MELDAS and MELSEC are registered trademarks of Mitsubishi Electric Corporation.

Microsoft

States and/or other countries.

Intel

subsidiaries in the United States and other countries.

Other company and product names that appear in this manual are trademarks or registered trademarks of the

respective company.

®

and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the United

®

, Pentium® and Celeron® are either trademarks or registered trademarks of Intel Corporation and its

Introduction

This manual describes the specifications of MITSUBISHI CNC 700/70 Series.

To safely use this CNC unit, thoroughly study the "Precautions for Safety" on the next page

before use.

Details described in this manual

At the beginning of each item, a table indicating it’s specification according to the model.

{

: Standard

U : Option

: Selection

: Special option

CAUTION

The items that are not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added.

Some functions may differ or some functions may not be usable depending on the NC

system (software) version.

General precautions

(1) When the contents of this manual is updated, the version (A, B, …) on the cover will be

incremented.

Precautions for Safety

Always read this manual, related manuals and attached documents before installation, operation,

programming, maintenance or inspection to ensure correct use.

Understand all the conditions described in this manual before using the unit.

We rank the safety precautions into "DANGER", "WARNING" and "CAUTION" for the manuals issued

by Mitsubishi, including this manual.

DANGER

WARNING

CAUTION

Note that even items ranked as " CAUTION", may lead to major results depending on the situation.

In any case, important information that must always be observed is described.

Not applicable in this manual.

When there is a great risk that the user could be subject to

fatalities or serious injuries if handling is mistaken.

When the user could be subject to fatalities or serious injuries

if handling is mistaken.

When the user could be subject to injuries or when physical

damage could occur if handling is mistaken.

DANGER

Not applicable in this manual.

1. Items related to product and manual

The items that are not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added.

Some functions may differ or some functions may not be usable depending on the NC

system (software) version.

2. Items related to start up and maintenance

Follow the power specifications (input voltage range, frequency range, momentary

power failure time range) described in this manual.

Follow the environment conditions (ambient temperature, humidity, vibration,

atmosphere) described in this manual.

!

Follow the remote type machine contact input/output interface described in this manual.

(Connect a diode in parallel with the inductive load or connect a protective resistor in

serial with the capacitive load, etc.)

WARNING

CAUTION

If the parameter is used to set the temperature rise detection function to invalid,

overheating may occur, thereby disabling control and possibly resulting in the axes

running out of control, which in turn may result in machine damage and/or bodily injury

or destruction of the unit. It is for this reason that the detection function is normally left

"valid" for operation.

The parameter for the temperature rise detection function will be validated forcibly

when the NC unit is turned ON.

CONTENTS

1. Control Axes................................................................................................................................1

1.1 Control Axes .........................................................................................................................1

1.1.1 Number of Basic Control Axes (NC Axes)...................................................................1

1.1.2 Max. Number of Axes (NC Axes + Spindles + PLC Axes)..........................................1

1.1.3 Max. Number of Auxiliary Axes (MR-J2-CT) ...............................................................2

1.1.4 Number of Simultaneous Contouring Control Axes.....................................................2

1.1.5 Max. Number of NC Axes in a Part System ................................................................2

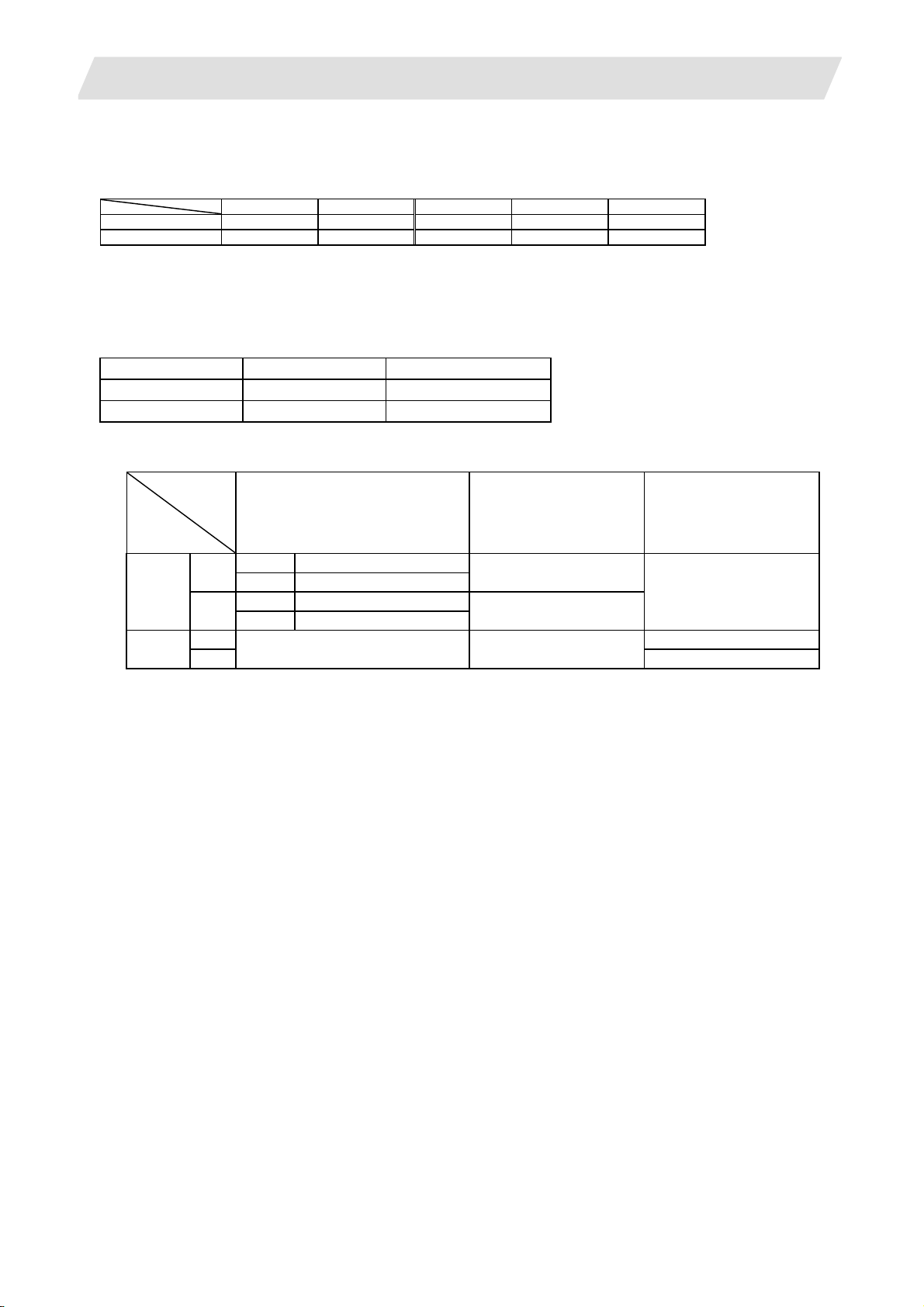

1.2 Control Part System..............................................................................................................2

1.2.1 Standard Number of Part Systems..............................................................................2

1.2.2 Max. Number of Part Systems.....................................................................................2

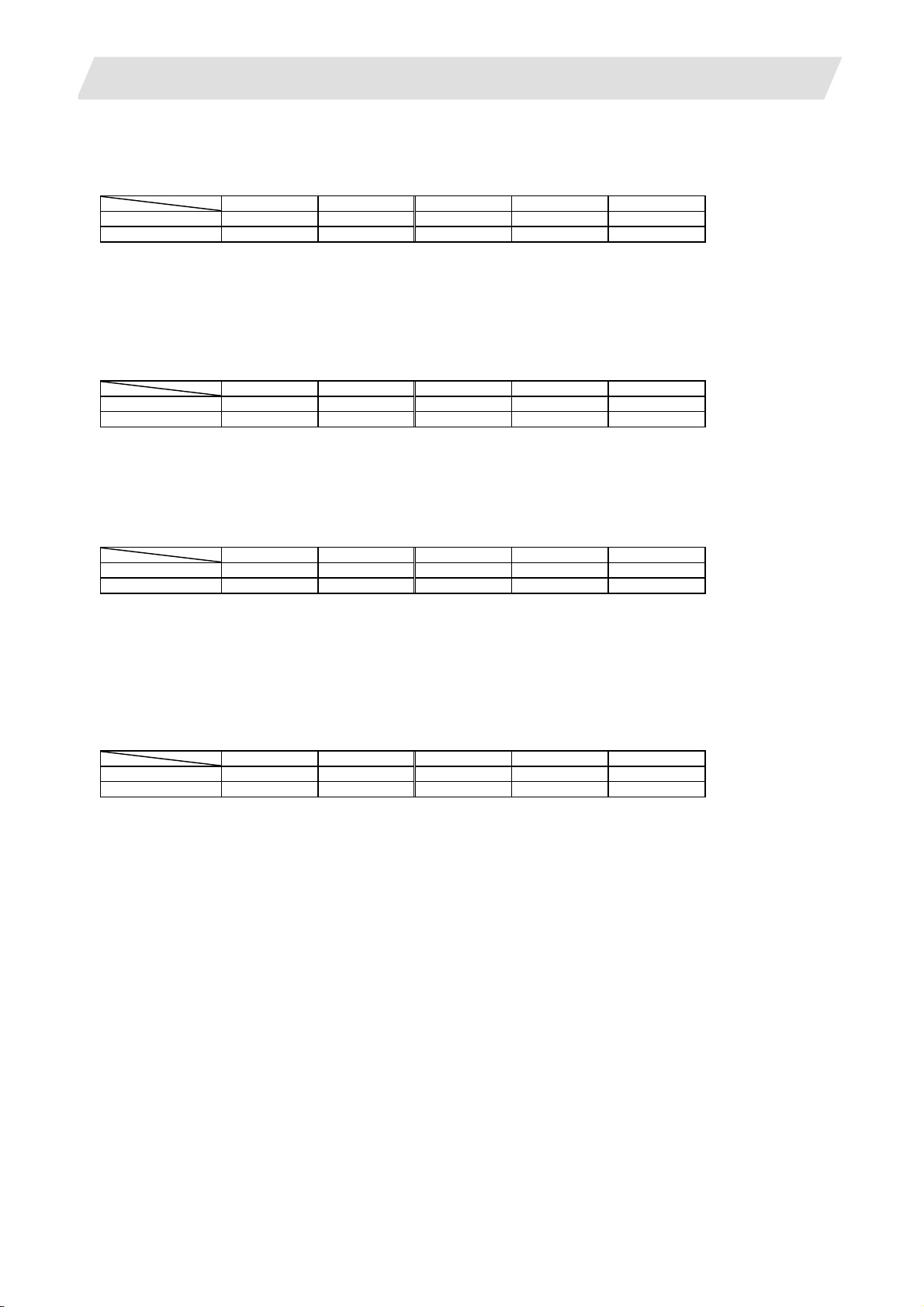

1.3 Control Axes and Operation Modes.....................................................................................3

1.3.1 Tape (RS-232C Input) Mode .......................................................................................3

1.3.2 Memory Mode..............................................................................................................3

1.3.3 MDI Mode.....................................................................................................................3

1.3.4 High-Speed Program Server Mode (CF Card in Control Unit)....................................3

1.3.5 Front IC Card Mode.....................................................................................................4

1.3.6 Hard Disk Mode ...........................................................................................................4

2. Input Command ..........................................................................................................................5

