Mitsubishi Electric GK-2509YS, GK-3009AS1, GK-2512AS, GK-3012AS1, GK-3506CS Specifications

...

Y05-005 Jul.2006(MEE)

Specifications subject to change without notice.

Single-phase unit

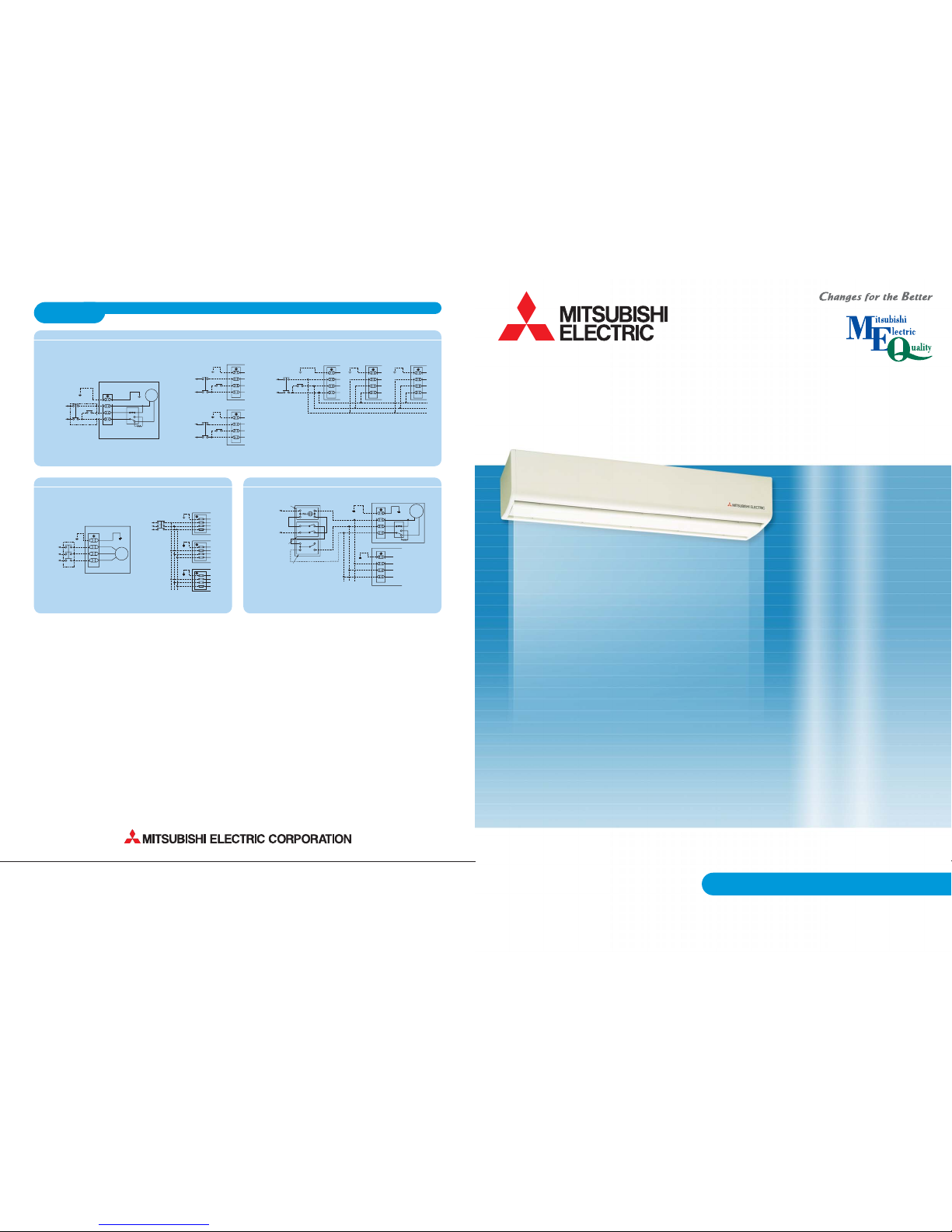

CONNECTION DIAGRAM

HIGH SPEED OPERATION

LOW SPEED OPERATION

FOR CONTROLLING A MULTIPLE NUMBER OF UNITS

Model GK-2509YS1,2512AS1

GK-3009AS1,3012AS1

GK-3506CS,3509CS,3512DS

POWER

SOURCE

INTERNAL WIRING

CONTROL SWITCH

ON/OFF

HIGH/LOW

TERMINAL

BLOCK

MOTOR

RELAY

7

5

1

3

8

WHITE

GREEN

LOW

HIGH

RED

RED

BLUE

WHITE

COMMON

POWER

SOURCE

ON

OFF

LOW

HIGH

COMMON

POWER

SOURCE

ON

ON

LOW

HIGH

COMMON

POWER

SOURCE

LOW

HIGH

COMMON

LOW

HIGH

COMMON

LOW

HIGH

COMMON

POWER

SOURCE

The opening for connecting the control switch is designed to accommodate a cabie with

a diameter of 1.6mm or 2.0mm only. (Therefore, a stranded cable cannot be connected.

)

AIR CURTAIN

ON/OFF Switch

Operation lamp

FS-04SW1-E

HIGH/LOW Switch

LOW

HIGH

COMMON

AIR CURTAIN

LOW

HIGH

COMMON

1

34

2

1

3

0

Wiring

Three-phase unit Connecting the FS-04SW1-E (For single-phase unit)

A Hidden Barrier

Giving Tangible Benefits

AIR CURTAIN

CONNECTION DIAGRAM

Model MK-5010T-E,5012T-E

POWER

SOURCE

INTERNAL WIRING

CONTROL SWITCH

ON/OFF

TERMINAL

BLOCK

MOTOR

MOTOR

GREEN

V

W

RED

BLACK

WHITE

U

POWER

SOURCE

V

W

U

V

W

U

V

W

U

FOR CONTROLLING A MULTIPLE NUMBER OF UNITS

AIR CURTAIN

HEAD OFFICE : TOKYO BLDG., 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

http://Global.MitsubishiElectric.com

GK/MK SERIES

MODEL

Traditional

air curtain design

TWIN NOZZLE

air curtain design

Twin Nozzle air curtain takes in air from above.

(Please allow a minimum distance 100mm~150mm between the air curtain and the ceiling.)

Motor

Twin Nozzle

Protector Guard

Airflow Louvers

Punched Metal

Propeller Fans

