C

MIT

SUBIS

C

HI ELECTRI

GOT Series

Human Machine Interface

Operating Manual (Introductory)

Art.-Nr.: 136208

01 08 2000

SH-080116-A

GOT900

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

SAFETY PRECAUTIONS

•

(Always read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the CPU module user's manual.

In this manual, the safety instructions are ranked as "WARNING" and "CAUTION".

•

WARNING

CAUTION

Note that the !CAUTION level may lead to a serious consequence according to t he circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and always forw ard it to the end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[Design Precautions]

!

WARNING

Some failures of the GOT main unit, communication board or cable may keep the outputs on or

•

off.

An external monitoring circuit should be provided to check for output signals which may lead t o a

serious accident.

Not doing so can cause an accident due to false output or malfunction.

If a communication fault (including cable disconnection) occurs during monitoring on t he GOT,

•

communication between the GOT and PLC CPU is suspende d and the GO T becomes

inoperative.

For bus connection : The CPU becomes faulty and the GOT inoperative.

A system where the GOT is used should be configured to perform any significant operation to

the system by using the switches of a device other than the GOT on the assumption that a GOT

communication fault will occur .

Not doing so can cause an accident due to false output or malfunction.

!

CAUTION

Do not bundle the control and communication cables with main-circuit, power or other wiring.

•

Run the above cables separately from such wiring and keep them a minimum of 100mm apart.

Not doing so noise can cause a malfunction.

A - 1 A - 1

[Mounting Precautions]

!

WARNING

Before installing or removing t he GO T main unit t o or from an enclos ure, alway s s wit ch off th e

•

GOT power externally in all phases.

Not doing so can cause a module failure or malfunction.

Before loading or unloading the communication board to or from the GOT, alway s switch off the

•

GOT power externally in all phases.

Not doing so can cause a module failure or malfunction.

!

CAUTION

The GOT should be used in the environment given in the general specifications of the GO T

•

user's manual.

Not doing so can cause an electric shock, fire, malfunction or product damage or deterioration.

When mounting the GOT main unit to an enclosure, tighten the mounting screws in the specifie d

•

torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to the damage of the screws or

module.

When loading the communication board to the GOT main unit, fit it to the connection interface of

•

the GOT and tighten the mounting screws in the specified torque range.

Undertightening can cause a drop, failure or malfunction.

Overtightening can cause a drop, failure or malfunction due to the damage of the screws or

module.

A - 2 A - 2

[Wiring Precautions]

!

WARNING

Before starting wiring, always switch off the GOT power externally in all phases.

•

Not doing so may cause an electric shock, product damage or malfunction.

!

CAUTION

Please make sure to ground FG terminal, LG terminal, and protective ground terminal of the

•

GOT power supply unit by applying Class D Grounding (Class 3 Gr ounding Method) or higher

which is used exclusively for the GOT.

Not doing so may cause an electric shock or malfunction.

Correctly wire the power supply module on the GOT after confirming the rated voltage and

•

terminal arrangement of the product.

Not doing so can cause a fire or failure.

Tighten the terminal screws of the GOT power supply section in the specified torque range.

•

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or

module.

Exercise care to avoid foreign matter such as chips and wire offcuts entering the module.

•

Not doing so can cause a fire, failure or malfunction.

Plug the bus connection cable by inserting it into the connector of the connected module until it

•

"clicks".

After plugging, check that it has been inserted snugly.

Not doing so can cause a malfunction due to a contact fault.

Plug the communication cable into the connector of the connected module and tighten the

•

mounting and terminal screws in the specified torque range.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or

module.

[Test Operation Precautions]

!

WARNING

Before performing test operation (bit device on/off, word device's present value changing,

•

timer/counter's set value and present value changing, buffer memory's present value changing)

for a user-created monitor screen, read the manual carefully to fully understand how to operate

the equipment.

During test operation, never change the data of the devices which are used to perform

significant operation for the system.

False output or malfunction can cause an accident.

A - 3 A - 3

[Startup/Maintenance Precautions]

!

WARNING

When power is on, do not touch the terminals.

•

Doing so can cause an electric shock or malfunction.

Before starting cleaning or terminal screw retightening, always switch off the power externally in

•

all phases.

Not switching the power off in all phases can cause a module failure or malfunction.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the screws or

module.

!

CAUTION

Do not disassemble or modify the module.

•

Doing so can cause a failure, malfunction, injury or fire.

Do not touch the conductive and electronic parts of the module directly.

•

Doing so can cause a module malfunction or failure.

The cables connected to the module must be run in ducts or clamped.

•

Not doing so can cause the module or cable to be damaged due to the dangling, motion or

accidental pulling of the cables or can cause a malfunction due to a cable connection fault.

When unplugging the cable connected to the module, do not hold and pull the cable portion.

•

Doing so can cause the module or cable to be damaged or can cause a malfunction due to a

cable connection fault.

[Disposal Precautions]

!

CAUTION

When disposing of the product, handle it as industrial waste.

•

A - 4 A - 4

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Aug., 2000 SH (NA) 080116-A

Japanese Manual Version SH-080111-A

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

2000 MITSUBISHI ELECTRIC CORPORATION

A - 5 A - 5

INTRODUCTION

Thank you for choosing the Mitsubishi Graphic Operation Terminal.

Before using the equipment, please read this manual carefully to use the equipment to its optimum.

CONTENTS

About manuals ...............................................................................................................................................A- 8

Abbreviations and generic terms in this manual ...........................................................................................A- 9

CHAPTER1 FUNDAMENTAL KNOWLEDGE 1- 1 to 1- 4

1.1 About GOT ...............................................................................................................................................1- 1

1.2 About GOT Operations............................................................................................................................1- 2

1.3 Mouse Usage and Operations.................................................................................................................1- 3

1.4 System Configuration Used in the Manual..............................................................................................1- 4

1.5 Procedures for Use of GOT.....................................................................................................................1- 4

CHAPTER2 SETTING FIGURES AND OBJECTS 2- 1 to 2- 2

2.1 Drawing a Figure......................................................................................................................................2- 1

2.2 Editing a Figure or Object........................................................................................................................2- 2

CHAPTER3 CREATING SCREENS 3- 1 to 3-15

3.1 Creating a Screen like This......................................................................................................................3- 1

3.2 Common Setting before Drawing............................................................................................................3- 2

3.2.1 Selecting GOT/PLC type...................................................................................................................3- 2

3.2.2 Setting screen switching device........................................................................................................3- 3

3.3 Creating the First Screen.........................................................................................................................3- 4

3.4 Setting Objects.........................................................................................................................................3- 5

3.4.1 Setting numerical display function .................................................................................................... 3- 5