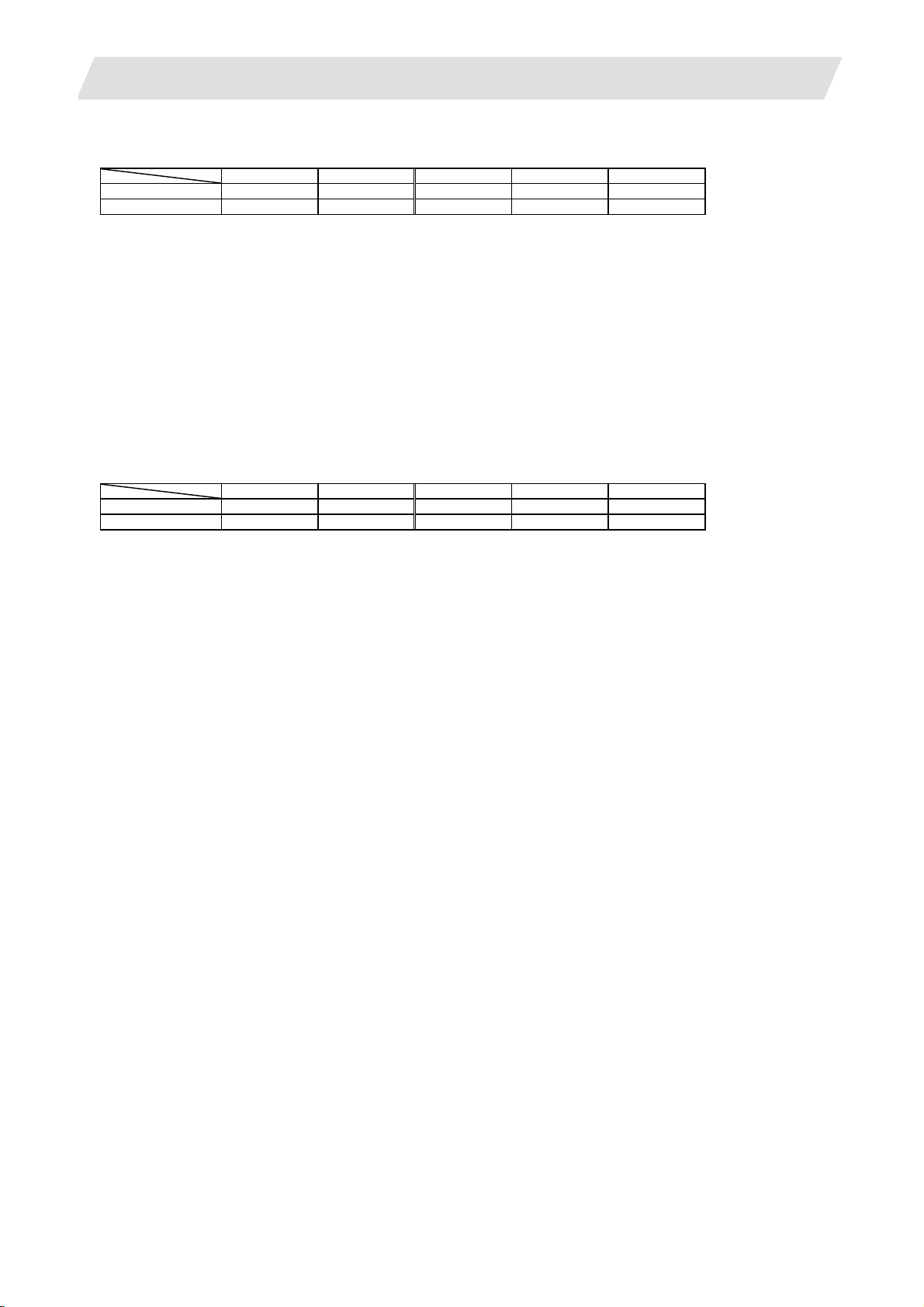

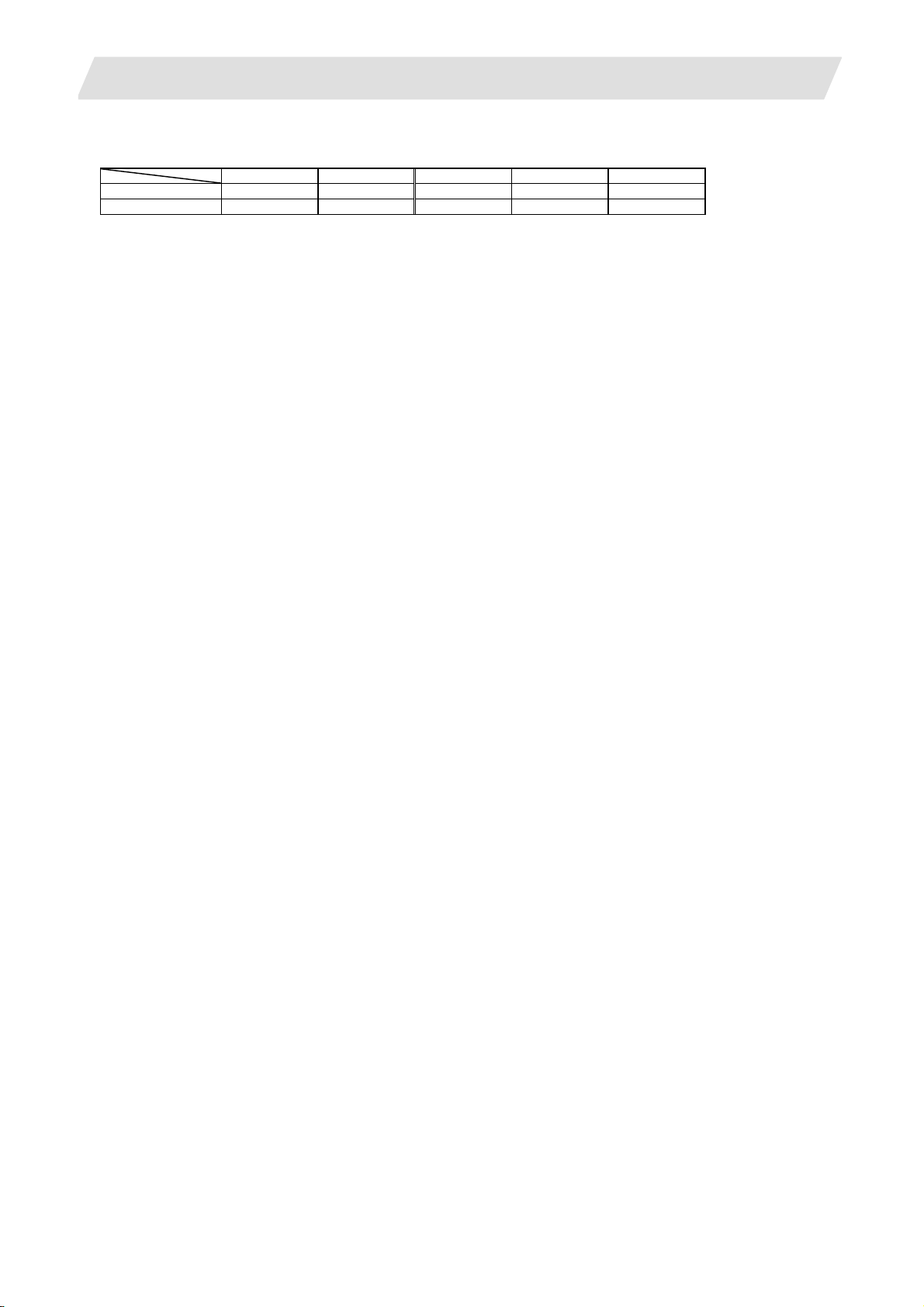

2.1 Data Increment .....................................................................................................................5

2.1.1 Least Command Increment .........................................................................................5

2.1.2 Least Control Increment...............................................................................................6

2.1.3 Indexing Increment.......................................................................................................6

2.2 Unit System...........................................................................................................................7

2.2.1 Inch/Metric Changeover...............................................................................................7

2.2.2 Input Command Increment Tenfold.............................................................................8

2.3 Program Format....................................................................................................................9

2.3.1 Program Format...........................................................................................................9

2.3.1.1 Format 1 for Lathe (G-code List 2, 3)..............................................................9

2.3.1.2 Format 2 for Lathe (G-code List 4, 5)..............................................................9

2.3.1.3 Special Format for Lathe (G-code List 6, 7)....................................................9

2.3.1.4 Format 1 for Machining Center (G-code List 1)..............................................9

2.3.1.5 Format 2 for Machining Center (M2 Format)..................................................9

2.3.1.6 MITSUBISHI CNC Special Format .................................................................9

2.4 Command Value.................................................................................................................10

2.4.1 Decimal Point Input I, II..............................................................................................10

2.4.2 Absolute/Incremental Command ...............................................................................11

2.4.3 Diameter/Radius Designation....................................................................................13

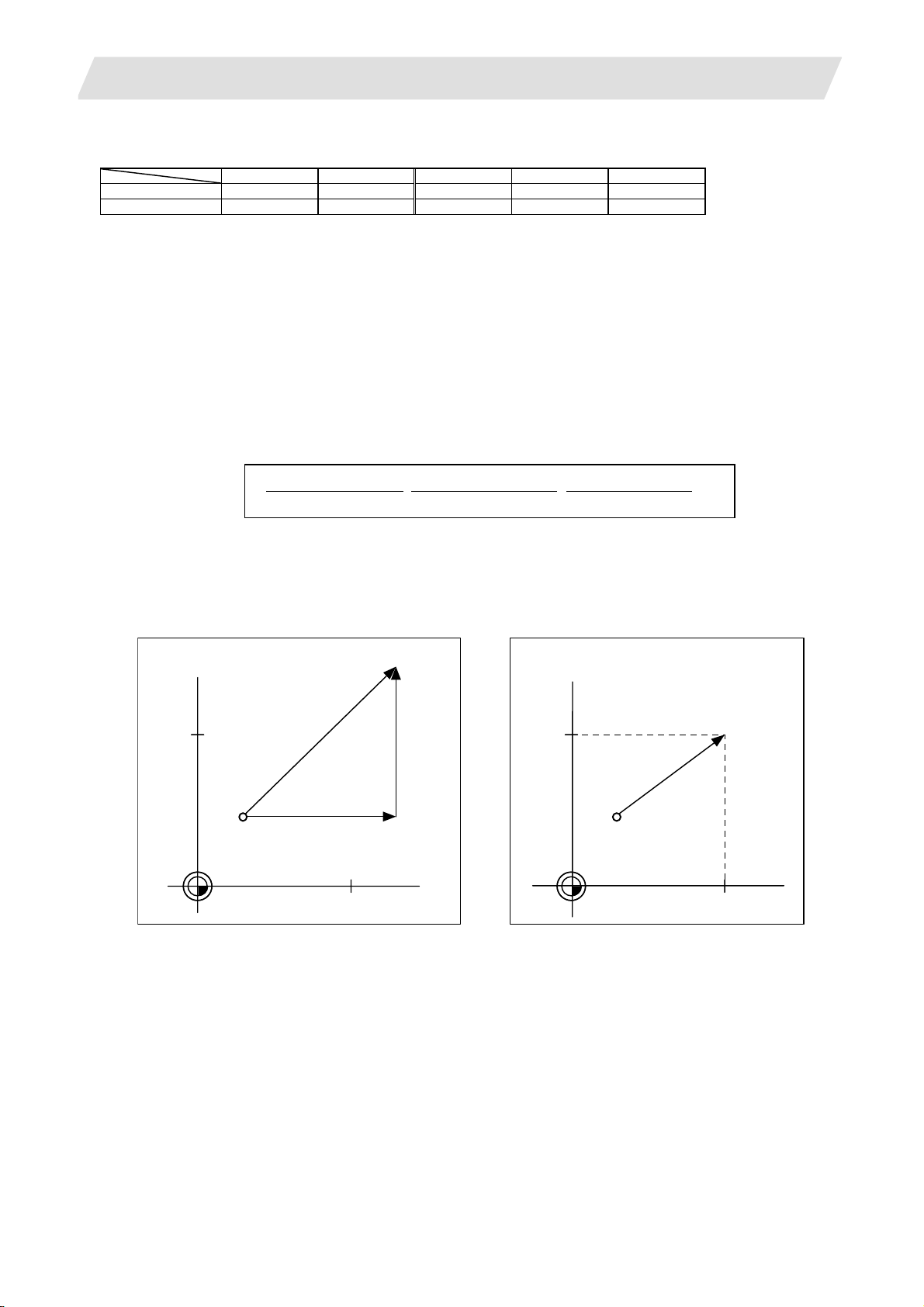

3. Positioning/Interpolation .........................................................................................................14

3.1 Positioning...........................................................................................................................14

