Mitsubishi FR-BU2-1.5K, FR-BU2-3.7K, FR-BU2-30K, FR-BU2-55K, FR-BU2-H7.5K Instruction Manual

...

INVERTER

INSTRUCTION MANUAL

Brake Unit

FR-BU2-1.5K to 55K

FR-BU2-H7.5K to H75K

Thank you for choosing this Mitsubishi Inverter option unit.

This instruction manual gives handling information and precautions for use of this equipment.

Incorrect handling might cause an unexpected fault. Before using the equipment, please read

this manual carefully to use the equipment to its optimum performance.

Please forward this manual to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect this product until you have read through

this instruction manual and appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full knowledge of the equipment, safety

information and instructions.

In this instruction manual, the safety instruction levels are classified into "WARNING" and

"CAUTION".

Assumes that incorrect handling may cause hazardous conditions,

WARNING

CAUTION

resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury, or may cause physical damage

only.

Note that even the level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

•

While power is on or when the brake unit is

running, do not open the front cover. You

may get an electric shock.

•

Do not run the brake unit with the front

cover removed. Otherwise, you may access

the exposed high-voltage terminals and

charging part and get an electric shock.

•

Even if power is off, do not remove the front

cover except for wiring or periodic

inspection. You may access the charged

inverter connected to the brake unit and get

an electric shock.

•

Before starting wiring or inspection, check

to make sure that the 3-digit LED brake unit

monitor is off, wait for at least 10 minutes

after the power supply has been switched

off, and check to make sure that there are

no residual voltage using a tester or the

like. The brake unit connected to the brake

unit is charged with high voltage for some

time after power off and it is dangerous.

•

Must be earthed (grounded).

•

Any person who is involved in the wiring or

inspection of this equipment should be fully

competent to do the work.

•

Always install the brake unit before wiring.

Otherwise, you may get an electric shock or

be injured.

•

Do not operate a switch with wet hands.

You may get an electric shock.

•

Do not subject the cables to scratches,

excessive stress, heavy loads or pinching.

Otherwise you may get an electric shock.

CAUTION

WARNING

2. Fire Prevention

CAUTION

• Mount the brake unit and resistor unit to

incombustible material. Installing it to

combustible materials directly or near

combustible materials can cause a fire.

• Turn off power when an alarm signal is

output. Otherwise, the brake resistor may

excessively overheat due to damage of the

brake transistor and such, causing a fire.

• Do not connect the resistor unit directly to

the DC terminals P/+ and N/-. This could

cause a fire.

3. Injury Prevention

CAUTION

• Apply only the voltage specified in the

instruction manual to each terminal.

Otherwise, burst, damage, etc. may occur.

• Ensure that the cables are connected to

the correct terminals. Otherwise, burst,

damage, etc. may occur.

• Always make sure that polarity is correct

to prevent damage, etc. Otherwise, burst,

damage may occur.

• While power is on or for some time after

power-off, do not touch the brake resistor as

it will be extremely hot. Doing so can cause

burns.

A-1

4. Additional Instructions

Also note the following points to prevent an

accidental failure, injury, electric shock, etc.

1) Transportation and mounting

CAUTION

• Transport the product using the correct

method that corresponds to the weight.

Failure to observe this could lead to

injuries.

• Do not stack the brake unit boxes higher

than the number recommended.

• Install the product in a place which can

withstand its weight according to the

information in the instruction manual.

• Do not install or operate the option unit if it

is damaged or has parts missing.

• When carrying the brake unit, do not hold

it by the front cover. It may fall off or fail.

• Do not stand or rest heavy objects on the

product.

• Check that the mounting orientation is

correct.

• Prevent screws, metal fragments or other

conductive bodies or oil or other

flammable substance from entering the

brake unit.

• As this brake unit is a precision

instrument, do not drop or subject it to

impact.

• Use the brake unit under the following

environmental conditions: Failure to fallow

may damage the product.

Ambient

temperature

Ambient

humidity

Storage

temperature

Atmosphere

Environment

Altitude/

vibration

*1Temperature applicable for a short time,

e.g. in transit.

(2) Trial run

-10°C to 50°C

(non-freezing)

90% RH or less

(non-condensing)

-20°C to 65°C *1

Indoors (free from

corrosive gas, flammable

gas, oil mist, dust and

dirt)

Maximum 1000m above

sea level, 5.9m/s

(conforms to JIS C

60068-2-6)

2

or less

3) Usage

WARNING

• Do not modify the equipment.

• Do not perform parts removal which is not

instructed in this manual. Doing so may

lead to fault or damage of the product.

(4) Emergency stop

CAUTION

• Provide a safety backup such as an

emergency brake which will prevent the

machine and equipment from hazardous

conditions if the inverter and brake unit

fail.

(5) Maintenance, inspection and parts

replacement

WARNING

• Do not test the brake unit with a megger

(measure insulation resistance).

(6) Disposal

CAUTION

• Treat as industrial waste.

(7) General instruction

Many of the diagrams and drawings in this

Instruction Manual show the products

without a cover, or partially open. Never

operate the products in this manner.

Always replace the cover and follow this

Instruction Manual when operating the

products.

CAUTION

• Before starting operation, confirm and

adjust the parameters. Setting parameter

different from the one set in the resistor

connected may not exhibit the best

performance or may cause resistor

overheat or alarm.

A-2

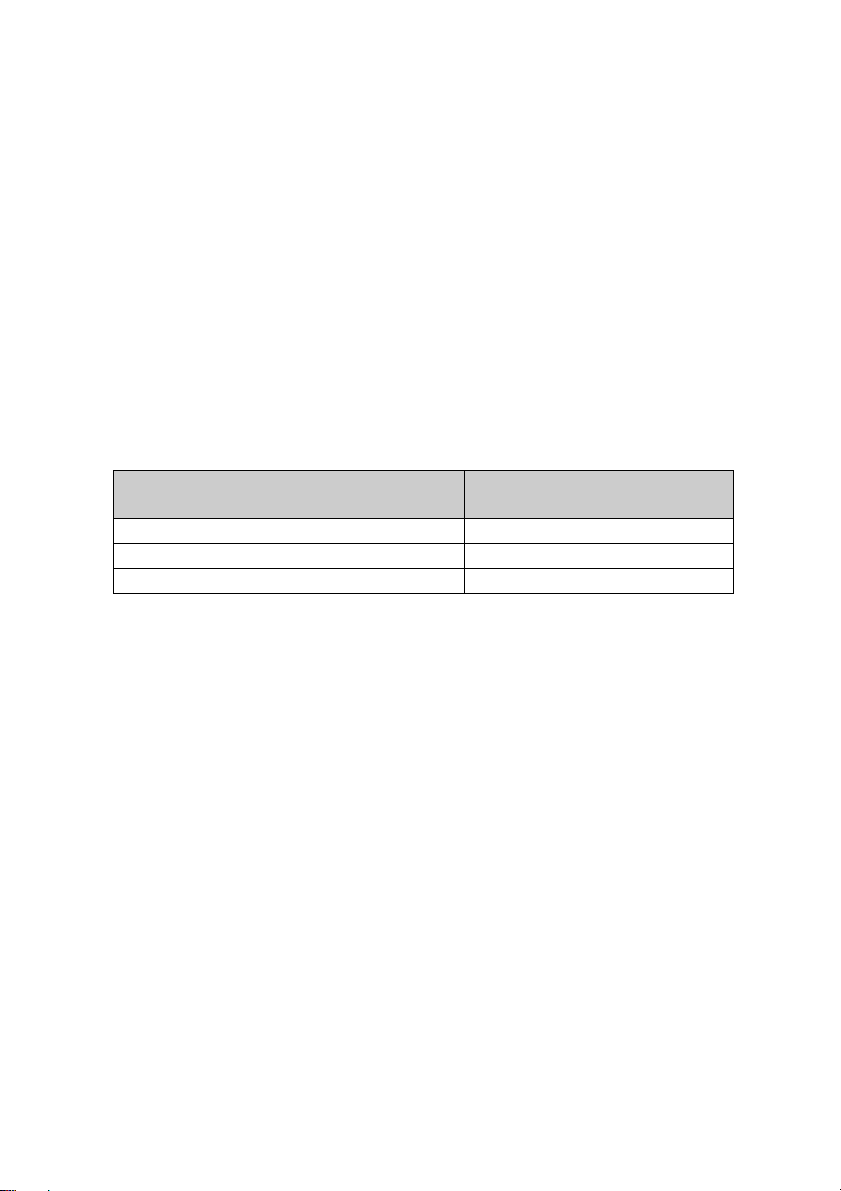

Brake unit (FR-BU2 type)

When running the motor with the FR series inverter, use this option unit

when a large brake torque is necessary such as when the motor is made to

run by the load, quick decerelation is required, etc.