3.4.2 Setting numerical input function........................................................................................................3- 7

3.4.3 Setting lamp display function............................................................................................................3- 8

3.4.4 Setting touch key function.................................................................................................................3-11

CHAPTER4 CREATING THE SECOND SCREEN 4- 1 to 4-14

4.1 Creating a Screen like This......................................................................................................................4- 1

4.2 Creating the Second Screen....................................................................................................................4- 2

4.3 Creating Comments.................................................................................................................................4- 3

4.4 Setting Objects.........................................................................................................................................4- 4

4.4.1 Setting touch key function for screen switching...............................................................................4- 4

4.4.2 Setting level display function.............................................................................................................4- 7

4.4.3 Setting panelmeter display function..................................................................................................4- 9

4.4.4 Setting alarm list display function .....................................................................................................4-11

4.5 Saving Created Screen Data...................................................................................................................4-13

4.6 Reading Saved Screen Data...................................................................................................................4-14

A - 6 A - 6

CHAPTER5 STARTING GOT FOR CHECKING 5- 1 to 5- 6

5.1 Connecting the Personal Computer and GOT........................................................................................5- 1

5.2 Installing the OS.......................................................................................................................................5- 1

5.3 Downloading Screen Data.......................................................................................................................5- 2

5.4 Connecting to PLC CPU..........................................................................................................................5- 3

5.5 Executing Monitoring ...............................................................................................................................5- 4

5.6 Upload ......................................................................................................................................................5- 5

5.7 Sequence Program Used in the Manual.................................................................................................5- 6

INDEX Index- 1

A - 7 A - 7

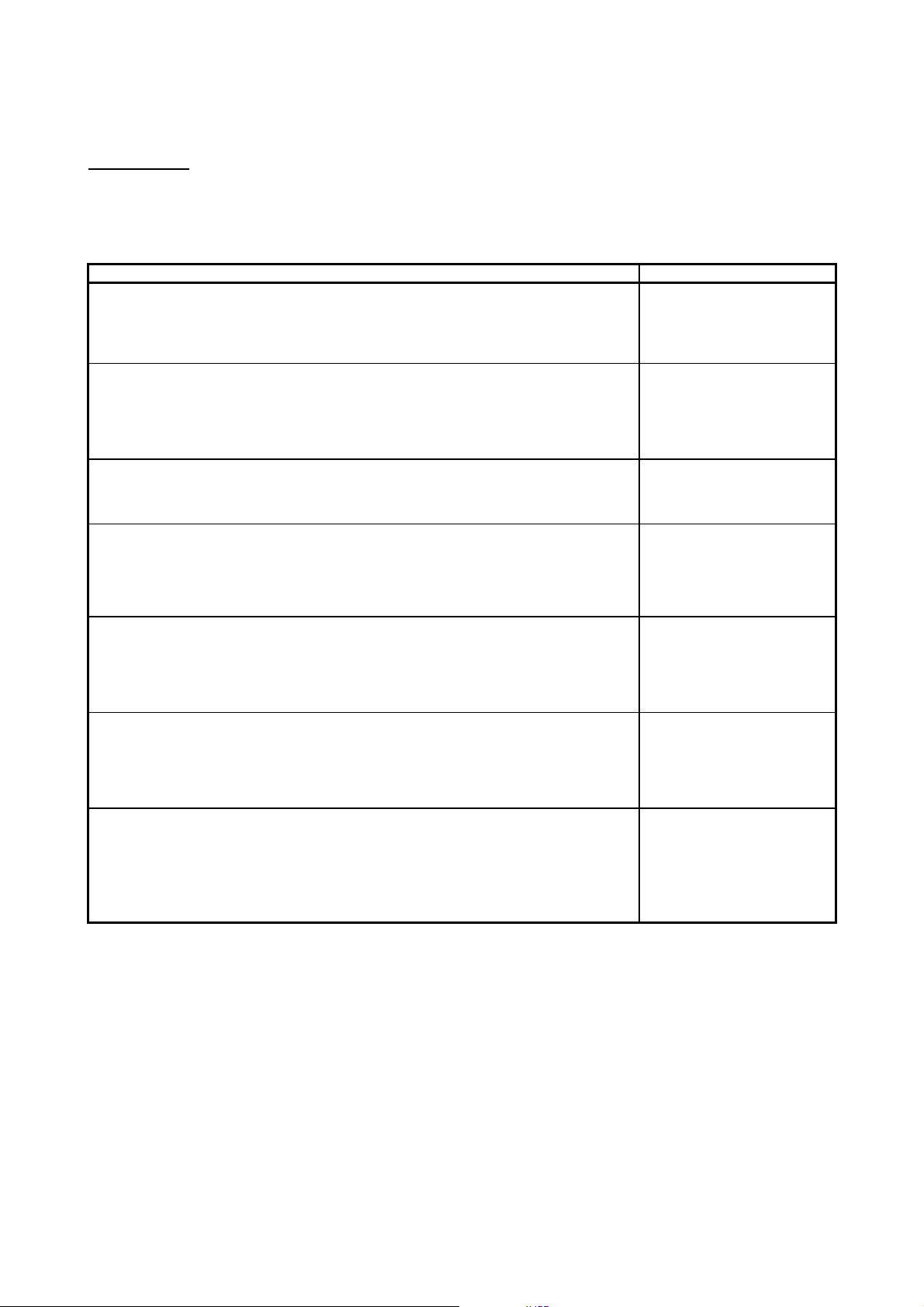

About Manuals

The following manuals related to this product are available. Obtain the manuals as

required the according to this table.

• Related manual

Manual name Manual number (Model code)

GT Works Version5/GT Designer Version5 Operating Manual (Start up M anual)

Describes how to install GT Works Version5/GT Designer Version5 into a personal computer and

how to browse the online manuals.

(Found in the packing of the GT Works Version5/GT Designer Version5)

GT Works Version5/GT Designer Version5 Reference Manual

Deals with the system configuration of GT Works Version5/GT Designer Version5, the screen

makeup of the GT Designer, the general description of various monitoring functions, the procedure

for displaying the monitor screen on the GOT, and how to use the help function.

(Available as option)

IB-0800143

(13JU06)

SH-080117

(13JF95)

GT Simulator Version5 Operating Manual

Explains the system configuration, screen makeup and using methods of GT Simulator.

(Available as option)

GOT-A900 Series User’s Manual (GT Works Version5/GT D esigner Version5

compatible Connection System Manual)

Gives the specifications, system configuration, setting method and connection diagram of each

connection form available for the GOT-A900 series.

(Available as option)

A985GOT/A975GOT/A970GOT/A960GOT User’s Manual

Explains the specifications, general system configuration, component devices, part names, option

unit loading methods, installation and wiring methods, maintenance and inspection methods, and

error codes of A985GOT/A975GOT/A970GOT/A960GOT unit.