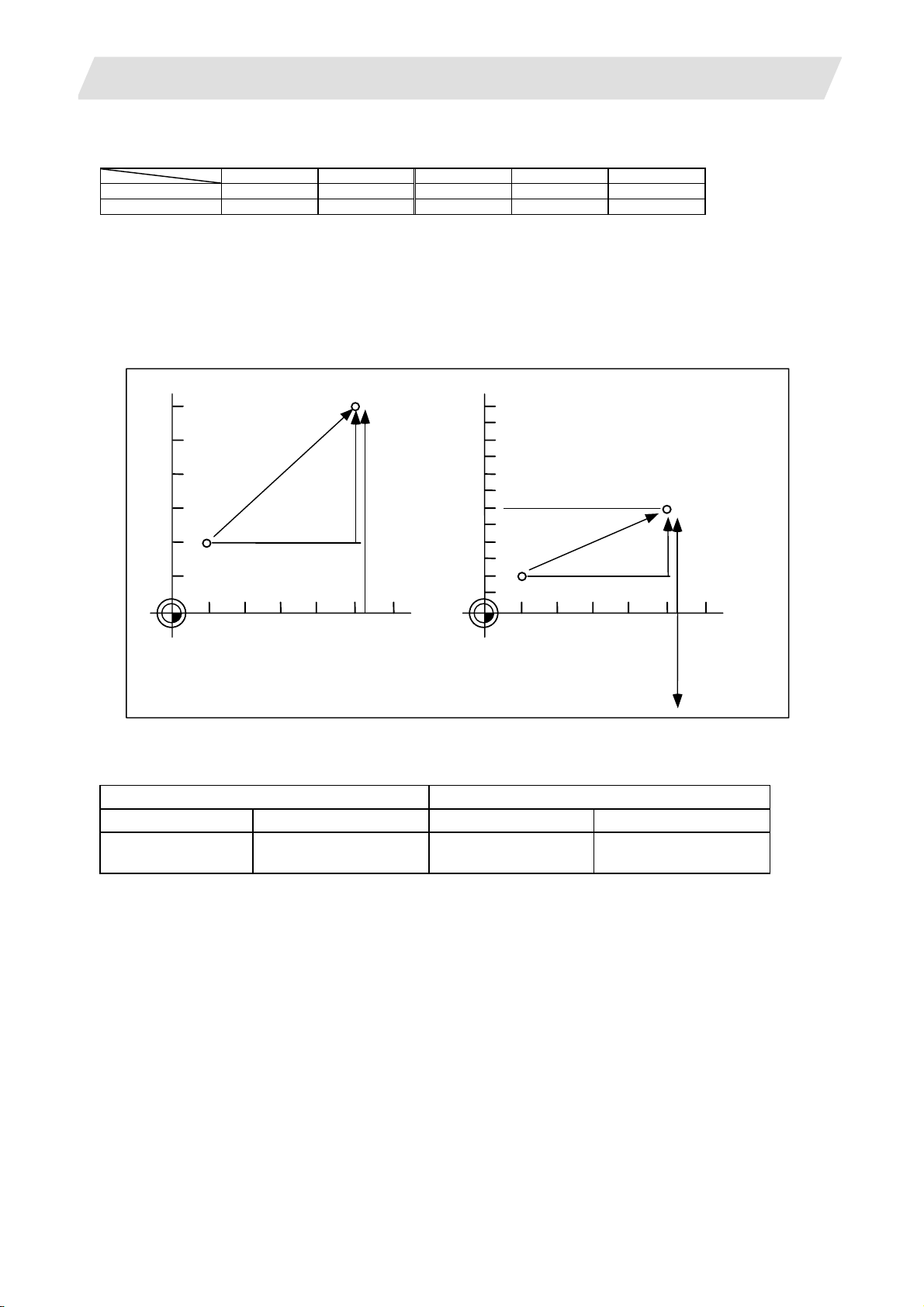

3.1.1 Positioning..................................................................................................................14

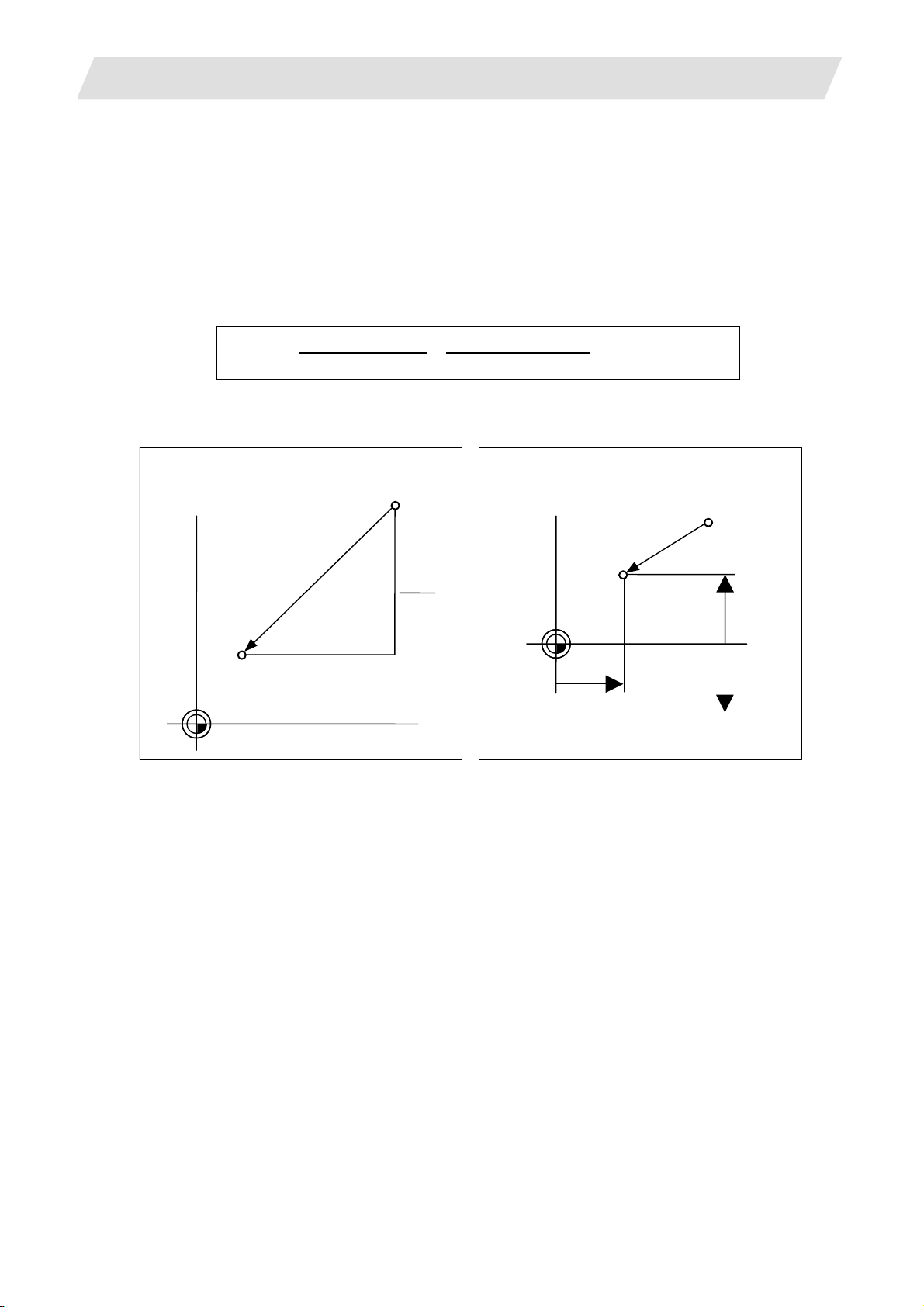

3.1.2 Unidirectional Positioning...........................................................................................15

3.2 Linear/Circular Interpolation................................................................................................16

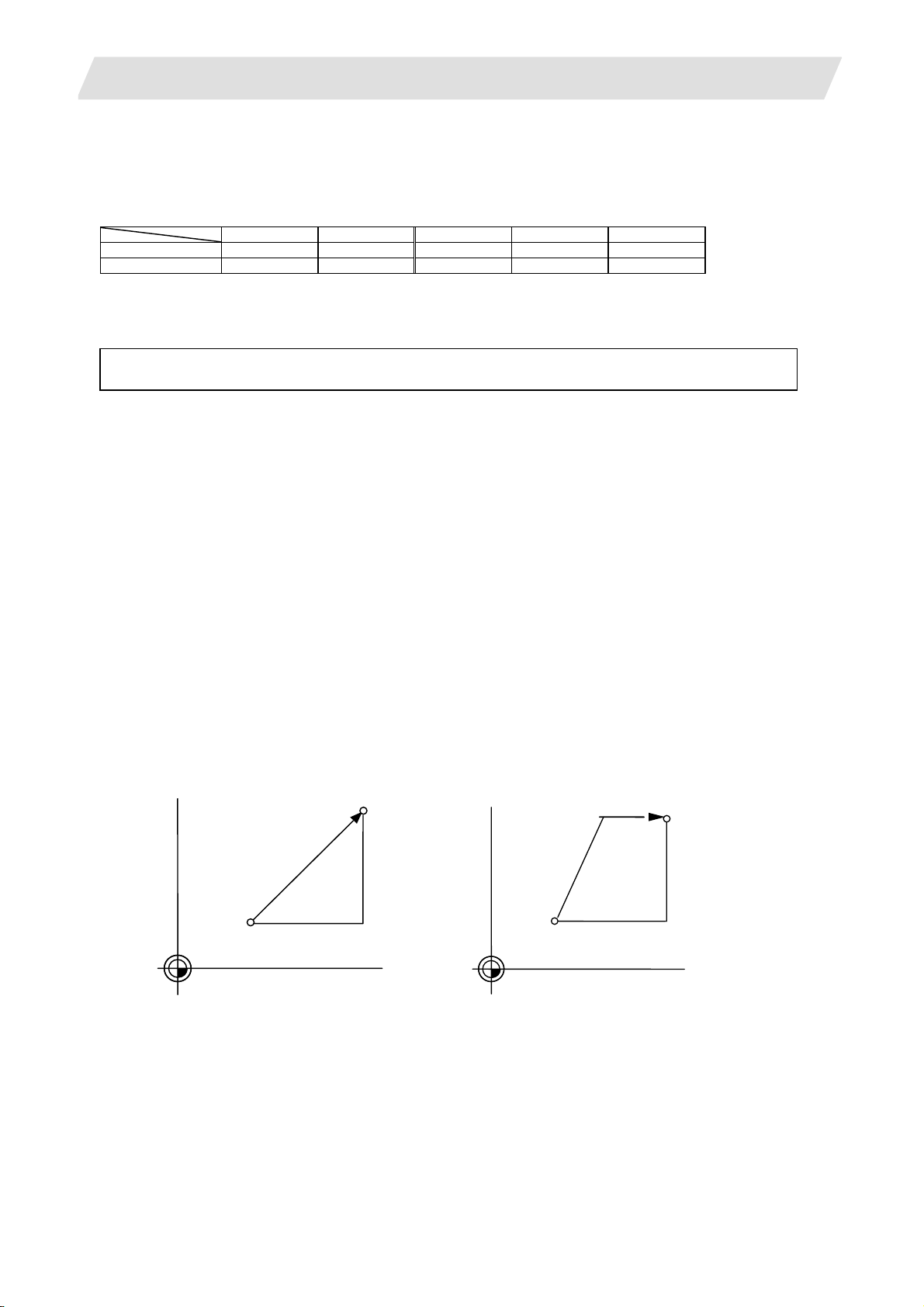

3.2.1 Linear Interpolation ....................................................................................................16

3.2.2 Circular Interpolation (Center/Radius Designation)...................................................17

3.2.3 Helical Interpolation....................................................................................................19

3.2.4 Spiral/Conical Interpolation........................................................................................21

3.2.5 Cylindrical Interpolation..............................................................................................23

3.2.6 Polar Coordinate Interpolation...................................................................................24

3.2.7 Milling Interpolation....................................................................................................25

3.2.8 Hypothetical Axis Interpolation...................................................................................26

3.3 Curve Interpolation..............................................................................................................27

3.3.2 Exponential Interpolation ...........................................................................................27

3.3.3 Spline Interpolation ....................................................................................................28

i

3.3.4 NURBS Interpolation..................................................................................................28

3.3.5 3-Dimensional Circular Interpolation..........................................................................29

4. Feed............................................................................................................................................30

4.1 Feed Rate...........................................................................................................................30

4.1.1 Rapid Traverse Rate (m/min) ....................................................................................30

4.1.2 Cutting Feed Rate (m/min).........................................................................................31

4.1.3 Manual Feed Rate (m/min)........................................................................................32

4.1.4 Rotary Axis Command Speed Tenfold......................................................................32

4.2 Feed Rate Input Methods...................................................................................................33

4.2.1 Feed per Minute (Asynchronous Feed).....................................................................33

4.2.2 Feed per Revolution (Synchronous Feed).................................................................35

4.2.3 Inverse Time Feed.....................................................................................................36

4.2.4 F 1-digit Feed.............................................................................................................37