Following three types of brake resistor as in the table below can be

connected to this option unit. FR-BU2 type break unit can be used as

substitute of the existing brake units (BU type, FR-BU-(H) type, MT-BU5

type).

Do not operate the conventional brake unit and FR-BU2 in parallel. Doing so

could cause an alarm or failure. Change all units to the FR-BU2 to operate in

parallel and connect the master/slave signal.

Compatible Brake Resistor and

Resistor Unit

GRZG type brake resistor BU type

FR-BR-(H) type resistor unit FR-BU-(H)

MT-BR5 type resistor unit MT-BU5 type

Perform wiring and parameter setting referring to page 15

Conventional Brake Unit

as the wiring

method and parameter setting method differ according to the brake resistor

combined.

CONTENTS

1 PRODUCT CHECKING AND PARTS IDENTIFICATION.................. 1

2 INSTALLATION ................................................................................. 2

3 WIRING ............................................................................................. 4

3.1 Terminals............................................................................................ 4

3.1.1 Brake unit...............................................................................................4

3.1.2 Resistor unit.........................................................................................11

3.2 Combinations of Brake Resistors for Brake

Unit and Used Wires......................................................................... 13

3.3 External Connection Diagram........................................................... 14

3.3.1 Connection with the inverter ................................................................14

3.4 Connection Example with the GRZG Type Brake Resitor ............... 16

3.4.1 When connecting one inverter and one brake unit .............................16

3.4.2 When connecting several brake units to one inverter.......................... 18

3.4.3 Master/slave operation when connecting several brake units ............. 19

3.5 FR-BR-(H) Connection Example with Resistor Unit ........................21

3.5.1 When connecting one inverter and one brake unit ..............................21

3.5.2 When connecting several brake units to one inverter.......................... 22

3.5.3 Master/slave operation when connecting several brake units ............. 23

3.6 Connection Example with MT-BR5 Type Resistor Unit ...................24

3.6.1 When connecting one inverter and one brake unit ..............................24

3.6.2 When connecting several brake units to one inverter.......................... 25

3.6.3 Master/slave operation when connecting several brake units ............. 26

3.7 Wiring Instructions ............................................................................28

4 OPERATION ................................................................................... 30

4.1 Control Panel.................................................................................... 30

4.2 Basic Operation ................................................................................31

4.3 Parameter List .................................................................................. 32

4.3.1 Mode switchover (Pr.0)........................................................................ 33

4.3.2 Multi-function monitor display (Pr.1, Pr.78).......................................... 34

4.3.3 Input terminal function selecttion (Pr.2, Pr.3).......................................36

4.3.4 Parameter write disable selection (Pr. 77)........................................... 37

4.3.5 Parameter clear ...................................................................................38

4.3.6 Alarm history clear ...............................................................................39

5 PROTECTIVE FUNCTIONS ........................................................... 40

5.1 Causes and Corrective Actions ........................................................ 40

I

5.2 Correspondence Between Digital and Actual Characters ................ 42

6 SPECIFICATIONS .......................................................................... 43

6.1 Brake Unit ........................................................................................ 43

6.2 Brake Resistor/Resistor Unit ............................................................ 43

7 PRECAUTIONS FOR MAINTENANCE AND INSPECTION ........... 44

7.1 Precautions for Maintenance and Inspection ................................... 44

7.2 Inspection Item................................................................................. 44

7.3 Periodic Inspection........................................................................... 45

7.4 Daily and Periodic Inspection........................................................... 46

7.5 Replacement of Parts....................................................................... 47

8 SELECTION .................................................................................... 48

9 OUTLINE DIMENSION DRAWINGS............................................... 51

10INSTRUCTIONS FOR UL, CSA STANDARD COMPLIANCE........ 56

II

MEMO

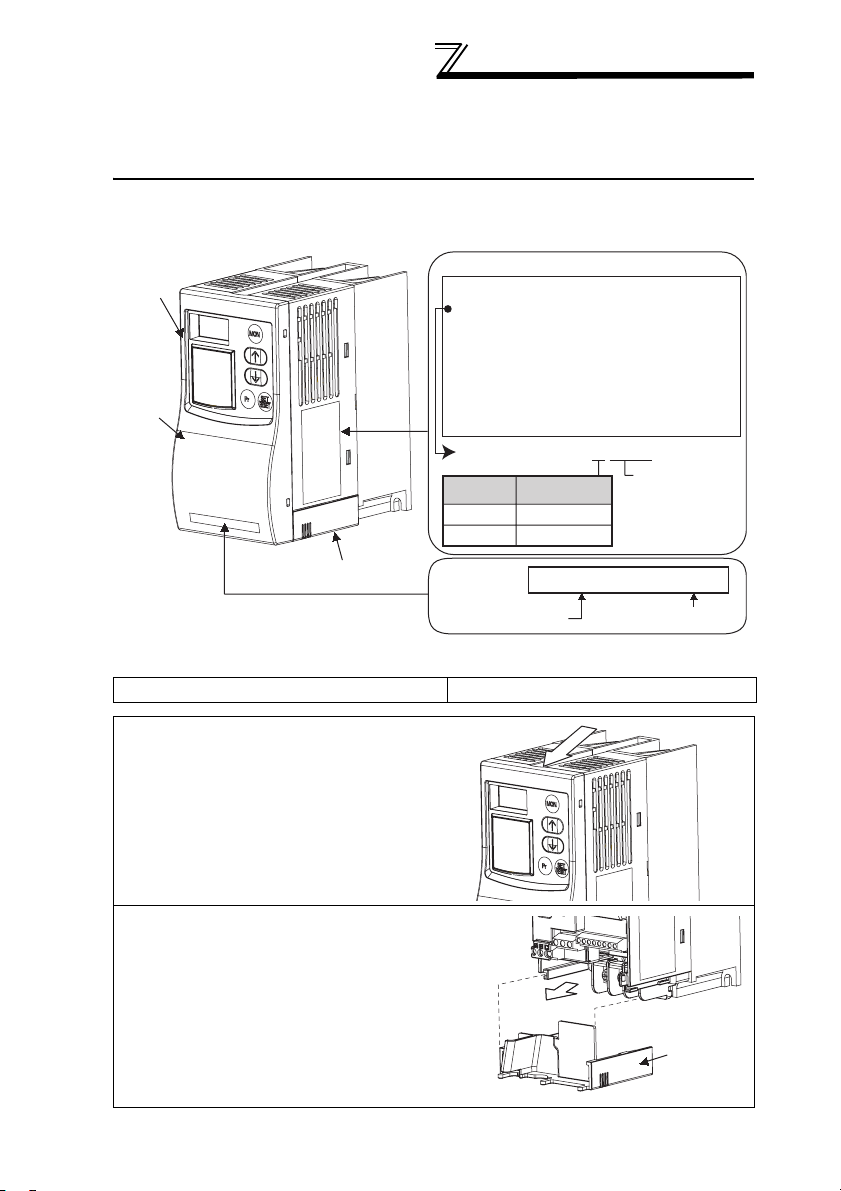

PRODUCT CHECKING AND

PARTS IDENTIFICATION

1 PRODUCT CHECKING AND PARTS

IDENTIFICATION

(1) Unpack the option unit and confirm that the product is as you ordered

and intact.