Base Switches

Rectification Plate

Protector Guard

Motor

Twin

Nozzle

ExtraFan

ExtraFan

Front Side

Mitsubishi Air Curtains are the Perfect Way to Provide Your Premises with a

Comfortable, Clean and Hygienic Environment While Saving Energy

with a Quiet, Efficient and Powerful Operation

Patent and design registration pending for the following countries & areas:

CHINA, HONG KONG, GREAT BRITAIN, THAILAND, MALAYSIA, SINGAPORE, TAIWAN.

Design registration pending: U.S.A., ITALY.

TWIN NOZZLE

The twin nozzle design ensures that less extraneous air

enters the air curtain, while the outflow is wider.

Resistance to the influence of external airflow has been

strengthened, greatly improving insulation against heat

and cold.

COMPACT DESIGNEXTRAFAN RECTIFICATION PLATE

Compact and stylish it blends in readily with your

interior design.

By adjusting the

installation angle of

the main unit, the

airflow angle can be

altered both internally

and externally.

ExtraFan is a major improvement over the Line Flow

Fan. The fan is driven by an energy efficient motor and

costs even less to operate.

The use of Axial Fan(ExtraFan)makes it easier to

maintain the unit and keep the air curtain in top

condition at all times. Moreover, the

improvements that have resulted from the change to

the Axial Flow Fan from the Line Flow Fan mean that

fan life is now even longer.

The machine can be

installed vertically or

horizontally according

to the available space.

Even Lower Energy Consumption

Easy Maintenance

Flexible Installation

Ultra-Compact Slim Design

Adjustable Airflow Angle

New innovations in high-tech

hydromechanics have made

Mitsubishi Electric’s ExtraFan

run so quiet it may seem to

lack the strength of

conventional, noisier models.

Not so.

The ExtraFan not only

reduces noise it is also the

secret behind the GK-35’s

powerful, high-volume airflow.