4.2.5 Manual Speed Command..........................................................................................37

4.3 Override ..............................................................................................................................38

4.3.1 Rapid Traverse Override............................................................................................38

4.3.2 Cutting Feed Override................................................................................................38

4.3.3 2nd Cutting Feed Override.........................................................................................38

4.3.4 Override Cancel.........................................................................................................39

4.4 Acceleration/Deceleration...................................................................................................40

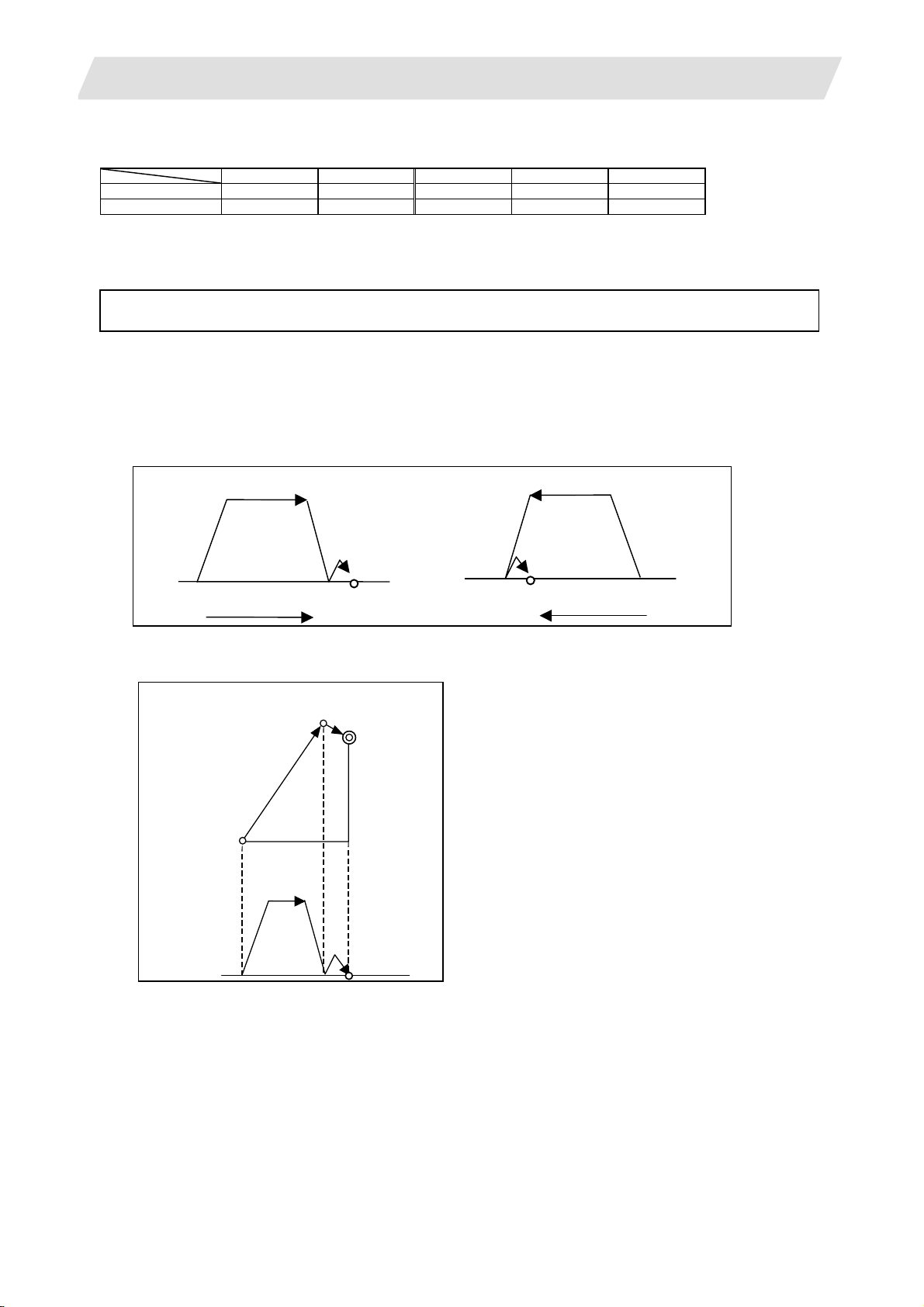

4.4.1 Automatic Acceleration/Deceleration after Interpolation ...........................................40

4.4.2 Rapid Traverse Constant Inclination Acceleration/Deceleration...............................42

4.5 Thread Cutting....................................................................................................................44

4.5.1 Thread Cutting (Lead/Thread Number Designation).................................................44

4.5.2 Variable Lead Thread Cutting....................................................................................46

4.5.3 Synchronous Tapping................................................................................................47

4.5.3.1 Synchronous Tapping Cycle.........................................................................47

4.5.3.2 Pecking Tapping Cycle .................................................................................49

4.5.3.3 Deep-hole Tapping Cycle..............................................................................51

4.5.4 Chamfering.................................................................................................................53

4.5.6 Circular Thread Cutting..............................................................................................54

4.6 Manual Feed.......................................................................................................................55

4.6.1 Manual Rapid Traverse..............................................................................................55

4.6.2 Jog Feed ....................................................................................................................55

4.6.3 Incremental Feed.......................................................................................................56

4.6.4 Handle Feed...............................................................................................................56

4.6.5 Manual Feed Rate B..................................................................................................57

4.6.6 Manual Feed Rate B Surface Speed Control............................................................58

4.7 Dwell ...................................................................................................................................59

4.7.1 Dwell (Time-based Designation)................................................................................59

5. Program Memory/Editing.........................................................................................................60

5.1 Memory Capacity................................................................................................................60

5.1.1 Memory Capacity (Number of Programs Stored)......................................................60

5.2 Editing.................................................................................................................................61

5.2.1 Program Editing .........................................................................................................61

5.2.2 Background Editing....................................................................................................62

5.2.3 Buffer Correction........................................................................................................63

6. Operation and Display..............................................................................................................64

6.1 Structure of Operation/Display Panel.................................................................................64

6.1.1 Color display (8.4-type LCD TFT)..............................................................................64

6.1.2 Color display (10.4-type LCD TFT)............................................................................64

6.1.3 Color display (10.4-type LCD TFT/WindowsXPe).....................................................64

6.1.4 Color display (15-type LCD TFT/WindowsXPe)........................................................64

6.1.5 Color touch-panel display (10.4-type LCD TFT/WIndowsXPe).................................64

6.1.6 Color touch-panel display (10.4-type LCD TFT)........................................................64

ii

6.2 Operation Methods and Functions.....................................................................................65

6.2.1 Operation Input ..........................................................................................................65

6.2.2 Absolute/Incremental Setting.....................................................................................65

6.2.5 Displayed Part System Switch...................................................................................65

6.2.6 Menu List....................................................................................................................66

6.2.7 Display Switch by Operation Mode............................................................................66

6.2.8 External Signal Display Switch..................................................................................66

6.2.10 Screen Saver ...........................................................................................................66

6.2.11 Parameter/Operation Guidance...............................................................................67

6.2.12 Alarm Guidance .......................................................................................................67

6.2.13 Machining Program Input Mistake Check Warning.................................................67

6.3 Display Methods and Contents...........................................................................................68

6.3.1 Status Display........................................................................................................... .68

6.3.2 Clock Display .............................................................................................................68

6.3.3 Operation Screen Display..........................................................................................68

6.3.4 Preparation Screen Display.......................................................................................69

6.3.5 Edit Screen Display....................................................................................................69

6.3.6 Diagnosis Screen Display..........................................................................................69

6.3.7 Maintenance Screen Display.....................................................................................69

6.3.8 Additional Language..................................................................................................70

6.3.8.1 Japanese.......................................................................................................70

6.3.8.2 English...........................................................................................................70

6.3.8.3 German..........................................................................................................70

6.3.8.4 Italian.............................................................................................................70

6.3.8.5 French ...........................................................................................................70

6.3.8.6 Spanish..........................................................................................................70

6.3.8.7 Chinese .........................................................................................................70

6.3.8.8 Korean...........................................................................................................71

6.3.8.9 Portuguese....................................................................................................71

6.3.8.10 Hungarian....................................................................................................71

6.3.8.11 Dutch...........................................................................................................71

6.3.8.12 Swedish.......................................................................................................71

6.3.8.13 Turkish.........................................................................................................71

7. Input/Output Functions and Devices .....................................................................................72

7.1 Input/Output Data................................................................................................................72

7.2 Input/Output I/F...................................................................................................................73

7.2.1 RS-232C I/F...............................................................................................................73

7.2.2 IC Card I/F..................................................................................................................74

7.2.2.1 I/F for CF Card in Control Unit................................................................................74

7.2.2.2 Front IC Card I/F.....................................................................................................74

7.2.3 Ethernet I/F.................................................................................................................74

7.2.4 Hard Disk I/F..............................................................................................................74

7.2.5 Floppy Disk I/F...........................................................................................................74

7.3 Computer Link.....................................................................................................................75

7.3.1 Computer Link B ........................................................................................................75

7.4 Others .................................................................................................................................76

7.4.1 Handy Terminal Connection......................................................................................76

8. Spindle, Tool and Miscellaneous Functions .........................................................................77

8.1 Spindle Functions (S) .........................................................................................................77

8.1.1 Spindle Control Functions..........................................................................................77

8.1.1.1 Spindle Digital I/F ..........................................................................................78

8.1.1.2 Spindle Analog I/F.........................................................................................78

8.1.1.3 Coil Switch.....................................................................................................78

8.1.1.4 Automatic Coil Switch....................................................................................78

8.1.1.5 Encoder Input I/F...........................................................................................79

iii

8.1.2 S Code Output ...........................................................................................................80

8.1.3 Constant Surface Speed Control...............................................................................81

8.1.4 Spindle Override ........................................................................................................82

8.1.5 Multiple-spindle Control .............................................................................................82

8.1.5.1 Multiple-spindle Control I...............................................................................83

8.1.5.2 Multiple-spindle Control II..............................................................................83

8.1.6 Spindle Orientation.....................................................................................................84

8.1.7 Spindle Position Control (Spindle/C Axis Control).....................................................85

8.1.8 Spindle Synchronization ............................................................................................86

8.1.8.1 Spindle Synchronization I..............................................................................86

8.1.8.2 Spindle Synchronization II.............................................................................87

8.1.9 Tool Spindle Synchronization I (Polygon)..................................................................88

8.1.9.1 Tool Spindle Synchronization IA (Spindle-Spindle Polygon)........................88

8.1.9.2 Tool Spindle Synchronization IB (Spindle-Spindle Polygon)........................89

8.1.9.3 Tool Spindle Synchronization IC (Spindle-NC Axis Polygon).......................90

8.2 Tool Functions (T)...............................................................................................................91

8.2.1 Tool Functions (T Command)....................................................................................91

8.3 Miscellaneous Functions (M)..............................................................................................92

8.3.1 Miscellaneous Functions............................................................................................92

8.3.2 Multiple M Codes in 1 Block.......................................................................................93

8.3.3 M Code Independent Output .....................................................................................93

8.3.4 Miscellaneous Function Finish...................................................................................94

8.3.5 M Code Output during Axis Traveling........................................................................95

8.4 2nd Miscellaneous Functions (B) .......................................................................................96

8.4.1 2nd Miscellaneous Functions...........................................................................96

9. Tool Compensation..................................................................................................................97

9.1 Tool Length/Tool Position...................................................................................................97

9.1.1 Tool Length Compensation........................................................................................97

9.1.2 Tool Position Offset..................................................................................................100

9.1.3 Tool Compensation for Additional Axes ..................................................................100

9.2 Tool Radius.......................................................................................................................101

9.2.1 Tool Radius Compensation .....................................................................................101

9.2.2 3-dimensional Tool Radius Compensation..............................................................103

9.2.3 Tool Nose Radius Compensation (G40/41/42) .......................................................104

9.2.4 Automatic Decision of Nose Radius Compensation Direction (G46/40).................105

9.2.5 Tool Radius Compensation Diameter Designation........................................105

9.3 Tool Compensation Amount.............................................................................................106