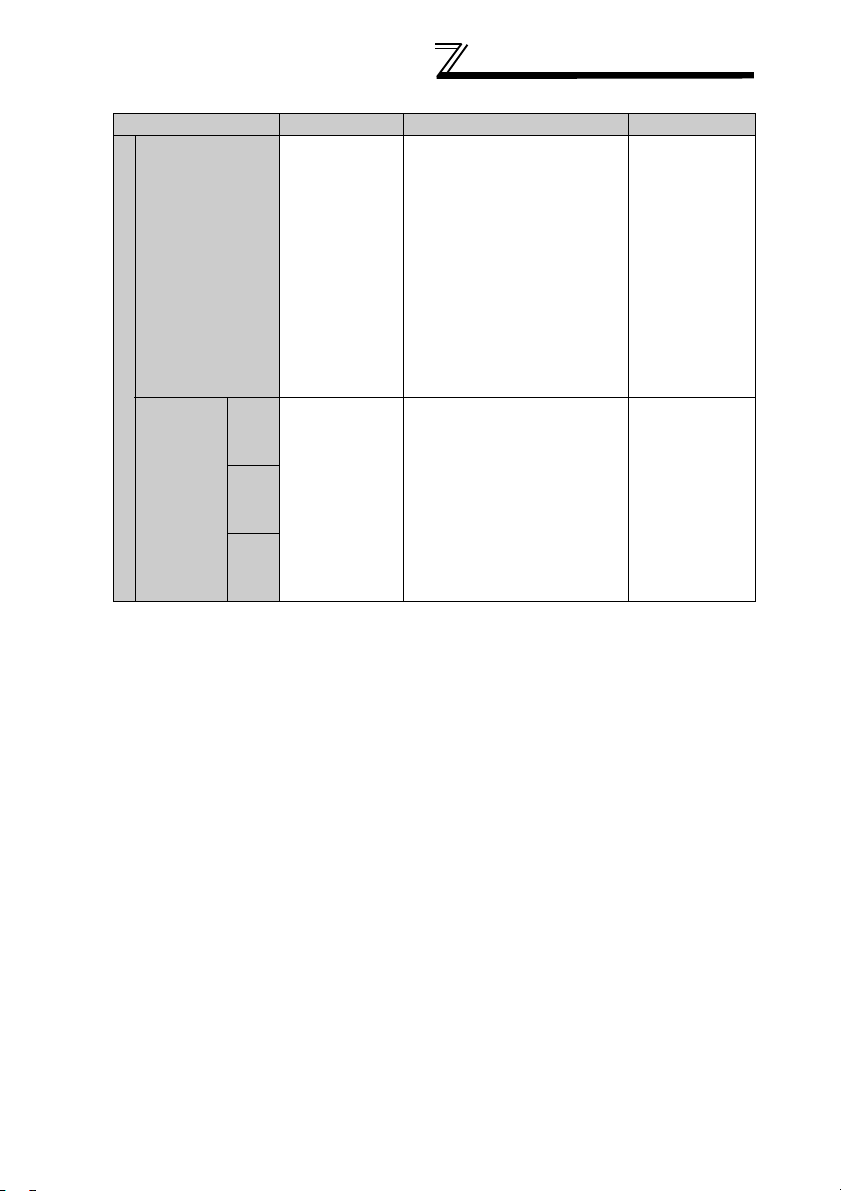

Operation

panel

Rating plate

MITSUBISHI BRAKE UNIT

MODEL FR-BU2-15K

for 200V class INVERTER

Front

cover

Wiring cover

SERIAL : XXXX

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

MODEL FR-BU2- H □□K

Applied power

No.

supply voltage

H

plate

200V class

400V class

Not used

Capacity

Brake unit type

FR-BU2-15K XXXXXX

Applied motor

capacity (kW)

SERIAL number

(2) Make sure that the package includes all accessories.

Brake unit (FR-BU2).........................1 Instruction manual ........................... 1

• Removal and reinstallation of the

front cover

Remove the front cover by pulling it

toward you in the direction of arrow.

To reinstall, match the cover to the

brake unit front and install it straight.

• Removal and reinstallation of the

wiring cover

The cover can be removed easily by

pulling it toward you.

To reinstall, fit the cover to the brake

Wiring cover

unit along the guides.

1

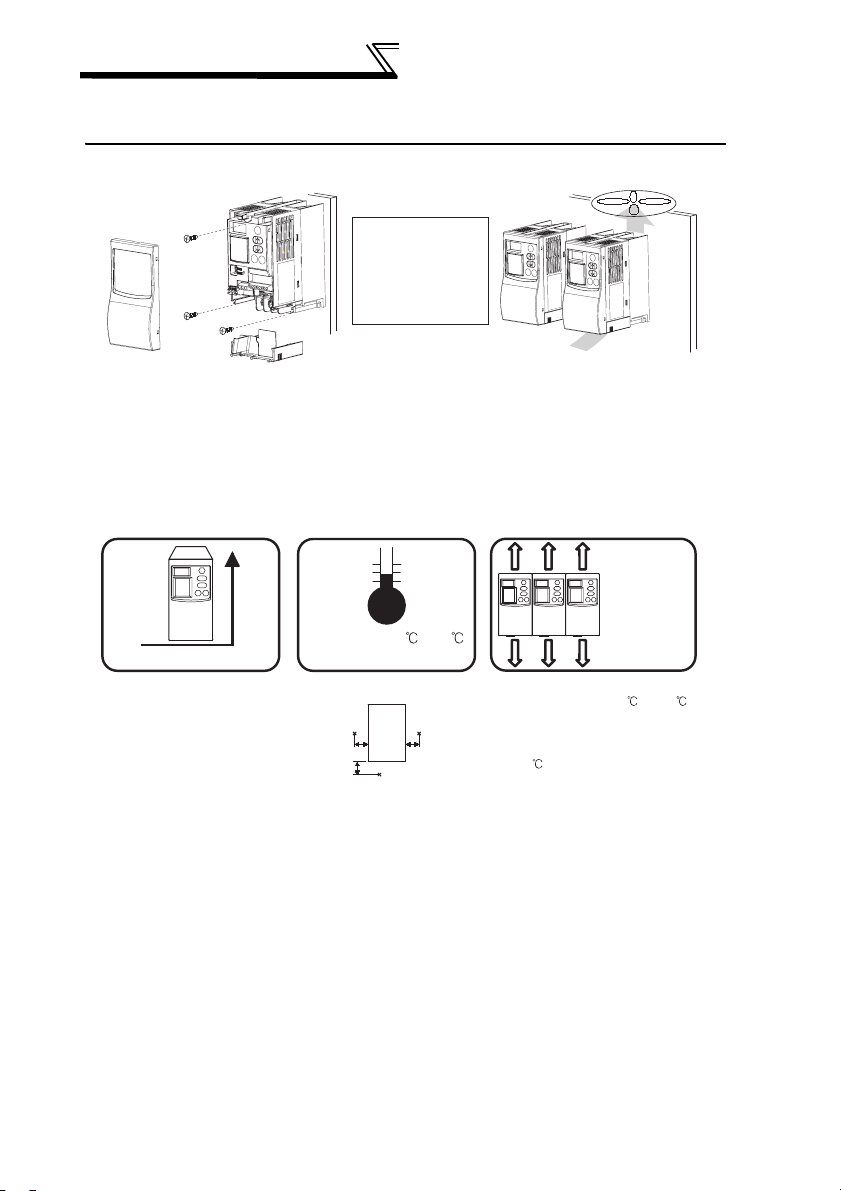

INSTALLATION

2 INSTALLATION

Enclosure surface mounting

Encasing multiple brake units

Remove the

front cover and

wiring cover to

fix the brake unit

to the surface.