(Available as option)

A950GOT/A951GOT/A953GOT/A956GOT User’s Manual

Explains the specifications, general system configuration, component devices, part names, option

unit loading methods, installation and wiring methods, maintenance and inspection methods, and

error codes of A950GOT/A951GOT/A953GOT/A956GOT unit.

(Available as option)

GOT-A900 Series Operating Manual (GT Works Version5/GT Designer Version5

compatible Extended • Option Functions Manual)

Provides the specifications of the utility, system monitoring, ladder monitoring, special function unit

monitoring, network monitoring functions and list editor functions available for the GOT-A900 series

and how to operate the dedicated monitor screen.

(Available as option)

SH-080120

(13JU09)

SH-080119

(13JR20)

SH-4005

(13JL70)

SH-080018

(13JL92)

SH-080118

(13JU08)

A - 8 A - 8

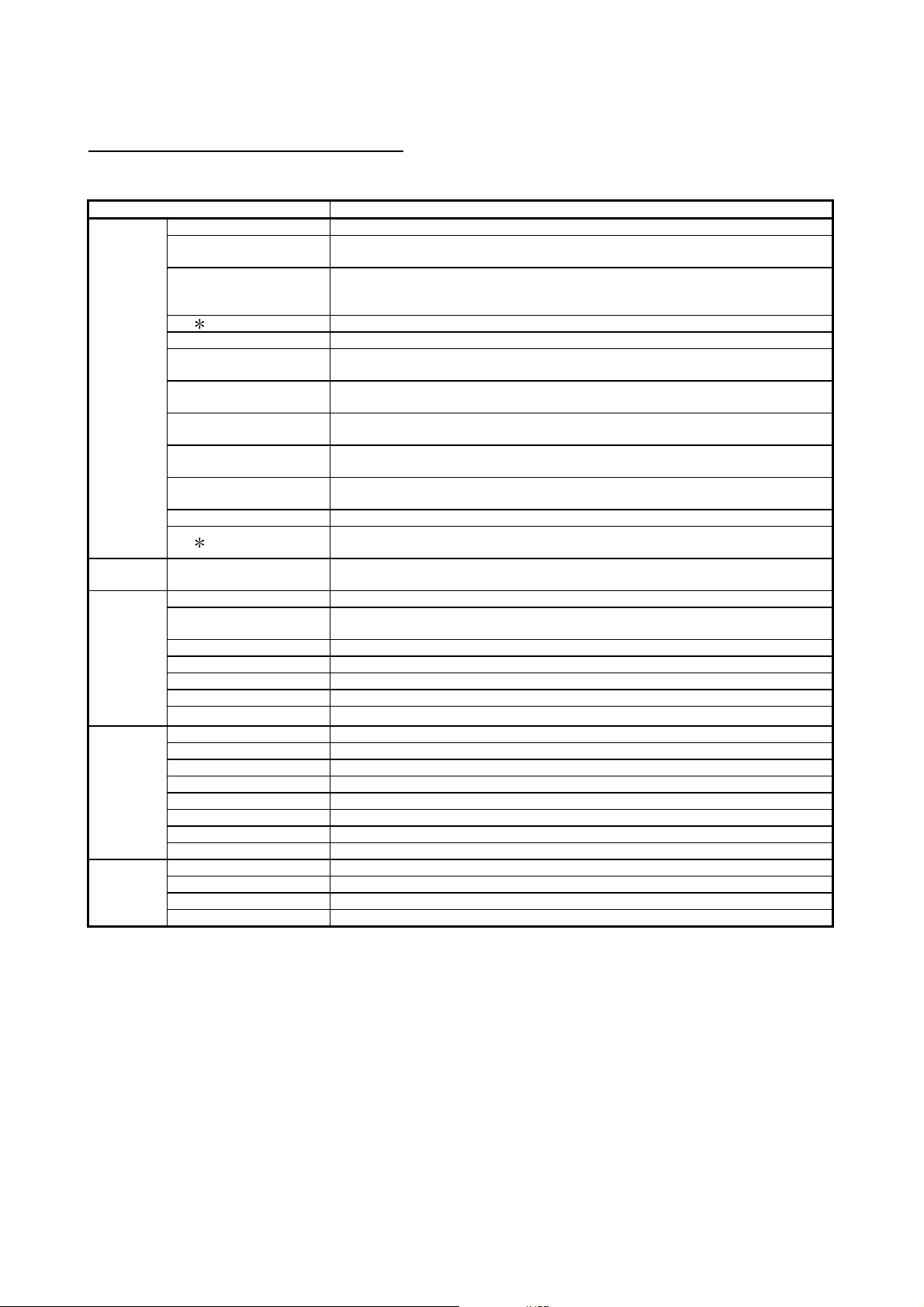

Abbreviations and generic terms in this manual

Abbreviations and generic terms used in this manual are described as follows:

Abbreviations and generic terms Description

A985GOT Generic term of A985GOT-TBA, A985GOT-TBD and A985GOT-TBA-EU

Generic term of A975GOT-TBA-B, A975GOT-TBD-B, A975GOT-TBA, A975GOT-TBD and

A975GOT-TBA-EU

Generic term of A970GOT-TBA-B A970GOT-TBD-B, A970GOT-TBA, A970GOT-TBD,

A970GOT-SBA, A970GOT-SBD, A970GOT-LBA, A970GOT-LBD, A970GOT-TBA-EU and

A970GOT-SBA-EU

Generic term of A956GOT-TBD, A956GOT-SBD, A956GOT-LBD, A956GOT-TBD-M3,

A956GOT-SBD-M3 and A956GOT-LBD-M3

Generic term of A953GOT-TBD, A953GOT-SBD, A953GOT-LBD, A953GOT-TBD-M3,

A953GOT-SBD-M3 and A953GOT-LBD-M3

Generic term of A951GOT-TBD, A951GOT-SBD, A951GOT-LBD, A951GOT-TBD-M3,

A951GOT-SBD-M3 and A951GOT-LBD-M3

Generic term of A951GOT-QTBD, A951GOT-QSBD, A951GOT-QLBD, A951GOT-QTBD-M3,

A951GOT-QSBD-M3 and A951GOT-QLBD-M3

Generic term of A950GOT-TBD, A950GOT-SBD, A950GOT-LBD, A950GOT-TBD-M3,

A950GOT-SBD-M3 and A950GOT-LBD-M3

Generic term of A956GOT, A953GOT, A951GOT, A951GOT-Q, A950GOT and A950 handy

GOT

Generic term of SW5D5C-GOTR-PACKE software package and SW5D5C-GOTR-PACKEV

software package

Abbreviation of GT Manager data editing software for GOT900

GOT

Communication board

Software

CPU

Others

A975GOT

A970GOT

A97 GOT Generic term of A975GOT and A970GOT

A960GOT Generic term of A960GOT-EBA, A960GOT-EBD and A960GOT-EBA-EU

A956GOT

A953GOT

A951GOT

A951GOT-Q

A950GOT

A950 handy GOT Generic term of A953GOT-SBD-M3-H and A953GOT-LBD-M3-H

GOT

A95

Bus connection board Generic term of A9GT-QBUSS, A9GT-QBUS2S, A9GT-BUSS and A9GT-BUS2S