9.3.1 Number of Tool Compensation Sets .......................................................................106

9.3.1.1 Number of tool compensation sets 20 Sets..............................................107

9.3.1.2 Number of tool compensation sets 40 Sets..............................................107

9.3.1.3 Number of tool compensation sets 80 Sets..............................................107

9.3.1.4 Number of tool compensation sets 200 Sets............................................107

9.3.1.5 Number of tool compensation sets 400 Sets............................................107

9.3.1.6 Number of tool compensation sets 999 Sets............................................107

9.3.2 Compensation Memory............................................................................................108

9.3.2.1 Tool Shape/Wear Compensation Amount..................................................108

10. Coordinate System...............................................................................................................111

10.1 Coordinate System Type and Setting.............................................................................111

10.1.1 Machine Coordinate System..................................................................................112

10.1.2 Coordinate System Setting....................................................................................113

10.1.3 Automatic Coordinate System Setting...................................................................114

10.1.4 Workpiece Coordinate System Selection..............................................................115

10.1.5 External Workpiece Coordinate Offset..................................................................117

10.1.6 Workpiece Coordinate System Preset (G92.1).....................................................118

10.1.7 Local Coordinate System.......................................................................................119

iv

10.1.8 Coordinate System for Rotary Axis........................................................................120

10.1.9 Plane Selection......................................................................................................121

10.1.10 Origin Set/Origin Cancel......................................................................................122

10.1.11 Counter Set..........................................................................................................124

10.2 Return .............................................................................................................................125

10.2.1 Manual Reference Position Return........................................................................125

10.2.2 Automatic 1st Reference Position Return..............................................................126

10.2.3 2nd, 3rd, 4th Reference Position Return...............................................................128

10.2.4 Reference Position Check.....................................................................................129

10.2.5 Absolute Position Detection...................................................................................130

10.2.6 Tool Change Position Return.................................................................................131

11. Operation Support Functions .............................................................................................132

11.1 Program Control..............................................................................................................132

11.1.1 Optional Block Skip................................................................................................132

11.1.2 Single Block ...........................................................................................................133

11.2 Program Test..................................................................................................................134

11.2.1 Dry Run..................................................................................................................134

11.2.2 Machine Lock.........................................................................................................134

11.2.3 Miscellaneous Function Lock.................................................................................134

11.2.4 Graphic Check .......................................................................................................135

11.2.4.1 Graphic Check....................................................................................................135

11.2.4.2 3D Solid Program Check....................................................................................135

11.2.5 Graphic Trace ........................................................................................................136

11.2.6 Machining Time Computation................................................................................136

11.3 Program Search/Start/Stop ............................................................................................137

11.3.1 Program Search.....................................................................................................137

11.3.2 Sequence Number Search ....................................................................................137

11.3.3 Verification Stop.....................................................................................................138

11.3.4 Program Restart.....................................................................................................139

11.3.5 Automatic Operation Start......................................................................................139

11.3.6 NC Reset................................................................................................................140

11.3.7 Feed Hold...............................................................................................................140

11.3.8 Search & Start........................................................................................................141

11.4 Interrupt Operation..........................................................................................................142

11.4.1 Manual Interruption................................................................................................142

11.4.2 Automatic Operation Handle Interruption..............................................................142

11.4.3 Manual Absolute Switch.........................................................................................143

11.4.4 Thread Cutting Cycle Retract ................................................................................144

11.4.5 Tapping Retract......................................................................................................145

11.4.6 Manual Numerical Value Command......................................................................146

11.4.8 MDI Interruption .....................................................................................................146

11.4.9 Simultaneous Operation of Manual and Automatic Modes...................................147

11.4.10 Simultaneous Operation of JOG and Handle Modes..........................................147

11.4.11 Reference Position Retract..................................................................................148

11.4.12 Tool Escape and Return......................................................................................149

11.4.13 Skip Retract..........................................................................................................149

11.4.14 PLC Interruption...................................................................................................149

12. Program Support Functions................................................................................................150

12.1 Machining Method Support Functions............................................................................150

12.1.1 Program..................................................................................................................150

12.1.1.1 Subprogram Control..................................................................................150

12.1.1.2 Figure Rotation..........................................................................................152

12.1.1.3 Scaling.......................................................................................................154

12.1.2 Macro Program ......................................................................................................155

12.1.2.1 User Macro................................................................................................155

v

12.1.2.2 Machine Tool Builder Macro .....................................................................158

12.1.2.3 Macro Interruption.....................................................................................159

12.1.2.4 Variable Command ...................................................................................160

12.1.2.4.1 100 Sets.....................................................................................161

12.1.2.4.2 200 Sets.....................................................................................161

12.1.2.4.3 300 Sets.....................................................................................161

12.1.2.4.4 600 Sets.....................................................................................161

12.1.2.4.5 (50+50 ´ Number of Part Systems) Sets...................................161

12.1.2.4.6 (100+100 ´ Number of Part Systems) Sets...............................161

12.1.2.4.7 (200+100 ´ Number of Part Systems) Sets...............................161

12.1.2.4.8 (400+100 ´ Number of Part Systems) Sets...............................161

12.1.3 Fixed Cycle ............................................................................................................162

12.1.3.1 Fixed Cycle for Drilling ..............................................................................163

12.1.3.2 Fixed Cycle for Drilling (Type II)................................................................170

12.1.3.3 Special Fixed Cycle...................................................................................171

12.1.3.4 Fixed Cycle for Turning Machining ...........................................................175

12.1.3.5 Compound Type Fixed Cycle for Turning Machining ...............................180

12.1.3.6 Compound Type Fixed Cycle for Turning Machining (Type II).................188

12.1.3.7 Small-diameter Deep-hole Drilling Cycle..................................................189

12.1.4 Mirror Image...........................................................................................................190

12.1.4.1 Mirror Image by Parameter Setting...........................................................190

12.1.4.2 Mirror Image by External Input..................................................................190

12.1.4.3 Mirror Image by G Code............................................................................191

12.1.4.4 Mirror Image for Facing Tool Posts...........................................................192

12.1.4.5 T Code Mirror Image for Facing Tool Posts..............................................192

12.1.5 Coordinate System Operation ...............................................................................193

12.1.5.1 Coordinate Rotation by Program ..............................................................193

12.1.5.2 Coordinate Rotation by Parameter ...........................................................195

12.1.5.3 3-dimensional Coordinate Conversion......................................................196

12.1.6 Dimension Input.....................................................................................................197

12.1.6.1 Corner Chamfering/Corner R....................................................................197

12.1.6.2 Linear Angle Command ............................................................................203

12.1.6.3 Geometric Command................................................................................204

12.1.6.4 Polar Coordinate Command .....................................................................208

12.1.7 Axis Control............................................................................................................209

12.1.7.1 Chopping...................................................................................................209

12.1.7.1.1 Chopping....................................................................................209

12.1.7.2 Normal Line Control ..................................................................................210

12.1.7.3 Circular Cutting..........................................................................................211

12.1.8 Multi-part System Control ......................................................................................212

12.1.8.1 Timing Synchronization between Part Systems.......................................212

12.1.8.2 Start Point Designation Timing Synchronization ......................................213

12.1.8.3 Mixed Synchronization Control.................................................................215

12.1.8.5 Control Axis Synchronization across Part Systems..................................216

12.1.8.6 Balance Cut...............................................................................................217

12.1.8.7 Common Memory for Part Systems..........................................................218

12.1.9 Data Input by Program...........................................................................................219

12.1.9.1 Parameter Input by Program.....................................................................219

12.1.9.2 Compensation Data Input by Program .....................................................220

12.1.10 Machining Modal..................................................................................................222

12.1.10.1 Tapping Mode .........................................................................................222

12.1.10.2 Cutting Mode...........................................................................................222

12.2 Machining Accuracy Support Functions.........................................................................223

12.2.1 Automatic Corner Override....................................................................................223

12.2.2 Deceleration Check................................................................................................224

12.2.2.1 Exact Stop Check Mode............................................................................225

vi

12.2.2.2 Exact Stop Check......................................................................................225

12.2.2.3 Error Detection..........................................................................................225

12.2.2.4 Programmable In-position Check..............................................................226

12.3 High-speed and High-accuracy Functions.....................................................................227

12.3.1 High-speed Machining Mode I (G05P1)................................................................227

12.3.2 High-speed Machining Mode II (G05 P2)..............................................................228

12.3.3 High-speed High-accuracy Control 1 (G05.1Q1) ..................................................229

12.3.4 High-speed High-accuracy Control 2 (G5P10000)................................................230

12.3.5 High-accuracy Control 1 (G61.1/G08)...................................................................232

12.3.6 High-accuracy spline interpolation1 (G61.2) .........................................................236

12.3.8 SSS Control ...........................................................................................................237

12.4 Programming Support Functions....................................................................................238

12.4.1 Playback.................................................................................................................238

12.4.3 Simple Programming .............................................................................................238

12.4.4 G code Guidance...................................................................................................239

13 Machine Accuracy Compensation.......................................................................................240

13.1 Static Accuracy Compensation.......................................................................................240

13.1.1 Backlash Compensation........................................................................................240

13.1.2 Memory-type Pitch Error Compensation ...............................................................241

13.1.3 Memory-type Relative Position Error Compensation ............................................242

13.1.4 External Machine Coordinate System Compensation...........................................243

13.1.5 Circular Error Radius Compensation.....................................................................243

13.1.6 Ball Screw Thermal Expansion Compensation.....................................................244

13.1.7 Machine Rotation Center Error Compensation .....................................................245

13.1.8 Position-dependent Gradually Increasing-type Backlash Compensation.............246

13.2 Dynamic Accuracy Compensation .................................................................................247

13.2.1 Smooth High-gain (SHG) Control..........................................................................247

13.2.2 Dual Feedback.......................................................................................................248

13.2.3 Lost Motion Compensation....................................................................................248

13.2.4 OMR II (Backlash with Filter).................................................................................249

13.2.6 OMR-FF.................................................................................................................250

13.2.7 Distance-coded Reference Position Detection......................................................251

14. Automation Support Functions ..........................................................................................252

14.1 Measurement..................................................................................................................252

14.1.1 Skip ........................................................................................................................252

14.1.1.1 Skip............................................................................................................252

14.1.1.2 Multiple-step Skip......................................................................................253

14.1.1.4 PLC Skip....................................................................................................254

14.1.1.5 Speed Change Skip..................................................................................254

14.1.2 Automatic Tool Length Measurement....................................................................256

14.1.3 Manual Tool Length Measurement 1.....................................................................258

14.1.4 Manual Tool Length Measurement 2.....................................................................260

14.1.5 Workpiece Coordinate Offset Measurement.........................................................261

14.1.6 Workpiece Position Measurement.........................................................................262

14.1.7 Rotation Measurement...........................................................................................264

14.2 Tool Life Management....................................................................................................265

14.2.1 Tool Life Management...........................................................................................265

14.2.1.1 Tool Life Management I ............................................................................265

14.2.1.2 Tool Life Management II ...........................................................................265

14.2.2 Number of Tool Life Management Sets.................................................................266

14.3 Others .............................................................................................................................267

14.3.1 Programmable Current Limitation..........................................................................267

14.3.2 Auto Power OFF....................................................................................................267

15. Safety and Maintenance.......................................................................................................268

15.1 Safety Switches ..............................................................................................................268

vii

15.1.1 Emergency Stop ....................................................................................................268

15.1.2 Data Protection Key...............................................................................................268

15.2 Display for Ensuring Safety ............................................................................................269

15.2.1 NC Warning............................................................................................................269

15.2.2 NC Alarm................................................................................................................269

15.2.3 Operation Stop Cause ...........................................................................................270

15.2.4 Emergency Stop Cause.........................................................................................270

15.2.5 Thermal Detection..................................................................................................270

15.2.6 Battery Alarm/Warning...........................................................................................271

15.3 Protection........................................................................................................................272

15.3.1 Stroke End (Over Travel).......................................................................................272

15.3.2 Stored Stroke Limit.................................................................................................272

15.3.2.1 Stored Stroke Limit I/II...............................................................................273

15.3.2.2 Stored Stroke Limit IB ...............................................................................275

15.3.2.3 Stored Stroke Limit IIB ..............................................................................275

15.3.2.4 Stored Stroke Limit IC...............................................................................276

15.3.3 Stroke Check before Travel...................................................................................276

15.3.4 Chuck/Tailstock Barrier Check ..............................................................................277

15.3.5 Interlock..................................................................................................................278

15.3.6 External Deceleration.............................................................................................278

15.3.8 Door Interlock.........................................................................................................279

15.3.8.1 Door Interlock I..........................................................................................279

15.3.8.2 Door Interlock II.........................................................................................280

15.3.9 Parameter Lock......................................................................................................281