When encasing multiple

brake units, install them

Leave enough clearances as

a cooling measure.

•Install the brake unit under the following conditions.

Vertical mounting

Vertical

Ambient temperature

and humidity

Temperature: -10 to 50

Humidity: 90%RH maximum

Brake unit

Measurement

position

5cm

Measurement

position

5cm5cm

in parallel as a cooling

measure.

* Permissible ambient

between brake units should be

Clearances

10cm or more

Brake units

can be closely

attached when

mounting in

lateral direction.*

10cm or more

temperature is -10 to 40

when mounting brake units

closely-attached. When

ambient temperature exceeds

40 , clearances

1cm or more.

2

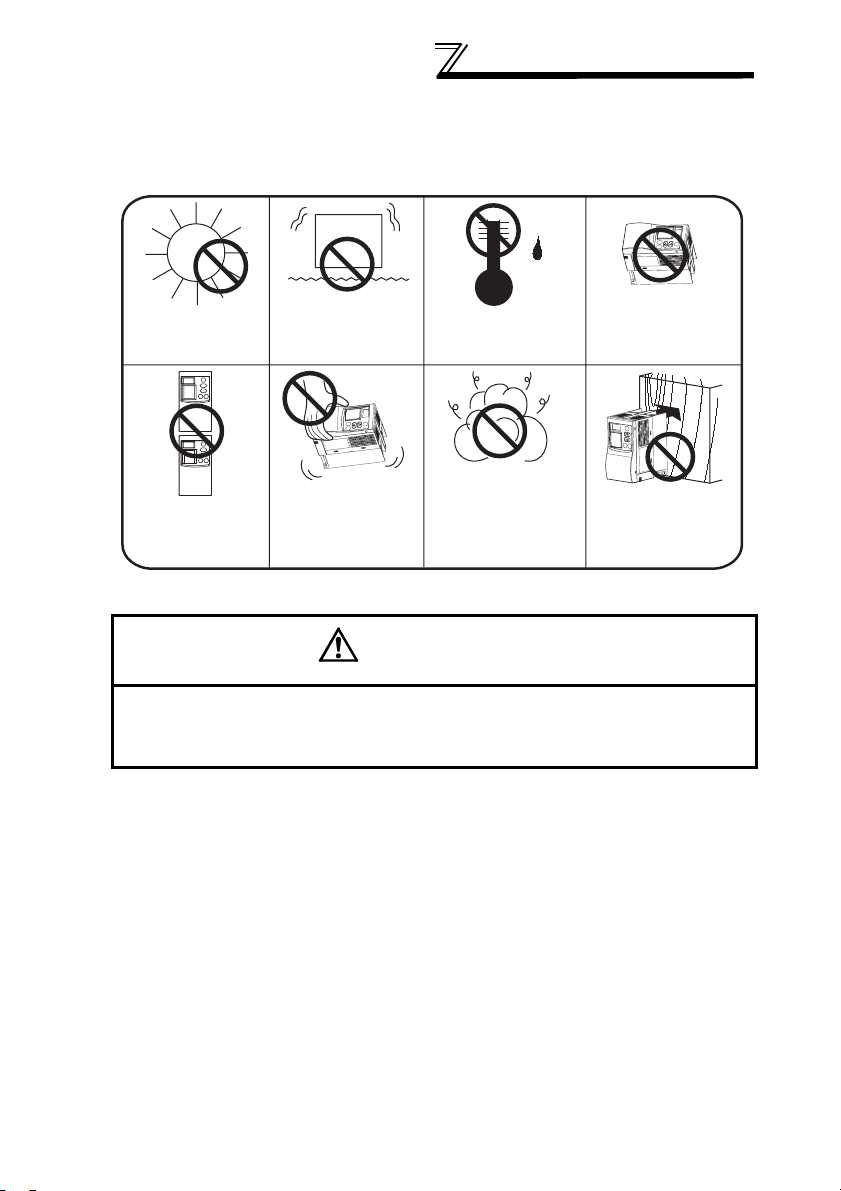

INSTALLATION

• The brake unit consists of precision mechanical and electronic parts. Never

install or handle it in any of the following conditions as doing so could cause

an operation fault or failure.

Horizontal

placement

Mounting to

combustible

material

Direct sunlight

Vertical mounting

(when mounting

inside an enclosure)

Vibration

2

(5.9m/s

or more)

Transportation by

holding the front

cover

High temperature,

high humidity

Oil mist,

flammable gas,

corrosive gas,

fluff, dust, etc.

CAUTION

Mount the brake unit and resistor unit to incombustible material.

Installing it to combustible materials directly or near combustible

materials can cause a fire.