GT Works Version5 SW5D5C-GTWORKS-E software package

GT Designer Version5

GT Designer Abbreviation of image creation software GT Designer for GOT900

GT Simulator Abbreviation of GT Simulator screen simulator GOT900

GT Converter Abbreviation of data conversion software GT Converter for GOT900

GT Debugger Abbreviation of debugging software GT Debugger

GT Manager

AnUCPU Generic term of A2UCPU, A2UCPU-S1, A3UCPU and A4UCPU CPU units

AnACPU Generic term of A2ACPU, A2ACPU-S1 and A3ACPU CPU units

AnNCPU Generic term of A1NCPU, A2NCPU, A2NCPU-S1 and A3NCPU CPU units

ACPU (Large Type) Generic term of AnUCPU, AnACPU and AnNCPU CPU units

A2US(H)CPU Generic term of A2USCPU, A2USCPU-S1 and A2USHCPU-S1 CPU units

AnS(H)CPU Generic term of A1SCPU, A1SHCPU, A2SCPU and A2SHCPU CPU units

A1SJ(H)CPU Generic term of A1SJCPU-S3 and A1SJHCPU CPU units

ACPU (Small Type) Generic term of A2US(H)CP U, AnS(H)CPU and A1SJ(H)CPU CPU units

Memory abbreviation of mmory (flash memory) in the GOT

OS Abreviation of GOT system software

Object Setting data for dynamic image

Personal Computer Personal computer where the corresponding software package is installed

A - 9 A - 9

1 FUNDAMENTAL KNOWLEDGE

CHAPTER1 FUNDAMENTAL KNOWLEDGE

MELSOFT

1

1.1 About GOT

This manual describes procedures for creating a simple screen and monitoring with the

GOT for learning basic operations.

If using the GOT for the first time, read this manual to become familiar with operation of

the GOT and the GT Designer.

POINT

The screen data and sequence programs created in Chapters 3 and 4 of this

manual are packed with GT Designer.

Use them as required to check settings, for example.

(1) What is the GOT?

The GOT can be used as an electronic operator panel which has achieved on its

monitor screen th e sw itch ope rat io n, la mp in di cat io n, da t a di splay , messa ge

display and other operations which were previously performed on an operator

panel.

Space saving

Cost reduction

(2) About monitor screen data to be display ed on the GOT

The monitor screen data to be displayed on the GOT are created on a personal

computer using the dedicated software (GT Designer).

You can perform the corresponding functions of the GOT by pasting display

frame figures called switch figure, lamp figure, numerical display and other

objects to create screens on GT Designer, and setting PLC CPU device memory

(bit, word) driven operating functions to the pasted objects.

The monitor screen data created are transferred to the GOT through an RS-232C

cable or PC card (memory card).

PC card

RS-232C cable Any of various connection cables

ConnectionScreen data transfer

Personal computer

GOT

1 - 1 1 - 1

PLC CPU

1 FUNDAMENTAL KNOWLEDGE

1.2 About GOT Operations

MELSOFT

This section briefly explains what operations the GOT will perform when it is connected

with the PLC CPU.