15.3.10 Program Protection (Edit Lock B, C) ...................................................................281

15.3.11 Program Display Lock..........................................................................................281

15.3.12 Safety Observation ..............................................................................................282

15.4 Maintenance and Troubleshooting.................................................................................283

15.4.1 Operation History...................................................................................................283

15.4.2 Data Sampling........................................................................................................283

15.4.3 NC Data Backup....................................................................................................284

15.4.4 MELDASNET.........................................................................................................284

15.4.4.1 Machine Tool Builder Network System.....................................................284

15.4.4.2 Anshin-net Service....................................................................................284

15.4.5 Servo Automatic Tuning.........................................................................................286

15.4.6 Automatic Backup..................................................................................................288

15.4.7 System Setup.........................................................................................................288

15.4.8 Servo/Spindle Waveform Display..........................................................................289

16. Drive System.........................................................................................................................290

16.1 Servo/Spindle..................................................................................................................290

16.1.1 Feed Axis...............................................................................................................290

16.1.1.1 MDS-D-V1/D-V2 (200V)............................................................................290

16.1.1.2 MDS-DH-V1/DH-V2 (400V) ......................................................................290

16.1.1.3 MDS-D-SVJ3 (200V).................................................................................291

16.1.2 Spindle ...................................................................................................................291

16.1.2.1 MDS-D-SP (200V).....................................................................................291

16.1.2.2 MDS-DH-SP (400V)..................................................................................291

16.1.2.3 MDS-D-SPJ3 (200V).................................................................................291

16.1.3 Auxiliary Axis..........................................................................................................291

16.1.3.1 Index/Positioning Servo : MR-J2-CT.........................................................291

16.1.4 Power Supply.........................................................................................................292

16.1.4.1 Power Supply : MDS-D-CV (200V)...........................................................292

16.1.4.2 Power Supply : MDS-DH-CV (400V) ........................................................292

16.1.4.3 AC Reactor for Power Supply...................................................................292

16.1.4.4 Ground Plate.............................................................................................292

viii

17. Machine Support Functions................................................................................................293

17.1 PLC.................................................................................................................................293

17.1.1 Built-in PLC Processing Mode...............................................................................293

17.1.2 PLC Functions........................................................................................................293

17.1.2.1 Built-in PLC Basic Function.......................................................................293

17.1.2.2 PLC Exclusive Instruction .........................................................................294

17.1.3 PLC Support Functions..........................................................................................297

17.1.3.1 Alarm Message Display ............................................................................297

17.1.3.2 Operator Message Display........................................................................297

17.1.3.3 Memory Switch (PLC Switch)....................................................................298

17.1.3.4 Load Meter Display ...................................................................................298

17.1.3.5 User PLC Version Display.........................................................................298

17.1.3.6 Multi-ladder Program Register and Execution..........................................298

17.1.4 Built-in PLC Capacity.............................................................................................299

17.1.5 Machine Contact Input/Output I/F..........................................................................299

17.1.6 Ladder Monitor.......................................................................................................304

17.1.7 PLC Development..................................................................................................304

17.1.7.1 On-board Development.............................................................................304

17.1.7.2 MELSEC Development Tool (GX Developer)...........................................304

17.1.8 PLC Parameter ......................................................................................................305

17.1.8.1 PLC Constant (150 Points) .......................................................................305

17.1.8.2 PLC Constant Extension (Up to 755 Points).............................................305

17.1.10 Pallet Program Registration.................................................................................306

17.1.11 Aditional PLC engine ...........................................................................................306

17.2 Machine Construction.....................................................................................................307

17.2.1 Servo OFF..............................................................................................................307

17.2.2 Axis Detachment....................................................................................................308

17.2.3 Synchronous Control .............................................................................................309

17.2.4 Inclined Axis Control..............................................................................................312

17.2.5 Position Switch.......................................................................................................313

17.2.7 Index Table Indexing..............................................................................................314

17.2.8 Auxiliary Axis Control (J2-CT)................................................................................315

17.2.9 Tool Length Compensation along the Tool Axis....................................................316

17.2.10 Tool Handle Feed & Interruption..........................................................................317

17.2.11 Tool Center Coordinate Display...........................................................................317

17.2.12 Tool Center Point Control ....................................................................................318

17.3 PLC Operation................................................................................................................320

17.3.1 Arbitrary Feed in Manual Mode .............................................................................320

17.3.2 Circular Feed in Manual Mode...............................................................................321

17.3.3 PLC Axis Control....................................................................................................323

17.4 PLC Interface..................................................................................................................324

17.4.1 CNC Control Signal................................................................................................324

17.4.2 CNC Status Signal.................................................................................................325

17.4.3 PLC Window ..........................................................................................................327

17.4.4 External Search......................................................................................................327

17.5 Machine Contact I/O.......................................................................................................328

17.6 External PLC Link...........................................................................................................329

17.6.3 CC-Link (Master/Slave)..........................................................................................329

17.6.4 PROFIBUS-DP (Master)........................................................................................335

17.7 Installing S/W for Machine Tools....................................................................................336

17.7.1 Customization (NC Designer)................................................................................336

17.7.2 User-defined Key...................................................................................................337

17.7.3 EZSocket I/F ..........................................................................................................337

17.7.4 APLC Release........................................................................................................338

17.7.5 Custom API Library................................................................................................338

ix

17.8 Others .............................................................................................................................339

17.8.1 Credit System.........................................................................................................339

17.8.2 NC Monitoring Tool................................................................................................339

Appendix 1. List of Specifications............................................................................................340

Appendix 2. 700 Series Installation Condition........................................................................341

2.1 Cabinet and Installation....................................................................................................341

2.1.1 Cabinet Construction ...............................................................................................341

2.1.2 General Specifications (Environment Conditions)...................................................347

2.2 Outline Drawing ................................................................................................................350

2.2.1 Control Unit ..............................................................................................................350

2.2.2 Display Unit..............................................................................................................353

2.2.2.1 FCU7-DA201 (8.4-type)..............................................................................353

2.2.2.2 FCU7-DA211 / FCU7-DA315 / FCU7-DA415 / FCU7-DA445 (10.4-type).353

2.2.2.3 FCU7-DA335 / FCU7-DA435 (15-type)......................................................355

2.2.2.4 FCU7-DA201 (8.4-type) / FCU7-DA211 (10.4-type) Rear View.................356

2.2.2.5 FCU7-DA315 / FCU7-DA415 / FCU7-DA445 / FCU7-DA335

/ FCU7-DA435 Rear View...........................................................................357

2.2.2.6 FCU7-EP102 (Front IC Card I/F Unit).........................................................358

2.2.3 Operation Panel I/O Unit..........................................................................................359

2.2.3.1 FCU7-DX670 / FCU7-DX671 / FCU7-DX770 / FCU7-DX771

Outline Drawing...........................................................................................359

2.2.4 Keyboard Unit ..........................................................................................................360

2.2.4.1 FCU7-KB021 / FCU7-KB022 (ONG Layout) ..............................................360

2.2.4.2 FCU7-KB041 (ABC Layout)........................................................................360

2.2.5 Hard Disk Unit..........................................................................................................361

2.2.5.1 FCU7-HD001-1 ...........................................................................................361

2.2.6 Floppy Disk Unit.......................................................................................................362

2.2.6.1 FCU7-FD221-1............................................................................................362

2.2.7 Card-sized I/O Card.................................................................................................363

2.2.7.1 HR361 / HR371 / HR381 / HR383..............................................................363

2.2.8 Remote I/O Unit Outline...........................................................................................365

2.2.8.1 FCUA-DX100 / FCUA-DX110 / FCUA-DX120 / FCUA-DX140

/ FCUA-DX101 / FCUA-DX111 / FCUA-DX121 / FCUA-DX141................365

2.3 Panel Cut Dimension Drawing / Installation Dimension Drawing ....................................366

2.3.1 Control Unit ..............................................................................................................366

2.3.2 Display Unit..............................................................................................................367

2.3.2.1 FCU7-DA201 (8.4-type)..............................................................................367

2.3.2.2 FCU7-DA211 / FCU7-DA315 / FCU7-DA415 / FCU7-DA445 (10.4-type).368

2.3.2.3 FCU7-DA335 / FCU7-DA435 (15-type)......................................................369

2.3.3 Operation Panel I/O Unit..........................................................................................370

2.3.3.1 FCU7-DX670 / FCU7-DX671 / FCU7-DX770 / FCU7-DX771....................370

2.3.4 Keyboard Unit ..........................................................................................................371

2.3.4.1 FCU7-KB021 / FCU7-KB022 (ONG Layout) ..............................................371

2.3.4.2 FCU7-KB041 (ABC Layout)........................................................................372

2.3.5 Hard Disk Unit..........................................................................................................373

2.3.5.1 FCU7-HD001...............................................................................................373

2.3.6 External Power Supply Unit.....................................................................................374

2.3.6.1 PD25............................................................................................................374

2.3.6.2 PD27............................................................................................................375

2.3.6.3 Mounting Direction and Clearance..............................................................375

2.3.7 Remote I/O Unit .......................................................................................................376

2.3.7.1 FCUA-DX100 / FCUA-DX110 / FCUA-DX120 / FCUA-DX140

/ FCUA-DX101 / FCUA-DX111 / FCUA-DX121 / FCUA-DX141................376

2.3.8 Manual Pulse Generator..........................................................................................377

2.3.8.1 UFO-01-2Z9 ................................................................................................377

x

2.3.8.2 HD60 ...........................................................................................................378

2.3.9 Synchronous Feed Encoder....................................................................................379

2.3.9.1 OSE-1024-3-15-68......................................................................................379

2.3.10 F Installation Plate..................................................................................................380

Appendix 3. 70 Series Installation Condition..........................................................................381

3.1 Cabinet and Installation....................................................................................................381

3.1.1 Cabinet Construction ...............................................................................................381

3.1.2 General Specifications (Environment Conditions)...................................................384

3.2 Outline Drawing ................................................................................................................386

3.2.1 Control Unit ..............................................................................................................386

3.2.1.1 FCU7-MU521/FCU7-MU522.......................................................................386

3.2.2 Display Unit..............................................................................................................388

3.2.2.1 FCU7-DU120-12 (8.4-type).........................................................................388

3.2.2.2 FCU7-DU140-12 (10.4-type).......................................................................388

3.2.3 Operation Panel I/O Unit..........................................................................................389

3.2.3.1 FCU7-DX710 / FCU7-DX711......................................................................389

3.2.3.2 FCU7-DX720 / FCU7-DX721 / FCU7-DX730 / FCU7-DX731....................390

3.2.4 Keyboard Unit ..........................................................................................................391

3.2.4.1 FCU7-KB024 (8.4-type) ..............................................................................391

3.2.4.2 FCU7-KB044 (10.4-type) ............................................................................391

3.2.5 Remote I/O Unit .......................................................................................................392

3.2.5.1 FCUA-DX100 / FCUA-DX110 / FCUA-DX120 / FCUA-DX140

/ FCUA-DX101 / FCUA-DX111 / FCUA-DX121 / FCUA-DX141................392

3.2.6 Card-sized I/O Card.................................................................................................393

3.2.6.1 HR361 / HR371 / HR381 / HR383..............................................................393

3.3 Panel Cut Dimension Drawing / Installation Dimension Drawing ....................................395

3.3.1 Display Unit..............................................................................................................395

3.3.1.1 FCU7-DU120-12 (8.4-type).........................................................................395

3.3.1.2 FCU7-DU140-12 (10.4-type).......................................................................396

3.3.2 Operation Panel I/O Unit..........................................................................................397

3.3.2.1 FCU7-DX710 / FCU7-DX711 / FCU7-DX720 / FCU7-DX721

/ FCU7-730 / FCU7-731..............................................................................397

3.3.3 Keyboard Unit ..........................................................................................................398

3.3.3.1 FCU7-KB024 (for 8.4-type).........................................................................398

3.3.3.2 FCU7-KB044 (for 10.4-type).......................................................................399

3.3.4 External Power Supply Unit.....................................................................................400

3.3.4.1 PD25............................................................................................................400

3.3.4.2 PD27............................................................................................................401

3.3.4.3 Mounting Direction and Clearance..............................................................401

3.3.5 Remote I/O Unit .......................................................................................................402

3.3.5.1 FCUA-DX100 / FCUA-DX110 / FCUA-DX120 / FCUA-DX140

/ FCUA-DX101 / FCUA-DX111 / FCUA-DX121 / FCUA-DX141...............402

3.3.6 Manual Pulse Generator..........................................................................................403

3.3.6.1 UFO-01-2Z9 ................................................................................................403

3.3.6.2 HD60 ...........................................................................................................404

3.3.7 Synchronous Feed Encoder....................................................................................405

3.3.7.1 OSE-1024-3-15-68......................................................................................405

MITSUBISHI CNC 700/70 Series Specifications List

xi

1. Control Axes

1.1 Control Axes

1. Control Axes

The NC axis, spindle, PLC axis and auxiliary axis are generically called the control axis.