3

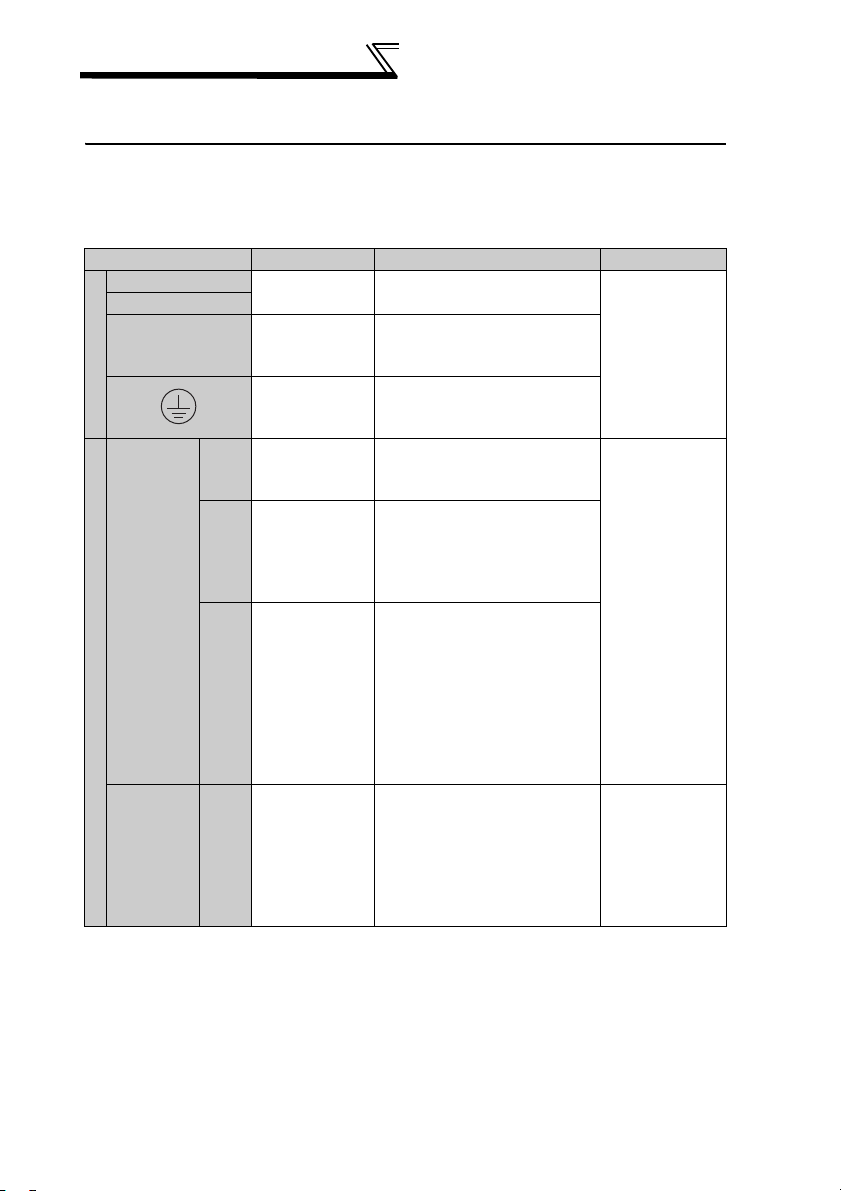

WIRING

3 WIRING

3.1 Terminals

3.1.1 Brake unit

Terminal Symbol Terminal Name Description Rating

P/+

N/-

PR*1

Main circuit

Contact

input

Control circuit

Master/

slave

signal

*1 Only a brake resistor should be connected to terminal PR. Doing so may damage the

brake unit.

*2 BUE-SD is connected with a jumper in the initial status. Remove a jumper when

using this signal. (When terminals are open, brake unit is not operated.)

*3 Do not connect terminals SD, PC and MSG each other or to the ground. Doing so

may damage the brake unit.

For sink logic (initial status), terminal SD acts as the common terminal of contact

input. For source logic (initial status), terminal PC acts as the common terminal of

contact input.

Brake unit input

terminal

Resistor

connection

terminal

Earth (Ground)

Brake operation

BUE

permission

signal

RES Reset input

Contact input

SD

*3

common

Brake

MSG

transistor

*3

driving signal

Connect to the inverter

terminal P and N.

Connect the brake resistor.

For earthing (grounding) the

brake unit. Must be earthed

(grounded).

Controls the brake operation.

Turning on the signal enables

brake operation.

Used to reset alarm output

provided when protective

circuit is activated. Turn on the

RES signal for more than 0.1s,

then turn it off.

Common terminal of the

control input

Brake transister driving signal

common

(for master/slave operation,

when connecting several brake

units to one inverter in parallel,

connect this signal to terminals

of other brake units.)

Brake transistor driving signal

terminal

(For master/slave operation,

when connecting several brake

units to on inverter in parallel,

connect this signal to terminals

of other brake units.)

*2

---

Voltage at

opening :

21 to 27VDC

Controls by open

collector output

or no voltage

contact signal.

---

4

Terminal Symbol Terminal Name Description Rating

When connecting the transistor

output (open collector output),

such as a programmable

External

transistor

PC *3

Control circuit

Relay

output

*3 Do not connect terminals SD, PC and MSG each other or to the ground.

Doing so may damage the brake unit.

For sink logic (initial status), terminal SD acts as the common terminal of contact

input. For source logic (initial status), terminal PC acts as the common terminal of

contact input.

common,

Contact input

common

(source)

A

Relay output 1

B

(Alarm output)

C

controller (PLC), connect the

positive external power supply

for transistor output to this

terminal to prevent a

malfunction caused by

undesirable currents.

When source logic has been

selected, this terminal serves

as a contact input common

terminal.

1 changeover contact output

indicates that the brake unit

protective function has

activated.

• Normal

Across B-C: Continuity

Across A-C: Discontinuity

• Alarm

Across B-C: Disontinuity

Across A-C: Continuity

230VAC 0.3A

30VDC 0.3A

WIRING

---

5

WIRING

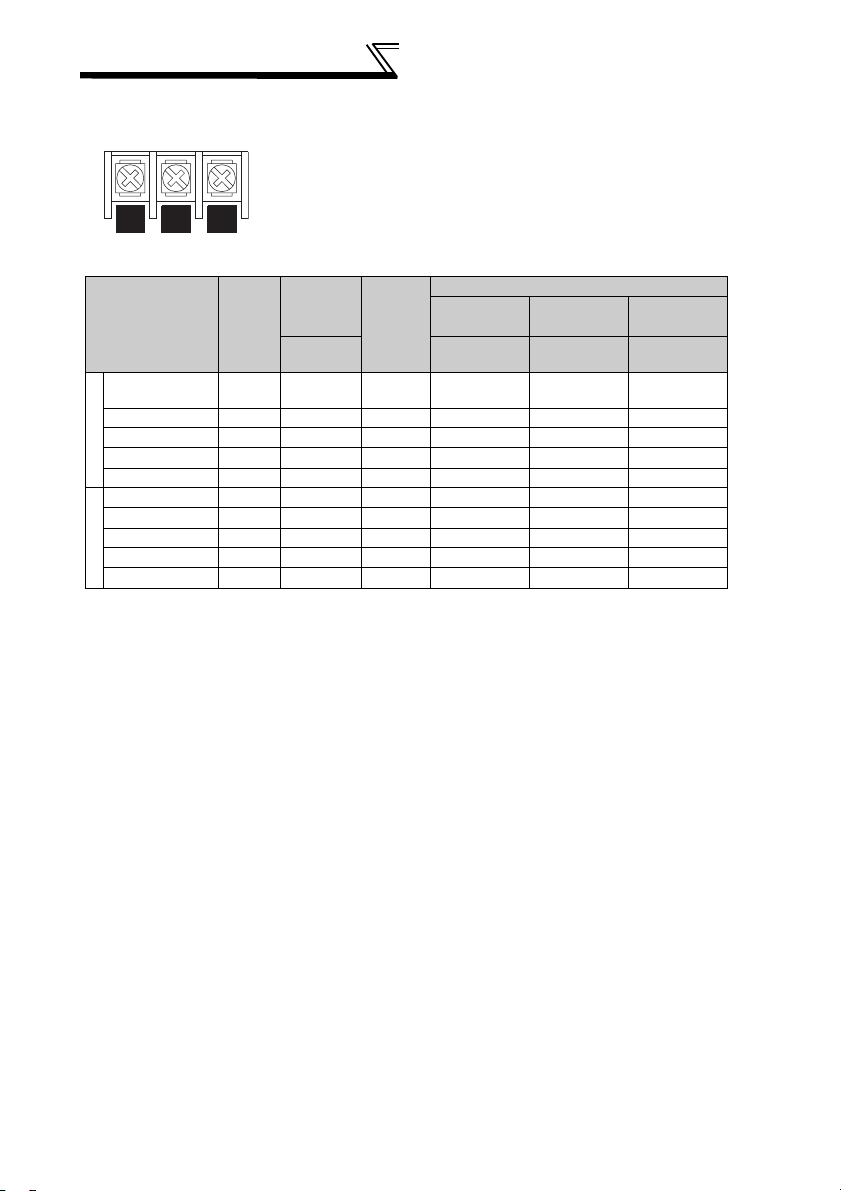

• Terminal arrangement of the main circuit terminal

N/-PRP/+

Cable size of the main circuit terminal

2

)

Cable Size

AWG

N/-

P/+, PR

Main

Circuit

Brake Unit Type

FR-BU2-1.5K/

3.7K

FR-BU2-7.5K M4 5.5-4 1.5 3.5 12 4

FR-BU2-15K M4 5.5-4 1.5 3.5 12 4

200V

FR-BU2-30K M5 5.5-5 2.5 5.5 10 6

FR-BU2-55K M6 14-6 4.4 14 6 16

FR-BU2-H7.5K M4 2-4 1.5 2 14 2.5

FR-BU2-H15K M4 5.5-4 1.5 3.5 12 4

FR-BU2-H30K M4 5.5-4 1.5 3.5 12 4

400V

FR-BU2-H55K M5 5.5-5 2.5 5.5 10 6

FR-BU2-H75K M6 14-6 4.4 14 6 16

Te rm i na l

Screw

Crimping

Te rm i na l

Size

P/+, PR

M4 2-4 1.5 2 14 2.5

N/-

Tightening

To rq u e

(N

• m)