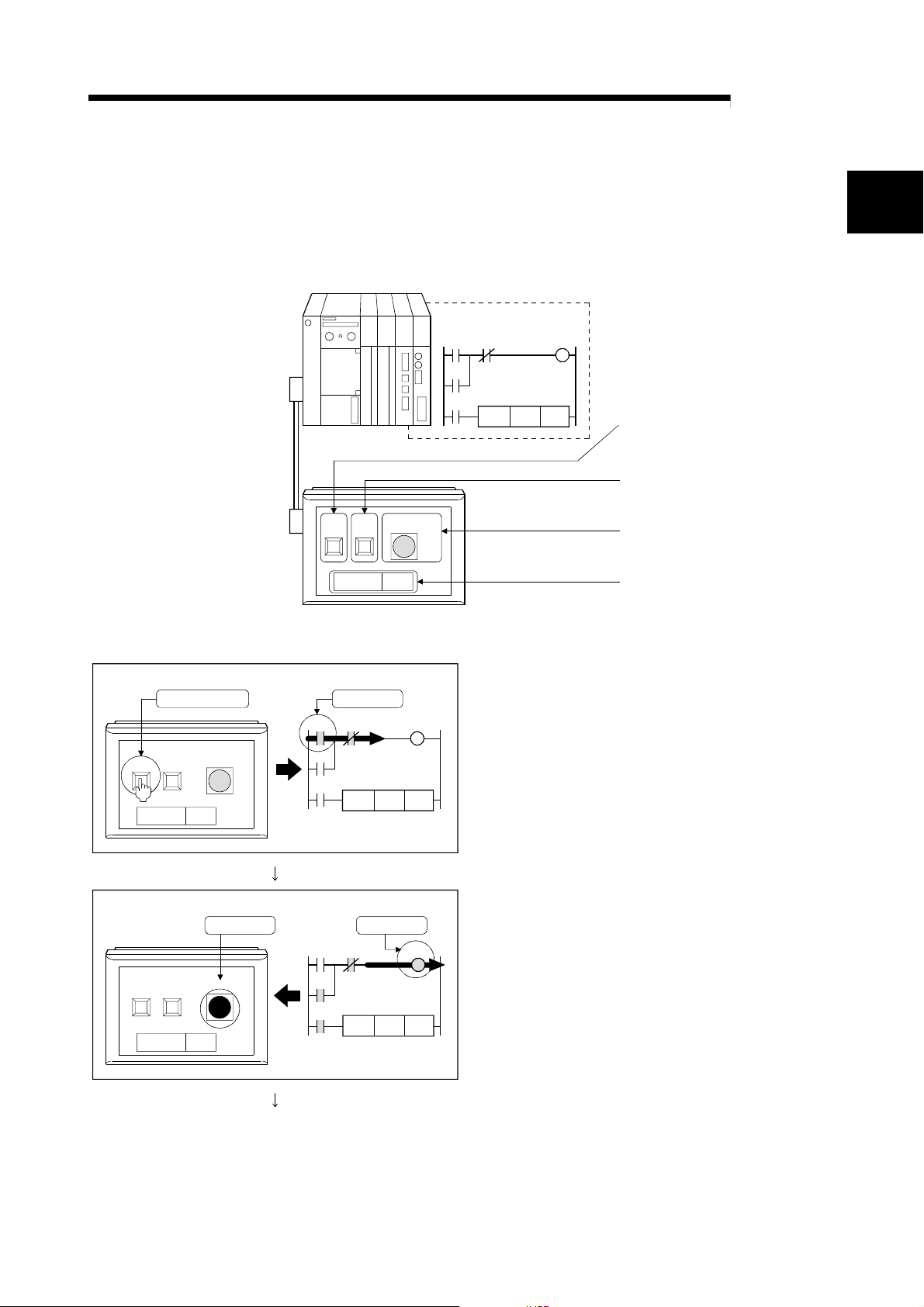

(1) System example

PLC CPU

Sequence program

M0

M1 Y10

Y10

<GOT settings made to figures>

Touch key setting

Bit momentary

Write device: M0

Touch key setting

Bit momentary

Write device: M1

Lamp display setting

Bit

Read device: Y10

Numerical display setting

Read device: D10, unsigned BIN

Indication: Unsigned decimal

Bus connection cable

GOT

Run Run lampStop

Data 1

123

Y10

K123MOV D10

(2) Operation explanation

1

(GOT) (PLC CPU )

Turns ON.Touch.

M0

M1 Y10

Y10

Y10

(PLC CPU )

M0

Y10

Y10

M1 Y10

(GOT)

Run

Run

Data

Data

Stop

Stop

Run lamp

0

Turns ON. Turns ON.

Run lamp

0

1) While the "Run" touch key of the GOT is touched,

the bit device "M0 " i s ON.

K123MOV D10

2) When the bit device "M0" turns ON, the bit device

"Y10" turns ON.

An ON figure also appears as the GOT's lamp

display where the monitor device is preset to the bit

device "Y10".

K123MOV D10

(To the followin g pa ge )

1 - 2 1 - 2

1 FUNDAMENTAL KNOWLEDGE

(From the previous page)

MELSOFT

(GOT)

(GOT)

Run

Stop

Data 123

Run

Stop

Data 123

"123" appears.

Run lamp

Touch.

Run lamp

Display tur ns OFF.

(PLC CPU )

"123" is stored into D10.

M0

M1

Y10

Y10

(PLC CPU )

M1 turns ON.

M0

M1 Y10

Y10

Y10

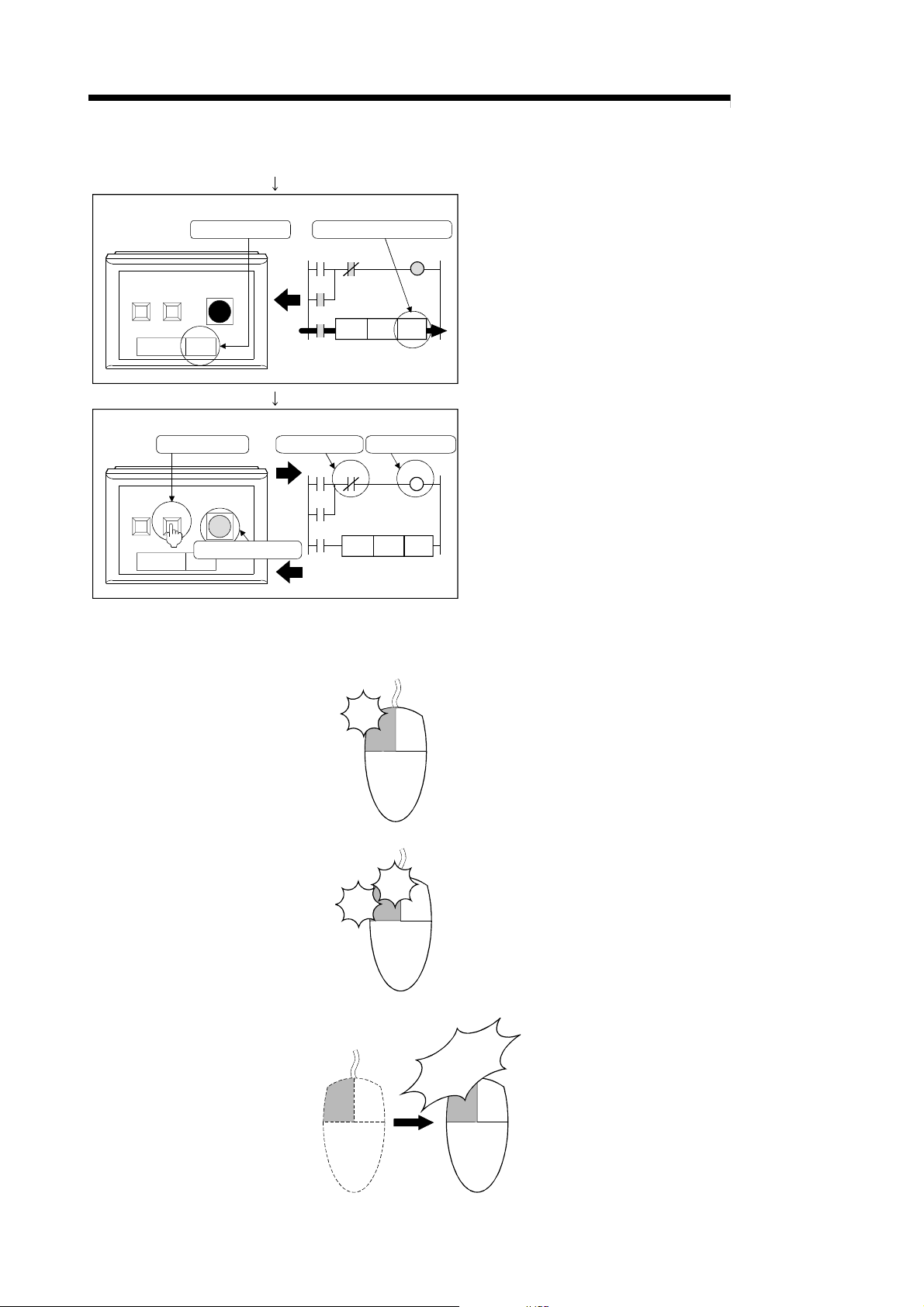

1.3 Mouse Usage and Operations

Describes basic operations of the mouse.

(1) Click

Y10

K123MOV D10

Y10 turns OFF.

K123MOV D10

Click

3) Since the bit device "M0" is ON, "123" is stored into

the word device "D10".