The NC axis is an axis that can be manually operated, or automatically operated with the machining program.

The PLC axis is an axis that can be controlled from the PLC ladder.

1.1 Control Axes

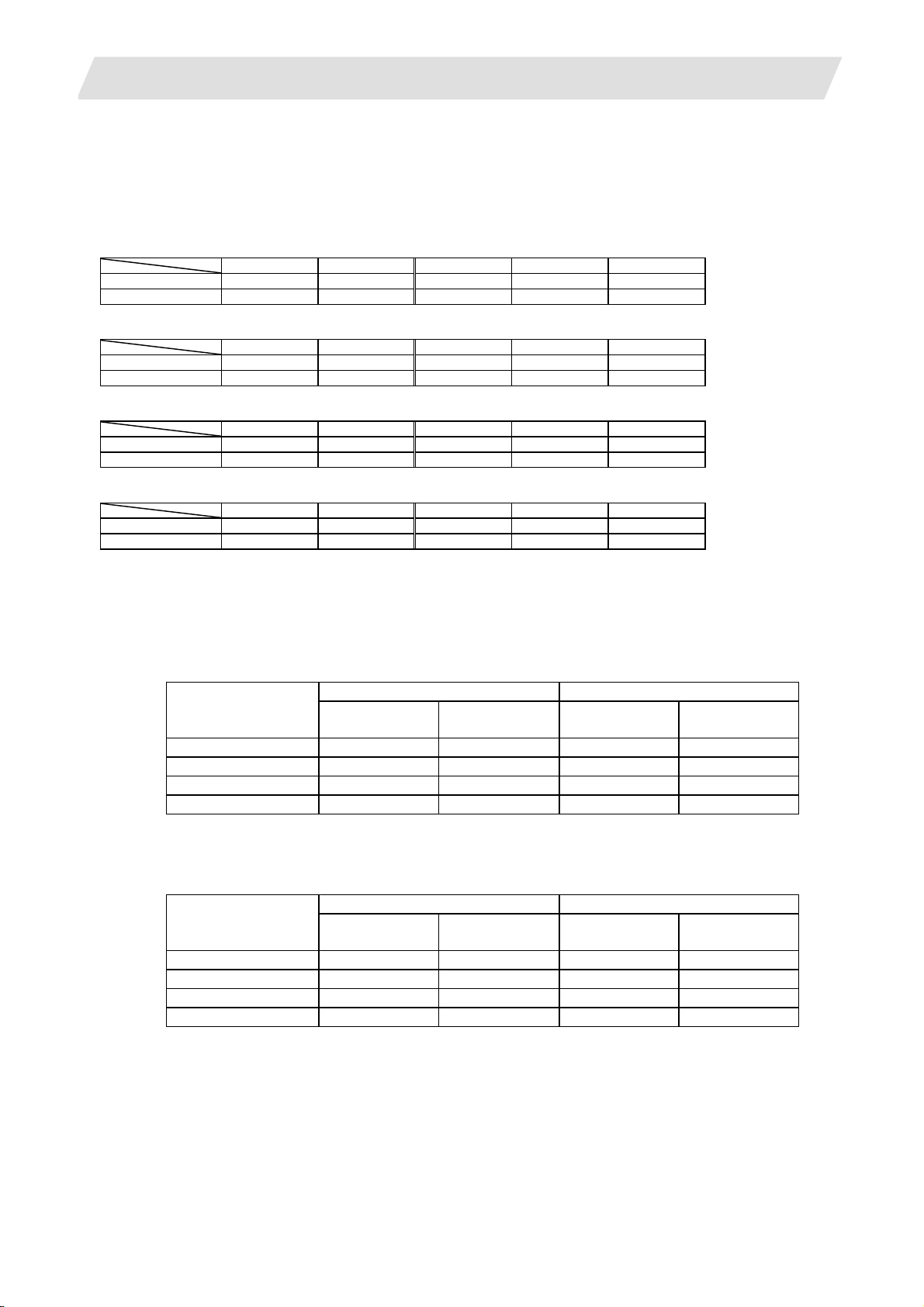

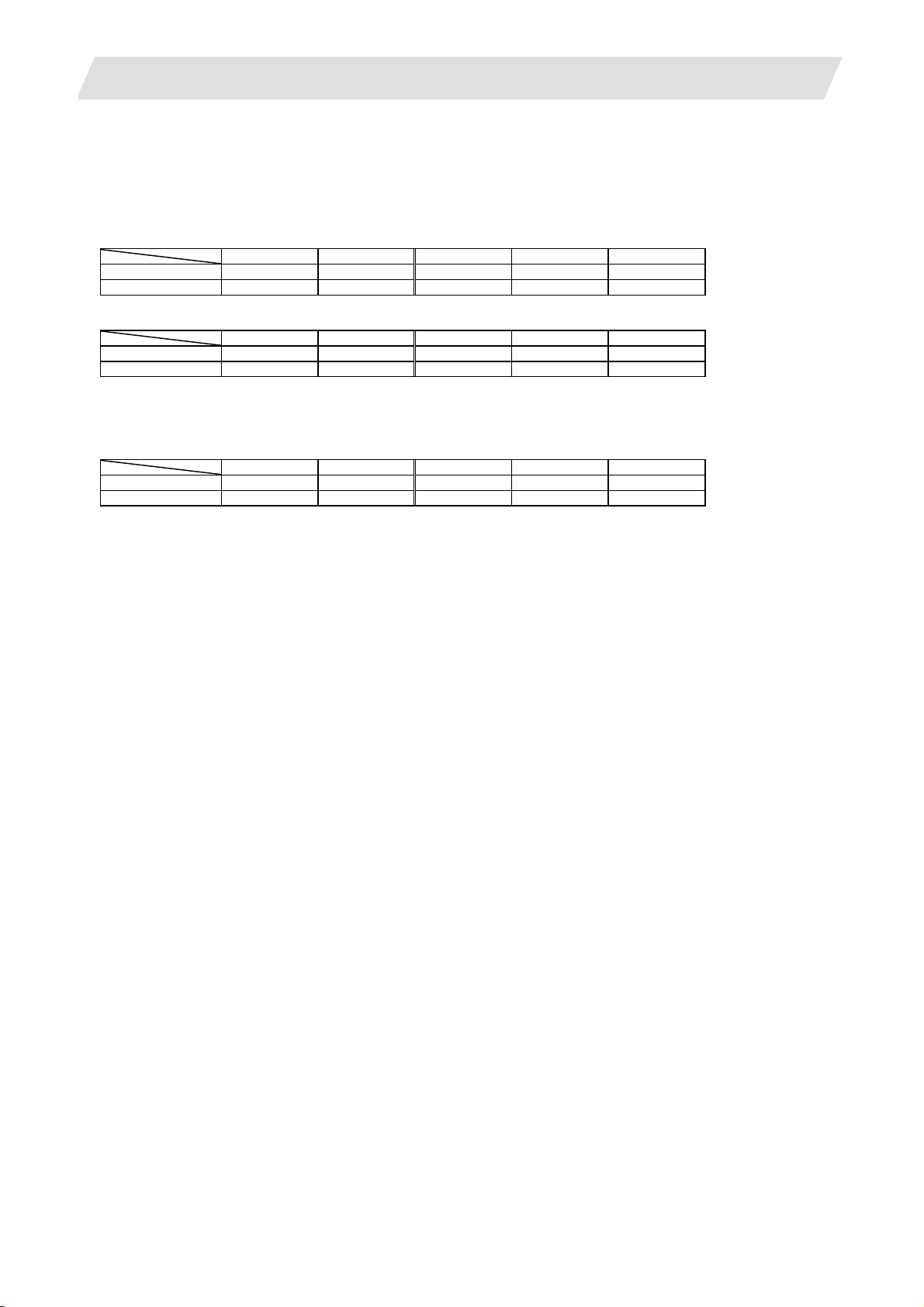

1.1.1 Number of Basic Control Axes (NC Axes)

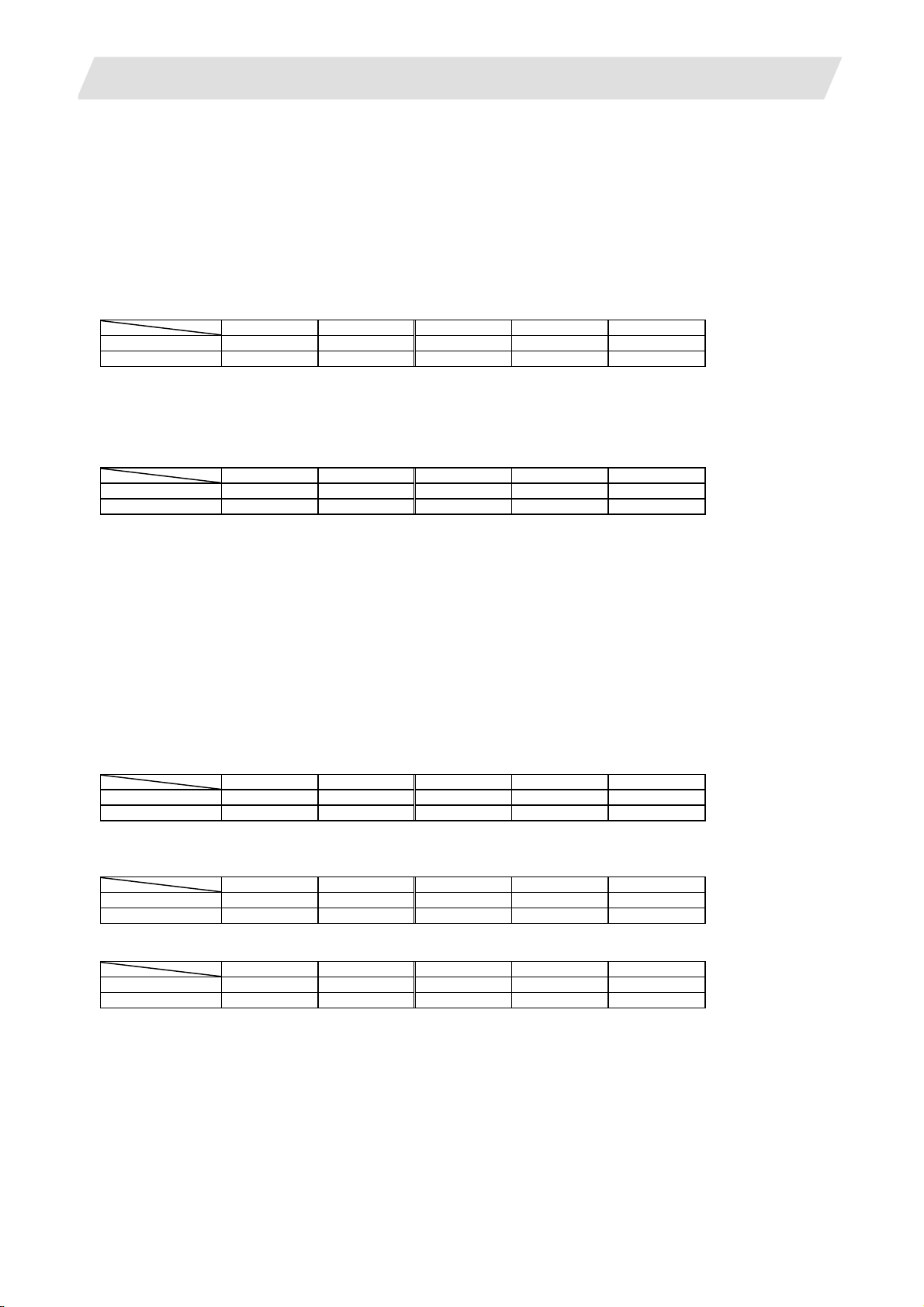

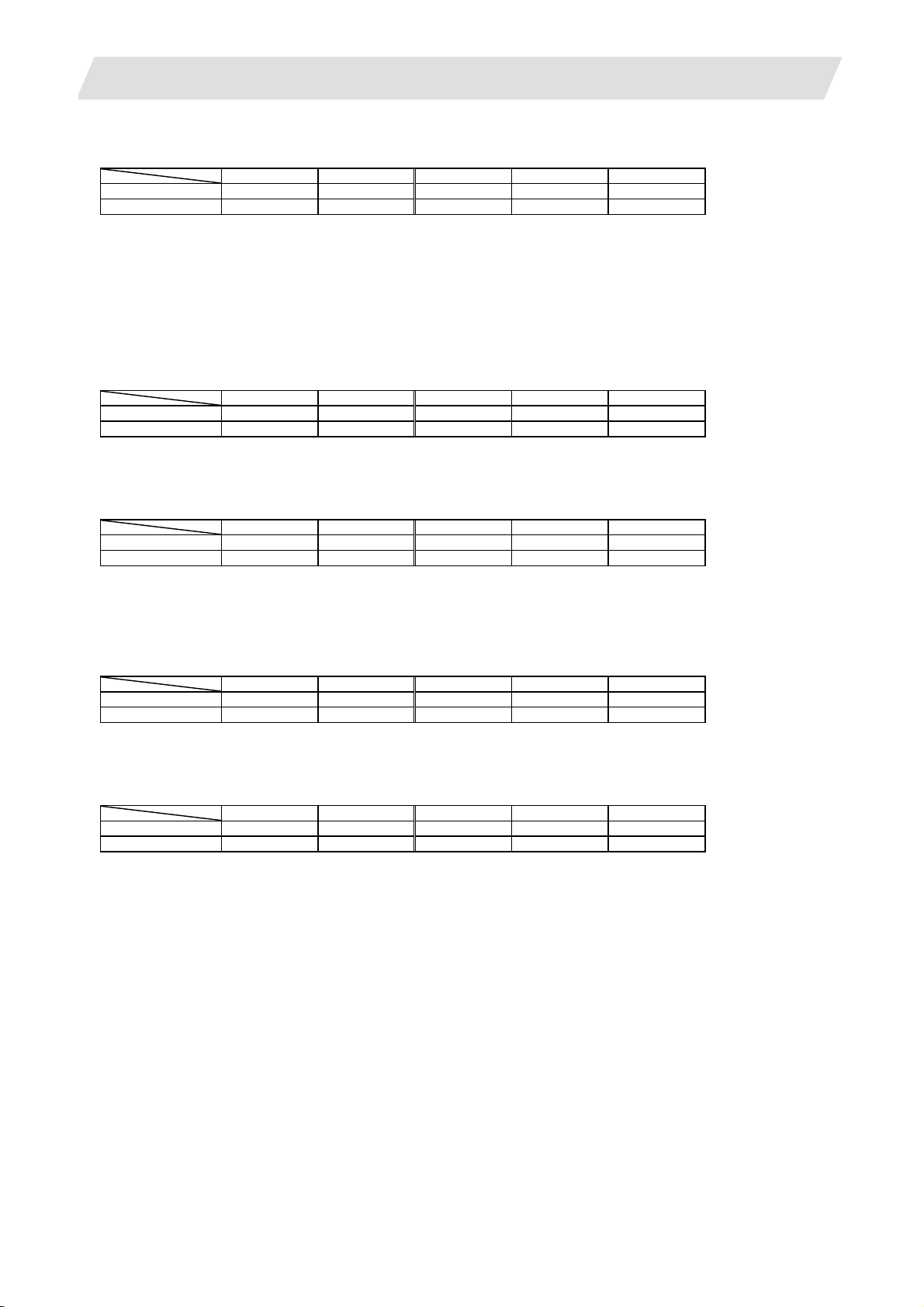

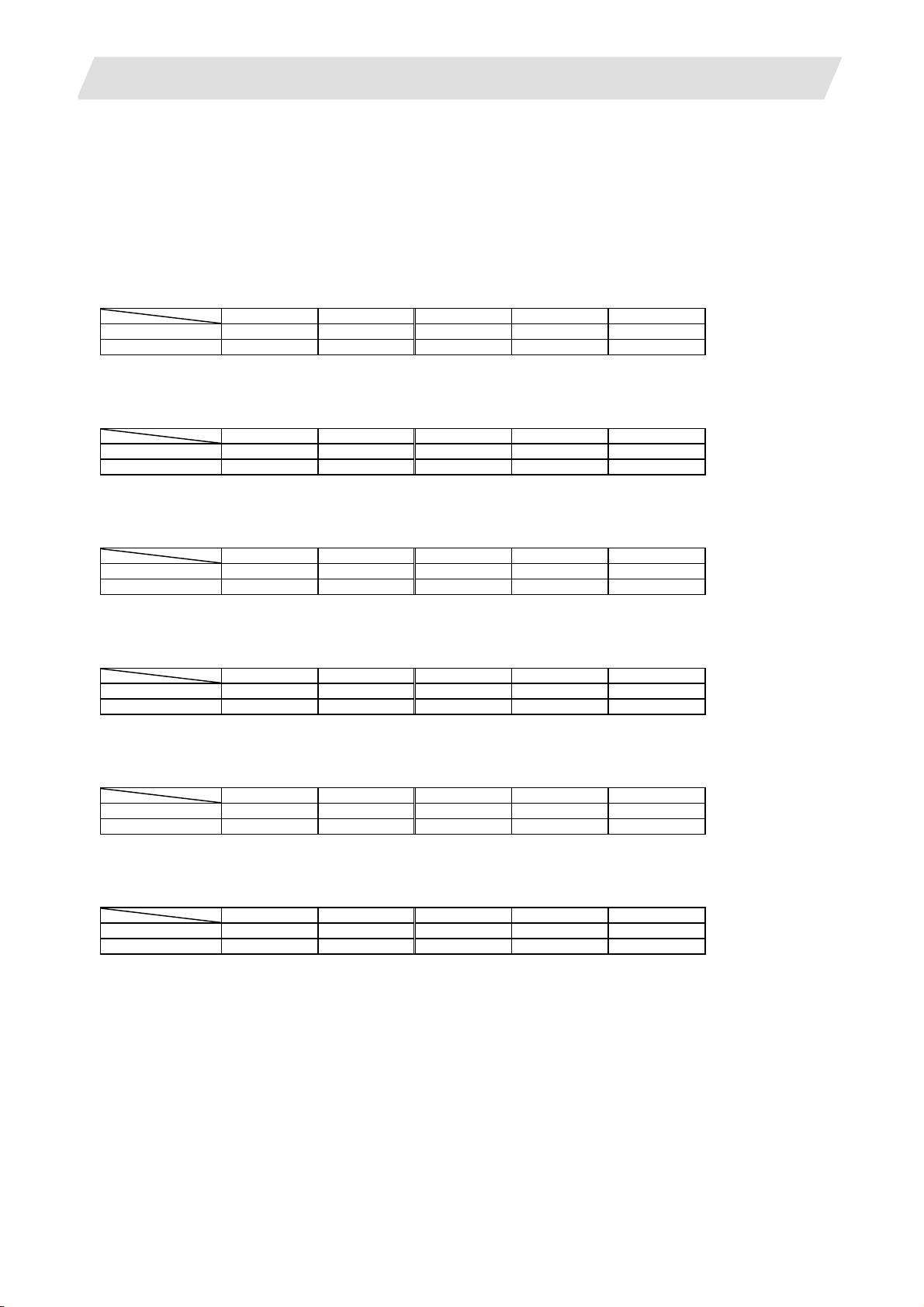

M70 Type B M70 Type A M720 M730 M750

M system {3 {3 {3 {3 {3

L system {2 {2 {2 {2 {2

1.1.2 Max. Number of Axes (NC Axes + Spindles + PLC Axes)

Max. number of axes (NC axes + spindles + PLC axes)

M70 Type B M70 Type A M720 M730 M750

M system 9 11 12 16 16

L system 9 11 12 16 16

A number of axes that are within the maximum number of axes, and that does not exceed the maximum