HIV cables,

etc. (mm

N/-

P/+, PR

PVC cables,

etc. (mm

N/-

P/+, PR

2

)

6

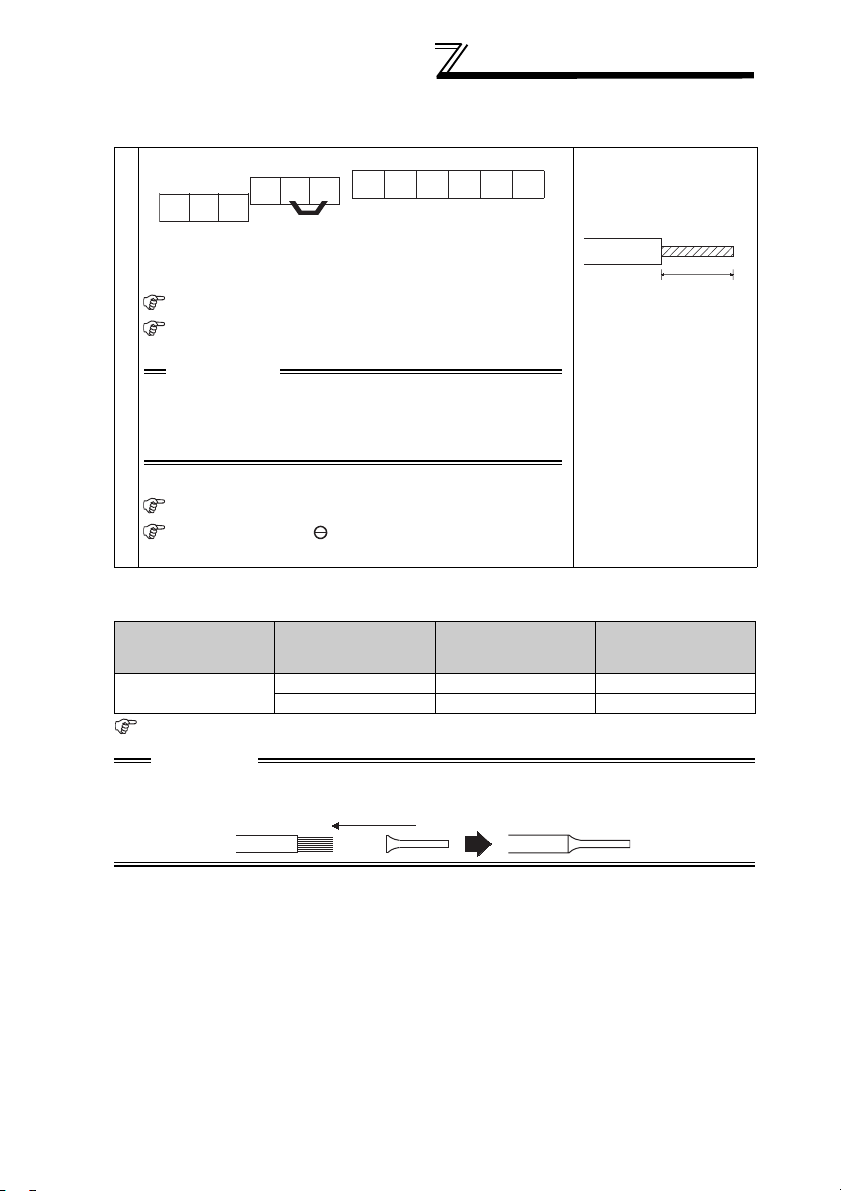

• Control circuit terminal layout

MSG

MSG

SD SD SD

AB

SD

Jumper

RES

BUE

PC

C

Loosen the terminal screw and insert the cable into the

terminal.

Screw size : M3

Tightening torque : 0.5N

•m to 0.6N•m

CAUTION

Undertightening can cause cable disconnection

or malfunction. Overtightening can cause a

short circuit or malfunction due to damage to

the screw or unit.

Control circuit terminal block

WIRING

Cable stripping size

6mm

Wire the stripped cable

after twisting it to

prevent it from

becoming loose.

In addition, do not

solder it.*

Cable size : 0.3mm

2

to 0.75mm

2

Screwdriver : Small flat-blade screwdriver

(Tip thickness : 0.4mm / tip width : 2.5mm)

* Information on bar terminals

Introduced products (as of June, 2006) : Phoenix Contact Co.,Ltd.

Terminal Screw Size

M3

Bar terminal crimping tool: CRIMPFOX ZA3 (Phoenix Contact Co., Ltd.)

Bar Terminal Model

(with insulation

sleeve)

Al 0.5-6WH A 0.5-6 0.3 to 0.5

Al 0.75-6GY A 0.75-6 0.5 to 0.75

Bar Terminal Model

(without insulation

sleeve)

Cable Size (mm2)

CAUTION

When using the bar terminal (without insulation sleeve), use care so that the twisted

wires do not come out.

7

WIRING

• Changing the control logic

The input signals are set to sink

logic when shipped from the

factory.

To change the control logic, the

jumper connector under the control

panel must be moved to the other

position.

• Change the jumper connector in

the sink logic position to source

logic position using tweezers, a

pair of long-nose pliers etc.

Change the jumper connector

position before switching power

on.

CAUTION

• Fully make sure that the front cover has been reinstalled securely.

• The front cover is fitted with the capacity plate and the brake unit with the

rating plate. Before reinstalling the front cover, check the serial numbers to

ensure that the cover removed is reinstalled to the brake unit from where it

was removed.

• The sink-source logic change-over jumper connector must be fitted in only

one of those positions. If it is fitted in both positions at the same time, the

brake unit may be damaged.