"123" also appears as the GOT's numerical display

where the monitor device is preset to the word

device "D10".

4) While the "Stop" touch key of the GOT is touched,

the bit device "M1" of the PLC CPU is ON.

Since the bit device "Y10" of the PLC CPU turns

OFF, the lamp display of the GOT turns OFF.

Press the left button of the mouse once, then

release without moving the mouse.

This is the most common operation.

Using the right button to perform this operation is

called "right-click".

(2) Double click

Press the left button of the mouse twice quickly

Click

Click

without moving the mouse. This operation is for

the left button only.

(3) Drag

Move the mouse while pressing the

left button.

Move the mouse

while the button

is pressed.

1 - 3 1 - 3

Using the right button to perform this

operation is called "right-drag".

1 FUNDAMENTAL KNOWLEDGE

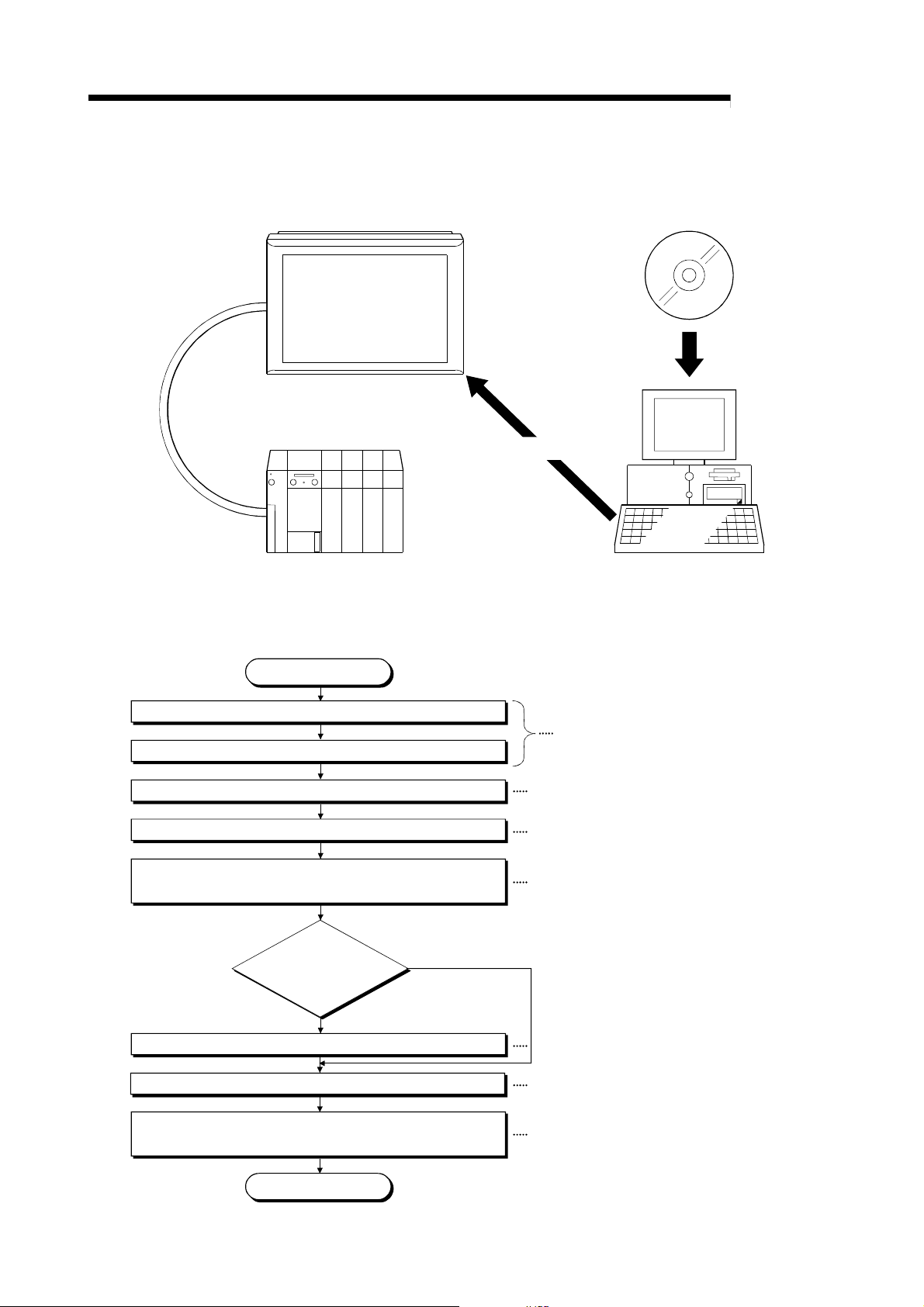

1.4 System Configuration Used in the M anual

A975GOT

Bus connection

Data tr ansfer

GT Works Version5

GT Designer Version5

Install

or

MELSOFT

PLC CPU (ACPU)

1.5 Procedures for Use of GOT

Describes the procedures from installation of the GT Designer to monitoring with the

GOT.

Start

Install the GT Designer.

Start the GT Designer.

Carry out common setting. Refer to 3.1

Prepare the user screen data.

Connect the GOT and the personal computer with RS-232C,

and turn ON the GOT.

Using the GOT

for the first time?

Personal computer

GT Works Version5/GT Designer Version5

Operating Manual (Start up Manual)

Refer to Chapter 3 and Chapter 4

Refer to 5.1

No

Yes

Install the OS and the communication driver.

Transfer the user screen data.

Connect to the PLC, and start monitoring.

(Turn OFF the GOT, then turn it ON again.)

