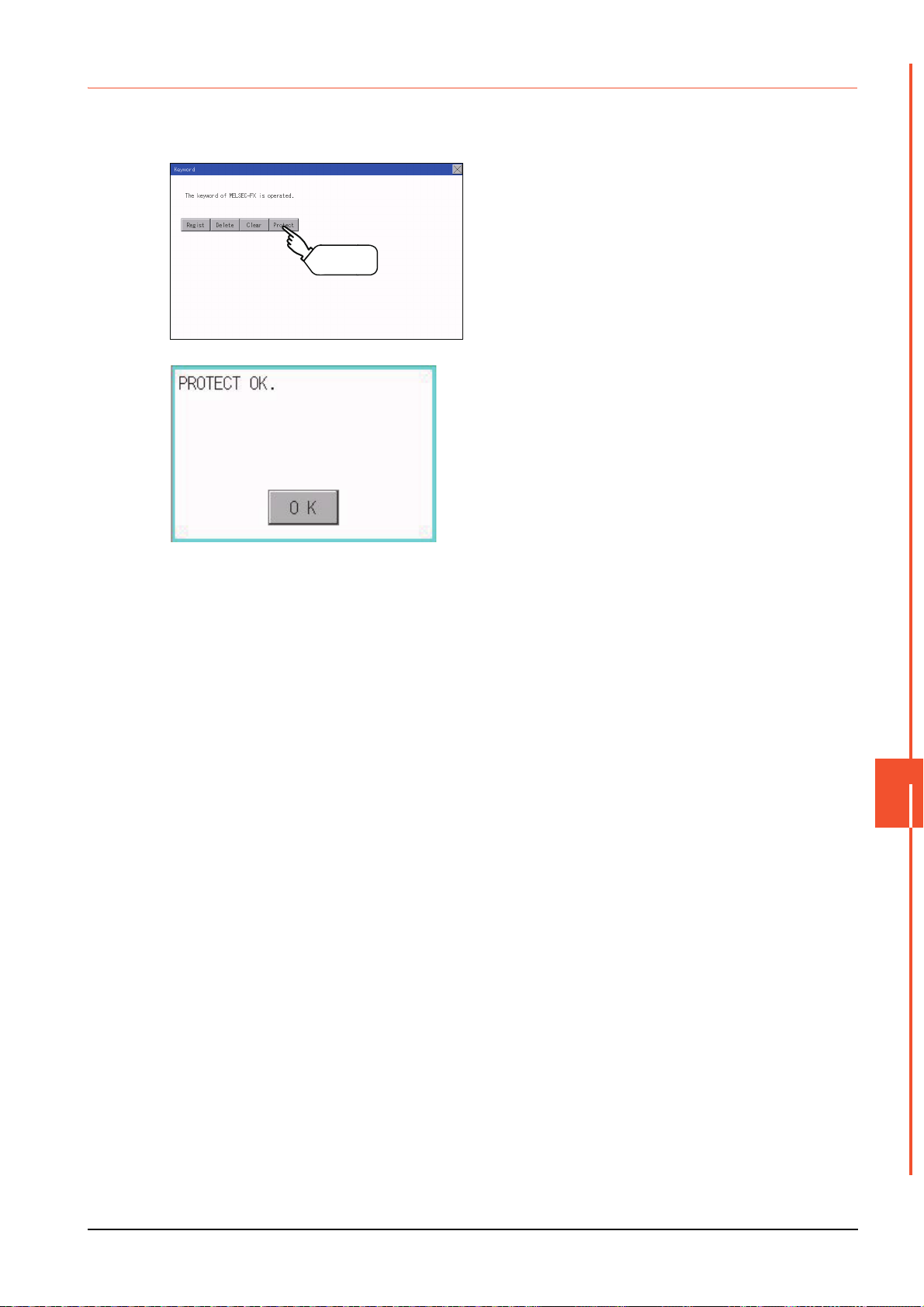

(A long conductor is an antenna radiating noise more efficiently.)