8

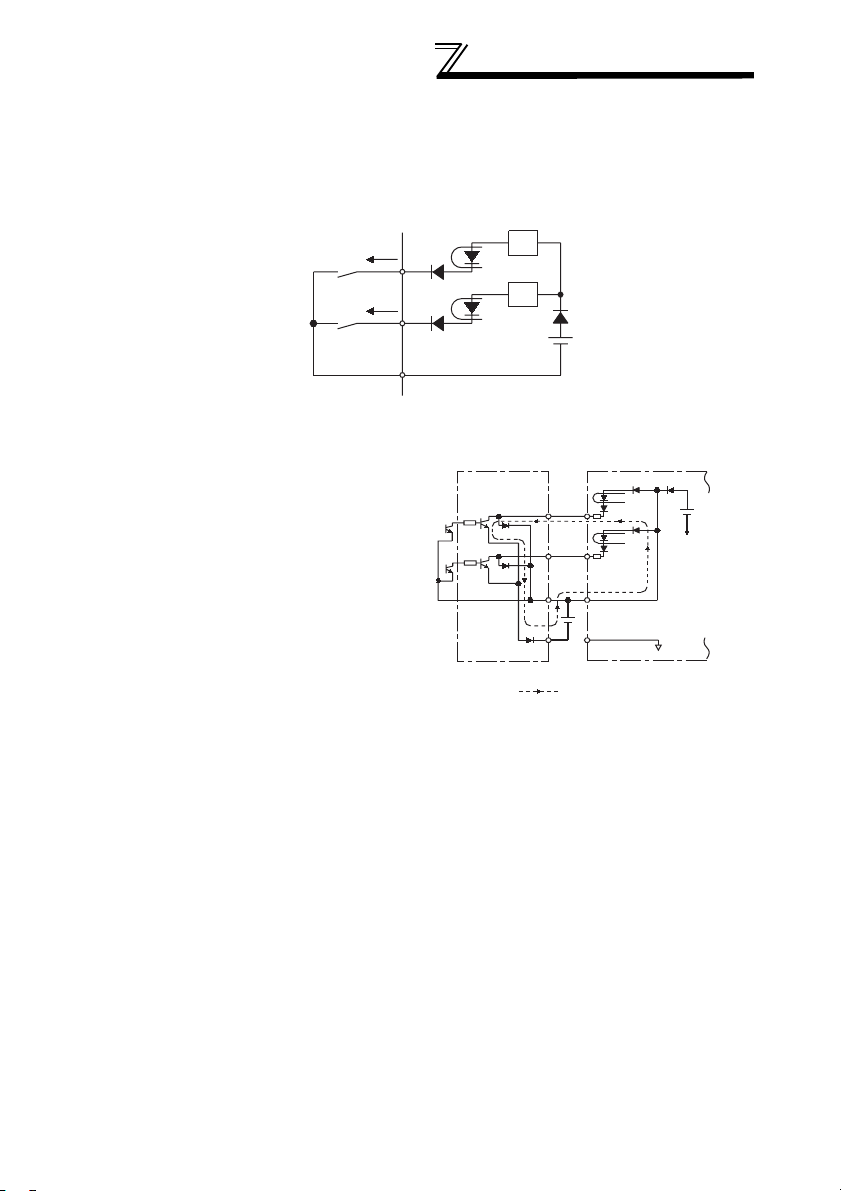

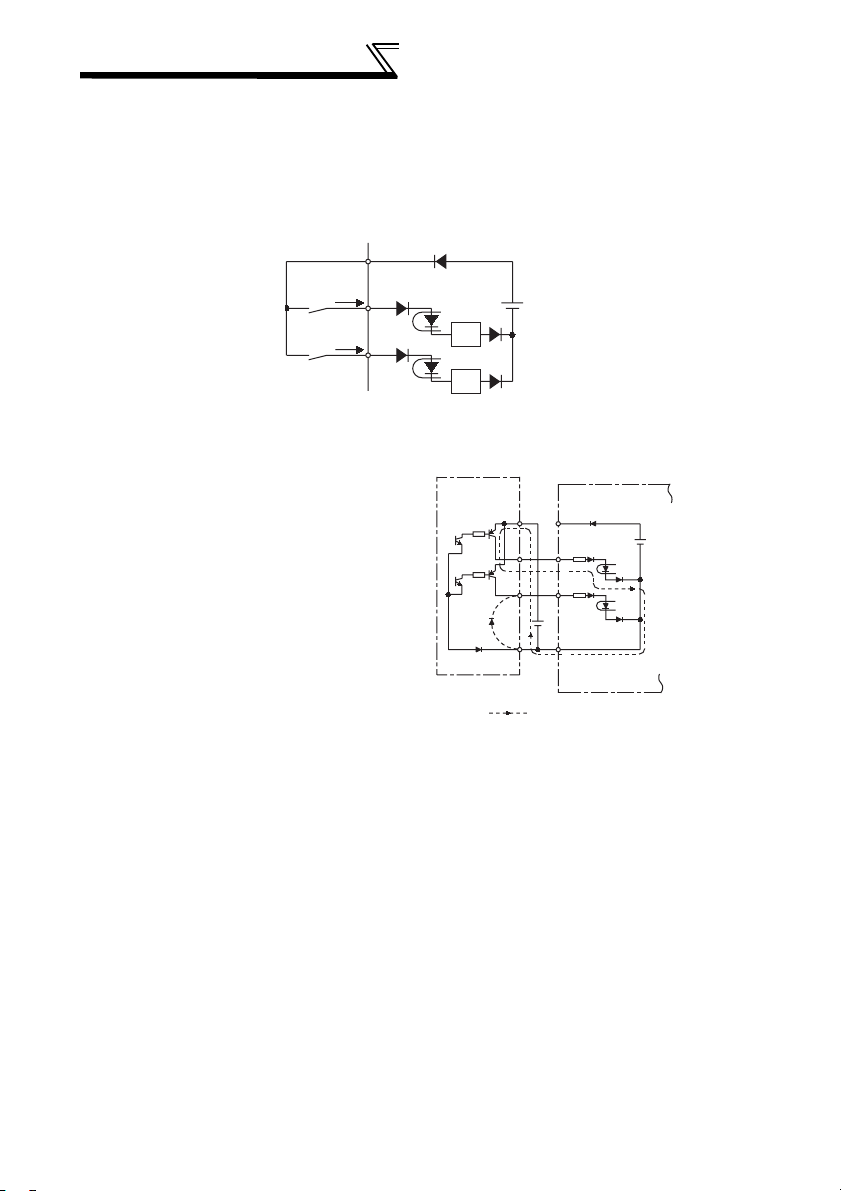

1) Sink logic type

• In sink logic, a signal switches on when a current flows from the

corresponding signal input terminal.

Terminal SD is common to the contact input signals.

WIRING

Power supply

• Connecting a positive terminal of

the external power supply for

transistor output to terminal PC

prevents a malfunction caused by

undesirable currents. (Do not

connect terminal SD of the brake

unit with terminal 0V of the external

power supply.)

BUE

RES

SD

R

R

AY40 type

transistor

output unit

1

2

RES

9

10

BUE

PC

SD

24VDC

Current flow

Brake unit

24VDC

(SD)

9

WIRING

2) Source logic type

• In this logic, a signal switches on when a current flows into the

corresponding signal input terminal.

Terminal PC is common to the contact input signals.

PC

Power

supply

BUE

• Connecting a 0V terminal of the

external power supply for transistor

output to terminal SD prevents a

malfunction caused by undesirable

currents.

RES

R

R

AY80 type

transistor

output unit

9

1

2

10

Current flow

Brake unit

PC

BUE

RES

SD

24VDC

24VDC

(SD)