End

Refer to 5.2

Refer to 5.3

Refer to 5.4 and 5.5

1 - 4 1 - 4

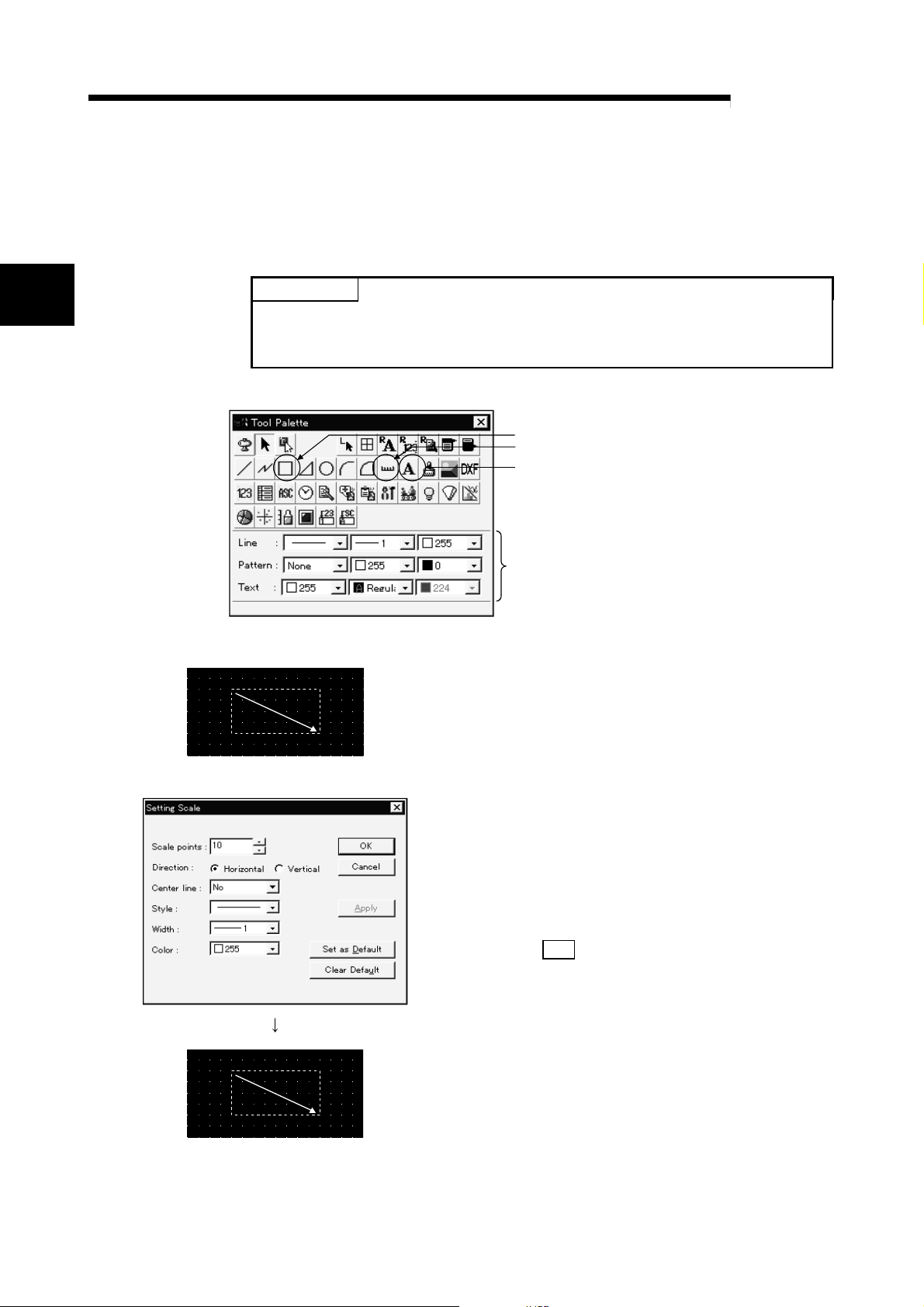

2 SETTING FIGURES AND OBJECTS

CAHPTER2 SETTING FIGURES AND OBJECTS

2.1 Drawing a Figure

Describes how to draw a figure.

MELSOFT

2

POINT

This chapter deals with only the drawing and editing of figures used in this manual.

For the drawing and editing of other figures, refer to the help function of GT

Designer.

When drawing a figure, click the icon of the figure you want to draw.

Click when drawing a rectangle.

Click when drawing a scale.

Click when entering a text.

When setting the attributes of a

figure or text, click the list box to

choose the attributes.

For details, refer to the GT Works

Version5/GT Designer Version5

Reference Manual.

(1) When drawing a rectangle

1)

2)

3)

1) Click the left mouse button at the start point of the

rectangle.

2) Drag the cursor to the end point.

3) Release the left mouse button. A rectangle appears.

(2) When drawing a scale

1) As the scale setting dialog box appears, make

settings.

Scale points: Se t t he numbe r of sca le poi nt s.

Direction: Choo se t he scale di rect ion.

Center line: Specify whether a line is drawn in the

scale center or not.

2) Click the OK

3) Press the left mouse button at the starting point of

3)

4)

5)

drawing the scale.

4) Drag the cursor to the end point.

5) Release the left mouse button. The scale appears.

2 - 1 2 - 1

button.