number given for the NC axis, spindle and PLC axis can be used.

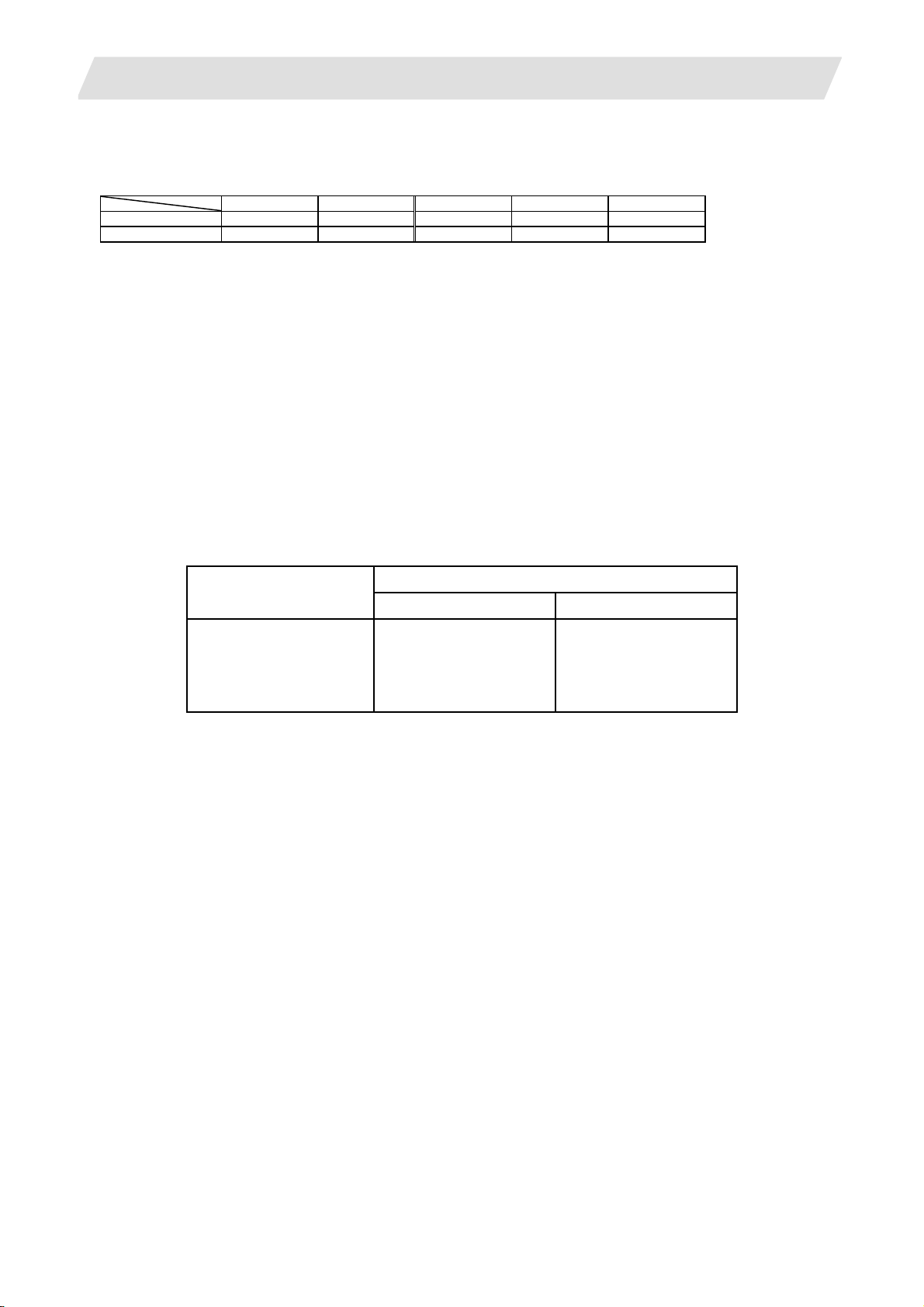

Connection specifications of NC axis, PLC axis and spindle

There are two channels with which the servo and spindle are connected.

Maximum 8 axes can be connected with each channel.

NC axis, PLC axis, spindle : These can be connected with the optical servo communication channel (OPT).

The connection number of first axis to eighth axis is assigned to each channel.

Connect them from the first axis in order.

More than one axis must be connected with the channel 1.

Max. number of NC axes (in total for all the part systems)

M70 Type B M70 Type A M720 M730 M750

M system 4 6 6 16 16

L system 4 7 12 16 16

Max. number of spindles

Includes analog spindles.

M70 Type B M70 Type A M720 M730 M750

M system 2 2 4 4 4

L system 2 3 4 4 4