Powerful airflow without the noise Ups speed while controlling direction

The rectification plate creates a highly directed, discshaped flow by transferring airflow from the propeller

fans without reduction to volume or velocity. The plate

forms the air into a smooth hemispherical wall,

producing a high-speed current in a single direction.

Standard typeStandard type High Power typeHigh Power type

COMPACT

DESIGN

TWIN

NOZZLE

EXTRAFAN

RECTIFICATION

PLATE

EXTRAFAN

1 2

3 4

(Assumptions)

This shop is housed in a two-story building. It

is surrounded by other buildings on three sides:

the back, the left and the right hand sides.

Noxious odors

Smoke

Dust

Exhaust gas

Winter cold

Summer heat Cool air

Warm air

Clean air

-

5

2

4

6

810

1

2

-

-

6

8

Without air curtain

With air curtai

n

C

ondition

s

Outside temp.

:

1

9

C

Refrigerato

r

2

Time (min

)

C

urtai

n

Lam

p

(

40W

)

8.5 20.5

8.5 4.1 Energy saved 16.4

8.5 Energy saved 19.51

8.7 37.8

8.7 11.3 Energy saved 26.5

8.7 Energy saved 35

2.8

0.

5

m

2

.

4

m

9

.

1

m

7

.3m

2

.

75

m

m

0.

5

In a cold-storage facility without an air curtain, the inside temperature

increases from -5 to +4ºC in as little as two minutes, but if an air curtain is

used this time is extended to about 10 minutes, or approximately five times as

long. If the door is left open for five minutes, the temperature goes up to 10ºC if

no air curtain is used, as opposed to 2ºC when one is used. It was also

discovered that when an air curtain was used, 50% less energy was required

to reduce the inside temperature to -5ºC.

Not only does the installation of an

air curtain help to maintain a

constant comfortable indoor

temperature, it saves energy too.

Install an automatic door to achieve

even more economical operation and a

more pleasant indoor environment.

This night time test ascertained the effectiveness of Mitsubishi air curtains in

shutting out insects. A 40W mercury lamp was placed inside an air curtain

ejected from a 4cm-wide vent at a velocity of 8m/sec. The insect shut-out rate

was 70-80%.

*Insects such as flies which have high flying power may ingress into the room from the vicinity of the

floor face where wind velocity is comparatively low.

Economic benefits of installing an air curtain. (Savings are calculated using an appropriate heating load factor

required to keep room temperature constant at 28ºC for a room measuring 66.4m2 in area.)

Revising the Performance

Records on Shut-Outs

Air Curtains-Increased Cold Storage Efficiency and Shut-Out Effect

Insect* Shut-Out Test

HEATING MODE

Economic benefits of installing an air curtain. (Savings are calculated using an appropriate cooling load factor to

keep room temperature constant at 28ºC in a room measuring 66.4m2 in area.)

COOLING MODE

SHUT-OUT FUNCTIONS

ECONOMIC BENEFITS

Unwanted Air Shut-Out Rate •Smell Shut-Out Rate •Dust Shut-Out Rate

Insect* Shut-Out Rate

70~90%

70~80%

Cooling load factor and air curtain-shut-out effect (kW)

Open plan premises

The doors are kept open and an air curtain is not used

Premises with an air curtain installed

Premises installed with either an air curtain or an

automatic door

Premises installed with both an air curtain and an

automatic door

Cooling

load facto

r

Energy loss due to other causes

Energy loss from the door are

a

29

kW

12.6

kW

9.5

kW

Heating load factor and air curtain shut-out effect (kW)

Open plan premises

The doors are kept open and an air curtain is not used

Premises with an air curtain installed

Premises installed with either an air curtain or an

automatic door

Premises installed with both an air curtain and an

automatic door

Heating

load factor

Energy loss due to other causes Energy loss from the door area

46.5

kW

20

kW

11.5

kW

<Assumptions for economic benefits calculations>

1.Environmental factors

2.

Both the air conditioner and the air curtain have the specifications and characteristics of 50Hz

.

(1)Floor space 66.4m

2

(2)Temperature and humidity

Coolin

g

m

ode

Heatin

g

1

8

_

_

2

8

7

0%

In

door

utdoo

r

Indoo

r

Temperatur

e

Humidit

y

utdoo

r

AIR CURTAIN

Loading...

Loading...