2 SETTING FIGURES AND OBJECTS

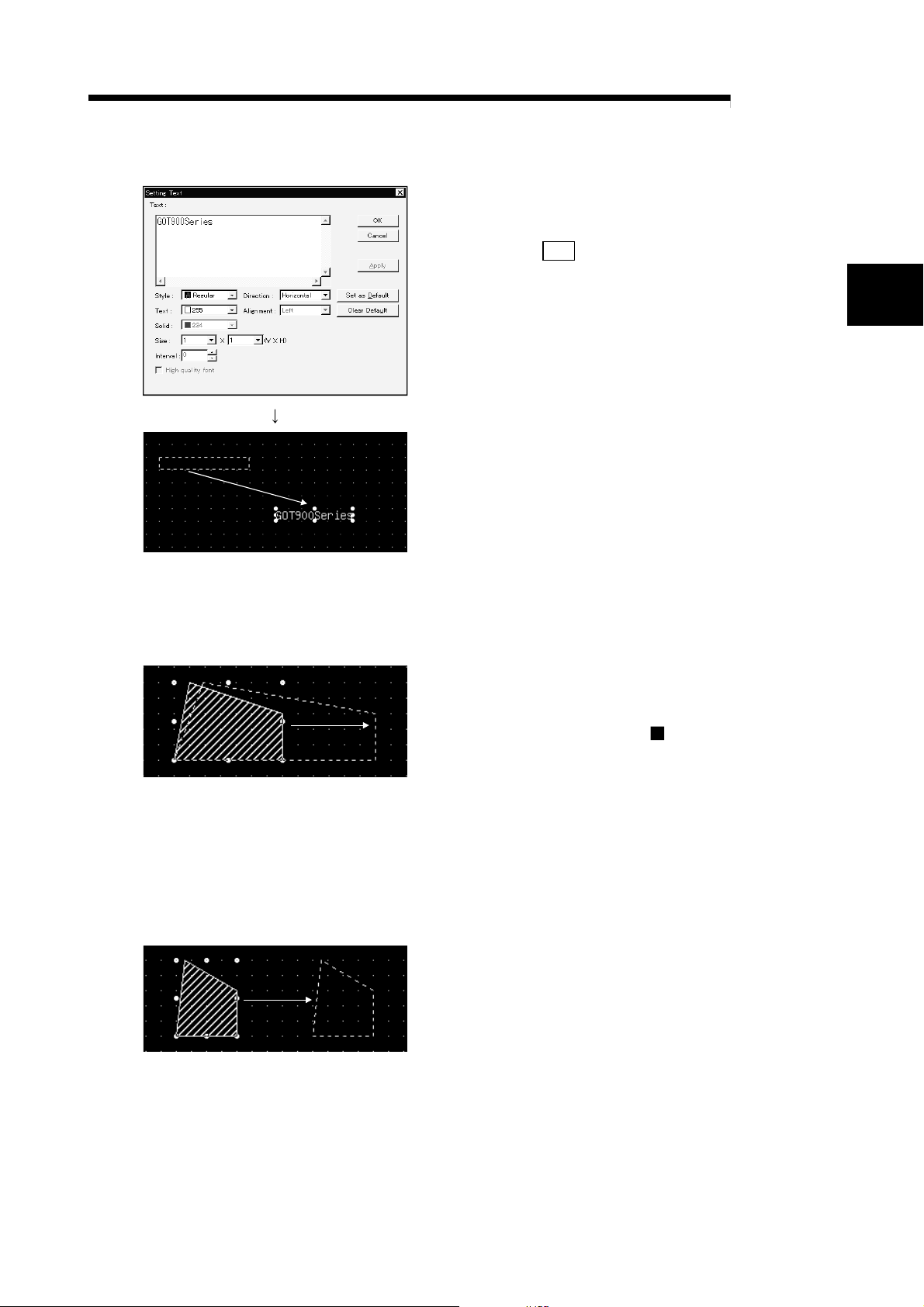

(3) When entering a text

MELSOFT

1) As the text/figure setting dialog box appears, enter a

text.

3)

2.2 Editing a Figure or Object (1) Resizing a figure or object

The following example enlarges a figure.

2) Click the OK

button.

2

3) A frame of display range appears at the upper-left of

the screen.

Move the frame to the desired position.

4)

4) Click the mouse button.

The character string appears.

1) Select the figure to enlarge.

2) Press the left mouse button at the handle of the

2) 3)

selected figure or object (

enlarge, then drag it.

3) Release the left mouse button. The figure or object

is resized.

• Holding down th e Shi ft key and changing the size

resizes the figu r e at eq ua l r atio s .

• Holding down th e C t rl key and changing the siz e

resizes the figure relative to the center.

(2) Copying a figure or object

The following example copies a figure.

1) Choose the fig u re to be copi ed .

2) Hold down the "Ctrl" button of the keyboard and drag

2) 3)

the figure .

3) Release the left button of the mouse at the position

you want to copy. This copies the figure.

) in the directio n to

2 - 2 2 - 2

3 CREATING SCREENS

CHAPTER3 CREATING SCREENS

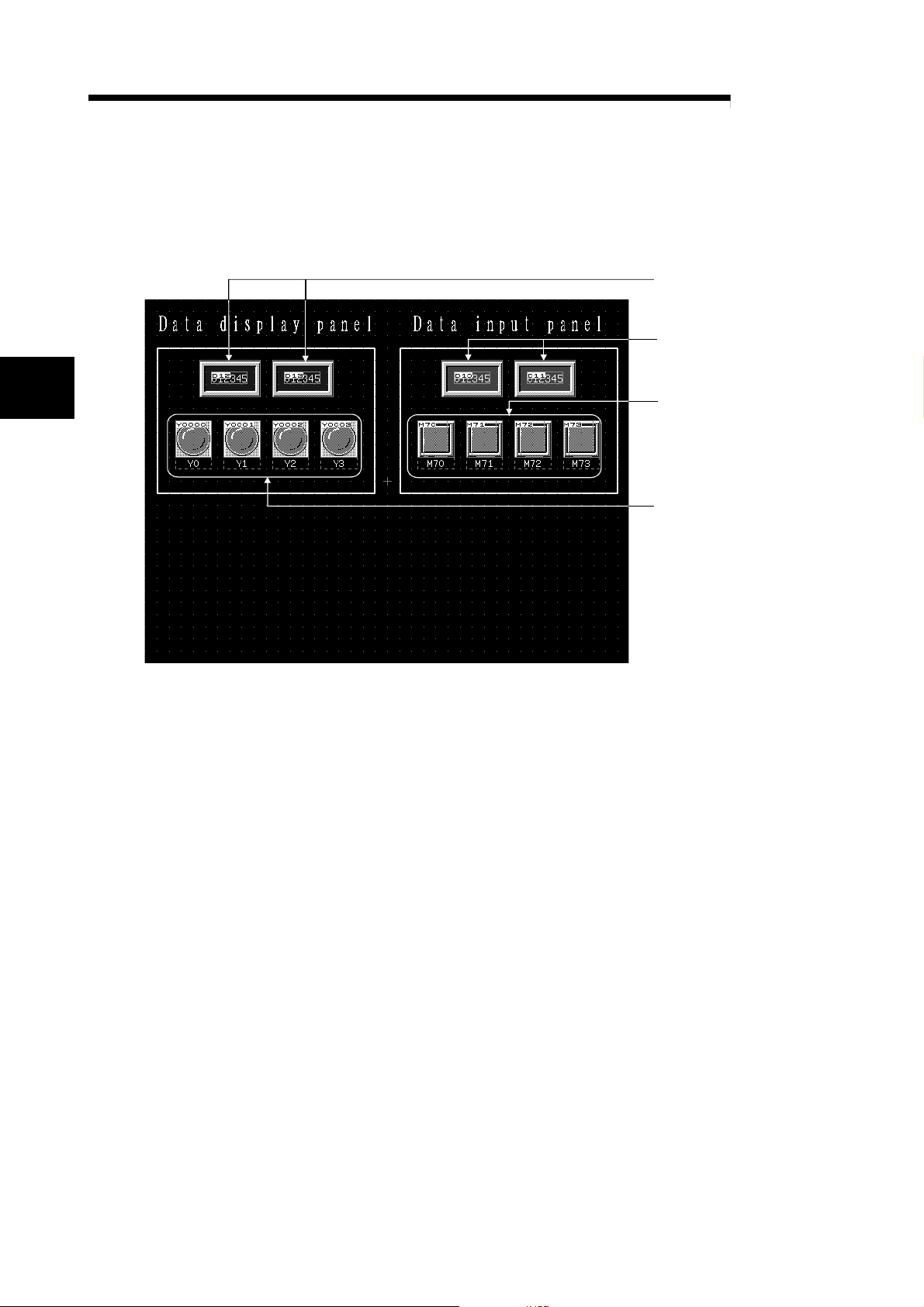

3.1 Creating a Screen like This

In this chapter, a screen as shown below is created.

MELSOFT

Numerical

display function

Numerical

input function

3

Touch key function

Lamp display function

3 - 1 3 - 1

Loading...

Loading...