10

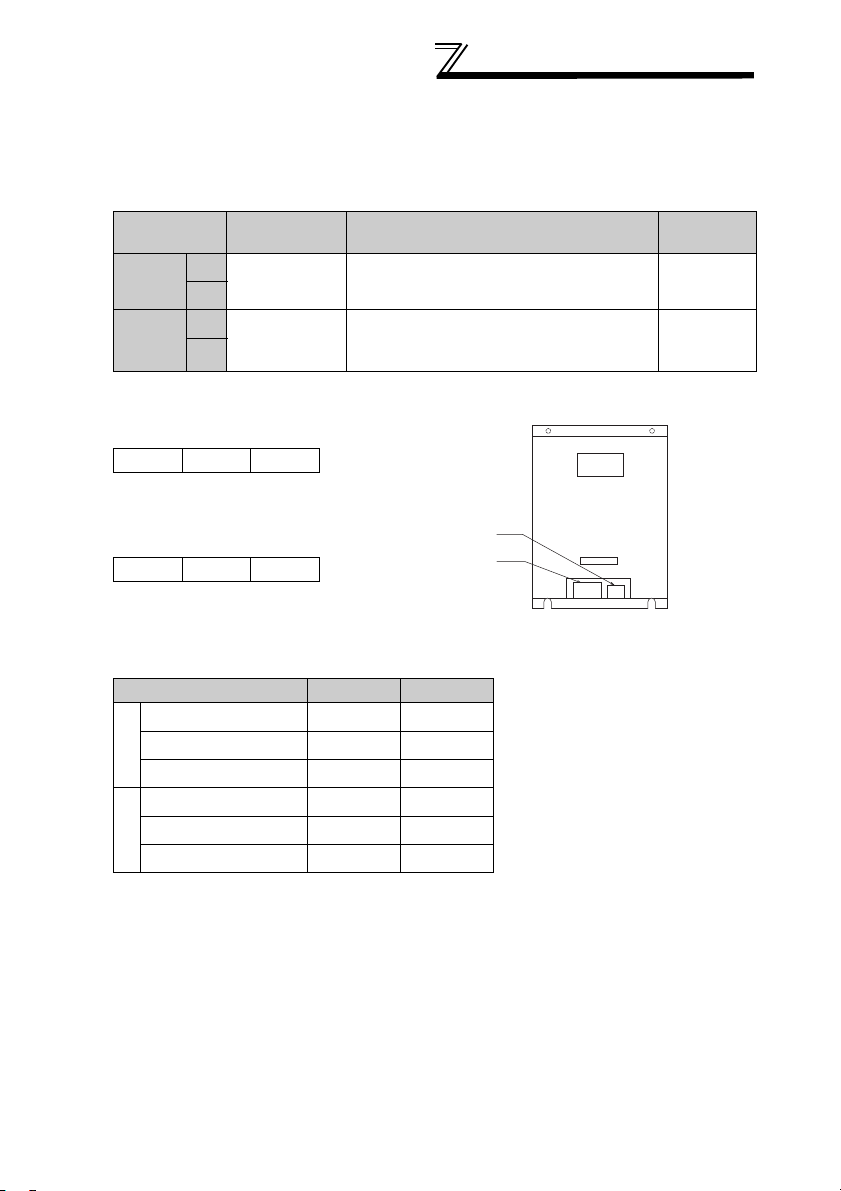

3.1.2 Resistor unit

(1) FR-BR-(H)

WIRING

Terminal

Symbol

Main

circuit

Control

circuit

• Terminal arrangement

Terminal Name Description Rating

P

Resistor unit

input resistance

PR

TH1

Alarm output

TH2

terminal

Connect to terminal P and PR of the brake

unit.

Output signal indicates resistor overheart

Resistor unit input terminal

PR P

TB1

Control circuit terminal block

arrangement

TH1 TH2

TB2

• Terminal screw size

Model TB1 TB2

FR-BR-15K

FR-BR-30K

200V

FR-BR-55K

FR-BR-H15K

FR-BR-H30K

400V

FR-BR-H55K M5 M3

M4 M3

M5 M3

M6 M3

M3 M3

M4 M3

---

1NC contact

110VAC, 5A

220VAC, 3A

<FR-BR resistor unit>

TB2

TB1

11

WIRING

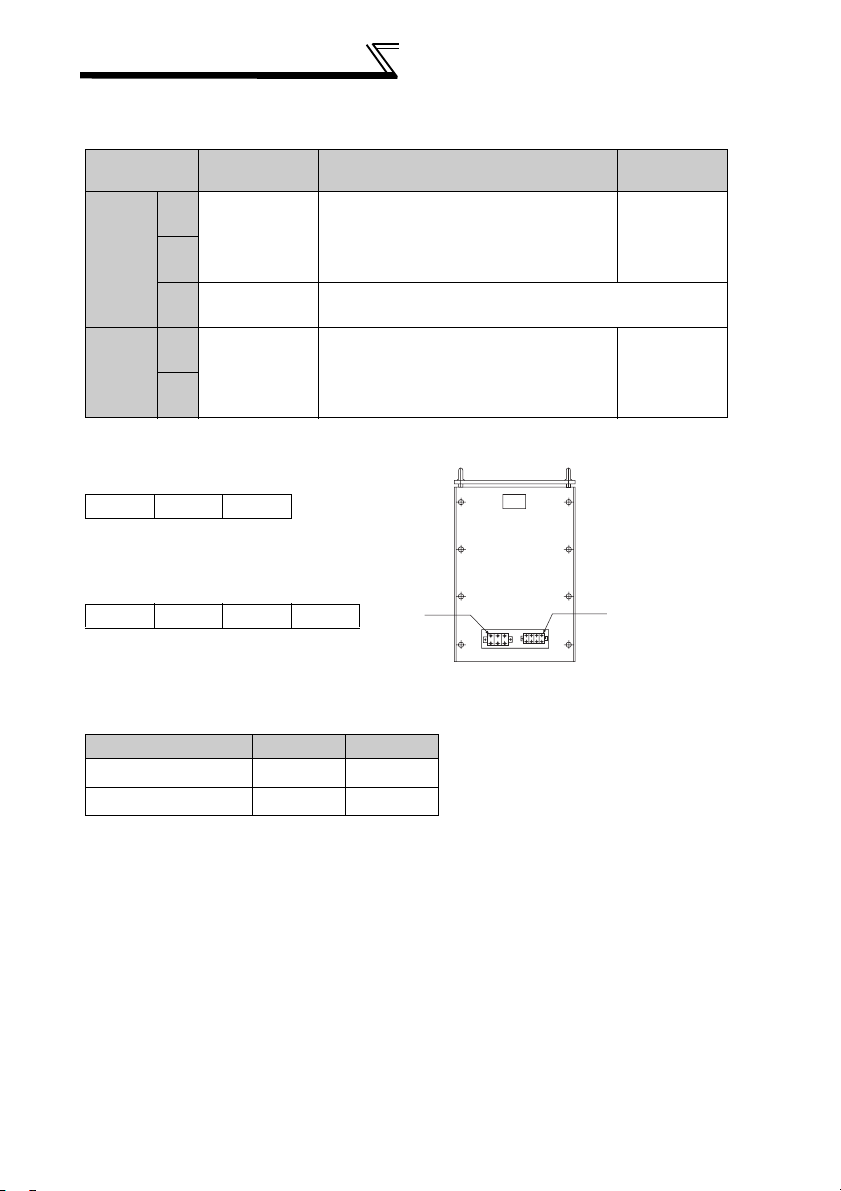

(2) MT-BR5

Terminal

Symbol

Main

circuit

Control

circuit

• Terminal arrangement

Terminal Name Description Rating

P

Resistor unit

input terminal

PR

E

Earth terminal

TH1

Alarm output

terminal

TH2

Connect to terminal P and PR of the

brake unit.

For earthing (grounding) of the resistor unit. Must be

earthed (grounded).

Output signal indicates resistor

overheart.

Resistor unit input terminal

PPR

TB1

Control circuit terminal block

arrangement

TH1 TH2 E

TB2

• Terminal screw size (MT-BR5)

<MT-BR5 resistor unit>

NP

TB1

---

1 NO contact,

110VAC, 5A

220VAC, 3A

TB2

Model TB1 TB2

MT-BR5-55K M6 M4

MT-BR5-H75K M6 M4

12

3.2 Combinations of Brake Resistors for Brake

Unit and Used Wires

WIRING

Brake Unit Type

FR-BU2-1.5K

FR-BU2-3.7K

FR-BU2-7.5K

FR-BU2-15K

200V class

FR-BU2-30K

FR-BU2-55K

FR-BU2-H7.5K

FR-BU2-H15K

FR-BU2-H30K

400V class

FR-BU2-H55K FR-BR-H55K 5.5

FR-BU2-H75K

Brake Resistor, Resistor

Unit Type

GZG 300W-50Ω (one)

GRZG 200-10Ω (three in series)

GRZG 300-5Ω (four in series) 3.5

GRZG 400-2Ω (six in series)

FR-BR-15K

FR-BR-30K 5.5

FR-BR-55K

MT-BR5-55K

GRZG 200-10Ω (six in series) 2

GRZG 300-5Ω (eight in series)

FR-BR-H15K

GRZG 400-2Ω (twelve in series)

FR-BR-H30K

MT-BR5-H75K 14

Cable Size (mm2)

2

2

3.5

14

3.5

3.5

13

Loading...

Loading...